Patents

Literature

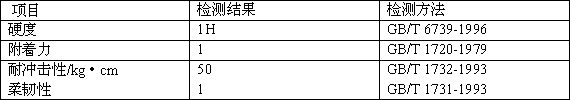

112results about How to "Reduce surface tack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

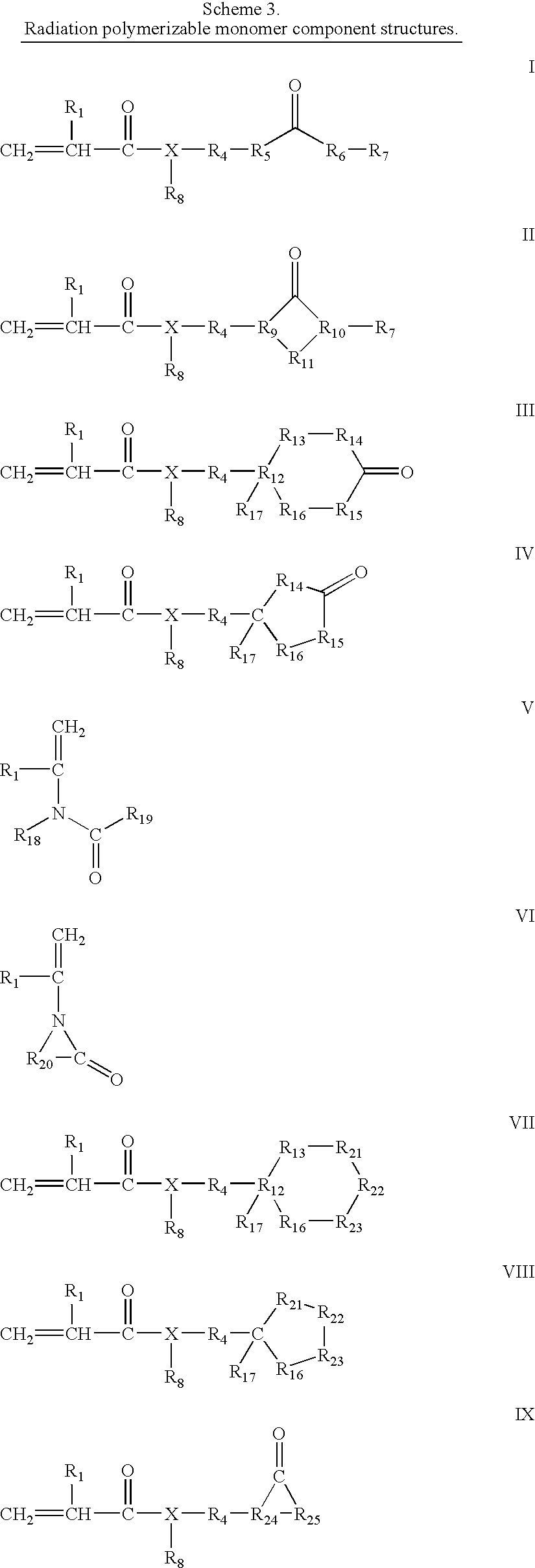

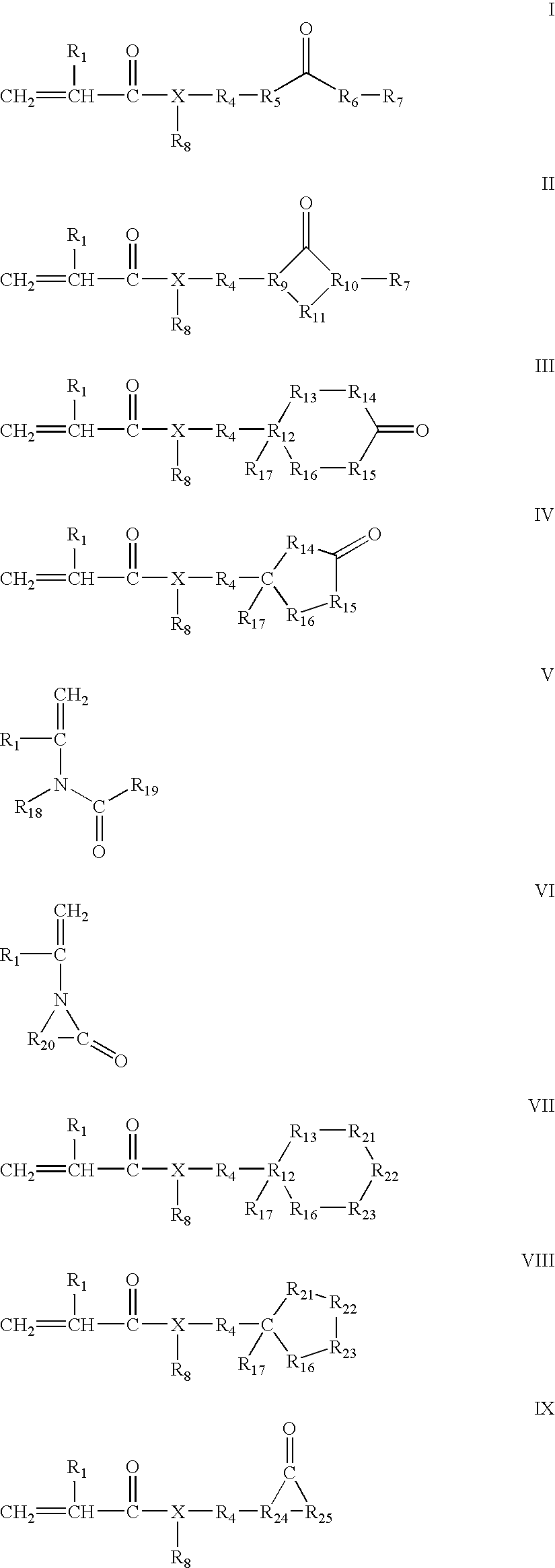

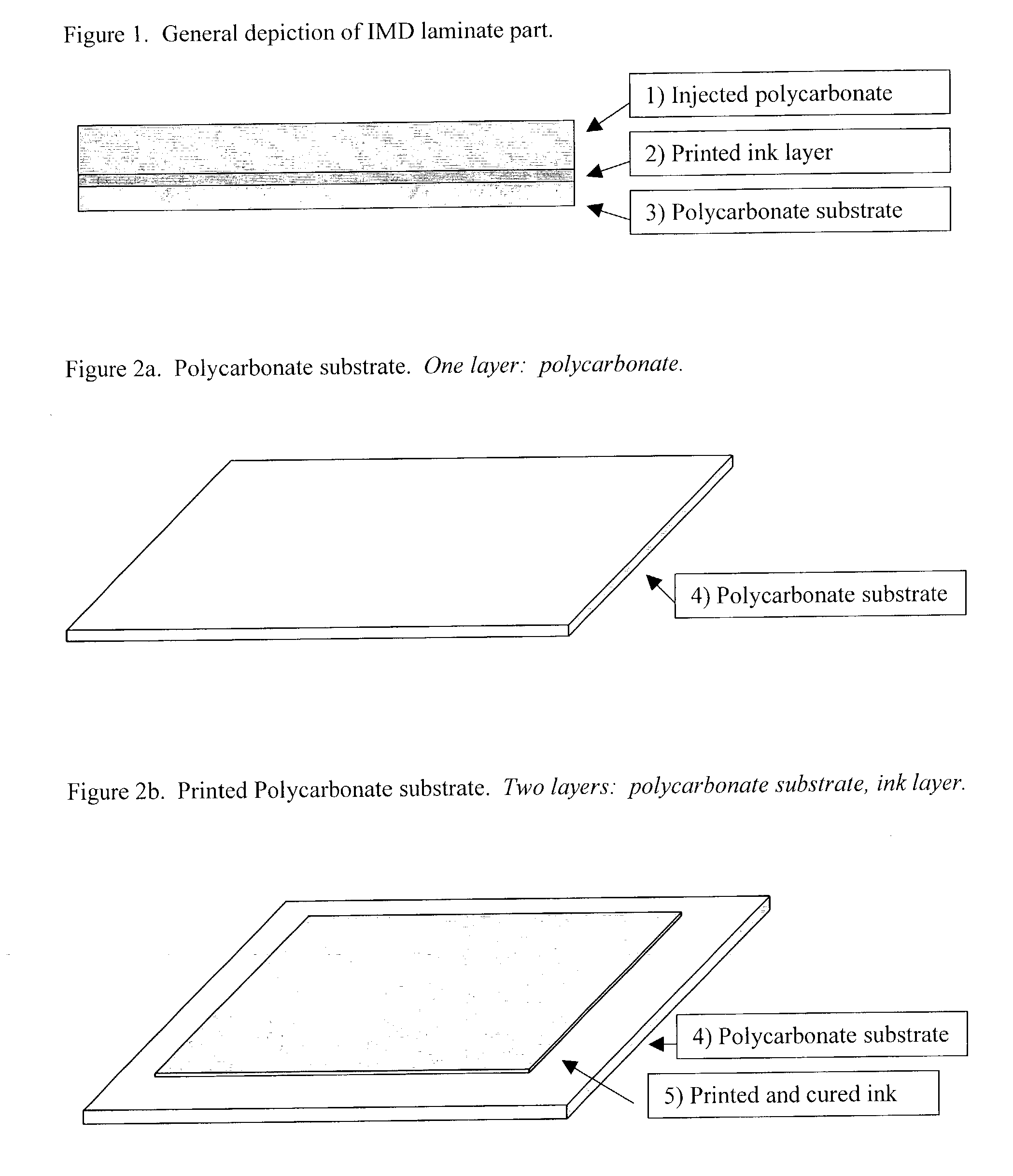

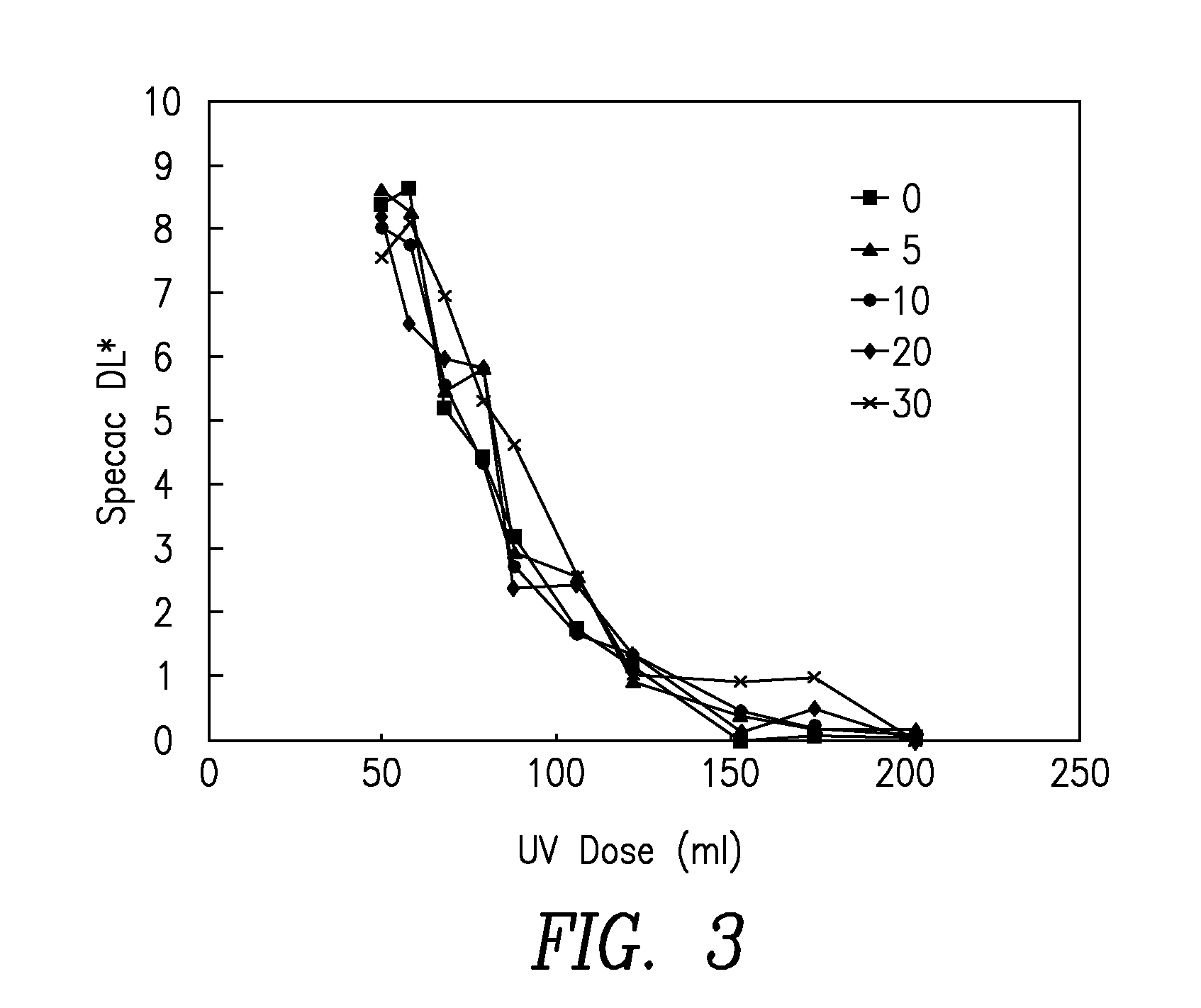

Flexible radiation curable compositions

InactiveUS20040152799A1Increase flexibilityReduce surface tackOrnamental textile articlesSynthetic resin layered productsMeth-Oligomer

Polymerizable compositions are described containing urethane (meth)acrylate oligomers and certain polymerizable monomers useful in thermoforming or in-mold decoration applications.

Owner:SURFACE SPECIALTIES

Medical devices having polymeric regions that contain fluorocarbon-containing block copolymers

ActiveUS20070117925A1Lower surface energyReduce surface tackHeart valvesCoatingsFluorocarbonGlass transition

In one aspect, the present invention provides implantable or insertable medical devices, which contain at least one polymeric region. The polymeric region contains at least one fluorocarbon-containing block copolymer, which, in turn, contains (a) at least one fluorocarbon-containing, low glass transition temperature (low Tg) copolymer chain and (b) at least one glass transition temperature (high Tg) polymer chain.

