Multistage granulation equipment for ceramic pug

A technology of ceramic mud and granulation equipment, which is applied in the direction of ceramic molding machines and manufacturing tools, which can solve the problems of reducing the efficiency of friction granulation, reducing the speed of equipment friction granulation, and sticking through holes, so as to overcome the problems of granulation The effect of low efficiency, improving drying speed and saving drying cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

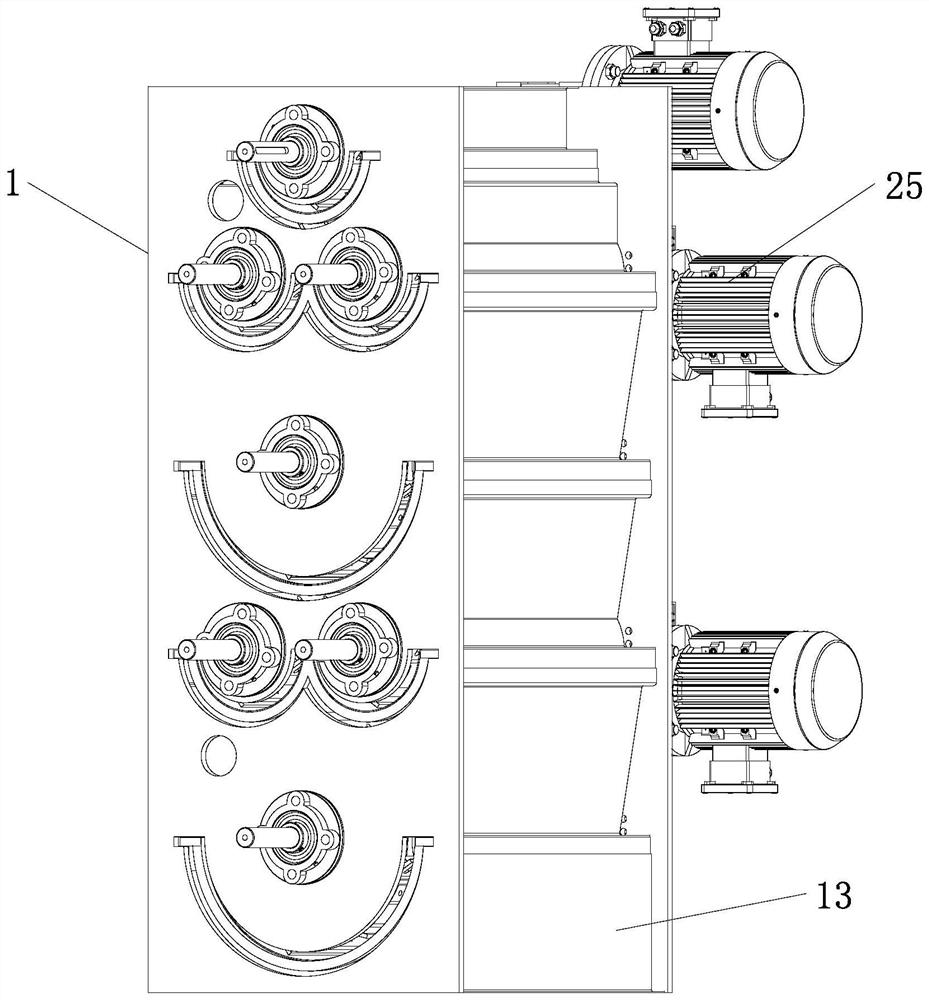

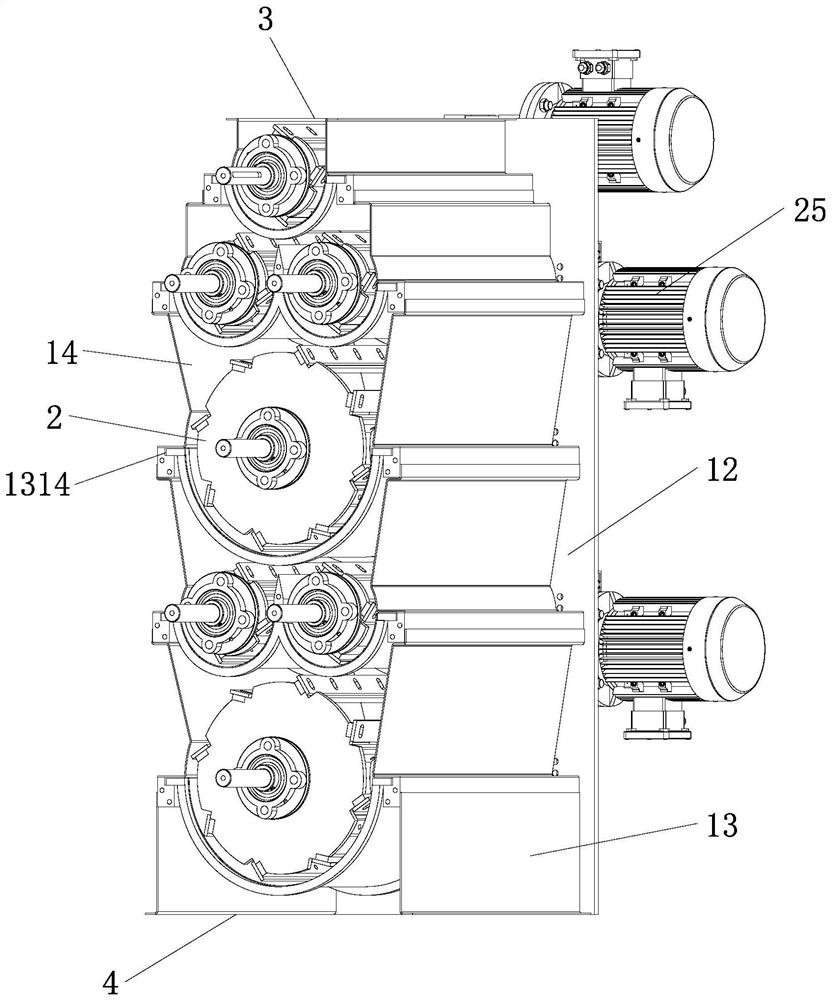

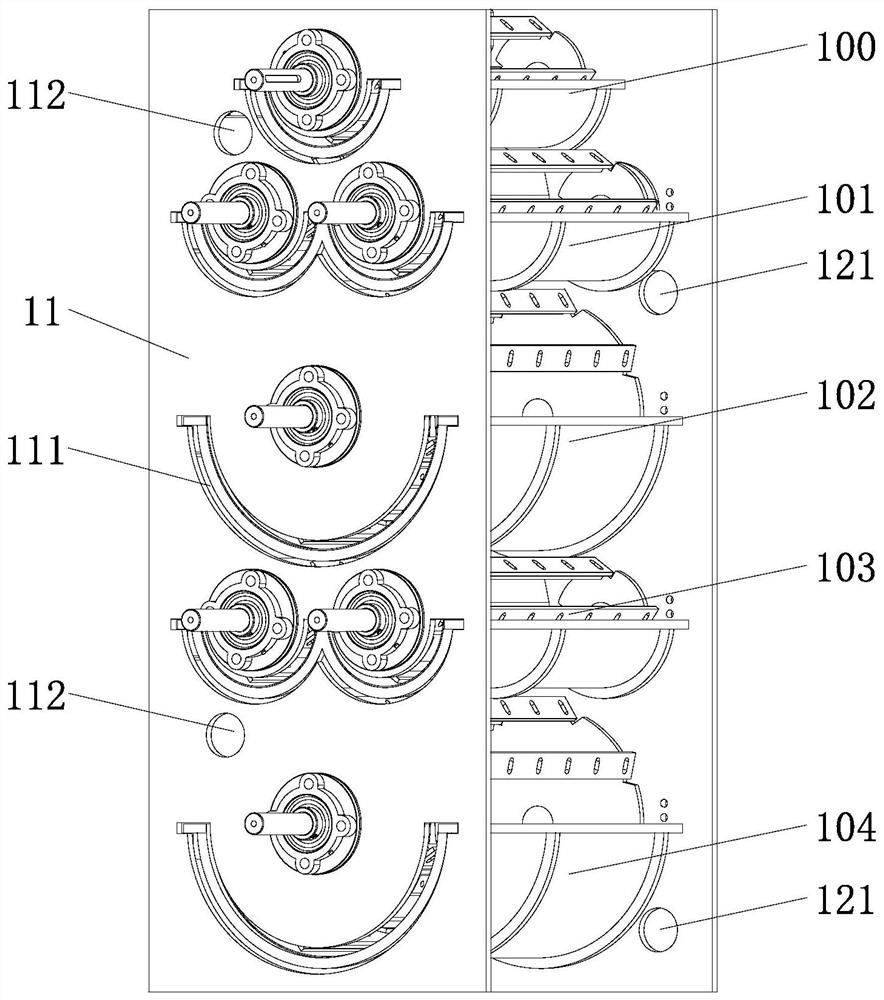

[0034] Such as Figure 1 to Figure 4 The shown multi-stage granulation equipment for ceramic mud includes a granulation bin 1. The overall shape of the granulation bin 1 is cuboid, and the interior is hollow. It includes a left side plate 11, a right side plate 12, a front baffle plate 13 and tailgate14. At least two friction granulation layers are arranged in the granulation bin 1, and at least one friction granulation assembly 2 is arranged on each friction granulation layer. In this embodiment, the granulation bin 1 is divided into the first friction granulation layer 100, the