Patents

Literature

408 results about "Water gap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A water gap is a gap that flowing water has carved through a mountain range or mountain ridge and that still carries water today. Such gaps that no longer carry water currents are called wind gaps. Water gaps and wind gaps often offer a practical route for road and rail transport to cross the mountain barrier.

Water gap lining layer material for continuous casting

The invention discloses a water gap lining layer material for continuous casting. The material is prepared from the following components in percent by weight: 20-60 percent of corundum, 0-30 percent of electrofusion zirconium mullite, 0-40 percent of fused silica, 3-40 percent of ceramic hollow sphere, 1-10 percent of light burning alumina, 2-6 percent of sintering assistant, 2-6 percent of phosphate bonding agent and 4-8 percent of solid phenolic resin bonding agent. A water gap for continuous casting produced by adopting the material is suitable for cold casting, and a lining basically has no nodule blocking phenomenon; the lining has high strength and does not have phenomena of chambering and abnormal erosion; a water gap has long service life; and the continuous casting production efficiency is improved.

Owner:SHANGHAI BAOMING REFRACTORIES CO LTD

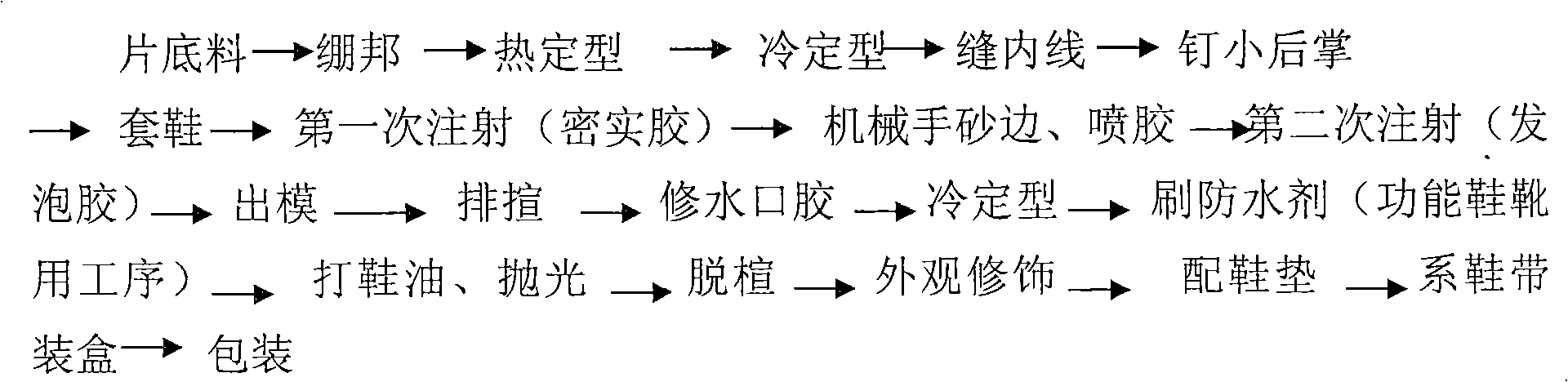

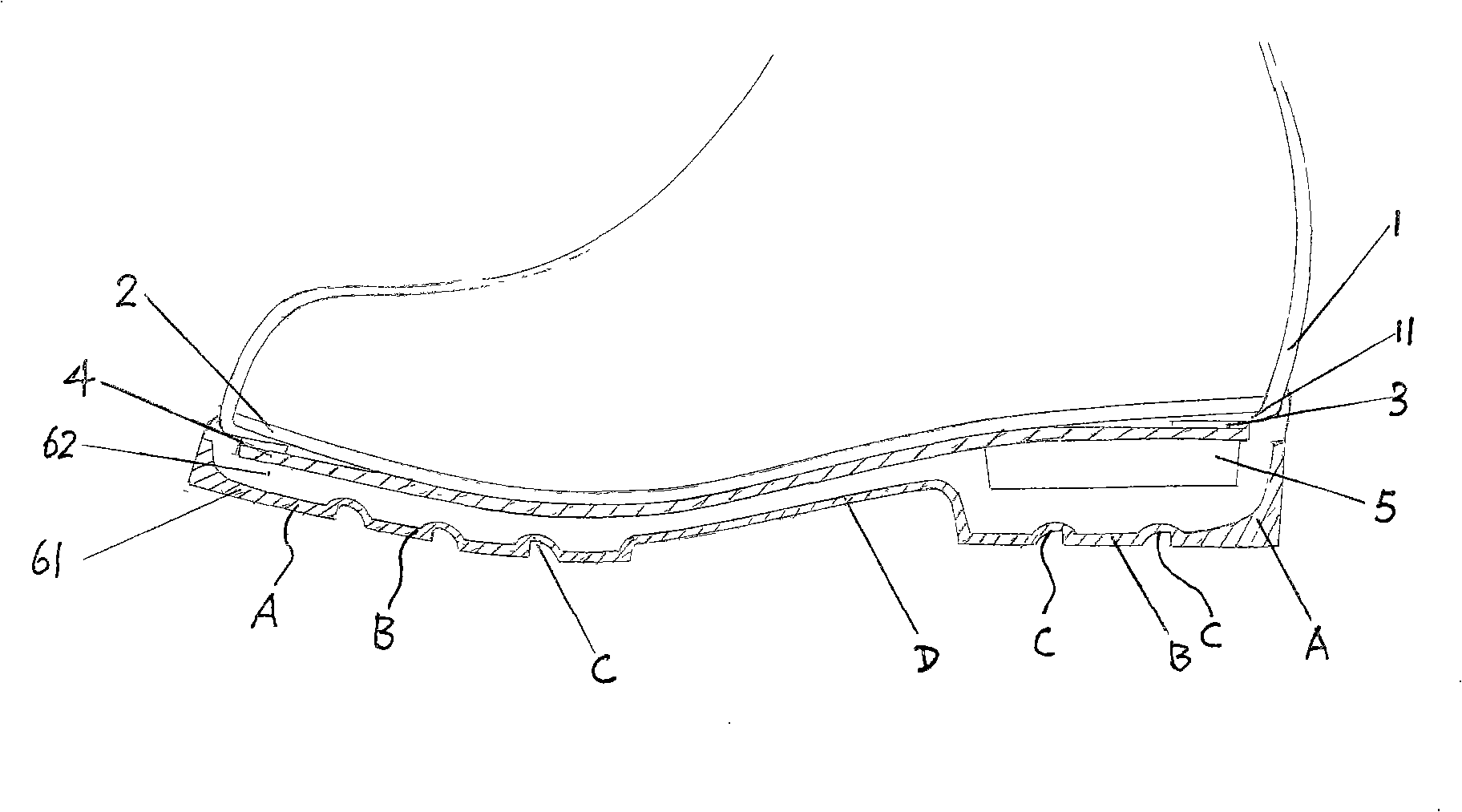

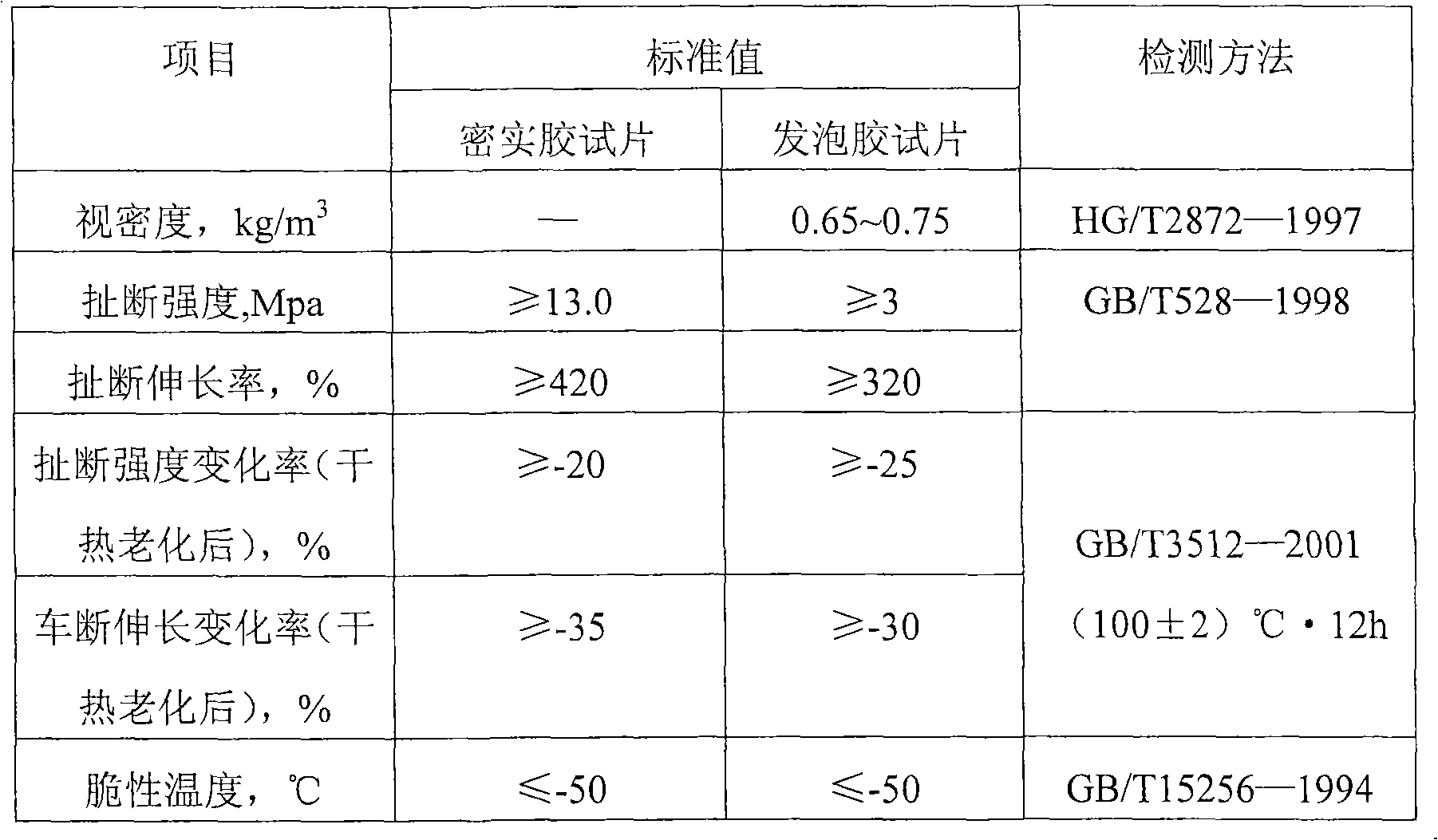

Duprene rubber double-density injection shoemaking method and functional shoes

The invention relates to a method for shoemaking by neoprene double-density injection. The method comprises the steps as follows: 1) after an upper, an inner sole and a middle sole are fixed in sequence, a small rear palm is nailed at the position of the heel of the middle sole to form a semifinished product of shoes; 2) dense glue is injected to a sole-centered die cavity for the first time, after a second last and a sole die are matched to be heated and pressed, the second last is removed to form a solid glue layer; then foaming adhesive is injected for the second time, an aluminium foot sheathed with the semifinished product of the shoe is put into the die cavity for matching moulds, heating and pressing, and a shoe blank is formed after mold stripping; 3) the shoe blank is processed for cold forming after being built with water gap glue, and the shoe is processed for subsequent treatment to obtain a finished product. A big sole of the invention comprises the solid glue layer and a foaming layer, thereby satisfying the wearing resistance and the strength requirement and also greatly reducing the weight of the sole simultaneously; the design of the grain of the big sole ensures that the thicknesses of the solid glue layer at different positions are changed to completely cater to the strength distribution characteristic when people walk; the heel of the shoe is added with the small rear palm, so the hardness at the heel is adjusted effectively. The finished product of the shoe manufactured by the invention has good forming performance and is substantial, firm, light and comfortable, and the method is suitable for manufacturing functional shoes.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