Owner:BOSTON SCI SCIMED INC

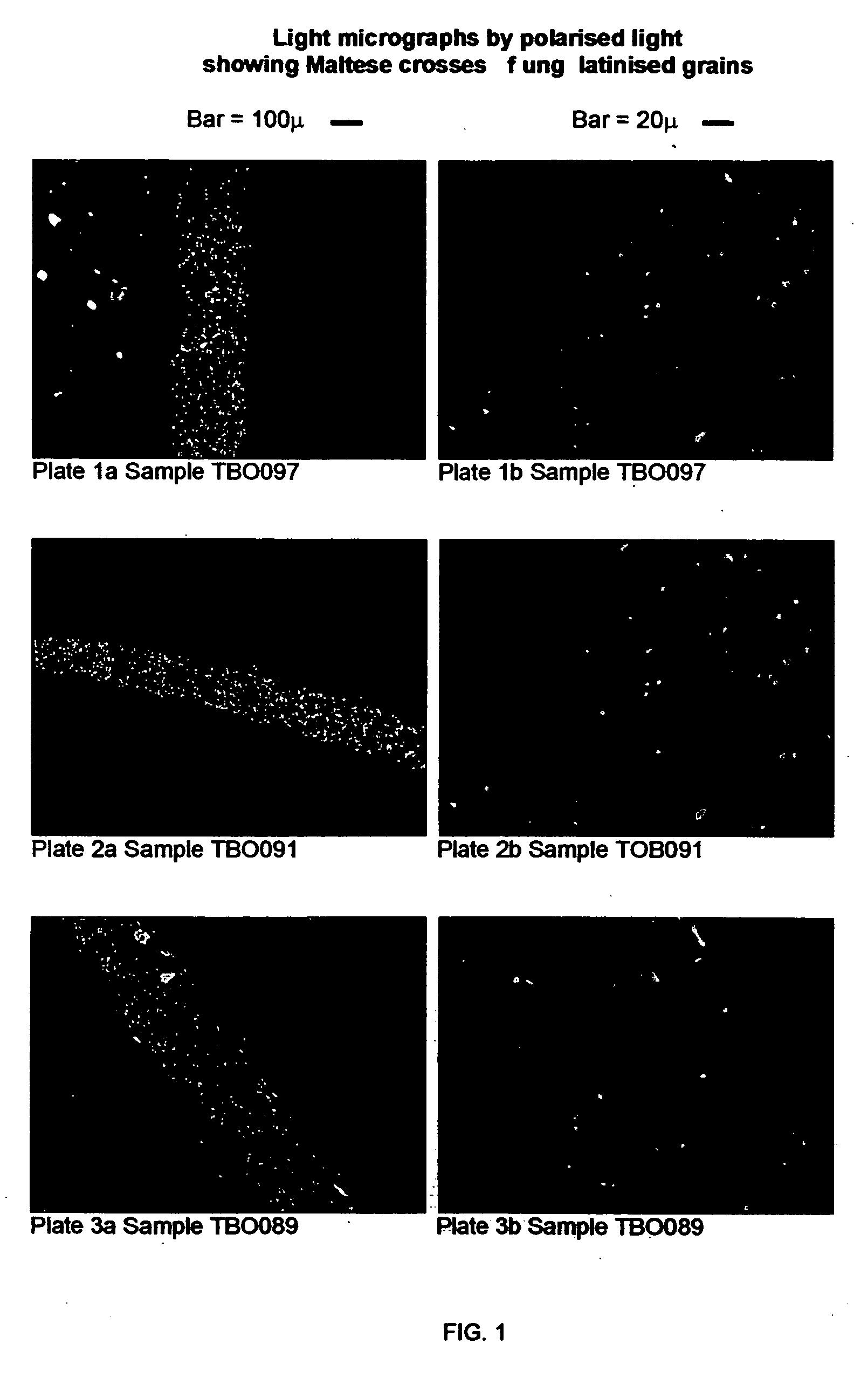

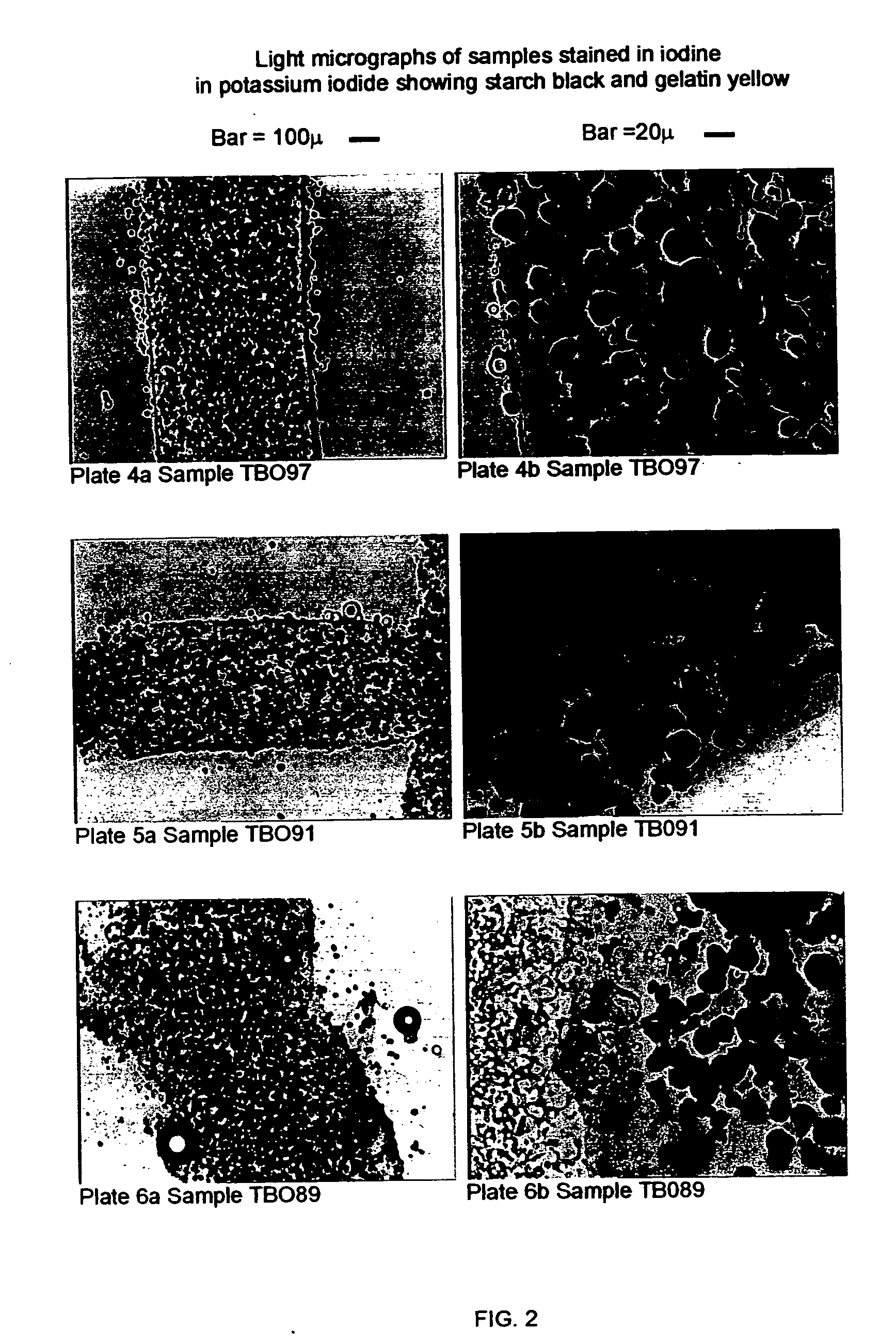

Chewable soft capsules containing ungelatinized starch

A soft chewable capsule film suitable for medicament or foodstuff encapsulation, and a method of fabricating capsules from such a film. Such capsules demonstrate fast rupture in the oral cavity, good mouth feel and chewability, and rapid dissolution of the shell components. In particular, the modified starch is substantially ungelatinized, due at least in part to the processing temperature, and may act as a water retention agent to promote hydration. Additionally, gelatins are selected for bloom strengths that result in a robust capsules that may be fabricated at a thinner wall thickness than previously experienced in the art. Accordingly, such thin capsules have a smaller mass than traditional capsules of the same size and dissolve more quickly than chewable capsules having greater thicknesses. The capsules may be fabricated by a rotary die process at speeds greater than those generally known for soft chewable capsules.

Owner:R P SCHERER TECH INC

Patching composition having tailorable appearance properties

InactiveUS20070062416A1Improve aestheticsAppearance properties of the compositions can be tailoredRoad surfaceAsphalt

Improved patching compositions can comprise one or more mineral aggregates and a binder, wherein the composition can be substantially free of asphalt and / or asphalt products. Due to the selection of the mineral aggregate(s), optional pigments and binder components, the improved patching compositions can have a light (i.e., gray, white, off white) color such that the improved patching compositions can be used to patch light colored concrete and pavement surfaces without the unsightly appearance associated with asphalt-based patching formulations. In some embodiments, the binder can comprise a mixture of one or more resins, polymers, oils, pigments and additives.

Owner:CRAFCO

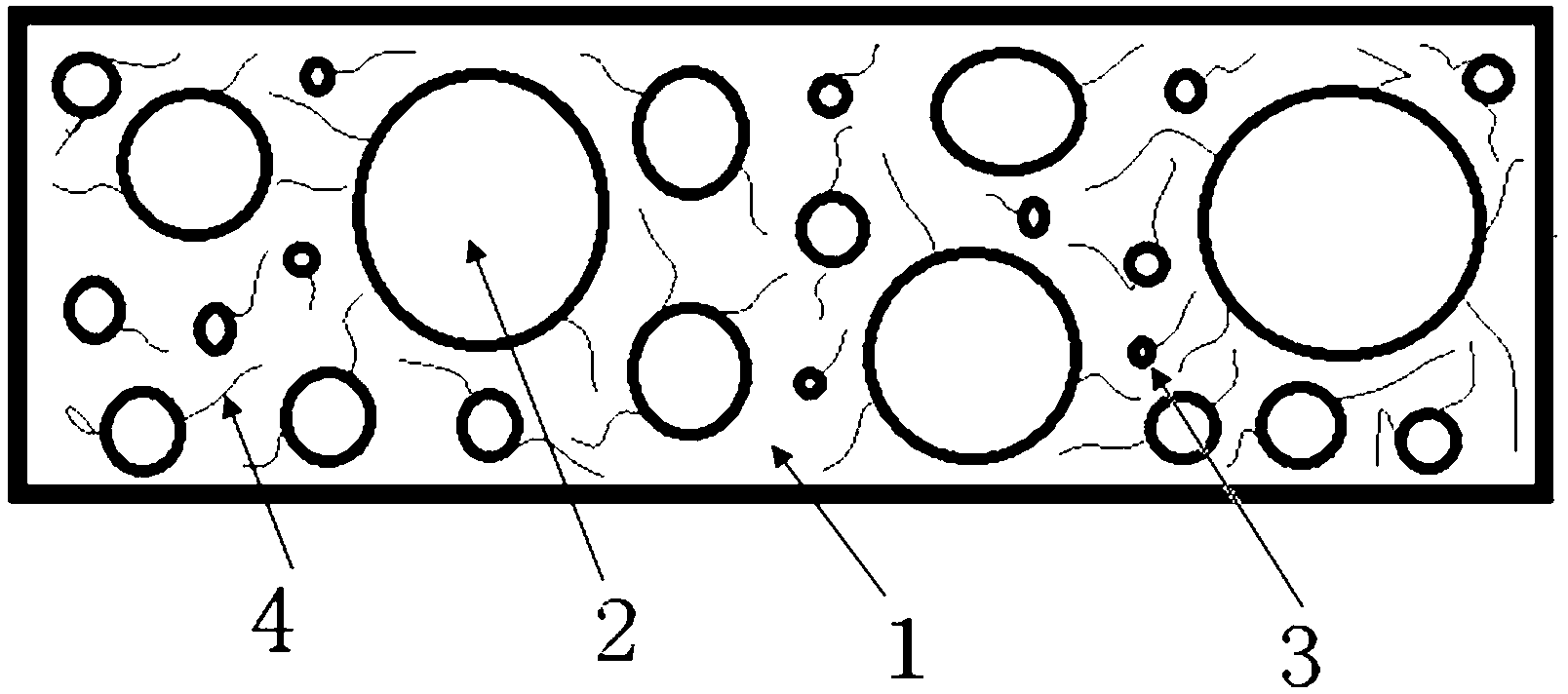

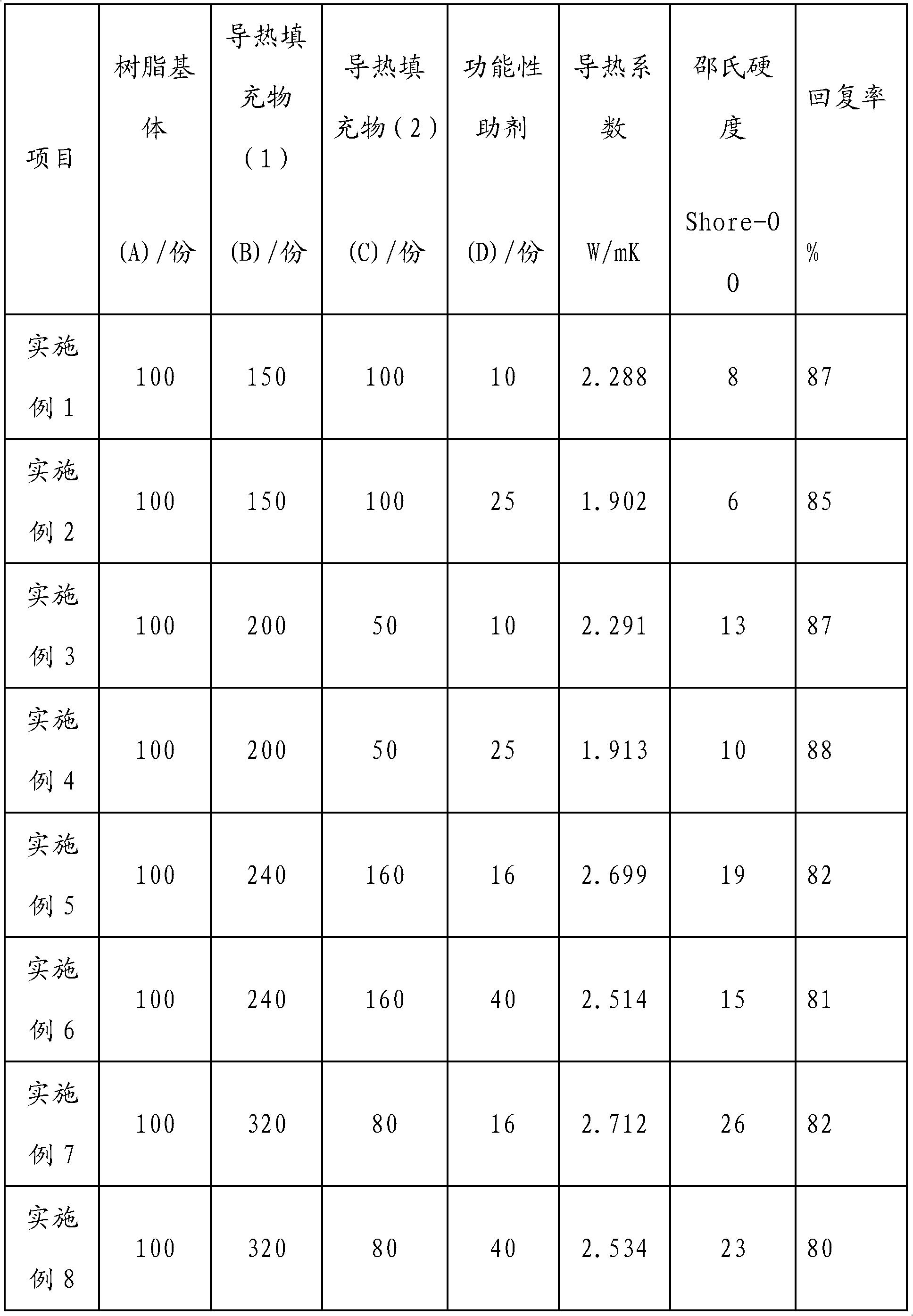

Heat-conductive gap interface material and preparation method thereof

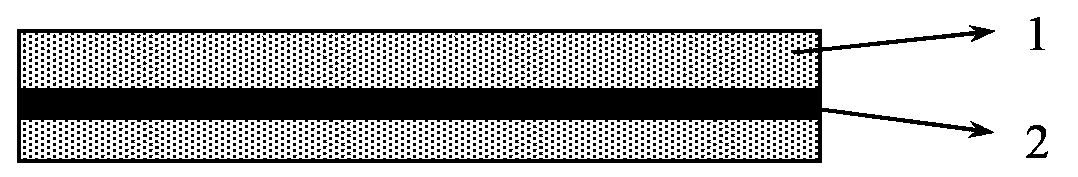

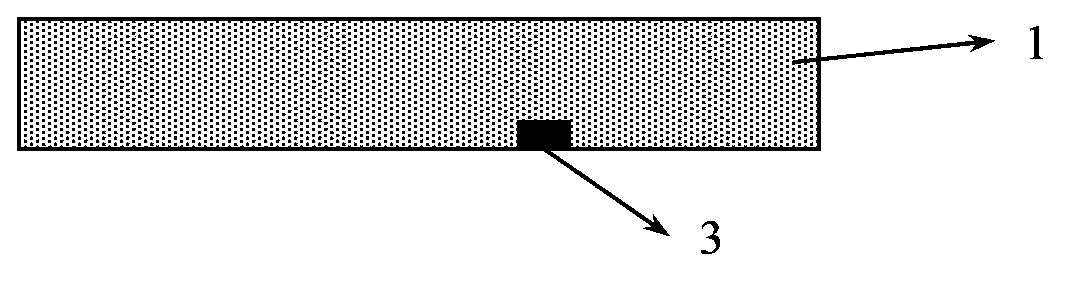

The invention relates to a heat-conductive gap interface material and a preparation method thereof. The heat-conductive gap interface material comprises 100 parts by weight of a resin matrix and 250-400 parts by weight of heat-conductive fillers, and also comprises an assistant; and the preparation method comprises the following steps: adding the assistant and the resin matrix into a stirrer, and carrying out first stirring to obtain a mixture; and adding a heat-conductive filler (2), carrying out second stirring, adding a heat-conductive filler (1), carrying out third stirring, and curing to obtain the heat-conductive gap interface material. The heat-conductive gap interface material has a small hardness, can avoid damages caused in the assembling process of microelectronic components, and can also fully fill the gaps of the microelectronic components.

