Patents

Literature

196 results about "Pre and post" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PRE and POST-conditions provide a set of conditions (a contract) for the programmer of the operation to meet. PRE and POST-conditions also help the reader and user to know what they can expect as the result of the operation upon the data structure.

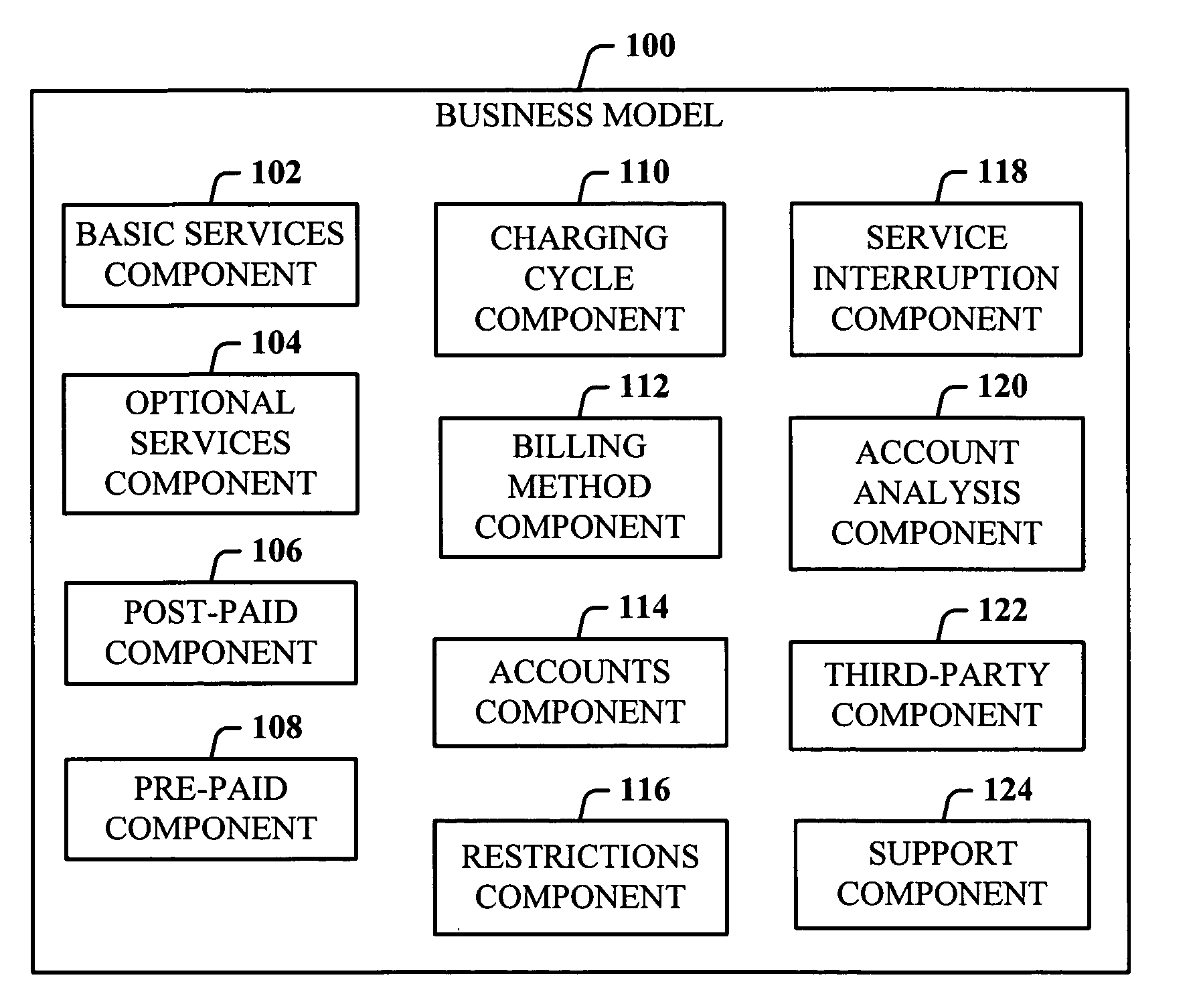

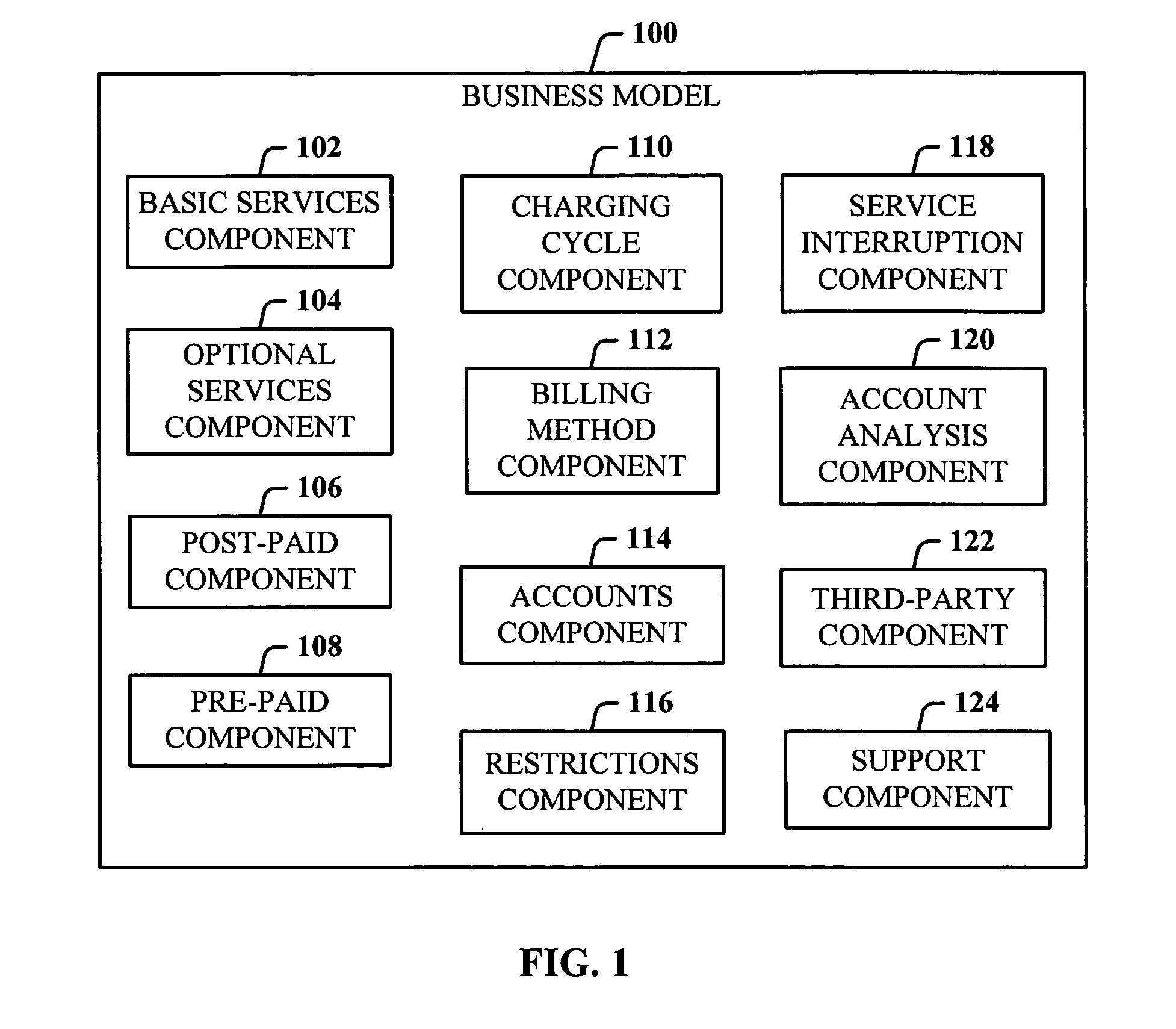

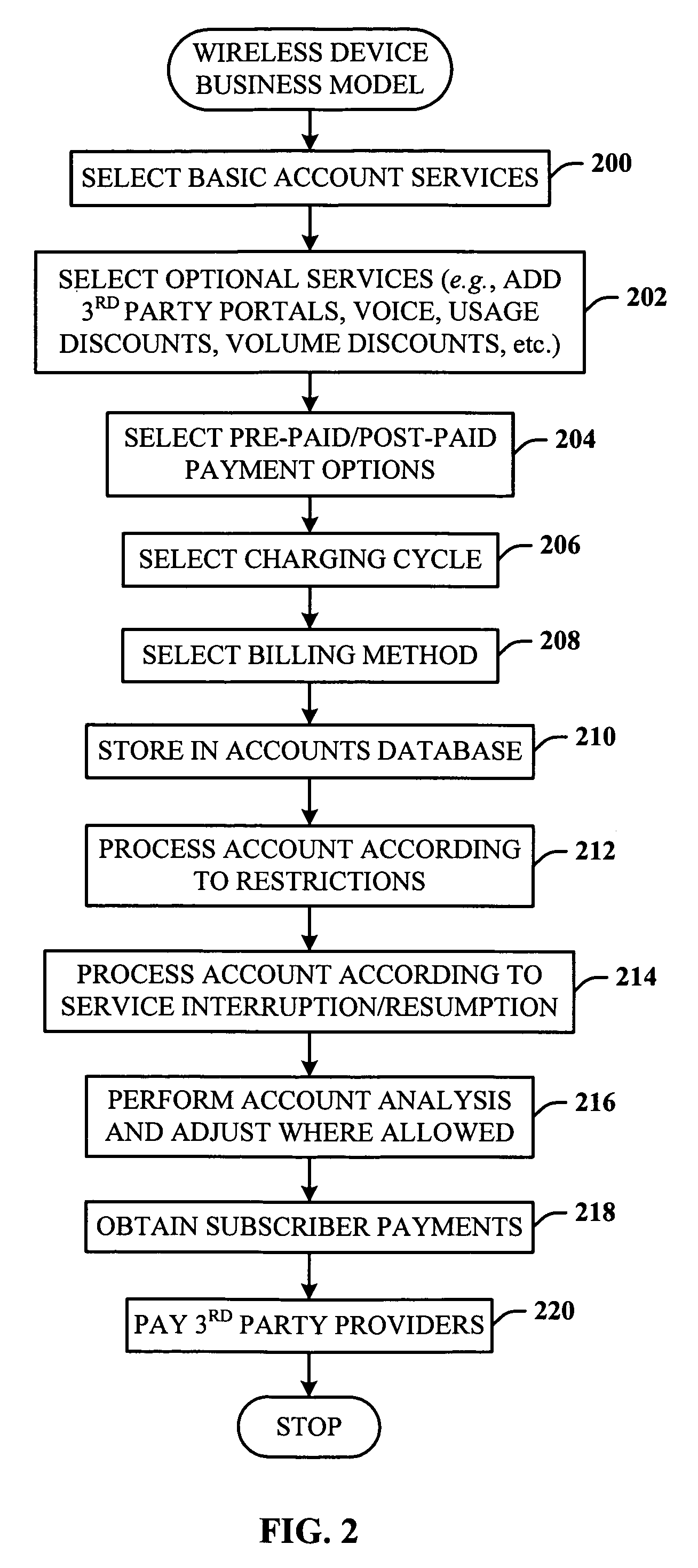

Dedicated wireless device business method

InactiveUS20060019632A1Easy accessAccounting/billing servicesTelephonic communicationThird partyComputer compatibility

Owner:AT&T MOBILITY II LLC

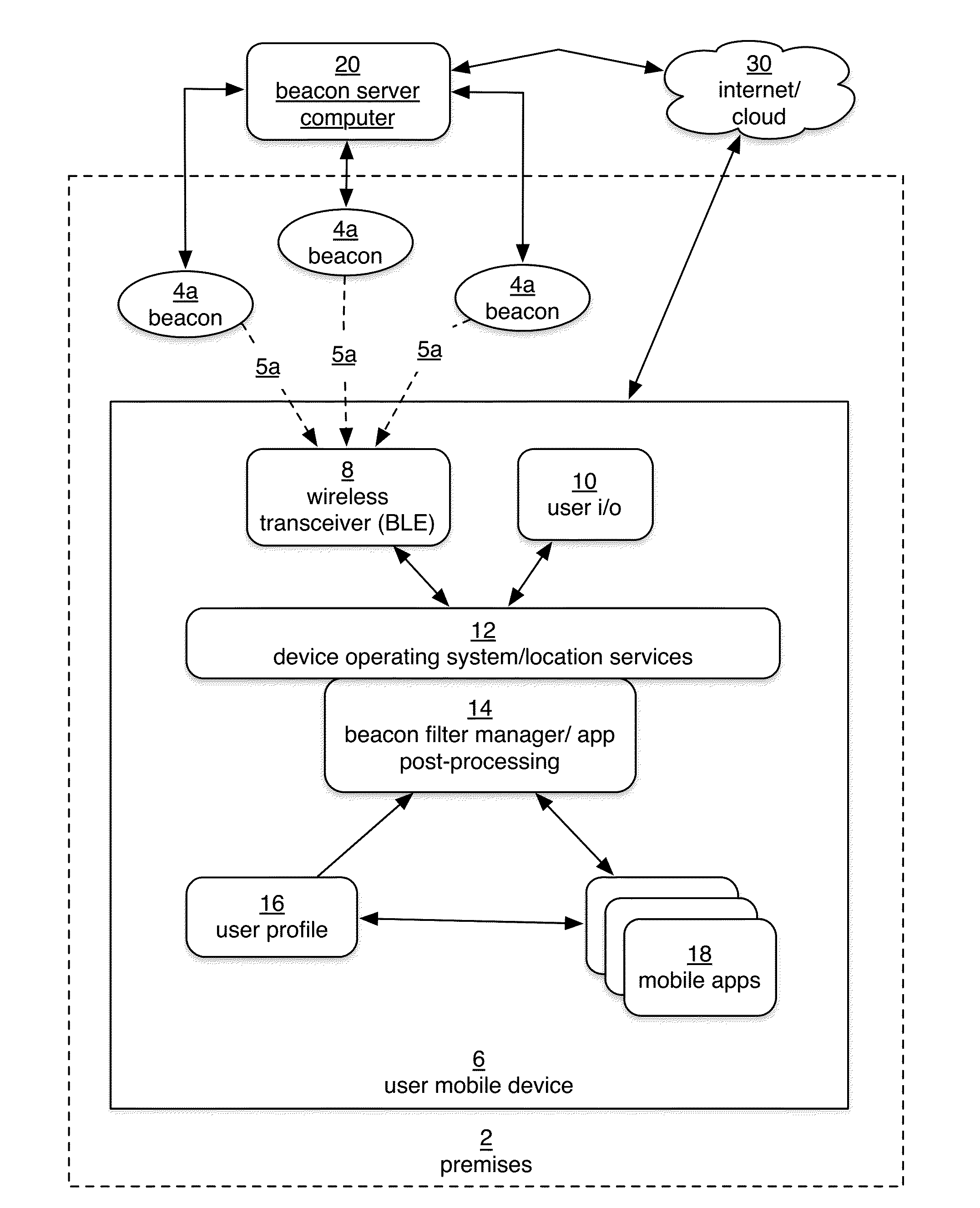

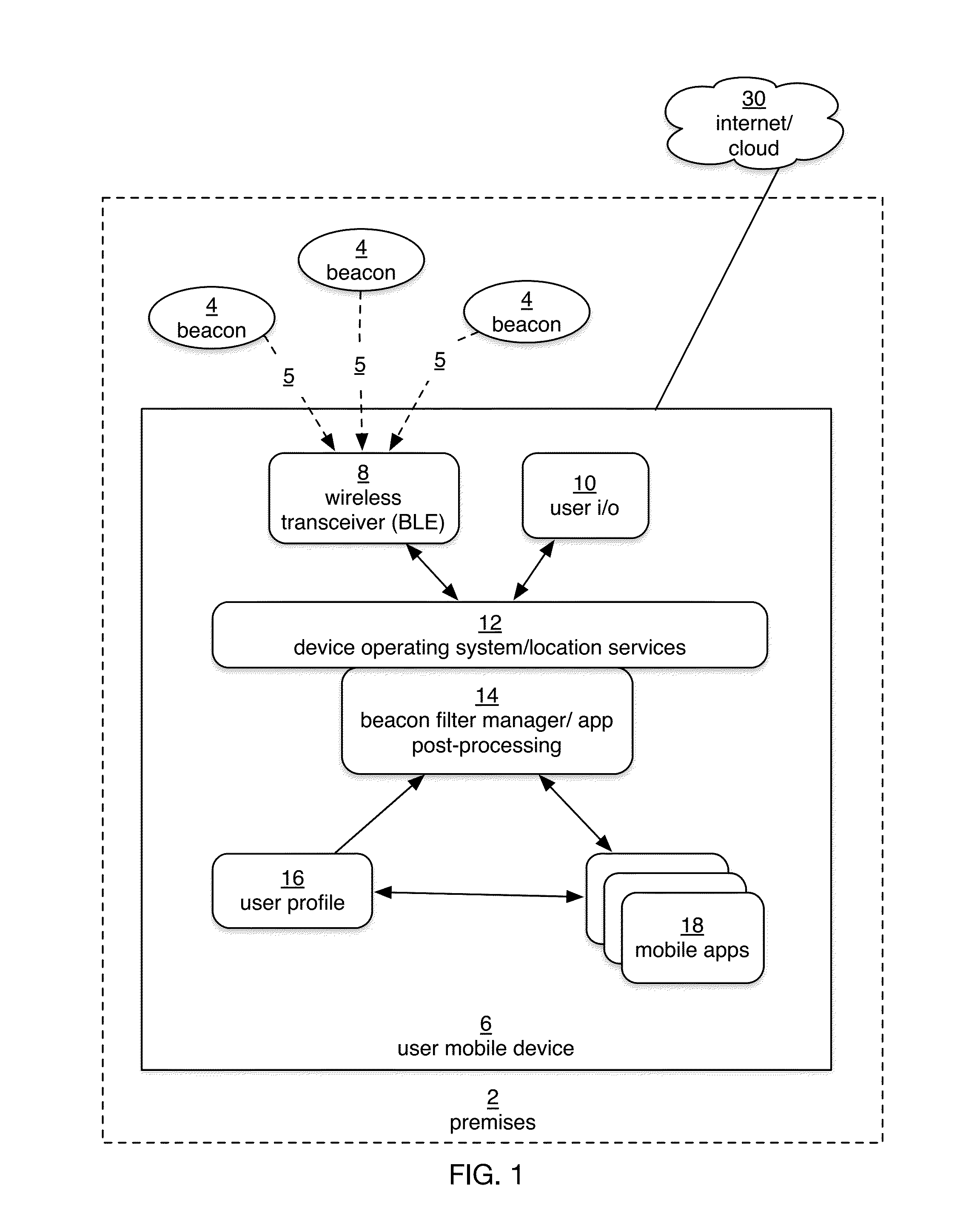

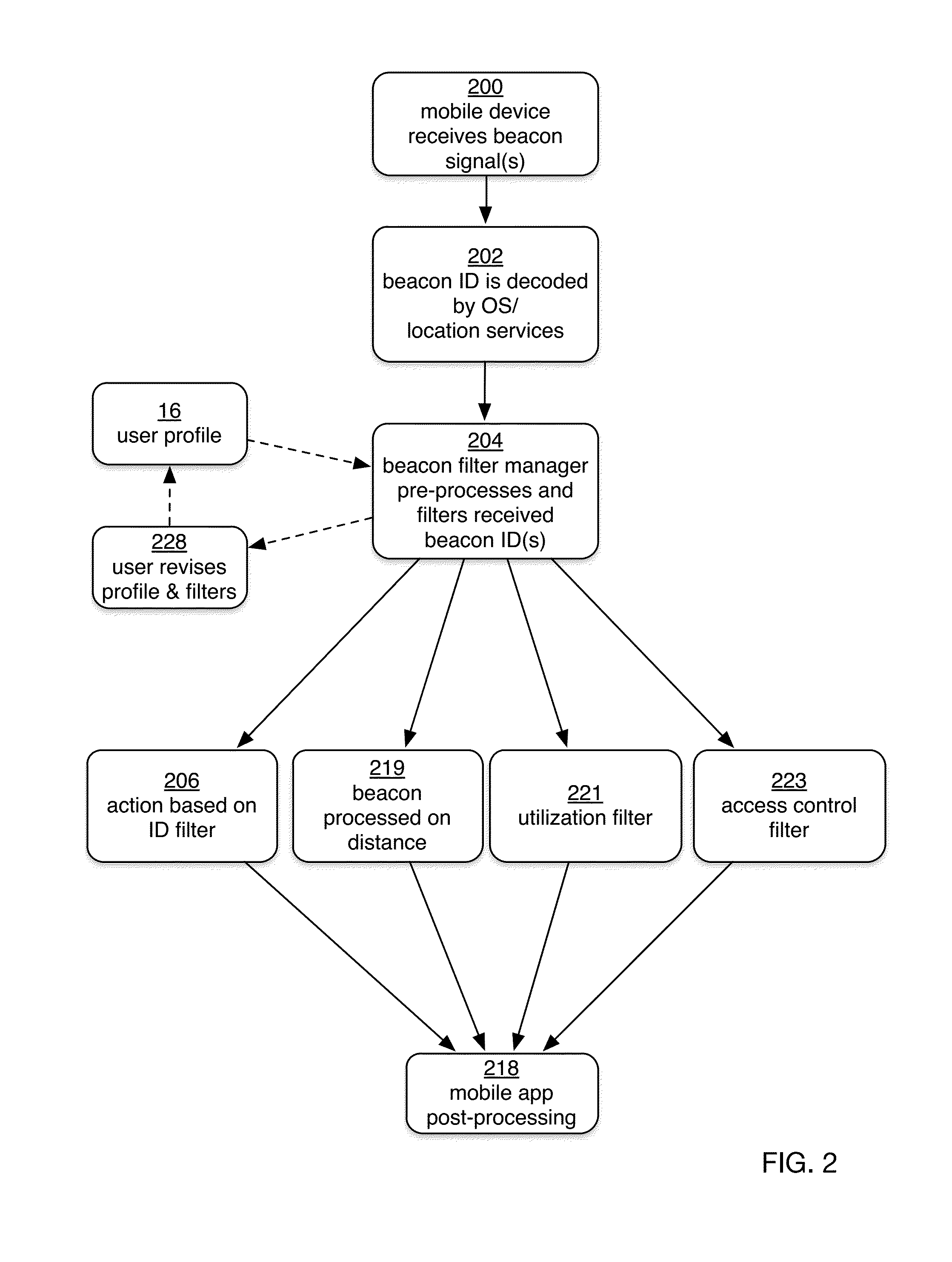

Method and system for pre and post processing of beacon id signals

A wireless beacon message management system and method of operating the system with a mobile device. At least one wireless beacon is strategically located in a premises, such as a building or other geocentrically defined area. Each wireless beacon has means for transmitting a wireless beacon signal, wherein the wireless beacon signal includes a beacon data message that has a beacon identification that identifies the beacon transmitting the signal, and optionally the content being delivered. A mobile device such as a smartphone, tablet or the like receives the wireless beacon signal and analyzes it to extract the beacon identification and optional beacon content. The mobile device may then apply one or more software filters to the beacon data message that enables the mobile device to initiate an action based on the filtered beacon data message.

