PVC building template and its making method

A technology of building formwork and PVC resin, which is applied in the field of construction, can solve the problems of poor heat resistance and impact resistance, and achieve the effects of improving stability, increasing heat-resistant deformation temperature, and enhancing impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

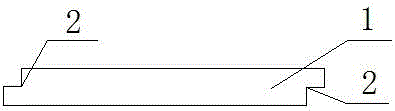

Image

Examples

Embodiment approach

[0021] Specific implementation method: first, 100 parts of PVC resin, 15 parts of alkali-free ground glass fiber, 13 parts of foam regulator HL-100, 1 part of lubricant ZB-601, 0.5 part of lubricant ZB-601 , 1 part of white foaming agent NC, 0.3 part of yellow foaming agent AC, 0.6 part of plasticizer, 26 parts of calcium powder filler CaCO 3 and 3.4 parts of stabilizer raw materials are put into the mixer, and the mixer is closed for mixing; then the mixed raw materials are sent into the hopper of the extruder through the pipeline, and the temperature of the electric heating in the extruder is kept at 115°C. It is extruded through an extruder to form it; the extruder is equipped with an indirect casing of cooling water, and the cooling water indirectly cools the extruded profile, and the water consumption of cooling water is 1t / h for each extruder; the extruder is equipped with traction The cooling machine and tractor transport the cooled profiles to the cutting area; finally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com