Patents

Literature

349results about "Flaw detection using microwaves" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

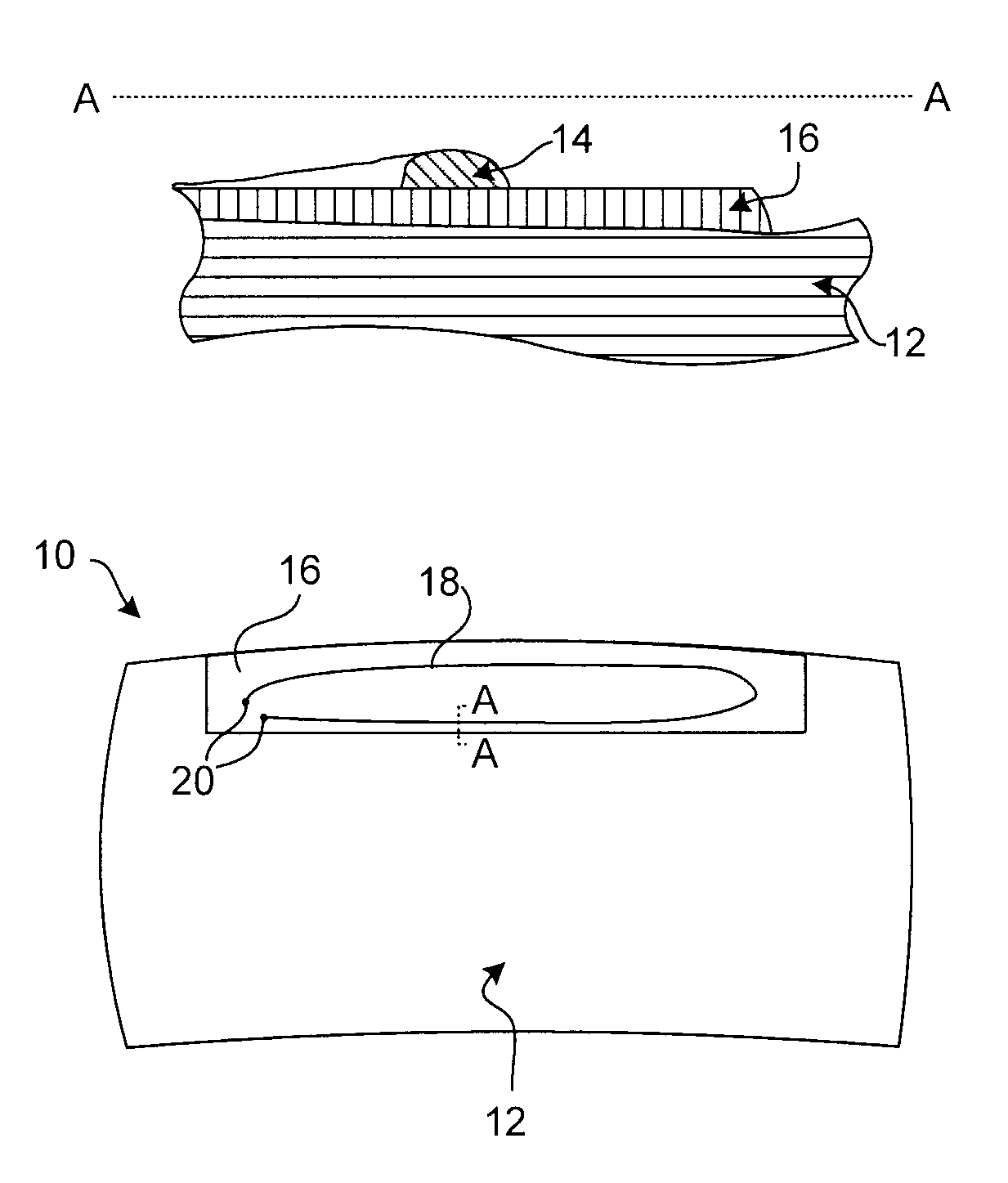

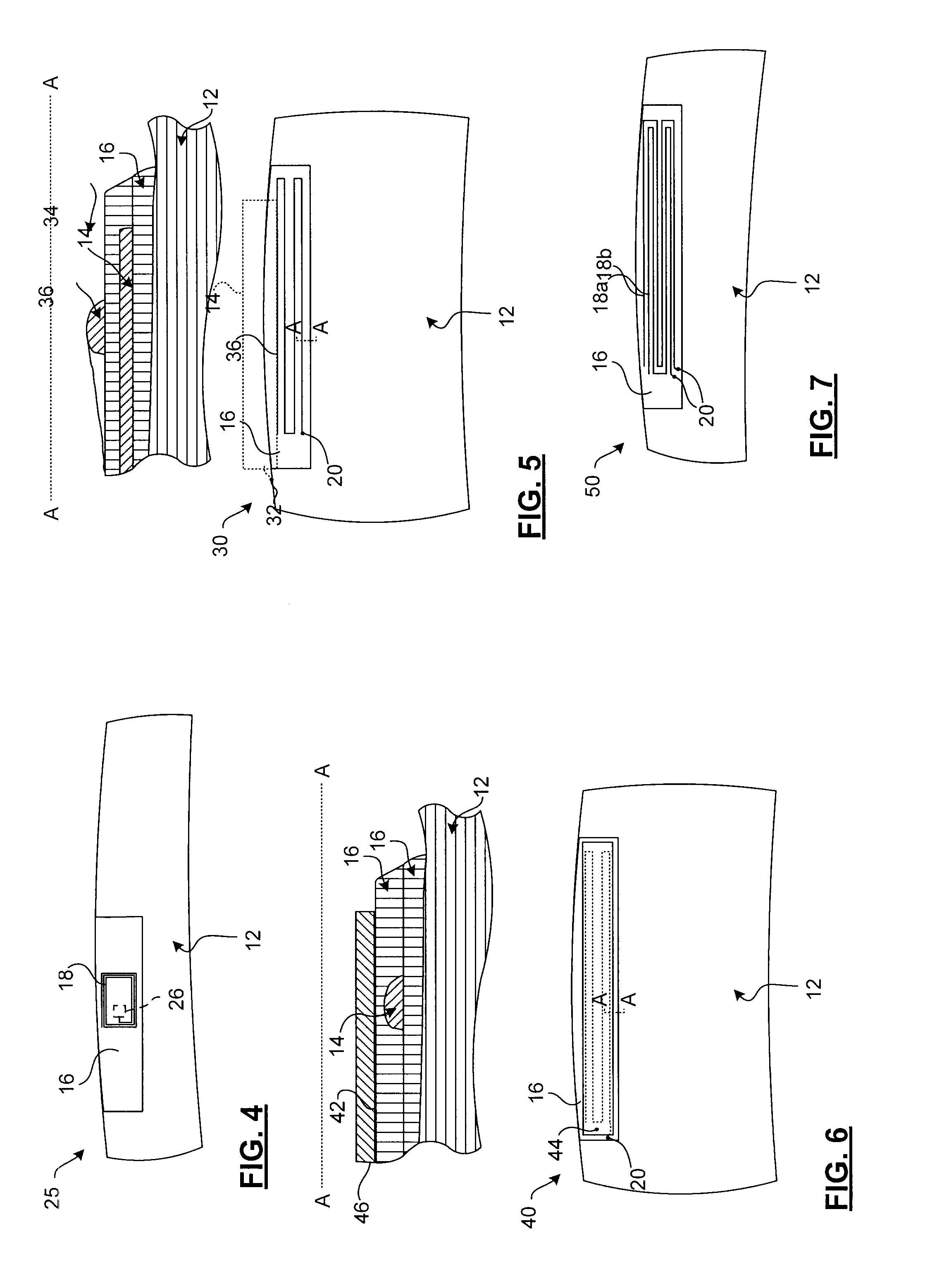

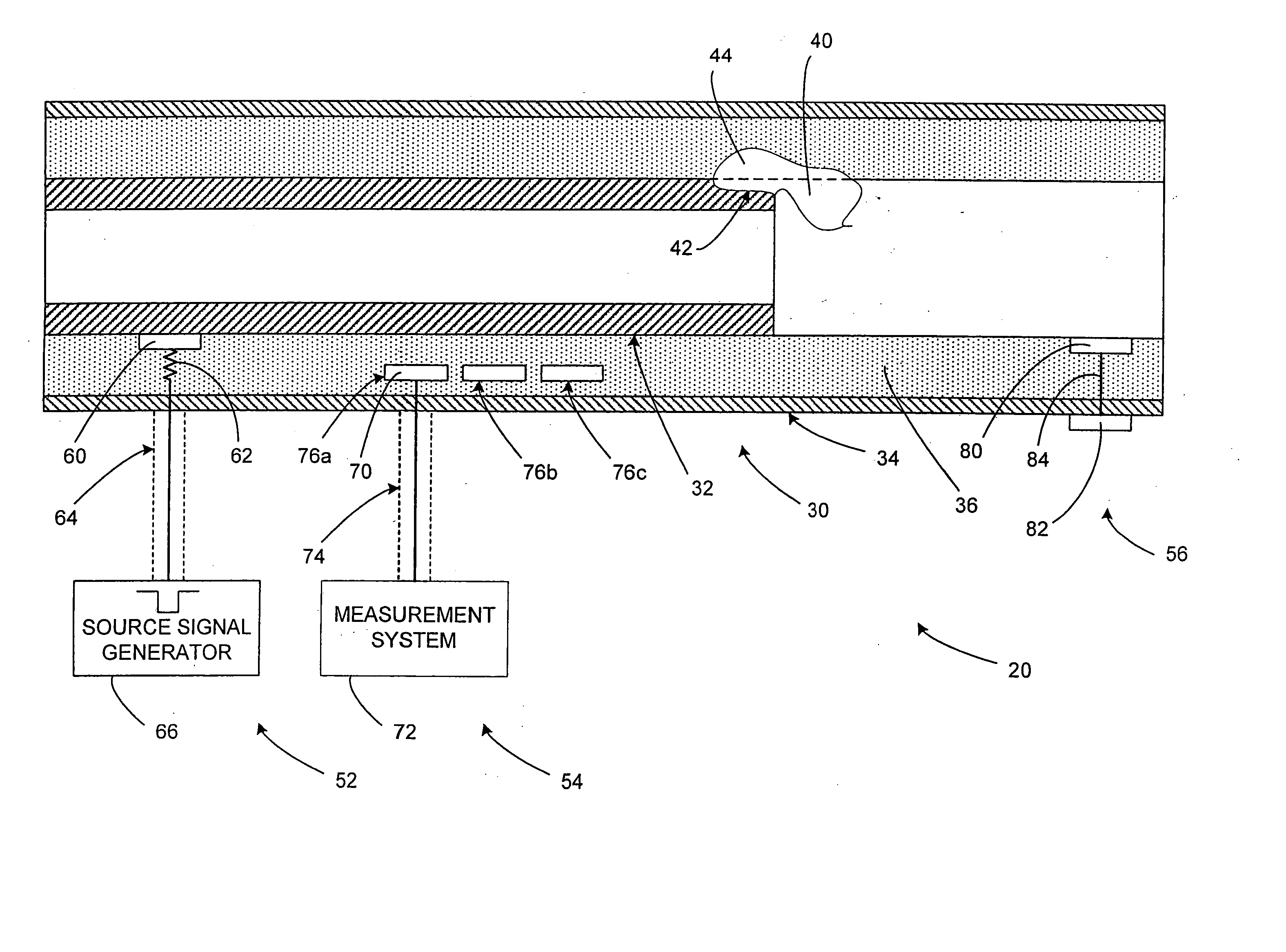

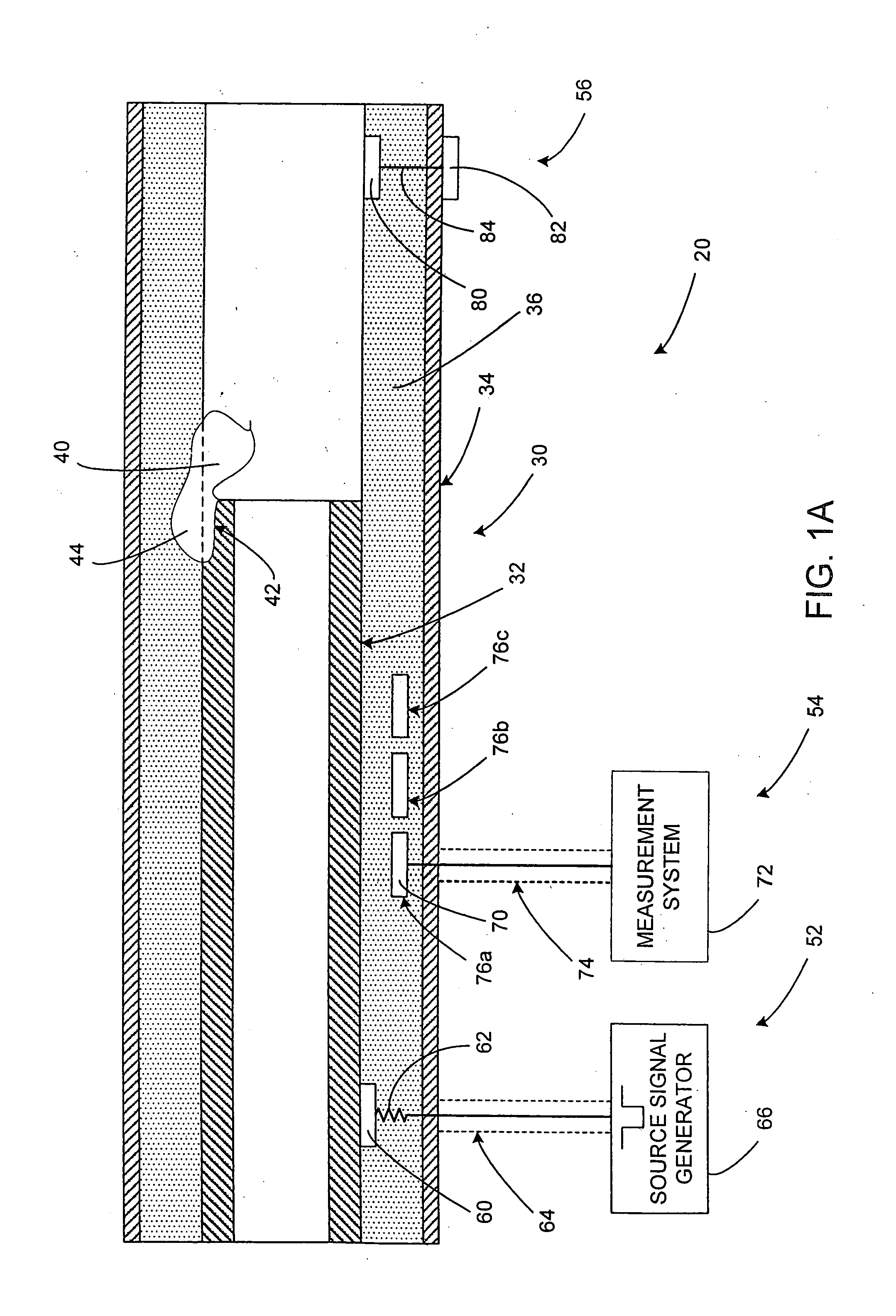

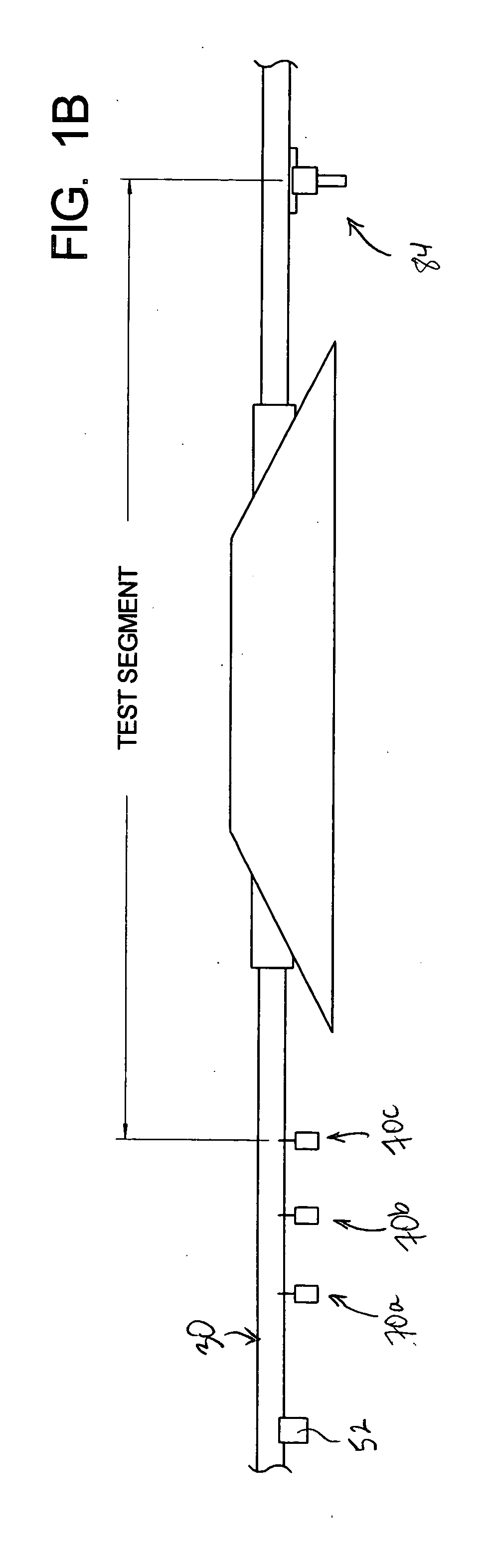

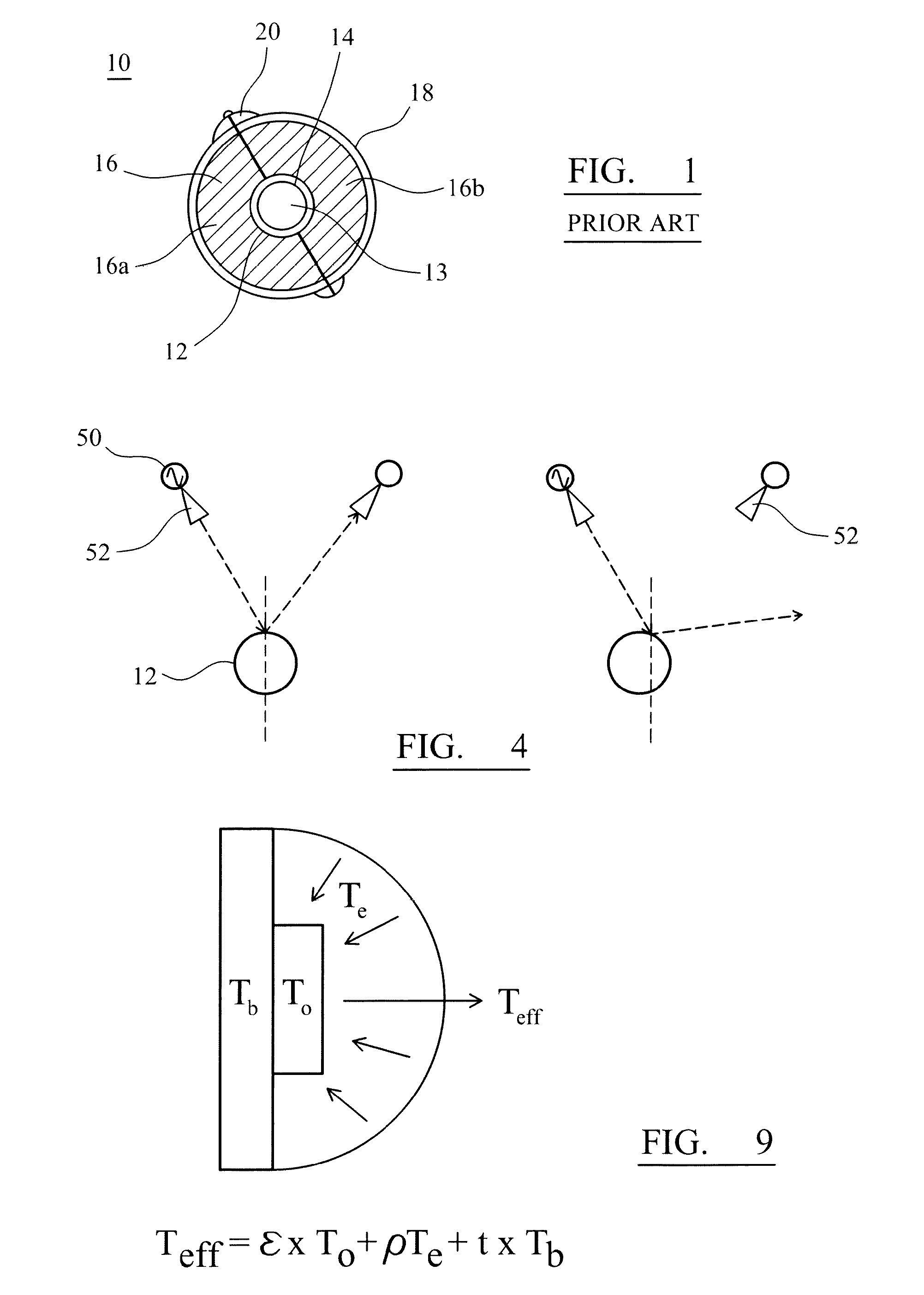

Material erosion monitoring system and method

ActiveUS20150276577A1Reduce confusionMultiple EffectsFurnace componentsWeather/light/corrosion resistanceMaterial ErosionMonitoring system

