Patents

Literature

944results about How to "Avoid making" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Three-dimensional design and manufacturing systems

ActiveUS20140156053A1Use directlyMinimize amount of processingAdditive manufacturing apparatusData processing applications3d print3d design

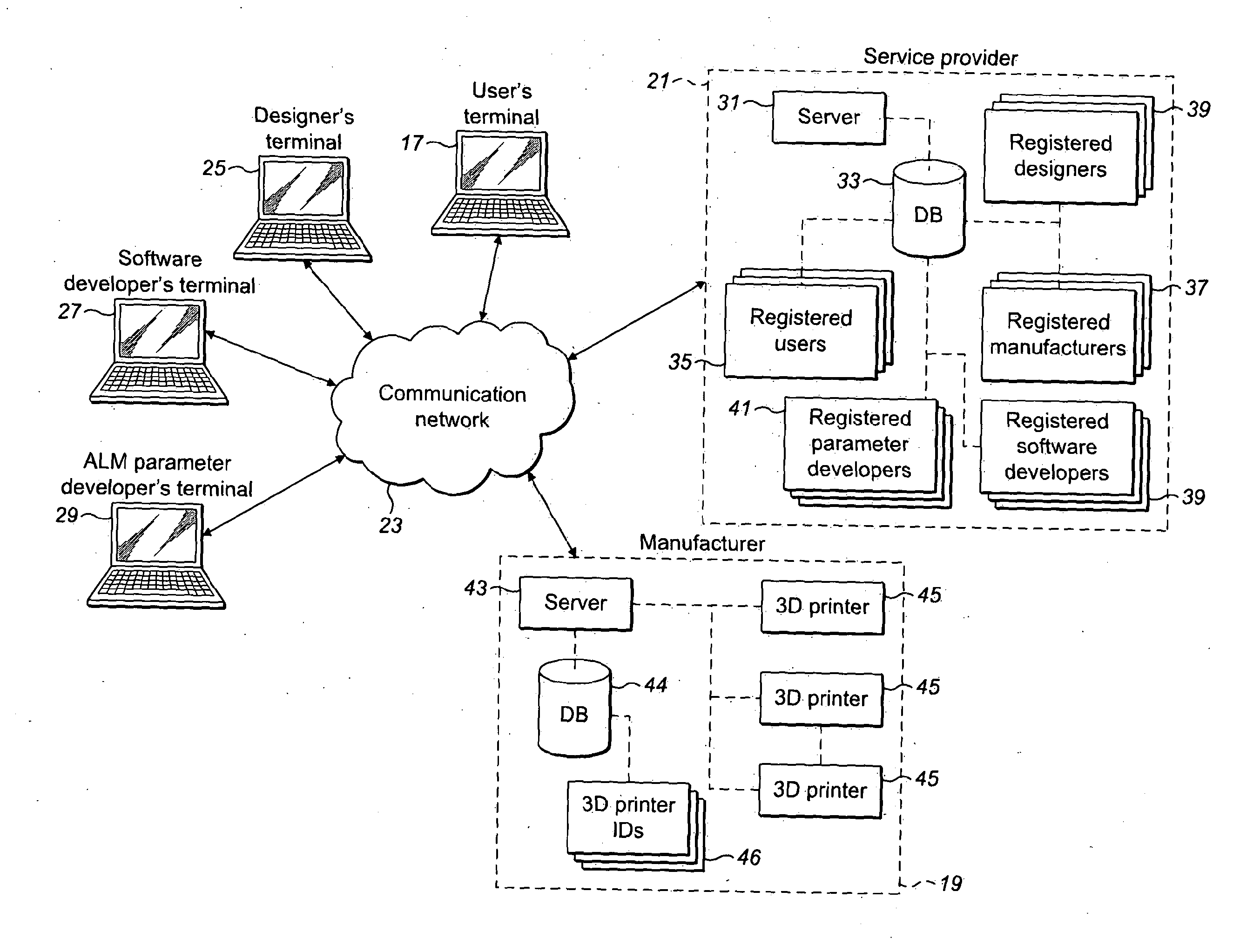

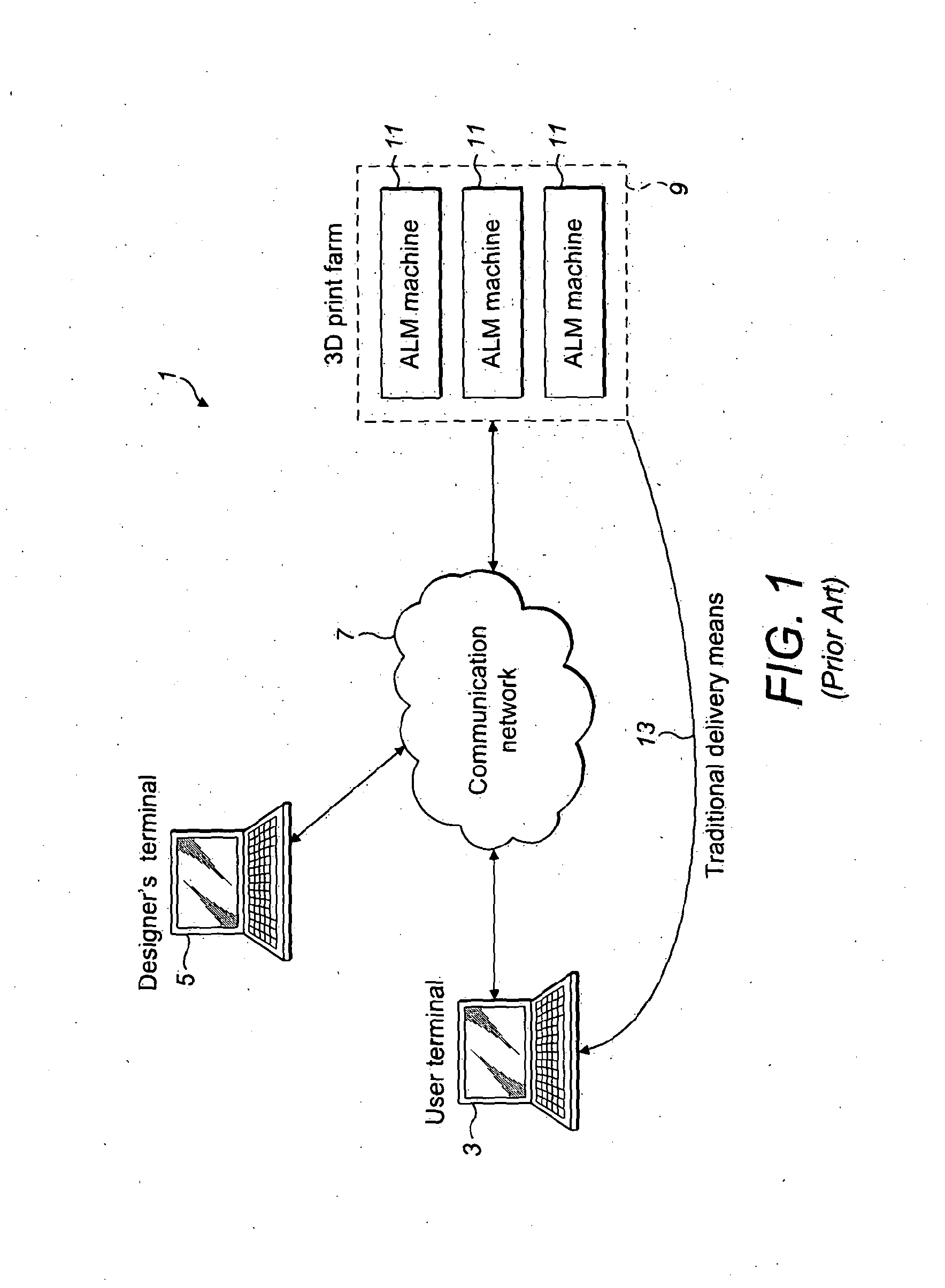

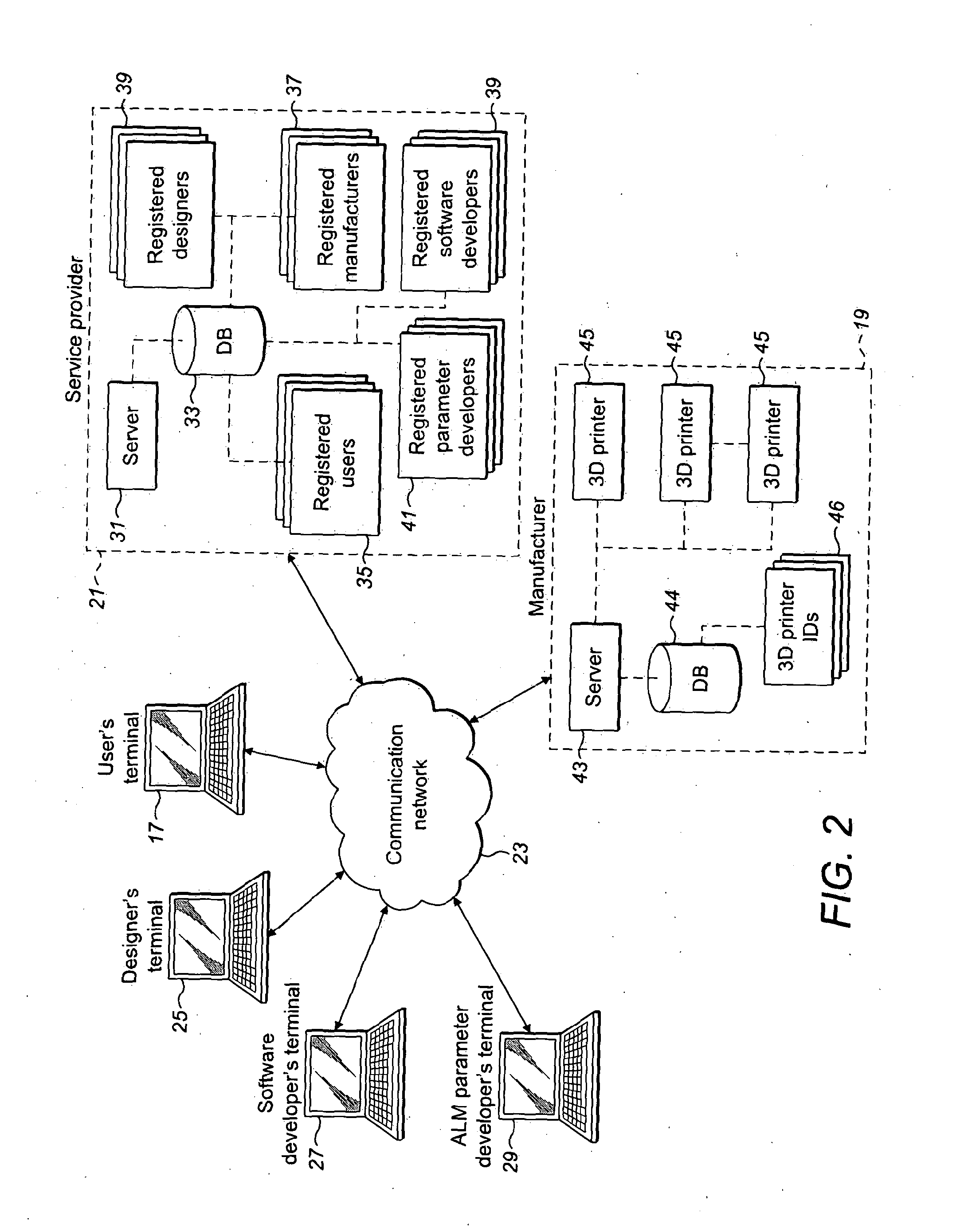

A method of authenticating the printing of a three-dimensional (3D) article at a 3D printer according to a 3D print file describing a three-dimensional design is described. The method comprises: receiving an authentication request from a 3D print server that is associated with the 3D printer, the request comprising a unique design identifier associated with a 3D design file and a unique 3D printer identifier associated with a 3D printer, the received unique 3D design identifier being related to the received 3D printer ter identifier in accordance with a first relationship; using at least one of the received unique identifiers to access a verifying 3D design identifier and a verifying 3D printer identifier, the verifying identifiers being related to each other in accordance with a second relationship; comparing the first and second relationships between the received and verifying identifiers; generating an authentication signal if the first relationship corresponds with the second relationship; obtaining a decryption key associated with the received identifiers in response to the authentication signal; and transferring the decryption key to the 3D print server to authenticate and enable the printing of the 3D article on the 3D printer.

Owner:DNA AM LTD

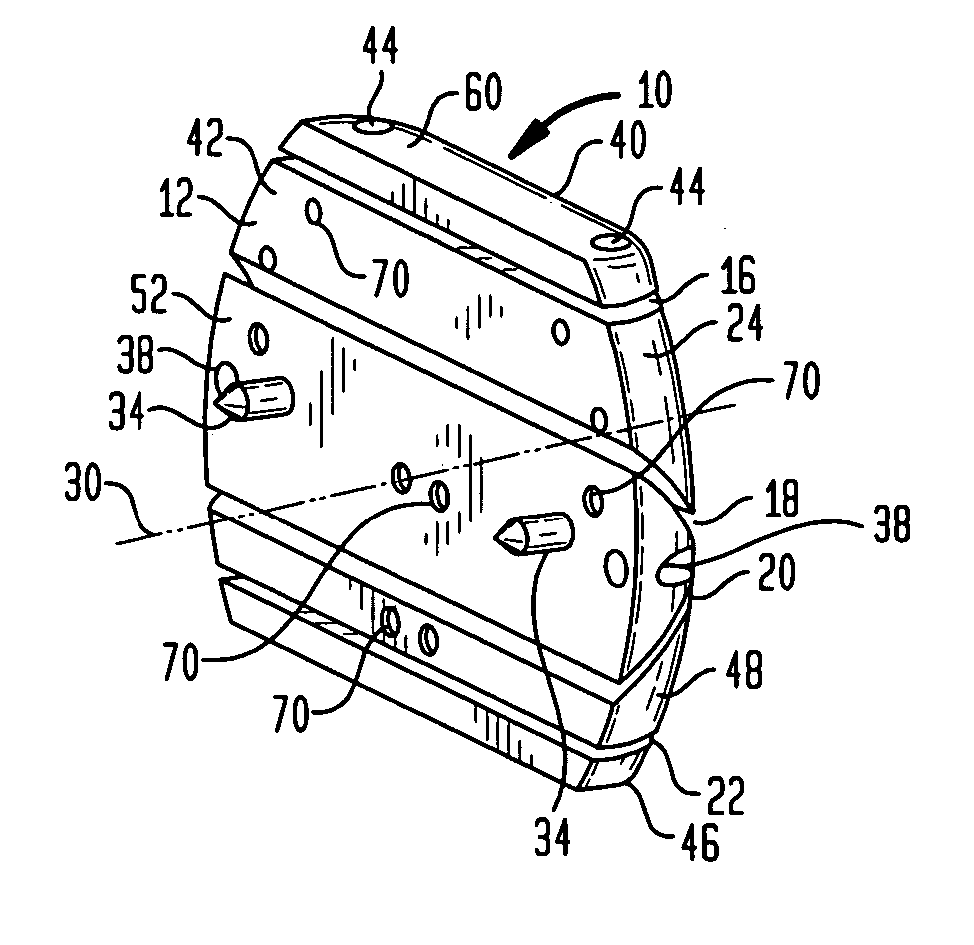

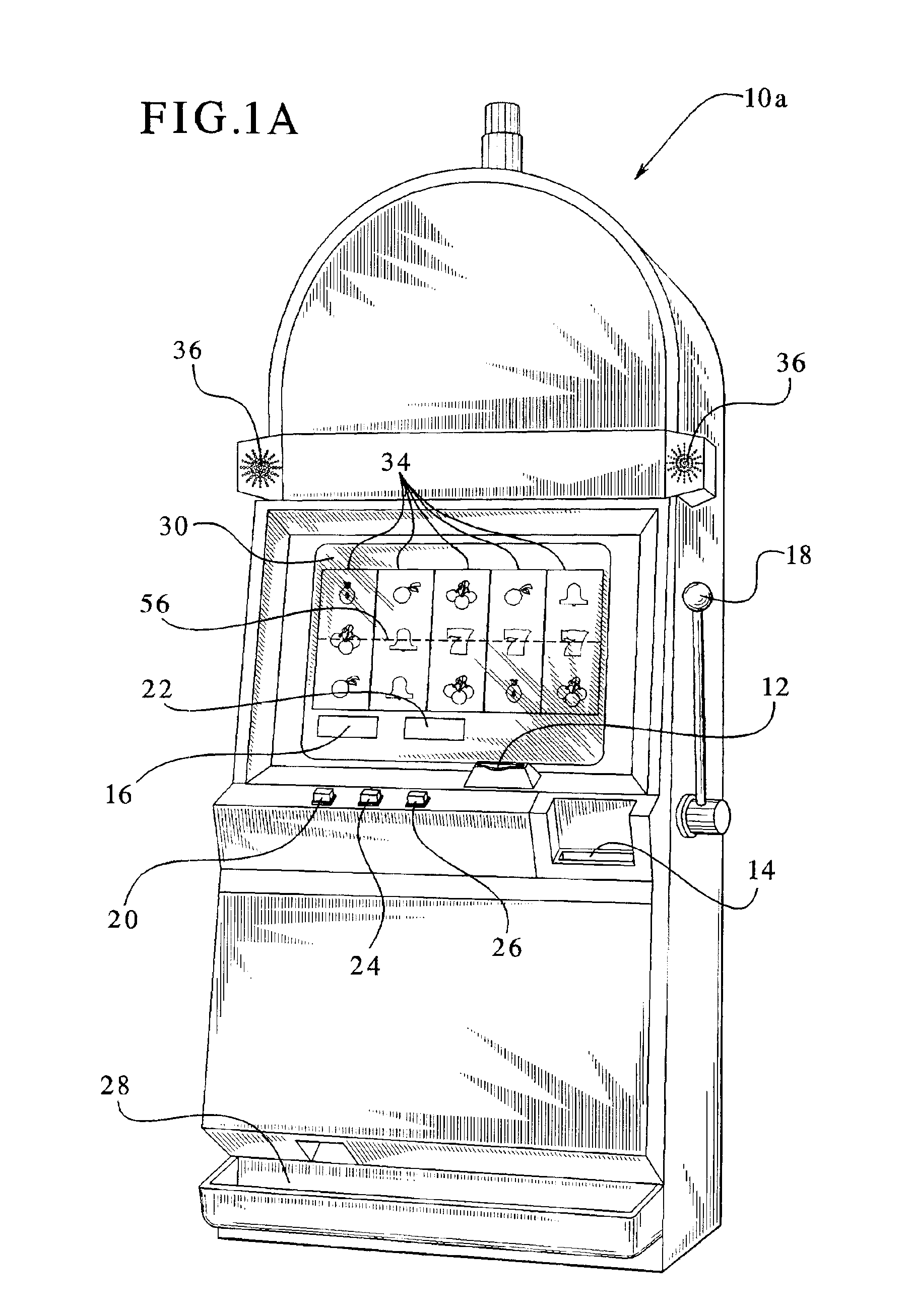

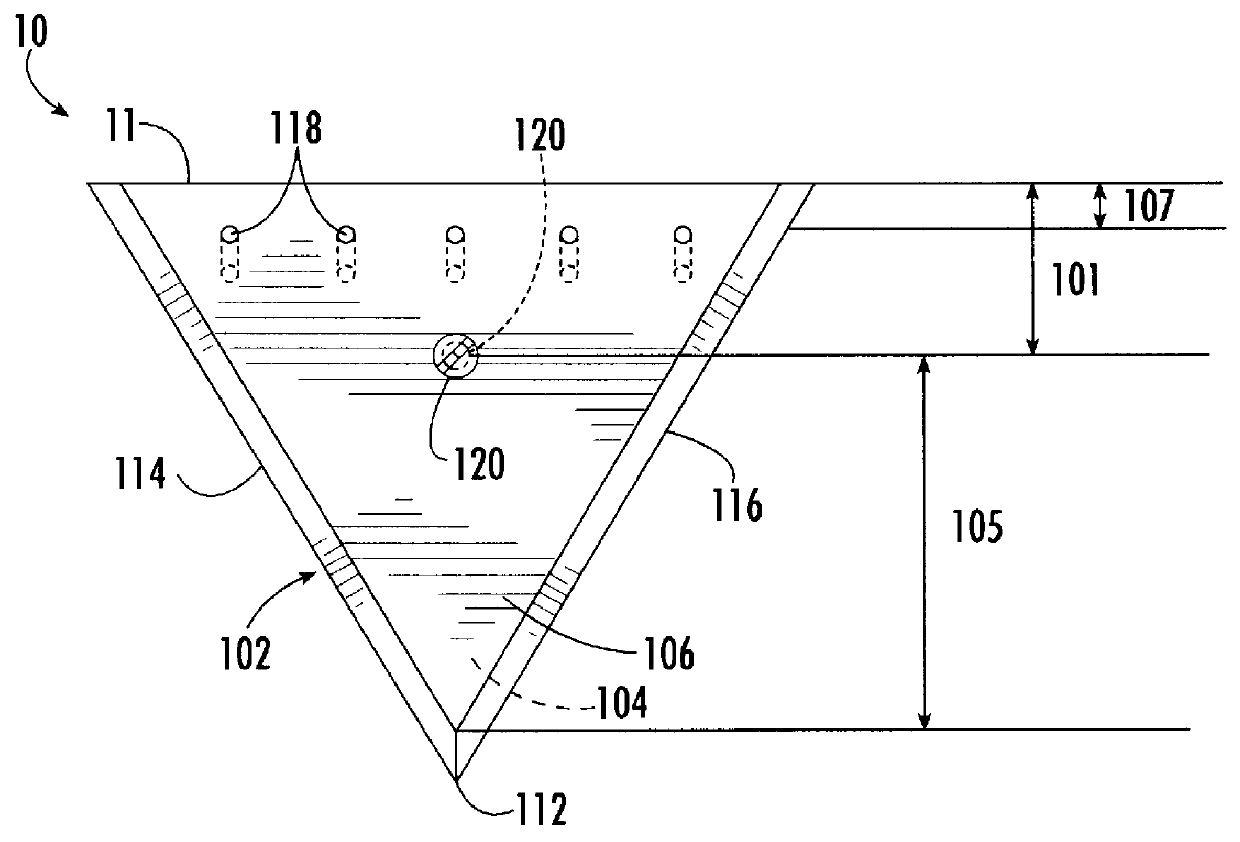

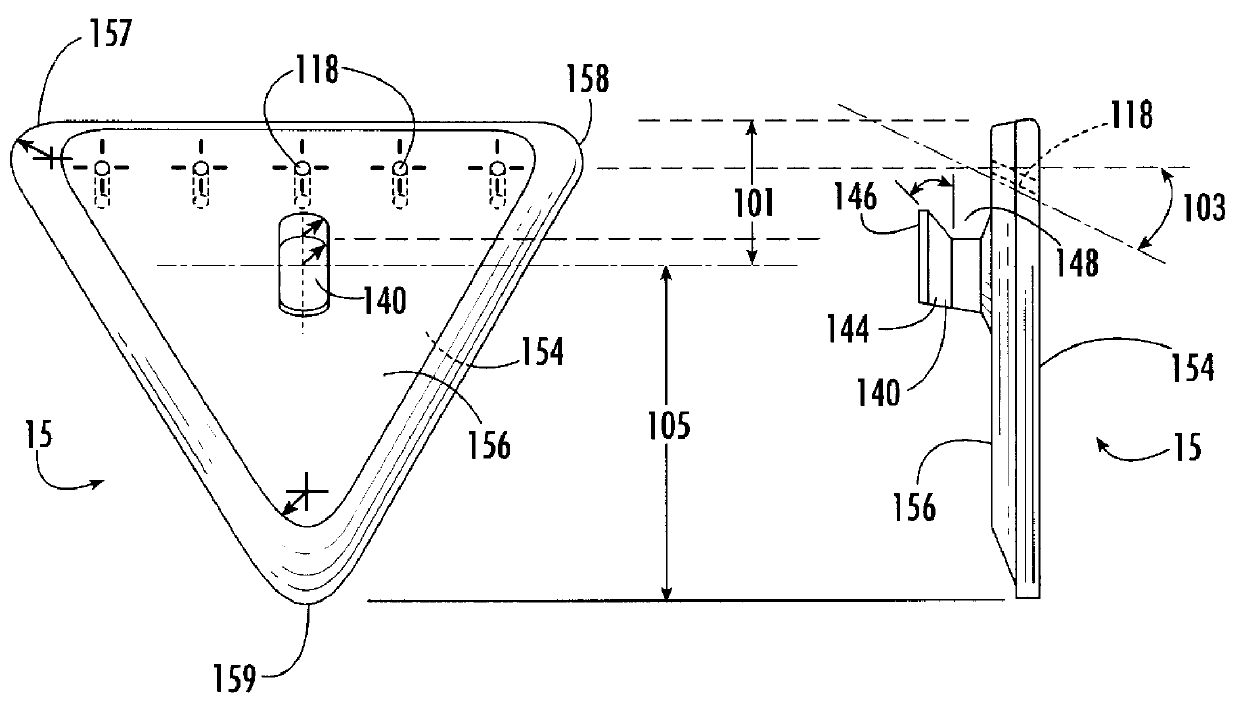

Bone shaped cutting block

ActiveUS20050240195A1Potential damageMaintaining amountNon-surgical orthopedic devicesSurgical sawsBone shapeBiomedical engineering

A cutting block for resecting a bone, particularly the distal femur, has a body with a first generally planar bone contacting surface to contact the resected distal surface of the femur. The body has a second surface spaced from the bone contacting surface along an axis perpendicular to said generally planar bone contacting surface. The body has a perimeter surface extending between the first and second surfaces, wherein the perimeter surface is at least partially curved with respect to the axis in both a direction generally perpendicular thereto and generally parallel thereto. The perimeter surface may be polished.

