Patents

Literature

714 results about "Chewiness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chewiness is the mouthfeel sensation of labored chewing due to sustained, elastic resistance from the food. Foods typically considered chewy include caramel, rare steak, and chewing gum. Chewiness is empirically measured by the metrics of chew count and chew rate.

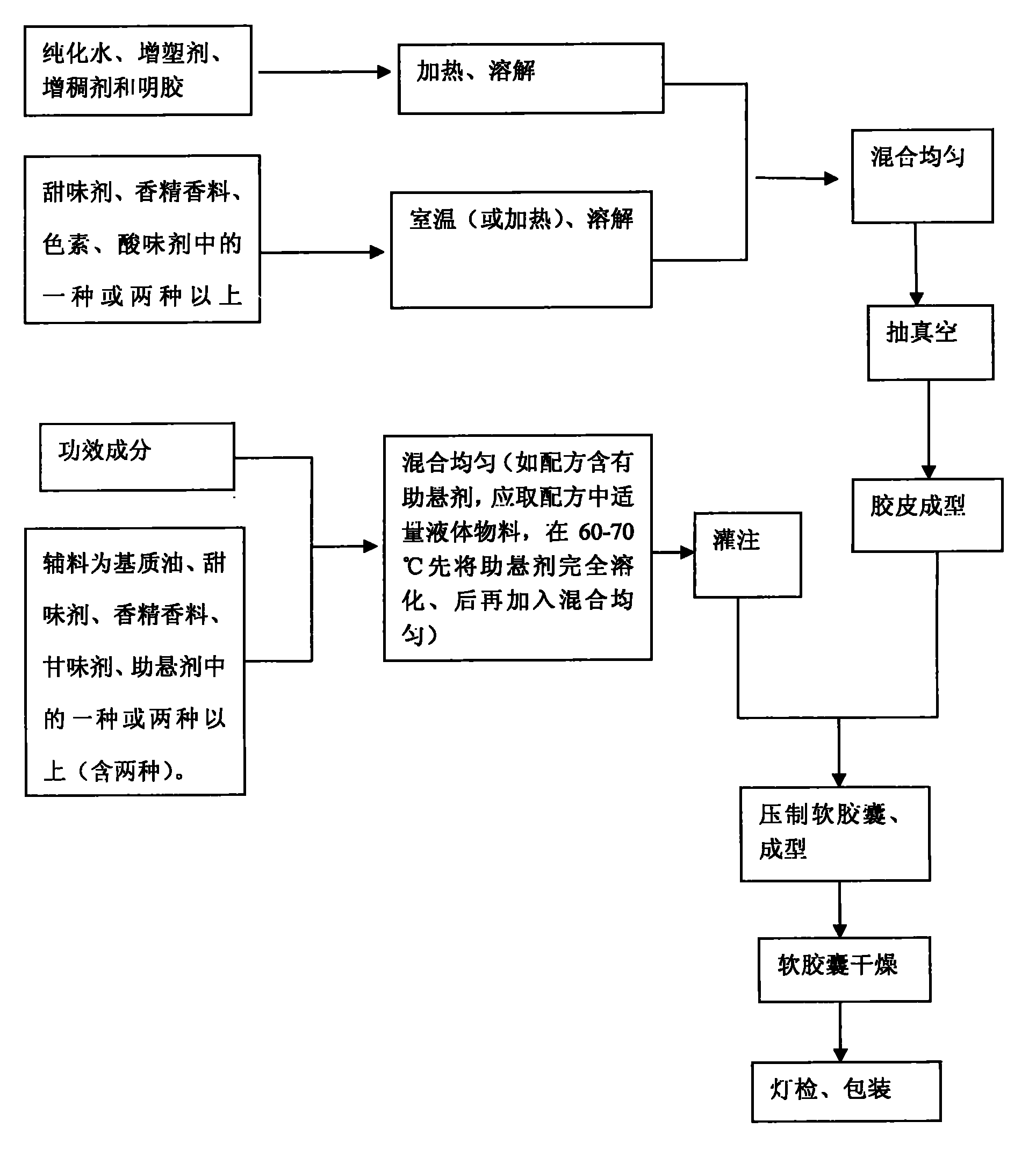

Chewable soft capsules and method for preparing same

ActiveCN101810336ADissolution stabilityRapid dissolutionFood shapingFood preparationFlavorPlasticizer

The invention discloses chewable soft capsules, which comprise capsule shells and contents sealed in the capsule shells. The chewable soft capsules are characterized by comprising the following raw materials in part by weight: 25 to 65 parts of glutin, 1 to 25 percent of thickening agent, 18 to 65 parts of plasticizer, 4 to 16 parts of water and a mixture containing one or more of 0.005 to 20 parts of sweetening agent, 0.005 to 2 parts of essence, 0.0001 to 10 parts of pigment and 0.0001 to 5 parts of acid additive. The invention also discloses a method for preparing the novel chewable soft capsules. The chewable soft capsules have the advantages of reasonable blending ratio, proper hardness, good temperature resistance, no adhesion, no deformation, stable storage, quick dissolution of effectively components and high chewiness; and when the chewing soft capsules are chewed, tastes of the capsule shells and the contents easily and uniformly spread in the mouth so as to cover up bad taste of raw materials.

Owner:SIRIO PHARMA CO LTD

Vegetable-based dog chew

A chew toy having a substantial component of vegetable matter wherein such vegetable matter, in dried and powdered or granulation form, is melted as it is injection molded. The process provides a chew toy with a consistency and chewability preferred by most dogs that is not attainable by known prior art baking or compression molding techniques.

Owner:T F H PUBLICATIONS

Potato noodles and preparation method thereof

The invention discloses potato noodles and a preparation method thereof, and relates to the field of processing of the potato noodles. According to the formula, the potato noodles provided by the invention comprise the following raw materials in parts by weight: 45-80 parts of wheat meal, 15-50 parts of whole potato flour, 1-5 parts of gluten powder and 35-45 parts of salt water, wherein the granularity of the whole potato flour is 100-180-mesh and the concentration of the salt water is 3%-9%. According to the preparation method provided by the invention, the problem that the whole potato flour is difficult to bond is further solved by adopting a secondary curing process and a gradient temperature-varying wetting drying process, and the noodles with good chewiness and mouth feel are prepared.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Highland barley, Litsea coreana and sweet potato beef jerky and preparation method thereof

InactiveCN103222644ANutritional diversityFull of nutritionFood preparationMonosodium glutamateFood flavor

The invention discloses highland barley, Litsea coreana and sweet potato beef jerky and a preparation method of the highland barley, Litsea coreana and sweet potato beef jerky. The highland barley, Litsea coreana and sweet potato beef jerky comprises the following raw materials, by weight ratio, 50-60 parts of beef jerky, 1-1.5 parts of salt, 2-3 parts of soybean sauce, 1-2 parts of monosodium glutamate, 5-10 parts of white sugar, 1.5-2 parts of yellow rice wine, 0.2-0.3 part of tsaoko amomum fruits, 0.5-0.8 part of Chinese red pepper, 0.3-0.4 part of cinnamon, 0.4-0.6 part of dried orange peel, 0.2-0.3 part of radix angelicae, 0.4-0.6 part of fresh ginger, 0.1-0.2 part of grape leaves, 5-8 parts of highland barley, 10-15 parts of Litsea coreana, 3-5 parts of dogbane leaves, 2-4 parts of mint, 1-2 parts of sunflower discs, 2-3 parts of wild chrysanthemum flowers and 8-12 parts of sweet potato powder. The highland barley, Litsea coreana and sweet potato beef jerky has the advantages of being rich in nutrition, red and bright in color and luster, tasty and special in flavor, having high elasticity and chewiness, Litsea coreana fragrance and sweet highland barley and sweet potato fragrance, and being novel, and is leisure food which is green, healthy, non-additive, suitable for people of all ages and both sexes, and capable of satisfying requirements of different crowds.

