Patents

Literature

204 results about "Bone shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bone type: One of the four basic bone shapes in the human skeleton. Long bones: Long bones have a tubular shaft and articular surface at each end. Short bones: Short bones also have a tubular shaft and articular surfaces at each end but are much smaller. Flat bones: Flat bones are thin and have broad surfaces.

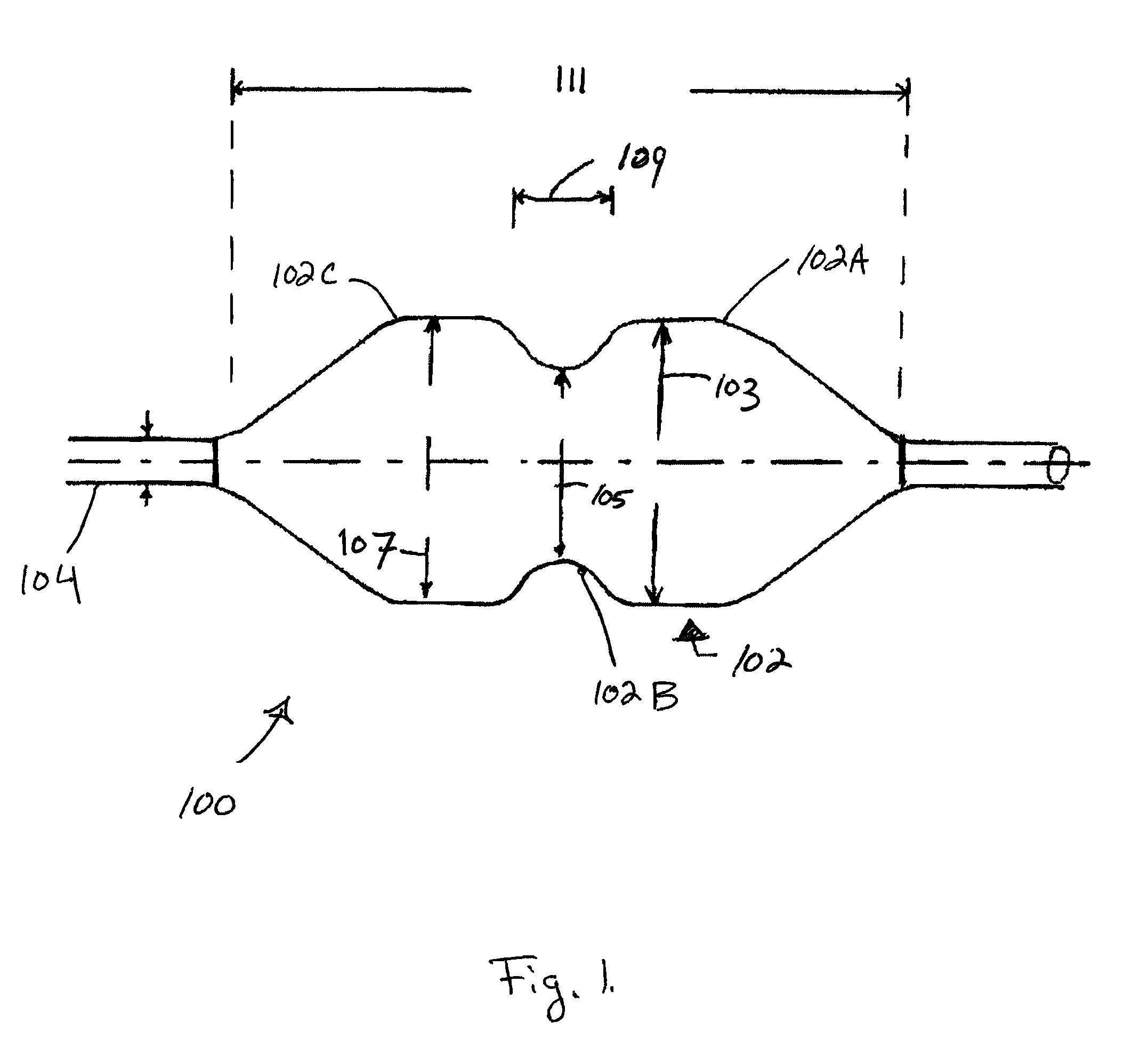

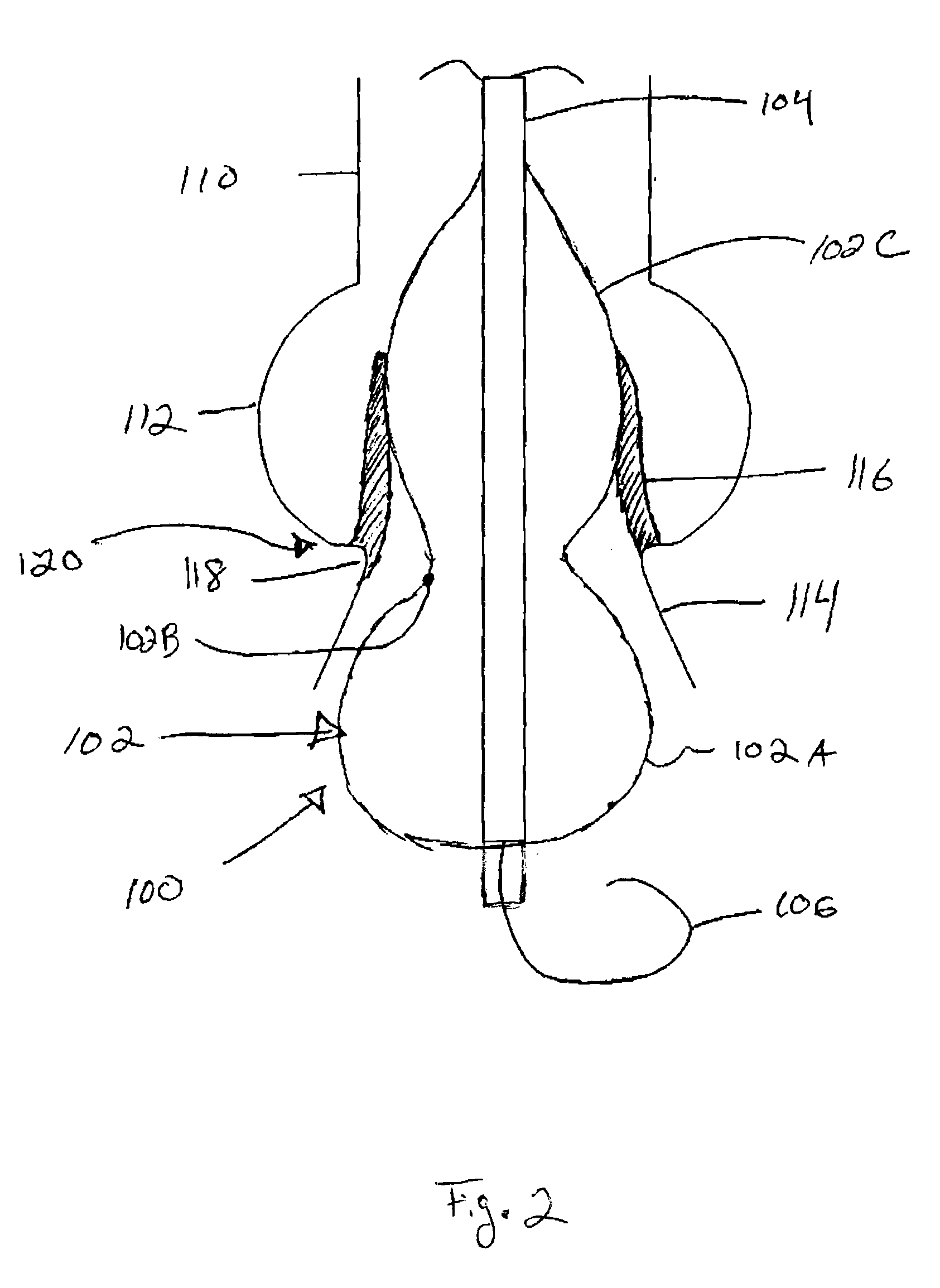

Valvuloplasty Catheter And Methods

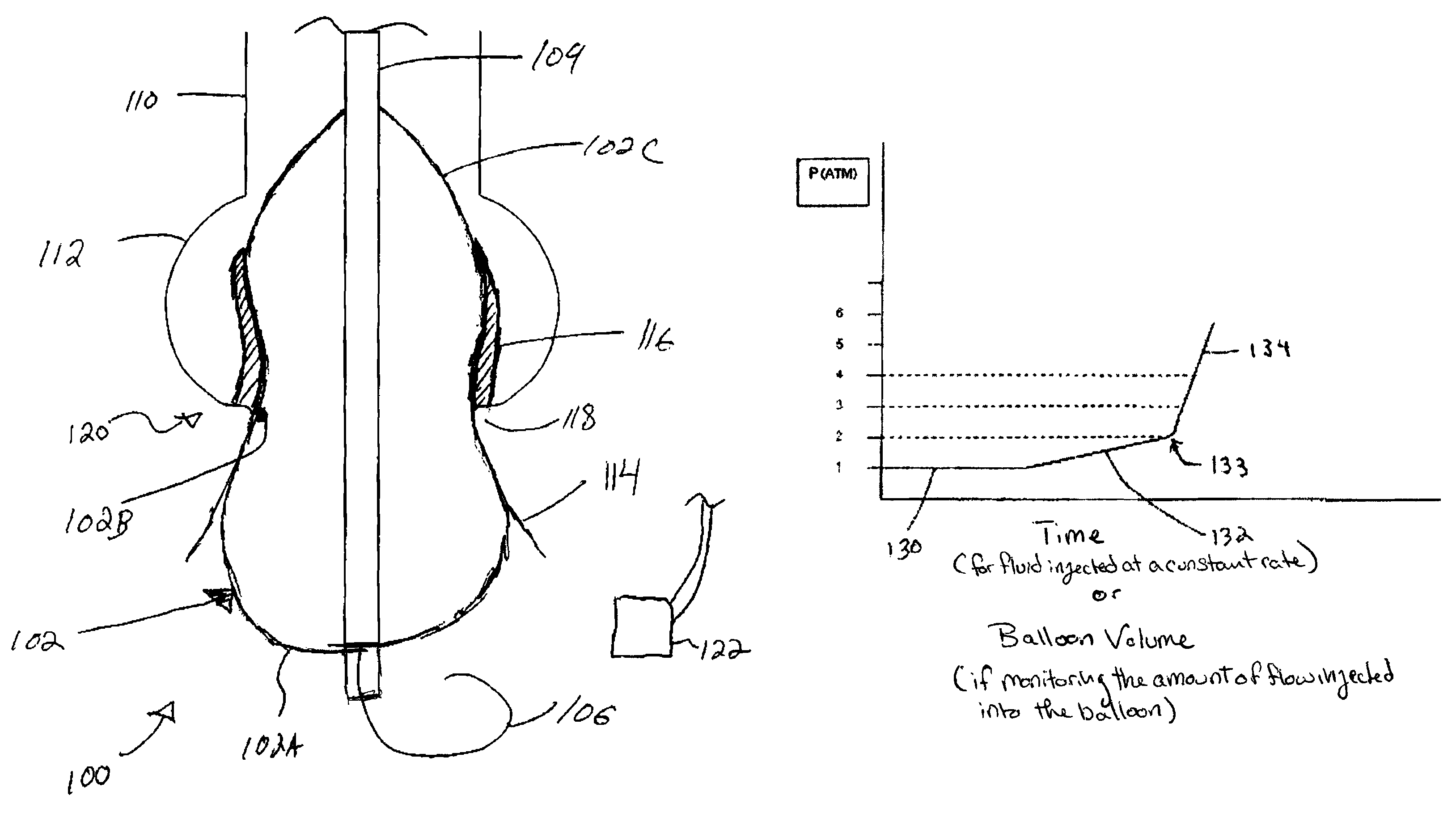

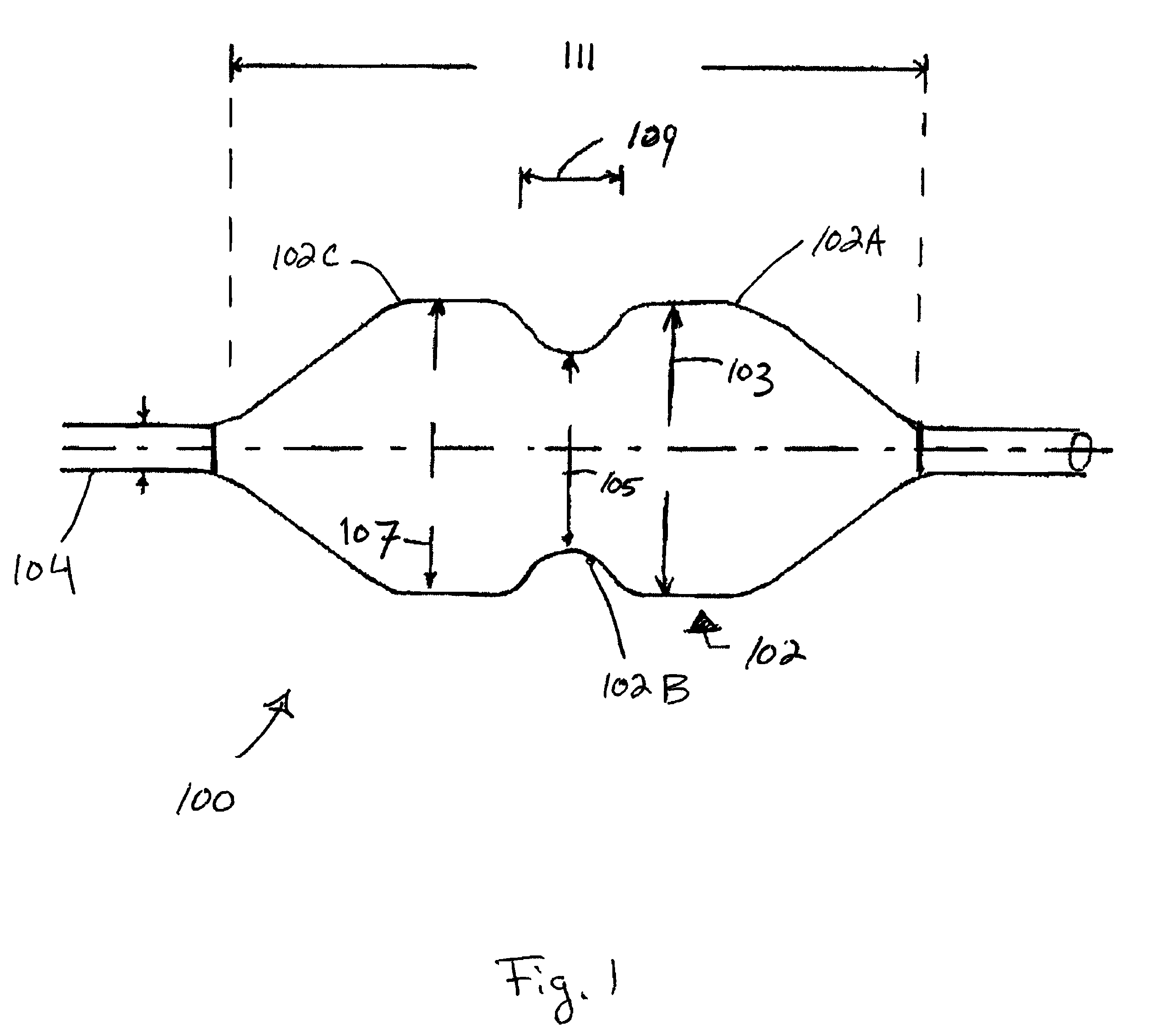

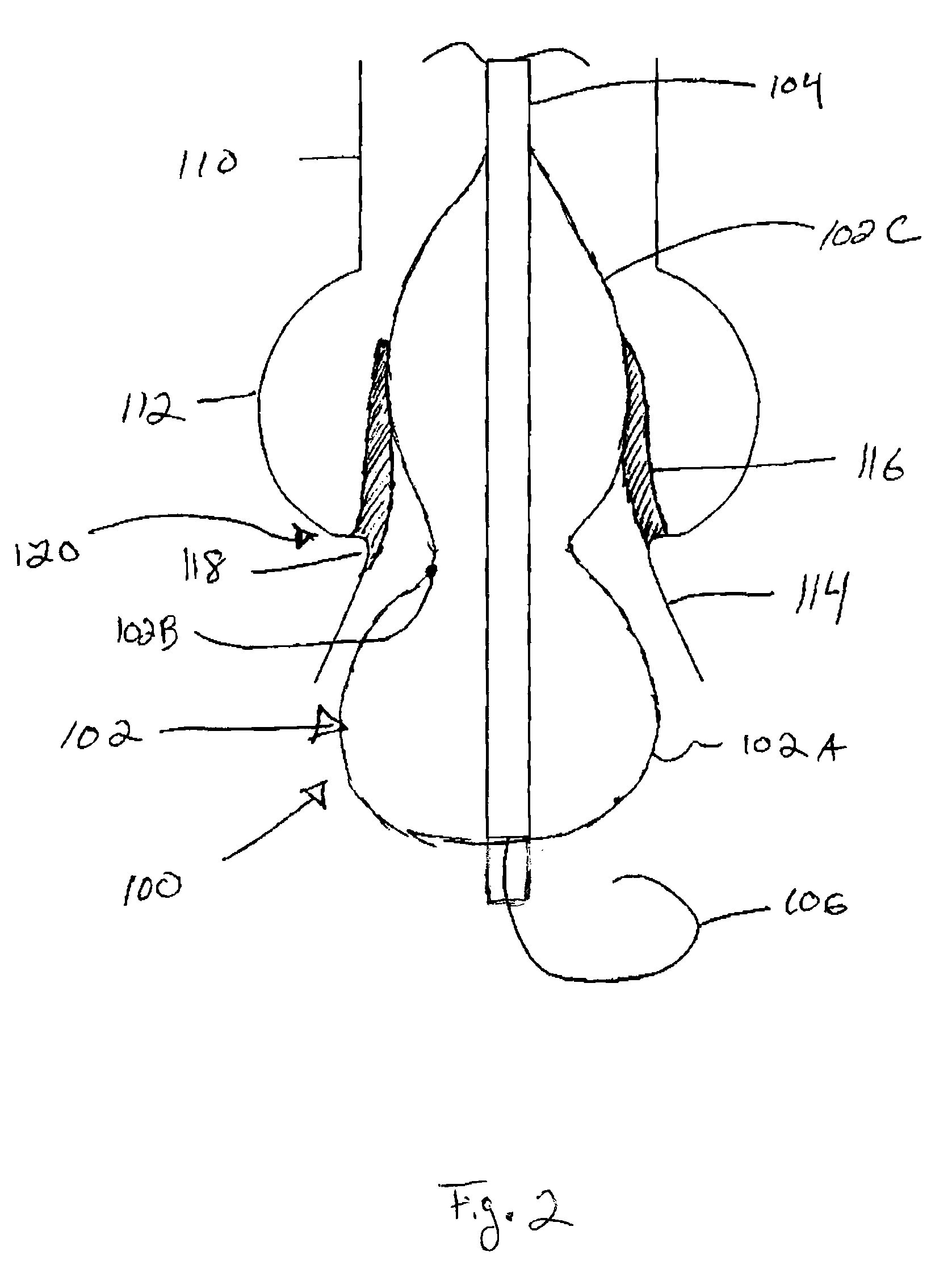

ActiveUS20100094209A1Small diameterAccurate measurementBalloon catheterSurgeryVolume CurveBone shape

A valvuloplasty catheter has a dog-bone shaped balloon with semi-compliant smaller diameter waist and non-compliant larger diameter bulbous end regions. The balloon centers across the valve with the waist adjacent to the annulus. One bulbous region serves to hyperextend the valve leaflets and the other assists in stabilizing the balloon position to reduce migration. The semi-compliant waist increases in diameter as fluid enters the balloon until it comes into contact with the valve annulus. The pressure within the balloon per unit of volume delivery has a greater slope after contact with the annulus than before resulting in a change in slope for the pressure versus volume curve. The diameter of the balloon and annulus are determined at this inflection point when the balloon contacts the annulus.

