Crack detection sensor based on microstrip antenna and detection method thereof

A technology of crack detection and microstrip antenna, which is applied in the direction of using microwave flaw detection, etc., can solve the problems of cumbersome signal processing, time-consuming and labor-consuming, background noise interference, etc., and achieve convenient wireless detection and signal processing, simple manufacturing, and low profile Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

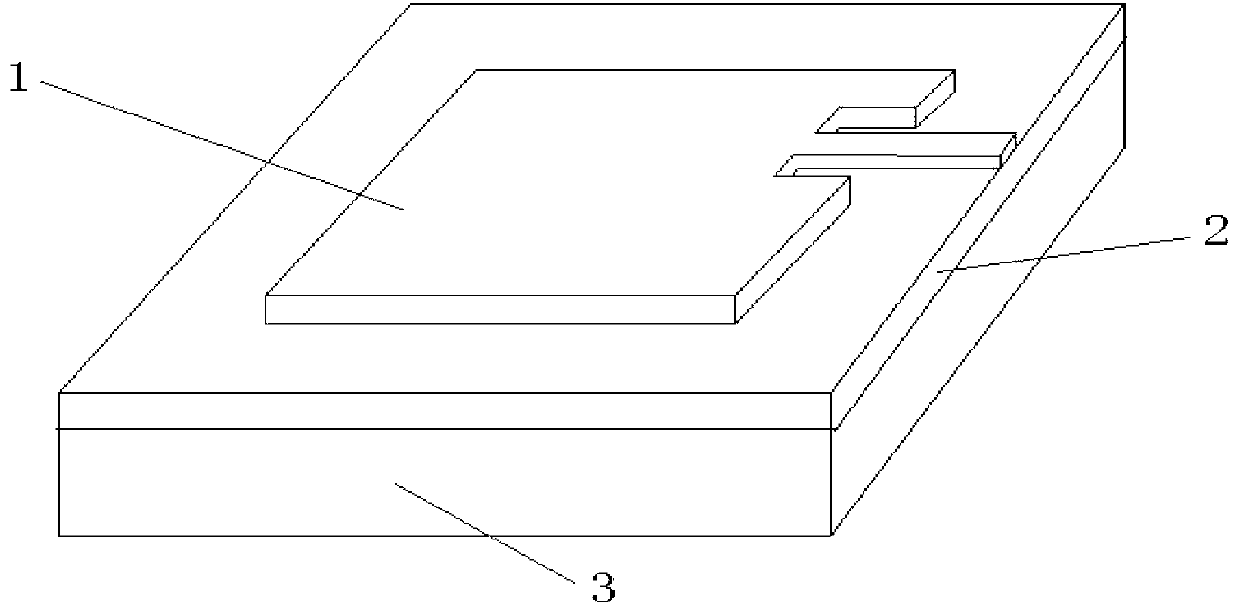

[0037] The material of the dielectric substrate 2 is polytetrafluoroethylene (R4B-265), a sheet with a size of 40mm*40mm*0.5mm, and the material of the conductor patch 1 is copper, and a metal film with a size of 16mm*20mm*0.035mm. The metal structure 3 to be tested is made of copper, a metal plate with a size of 40mm*40mm*3mm, and the corresponding theoretical resonant frequencies of the sensor designed in this way are 4.59GHz and 5.68GHz. When the sensor is working, the length and direction of the crack can be obtained by measuring the drift of the resonance frequency.

