Patents

Literature

584results about How to "Good for volatilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

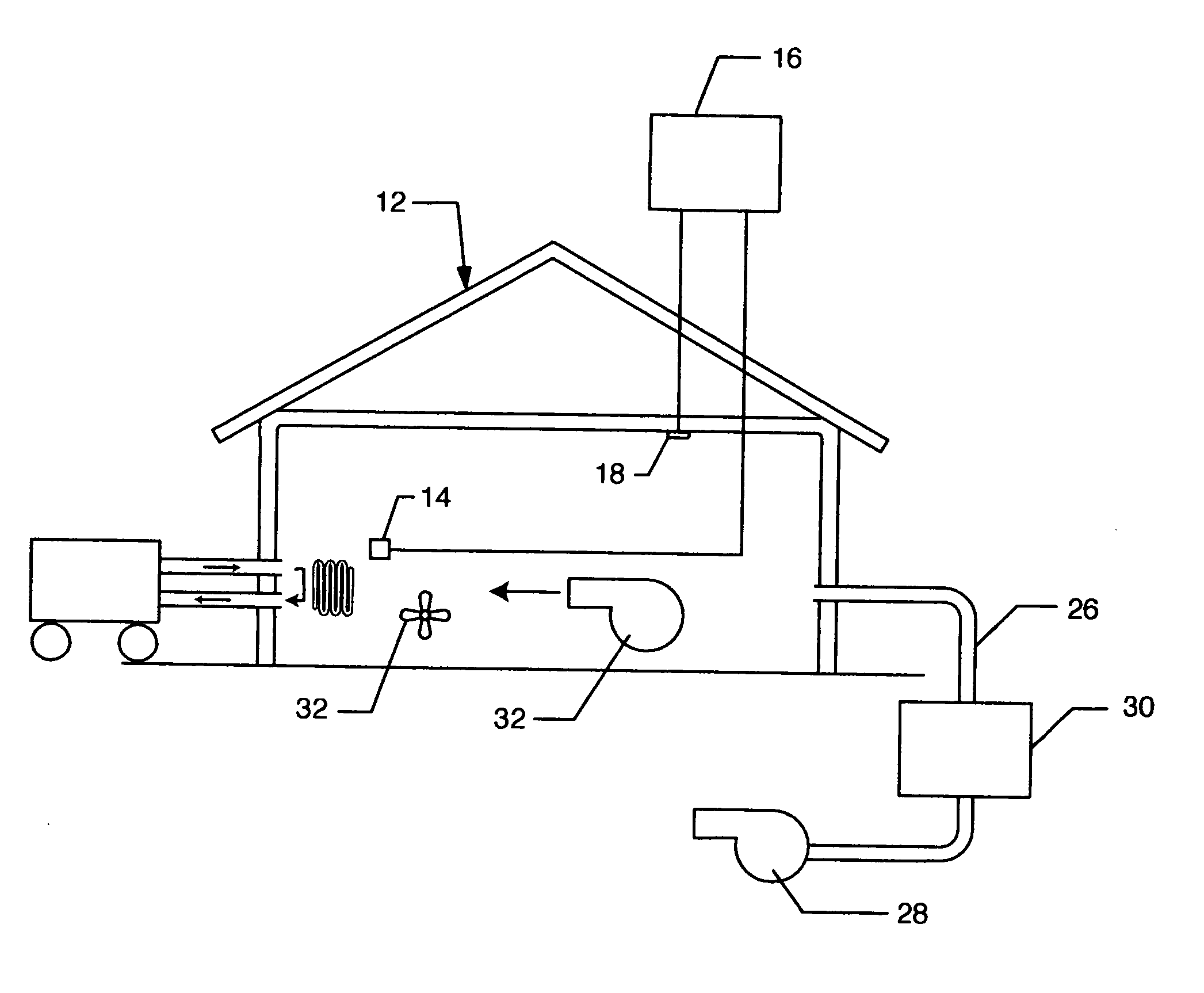

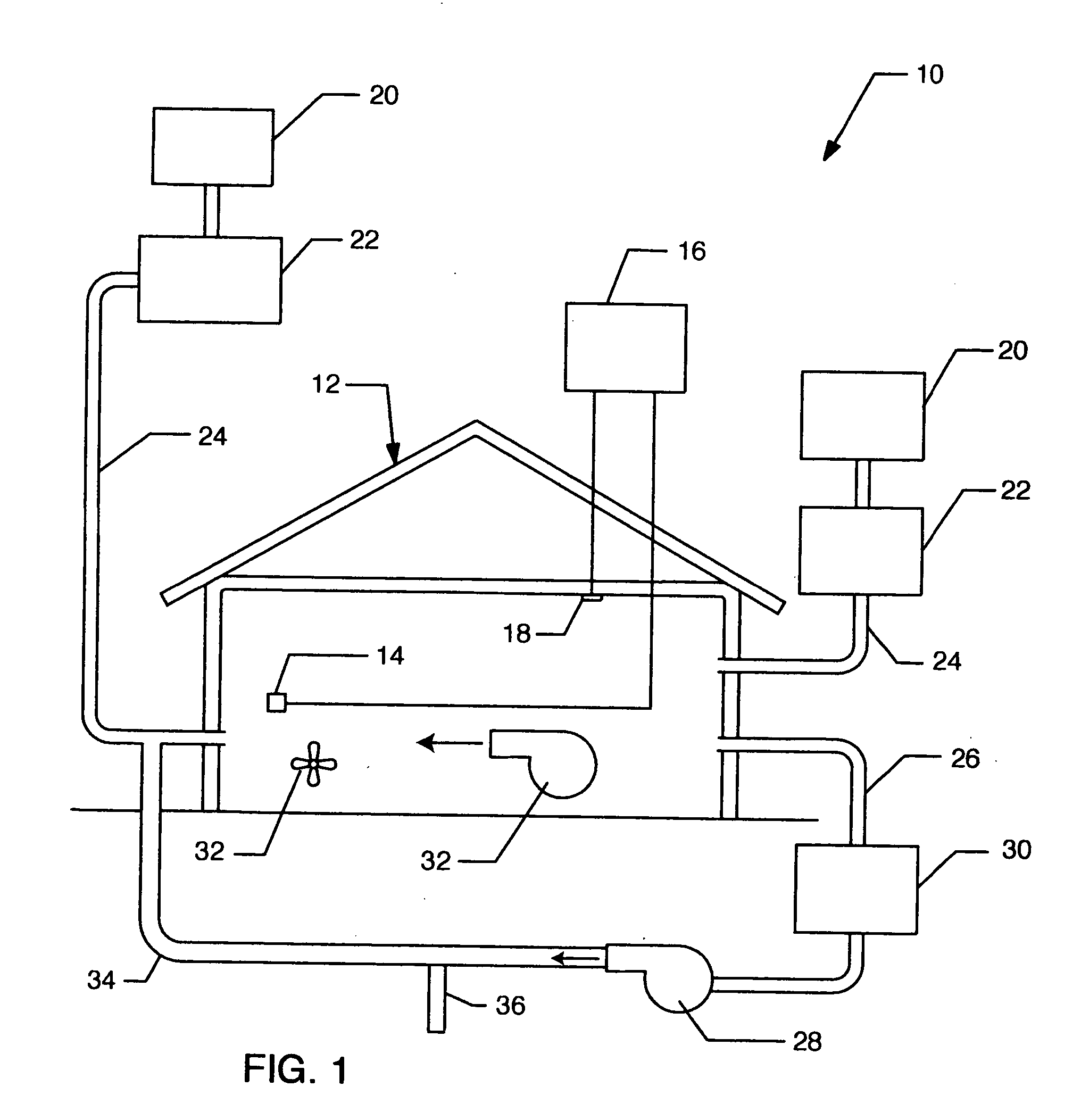

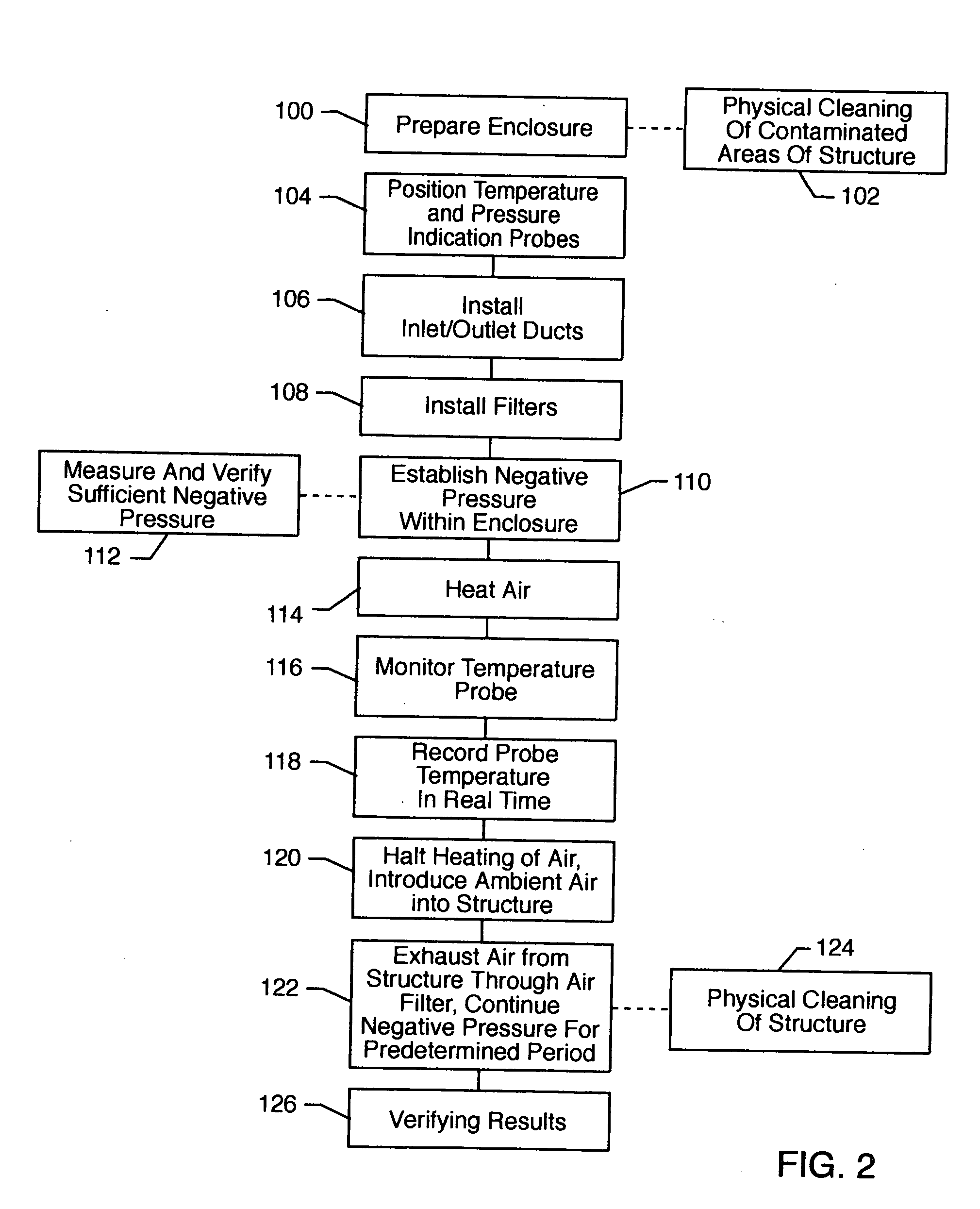

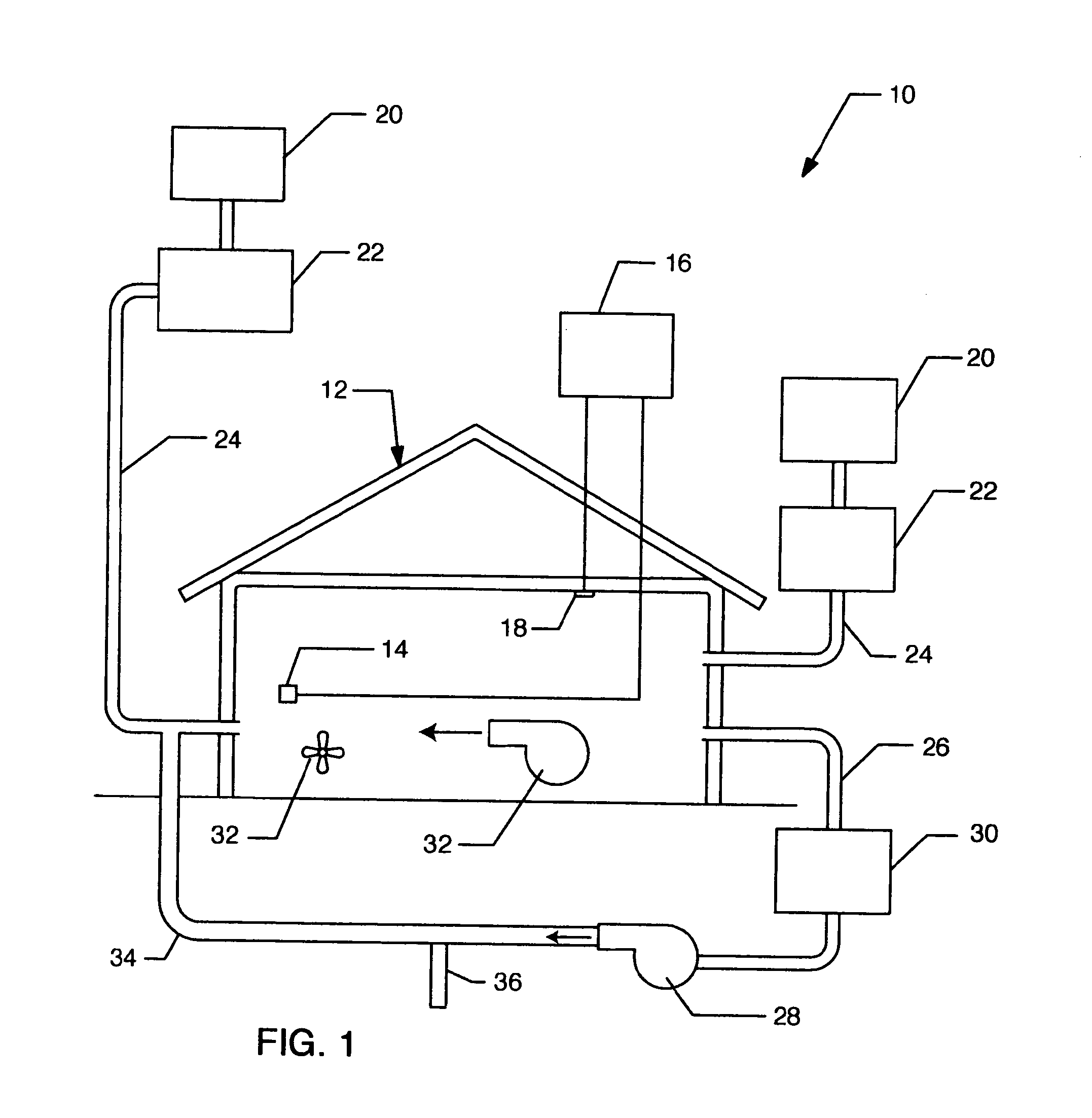

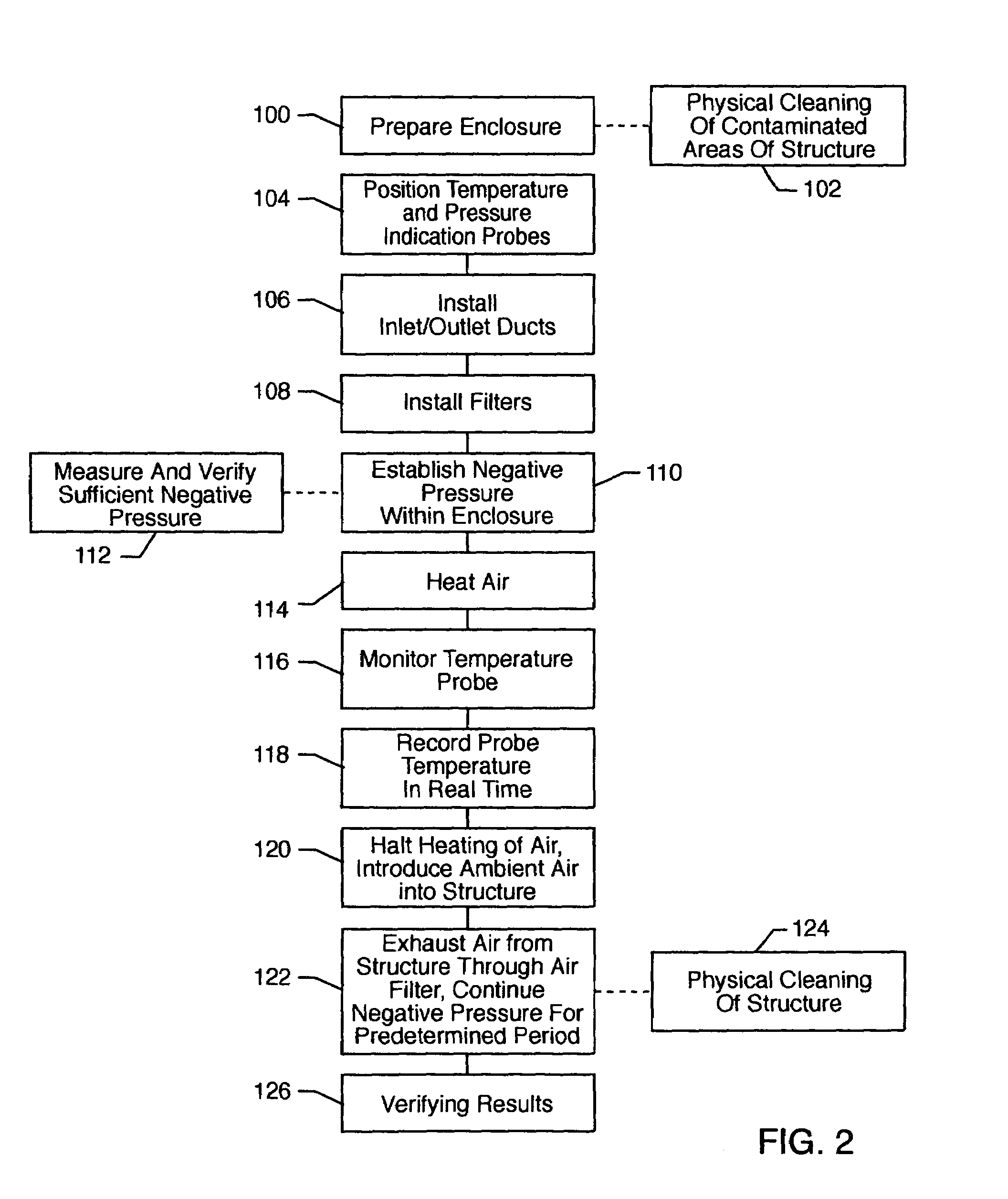

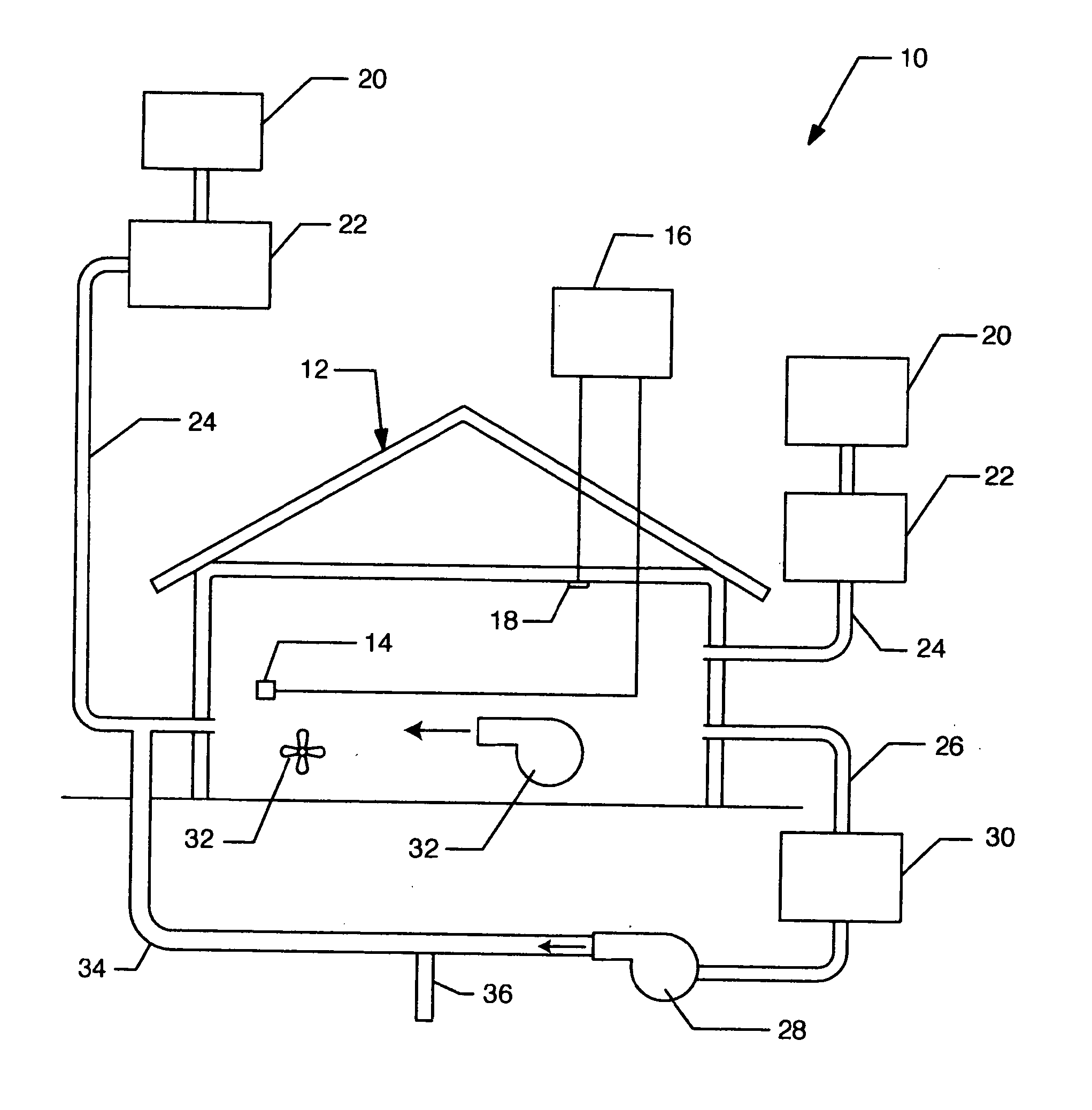

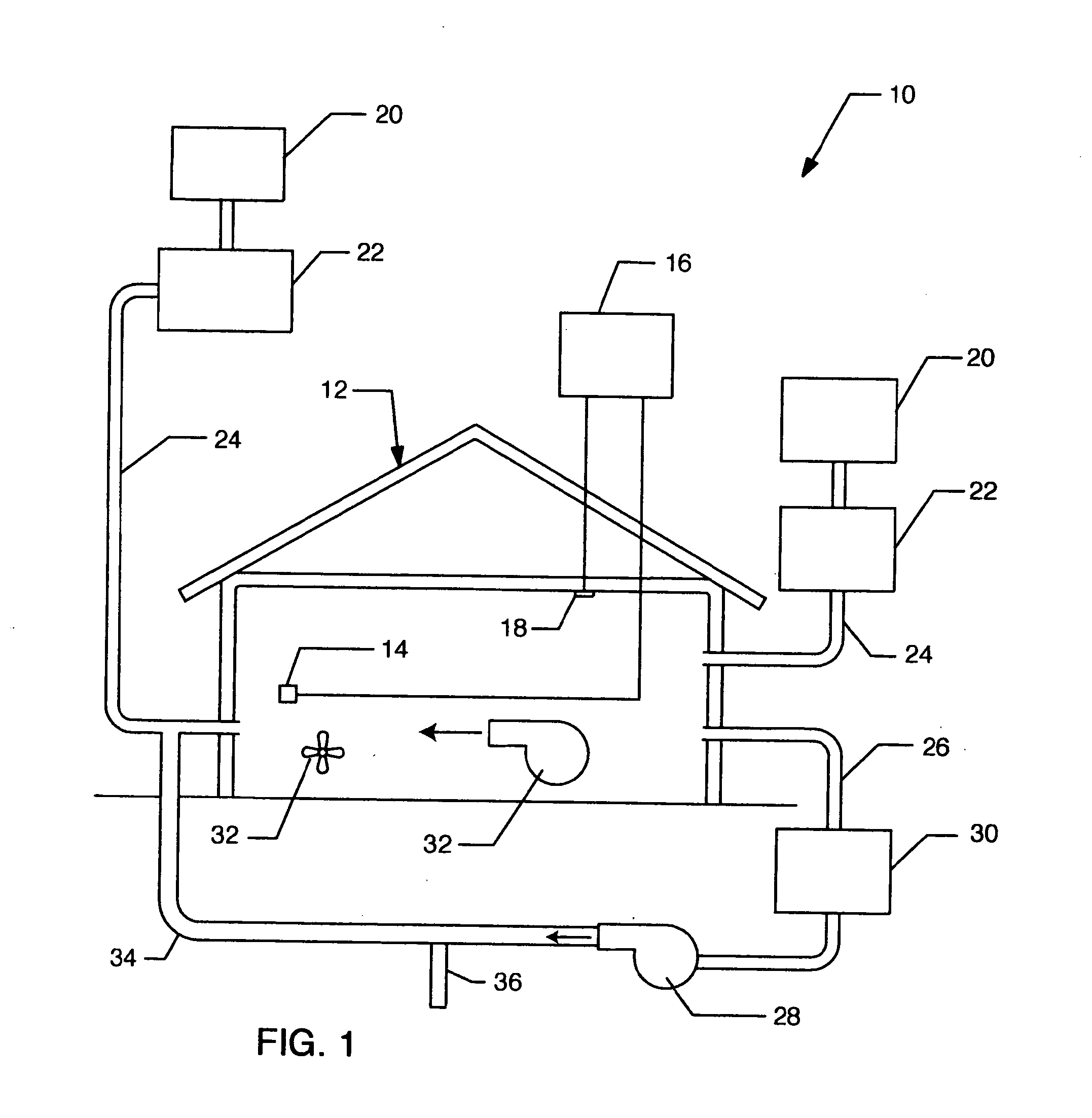

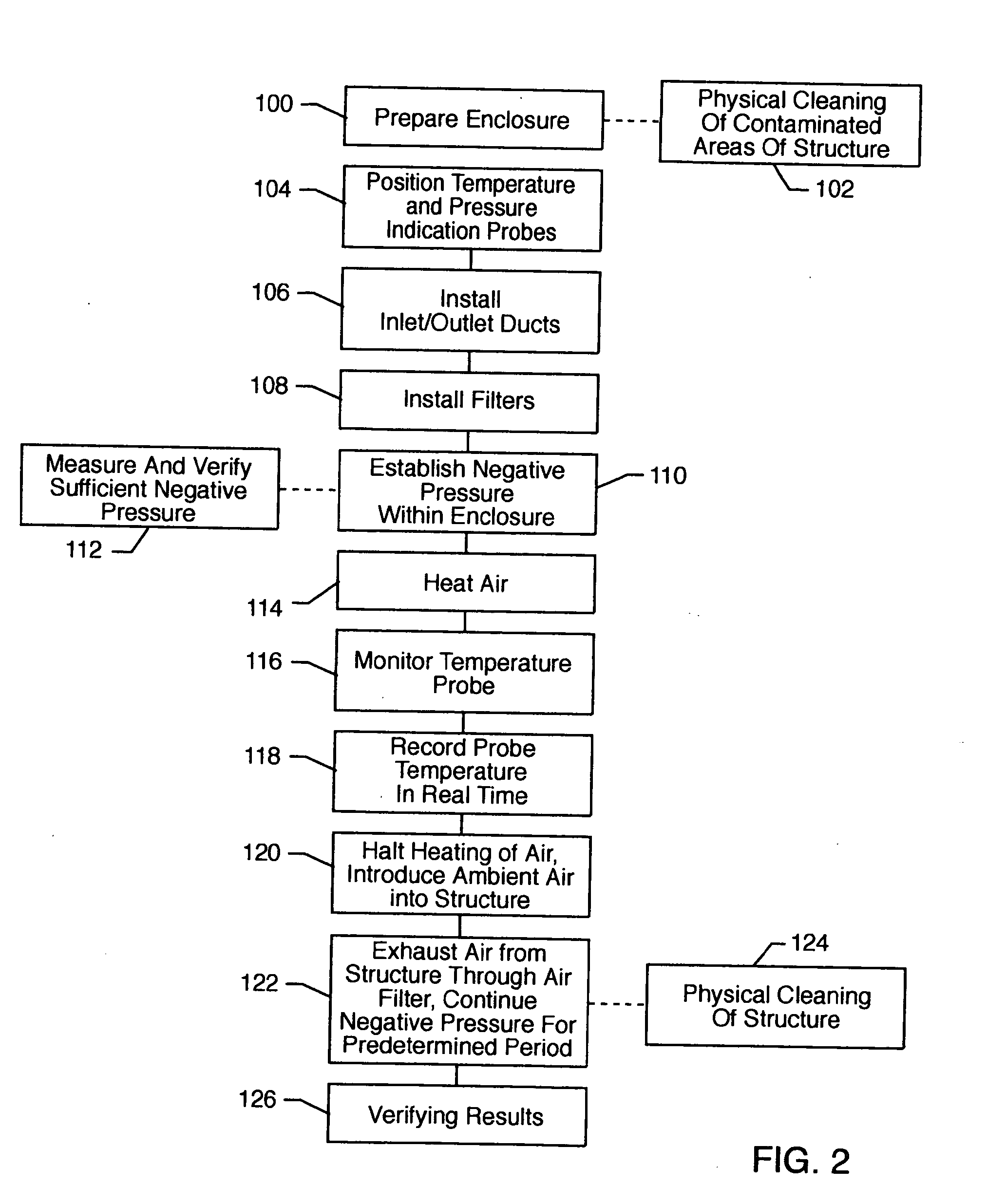

Method for removing or treating harmful biological and chemical substances within structures and enclosures

InactiveUS20050220662A1Efficient killingEfficient removalMechanical apparatusDeodrantsCompound (substance)Engineering

A process for removing or treating harmful biological and chemical substances from an enclosure, such as a building or vehicle by using heated air. The method of the present invention is non-toxic and can be performed in a relatively short amount of time while effectively killing and removing a large proportion of dead organisms and substantially reducing volatile organic compounds.

Owner:THERMAPURE

Method of treating for pests

InactiveUS7690148B2Efficient killingEfficient removalMechanical apparatusGas treatmentVolatile organic compoundChemical substance

