Patents

Literature

105results about How to "Guaranteed service performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

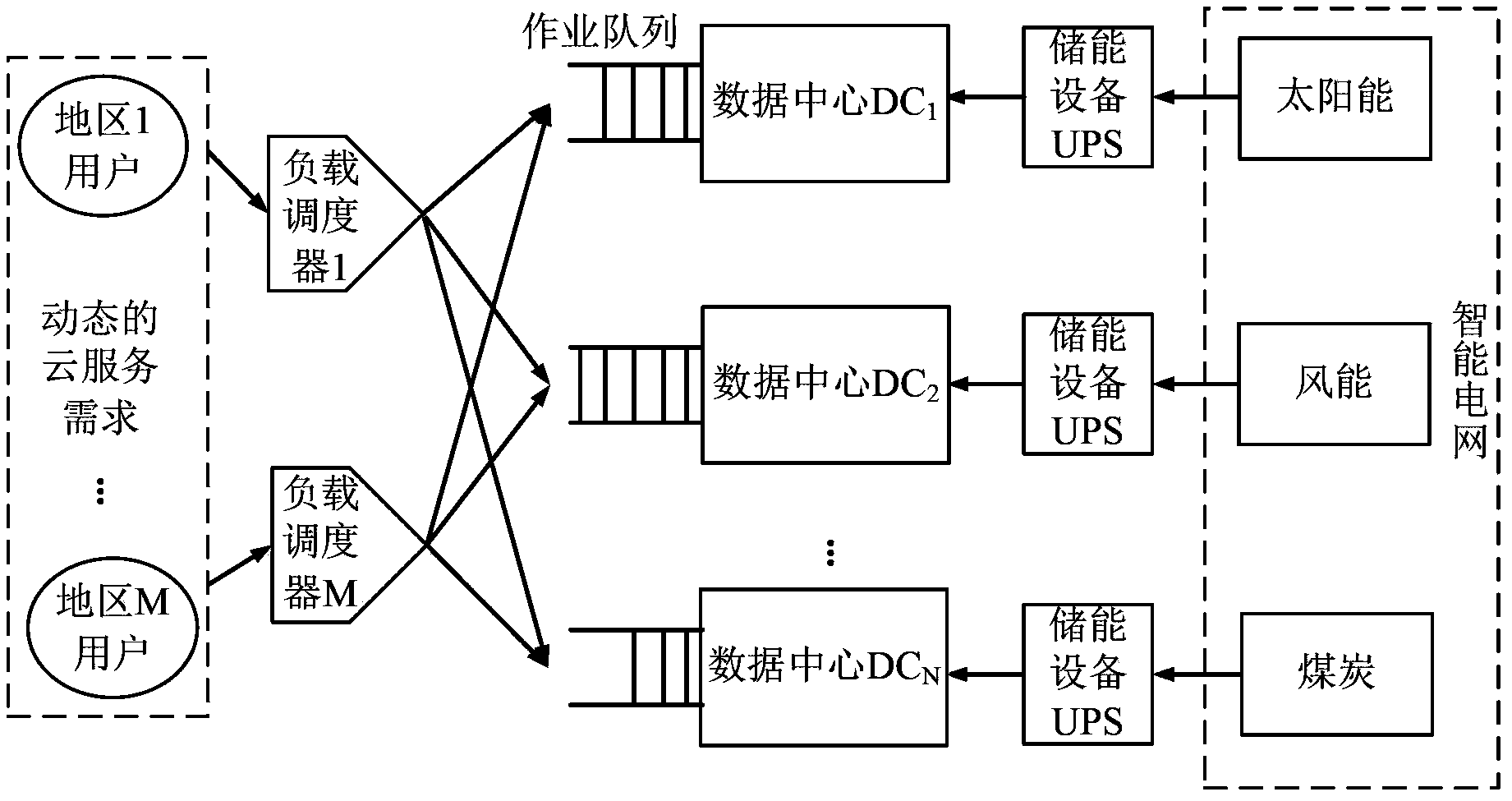

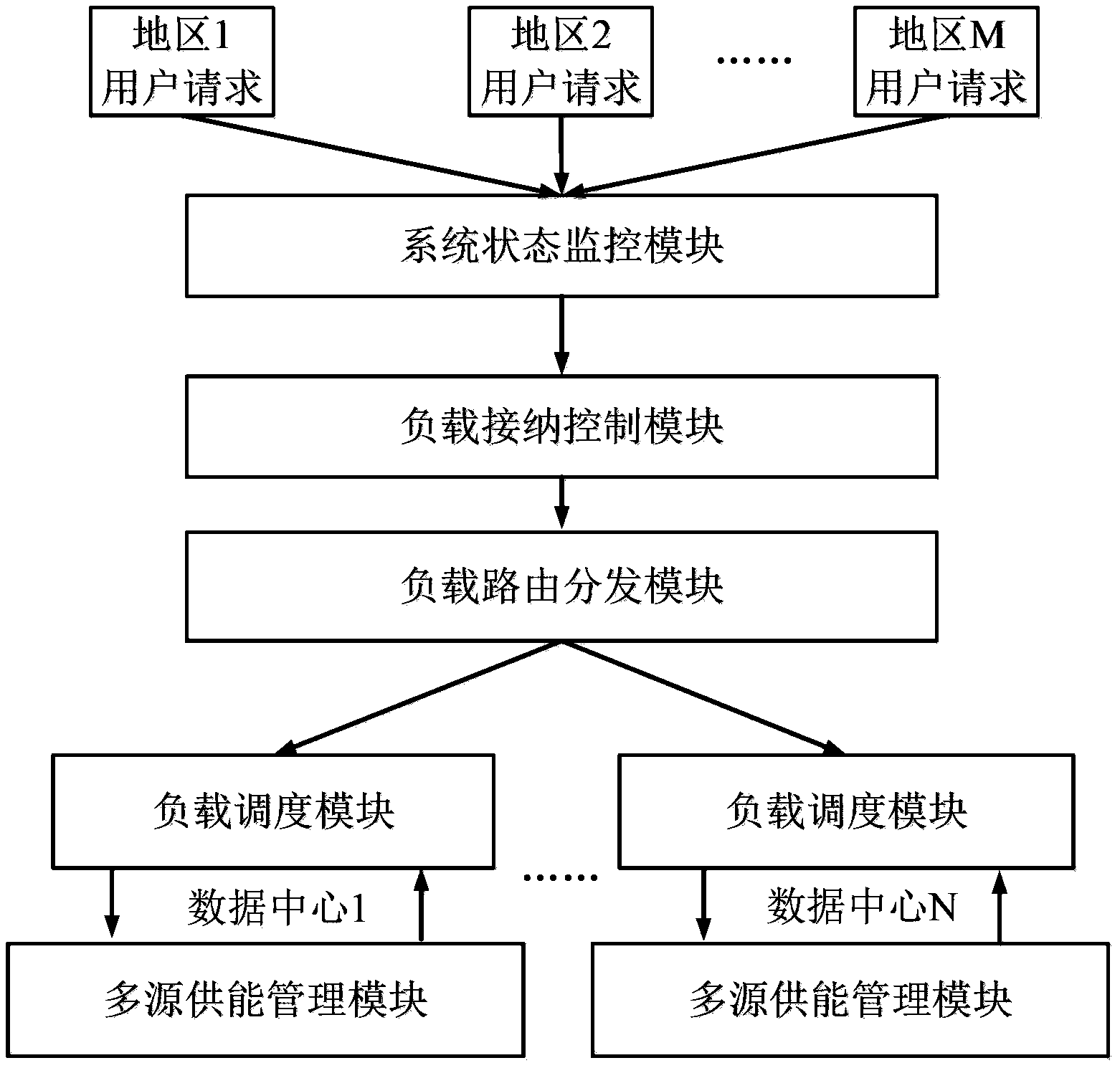

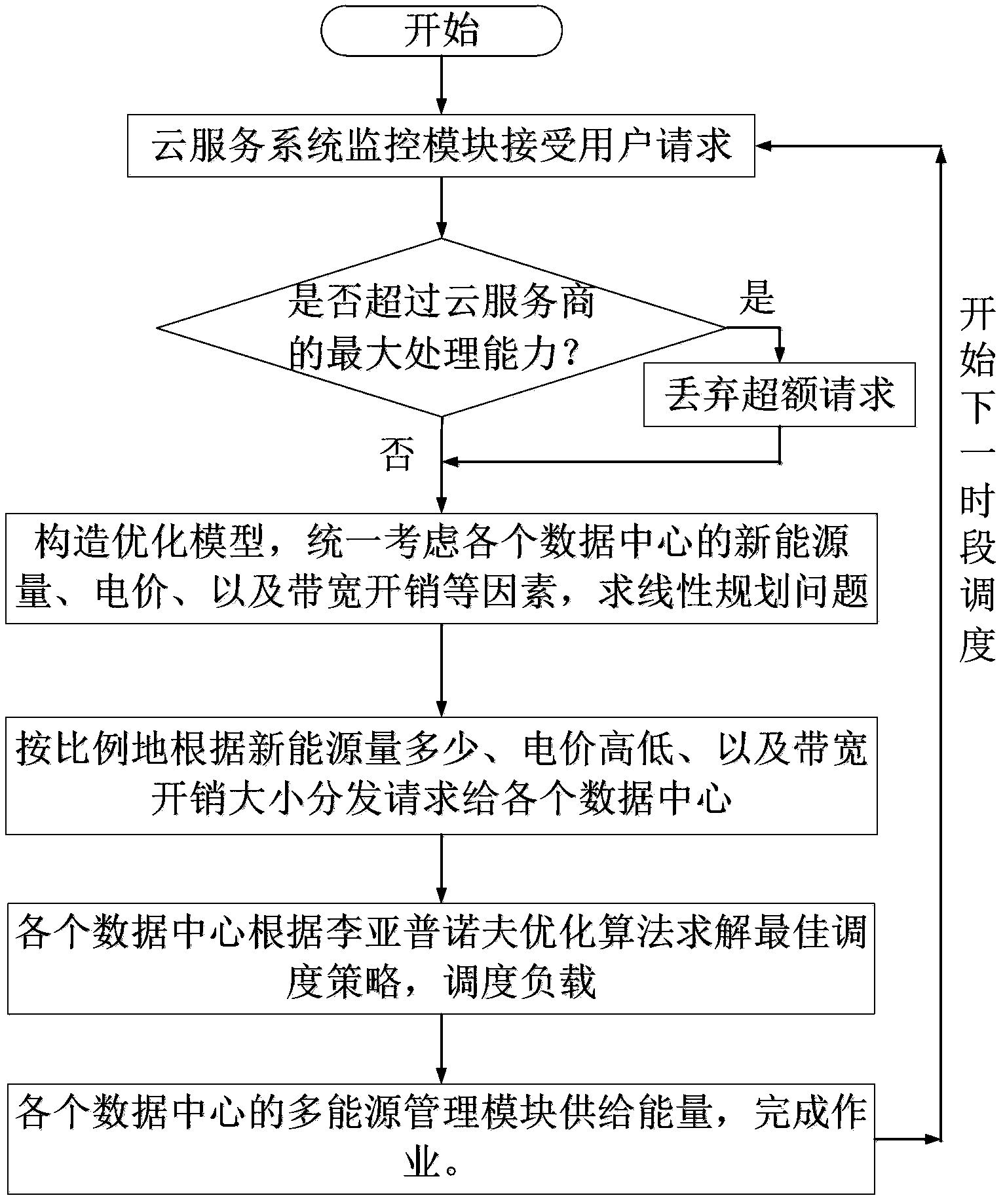

Cloud service distributed data center system and load dispatching method thereof

ActiveCN103384272AMinimize operational overheadLow electricity priceTransmissionElectricity priceNew energy

The invention discloses a cloud service distributed data center system which comprises a system state monitoring module, a load admission control module, a load routing distribution module, a load dispatching module and a multi-source energy supply management module. The system state monitoring module is used for acquiring cloud service requests from different users, recording the cloud service requests and information related to the cloud service requests and transmitting the cloud service requests to the load admission control module, the load admission control module is used for selecting parts of the cloud service requests according to the number of the received cloud service requests and transmitting the cloud service requests to the load routing distribution module, and the load routing distribution module is used for distributing the received cloud service requests to corresponding data centers for processing. The cloud service distributed data center system can solve the problems that a data center energy supply system in an existing system is high in long-term operating expenditure and unstable in new energy supply, electricity price fluctuates, and system data or stable distribution needs to be acquired in advance.

Owner:HUAZHONG UNIV OF SCI & TECH

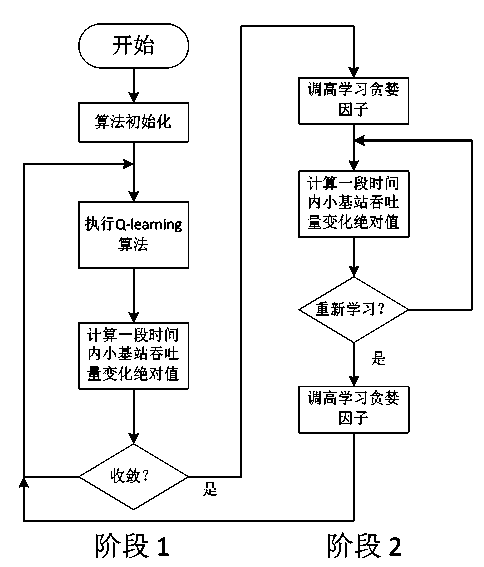

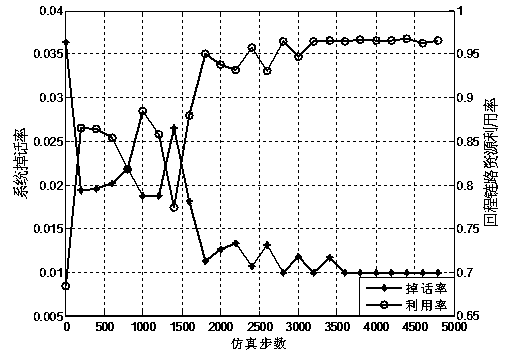

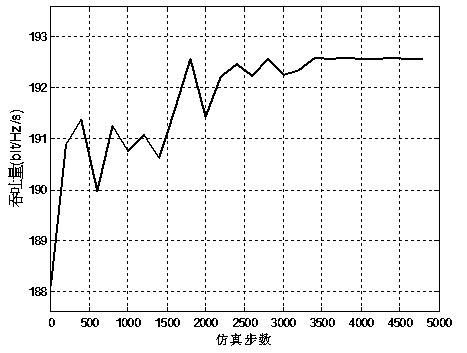

Distribution type method for adjusting small base station transmitting power bias values in self-adaptive mode

ActiveCN103906076ATake advantage ofIncrease capacityPower managementNetwork planningSystem capacityMacro base stations

The invention discloses a distribution type method for adjusting small base station transmitting power bias values in a self-adaptive mode. Under the condition that the return link capacity of a small base station is limited, the Q-learning method in machine learning is used for adjusting small base station transmitting power bias in the self-adaptive mode to share macro honeycomb loads, and the utilization rate of small base station return link resources is improved. Through the Q-learning method in machine learning, each small base station can conveniently monitor the number of peripheral users and changes of user distribution in real time, reference signal power bias values of the small base station are timely adjusted to obtain the optimal bias value selection under the current condition, and therefore the resources of the small base station are fully utilized for achieving the load sharing function for a macro bass station. The method can effectively improve system capacity and the covering effect, facilitates operation cost saving of the macro base station, and achieves green communication.

Owner:CERTUS NETWORK TECHNANJING

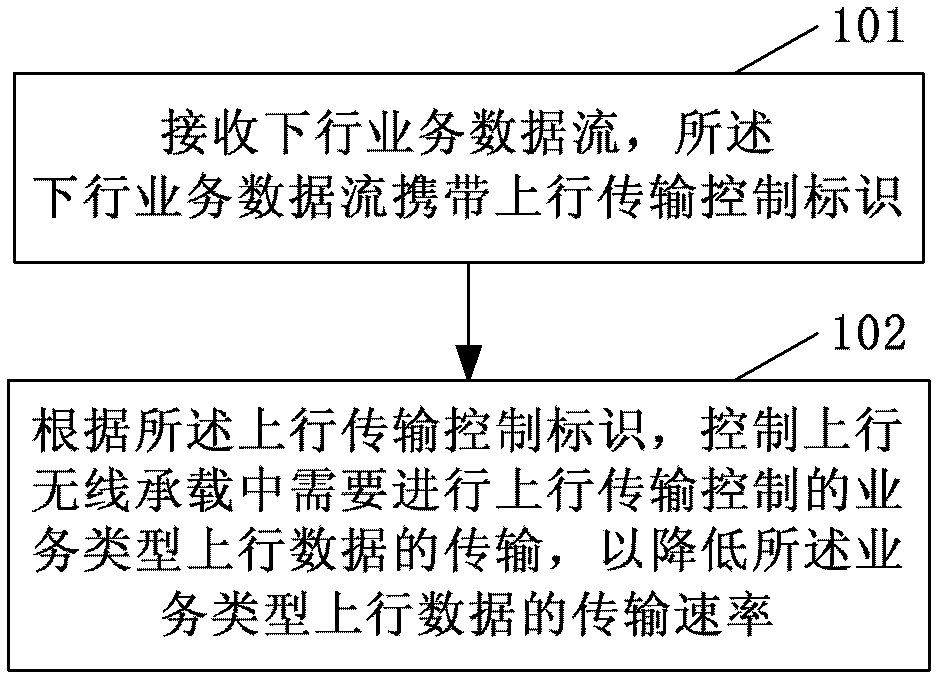

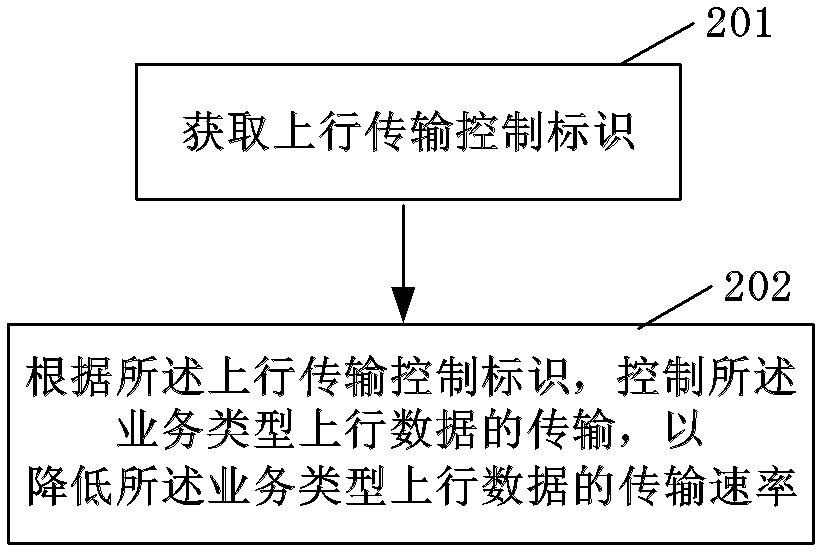

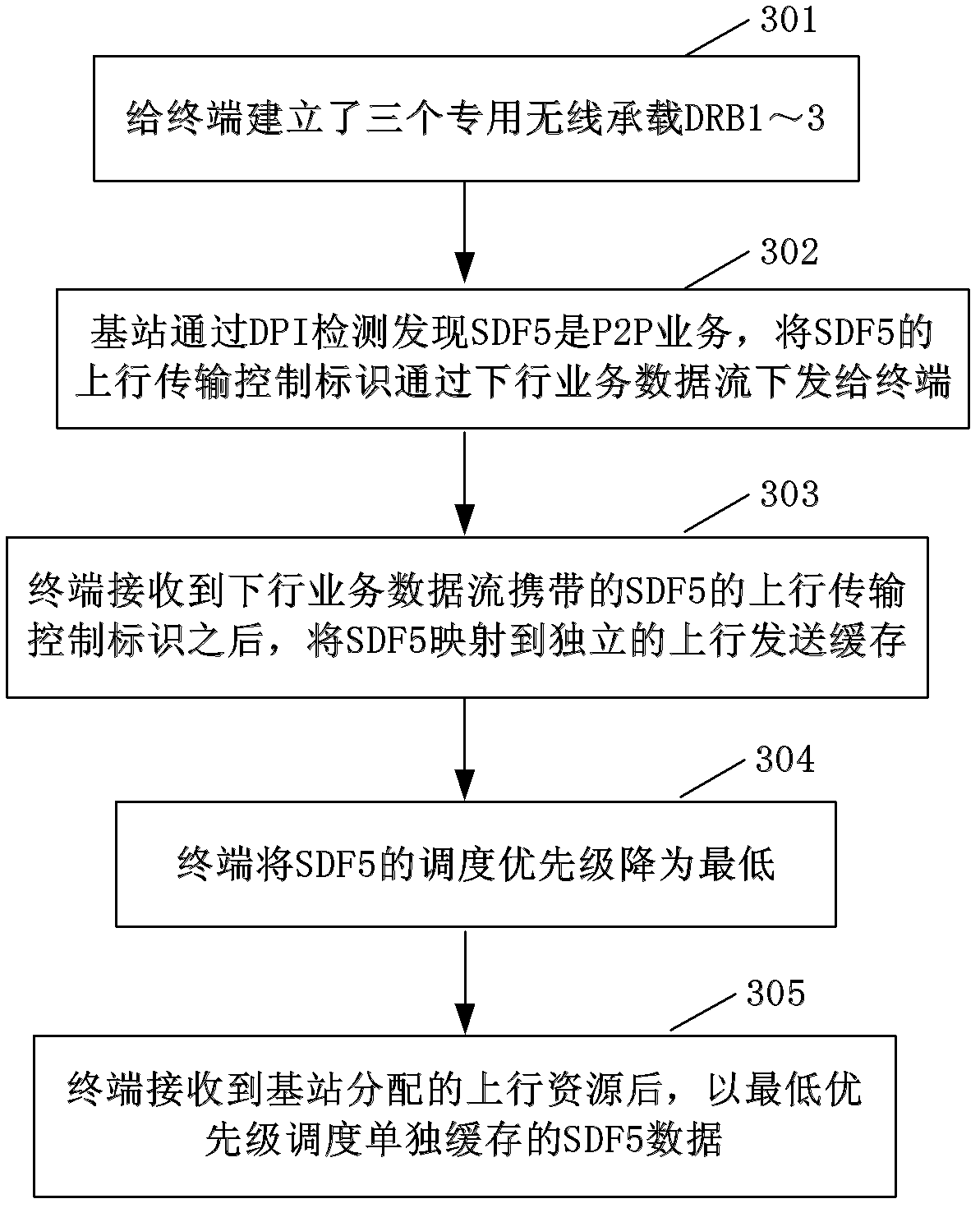

Method for guaranteeing quality of uplink service, base station and user equipment

ActiveCN102883457ALow transfer rateIssues Affecting Service QualityNetwork traffic/resource managementConnection managementQuality of serviceData stream

The embodiment of the invention provides a method for guaranteeing the quality of an uplink service, a base station and user equipment. The method for guaranteeing the quality of the uplink service comprises the following steps of: receiving a downlink service data stream, wherein the downlink service data stream carries an uplink transmission control identifier; and according to the uplink transmission control identifier, controlling the transmission of service type uplink data, which are required to be subjected to uplink transmission control, in an uplink radio bearer. Therefore, the transmission rate of the service type uplink data is reduced. By the technical scheme provided by the embodiment of the invention, in a mode of concentratively scheduling uplink resources, the data identified from the dedicated radio bearer are controlled, so that the quality of the uplink service can be guaranteed.

Owner:HUAWEI TECH CO LTD

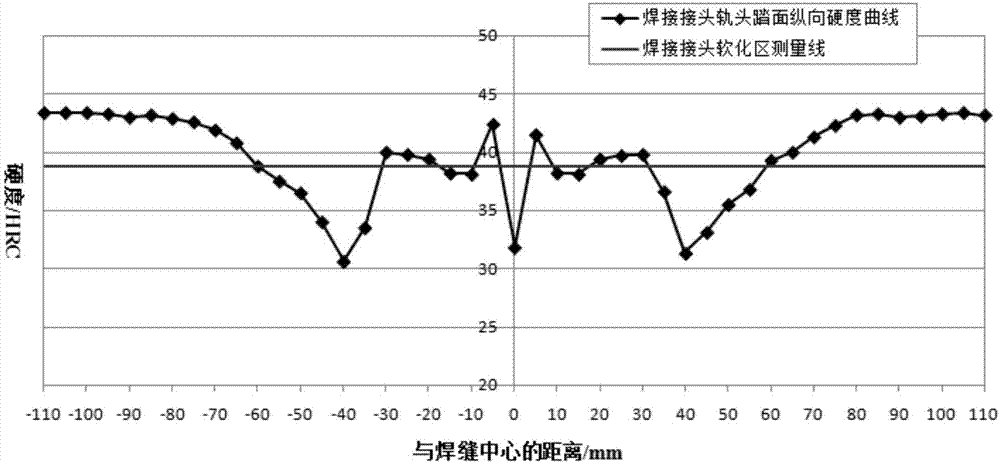

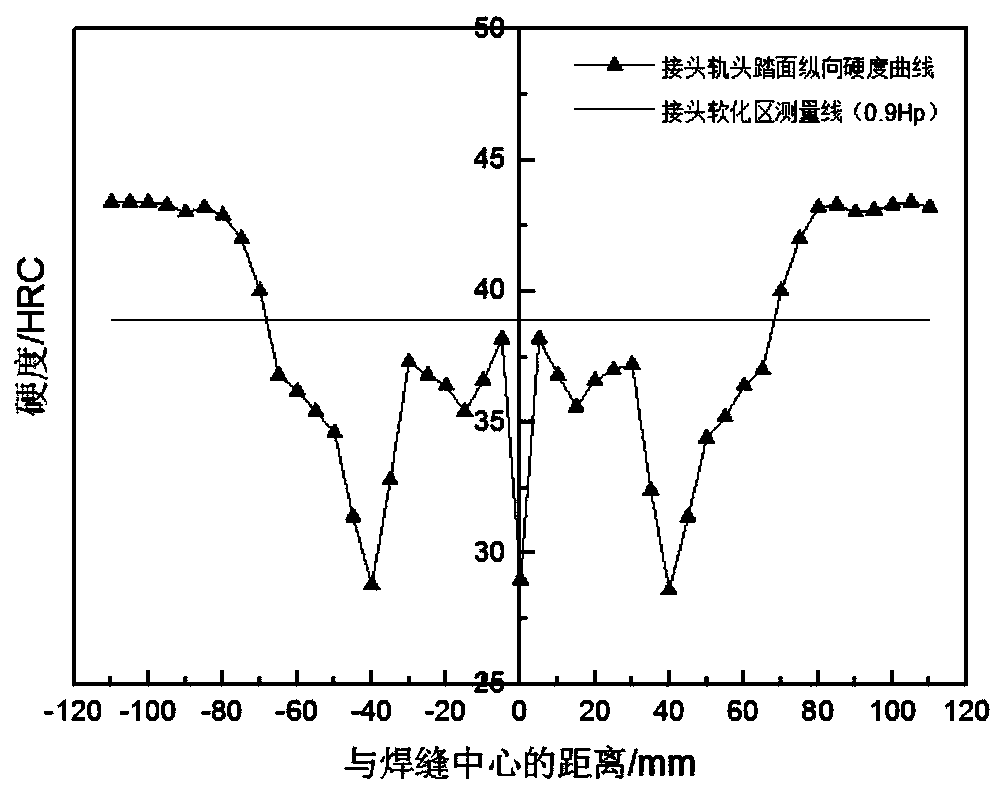

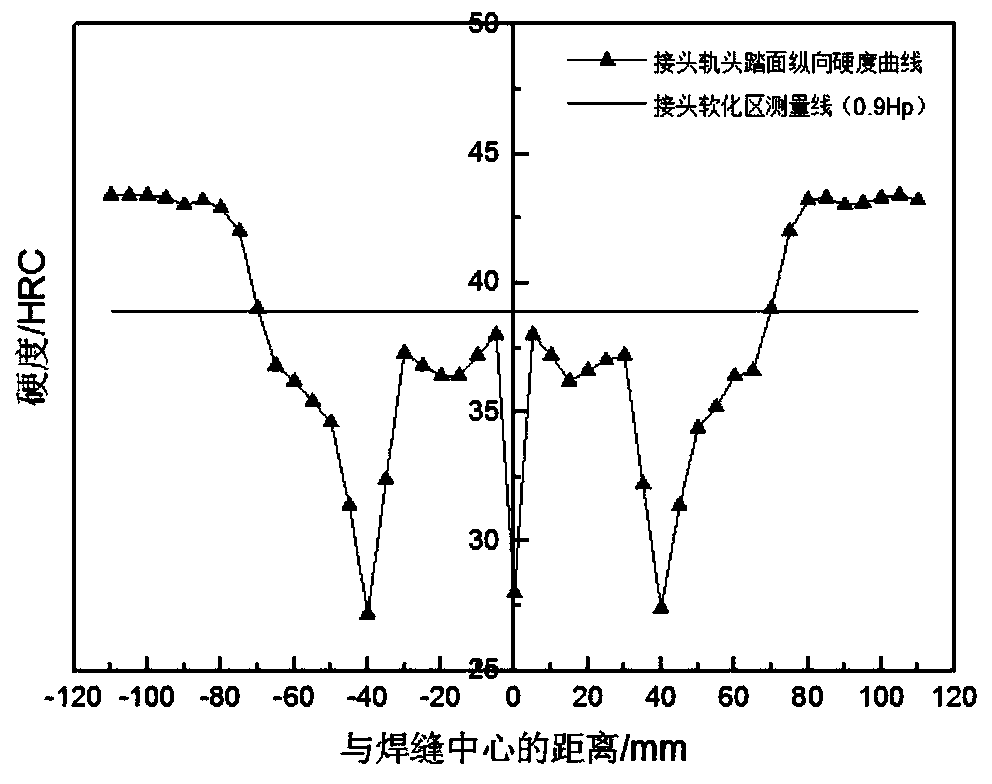

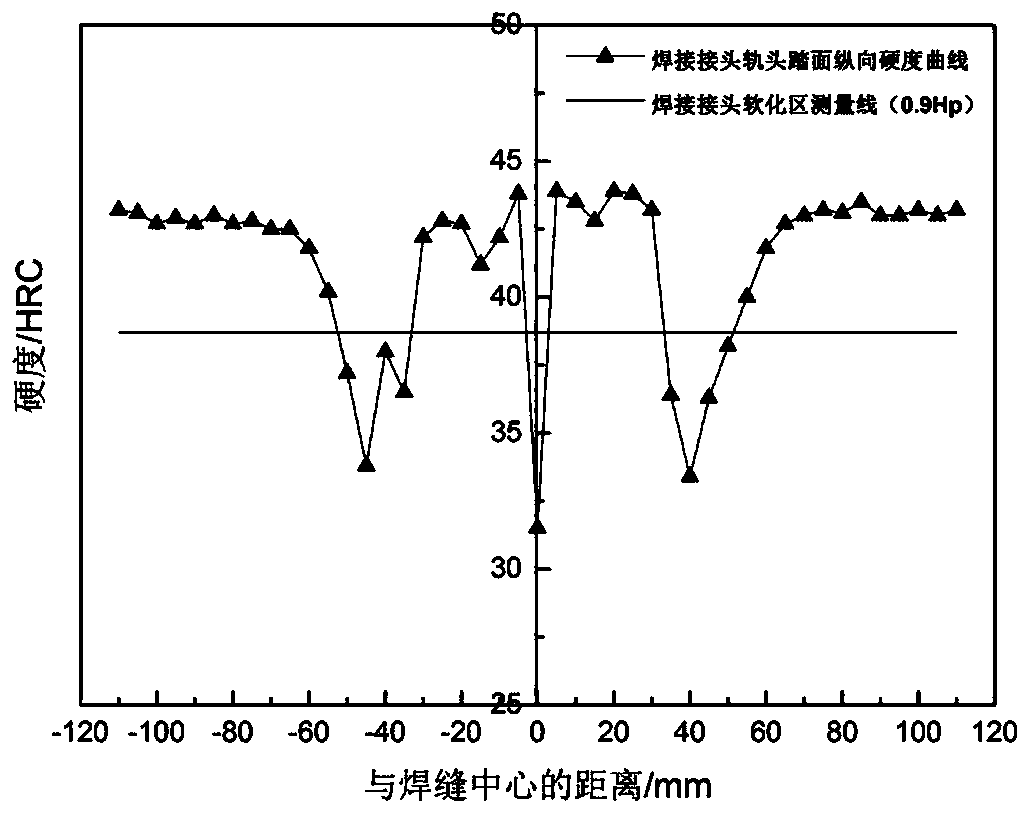

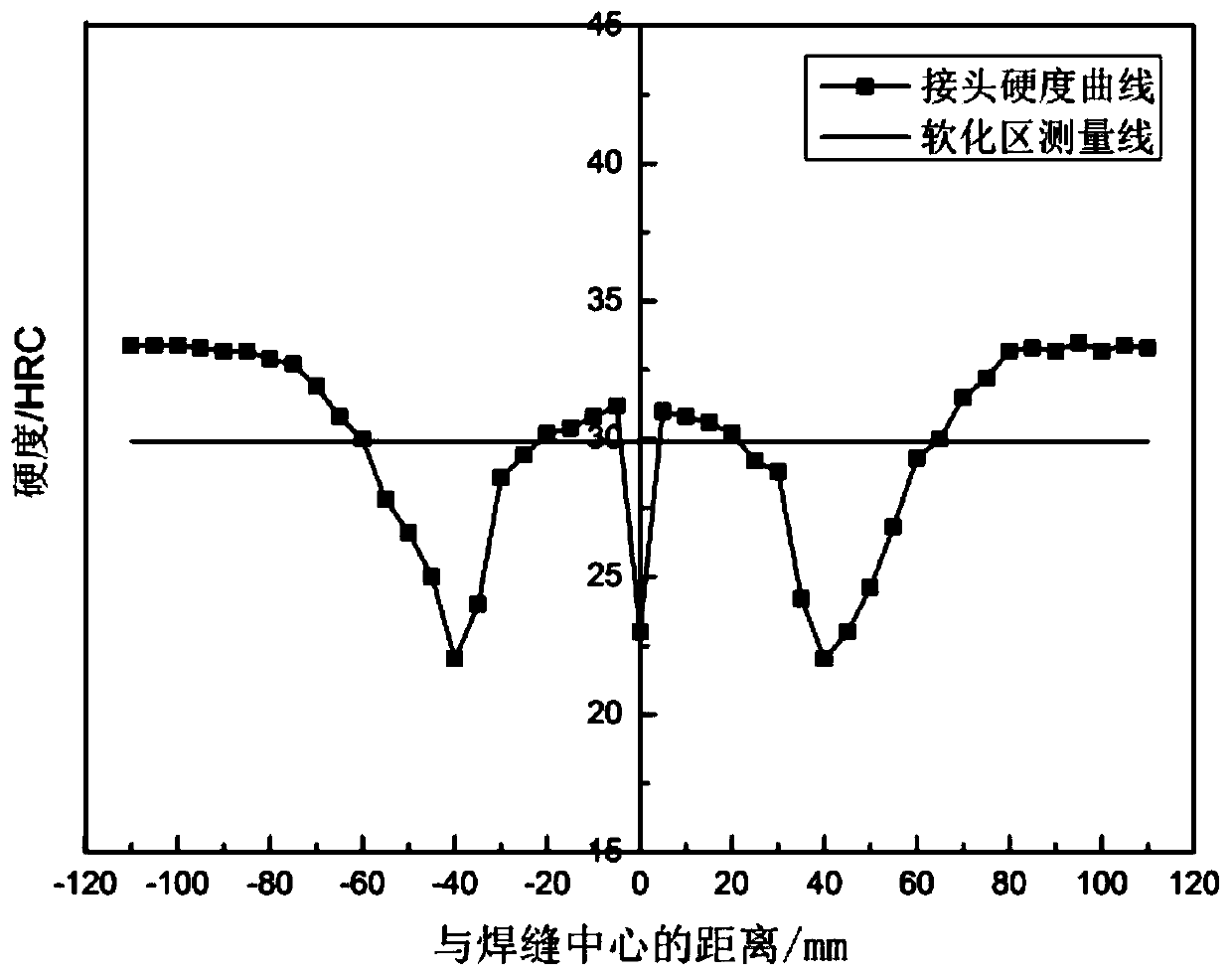

Postweld heat treatment method for bainite steel rail welded joint

ActiveCN107385188AGuaranteed service performanceEnsure the safety of railway operationRailsIncreasing energy efficiencyCooling temperatureElectric heating