Owner:HOWMEDICA OSTEONICS CORP

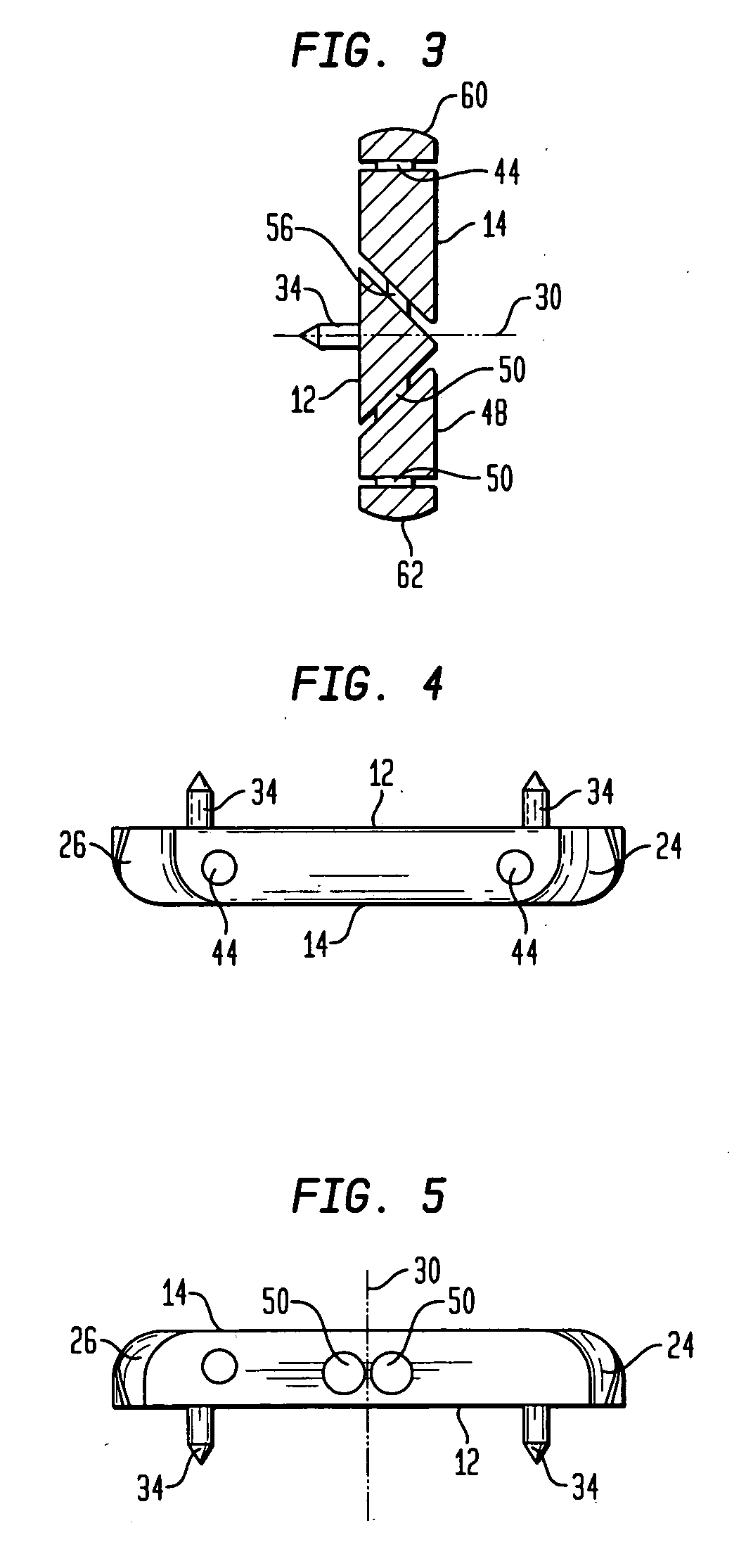

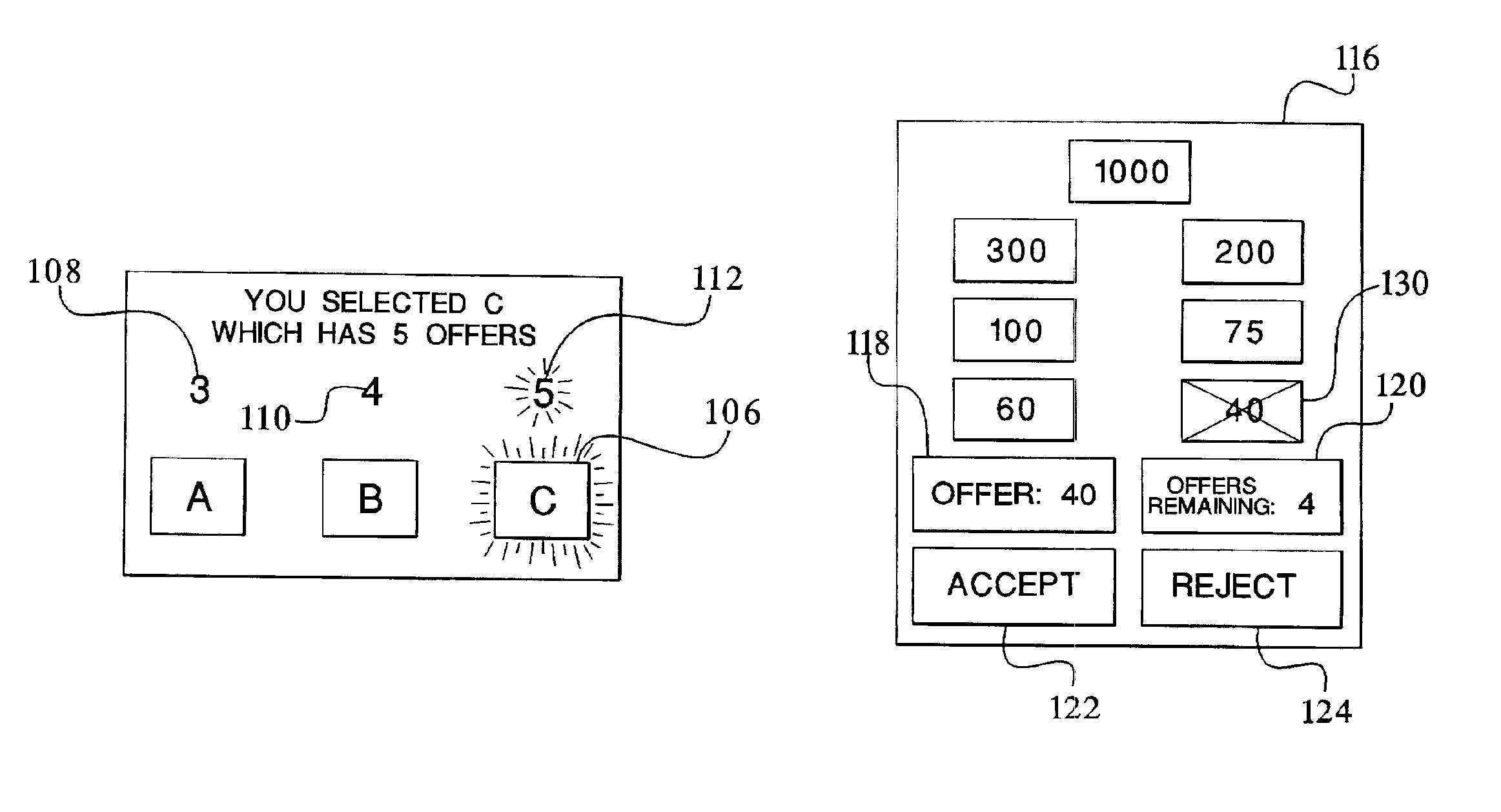

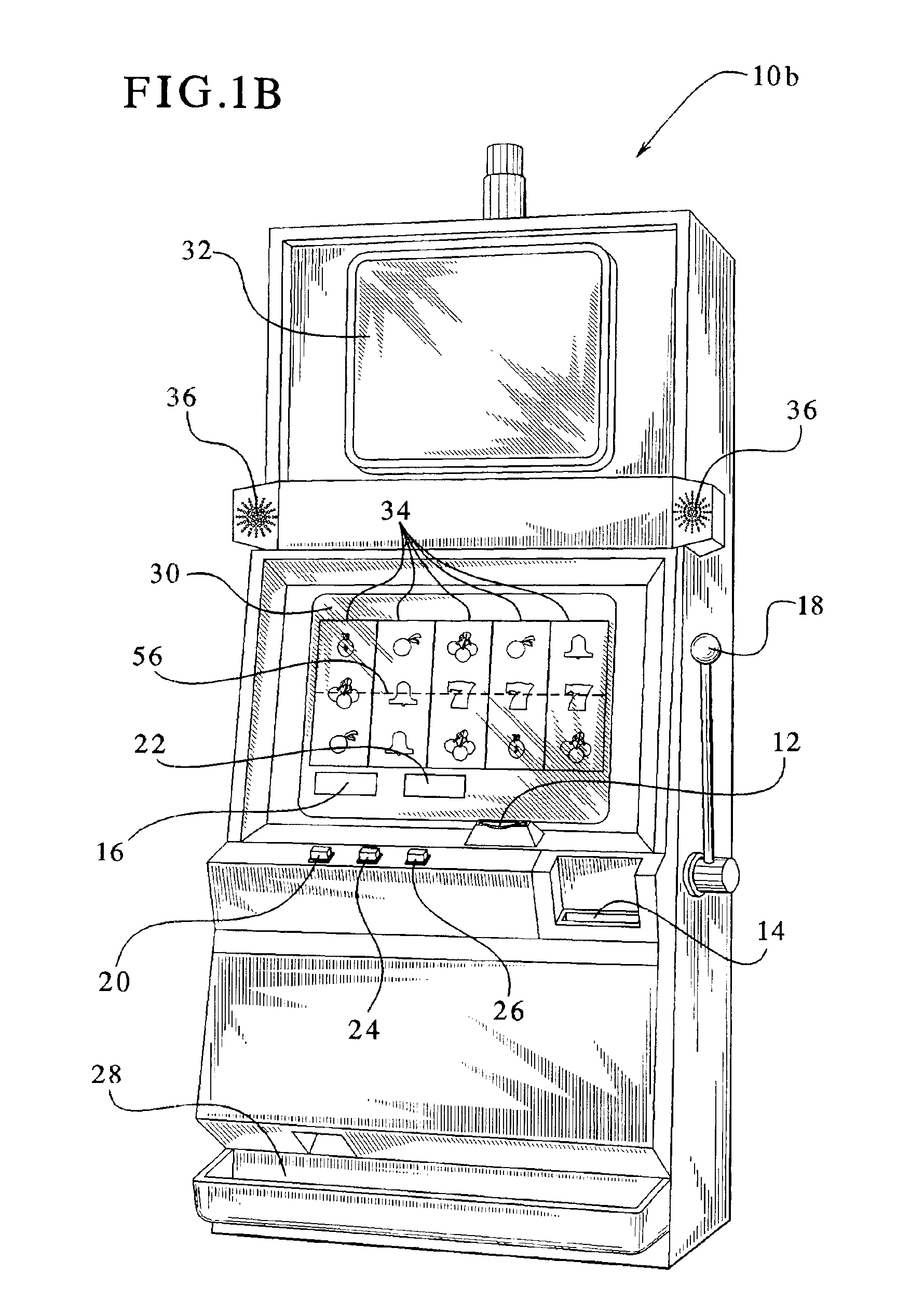

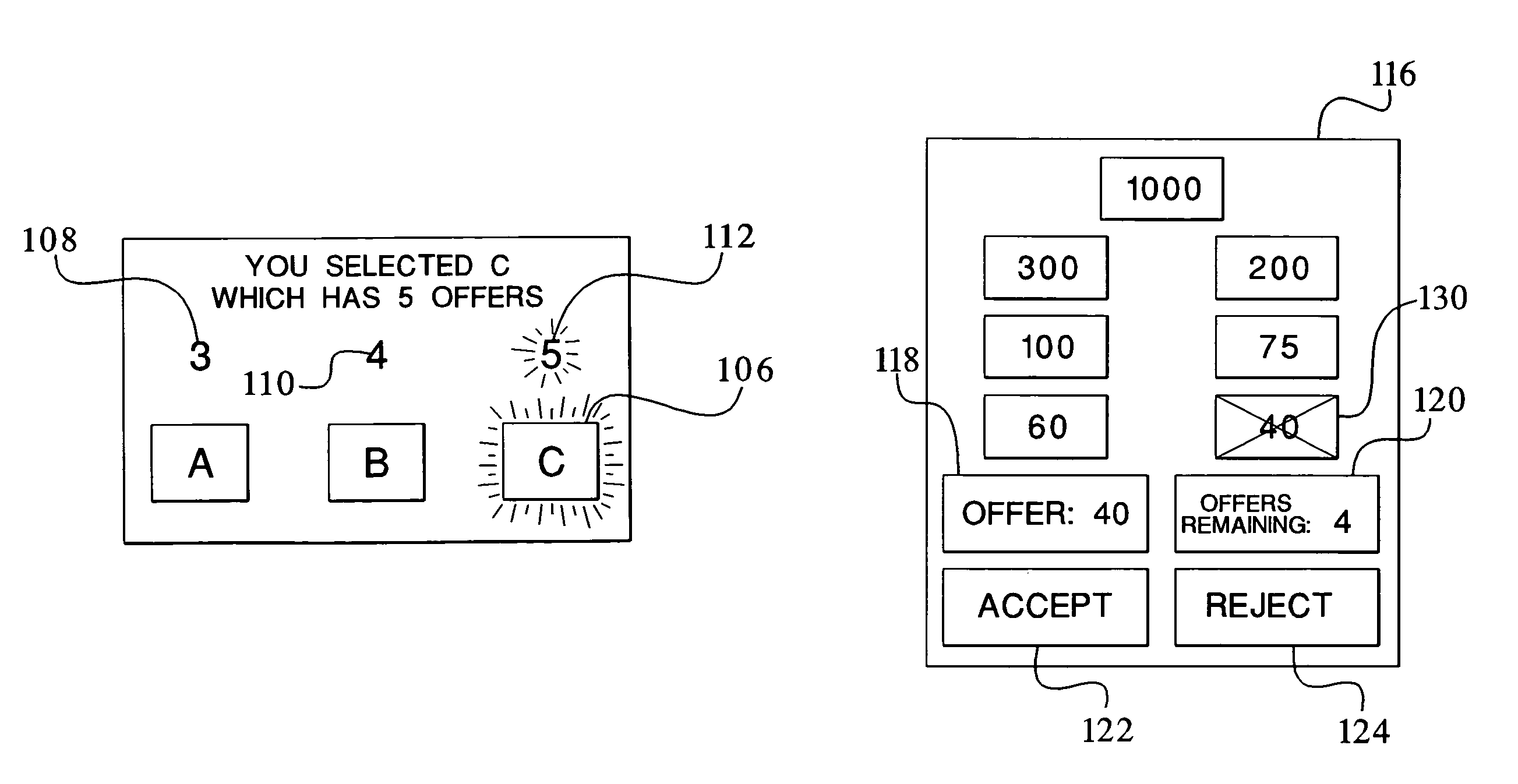

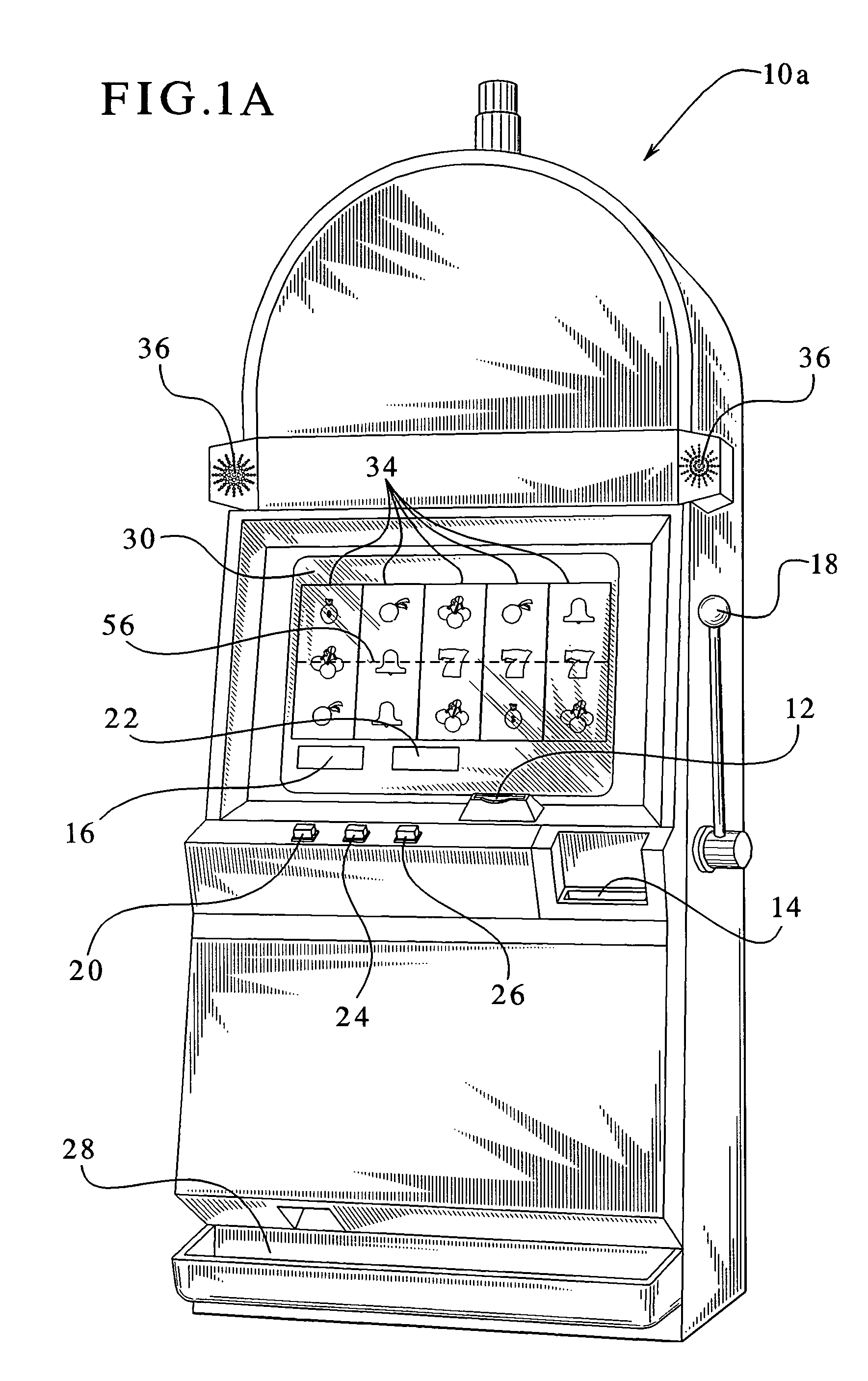

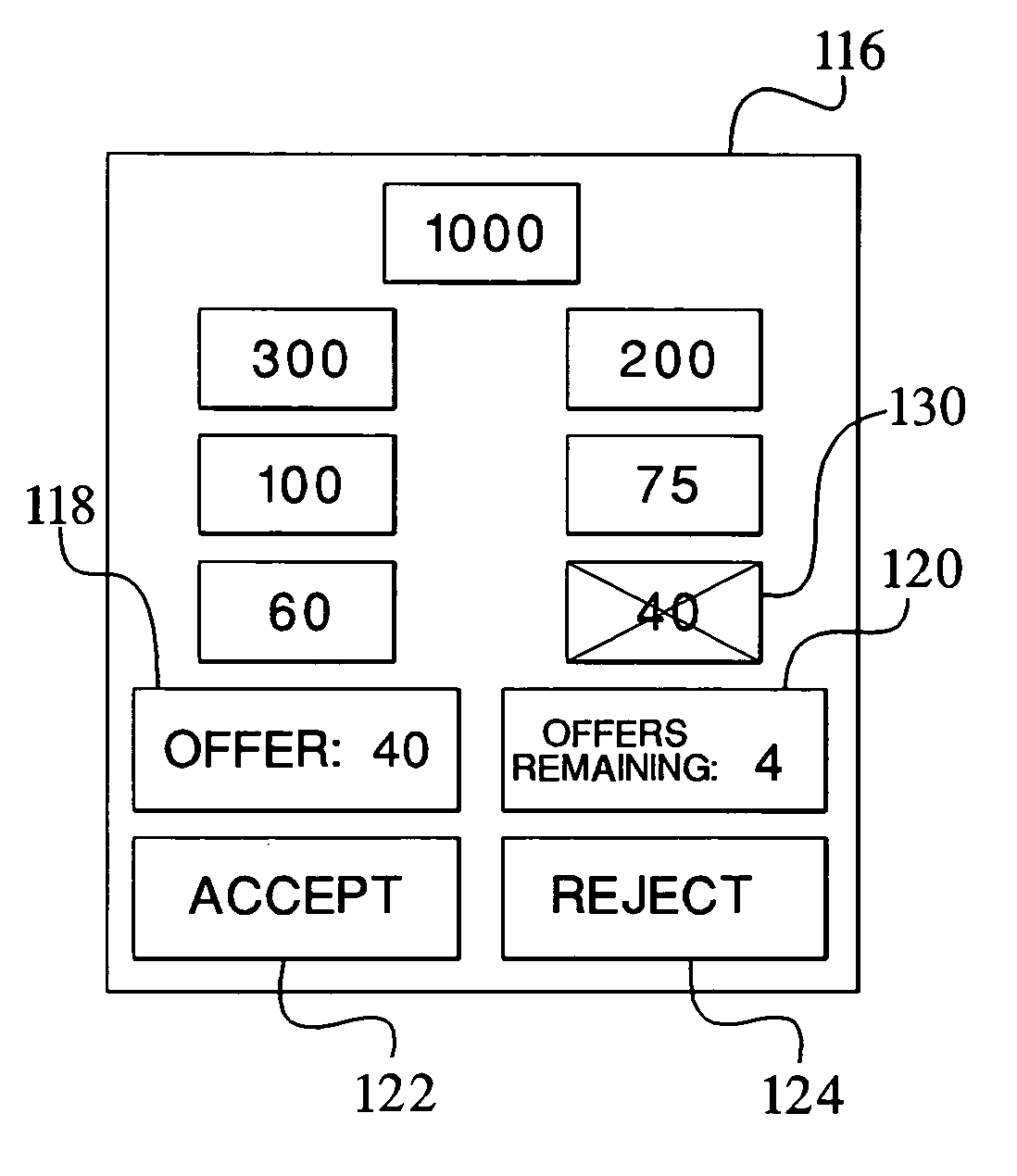

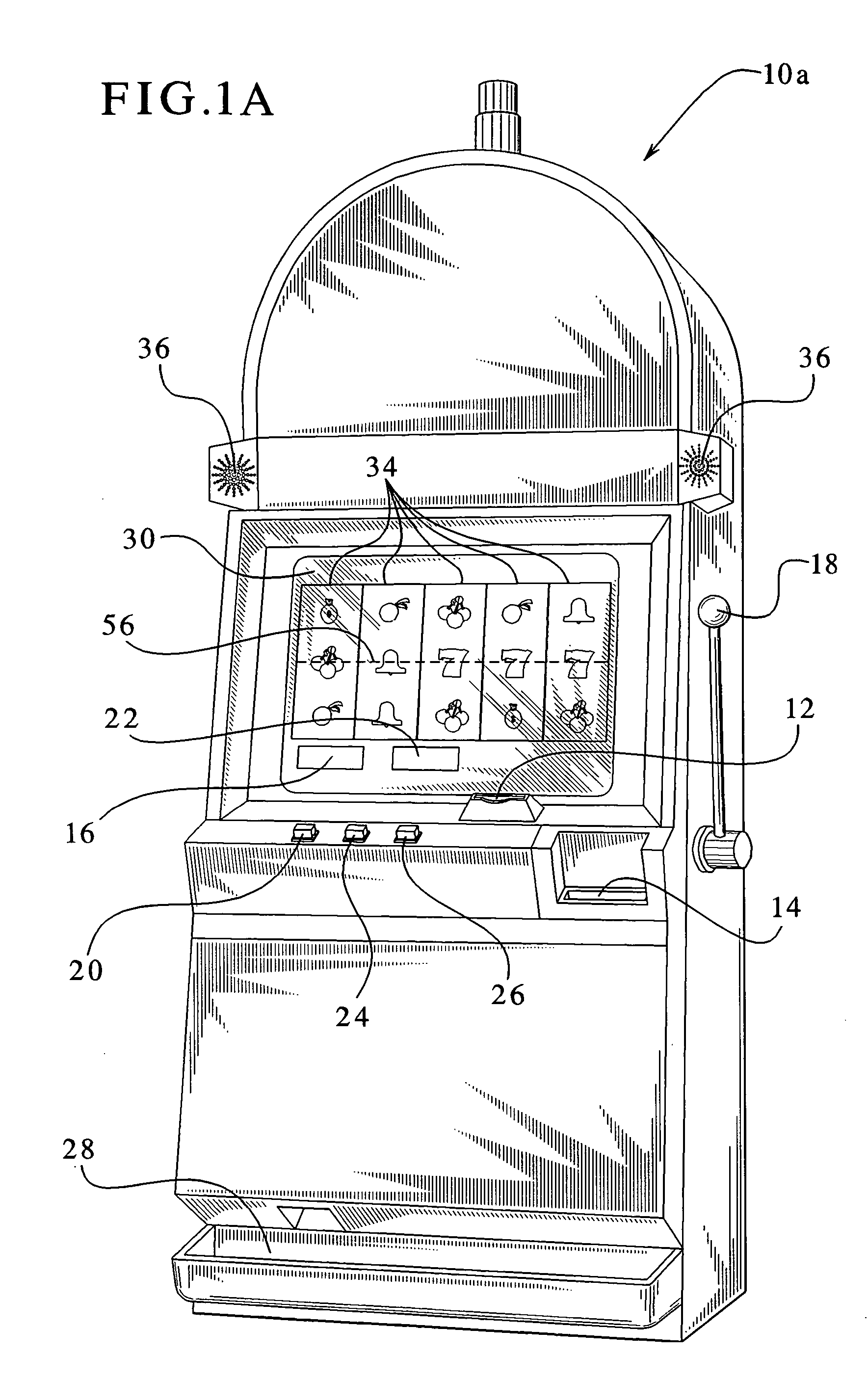

Gaming device having improved offer and acceptance bonus scheme

InactiveUS6899623B2Improved offerImproved acceptance bonus schemeCard gamesApparatus for meter-controlled dispensingEngineeringHuman–computer interaction

Owner:IGT

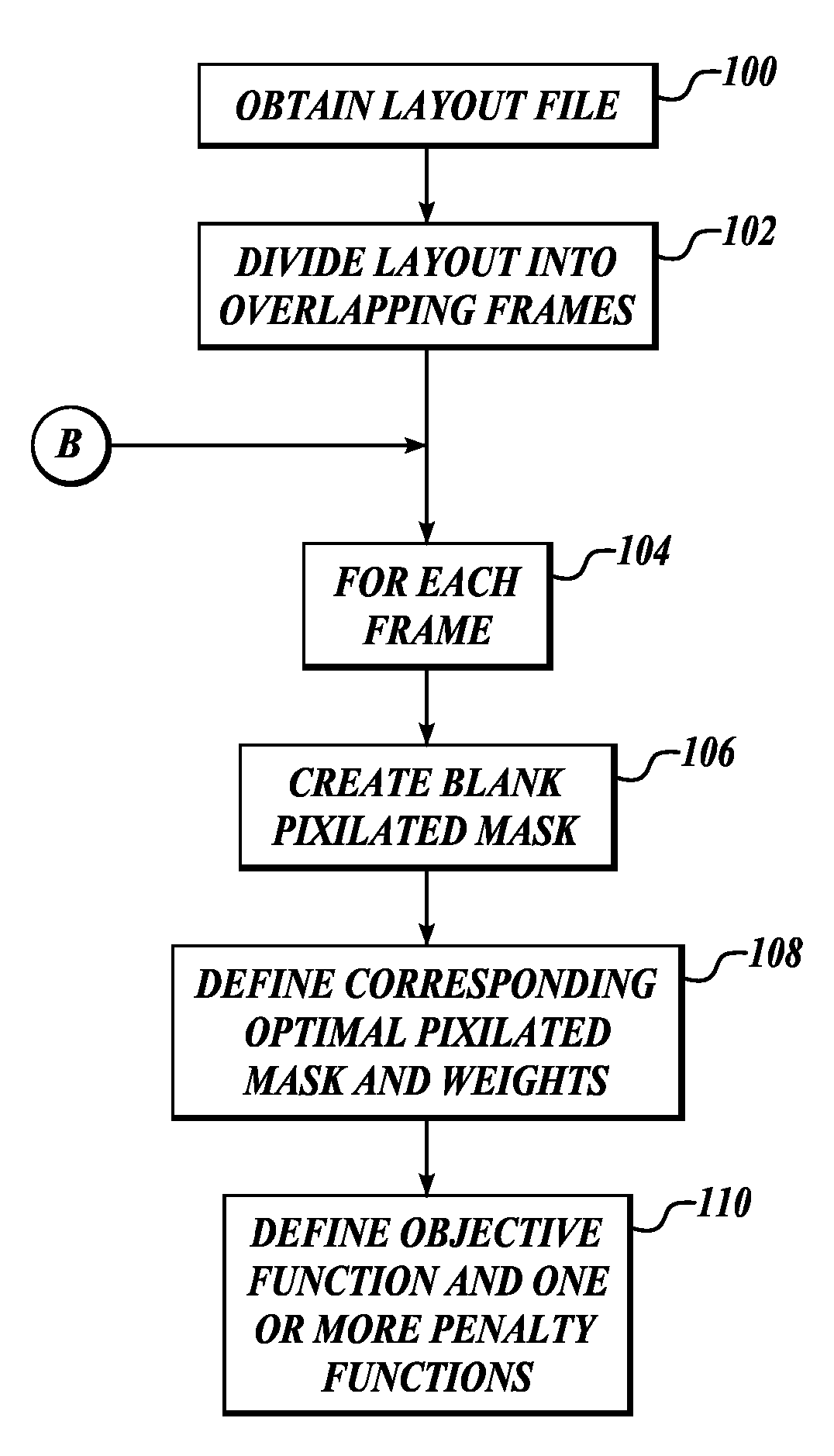

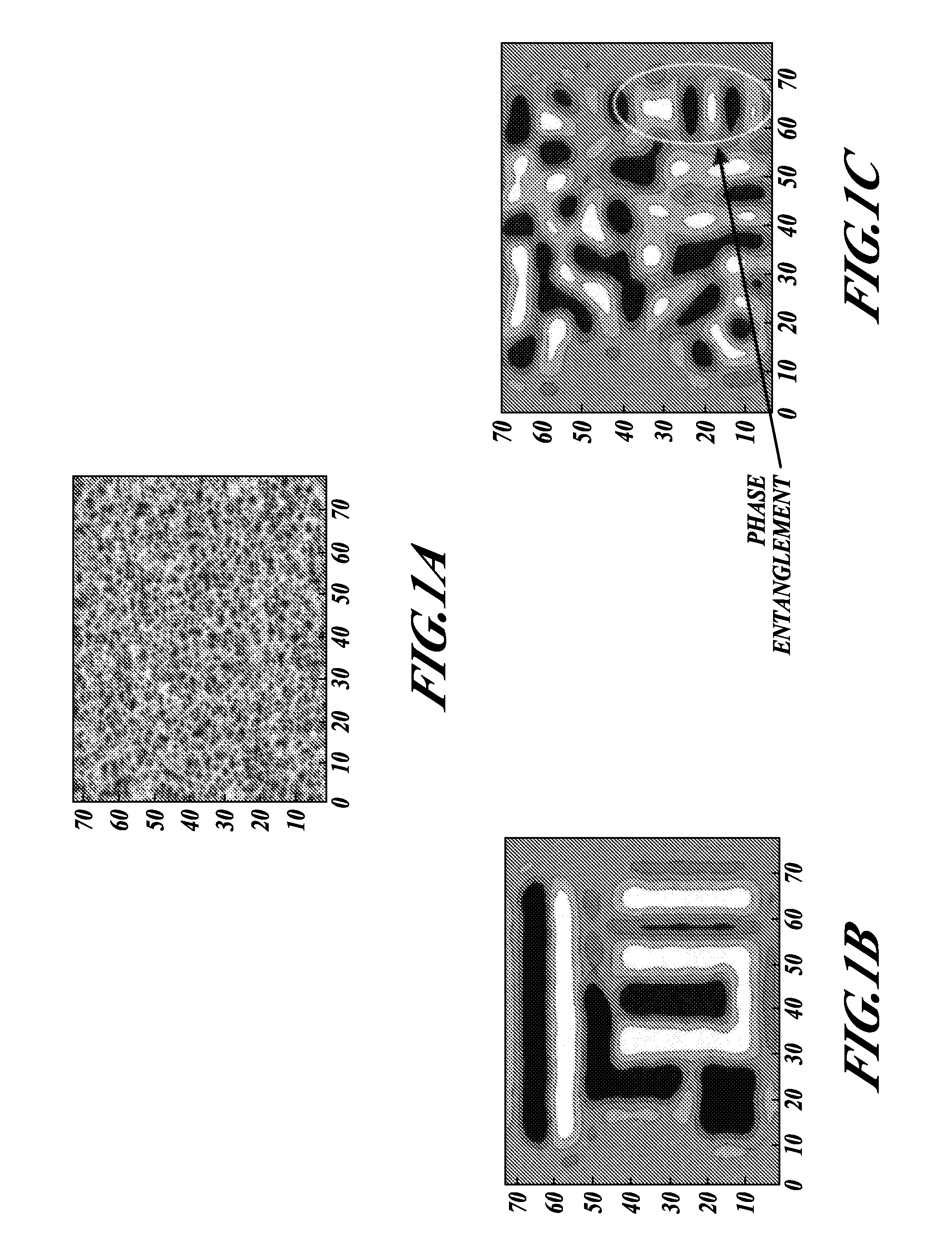

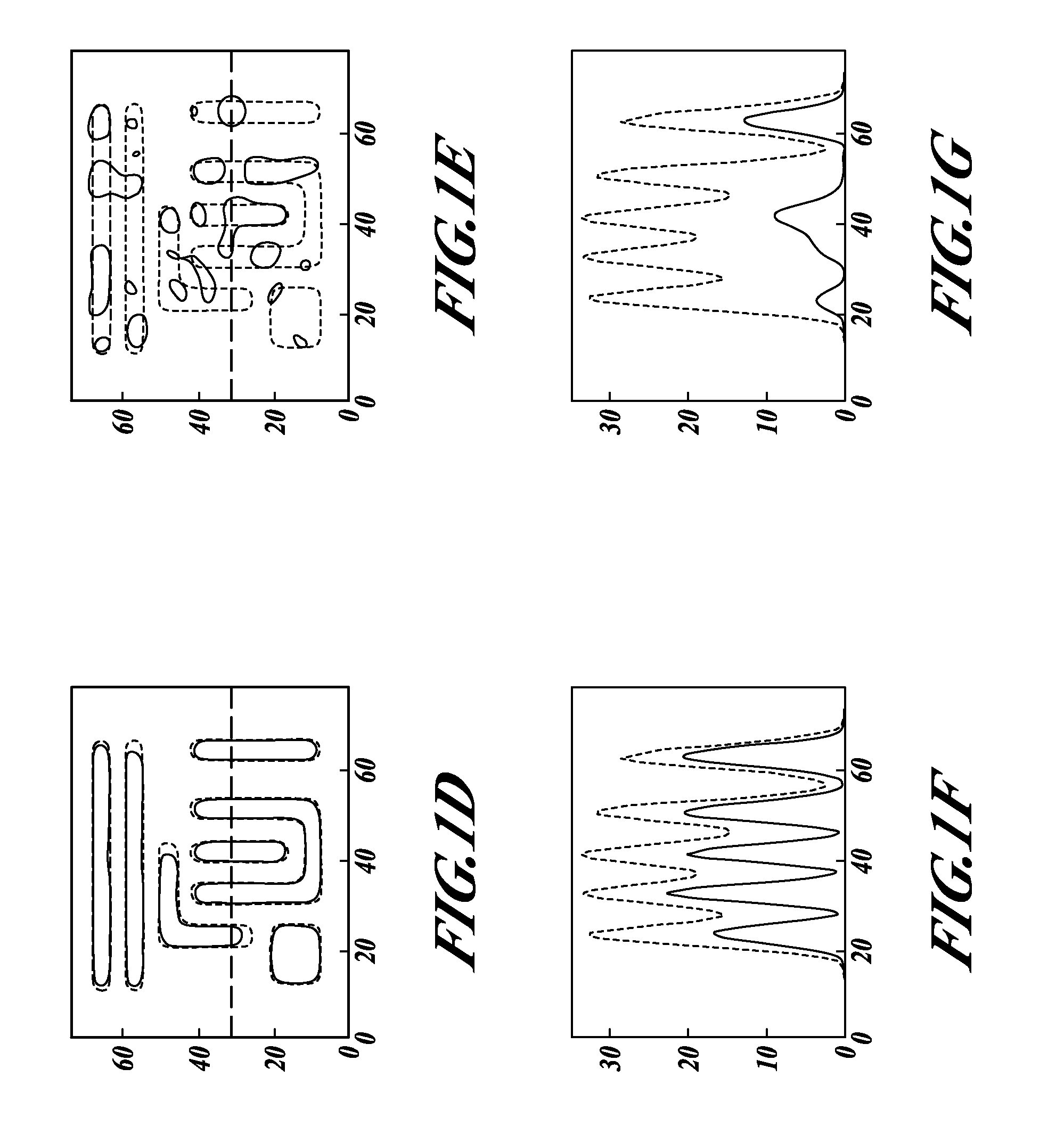

Calculation system for inverse masks

ActiveUS20070198963A1Improve fidelityAvoid makingOriginals for photomechanical treatmentSpecial data processing applicationsComputer science

A system for calculating mask data to create a desired layout pattern on a wafer reads all or a portion of a desired layout pattern. Mask data having pixels with transmission values is defined along with corresponding optimal mask data pixel transmission values. An objective function is defined that compares image intensities as would be generated on a wafer with an optimal image intensity at a point corresponding to a pixel. The objective function is minimized to determine the transmission values of the mask pixels that will reproduce the desired layout pattern on a wafer.

Owner:SIEMENS PROD LIFECYCLE MANAGEMENT SOFTWARE INC

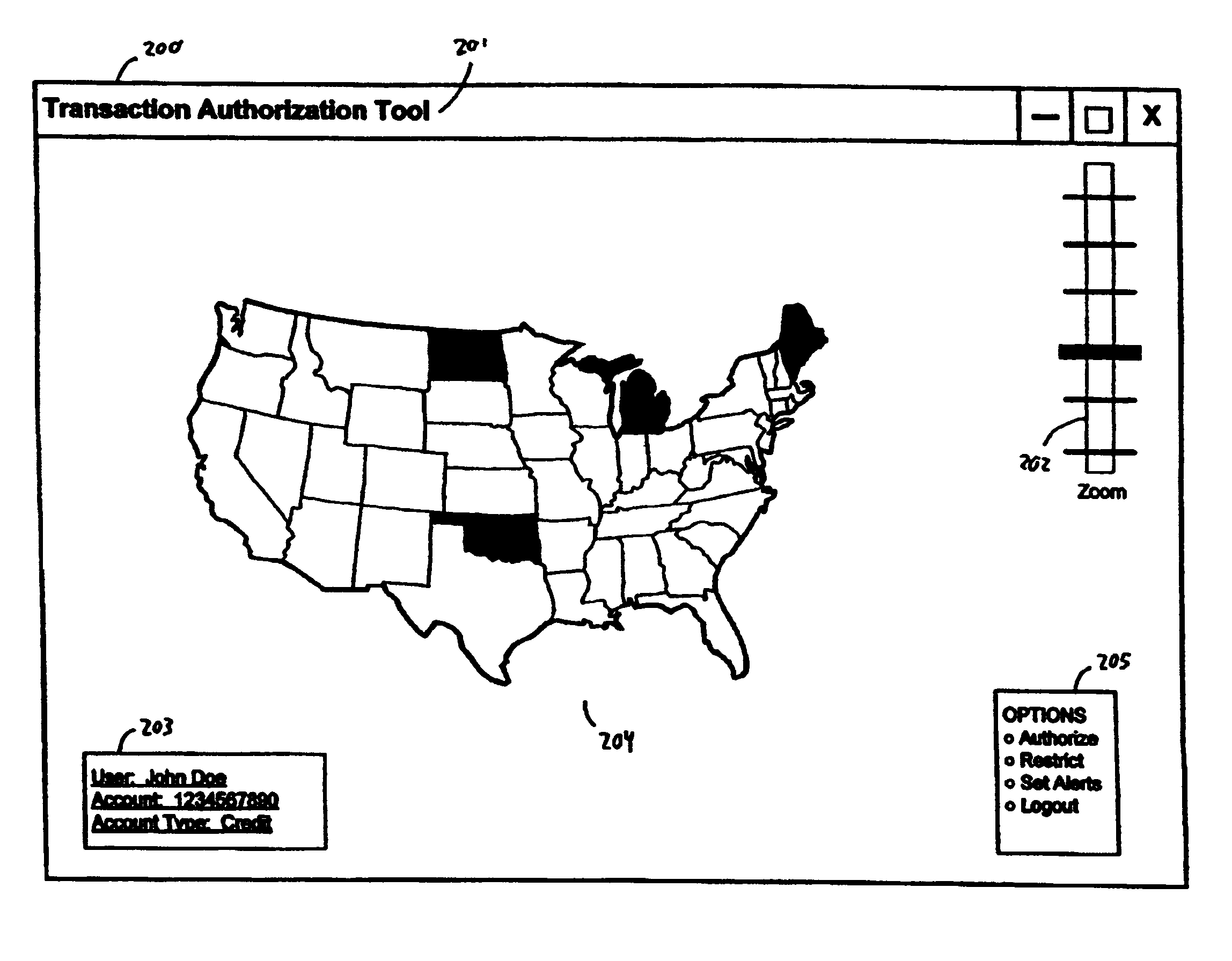

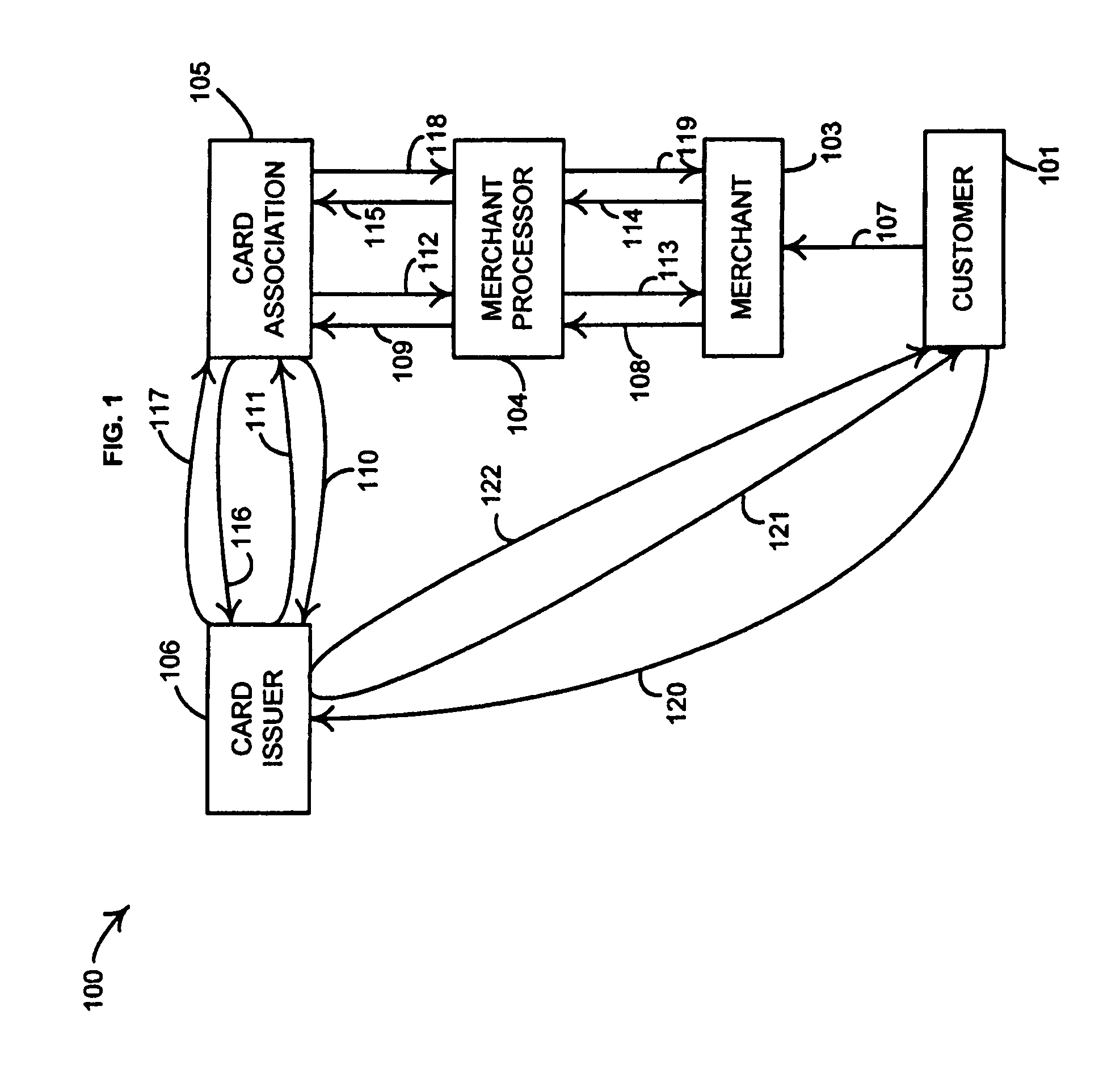

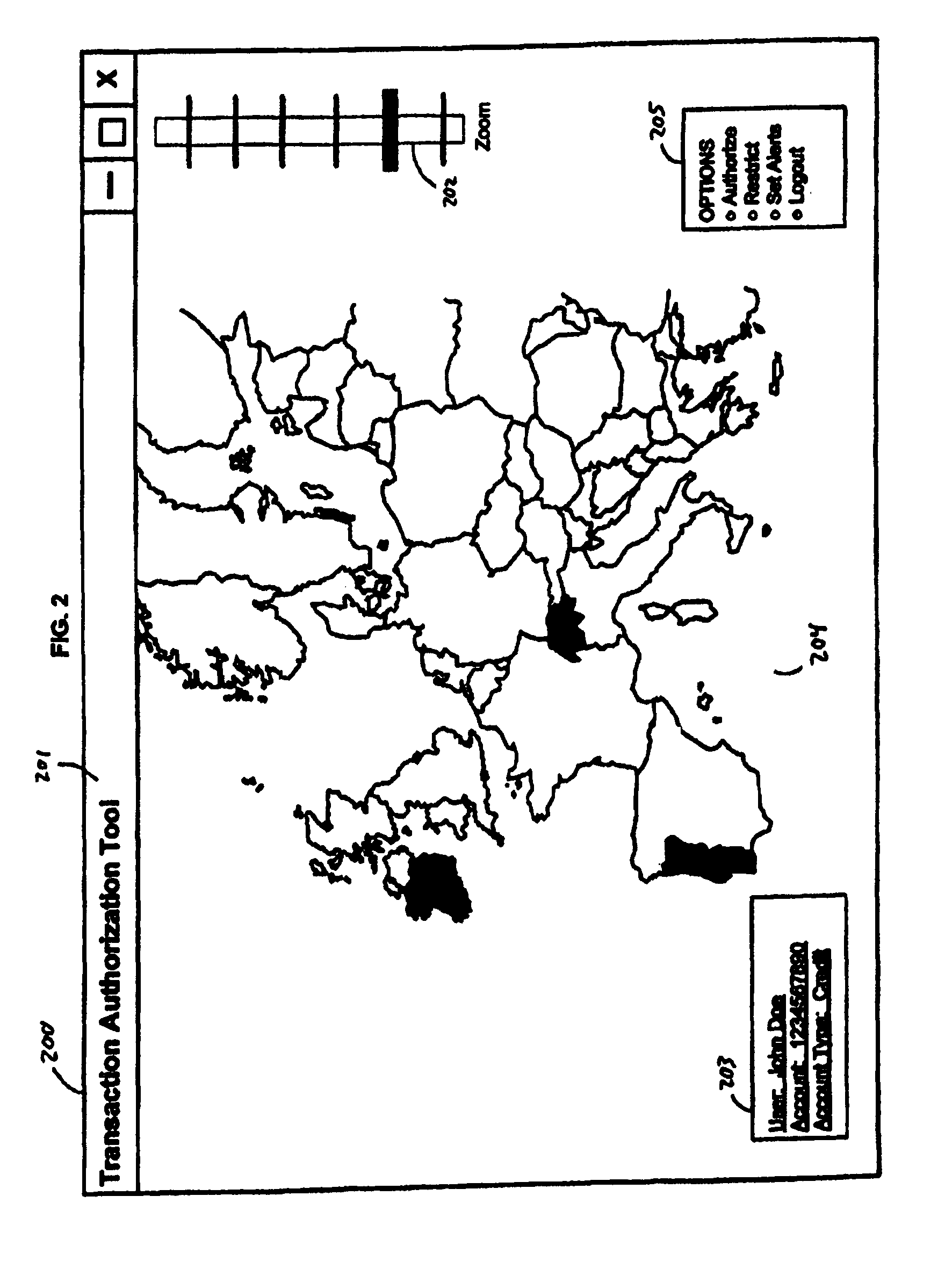

Method and system for authorizing card account transactions by geographic region

ActiveUS7857212B1Improve the level ofAvoid makingReservationsPoint-of-sale network systemsGeographic regionsAuthorization

A method and system for authorizing card account transactions by geographic region by providing data for a user interface displaying geographic regions and merchant locations each corresponding to the location of a merchant where a transaction using a card account may be initiated, receiving a user interface selection representing a request to authorize or restrict card account transactions, receiving authorization requests for desired transactions, and authorizing or restricting the transactions in accordance with the request.