Owner:POSTREL RICHARD

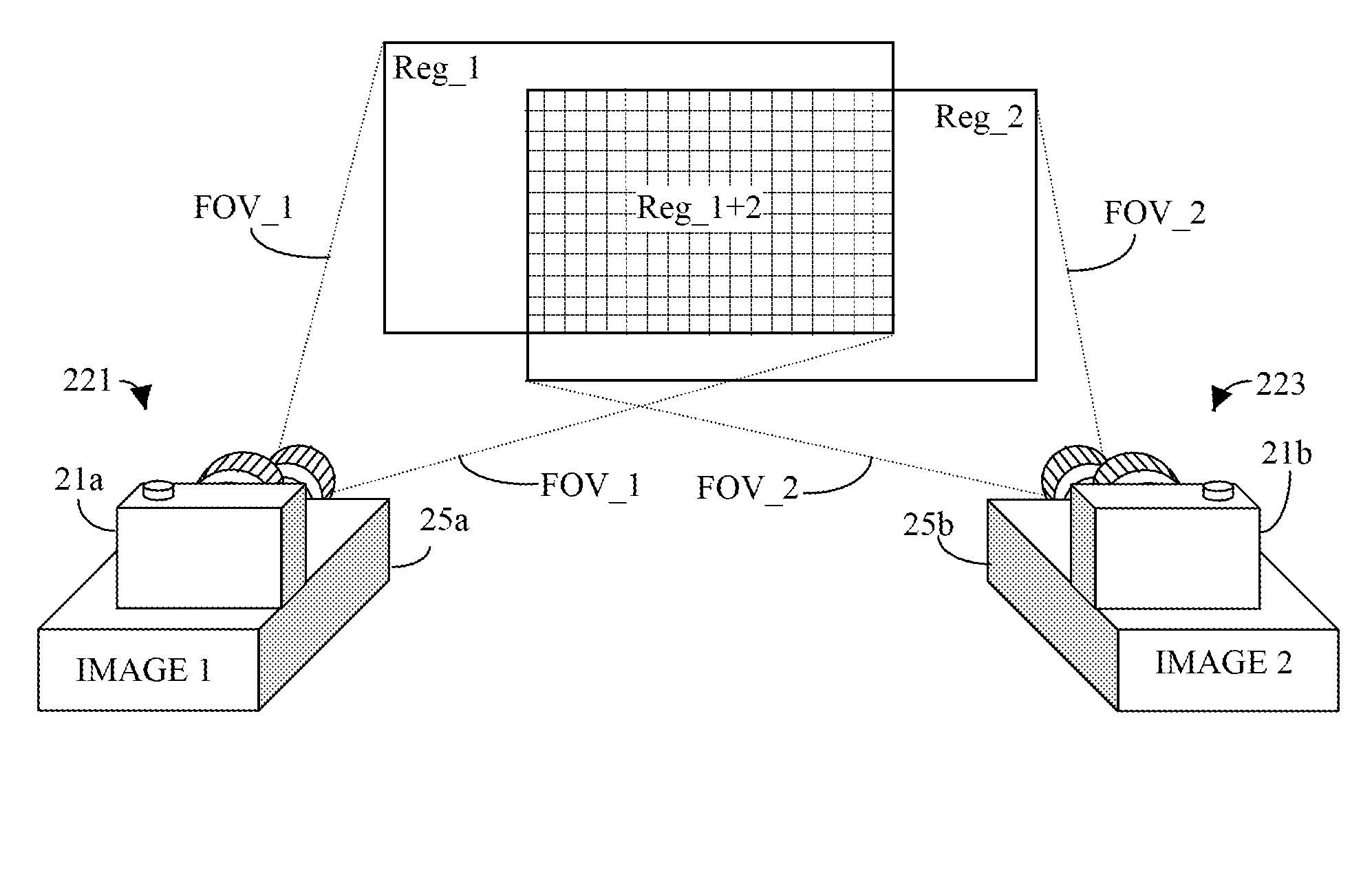

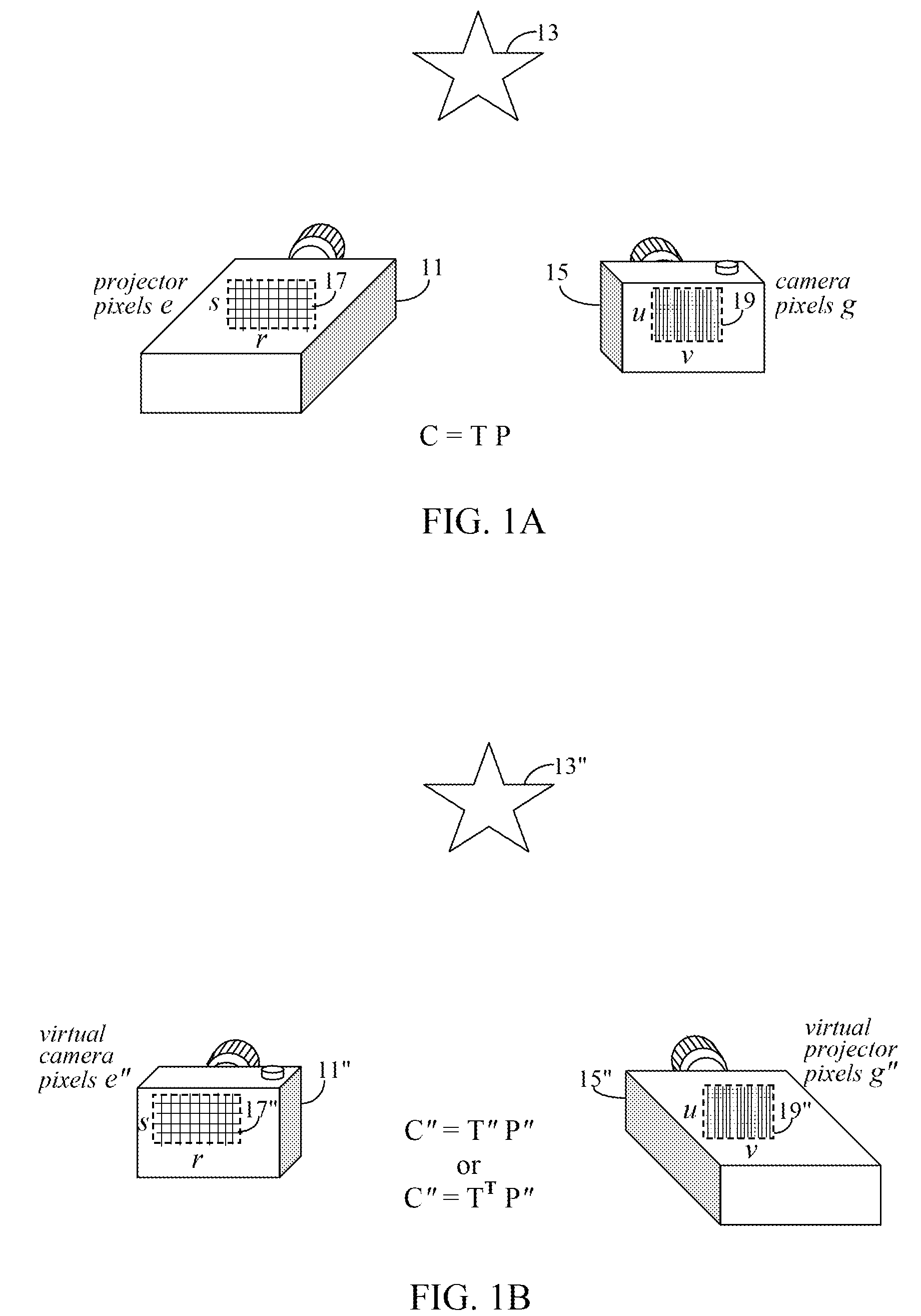

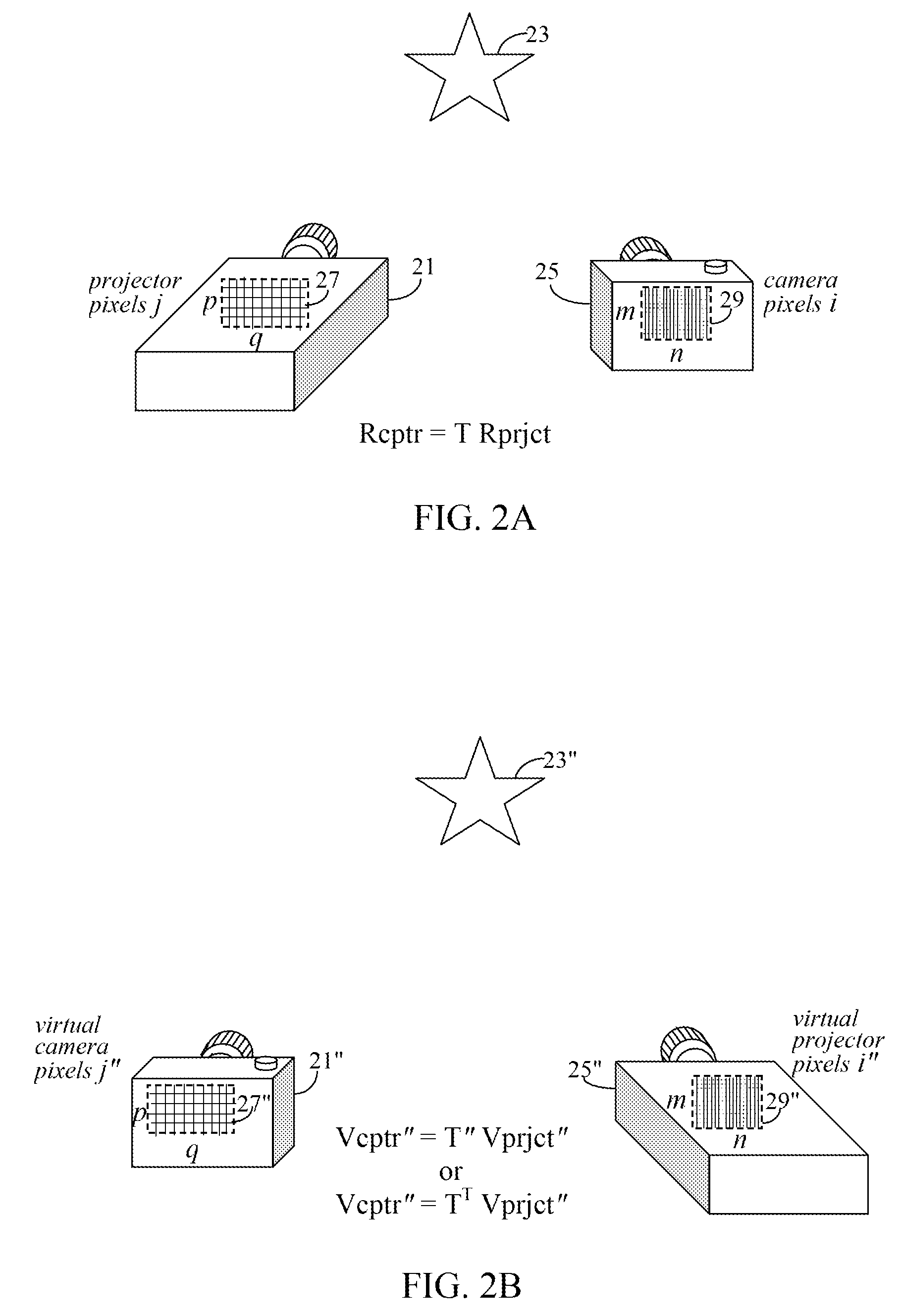

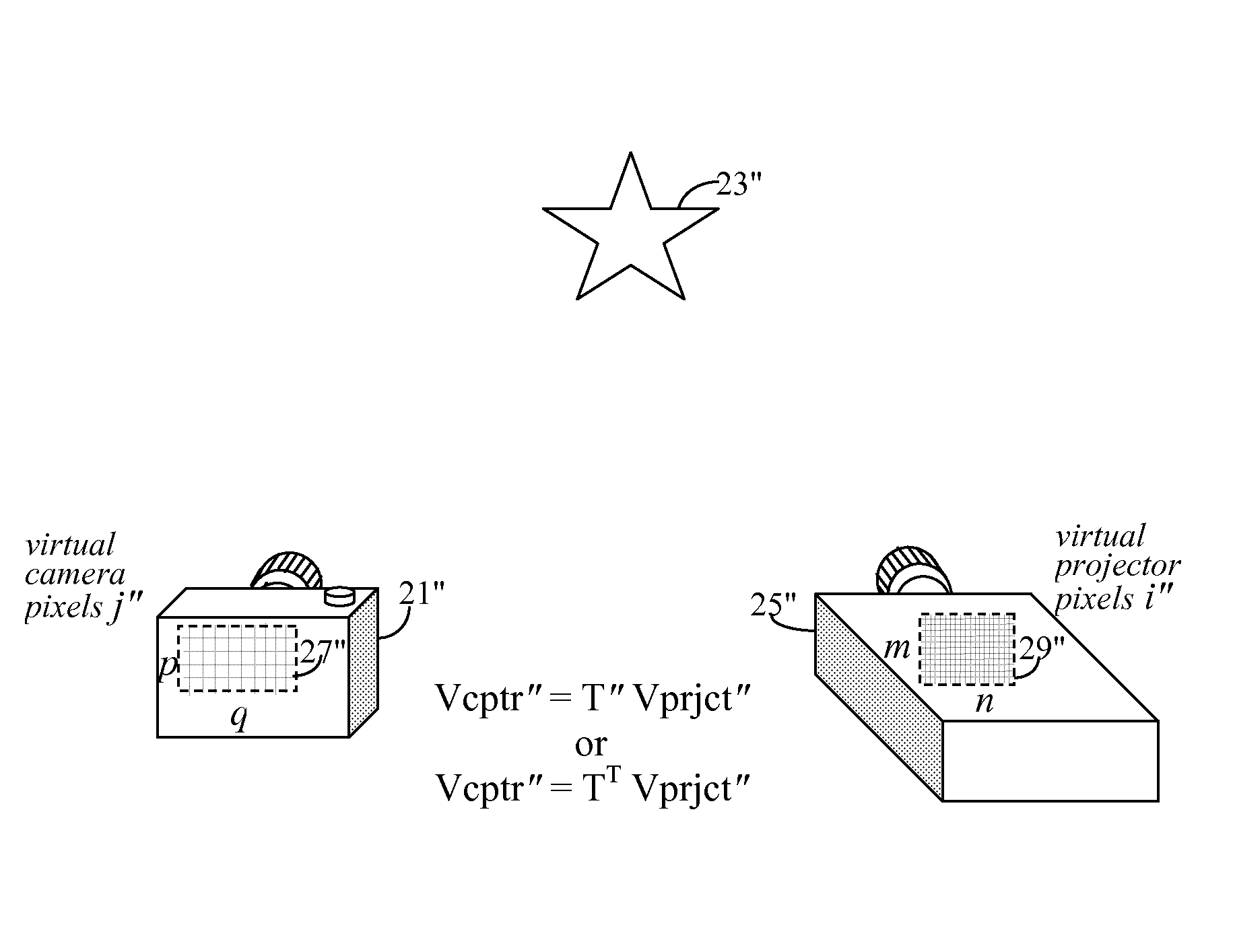

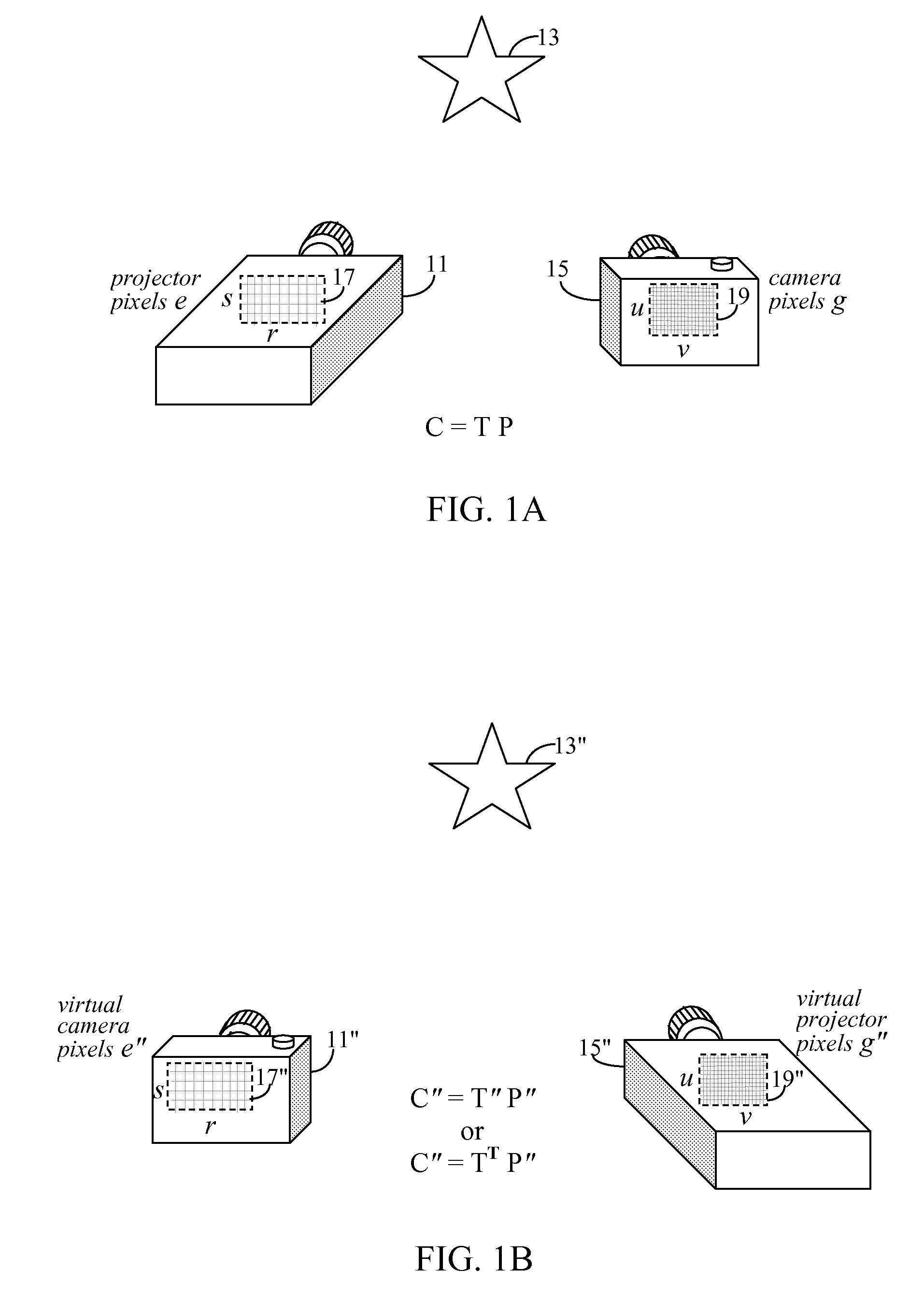

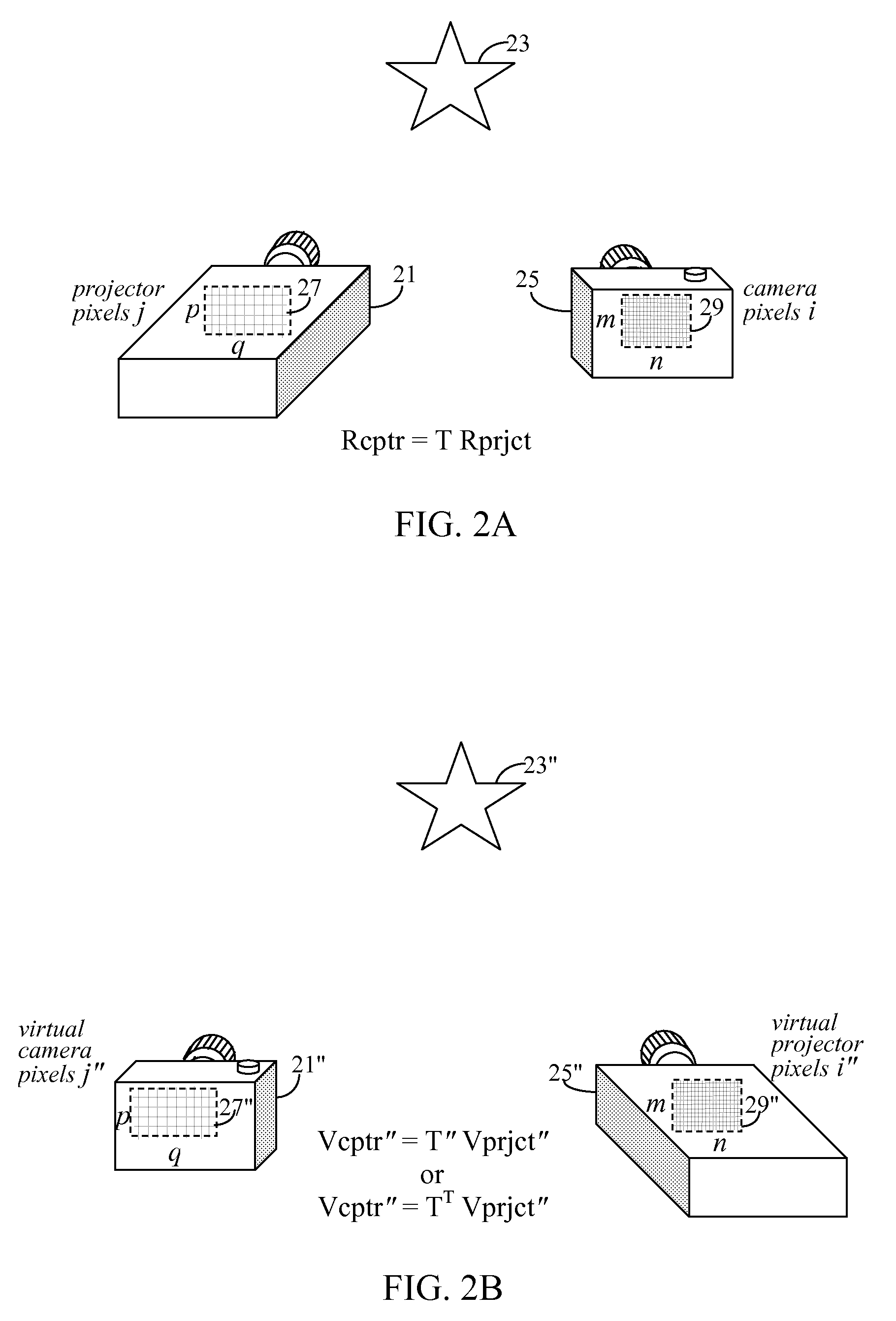

View projection matrix based high performance low latency display pipeline

InactiveUS8013904B2Easy to shipEasy to implementTelevision system detailsPicture reproducers using projection devicesHat matrixImaging processing

A projection system uses a transformation matrix to transform a projection image p in such a manner so as to compensate for surface irregularities on a projection surface. The transformation matrix makes use of properties of light transport relating a projector to a camera. A display pipeline of user-supplied image modification processing modules are reduced by first representing the processing modules as multiple, individual matrix operations. All the matrix operations are then combined with, i.e., multiplied to, the transformation matrix to create a modified transformation matrix. The created transformation matrix is then used in place of the original transformation matrix to simultaneously achieve both image transformation and any pre and post image processing defined by the image modification processing modules.

Owner:SEIKO EPSON CORP

Small memory footprint light transport matrix capture

ActiveUS8106949B2Easy to shipEasy to implementTelevision system detailsTelevision system scanning detailsImaging processingProjection image

A projection system uses a transformation matrix to transform a projection image p in such a manner so as to compensate for surface irregularities on a projection surface. The transformation matrix makes use of properties of light transport relating a projector to a camera. A display pipeline of user-supplied image modification processing modules are reduced by first representing the processing modules as multiple, individual matrix operations. All the matrix operations are then combined with, i.e., multiplied to, the transformation matrix to create a modified transformation matrix. The created transformation matrix is then used in place of the original transformation matrix to simultaneously achieve both image transformation and any pre and post image processing defined by the image modification processing modules.

Owner:SEIKO EPSON CORP

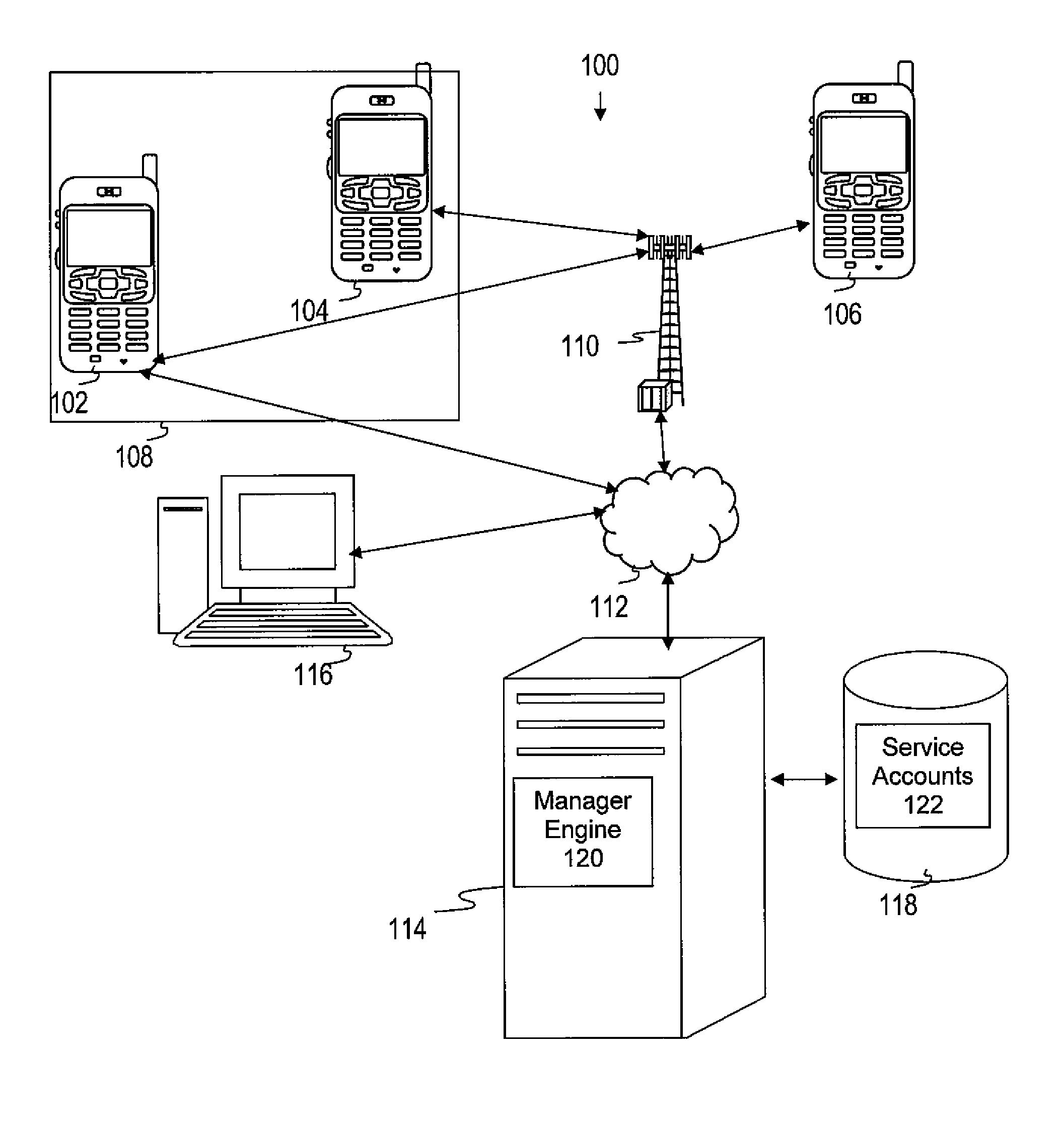

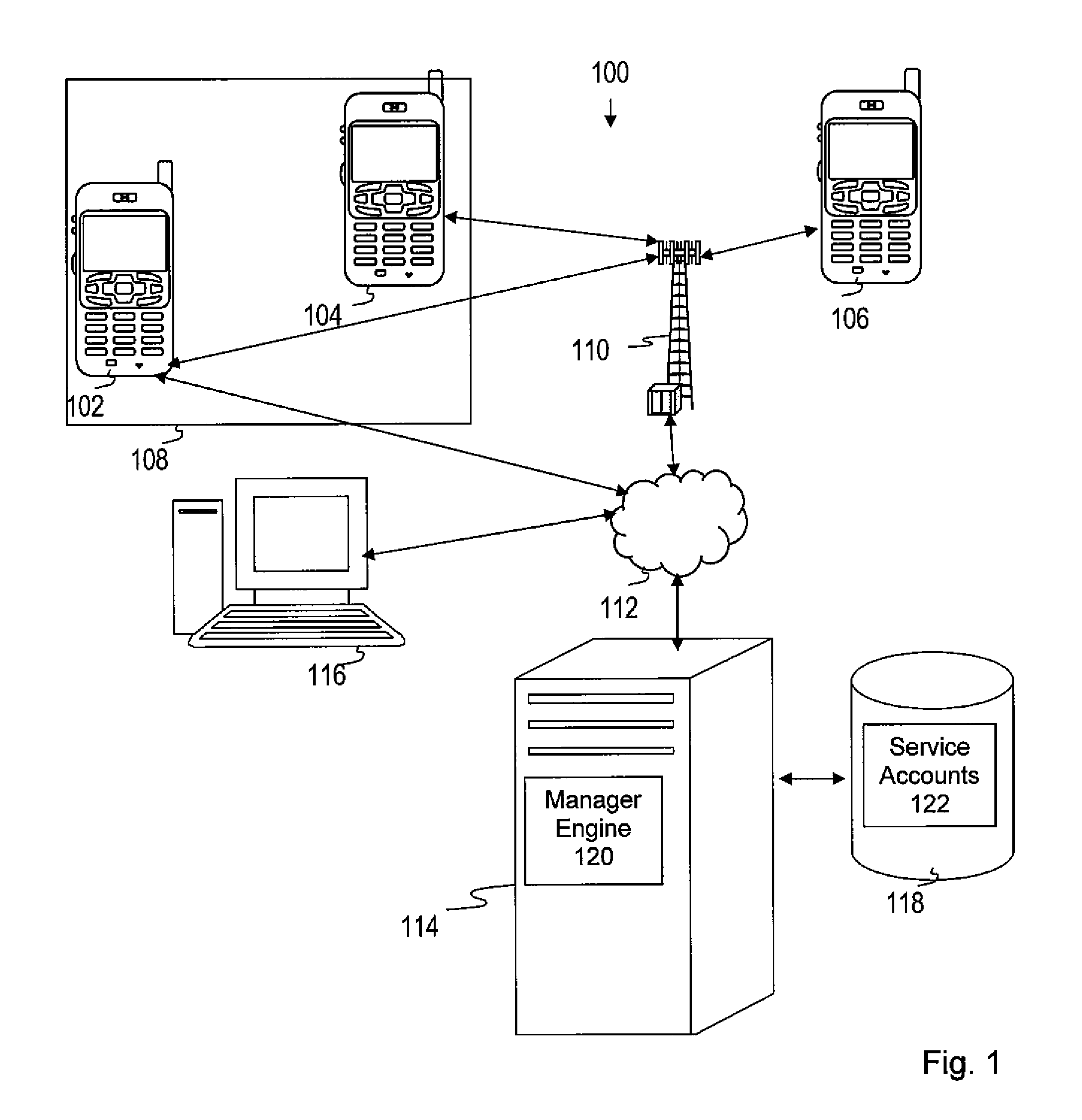

Pre and post-paid service plan manager

A service plan manager is provided, including a manager engine and a storage device to store data for a service account that comprises a pre-paid service plan associated with a first communication device and a post-paid service plan associated with a second communication device. The manager engine determines whether a balance associated with the pre-paid service plan is below a threshold, and communicates a request for increasing the balance to a device associated with the service account if the balance associated with the pre-paid service plan is below the threshold. The manager engine discontinues service for the first communication device until an approval of the request for increasing the balance is received, increases the balance in response to a receipt of the approval of the request for increasing the balance, and adds an amount associated with increasing the balance to an invoice associated with the service account.

Owner:T MOBILE INNOVATIONS LLC

Skin grafting devices and methods

The present invention provides skin grafting and devices that comprise a systematic approach to the process of skin grafting, i.e., harvesting, post-excision processing and application of donor skin and pre and post-graft treatment of the recipient site.

Owner:KCI LICENSING INC

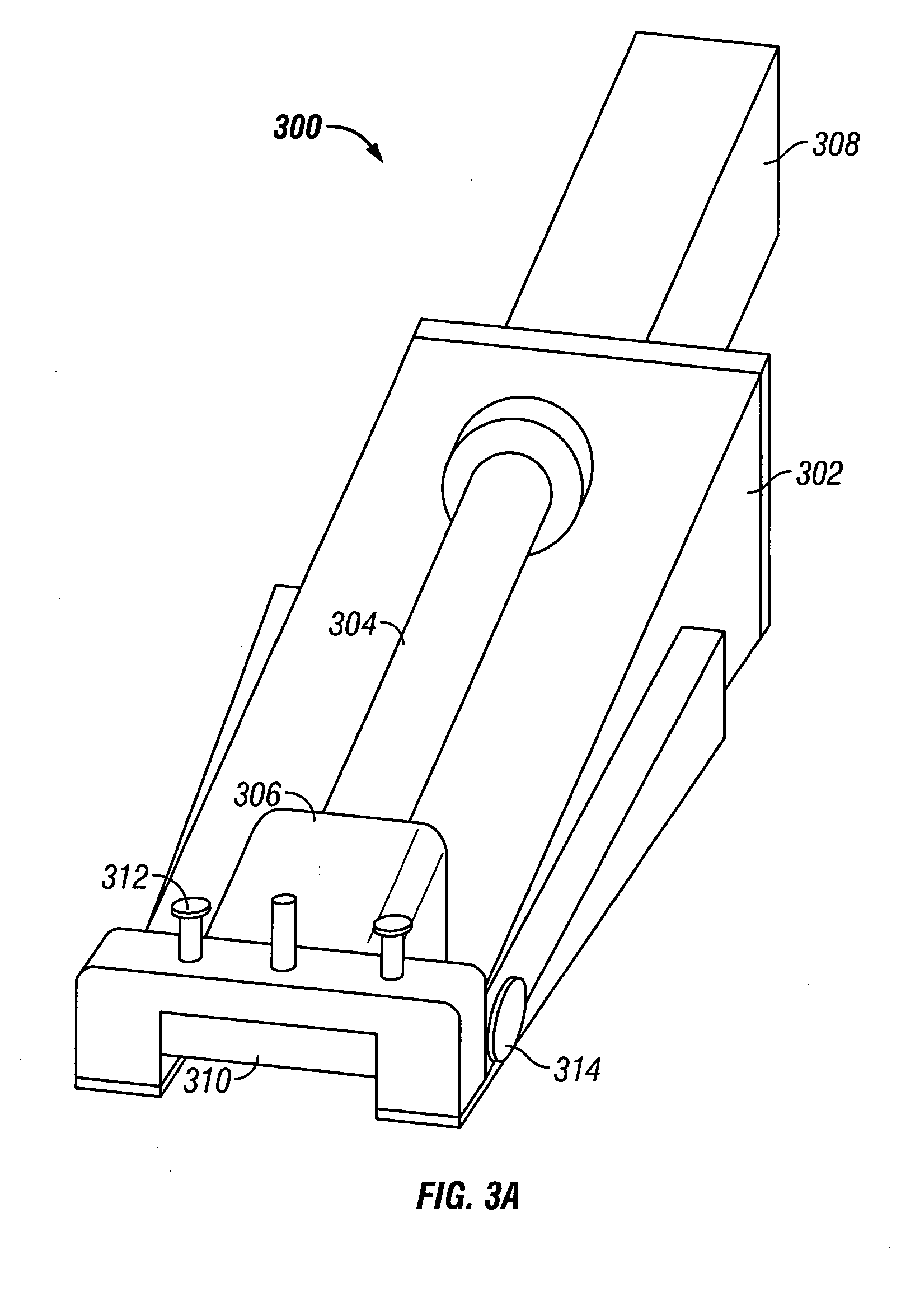

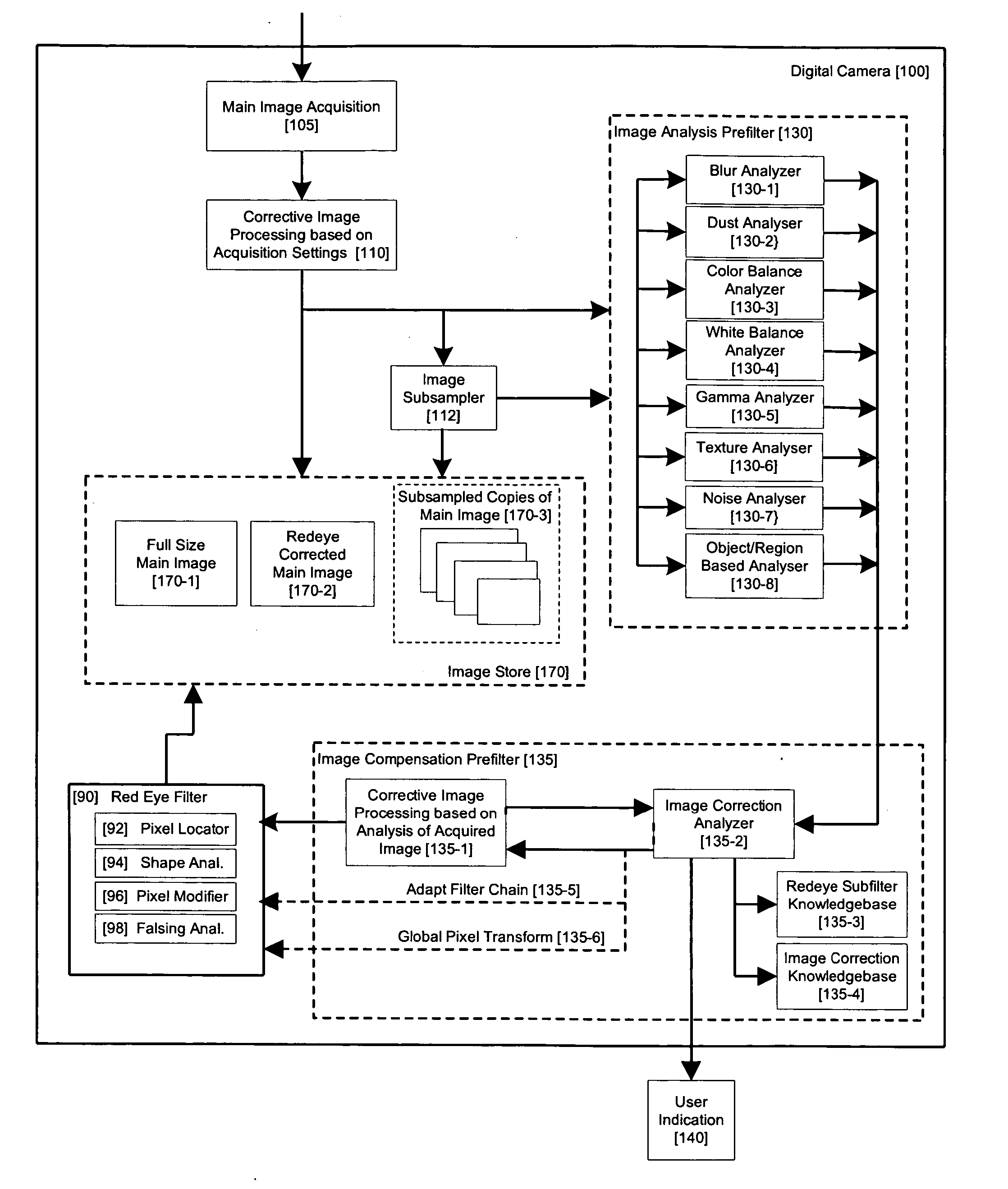

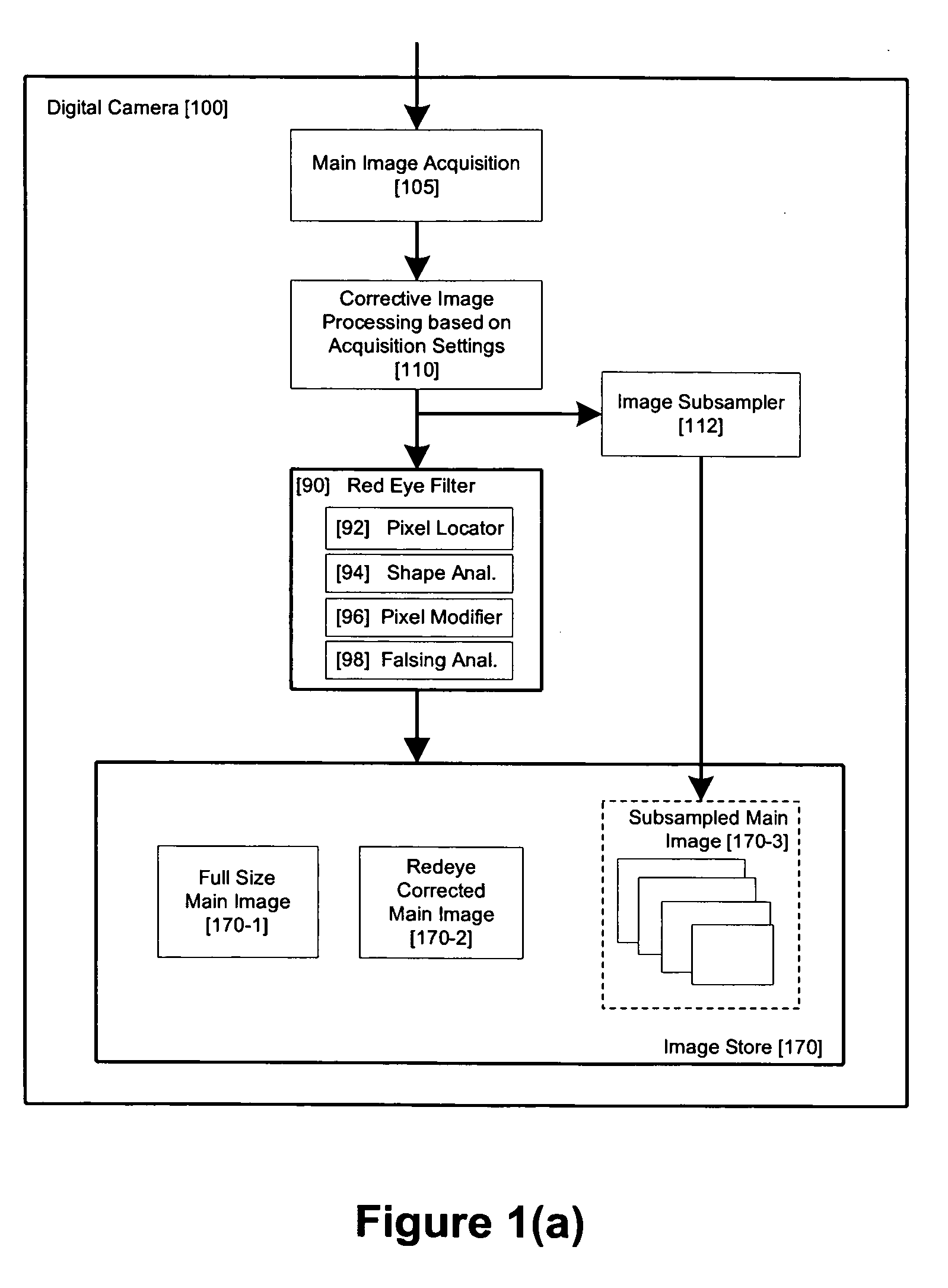

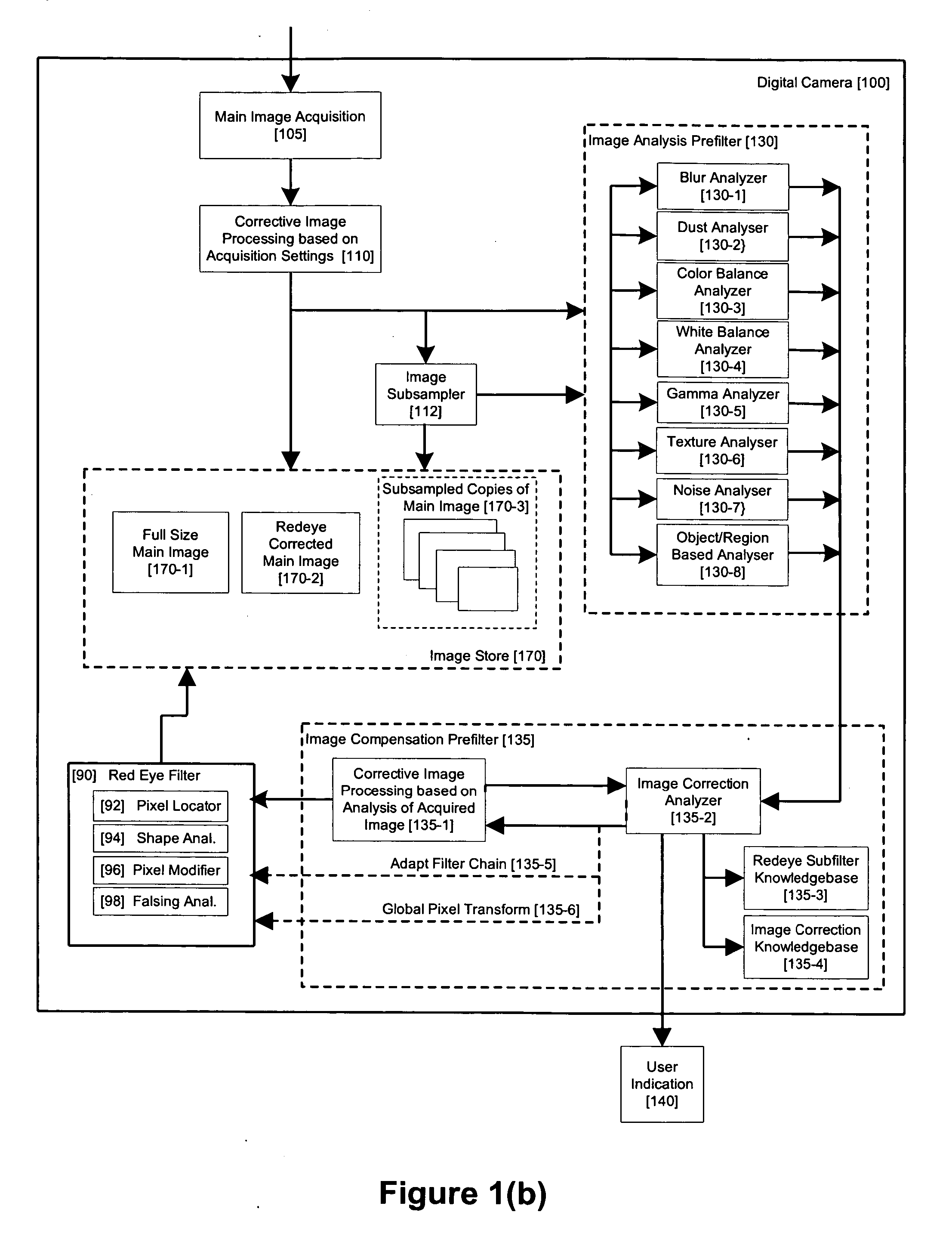

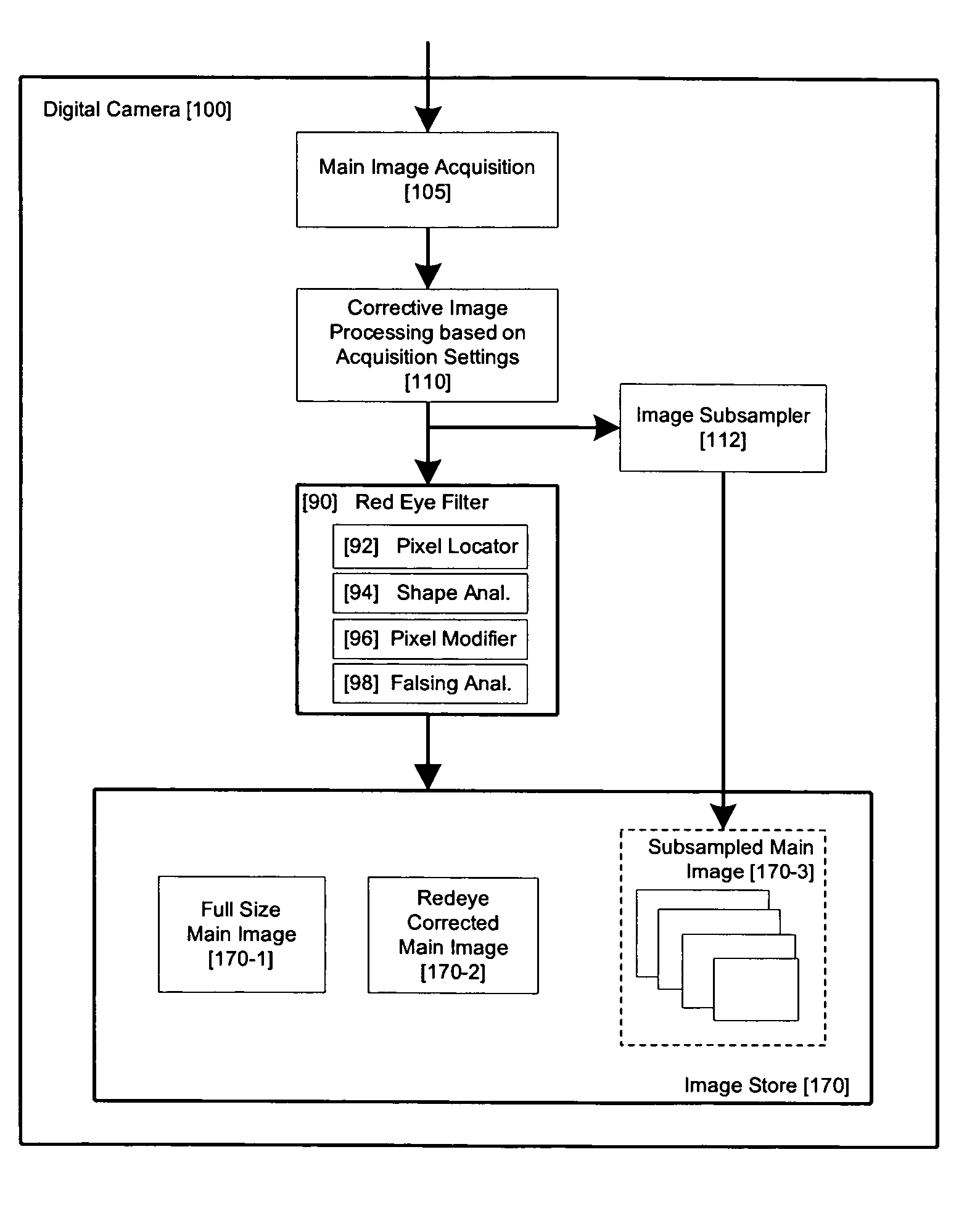

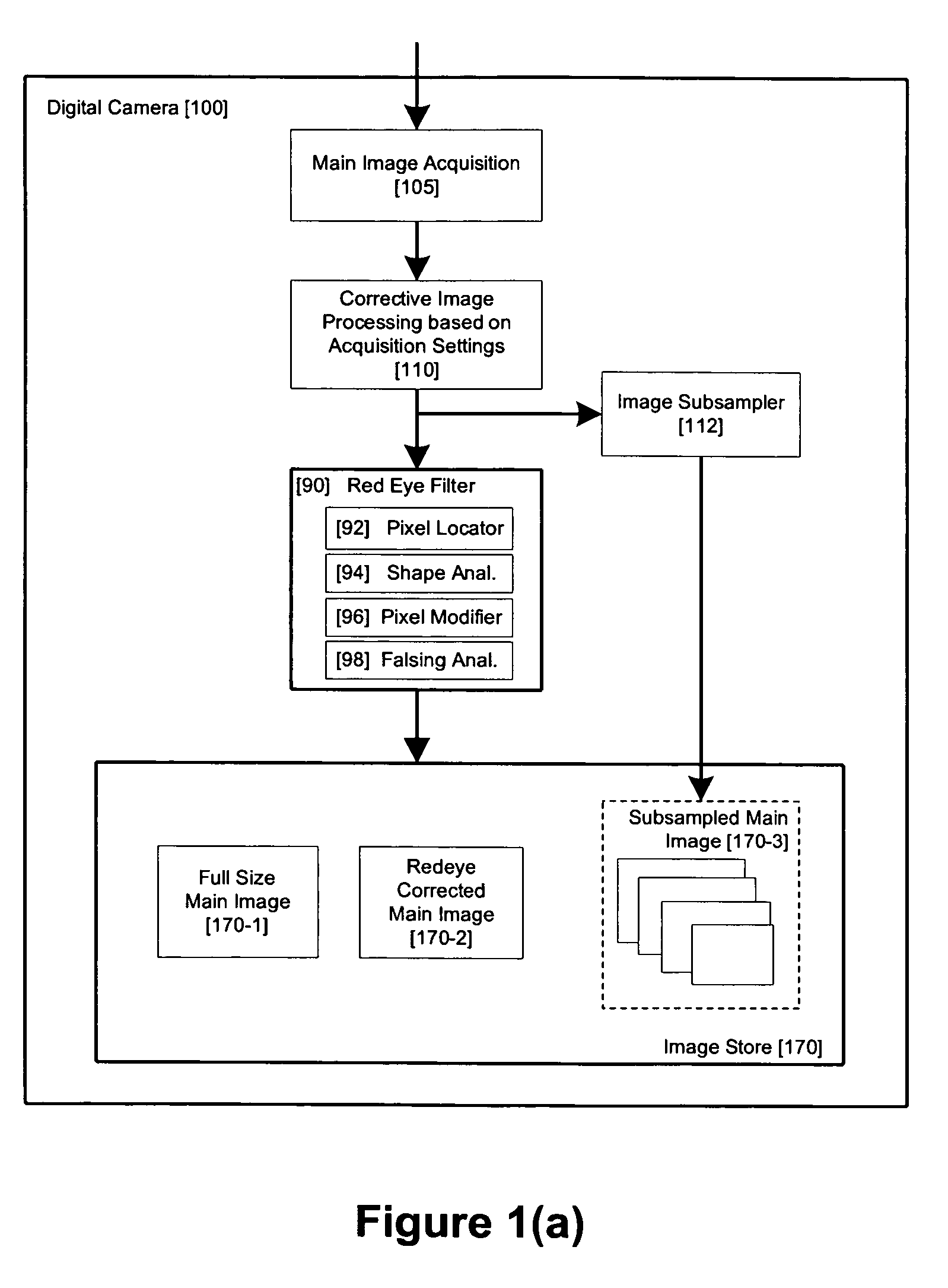

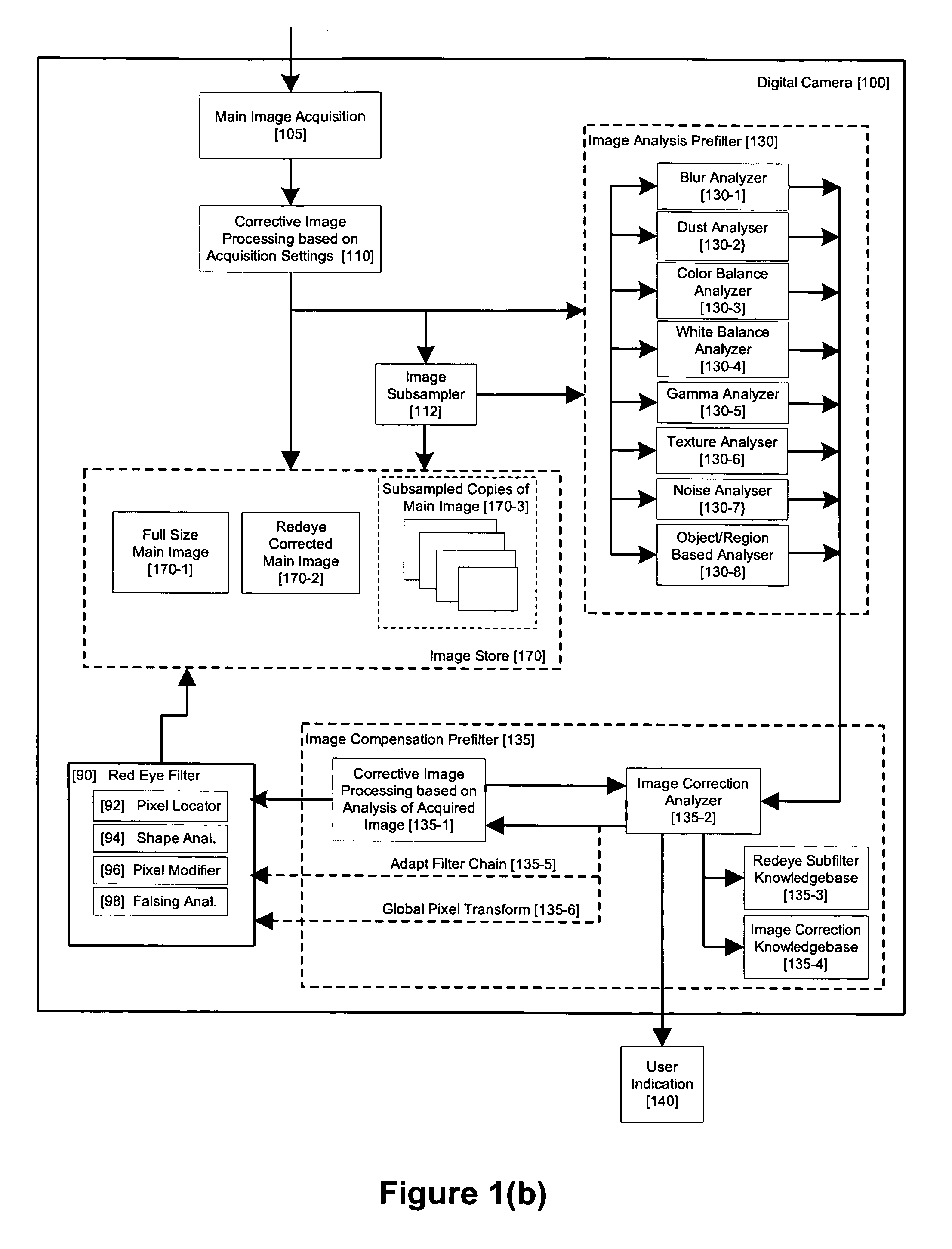

Method and apparatus for red-eye detection in an acquired digital image based on image quality pre and post filtering

ActiveUS20060093213A1Reduce false alarm rateIncrease success rateImage enhancementImage analysisImaging qualityImage correction

A method for red-eye detection in an acquired digital image comprises acquiring a first image and analyzing the first acquired image to provide characteristics indicative of image quality. The process then determines if one or more corrective processes can be beneficially applied to the first acquired image according to the characteristics. Any such corrective processes are applied and red-eye defects are detected in an established order established according to determination and analysis of characteristics of the corrective process and / or resulting image qualities. Defect correction can comprise applying one or more image correction operations, or a chain of two or more red-eye filters to the first acquired image. In this case, prior to the detecting step, it is determined if the red-eye filter or red eye filter chain should be applied before or after image corrective processes and whether the red eye filter can be adapted in accordance with the characteristics. The red-eye filter and the order in which it is executed in relation to the various image corrective operations may be adapted accordingly.