Owner:BENGBU FENGMU BEEF & MUTTON PRODS

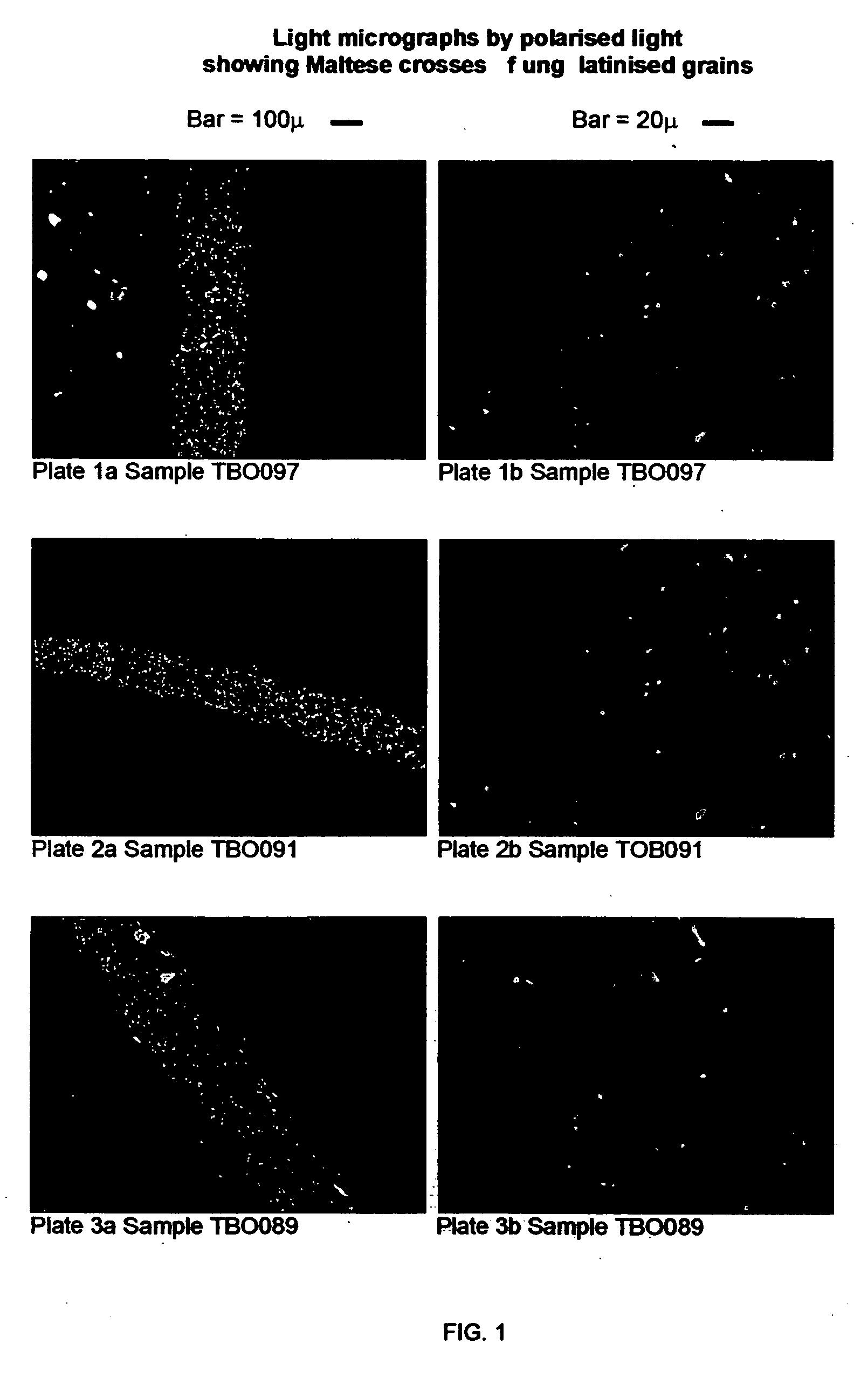

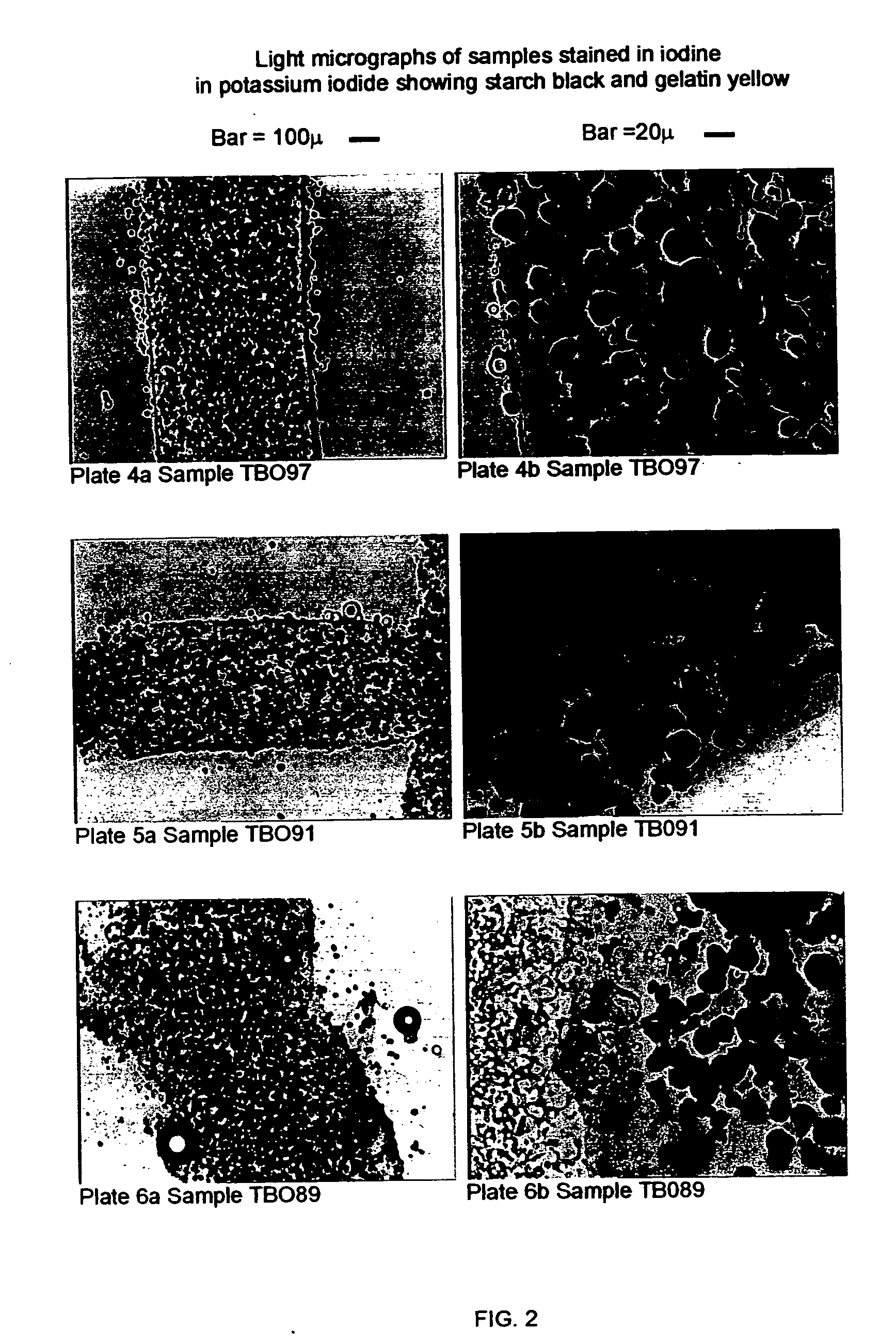

Chewable soft capsules containing ungelatinized starch

A soft chewable capsule film suitable for medicament or foodstuff encapsulation, and a method of fabricating capsules from such a film. Such capsules demonstrate fast rupture in the oral cavity, good mouth feel and chewability, and rapid dissolution of the shell components. In particular, the modified starch is substantially ungelatinized, due at least in part to the processing temperature, and may act as a water retention agent to promote hydration. Additionally, gelatins are selected for bloom strengths that result in a robust capsules that may be fabricated at a thinner wall thickness than previously experienced in the art. Accordingly, such thin capsules have a smaller mass than traditional capsules of the same size and dissolve more quickly than chewable capsules having greater thicknesses. The capsules may be fabricated by a rotary die process at speeds greater than those generally known for soft chewable capsules.

Owner:R P SCHERER TECH INC

Energy stick and preparation method thereof

The invention relates to an energy bar which contains 0.5-10 parts of collagen peptide by weight. The energy bar further contains 0-40 parts of grain flour, 10-60 parts of albumen powder, 0-8 parts of puffed grain granules or nut granules, 10-30 parts of syrup, 4-20 parts of grease and 0-2 parts of nutrients by weight. The invention has the advantages that the energy bar has good moisturizing effect, thereby mitigating the loss of moisture during storage, ensuring the softness and the chewiness of the energy bar, and prolonging the shelf life. Moreover, the energy bar has a diverse nutritional value, thereby providing additional collagen to human body, in particular to athletes who need to deal with osteoarthrosis.

Owner:BEIJING COMPETITOR SPORTS SCI & TECH

Gum based chewing product and process for preparing the same

InactiveUS20040107971A1Increase capacityReduce intakeTobacco treatmentAerosol deliveryBiotechnologyBetel nuts

A gum based chewing product, particularly a chewing / bubble gum, contains a synthetic or natural betel nut source, an alkaloid-like composition such as nicotine or other such alkaloids like caffeine, theine etc. from natural or synthetic origin for its source. The product preferably has taste enhancers like lime and / or catechu. A process for preparing the gum based chewing product. The product has improved high smoothness, less saliva generation, excellent overall taste and chewing properties. The gum pieces deliver 1 to 12.6 mg of nicotine per piece.

Owner:DALMIA CENT FOR RES & DEV

Feed for breeding porcupines and preparation method thereof

The invention relates to feed for breeding porcupines. The feed contains corn flour, tapioca flour, sweet potato flour, kudzu root powder, peanut powder, silkworm chrysalis powder, cod liver oil, dry yeast, angelica powder, pistachio nut powder and chicken cashew nut powder. According to the formula, the feed provides complete and a plenty of nutrients for porcupine breeding, and the growth feed contains fat, carbohydrates, crude fibers and minerals, so that the growth of the porcupines can be promoted, and the resistance of the porcupines can be improved. Furthermore, the feed is suitable for the mouth feel of the porcupines, has certain elasticity and chewiness and is suitable for the tooth grinding of the porcupines. The phenomenon that the porcupines disorderly nibble and chew is prevented.

Owner:徐玉文

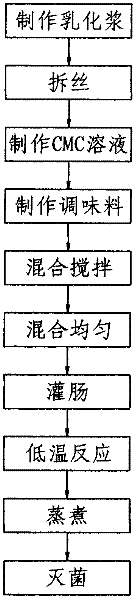

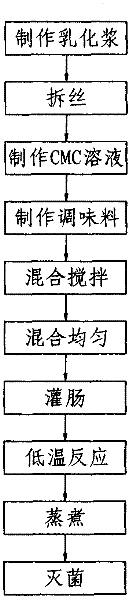

Peanut vegetarian meat ham and production method thereof

Owner:QINGDAO CHANGSHOU FOOD

Low temperature fermenting Lactobacillus casei and method for preparing hard yark milk cheese from Lactobacillus casei

The invention discloses low temperature fermenting Lactobacillus casei and a method for preparing hard yark milk cheese from Lactobacillus casei. The Lactobacillus casei which has a preservation number of CGMCC4775 has a low temperature fermentation capability. The method for preparing the hard yark milk cheese from Lactobacillus casei comprises steps of raw milk sterilization, inoculation, fermentation, enzyme addition, milk curding, cutting, whey discharging, pile brewing, squeeze-molding, packaging, and maturation. The hard yark milk cheese, which is prepared in the invention, is milky in color and has the characteristics of rich milk fragrance, uniform quality and abundant nutrition, has the advantages of good hardness, good elasticity, good cohesiveness and good chewiness.

Owner:GANSU AGRI UNIV

Making method of additive-free cubilose gelled food

The invention discloses a making method of additive-free cubilose gelled food. The additive-free cubilose gelled food is made through soaking, impurity removal, slow fire pre-boiling, high-pressure heating, centrifugal separation, clear solution drying, powder extrusion and re-watering formation, wherein powder extrusion is carried out in a way that cubilose powder pulverized after being freeze-dried or cubilose powder dried by atomizing is extrusion-molded under the pressure of 10-100KN; re-watering molding is carried out in a way that deionized water of which the dry weight mass is 2-15 times of that of the extruded cubilose product is added into the cubilose product, and the cubilose gelled food is finally obtained after the deionized water is absorbed and balanced. On the basis of improving the cubilose eating safety, the cubilose gelled food has attractive appearance, great elasticity and great chewiness.