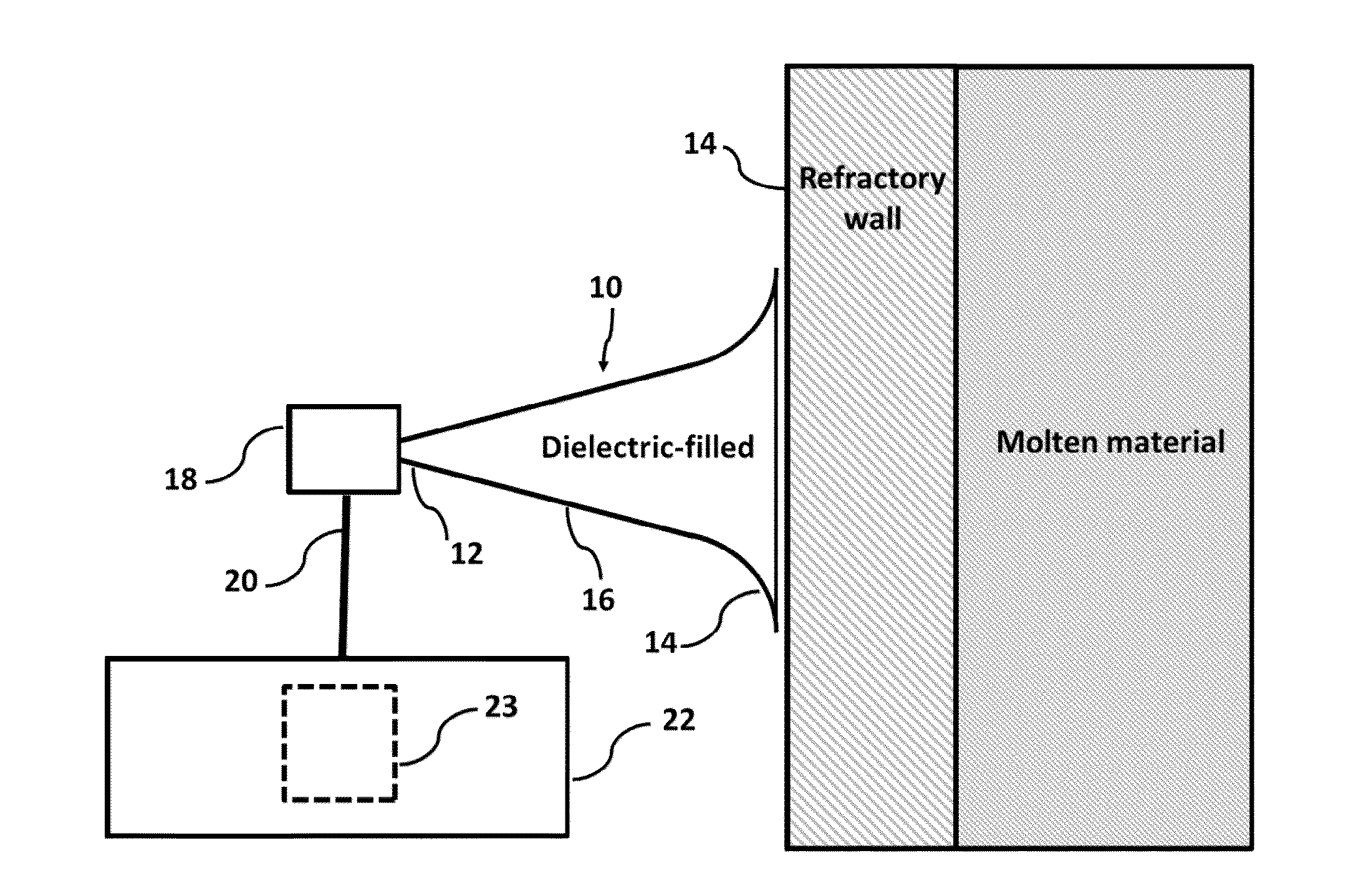

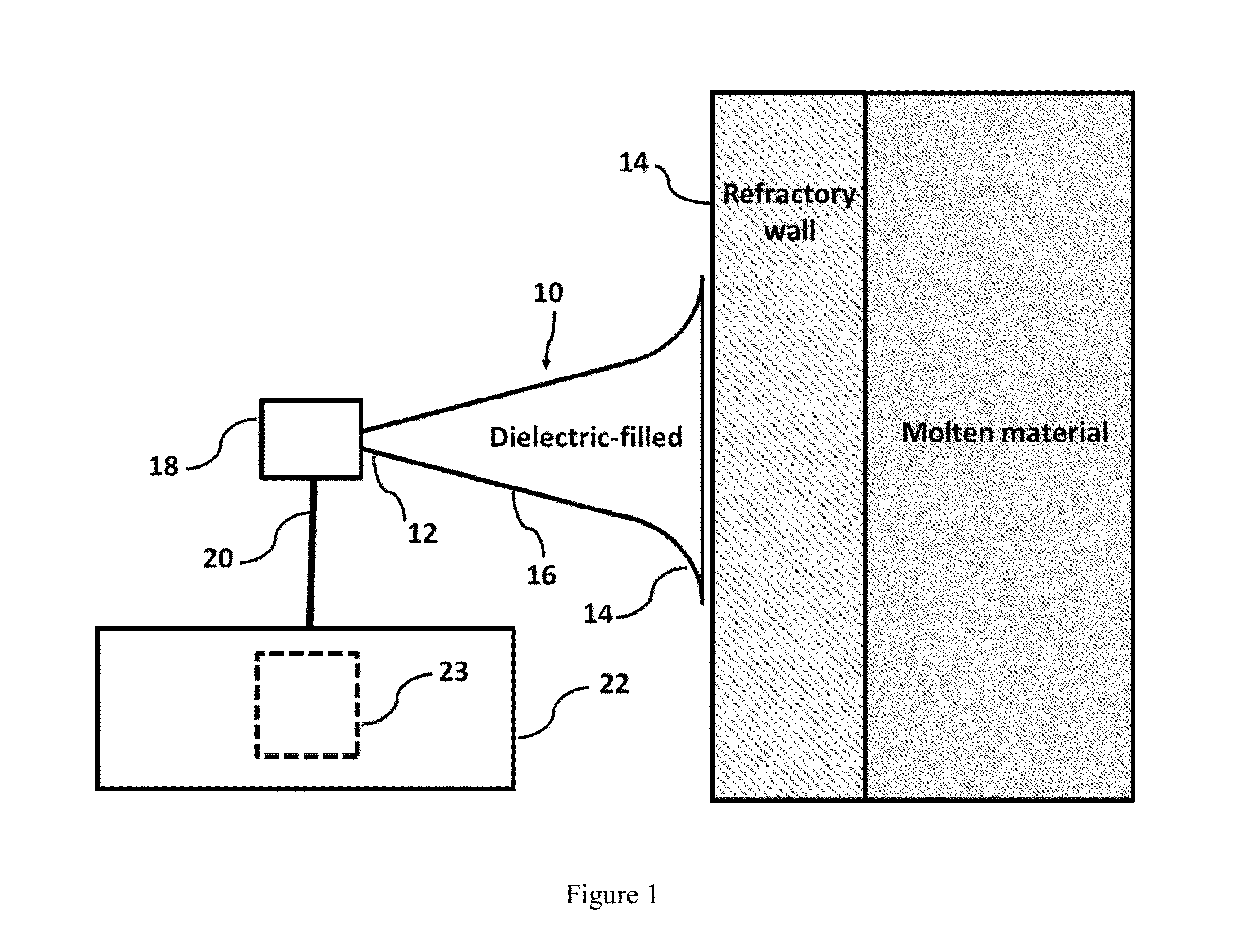

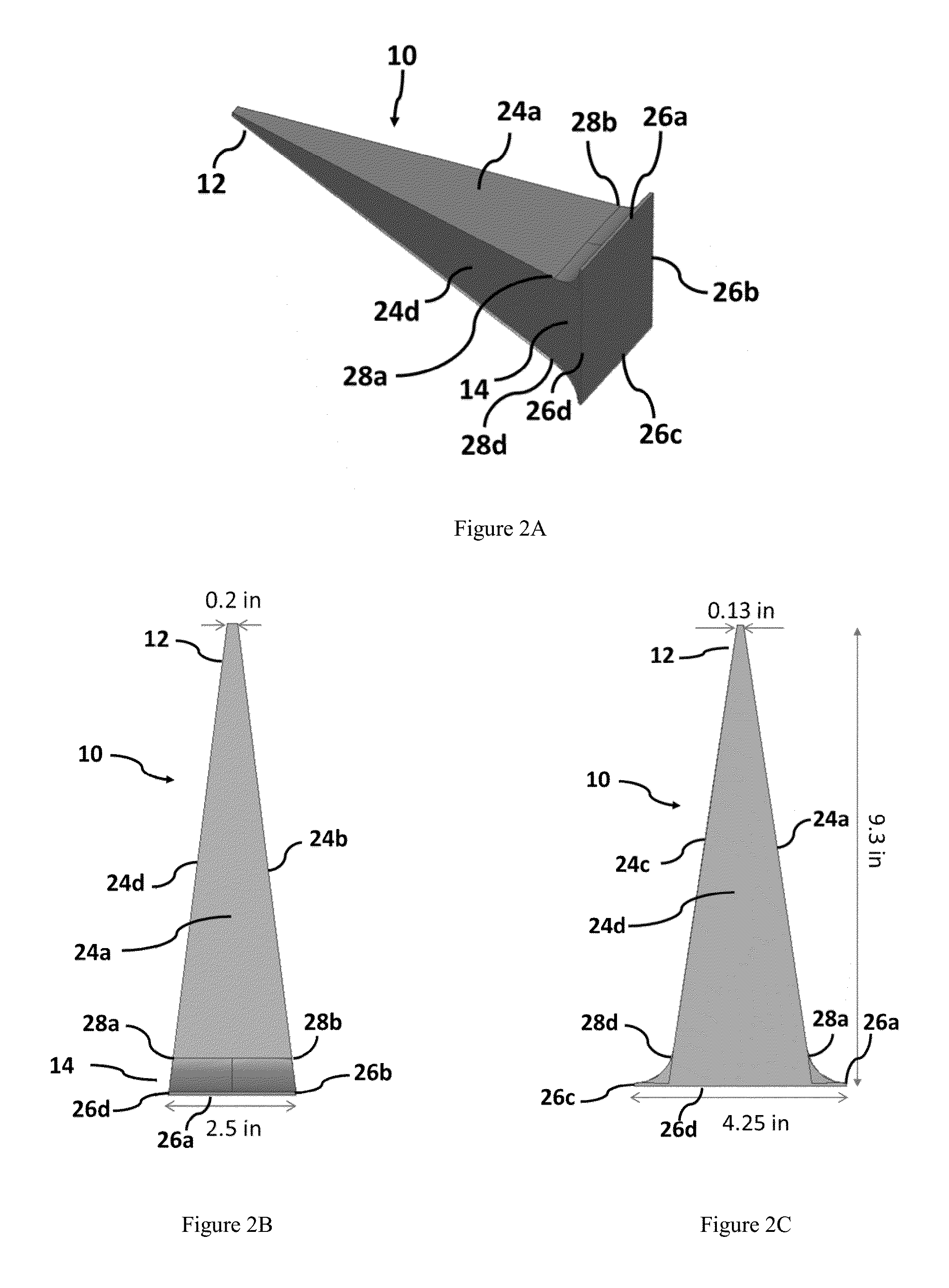

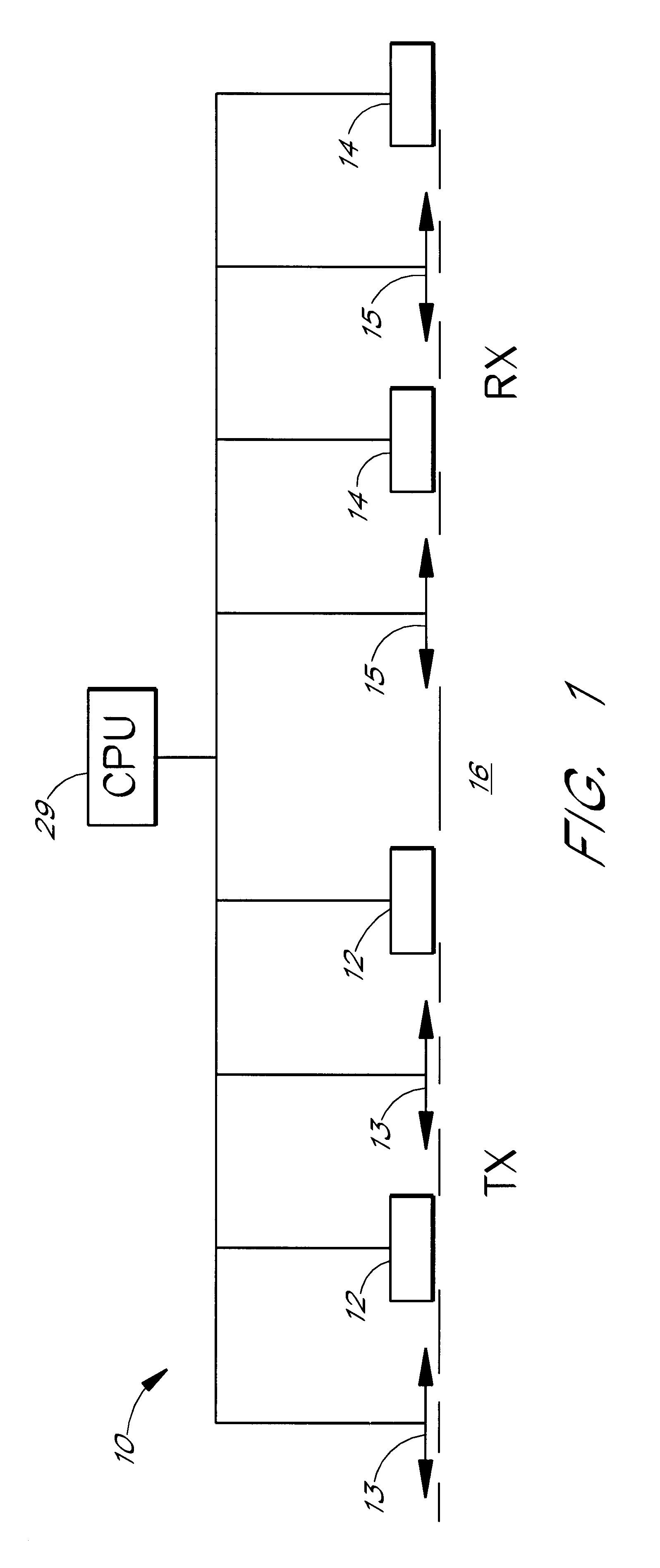

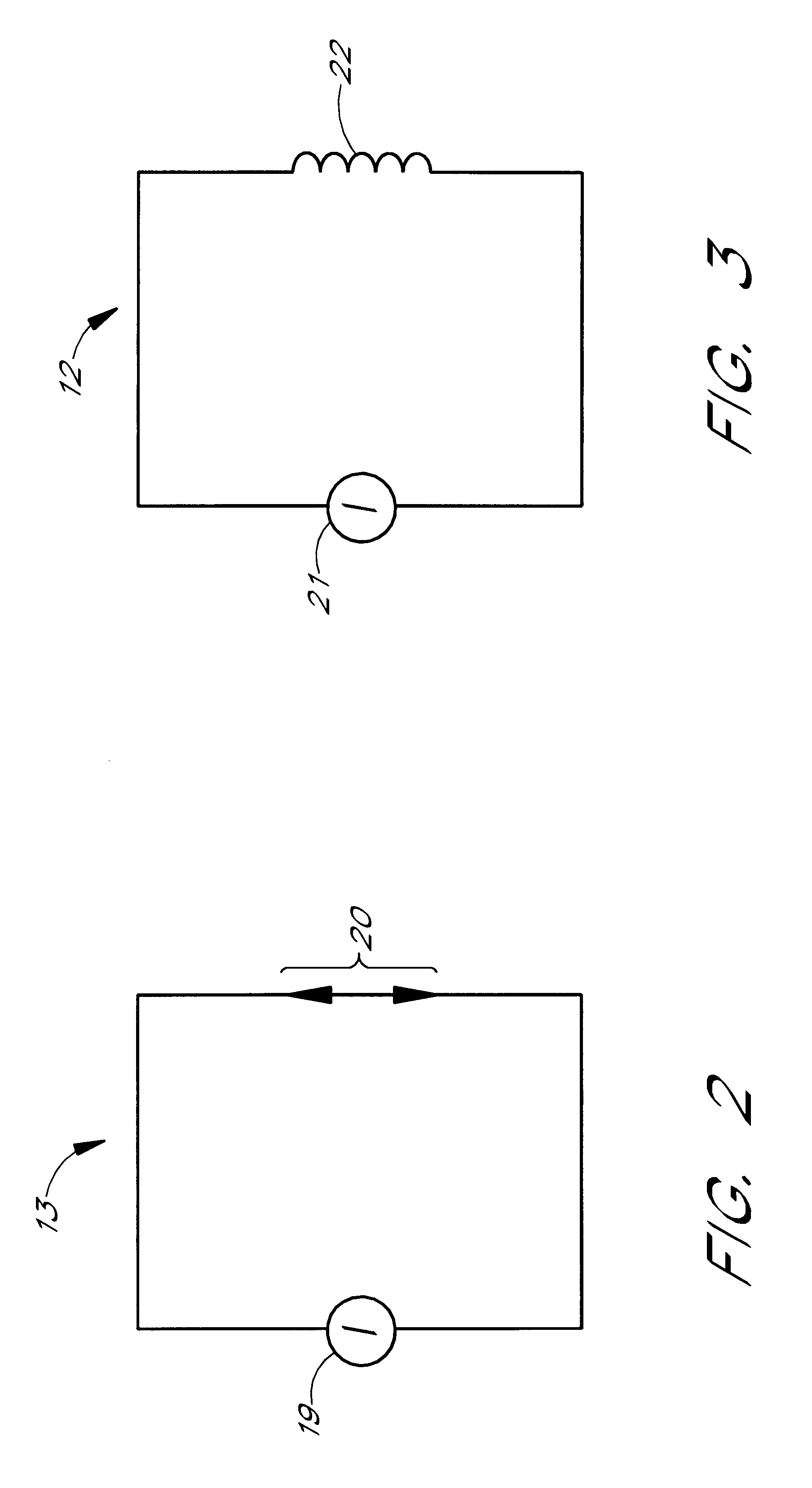

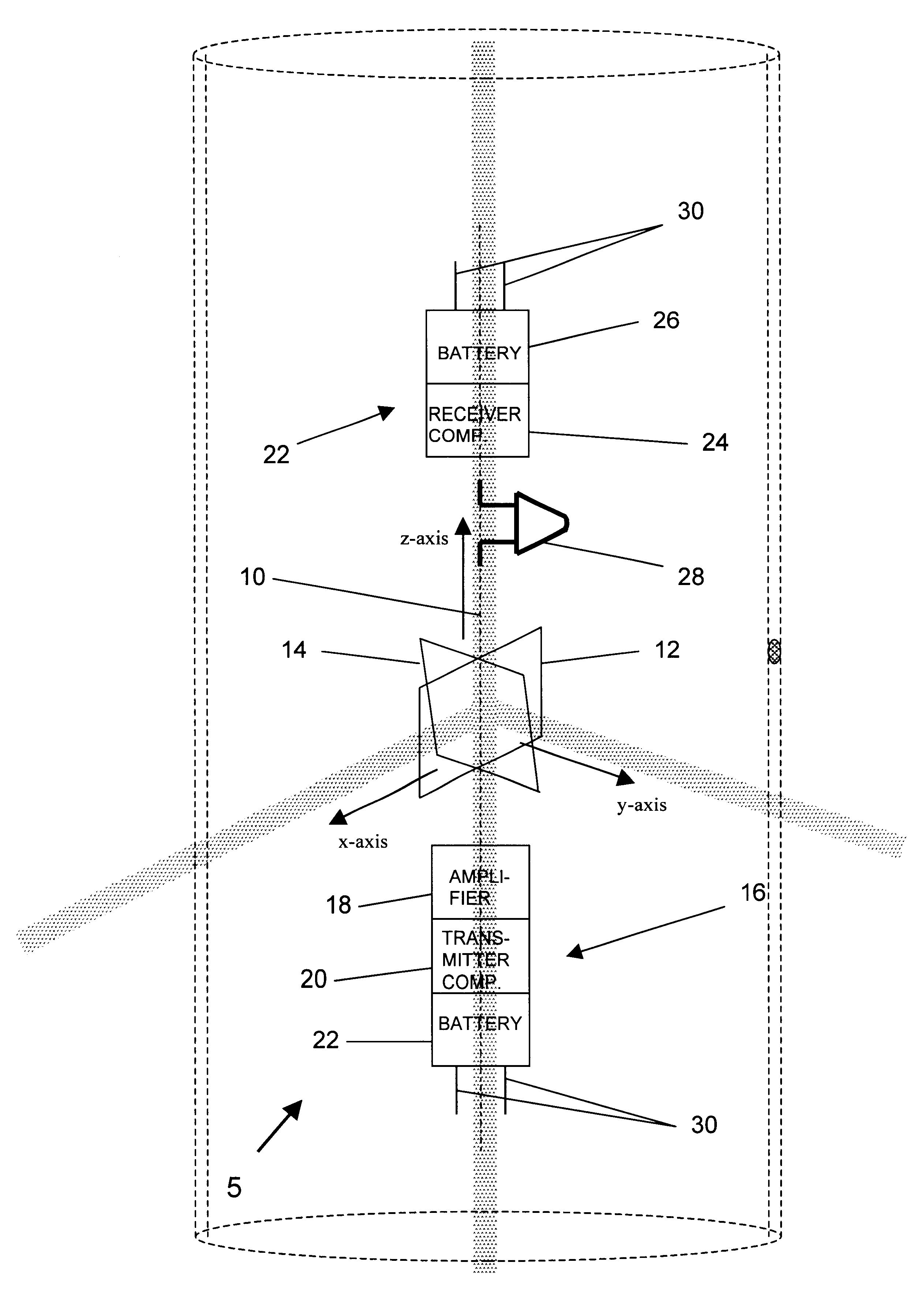

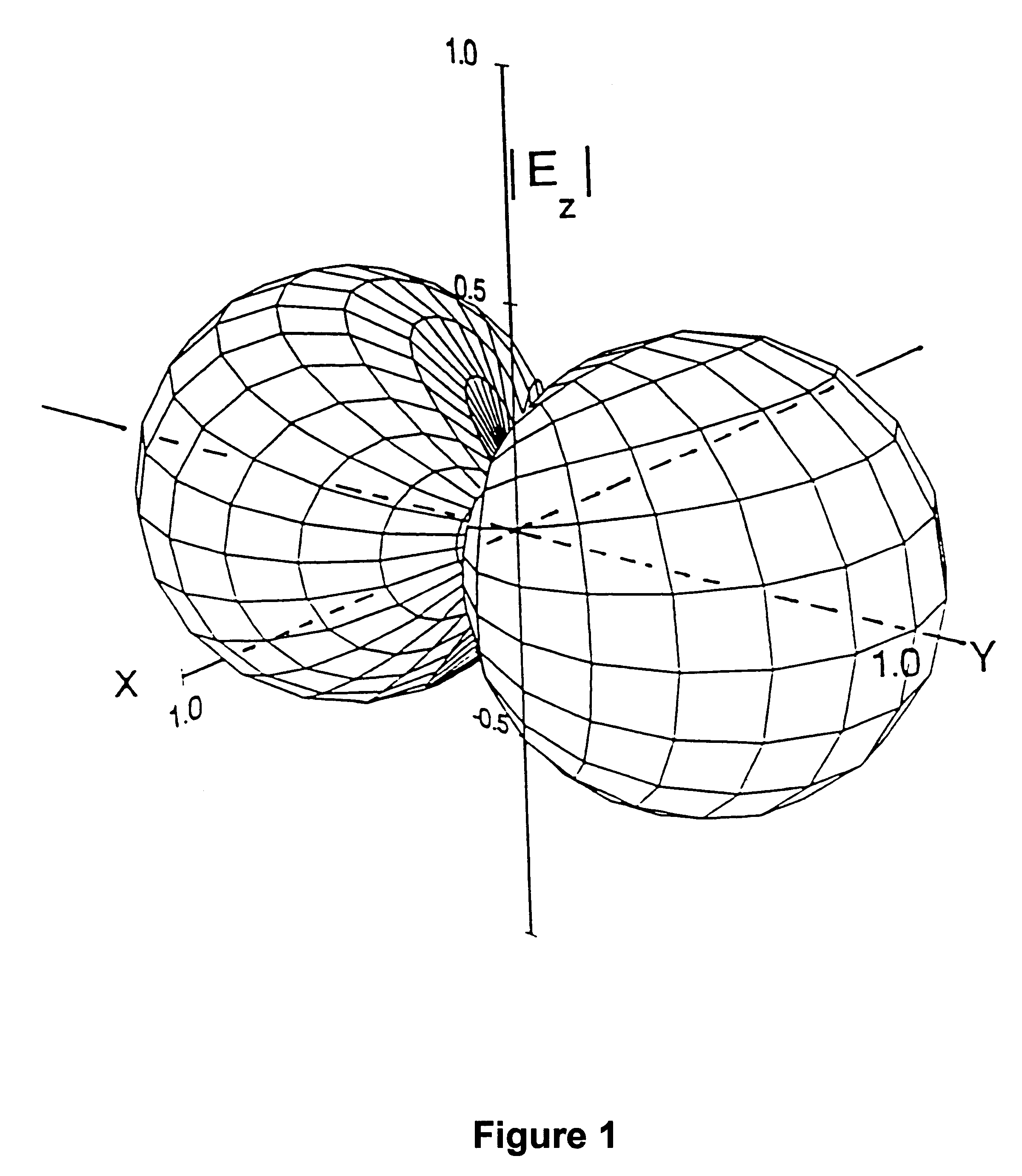

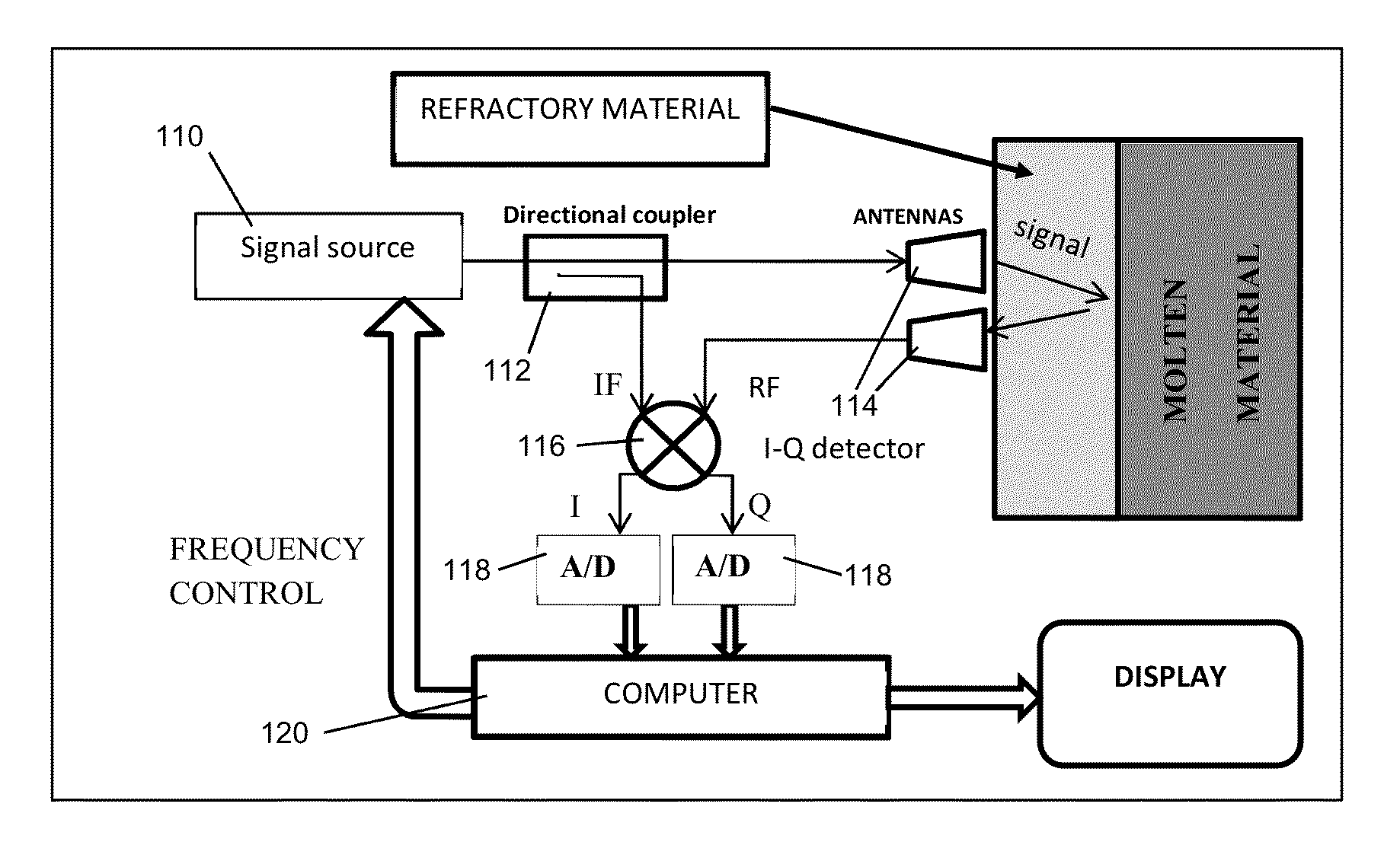

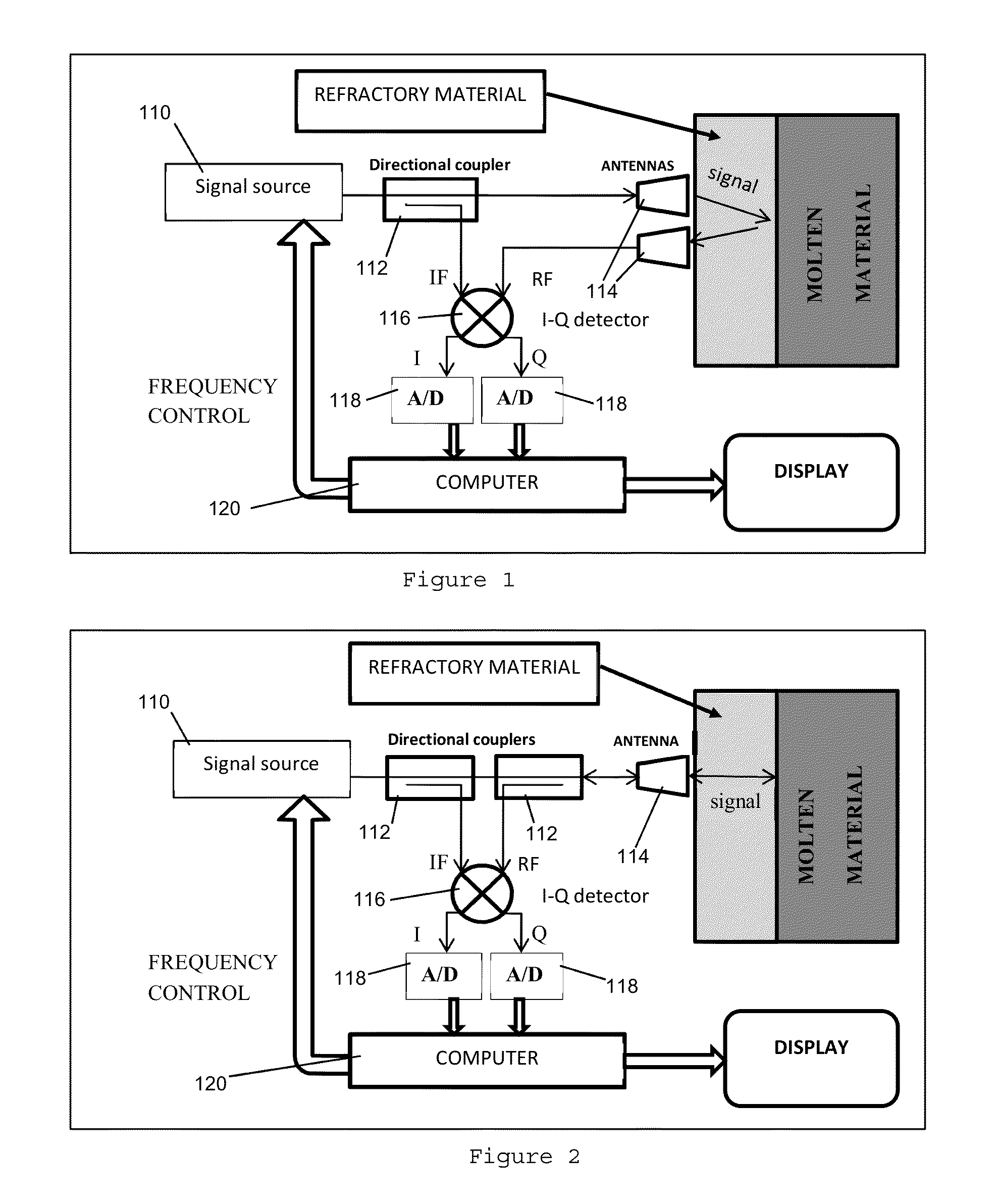

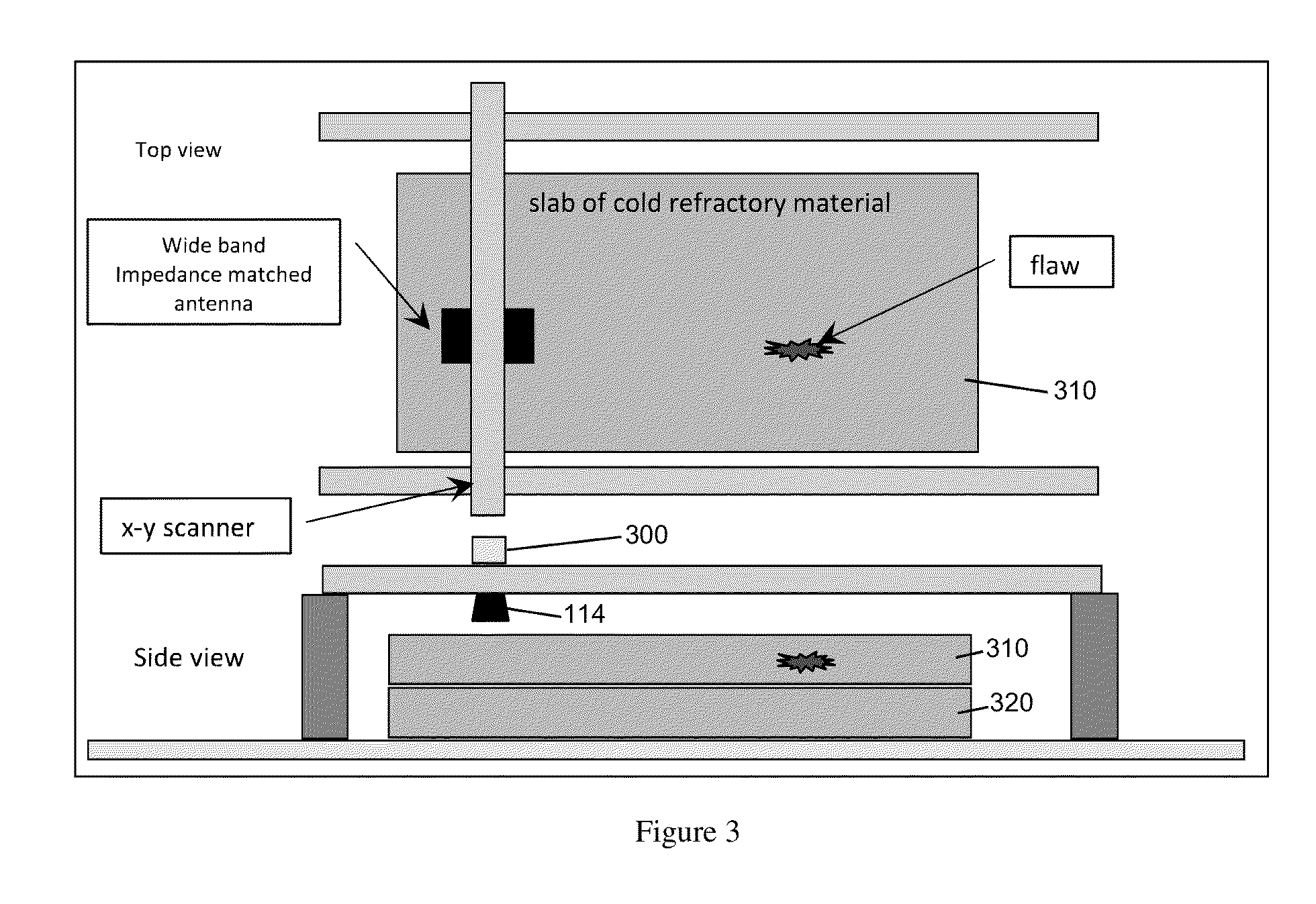

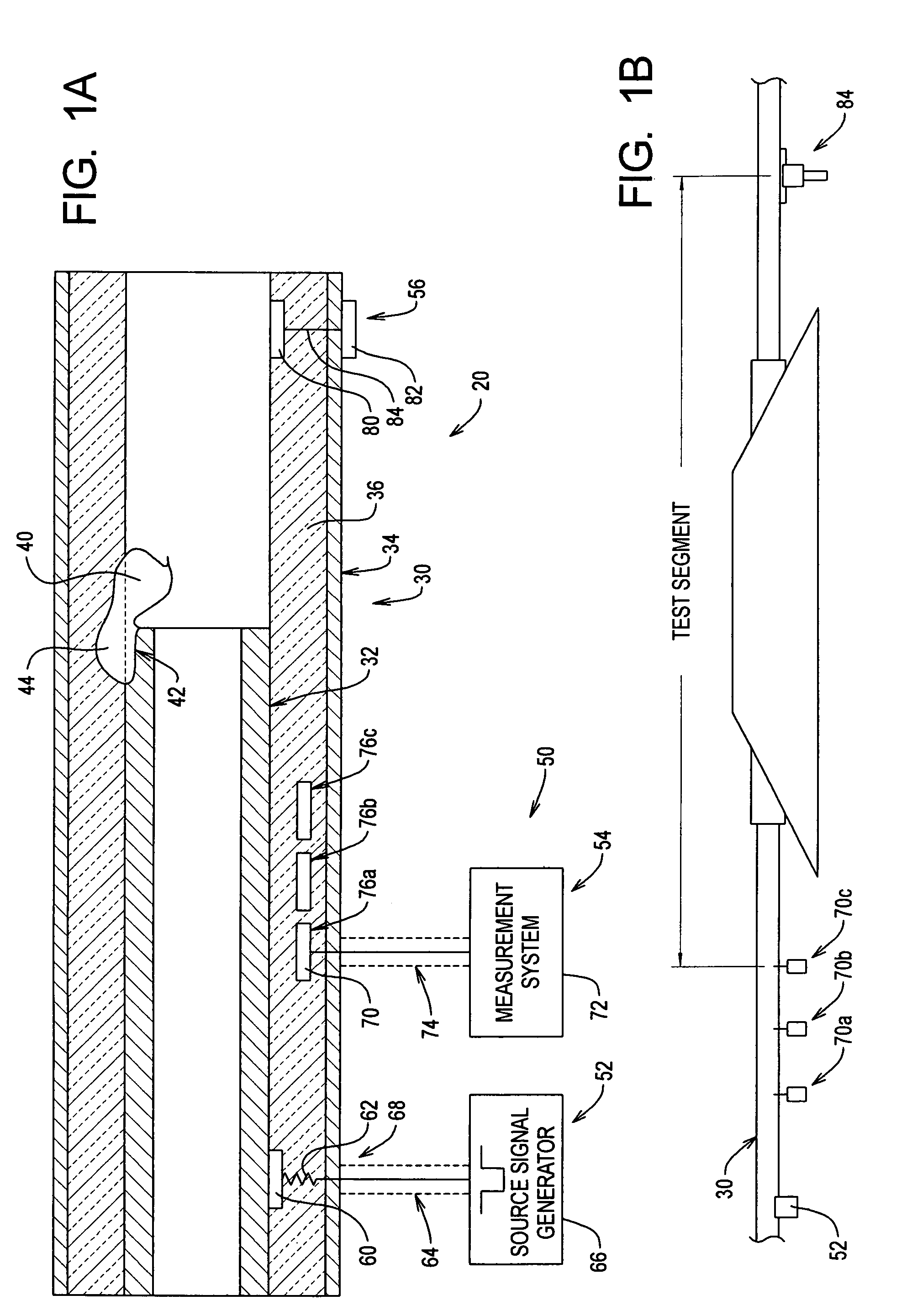

Disclosed is an improved system and method to evaluate the status of a material. The system and method are operative to identify flaws and measure the erosion profile and thickness of different materials, including refractory materials, using electromagnetic waves. The system is designed to reduce a plurality of reflections, associated with the propagation of electromagnetic waves launched into the material under evaluation, by a sufficient extent so as to enable detection of electromagnetic waves of interest reflected from remote discontinuities of the material. Furthermore, the system and method utilize a configuration and signal processing techniques that reduce clutter and enable the isolation of electromagnetic waves of interest. Moreover, the launcher is impedance matched to the material under evaluation, and the feeding mechanism is designed to mitigate multiple reflection effects to further suppress clutter.

Owner:PANERATECH

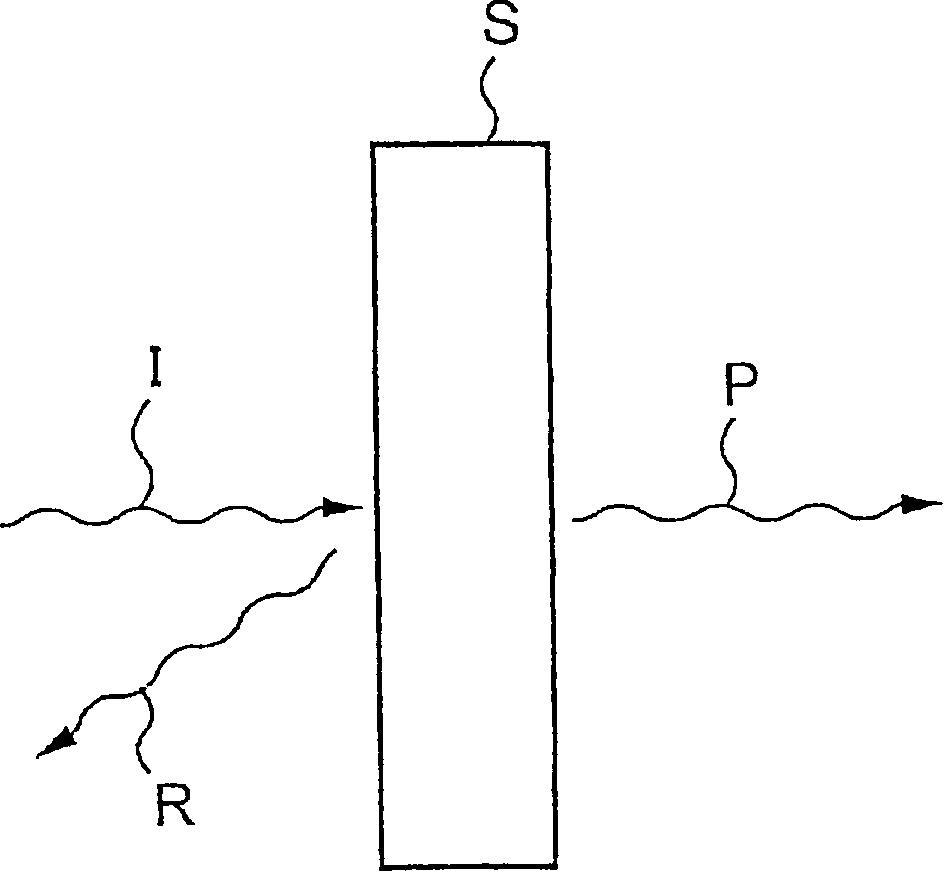

Method of broad band electromagnetic holographic imaging

InactiveUS6253100B1Simple hardware arrangementSimple softwareResistance/reactance/impedenceSurgeryHuman bodyHolographic imaging

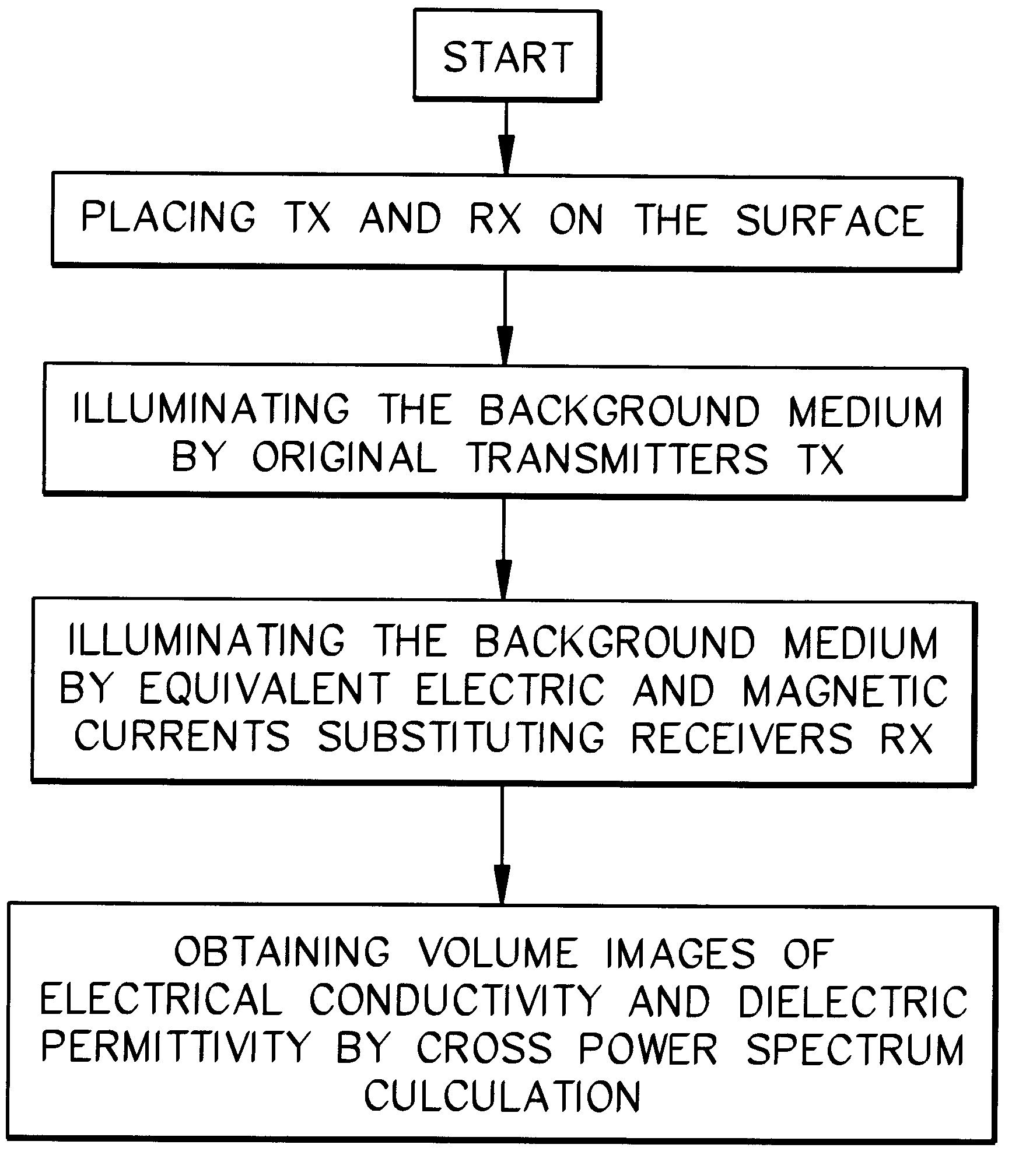

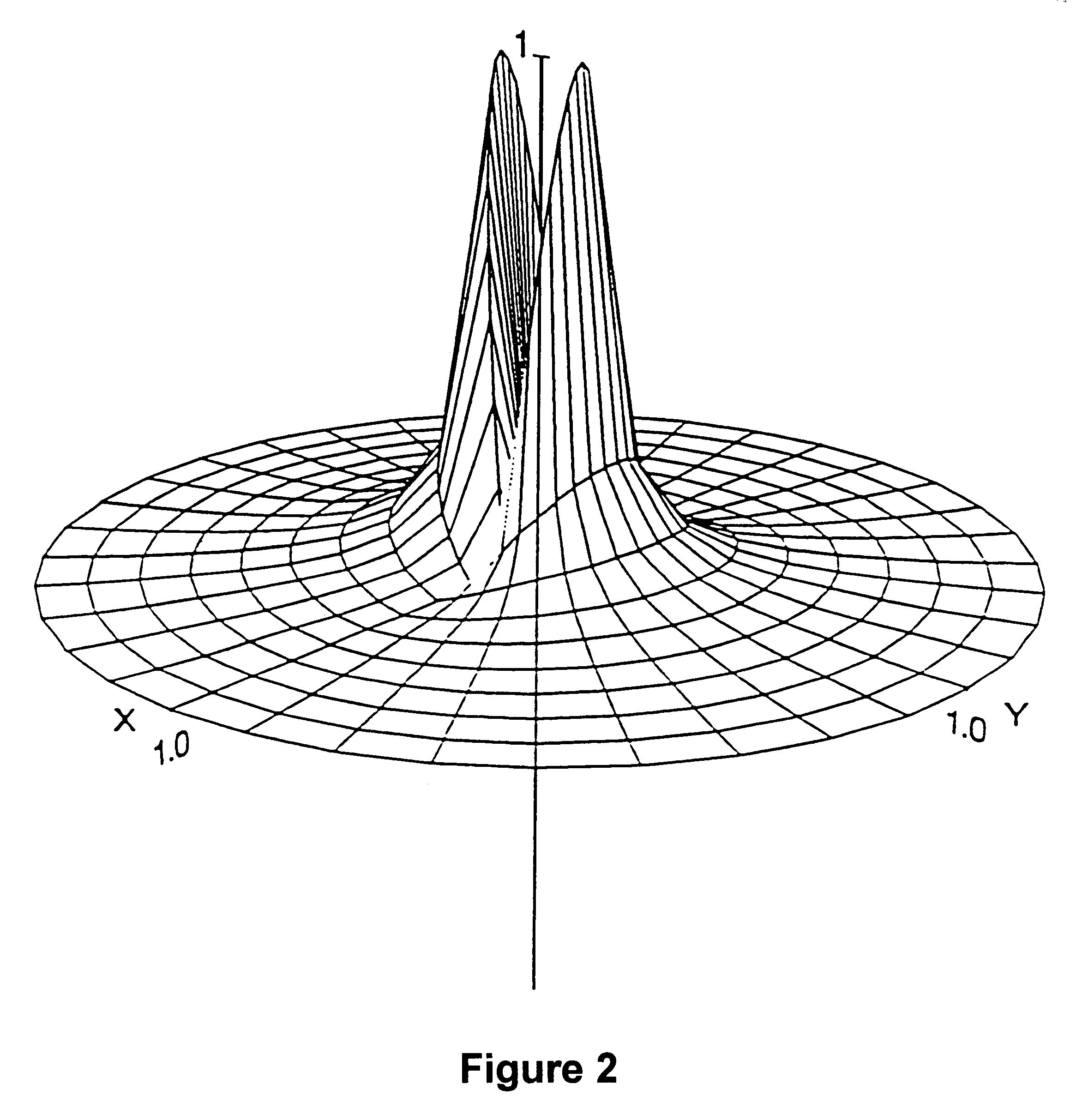

A method of imaging an object, such as a diseased human heart or bone, in a nontransparent medium, such as the human body, involves placing an array of transmitters and receivers in operational association with the medium. The transmitters generate a harmonic (frequency domain) or pulse (time domain) primary electromagnetic field (EM) which propagates through the medium. The primary field interacts with the object to produce a scattered field, which is recorded by the receivers. The scattered EM field components measured by the receivers are applied as an artificial EM field to generate a backscattering EM field. Cross power spectra of the primary and backscattering fields (in the frequency domain) or cross correlation between these fields (in the time domain) produce a numerical reconstruction of an EM hologram. The desired properties of the medium, such as conductivity or dielectric permittivity, are then derived from this hologram.

Owner:THE UNIV OF UTAH

Method and apparatus for detecting external cracks from within a metal tube

InactiveUS6271670B1Resistance/reactance/impedenceFlaw detection using microwavesRadarScattering loss

A method and tool using a continuous electromagnetic wave from a transverse magnetic-dipole source with a coaxial electric-dipole receiver is described for the detection of external sidewall cracks and other anomalies in boiler tubes and other enclosures. The invention utilizes the concept of radar backscatter rather than eddy-currents or ultrasound, which are sometimes used in prior art crack-detection methods. A numerical study of the distribution of the fields shows that the direct transmission from the source to the receiver is reduced from that in free space. Further, if the diameter of the receiver dipole is made sufficiently small, it should be possible to detect cracks with a scattering loss of up to -40 dB in thin-walled boiler tubes.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

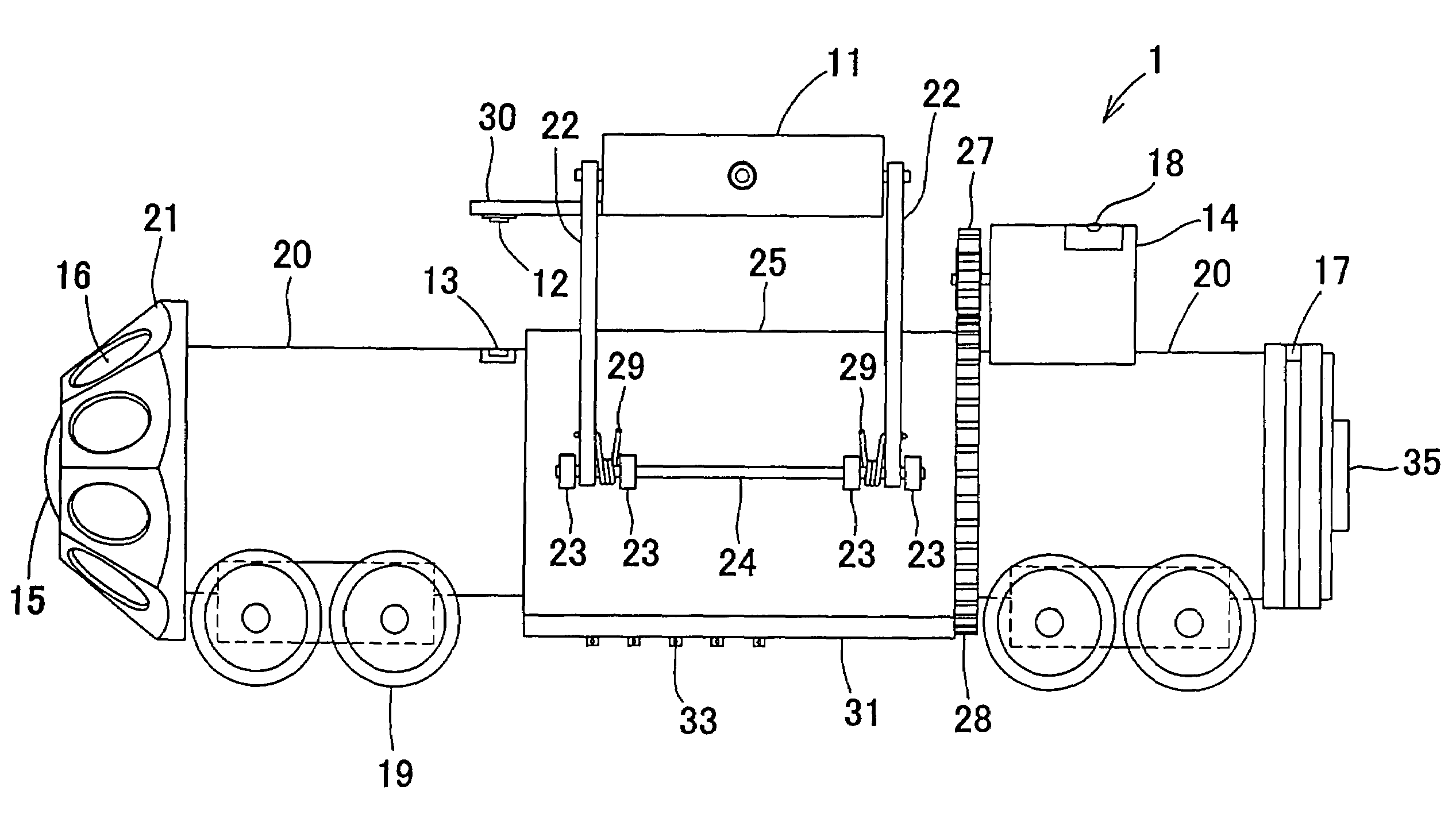

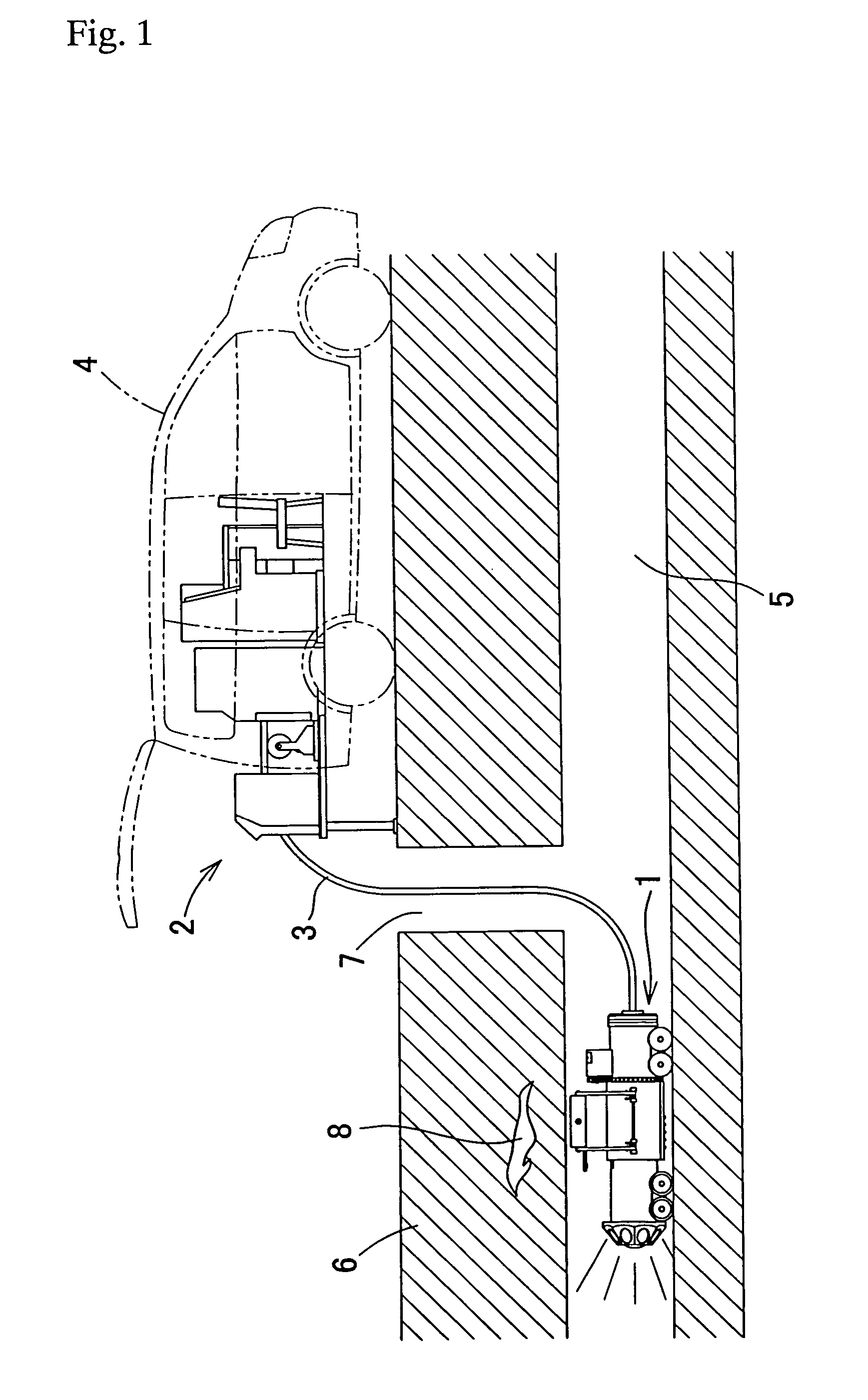

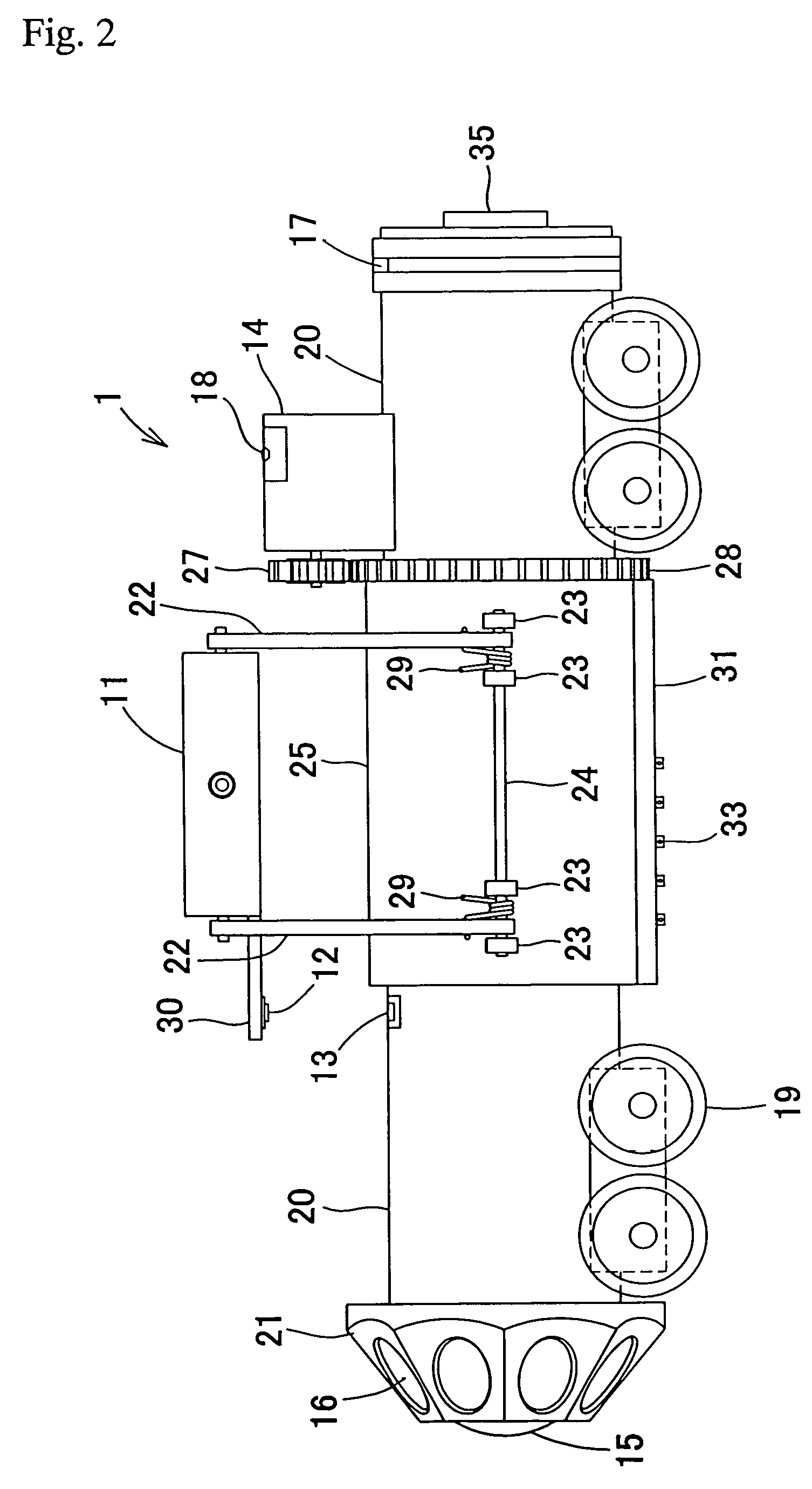

Device and method for inspecting inside of underground pipe line and method of inspecting concrete on inside of underground pipe line for deterioration

