Patents

Literature

455 results about "Skin grafting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

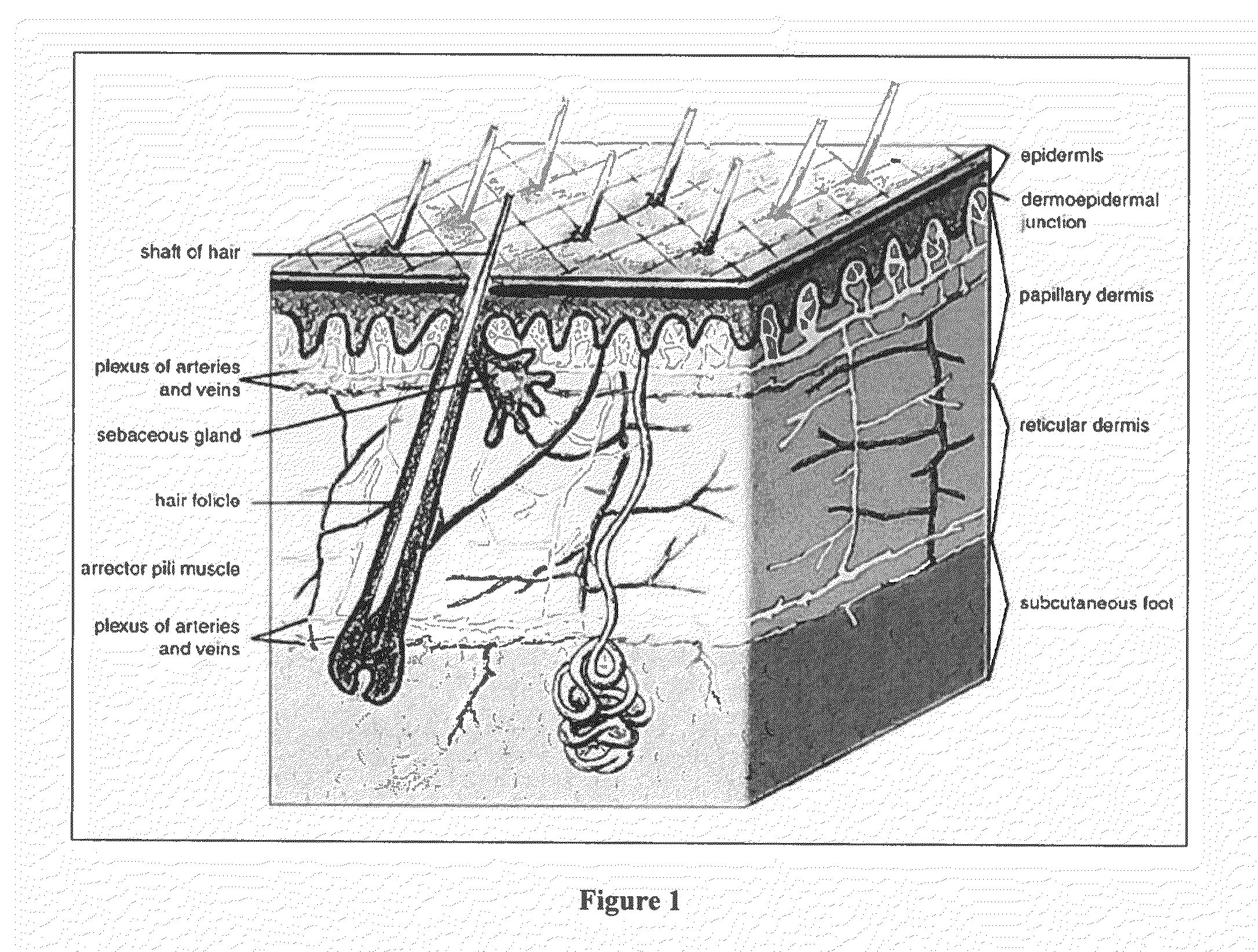

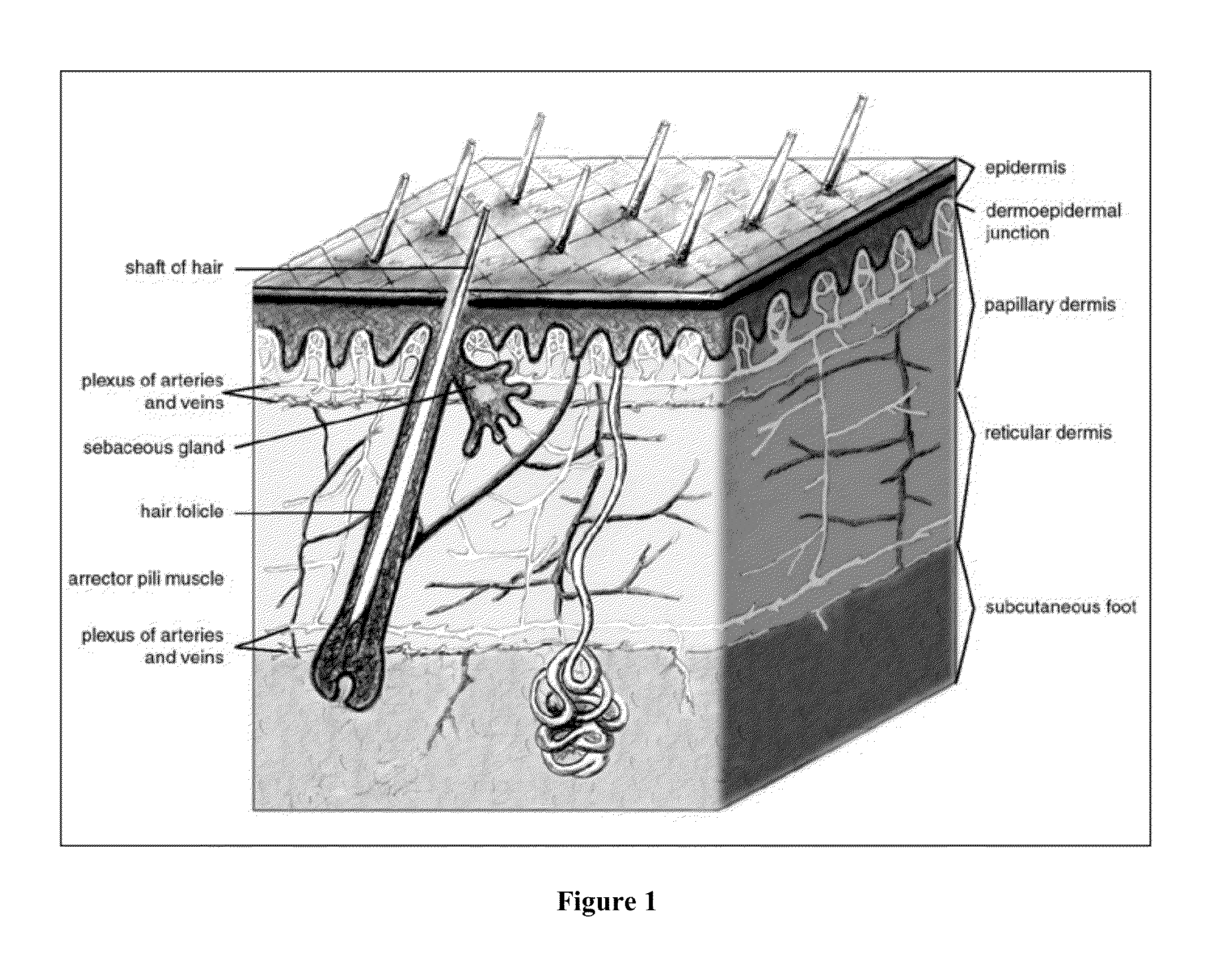

Skin grafting is a type of graft surgery involving the transplantation of skin. The transplanted tissue is called a skin graft.

Complaint implantable medical devices and methods of making same

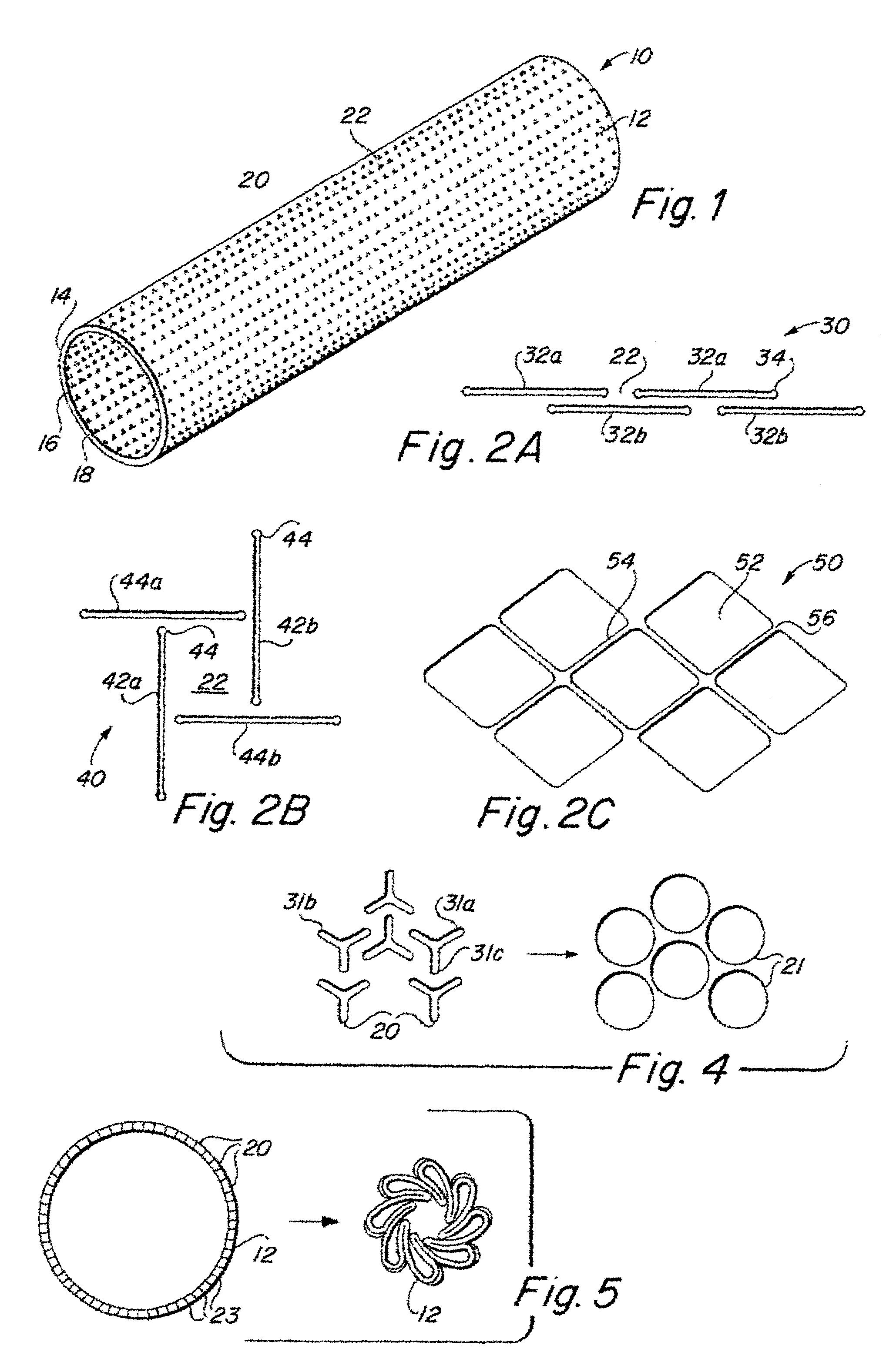

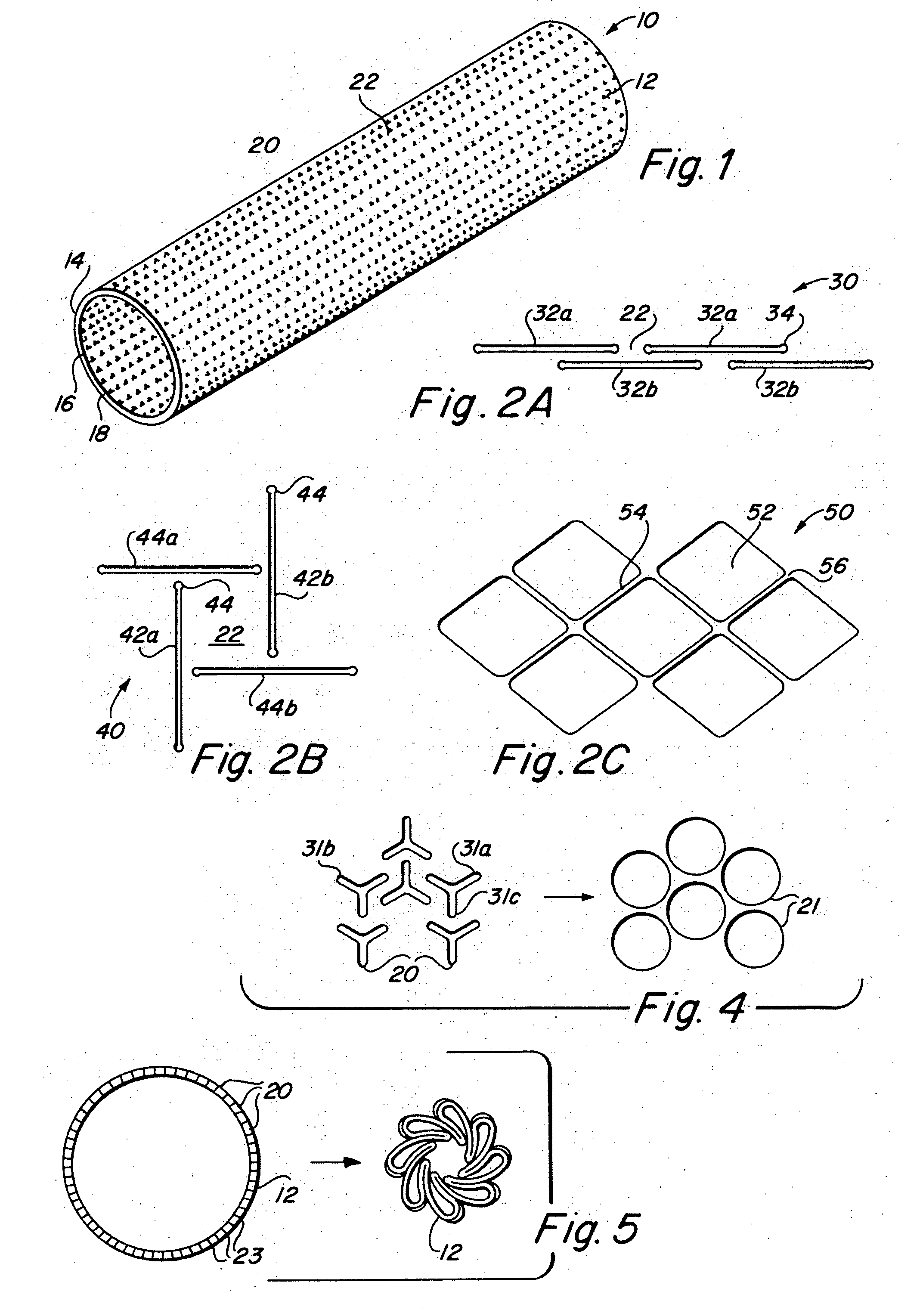

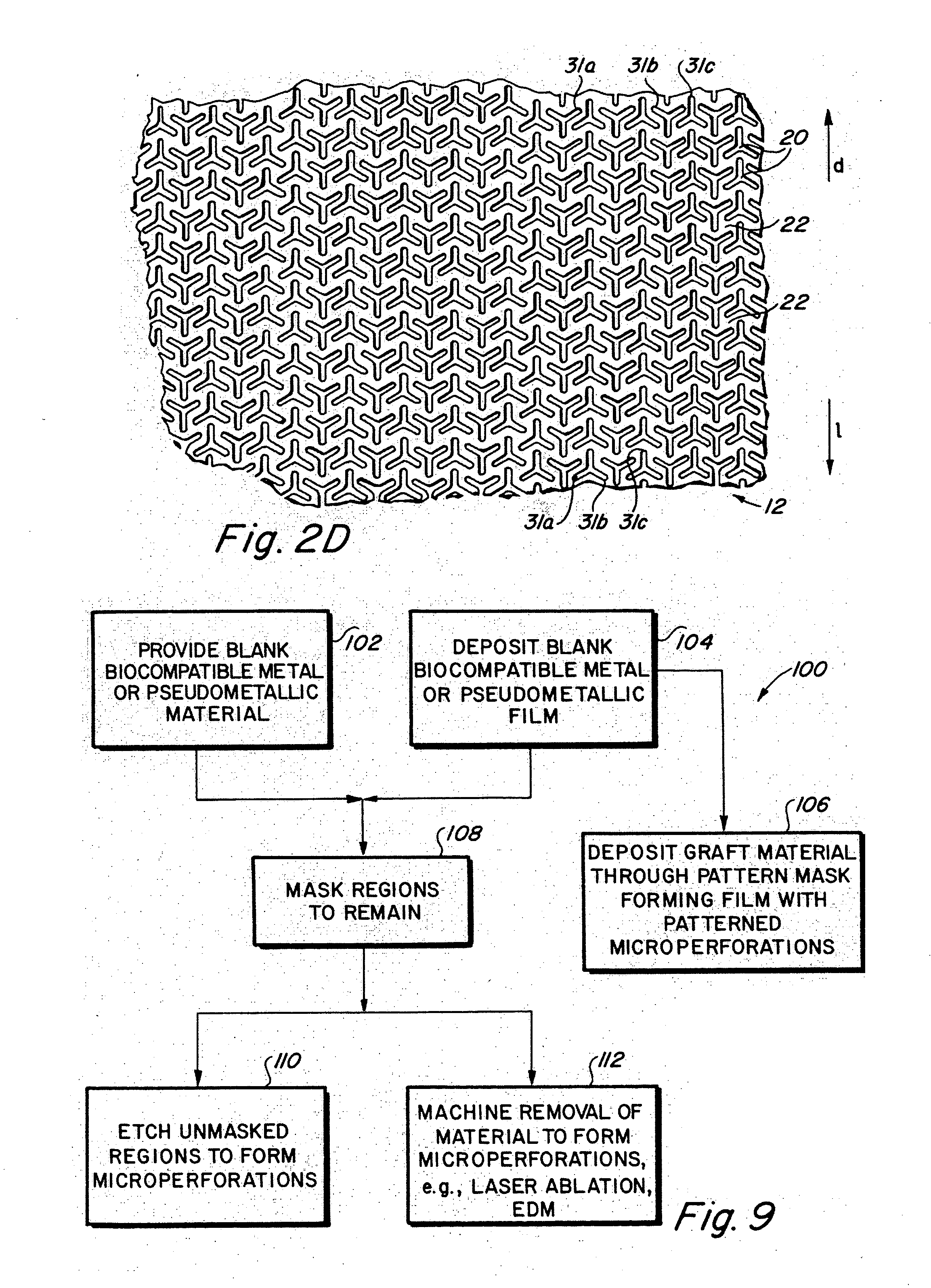

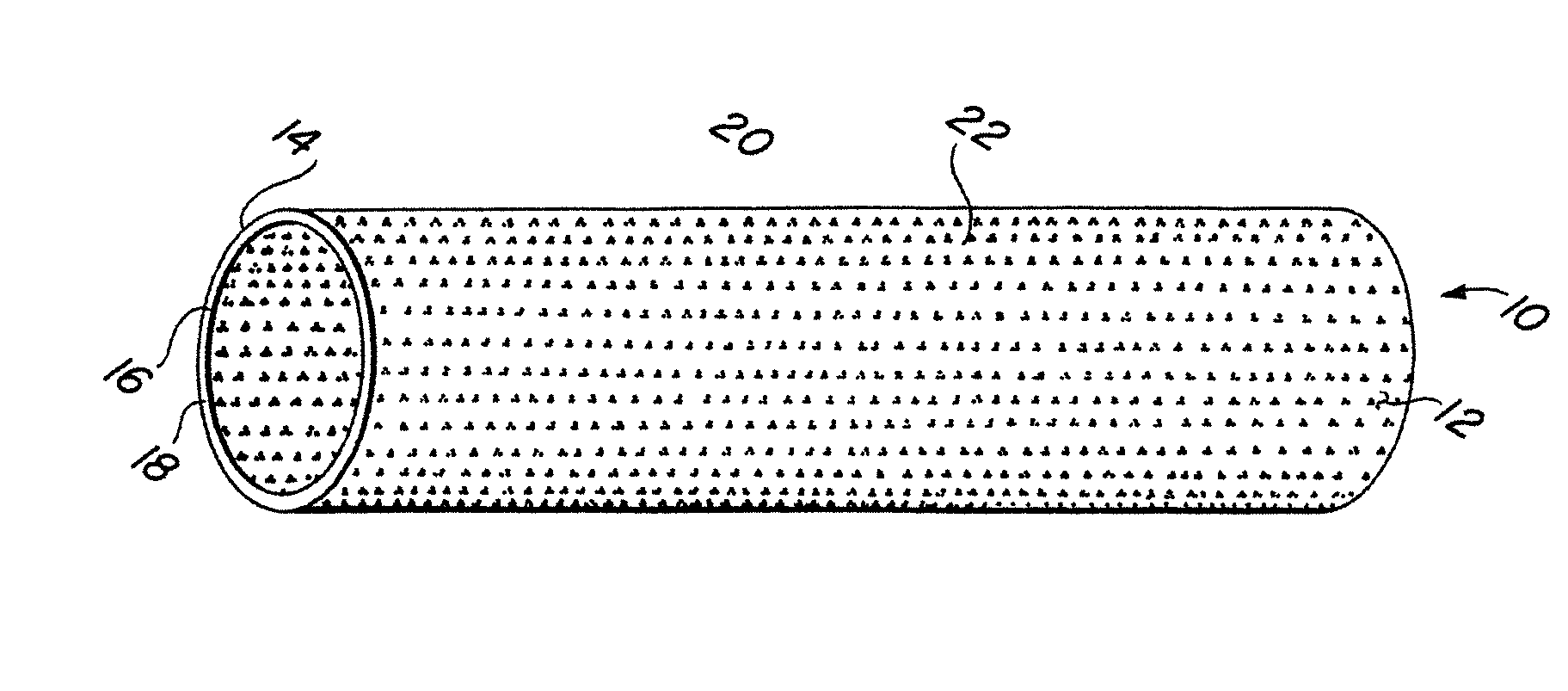

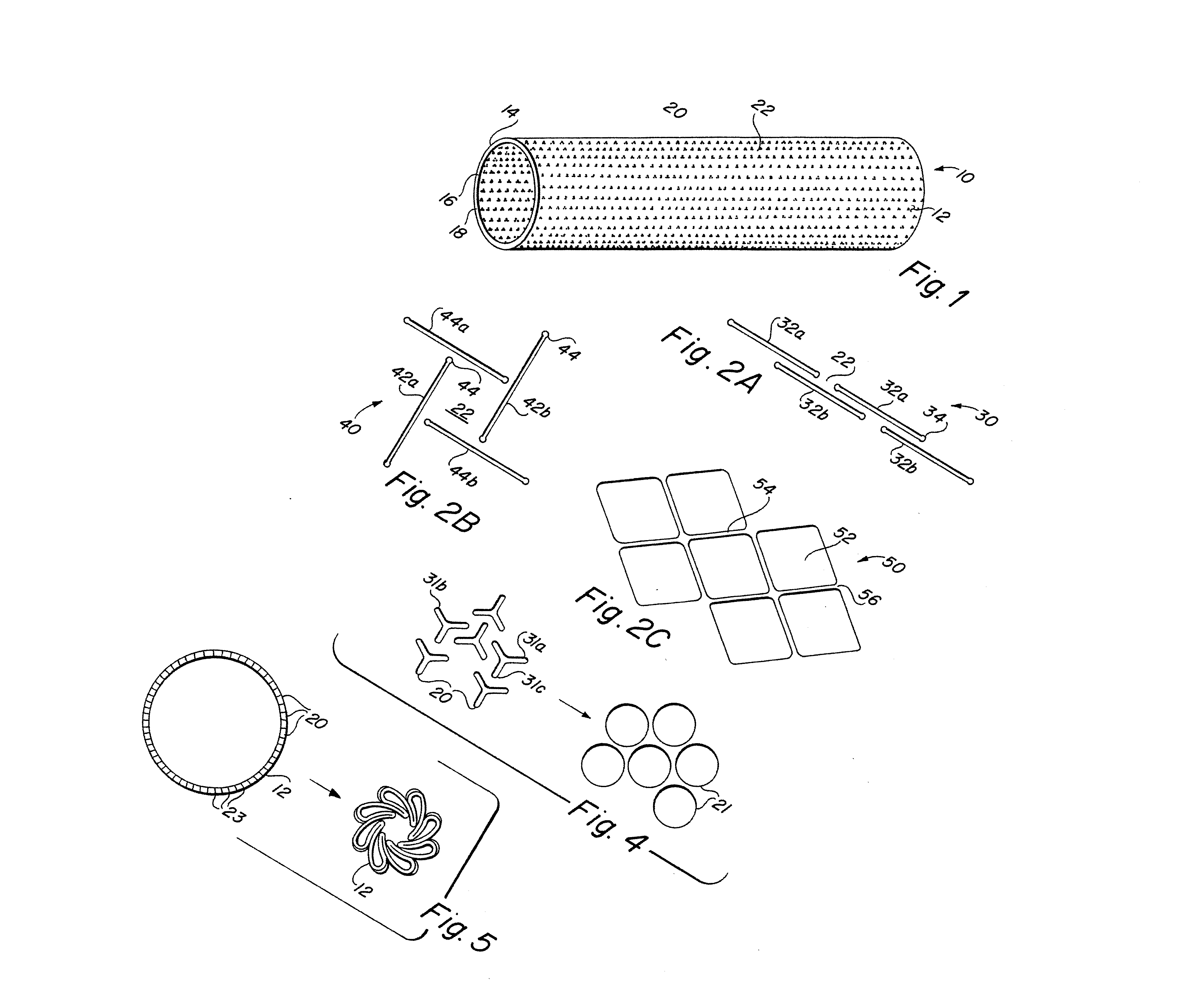

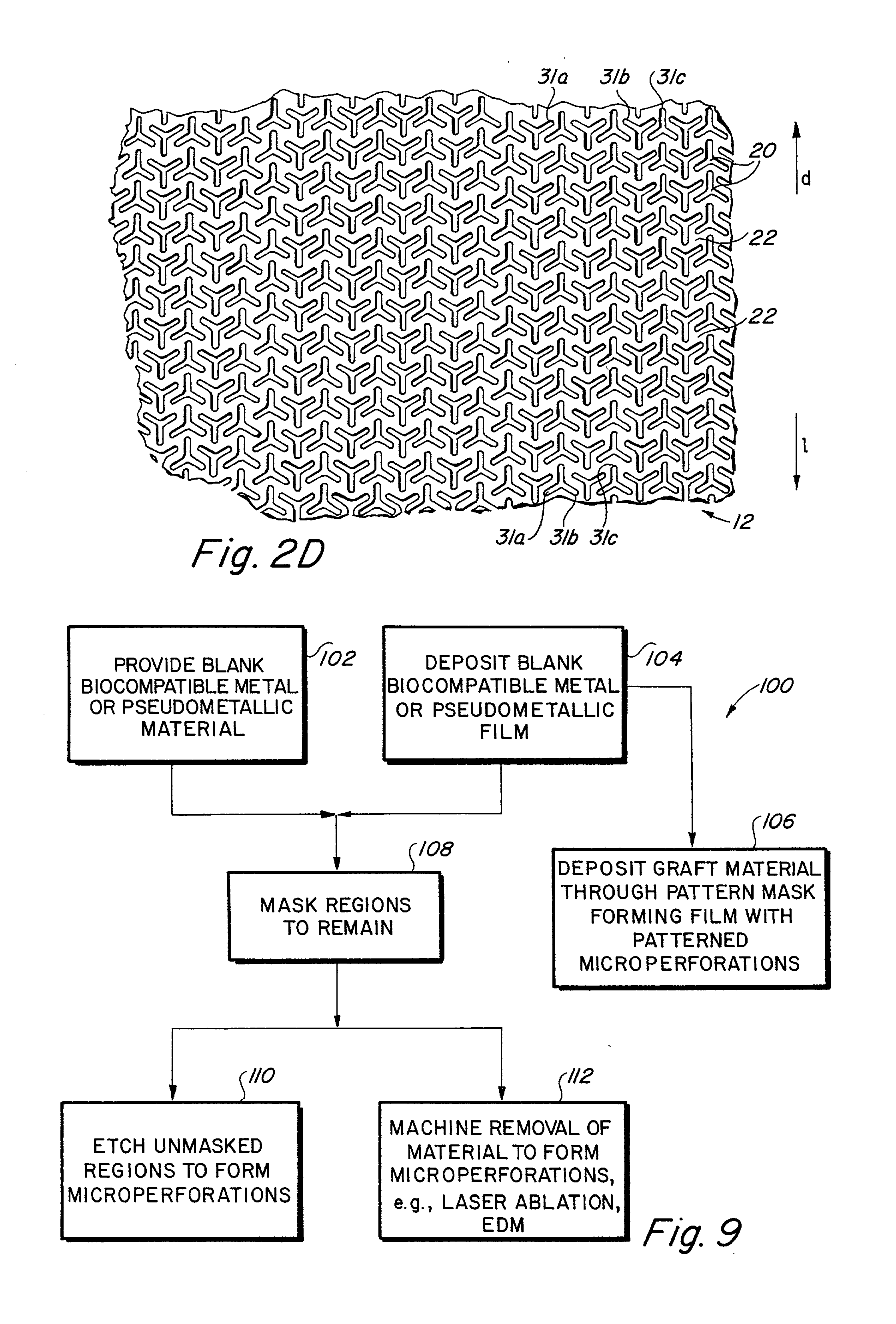

InactiveUS6936066B2Give flexibilityFacilitating transmural endothelializationStentsHeart valvesSurgical GraftMetallic materials