Owner:INTERVALVE MEDICAL INC

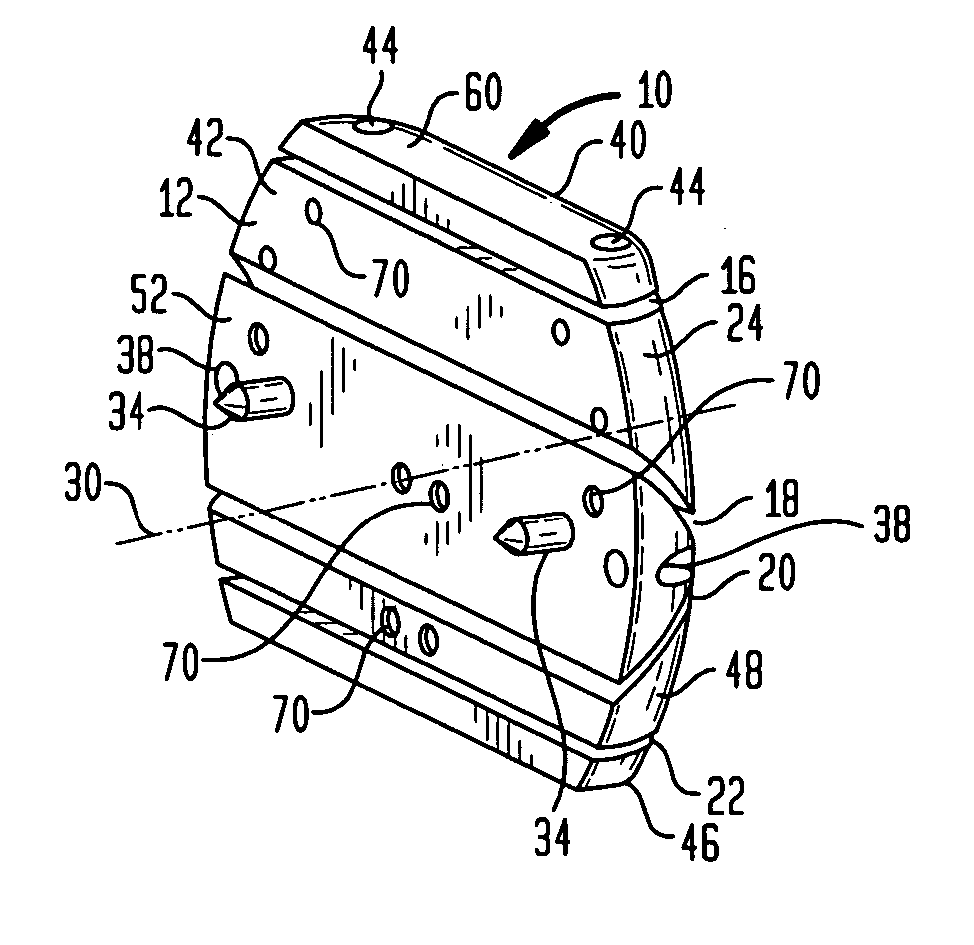

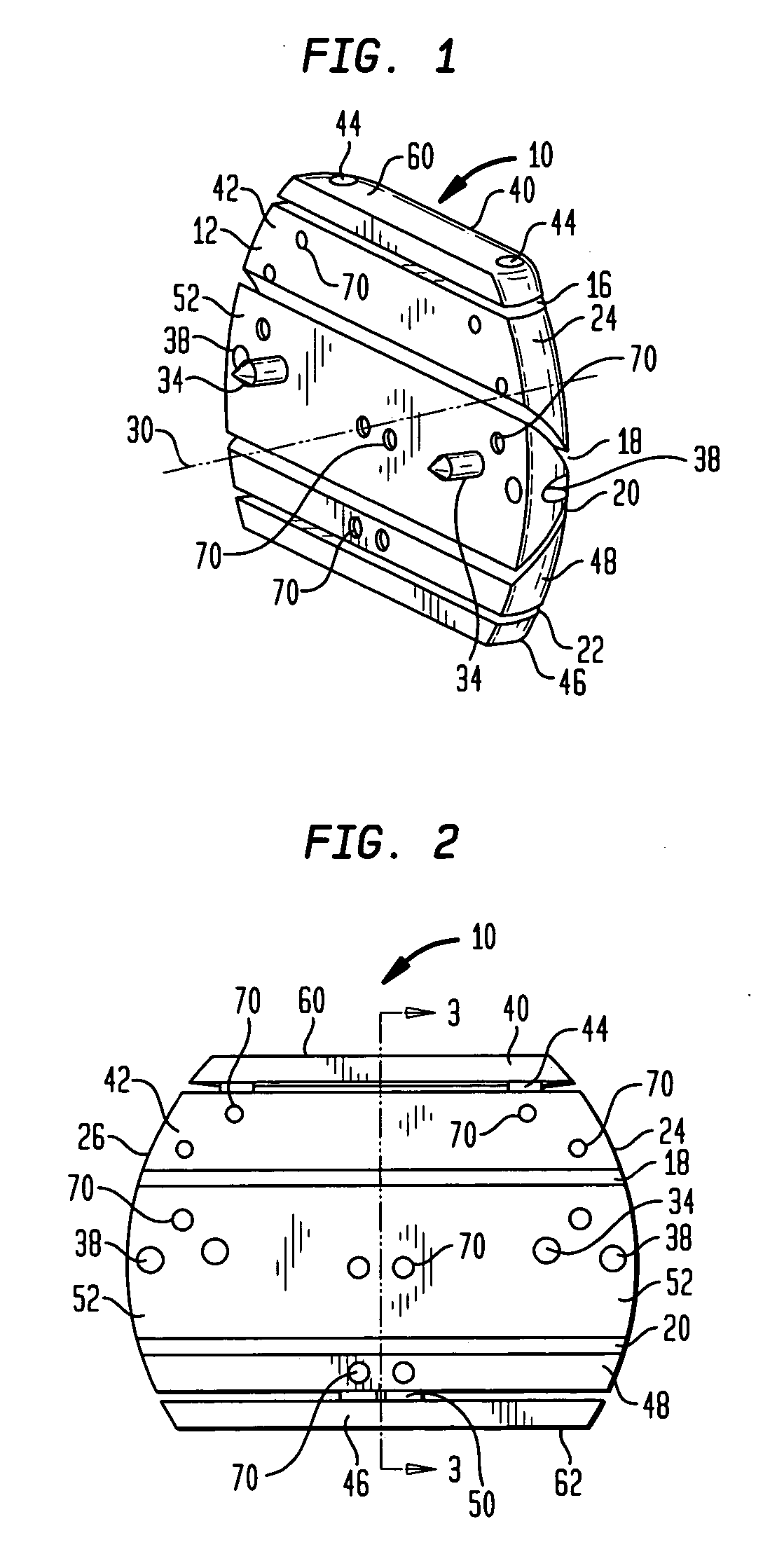

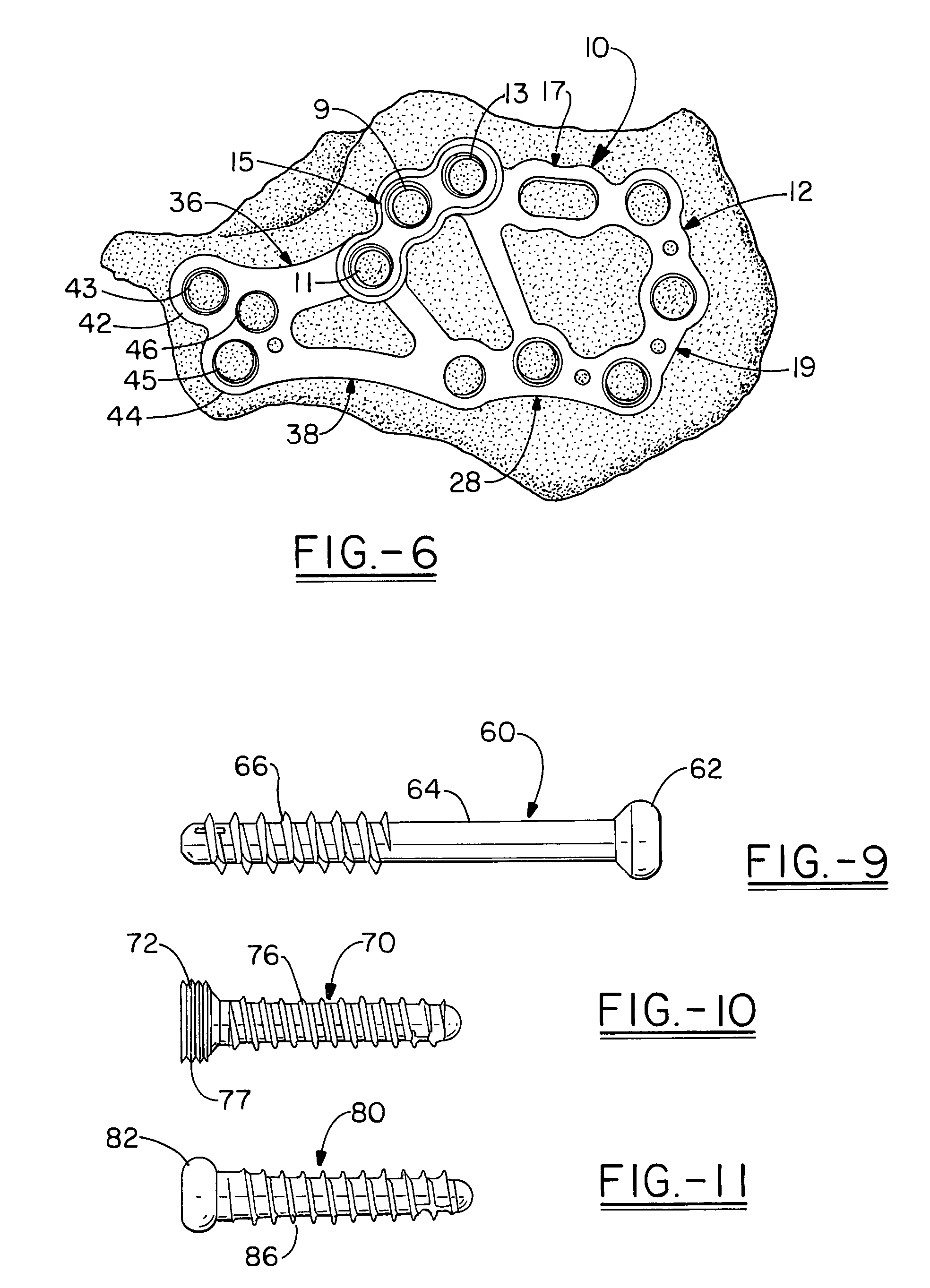

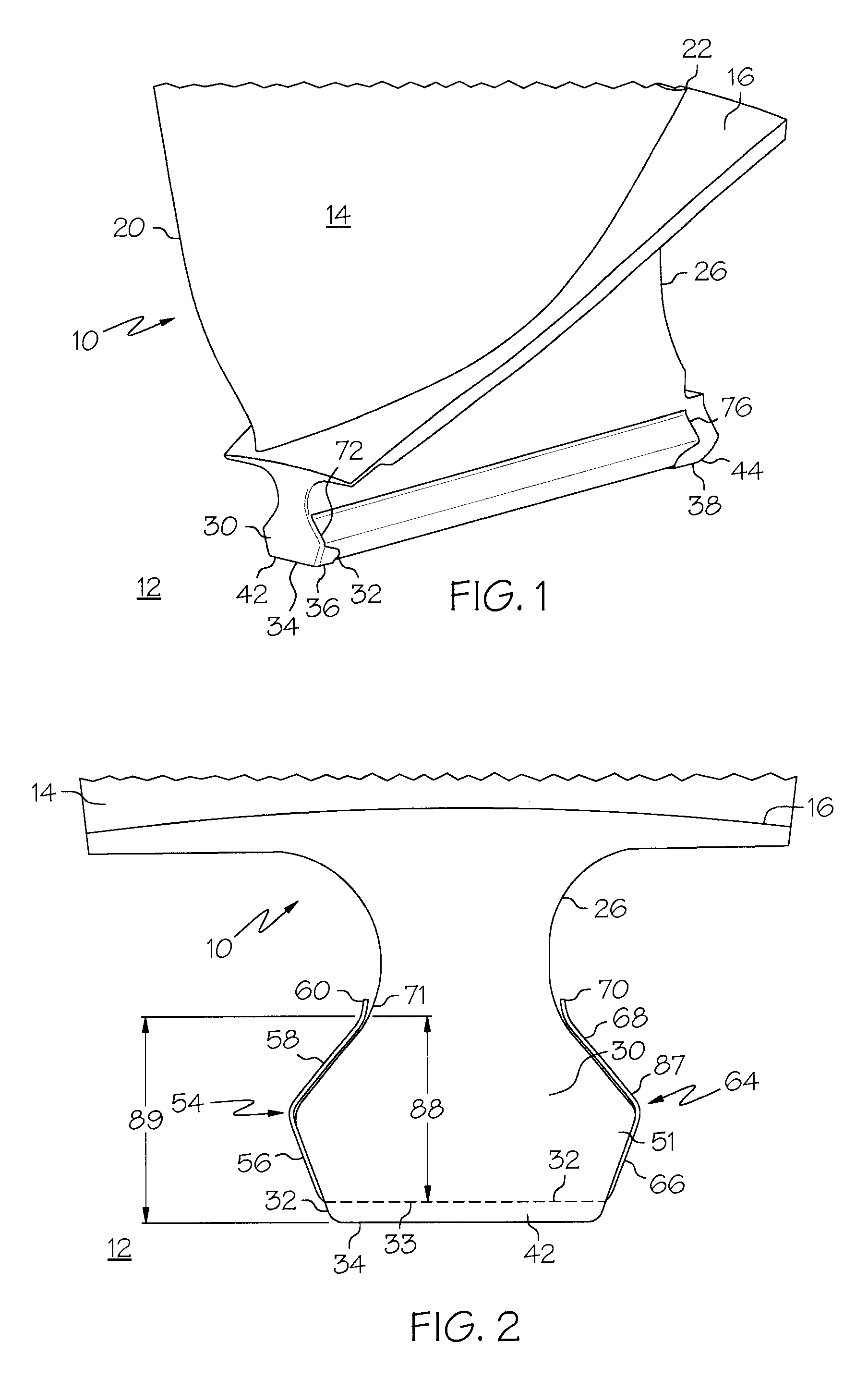

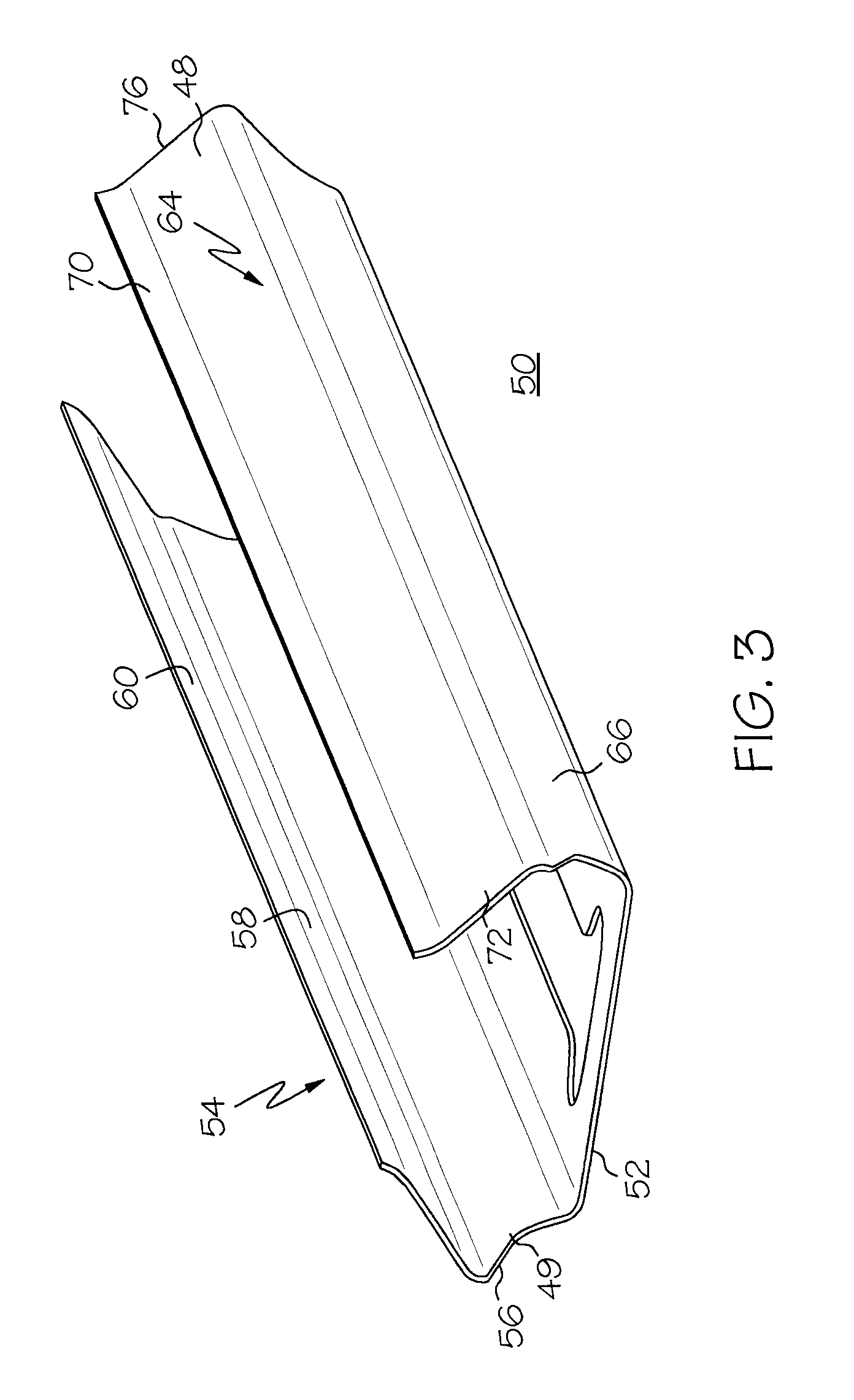

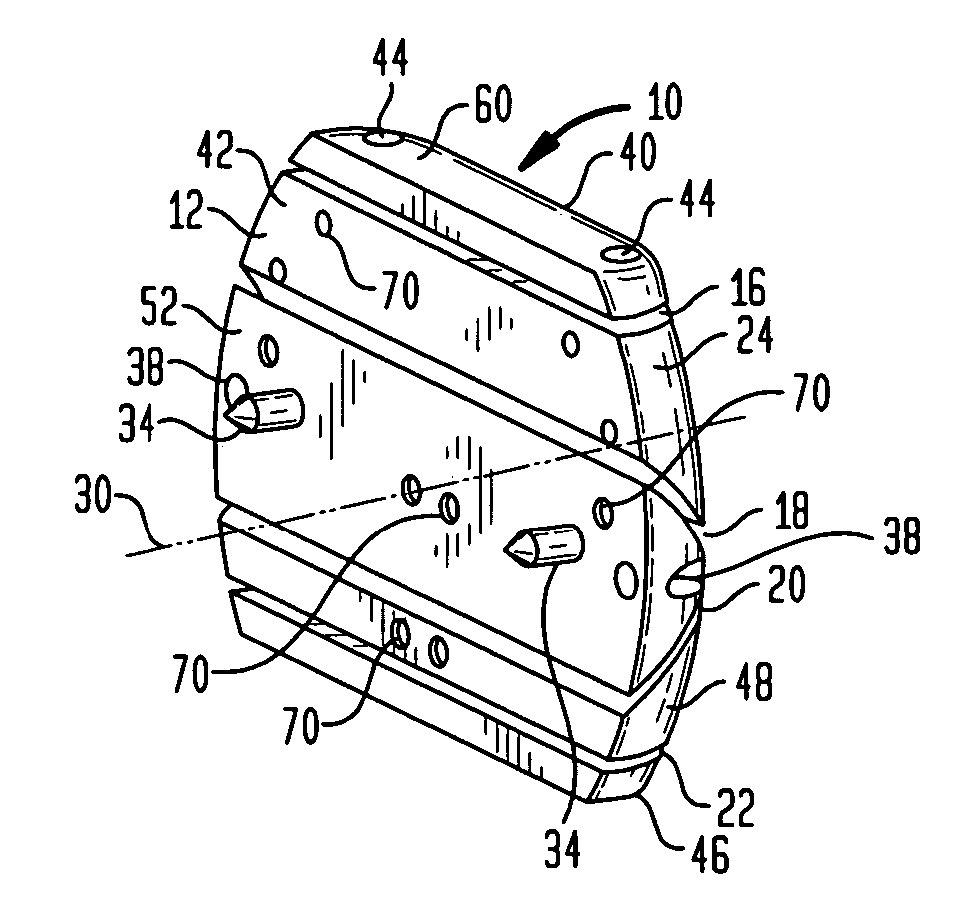

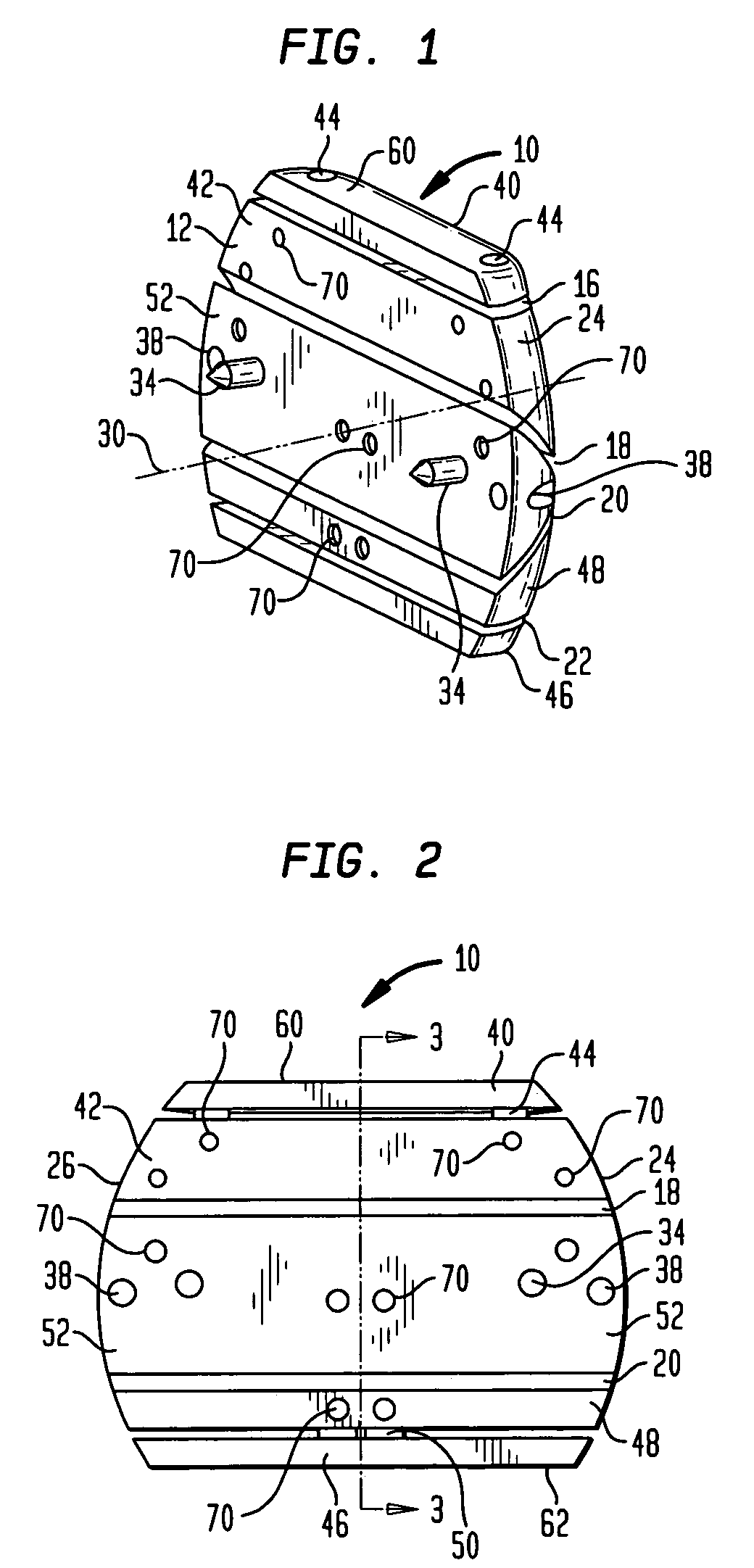

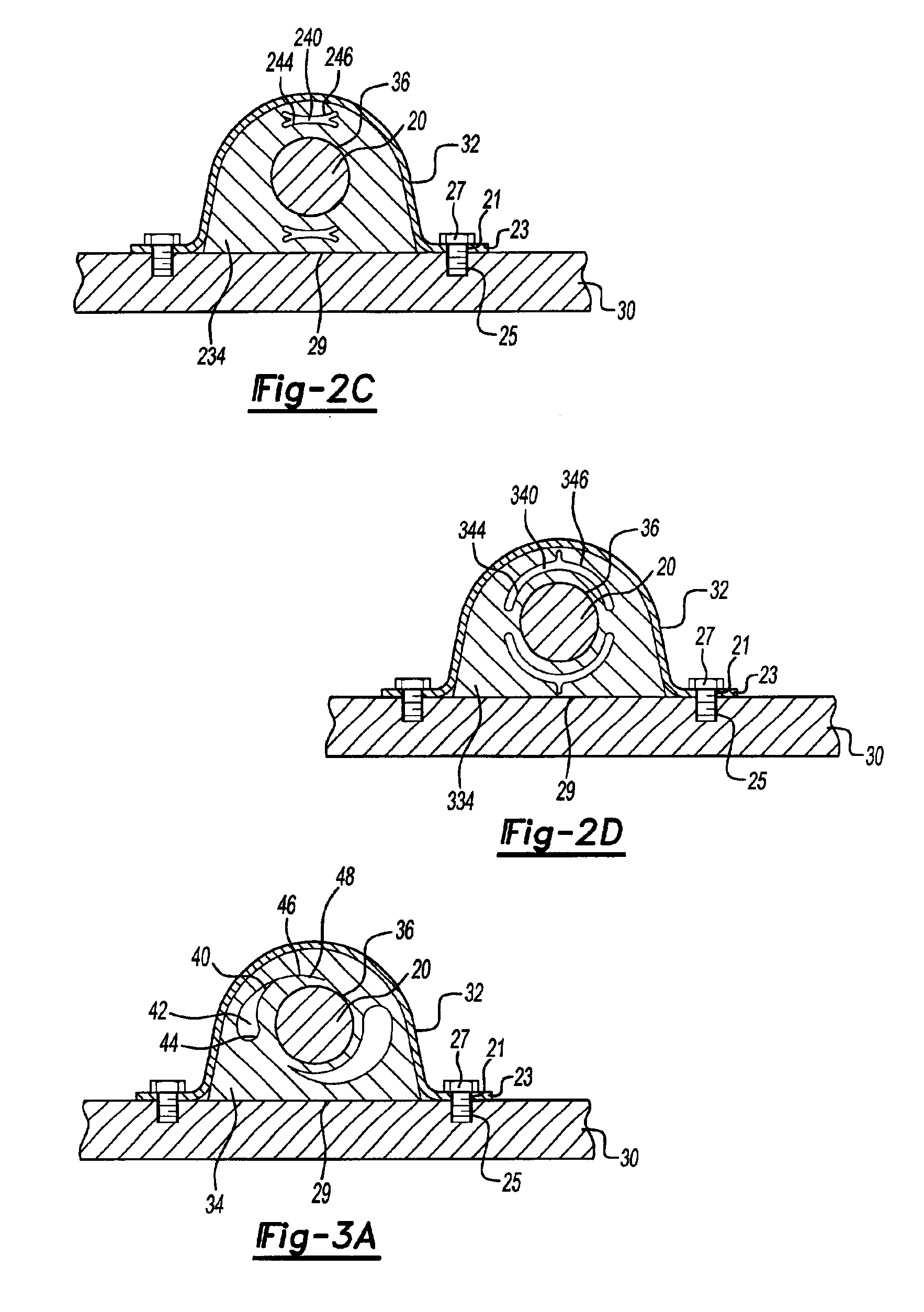

Bone shaped cutting block

ActiveUS20050240195A1Potential damageMaintaining amountNon-surgical orthopedic devicesSurgical sawsBone shapeBiomedical engineering

A cutting block for resecting a bone, particularly the distal femur, has a body with a first generally planar bone contacting surface to contact the resected distal surface of the femur. The body has a second surface spaced from the bone contacting surface along an axis perpendicular to said generally planar bone contacting surface. The body has a perimeter surface extending between the first and second surfaces, wherein the perimeter surface is at least partially curved with respect to the axis in both a direction generally perpendicular thereto and generally parallel thereto. The perimeter surface may be polished.

Owner:HOWMEDICA OSTEONICS CORP

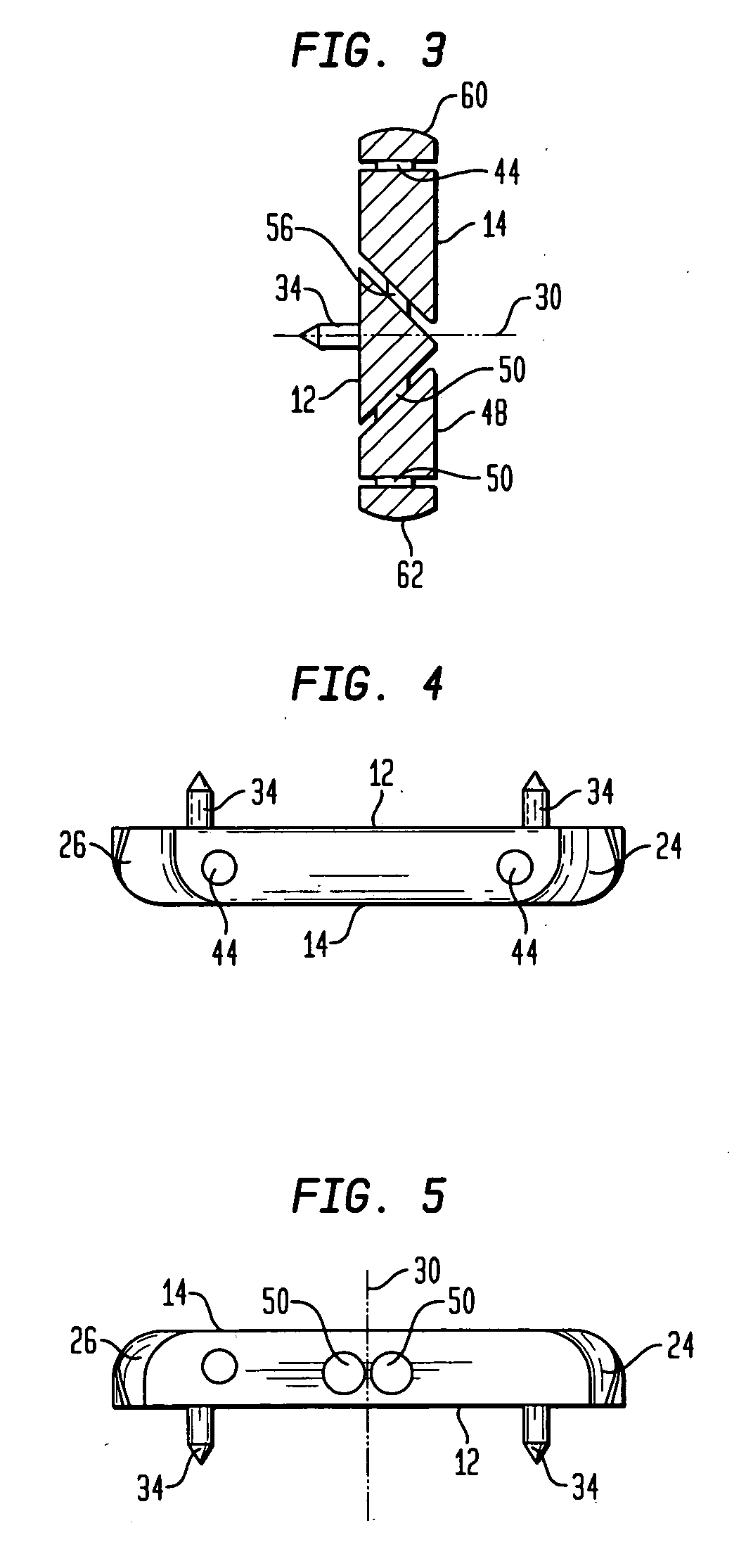

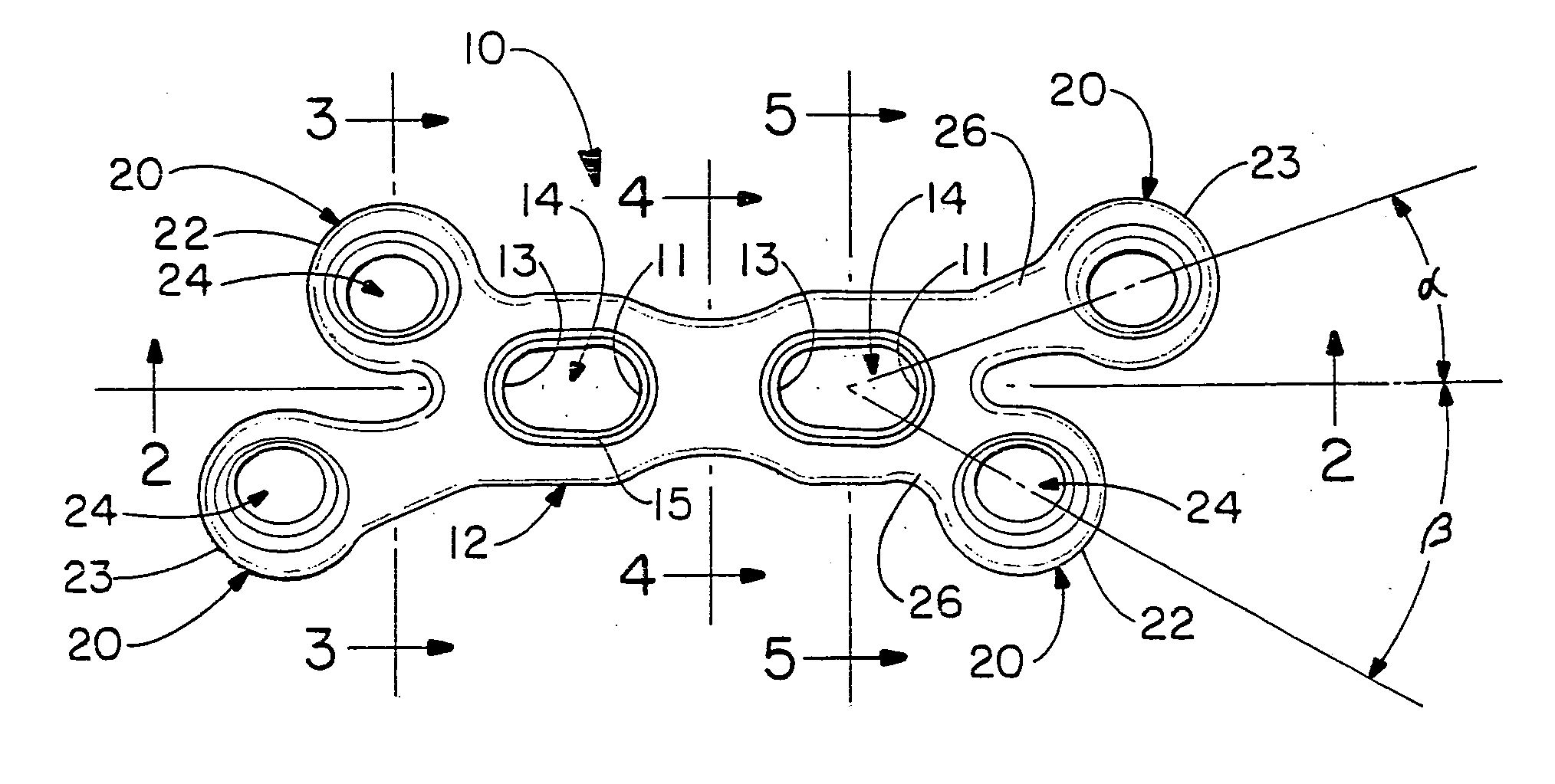

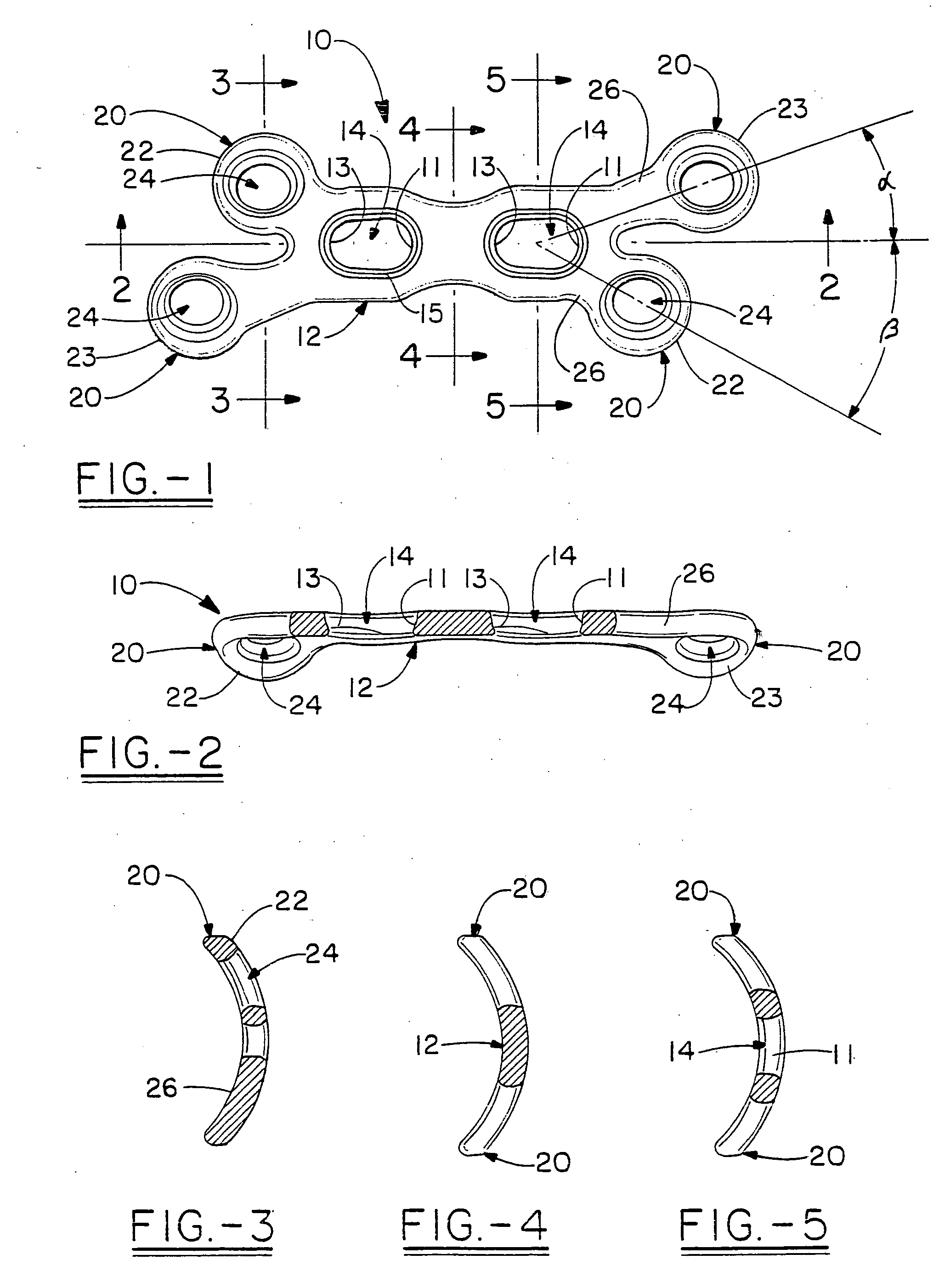

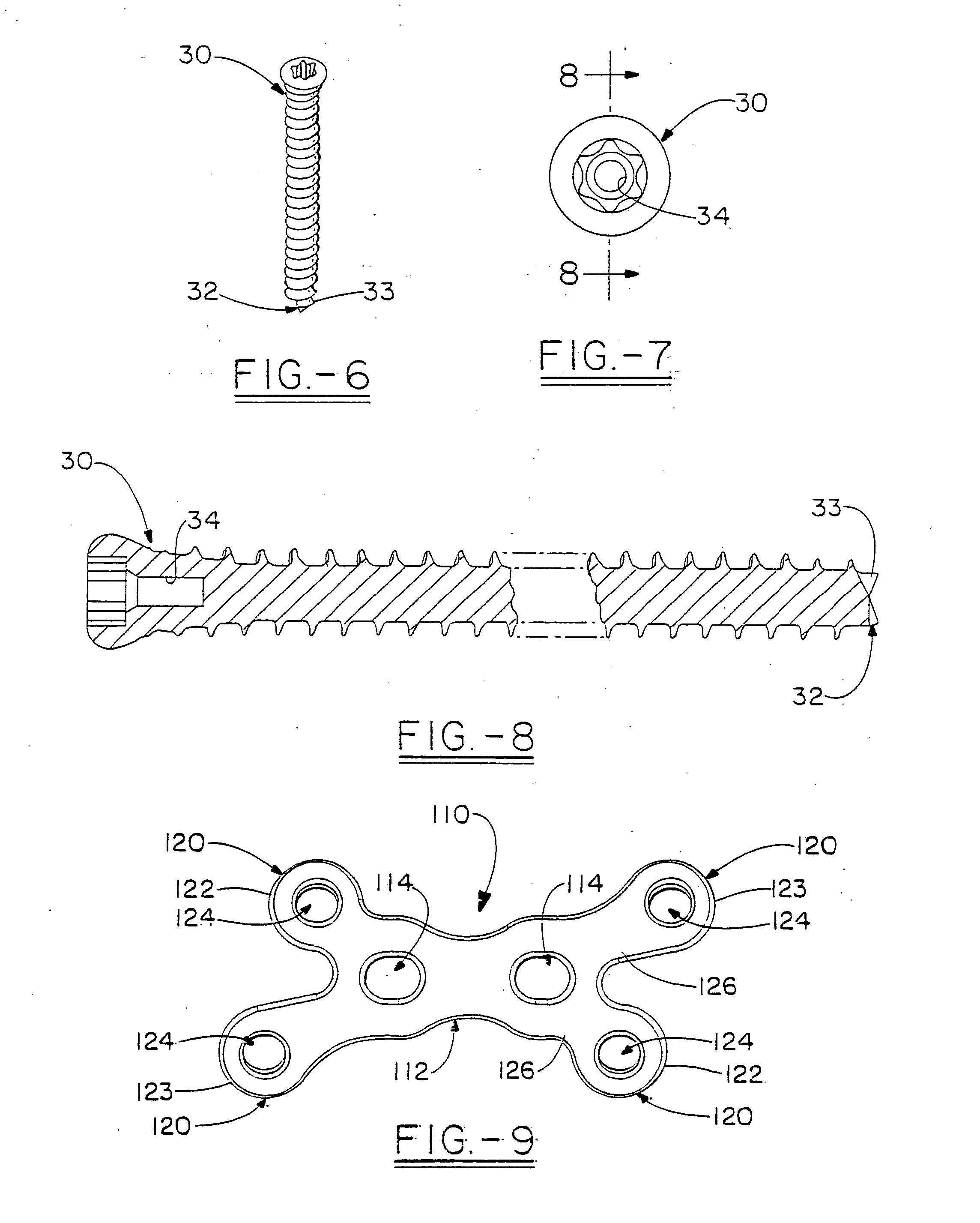

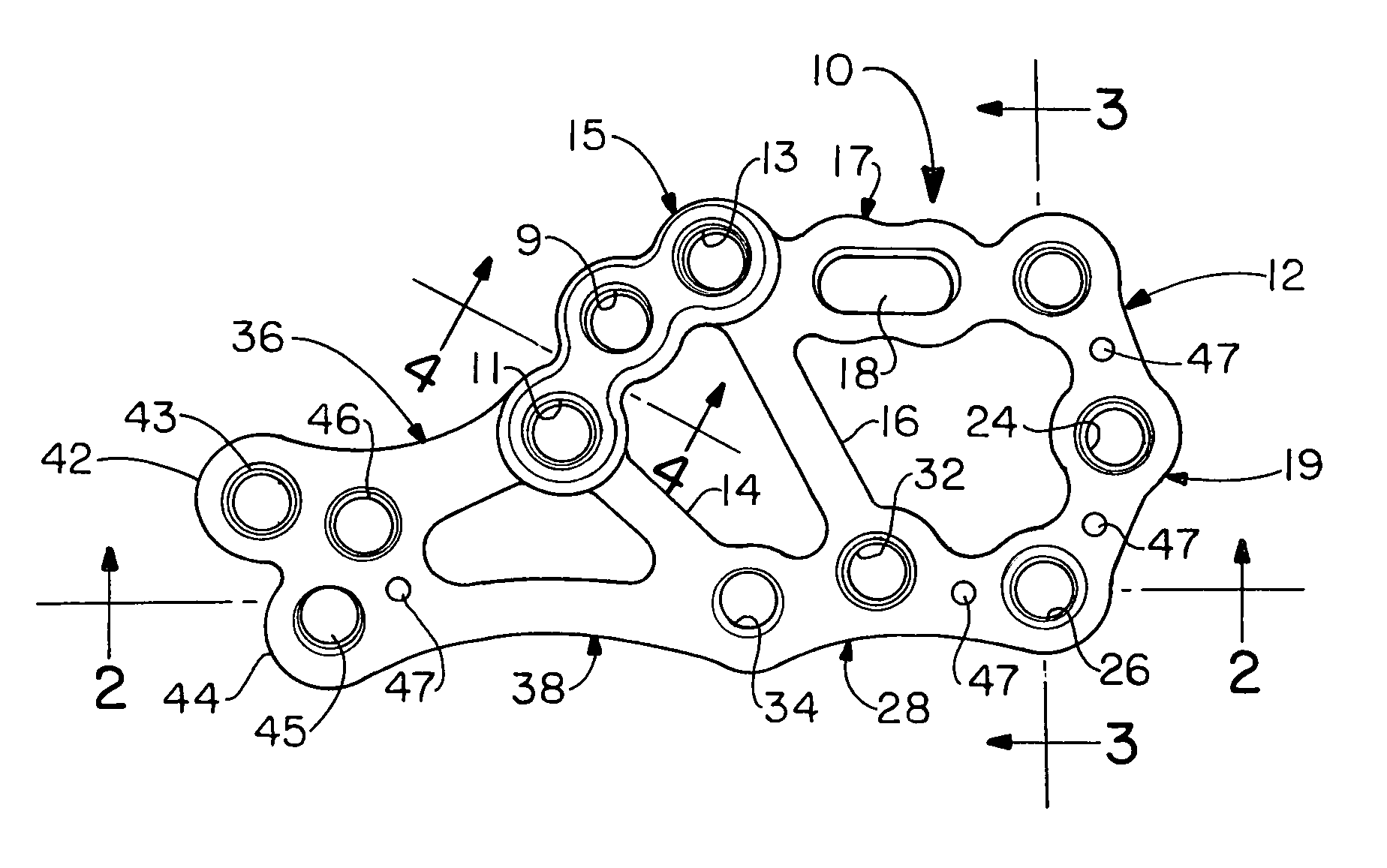

Orthopedic plate for use in small bone repair

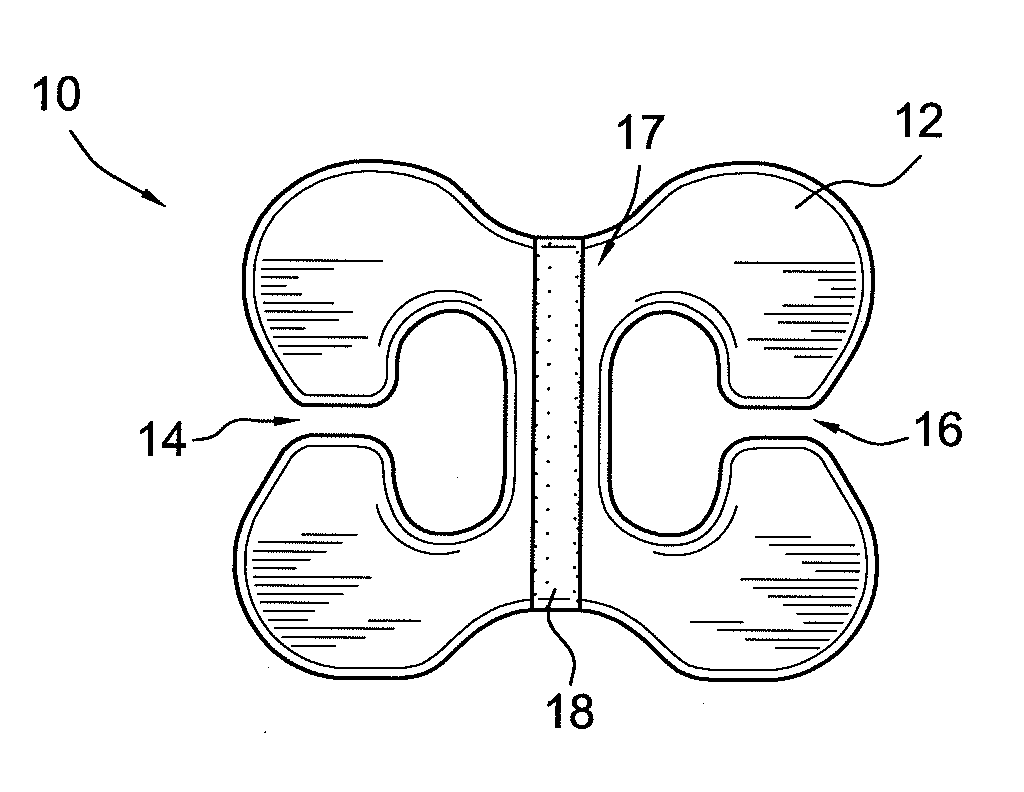

The present invention relates to an orthopedic plate and screw system and instruments for surgical fixation of a small bone or bones. The plate facilitates three dimensional contouring to provide for a variety of applications and to accommodate individual variation in bone shape. The plate has a modified x shape including a central trunk portion including one or more screw holes along a longitudinal axis and a set of divergent upper and an oppositely extending set of divergent lower arms, each arm including screw holes which are placed at a radially equal distance but which diverging asymmetrically from the longitudinal axis relative to its paired upper or lower mate. The screws of the system are self-starting, self-tapping screws including the option of partial or full cannulation.