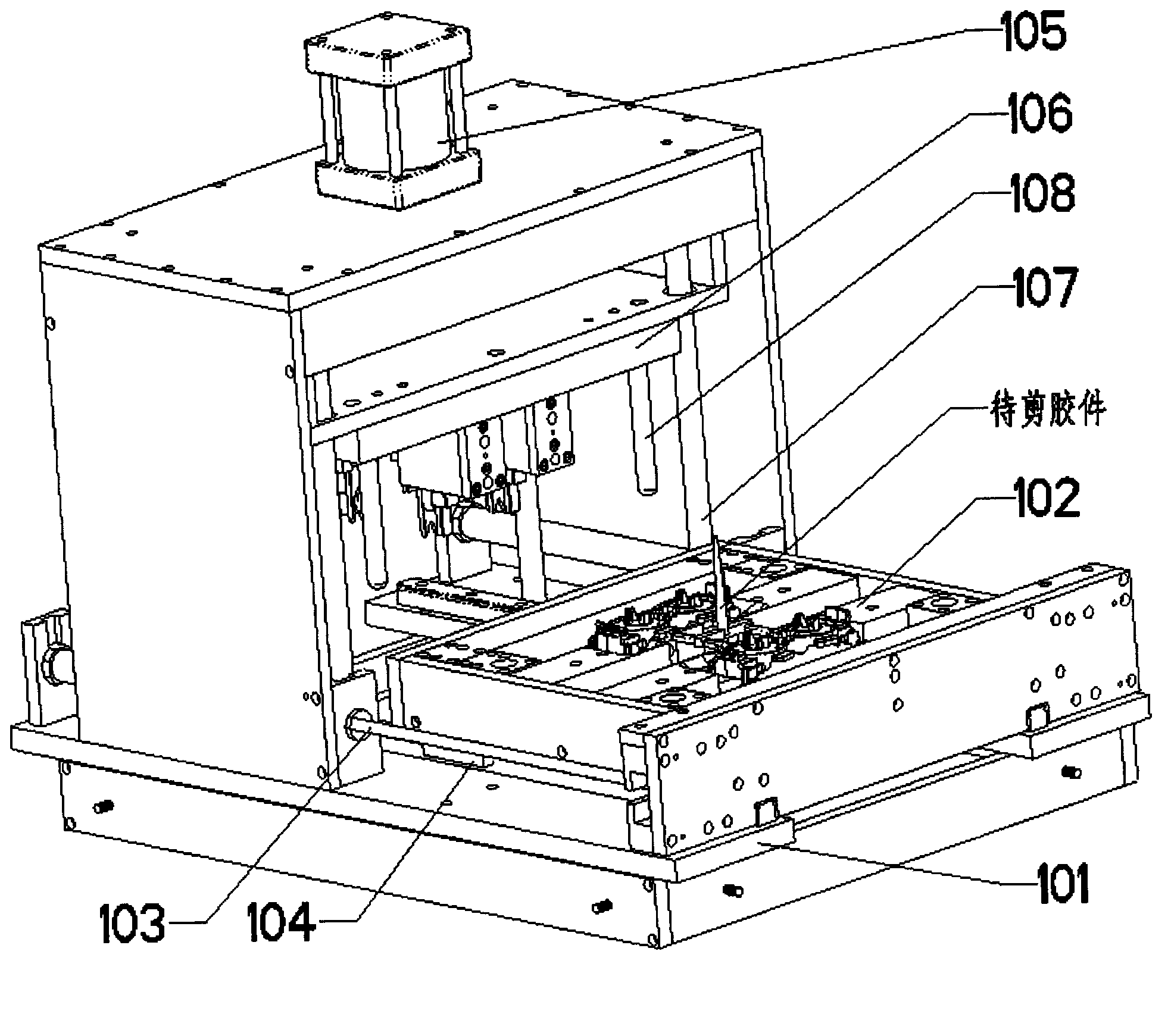

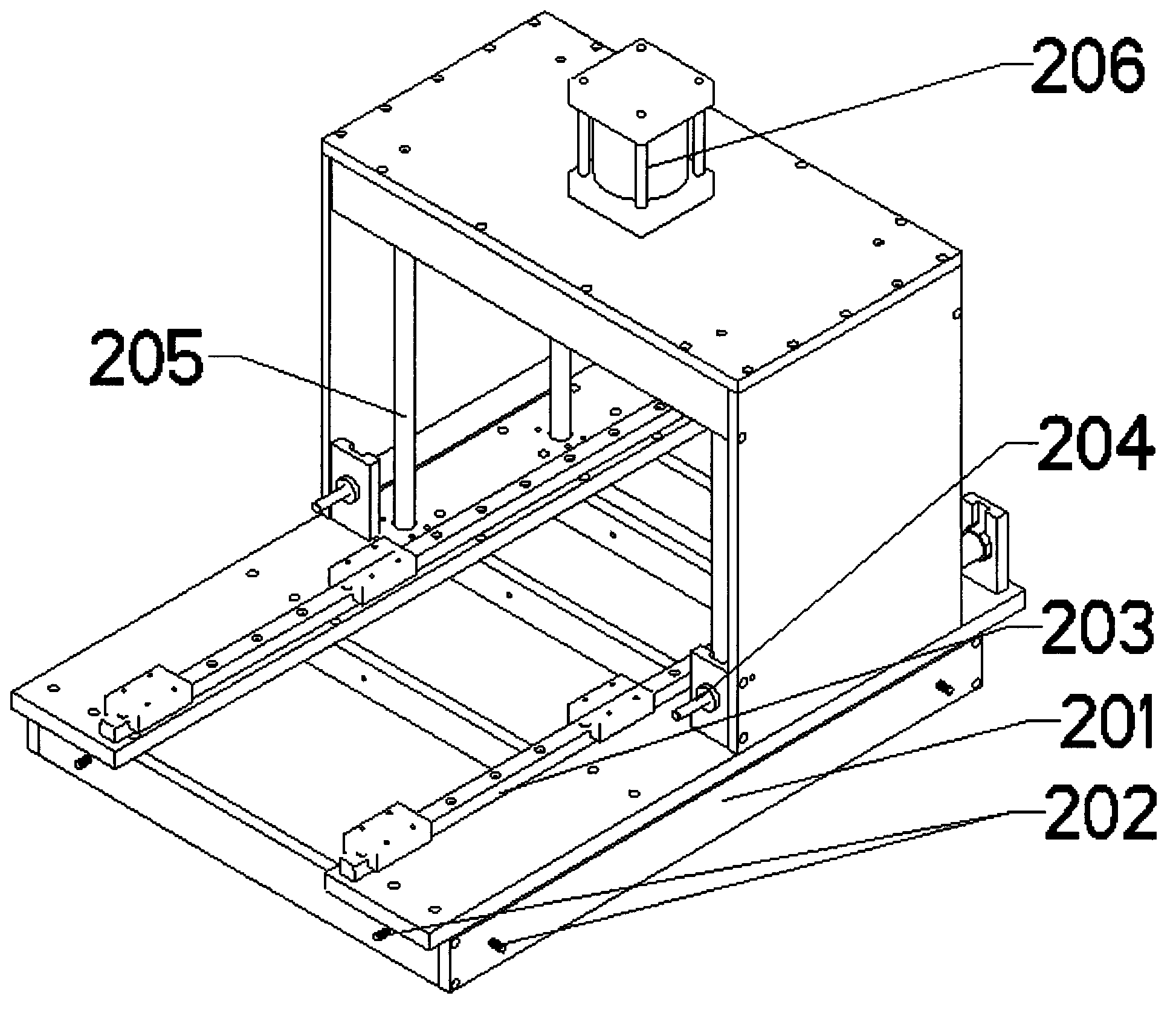

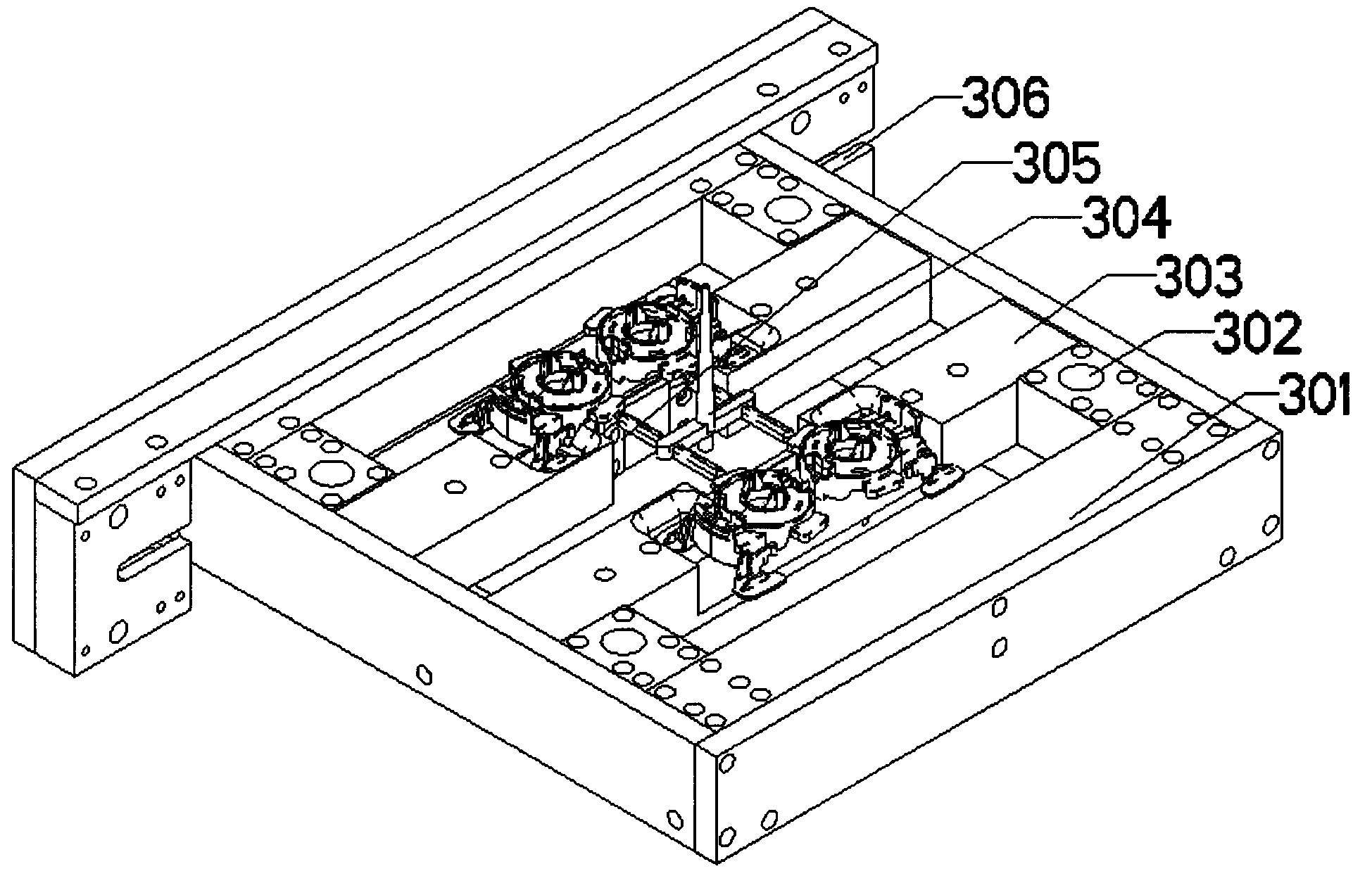

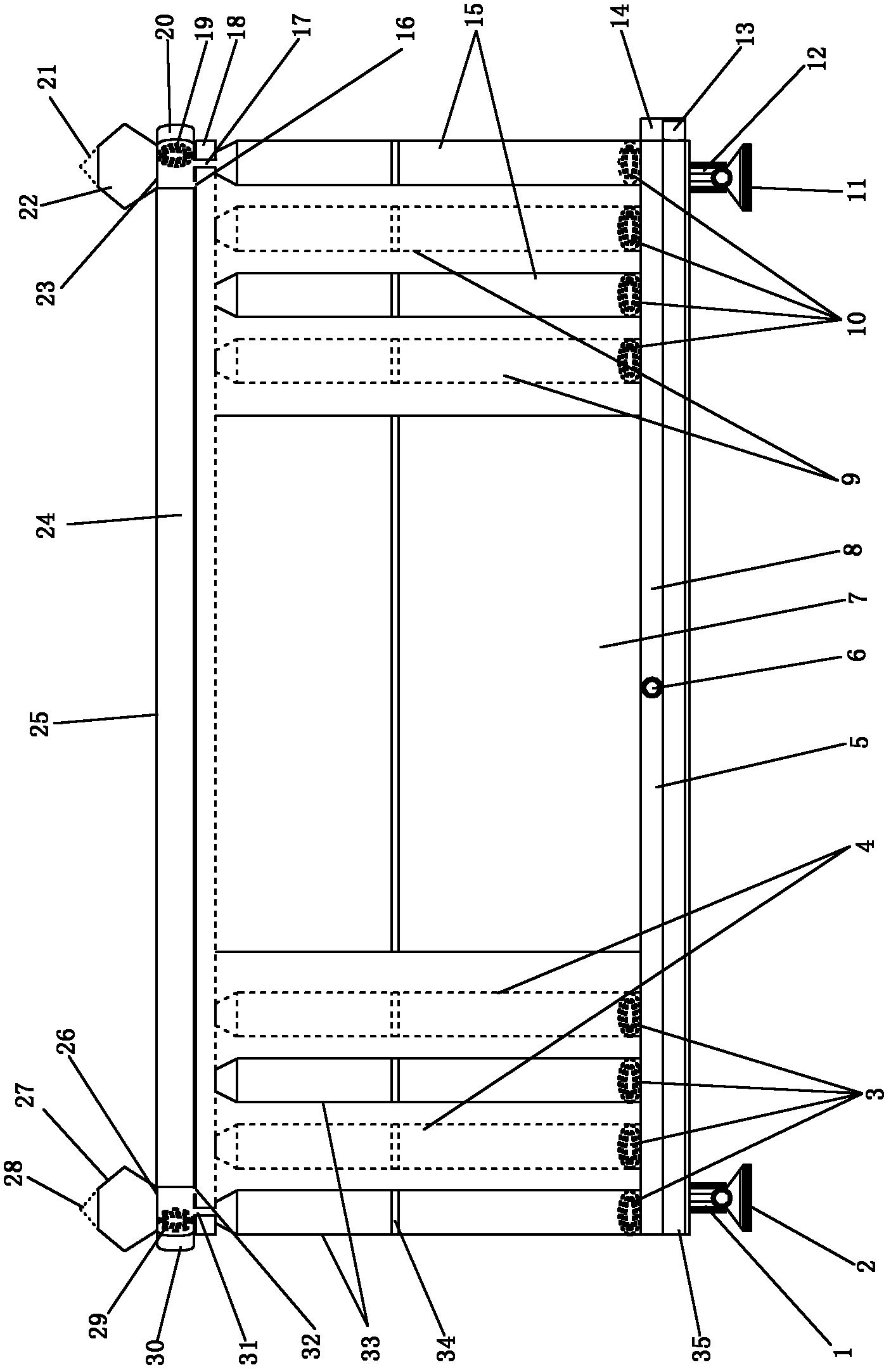

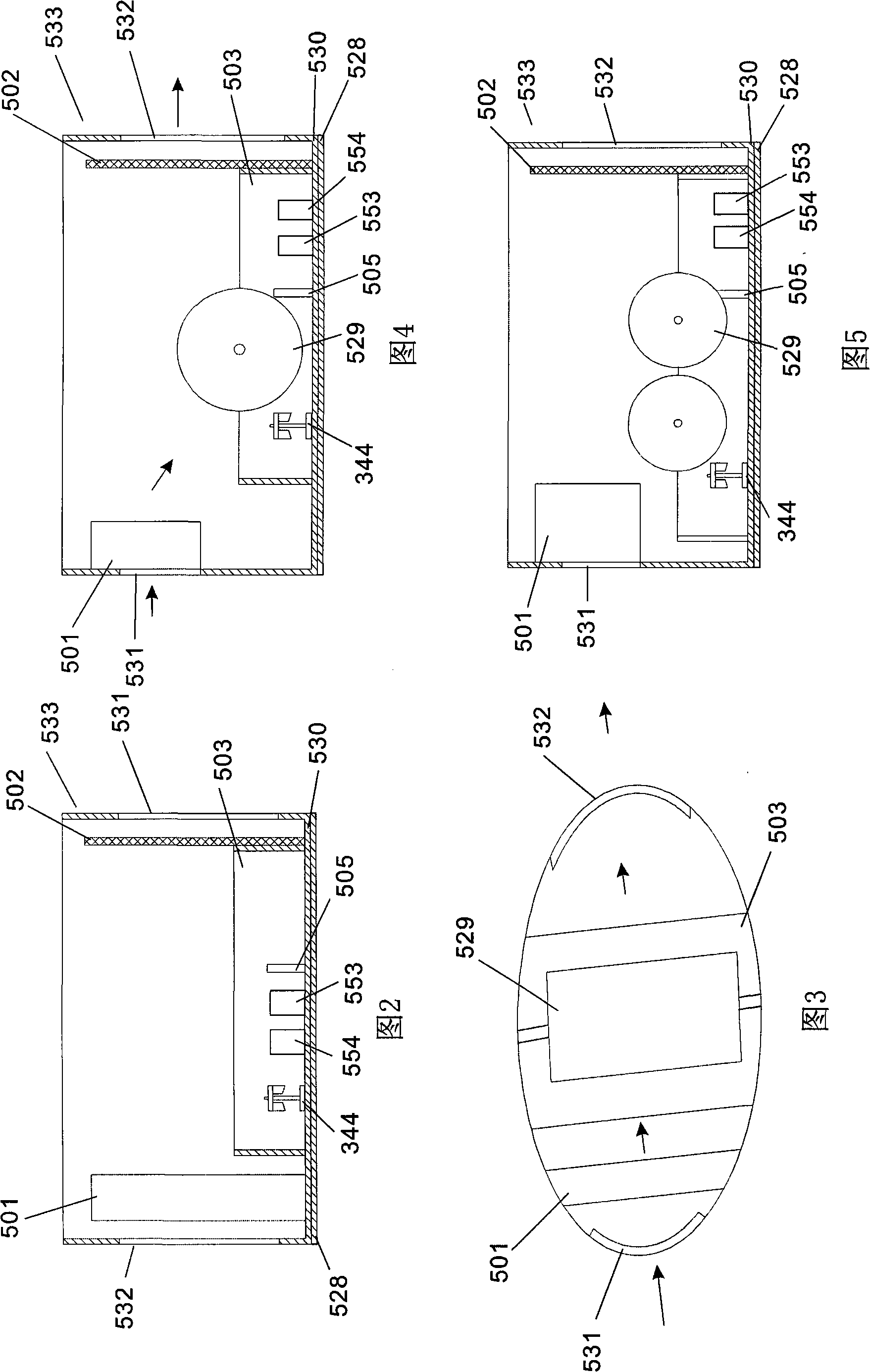

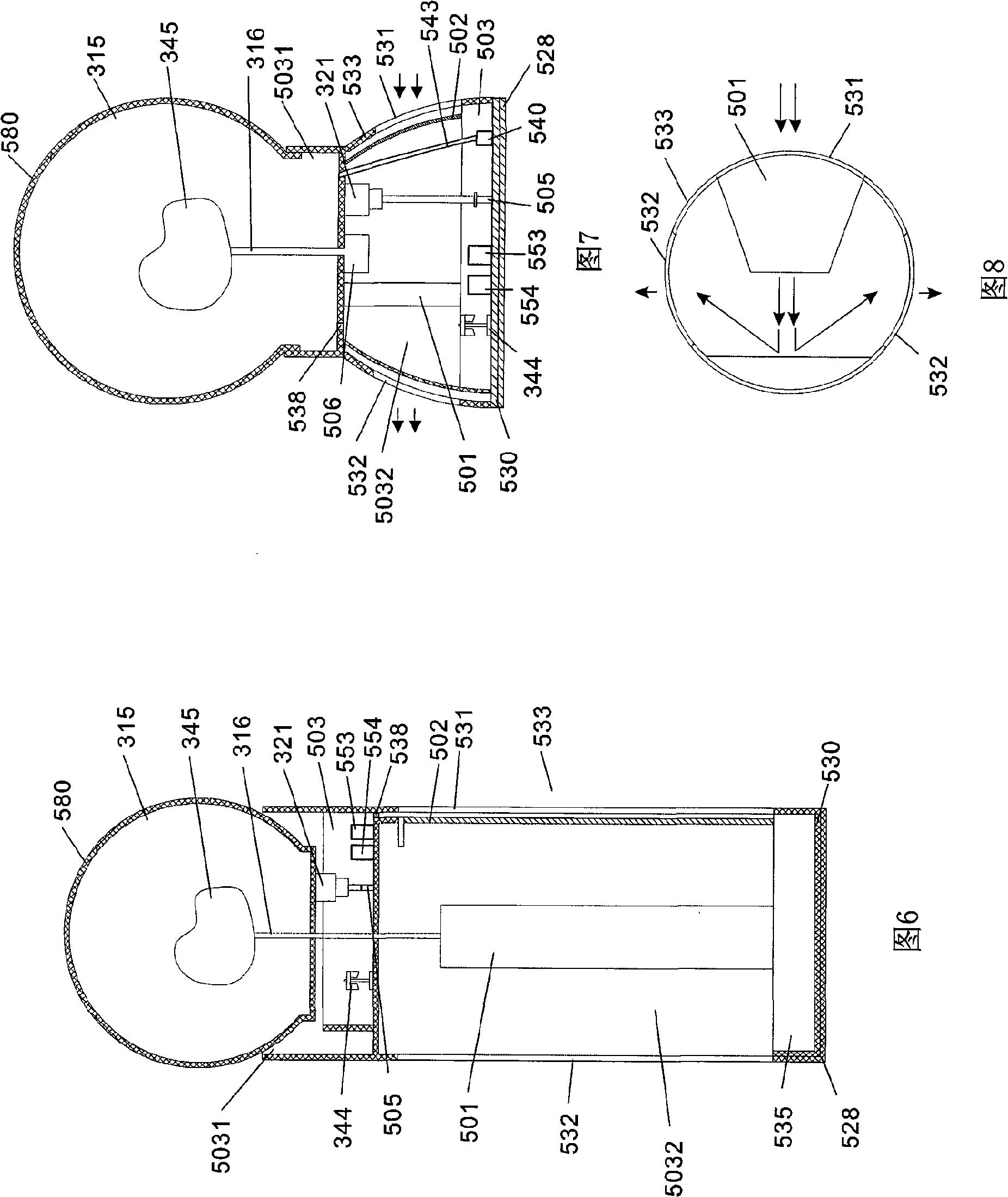

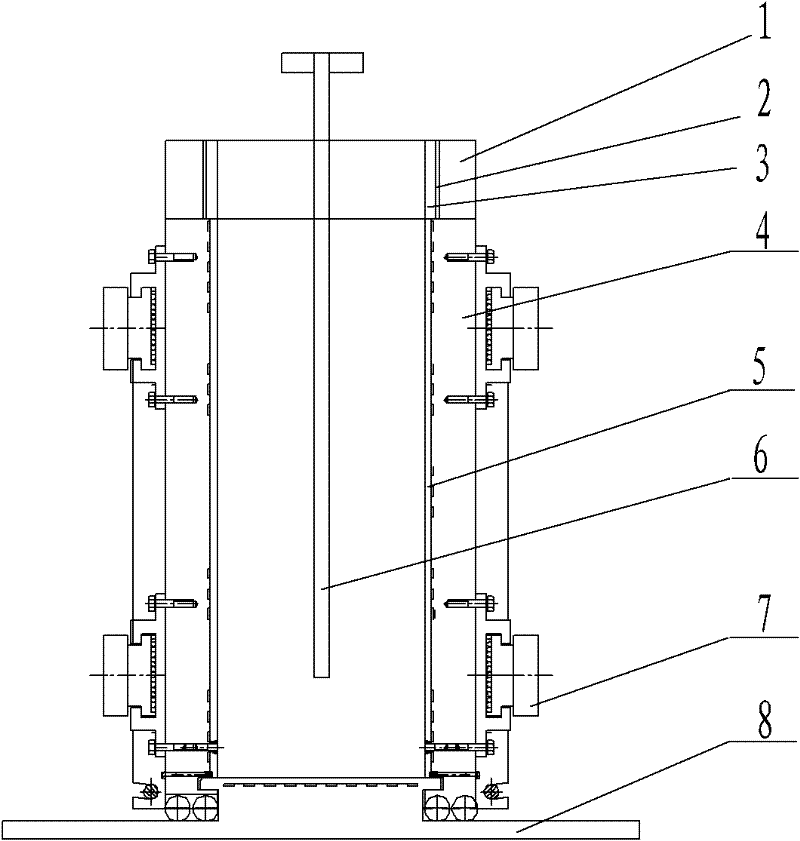

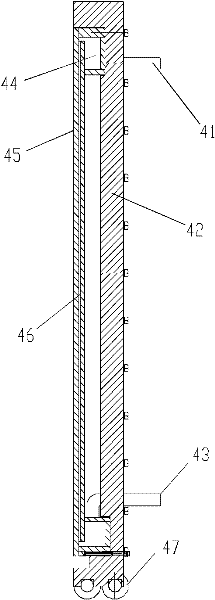

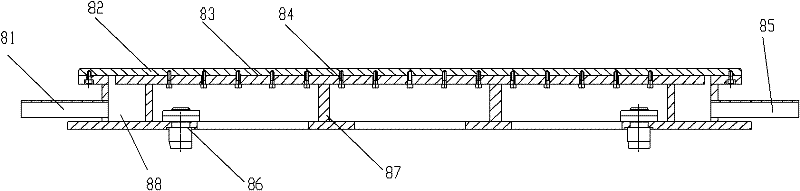

Water gap shearing equipment

The invention provides water gap shearing equipment, comprising a main body machine case and a main body frame, wherein the main body frame comprises an upper platform and a lower platform; a linear lead rail and a horizontal propelling cylinder are arranged on the lower platform; a plastic product positioning device is arranged on the linear lead rail; the horizontal propelling cylinder is used for propelling the plastic product positioning device; a main cutting cylinder and an upper knife rest connected with the main cutting cylinder are arranged on the upper platform; at least two guide shafts for shearing and positioning and a guide post for guiding the upper knife rest to move up and down are arranged on the upper knife rest; the main body frame is provided with an adjusting screw for adjusting change of a front position between the main body machine case and the main body frame; at least one plastic product positioning die is arranged on the plastic product positioning device; a lower auxiliary shearing knife is arranged on the positioning die; at least one knife tackle positioning template is arranged below the upper knife rest; and an upper shearing knife tackle is arranged on the knife tackle positioning template. Thus, the cost can be reduced; and the shearing efficiency and quality are improved.