Owner:CAPITAL ONE SERVICES

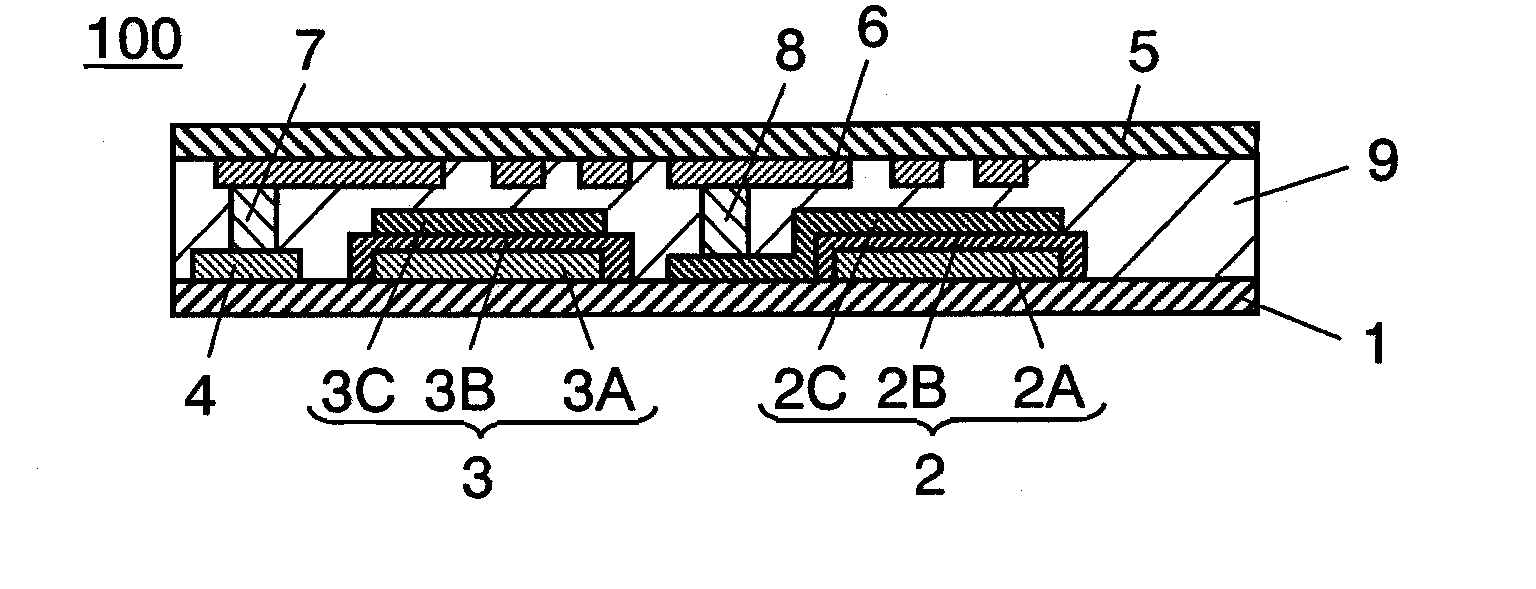

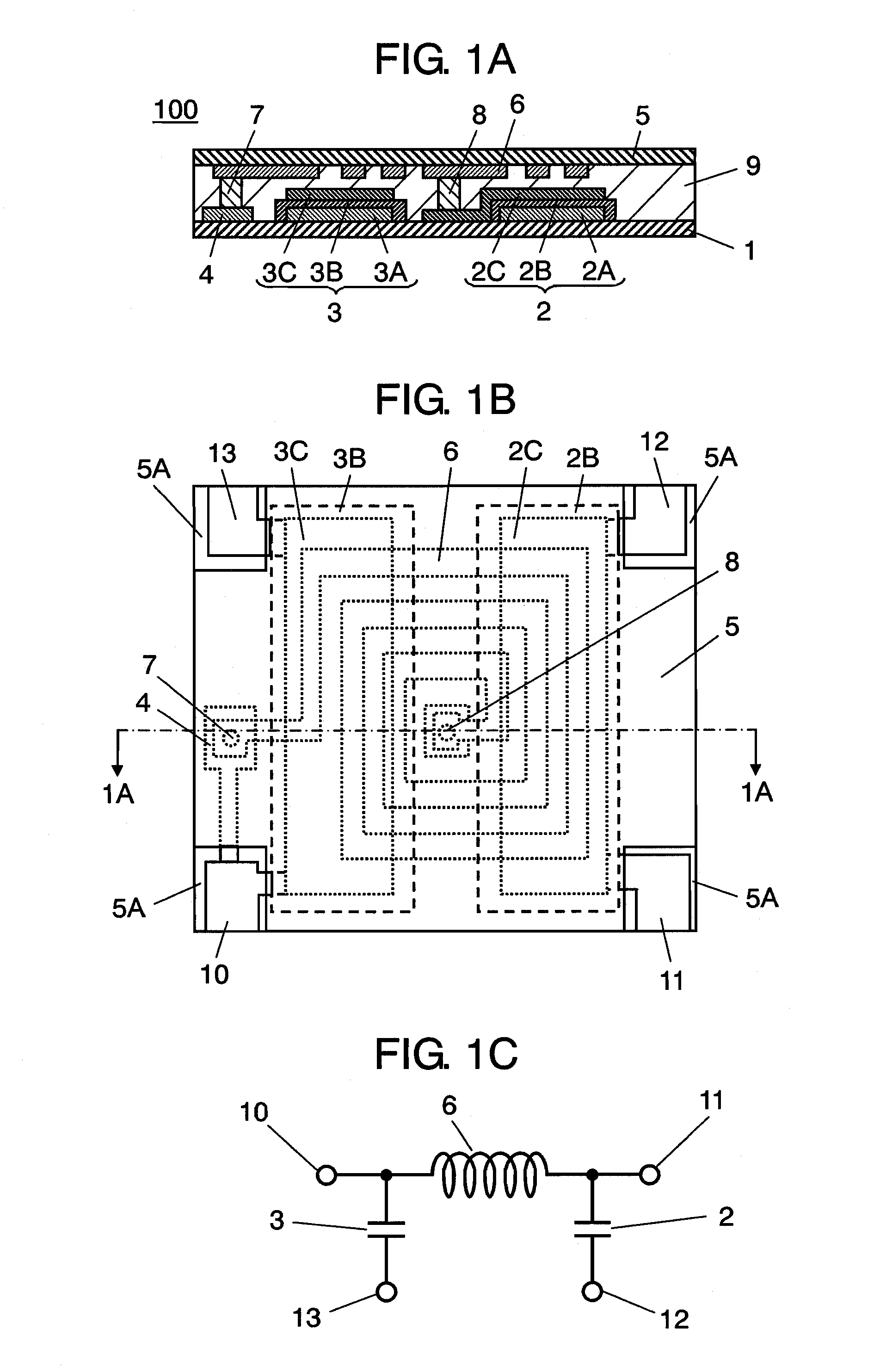

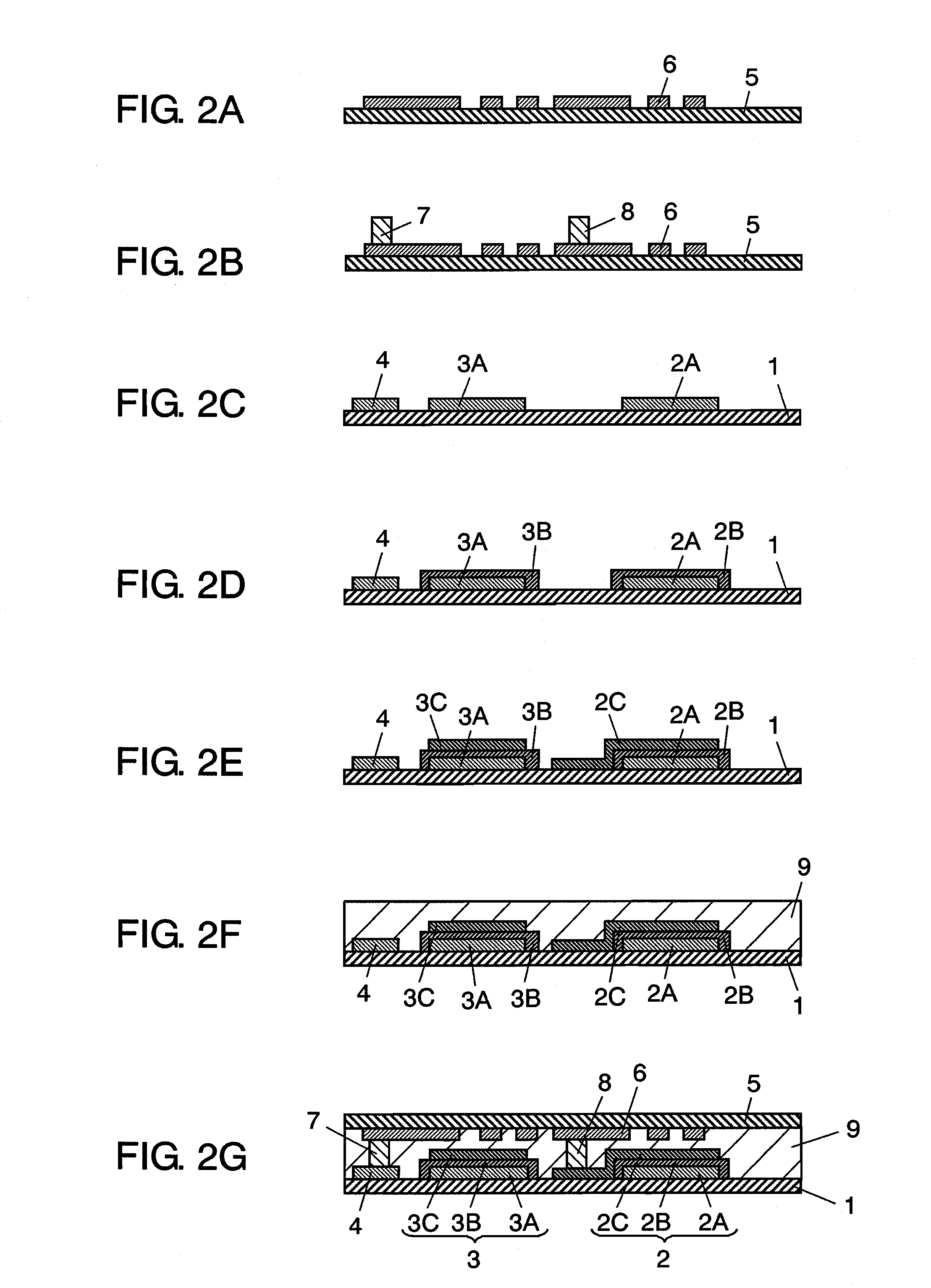

Sheet-like composite electronic component and method for manufacturing same

InactiveUS20100090781A1Avoid defectsGood yield rateMultiple-port networksPrinted circuit detailsElectrical conductorEngineering

To provide a configuration including a first sheet substrate, on which a first thin film electronic component is formed on at least one main face, and an external connection terminal for connecting to an external circuit is formed one main face or the other face; a second sheet substrate, on which a second thin film electronic component is formed on at least one face; an insulator connection resin layer for fixing the first sheet substrate and the second sheet substrate opposing the first thin film electronic component against the second thin film electronic component; and an interlayer connection conductor for electrically connecting electrode terminals, which have been set in advance, of the first thin film electronic component and the second thin film electronic component.

Owner:PANASONIC CORP

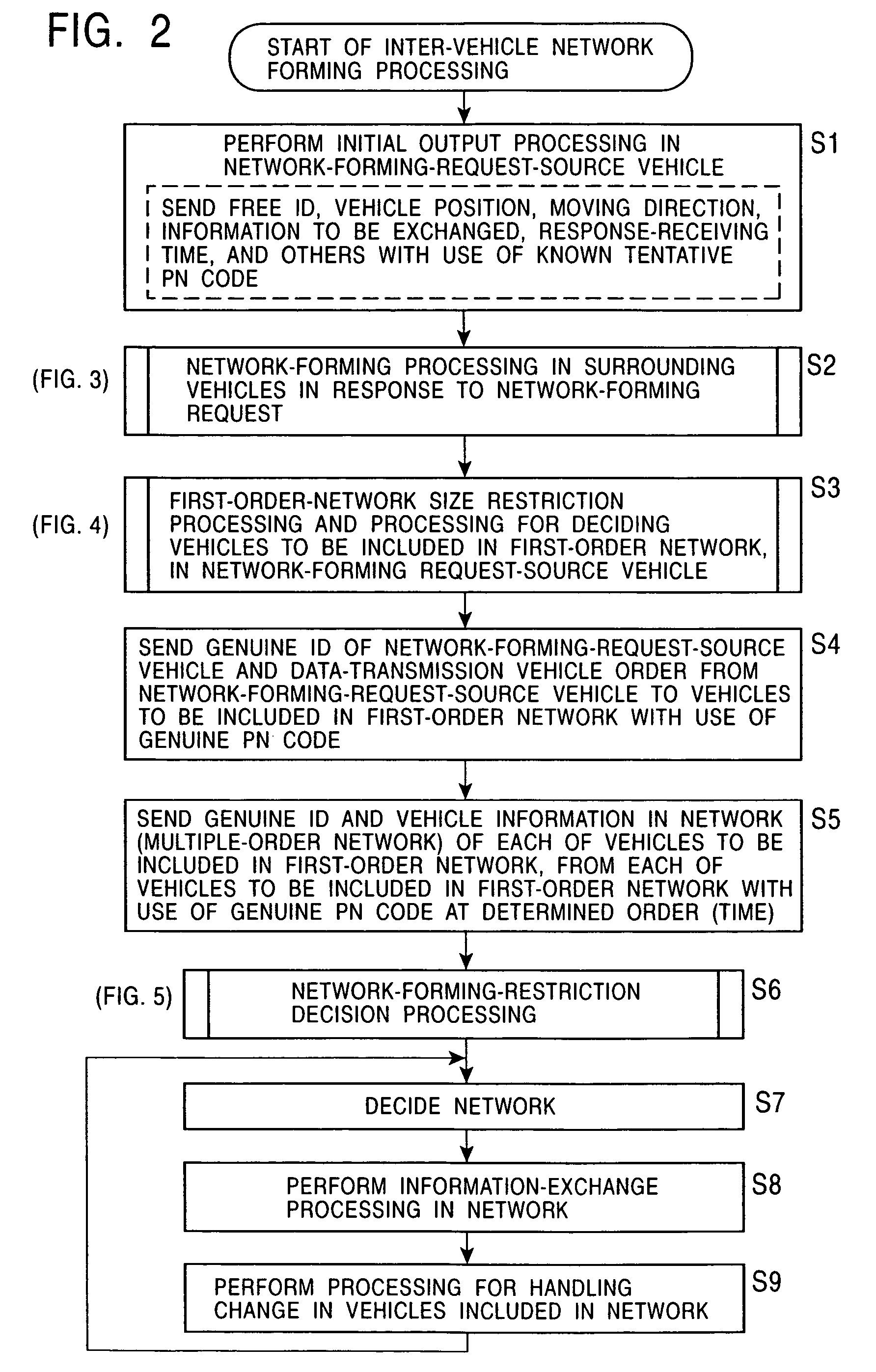

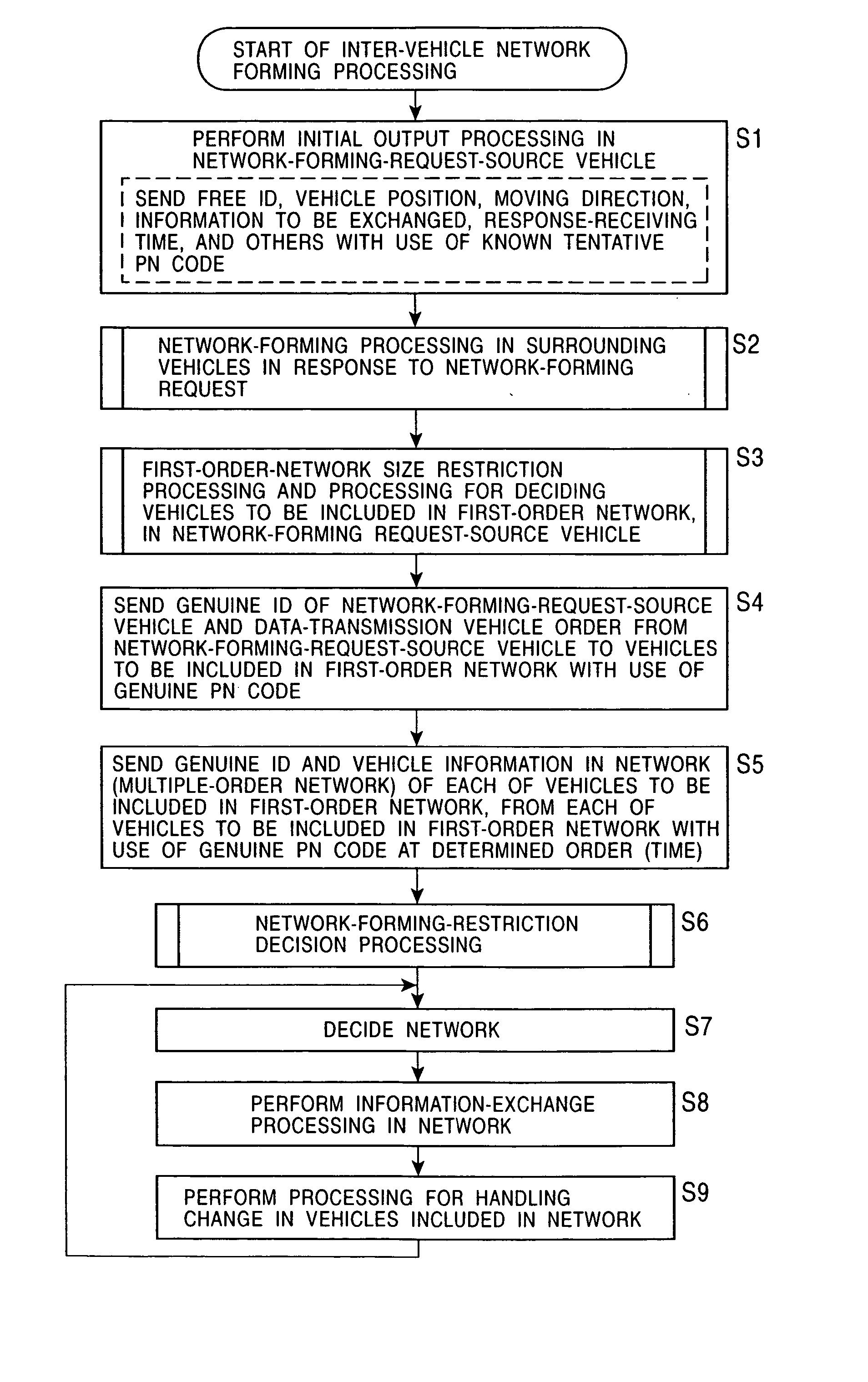

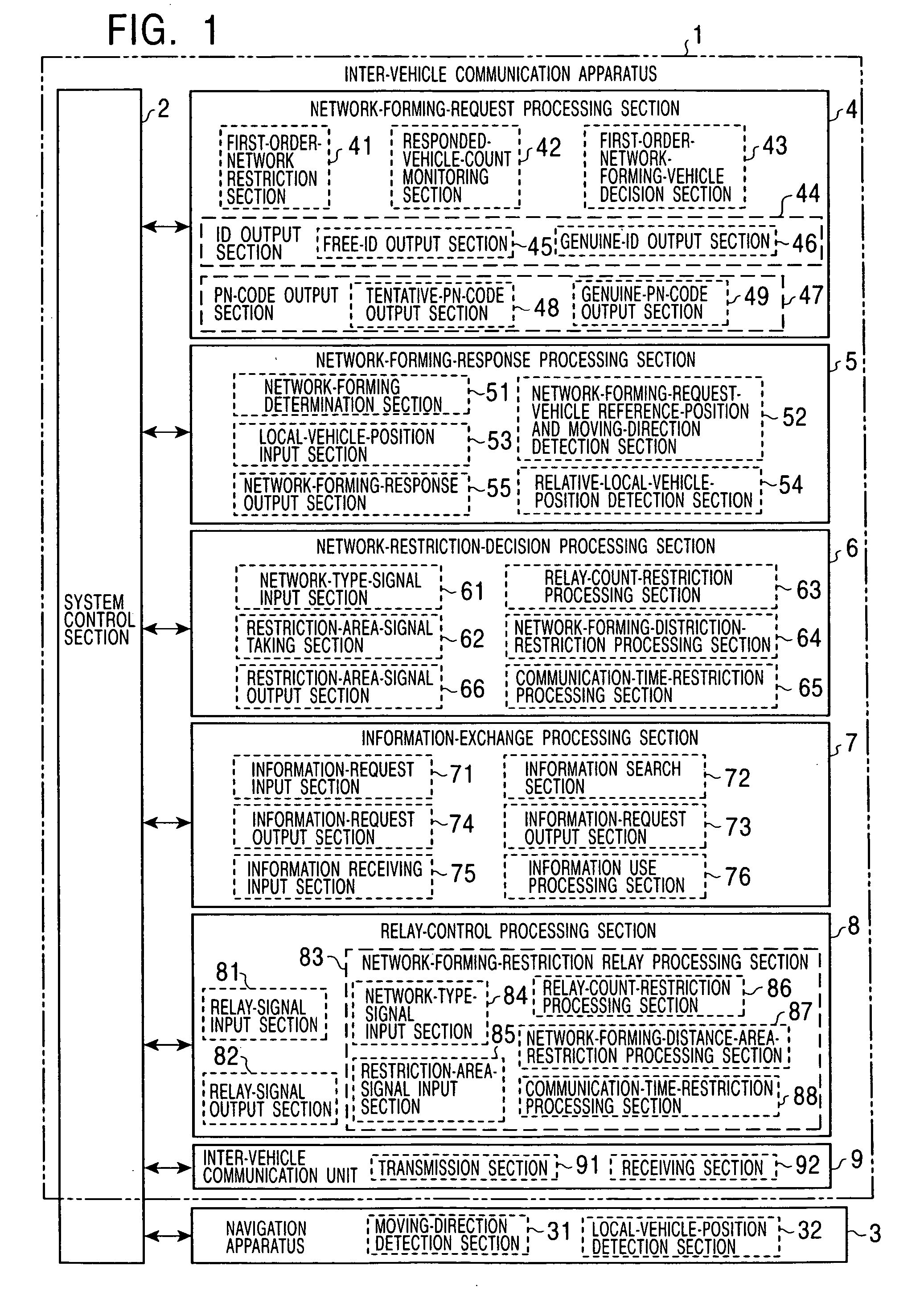

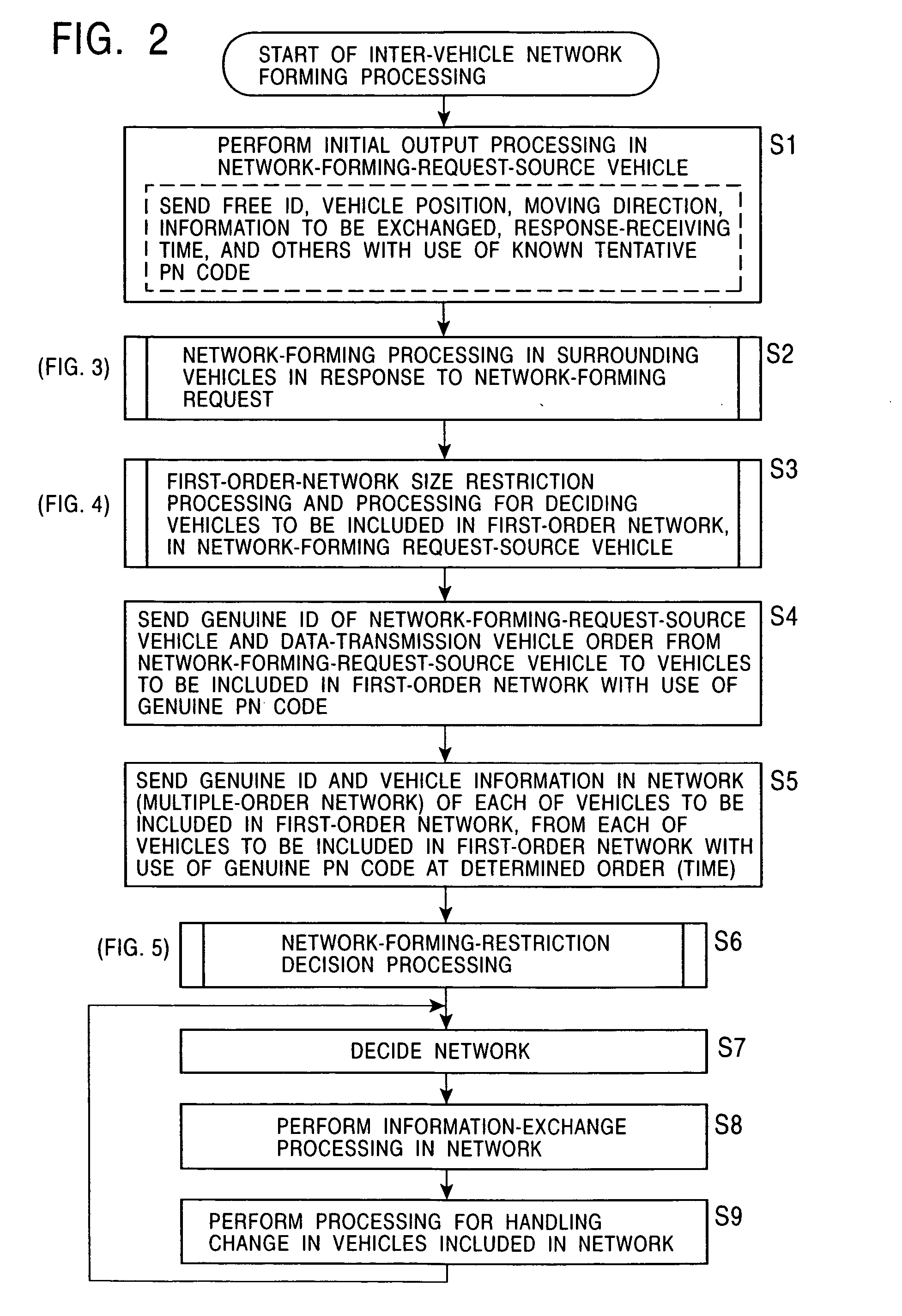

Inter-vehicle communication apparatus and method with restrictions on size of network

InactiveUS7272357B2Avoid interferenceRestrict formArrangements for variable traffic instructionsAssess restrictionArea networkInter vehicle communication

Owner:ALPINE ELECTRONICS INC

Analgetic dosage forms that are resistant to parenteral and inhalation dosing and have reduced side effects

InactiveUS20050165038A1Side-effect be reduceEliminate side effectsPowder deliveryBiocideDrugPharmaceutical preservatives

The invention provides a novel solid pharmaceutical dosage form which includes an opiate, an opiate antagonist admixed with the analgetic (opiate agonist) and an amount of a hydrocolloid containing excipient which is effective to form a non-injectable slurry when the dosage form is contacted with water. In addition the dosage form contains pure naloxone in enteric coated form which is designed to release in the colon to prevent or relieve constipation. Thus the formulation, because of the enteric coated naloxone and the hydrocolloid excipient(s), has reduced side effects as compared with formulations which do not contain these features.

Owner:GORDON MAXWELL

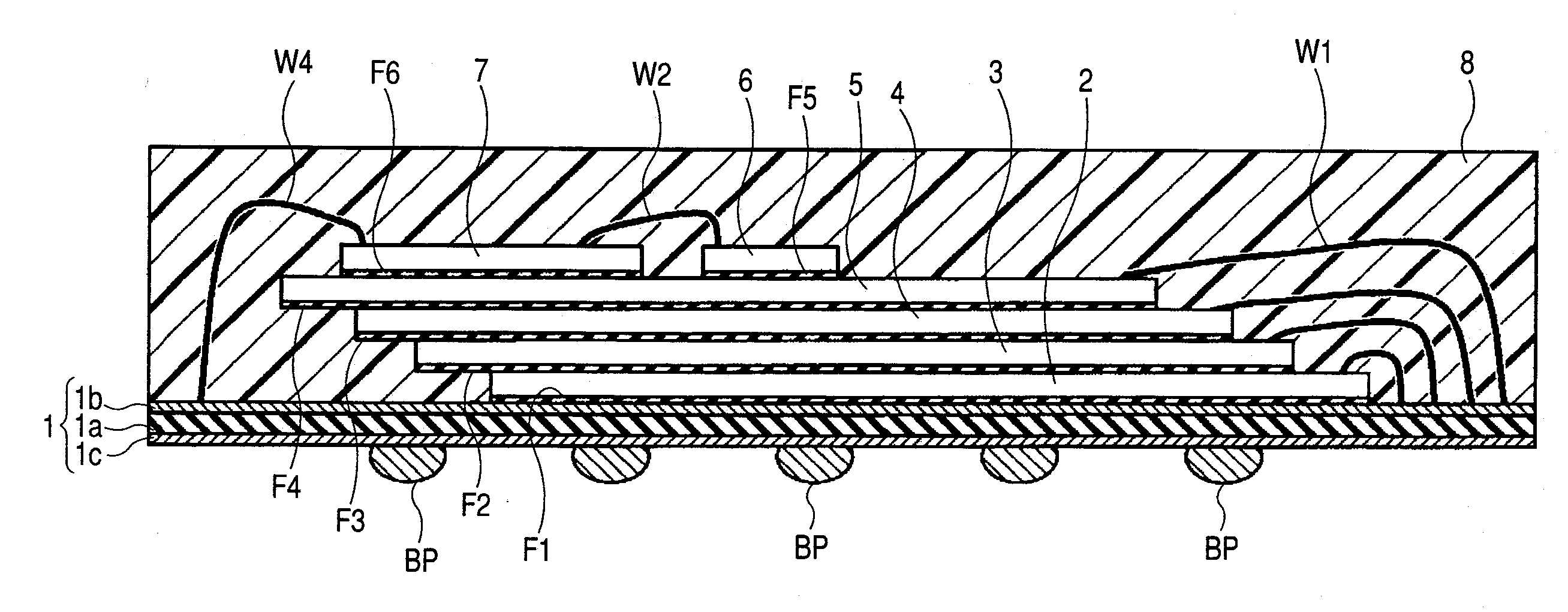

Semiconductor device, interposer chip and manufacturing method of semiconductor device

ActiveUS20070170573A1Avoid makingImprove performanceSemiconductor/solid-state device detailsSolid-state devicesMicrocomputerMemory chip

The semiconductor device with which bonding wires cannot contact easily is offered.In this semiconductor device, memory chips are stacked on the surface of a wiring substrate, a microcomputer chip and an interposer chip are arranged on the surface of the memory chip, and the pad of a microcomputer chip and the pad of an interposer chip arranged almost circularly are connected by a bonding wire. Therefore, since the transfer pressure of liquid resin for sealing can be weakened with a wire, contact of the wires by deformation of a wire can be prevented.

Owner:RENESAS ELECTRONICS CORP

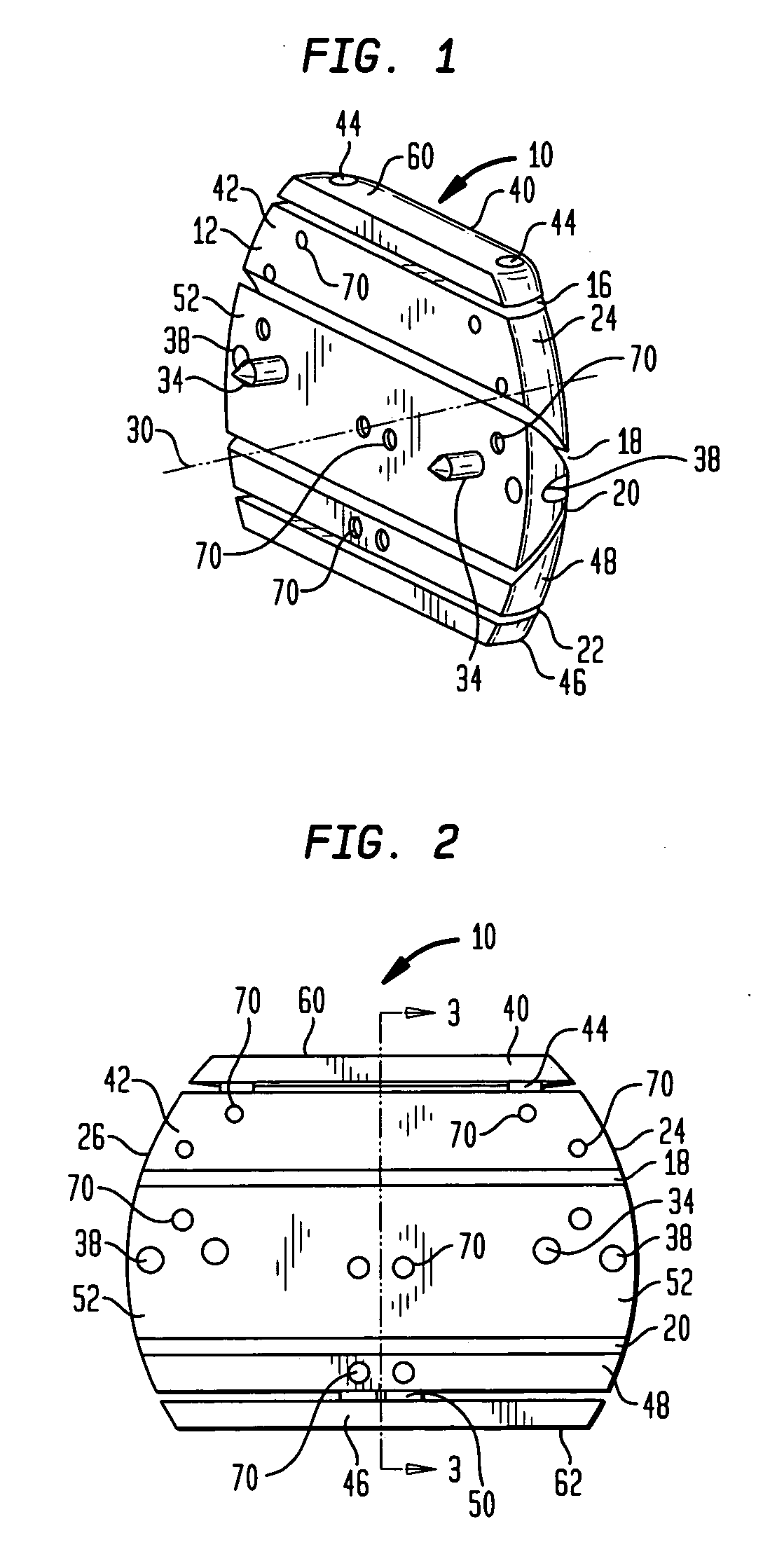

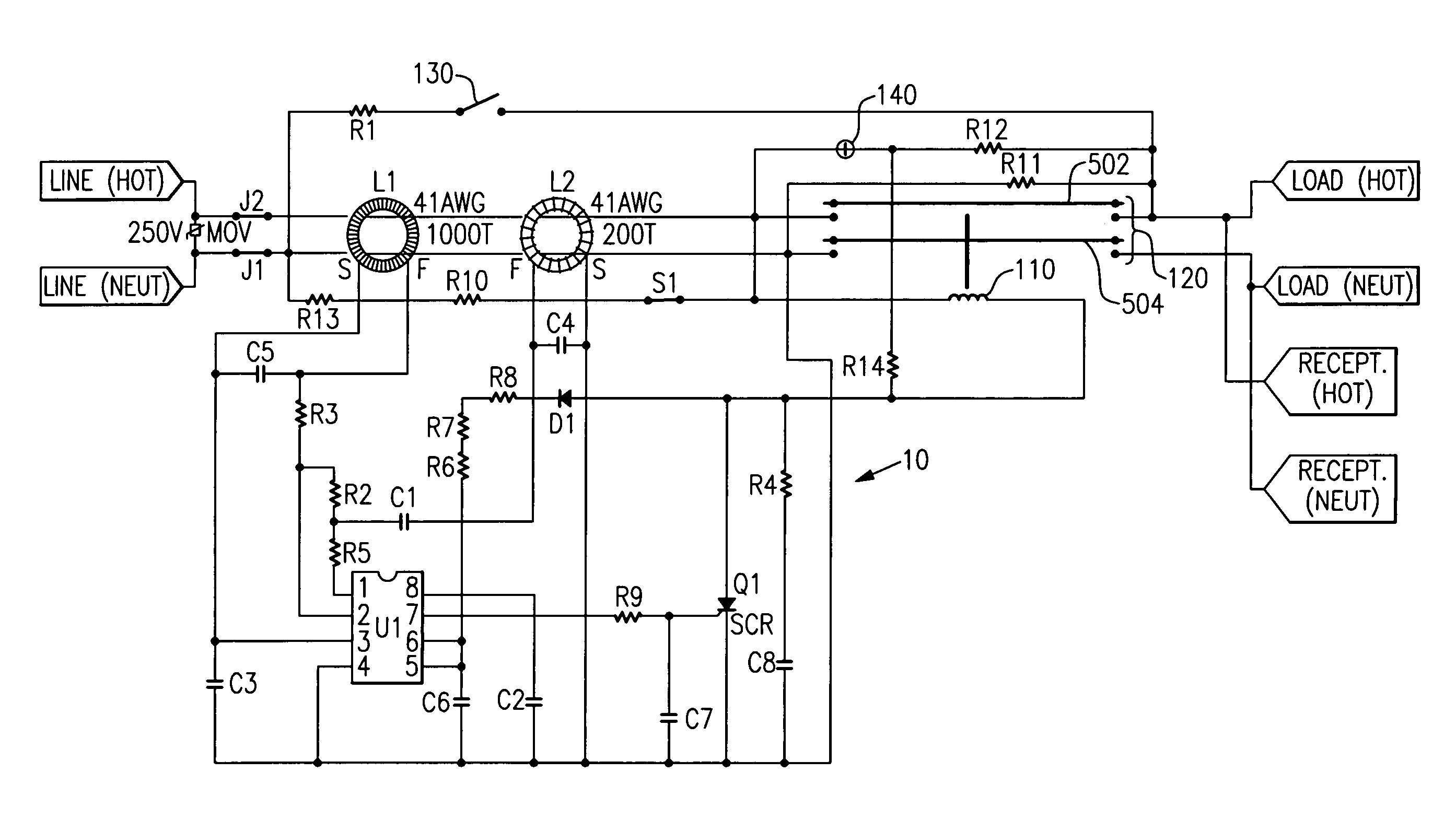

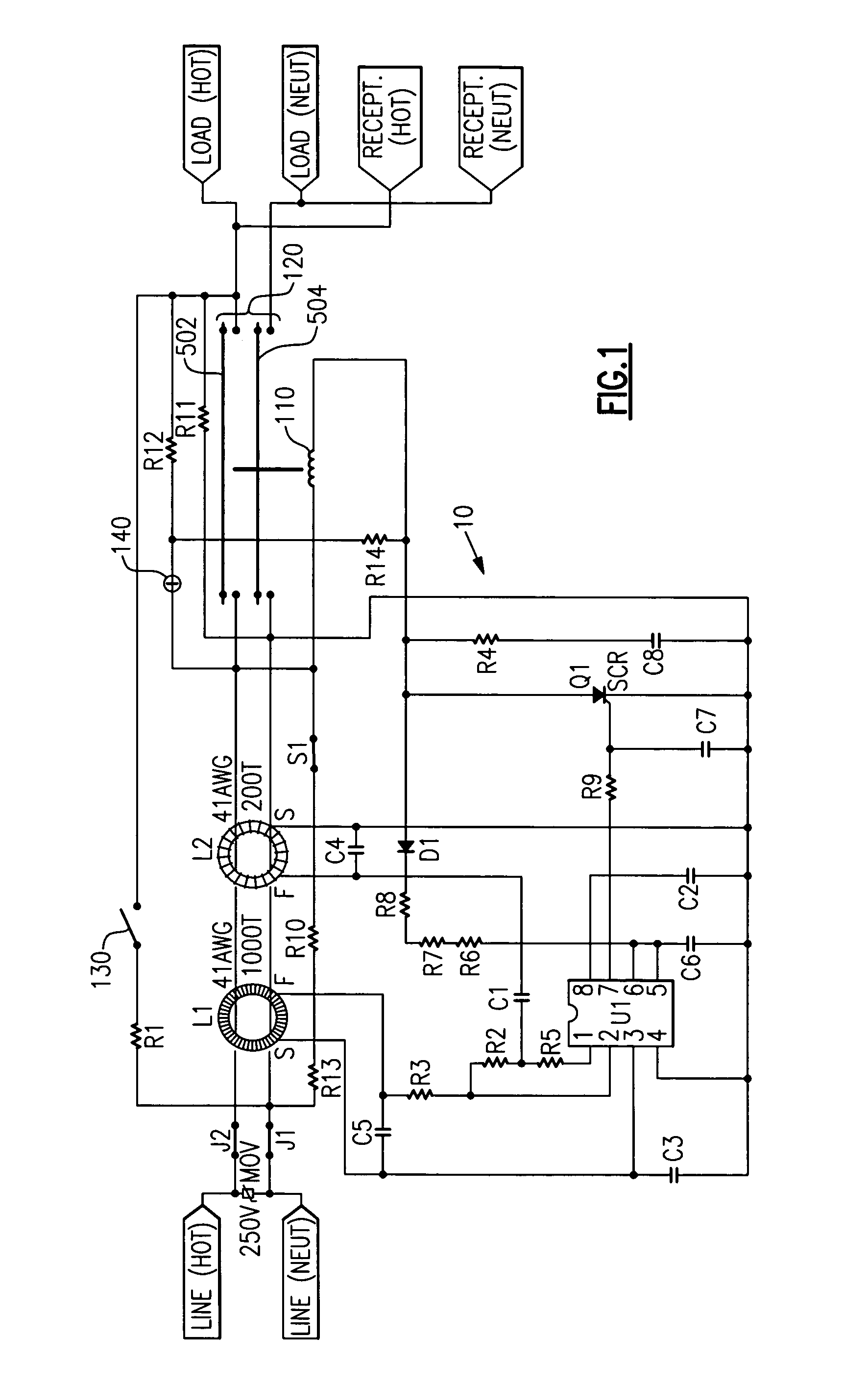

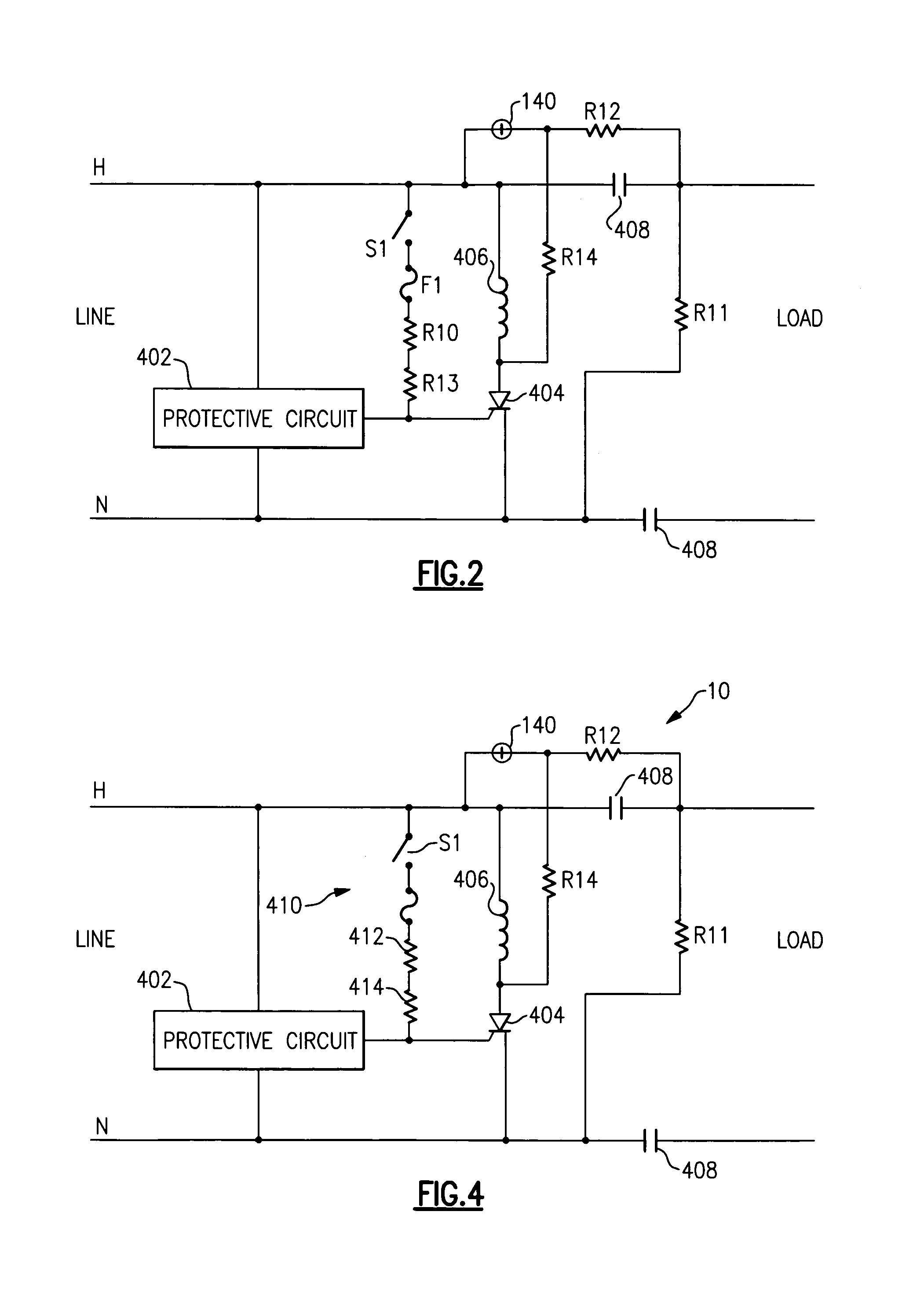

GFCI with miswire lockout

InactiveUS7212386B1Eliminates hazardous conditionEasy to manufactureProtective switch detailsSwitch operated by earth fault currentsEngineeringActuator

The present invention is directed to an electrical wiring protection device that includes a housing assembly having at least one line terminal and at least one load terminal partially disposed therein. A first conductive path is electrically coupled to the at least one line terminal. A second conductive path is electrically coupled to the at least one load terminal, the second conductive path being connected to the first conductive path in a reset state. A fault detection circuit is coupled to the first conductive path. The fault detection circuit is configured to generate a fault detection signal in response to detecting at least one fault condition. A wiring state detection circuit is coupled to the first conductive path. The wiring state detection circuit selectively provides a wiring state detection signal when the at least one line terminal is coupled to a source of AC power, and not providing the wiring state detection signal otherwise. An actuator assembly is configured to provide an actuation stimulus in response to the fault detection signal or the wiring state detection signal. A circuit interrupter is coupled to the actuator assembly. The circuit interrupter is configured to disconnect the first conductive path and the second conductive path in response to the actuation stimulus.

