Patents

Literature

375 results about "Ground glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ground glass is glass whose surface has been ground to produce a flat but rough (matte) finish, in which the glass is in small sharp fragments. Ground glass surfaces have many applications, ranging from ornamentation on windows and table glassware to scientific uses in optics and laboratory glassware.

Composition of materials for use in cellular lightweight concrete and methods thereof

InactiveUS6488762B1Economical and stableImprove mechanical propertiesSolid waste managementCeramicwarePortland cementMaterials science

A more economical and light-color cellular concrete is provided by the replacement of Portland cement with ground glass powder in a cellular lightweight concrete mixture and the resulting method to make cellular concrete products. The use of ground glass also increases the stability of the cellular lightweight concrete mixture during the foaming or aeration process. The products are suitable for use in structural applications, insulation, and as a lightweight aggregate.

Owner:ADVANCED MATERIALS TECHNOLOGIES

Water-based baking paint for glass substrate and preparation and use methods thereof

InactiveCN101845255ASimplify the construction processMeet the use requirementsCoatingsPolymer scienceAcrylic resin

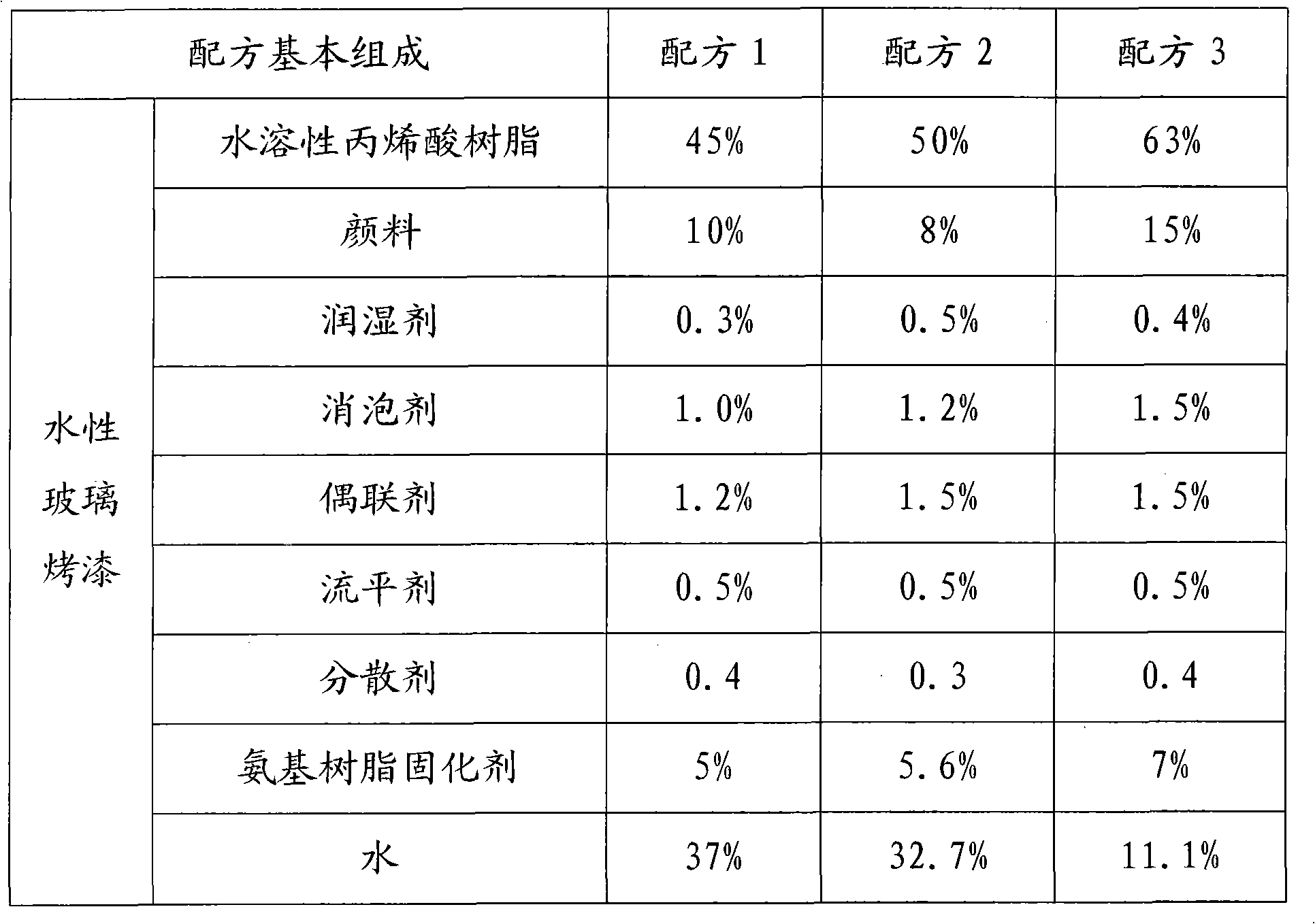

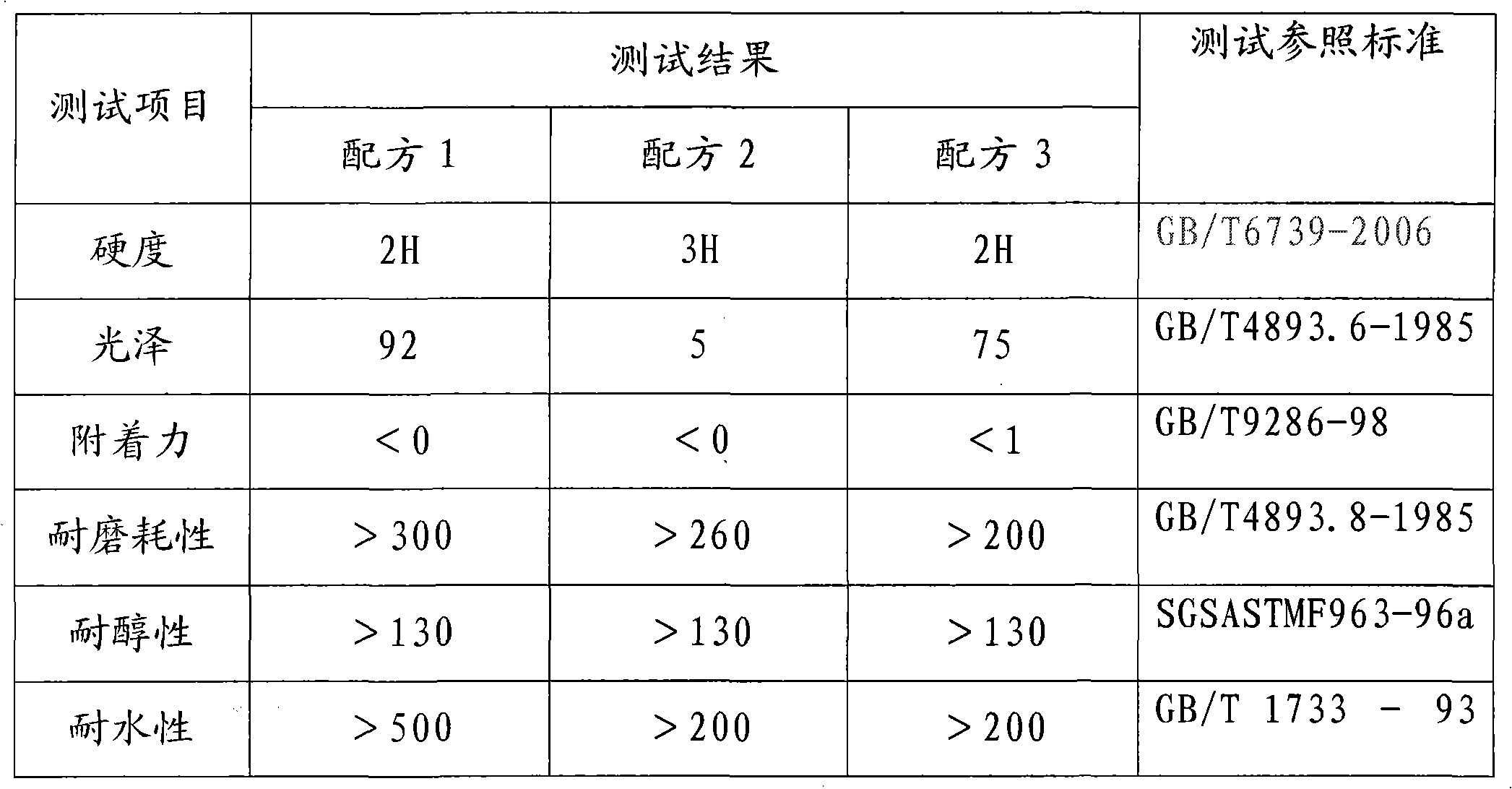

The invention discloses a water-based baking paint for a glass substrate and a preparation method and the application thereof; the formula of the water-based glass baking paint comprises the following components in parts by weight: 45 to 63 percent of water-soluble acrylic resin, 5 to 7 percent of methylated amino resin, 5 to 15 percent of water-based paste, 1.2 to 1.5 percent of coupling agent, 2 to 5 percent of additive and 25 to 30 percent of deionized water. When the baking paint is prepared, first the water-soluble acrylic resin, defoamer, wetting agent, leveling agent, dispersant and some water are sequentially added into a stirring tank to be stirred, is added with the water-based slurry and the like to be stirred and dispersed at high speed; and finally the methylated amino resin, the coupling agent and the rest water are sequentially added in to be stirred into a uniform coating system. The invention also provides a use method of the glass baking paint. When being applied to ground glass, hard glass and other substrates, the coating has the advantages of simple preparation process, convenient construction, strong coating adhesion, high hardness, water resistance, good heat resistance and the like.

Owner:FUJIAN HANSEN PAINT

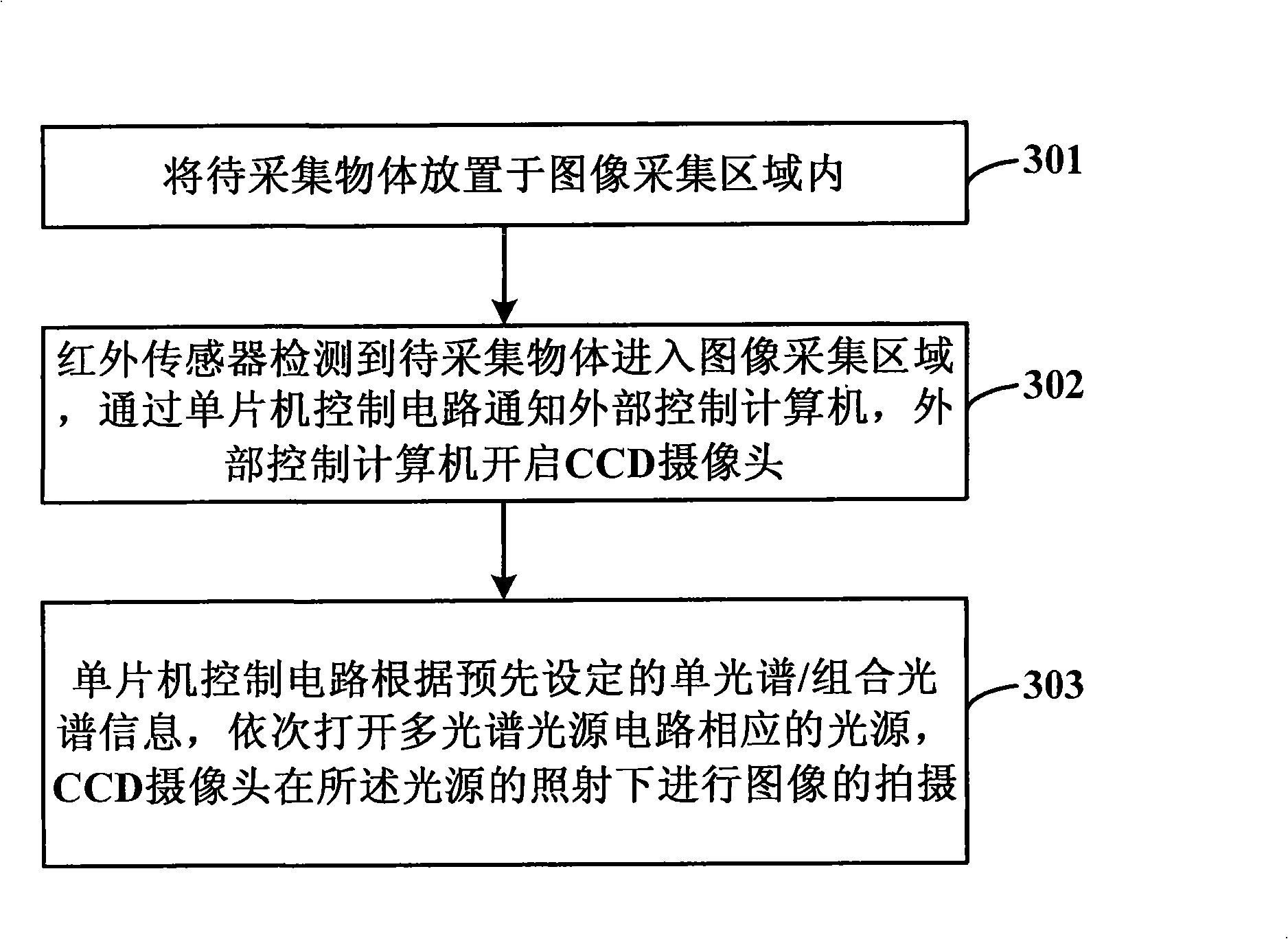

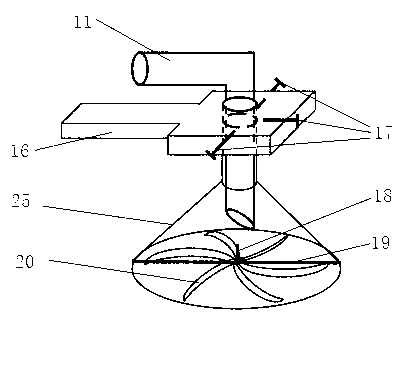

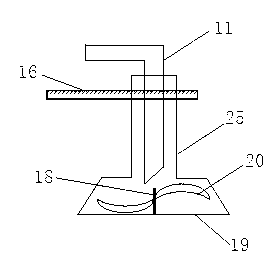

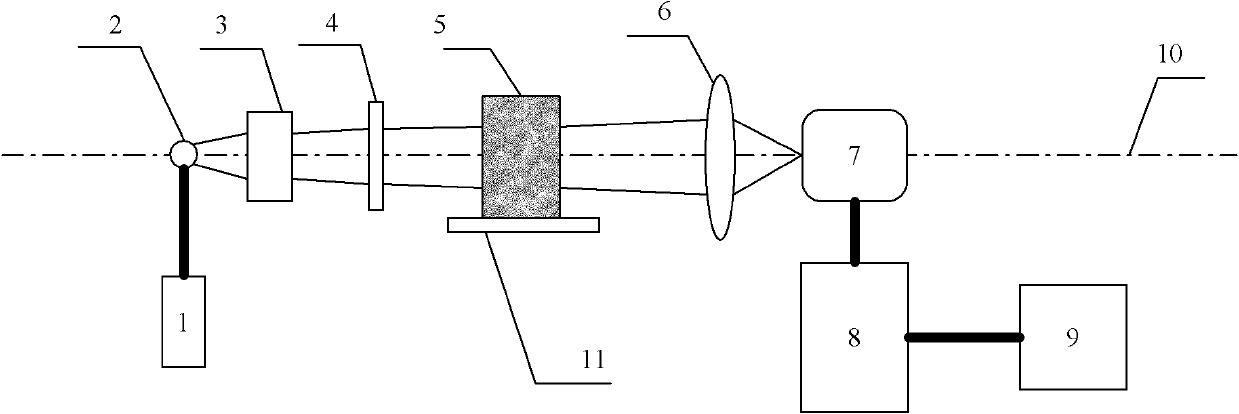

Multi-optical spectrum image collecting device and method

ActiveCN101493884ALarge amount of informationImprove accuracyCharacter and pattern recognitionMicrocontrollerPalm print