The invention discloses a postweld heat treatment method for a bainite steel rail welded joint and relates to the technical field of railway steel rail manufacturing. Through the provided postweld heat treatment method for the bainite steel rail welded joint, the tread longitudinal hardness of the bainite steel rail welded joint can be controlled in a reasonable range. The method sequentially comprises the following steps that A, the welded joint, obtained through welding, with the temperature being 1500-1600 DEG C is primarily cooled to 150-250 DEG C, and natural cooling in the air is adopted as the mode of primary cooling; B, the welded joint is heated to 880-960 DEG C through a medium frequency induction profiling electric heating coil and / or an oxygen-acetylene flame profiling heater; and C, the welded joint is subjected to secondary cooling, secondary cooling is stopped when the welded joint is cooled to 180-250 DEG C, then the welded joint is subjected to tertiary cooling instantly and cooled to the room temperature of 5-40 DEG C, secondary cooling is conducted in the form of rapid cooling by applying coolants, the starting cooling temperature of secondary cooling is 800 DEG C or above, and natural cooling in the air is adopted as the mode of tertiary cooling.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD

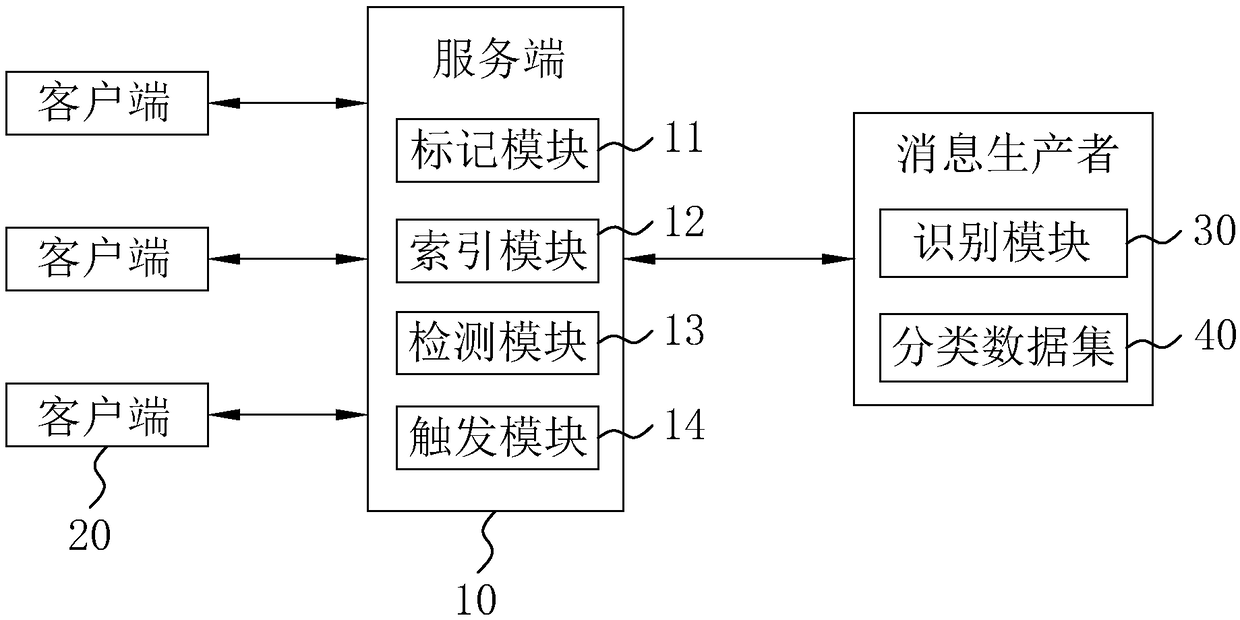

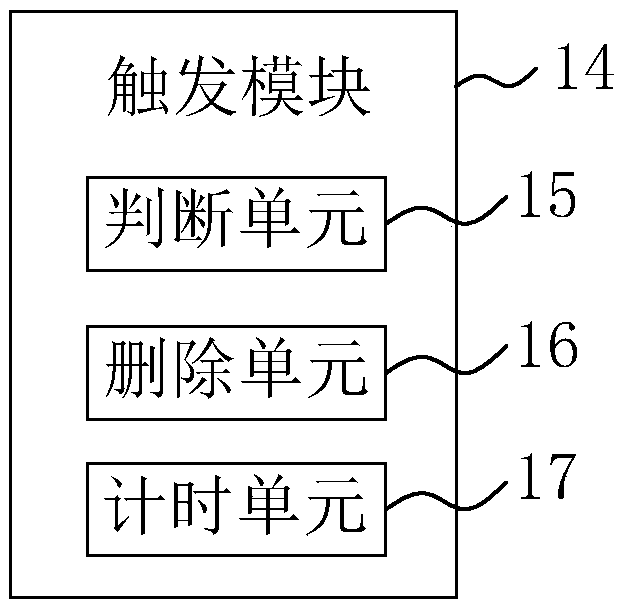

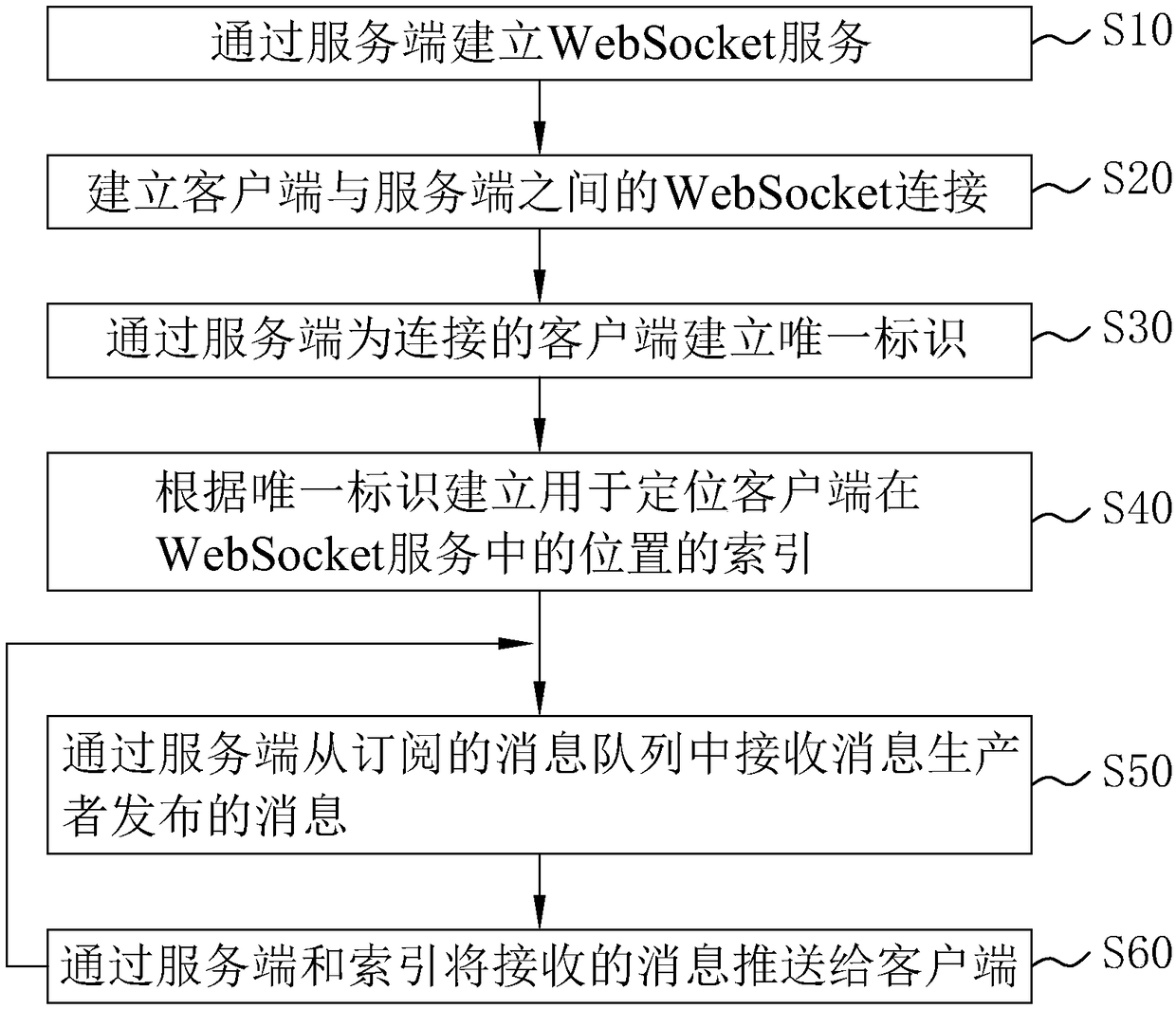

Bidirectional real-time communication system and method based on WebSocket and message queue

InactiveCN109361770APush smoothPrecise pushTransmissionClient-sideProtocol for Carrying Authentication for Network Access

The invention discloses a bidirectional real-time communication system and method based on a WebSocket and a message queue and relates to the technical field of communication. The problem that an existing real-time communication scheme based on the WebSocket protocol is liable to result in the condition that rear end service and a database need to bear a great deal of concurrent pressure is solved. According to the technical scheme key point, the system comprises a server and clients. The server comprises a marking module which is used for establishing unique identifications for the clients connected with the server, and an index module which is used for establishing indexes according to the unique identifications established by the marking module, wherein the indexes are used for positioning positions of the clients in WebSocket service. The server receives messages issued by a receiving message producer from a subscribed message queue in a message queue consumer mode and pushes the received messages to the clients according to the indexes. The server receives the messages passively and then pushes the messages to the corresponding clients, so the performance problem resulting from polling is solved.

Owner:苏州创旅天下信息技术有限公司

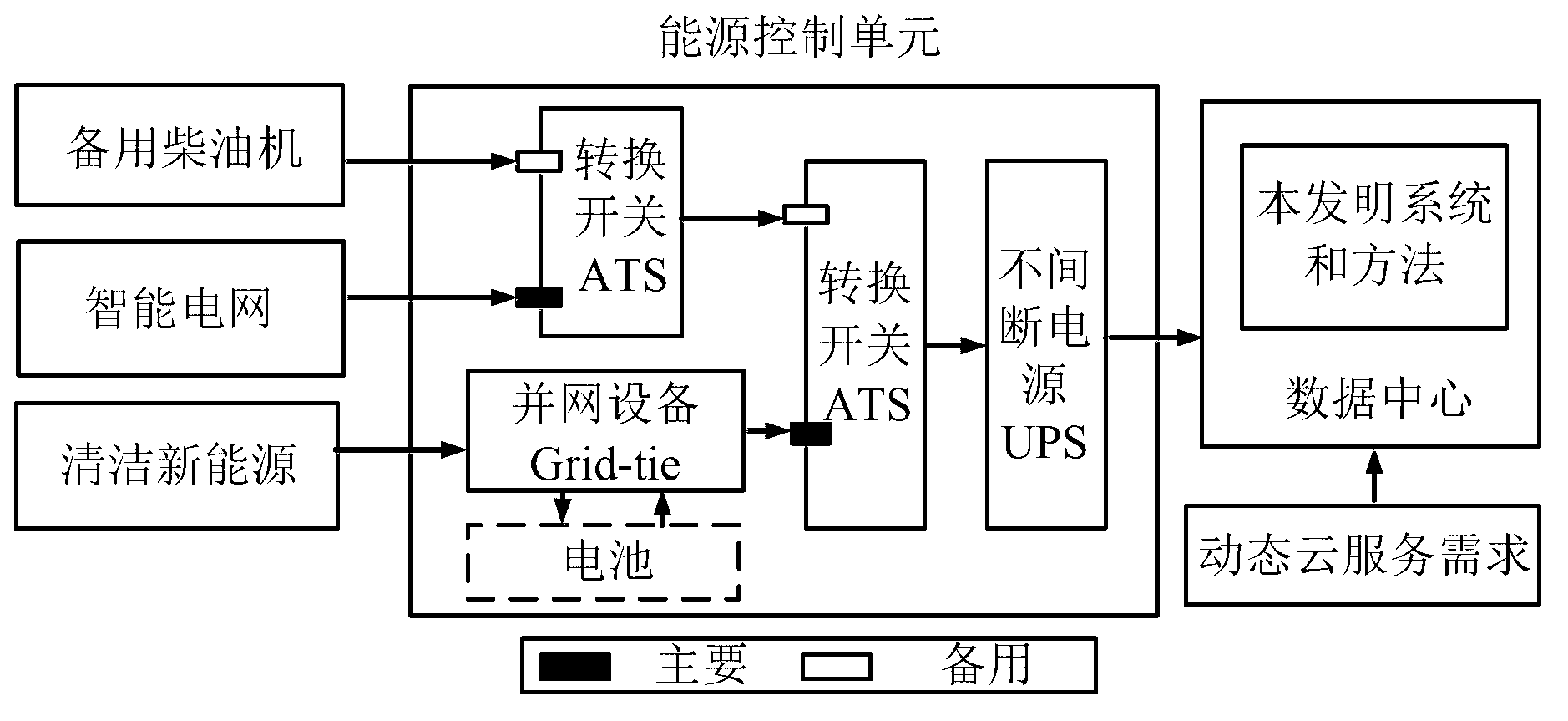

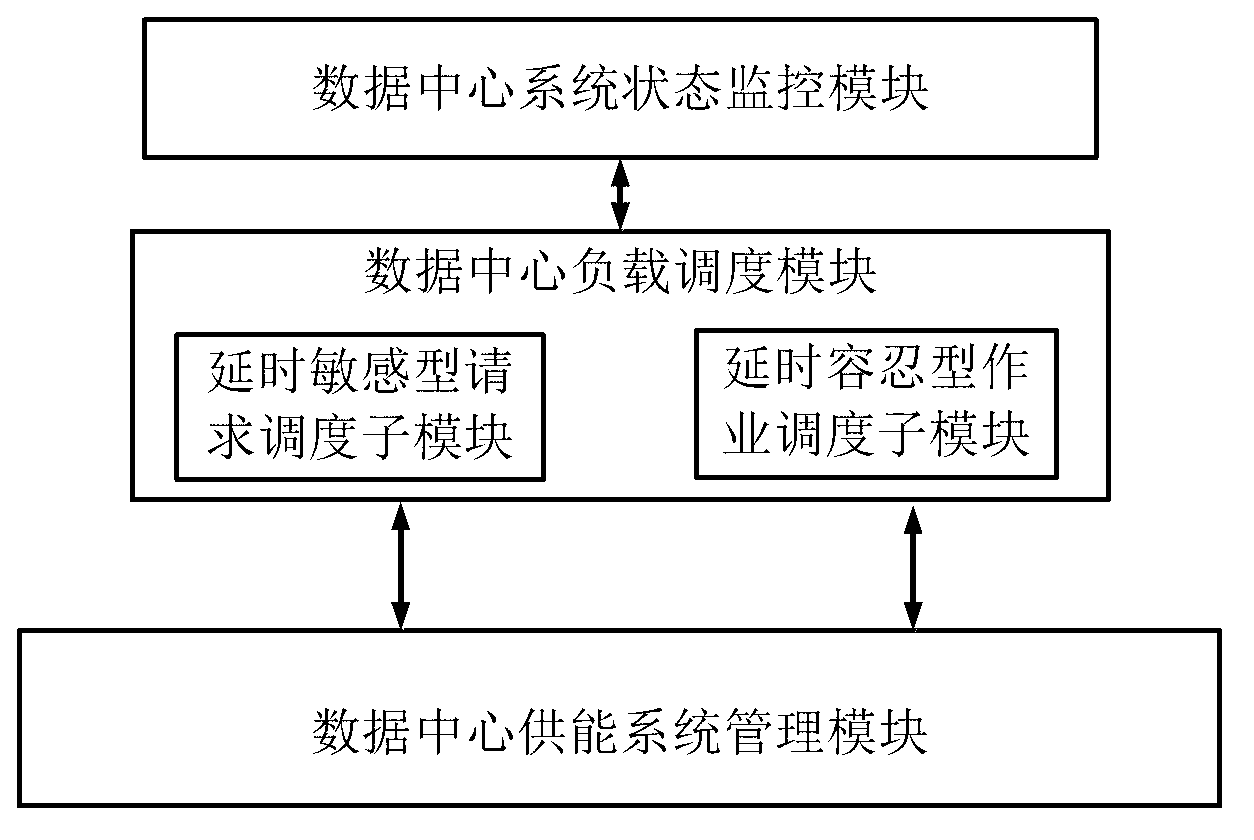

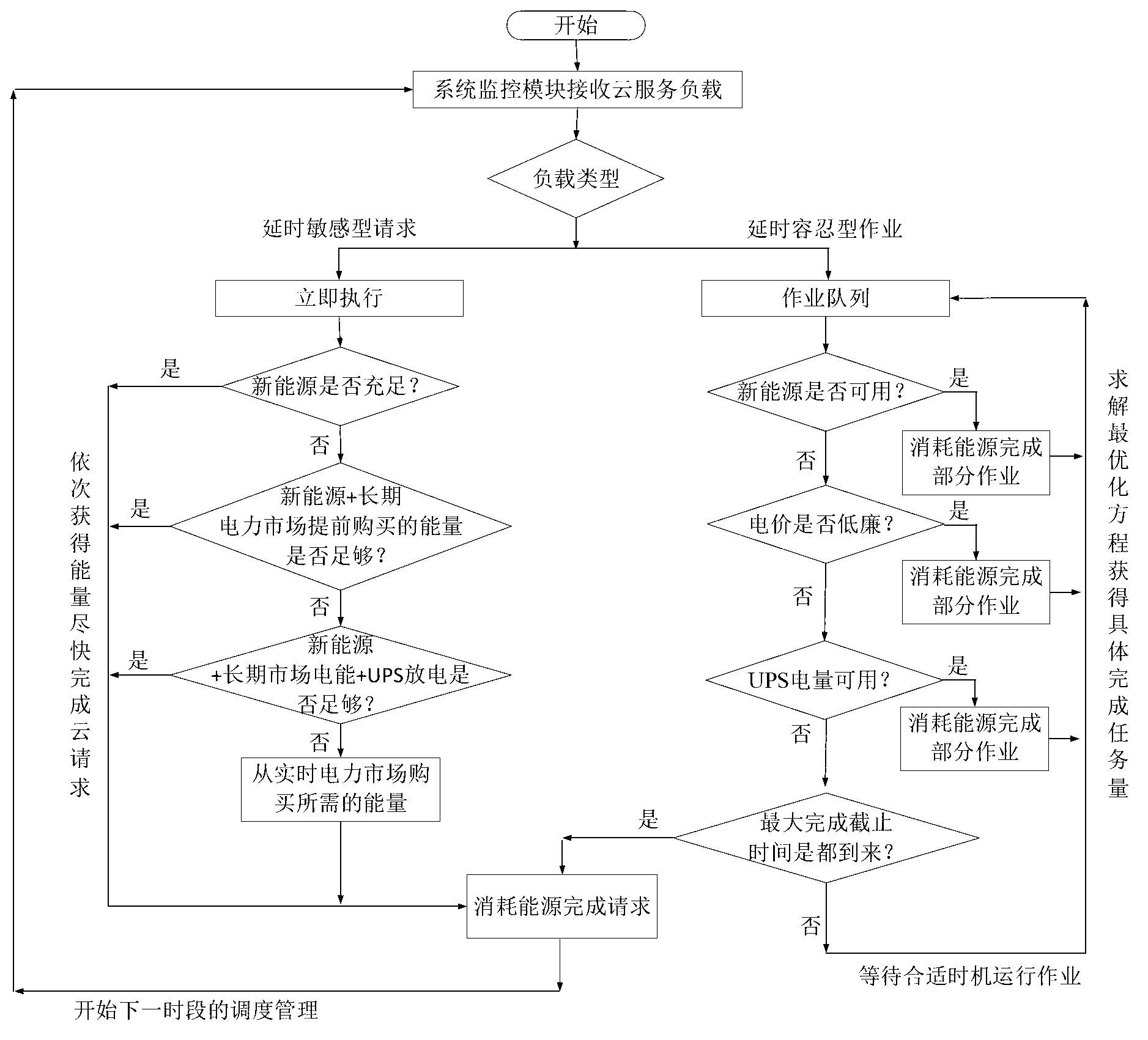

Multi-energy online control method and system for data center under dynamic cloud service request

ActiveCN103297505AMinimize operational overheadLow electricity priceTransmissionControl systemSystems management

The invention discloses a multi-energy online control system for data centers under dynamic cloud service requests. The multi-energy online control system for data centers under dynamic cloud service requests comprises a system status monitoring module, a load scheduling module and a multi-source energy supply system management module, wherein the load scheduling module comprises a delay-sensitive request scheduling sub-module and a delay tolerant job scheduling sub-module. The system status monitoring module is used for receiving service requests from a user's cloud service every once in a while, determining whether the cloud service request is a delay-sensitive request or a delay tolerant job, and sending the cloud service request belonging to the delay-sensitive request to the delay-sensitive request scheduling sub-module of the load scheduling module while sending the cloud service request belonging to the delay tolerant job to the delay tolerant job scheduling sub-module of the load scheduling module. The multi-energy online control system for data centers under dynamic cloud service requests has the advantages that long-term operating cost of data center energy supply system can be optimized, no system data is needed to be obtained in advance, and no steady state distribution is needed to be assumed.

Owner:HUAZHONG UNIV OF SCI & TECH

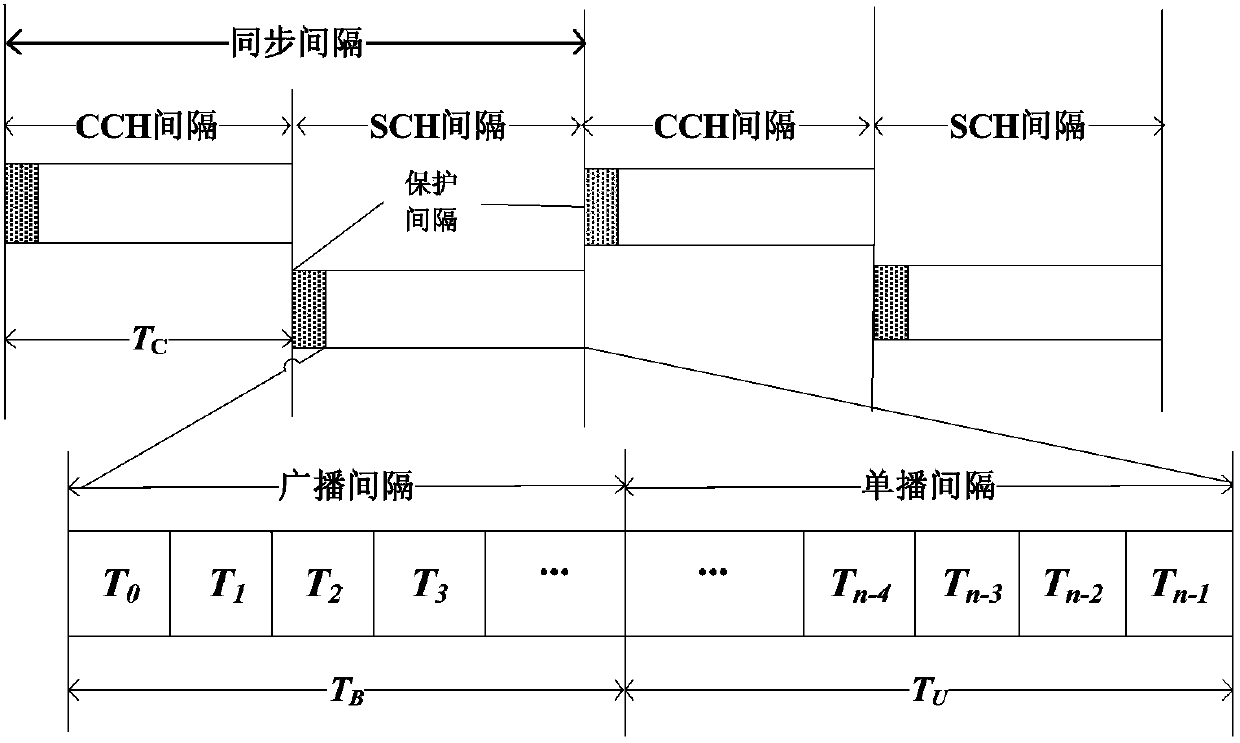

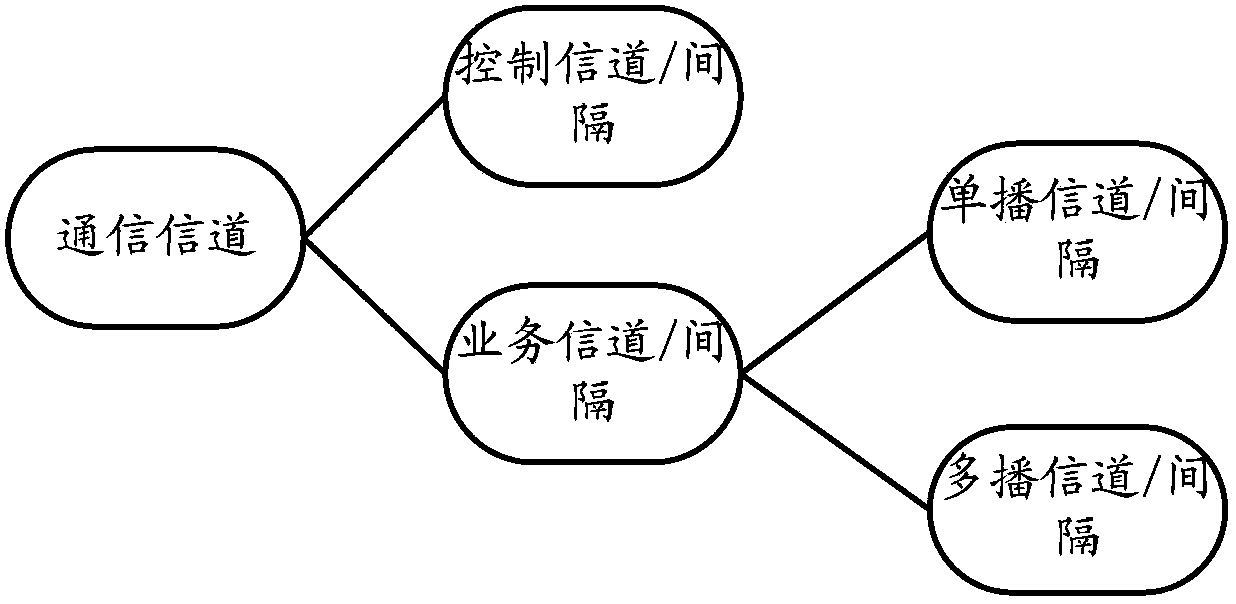

Self-adaption multi-service resource allocation method and device

ActiveCN103402261AGuaranteed service performanceQuality assuranceWireless communicationTime delaysBase station

The invention provides a self-adaption multi-service resource allocation method and a self-adaption multi-service resource allocation device, wherein the method comprises the steps that the self-adaption multi-service resource allocation method is characterized by comprising the steps that a plurality of services received from one or a plurality of user requests are classified; and on the basis of service classification, the specific gravity of homogeneous services is obtained for regulating the transmission resource allocation of service channels in communication channels. The method and the device have the advantages that the real-time changes of user request service contents are tracked through a base station, homogeneous services and heterogeneous services in the user request services are analyzed and counted, the specific gravity of homogeneous services is obtained for regulating the transmission channel resource allocation in service channels, the transmission resource configuration realizes the optimization, and the defects that the time delay uncertainty is caused, the fixed unicast transmission efficiency of the service channels is low, the bandwidth resources are wasted, the network load increase pressure is overgreat, and the performance of the whole system is influenced are avoided.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Local coating defect repairing method for carbon/carbon composite material

The invention relates to a local coating defect repairing method for a carbon / carbon composite material. A coating repairing agent prepared from a thermosetting resin and an inorganic filling material is coated on a coating defect position. A coating crack defect is repaired by crack / hole filling and reinforcement repair and coating extension, and therefore the surface of the defect is coated with the repairing agent and the repairing agent permeates into the defect interior, thus forming a continuous layer and preventing carbon atoms from oxidation reaction with oxygen atoms. Then a drying and curing process is performed in an air dry oven or a ventilating environment. Finally, the thickness and the compactness of the repairing agent are increased through a vacuum impregnation and drying method. The repairing method is simple, convenient and prone to achievement. The repaired carbon / carbon composite material has good performances and high quality. The local defect area of the antioxidant carbon / carbon composite material is effectively protected from being oxidized and ablated in an oxidation environment with a temperature lower than 1200 DEG C, thus achieving long-time using and repeated using of a high-performance antioxidant carbon / carbon composite material coating.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