A process for removing or treating harmful biological and chemical substances from an enclosure, such as a building or vehicle by using heated air. The method of the present invention is non-toxic and can be performed in a relatively short amount of time while effectively killing and removing a large proportion of dead organisms and substantially reducing volatile organic compounds.

Owner:THERMAPURE

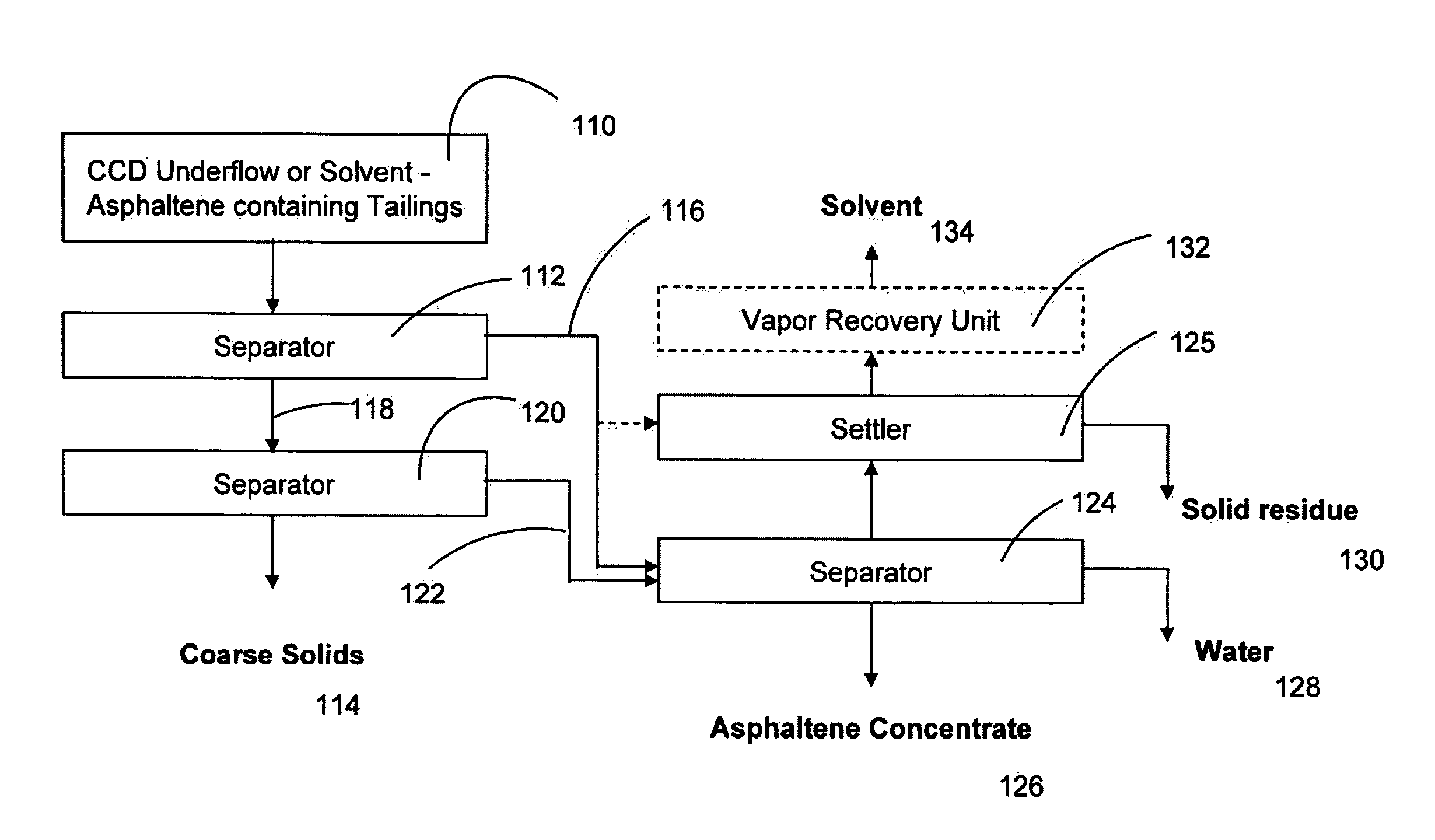

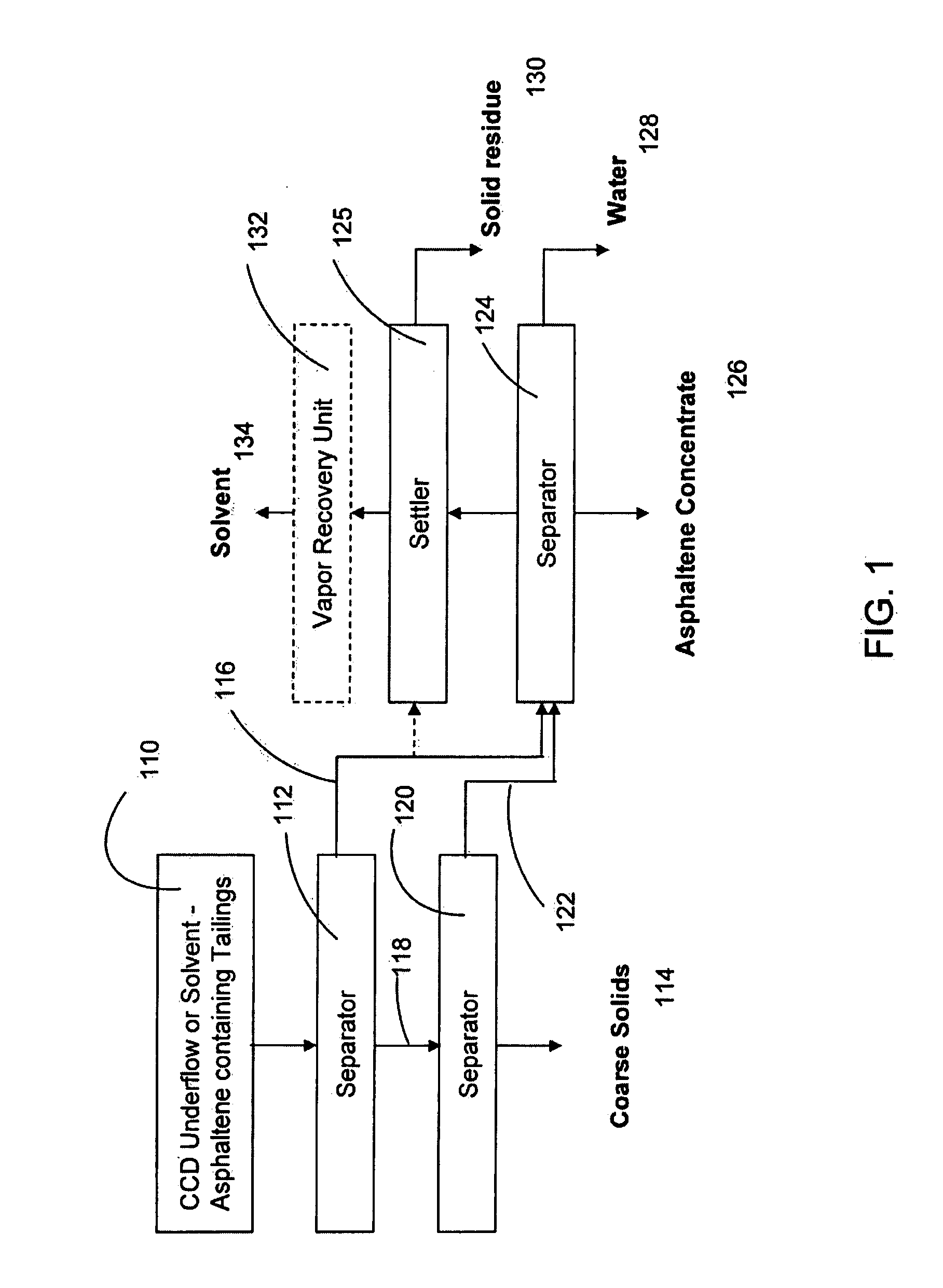

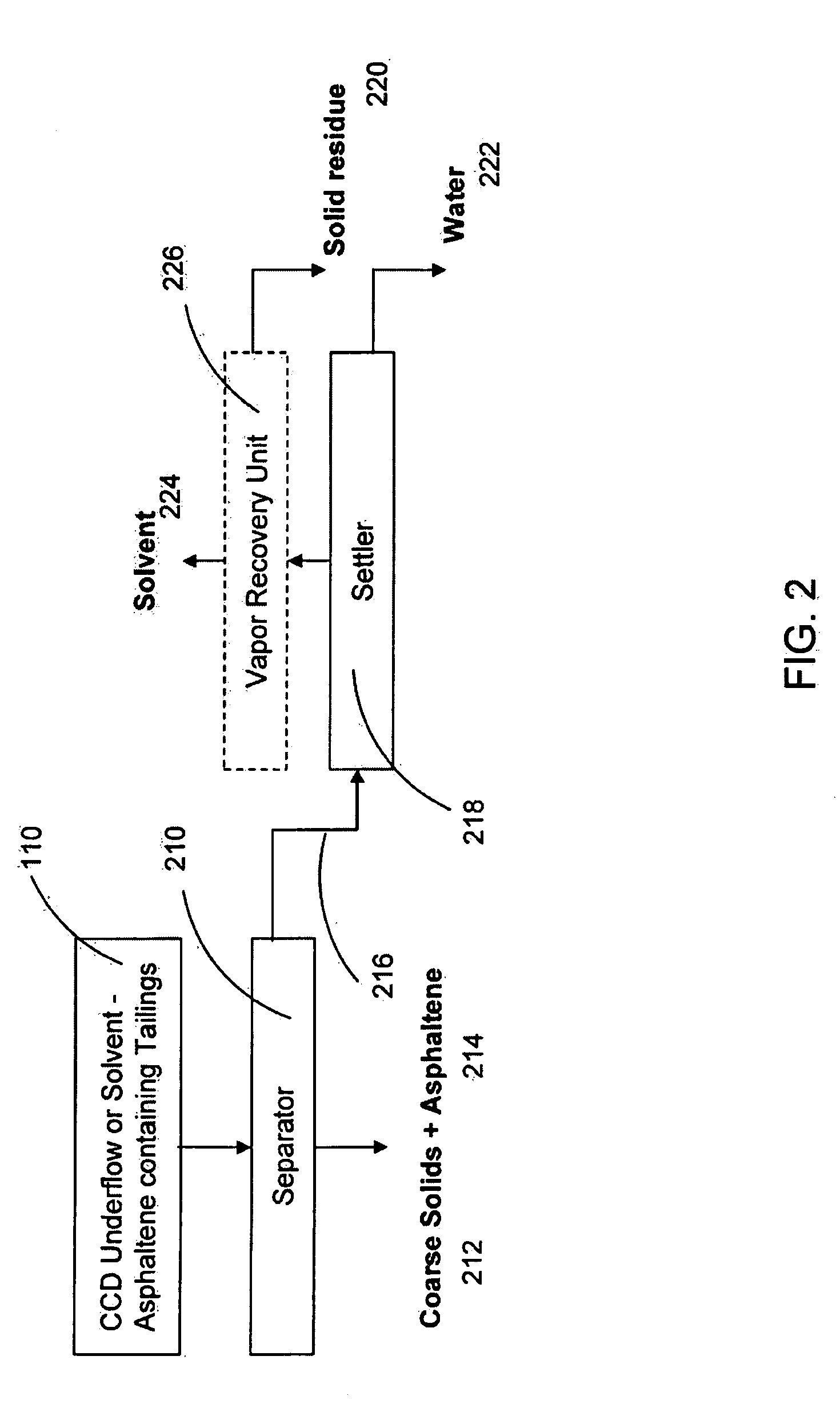

Separation of tailings that include asphaltenes

ActiveUS20080156702A1Easy and less energy intensiveSeparation easy and lessWorking-up pitch/asphalt/bitumenLiquid hydrocarbon mixture productionHydrocarbon solventsCyclonic separation

Various systems and methods are described that can be used as part of a process to separate bitumen from oil sands. The process may include adding a hydrocarbon solvent to a bitumen containing extract. The tailings from this process may contain a significant amount of solvent. The solvent may be recovered from the tailings with a tailings solvent recovery unit that utilizes negative pressure to significantly reduce the cost of the process in comparison to a conventional steam stripping unit. In one embodiment, the tailings may also separated prior to entering the tailings solvent recovery unit with a gravity separation apparatus or a cyclonic separation apparatus, such as a hydrocyclone.

