Photocurable material for sealing, sealing method, sealing material, and case using sealing material

A light-curable and sealing material technology, applied in chemical instruments and methods, sealing devices, transportation and packaging, etc., can solve the problems of unsuitable sealing materials for shells, and achieve good storage stability, high tensile strength, surface less viscous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0125] The present invention will be described in detail below through reference examples and embodiments. Furthermore, these embodiments are only used to illustrate the present invention, and do not limit the present invention in any way.

[0126] [experiment method]

[0127] (1) Tensile strength and elongation at break

[0128] A sheet of a UV resin cured product with a thickness of 1 mm was punched into a No. 3 dumbbell in accordance with JIS K 6251 to prepare a test piece. A tensile test was carried out under the conditions of a test temperature of 23°C and a tensile speed of 100 m / min, and the tensile strength and elongation at break were measured.

[0129] ·Tensile strength at breaking point [MPa] = breaking strength / film cross-sectional area

[0130] ·Elongation [%] = (elongation at break / reference length [20mm])×100

[0131] (2) Hardness

[0132] According to JIS K 6253, the thickness of the UV resin cured product is about 1mm, and the thickness is about 10mm. The sample is meas...

Embodiment 1

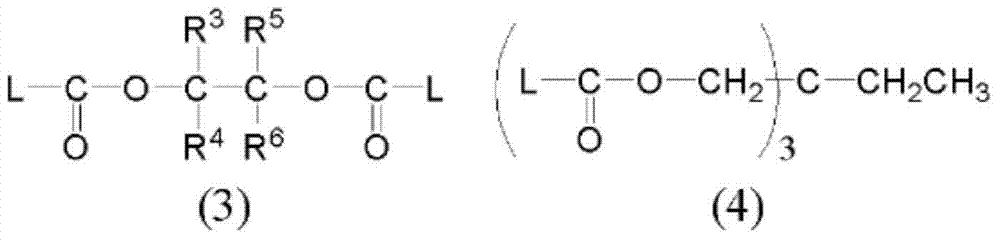

[0146] 100 parts by weight of urethane acrylic oligomer A (manufactured by Nippon Synthetic Chemical Co., Ltd.: UV-3000B) with a weight average molecular weight of 18,000, and phenol acrylate as an acrylic monomer (manufactured by Daiichi Pharmaceutical Co., Ltd.: Nibe Frontea PHE-2) 60 parts by weight, pentaerythritol tetrakis(3-mercaptobutyrate) (manufactured by Showa Denko Co., Ltd.: Karena MT PE1) with a molecular weight of 544.8 as tetrafunctional (secondary) polythiol A, 8 parts by weight, viscosity Adjusting agent (manufactured by Nippon Aerosil Co., Ltd.: AEROSIL200) 8 parts by weight was uniformly vacuum-mixed with a stirrer, and then 1-hydroxy-cyclohexyl-phenyl-ketone (manufactured by BASF J. P. Co., Ltd.) was added as a photopolymerization initiator: イルガキュア 184) 2 parts by weight, 0.02 parts by weight of 1,4-benzenediol (manufactured by Mitsui Chemicals Co., Ltd.: hydroquinone) as a stabilizer, and uniformly mixed and deaerated with a stirrer to obtain the photocurable...

Embodiment 2

[0148] 100 parts by weight of urethane acrylic oligomer A (manufactured by Nippon Synthetic Chemical Co., Ltd.: UV-3000B) with a weight average molecular weight of 18,000, and phenol acrylate as an acrylic monomer (manufactured by Daiichi Pharmaceutical Co., Ltd.: Nibe Frontea PHE-2) 60 parts by weight, pentaerythritol tetrakis(3-mercaptobutyrate) (manufactured by Showa Denko Co., Ltd.: Karean MT PE1) with a molecular weight of 544.8 as tetrafunctional (secondary) polythiol A, 23 parts by weight, viscosity Adjusting agent (manufactured by Nippon Aerosil Co., Ltd.: AEROSIL200) 8 parts by weight was uniformly vacuum-mixed with a stirrer, and then 1-hydroxy-cyclohexyl-phenyl-ketone (manufactured by BASF J.P. イルガキュア 184) 2 parts by weight, 0.02 parts by weight of 1,4-benzenediol (manufactured by Mitsui Chemicals Co., Ltd.: hydroquinone) as a stabilizer, and uniformly mixed and deaerated with a stirrer to obtain the photocurable seal of the present invention material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com