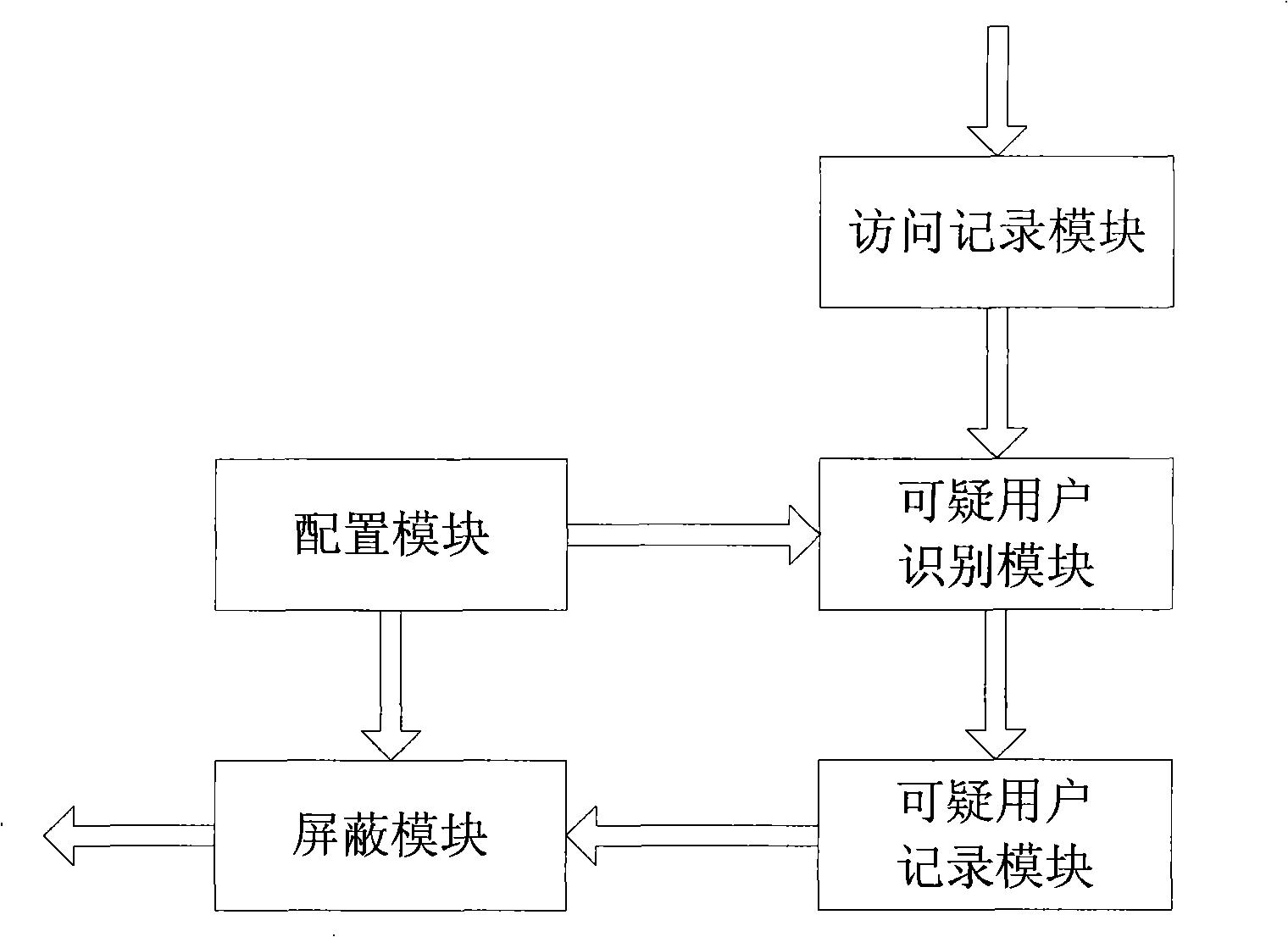

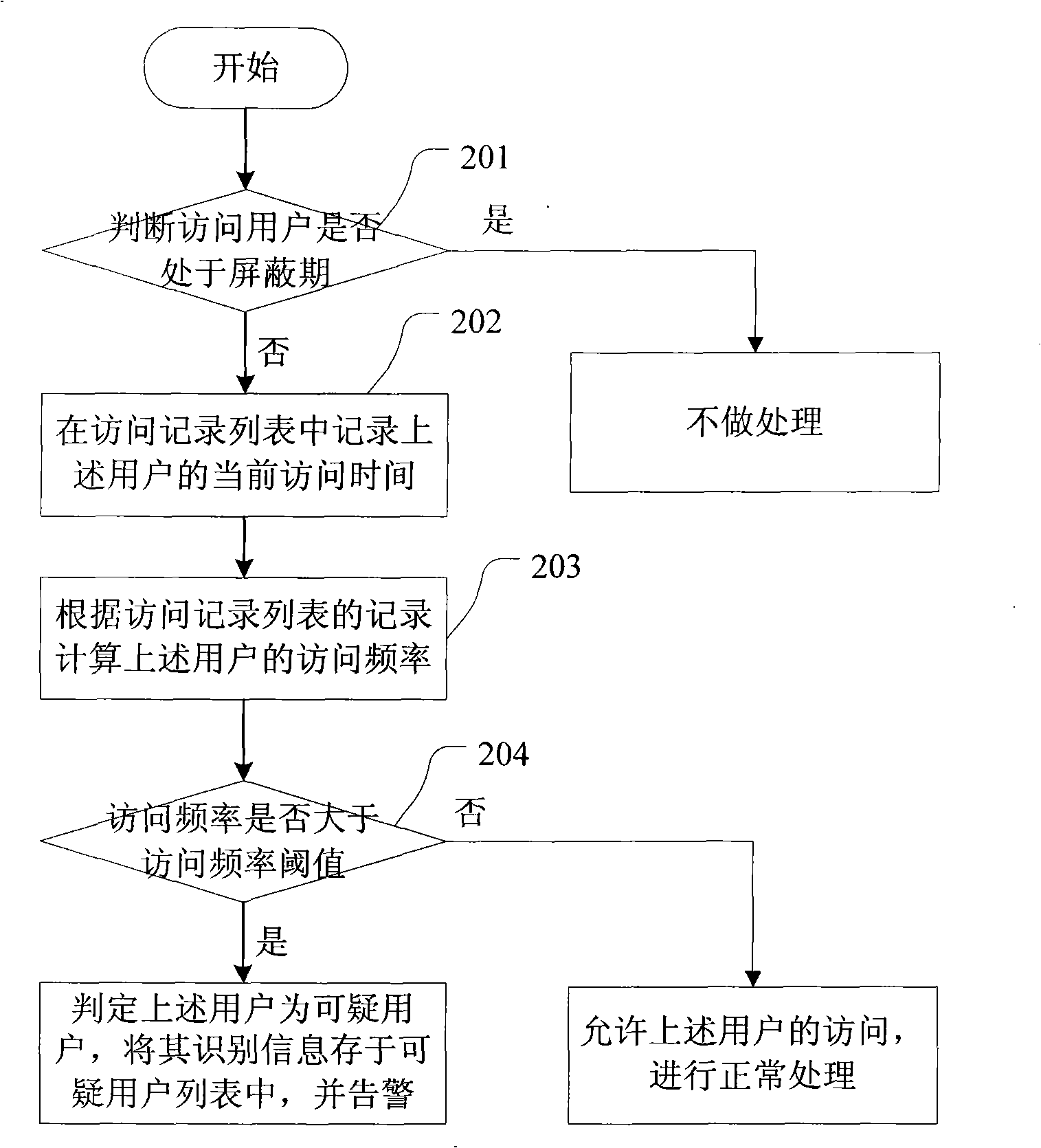

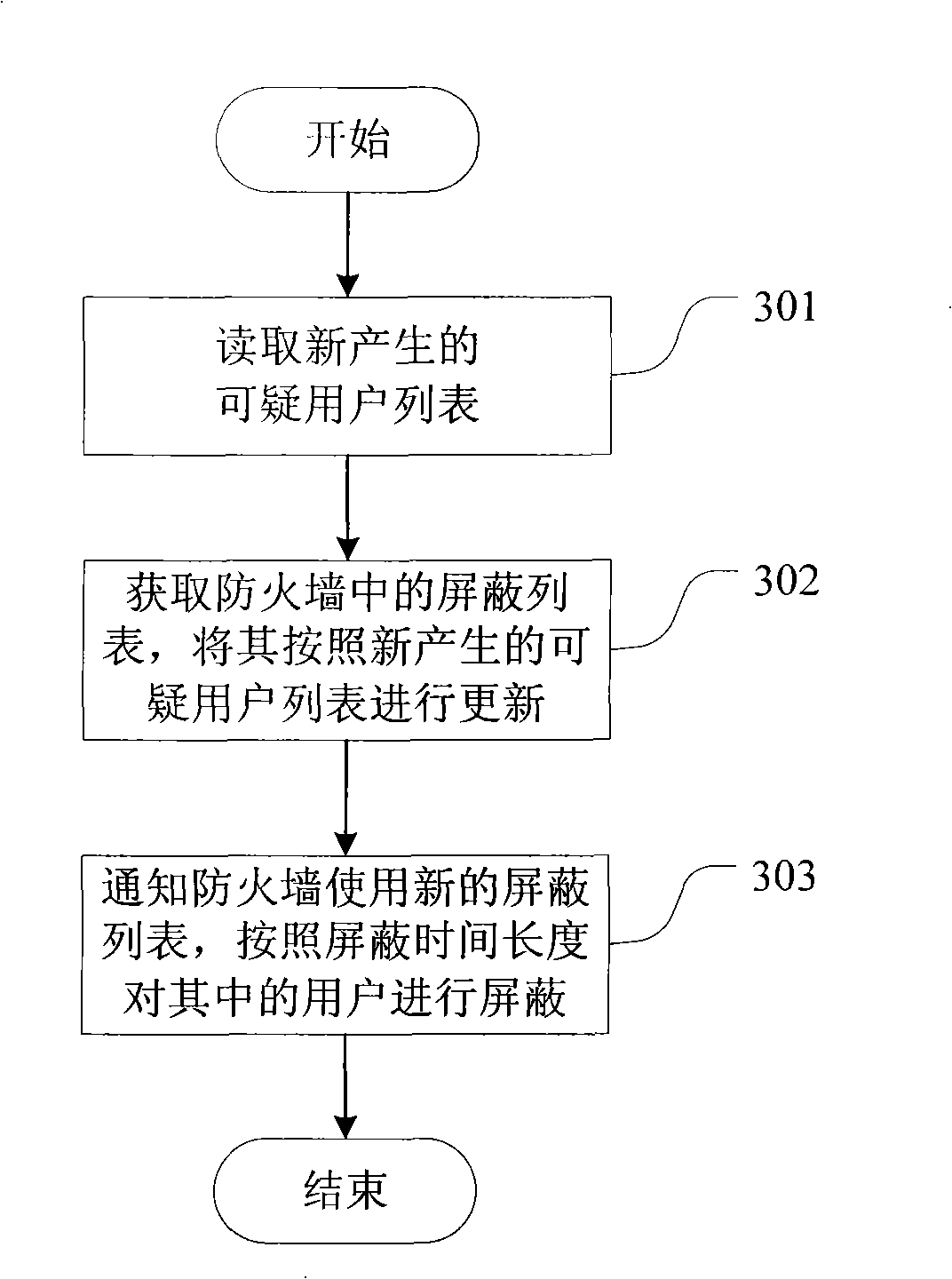

Apparatus and method for preventing frequent accesses to electronic program menu server by suspicious users

InactiveCN101404654AAvoid frequent visitsGuaranteed service performanceSpecific information broadcast systemsTransmissionInternet privacyAccess frequency

The invention discloses a device for preventing a suspicious user from frequently accessing an electronic program guide server and a method thereof. The device comprises a suspicious user identifying module, a suspicious user record module and a shielding module. The method comprises the following steps: when a user accesses the electronic program guide server, the suspicious user identifying module identifies a suspicious user according to the accessing frequency of the user, and delivers the suspicious user to the suspicious user record module for recording; then, the shielding module sets a firewall to shield the suspicious user. The invention can effectively avoid a user maliciously and frequently accessing the EPG server in a short time, and ensure the service capability and stability of the EPG server, thereby maintaining the benefit of other users.

Owner:ZTE CORP

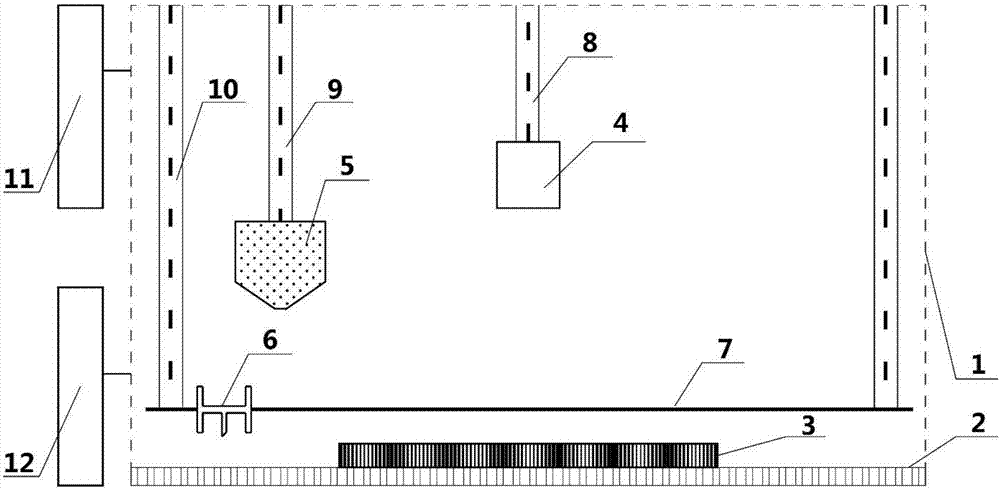

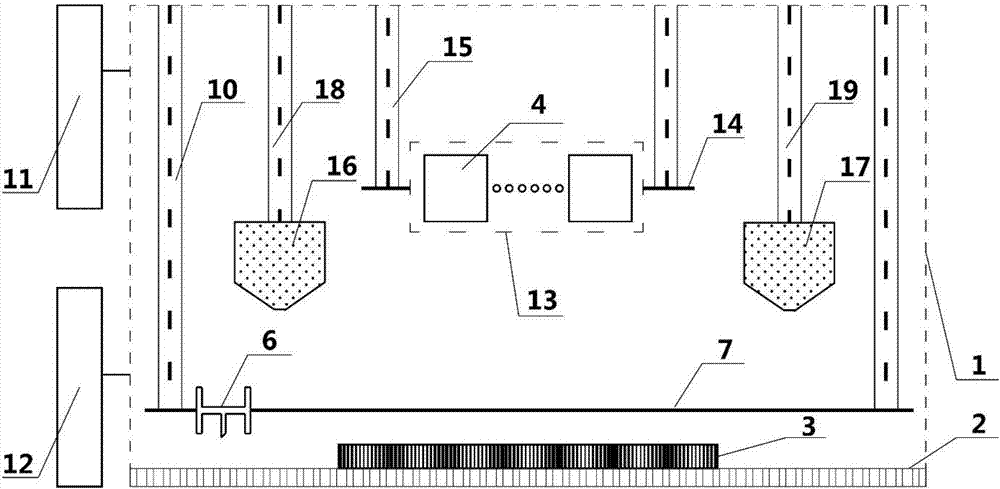

Laser additive manufacturing device and method

PendingCN107570706AReduce fillingLower acquisition costsAdditive manufacturing apparatusIncreasing energy efficiencyGalvanometerThin walled

The invention discloses a laser additive manufacturing device and method. The laser additive manufacturing device comprises a forming cabin, a working platform, a substrate, a scanning galvanometer assembly, a powder presetting assembly, an atmosphere regulating assembly, a lifting assembly and a central control system; when the laser additive manufacturing device is applied to the forming of a metal component, the scanning galvanometer assembly is not only used for the layer-by-layer selective melting of slice layers of the metal components above the fixedly-positioned substrate, but also used for the layer-by-layer selective melting of enclosed thin walls above the substrate; and the enclose thin walls are matched with the slice outline of the metal component, and capable of accommodating a metal powder bed. The laser additive manufacturing device and method disclosed by the invention have the advantages that the forming space is flexible and adjustable as well as the powder utilization ratio is high; and the high-quality low-cost additive manufacturing of metal components of various sizes and shapes can be achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

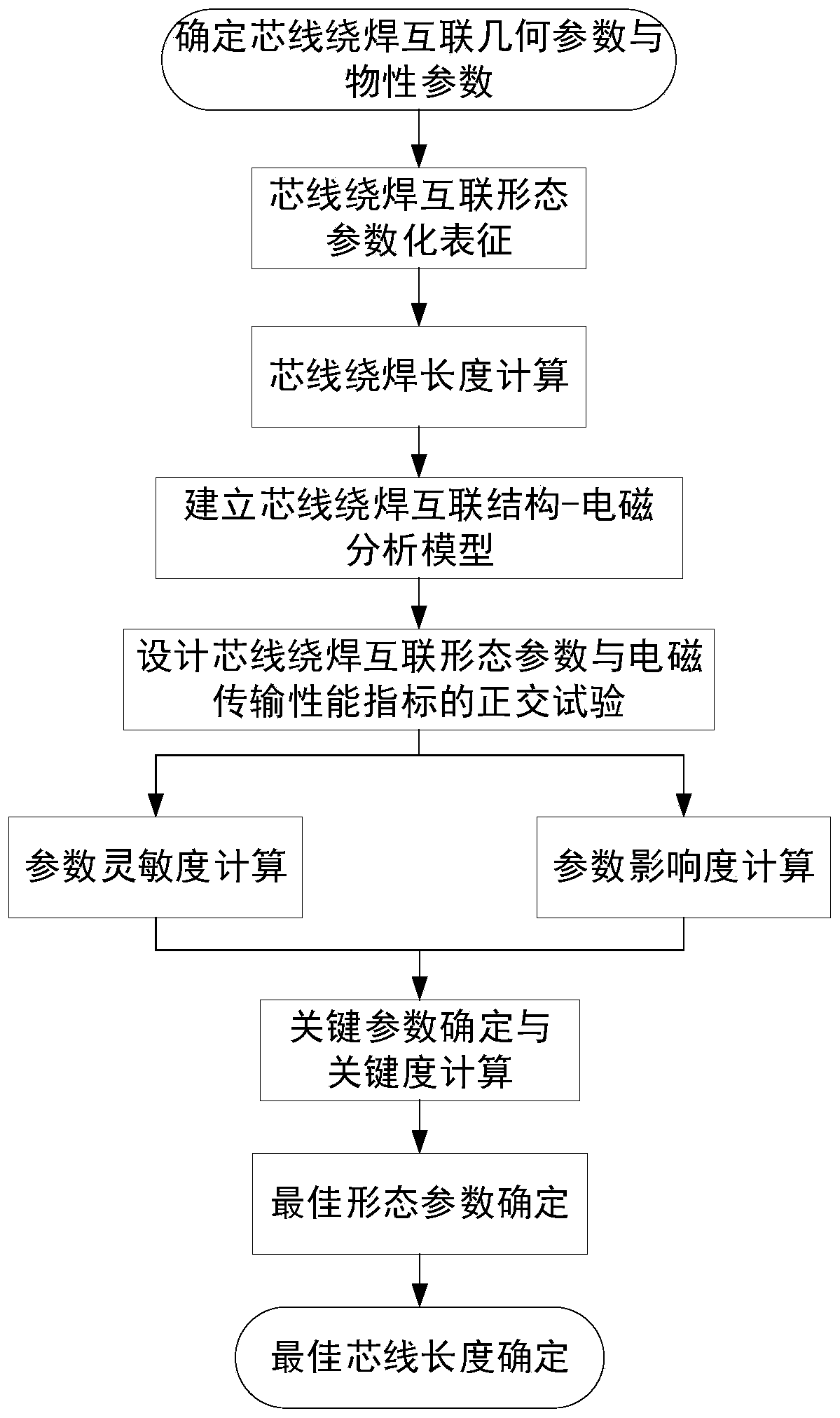

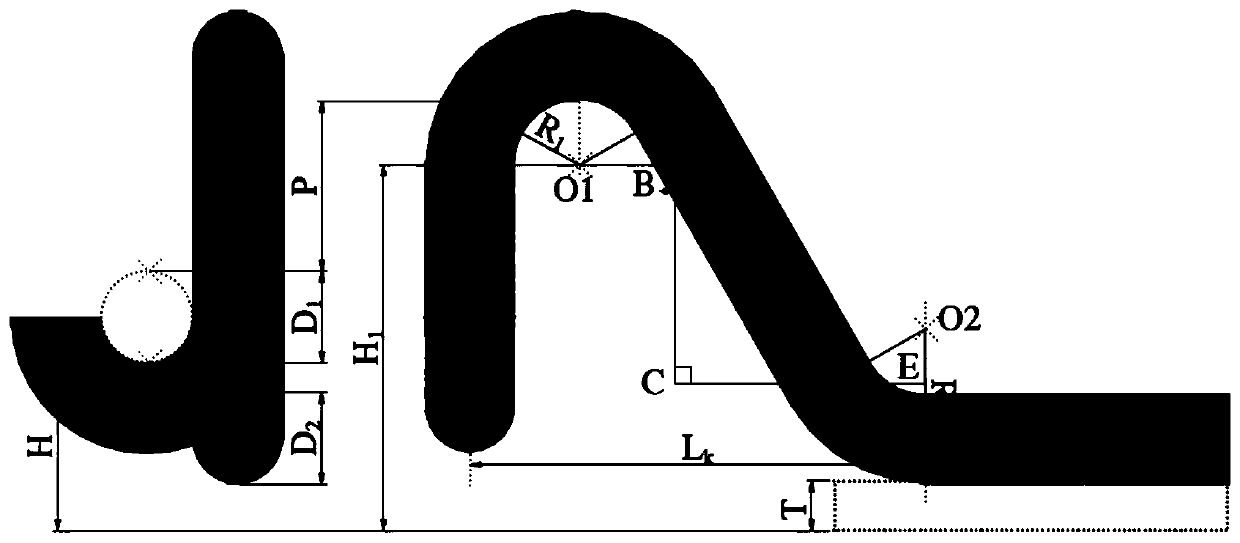

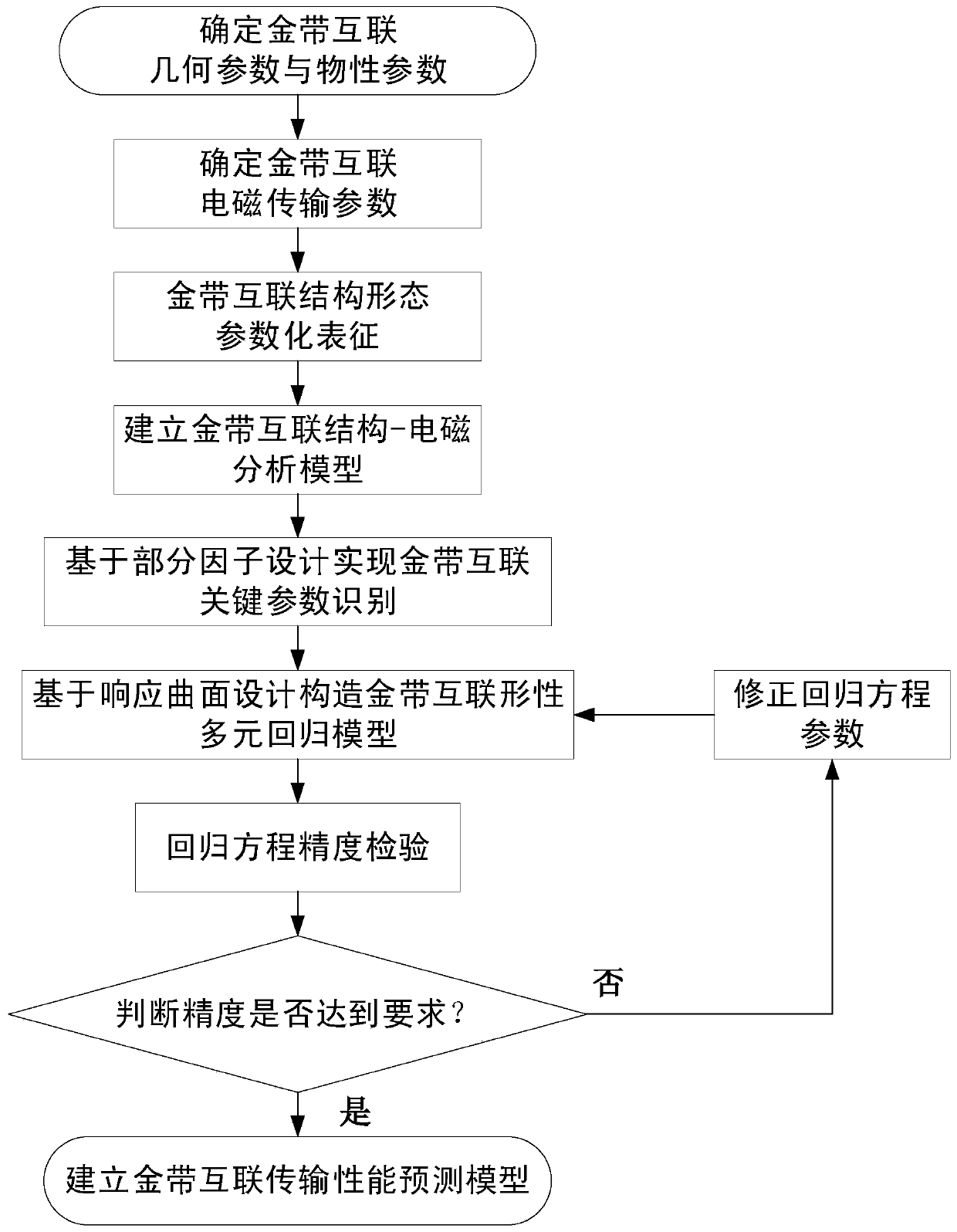

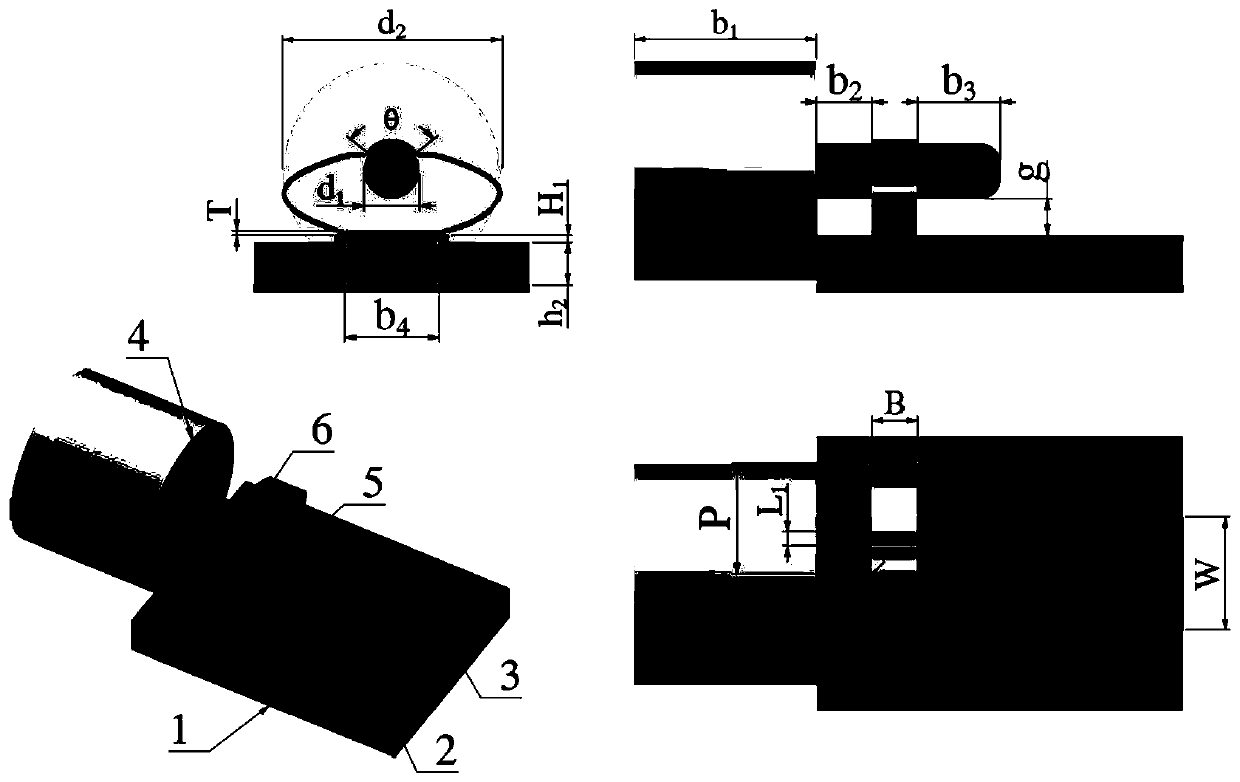

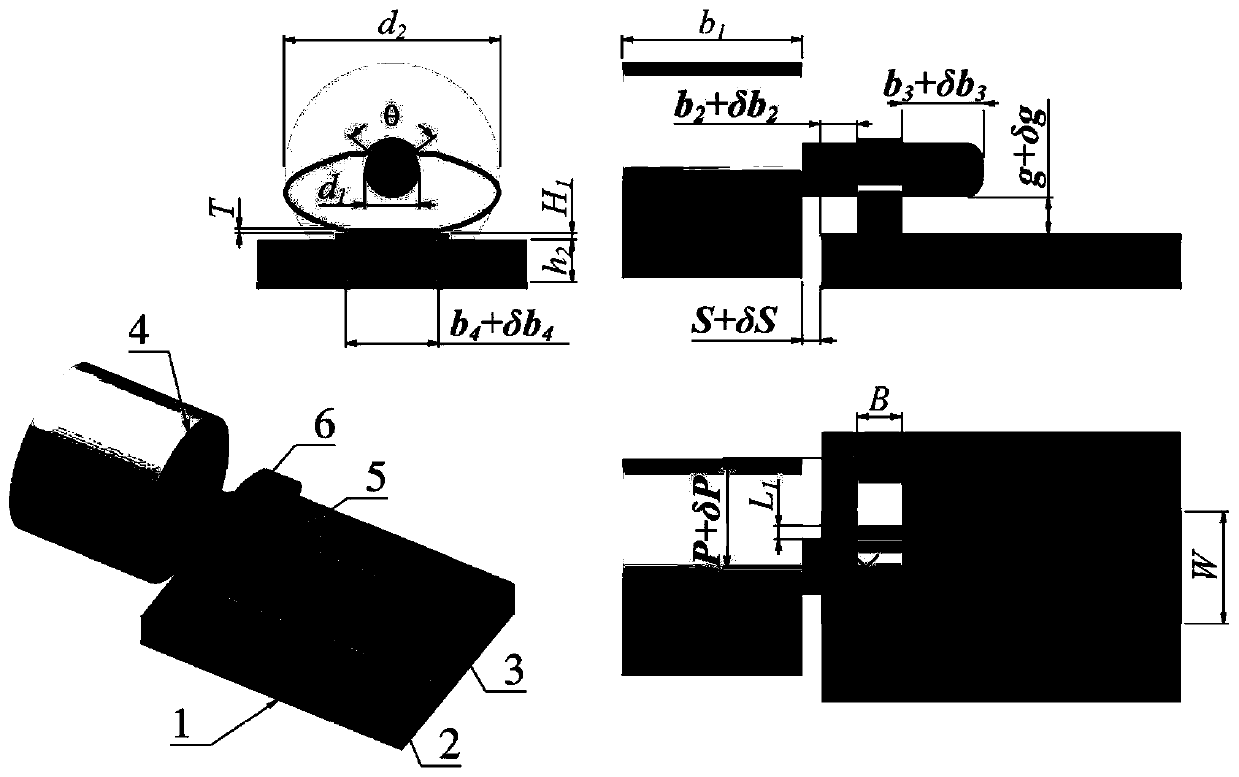

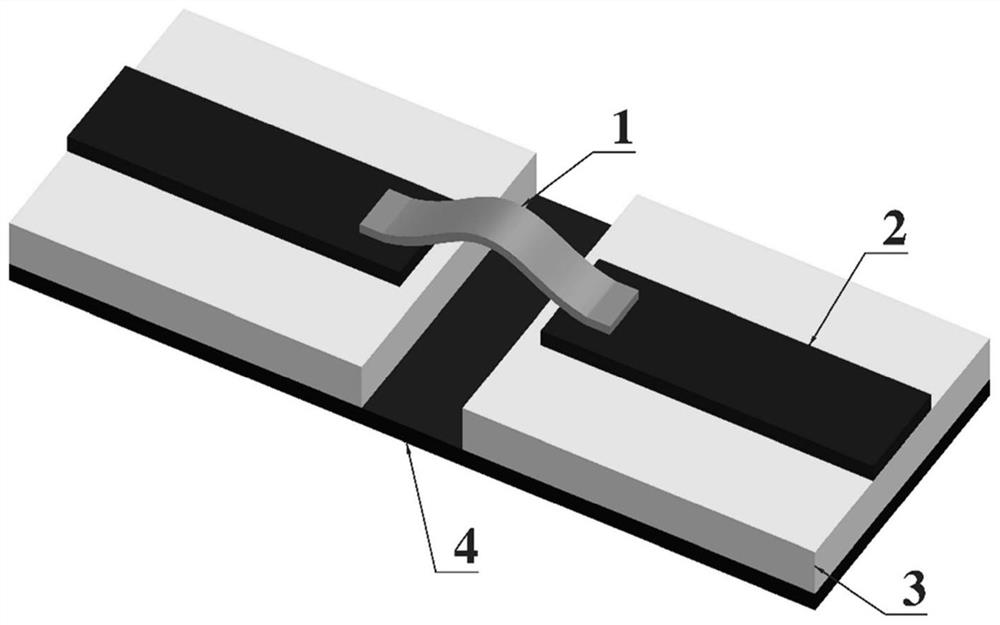

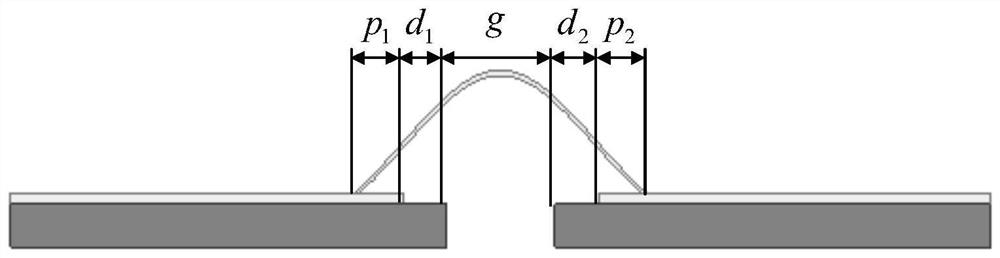

Method for determining optimal shape parameters of core wire winding and welding interconnection for electrical performance of microwave component

ActiveCN110069862AImprove work efficiencyReduce development costsDesign optimisation/simulationSpecial data processing applicationsMicrowaveEngineering

The invention discloses a method for determining optimal shape parameters of core wire winding and welding interconnection for the electrical performance of a microwave component, and the method comprises the steps: determining geometric parameters and physical parameters of the core wire winding and welding interconnection, carrying out the parametric representation of the shape of the core wirewinding and welding interconnection, calculating the length of a core wire in a core wire winding and welding interconnection structure, and building a core wire winding and welding interconnection structure-electromagnetic analysis model, designing an orthogonal test of the core wire winding and welding interconnection shape parameters and the electromagnetic transmission performance indexes, andcalculating the sensitivity of the core wire winding and welding interconnection shape parameters and the influence degree of the core wire winding and welding interconnection shape parameters; determining core wire winding and welding interconnection form key parameters and performing parameter criticality calculation; determining core wire winding and welding interconnection optimal shape parameters oriented to electromagnetic transmission; and determining the core wire winding and welding interconnection optimal core wire length facing electromagnetic transmission. The method can guide thedesign and optimization of the microwave assembly and improve the development quality of microwave products.