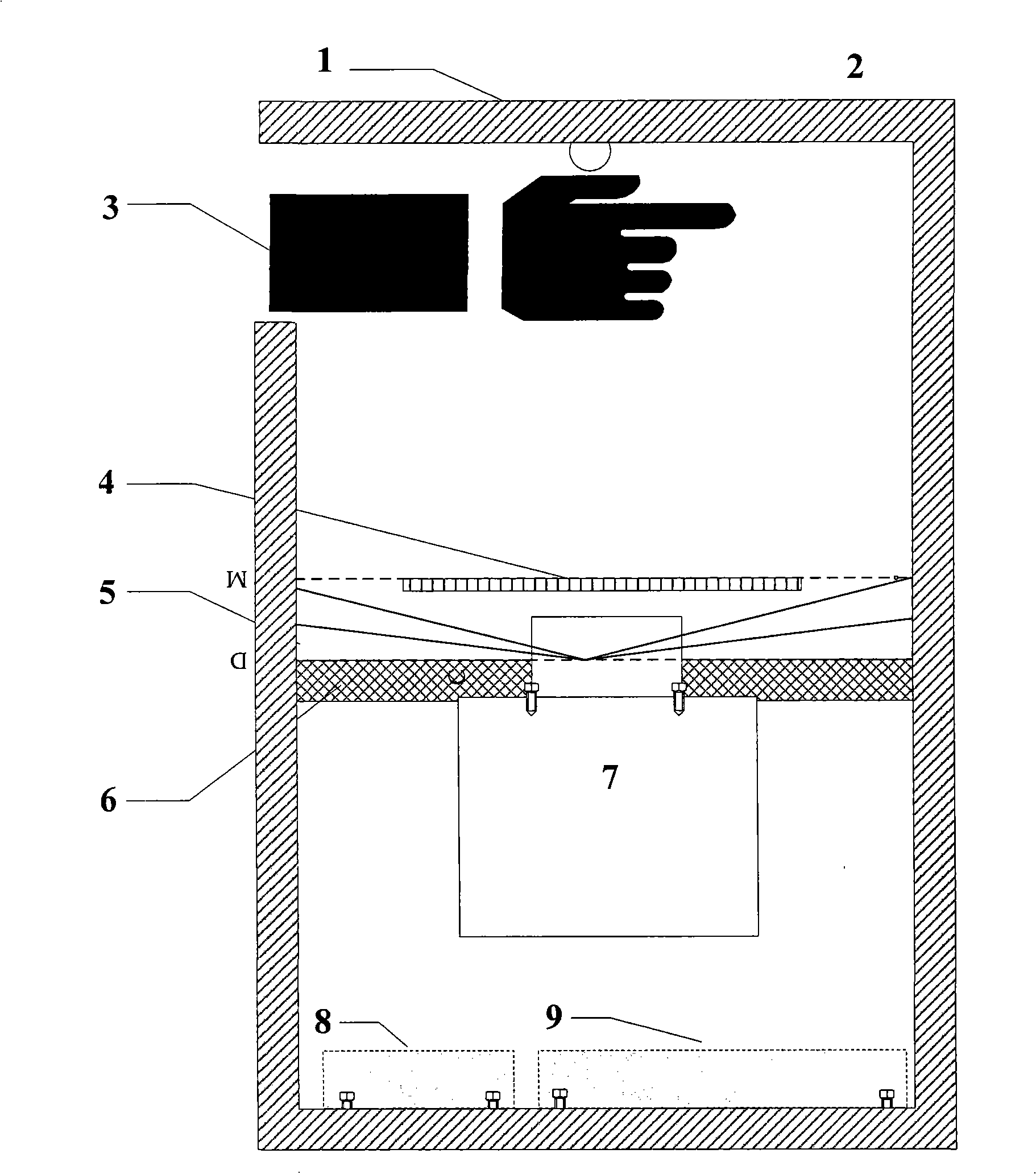

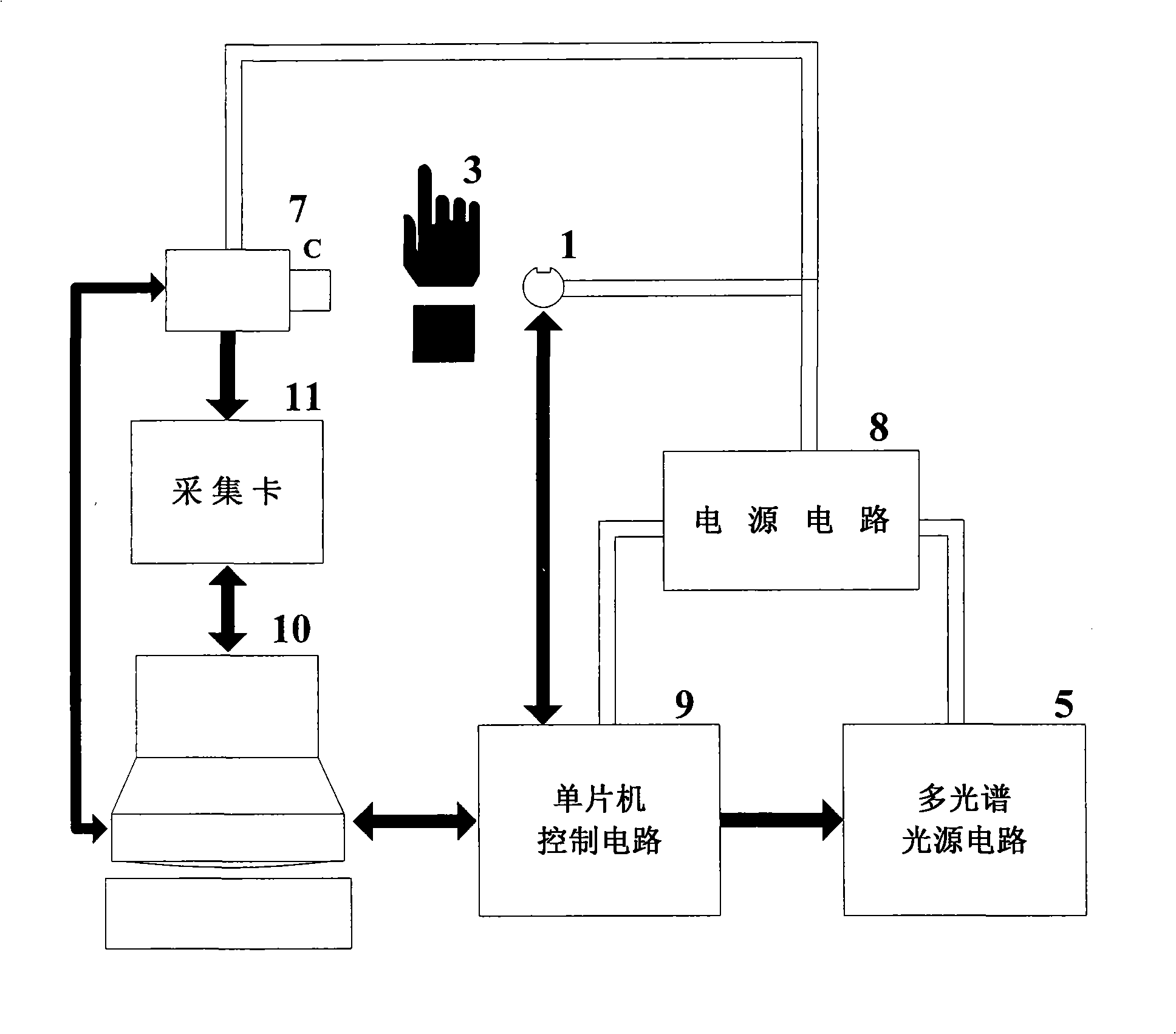

The invention discloses a device for collecting a multispectral image and a method thereof. The device at least comprises an infrared sensor (1), a device cover (2), ground glass (4), a multispectral light source circuit (5), a device transverse plate (6), a CCD camera (7), a power circuit (8) and a singlechip controlling circuit (9). Under a multi-spectral condition, the device and the method adopt active light of a single band and / or combined band of 400nm to 1,060nm to illuminate a palm to realize image shoot; and a light source is adjusted through a computer soft control method to realize high-quality image acquisition, display and storage. The utilization device and the method are used for obtaining high-quality palm images under the multi-spectral condition, and information including a palm print, a finger print, a palm vein and the like, thus solving problems of in vivo detection and improving the accuracy and safety of a palm biometrics identification system.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

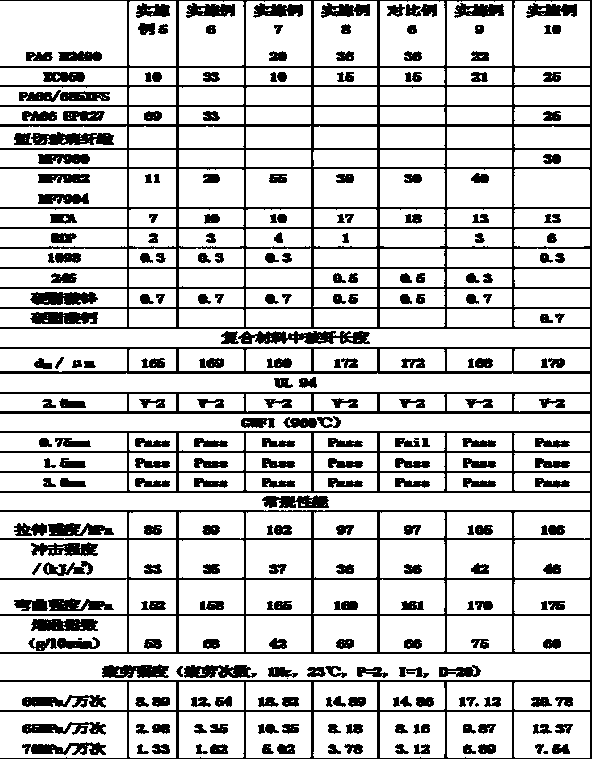

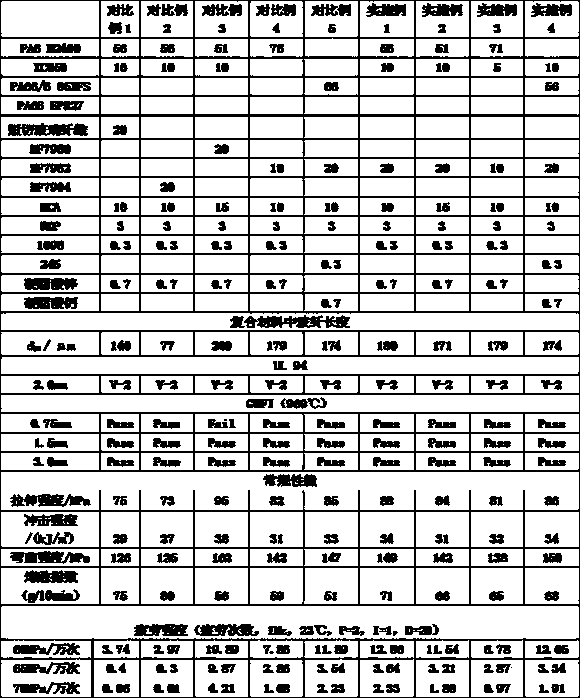

Antifatigue high-glowing-filament-property halogen-free flame-retardant reinforced polyamide composite material, and preparation method and application thereof

The invention discloses an antifatigue high-glowing-filament-property halogen-free flame-retardant reinforced polyamide composite material which comprises the following components in percentage by weight: 35-97% of thermoplastic polyamide, 1-55% of ground glass fiber, 1-30% of halogen-free flame retardant, 0.1-8% of glowing filament modifying assistant and 0.1-2% of processing assistant. The halogen-free flame-retardant reinforced polyamide composite material has the advantages of antifatigue property, high glowing filament property, higher flowability and excellent mechanical properties, and can be widely used for electronic and electric appliances especially in low-voltage electric appliance industry.

Owner:TIANJIN KINGFA NEW MATERIAL +1

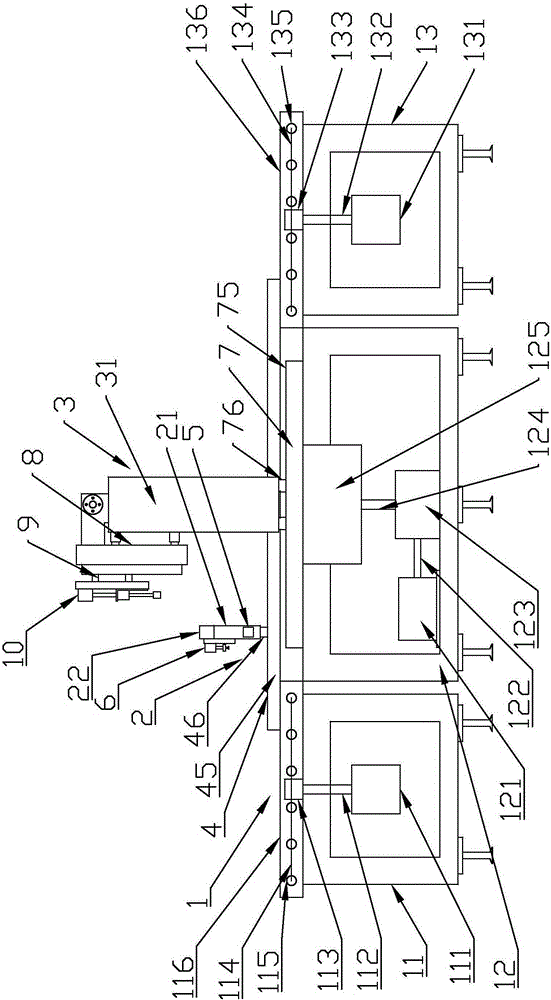

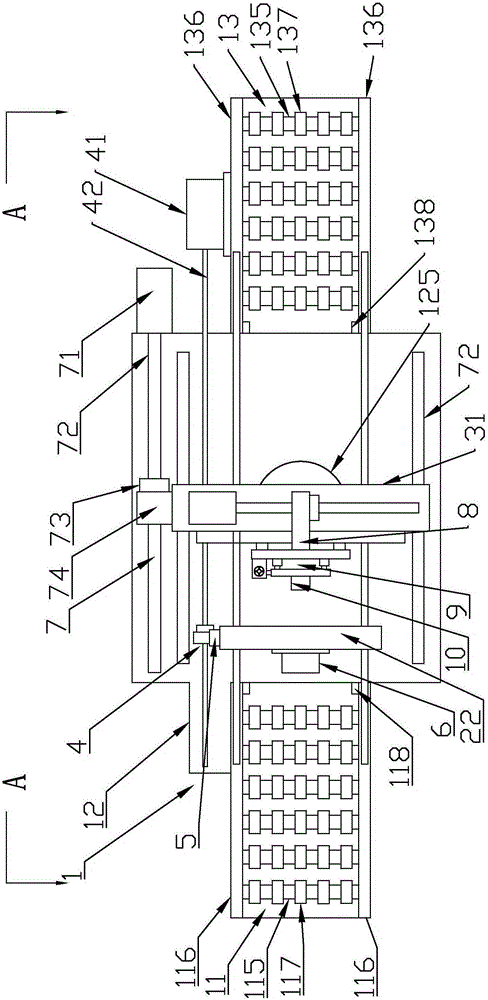

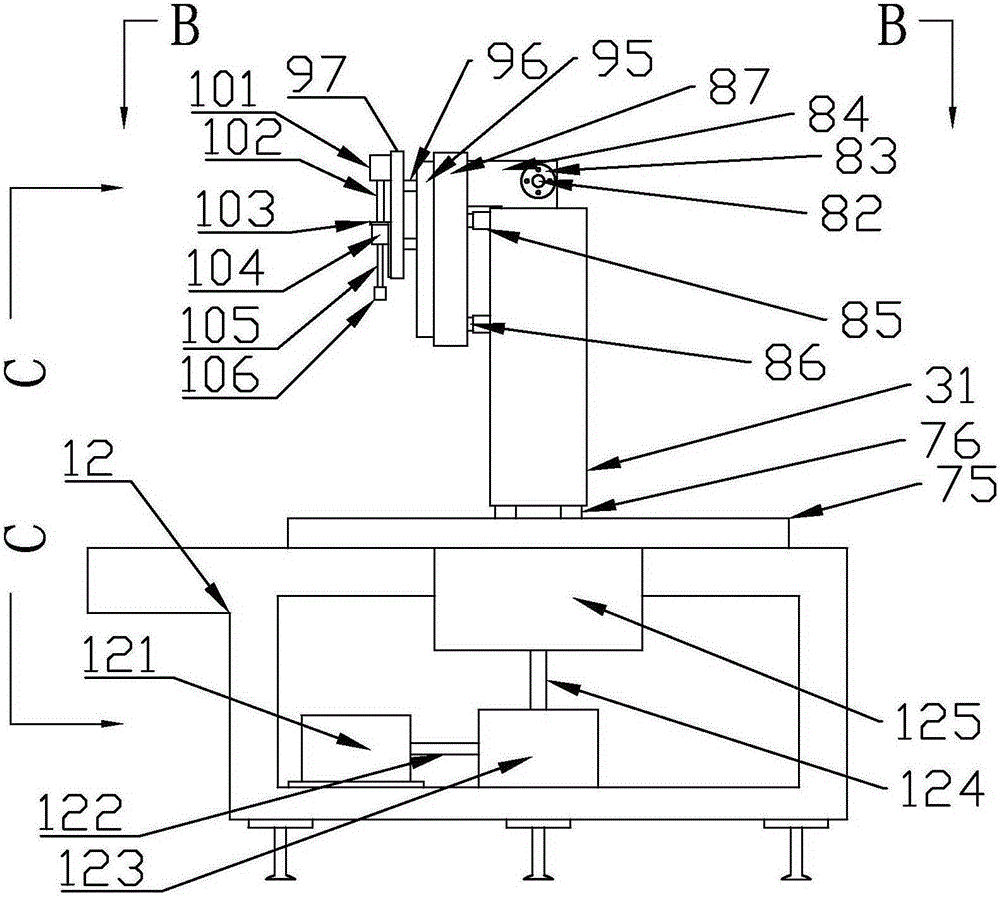

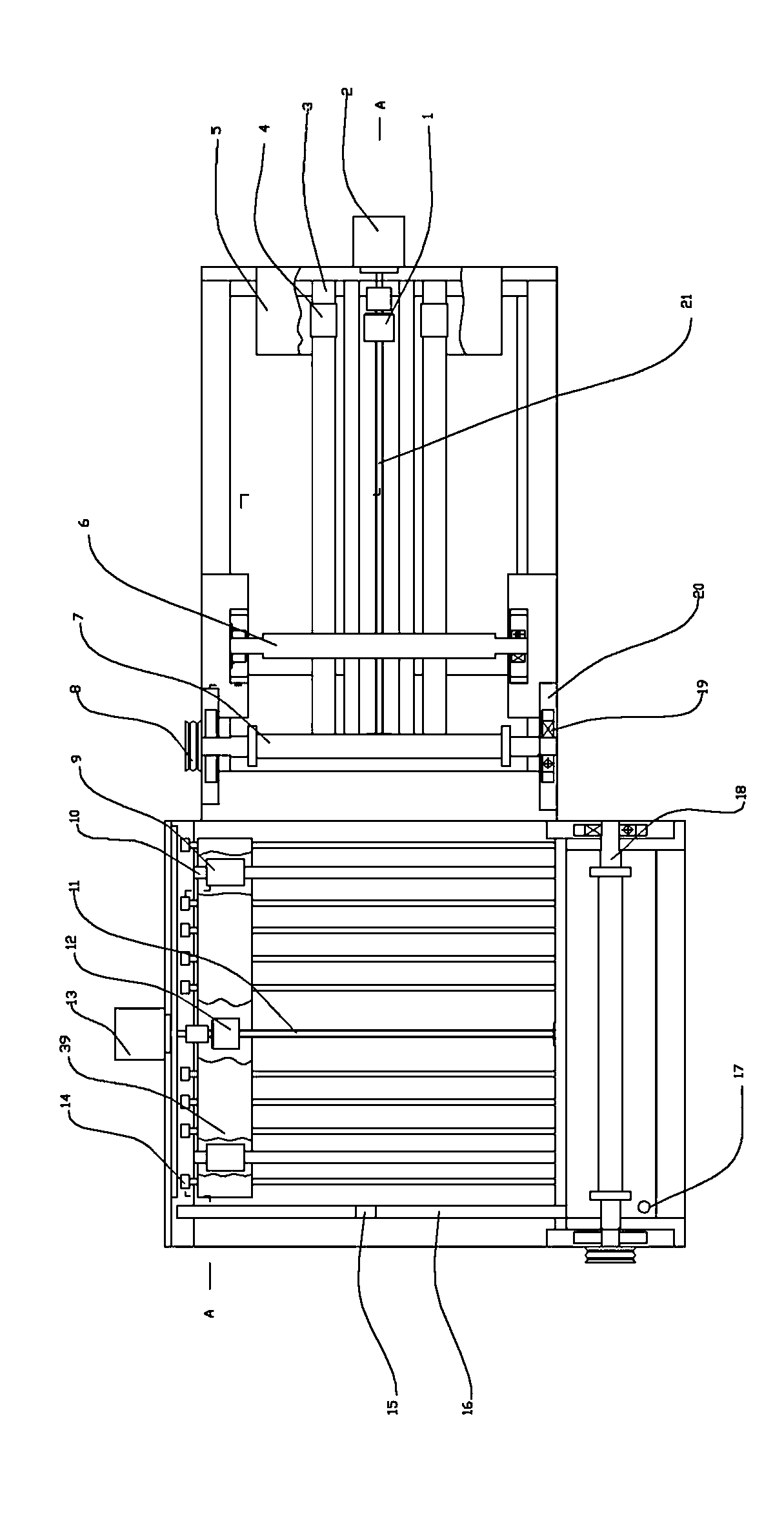

Full-automatic linear edge grinding machine for glass production

InactiveCN105215812ASolve the edging problemSimple structureEdge grinding machinesGrinding carriagesEngineeringPortal frame

The invention discloses a full-automatic linear edge grinding machine for glass production. The full-automatic linear edge grinding machine comprises machine frames which comprise the feeding machine frame, the main machine frame and the discharging machine frame. A conveying mechanical hand and an edge grinding device are arranged on the main machine frame, and an edge grinding workbench is arranged in the main machine frame; the conveying mechanical hand comprises an X-direction conveying mechanism, a Y-direction clamping mechanism and a suction cup mechanism. The X-direction conveying mechanism is fixedly mounted on the main machine frame and provided with a vertical conveying frame. The Y-direction clamping mechanism is fixedly mounted on the side face of the vertical conveying frame. The suction cup mechanism is fixedly mounted at the upper end of the vertical conveying frame. The edge grinding device comprises an X-direction moving mechanism, a Y-direction moving mechanism, a lifting mechanism and a grinding mechanism. The X-direction moving mechanism is fixedly mounted on the main machine frame and provided with a portal frame. The Y-direction moving mechanism, the lifting mechanism and the grinding mechanism are all fixedly mounted on the portal frame. The full-automatic linear edge grinding machine is simple in structure, high in automation degree and capable of precisely positioning glass to greatly improve the smoothness of ground glass workpieces.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