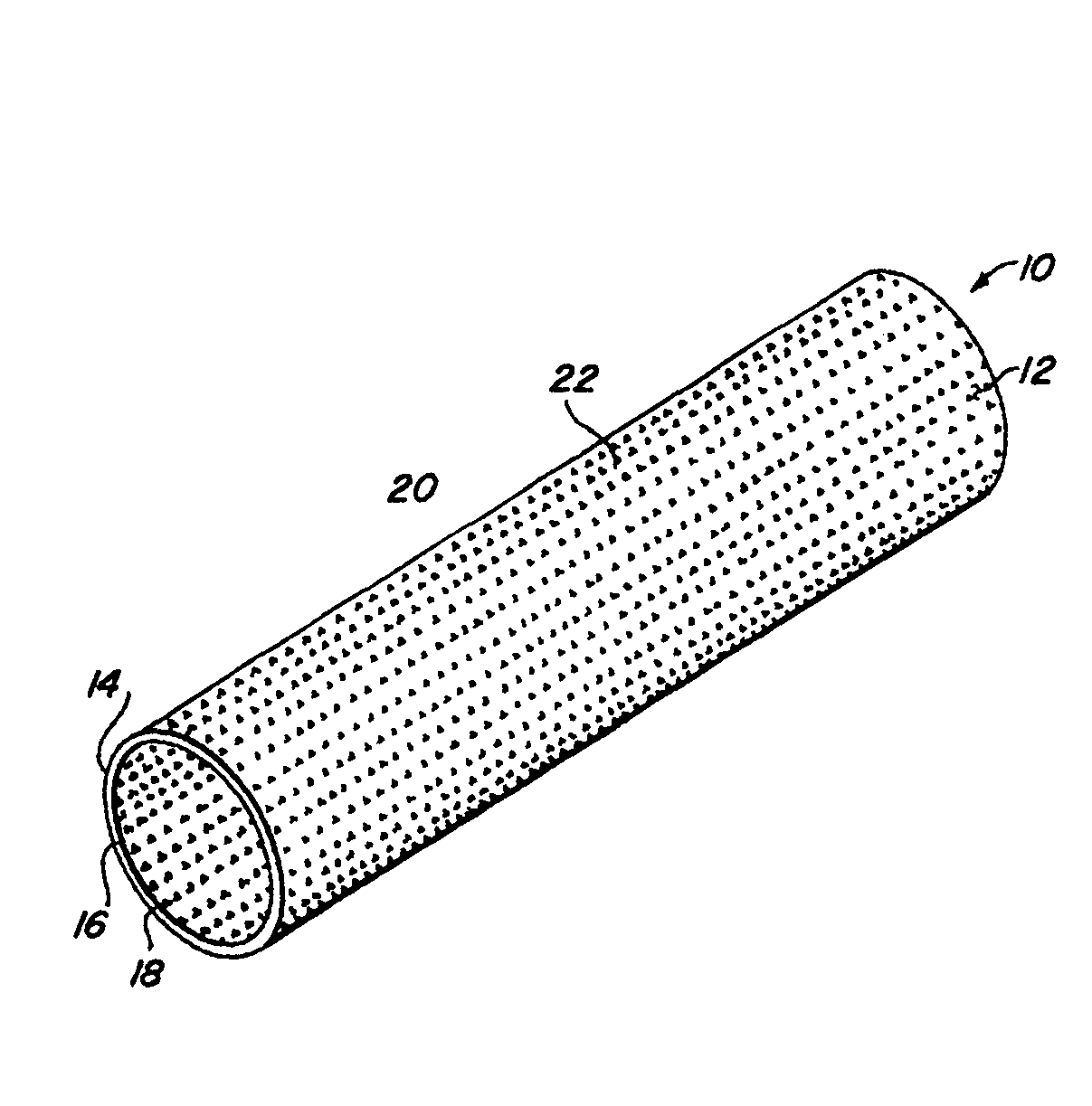

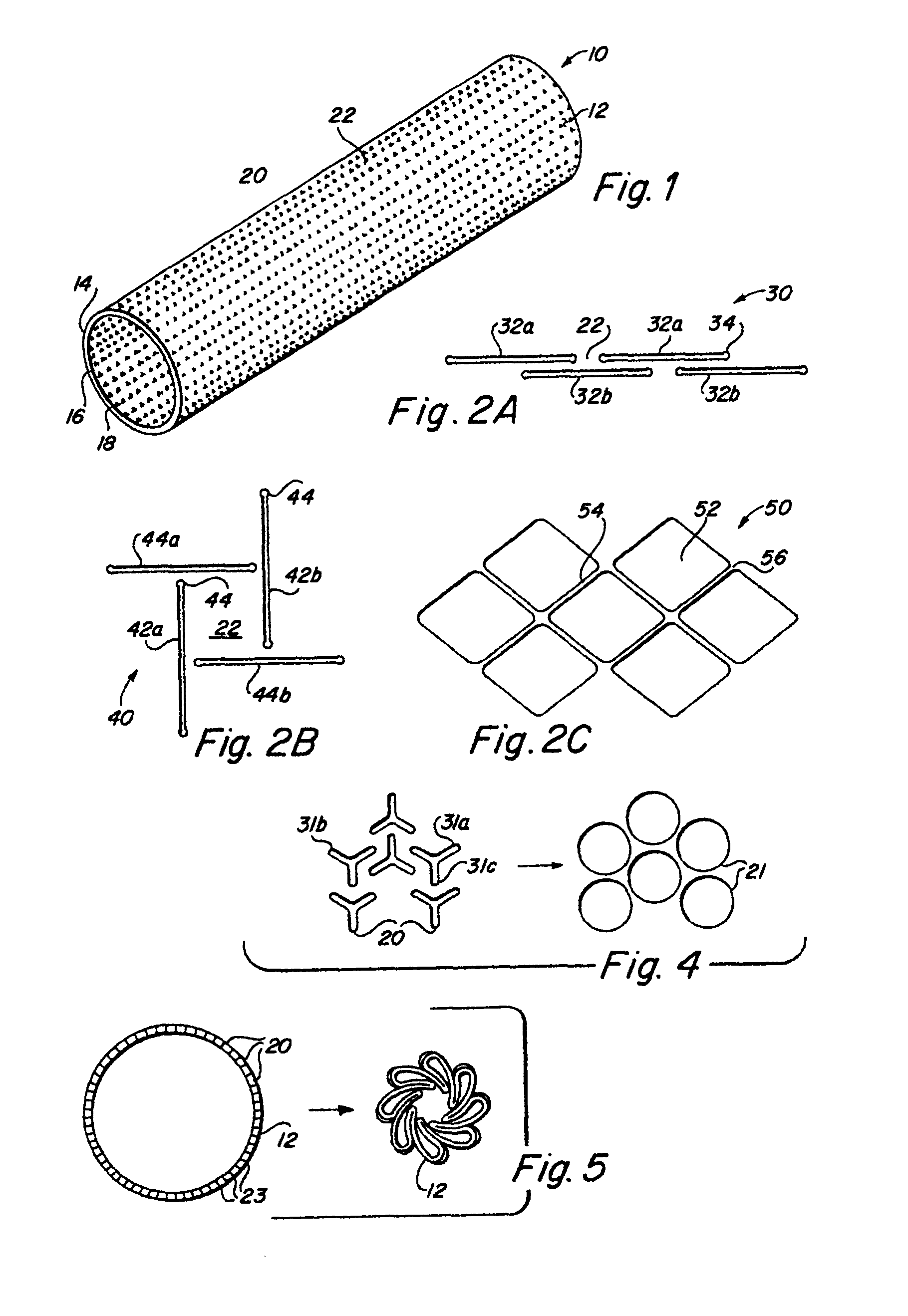

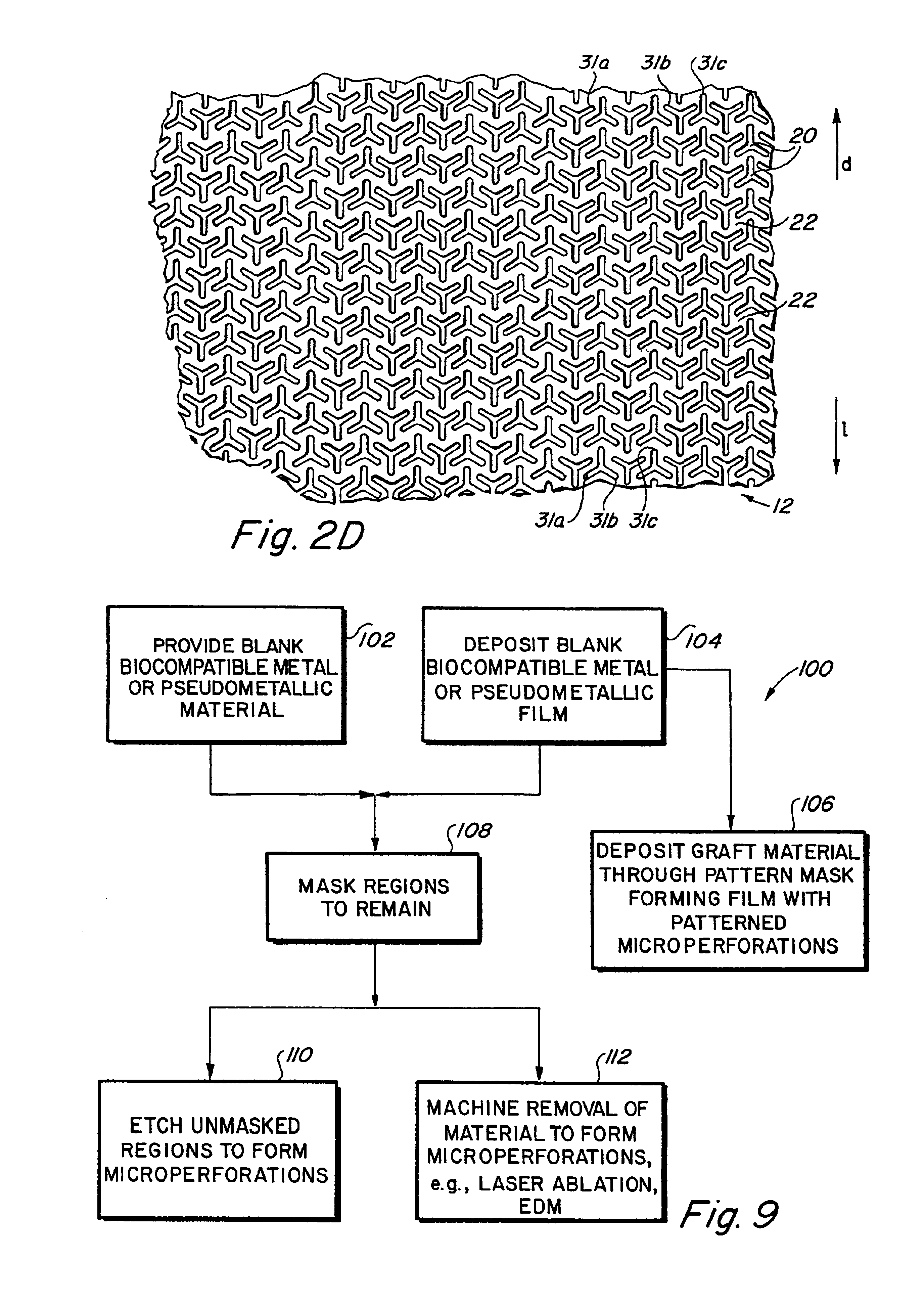

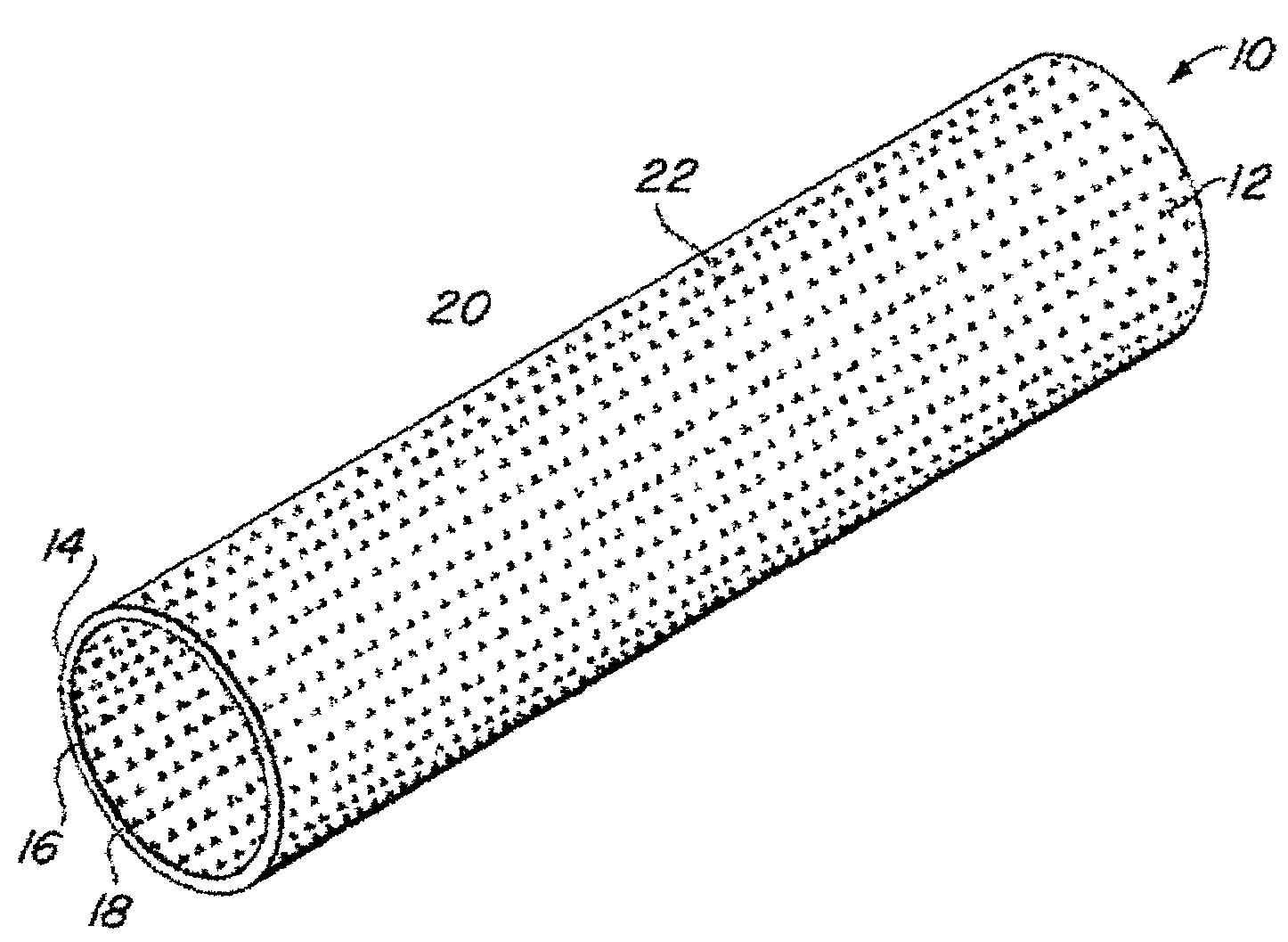

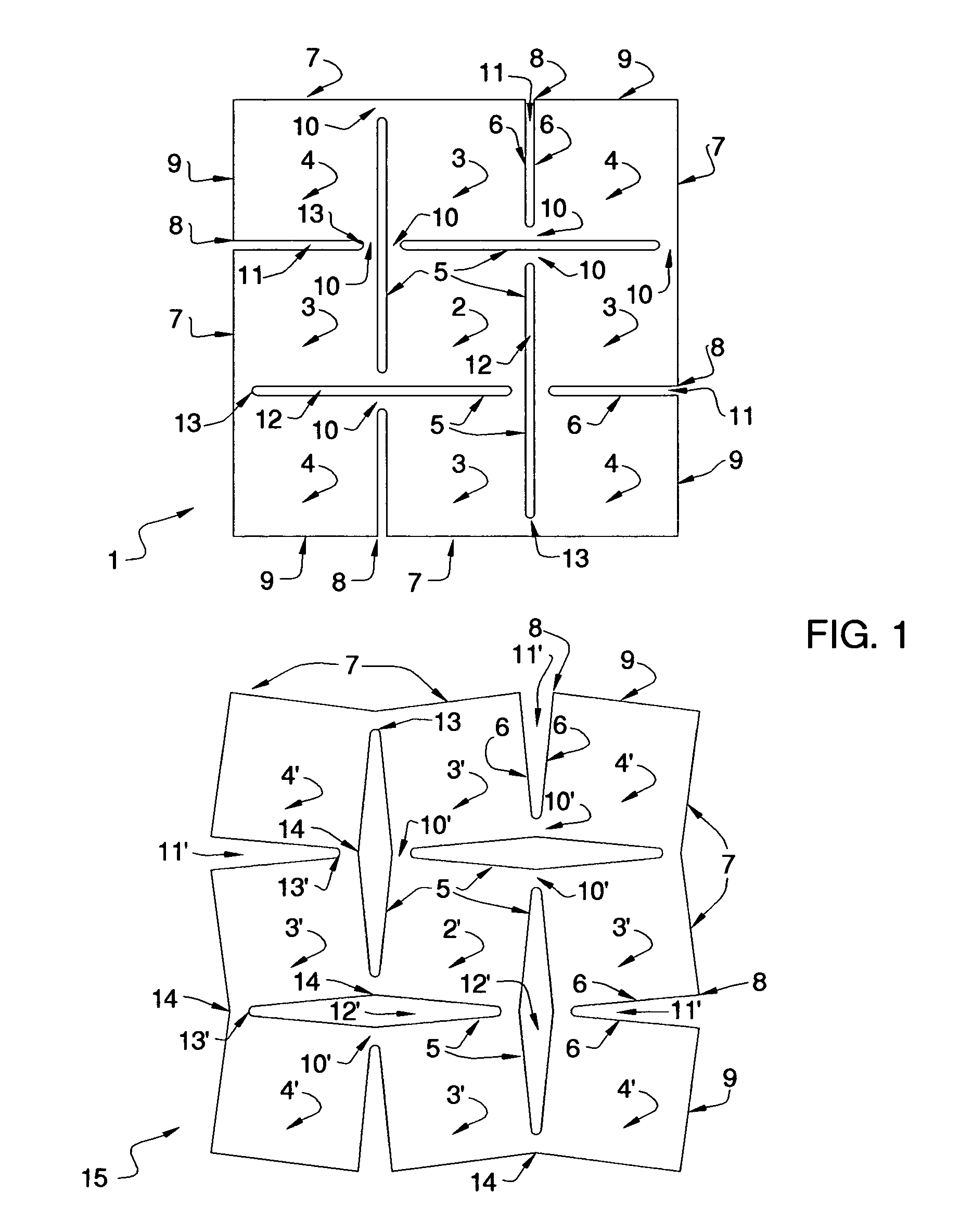

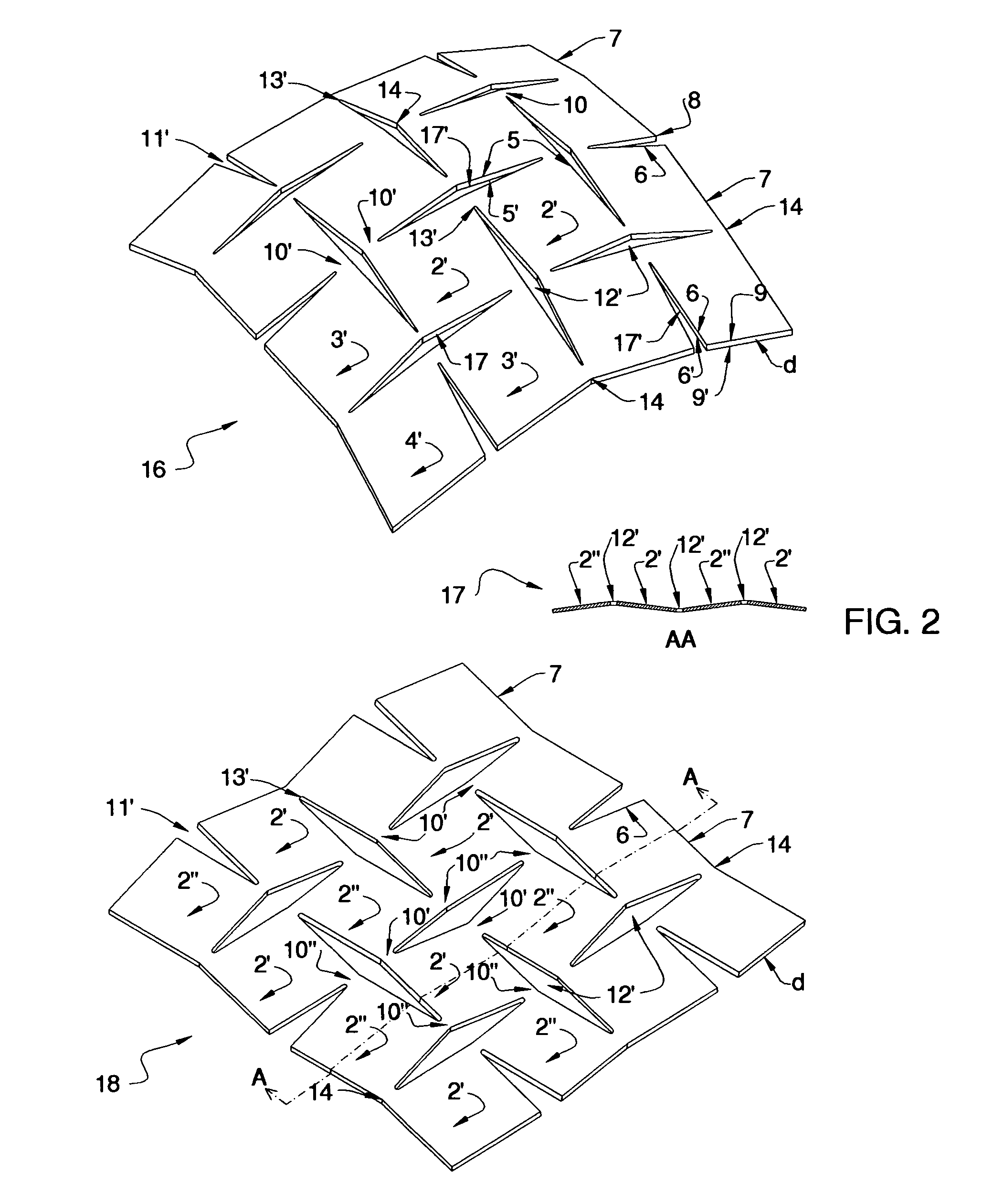

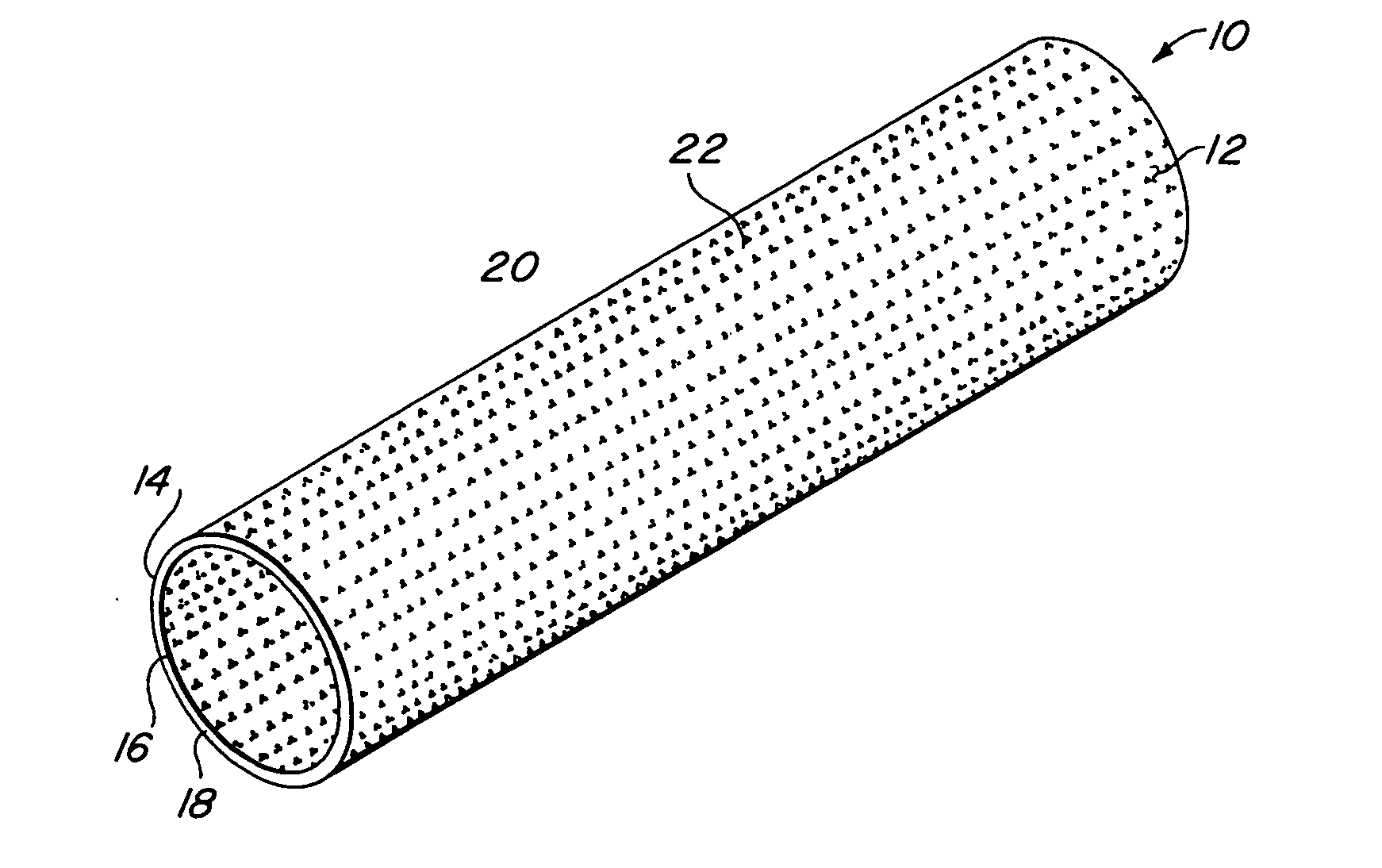

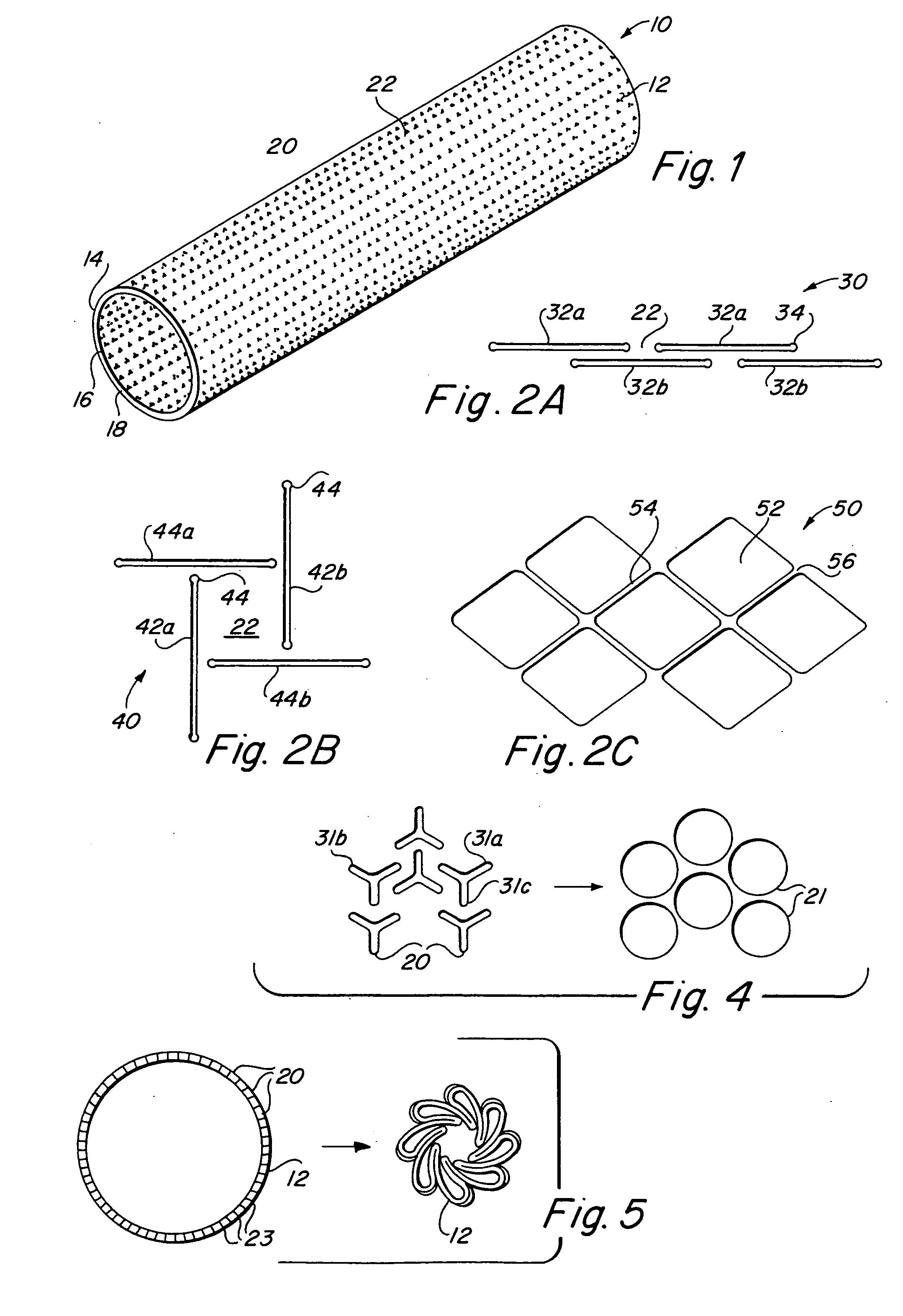

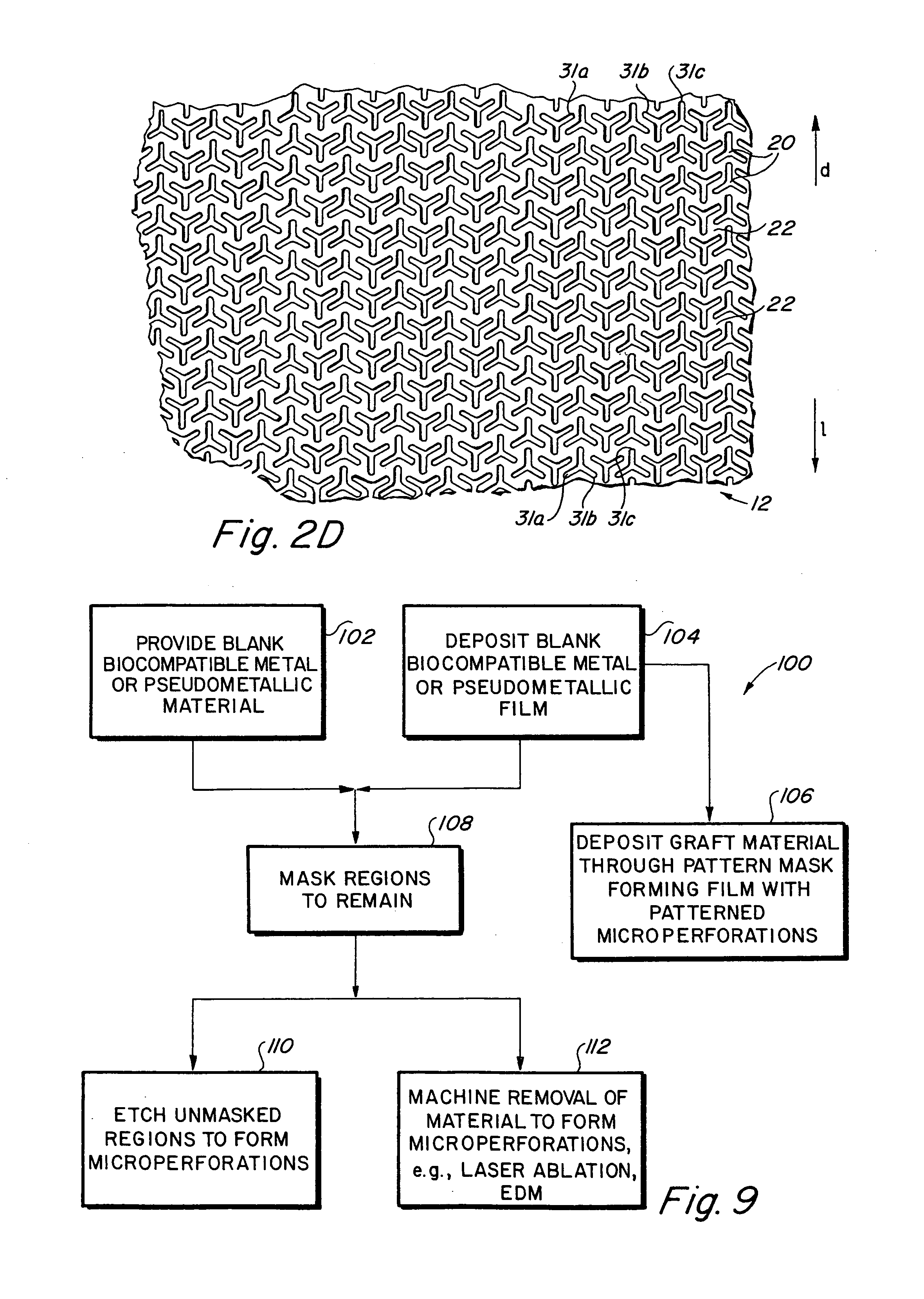

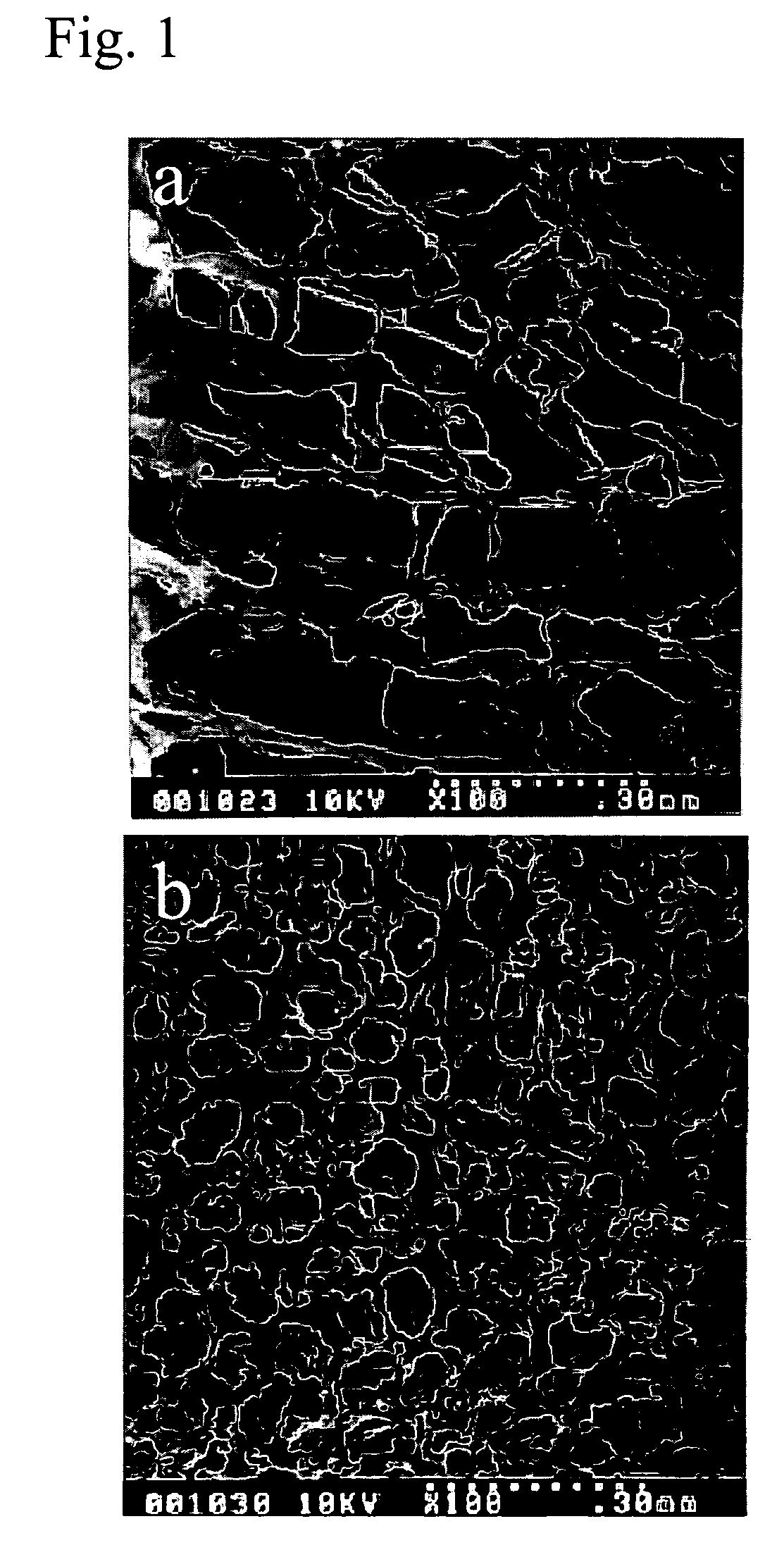

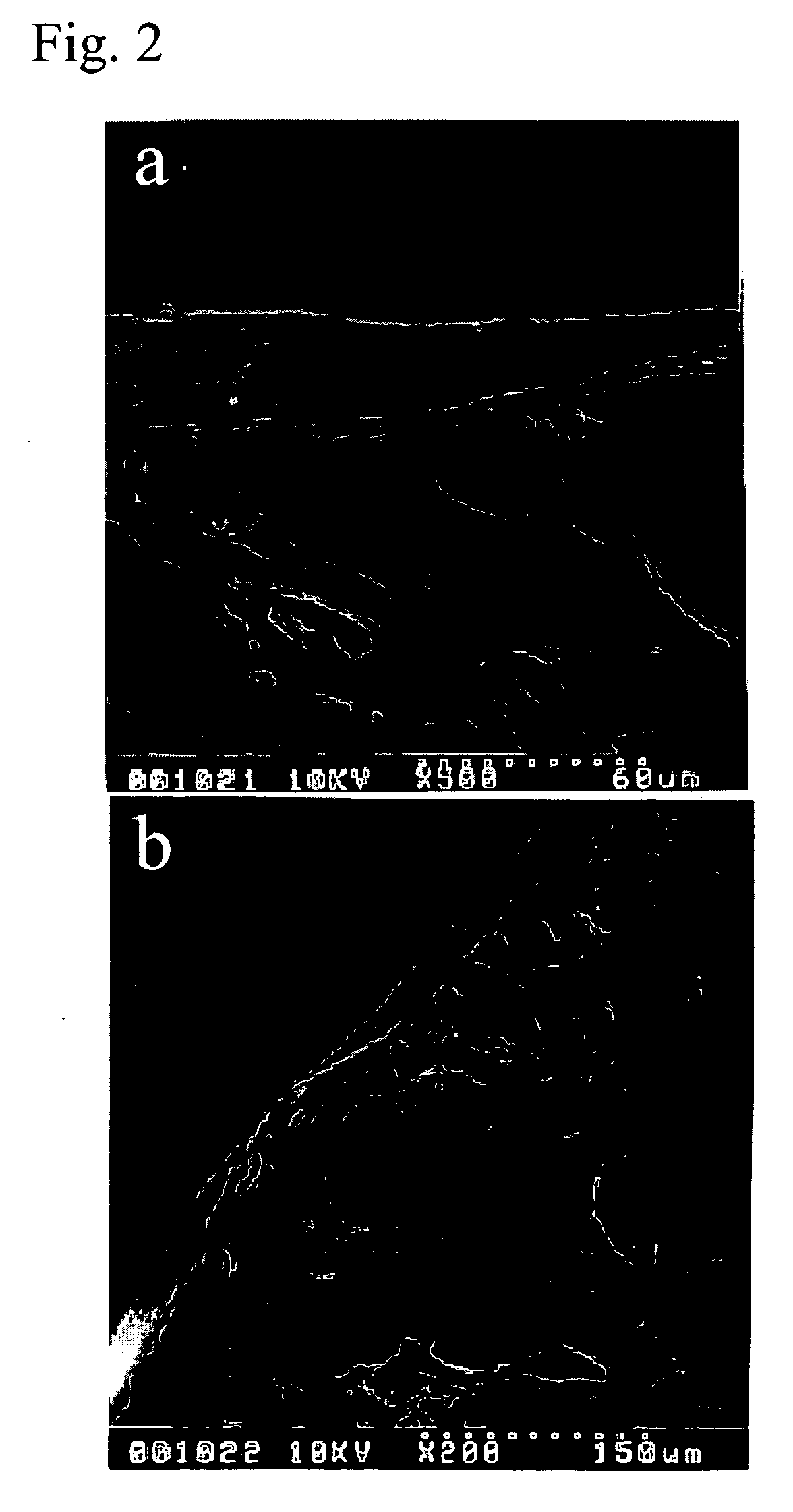

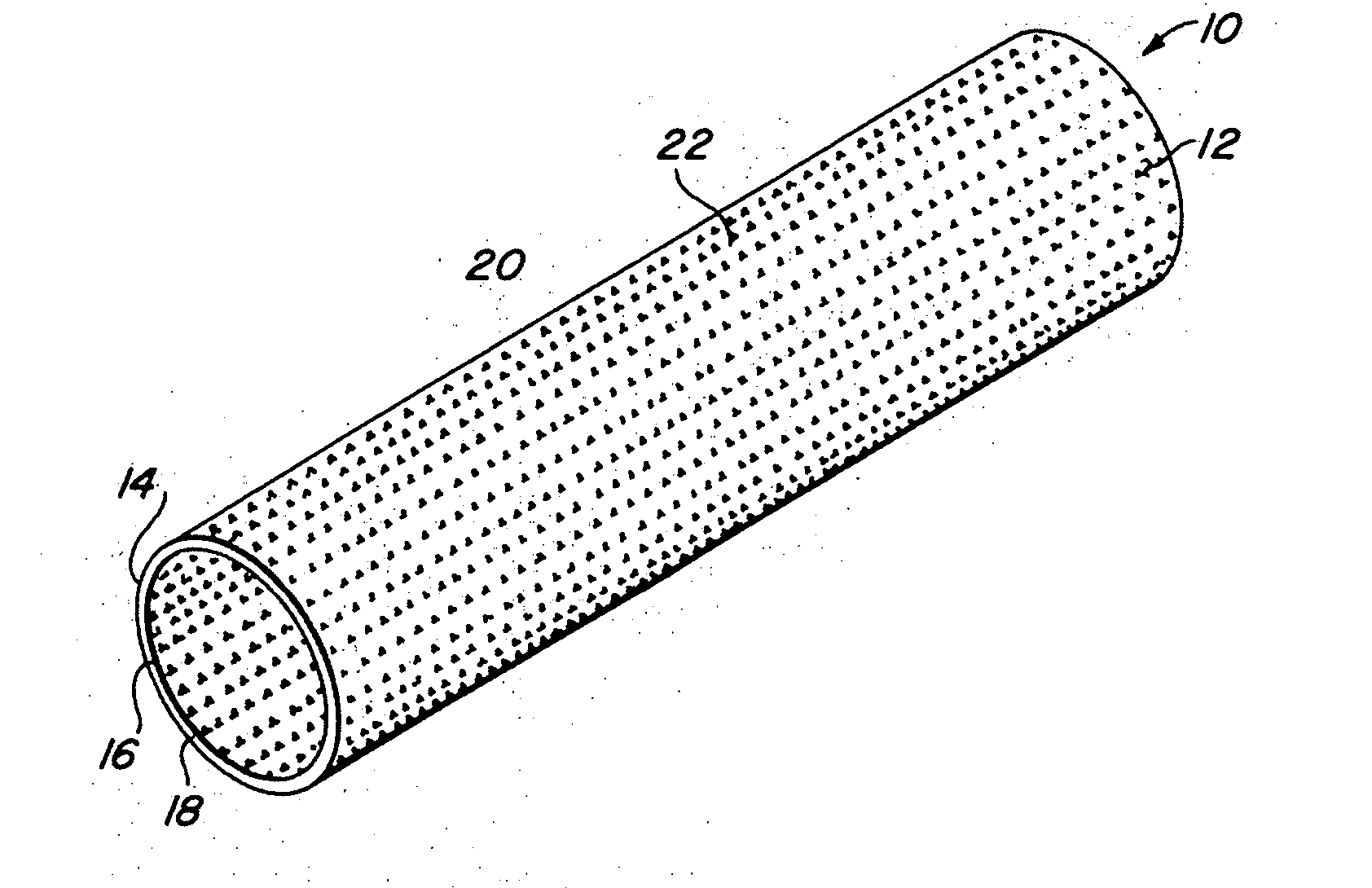

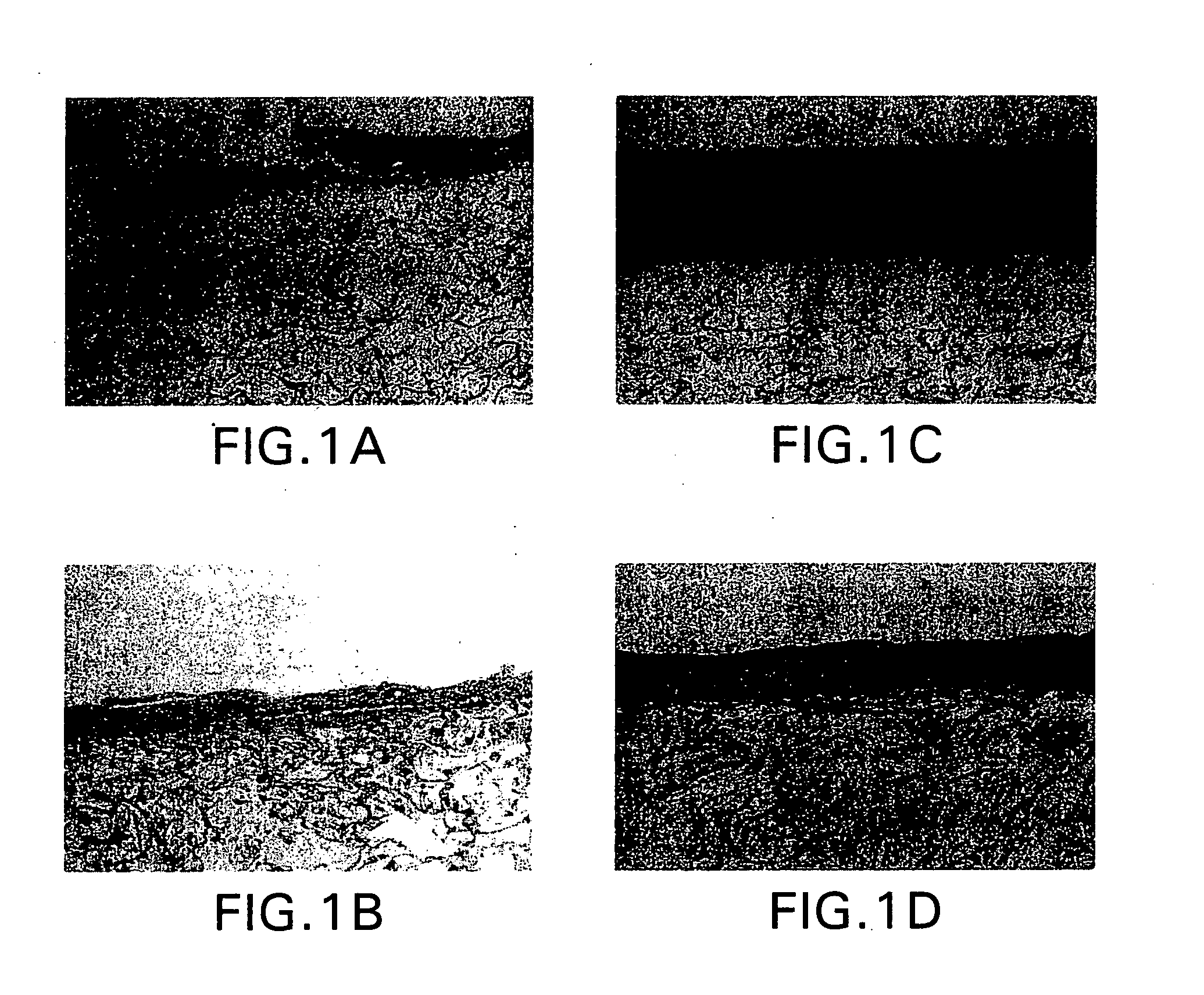

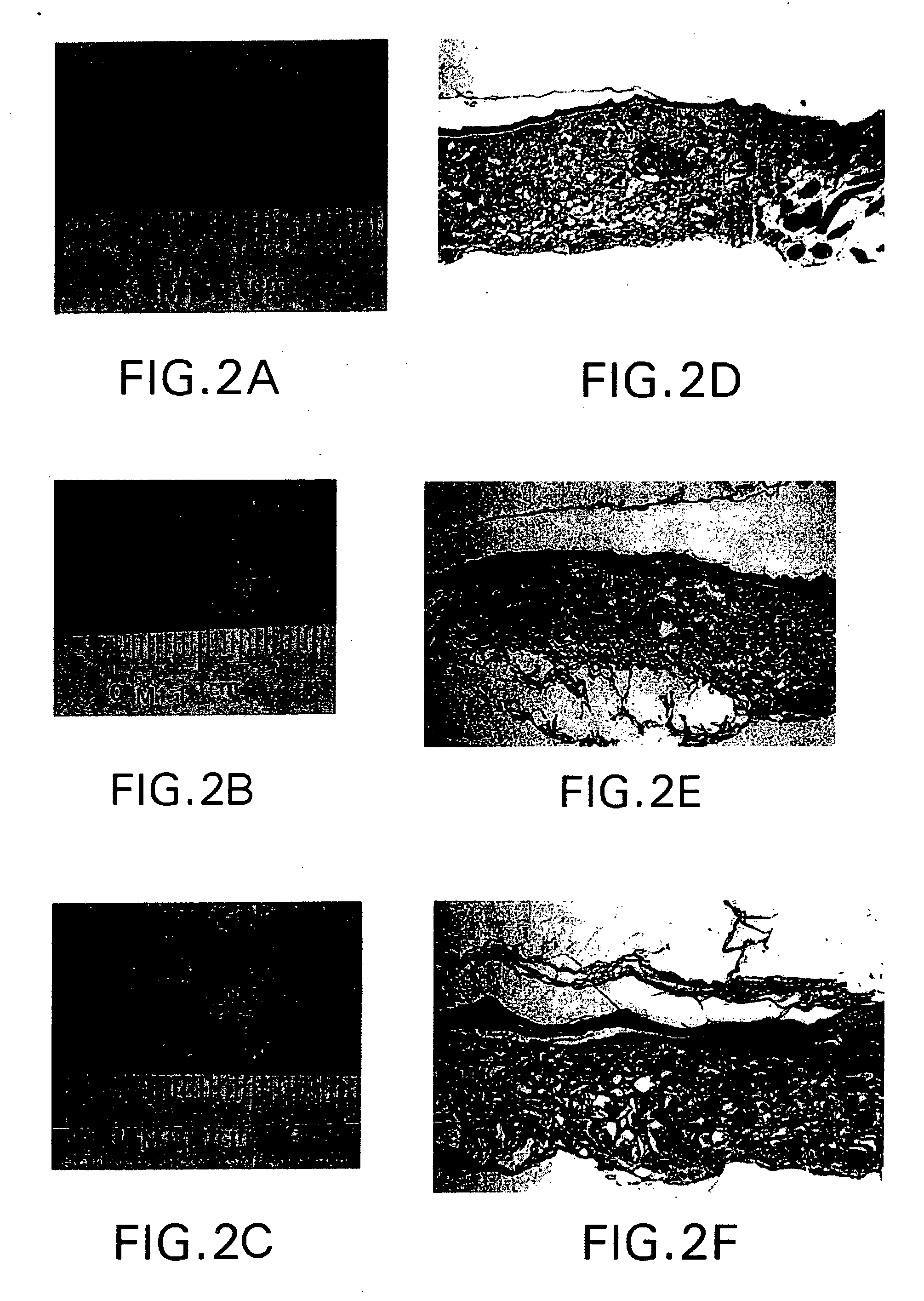

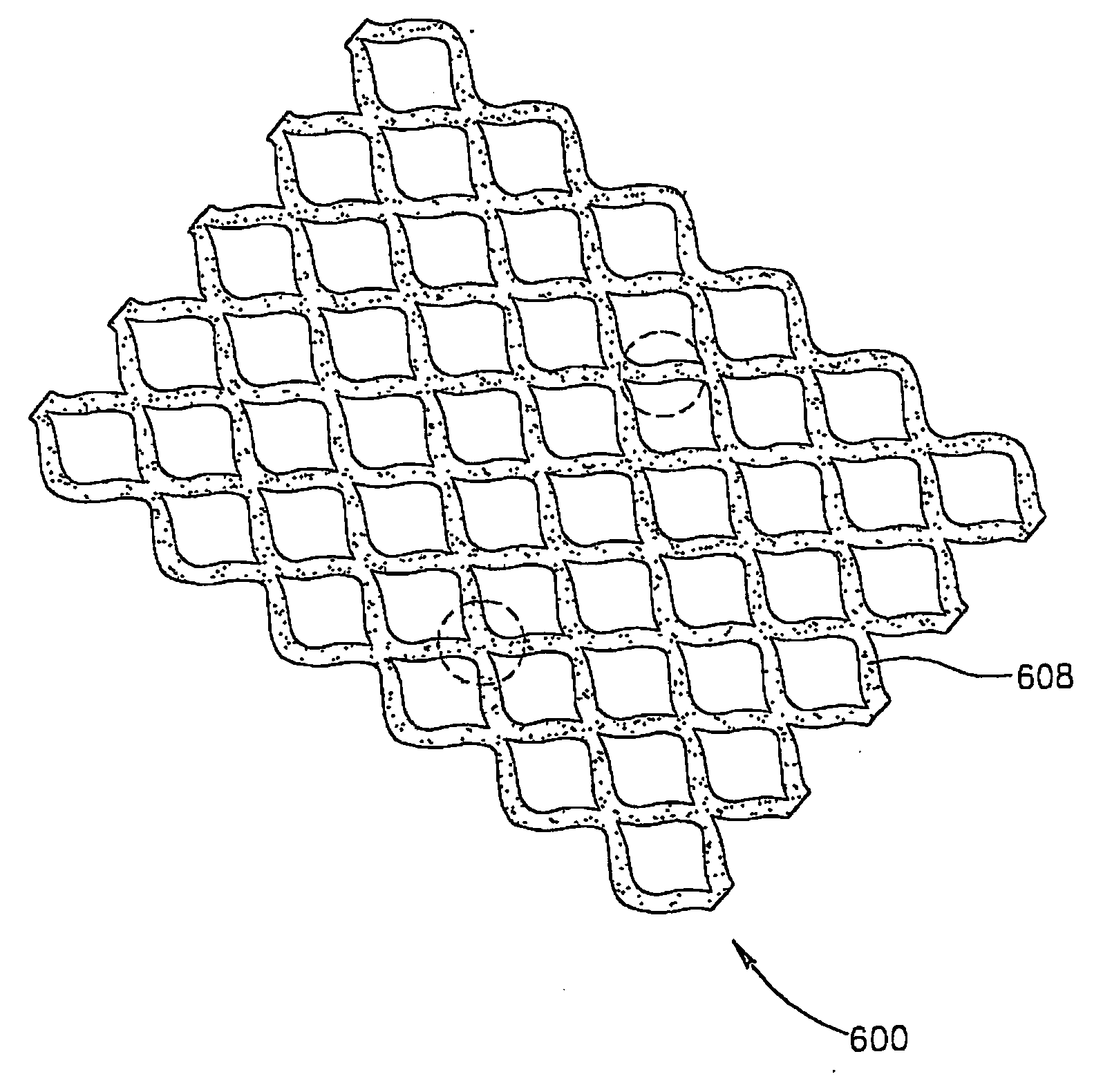

Implantable medical grafts fabricated of metallic or pseudometallic films of biocompatible materials having a plurality of microperforations passing through the film in a pattern that imparts fabric-like qualities to the graft or permits the geometric deformation of the graft. The implantable graft is preferably fabricated by vacuum deposition of metallic and / or pseudometallic materials into either single or multi-layered structures with the plurality of microperforations either being formed during deposition or after deposition by selective removal of sections of the deposited film. The implantable medical grafts are suitable for use as endoluminal or surgical grafts and may be used as vascular grafts, stent-grafts, skin grafts, shunts, bone grafts, surgical patches, non-vascular conduits, valvular leaflets, filters, occlusion membranes, artificial sphincters, tendons and ligaments.

Owner:VACTRONIX SCI LLC

Self-supporting metallic implantable grafts, compliant implantable medical devices and methods of making same