Owner:FOTONATION LTD

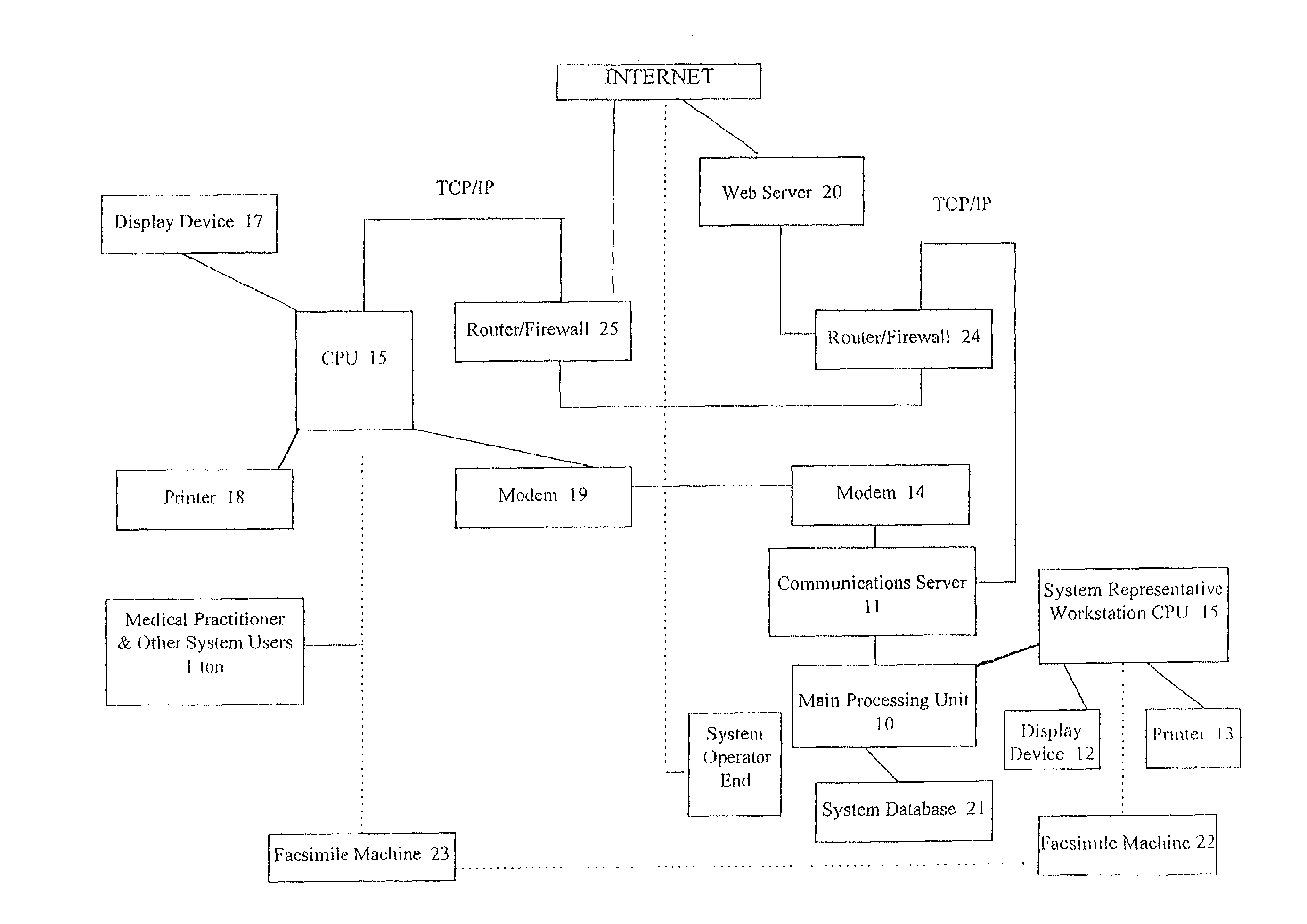

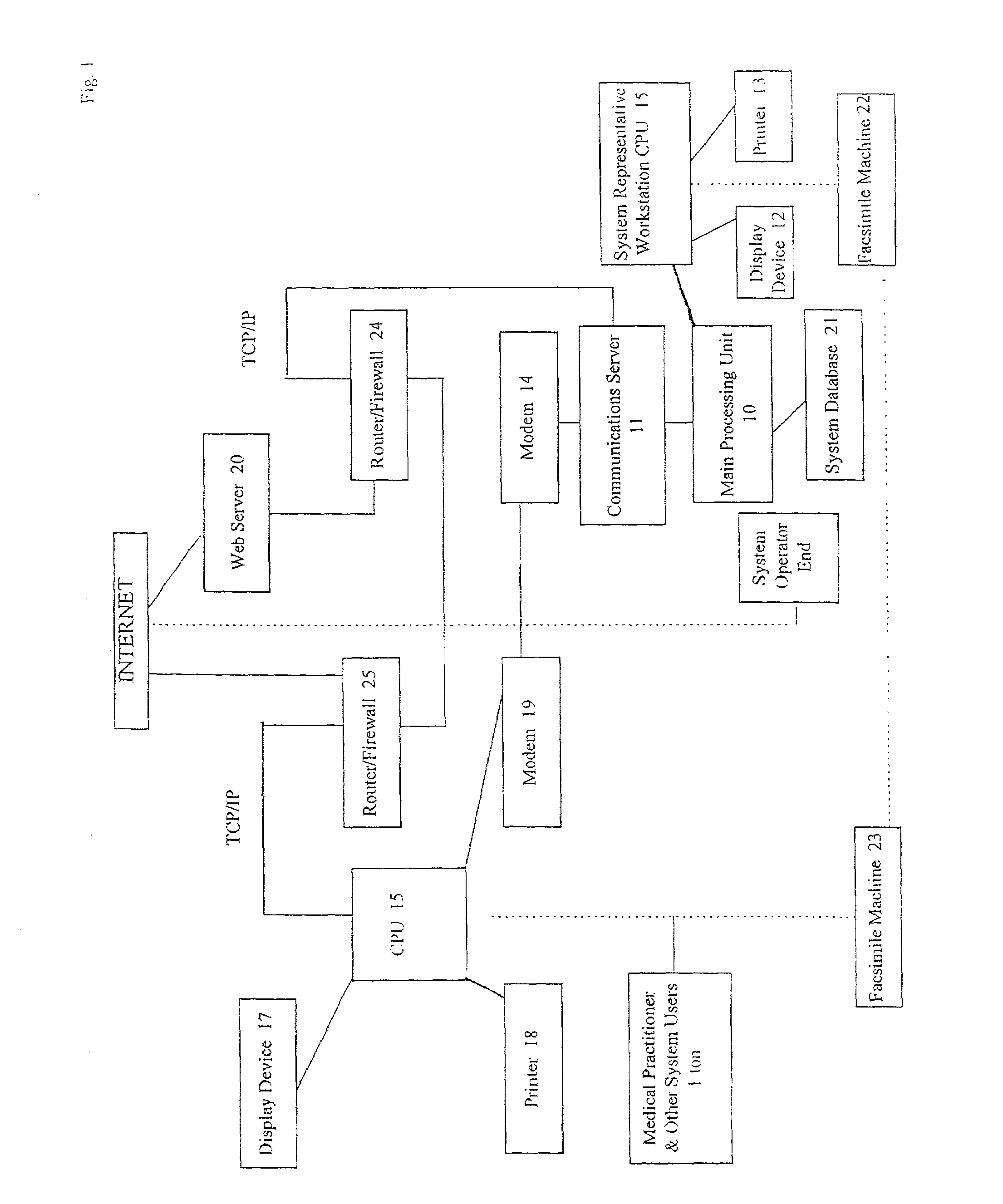

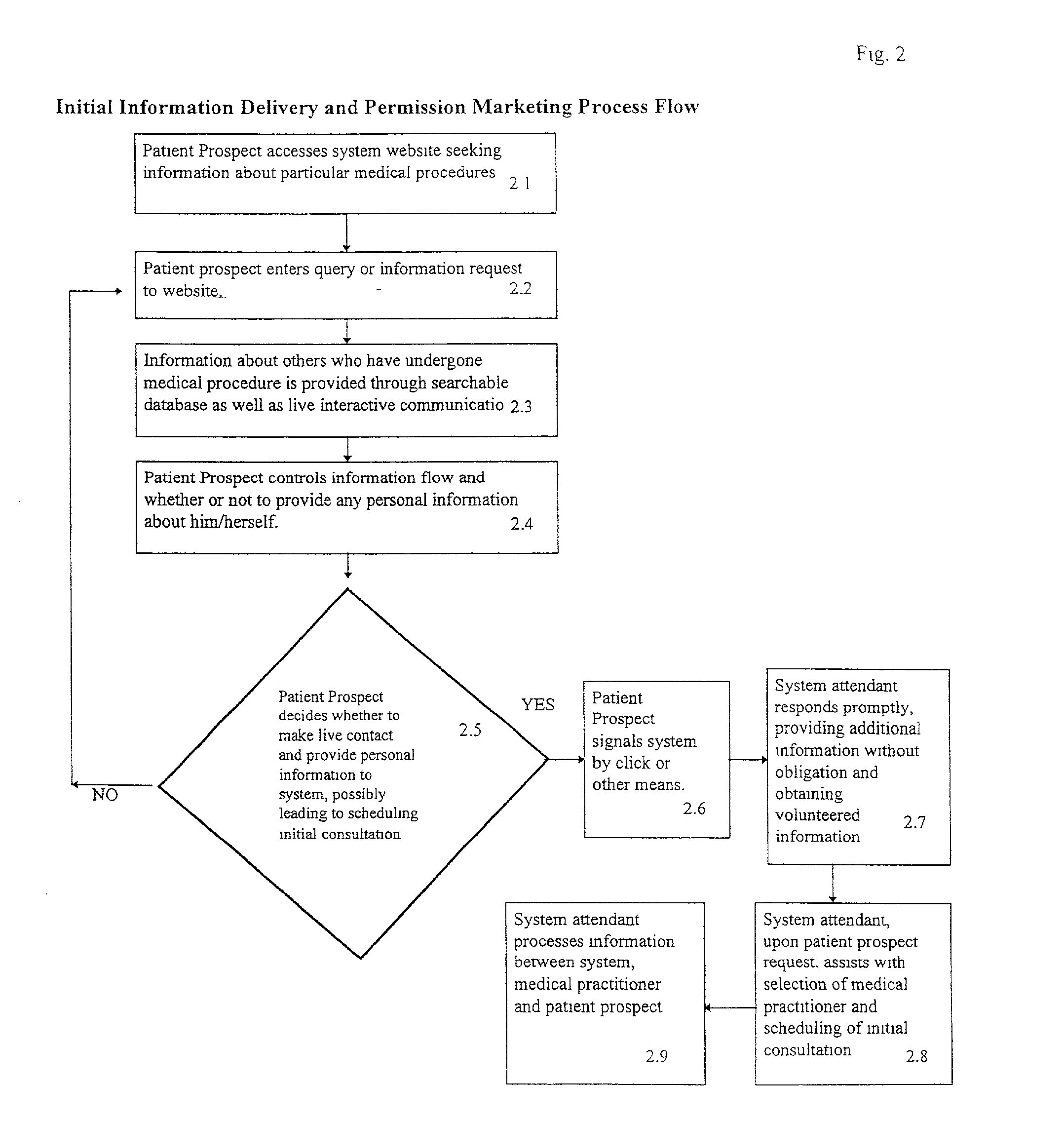

Method and system for providing pre and post operative support and care

The present invention provides a system for providing support and care to persons considering or undergoing a medical procedure. The system includes a means for a provider to receive, process, and provide information regarding the persons to and from the persons and medical practitioners. Similarly, means for the provider to; provide information and positive reinforcement to the persons regarding said medical procedure being considered or undergone; to schedule and coordinate medical consultations and said medical procedure between said persons and said medical practitioners, and to receive, process, and deliver care orders and medicaments from said medical practitioners to said persons are also includes.

Owner:SMG TRUST

Method and apparatus for red-eye detection in an acquired digital image based on image quality pre and post filtering

ActiveUS7436998B2Reduce false alarm rateIncrease success rateImage enhancementImage analysisImaging qualityImage correction

A method for red-eye detection in an acquired digital image comprises acquiring a first image and analyzing the first acquired image to provide characteristics indicative of image quality. The process then determines if one or more corrective processes can be beneficially applied to the first acquired image according to the characteristics. Any such corrective processes are applied and red-eye defects are detected in an established order established according to determination and analysis of characteristics of the corrective process and / or resulting image qualities. Defect correction can comprise applying one or more image correction operations, or a chain of two or more red-eye filters to the first acquired image. In this case, prior to the detecting step, it is determined if the red-eye filter or red eye filter chain should be applied before or after image corrective processes and whether the red eye filter can be adapted in accordance with the characteristics. The red-eye filter and the order in which it is executed in relation to the various image corrective operations may be adapted accordingly.

Owner:FOTONATION LTD

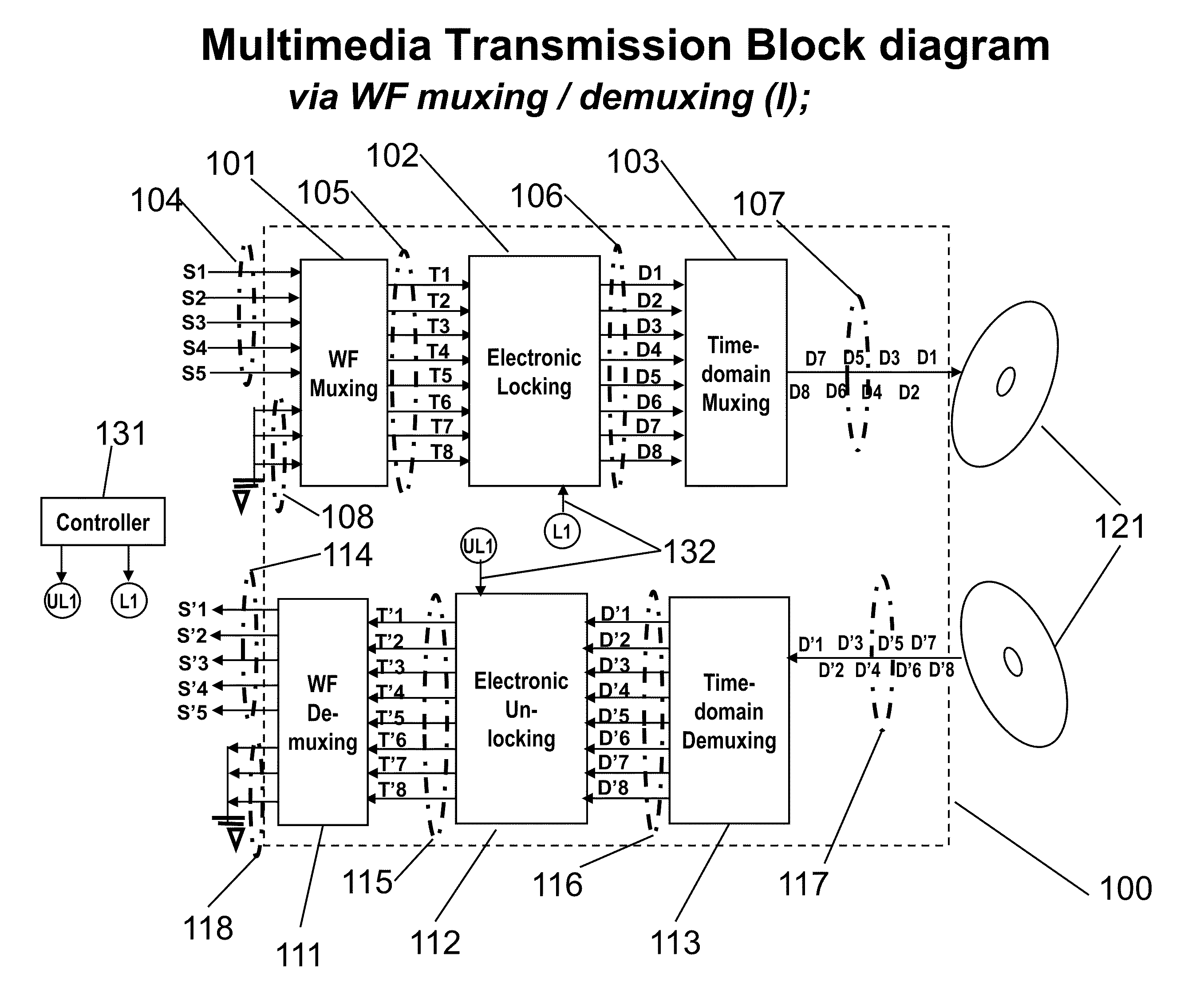

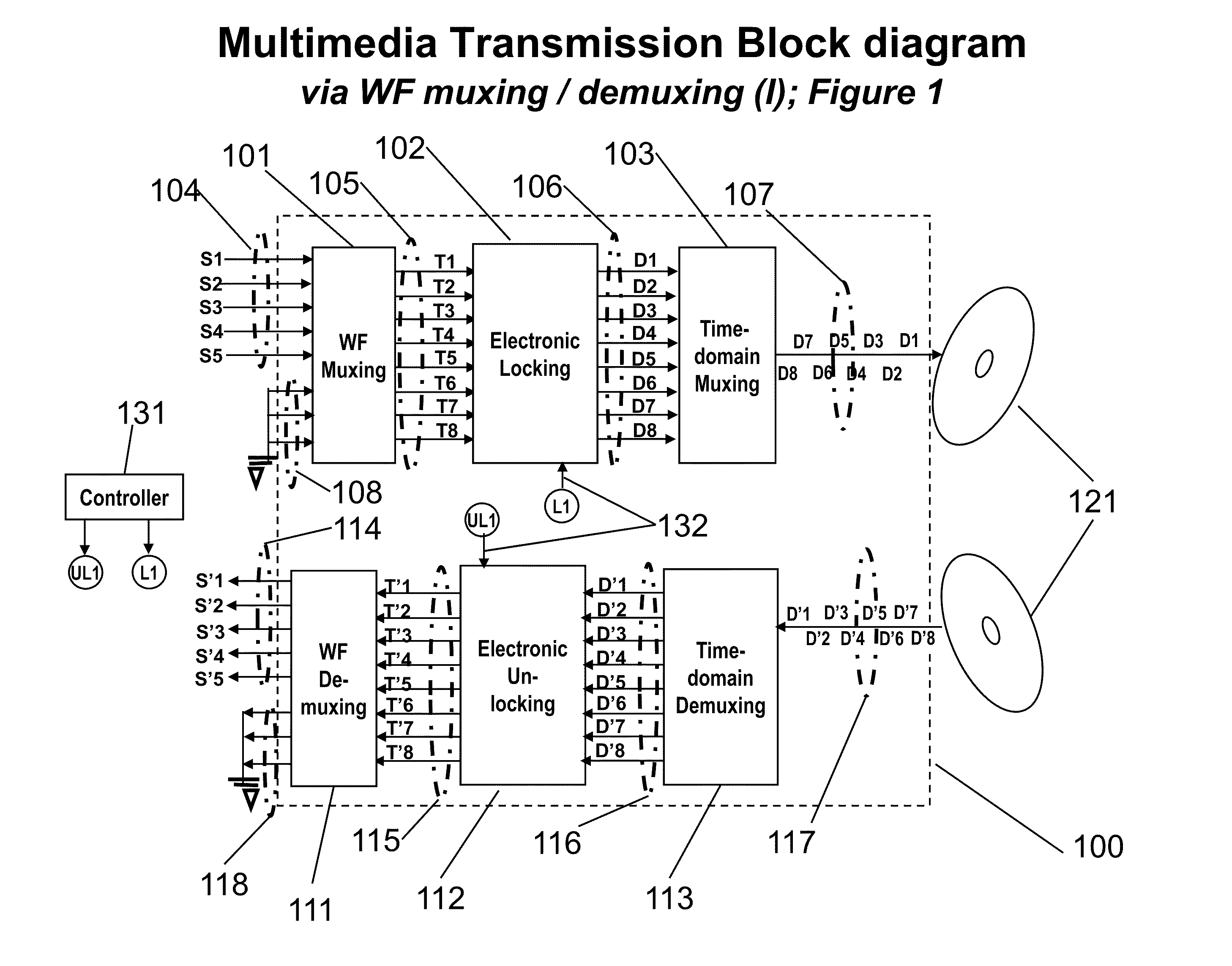

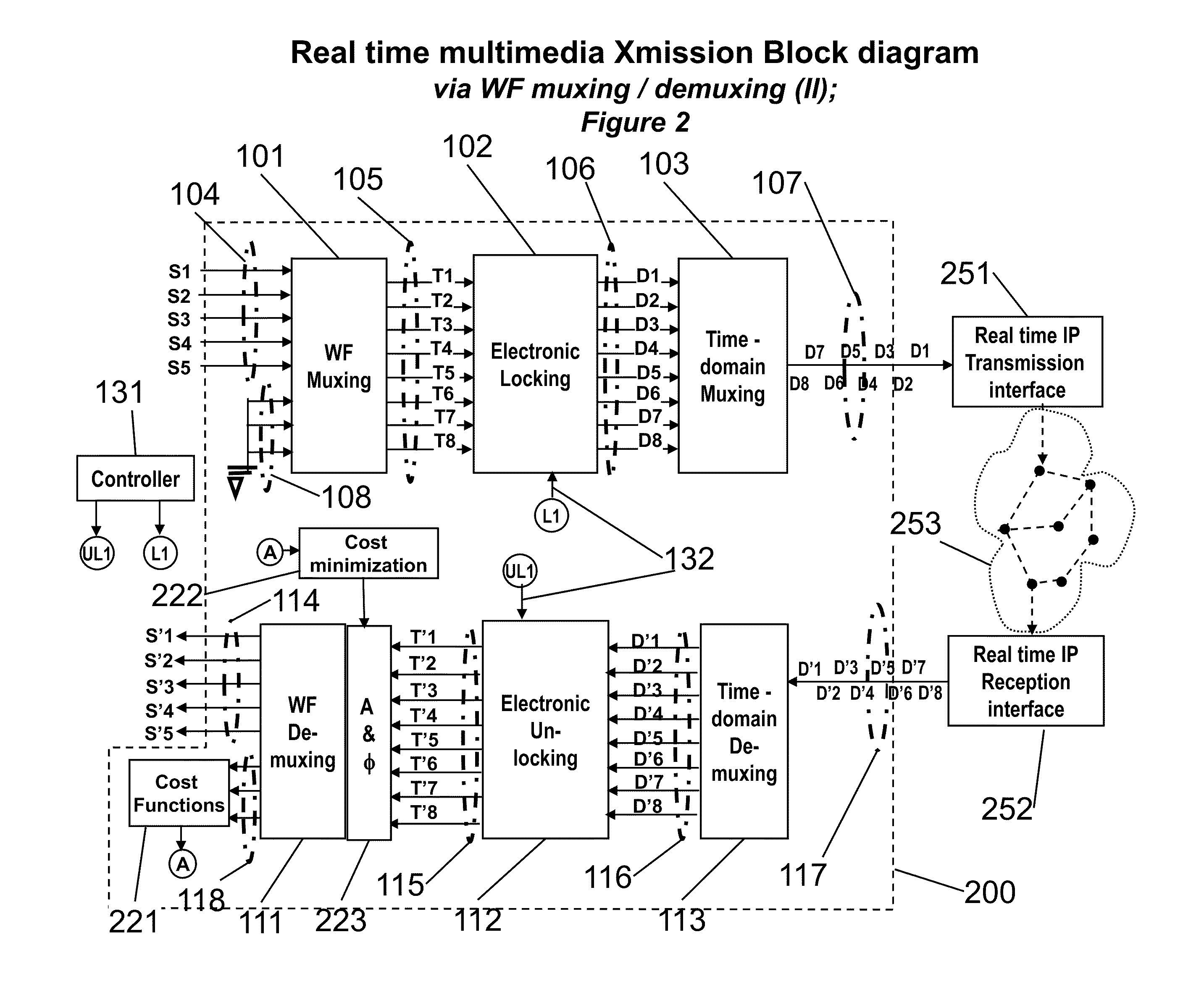

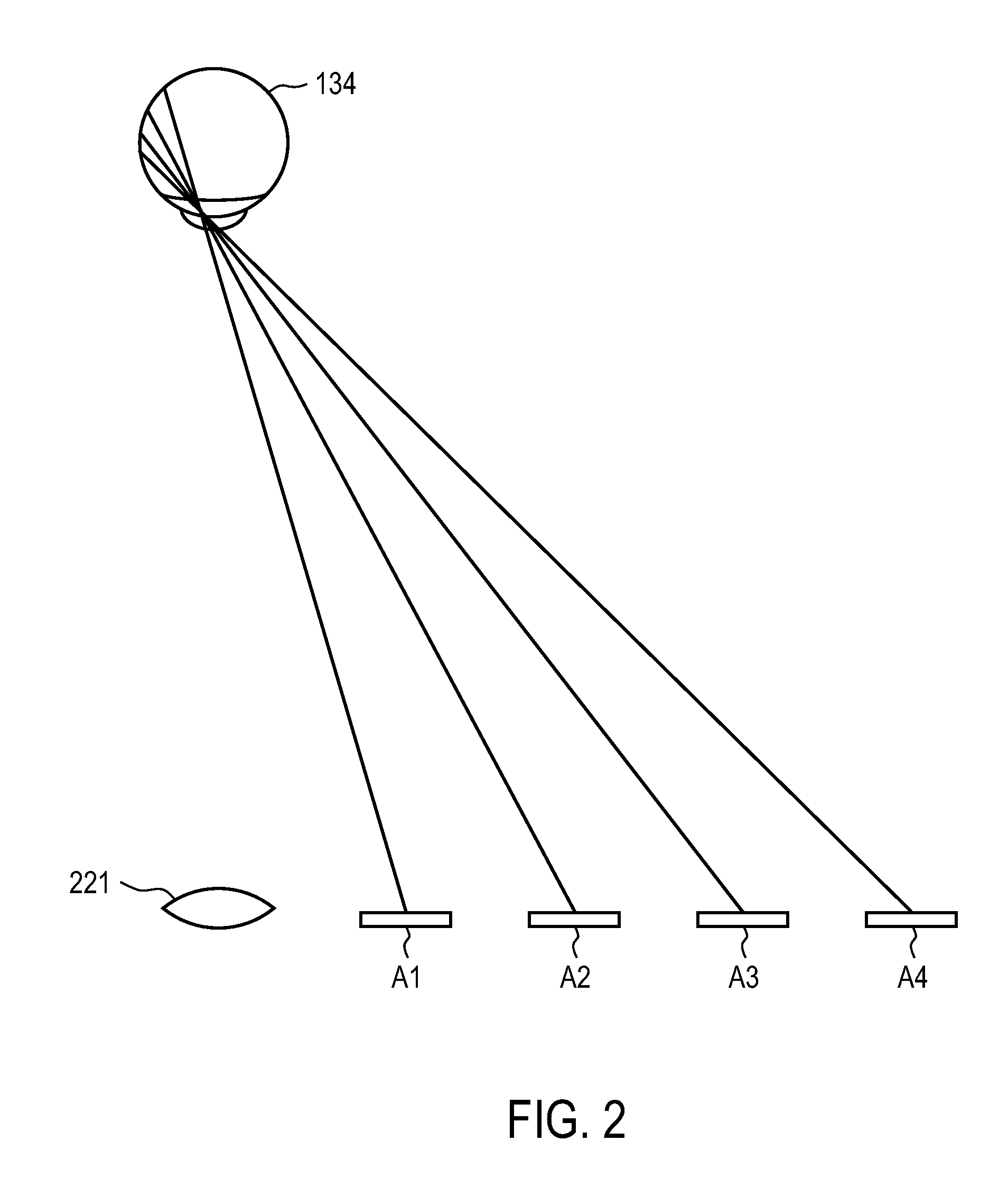

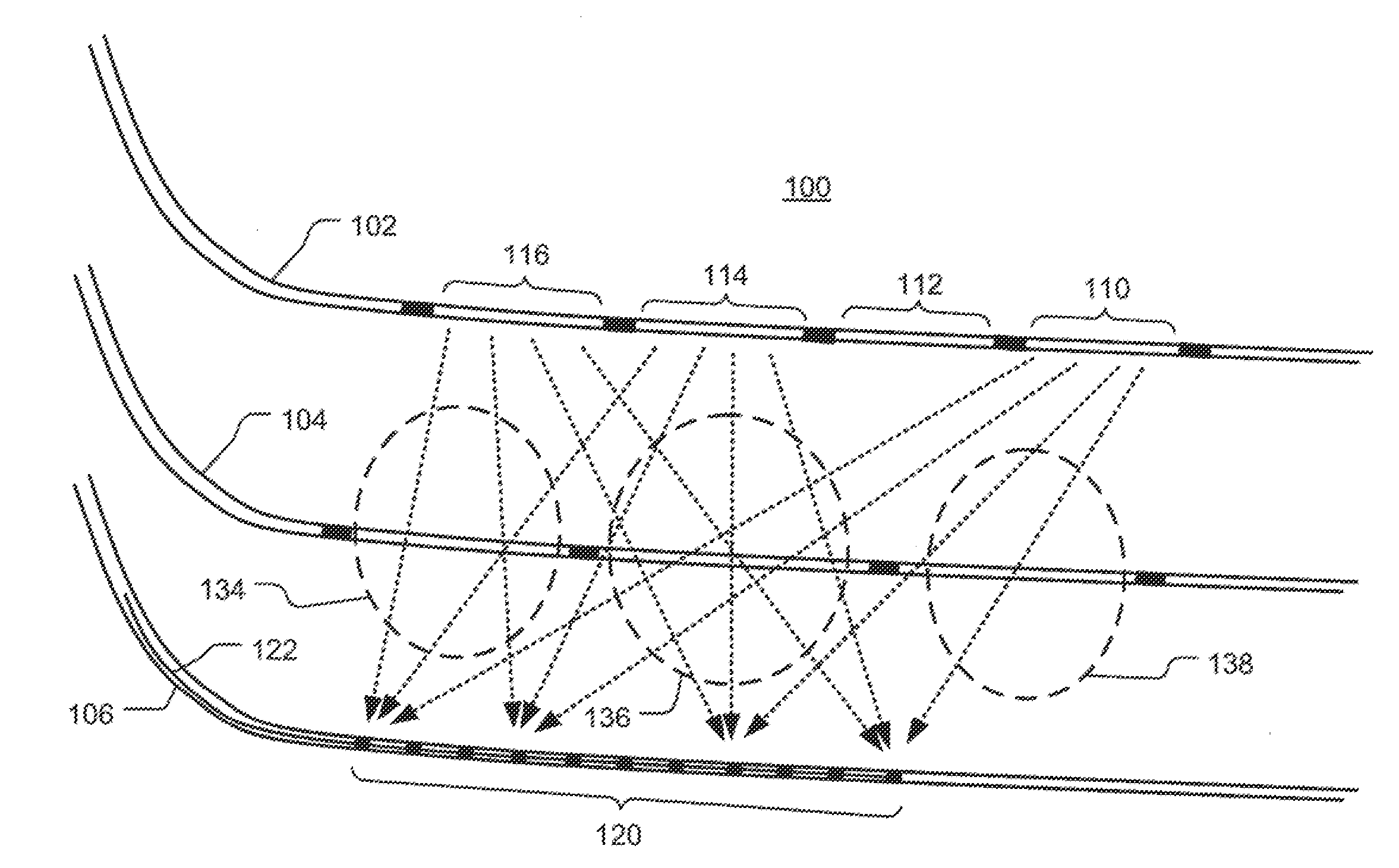

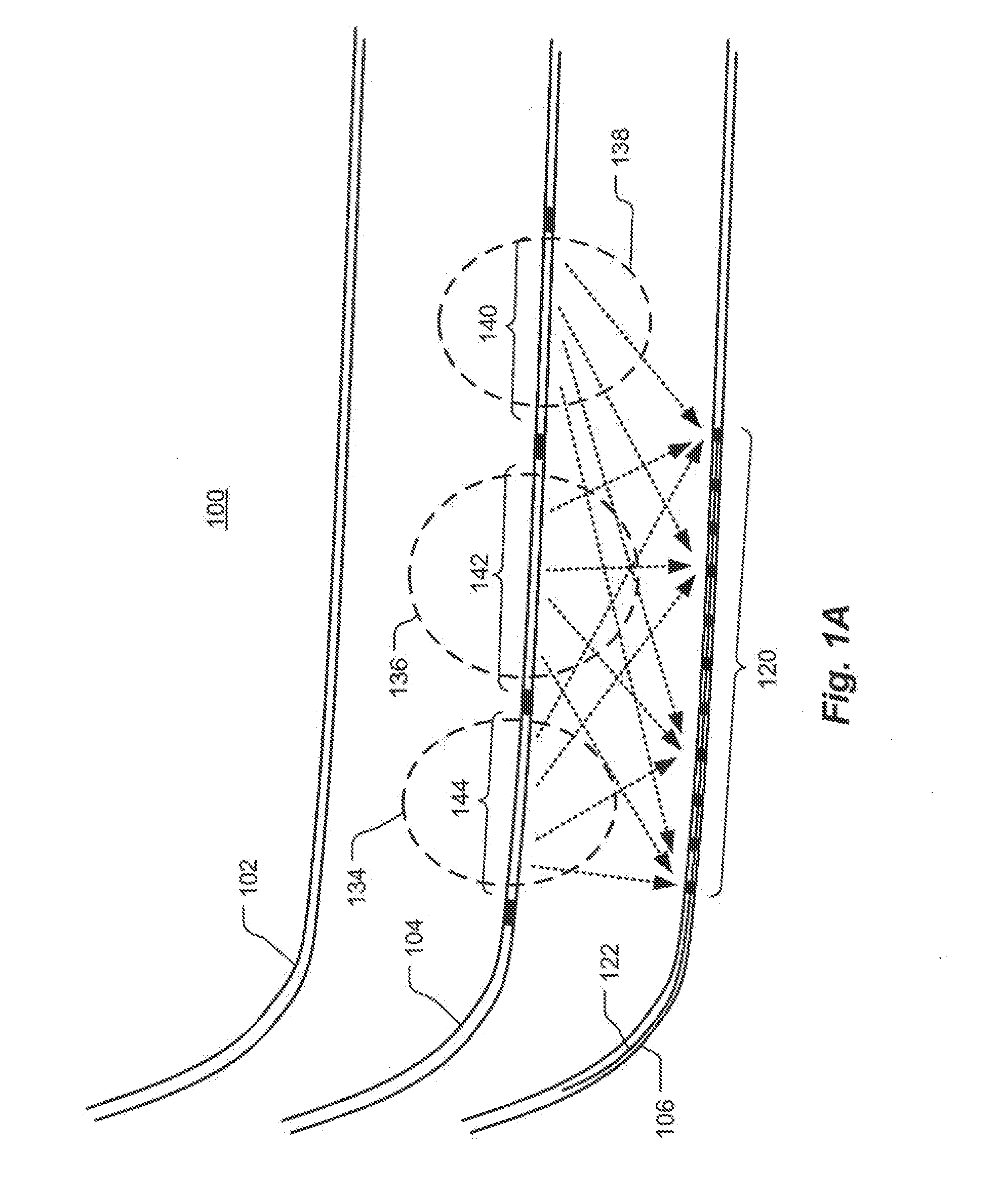

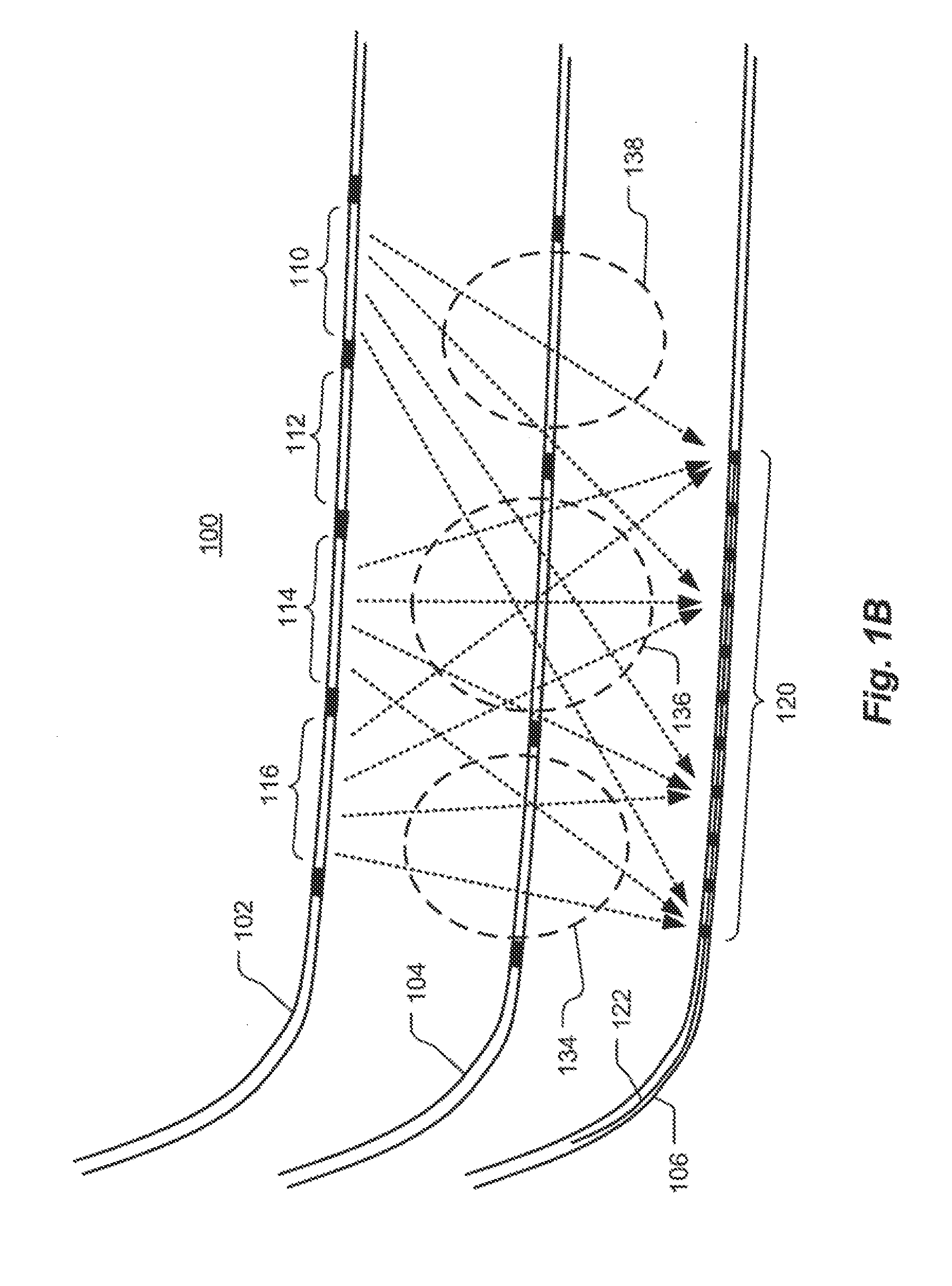

Novel Karaoke and Multi-Channel Data Recording / Transmission Techniques via Wavefront Multiplexing and Demultiplexing