Owner:XIDIAN UNIV

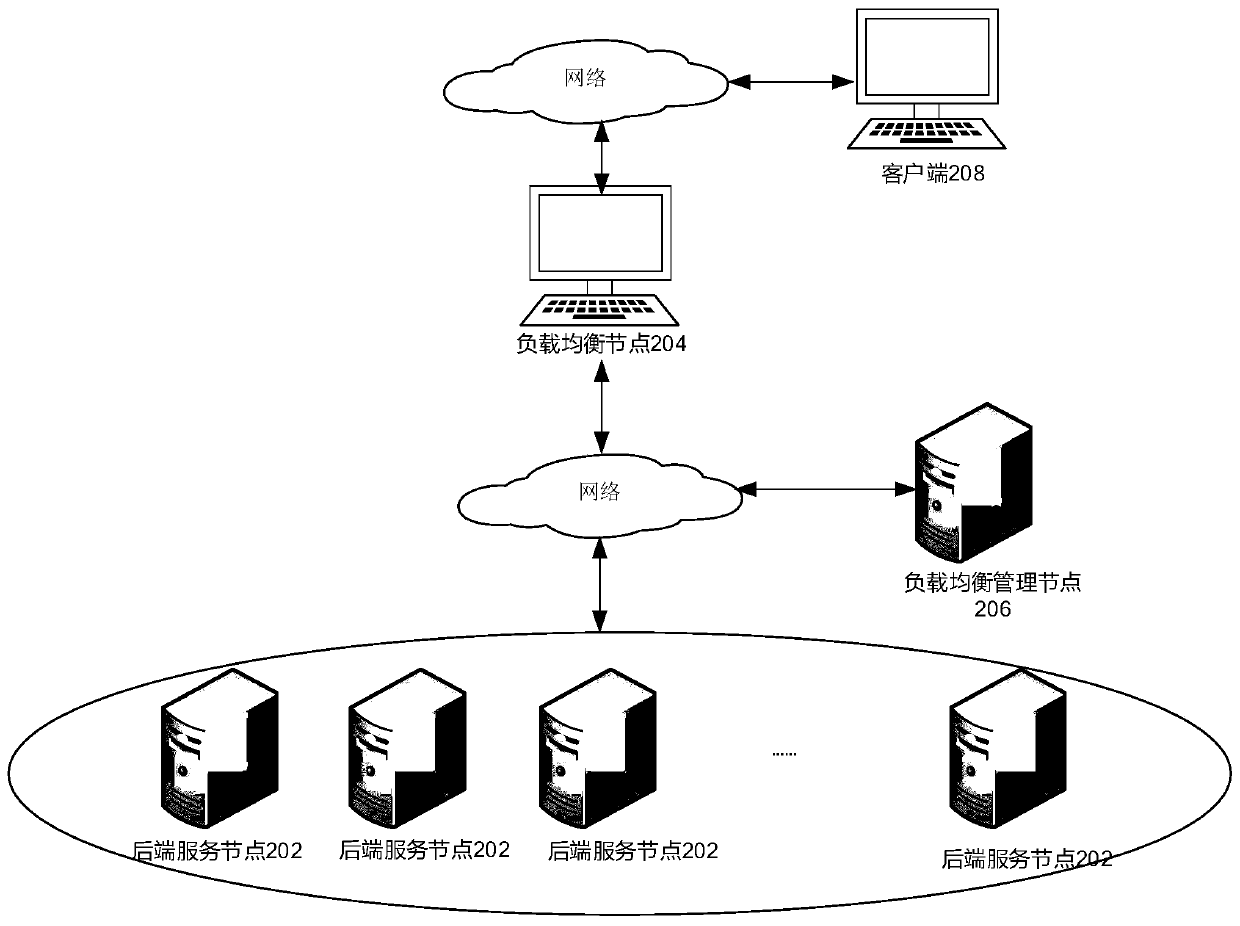

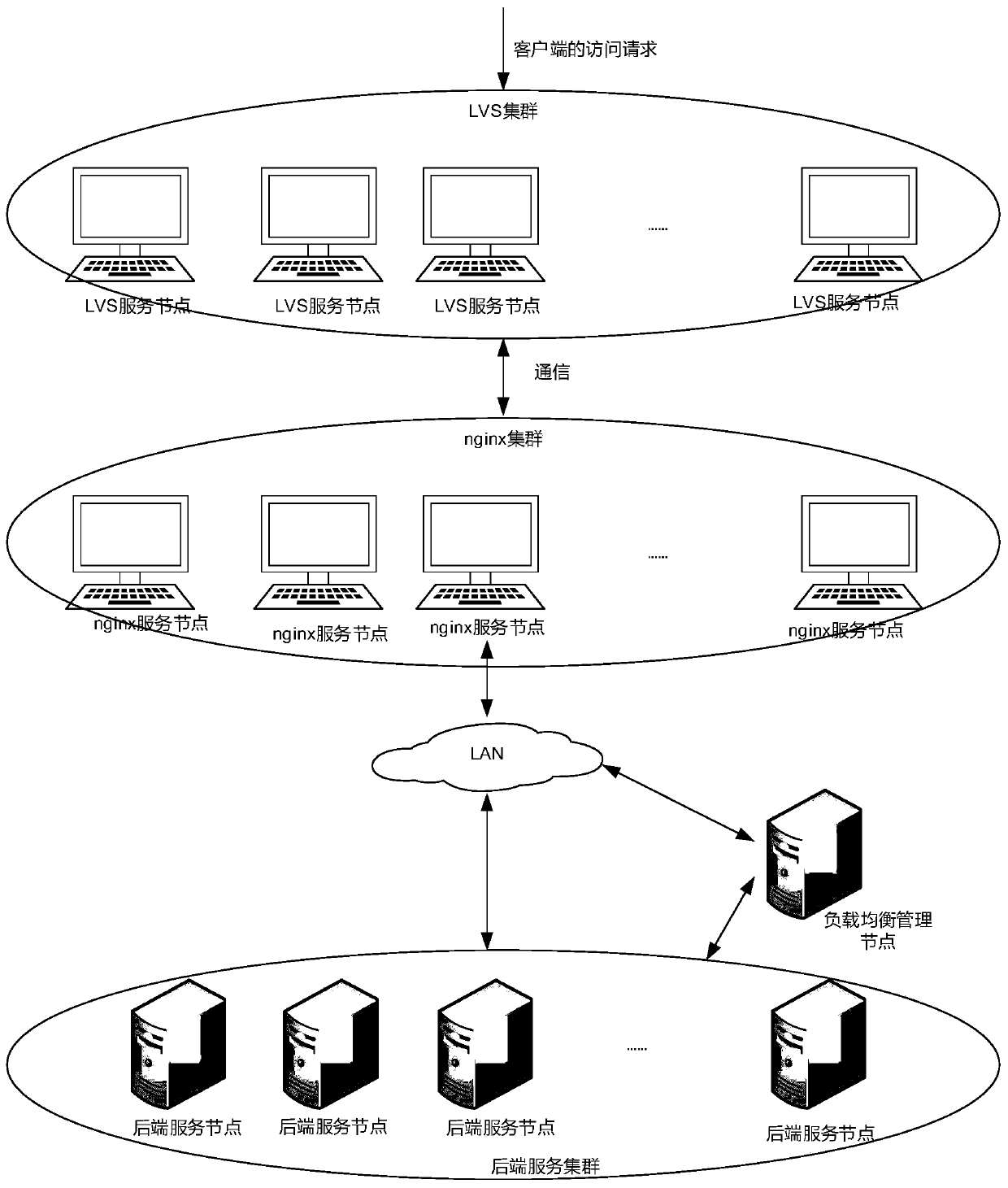

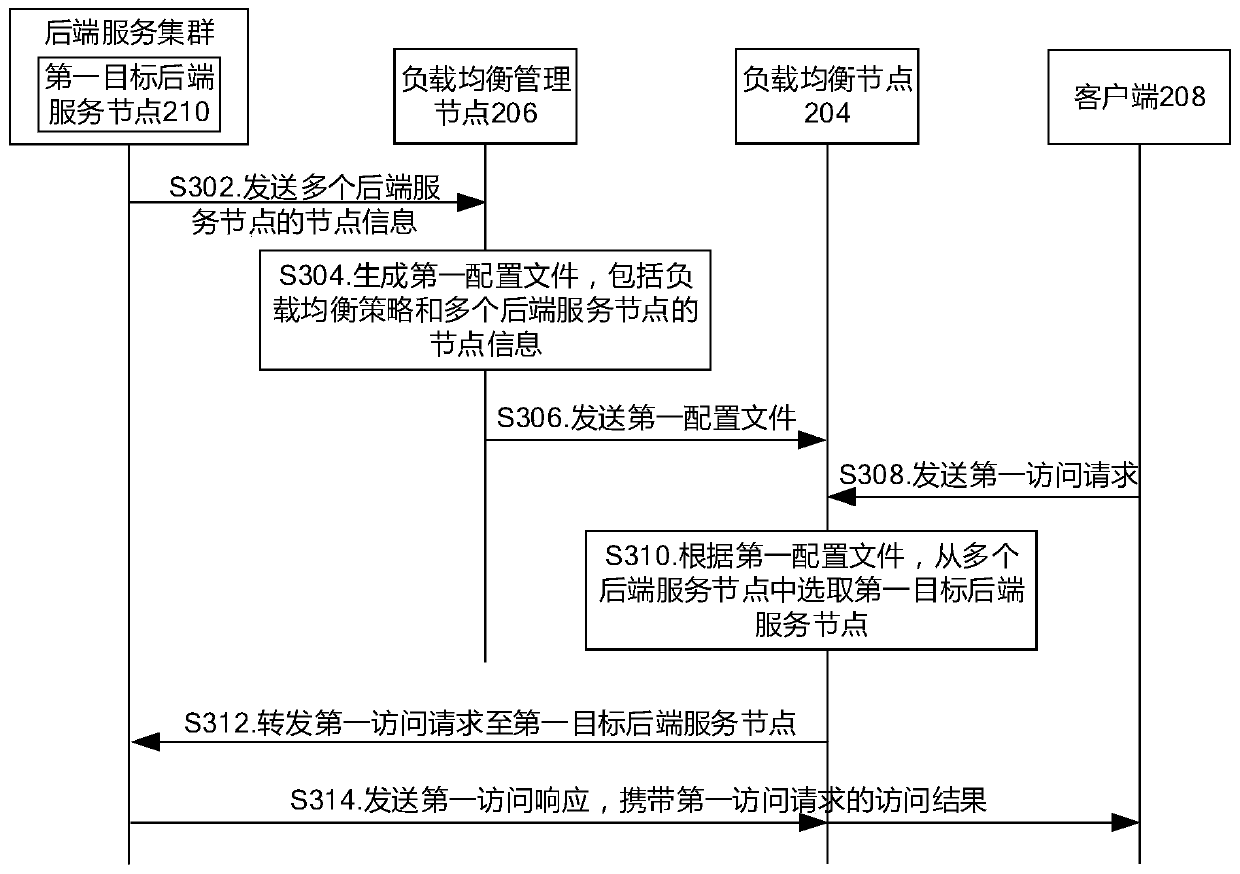

Load balance management method and related device

Owner:HUAWEI CLOUD COMPUTING TECH CO LTD

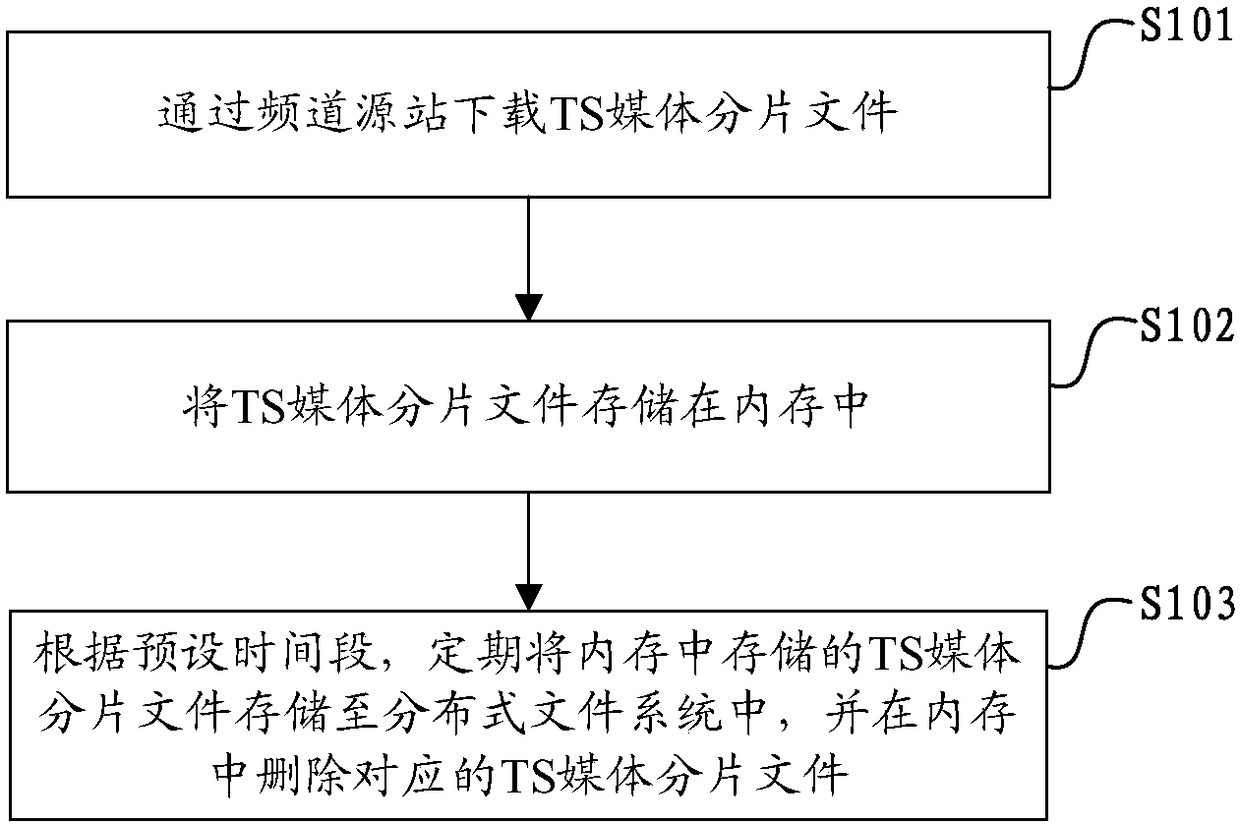

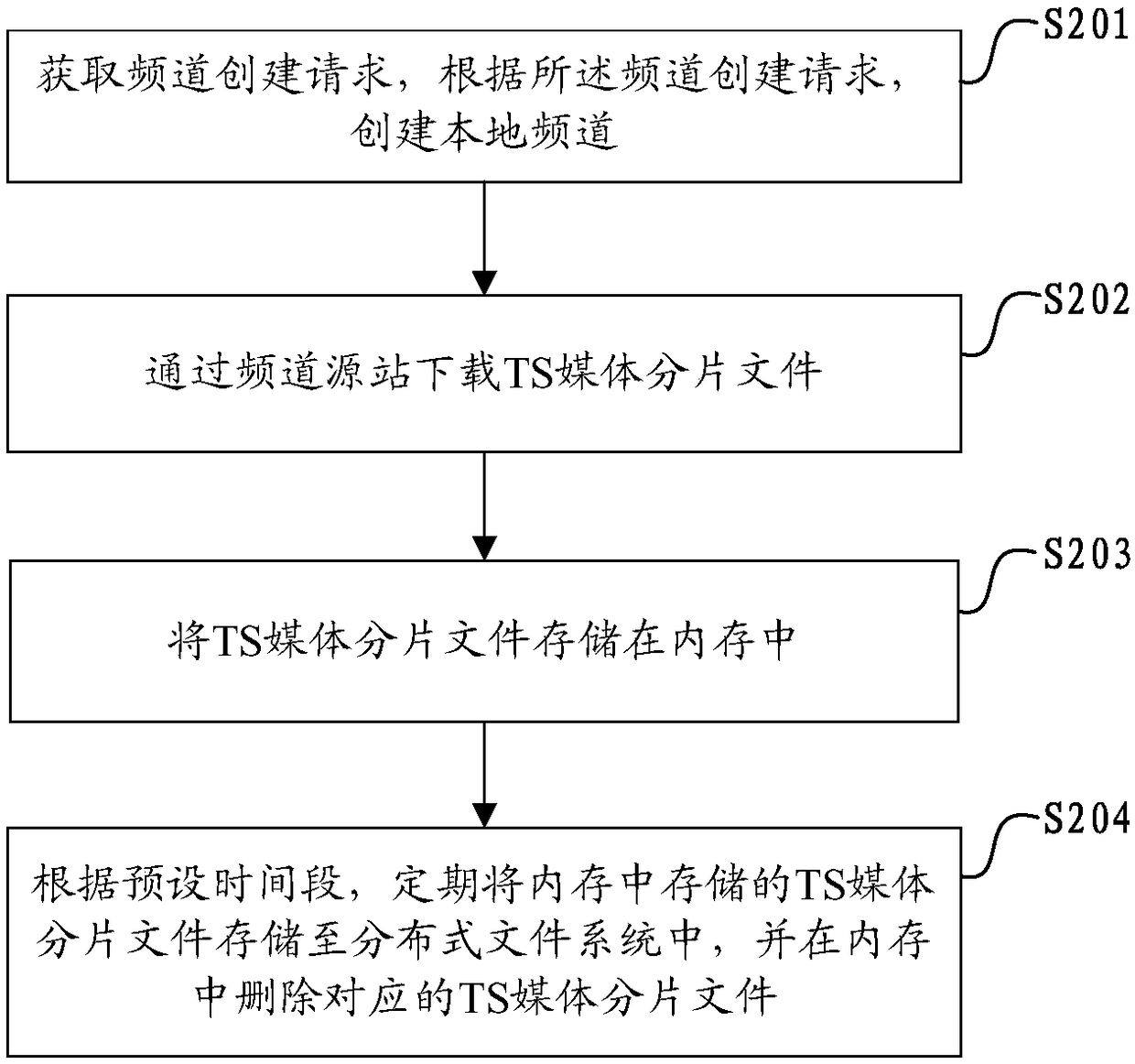

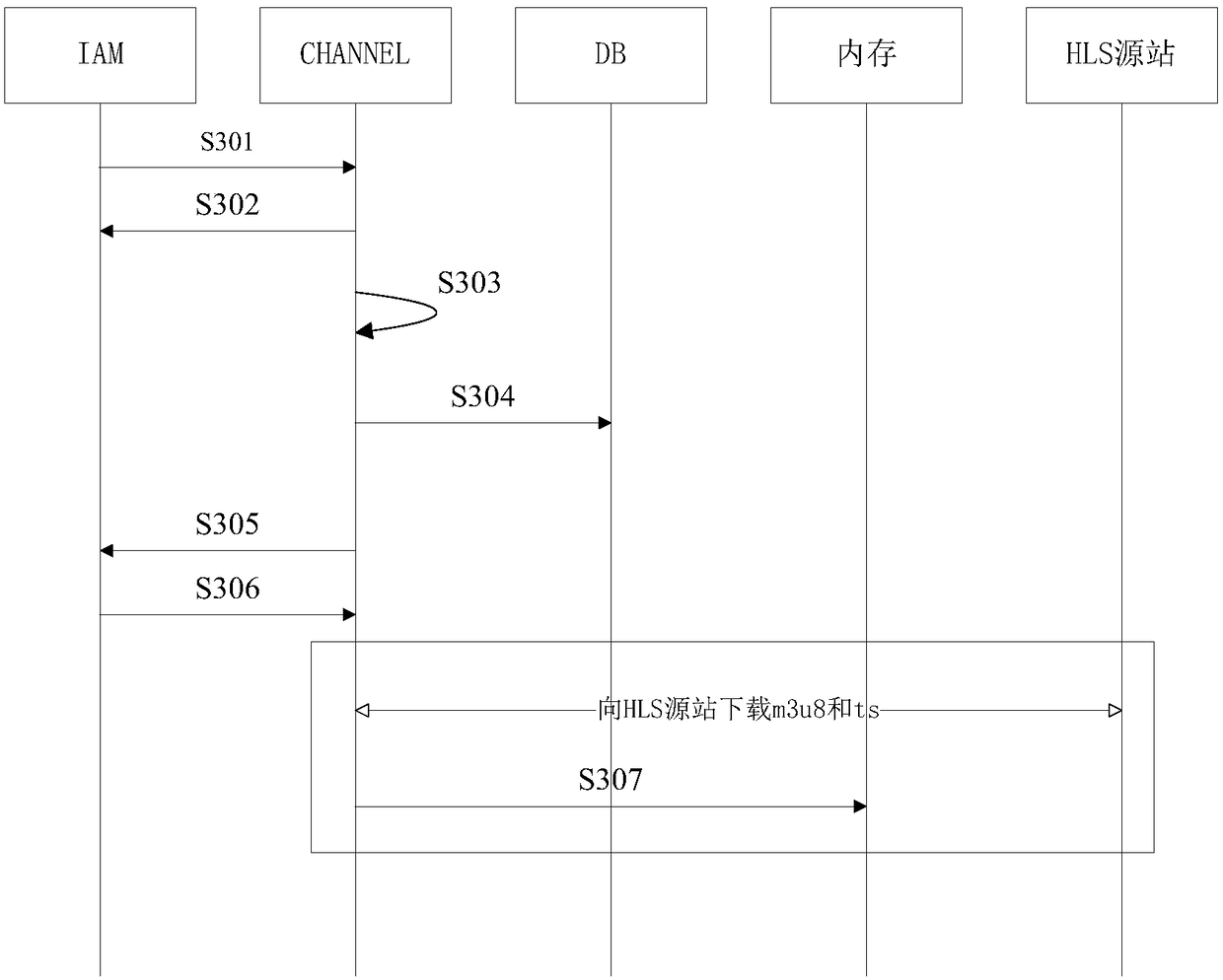

Caching and playing method and system of live playback

InactiveCN108513162AReduce dependenceNo loss of storage spaceSelective content distributionDistributed File SystemFixed time

The invention discloses a caching and playing method and system of live playback, and belongs to the technical field of the streaming media. The method comprises the following steps: downloading a TSmedia slice file through a channel source station; storing the TS media slice file in a memory; storing the TS media slice file stored in the memory in a distributed file system at the fixed time according to the preset time period, and deleting the corresponding TS media slice file in the memory. The TS media slice file downloaded through the channel source station is stored in the memory, and the TS media slice file stored in the memory is stored in a distributed file system at the fixed time according to the preset time period, the problem that the storage is performed only depending on theDFS in the prior art is overcome, the classified cache mechanism is realized in the premise of not losing a lot of storage space and reducing the dependence on the DFS, the storage resource is saved,the dependence on the DFS is reduced, and the live security is improved.

