Heat pipe with composite capillary wick structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

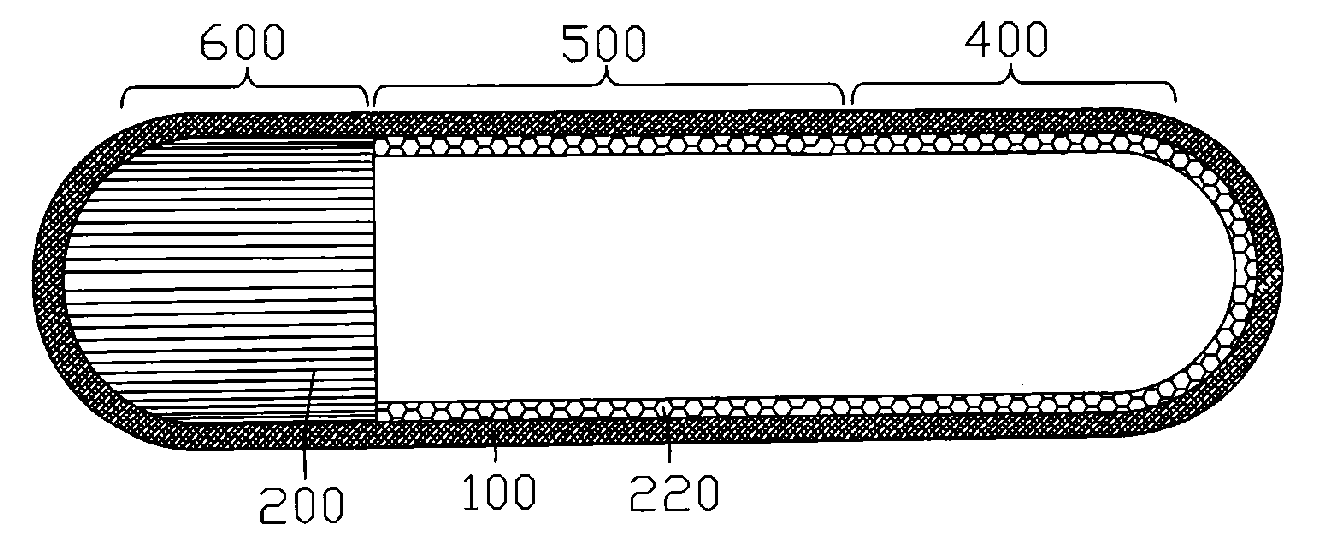

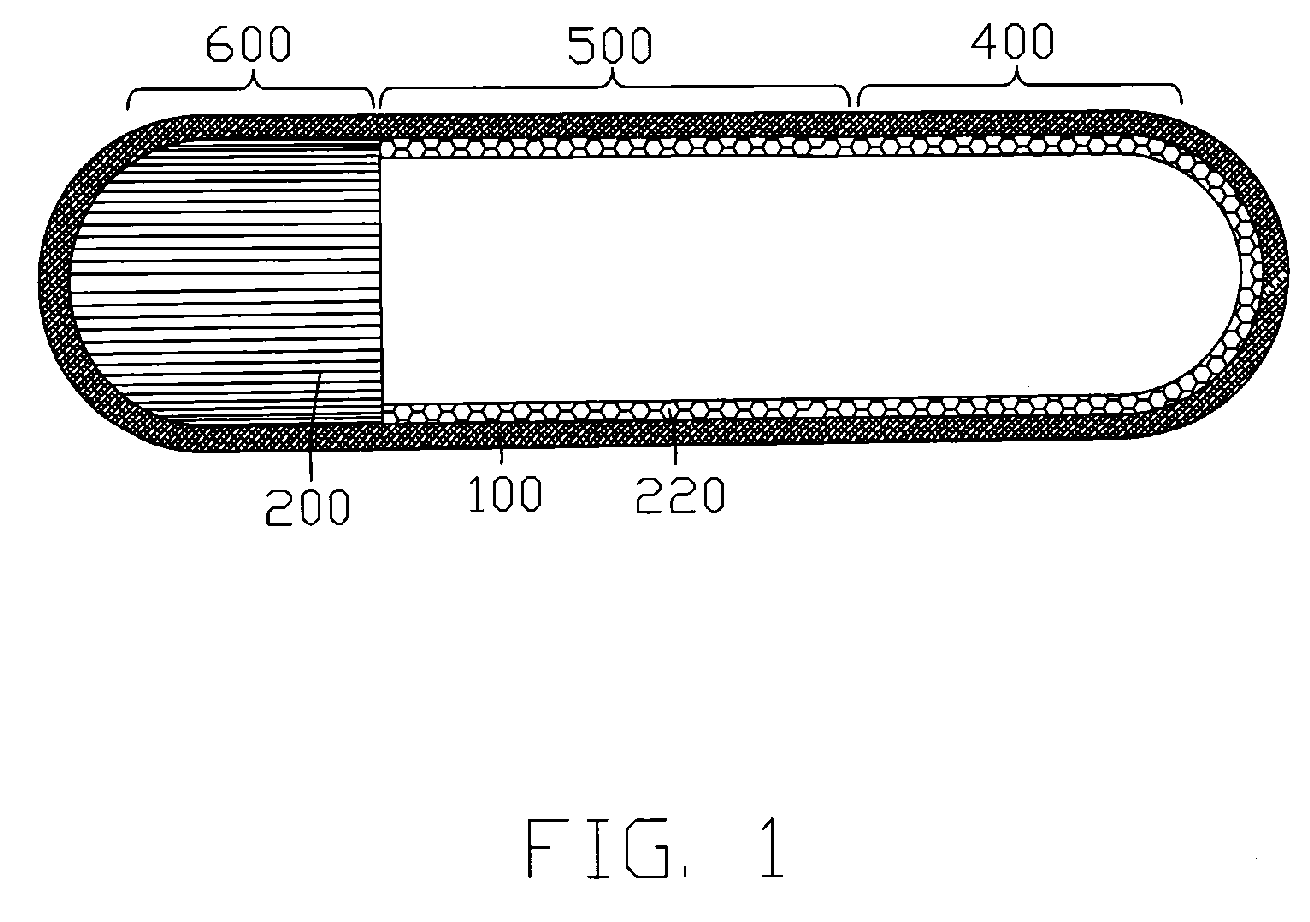

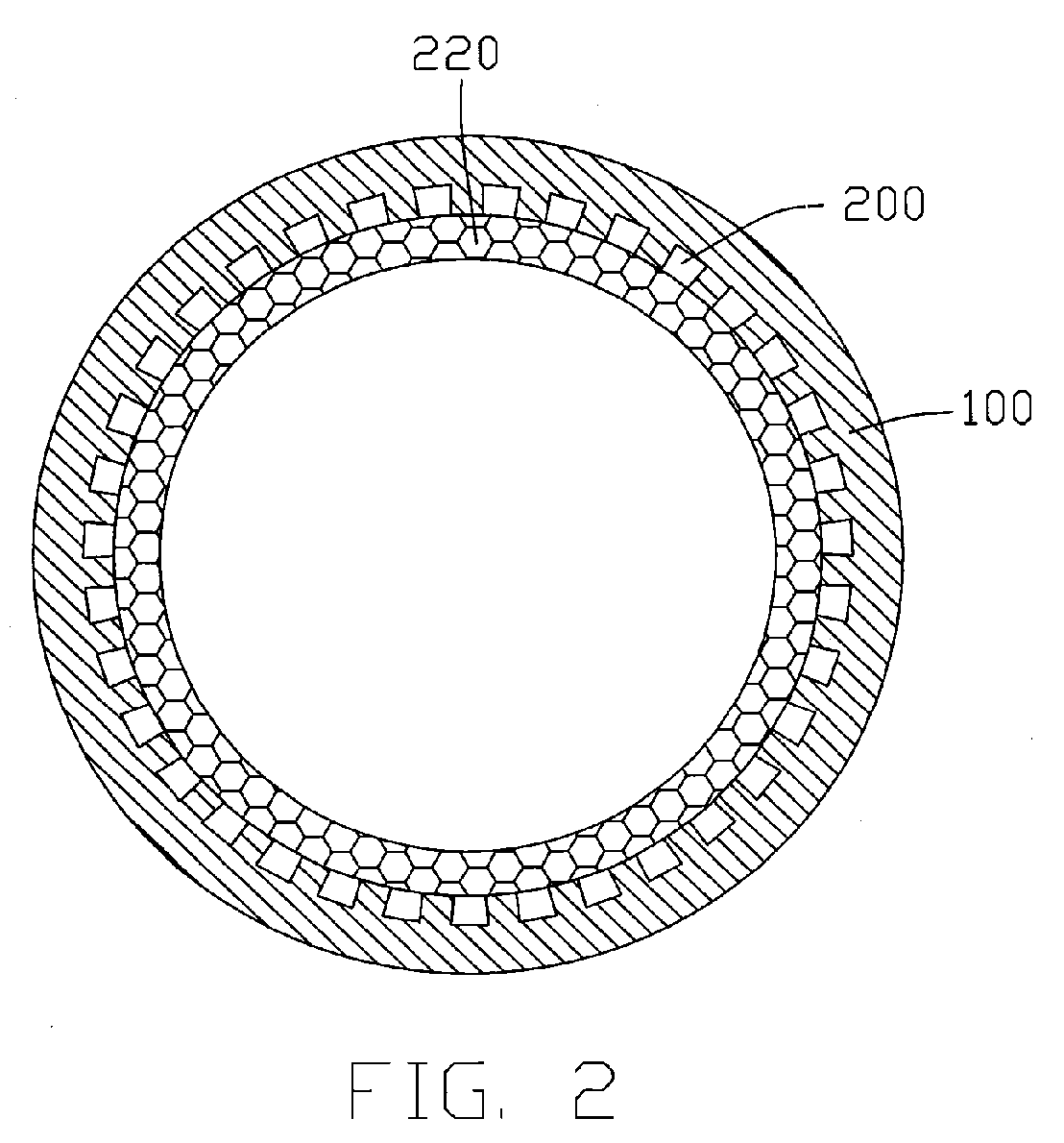

[0014]FIG. 1 illustrates a heat pipe in accordance with a first embodiment of the present invention. The heat pipe comprises a casing 100 and a composite capillary wick (not labeled) arranged on an inner wall of the casing 100. The casing 100 comprises an evaporating section 400 at one end and a condensing section 600 at an opposite end thereof, and a central section (i.e., adiabatic section) 500 located between the evaporating section 400 and the condensing section 600. The casing 100 is made of highly thermally conductive materials such as copper or copper alloys and filled with a working fluid (not shown), which acts as a heat carrier for carrying thermal energy from the evaporating section 400 to the condensing section 600. Heat that needs to be dissipated is transferred firstly to the evaporating section 400 of the casing 100 to cause the working fluid therein to evaporate. Then, the heat is carried by the working fluid in the form of vapor to the condensing section 600 where t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com