Owner:CANADIAN NATURAL UPGRADING LTD +1

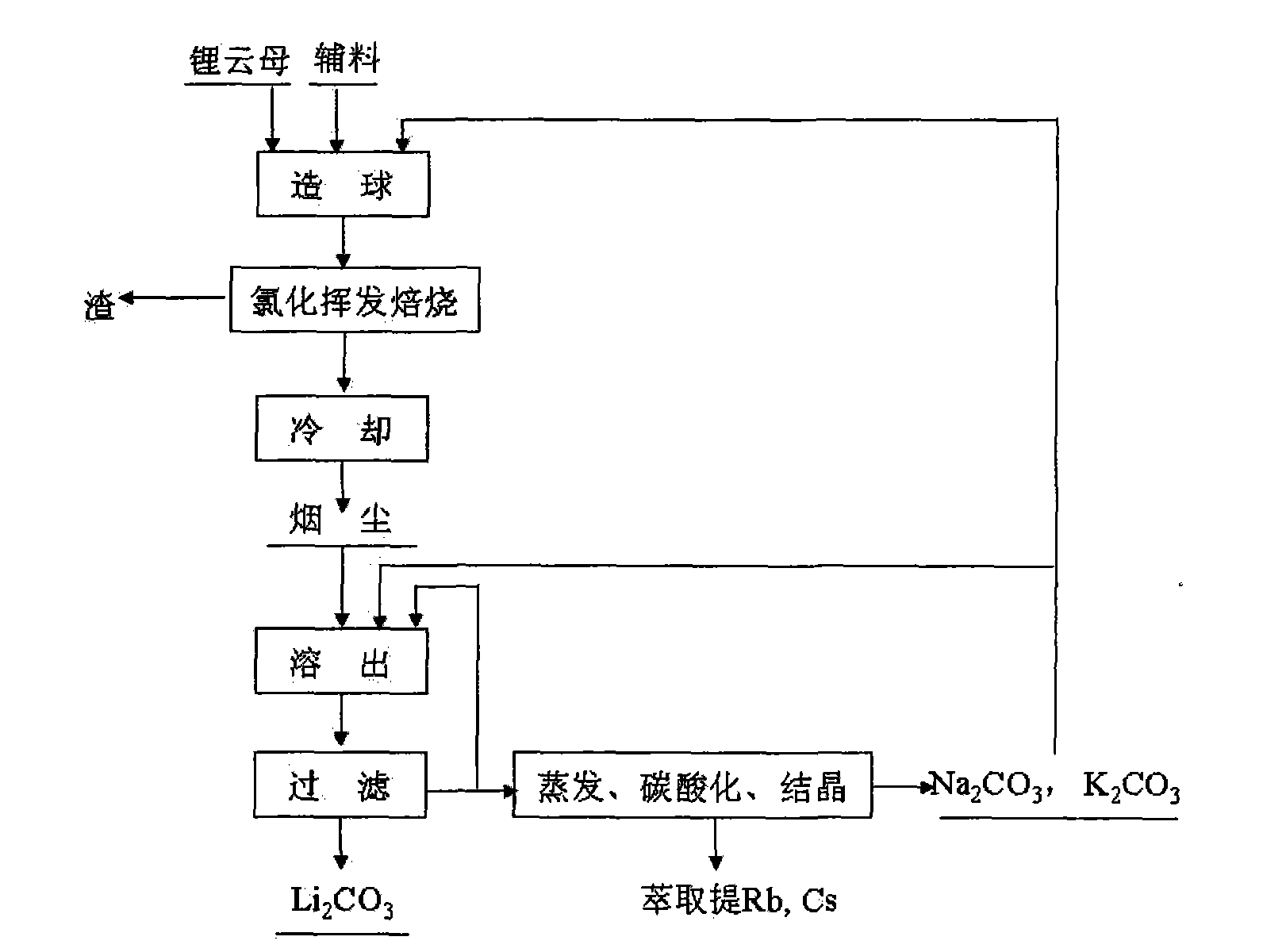

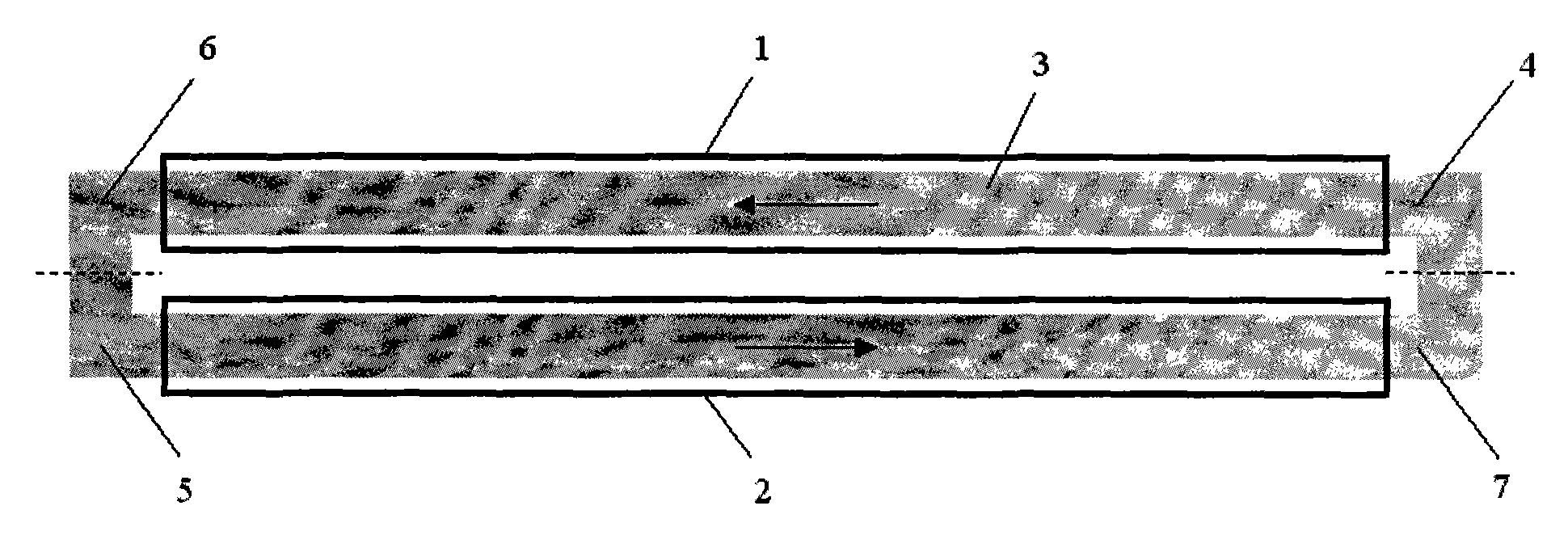

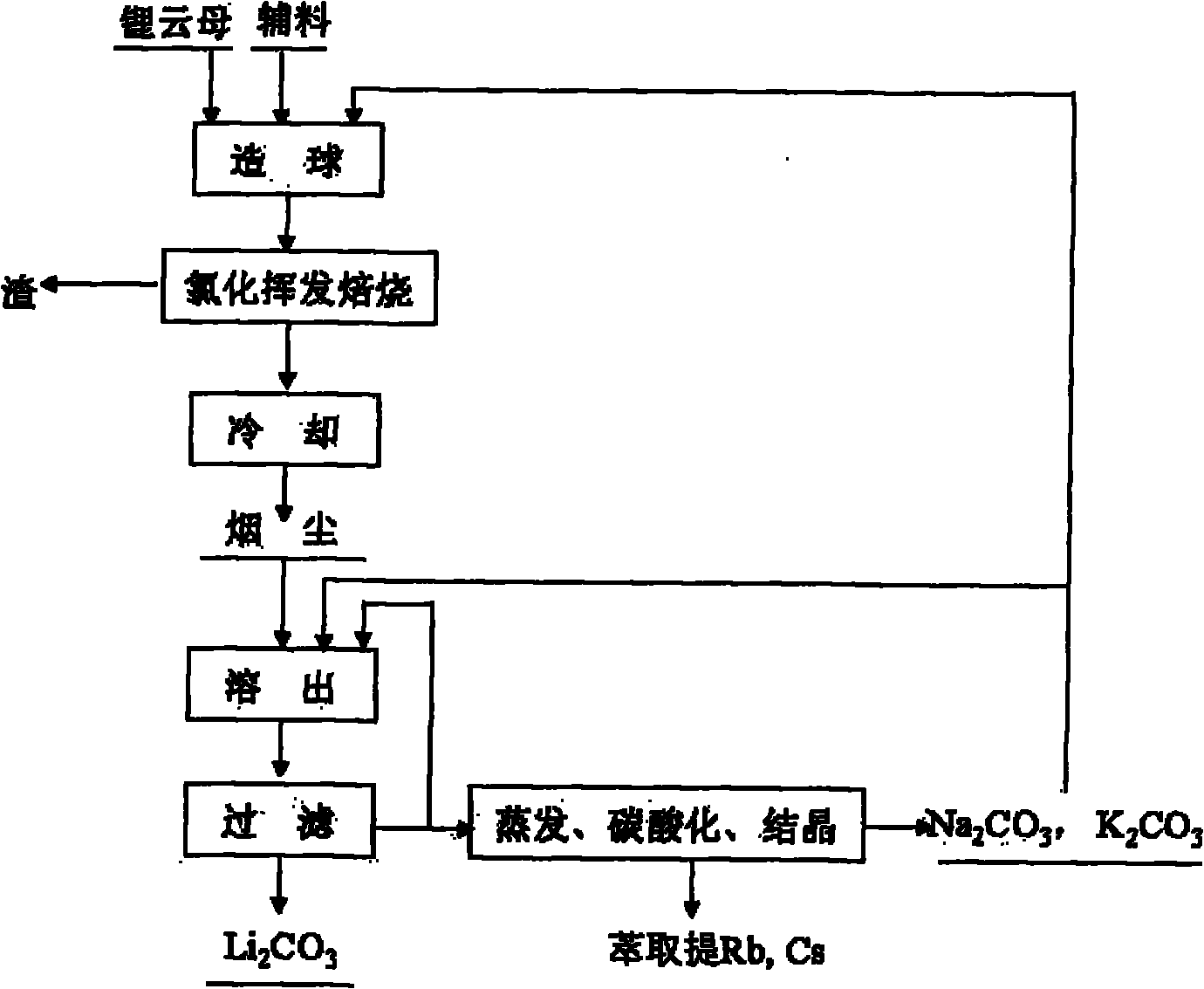

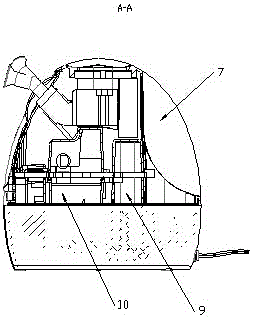

Method and device for extracting lithium from lapidolite by chloridizing roasting method

The invention discloses a method and a device for extracting lithium, which is used for preparing lithium carbonate, from a lapidolite ore by a chloridizing roasting method. The method comprises the following steps of: firstly, mixing the lapidolite ore, calcium chloride and sodium hydroxide with a compound bonding agent for pellet fabrication; secondly, performing chloridizing roasting in a square-frame shaped track type roasting furnace; thirdly, leaching out soot dust by using solution containing sodium carbonate and potassium carbonate to ensure that potassium, sodium, rubidium and cesium enter the solution and convert the lithium into lithium carbonate; fourthly, filtering the mixture to obtain a lithium carbonate solid, and circularly using the filtrated mother liquor to leach out the soot dust; fifthly, when an alkali metal salt is close to be saturated, indirectly heating the filtrated mother liquor by using the residual heat of the gas in the roasting furnace to evaporate part of water; sixthly, passing CO2 into the filtrated mother liquor to perform carbonation; and seventhly, performing cooling crystallization to separate out a mixed salt of the sodium carbonate and the potassium carbonate, returning part of the mixed salt which is used as an auxiliary material mixed and roasted with lapidolite for cyclic utilization, using another part of the mixed salt as a carbonate reagent needed in dissolution, and using the rest part of the mixed salt as byproducts of the sodium carbonate and the potassium carbonate. The method has the advantages of high lithium recovery rate, good material comprehensive utilization, large equipment productivity, high production efficiency, small water consumption in the process and less wastewater discharge.

Owner:CENT SOUTH UNIV

Method for removing or treating harmful biological and chemical substances within structures and enclosures

InactiveUS20090071062A1Efficient killingEfficient removalMechanical apparatusGas treatmentChemical compoundEngineering

A process for removing or treating harmful biological and chemical substances from an enclosure, such as a building or vehicle by using heated air. The method of the present invention is non-toxic and can be performed in a relatively short amount of time while effectively killing and removing a large proportion of dead organisms and substantially reducing volatile organic compounds.

Owner:THERMAPURE

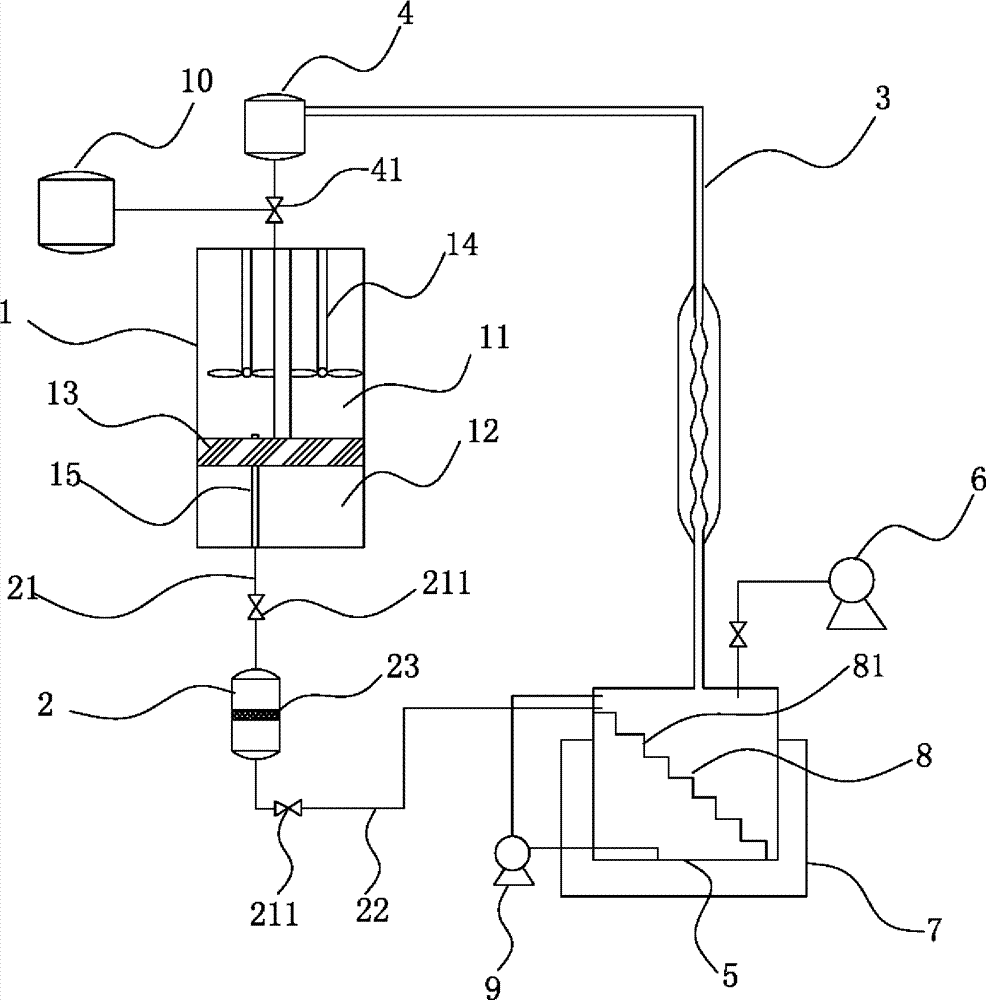

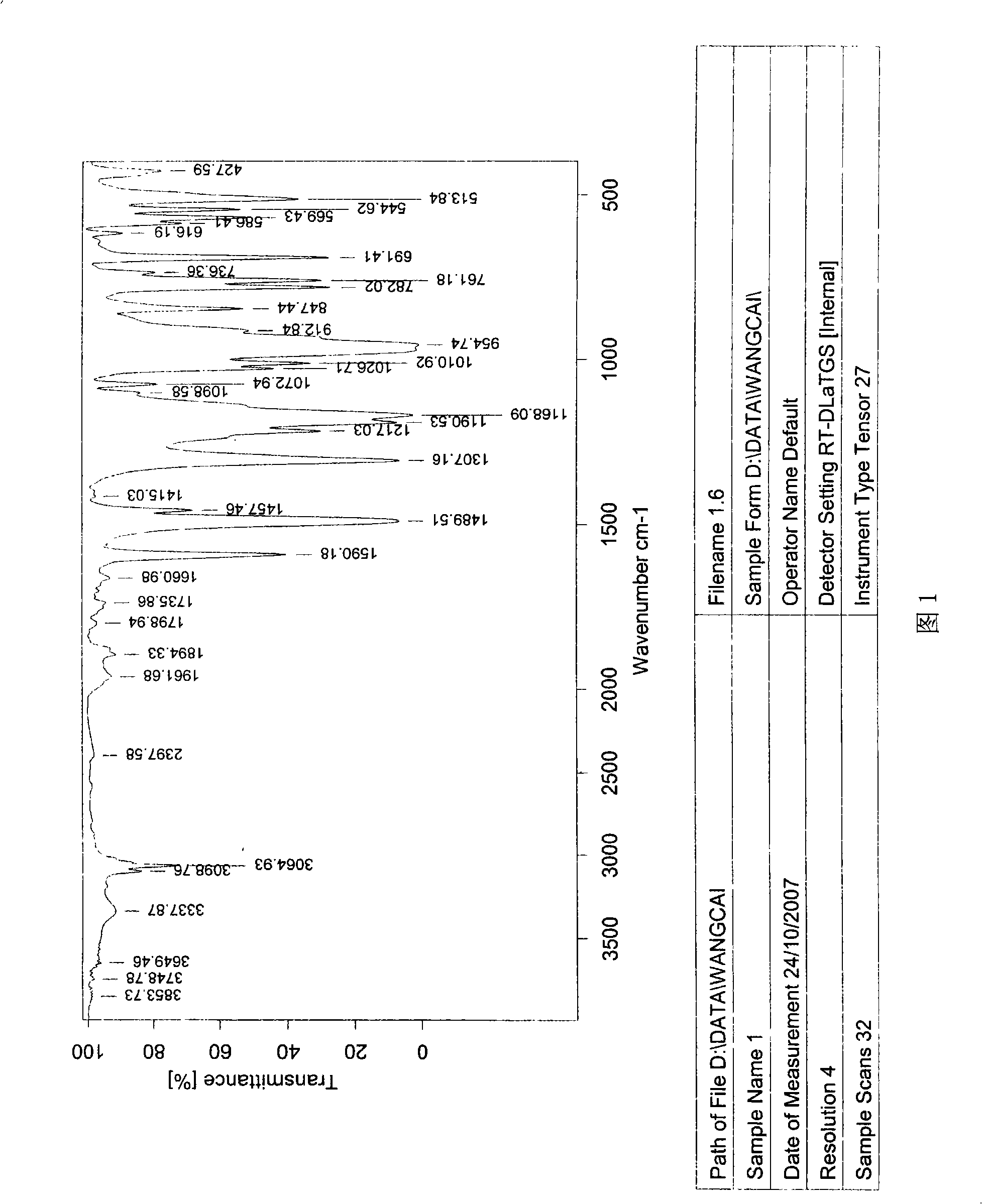

Device and method for extracting and concentrating traditional Chinese medicine

InactiveCN103041614AIncrease pressureIncrease the heat exchange areaEvaporationSolid solvent extractionPharmacy medicineProcess engineering

The invention relates to the technical field of extracting and concentrating of the traditional Chinese medicine, and in particular relates to a method and a device for extracting and concentrating the traditional Chinese medicine. The method for extracting and concentrating structurally comprises an extracting unit and a concentrating unit, wherein the extracting unit comprises an extracting tank and a liquid medicine storage tank, wherein a piston capable of moving up and down is arranged in the extracting tank; when the piston moves upwards under the action of the driving force, dredges of decoction in a pressurizing chamber are pressurized and further squeezed; the concentrating unit comprises a concentrating container, a vacuum pump and a heating device for heating up the concentrating container, wherein a step-shaped evaporation plate assembly of a liquid medicine thin film is formed in the concentrating container, so that the liquid medicine can be circulated and concentrated. Compared with the prior art, the extracting and concentrating efficiency is high, the heating time is short, and the damages to the active ingredients of the medicine are reduced.