Owner:ZTE CORP

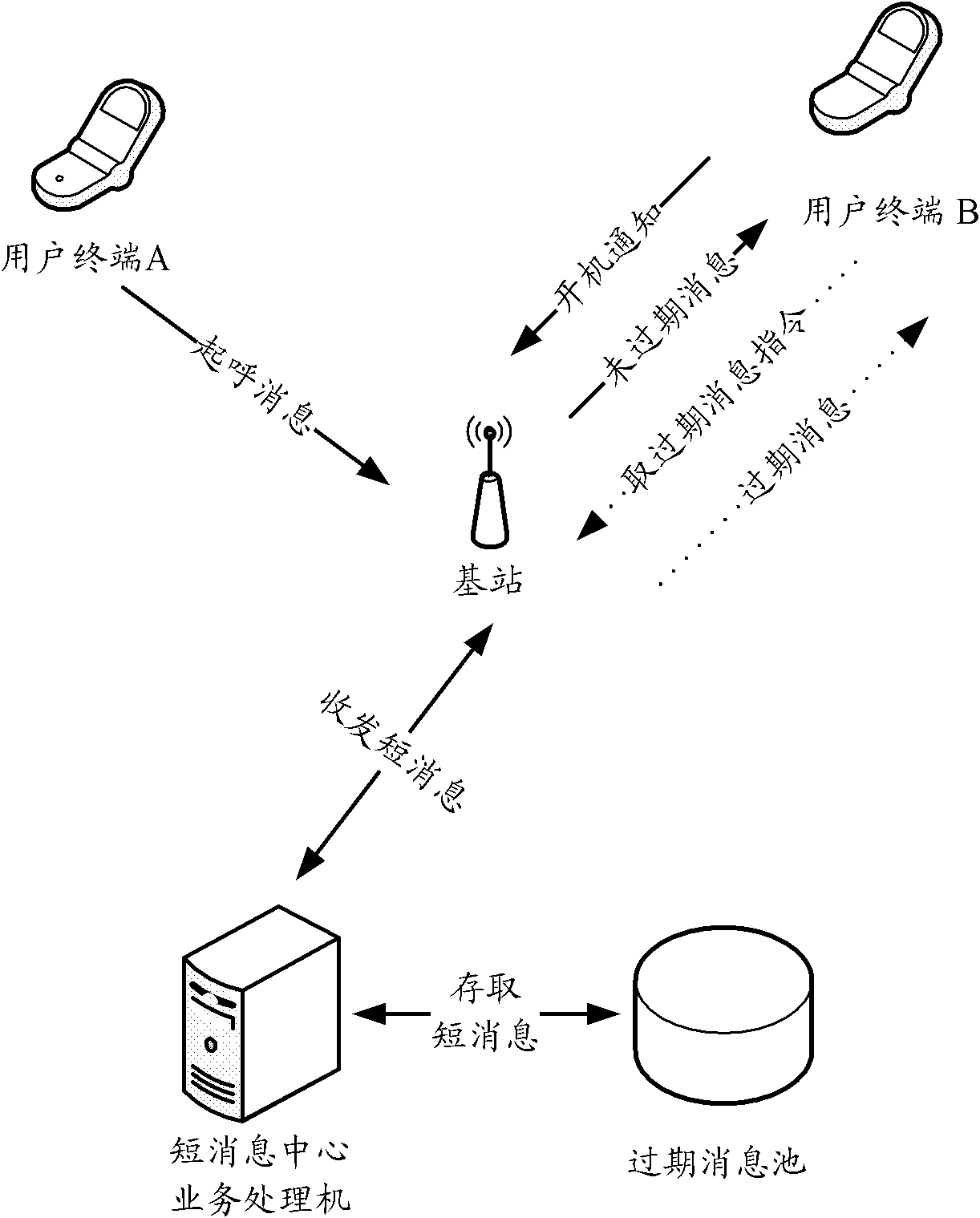

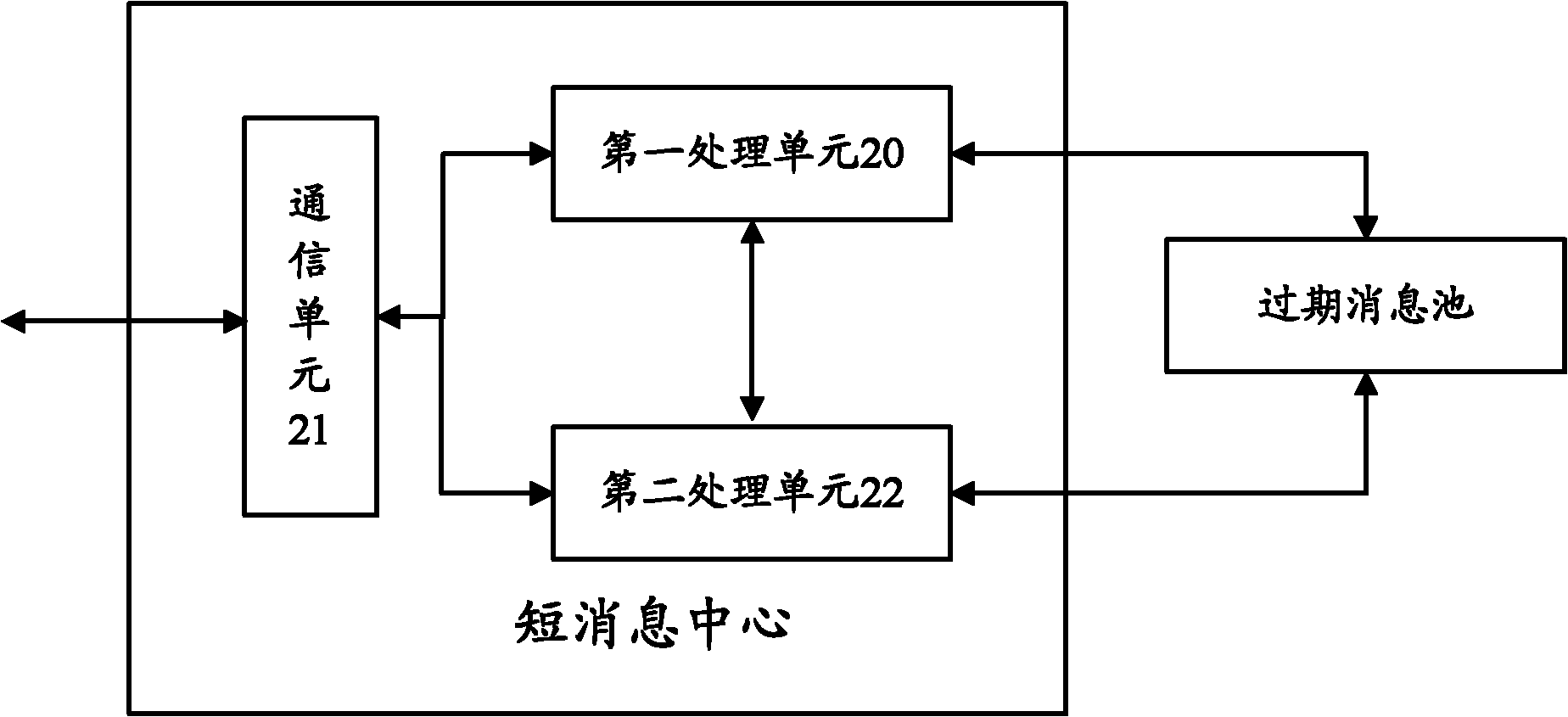

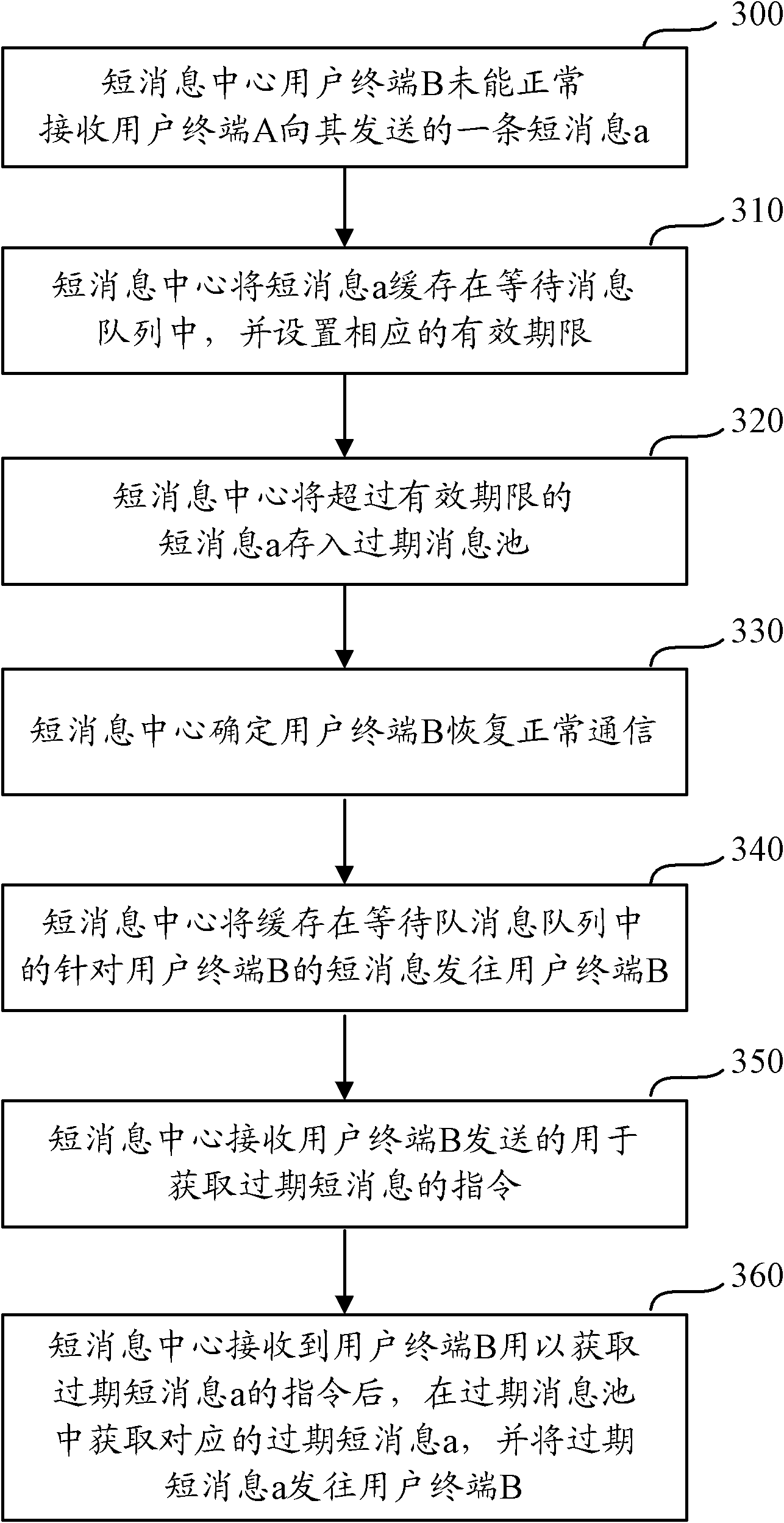

Method and device for processing expired short message

InactiveCN102740243ALittle impact on performanceGuaranteed service performanceMessaging/mailboxes/announcementsTransmissionUser needsQuality of service

The invention discloses a method and a device for processing an expired short message, aiming at sending a short message to a destination user terminal according to user demand after the short message expires. The method comprises the following steps: a short message center transfers a short message to an expired message pool instead of deleting it after the short message expires; and when receiving an instruction sent by a destination user terminal for acquiring the expired short message, the short message center looks up in the expired message pool to see if there is an expired short message that satisfies query criteria contained in the instruction, takes out the expired short message that satisfies the query criteria from the expired message pool and sends to the destination user terminal. In this way, a short message can be sent to a destination user terminal according to user demand after the short message expires, thereby improving the service quality of a system. Moreover, as the expired short message is sent according to the user demand, the impact on performance of the short message center is very low and no more running load is placed on the short message center, thus ensuring service performance of the short message center.

Owner:ZTE CORP

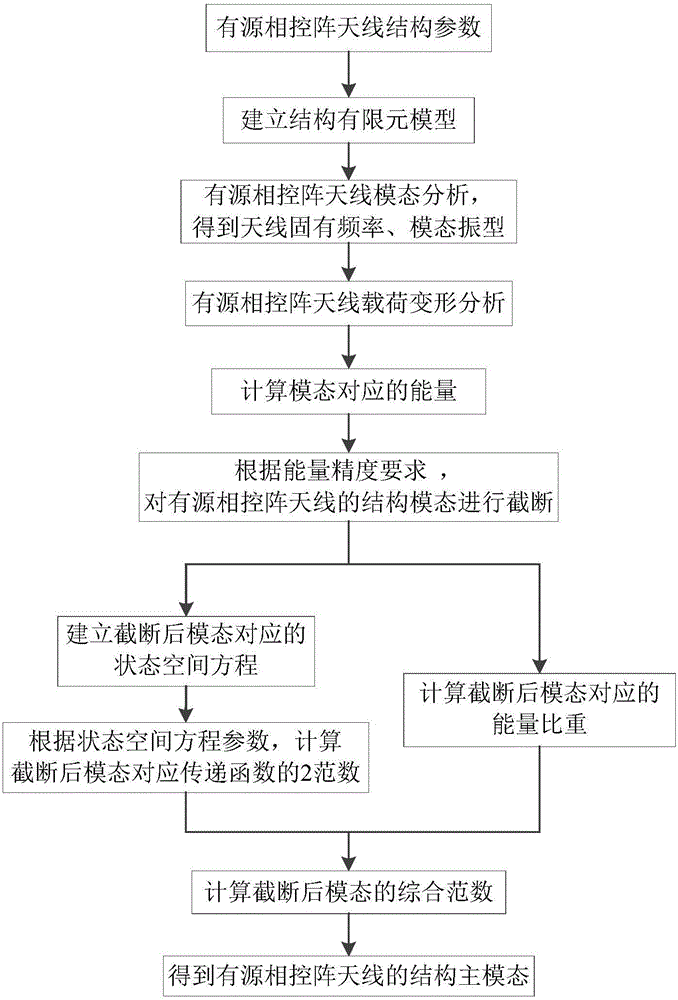

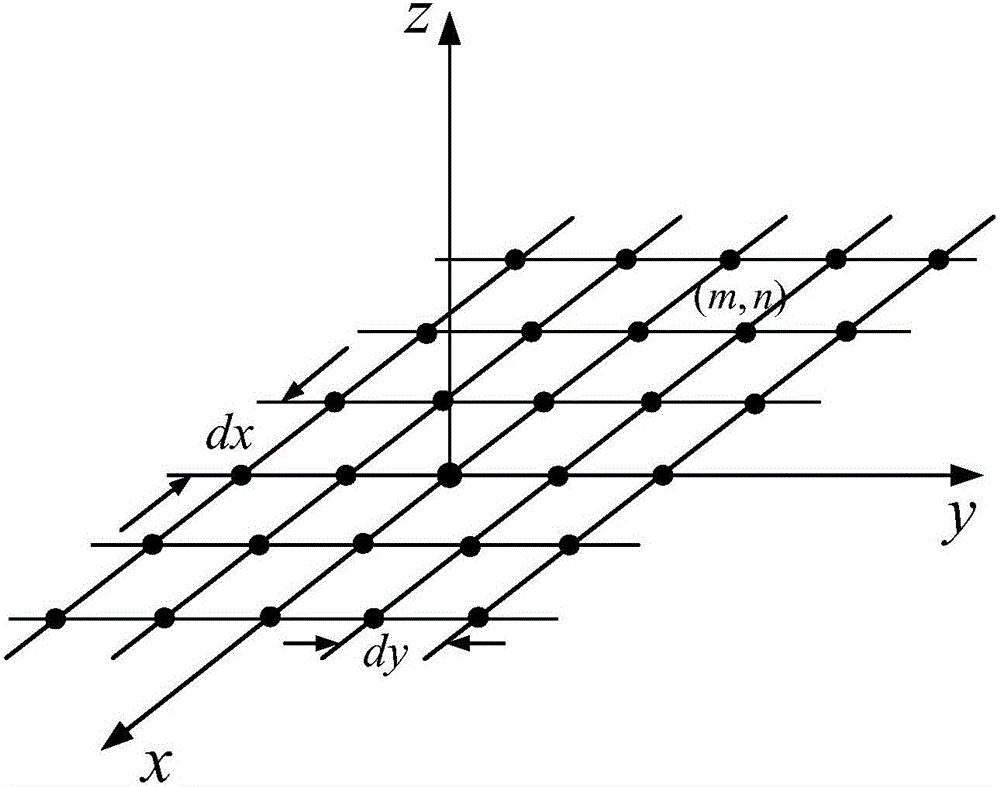

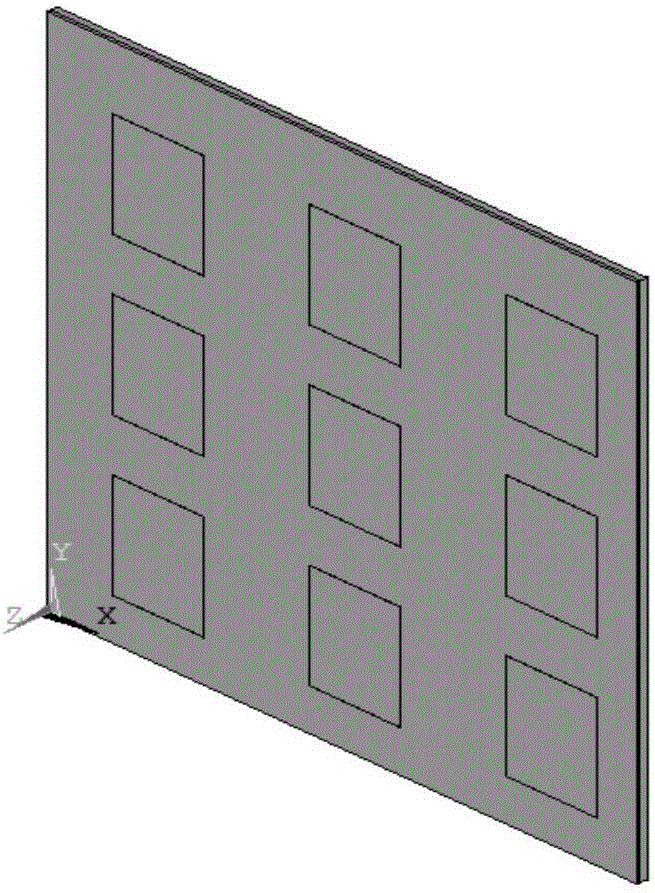

Structural dominant mode determination method for active phased array antenna

ActiveCN106354910AGuaranteed service performanceReduce dimensionalityDesign optimisation/simulationSpecial data processing applicationsElement modelActive phase

The invention discloses a structural dominant mode determination method for an active phased array antenna. The method comprises the steps that 1, parameters of the active phased array antenna are determined, and a finite element model of the antenna is established; 2, antenna natural frequency and a modal shape are obtained through modal analysis; 3, antenna load-deformation is analyzed; 4, output energy corresponding to antenna structural modes is calculated; 5, the antenna structural modes are truncated according to the energy precision requirement; 6, the proportion of energy corresponding to the truncated modes is obtained; 7, a state space equation corresponding to the truncated modes is established; 8, 2-norms of a transfer function corresponding to the truncated modes are calculated according to parameters of the state space equation of the truncated modes; 9, comprehensive norms of the truncated modes are calculated; 10, the comprehensive norms of the truncated modes are ranked from large to small for selection of a dominant mode, and the structural dominant mode of the active phased array antenna is obtained. The method can guide dynamic modeling and pointing control of the active phased array antenna to guarantee antenna service performance.

Owner:XIDIAN UNIV

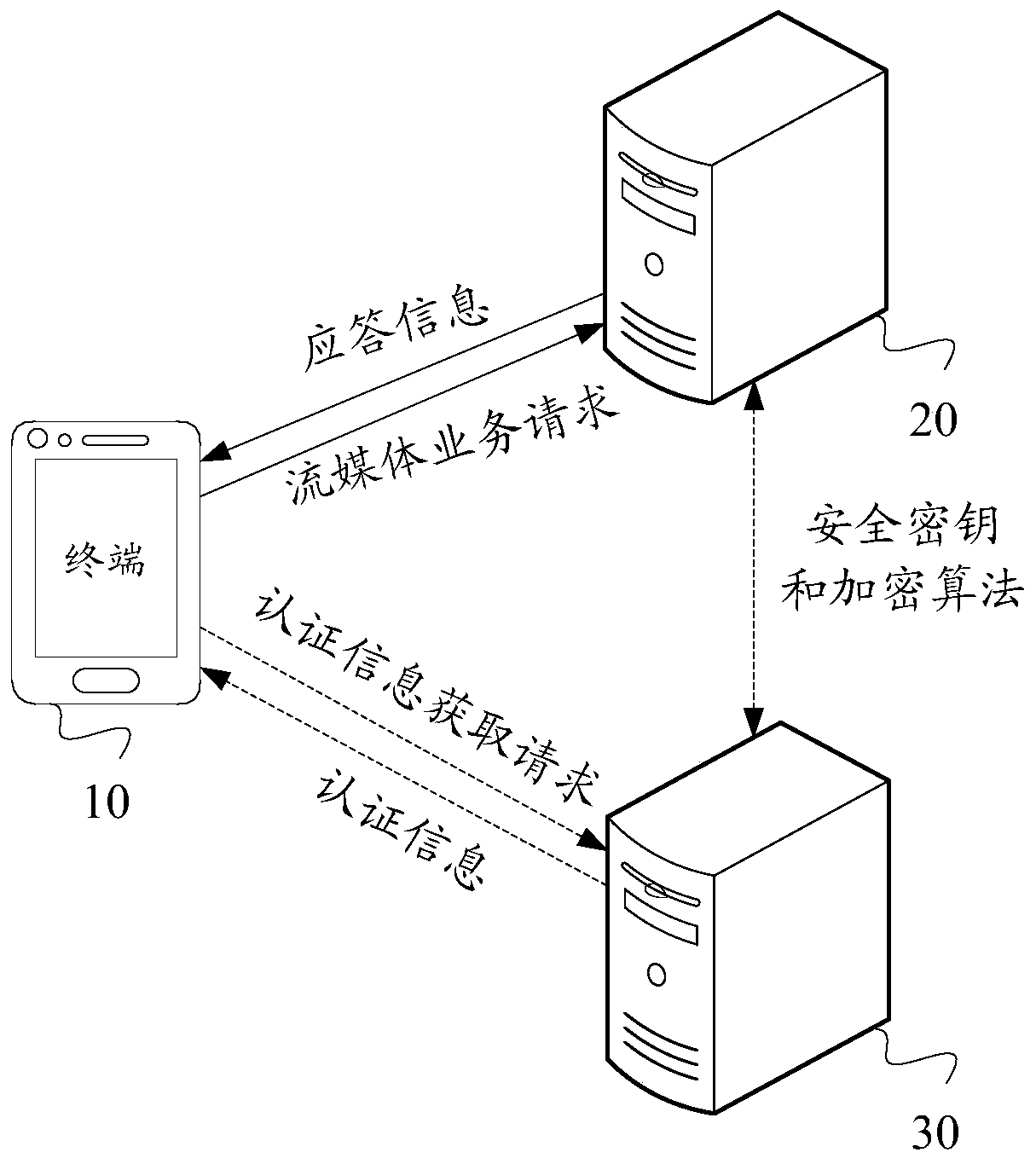

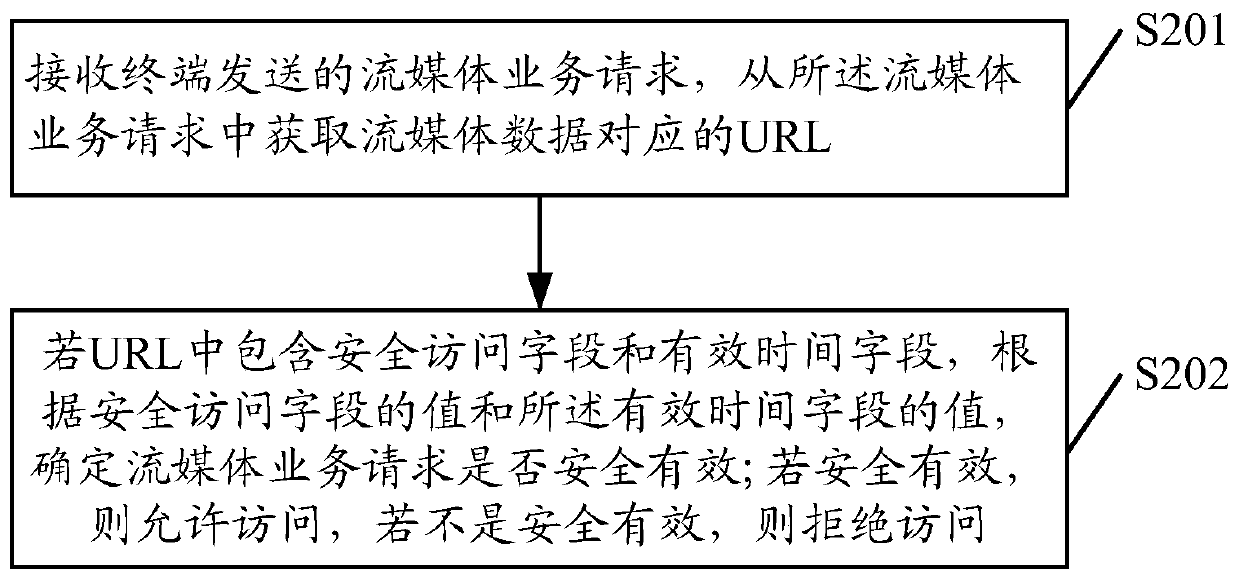

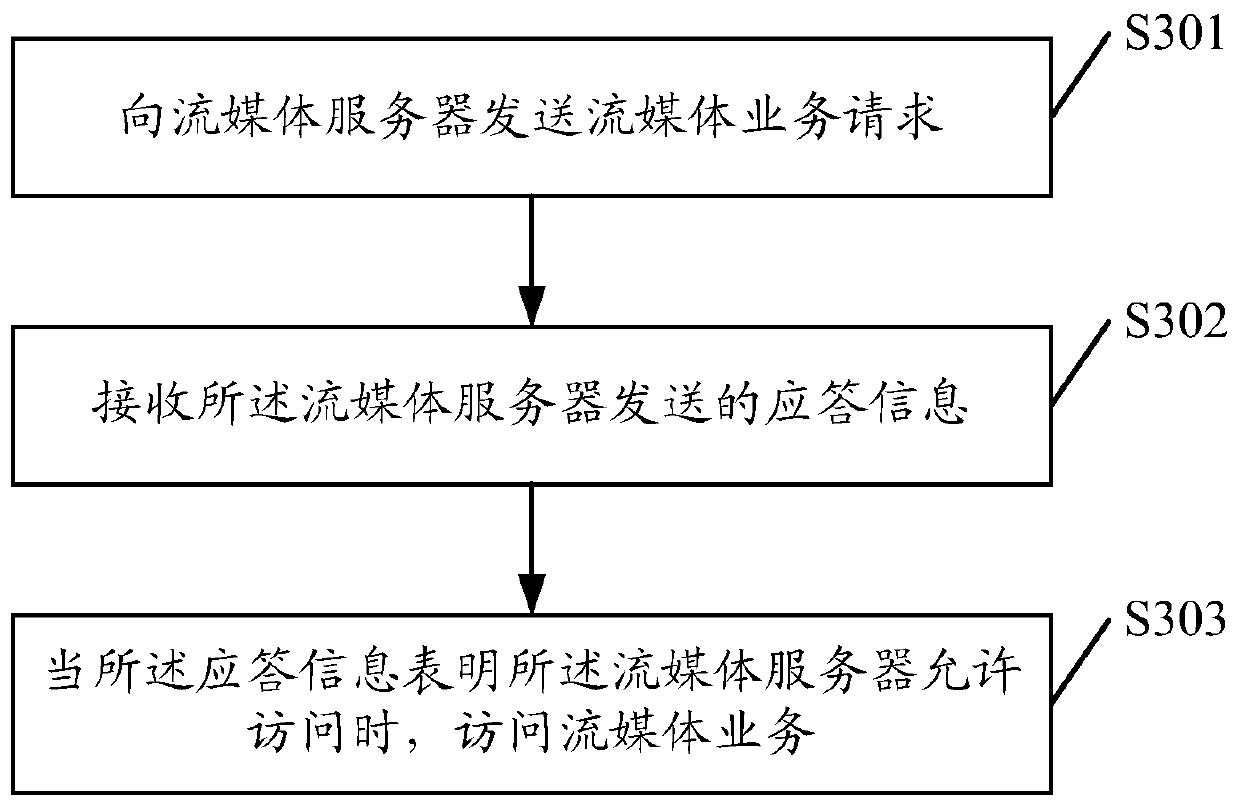

Streaming media data processing method and device, related equipment and medium

ActiveCN109768977AAvoid disk wasteGuaranteed service performanceTransmissionMedia serverEffective time

The invention discloses a streaming media data processing method, which comprises the following steps: receiving a streaming media service request sent by a terminal, and obtaining a URL correspondingto streaming media data from the streaming media service request; if the URL contains the safety access field and the effective time field, determining whether the streaming media service request issafe and effective or not according to the value of the safety access field and the value of the effective time field; if the streaming media service request is safe and effective, allowing access; and if the streaming media service request is not safe and effective, refusing access. According to the method, security access authentication is carried out by introducing a security access field and an effective time field; according to the method and the device, the disk waste caused by junk streaming media data which does not conform to the real service condition is avoided, the service performance of the streaming media server is guaranteed, illegal persons are prevented from pulling the streaming media data from the streaming media server to check private information, and the information security is guaranteed. The invention further discloses a device, equipment and a medium.

Owner:杭州云毅网络科技有限公司

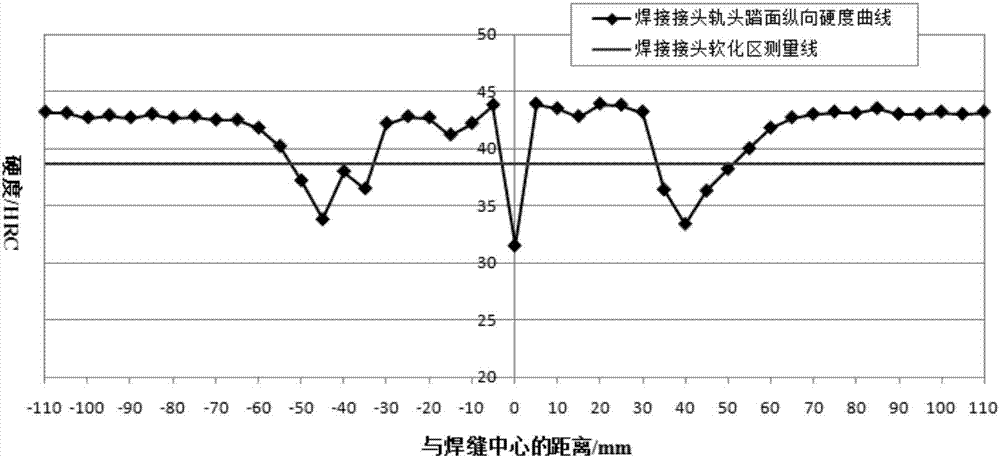

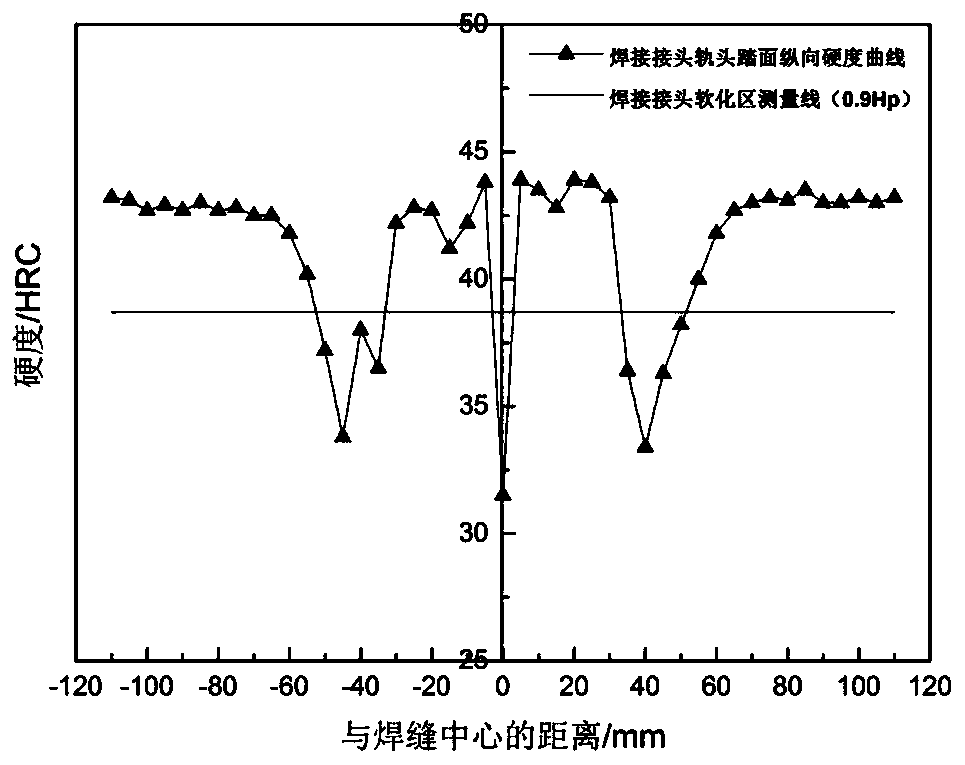

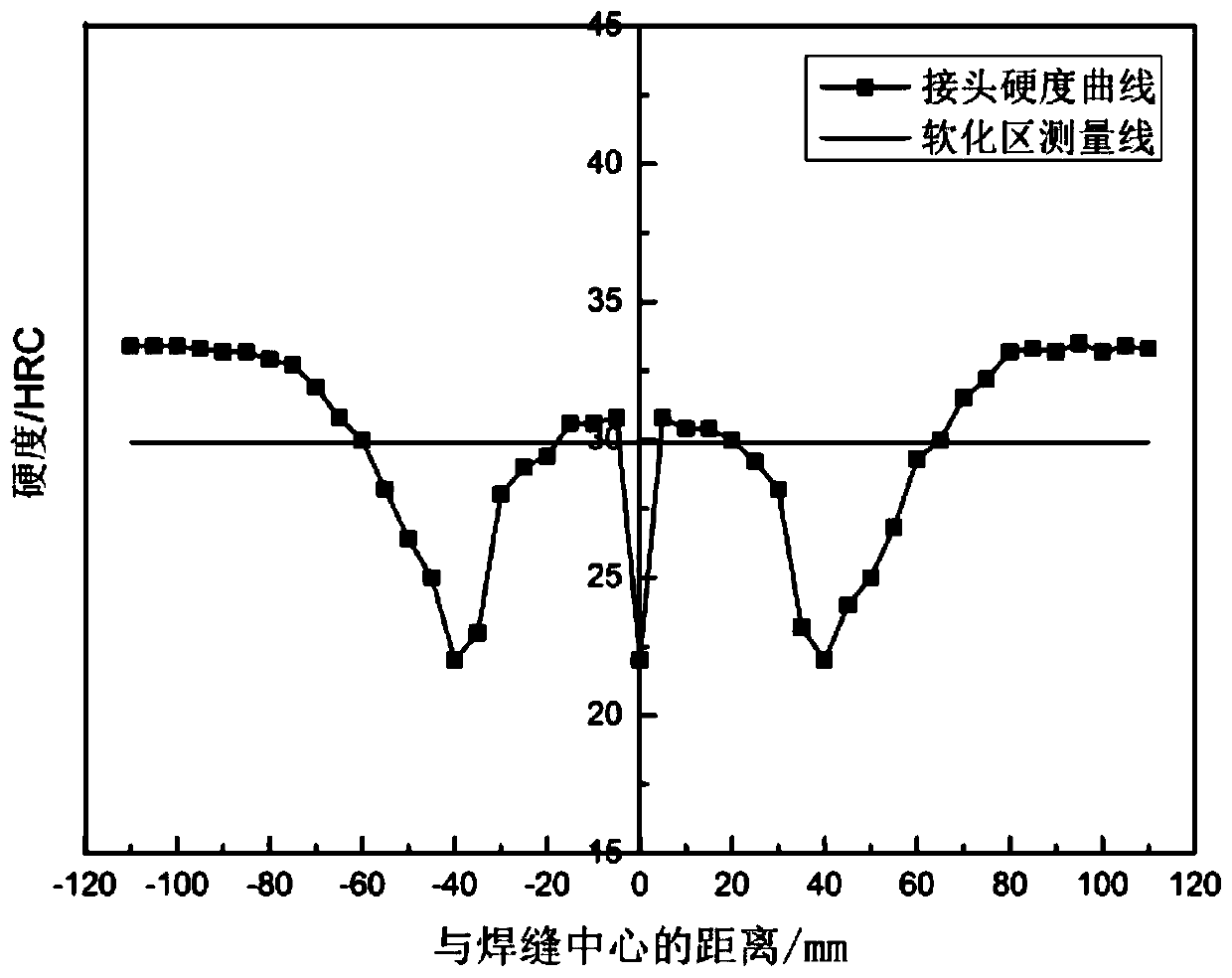

Post-welding heat treatment method for bainite steel rails

InactiveCN110331274AGuaranteed uptimeImprove fatigue lifeFurnace typesHeat treatment furnacesRoom temperatureWeld seam

The invention discloses a post-welding heat treatment method for bainite steel rails, and belongs to the technical field of steel rail welding. The invention aims to make up the defects of the existing post-welding heat treatment technology for steel rails and provides the post-welding heat treatment method for bainite steel rails. The method comprises the following steps of carrying out first cooling on a bainite steel rail welding joint at the temperature of 1100-1300 DED C to 260-350 DED C, then heating the welding joint obtained by the first cooling to 780-870 DED C, then, performing secondary cooling to 450-510 DED C, and then, performing a third cooling to the room temperature of 10-40 DED C. According to the method, the post-welding heat treatment process of the bainite steel rail is reasonably established, so that the metallurgical structure of the steel rail joint is free of martensite, and meanwhile, the average hardness in a region with the distance of + / -70 mm from the center of a welding seam is 80-85% of a steel rail base material, and the fatigue life of the bainite steel rail joint reaches 4 million times or more.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