Owner:SHENZHEN DARBOND INTERFACE MATERIALS

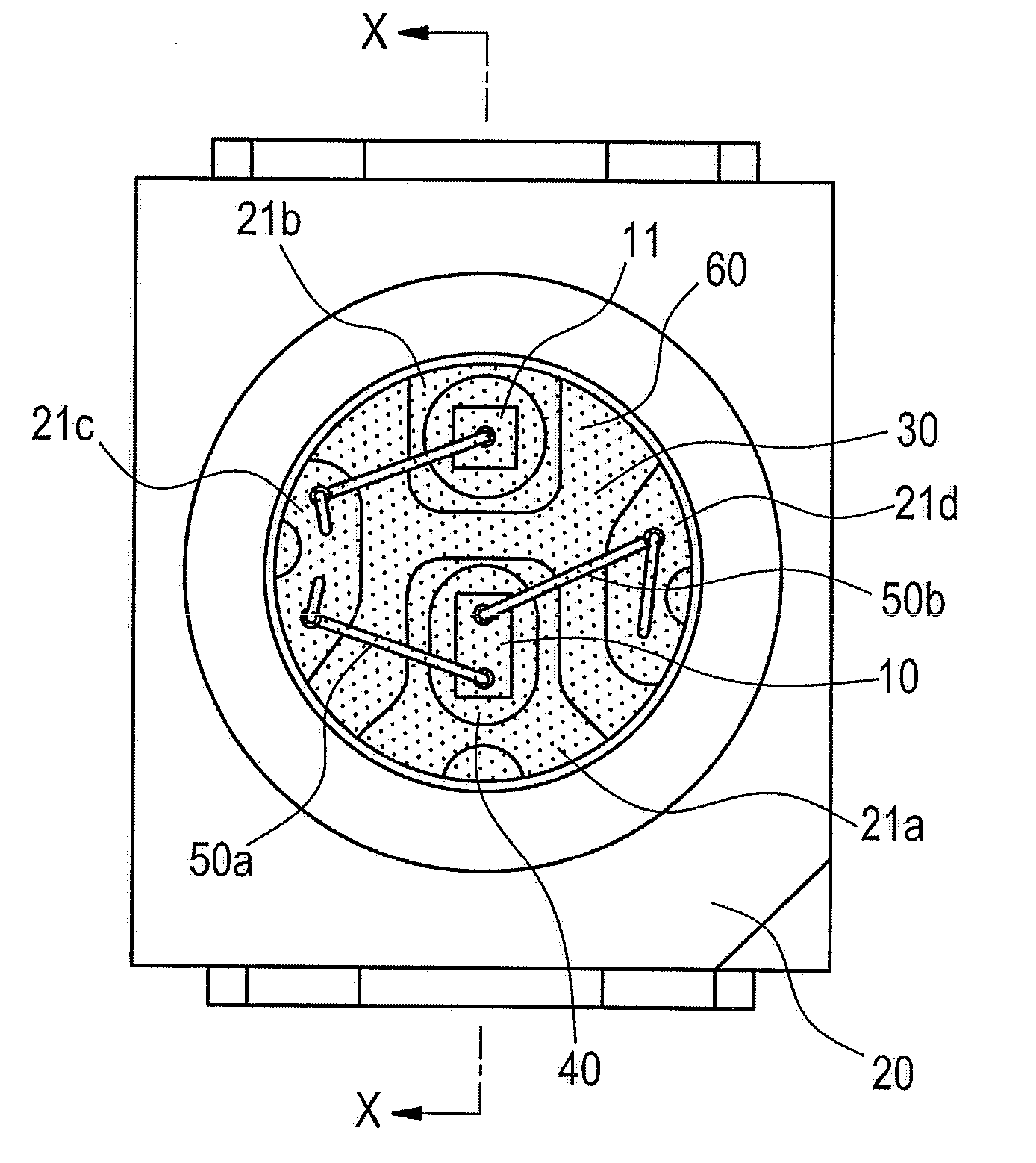

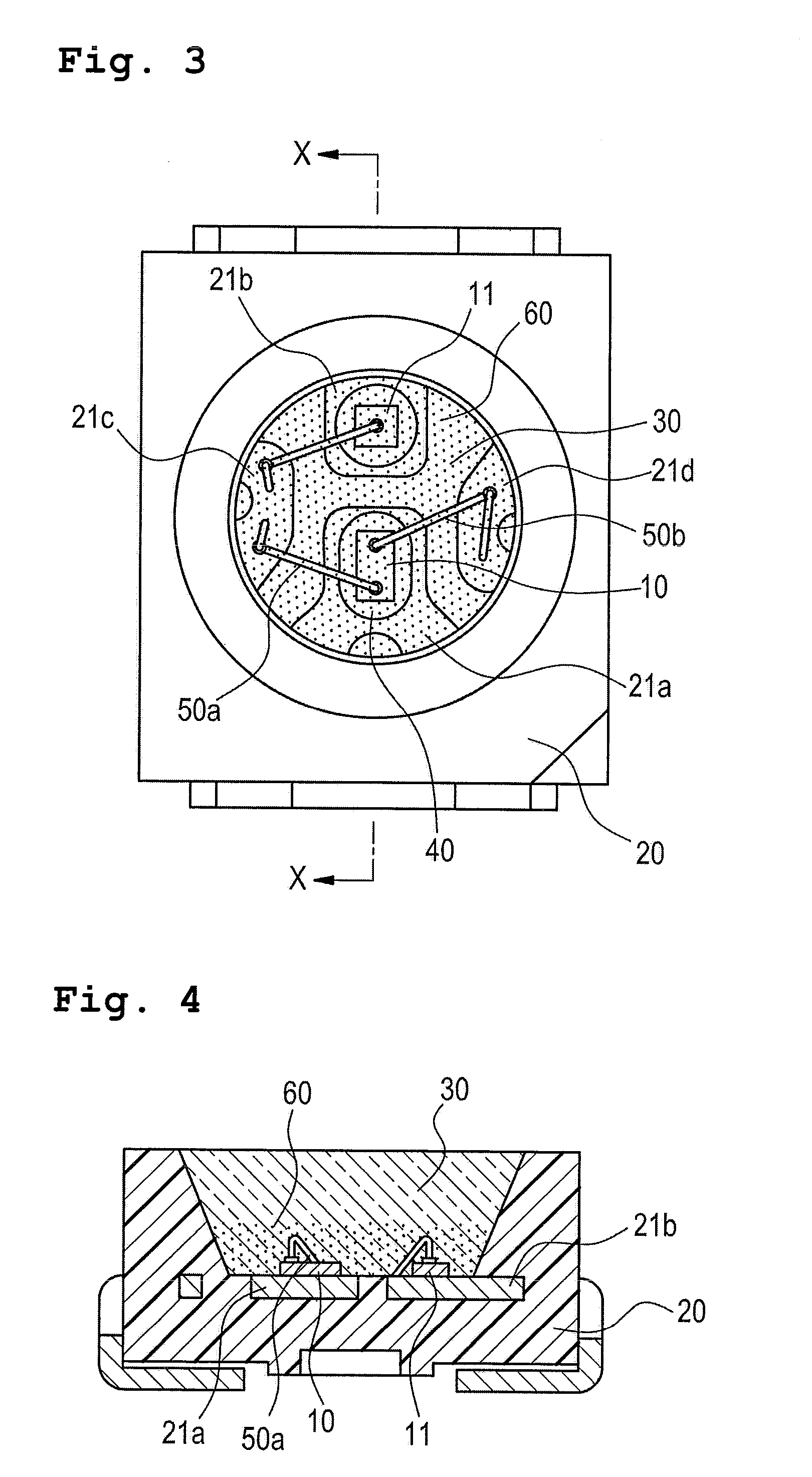

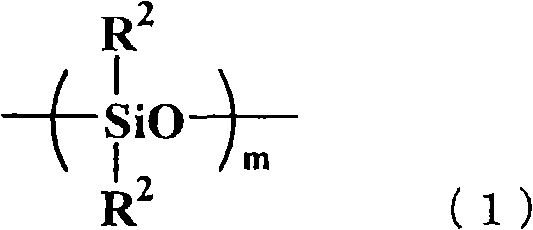

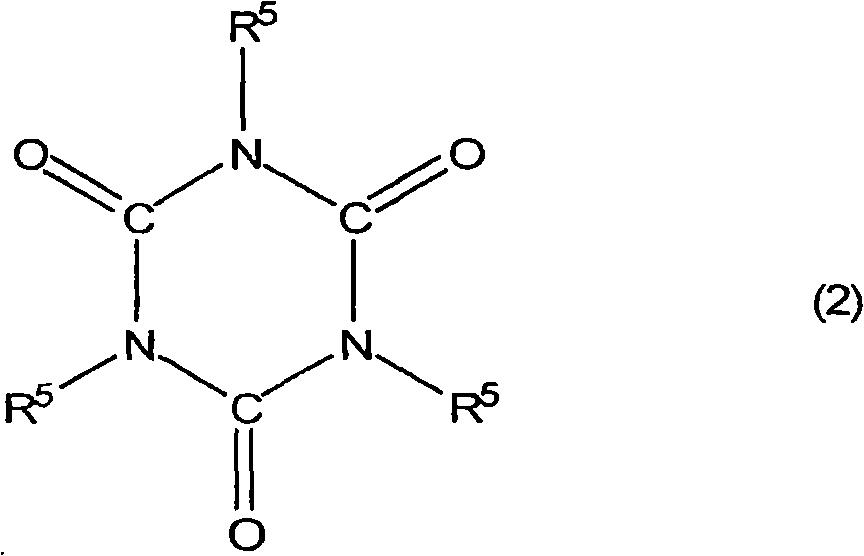

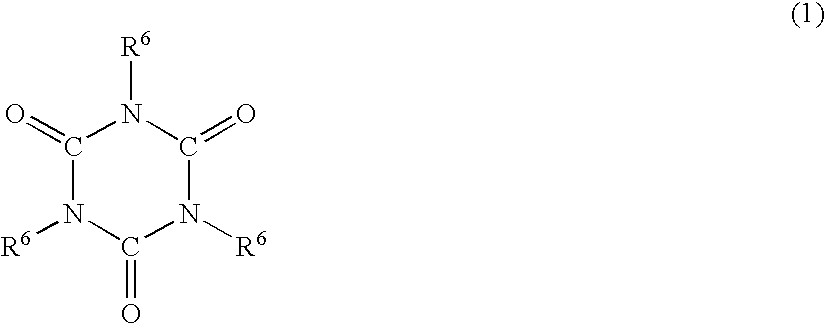

Composition encapsulating optical semiconductor and optical semiconductor device using same

ActiveUS20100224906A1Improve adhesionReduce surface tackOther chemical processesSolid-state devicesMetal catalystSilicon

A composition for encapsulating optical semiconductors. The composition comprises (A) a mixture of a linear alkenyl group-containing organopolysiloxane and an alkenyl group-containing organopolysiloxane resin containing at least one SiO2 unit, (B) a mixture of a linear organohydrogenpolysiloxane containing two or more SiH groups and a branched organohydrogenpolysiloxane that is liquid at 25° C., (C) a platinum group metal catalyst, and (D) a linear or cyclic organopolysiloxane having at least two functional groups selected from the group consisting of alkenyl groups, alkoxysilyl groups and epoxy groups bonded to silicon atoms. A cured product of the composition exhibits dramatically reduced surface tack, and therefore using the composition for encapsulating optical semiconductor elements improves the optical semiconductor device yield.

Owner:SHIN ETSU CHEM IND CO LTD

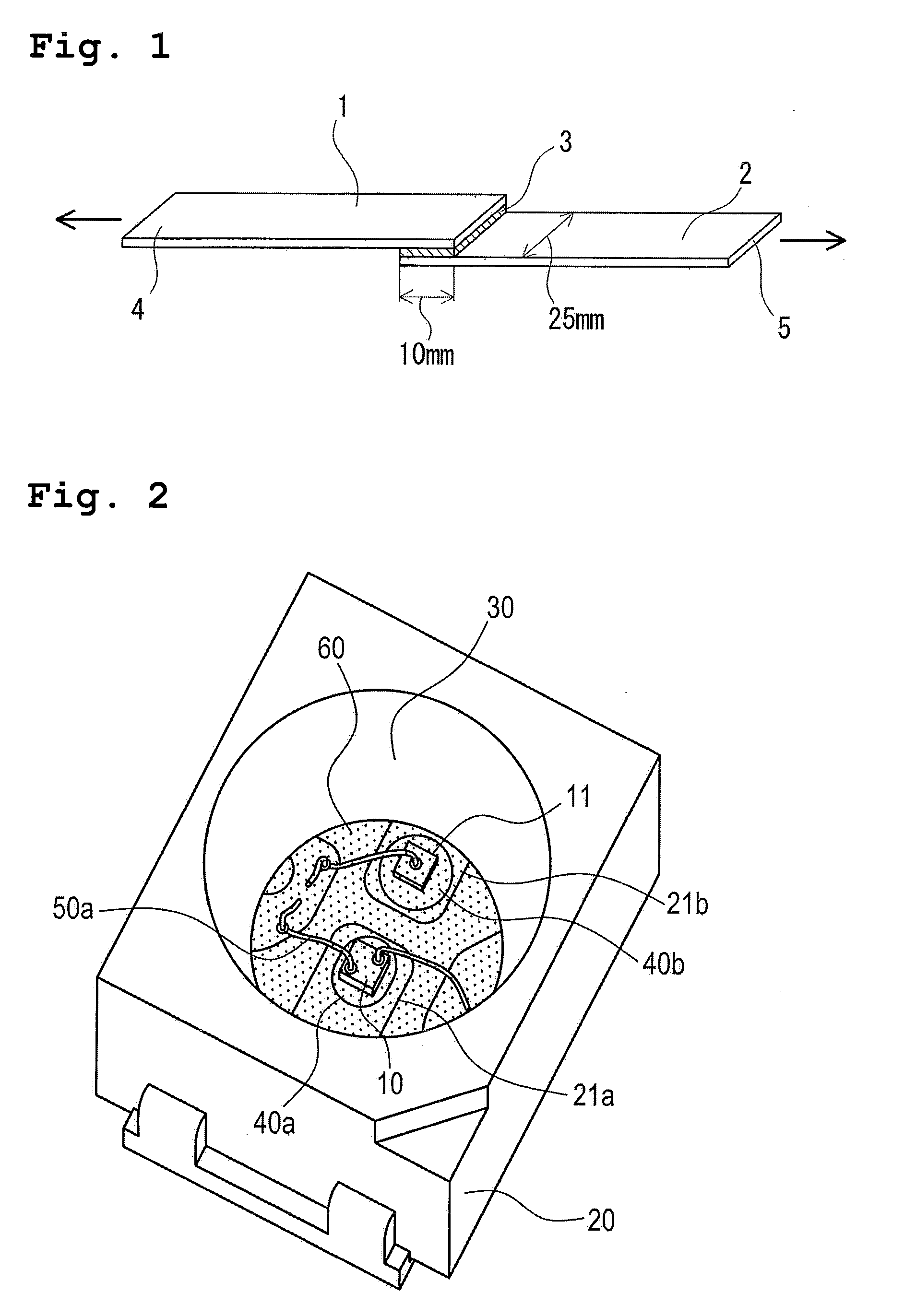

Hot melt pressure sensitive adhesives for disposable articles

InactiveUS20050013996A1Increase stickinessImproved adhesion to polyolefinsAdhesive processesFilm/foil adhesivesPolymer scienceAntioxidant

A hot melt pressure sensitive adhesive (HMPSA) is obtained by combining a linear A-B-A block copolymer, wherein the B component is polyisoprene and the A component is polystyrene (S-I-S), at least one compatible tackifying resin, at least one plasticizer, antioxidant(s) and stabilizer(s) and optionally a wax, wherein the A-B-A block copolymer contains 0 to 10% by weight residual A-B diblock. The HMPSA is suitable as a positioning adhesive for disposable articles like plasters, bandages, sanitary napkins, e.g. feminine napkins, adult incontinent pads or diapers. The HMPSA has a viscosity from 3,500 mPas to 25,000 mPas at 140° C. and exhibits adhesion values from 1.0 to 3.0 N / cm at coat weights of 10 to 25 grams per square meter.

Owner:HATFIELD STEPHEN F

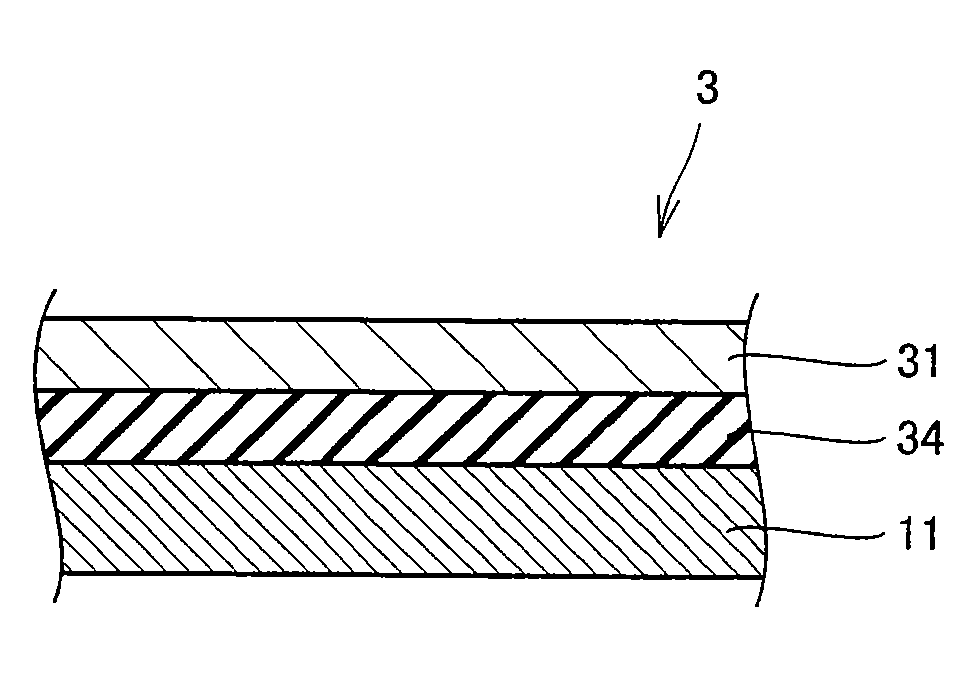

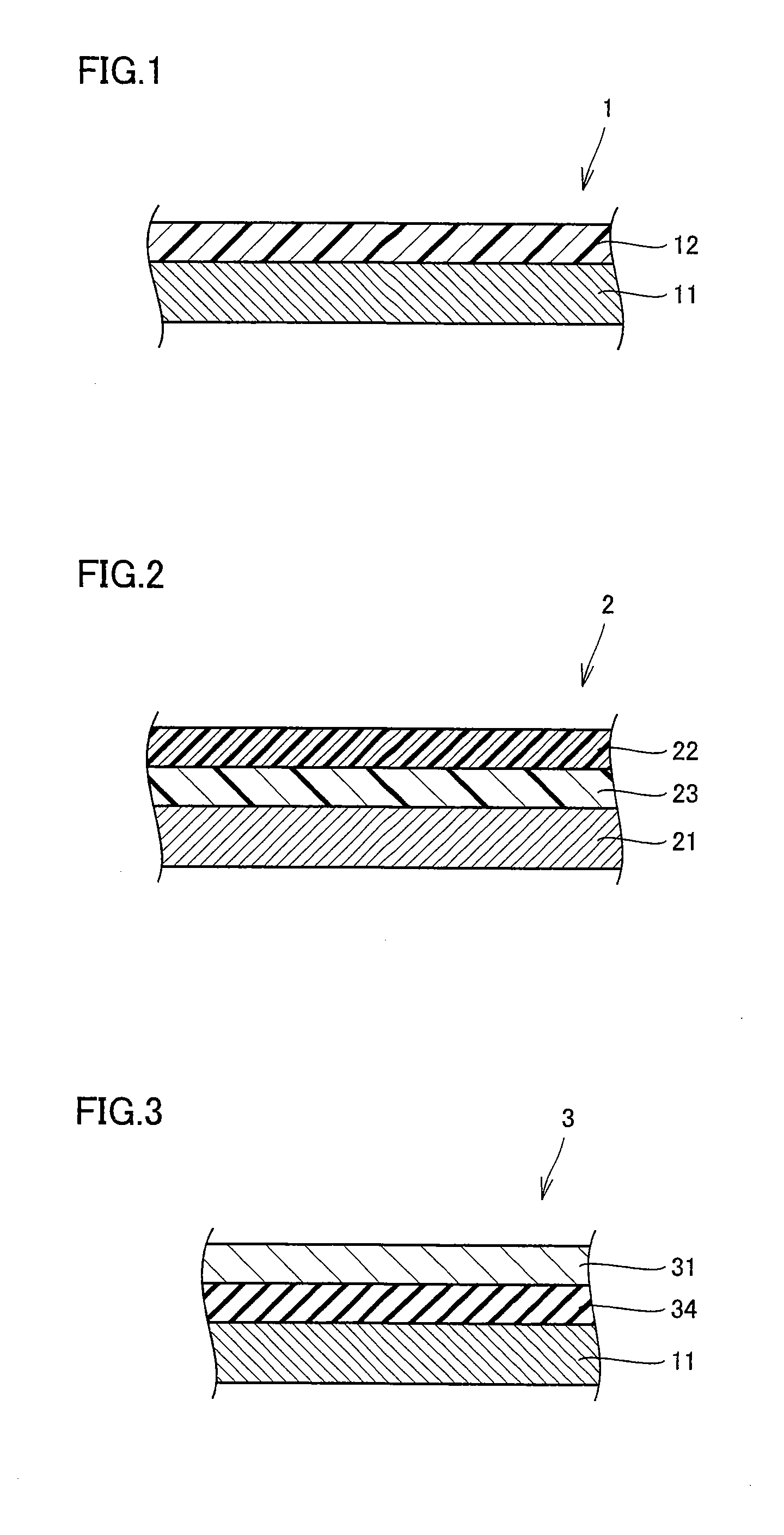

Curable silicone resin composition, cured product thereof, and opaque silicone adhesive sheet formed from the composition

ActiveCN101671483AEasy curingImprove bendabilityFilm/foil adhesivesNon-linear opticsMechanical propertySilicone adhesive

Disclosed are a curable silicone resin composition, a cured product thereof, and the opaque silicone adhesive sheet formed from the conposition. The curable silicone resin composition is solid at roomtemperature, the composition including: (A) an organopolysiloxane having a resin structure consisting of specific siloxane units, (B) an organohydrogenpolysiloxane having a resin structure consistingof specific siloxane units, (C) a platinum group metal-based catalyst, (D) either one or both of an opaque pigment and an opaque dye, and (E) a reaction retarder, in which a layer of thickness 100 [mu]m formed from a cured product of the composition exhibits a light transmittance of not more than 5% across the entire visible light range. The composition is solid at room temperature and thereforeeasy to handle. Further, the composition is useful for producing an opaque silicone adhesive sheet. A cured product obtained by curing the composition can be used to protect a liquid crystal electrodeand shield the electrode from light, thereby preventing malfunction of the driver IC, and also exhibits excellent mechanical properties and flexibility, and displays minimal surface tack.