Owner:GUANGDONG MEDICAL UNIV

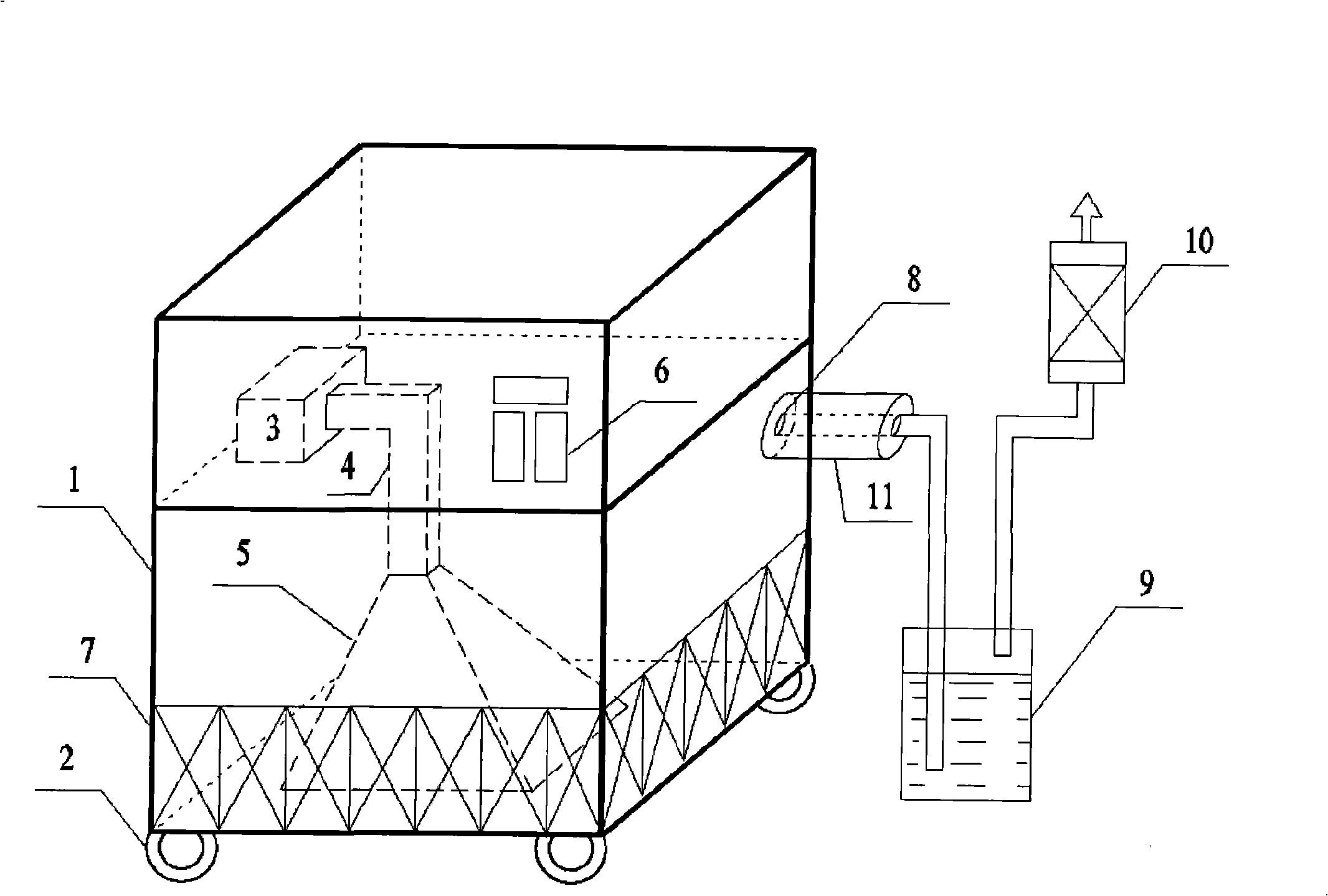

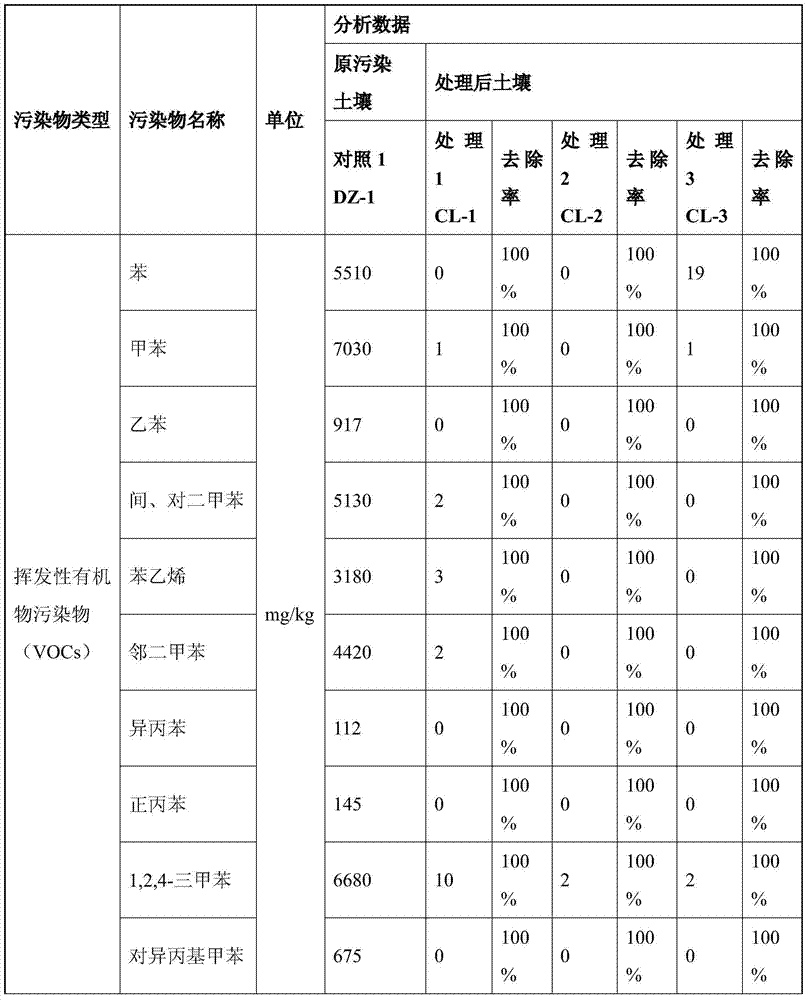

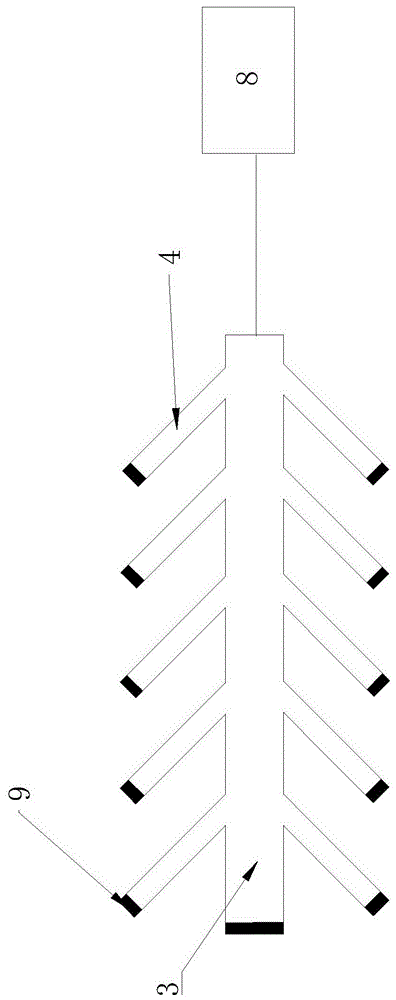

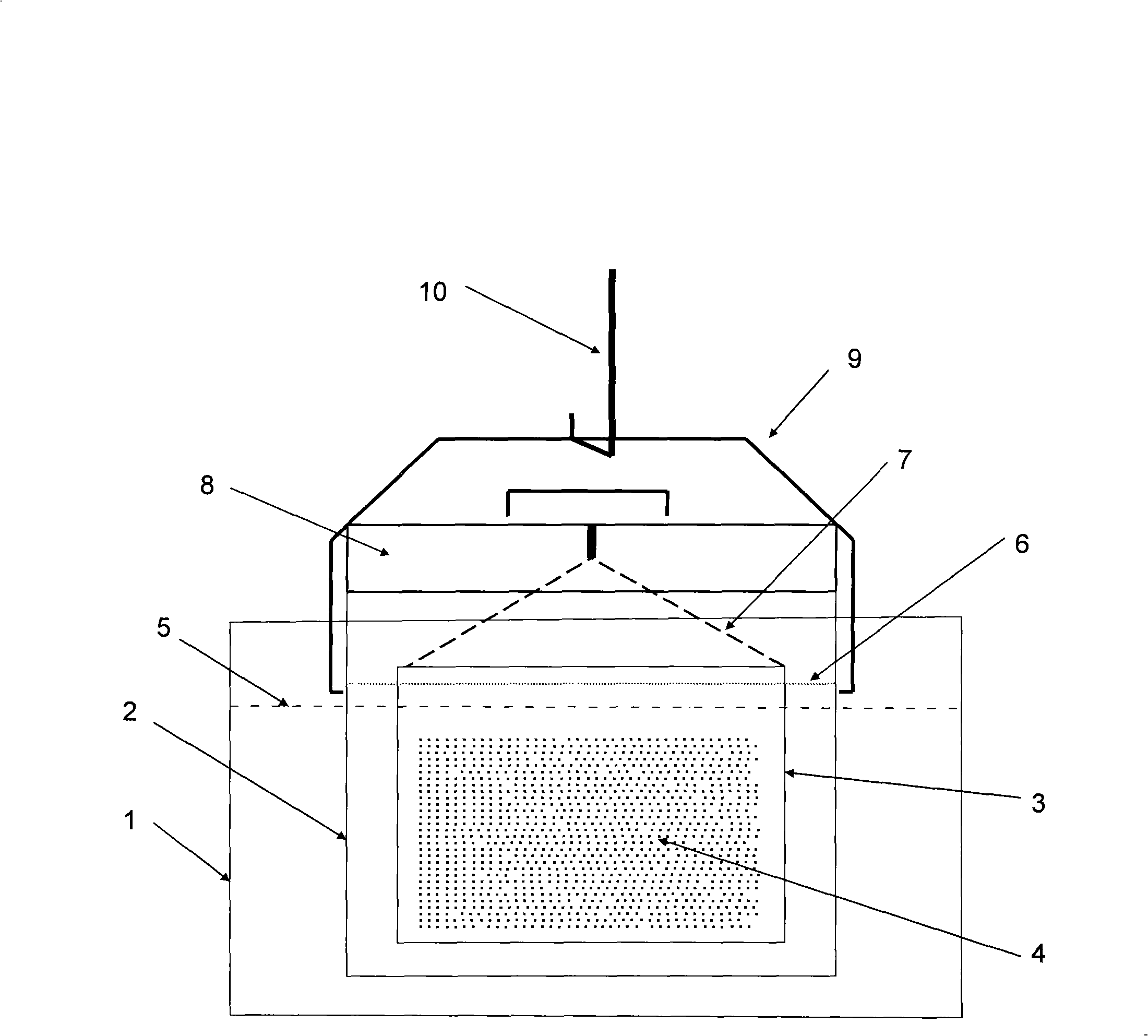

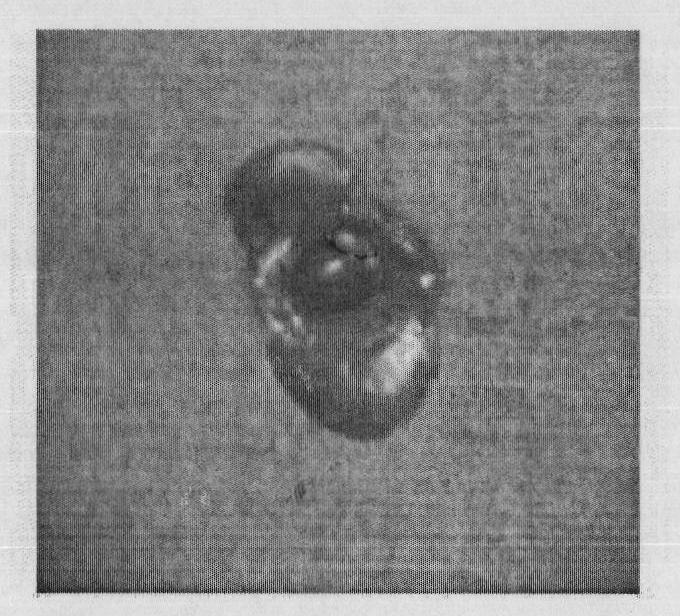

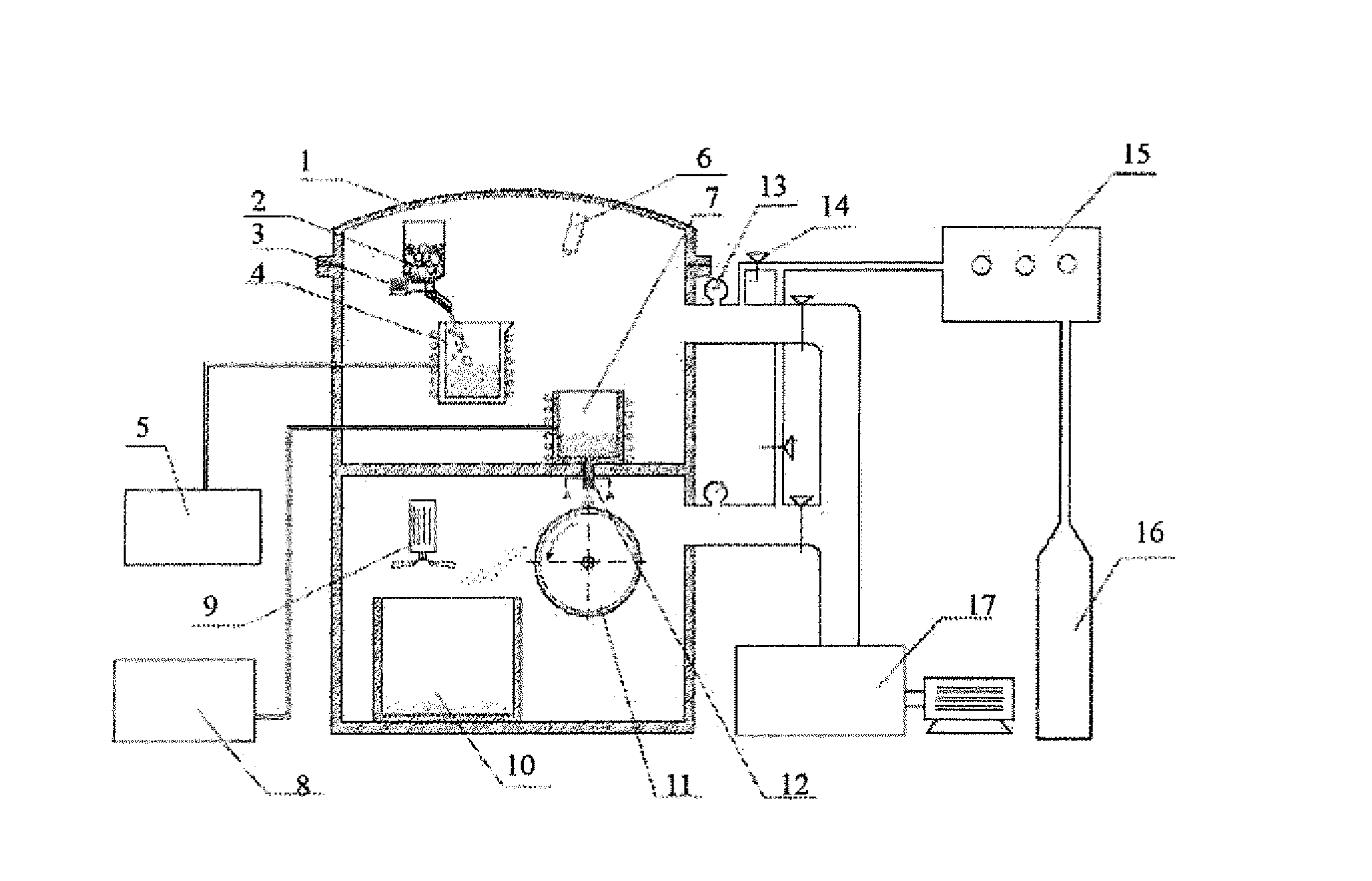

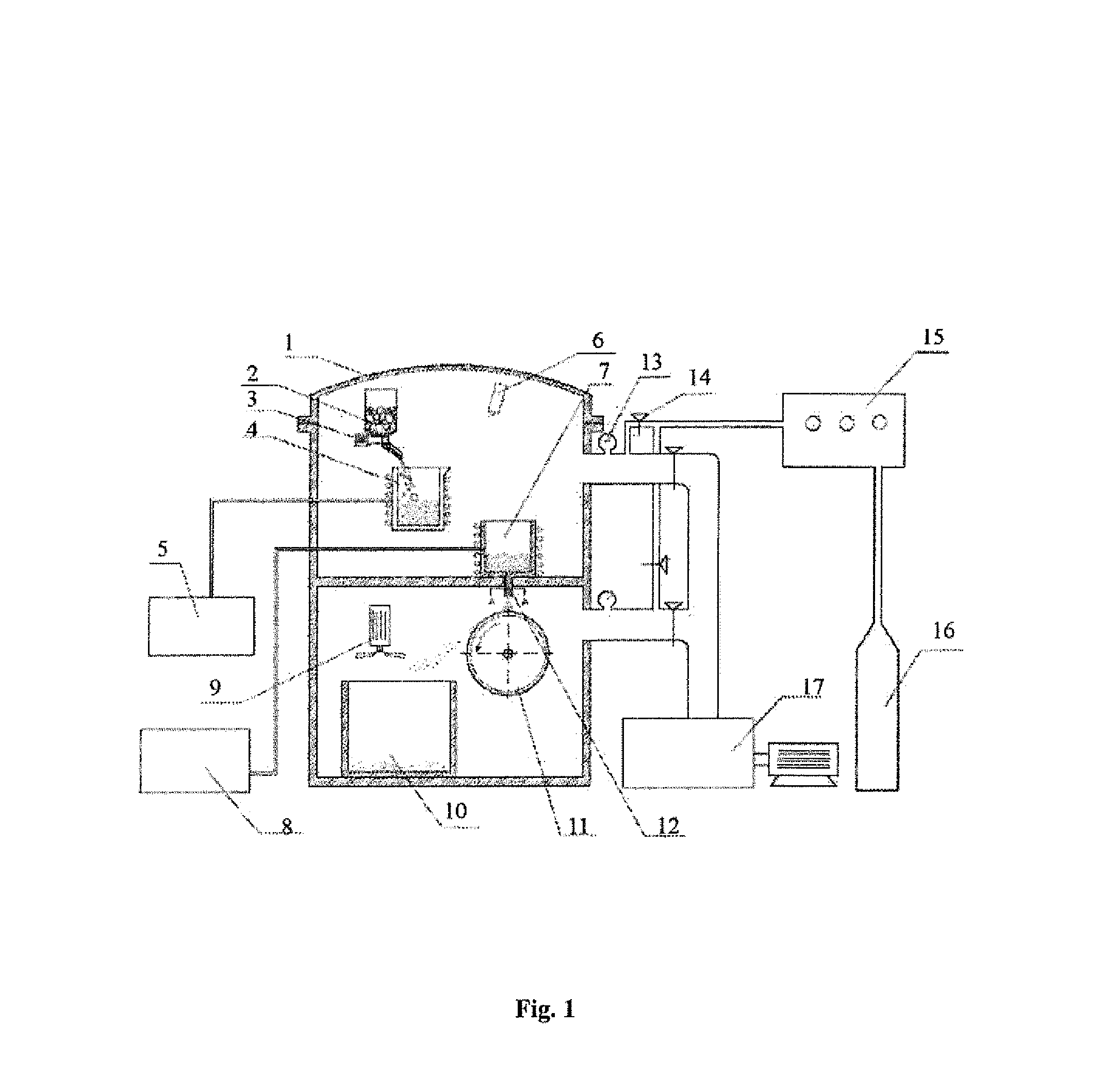

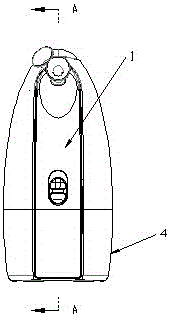

In situ microwave repairing method and apparatus of contaminated soil

InactiveCN101513643AGood for volatilizationPromote degradationContaminated soil reclamationMasersElectricityMicrowave

The invention belongs to the technical field of pollutant disposal in related soil for environmental protection, relating to an in situ microwave repairing method and apparatus of contaminated soil. In the invention, microwave is used as a heat source, different microwave absorbents are added to the soil according to the characteristics of pollutant and are mixed uniformly; the absorption and heat-transfer capabilities of contaminated soil system for the microwave are strengthened by using the effect between the microwave and the absorbents so that each pollutant in the soil is treated by three mechanism such as evaporation, decomposition or being fixed. The apparatus uses a moveable microwave case, the microwave generator is arranged inside the microwave case, the radiation port of a radiator is arranged at the opening of the case bottom and is connected with the microwave generator by wave guide, the case is provided with a controller electrically connected with the microwave generator, and the bottom of the case is provided with a microwave shield cover capable of being disassembled. The method has short processing time, flexible operation, strong universality and high efficiency, does not pollute the environment and brings new secondary pollution and is an efficient method for in situ repair of contaminated soil.

Owner:HUAZHONG UNIV OF SCI & TECH

Titanium alloying milling solution and milling technique used for the same

The present invention discloses a titanium alloy chemical milling solution and its application milling process, which mainly contains nitric acid and hydrofluoric acid as the main components of mixed acid acidic corrosion solution, sodium lauryl sulfate, ethylene glycol n-butyl ether and / or or urea additives. The surface tension of the solution is maintained at a stable value by using the present invention. The adsorption of ethylene glycol n-butyl ether can reduce the interfacial tension and increase the chemical milling rate. Sodium lauryl sulfate, which improves the fluidity of the solution, can eliminate excessive corrosion of the metal at the root of the chemical milling fillet, and prevent the appearance of "grooves", "slopes" and "ripples". Sodium nitrate prevents the formation of scale of alloying elements on the surface of the chemical milling groove, improves the surface finish of the chemical milling surface and facilitates maintenance of the equipment. Urea can effectively absorb the nitrogen-containing gas produced in the chemical milling process, reduce the volatilization of acid liquid, and avoid pollution to the environment. The invention does not need heating equipment, the amount of hydrogen added is less than 9ppm, the service life of the solution is long, hydrogen embrittlement does not occur, and the process has little influence on the fatigue performance of the material.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

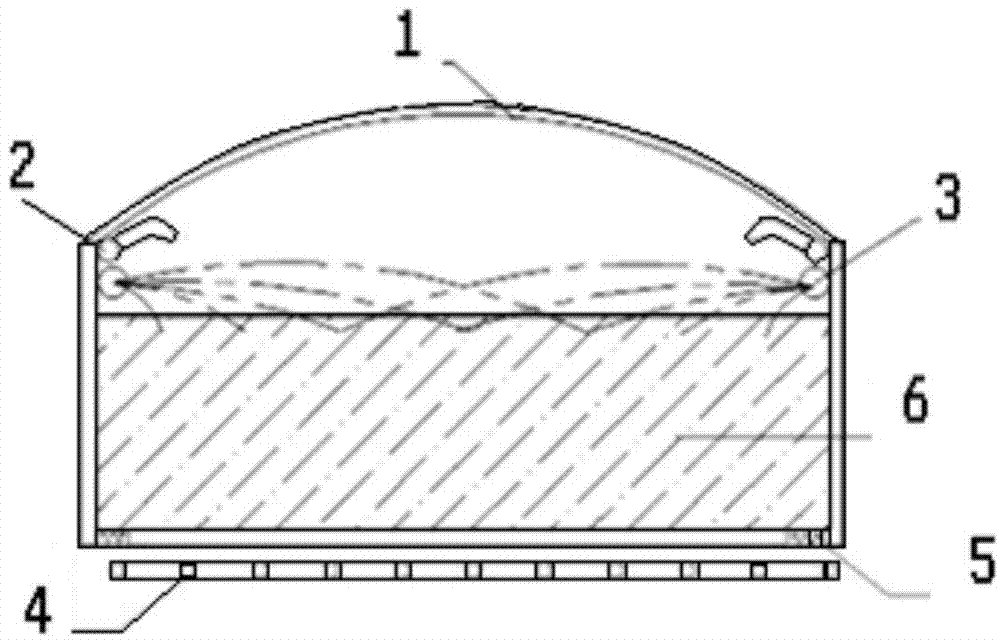

Organic-polluted soil restoration method

InactiveCN104759463APromote decompositionGood for volatilizationContaminated soil reclamationPollution soilGreenhouse

The invention relates to an organic-polluted soil restoration method. Excavated polluted soil is divided into two types of soil, the first type of the soil contains non-aqueous phase liquid and the second type of the soil does not contain non-aqueous phase liquid. The method comprises the following steps of carrying out crushing and screening on the polluted soil containing non-aqueous phase liquid by a crushing-screening combined device, simultaneously, carrying out flushing pre-treatment by a surfactant, uniformly spreading and stacking all the polluted soil subjected to crushing and screening in an enclosed greenhouse, heating the polluted soil to a temperature of 80-100 DEG C by a geothermal system at the lower part of the polluted soil, keeping the temperature of the heated polluted soil in a range of 80-100 DEG C for 2-4h, then spraying a first oxidizing agent to the polluted soil by a spraying system in the enclosed greenhouse, then carrying out heating treatment on the polluted soil to a temperature of 60-80 DEG C and keeping the temperature for 6-10h.

Owner:NANJING SREMOL ENVIRONMENTAL TECH

Method for improving stability of polypeptide active pharmaceutical ingredients

ActiveCN106188218AChange particle shapeChange moistureOxytocins/vasopressinsThymosin peptidesOxytocinBivalirudin

The invention discloses a method for improving the stability of polypeptide active pharmaceutical ingredients. The polypeptide active pharmaceutical ingredients comprise but are not limited to bivalirudin, octreotide acetate, lanreotide acetate, eptifibatide or cetrorelix acetate, ganirelix acetate, degarelix, liraglutide, oxytocin, thymosin alpha1, leuprolide acetate, goserelin acetate, terlipressin or linaclotide. The method comprises the steps that after polypeptide drugs are salified, a polypeptide solution containing compensation ions is obtained, and a target polypeptide product is prepared through an ultralow temperature vacuum freeze-drying method. According to the method for improving the stability of the polypeptide active pharmaceutical ingredients, the problem that the polypeptide active pharmaceutical ingredients are prone to degradation after being placed for a long time is solved, the uniformity of the product is improved, and the drug risk is reduced.