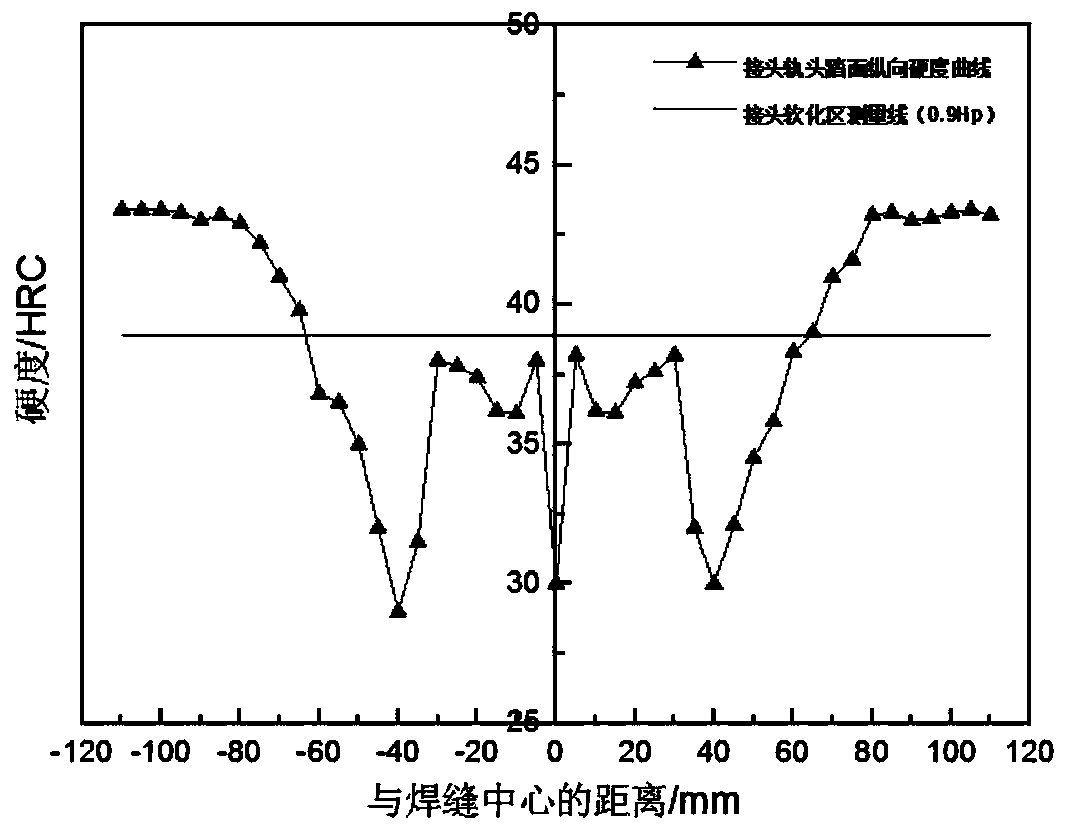

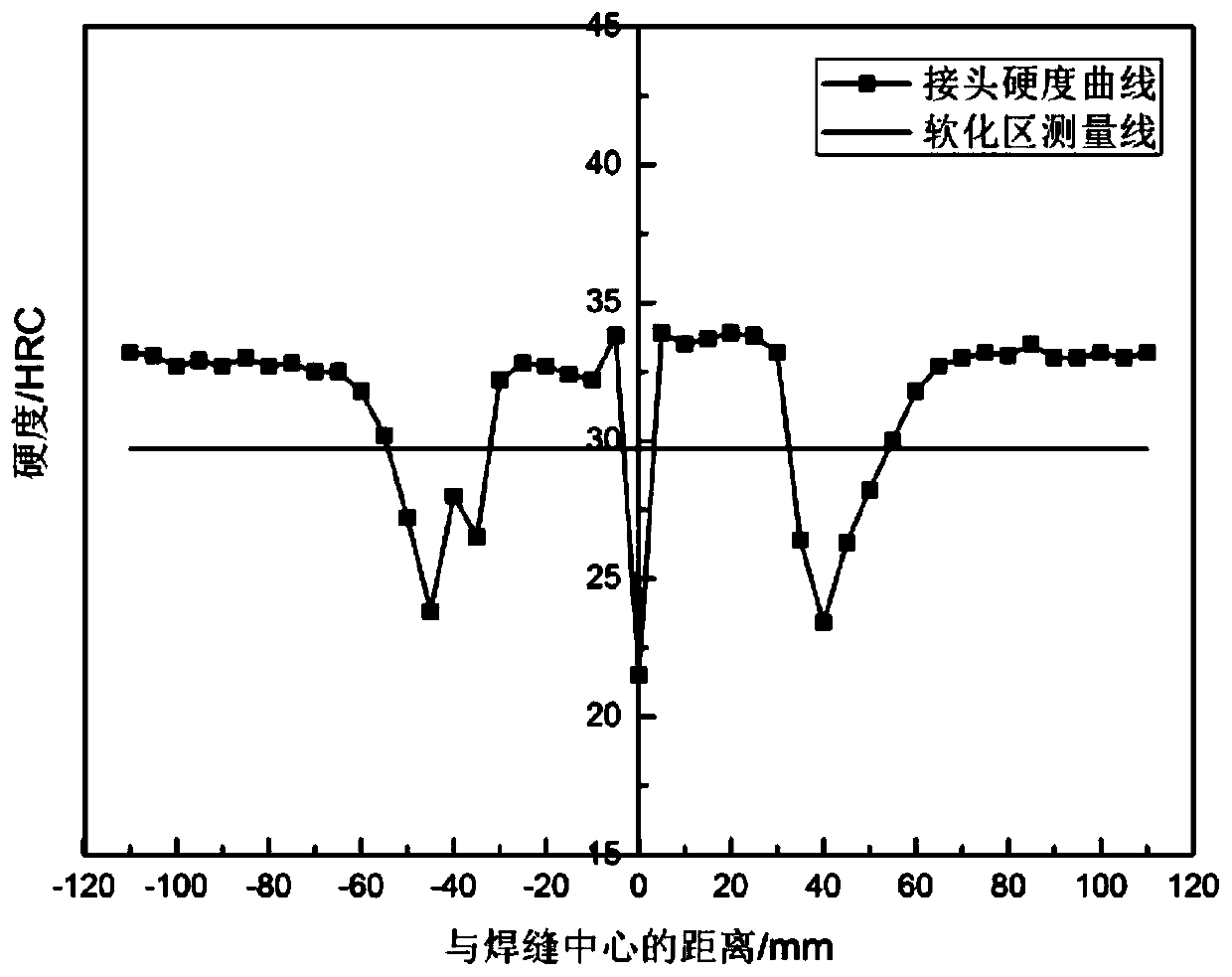

Post-welding heat treatment method for bainite steel rails

InactiveCN110331275AGuaranteed operational safetyImproved \"saddle\" wearFurnace typesHeat treatment furnacesRoom temperatureWeld seam

The invention discloses a post-welding heat treatment method for bainite steel rails, and belongs to the technical field of steel rail welding. The invention aims to make up the defects of the existing post-welding heat treatment technology for steel rails and provides the post-welding heat treatment method for bainite steel rails. The method comprises the following steps of carrying out first cooling on a bainite steel rail welding joint at the temperature of 1100-1300 DED C to 260-350 DED C, then heating the welding joint obtained by the first cooling to 780-870 DED C, then, performing secondary cooling to 360-420 DED C, and then, performing a third cooling to the room temperature of 10-40 DED C. According to the method, the post-welding heat treatment process of the bainite steel rail is reasonably established, so that the martensite structure content is less than or equal to 3%, the average hardness in a region of + / -70 mm from the center of a welding seam is 80-85% of a steel railbase material, and the fatigue life of a bainite steel rail joint reaches more than 3.5 million times.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

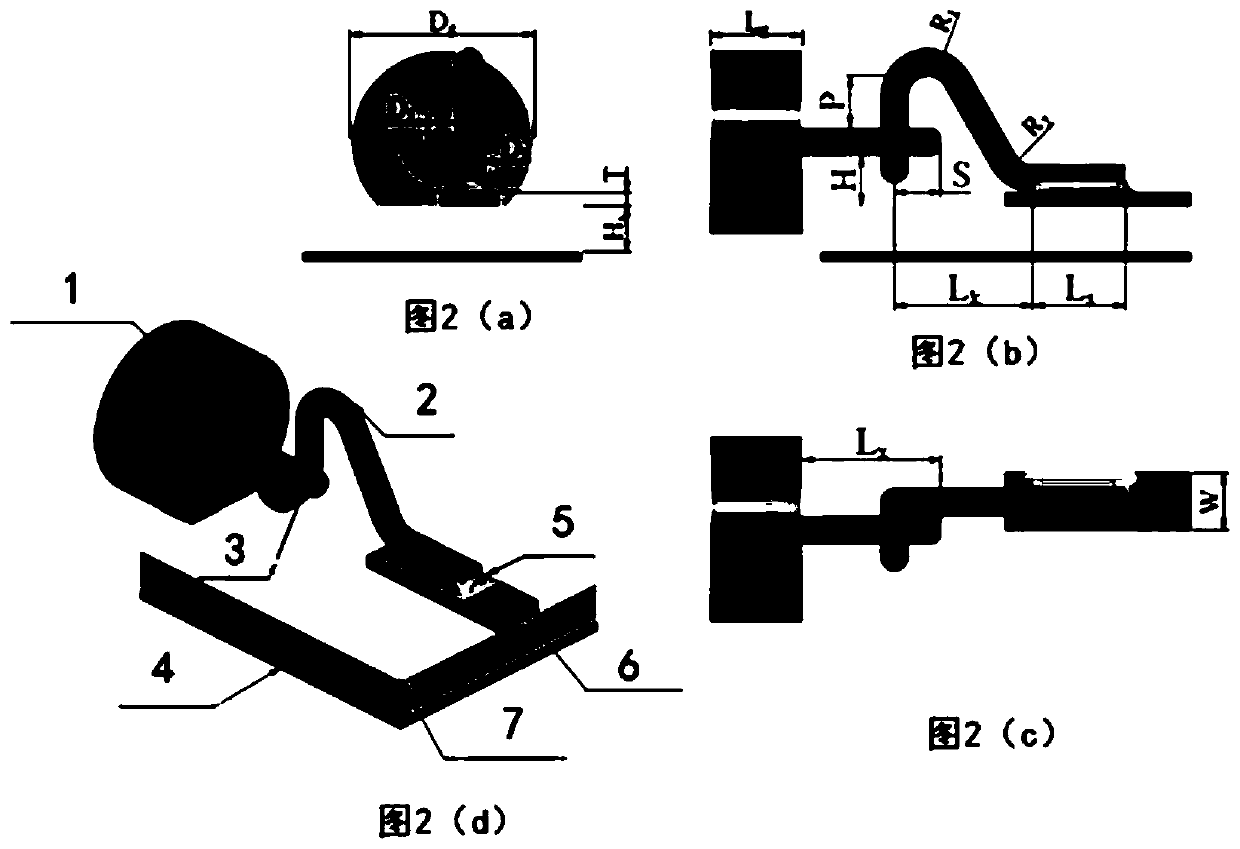

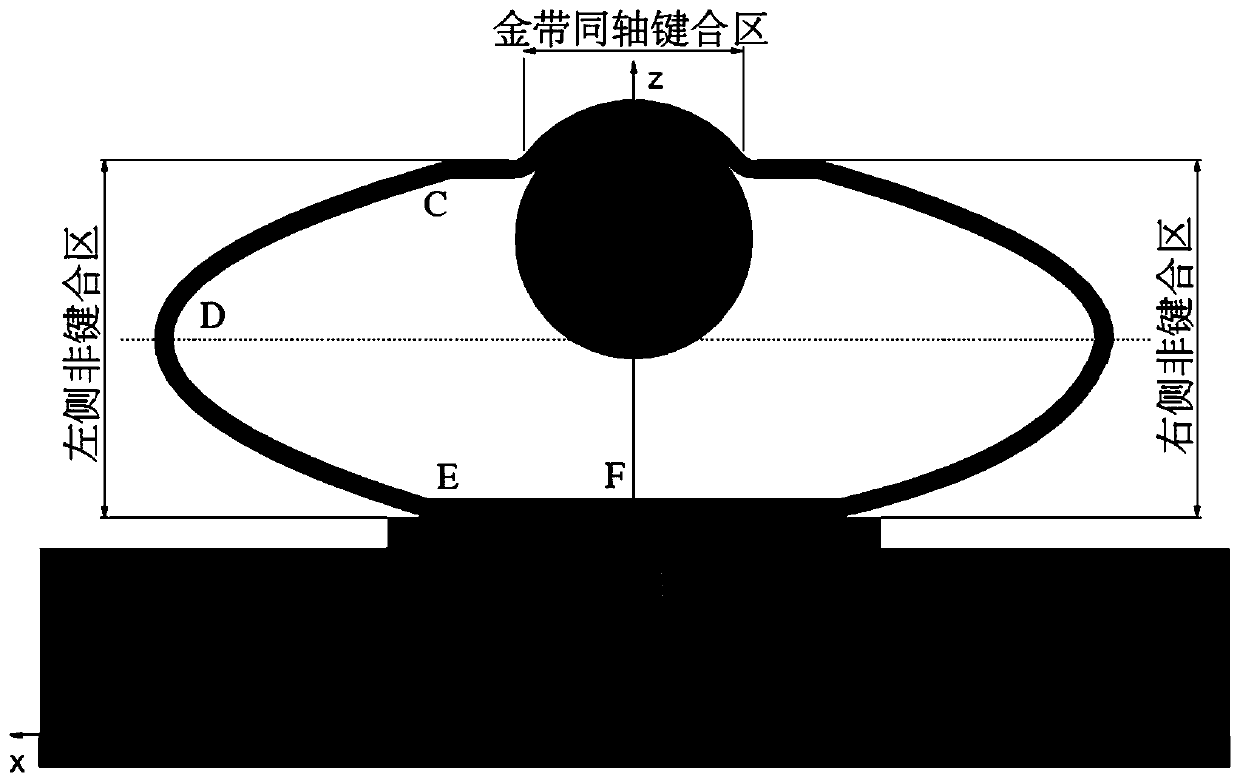

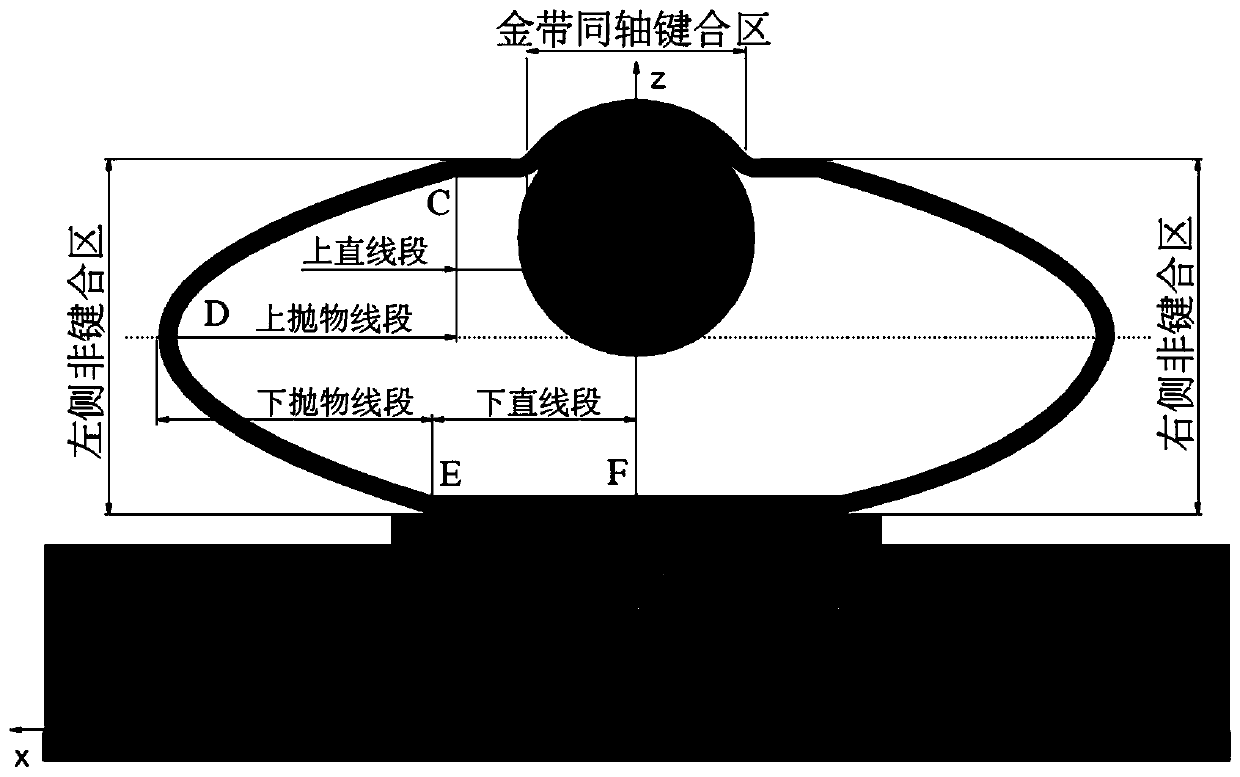

Microwave assembly gold belt interconnection transmission performance prediction method based on interconnection form

ActiveCN110533319ASolve the problems of unclear impact correlation and unclear direction of precise optimization designImprove work efficiencyForecastingResourcesInterconnectivityMicrowave

The invention discloses a microwave assembly gold belt interconnection transmission performance prediction method based on an interconnection form, and the method comprises the steps: determining goldbelt interconnection geometric parameters, physical parameters and electromagnetic transmission parameters, carrying out parametric representation of a gold belt interconnection structure form, and building a gold belt interconnection structure-electromagnetic analysis model; screening and recognizing shape effect key parameters a; constructing a gold belt interconnectivity multiple regression model; regression equation precision inspection and parameter correction; and establishing a gold strip interconnection transmission performance prediction model. Key parameter identification of the microwave assembly gold belt interconnection structure for high-frequency signal transmission can be realized A gold strip interconnection transmission performance prediction model is established, and the model can realize accurate prediction from microwave interconnection structure morphological parameters to signal transmission performance, can be used for guiding design, manufacturing and optimization of microwave components, effectively improves the development quality of microwave products, saves the cost and shortens the development period.

Owner:XIDIAN UNIV

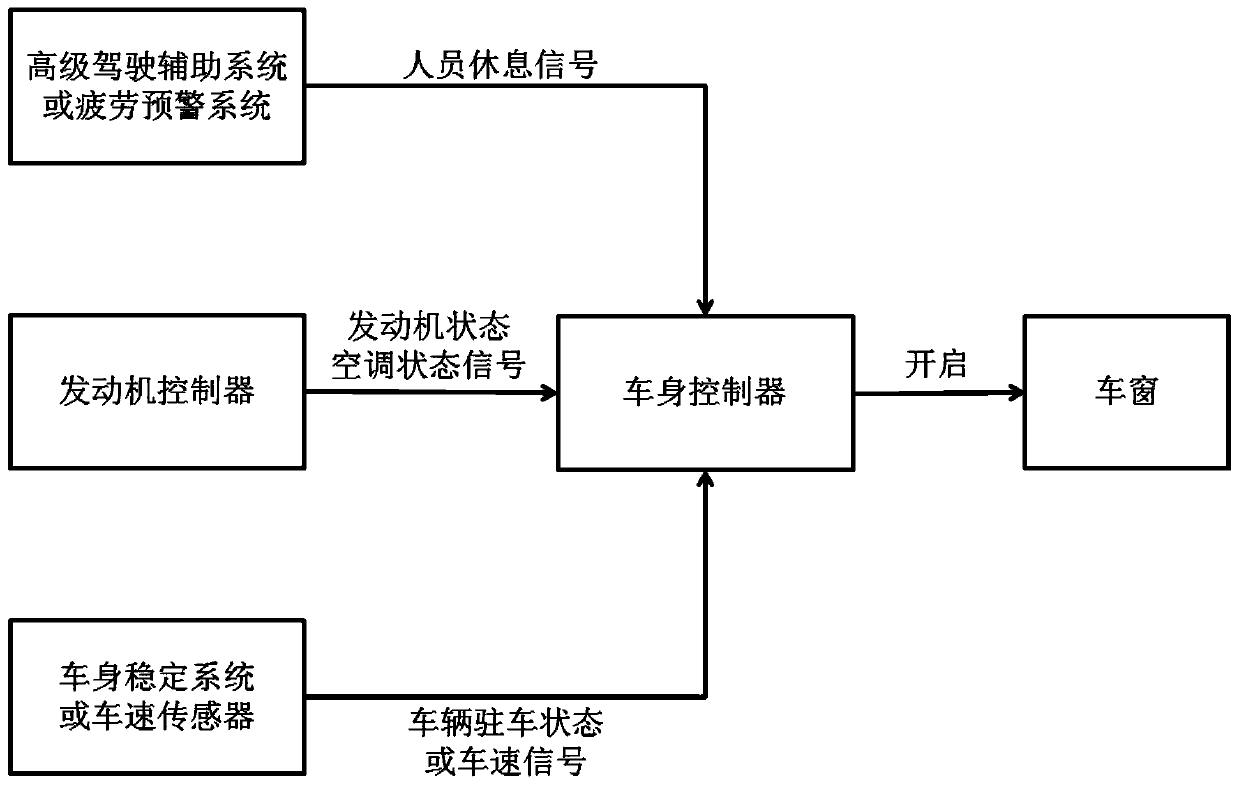

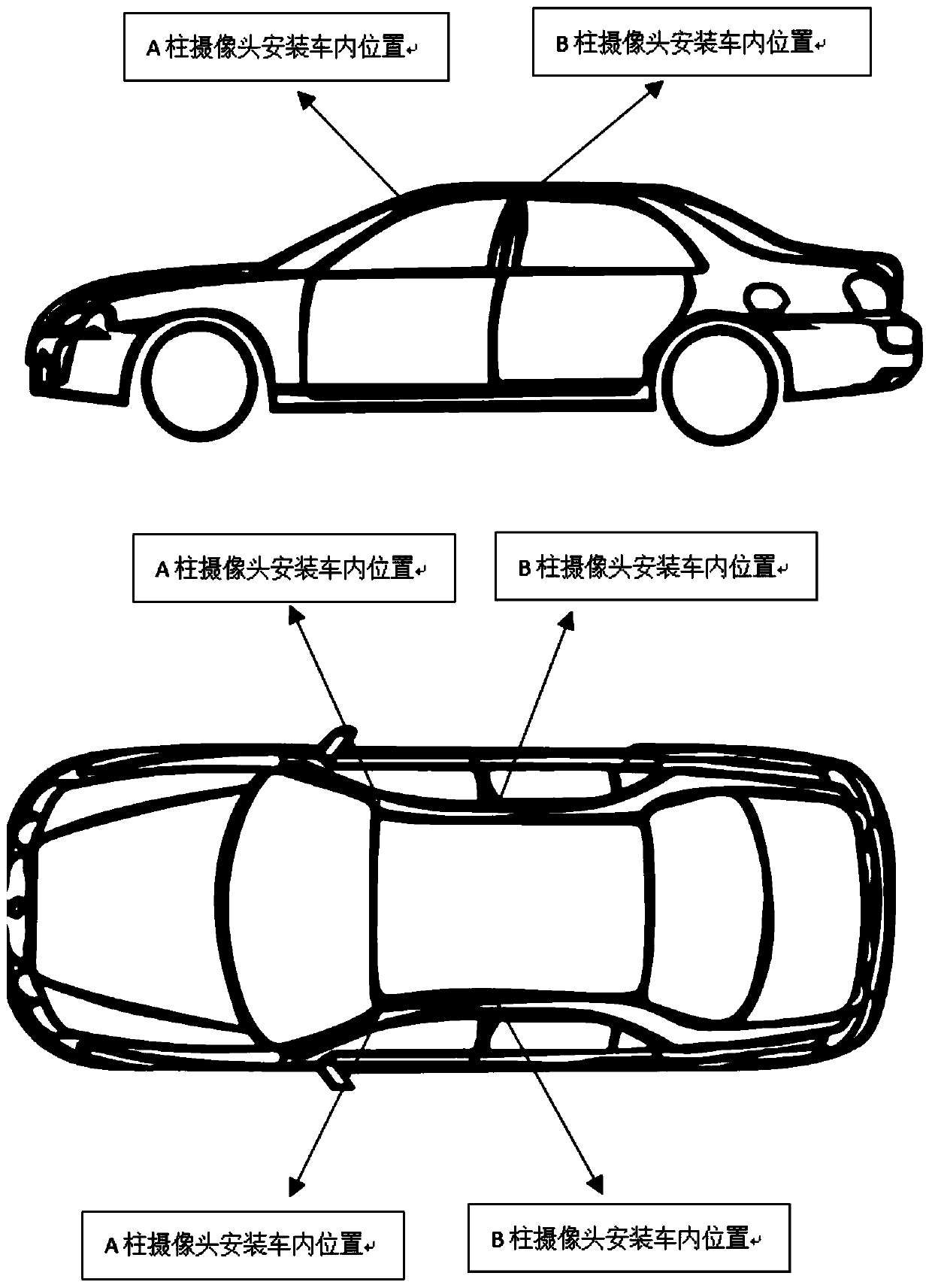

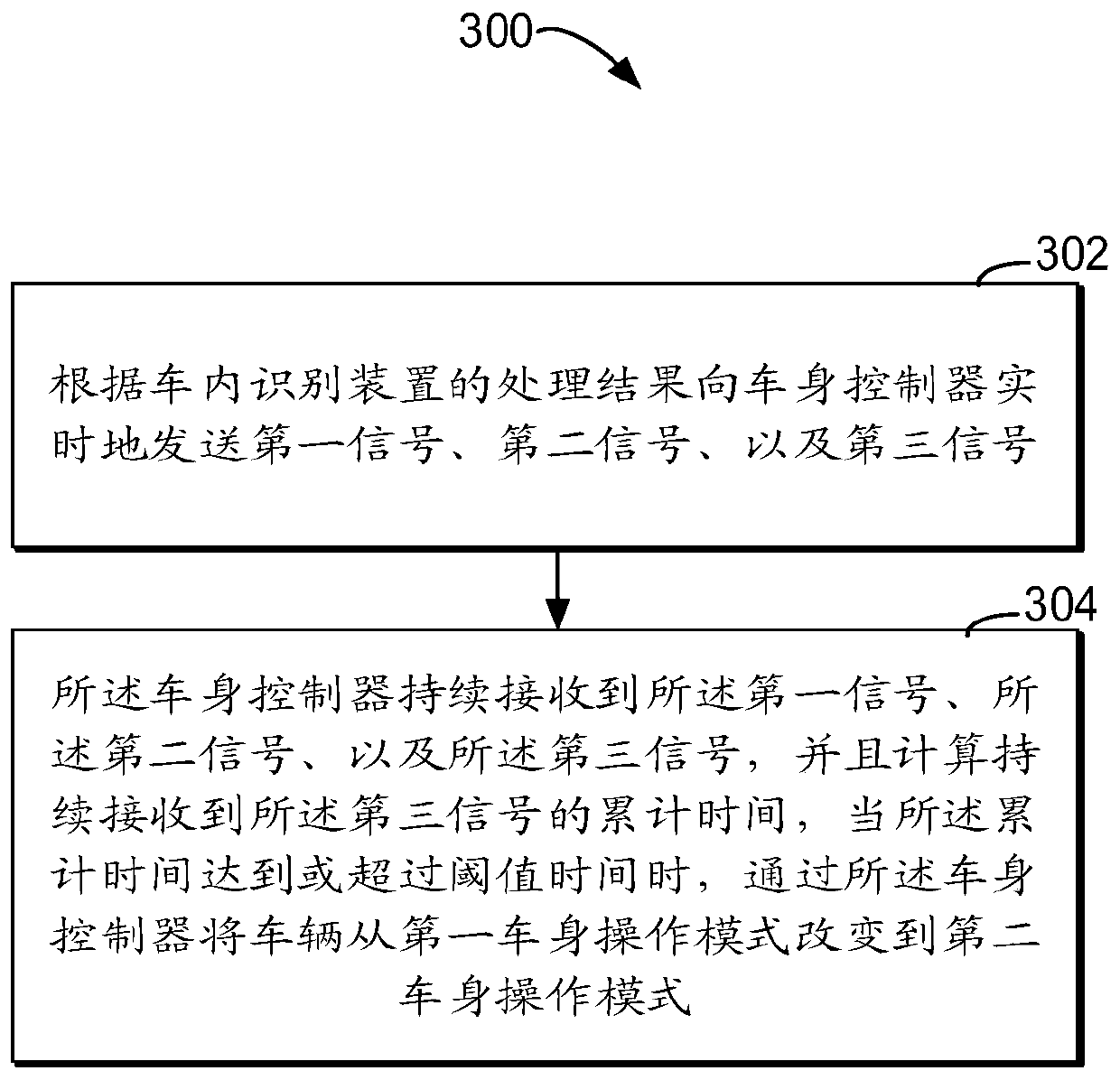

In-vehicle suffocation prevention method based on camera and computer readable medium

The invention provides an in-vehicle suffocation prevention method, an in-vehicle suffocation prevention method based on a camera and a computer readable medium. The method comprises the following steps of sending a signal that a vehicle is in a parking state (or the vehicle speed is in a zero state) to a vehicle body controller in real time according to a processing result of an in-vehicle identification device; sending a signal that a vehicle-mounted air conditioner is in an on state to the vehicle body controller in real time; continuously sending a signal that a person in the vehicle is ina rest state (an eye closing state or a lying state) to the vehicle body controller in real time; continuously receiving the signal that the vehicle is in the parking state (or the vehicle speed is in the zero state), the signal that the vehicle-mounted air conditioner is in the on state and the signal that the person in the vehicle is in the rest state (the eye closing state or the lying state),calculating the cumulative time of continuously receiving the signal that the person in the vehicle is in the rest state or the lying state, and when the cumulative time reaches or exceeds the threshold time, changing the mode from a window or sunroof closing mode to a window or sunroof opening mode. In addition, the invention further provides the in-vehicle suffocation prevention method based onthe camera.