Owner:WRIGHT MEDICAL TECH

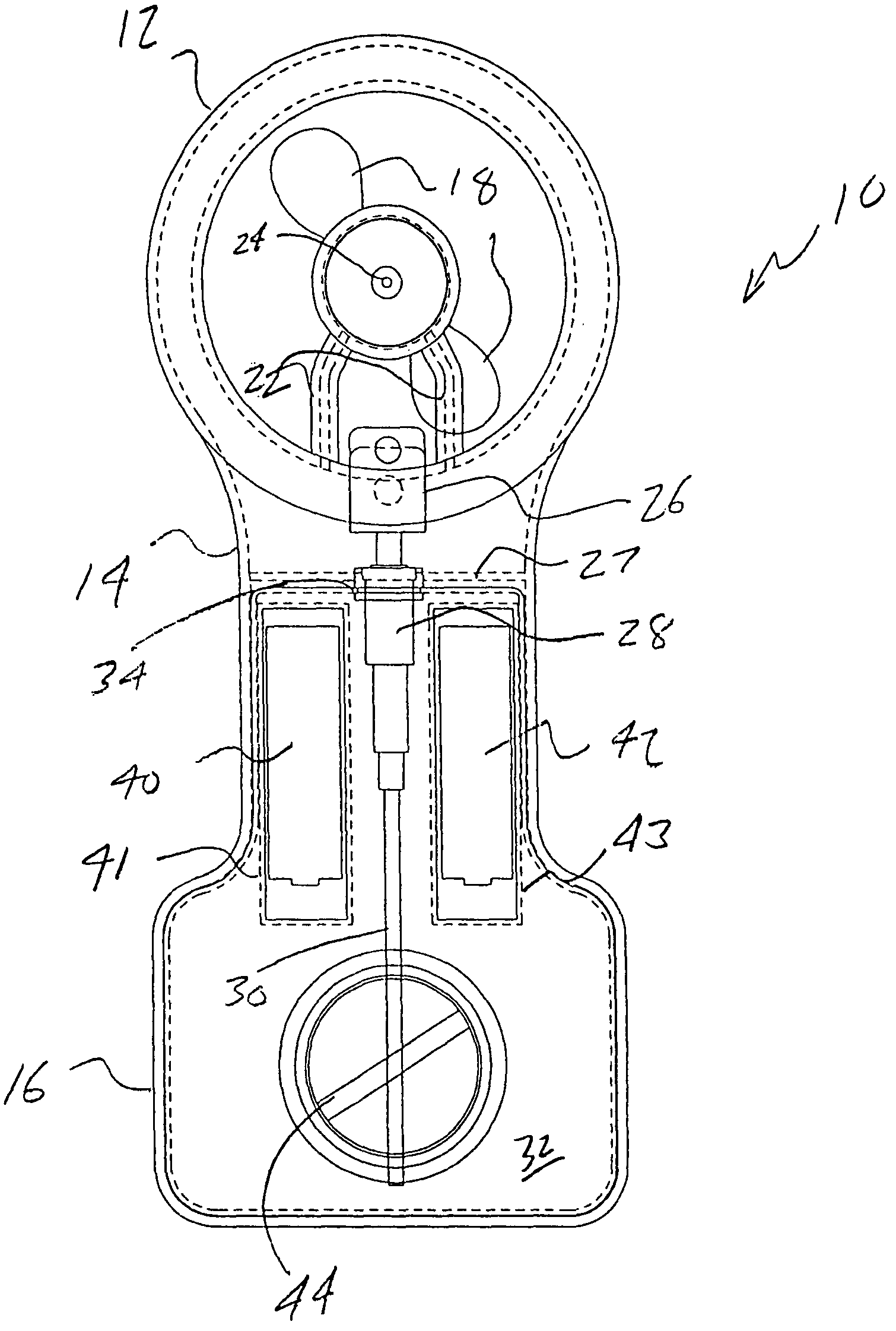

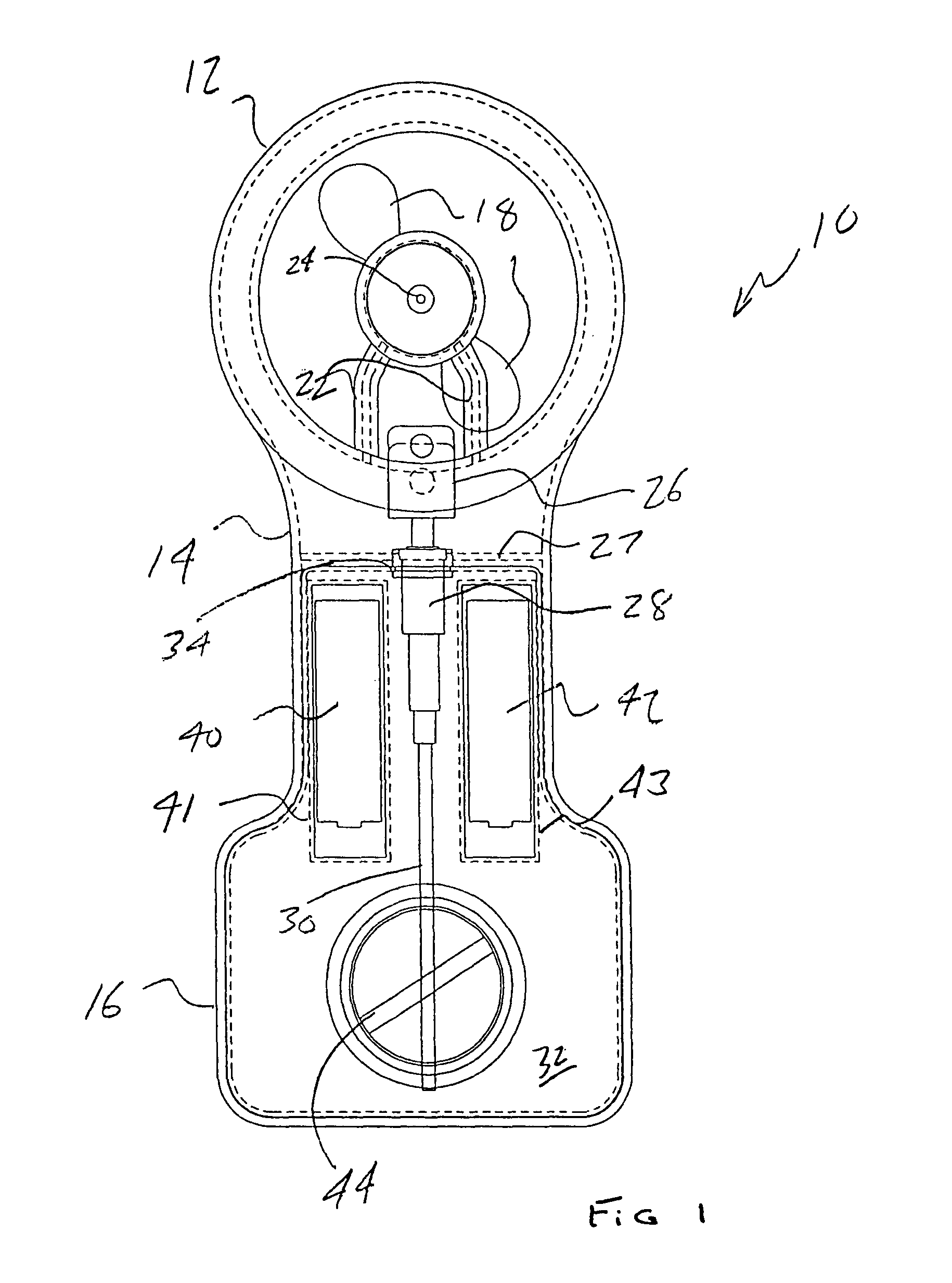

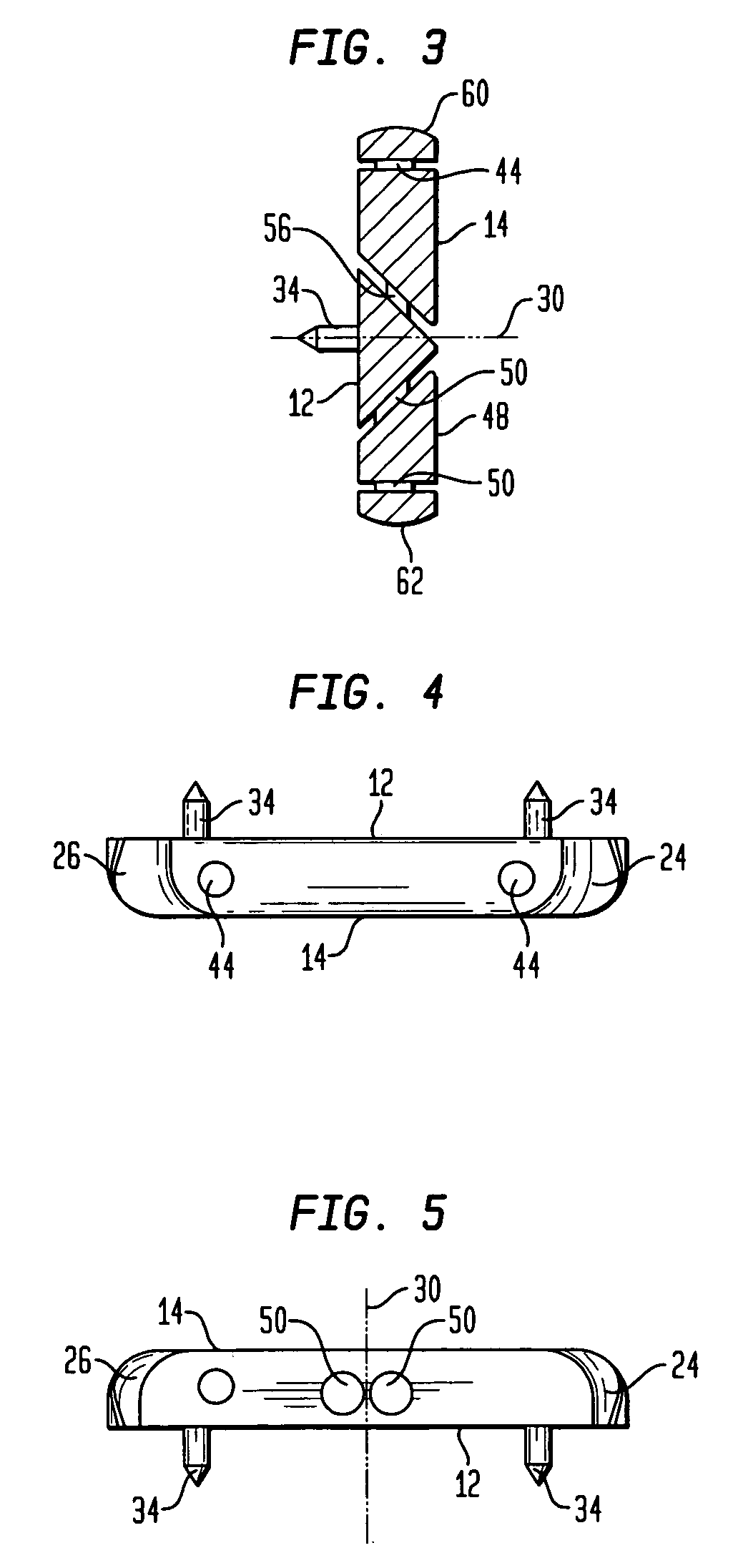

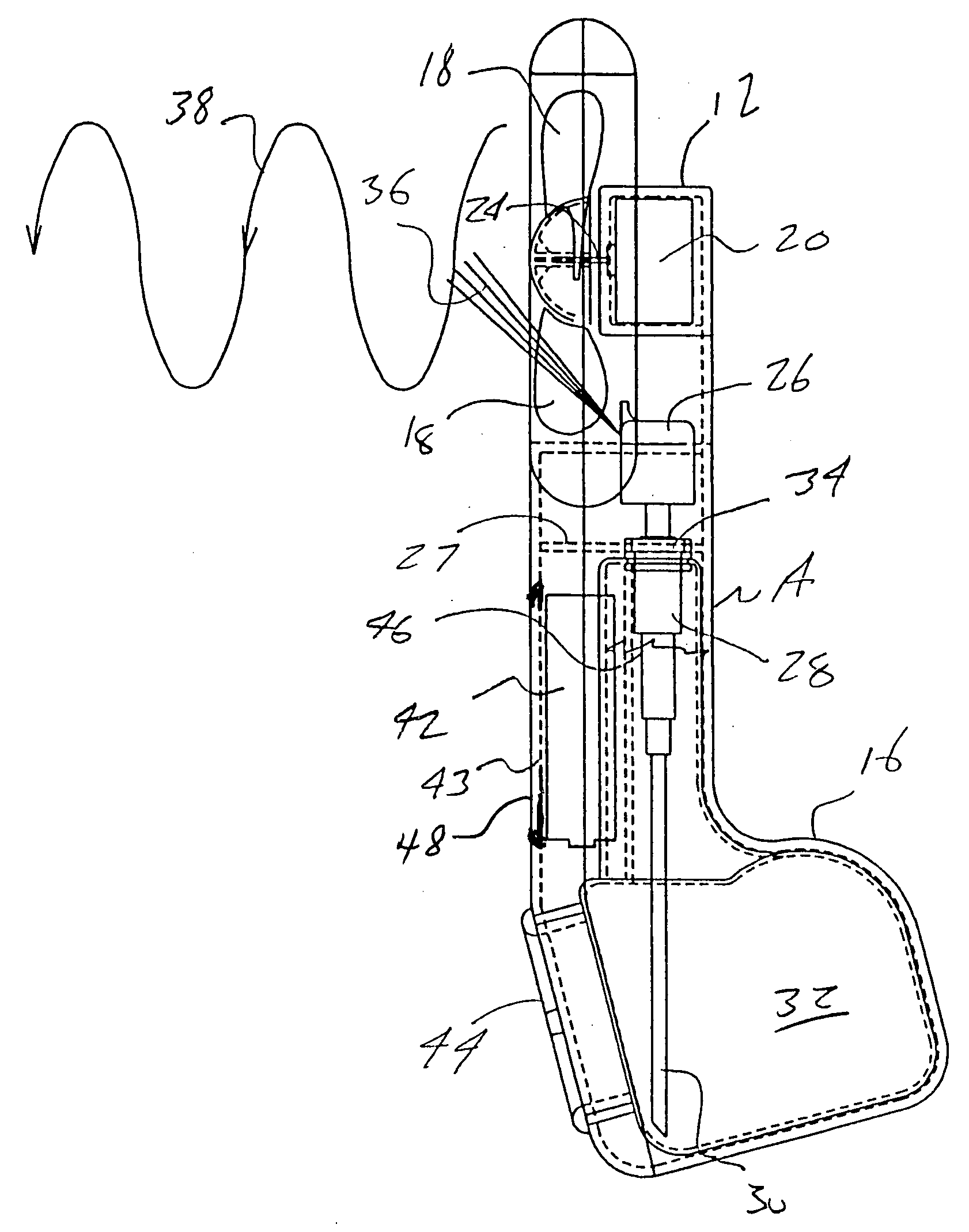

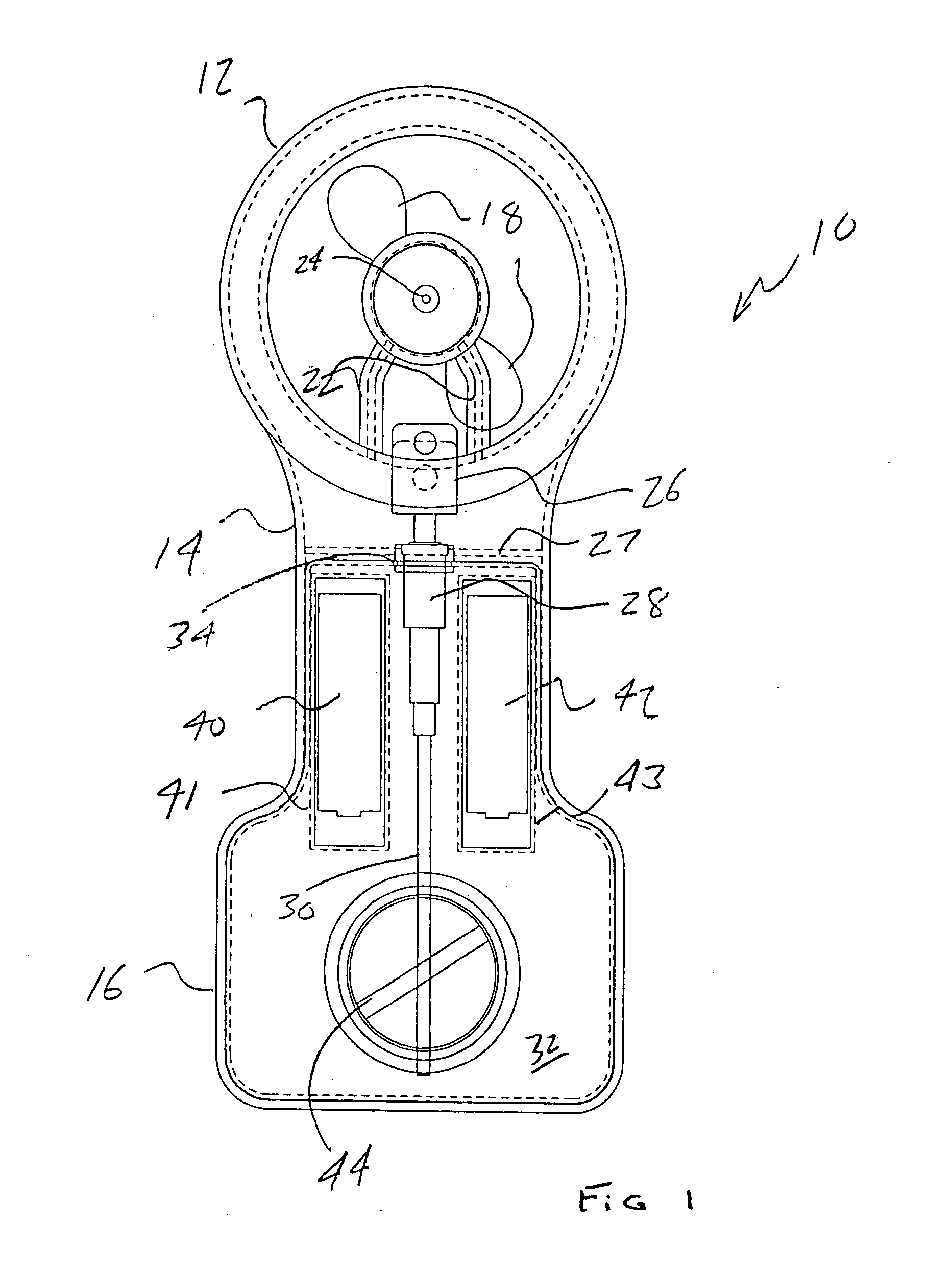

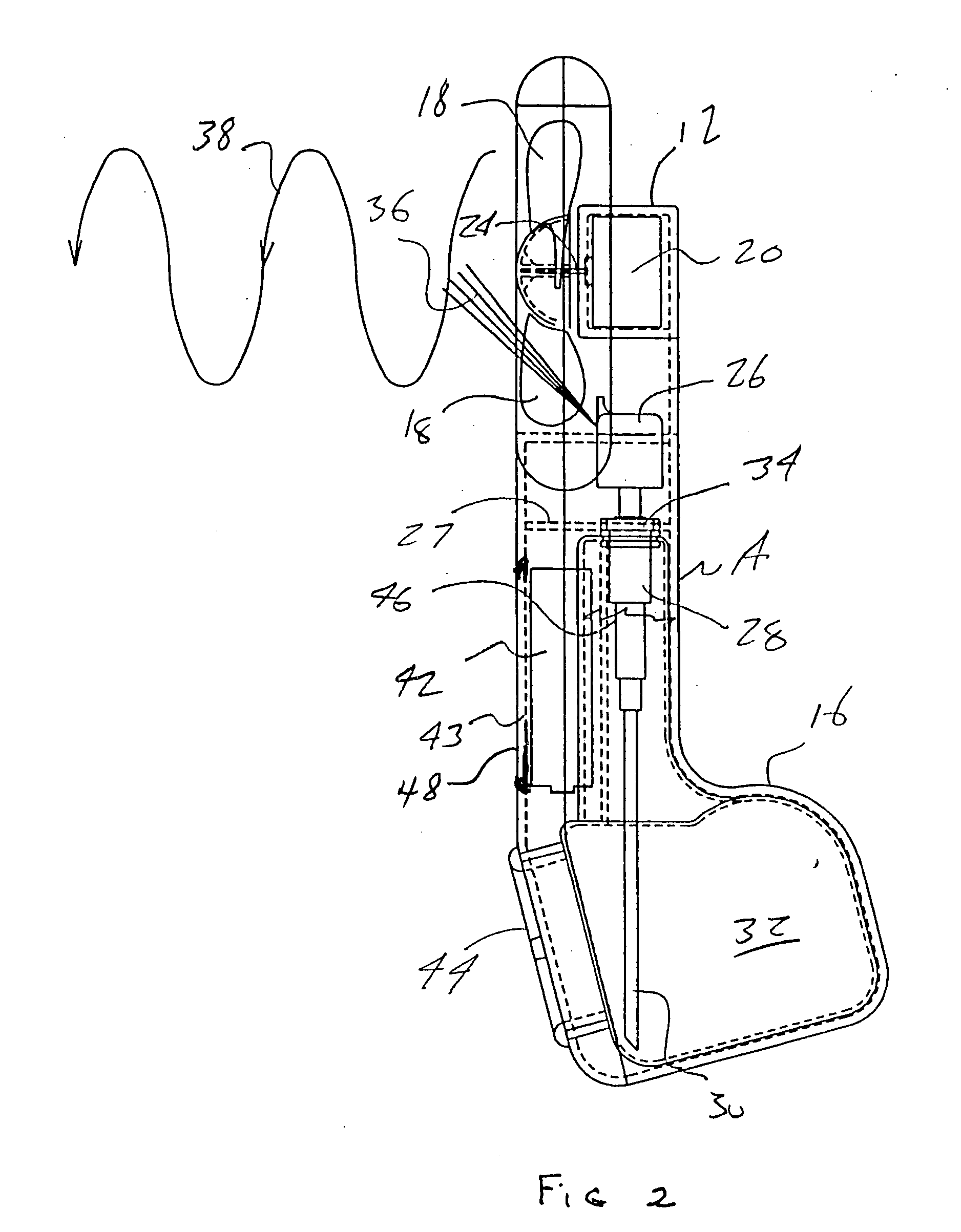

Handheld water misting fan with improved air flow

The present invention is directed to an improved handheld water misting fan device wherein the power source compartment is positioned within the device at a location remote from the fan motor thereby to remove any structure from the area bounded by the fan shroud. The relocation of the power source compartment leaves the area bounded by the shroud substantially unobstructed thereby to improve air flow. The device is formed in a dog bone shaped configuration to provide a narrow handle section for improved grippability, and an enlarged fluid reservoir at the lower end thereof for greater reservoir capacity.

