Water-based baking paint for glass substrate and preparation and use methods thereof

A glass baking paint, glass substrate technology, applied in the direction of coating, can solve the problem that it is difficult to meet people's color requirements, and achieve the effect of good physical and mechanical properties, simple construction process and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

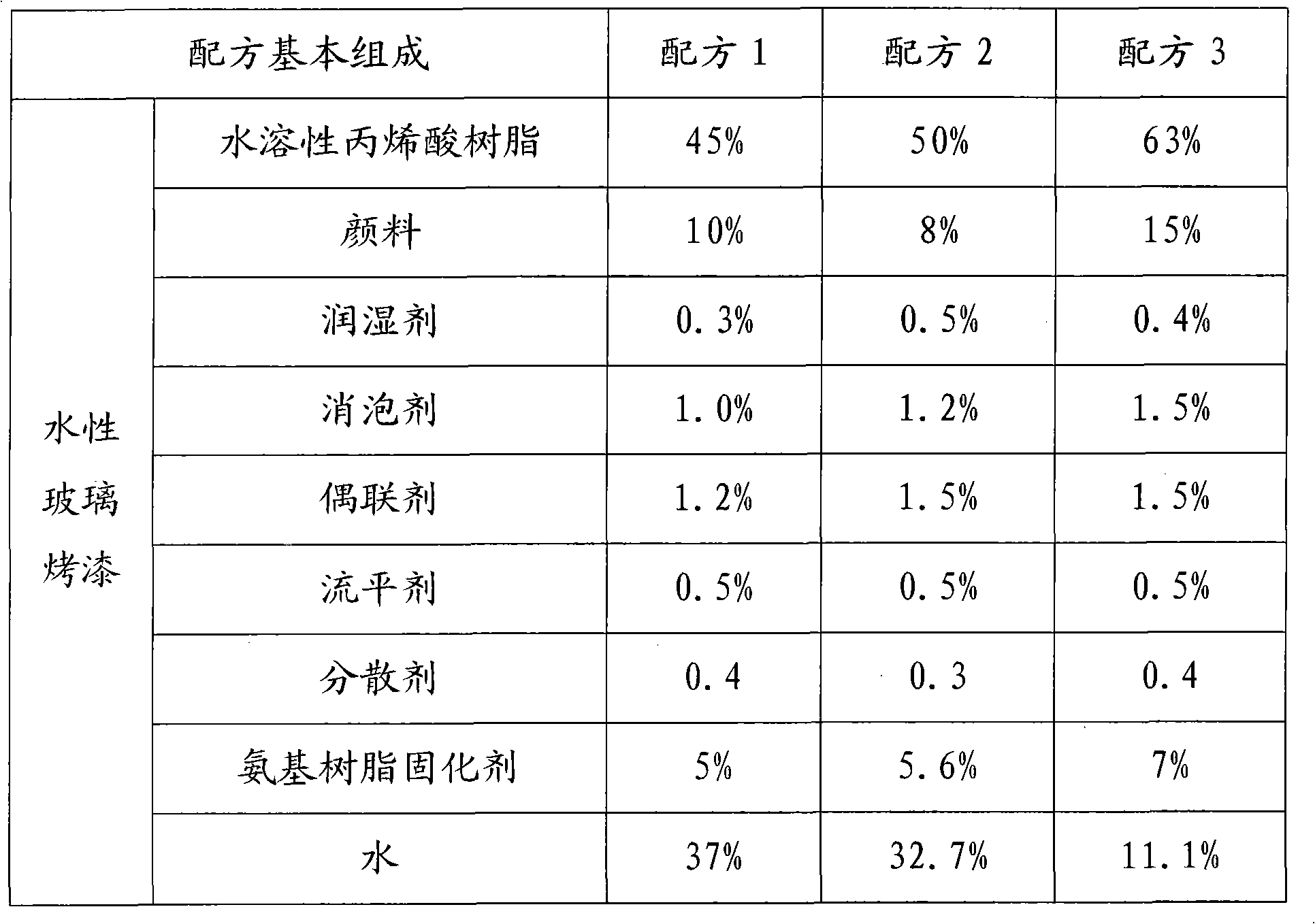

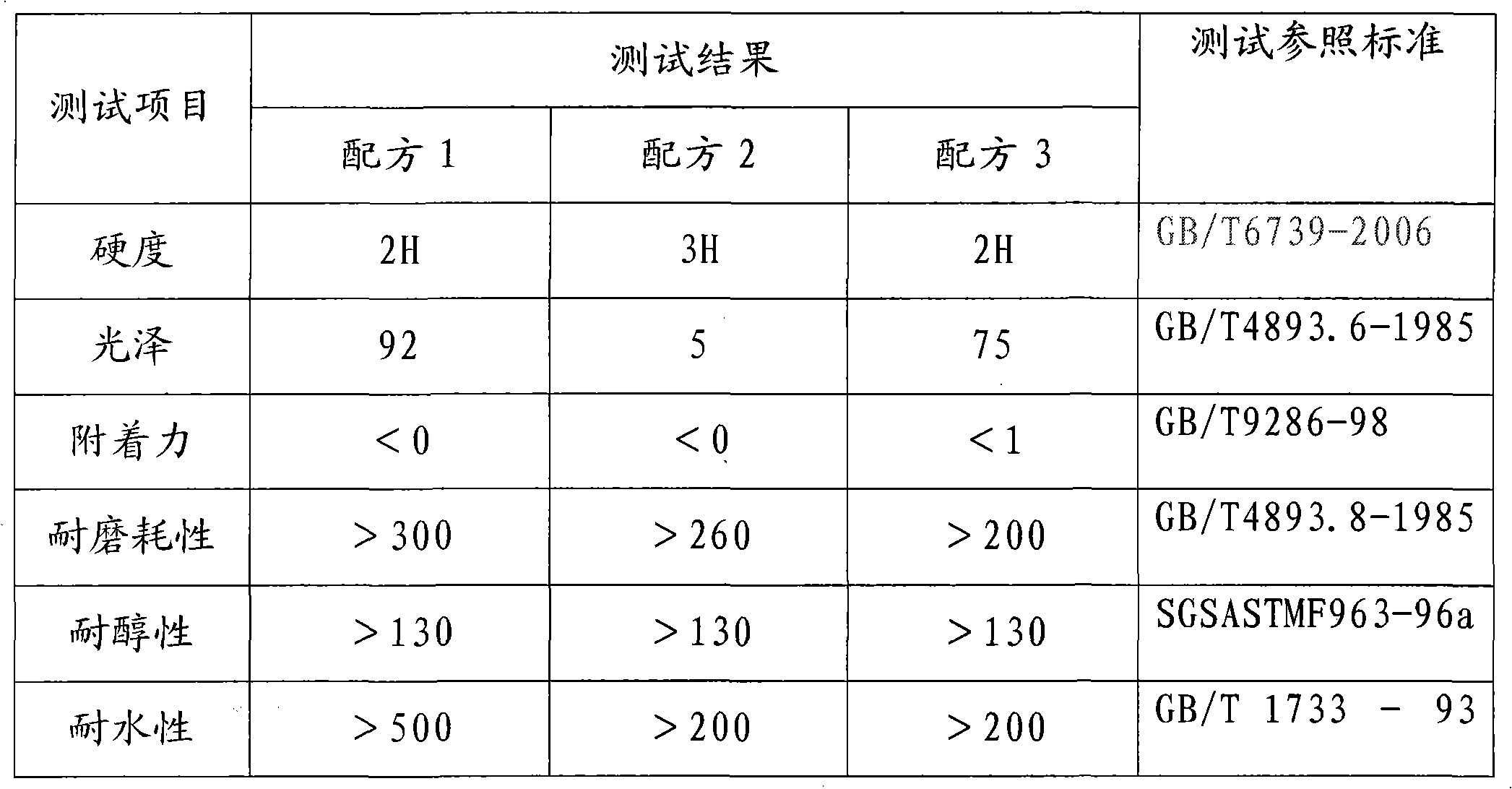

[0023] See formula 1 in formula table 1 for details

[0024] According to formula 1, take 45 parts of water-soluble acrylic resin, 1.0 part of defoamer, 0.3 part of wetting agent, 0.5 part of leveling agent, 0.4 part of dispersant and 20 parts of water into the stirring tank , under the condition of 400-600r / min speed, stir for 3-5min to mix evenly, add 10 parts of water-based transparent color paste, stir and disperse at a high speed of 800-1000r / min for about 30min, then add 1.2 parts of even Mixing agent, 5 parts of methyl etherified amino resin, 17 parts of water, stirring at 300-500 rpm for 3-5 minutes to form a uniform coating system is to complete the preparation process of the above-mentioned baking varnish.

[0025] When using the above-mentioned water-based glass baking varnish, add water 0.5 times of the water-based baking varnish to adjust to the construction viscosity, apply it on the glass substrate, and finally bake at high temperature. Baking, leveling, removi...

Embodiment 2

[0027] See formula 2 in formula table 1 for details