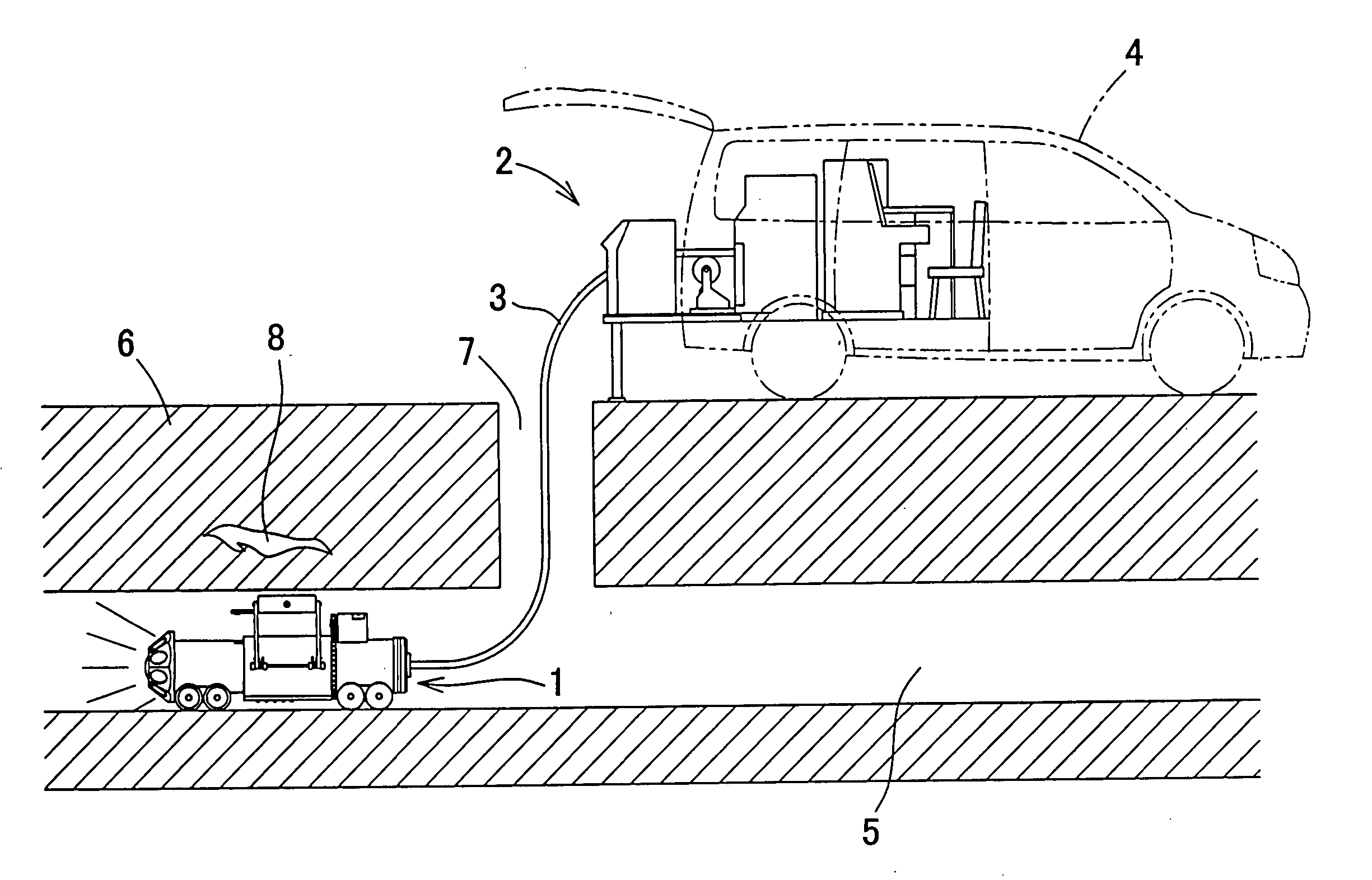

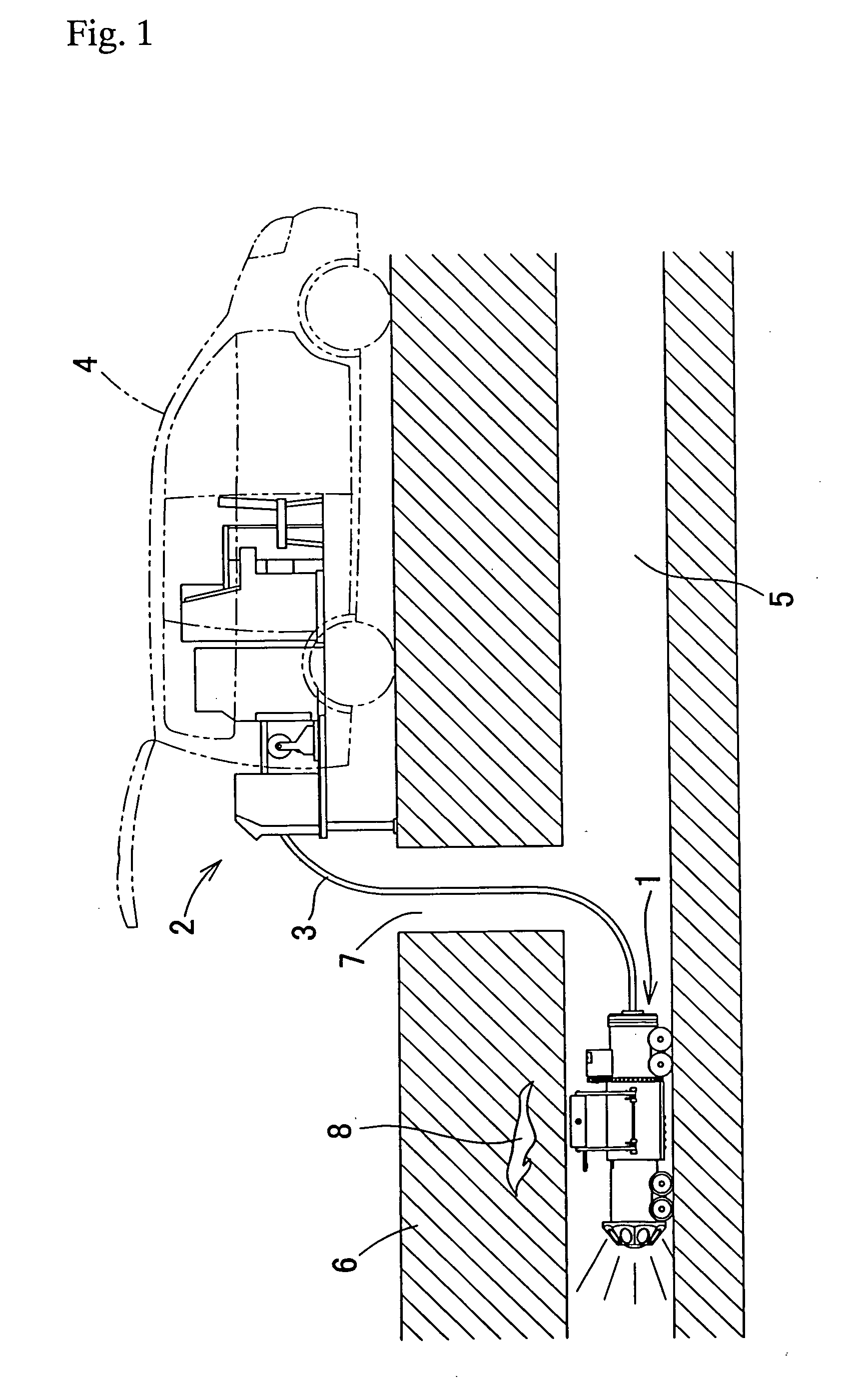

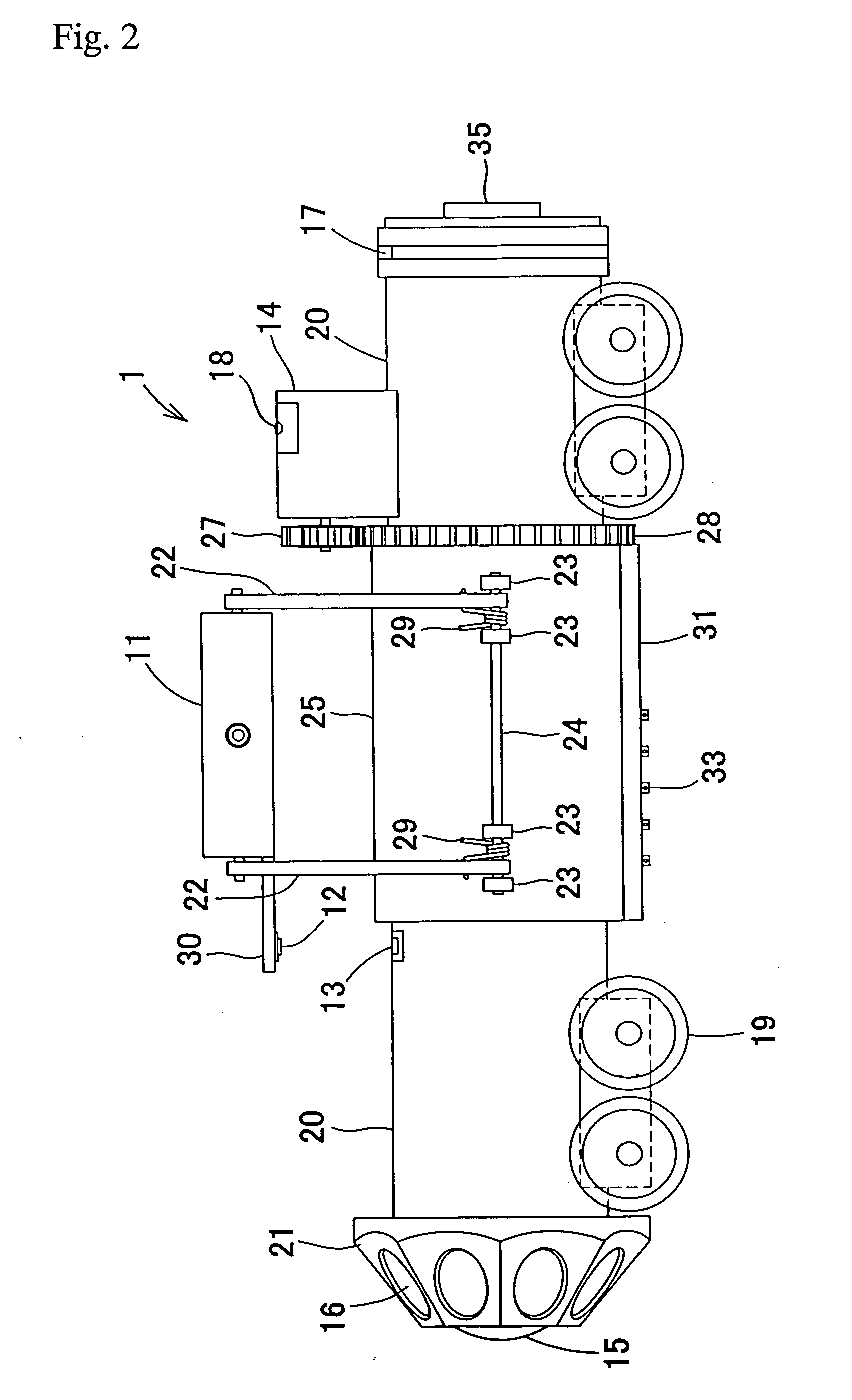

InactiveUS20050115337A1Reliably determinedAccurate measurementHollow article cleaningStructural/machines measurementFisheye lensGyroscope

A device for inspecting the inside of an underground pipe line which makes it possible to search for cavities on the outside of the underground pipe over the entire internal peripheral surface of the underground pipe, that is, not only upward of the underground pipe, but also toward both sides and downward thereof, to obtain detailed images of the inner peripheral surface of the pipe line without using a complex mechanism, and to display patterns of cracks and irregularities on the inner peripheral surface of the underground pipe by three-dimensional convergence images. The device comprises a pipe line internal self-propelled vehicle and an on-ground control unit, and the pipe line internal self-propelled vehicle is provided with a radar antenna, a camera equipped with a fisheye lens, a gyro, a laser sensor, and an infrared encoder.

Owner:BURN AM

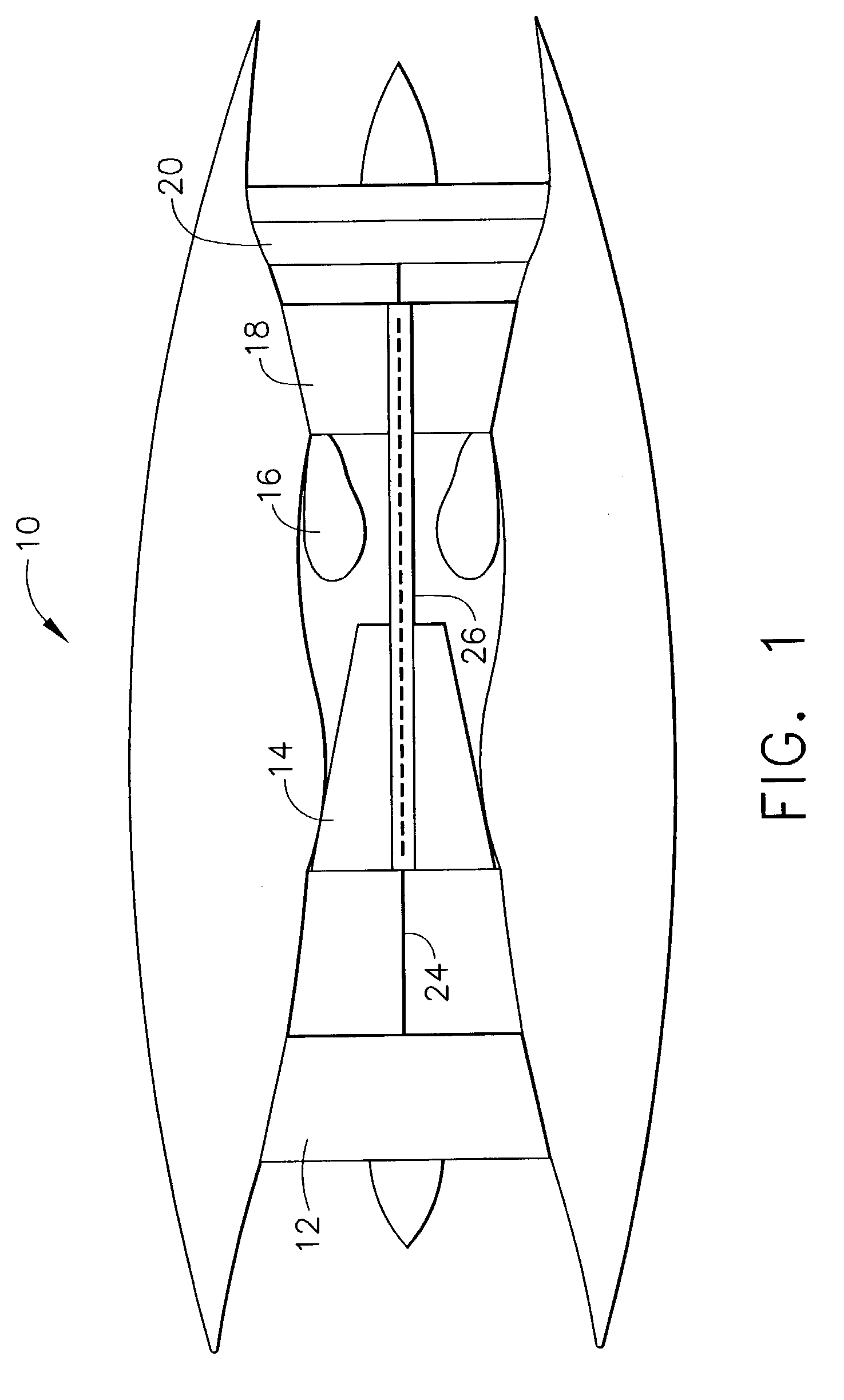

System and method for inspecting a wind turbine blade

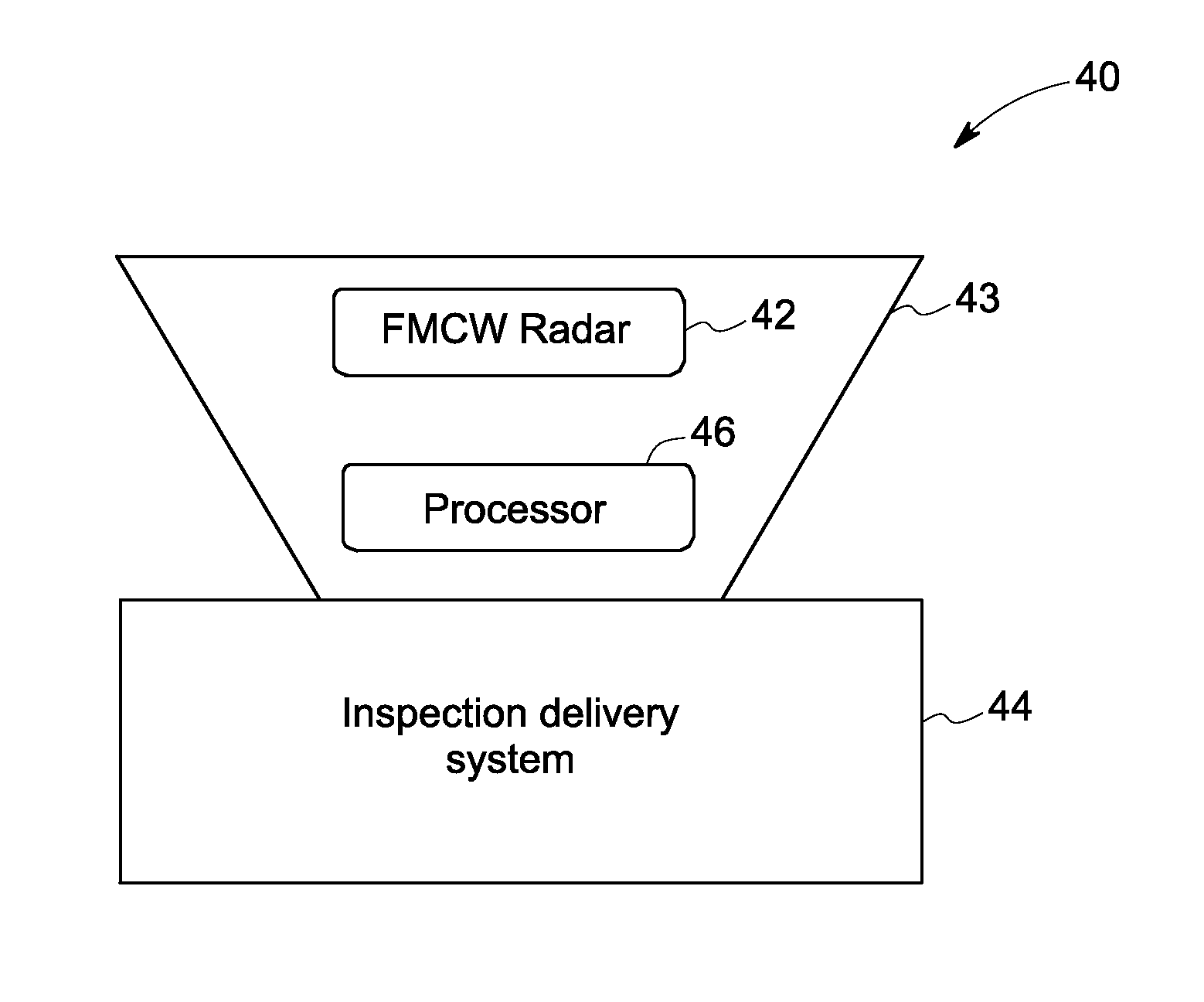

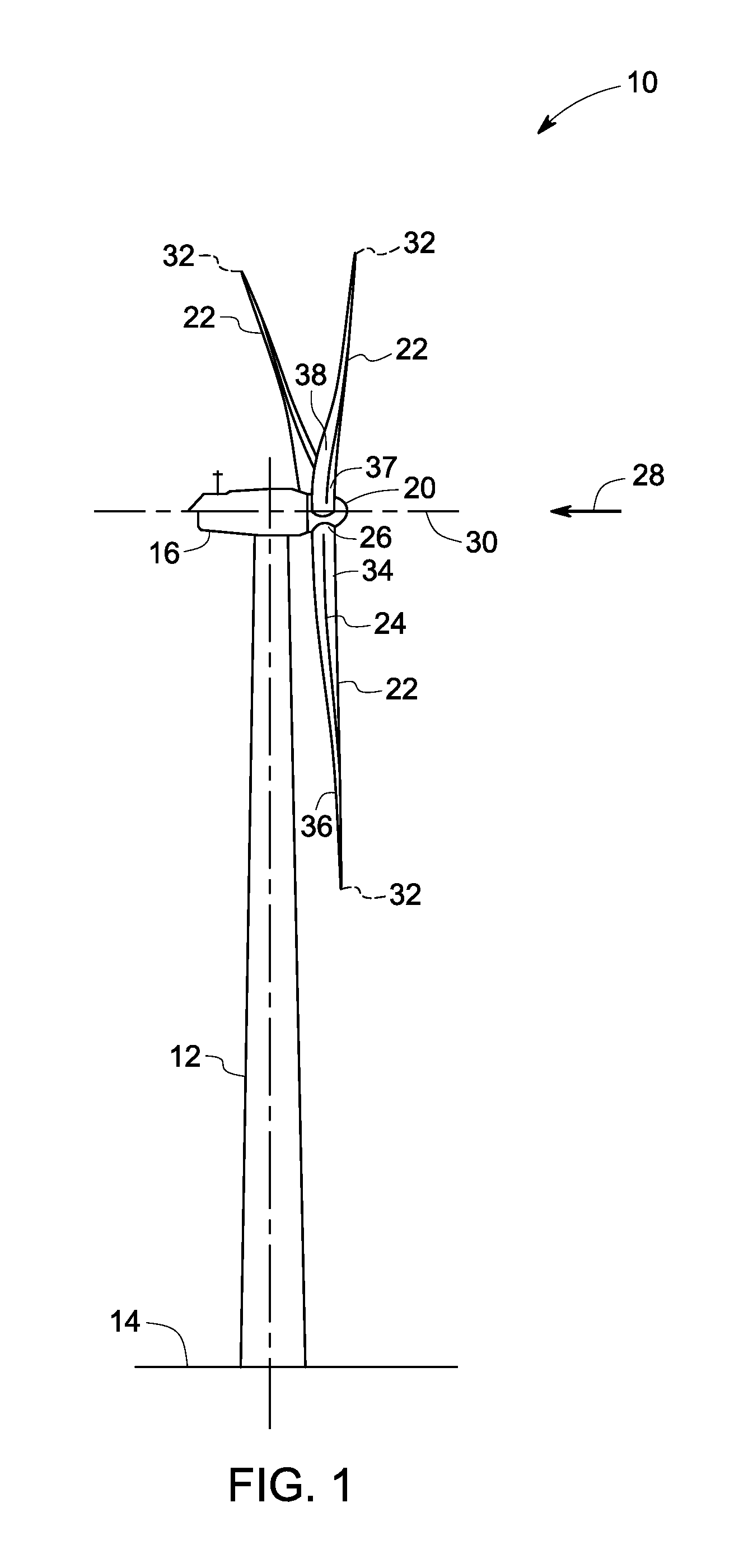

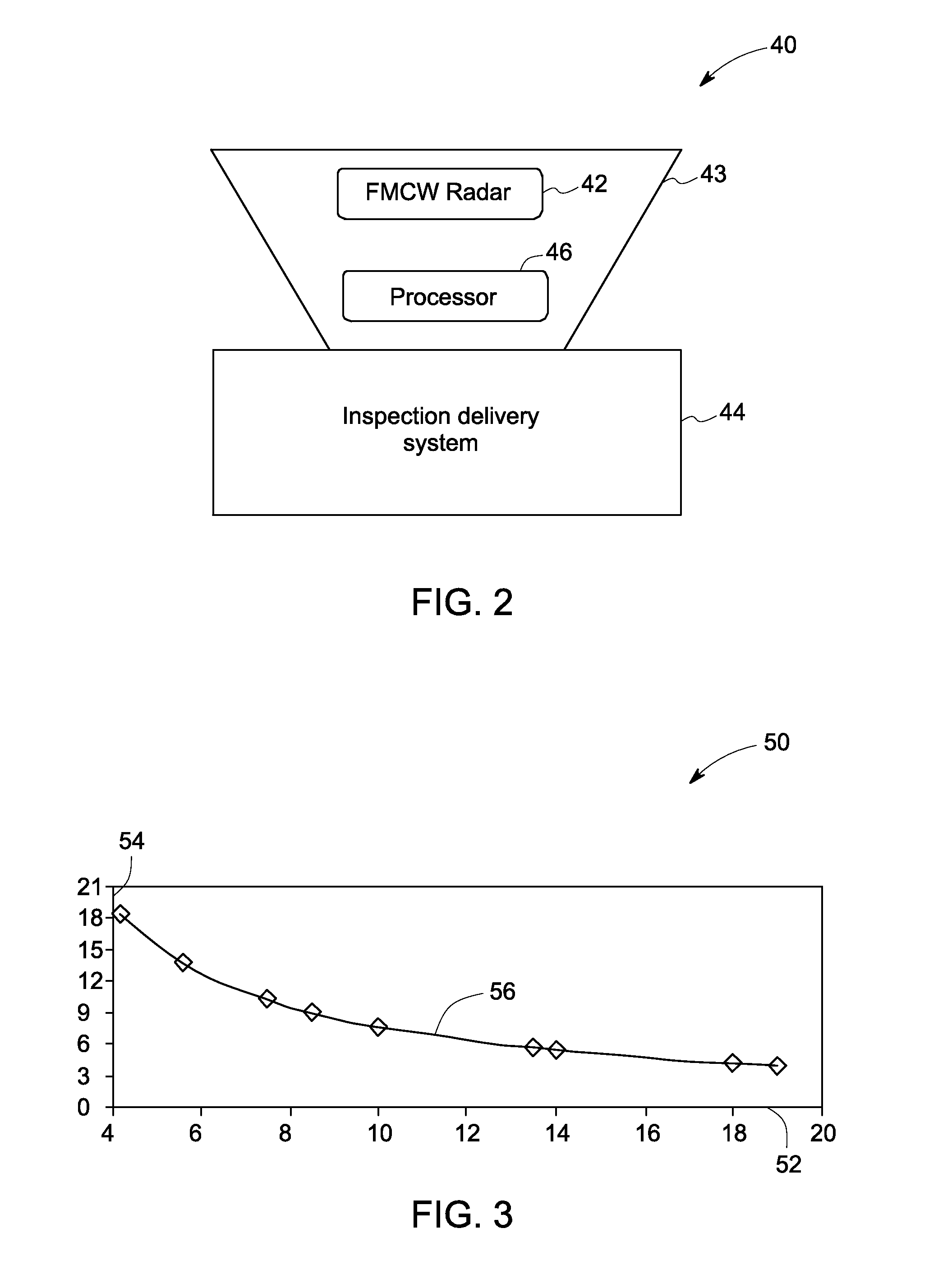

A wind turbine blade inspection system includes a frequency modulated continuous wave radar system configured to be movable with respect to a wind turbine blade while transmitting reference microwave signals and receiving reflected microwave signals and a processor configured for using a synthetic aperture analysis technique to obtain a focused image of at least a region of the wind turbine blade based on the reflected microwave signals.

Owner:GENERAL ELECTRIC CO

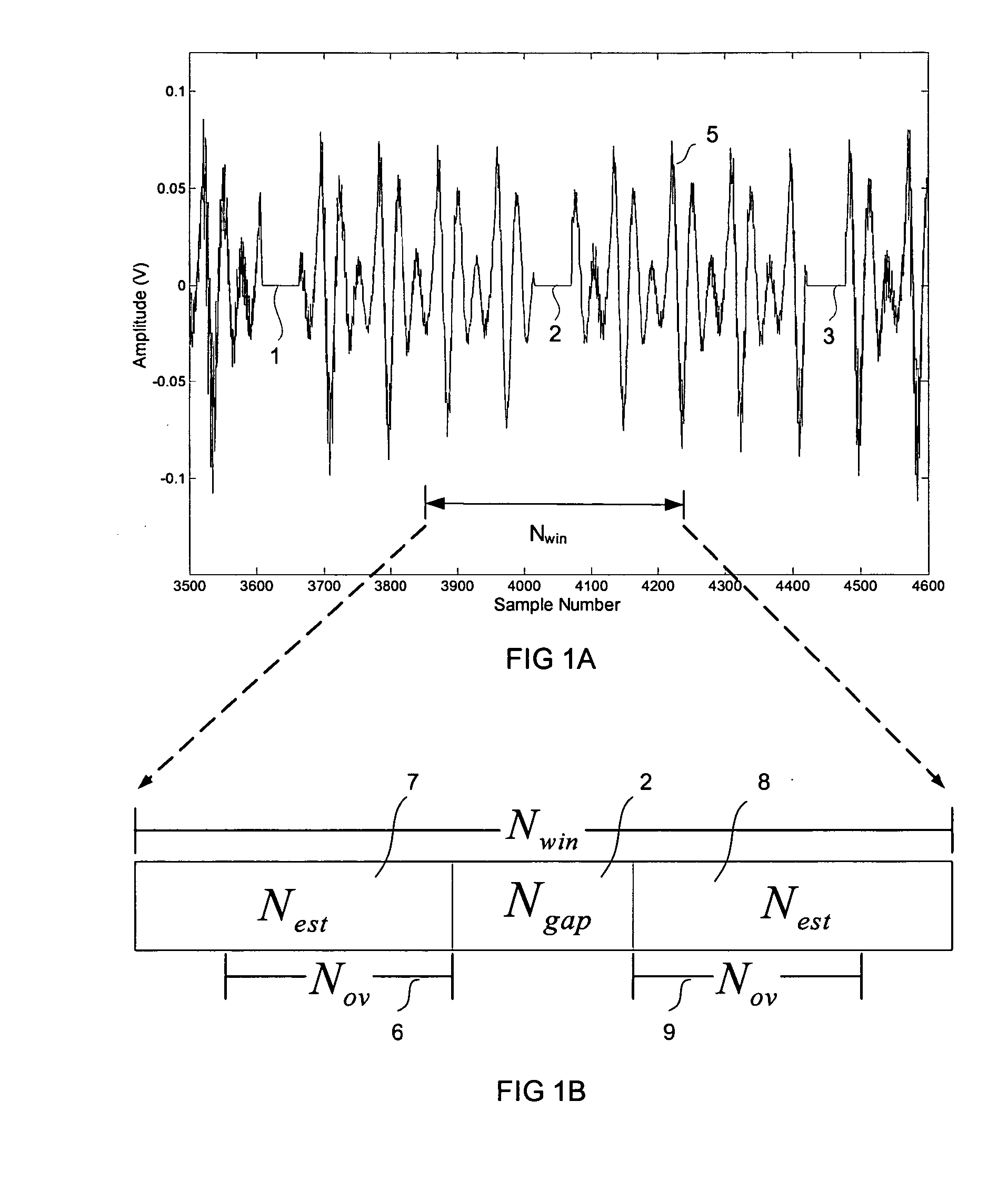

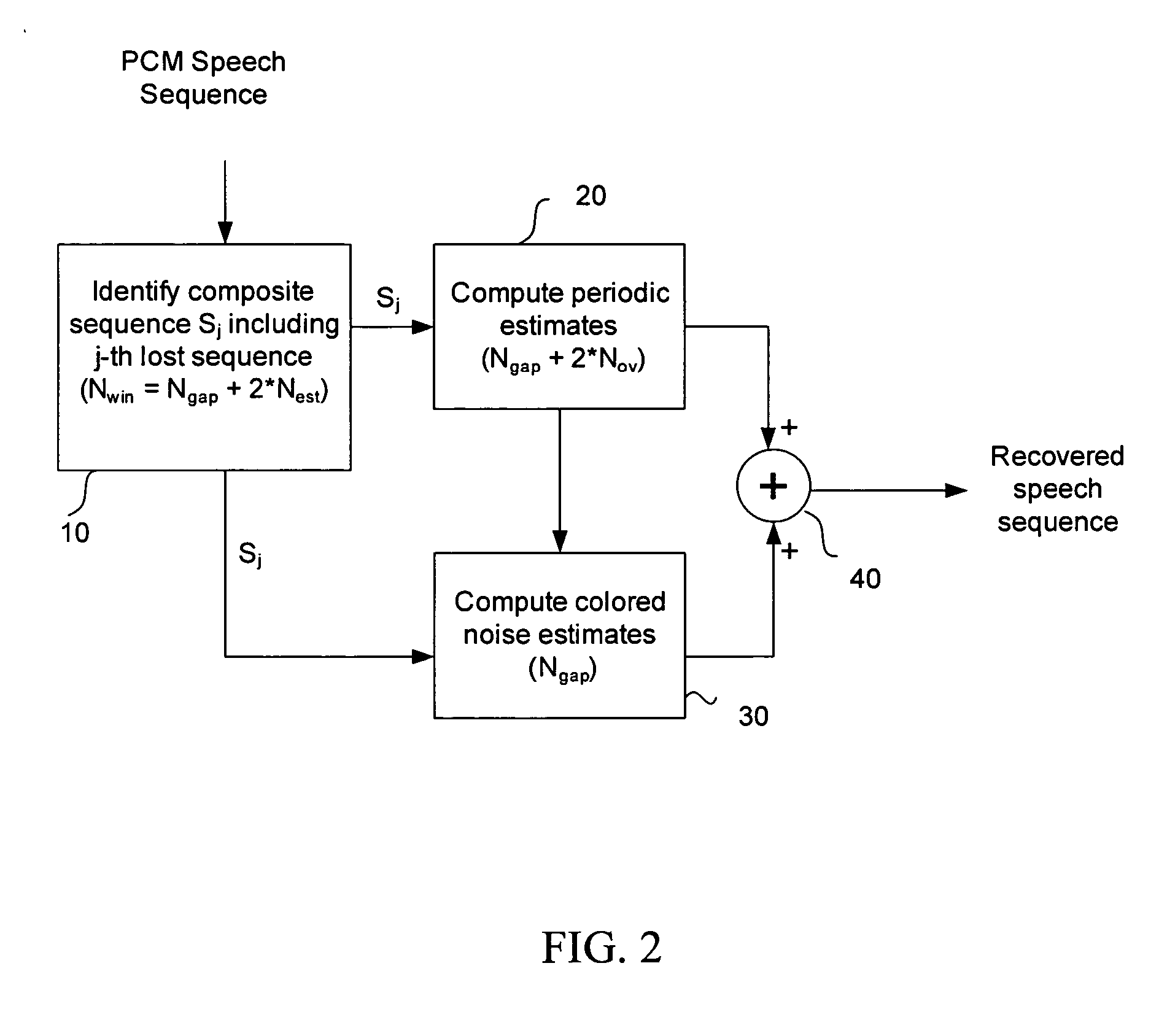

Method for recovery of lost speech data

InactiveUS20050015242A1Radiating elements structural formsSpeech recognitionAdaptive filterLinearity

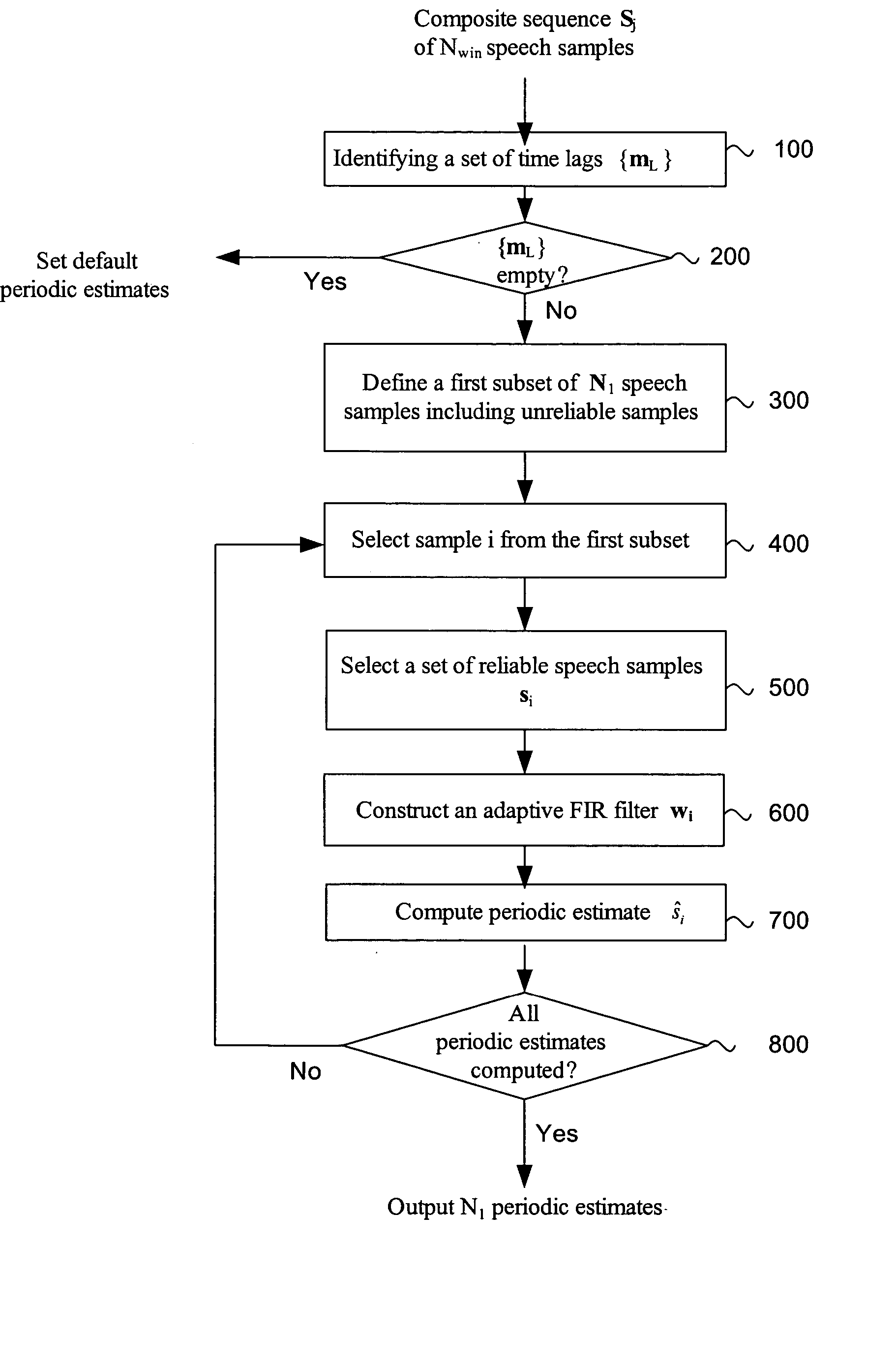

A method for lost speech samples recovery in speech transmission systems is disclosed. The method employs a waveform coder operating on digital speech samples. It exploits the composite model of speech, wherein each speech segment contains both periodic and colored noise components, and separately estimates these two components of the unreliable samples. First, adaptive FIR filters computed from received signal statistics are used to interpolate estimates of the periodic component for the unreliable samples. These FIR filters are inherently stable and typically short, since only strongly correlated elements of the signal corresponding to pitch offset samples are used to compute the estimate. These periodic estimates are also computed for sample times corresponding to reliable samples adjacent to the unreliable sample interval. The differences between these reliable samples and the corresponding periodic estimates are considered as samples of the noise component. These samples, computed both before and after the unreliable sample interval, are extrapolated into the time slot of the unreliable samples with linear prediction techniques. Corresponding periodic and colored noise estimates are then summed. All required statistics and quantities are computed at the receiver, eliminating any need for special processing at the transmitter. Gaps of significant duration, e.g., in the tens of milliseconds, can be effectively compensated.