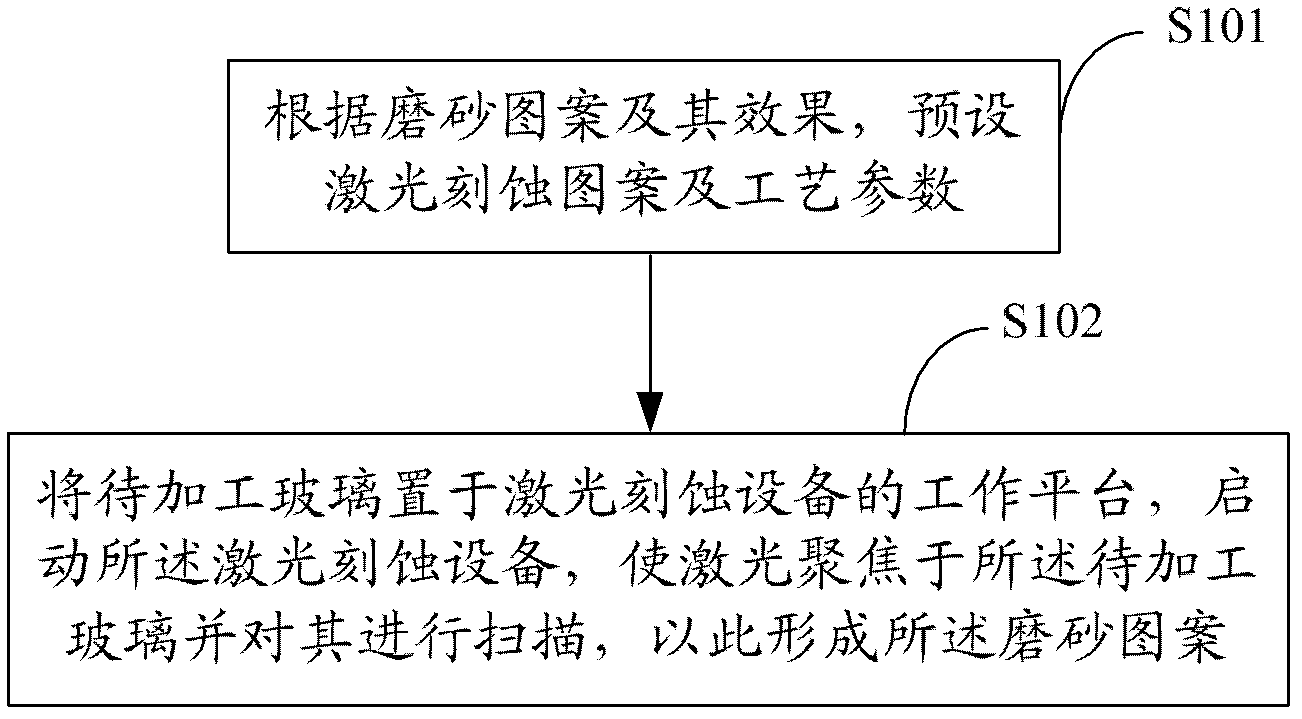

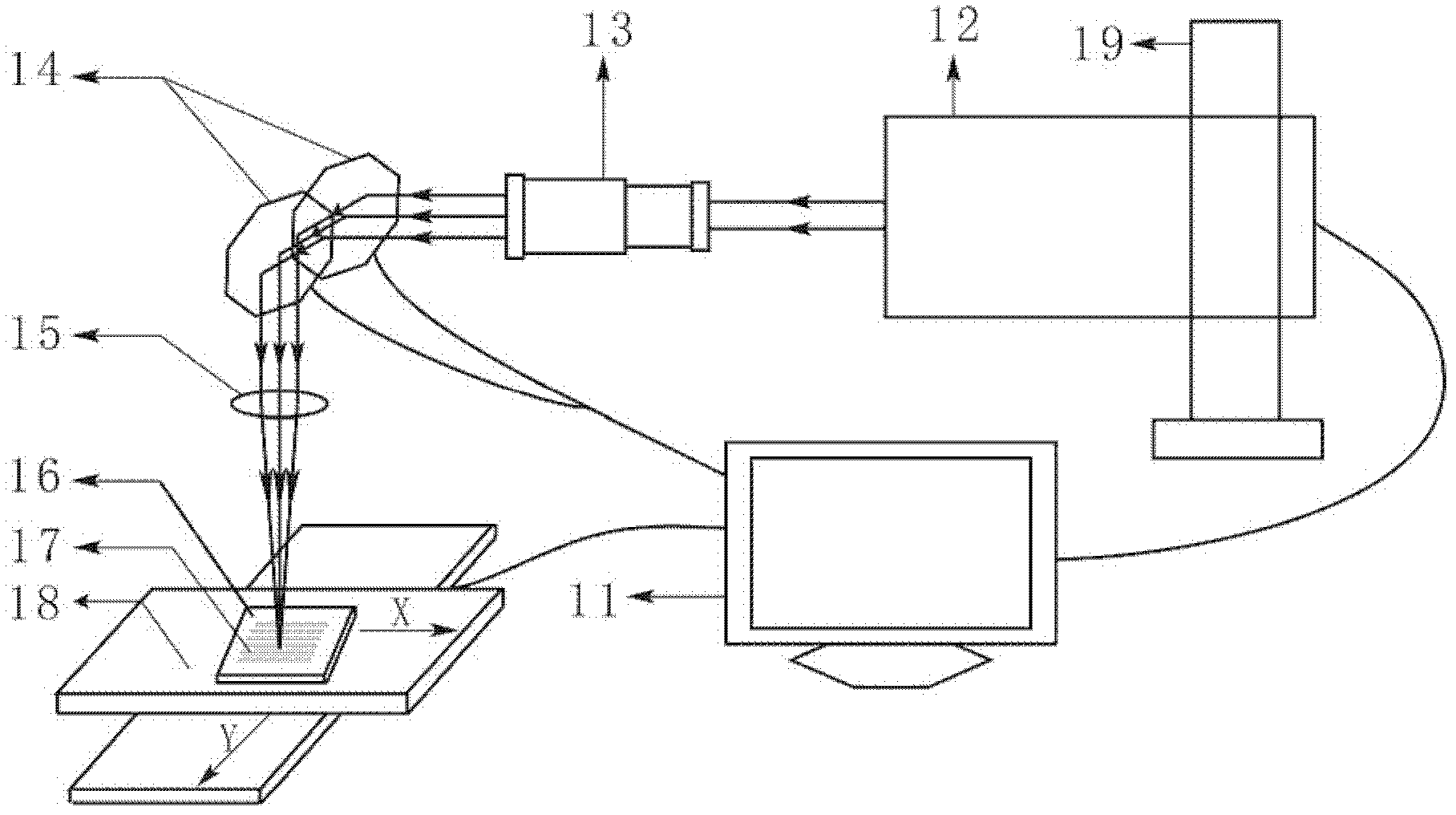

Manufacturing method of ground glass

ActiveCN103042310AImprove qualityImprove yieldLaser beam welding apparatusLaser etchingLaser processing

The invention is suitable for the technical field of laser machining and provides a manufacturing method of ground glass. The manufacturing method includes the following steps: presetting a laser etching pattern and technological parameters according to a ground pattern and a ground pattern effect; and placing glass to be processed on a working platform of a laser etching device, starting the laser etching device, and enabling a laser to be focused on the glass to be processed and scan the glass so as to form the ground pattern. The laser is used for performing non-contact process on common glass so as to enable the common glass to become the ground glass, a base body of the glass cannot be damaged, and the manufacturing method facilitates improvement of quality and finished product rate of the ground glass.

Owner:HANS LASER TECH IND GRP CO LTD

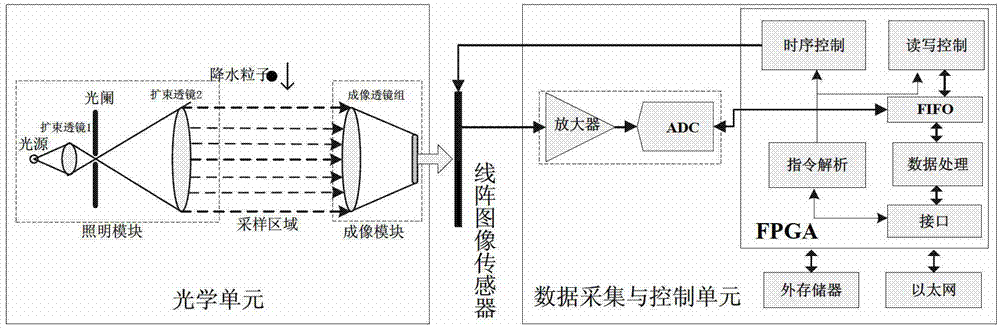

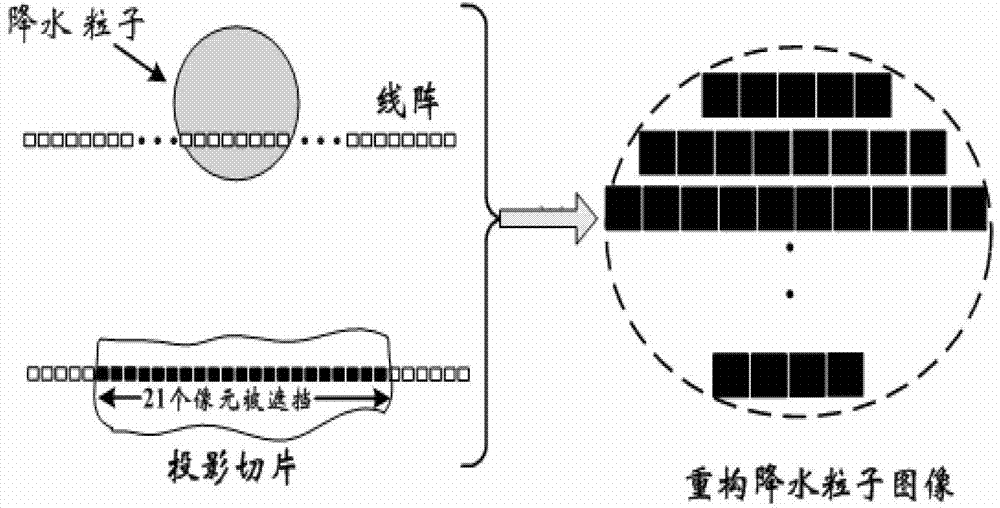

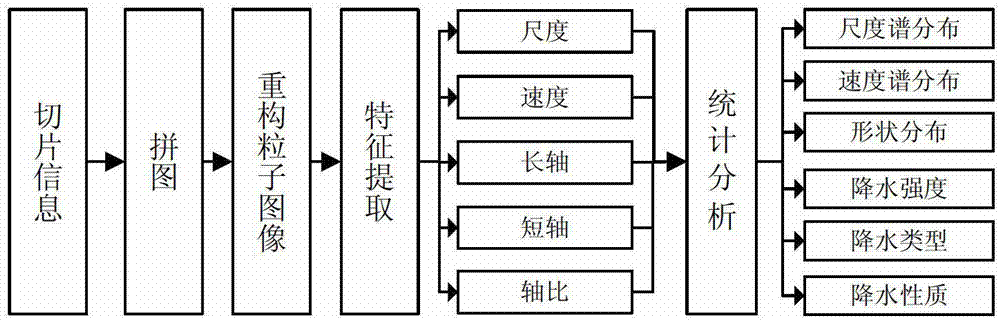

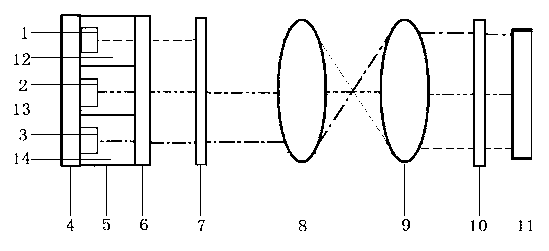

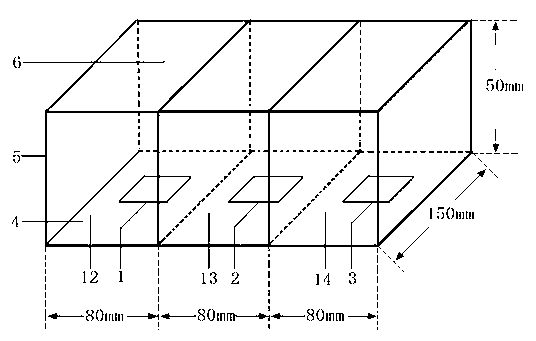

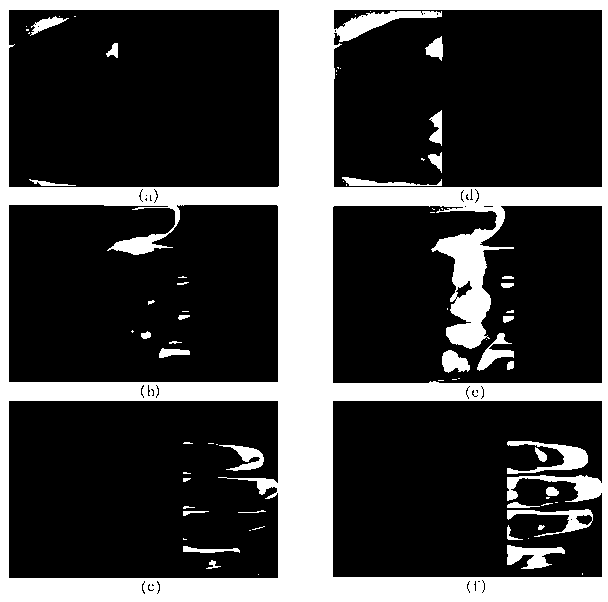

Rainfall and snowfall automatic observation method based on parallel light large visual field

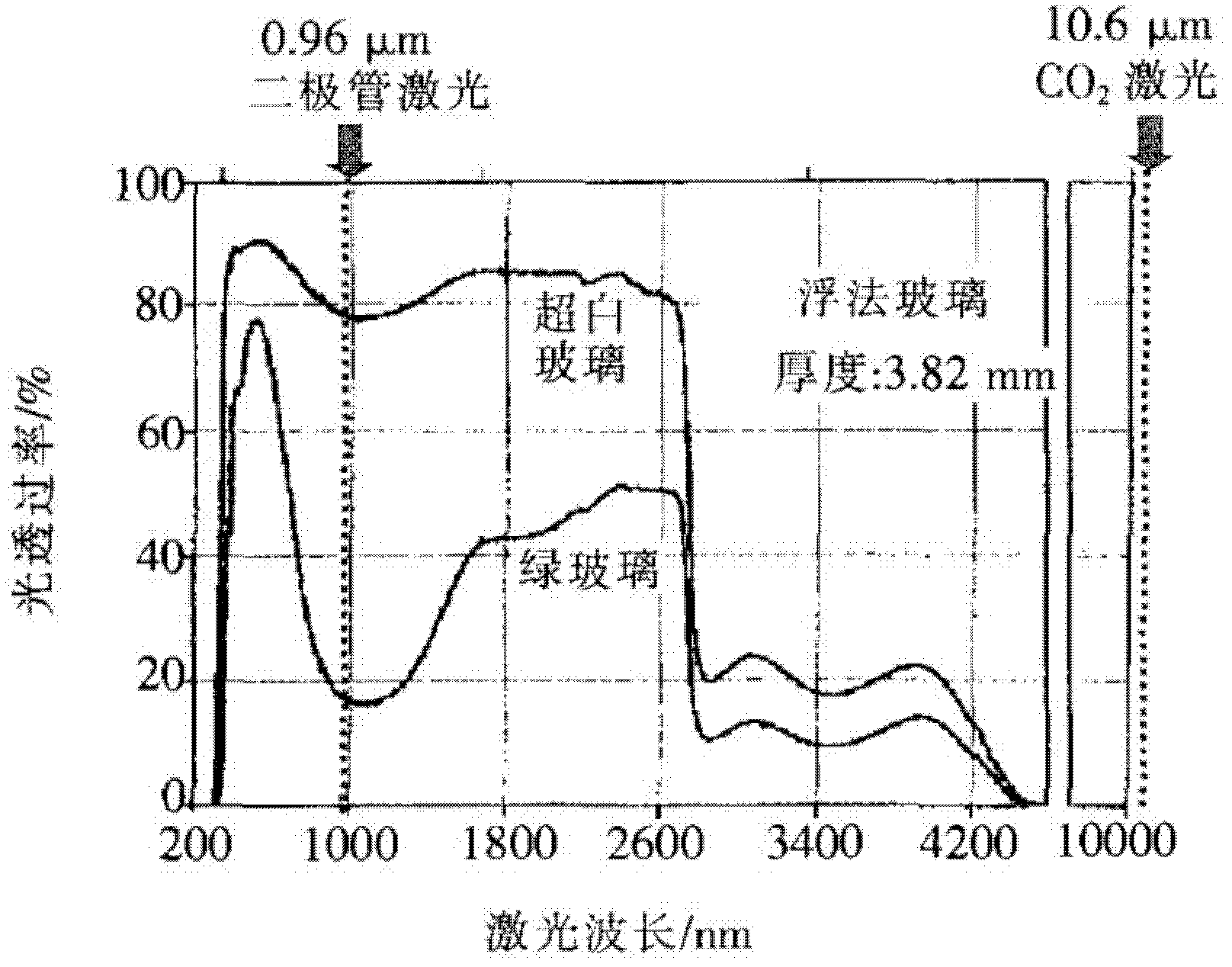

InactiveCN103033857AAccurate judgmentAvoid image distortionRainfall/precipitation gaugesCamera lensSensor array

Provided is a rainfall and snowfall automatic observation method based on a parallel light large visual field. Data is transmitted to a terminal computer and corresponding software modules through utilization of an optical unit, a linear array imaging sensor array, a data acquisition control unit and a transmission unit. The optical unit comprises a large visual field collimator and an imaging system. The collimator comprises a collimated light source, a diaphragm and a collimating lens set. A high-brightness light emitting diode (LED) light source or a semiconductor laser is adopted as the collimated light source, and even and stable parallel light is obtained through a piece of ground glass, the diaphragm and the collimating lens set. An imaging camera lens is arranged in front of the outgoing end of the collimator, receives the parallel light emitted from the collimator, and projects the parallel light on a linear array imaging sensor after the parallel light is optically enlarged. The shape, the equivalent size, the falling end speed and other information of a single rainfall grain can be obtained, and therefore automatic identification of rainfall phenomenon and calculation of statistical characteristics of rainfall micro-physical parameters can be achieved.

