Method for building container bottom of carbon-containing molten steel container

A ladle and carbon steel technology, applied in the field of masonry with carbon ladle bottom, can solve the problems of tank wall brick damage, masonry wall removal, high refractory cost, etc., achieve stable operation, reduce refractory cost, and reduce the The effect of material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

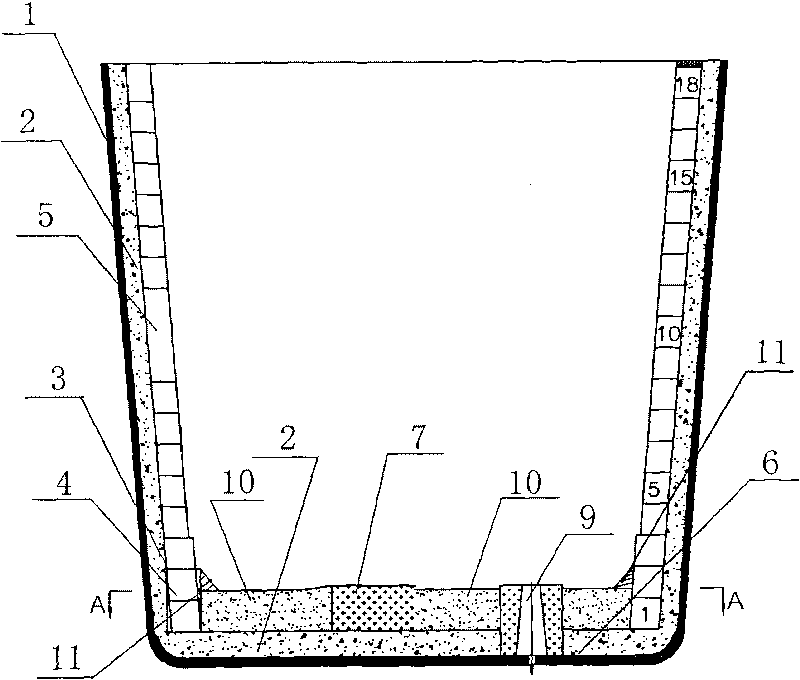

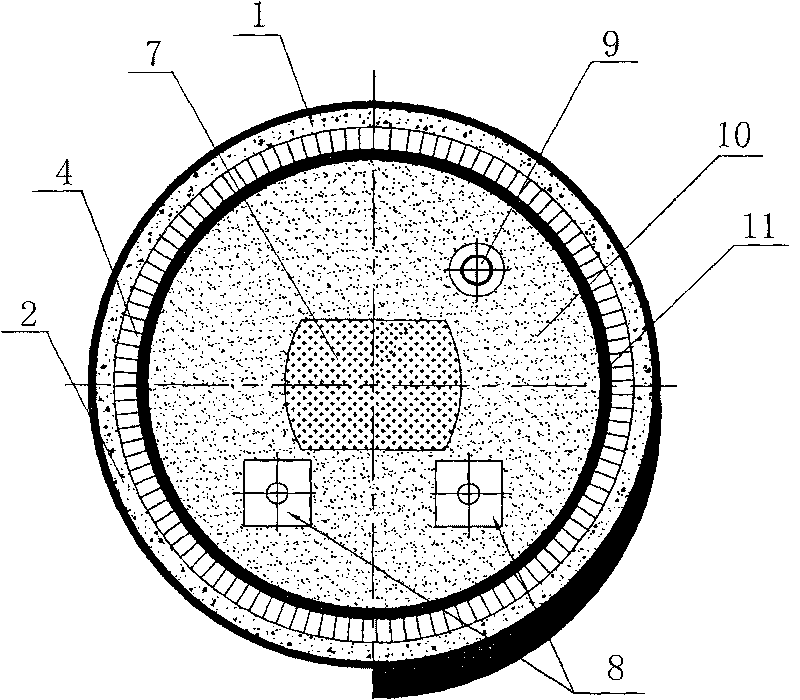

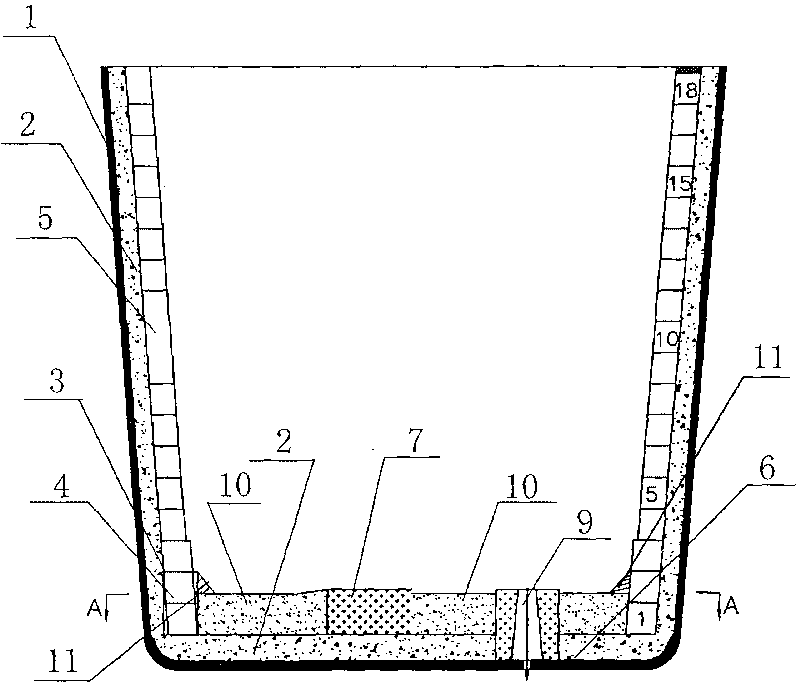

[0022] Describe in detail below in conjunction with accompanying drawing:

[0023] A kind of masonry method with carbon steel ladle bottom, its steps:

[0024] 1) pouring the high-aluminum castable layer 2 in the ladle shell 1 first;

[0025] 2) The three lower layers of the ladle wall working layer 3 are built with carbon-free prefabricated blocks to form a carbon-free working layer 4, and then the original carbon-containing working layer 5 with carbon bricks is built;

[0026] 3) Install carbon-free prefabricated blocks 7, breathable bricks 8, and sliding nozzles 9 in the impact zone on the high-alumina castable layer 2 at the bottom of the ladle 6;

[0027] 4) Casting a carbon-free castable layer 10 in the non-impact zone on the high-alumina castable layer 2 at the bottom of the ladle 6;

[0028] 5) After the pouring of the ladle bottom 6 is completed, on the carbon-free castable layer 10 , along the carbon-free working layer 4 , fill the slope-type surrounding wall 11 wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com