InactiveUS20110197740A1Quality improvementEnhance security and integrityElectrophonic musical instrumentsTime-division multiplexComputer hardwareFrequency spectrum

An advanced channel storage and retrieving system is achieved that is capable of simultaneously transporting multiple-stream data concurrently, with encryptions and error detection and limited correction capability using wavefront (WF) multiplexing (muxing) at the pre-processing and WF demultiplexing (de-muxing) in the post-processing. The WF muxing and demuxing processing can be applied for multiple signal streams with similar contents and format such as cable TV delivery systems or multiple signal streams with very distinct contents and format such as Karaoke multimedia systems. The stored or transported data are preprocessed by a WF muxing processor and are in the formats of multiple sub-channels. Signals in each sub-channel are results of unique linear combination of all the input signals streams. Conversely, an input signal stream is replicated and appears on all the sub-channels. Furthermore the replicated streams in various sub-channels are “linked” together by a unique phase weighting vector, which is called “wavefront” or WF. Various input signal streams will feature different WFs among their replicated signal streams in the sub-channels. The WF muxing processing is capable to generating a set of orthogonal WFs, and the WF demuxing processing is capable of reconstituting the input signal streams based on the retrieved sub-channel data only if the orthogonal characteristics of a set of WFs are preserved. Without the orthogonality among the WF, the signals in sub-channels are mixed and become effectively pseudo random noise. Therefore, an electronic locking mechanism in the preprocessing is implemented to make the WFs un-orthogonal among one another. Similarly, an electronic un-locking mechanism in the post-processing is implemented to restore the orthogonal characteristics among various WFs embedded in the sub-channel signals. Some of the phenomena due to the selected locking mechanisms are reproducible in nature, such as wave propagating effects, and other are distinctively man-made; such as switching sub-channel sequences. There are other conventional encryption techniques using public and private keys which can be applied in conjunction with the WF muxing and de-muxing processor, converting plain data streams into ciphered data streams which can be decoded back into the original plain data streams. An encryption algorithm along with a key is used in the encryption and decryption of data. As to the optional parallel to serial and serial to parallel conversions in the pre and post processing, respectively, we assume that transmissions with single carrier are more efficient than those with multiple carriers. We also assume single channel recording is more cost effective than multiple channel recording. However, there are occasions that continuous spectrum is hard to come-by. We may use fragmented spectrum for transmissions. There are techniques to convert wideband waveforms using continuous spectra into multiple fragmented sub-channels distributed on non-continuous frequency slots. Under these conditions we may replace the parallel to serial conversion processing by a frequency mapping processor.

Owner:SPATIAL DIGITAL SYST

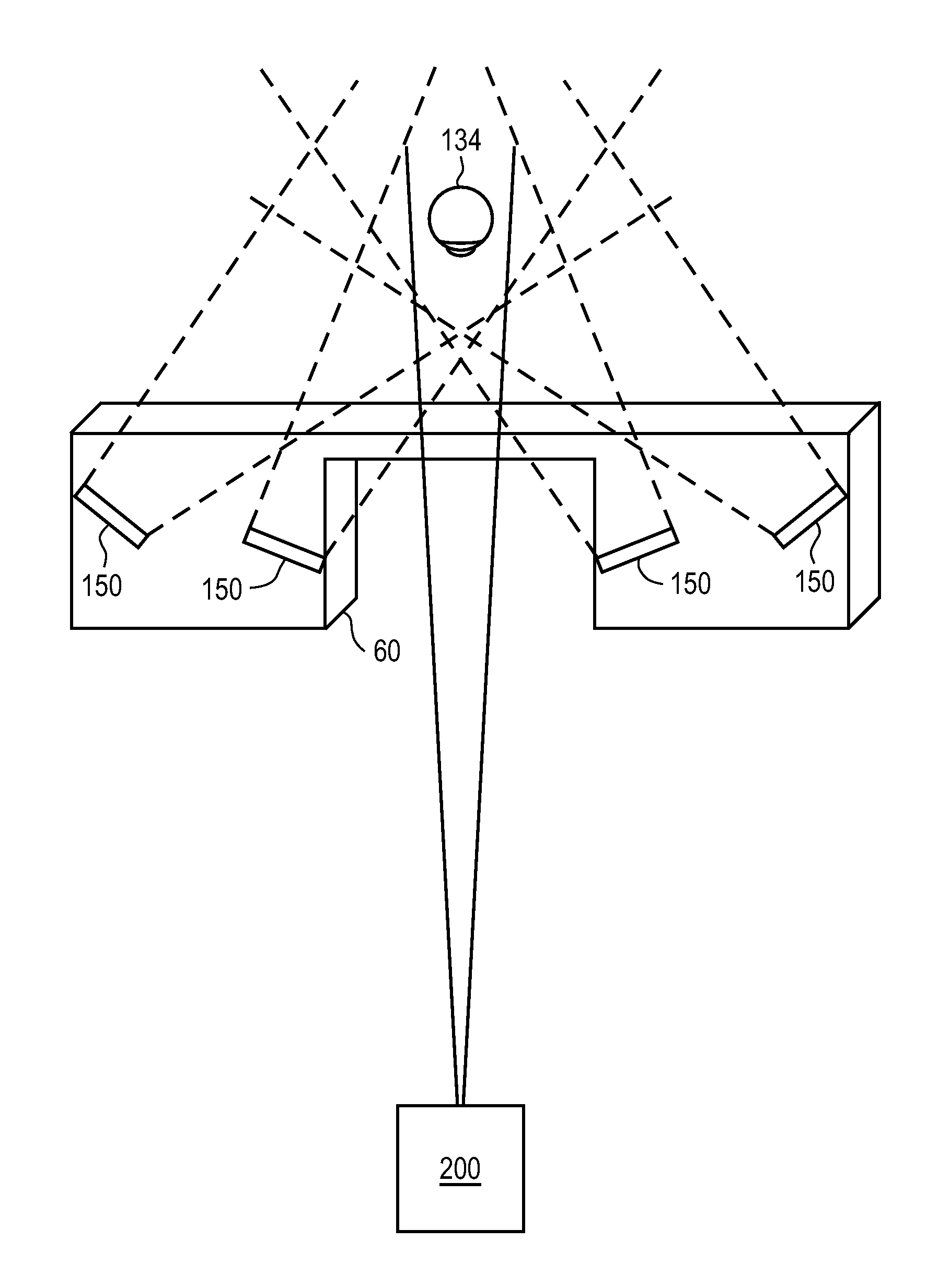

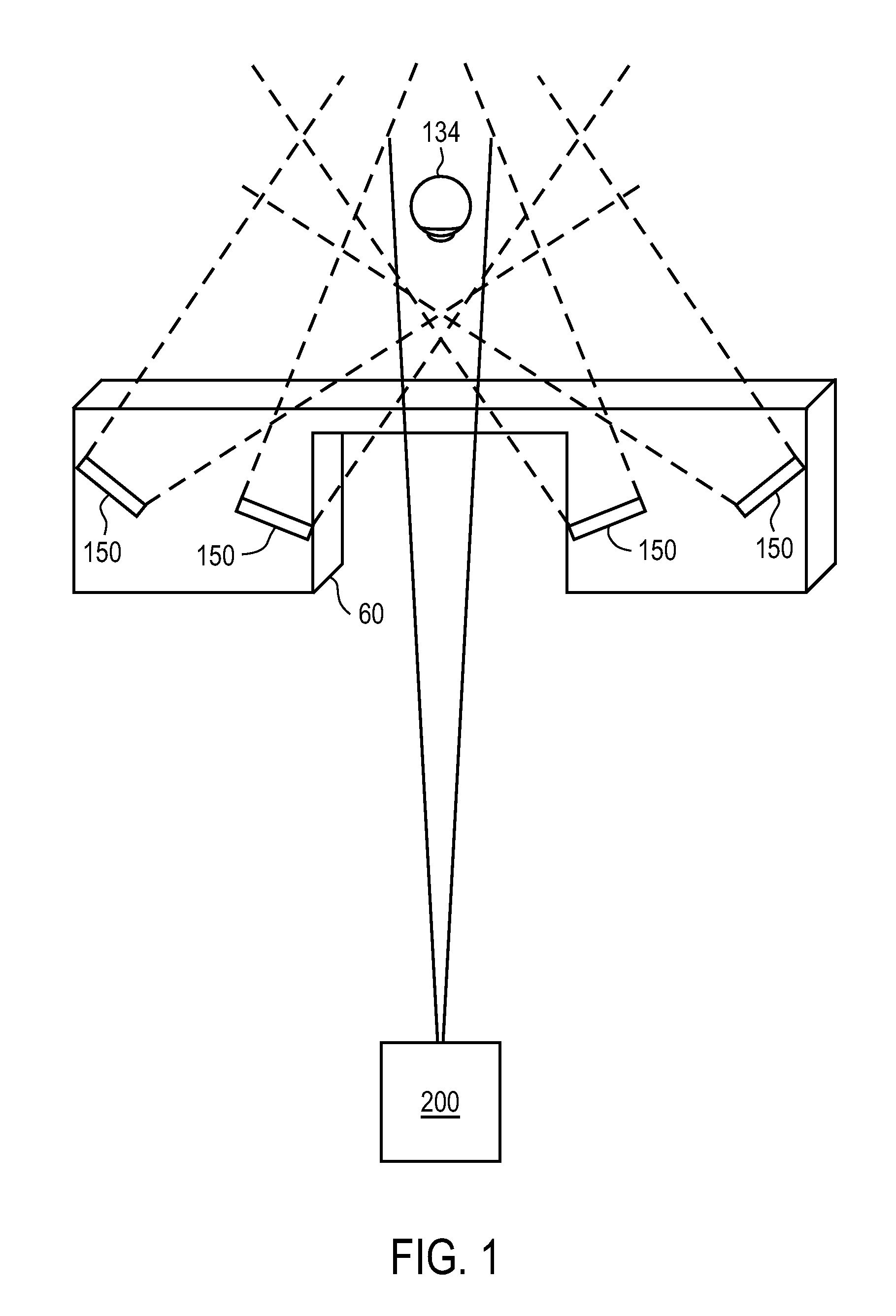

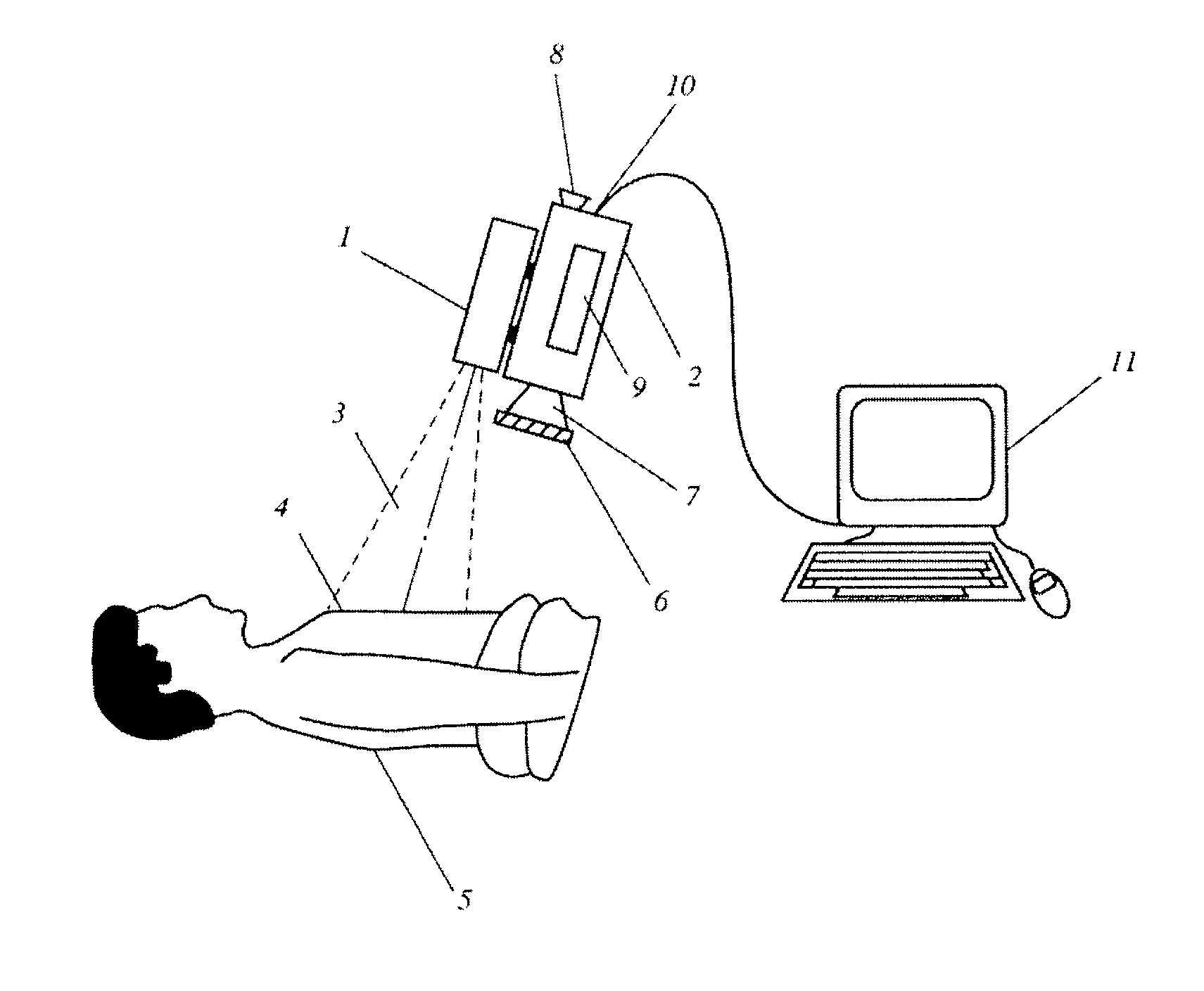

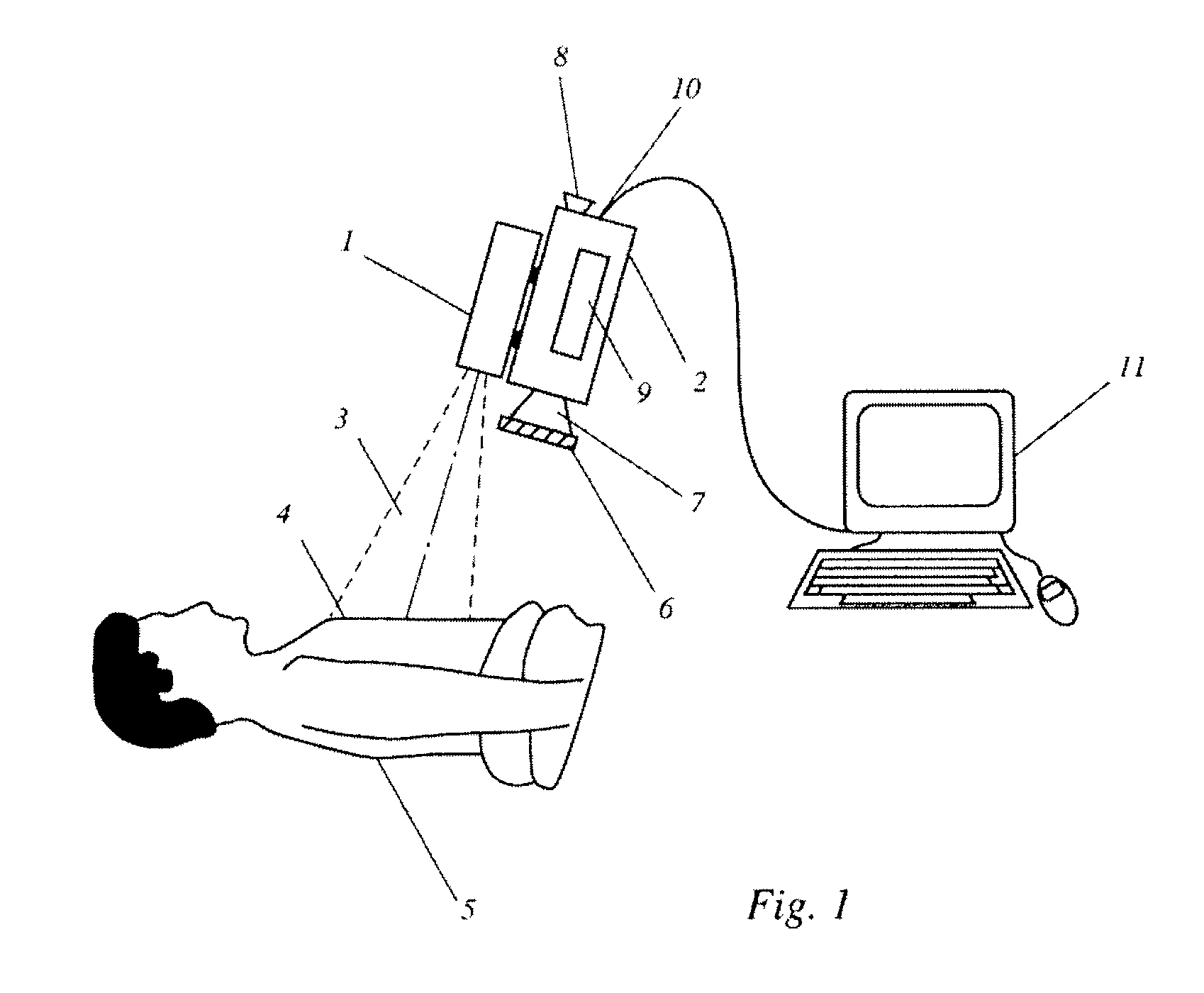

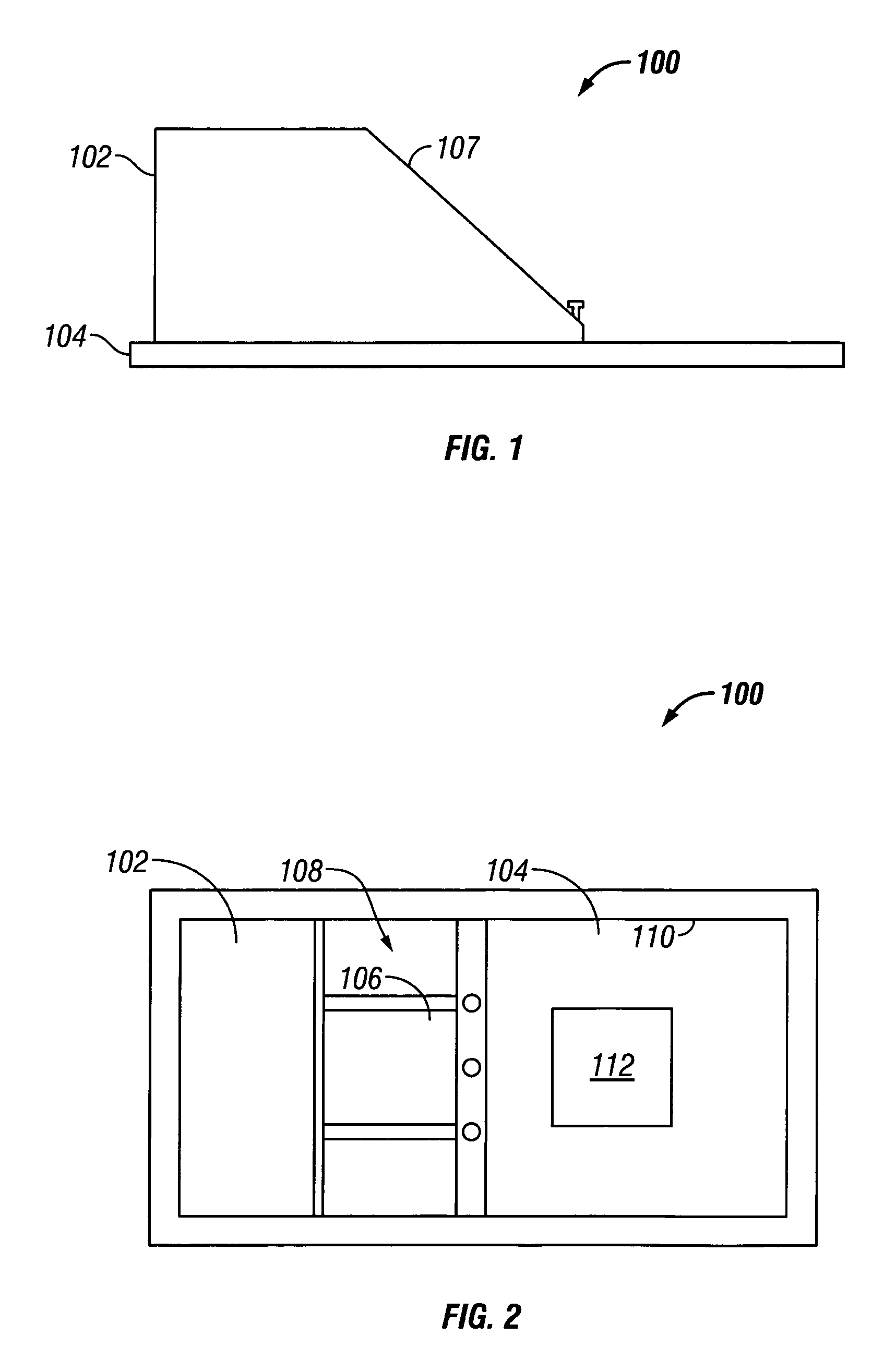

On-axis illumination for iris imaging

ActiveUS8092021B1Solve the lack of resolutionExtend usable exposure timeAcquiring/recognising eyesOthalmoscopesParallaxOptical axis

The present invention provides a rapid, high quality iris imaging system. In one embodiment, on-axis illumination is used. A single steering mechanism steers both the camera and the illumination, without parallax issues. The illumination beam can be combined along the camera's optical axis before or after the fine steering and focus correction mechanism. In a pre-correction configuration, the iris illumination spot can be reduced in size to be only slightly larger than the iris. In both the pre and post-correction configuration, the eye safety limits will be most critical at the subject, which allows for maximization of the illumination flux.

Owner:TASCENT INC

Nutritional conjunctive support therapy for recovery in animals following stress or illness

ActiveUS20070009502A1Good treatment effectRapid preventionBiocideBacteria material medical ingredientsHeifer calfFluid replacement

A composition of probiotics, vitamins and minerals, electrolytes with glutamine and glucose along with medium chain triglycerides are provided as a supplement to animals. This is administered to cattle, calves, sheep, pigs, horses, dogs, and cats that are experiencing stress and or are undergoing medical drug therapy to treat conditions of diseases along with pre and post operative surgical conditions. The composition helps correct imbalances in beneficial bacteria, provides energy and helps in rehydration to reduce recovery time from stress or in disease treatment in these animals.

Owner:VETAB PLUS

Volume imaging for hydraulic fracture characterization

InactiveUS20110188347A1Fluid removalSeismology for water-loggingVolumetric imagingHydraulic fracturing

Methods and systems are described for measuring effects of a hydraulic fracturing process. The techniques can utilizes cross-well seismic technology, such as used in Schlumberger's DeepLook-CS tools and service, or in some case surface to borehole or borehole to surface seismic technology. The downhole seismic sources at known locations can be conventional sources or can be other types of equipment operating at known locations such as perforation guns. The source is activated or swept creating energy which is transmitted through the formation. The energy is recorded at the receiver array and processed to yield a tomographic image indicating changes in the subterranean formation resulting from the hydraulic fracturing process. The process can be performed pre and post hydraulic fracture stimulation to generate a difference image of propped fractures in the reservoir.