second friction granulation layer 101, the third friction granulation layer 102, the fourth friction granulation layer 103 and the fifth friction granulation layer from top to bottom. Friction granulation layer 104, wherein the number of friction granulation components 2 in odd-numbered friction granulation layers, that is, the first, third, and fifth friction granulation layers, is 1, and even-numbe...

Embodiment 2

[0044] The difference between this embodiment and the first embodiment is that: the granulation bin 1 is provided with more than one air outlet 112, and the air outlet 112 is arranged on the left side plate 11, and the air outlet 112 is connected with the exhaust fan through a pipe. A negative pressure zone is formed in the granulation bin 1 by exhausting the air.

[0045] When the water content of the ceramic mud to be processed is 8% to 10% (that is, the water content of the ceramic powder particles that are finally used to make bricks), and the water content of a single ceramic mud is relatively uniform. Since this kind of ceramic mud is relatively dry, fine powder with a mesh number less than 120 mesh will be formed during the friction granulation process. These fine powders are too fine to be used in the subsequent distributing process, so they need to be removed.

[0046] During the process of friction granulation, when the scraper 22 rotates, it will disturb the airflow...

Embodiment 3

[0050] The difference between this embodiment and the first embodiment is that: the granulation bin 1 is provided with more than one air inlet 121 and air outlet 112, and the air outlet 112 and the air inlet 121 are respectively connected to the exhaust fan and the blower through pipes.

[0051] In this example, if image 3 As shown, there are two air outlets 112 and two air inlets 121 respectively, and they are respectively opened on the left side panel 11 and the right side panel 12 . Wherein the air inlet 121 is arranged respectively under the arc-shaped screen cloth 23 of the second and the fifth friction granulation layer; below. The number of air inlets 121 and air outlets 112 can be increased or decreased as required, and the positions of the air inlets 121 and 112 can be set so as to facilitate the sufficient flow of the airflow in the granulation bin 1 .

[0052] Hot air or dry air can be passed into the air inlet 121 .

[0053] When the water content of the cerami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com