Owner:PLA UNIV OF SCI & TECH

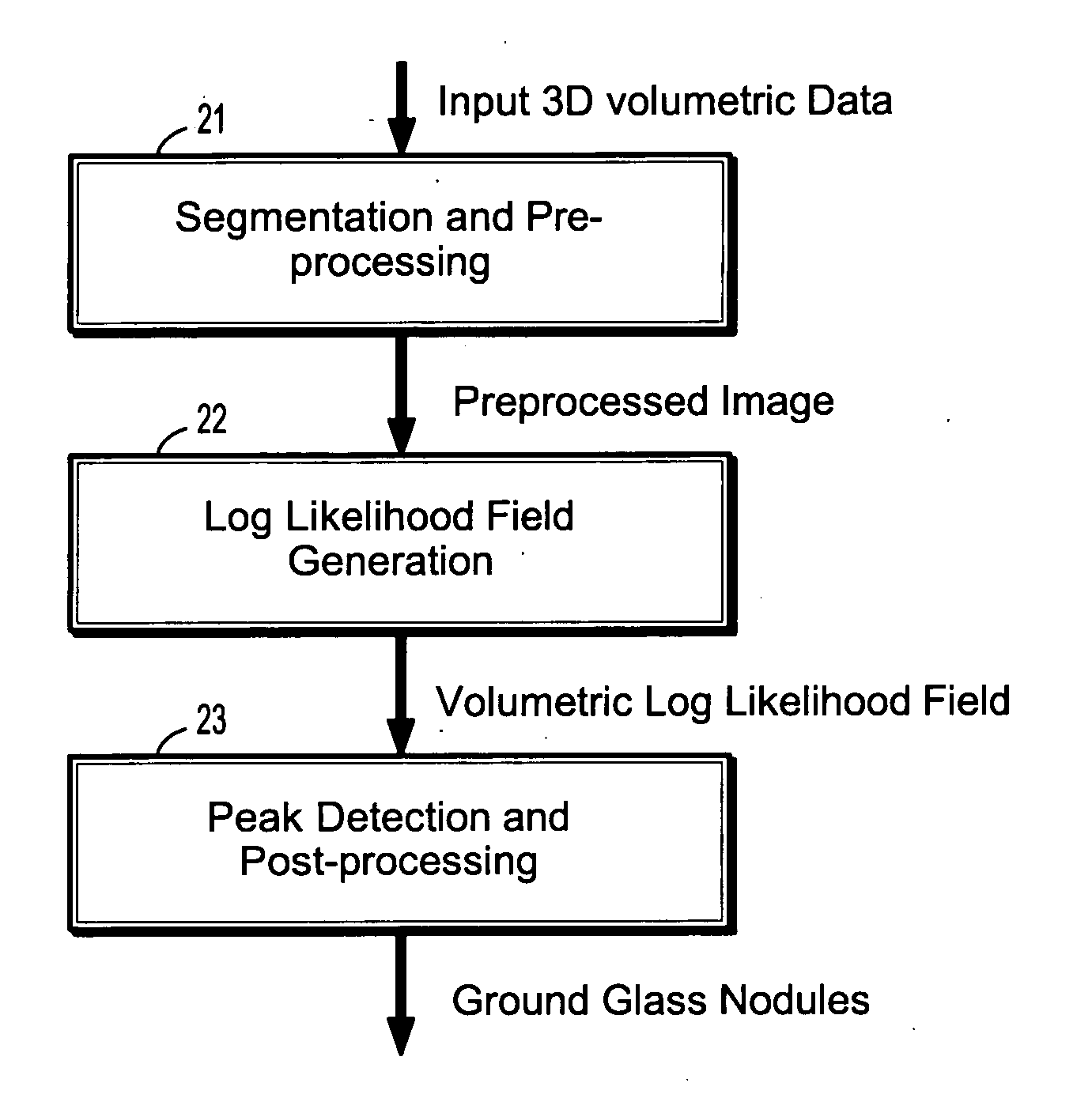

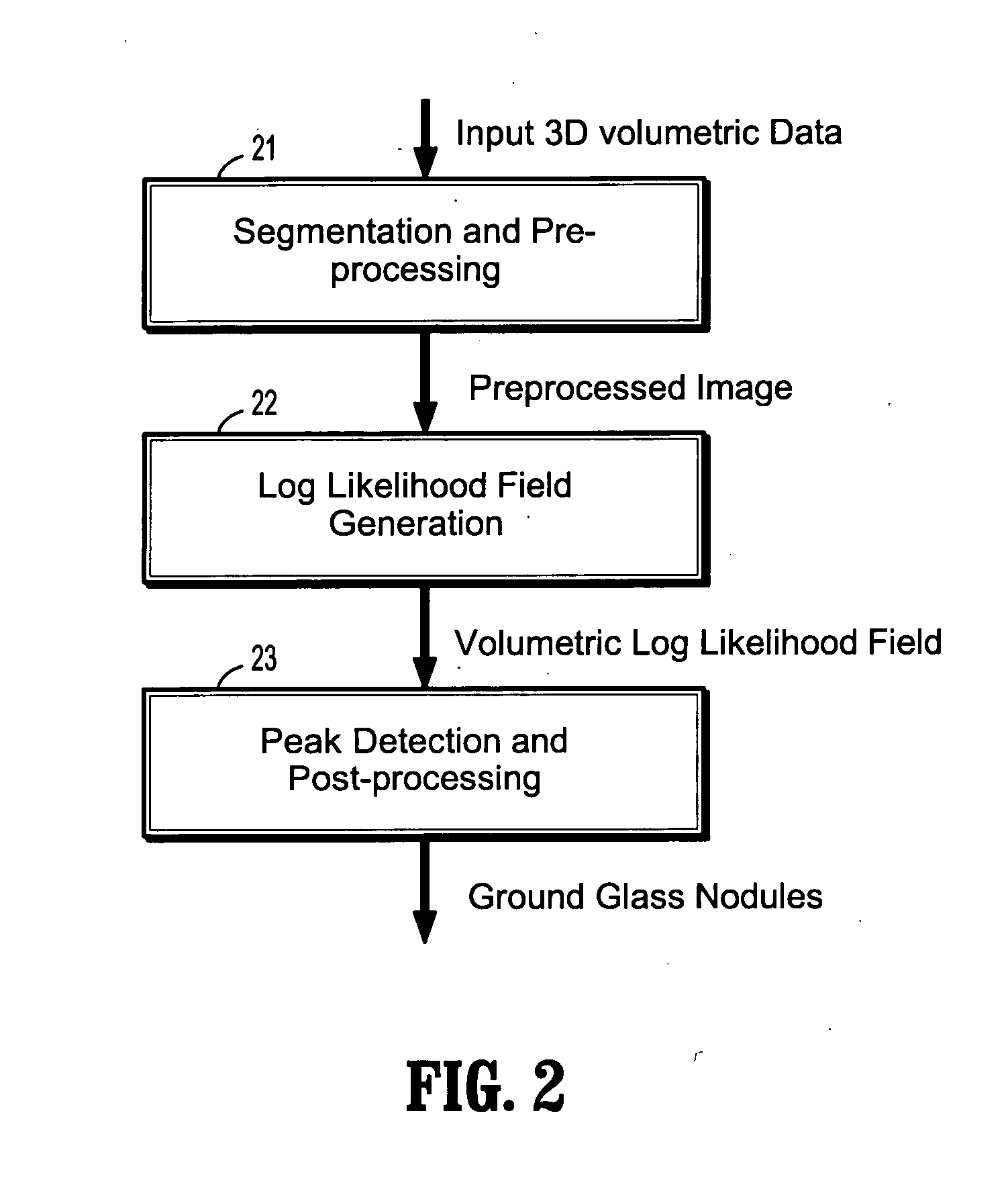

System and method for detecting ground glass nodules in medical images

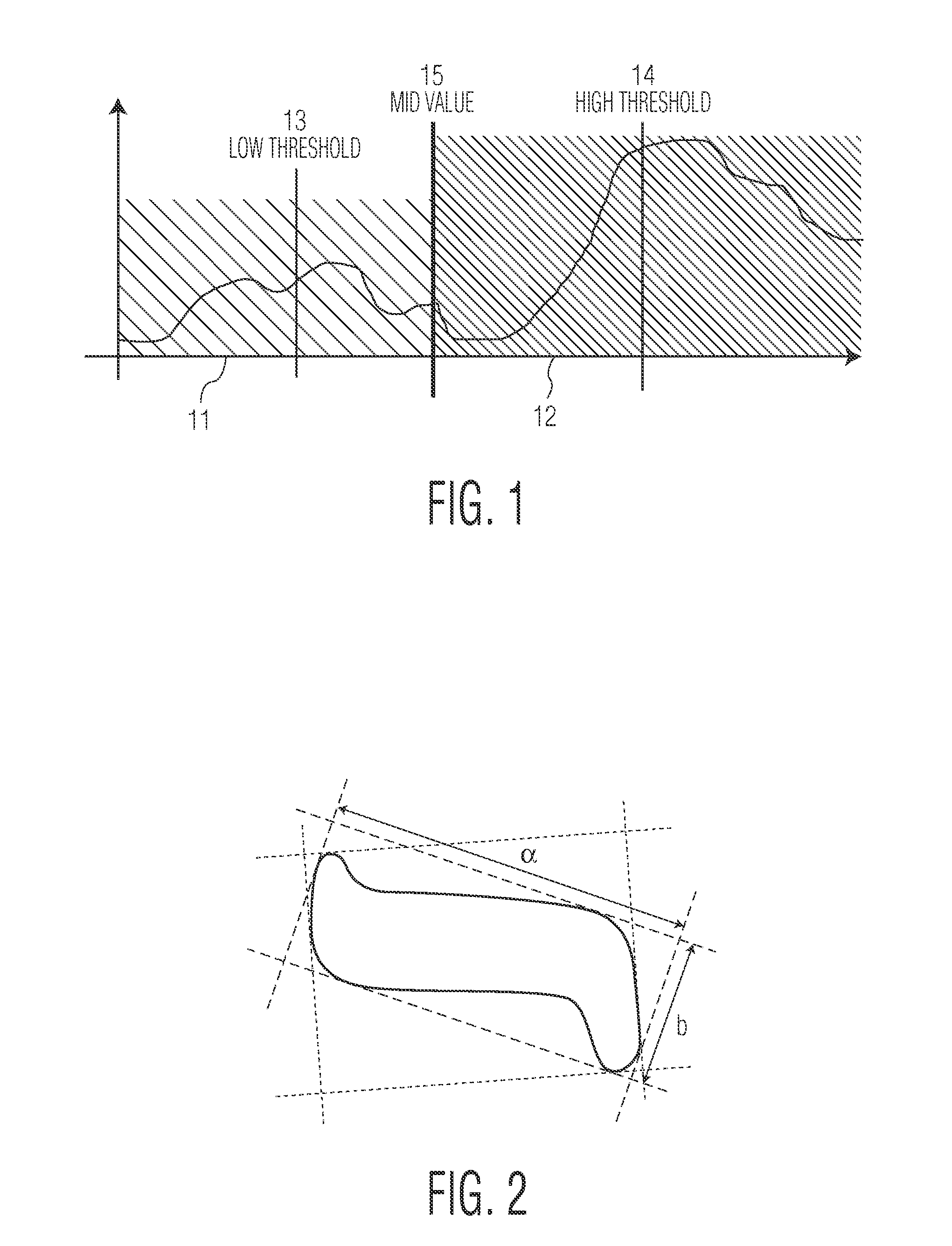

Detecting ground glass nodules in medical images includes calculating a probability distribution function of background lung tissue in a chest image, estimating a variation range of the background tissue probability distribution function, estimating a probability distribution function of an image point belonging to a ground glass nodule from the variation range of the background tissue probability distribution function by using a function corresponding to the variation range of the background tissue probability distribution function, and calculating a log likelihood function of the image from the background tissue probability distribution function and the estimated ground glass nodule probability distribution function, wherein the log likelihood function represents the confidence that a point in the image is not part of a ground glass nodule. The log likelihood function value for each point is compared to a confidence value of the background tissue, to determine if the point is a candidate ground glass nodule location.

Owner:SIEMENS HEATHCARE GMBH

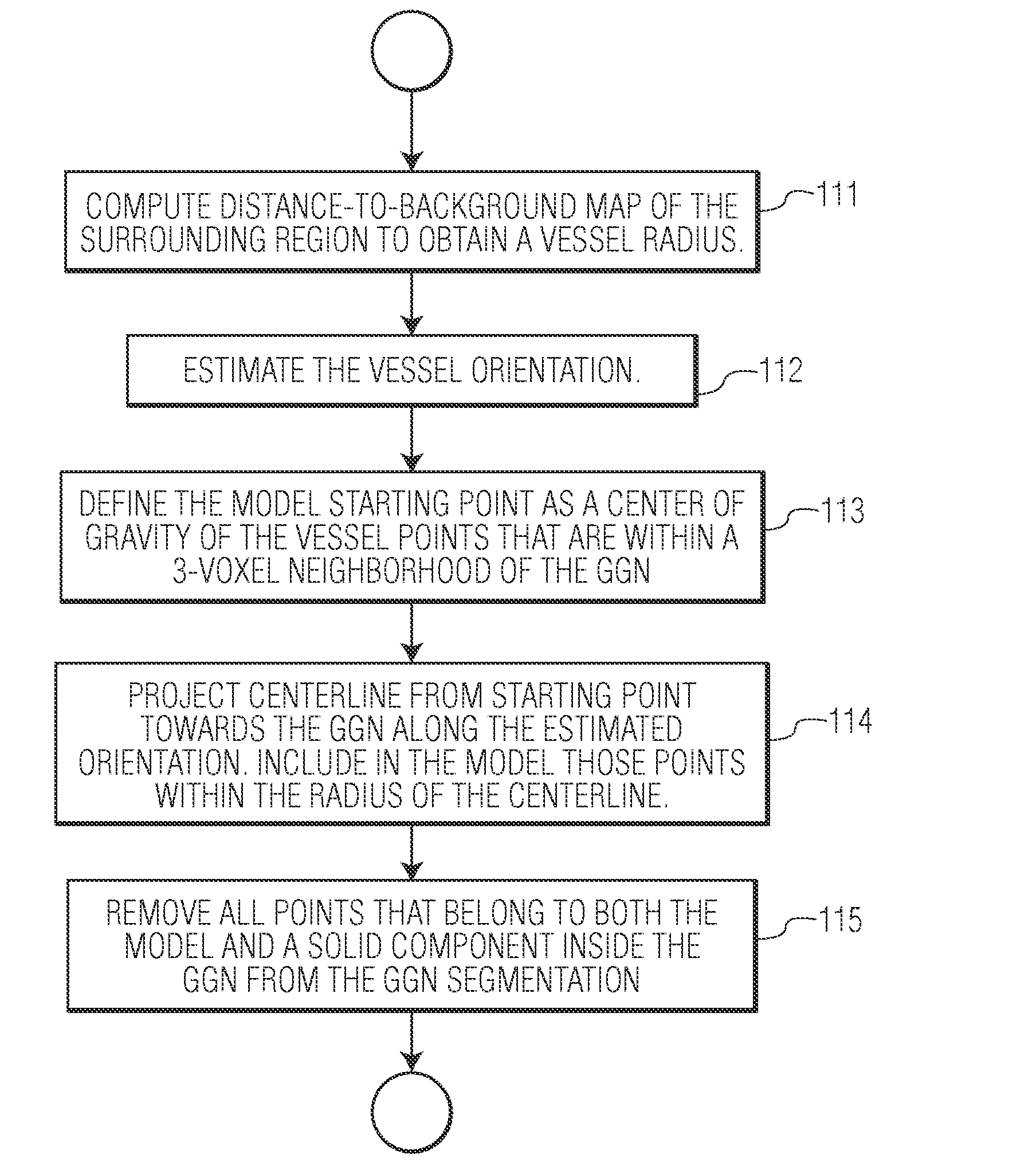

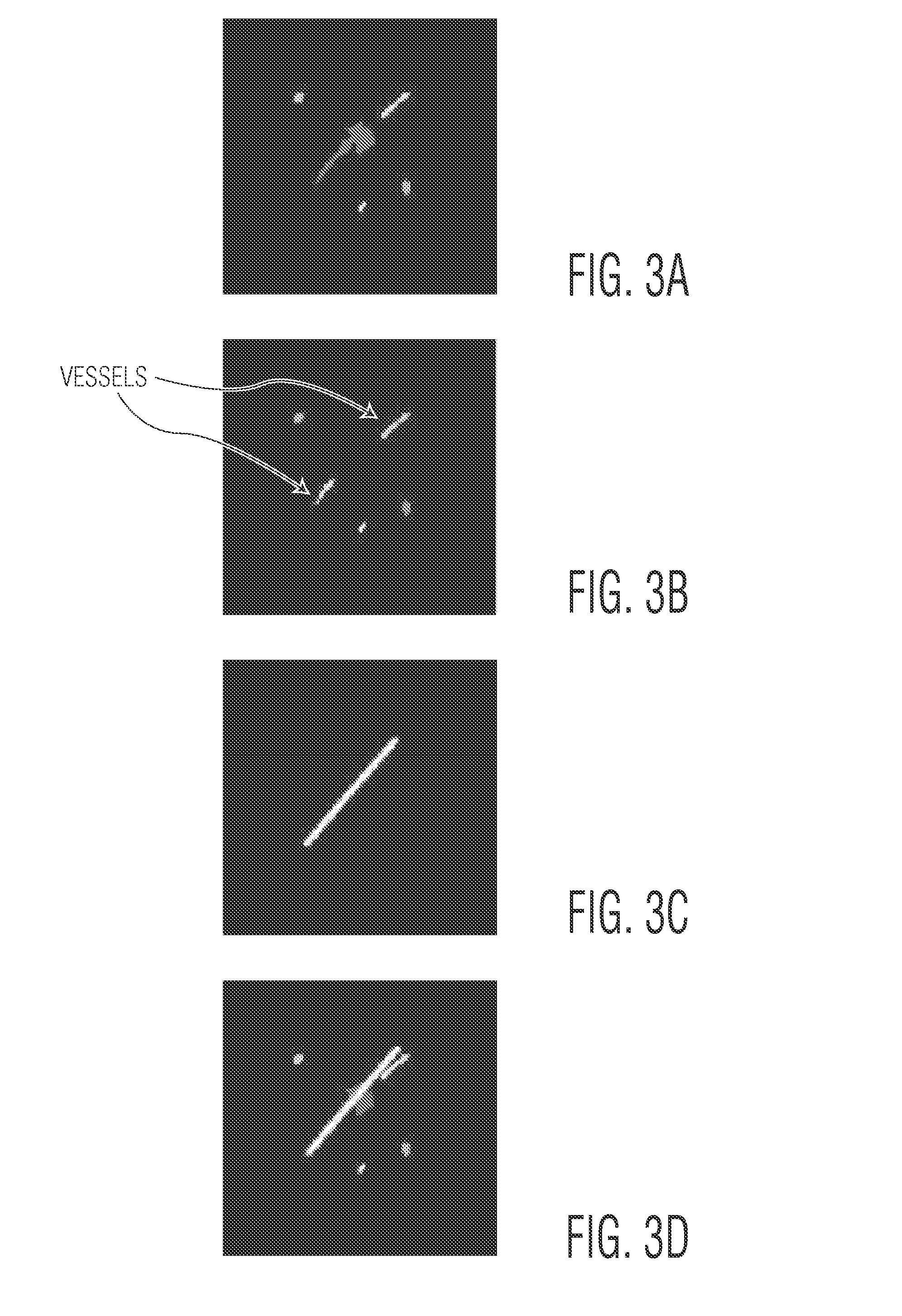

System and Method for Solid Component Evaluation in Mixed Ground Glass Nodules

InactiveUS20080040083A1Fast and consistent and repeatable computationEvaluate the likelihood of malignancy of GGNsImage enhancementImage analysisSolid componentHigh intensity

A method for segmenting a solid component (SC) in a ground glass nodule (GGN) includes providing a digitized image that includes a segmented GGN, the image comprising a plurality of intensities corresponding to a 3-dimensional grid of points, computing an intensity threshold that distinguishes a high intensity solid component of the GGN from a low intensity non-solid component, and applying the intensity threshold to identify a SC of the GGN and to identify regions of interest around the GGN, detecting whether or not a region of interest is a vessel, calculating a model for a detected vessel based on a radius and orientation of the vessel, and removing from the GGN segmentation all points that belong to both the model and the SC inside the GGN, and verifying whether a structure resulting from excluding the points qualifies as an SC.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