Owner:O2COOL

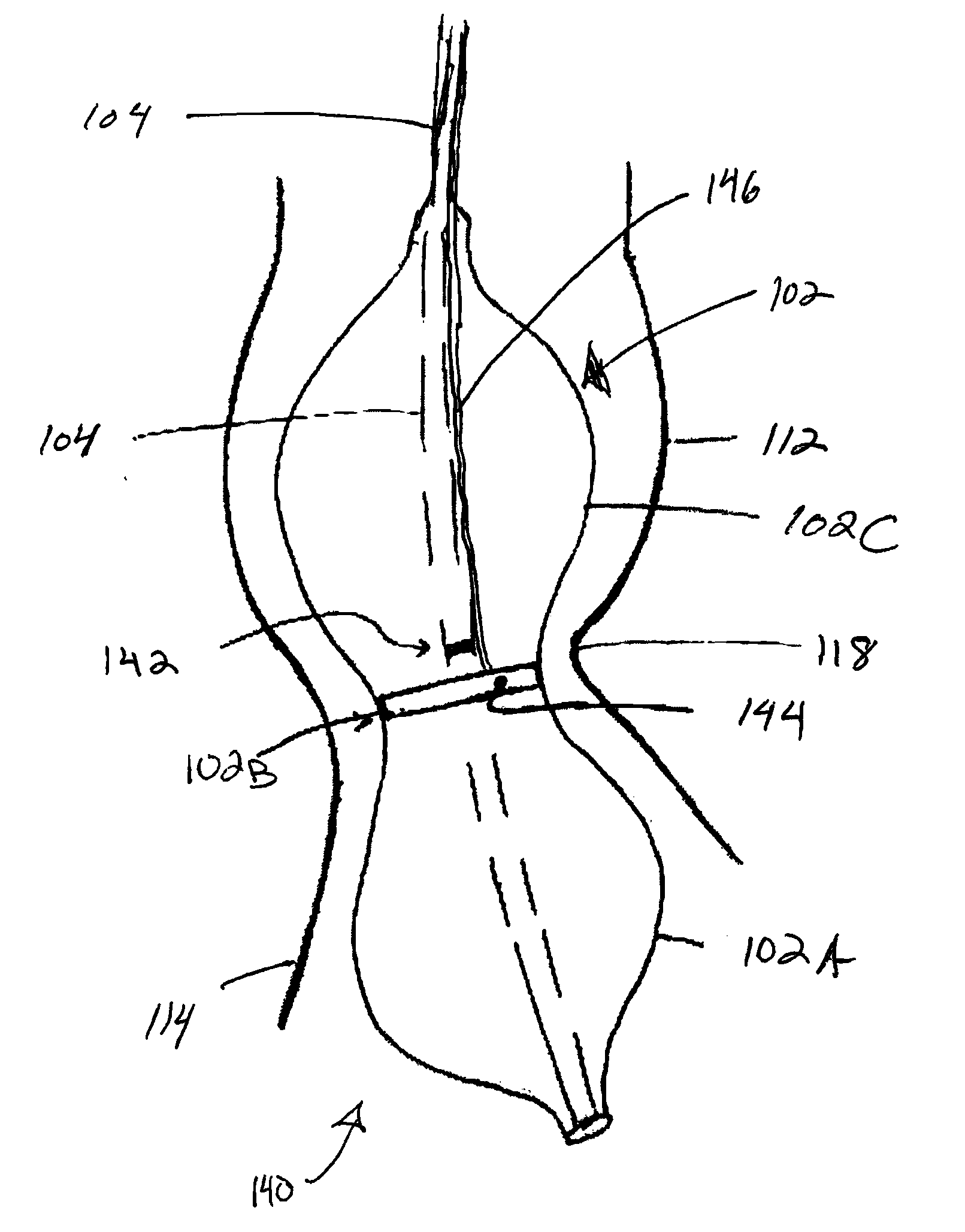

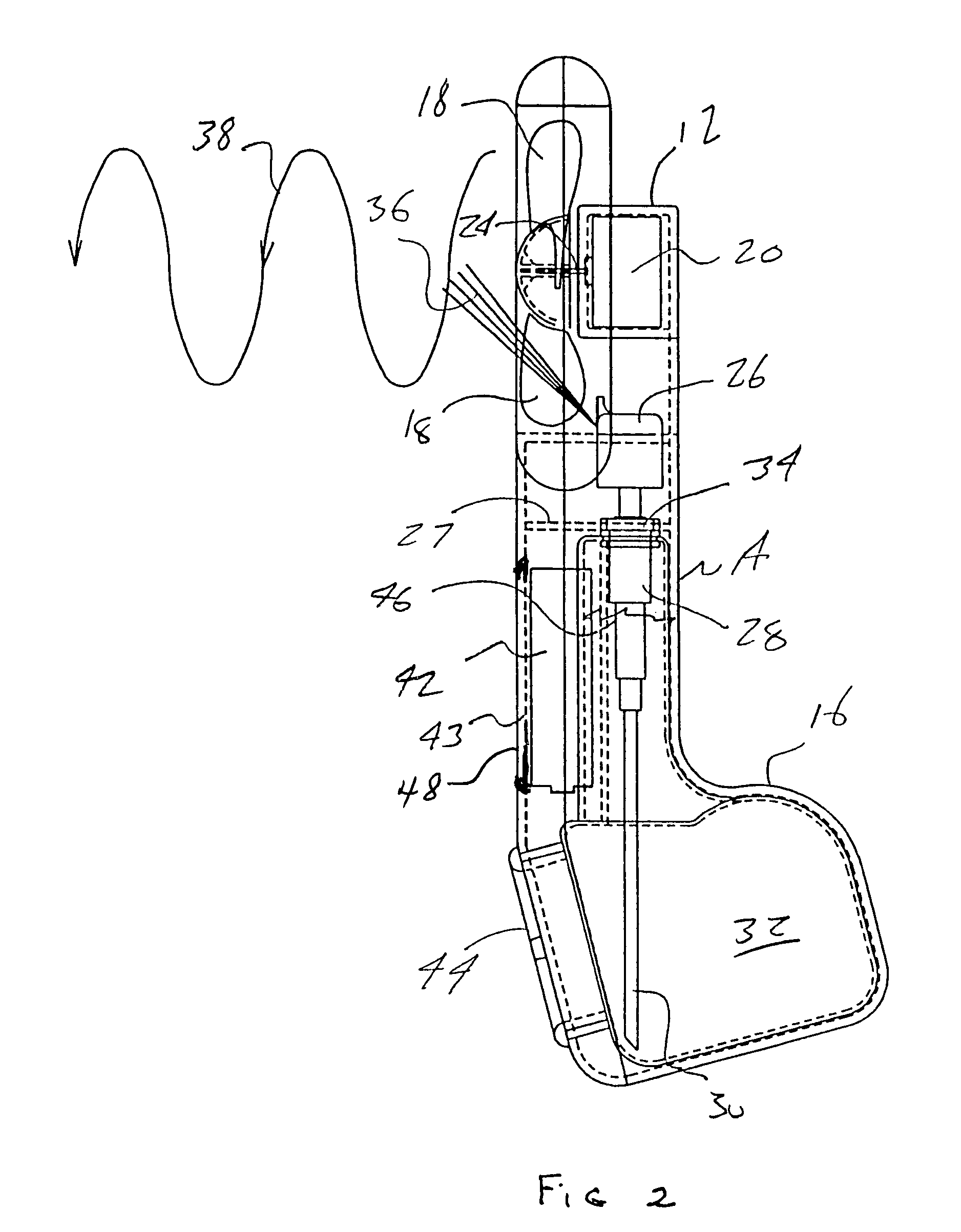

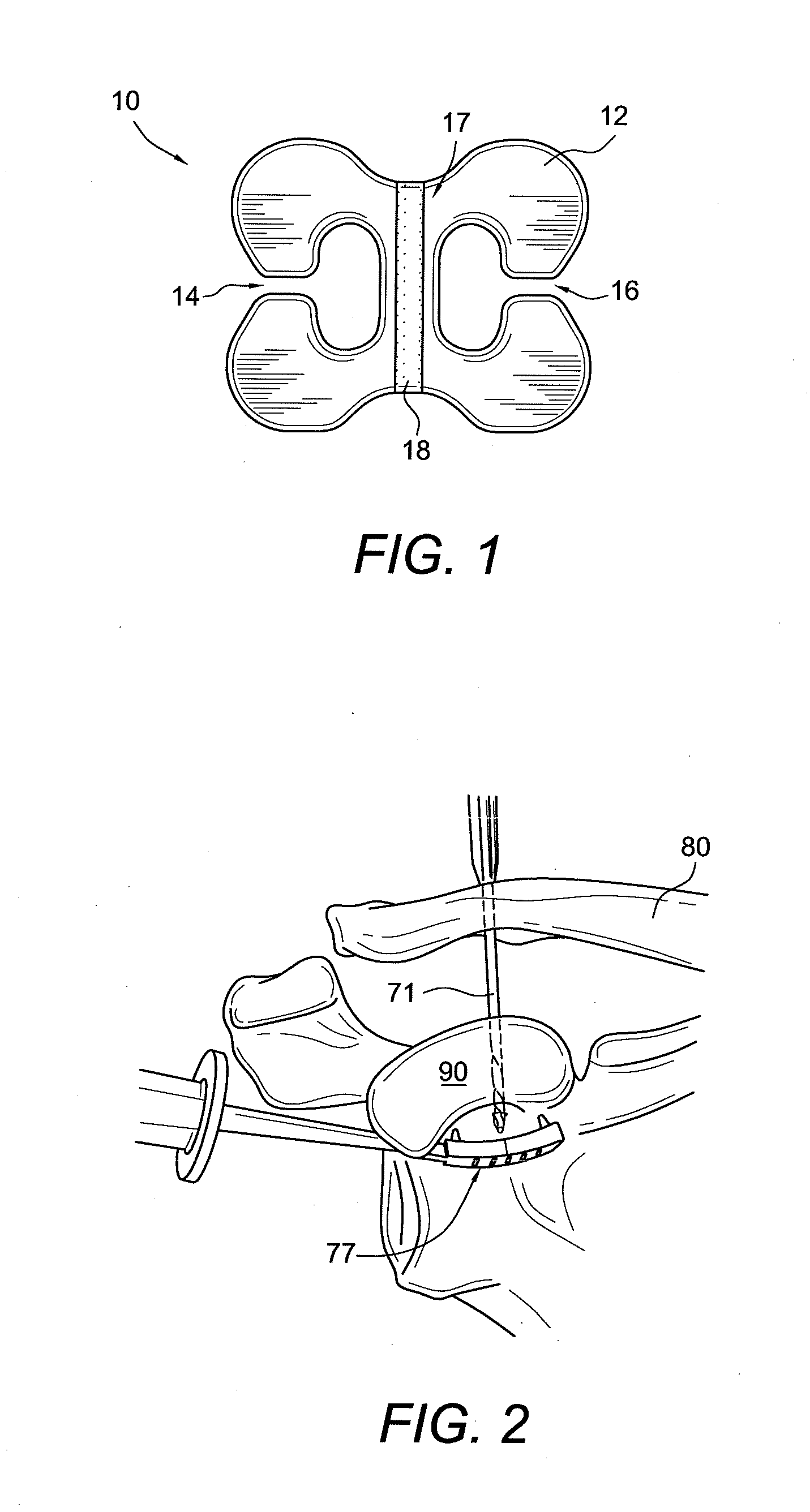

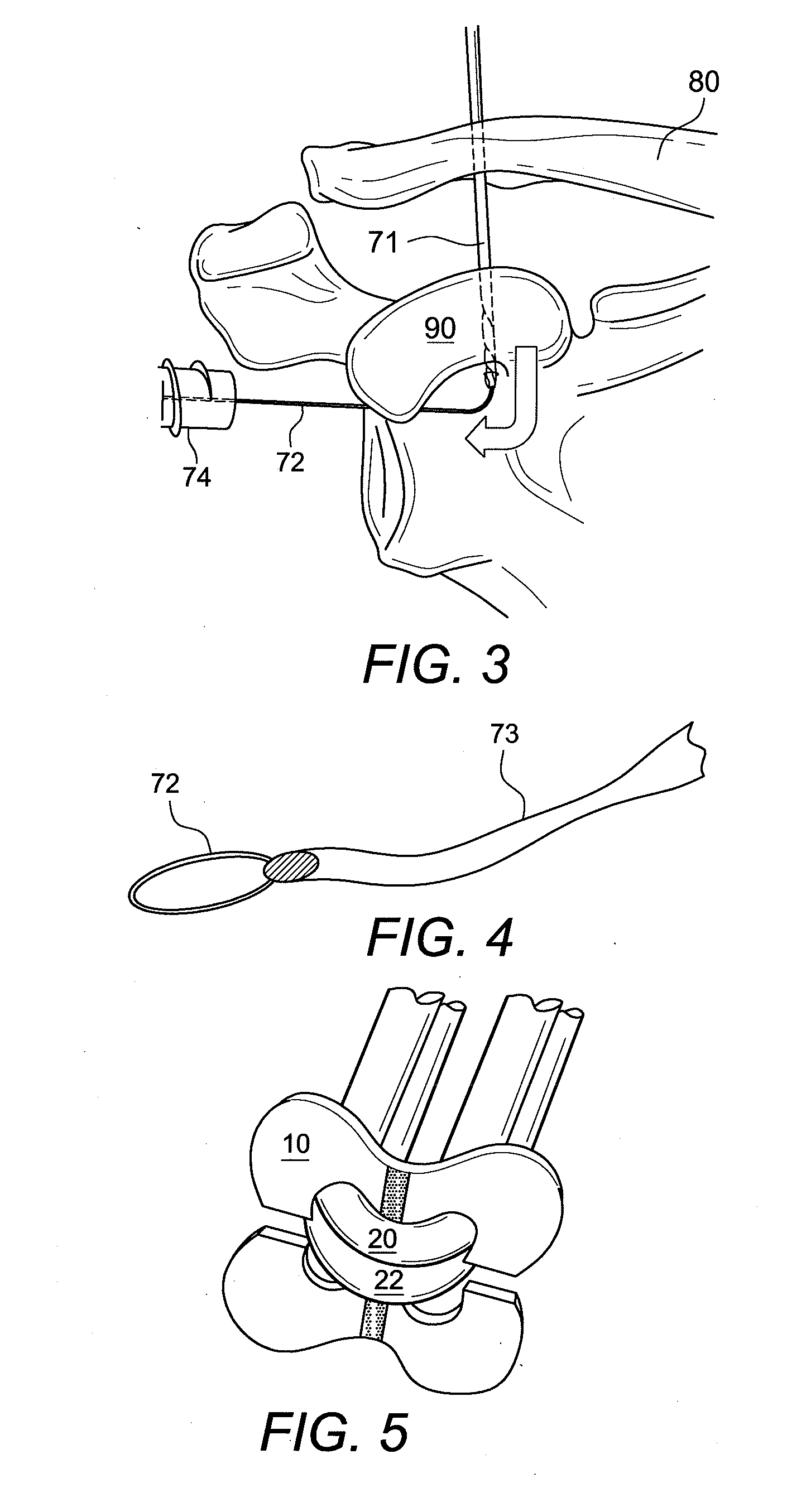

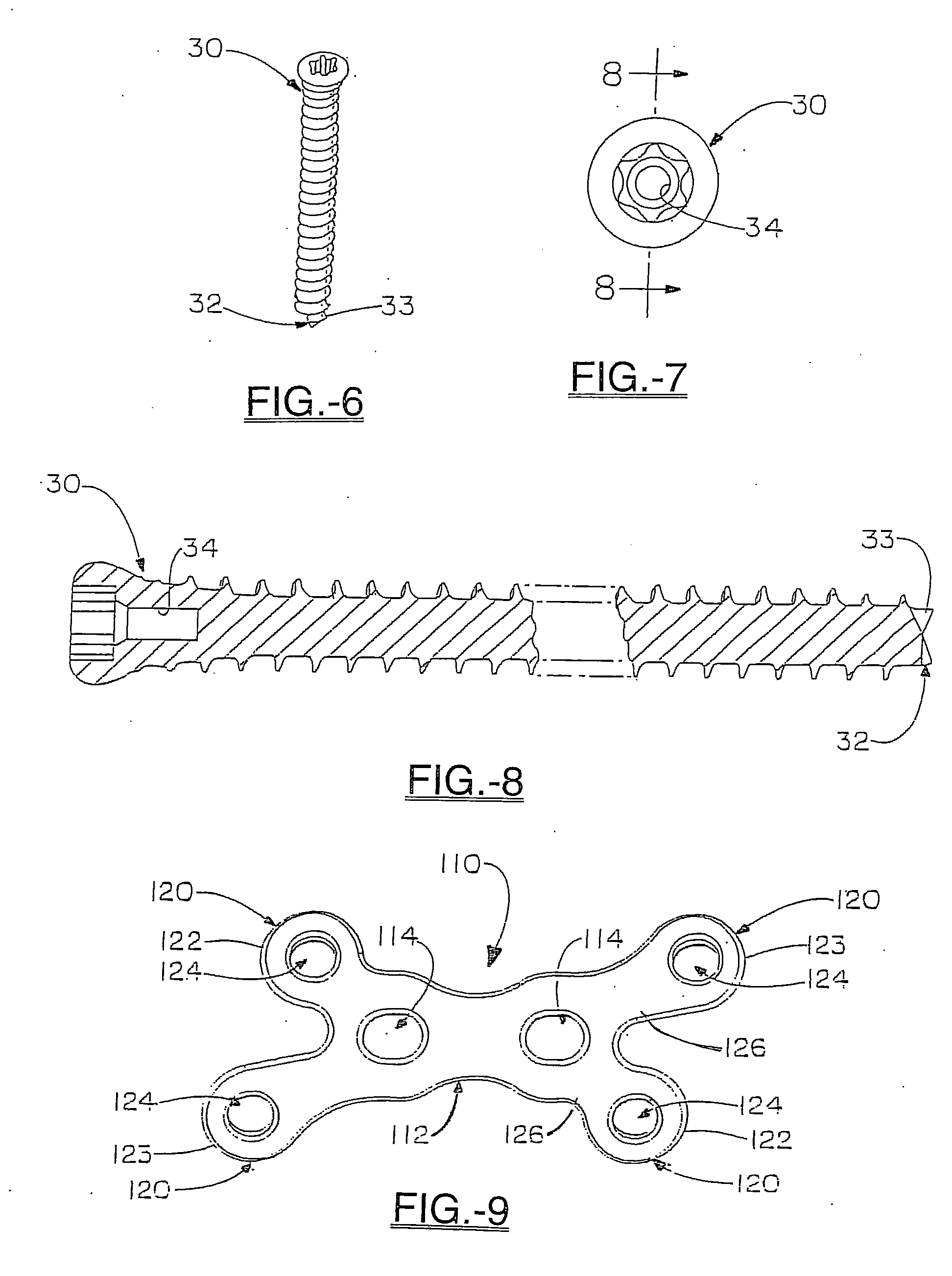

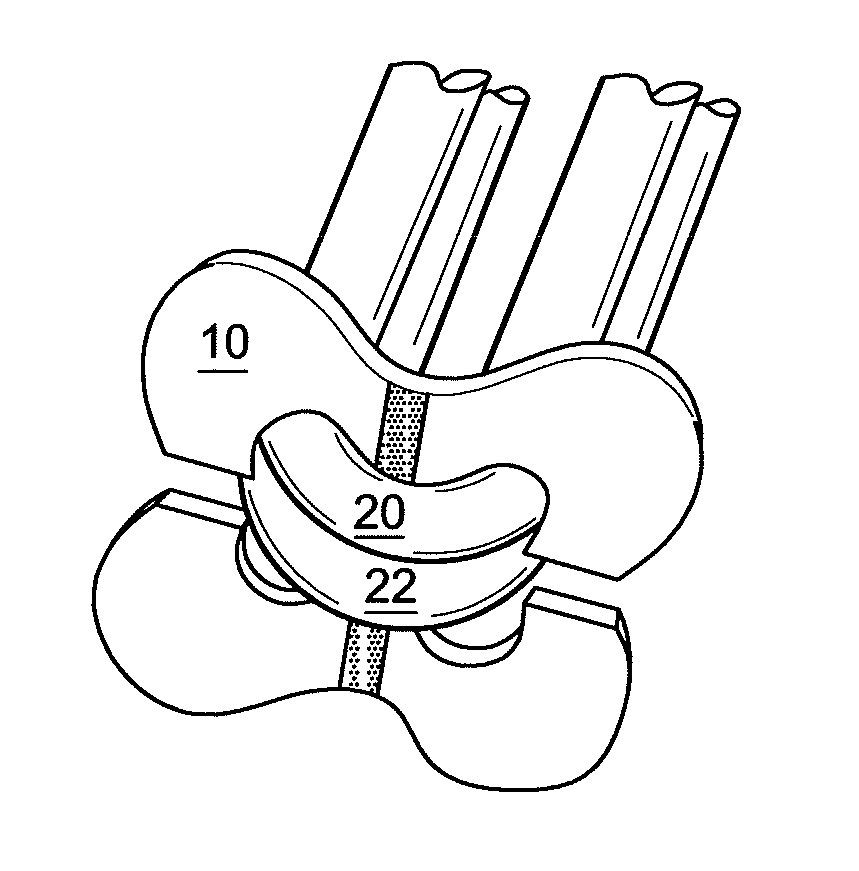

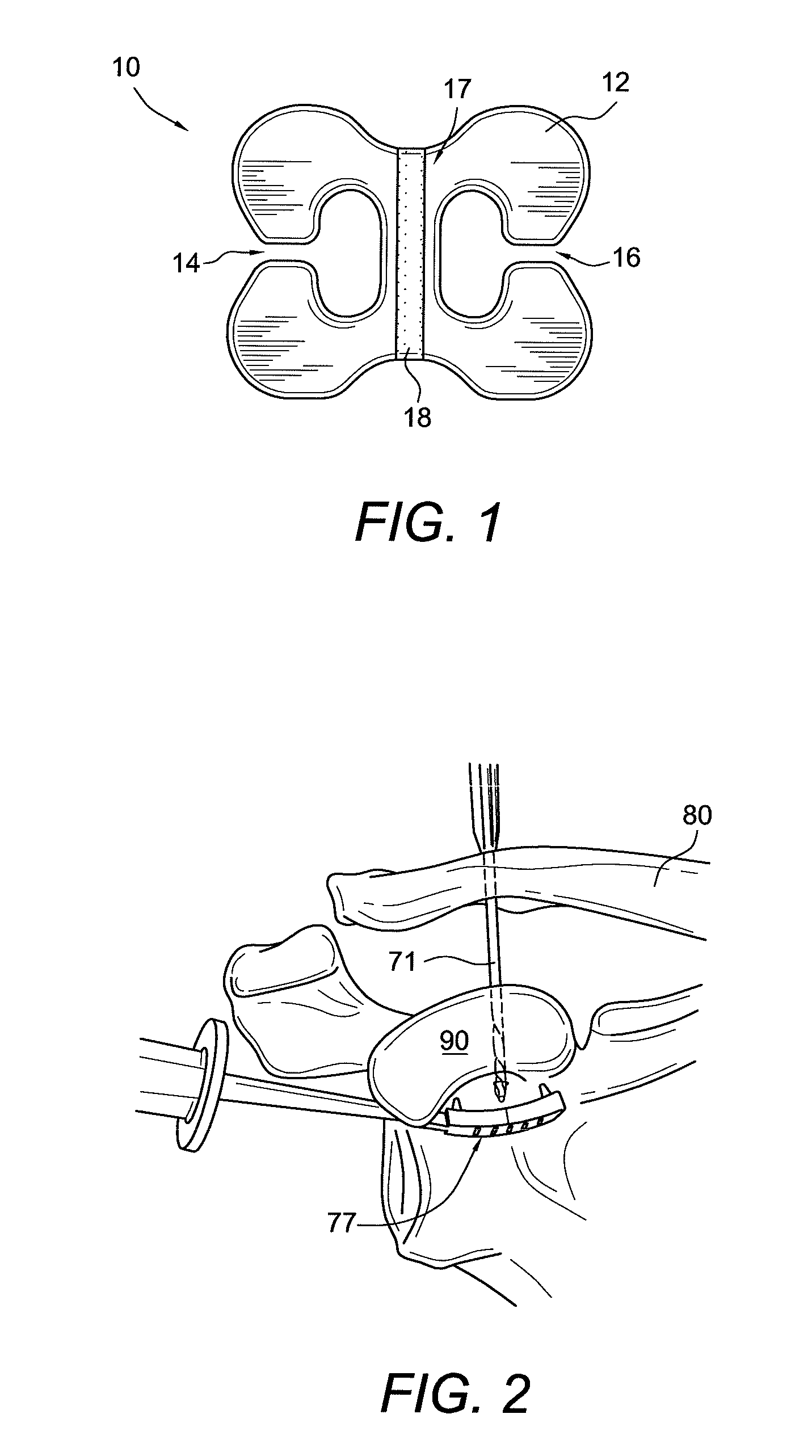

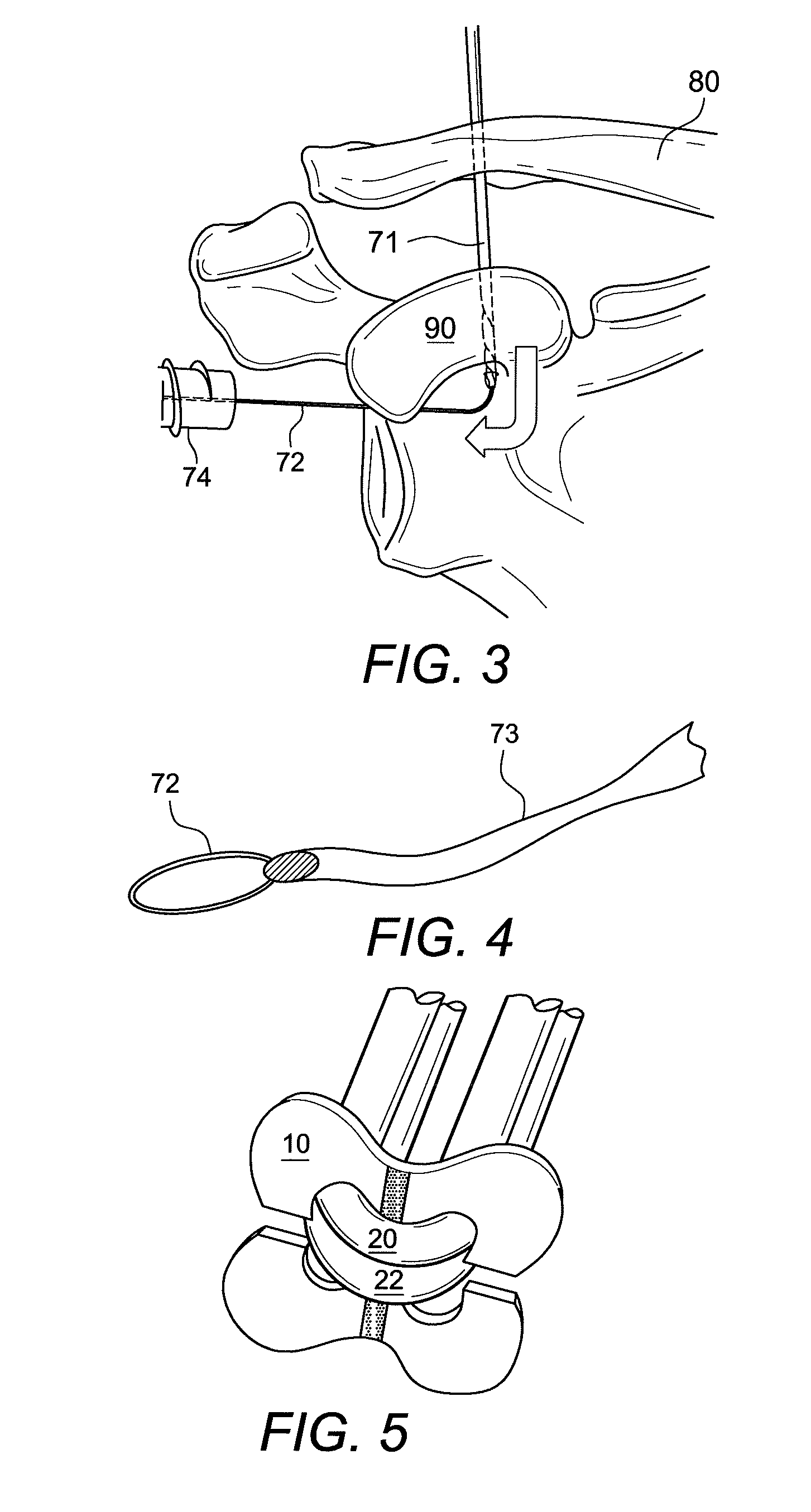

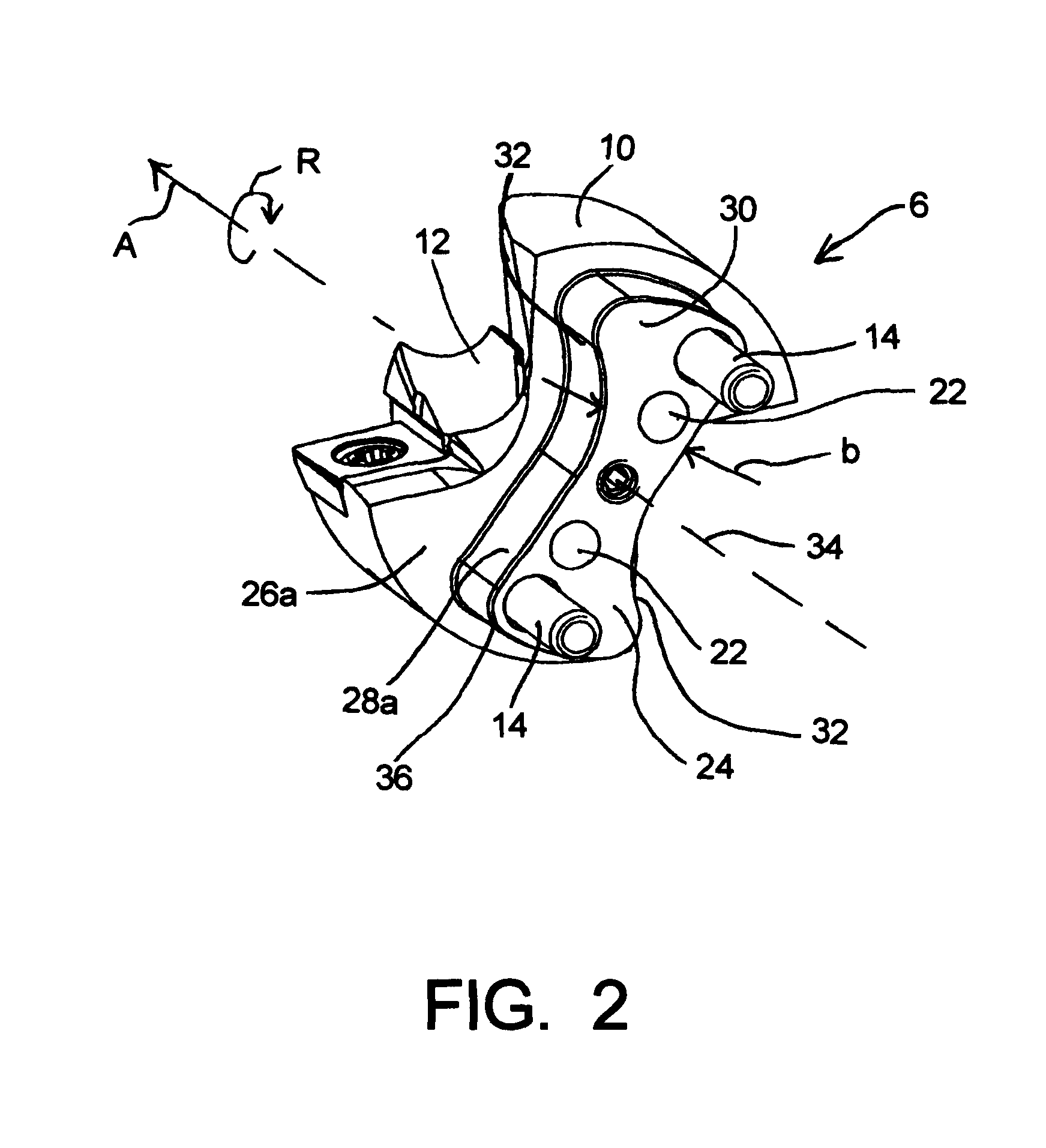

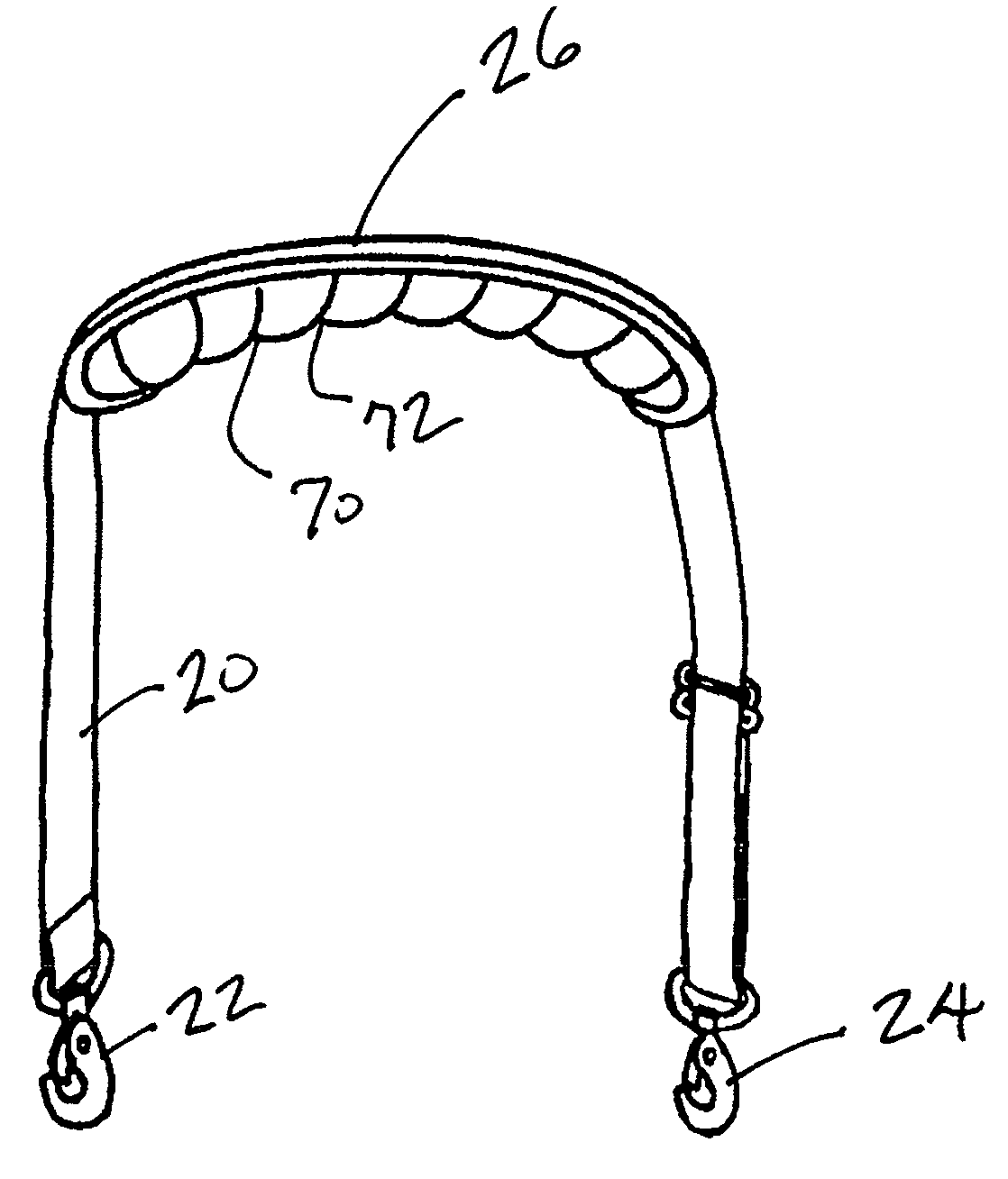

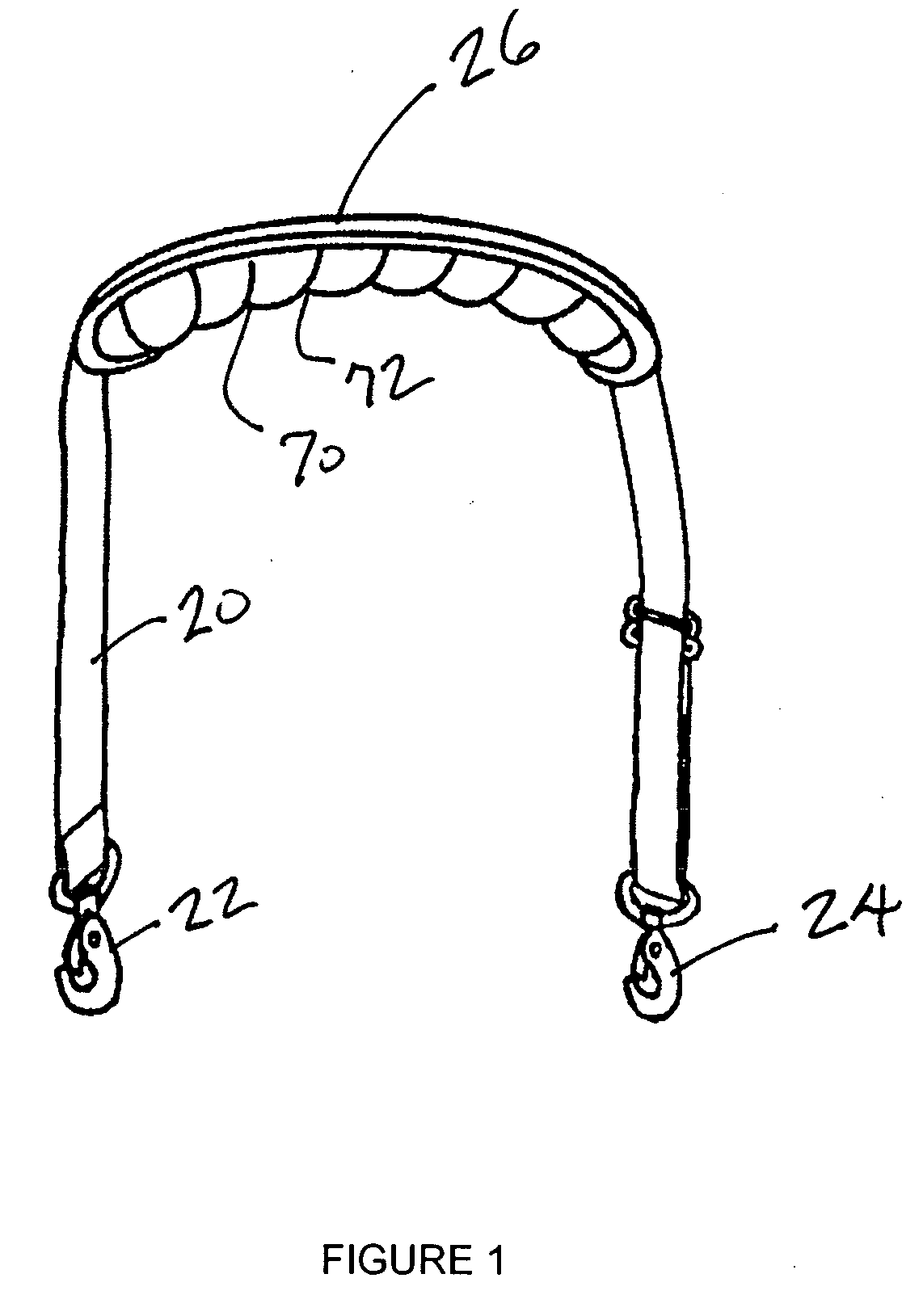

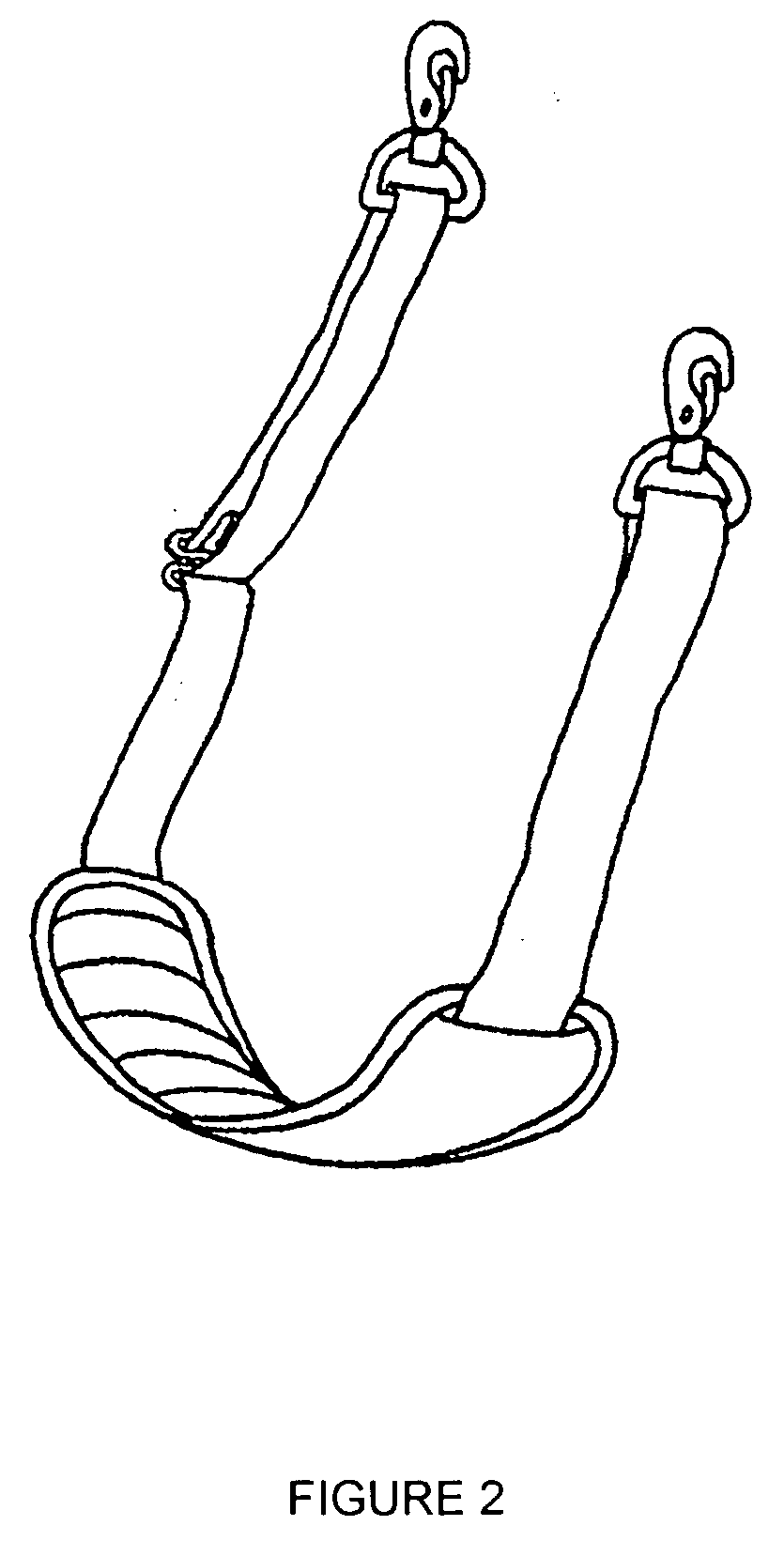

Acromioclavicular joint fixation using suture button contstruct with dog bone-shaped button

Methods and systems for AC joint repair using a fixation device having a specific “dog bone” configuration in a minimally invasive approach. One AC fixation system is formed of dog bone shaped buttons and at least one suture tape used to secure the buttons during an AC joint repair. The buttons are provided with openings that allow the passage of suture / tape limbs. Another AC joint fixation system is formed of a metal button inserted over a fused / joined construct having multiple flexible strands. The fused / joined construct is formed of multiple independent and separate suture strands and / or suture tapes that are joined (fused together) at about the midpoint of the tapes and / or sutures, resulting in multiple independent limbs of suture / tape. A suture tape loop construct having an integrally formed eyelet at one end of the loop may also be used in the fixation systems.

Owner:ARTHREX

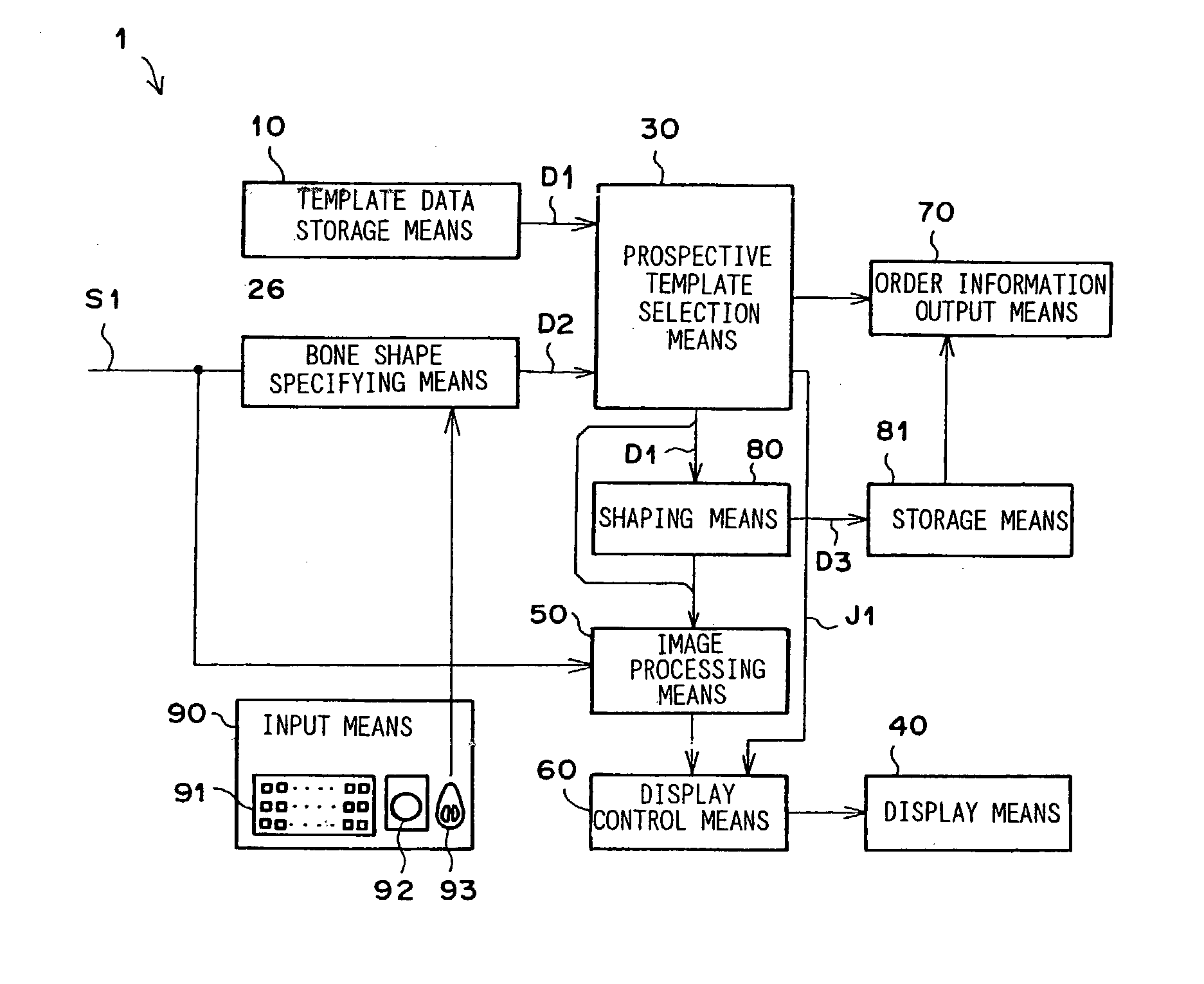

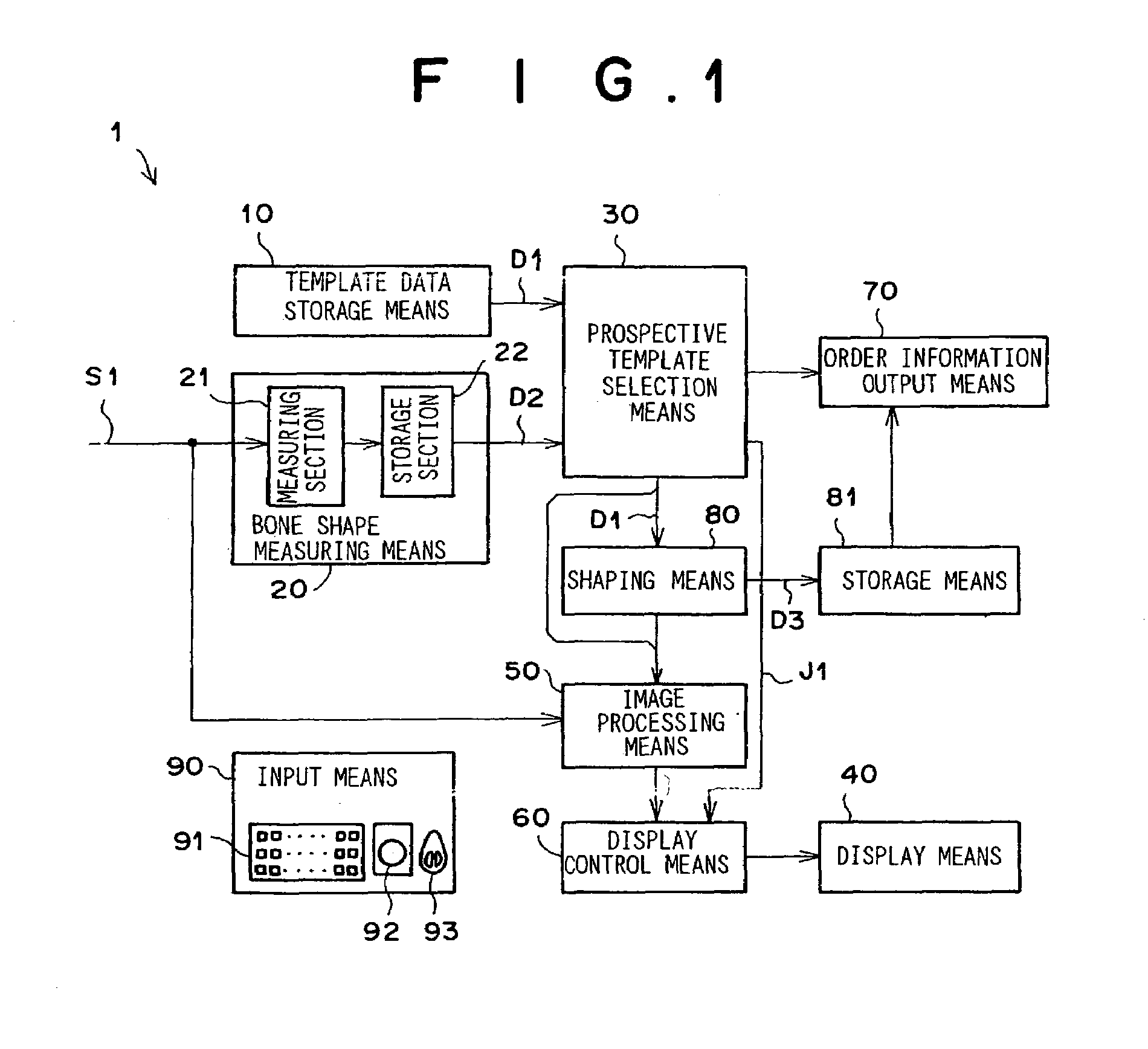

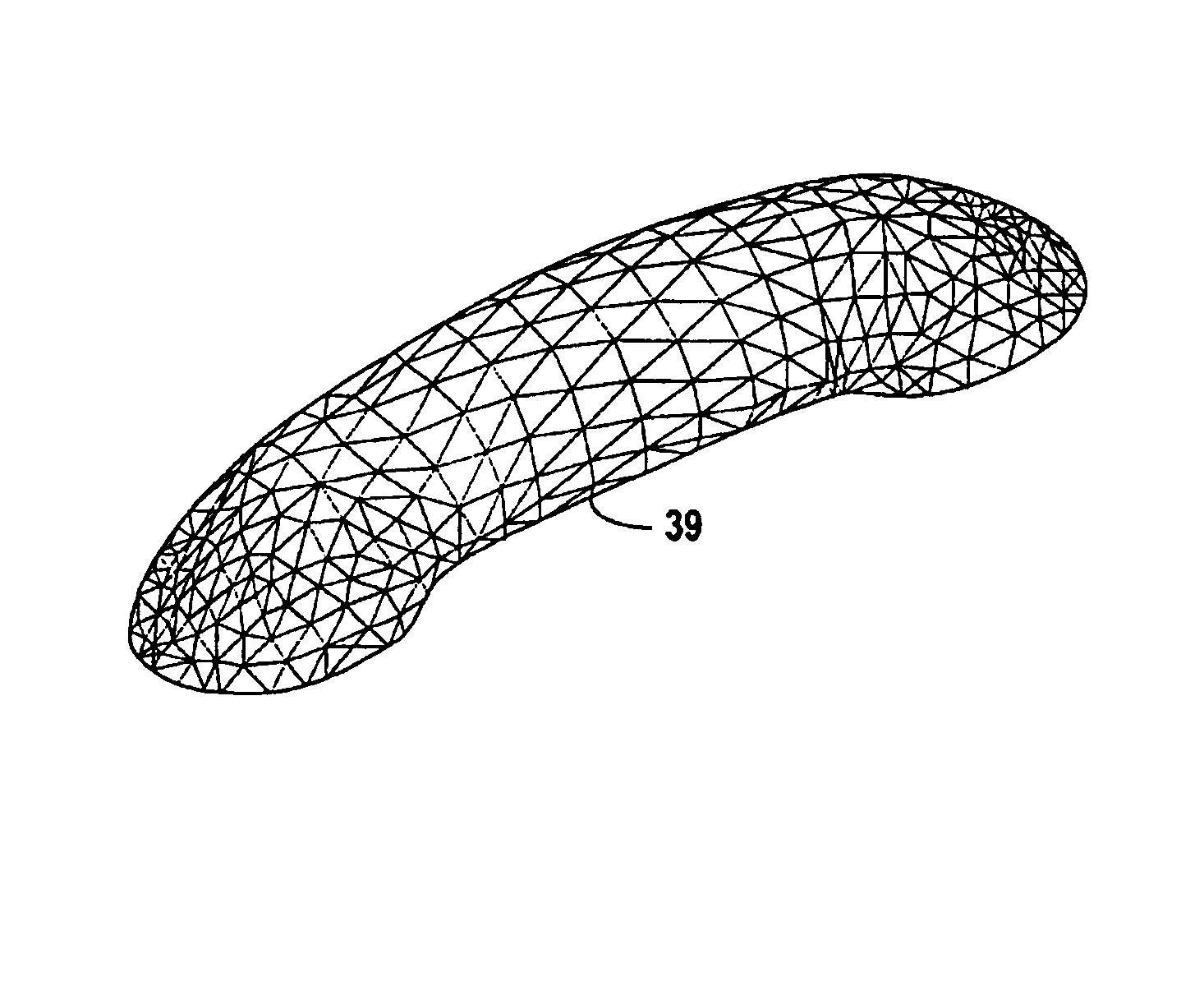

Artificial bone template selection system, artificial bone template display system, artificial bone template storage system and artificial bone template recording medium

InactiveUS7039225B2Valid choiceShort timePerson identificationCharacter and pattern recognitionSelection systemArtificial bone

An artificial bone template selection system includes a template data storage system in which template data representing a plurality of templates representing a plurality of artificial bones of different shapes is stored. A bone shape measuring system measures the shape of bone to be supplemented by artificial bone on the basis of bone image data representing an image including the bone to be supplemented by artificial bone. A prospective template selection system selects at least one template the shape of which substantially conforms to the shape of the bone to be supplemented by artificial bone as measured by the bone shape measuring system out of the plurality of templates represented by the template data.

