Bionic gradient knee femoral prosthesis structure and a production method thereof

A technology for a femoral prosthesis and a manufacturing method, which is applied in the field of bionic gradient knee joint femoral prosthesis structure and its manufacturing, can solve the problems of difficulty in realizing gradient porosity change, complicated preparation process and high preparation cost, and achieves light weight and guaranteed mechanical properties. Performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

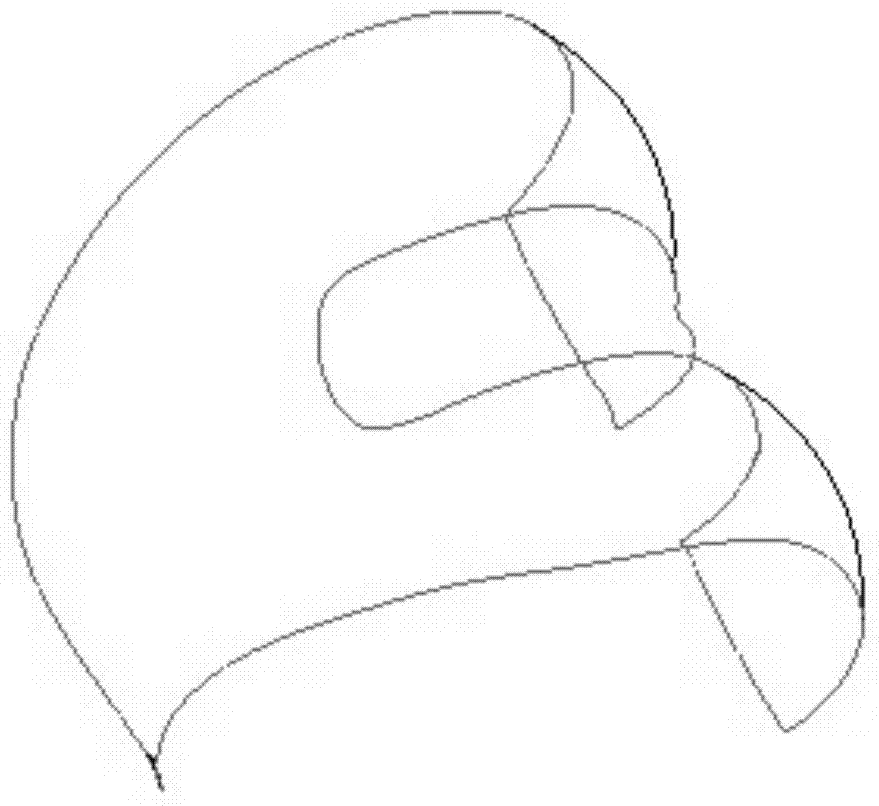

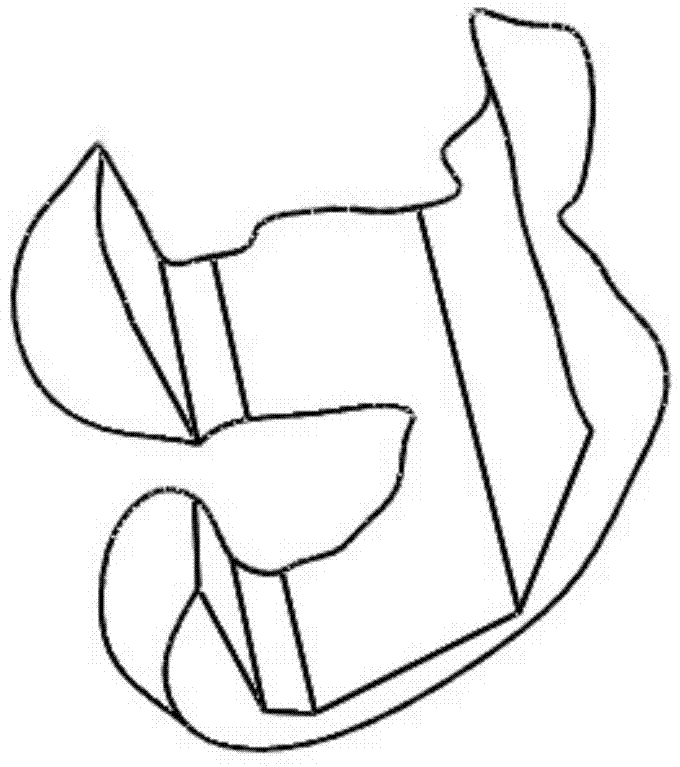

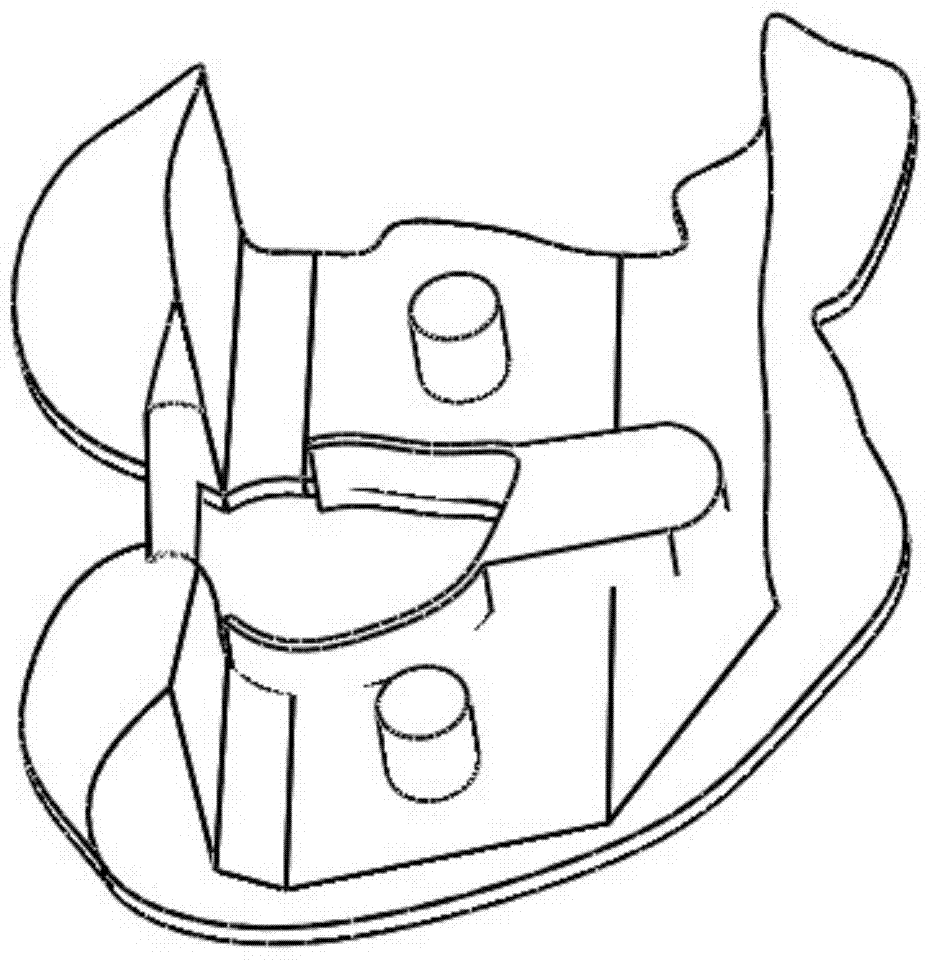

[0036] Such as Figure 4 As shown, the bionic prosthesis of this embodiment includes: a smooth curved shell based on the shape of the original distal end of the femur, a fully covered fitting surface after osteotomy, a gradient porous structure, and a fixing device. Stretch to the surface of the original distal femur, and replace the entity with a thickness of more than 5mm from the curved surface with a gradient porous structure. The fixation device is generated on the inner distal plane of the femoral prosthesis. The area to be replaced by the prosthesis is excised and replaced by the upper femoral prosthesis. Therefore the femoral prosthesis is divided into the curved surface feature that cooperates with the tibial prosthesis below, the femoral prosthesis medial surface feature that cooperates with the femoral osteotomy retainer, and the fixation feature in order to fix the femoral prosthesis and the femoral osteotomy retainer. The core of the present invention is to adopt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com