Owner:深圳市壹零壹精密设备有限公司

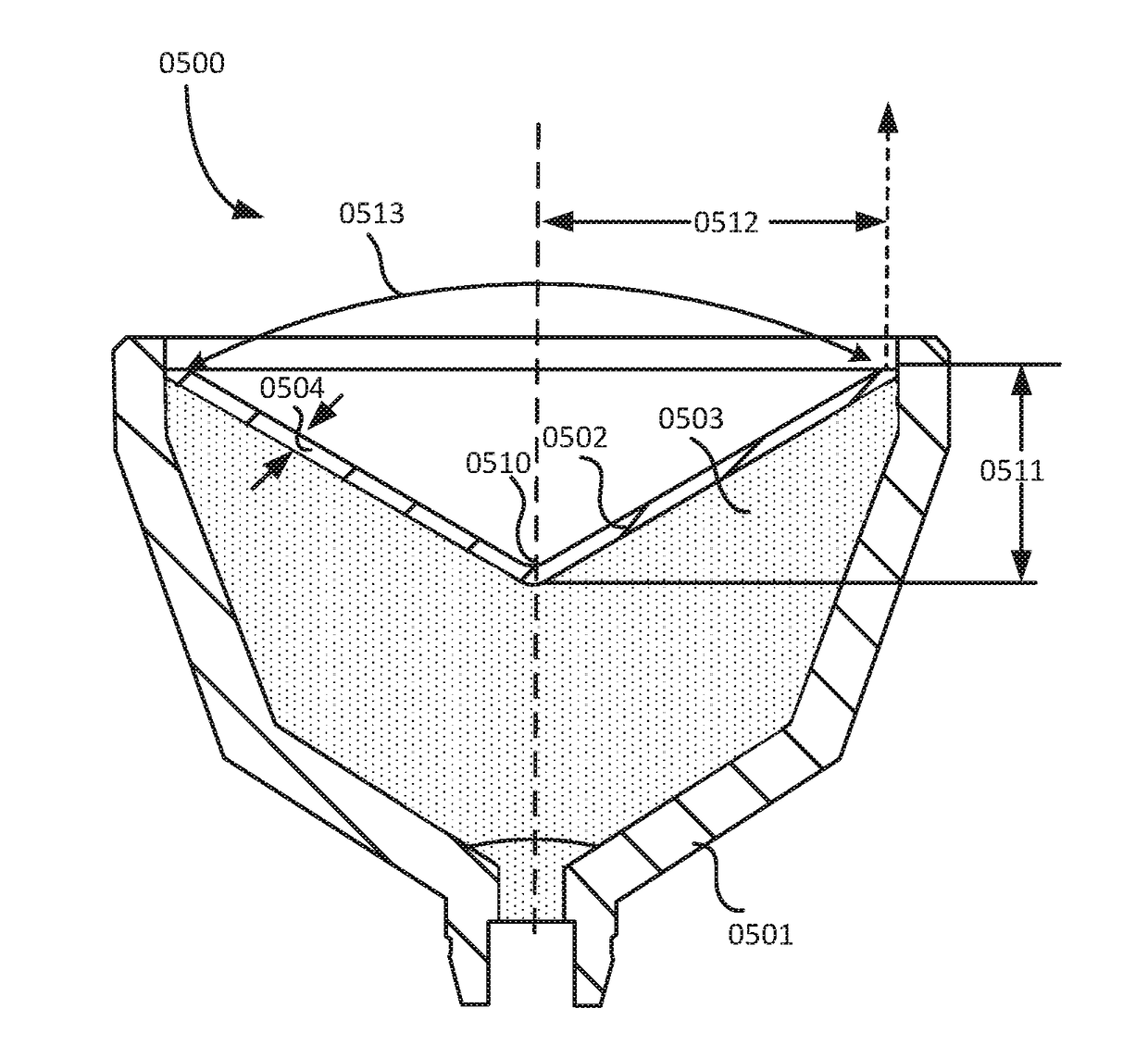

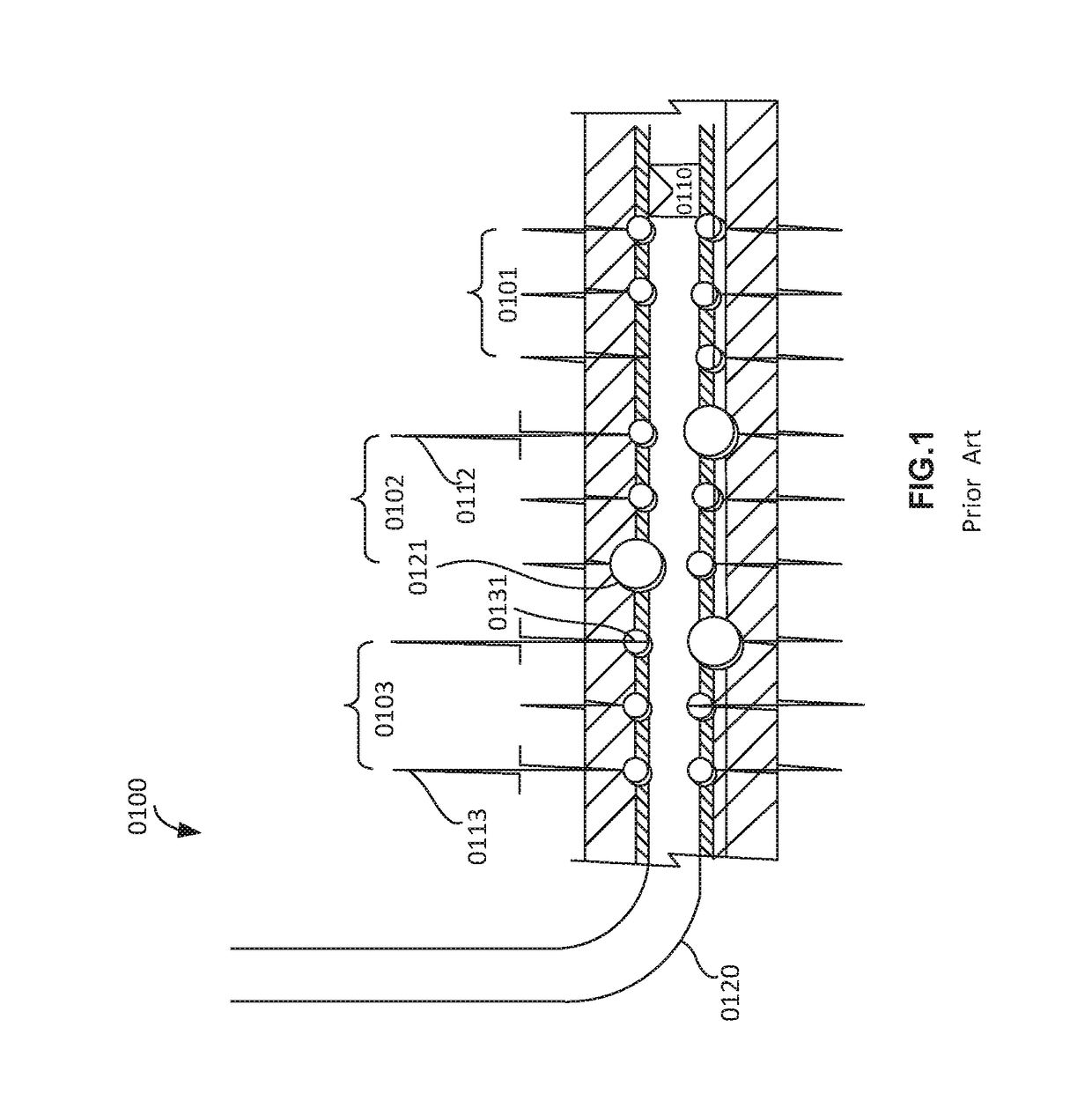

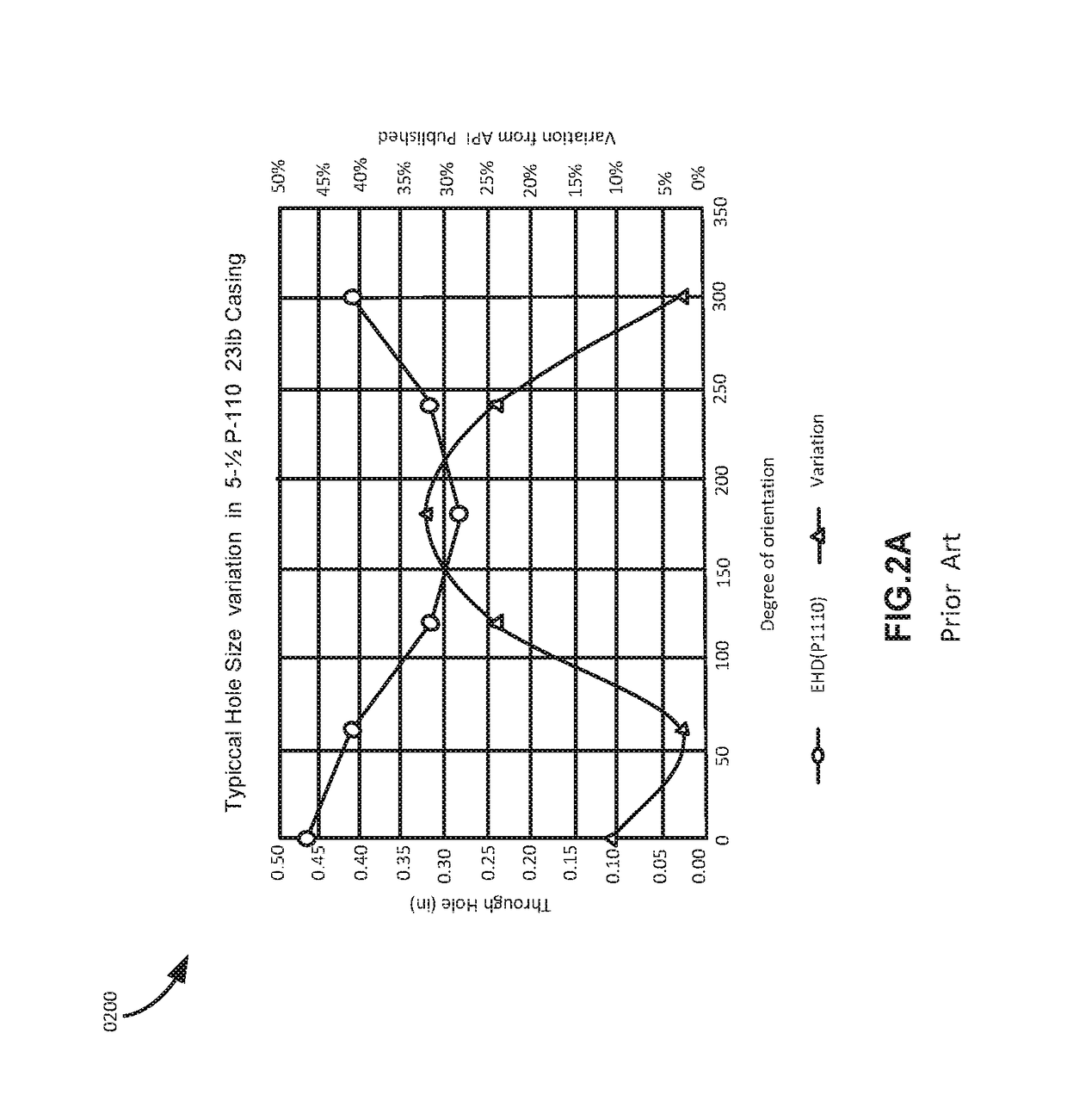

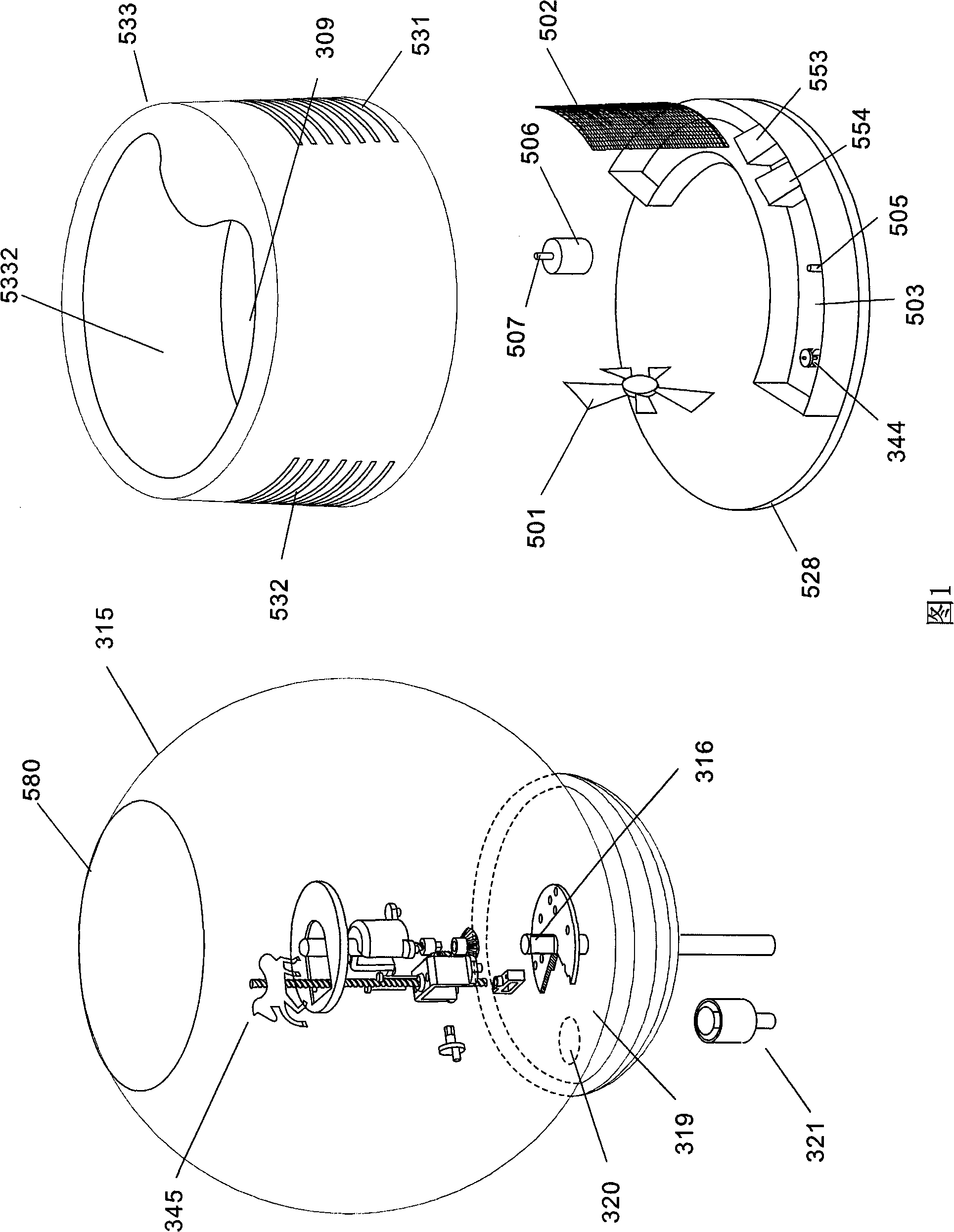

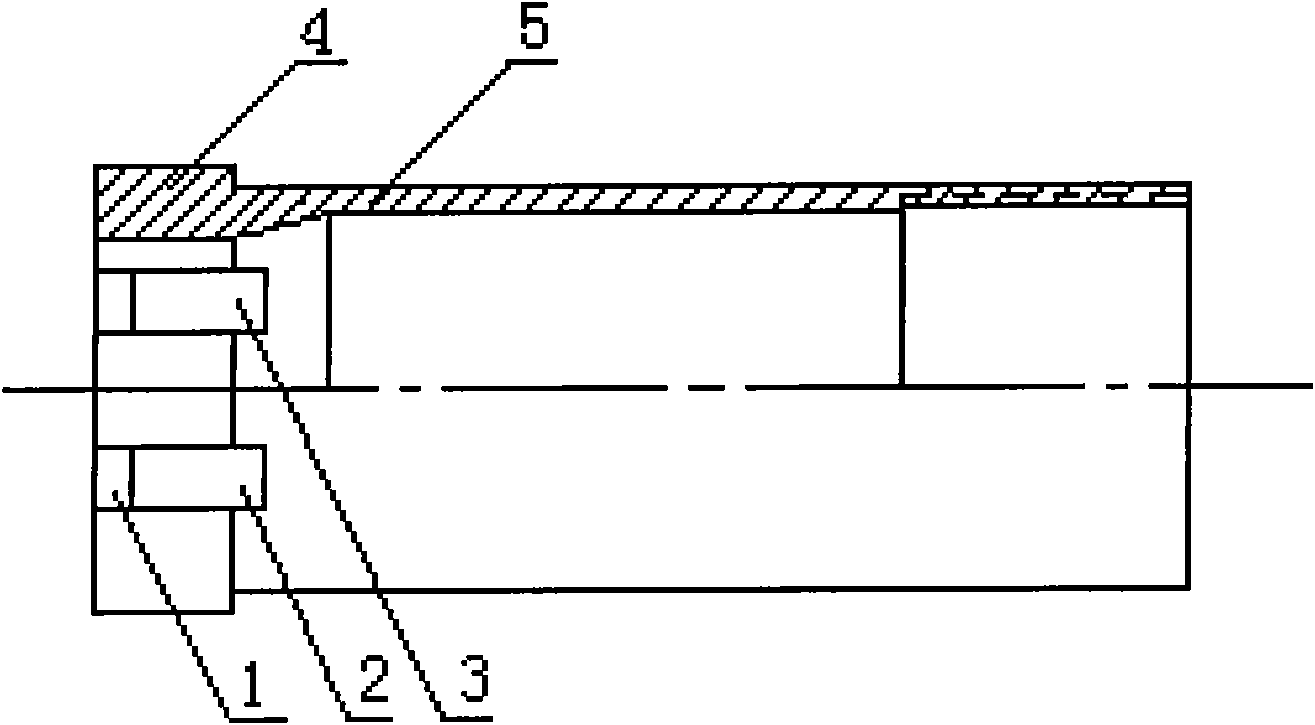

Constant entrance hole perforating gun system and method

A shaped charge that includes a case, a liner positioned within the case, and an explosive filled within the case. The liner is shaped with a subtended angle ranging from 100° to 120° about an apex, a radius, and an aspect ratio such that a jet formed with the explosive creates an entrance hole in a well casing. The jet creates a perforation tunnel in a hydrocarbon formation, wherein a diameter of the jet, a diameter of the entrance hole diameter, and a width and length of the perforation tunnel are substantially constant and unaffected with changes in design and environmental factors such as a thickness and composition of the well casing, position of the charge in the perforating gun, position of the perforating gun in the well casing, a water gap in the wellbore casing, and type of the hydrocarbon formation.

Owner:WELLS FARGO BANK NAT ASSOC +1

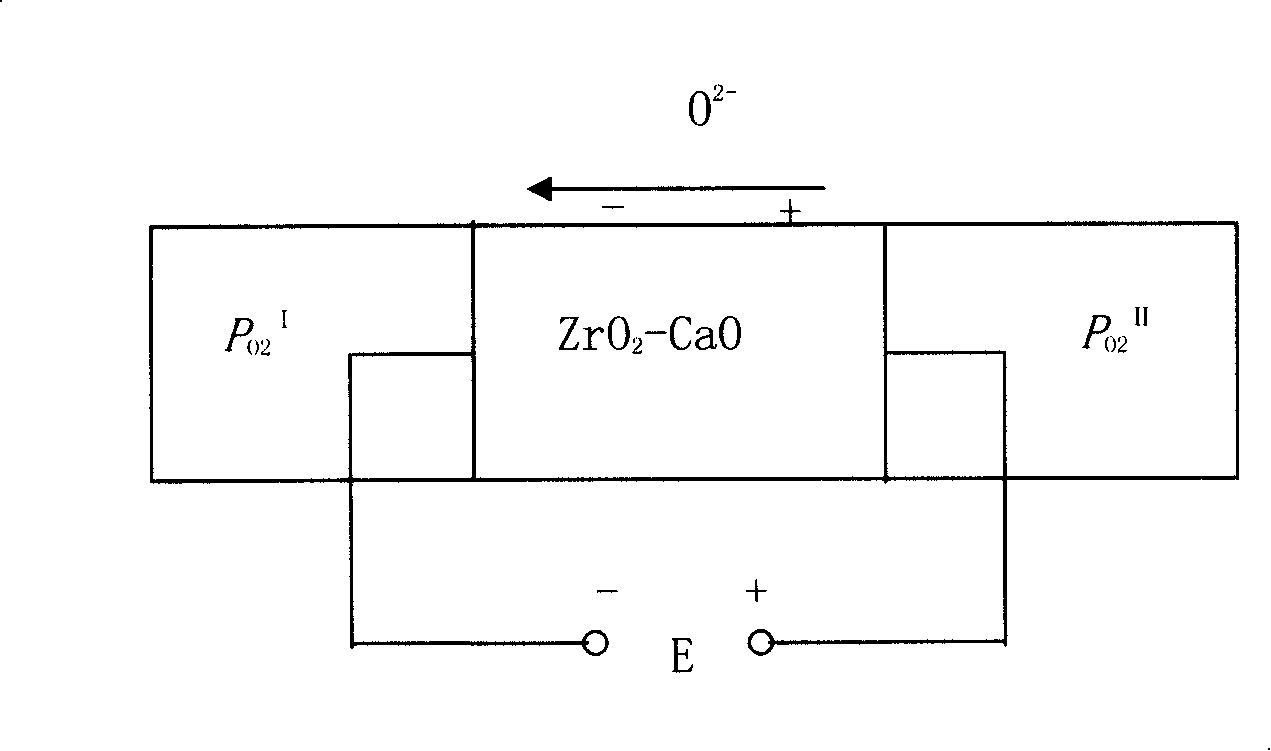

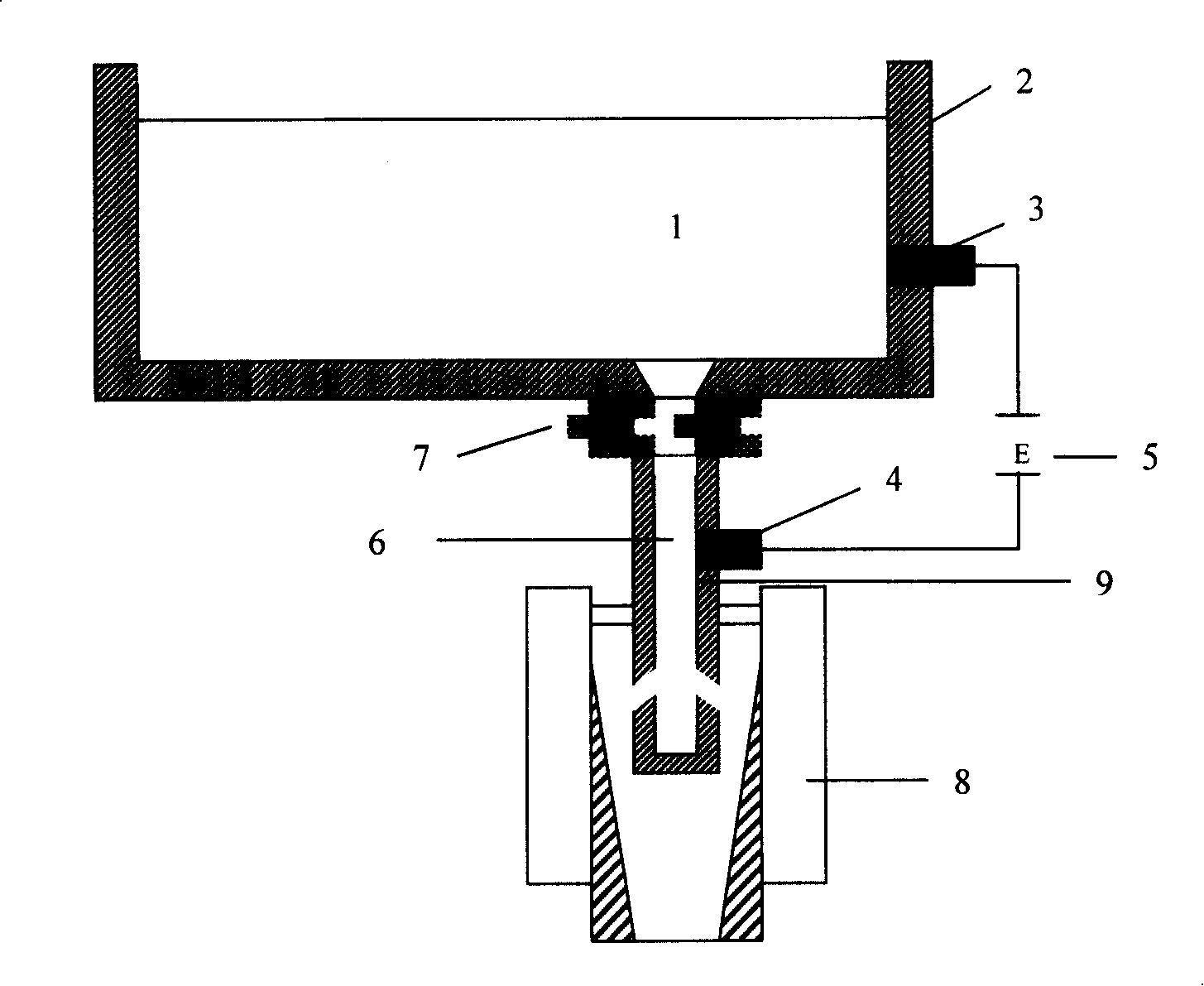

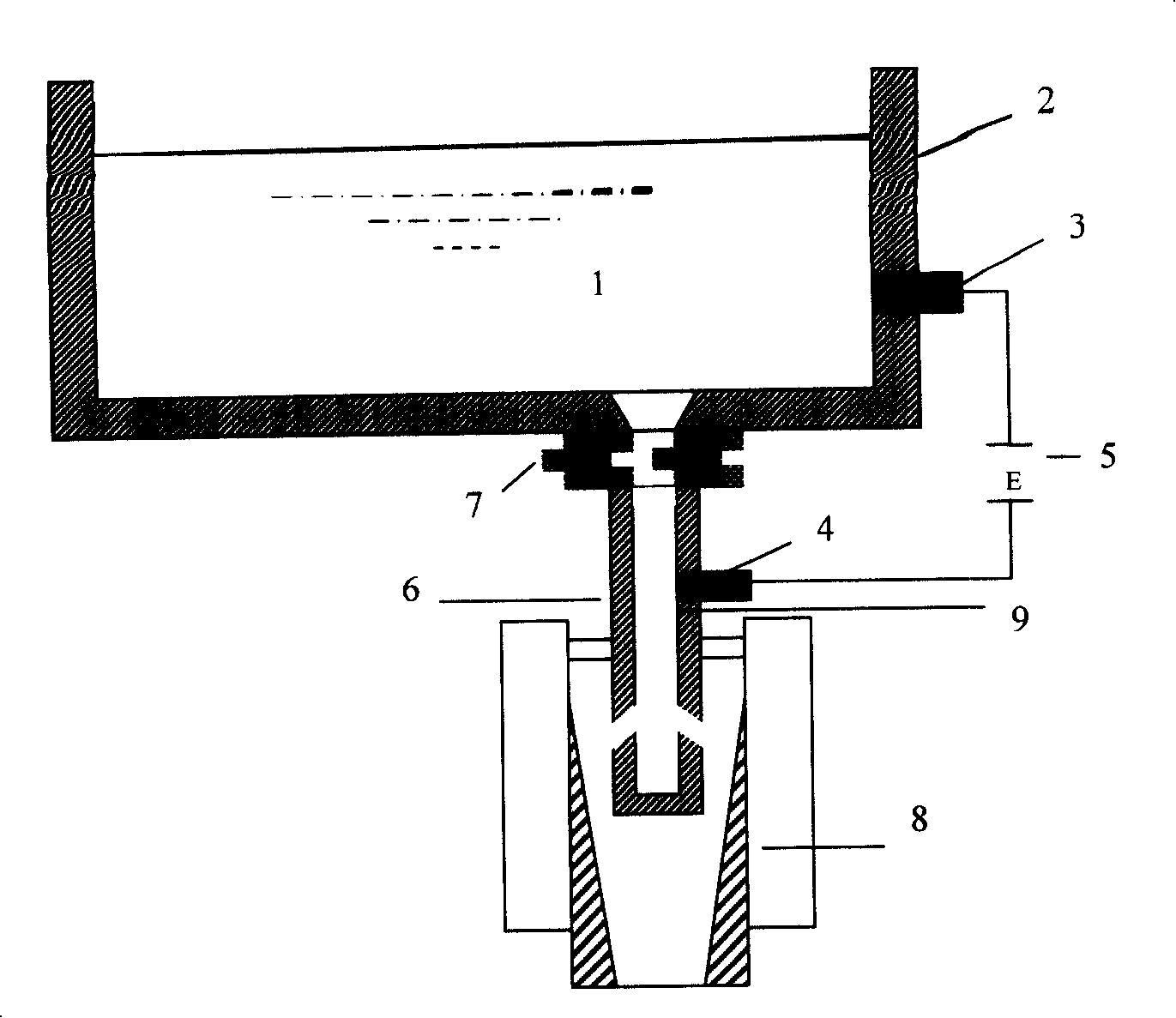

Method for preventing cast steel stove continuous casting water gap from obstruction and reducing erosion

The invention relates to an anti-block and erosion-reducing method for continuous casting nozzle, which has the advantages that: a DC electric field is applied between an inner wall of the continuous casting nozzle and a plurality of liquid steels; based on the specific situation of the blockage and erosion in the nozzle, the adhesion speed of the oxide in the liquid steels to the inner wall is controlled by changing the polarities of the electric field in the inner wall of the nozzle, so as to prevent the blockage and erosion of the nozzle.