Implantable medical grafts fabricated of metallic or pseudometallic films of biocompatible materials having a plurality of microperforations passing through the film in a pattern that imparts fabric-like qualities to the graft or permits the geometric deformation of the graft. The implantable graft is preferably fabricated by vacuum deposition of metallic and / or pseudometallic materials into either single or multi-layered structures with the plurality of microperforations either being formed during deposition or after deposition by selective removal of sections of the deposited film. The implantable medical grafts are suitable for use as endoluminal or surgical grafts and may be used as vascular grafts, stent-grafts, skin grafts, shunts, bone grafts, surgical patches, non-vascular conduits, valvular leaflets, filters, occlusion membranes, artificial sphincters, tendons and ligaments.

Owner:VACTRONIX SCI LLC

Silver-containing, sol/gel derived bioglass compositions

Silver-containing, sol-gel derived bioactive glass compositions and methods of preparation and use thereof are disclosed. The compositions can be in the form of particles, fibers and / or coatings, among other possible forms, and can be used, for example, for treating wounds, improving the success of skin grafts, reducing the inflammatory response and providing anti-bacterial treatments to a patient in need thereof. Anti-bacterial properties can be imparted to implanted materials, such as prosthetic implants, sutures, stents, screws, plates, tubes, and the like, by incorporating the compositions into or onto the implanted materials. The compositions can also be used to prepare devices used for in vitro and ex vivo cell culture.

Owner:IMPERIAL INNOVATIONS LTD

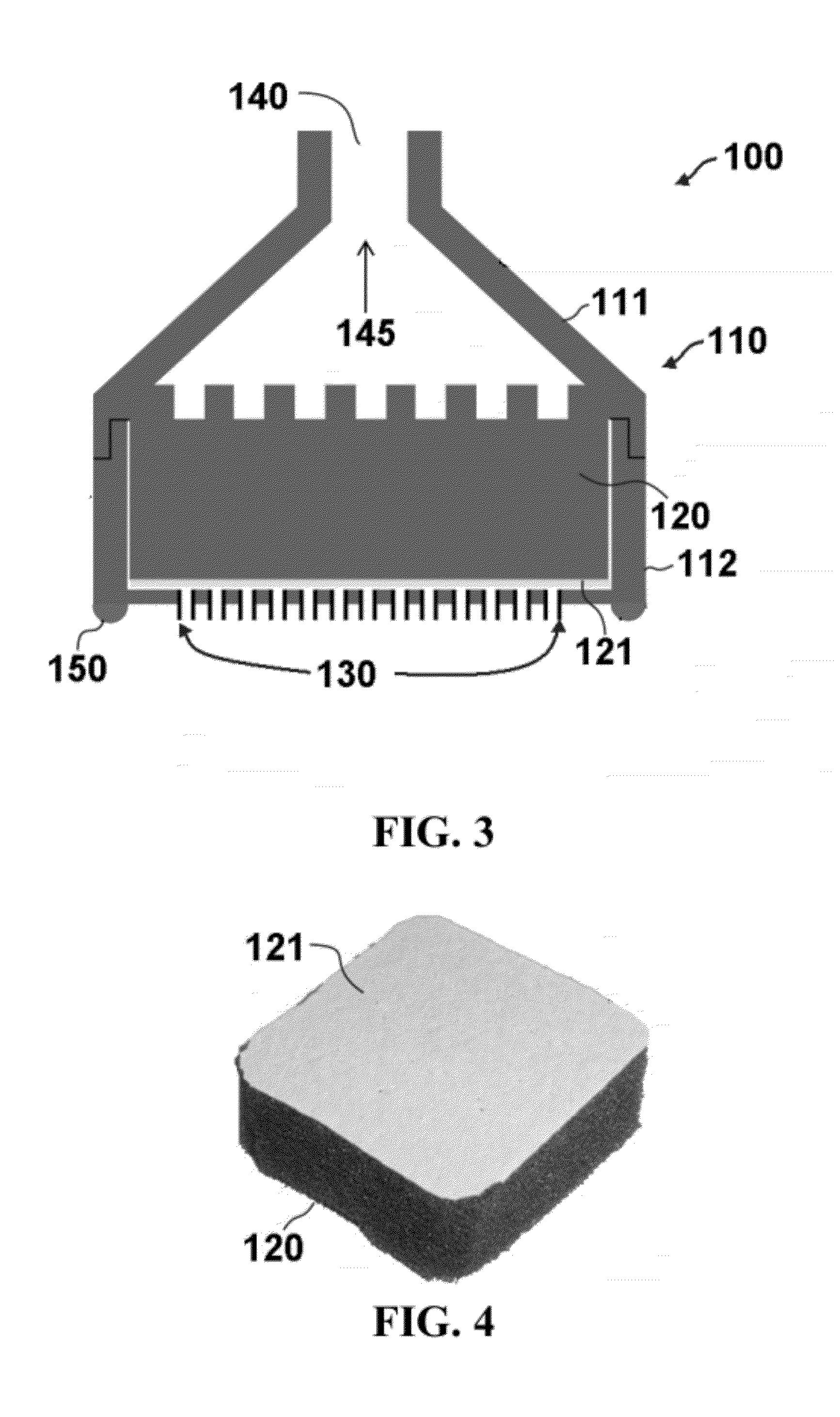

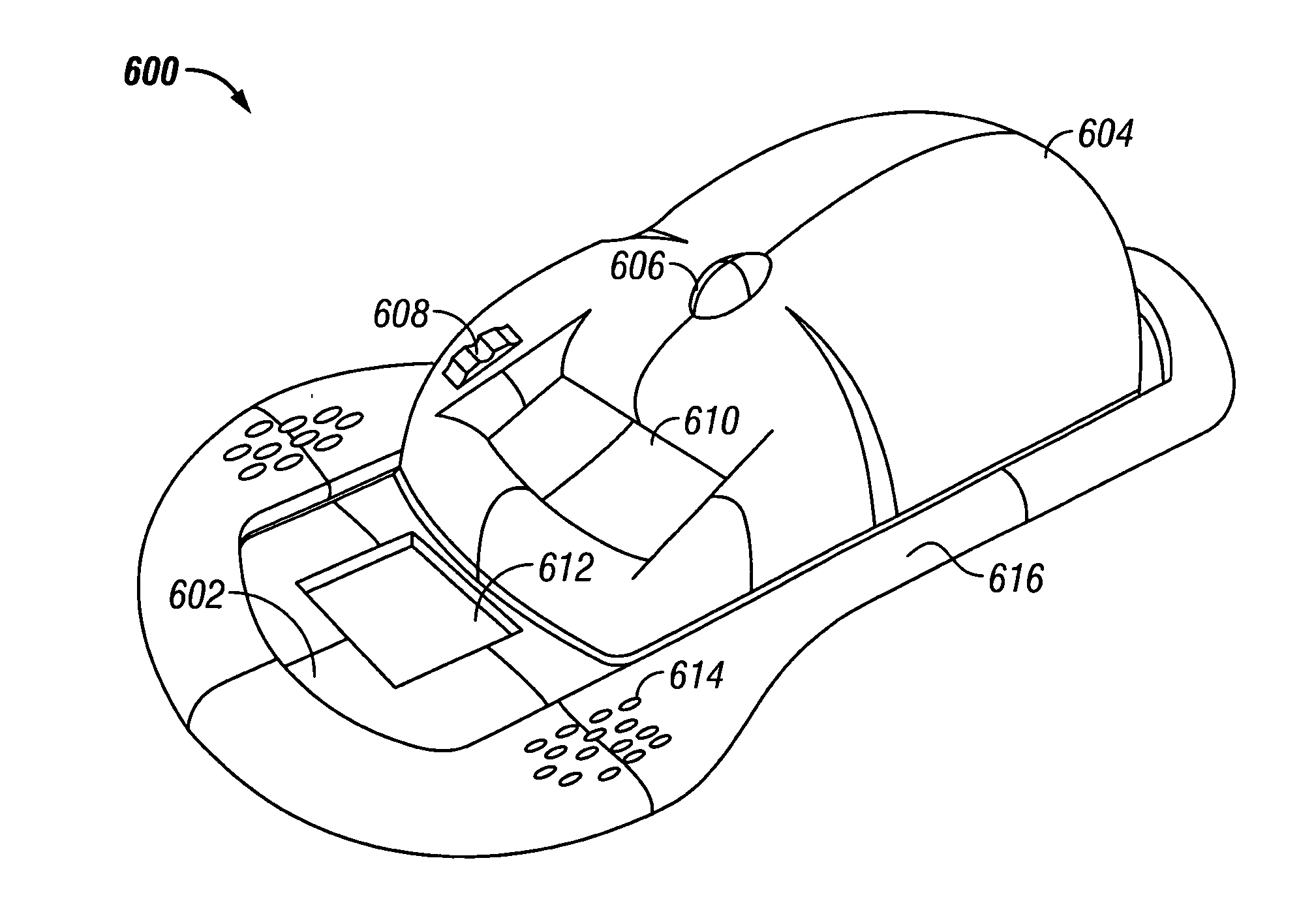

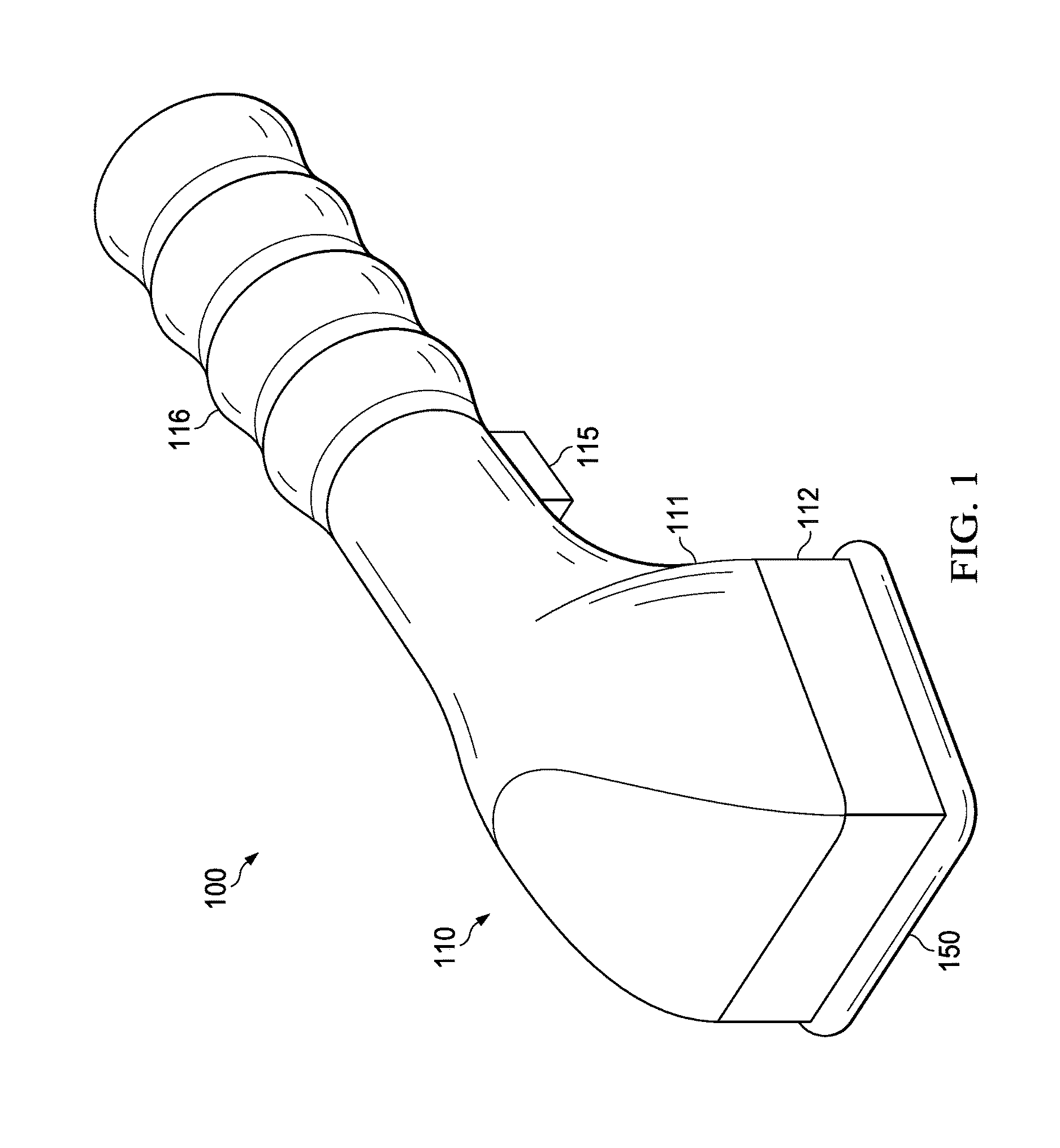

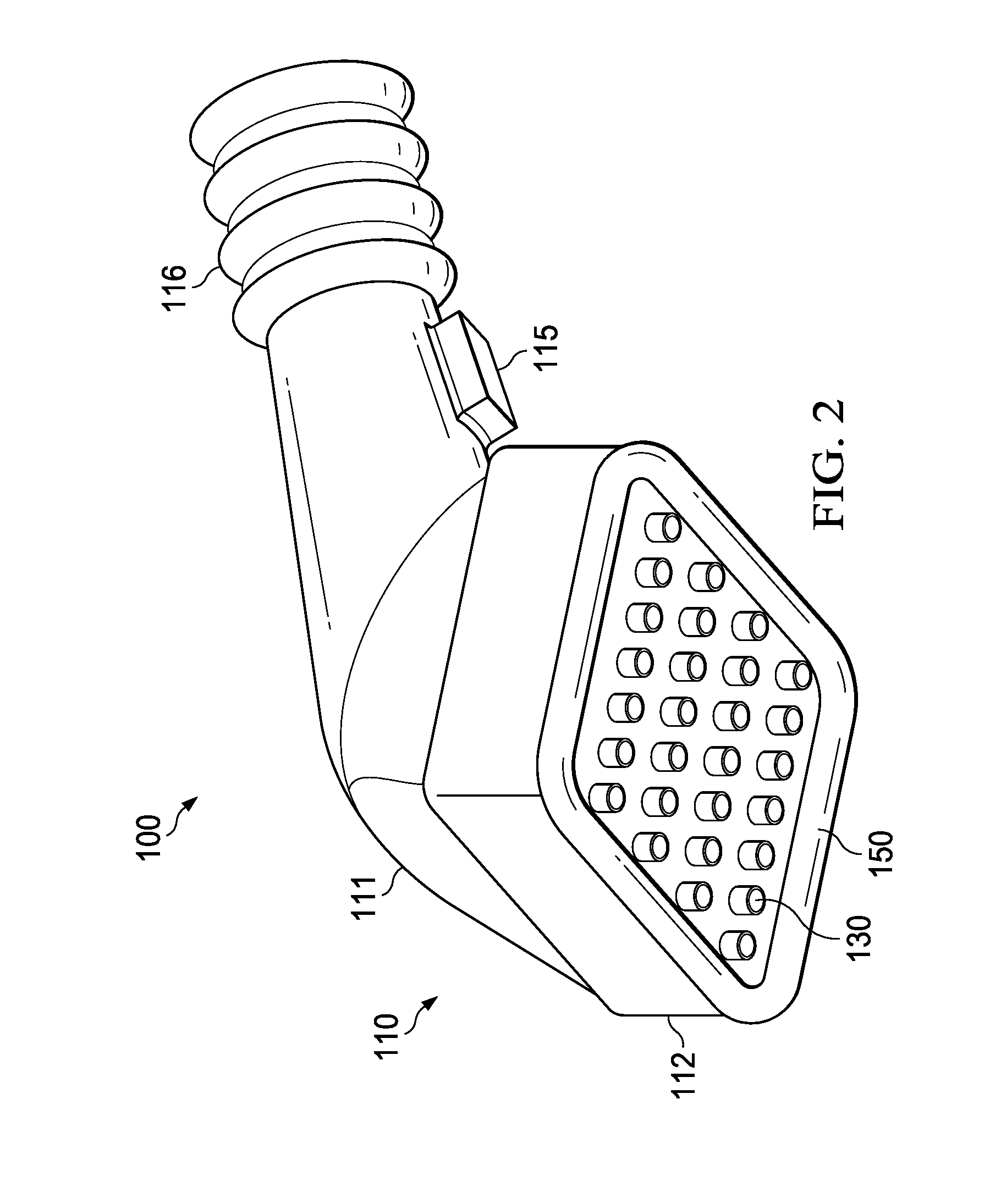

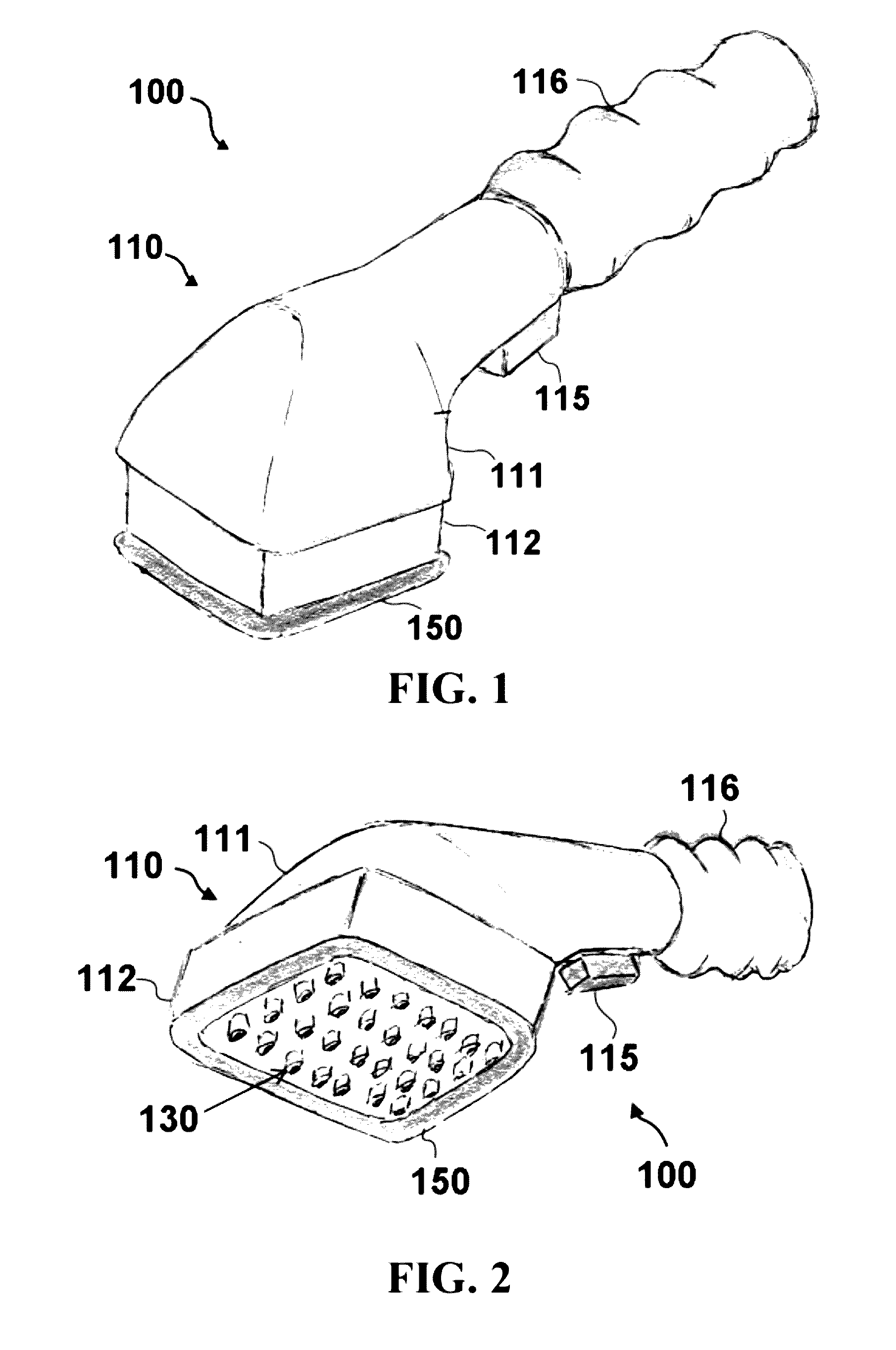

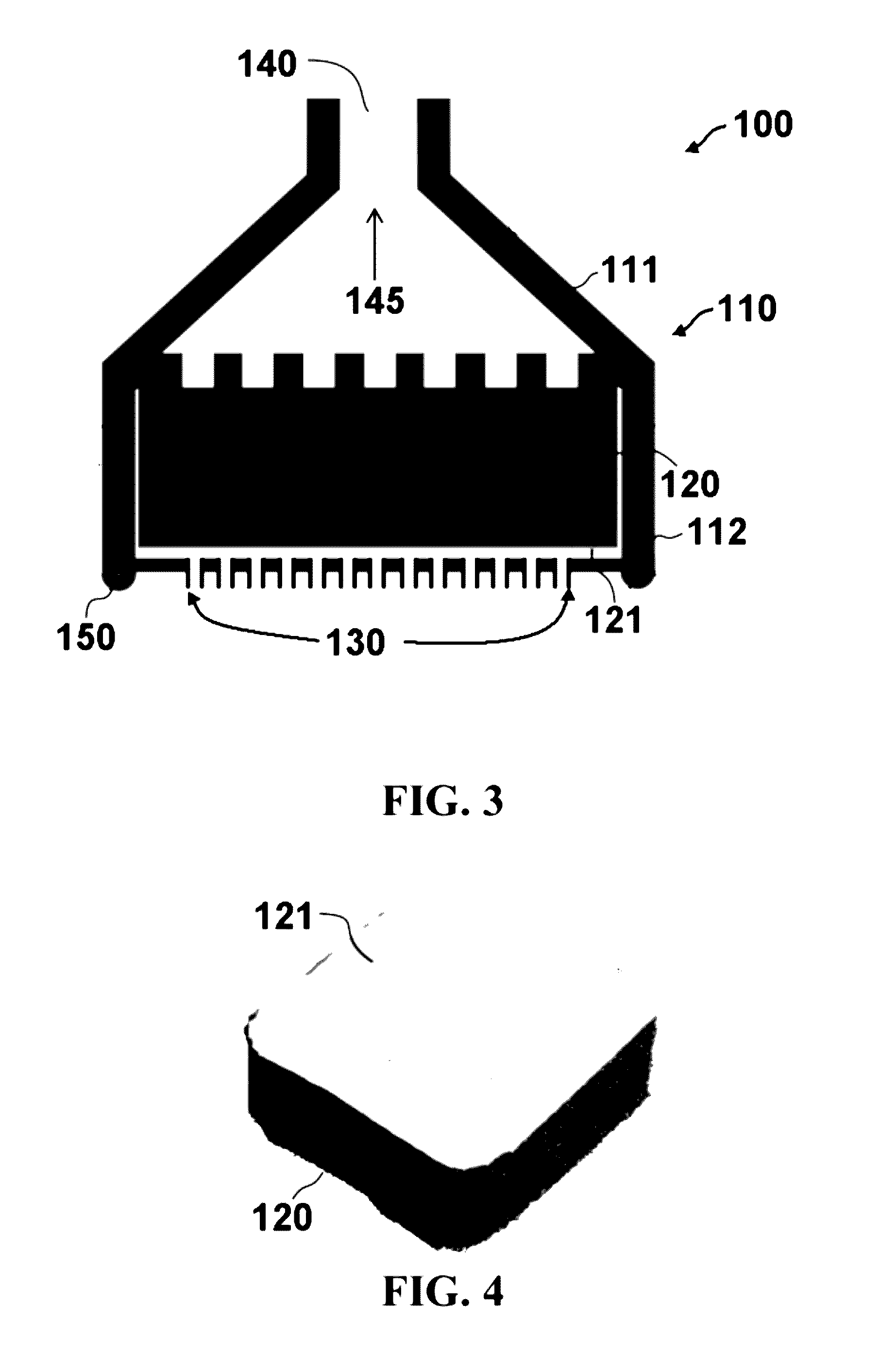

Skin graft devices and methods

ActiveUS20120271320A1Vaccination/ovulation diagnosticsExcision instrumentsSkin graftingSkin transplantation

