Brittle material test piece moulds and matching tensile test cramping apparatus thereof

A technique for tensile testing and brittle materials, applied in the analysis of materials, strength characteristics, instruments, etc., can solve the problems of complex production of test pieces, the strength of test pieces should not be too large, and no fixtures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

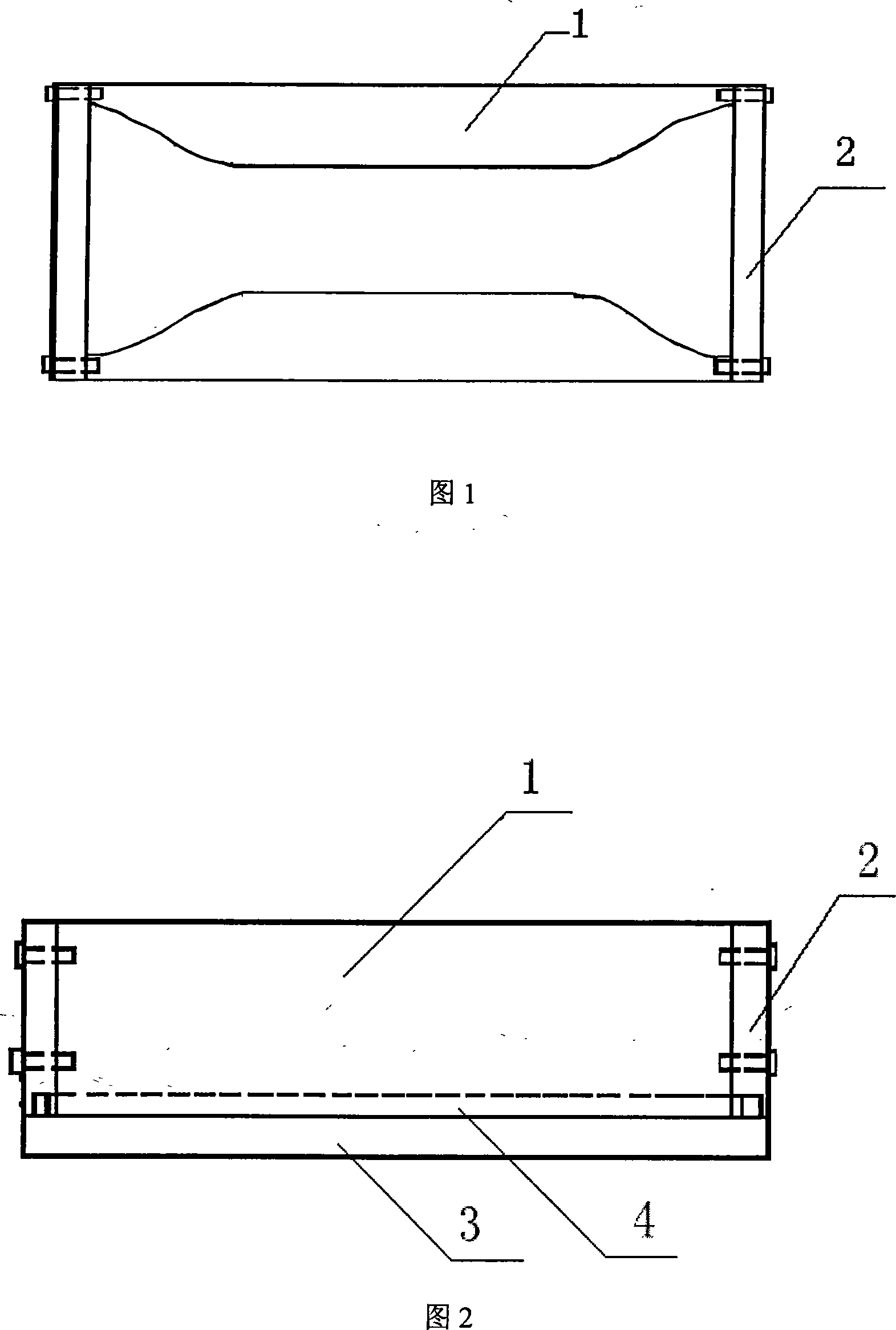

[0018] In Fig. 1 and Fig. 2, two side panels 1 and two end panels 2 are connected by bolts, a waterproof groove 4 is provided on the bottom panel 3, and the side panel 1 and the end panel 2 are connected to the bottom panel 3 through the waterproof groove 4.