Owner:BAOSHAN IRON & STEEL CO LTD

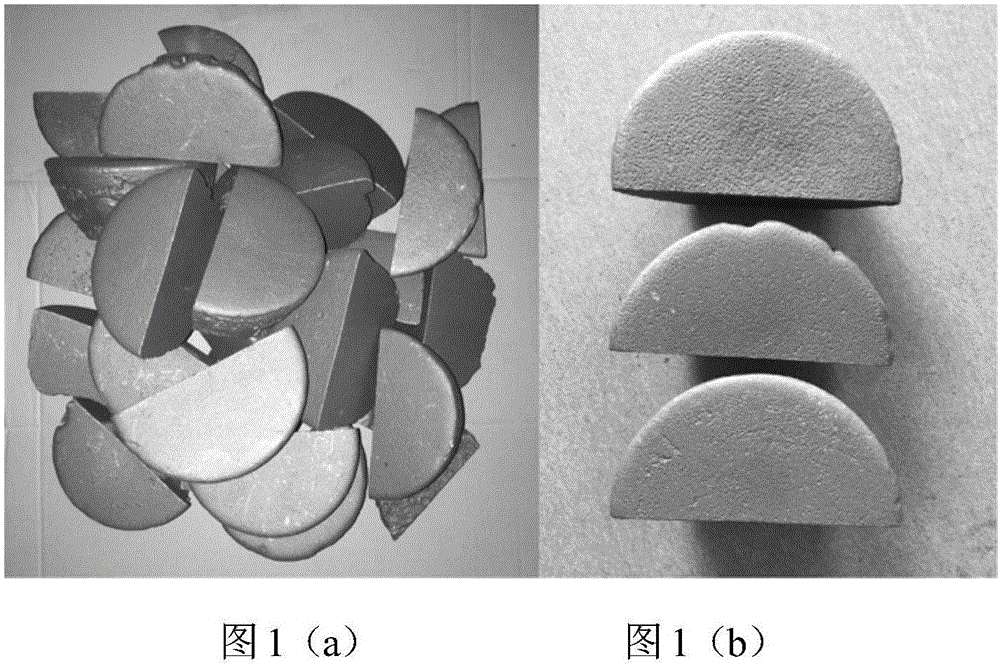

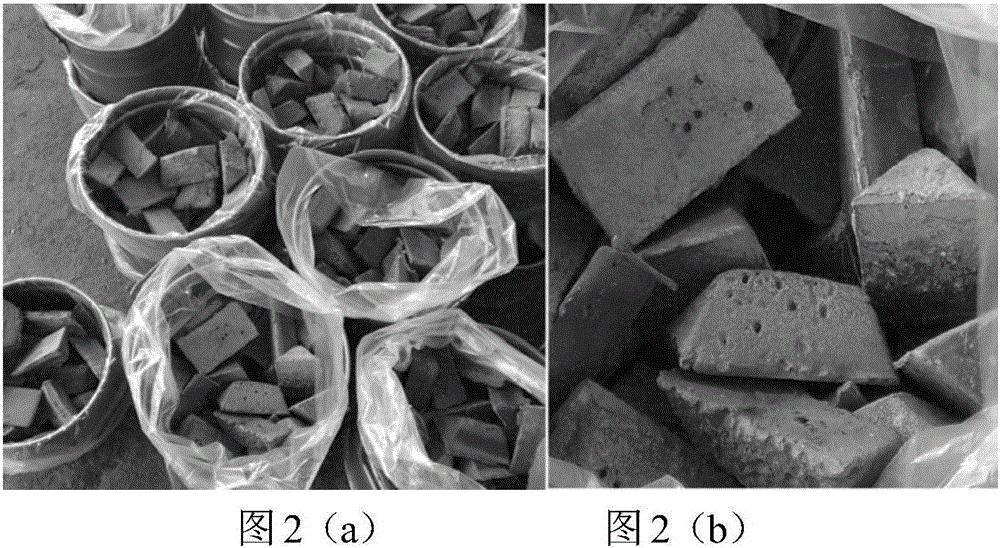

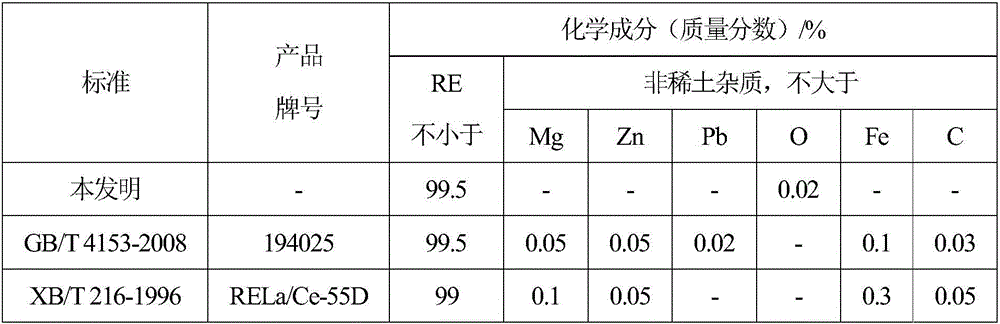

High-purity rare earth metal and preparation method and application thereof

The invention relates to the field of manufacturing of high-quality metal materials, in particular to high-purity rare earth metal and a preparation method and application thereof. The high-purity rare earth metal is characterized in that the total content of rare earth metal is higher than 99.5%, and the oxygen content O is not higher than 0.02% (by weight percentage). The high-purity rare earth metal is obtained by electrolysis of oxide rare earth or rare earth oxide villiaumite and solidified under airtight / protective atmosphere. The main rare earth element of the high-purity rare earth metal is lanthanum and cerium. The high-purity rare earth metal is mainly applied to, but not limited to, the fields of manufacturing of high-quality steel for continuous casting or die casting, high-quality structural steel for equipment manufacturing, special steel, aluminum alloy, magnesium alloy and other metal materials. Additives are provided for equipment manufacturing and high-quality steel materials, molten steel is purified, grains are refined, inclusions are modified, the performance of the steel materials is stably improved, and the negative effects of thick inclusions, water gap blockage, performance deterioration and the like caused by rare earth additives in the steel materials are avoided.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

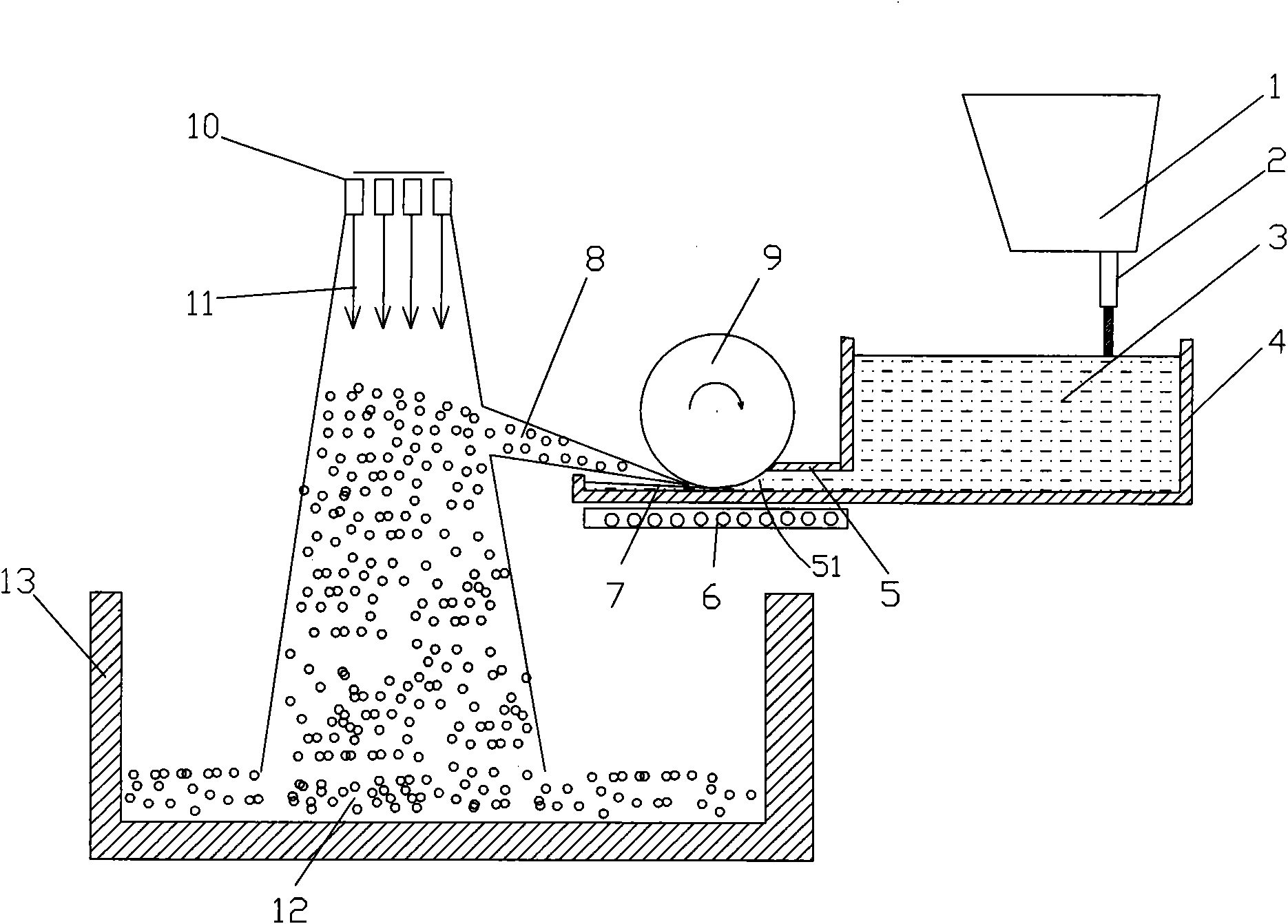

Method and device for preparing metal powder

ActiveCN101637823AConvenient for centralized collectionThere is no need to consider the uniform distribution problemMetal particleAlloy

The invention relates to a method for preparing metal powder, which comprises the following steps that: a master alloy to be prepared is melted; the metal liquid is heated to a certain temperature, poured into a ladle, and injected into a pouring box through a water gap, the outlet end of the pouring box is provided with a film prefabricating guide groove for controlling the molten steel to a certain width, the far end on the top surface of the guide groove is provided with an opening and a high-temperature roller rotating at a high speed, the roller maintains a certain distance from the bottom of the film prefabricating guide groove, and the metal liquid is formed into a film by the roller and the film prefabricating guide groove; the roller rotates at a high speed, and throws away the molten metal attached on the surface when passing through the molten steel film so as to form molten drops; and a gas nozzle for jetting a cooling medium is arranged above the molten drops, and the molten drops are jetted and cooled by the cooling medium in the process of movement and are solidified at a very quick speed to form metal particles falling into a holding tank so as to form the metal powder.

Owner:BAOSHAN IRON & STEEL CO LTD

Bearing steel GCr15 production technology capable of preventing plugging of continuous casting water gap

ActiveCN103103443AAvoid secondary oxidationImprove cleanlinessManufacturing convertersAlkalinitySlag

The invention relates to a bearing steel GCr15 production technology capable of preventing the plugging of a continuous casting water gap. The technology route comprises the steps of a top and bottom combined blow converter, an LF refining furnace, VD vacuum degassing and six-strand billet continuous casting of a Comcast six machine in sequence, the top and bottom combined blow converter conducts dephosphorization by adopting a double-slag method, the high catch carbon [C] at finishing point is more than or equal to 0.25%, final slag alkalinity before tapping is over 3.5, Als content in the molten steel in refining of the LF refining furnace is controlled to be over 0.05%, and Als / Alt is more than 95%; and argon blowing protection is conducted in the whole process of the continuous casting procedures, and low-pulling rate weak-cooling technology is adopted. Under the conditions of the technology, the cleanness of the molten steel can be improved, the non-metallic inclusion can be reduced, the plugging phenomenon of the continuous casting water gap can be prevented, the quality of the continuous casting blank can be improved, and the cost of the casting blank can be lowered, thereby finally improving the product quality.

Owner:TIANJIN IRON & STEEL GRP

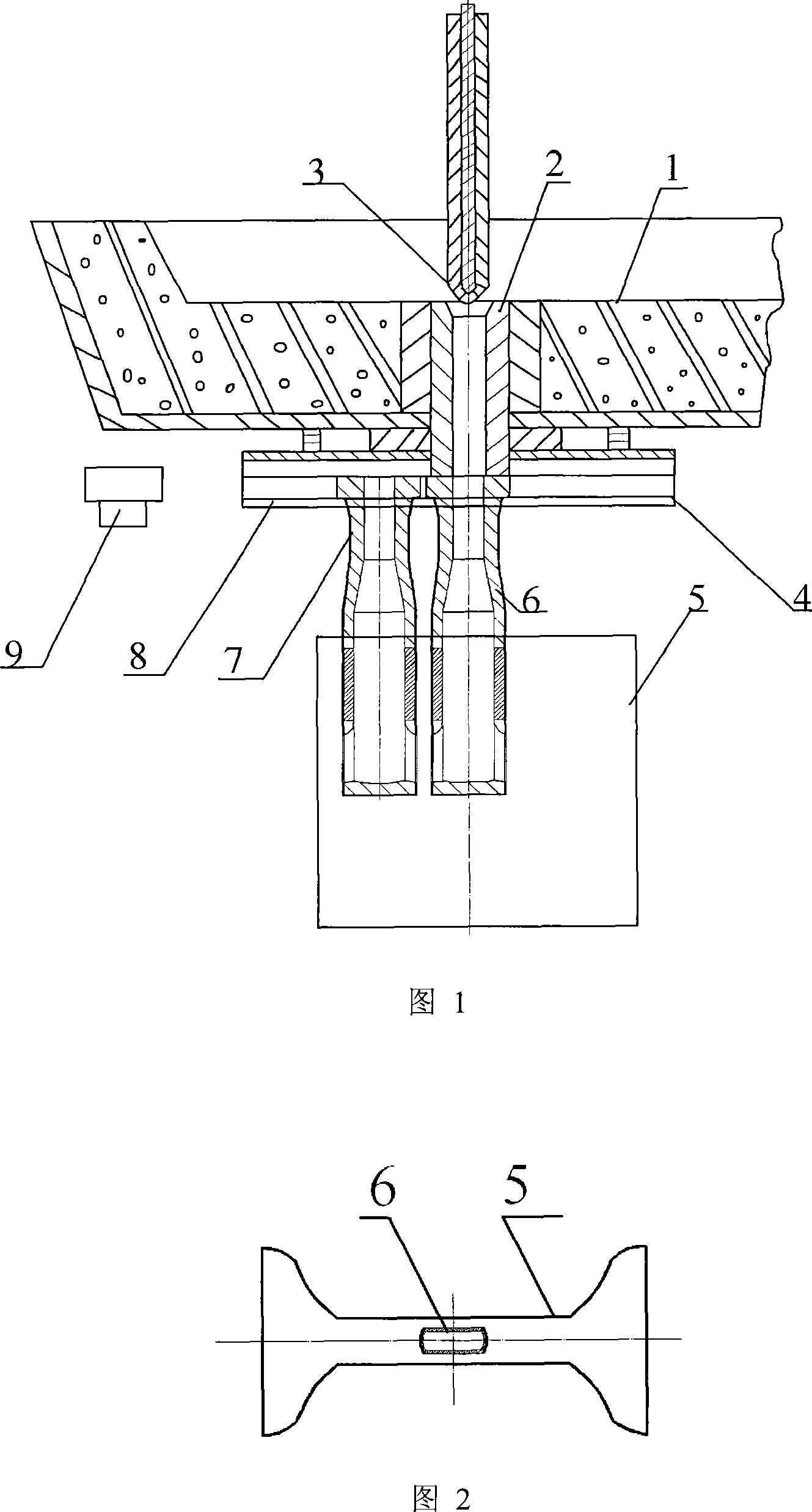

Method and device for carrying out protected casting for shaped blank continuous casting by using single immersed nozzle

InactiveCN101091982AAchieving protective castingReduce the chance of secondary oxidationWater gapTundish

The invention relates to a method and device that adopts water gap to take shaped blank continuous casting protecting casting. It inserts a dipped water gap into the center position of shaped blank crystallizer web to take casting. The upper part of dipped water gap connects to upper water gap of pouring basket. Molten steel flowing channel is formed between pouring basket and crystallizer. The stopper is used to control molten steel flow control to realize indicating control in crystallizer. The invention could realize full process protecting cast of shaped blank continuous casting to ensure cleanliness of molten steel.

Owner:LAIWU IRON & STEEL GRP

Steel for marine riser flange of marine deepwater drilling and manufacturing method of marine riser flange

InactiveCN102191442AImprove strength and toughnessMeet the technical requirements of low-carbon high-strength toughnessDrilling rodsDrilling casingsElectric arc furnaceDeepwater drilling

The invention discloses steel for a marine riser flange of marine deepwater drilling. The steel comprises the following components in percentage by weight: 0.13 to 0.21 percent of C, 1.65 to 1.95 percent of Mn, 0.25 to 0.35 percent of Mo, 0.03 to 0.09 percent of Nb, 0.02 to 0.08 percent of V, less than or equal to 0.015 percent of Ti, 0.5 to 0.9 percent of Ni, 0.07 to 0.2 percent of Cu, less than or equal to 0.15 percent of Cr, less than or equal to 0.22 percent of Si, less than or equal to 0.01 percent of S, less than or equal to 0.02 percent of P and the balance of Fe. The invention also discloses a manufacturing method of the marine riser flange of marine deepwater drilling. The method comprises the following steps of: preparing the materials according to the content of the components, and smelting the materials in an arc furnace to obtain molten steel, and heating the molten steel with arc in vacuum and stirring the molten steel by blowing argon to degas the molten steel; casting a steel ingot, blowing an inert gas through a blowing sliding water gap, balancing the components and the temperature and purifying the molten steel; forging the obtained steel ingot and annealing the steel ingot after forging; machining and polishing the steel ingot; and performing die forging on the steel ingot to obtain the finished product of the marine riser flange. By the manufacturing method, each mechanical property of the steel and the marine riser flange meets the requirements on API related steel for marine riser flange by setting the best component proportion and a heat treatment process.

