Laser additive manufacturing device and method

A laser additive and equipment technology, applied in the field of additive manufacturing, can solve the problems that the actual laying thickness of the metal powder layer deviates from the preset value, affects the forming accuracy and service performance of metal components, and has high design, assembly and maintenance costs. The complexity of the process and the difficulty of operation are reduced, the forming accuracy and service performance are guaranteed, and the effect of reducing the difficulty of cleaning and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

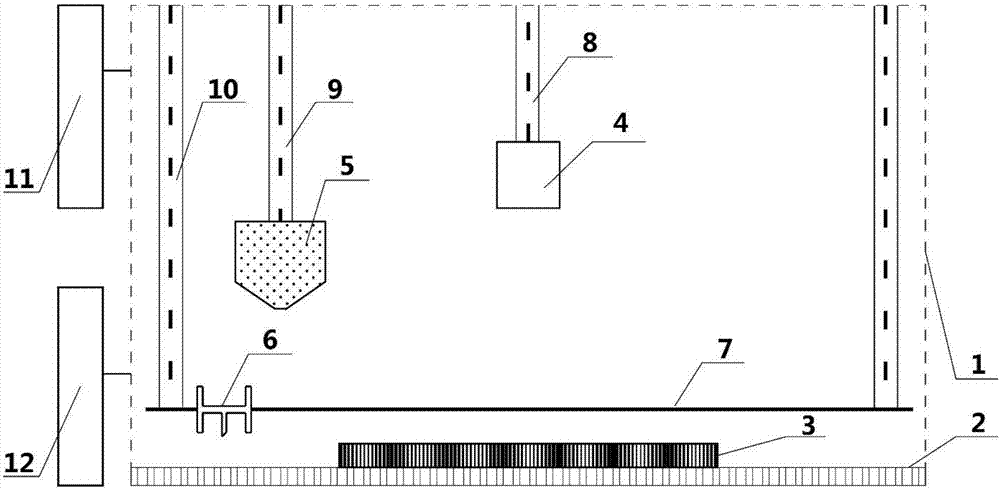

[0031] Such as figure 1 As shown, a laser additive manufacturing equipment provided by the example of the present invention includes a forming cabin 1, a working platform 2, a substrate 3, a scanning galvanometer assembly, a powder presetting assembly, an atmosphere control assembly 11, a lifting assembly and a central control system 12.

[0032] The working platform 2 is located at the lower part of the forming cabin 1, and the base plate 3 is fixedly installed on the surface of the working platform 2;

[0033]The scanning galvanometer assembly includes a scanning galvanometer 4, and the scanning galvanometer 4 is connected to a laser source by connecting an optical path, and the powder preset assembly includes a powder storage hopper 5, a powder spreader 6 and a first moving mechanism 7; The powder device 6 is used to receive the metal powder provided by the powder storage hopper 5, and is driven by the first moving mechanism 7 to pre-set a metal powder layer above the subs...

Embodiment 2

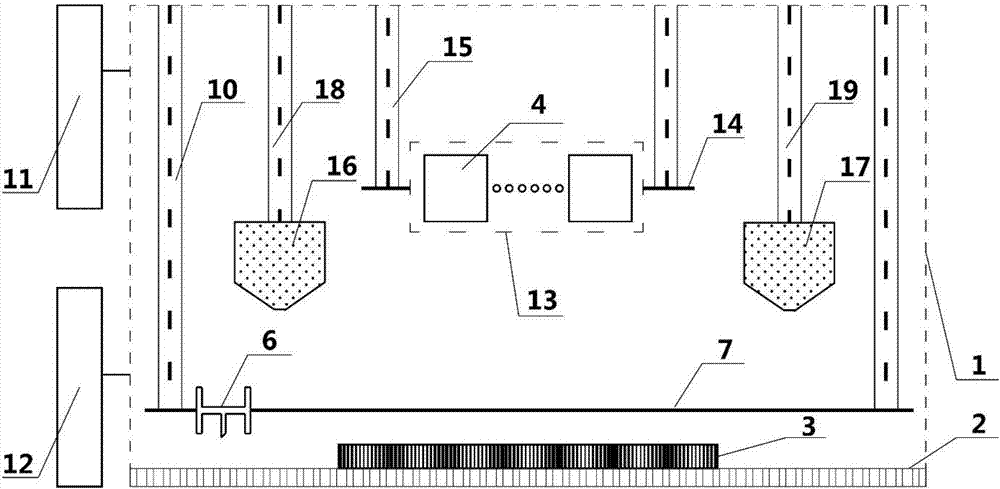

[0045] Such as figure 2 As shown, a laser additive manufacturing equipment provided by the example of the present invention includes a forming cabin 1, a working platform 2, a substrate 3, a scanning galvanometer assembly, a powder presetting assembly, an atmosphere control assembly 11, a lifting assembly and a central control system 12.

[0046] The working platform 2 is located at the lower part of the forming cabin 1, and the base plate 3 is fixedly installed on the surface of the working platform 2;

[0047] Described scanning vibrating mirror assembly comprises several scanning vibrating mirrors 4 (number ≥ 2), and they constitute scanning vibrating mirror array 13; Every scanning vibrating mirror 4 all connects optical path by connecting optical path with laser source; Scanning vibrating mirror assembly also includes The fifth moving mechanism 14 is used to drive the scanning galvanometer array 13 to move in the horizontal direction to realize the mobile selective melt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com