Owner:3M INNOVATIVE PROPERTIES CO

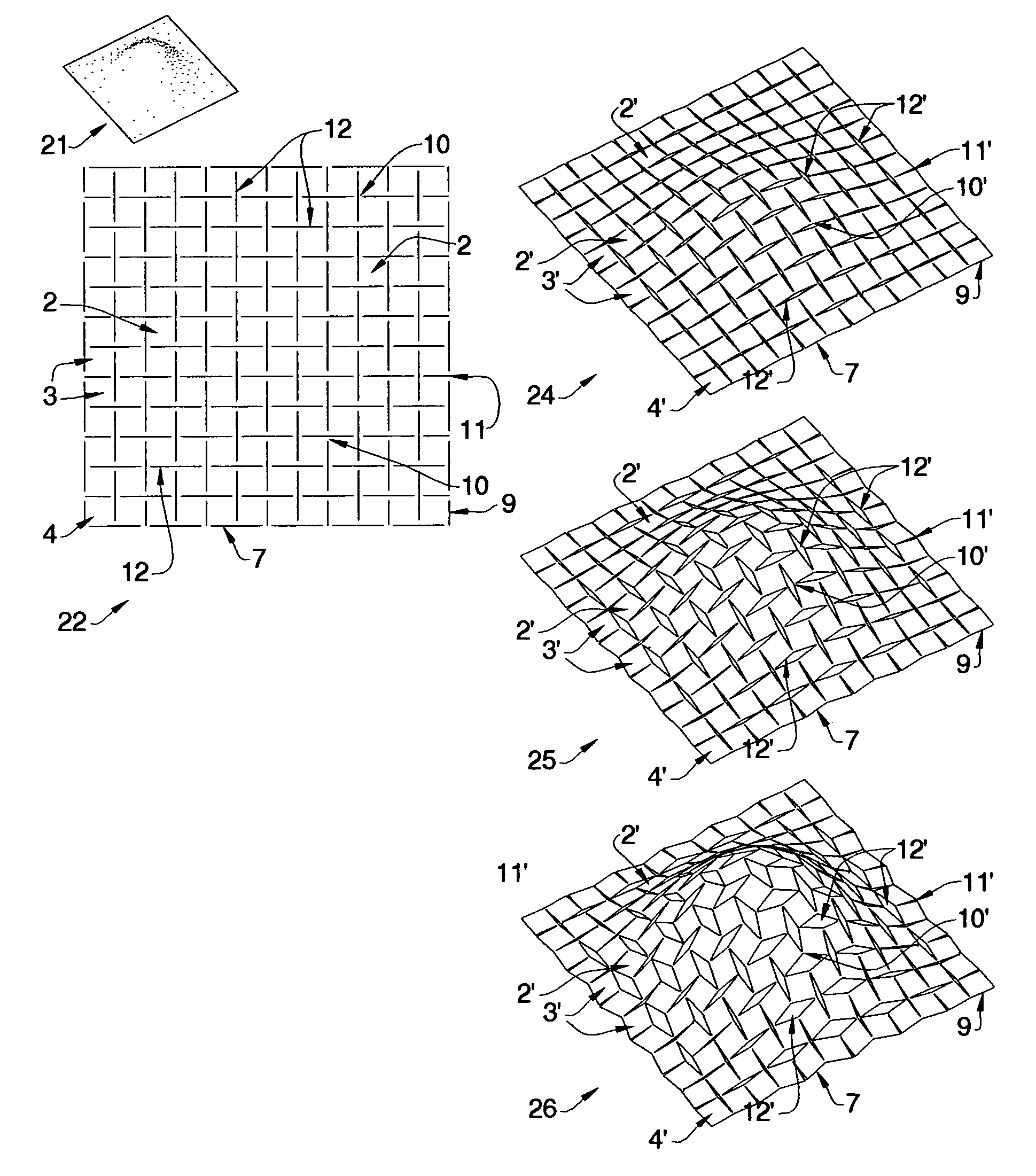

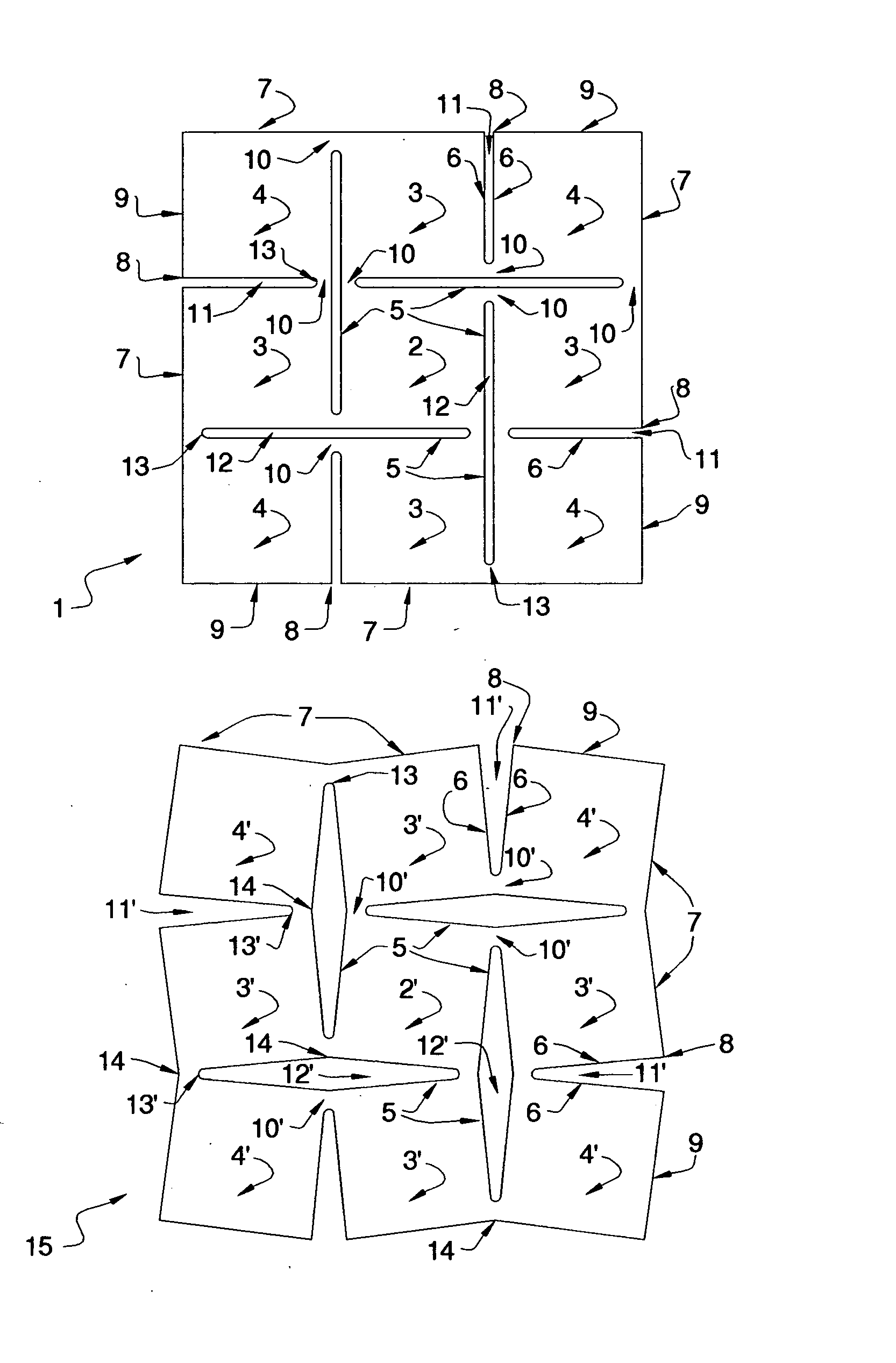

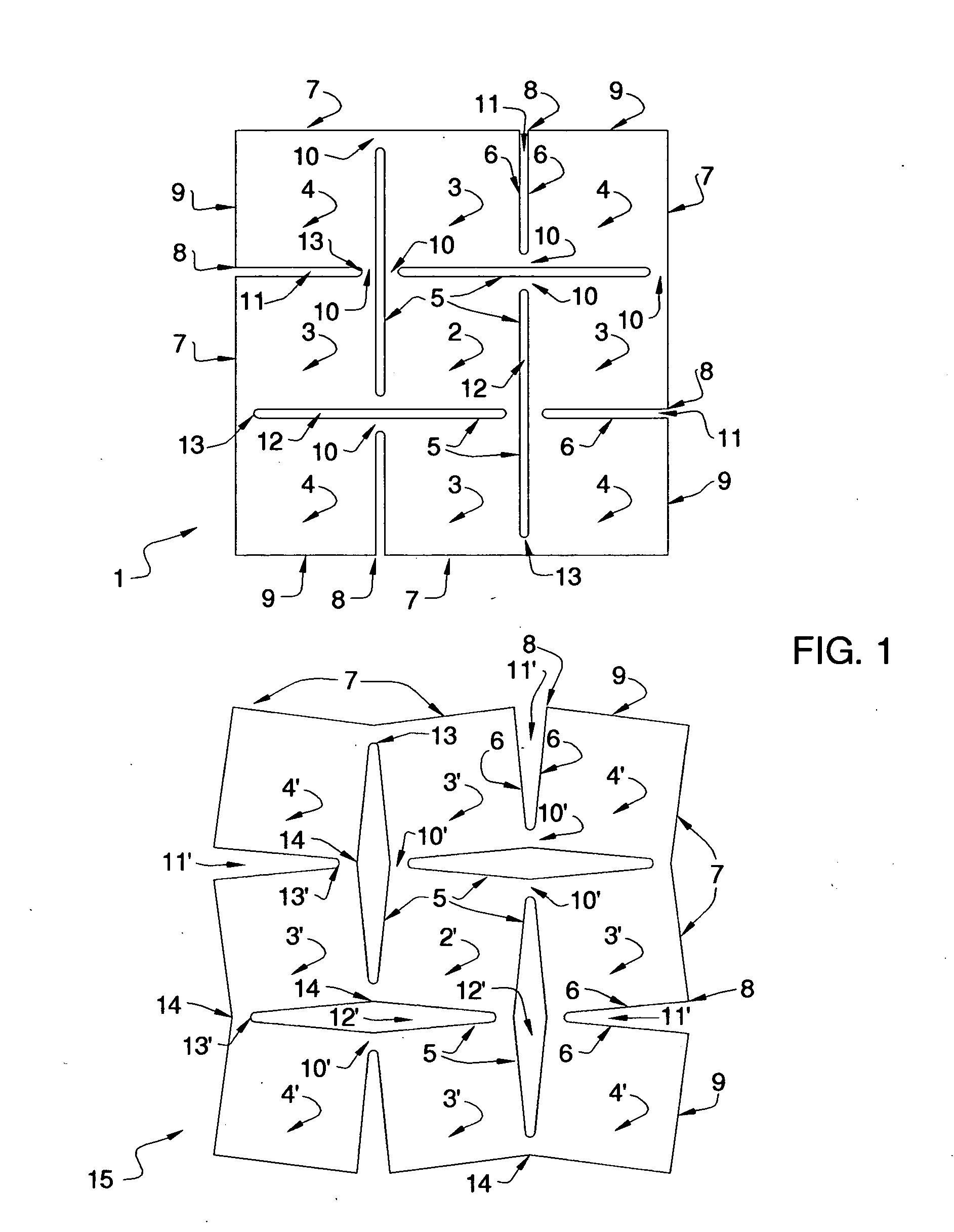

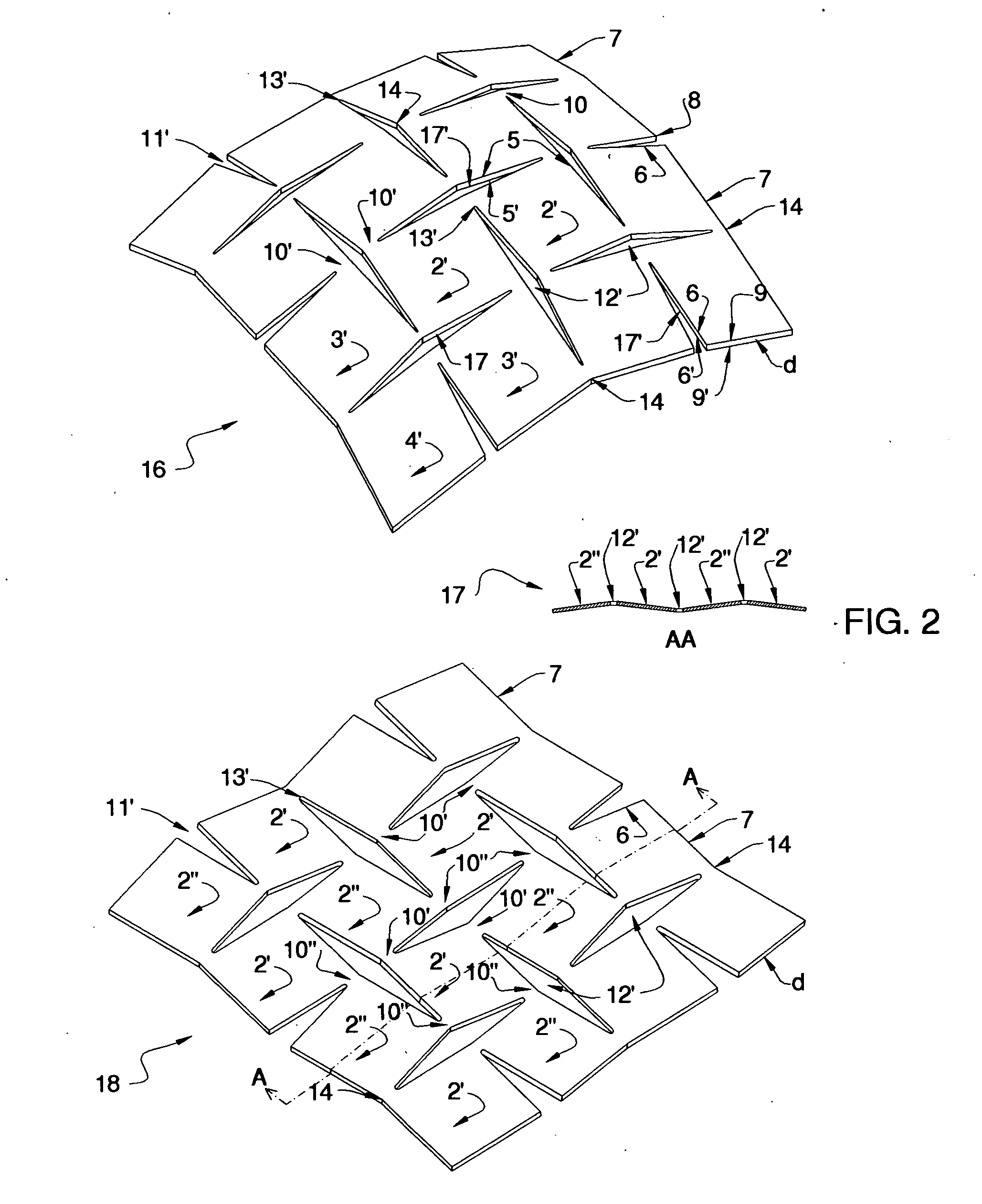

Multi-directional and variably expanded sheet material surfaces

ActiveUS8084117B2Efficient use ofIncrease surface areaPaper/cardboard articlesFloorsLaser cuttingMulti directional

Owner:LALVANI HARESH

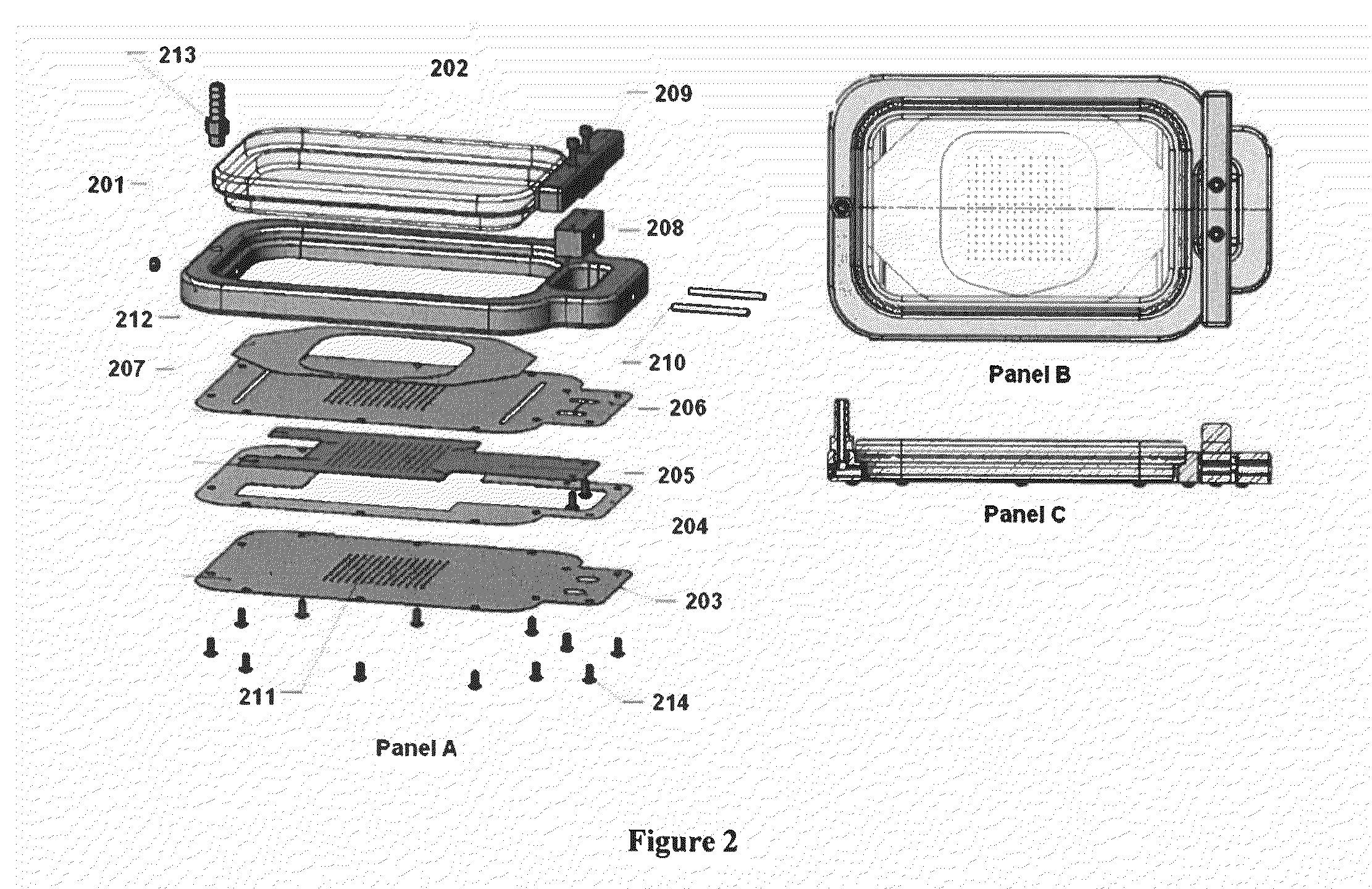

Skin grafting devices and methods

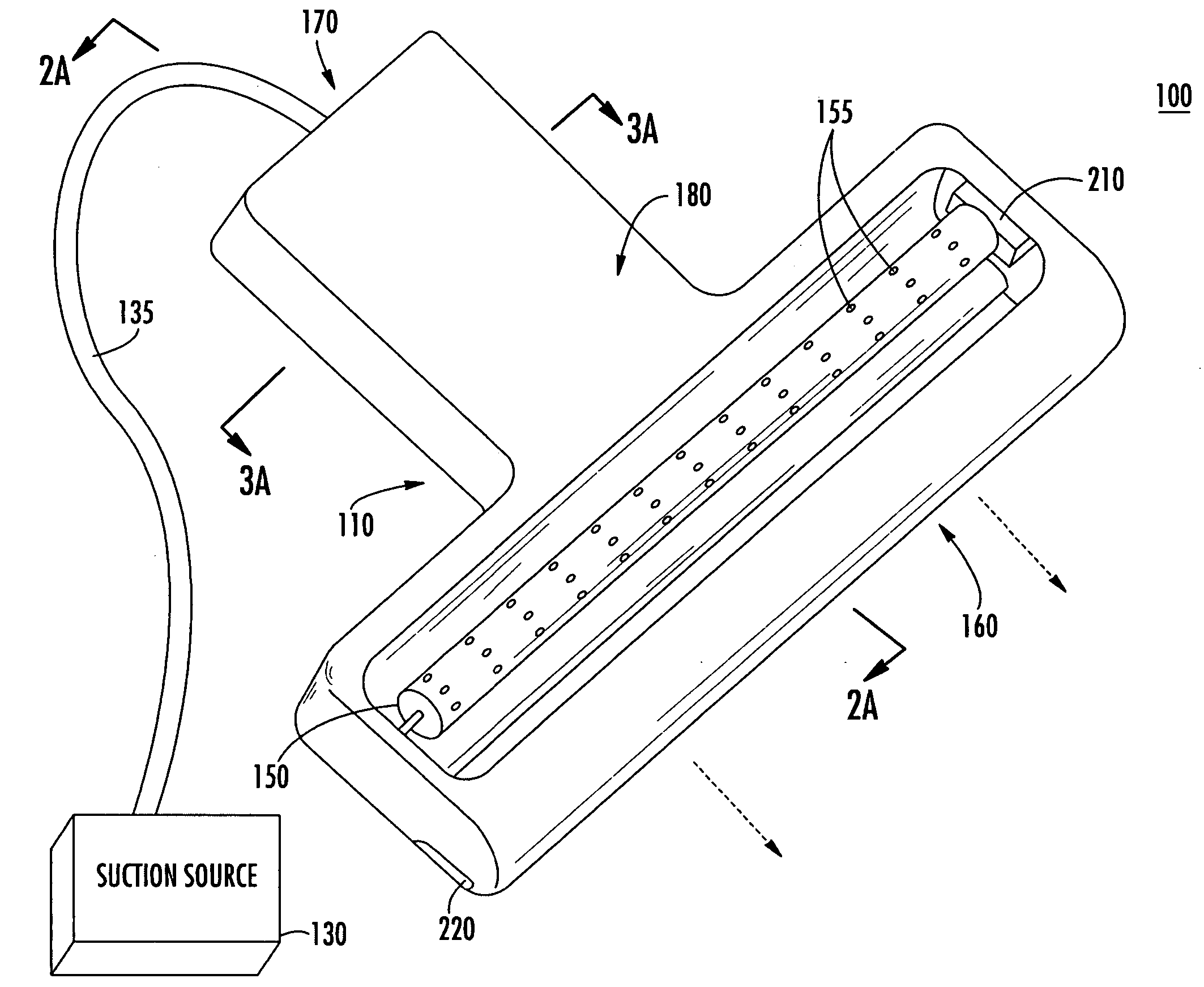

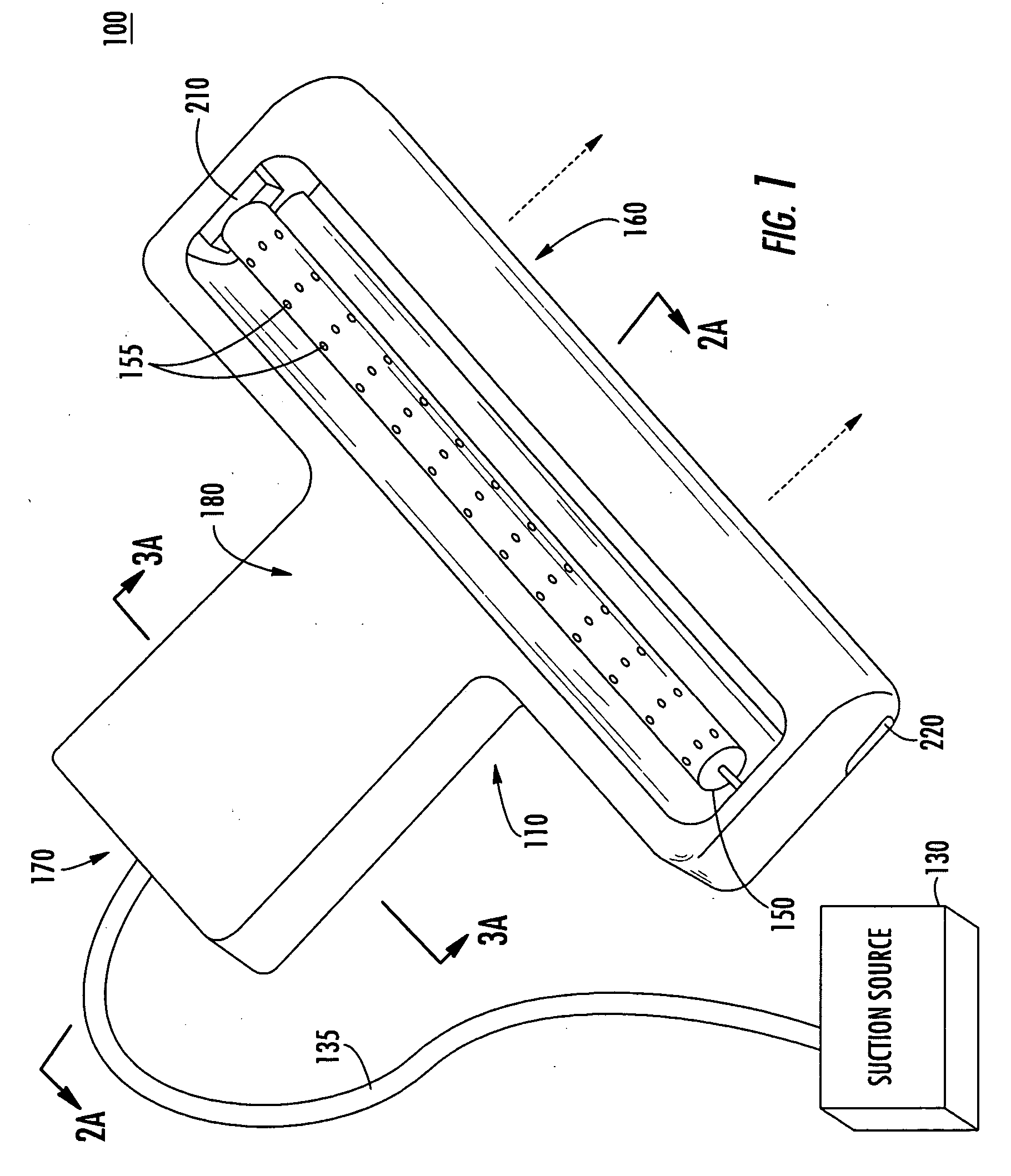

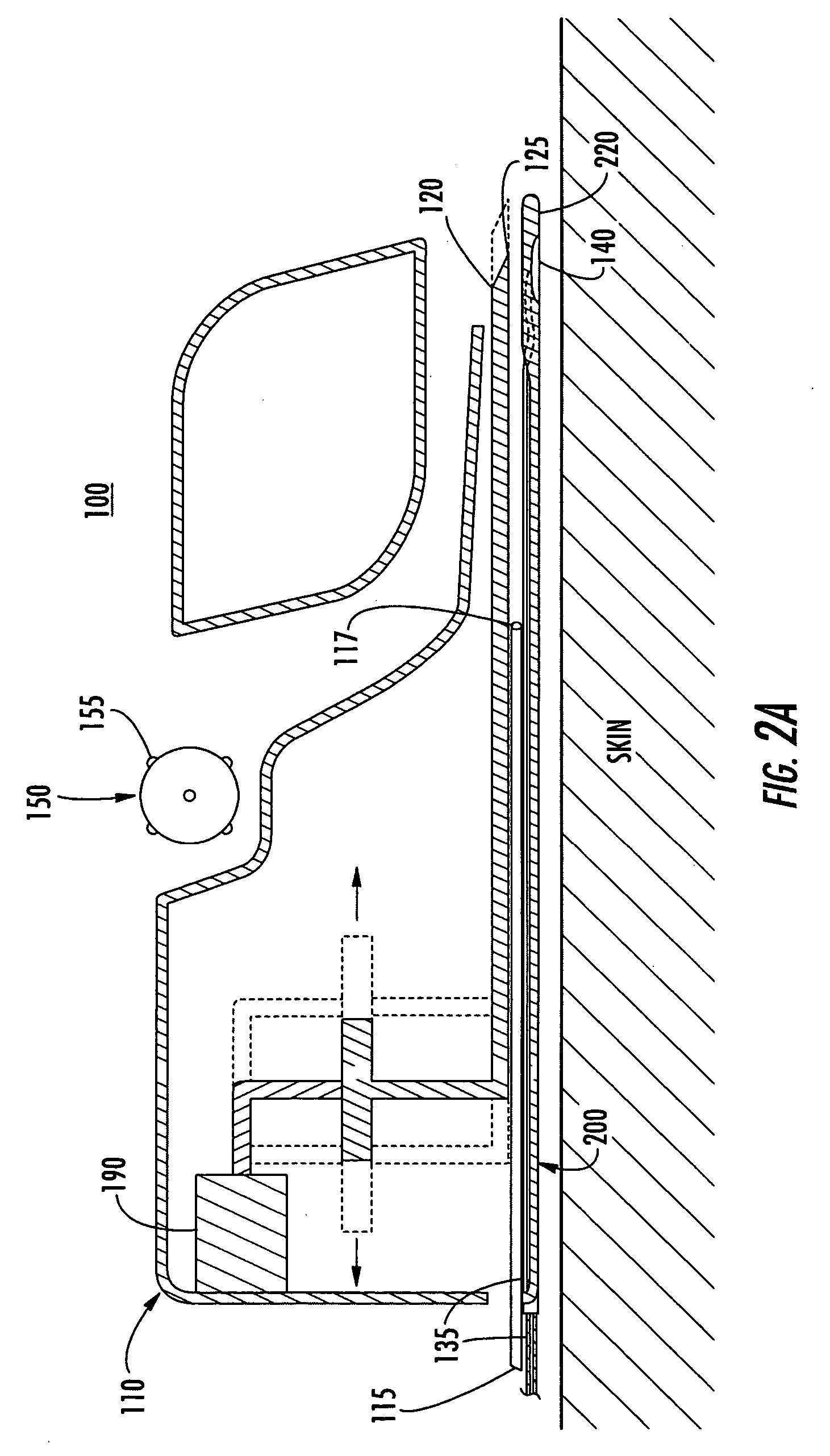

The present invention provides skin grafting and devices that comprise a systematic approach to the process of skin grafting, i.e., harvesting, post-excision processing and application of donor skin and pre and post-graft treatment of the recipient site.

Owner:KCI LICENSING INC

Multi-directional and variably expanded sheet material surfaces

ActiveUS20070122590A1Efficient use ofIncrease surface areaPaper/cardboard articlesFloorsLaser cuttingNanoscopic scale

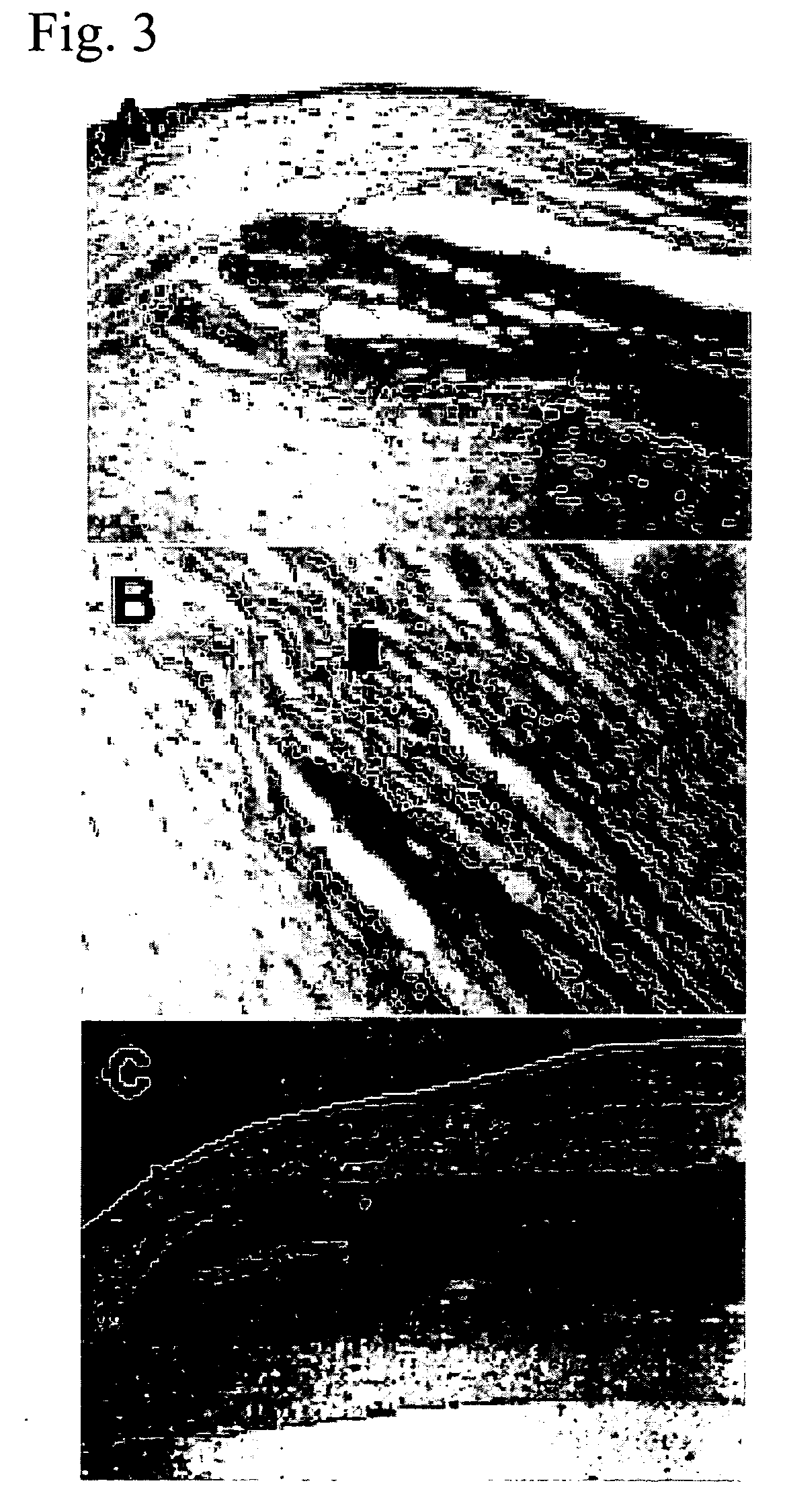

Expandable surfaces made from sheet materials with slits distributed on the surface of sheet material where the surfaces expand by application of force along or / and across the surface of sheet material. The unexpanded surfaces are flat sheets, or closed surfaces like cylinders, spheres, tubes, or custom-designed organic shapes marked with pre-formed or post-formed slit designs. The expanded surfaces can be single units or modules which can be attached to one another through various means. The sheet materials range from hard surfaces like metals, to softer materials like papers and plastics, or pliable materials like fabrics, rubbers, synthetic surfaces or bio-surfaces. The slits are arranged in patterns ranging from periodic, non-periodic to irregular designs. The slits can be straight, bent, curved or irregularly shaped with even or uneven spacing. Slitting can be achieved by digital cutting or punching devices like laser-cutting, water-jet cutting, digital punching, automated dies, etc. or pre-formed when casting the sheet material. Force can be applied manually with tools or through the use of machines and special set-ups. Applications range from architectural surfaces, walls, ceilings, panel systems, structures and sculpture. On a smaller scale, applications include containers, packaging material, fabrics and human wear. On micro- to nano-scale, applications range from expandable surfaces for gauzes, band-aids, stent designs, skin grafts, semi-permeable membranes and micro-filters for various industries including purification of fluids and chemical substances.

