Patents

Literature

48results about How to "Uniform thermal expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

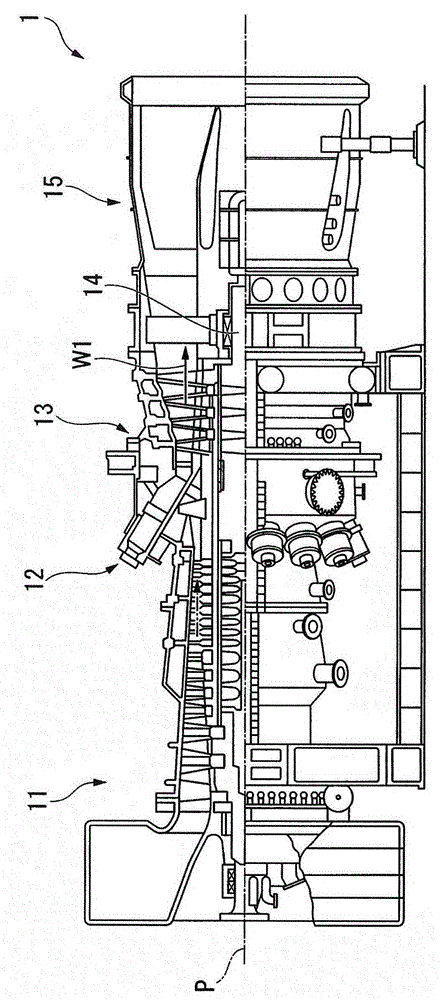

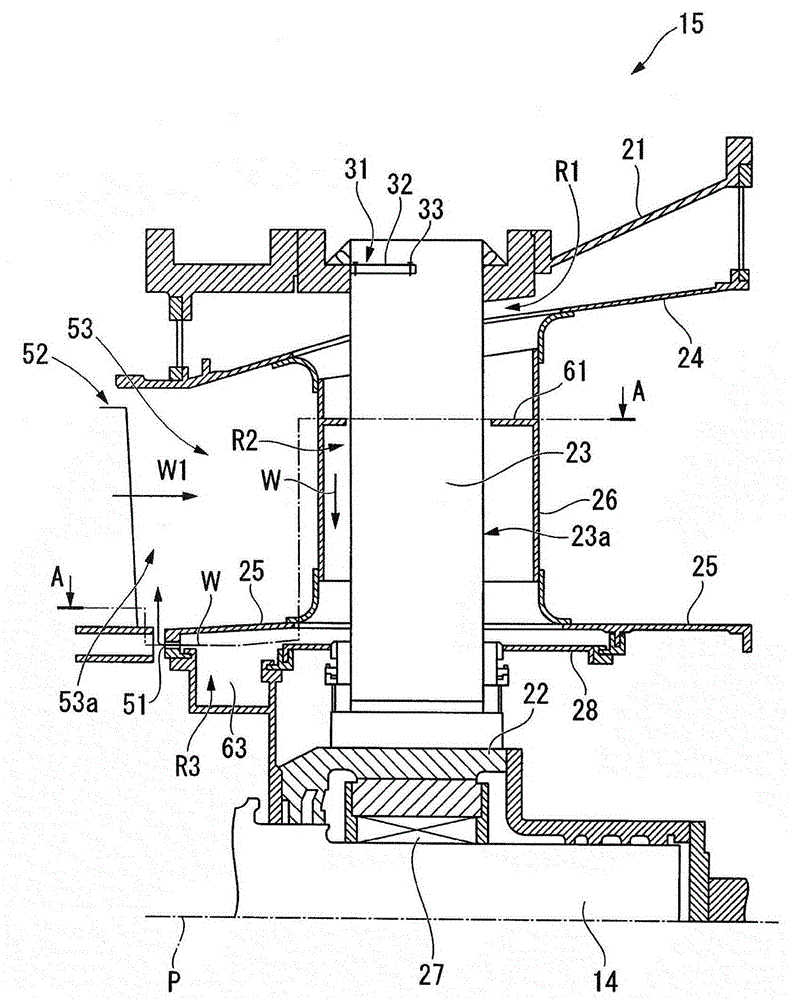

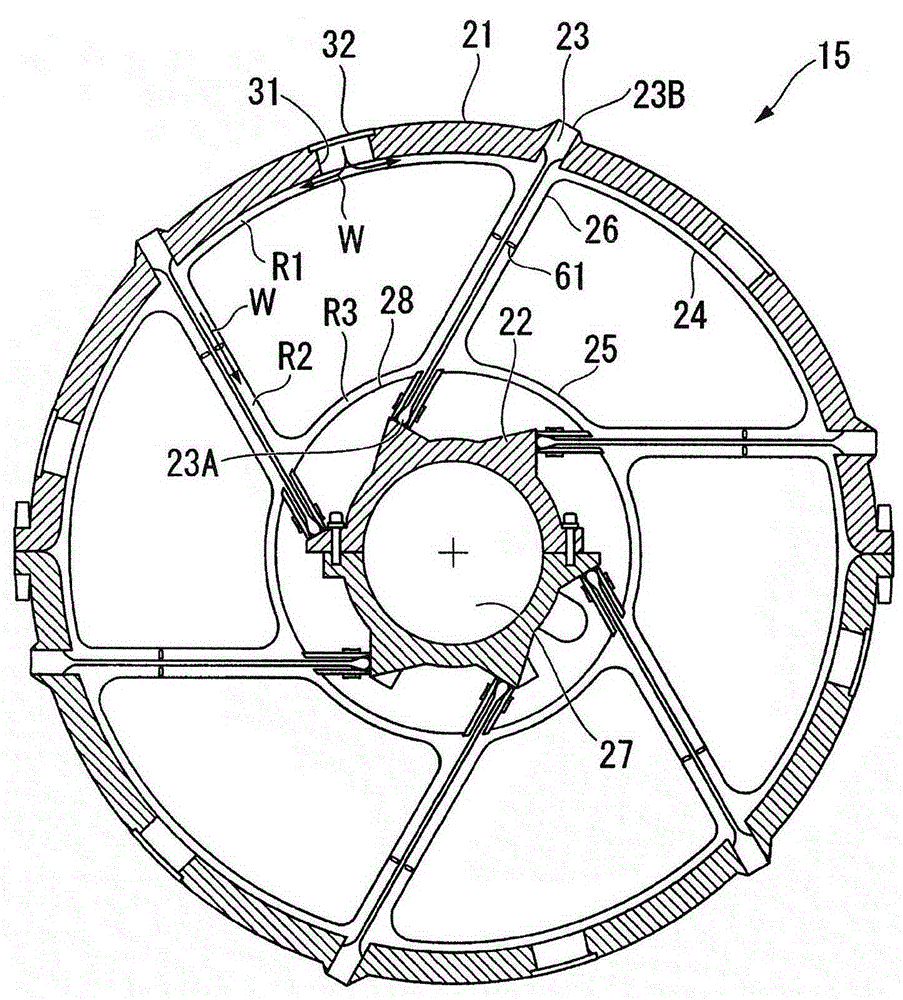

Gas turbine

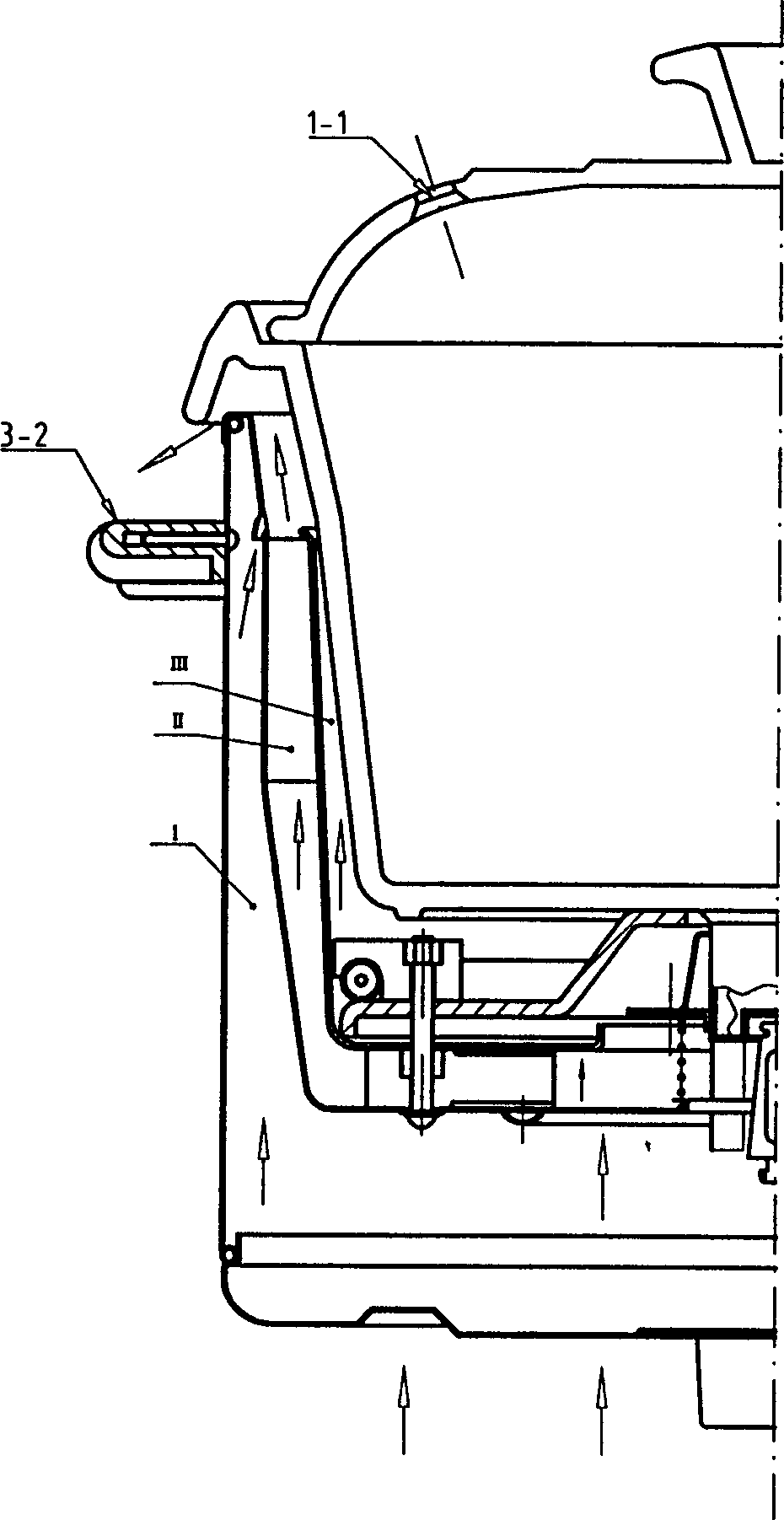

InactiveCN103109045AUniform thermal expansionAvoid Axial MisalignmentEngine manufactureTurbine/propulsion engine coolingGas turbinesAerospace engineering