Owner:FUJIFILM CORP

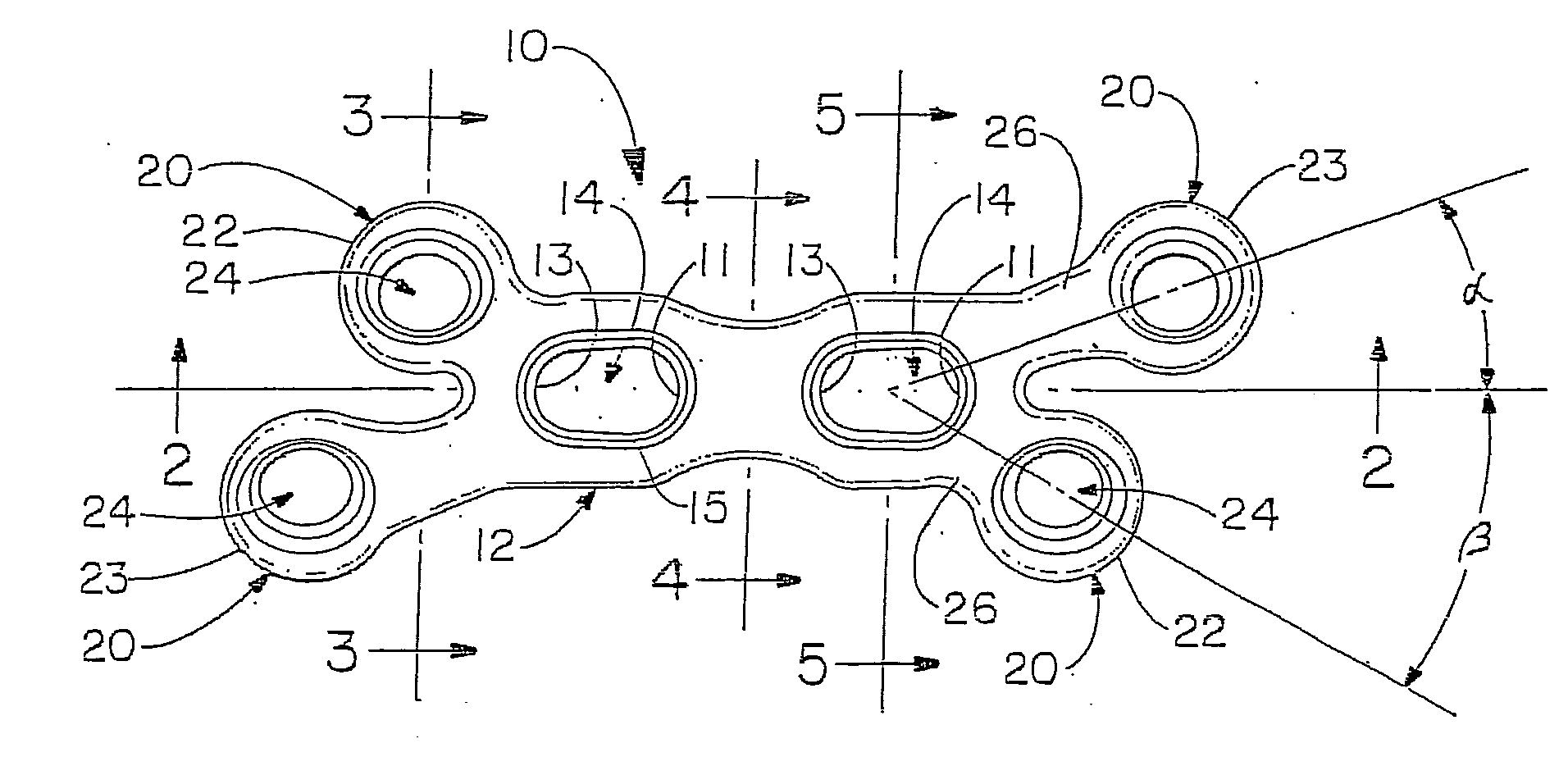

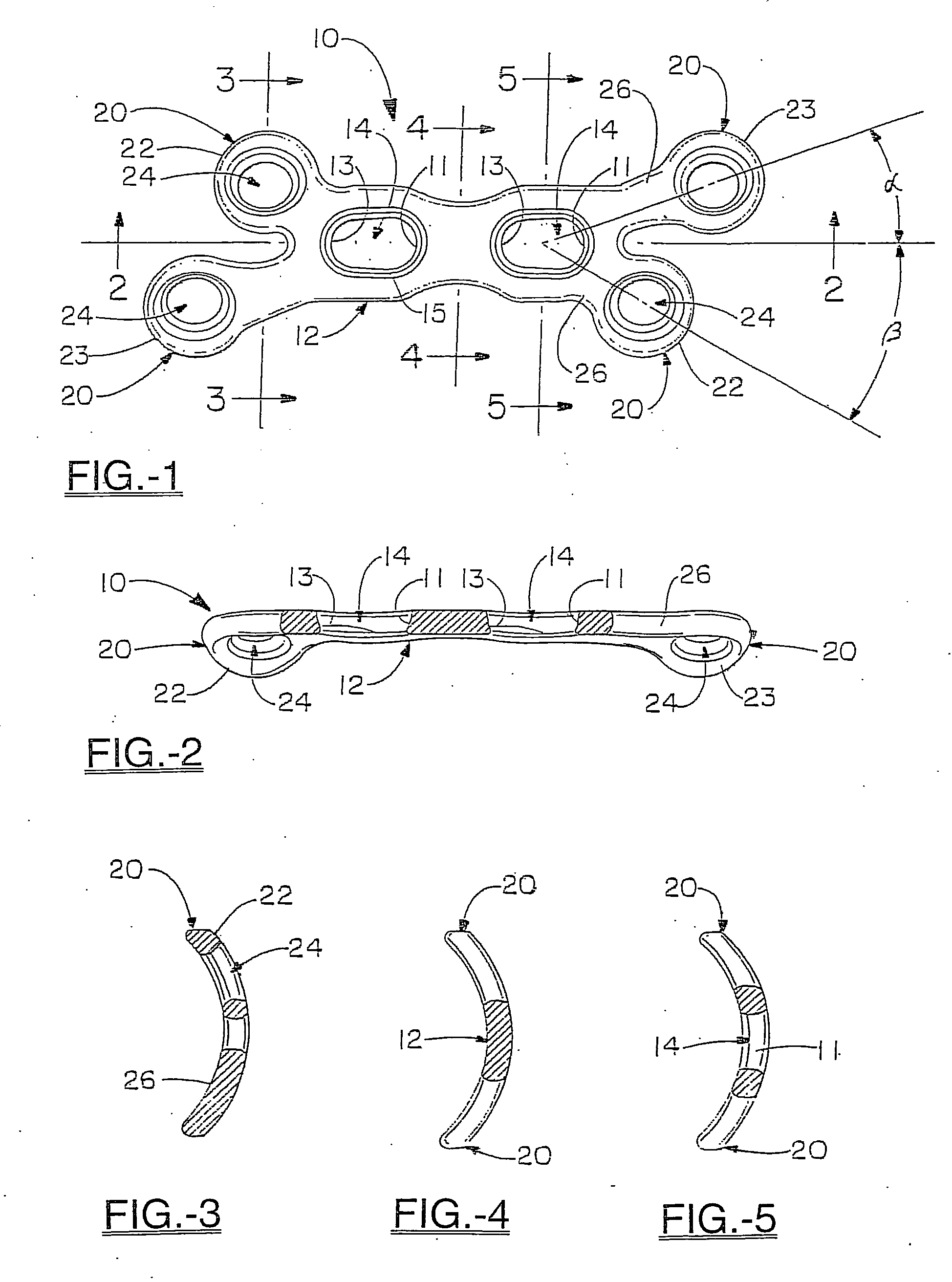

Orthopedic plate

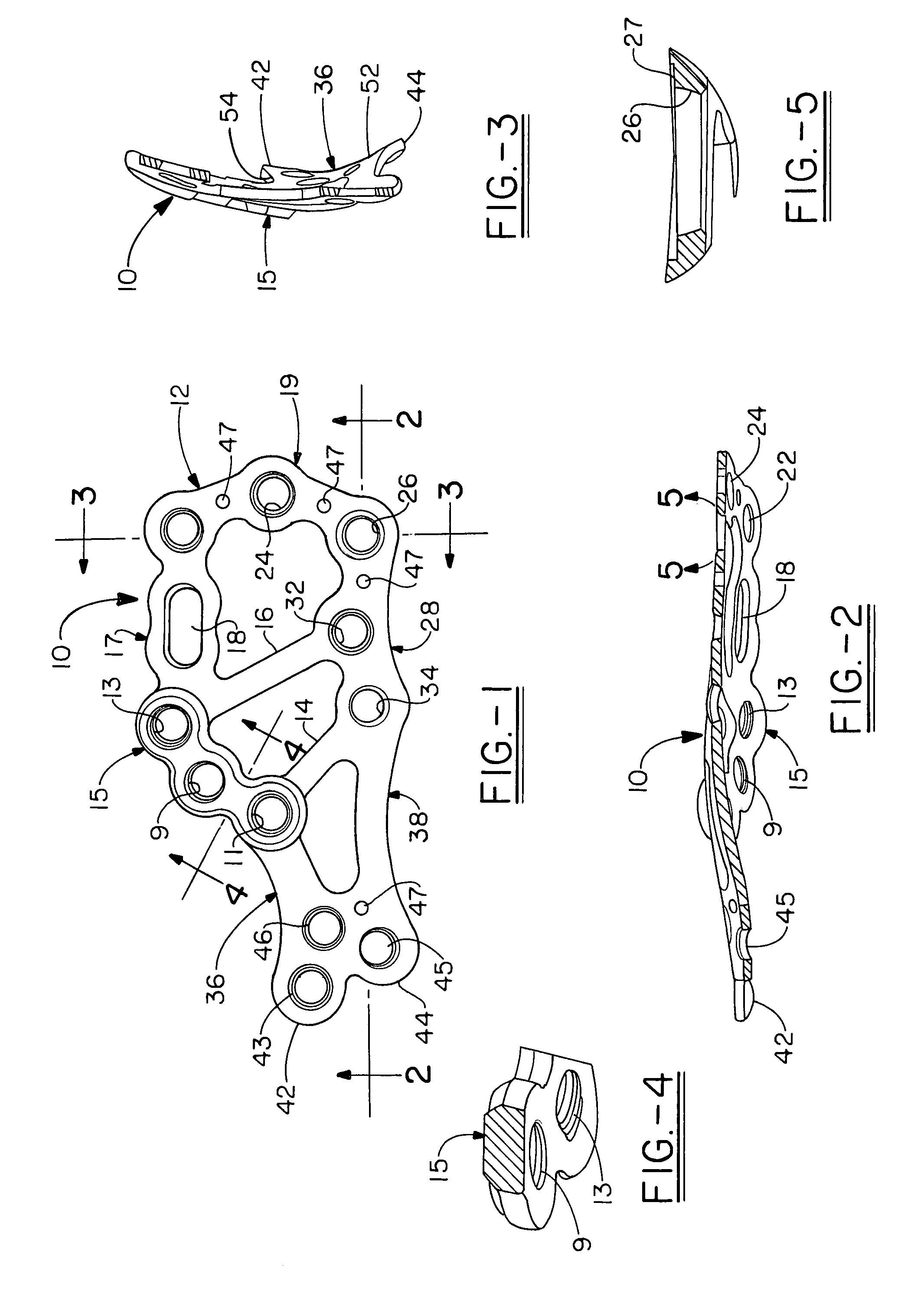

ActiveUS20060200145A1Increased pull-out strengthAvoid confictJoint implantsBone platesSmall patellaeBone tissue

The present invention relates to an orthopedic plate and screw system and instruments for surgical fixation of a small bone or bones including specifically the small bones of the spine. The plate facilitates three dimensional contouring to provide for a variety of applications and to accommodate individual variation in bone shape. The plate has a modified x shape including a central trunk portion including one or more screw holes along a longitudinal axis and a set of divergent upper and an oppositely extending set of divergent lower arms, each arm including screw holes which are placed at a radially equal distance but which diverging asymmetrically from the longitudinal axis relative to its paired upper or lower mate. The screws of the system are self-starting, self-tapping screws including the option of partial or full cannulation. In a further embodiment, the plate is intended for use through the length of the spine.

Owner:ORTHOHELIX SURGICAL DESIGNS

Calcaneal plate

The present invention is a fully contoured calcaneal plate having substantially no planar surfaces except at the origin. The contoured plate includes radiused sections, one extending inferior to superior is curved inferior to superior in a shape which is close to cylindrical and which approximates the shape of the cuboid bone. The second radiused section is curved in the vicinity of the anterior strut, and in particular at the inferior portion of the plate, to accommodate the peroneal tubercle. The plate has a rectangular or modified ovoid body section and a dog boned shaped tail with triangular placed holes for fixation.

Owner:ORTHOHELIX SURGICAL DESIGNS

Valvuloplasty catheter and methods

Owner:INTERVALVE MEDICAL INC

Bionic gradient knee femoral prosthesis structure and a production method thereof

ActiveCN103584931AImprove adaptabilityAdapt to exerciseAdditive manufacturing apparatusJoint implantsKnee JointFemoral prosthesis

The invention discloses a bionic gradient knee femoral prosthesis structure and a production method thereof. The prosthesis structure comprises a smooth curved-surface shell, a post-osteotomy completely-covering joint face, a gradient porous structure and a fixing device. The curved-surface shell is based on the shape of the distal end of a connate femur. The post-osteotomy completely-covering joint face reversely spreads to the distal-end curved surface of the connate femur. A solid more than 5mm distant from the curved surface is replaced by the gradient porous structure, and the fixing device is formed on the distal-end plane on the inner side of a femoral prosthesis. Compared with conventional standard prostheses, the prosthesis structure has the advantages that matching degree is high, and the prosthesis highly fits the bone shape of a connate knee and is adaptable to motions of a patient. The bionic gradient knee femoral prosthesis structure is easy to produce, and conventional production methods for conventional bionic gradient prostheses are complex; by the 3D (three-dimensional)-printing production method, prostheses can be customized according to individual differences of patients, production period is short, cost is low, and a possibility for application and development of individualized therapy is provided.