Owner:HER MAJESTY THE QUEEN & RIGHT OF CANADA REPRESENTED BY THE MIN OF IND THROUGH THE COMM RES CENT

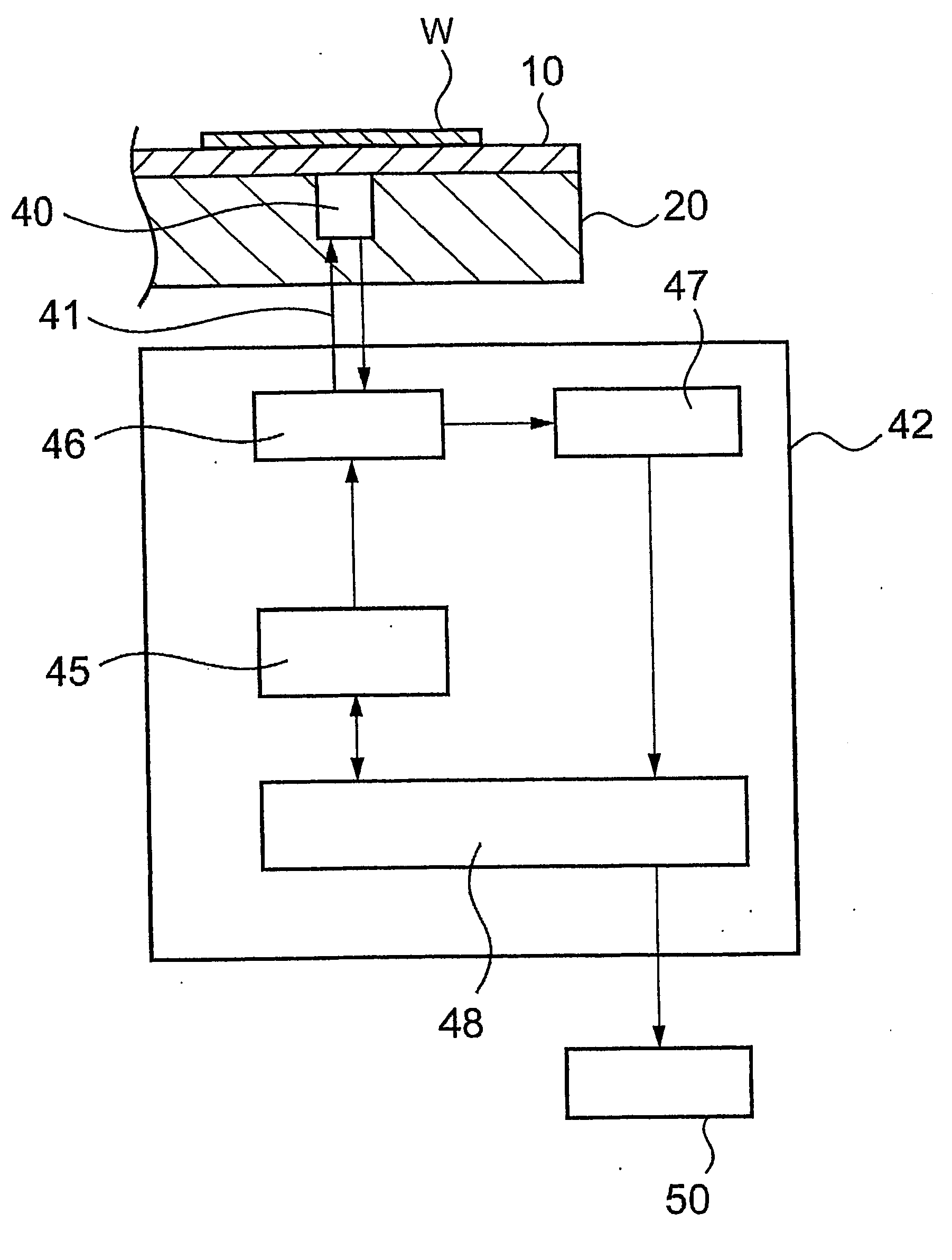

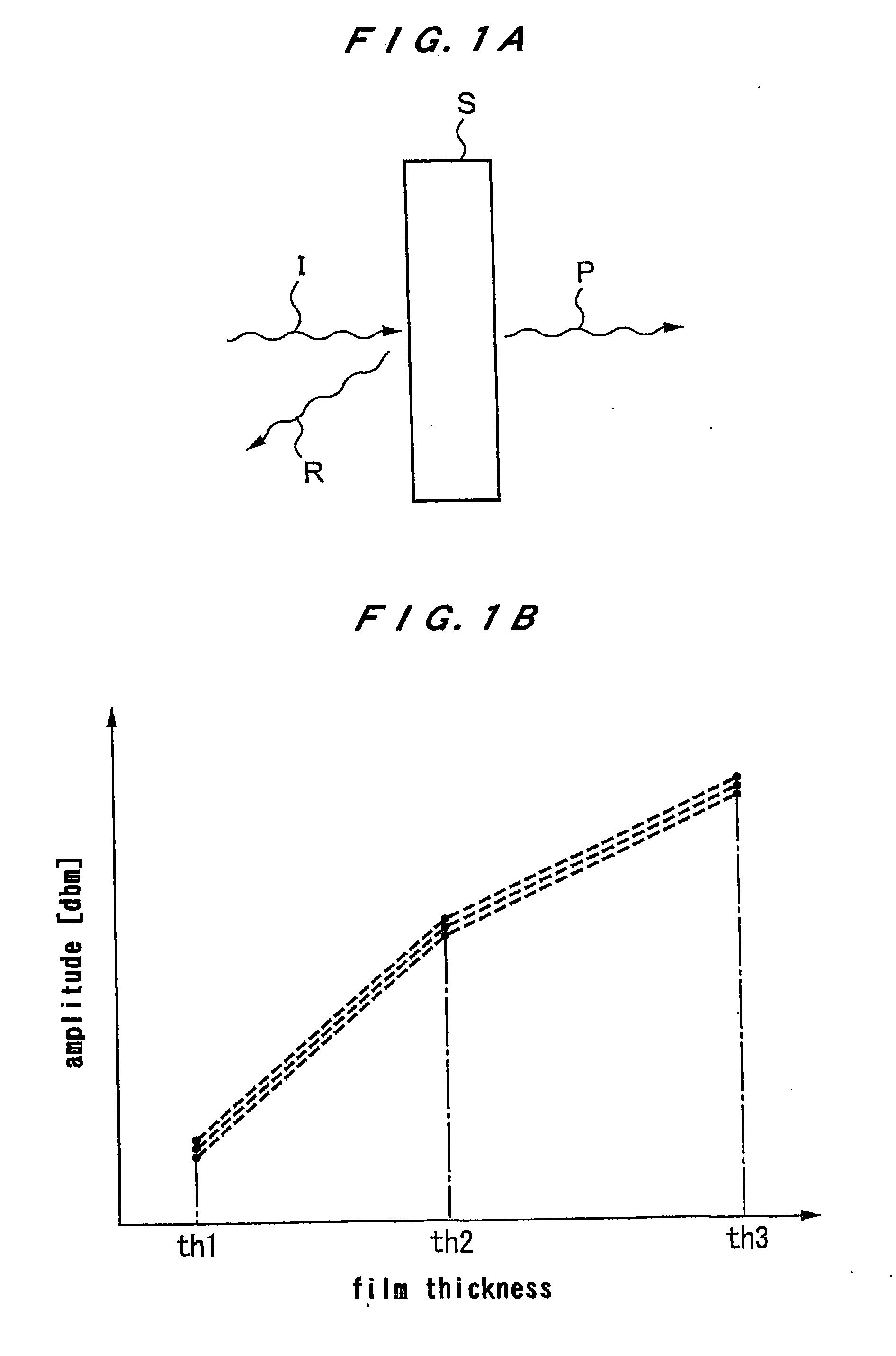

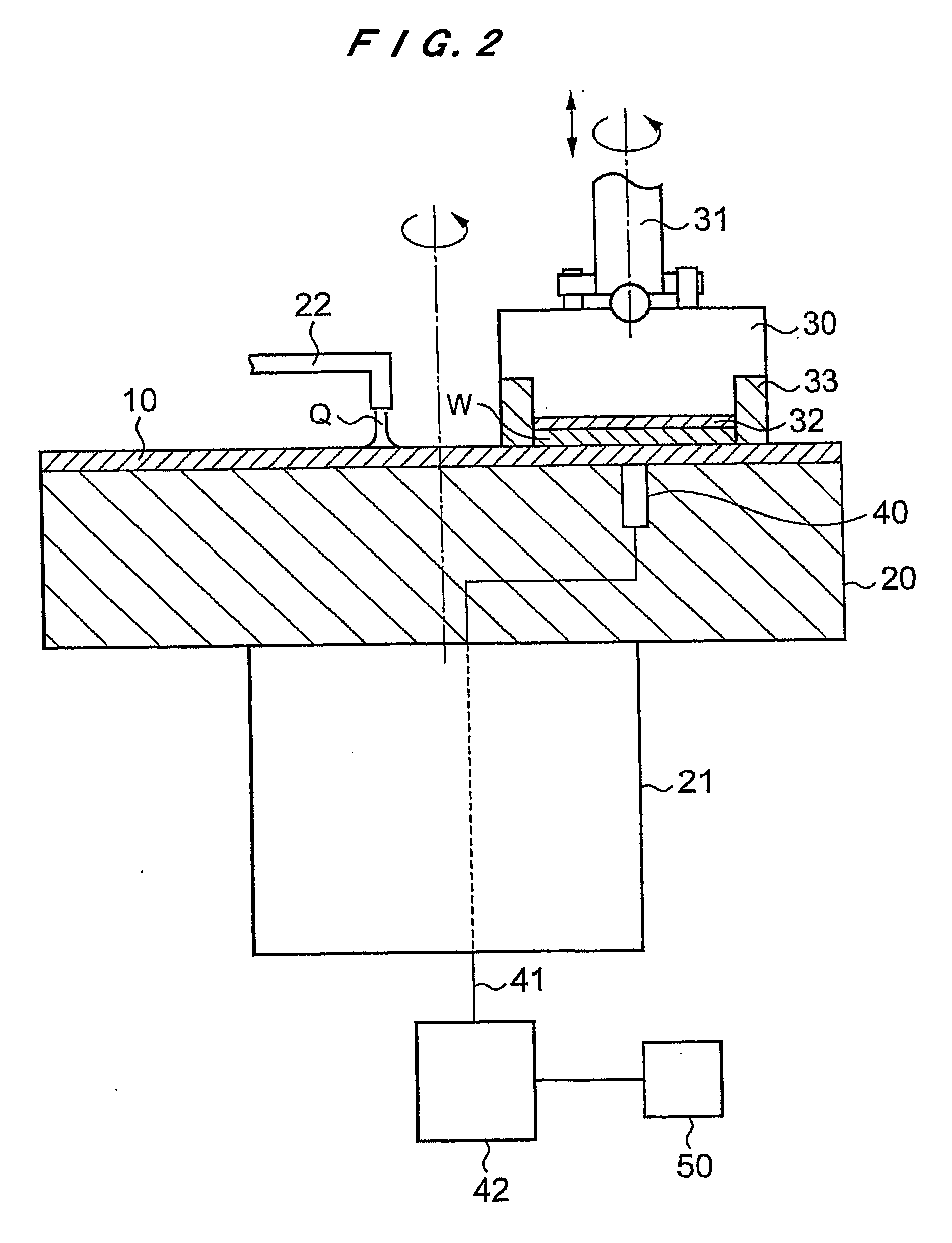

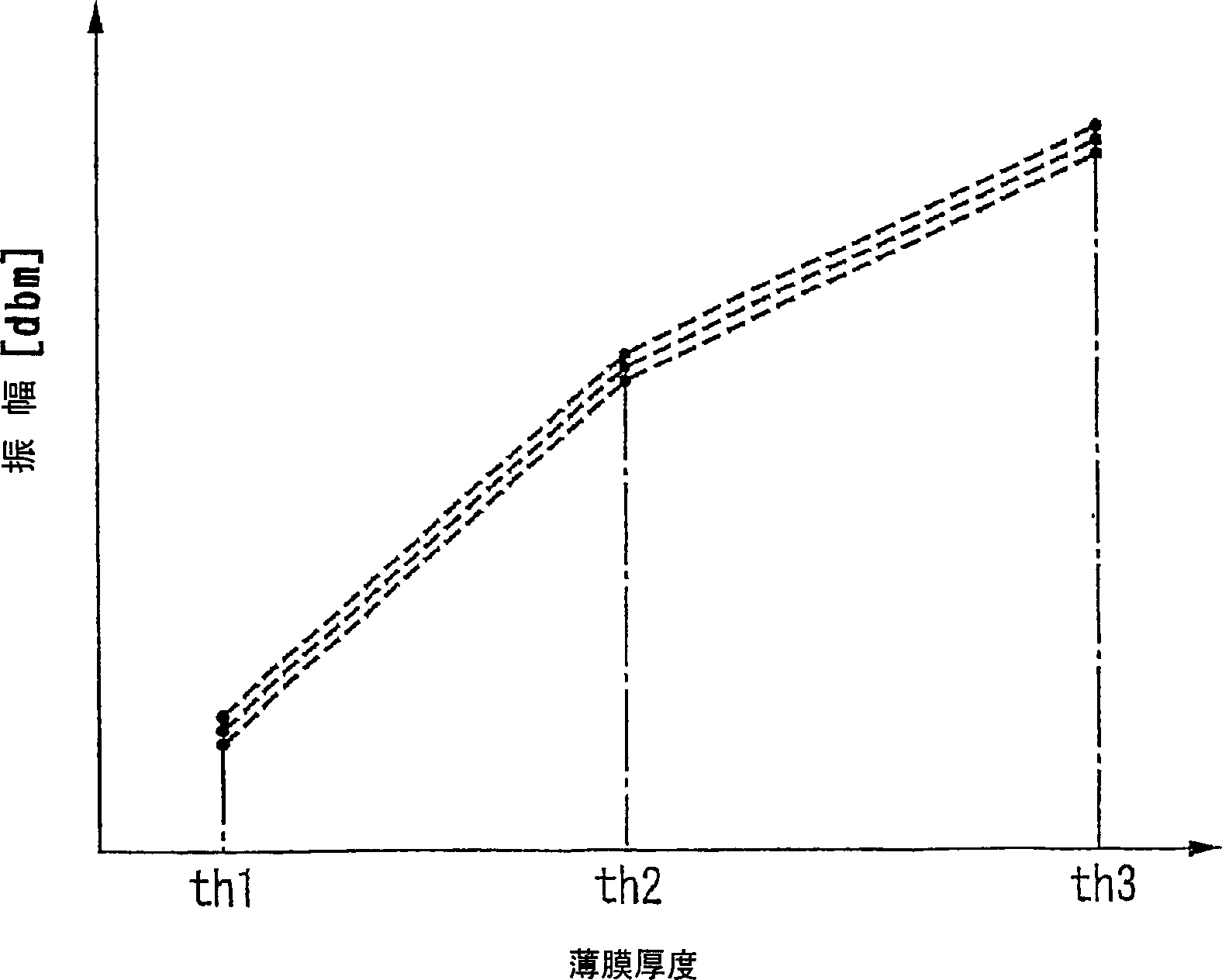

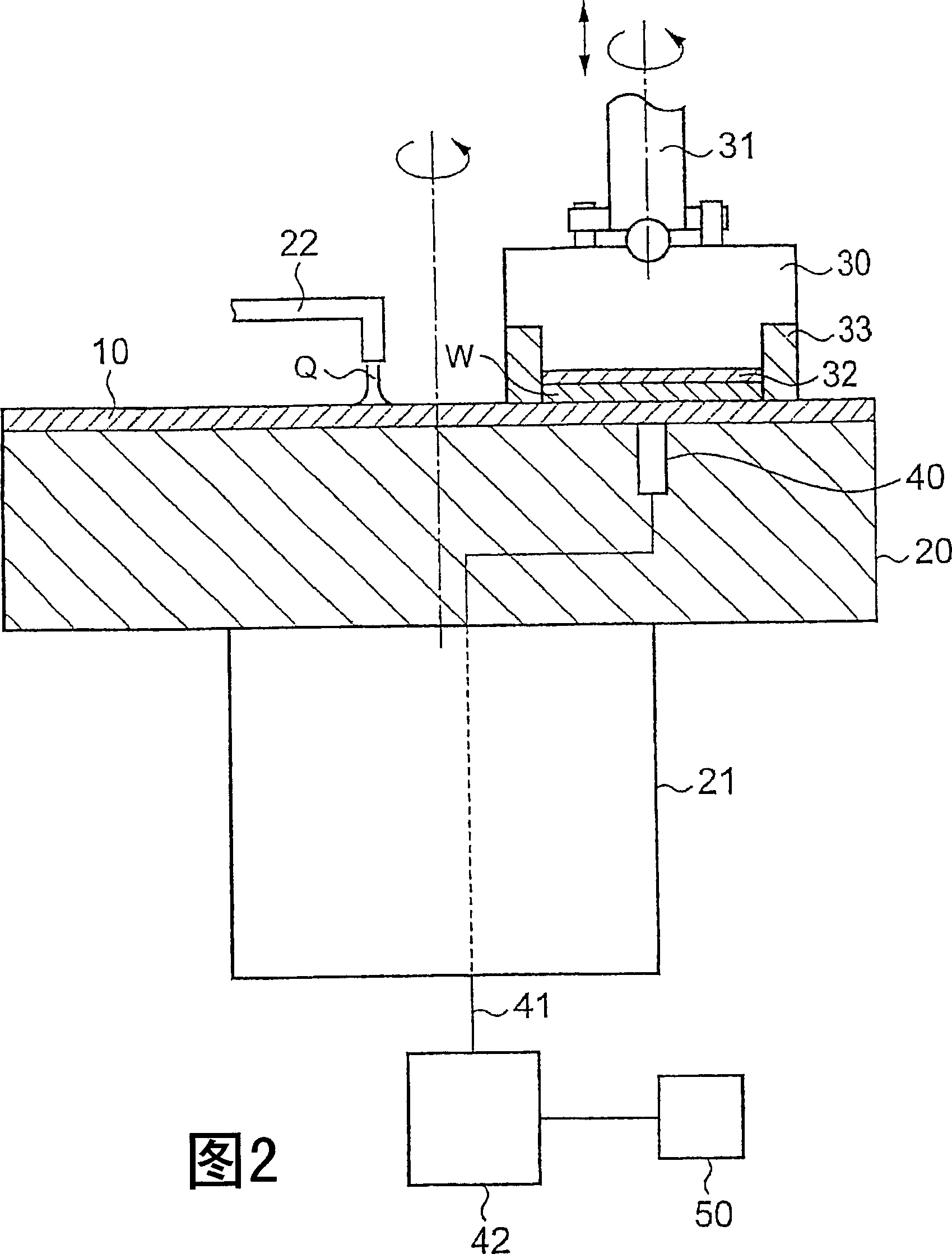

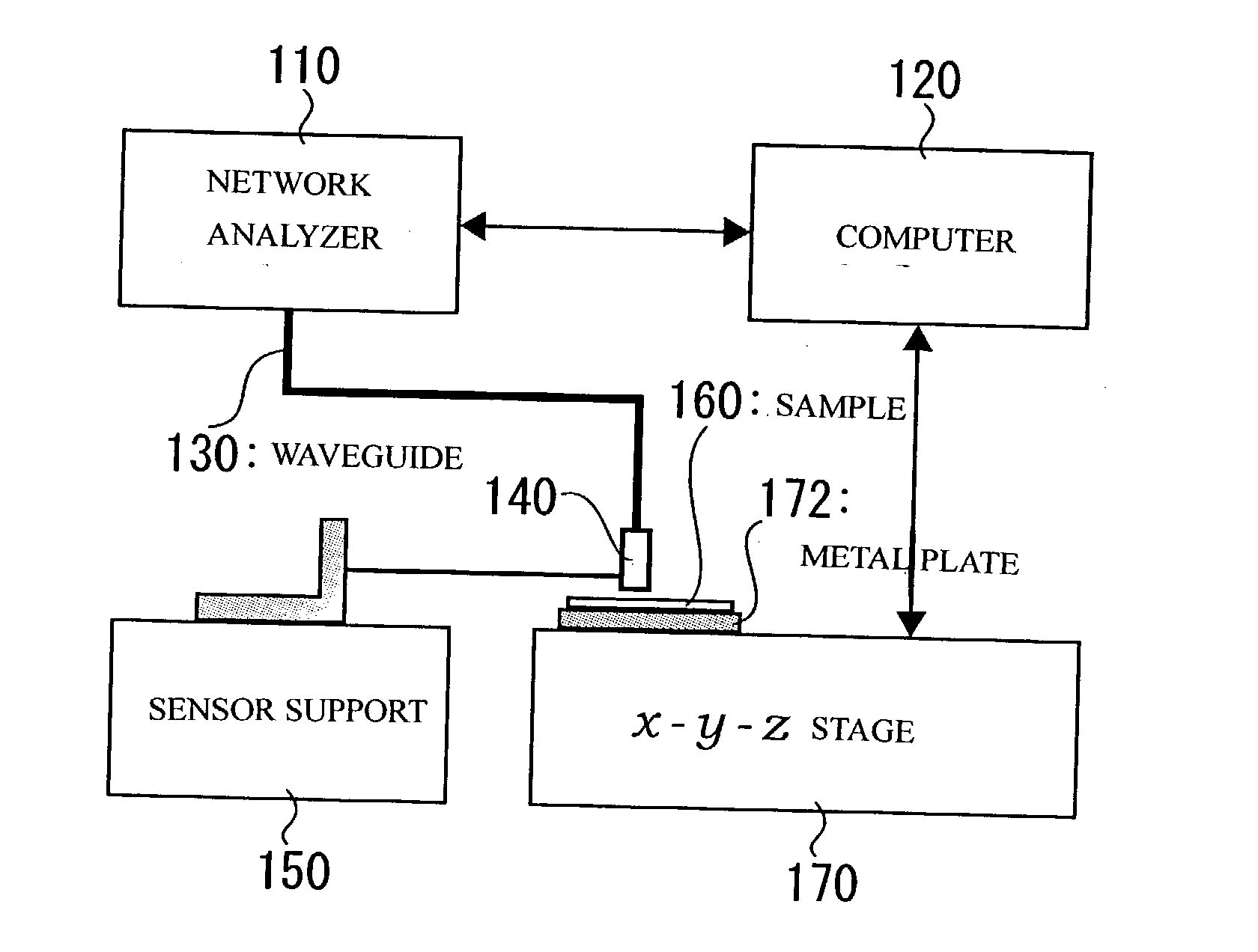

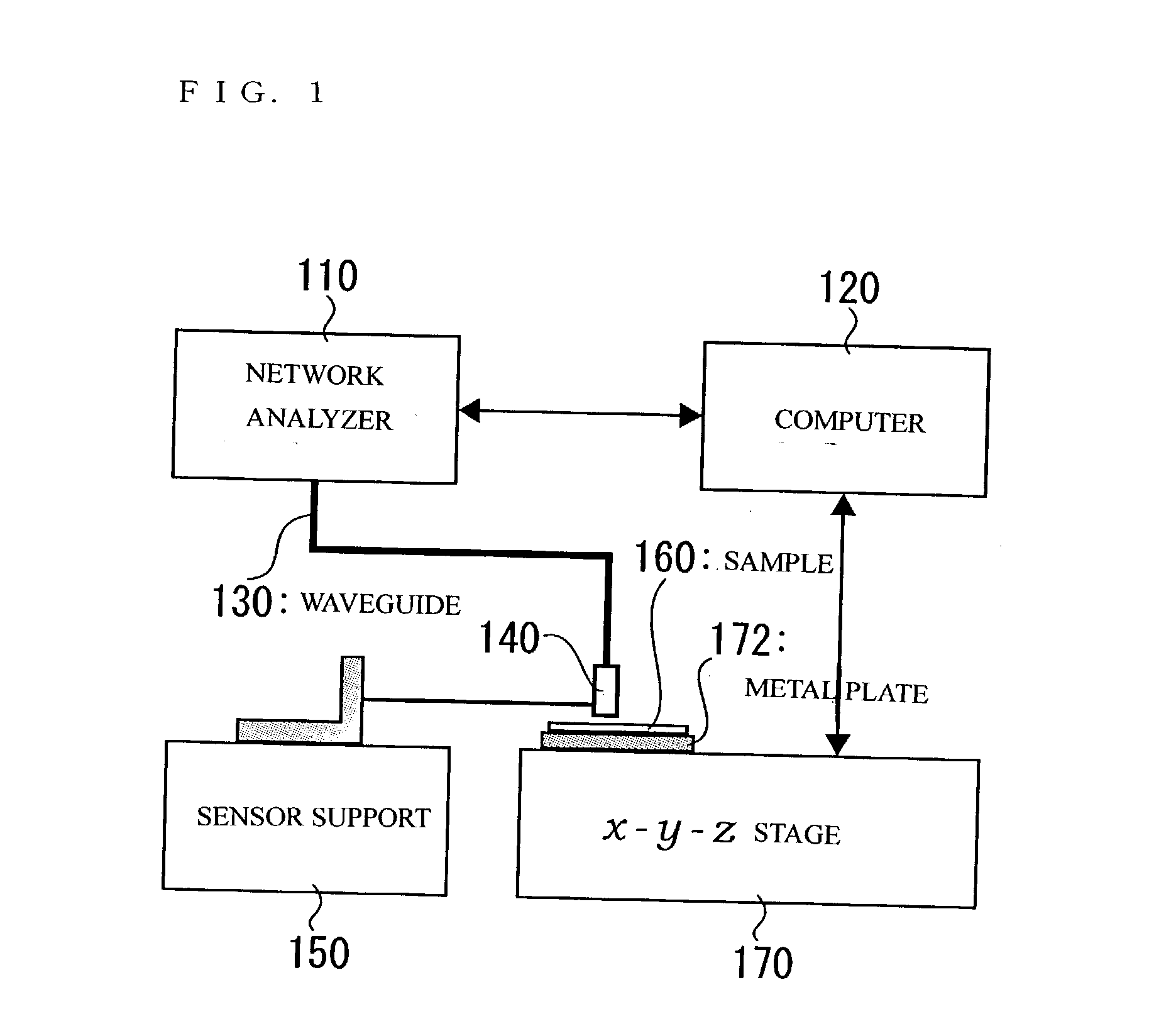

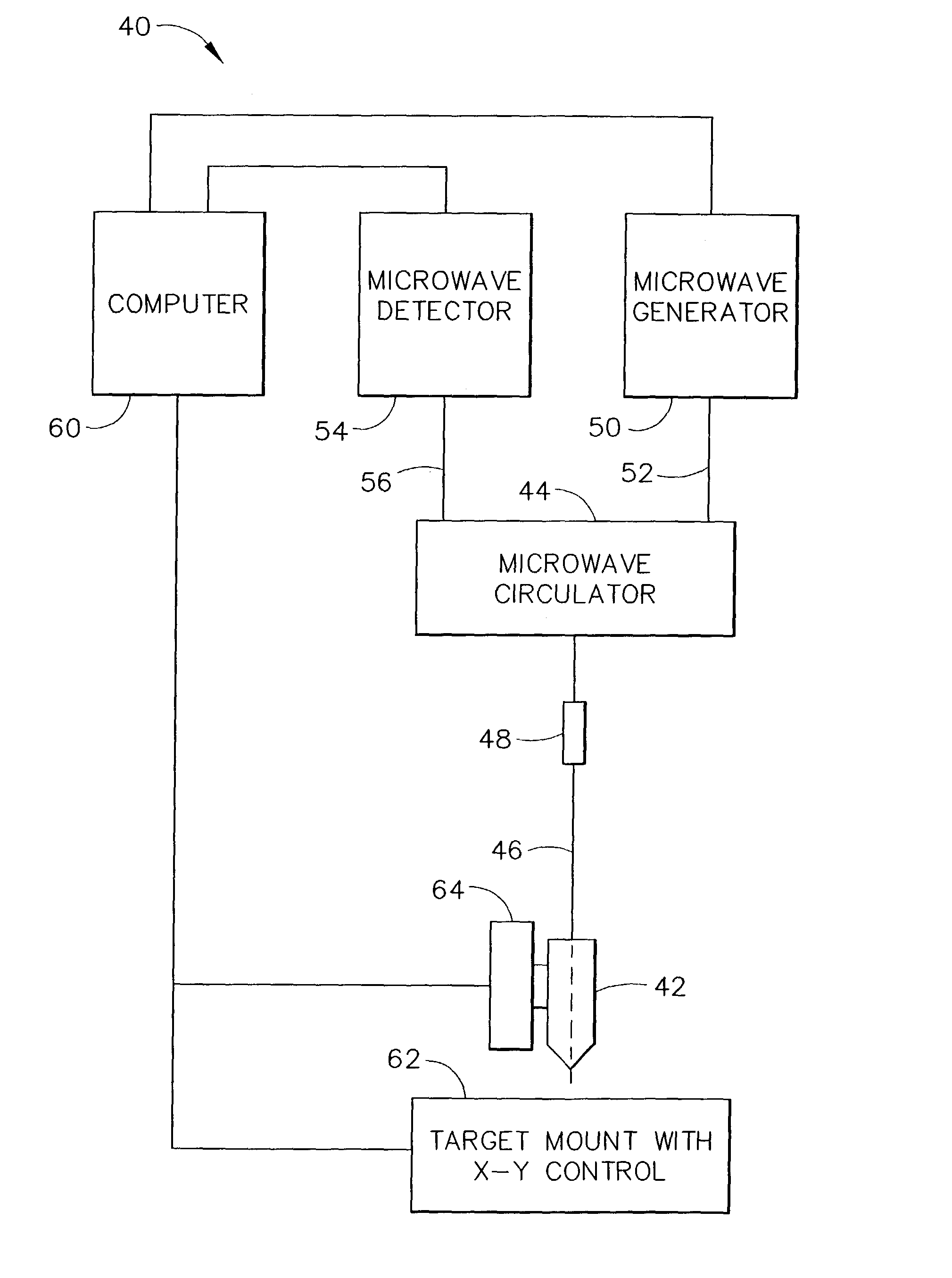

Measuring apparatus

InactiveUS20060164104A1Reduce manufacturing costAccurate measurementSemiconductor/solid-state device testing/measurementResistance/reactance/impedenceMeasurement deviceMeasuring instrument

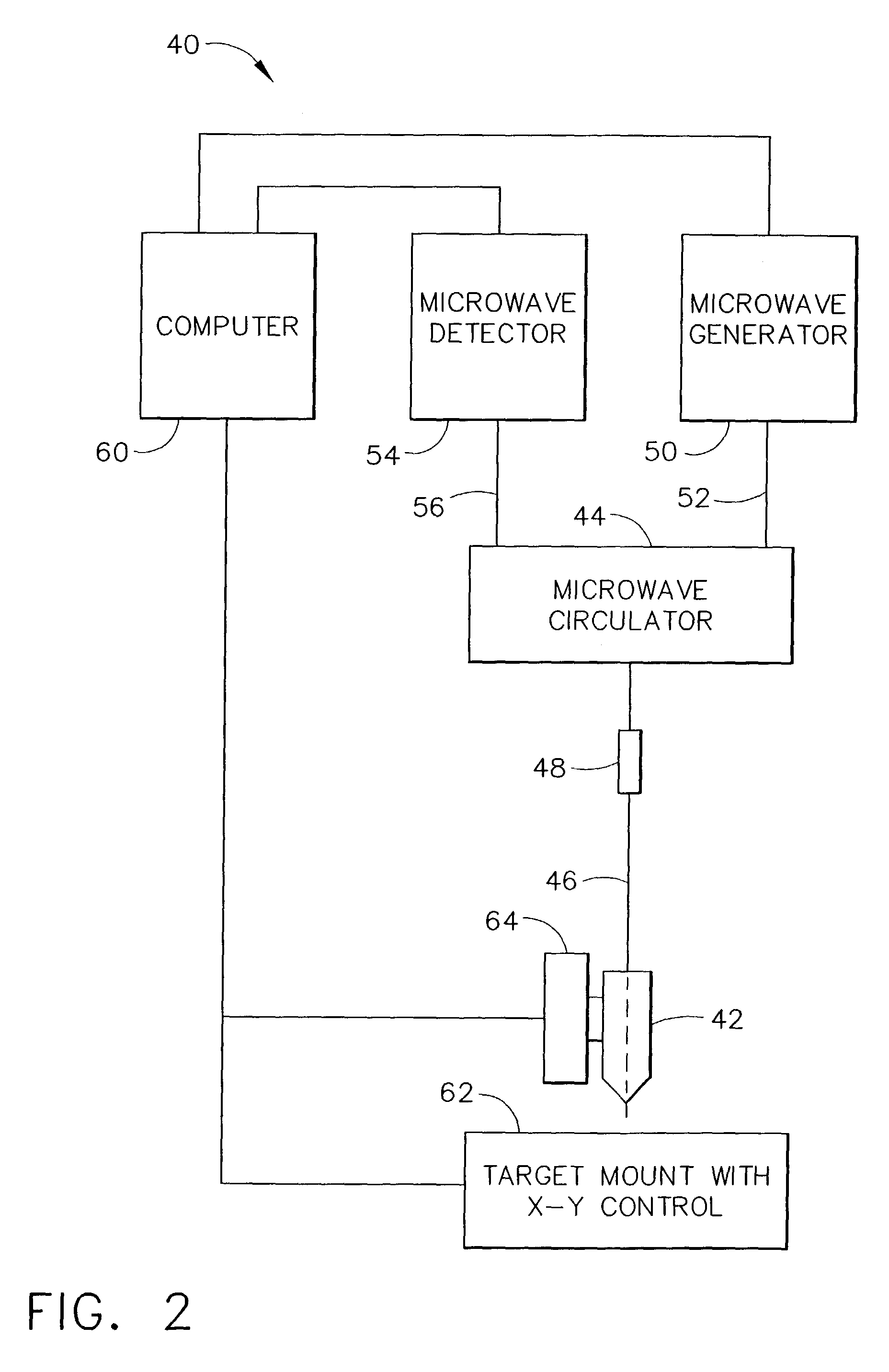

The present invention relates to a measuring apparatus for measuring a thickness or the like of a thin film formed on a surface of a substrate such as a semiconductor wafer. The measuring apparatus includes a microwave emission device (40) for emitting a microwave to a substance, a microwave generator (45) for supplying the microwave to the microwave emission device (40), a detector (47) for detecting an amplitude or a phase of the microwave which has been reflected from or passed through the substance, and an analyzer (48) for analyzing a structure of the substance based on the amplitude or the phase of the microwave which has been detected by the detector (47).

Owner:EBARA CORP

Device and method for inspecting inside of underground pipe line and method of inspecting concrete on inside of underground pipe line for deterioration

InactiveUS7131344B2Improve accuracyImprove detection accuracyHollow article cleaningStructural/machines measurementCamera lensFisheye lens

A device for inspecting the inside of an underground pipe line which makes it possible to search for cavities on the outside of the underground pipe over the entire internal peripheral surface of the underground pipe, that is, not only upward of the underground pipe, but also toward both sides and downward thereof, to obtain detailed images of the inner peripheral surface of the pipe line without using a complex mechanism, and to display patterns of cracks and irregularities on the inner peripheral surface of the underground pipe by three-dimensional convergence images. The device comprises a pipe line internal self-propelled vehicle and an on-ground control unit, and the pipe line internal self-propelled vehicle is provided with a radar antenna, a camera equipped with a fisheye lens, a gyro, a laser sensor, and an infrared encoder.