Owner:BAOJI PETROLEUM MASCH CO LTD

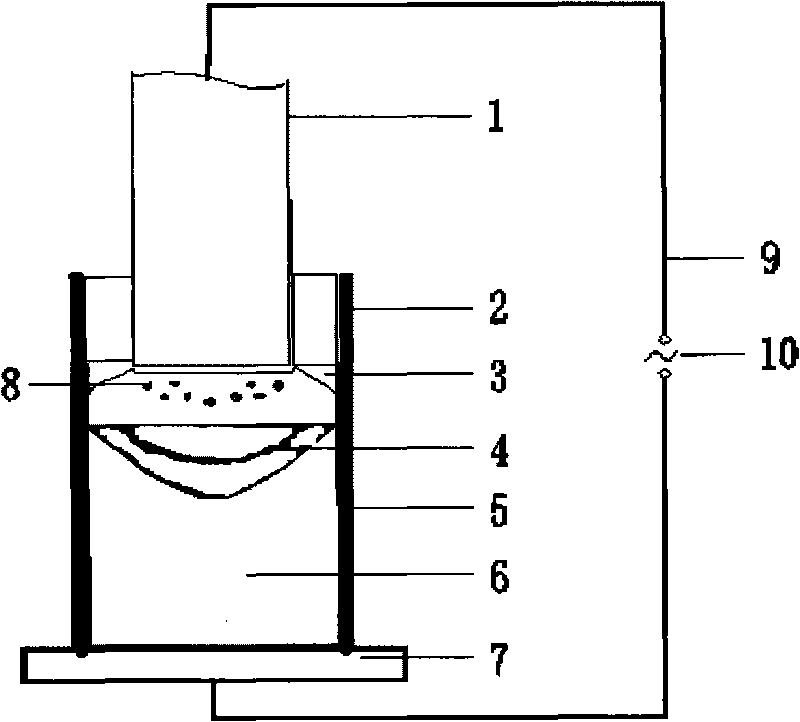

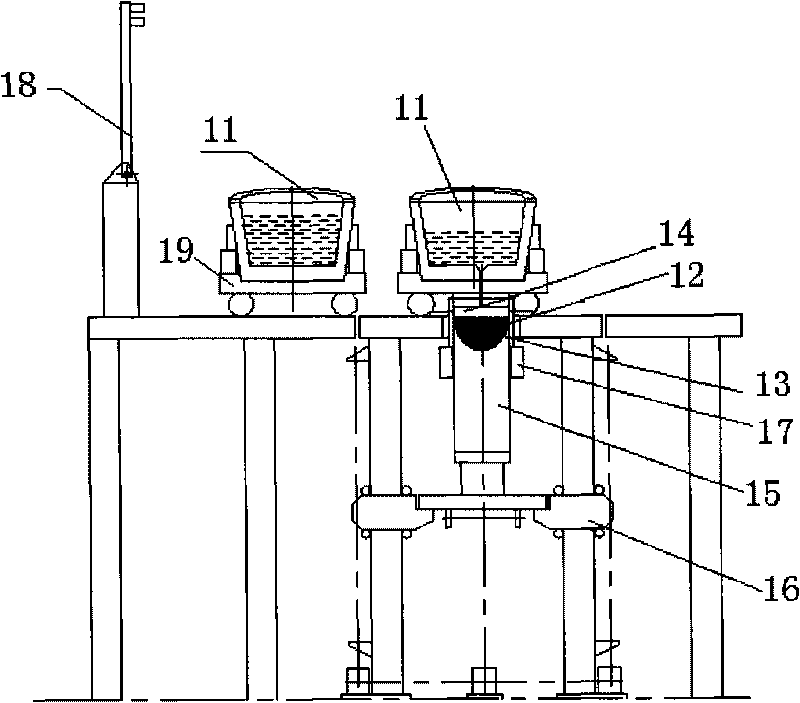

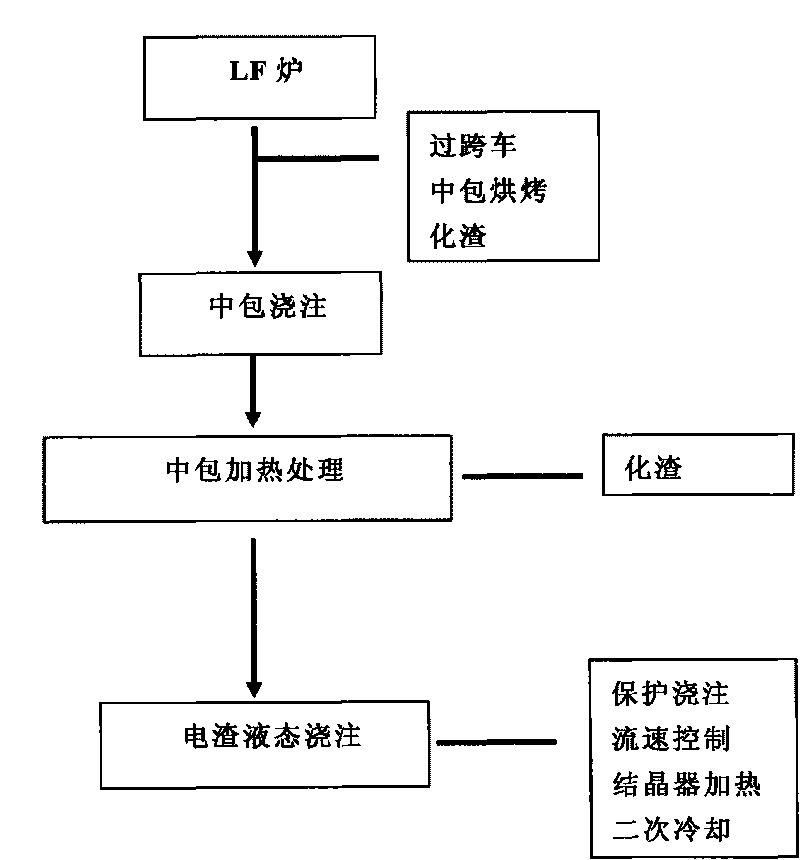

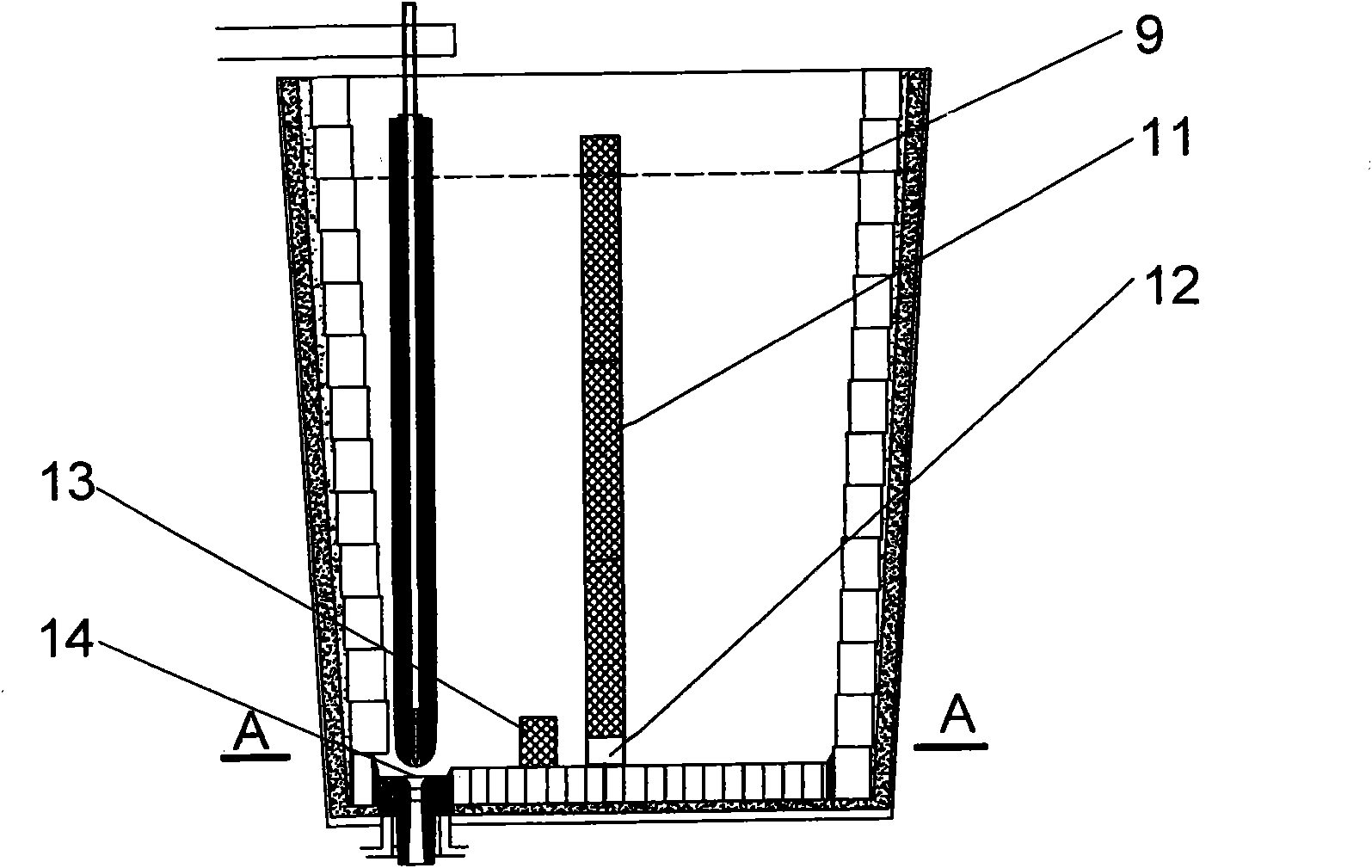

Electric slag liquid pouring method

ActiveCN101748282AReduce manufacturing costSimple processIncreasing energy efficiencyLiquid stateMolten salt

The invention discloses an electric slag liquid pouring method. The method comprises the following steps: injecting refined molten steel into a tundish, and starting an induction heating power supply of the tundish to heat the molten steel; sealing a dummy ingot device and a crystallizer, then decomposing the liquid furnace slag of predetermined weight in the crystallizer by using a slag decomposing arm, shifting a tundish car to a pouring station, performing centering on a pouring water gap and the crystallizer and pouring the molten steel; when the molten slag liquid level reaches a preset height, beginning stripping, and simultaneously switching on high voltage to make the current pass through the molten slag and place the furnace slag in a high-temperature melting state, wherein the stripping speed is matched with the speed of pouring the liquid molten steel; and opening a secondary cooling device after steel ingots are discharged from the crystallizer so that electric slag liquidpouring is finished. The electric slag liquid pouring method can greatly improve the production efficiency and reduce the production cost.

Owner:SHENYANG DONGDA MATERIAL ADVANCED PREPARATION TECH ENG RES CENT +1

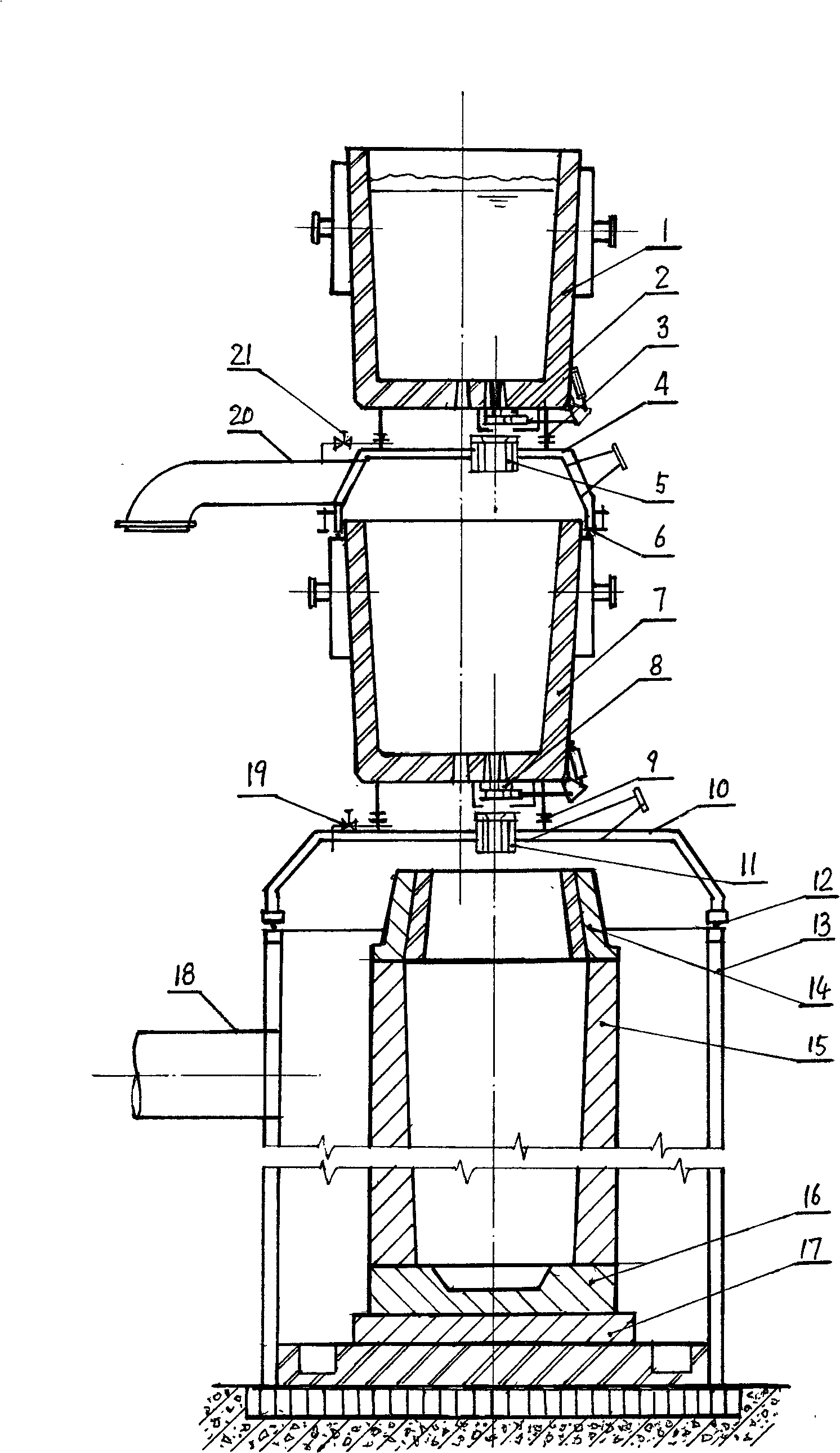

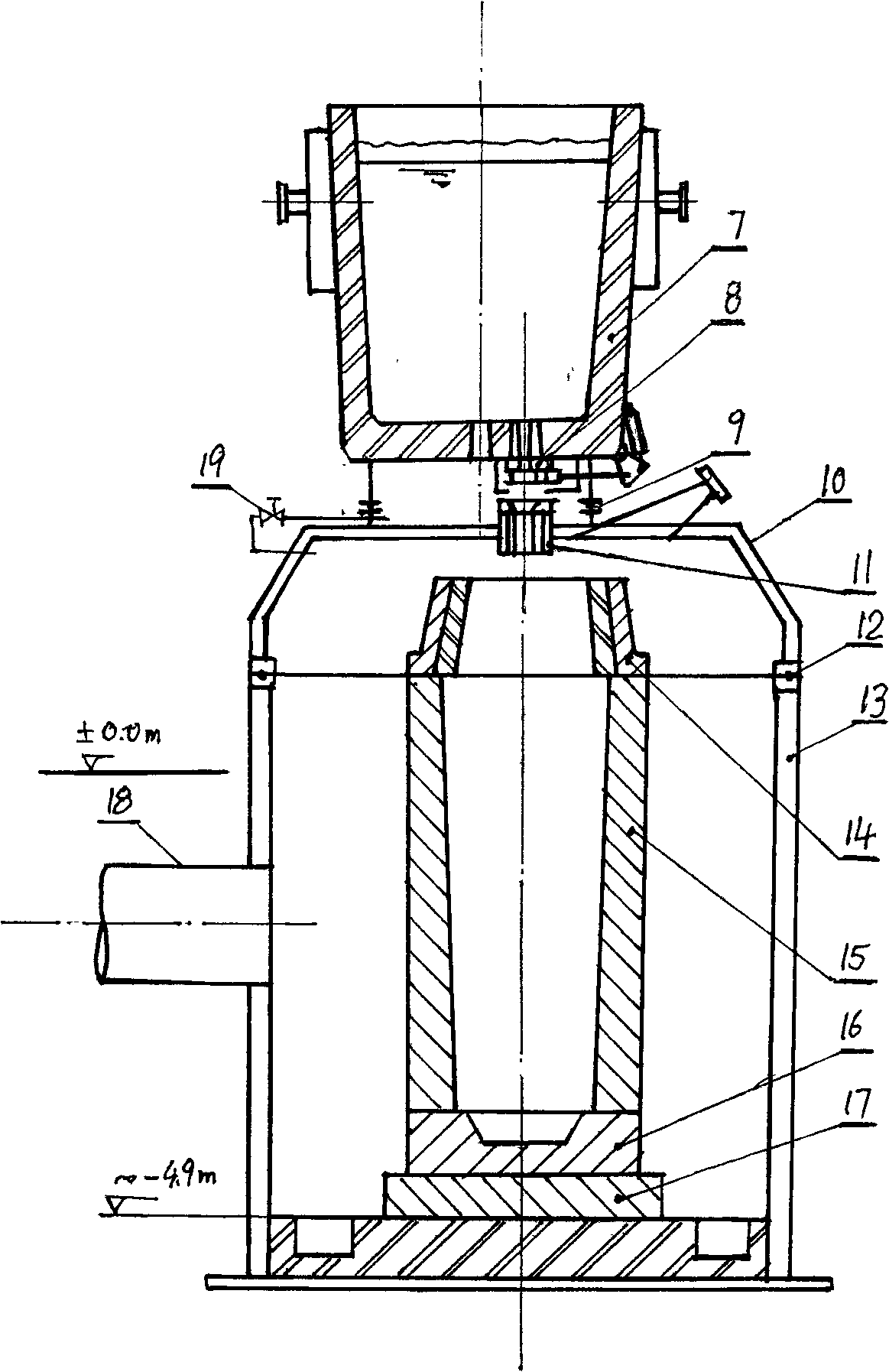

Tundish with baffle wall for vacuum cast ingot

ActiveCN101774014AExtended stayFluctuation of liquid level is smallMelt-holding vesselsIngot castingSlag

The invention discloses a tundish with a baffle wall for a vacuum cast ingot, belonging to the technical field of vacuum cast ingot. A baffle wall is arranged in the tundish, and the bottom of the baffle wall is provided with a steel channel; the bottom surface of the tundish on the water gap side is provided with a training wall which is higher than the upper top surface of the steel channel; and after passing through the steel channel and the training wall, molten steel forms a flow field inclining upwards. The tundish with a baffle wall for a vacuum cast ingot is characterized in that the baffle wall and the training wall are arranged in the tundish during vacuum ingot casting, which controls and improves the molten steel flowing mode in the tundish, relatively prolongs the retention period of molten steel in the tundish, prevents the tundish water gap from entrapping slag, provides favorable conditions for floating and removing impurities in molten steel, and improves the internal quality of the steel ingot.