[0019] When the present invention is installed, after the parts of the mold are connected, brittle materials can be poured into it. When connecting, the bolts must be tightened, and the waterproof groove 4 should be clamped tightly to prevent slurry leakage; Residues are cleaned up.

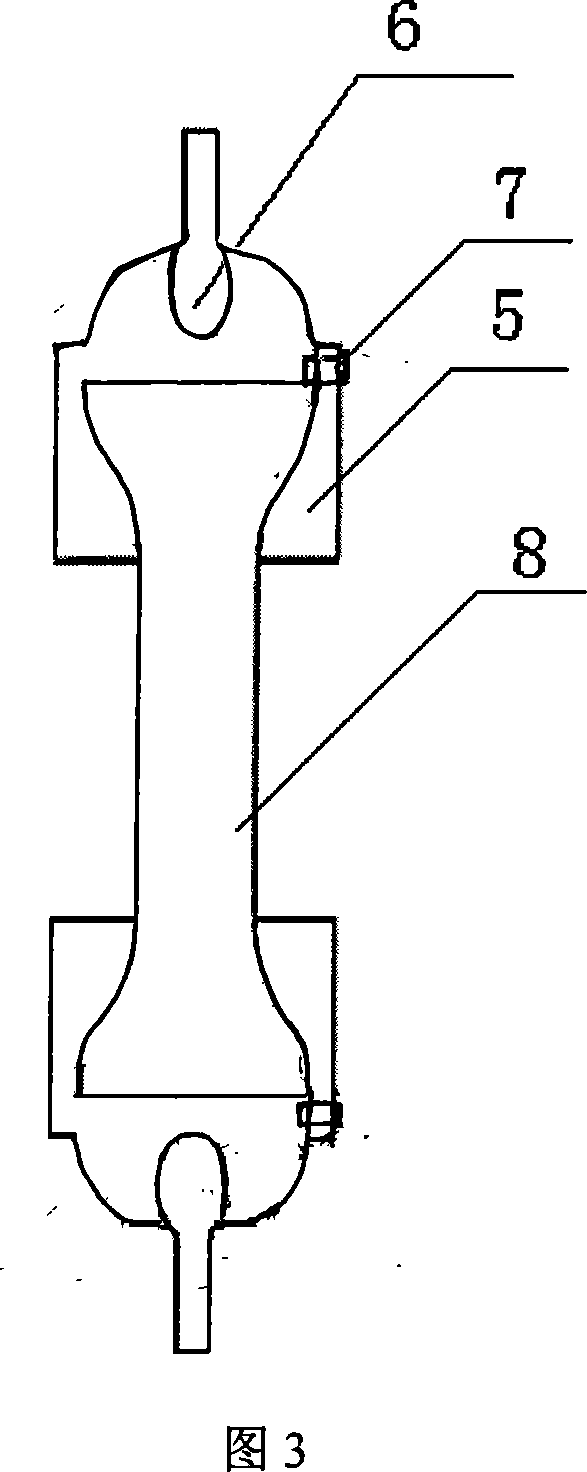

[0020] After the bone shape test piece 8 is made, it is taken out and transported to the test tensile fixture by the transmission chain.

[0021] In FIG. 3 , a connecting ball joint 6 is provided on the collet 5 , and the collet 5 is composed of two parts, which are connected by bolts 7 . All parts must be processe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com