Owner:BURN AM

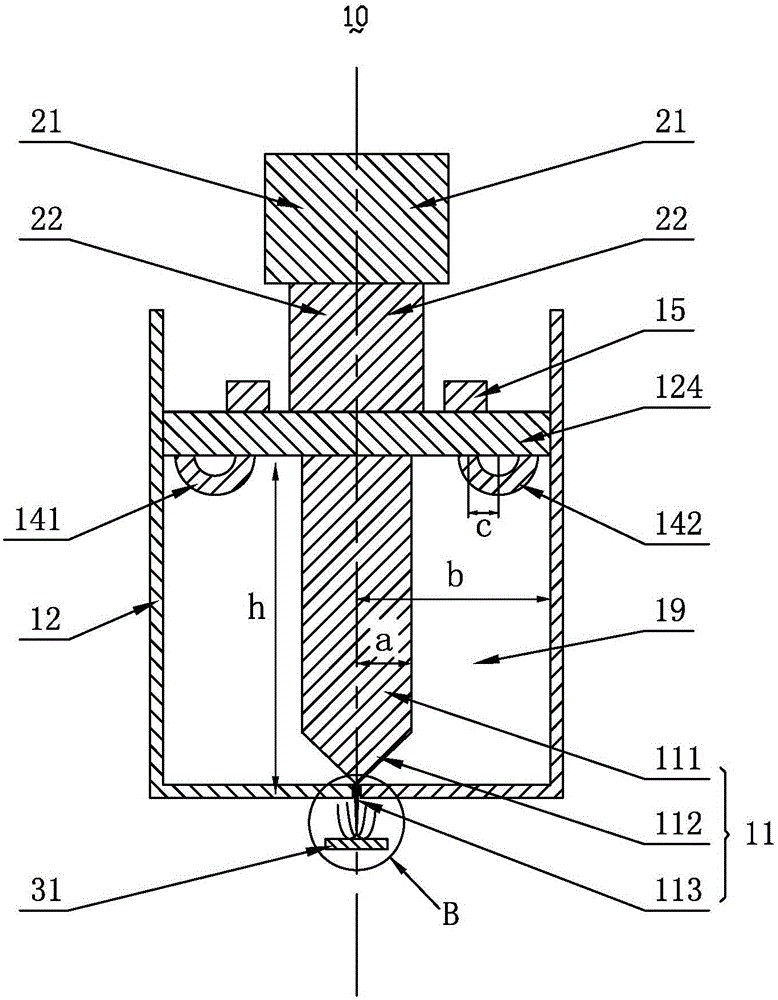

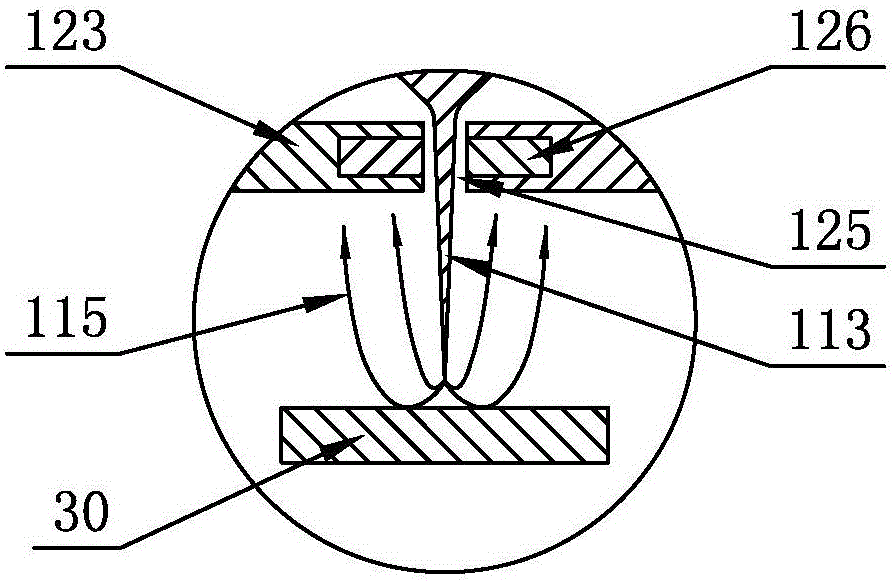

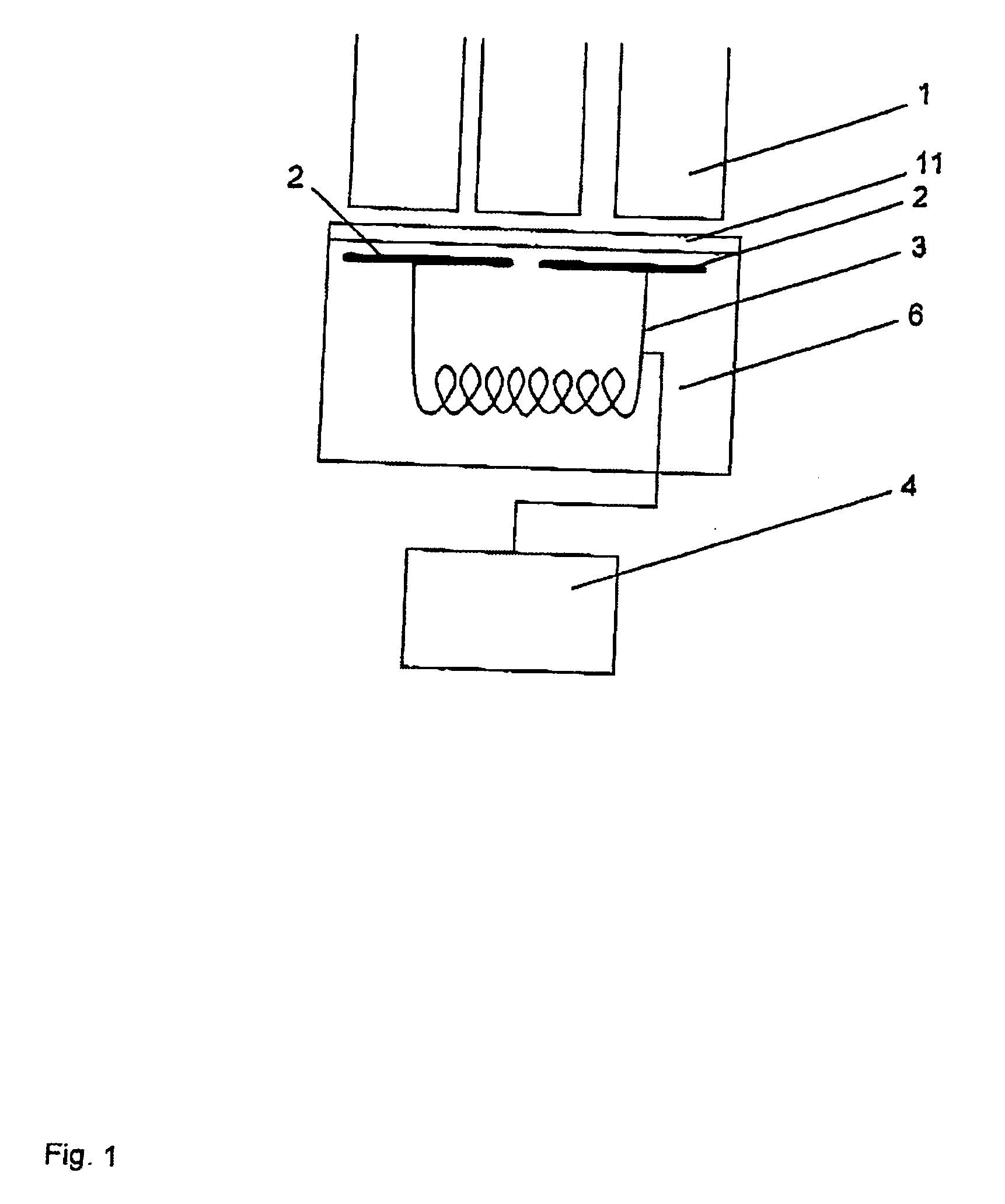

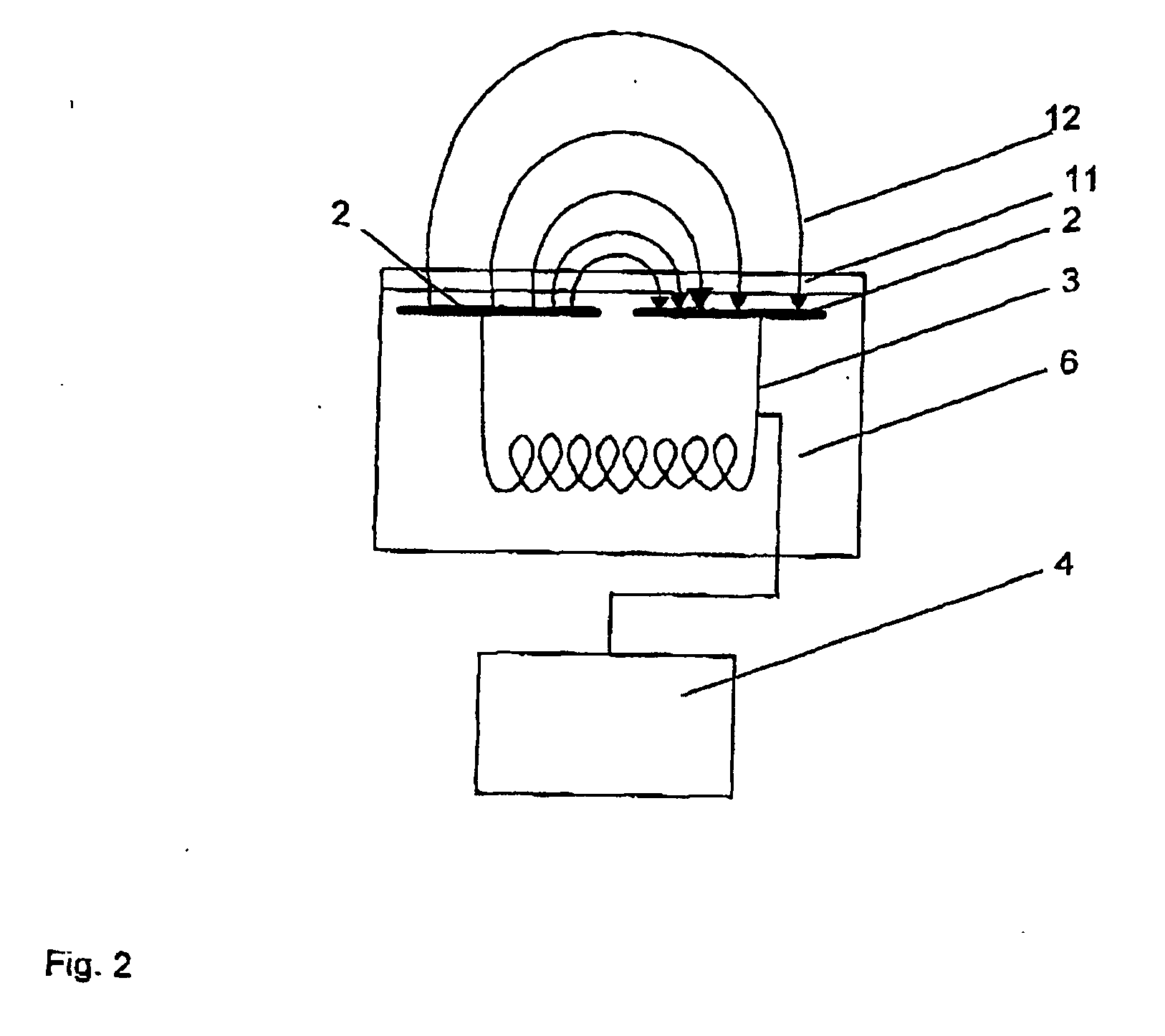

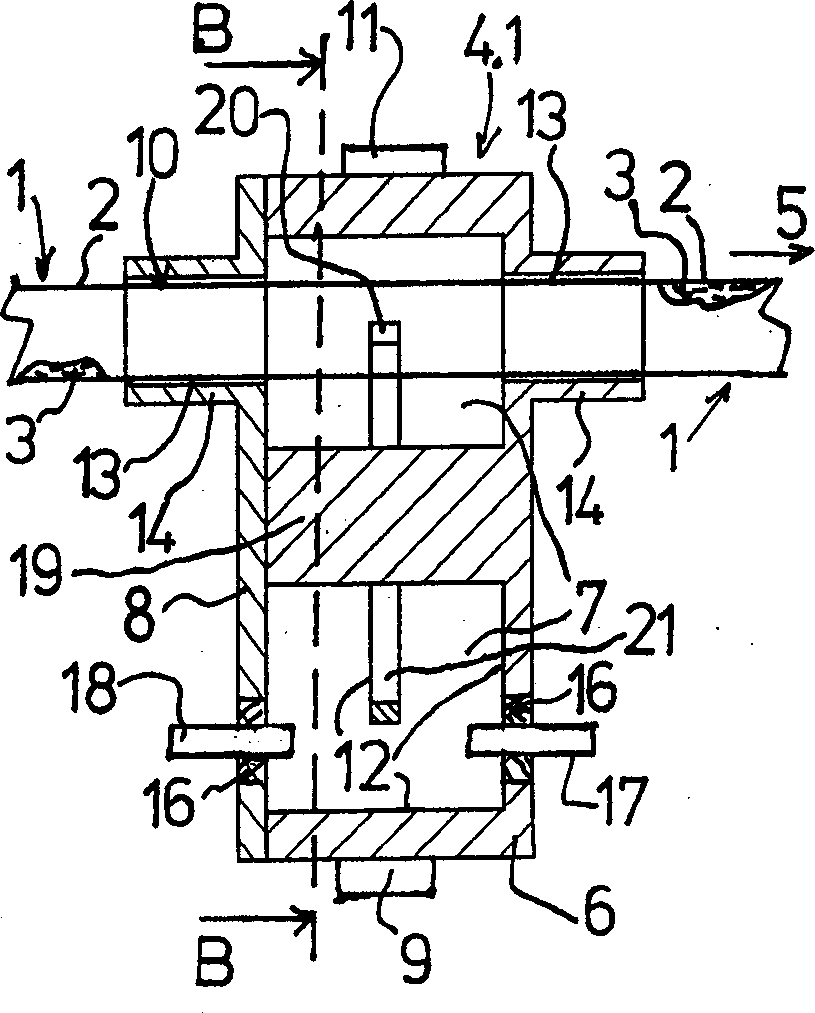

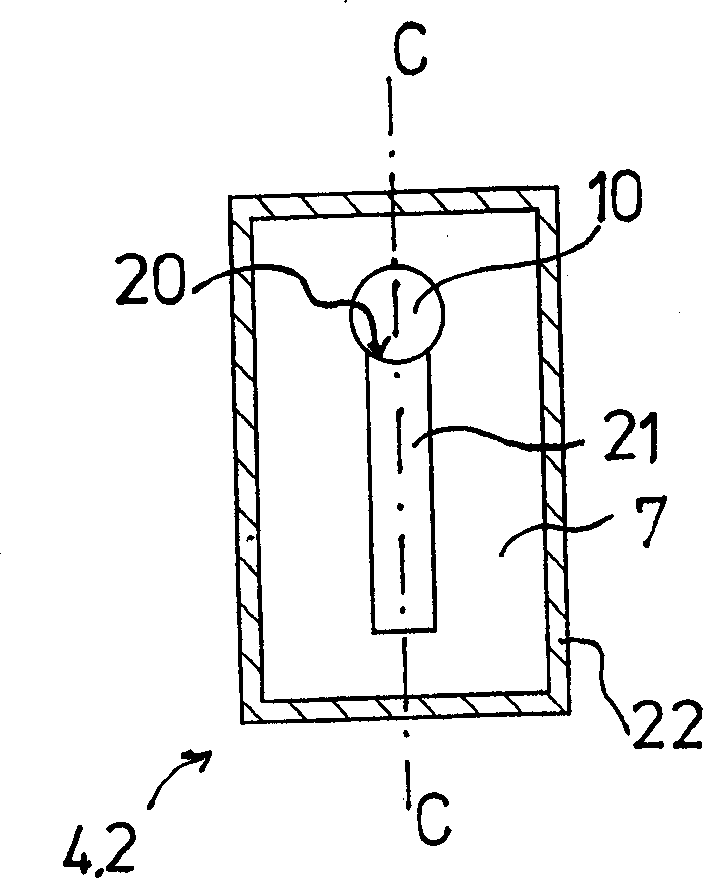

Microwave probe for furnace refractory material

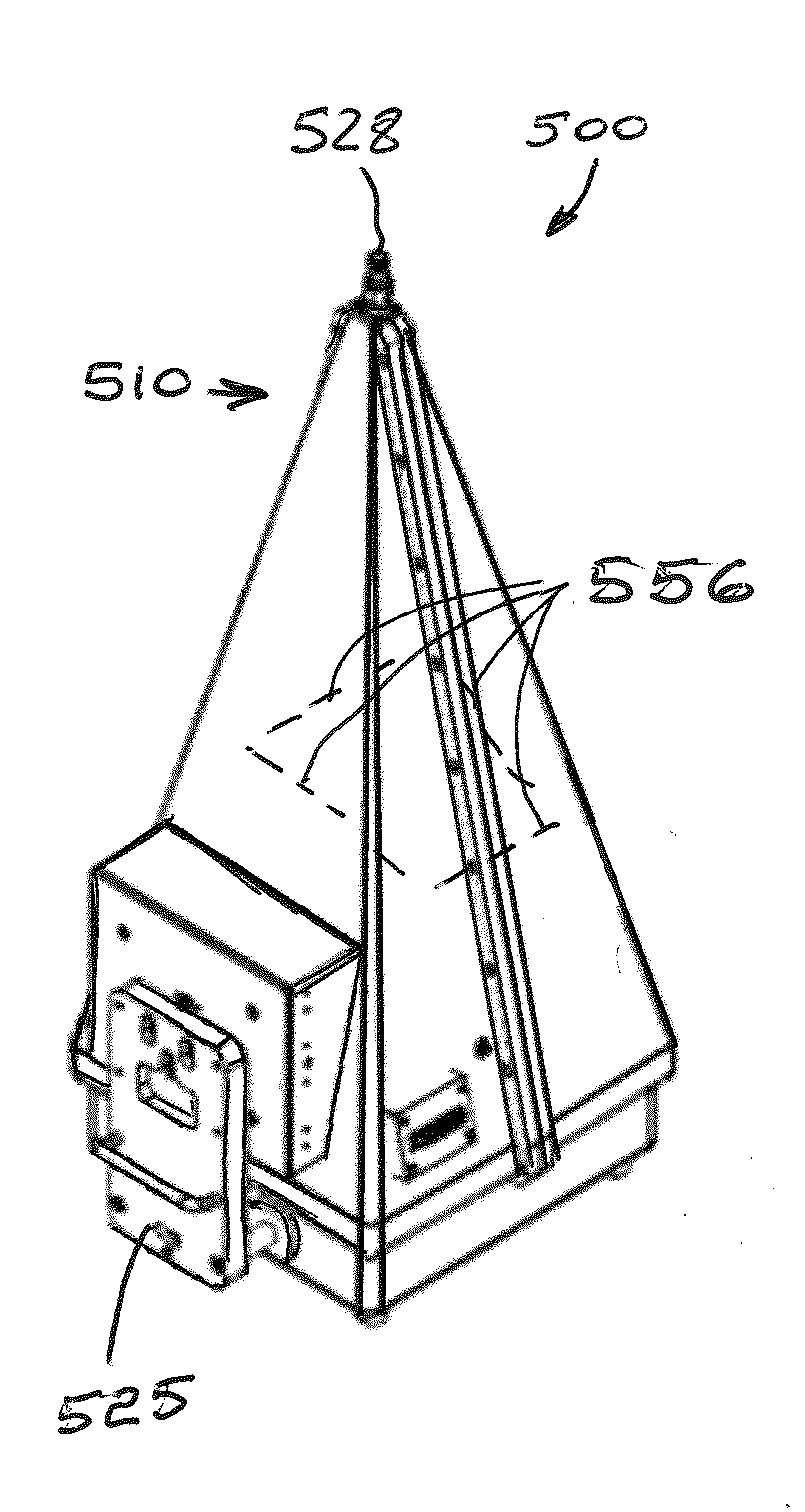

ActiveUS20130144554A1Reduce lossesGood signal isolationFurnace componentsMaterial analysis by optical meansElectricityTime delays

Disclosed is a system and method to aid in these inspections that avoid the disadvantages of the prior art. The system and method are operative to take thickness measurements of, and thus evaluate the condition of, materials including but not limited to refractory materials, operating in frequency bands that result in less loss than previously known technologies, and utilizing a system configuration and signal processing techniques that isolate the reflected signal of interest from other spurious antenna reflections, particularly by creating (through the configuration of the antenna assembly) a time delay between such spurious reflections and the actual reflected signal of interest, thus enabling better isolation of the signal of interest. Still further, the antenna assembly is intrinsically matched to the material to be probed, such as by impedance matching the antenna to the particular material (through knowledge of the dielectric and magnetic properties of the material to be evaluated) to even further suppress spurious reflections.

Owner:PANERATECH

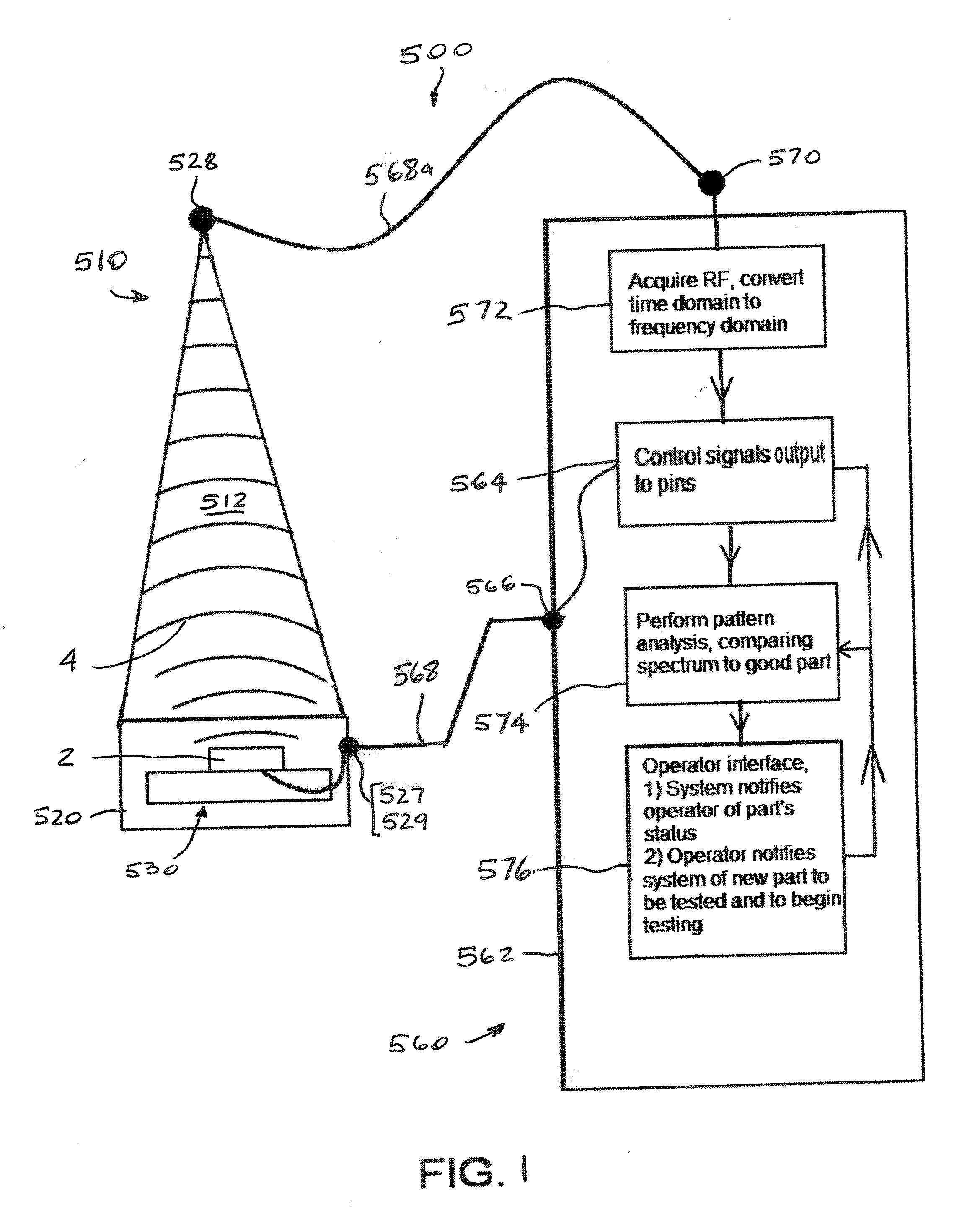

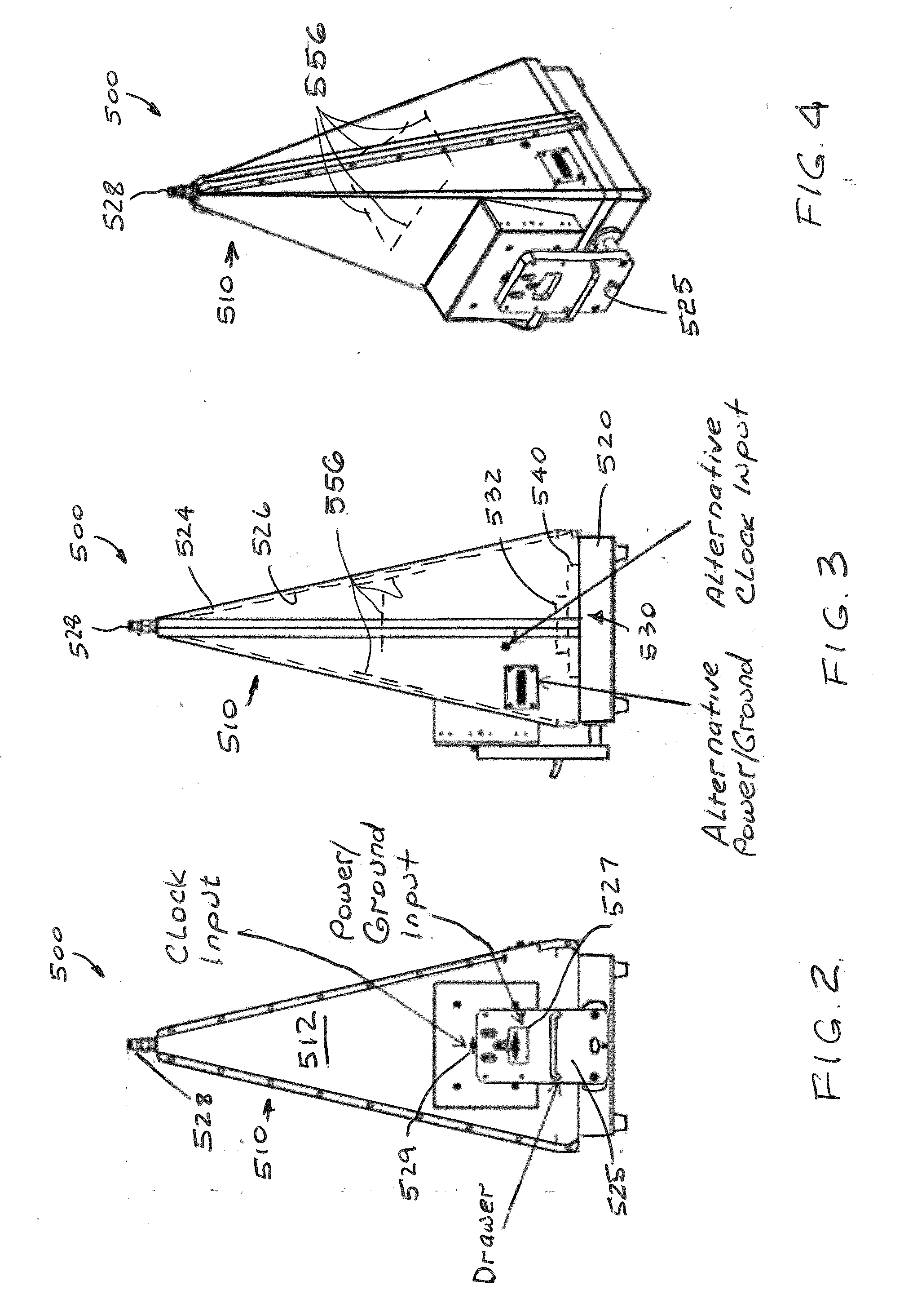

Method and Apparatus for Detection and Identification of Counterfeit and Substandard Electronics

ActiveUS20150137830A1Eliminate needResistance/reactance/impedenceSolid-state devicesElectronicsElectronic equipment

An apparatus for detecting a condition or authenticity of one or more electronic devices includes an enclosure having an antenna integrated therewithin, a fixture mounted within a hollow interior of the enclosure, the fixture being configured to receive the one or more electronic devices and connect one or more signals to each of the one or more electronic devices and a sensor and controller assembly connected to the antenna and configured to process a signature of an emission of a radiofrequency (RF) energy from of one or more electronic devices having the one or more signals connected thereto.

Owner:NOKOMIS

Surface-Mounted Crack Detection

InactiveUS20100225497A1Resistance/reactance/impedenceConductive materialPercent elongationSurface mounting

A cementitious compound provides a brittle undercoat for making a surface-mounted crack sensor on a surface. A low percent elongation and low tensile strength of the cementitious compound have proven valuable in ensuring that cracks in the underlying surface are transmitted through the undercoat so that a trace of conductive ink or paint on the undercoat more reliably detects the crack.

Owner:NAT RES COUNCIL OF CANADA

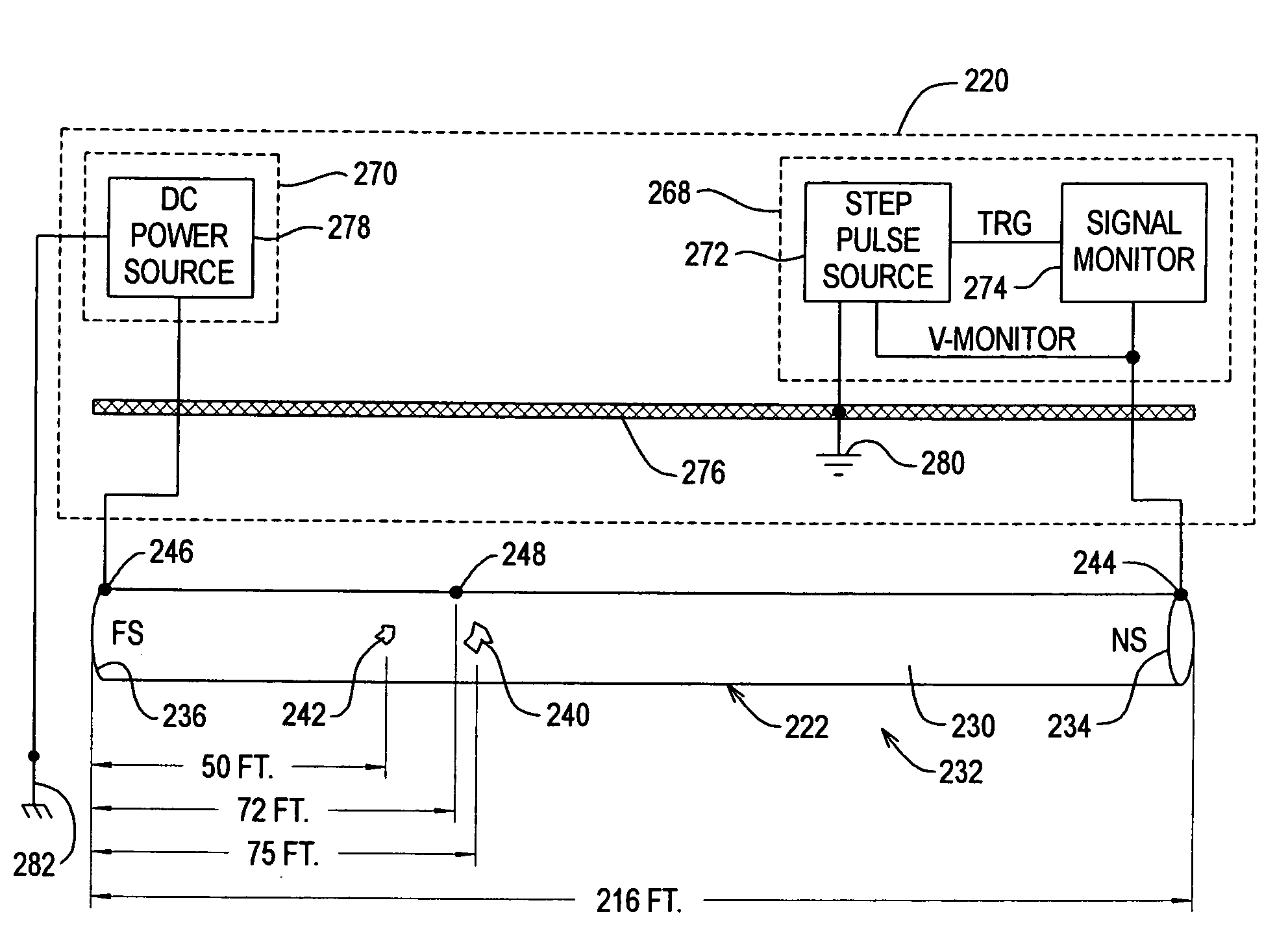

Systems and methods for non-destructively testing conductive members employing electromagnetic back scattering

InactiveUS20050007121A1Weather/light/corrosion resistanceFault location by pulse reflection methodsNon destructiveAnomaly detection

A method of determining an anomaly in a pipe system. The pipe system comprises a pipe, insulation around the pipe, and shielding around the insulation. An electrical pulse is applied to a test location on the pipe remote from the anomaly to cause an applied signal to travel along the pipe through the anomaly. At least one reflected signal caused by the applied signal traveling through the anomaly is detected. The at least one reflected signal is analyzed for characteristics associated with the anomaly.

Owner:PROFILE TECH

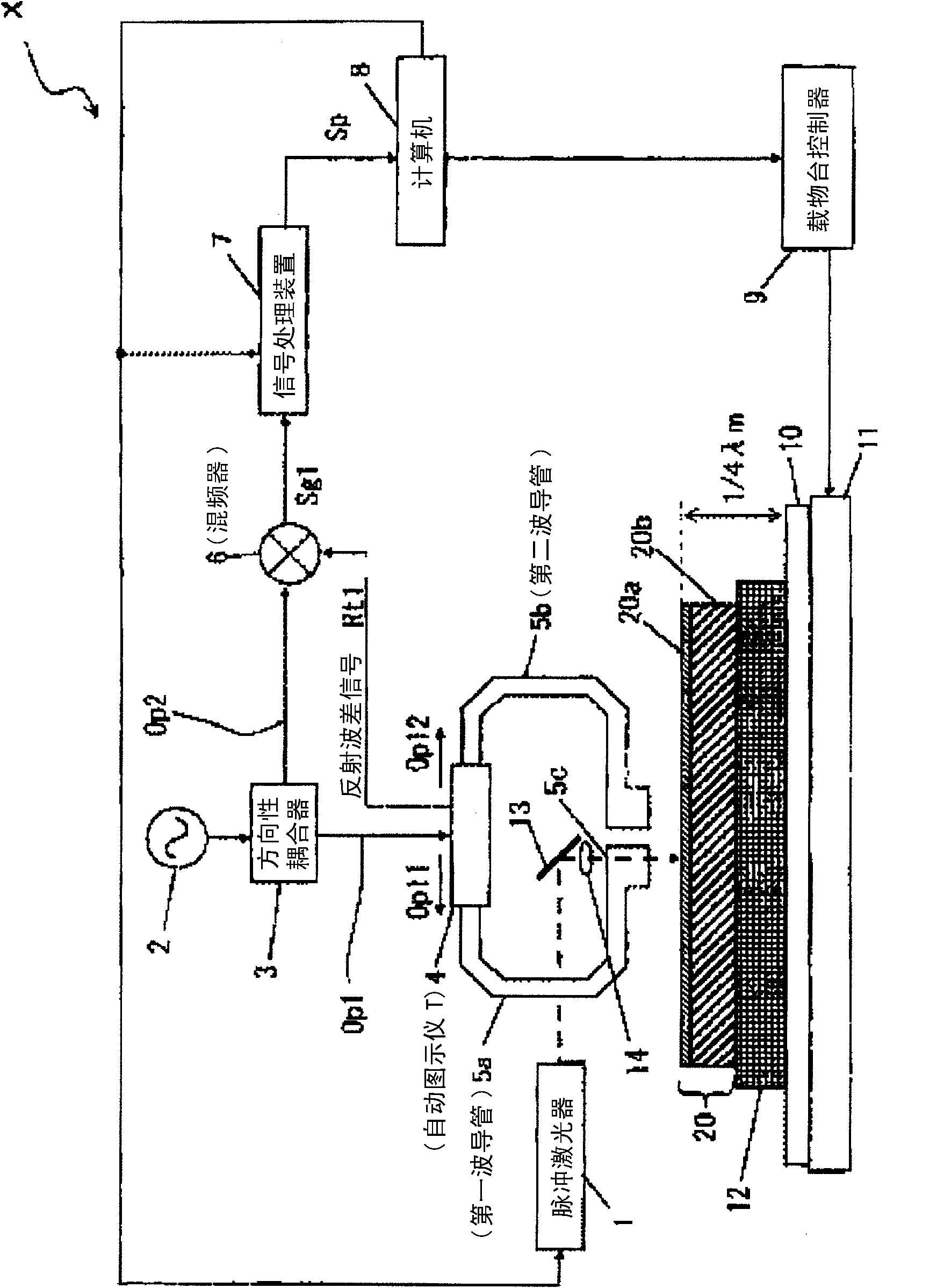

Measuring apparatus

InactiveCN1806158AAccurate measurementReduce manufacturing costSemiconductor/solid-state device testing/measurementUsing wave/particle radiation meansMicrowave emissionSemiconductor

The present invention relates to a measuring apparatus for measuring a thickness or the like of a thin film formed on a surface of a substrate such as a semiconductor wafer. The measuring apparatus includes a microwave emission device (40) for emitting a microwave to a substance , a microwave generator (45) for supplying the microwave to the microwave emission device (40), a detector (47) for detecting an amplitude or a phase of the microwave which has been reflected from or passed through the substance, and an analyzer (48) for analyzing a structure of the substance based on the amplitude or the phase of the microwave which has been detected by the detector (47).

Owner:EBARA CORP

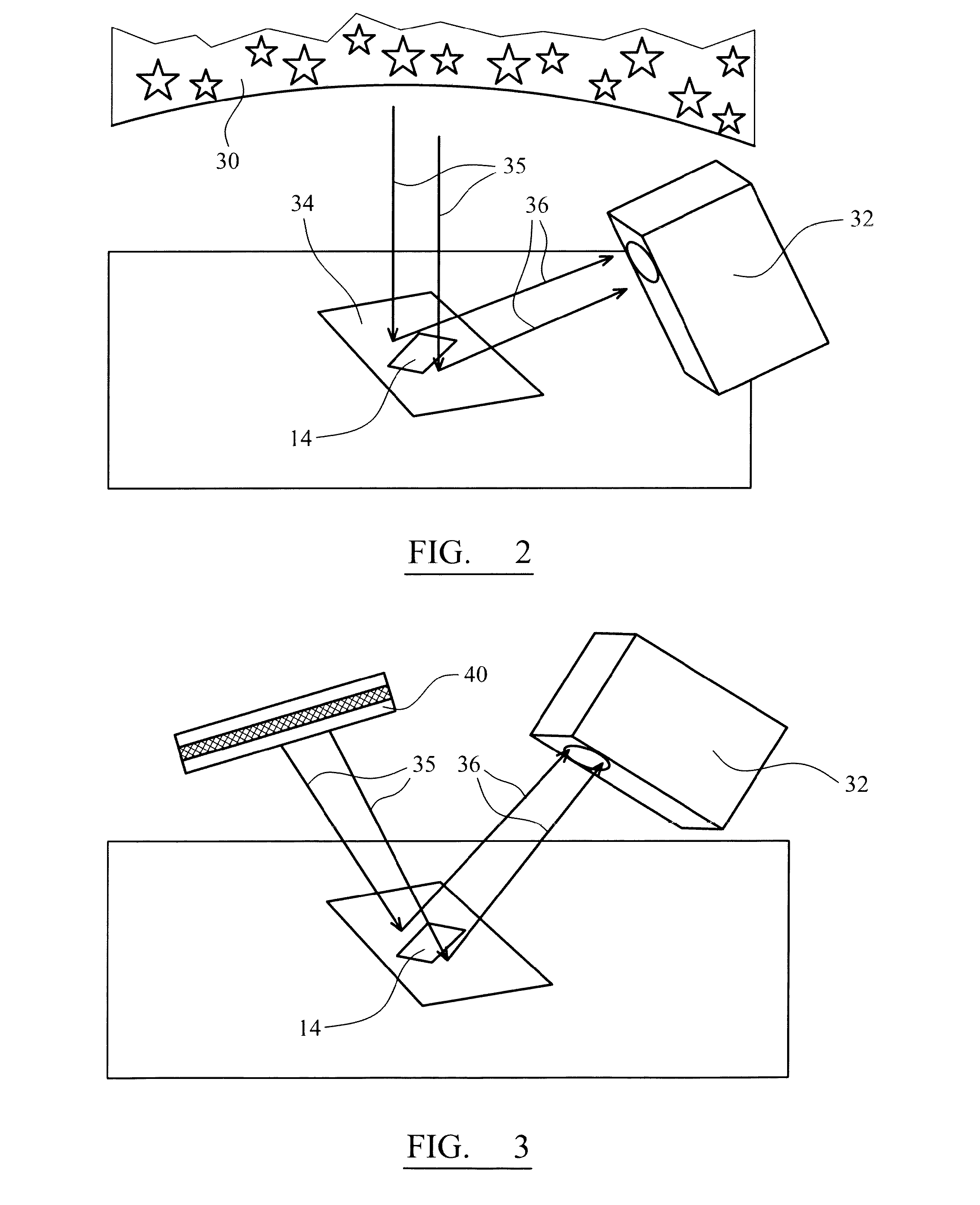

Detection system and method of detecting corrosion under an outer protective layer

ActiveUS20160003734A1High precisionShort timeRadiation pyrometryWeather/light/corrosion resistanceThermal insulationProtection layer

Incoherent millimetre wave, sub-millimetre wave and terahertz test signals are used to probe metal substrates that are covered by a protective coating or outer layer, such as paint or thermal insulation, obscuring direct assessment of the substrate. The incoherent test signals, which may be from a naturally occurring passive source (such as the sky) and / or from an active noise source, provide signal dispersion and angular variation of the test signals with respect to angular incidence to the substrate. Illumination of the substrate permits differentiation between un-corroded and corroded sections of the sample because reflectivity (and emissivity) from a metal-based substrate is heavily dependent on the surface resistivity which in turn is dependent on the corroded state. A detector / camera is arranged to pick up reflections from the substrate and an associated control system identifies regions of the sample that reflect the test signal illumination differently or otherwise indicate a variation from a reference value. The differences therefore signify the presence or lack of corrosion or, indeed, the presence of other abnormalities within or on the substrate.

Owner:SUBTERANDT

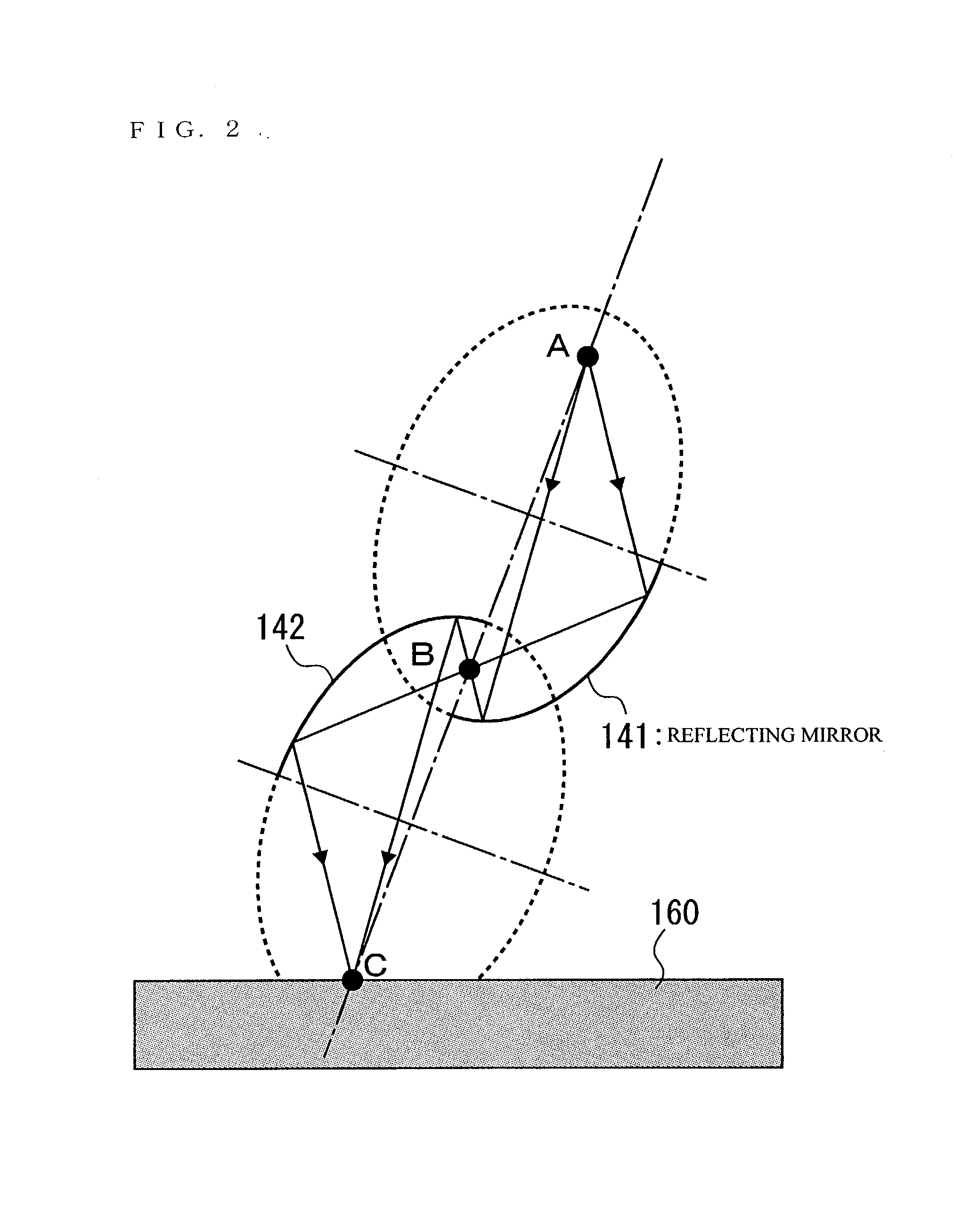

Noncontact measuring system for electrical conductivity

InactiveUS20040100280A1Semiconductor/solid-state device testing/measurementResistance/reactance/impedenceMicrowavePhase difference

The invention provides a noncontact measuring system for electrical conductivity, which uses a microwave. In the measuring system for electrical conductivity, the microwave generated in a network analyzer (NA) 110 is guided to a surface of a silicon wafer (sample) 160 through a waveguide 130 and a sensor 140. The surface of the silicon wafer 160 is irradiated with the microwave, and the sensor 140 receives the reflected microwave. The electrical conductivity of the silicon wafer 160 is measured in such a manner that a computer (personal computer) 120 calculates the electrical conductivity from an amplitude ratio A and phase difference theta to a reflected wave of the silicon wafer 160, which is determined with the network analyzer 110. The computer 120 performs not only the calculation of the measurement but also whole control of the measuring system such as positioning of the sample.