Owner:SINOPEP ALLSINO BIOPHARMACEUTICAL CO LTD

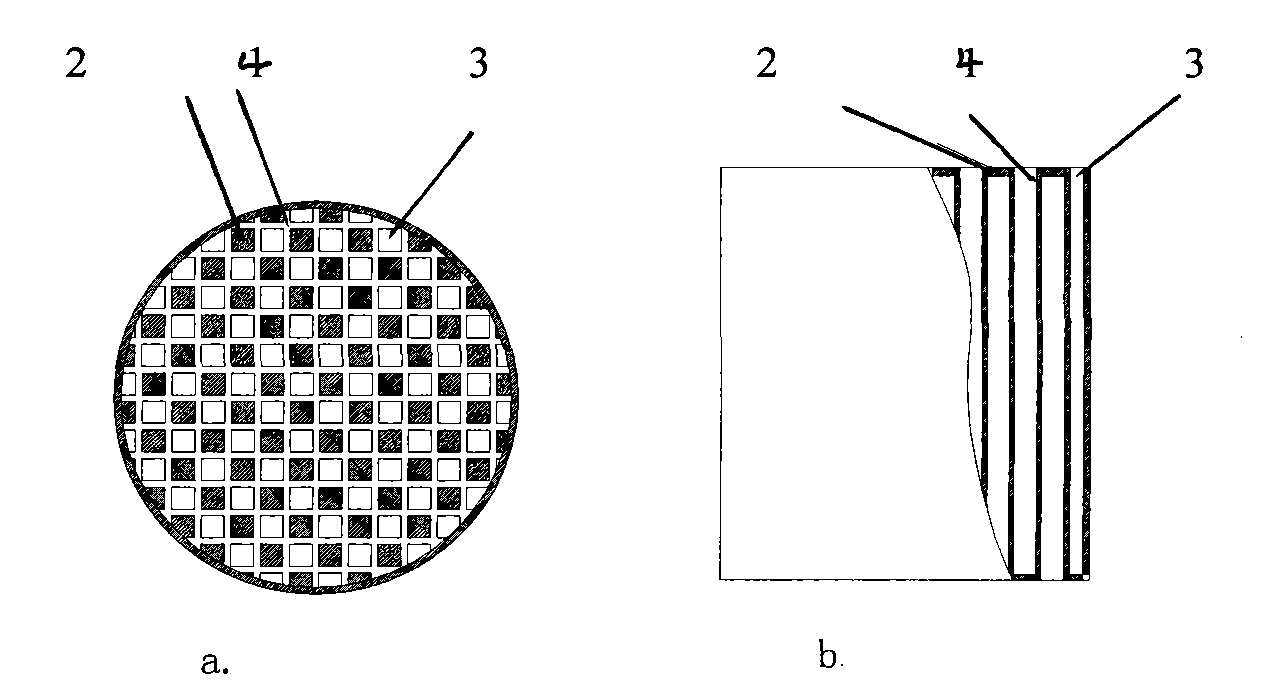

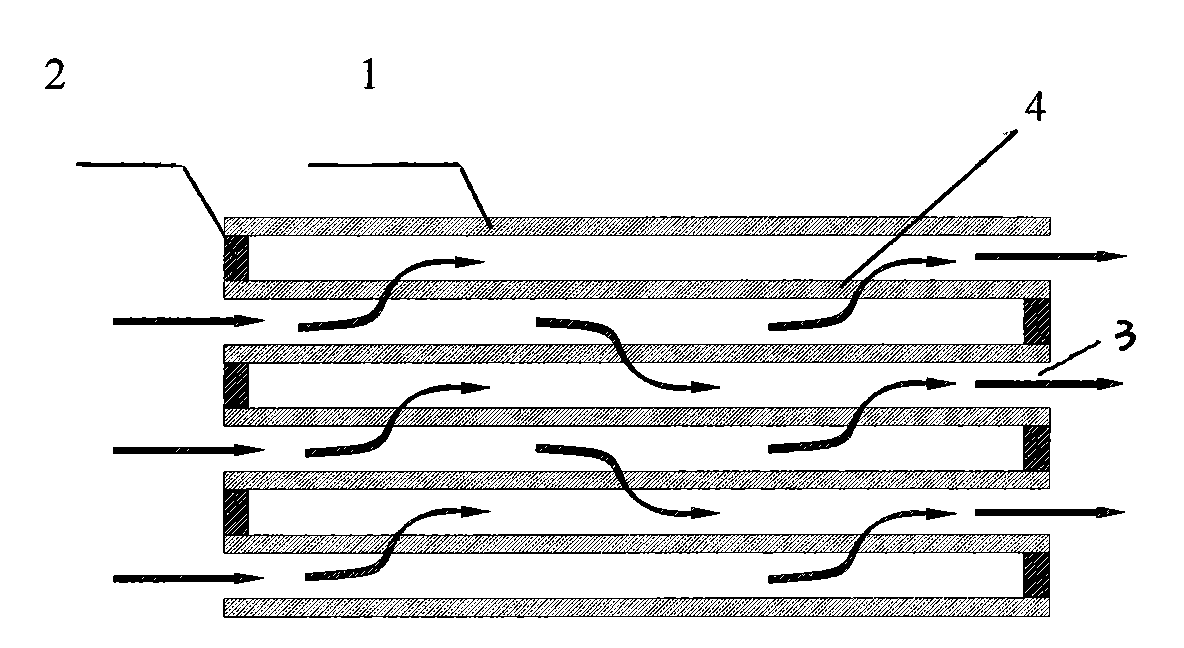

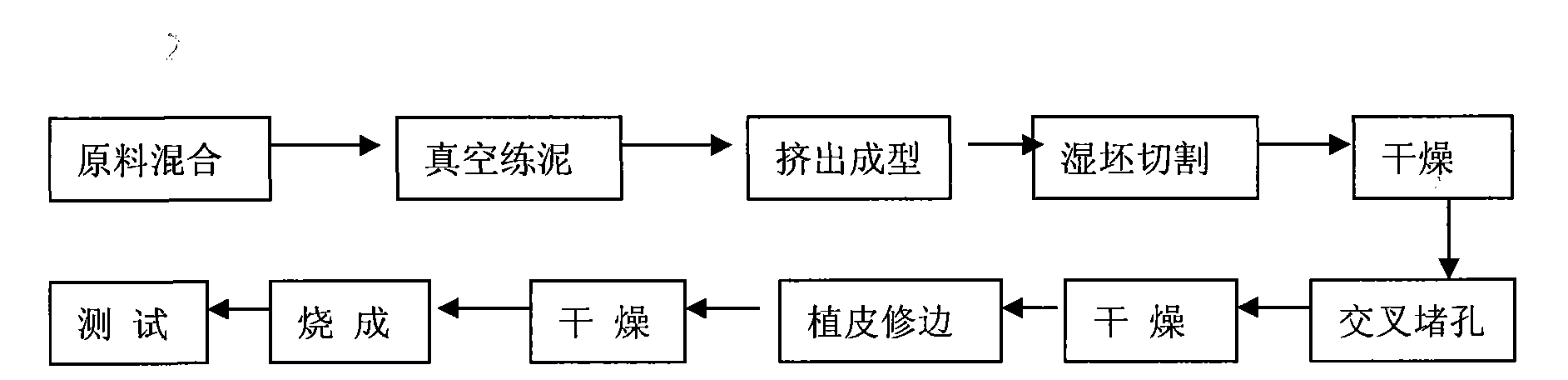

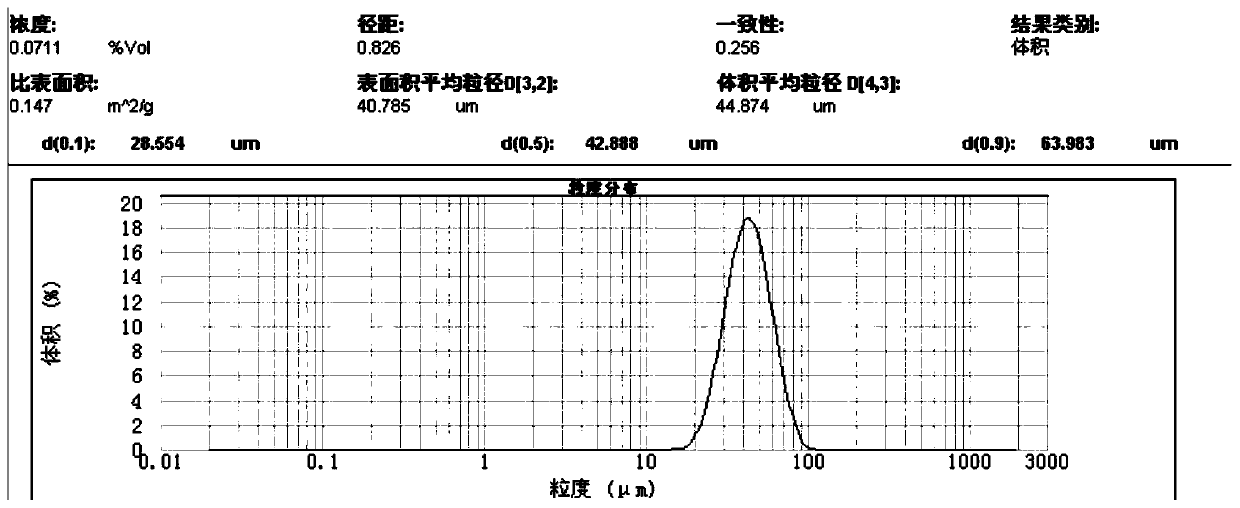

Method for preparing wall-flow honeycomb ceramic filter

InactiveCN101612499ALarge apertureEffective in filtering black smokeExhaust apparatusSilencing apparatusSkin graftingMicrowave

The invention relates to a method for preparing a wall-flow honeycomb ceramic filter, which combines a cordierite honeycomb ceramics material and a special pore-forming agent. Raw materials comprise the following components, mass portions and grain diameters: kaolin is 35 to 45 portions, and the average grain diameter is less than or equal to 5 mu m; talcum is 20 to 30 portions, and the average grain diameter is 15 mu m; alpha-alumina is 4 to 9 portions, and the average grain diameter is less than or equal to 2 mu m; the pore-forming agent consisting of carbon granules or / and organic polymeric particles is 5 to 15 portions, and the average grain diameter is 10 to 20 mu m; and a bonding agent is 3 to 7 portions. The method comprises the following steps: evenly mixing the components and 20 to 30 portions of water to prepare a blank; completing the conversion from the blank to plastic mud after performing vacuum degassing for 2 to 3 times; staling the plastic mud for 24+ / -8 hours, and squeezing out the plastic mud through a mould of an extruder; performing microwave drying on the plastic mud to obtain a dry blank; and performing cross hole blocking, drying, skin grafting and trimming on the dry blank, and finally performing a sintering working procedure to manufacture a product.

Owner:JIANGSU GAOCHUN CERAMICS +1

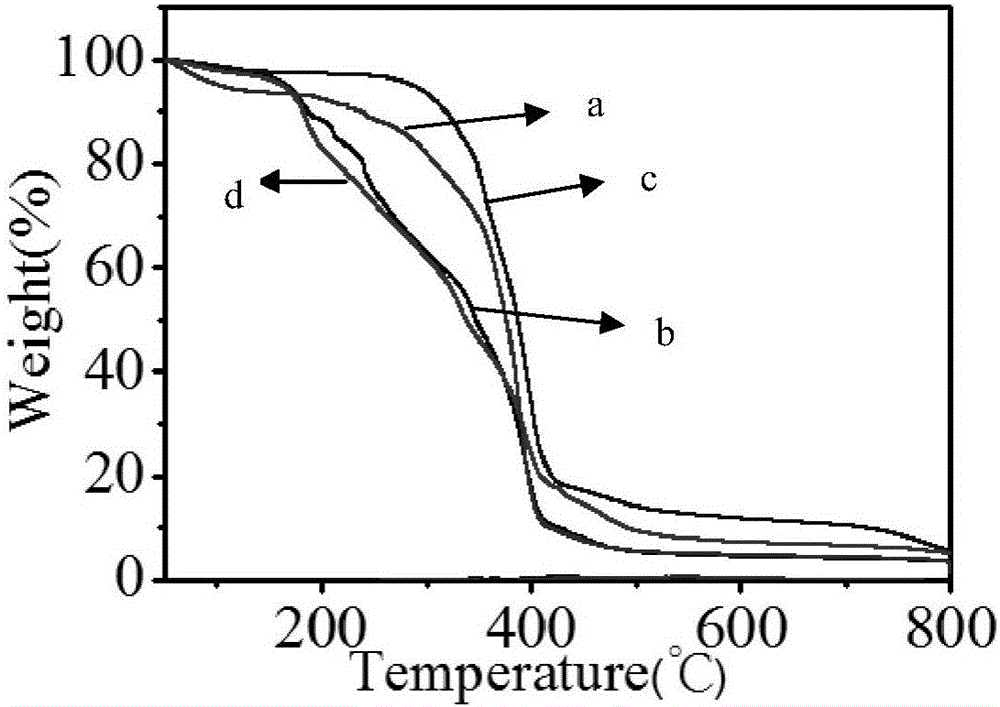

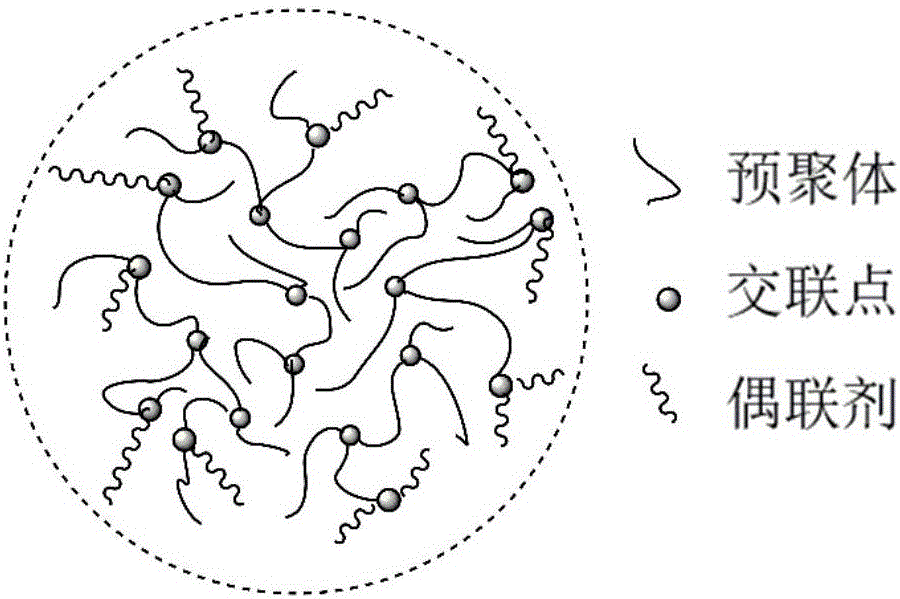

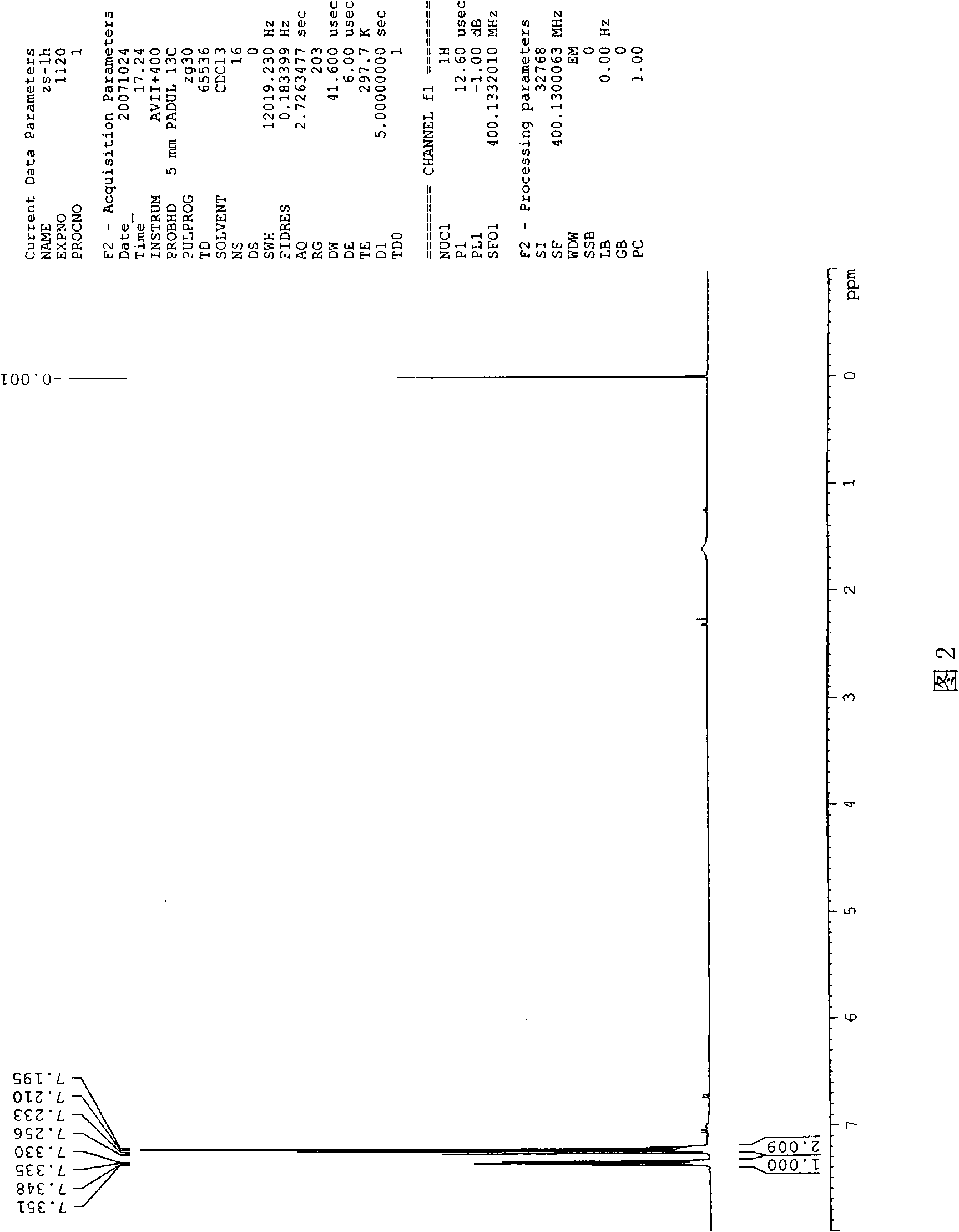

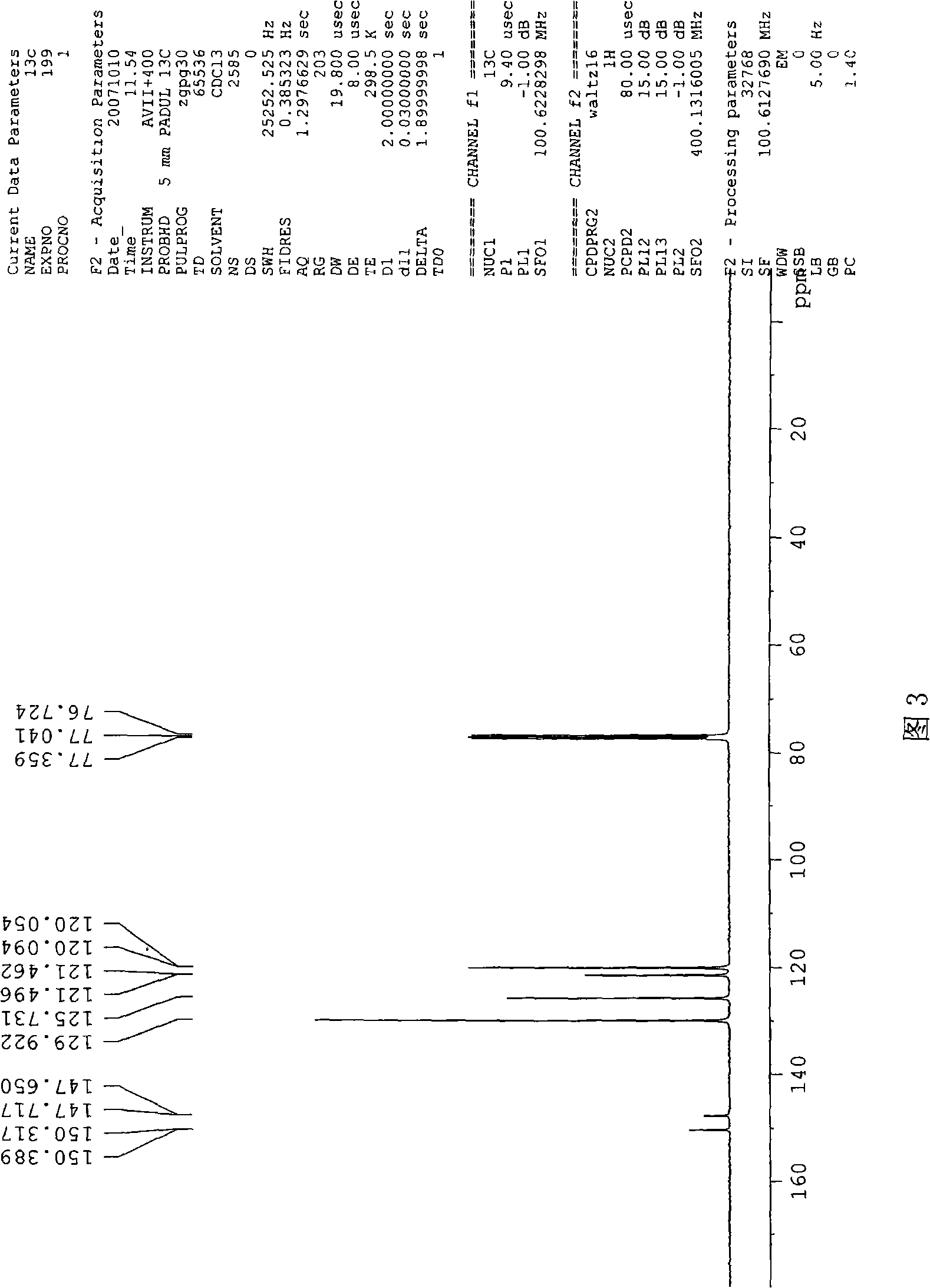

Phosphorus-containing network structure flame retardant

The invention relates to a network structure flame retardant. A phosphorus-containing macromolecular network structure flame retardant is developed aiming at the defects that the existing small-molecule flame retardant is easy to volatilize and emigrate, polymer flame retardants are less in types and the application field is limited. The preparation method comprises the following steps: preparing linear prepolymers, namely changing reaction conditions so as to obtain the linear prepolymers of different polymerization degrees; adding trifunctional cross-linked components so as to obtain a macromolecular flame retardant of different network structures; and finally, obtaining the final product through functional group end capping. According to the product, the problems of volatilization and transfer of the small-molecule flame retardant is improved, and the thermal decomposition behavior of the flame retardant can be regulated by changing the structure and reaction degree, so that products suitable for different polymer matrixes can be obtained. The raw materials used in the invention are wide in source and low in price, the polymerization process is mild in conditions and easy to produce, and the flame retardant is controllable in structure and can be independently taken as an intumescent flame retardant or serve as a charring agent or can be compounded with other flame retardants.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

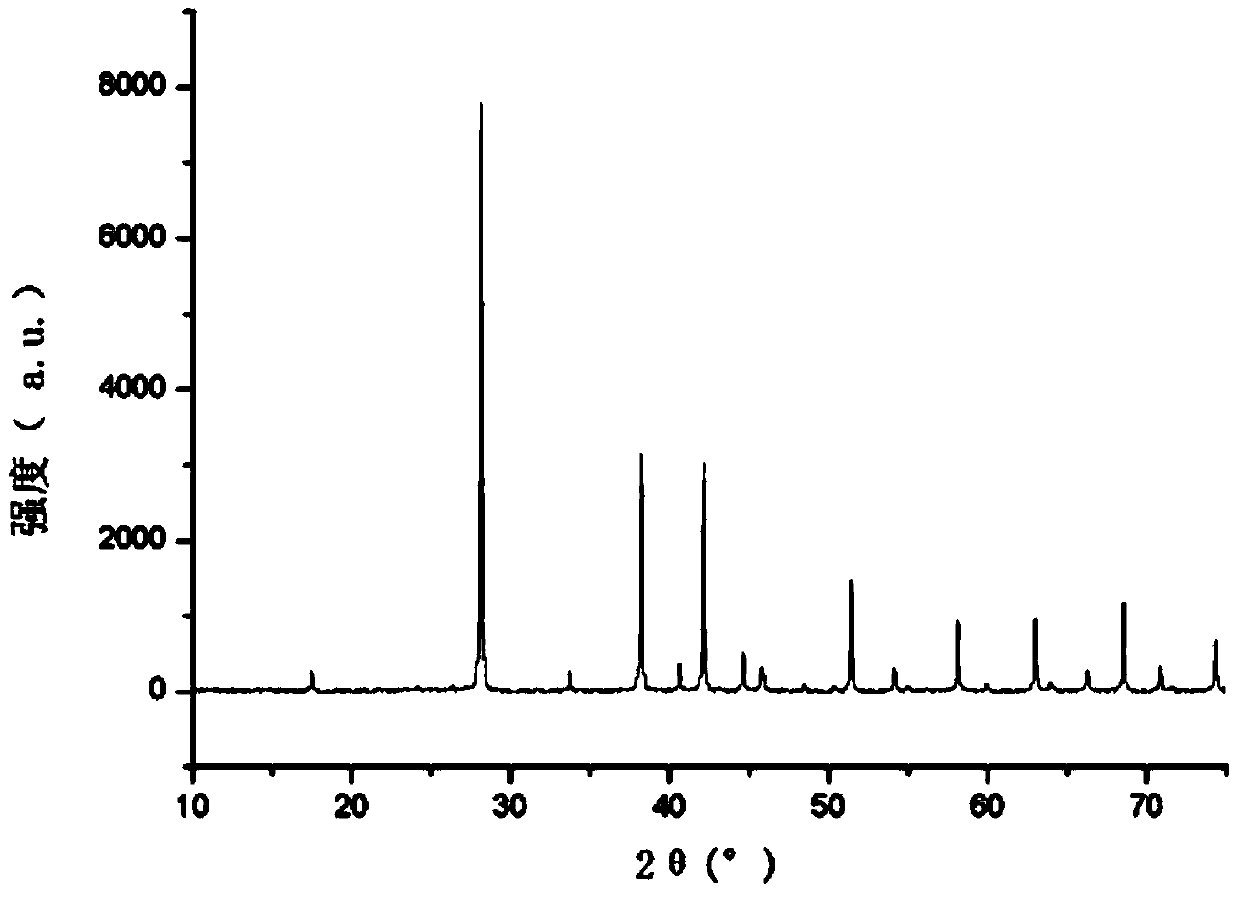

Combustion synthesis method of sub-micron titanium carbide nitride powder

InactiveCN1699284AHigh puritySmall granularityNitrogen compoundsTitanium compoundsSynthesis methodsAcid washing

Disclosed is a combustion synthesis method of sub-micron titanium carbide nitride powder which comprises proportioning base raw material and thinning agent, the base material includes titanium oxide 55-62%, magnesite powder 20-40%, carbon black 0-20%, the thinning agent is carbon azotized titanium powder, the weight of the thinning agent is 0-2.3 times of the base raw material. The preparation process comprises high temperature drying, ball grinding, mixing homogeneously, cooling down with circulating water, reacting at the presence of nitrogen, cooling down and acid-washing, water scrubbing, filtering and drying to obtain the end product.