Owner:QOROS

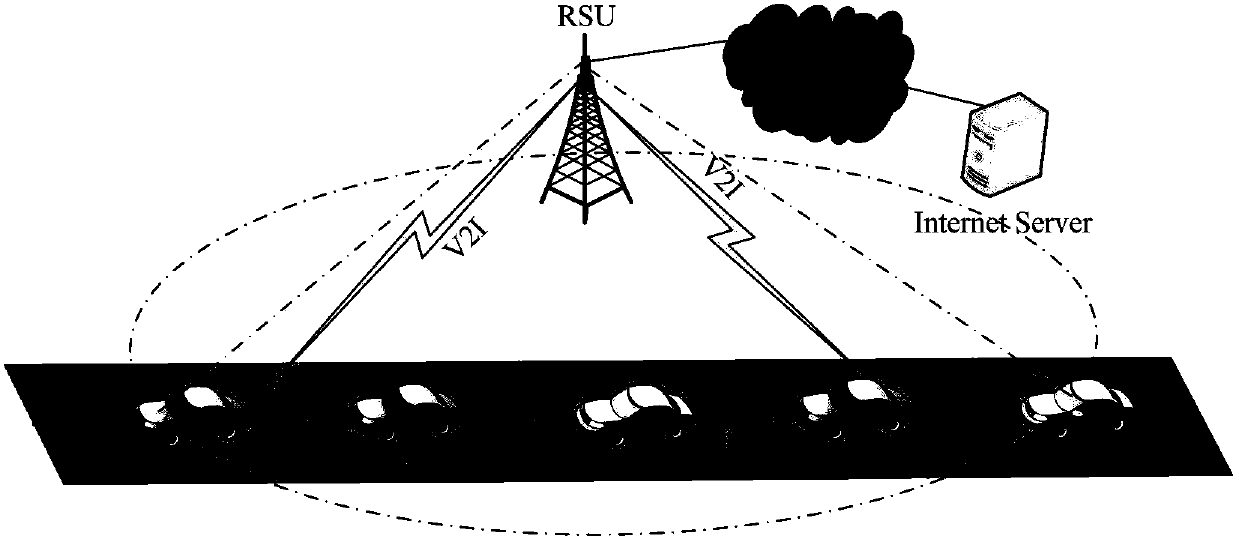

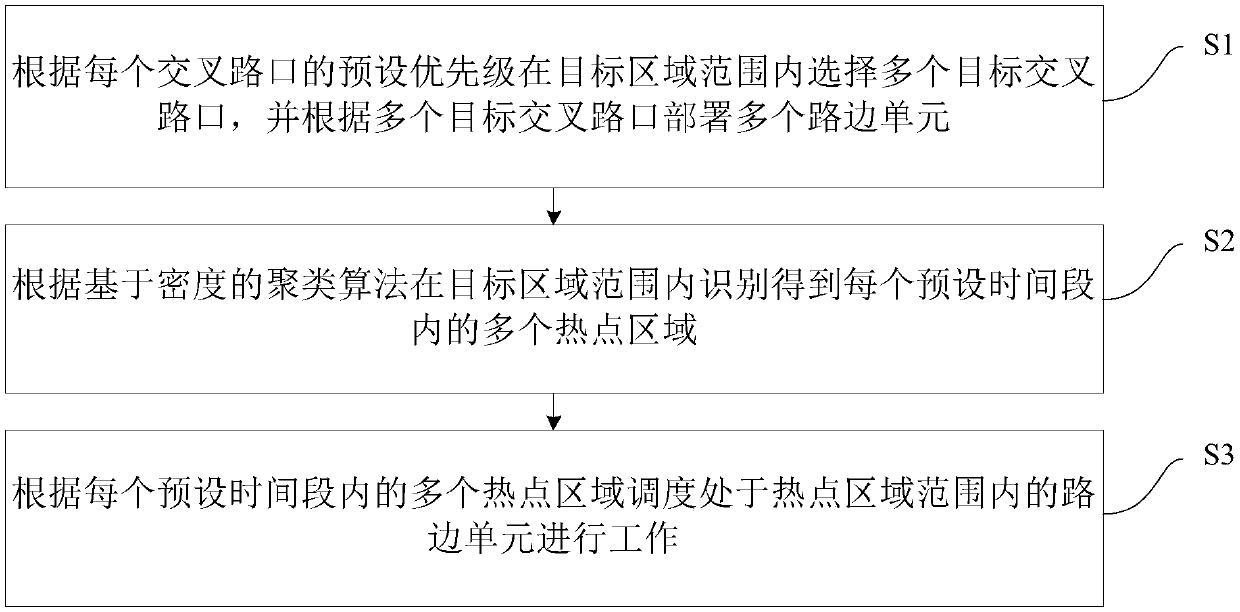

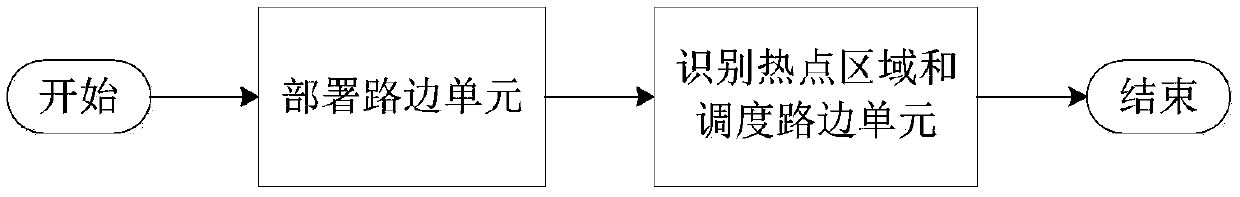

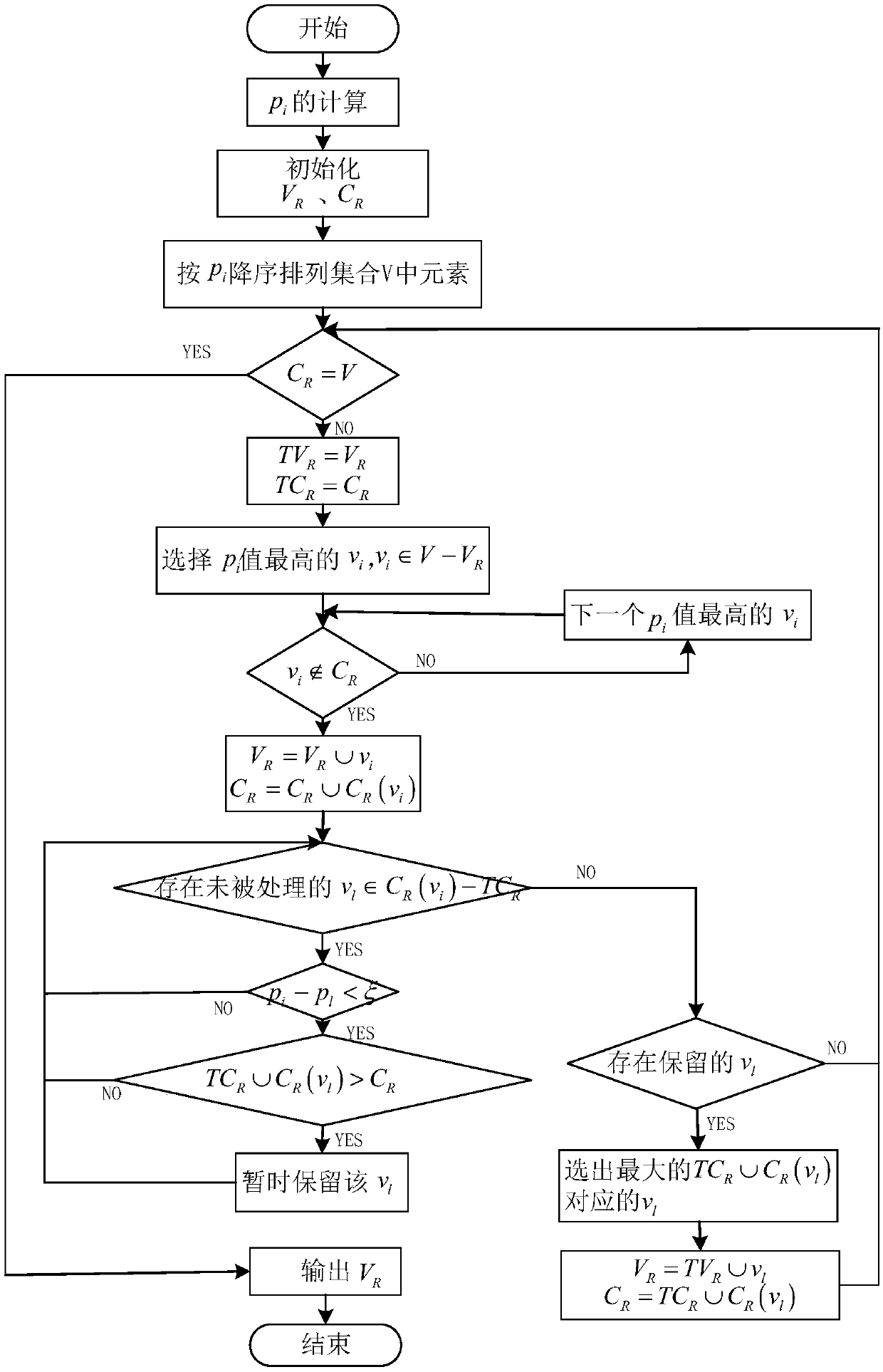

Method and device for deploying and scheduling roadside units in urban vehicle network

ActiveCN109615857AGuaranteed service performanceImprove energy resource utilizationGeometric CADDetection of traffic movementQuality of serviceCluster algorithm

The invention discloses a method and device for deploying and scheduling roadside units in an urban vehicle network. The method for deploying and scheduling the roadside units in the urban vehicle network comprises the following steps that S1, a plurality of target intersections are selected within a target area range according to a preset priority of each intersection to deploy the multiple roadside units according to the multiple target intersections; S2, multiple hotspot areas in each preset time period are identified in the target area range according to adensity-based clustering algorithm; and S3, the roadside units within the hotspot areas are scheduled to work according to the multiple hotspot areas within each preset time period. According to the method for deploying and schedulingthe roadside units in the urban vehicle network, the working state and the dormant state of the roadside units can be adjusted and controlled within a specified time period without affecting connection and service quality, and the energy resource utilization rate of the vehicle network is increased.

Owner:CAPITAL NORMAL UNIVERSITY

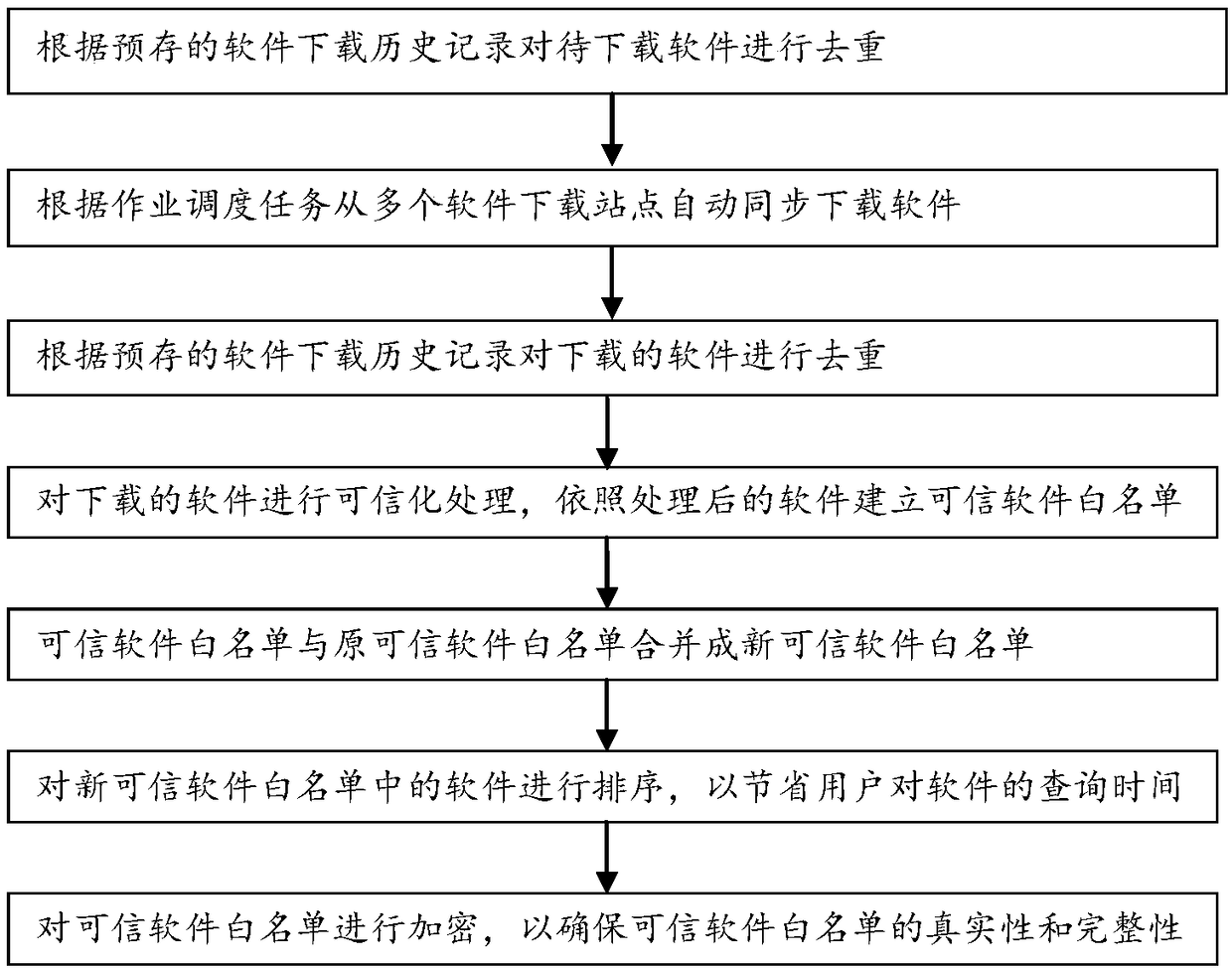

A method for constructing a trusted software whitelist

InactiveCN108989304ALow professional knowledge requirementLower skill requirementsComputer security arrangementsTransmissionInternet usersSoftware trustworthiness

The invention provides a method for constructing a trusted software whitelist. The method comprises: automatically synchronously downloading software from a plurality of software downloading sites according to a job scheduling task; making a trusted judgment on the downloaded software, and establishing a trusted software whitelist according to the trusted software. The trusted software whitelist construction method of the invention automatically obtains an executable program in the Internet range, so as to maximize the coverage of software programs that Internet users may use, by using the software trustworthiness analysis tool to obtain the software program trustworthiness analysis of obtained software programme, a corresponding trusted software whitelist is generated and provided for Internet users to download and use, which can greatly reduce the professional knowledge and skill requirements of users, improve the usability of the trusted software whitelist mechanism, thus promotingthe application of the trusted software whitelist mechanism, and improving the level and ability of network security prevention.

Owner:北京广成同泰科技有限公司

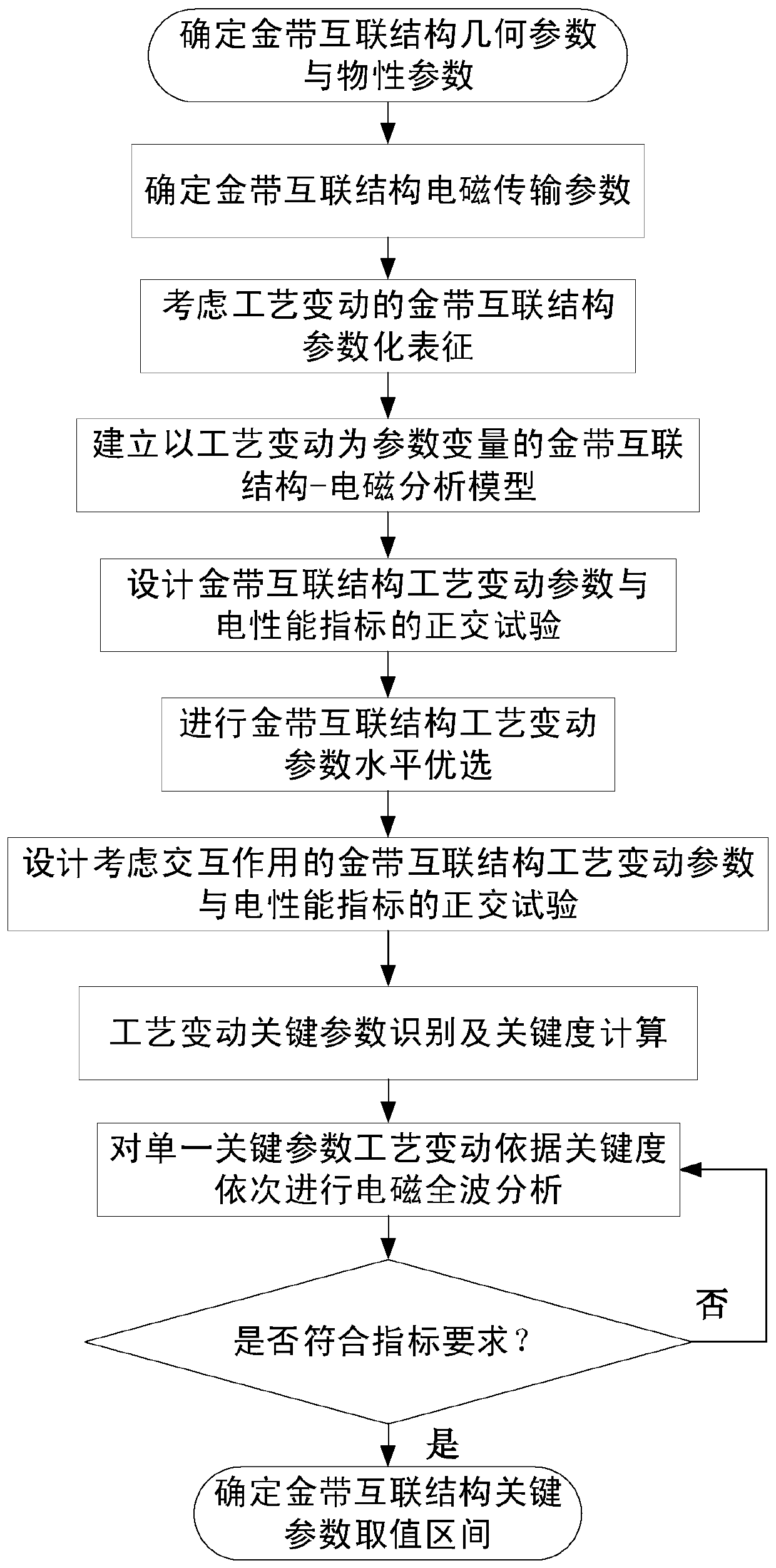

Electromagnetic transmission-oriented gold belt interconnection structure key parameter value interval determination method

ActiveCN110532677AImprove work efficiencyReduce development costsSpecial data processing applicationsElectricityMicrowave

The invention discloses an electromagnetic transmission-oriented gold belt interconnection structure key parameter value interval determination method. The method comprises the steps of determining gold belt interconnection structure geometric parameters, physical property parameters and electromagnetic transmission parameters; performing parametric representation on the gold strip interconnectionstructure considering the process change, and establishing a gold strip interconnection structure-electromagnetic analysis model; designing an orthogonal test of process variation parameters and electrical performance indexes of the gold strip interconnection structure, and carrying out level optimization on the variation parameters; designing an orthogonal test, key parameter identification andcriticality calculation of process variation parameters and electrical performance indexes of the gold strip interconnection structure considering interaction, and determining a value interval of keyparameters of the gold strip interconnection structure. The method can guide the design and optimization of the high-performance microwave assembly considering the process and manufacturing conditions, and improves the development quality of high-performance microwave products.

Owner:XIDIAN UNIV

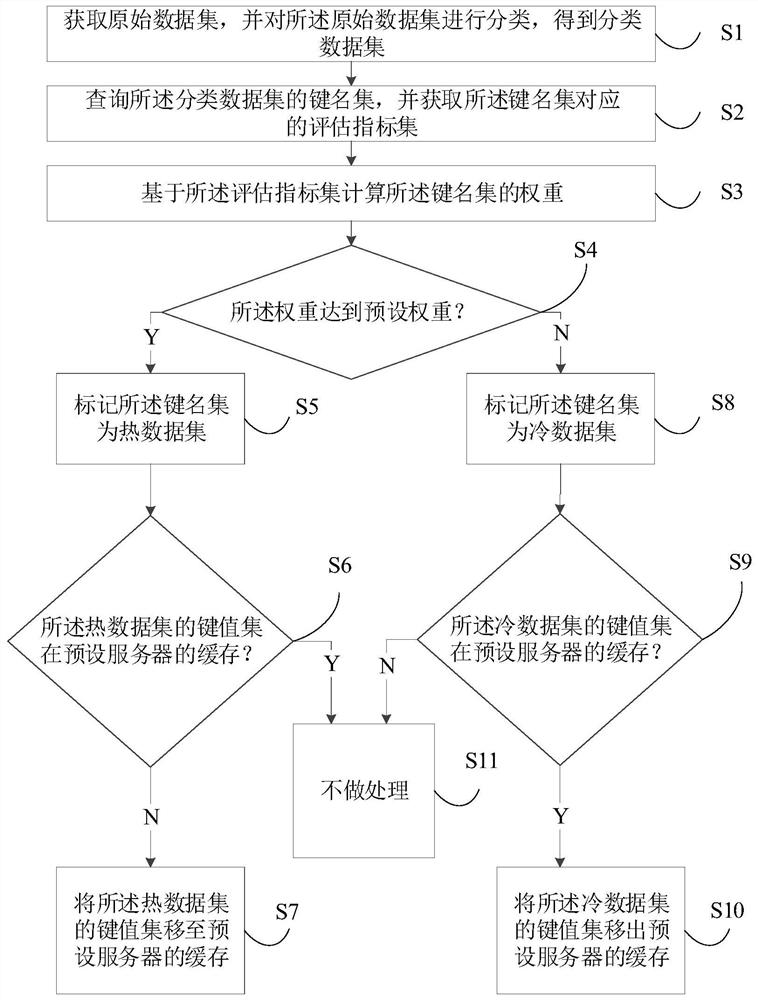

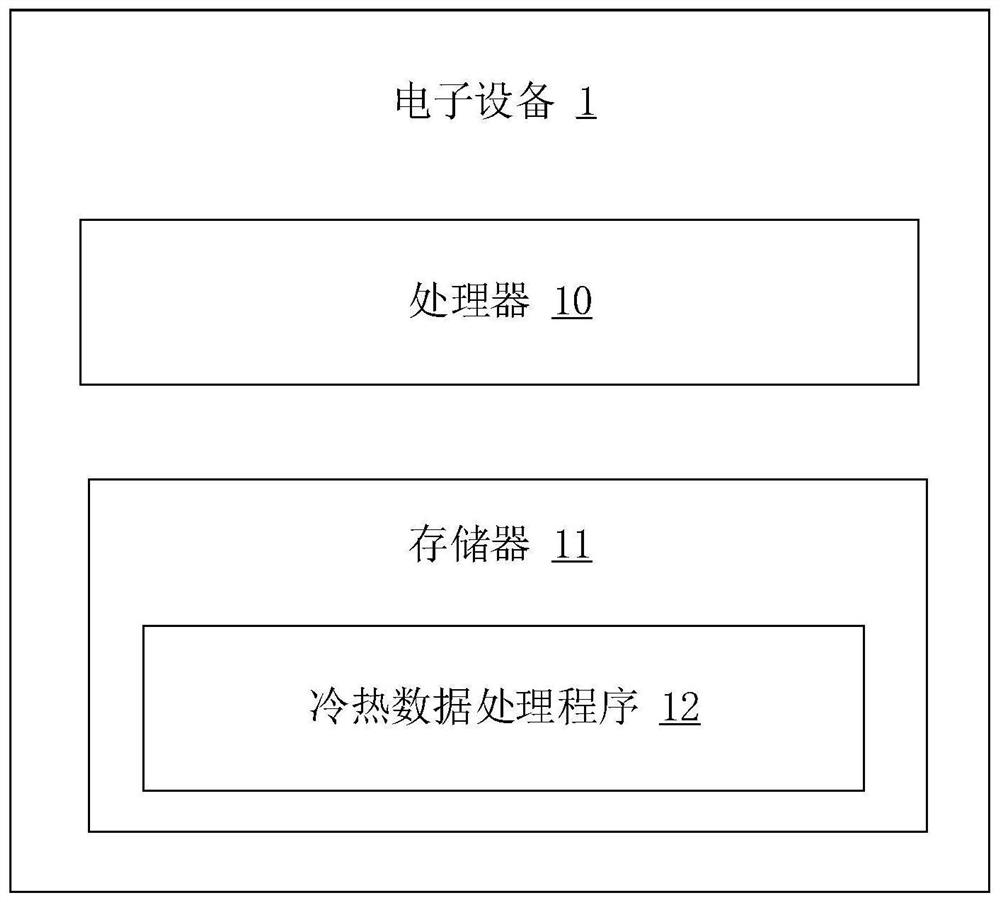

Cold and hot data processing method and device, electronic equipment and storage medium

PendingCN112699142AEfficient accessReduce wasteDatabase updatingRelational databasesData setValue set

The invention relates to the field of data storage, and discloses a cold and hot data processing method, which comprises the steps of obtaining an original data set, classifying the original data set to obtain a classified data set, querying a key name set of the classified data set, obtaining an evaluation index set corresponding to the key name set, calculating the weight of the key name set based on the evaluation index set, judging whether the weight reaches a preset weight or not, if the weight reaches the preset weight, marking the key name set as a hot data set, and moving a key value set of the hot data set to a cache, and if the weight does not reach the preset weight, marking the key name set as a cold data set, and moving the key value set of the cold data set out of the cache. The invention further provides a cold and hot data processing device, electronic equipment and a storage medium. The invention also relates to a blockchain technology, and the hot data set can be stored in a blockchain node. According to the invention, efficient data query can be realized, and the data storage cost is reduced.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

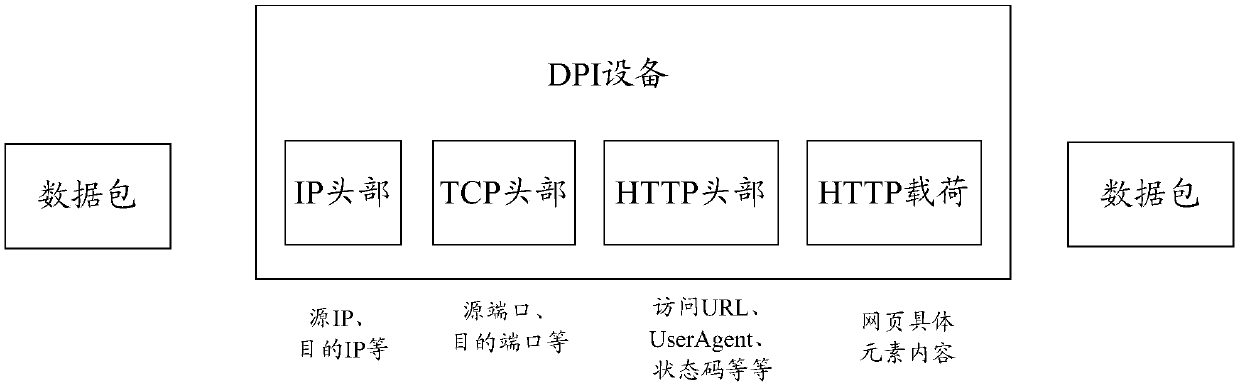

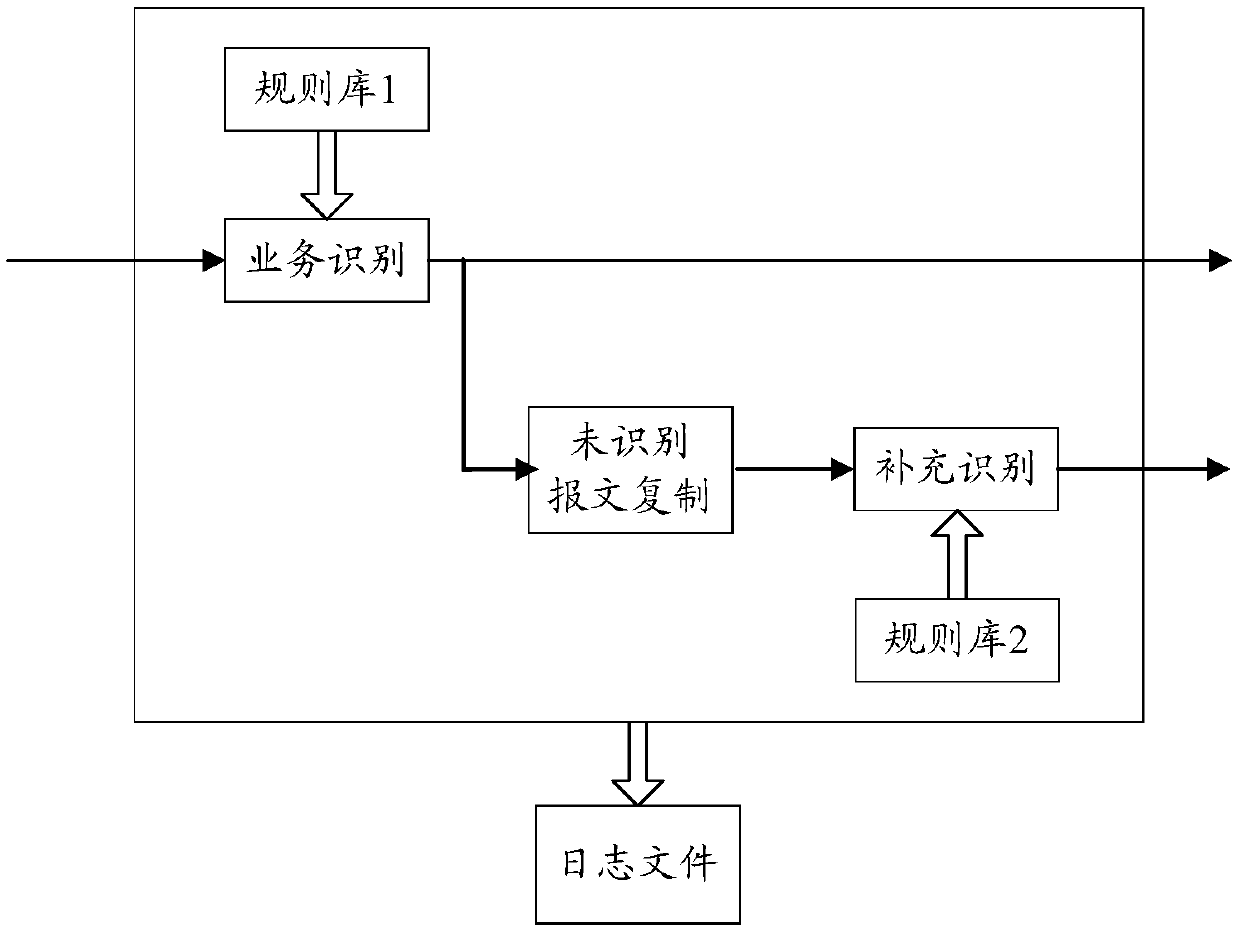

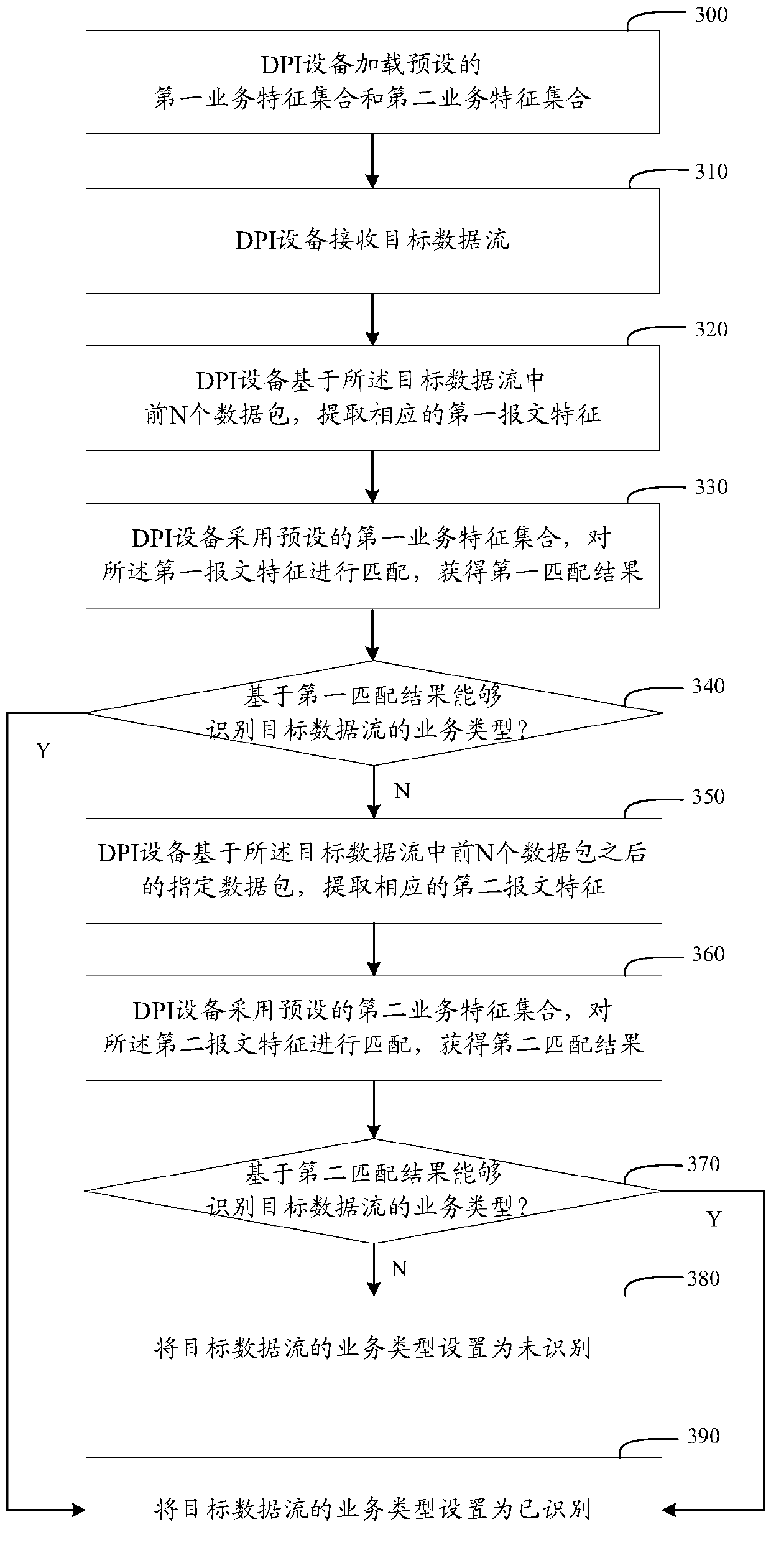

Method and device for realizing DPI identification

InactiveCN111404768AImprove business recognition rateReduce consumptionData switching networksData packData stream

The invention relates to the field of communications, particularly relates to a method and a device for realizing DPI identification. The method is used for improving the service identification rate of DPI equipment. The method comprises the following steps: using a first set of traffic features to perform service type identification on the first N data packets in the target data stream; after failure, using a second set of traffic features to perform supplementary service type identification on data packets at specified positions after the first N data packets in the target data stream. Therefore, for the target data stream of the data packet with the business feature appearing at the rear position, accurate service type identification can be realized, so that the service identification rate of the DPI equipment is effectively improved, and the detection missing condition is avoided. Meanwhile, the DPI equipment only analyzes the data packet at the specified position and does not needto analyze all the data packets in sequence when the supplementary service type is identified, so that the consumption of the DPI equipment is effectively reduced, the overload of the DPI equipment is avoided, and the service performance of the DPI equipment is further ensured.