Owner:CHINA FIRST HEAVY IND

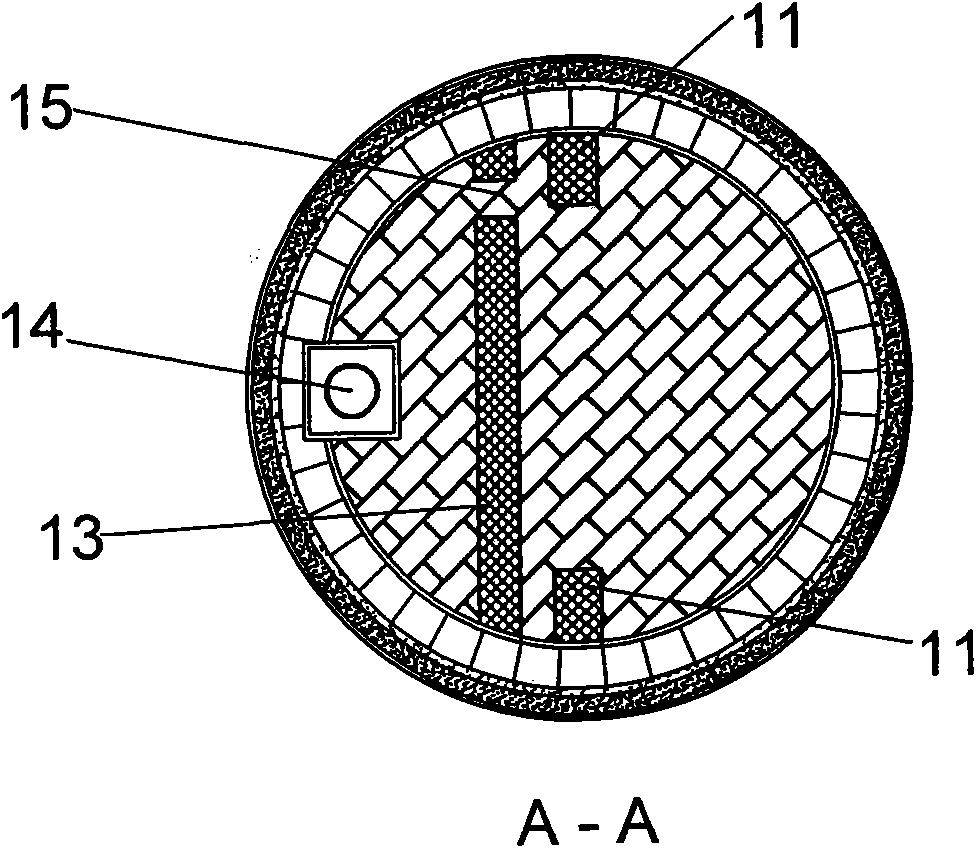

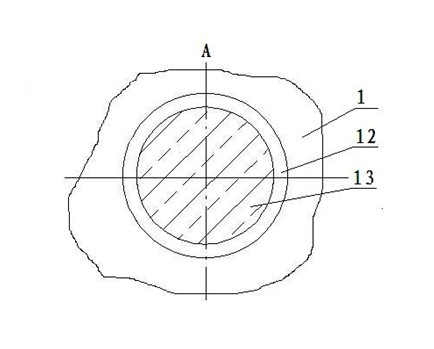

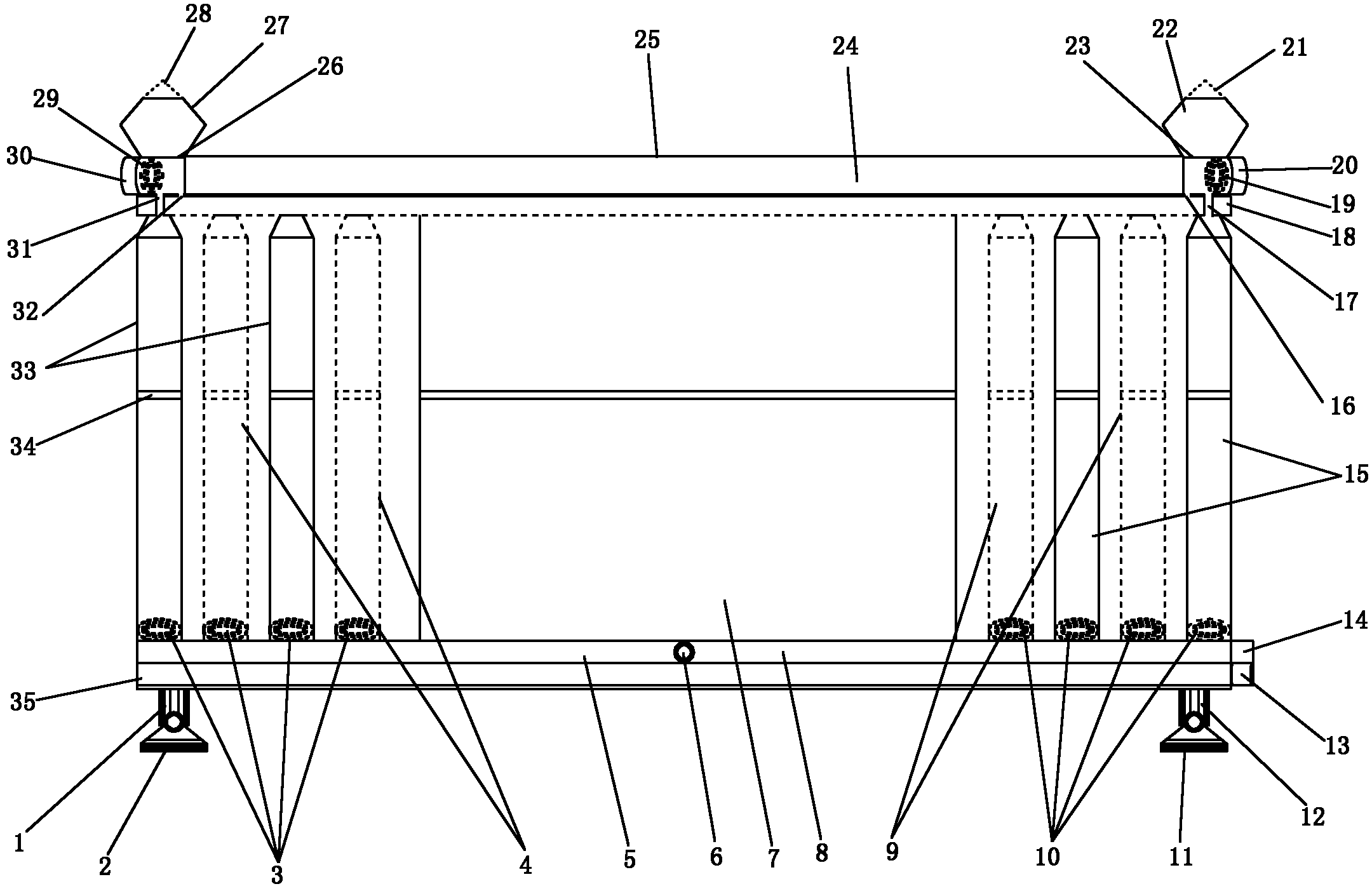

Water cooling channel for large beam blank continuous casting crystallizer

The invention belongs to a cooling casting blank or casting mould device and relates to a water cooling channel for a large beam blank continuous casting crystallizer,,and particularly to a copper plate cooling device for a beam blank continuous casting crystallizer. The copper plate cooling channel is characterized in that: a web water gap, a R angle water gap, a bevel water gap, a flange inner angle water hole and a flange top water hole are formed on a broadside copper plate according to the characteristics of the copper plate shape and heat face heat flux; the water gaps without corners are distributed uniformly, and the water gaps at R angle are dense, and few water holes are arranged at concave corners; and a cooling water tank is arranged outside a narrow side copper plate. The copper plate cooling channel has the advantages that cooling water channels are arranged in areas, the number of cooling water channels is reduced, water gap diameter is reduced, and processing quantity is reduced; the water gaps are arranged reasonably, temperature peak value at the R angle is eliminated, the temperature gradient is reduced, the cooling strength of the flange top is weakened, the overall temperature of the copper plate tends to be uniform, the working environment of the copper plate and blank heat transmission condition are improved, the cooling effect is good, and water is saved; deformation and abrasion of the copper plate are reduced, and service life is prolonged; the surface quality of blanks is remarkably improved, the cogging yield is improved, and continuous casting production can be performed smoothly.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

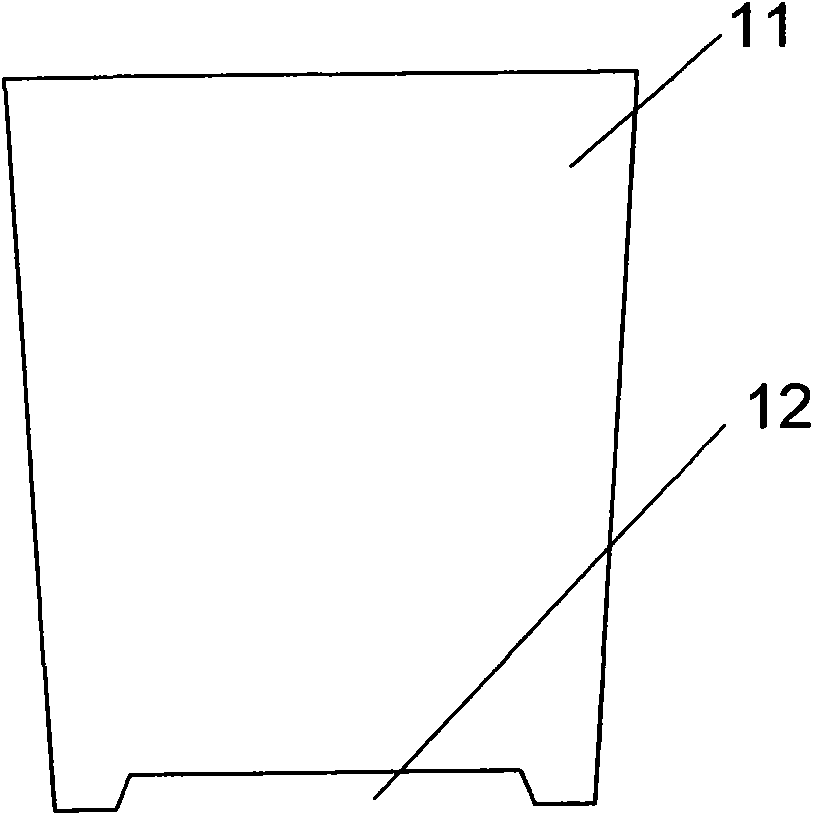

Aluminium-carbon water gap for continuous casting

InactiveCN1927507AReduce consumptionReduce pollutionMolten metal conveying equipmentsSpecific gravityWater gap

The invention relates to an aluminum carbon water open used in casting. Wherein, it uses baked bauxite chamotte powder to replace electro-melting corundum, to be mixed, shaped and sintered by other material. And the bauxite chamotte has abundant resource and low cost, therefore, the invention can reduce 36 million yuan / year. And the strength at normal temperature, the anti-bend strength at high temperature and the vibration resistance of water open are all improved. Since the specific weight of bauxite chamotte is lower than electro-melting corundum, it can reduce 1% weight.

Owner:山东耐材集团中齐耐火有限公司

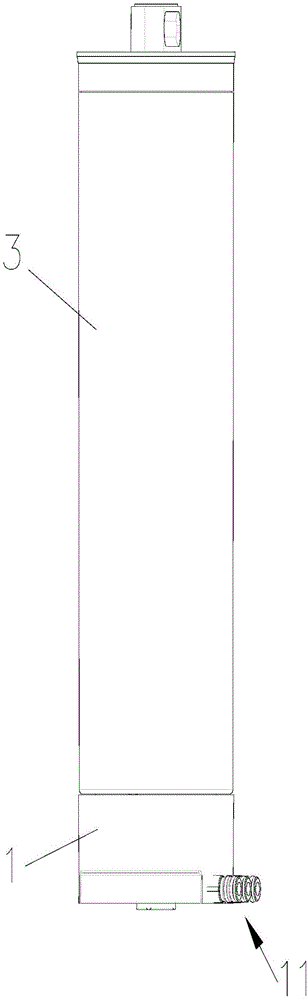

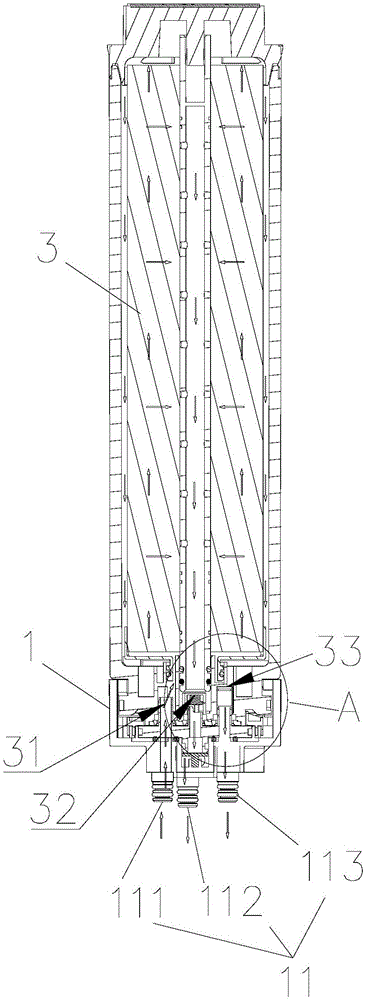

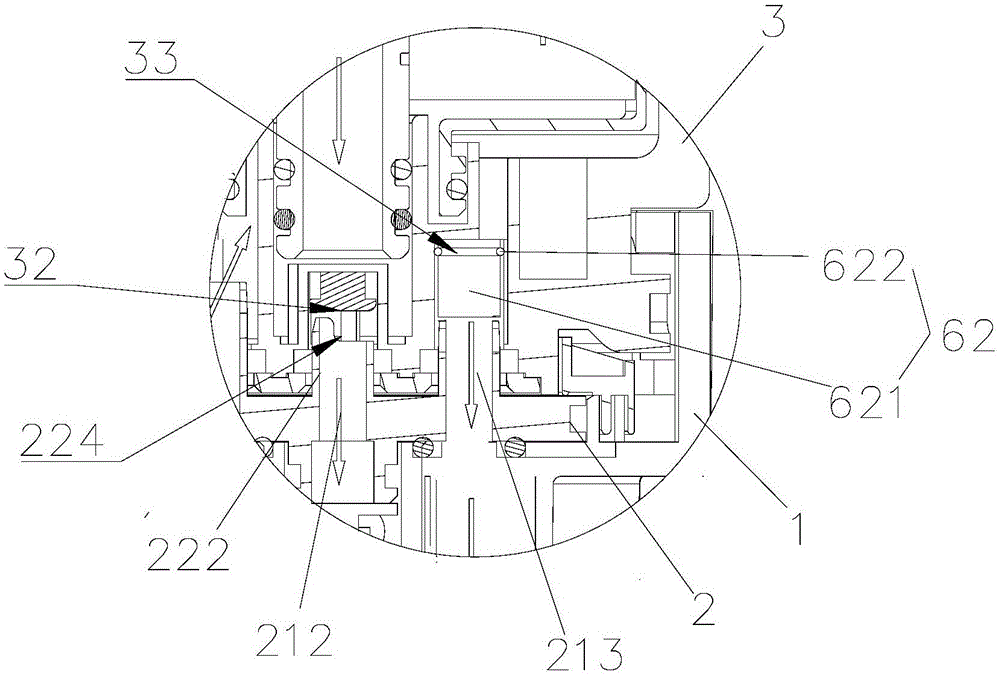

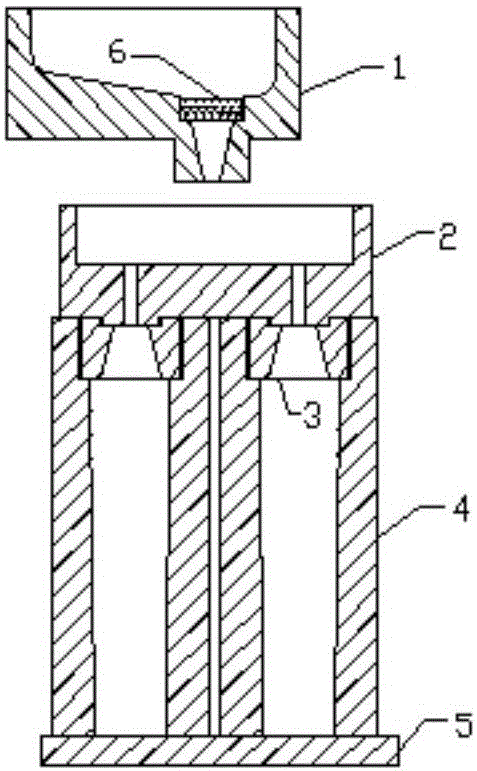

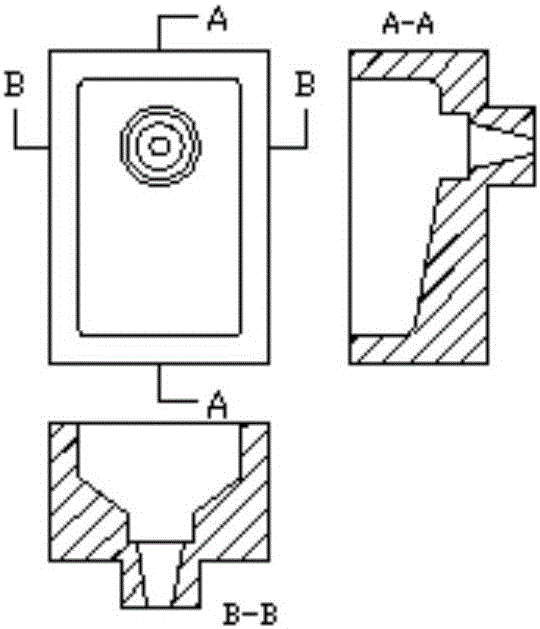

Filter element device and filter element seat

ActiveCN105080191APrevent leakageImprove sealingReverse osmosisStationary filtering element filtersWater flowEngineering

The invention discloses a filter element device and a filter element seat. The filter element device comprises a seat body and a filter element, wherein a plurality of first water flow channels are formed in the seat body; the filter element has a plurality of water gaps corresponding to the first water flow channels; the filter element device further comprises a water retaining piece between the seat body and the filter element; a plurality of second water flow channels corresponding to the plurality of first water flow channels and the plurality of water gaps are arranged on the water retaining piece; the water retaining piece can revolve relative to the seat body so as to get a communication position or a stop position between the water retaining piece and the seat body; in the communication position, the second water flow channels are communicated with the first water flow channels; in the stop position, at least one second water flow channel changes the relative circumferential position so as to disconnect communication with the first water flow channels. The filter element seat comprises the seat body and the water retaining piece. Therefore, in the stop position, at least residual water can be prevented from leaking out through the water flow channels disconnected in communication. Therefore, the sealing property and practicality of the filter element device and the filter element seat are effectively enhanced.

Owner:FOSHAN VIOMI ELECTRICAL TECH +2

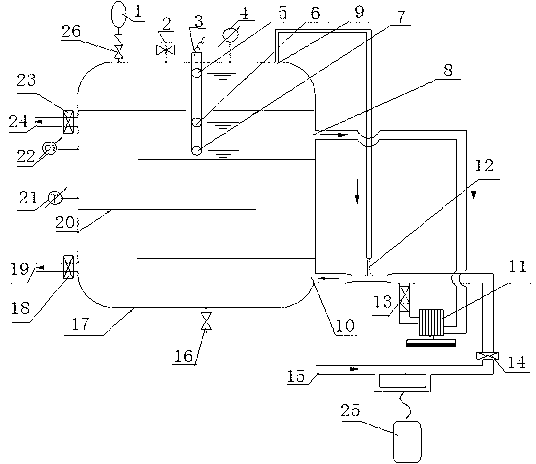

Water-fertilizer-gas integrated irrigation control system and control method

InactiveCN103314697AIntegrated Irrigation RealizationA wide range of incorporation ratiosClimate change adaptationWatering devicesAir cycleOxygen controller

The invention discloses a water-fertilizer-gas integrated irrigation control system and control method. The control system comprises a pressure-bearing water tank (17), wherein the pressure-bearing water tank (17) is provided with a pressure safety valve (2), a water level controller (3), a pressure controller (4), an inner circulating water gap (8), an air circulation port (9), a water inlet (10), a drain outlet (16), a low-post water outlet (19), a guide plate (20), a temperature transmitter (21), a dissolved oxygen controller (22) and a high-post water outlet (24), and a fertilization and air-entrapping device is arranged outside the pressure-bearing water tank (17); through the control of water inlet and outlet and aeration, a function of carrying out automatic aeration on liquid in the pressure-bearing water tank (17) can be achieved so as to achieve a preset water-gas mixing ratio. The system can realize water-fertilizer-gas integrated irrigation, thereby greatly increasing the water and fertilizer utilization efficiencies of crops.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

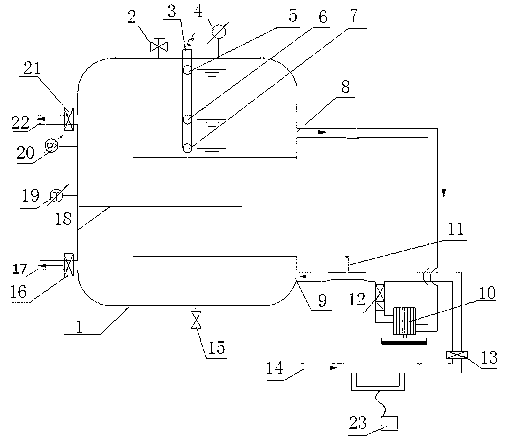

Water supply system for water-fertilizer-gas efficient coupling irrigation and irrigation method

InactiveCN103314696ARealize integrated irrigationA wide range of incorporation ratiosPressurised distribution of liquid fertiliserAgriculture gas emission reductionOxygen controllerEngineering

The invention discloses a water supply system for water-fertilizer-gas efficient coupling irrigation and an irrigation method, which are characterized in that the system comprises a pressure-bearing water tank (1) and an aeration and fertilizing component, wherein the pressure-bearing water tank (1) is provided with a pressure safety valve (2), a water level controller (3), a pressure controller (4), an inner circulating water gap (8), a water inlet (9), a drain outlet (15), a low-post water outlet (17), a guide plate (18), a temperature transmitter (19), a dissolved oxygen controller (20) and a high-post water outlet (22); through the control of water inlet and outlet and aeration, a function of carrying out automatic aeration on liquid in the pressure-bearing water tank (1) can be achieved so as to achieve a preset water-gas mixing ratio. The system can realize water-fertilizer-gas integrated irrigation, therefore, a soil environment of root zones can be significantly improved, and the water and fertilizer utilization efficiencies of crops can be significantly increased.