Owner:SHIN ETSU CHEM IND CO LTD

Thermosettable compositions useful for producing structural adhesive foams

The use of an adduct of an isocyanate resin and an isocyanate-reactive liquid or semi-solid epoxy resin in an expandable thermosettable composition helps to reduce the tackiness of the composition and also increases its dimensional stability, as compared to compositions in which only non-adducted liquid or semi-solid epoxy resins are present

Owner:HENKEL CORP

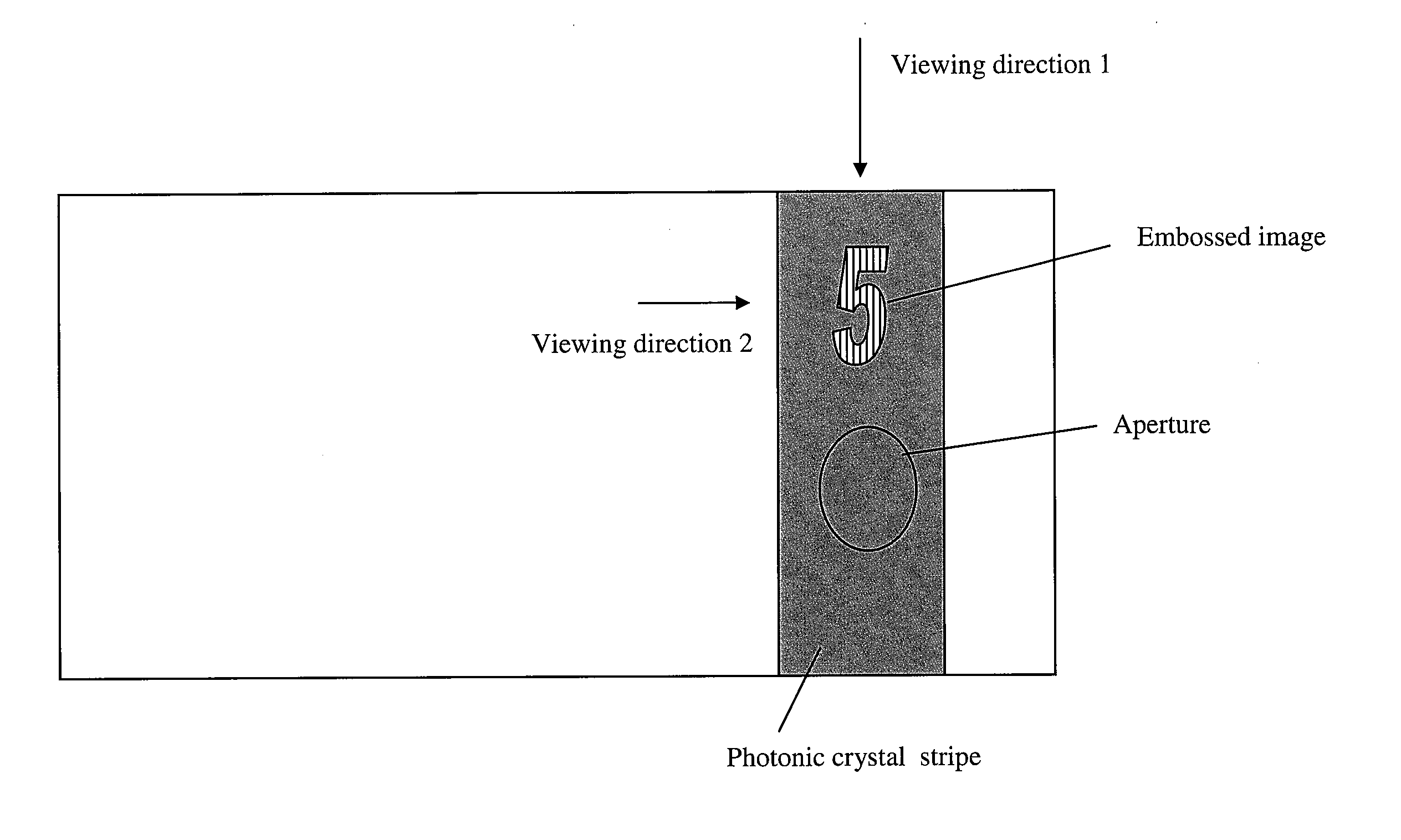

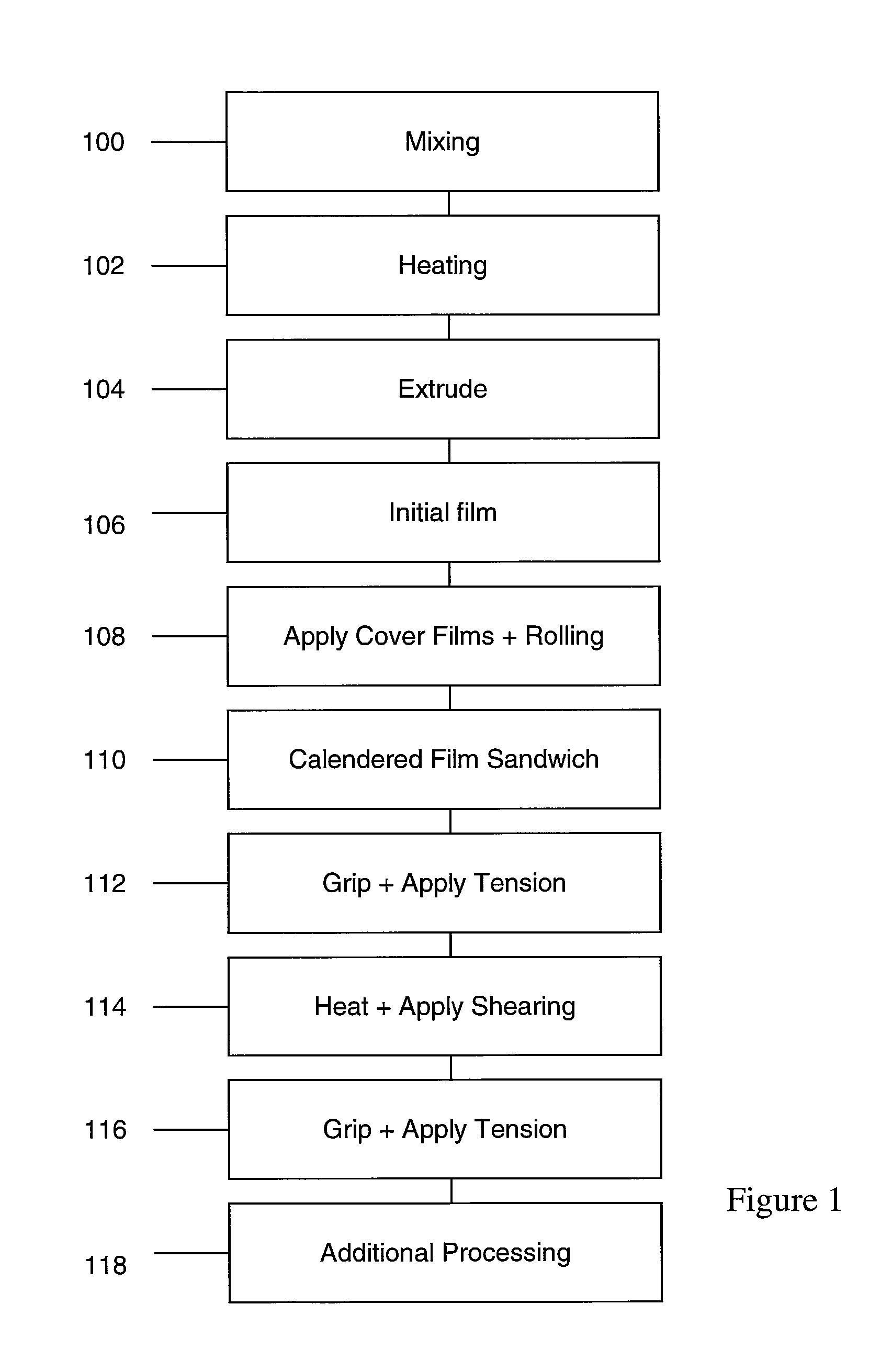

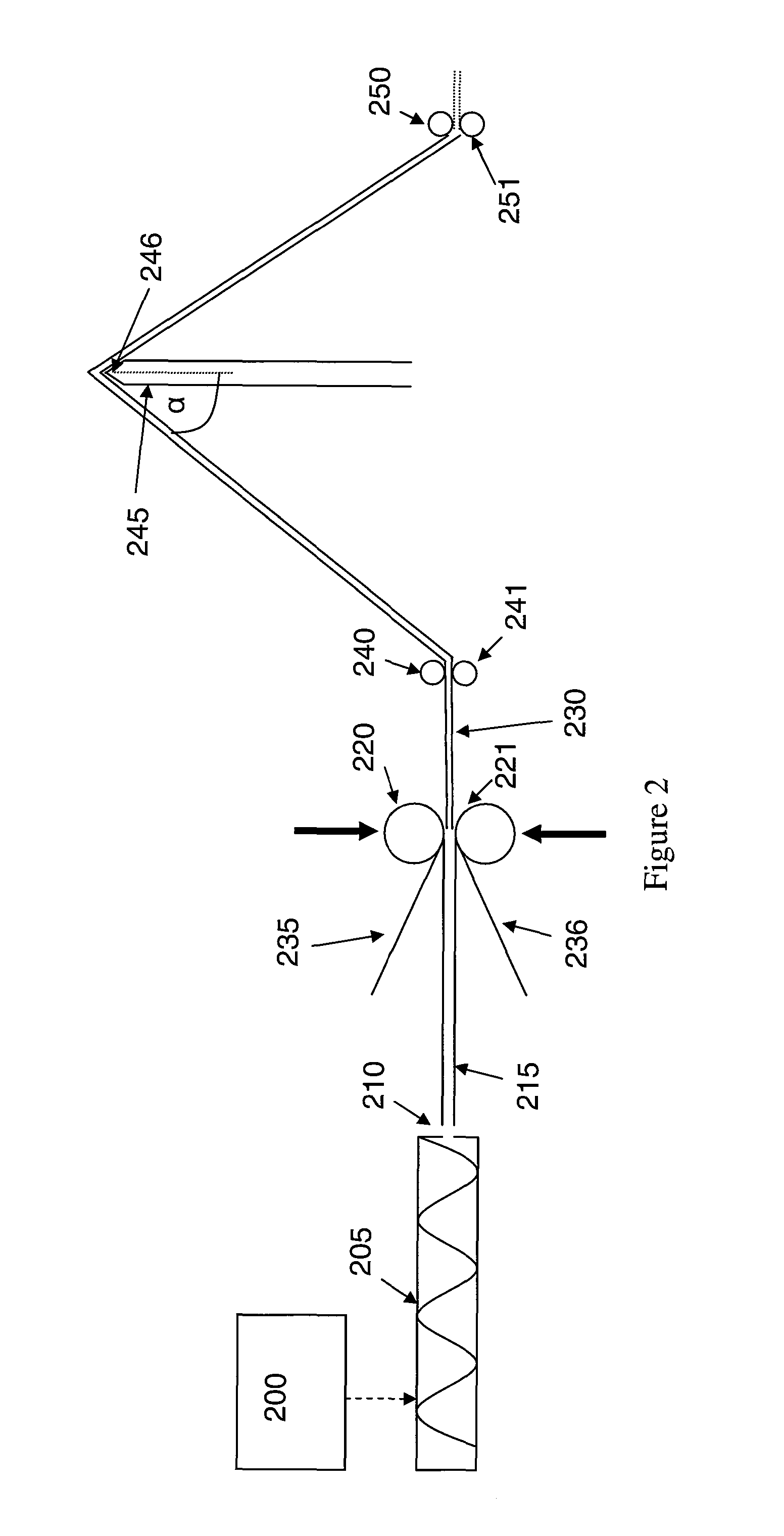

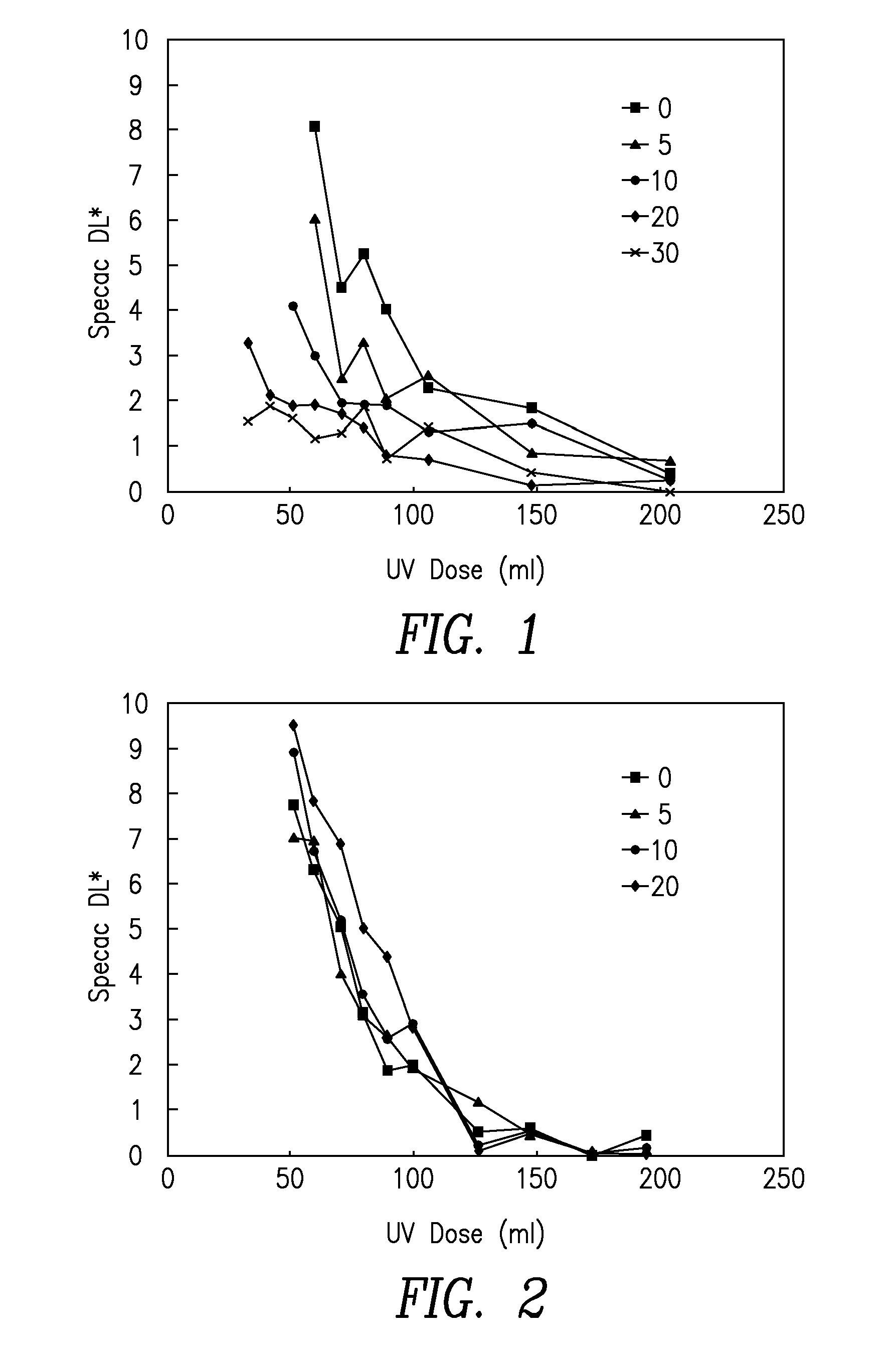

Method of forming a photonic crystal material

InactiveUS20120161431A1Efficient productionEnsure long-term stabilityDiffusing elementsConfectioneryShear stressPhotonic crystal structure

A method of forming a film of photonic crystal material. A first process is performed upon a material capable of having a photonic crystal structure, this process causing deformation of the material so as to form a film in which incident light received by the material is selectively reflected or transmitted to generate a first optical effect in the film. A second process is performed upon substantially all of the film which applies a shear stress to the film. This causes a change in the material structure so as to generate a second optical effect in the film, different from the first optical effect, in response to incident light. Security films, devices, articles and documents formed using the method are also discussed.

Owner:DE LA RUE INT LTD

Leather-like sheet

ActiveUS20100068499A1Fine surfaceImprove bending resistanceOrganic chemistryMixing methodsCross-linkPolymer science

A leather-like sheet is provided having a substrate layer and a surface skin layer in which the surface skin layer is composed of a cross-linked product of a polyurethane hot-melt composition containing 100 parts by mass of a urethane prepolymer, 5 parts by mass to 40 parts by mass of a coloring agent containing a polyol, 5 parts by mass to 50 parts by mass of multi-functional (meth)acrylate, and 0.5 parts by mass to 5 parts by mass of a photopolymerization initiator, wherein the urethane prepolymer can be obtained by reacting 5% to 50% of the number of isocyanate groups in a urethane prepolymer containing isocyanate groups that is obtained by reacting a polyol containing 40% by mass or more of polytetramethylene glycol and a polyisocyanate with a (meth)acrylate containing a hydroxyl group. This leather-like sheet has an excellent surface grade while maintaining excellent suppleness and bending resistance.