Owner:BEIJING NATON TECH GRP CO LTD +1

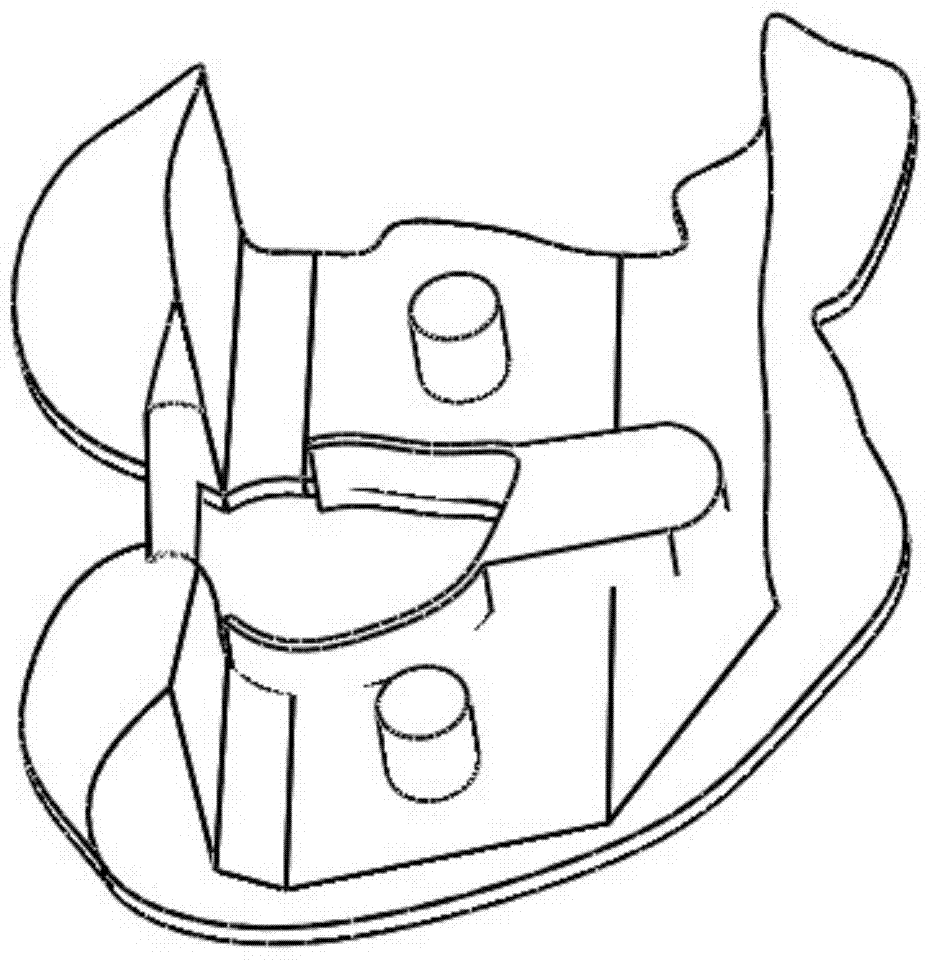

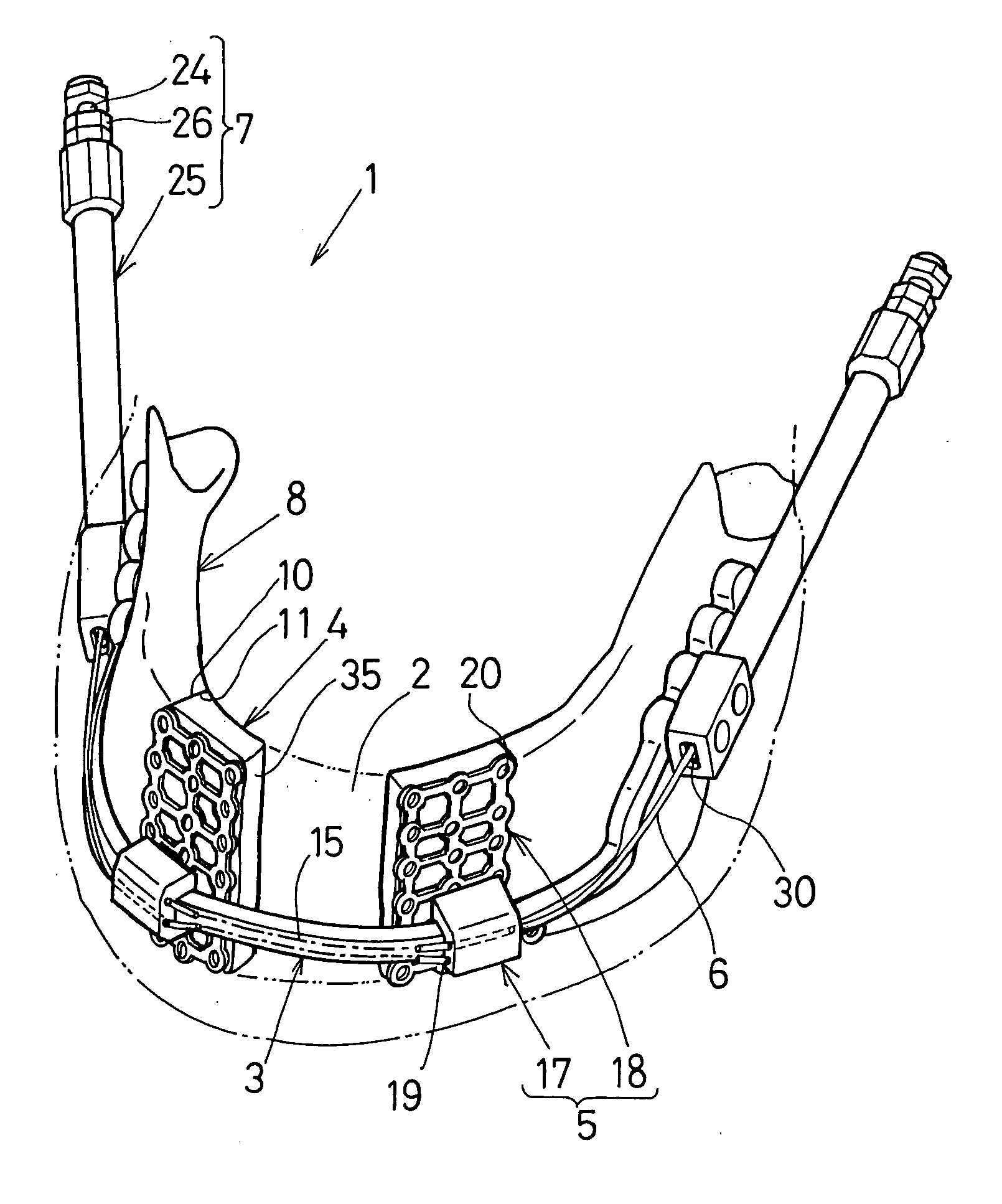

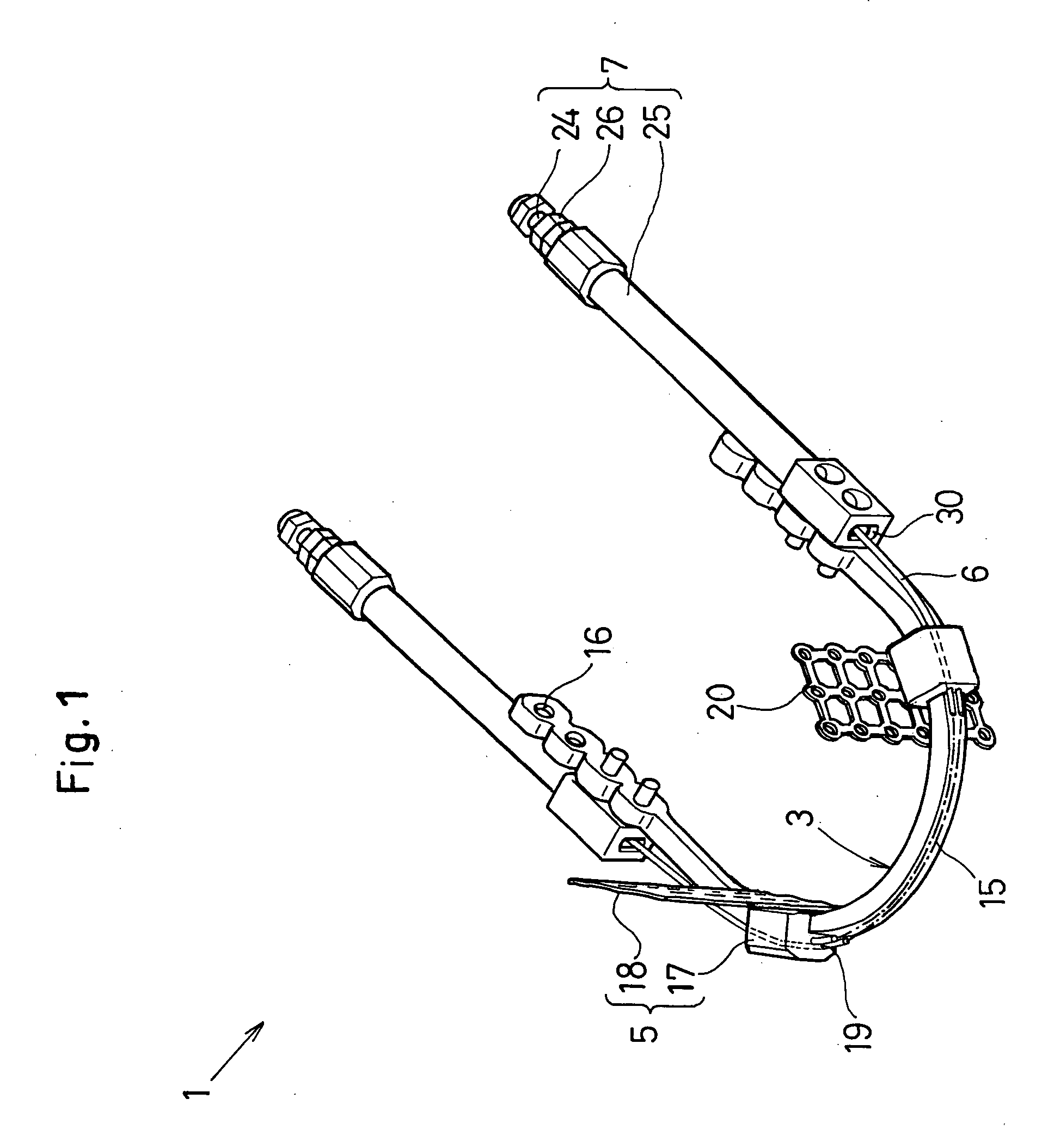

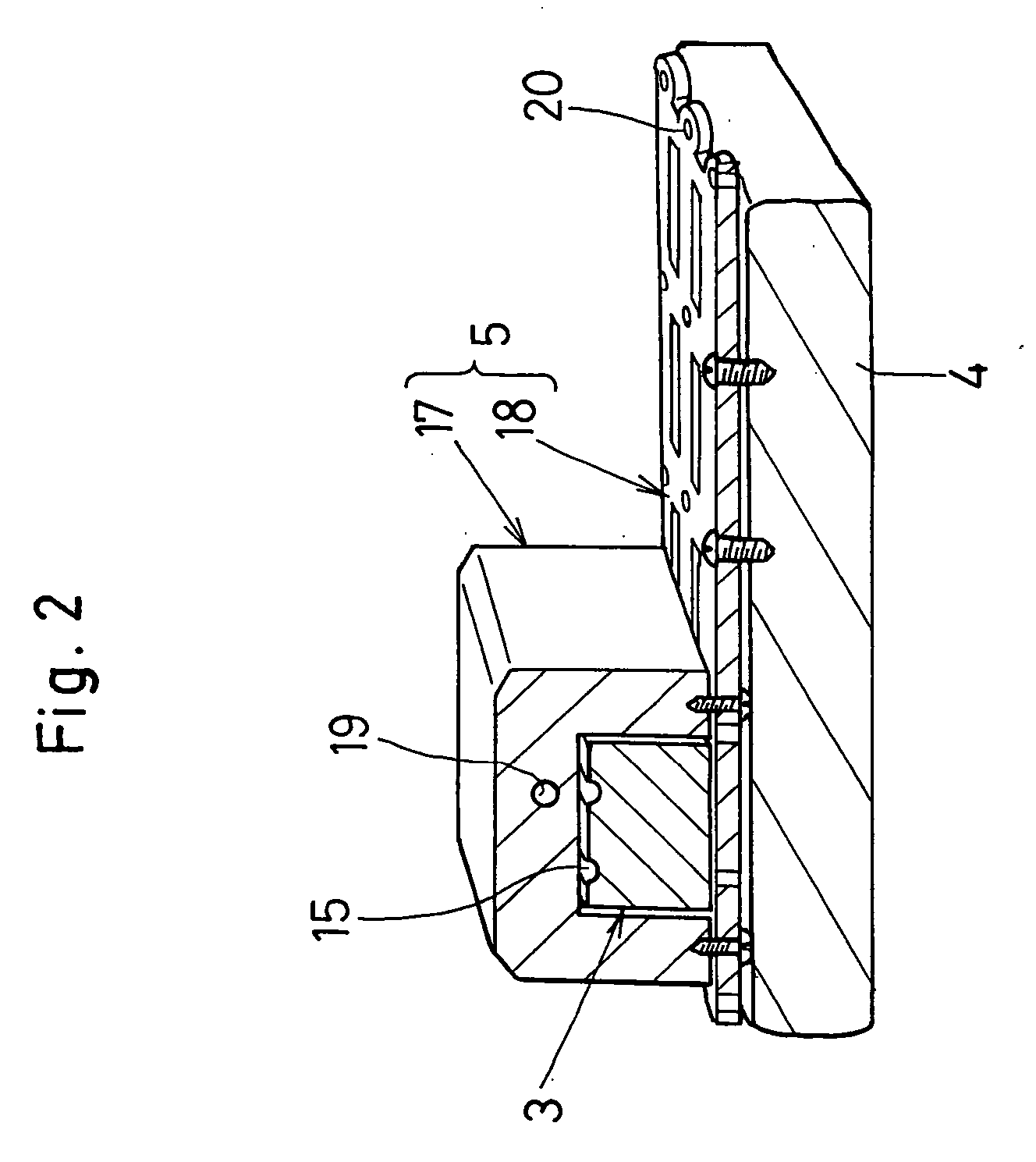

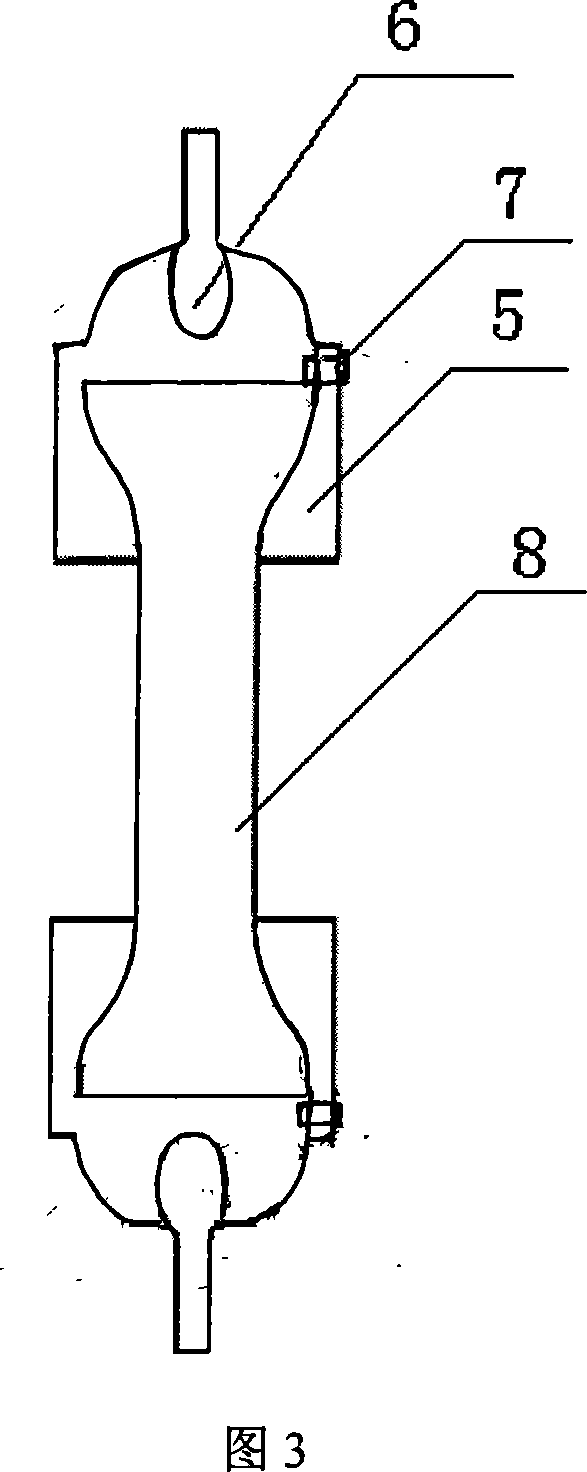

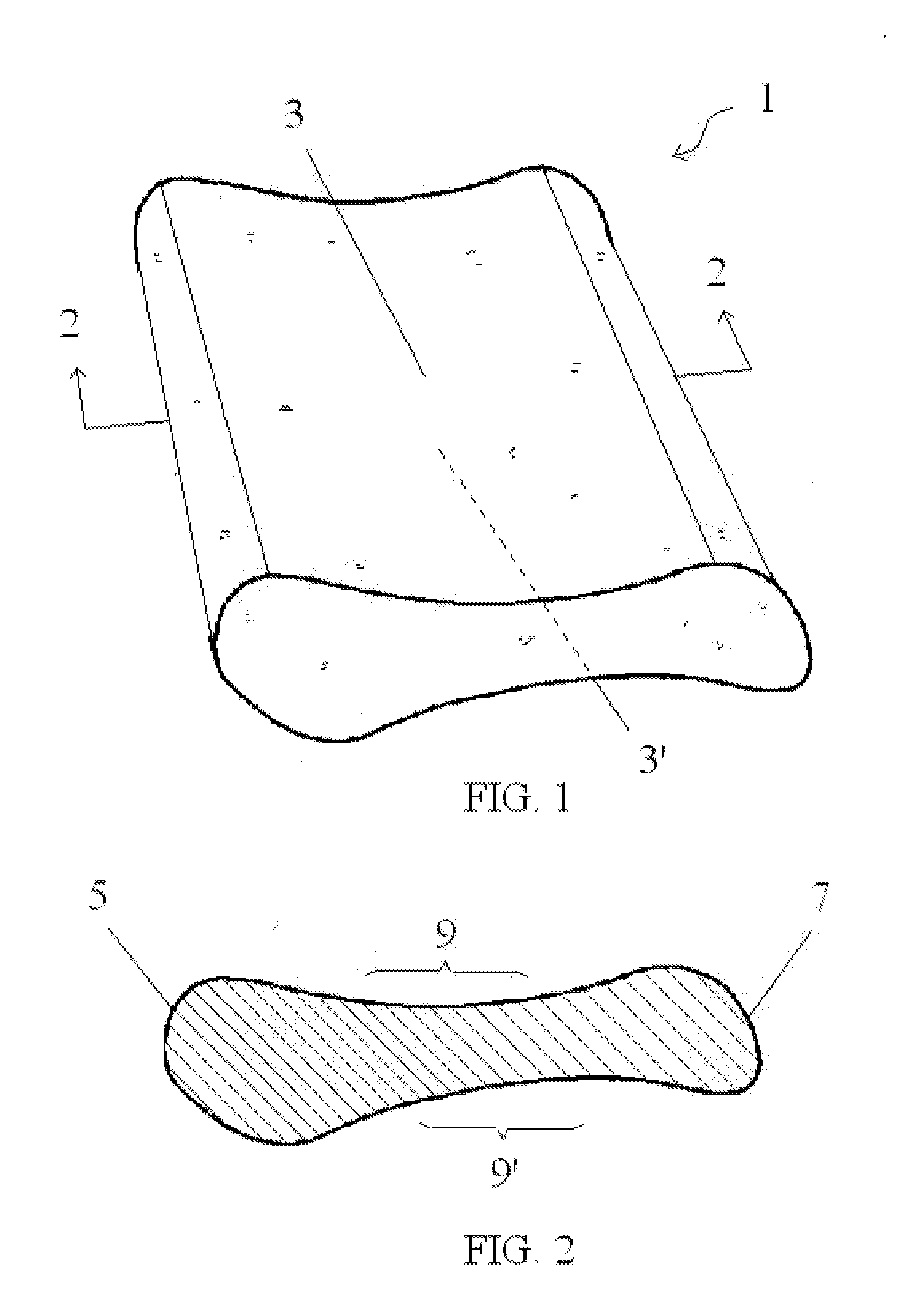

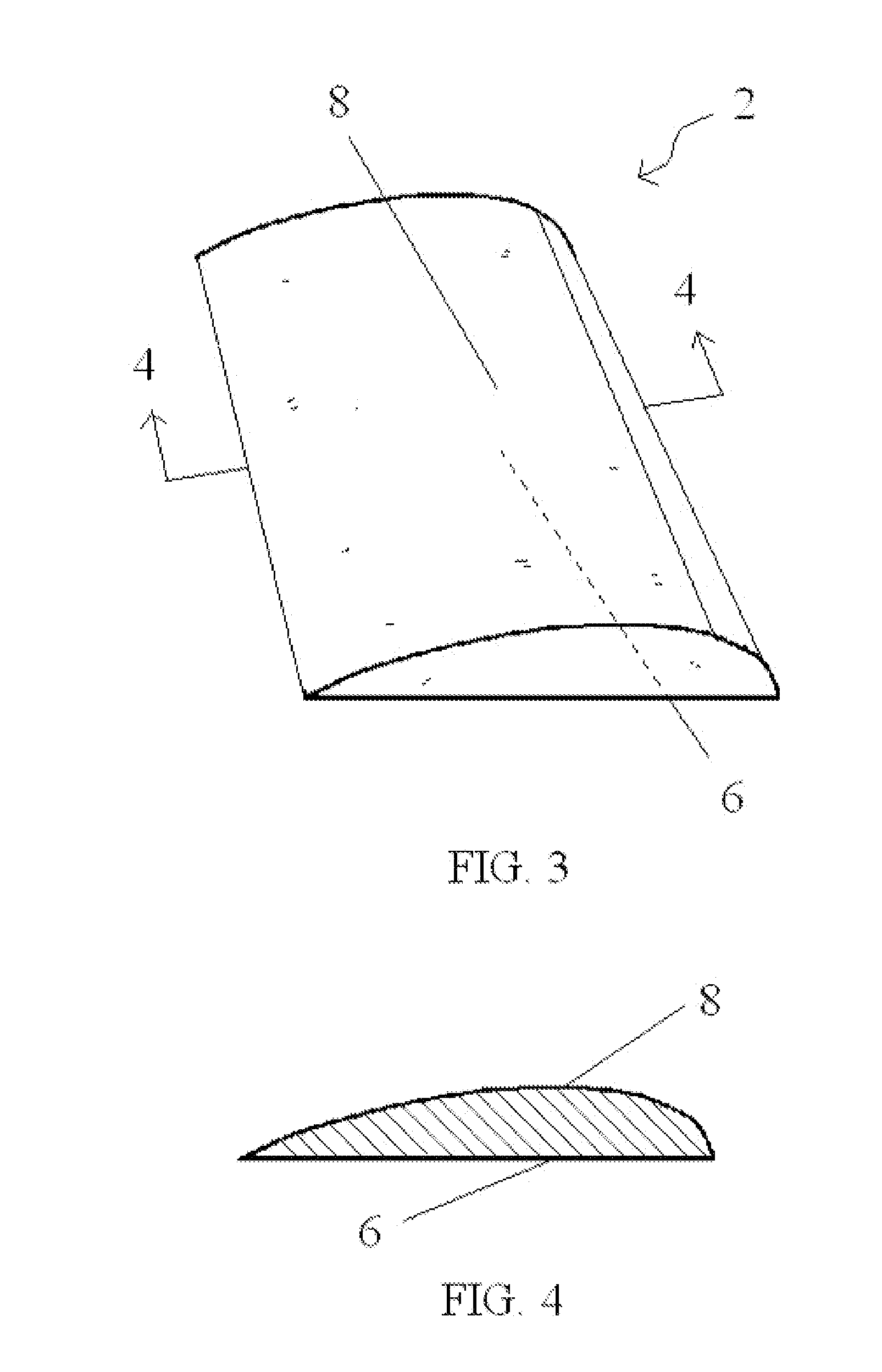

Callus elongating/regenerating device

In a callus elongating / regenerative device (1), a plate (3) is provided in a bar-shaped fashion to move in a three-dimensional direction depending on a pre-mutilated bone shape so as to bridge a mutilated bone portion (2). A bone cut end (8) is severed to produce two bone pieces (4) which are held by brackets (5). The brackets (5) are pulled to move along the plate (3) to three-dimensionally extend a callus (9) osteoplastically formed between a severed bone end (10) and a severed end surface (11). Since the brackets (5) are formed to move while surrounding the plate (3), the sizes of the plate (3) and the brackets (5) are such a degree as to be placed in a wound to-be osteoplastically treated. Thus, the callus (9) can be three-dimensionally extended with a most part of the callus elongating / regenerative device (1) retained in the wound.

Owner:NIHON STRYKER +2

A kind of chewing pet food and its production process

InactiveCN102258143AMeeting nutritional needsSatisfy chewing instinctFood processingAnimal feeding stuffSpherical shapedBone shape

The invention discloses a chewing pet food, which is characterized in that it contains the following raw materials and is prepared according to the following weight ratio: edible meat: 50-80 parts, moisturizing agent: 5-20 parts, edible gum: 2-16 parts servings, plant protein: 4-15 servings, the pet chews produced not only have the advantages of good toughness and chewiness of traditional chewing products, but also greatly improve the disadvantages of poor palatability of traditional chewing products, which can reach The double function of making pets play and eat reduces the waste of resources and the pollution of the environment. The present invention takes edible meat as the main raw material, adds certain auxiliary materials for cutting and mixing, and is made into bone shape, bone shape, rod shape, heart shape through processes such as extrusion and baking, and is woven into spherical shape, ponytail shape, and twist shape. Chewing pet products in various shapes, the process mostly uses mechanical equipment, which reduces the use of labor, reduces costs, improves processing efficiency, and expands the product line.

Owner:YANTAI CHINA PET FOODS GRP

Acromioclavicular joint fixation using suture button contstruct with dog bone-shaped button

Methods and systems for AC joint repair using a fixation device having a specific “dog bone” configuration in a minimally invasive approach. One AC fixation system is formed of dog bone shaped buttons and at least one suture tape used to secure the buttons during an AC joint repair. The buttons are provided with openings that allow the passage of suture / tape limbs. Another AC joint fixation system is formed of a metal button inserted over a fused / joined construct having multiple flexible strands. The fused / joined construct is formed of multiple independent and separate suture strands and / or suture tapes that are joined (fused together) at about the midpoint of the tapes and / or sutures, resulting in multiple independent limbs of suture / tape. A suture tape loop construct having an integrally formed eyelet at one end of the loop may also be used in the fixation systems.

Owner:ARTHREX

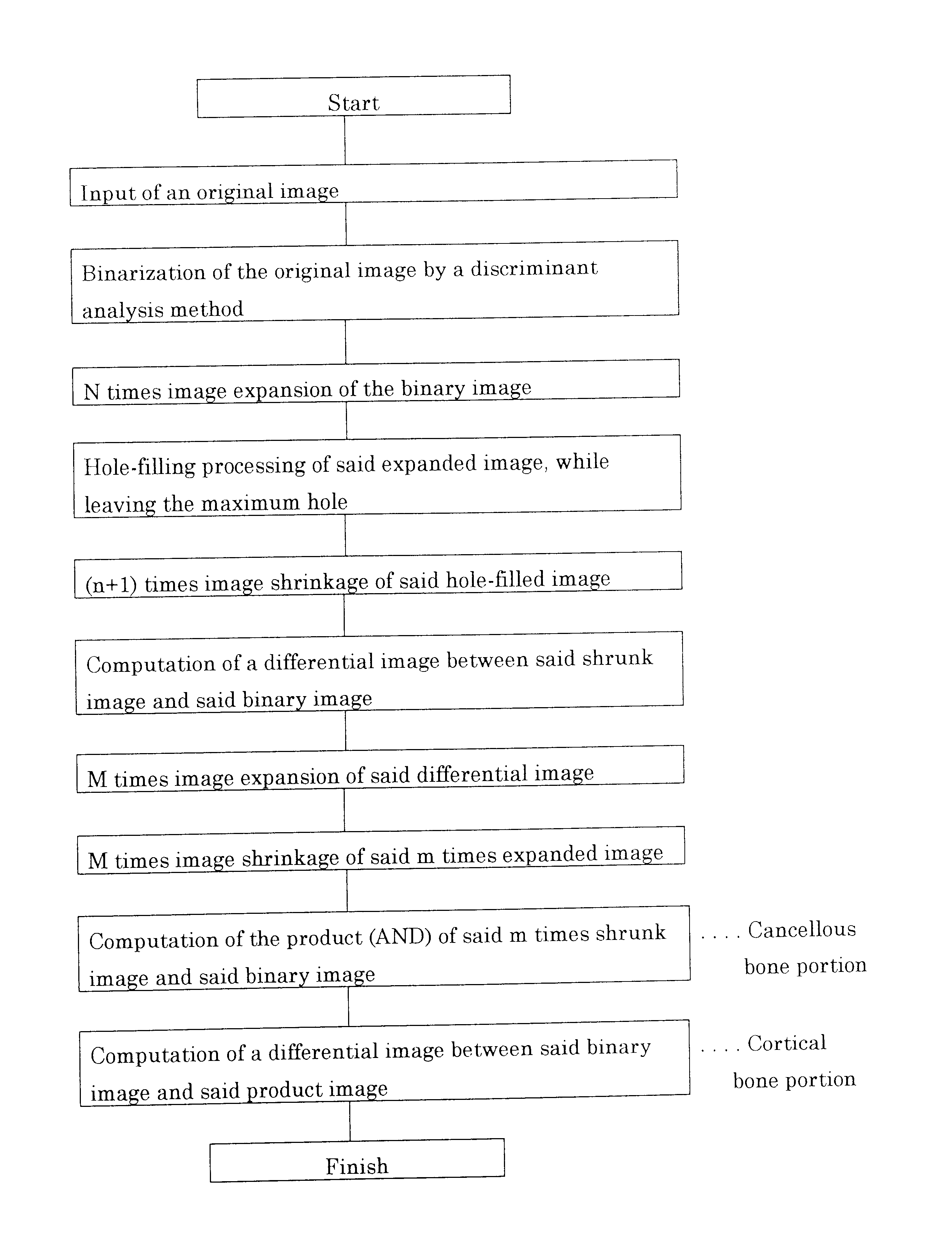

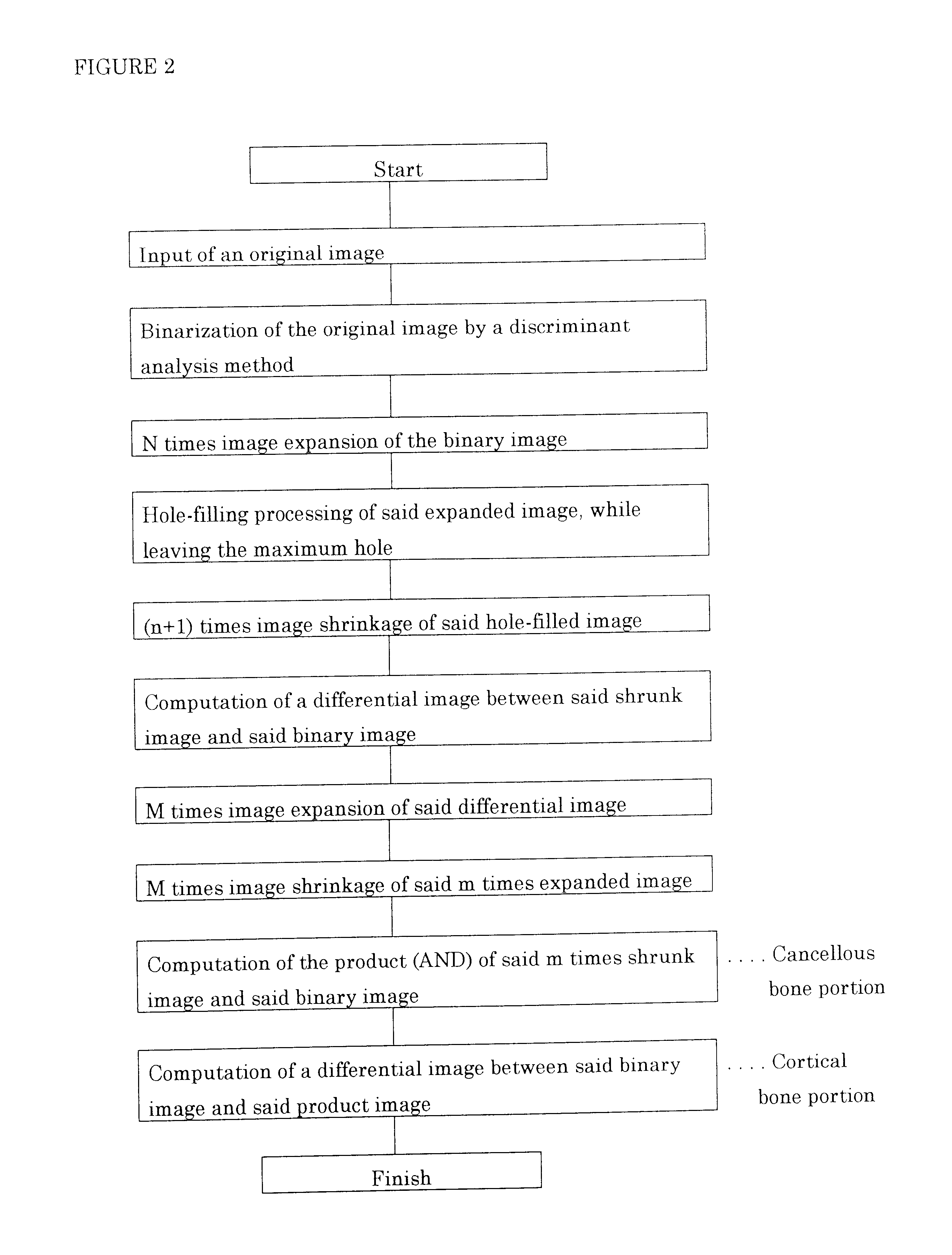

Bone measuring method

InactiveUS6839457B1Increase speedGood repeatabilitySurgeryCharacter and pattern recognitionBone structureBone Cortex

This invention relates to a bone measurement method for measuring a bone shape, structure and architecture on the basis of the tomographic images of a test bone or joint, in more detail, to a bone measurement method characterized by having a template image extraction step for obtaining a wholly continued template image of a bone inner portion surrounded by a cortical bone from the binary image of a test bone cross section, and separating a cortical bone and a cancellous bone by the product of said template image and said binary image, as a bone measurement method which enables the automatic, high-speed and repeatable separation of a cortical bone and a cancellous bone on the basis of the binary image of a test bone or joint cross section and by which a separated three-dimensional image of the cortical bone portion and the cancellous bone portion is obtained as the bases for a non-invasive analyses of three-dimensional bone structure, bone strength, and the like.

Owner:TEIJIN LTD

Snap on blade shim

A gas turbine engine blade root shim includes a dovetail shim portion with a dovetail shape and a longitudinally extending substantially flat base and distal first and second longitudinally spaced apart forward and aft ends. Transversely spaced apart first and second walls extend upwardly from the base which includes at least two longitudinally extending elongated base apertures. Each of the base apertures includes a main region and longitudinally spaced apart rounded end regions. Dog-bone-shaped base apertures or rounded end base apertures having semi-circular rounded end regions may be used. The shim is designed for a blade dovetail root with a root slot formed in a bottom of the dovetail root. The dovetail shim portion with the dovetail shape substantially conforms to at least a portion of a cross-sectional dovetail shape of the dovetail root through the root slot. The base is disposed within the root slot.

Owner:GENERAL ELECTRIC CO

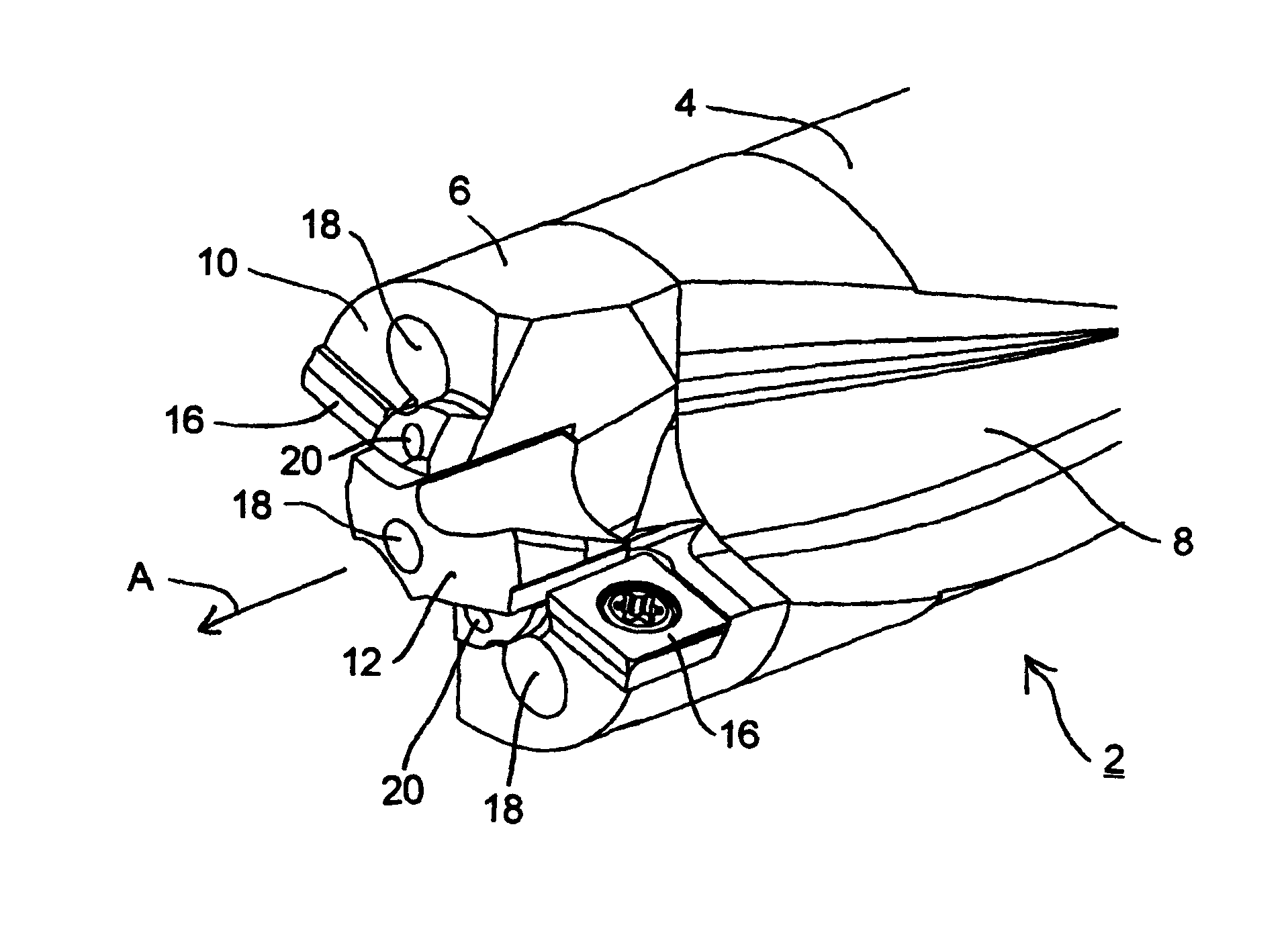

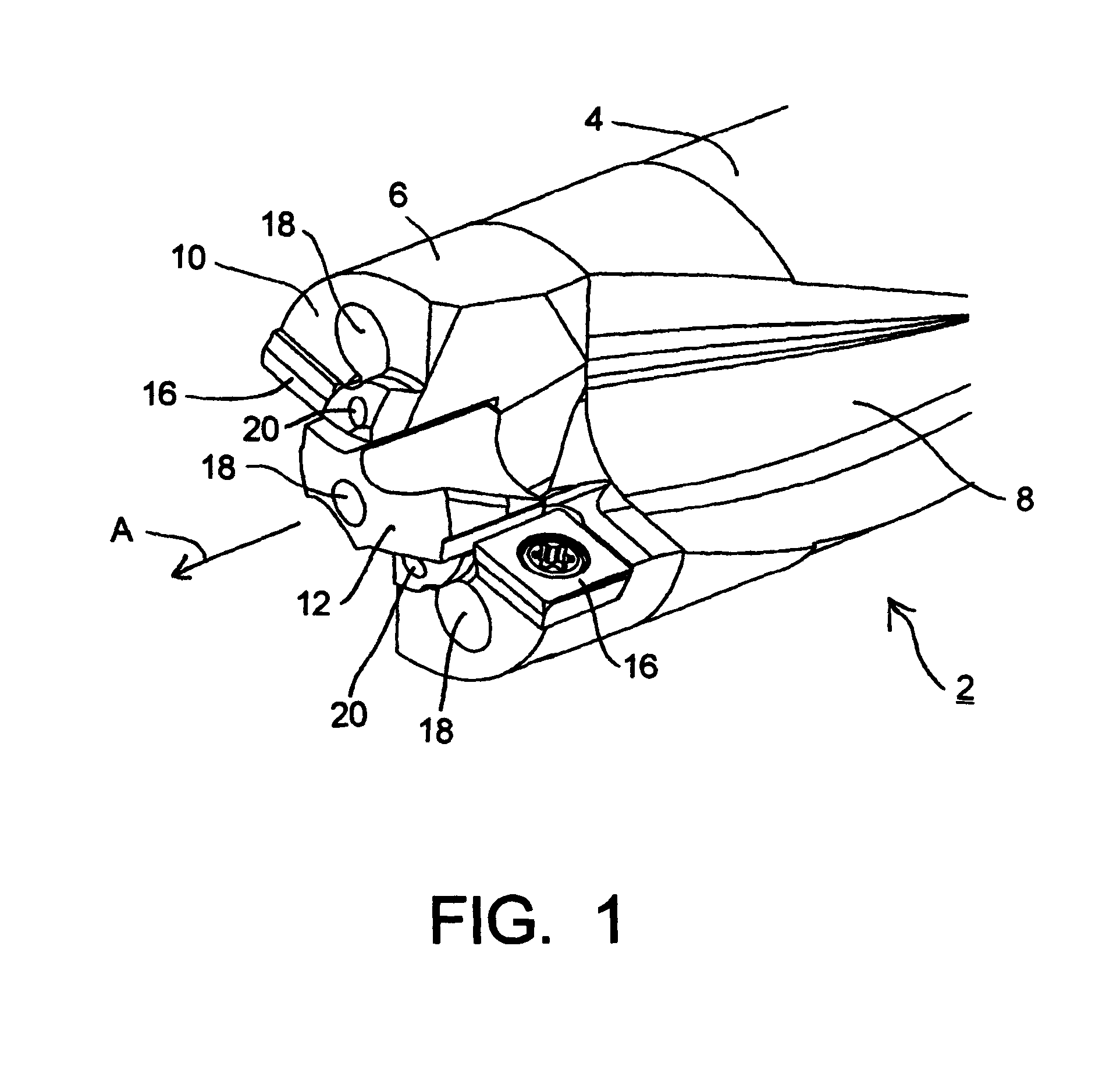

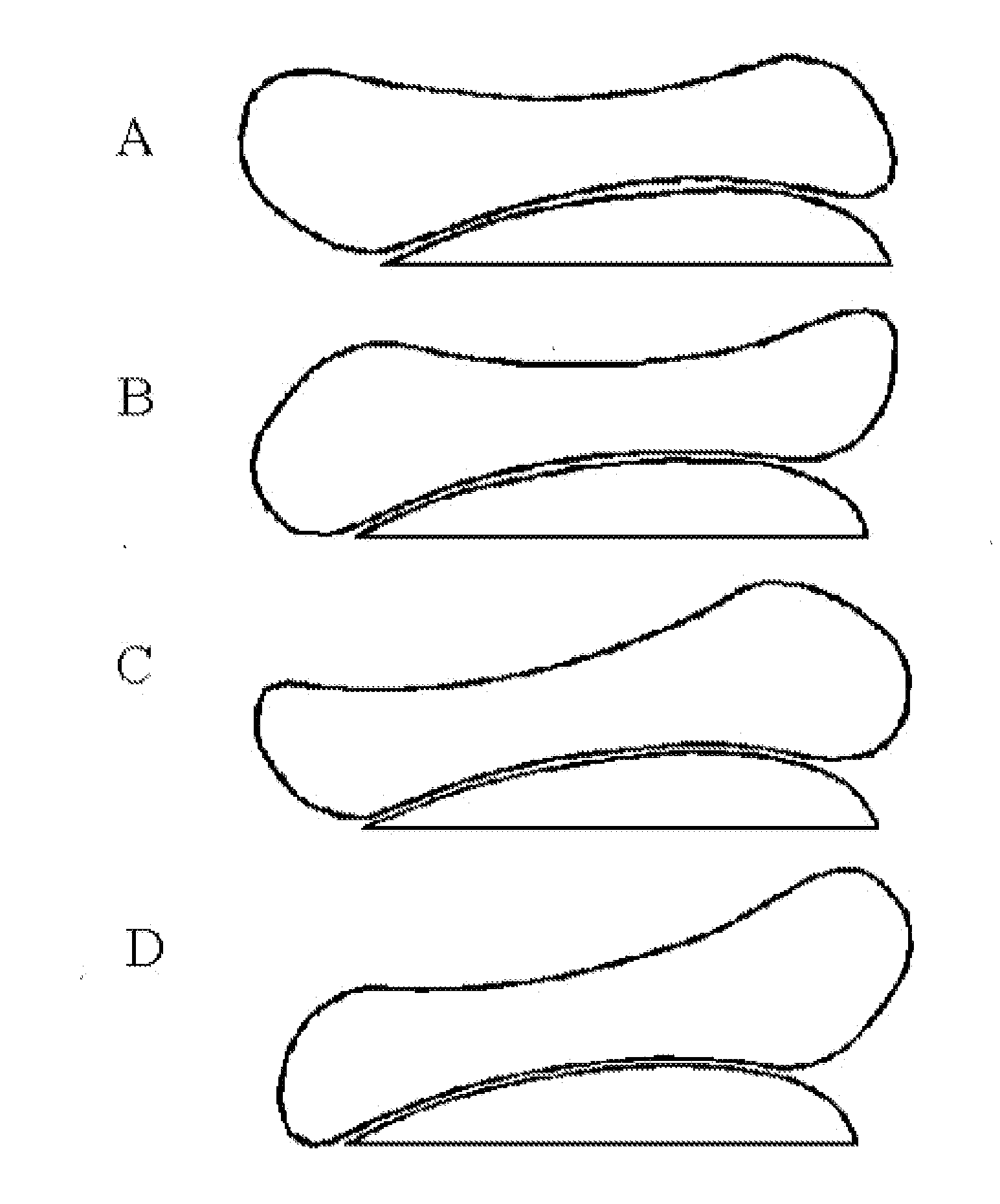

Drill, a drill assembly, and a tool head for a cutting tool

ActiveUS8376669B2Minimizes and restricts formationReduce riskDrill bitsWood turning toolsEngineeringBone shape

A drill includes a tool body having a fluted portion having a second end and a tool head portion, having a cutting tip and at least one cutting edge, removably connected to the second end of the fluted portion. The fluted portion includes a receiving pocket disposed in the second end and is defined by a peripheral side wall extending about the periphery of the receiving pocket. The tool head portion includes a driving projection configured to be inserted into the receiving pocket. The driving projection and receiving pocket have corresponding elongated, curvilinear, dog-bone shapes. The driving projection includes a first end portion, a second end portion, and a central portion disposed between connecting the first end portion and the second end portion. The first end portion and the second end portion each have a width that is substantially greater than a width of the central portion.

Owner:KENNAMETAL INC

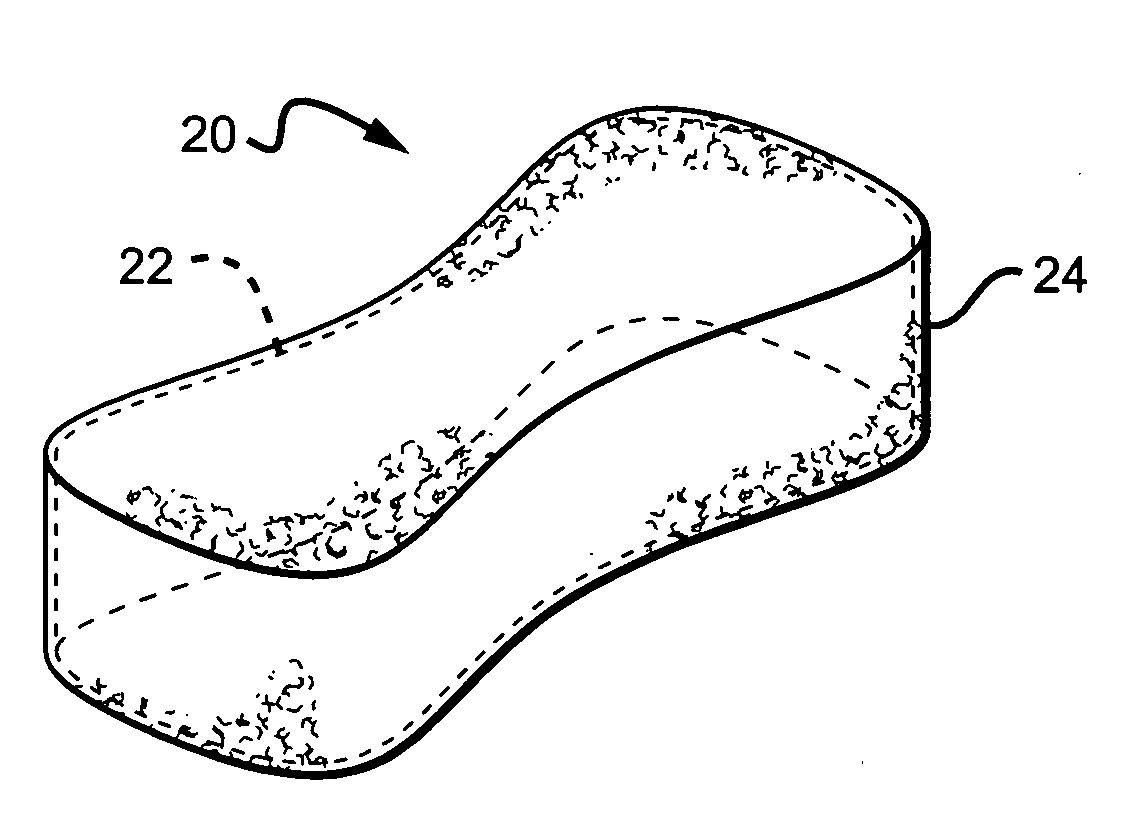

Sponge and cloth cleaning device

A relatively thick sponge has a washable microfiber cloth that removably covers at least a portion of the sponge, and is particularly well adapted for automotive use by virtue of a microfiber pile on the cloth. Preferred cloth coverings have microfibers with a length (pile height) of between 0.5 and 0.11 cm, and more preferably between 0.7 and 0.9 cm. The sponge can be any suitable size and shape, but is preferably dog bone shaped, having a length of at least 10 cm, a width of at least 6 cm, and a thickness of at least 2 cm. The cloth is preferably sized and dimensioned to completely enclose the sponge.