Owner:LUDONG UNIVERSITY

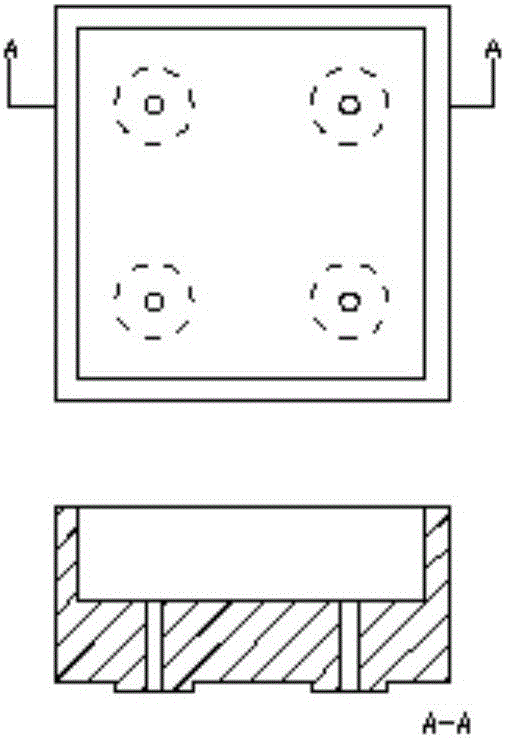

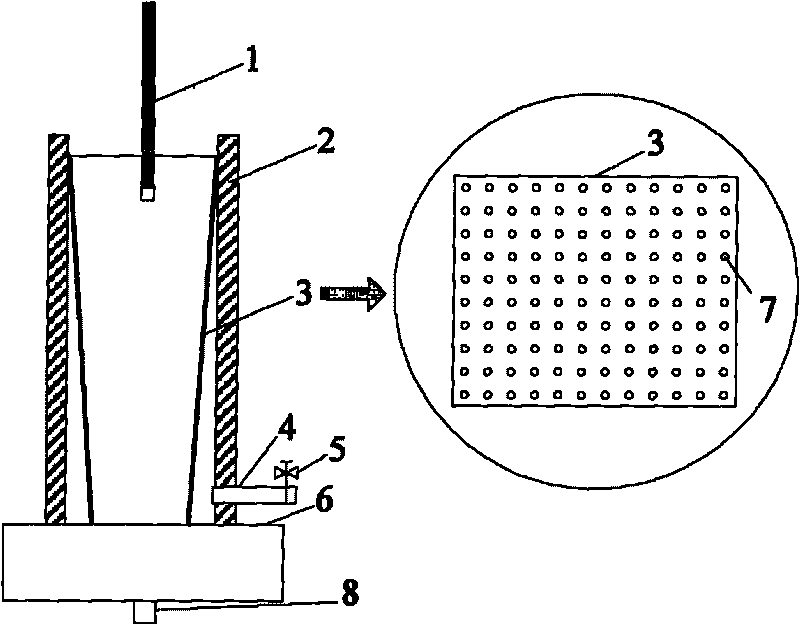

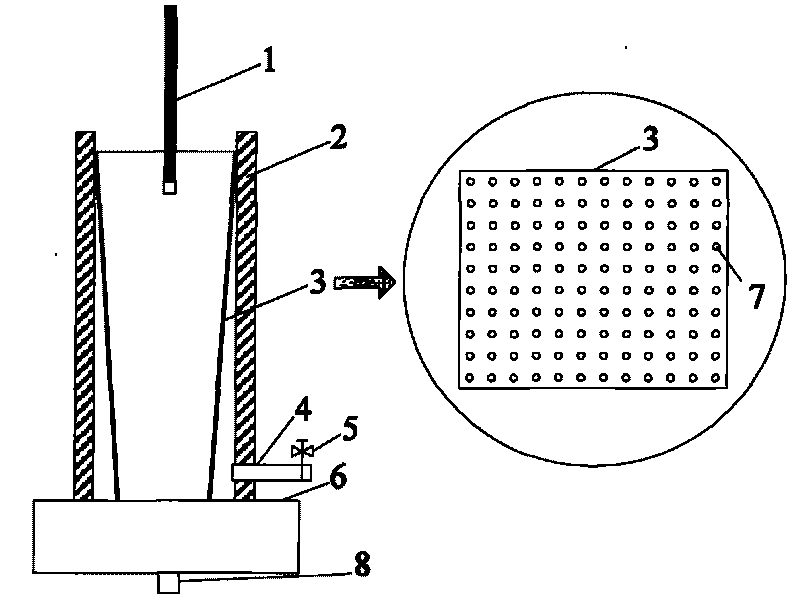

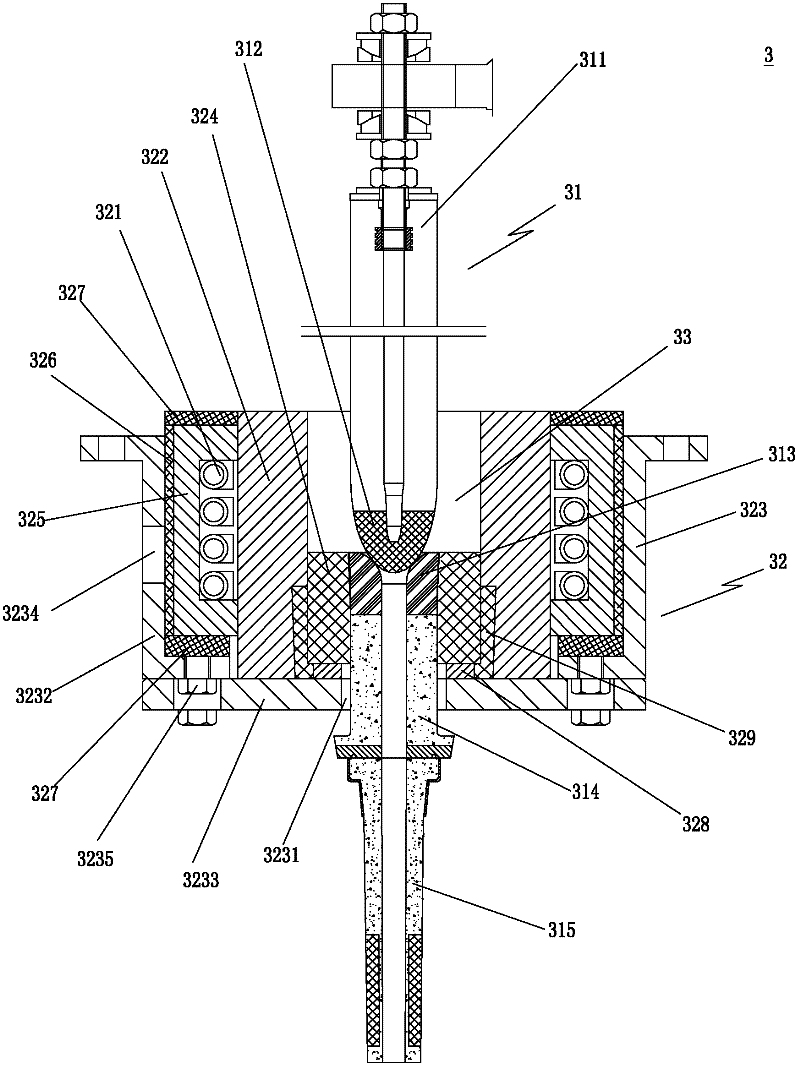

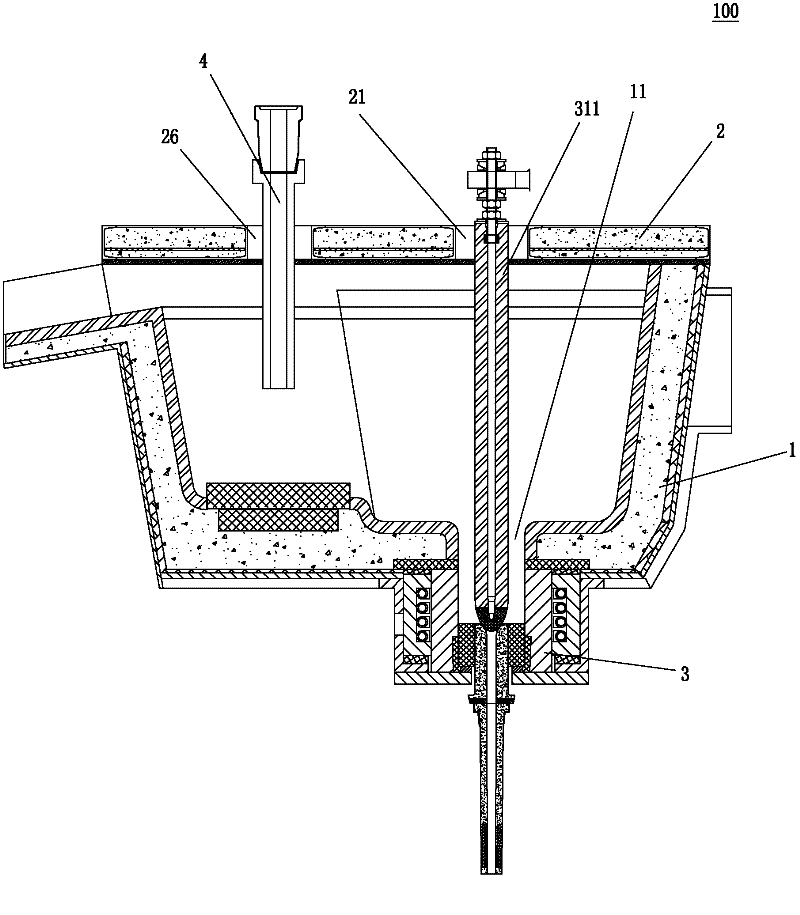

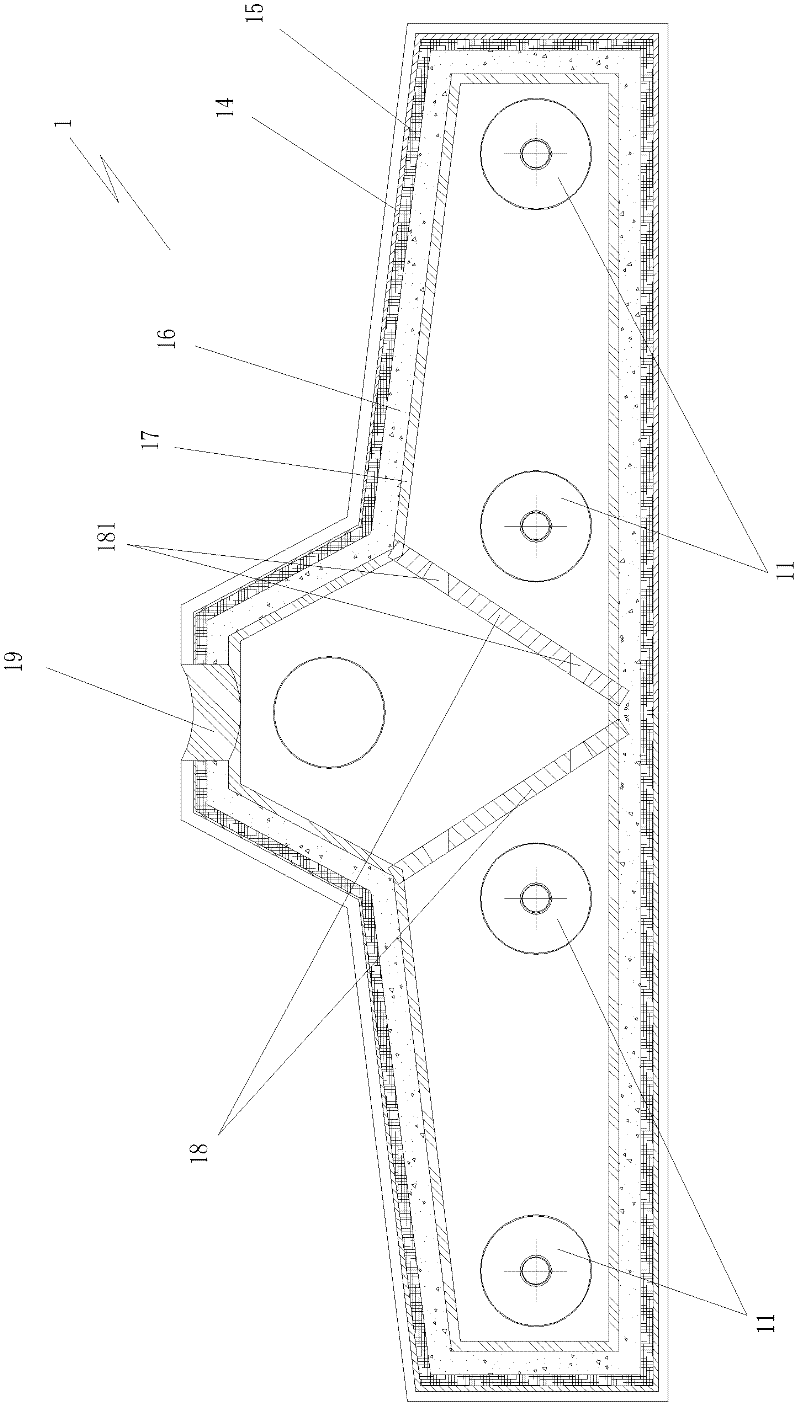

Small-capacity master alloy casting system

InactiveCN105750515AExtend the floating timeTo promote floatingMelt-holding vesselsIngot casting plantsPorosityRefractory

The invention discloses a small-capacity master alloy casting system.The whole system is mainly composed of a prefabricated tundish, a square four-hole diverter, an embedded exothermic riser, an ingot mold and a refractory bottom plate, wherein the prefabricated tundish is provided with a zirconium oxide filter and internally provided with three oblique faces and one vertical face.The square four-hole diverter is connected with the embedded exothermic riser through refractory mortar, and the embedded exothermic riser is connected with the ingot mold through the refractory mortar.The three faces, away from a water gap, inside the prefabricated tundish are the oblique faces, the face, close to the water gap, inside the prefabricated tundish is the vertical face, and the porosity of the zirconium oxide filter in the tundish is 10 ppi.An inner hole of the ingot mold has taper, and the taper is about 3 degrees.According to the casting system, a single-station casting mode is adopted, and the diameter of produced master alloy is 80-90 mm.The casting system can be used for master alloy round bar production with testing or small-lot production as the purpose, produced master alloy round bars are free of shrinkage cavities, and the quality of products is good.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Device and method for cleaning tundish upper water gap nodules

ActiveCN108176844AImprove continuous casting outputReduce production lossMelt-holding vesselsEngineeringSteel bar

The invention belongs to the technical field of steel metallurgy and particularly relates to a device and method for cleaning tundish upper water gap nodules. In the continuous casting process, when the tundish upper water gap nodule phenomenon appears, the opening degree of a plug bar is turned down, the pulling speed is reduced to 20-30% of the normal pulling speed, a segment of round steel barcontaining a calcium core is inserted into the tundish upper water gap from the hollow plug bar, steel shells at concave points or concave lines are molten by steel liquid, concave holes or gaps appear in the surface of the periphery of the round steel bar, the calcium core inside the round steel bar is heated to be a gaseous state, the gaseous calcium is sprayed out from the concave holes or thegaps to Al2O3 nodules inside the tundish upper water gap, and the calcium reacts with the Al2O3 nodules. By means of the device and method for cleaning the tundish upper water gap nodules, the cleaning time for the Al2O3 nodules is just 1-5 minutes which is far less than the time for continuous casting order replacement, the improvement of continuous casting production quantity is facilitated, thecaused production loss is far less than that caused by the replacement of a tundish, the plug bar will not be eroded, and the service life of the plug bar will not be shortened.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

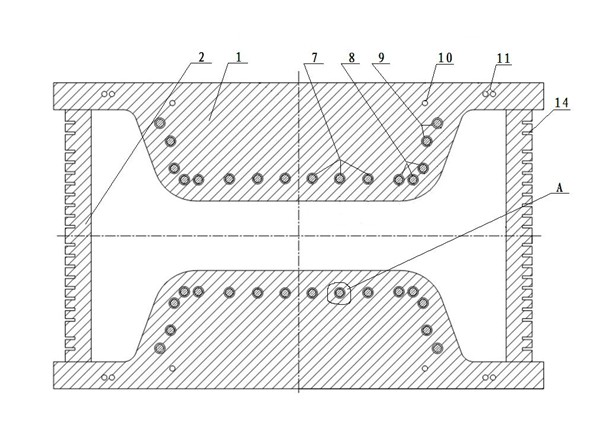

Continuous-casting crystallizer simulation method by taking shell thickness and flowing quality balance into consideration and device thereof

InactiveCN101745612APhysical description realImprove billet qualitySpecial data processing applicationsMolten steelWater gap

The invention relates to a continuous-casting crystallizer simulation method by taking shell thickness and flowing quality balance into consideration and a device thereof; the simulation steps are as follows: (1) a simulation model of a crystallizer is built, and the thickness of a casting blank shell at different position in the simulation model is considered; (2) the simulation model is operated, molten steel running is simulated in the simulation model, the molten steel quantity is gradually reduced in the flowing process, and the reduced amount corresponds to the quantity of practical molten steel for forming the casting blank shell. In the invention, the blank shell and the flowing quality in the crystallizer are balanced, the physical description of the flowing condition in the crystallizer is real, the optimization of the flow field and the water gap structural parameters in the crystallizer are more accurate, the change rule of the flowing condition in the crystallizer can be accurately obtained, so as to reflect the continuous casting practical condition really and lead the flow field and the water gap structural parameters in the crystallizer to be in accordance to the practical condition, thereby having great significance for the optimization of the continuous-casting process parameters and water gap parameters and improving the casting blank quality.