Owner:DAINIPPON INK & CHEM INC

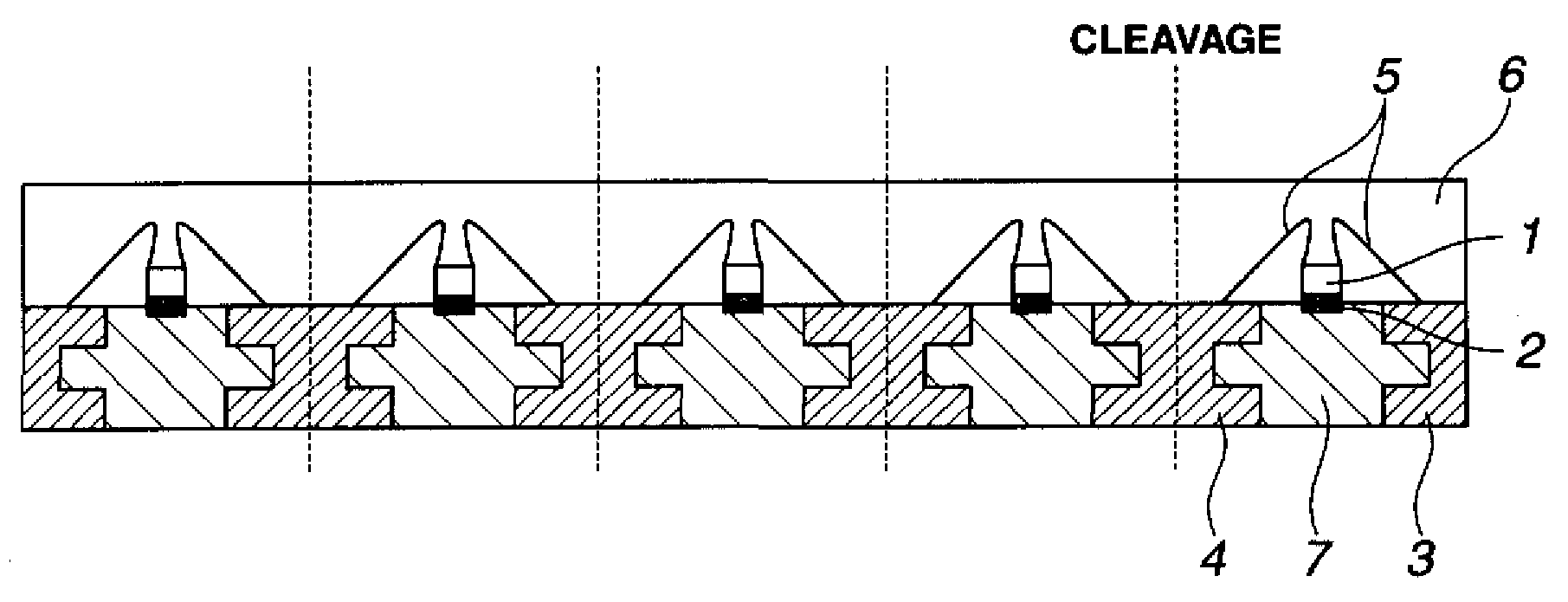

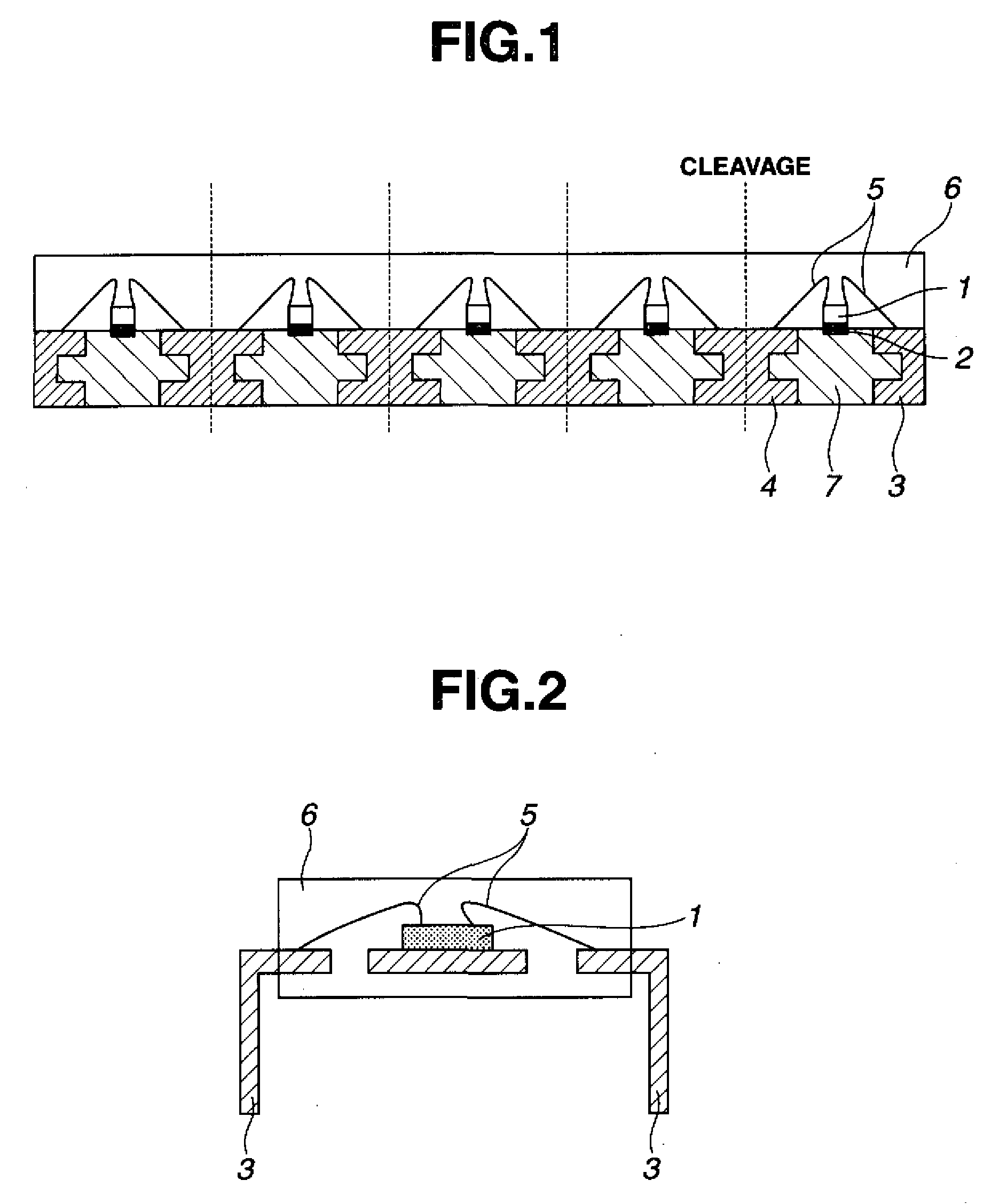

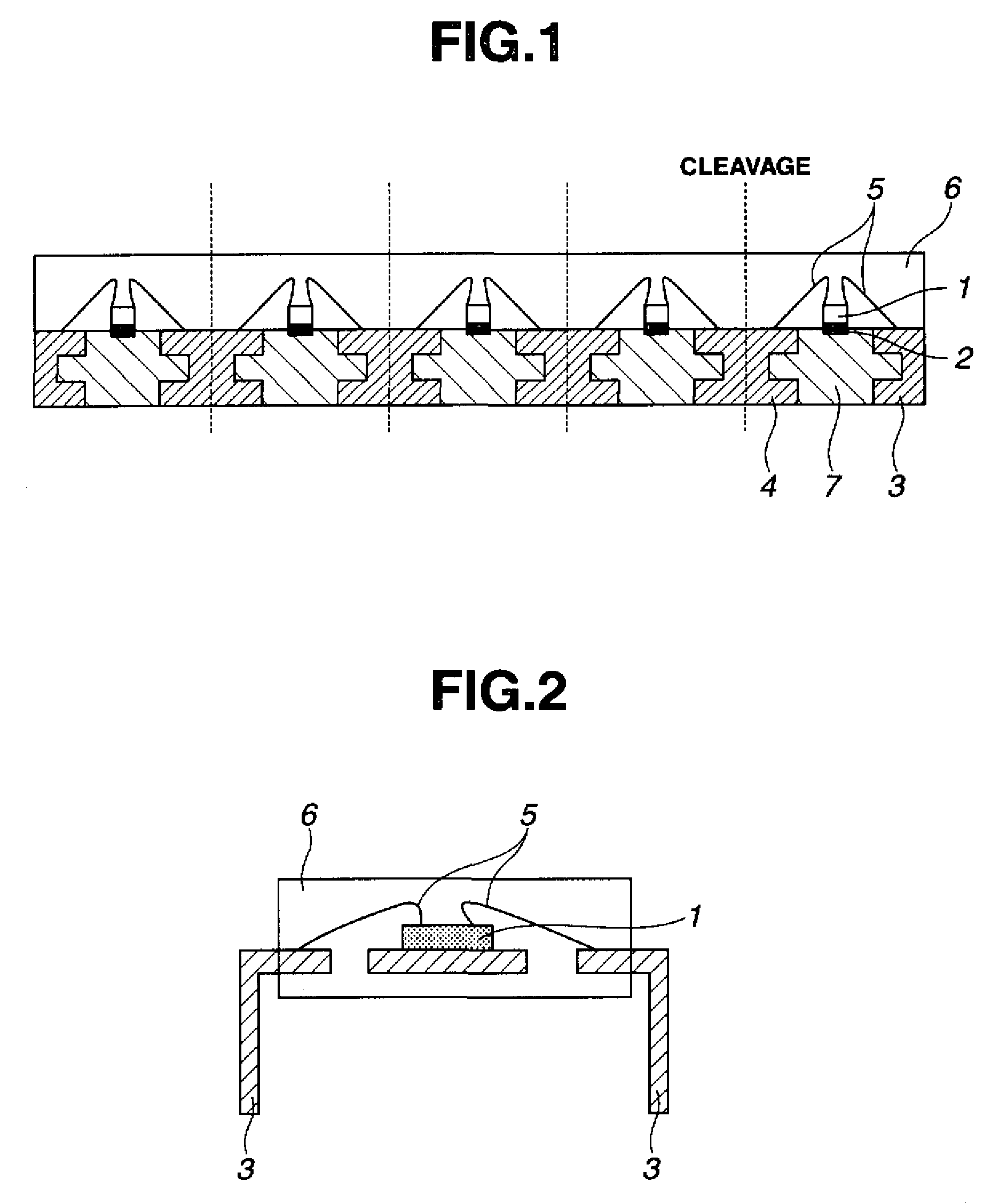

Semiconductor device encapsulated by silicone resin composition, and silicone resin tablet for encapsulating semiconductor device

ActiveUS20080021136A1Good flexibilityReduce surface tackSemiconductor/solid-state device detailsSolid-state devicesPolymer scienceDevice material

A semiconductor device which is not a light emitting semiconductor device is provided. This device is encapsulated with a silicone resin composition which is solid at room temperature and liquid at molding temperature, and which cures into a transparent article having a hardness measured by Type D durometer according to JIS K 6253 of at least 30 and an elongation in a tensile test of at least 5%.

Owner:SHIN ETSU CHEM IND CO LTD

Curable compositions

InactiveUS7081494B2Reduce surface tackGood coating effectSpecial tyresOrganic dyesPlasticizerSilanol

The present invention has for its object to provide a curable composition which, despite its low viscosity, gives a cured product with a high gel fraction, low residual tack, low modulus, high elongation, and good flexibility.The present invention relates to a curable composition comprising the following two components:(A) a vinyl polymer having at least one crosslinking silyl group on the average per molecule: and(B) a photocurable substance, (C) an air oxidation-curable substance, (D) a high molecular plasticizer, (E) a reactive plasticizer or (F) a compound having one silanol group in its molecule and / or a compound capable of reacting with moisture to give a compound having one silanol group in the molecule.

Owner:KANEKA CORP

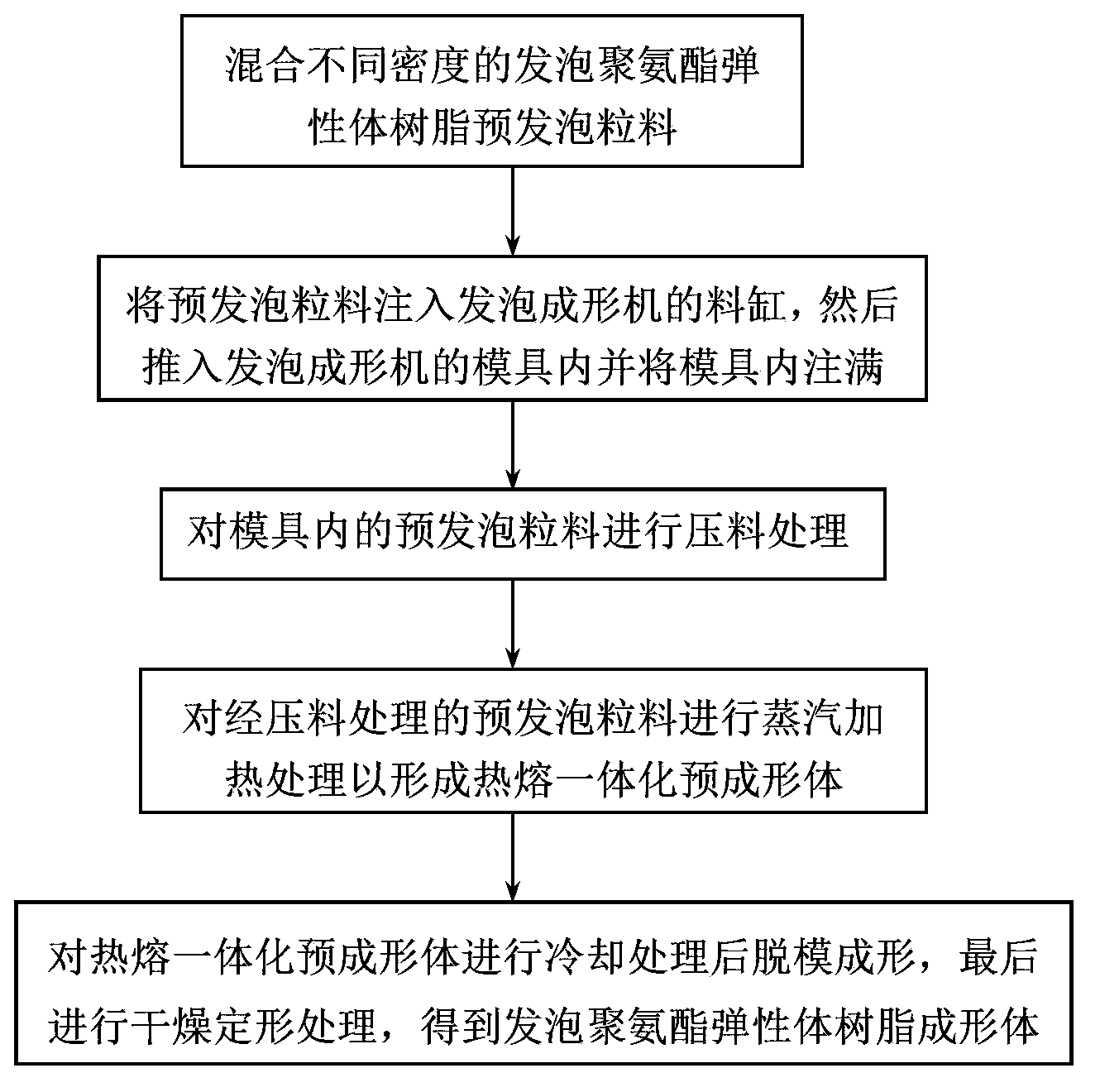

Polyurethane elastomer forming method and sports safety protective article made by adopting polyurethane elastomer forming method

The invention relates to a foamed polyurethane elastomer forming method. The method comprises the following steps: mixing pre-foamed resin granules, with different densities, of a foamed polyurethane elastomer; injecting the granules into a cylinder of a foaming forming machine, then pushing the granules into a mold, and fulfilling the mold with the granules; pressing the granules in the mold; heating the pressed granules by virtue of steam to form a hot-melt integrated pre-formed body; cooling the pre-formed body, removing the mold, finally drying, and stereotyping the pre-formed body to obtain the resin formed body of the foamed polyurethane elastomer. The invention also provides a foamed polyurethane elastomer resin sports safety protective article made according to the method. Compared with an EVA material, for the resin formed boy of the foamed polyurethane elastomer, made according to the method, the elasticity is obviously improved, and the safety protection performance of a product can be improved.

Owner:DONGGUAN TANGXIA YIFENG SPORTS TECH CO LTD

Hot melt adhesive for bonding cable heat shrinkage bush

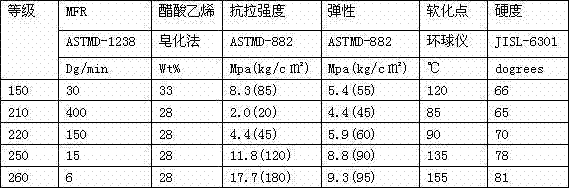

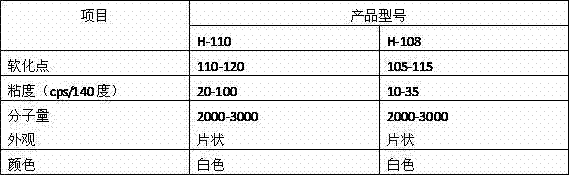

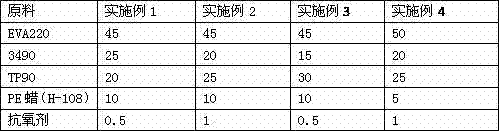

ActiveCN103709963AImprove heat resistanceSmall molecular weightMineral oil hydrocarbon copolymer adhesivesPolymer scienceHot melt

The invention relates to a hot melt adhesive for bonding a cable heat shrinkage bush. The hot melt adhesive comprises, by weight, 40-60 parts of ethylene-vinyl acetate, 10-20 parts of PE hot melt adhesive, 10-30 parts of a tackifying resin, 1-10 parts of wax and 0-5 parts of an assistant, and the modified PE hot melt adhesive is extrusion-grade linear PE. The hot melt adhesive for bonding a cable heat shrinkage bush has the advantages of required bonding strength, low-temperature use, good adhesion resistance, and satisfying of transport requirements after use.

Owner:江阴伟韬塑料新材料有限公司

Semiconductor device encapsulated by silicone resin composition, and silicone resin tablet for encapsulating semiconductor device

ActiveUS7807736B2Good flexibilityImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesPolymer scienceDevice material

A semiconductor device which is not a light emitting semiconductor device is provided. This device is encapsulated with a silicone resin composition which is solid at room temperature and liquid at molding temperature, and which cures into a transparent article having a hardness measured by Type D durometer according to JIS K 6253 of at least 30 and an elongation in a tensile test of at least 5%.

Owner:SHIN ETSU CHEM CO LTD

Preparation method of high-solid-content low-viscosity acrylate emulsion for sealing gum

InactiveCN103232566AMake up for the shortcomings of aggregationHigh solid contentOther chemical processesEster polymer adhesivesEmulsionChemistry

The invention relates to a preparation method of a high-solid-content low-viscosity acrylate emulsion for sealing gum. The preparation method is characterized by comprising the following steps of: in the presence of nitrogen, adding acrylate, a reactive emulsifier monomer, a latex protective agent and water to a vessel in a certain proportion, and uniformly stirring at room temperature to obtain a mixture liquid; and carrying out vacuumization and nitrogen introduction on a reactor repeatedly for three times, heating to 70-90 DEG C, adding an initiator aqueous solution which accounts for 0.1-0.8wt% of the monomer, dropwise adding 40 percent of the mixture liquid to the reactor, reacting for 15-30 minutes, adding a certain mass of anionic and non-ionic emulsifiers to the rest 60 percent of the mixture liquid to prepare a pre-emulsion, simultaneously dropwise adding the pre-emulsion and the initiator aqueous solution to the reactor, and keeping the constant temperature for 50 minutes after dropwise adding to prepare the acrylate emulsion. The preparation method has the advantages that the emulsion is high in solid content (70-82 percent), low in viscosity (300-600 mpa.s) and good in stability. The preparation method is used for preparing the acrylate-series sealing gum which is high in drying speed and small in shrinkage rate by adding the emulsion to filling and pigment paste.

Owner:LUDONG UNIVERSITY

Medical devices having polymeric regions that contain fluorocarbon-containing block copolymers

ActiveUS8034874B2Lower surface energyReduce surface tackHeart valvesCoatingsPolymer scienceChemical compound

In one aspect, the present invention provides implantable or insertable medical devices, which contain at least one polymeric region. The polymeric region contains at least one fluorocarbon-containing block copolymer, which, in turn, contains (a) at least one fluorocarbon-containing, low glass transition temperature (low Tg) copolymer chain and (b) at least one glass transition temperature (high Tg) polymer chain.