Owner:CHINA MOBILE COMM LTD RES INST +1

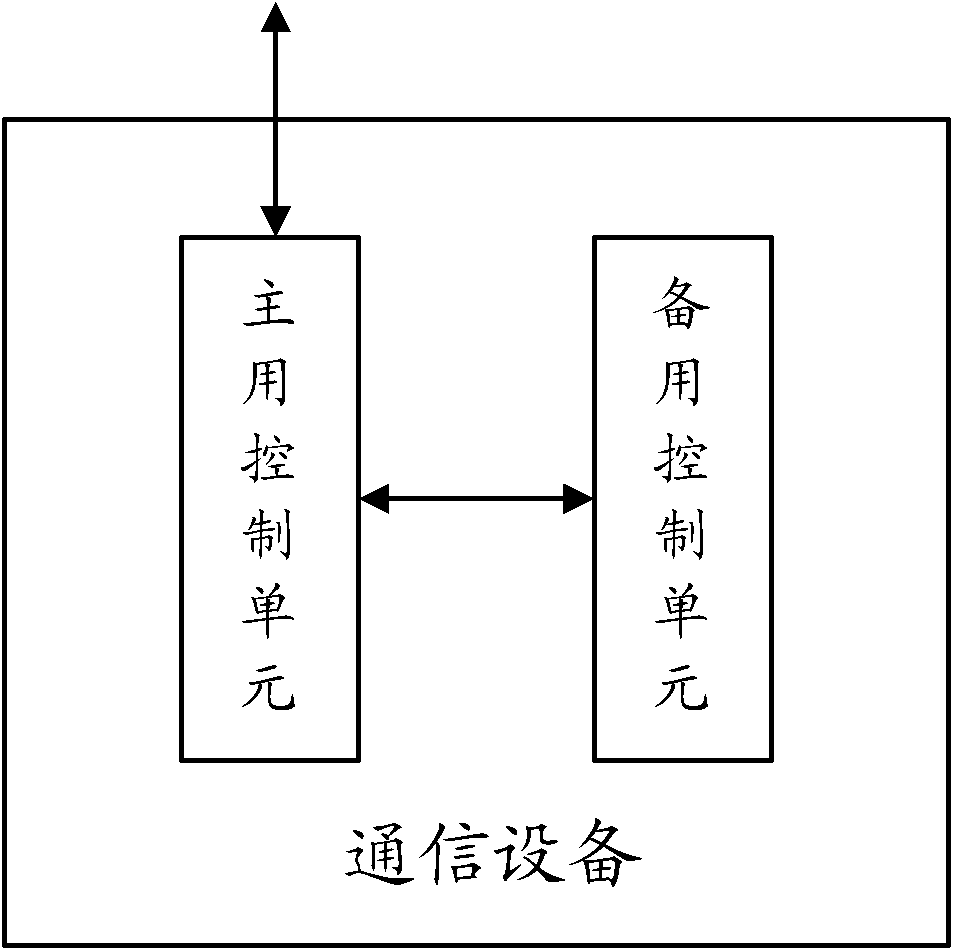

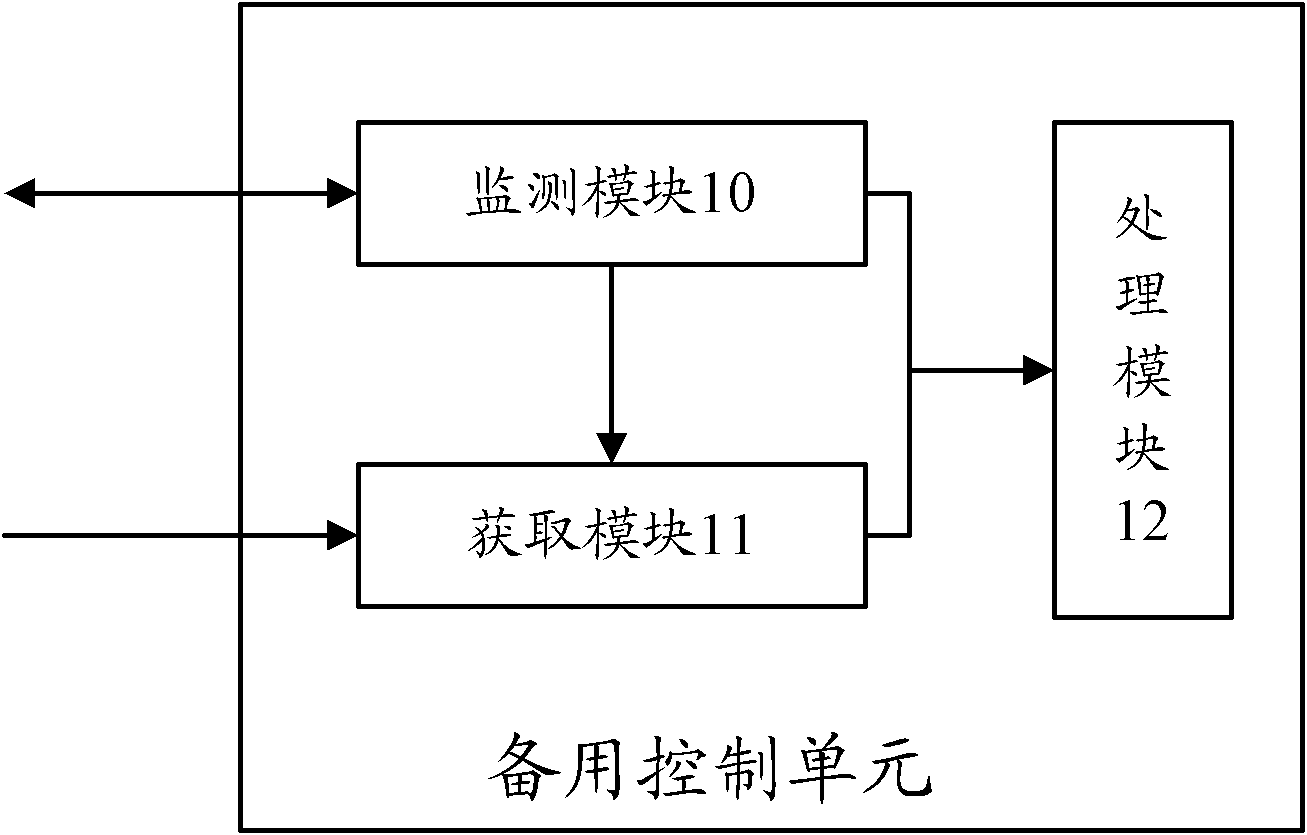

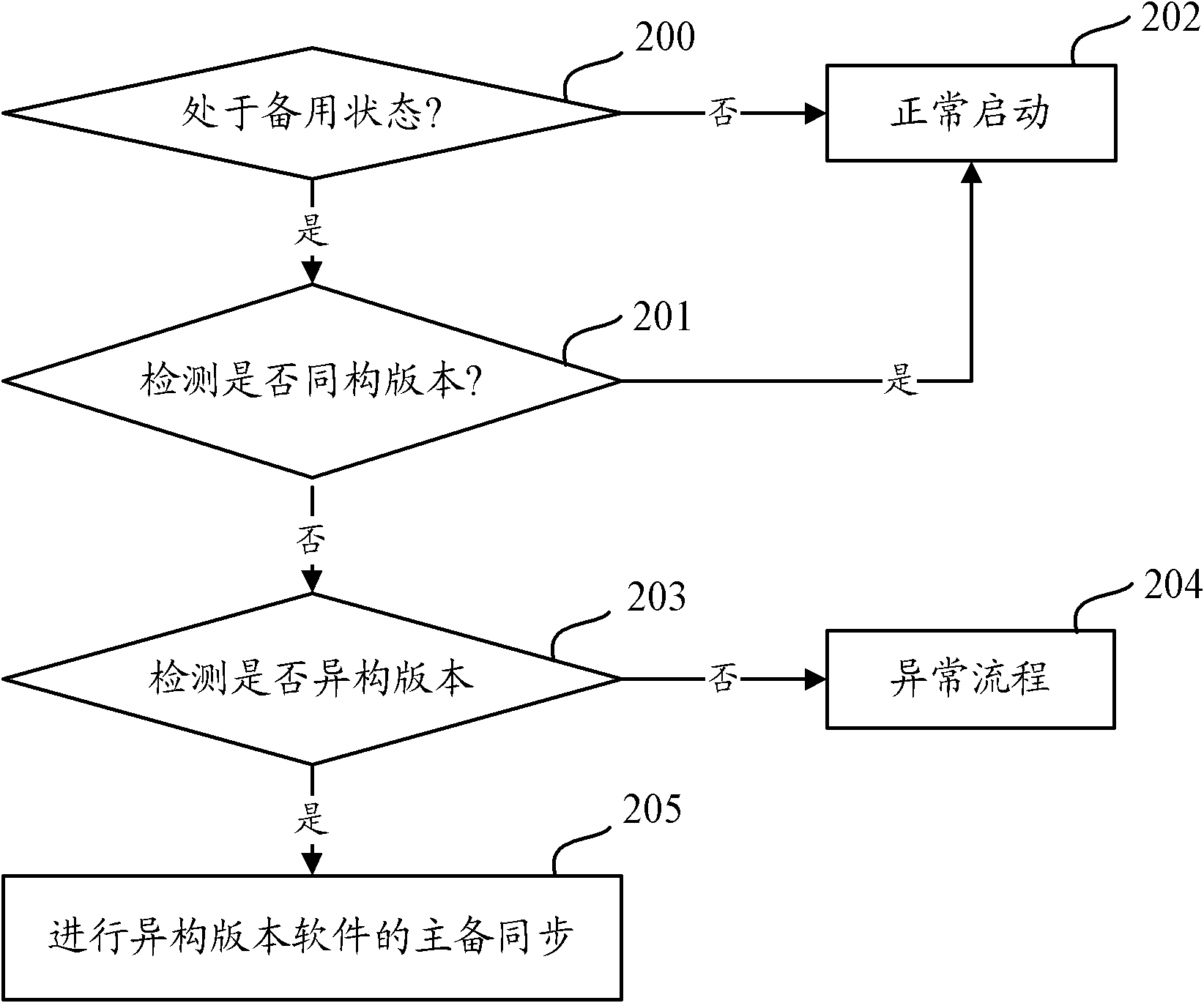

Method and device for implementing software version synchronization

ActiveCN102073523AGuaranteed service performanceNo confusionProgram loading/initiatingSoftware deploymentDependabilityCommunication device

The invention relates to the field of communication, in particular to a method and a device for implementing software version synchronization for ensuring the service performance of communication equipment. The method comprises the following steps of: after a spare control unit is started, monitoring a software version operated on a primary control unit; and when the software version operated on the primary control unit and a local operated software version are heterogeneous versions is determined, acquiring the software version operated on the primary control unit, and synchronizing the local operated software version based on the acquired software version operated on the primary control unit. Therefore, the software versions of the primary and spare control units are consistent, and the compatibility of the software versions is improved; and no matter when the primary control unit and the spare control unit are switched, chaos is not caused to the processing flow of the communication equipment, the service performance of the communication equipment is ensured to a certain degree, and the service reliability of the communication equipment in abnormal events is improved.

Owner:ZTE CORP

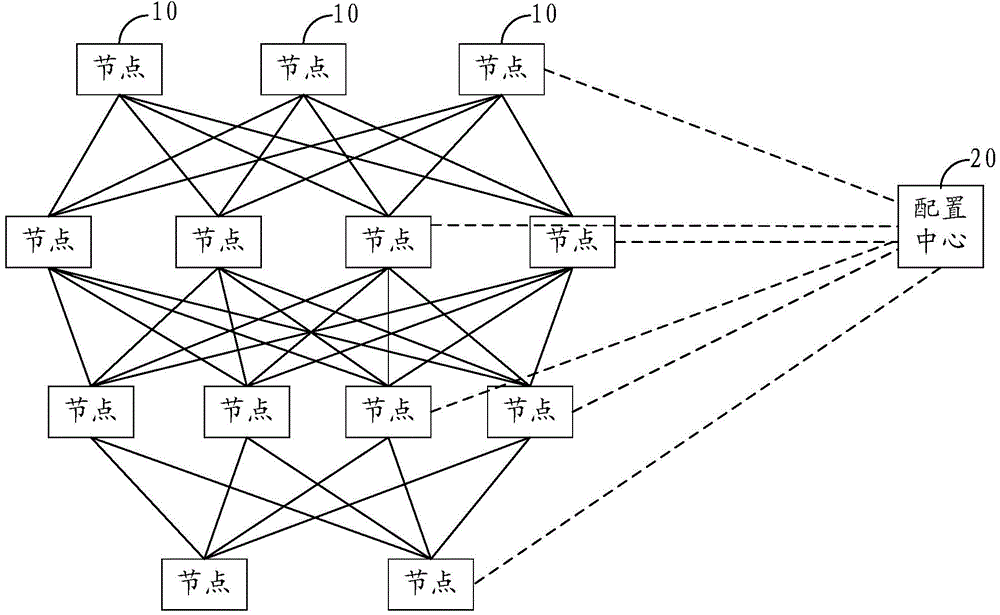

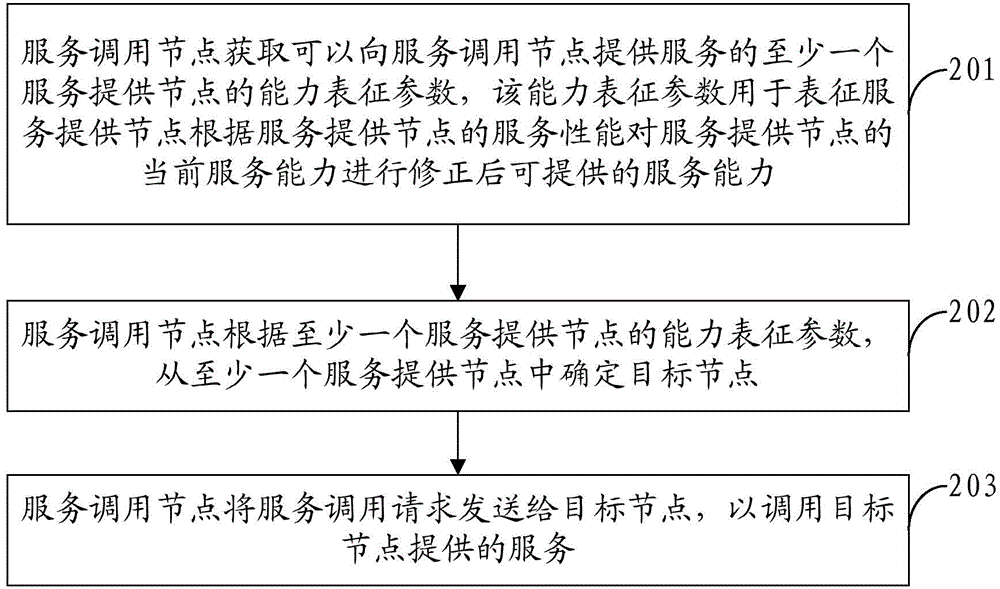

Service calling method, service providing method, and node

ActiveCN105430028AGuaranteed service performanceBalance handling stressTransmissionDistributed computingService provisioning

The application provides a service calling method, a service providing method, and nodes. The service calling method includes the following steps: a service calling node obtains the capability representation parameter of at least one service providing node that provides service to the service calling node, wherein the capability representation parameter is used for representing the service capability of the service providing node after the current service capability of the service providing node is corrected according to the service performance of the service providing node; a target node is determined from at least one service providing node on the basis of the capability representation parameter of at least one service providing node; and a service calling request is sent to the target node to call service provided by the target node. According to the technical scheme of the application, the processing pressure of nodes in a distributed cluster can be balanced, and the service capability of the distributed cluster can be improved.

Owner:ADVANCED NEW TECH CO LTD

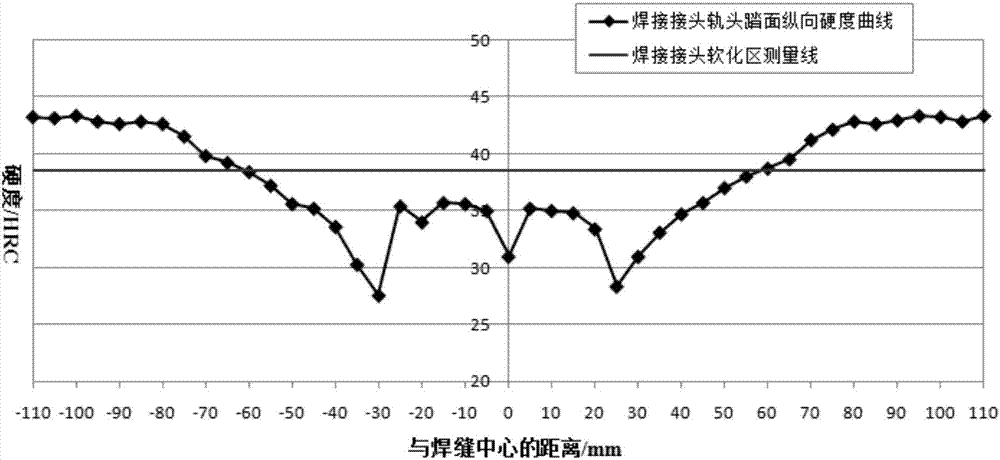

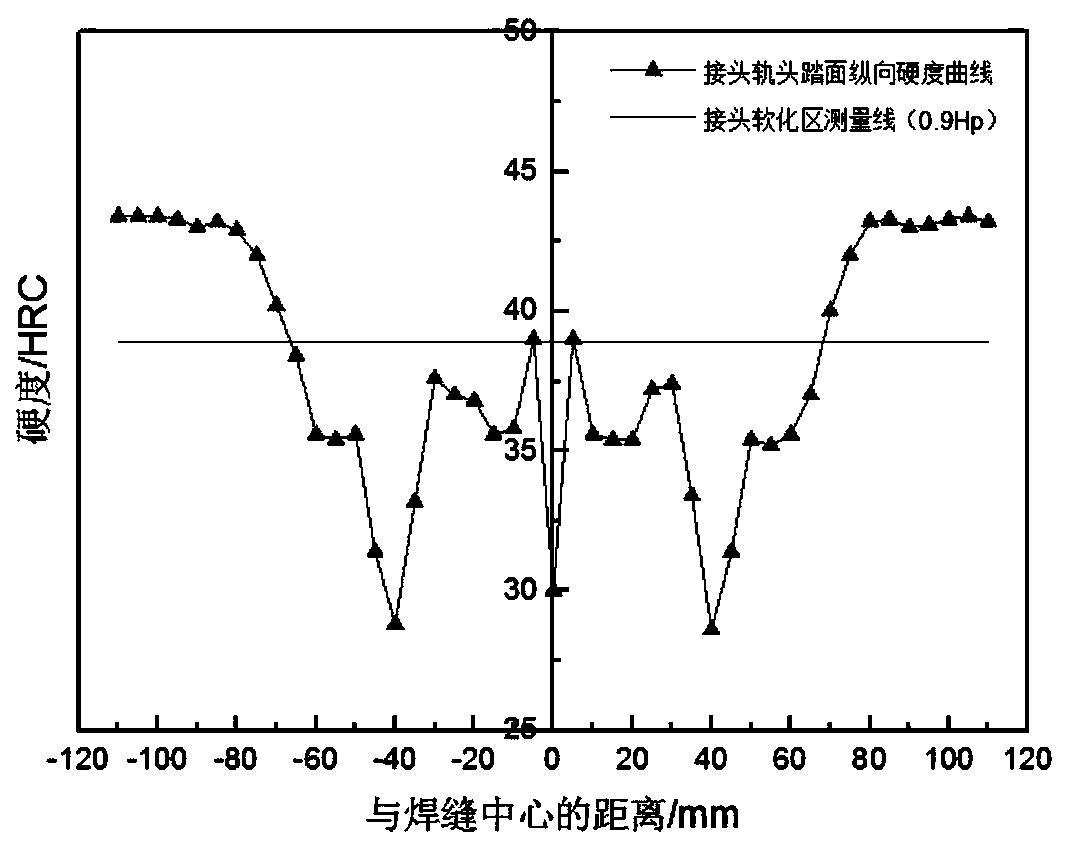

Hypoeutectoid steel rail post-weld heat processing method

InactiveCN110438326AControl service performanceGuaranteed service performanceFurnace typesHeat treatment furnacesFree coolingHardness

The invention discloses a hypoeutectoid steel rail post-weld heat processing method, and belongs to the technical field of railway steel rail manufacturing. The hypoeutectoid steel rail post-weld heatprocessing method can achieve the effects that the tread longitudinal hardness of a hypoeutectoid steel rail welding joint can be controlled within a reasonable range. The heat processing method sequentially comprises the following steps that A, first cooling is carried out on the welding joint with the temperature of 1100-1400 DEG C to be not higher than 200 DEG C, wherein welding joint is obtained by welding hypoeutectoid steel rails, and the first cooling mode is natural cooling in air; B, the welding joint is heated to 840-920 DEG C; and C, second cooling is carried out on the welding joint, the second cooling is stopped when the welding joint is cooled to 320-400 DEG C, then third cooling is carried out until the welding joint reaches 5-40 DEG C, and the welding joint with the longitudinal hardness of the rail head tread being 85%-90% of the average hardness of the steel rail base material is obtained, wherein the second cooling mode is rapid cooling in which a cooling medium isapplied, the cooling temperature of the second cooling is 800 DEG C or above, and the third cooling mode is natural cooling in the air.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

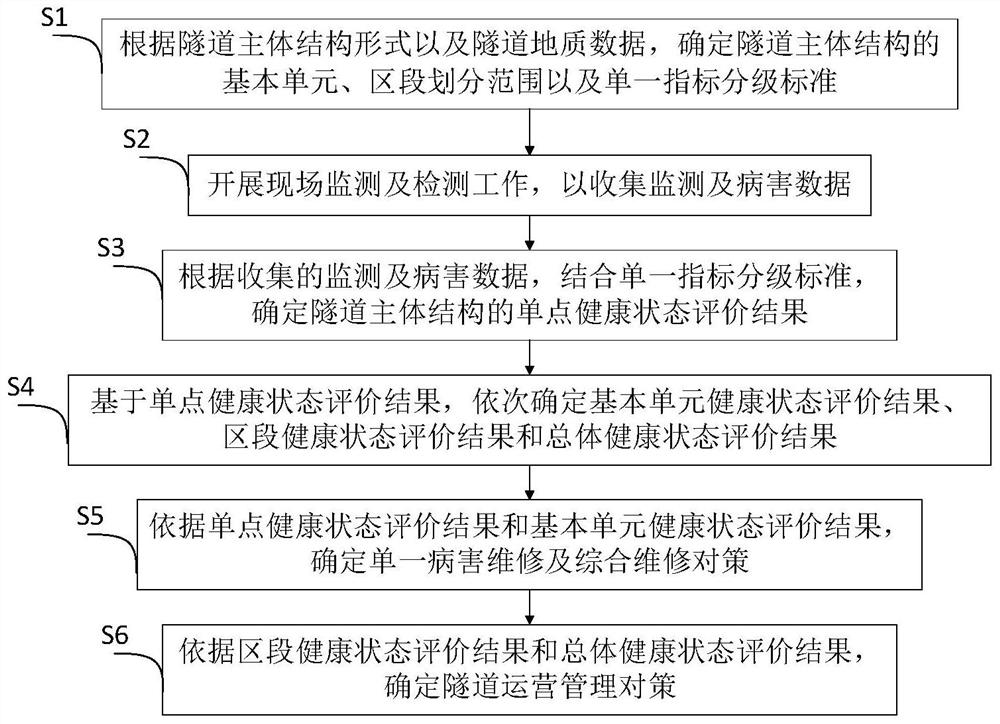

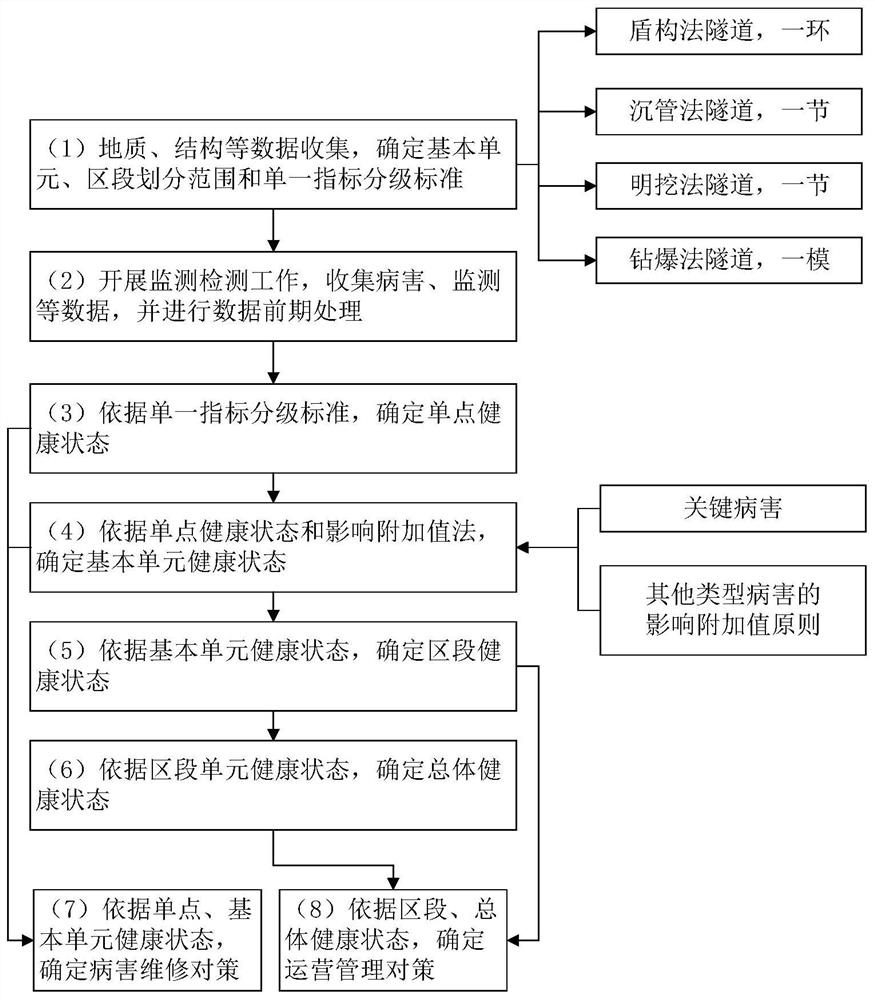

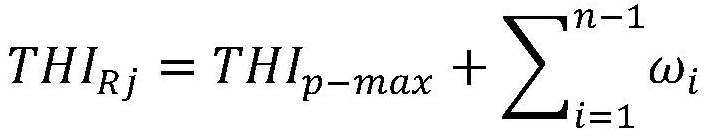

Tunnel main body structure health state evaluation and maintenance strategy determination method

ActiveCN112036734AReliable evaluationGuaranteed service performanceGeometric CADDesign optimisation/simulationDiseaseEvaluation result

The invention relates to a tunnel main body structure health state evaluation and maintenance strategy determination method, which comprises the steps of determining basic units, section division ranges and single index grading standards of a tunnel main body structure according to a tunnel main body structure form and tunnel geological data; collecting monitoring and disease data, and determininga single-point health state evaluation result of the tunnel main body structure in combination with a single index grading standard; based on the single-point health state evaluation result, sequentially determining a basic unit, a section and an overall health state evaluation result; determining a single disease maintenance and comprehensive maintenance strategy according to the single-point health state evaluation result and the basic unit health state evaluation result; and determining a tunnel operation management strategy according to the section health state evaluation result and the overall health state evaluation result. Compared with the prior art, the method has the advantages that the health state of the basic unit can be reliably evaluated, so that the problems of follow-up decision errors, incomplete maintenance or excessive maintenance caused by inaccurate evaluation are solved.

Owner:TONGJI UNIV +1

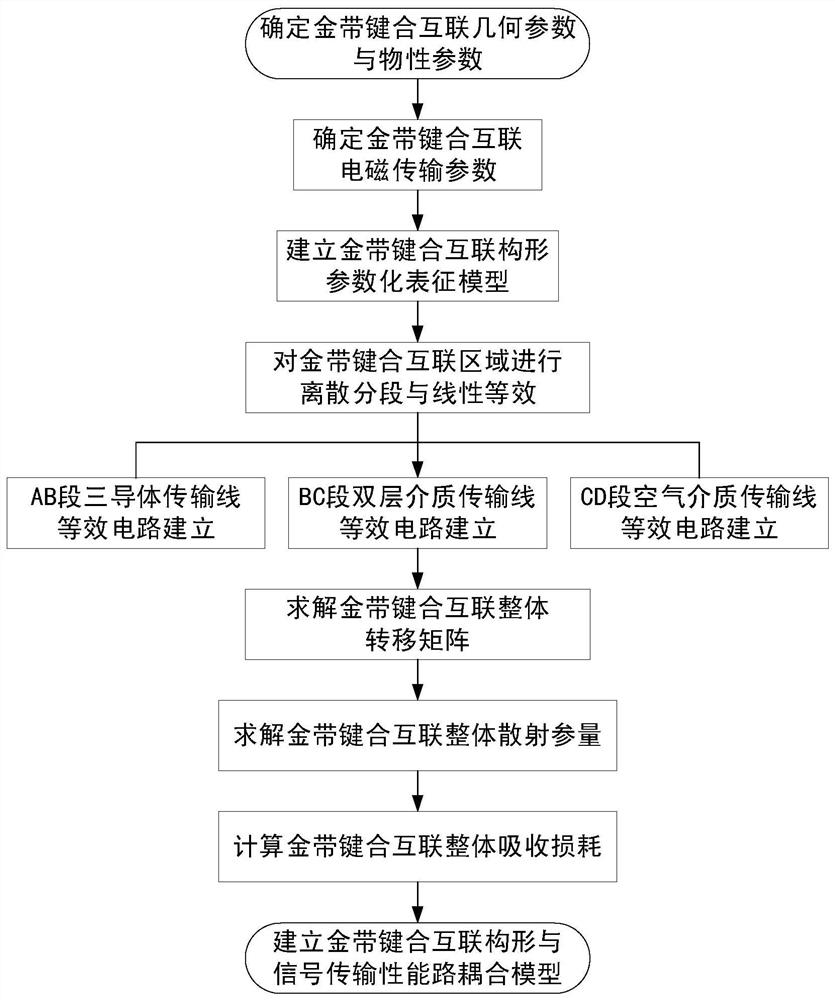

Microwave component circuit coupling transmission performance prediction method based on gold belt bonding configuration

ActiveCN112084738AImprove work efficiencyReduce development costsComputer aided designSpecial data processing applicationsMicrowaveInterconnection

The invention discloses a microwave component circuit coupling transmission performance prediction method based on a gold belt bonding configuration. The method comprises the following steps: determining gold belt bonding interconnection geometry, physical properties and interconnection electromagnetic transmission parameters; establishing a configuration parameterization representation model; establishing an interconnection area piecewise discrete and linear equivalent circuit; solving a gold belt bonding interconnection integral transfer matrix, scattering parameters and absorption loss; andestablishing a gold belt bonding interconnection configuration and signal transmission performance circuit coupling model. According to the method, gold belt bonding interconnection configuration parametric representation modeling can be realized, and gold belt bonding interconnection configuration and signal transmission performance path coupling model construction is realized. By utilizing thecoupling model, accurate prediction from the morphological parameters of the microwave interconnection structure to the signal transmission performance can be realized, the design and optimization ofa high-performance microwave assembly are guided, the development quality of microwave products is effectively improved, the cost is saved, and the development period is shortened.

Owner:XIDIAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com