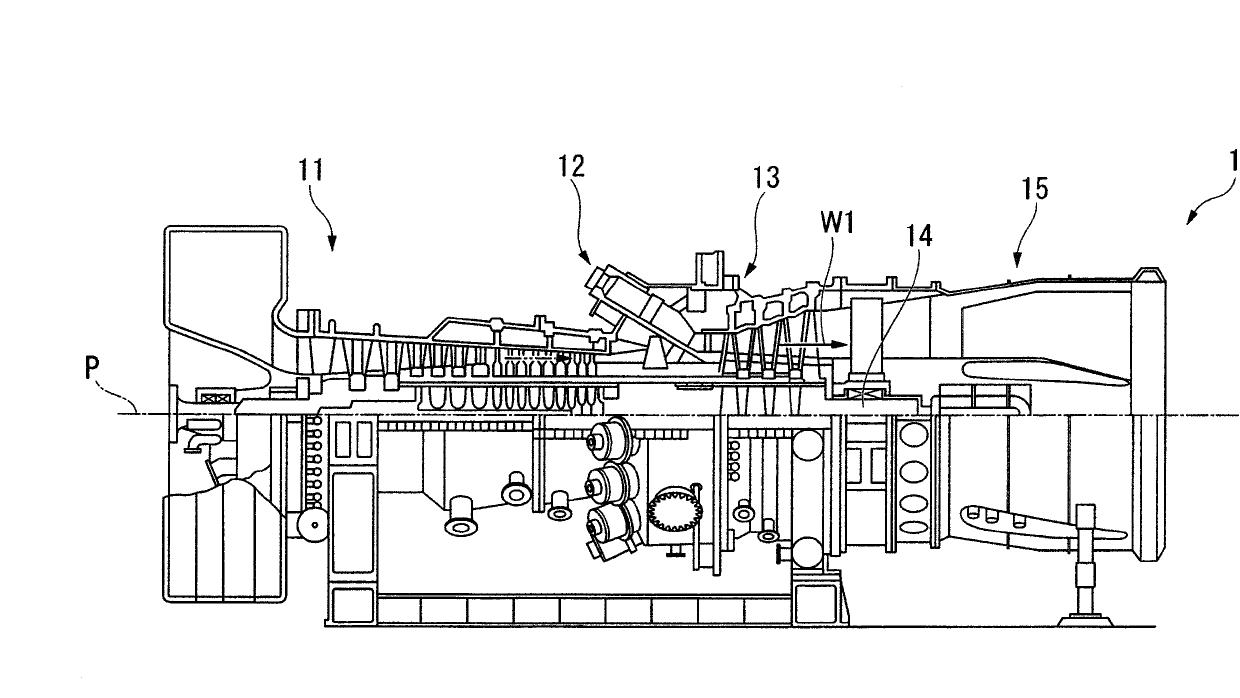

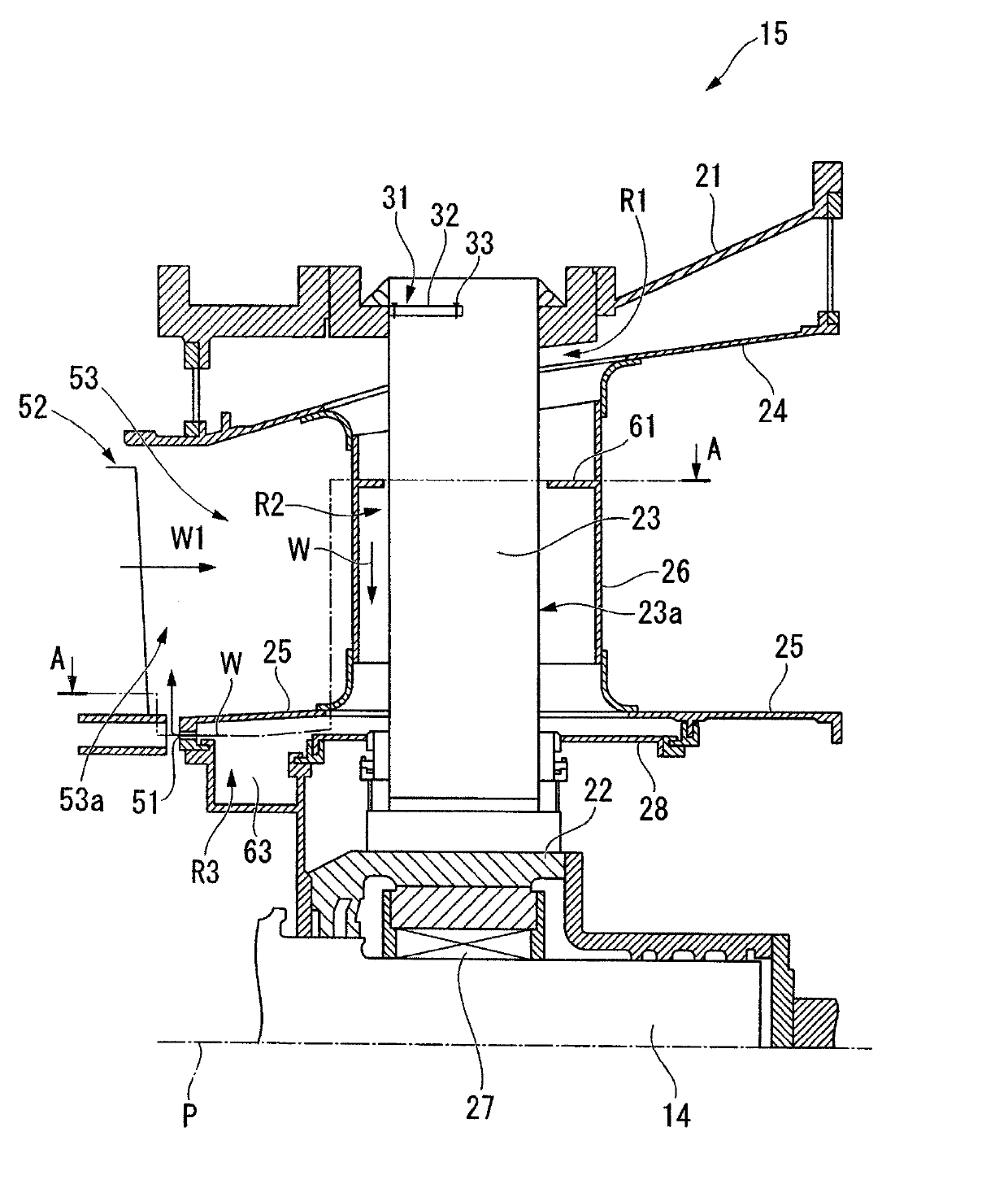

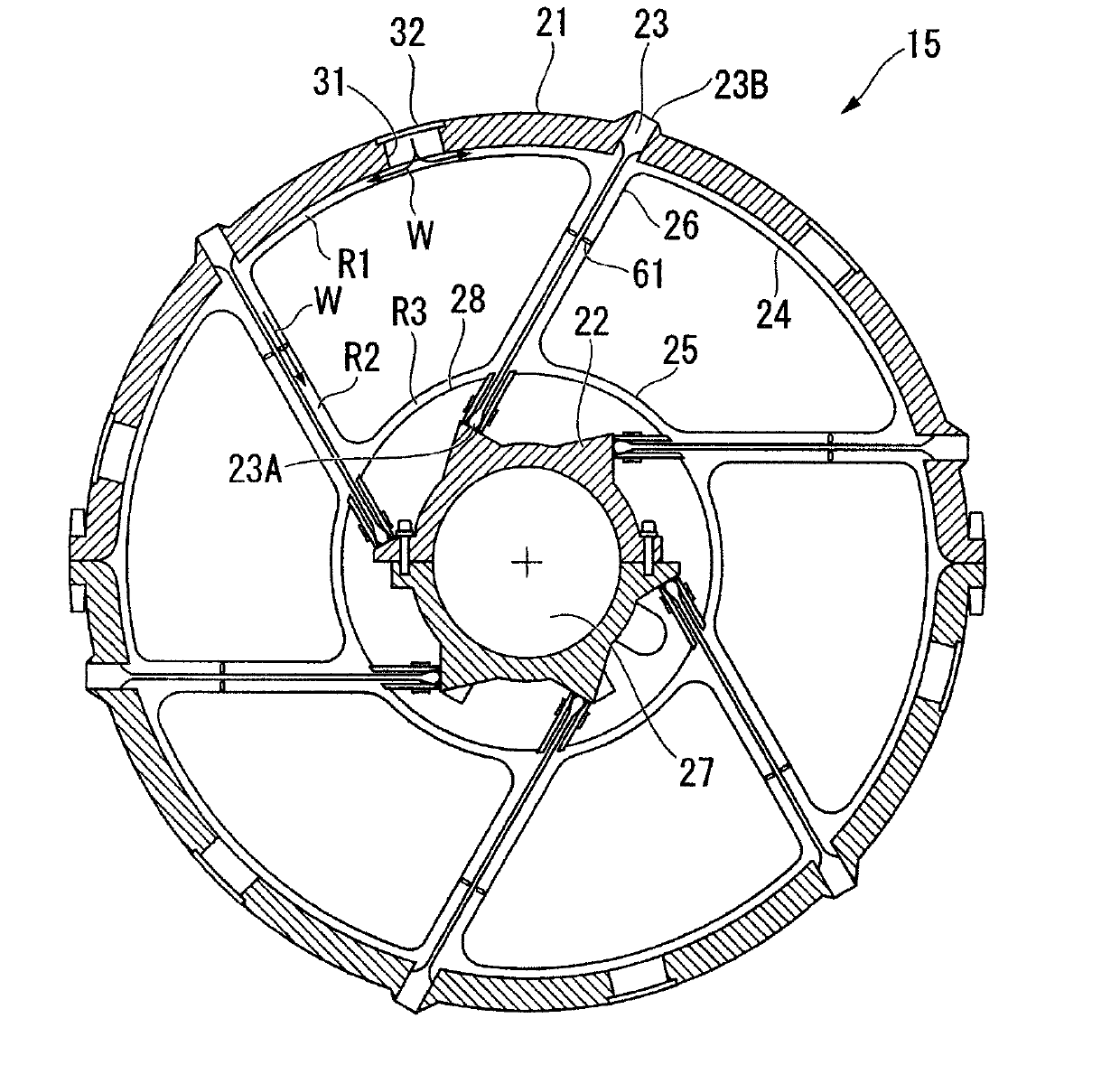

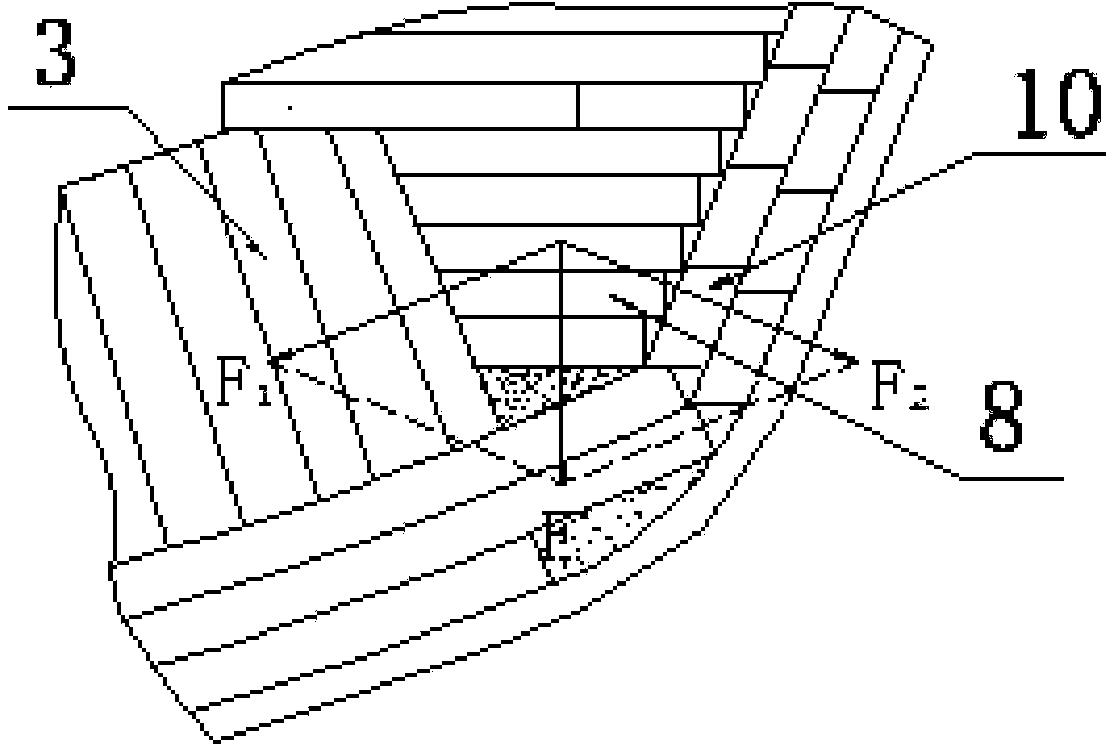

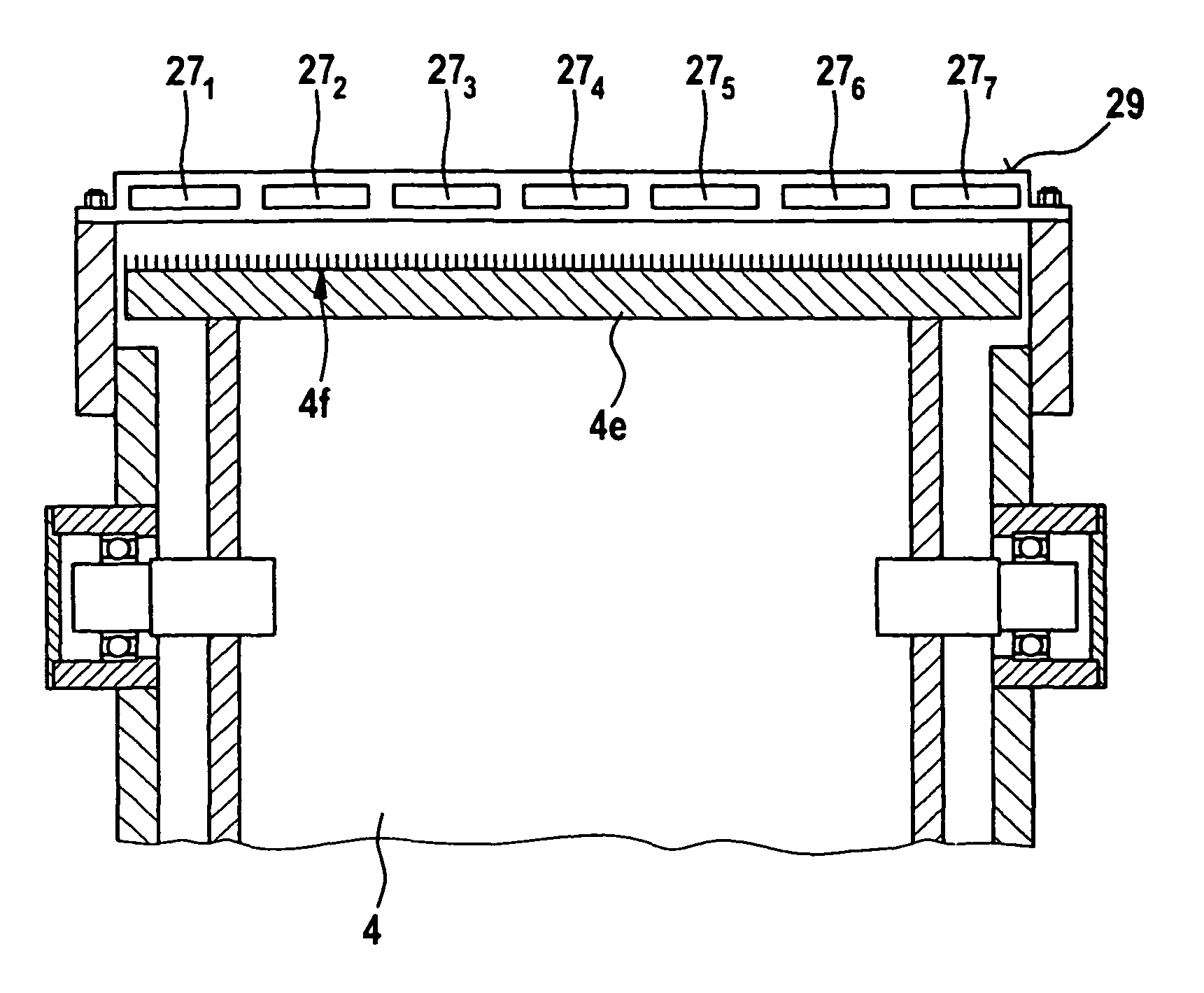

The present invention is a gas turbine that prevents heat-related axial misalignment of the rotary shaft of a rotor, said gas turbine being provided with: a strut (23); outer diffuser (24); an inner diffuser (25); a strut cover (26); and a partition wall (28). The gas turbine is provided with: an inflow port (31) through which cooling air (W) is drawn in; a first flow path (R1) formed between a casing wall (21) and the outer diffuser (24); a second flow path (R2) formed between the strut (23) and the strut cover (26); a third flow path (R3) formed between the inner diffuser (25) and the partition wall (28); and an outflow port (51) provided on the inner diffuser (25).