Owner:LALVANI HARESH

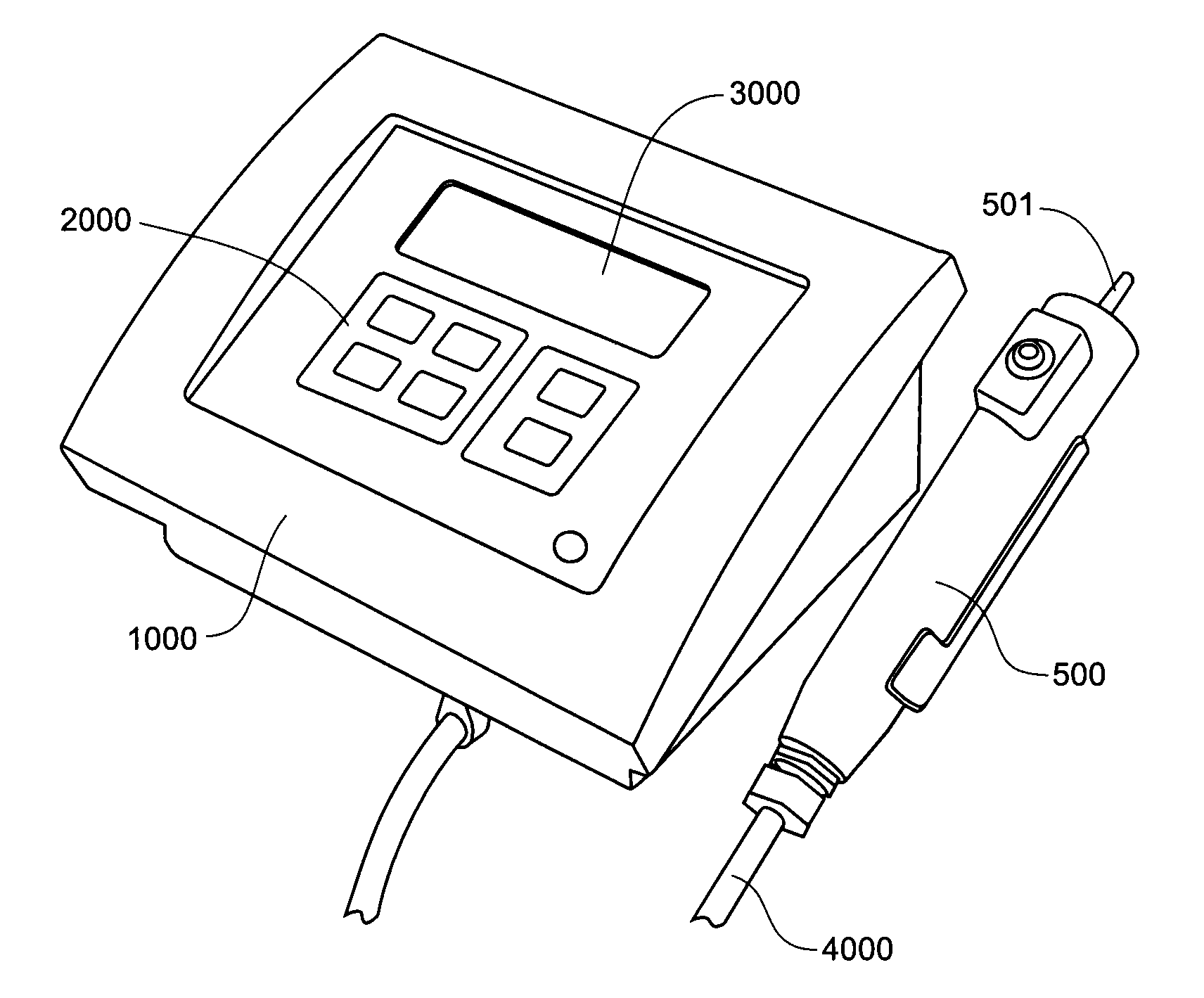

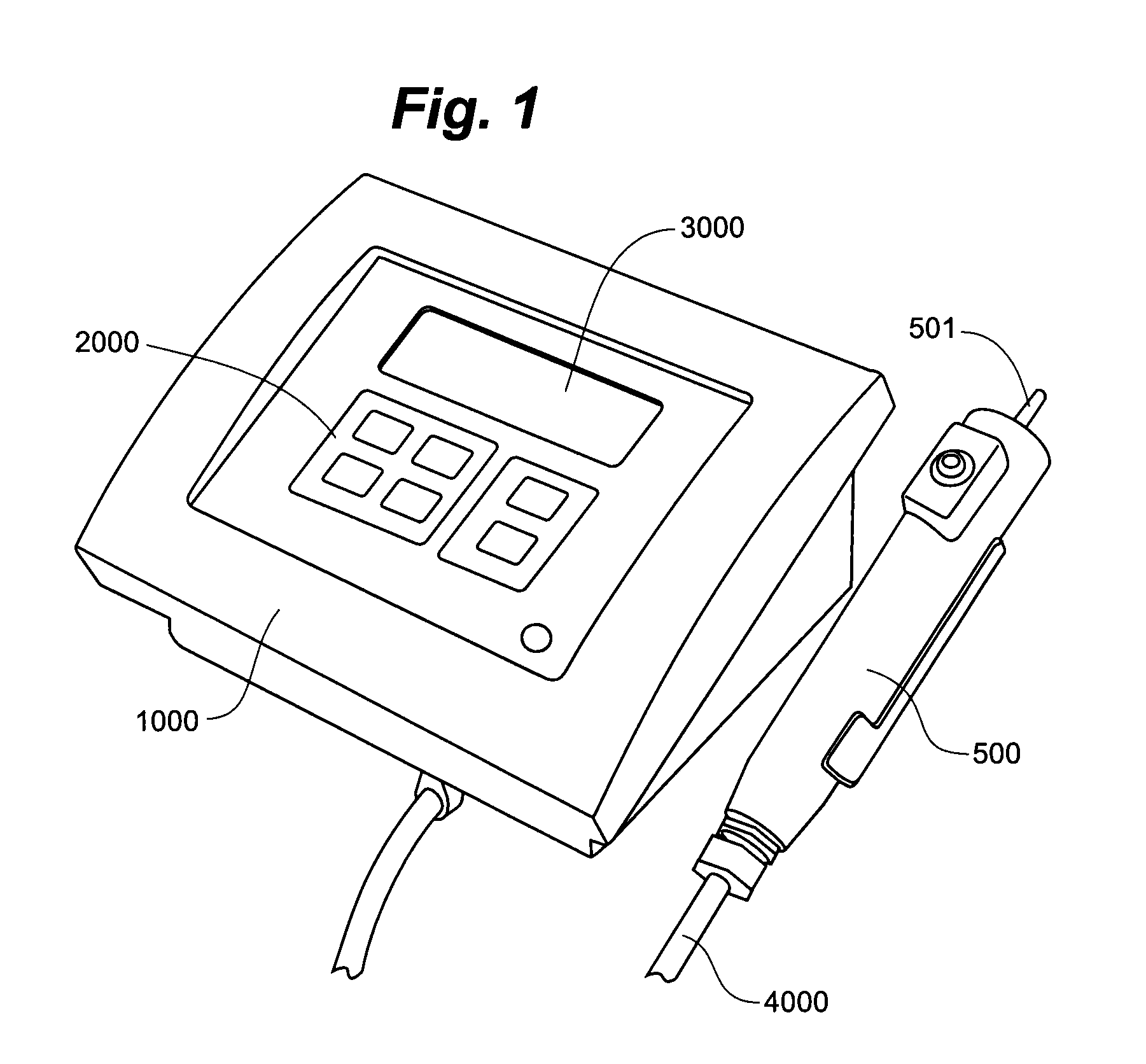

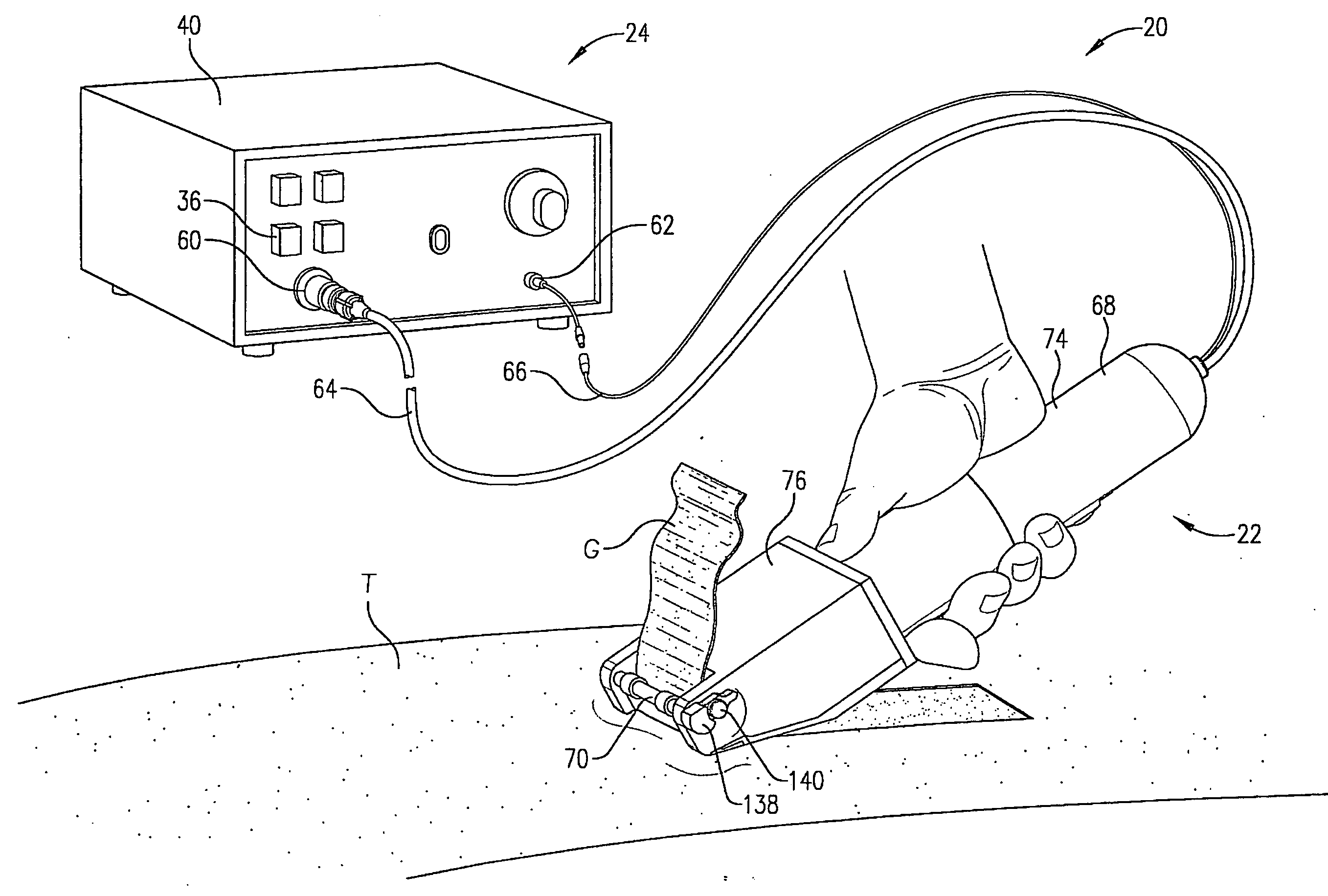

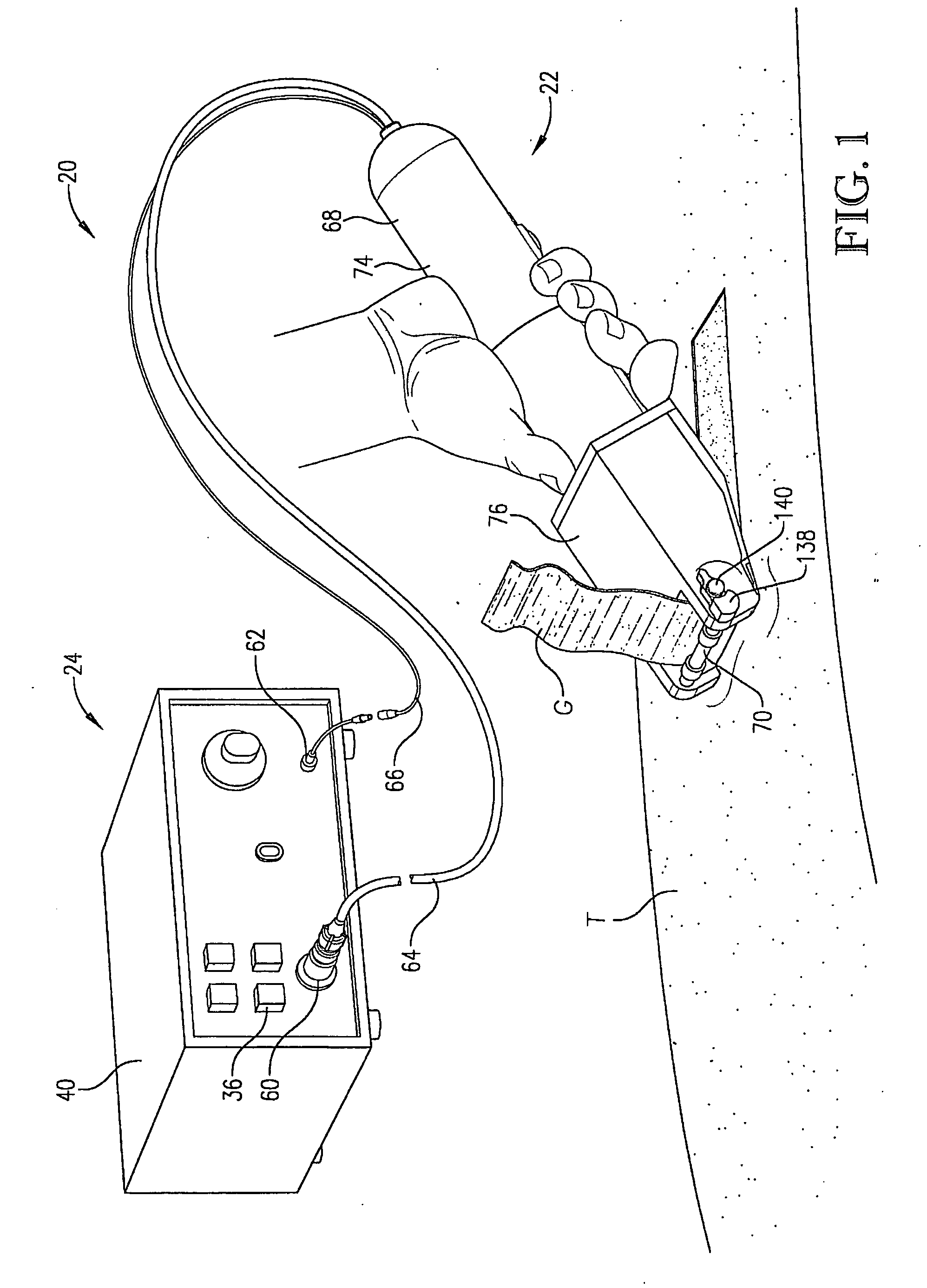

Methods of Skin Grafting Using Ultrasound

InactiveUS20100022919A1Reduction in bacterial burdenRelieve painUltrasound therapySurgerySkin graftingBiomedical engineering

Owner:CELLERATION INC

Compliant implantable medical devices and methods of making same

Owner:VACTRONIX SCI LLC

Microblister skin grafting

ActiveUS20130204273A1Reducing patient harm and discomfortAdd featureSurgical instruments for heatingSkin graftingBlisters

Owner:3M INNOVATIVE PROPERTIES CO

Beneficial effects of increasing local blood flow

InactiveUS20110028548A1Increase oxygenationImprove tissue nutritionBiocidePeptide/protein ingredientsArginineNitric oxide

Owner:STRATEGIC SCI & TECH

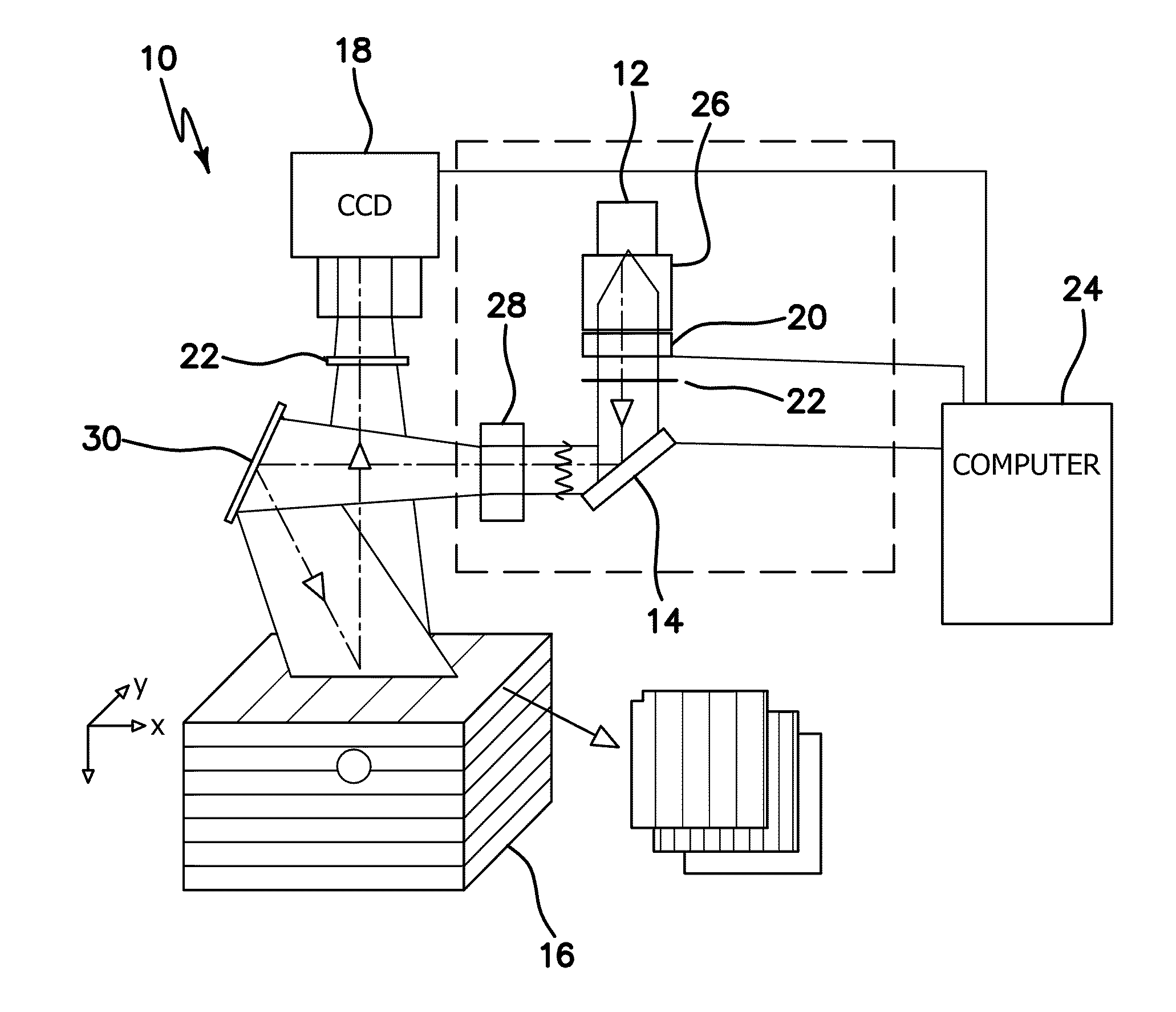

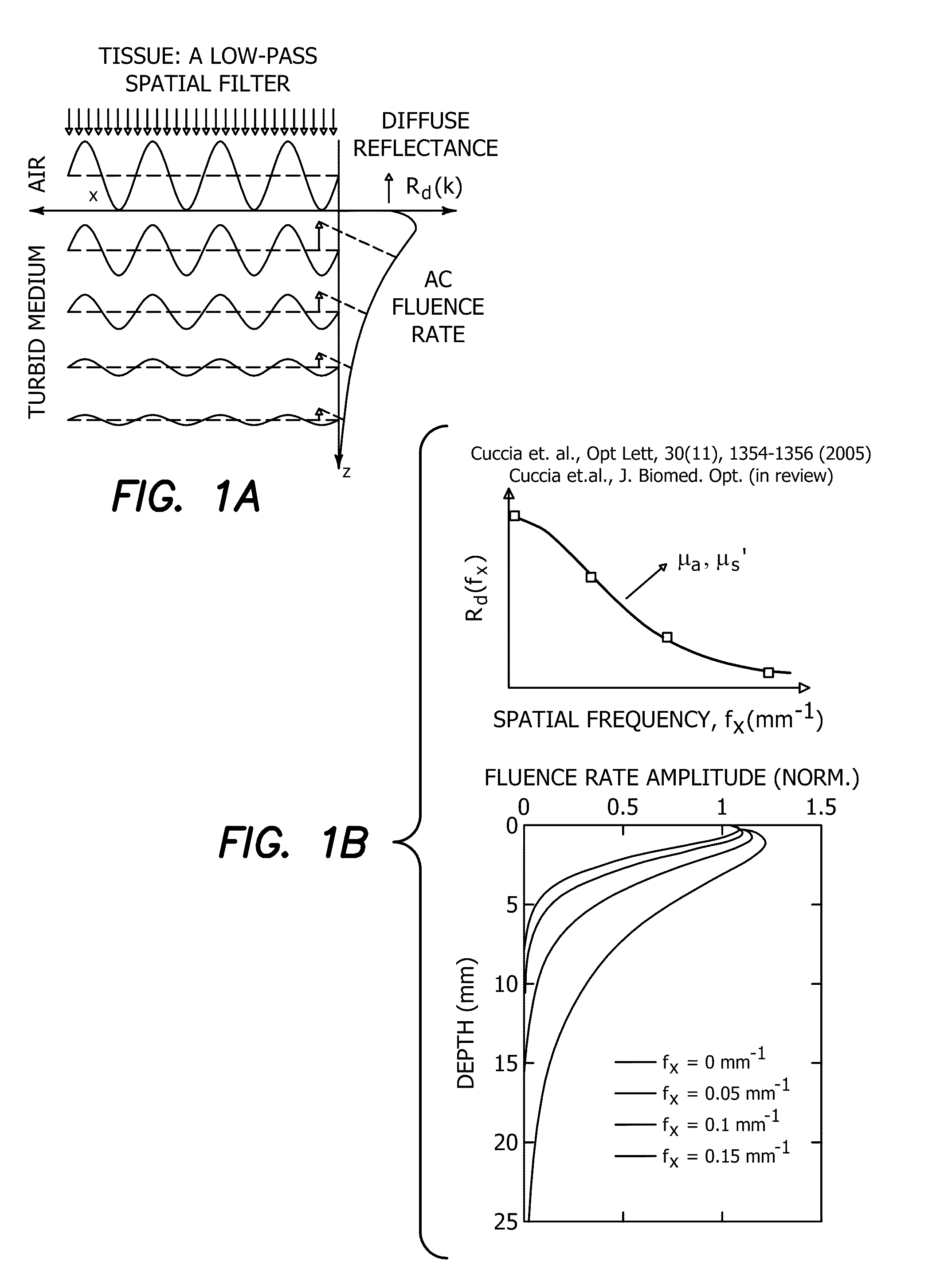

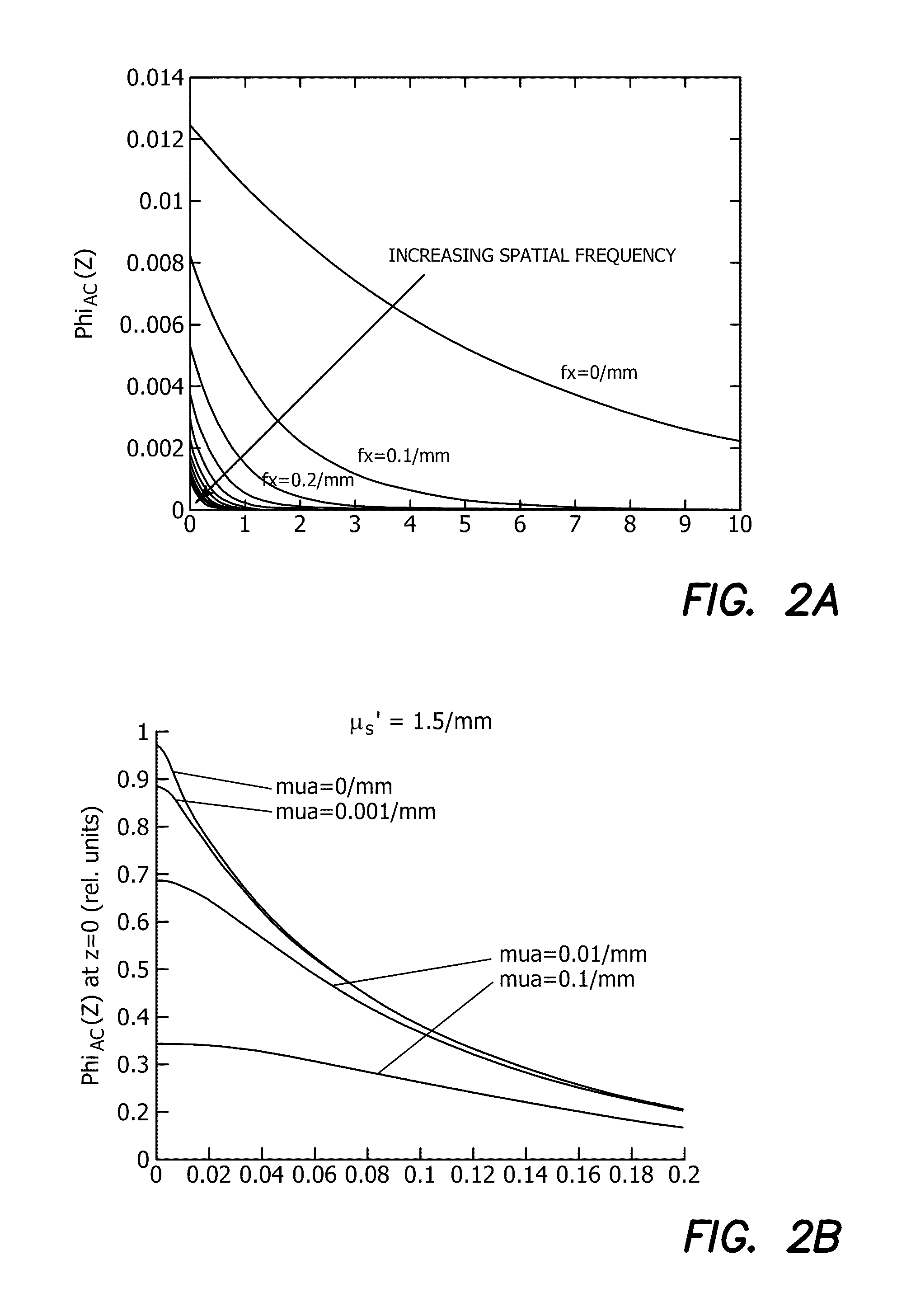

Method for performing qualitative and quantitative analysis of wounds using spatially structured illumination

InactiveUS20100210931A1High sensitivityReduce sensitivityDiagnostics using lightSensorsDiseaseQualitative property

A method of noncontact imaging for performing qualitative and quantitative analysis of wounds includes the step of performing structured illumination of surface and subsurface tissue by both diffuse optical tomography and rapid, wide-field quantitative mapping of tissue optical properties within a single measurement platform. Structured illumination of a skin flap is performed to monitor a burn wound, a diabetic ulcer, a decubitis ulcer, a peripheral vascular disease, a skin graft, and / or tissue response to photomodulation. Quantitative imaging of optical properties is performed of superficial (0-5 mm depth) tissues in vivo. The step of quantitative imaging of optical properties of superficial (0-5 mm depth) tissues in vivo comprises pixel-by-pixel demodulating and diffusion-model fitting or model-based analysis of spatial frequency data to extract the local absorption and reduced scattering optical coefficients.

Owner:RGT UNIV OF CALIFORNIA

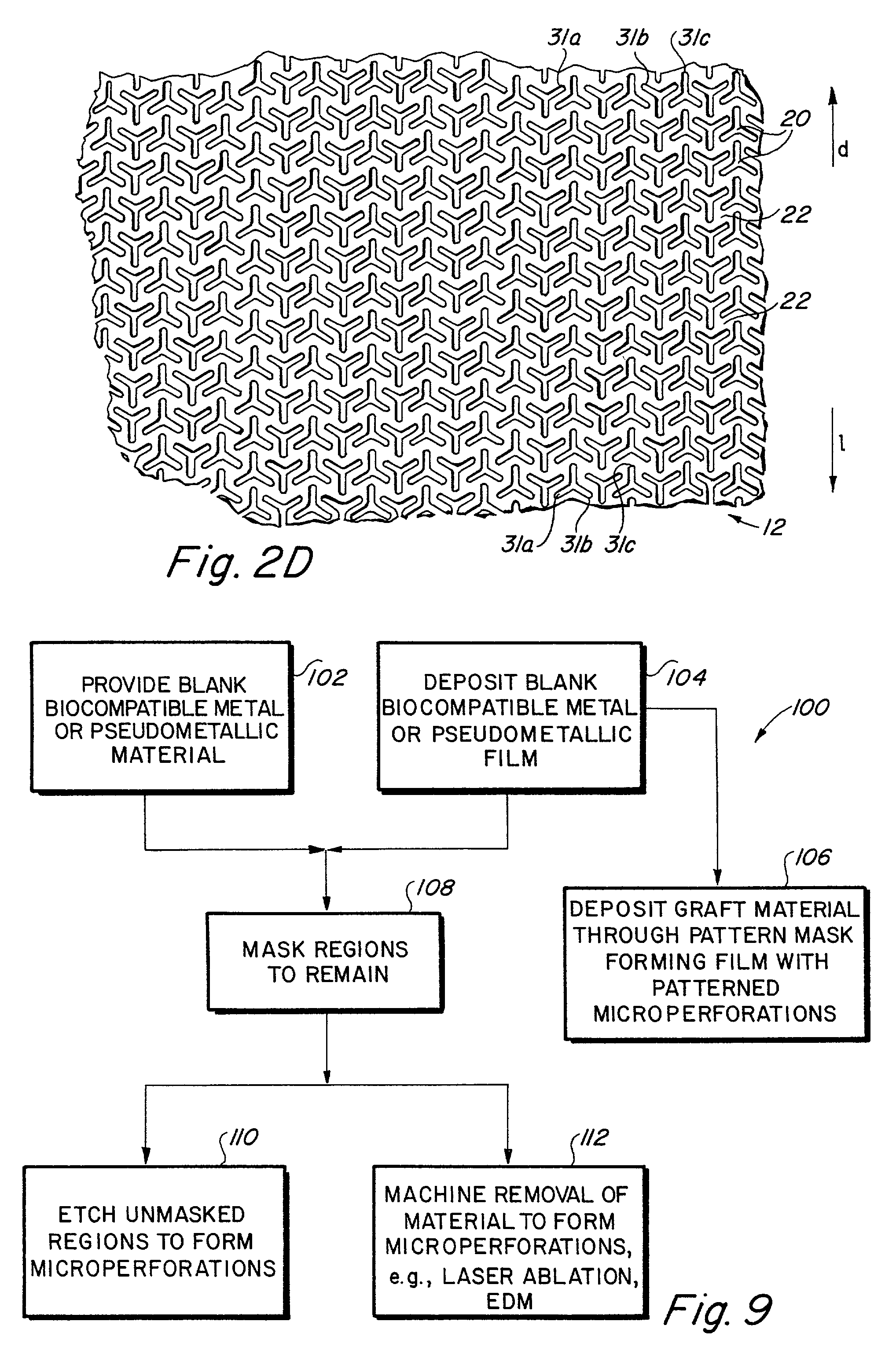

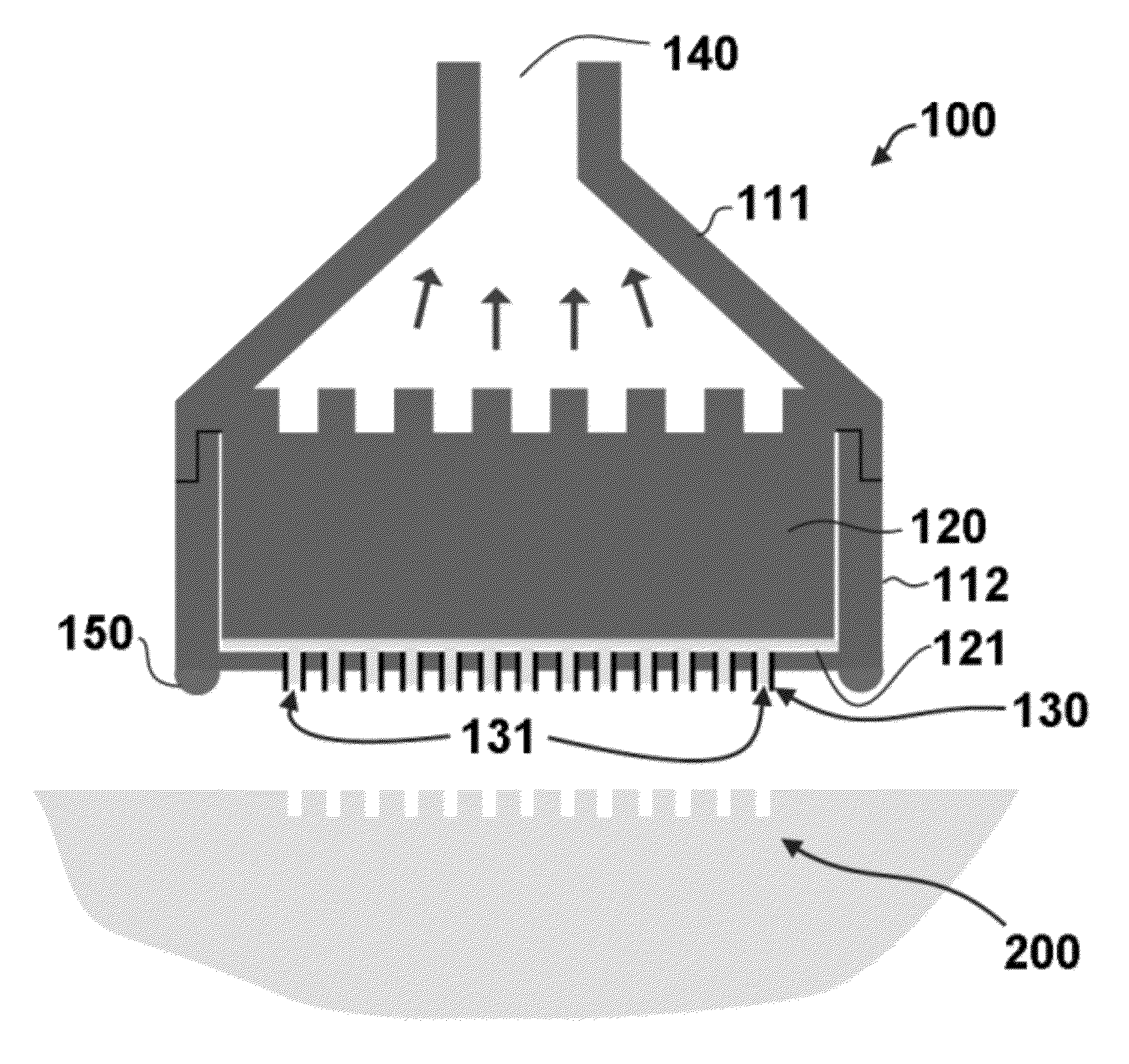

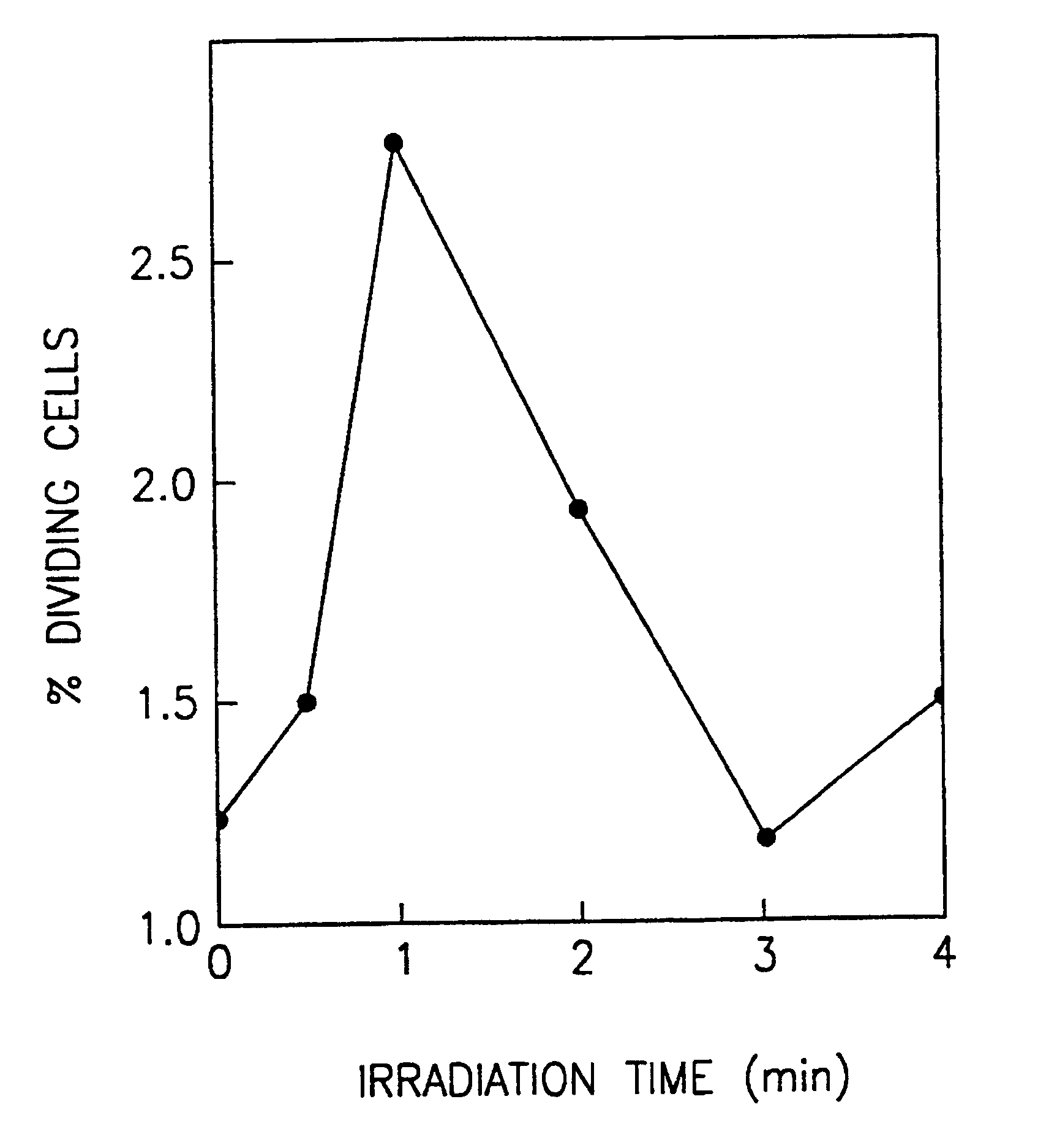

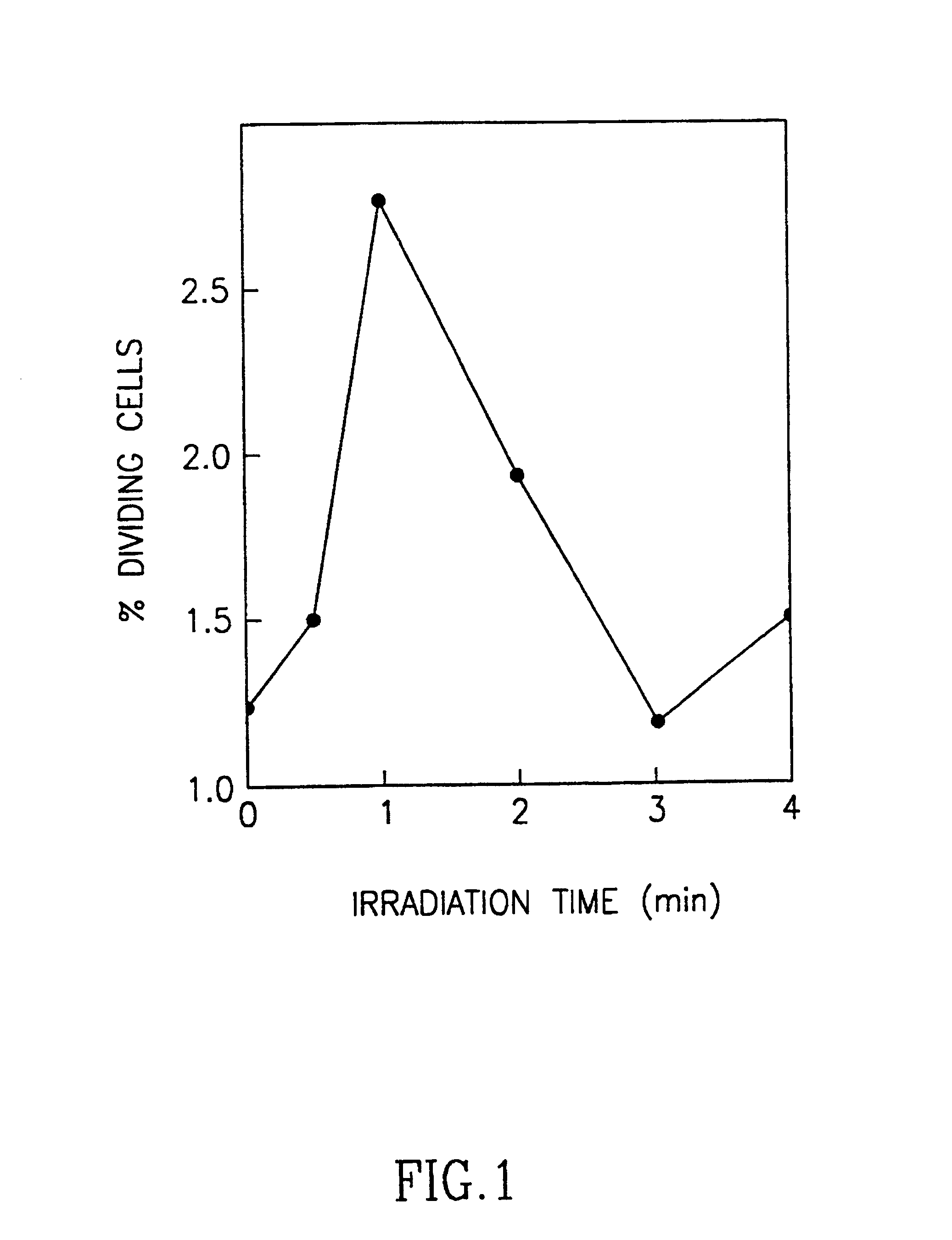

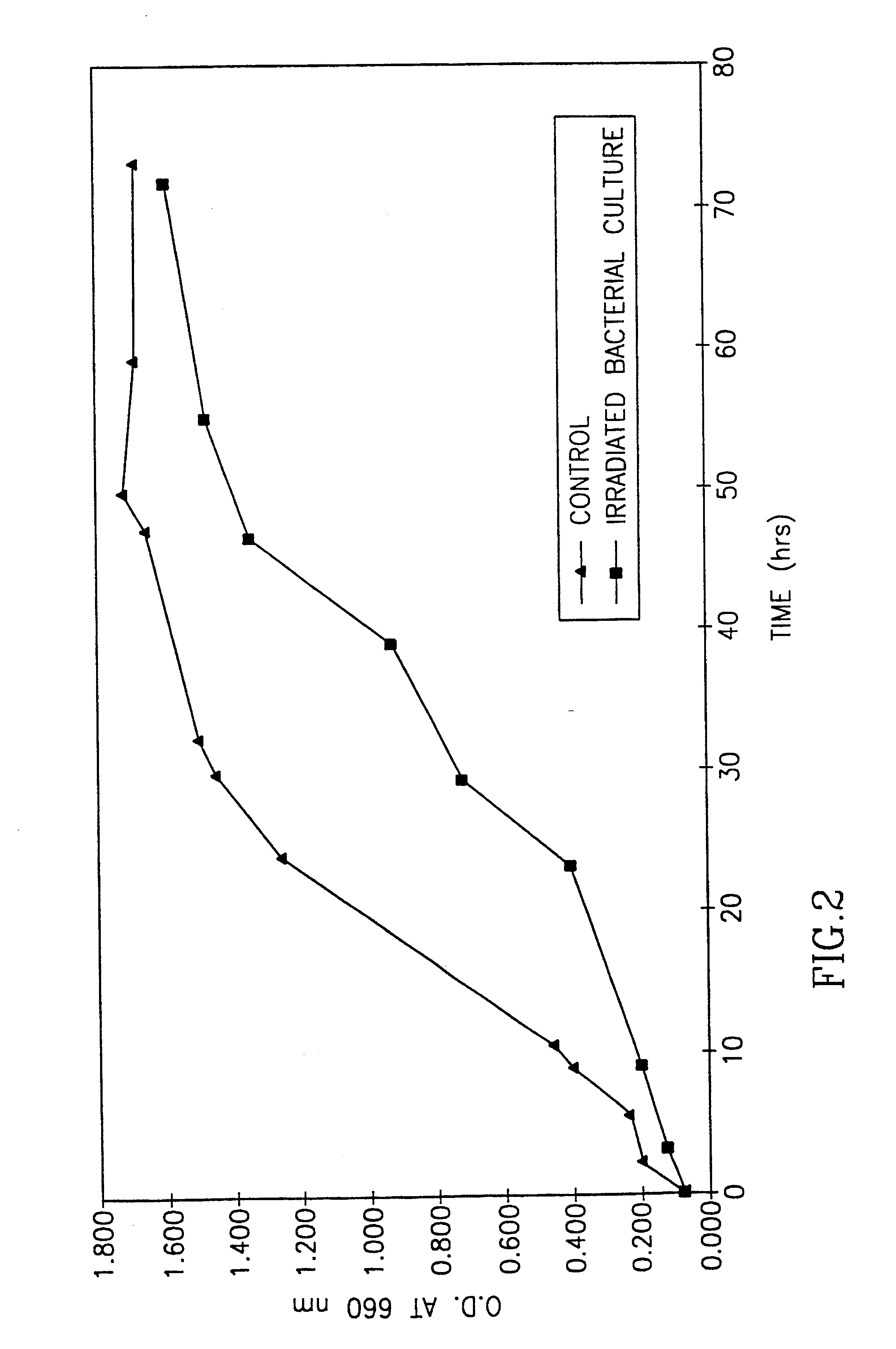

Device for light irradiation onto tissue

A method and device for inducing or promoting growth and proliferation of skin cells or tissue or for controlling bacterial skin infection is described. The skin cells are irradiated with a low-intensity broad spectrum light at a wavelength of between about 340 to 3,000 nm. The increase in rate of cultivated cells is useful for example to obtain skin-like tissue needed for skin grafts or for promoting healing of skin wounds or lesions. Light-induced skin bacteria control is useful for example in the treatment of bacterial infections of the skin.

