Microwave assembly gold belt interconnection transmission performance prediction method based on interconnection form

A technology of microwave components and prediction methods, which is applied in the direction of prediction, complex mathematical operations, resources, etc., can solve the problems of high-frequency microwave signal transmission performance impact, low work efficiency, stay, etc., to ensure product service performance, improve work efficiency, The effect of reducing the development cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

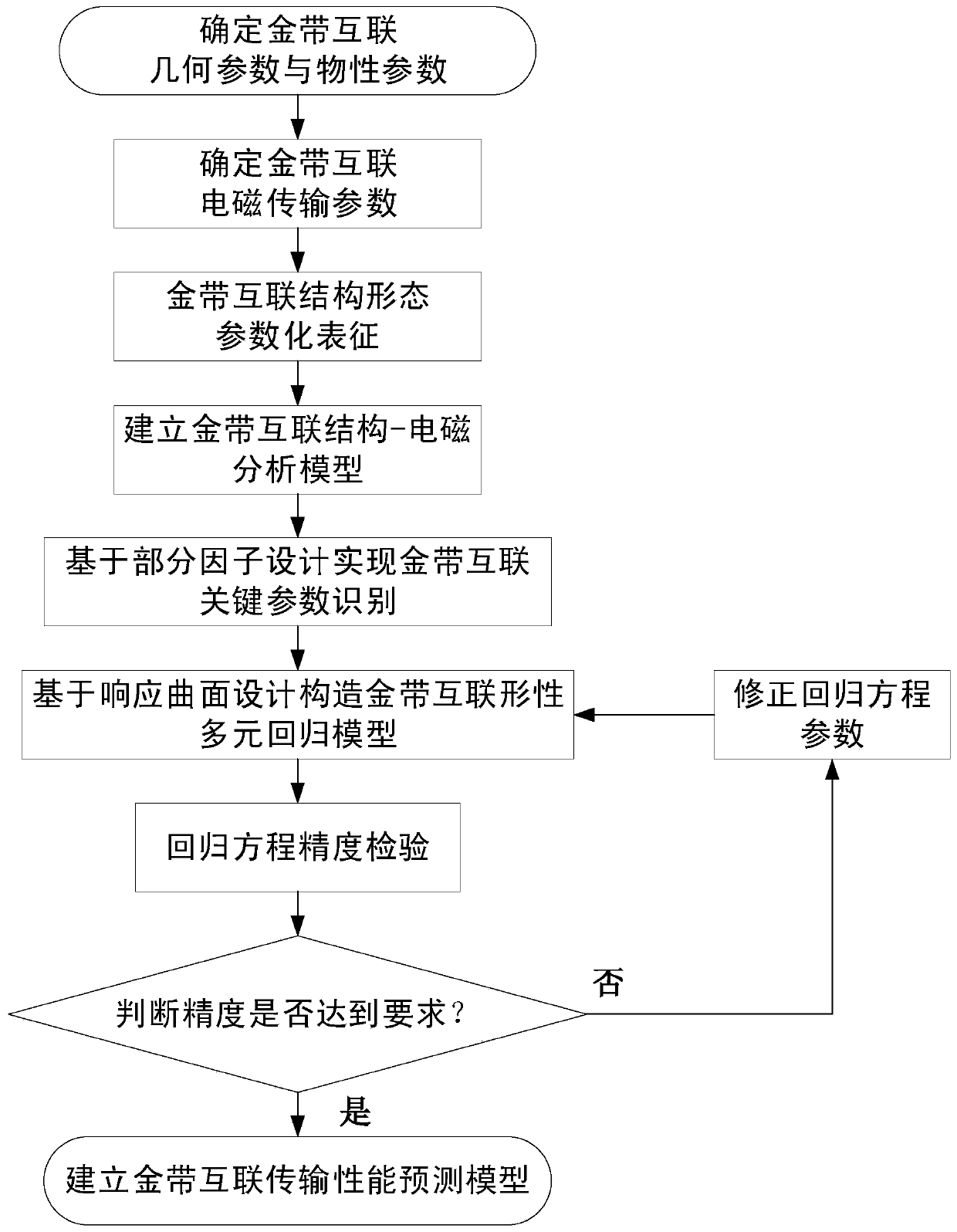

[0049] refer to figure 1 , the present invention is a method for predicting the transmission performance of microwave component gold ribbon interconnection based on the interconnection form, and the specific steps are as follows:

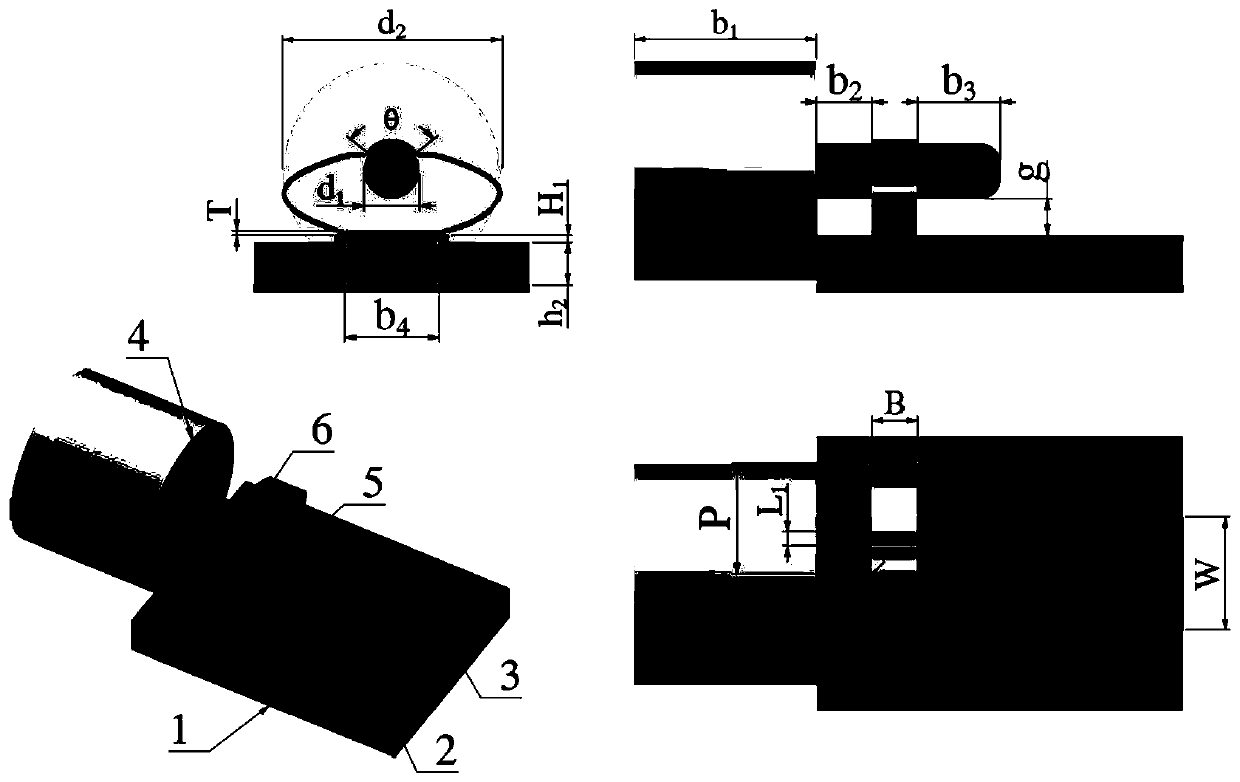

[0050] Step 1. Determine the geometric parameters and physical parameters of the gold ribbon interconnection in the microwave component

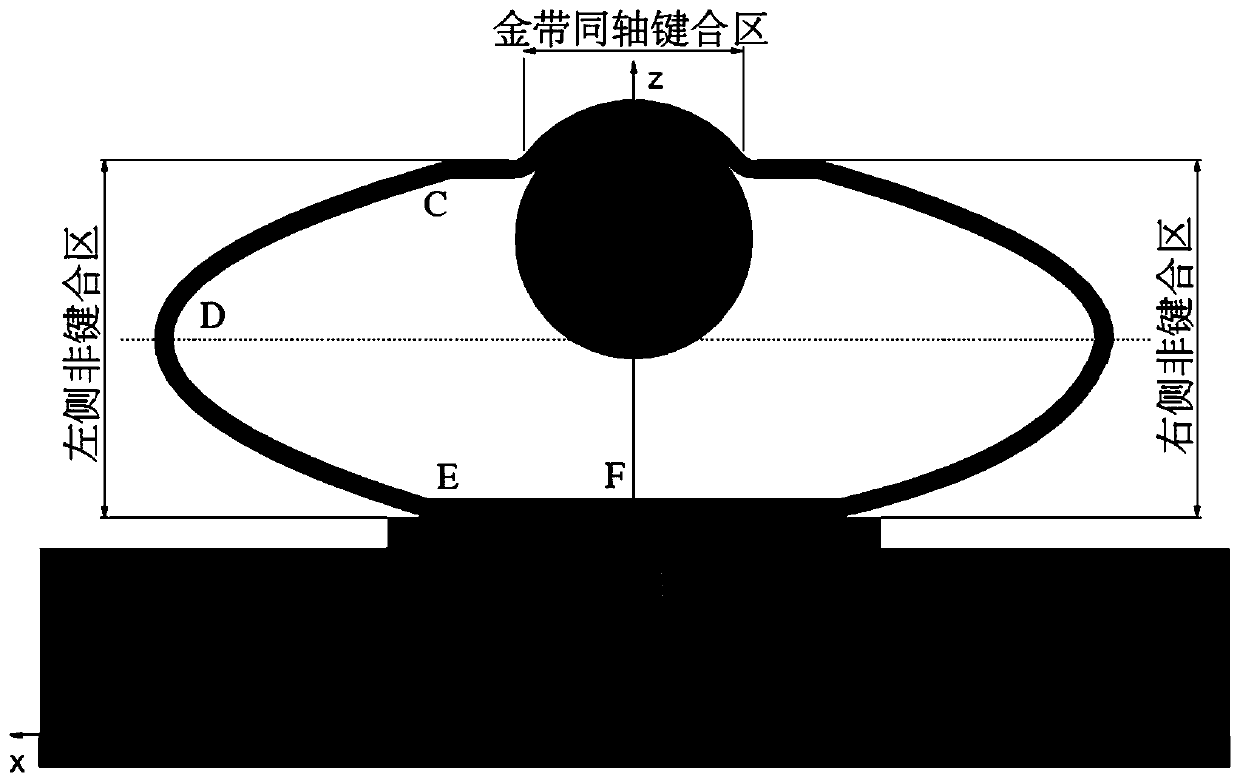

[0051] refer to figure 2 As shown, the interconnection point in the high-frequency microwave component consists of a ground plate 1, a dielectric substrate 2 is distributed on the upper layer of the ground plate 1, a microstrip conductor 3 is arranged on the dielectric substrate 2, and an inner conductor protrudes from the inside of the glass insulator 4. 5. The upper end of the gold strip 6 is connected to the inner conductor 5 , and the lower end is connected to the microstrip conducto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com