Owner:HARBIN INST OF TECH

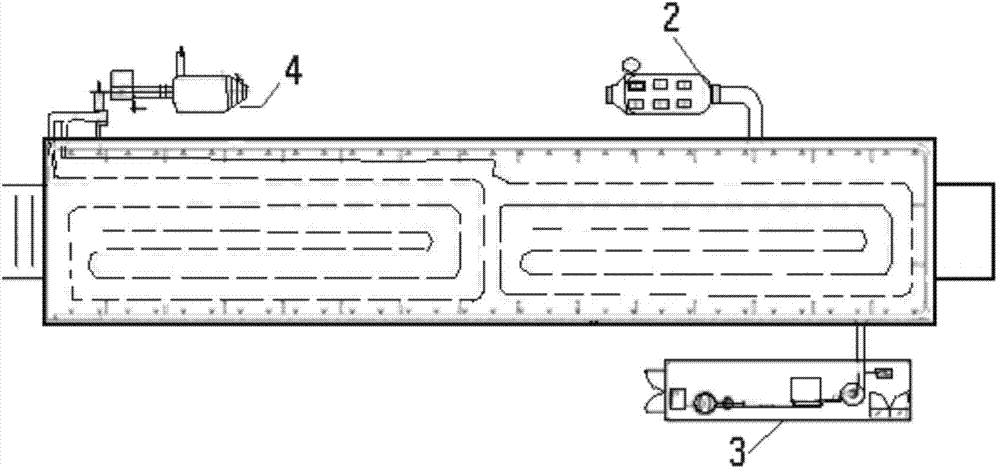

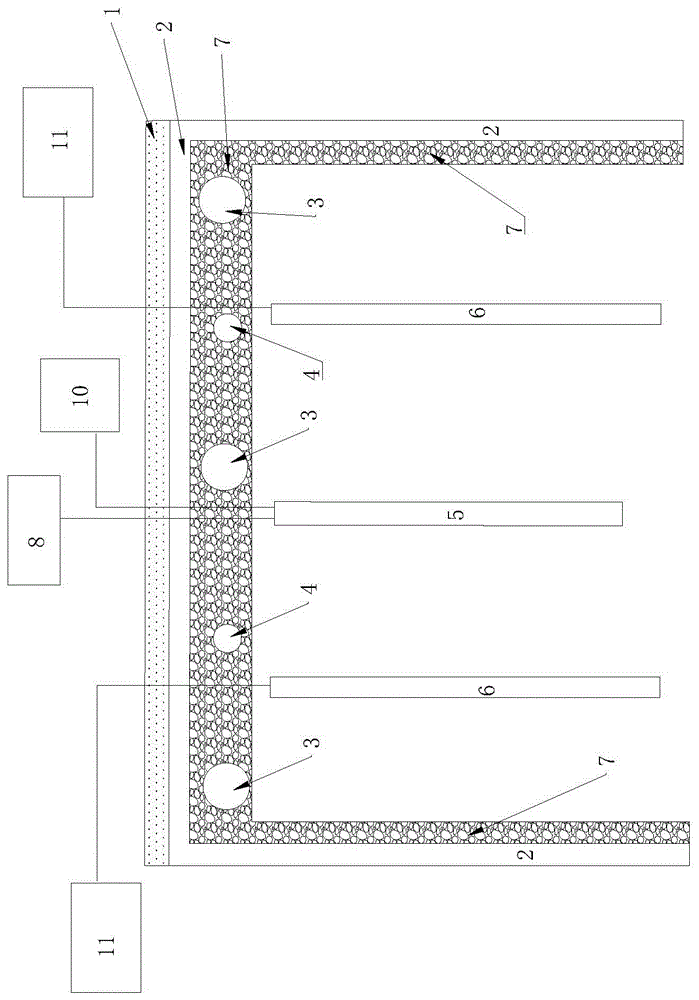

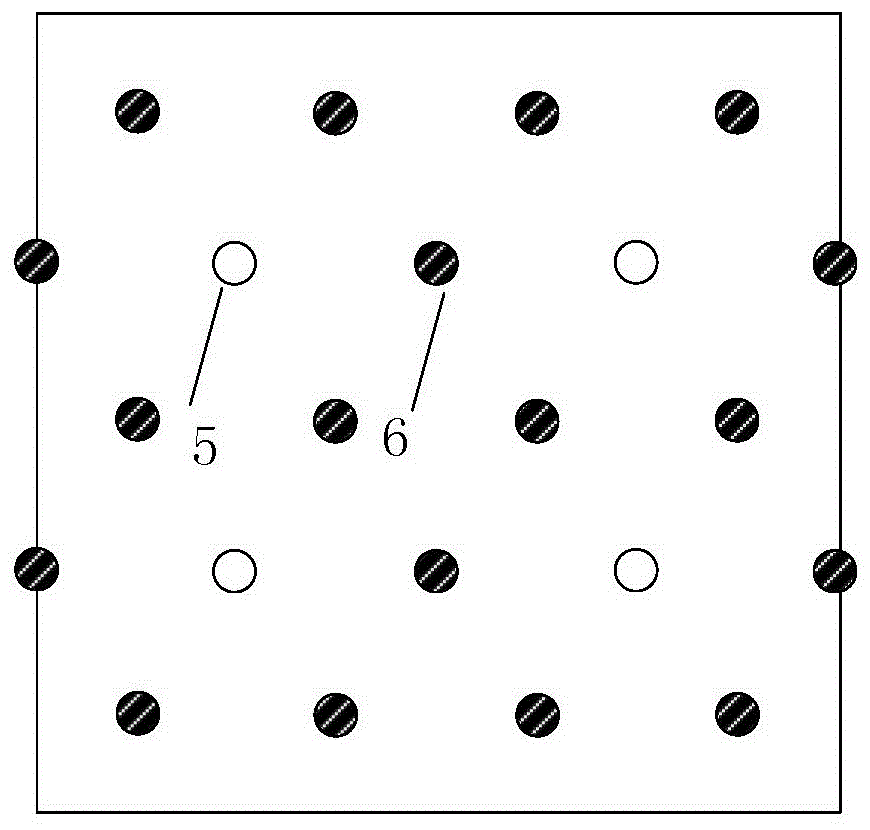

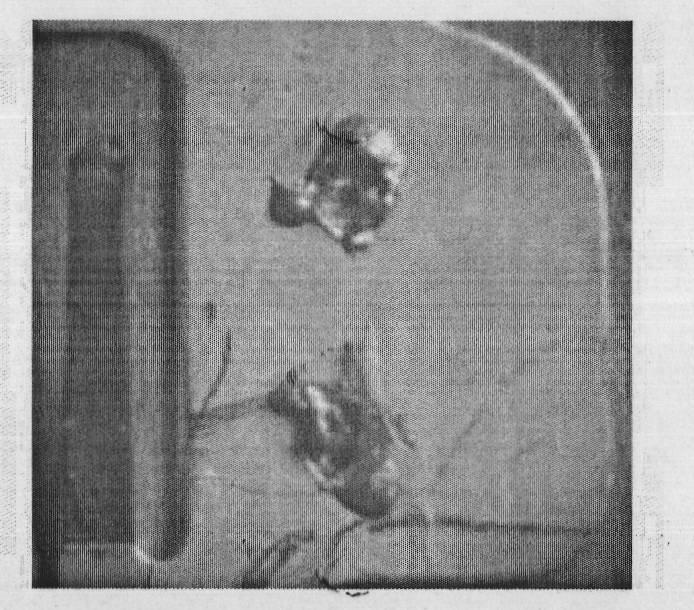

Organic contaminated site reinforced repair system and process

PendingCN106734167AFacilitated DiffusionGood for volatilizationContaminated soil reclamationSulfate radicalsCompound (substance)

The invention discloses an organic contaminated site reinforced repair system which comprises an extraction system, a medicament injection system, a heating system and a blocking repair layer. According to the organic contaminated site reinforced repair system, the in-situ thermal desorption technology and the chemical oxidization technology are combined, meanwhile, a repair material layer is added, the repair material layer is prepared from slow release oxidization materials and mainly prepared from persulfate, natural clay materials, nonmetallic mineral, cement and the like, and sulfate radical produced after persulphate reaction can be fixed. By means of the repair system, on one hand, the organic contaminated site in-situ thermal desorption repair cost can be reduced; on the other hand, the in-situ chemical oxidation repair efficiency can be improved, secondary pollution can be reduced, accordingly, the repair cost is reduced, and the repair efficiency is improved.

Owner:BEIJING GEOENVIRON ENG & TECH

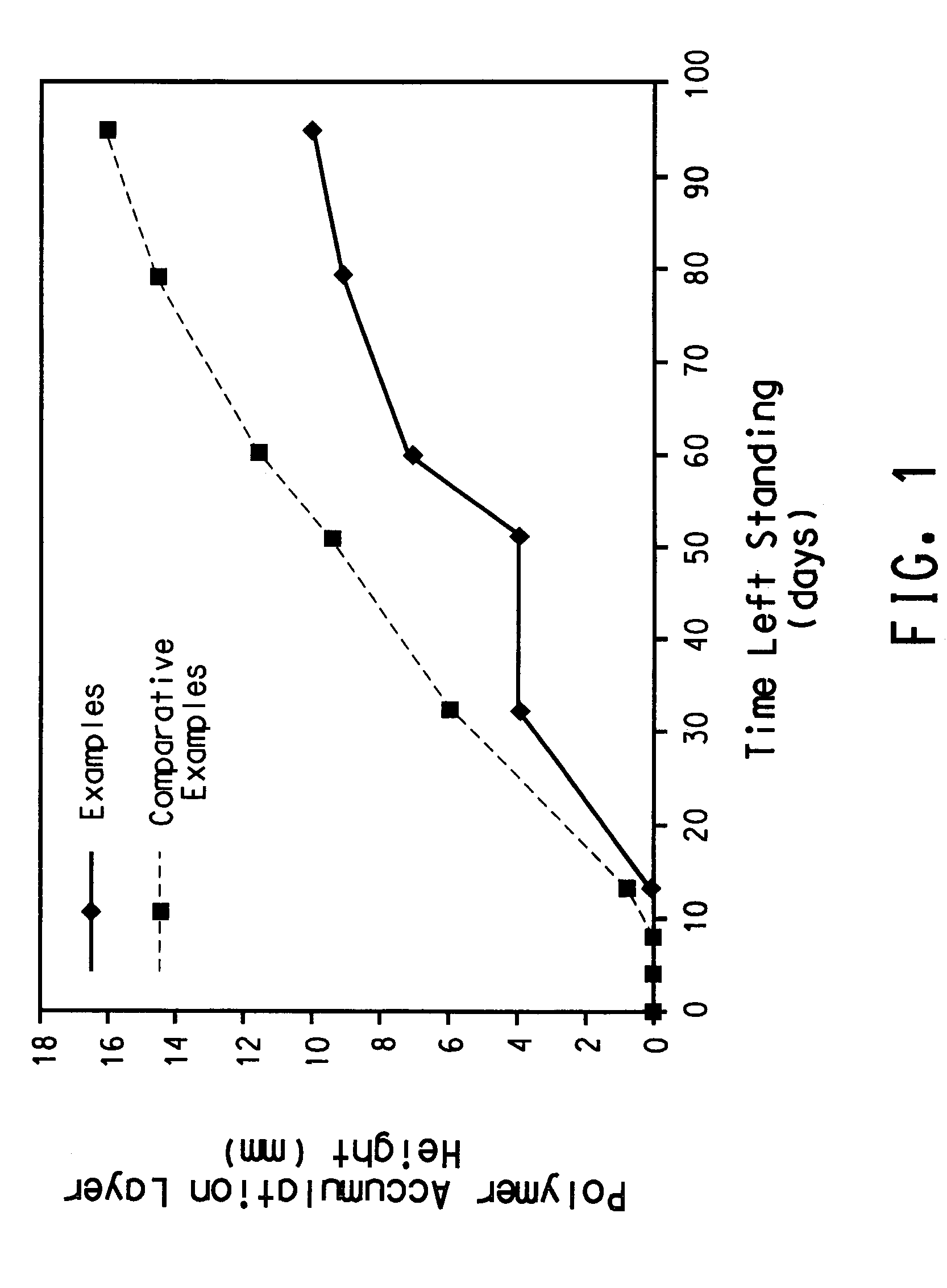

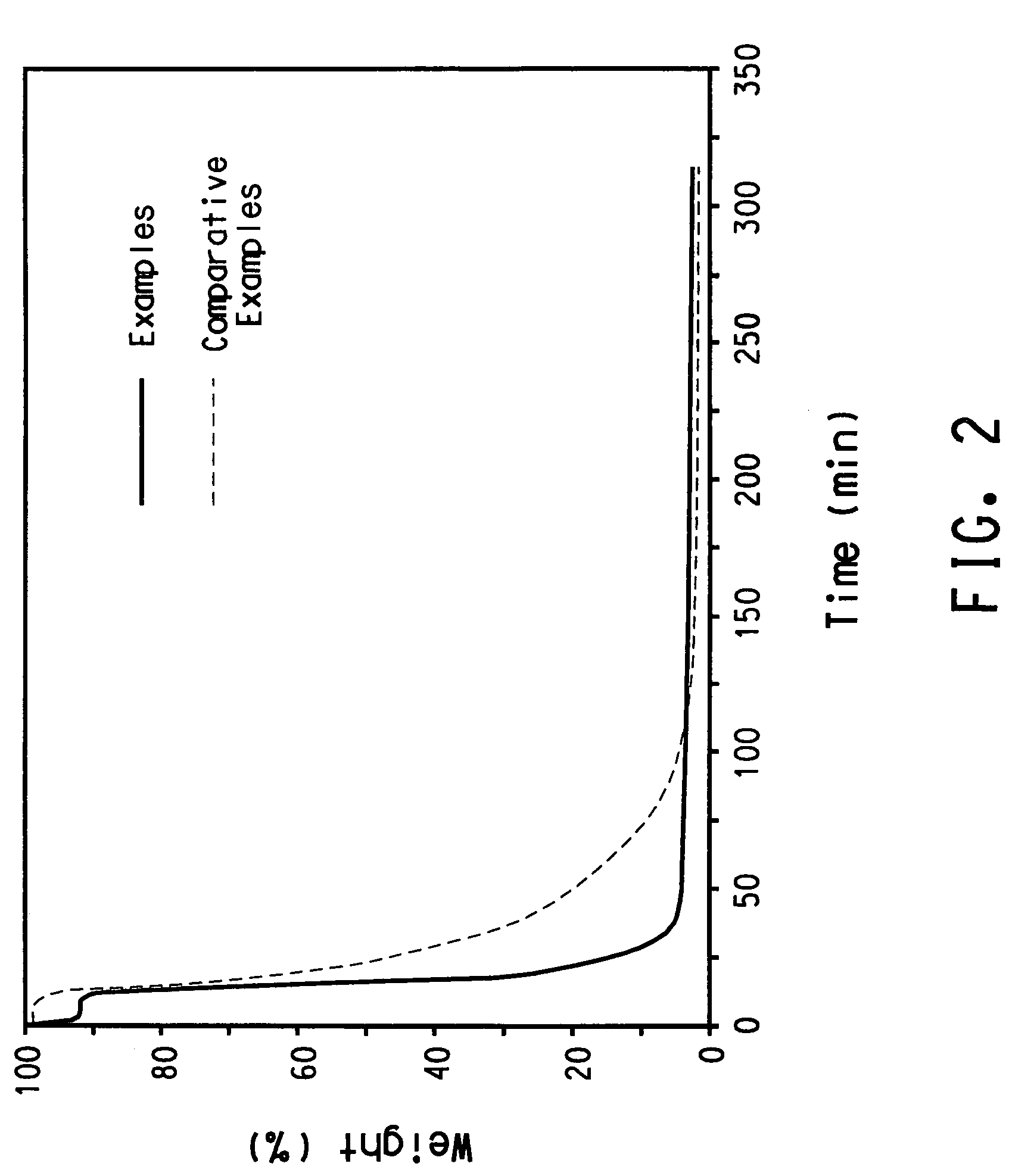

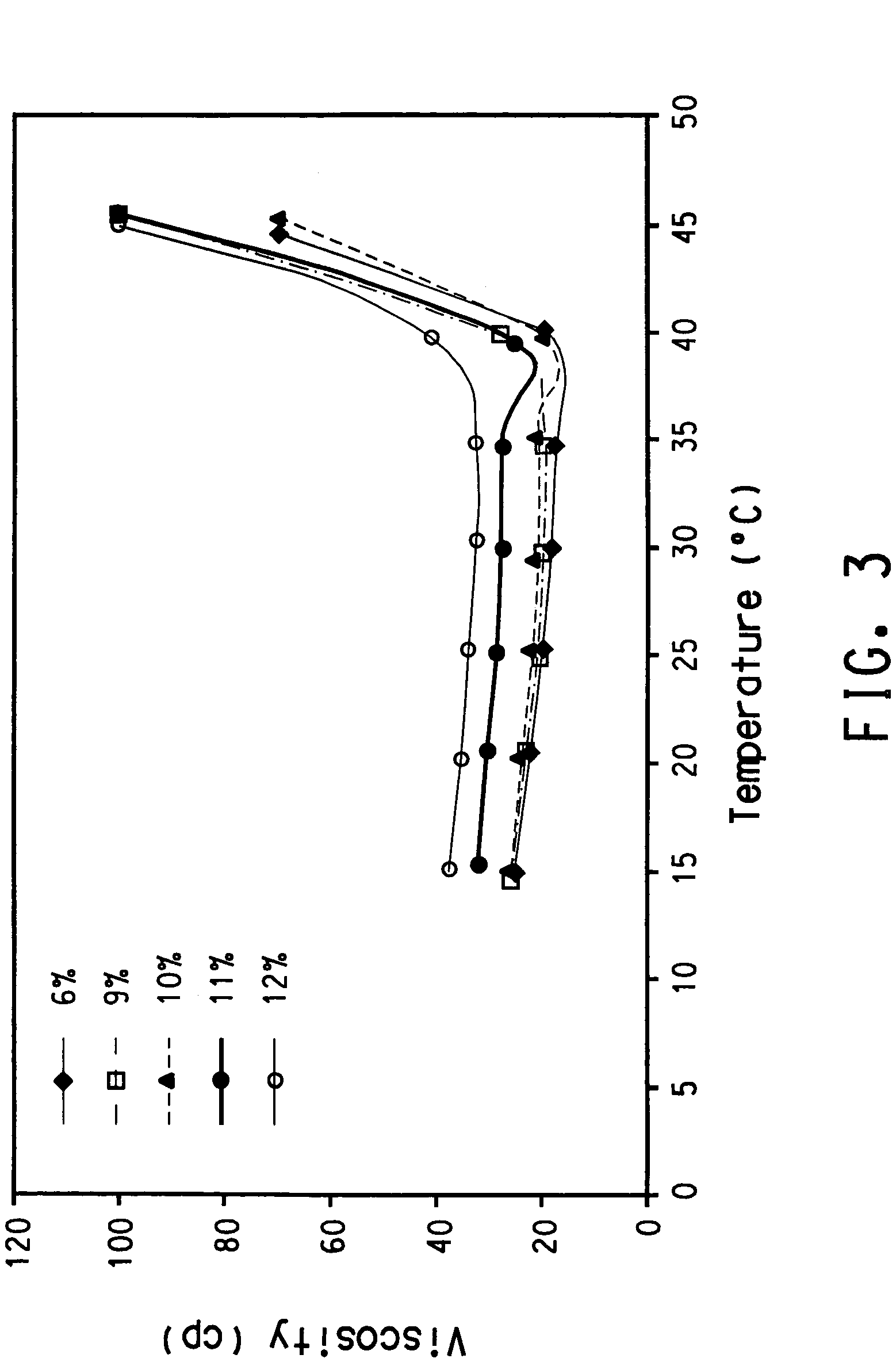

Fluoropolymer dispersion and electrode composition containing same

InactiveUS7659335B2Improve stabilityHigh viscosityCell electrodesFilm/foil adhesivesFluoropolymerSURFACTANT BLEND

A composition comprising an aqueous dispersion of fluoropolymer particles stabilized with a polyoxyethylene alkyl ether surfactant having a polydispersity index, Mw / Mn, of 1.15 or less, useful in compositions comprising electrode material.