Owner:南京铂智氏能电子科技有限公司

Composite nutritional isolated soybean protein bean curd and making method thereof

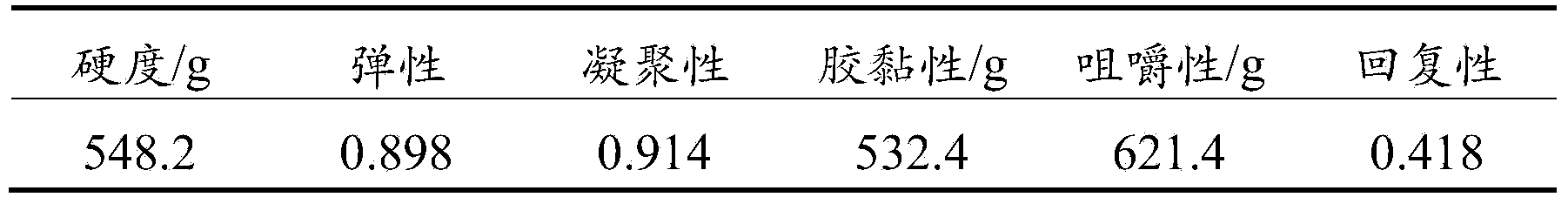

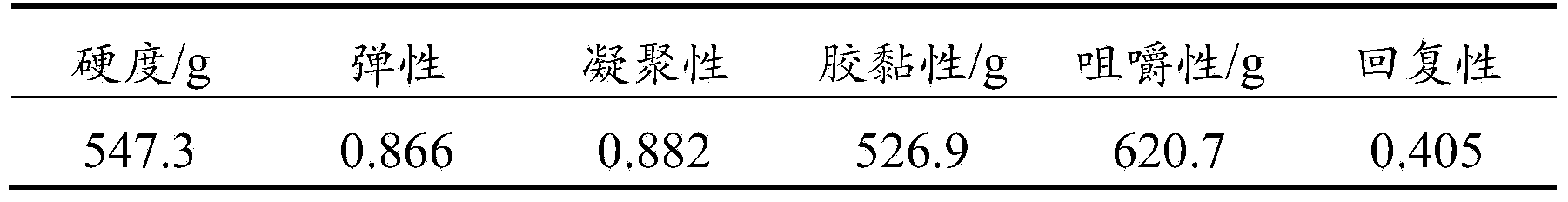

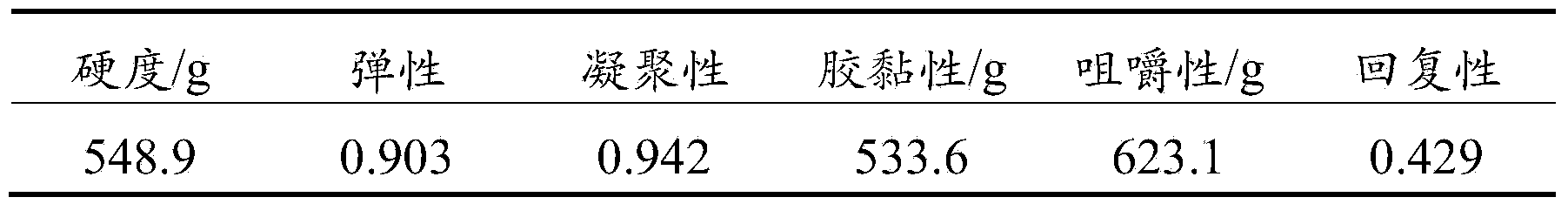

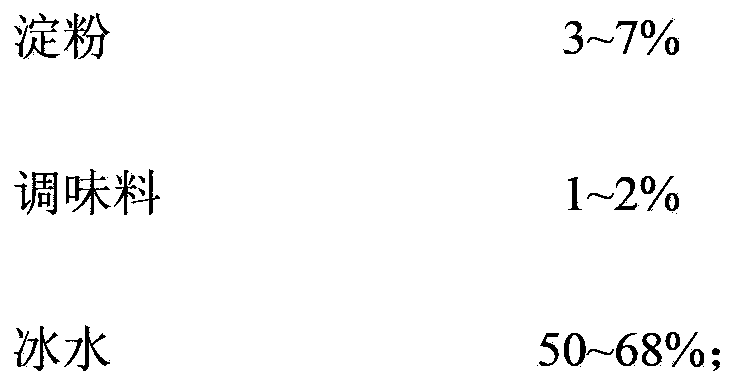

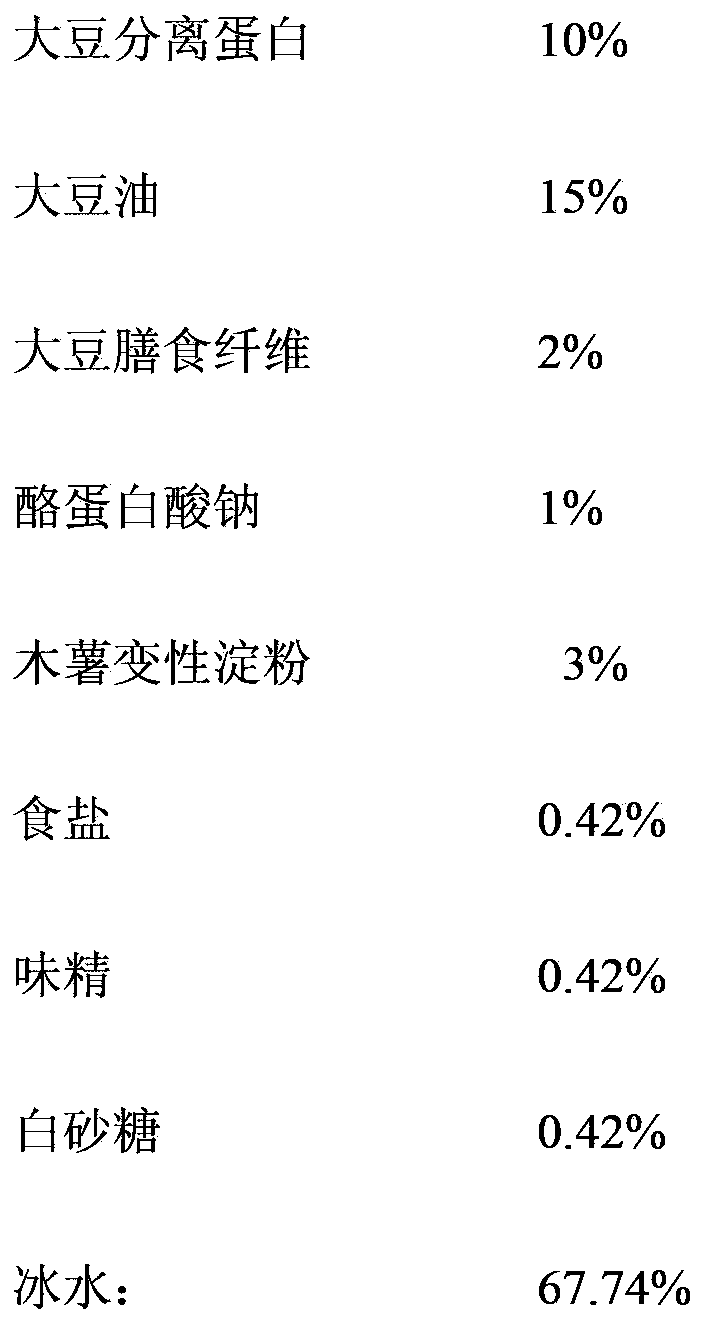

The invention discloses a composite nutritional isolated soybean protein bean curd. The composite nutritional isolated soybean protein bean curd comprises, by mass, 10-13% of isolated soybean protein, 1-2% of a soybean dietary fiber, 0.5-1% of sodium caseinate, 10-26% of plant oil, 3-7% of starch, 1-2% of a seasoning, and 50-68% of ice water. The composite nutritional isolated soybean protein bean curd fully utilizes the high gel property of the isolated soybean protein, is not added with a coagulant, has the characteristics of good chewiness, smooth and tender mouthfeel and high nutritional values, can supplement dietary fibers required by human bodies, and is suitable for eating methods comprising decocting, stir-frying, cooking, frying, cold-mixing and the like.

Owner:山东禹王生物技术有限公司

Drunken tilapia snack food and processing method thereof

The invention discloses a drunken tilapia snack food and a processing method thereof. Tilapia fillets are prepared into semi-dried drunken fillets through the steps of picking, inebriating, vacuum microwave drying and the like. By controlling the drying conditions, the flavoring material and original chewiness of the drunken fish are well maintained while the water content of the drunken fish is improved, and thus the drunken fish is good in flavor and taste. The process is capable of shortening the production period, reducing the production cost, and facilitating production. The drunken tilapia snack food processed by the method disclosed by the invention is natural in flesh color, compact, fresh and tender in meat, proper in salt taste, hardness and moisture, free from intermuscular fishbone, and suitable for people of all ages. The method is further suitable for small and medium freshwater fish, such as colussoma brachypomum, without or with less intermuscular fishbone.

Owner:GUANGDONG YUJIA AQUATIC FOOD

Method for processing weakly acidic normal temperature fresh-keeping wet noodles

InactiveCN102308956AGuaranteed shelf lifeAvoid "sour" problemsFood preparationProcess engineeringSouring

The invention discloses a method for processing weakly acidic normal temperature fresh-keeping wet noodles. The method adopts added natural nisin as an antiseptic, and adopts processes of post-slaking, post-washing, alcohol spraying and packaging with high resistance and isolation film bags, and a high temperature and short time sterilization technique to produce, so a problem of "souring" of the noodles caused by an acid dipping technology for reaching a shelf-life of traditional wet noodles in later processes is avoided, thereby shortages of soft rotten and non-chewy noodles caused by high temperature and long time sterilization in the later processes are solved.