Owner:CHONGQING UNIV

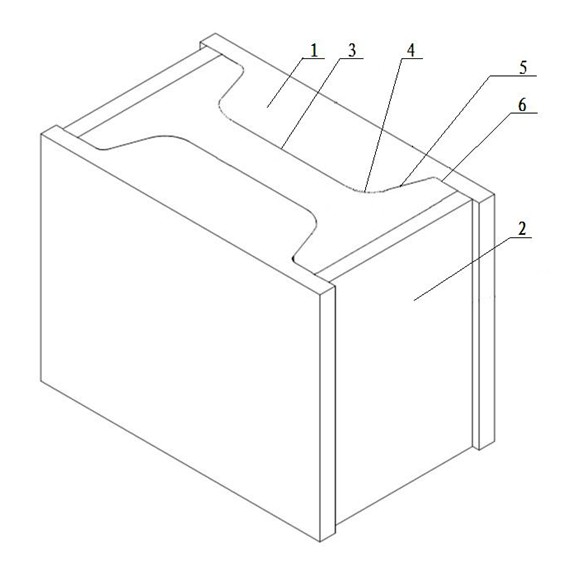

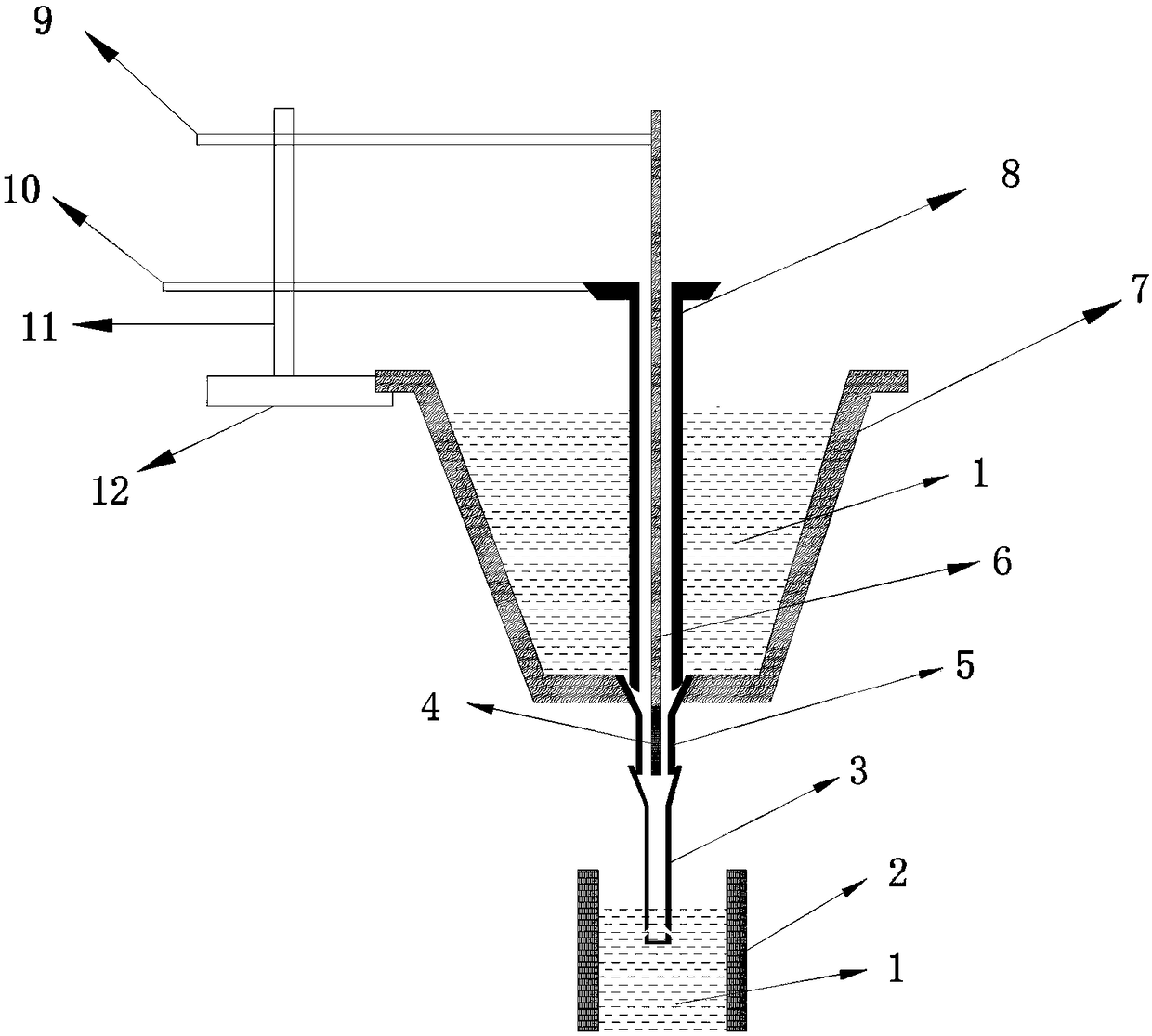

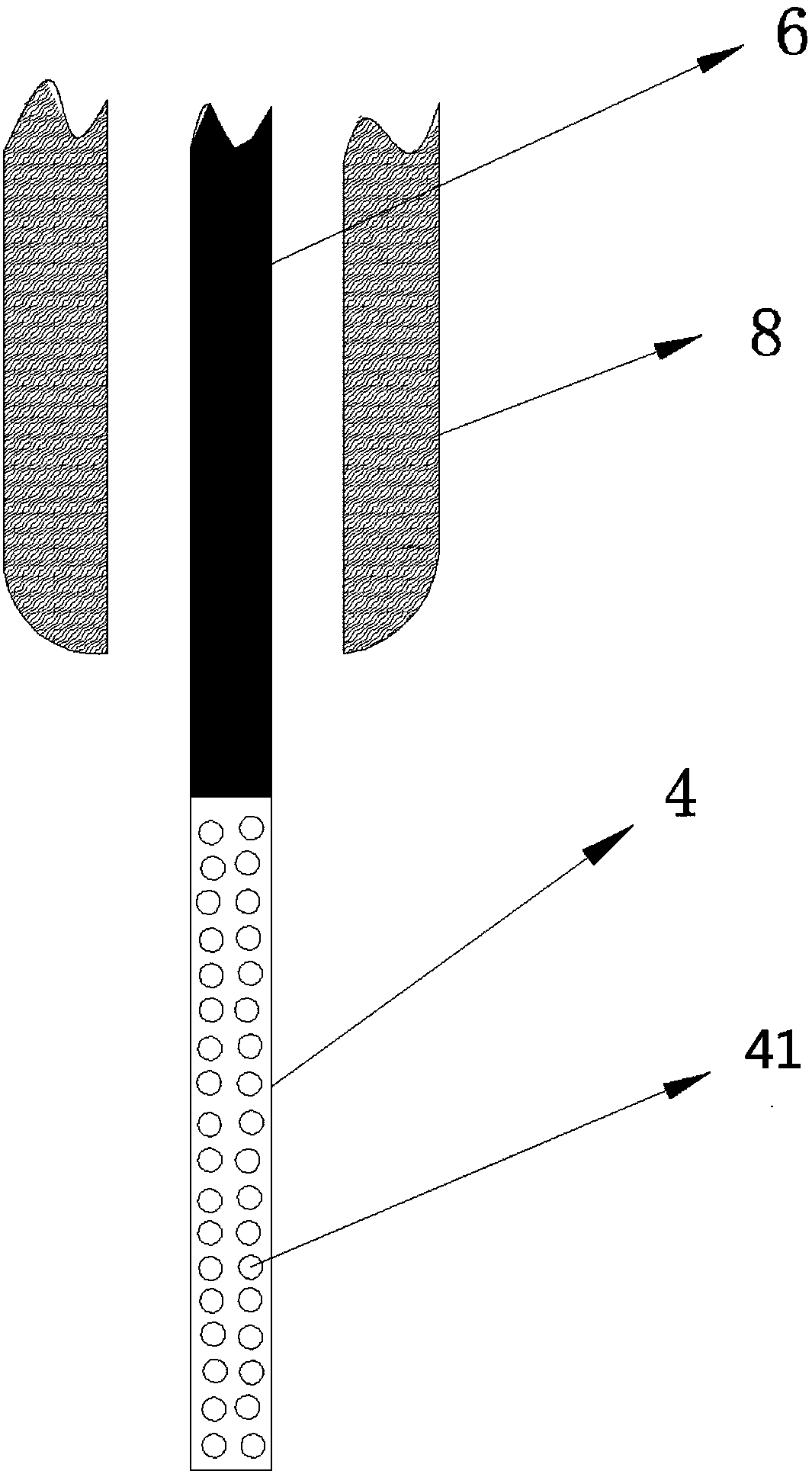

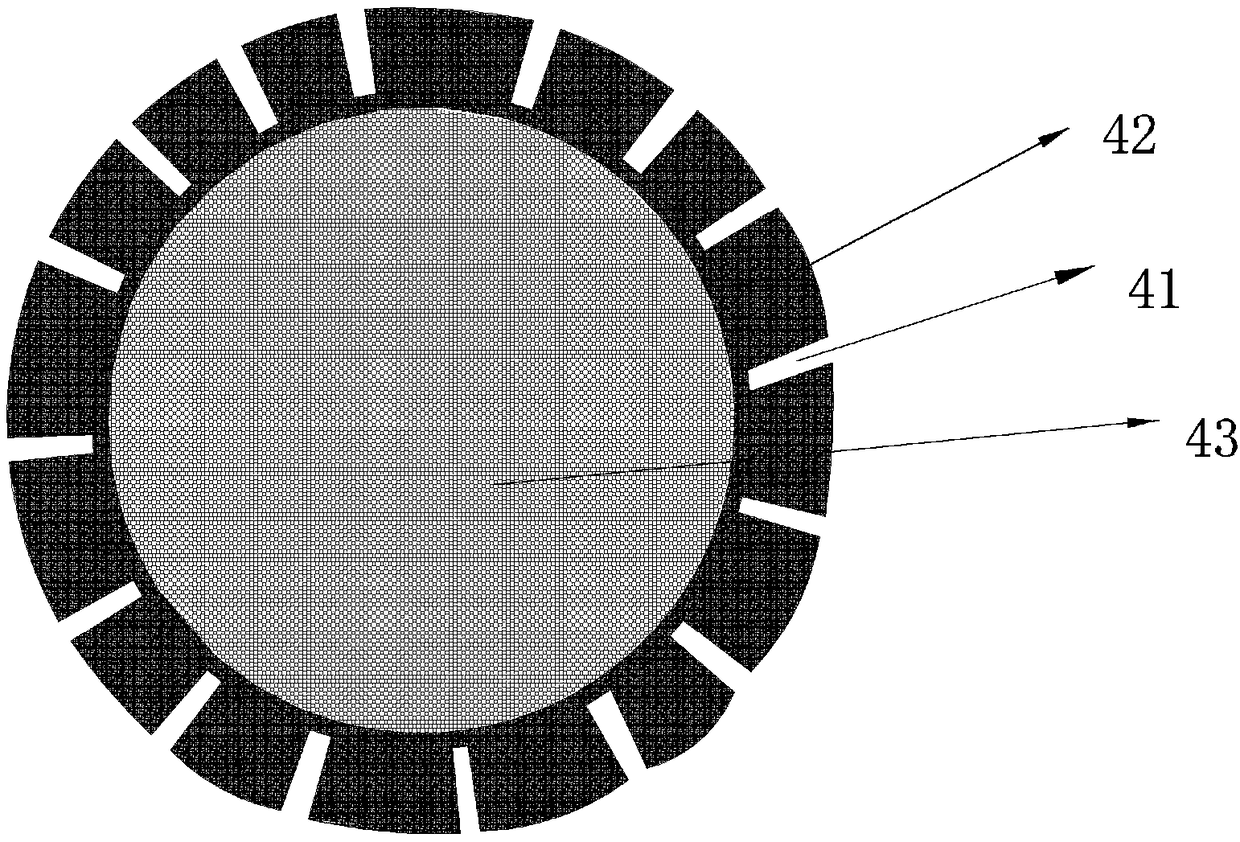

Tundish with electromagnetic heating water gaps

ActiveCN102228986AAvoid cloggingImprove heating efficiencyMelt-holding vesselsTemperature controlEngineering

The invention discloses a tundish with electromagnetic heating water gaps. Special electromagnetic heating water gaps are arranged on the bottom of the tundish body, so as to form the tundish capable of adjusting and controlling stream temperature of the water gap. One or more electromagnetic heating water gaps can be mounted on the bottom of the tundish according to the need, so as to form a tundish capable of controlling stream temperature of each water gap independently. The tundish is high in heating efficiency and capable of adjusting and controlling temperature of each pouring stream temperature independently, so that purposes of realizing optimum pouring temperature, avoiding block of water gaps, reaching low-superheat degree pouring and increasing quality of casting blanks are achieved; the tundish can be widely applied to metallurgy continuous casting production, particularly to production of multi-stream, multi-stream and large-section, and oversized-section continuously cast blooms; the tundish is accurate in temperature control, high in controllability, low in operation cost, and capable of increasing quality of products remarkably and reducing production cost.

Owner:北京京诚华宇建筑设计研究院有限公司

Multifunctional traffic safety barrier

InactiveCN102493379ARealize automatic spray washingRealize automatic spray cleaning and energy savingRoad cleaningRoadway safety arrangementsElectricityEngineering

A multifunctional traffic safety barrier relates to a barrier; the barrier comprises a supporting body device, an energy-saving device and a spray system, wherein the supporting body device comprises a left lifting rod, a right lifting rod, a left anchor block, a right anchor block, a square groove pipe, a left casing pipe and a right casing pipe; the energy-saving device comprises an electricitystorage plate, an electricity storage rod, a left energy-saving lamp and a right energy-saving lamp; and the spray device comprises a water inlet pipe, a water distributing valve, a left water pipe, a right water pipe, a left spray pipe, a left bank tube, a right spray pipe, a right bank tube, a left turbine, a right turbine, a left rotating wheel, a right rotating wheel, a square spraying pipe, a left water gap, a right water gap, a left drain port, a right drain port and an outer rotary drum. The multifunctional traffic safety barrier has the advantages of exquisite and elegant structure, excellent performance, wide application, self-cleanness, energy conservation, environmental friendliness, convenience and efficiency in installation and carrying, safety, reliability, durability and lower manufacturing cost, i.e. very remarkable comprehensive cost performance and traffic safety benefits by analyzing, combining, optimizing, improving and innovating the advantages of various traffic barriers at home and abroad and organically setting technologies such as automatic spraying, energy conservation, environmental friendliness and the like.

Owner:LIUZHOU JINGYANG ENERGY SAVING TECH RES DEV

Air purifying humidifier

InactiveCN101280946AImprove viewing valueDispersed particle filtrationLighting and heating apparatusRotational axisWater channel

The invention discloses an air purifying humidifier for resolving technical matters that the air purifying humidifier is more beautiful and has arrangement and view value in use. The invention employs following technical schemes that an air purifying humidifier includes a base plate and water tank, the water tank is arranged on the base plate, a first hole is arranged on the base plate, the first hole has a fan built-in, an auxiliary water channel is arranged on the base plate, the water tank has a first in and out water gap arranged on, the first in and out water gap has an in and out penstock arranged on, the water tank has a rotation axis arranged inside or outside, one end of the rotation axis is connected to output shaft of a motor, the other end is connected to decorations or an extension mechanism. Comparing with the present technology, the invention changes operation structure of static humidifier, a transmission mechanism is provided, and internal action of the water tank such as action of the decorations can be seen by users, thereby obtaining more beautiful effects with view and admire value.

Owner:福智海研究院

Equipment and technique for ladle-to-ladle, degasification and vacuum ingot casting of multiple-slide runner ladle

InactiveCN101352755ASimple processMelt-holding vesselsMolten metal conveying equipmentsIngot castingLiquid slag

A device for the pouring and degassing of a plurality of sliding water gap packets as well as casting ingots in vacuum and a technique thereof belong to the field of vacuum steel flow degassing method. The invention avoids the defect of polluting the molten steel generated by the secondary oxidation when the sliding water gap packets pour to the middle packet of a plug stick in the atmosphere during the existing ingot casting method in vacuum. The invention comprises a plurality of slide water tap packets and degassing covers as well as vacuum chambers, etc. The vacuum chamber filled with an ingot mold is vacuumized, and then the middle packet of the sliding water tap filled with protective slag after being baked is sat on the cover of the vacuum chamber and is buckled with the degassing cover for vacuumizing. The first packet of the molten steel is sat on the degassing cover; the water tap is opened for pouring and degassing; the water tap of the middle packet is opened for begging casting ingots in vacuum when a regulated time arrives; after the first packet of the molten steel is cast, the lower of the degassing cover breaks the vacuum to hoist away the empty packet and a new packet is sat; then after the new packet is vacuumized, the water tap of the new packet is poured and degassed; the molten steel is supplemented to the middle packet to continuously carry out ingot casting in vacuum, thus finishing casting a heavy ingot. As liquid slag in the middle packet obstructs the atmosphere and the molten steel when pouring, degassing and breaking the vacuum, the device and the technique avoid the defects like 'secondary oxidation' of the existing ingot casting method.

Owner:冬燕

Automobile accessory die casting method

InactiveCN105215314AHigh tensile strengthMetamorphic refinement tissue improvementHeat resistanceDie casting

The invention discloses an automobile accessory die casting method and relates to the technical field of metal die casting. Aluminum alloy is adopted. The method includes the following steps of melting, modification for gas removal, die casting, cooling and annealing, and die casting of a product is completed. According to the method, because the aluminum alloy is adopted, the tensile strength, the modified and refined structure, the heat resistance, the ductility and the plasticity of the product are obviously improved; the pore reject ratio in the die-cast element is greatly reduced, and the product yield is increased to over 90%. Gas removal is carried out in the melting process, so that bubbles are avoided in the die-cast element, and product toughness is good after annealing. A vacuum casting mode is adopted so that a cast surface can be fine and a bright or texture surface can be generated. Besides, waste can be reduced during production, water gaps or abundant waste can be recycled, and cost is reduced.

Owner:ANHUI HUOSHAN LONGXIN METAL TECH CO LTD

Glaze-crawling-proof protection coating for immersion type water gap slag line and preparation method of glaze-crawling-proof protection coating

The invention discloses a glaze-crawling-proof protection coating for an immersion type water gap slag line and a preparation method of the glaze-crawling-proof protection coating. The coating is prepared from a main material, water and dextrin; the main material is prepared from the following components in percentage by weight: 62 percent to 66 percent of tabular corundum, 15 percent to 17 percent of Suzhou clay, 3 percent to 5 percent of bentonite, 12 percent to 16 percent of active aluminum oxide and 0.5 percent to 1 percent of sodium silicate; the weight ratio of the water to the dextrin to the main material is (31 to 33):(0.6 to 0.8):100. The glaze-crawling-proof protection coating disclosed by the invention can be used for effectively preventing an anti-oxidization coating of the immersion type water gap slag line part from generating glaze crawling, so that the strength and anti-corrosion performance of the immersion type water gap slag line are improved, and the service life of an immersion type water gap can be prolonged for 2.5 hours to 3.5 hours.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

Efficient diamond drill for repairing concrete sleeper and fabricating method thereof

InactiveCN101579892AImprove protectionNot easily oxidizedStone-like material working toolsBronzeWater gap

The invention discloses an efficient diamond drill for repairing a concrete sleeper and a fabricating method thereof and relates to the technical field of drill fabrication. The efficient diamond drill solves the technical problems that the production efficiency is improved and the production cost is lowered during the fabrication of the diamond drill for repairing the concrete sleeper. The diamond drill comprises a drill base body and a drill labial part connected with the head end of the drill base body, the top end of the drill labial part is provided with a plurality of drill water gaps separating the top end of the drill labial part into a plurality of drill teeth. The efficient diamond drill is characterized in that a working layer of the drill labial part contains 18-30 weight percent of diamond, metallic bond of the working layer of the drill labial part consists of framework components and bonding components, the weight proportion of the framework components to the bonding components is 35:65 to 45:55, the framework components include WC, and the like; and the bonding components comprise Ni, Co, Mn, 663 bronze, and the like. The fabricating technique of the diamond drill has the characteristics of improving the production efficiency and lowering the production cost.

Owner:上海钻圣和新材料科技有限公司

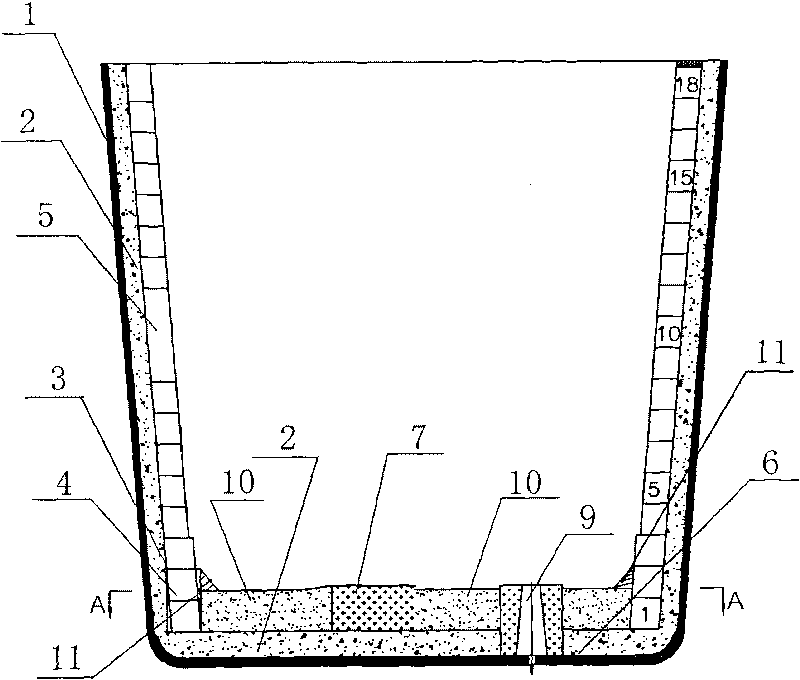

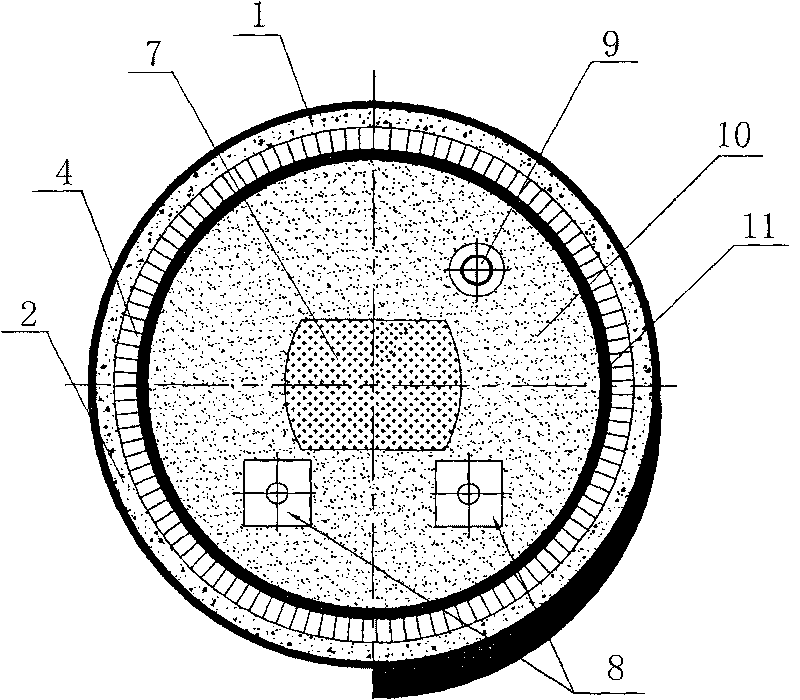

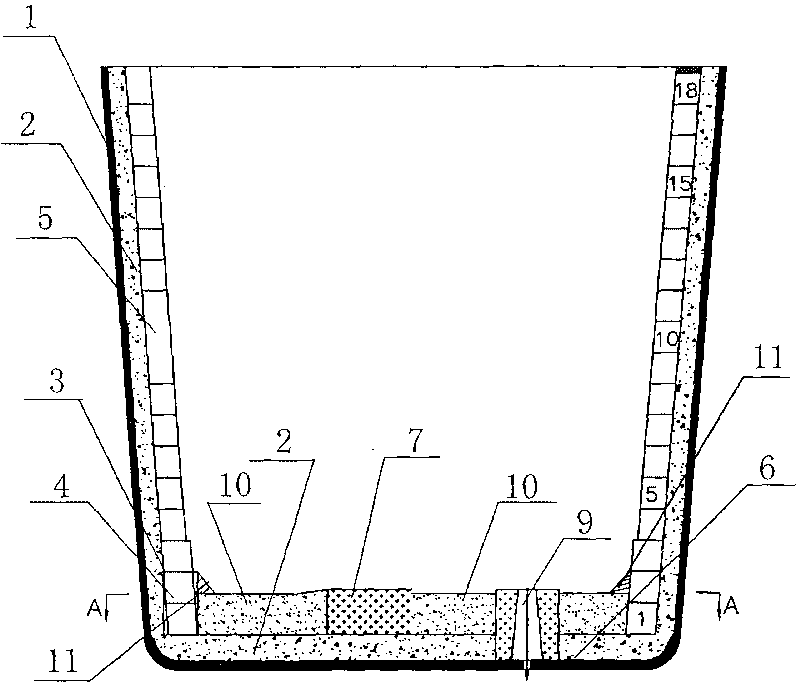

Method for building container bottom of carbon-containing molten steel container

The invention relates to a method for building the container bottom of a carbon-containing molten steel container, which comprises the following steps: firstly, pouring a high-aluminum pouring material layer 2 into a casing 1 of the molten steel container; building a carbon-free working layer 4 below a working layer 3 at the wall of the molten steel container and a carbon-containing working layer 5 above the working layer 3 at the wall of the molten steel container by three layers of carbon-free precast blocks 7; arranging the carbon-free precast blocks 7, a ventilation brick 8 and a slide water gap 9 at an impact area on the high-aluminum pouring material layer 2 at the container bottom 6 of the molten steel container; pouring a carbon-free pouring material layer 10 at a non-impact area on the high-aluminum pouring material layer 2 at the container bottom 6 of the molten steel container; and after pouring the container bottom 6 of the molten steel container, filling by a carbon-free pouring material along the carbon-free working layer 4 on the carbon-free pouring material layer 10 into a slope type encircling wall 11. The invention solves the change of physical properties, such as carbon-containing brick chalking, folding strength and the like, caused by the water of a pouring material at the container bottom of the molten steel container, controls steel clamping caused by the replacement of the bottom, has more stable running of the impact area at the bottom of a tank and is beneficial to the unity of large back molten steel containers with various varieties.

Owner:武钢集团有限公司

Manufacturing tool of high-compact wide and thick plate blank for wide and thick plate rolling mill and method

The invention relates to the field of manufacturing field of a wide and thick plate blank for a wide and thick plate rolling mill, in particular to a manufacturing tool of a high-compact wide and thick plate blank for the wide and thick plate rolling mill, solving the problems of oxidation with impurities, hole shrinkage, looseness, cracks and the like of the plate blank. The manufacturing tooling is provided with a heat-insulating riser, moving dies, water cooling inner sleeves, a long water gap, hydraulic cylinders, a water cooling chassis and a hydraulic power system providing the externalforce; all the moving dies are combined on the water cooling chassis by utilizing the external force, and the heat-insulating risers are arranged at the upper parts of the moving dies; simultaneously, the long water gap is preheated, and before casting, the long water gap is arranged at the center of a cavity to wait for casting; in the casting process, the long water gap and a ladle steel outletare butted, a ladle is opened, and molten steel enters the cavity from the long water gap; molten metal is solidified in a water cooling mold, the hydraulic system is adopted to provide external force, so as to lead the plate blank to be crystallized under the pressure action; after the solidification is finished, boxing and riser cutting are carried out on the wide and thick plate blank under the high-temperature state; and finally, the wide and thick plate blank is placed in a heat treatment furnace for annealing treatment.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Forging process of large axle-shaped forgings

The invention discloses a forging process of large axle-shaped forgings, and belongs to the technical field of machining of the large axle-shaped forgings. The process comprises the following steps that (1) blanks are selected, and risers and water gaps are cut off; (2) the blanks are put into a furnace, and gaps are reserved among the blanks; (3) the blanks inside the furnace are subjected to primary heating, primary heat insulation treatment, upsetting and drawing out in sequence, and the forging ratio is 4-5; (4) secondary heating, secondary heat insulation treatment, upsetting and drawing out are conducted in sequence, and the forging ratio is 3-4; (5) thrice heating, thrice heat insulation treatment, upsetting and drawing out are conducted in sequence, and the forging ratio is 1.8-3.1; and (6) the large axle-shaped forgings are subjected to normalization treatment immediately. The surfaces and the interiors of the large axle-shaped forgings are free of cracks; the chemical components of the large axle-shaped forgings are uniform and stable in structure; and the large axle-shaped forging products are good in quality and high in economic benefit.

Owner:ANHUI RUIJIE FORGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com