Owner:DUPONT MITSUI FLUOROCHEMICALS CO LTD

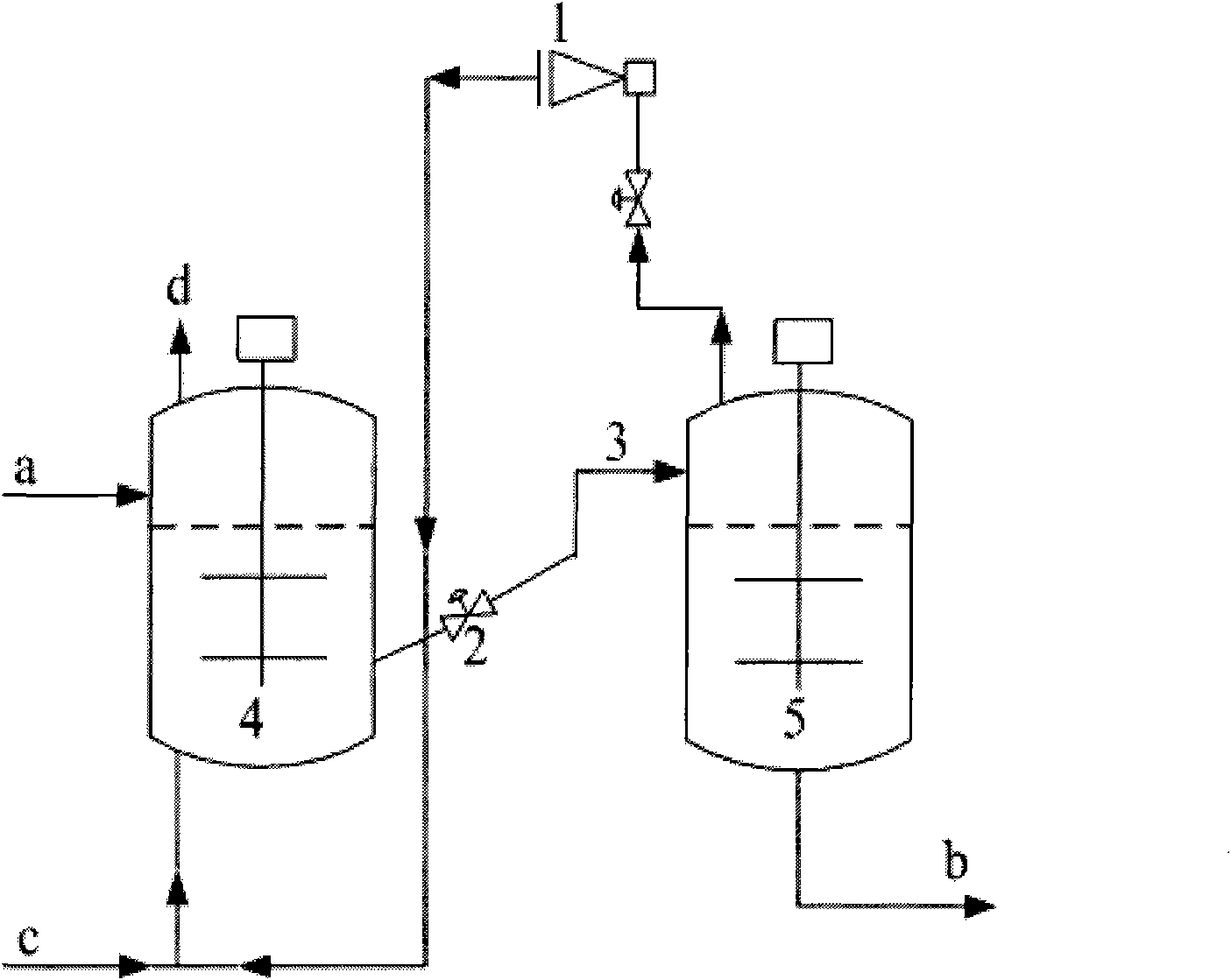

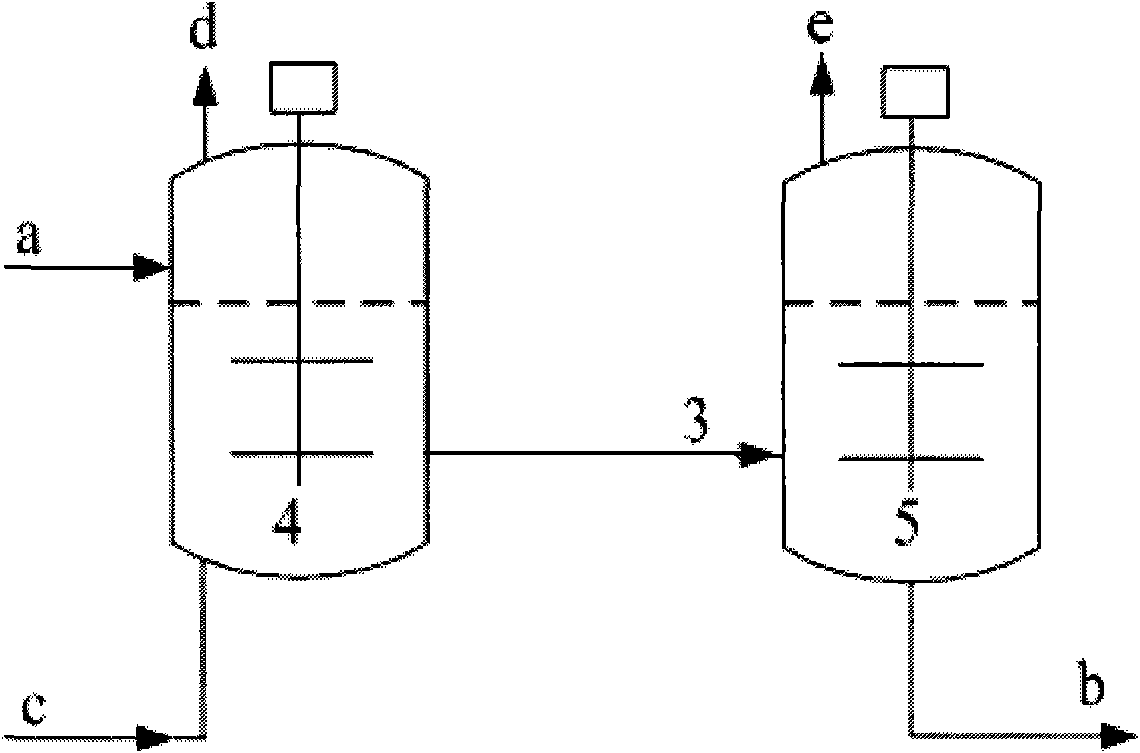

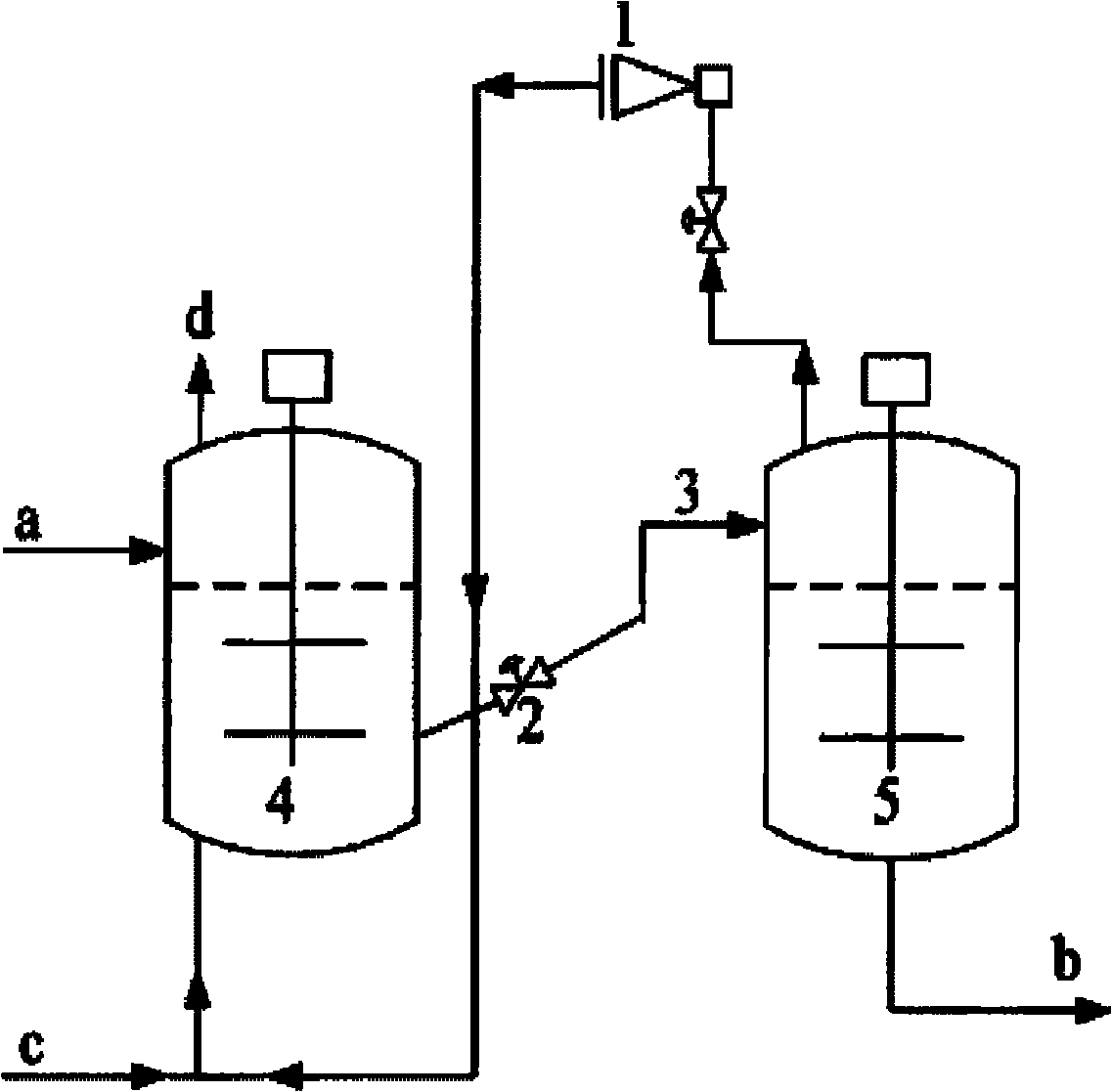

Method for depriving solvent for cis-polybutadiene

The invention relates to a method for depriving a solvent for cis-polybutadiene, which is mainly used for solving the problems of high consumption of solvent naphtha and large consumption of water vapor in the prior art. The technical scheme adopted by the invention comprises the following steps: a) injecting a material stream I containing rubber liquid cement and hot water from the upper part ofa first cohesion kettle, ejecting a material stream II containing water and solvent from the top of the first cohesion kettle, and ejecting a material stream III from an overflow pipe at the lateral part of the first cohesion kettle, wherein the flow capacity of the material stream III is controlled by a liquid level controlling system; b) feeding the material stream III from a gas phase spatial position in the second cohesion kettle, after the material stream containing water and solvent is drawn out by vacuum-pumping equipment, feeding the material stream containing water and solvent into the bottom of the first cohesion kettle together with the supplementary fresh steam, and carrying out cohesion, thus obtaining a material containing cis-polybutadiene at the bottom of the second cohesion kettle; and c) obtaining the solvent after the stream II containing water and solvent is subjected to separation. By utilizing the technical scheme provided by the invention, the problems in the prior art can be better solved; and the method for deprivating the solvent for cis-polybutadiene can be applicable to the industrial production for deprivating the solvent for the cis polybutadiene.

Owner:CHINA PETROLEUM & CHEM CORP

Emulsified liquid capable of replacing oil products and preparation method of emulsified liquid

The invention discloses emulsified liquid capable of replacing oil products. The emulsified liquid is prepared from the following components in percentage by weight: 30%-55% of naphthenic base oil, 10%-35% of an extreme-pressure lubricant, 0-10% of an oily lubricant, 2%-5% of an anionic emulsifier, 5%-12% of a nonionic emulsifier, 2%-10% of organic alcohol amine, 5%-10% of a rust inhibitor, 0.1%-1% of a copper corrosion inhibitor, 0-4% of a bactericide, 0-1% of a mildew preventive, 0-3% of a coupling agent and 0-10% of water. The formula of the emulsified liquid does not contain silicon, boron, phosphorus and formaldehyde, and the emulsified liquid is safe and environmentally friendly; on the other hand, by virtue of the emulsified liquid, the processing effects of the oil products can be realized, but the cost of the emulsified liquid is far lower than the costs of the oil products, so that the production cost of a user can be greatly lowered by virtue of the emulsified liquid.

Owner:NANJING KERUN LUBRICANTS +1

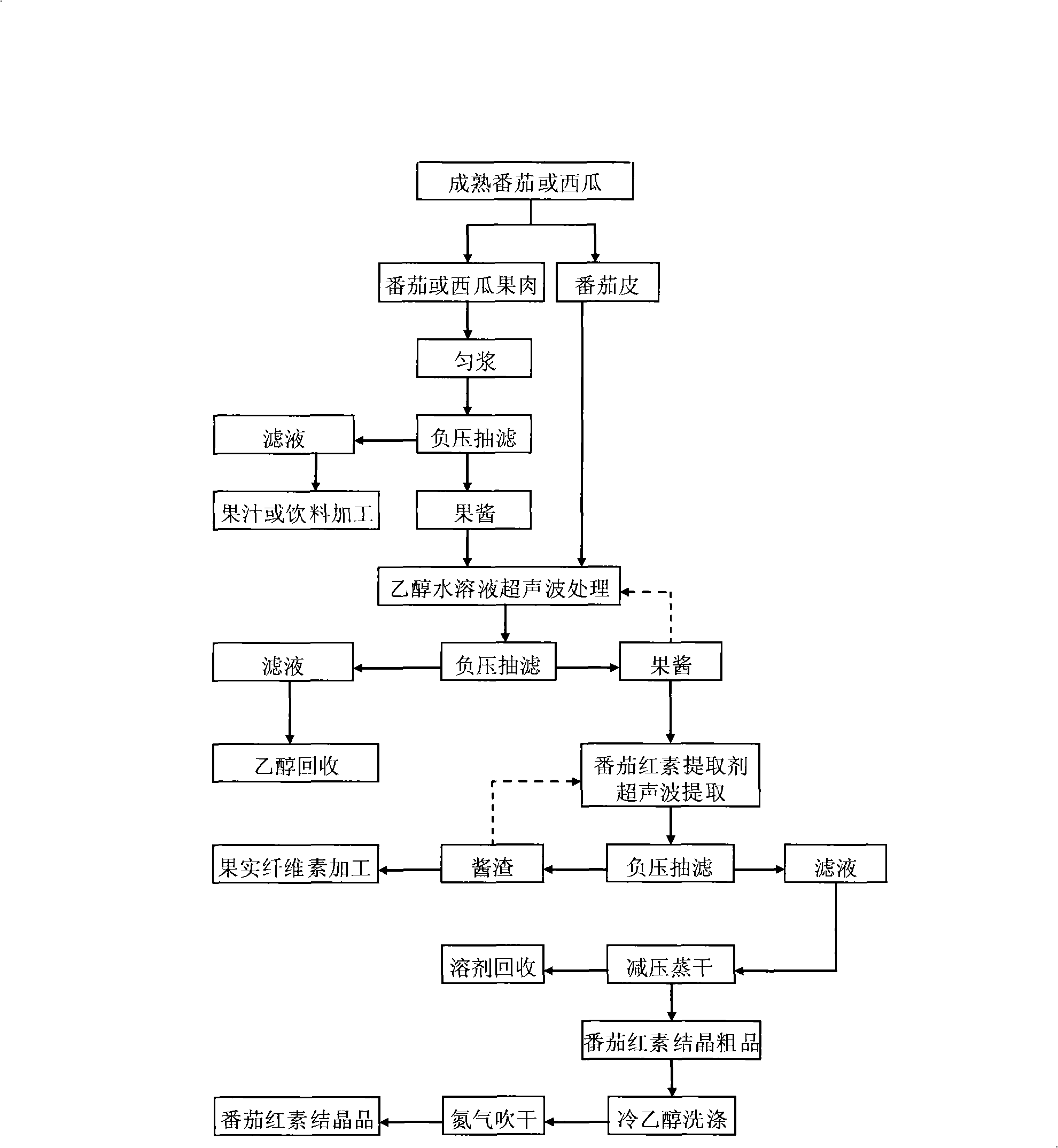

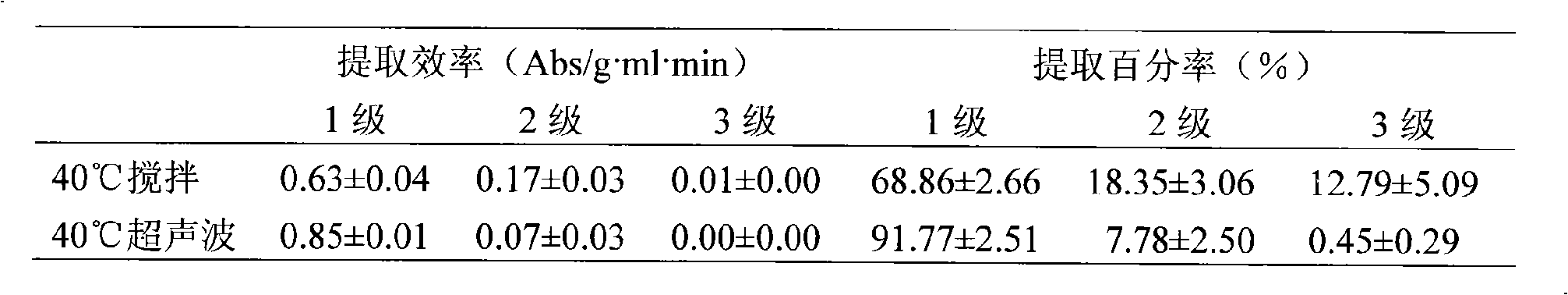

Method for preparing and abstracting lycopene

InactiveCN101289364AHigh speedHigh extraction rateHydrocarbon purification/separationHydrocarbonsLycopeneFood engineering

The invention discloses an extraction preparation method of lycopene, belonging to the technical field of food engineering. The method uses tomatoes or watermelon flesh as raw materials and adopts the technology of ultrasonic and extraction bags, which comprises the following steps: (1) the treatment of the raw materials and beating; (2) the separation of solid puree and liquid puree of fruit puree; (3) the ethanol water treatment of jam;(4) the extraction of the lycopene extractant of the jam and (5) the preparation of crystallization products of the lycopene. The extraction time of the invention is reduced to 10 to 60min from the10 to 20h of conventional time, and moreover the purity content of products is obviously improved from 10 to 20 percent in general to 70 to 80 percent. Therefore, the extraction preparation method is characterized by being efficient and fast, being convenient to be operated, low cost, high content of lycopene in the products, etc and is suitable for the promotion and the application in the industrialized and large scale production enterprises of natural lycopene with high purity.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

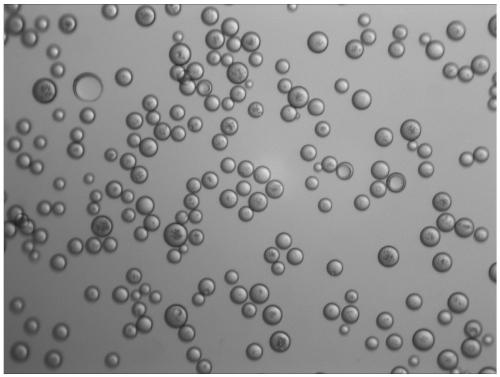

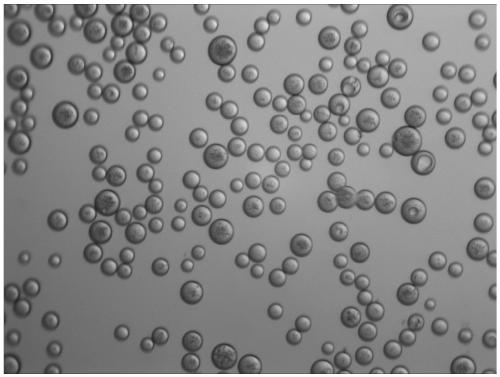

Polylactic acid porous microspheres as well as preparation method and application thereof

InactiveCN111298196AHigh recovery rateGood for volatilizationPharmaceutical delivery mechanismProsthesisFreeze-dryingFibrosis

The invention relates to a preparation method of polylactic acid porous microspheres. The method comprises the following steps: respectively preparing an oil phase solution and a water phase solution;pouring the oil phase solution into the water phase solution, and performing uniform stirring to obtain an O / W emulsion; stirring the O / W emulsion to obtain a polylactic acid microsphere suspension,screening out microspheres with a target particle size from the polylactic acid microsphere suspension, and performing collection to obtain semi-finished polylactic acid microspheres; and performing freeze-drying on the semi-finished polylactic acid microspheres to obtain the finished polylactic acid microspheres. The invention provides the polylactic acid porous microspheres, and the polylactic acid porous microspheres are prepared by using the above method. The invention also provides an application of the polylactic acid porous microspheres as a facial filler. The polylactic acid porous microspheres can produce encapsulation and fibrosis through a chronic inflammatory tissue reaction to stimulate human collagen proliferation to achieve the effect of filling beauty, and the porous structure characteristic can effectively reduce the residual of organic reagents, thereby ensuring the safety of the product.

Owner:CHANGZHOU INST OF MATERIA MEDICA

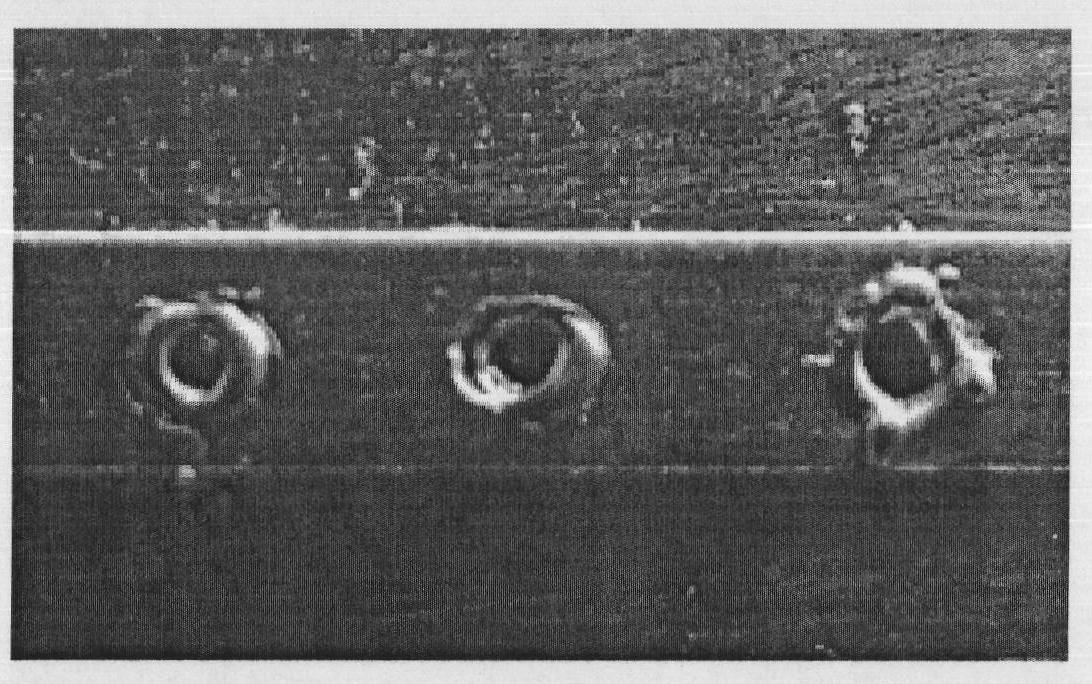

Laser welding method for dissimilar metals

InactiveCN102211253AEasy transitionGood for volatilizationLaser beam welding apparatusLaser beamsLow melting point

The invention discloses a laser welding method for dissimilar metals, which is used for welding a high-melting-point metal workpiece and a low-melting-point metal workpiece. A gap is formed between the high-melting-point metal workpiece and the low-melting-point metal workpiece, and a laser beam irradiates from one side of the high-melting-point metal workpiece to one side of the low-melting-point metal workpiece to realize welding, so that low-melting-point metal vapor is easily volatilized, a combining part between the two workpieces is more uniformly and controllably heated, heat is more reasonably distributed, and the phenomena of splashing, perforating and the like can be avoided.

Owner:HANS LASER TECH IND GRP CO LTD

Restoration method for heavy metal and (or) organic hydrocarbon contaminated soil

ActiveCN107457252AEnhanced interactionImprove adsorption capacityOther chemical processesContaminated soil reclamationRestoration methodSlag

The invention provides a restoration method for heavy metal and (or) organic hydrocarbon contaminated soil. The restoration method comprises the following steps of: (1) mixing a molecular sieve, cyclodextrin, activated carbon, diatomite, ferrous sulfate, enzyme slag, plant ash and active iron powder to obtain a mixture, adding clay to knead the mixture, and rolling the mixture into an adsorbing base body with a hierarchical pore structure, and embedding the adsorbing base body into contaminated soil; (2) preparing a restoration agent solution containing cyclodextrin, enzyme and potassium tripolyphosphate to leach the contaminated soil, and adsorbing and preserving; and (3) repeating the step (2) by many times. According to the restoration method provided by the invention, restoration agent solution leaching is combined with adsorbing of the base body with the hierarchical pore structure, so that heavy metal and (or) organic hydrocarbon substance pollutants in the soil are removed in a compounded mode, and therefore, the restoration method is suitable for municipal sludge treatment, and restoration for a contaminated building site, an industrial and mineral waste site, wetland soil obtained by returning farmland to lake (sea) and a wetland park, is simple and easy to operate, is free of secondary pollution, and can be used for industrial production.