Owner:MITSUBISHI HITACHIPOWER SYST LTD

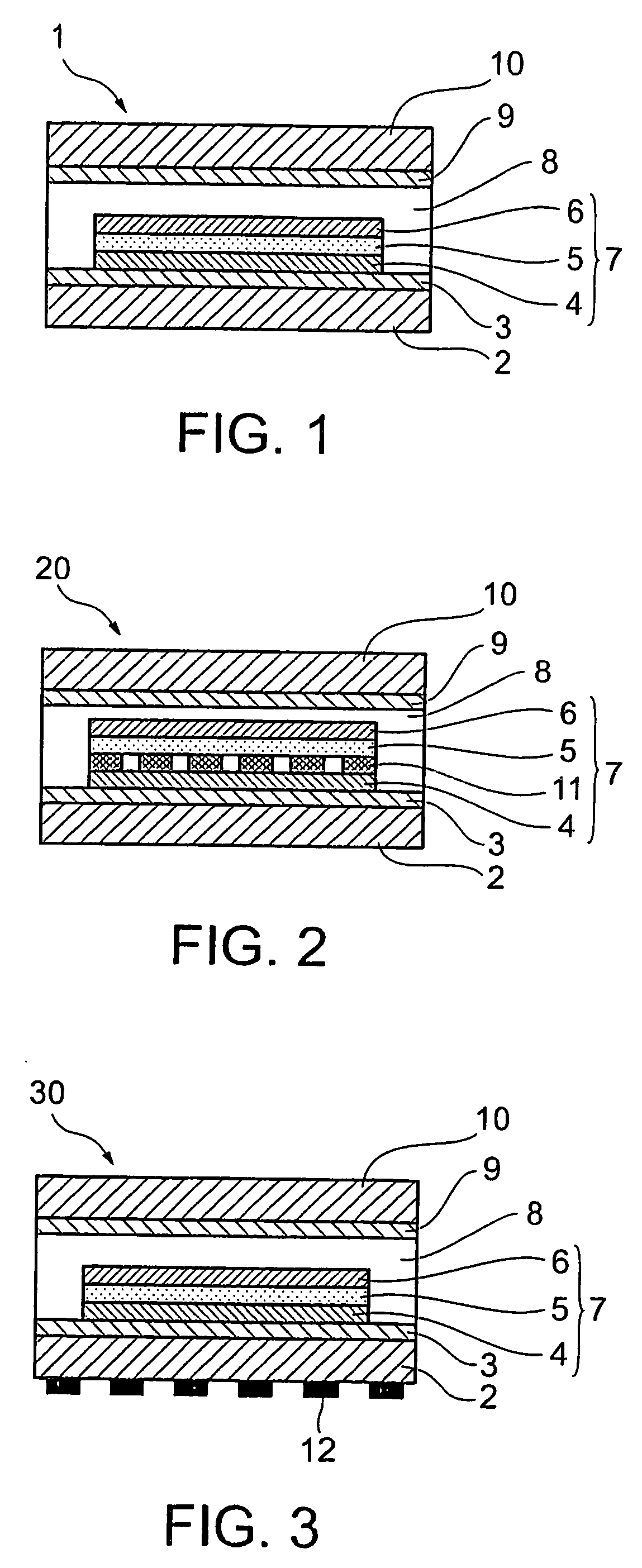

El device and display using same

InactiveUS20050269951A1Uniform rigidityUniform thermal expansionDischarge tube luminescnet screensElectroluminescent light sourcesDisplay deviceEngineering

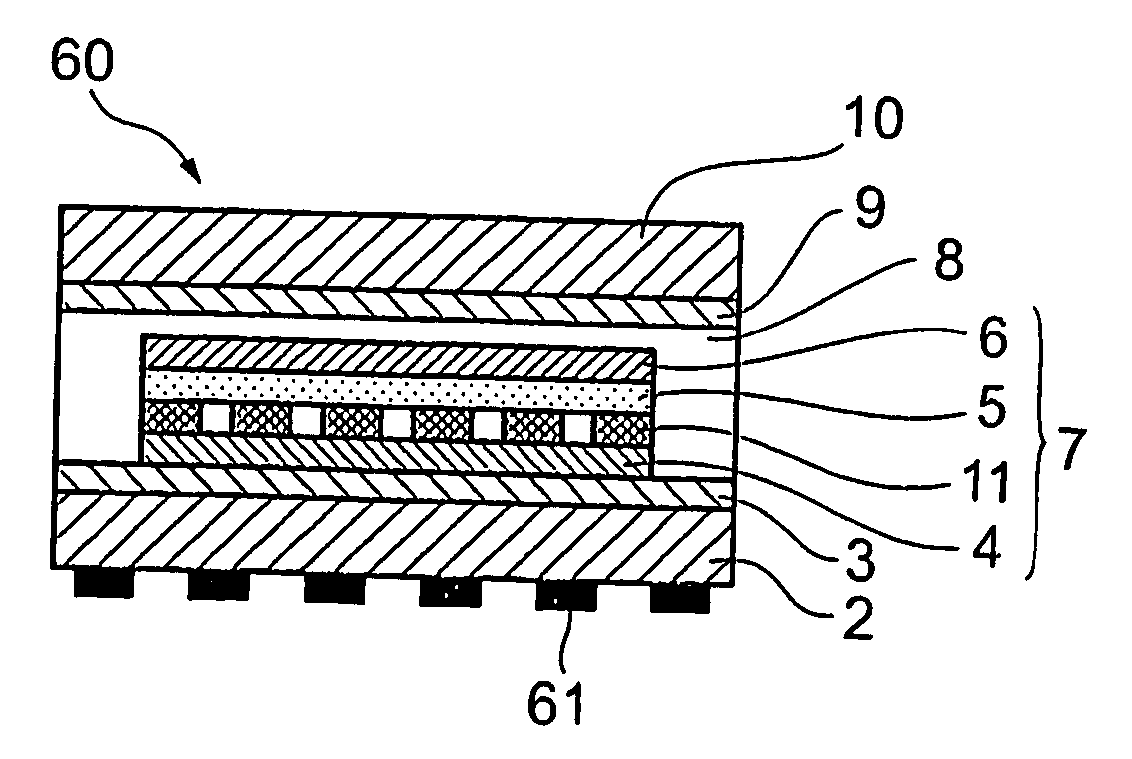

Disclosed is an EL element in which the rigidity and thermal expansion of the whole EL element is homogeneous, the spacing between film substrates provided respectively on both sides of the EL element can be kept constant, and the whole EL element is flexible. The EL element comprises a first film substrate, an EL part, and a sealant layer, the EL part comprising a first electrode, an EL layer, and a second electrode and being provided on a part of a surface of the first film substrate, the sealant layer being provided to cover the EL part and to cover the EL part-free part of the surface of the first film substrate in such a manner that the sealant layer covering the EL part is contiguous with the sealant layer covering the EL part-free part of the surface of the first film substrate.