Owner:FUZHOU CHANGSHENG FOOD

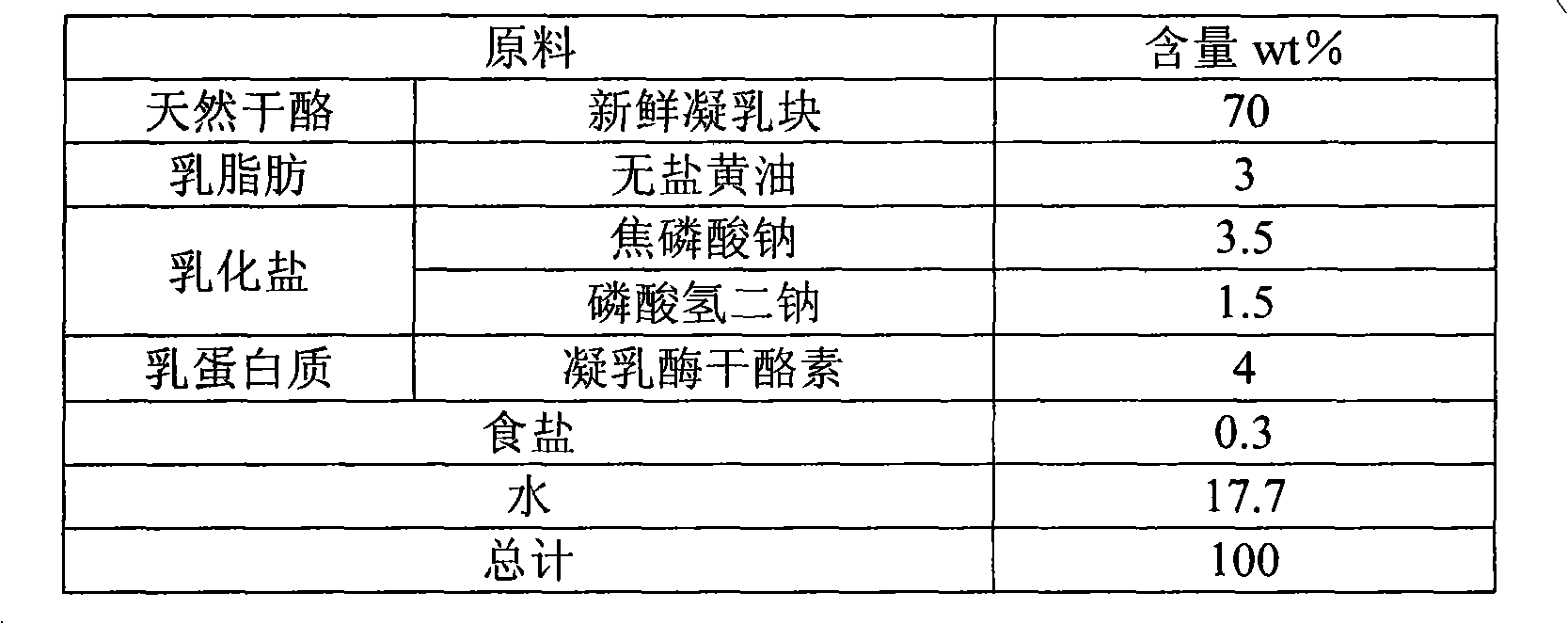

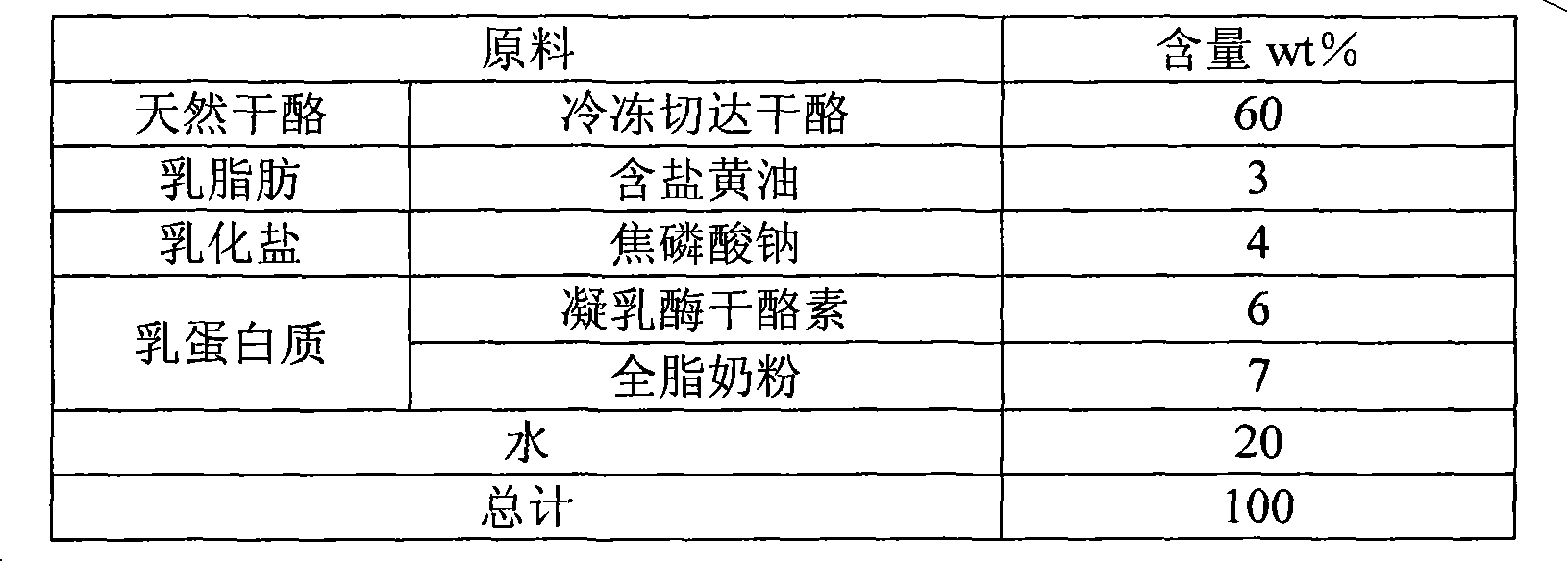

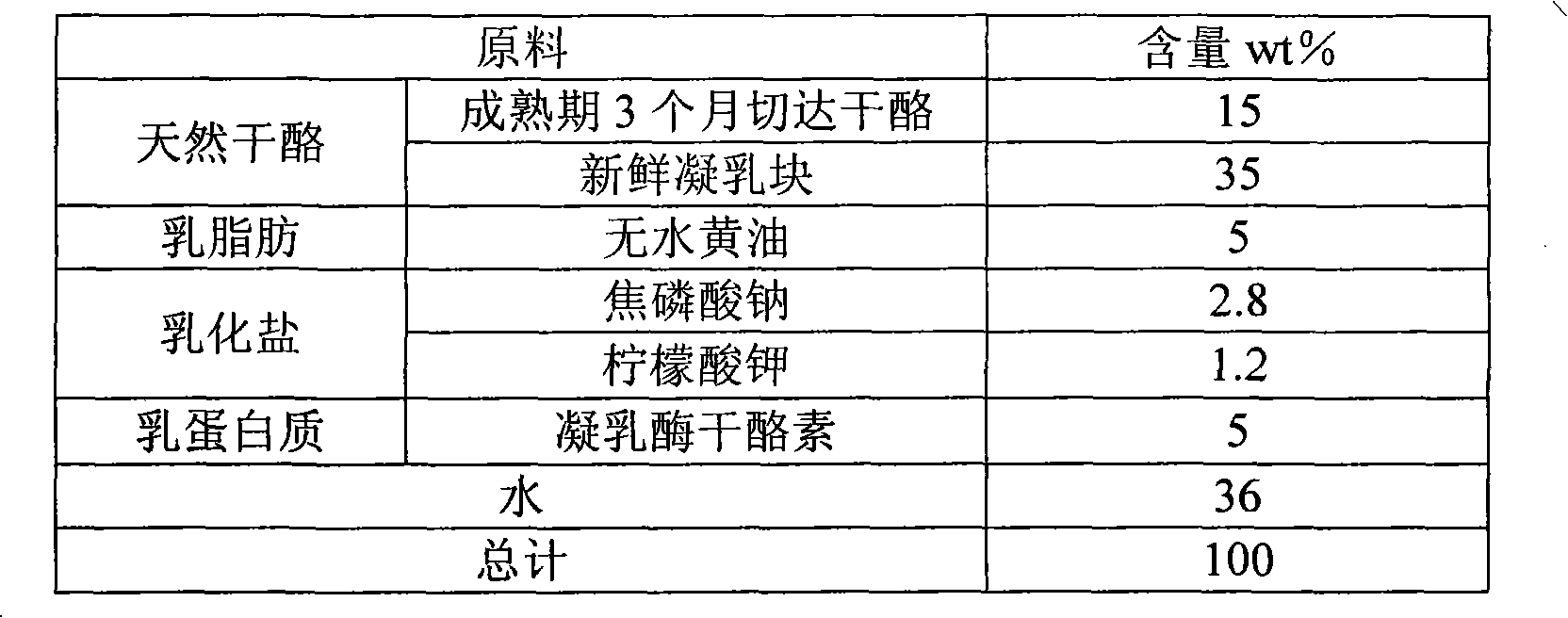

Preparation method of processed cheese and processed cheese prepared thereby

ActiveCN101926390ASimple production processImprove chewinessCheese manufactureLow speedPyrophosphate

The invention discloses a preparation method of processed cheese, which comprises the following operation steps: 1) fusing and mixing raw materials: the raw materials comprise natural cheese, emulsifying salt, lactoprotein and water, wherein the natural cheese is fresh cheese and / or Cheddar cheese with a mature period within 3 months, and the emulsifying salt comprises pyrophosphate; 2) sterilizing; 3) stirring and emulsifying; 4) cooling at low speed; 5) refrigerating and placing; 6) fusing once again; 7) performing ultra high temperature short time sterilization; 8) stirring and emulsifying once again; and 9) cooling at low speed once again to obtain the product. The invention also discloses the processed cheese prepared by the method. The processed cheese in the invention has no deformation and collage after being boiled for less than 15min in boiling water, and can meet the requirements of catering industry; and the processed cheese in the invention has good chewiness, texture and taste.

Owner:BRIGHT DAIRY & FOOD

Preparation method of hybrid gel candy

InactiveCN102726584AIncrease elasticityImprove chewinessConfectionerySweetmeatsGlucose-Fructose SyrupFiltration

The invention belongs to the technical field of food, and in particular relates to a preparation method of a hybrid gel candy. The method includes the following steps of: weighing raw materials according to a proportion; mixing gelatin uniform under a temperature of 40-80DEG C, conducting standing and heat preservation for 0.5-2h for standby use; adding glucose syrup and white granulated sugar into filtered water, and carrying out sugar boiling at a temperature of 70-125DEG C so as to obtain a syrup; adding gelatin, essence, an acid solution and a pigment into the syrup respectively, mixing them uniformly and performing filtration so as to obtain a sugar solution; and injecting the sugar solution into a starch die, after molding, separating the candy therein from the starch die, then conducting drying, cooling and starch clearing, thus obtaining the hybrid gel candy. Compared with the prior art, the method of the invention strictly controls the quality of supplied materials and parameters in the production process, so that the prepared hybrid gel candy not only has good elasticity and chewiness, and is also in line with the safety and health standards. In addition, the method provided in the invention has simple process, easily controllable production process, and strictly controlled production sanitation, thus ensuring eater safety.