[0028] According to formula 2, take 50 parts of water-soluble acrylic resin, 1.2 parts of defoamer, 0.4 parts of wetting agent, 0.5 parts of leveling agent, 0.3 parts of dispersant and 25 parts of water into the stirring tank , under the condition of 400-600r / min speed, stir for 3-5min to mix evenly, add 8 parts of matting slurry, stir and disperse at a high speed of 800-1000r / min for about 30min, then add 1.5 parts of coupling Agent, 5.6 parts of methyl etherified amino resin, 7.2 parts of water, stirred at 300-500 rpm for 3-5min to form a uniform coating system and complete the preparation process of the above baking varnish.

[0029] When the above-mentioned water-based glass baking paint is used, add 1 times the water of the water-based baking paint to adjust to the construction viscosity, apply it on the glass substrate, and finally bake at high temperature. Baking, leveling, and removing water; baking time is about 1...

Embodiment 3

[0031] According to formula 3, take 63 parts of water-soluble acrylic resin, 1.5 parts of defoamer, 0.4 parts of wetting agent, 0.5 parts of leveling agent, 0.4 parts of dispersant and 5 parts of water into the stirring tank , under the condition of 400-600r / min speed, stir for 3-5 minutes to mix evenly, add 10 parts of water-based transparent color paste and 5 parts of pearl paste, stir and disperse at 800-1000r / min for about 30 minutes, and then pour into the stirring tank in turn Add 1.5 parts of coupling agent, 7 parts of methyl etherified amino resin, and 6.1 parts of water, and stir at 300-500 rpm for 3-5 minutes to form a uniform coating system to complete the preparation process of the above baking varnish.

[0032] When using the above-mentioned water-based glass baking varnish, add water 0.8 times of the water-based baking varnish to adjust to the construction viscosity, apply it on the glass substrate, and finally bake at high temperature. Baking, leveling, and remo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com