Owner:SCHLUMBERGER TECH CORP

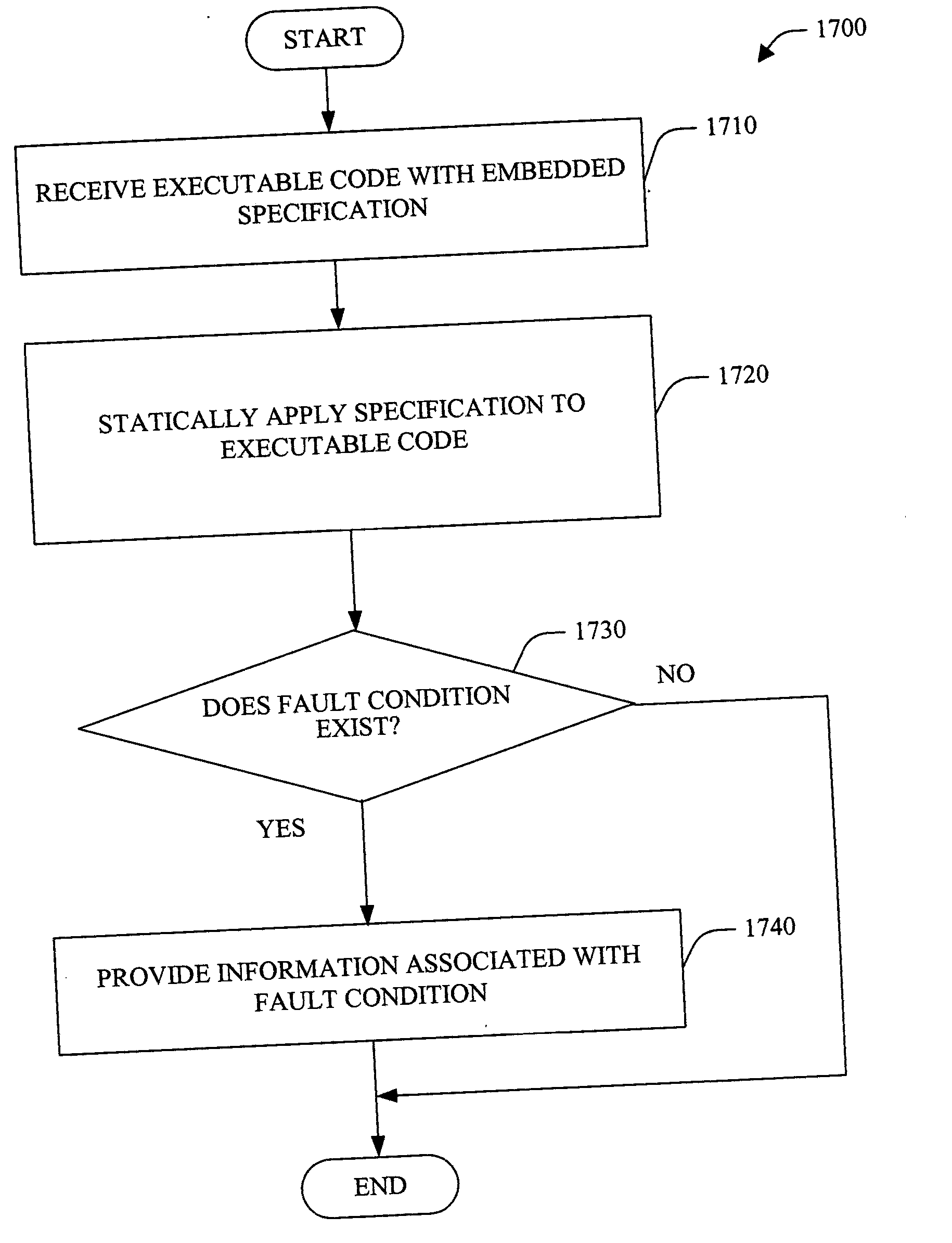

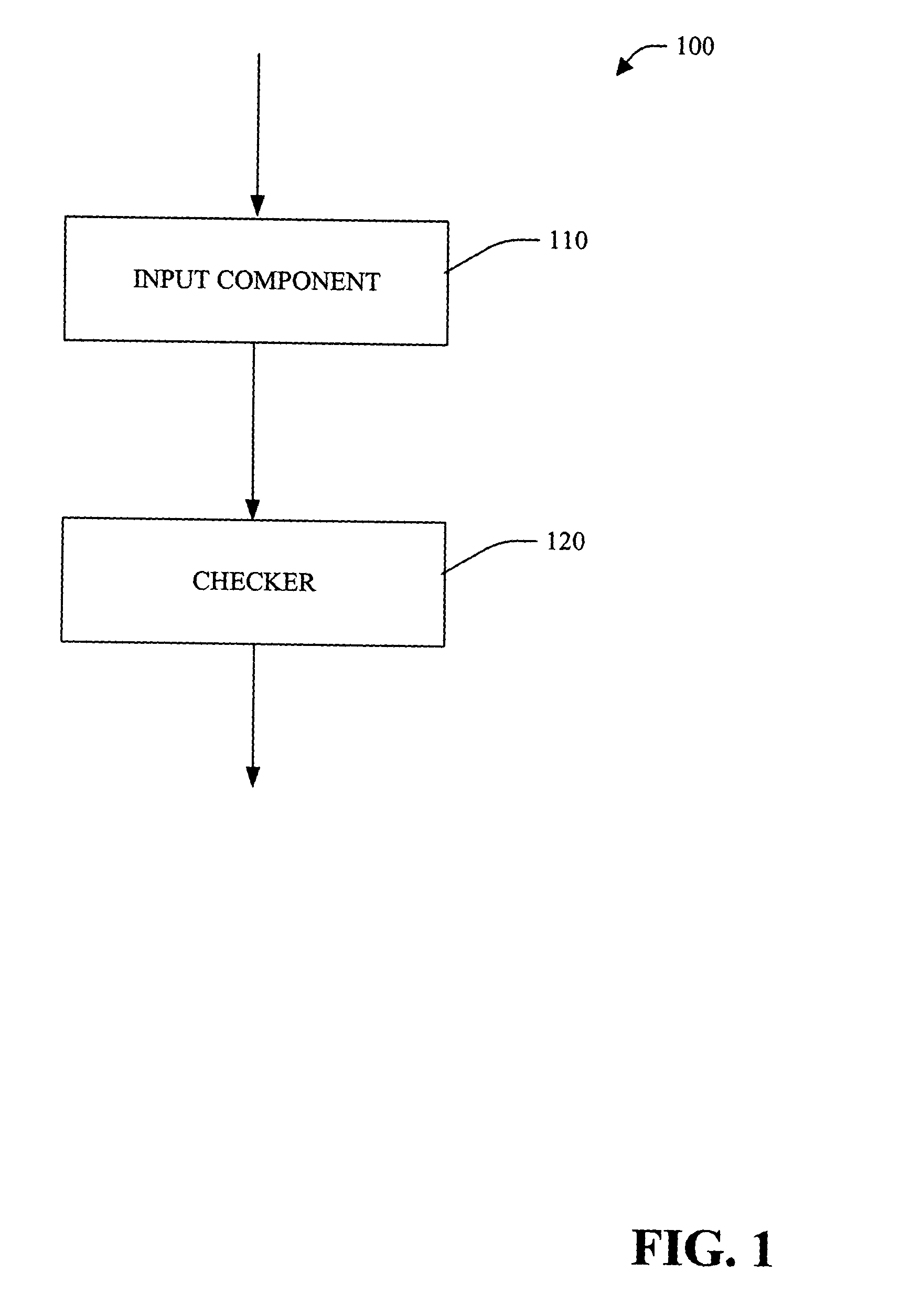

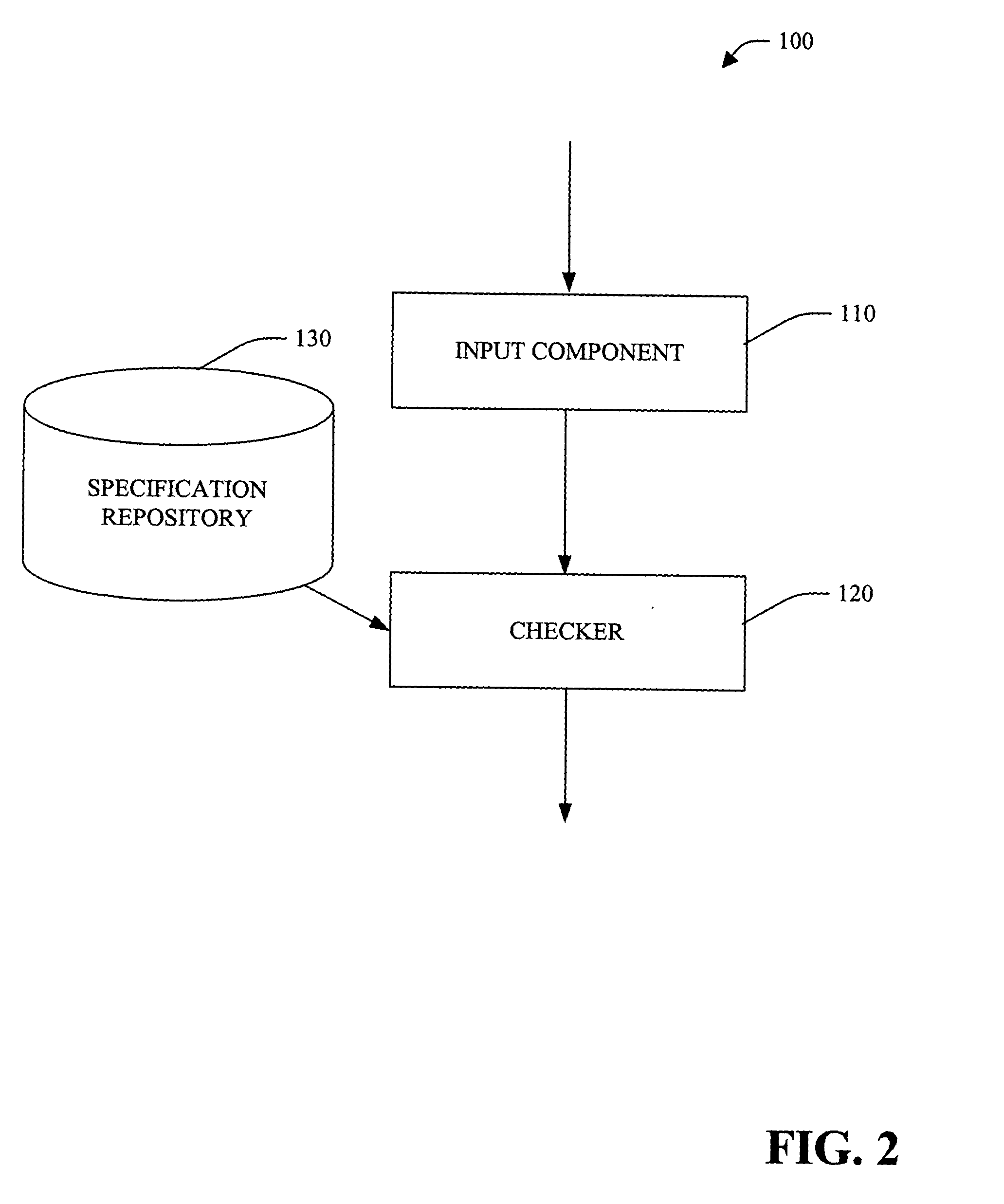

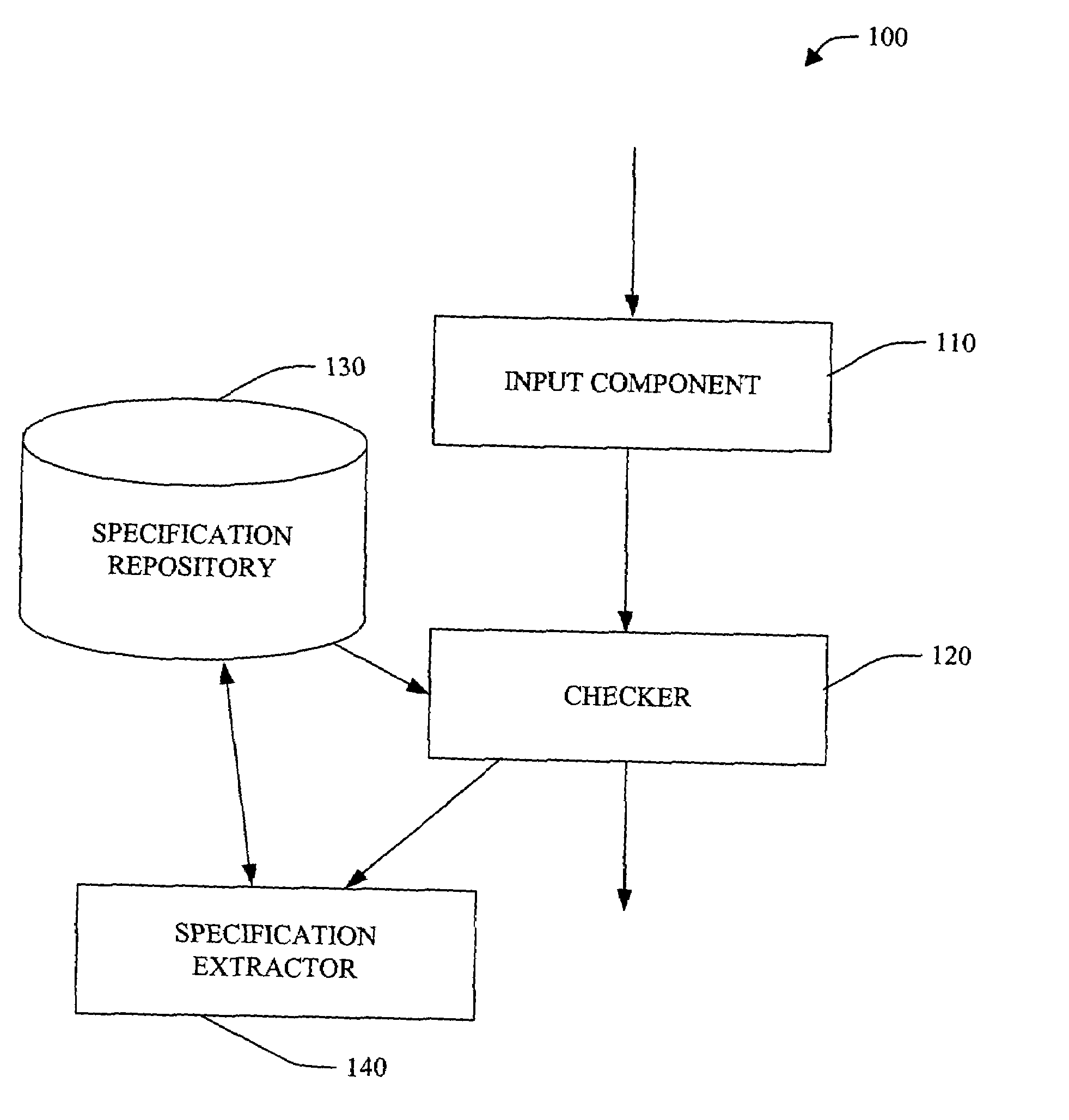

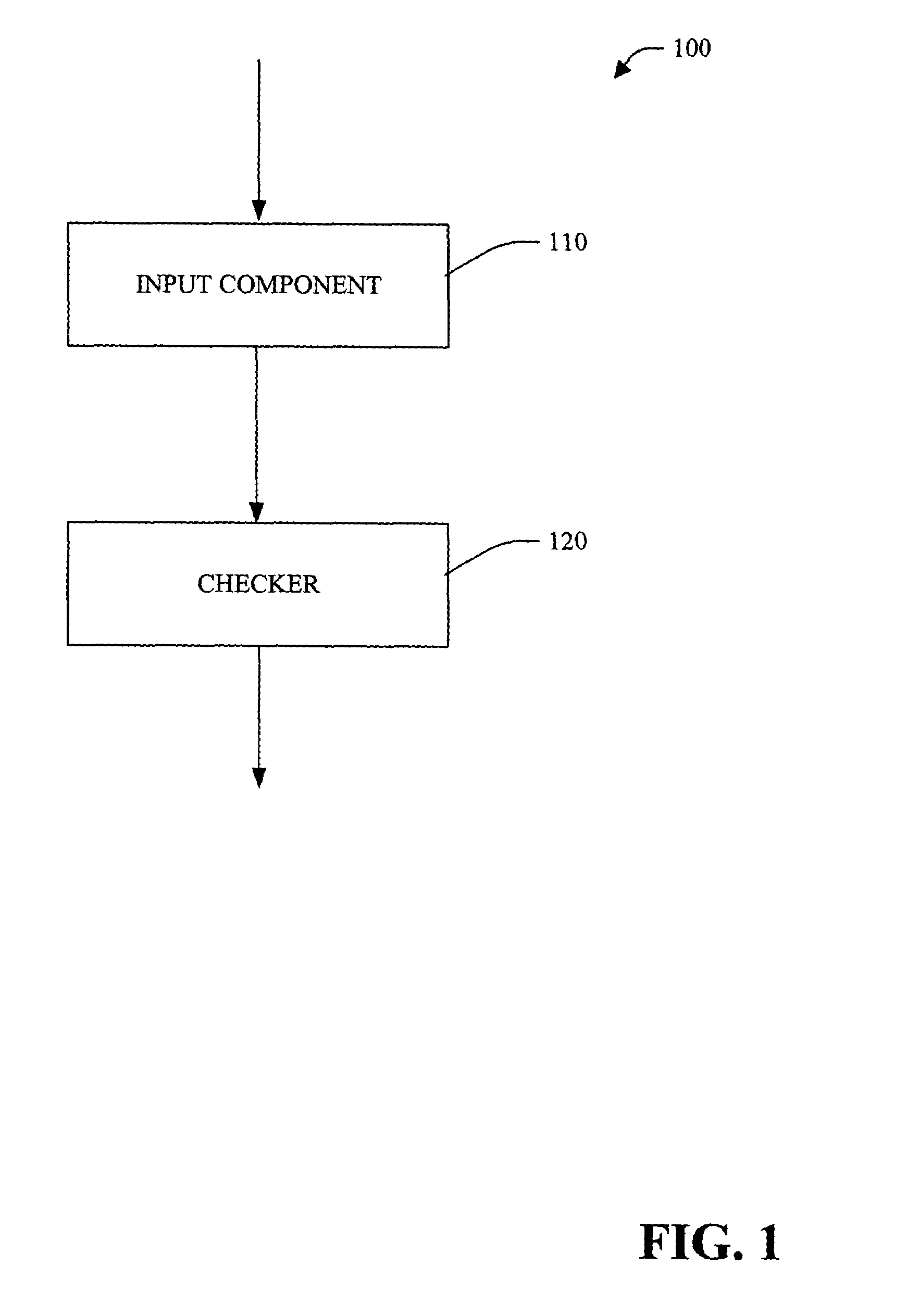

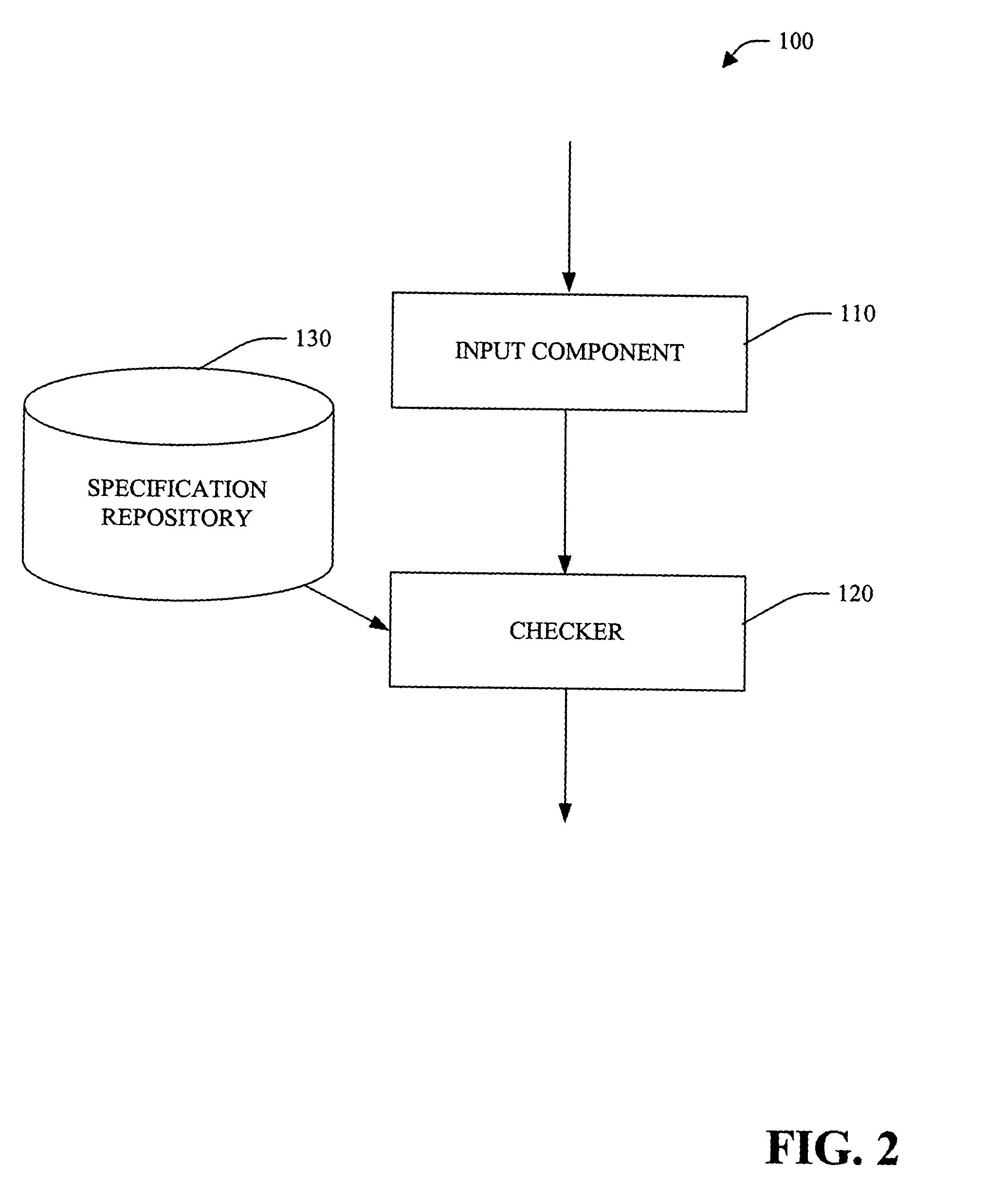

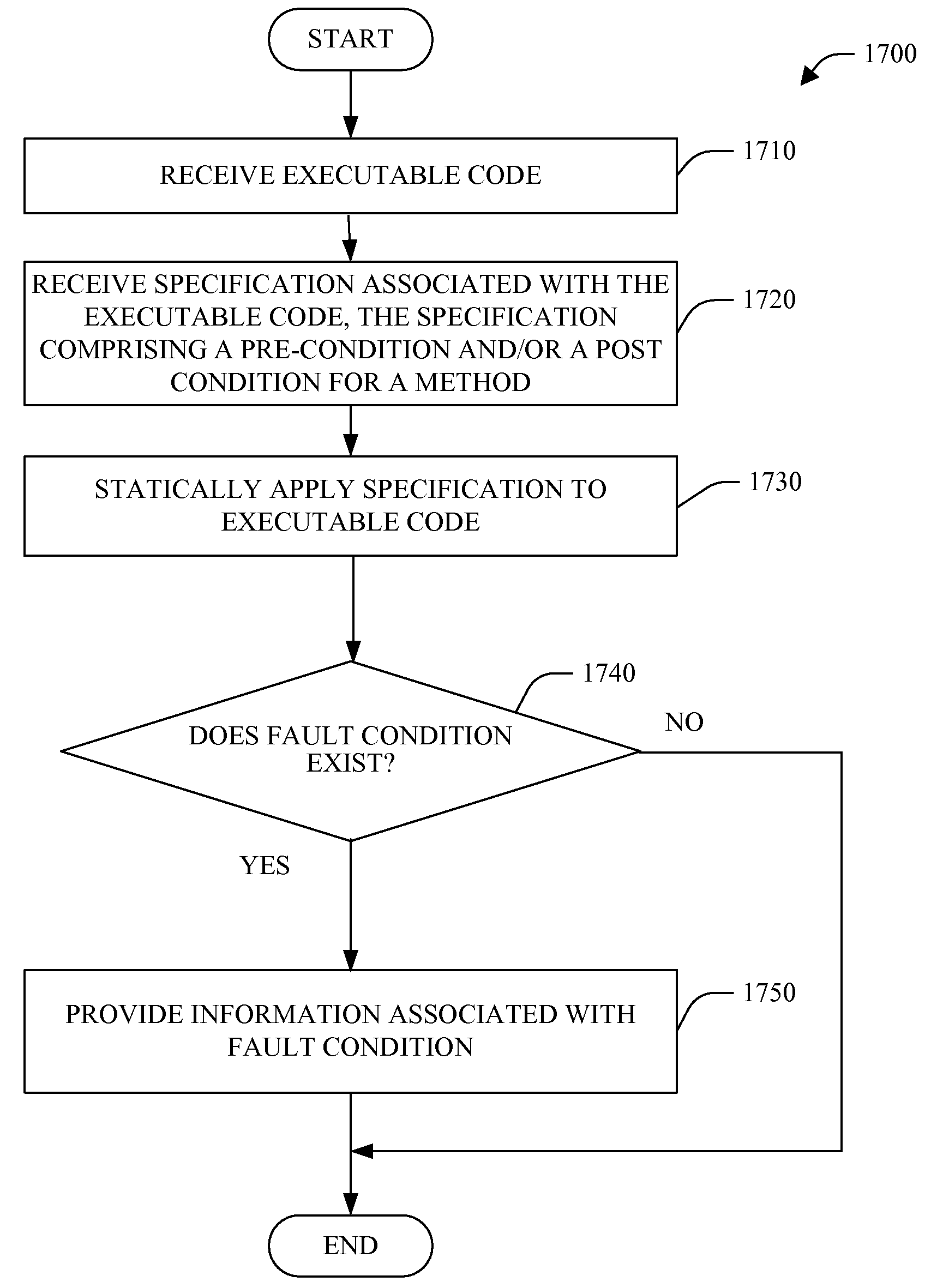

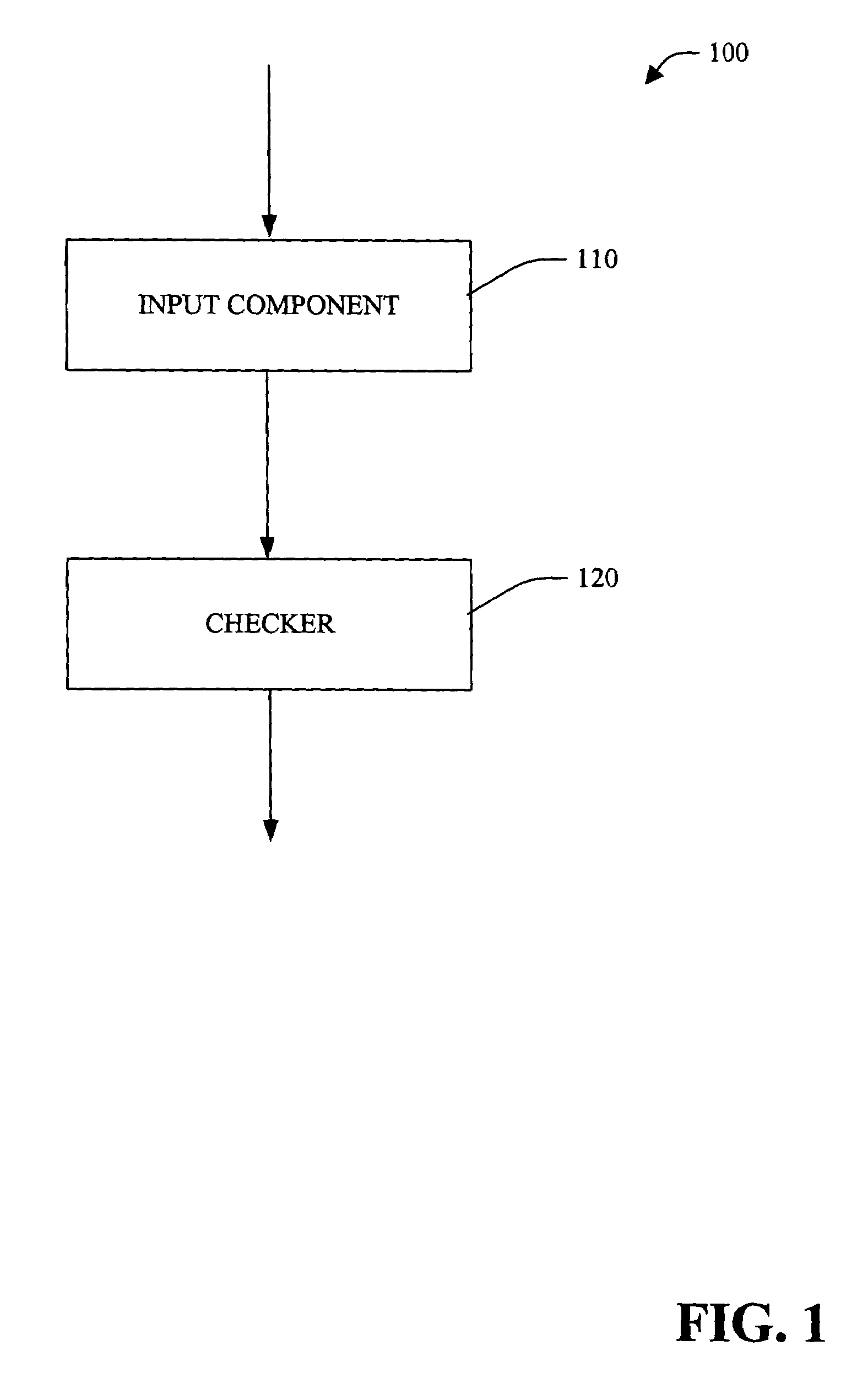

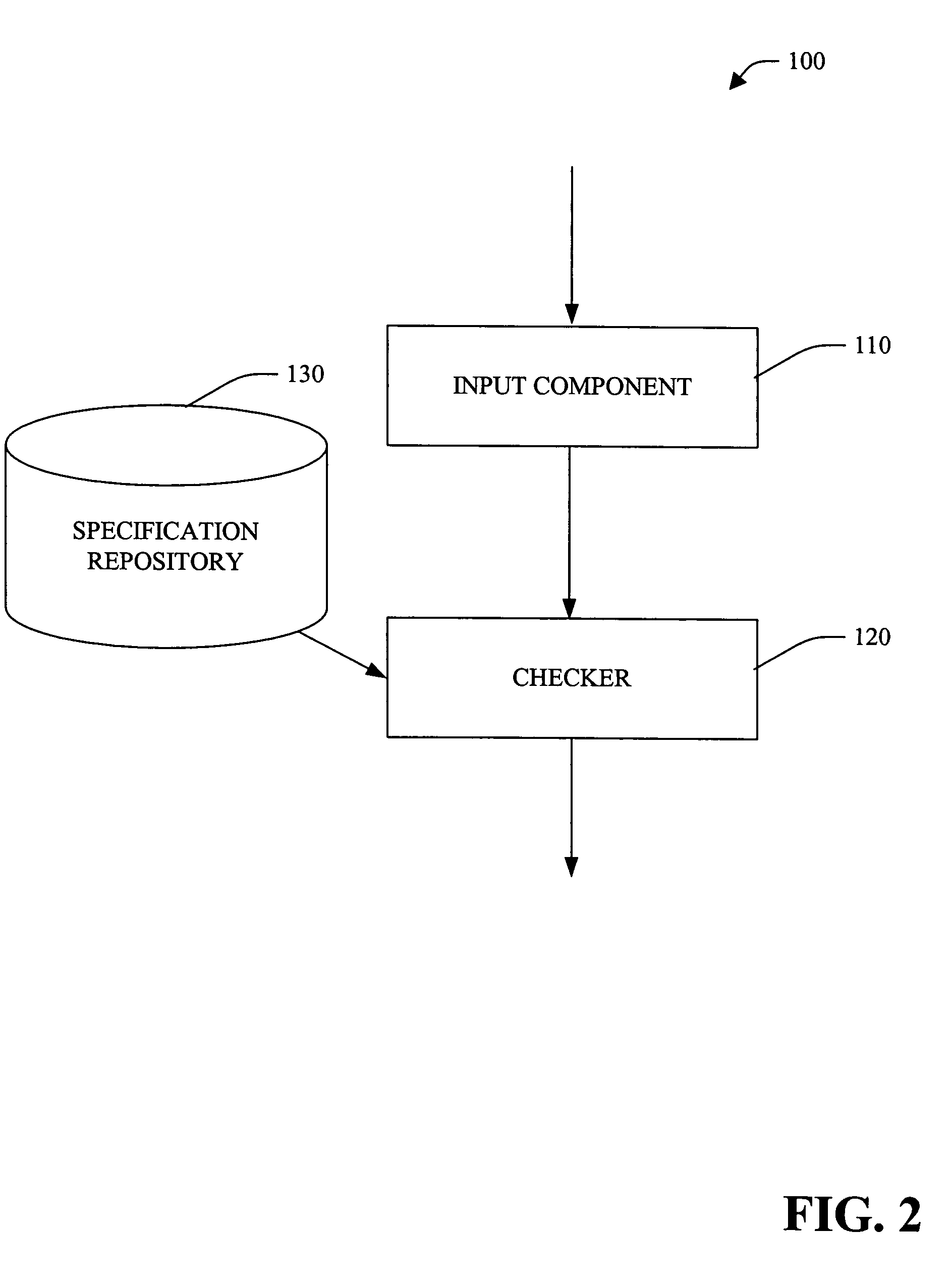

Persisted specifications of method pre-and post-conditions for static checking

ActiveUS20050066319A1Easy to checkFacilitate static checkingSoftware engineeringSpecific program execution arrangementsObject codeFinite-state machine

A system and method employing pre- and / or post-condition(s) specified at a source code level and persisted (e.g., in associated object code and / or a specification repository) facilitating static checking of the object code is provided. The system and method are based, at least in part, upon a framework that employs rules for using an interface to be recorded as declarative specifications in an existing language. The system can employ a range of annotations that allow a developer to specify interface rule(s) with varying precision. At the simplest end of the range, a specifier can mark those methods that allocate and release resource(s). A specifier can also limit the order in which an object's methods may be called to the transitions of a finite state machine. At the more complex end of the range, a specifier can give a method a plug-in pre- and post condition, which is arbitrary code that examines an object's current state and a static approximation of the method's actuals, decides whether the call is legal and returns the object's state after the call.

Owner:MICROSOFT TECH LICENSING LLC

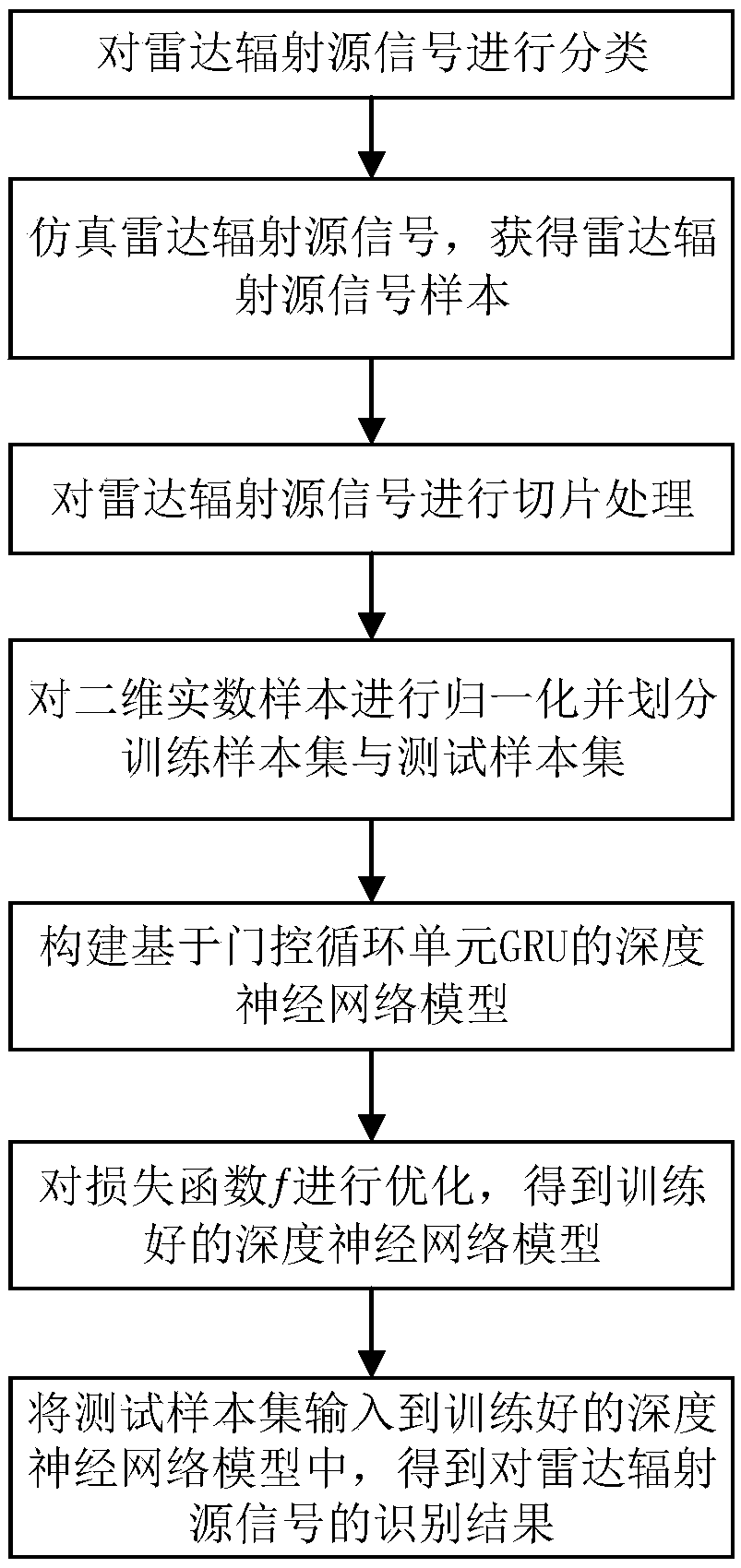

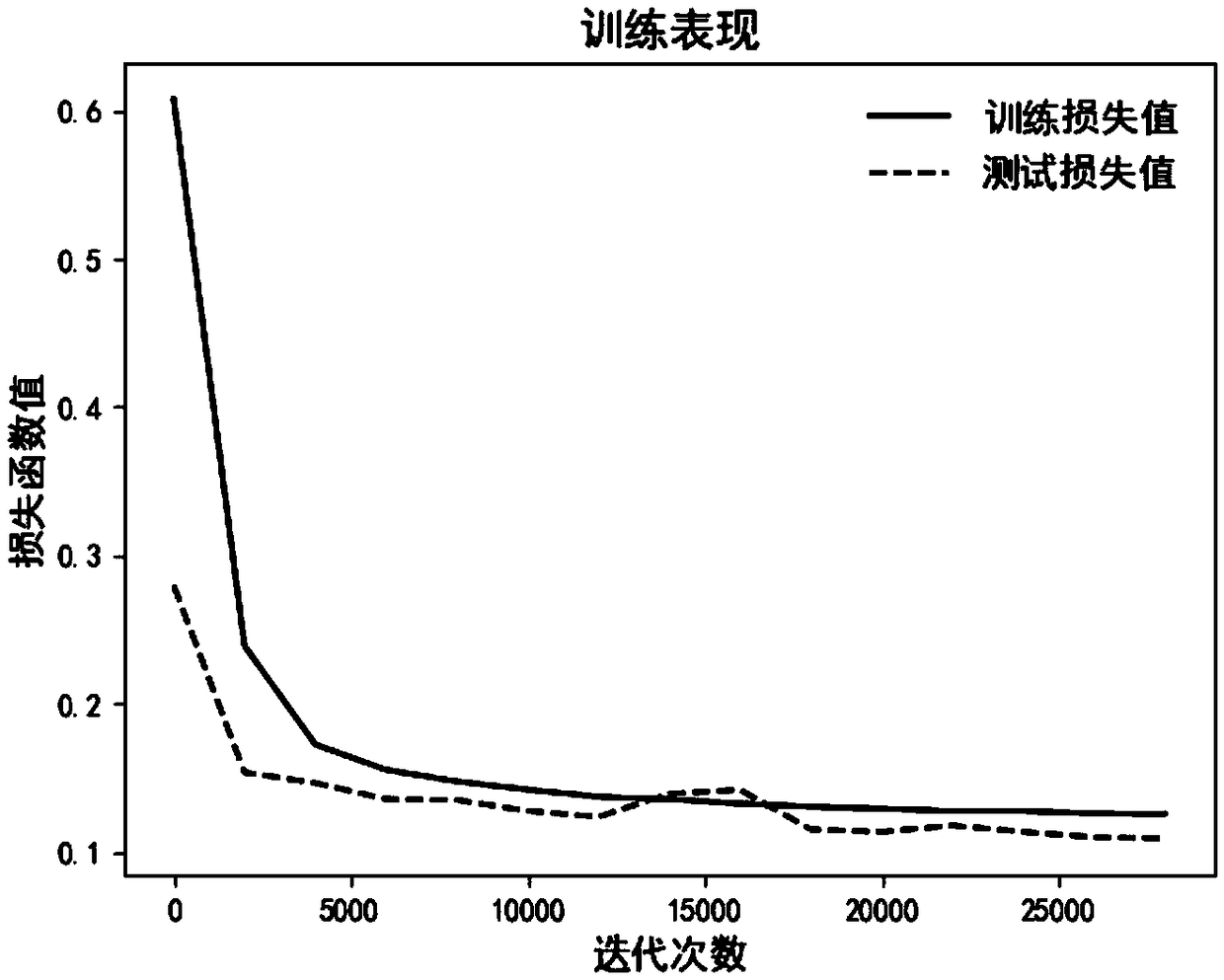

Intelligent emitter identification method based on GRU depth convolution network

ActiveCN109271926AIncrease diversityOvercome the disadvantage of requiring a lot of prior knowledgeCharacter and pattern recognitionTest sampleNetwork model

The invention relates to an intelligent emitter identification method based on GRU depth convolution network, which mainly solves the problem that the serialization characteristics of radar emitter signals can not be extracted by the prior art. The scheme comprises the following steps: radar emitter signals are classified; the radar emitter signals are simulated and sliced, the sliced samples areconverted into two-dimensional real samples, and the two-dimensional real samples are normalized and divided into training sample set and test sample set, a depth neural network based on gated circulation unit GRU is constructed; the training sample set is inputted into the depth neural network, and the trained depth neural network model is obtained by optimizing the loss function, the test sampleset is input into the trained depth neural network model, and the recognition result of radar emitter signal is obtained. The invention can extract pre-and post-correlation features of signals, avoids manual feature extraction and prior knowledge, has low complexity and accurate classification result, and can be used for radar emitter identification under complex electromagnetic environment.

Owner:XIDIAN UNIV

Persisted specifications of method pre-and post-conditions for static checking

ActiveUS7421680B2Easy to checkFacilitate static checkingSoftware engineeringSpecific program execution arrangementsObject codeFinite-state machine

A system and method employing pre- and / or post-condition(s) specified at a source code level and persisted (e.g., in associated object code and / or a specification repository) facilitating static checking of the object code is provided. The system and method are based, at least in part, upon a framework that employs rules for using an interface to be recorded as declarative specifications in an existing language. The system can employ a range of annotations that allow a developer to specify interface rule(s) with varying precision. At the simplest end of the range, a specifier can mark those methods that allocate and release resource(s). A specifier can also limit the order in which an object's methods may be called to the transitions of a finite state machine. At the more complex end of the range, a specifier can give a method a plug-in pre- and post condition, which is arbitrary code that examines an object's current state and a static approximation of the method's actuals, decides whether the call is legal and returns the object's state after the call.