Owner:MEGUIARS

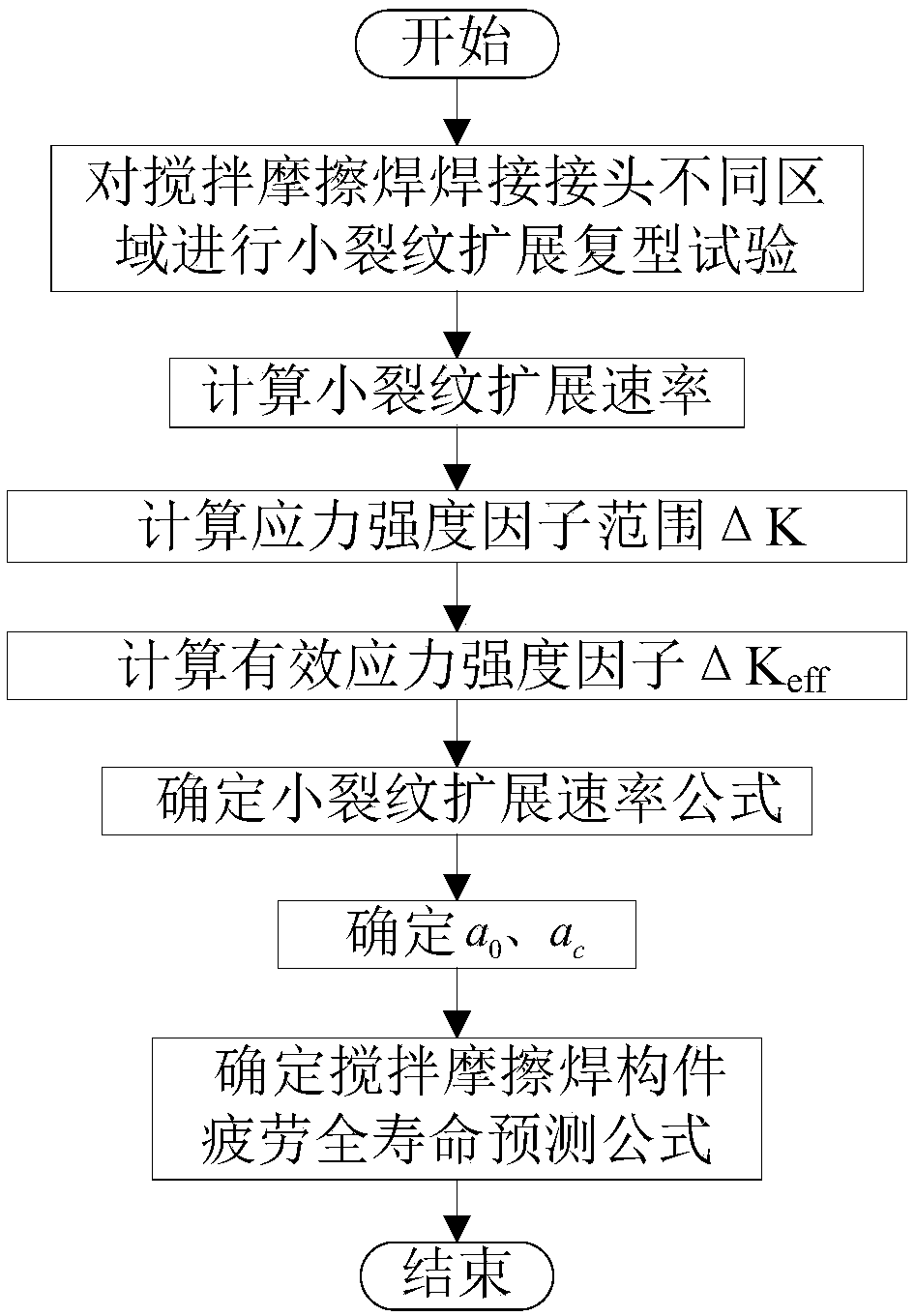

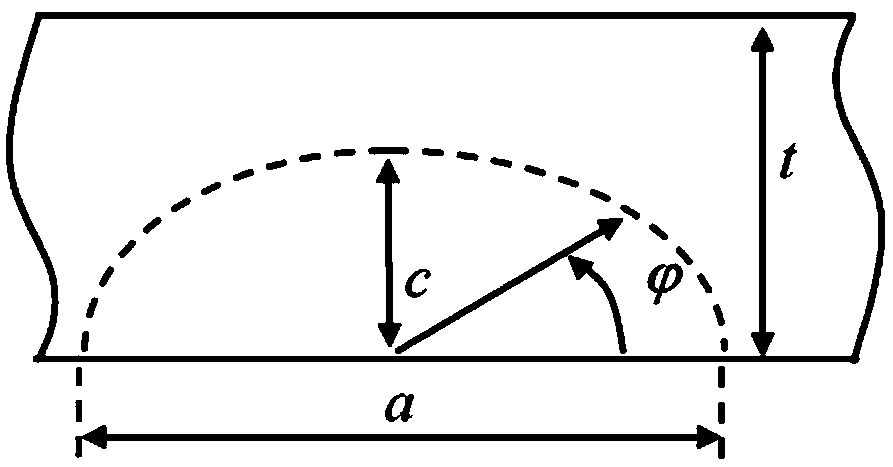

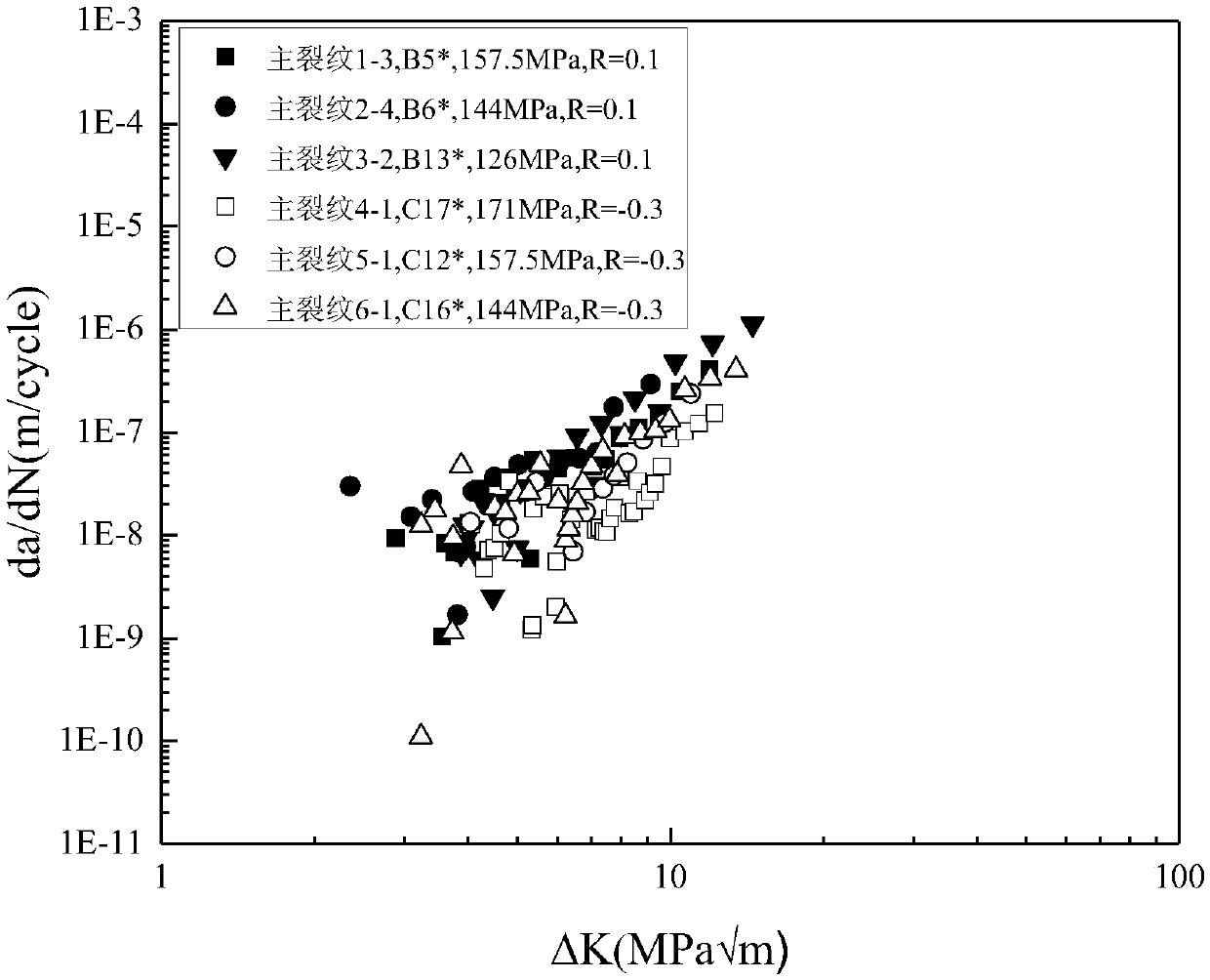

Fatigue life prediction method for friction stir welded component based on small crack propagation

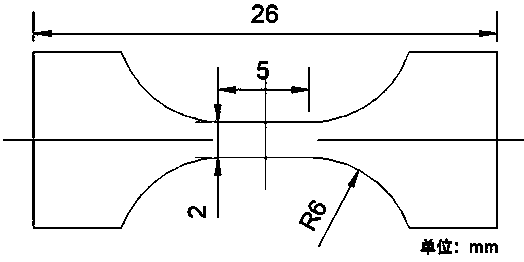

ActiveCN108920792AEasy to calculateThe calculation method is accurateDesign optimisation/simulationSpecial data processing applicationsBone shapeMaterials science

The invention discloses a fatigue life prediction method for a friction stir welded component based on small crack propagation, and belongs to the technical field of fatigue diagnosis and analysis ofmechanical structures. The method comprises the steps that a bone-shaped flat plate sample is prepared, fatigue small crack propagation replica tests under different stress loads and different stressratios are conducted on different areas of a joint, and a secant method is adopted for calculating the propagation rate of small cracks; a New-Raju model is adopted for calculating the stress intensity factor range of the small cracks of the joint; c values in the depth direction and a / 2 values in the vertical direction of semi-arc shapes of fatigue crack propagation zones in fracture shapes of different areas of the joint, and the depth-to-length ratio 2c / a of the cracks is calculated; a curve of the propagation rate of the cracks along with the change of the stress intensity factor range isdrawn; an effective stress intensity factor is calculated; a formula of the propagation rate of the small cracks is determined; an initial crack size a0 and a critical crack size ac are determined; the formula of the propagation rate of the small cracks is integrated to obtain the fatigue life of the welded component. By means of the scheme, the fatigue life of the friction stir welded component can be more easily and accurately predicted.

Owner:BEIJING UNIV OF TECH

Novel stick-bone shaped dog chews and method for preparing same

ActiveCN101703164AEnhance interestIncrease appetiteFeeding-stuffAnimal feeding stuffAdditive ingredientSting fish

The invention provides novel stick-bone shaped dog chews and a method for preparing the same, and relates to the technical field of pet foods. The preparation method comprises the steps of coating stuffing on self-made base extruded fishy smell skins, rolling the fishy smell skins into sticks, and cooking and drying the fishy smell skins to obtain the finished product, wherein the dog chews consist of 40 to 80 percent of self-made extruded fishy smell skins and 20 to 60 percent of stuffing in weight percentage; and the stick-bone shaped dog chews are attractive to dogs, can enhance interest and appetite of dogs on the product and do not make dogs boring after the dogs take the stick-bone shaped dog chews regularly, and simultaneously, the fishy smell skins and the stuffing can supply nutrient components needed by dogs, so that the product can be used as a regular food for dogs, and can also make teeth of dogs healthy and clean, effectively improve bowel functions of dogs and better help pets to strengthen bones and body conditions.

Owner:青岛喜跃生命健康科技有限公司

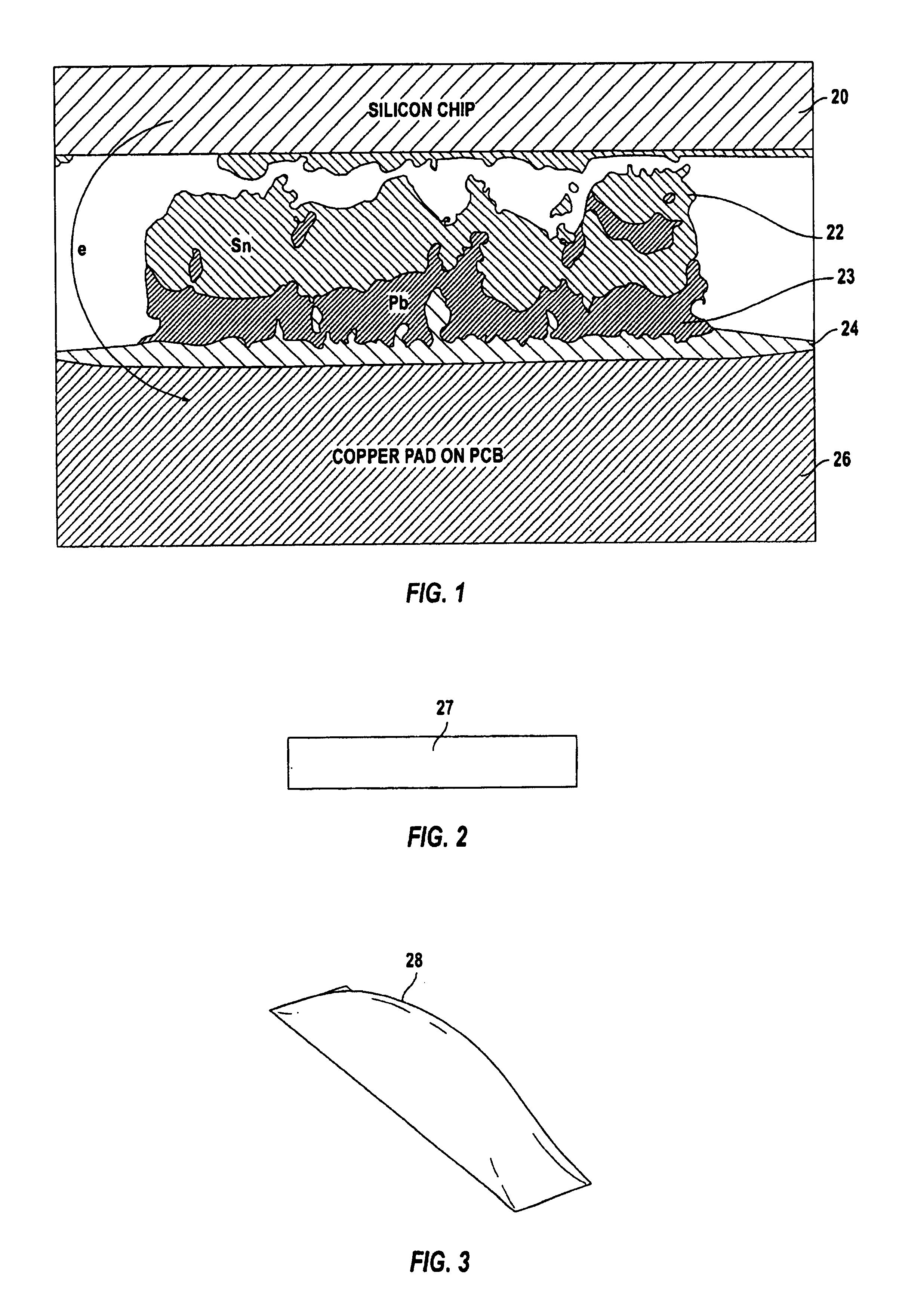

Solder bar for high power flip chips

InactiveUS7057292B1Increase the cross-sectional areaReduce current densityPrinted circuit assemblingSemiconductor/solid-state device detailsMetallurgySolder ball

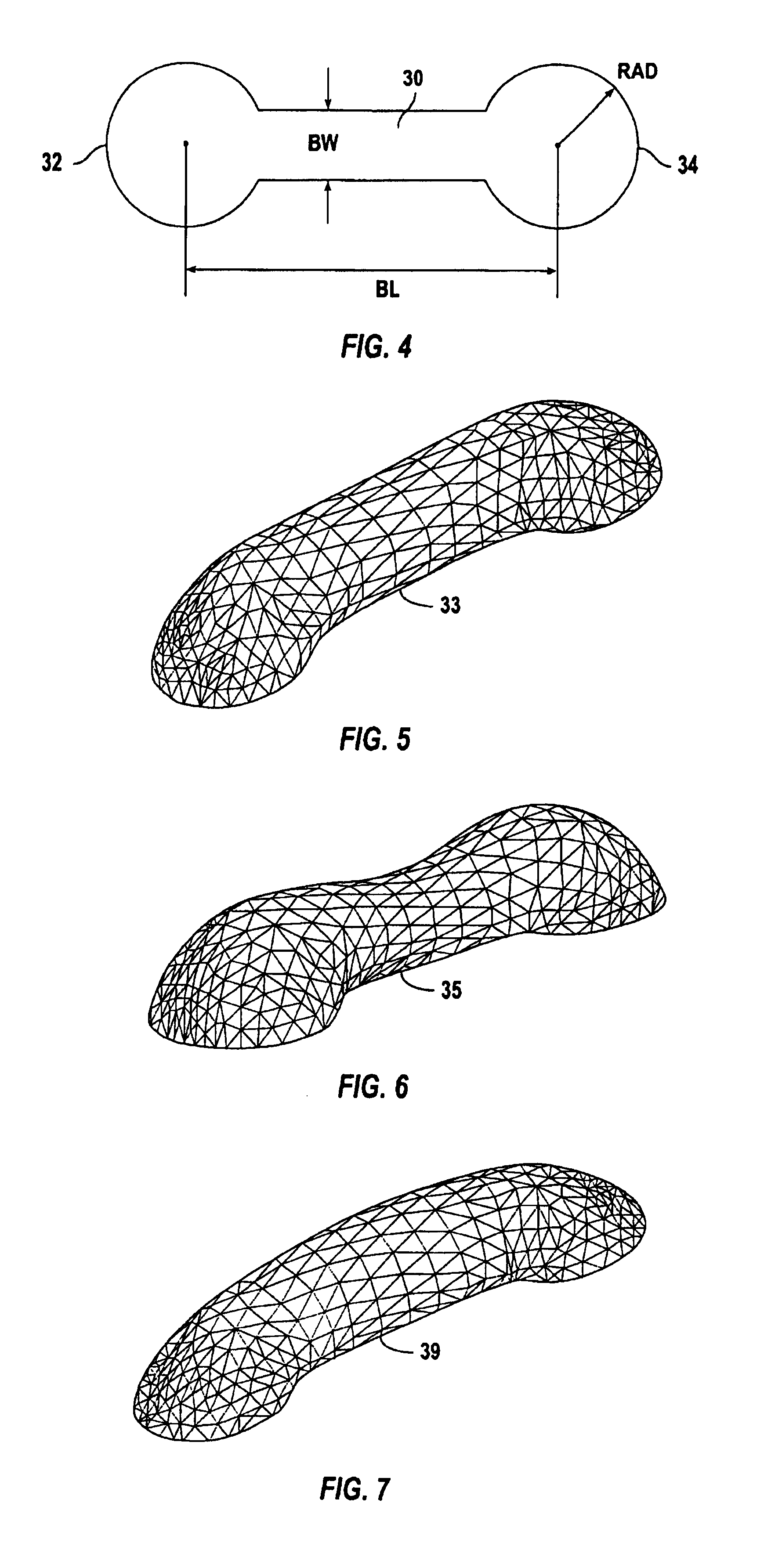

A solder bar compatible with conventional flip chip technology fabrication methods for high power / high current applications includes first and second generally circular solder pads of diameter D formed upon a substrate and connected by a solder bar pad of width BW. The centers of the generally circular solder pads are spaced apart by distance BL (bar length). A mass of solder having volume VB is formed over the first and second generally circular solder pads and over the solder bar pad to form a dog-bone shaped solder bar. The solder bar reaches height H1 above the centers of the first and second generally circular solder pads, and reaching height H2 above the midpoint of the solder bar pad. The values for diameter D, bar length BL, bar width BW, and solder volume VB are selected in such manner that H1 and H2 are approximately equal. Conventional circular (as viewed from above) solder bumps can be formed upon the same substrate; in this case, heights H1 and H2 are made approximately equal to the height of the conventional solder bumps.

Owner:FLIPCHIP INT

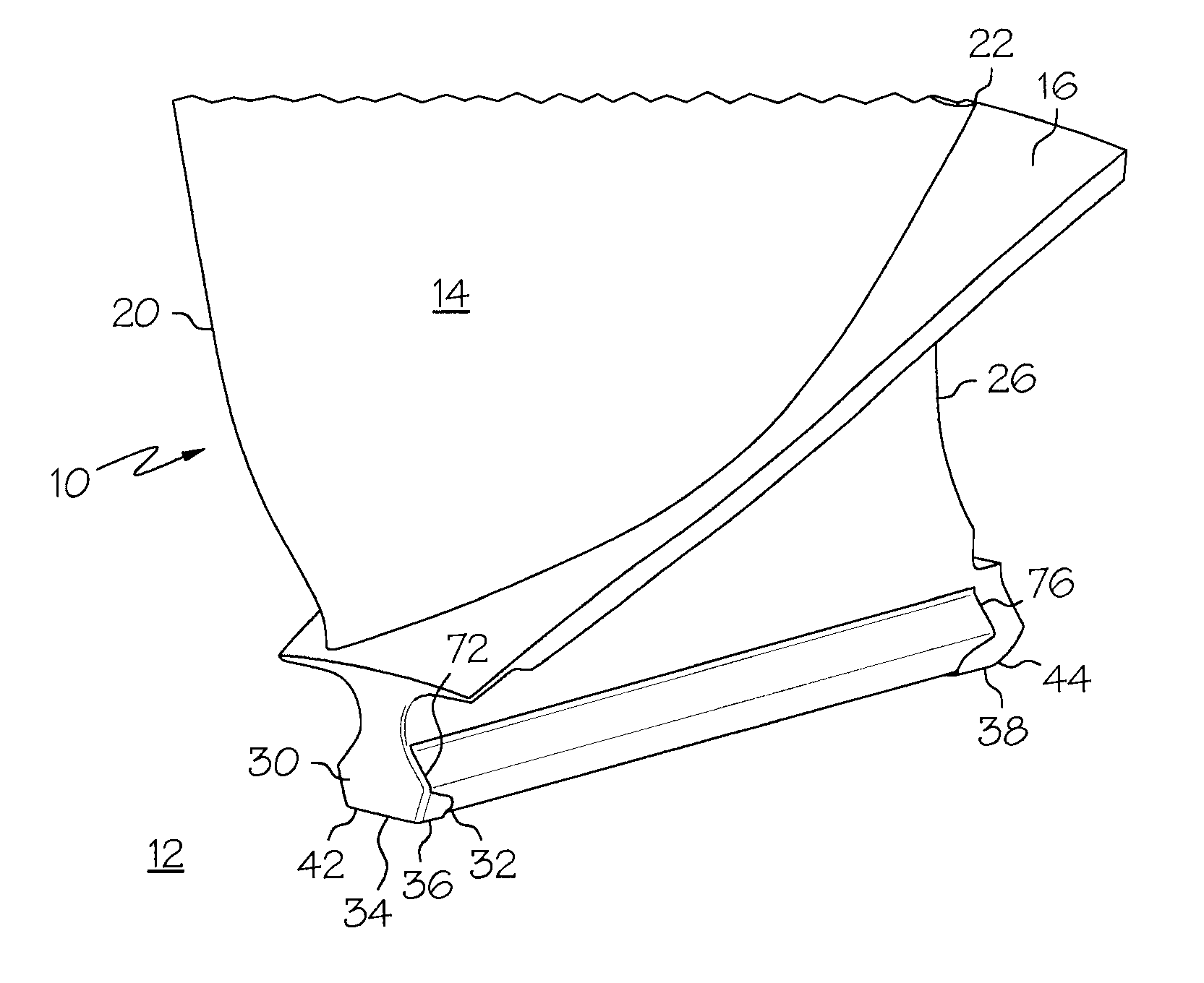

Bone shaped cutting block

ActiveUS7666187B2Potential damageMaintaining amountNon-surgical orthopedic devicesSurgical sawsBone shapeBiomedical engineering

A cutting block for resecting a bone, particularly the distal femur, has a body with a first generally planar bone contacting surface to contact the resected distal surface of the femur. The body has a second surface spaced from the bone contacting surface along an axis perpendicular to said generally planar bone contacting surface. The body has a perimeter surface extending between the first and second surfaces, wherein the perimeter surface is at least partially curved with respect to the axis in both a direction generally perpendicular thereto and generally parallel thereto. The perimeter surface may be polished.

Owner:HOWMEDICA OSTEONICS CORP

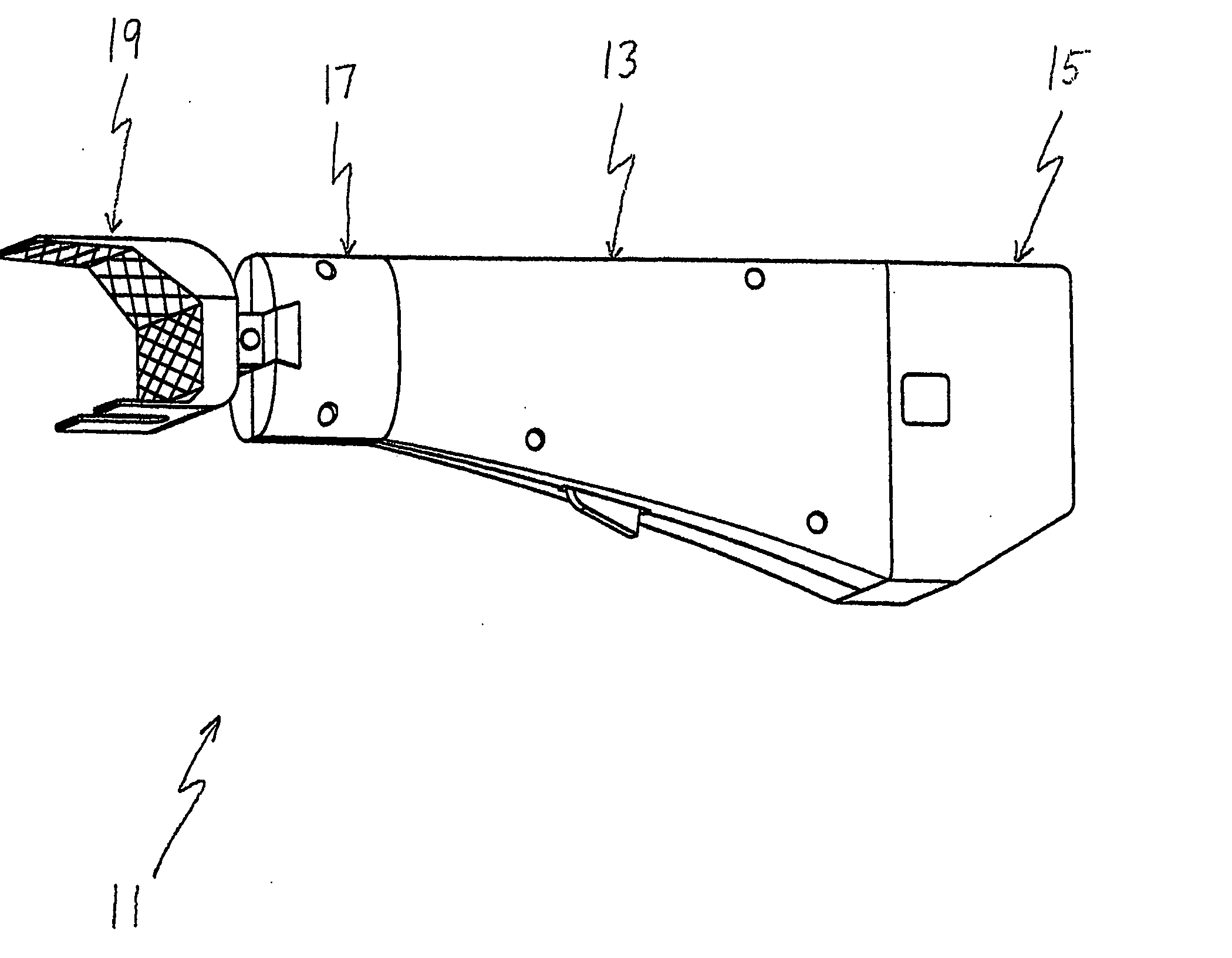

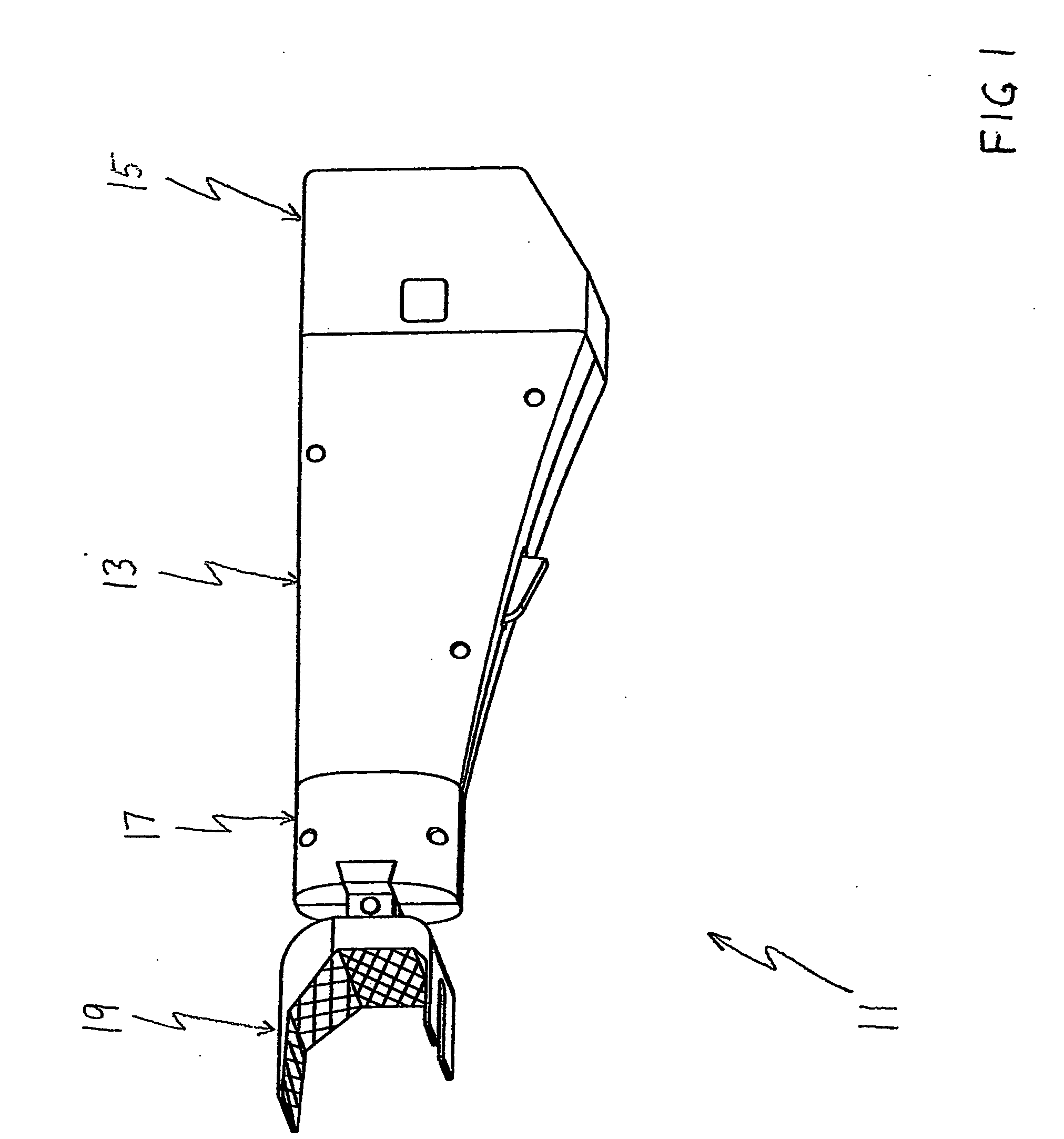

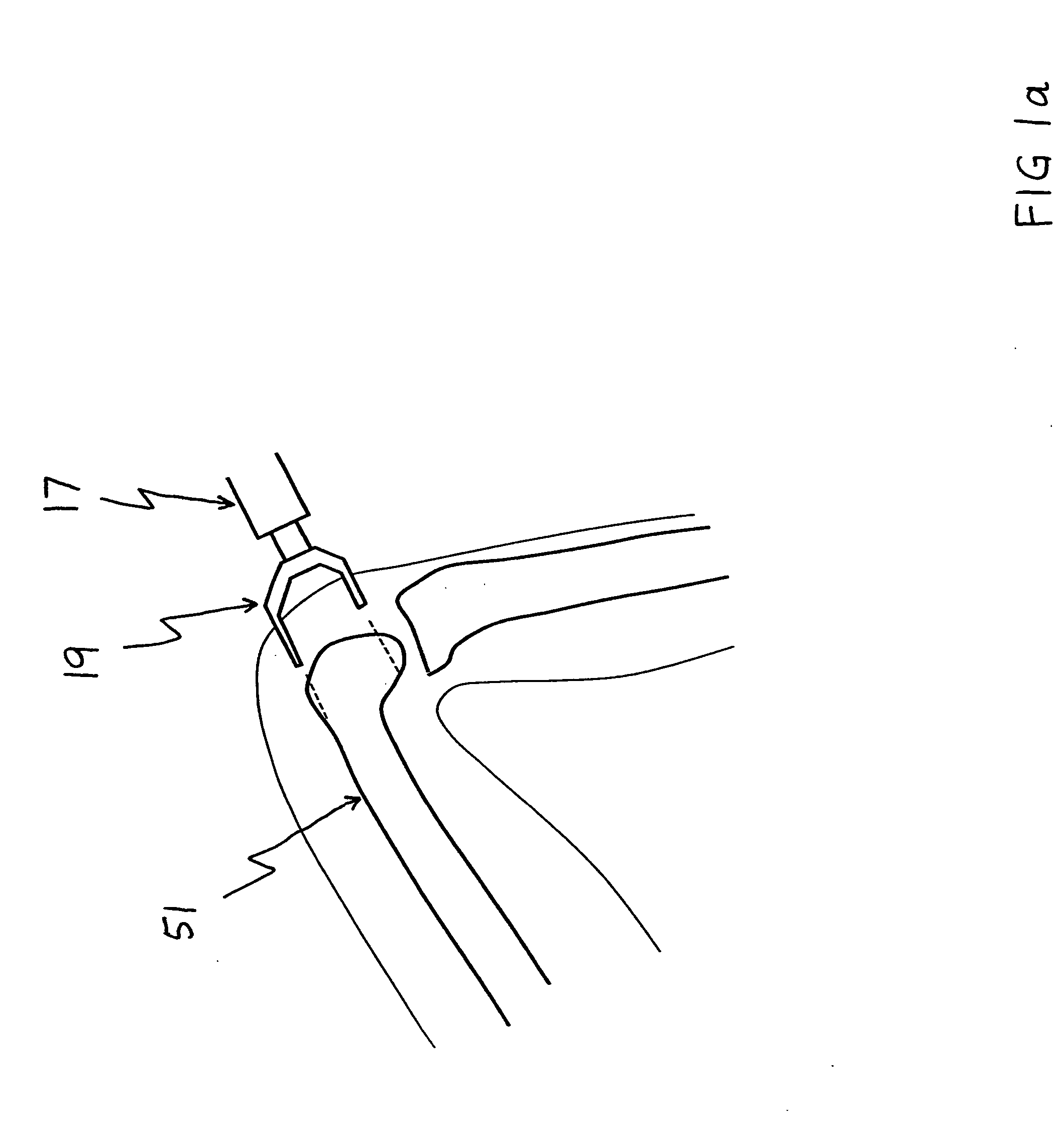

Bone shaping device for knee replacement

InactiveUS20050192584A1Reduction in time taken to cutReduction in to shape bone surfaceDiagnosticsSurgical navigation systemsTibiaKnee Joint

A bone surgery device with a reciprocating cutting head. The device comprises several sets of shaping surfaces sometimes including cutting blades, which are located and oriented so as to shape the distal end of the femur and the proximal end of the tibia for total knee replacements and unicompartmental knee replacements. The device, which may be hand directed or aided by spatial and directional guiding mechanisms or an optical navigation system, may also include both coolant supply for controlling heat during bone cutting and shaping, and a suction method for carrying away fluid and debris. The device is substantially configured to the artificial joint component to be attached thereto.