Owner:PASS SEYMOUR

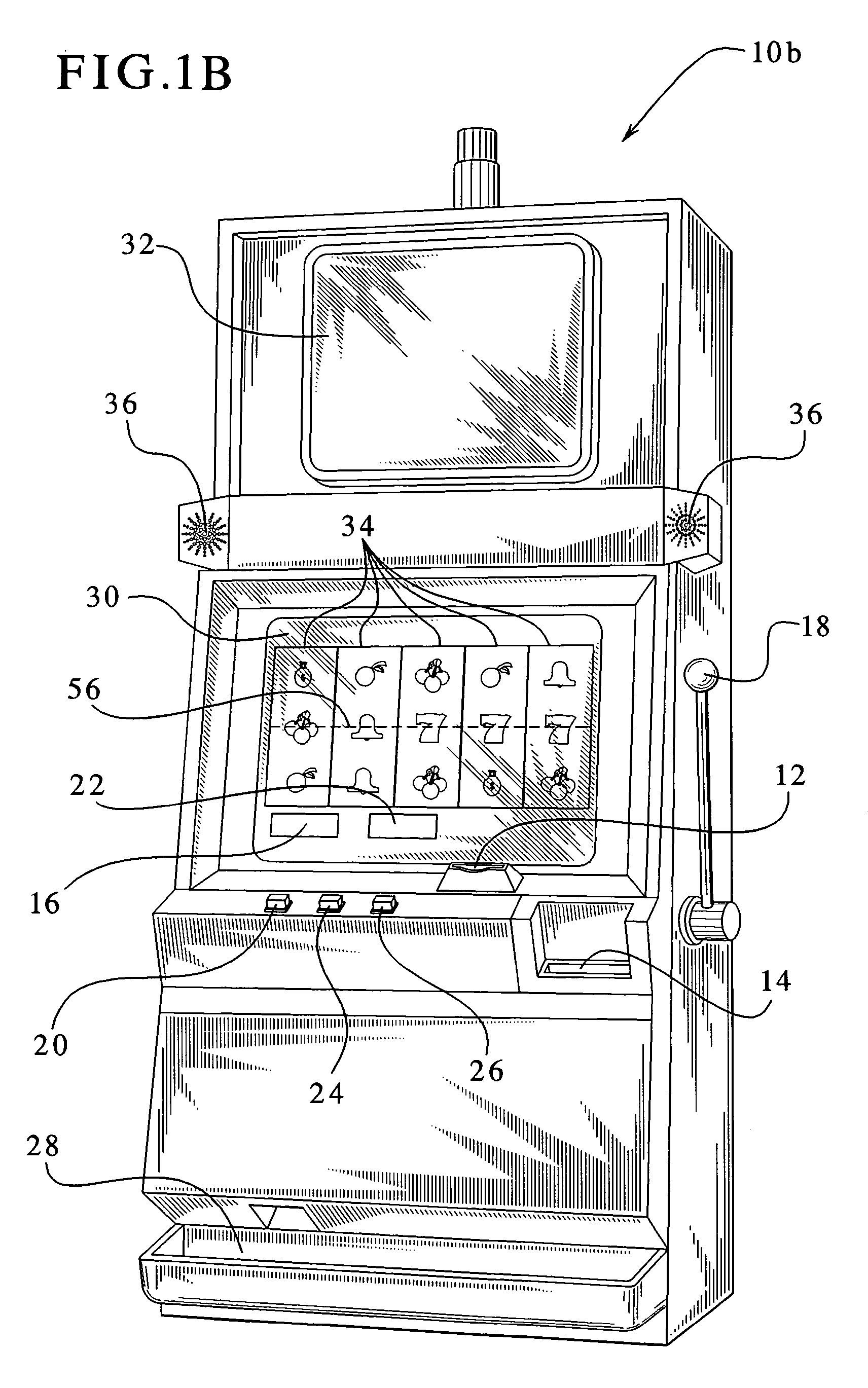

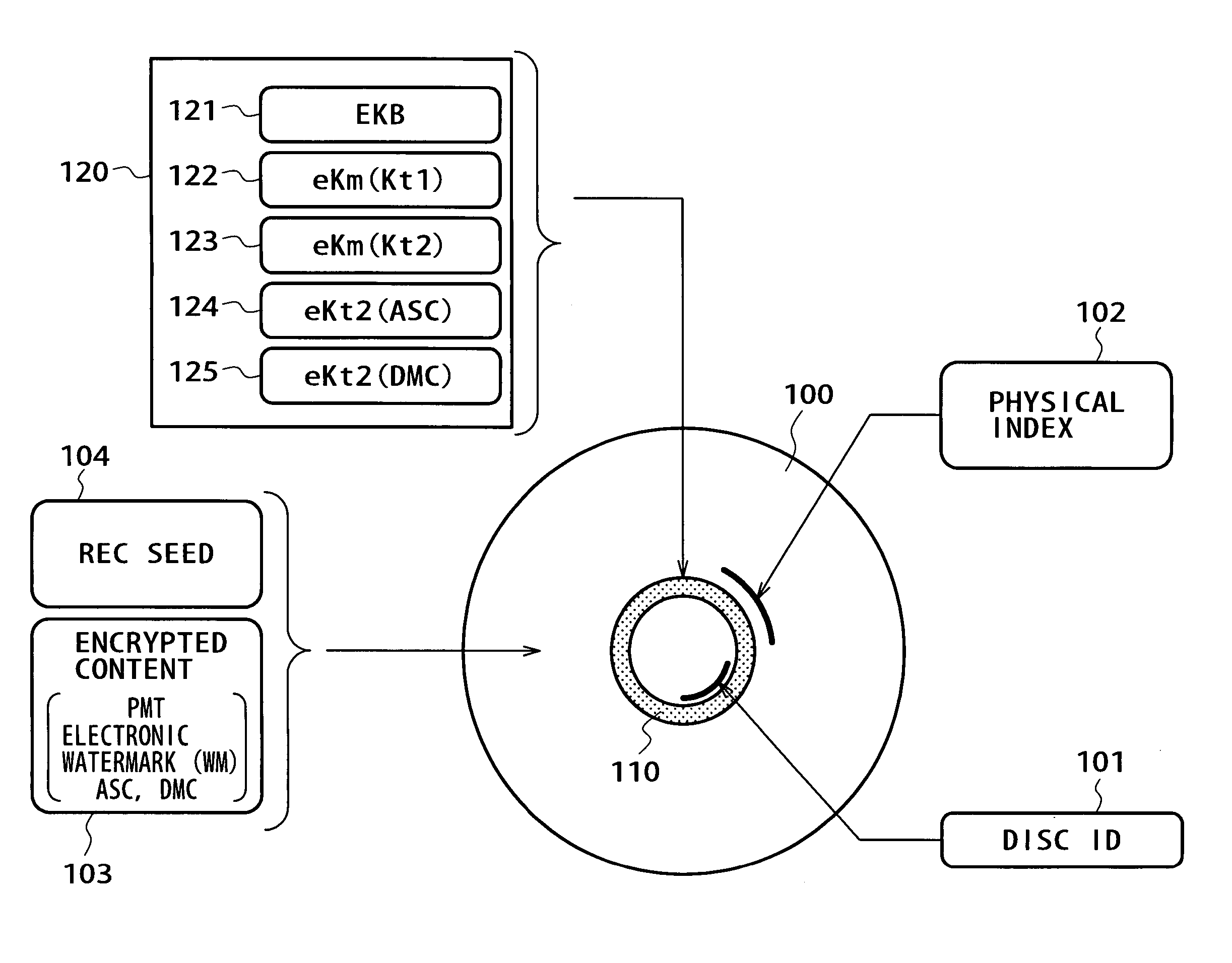

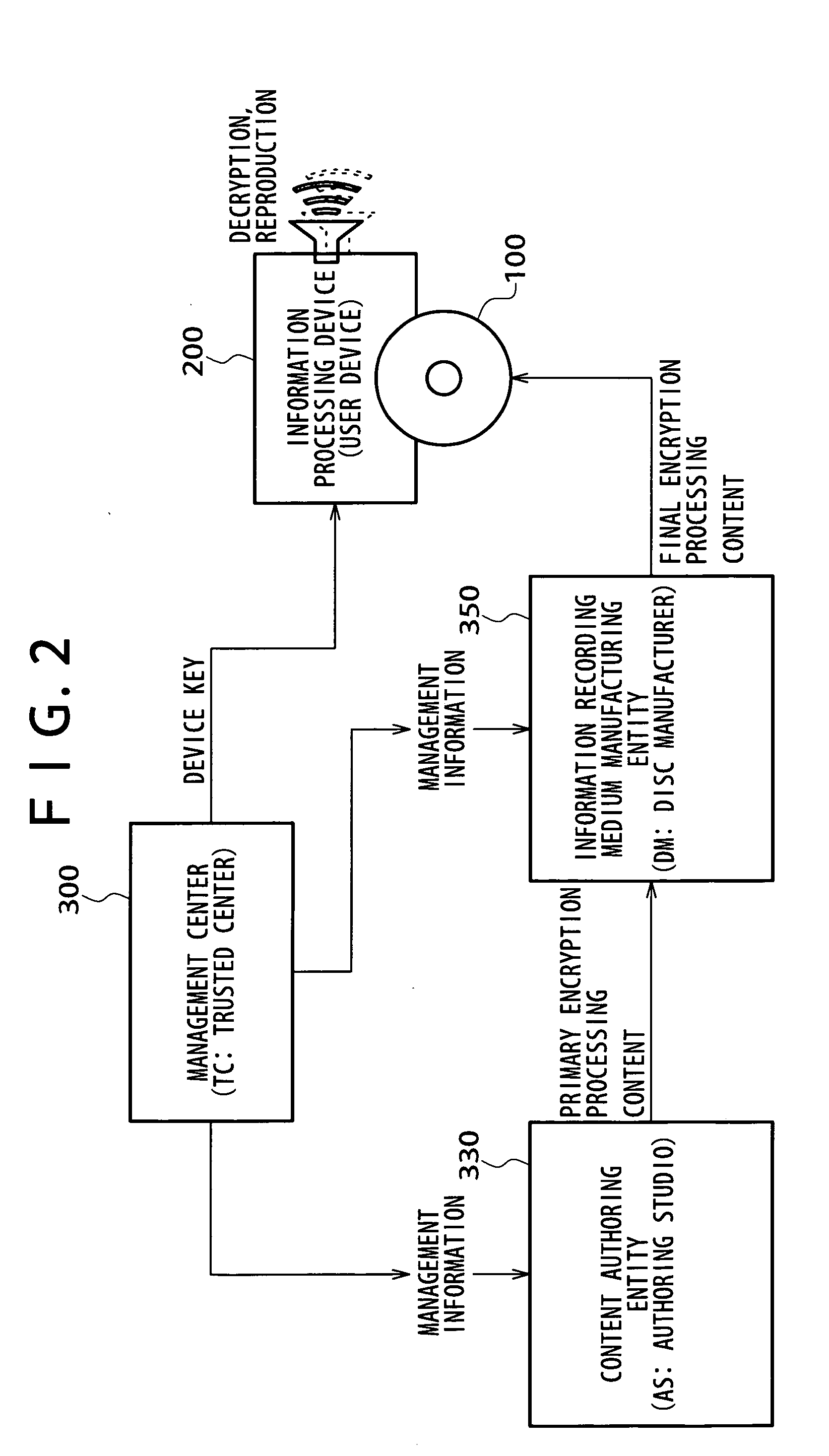

Information recording medium, data processing method, and computer program

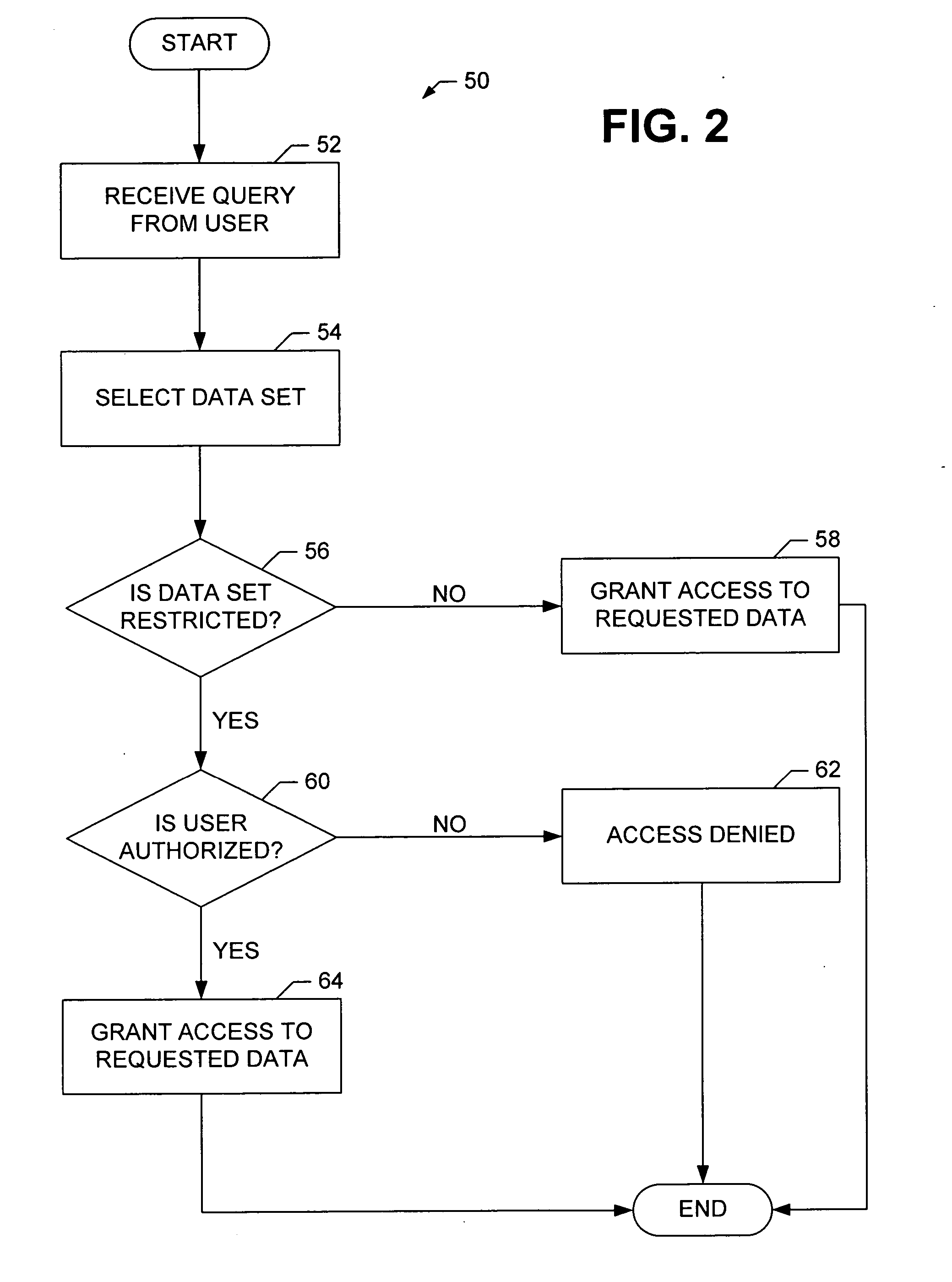

InactiveUS20060150251A1Prevention of leakage of identification informationPrevent leakageKey distribution for secure communicationDigital data processing detailsData setManufacturer code

The present invention provides a configuration for preventing each entity code stored in information recording media from being leaked. Authoring studio code (ASC) and disc manufacturer code (DMC) are encrypted without failure and the encrypted codes are stored in information recording media. The data setting location in program map table (PMT) is controlled such that these entity codes will not overlap the seed area that provides key generating information, so that, if the packet storing the program map table storing authoring studio code (ASC) and disc manufacturer code (DMC) is set to an arbitrary position in a content packet sequence, these entity codes will not overlap the seed area that is non-encrypted data, thereby preventing these entity codes from being leaked outside.

Owner:SONY CORP

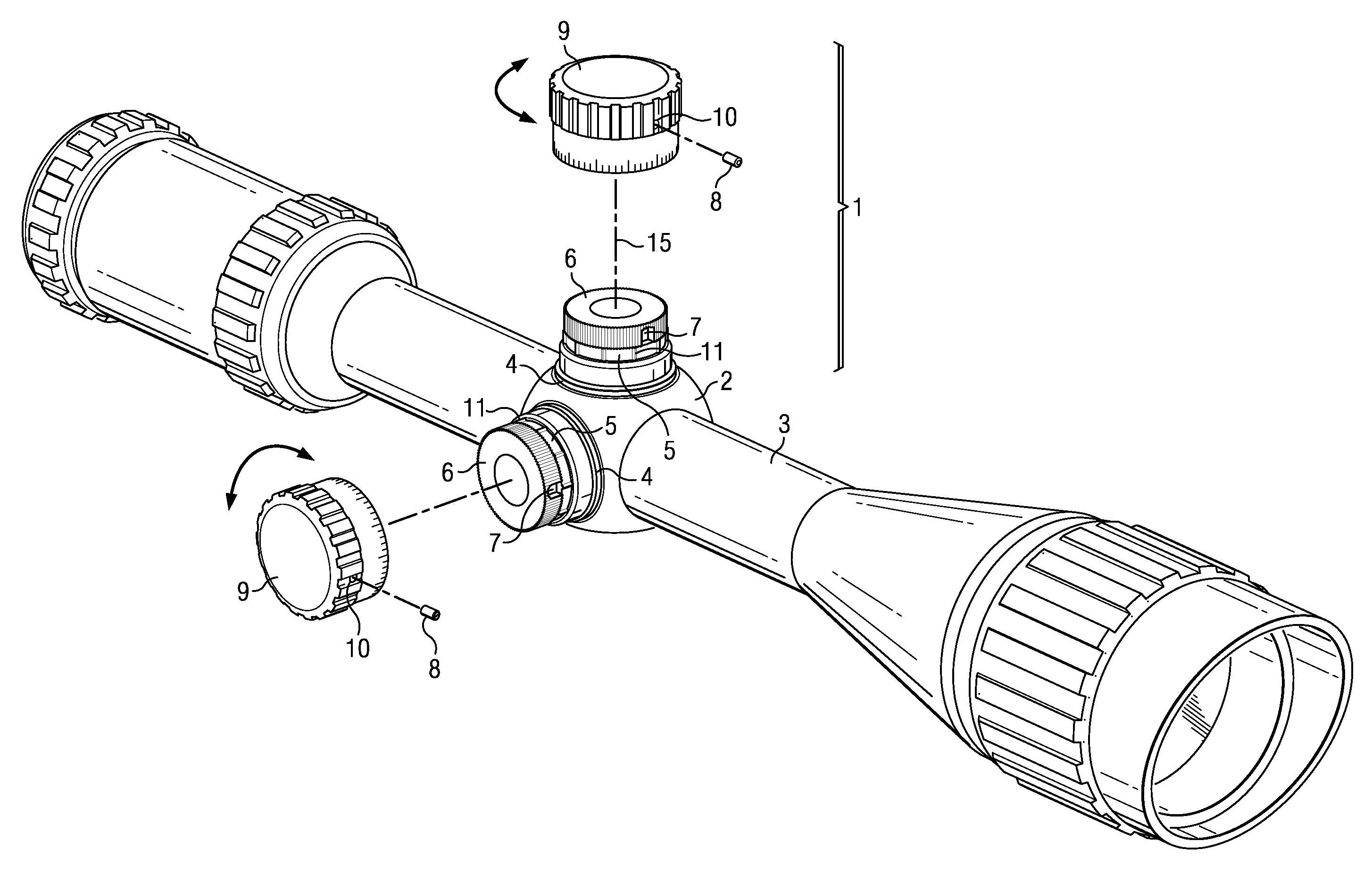

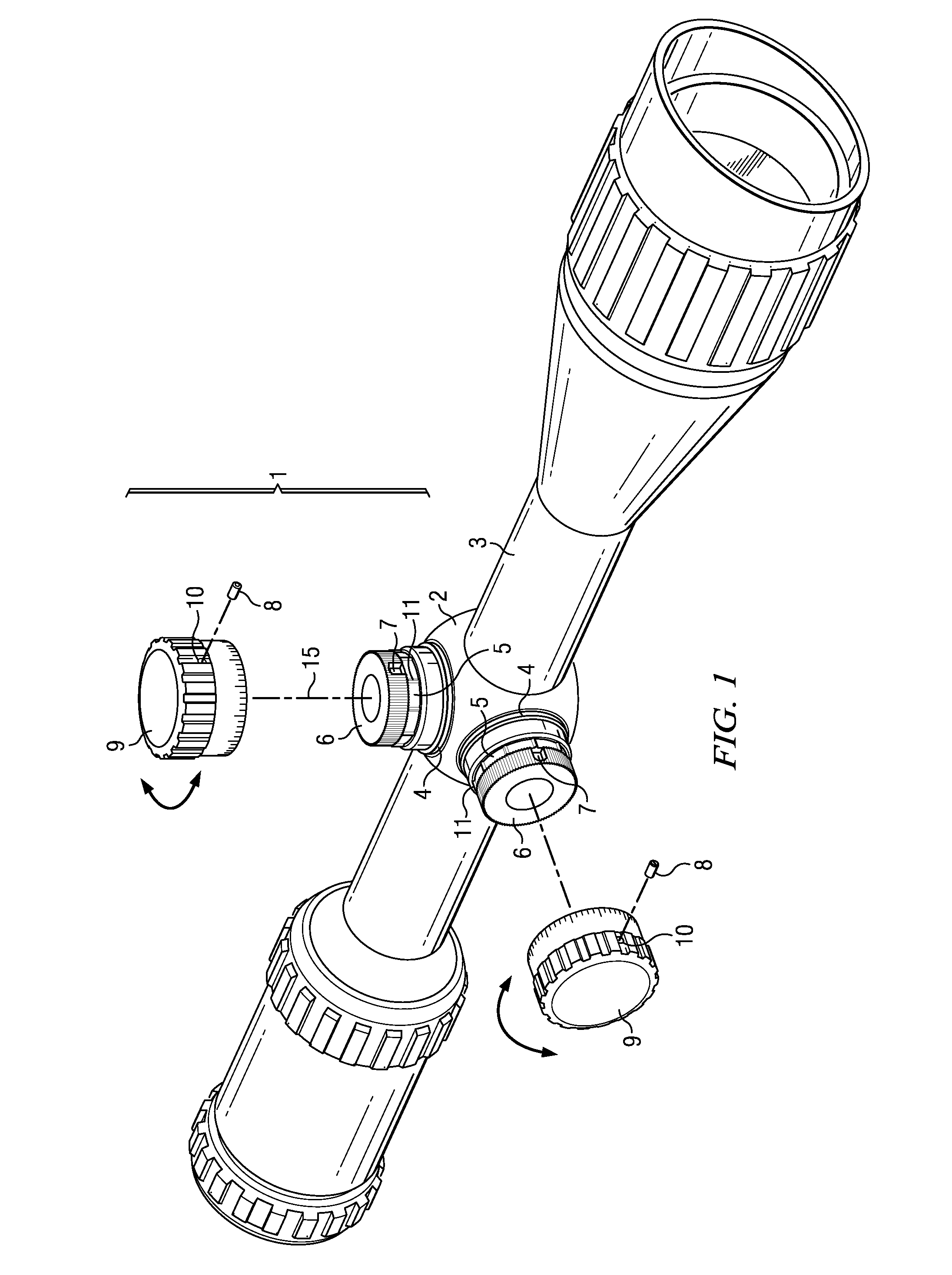

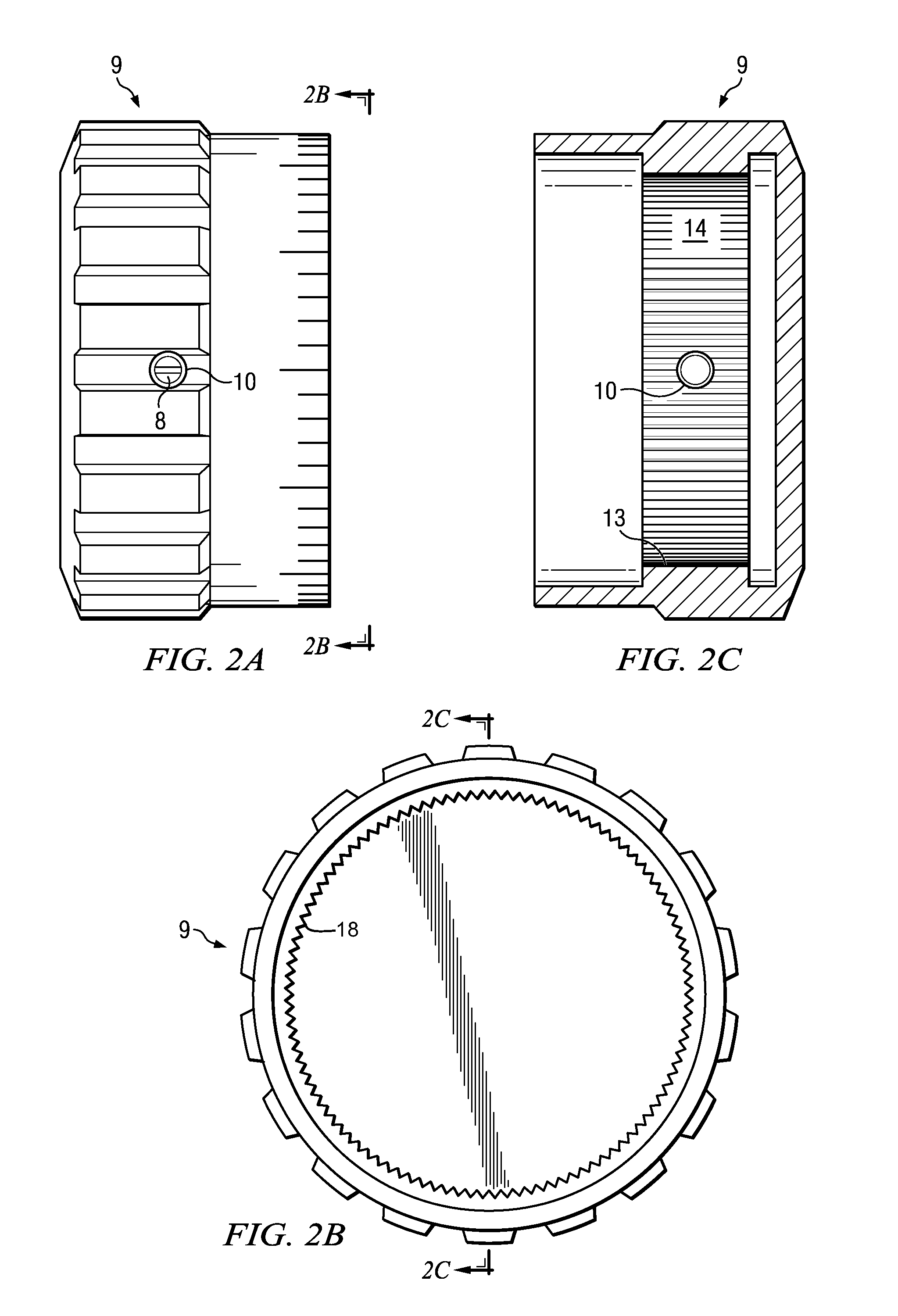

Adjustable locking windage and elevation knob

ActiveUS7997163B2Well formedDamage is causedControlling membersMechanical apparatusEngineeringMechanical engineering

Owner:PLASTICAN +1

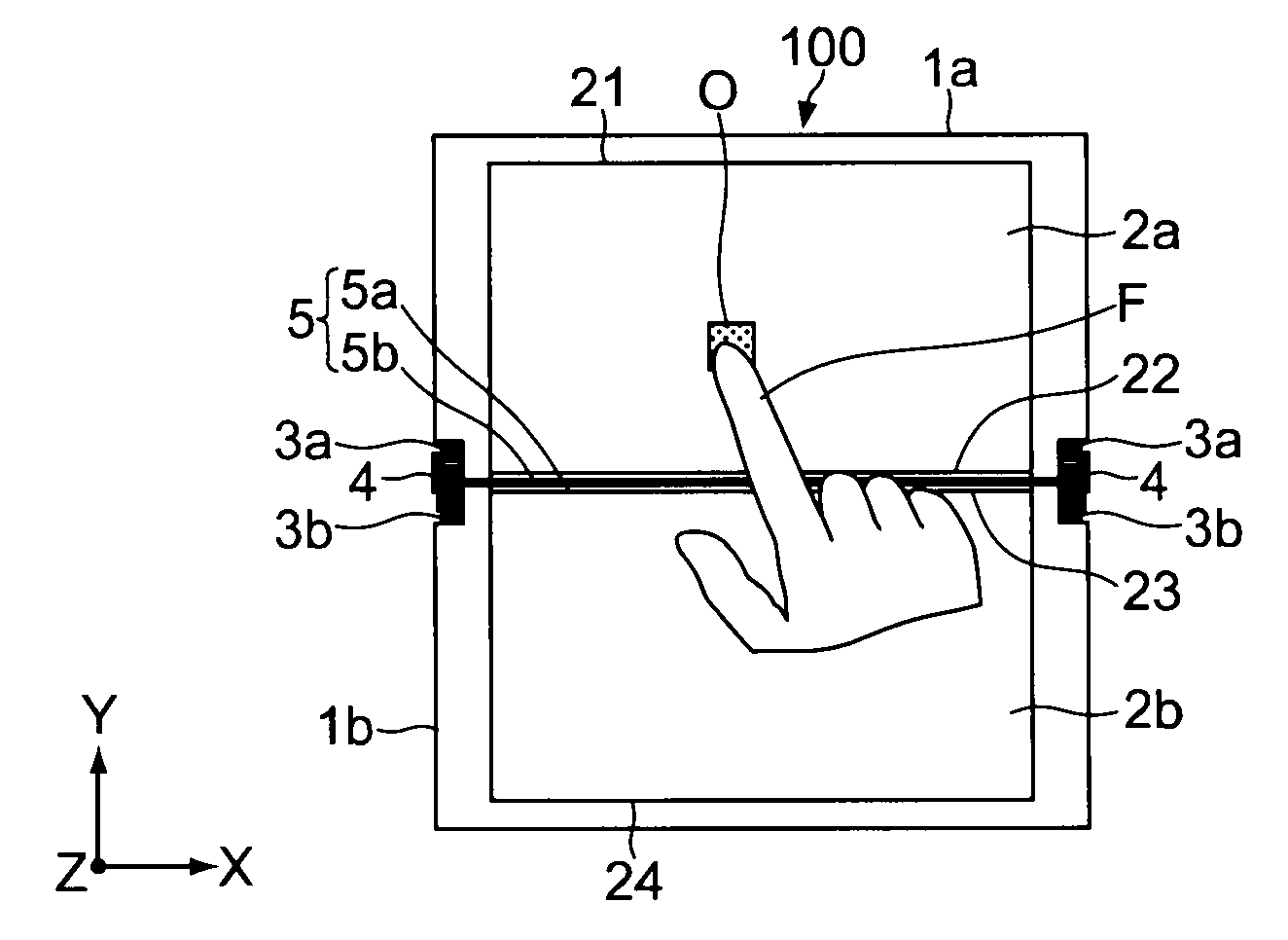

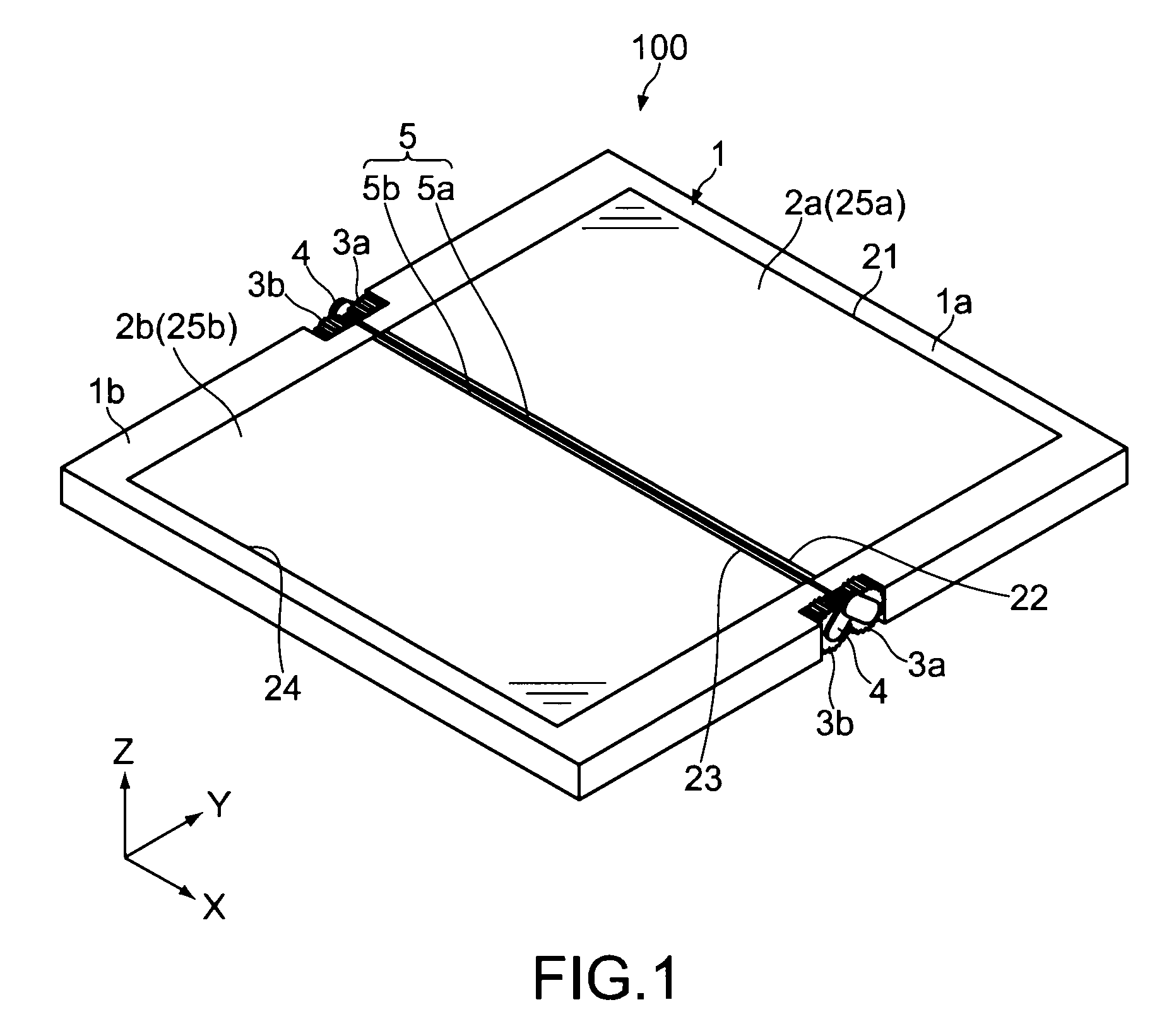

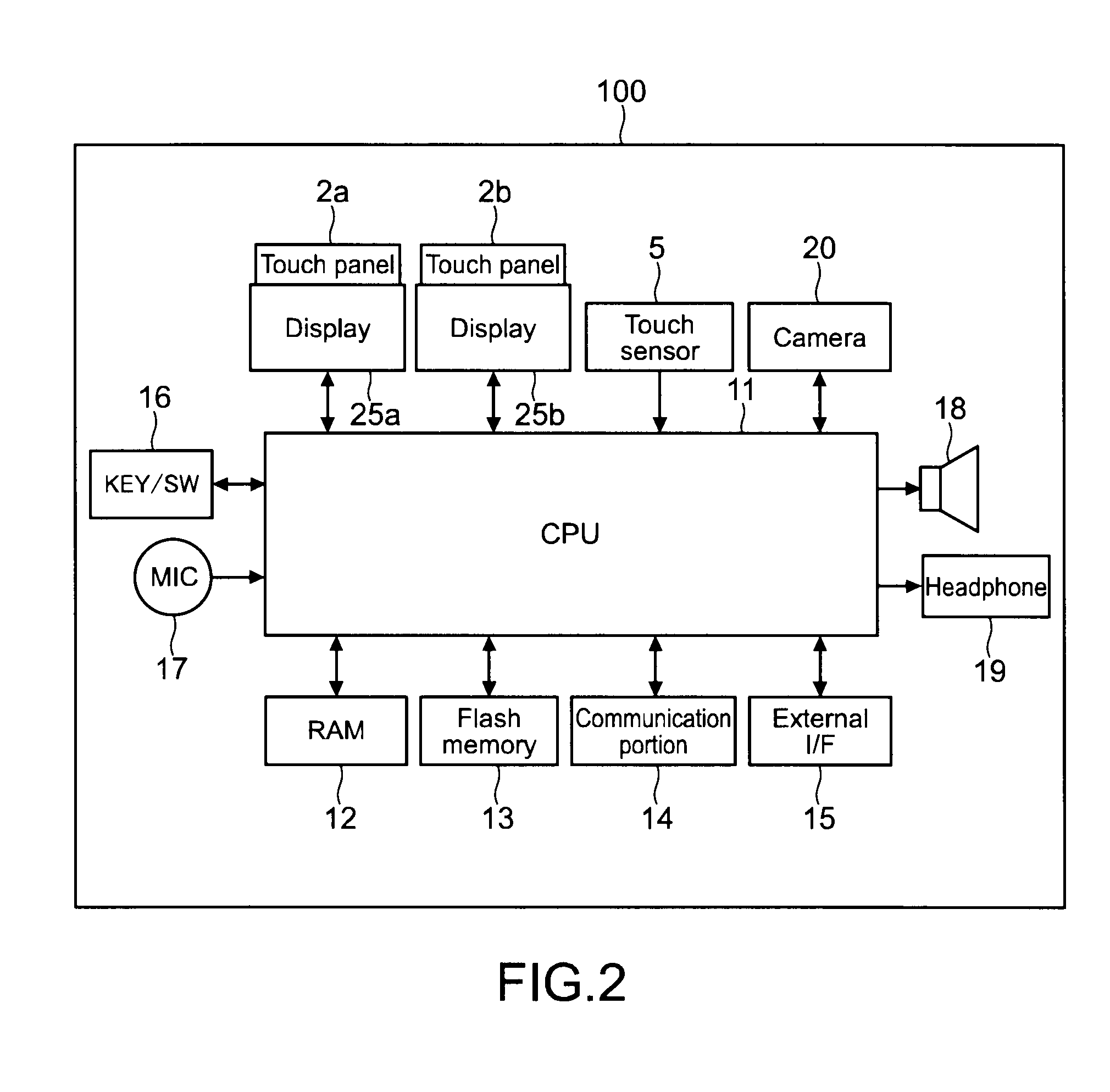

Information processing apparatus, information processing method, and program

InactiveUS20100259494A1Positively detectingAvoid makingDigital data processing detailsInput/output processes for data processingTouch panelInformation processing

An information processing apparatus includes a first touch panel, a second touch panel, a touch sensor, and a controller. The first touch panel displays an object and detects a first touch operation of a user on the object. The second touch panel detects a second touch operation of the user. The touch sensor is provided between the first touch panel and the second touch panel and detects a third touch operation of the user. The controller moves the object displayed on the first touch panel in accordance with the first touch operation, and displays the object on the second touch panel when the third touch operation is detected within a first time period since the first touch operation has become undetected and the second touch operation is detected within a second time period since the third touch operation is detected.