Owner:MICROSOFT TECH LICENSING LLC

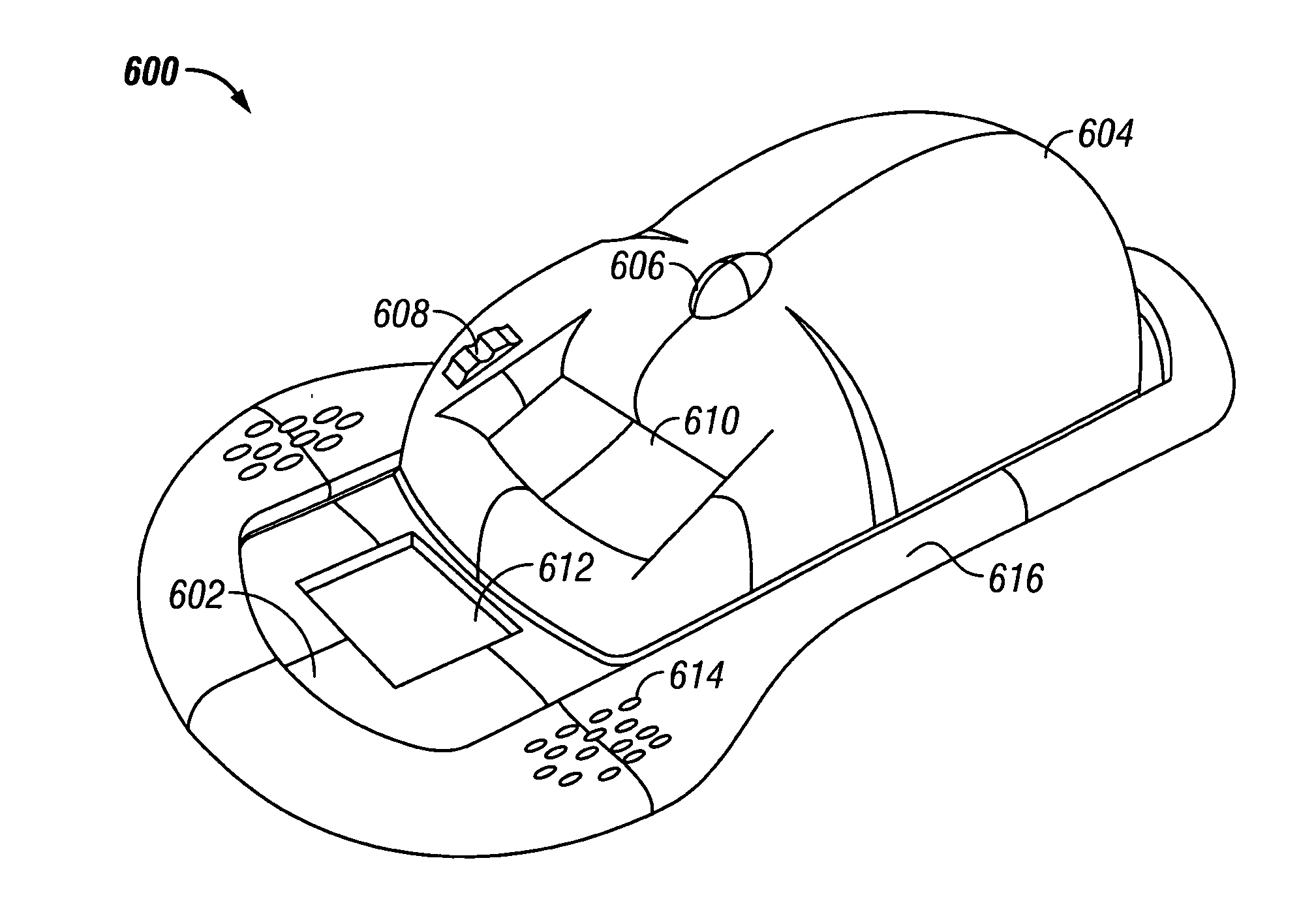

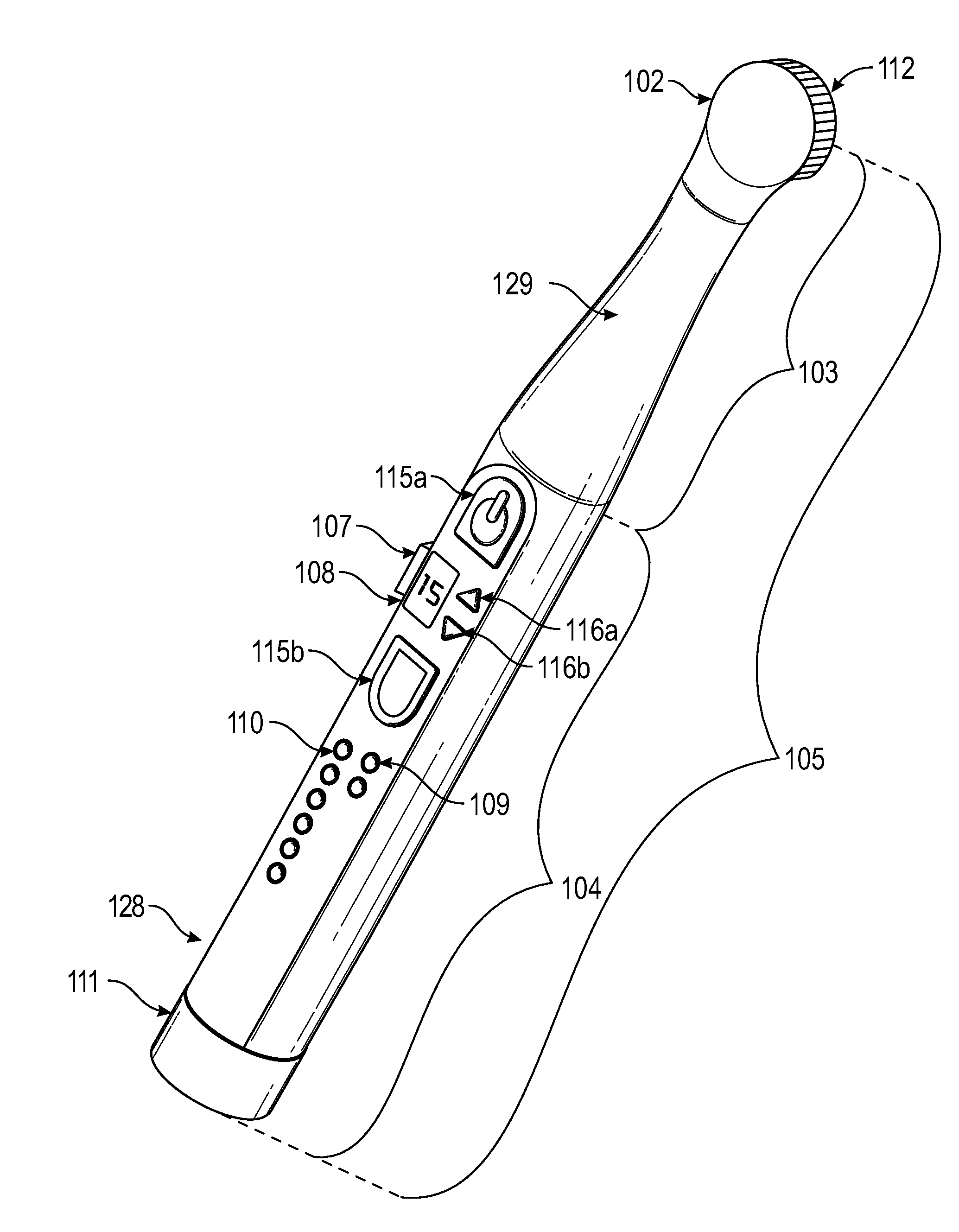

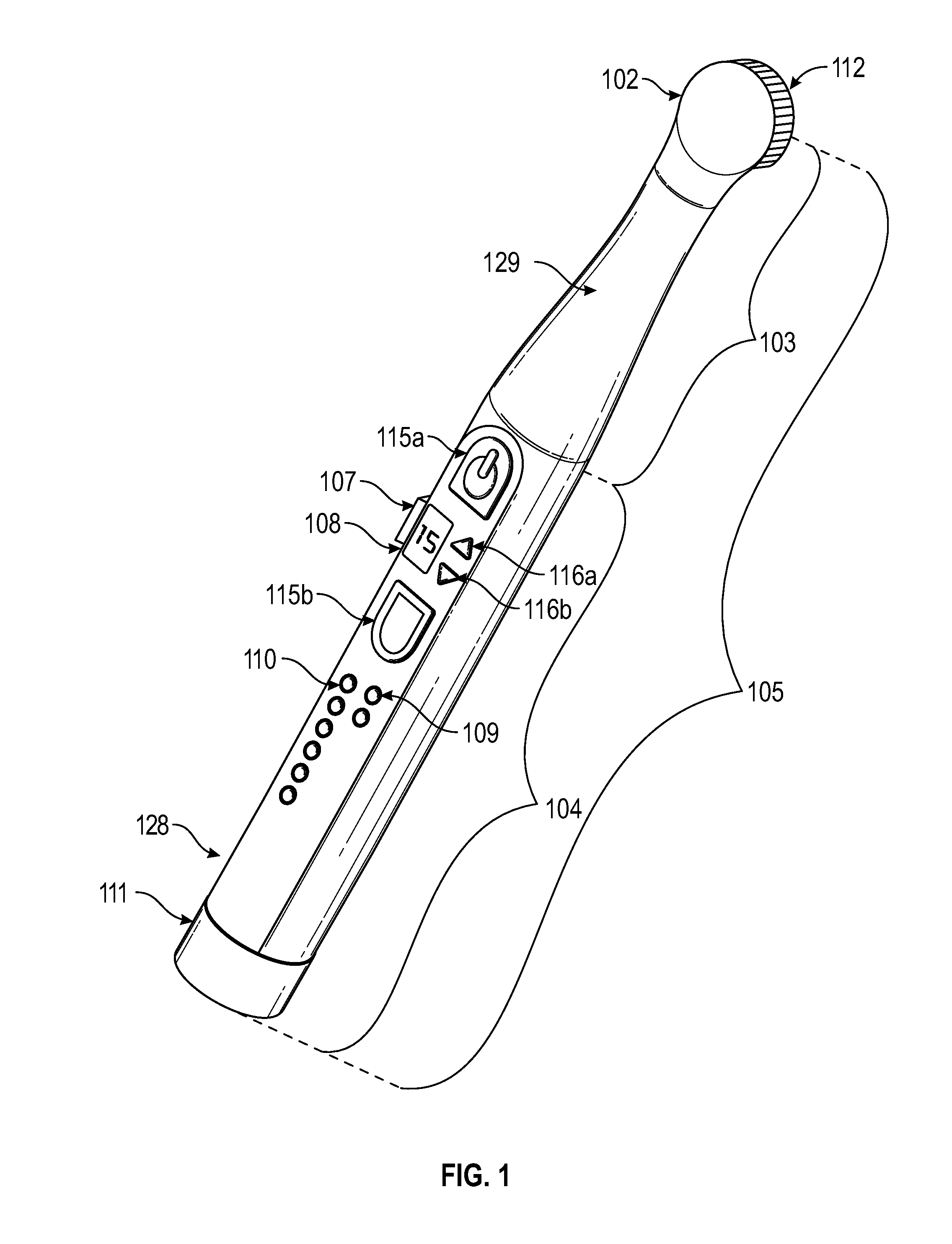

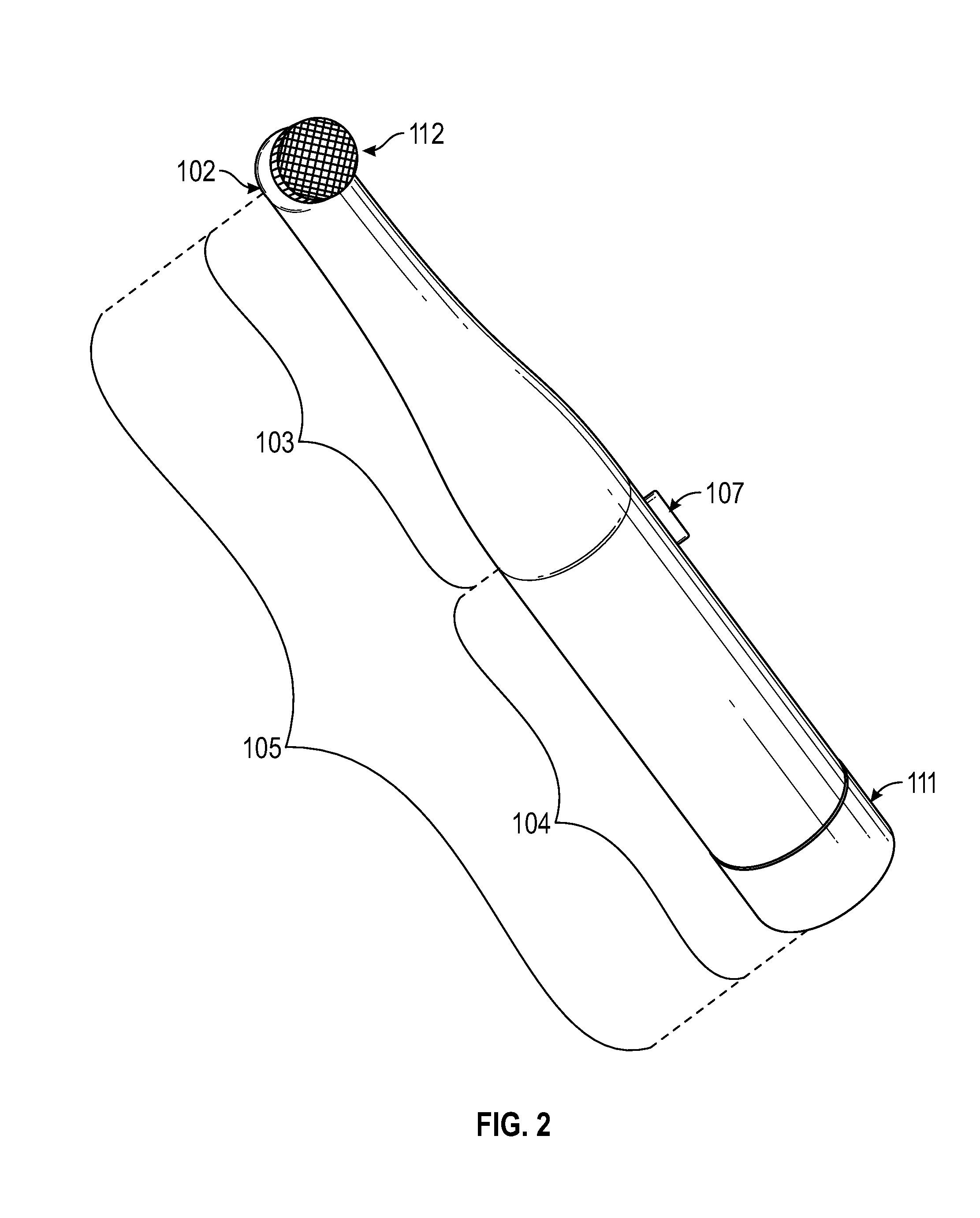

Pre and post anesthetic cooling device and method

InactiveUS20160242956A1Relieve painEfficient conductionTherapeutic coolingTherapeutic heatingTemperature controlMedicine

Thermoelectric anesthetic cooling devices allow for temperature controlled cooling of the skin / epidermis or mucous membrane / mucosa, to alleviate pain associated with medical treatment such as injections and skin ablation applied to the human body. The cooling device comprises a body that efficiently conducts heat away from the thermoelectric section of the device. The device body comprises a proximal gripping end (i.e., handle) connected to a distal head section by a neck section.

Owner:PILBY GOMEZ JENNIFER MARIE

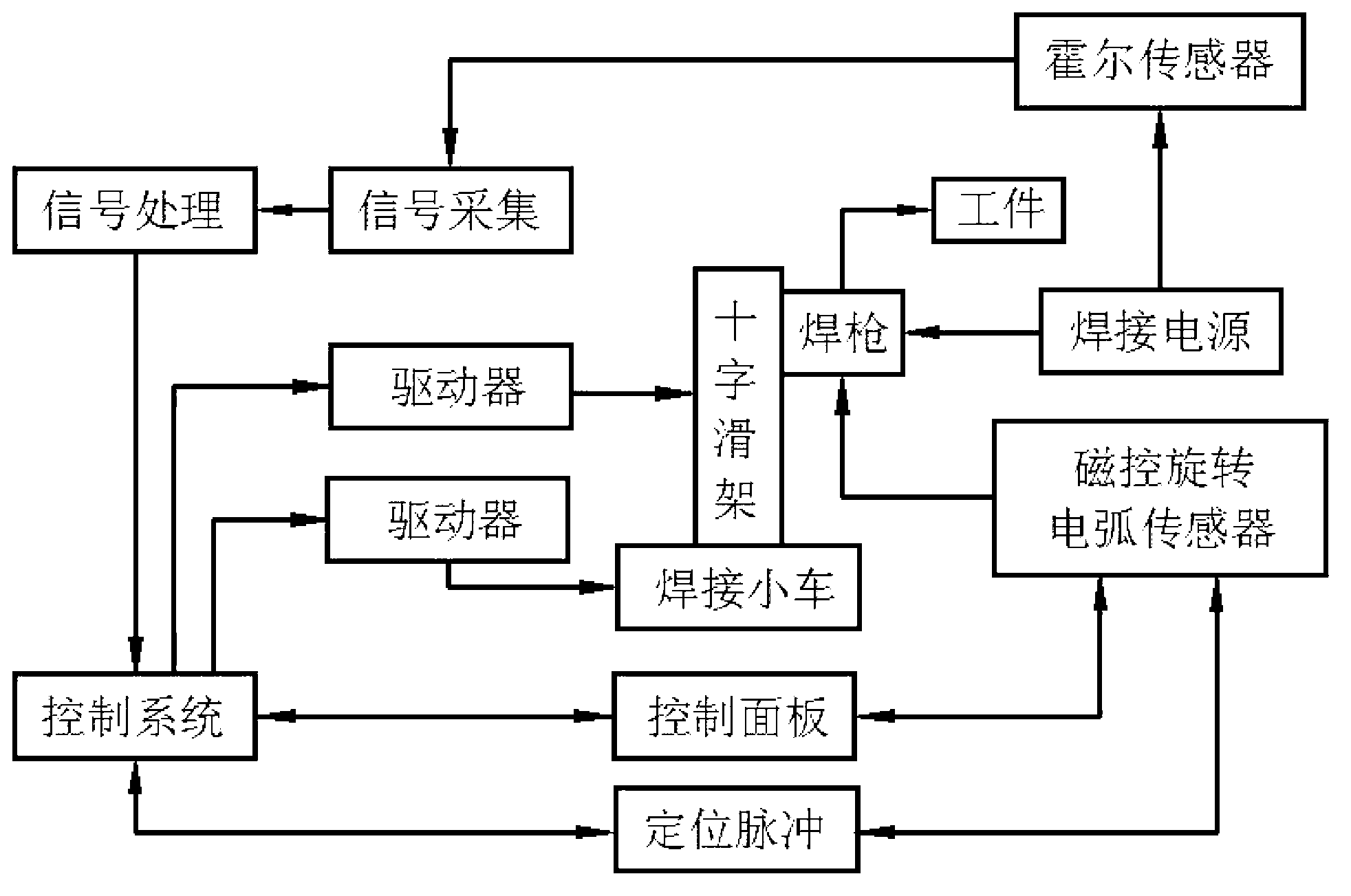

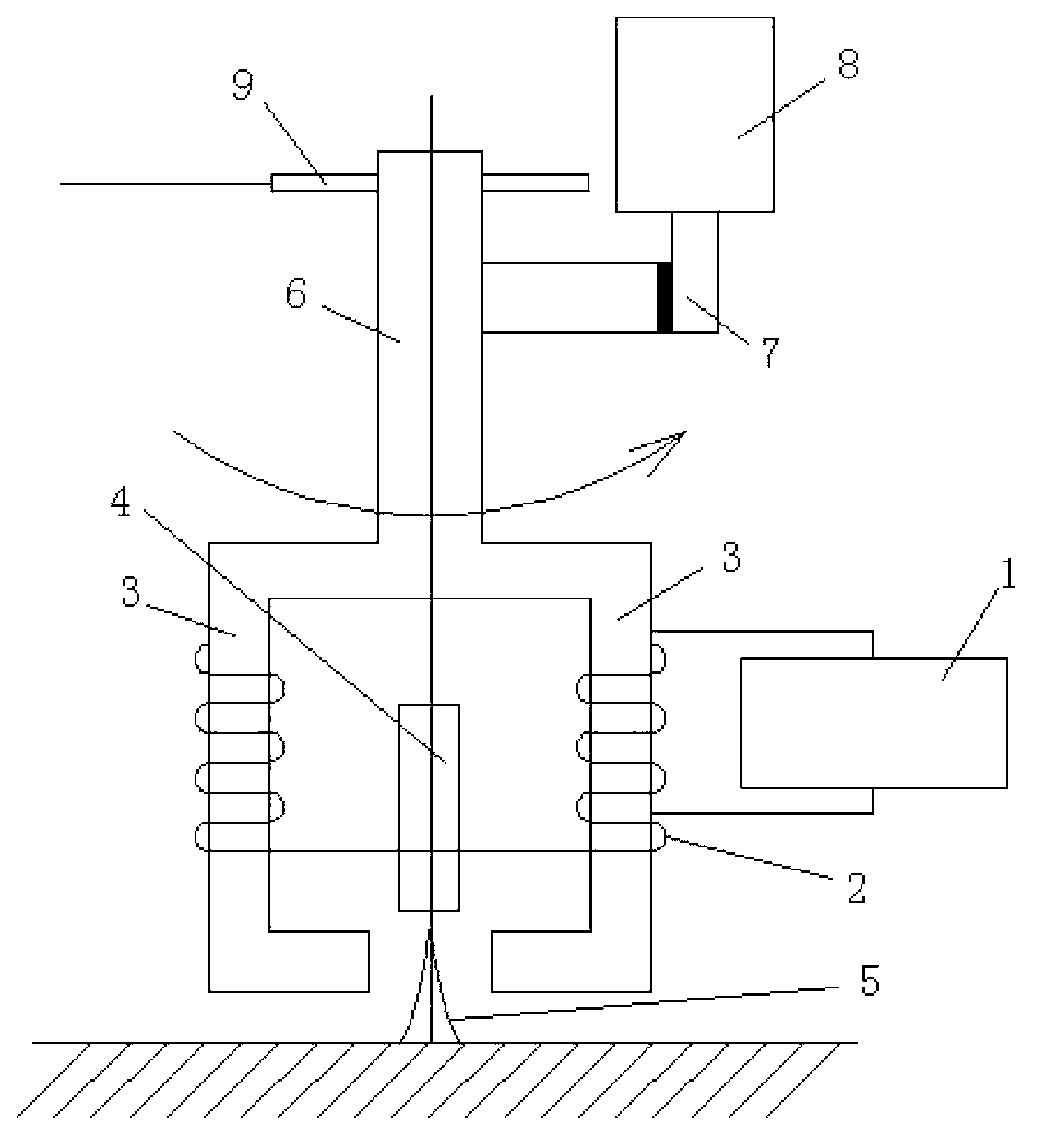

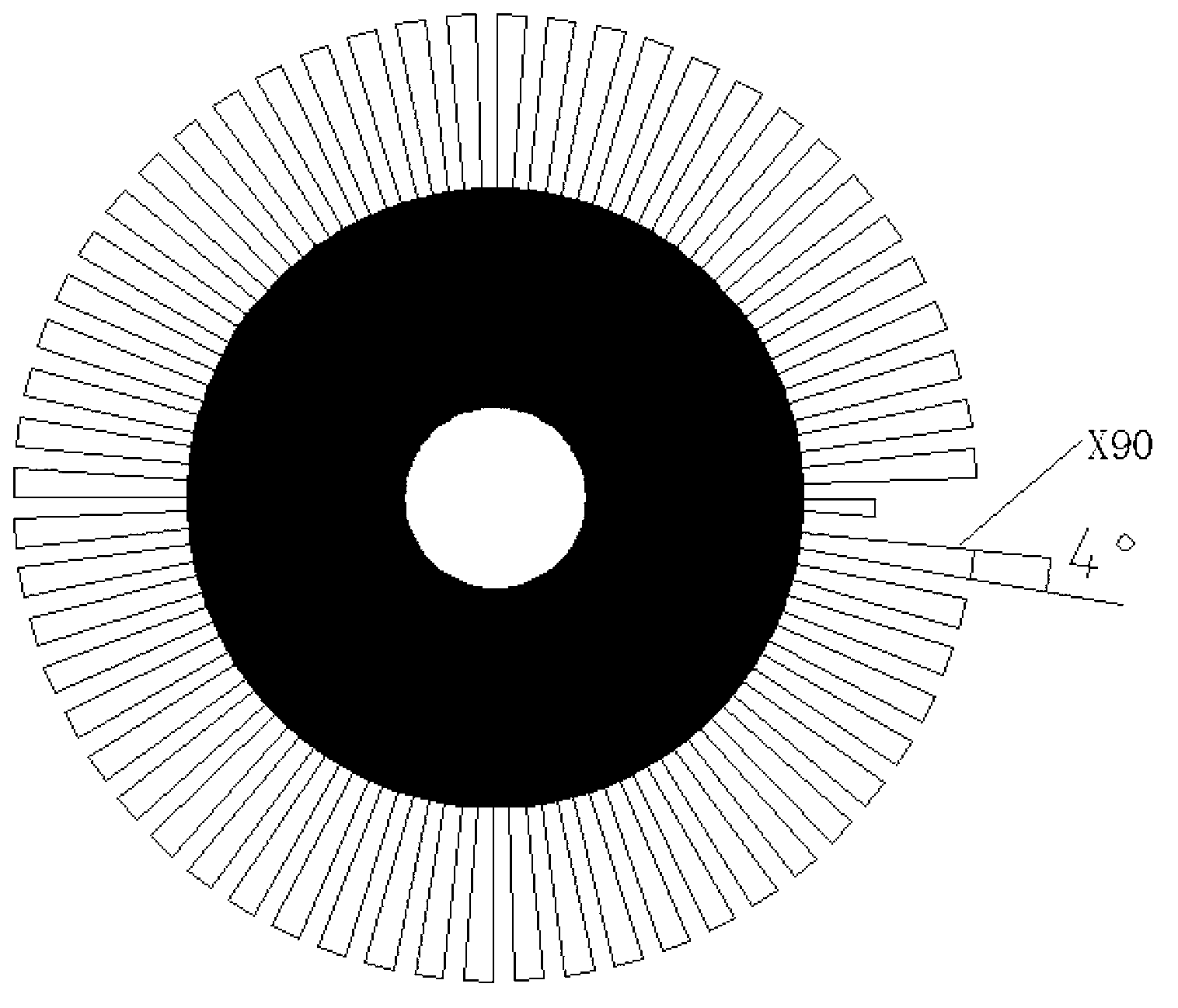

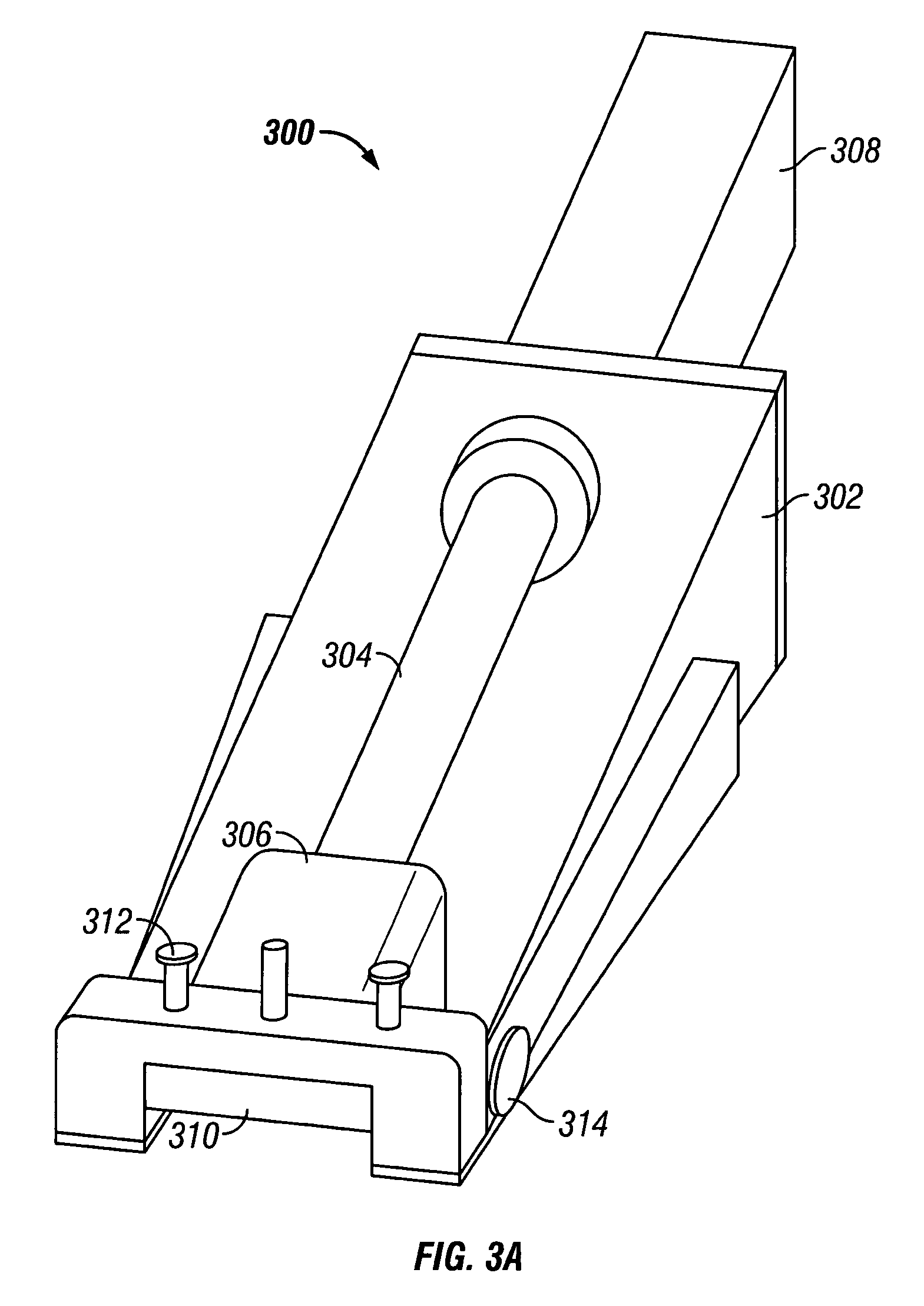

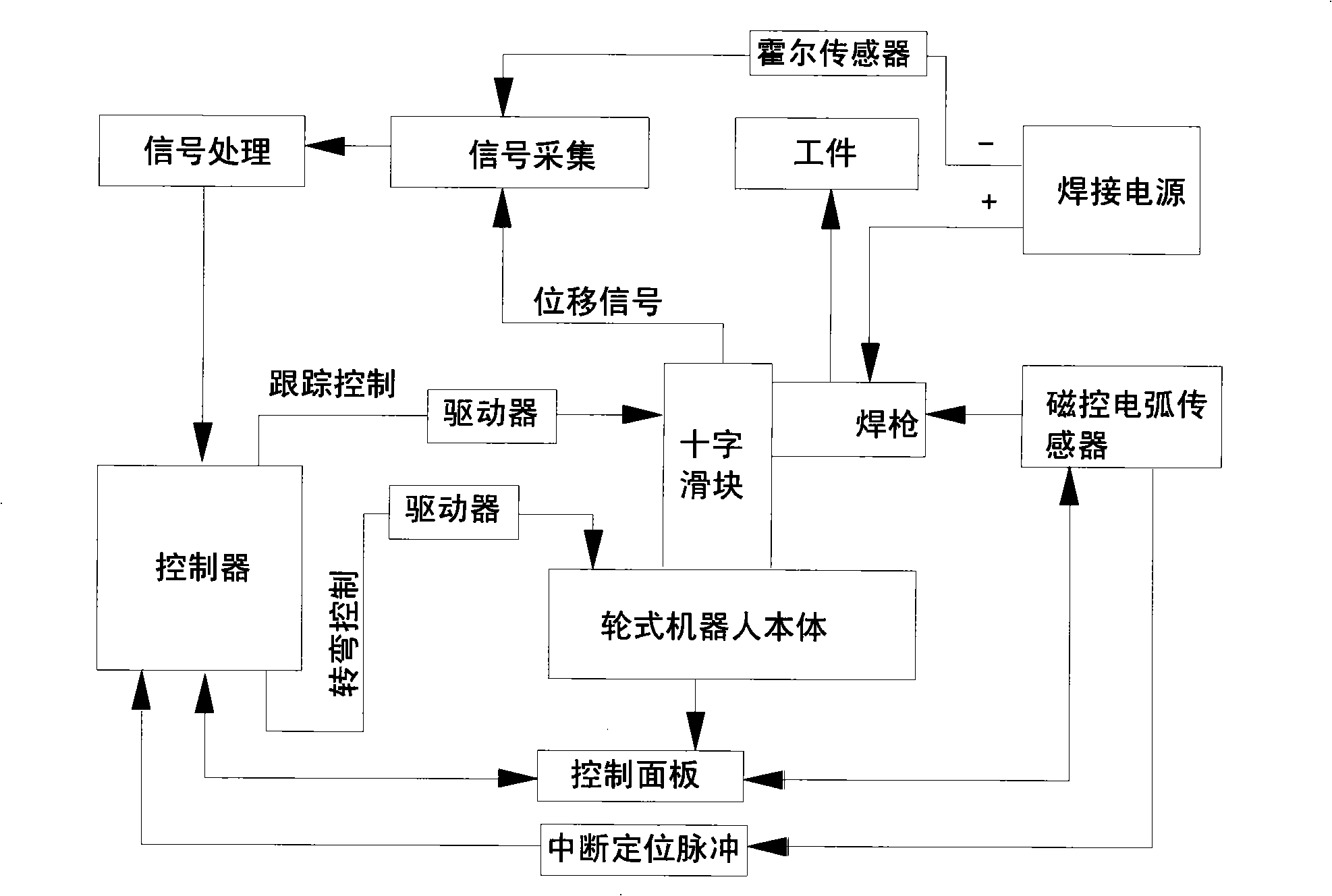

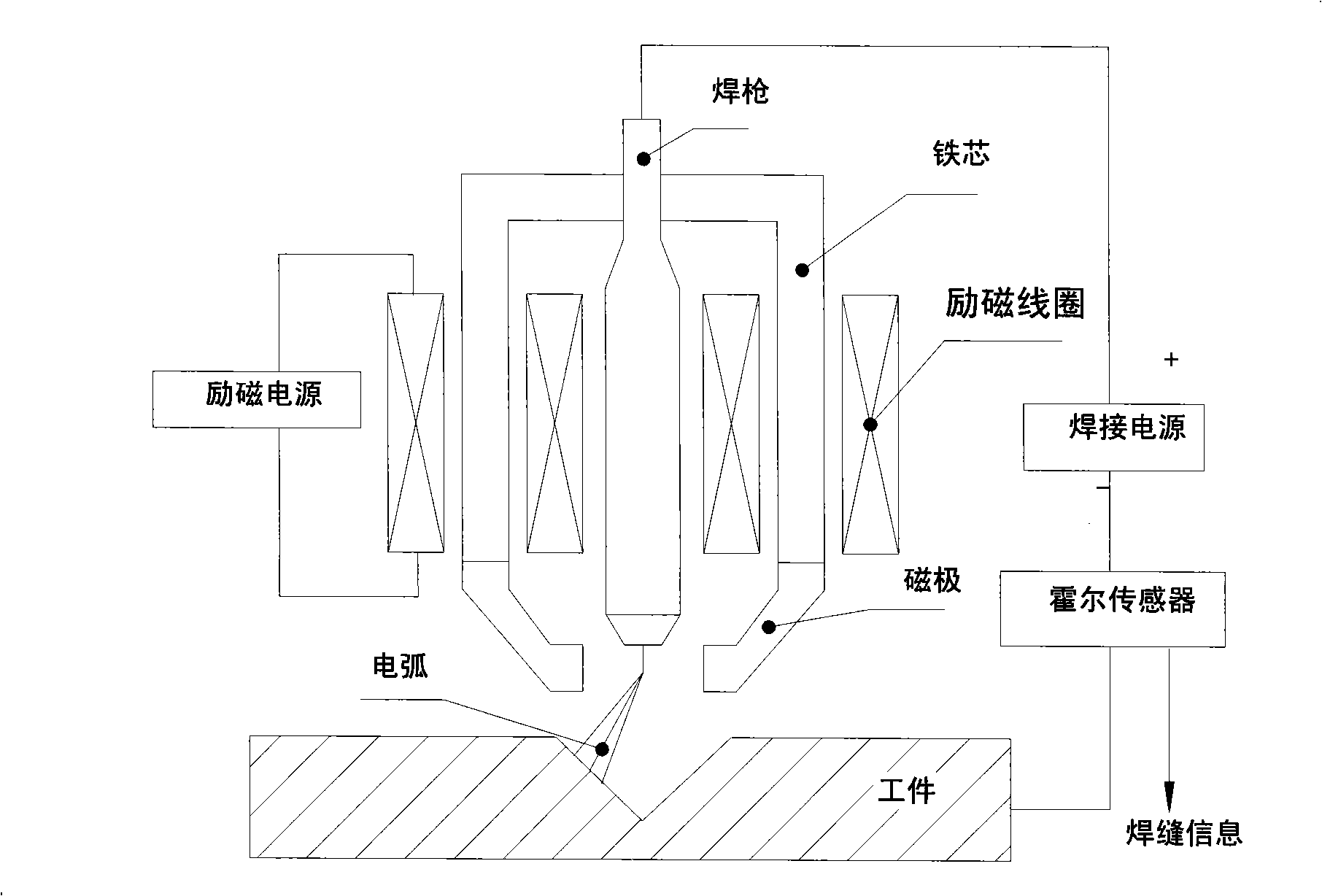

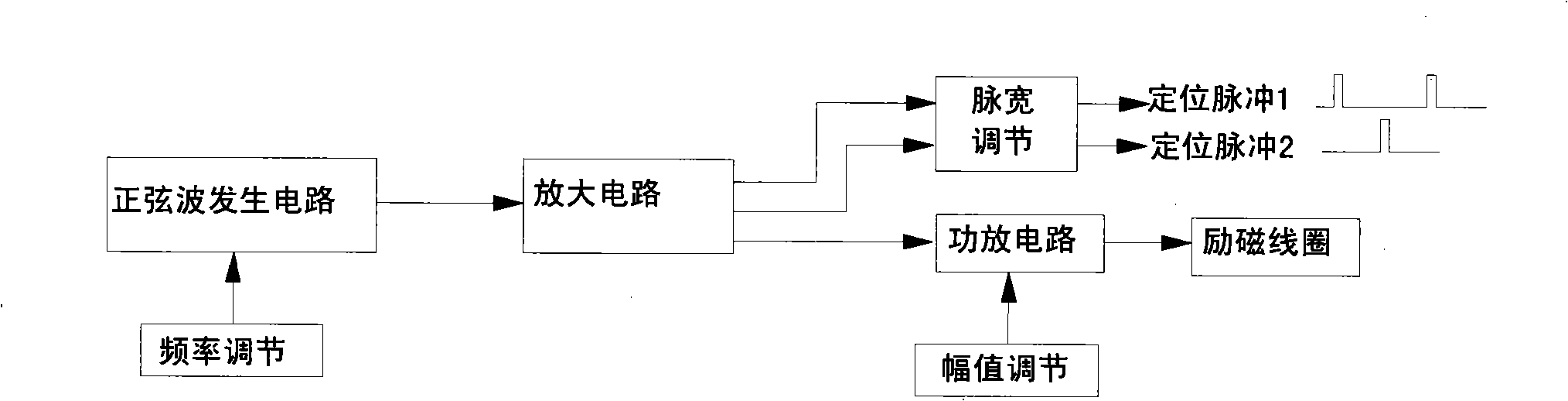

Magnetic control rotating arc sensing real-time weld joint tracking system and method

InactiveCN102848052AImprove real-time performanceImprove stabilityArc welding apparatusAutomatic controlControl system

The invention belongs to the technical field of welding automatic control, and particularly relates to a magnetic control rotating arc sensing real-time weld joint tracking system and a magnetic control rotating arc sensing real-time weld joint tracking method. The technical point is that a magnetic control rotating arc sensor is applied to automatically tracking a weld joint; a rotating magnetic field is exerted to the welding arc, so that the weld joint can be scanned through the welding arc at a certain frequency, and then the characteristic parameter for showing the position of a weld gun relative to the position of the weld joint can be acquired; a hall sensor is used for acquiring a welding current signal, and the welding current signal is fed into a control system to be subjected to digital filter and corresponding program operation; and a tracking performing mechanism is controlled to properly adjust the weld gun, therefore, the weld gun can be aligned to the center of the weld joint so as to track the weld joint. With the adoption of the system and the method, the requirement on automatic tracking of the weld joint can be met; the weld gun is directly arranged on the magnetic control rotating arc sensor, and the problem due to front installing and rear installing can be avoided; and the system and the method have the characteristics of being good in real-time capability, low in cost, high in stability and high in precision.

Owner:XIANGTAN UNIV

Method for evaluating blush in myocardial tissue

ActiveUS20100305454A1Eliminate strengthAvoid excessive intensityImage enhancementMedical imagingFluorescenceCardiac muscle

Vessel perfusion and myocardial blush are determined by analyzing fluorescence signals obtained in a static region-of-interest (ROI) in a collection of fluorescence images of myocardial tissue. The blush value is determined from the total intensity of the intensity values of image elements located within the smallest contiguous range of image intensity values containing a predefined fraction of a total measured image intensity of all image elements within the ROI. Vessel (arterial) peak intensity is determined from image elements located within the ROI that have the smallest contiguous range of highest measured image intensity values and contain a predefined fraction of a total measured image intensity of all image elements within the ROI. Cardiac function can be established by comparing the time differential between the time of peak intensity in a blood vessel and that in a region of neighboring myocardial tissue both pre and post procedure.