Owner:陈瑞武

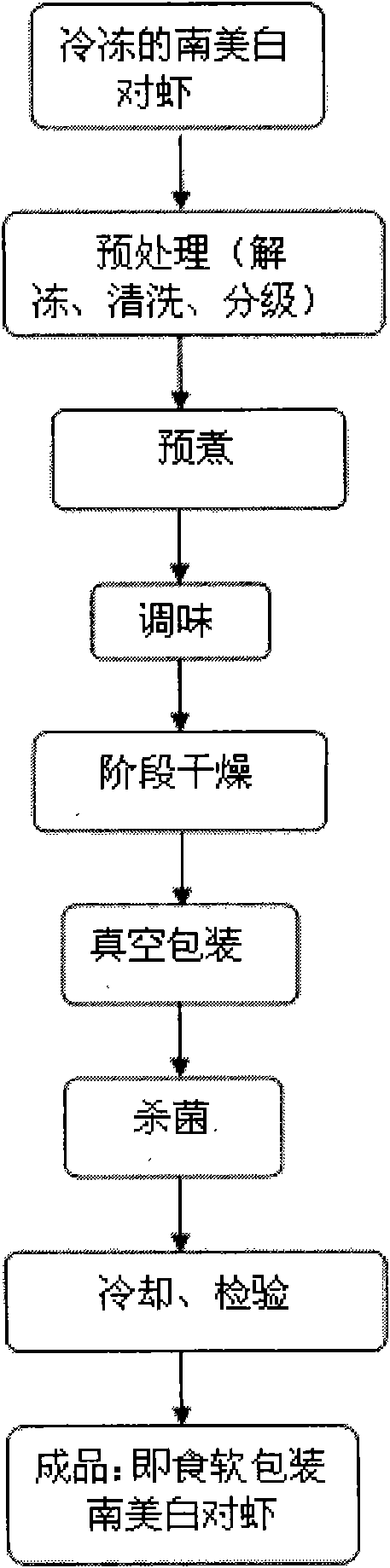

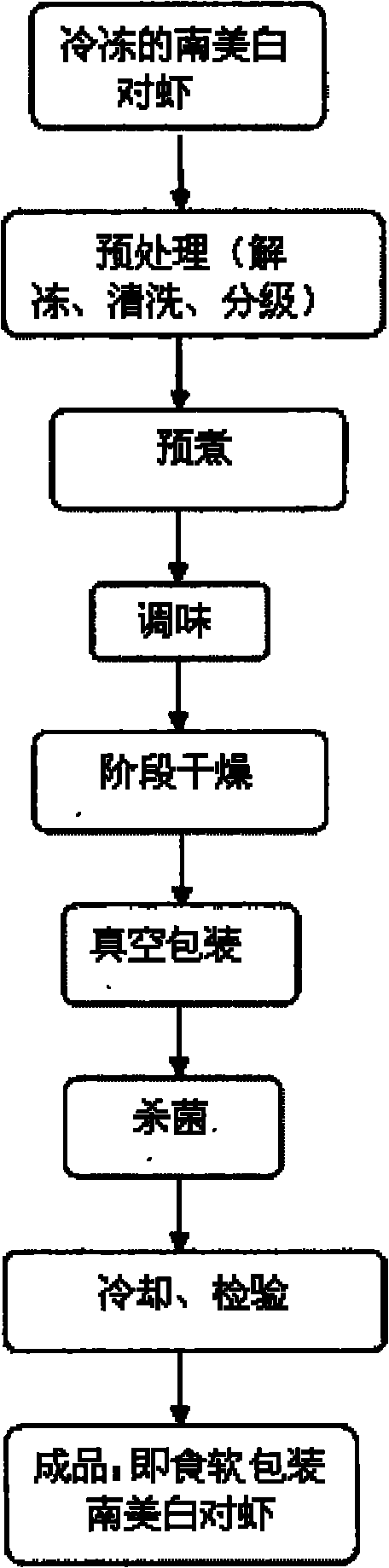

Method for processing instant flexibly-packaged penaeus vannamei boone

The invention discloses a method for processing instant flexibly-packaged penaeus vannamei boone, which comprises the following steps: (1) unfreezing, washing and grading frozen penaeus vannamei boone; (2) placing the unfrozen penaeus vannamei boone into boiling water for pre-boiling, taking penaeus vannamei boone out, and draining the penaeus vannamei boone; (3) placing the penaeus vannamei boone in seasoning liquid to preserve the penaeus vannamei boone at normal temperature; (4) drying the preserved penaeus vannamei boone; (5) packing the penaeus vannamei boone under vacuum; and (6) sterilizing the packaged penaeus vannamei boone. The method is simple and convenient in manufacturing steps and low in production cost; the prepared instant flexibly-packaged penaeus vannamei boone has the advantages of convenience, rich nutrients, attractive appearance, nice taste and high chewiness.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Miscellaneous grain and miscellaneous bean instant noodles for children and preparation method of same

InactiveCN102696968AConquer rough tasteConquer bad colorFood preparationPolygonum fagopyrumInstant noodle

The invention discloses a miscellaneous grain and miscellaneous bean instant noodles for children and a preparation method of the noodles, and belongs to the technical field of intensive processing of agricultural products. The instant noodles are creatively developed according to the basic principles of food nutriology, diet pagoda and characteristics of demand for nutritious food of children at age 2 to 12, and are characterized by the following aspects: wheat meal, maize meal or maize kernels are taken as the basic material; oat, buckwheat, millet, black kerneled rice, jumble beans and green beans are taken as auxiliary material; physical indexes including hardness, glutinosity, resilience, cohesiveness, elasticity, gumminess and chewiness are taken as product quality testing indicators; and the core technical parameters of preprocessing, mixing, extrusion, swelling, forming and drying of the basic and the auxiliary materials are optimized. The instant noodles are suitable for being taken by children at the age 2 to 12, do not need to be boiled at a high temperature, only need to be directly soaked in mild water or purified water for 15 to 25 minutes, have the characteristics of having balanced nutrient and being fast food, convenient, green, safe and easy to ingest, and can particularly meet food demand under irresistible natural disaster and special environment.

Owner:JILIN UNIV

Meat quality improver for grass carps and preparation method for meat quality improver

The invention discloses a meat quality improver for grass carps and a preparation method for the meat quality improver. The meat quality improver is prepared from the following raw materials in part by weight: 5 to 10 parts of astragalus, 5 to 10 parts of Codonopsis pilosula, 10 to 15 parts of eucommia bark, 5 to 10 parts of lycopene, 1 to 5 parts of plumepoppy extract, 8 to 15 parts of phytase, 1 to 3 parts of cysteamine, 20 to 40 parts of lactosucrose and 20 to 40 parts of montmorillonite. The invention has the advantages that: active ingredients for improving the meat quality of freshwater fishes are scientifically matched; and the meat quality improver can remarkably improve the growth of cultured fishes and reduce the fat content of the fishes, and also improves the elasticity of muscle, chewiness, hardness and cohesion so as to ensure that the meat is fresh and delicious.

Owner:CHANGSHA UNIVERSITY

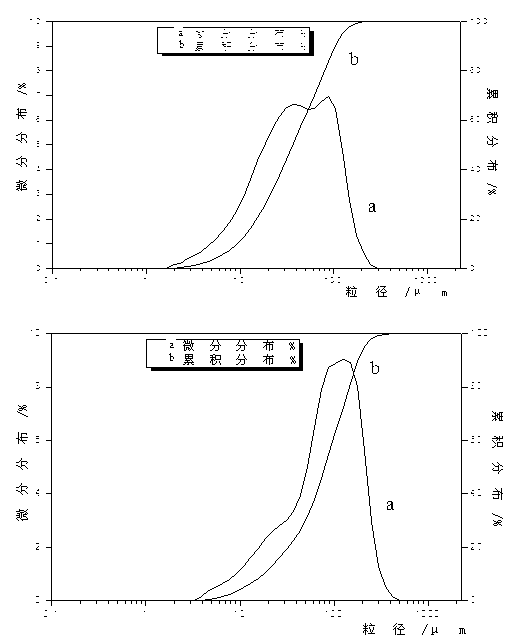

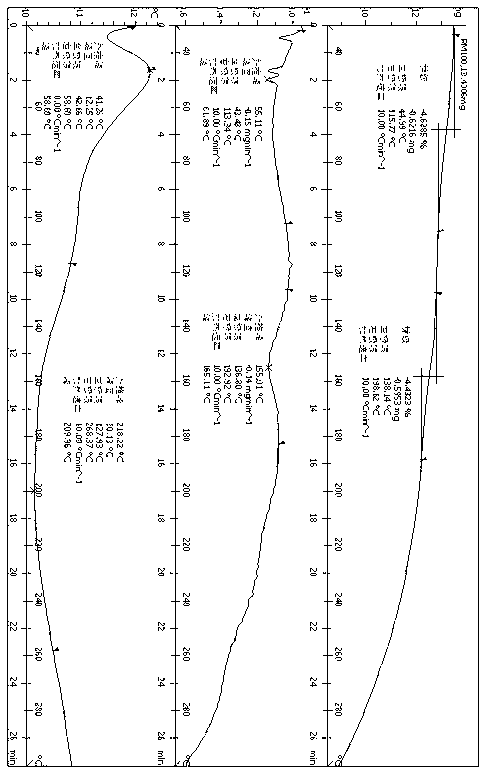

Preparation of barley grass powder and domestic fungus powder compounded chewing tablet, and medium short wave infrared drying method

Preparation of barley grass powder and domestic fungus powder compounded chewing tablet, and a medium short wave infrared drying method, and belongs to the field of the research and development of health-care foods. The chewing tablet is prepared by using the barley grass powder and the domestic fungus fine powder as main raw materials and recombining with other food filling agents. The chewing tablet is prepared by the steps of smashing barley grass crude powder with a PM100 planetary mill; screening the smashed barley grass crude powder with a 200-mesh screen; and mixing the barley grass micro powder and the domestic fungus fine powder with the other food filling agents according to a certain proportion, adopting wet granulation, demoulding and medium short wave infrared drying. The moisture in a final product of the chewing tablet is not higher than 7%. The chewing tablet has the functions of nutrition and health; influences on heat sensitive components during the smashing process can be reduced by employing the PM100 planetary mill, because PM100 planetary mill has large diameter of a sun wheel, high speed ratio and high efficiency; drying time is shortened; work efficiency is increased; and energy is saved by using the medium short wave infrared drying. The obtained product has stronger frangrance, relatively good conservation for flavor components, relatively low product hardness and relatively good chewiness, and is helpful for the manufacture of the product.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