Owner:SONY CORP

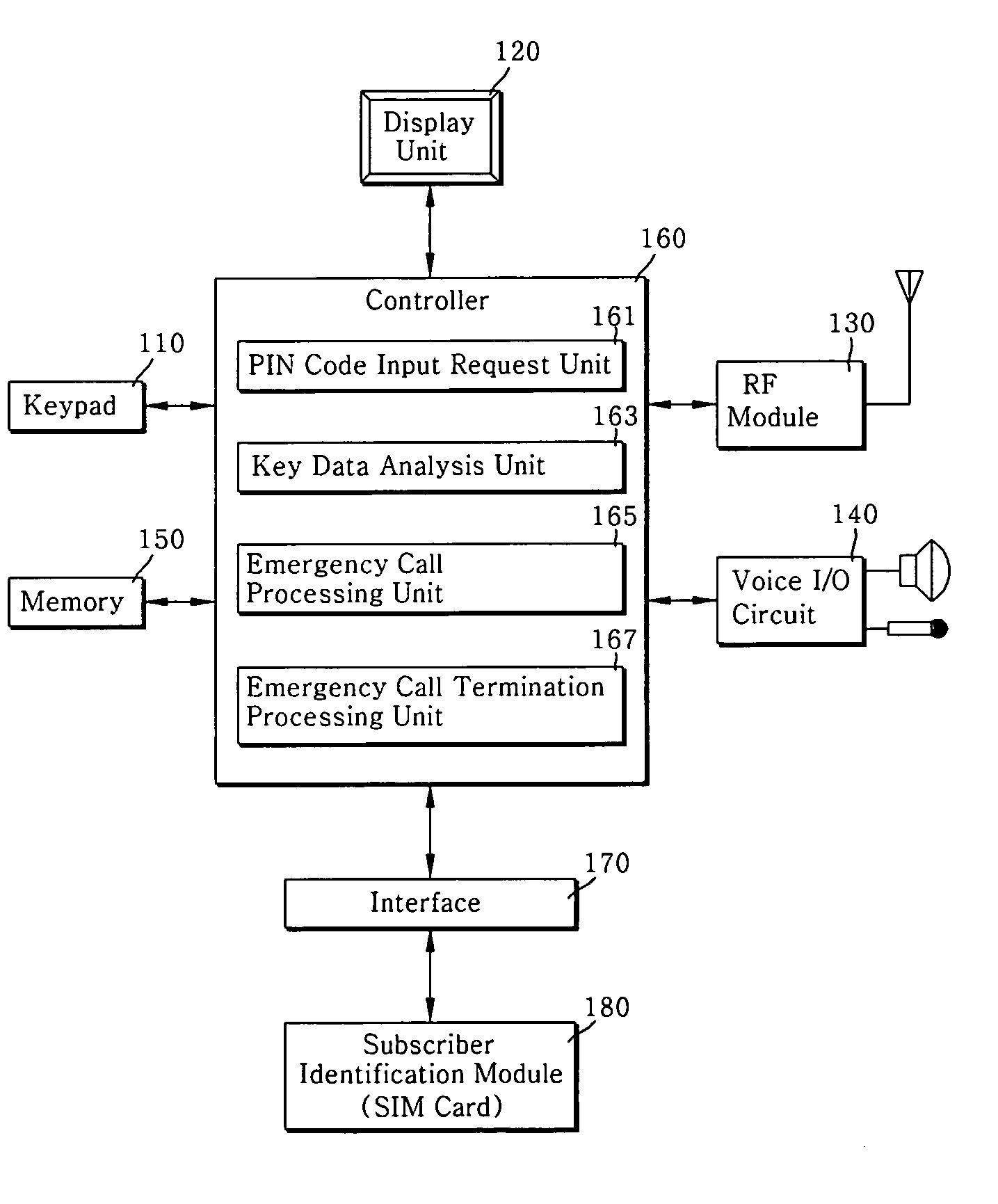

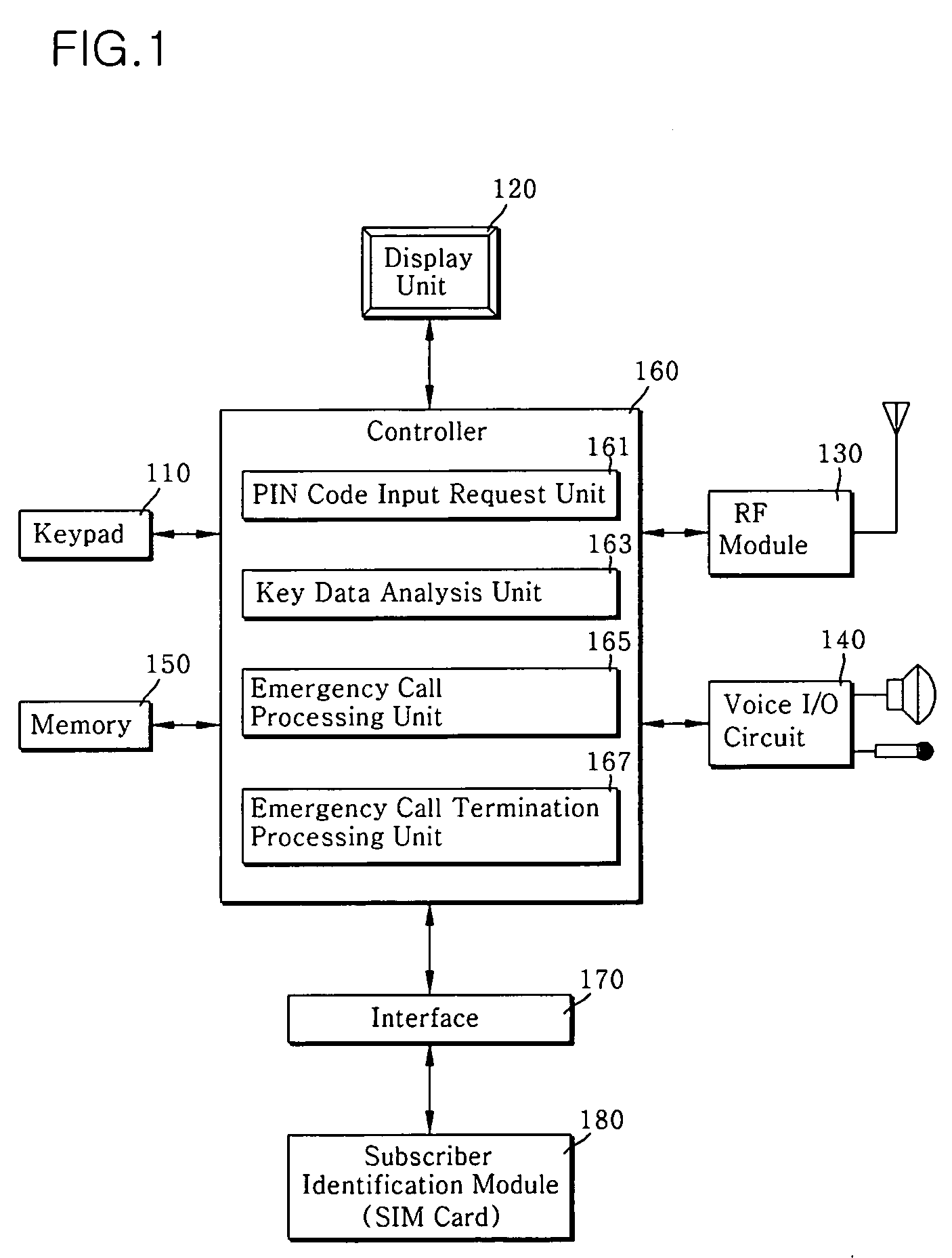

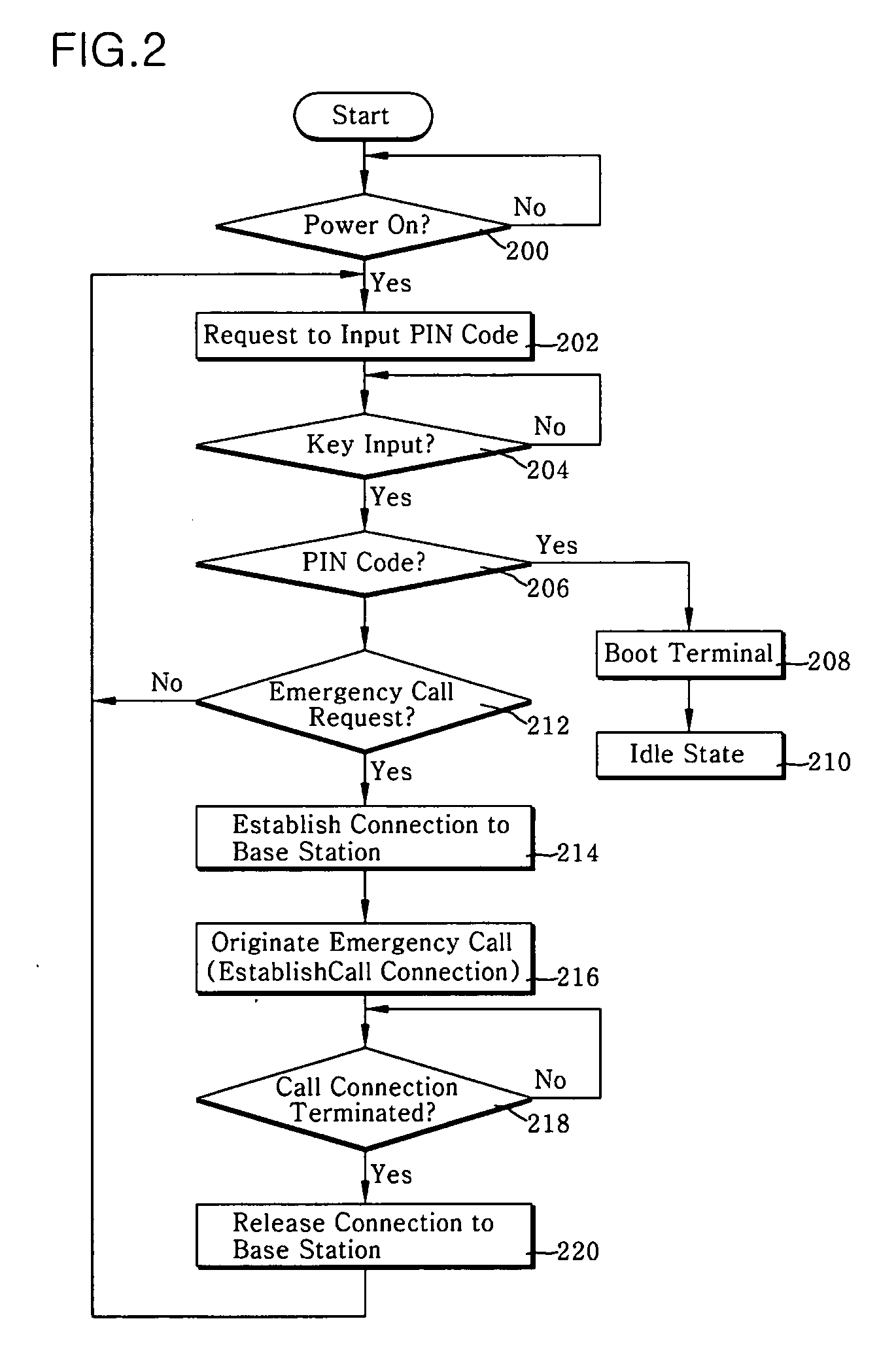

Mobile communication terminal having emergency call function and method of processing emergency call request in the mobile communication terminal

InactiveUS20060084463A1Avoid makingSubstation equipmentTransmissionRF moduleSubscriber identity module

Disclosed herein are a mobile communication terminal equipped with a subscriber identification module and a method of processing an emergency call request in the mobile communication terminal. The mobile communication terminal includes: a keypad; a display unit; a RF module for communicating with a base station; and a controller for performing the overall control of the mobile communication terminal, the controller including: a PIN code input request unit for displaying a PIN code input request on the display unit when terminal booting is requested; a key data analysis unit for analyzing key data inputted through the keypad when the PIN code input request unit requests to input the PIN code; and an emergency call processing unit for searching for the base station and establishing a call connection to the base station when the key data is determined to be an emergency call request by the key data analysis unit.

Owner:CURITEL COMM

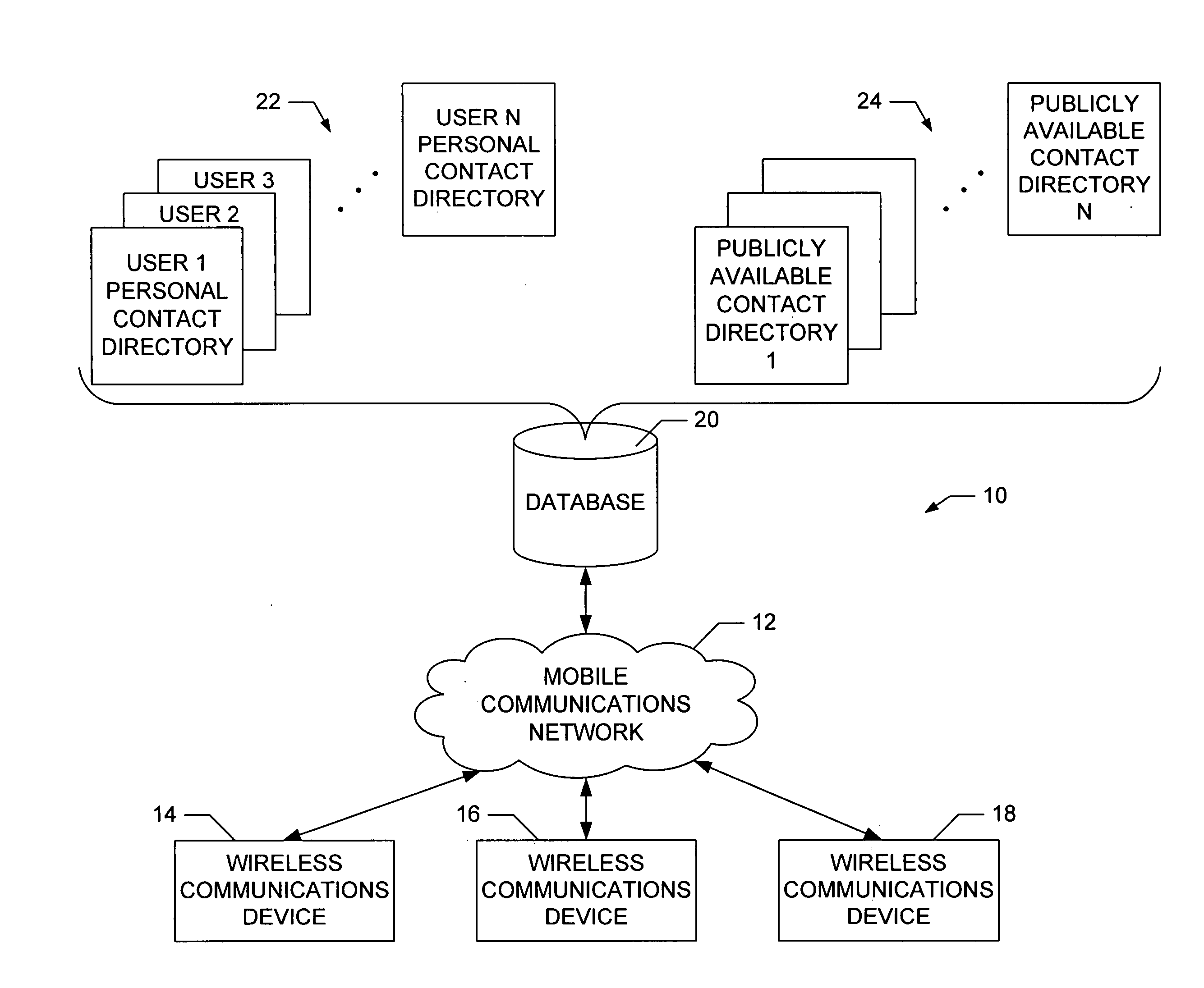

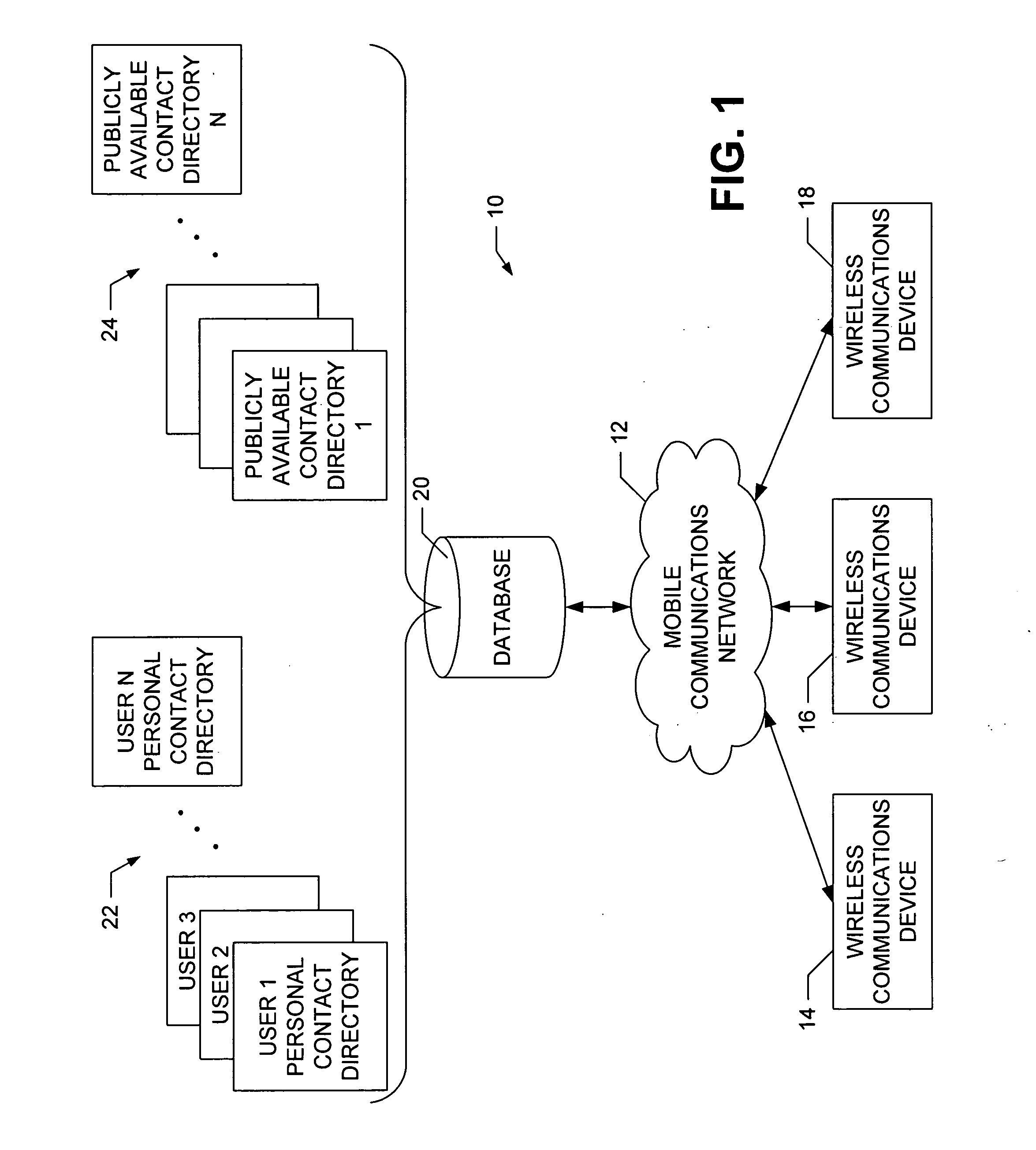

System and method for sharing a personal contact directory

InactiveUS20070066288A1Avoid makingSpecial service for subscribersWireless networksUser verificationPassword

A mobile communications network system includes a centralized data storage device and a plurality of wireless communication devices, wherein the centralized data storage device stores a personal contact directory of a first user that can be accessed by a second user. Preferably, the mobile communications network system further comprises a user verification module for granting access to the second user if the first user previously authorized the second user to have such access. The user verification module can authorize a user by verifying a unique identifier of the wireless communication device or a password inputted by a user.

Owner:CINGULAR WIRELESS II LLC

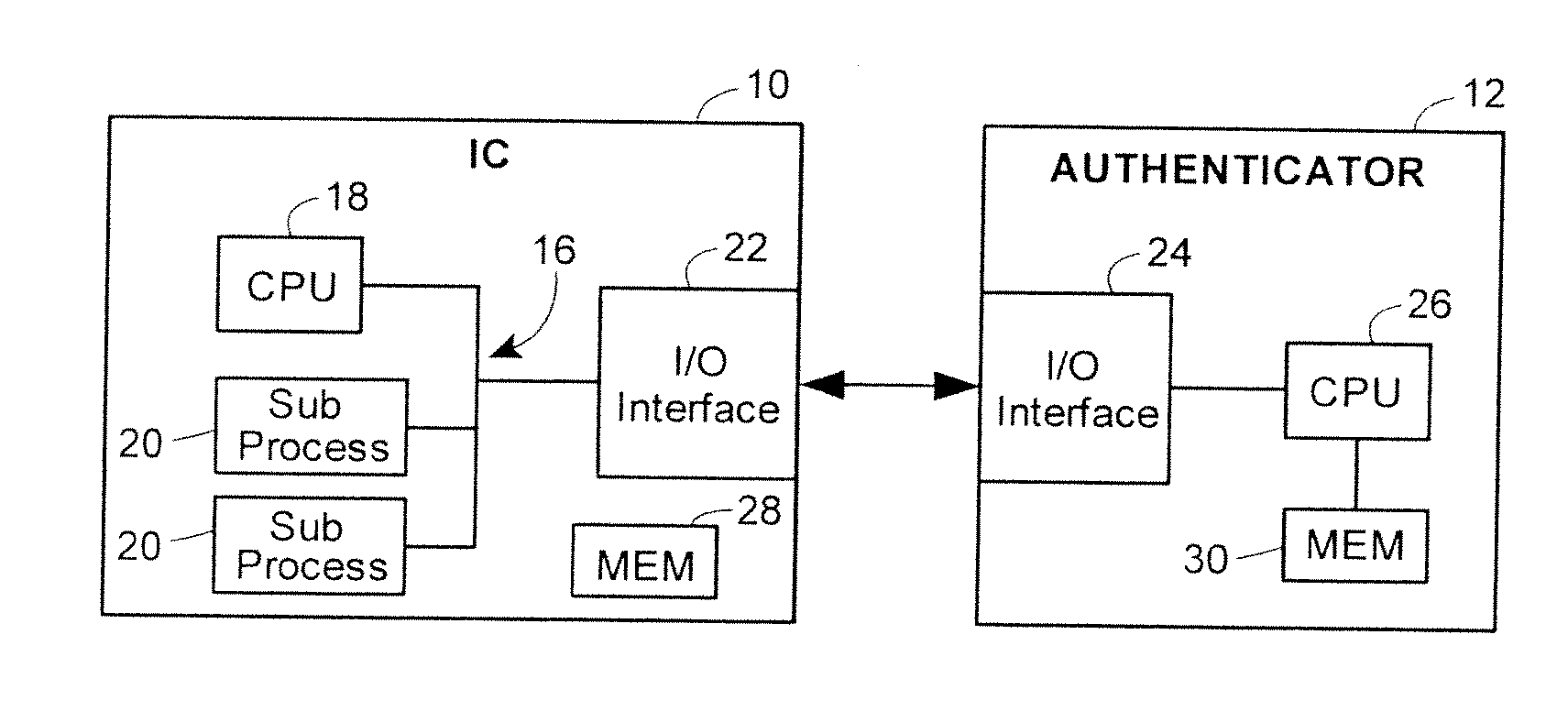

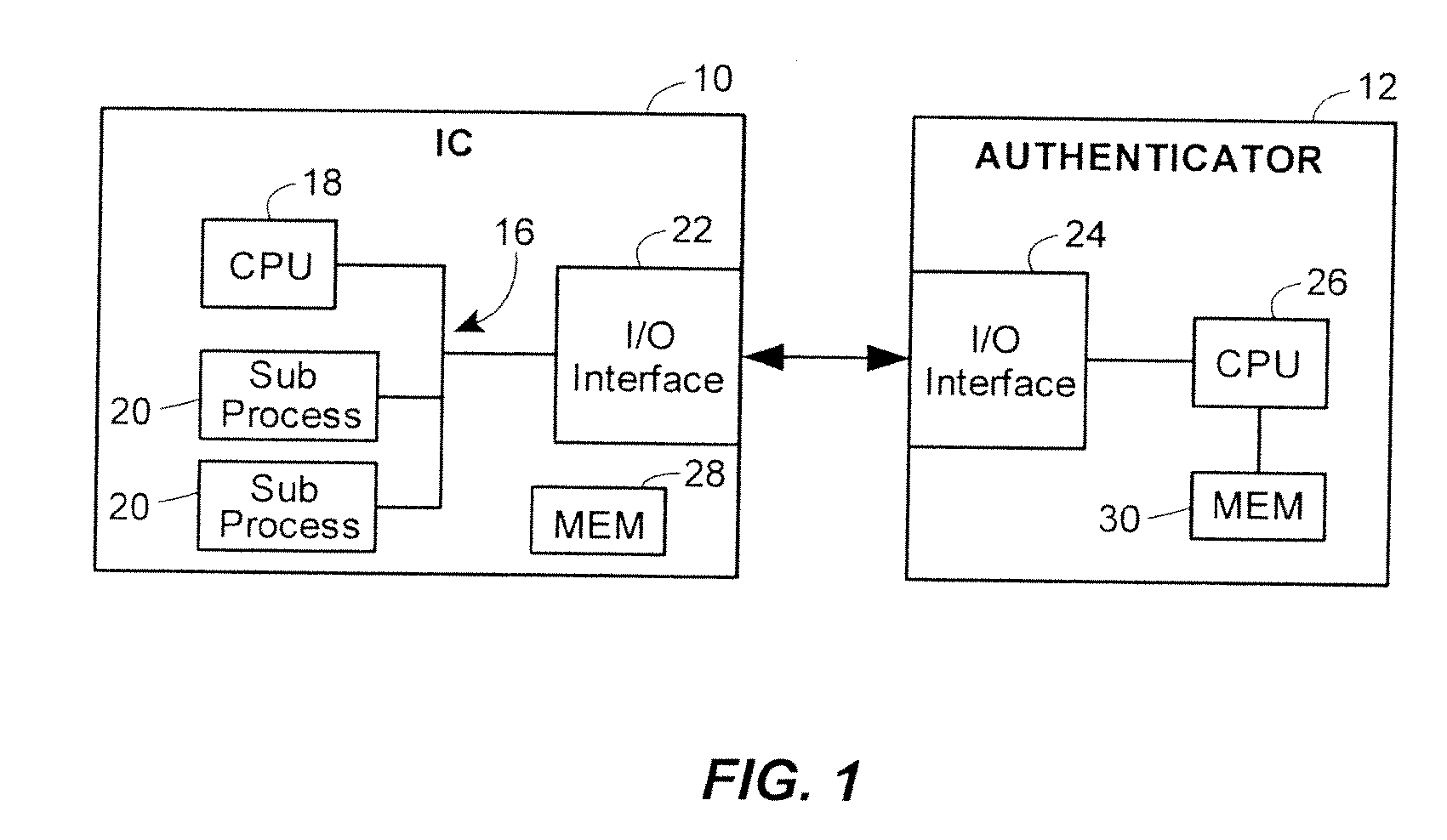

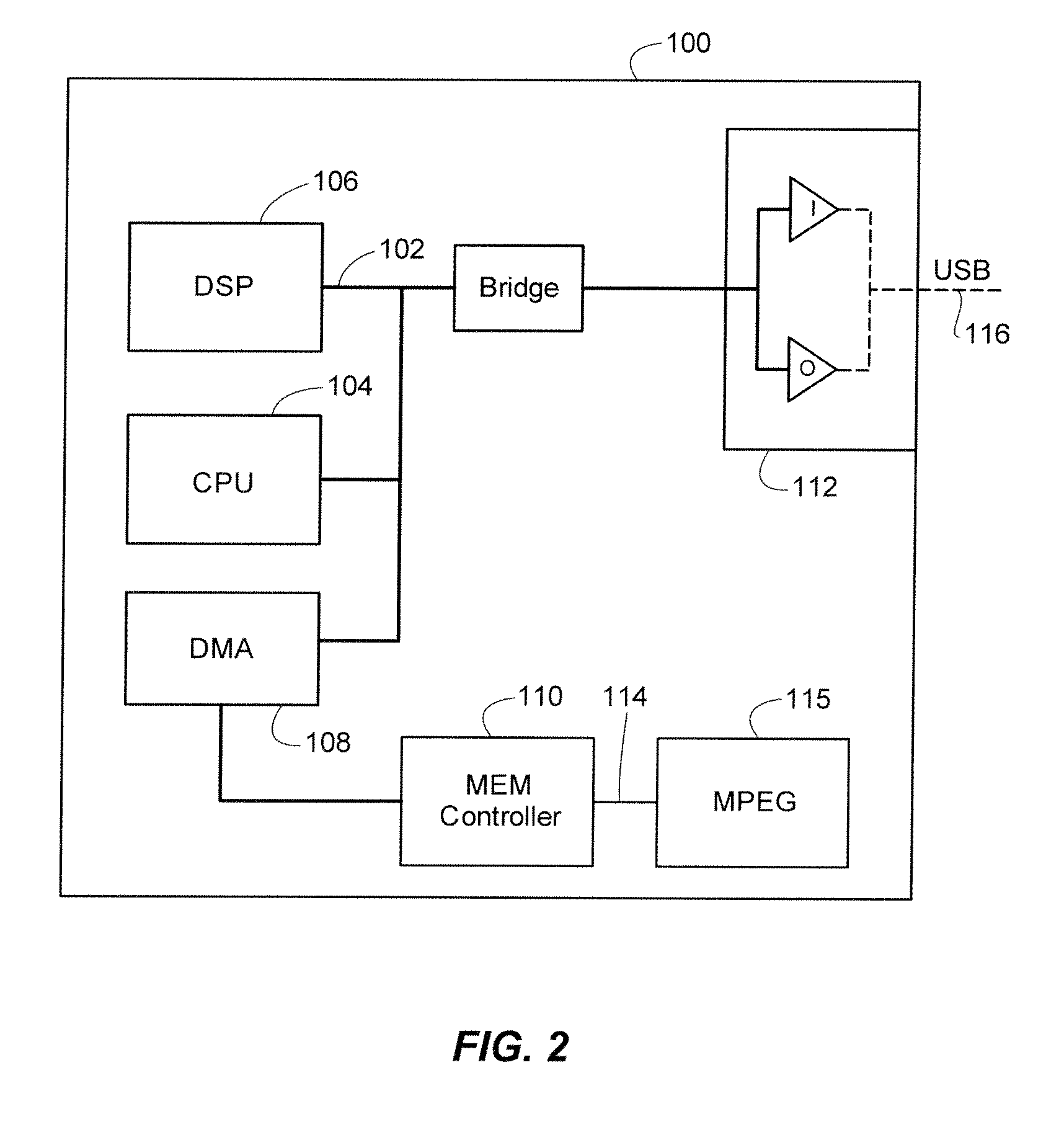

Protecting Hardware Circuit Design by Secret Sharing

InactiveUS20100287374A1Avoid makingUser identity/authority verificationInternal/peripheral component protectionEmbedded systemIntegrated circuit

Techniques are able to lock and unlock and integrated circuit (IC) based device by encrypting / decrypting a bus on the device. The bus may be a system bus for the IC, a bus within the IC, or an external input / output bus. A shared secret protocol is used between an IC designer and a fabrication facility building the IC. The IC at the fabrication facility scrambles the bus on the IC using an encryption key generated from unique identification data received from the IC designer. With the IC bus locked by the encryption key, only the IC designer may be able to determine and communicate the appropriate activation key required to unlock (e.g., unscramble) the bus and thus make the integrated circuit usable.

Owner:RICE UNIV +1

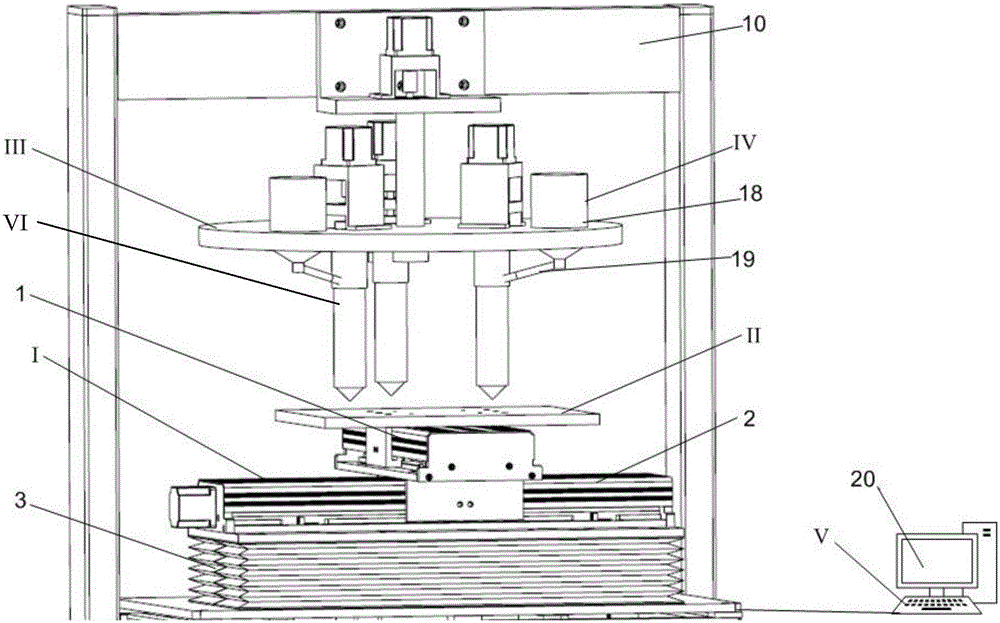

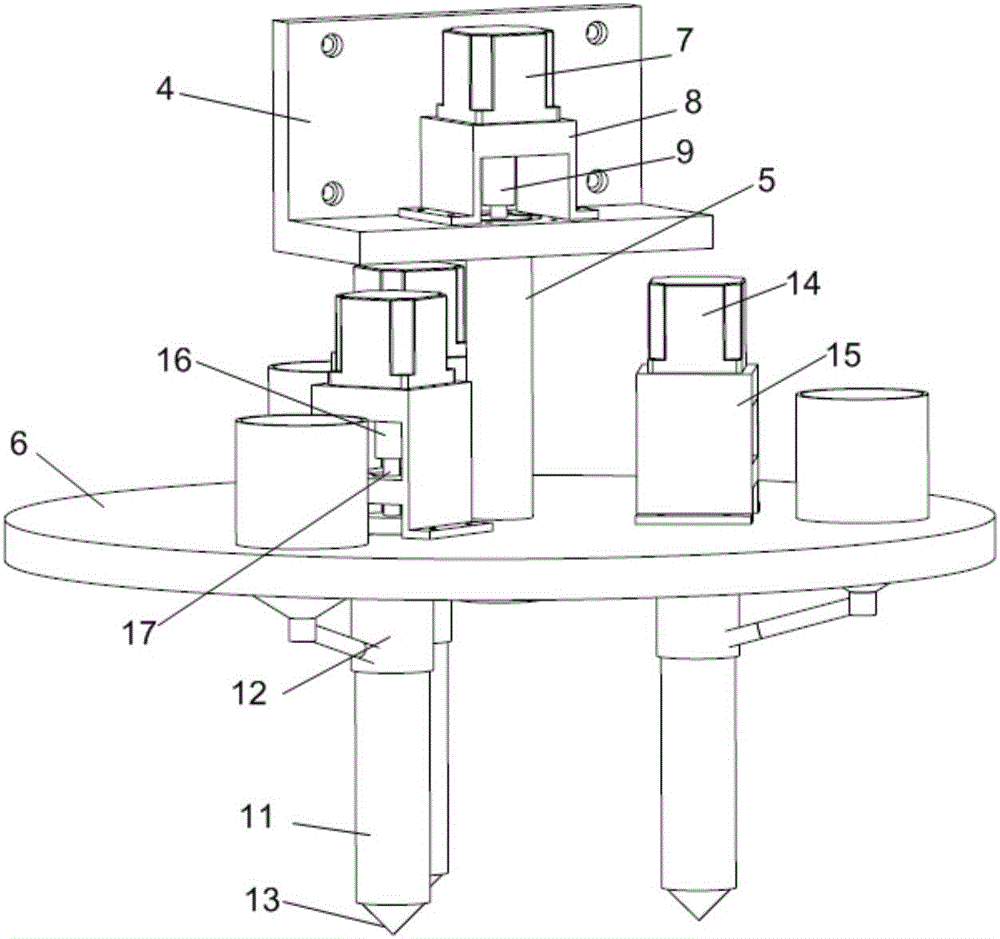

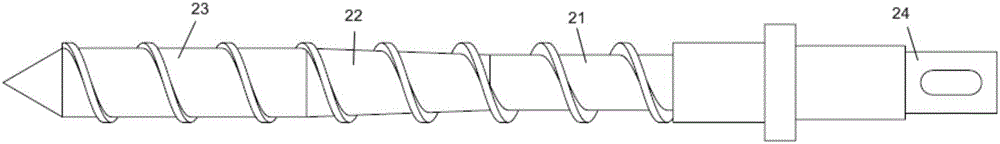

3D printing device suitable for multi-material workpieces

ActiveCN105058789AThe overall structure is simple and reliableHigh degree of automationAdditive manufacturing apparatusHysteresisMulti material

The invention discloses a 3D printing device suitable for multi-material workpieces. The 3D printing device comprises three-dimensional moving structures, a workbench, a rotary plate type sprayer switching device, a feeding system and a control system. The three-dimensional moving structures comprise the X-axis moving structure, the Y-axis moving structure and the Z-axis moving structure. The workbench is fixedly connected with the X-axis moving structure and is driven by the X-axis moving structure and the Y-axis moving structure to perform horizontal motion and driven by the Z-axis moving structure to perform vertical motion. The rotary plate type sprayer switching device comprises a rotary plate and a motor; multiple segmented screw rod sprayer devices are mounted on the rotary plate in the circumferential direction, and the rotary plate is driven by the motor to rotate for switching. The feeding system is used for providing pulp for the segmented screw rod sprayer devices. The control system is used for controlling the movement of the three-dimensional moving structures and the rotary plate and extrusion of the pulp in the segmented screw rod sprayer devices. According to the 3D printing device, the selecting range of processing materials is expanded, and the 3D printing device has the advantages of being high in work efficiency, low in production cost and the like, and can effectively reduce material hysteresis and flowing phenomena.