Owner:STRYKER EUROPEAN OPERATIONS LIMITED

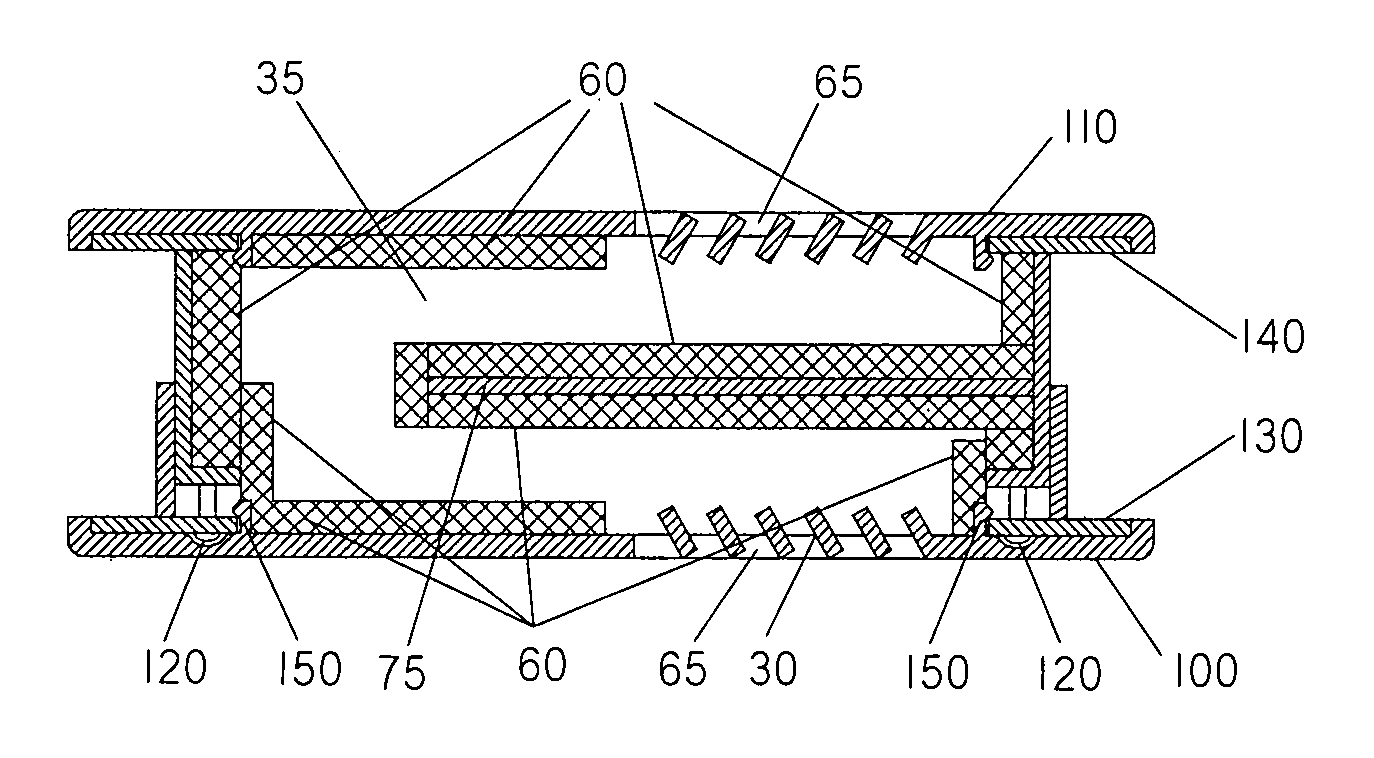

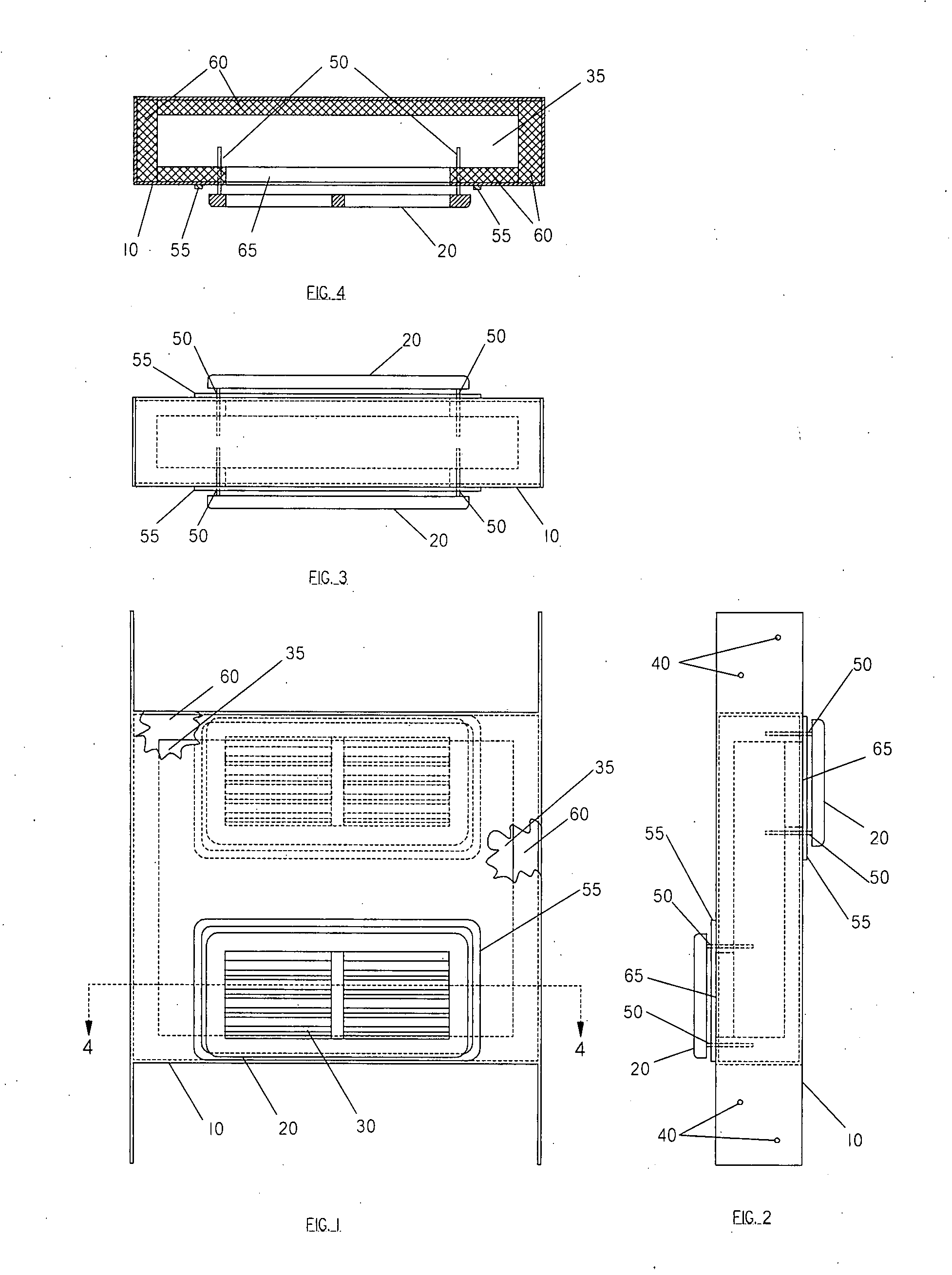

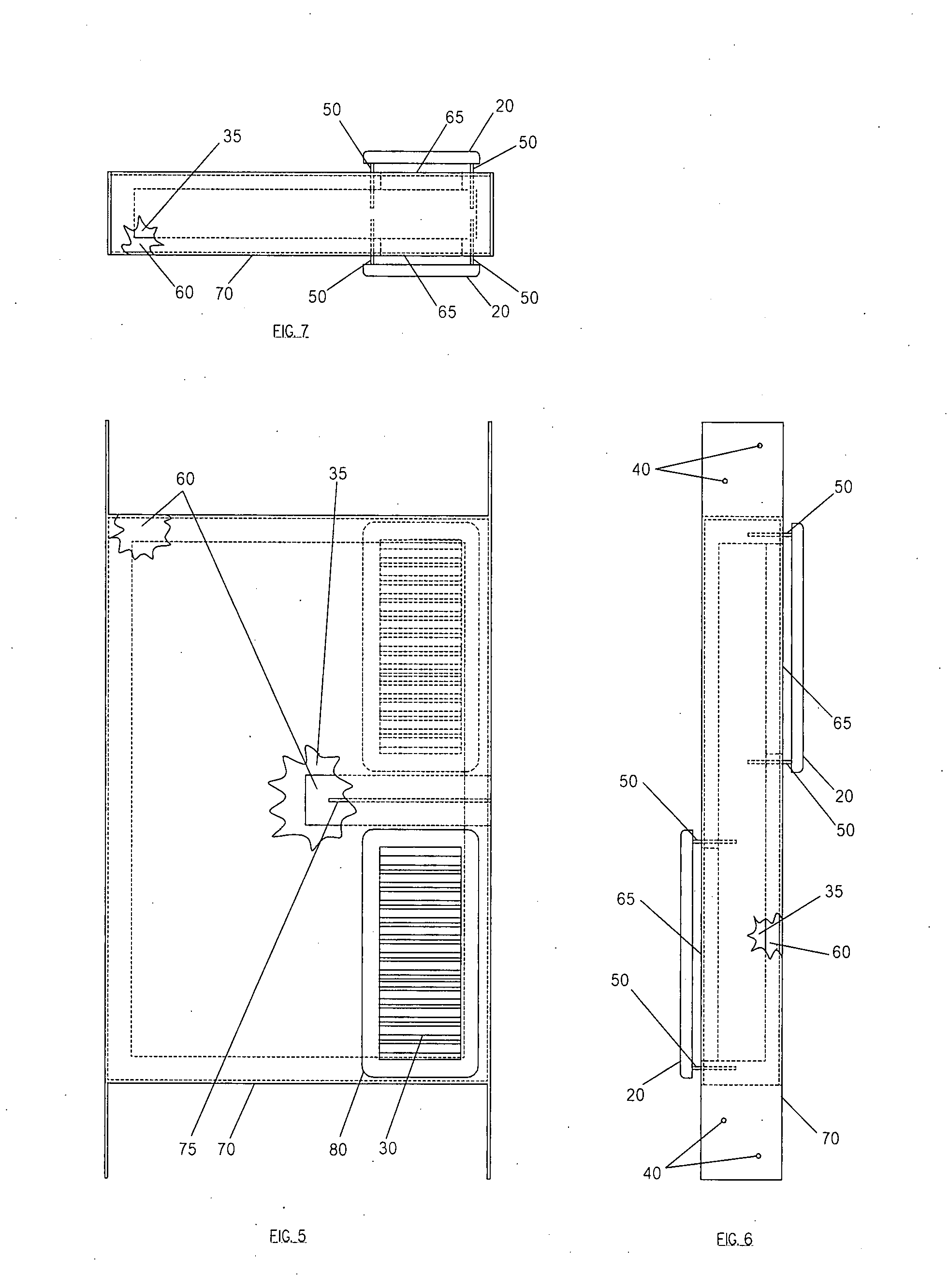

Sound attenuating air vent

An device that allows air flow while attenuating sound for the purposes of allowing air to flow between rooms in a structure such as a house or building. The device consists of an air passageway that attenuates sound and covers at each end of the passageway. The covers allow air flow while providing an aesthetically pleasing appearance. Multiple embodiments support pre and post construction scenarios as well access to the interior of the device for cleaning purposes.

Owner:OWENS ROBERT LEE

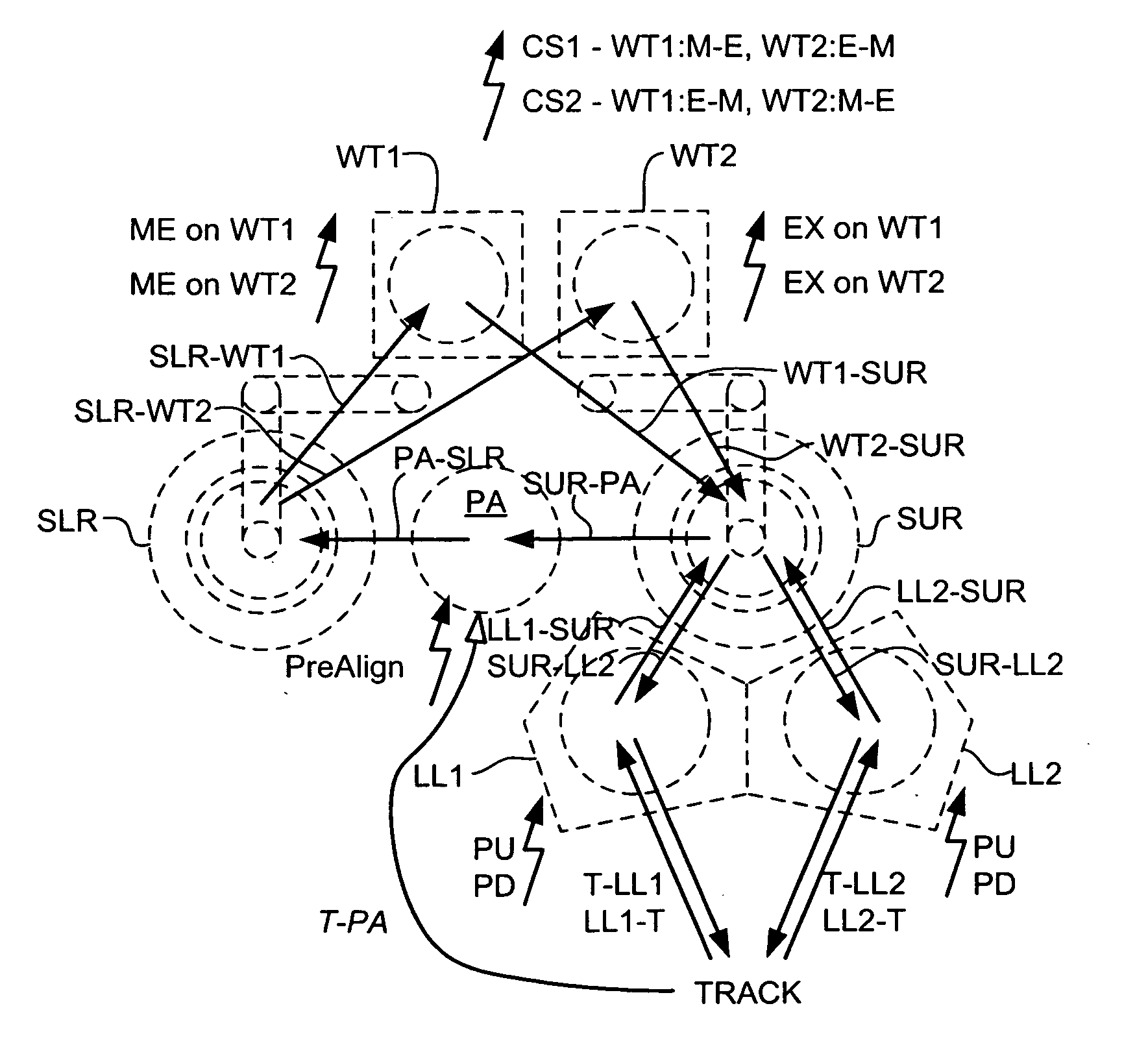

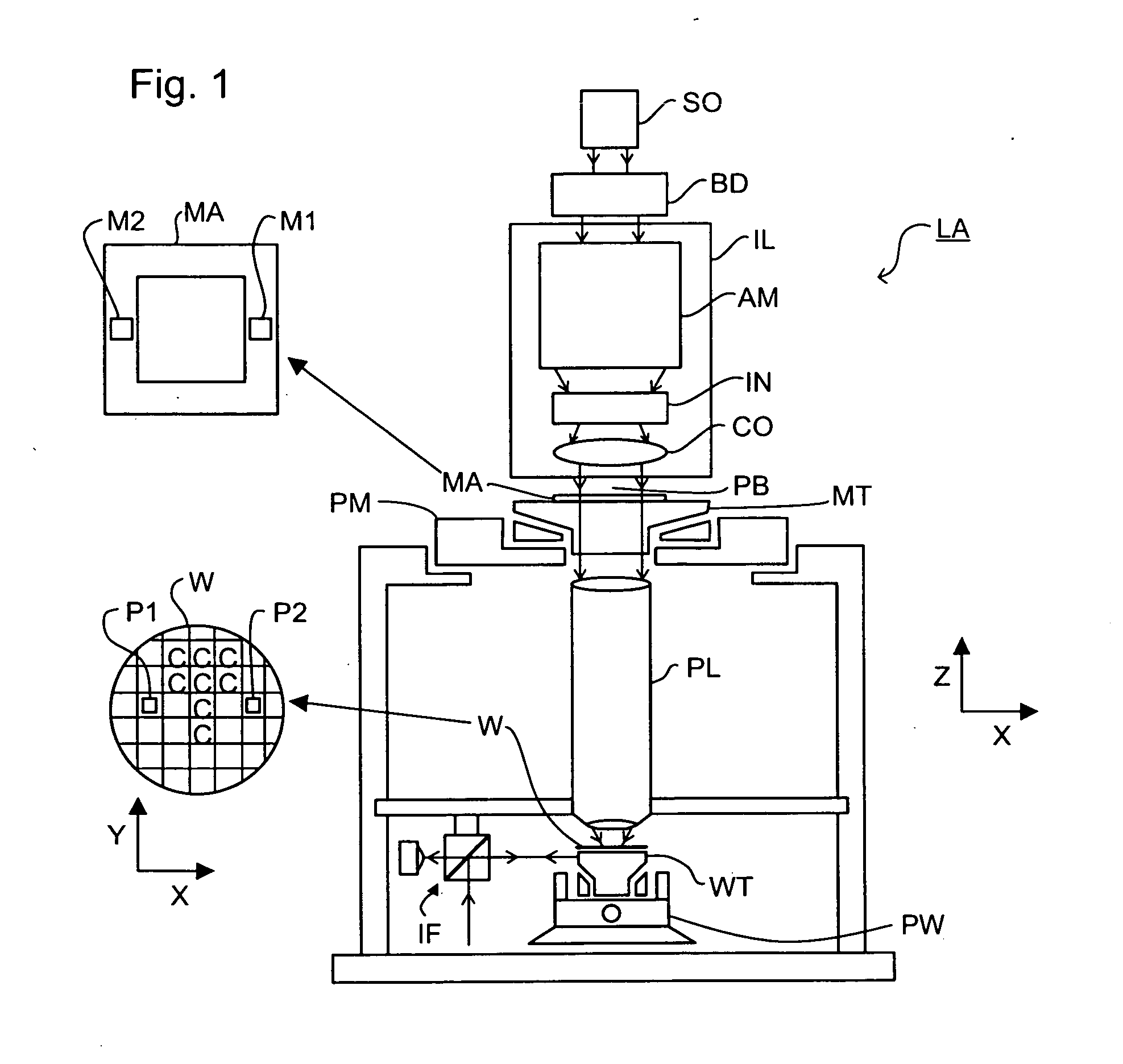

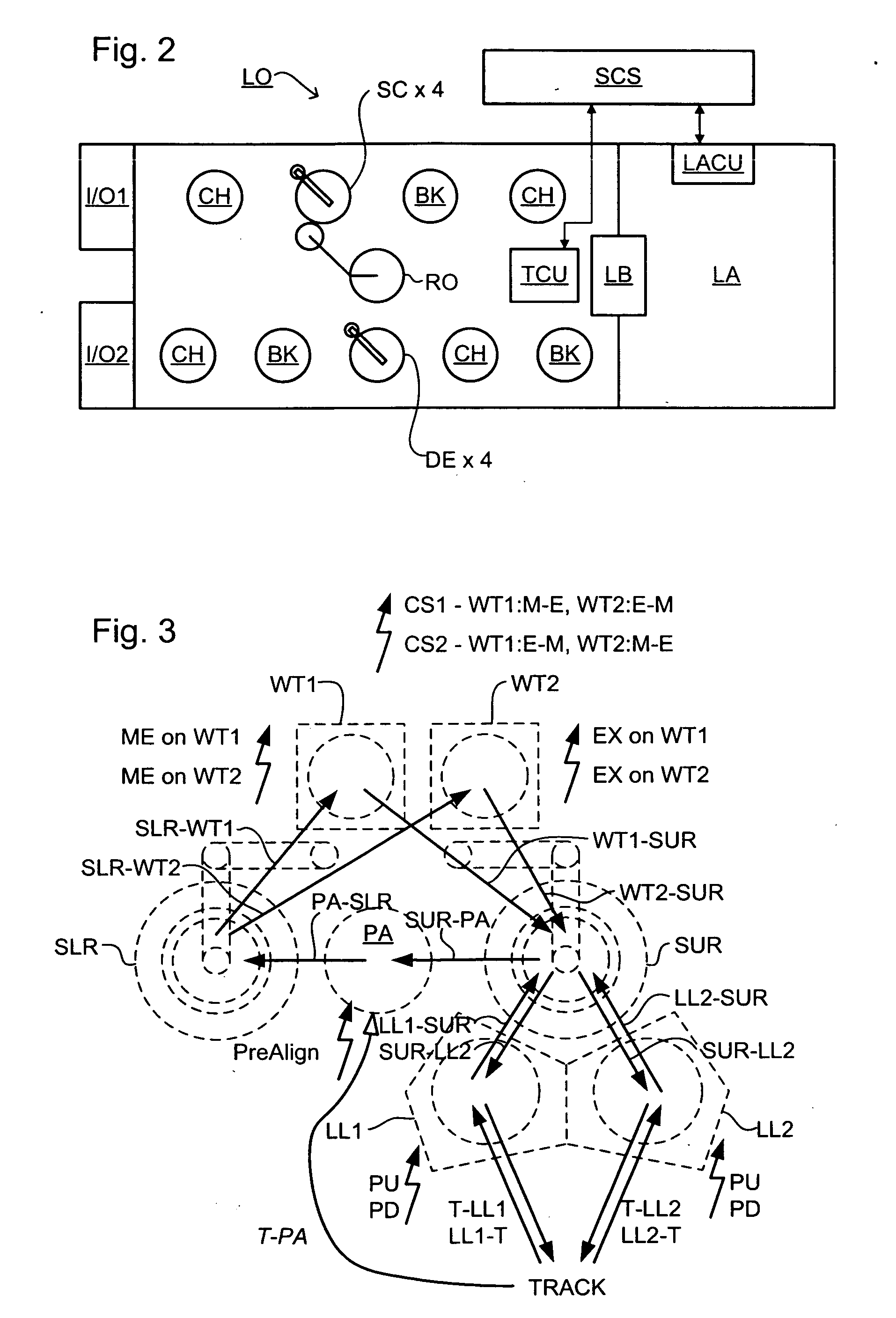

Method of operating a lithographic processing machine, control system, lithographic apparatus, lithographic processing cell, and computer program

InactiveUS20050102723A1Semiconductor/solid-state device manufacturingTotal factory controlControl systemMachine

Scheduling of tasks in a lithographic apparatus, track unit or lithocell is performed by maintaining a register of the state of the machine and a database of tasks performable by the machine, generating possible sequences of tasks based on pre- and post-conditions on the system state (rather than a precedence relation) and selecting a sequence from the generated sequences that meets a given beginning state of the machine and a desired end state. Embodiments of the invention also allow for automated recovery from exceptions.

Owner:ASML NETHERLANDS BV

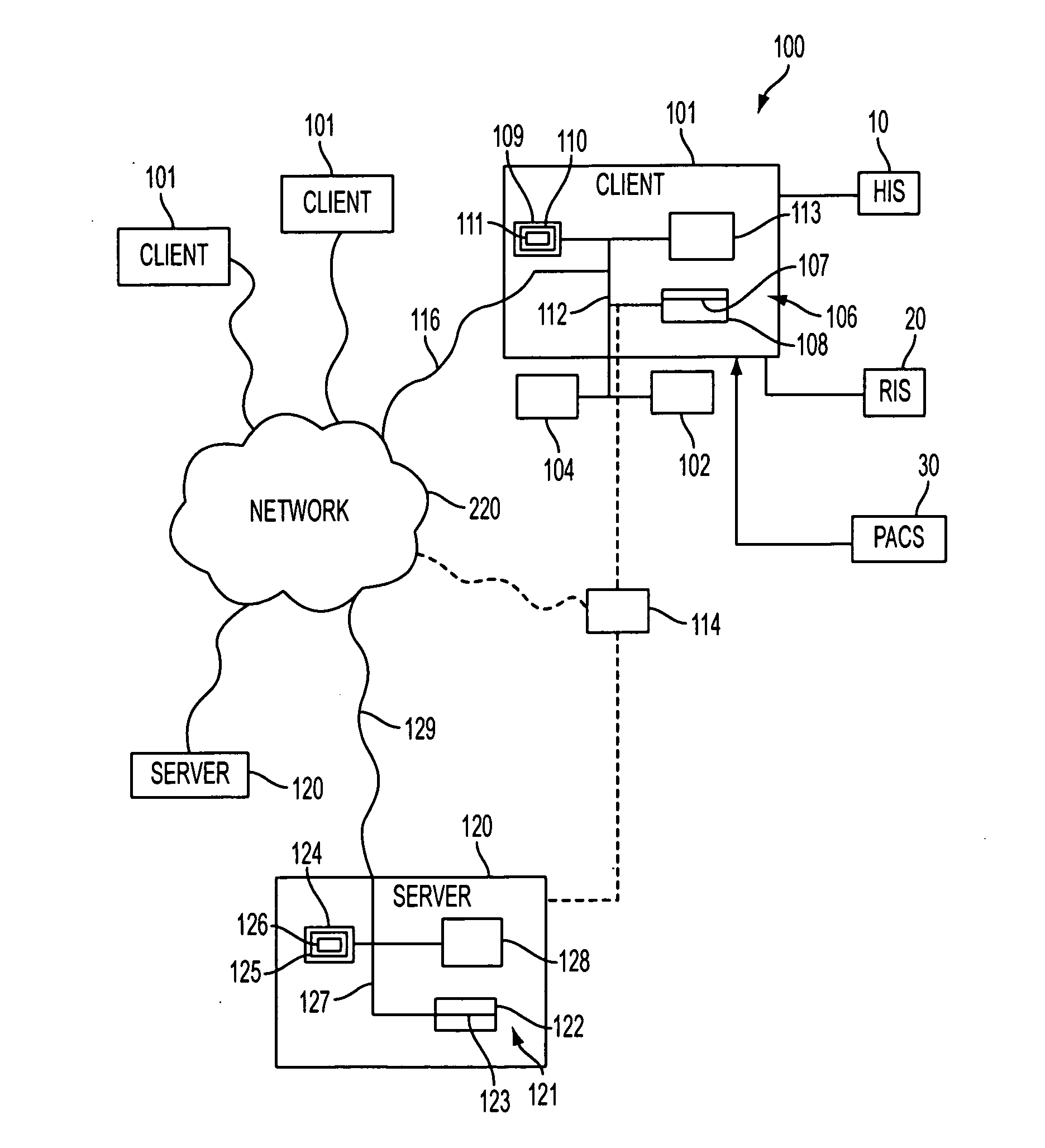

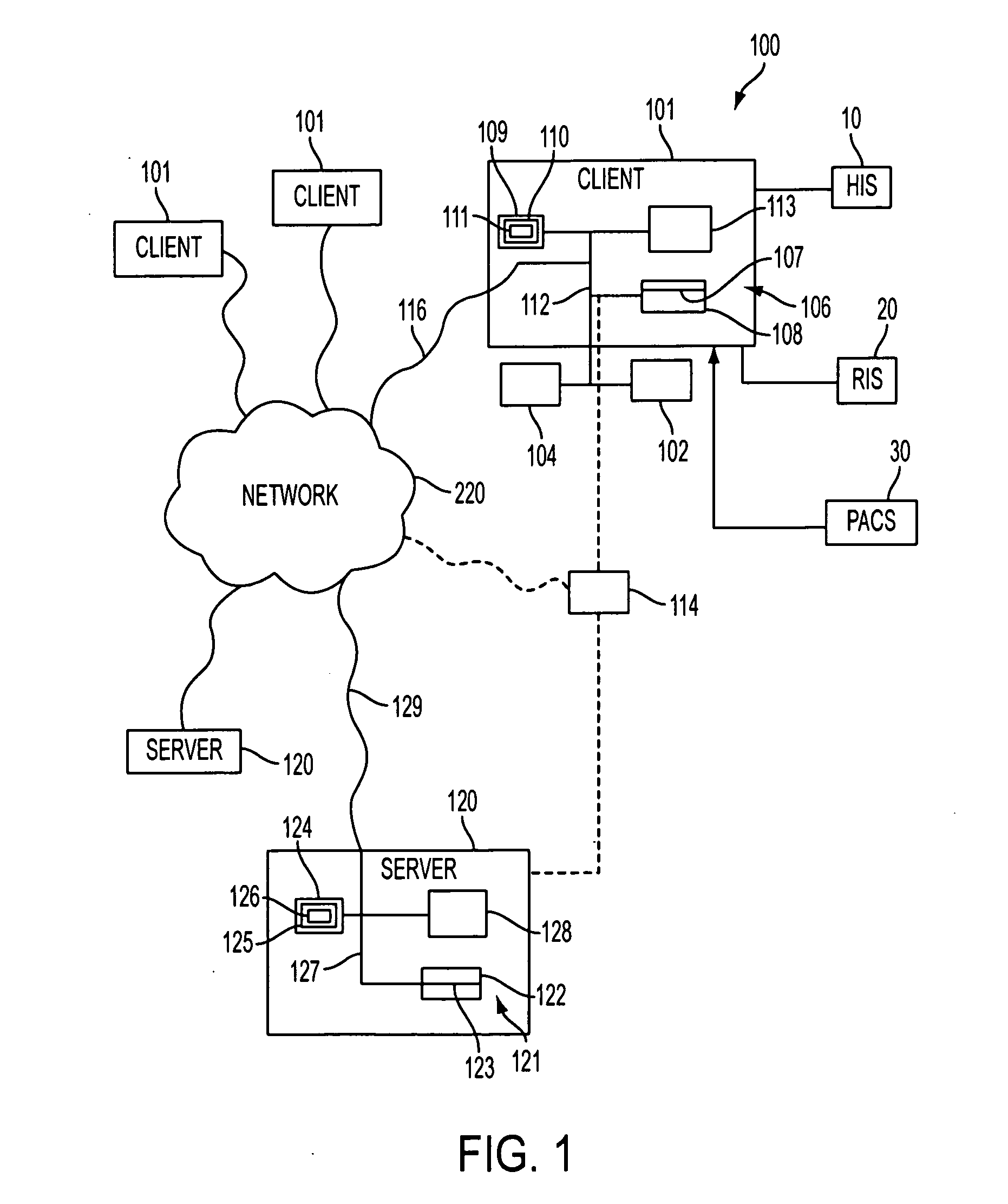

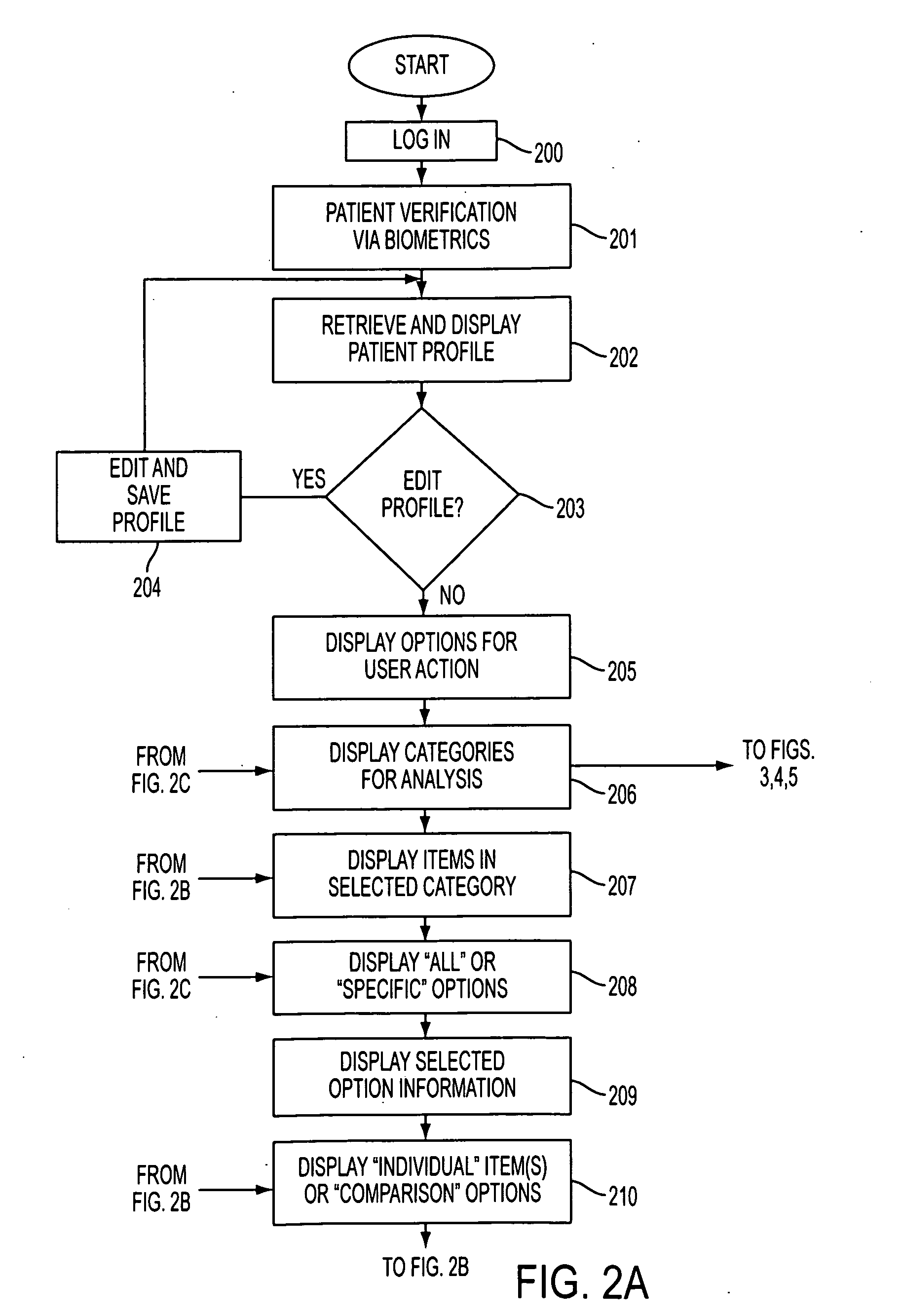

Method and apparatus for analyzing data on medical agents and devices

InactiveUS20120078648A1Enhanced medical educationInformed healthcareMedical data miningData processing applicationsClinical trialDecision taking

The present invention relates to an itemized analytical tool which creates a series of standardized and objective metrics related to each individual step in the overall process of pharmaceutical development and delivery. The individual steps can be divided into two main sections: pre and post regulatory approval. Pre-approval data analysis relates to the various steps involved in clinical trials, while post-approval analysis relates the multiple steps related to everyday use. The data analytics take into account the various contributions individual stakeholders and institutions play in determining overall safety and effectiveness of medical agents. The agent-specific data can in turn be cross referenced with individual patient and disease specific data, in order to provide customizable decision support.