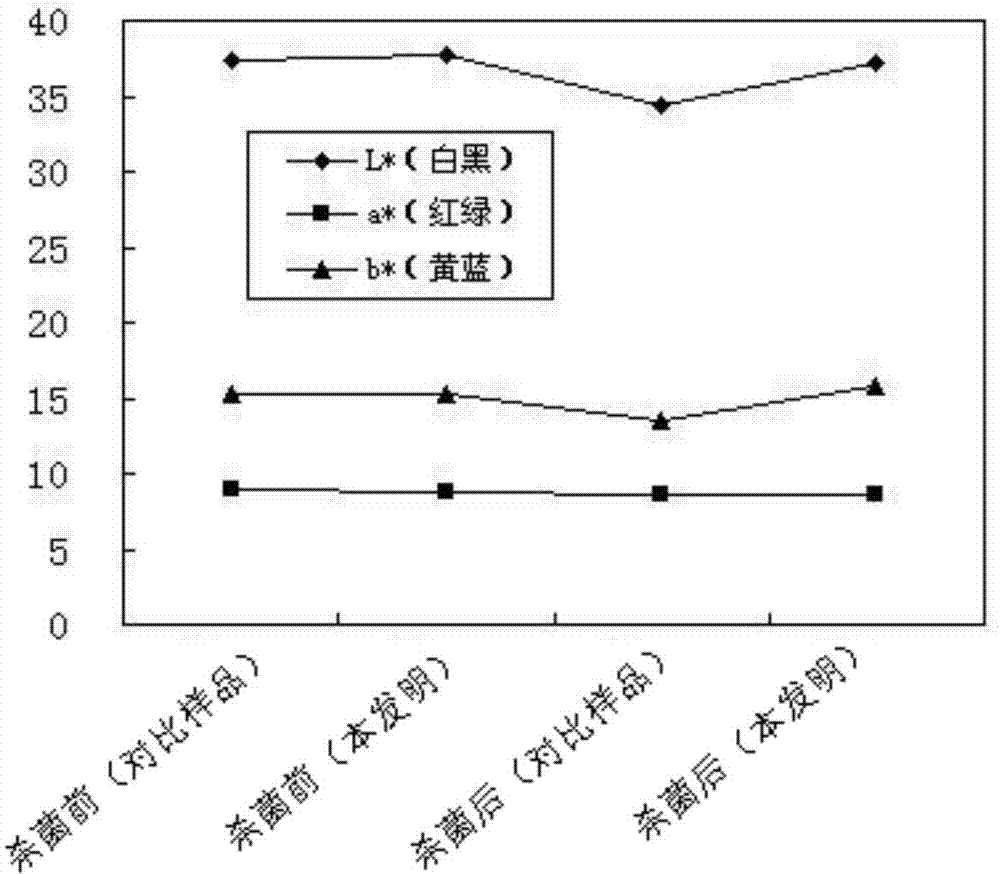

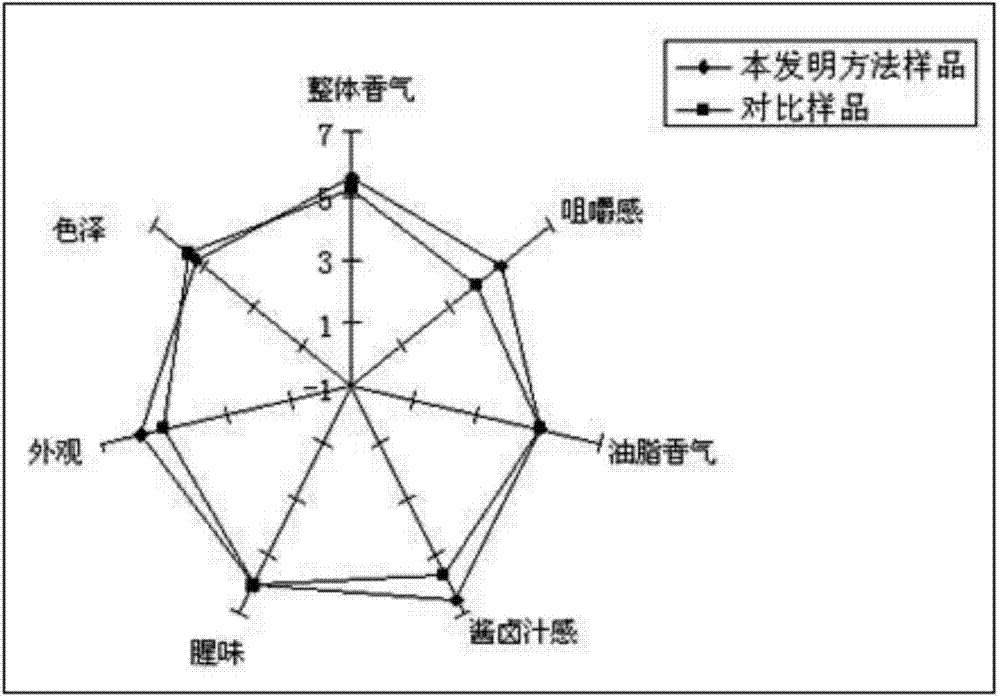

Accessories and method for making marinated products using accessories

Accessories and a method for making marinated products using the accessories relate to the technical field of meat processing. The accessories include galangal, dried bay leaves, star anise, pepper, Chinese red pepper, Sichuan pepper, cassia bark, fennel seeds, licorice root, nutmeg, amomum fruits, lemongrass and chili pepper. The method for making marinated products using the accessories mainly includes the steps of raw material selection and sorting, pre-boiling, stewing the accessories, re-boiling to season the raw material, primary packaging, sterilization and secondary packaging. The method combining traditional production process and industrial production process has complementary advantages of the traditional production process and the industrial production process, marinated products made by the method well retain color, fragrance, flavor and nutrients of sliced dried beef, the storage and quality guarantee of the products are facilitated , high chewiness of the products is maintained, and the products have the characteristics of uniform color, high yield and the like. The products produced by the method can meet needs of different people to the maximum extent.

Owner:燕凤兰

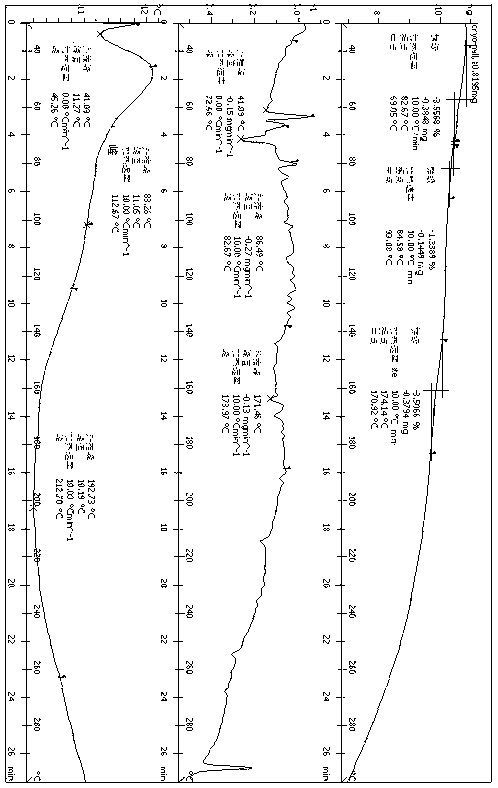

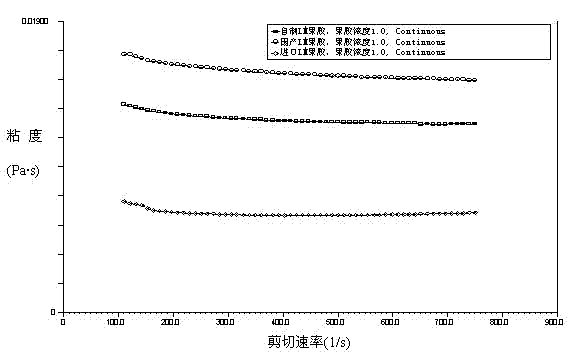

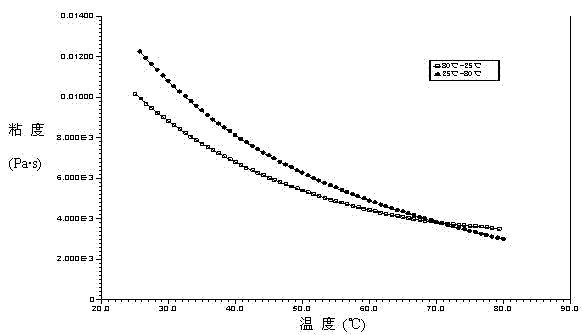

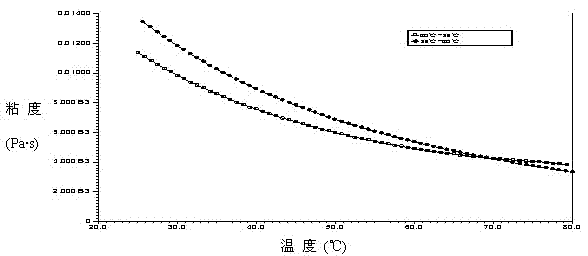

Preparation method of low-ester pectin

The invention discloses a preparation method of low-ester pectin. The method comprises the following steps of: smashing fresh orange peel, putting into warm water with the temperature of about 45 DEG C to soak for 30 minutes; removing moisture and mixing pretreated orange peel blocks with water, controlling the pH value to 7.0-11.0; removing ester from the pretreated orange peel blocks under the conditions that pH is controlled to 7.0-11.0, the temperature is controlled to 10-50 DEG C and the time is controlled to 60-120 minutes; spinning to be dry by means of centrifugal separation after the ester is removed, and pouring out an upper-layer cleaning liquid; adding an acid extracting solution into filter residue, filtering by gauze, and carrying out vacuum rotary evaporation on filter liquor to obtain concentrated liquor; and adding absolute ethyl alcohol into the concentrated liquor, precipitating for 1 hour, carrying out suction filtration, and drying at the temperature of 40 DEG C to obtain the low-ester pectin. The low-ester pectin obtained by the preparation method is good in chewing performance. The viscosity of the obtained low-ester pectin is less changed along with the shear force, and is less influenced by the temperature.