Owner:BOSTON SCI SCIMED INC

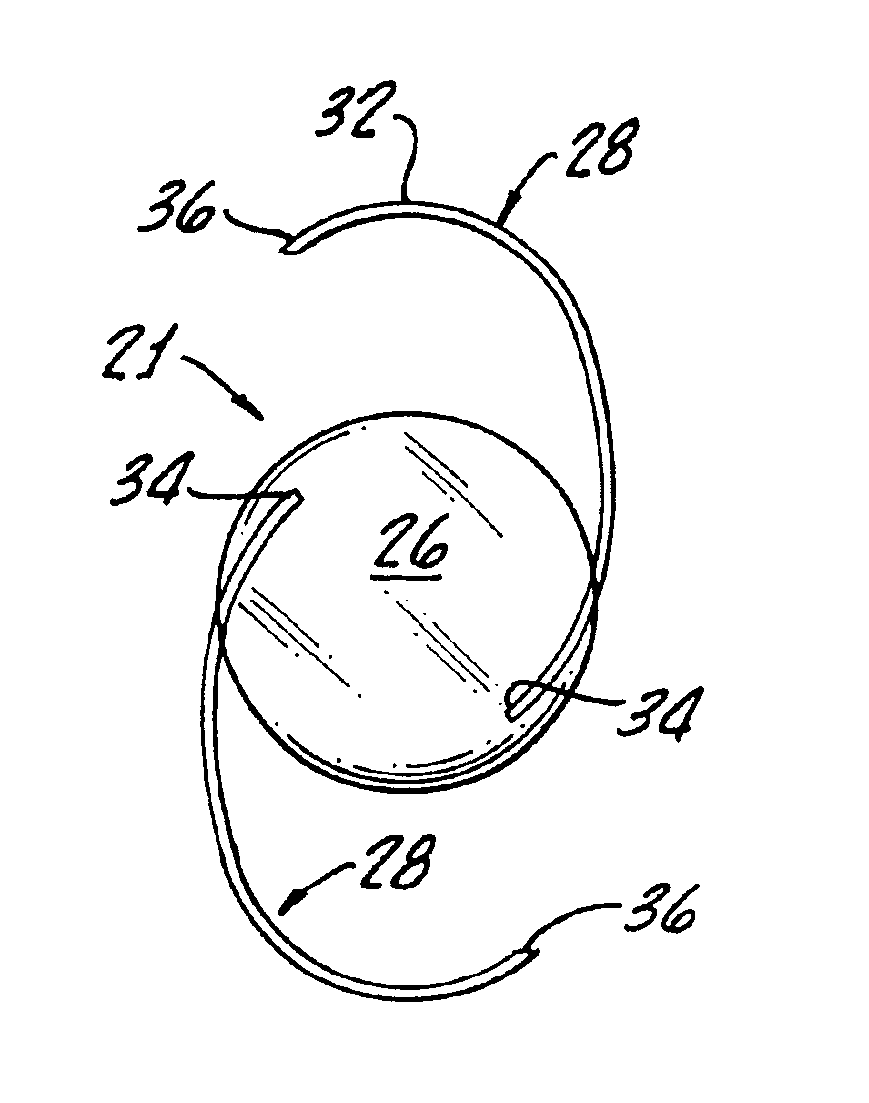

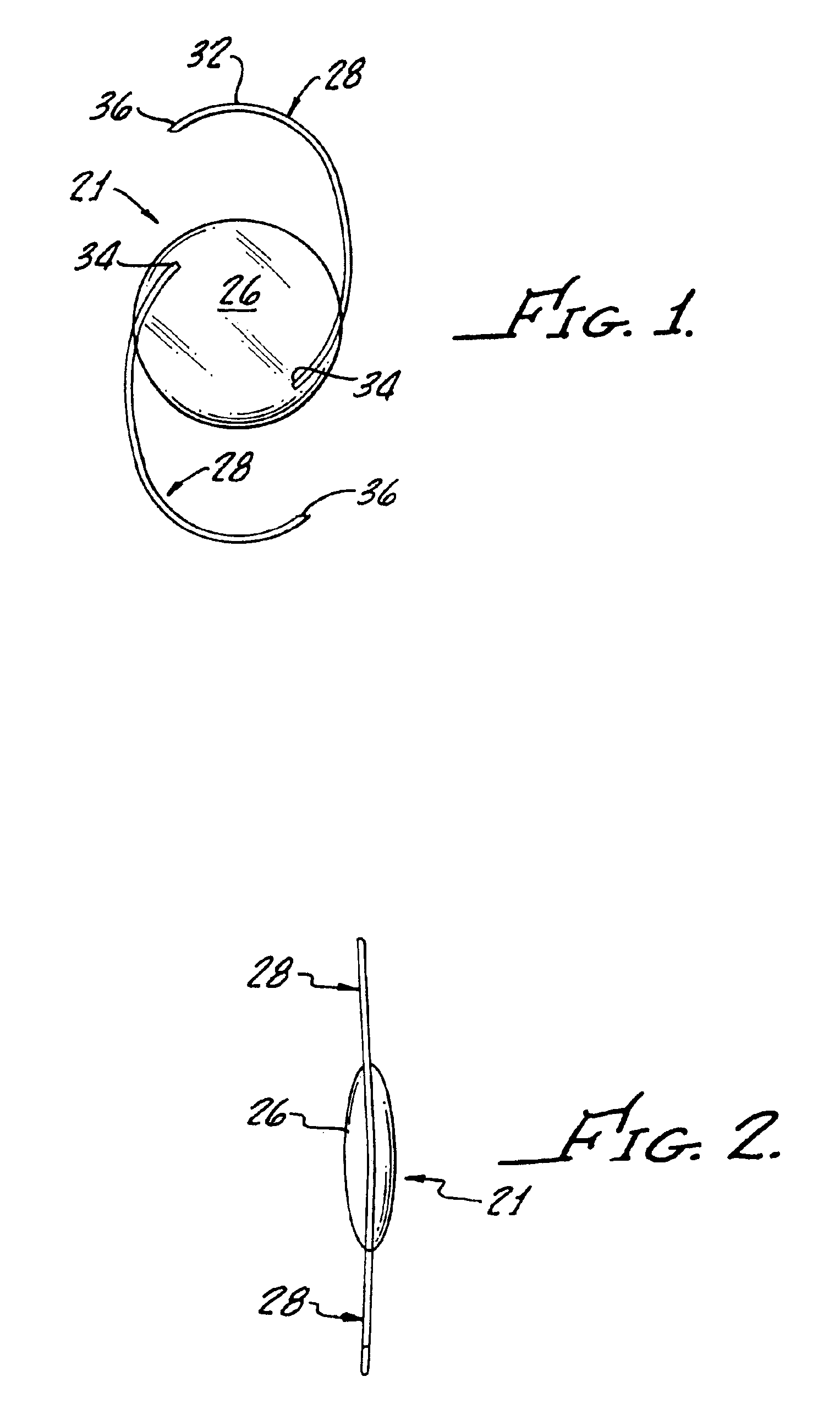

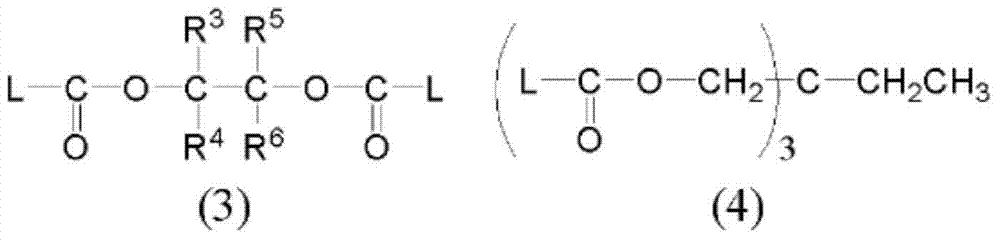

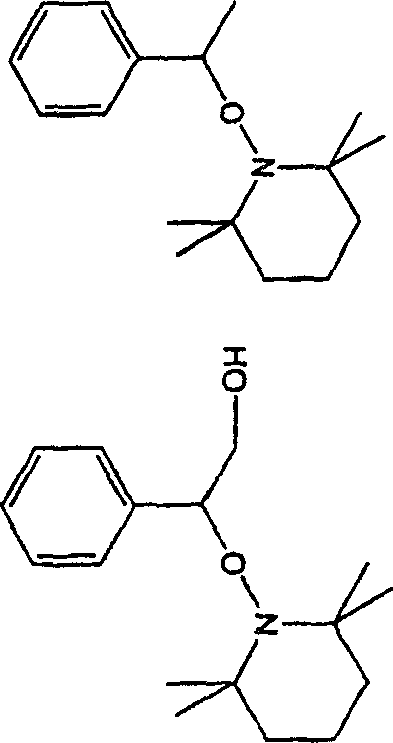

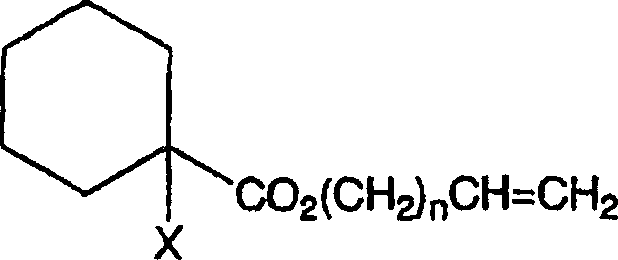

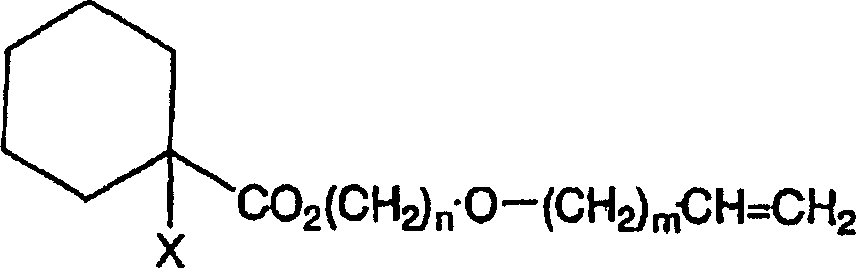

Intraocular lenses made from polymeric compositions and monomers useful in said compositions

InactiveUSRE38935E1Reduce surface tackEffective and easy to practiceTissue regenerationIntraocular lensMethacrylateAcrylate ester

Ophthalmic lenses, such as intraocular lenses, include crosslinked polymeric materials having a first constituent derived from a first monomeric component selected from the group consisting of 2-phenylpropyl acrylate or methacrylate and mixtures thereof, and a second constituent derived from a second component in an amount effective as a crosslinker in the crosslinked polymeric material. The crosslinked polymeric material has branched chain alkyl groups, in an amount effective to reduce the tackiness of the crosslinked polymeric material relative to a substantially identical crosslinked polymeric material without branched chain alkyl groups.

Owner:JOHNSON & JOHNSON SURGICAL VISION INC

Hot Melt Silicone and Curable Hot Melt Composition

A hot melt silicone that is non-flowable at 25° C. and that has a melt viscosity at 100° C. of 5,000 Pa·s or less, the hot melt silicone being formed by subjecting (A) an alkenyl group-containing organopolysiloxane in which 10 mol % or greater of all of silicon atom-bonded organic groups is a phenyl group, and (B) an organopolysiloxane having at least two silicon atom-bonded hydrogen atoms in a molecule to hydrosilylation reaction in the presence of (C) a hydrosilylation reaction catalyst; and a curable hot melt composition comprising: (I) the hot melt silicone; (II) an organopolysiloxane which has at least two silicon atom-bonded hydrogen atoms in a molecule and in which the amount of silicon atom-bonded hydrogen atom is 0.5 mass % or greater; and (III) a hydrosilylation reaction catalyst. The hot melt silicone is non-flowable at 25° C., has a low surface stickiness, and easily melts by heating. Furthermore, this curable hot melt composition has both hot melt properties and curability.

Owner:DOW TORAY CO LTD

Improvements in or relating to laminates

This invention relates to a use of a non-woven thermoplastic resin in combination with a curable moulding material comprising a fibrous reinforcement material and a thermoset resin material by bringing the thermoplastic resin in contact with the curable moulding material during or following assembly of the moulding material. The thermoplastic resin has a melting point below the gel temperature of the thermoset resin material to reduce the void fraction and increase the ILSS of a cured moulding manufactured from said moulding material forming a laminate structure in comparison to a cured moulding manufactured from said moulding material in which the fabric is absent forming the laminate structure.

Owner:HEXCEL COMPOSITES LTD (GB)

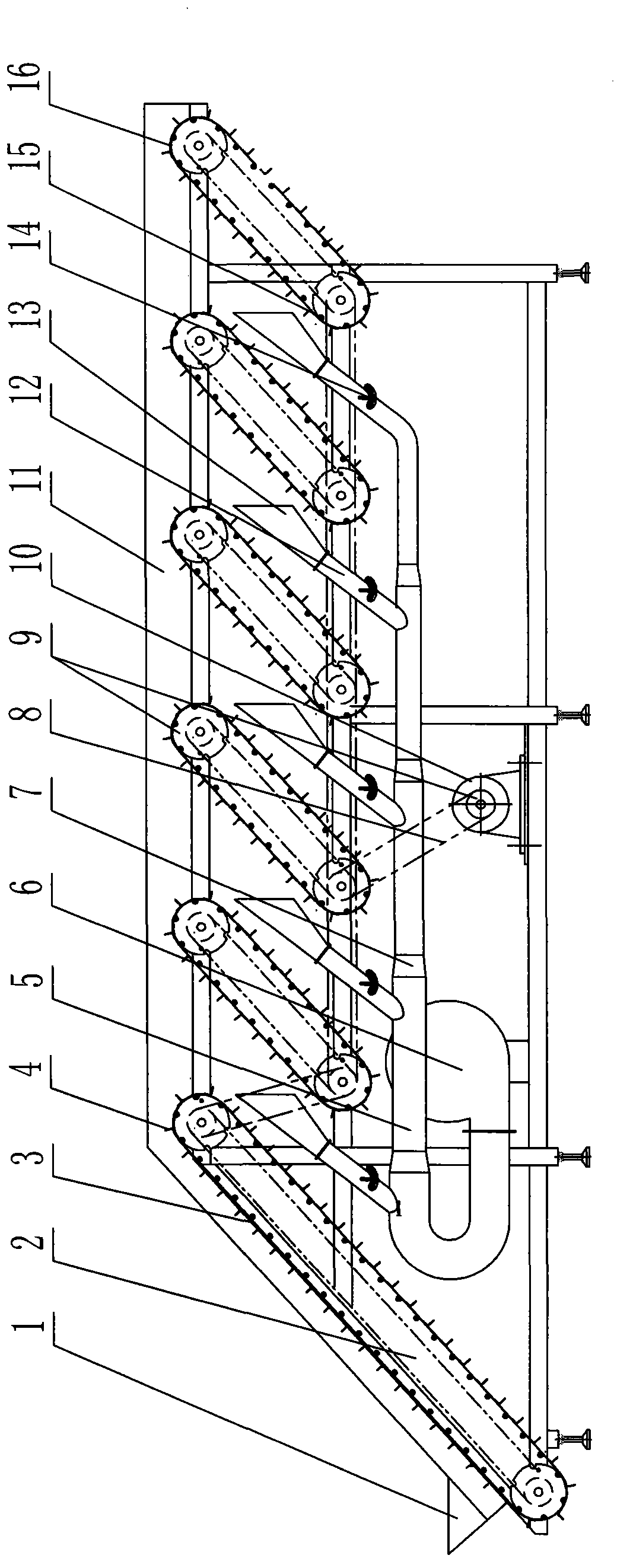

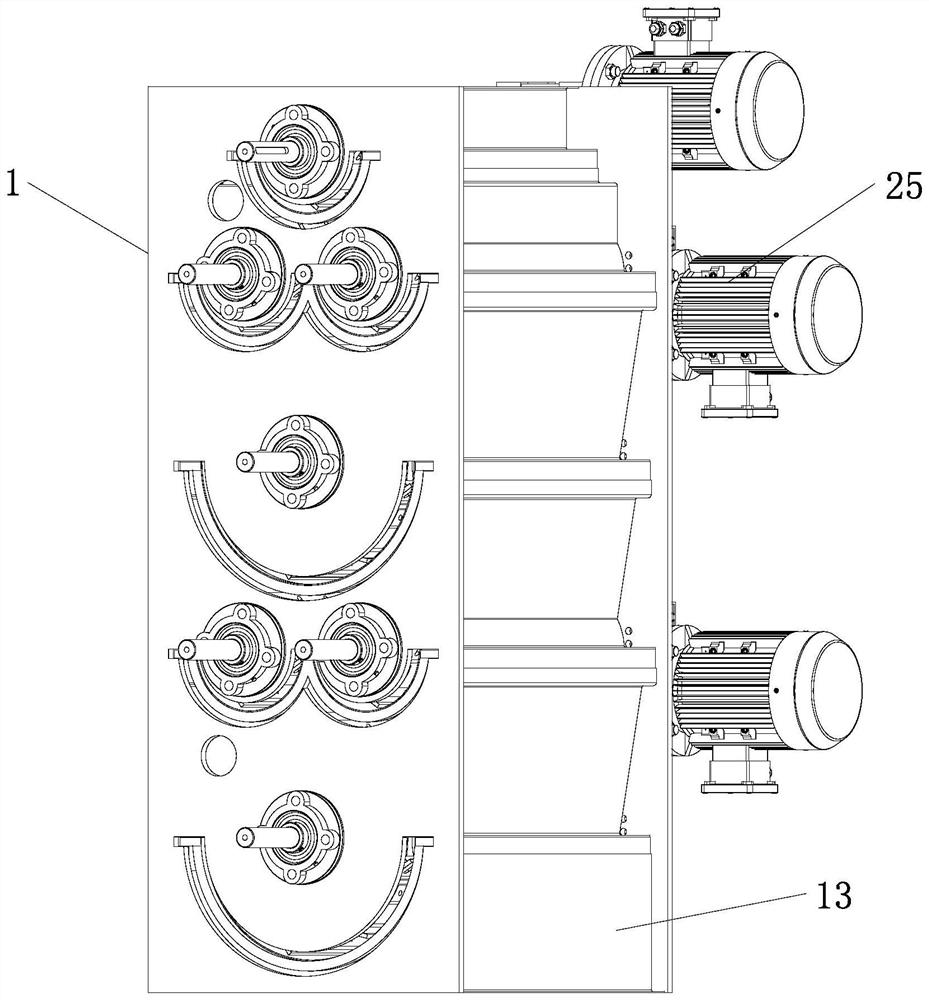

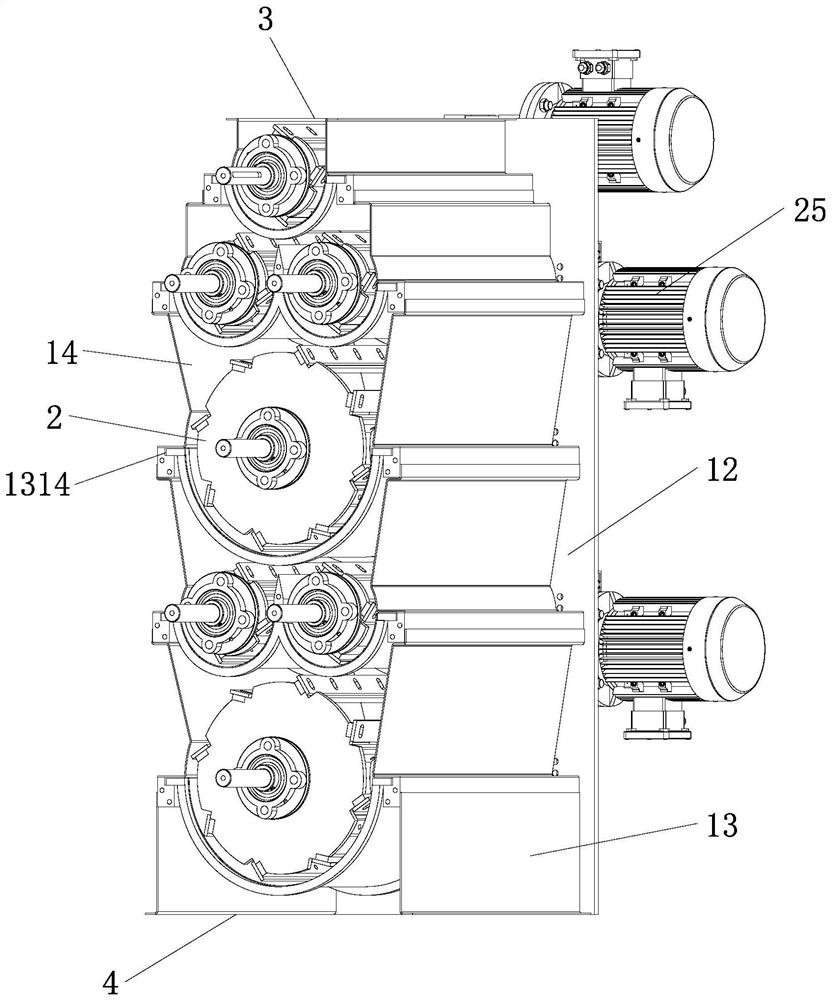

Automatic stillage air-drying machine

InactiveCN103255017AGood total power consumptionSmall total power consumptionAlcoholic beverage preparationSmall footprintSprocket

The invention relates to an automatic stillage air-drying machine, and aims to provide an automatic stillage air-drying machine which is low in energy consumption, high in cooling efficiency, small in occupied area and convenient to use, can promote fermentation and cannot be cleaned. The automatic stillage air-drying machine comprises a stander, inclined conveyers arranged on the stander, an air supply device and a driving motor, wherein the driving motor is connected with the inclined conveyers through chain wheels and chains. The structural key point is that a plurality of inclined conveyers are arranged; and the material feeding end of the back inclined conveyer is arranged below the material discharging end of the front inclined conveyer.