Owner:QRAY

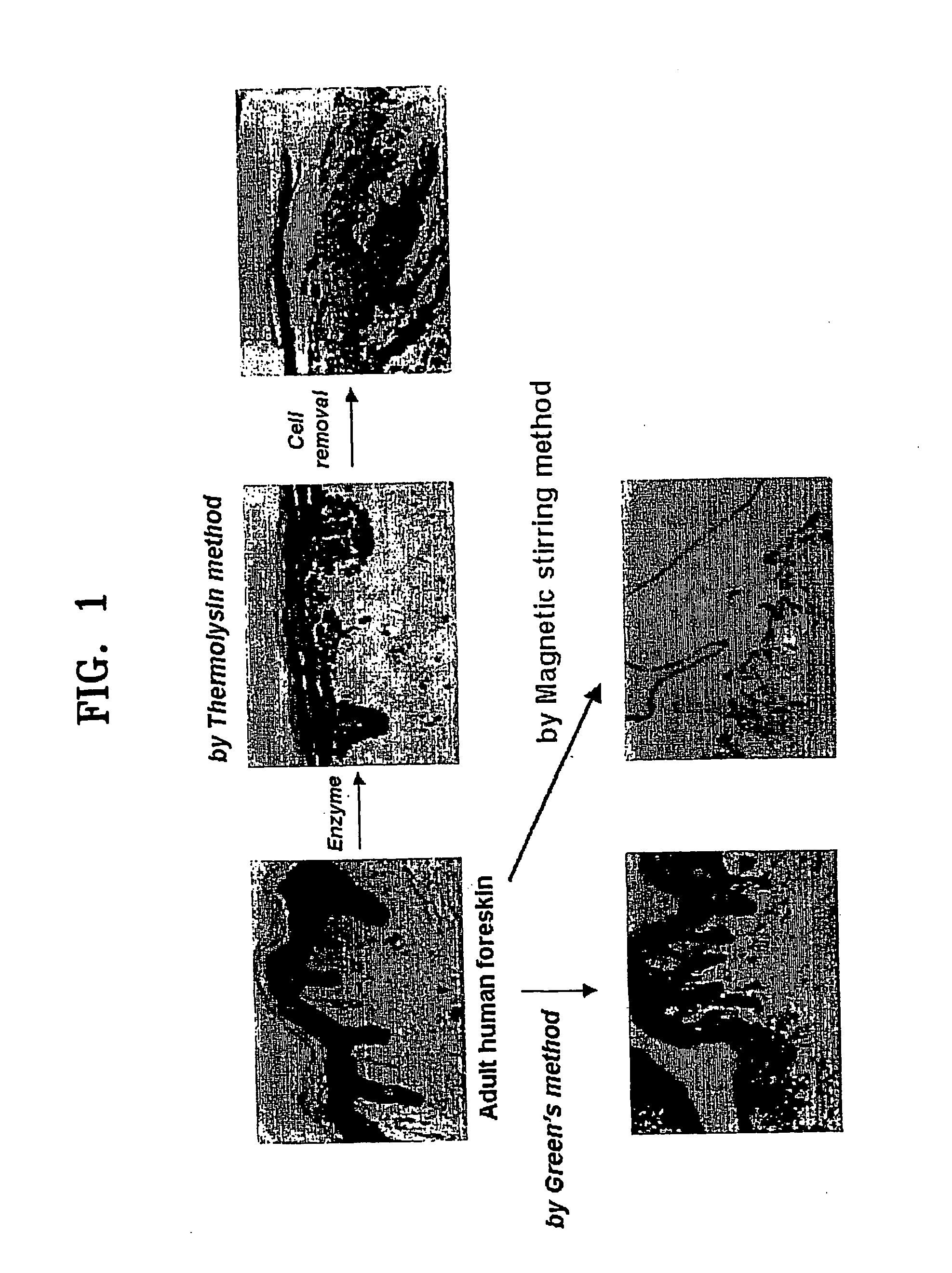

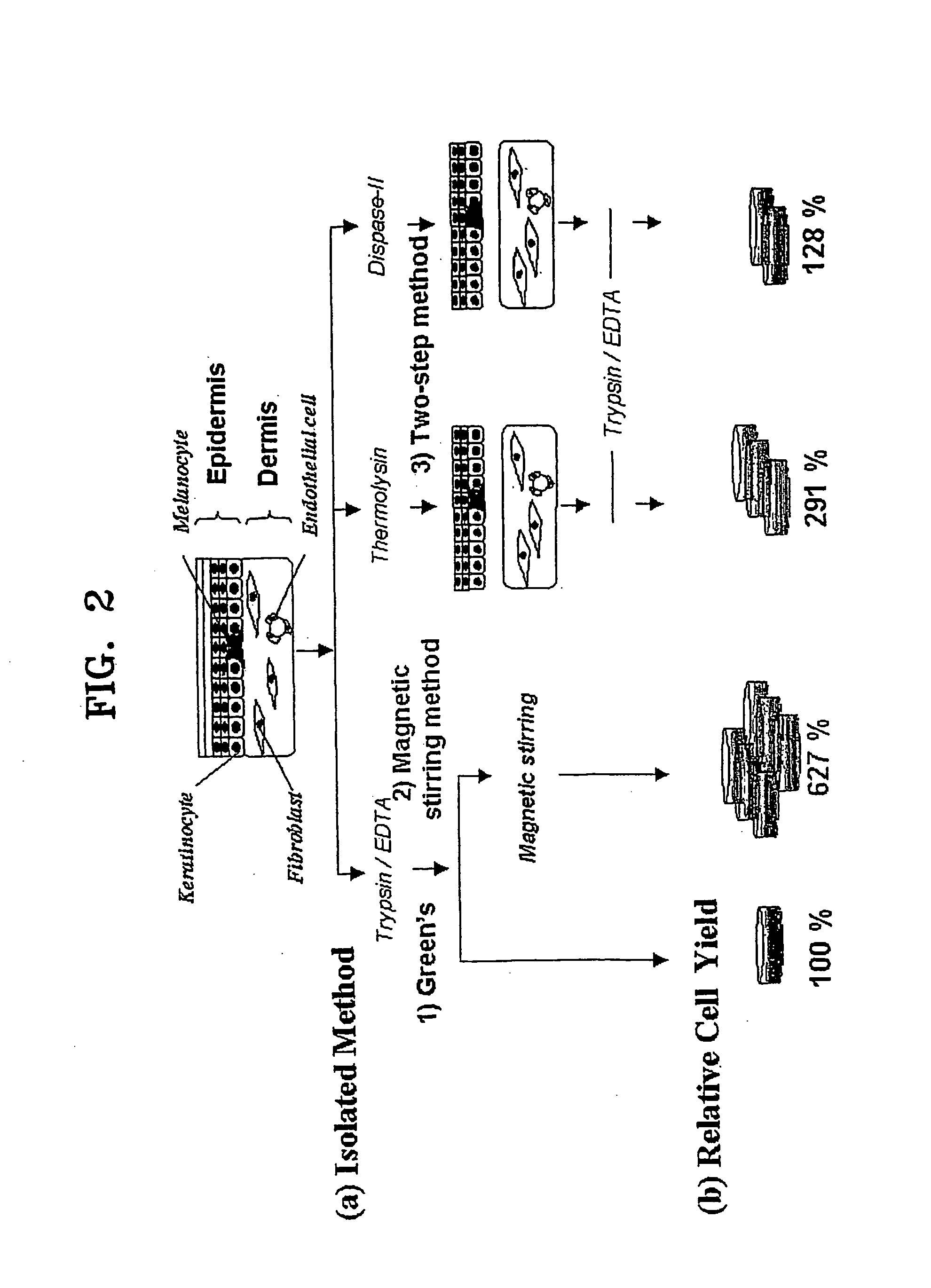

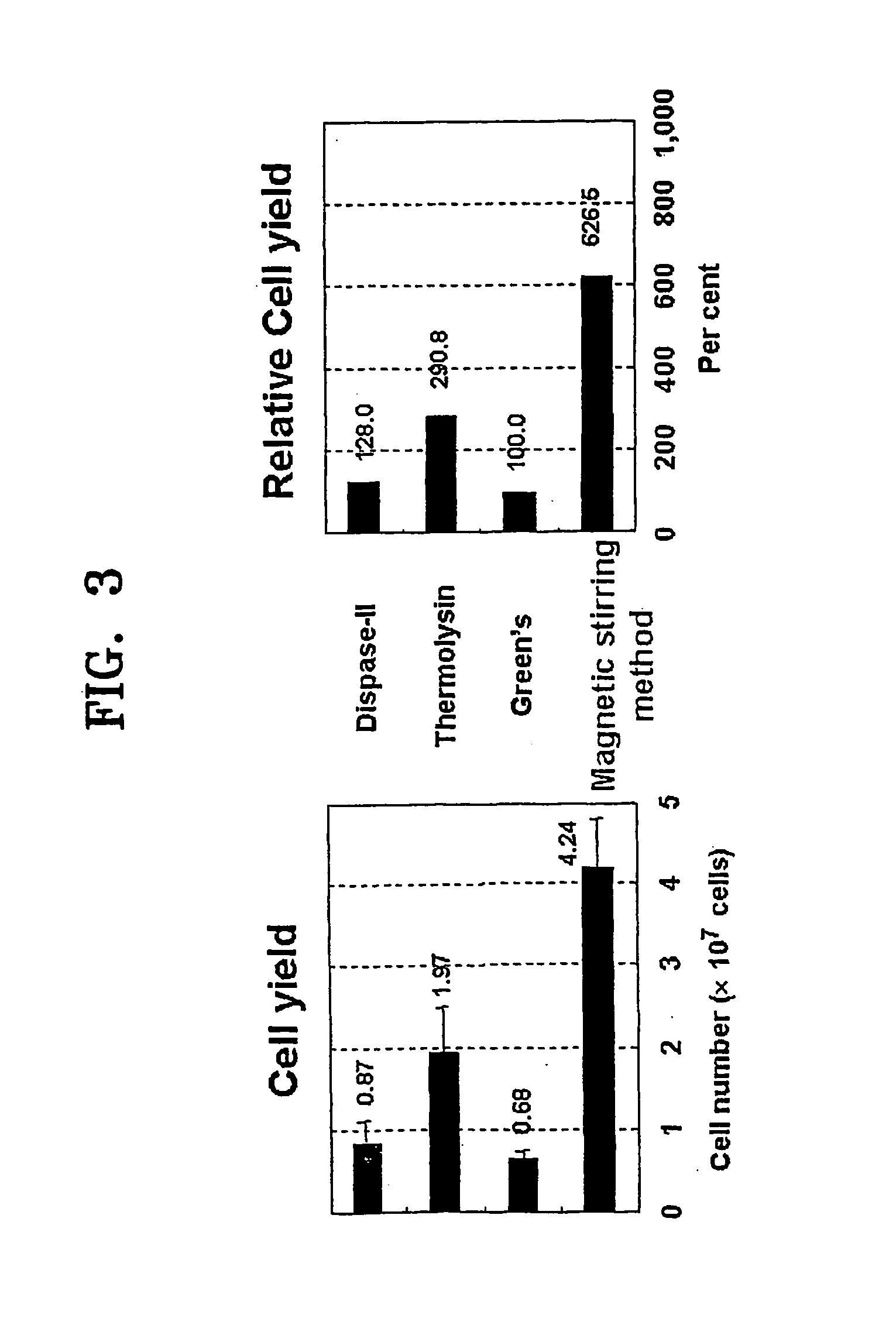

Method of isolating epithelial cells, method of preconditioning cells, and methods of preparing bioartificial skin and dermis with the epithelial cells or the preconditioned cells

InactiveUS20060105454A1Increased cell yieldEasy to implantCell dissociation methodsEpidermal cells/skin cellsDamages tissueTrypsin

A method of isolating epithelial cells from a human skin tissue or internal organ tissue using trypsin and ethylenediamine tetraacetic acid (EDTA) simultaneously with the application of magnetic stirring, a method of preconditioning isolated biological cells by the application of physical stimulus, i.e., strain, are provided. Epithelial cells can be isolated by the method with increased yield, colony forming efficiency (CFE), and colony size. Also, the increased percentage of stem cells in isolated cells is advantageous in therapeutic tissue implantation by autologous or allogeneic transplantation. In skin cells preconditioned by the application of strain, cell division is facilitated, and the secretion of extracellular matrix components and growth factors and the activity of matrix metalloproteinases (MMPs) are improved. When preconditioned cells are implanted by autologous or allogeneic transplantation to heal a damaged tissue, the improved cell adhesion, mobility, and viability provides a biological adjustment effect against a variety of stresses or physical stimuli which the cells would undergo after implantation, with improved capability of integration into host tissue, thereby markedly improving the probability of success in skin grafting.

Owner:KOREA INST OF RADIOLOGICAL & MEDICAL SCI

Dermal substitute consisting of amnion and biodegradable polymer, the preparation method and the use thereof

InactiveUS20050107876A1Less inflammatory responseMaintain formSkin implantsTissue cultureSecond-Degree BurnBiocompatibility Testing

The present invention relates to a dermal substitute comprising the biodegradable polymer such as collagen and the biomaterial such as amnion, the preparation method and the use thereof. Specifically, the present invention provides with an amnion-collagen sponge complex structure prepared by attaching, inserting or incorporating an amnion obtained from placenta to / in collagen. Inventive dermal substitute can be applied to surgery and wound requiring skin graft, for example, severe burns such as second-degree burn, without rejection by immune system. Further, inventive dermal substitute with amnion instead of silicone membrane has several advantages, such as better biocompatibility, anti-inflammatory activity and promoting activity of wound healing and commercial utilization as basement membrane. Also, inventive complex structure can be used as the basic matrix of bio-artificial skin for culturing cells and the biodegradable basic matrix for preparing artificial organs.

Owner:SK BIOLAND CO LTD

Metallic implantable grafts and method of making same

ActiveUS20050033418A1Promote endothelializationGive flexibilityStentsSurgerySurgical GraftLigament structure

Implantable medical grafts fabricated of metallic or pseudometallic films of biocompatible materials having a plurality of microperforations passing through the film in a pattern that imparts fabric-like qualities to the graft or permits the geometric deformation of the graft. The implantable graft is preferably fabricated by vacuum deposition of metallic and / or pseudometallic materials into either single or multi-layered structures with the plurality of microperforations either being formed during deposition or after deposition by selective removal of sections of the deposited film. The implantable medical grafts are suitable for use as endoluminal or surgical grafts and may be used as vascular grafts, stent-grafts, skin grafts, shunts, bone grafts, surgical patches, non-vascular conduits, valvular leaflets, filters, occlusion membranes, artificial sphincters, tendons and ligaments.

Owner:VACTRONIX SCI LLC

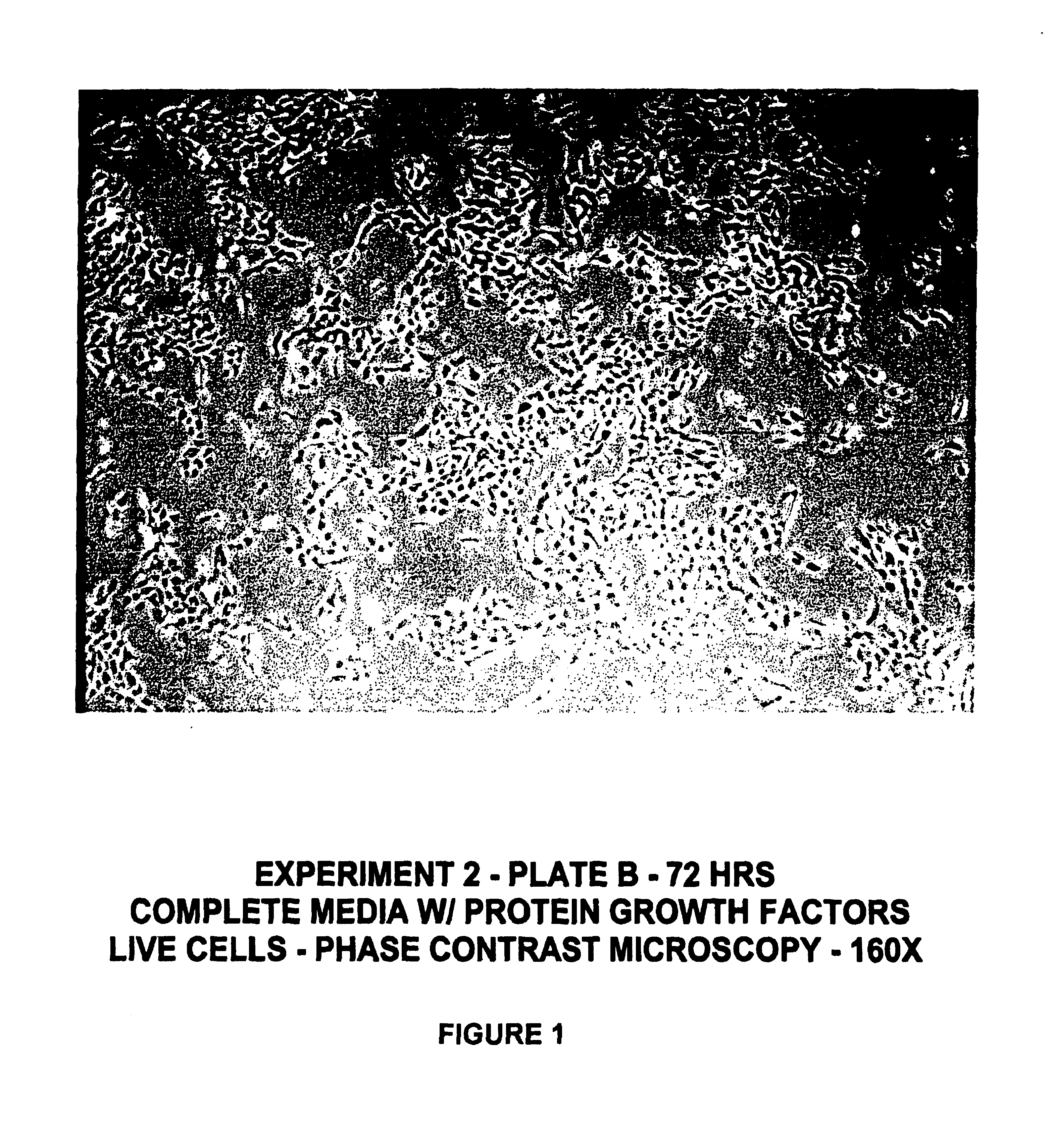

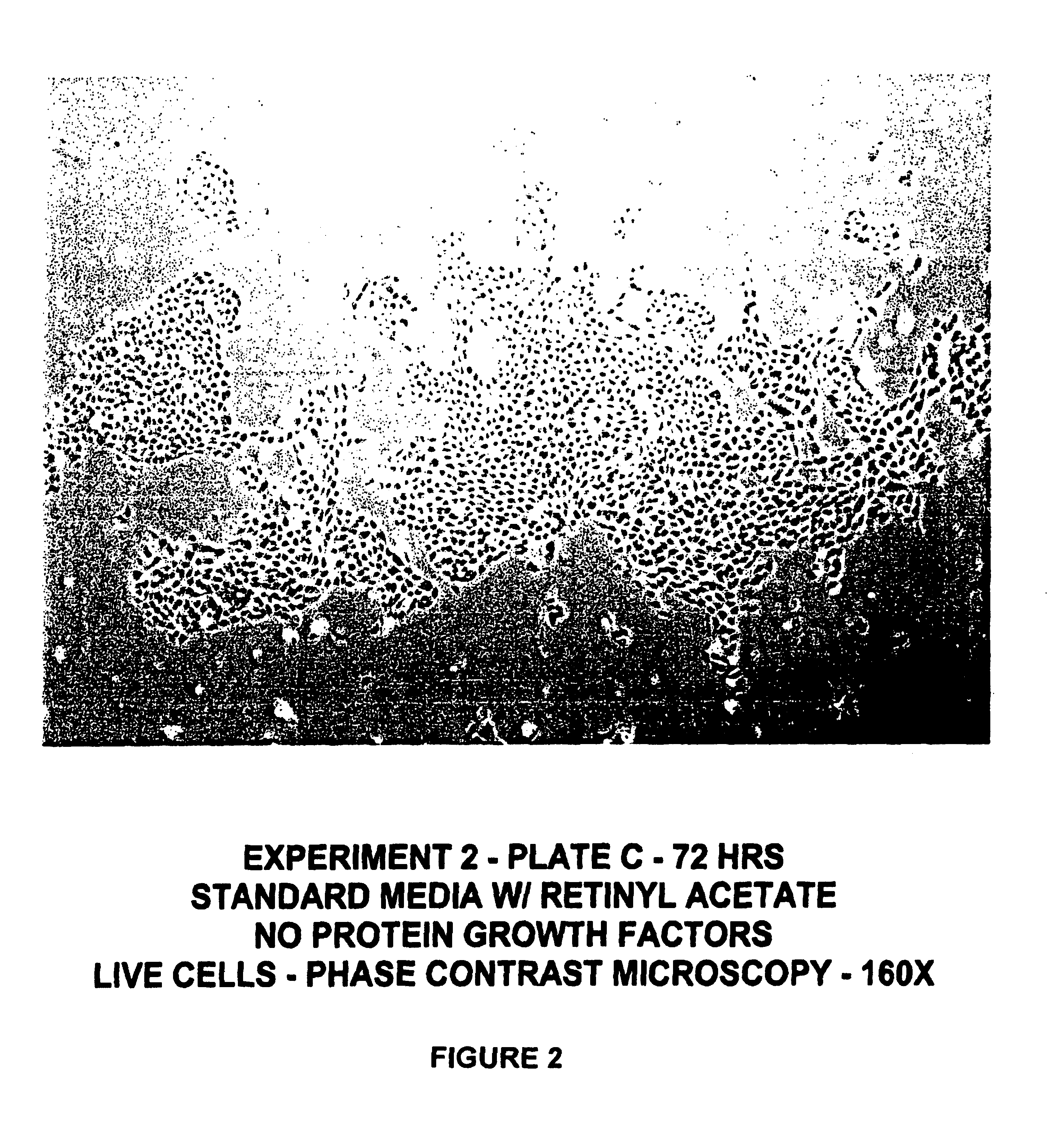

Protein-free defined media for the growth of normal human keratinocytes

Improvements are made to a novel media that replace the requirement for all protein growth factors by the addition to the medium of physiological concentrations of retinyl acetate. The media are serum-free, companion cell or feeder layer-free and organotypic, matrix free solutions for the cultivation of clonally competent basal keratinocytes. The media and methods are useful in the production of epidermal epithelial tissue that is suitable for skin grafting.

Owner:BIOPLAST MEDICAL

Self-supporting metallic implantable grafts, compliant implantable medical devices and methods of making same

InactiveUS20070250156A1Give flexibilityFacilitating transmural endothelializationStentsBlood vesselsSurgical GraftMetallic materials

Implantable medical grafts fabricated of metallic or pseudometallic films of biocompatible materials having a plurality of microperforations passing through the film in a pattern that imparts fabric-like qualities to the graft or permits the geometric deformation of the graft. The implantable graft is preferably fabricated by vacuum deposition of metallic and / or pseudometallic materials into either single or multi-layered structures with the plurality of microperforations either being formed during deposition or after deposition by selective removal of sections of the deposited film. The implantable medical grafts are suitable for use as endoluminal or surgical grafts and may be used as vascular grafts, stent-grafts, skin grafts, shunts, bone grafts, surgical patches, non-vascular conduits, valvular leaflets, filters, occlusion membranes, artificial sphincters, tendons and ligaments.

