Method for determining optimal shape parameters of core wire winding and welding interconnection for electrical performance of microwave component

A technology of microwave components and morphological parameters, which is applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of inability to accurately and quickly give the interconnection shape, high labor cost, and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

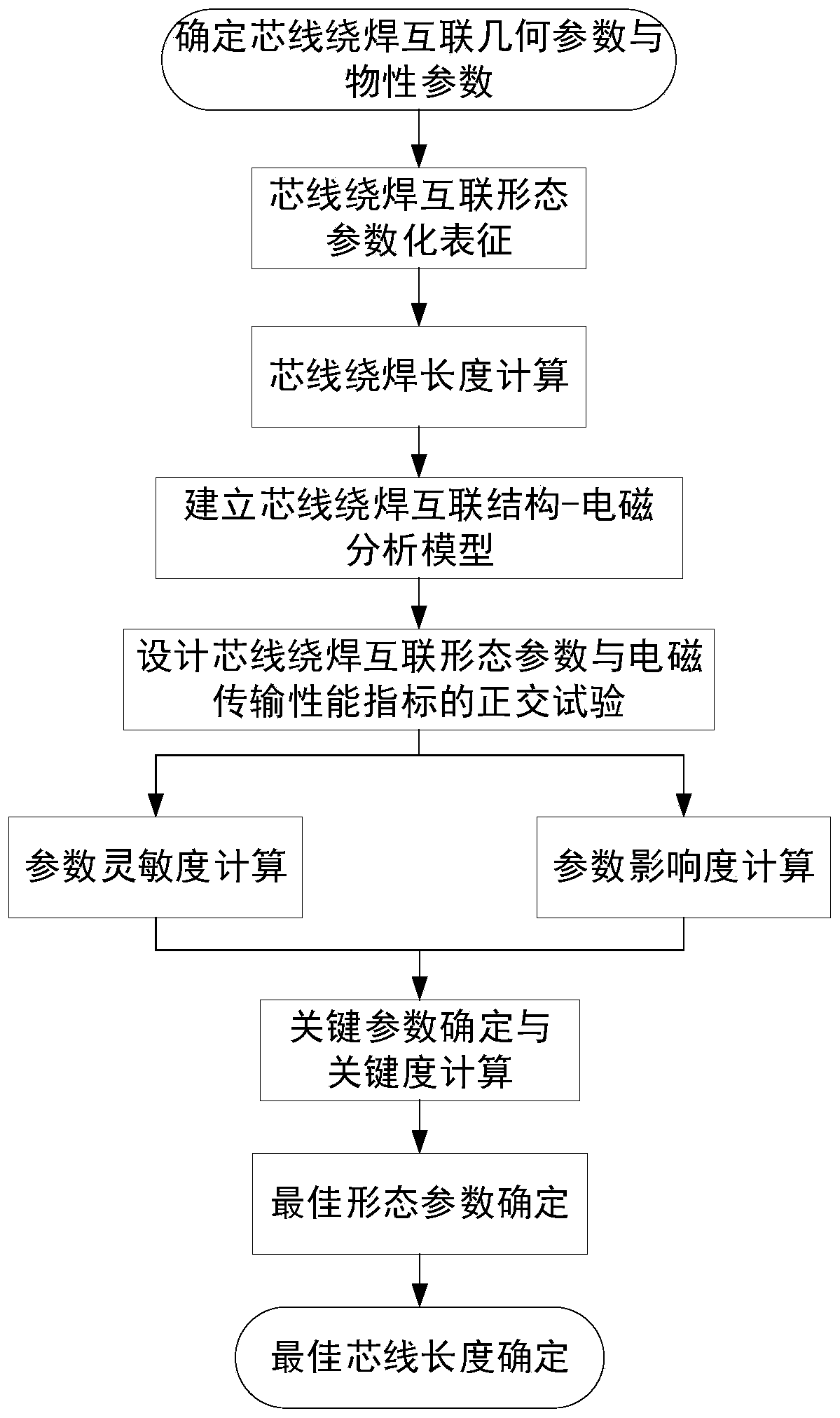

[0069] refer to figure 1 , the present invention is a method for determining the best shape parameters of the core wire soldering interconnection oriented to the electrical performance of microwave components, and the specific steps are as follows:

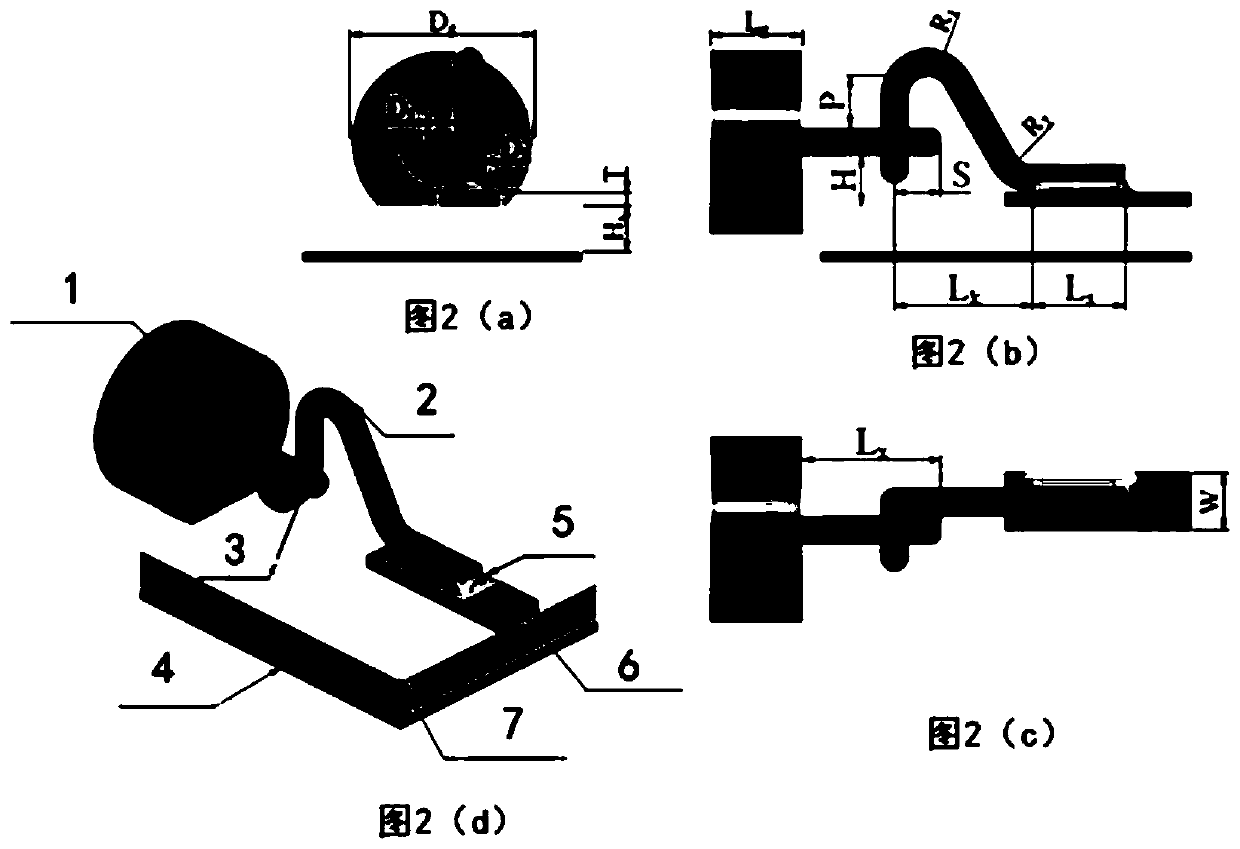

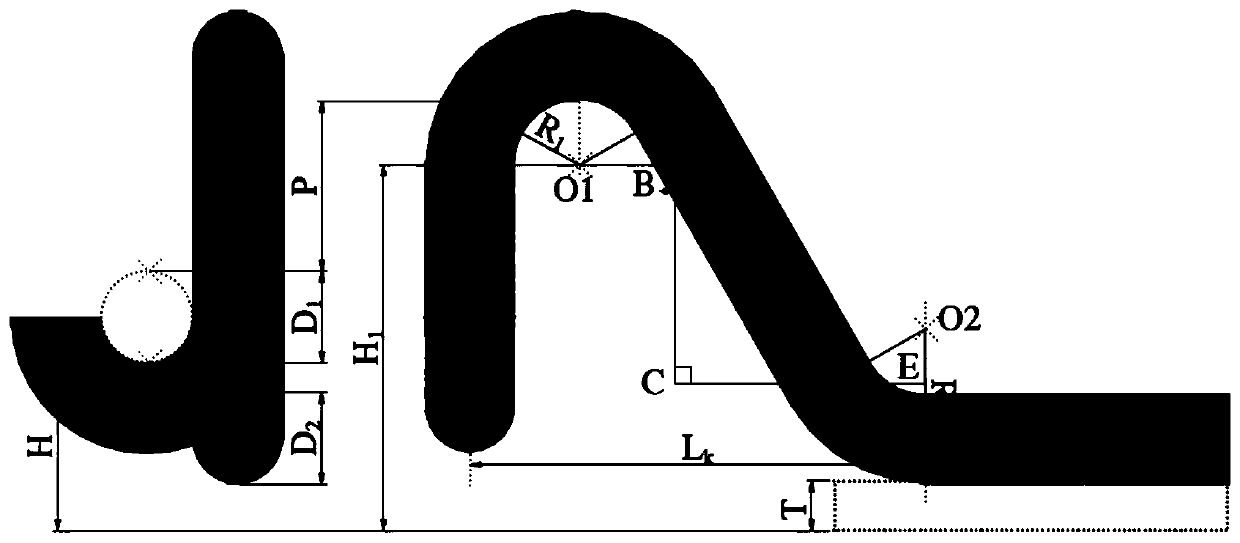

[0070] Step 1. Determine the geometric parameters and physical parameters of the core wire soldering interconnection in the microwave component

[0071] Referring to Fig. 2 (a)-(d), the high-frequency microwave assembly includes a ground plate 4, a dielectric substrate 7 is distributed on the upper layer of the ground plate 4, and the microstrip line 6 arranged on the dielectric substrate 7 is welded by solder 5. The core wire 2 is connected to the glass medium 1 through the lead wire 3 . According to the specific requirements of the interconnection of high-frequency microwave components, the geometric pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com