Owner:HUAZHONG UNIV OF SCI & TECH

Gaming device having improved offer and acceptance bonus scheme

InactiveUS20050187010A1Avoid makingApparatus for meter-controlled dispensingVideo gamesEngineeringHuman–computer interaction

Owner:IGT

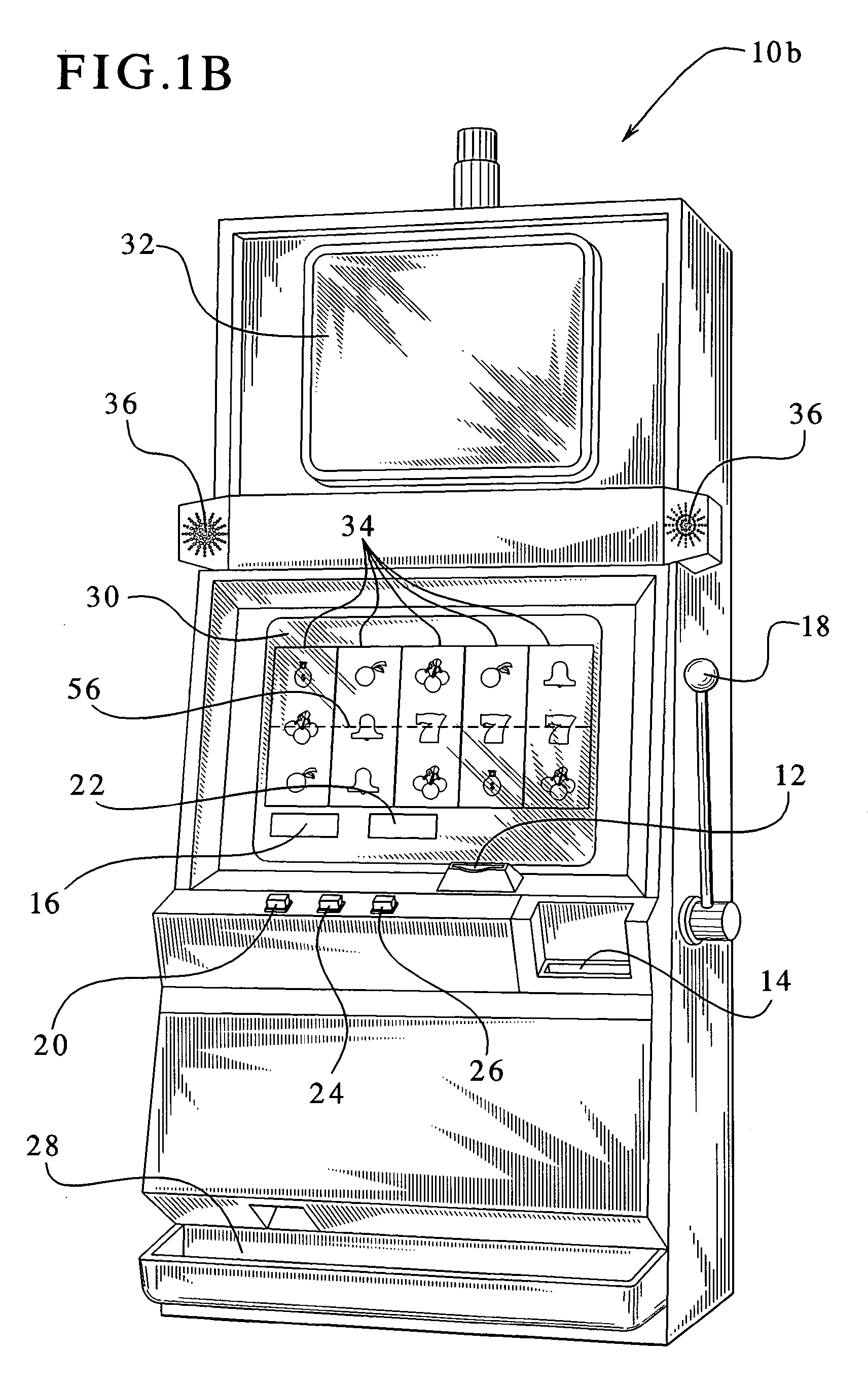

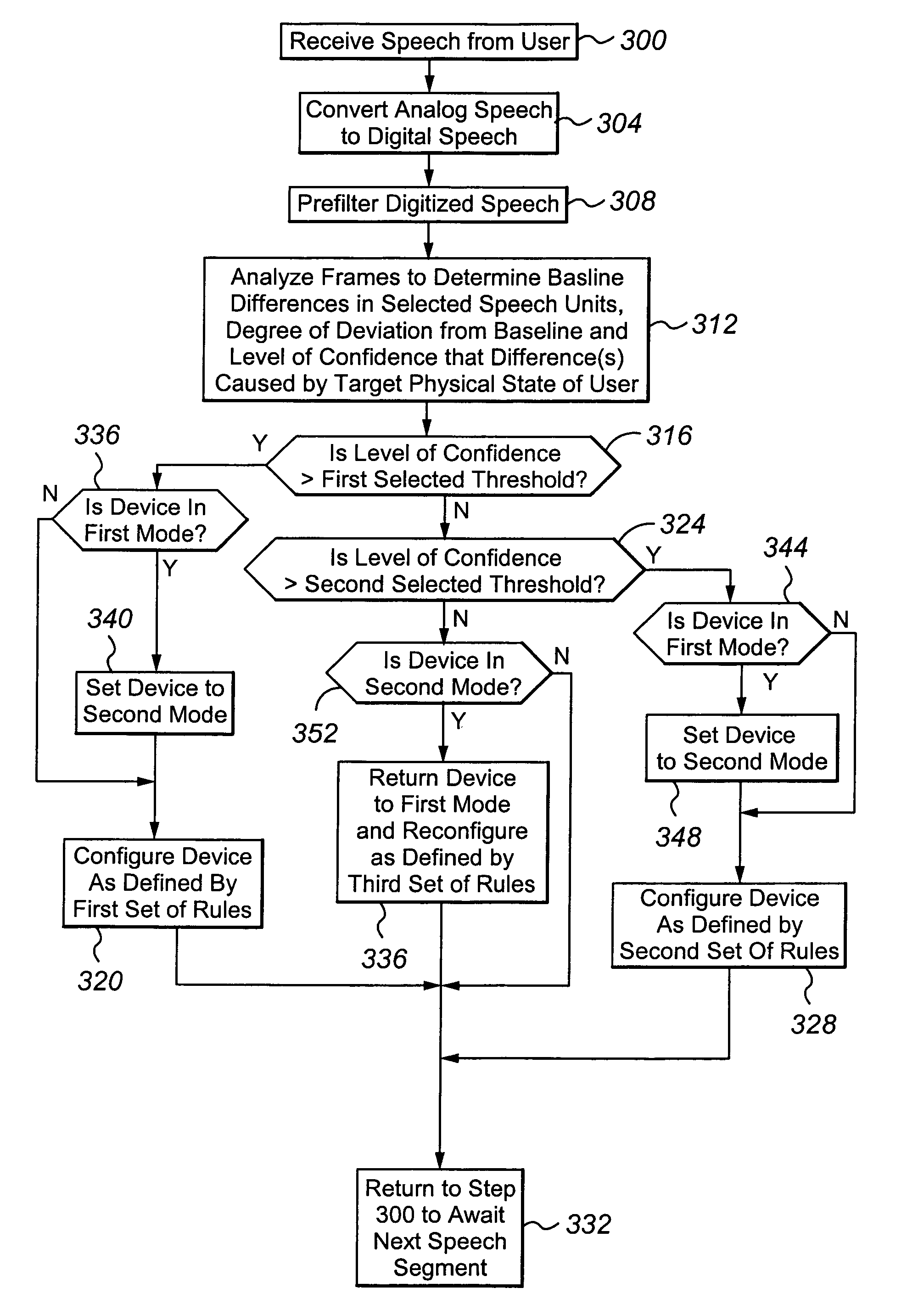

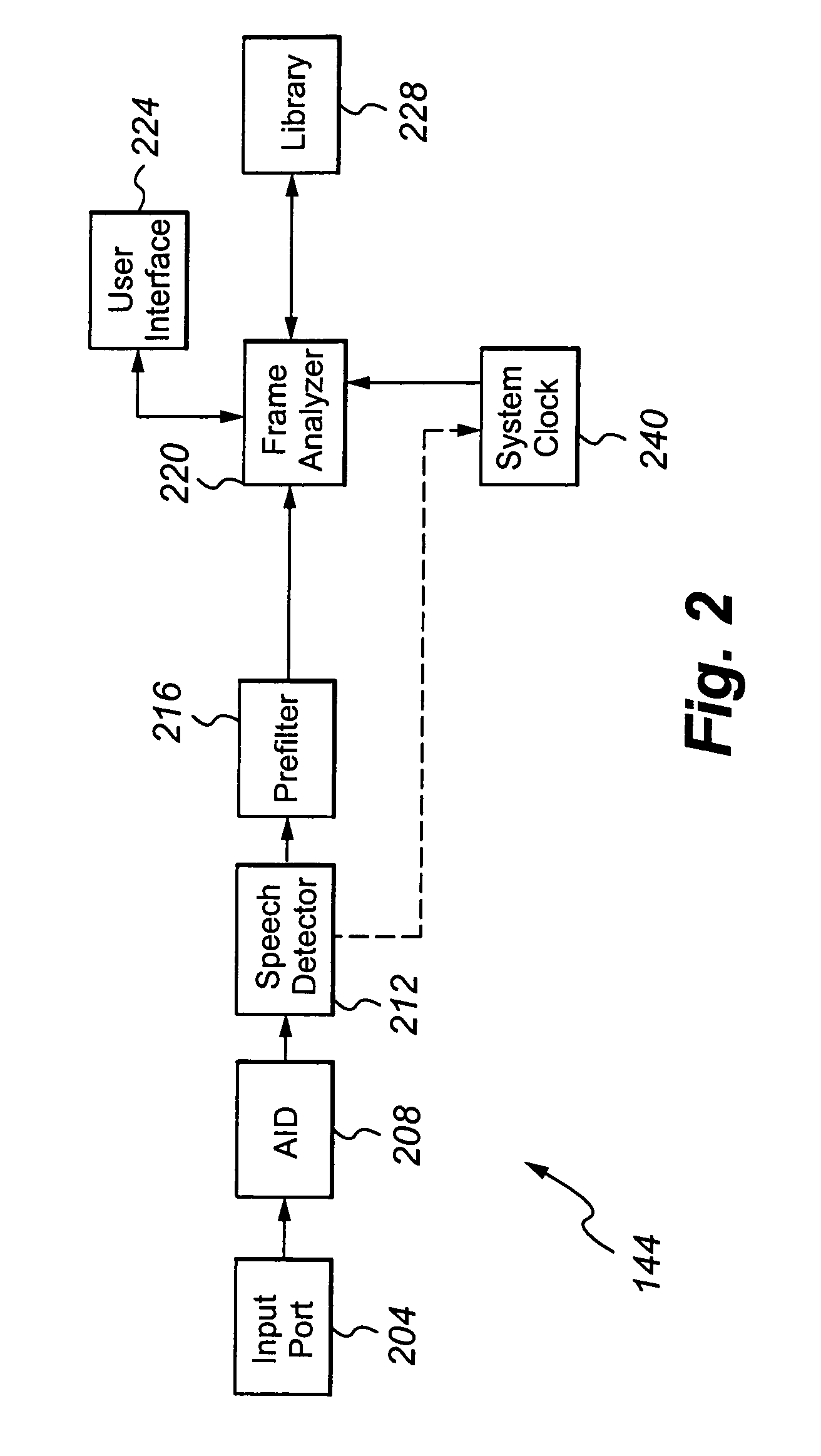

Dynamic user interface for the temporarily impaired based on automatic analysis for speech patterns

ActiveUS7962342B1Avoid makingPublic address systemsSpecial service for subscribersSpeech patternsHuman–computer interaction

In one embodiment, the present invention is directed to reconfiguration of a communication device or other network node based on a determination that a user has a target (altered) physical condition.

Owner:AVAYA INC

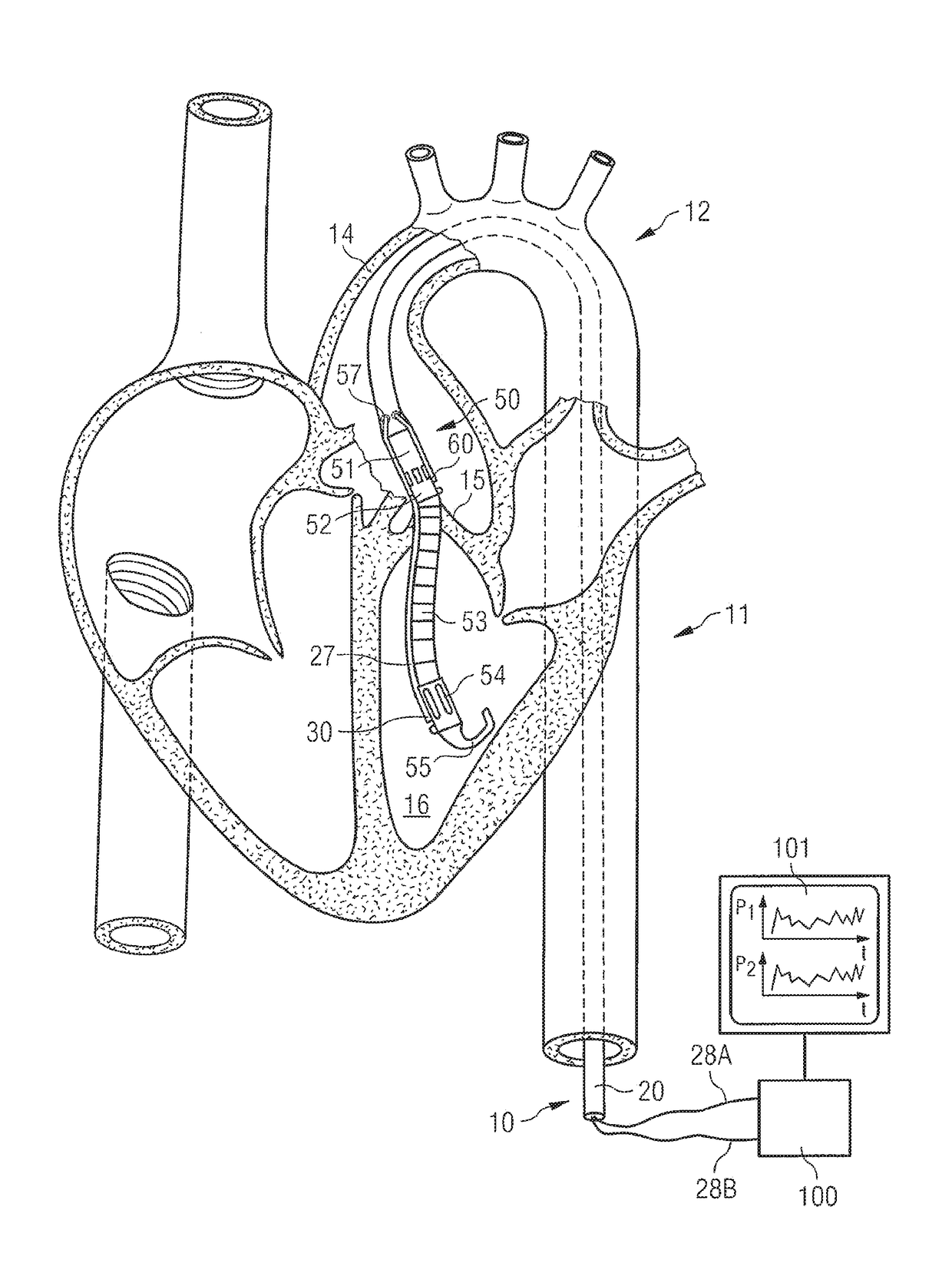

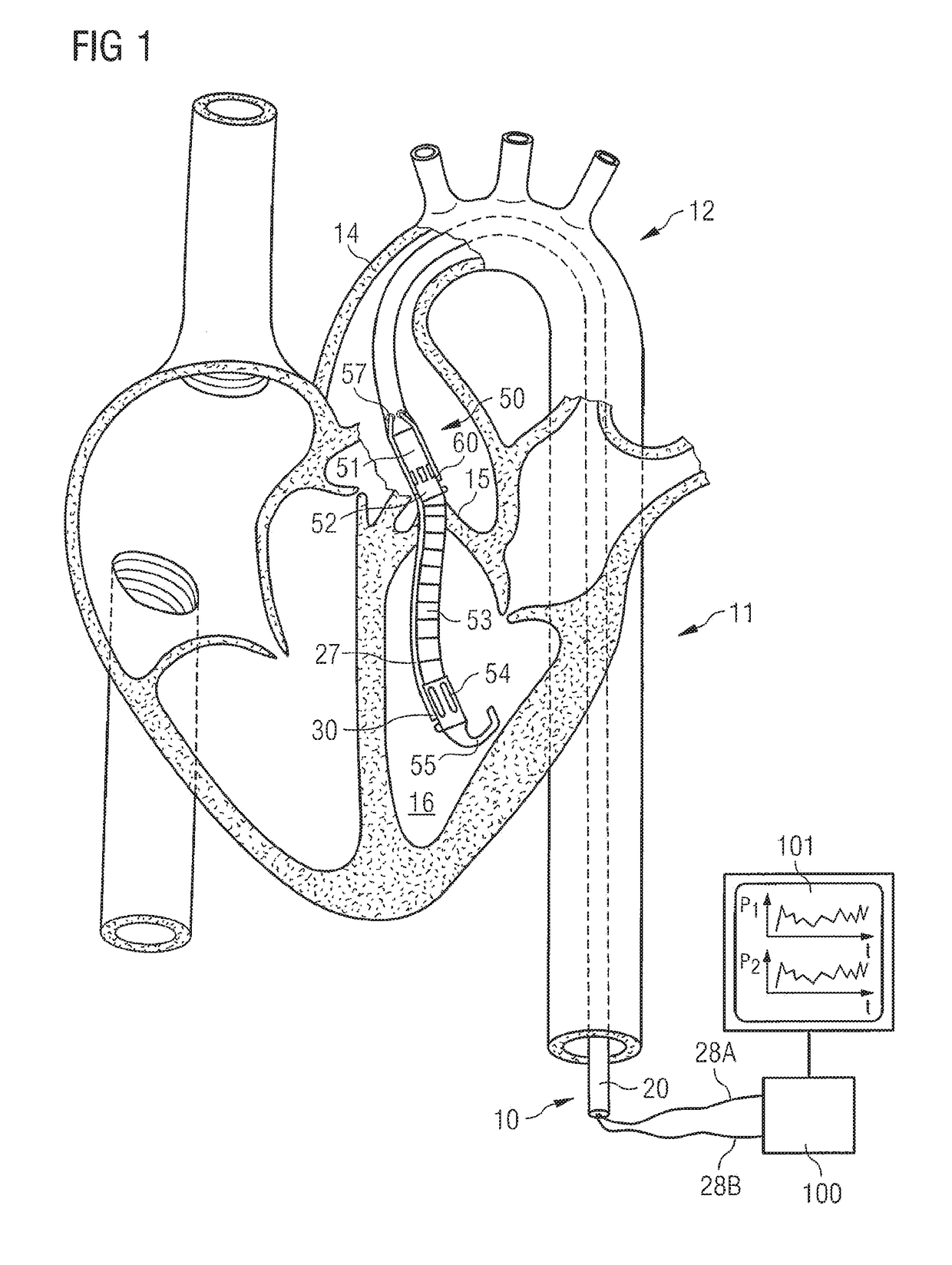

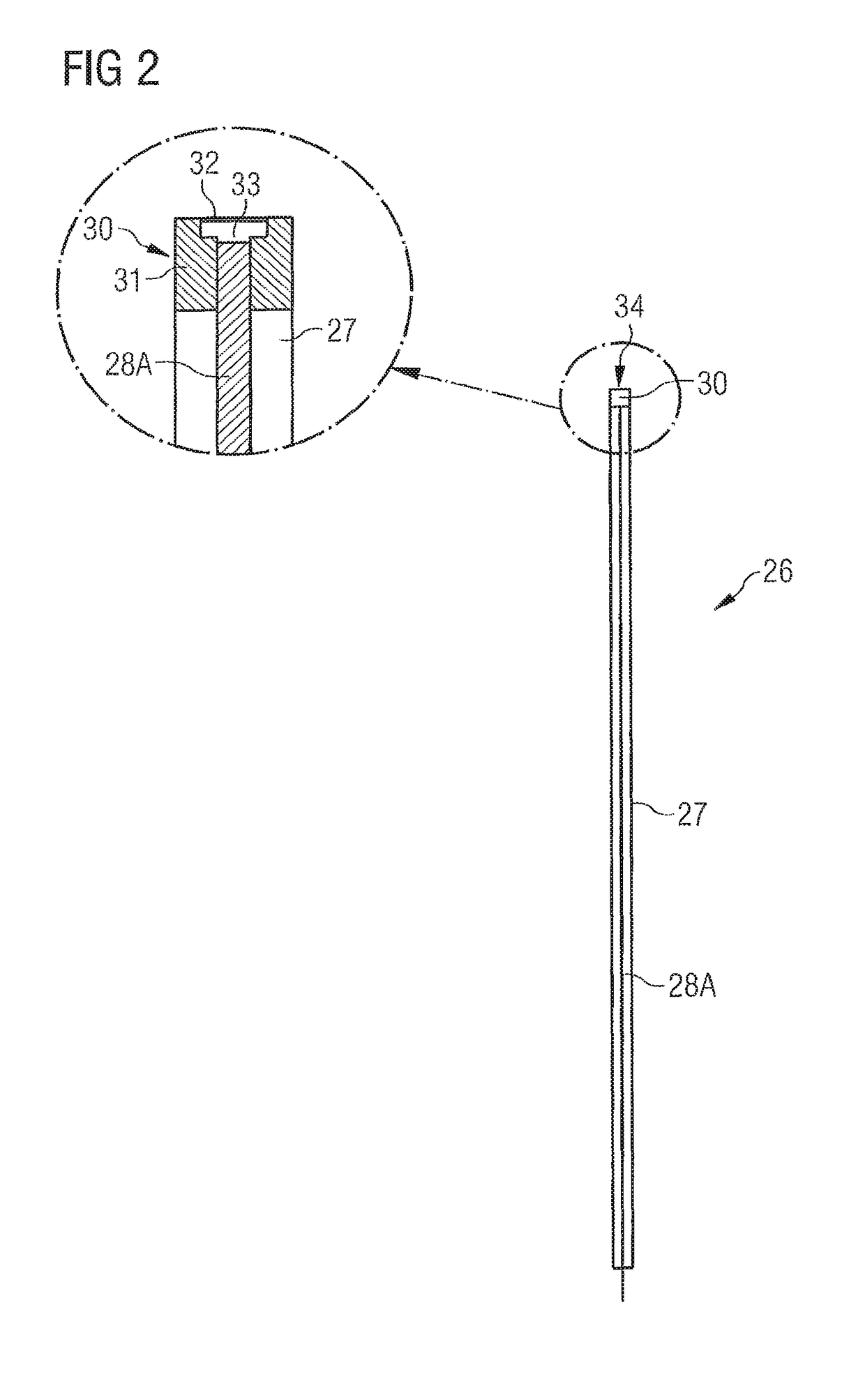

Catheter system and intravascular blood pump comprising said catheter system

ActiveUS9669144B2Simple structureReduce manufacturing costControl devicesBlood pumpsMedicineBlood pump

A catheter (20), which can be part of an intravascular blood pump, possesses a kink sensor which extends over the total length of the catheter and comprises an optical fiber (28A). The optical fiber is attached to an evaluation device (100) which evaluates a preset light quantity transmitted through the optical fiber as to whether a part of the light quantity is coupled out of the optical fiber along the length of the optical fiber. This is interpreted as a kink event and displayed. The optical fiber preferably utilized for the kink sensor is the optical fiber of an optical pressure sensor.

Owner:ABIOMED EURO

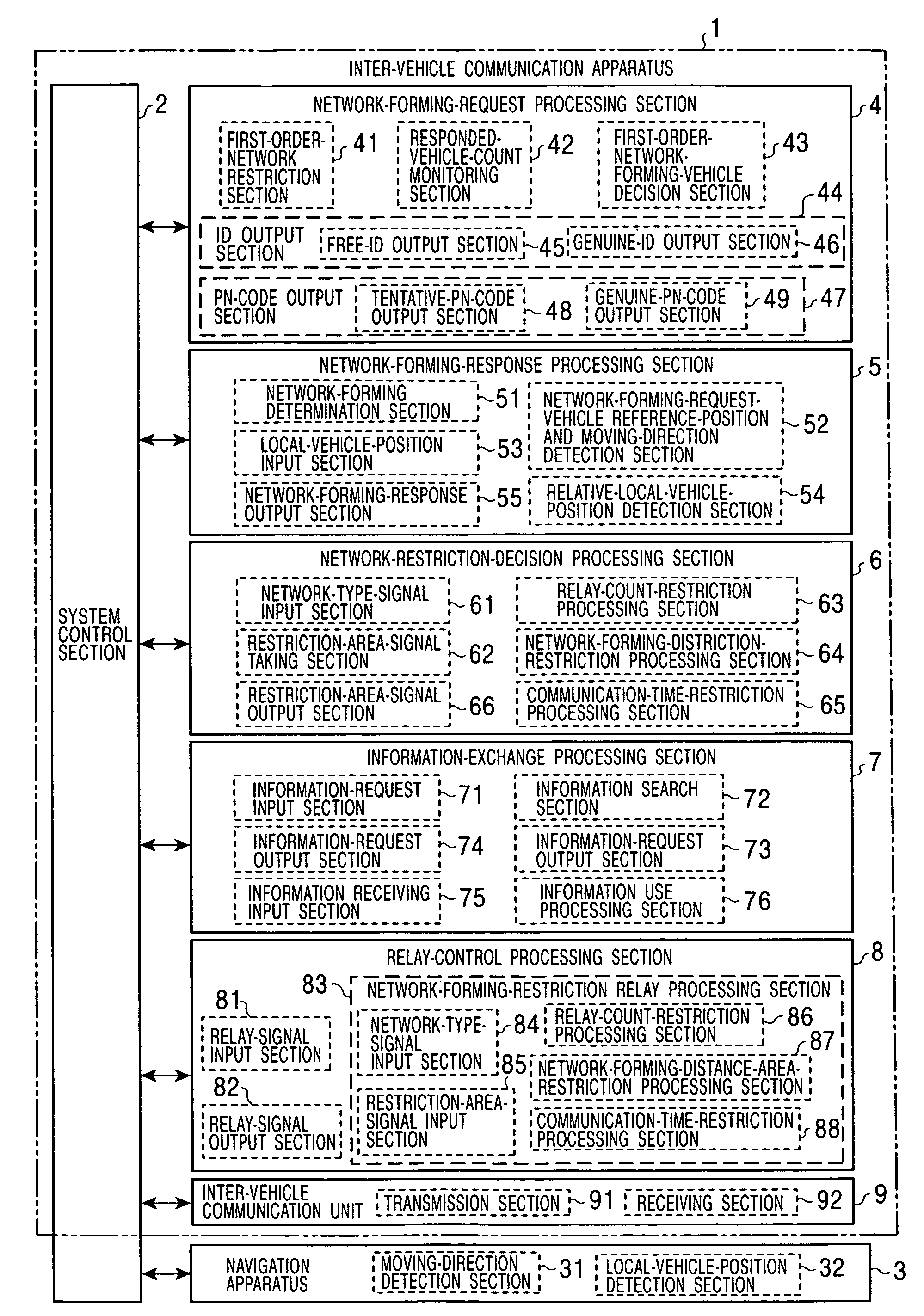

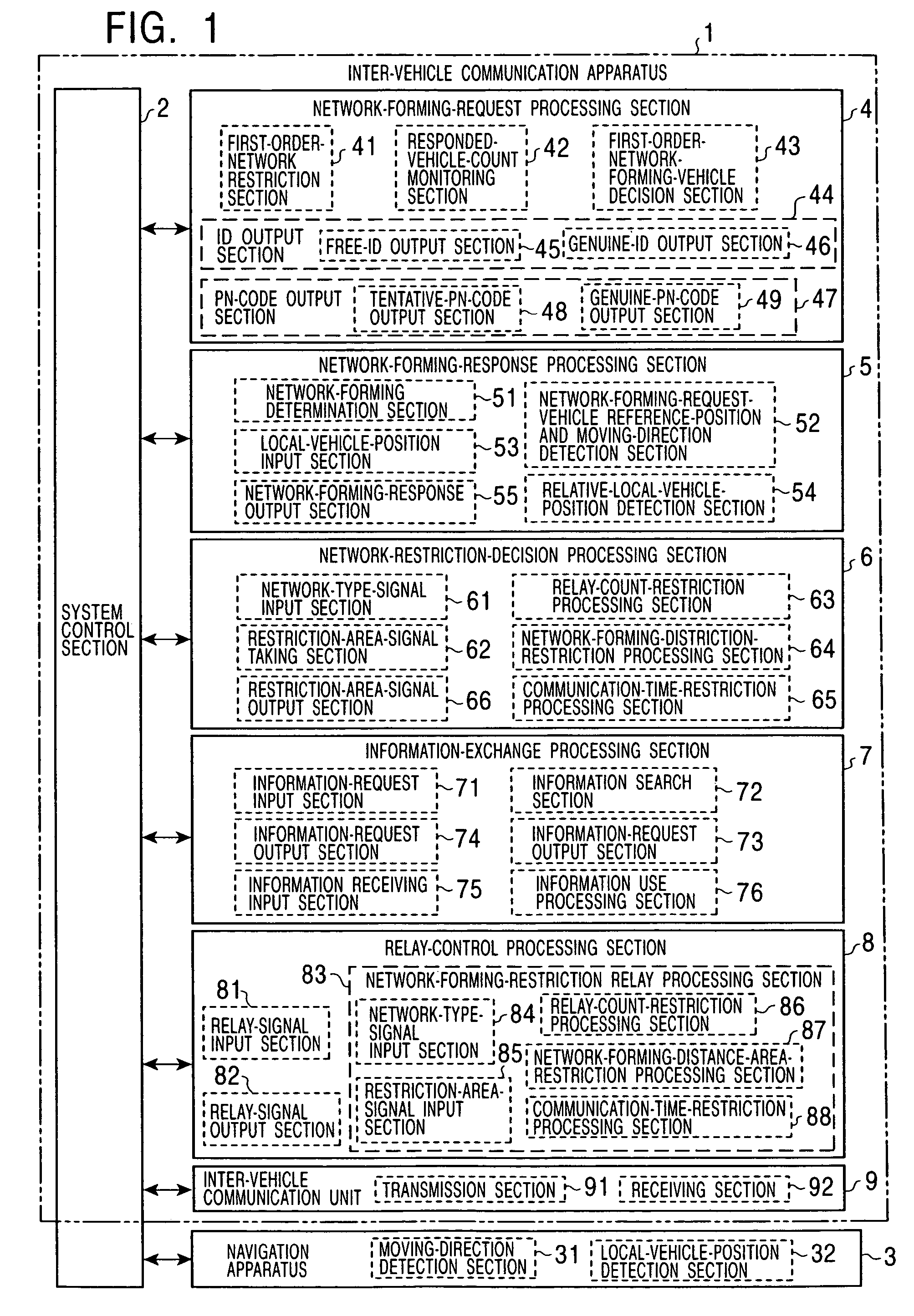

Inter-vehicle communication apparatus

InactiveUS20050003844A1Easily apply appropriate restrictionPrevent PN codeArrangements for variable traffic instructionsAssess restrictionArea networkTrunking

When a network is formed among vehicles with the use of inter-vehicle communication units, a network-forming-request-source vehicle sends its position serving as a reference position, its moving direction, and requested information to surrounding vehicles by the use of a free ID. Among the surrounding vehicles, vehicles which are to subscribe to the network receive the position, the moving direction, and the requested information, determine where the vehicles are positioned among positions specified in advance relative to the reference position, and respond at a timing corresponding to their positions by the use of free IDs. The network-forming-request-source vehicle receives the responses, stops receiving responses when the number of responded vehicles reaches an appropriate number of vehicles, and sends its genuine ID and a vehicle communication order. Then, a restriction, such as a restriction based on the number of times relay processes are allowed, a restriction based on a predetermined-distance area from the center of balance or the center, or a restriction based on a communication period equal to a predetermined time or shorter from when the network is formed, all of which correspond to the type of network, is applied to form an appropriate-area network.