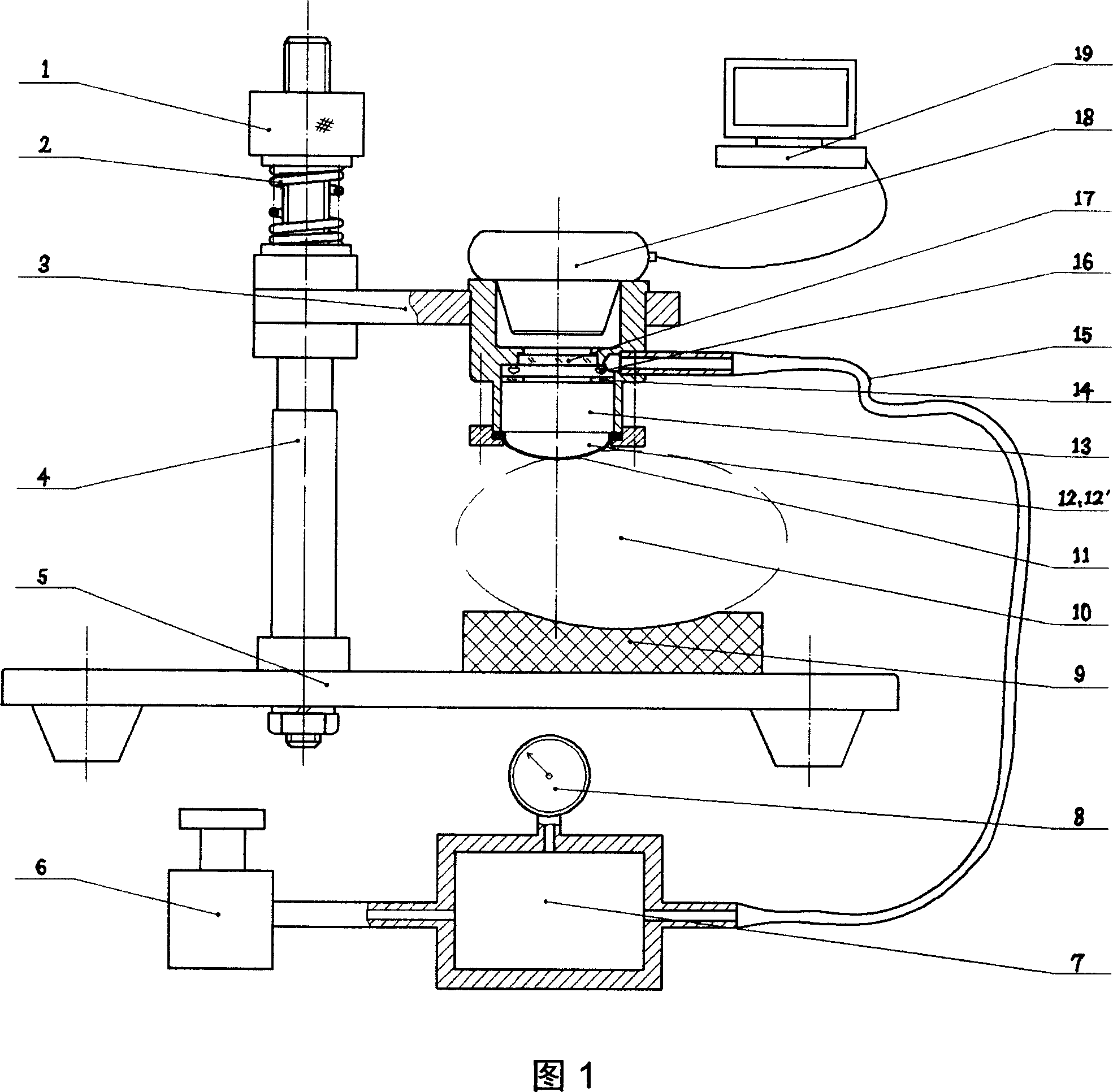

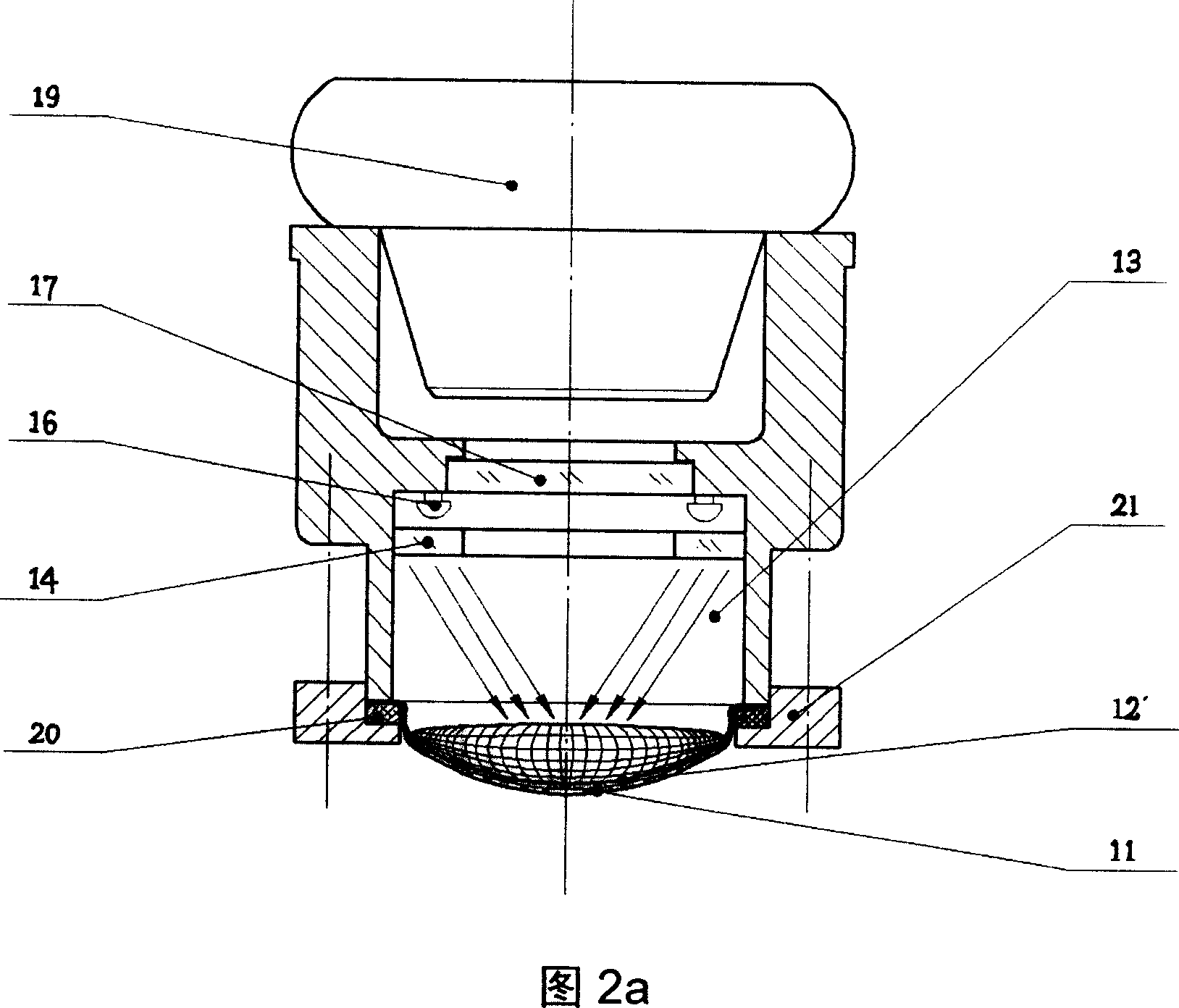

Sphygmus dynamic image information collecting system

A pulse dynamic image acquisition system involves herbalist medicine diagnosis device, especially the pulse information collection devices. The sealed pressure cavity is fixed on the level bracket, and the level bracket is fixed on the vertical columns. Flexible contact is fixed on the top of the sealed pressure cavity, the air pump is linked with the air pressure buffer cavity and the air pressure buffer cavity is linked with the sealed pressure cavity by the air circuit. The membrane with veins is affixed to the lining of the flexible contact, the lighting is fixed in the sealed pressure cavity the where above the flexible contact. The image acquisition device is installed on the upside of sealed pressure cavity, and the image acquisition devices connected with the computer through the signal line. A piece of ground glass is fixed between the lighting and the flexible contact. The invention can detect the image of the skin surface of the position where it feels the pulse when pulse throbs, and then gets multi-dimensional, comprehensive and dynamic image information of pulse.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Flame-retardant polyamide compositions filled with ground glass

InactiveUS20120165439A1Less adverse effect on fire performanceImprove propertiesGroup 4/14 element organic compoundsSpecial tyresFiberPolyamide

The present invention relates to flame-retardant compositions based on a thermoplastic polyamide comprising non-fibrous and unfoamed ground glass with specific particle size distribution, geometry and size, and also to the production and the use of the compositions of the invention for producing products, preferably fibres, foils and mouldings of any type.

Owner:LANXESS DEUTDCHLAND GMBH

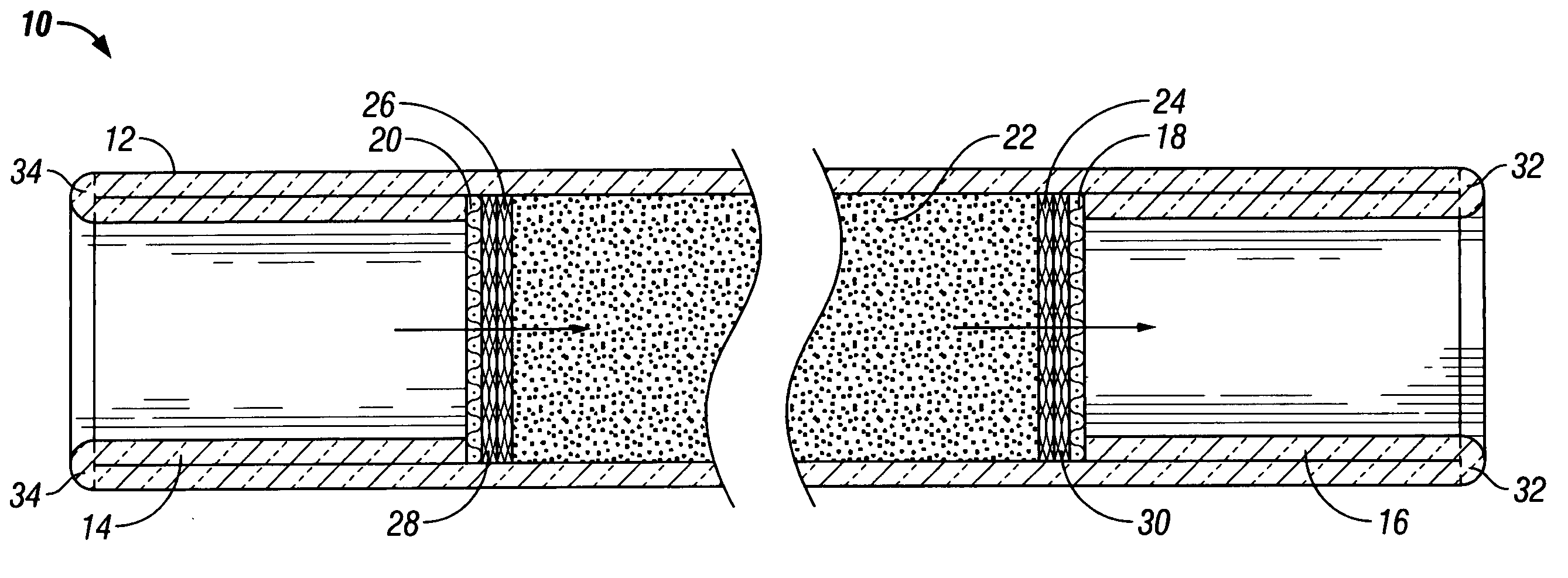

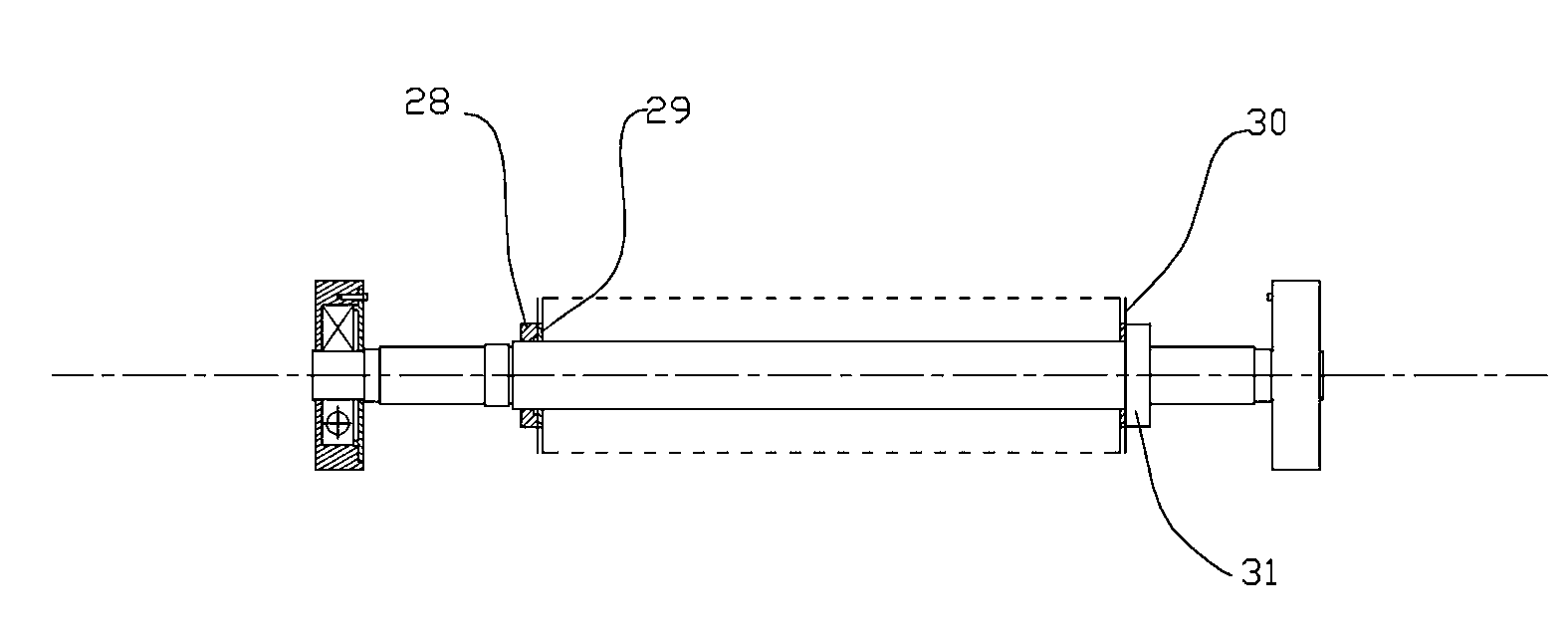

Centerless ground thermal desorption tube and method without frit

InactiveUS20050180893A1Easy constructionThe material is lowAnalysis using chemical indicatorsWithdrawing sample devicesFritSorbent

A centerless ground thermal desorption tube comprises an outer barrel and one or more inner spacers insertably positioned within the outer barrel. A suitable sorbent material is positioned within the outer barrel which may be held in place by friction and / or with glass wool plugs, and / or screens, and / or the inner spacers. In one preferred embodiment one glass inner spacer is fused to one end of a glass outer barrel prior to the glass outer barrel being centerless ground to a high precision. The sorbent and / or any wool plugs and / or screens are inserted into a second opposite end of the outer barrel after the centerless grinding process. A second glass is fused to the second end of the glass outer barrel whereby the glass fusing may change the precise tolerance of the centerless ground glass outer barrel at the second end only.

Owner:HANDLY ROBERT A

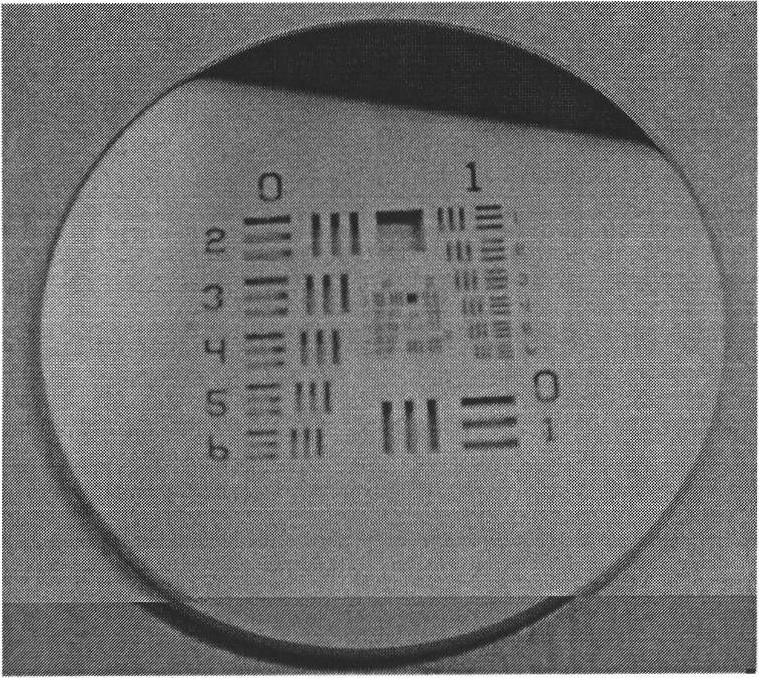

Resolution test device of ultraviolet image intensifier

InactiveCN102564733AShorten the transmission distanceReduce the effect of aberrationTesting optical propertiesUltraviolet lightsOptoelectronics

The invention discloses a resolution test device of an ultraviolet image intensifier. Two spherical reflectors and two plane reflectors are placed on a base in a straight line; and the two plane reflectors are respectively placed at focus points of the two spherical reflectors, so as to form a coaxial reflection type optical system. A resolution target is placed at the focus point of the coaxial reflection type optical system; a light source is placed in back of the resolution target; ground glass is located between the resolution target and an ultraviolet light source; an image intensifier is placed on a multi-dimensional adjusting table; and a microscope is mounted on the multi-dimensional adjusting table and can be used for observing a fluorescent screen image of the resolution target. According to the test demands, a user selects the resolution target and the image intensifier is shifted to a position of a focal plane of the optical system, so as to obtain the resolution of the ultraviolet image intensifier. The resolution test device disclosed by the invention has the advantages of small appearance size and volume, and convenience for resetting. Furthermore, the transmission distance of an ultraviolet target in atmosphere is reduced, the influence of the image difference is greatly reduced, and a clear image can be obtained under a condition of a short focus distance.

Owner:NANJING UNIV OF SCI & TECH

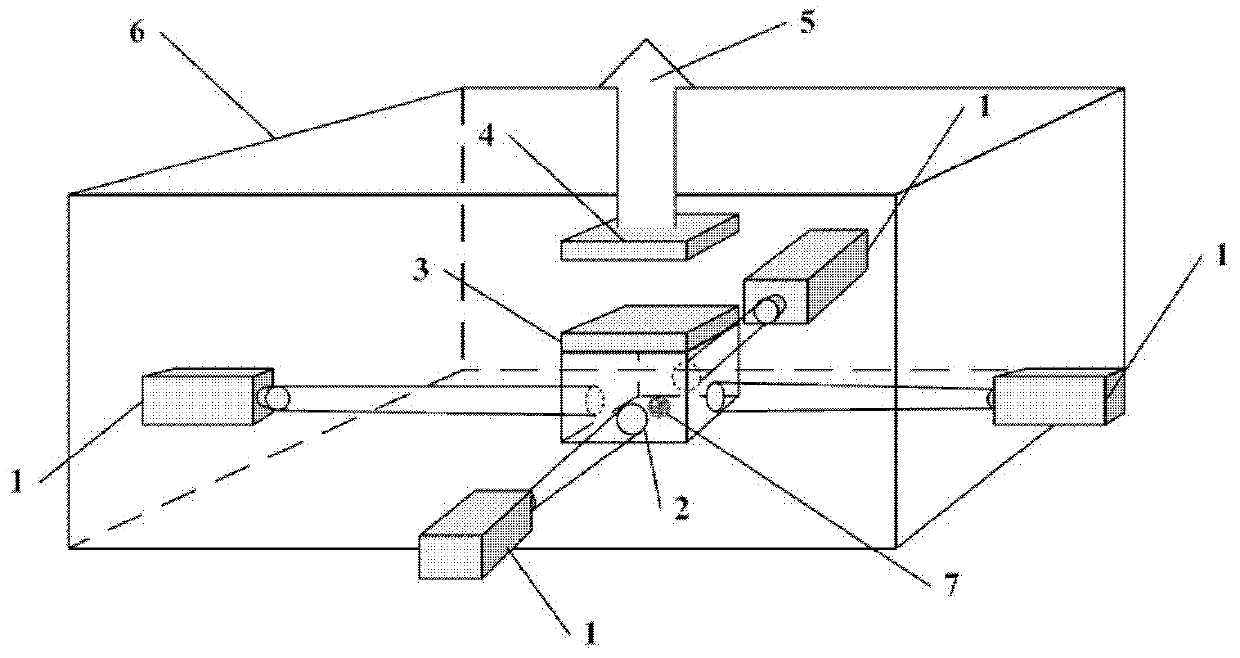

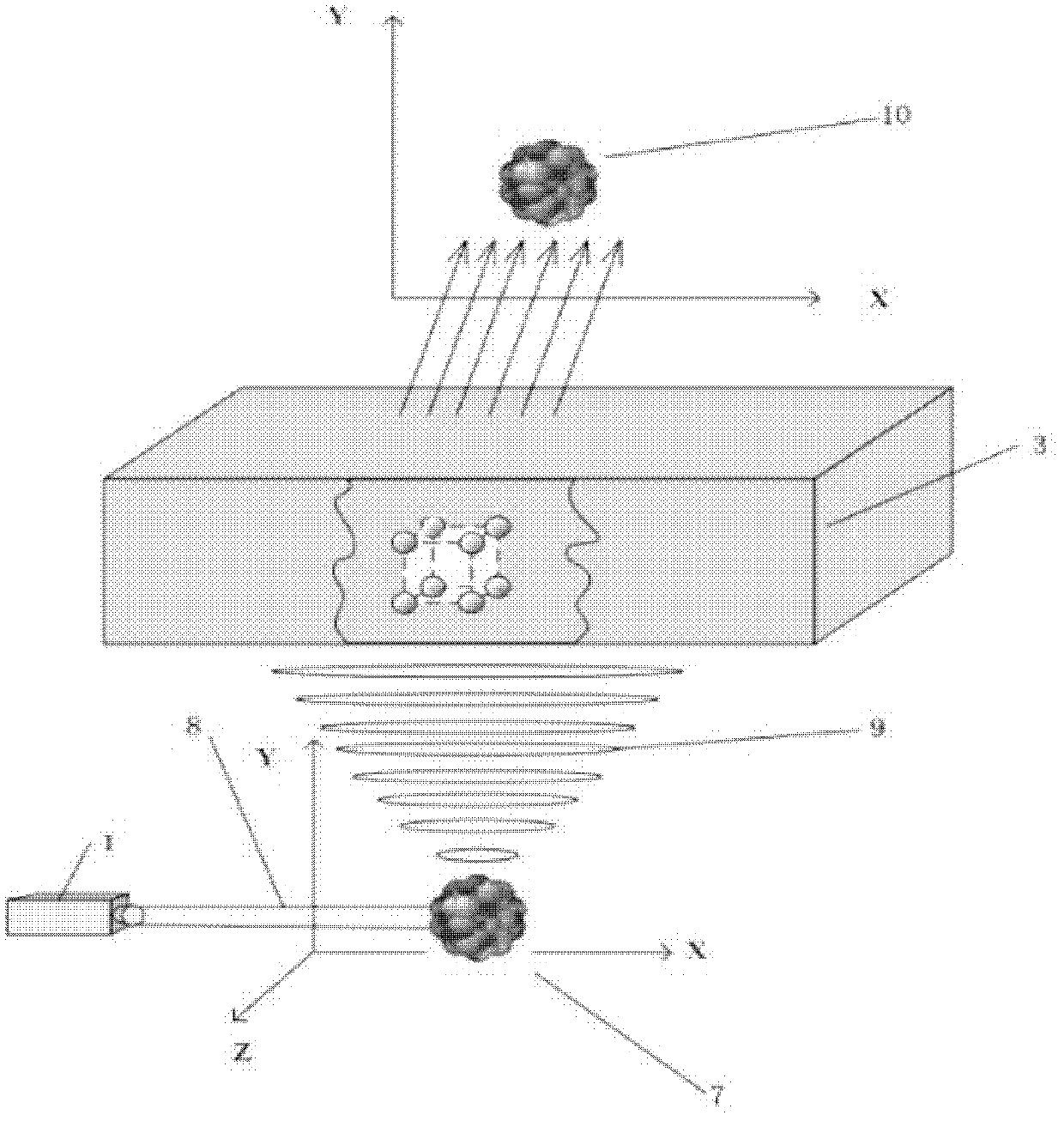

Three-dimensional opto-acoustic imaging system based on acoustic lens and sensor array and method

InactiveCN102608036AUniform thermal expansionAccurate recordMaterial analysis by optical meansSensor arrayDisplay device

The invention relates to a three-dimensional opto-acoustic imaging system based on an acoustic leans and a sensor array and a method. The system is a cube experimental table and mainly comprises a laser device, a beam expander, the phonon crystal lens, the opto-acoustic sensor array, a data bus, a ground glass container, a data acquisition module and a computer for image processing, center points of four side surfaces of the cube ground glass container are irradiated by laser, so that a sample is uniformly irradiated by the laser via dispersion of ground glass, and is uniformly heated and expanded, acoustic signals generated by expansion of the sample focus to form a beam, the opto-acoustic sensor array, the data acquisition module and the computer for image processing acquire and record opto-acoustic three-dimensional imaging data in real time, and a three-dimensional light absorption distribution image of the detected sample can be directly seen from a display via image processing. The three-dimensional opto-acoustic imaging system has the advantages of complete functions, stable performance, low cost and the like, and can be widely applied to the fields of biology, medical science, material analysis and the like.