Owner:SHANGHAI INST OF TECH

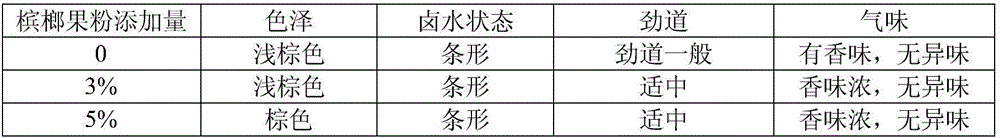

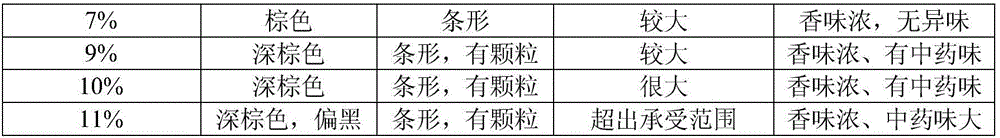

Areca catechu processing method capable of improving chewiness of areca catechu

InactiveCN106387737AImprove the taste of strengthRealize the health functionFood scienceArecolineAreca palm

The invention belongs to the technical field of food processing, and particularly relates to an areca catechu processing method capable of improving chewiness of areca catechu. Areca catechu fruit powder is added to areca catechu brine, wherein the mass ratio of the areca catechu fruit powder to the areca catechu brine is (3 to 10) to (90 to 97). According to the areca catechu processing method, the areca catechu fruit powder is added to the brine to obtain a mixture, the mixture is further added into the areca catechu, and effective components can be furthest exerted, so that the original chewy mouth feel of the areca catechu can be improved. The areca catechu fruit powder reserves original arecoline, phenols and the like in the areca catechu, so that original health-care functions of the areca catechu can be sufficiently realized, and the effects of refreshing and restoring consciousness, killing parasites, promoting diuresis, diminishing inflammation, promoting digestion and the like can be achieved.

Owner:HUNAN ONYEAR FOOD

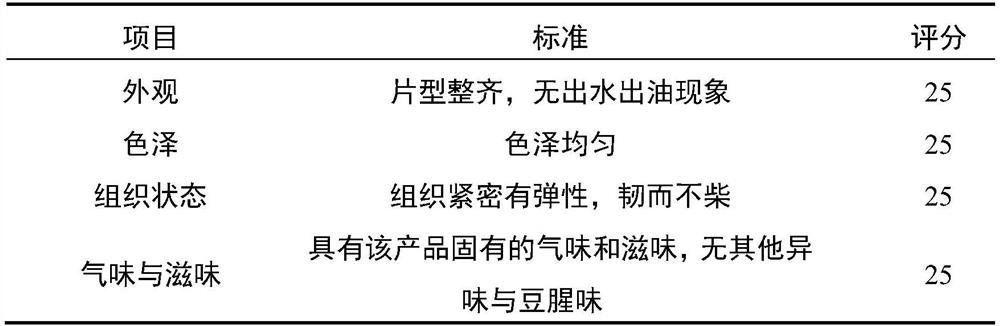

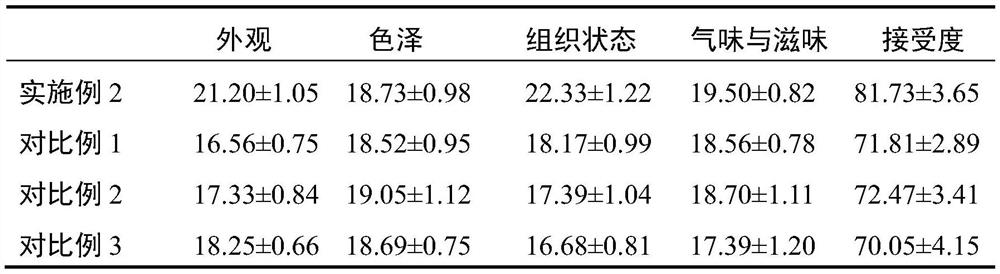

Dried vegetarian meat slice and processing method thereof

InactiveCN112167424AEfficient removalHas hardnessProteins working-up by texturisingFood ingredientsBiotechnologyVegetable oil

The embodiment of the invention provides a dried vegetarian meat slice and a processing method thereof. The dried vegetarian meat slice comprises the following raw materials of, in parts by weight, 20-40 parts of vegetarian meat blank, 8-15 parts of soybean isolate protein powder, 8-15 parts of wheat protein powder, 1-5 parts of starch, 0.1-3 part of sodium alginate, 0.5-1.5 parts of monascus red,10-18 parts of vegetable oil, 5-15 parts of seasonings and 20-45 parts of water, the vegetarian meat blank is prepared by uniformly mixing 30-50 parts of soybean protein, 20-40 parts of wheat protein, 5-10 parts of potato starch, 3-5 parts of white granulated sugar, 1-2 parts of salt, 1-2 parts of light soy sauce, 3-5 parts of spice powder and 10-20 parts of water, and carrying out twin-screw extrusion treatment at 80-160 DEG C. According to the embodiment of the dried vegetarian meat slice and the processing method thereof, the dried vegetarian meat slice which has elasticity and chewiness similar to those of meat, is nutritional and delicious is obtained, and the dried vegetarian meat slice conforms to the current high-protein low-fat diet pursuit of people, and has favorable market prospects.

Owner:CHINA MEAT RES CENT

Special diabetes patient nutrition compounding noodle flour and preparation method thereof

ActiveCN103431373ATo promote metabolismGuarantee the safety of lifeFood preparationDiabetes mellitusTremella

The present invention provides special noodle flour, particularly relates to special nutrition enhanced noodle flour, and belongs to the technical field of food science. The noodle flour comprises the following components, by weight, 200-300 parts of high strength wheat flour, 20-30 parts of amorphophallus konjac powder, 3-6 parts of obtuseleaf senna seed, 5-8 parts of hawthorn, 3-6 parts of white tremella, 2-3 parts of tuckahoe, 1-3 parts of purslane, 3-6 parts of pine pollen, 3-5 parts of lobed kudzuvine root, 3-6 parts of pumpkin powder, 5-10 parts of medlar, 5-10 parts of common yam rhizome powder, 3-6 parts of lotus leaf, 1-3 parts of mythic fungus powder, 3-6 parts of red date, 2-4 parts of oligosaccharide, 3-5 parts of abalone, 3-5 parts of sea cucumber, 3-4 parts of spiral algae dry powder, and 7-10 parts of lotus seed. According to the special diabetes patient nutrition composite noodle flour, a certain effect is provided for treatment and prevention of diabetes, and the prepared noodle has characteristics of smooth taste and chewiness, and meets habits of people.

Owner:安徽省凤宝粮油食品(集团)有限公司

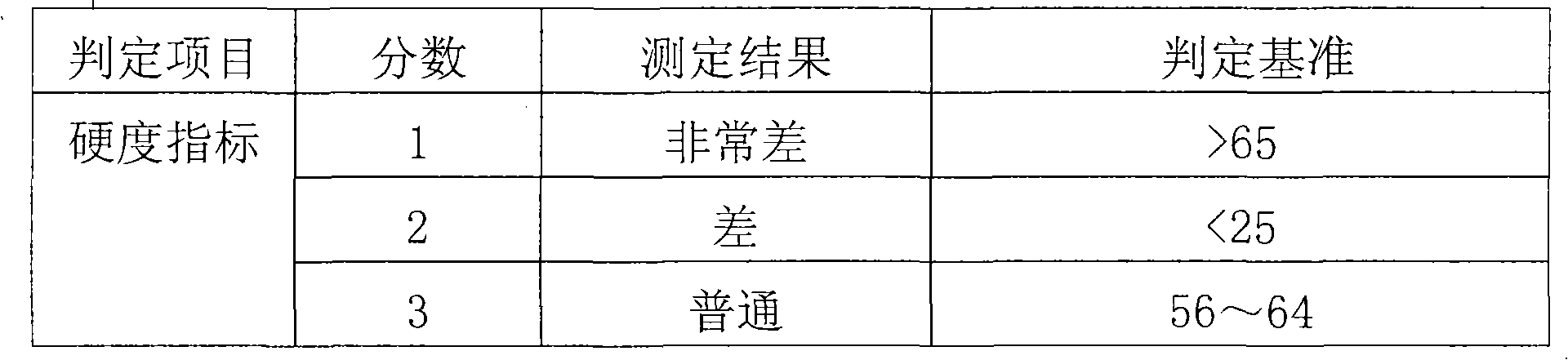

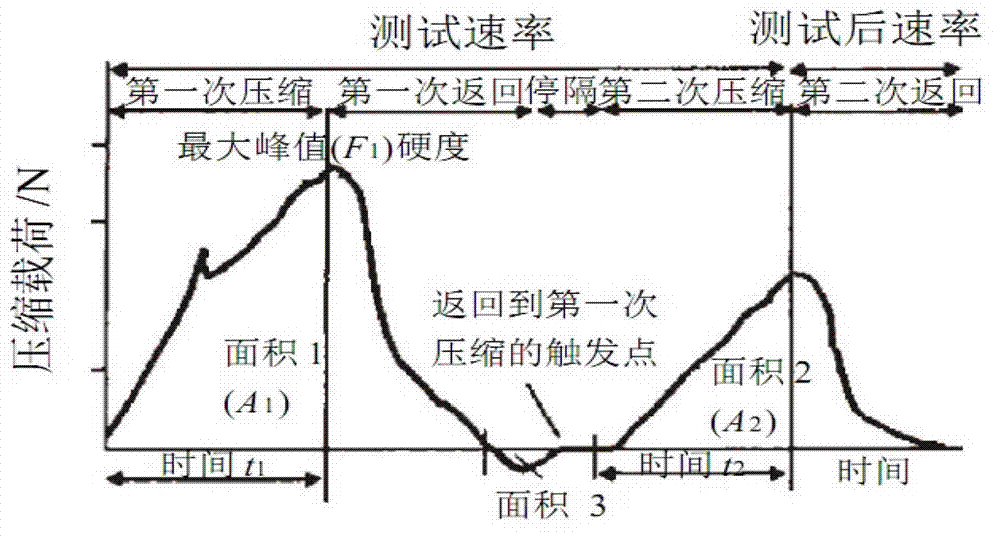

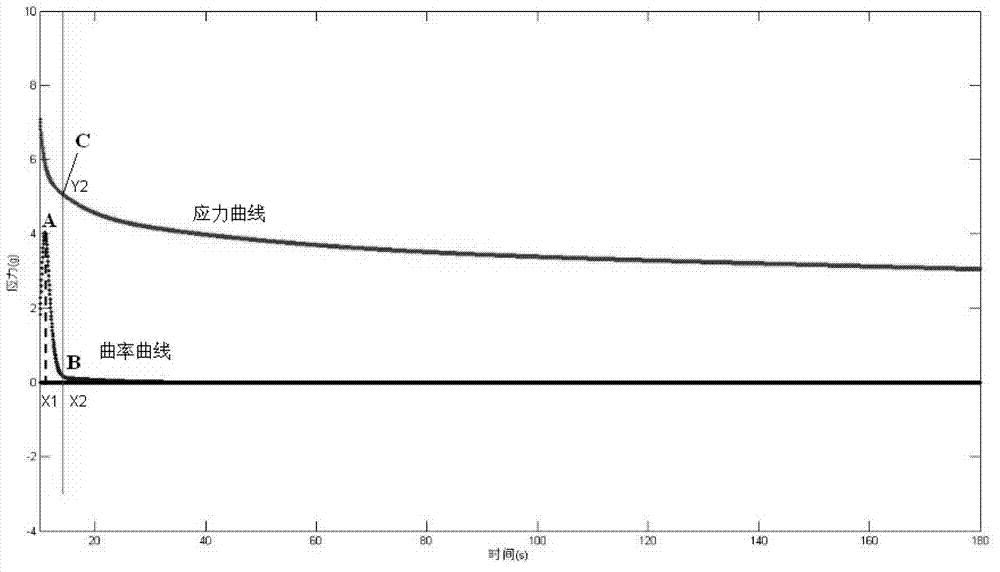

Determination method for texture properties of meat product

ActiveCN102830027AHelp to improveContribute to standardizationUsing mechanical meansInvestigating material hardnessCurve fittingHardness