Owner:蓝畅

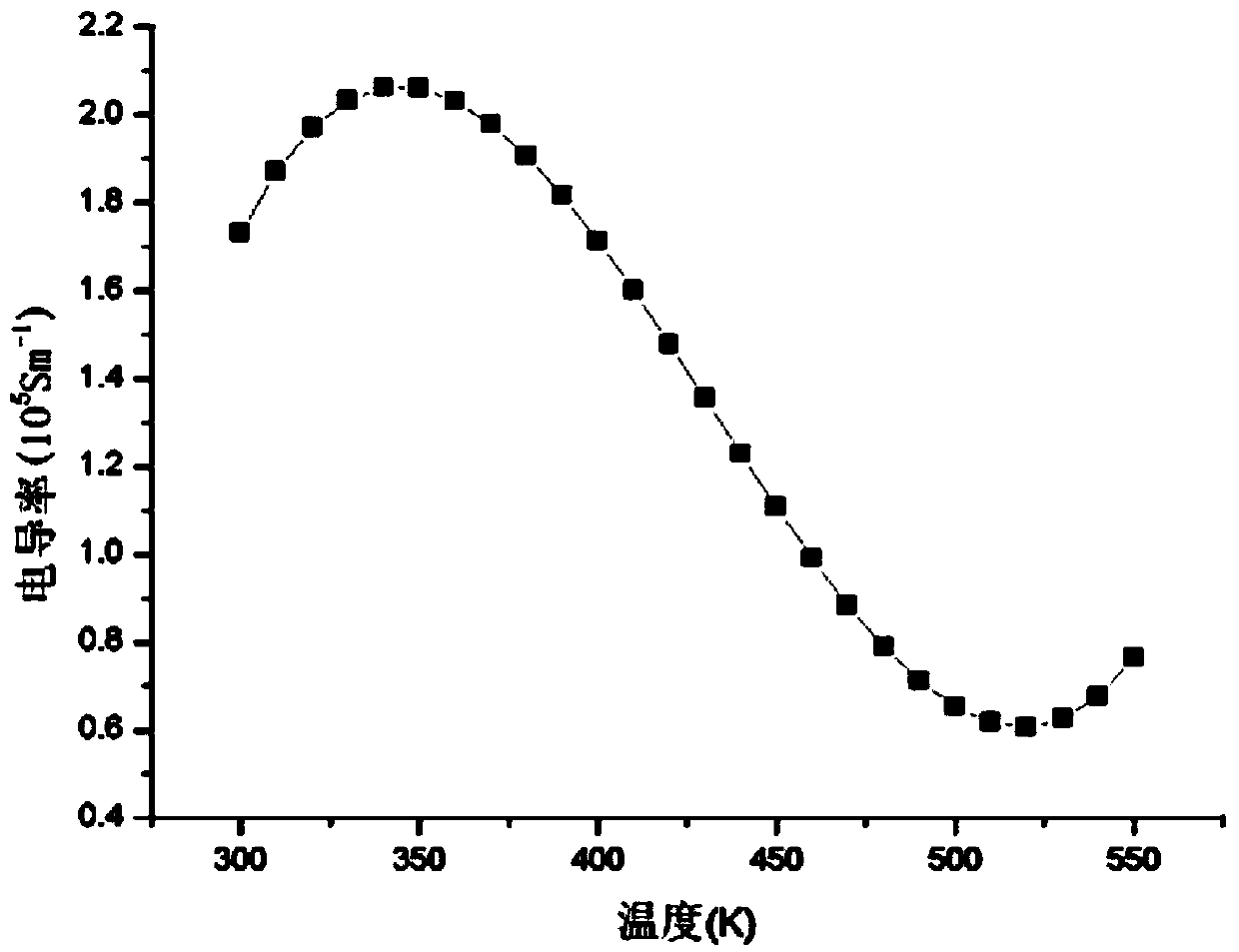

Preparation method of flexible pyroelectric film

The invention discloses a preparation method of a flexible pyroelectric film. The preparation method comprises the following steps of compounding a pyroelectric material casting ingot; grinding and screening the compounded pyroelectric material casting ingot, and obtaining a pyroelectric material powder; mixing an adhesive, a dispersive agent and an organic solvent, uniformly stirring, and preparing a slurry; uniformly mixing and stirring the pyroelectric material powder and the slurry, so as to obtain a mixture material; depositing the mixture material on a flexible substrate by a screen printing method or a tape casting method, and obtaining a precursor of the flexible pyroelectric film; drying the precursor, sintering by microwave, and cooling, so as to obtain the flexible pyroelectric film. The method has the advantages that the bottleneck of the process of using pyroelectric material with high melting point to prepare the film on the flexible substrate with low melting point is overcome, and the flexible pyroelectric film with high quality and excellent pyroelectric property can be obtained under the conditions of shorter time and lower sintering temperature.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Non-halogen phosphoric acid ester combustion inhibitor for engineering plastic and method of preparing the same

ActiveCN101319057ASufficient supplyReduce investmentFireproof paintsPhosphoric Acid EstersManufacturing cost reduction

The invention relates to a halogen-free phosphate fire retardant used for engineering plastics and a method for producing the same, belonging to the engineering plastic fire retardant and the method for synthesizing the engineering plastic fire retardant technical field. The chemical name of the fire retardant is hydroquinone double phenyl bisphosphate oligomer, and the chemical structural formula is shown on the bottom right. The method comprises the following processing steps: firstly, the method adopts hydroquinone and phosphorus oxychloride as raw materials and a lewis acid as a catalyst for heating reaction; and secondly, the reaction mixture is heated up and dripped with phenol for reaction by taking the lewis acid as the catalyst. The production method has sufficient supply of the raw materials and simple reaction conditions, can reduce the manufacturing cost, and makes products have obvious price advantage; and simultaneously the material has the characteristics of zero halogen, low smoke, low toxity, low corrosiveness, high heat distortion temperature, good fire resistance, good processability, capability of being recycled, etc., and can be widely used as the fire retardant of various engineering plastics.

Owner:ZHEJIANG WANSHENG

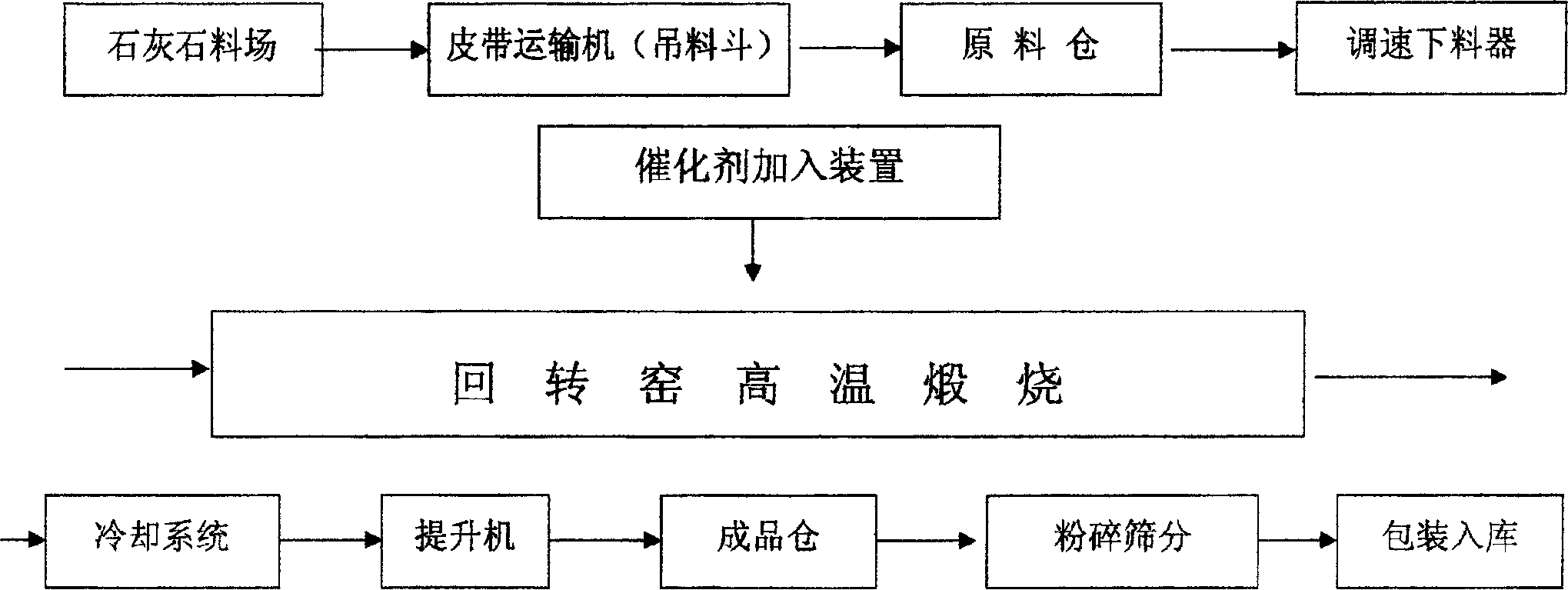

Method for manufacturing melt-spinning alloys and apparatus thereof

InactiveUS20130014860A1Good for volatilizationImprove efficiencyFurnace componentsMagnetic materialsMetallic materialsQuenching

The application provides a method for manufacturing melt-spinning alloys and an apparatus thereof, which belongs to the technical field of metal materials and preparation thereof. The main feature of method including steps of melting alloy and jetting the molten alloy for rapid-quenching is that alloy melting and rapid-quenching are respectively implemented in independent environments, and the pressure of the two environments can be adjusted separately. The method can realize uniformity control of rapid-quenching velocity by controlling the melting and quenching pressure respectively, which has the advantages of increased rapid-quenching cooling rate, improved melt-spinning alloys thickness uniformity, reduced probability of nozzle clogging.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Method for preparing novel conductive ceramic evaporation boat by combustion synthesis

The invention discloses a method for preparing a conductive ceramic evaporation boat by combustion synthesis, which relates to a method for preparing the conductive ceramic evaporation boat. The method solves the problems that the method for preparing a conductive ceramic material of a conventional conductive ceramic evaporation boat has large energy consumption, high cost and long production period and a massive material of the conductive ceramic evaporation boat has poor uniformity. The method comprises the steps of: 1, weighing raw materials; 2, performing ball-mill mixing on the raw materials; 3, performing pressure forming to obtain a preformed blank, and then igniting to make preformed blank perform a self-propagating combustion reaction to obtain a conductive ceramic composite material; and 4, cutting and processing the conductive ceramic composite material to obtain the conductive ceramic evaporation boat. The method has the advantages of low energy consumption, low cost and short production period, finishes the reaction within a few minutes, adopts a hot isostatic pressing method to pressurize the material, obtains the composite material with good uniformity, and further obtains the evaporation boat with good uniformity. The method can manufacture the large-size material of the conductive ceramic evaporation boat with the diameter of between 40 and 200mm and the length of between 50 and 1,000mm.

Owner:HARBIN INST OF TECH

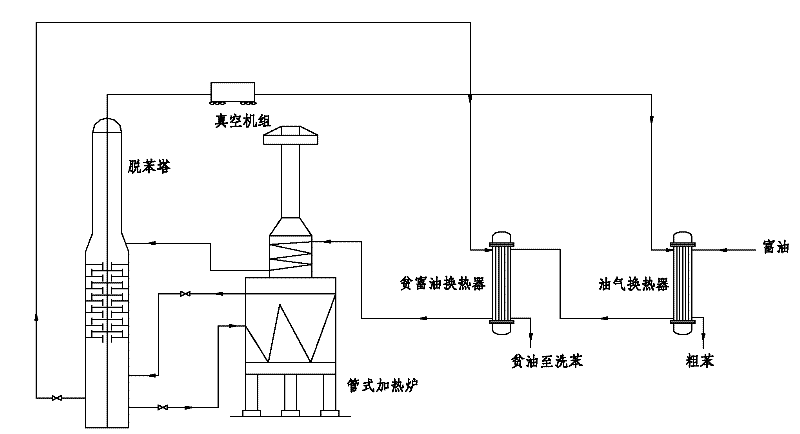

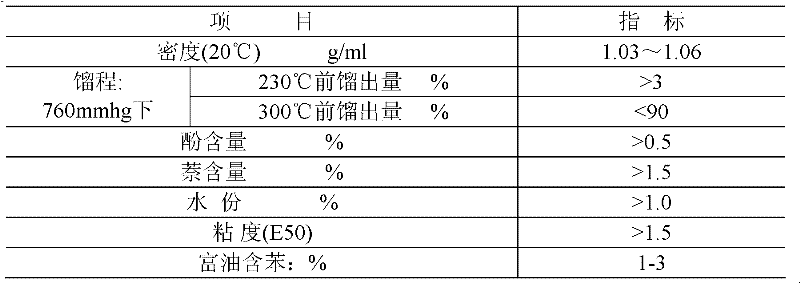

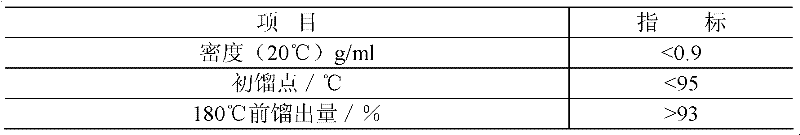

Tubular furnace method pressure-reduced debenzolization and distillation process

InactiveCN102199070AReduce the temperatureGood for volatilizationDistillation purification/separationCombustible gas purificationBenzeneProcess engineering

The invention discloses a tubular furnace method pressure-reduced debenzolization and distillation process. The process comprises the following steps of: carrying out heat exchange on rich oil from a benzene washing section by using an oil-gas heat exchanger and a lean oil-rich oil heat exchanger, entering the convection section of a tubular heating furnace for heating to 175-185 DEG C, then entering a debenzolization tower for debenzolization and distillation, collecting a crude benzene product from the tower top and returning lean oil at the tower bottom to a benzene washing tower, wherein the tower top pressure of the debenzolization tower is 13.3-70 kPa and the tower bottom pressure is 23.3-80 kPa; and the tower top temperature is 40-80 DEG C and the tower bottom temperature is 195-270 DEG C. Compared with traditional debenzolization processes, the pressure-reduced debenzolization and distillation process mainly has the advantages that: 1. the operation can be carried out under a negative pressure, and steam stripping can be omitted; 2. the yield of crude benzene is improved by 0.05-0.35%; 3. steam is not used; 4. since a regenerator is not used, the process structure is more compact and the occupation area is smaller; and 5. One oil-water separator is omitted, the regenerator is not used and a novel debenzolization tower is designed, thus effectively saving equipment investment cost.

Owner:上海同特化工科技有限公司

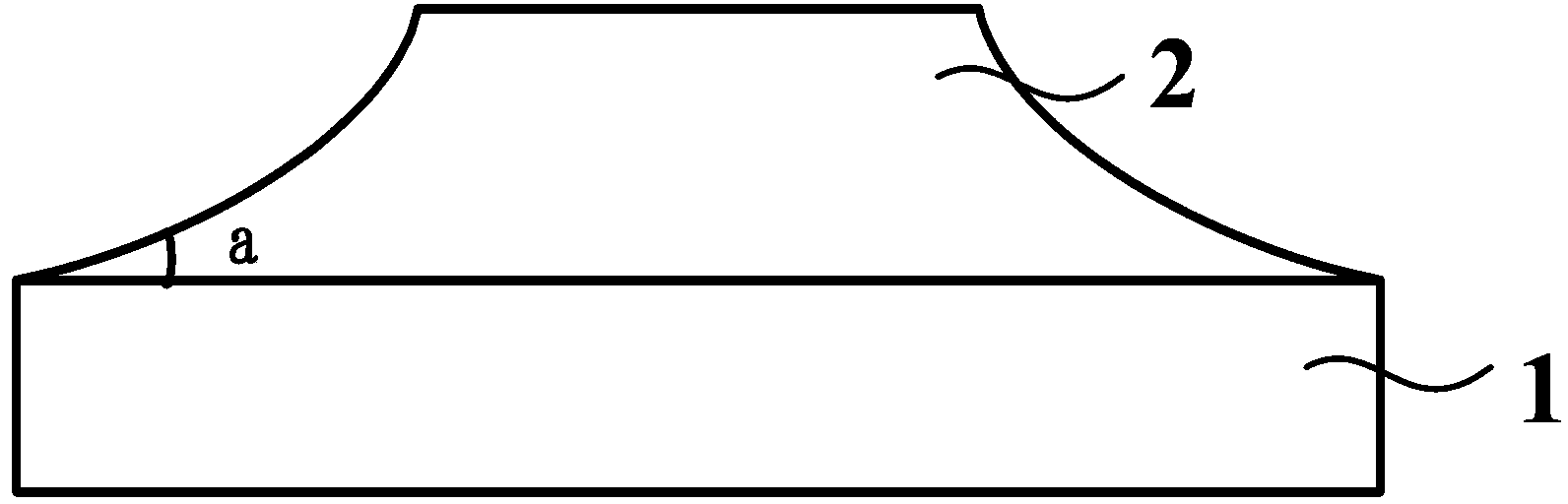

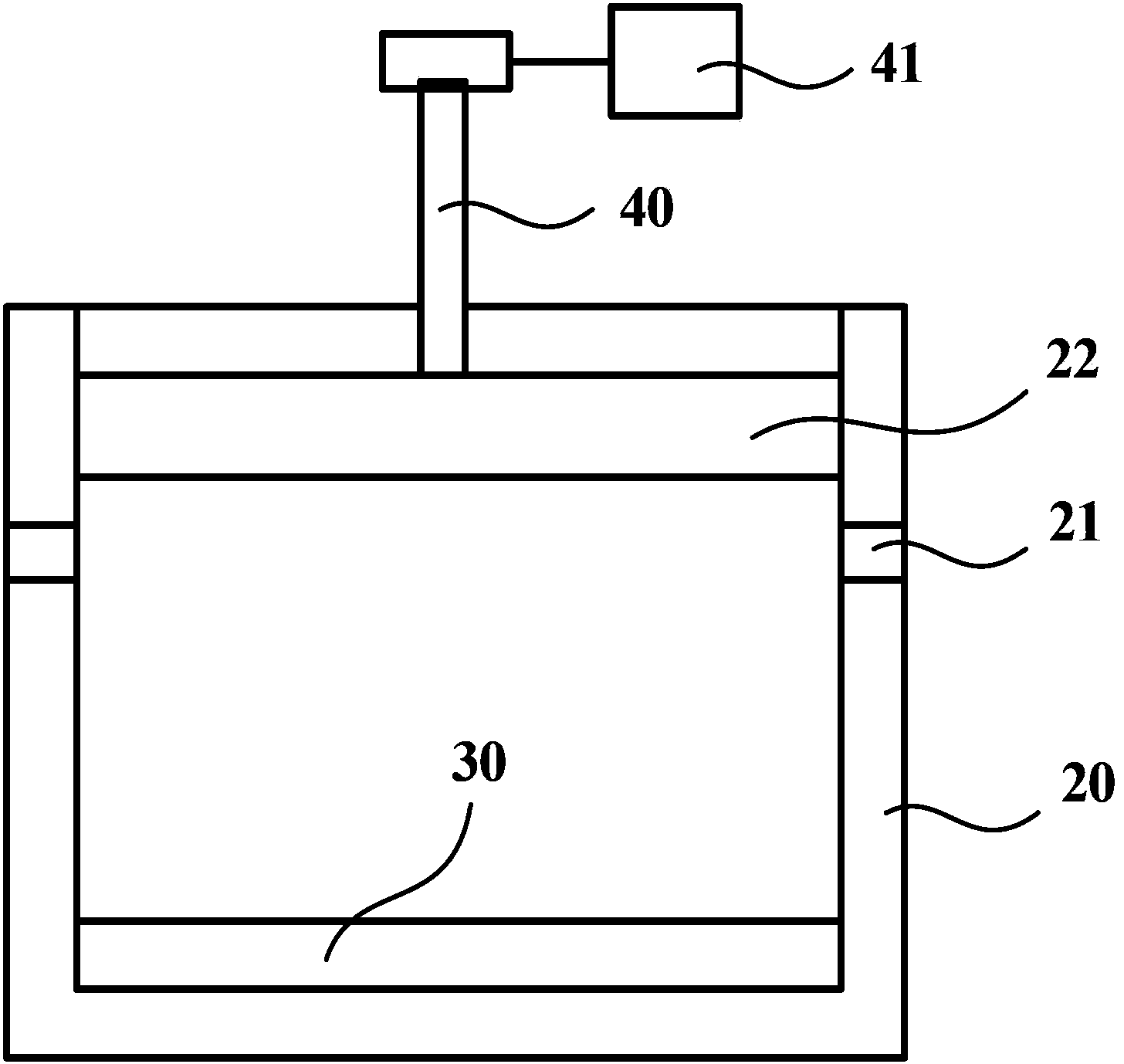

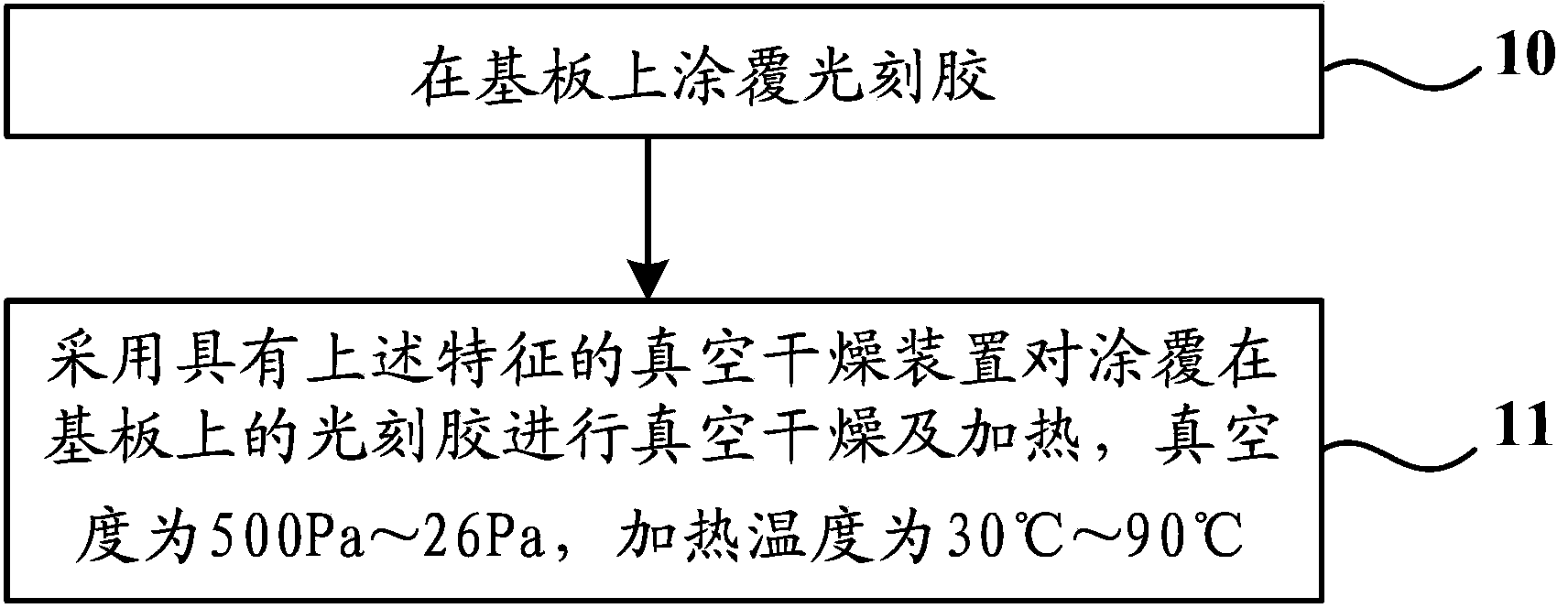

Vacuum drying device and photolithographic process

InactiveCN103353209AIncrease bank angleImprove adhesionDrying using combination processesDrying solid materials without heatVacuum pumpingPulp and paper industry

The invention relates to the technical field of substrate manufacture, in particular to a vacuum drying device and a photolithographic process which are used for improving the photolithographic accuracy. The disclosed vacuum drying device comprises a vacuum chamber provided with exhaust vents and a chamber door, a vacuum pumping device communicated with the exhaust vents, as well as a heating assembly arranged in the vacuum chamber. When the vacuum drying device is adopted for performing vacuum drying on a substrate coated with photoresist, heating and vacuum drying simultaneously act on the photoresist, so that less hardening film is produced, the residual quantity of a solvent in the photoresist is reduced, and the photolithographic accuracy is improved. The invention further discloses a photolithographic process which comprises steps as follows: the substrate is coated with the photoresist; and the vacuum drying device with the characteristics is adopted for performing vacuum drying and heating on the photoresist coating the substrate at the vacuum degree ranging from 26 Pa to 500 Pa at the heating temperature ranging from 30 DEG C-90 DEG C.

Owner:BOE TECH GRP CO LTD +1

Fragrant rotary face steamer

ActiveCN105943363AExpand the scope ofFree adjustmentMedical devicesBathing devicesEngineeringWater tanks

The invention relates to a fragrant rotary face steamer which comprises a shell, an evaporation unit and a storage unit. The evaporation unit comprises a water tank and a rotary nozzle. The water tank and the rotary nozzle are installed at the two ends of the shell respectively. A hot steam generator, a cold steam generator and a driving plate are installed at the positions, between the water tank and the rotary nozzle, in the shell. The storage unit comprises a storage cavity formed in the shell. An upper cover is arranged at the upper end of the storage cavity. The bottom end of the storage cavity is communicated with an evaporation pipeline. The rotary nozzle can be driven by a driving mechanism to rotate or swing up, down, left and right. The fragrant rotary face steamer has the advantages that the driving mechanism can drive the rotary nozzle to rotate freely within 360 degrees and swing within 180 degrees, and therefore the problem that in a traditional structure, the nozzle adjustment range is small is solved.

Owner:NVISION ELECTRICAL APPLIANCE

Acne treating compound Chinese medicine prepn

InactiveCN101019948AAntibacterial and antipruriticInhibition of keratinizationDermatological disorderMolluscs material medical ingredientsMentholSide effect

The acne treating compound Chinese medicine preparation is prepared with ginseng, pearl powder, honeysuckle, dahurian angelica root, almond and other eight kinds of Chinese medicinal materials. The preparation process includes washing the medicine materials, crushing, decocting, filtering, centrifuging to obtain supernatant, concentrating, adding pearl powder, menthol, far infrared nanometer ceramic powder, etc, high temperature sterilizing, adding glycerin and ethanol. It has functions of resisting bacteria, relieving itch, reducing oil secretion, etc. and thus obvious acne treating effect and no side effect.

Owner:许炎军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com