Owner:DAI NIPPON PRINTING CO LTD

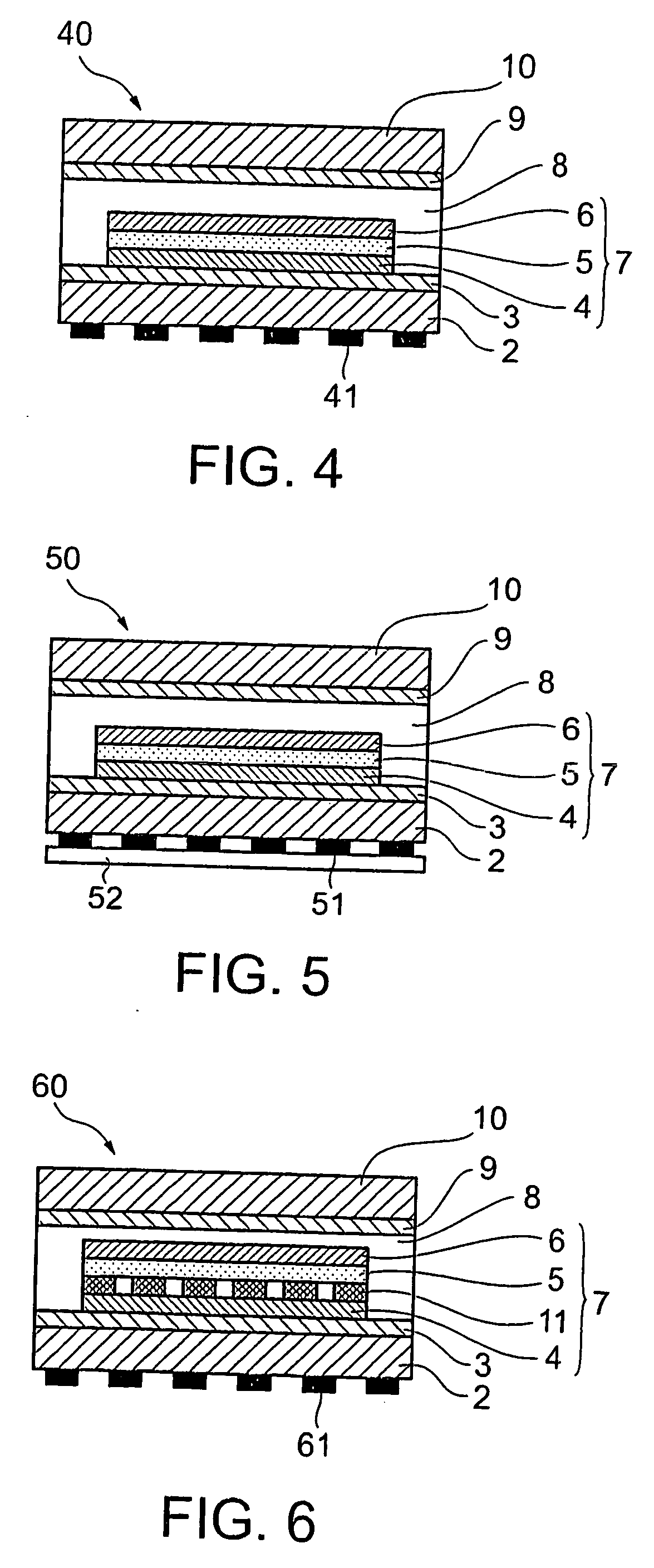

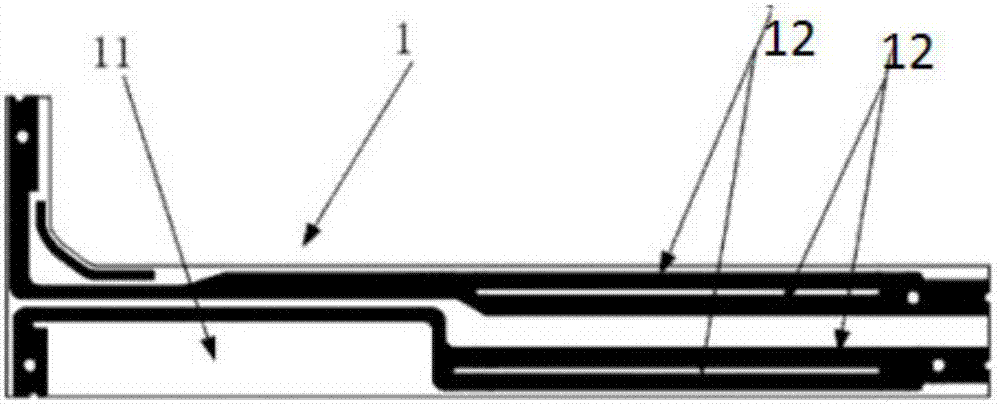

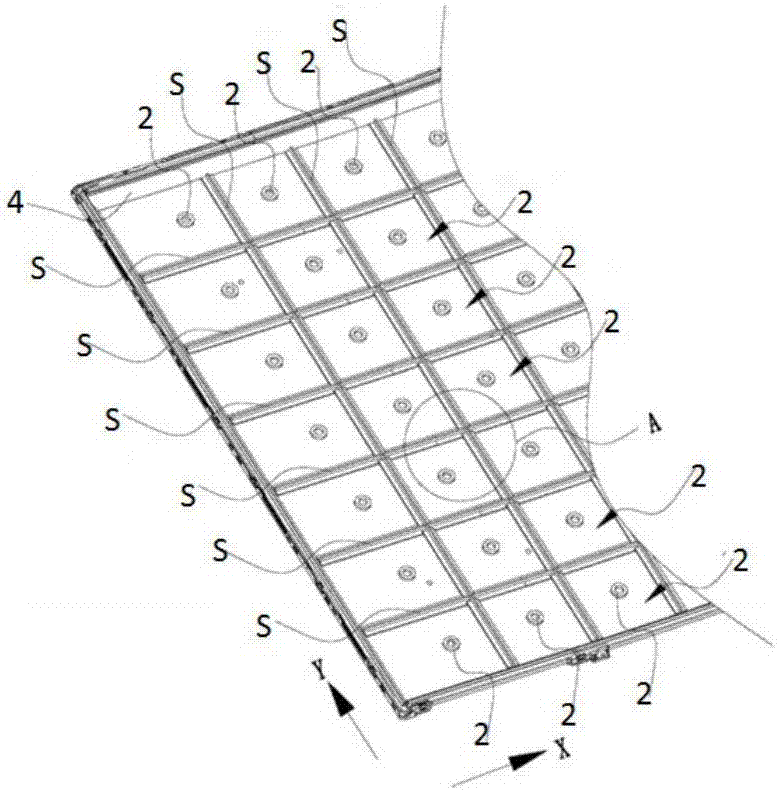

Pre-stretching base and manufacture method thereof and electron device and manufacture method thereof

ActiveCN108597376AUniform thermal expansionGuaranteed uniformityLamination ancillary operationsSolid-state devicesElectronMaterials science

The invention discloses a pre-stretching base and a manufacture method thereof and an electron device and a manufacture method thereof, and relates to the technical field of base pre-stretching. In order to solve the problem that an existing pre-stretching base manufacture method can not form the pre-stretching base with a large area and even pre-stretching quantities, the manufacture method of the pre-stretching base includes the following steps that under the environment with temperature high than preset temperature, at least two layers of films are successively formed on a carrier plate, and thermal expansivity coefficients of the at least two layers of films are different; and the at least two layers of films are separated from the carrier plate, and the pre-stretching base is obtained. The manufacture method of the pre-stretching base is used for manufacturing the pre-stretching base.

Owner:BOE TECH GRP CO LTD

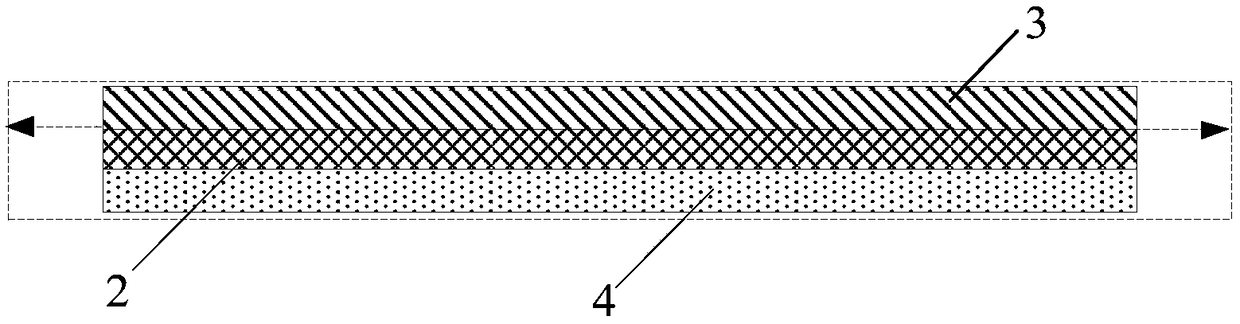

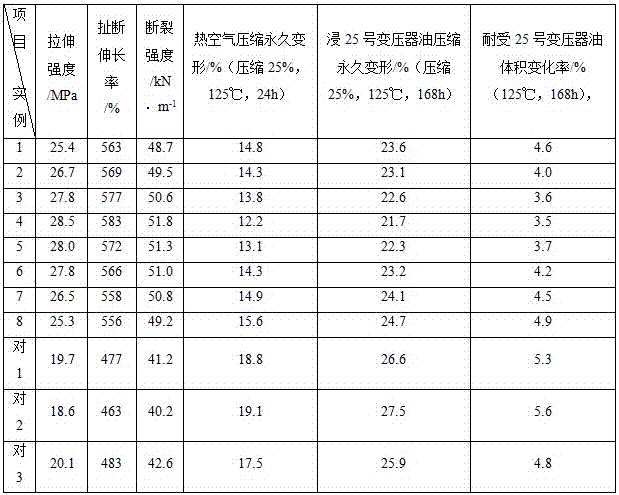

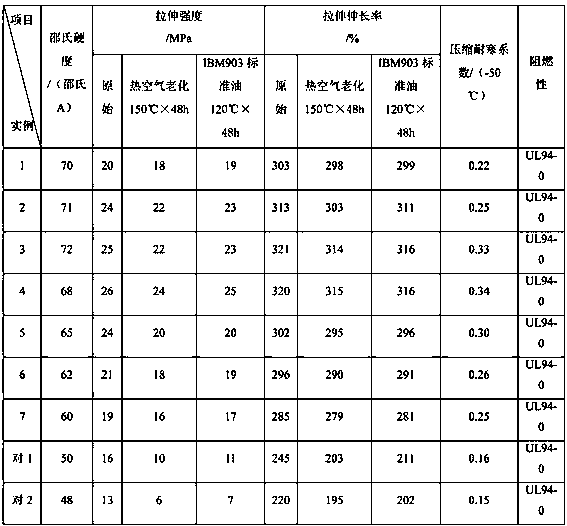

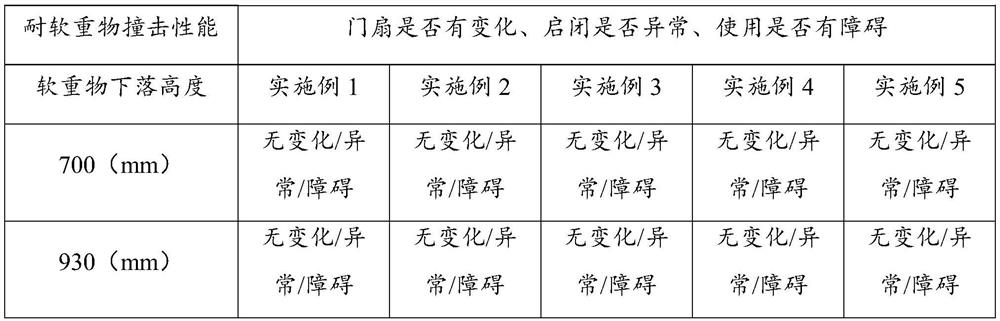

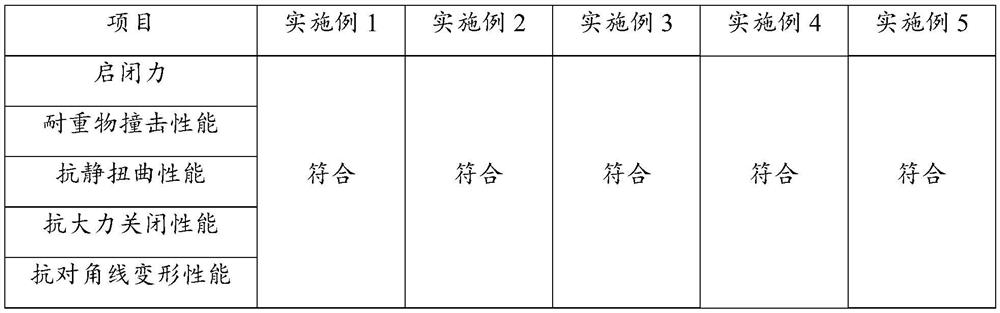

Rubber material for sealing ring of transformer and preparation method of rubber material

ActiveCN106883472AGood oil resistanceImprove wear resistanceBuilding insulationsRubber materialCross-link

The invention belongs to the technical field of sealing materials and particularly relates to a rubber material for a sealing ring of a transformer and a preparation method of the rubber material. The rubber material is prepared from the following raw material in parts by weight: 50-70 parts of nitrile rubber, 20-30 parts of acrylic rubber, 5-10 parts of epichlorohydrin rubber, 3-8 parts of wood fibers, 5-10 parts of nanometer titania, 15-25 parts of a fortifier, 1-5 parts of an anti-aging agent, 1-3 parts of an accelerate, 1-3 parts of sulfur, 3-6 parts of zinc oxide, 4-8 parts of stearic acid, 3-6 parts of asphalt, 1-3 parts of chlorinated paraffin, 10-15 parts of a plasticizer and 5-15 parts of a cross-linking agent. The rubber material for the sealing ring of the transformer is high in strength, small in compressive deformation and excellent in anti-aging performance.

