Nylon 66 composite material, preparation method thereof and electronic device

A composite material and nylon technology, applied in the field of nylon 66 composite material and its preparation, can solve the problems of poor antistatic performance and limited application, and achieve the effects of good thermal conductivity, antistatic performance and excellent physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

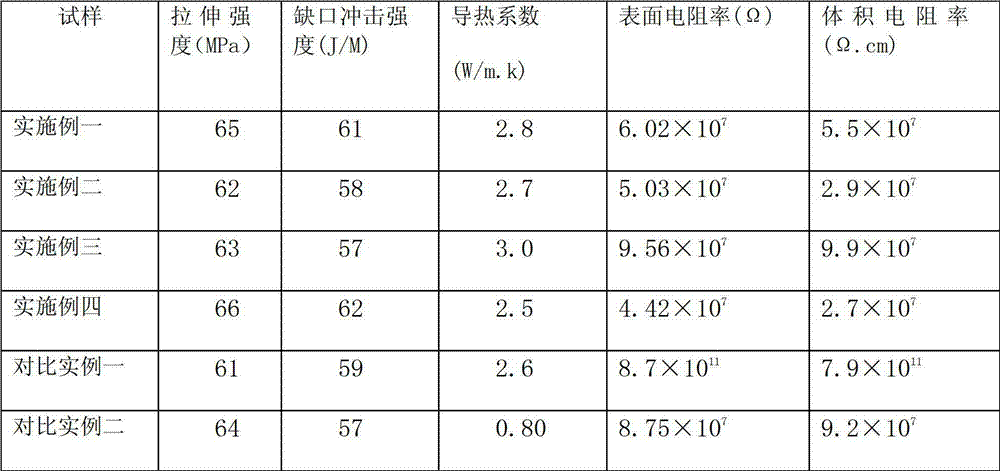

Examples

Embodiment 1

[0042] The nylon 66 composite material provided in this embodiment is formulated by weight percentage from the following raw materials: 48.7% of PA66 resin, 10% of toughening agent, aluminum nitride or silicon carbide treated by coupling agent (or both according to Weight 1:1 mix) 25%, graphite 12%, compatibilizer 3%, lubricant 0.5%, antioxidant 0.4%, coupling agent 0.2%, nucleating agent 0.2%. Wherein, the aluminum nitride or silicon carbide (or a mixture of the two by weight 1:1) is a heat conduction powder, and the graphite is an antistatic agent.

[0043] Here, the heat-conducting powder is treated by the coupling agent, which specifically includes the following steps: dilute the titanate coupling agent accounting for 0.1-2% of the weight of the heat-conducting powder with an anhydrous solvent, and then add the diluted coupling agent Put it into the heat-conducting powder, heat and stir at a high speed, and after mixing for 1-2 hours, the solvent is completely volatilized ...

Embodiment 2

[0047] The difference from Example 1 is that the nylon 66 composite material provided in this example is prepared from the following raw materials by weight percentage: 48.7% of PA66 resin, 10% of toughening agent, aluminum nitride treated with coupling agent Or silicon carbide (or both by weight 1:1 mixture) 22%, graphite 15%, compatibilizer 3%, lubricant 0.5%, antioxidant 0.4%, coupling agent 0.2%, nucleating agent 0.2%. Wherein, the aluminum nitride or silicon carbide (or a mixture of the two by weight 1:1) is a heat conduction powder, and the graphite is an antistatic agent.

[0048] Here, the raw materials are weighed according to the following weight percentages, PA66 resin 48.7%, toughening agent 10%, aluminum nitride or silicon carbide treated by coupling agent (or the two are mixed by weight 1:1) 22%, graphite 15%, compatibilizer 3%, lubricant 0.5%, antioxidant 0.4%, coupling agent 0.2%, nucleating agent 0.2%. Then pour the above raw materials into a mixing barrel an...

Embodiment 3

[0050] The difference from Example 1 is that the nylon 66 composite material provided in this example is prepared from the following raw materials by weight percentage: 40.8% of PA66 resin, 9% of toughening agent, aluminum nitride treated with coupling agent Or silicon carbide (or both by weight 1:1 mixture) 34%, graphite 11%, compatibilizer 3.6%, lubricant 0.2%, antioxidant 0.7%, coupling agent 0.4%, nucleating agent 0.3%. Wherein, the aluminum nitride or silicon carbide (or a mixture of the two by weight 1:1) is a heat conduction powder, and the graphite is an antistatic agent.

[0051] Here, the raw materials are weighed according to the following weight percentages, PA66 resin 40.8%, toughening agent 9%, aluminum nitride or silicon carbide treated by coupling agent (or the two are mixed by weight 1:1) 34%, graphite 11%, compatibilizer 3.6%, lubricant 0.2%, antioxidant 0.7%, coupling agent 0.4%, nucleating agent 0.3%. Then pour the above raw materials into a mixing barrel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com