Owner:VACTRONIX SCI LLC

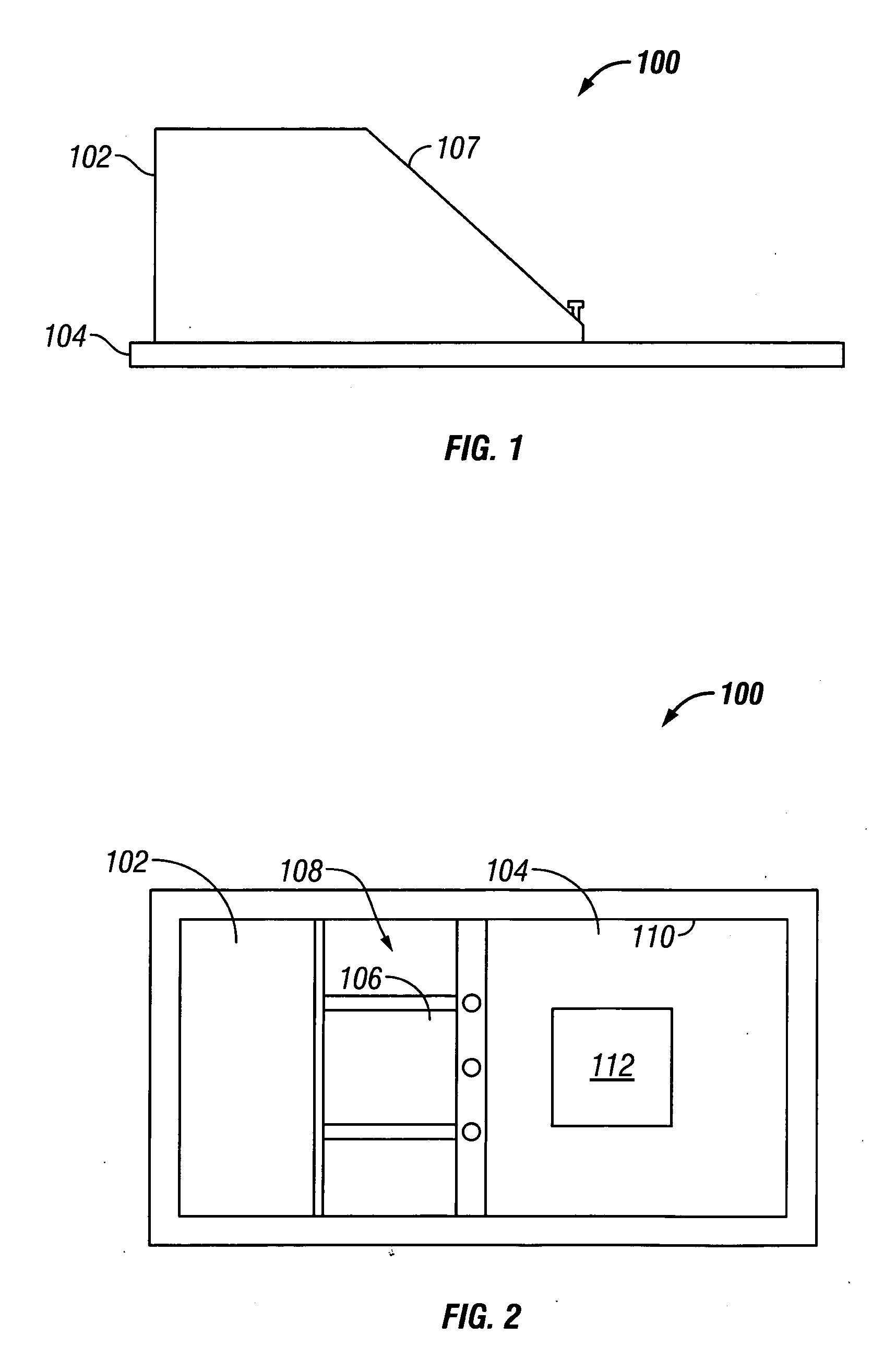

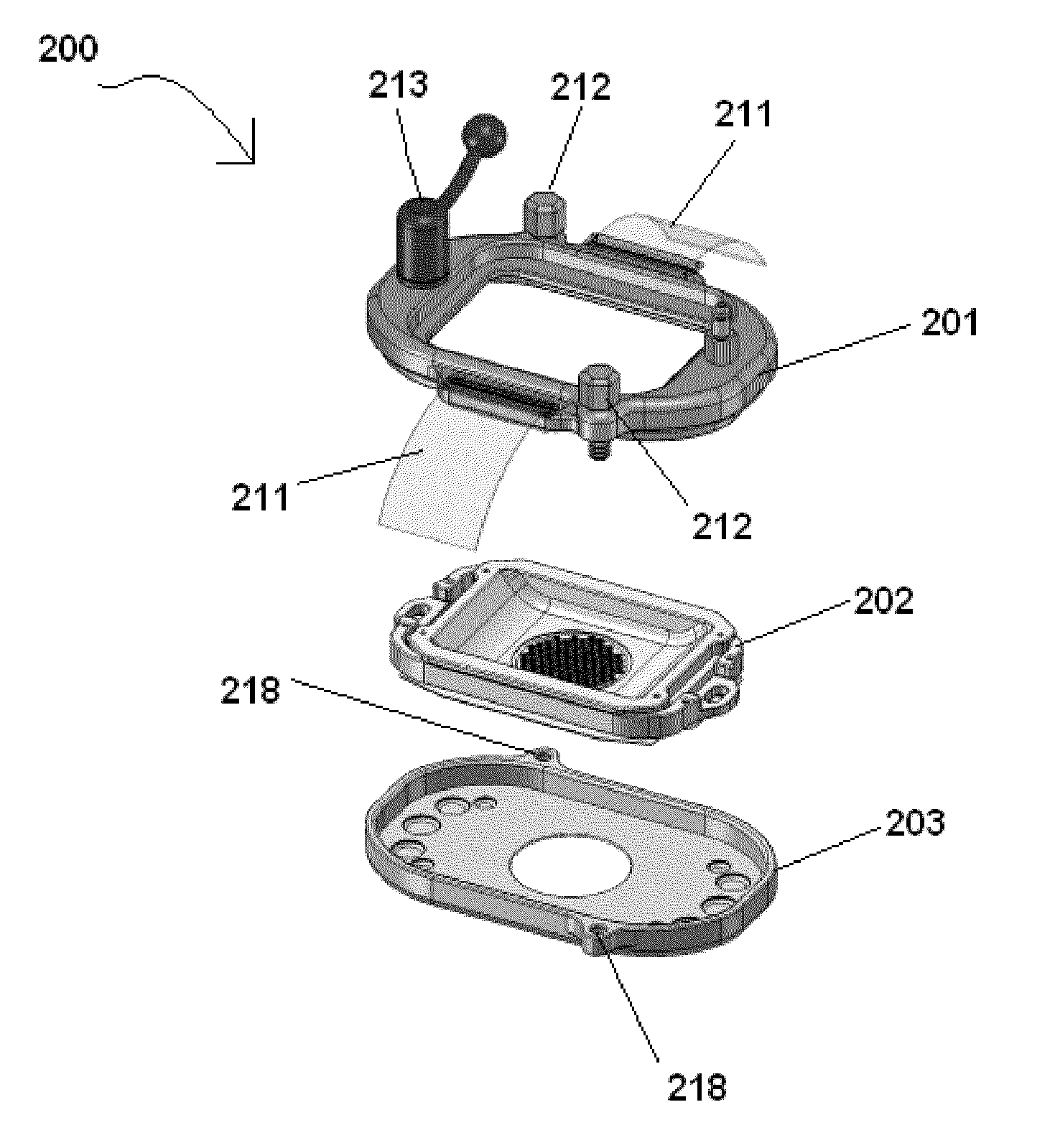

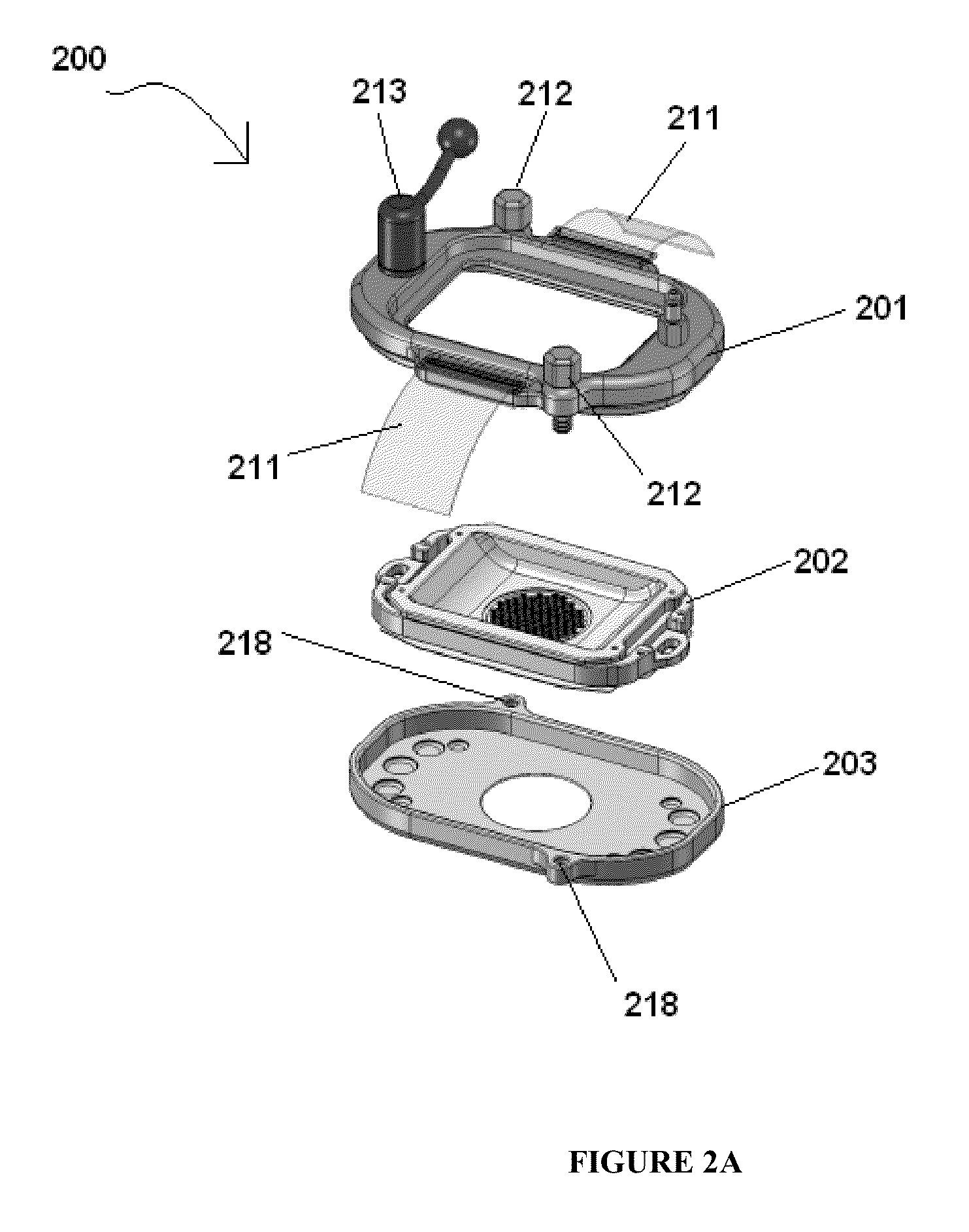

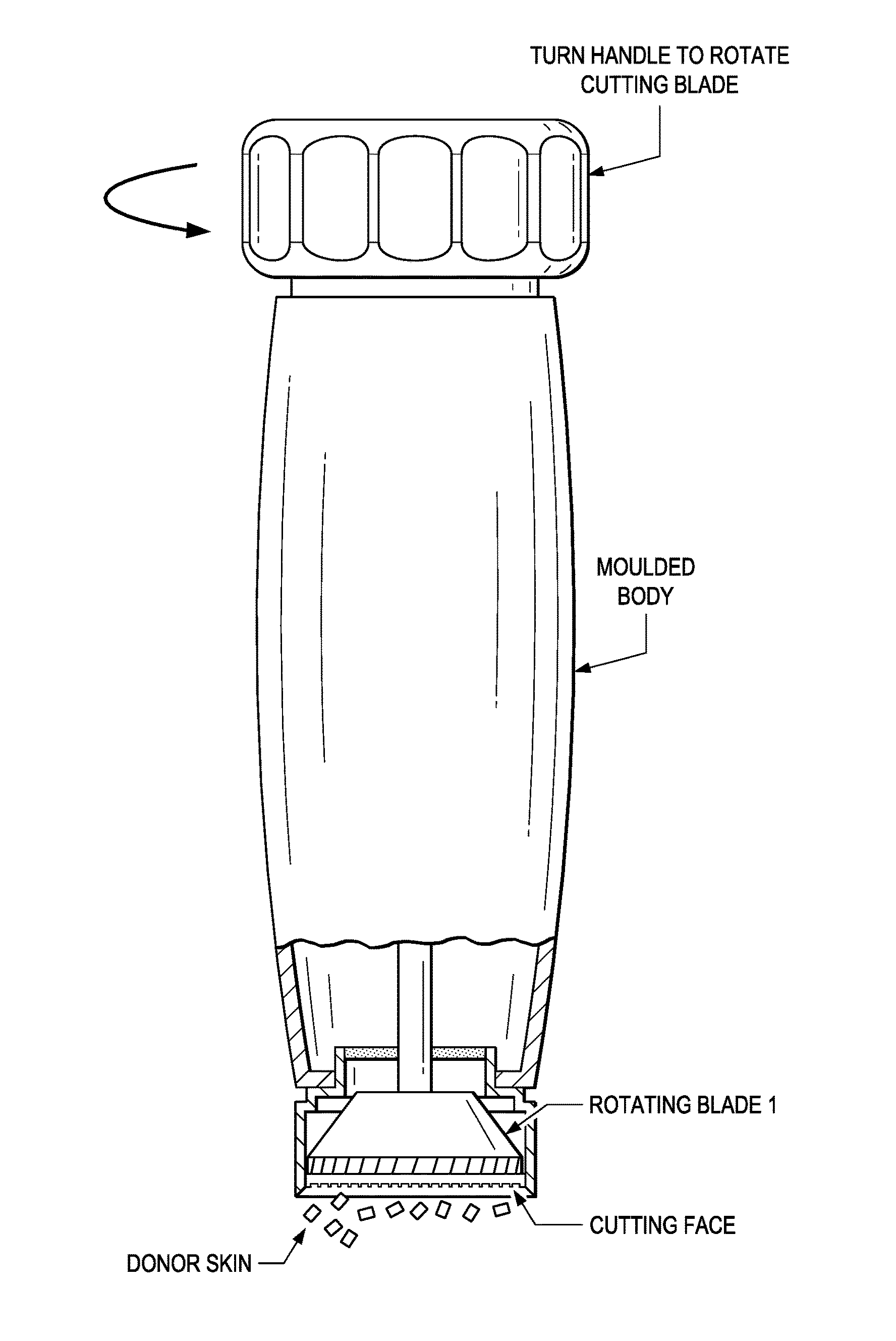

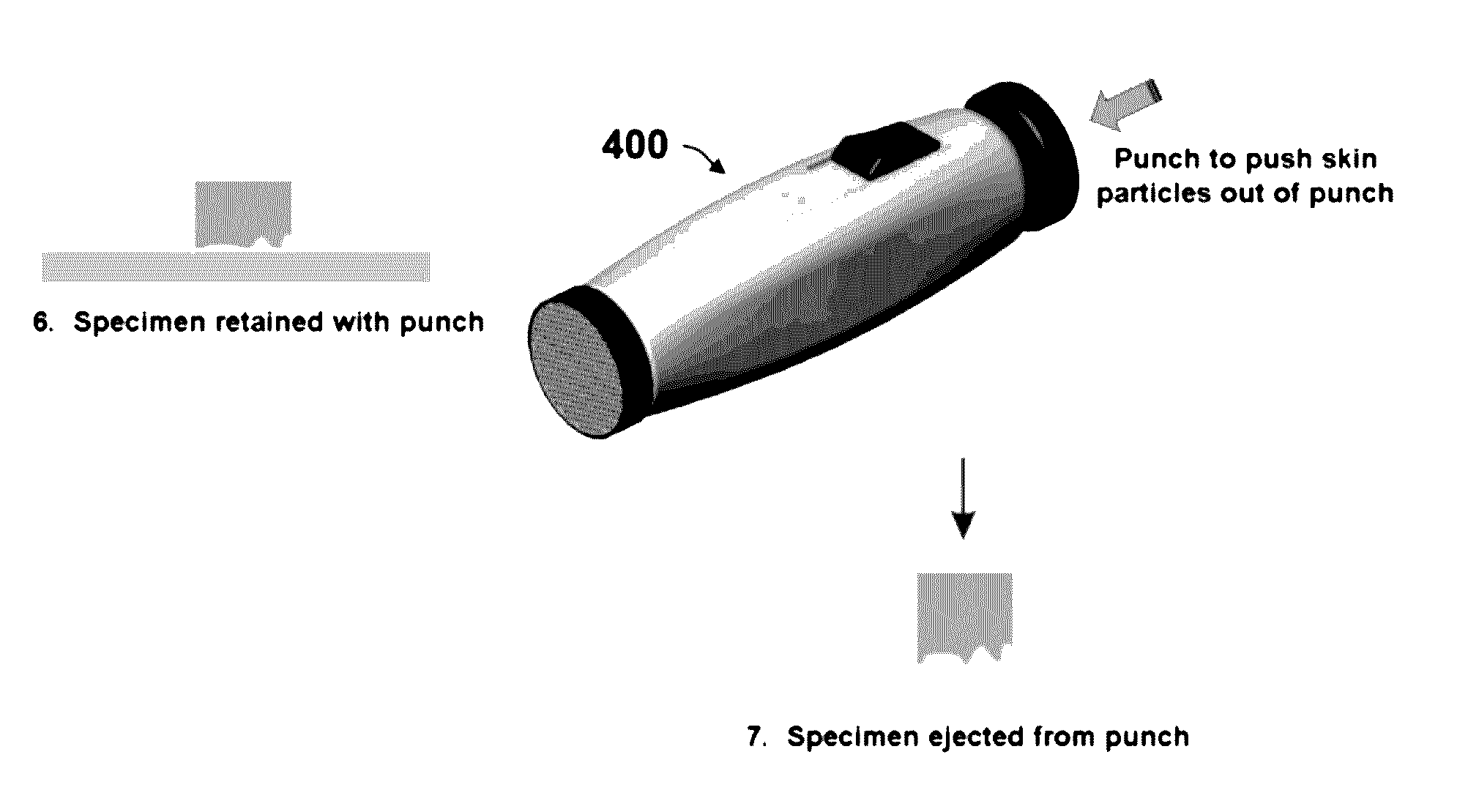

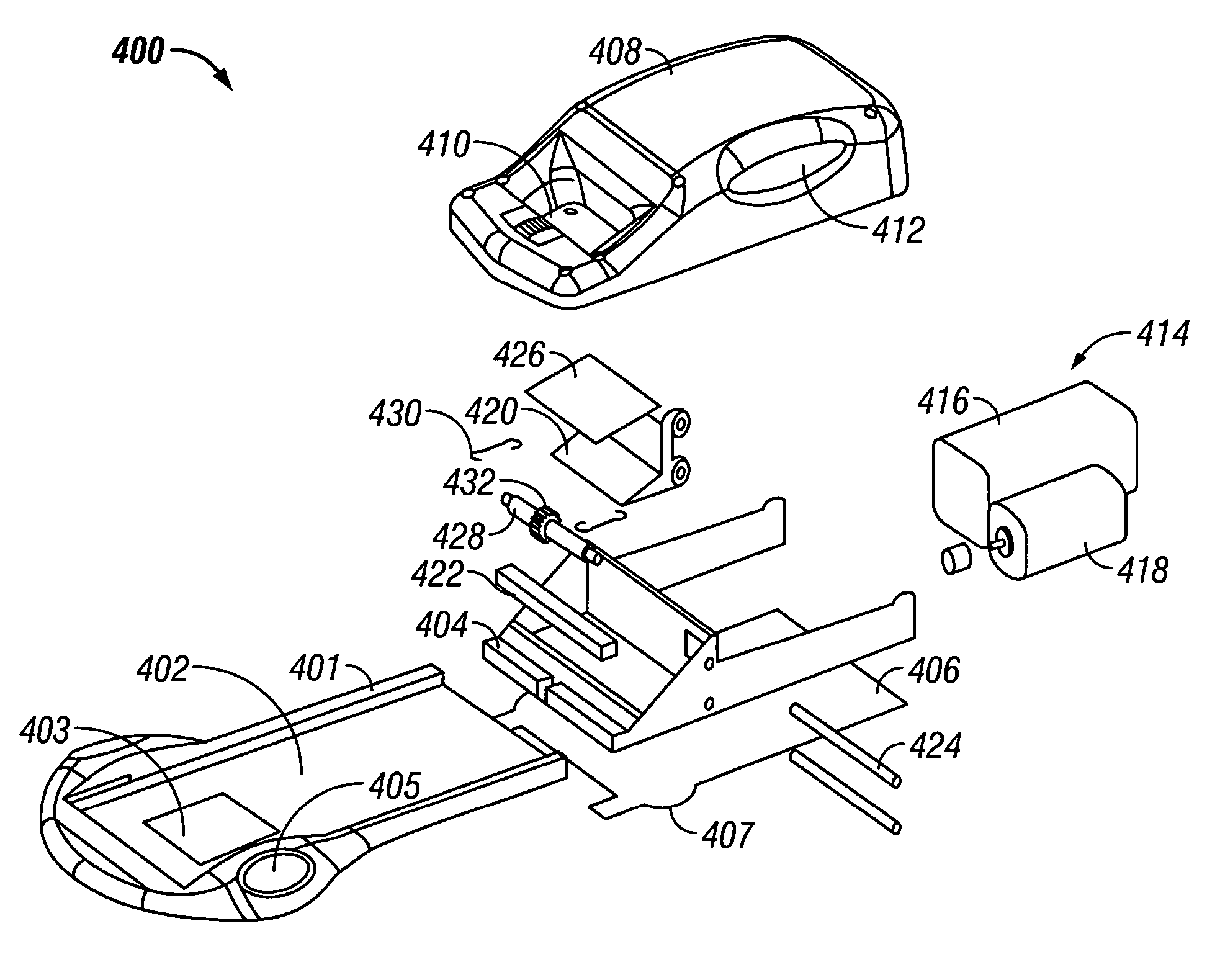

Methods of manufacturing devices for generating skin grafts

The invention generally relates to methods for manufacturing components for use in a device for generating substantially planar micrografts. The methods of the invention provide for the manufacture of substantially uniform components for a cutter contained within the device, the cutter configured to cut a blister in order to produce a substantially planar graft.

Owner:MOMELAN +1

Skin graft devices and methods

ActiveUS20170042561A1Vaccination/ovulation diagnosticsExcision instrumentsSkin graftingSkin transplantation

Owner:SOLVENTUM INTPROP CO

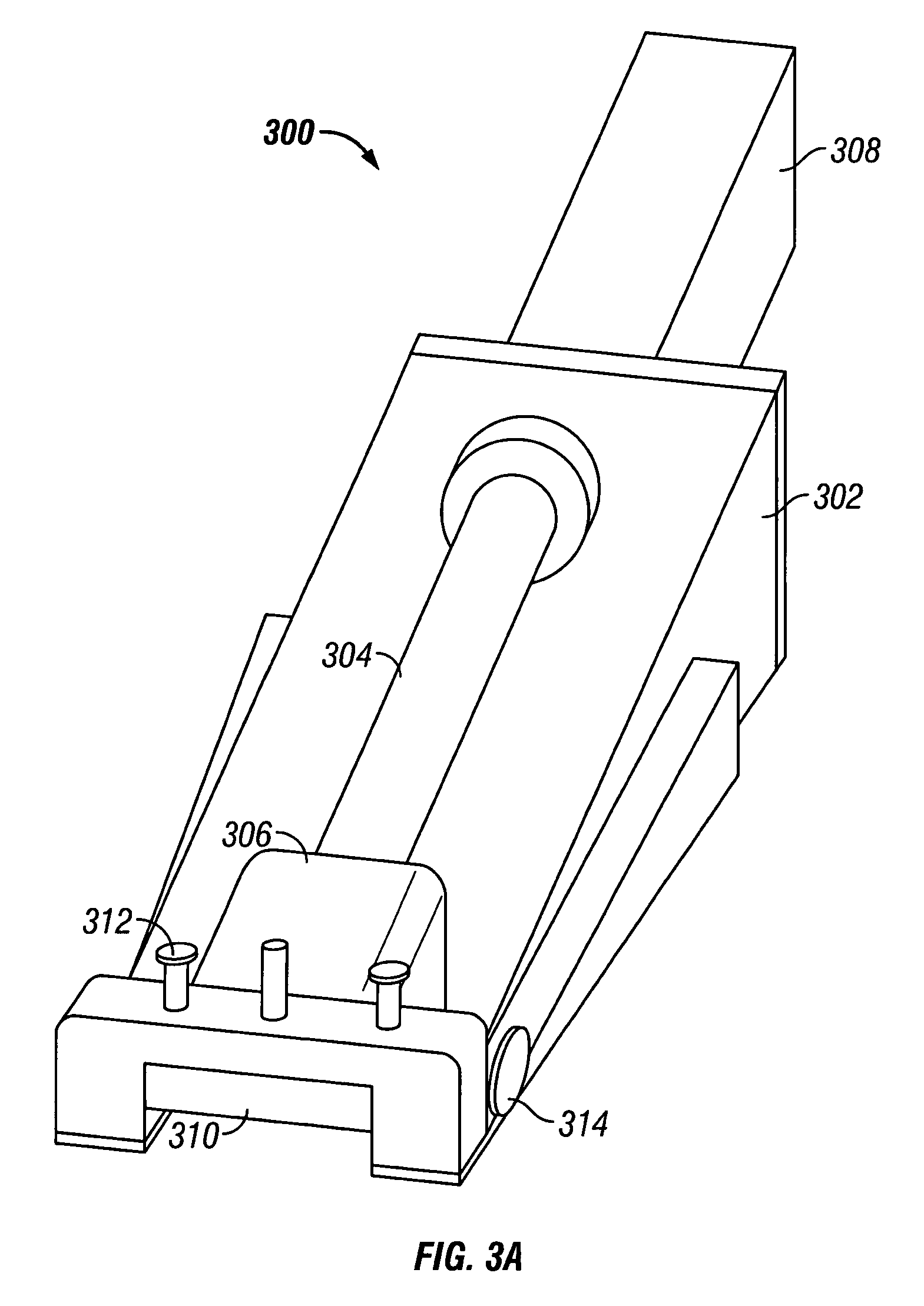

Dermatome with ultrasonic cutting blade

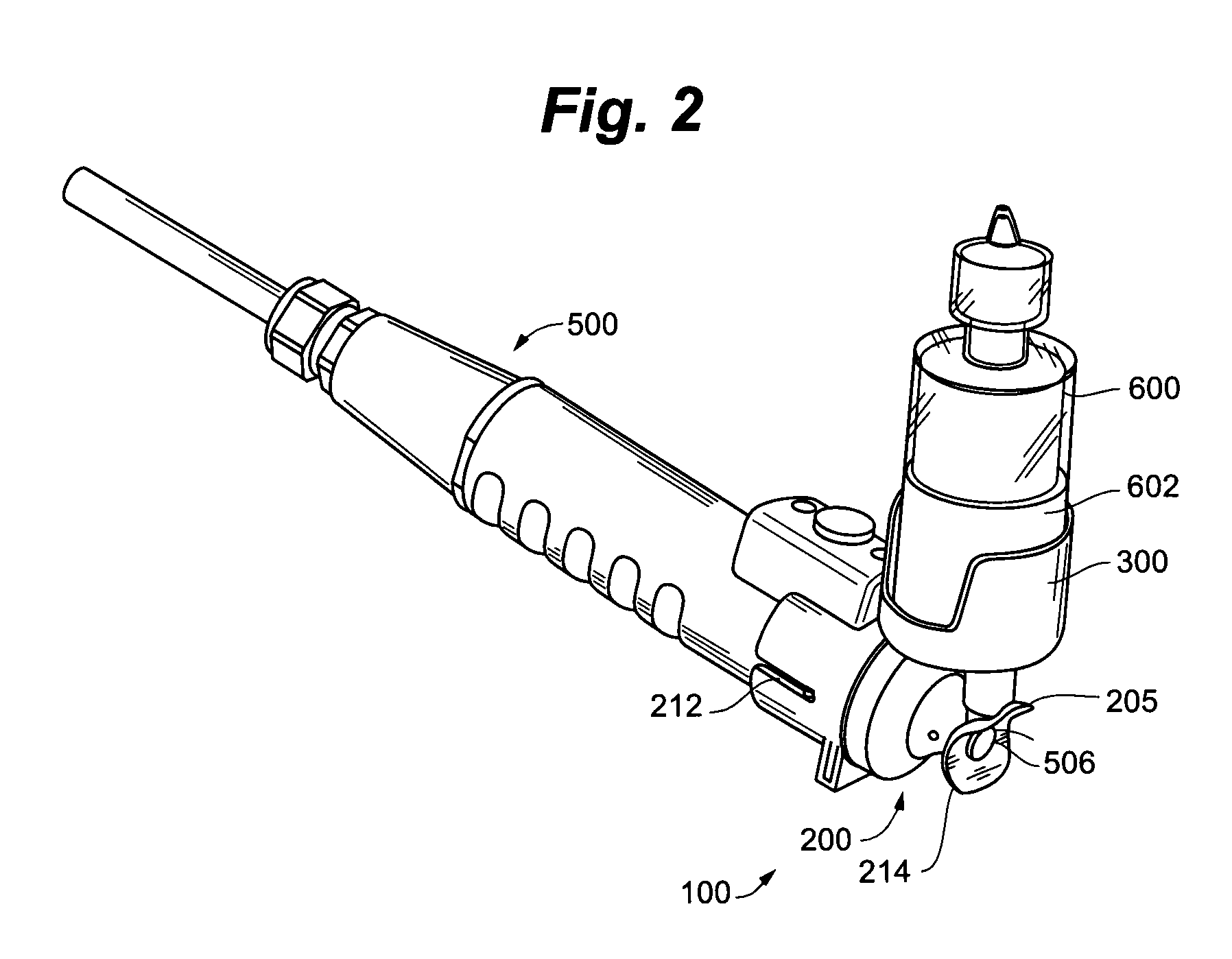

InactiveUS20090138027A1Ultrasonic frequency is limitedSurgeryEye treatmentSkin graftingSkin transplantation

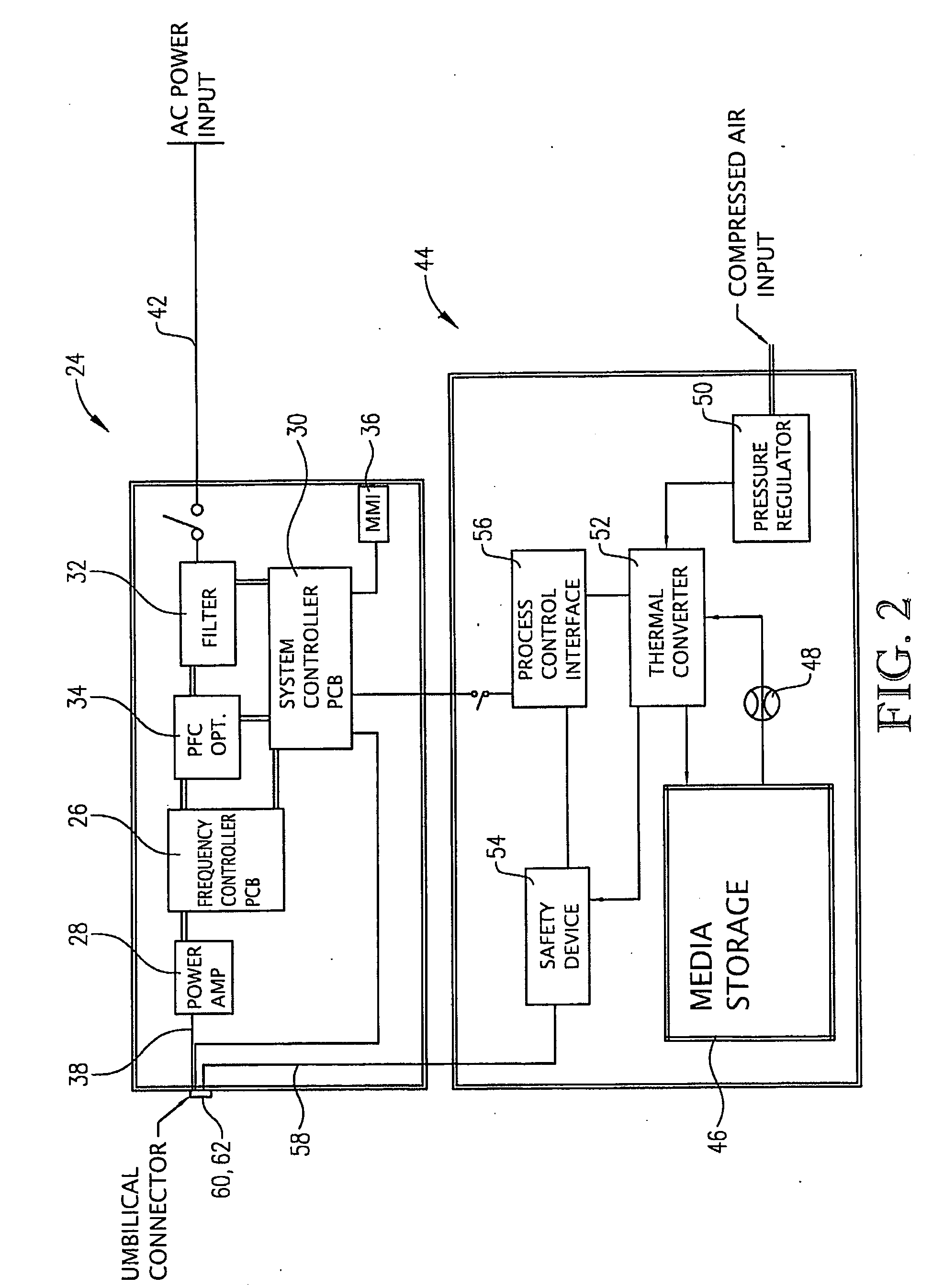

A dermatome assembly is operable to harvest a skin graft and includes an ultrasonic dermatome and a power supply. The ultrasonic dermatome includes a body and an ultrasonic blade assembly mounted in the body. The blade assembly includes a frequency generator and a cutting horn powered by the frequency generator. The cutting horn is spaced apart from the body so that the body is restricted from damping vibrational movement of the cutting horn. The dermatome assembly is operable to precisely control the thickness of the cut skin graft and also restrict the cutting horn from overheating.

Owner:DADSON MFG CORP

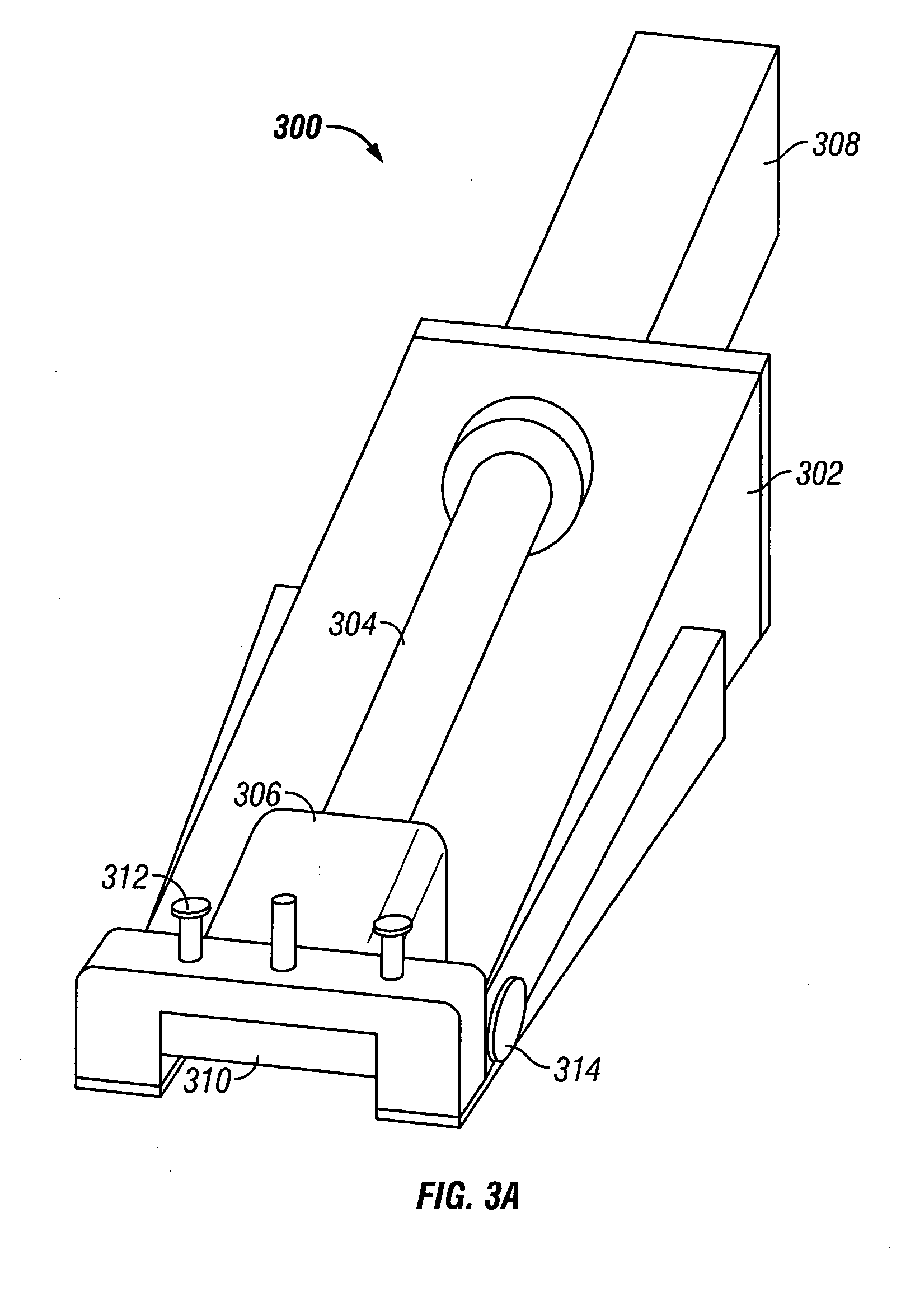

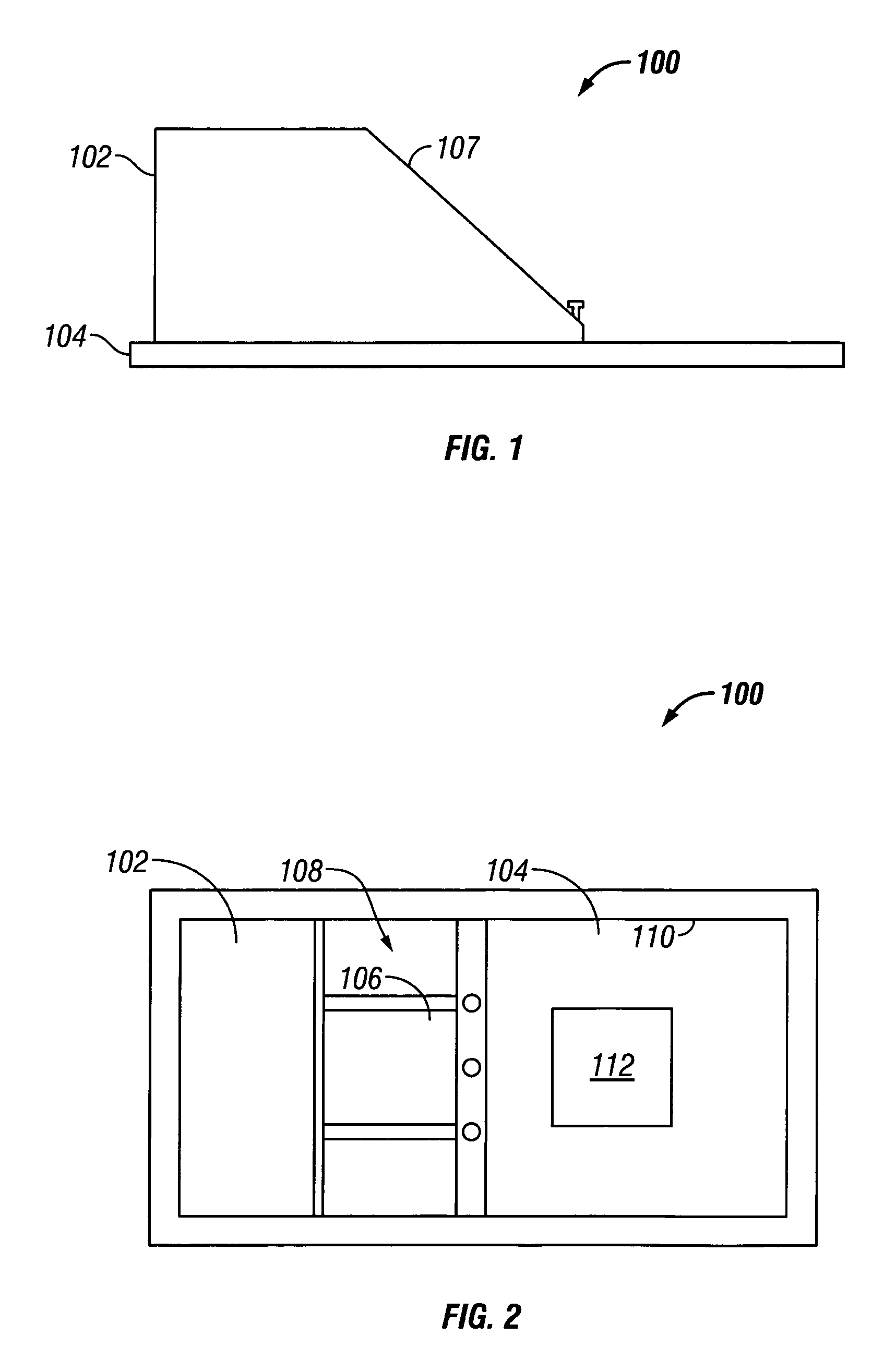

Devices and systems for separating and preparing skin

InactiveUS20050101972A1Eliminate unsuccessfulEliminate rudimentaryDiagnosticsSurgerySkin graftingPreparing skin

A skin graft preparing system includes a surgical device having a housing with a front end defining a forward direction and a rear end defining a rear direction for moving along skin in the forward direction. Cutting structure is moveably coupled to the housing for separating skin from the body where the cutting structure has a cutting portion. The cutting portion cyclically translates in the forward and rear direction without lateral movement. The skin graft preparing system also includes a skin graft preparing device having a base structure, one or more skin feeding structures, one or more skin preparing structures, and one or more skin collecting structures coupled to the base structure. The skin supporting structure from the surgical device provides the skin feeding structure of the skin graft preparing device.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Skin graft devices and methods