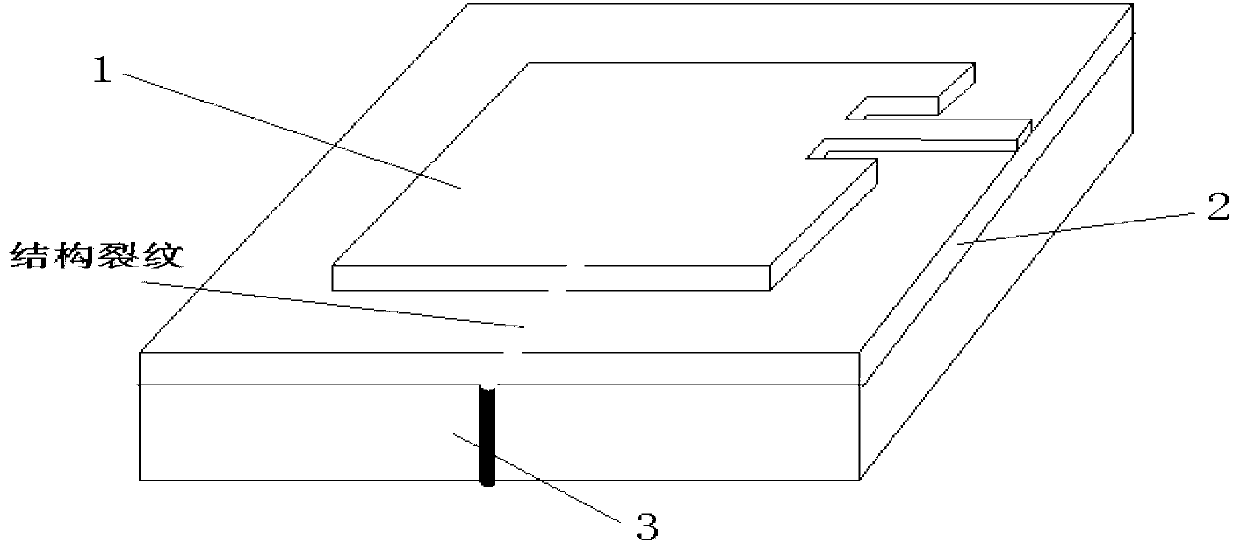

[0038] Such as figure 2 , taking the detection of the central crack length along the patch length as an example. As the crack length increases, due to the resonant frequency f parallel to the patch length direction 01 basically unchanged, the resonant frequency f parallel to the width direction 10 gradually decreases, for this crack length depends on the resonant frequency f 10 The amount of drift can b...

Embodiment 2

[0040]The sensor is made of laminated board Rogers4350B. The dielectric substrate 2 is a sheet with a size of 40mm*25mm*0.44mm. The material of the conductor patch 1 is copper, and the size is a metal film with a size of 15.25mm*12.75mm*0.035mm. The material of the metal structure 3 to be tested is LY12CZ aluminum alloy plate, the size is 40mm*25mm*5mm, and the corresponding resonant frequency of the sensor designed in this way is 5.1GHz and 6.1GHz. When the sensor is working, the length and direction of the crack can be obtained by measuring the drift of the resonance frequency.

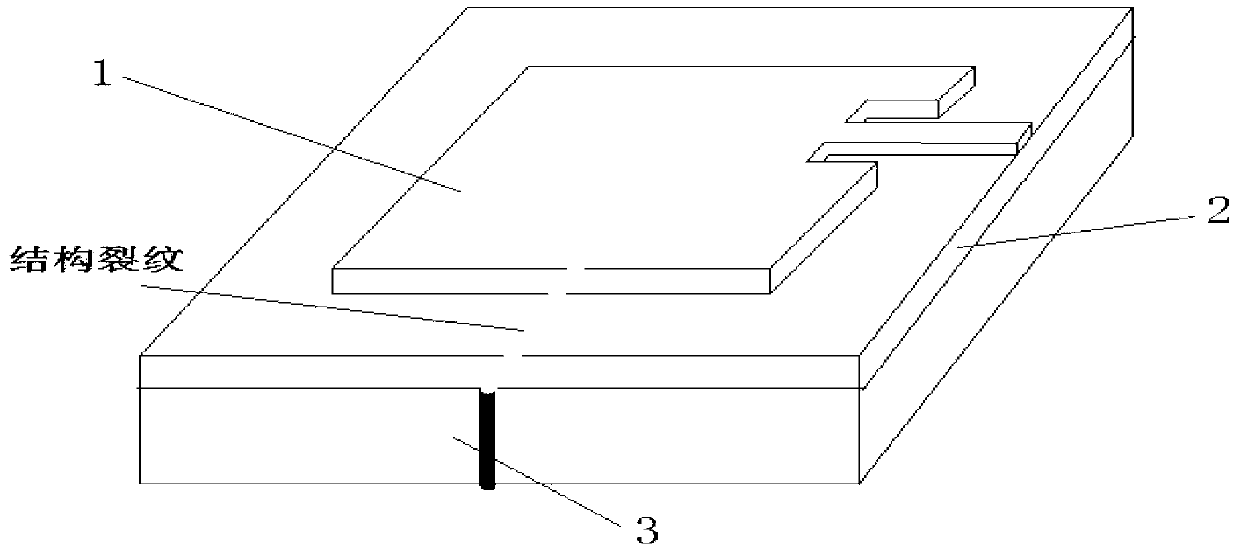

[0041] Such as image 3 As shown, any central crack parallel to the length direction of the microstrip antenna, when the crack length coincides with the microstrip antenna patch extends from 0 to 15mm, the corresponding resonant frequency f 10 Decreasing from 6.1GHz to 2.5GHz, the crack length is roughly linear with the frequency drift, and the detection sensitivity is 0.24GHz / mm.

[0042] Such as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com