Owner:TOHOKU TECHNO ARCH CO LTD

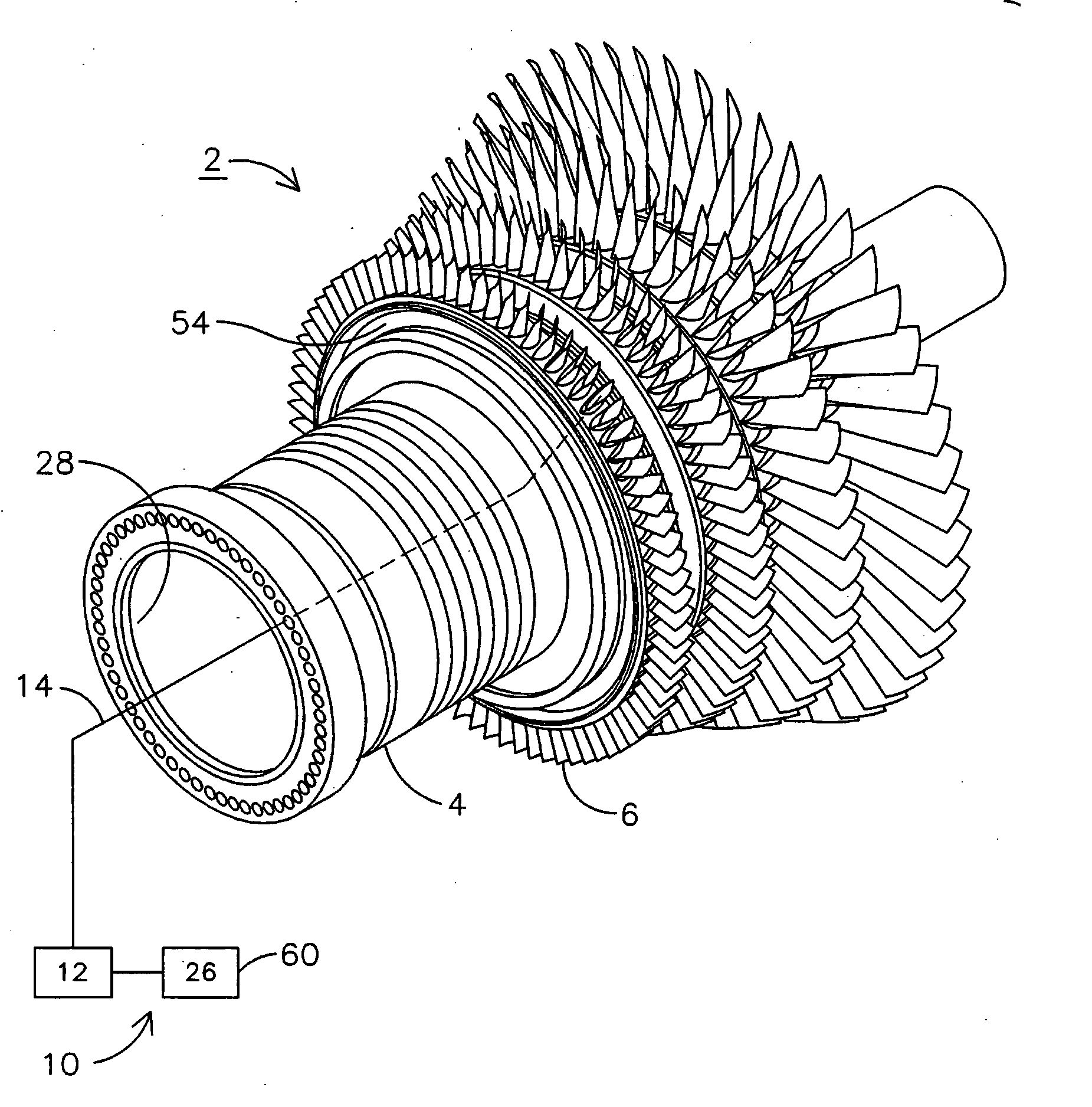

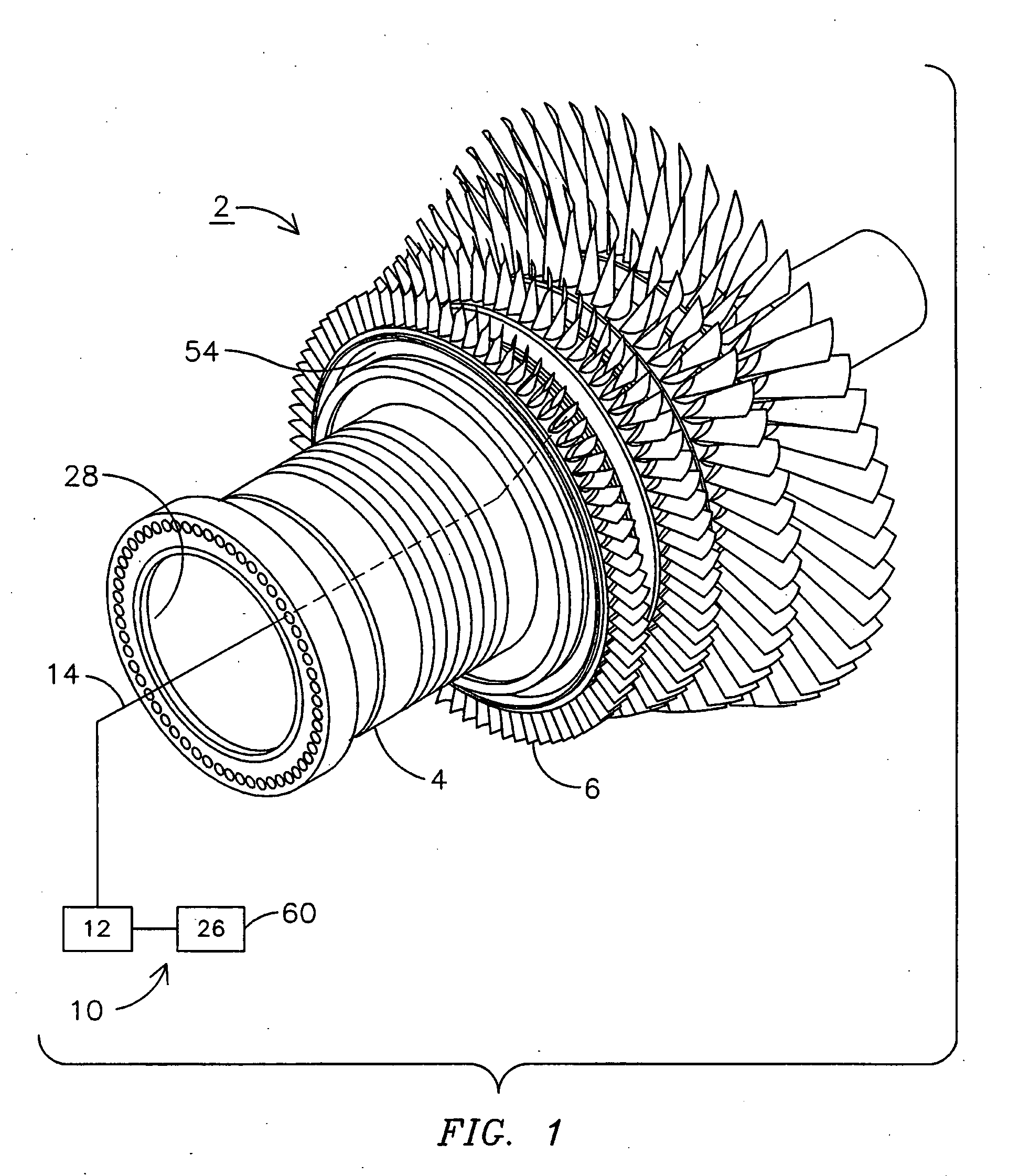

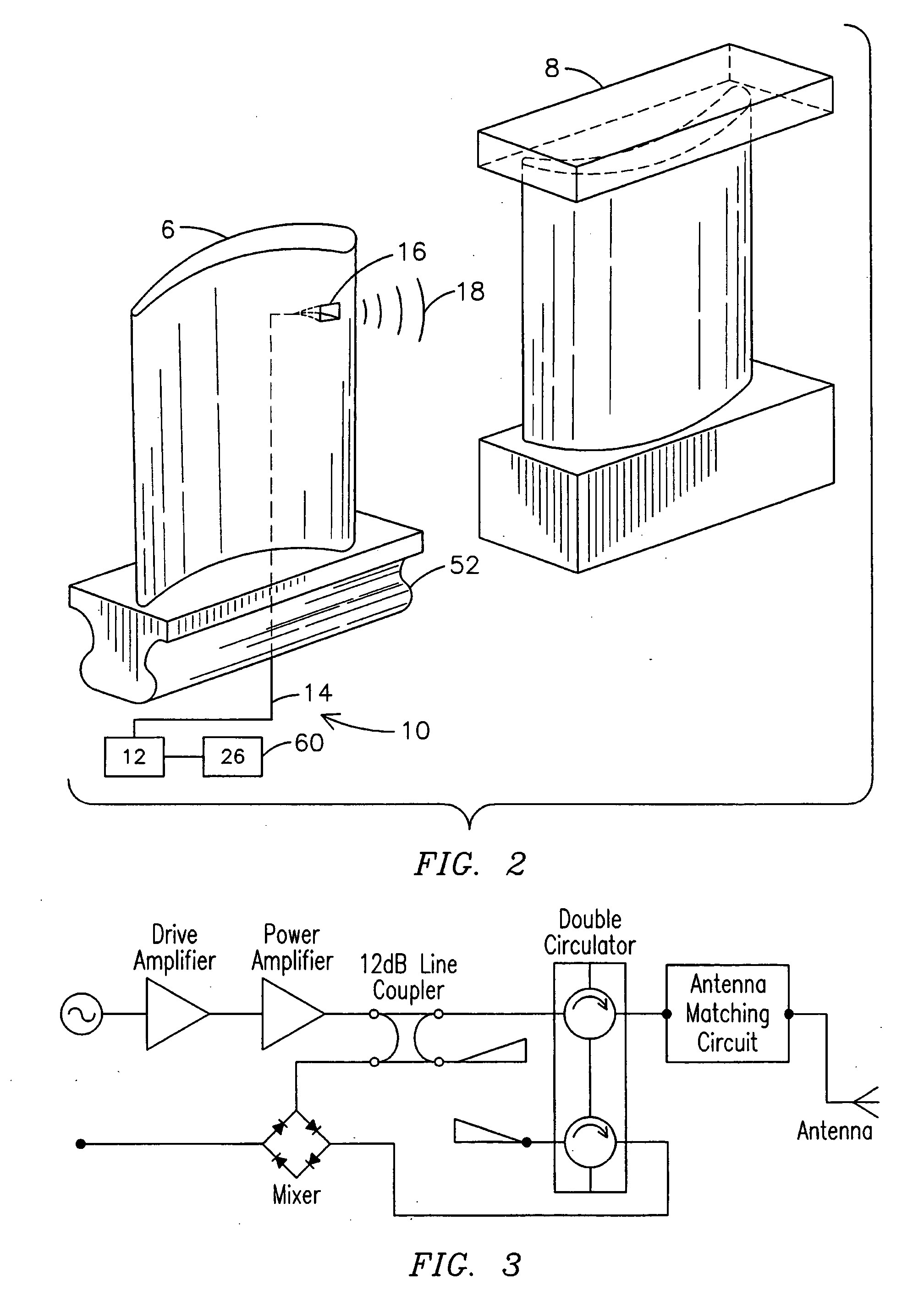

Doppler radar sensing system for monitoring turbine generator components

InactiveUS20050264275A1Material analysis by electric/magnetic meansMagnetic property measurementsRadarEngineering

The invention provides a sensing system and a method for monitoring the damage to turbine components in a turbine generator. The sensing system comprises an electromagnetic wave generator that generates an electromagnetic wave; a transmitter that transmits the generated electromagnetic wave from a first turbine component; a second turbine component that receives the transmitted electromagnetic wave and reflects the electromagnetic wave; a receiver that receives the reflected electromagnetic wave; and a processor that interprets the received electromagnetic wave.

Owner:SIEMENS AG

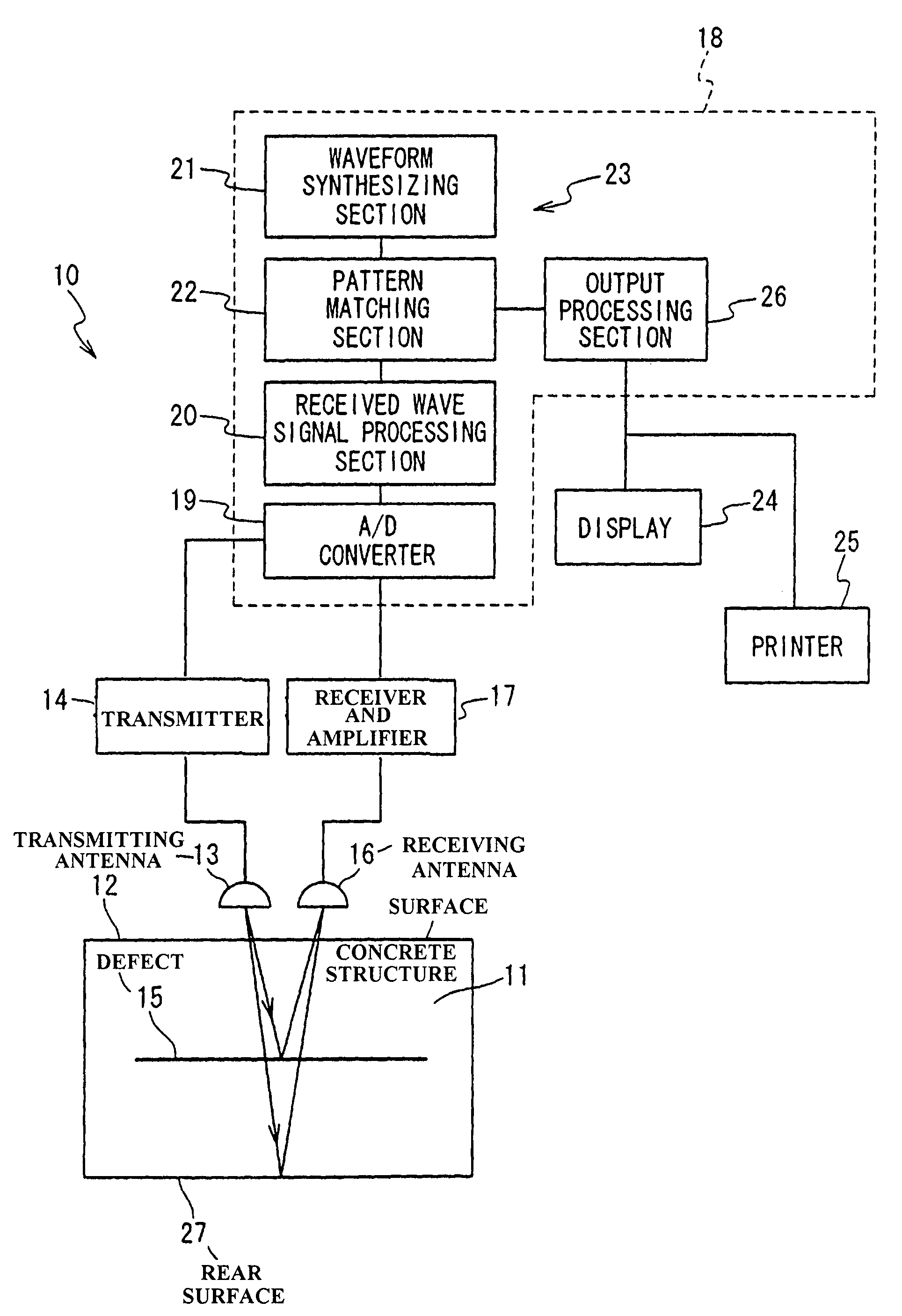

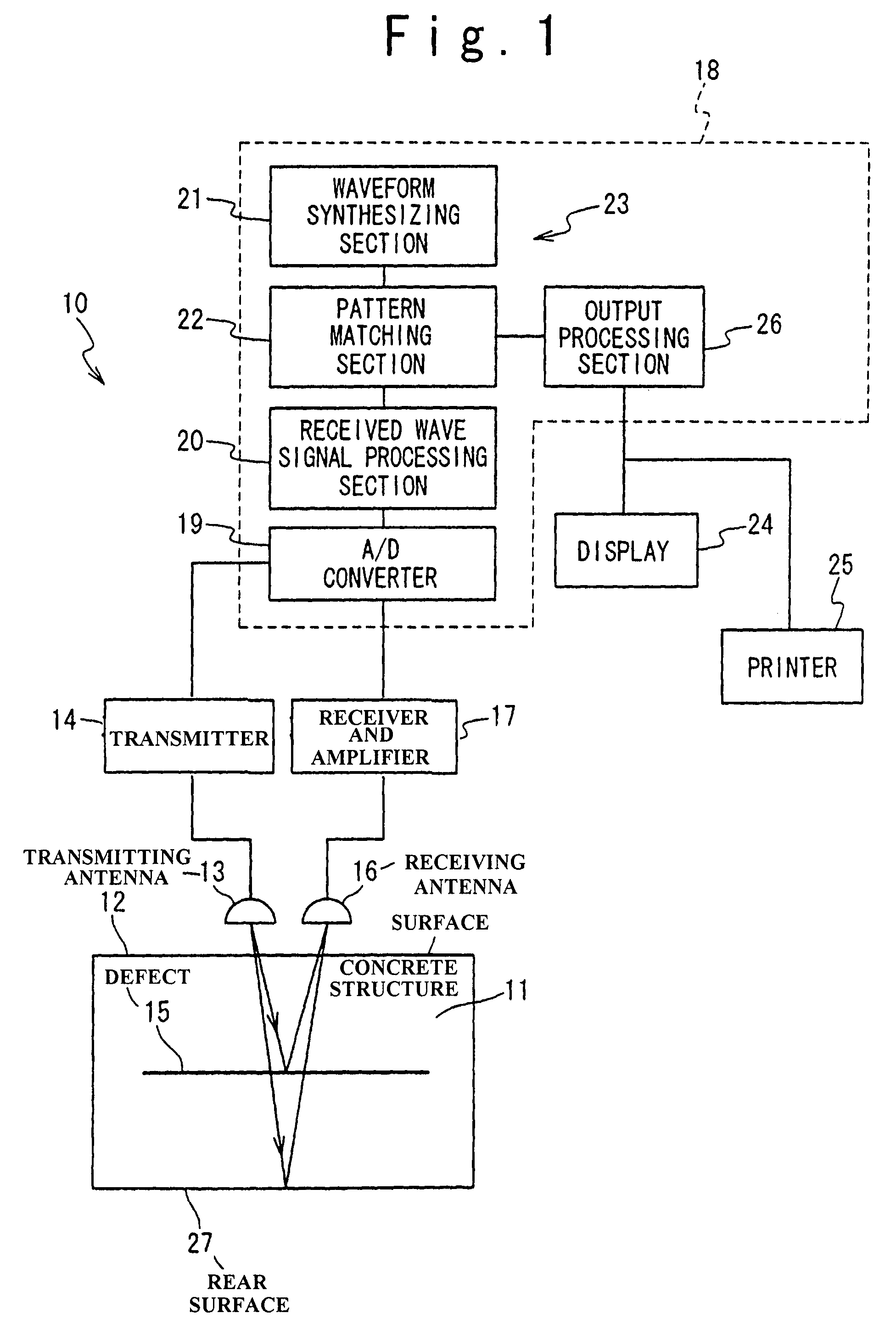

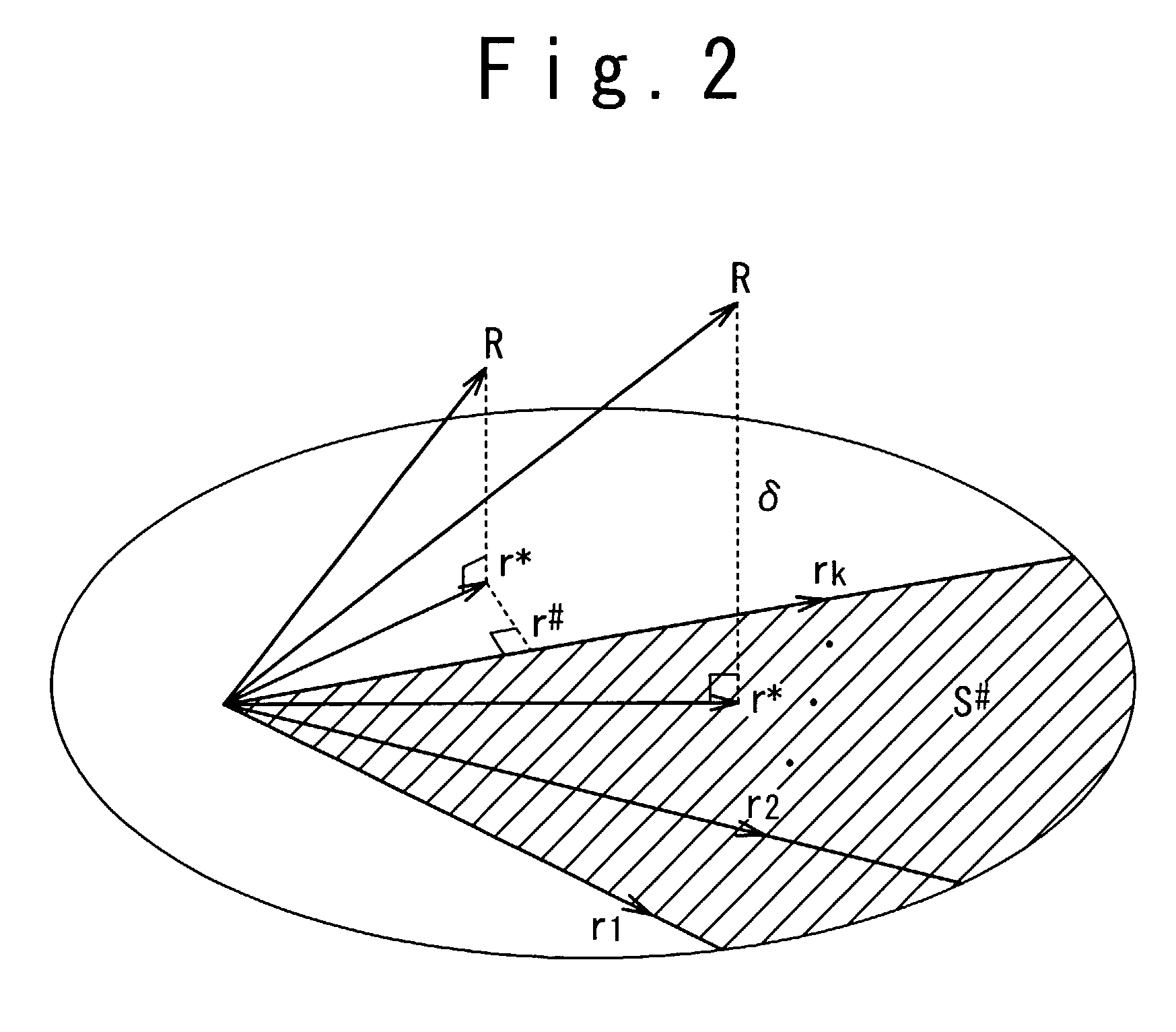

Apparatus and method for non-destructive inspection

InactiveUS7075315B2Short timeImprove accuracyResistance/reactance/impedenceOptically investigating flaws/contaminationNon destructivePattern matching

A non-destructive inspection apparatus includes a transmitting section, a reception section and a processing unit. The transmission section irradiates an electromagnetic wave signal toward an inspection target. The reception section receives a reflected electromagnetic wave signal from the inspection target to generate a received wave signal. The processing unit generates a fundamental reflected wave signal predicted to be received from each reflection point of the inspection target, and determines the existence or nonexistence of any defects in the inspection target and the details of the defect, if it exists, based on a pattern matching between a waveform of the received wave signal and a waveform of a linear combination of fundamental reflected wave signals.

Owner:MITSUBISHI HEAVY IND LTD

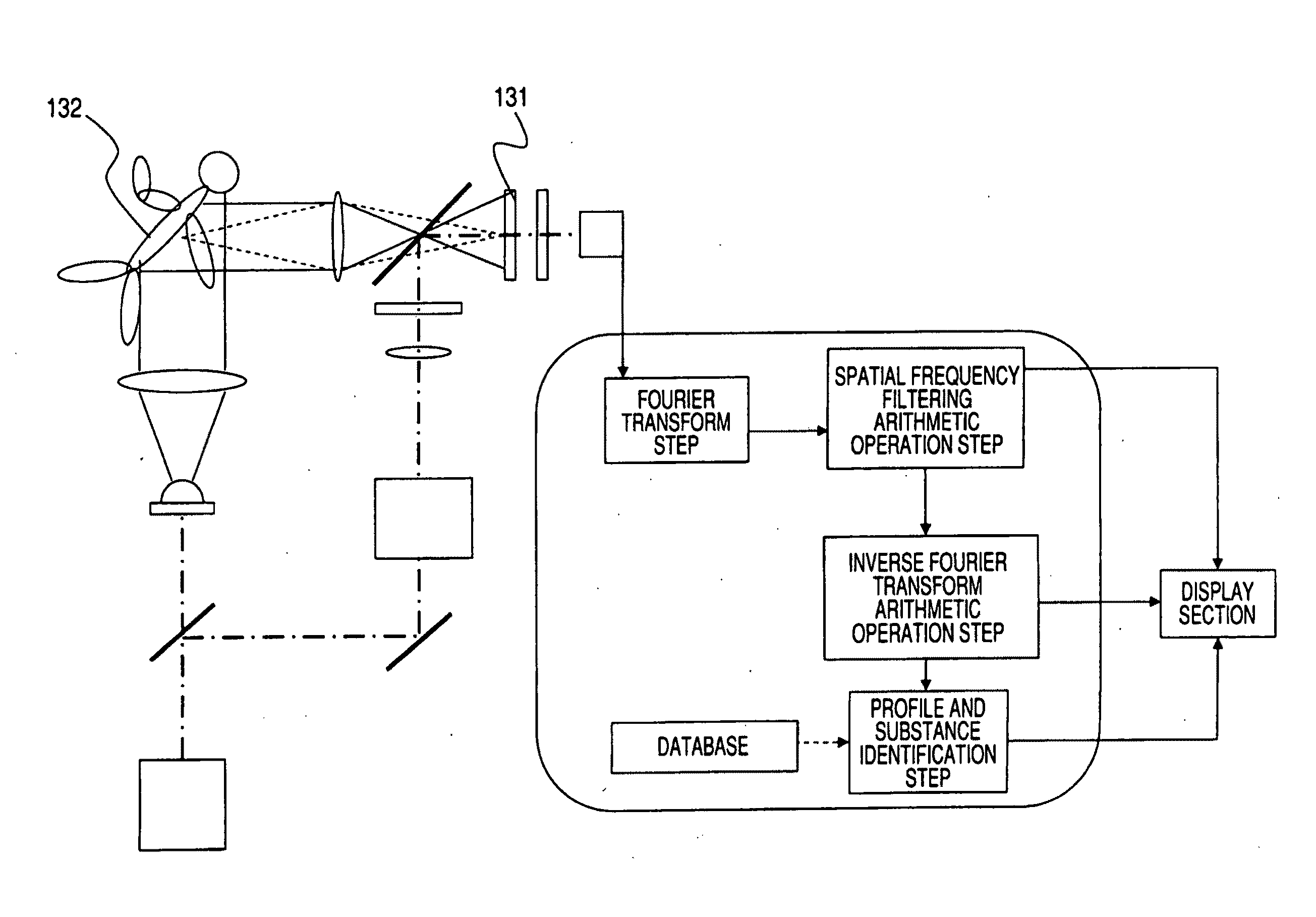

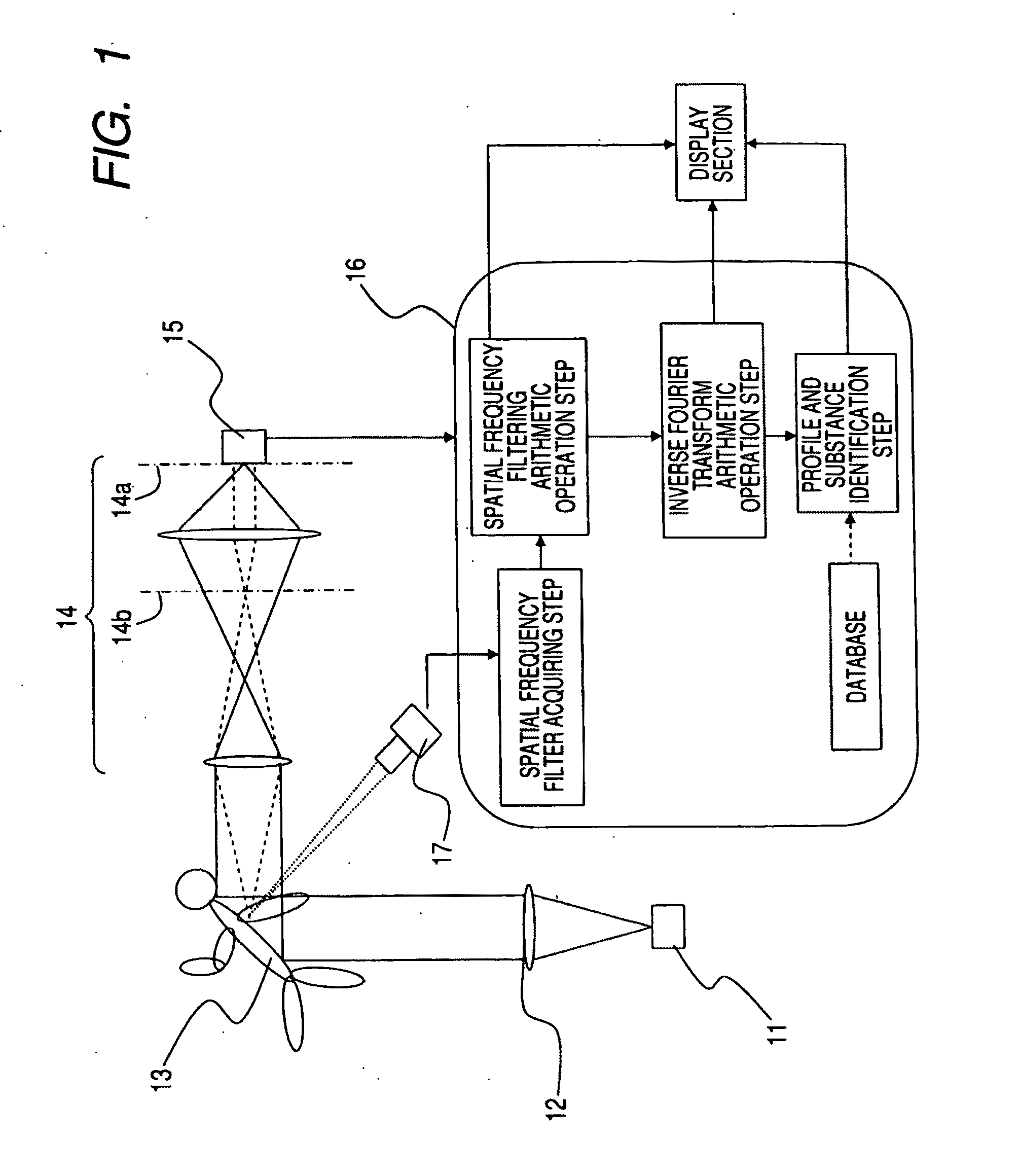

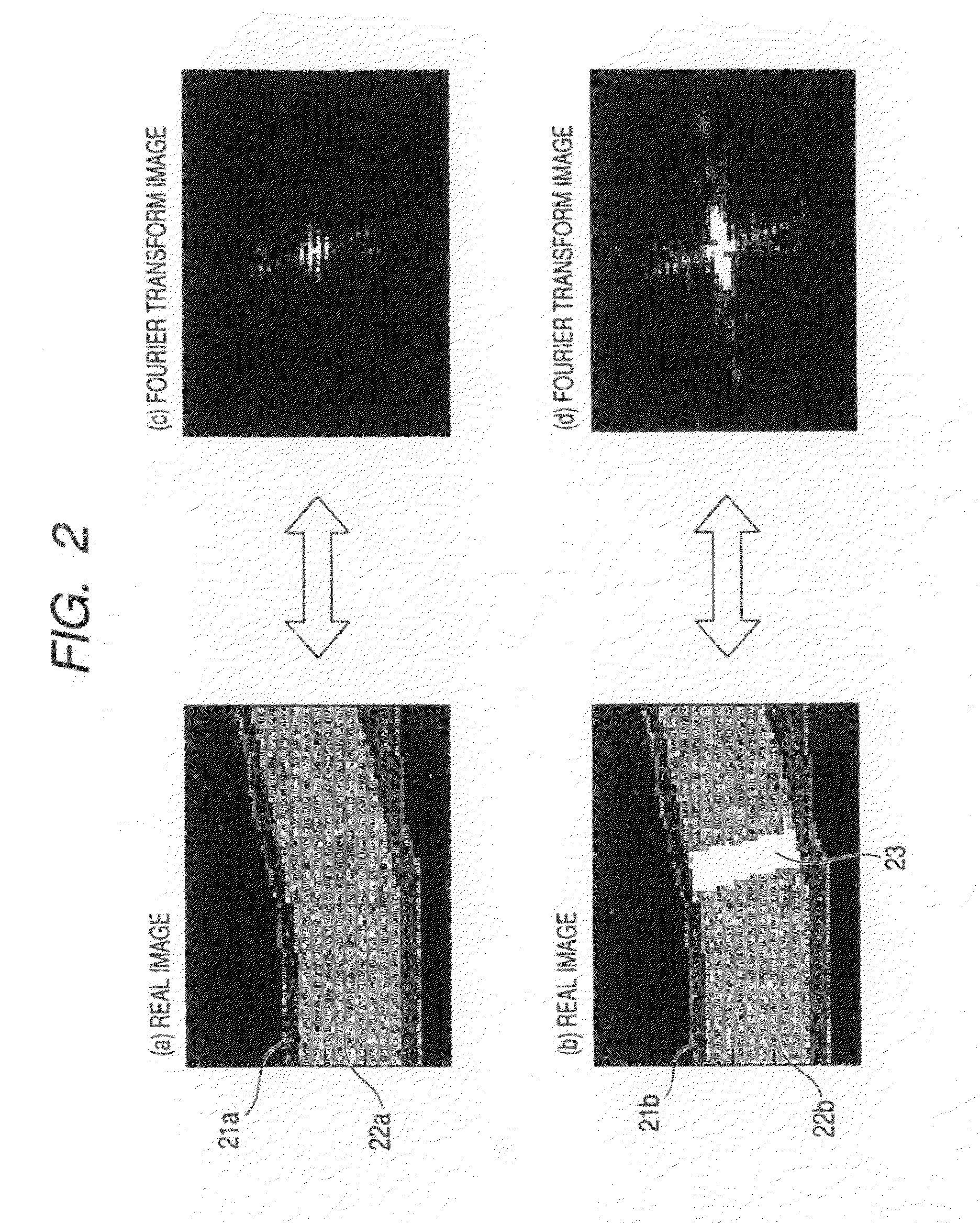

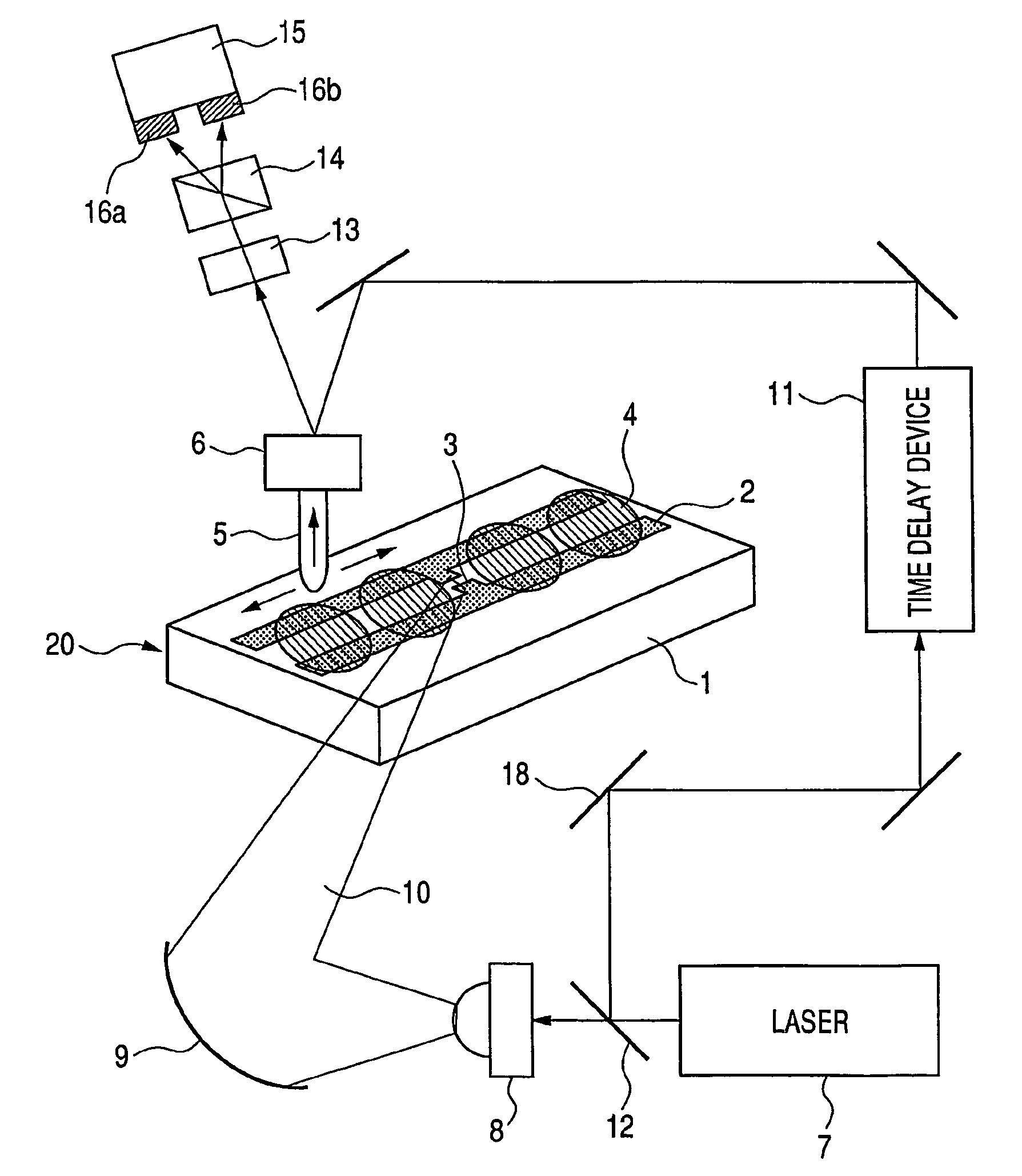

Imaging method and apparatus

InactiveUS20100171835A1Improve confidentialityPrivacy protectionTelevision system detailsColor television detailsFourier transform on finite groupsSpatial frequency

An object of examination is irradiated with an electromagnetic wave including a frequency component from 30 GHz to 30 THz and a Fourier transform image of the transmitted or reflected electromagnetic wave from the object of examination is obtained. The obtained Fourier transform image is subjected to a spatial frequency filtering processing. This method can visualize only the part to be visualized in an imaging operation using a terahertz wave.

Owner:CANON KK

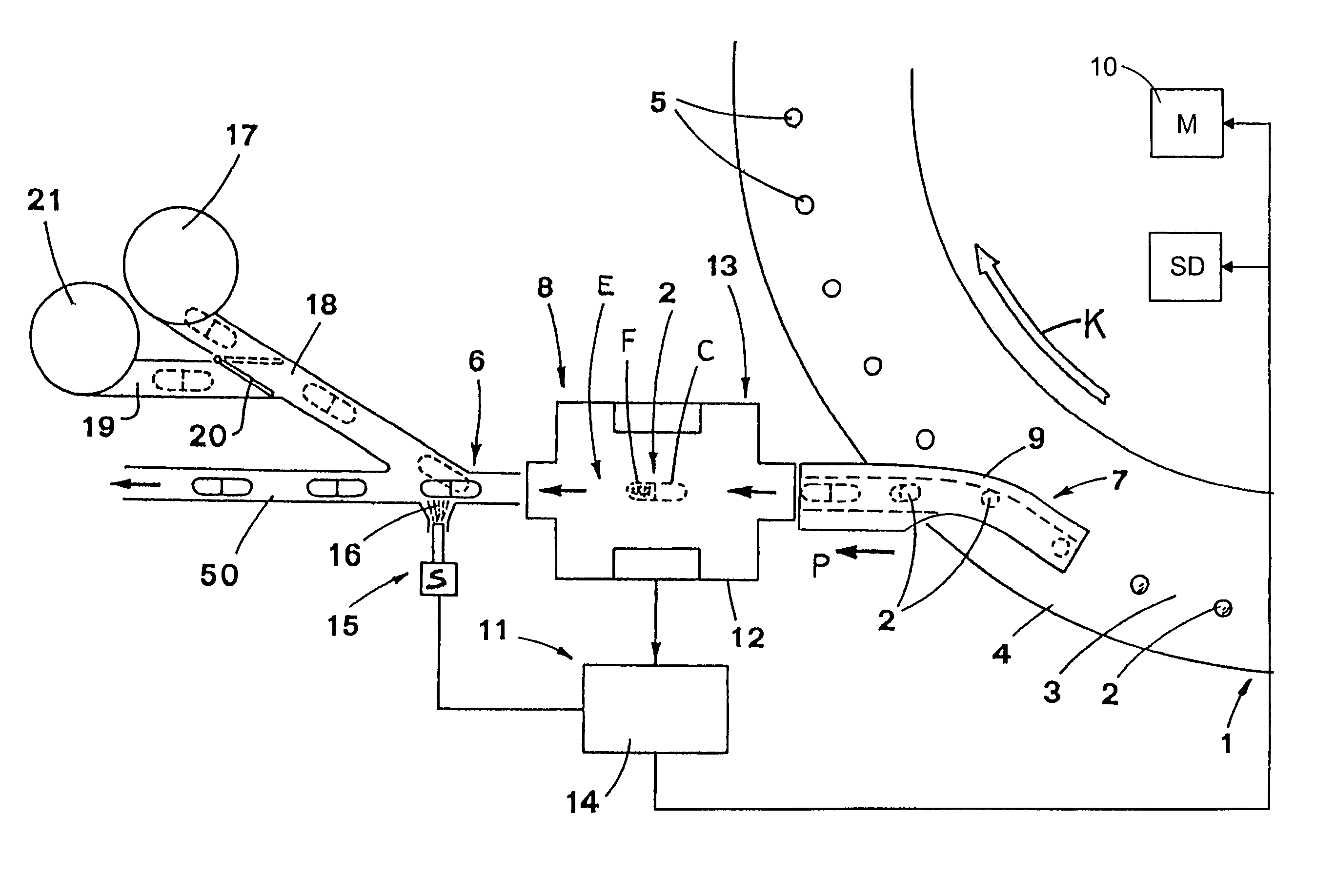

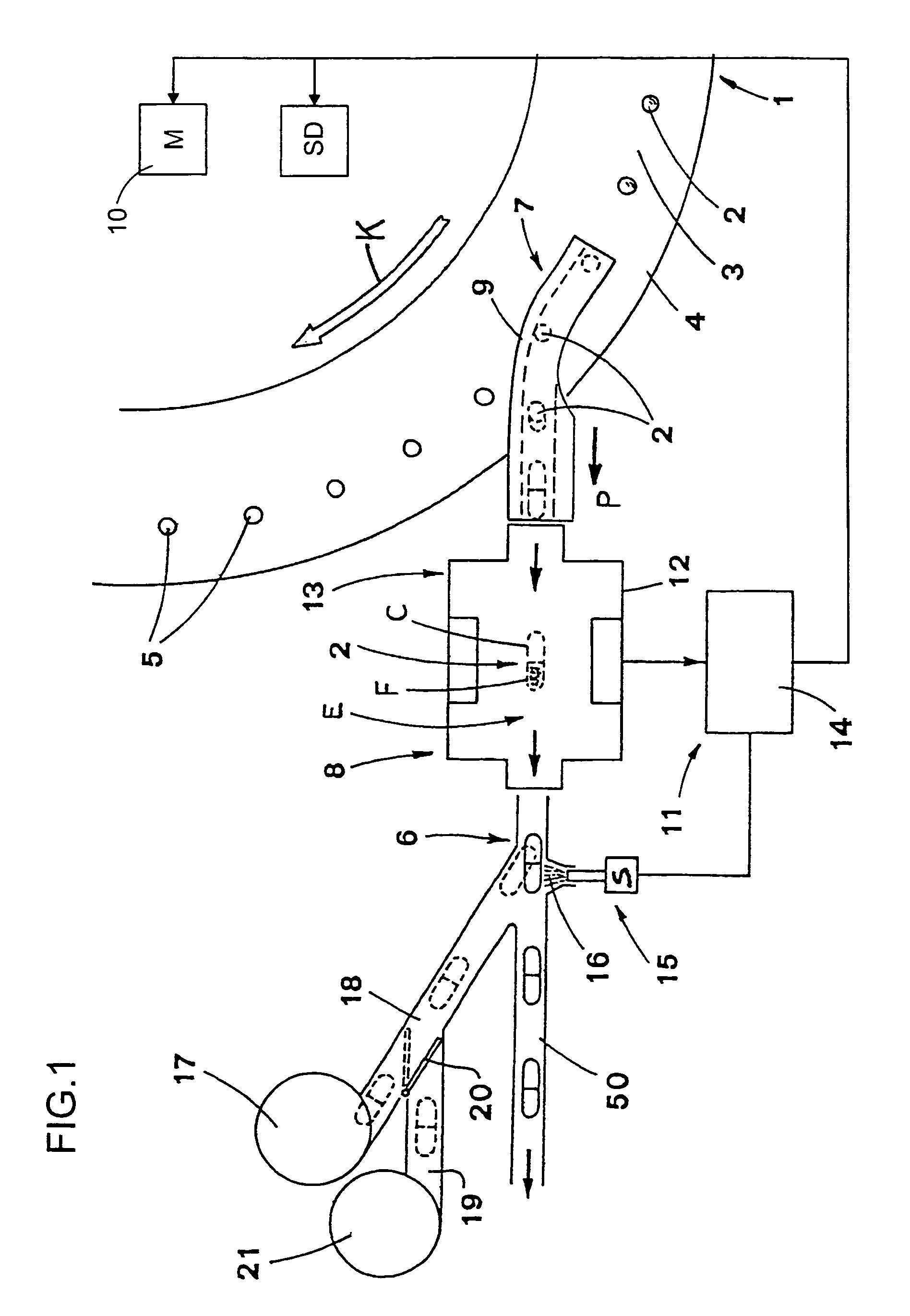

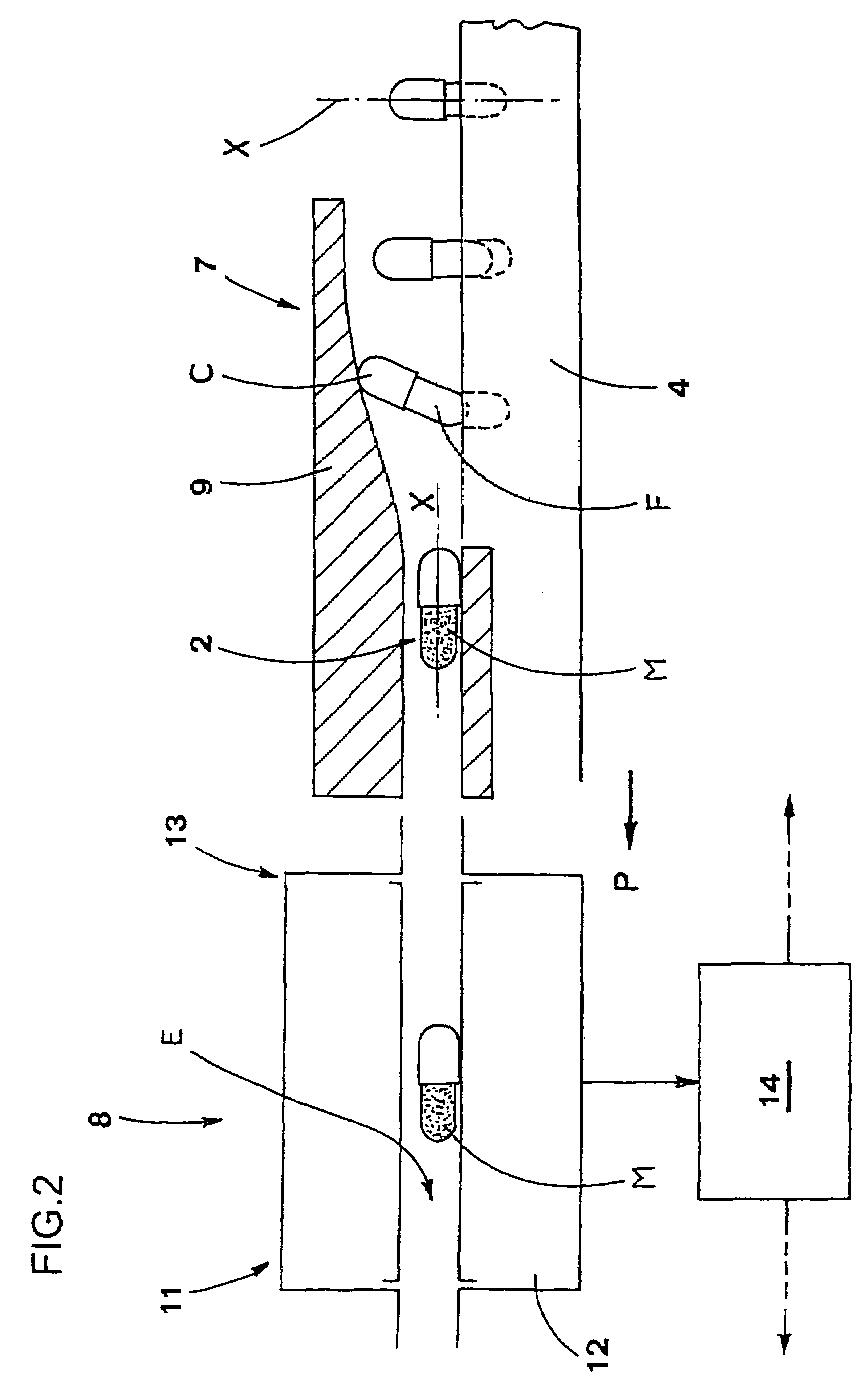

Method for monitoring the properties of pharmaceutical articles

InactiveUS7042231B2Resistance/reactance/impedenceMaterial analysis by electric/magnetic meansMicrowaveEngineering

In a method for monitoring the properties of pharmaceutical articles (2), in particular capsules (2), in a machine (1) that makes the articles (2), the pharmaceutical articles (2) are fed in single file from a station (3) where the articles (2) are made to an article (2) outfeed portion (6) of the machine (1) along a defined feed path (P) passing through an inspection station (8). In the inspection station (8) each pharmaceutical article (2) passes through an electromagnetic field (E) created by microwave radiation.