Owner:3M INNOVATIVE PROPERTIES CO

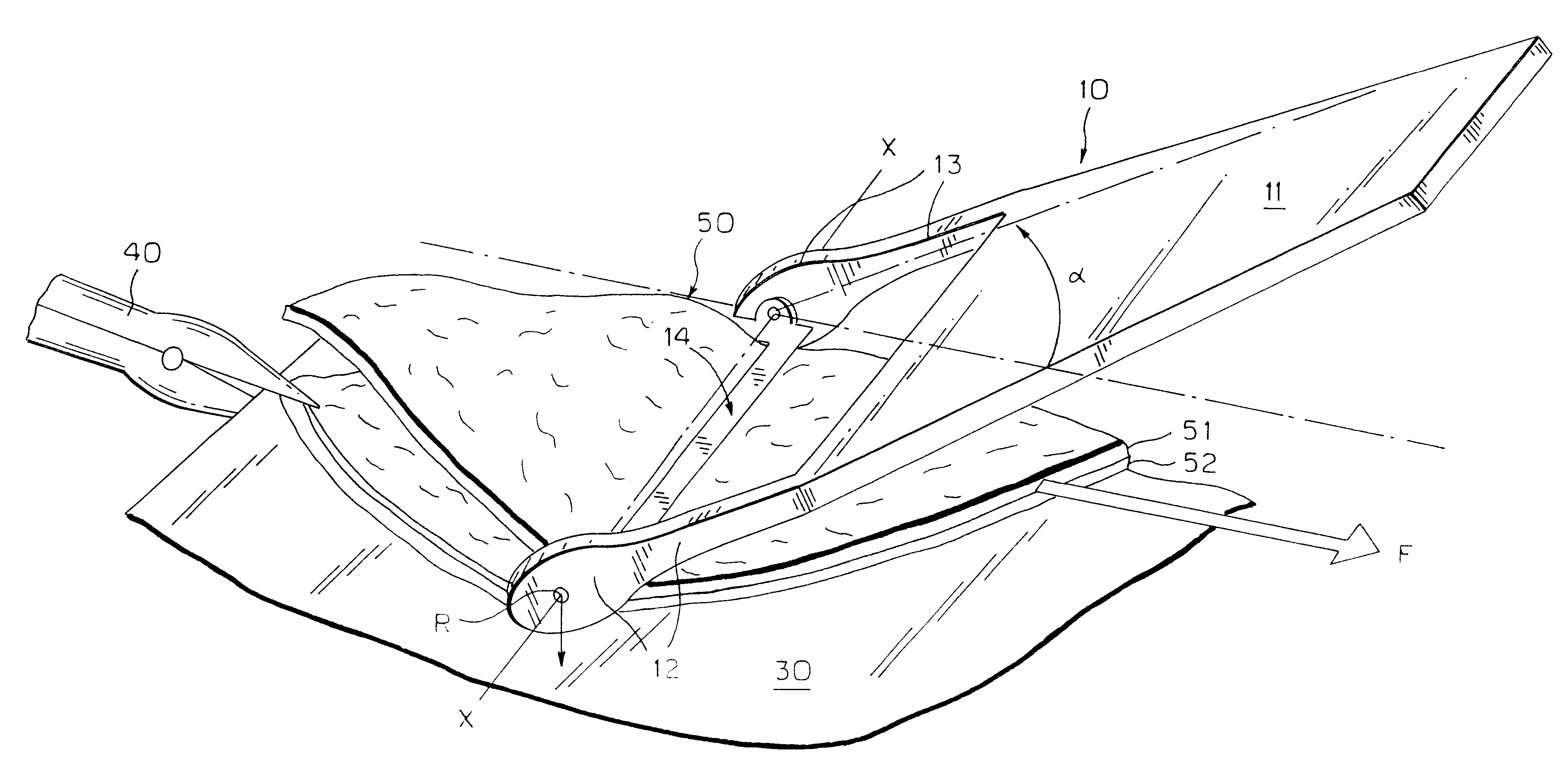

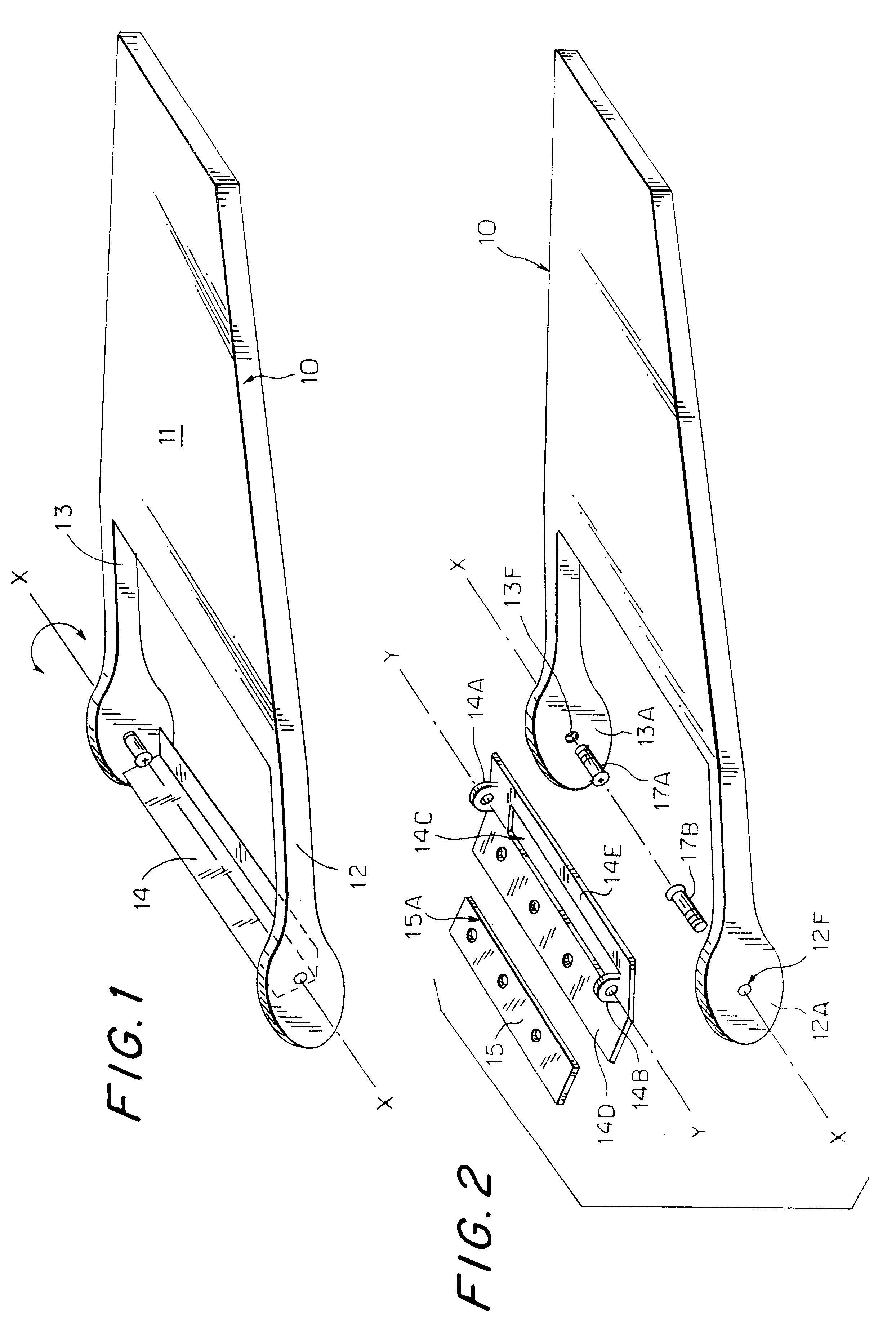

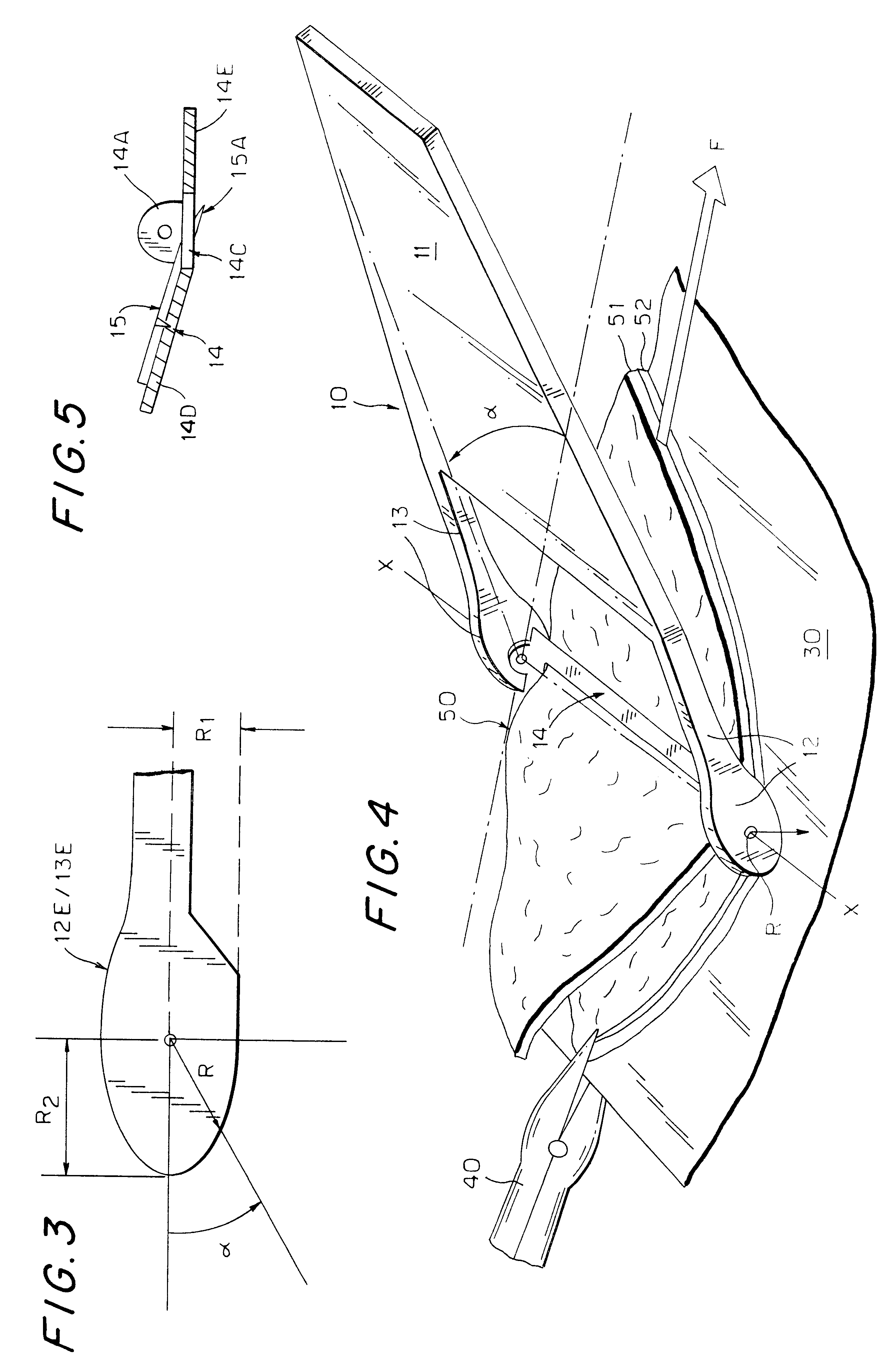

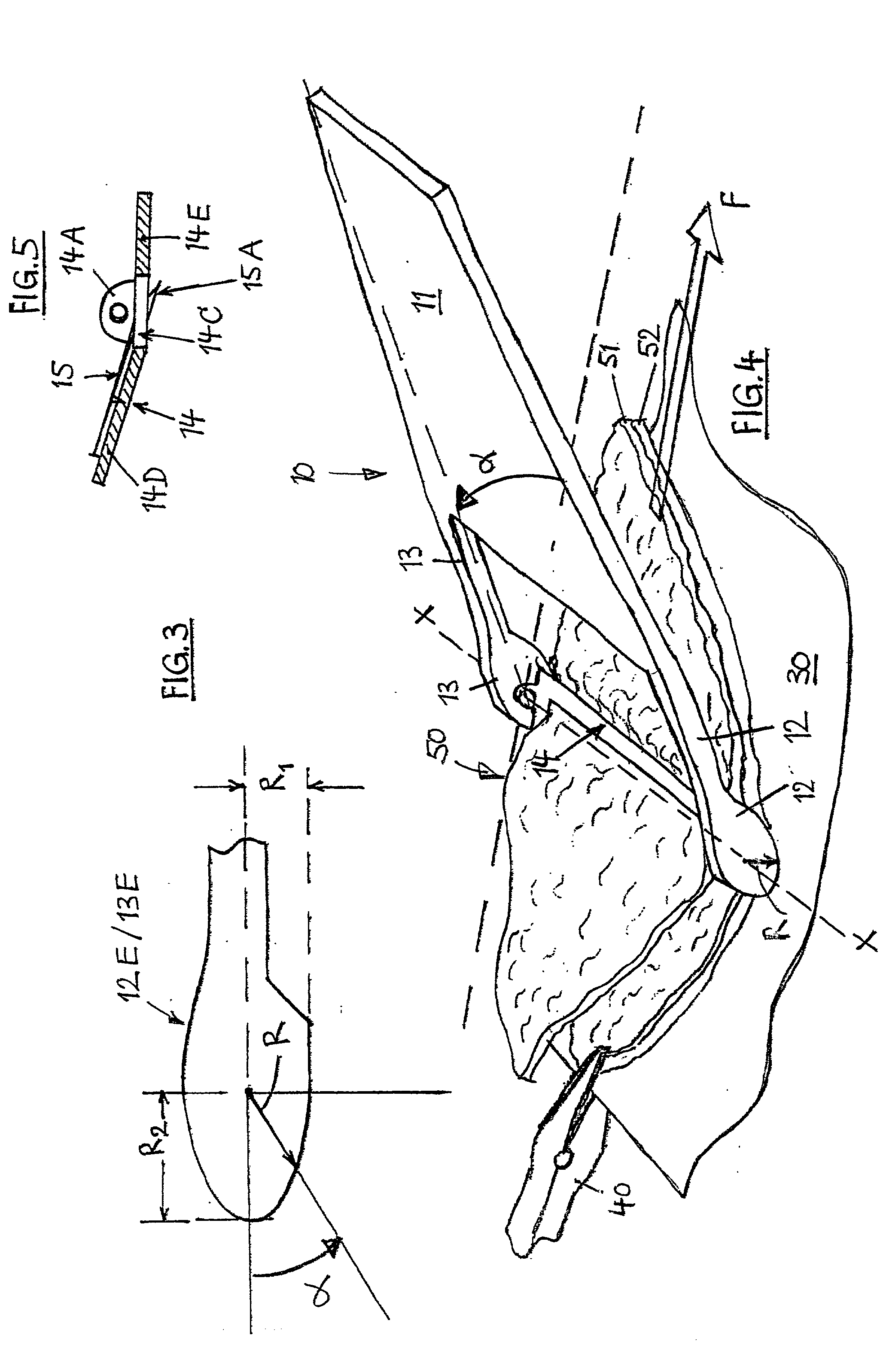

Hand-held device for preparation of a skin graft by tangential excision of layers of tissue

Owner:KASTEN KLAUS

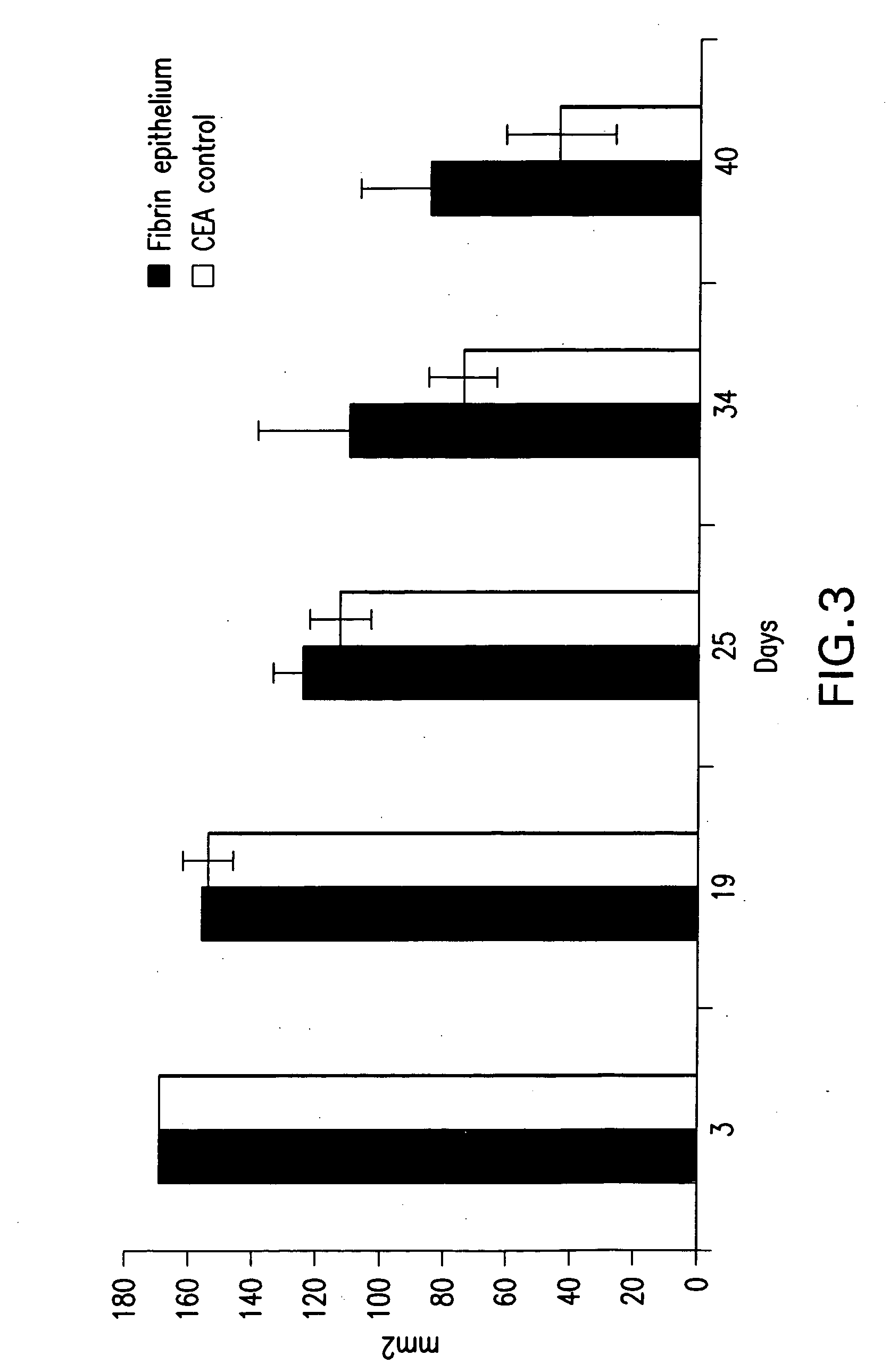

Fibrin cell supports and method of use thereof

InactiveUS20060240555A1Reduce probabilityPeptide/protein ingredientsEpidermal cells/skin cellsSkin graftingThrombin activity

The present invention relates to fibrin cell supports for cell cultures formed by the mixture of plasma proteins including fibrinogen and thrombin. The fibrin cell supports are preferably used for preparing a culture of cells such as keratinocytes, recovering the culture in the form of a reconstituted tissue, and transporting same. The reconstituted tissue is particularly suitable for use as a skin graft.

Owner:DFB PHARMA

Skin grafting devices and methods

Owner:3M INNOVATIVE PROPERTIES CO

Method and apparatus for production of a skin graft and the graft produced thereby

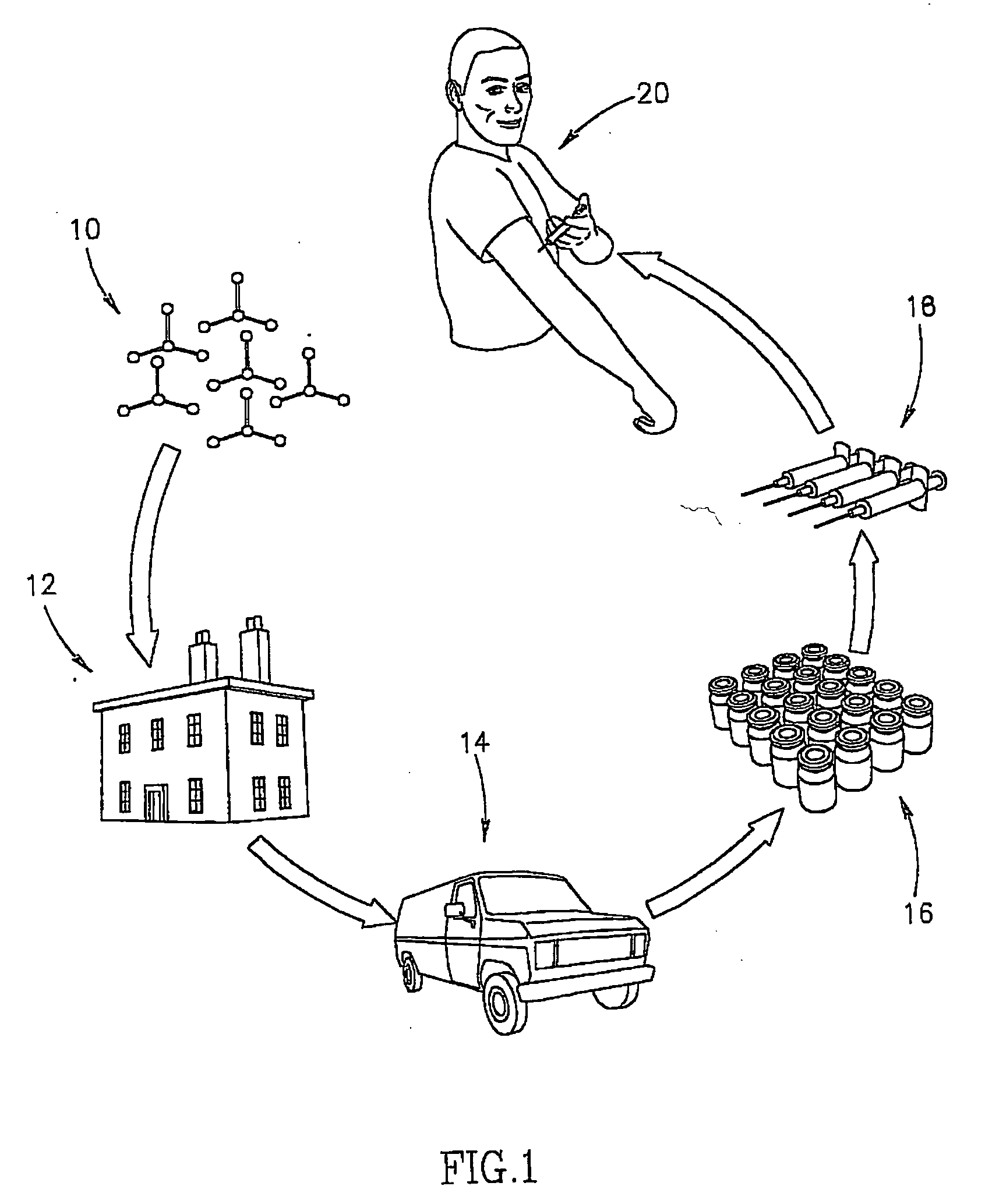

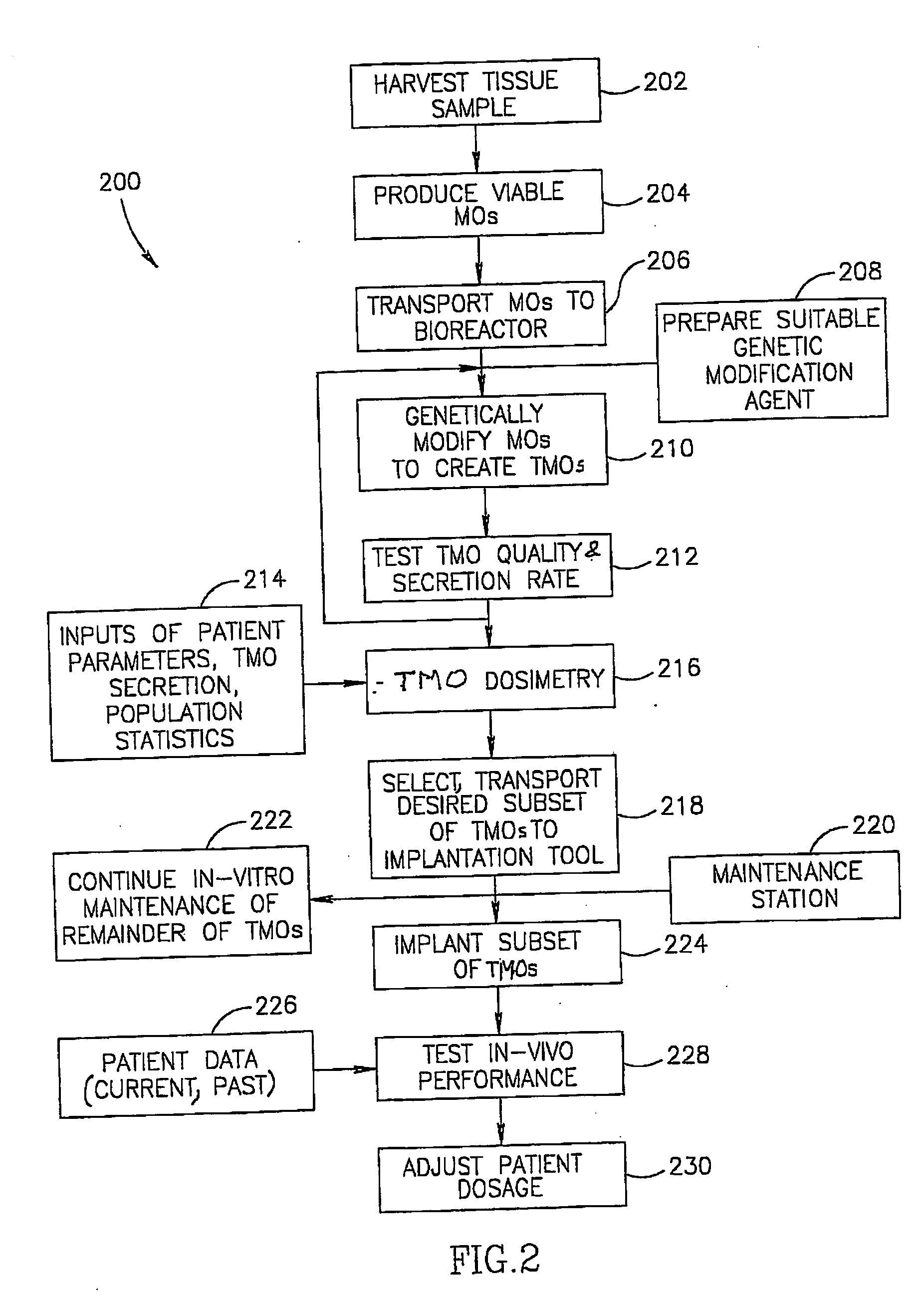

InactiveUS20070183974A1Easy and exact determinationFunction increaseBiological substance pretreatmentsPeptide/protein ingredientsSkin graftingBiomedical engineering

Owner:MEDGENICS INC

Medical dressing and its preparation method and application

InactiveCN101284145AReduce stimulationImprove repair abilityAbsorbent padsBandagesSkin graftingChitin formation

The invention discloses a dressing for medical use, a preparation method and an application thereof. The dressing comprises one or more of chitin derivative, chitosan derivative or water soluble chitin 1-100 wt%, water 0-99 wt%, and filler 0-60 wt%. The preparation method comprises respectively dissolving one or more of the chitin derivative, chitosan derivative or water soluble chitin into water to obtain 0.5-10 wt% aqueous solution, mixing intensively, adding 0-15 wt% filler, mixing intensively, vacuum de-bubbling to obtain hydrocolloid dressing, and subsequently obtaining filmy dressing, spongeous dressing or non-woven fabric dressing. The preparation method has simple process, and can be used for restoring skin wound such as operative incision in clinic, skin graft region, burn, scald, ulcer or bedsore.

Owner:WUHAN RUIER BIOTECH

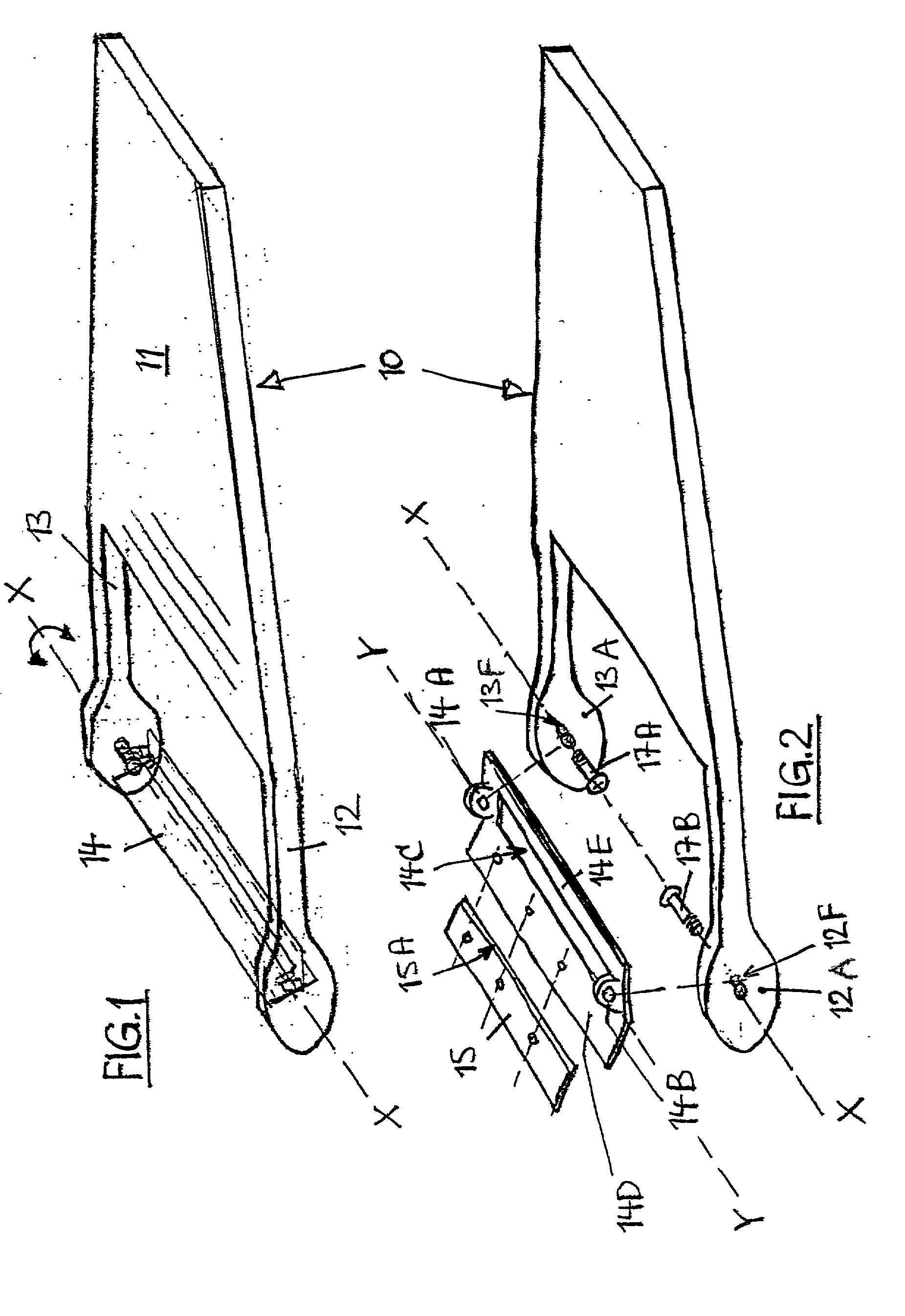

Hand-held device for preparation of a skin graft by tangential excision of layers of tissue

Hand-held appliance for preparation of an excised skin graft, that is placed upon a plane surface, by tangential excision of tissue below the epidermis to produce a trimmed skin graft of desired remaining tissue layers and thickness with a blade that is held between two holding rods, that can be placed on a plane surface and that is held in a height-adjustable axis parallel to the surface. The end regions of the rods are shaped so that the distance between the axis and the contact surface of the edge of the end regions to the surface changes at least by sections, while the minimal distance and the maximal distance define the lowest and the highest cutting plane, respectively, so that the distance of the cutting plane is defined by the operating angle between the plane of the rods and the surface.

Owner:KASTEN KLAUS

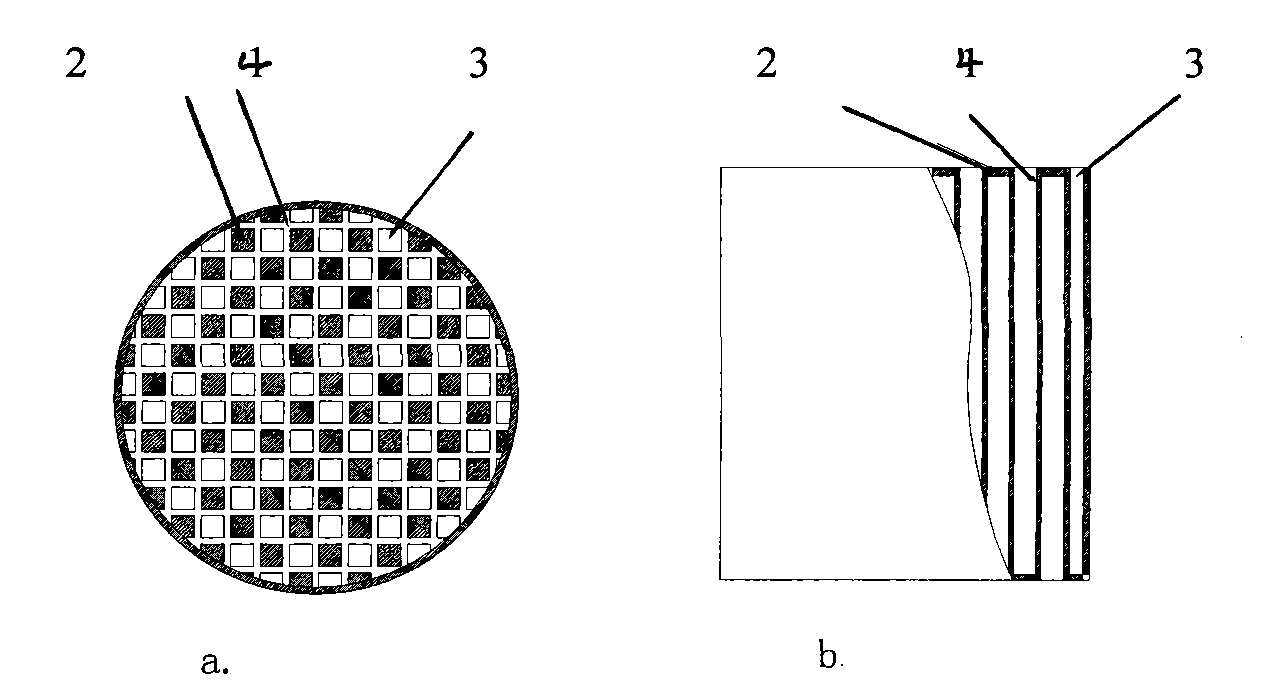

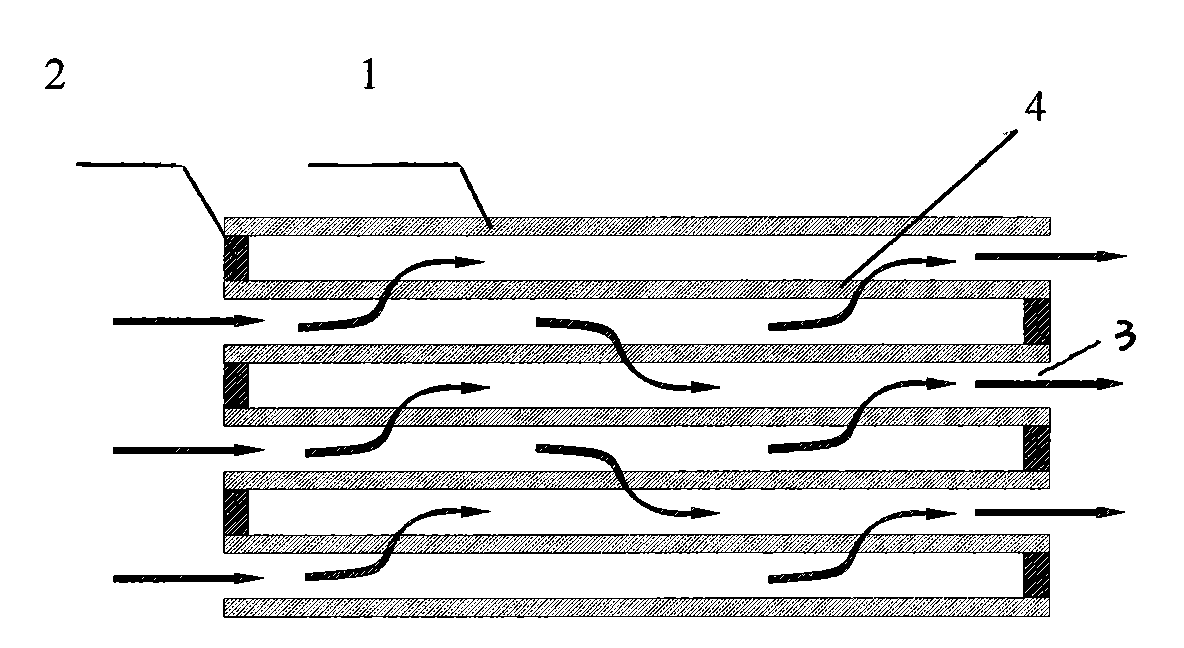

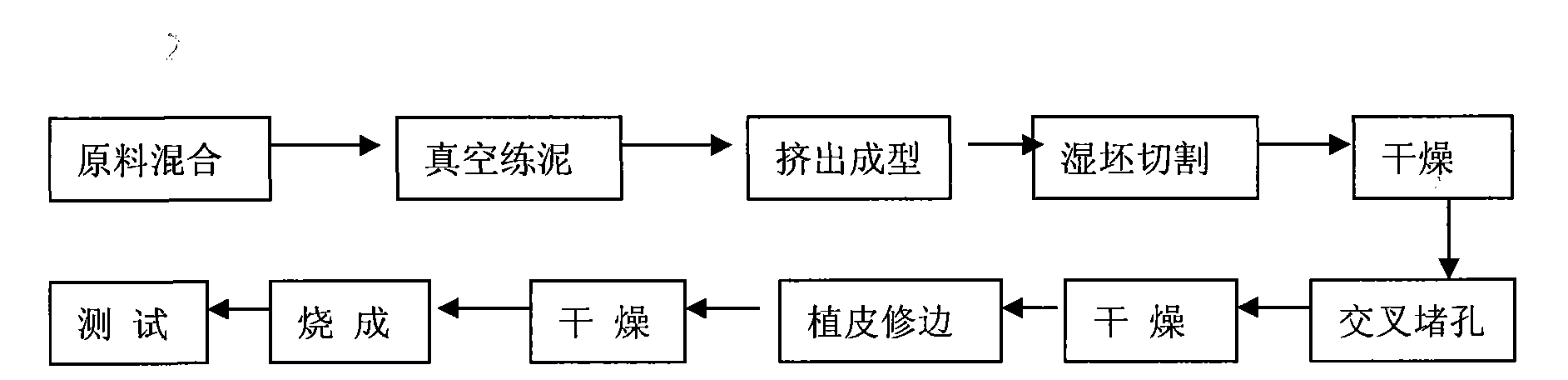

Method for preparing wall-flow honeycomb ceramic filter

InactiveCN101612499ALarge apertureEffective in filtering black smokeExhaust apparatusSilencing apparatusSkin graftingMicrowave

The invention relates to a method for preparing a wall-flow honeycomb ceramic filter, which combines a cordierite honeycomb ceramics material and a special pore-forming agent. Raw materials comprise the following components, mass portions and grain diameters: kaolin is 35 to 45 portions, and the average grain diameter is less than or equal to 5 mu m; talcum is 20 to 30 portions, and the average grain diameter is 15 mu m; alpha-alumina is 4 to 9 portions, and the average grain diameter is less than or equal to 2 mu m; the pore-forming agent consisting of carbon granules or / and organic polymeric particles is 5 to 15 portions, and the average grain diameter is 10 to 20 mu m; and a bonding agent is 3 to 7 portions. The method comprises the following steps: evenly mixing the components and 20 to 30 portions of water to prepare a blank; completing the conversion from the blank to plastic mud after performing vacuum degassing for 2 to 3 times; staling the plastic mud for 24+ / -8 hours, and squeezing out the plastic mud through a mould of an extruder; performing microwave drying on the plastic mud to obtain a dry blank; and performing cross hole blocking, drying, skin grafting and trimming on the dry blank, and finally performing a sintering working procedure to manufacture a product.

Owner:JIANGSU GAOCHUN CERAMICS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com