Owner:黄先全

High-performance oil-absorbing polyacrylate resin and preparation method thereof

InactiveCN107200810APromote absorptionSingle shapeOther chemical processesMonomer compositionOil retention

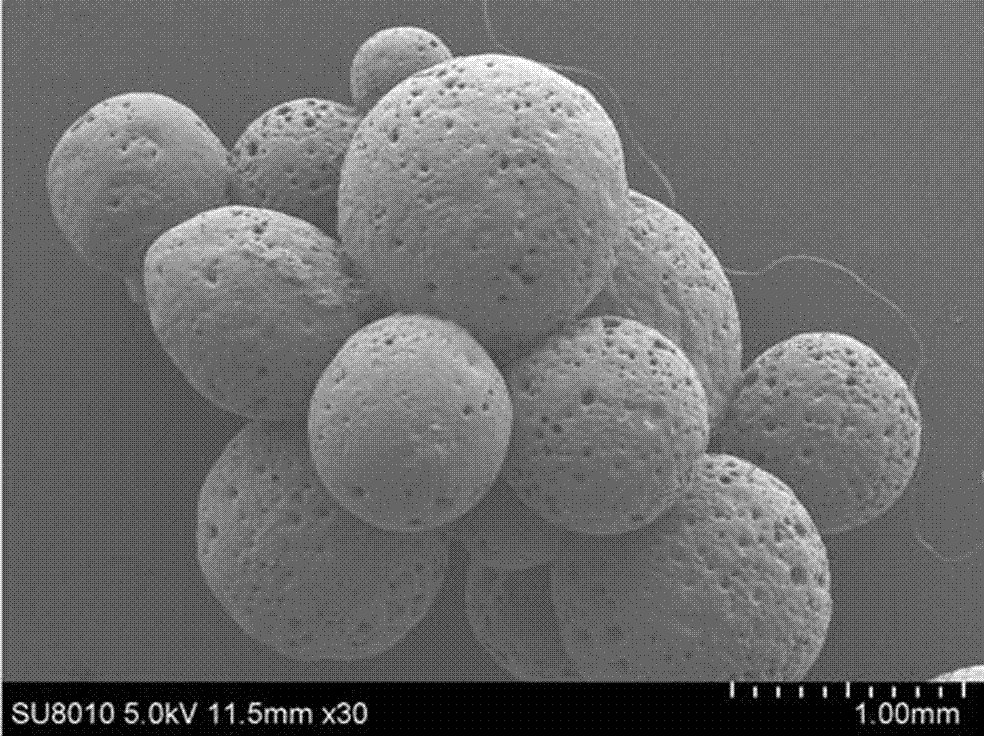

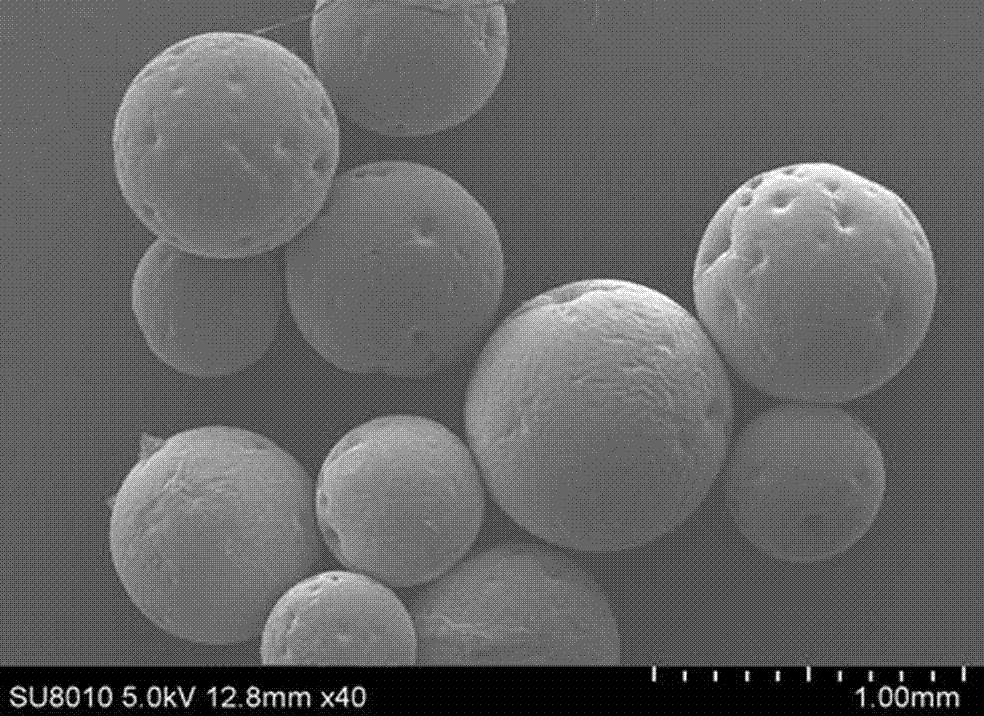

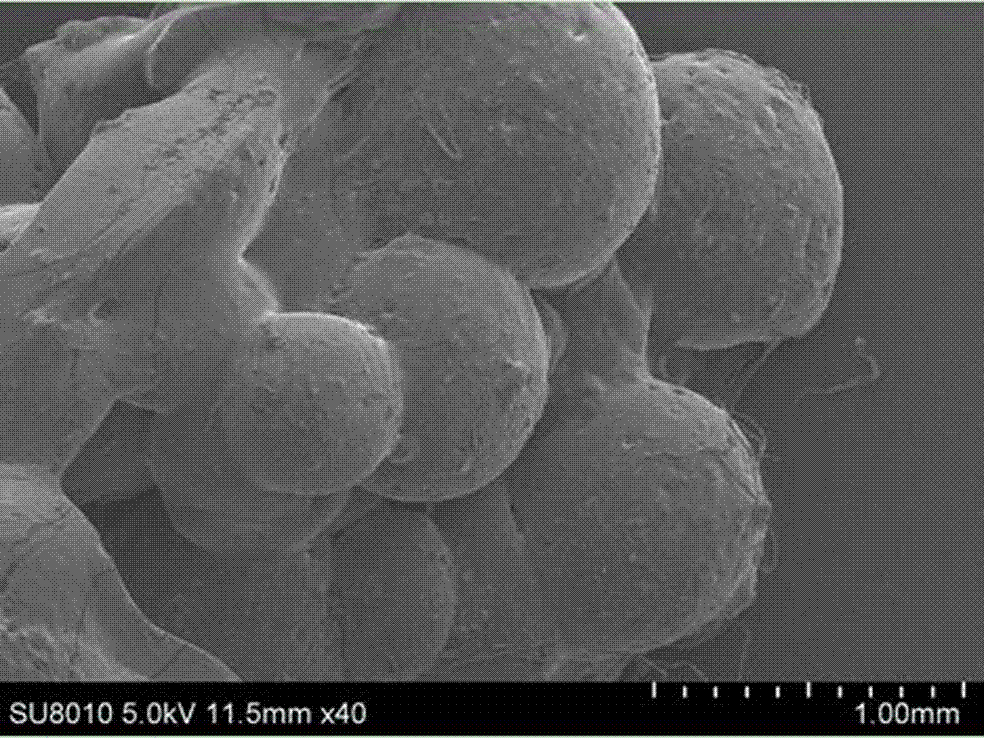

The invention discloses high-performance oil-absorbing polyacrylate resin and a preparation method thereof. Through adoption of common alkyl acrylate and acrylate monomers, through optimization of the monomer composition, improvement on the monomer ratio and introduction of an ethylene-propylene-diene monomer rubber structural agent, and through suspension polymerization, particle-like high-performance oil-absorbing resin having a good surface morphology and free of surface adhesion is prepared. The resin has good oil-absorbing performance, the oil absorption multiple, the oil absorption speed rate and the oil retention rate thereof are obviously superior to those of ordinary oil-absorbing resin materials in the market, and defects of the conventional oil-absorbing materials are overcome, so that the resin has a good application prospect in the fields of petrochemical industry, military affairs, environmental treatment and the like.

Owner:ZHONGBEI UNIV

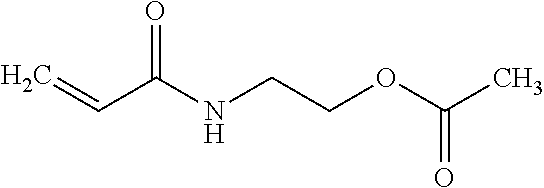

Digital printing inks

The present invention provides digital printing inks comprising one or more acrylamides. Particularly preferred are inks containing diacetone acrylamide. The inks of the invention show good cure speed, blocking resistance, tack free cure, stability and resistance to blocking, and adhesion to the substrate. The inks of the invention are useful for replacing the currently used inks containing odiferous and toxic components.

Owner:SUN CHEM CORP

Methods for releasably attaching substrates using hot melt pressure sensitive adhesives

InactiveUS20060142447A1Improve compatibilityLight colorAdhesive processesFilm/foil adhesivesPolymer scienceAntioxidant

A hot melt pressure sensitive adhesive (HMPSA) is obtained by combining a linear A-B-A block copolymer, wherein the B component is polyisoprene and the A component is polystyrene (S-I-S), at least one compatible tackifying resin, at least one plasticizer, antioxidant(s) and stabilizer(s) and optionally a wax, wherein the A-B-A block copolymer contains 0 to 10% by weight residual A-B diblock. The HMPSA is suitable as a positioning adhesive for disposable articles like plasters, bandages, sanitary napkins, e.g. feminine napkins, adult incontinent pads or diapers. The HMPSA has a viscosity from 3,500 mPas to 25,000 mPas at 140° C. and exhibits adhesion values from 1.0 to 3.0 N / cm at coat weights of 10 to 25 grams per square meter.

Owner:HATFIELD STEPHEN F

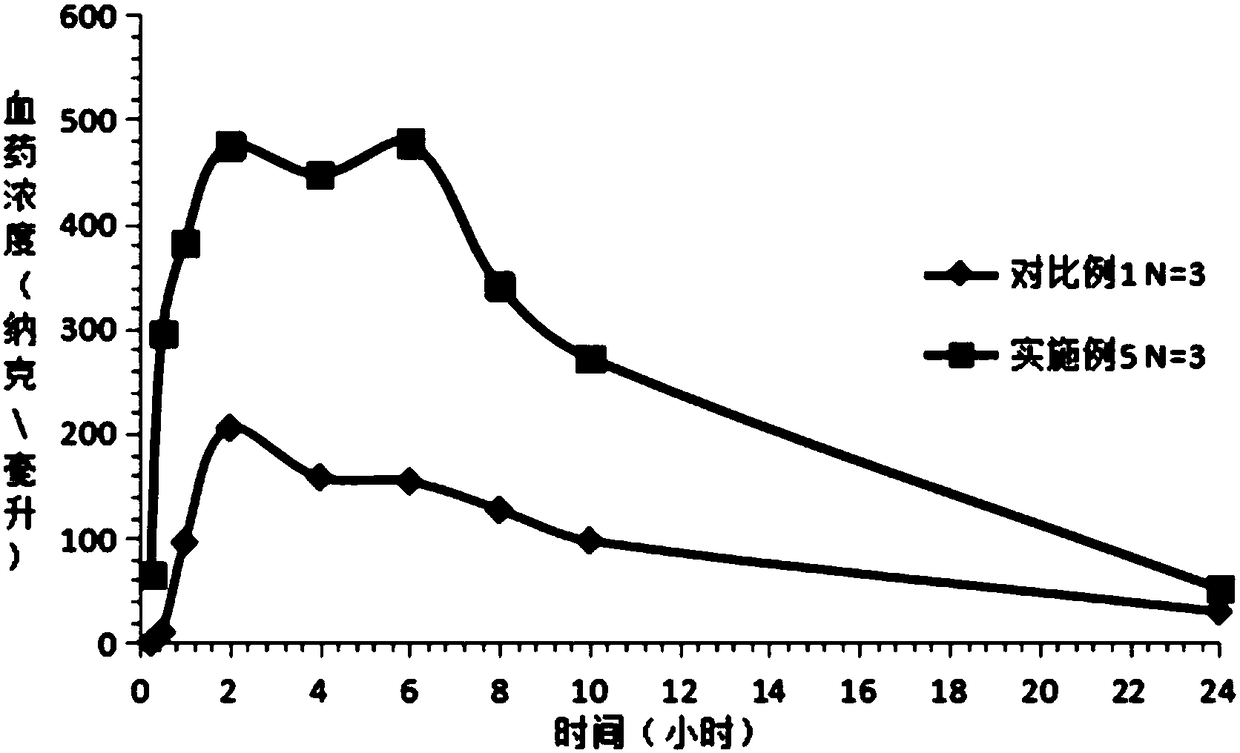

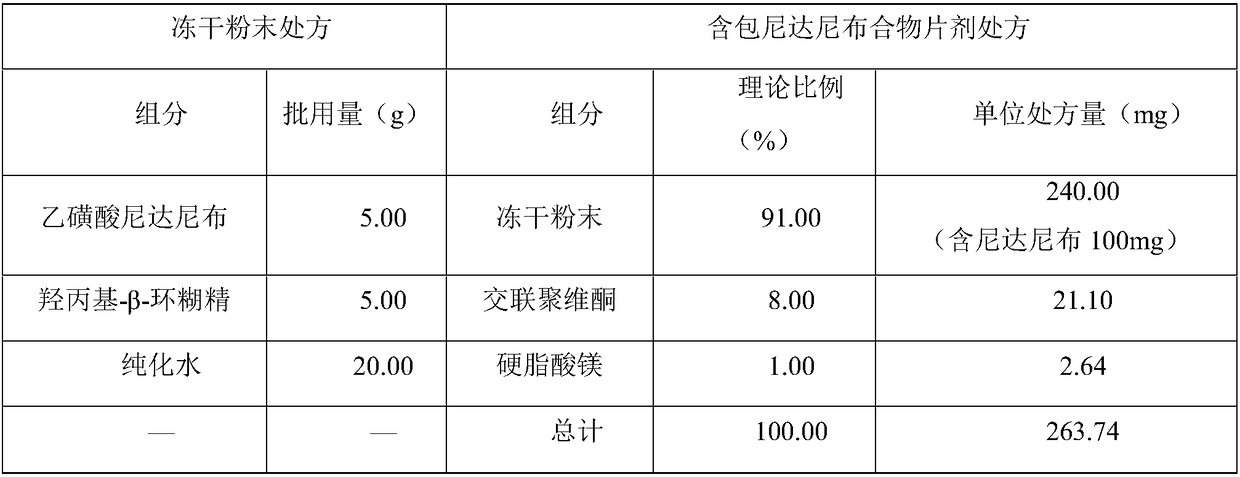

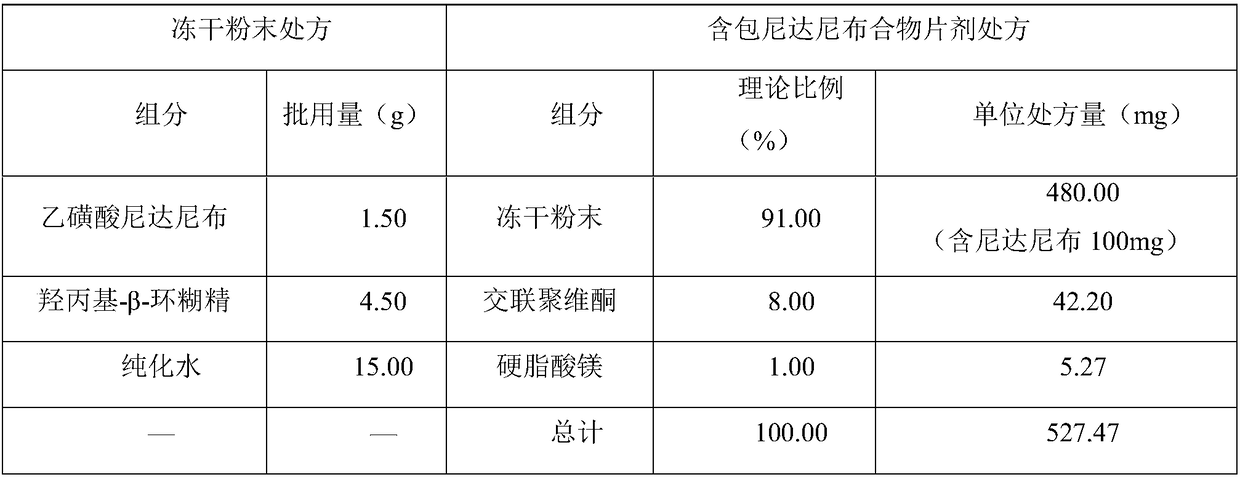

Nintedanib inclusion compound and preparation and preparation method thereofof preparation

PendingCN108144069AImprove solubilityImprove bioavailabilityOrganic active ingredientsPill deliveryTherapeutic effectPharmaceutical Aids

The invention provides a Nnintedanib inclusion compound and preparation and a preparation method thereofof the preparation. The inclusion compound comprises a main drug and an inclusion material, wherein the main drug is Nnintedanib or pharmaceutically acceptable salt in pharmacy, and the inclusion material is cyclodextrin or a derivative of cyclodrxtrin. The inclusion compound can sharply improvethe drug solubility of a simulated intestinal solution, the probability of the drug being separated out in the intestinal canal is lowered, and accordingly the bioavailability of the drug is improved. The inclusion compound and the preparation prepared from the inclusion compound and pharmaceutically acceptable ingredients in the pharmacy can outstandingly improve the dissolution degree and the dissolution rate of the drug in the simulated intestinal solution, the bioavailability of the drug is improved, meanwhile, the inclusion compound and the preparation have good stability, thus the flexibility and compliance of drug taking of patients are improved, and accordingly the treatment effect of the drug is improved. In addition, the invention provides a preparation method of the medicinal preparation of the Nnintedanib inclusion compound, no specific equipment is needed, the technology is simple, the production cost is low, and the preparation method is suitable for industrialized production.