Owner:ZHONGBEI UNIV

Preparation method for colored glass beads

InactiveCN102898003AAvoid the disadvantages of single color, unstable color, high production cost, etc.Improve efficiencyGlass shaping apparatusGlass productionGlycerolSlurry

The invention provides a preparation method for colored glass beads; and the preparation method comprises the following steps of: after uniformly mixing SiO2 powder, CaO powder, Na2O powder, K2O powder, Al2O3 powder, ZnO powder and Sb2O3 powder, forming a batch material; pouring a glass liquid after the batch material is melted into water, quenching the glass liquid in the water; grinding water-quenched glass fragments to a particle size of 10-200 microns; and then nodulizing the ground glass fragments in a bead forming furnace, so as to obtain a parent glass bead; pouring water, glycerol and dextrin into a beaker; after uniformly mixing the water, the glycerol and the dextrin, adding a mixture to a mixture of AgNO3, CuCl, Cu2O, SnO, FeSO4.7H2O, zinc powder and pulverized coal; uniformly mixing the two mixtures; and ball-milling the mixtures so as to obtain a coloring ion diffusion slurry for a colored glass bead; and mixing the parent glass bead and the coloring ion diffusion slurry so as to form a mixed material; pouring the mixed material into a stainless steel mold; heating the stainless steel mold to 550-650 DEG C; preserving the heat of the stainless steel mold for 5-10 minutes; and cooling the stainless steel mold so as to obtain ion diffused and colored glass bead. According to the invention, defects of single color, instable color, high production cost and the like in the traditional preparation method are avoided.

Owner:SHAANXI UNIV OF SCI & TECH

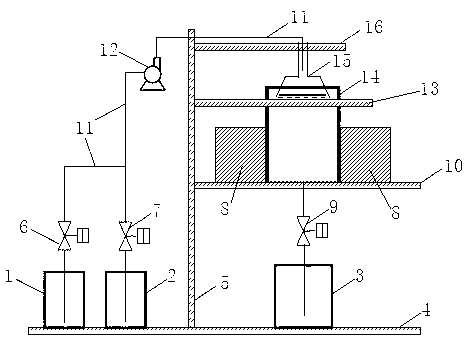

Integrated device and method used for detecting COD (Chemical Oxygen Demand) and cleaning cuvette automatically

InactiveCN103230912AReduce mechanical structure complexityReduce manufacturing costHollow article cleaningMaterial analysis by optical meansCleansing AgentsGuide tube

The invention discloses an integrated device and method used for detecting COD (Chemical Oxygen Demand) and cleaning a cuvette automatically. A water spraying structure is arranged at an upper opening part of the cuvette; the upper part of the water spraying structure is connected to an automatic pump through a water flow guide pipe; through the water flow guide pipe, the automatic pump is respectively connected to a distilled water bottle containing distilled water after passing through a distilled water electromagnetic valve and a cleaning agent bottle containing a cleaning agent after passing through a cleaning agent electromagnetic valve; ultrasonic cleaning devices are tightly adhered at the outer sides of two pieces of ground glass of the cuvette; and an optical detection device is arranged aside the optical outer side surface of the cuvette. A single-chip control system controls the distilled water electromagnetic valve, the cleaning agent electromagnetic valve, a waste liquid pond electromagnetic valve, the ultrasonic cleaning devices, the optical detection device and the automatic pump to work; the distilled water or cleaning agent is input and sprayed on the inner wall of the cuvette; the cuvette is cleaned with the cooperation of the ultrasonic cleaning device; and after the cleaning, the COD detection is finished when a photoelectric detection device works. Therefore, the cleaning quality is guaranteed, an exact and reliable measuring value is obtained, and a high automation degree is achieved.

Owner:JIANGSU UNIV

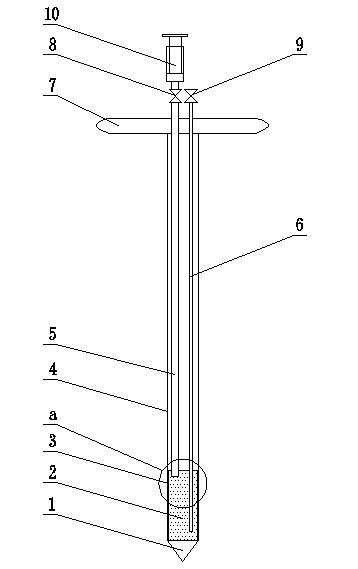

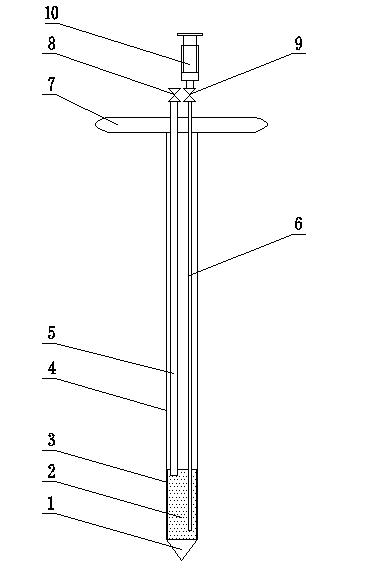

Soil or settlement soluble iron in-situ sampling device and in-situ sampling and testing method thereof

InactiveCN101915682AAvoid harmSimple and orderly operationMaterial analysis by observing effect on chemical indicatorWithdrawing sample devicesBottleChina clay

The invention discloses a soil or settlement soluble iron in-situ sampling device and an in-situ sampling and testing method thereof, which relate to a soil or settlement soluble iron sampling device and a sampling and testing method thereof. The method solves the problems of high destructiveness, long time consumption, incapability of stabilizing Fe<2+> and Fe<3+> at the same time and low measurement result accuracy of the conventional soluble iron in-situ sampling and testing method. In the sampling device of the invention, a stainless steel drilling bit, a china clay water collecting tube and a second stainless steel are arranged from bottom up; and a plastic exhaust pipe and a plastic water draining pipe are inserted into a second stainless steel pipe. The method comprises the following process steps: drilling a sampling point with the drill bit; exhausting air to produce negative pressure; waiting for collecting water; preparing a color-developing agent; absorbing the color-developing agent and pore water; injecting into a brown ground glass stoppered bottle; measuring the Fe<2+> content by using a colorimetric method; measuring the total iron content by using the colorimetric method; and obtaining the Fe<3+> content by substracting the Fe<2+> content from the total iron content. The device and the method are suitable to be used in soil or settlement soluble iron in-situ sampling and test techniques.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

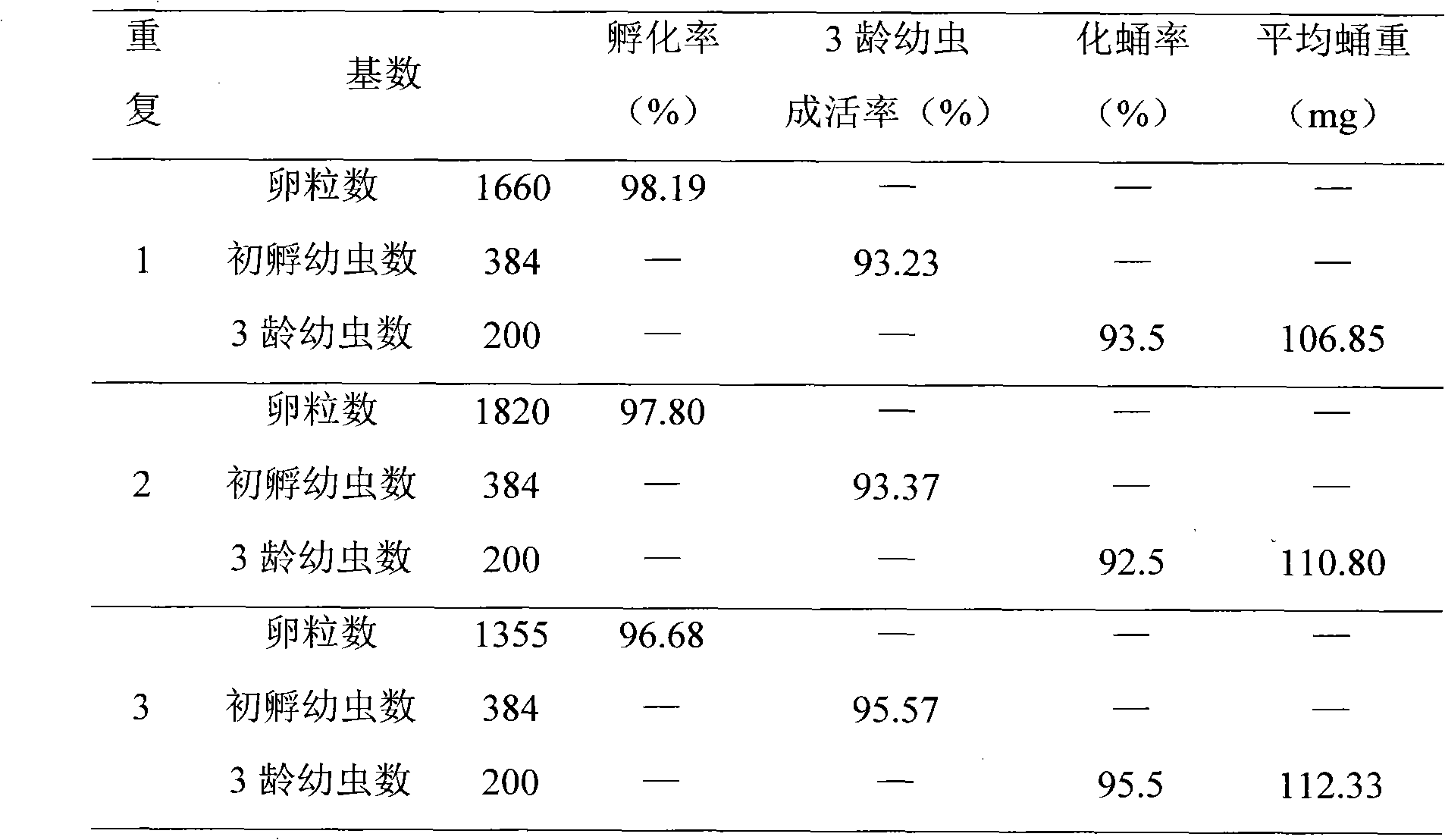

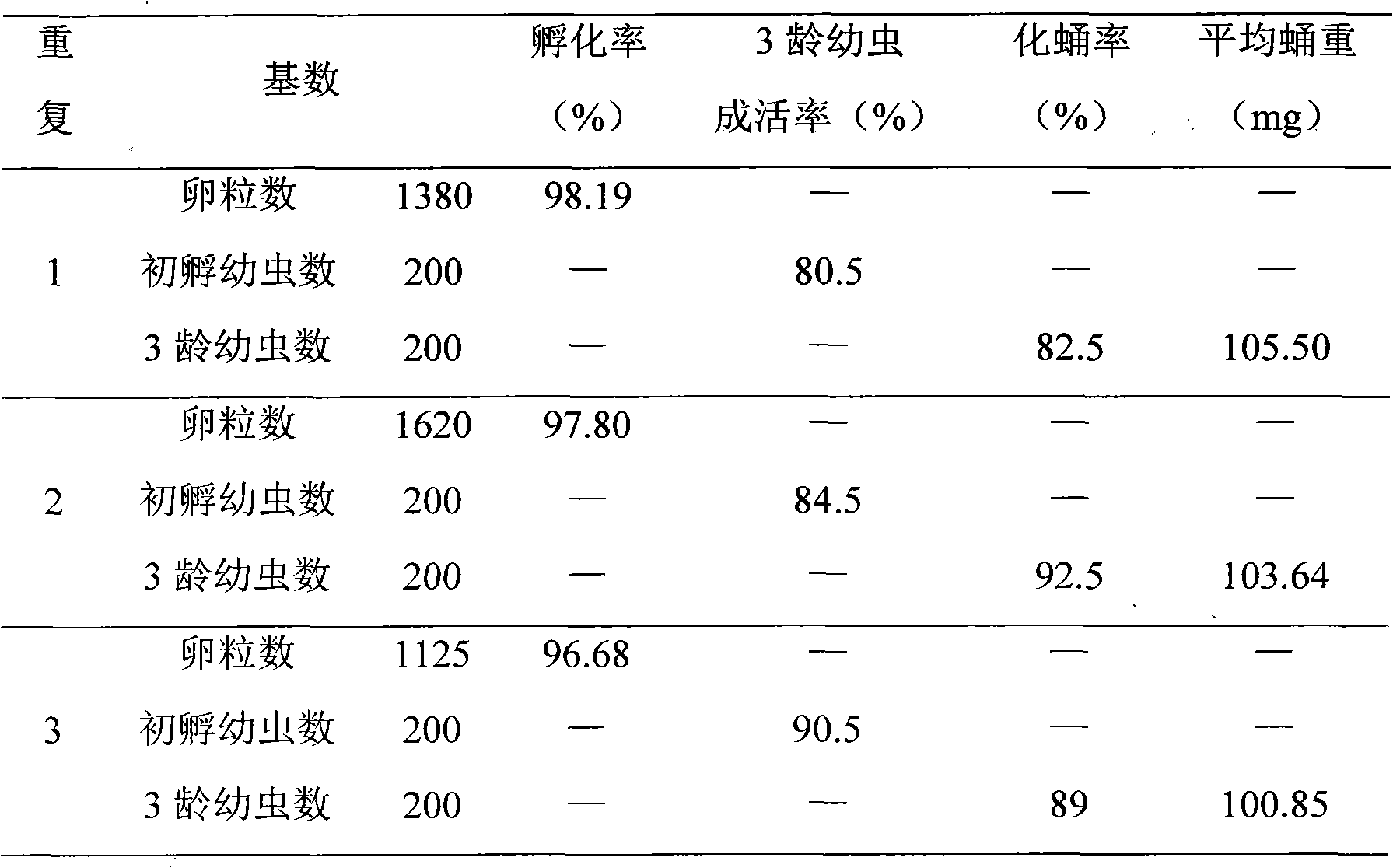

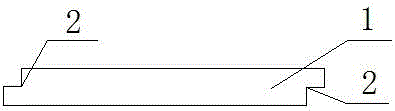

Artificial rearing method of larvae of beet armyworm

InactiveCN102113471AImprove hatchabilityOvercome the disadvantage of high mortalityAnimal husbandryArtificial rearingAlcohol

The invention discloses an artificial rearing method of larvae of beet armyworm, and the method comprises the following steps: (1) placing eggs of the beet armyworm in a ground glass hatching jar, placing fresh young cabbage leaves after surface disinfection by 75% of alcohol in the jar and sealing by using three-layer gauze till hatching; (2) selecting the freshly hatched larvae of the beet armyworm into a 24-hole insect rearing plate loaded with artificial feed, and rearing till 3 ages; and (3) transferring the 3-age larvae of the beet armyworm into flat bottom glass finger-shaped pipes loaded with the artificial feed, enabling each pipe to contain two larvae, and rearing till pupation. The method is simple, the rearing process occupies small space, the survival rate of the larvae is high, and a large number of standard test insects can be obtained.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Method for preparing composite oxide polishing powder

InactiveCN104497887AFast dryingSmall particle sizePolishing compositions with abrasivesCeriumSilicon oxide

The invention discloses a method for preparing composite oxide polishing powder. The polishing powder serves as a grinding material and mainly comprises cerium oxide, silicon oxide, zirconium oxide, aluminum oxide and titanium oxide, wherein the cerium oxide and other oxides have good synergetic polishing effect. In the composite oxide polishing powder, the content of SiO2 is equal to 20-40 percent, the content of CeO2 is equal to 75-90 percent, and the amount of three oxide additives such as ZrO2, Al2O3 and TiO2 is 5-10 percent. In order to improve the polishing effect, a dispersing agent is added into the synthesis and preparation process, and the prepared composite oxide polishing powder can achieve an excellent polishing and grinding effect. The composite oxide polishing powder is prepared by the steps of precipitating, performing suction filtration, washing, performing precipitation transformation, size mixing, uniformly stirring and mixing, performing spray drying and roasting. The composite oxide polishing powder has the advantages of high suspension property and dispersity, small particle size, narrow particle size, large erosion quantity and high surface smoothness of the polished and ground glass.

Owner:包头市华辰稀土材料有限公司

PVC building template and its making method

InactiveCN104371209AHigh hardnessImprove heat deflection temperatureForming/stuttering elementsFiberGlass fiber

The invention belongs to the field of buildings, and concretely relates to a PVC building template and its preparation method. The mainly PVC building template is made by using PVC resin and alkali-free ground glass fibers as main materials and using a foaming regulator HL-100, a lubricant ZB-601, a lubricant AP, a white foaming agent NC, a yellow foaming agent AC, a plasticizer, a calcium powder filler CaCO3 and a stabilizer as auxiliary materials. The making method comprises the steps of main material and the auxiliary material blending, extrusion forming, traction and product cutting. The PVC building plate has the advantages of improved hardness, enhanced impact resistance, improvement of the stability of the PVC resin, and increased heat deformation resistance temperature.