Owner:REINER BRUCE

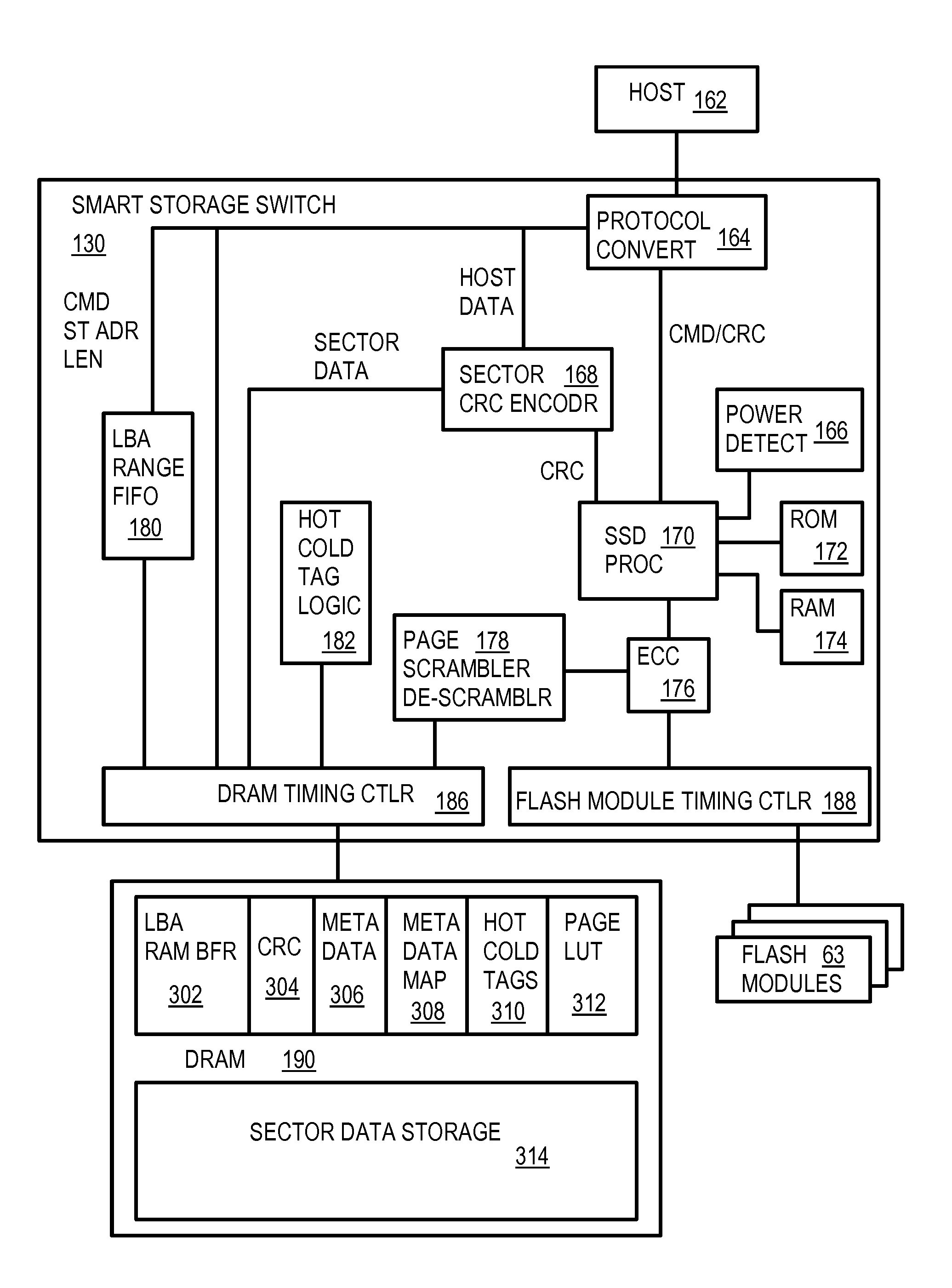

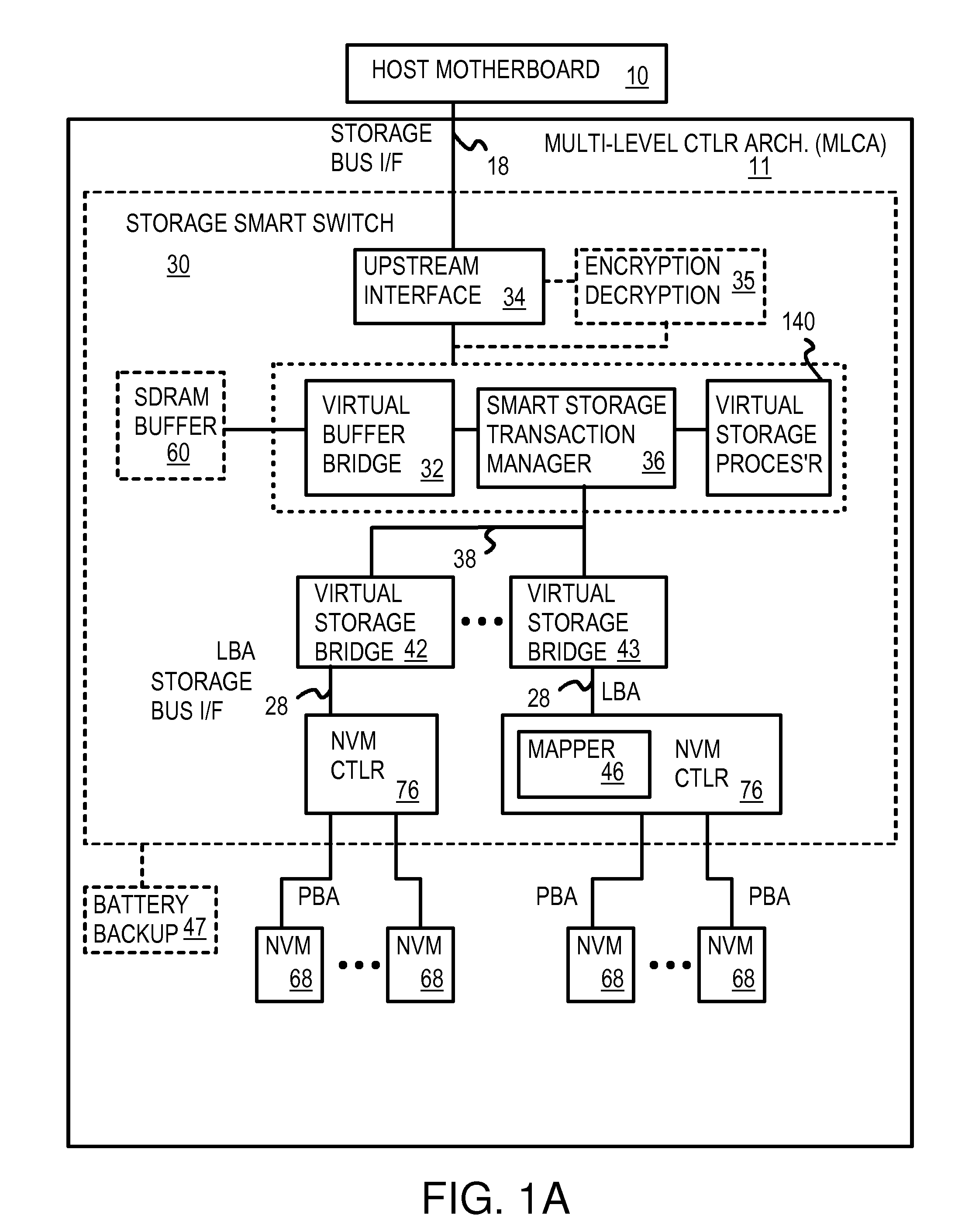

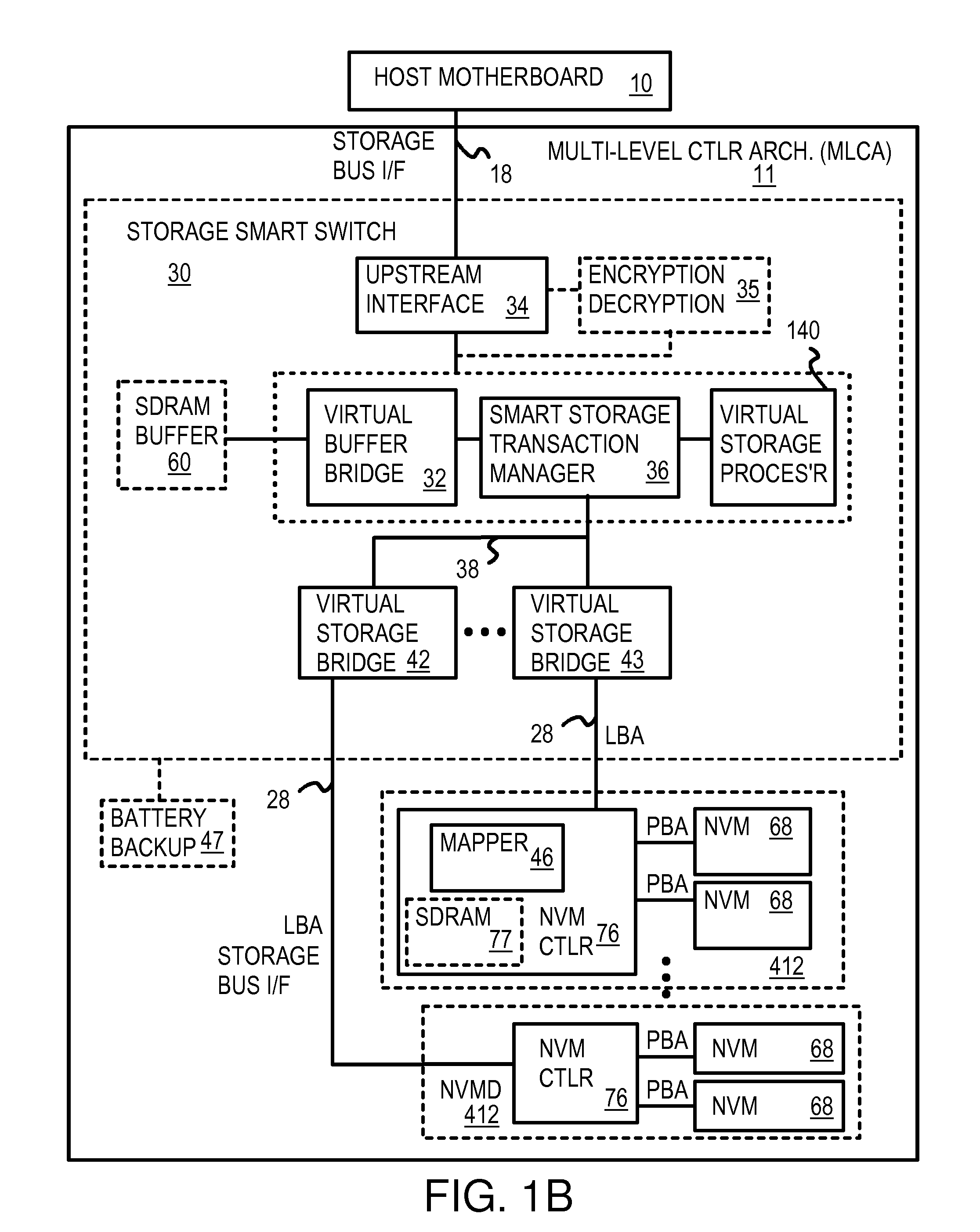

Flash-memory system with enhanced smart-storage switch and packed meta-data cache for mitigating write amplification by delaying and merging writes until a host read

InactiveUS8452912B2Memory architecture accessing/allocationRead-only memoriesWrite amplificationLogical block addressing

Owner:SUPER TALENT TECH CORP

Skin grafting devices and methods

Owner:3M INNOVATIVE PROPERTIES CO

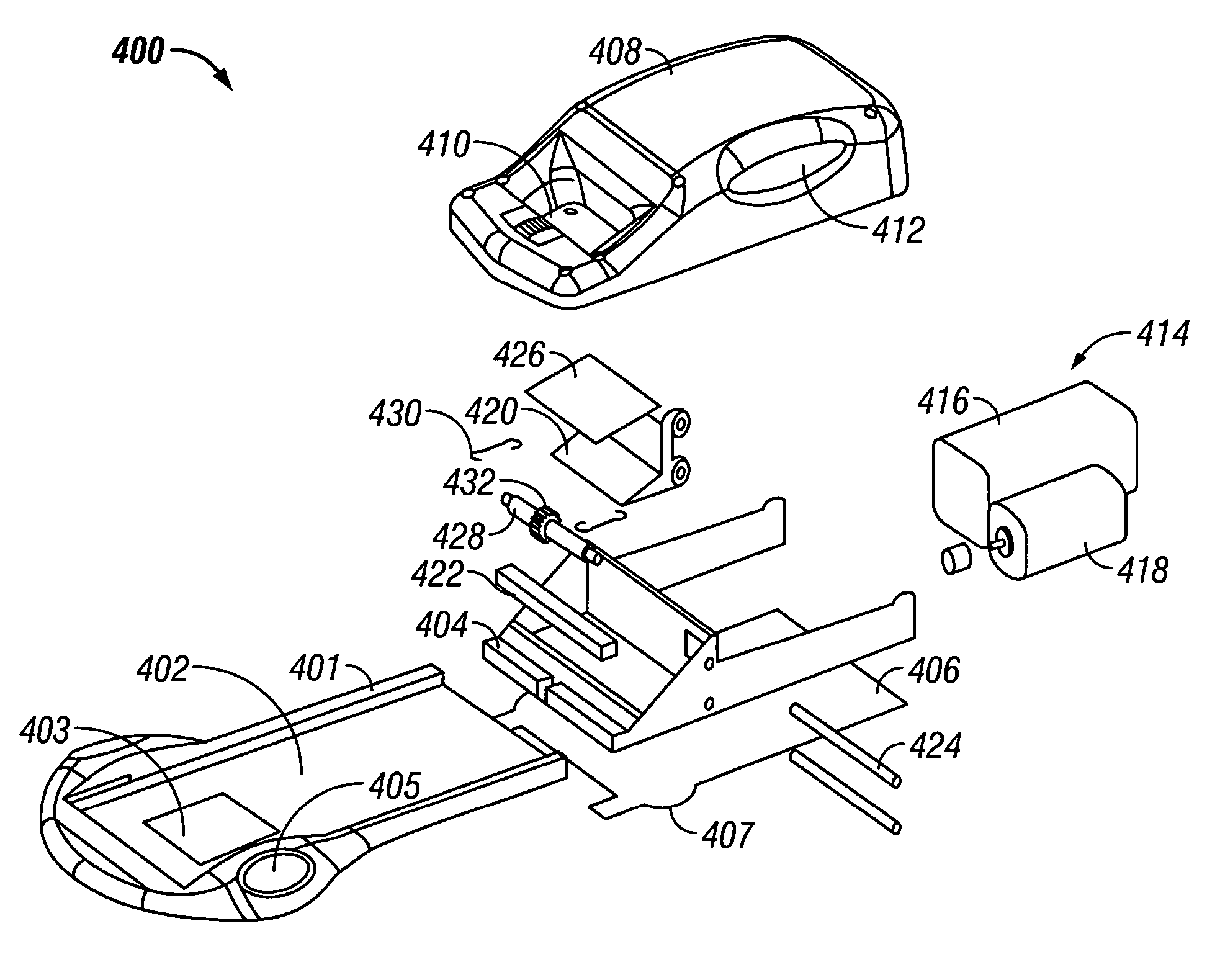

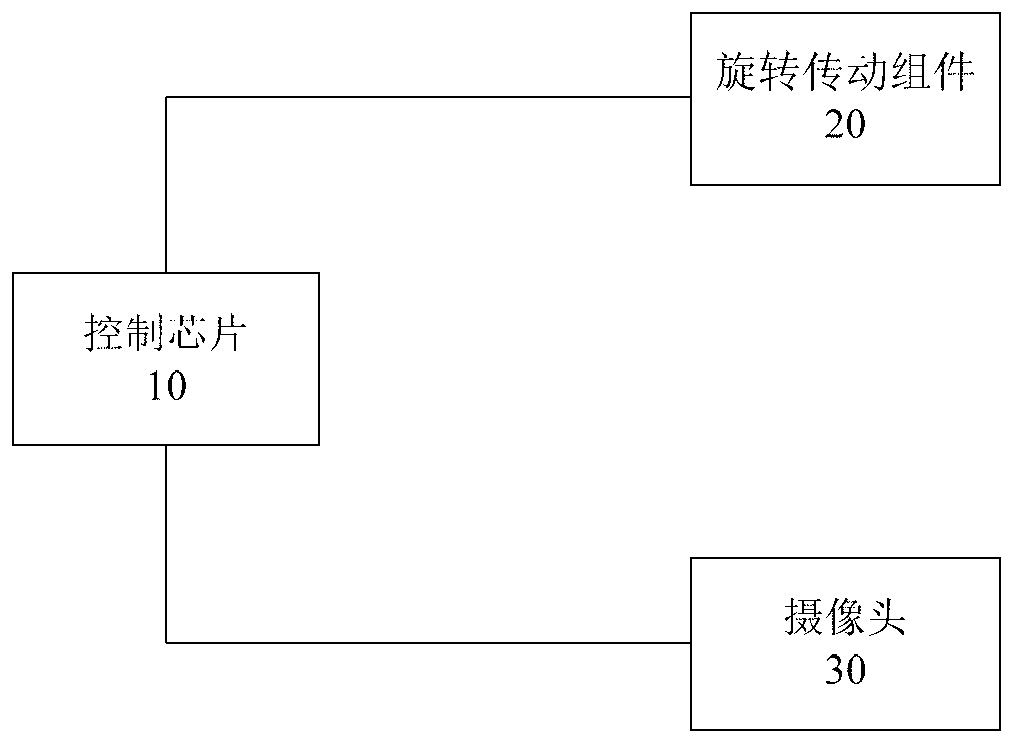

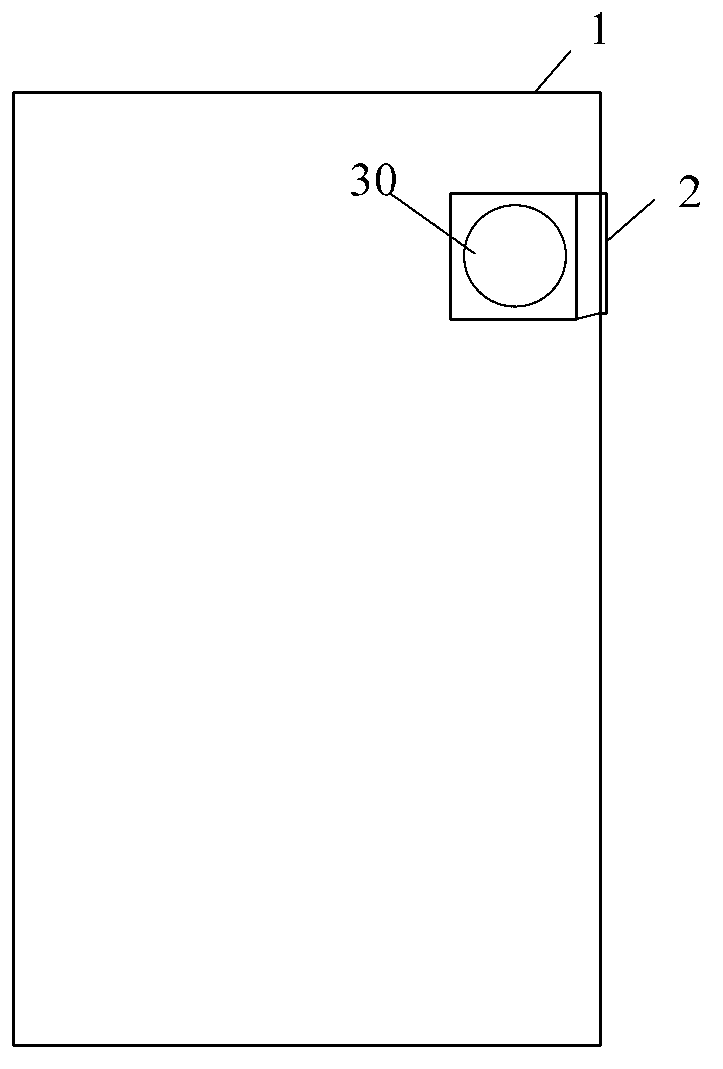

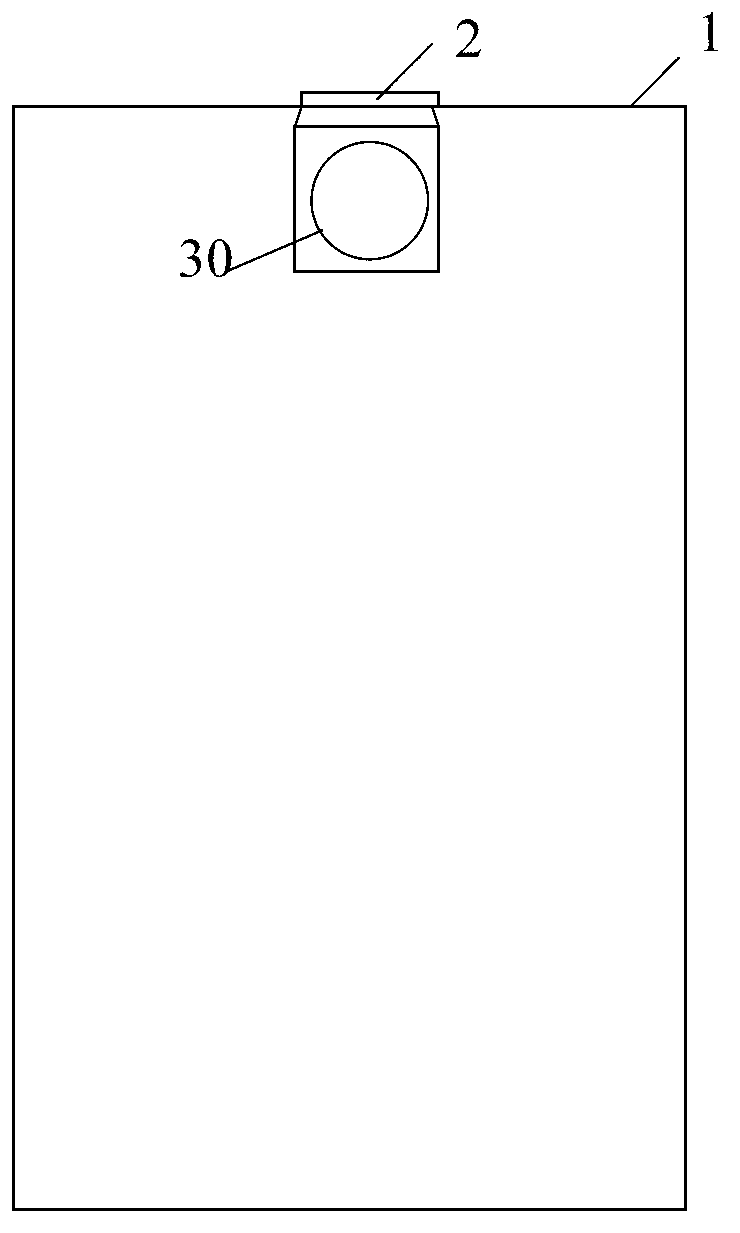

Intelligent terminal and camera rotating photographing method thereof

ActiveCN103024106AGuaranteed pixelsLow costTelevision system detailsColor television detailsEngineeringRotation control

The invention relates to an intelligent terminal and a camera rotating photographing method thereof. The intelligent terminal comprises a casing, a control chip and a camera, the intelligent terminal further comprises an rotation mechanism installed on the casing, the rotation mechanism particularly comprises a rotation shaft and a rotation transmission assembly, the camera is fixed on the rotation shaft, and the control chip is used for sending rotation control signals to the rotation transmission assembly to drive the camera to rotate preset angles and sending shooting signals to collect image signals of the camera. The rotation shaft is installed on the casing, the camera is fixed on the rotation shaft to control the camera to rotate to the preset angle to shoot, accordingly effects of dual cameras can be achieved by rotating a single camera for 180 degrees, cost is reduced, and simultaneously shooting pixels of the image in preposition and postposition state are guaranteed.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Plug-in pre- and postconditions for static program analysis

InactiveUS7526755B2Easy to checkError detection/correctionSpecific program execution arrangementsPostconditionObject code

A system and method employing pre- and / or post-condition(s) specified at a source code level and persisted (e.g., in associated object code and / or a specification repository) facilitating static checking of the object code is provided. The system and method are based, at least in part, upon a framework that employs rules for using an interface to be recorded as declarative specifications in an existing language.A specifier can give a method a plug-in pre- and postcondition, which is arbitrary code that examines an object's current state and a static approximation of the method's actuals, decides whether the call is legal and returns the object's state after the call.

Owner:MICROSOFT TECH LICENSING LLC

Real time technique for tracking weld joints of gas metal arc welding by magnetic controlled electric arc sensor

InactiveCN101327545AImprove real-time performanceGood tracking effectArc welding apparatusWelding power supplyPre and post

The invention discloses a real-time follow-up technique of a magnetic controlling arc sensing welding line of gas metal arc welding, which belongs to a welding control technique. The invention mainly solves the problems of complex structure, high cost, unstable performance and poor real-time performance, etc, of the prior gas metal arc welding line follow-up system. The invention adopts the technical proposal that the real-time follow-up technique comprises a magnetic controlling voltaic arc sensor, a welding system composed of a welding torch, a welding electric source and so on, a control system, a follow-up actuating mechanism composed of a set of cross sliding guides, a wheel robots and so on; wherein, the magnetic controlling voltaic arc sensor is directly installed on the welding torch, which is used for gas metal-arc welding process, to collect the horizontal and the vertical deviation signals of the welding line; the processed signals are input in a microcomputer for processing by software; the real-time control follow-up actuating mechanism is capable of automatically following up the welding line. The technique achieves automatic following up of the welding line in gas metal arc welding. The magnetic controlling arc sensor is installed on the welding torch used for gas metal-arc welding process, which eliminates the problems of preposing and postposing, and has the characteristics of good real-time performance, low cost, high stable performance and high precision.

Owner:XIANGTAN UNIV

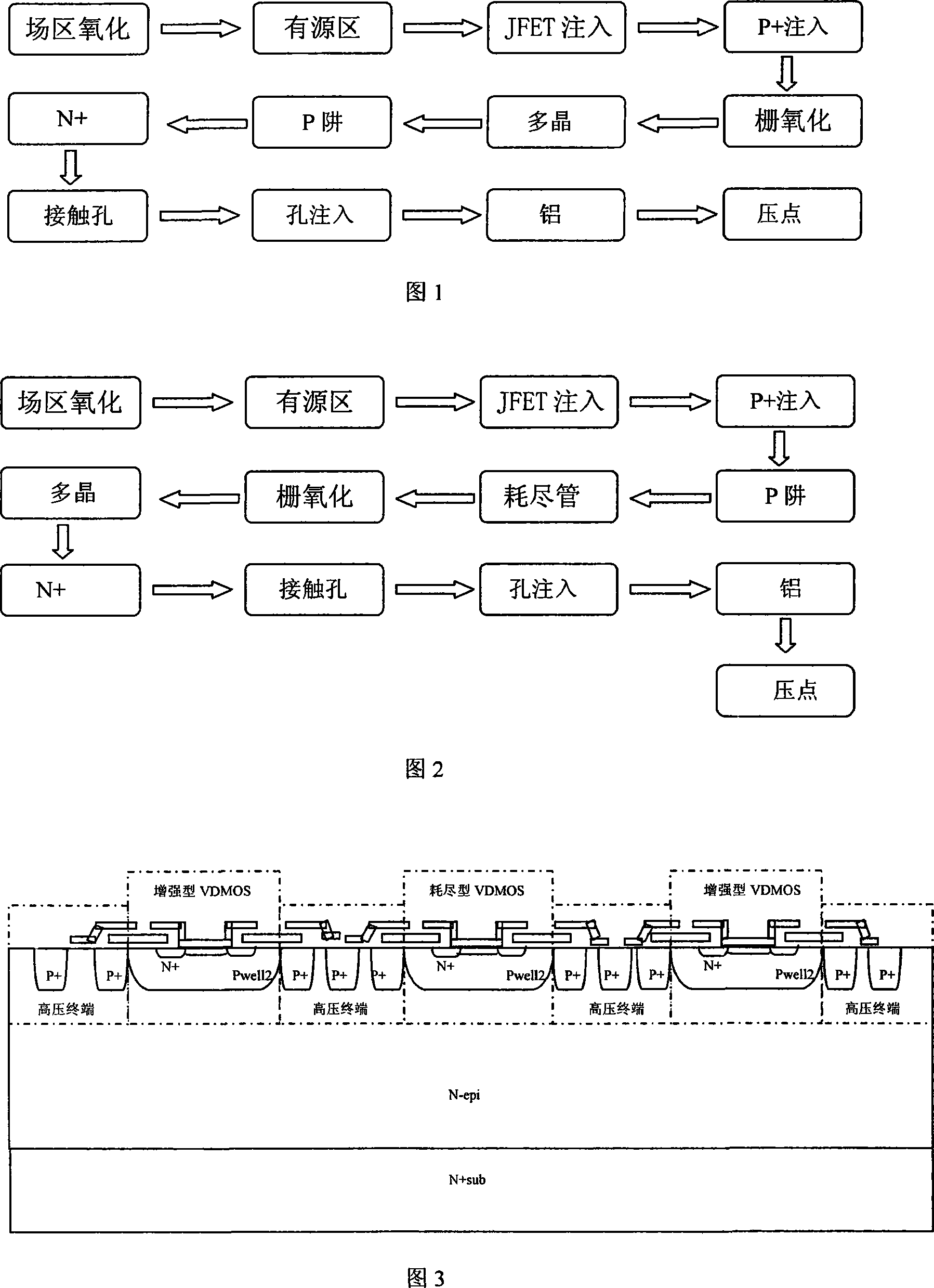

Single chip integration making technology for enhanced and consumption-up vertical dual diffusion field effect pipe

ActiveCN101127327AImprove compatibilityIncreased photolithographic injectionSemiconductor/solid-state device manufacturingBiochemical engineeringVoltage regulation

The utility model relates to a monolithic fabrication technology for the enhanced and depletion VDMOS, belonging to a technology applying for fabricating a enhanced and a depletion VDMOS with a high voltage (650V) common drain in one IC, which is characterized in that the material of the VDMOS adopting a N(100) substrate doped arsenic, which has a resistivity below 0.005 Omega-CM, the thickness of the epitaxy is 55Mum, the resistivity of the epitaxy is 24 Omega-CM. The withstand voltage can be stable on 650V, and up to 700V. To add a depletion VDMOS on the surface of the enhanced VDMOS, the depletion area needs a individual switching voltage adjustment, which is adding once more VT impurity, while adjusting the pre-and post process. The utility model has the advantages of fewer photoetching, low cost and simple fabricating control.

Owner:WUXI CRYSTAL SOURCE MICROELECTRONICS CO LTD

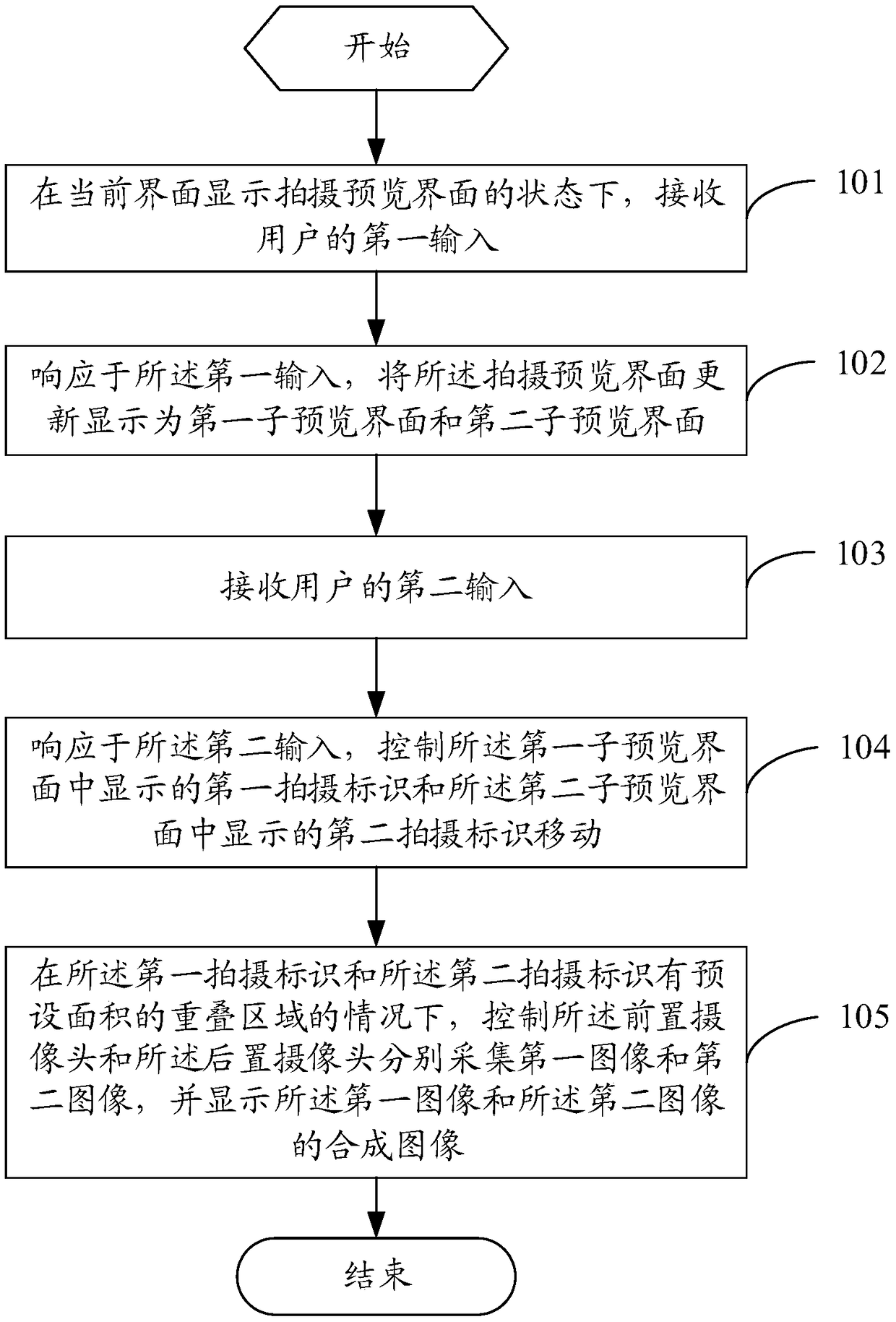

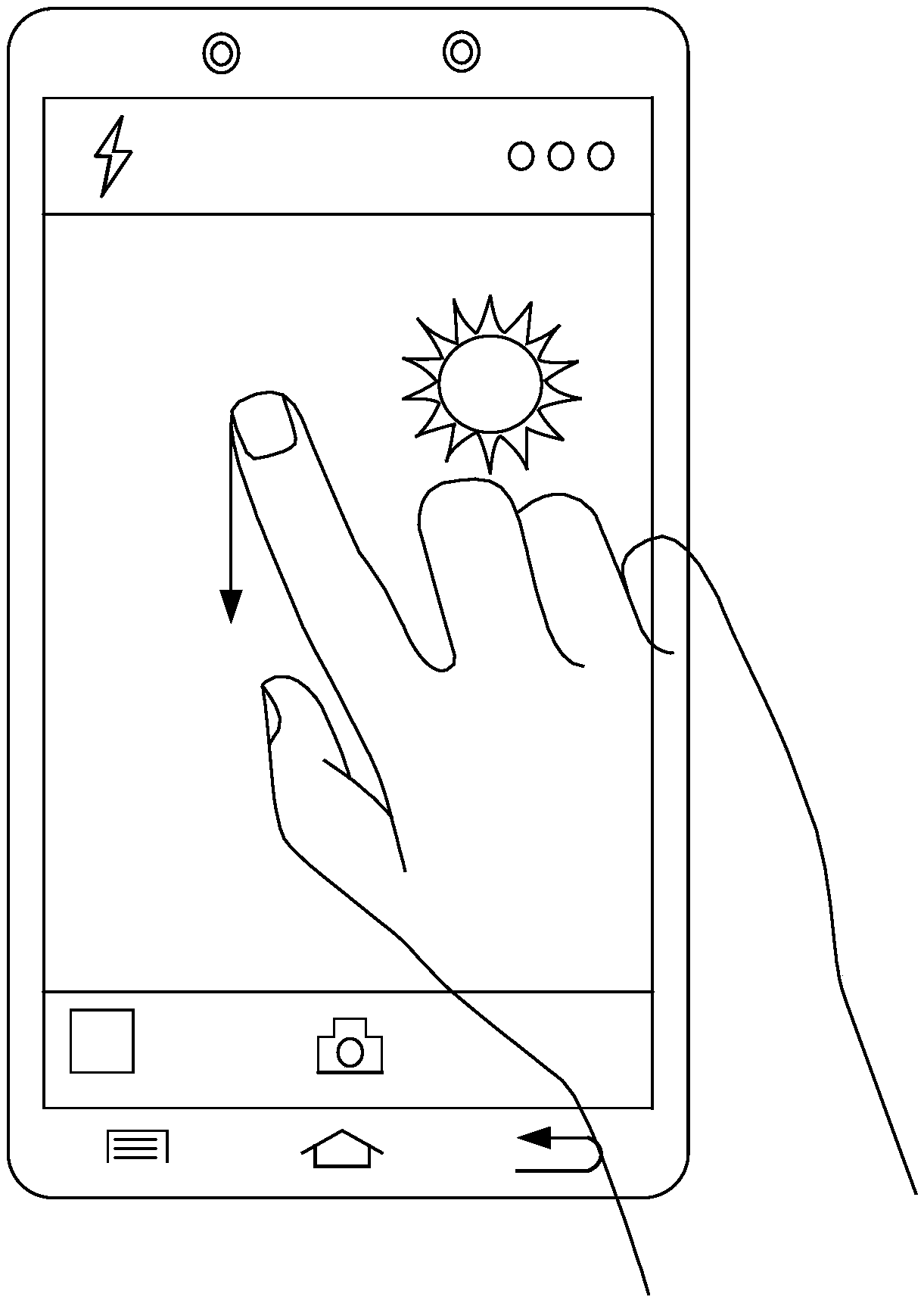

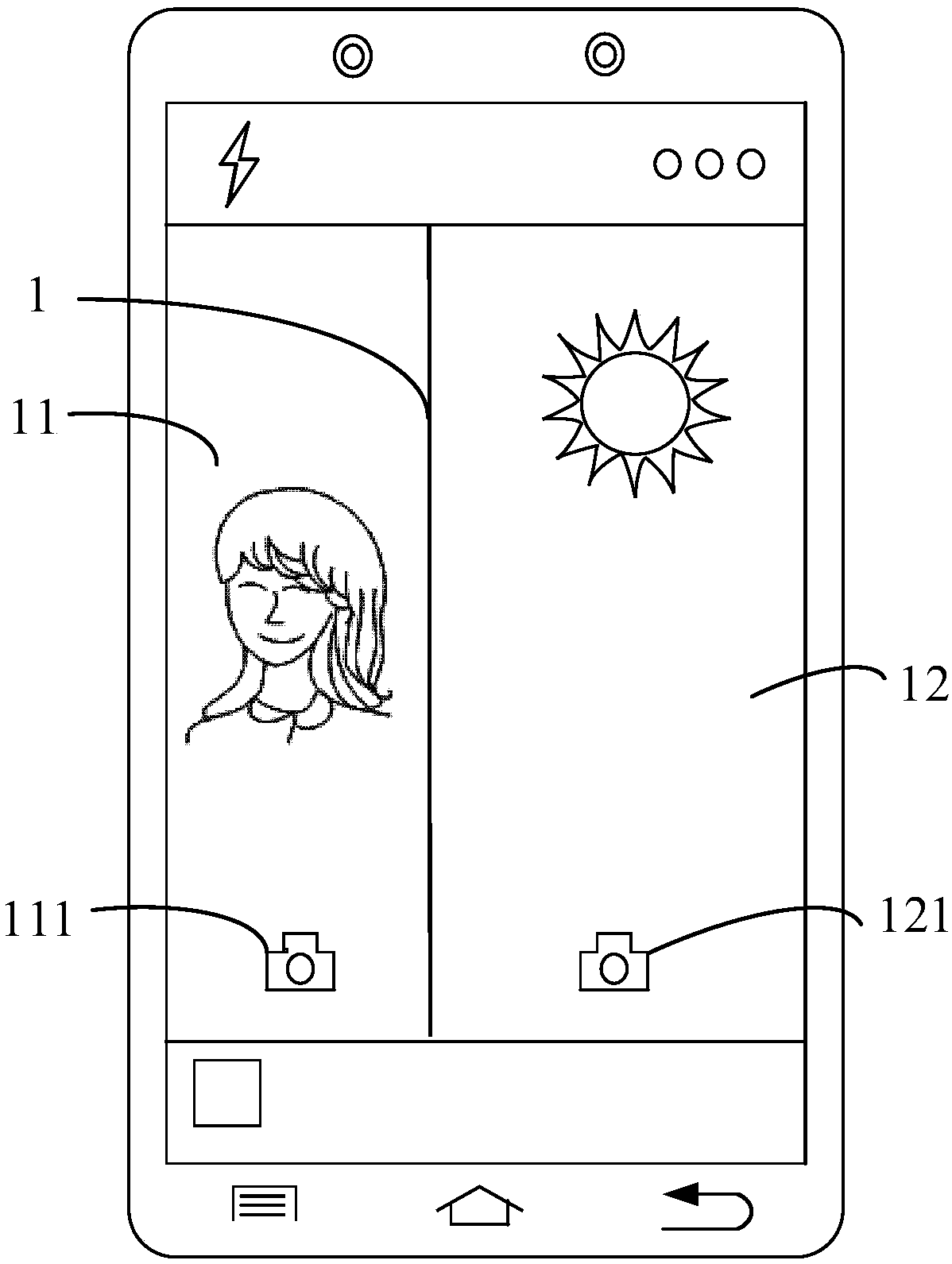

Photographing method and mobile terminal

ActiveCN108234891AEasy to operateTelevision system detailsColor television detailsComputer terminalPre and post

The invention relates to the technical field of communication, and provides a photographing method and a mobile terminal. By the aid of the photographing method and the mobile terminal, the problem oftedious operation in synthesized image generation procedures can be solved. The photographing method includes receiving first input of users under the condition of a state that shooting preview interfaces are displayed on current interfaces; updating the shooting preview interfaces to display first child preview interfaces and second child preview interfaces in response to the first input; receiving second input of the users; allowing first shooting identification displayed in the first child preview interfaces and second shooting identification displayed in the second child preview interfaces to move under the control in response to the second input; acquiring first images and second images by the aid of a front camera and a rear camera under the control under the condition that the first shooting identification and the second shooting identification are overlapped, and displaying synthesized images of the first images and the second images. The photographing method and mobile terminal have the advantages that every two corresponding images shot by the aid of the front camera and the rear camera can be synthesized to obtain the single corresponding image by the mobile terminal when the first shooting identification and the second shooting identification have overlapped regions, and synthesized image generation procedures are easy to operate.

Owner:VIVO MOBILE COMM CO LTD

Method for rapidly replacing tundish in molten steel continuous casting process

The invention discloses a method for rapidly replacing a tundish in the molten steel continuous casting process. After pouring stopping of a crystallizer, heating type protection slag is rapidly laid and scattered on the molten steel liquid level in the crystallizer, the aluminum component is rapidly oxidized, a proper amount of heat is released, heating and heat preservation are conducted on molten steel in the crystallizer, crusting and excessively fast blank shell shrinkage due to temperature reduction of the molten steel liquid level are effectively prevented, an immersed water gap in a new tundish can be smoothly inserted in the molten steel in the crystallizer, and the rapid replacing success rate of the tundish is increased. By means of the method, rapid tundish replacing can be conducted when the molten steel liquid level in the crystallizer is high, the molten steel liquid level in the crystallizer is not obviously changed all the time in the whole tundish replacing process, the situation that when the tundish is replaced at the low liquid level, the huge rising and falling changes happen to the molten steel liquid level in the crystallizer is avoided, and the continuous casting stability and pre-and-post consistency of the cast blank quality before temporary pouring stopping and after pouring starting is conducted again are guaranteed.

Owner:SHANDONG IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com