Owner:国网河南省电力公司方城县供电公司

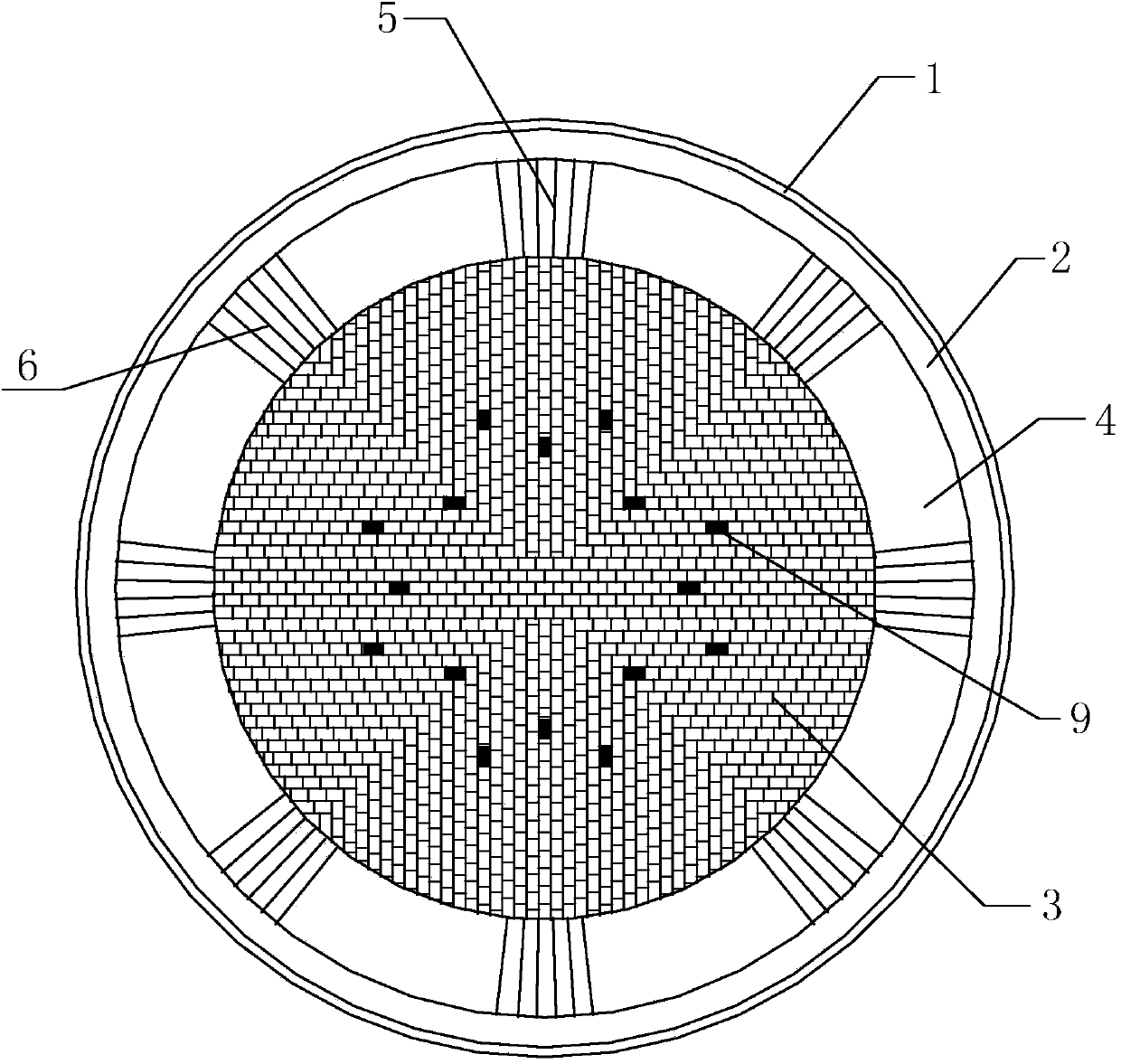

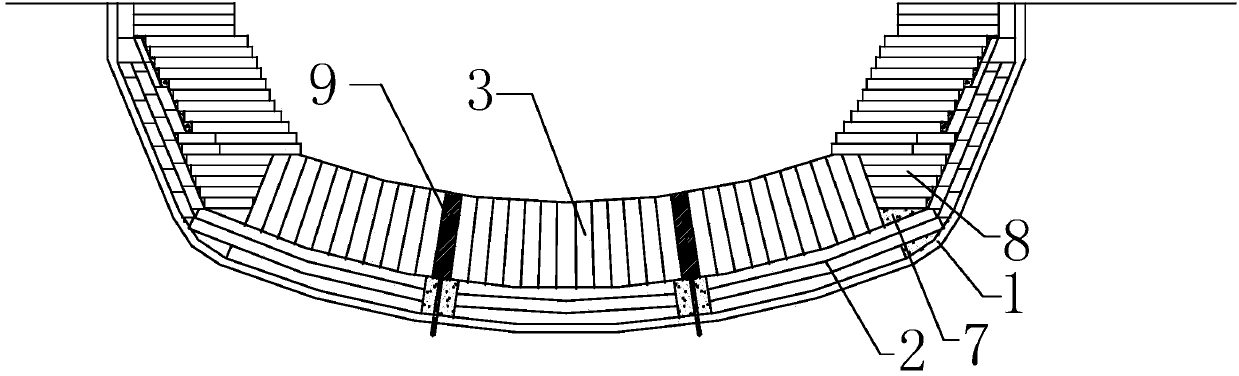

Converter bottom structure with multi-point rider brick deploying and controlling and building method of converter bottom structure

ActiveCN103740886ALarge room for adjustmentNot easy to produceManufacturing convertersEngineeringElectrical and Electronics engineering

The invention provides a converter bottom structure with multi-point rider brick deploying and controlling and a building method of the converter bottom structure. The converter bottom structure comprises a converter bottom shell. A permanent magnesite brick layer is built in the converter bottom shell, converter bottom part work layers are symmetrically built in a cross, and then magnesia carbon bricks are adopted to flatly build pressing edge part work layers round the outer edges of the converter bottom part work layers. When the pressing edge part work layers are built, four endpoint positions corresponding to the cross axes of the converter bottom part work layers respectively adopt magnesia carbon rider bricks to build main rider brick areas. The inner parts of the pressing edge part work layers between every two main rider brick areas respectively adopt the magnesia carbon rider bricks to build at least one auxiliary rider brick area. One side of each magnesia carbon rider brick is an inclined plane, and the inclined plane is in tight contact with the outer surface of each magnesia carbon brick of the outermost ring of the converter bottom part work layers in the building process. The converter bottom structure with multi-point rider brick deploying and controlling combines the advantages of cross building, also overcomes the disadvantages of the cross building, and has a wide popularization and application value.

Owner:武汉精鼎科技股份有限公司

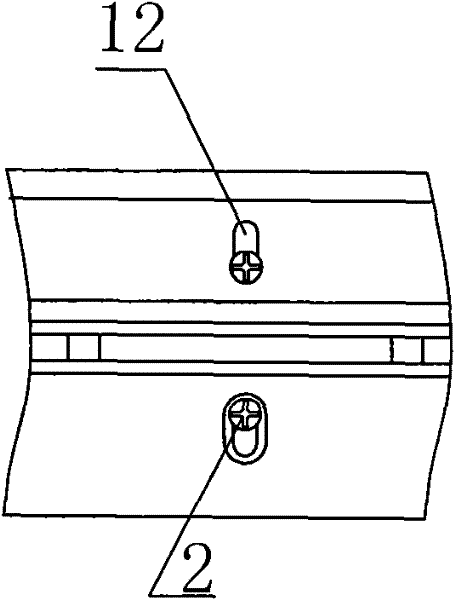

Flexible liquid crystal module and flexible liquid crystal display device

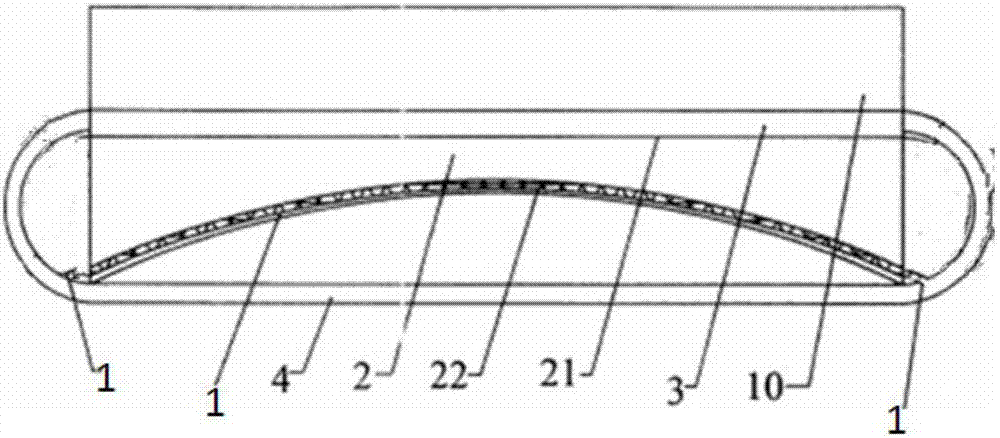

InactiveCN107331298ALimit bloatEliminate warpingStatic indicating devicesOptical light guidesElectrical conductorLiquid-crystal display

The invention provides a flexible liquid crystal module. The flexible liquid crystal module comprises a back plate, LED light strips, light guide plates and diffusion plates, wherein the LED light strips, the light guide plates and the diffusion plate are sequentially arranged on the back plate; the upper surface of each light guide plate is planar, the lower surface of each light guide plate is curved, each light guide plate is divided into multiple array modules in a horizontal direction, each light guide plate facing the vertical direction of the LED light strips is divided into two plates, the side surfaces of every two light guide plates in the vertical direction are attached to two reflective sheets respectively, a gap is formed between every two adjacent light guide plates, and every two reflective sheets are connected through at least two elastic components; each LED light strip comprises a flexible circuit board, and multiple groups of electric conductors and LED chips which are printed on the flexible circuit board and in parallel connection, and each flexible circuit board is provided with multiple micro-arrays, wherein the heights of the micro-arrays are different, but the arc shapes formed by the micro-arrays are equal to the lower surfaces of the light guide plates. Thus, the expansion and support problems during heating are well solved, the structure is simplified, and the cost is saved.