Owner:ALPINE ELECTRONICS INC

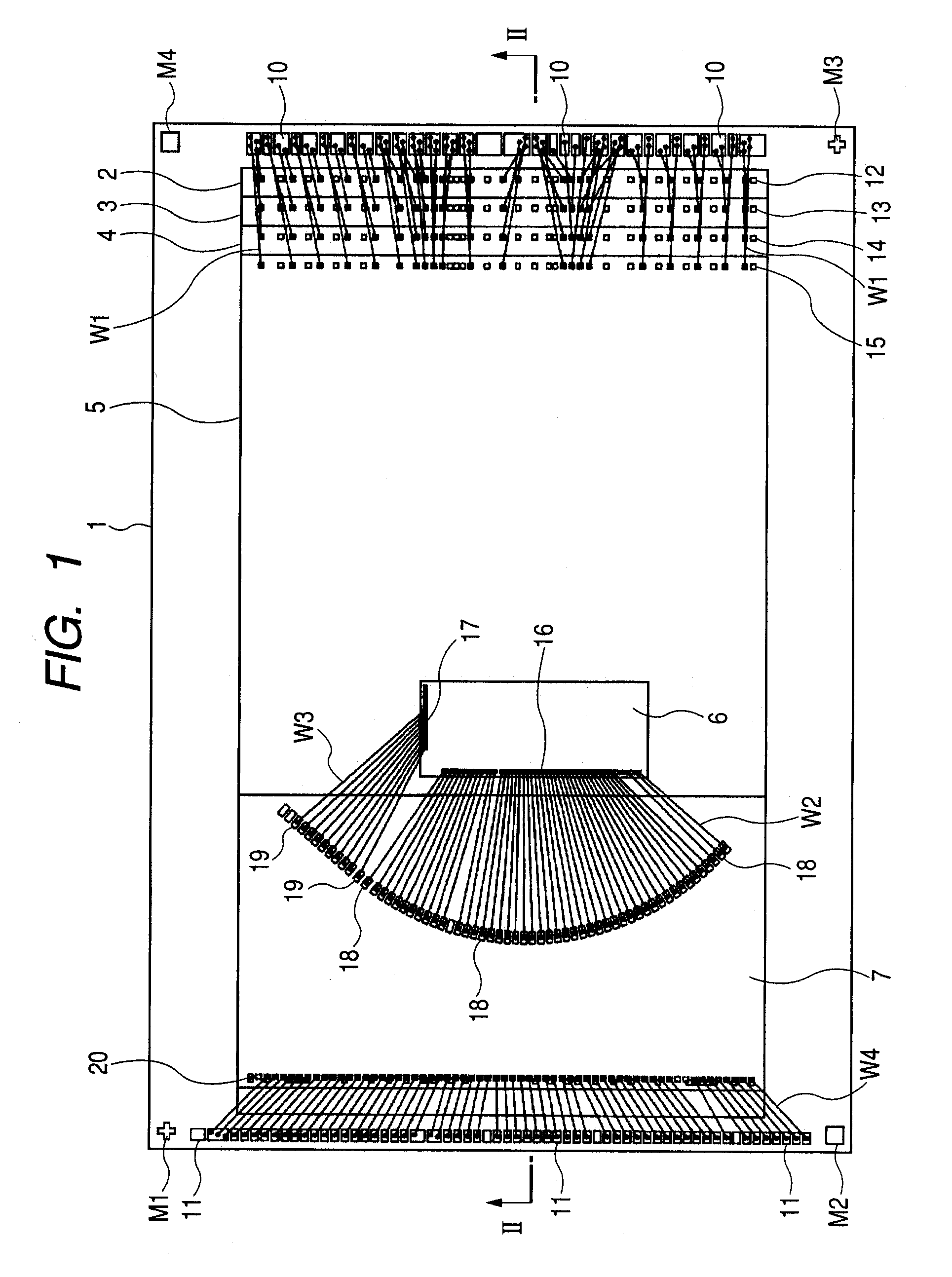

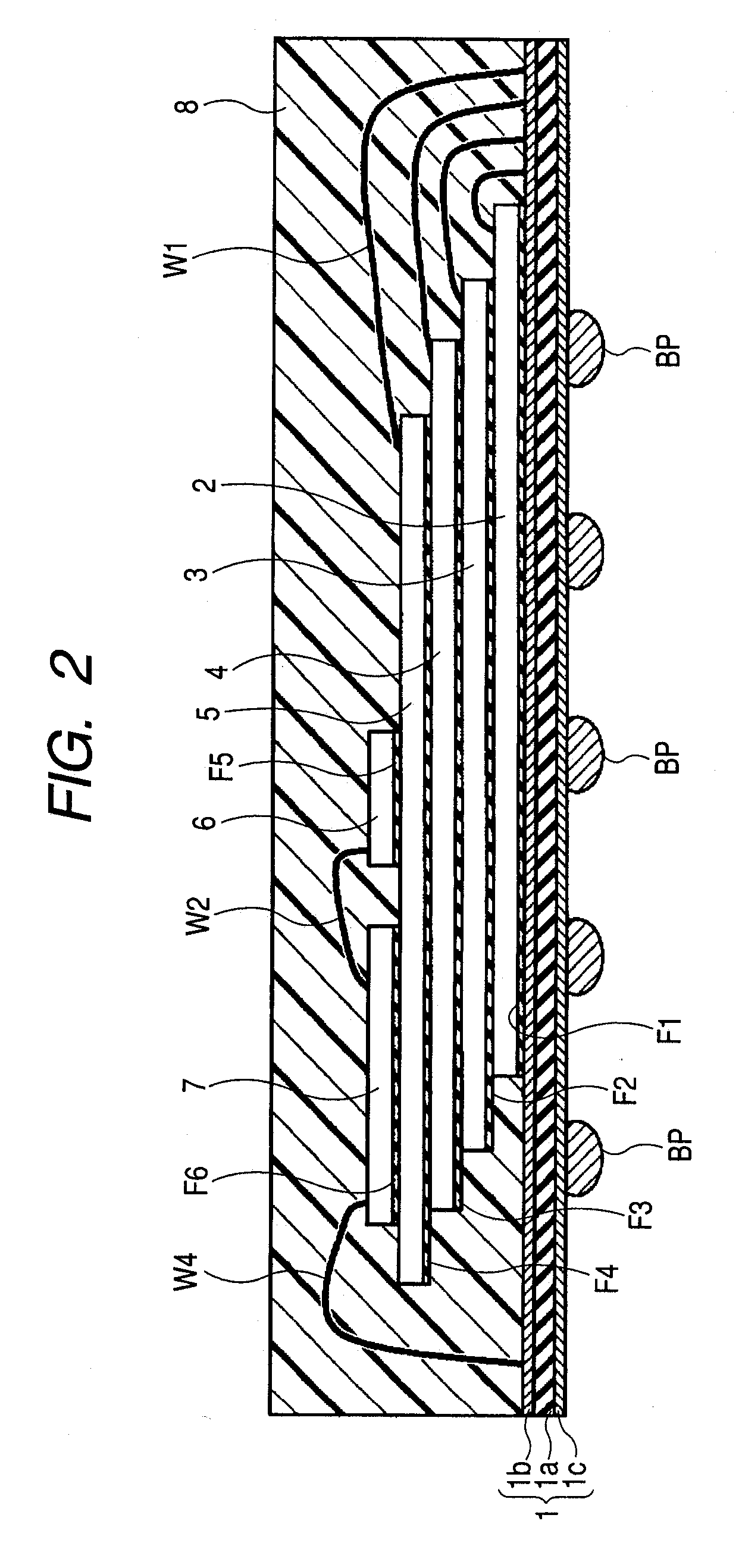

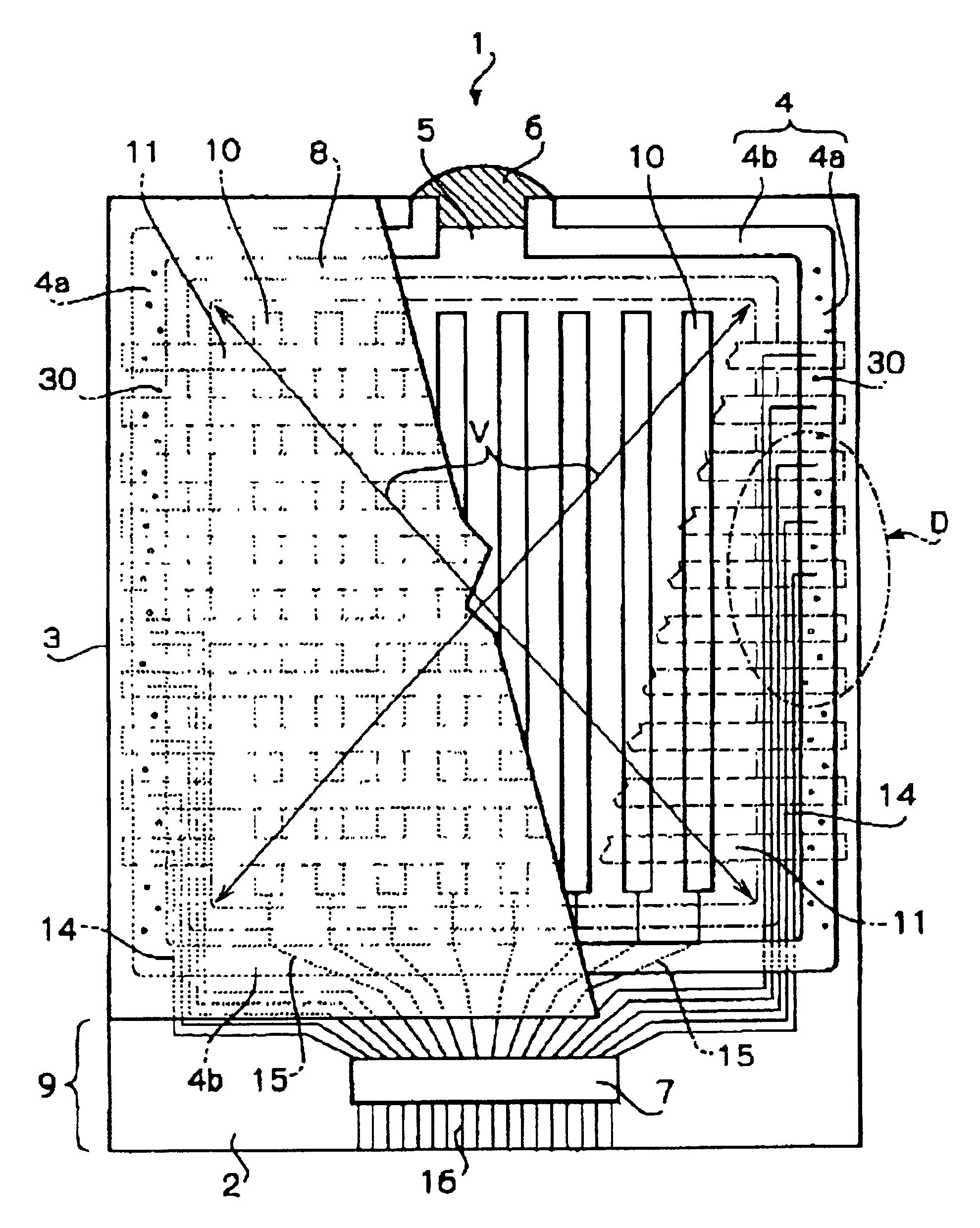

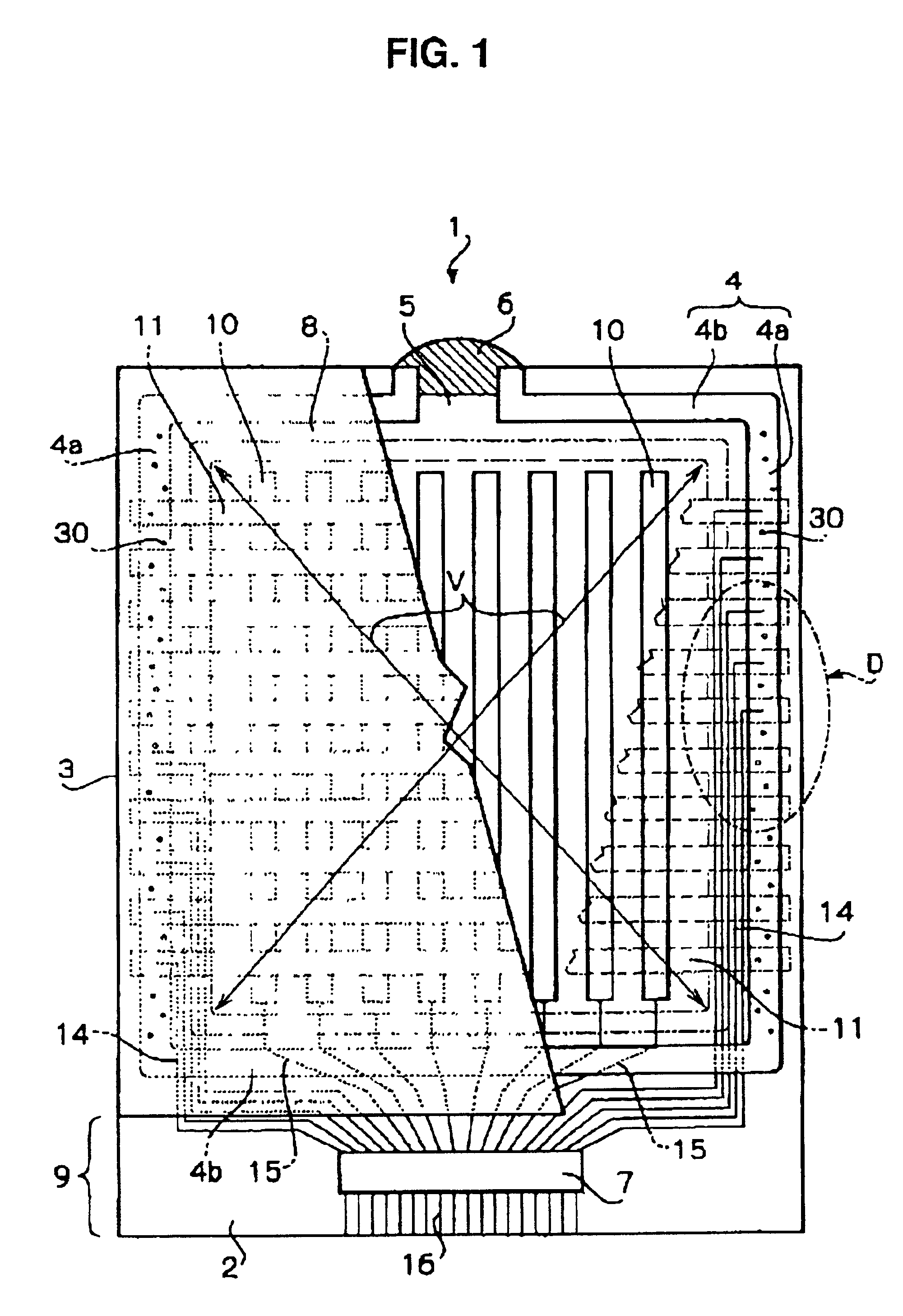

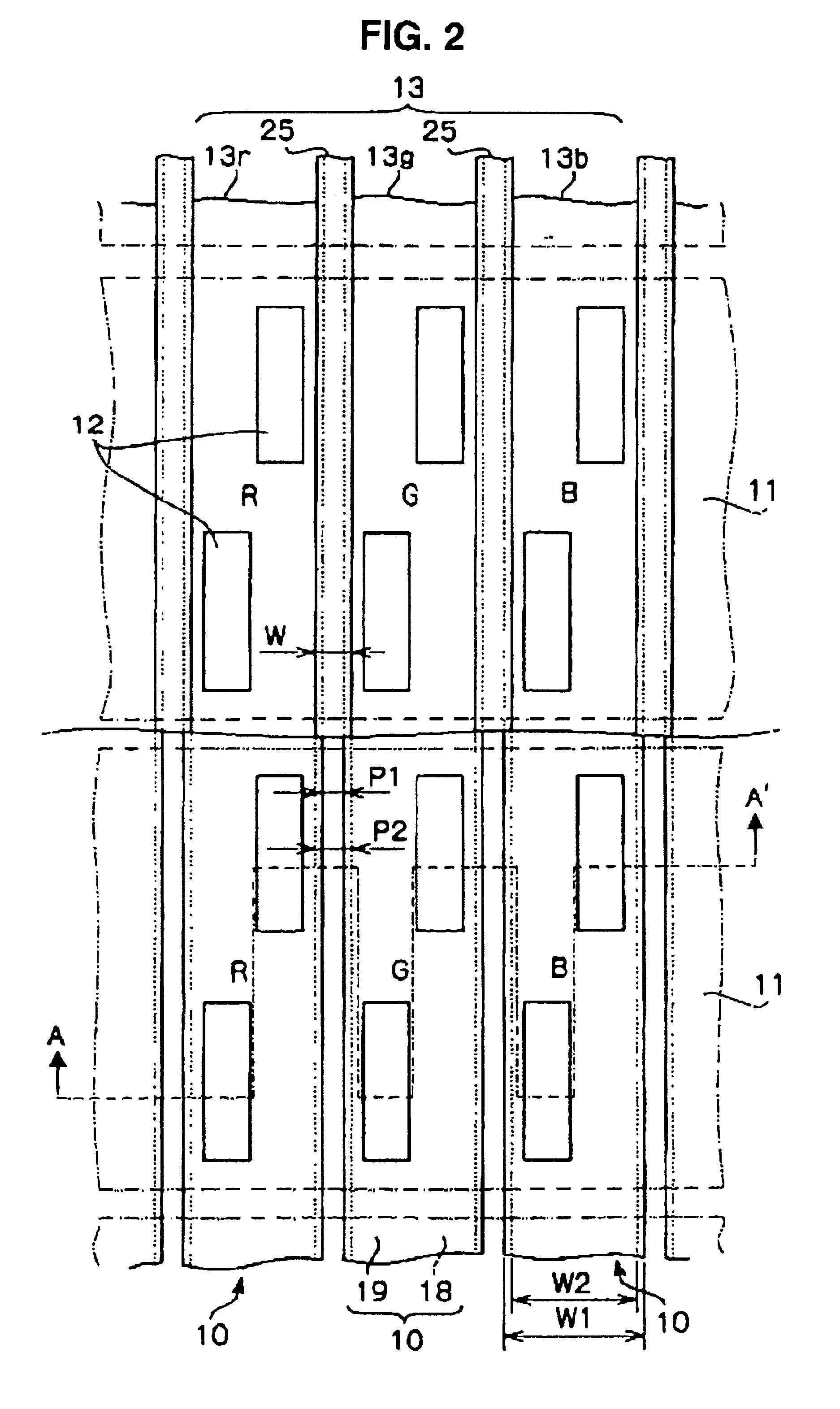

Electrooptic device and electronic apparatus

InactiveUS6888606B2Avoid makingImprove display qualitySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringElectrode

A liquid crystal device 1, that is, an electrooptic device, has a second electrode 11 provided so as to oppose a first electrode 10, and a liquid crystal provided between the first electrode 10 and the second electrode 11. This liquid crystal device 1 further has a first substrate 2 on which the first electrode 10 is provided and a wire 14 which is formed on the first substrate 2 and is electrically connected to the second electrode 11 at a conduction position 4a. Since the wire 14 extends inside the conduction position 4a, the picture frame region that is outside a sealing material 4 can be decreased.

Owner:SEIKO EPSON CORP

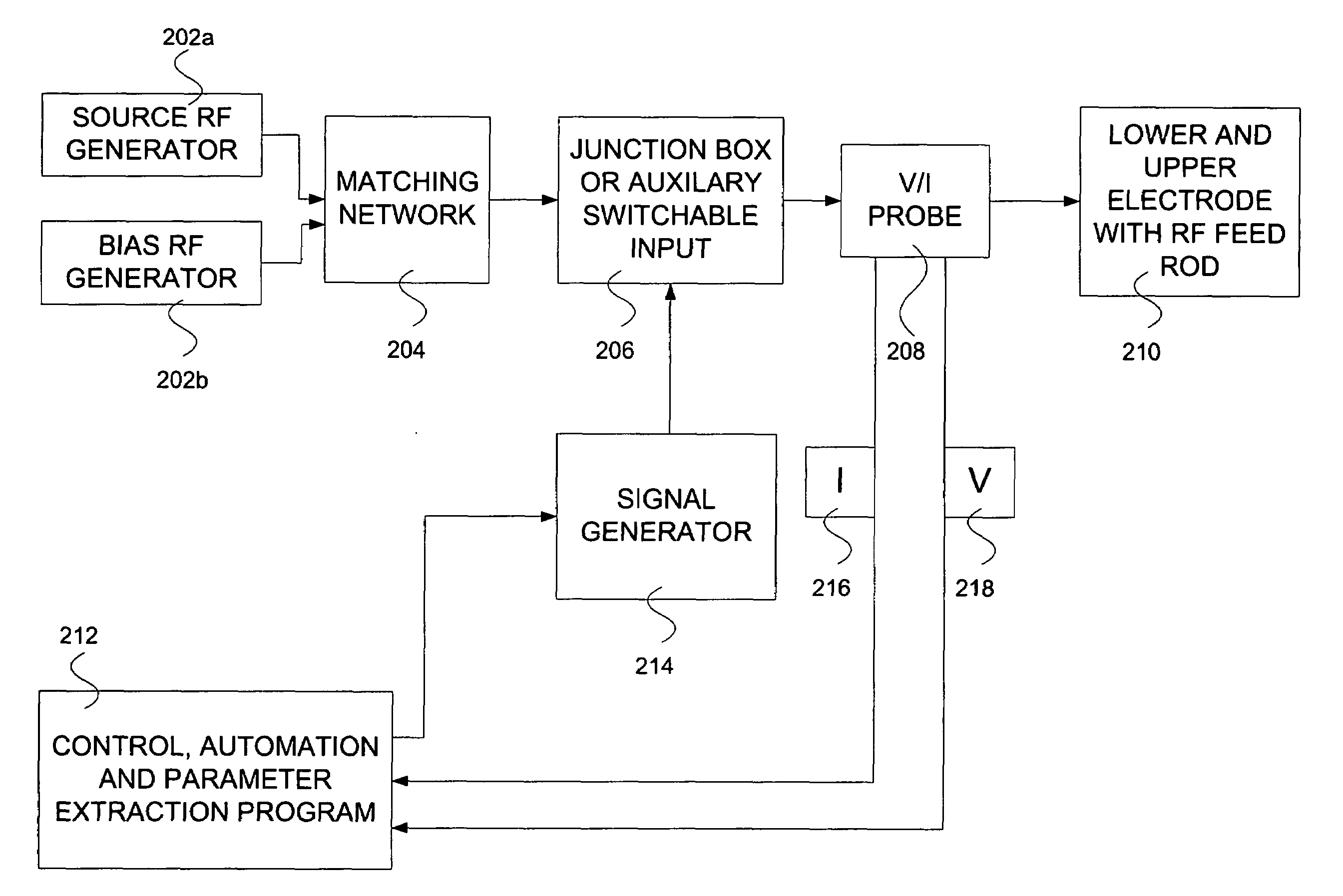

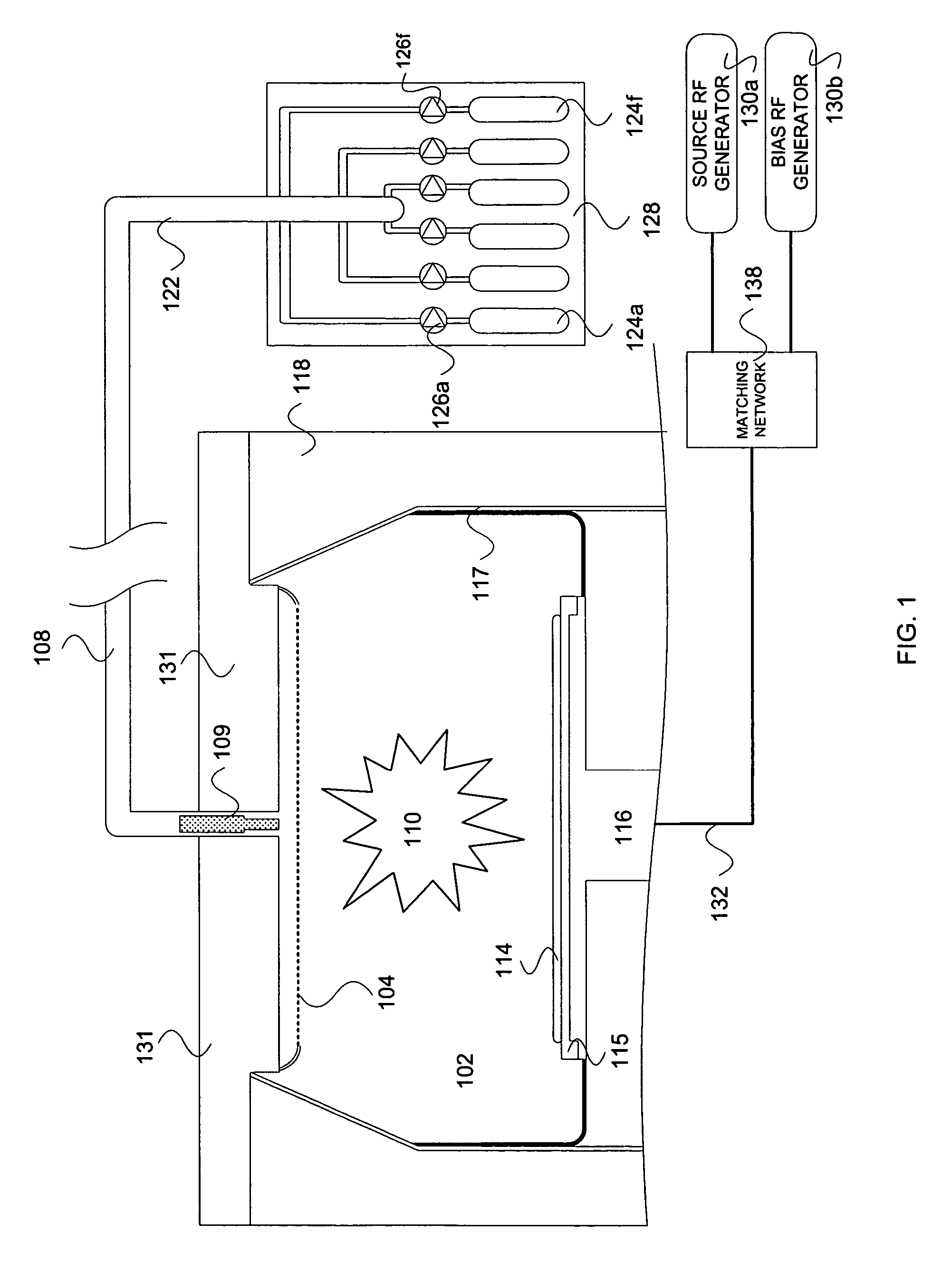

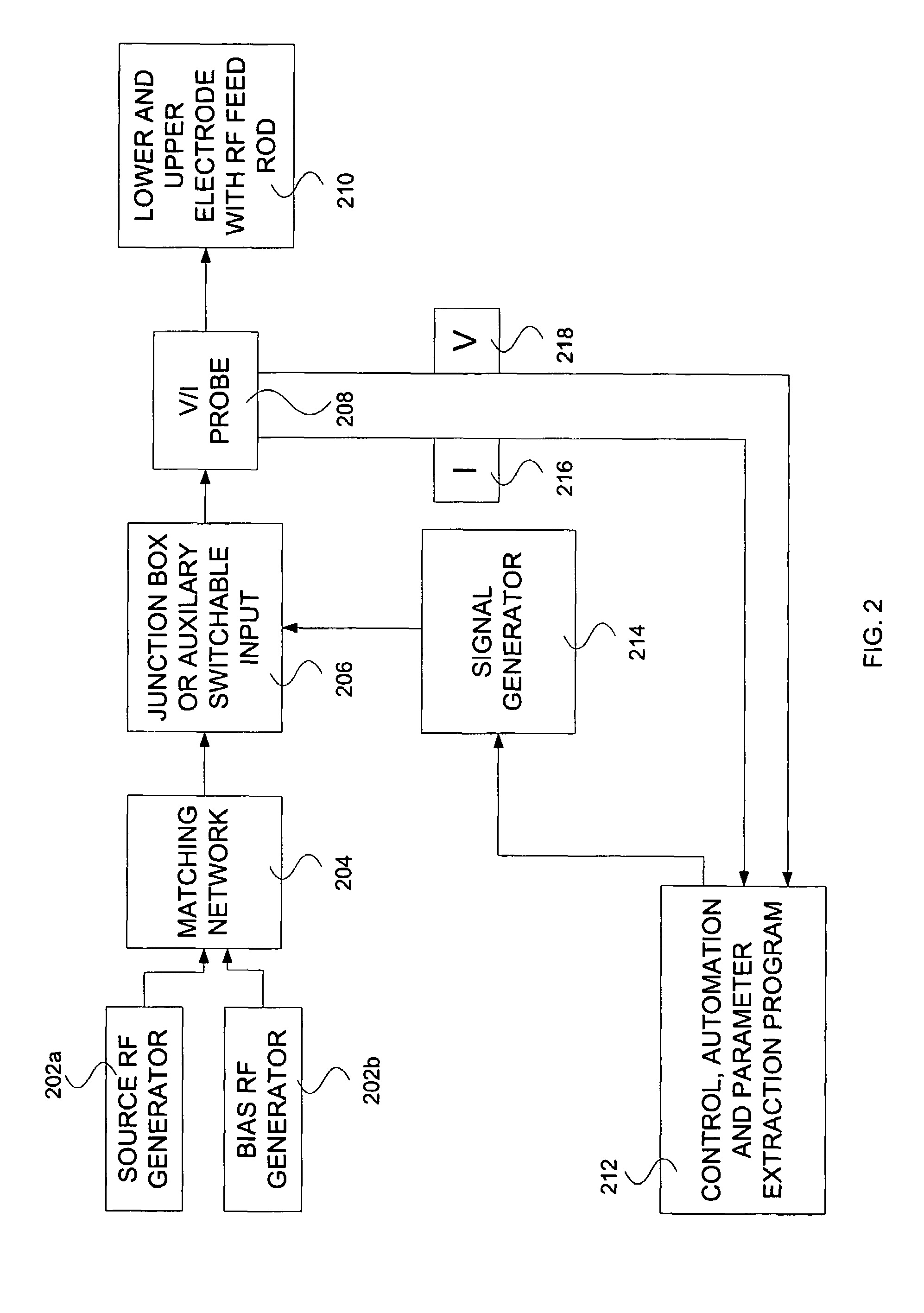

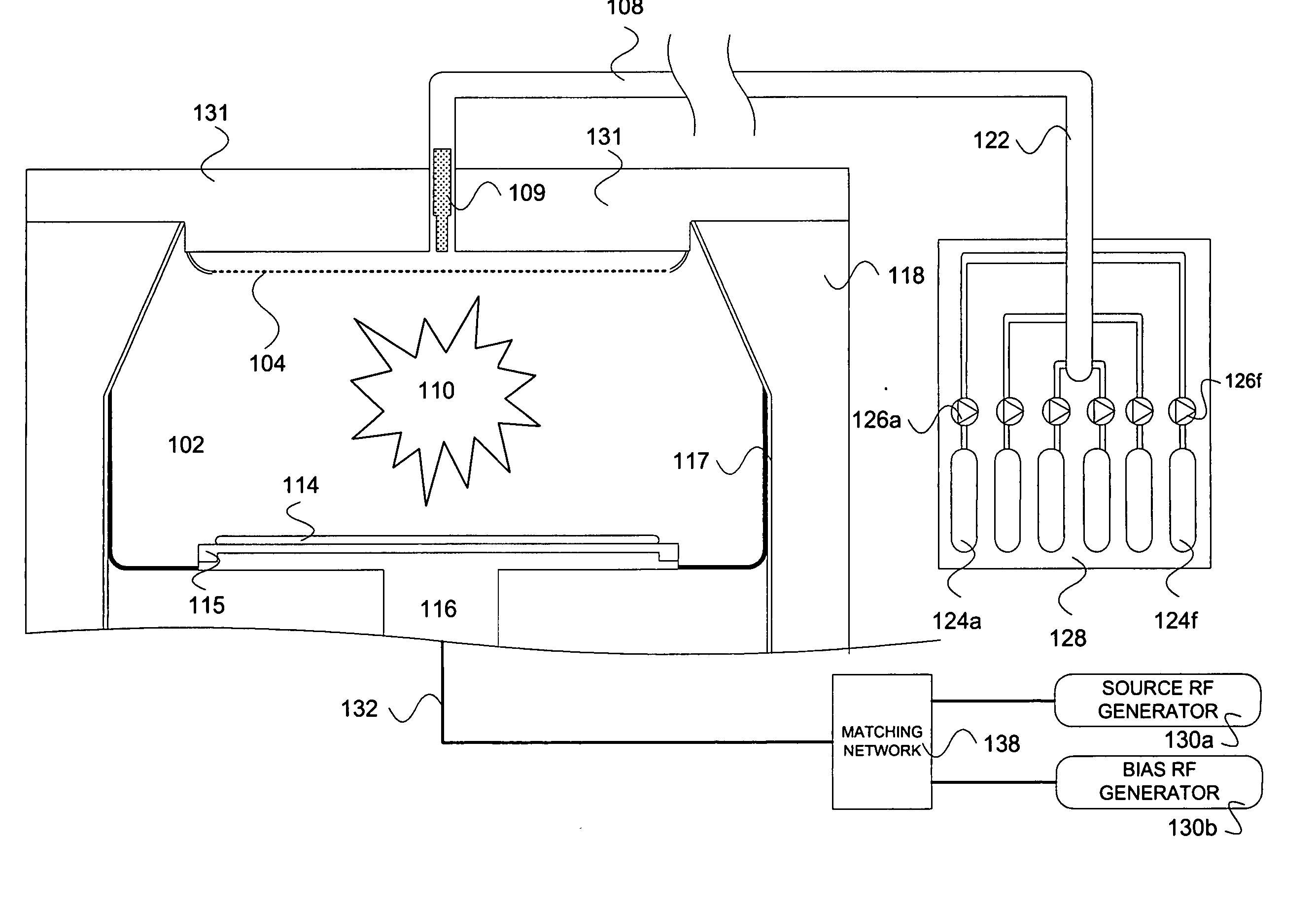

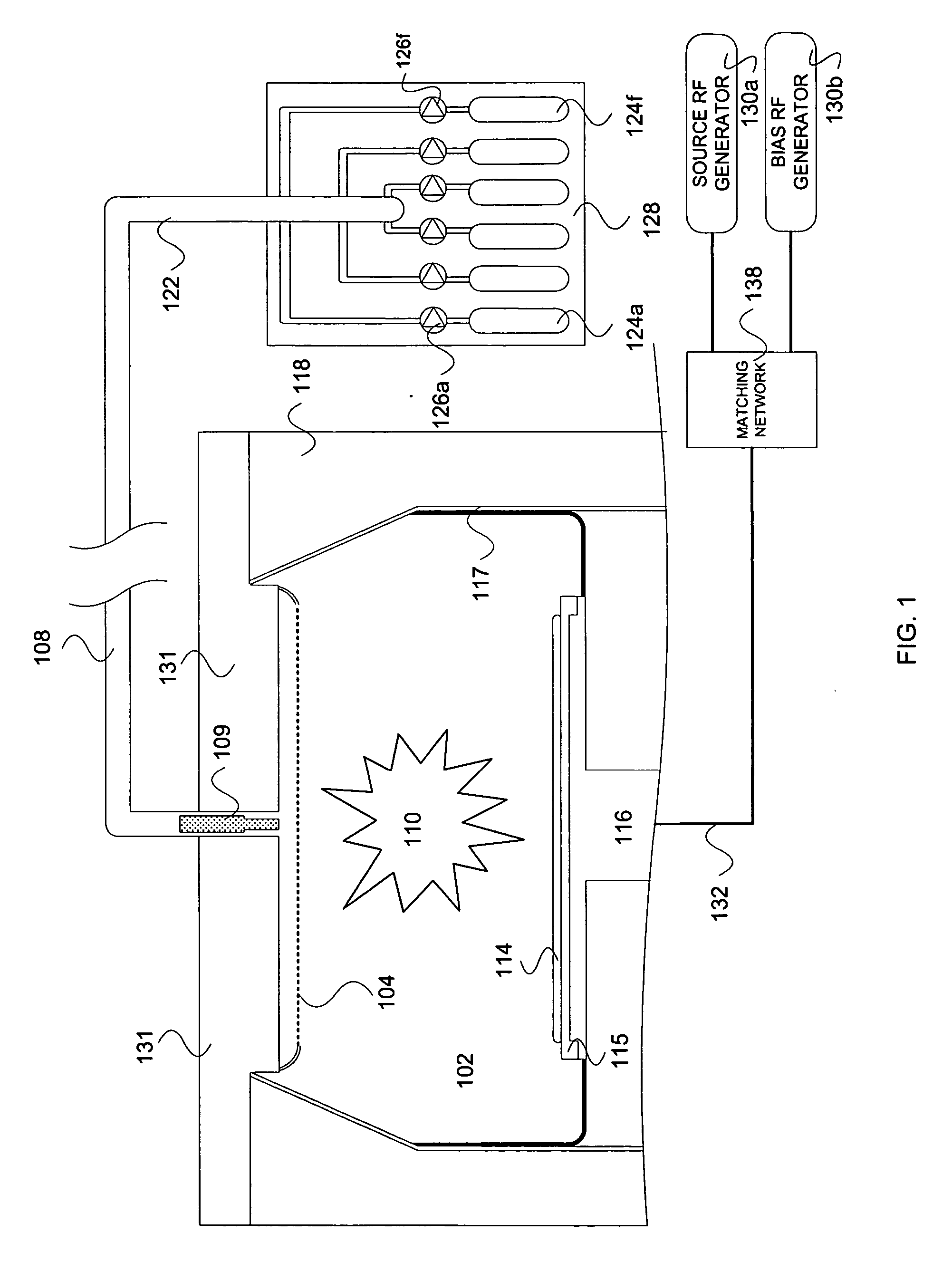

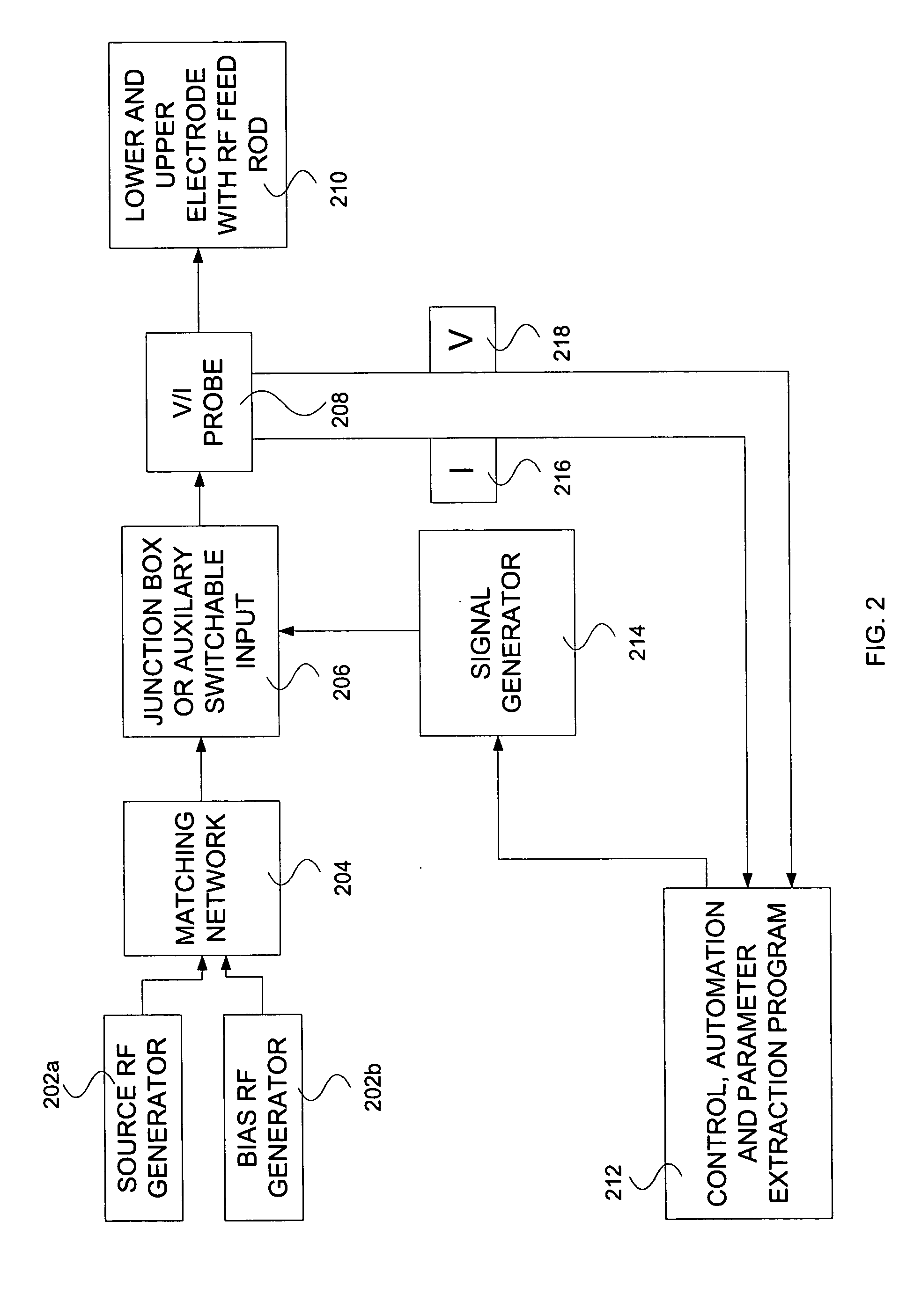

Methods and array for creating a mathematical model of a plasma processing system

InactiveUS7435926B2Avoid makingSimple calculationElectric discharge tubesDecorative surface effectsElectricityMathematical model

A method of creating a simplified equivalent circuit model of a plasma processing system, including an electrical measuring device, a lower electrode, an upper electrode, and a signal generator device is described. The method includes creating a simplified equivalent circuit equation, including a set of variables, of the plasma processing system, wherein the electrical measuring device comprises a first subset of variables, the lower electrode comprises a second subset of variables, the upper electrode comprises a third subset of variables, and the signal generator device comprises a forth subset of variables. The method also includes generating a set of signals, each of the set of signals being generated at a different frequency, wherein the signal generator device is coupled to the electrical measuring device, the lower electrode, and the upper electrode. The method further includes measuring the set of signals with the electrical measuring device, wherein at least one measured signal is generated for each of the set of variables; and, creating a simplified equivalent circuit model from the set of signals.