Owner:WALKER PETER STANLEY +1

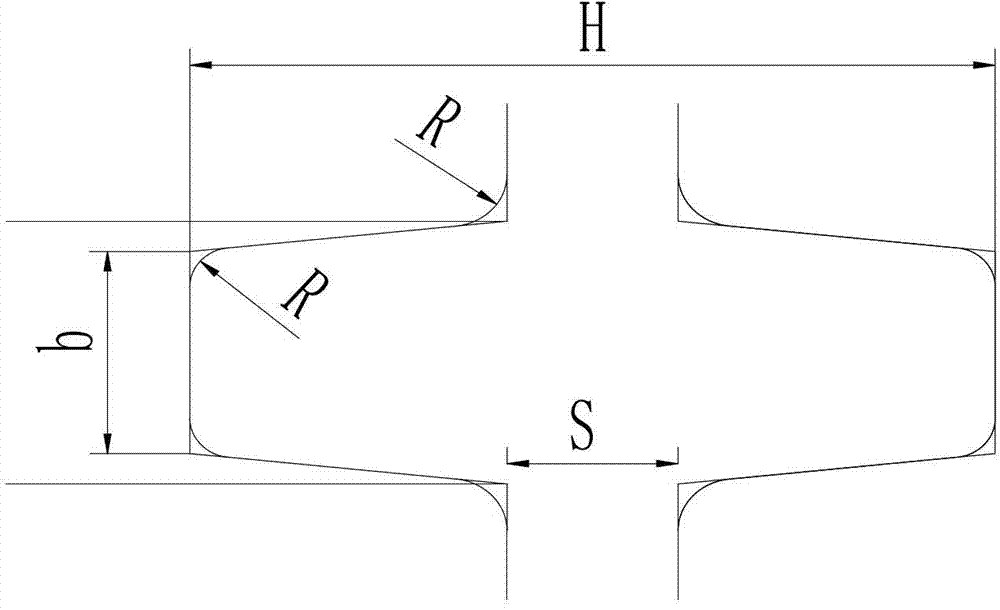

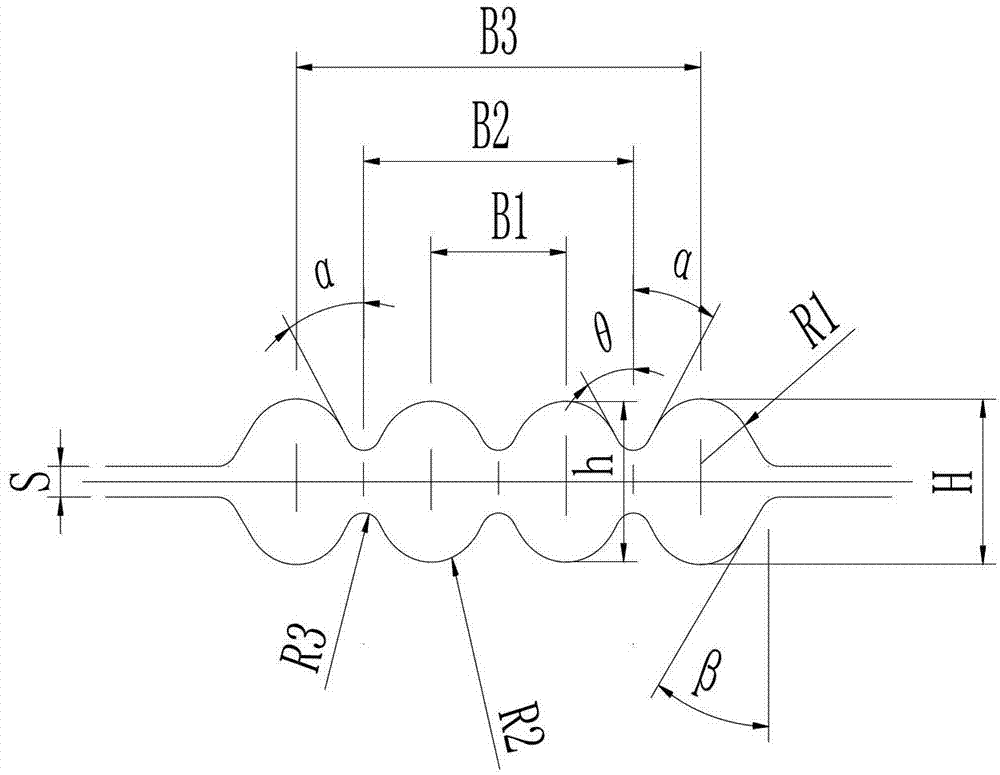

Four-line segmentation rolling technology of deformed steel bar with diameter of 10mm

ActiveCN103071674AIncrease productionReduce labor intensityRollsMetal rolling arrangementsSteel barUltimate tensile strength

The invention relates to a four-line segmentation rolling technology of a deformed steel bar with a diameter of 10mm, and the technology is characterized in that 150 square billets are sequentially rolled by six rough rolling units and 8 medium rolling units, rolled pieces are machined into flat steel, the rolled pieces then enter a fine rolling unit 15H to be machined into 0.4-mm dog-bone-shaped rolled pieces with the size of the middle part being smaller than that of the two sides, the rolled pieces enter a 16 H / V frame rolling machine for segmentation in a centering way, because the distance of two middle holes is identical in the design of the pre-segmentation and a segmentation hole, the rolled pieces under the pre-segmentation can be precisely centered in the segmentation hole, the rolled pieces are rolled into four parallel-connection rolled pieces with a ligament of 0.7mm, then the four parallel-connection rolled pieces are subjected to three-time segmentation through a front segmentation wheel and a rear segmentation wheel, which are installed on a 16 H / V outlet, then the two middle parallel-connection rolled pieces are twice cut into four independent rolled pieces, the four rolled pieces respectively and individually enter a roll groove passage of 17H and 18H / V frame rolling machines to be respectively rolled into four deformed steel bar finished products with the diameter of 10mm, the same size and the same shape. Through the technology, the yield per hour of the deformed steel bar with the diameter of 10mm is increased, the production cost is reduced, the production efficiency is increased, and the labor intensity of operators is alleviated.

Owner:TIANJIN IRON & STEEL GRP

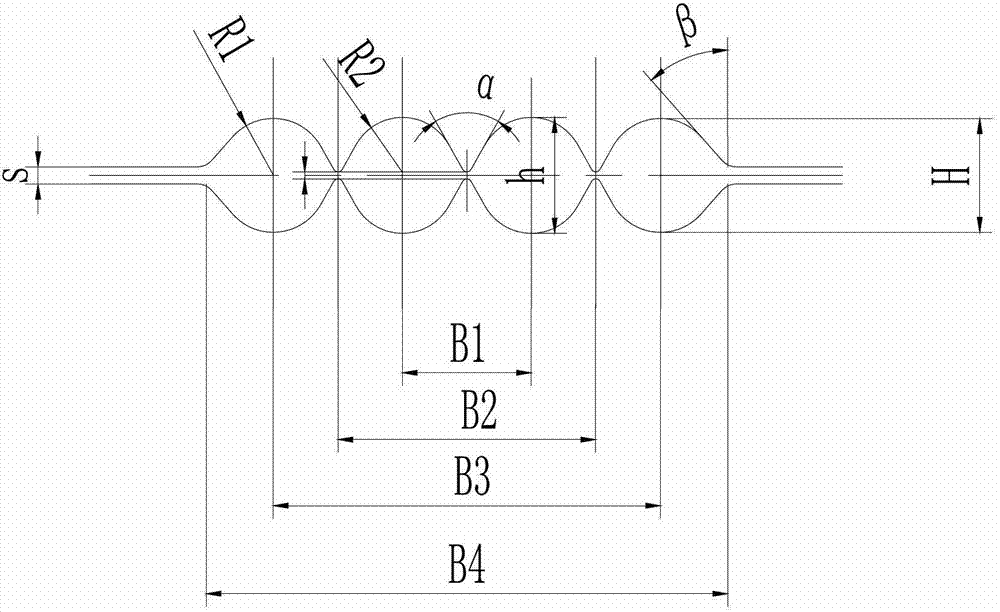

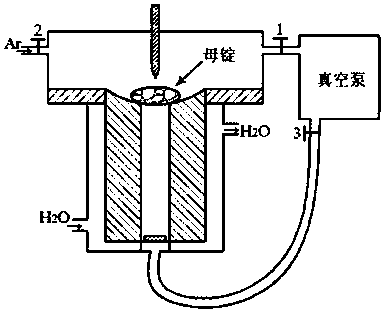

Method for improving Al0.3CoCrFeNi high-entropy alloy intensity

ActiveCN109797303AFine grain boundaryUniform tissueVacuum evaporation coatingSputtering coatingHigh entropy alloysWire cutting

The invention discloses a method for improving Al0.3CoCrFeNi high-entropy alloy intensity. Five kinds of analytical pure metals of Al, Co, Cr, Fe and Ni are blended according to the atomic ratio of 0.3 to 1 to 1 to 1 to 1, smelting is carried out in a vacuum arc melting furnace, the molten alloy is subjected to suction casting to form plate-shaped high-entropy alloy materials with 2mm thickness, 10mm width and 85mm length, and then a high-entropy alloy is subjected to cold rolling and annealing heat treatment to eliminate the residual internal stress, generated in the casting process, of the high-entropy alloy; and then a wire cutting machine is used for cutting bone-shaped standard tensile samples with a standard distance of 5mm, the front faces and back faces and the two side faces of the tensile samples are polished, and the polished samples are subjected to a double-glow chromizing test by using a double-glow metal furnace, and finally, the obtained samples are strengthened high-entropy alloy samples. According to the method for improving the Al0.3CoCrFeNi high-entropy alloy intensity, through a double-glow chromizing technology, the friction coefficient of the high-entropy alloy is reduced, and the amplitude is greatly reduced.

Owner:TAIYUAN UNIV OF TECH

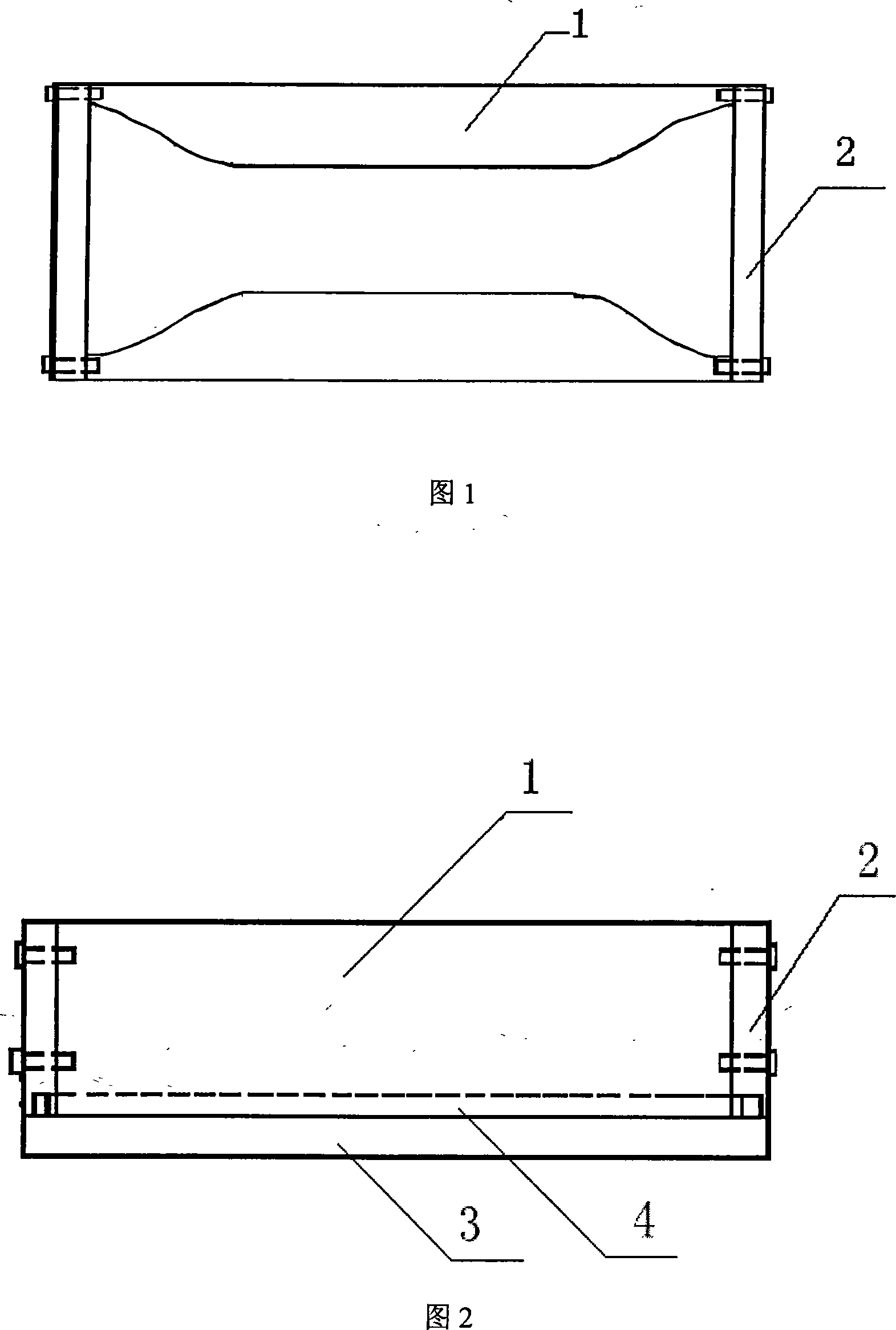

Brittle material test piece moulds and matching tensile test cramping apparatus thereof

The invention relates to a brittle material sample die and a matched tension test fixture and includes a die and a fixture. A conveyer chain is arranged between the die and the fixture. The die includes a side surface plate, an end surface plate and a bottom plate. The side surface plate and the end surface plate are connected by a connecting element. The bottom plate is provided with a waterproof groove. The side surface plate and the end surface plate are connected with the bottom plate through the waterproof groove. The fixture includes a collet which is provided with a collecting spherical hinge. The collet consists of two parts and the two parts are connected through a connecting element. When the die is mounted, after each part is connected, a brittle material can be poured in the die to manufacture a bone-shaped sample. The enlarging end and the uniform section of the bone-shaped sample are transferred by a smooth curved surface. When the sample is stretched, a collet bolt is screwed out firstly and the bolt is screwed tightly after the sample is arranged in the collet. A tension test can be carried through after the connecting spherical hinge and the tension collet of a tension tester are connected. The invention has the advantages of simple structure, convenient dismounting, low cost, good manufacture effect, large holding area and excellent cooperation with the sample shape, etc.

Owner:SHANDONG UNIV

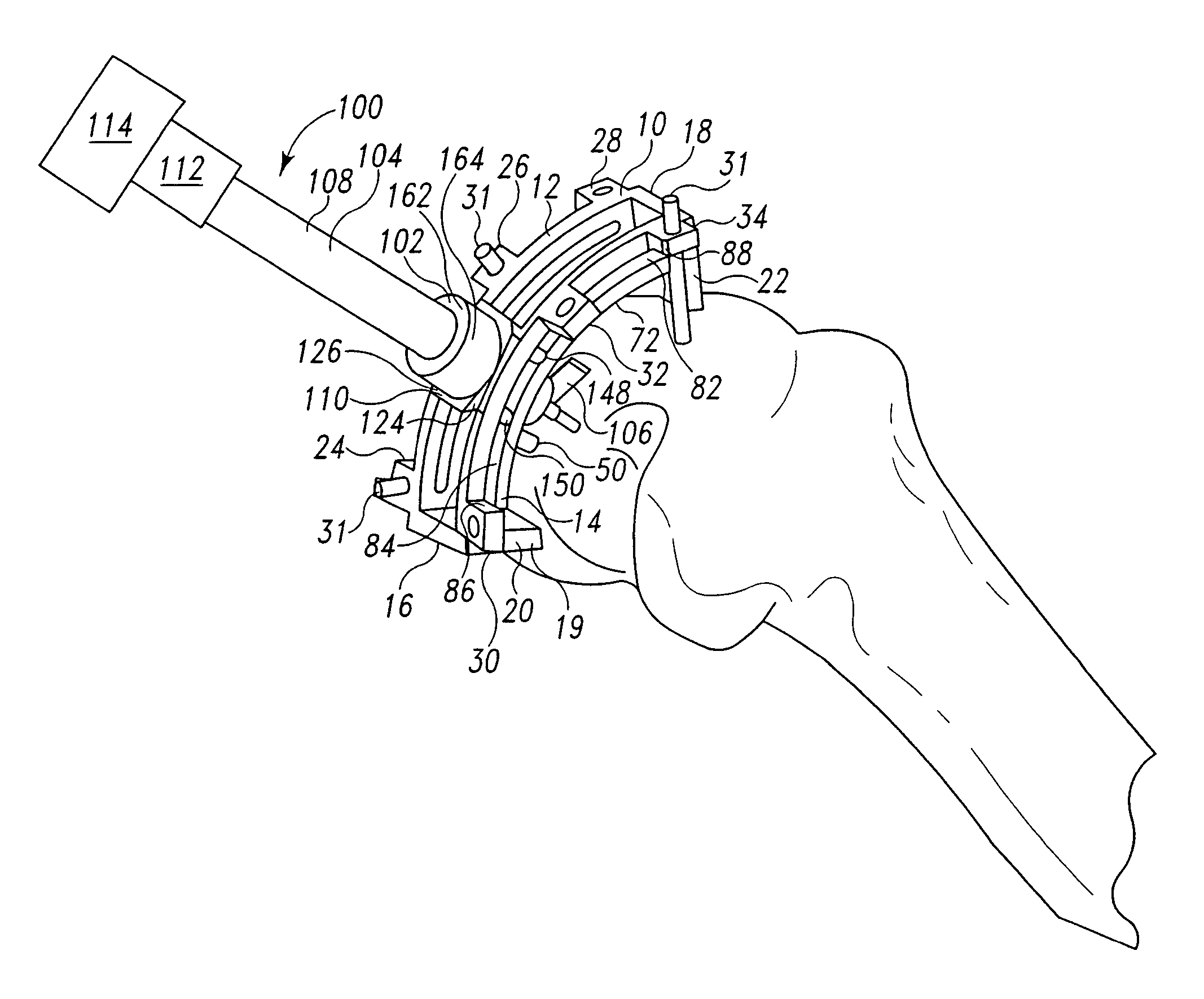

Bone shaping instrument and method for using the same

ActiveUS7766913B2More kinematically correctLess invasive surgeriesJoint implantsNon-surgical orthopedic devicesReciprocating motionProsthesis

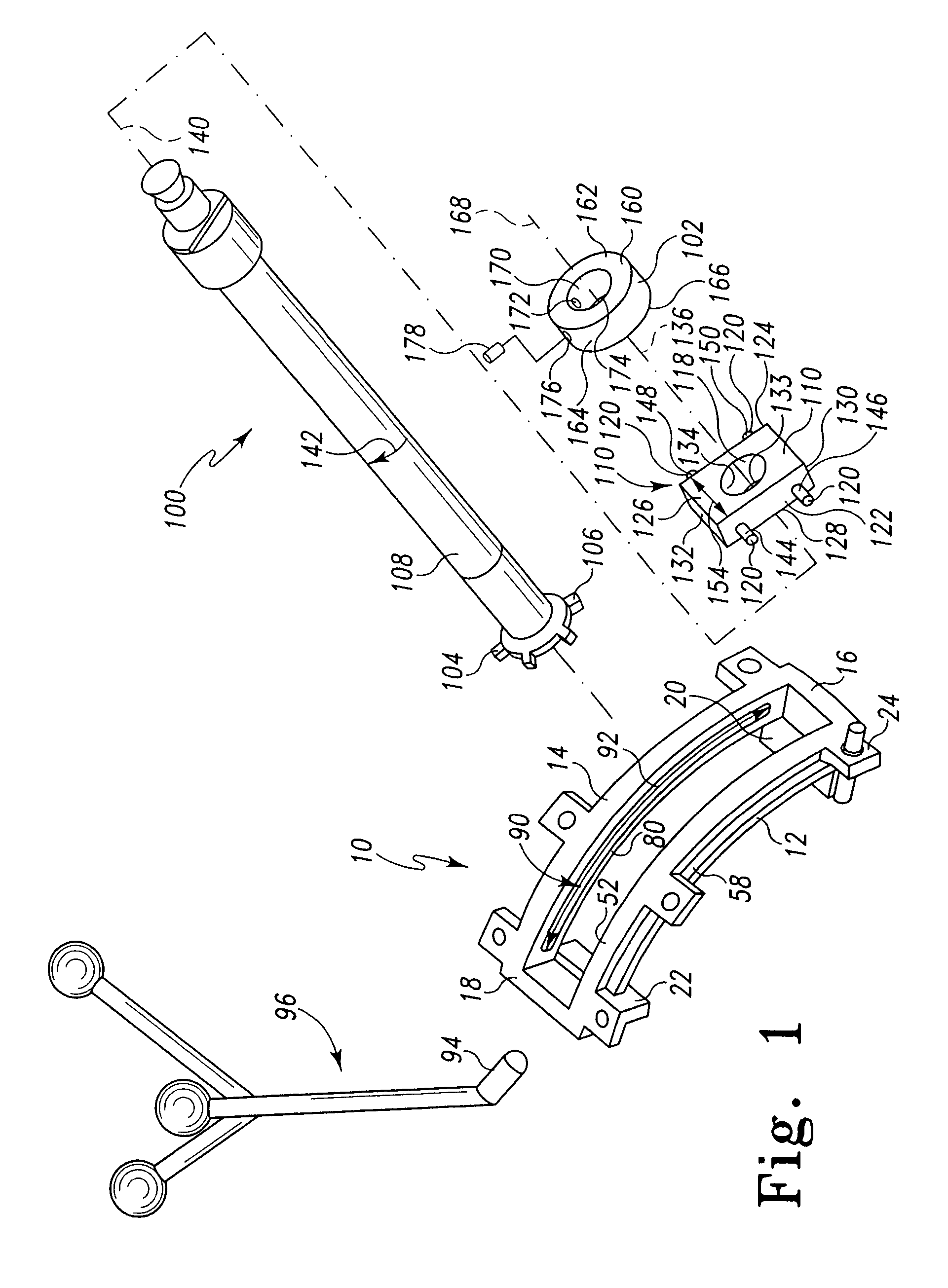

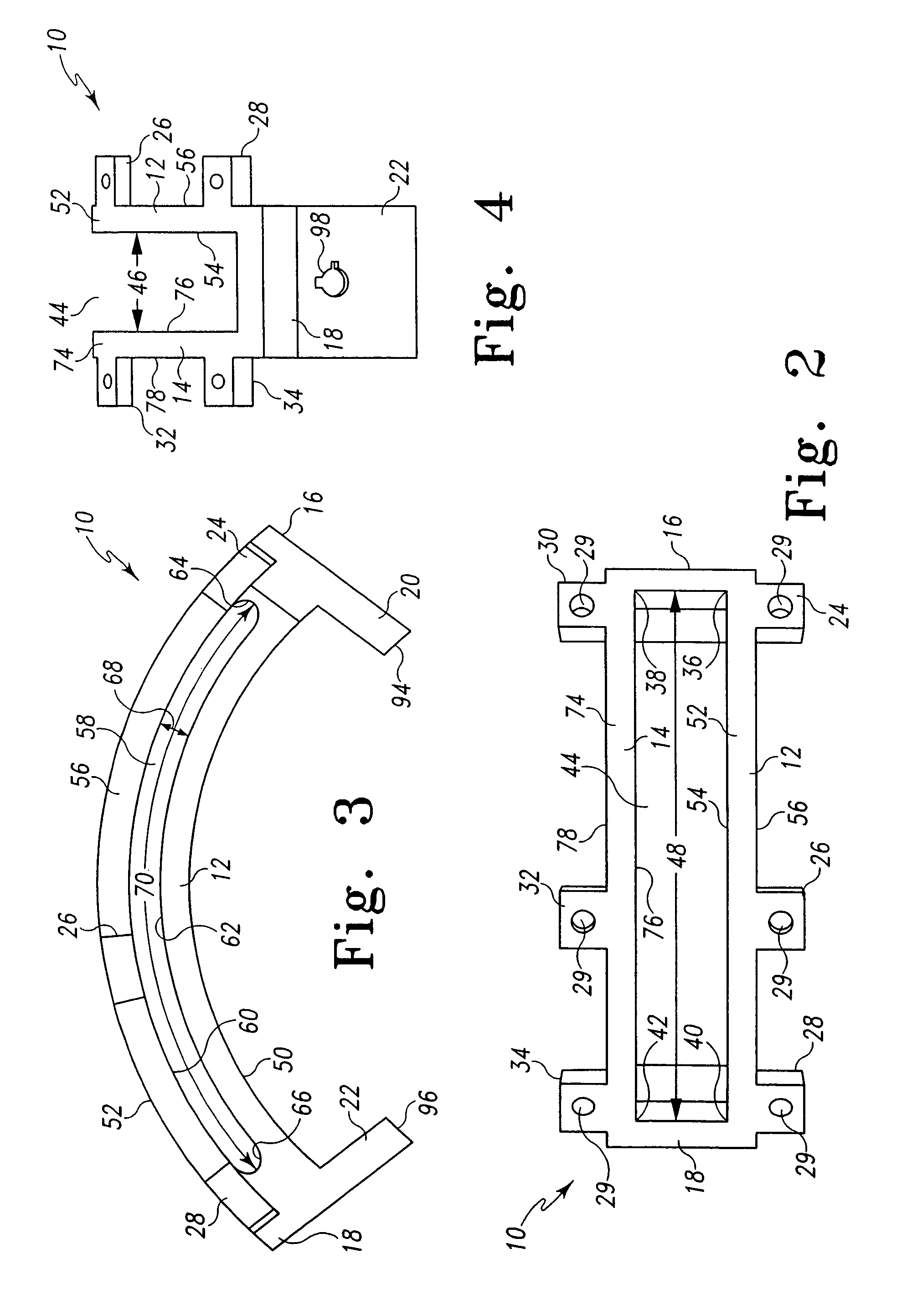

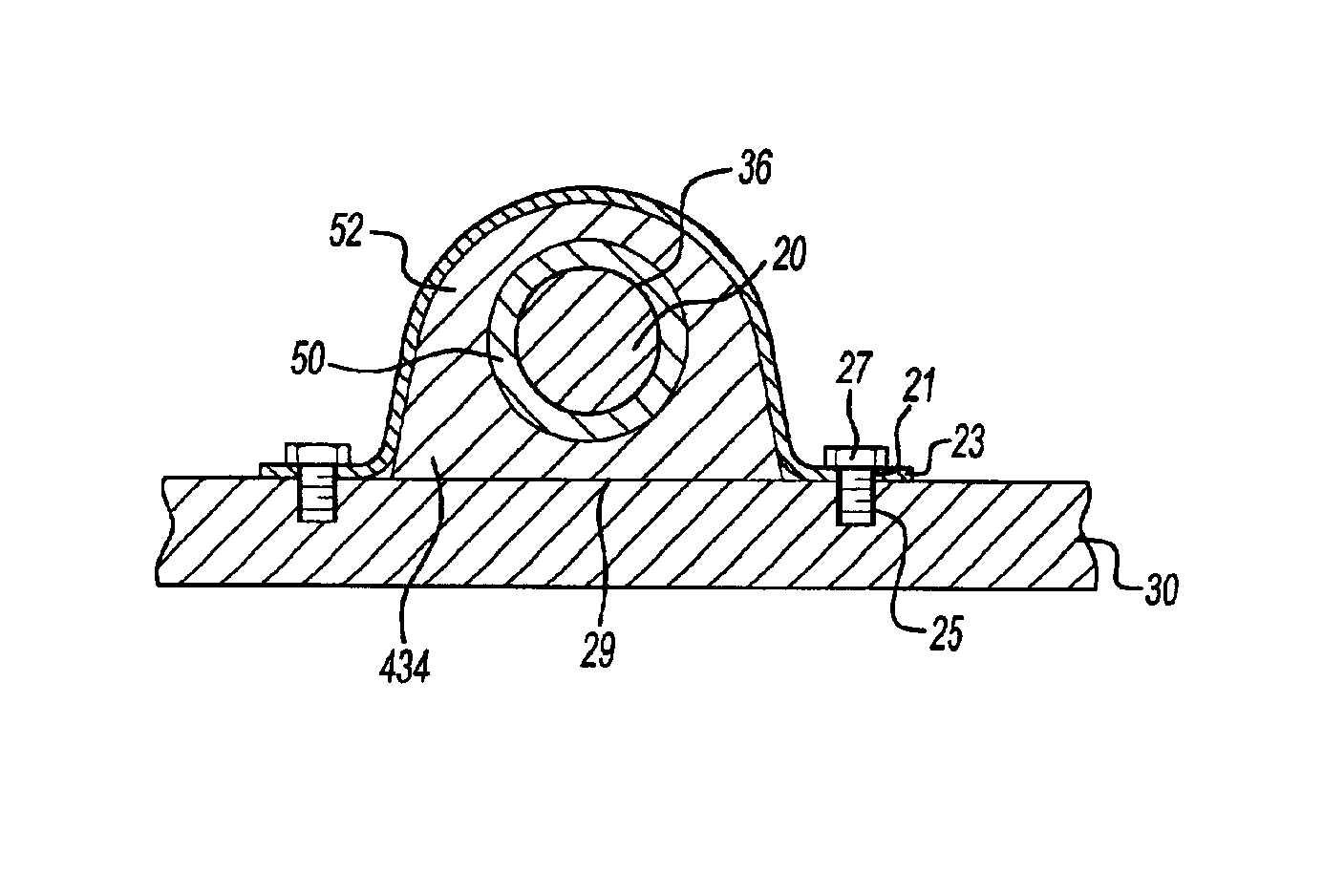

A bone resection tool for resecting an end of a bone along a surface having a curvature comprises a guide, a cutting tool and a track follower. The guide is configured to be removably attached in a fixed position to the end of the bone. The guide is configured to include a track exhibiting a curvature generally corresponding to the curvature of the surface to be resected in the bone. The cutting tool includes a cutting face. The track follower is configured to couple to the cutting tool and cooperate with the track to facilitate reciprocation of the cutting tool relative to the guide to induce the cutting face to resect the bone along the surface having the curvature. A method for cutting a bone along a curved surface conforming to the curvature of a curved surface of the underside of a prosthetic component comprises the steps of incising the tissue surrounding the surface of the bone, positioning a guide alongside the surface of a bone to be cut, affixing the guide to the bone, interconnecting a cutter having a cutting face with the guide, maintaining the cutting face generally parallel to the tangent of the curved surface and traversing the cutting face along the bone while guiding the cutter along the track. The tissue incision incises the tissue surrounding the surface of the bone to be cut in a minimally invasive fashion. The positioned guide includes a track configured to assimilate the curvature of the curved surface of the underside of the prosthetic component.

Owner:DEPUY PROD INC

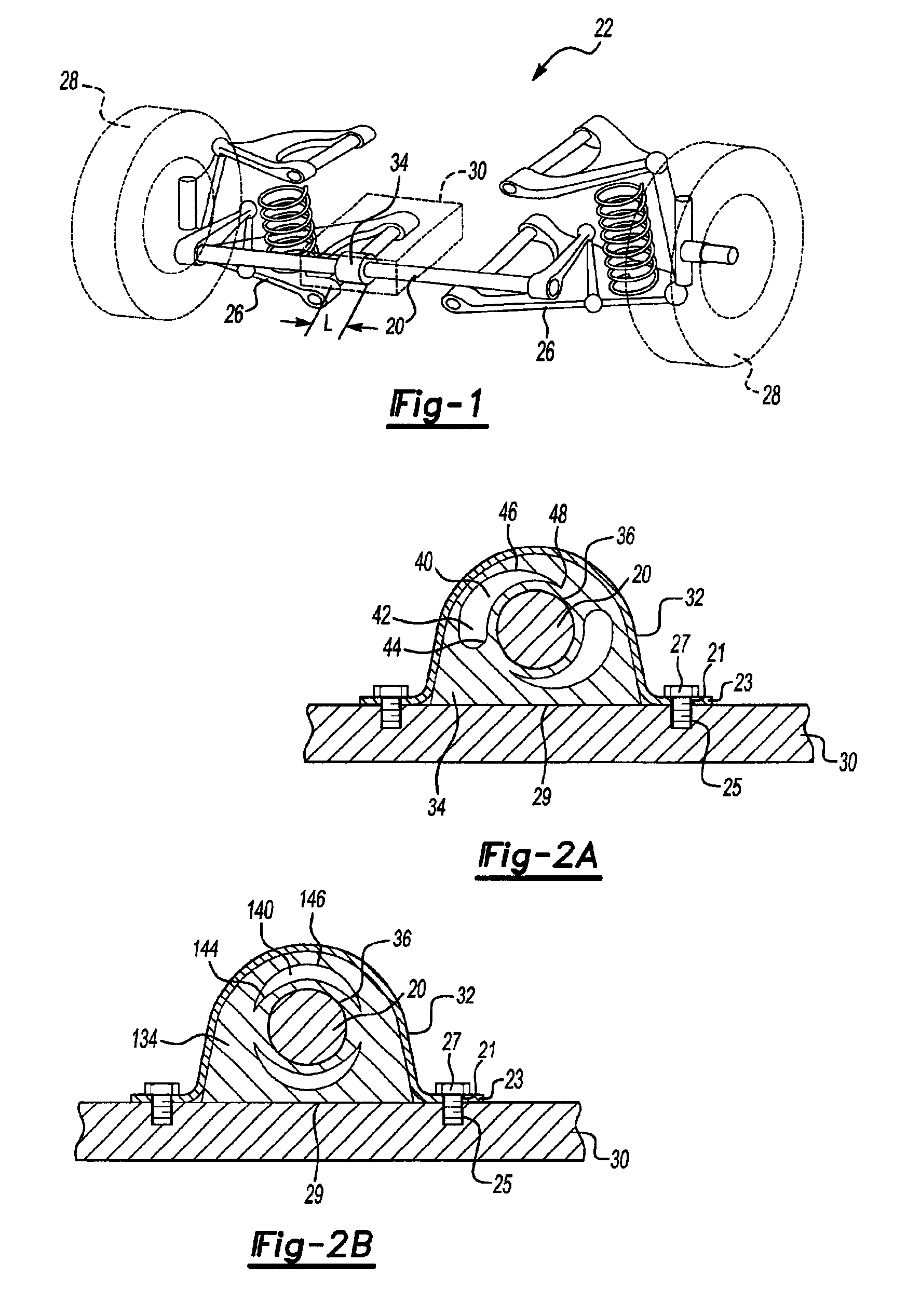

Variable rate bushing for stabilizer bar

InactiveUS6854750B2Increasing stiffness rateReducing axial twistTorsion springsInterconnection systemsSoft materialsBone shape

A variable rate bushing passively controls the stiffness of a stabilizer bar. During normal vehicle operation, the stabilizer bar is compliant. As twist increase, the resistance increases. In one embodiment, the variable rate bushing includes at least one void which compresses as the vehicle turns. As the stabilizer bar axially twists, the void compresses and the rate of the bushing increases, reducing axial twist and increasing stiffness of the stabilizer bar. In one embodiment, the voids are teardrop shaped, arc shaped, or bone shaped. Alternatively, the bushing includes an inner layer of softer material and an outer layer of harder material to control stabilizer bar stiffness. Also, the bushing may include a molded insert made of a hard material inserted into a softer material to control the stiffness of the stabilizer bar.

Owner:MERITOR LIGHT VEHICLE TECH LLC

Handheld water misting fan with improved air flow

The present invention is directed to an improved handheld water misting fan device wherein the power source compartment is positioned within the device at a location remote from the fan motor thereby to remove any structure from the area bounded by the fan shroud. The relocation of the power source compartment leaves the area bounded by the shroud substantially unobstructed thereby to improve air flow. The device is formed in a dog bone shaped configuration to provide a narrow handle section for improved grippability, and an enlarged fluid reservoir at the lower end thereof for greater reservoir capacity.

Owner:O2COOL

Shoulder strap

InactiveUS20080006661A1Inhibit chafingAvoid diggingTravelling sacksShoulder strapEngineeringShoulder girdle structure

Owner:TRAVEL CADDY

Multi-position cervical pillow and an adjustable pillow set thereof

The present invention pertains to a multi-position cervical pillow and an adjustable pillow set thereof to support a user's head and neck. In a preferred embodiment, the multi-position cervical pillow comprises a rectangular memory foam pad, the transversal cross section of which is bone-shaped with two lobes protruded towards two opposite lateral ends and a shallow trough in between forming a concave head support portion on each of the two support surfaces; said two lobes are different in size and asymmetrical in shape. By inverting and reversing the pillow pad it provides four unique positions. An adjustable pillow set comprises a main multi-position cervical pillow and an unattached ancillary pillow, the upper surface of the latter has a transversally convex, asymmetrical curvature for the main pillow to stack and slide on top of it, forming four stacking configurations, with each providing two unique positions.

Owner:SUN XI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com