Method for preparing wall-flow honeycomb ceramic filter

A technology of honeycomb ceramics and filters, which is applied in the field of preparation of wall-flow honeycomb ceramic filters, can solve the problems of high thermal expansion coefficient and mechanical strength, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

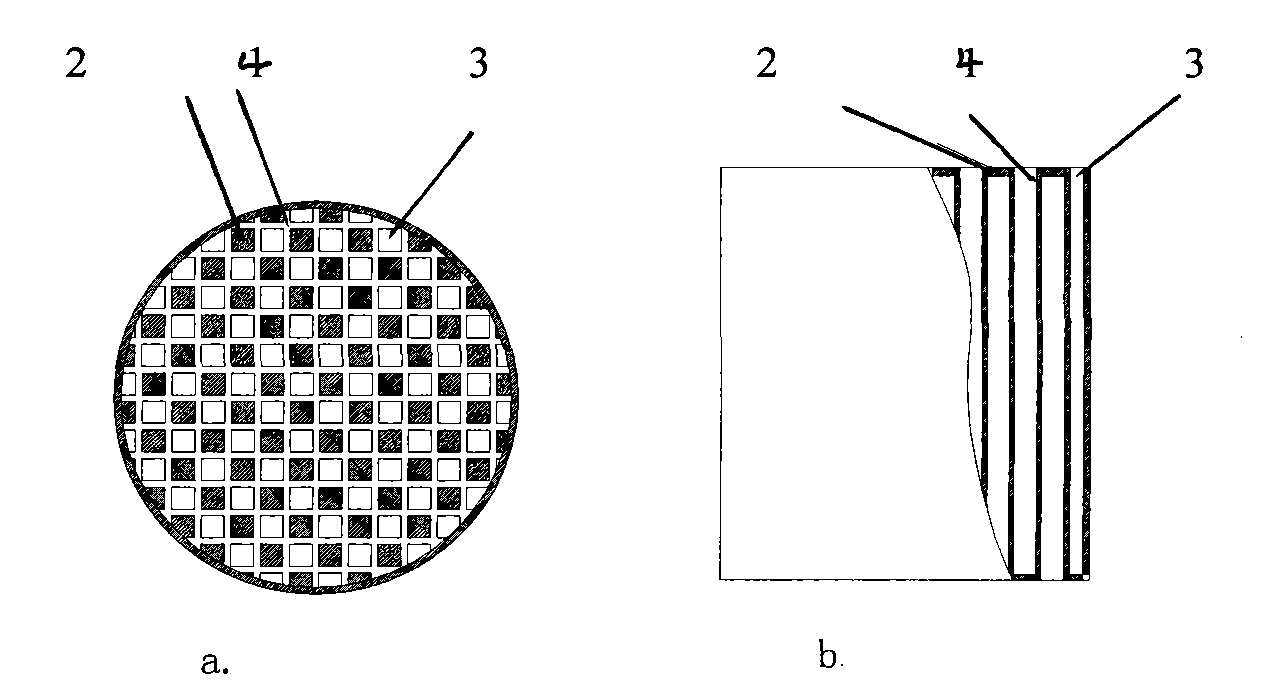

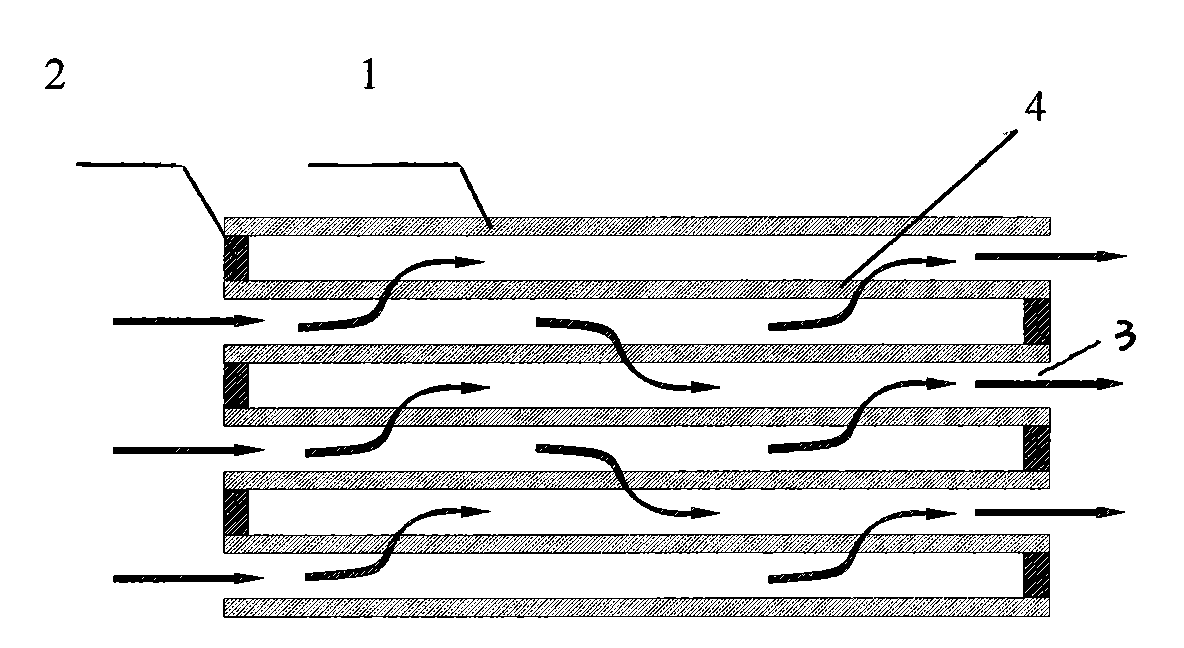

[0020] Wall-flow honeycomb ceramic filter such as figure 1 , figure 2 Shown: 1 is the outermost wall, 2 is the closed cell at the end, 3 is the opening at the end, and 4 is the filter wall.

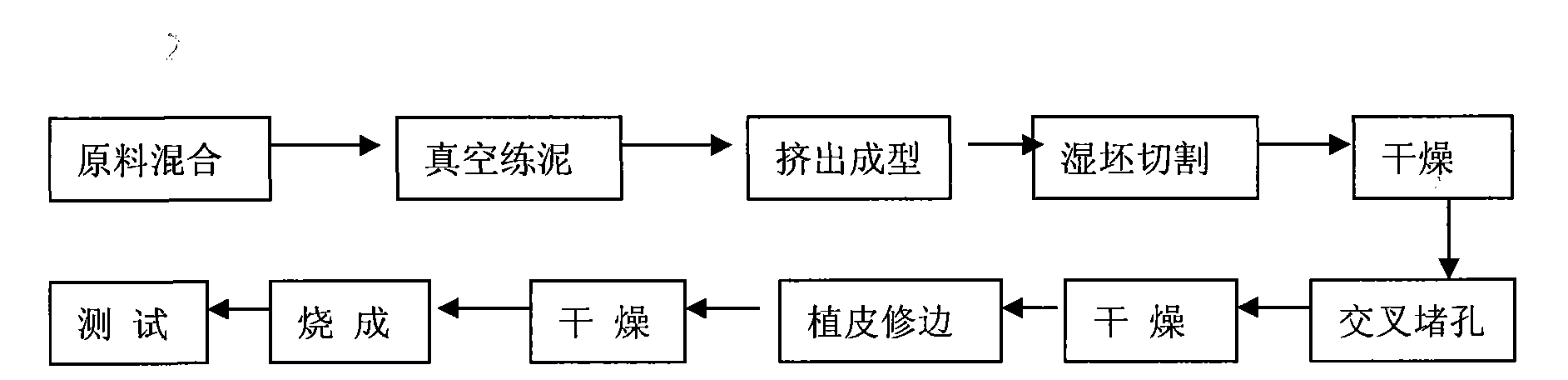

[0021] The embodiment of the wall-flow type honeycomb ceramic filter body comprises raw material processing, molding and firing, and concrete technical route is as follows (see image 3 ):

[0022]First, 35-45 parts of kaolin, with an average particle size of ≤5 μm, 20-30 parts of talc, with an average particle size of 15 μm, 4-9 parts of α-alumina, with an average particle size of ≤2 μm, and pore-forming agents (including carbon particles or organic High polymer molecular particles can also be a mixture of the two, and the weight ratio of the two mixed is 2-8:8-2; carbon particles include coal powder, and organic polymer particles include various high-molecular particles or fibrous polymers, such as Polyethylene, polypropylene, polyester can all be burned at high temperature) 5-15 pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com