Owner:YANCHENG HUAXU OPTOELECTRONICS TECH CO LTD

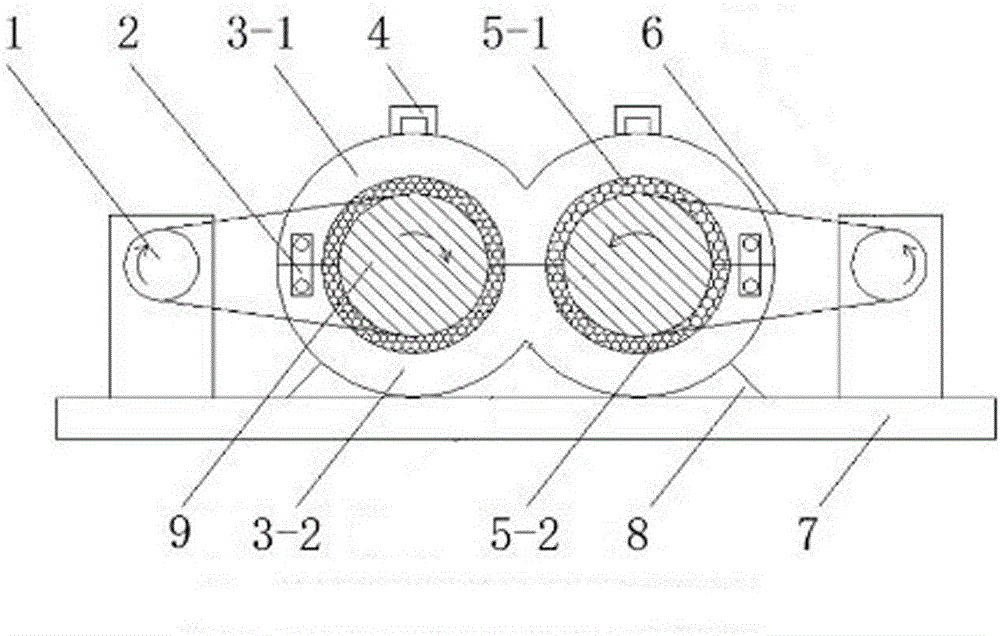

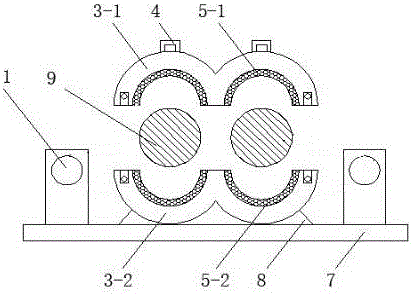

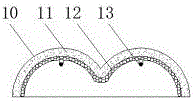

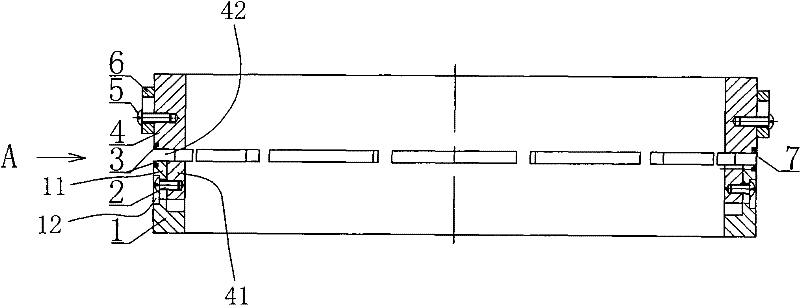

Offline preheating device for hot mill rollers

ActiveCN106140820AEasy to shapeUniform thermal expansionRollsProfile control deviceEngineeringHeating furnace

The invention discloses an offline preheating device for hot mill rollers. The offline preheating device comprises a heating furnace, a base and two power devices. The power devices are arranged at the two opposite ends of the base correspondingly. The heating furnace is arranged between the two power devices and is in a gourd shape. The heating furnace is formed by oppositely combining an upper half furnace body and a lower half furnace body which are symmetric. An upper heating layer is arranged along the inner wall of the upper half furnace body, and a lower heating layer is arranged along the inner wall of the lower half furnace body. After the upper half furnace body and the lower half furnace body are combined oppositely to form the heating furnace, a heating layer is formed by the upper heating layer and the lower heating layer, and a heating cavity is defined by the heating layer. The heating cavity is divided into two cylindrical chambers which are arranged in parallel and communicate with each other. Bearings are arranged at the two ends of each chamber. The pair of rollers to be heated are placed in the two chambers correspondingly, after shaft shoulders at the two ends of the rollers are supported on the bearings, the power devices are used for driving the rollers to rotate synchronously in the preheating process. The offline preheating device is simple in structure, convenient to operate and even in roller heating, an ideal roller shape can be obtained, and therefore the titanium plate rolling plate shape is improved, and a use effect is good.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Highway composite acoustic panel material and preparation method thereof

InactiveCN108395628AImprove flame retardant performanceImprove corrosion resistanceAntioxidantPolypropylene

The invention discloses a highway composite acoustic panel material and a preparation method thereof, and relates to the field of acoustic panels. The highway composite acoustic panel material is prepared from the following raw materials in parts by weight: 20-30 parts of waste polypropylene plastic particles, 8-15 parts of polypropylene, 8-15 parts of vinyl-vinyl acetate copolymer, 6-12 parts ofglass bead, 15-20 parts of expanded perlite, 5-10 parts of mica powder, 4-8 parts of fiberglass, 3-6 parts of nano titanium dioxide, 3-6 parts of nano silicon nitride, 10-18 parts of lignocellulose, 3-5 parts of hydroxymethyl cellulose, 2.5-3.6 parts of silane coupling agent, 1.8-3.5 parts of antioxidant and 2.8-4.2 parts of flame retardant. The acoustic panel material is prepared by taking the waste polypropylene plastic particles as a main raw material, the waste is recycled, the production cost is low, the material is excellent in flame resistance, corrosion resistance, water resistance andsound insulation property, and the preparation method is simple.

Owner:合肥慧林建材有限公司

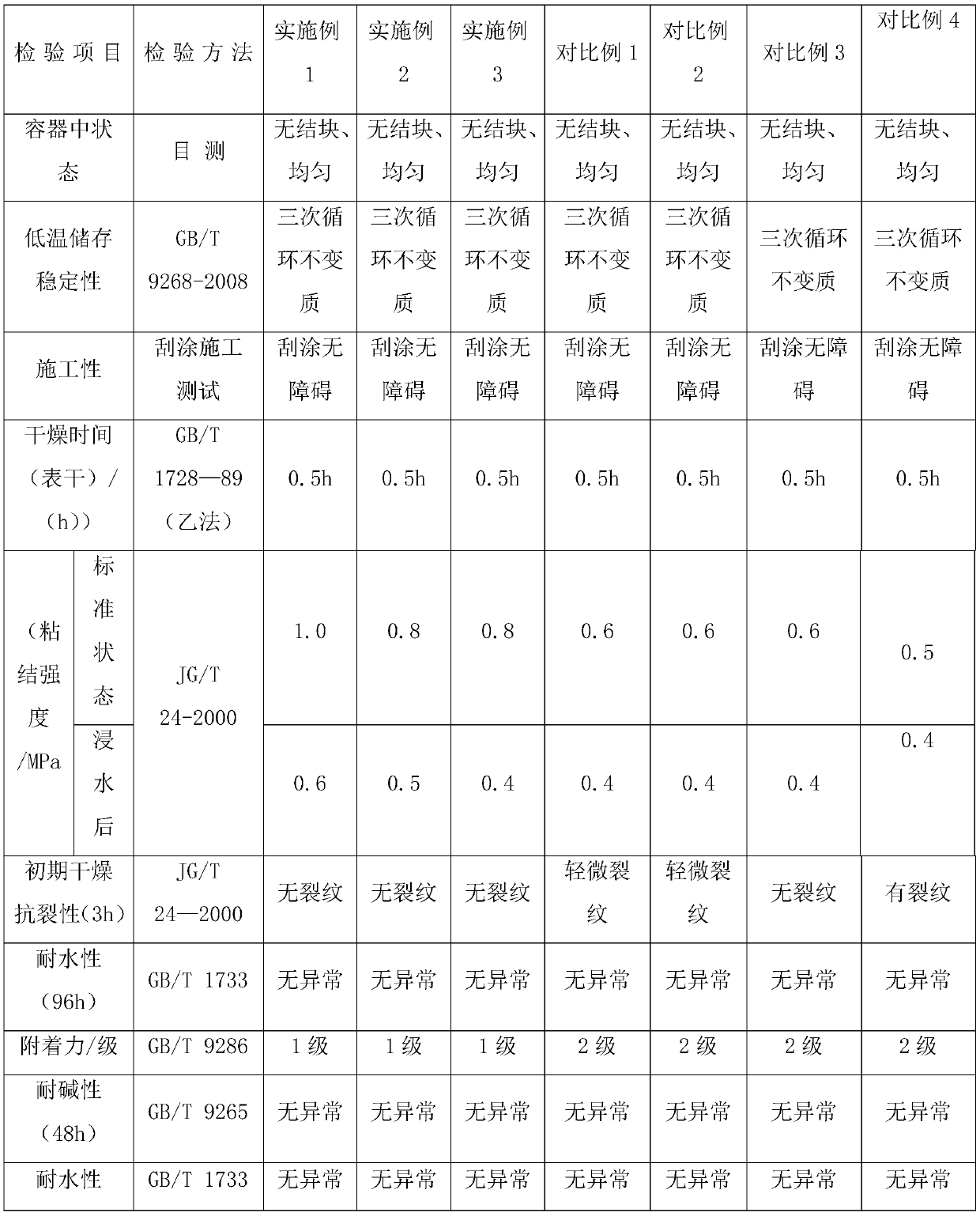

Water-based terrace phase-change epoxy putty coating and preparation method thereof

InactiveCN110964408ARealize the control effectAvoid bulgingEpoxy resin coatingsFiberCrack resistance

The invention discloses a water-based terrace phase-change epoxy putty coating and a preparation method thereof. The water-based terrace phase-change epoxy putty coating is formed by compounding a component A, a component B and a component C; the component A comprises, by weight, 30-50 parts of a waterborne epoxy curing agent, 30-40 parts of deionized water, 0.1-0.3 part of a defoaming agent, 0.1-0.4 part of a dispersing agent, 0.2-0.6 part of a base material wetting agent, 0.8-1.2 parts of a leveling agent and 10-20 parts of a microcapsule phase change material; the component B comprises, byweight, 85-95 parts of waterborne epoxy resin and 5-15 parts of aliphatic glycidyl ether, and the aliphatic glycidyl ether meets the following requirements: (1) the viscosity at 40 DEG C is 3-7 mpa.s,and (2) the epoxy equivalent is 290-310 g / eq; and the component C comprises, by weight, 80-100 parts of 200-mesh quartz powder and 1.5-4.5 parts of a composite fiber. The addition of the microcapsulephase-change material and the composite fiber greatly improves the cracking resistance and adhesive force of the putty coating.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