Owner:JIANGSU CHENGBANG NEW MATERIAL

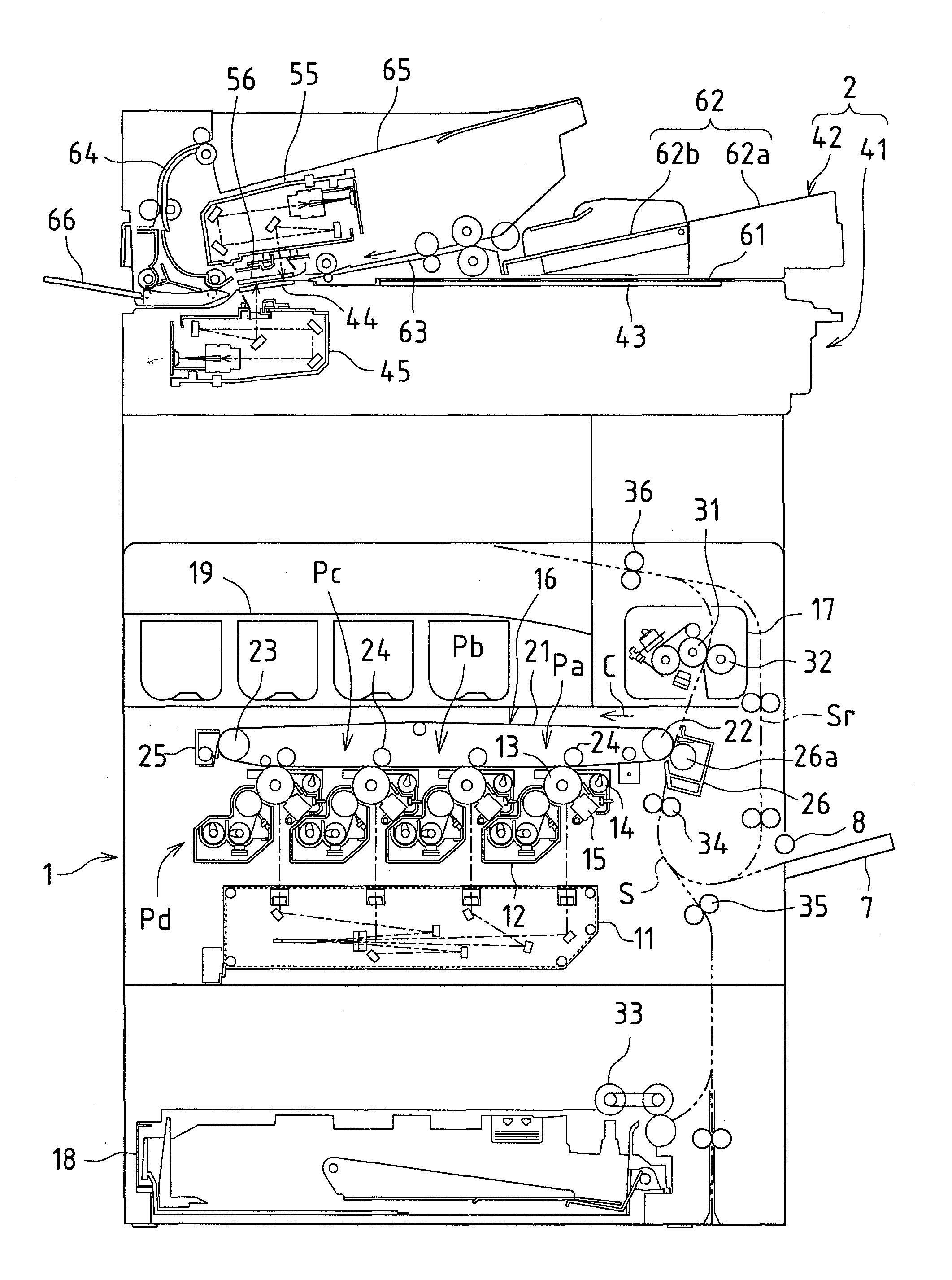

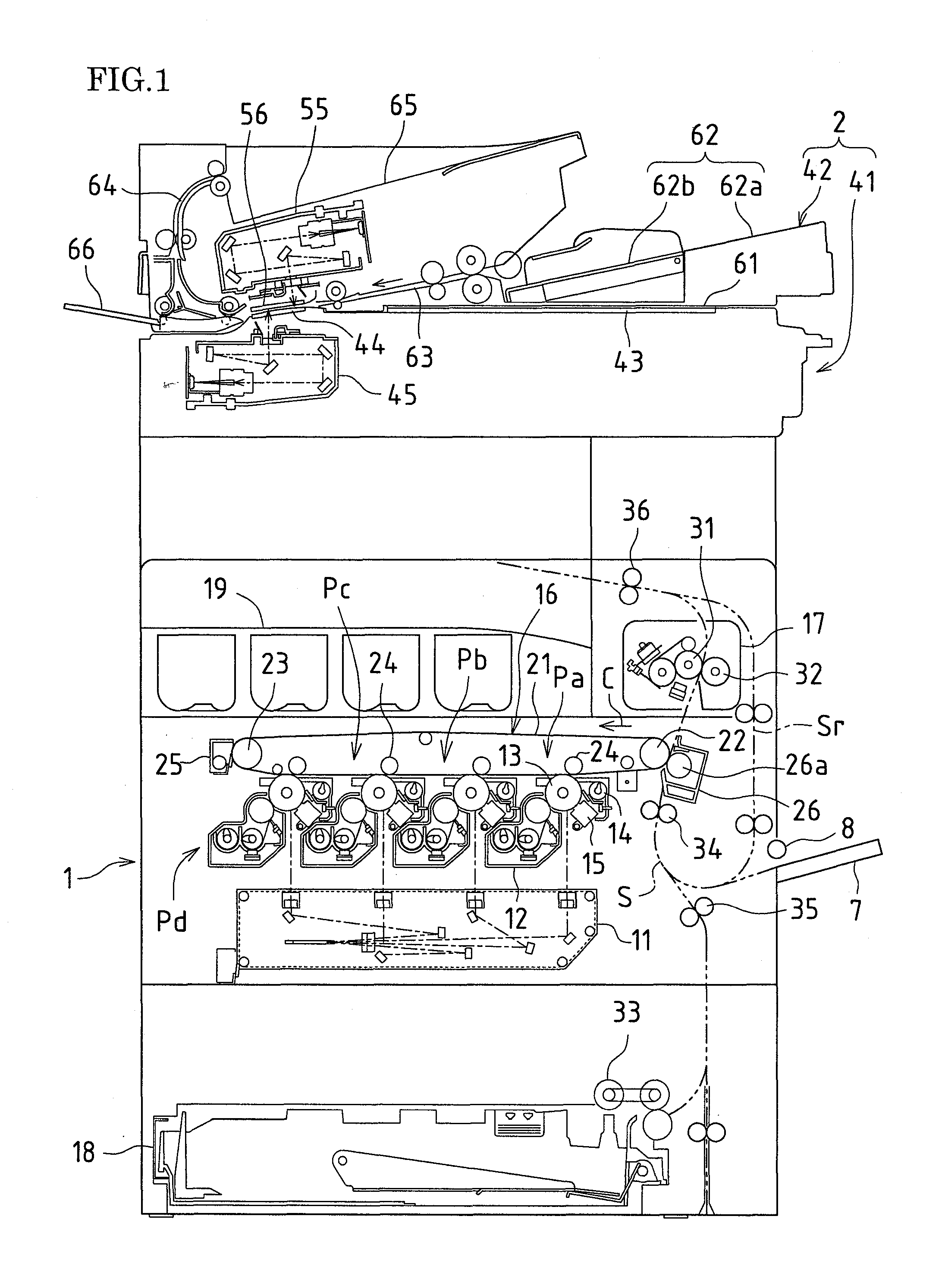

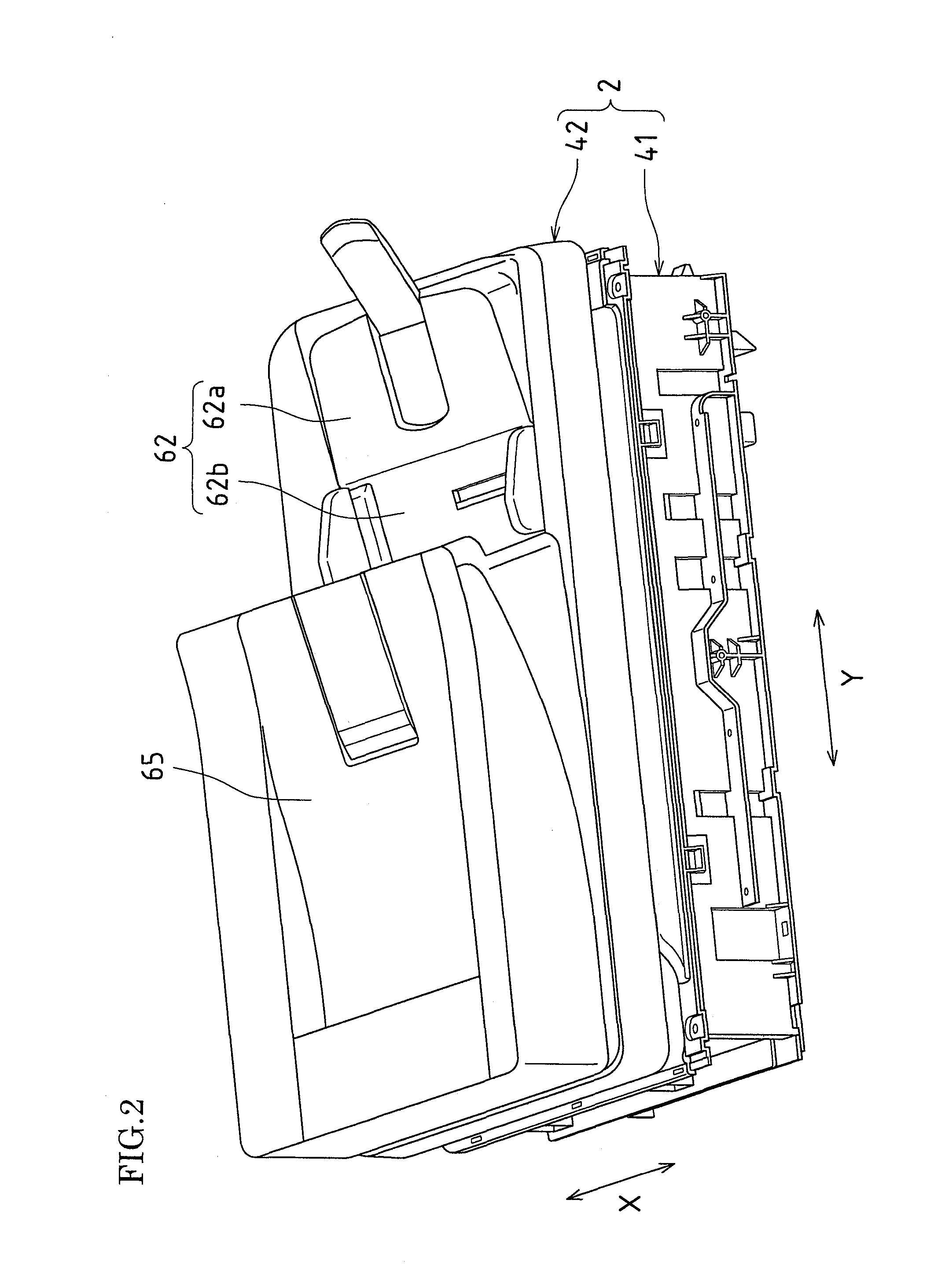

Image reading apparatus and image forming apparatus including the same

ActiveUS20120008155A1The implementation process is simpleLow costDigitally marking record carriersDigital computer detailsImage formationEngineering

A transparent sheet is attached onto an inclined surface of an original guide plate of an image reading apparatus, and similarly, a transparent sheet is attached onto an inclined surface at an edge portion of a reading guide plate, thereby preventing an original from being chipped by the ground glass-like inclined surfaces and illumination light from being diffused by the ground glass-like inclined surfaces.

Owner:SHARP KK

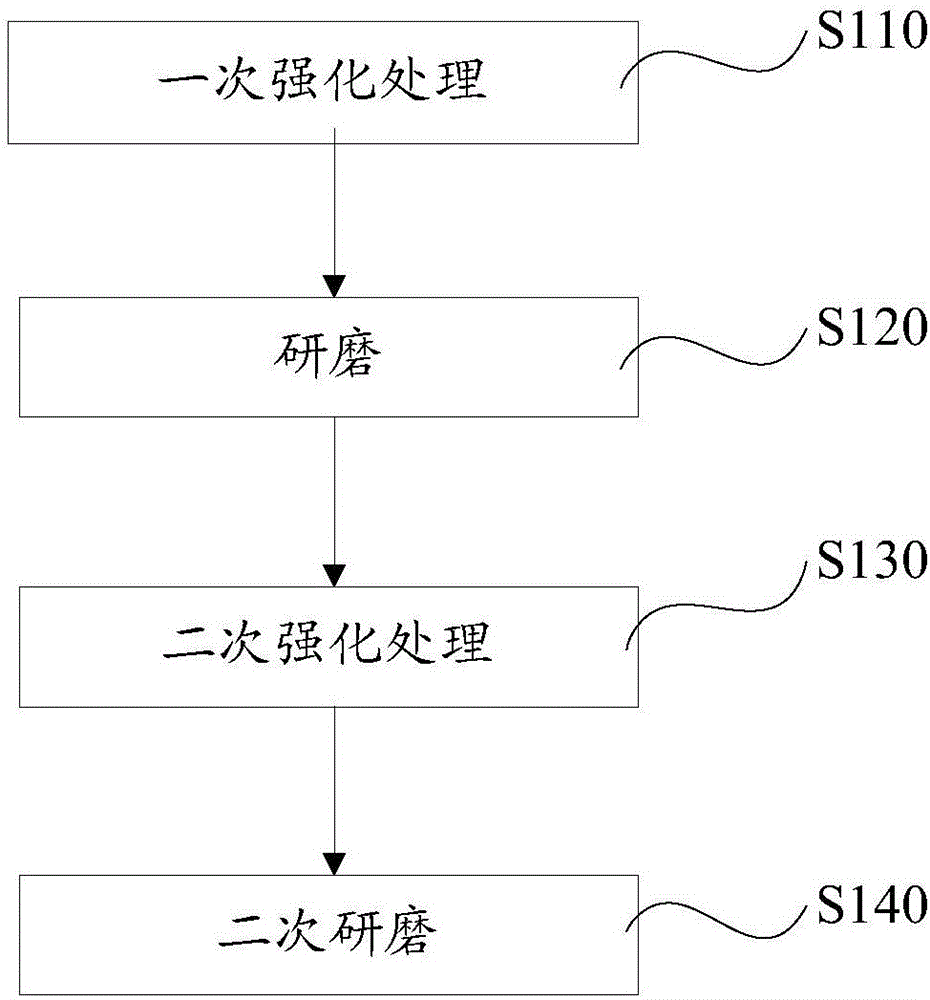

Processing method of glass substrate

InactiveCN106830709AGuaranteed StrengthRetention of the effect of intensive treatmentLapping machinesMetallurgyUltimate tensile strength

The invention relates to a processing method of a glass substrate. The processing method of the glass substrate comprises the following steps: providing the glass substrate, wherein the glass substrate is provided with a first surface and a second surface which are opposite to each other; performing primary strengthening treatment on at least one surface of the first surface and the second surface of the glass substrate; grinding the glass substrate subjected to primary strengthening treatment; and performing secondary strengthening treatment on at least one surface of the ground glass substrate. Secondary strengthening treatment is conducted after grinding, so the processing method avoids the fact that a thin pressure stress layer formed by secondary strengthening treatment is eliminated in the grinding processing process as compared with the traditional processing method, the effect of strengthening treatment is retained, and the strength of the glass substrate is guaranteed.

Owner:NANCHANG O FILM OPTICAL TECH

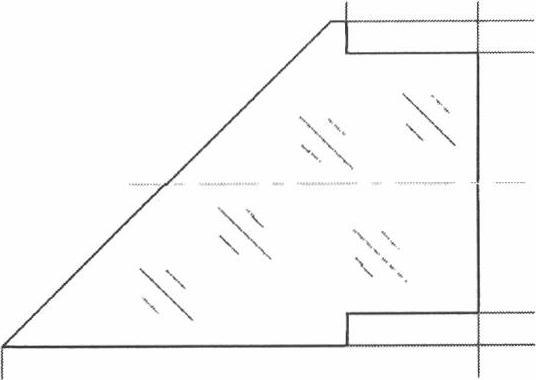

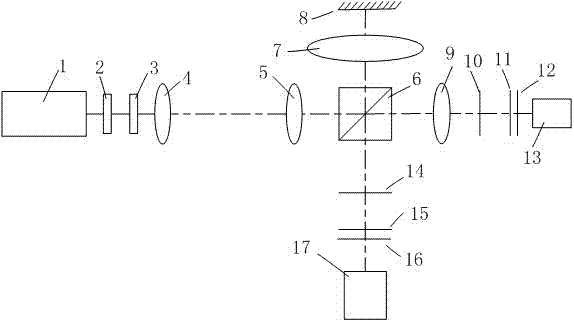

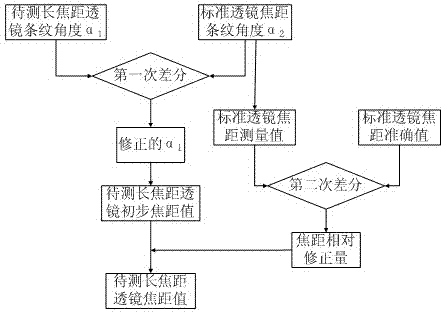

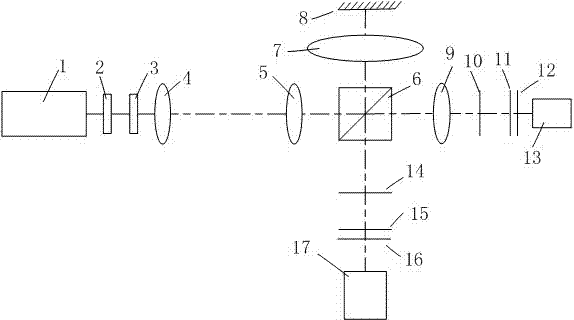

Compound differential type long-focus measuring device based on Talbot effect

ActiveCN102252824AAccurate correctionHigh measurement accuracyTesting optical propertiesLong-focus lensBeam splitter

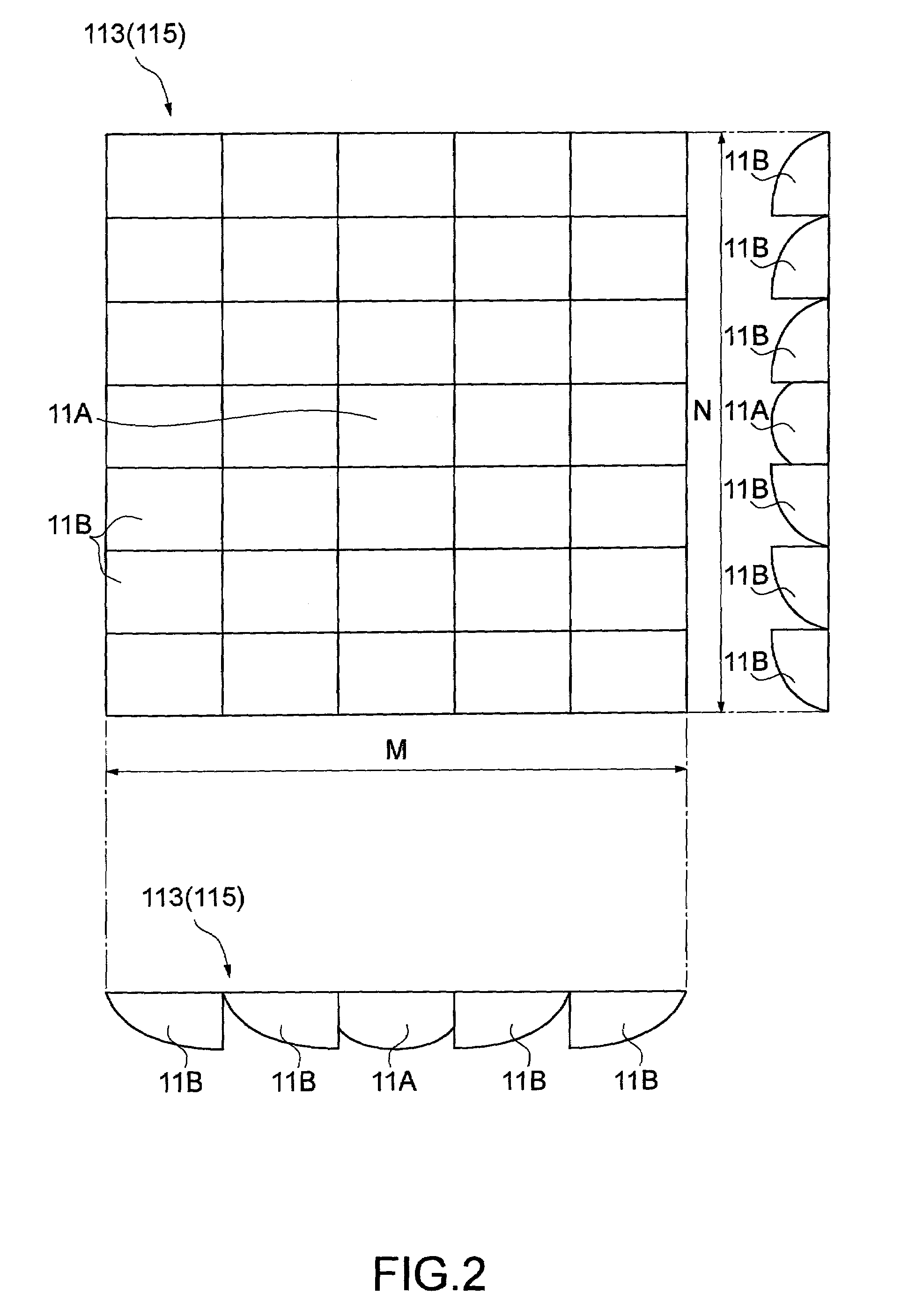

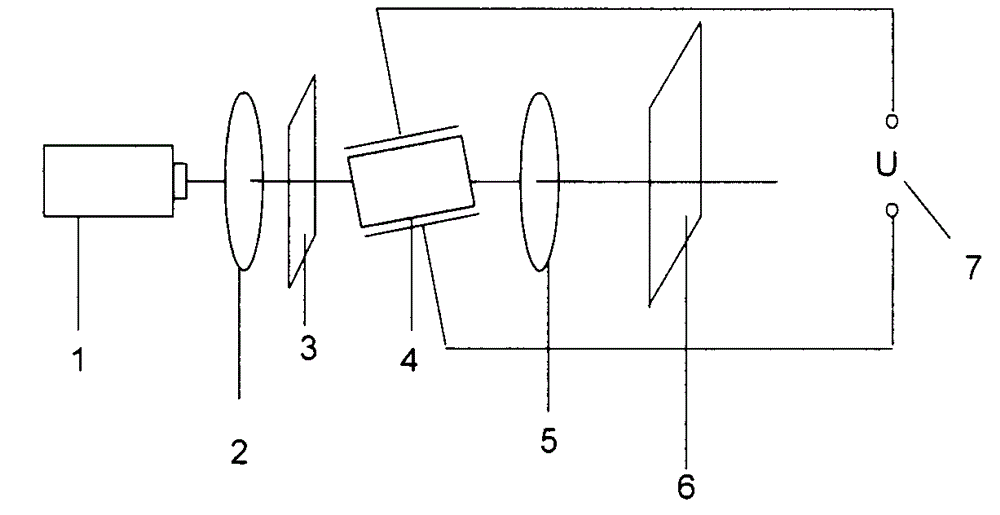

The invention discloses a compound differential type long-focus measuring device based on a Talbot effect. The light of a laser source runs through a polaroid, a lambda / 4 wave plate, a microscope objective and a collimating mirror, to be divided into two beams by a beam splitter prism, wherein one beam is incident to a standard lens, a first grating and a second grating, to form moire fringes on first ground glass, the first CCD (Charge Coupled Device) is used for collecting the fringes and inputting the fringes to a computer so as to calculate the angle alpha 1 of the fringes, to get a standard lens focus; the other beam is incident to a long-focus lens to be measured, reflected by a reflector and then incident to third and fourth gratings, to form moire fringes on second ground glass, and a second CCD is used for collecting the fringes and inputting the fringes to the computer so as to calculate the angle alpha 2 of the fringes; the alpha 1 and alpha 2 are subjected to differential treatment and the alpha 1 is corrected to obtain a long-focus value; and the standard lens focus and the known standard value thereof are subjected to differential treatment and the long-focus value to be measured is corrected to obtain a focus value of the long-focus lens to be measured finally. According to the device disclosed by the invention, the external interference is eliminated by adopting the two differential treatments, and the high precision measurement for the long-focus lens can be realized.