Owner:IMA IND MASCH AUTOMATICHE SPA

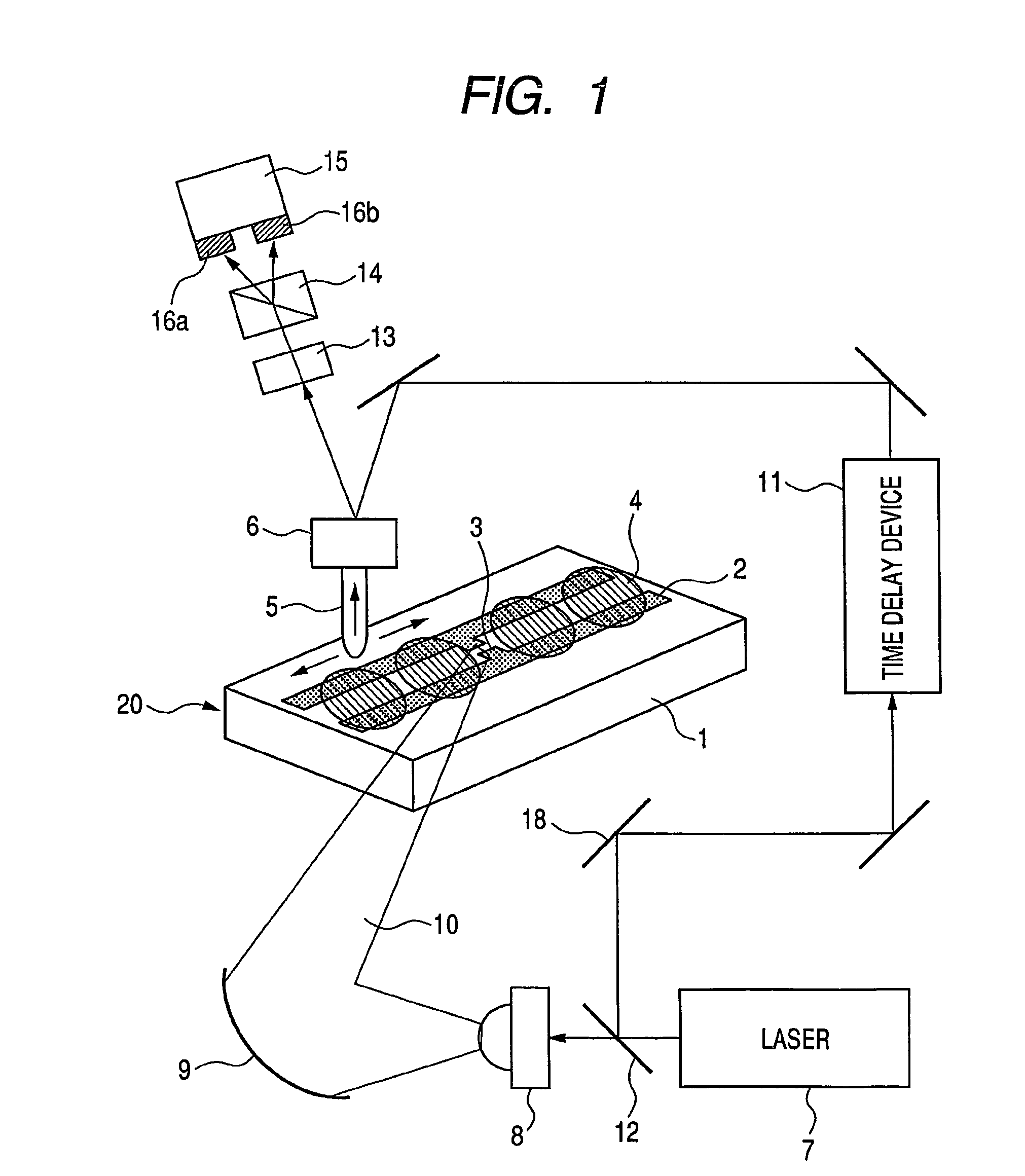

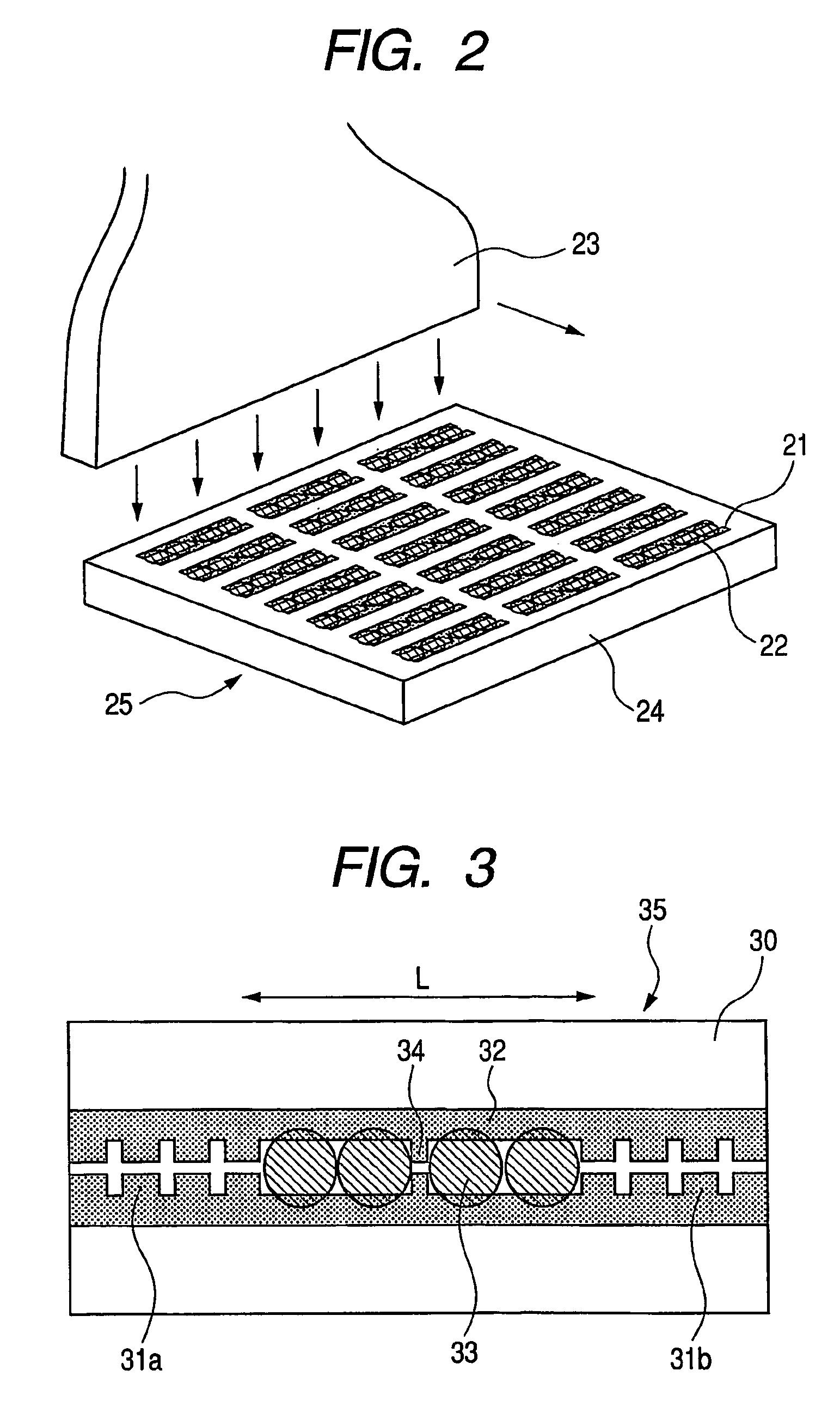

Terahertz sensing apparatus using a transmission line

InactiveUS7564034B2Increase speedLow costRadiation pyrometryColor/spectral properties measurementsCouplingSpatial interaction

A sensing apparatus is provided which comprises a chip (20) in which a transmission line (2) for propagating an electromagnetic wave is formed on a substrate (1), an electromagnetic wave generator (7) for generating an electromagnetic wave (10), a coupling means (9), and a detector (5) for detecting a propagation state of an electromagnetic wave at an arbitrary location on the transmission line, of the electromagnetic wave propagating through the transmission line (2). An interaction between an object (4) disposed in the vicinity of the transmission line (2) and the electromagnetic wave is detected by the detector (5) to sense a spatial interaction state of the object (4) with the electromagnetic wave.

Owner:CANON KK

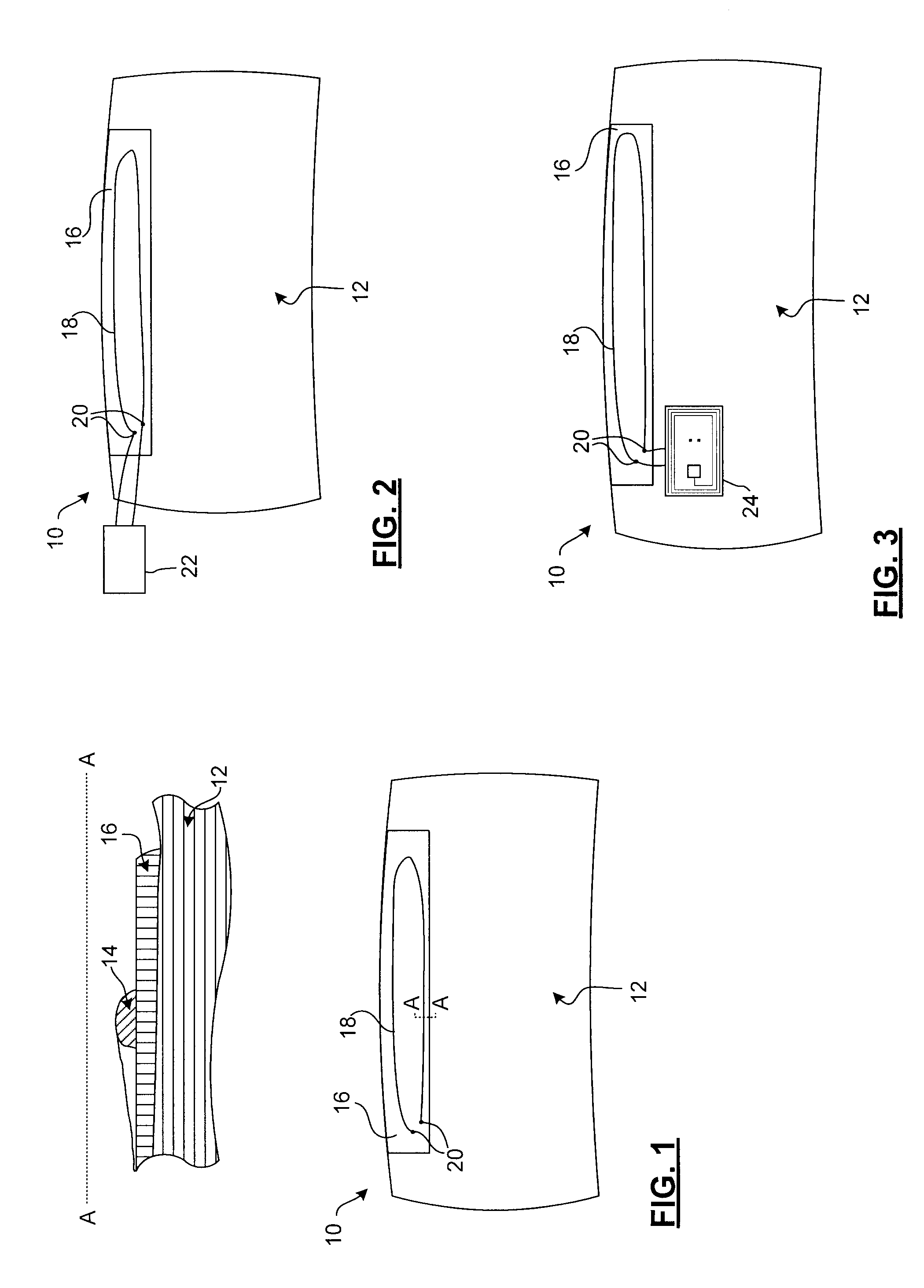

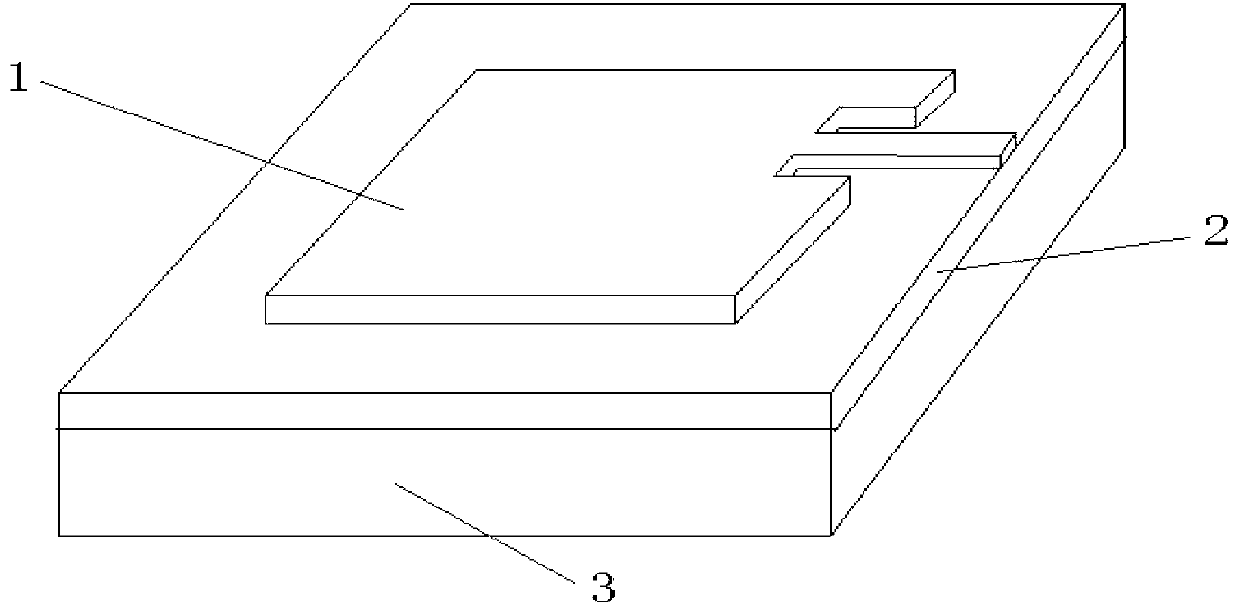

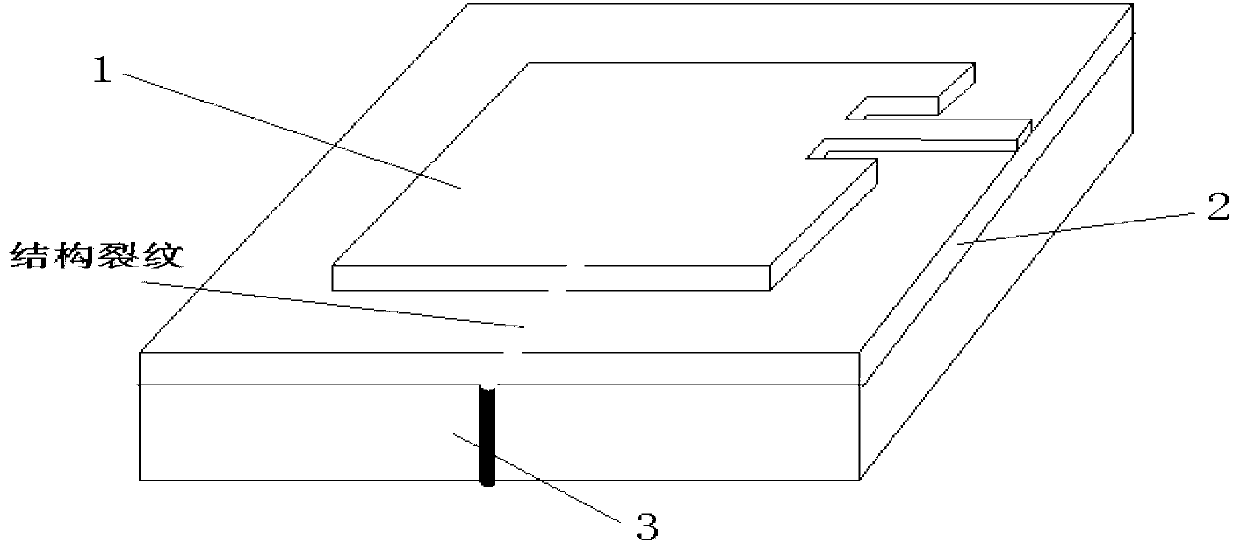

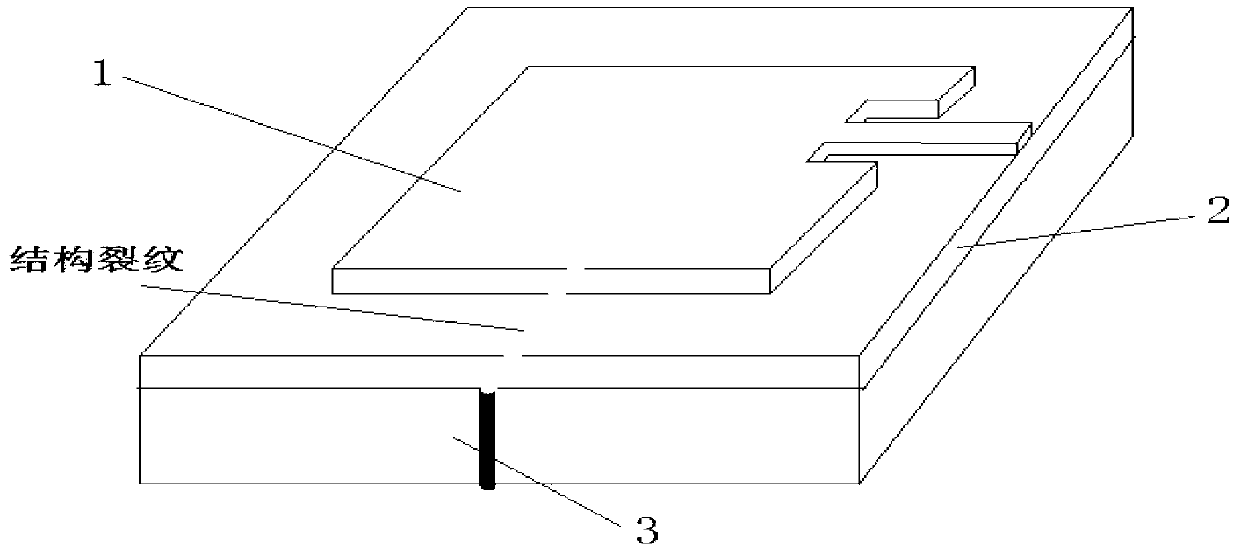

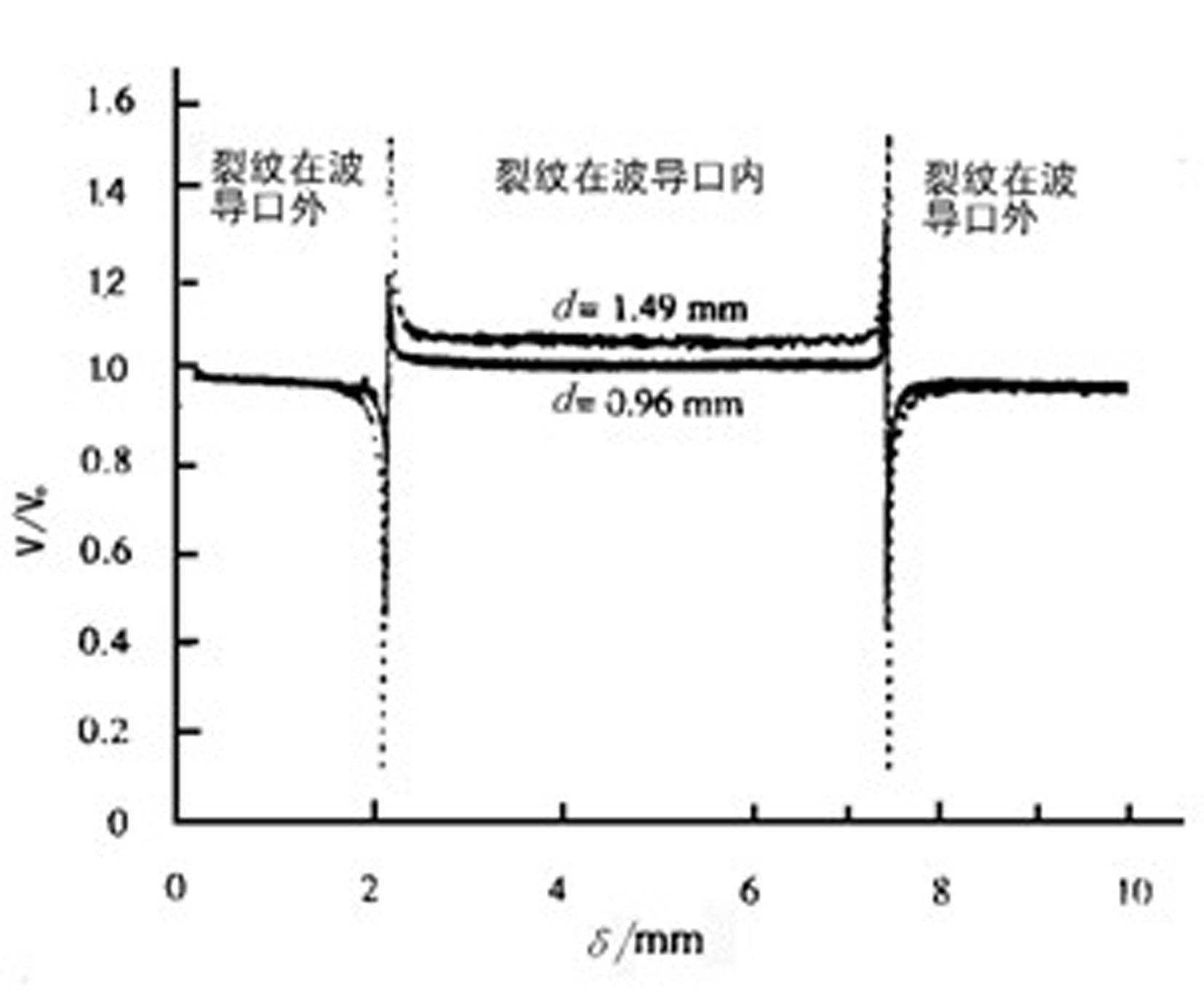

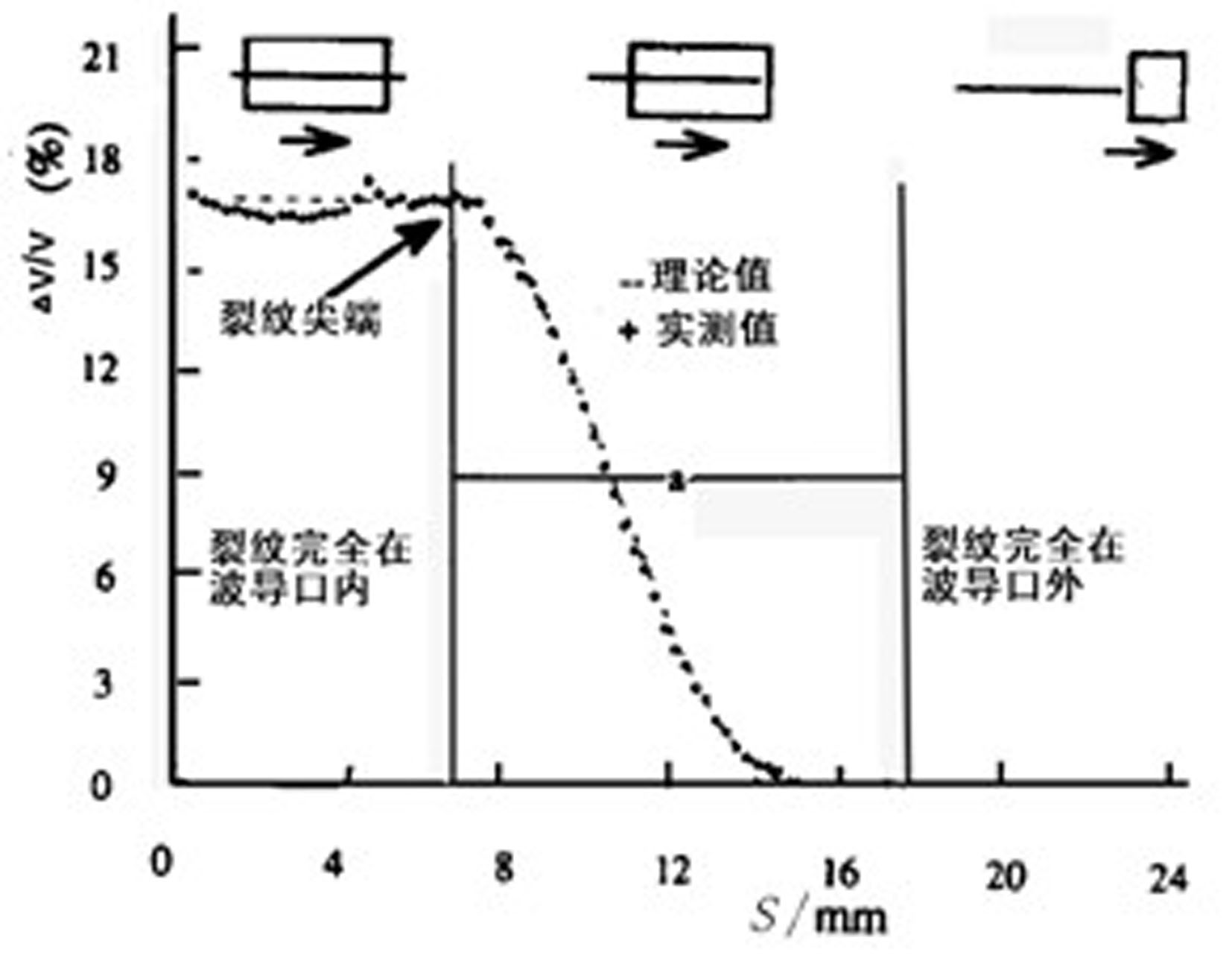

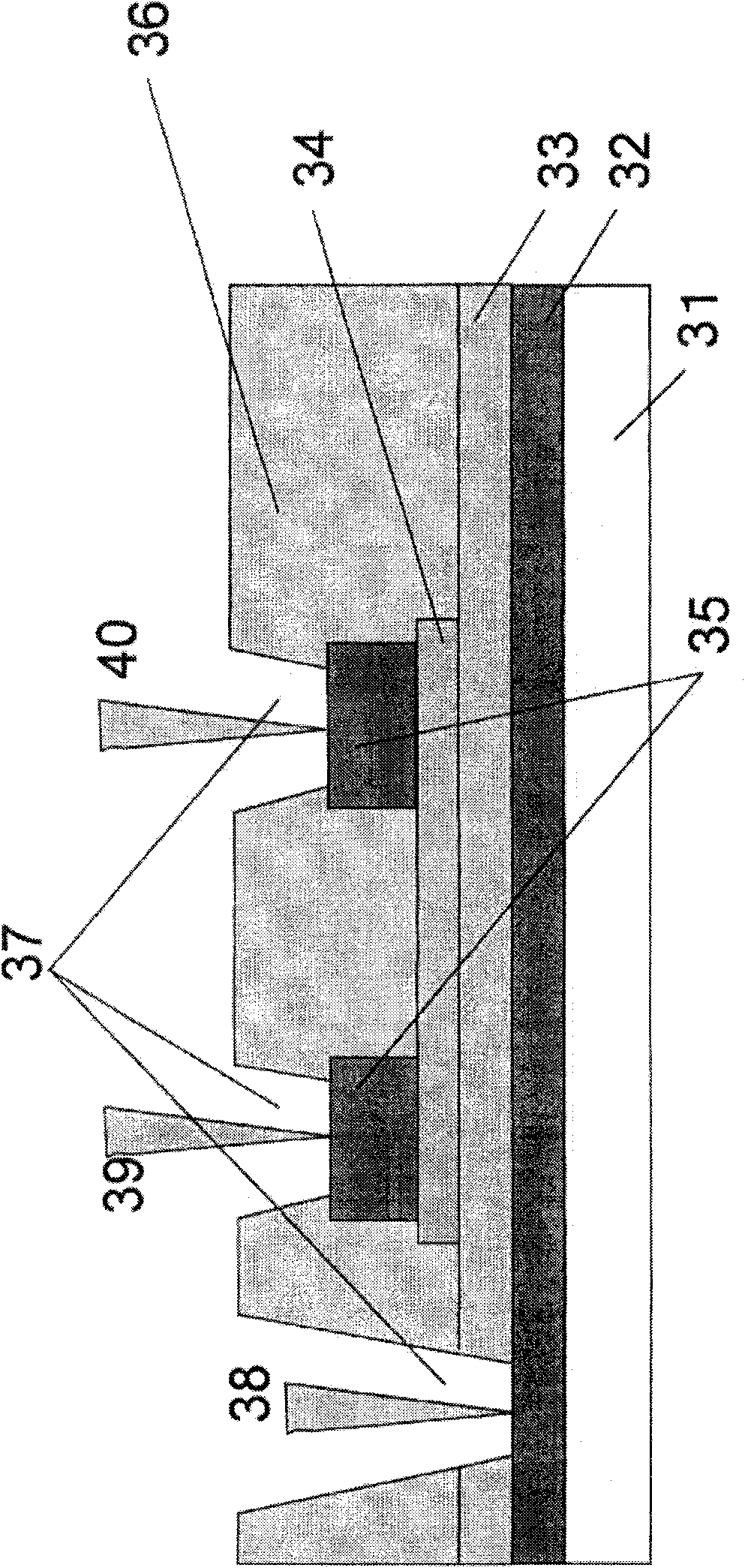

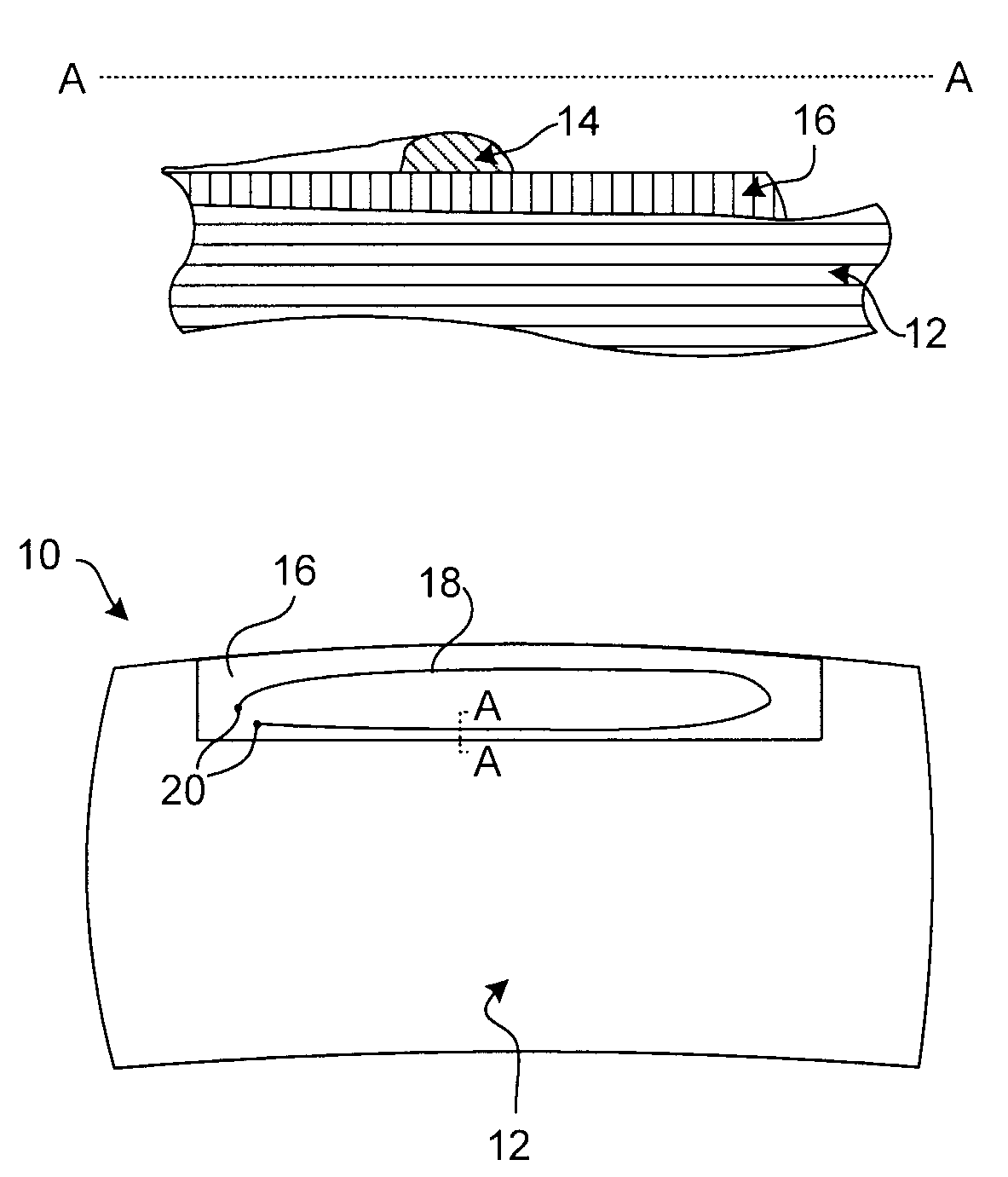

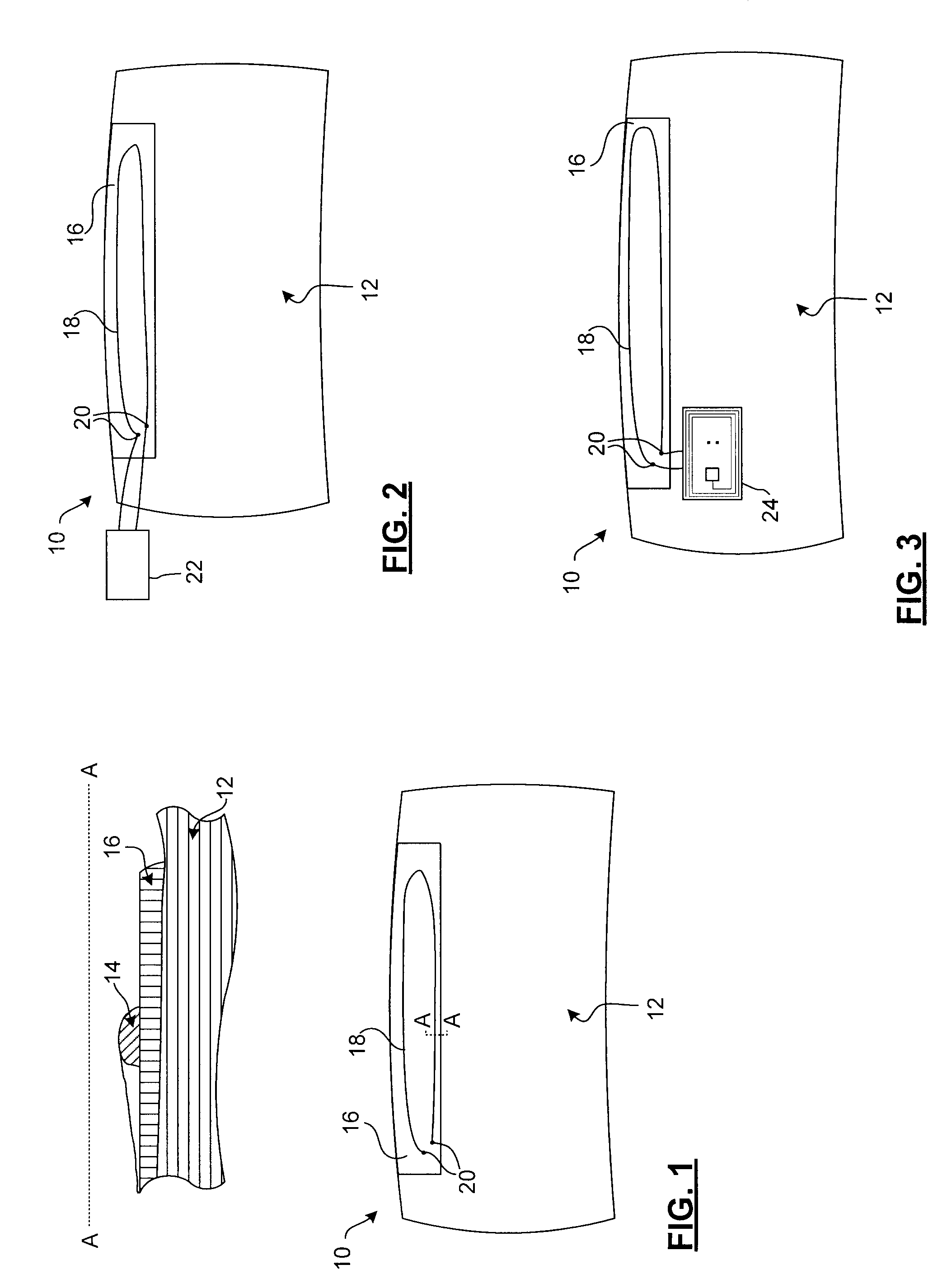

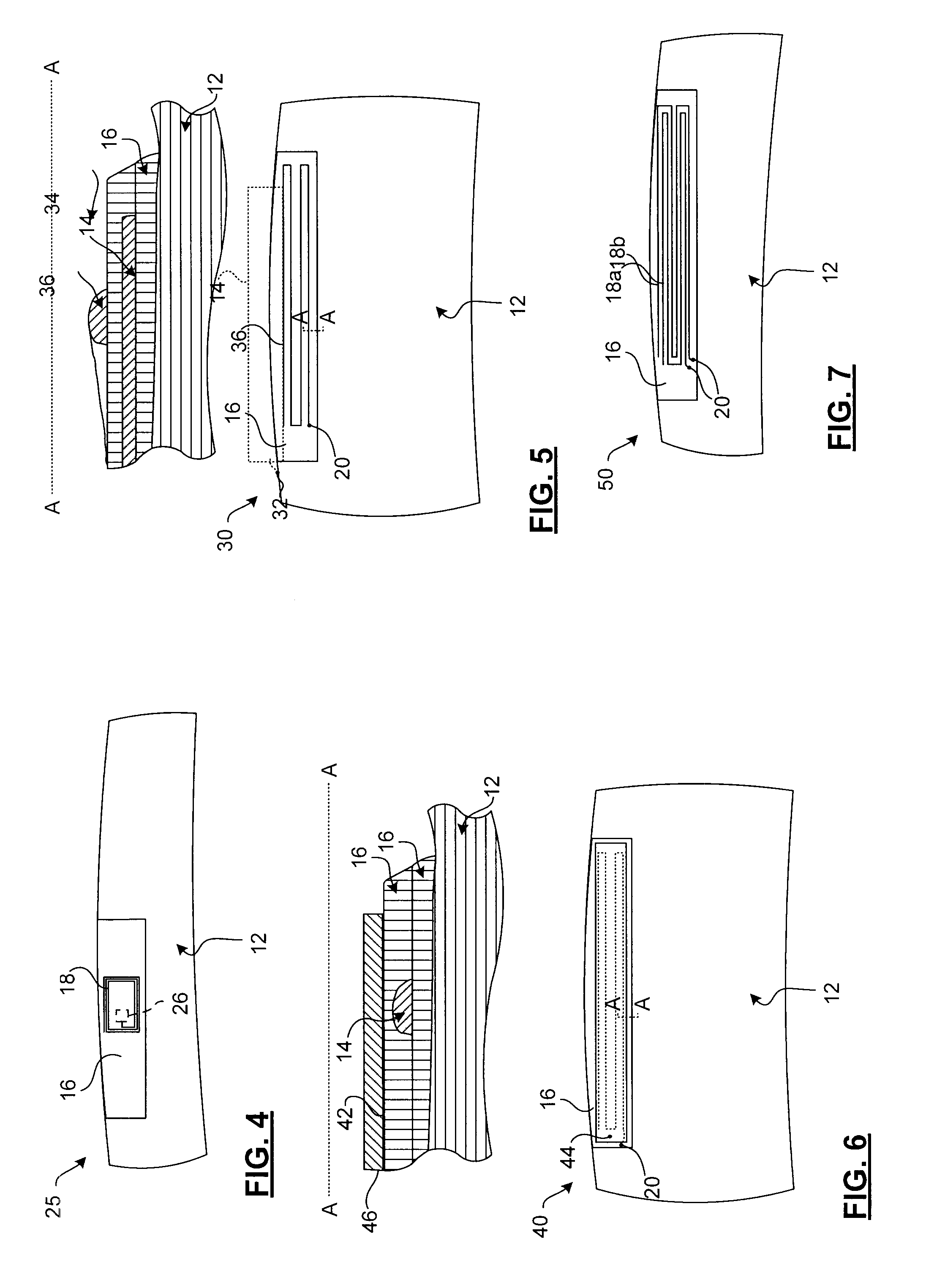

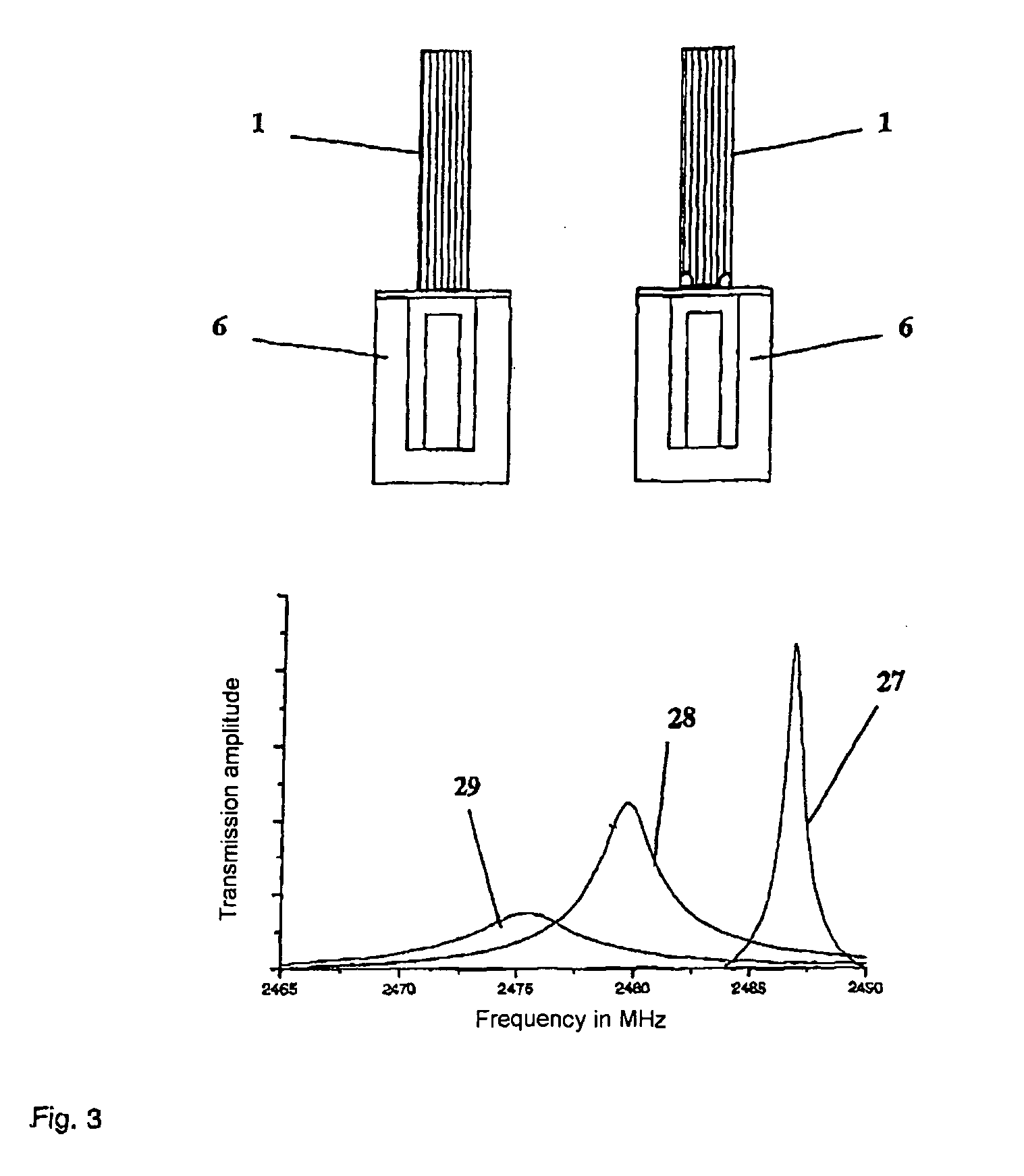

Crack detection sensor based on microstrip antenna and detection method thereof

InactiveCN103344652AReduce volumeReduce weightFlaw detection using microwavesEtchingElectrical conductor

The invention provides a crack detection sensor based on a microstrip antenna and a detection method thereof. The invention is characterized in that the crack detection sensor comprises a dielectric substrate, one surface of the dielectric substrate is provided with a conductor patch through etching, deposition or corrosion, and the other surface of the dielectric substrate is adhered on a to-be-detected structure to form the complete sensor. According to the invention, a relationship between the length and the direction of a crack and resonant frequencies of radiation modes respectively parallel to the length direction and the width direction of the patch of the microstrip antenna can be established, and the length and the direction of the crack can be obtained based on the shifts of the resonant frequencies. The crack detection sensor based on the microstrip antenna provided by the invention has the advantages of a small size, light weight, low profile, capacity of being conformal to a carrier, simple manufacturing, low cost, etc.; moreover, the crack detection sensor employs microwave detection technology, which facilitates wireless detection and signal processing.