The invention discloses a determination method for texture properties of a meat product. The method comprises the following steps: 1) preparing meat samples from a meat product and detecting the meat samples with a texture analyzer; 2) carrying out curve fitting by using MATLAB so as to obtain a stress curve of the samples, calculating a function of curvature of each point on the stress curve, carrying out fitting on the calculated curvature so as to obtain a curvature curve and screening out indexes consisting of X1, X2, X2-X1 and Y2 on the curves; and 3) reflecting hardness, cohesiveness, gumminess and chewiness of the meat product by using the indexes consisting of X1, X2, X2-X1 and Y2, wherein the greater the indexes are, the better the hardness, the cohesiveness, the gumminess and the chewiness are. According to the invention, the effective indexes used for determination of continuous stress are screened out, which is beneficial for improvement and standardization of texture determination of meat products, and the problem of lacking of effective indexes in texture determination of meat products under the condition of continuous stress is overcome.

Owner:NANJING AGRICULTURAL UNIVERSITY

Composite ecological coagulant and its preparation method and application in producing fruit and vegetable color bean curd

InactiveCN101283744ADeliciousGreat tasteCheese manufactureFood preparationGlucono delta-lactoneThreonine

The invention discloses an ecological compound coagulant, its production method and the use in producing colorful vegetable / fruit bean curd. The ecological compound coagulant contains the flowing components in weight parts: 20-30 weight parts of CaSO4, 0.8-1.5 weight parts of glucono-delta-lactone, 0.1-0.2 weight parts of calcium hydrogen phosphate, 0.05-0.1 weight parts of potassium tartrate, 0.3-0.4 weight parts of sodium hydrogen phosphate, 0.8-0.9 weight parts of fumaric acid, 0.15-0.25 weight parts of corn starch and 0.8-0.9 weight parts of surfactant. The surfactant is selected from lysine, methionine, tryptophan, phenylalanine, valine, leucine, isoleucine, threonine, and a combination thereof. The coagulant ensures elasticity, chewiness and smooth mouthfeel of bean curd, and prevents the bean curd to be broken and cracked during the slicing or shredding process.

Owner:刘子余

Processing method of sauce-flavor cured pork ribs

The invention relates to the technical field of meat products processing and particularly relates to a processing method of sauce-flavor cured pork ribs. The processing method provided by the invention comprises the following steps of: preparing the pork ribs to the sauce-flavor cured pork ribs by using pork ribs as raw materials, and through such steps as cutting, salting, air drying, roasting, frying, packaging and high temperature sterilizing. The processing method is used for solving the problems of long low temperature air drying time or product quality degradation caused by high temperature roasting of the cured short ribs, solving the problems of flaccid tissues and lacking of chewiness of the sauce spiced pork ribs after being sterilized at high temperature and solving the problems that the cured short ribs lack sauce flavor and the grease is liable to separate out to affect sensory quality after being sterilized. The products processed by the processing method is rich in sauce flavor, fragrant in cured meat flavor and tough and tensile in meat quality, thereby being flavor rib snack food both having the characteristics of rich sauce flavor of the sauce spiced pork ribs and having the advantages of fragrant cured meat flavor of the cured pork ribs.

Owner:TENGQIAO FOOD CO LTD

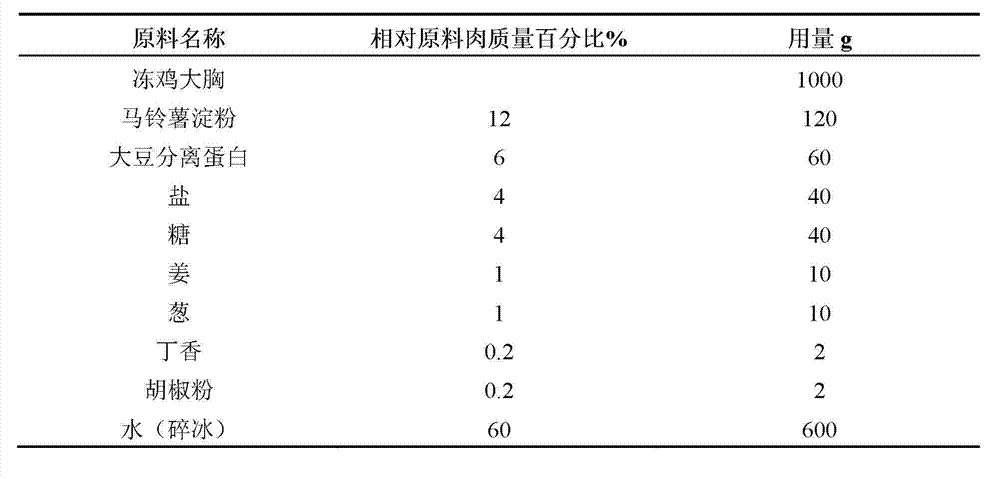

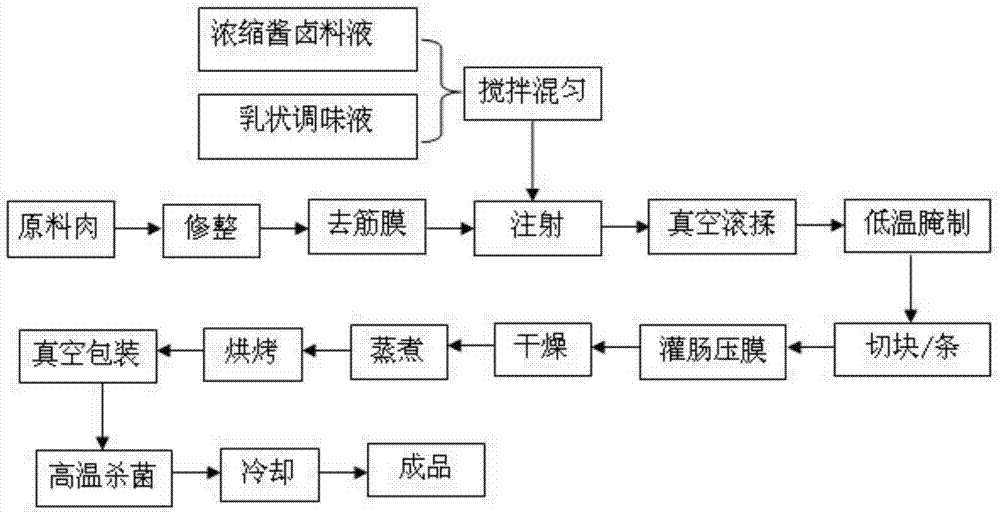

Wet-state meat braised with sauce and automatic continuous production method thereof

The invention discloses wet-state meat braised with sauce and a production method thereof. The wet-state meat braised with the sauce has the following raw material formula in parts by weight: 10-90 parts of livestock meat, 1-60 parts of milky seasoning liquid and 1-30 parts of sauce braising material liquid. After the milky seasoning liquid and the sauce braising material liquid are injected into meat blocks, interval vacuum rolling is carried out, so that the taste and the flavor of two types of seasoning liquid and the meat are completely kept; low-temperature drying-high-temperature boiling-low-temperature drying subsection type operation is adopted so that the fiber feeling of the meat is enhanced very well and the meat braised with the sauce has good chewiness and tenderness and the nutritional value of the meat braised with the sauce is improved very well; the package product is sterilized at a high temperature and a preservative does not need to be added so that the shelf life of the meat braised with the sauce is prolonged very well and can reach more than 10 months; and in total, the wet-state meat braised with the sauce, disclosed by the invention, not only has strong mea fiber feeling, good chewiness and high nutritional value, but also has stable product quality, complete shape and stable net content, and is suitable for industrialized production.

Owner:UNI PRESIDENT ENTERPRISES CHINA INVESTMENT CO LTD KUNSHAN RES & DEV CENT +1

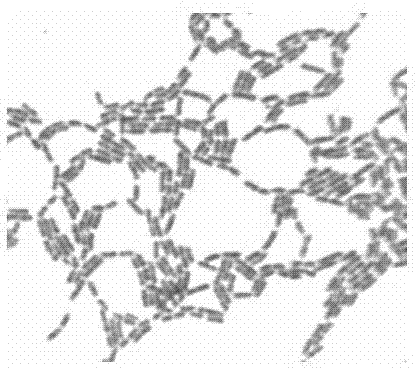

Flavored recombined fish candy snack food and preparation method thereof

InactiveCN103948049AReduce fishy smellStay nourishedFood ingredientsFood preparationBiotechnologyNutrition

The invention provides a flavored recombined fish candy snack food and a preparation method thereof. The flavored recombined fish candy is a dehydrated snack food which is prepared by comprehensively utilizing fish processing leftover-minced fish or offal fish and scientifically adding textured soybean protein (TSP) by a recombination technique. The preparation method comprises the following steps: defreezing fish, selecting, rinsing, removing fishy smell by biofermentation, rinsing, steaming, separating fish fibers, adding TSP fibers, stir-frying while adding seasonings, adding an exogenous adhesive, mixing, spreading on a tray, forming, drying and packaging to obtain the finished product. The flavored recombined fish candy is a dried recombined fish snack food with the texture, chewiness and nutrition of natural fish fibers, conforms to the new diet concept of nutrition and good taste of consumers, solves the problem in comprehensive utilization of processing byproducts, creates higher economic value for the enterprise, and has practical instruction meanings for enhancing the aquatic product deep processing level.

Owner:FUJIAN AGRI & FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com