Owner:ZHEJIANG UNIV

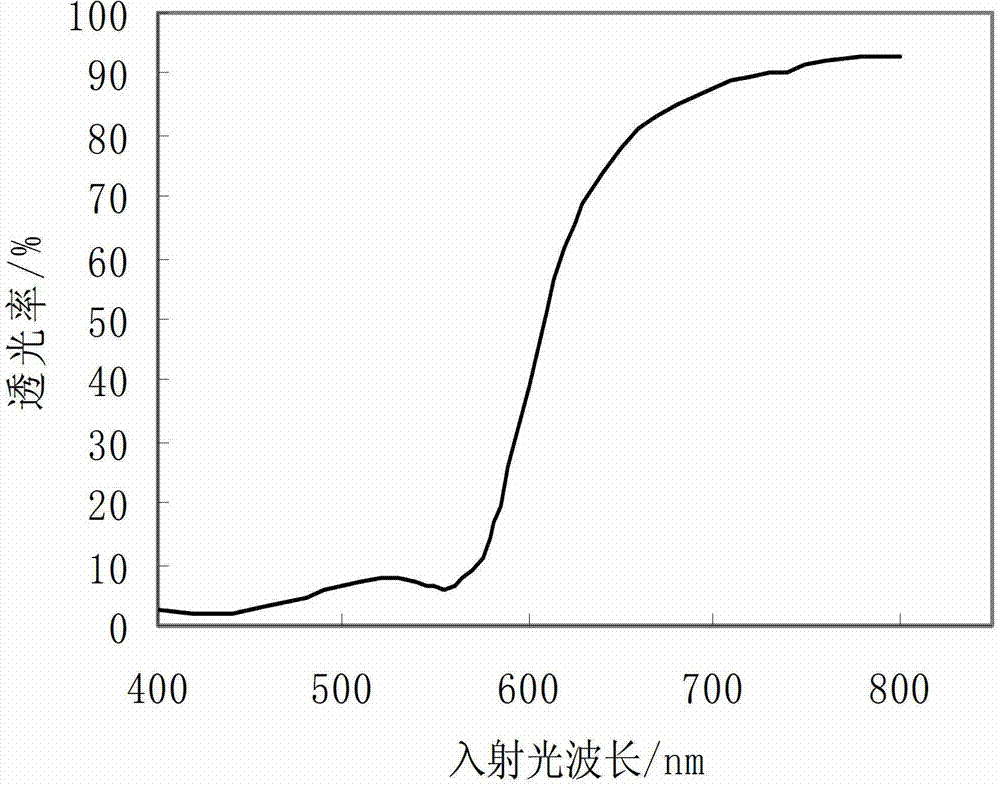

Detection device for detecting macro-defects in infrared glass

InactiveCN102175690AStrong adaptability to changes in thickness and sizeQuick shotOptically investigating flaws/contaminationImaging processingOptical axis

The invention discloses a detection device for detecting macro-defects in infrared glass, wherein an infrared light source, a circular tube, infrared transmitting flat ground glass, an infrared lens and an infrared planar array imaging detector are arranged in sequence; a detected infrared glass sample is placed between the infrared transmitting flat ground glass and the infrared lens; the inner wall of the circular tube is black and provided with screw threads capable of eliminating parasitic lights; the ratio phi1 / phi2 of the inner diameter phi1 of the circular tube to the diameter phi2 of the detected infrared glass sample is larger than or equal to 1 / 3 and less than or equal to 1, and the ratio L / phi1 of the length L of the circular tube to the inner diameter phi1 of the circular tube is larger than or equal to 5; the infrared light source, the infrared lens and the infrared planar array imaging detector share one optical axis; an adjustable power supply supplies power to the infrared light source; the infrared planar array imaging detector is connected to an image processing module; the image processing module is connected to a display; and the device uses a transmission imaging method, and can fast shoot detective images in the glass. The device provided by the invention has the advantages that the structure is simple, the cost is low, the operation is fast and convenient, the internal defects of infrared glasses with inner diameters from several to dozens of millimetres can be detected, and the adaptability to the thickness change of the glass is strong.

Owner:NINGBO UNIV

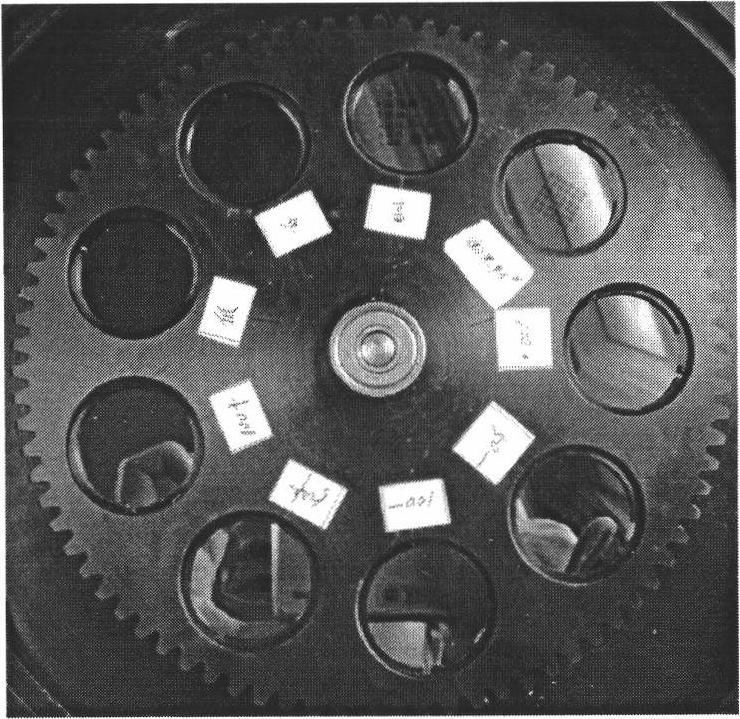

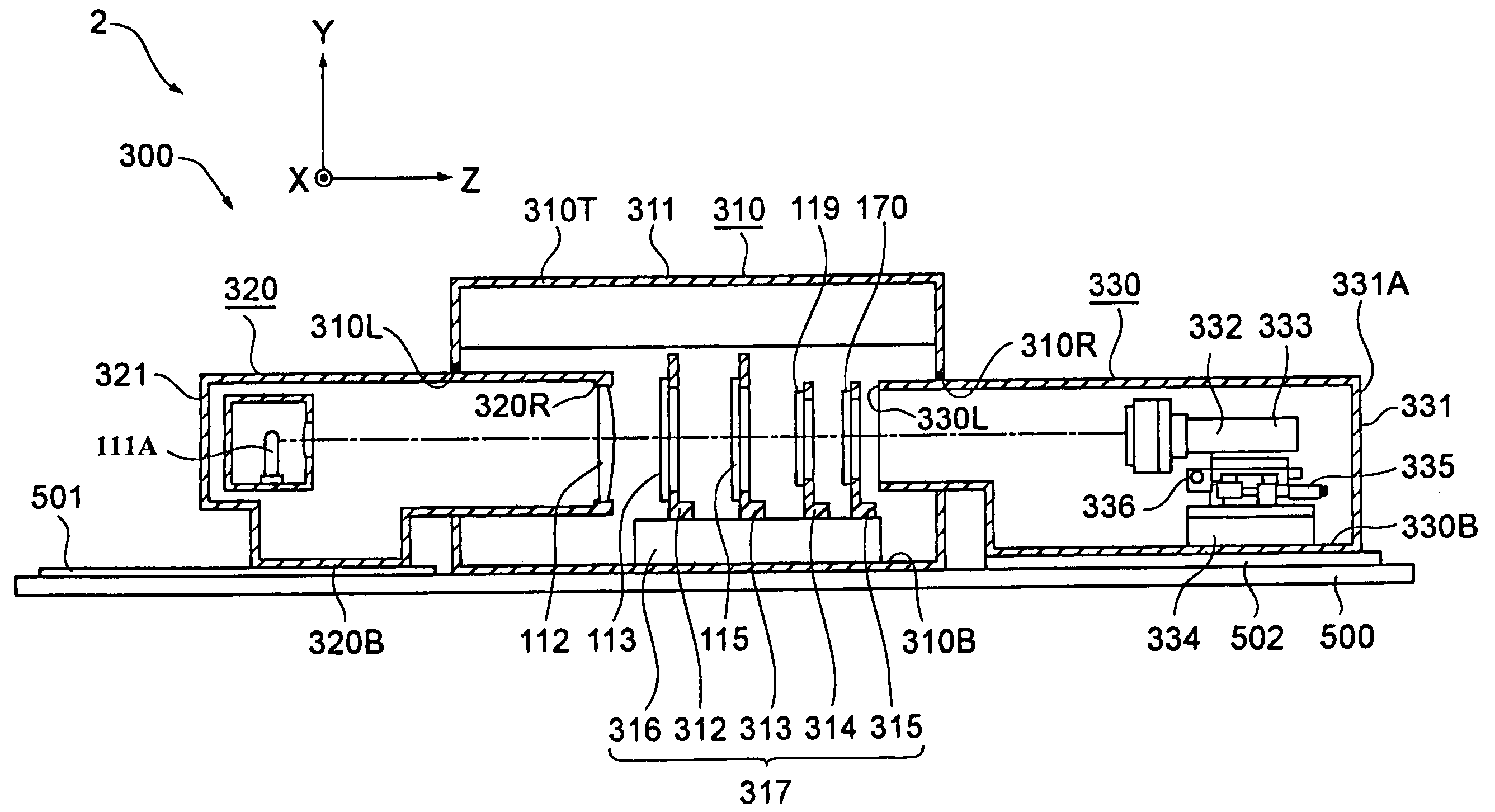

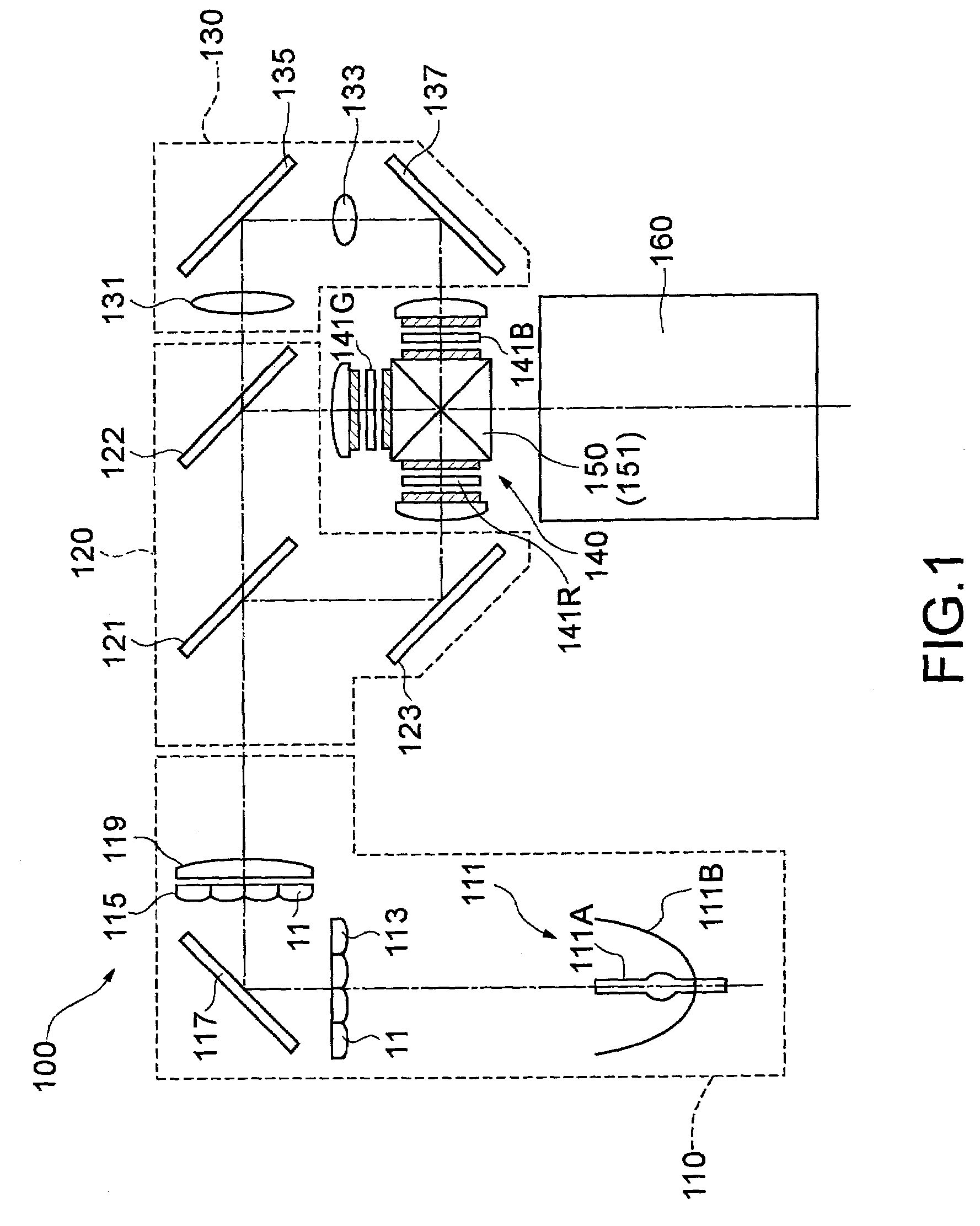

Device for inspecting illumination optical device and method for inspecting illumination optical device

InactiveUS7289655B2Easy to calculateEfficient detectionMaterial analysis by optical meansCharacter and pattern recognitionLuminous fluxTest object

The invention provides a device to inspect an illumination optical device and a method to inspect an illumination optical device that make it possible to efficiently inspect illumination optical devices and to control manufacturing cost. A lens array inspecting device is provided with a light source device to emit a parallel luminous flux, lens array holders to retain lens arrays, which are test objects that split the parallel luminous flux into a plurality of partial luminous fluxes, and a ground glass on which the optical images of the luminous fluxes emitted through the lens arrays are projected. On the ground glass, a parting frame appropriate to a design illumination region is formed. Therefore, whether the lens arrays are defective or non-defective can be determined by checking whether the optical images projected onto the ground glass include the area of the parting frame.

Owner:SEIKO EPSON CORP

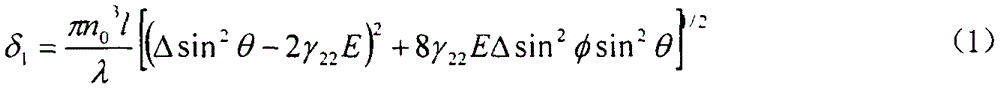

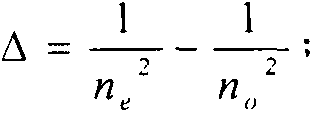

Electro-optical crystal electro-optical factor measure method and device

ActiveCN104931812AEasy to adjustLow costElectrical testingTesting optical propertiesEntrance angleDiffusion

An electro-optical crystal electro-optical factor measure method and device comprises the following steps: a laser with visible wave bands passes a polarizing lens, a ground glass, a to be tested electro-optical crystal and a polarization analyzer in sequence, and a white screen receives an exit light spot and an interference pattern formed by diffusion light caused by the ground glass; a polarization direction of the polarizing lens and the polarization analyzer is vertical, and an adjustable DC voltage is applied to the to be tested electro-optical crystal; firstly, select a property laser entrance angle ([theta]0, [phi]0) through theory analysis, wherein the ([theta]0, [phi]0) refer to angles between an entrance laser propagation direction and each electric induction main shaft of the to be tested electro-optical crystal; in measurement, the DC voltage applied to the to be tested electro-optical crystal is adjusted to OV, an angle between the to be tested electro-optical crystal and the entrance laser is tuned, so the exit light spot can fall on a dark zone, corresponding to the entrance angle ([theta]0, [phi]0), in the interference pattern; the DC voltage is gradually boosted and the exit light spot position in the process does not change, and the interference pattern will change; when the exit light spot fall on next adjacent dark zone on the interference pattern again, the DC voltage value U is recorded; the corresponding electro-optical factor can be obtained through theory calculation.

Owner:NANKAI UNIV

Energy-saving, environment-friendly and thermal-insulating material

InactiveCN104710190ASatisfactory melt flow rateHigh flame retardant efficiencyCeramicwareFiberCross-link

The invention discloses an energy-saving, environment-friendly and thermal-insulating material which comprises the following raw materials in parts by weight: 20-28 parts of brominated polystyrene, 5-11 parts of a plant cement foaming agent, 8-16 parts of a cross-linking agent, 40-50 parts of glass fibers, 21-28 parts of mineral slag, 13-21 parts of epoxy resin and 33-41 parts of water. During preparation, the glass fibers are ground, the ground glass fibers and the mineral slag are added into a gravity-free mixing and stirring machine, and a mixture A is obtained; brominated polystyrene and the plant cement foaming agent are put into the stirring machine for performing stirring, the water is added, and a mixture B is obtained; the mixture A is added into the mixture B, and stirring is performed; the cross-linking agent and the epoxy resin are added, and a mixture C is obtained; the mixture C is injected into a mould, and limiting extrusion and curing are performed to obtain the energy-saving, environment-friendly and thermal-insulating material. The energy-saving, environment-friendly and thermal-insulating material is fire-resistant, flame-retardant, high in thermal insulation performance and stable in quality; all adopted raw materials are nontoxic and harmless, so that the material is safe and environment-friendly; moreover, the raw materials are low in price and easily available, so that the material is suitable for floor heating projects and roof insulation projects.

Owner:高彬

Preparation method of ground glass cover plate with gradual change effect

ActiveCN108515462ASand blasting effectBeautiful sandblasting effectBlast gunsAbrasive blasting machinesSand blastingSurface roughness

The invention discloses a preparation method of a ground glass cover plate with a gradual change effect. The preparation method comprises the following steps: S1, sand blasting: manufacturing a frosted layer on the surface of a glass substrate by utilizing a sand blasting technology and achieving a gradual change effect of the frosted layer by changing an included angle between the spraying direction of a nozzle and a surface normal of the glass substrate and changing a spraying velocity of the nozzle; S2, etching: etching the sand blasted glass substrate to reduce the surface roughness of theglass substrate. According to the preparation method disclosed by the invention, a glass substrate sand blasting effect is changed by changing an angle and a spraying velocity of the nozzle, so thata gradual change frosted effect of glass is achieved; the sand blasted glass substrate is etched to reduce the surface roughness of the glass substrate, and the gradual change effect is more attractive. The preparation method disclosed by the invention has the advantages of simpleness and high product yield; in actual use, fingerprints are not prone to appearing, appearance attractiveness of a product is higher, and competitiveness of the product on market is further improved.

Owner:TRULY OPTO ELECTRONICS

System and method for obtaining complete palm vein image

InactiveCN103258199ASimple structureExperiment operation is simpleCharacter and pattern recognitionLight-emitting diodeLight intensity

Owner:ZHEJIANG UNIV

Numerical control particle glass cutting machine

InactiveCN102701578ASave the breaking processEliminates the need for edgingGlass severing apparatusGlass productionCircular discFlat glass

The invention discloses a numerical control particle glass cutting machine. The numerical control particle glass cutting machine comprises an X-direction cutting mechanism and a Y-direction cutting mechanism which are controlled by a programmable logic controller (PLC), wherein a glass sheet is transmitted to a cutting device by a transmission device for cutting; the cutting device consists of a knife flywheel shaft and a plurality of groups of disc knife flywheels which are sleeved in the axial direction of the knife flywheel shaft in parallel and at intervals; and the glass sheet is cut into strips and then is cut into particles. By the numerical control particle glass cutting machine, the line-marking and sheet-breaking process of the traditional flat glass cutting machine is changed; the plurality of disc knife flywheels are arranged on the knife flywheel shaft in the X direction and the Y direction in parallel and are driven by the external power along the knife flywheel shaft to rotate, and the rotating knife flywheels directly cut off the flat glass, so the sheet-breaking procedure is saved; carborundum is distributed on two sides of the cutting edges of the disc knife flywheels, so that the cutting section of the glass is smooth and flat like that of the ground glass, so the edging process is saved and three procedures are finished at one step; in addition, tens of, even hundreds of knife flywheels can be assembled on the knife flywheel shaft to work, so the production efficiency is improved obviously.

Owner:苏家亮

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com