Owner:LAM RES CORP

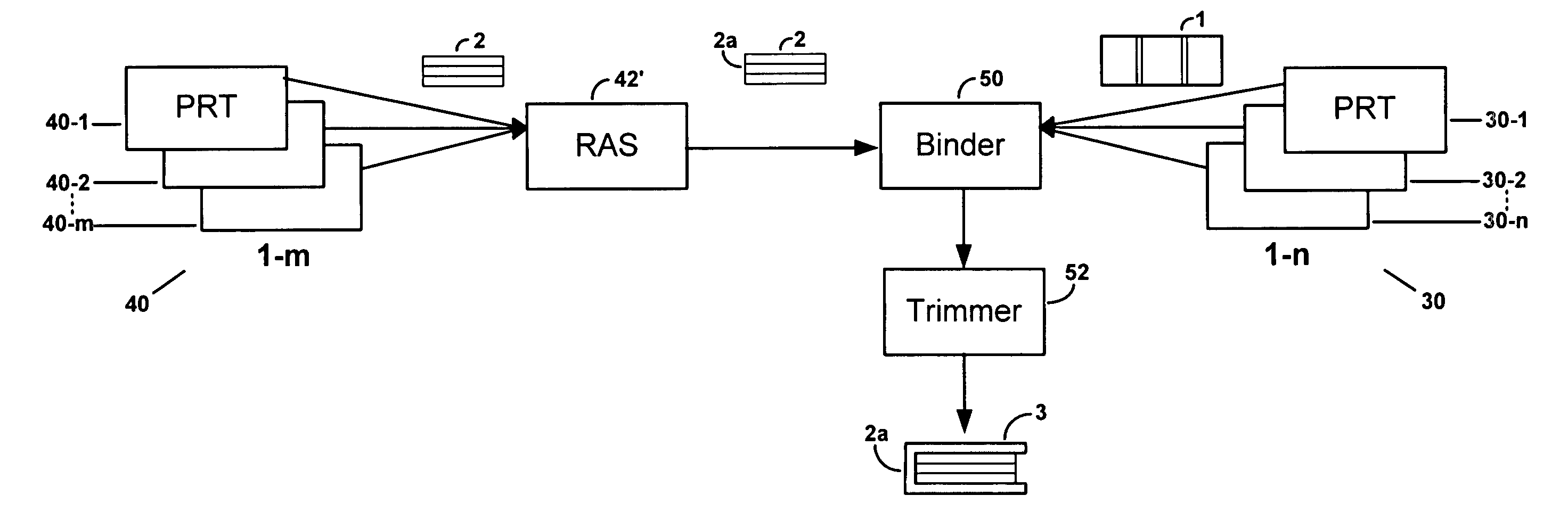

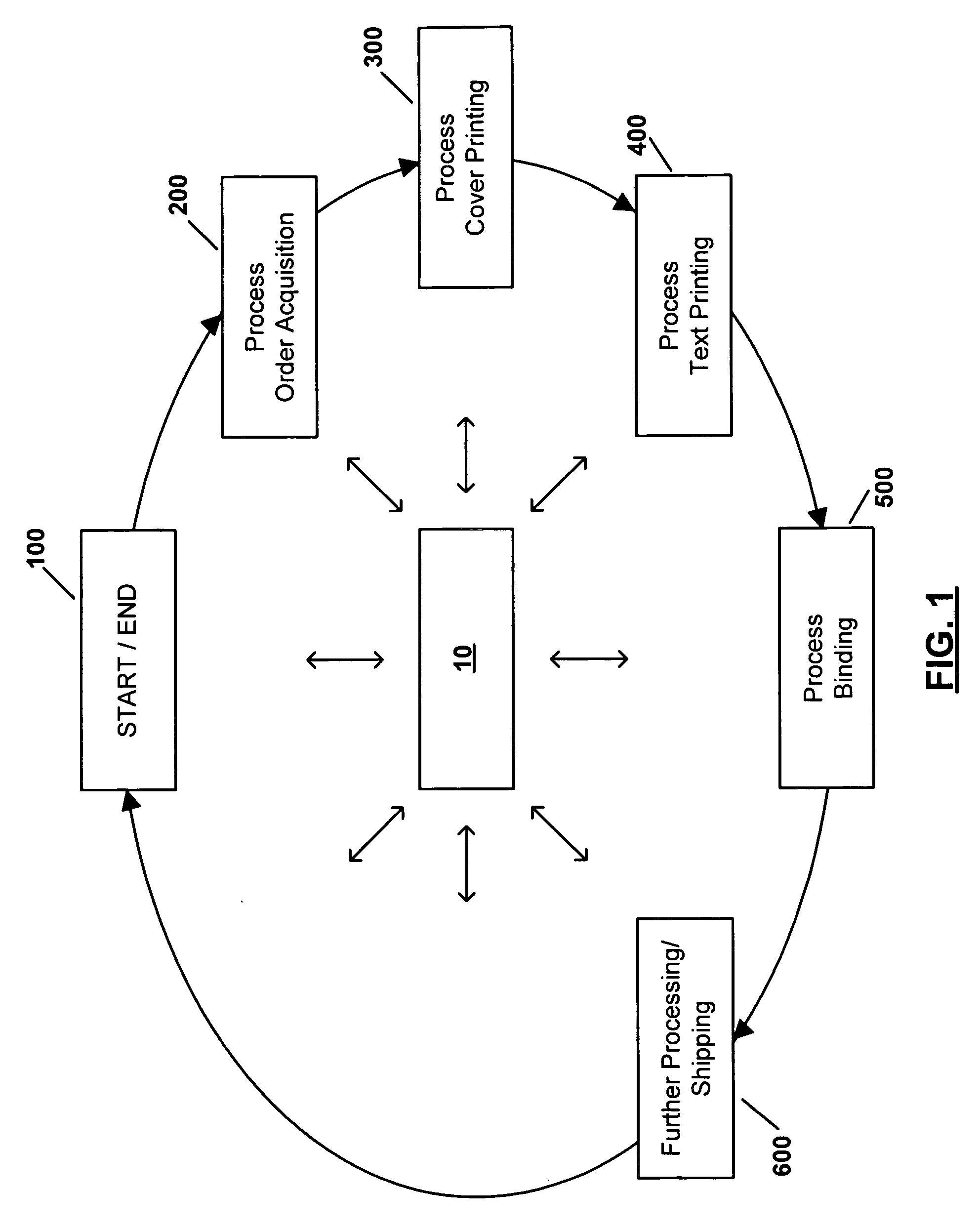

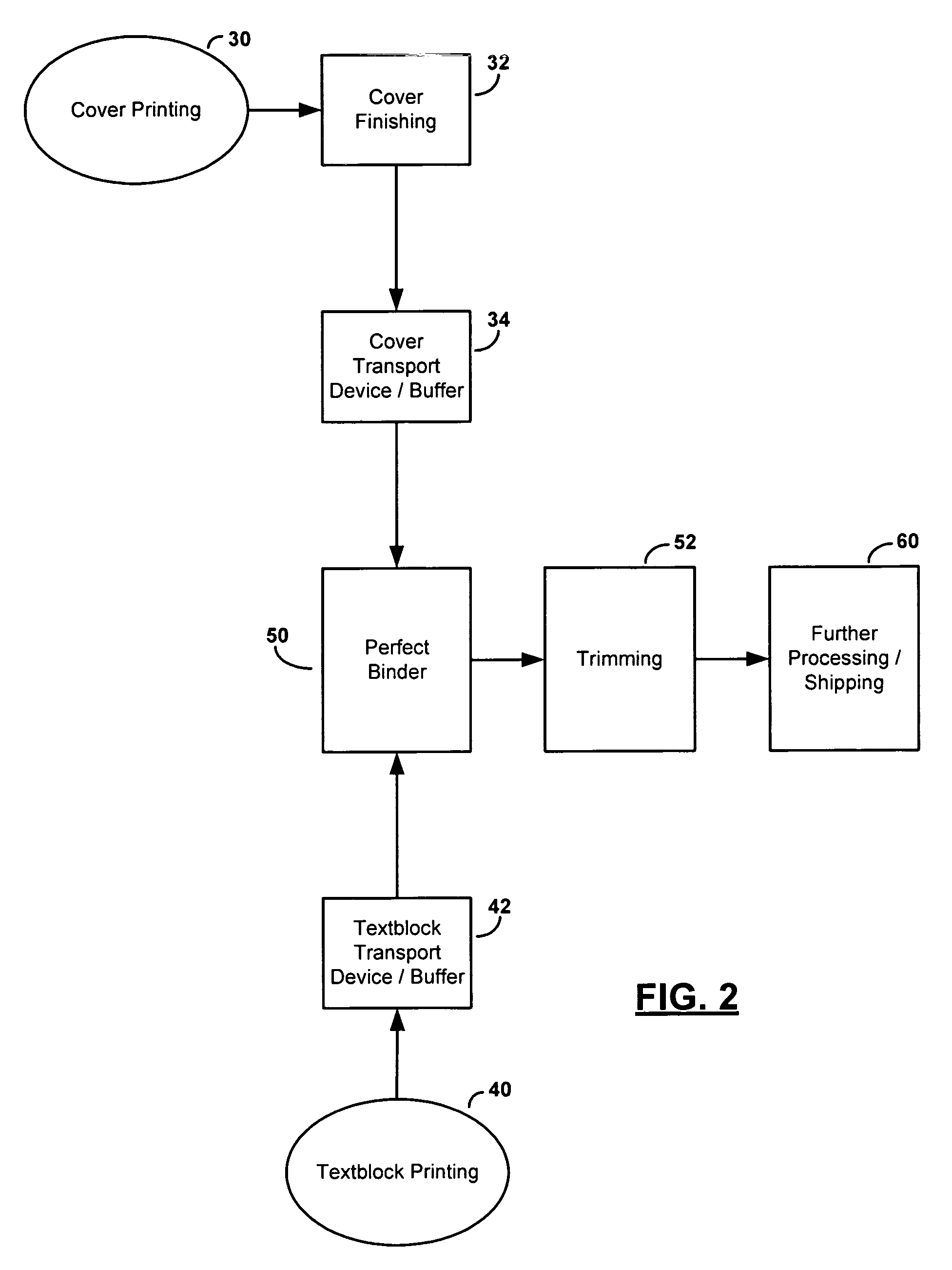

System for and a method of producing a book on demand

InactiveUS20060028662A1More sensitiveMore time-consumeDigitally marking record carriersOther printing matterComputer control systemEngineering

A system for manufacturing a book on demand includes a first printing unit for printing a first component of the book (i.e. a cover), a second printing unit for printing a second component of the book (i.e. a text block), and a binding station for binding the first component and the second component together. The system may further include a computer control system receiving information relating to the book to be manufactured, the information comprising information relating to the content of said first or second component and information relating to the finished size of the book. The computer control system initiates—among other functions—manufacture of the first component by said first printing unit, receives a signal that the printing of the first component is successful and, after receipt of this signal, initiates printing of the second component by said second printing unit. The first component could be stored in a buffer until the second component is ready. The advantage of this hierarchy is that the process which is more time consuming and / or sensitive with respect to disturbances and / or more expensive can control the over-all process. Rejects of completed books not fulfilling the quality criteria are avoided and down-times minimized. Also avoided is the requirement to store the second component until the first component is ready.

Owner:EPAC TECH

Methods and array for creating a mathematical model of a plasma processing system

InactiveUS20050217797A1Avoid makingSimple calculationElectric discharge tubesDecorative surface effectsElectricityMathematical model

A method of creating a simplified equivalent circuit model of a plasma processing system, including an electrical measuring device, a lower electrode, an upper electrode, and a signal generator device is described. The method includes creating a simplified equivalent circuit equation, including a set of variables, of the plasma processing system, wherein the electrical measuring device comprises a first subset of variables, the lower electrode comprises a second subset of variables, the upper electrode comprises a third subset of variables, and the signal generator device comprises a forth subset of variables. The method also includes generating a set of signals, each of the set of signals being generated at a different frequency, wherein the signal generator device is coupled to the electrical measuring device, the lower electrode, and the upper electrode. The method further includes measuring the set of signals with the electrical measuring device, wherein at least one measured signal is generated for each of the set of variables; and, creating a simplified equivalent circuit model from the set of signals.

Owner:LAM RES CORP

Wall hanger, mounting kit, and method

InactiveUS6042078ASmall diameterAvoid makingPicture framesDispensing apparatusStructural engineering

The wall hanger of the present invention is designed to minimize the damage done to a wall when hung thereon. The wall hanger has a plurality of narrow bores angling generally downward through which pleating pins may be inserted to anchor the wall hanger. The wall hanger additionally has a support member from which may be hung an object. The bores and support member are configured to maximize a proportion of gravitational stress transferred to the wall to relieve stress on the pins. A pilot tool is also disclosed that starts a hole in the wall through the bores in the hanger and then is used to push a pin through the bore, into the pretapped hole in the wall, and further into the wall until its head is flush with the hanger. A kit is provided that consists of a wall hanger and a mounting tool. In addition, a method is provided for mounting a wall hanger to a wall.

Owner:DONOVAN CHARLES A

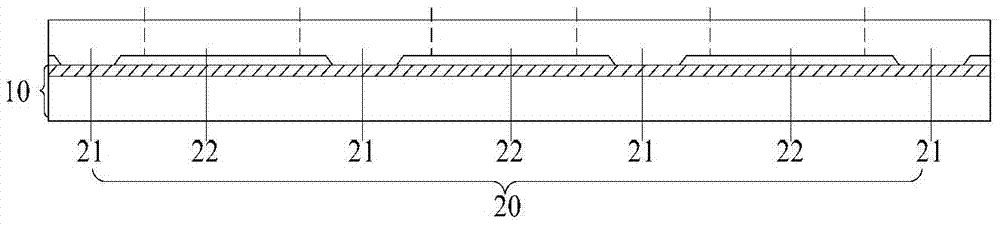

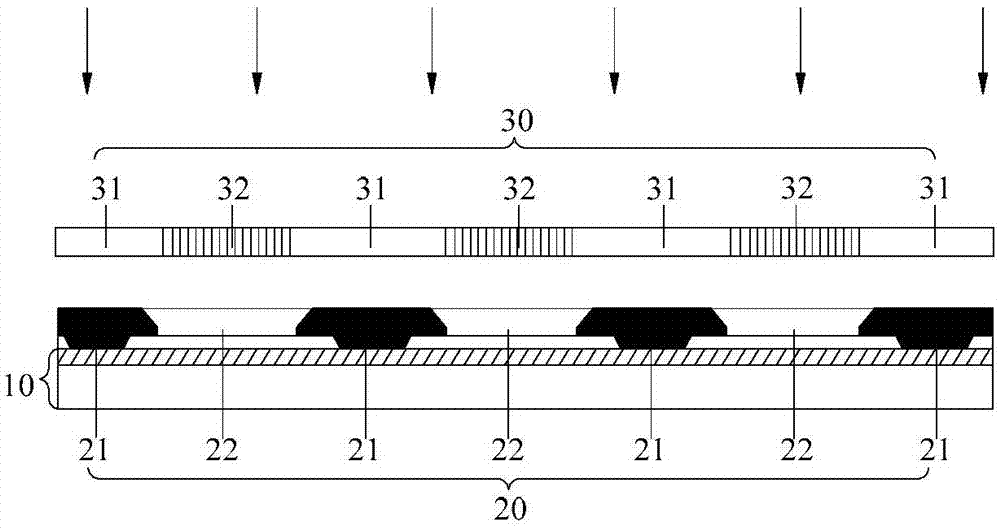

Preparation method of display substrate, display substrate and display device

ActiveCN105448825AEliminates the problem of aperture ratio dropIncrease opening ratioSolid-state devicesSemiconductor/solid-state device manufacturingColor gelDisplay device

The invention provides a preparation method of a display substrate, the display substrate and a display device, relates to the technical field of display, and aims at solving the problem that the aperture opening ratio is reduced due to the fact that a color light filter is fabricated on an array substrate. The preparation method of the display substrate comprises the steps as follows: a thin-film transistor array is prepared on a substrate to form the array substrate; a pixel definition layer is formed in a non-pixel region of the array substrate by a composition process; photochromic materials are evenly distributed in the pixel definition layer; the pixel definition layer containing the photochromic materials is converted into a shading state from a transmitting state under the action of illumination; and the pixel definition layer is converted into a shading irreversible state from the transmitting state. The preparation method of the display substrate provided by the invention is used for preparing the color light filter on the array substrate.

Owner:BOE TECH GRP CO LTD

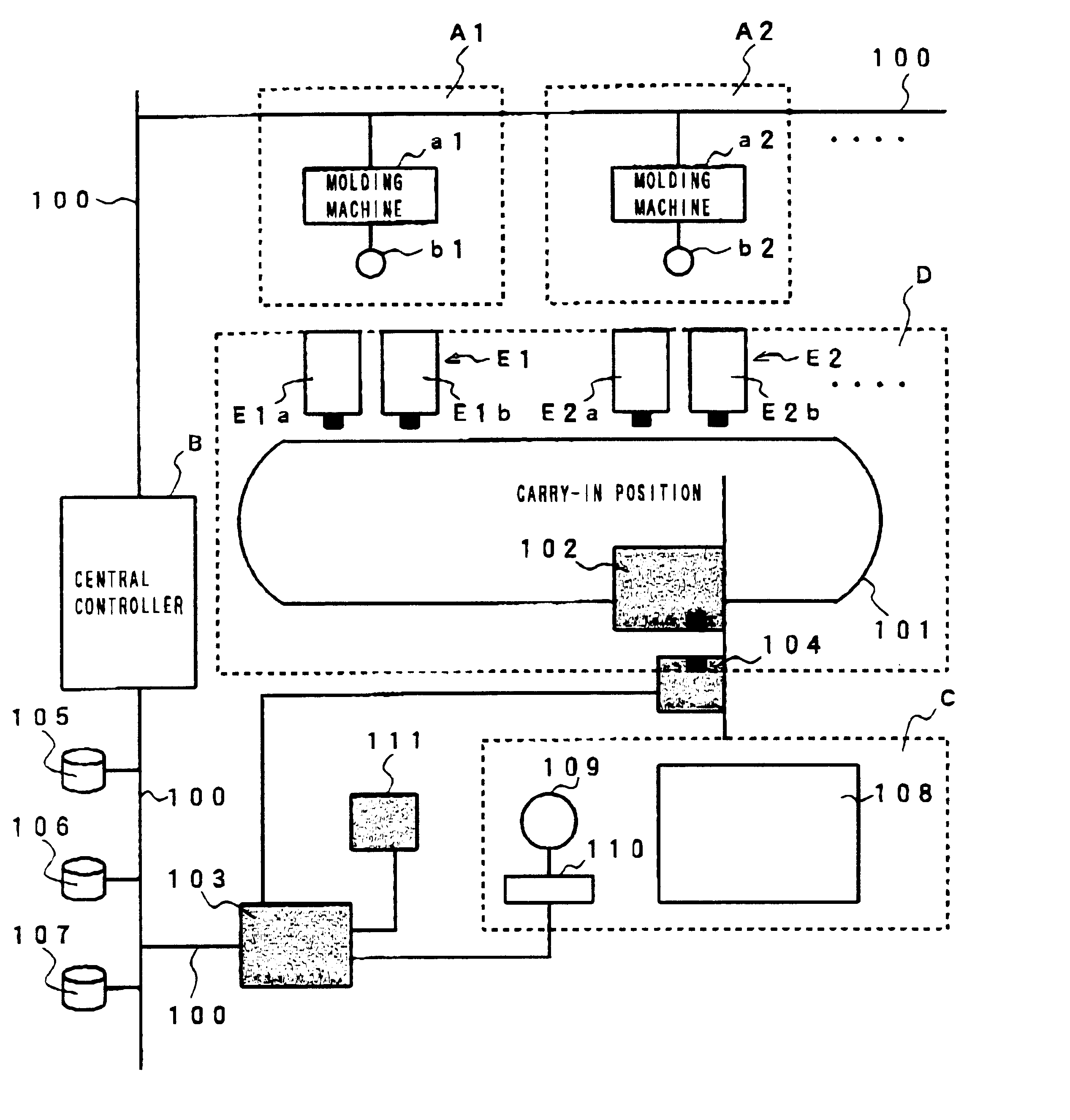

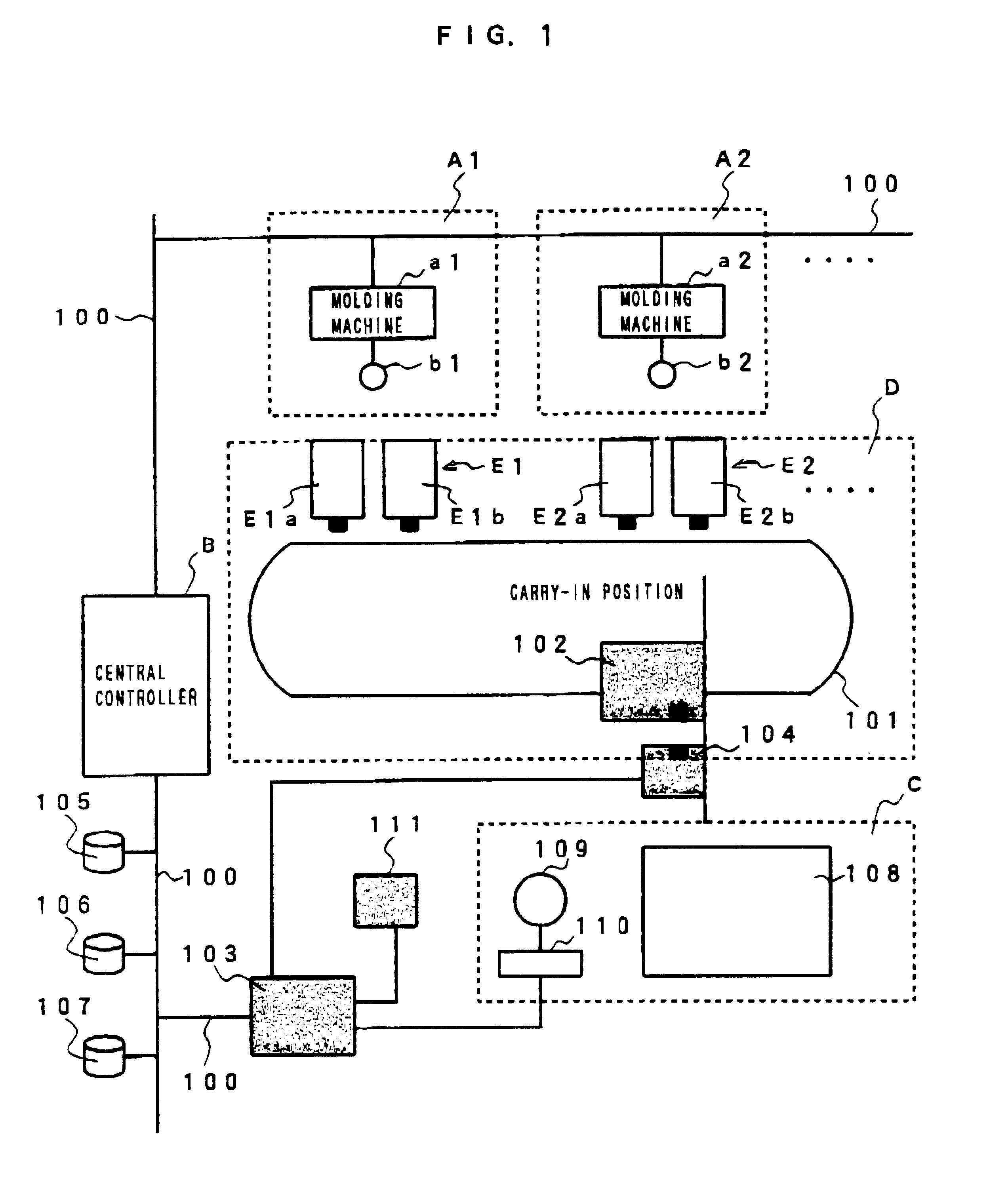

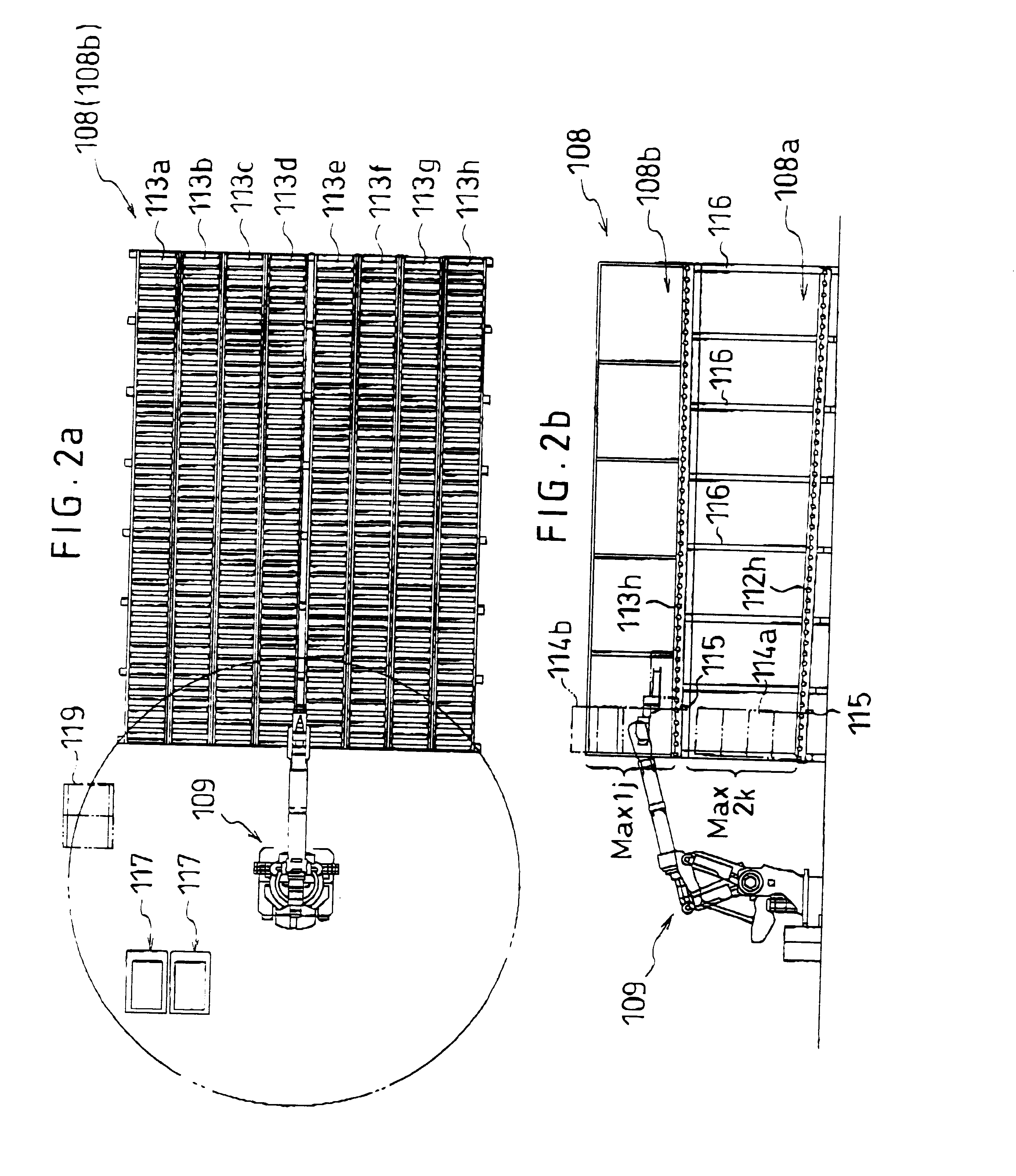

Information transmitting system for use in factory

InactiveUS6516234B2Low costAvoid makingDigital data processing detailsAssembly machinesEngineeringEthernet

An information transmitting system for use in a factory, which is capable of transmitting information among controllers simply without the complicated lead-around of a communication line nor the need of complicated communication protocol. A controller for every molding cell Ai, where i=1,2 . . . max and max is a maximum number of molding cells, a conveyance controller to control an automatic conveyor, a stock cell and a centralized controller are connected to each other via an Ethernet line to provide a common information storage unit, and information is transmitted among the controllers through the common information storage unit. Since there is no need of parallel communication lines between the controllers, an I / O port or a communication line may be prevented from increasing in number and the lead-around of the communication line is prevented from being complicated, resulting in a reduction of cost required for setting up the devices.

Owner:FANUC LTD

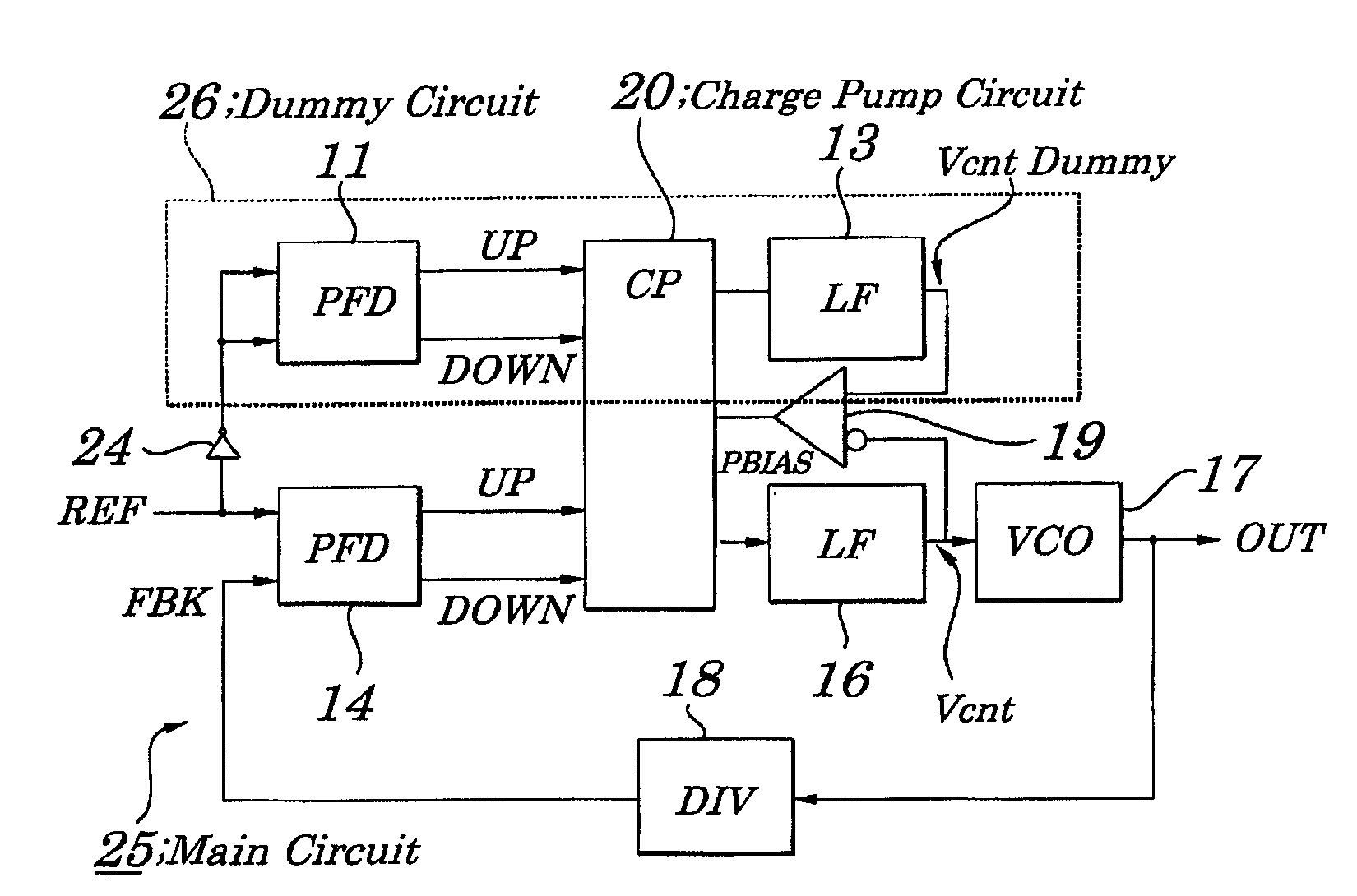

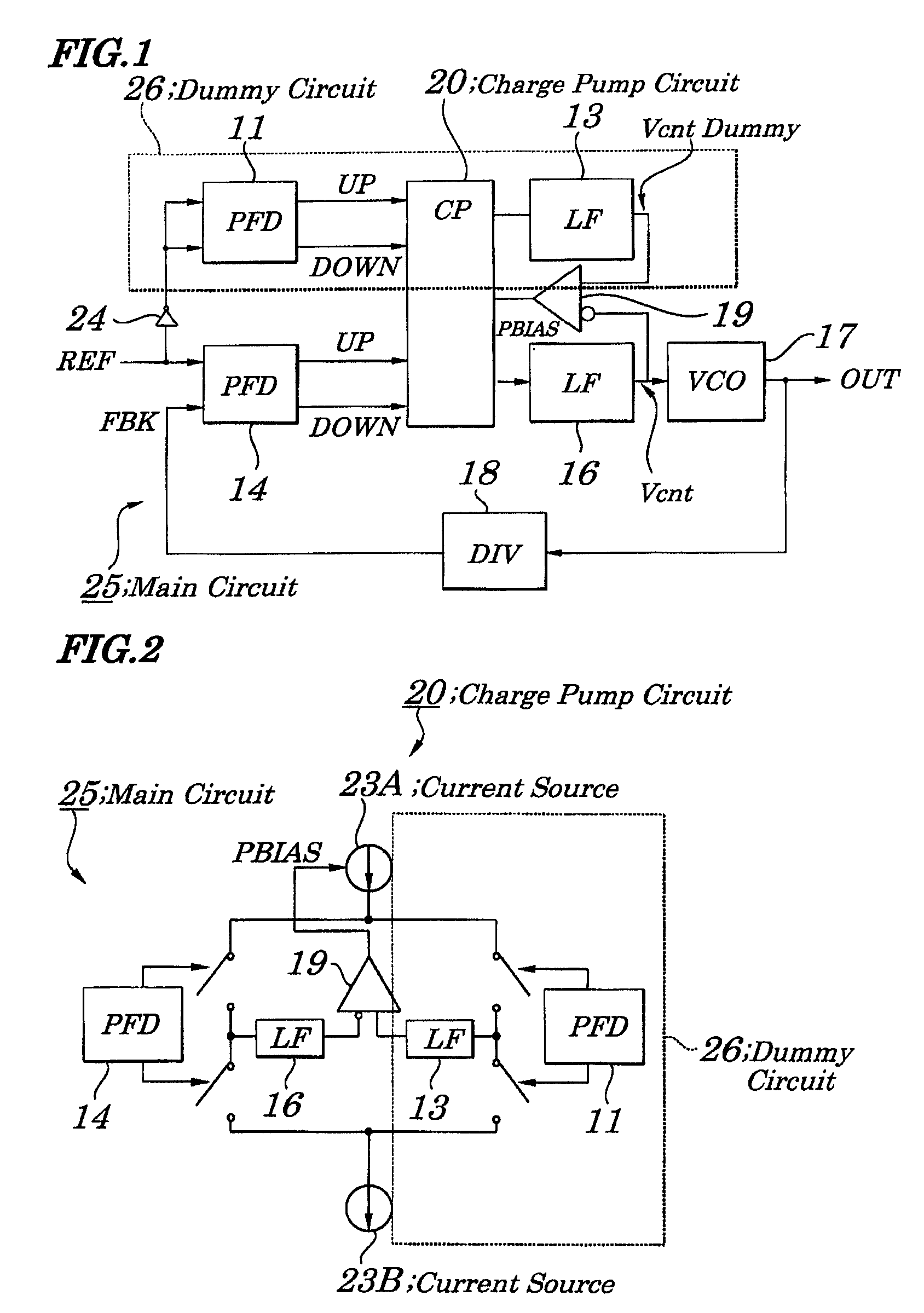

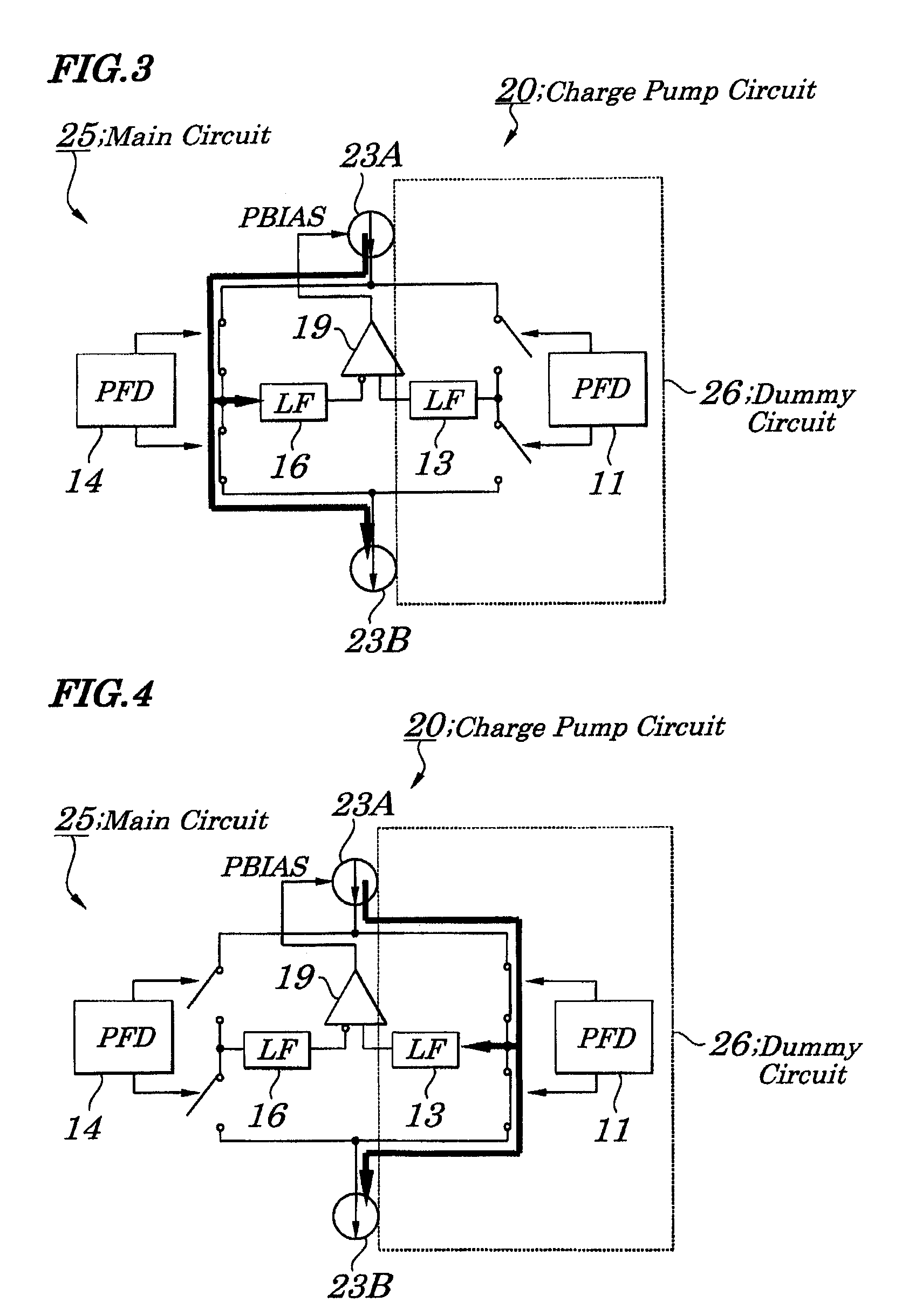

Pll circuit

InactiveUS20070229129A1Prevent manufactureReducing phase offsetPulse automatic controlCharge and dischargeEngineering

A PLL (Phase Locked Loop) circuit having a main circuit and a dummy circuit is provided which is capable of reducing a phase offset between a reference clock and a feedback clock. In the PLL circuit, a phase of each of the reference clock and feedback clock each received through either of a pair of input terminals is compared by a phase frequency detector to output an UP or DOWN signal and phases of reference clocks received through two input terminals are compared by a dummy phase frequency detector to output a dummy UP or dummy DOWN signal. According to a differential in output voltage between a first charge pump of the main circuit and a second charge pump of the dummy circuit, current sources are controlled to charge or discharge the first and second charge pumps. The current sources are used to charge and discharge the second charge pump while being not used for charge and discharge of the first charge pump.

Owner:NEC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com