Owner:SUNSHINE LAKE PHARM CO LTD

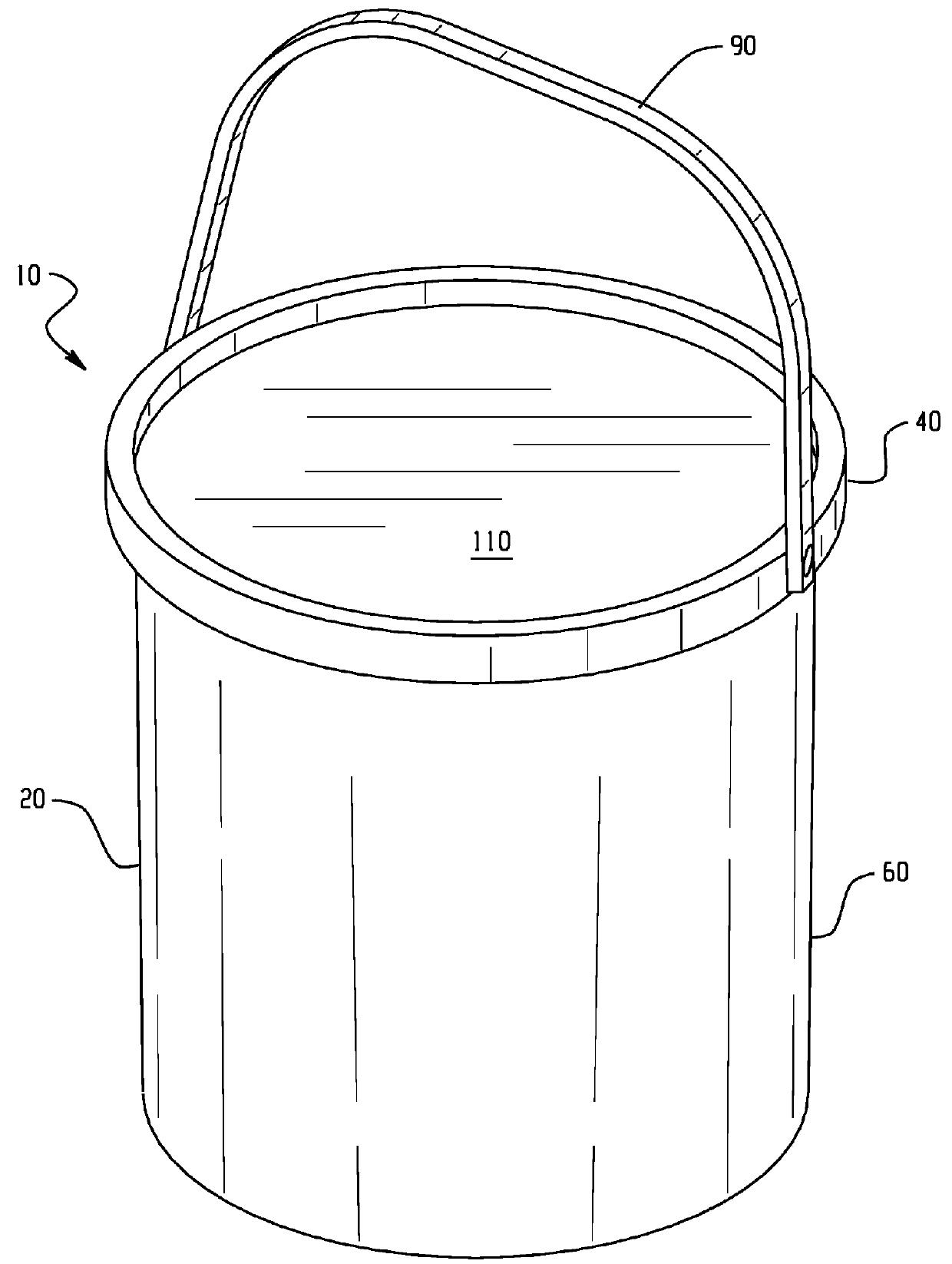

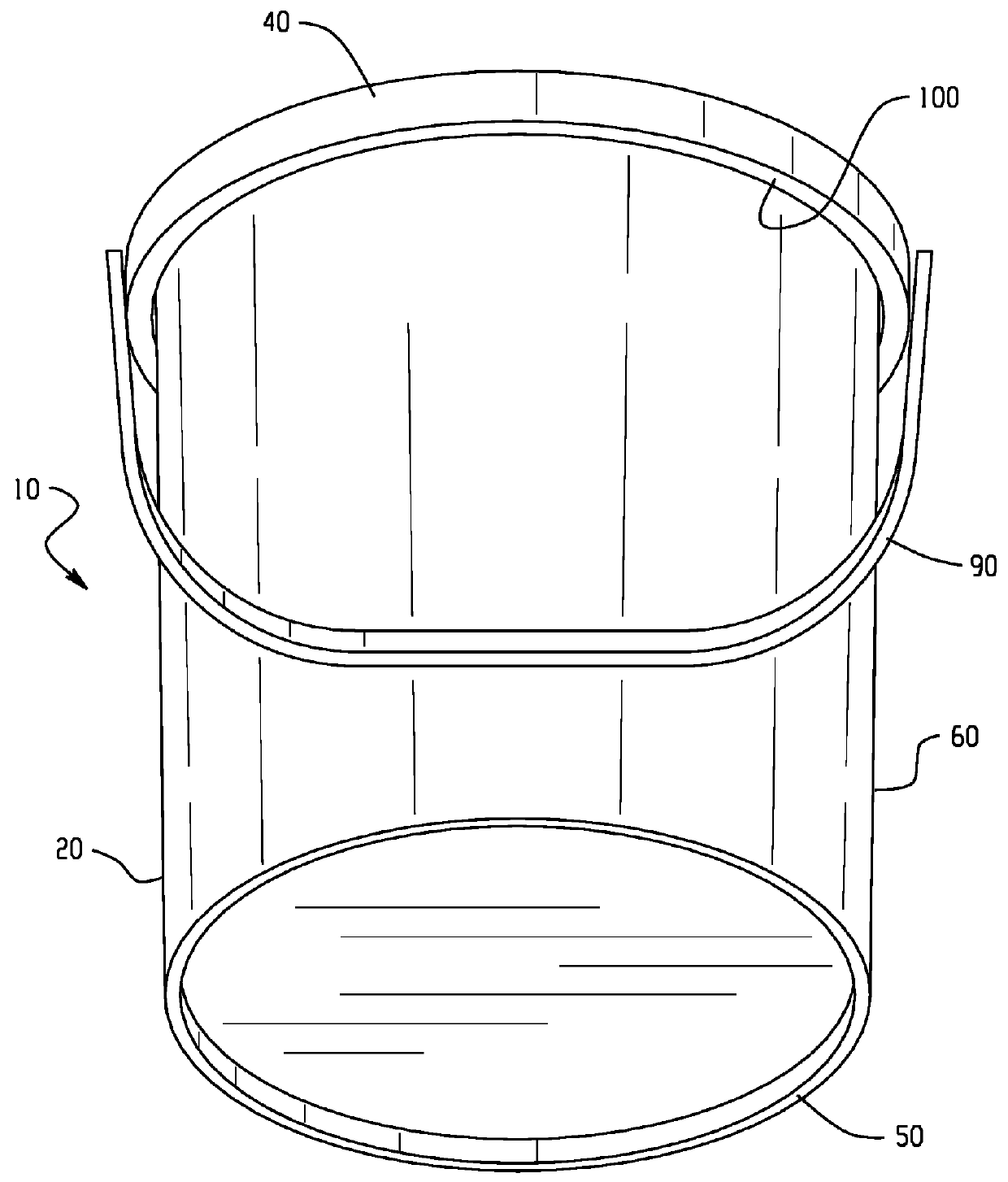

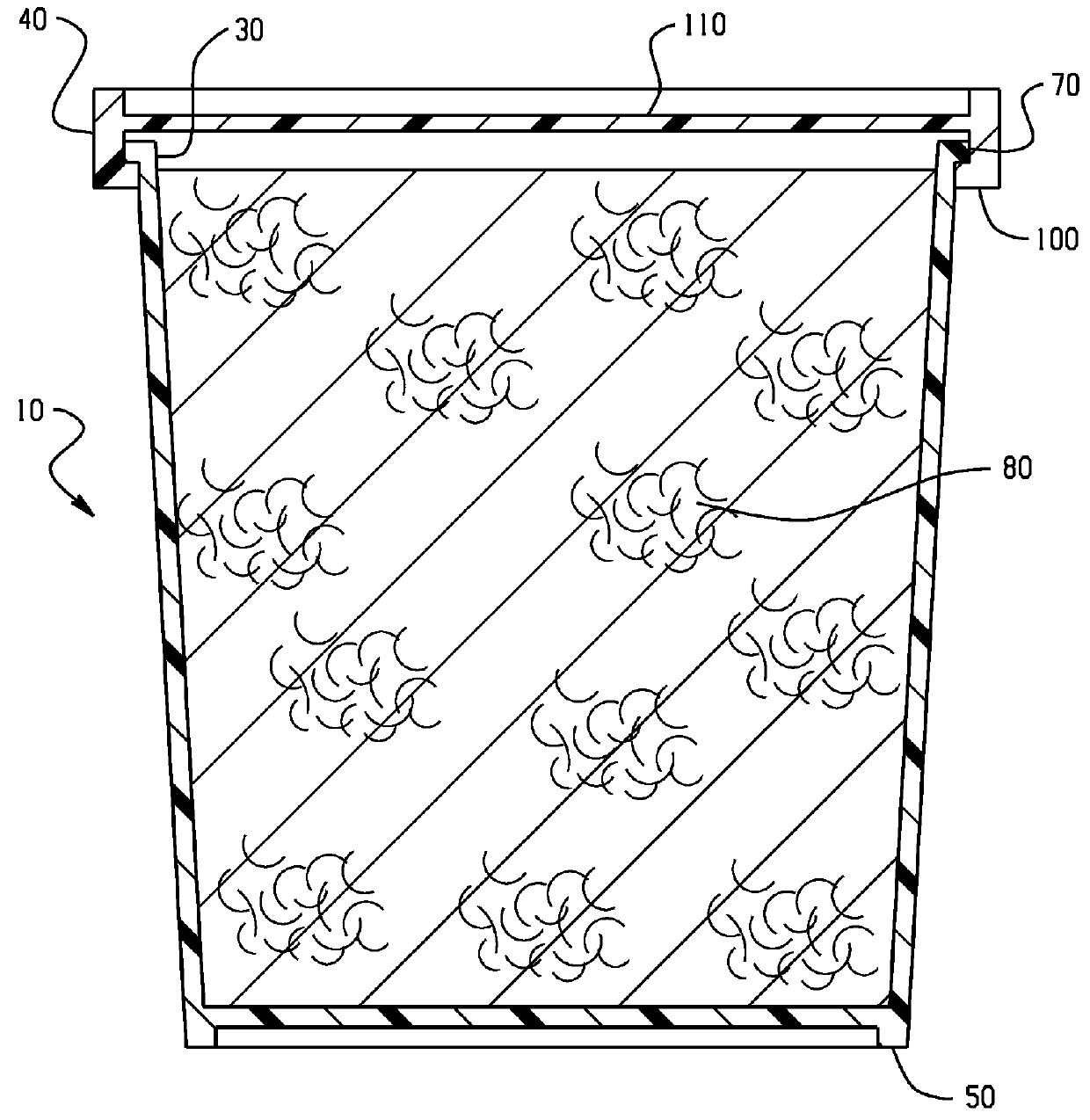

Meltable crack sealant packaging

ActiveUS9248588B2Reduce surface tackPoint becomes highRemovable lids/coversPaving detailsEngineeringMechanical engineering

A meltable crack sealant package that includes a polymeric container and a crack sealant material contained therein. The polymeric container includes a bottom portion including a rigid base and an upwardly extending rigid sidewall that terminates in and define an opening. The rigid base and upwardly extending rigid sidewall cooperate to define a reservoir. A rigid lid portion operatively engages with the bottom portion to close off the opening and thereby seal the crack sealant material within the reservoir in a watertight manner. Methods of making and using the meltable crack sealant package are also disclosed.

Owner:P & T PROD

Photocurable material for sealing, sealing method, sealing material, and case using sealing material

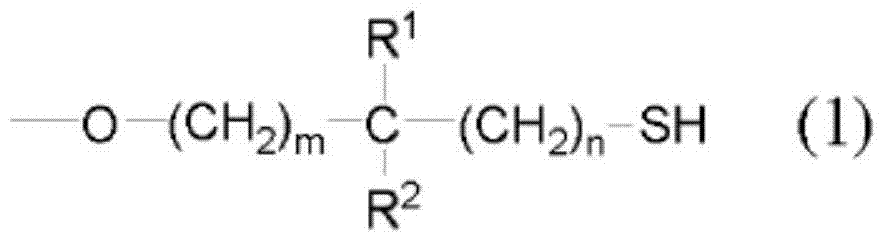

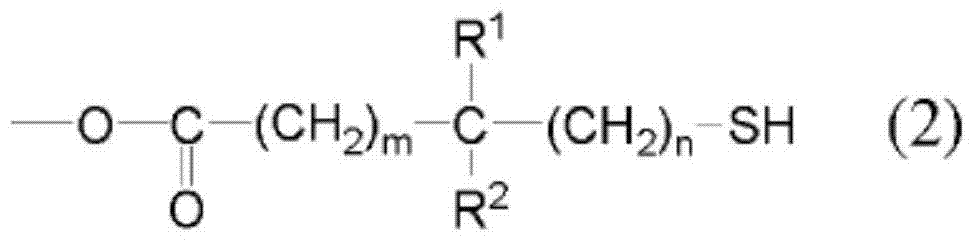

ActiveCN104755579AReduce surface tackHigh compression recovery ratioOther chemical processesVehicle sealing arrangementsOligomerHardness

This photocurable material for sealing, which contains (A) an oligomer that contains a (meth)acryloyl group and has a weight average molecular weight of 10,000-30,000, (B) a (meth)acrylate monomer, (C) a polythiol compound, and if necessary, (D) a carbodiimide compound, has high recoverability from compression, high tensile strength, excellent flexibility, and if necessary, low hardness. Consequently, this photocurable material for sealing is capable of providing a sealing material that exhibits excellent sealing characteristics such as excellent airtightness and waterproof properties, while having less surface tackiness, and the like.

Owner:BOSTIK SA

Curable composition

The present invention provides a curable composition comprising the following two components: an acrylic polymer or a methacrylic polymer with a number average molecular weight of 500-1,000,000, which has at least one crosslinkable functional group per molecule on average, The crosslinkable functional group is selected from crosslinkable silyl groups, alkenyl groups, hydroxyl groups, polymerizable carbon-carbon double bonds and epoxy groups, and polymer plasticizers with a number average molecular weight of 500-15000.

Owner:KANEKA CORP

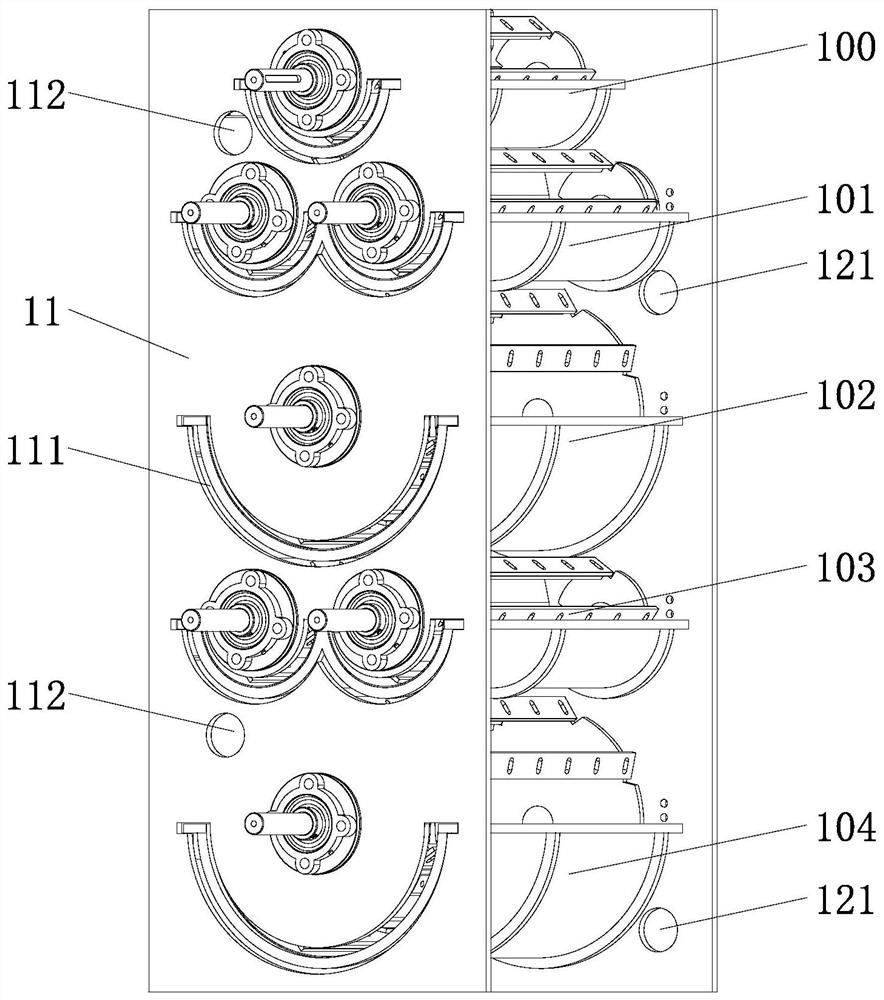

Multistage granulation equipment for ceramic pug

PendingCN112606170AOvercoming the problem of low granulation efficiencyRealize multi-stage continuous granulationCeramic shaping apparatusPore diameterSieve

The invention relates to the technical field of ceramic powder processing equipment, in particular to multistage granulation equipment for ceramic pug. The multistage granulation equipment for the ceramic pug comprises a granulation bin, wherein at least two friction granulation layers are arranged in the granulation bin; at least one friction granulation assembly is arranged on each friction granulation layer; and the pore diameter of each sieve pore of the friction granulation assembly at the lower layer is smaller than the pore diameter of each sieve pore of the friction granulation assembly at the upper layer corresponding to the friction granulation assembly at the lower layer. According to the multistage granulation equipment for the ceramic pug provided by the invention, the multiple friction granulation layers are arranged, and the sizes of powder particles prepared by the friction granulation assemblies of different friction granulation layers are reduced layer by layer, so that the problem of low granulation efficiency of existing single-layer granulation equipment is solved; in addition, dry air or hot air flow is introduced into the granulation bin through the air inlet, so that the mobility and / or the temperature of the air flow in the granulation bin are / is improved, and the powder particles are dried; and due to the fact that the specific surface area of the granulated particles is large, the drying speed is high, the drying cost is low, the surface viscosity of the dried powder particles is reduced, and the dried powder particles can fall off from the sieve pores easily.

Owner:FOSHAN LANZHIJING SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com