Owner:XI AN JIAOTONG UNIV

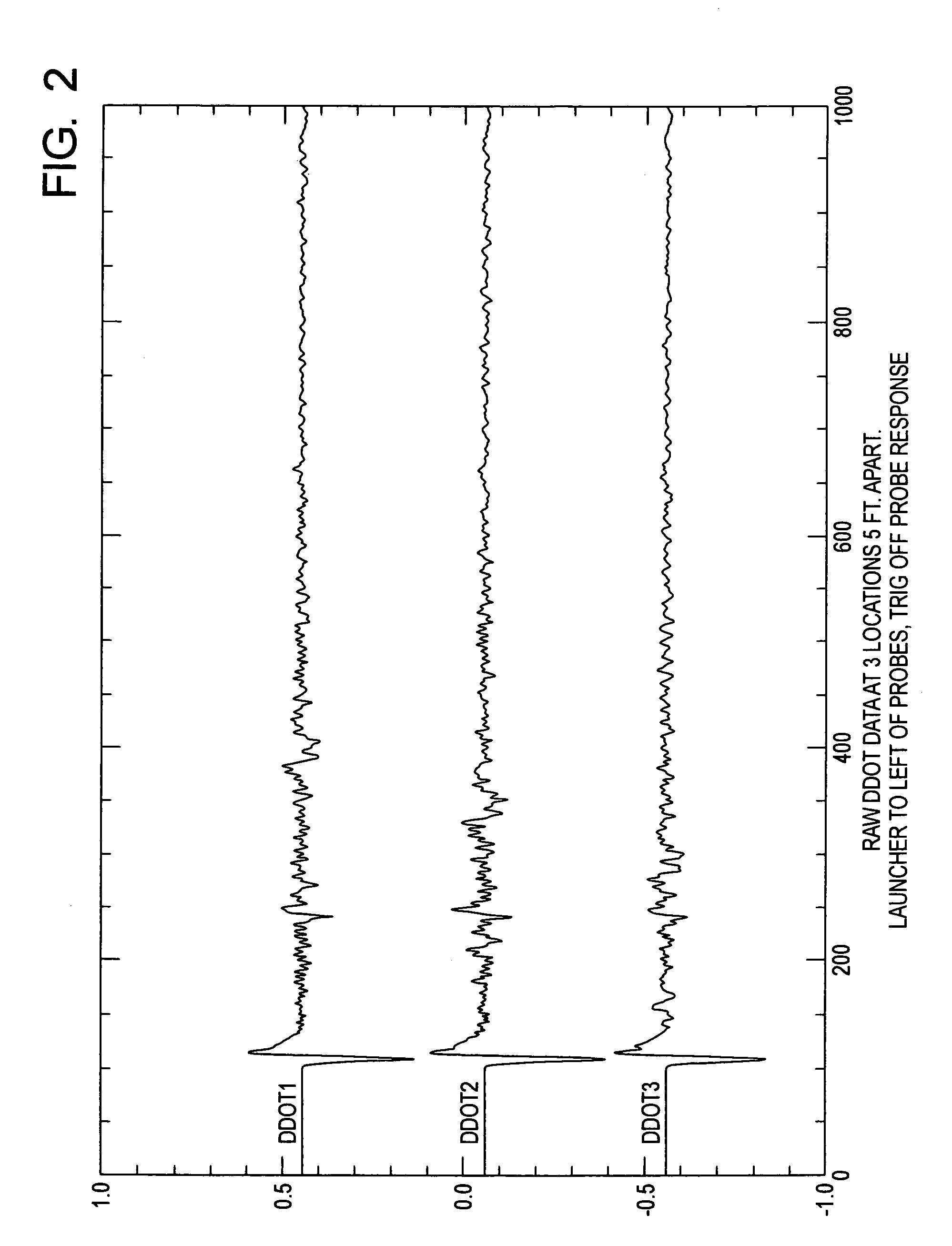

Systems and methods for testing conductive members employing electromagnetic back scattering

InactiveUS7196529B2Weather/light/corrosion resistanceResistance/reactance/impedenceEngineeringCorrosion

A system or method of analyzing a conductive member for the presence an anomaly. A test source signal is applied to a first test location on the elongate conductive member remote from the corrosion to cause the test source signal to travel along the pipe through the anomaly. At least one test return signal caused by the test source signal traveling through the anomaly is detected. The at least one test return signal for characteristics associated with the anomaly. Optionally, a perturbation may be applied to the elongate conductive member to place the conductive member in a perturbed state in which the electromagnetic characteristics of the conductive member at the anomaly are altered. The test source signal is applied to the first test location when the conductive member is in the perturbed stated.

Owner:EMGWIP LLC

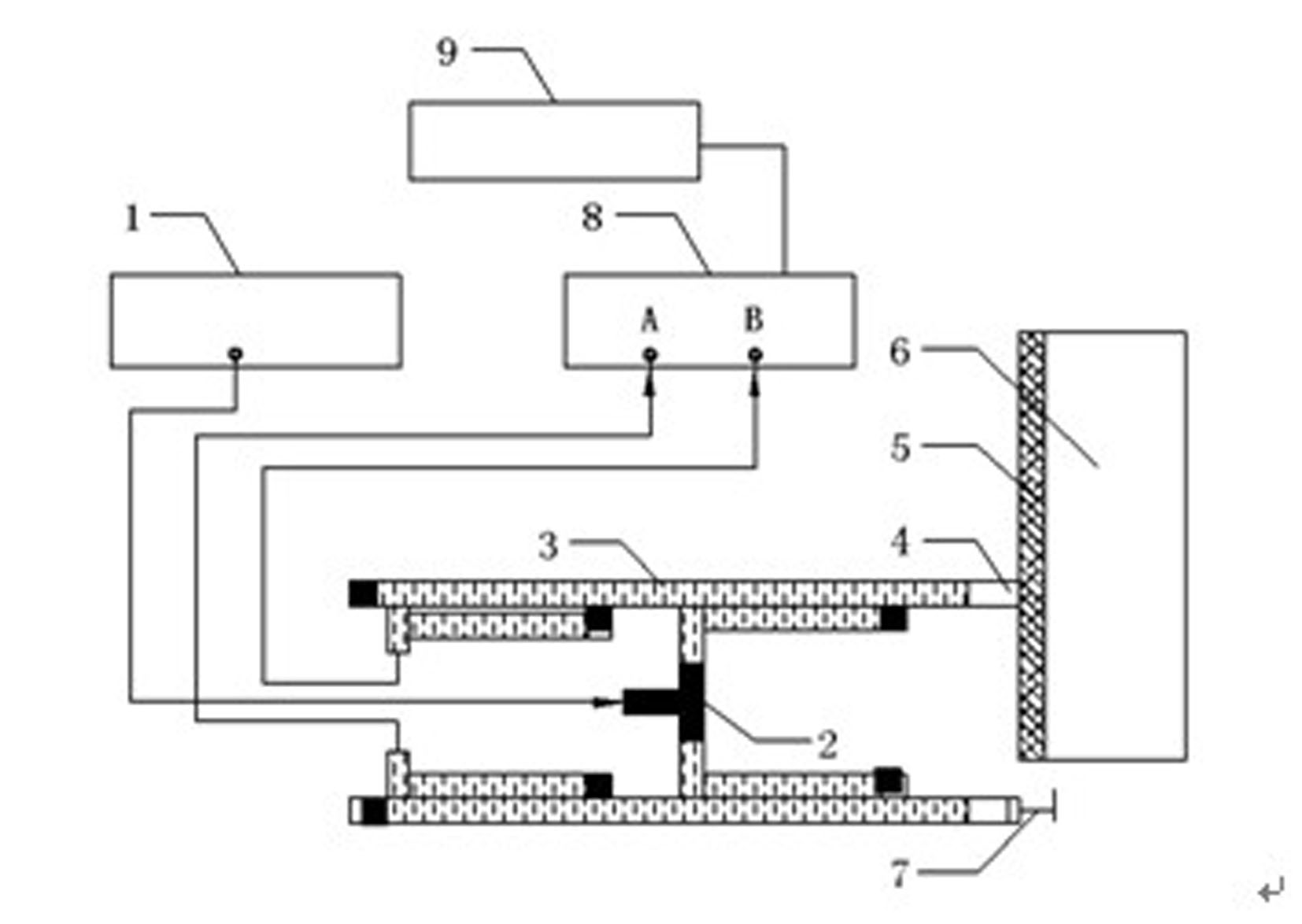

Microwave nondestructive testing device of metal surface defects and testing method thereof

InactiveCN102253058ARealize automated detectionFlaw detection using microwavesThermodynamicsMicrowave nondestructive testing

The invention provides a microwave nondestructive testing device of metal surface defects and a testing method thereof. The device is characterized in that a T-shaped tube is in signal connection with a microwave frequency scanning meter via a waveguide-coaxial transducer; a first waveguide and a second waveguide of the T-shaped tube are respectively connected with input ends corresponding to a directional coupler; when a main waveguide receives signals, the two arms of the first waveguide and the second waveguide trigger equal-amplitude and cophase microwave signals; the directional coupler is provided with a waveguide probe and a short-circuiting piston at a first port and a second port; the corresponding end of the waveguide probe is connected to a testing end B of a microwave vector network analyzer via the waveguide-coaxial transducer; and the corresponding end of the short-circuiting piston is connected to a testing end A of the microwave vector network analyzer via the waveguide-coaxial transducer. The method is characterized by pressing the waveguide probe vertically close to the tested metal or nonmetal surface to scan the tested metal or nonmetal surface during testing. The device and the method realize positioning and quantitative direct testing of the metal surface defects and automated testing integrating testing, recording, analyzing, processing and filing.

Owner:TAIYUAN UNIV OF TECH

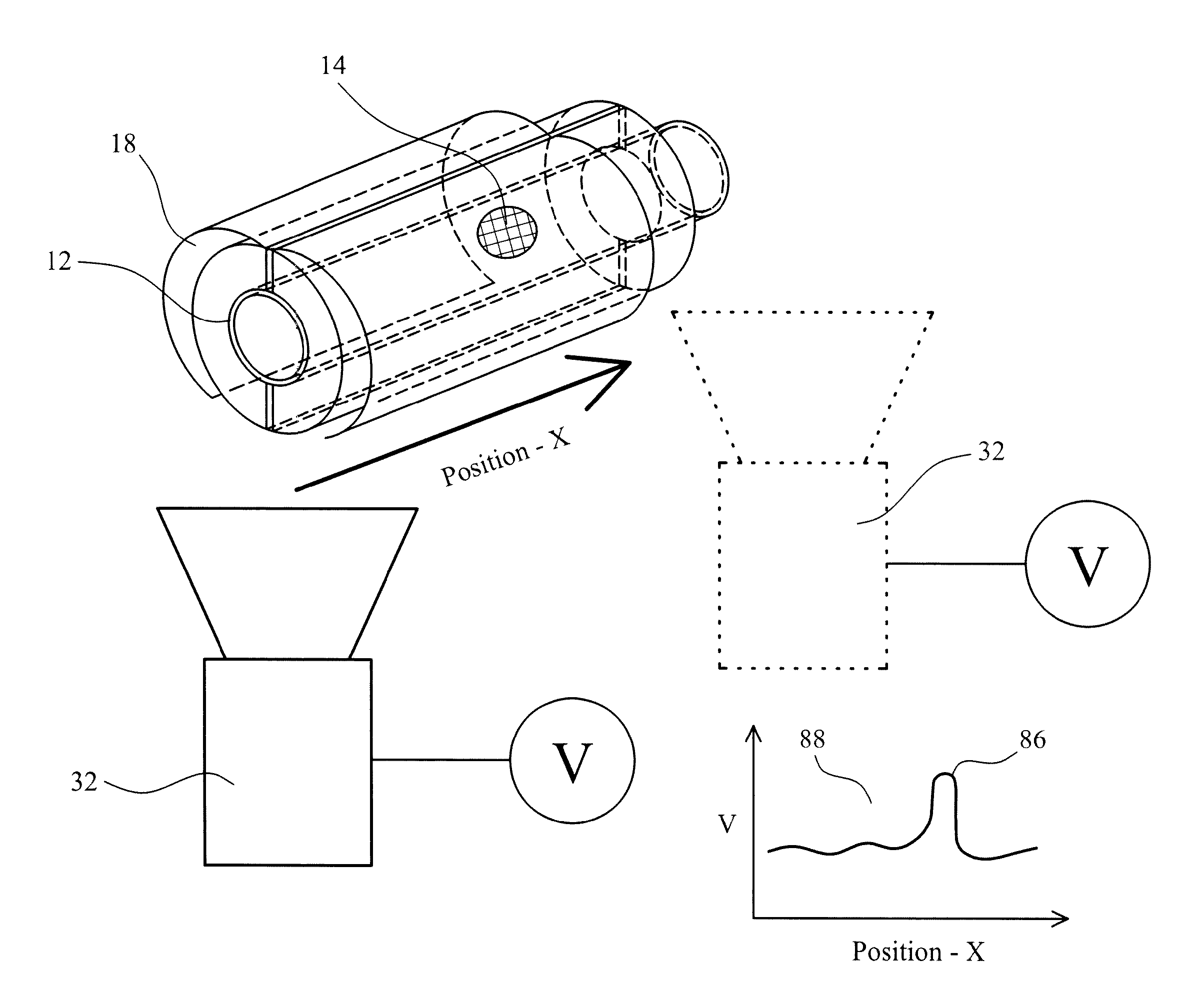

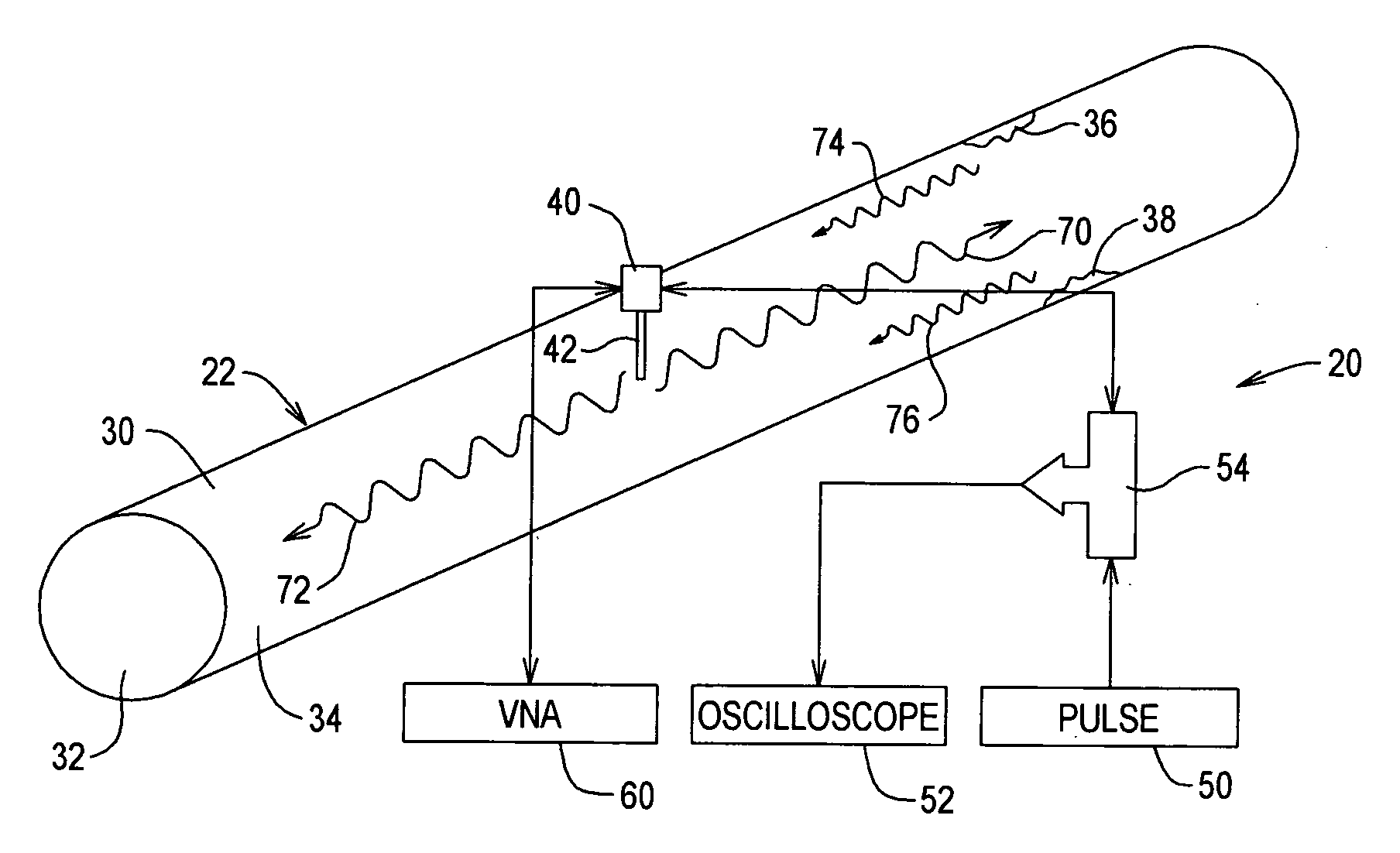

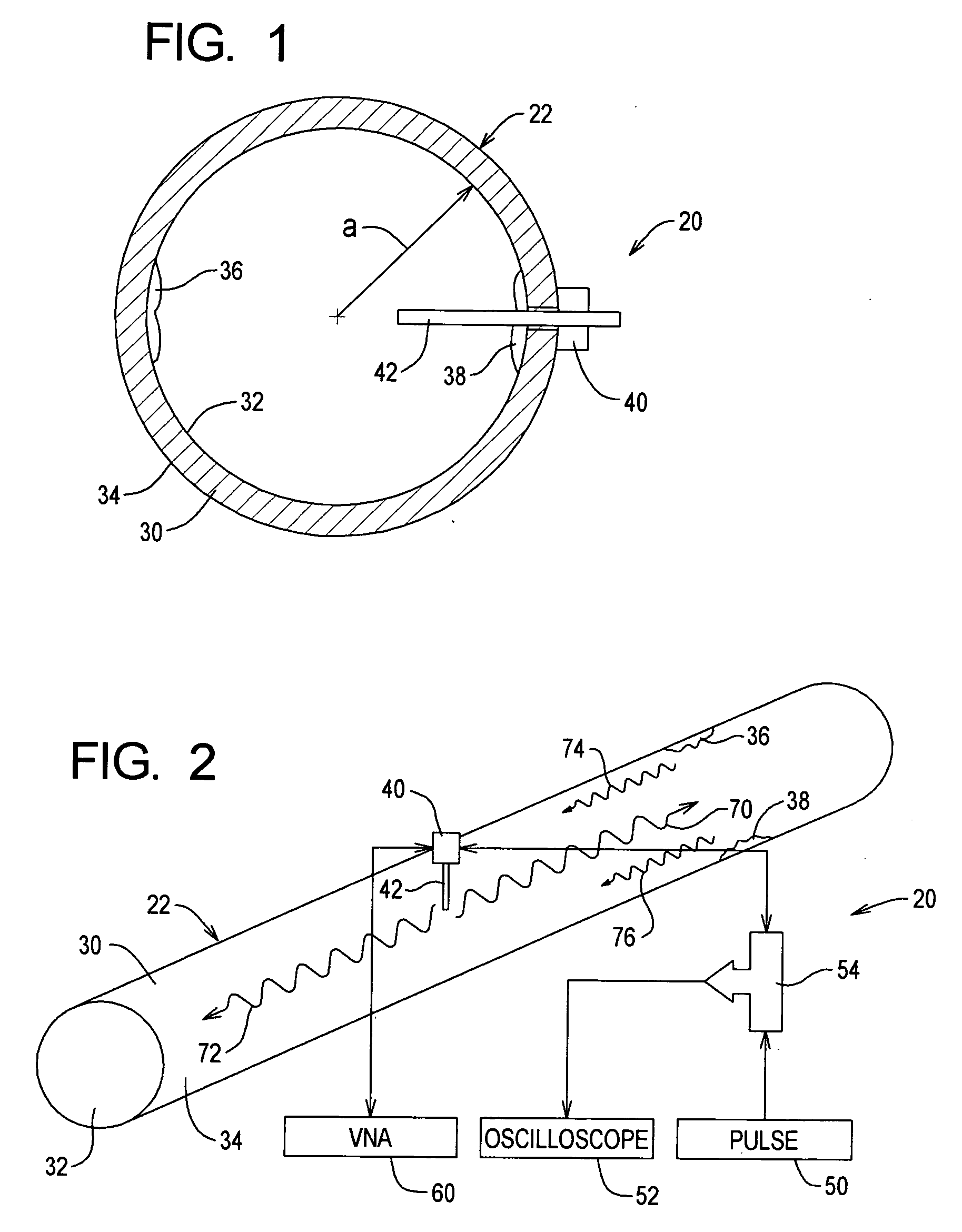

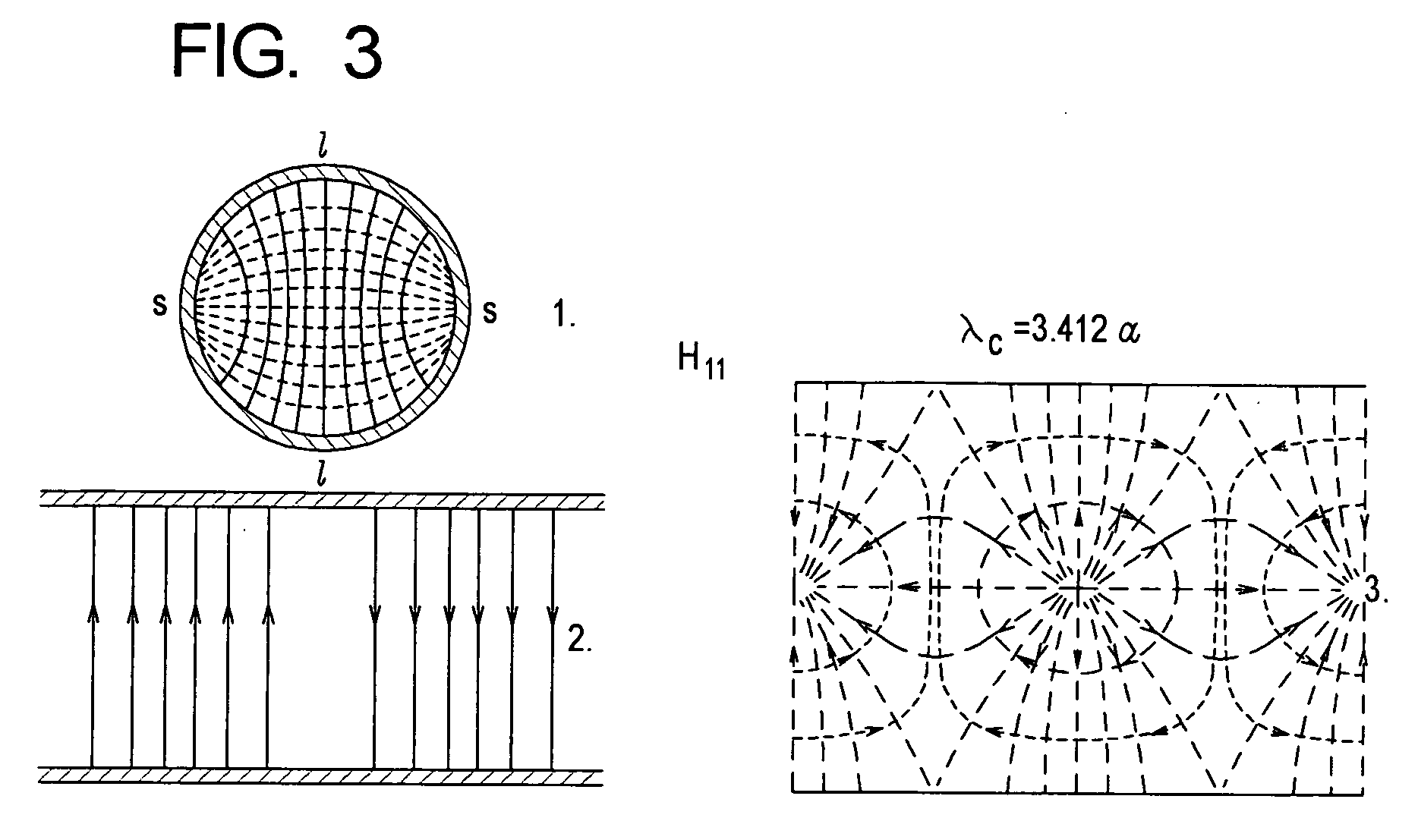

Systems and methods for detecting anomalies on internal surfaces of hollow elongate structures using time domain or frequencey domain reflectometry

InactiveUS20080143344A1Resistance/reactance/impedenceFault location by pulse reflection methodsLine tubingElectromagnetic spectrum

Systems and methods for detecting anomalies, such as corrosion, on internal surfaces of hollow elongate bodies, such as pipelines. The pipeline is treated as a circular waveguide, and a fast rise time pulse or a spectrum of electromagnetic waves is launched down the waveguide to perform time domain, or equivalent of time domain (e.g., frequency domain), reflectometry. Anomalies in the internal structure of the pipeline cause reflections which can be measured and related to the physical parameters of the pipeline structure and identified to a particular location.

Owner:EMGWIP LLC

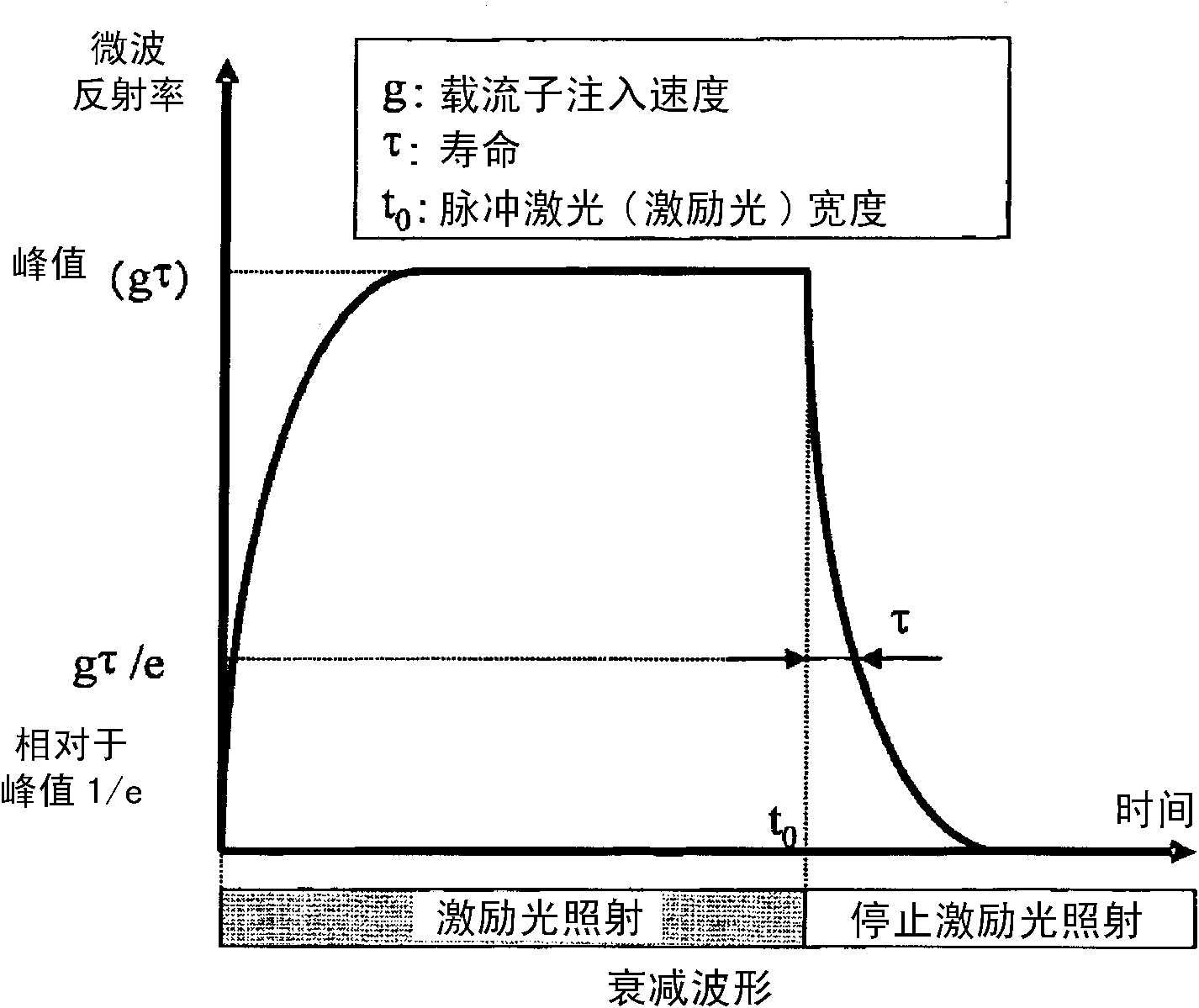

Method for estimating oxide semiconductor thin film and method for managing quality of oxide semiconductor thin film

ActiveCN102313849AEvaluate mobilityAccurate Quality ManagementScattering properties measurementsElectrical testingMicrowaveReflected waves

The invention provides a method for estimating oxide semiconductor thin films and a method for managing the quality of oxide semiconductor thin films. The methods are applied for estimating and determining the electrical performances of the oxide semiconductor thin films in a non-contact and electrode-free way. The method comprises the steps of irradiating exciting light and microwave on samples equipped with oxide semiconductor thin films; stopping the irradiation of the exciting light after achieving the maximum value of the reflecting wave of the microwave from the oxide semiconductor thin film which is changed due to the irradiation of the exciting light; detecting the change of the reflectivity of the reflecting wave of the microwave from the oxide semiconductor thin film after the irradiation of the exciting light is stopped; and determining the mobility of the oxide semiconductor thin film according to the calculated service lifetime value derived from the detected value.

Owner:KOBE STEEL LTD

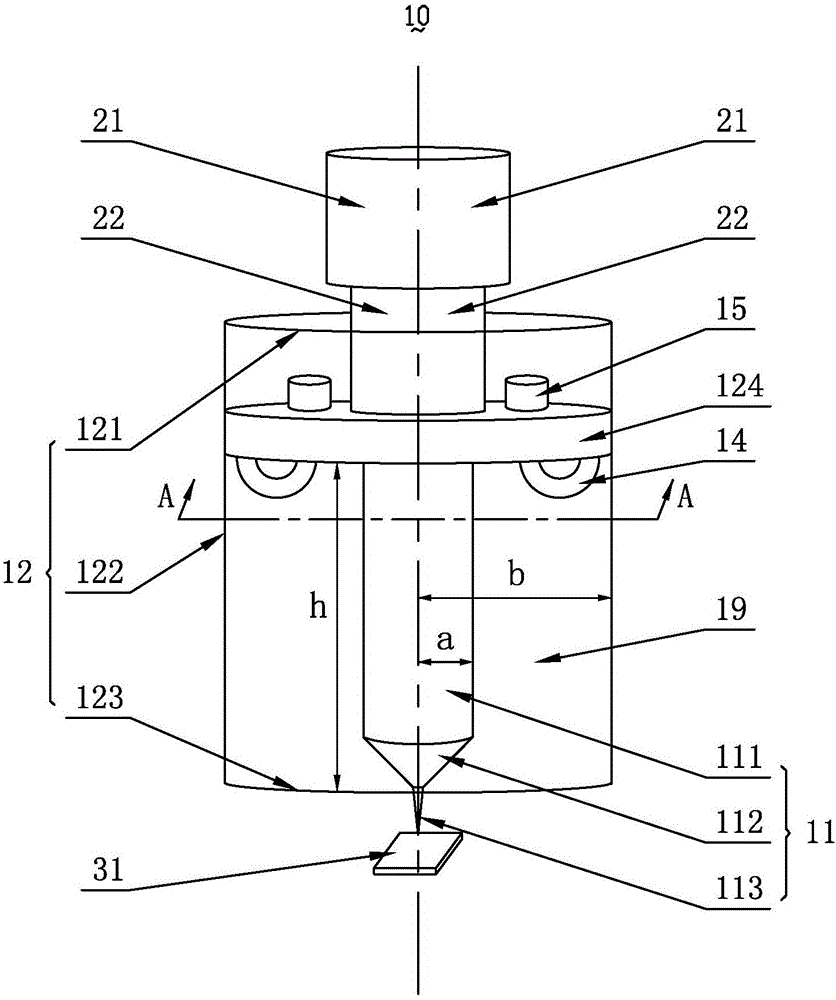

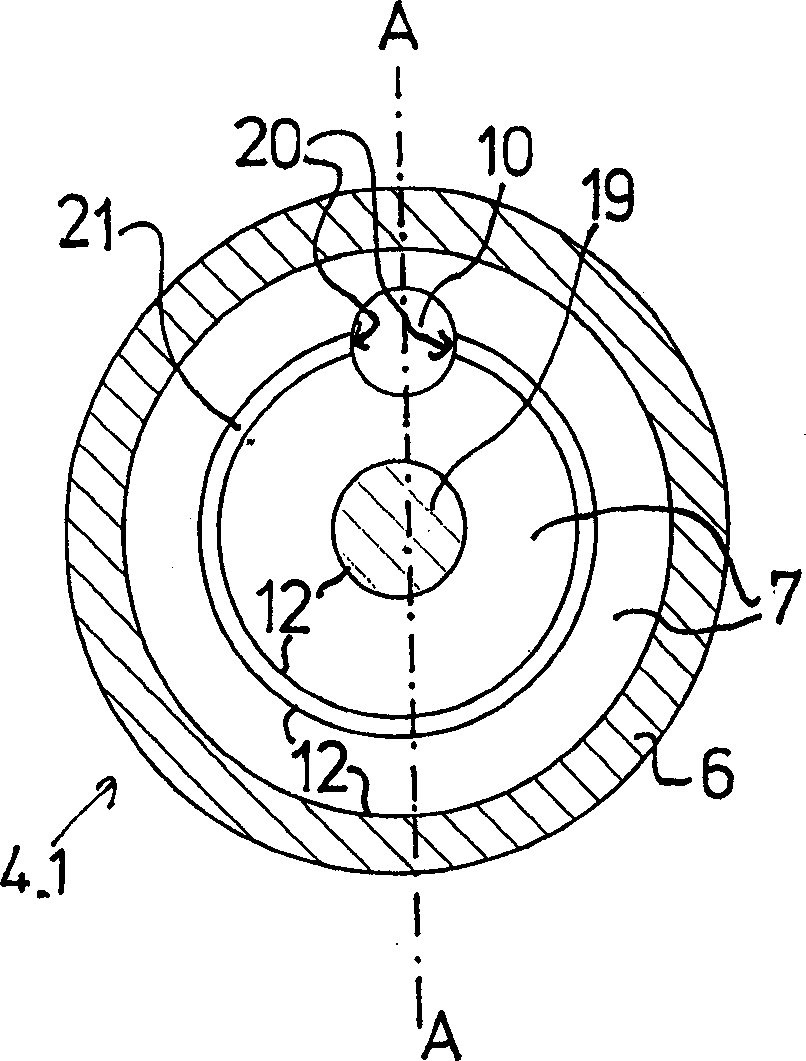

Coaxial resonant cavity and applications thereof

ActiveCN106099301AHigh quality factorRaise the resonant frequencyDielectric property measurementsResonatorsResonant cavityElectricity

The invention relates to the technical field of microwaves and particularly relates to a coaxial resonant cavity and applications thereof. The coaxial resonant cavity comprises a coupling mechanism and a cavity body, wherein the coupling mechanism is used for excitation or coupling of microwaves in the cavity body; the coaxial resonant cavity also comprises a probe extending out of the cavity body, and the probe and the cavity body are coaxially set; the cavity body is a circular column, and the ratio of the exradius to the inradius of the circular column is (3-5) to 1. On the basis of not reducing the size of the coaxial resonant cavity, through controlling the ratio of the exradius to the inradius of the circular column to be (3-5) to 1, the resonant efficiency can be effectively improved. The invention also provides a material dielectric constant test system, a microwave detection device, a filter and a microwave sterilization device by adopting the coaxial resonant cavity.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Non-destructive determination of machining induced surface defects on metal parts

A non-destructive method of detecting and measuring machining induced surface defects on gas turbine engine components is provided. In an exemplary embodiment, the method includes positioning an evanescent microwave microscope probe adjacent a turbine component surface, and scanning the turbine component surface by moving at least one of the evanescent microwave microscope probe and the component surface in an x-y plane while maintaining a predetermined distance between the probe and the component surface constant.

Owner:GENERAL ELECTRIC CO

Surface-mounted crack detection

InactiveUS8059008B2Resistance/reactance/impedenceConductive materialSurface mountingPercent elongation

Owner:NAT RES COUNCIL OF CANADA

Apparatus and method for detection and segregation of faulty cigarettes

ActiveUS20070000503A1Prevent penetrationReduce the numberTobacco treatmentResistance/reactance/impedenceElectromagnetic fieldRadio frequency

Owner:TEWS ELEKTRONIK GMBH & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com