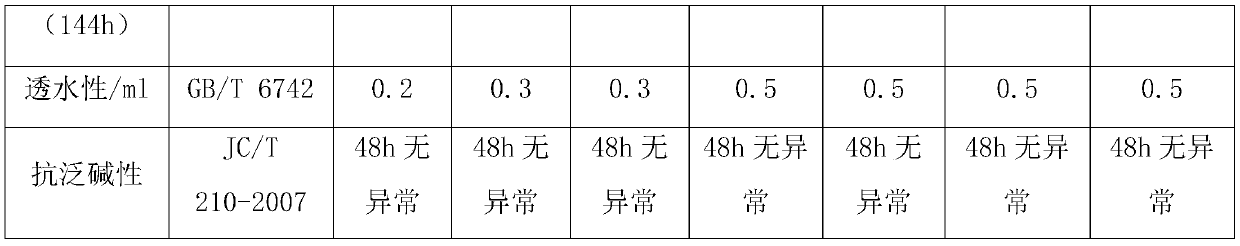

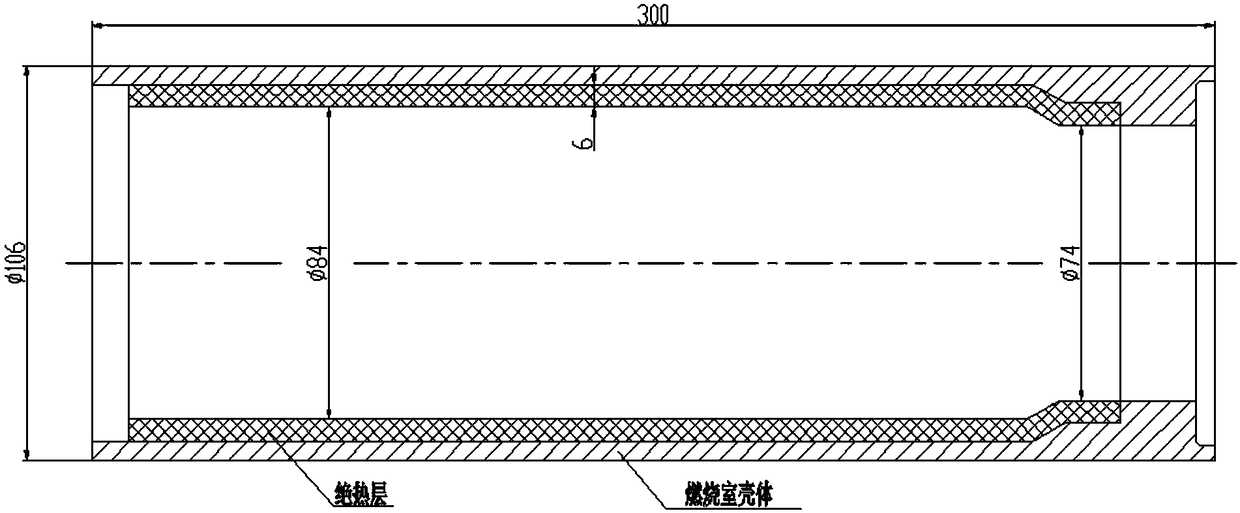

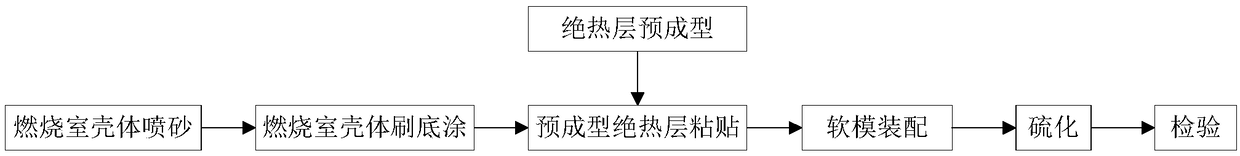

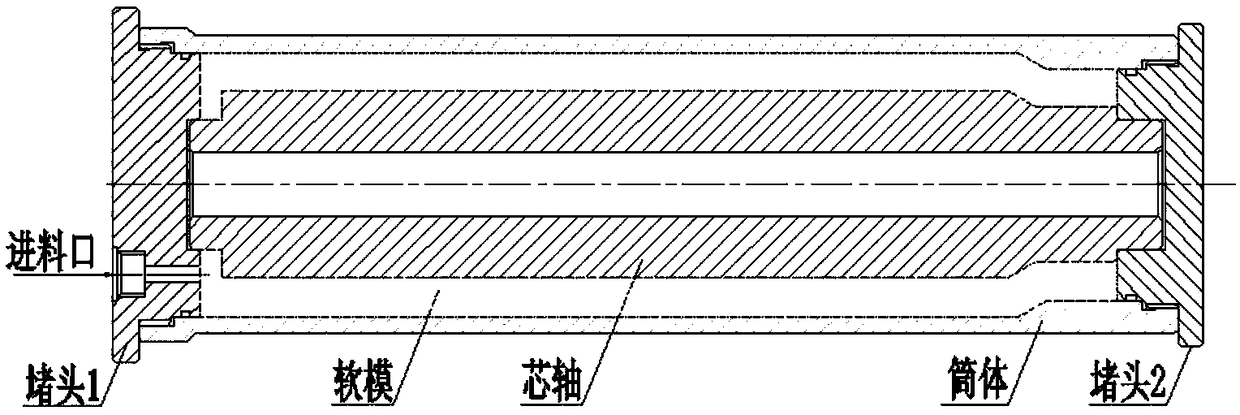

Bonding forming method of silicone rubber soft mold pressing heat insulation layer

The invention provides a bonding forming method of a silicone rubber soft mold pressing heat insulation layer. The method comprises the following steps: firstly preforming a required non-vulcanized heat insulation layer through a tool, wherein a shape, a structure, thickness and the like of the preformed heat insulation layer meet design requirements; pasting the preformed heat insulation layer ina housing of a combustion chamber, and performing pressing vulcanization under a temperature condition required by vulcanization of the heat insulation layer by taking a tool formed by a silicone rubber material with a high expansion coefficient as a pressing medium. The method can improve compactness of the heat insulation layer, ensures a high precision molding surface and thickness of the heatinsulation layer and lowers the production cost.

Owner:西安长峰机电研究所

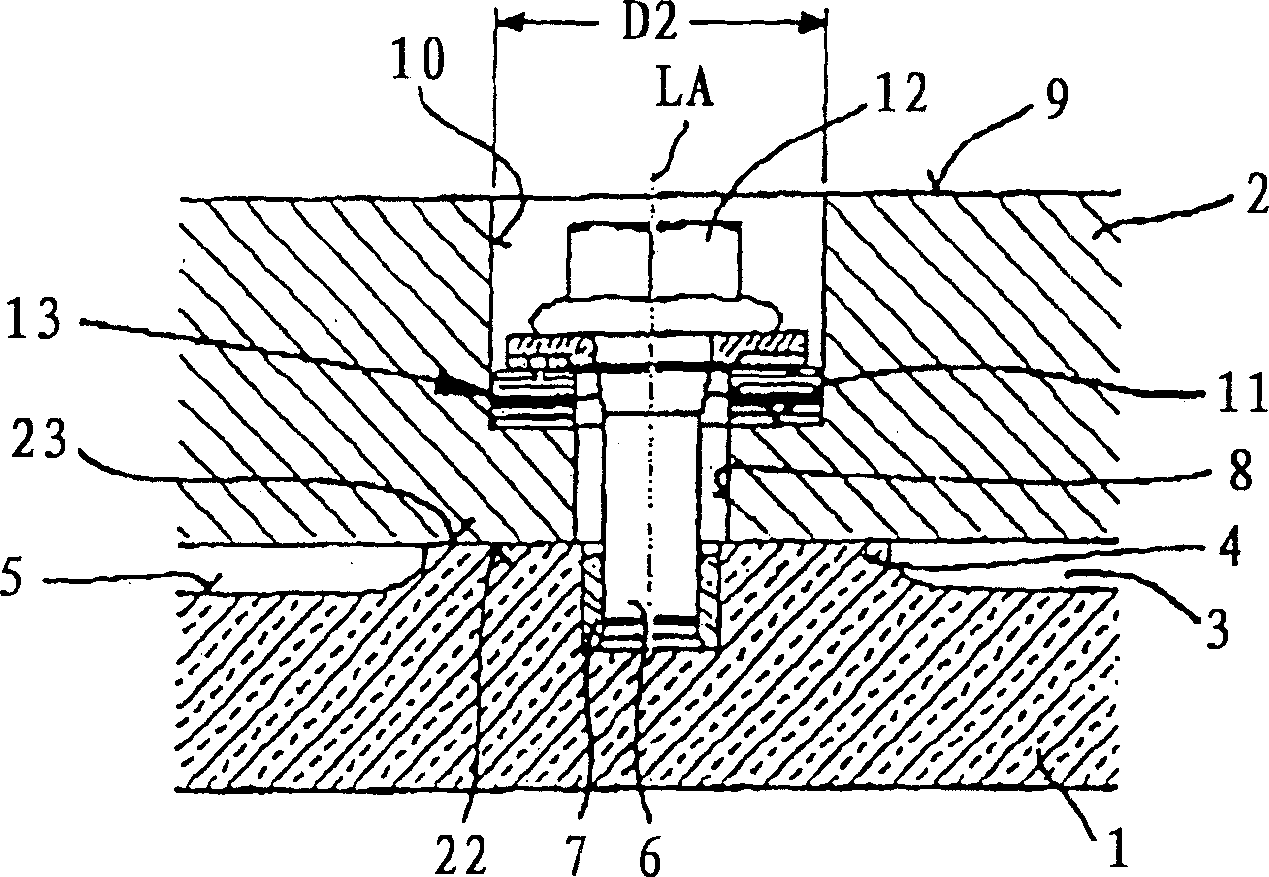

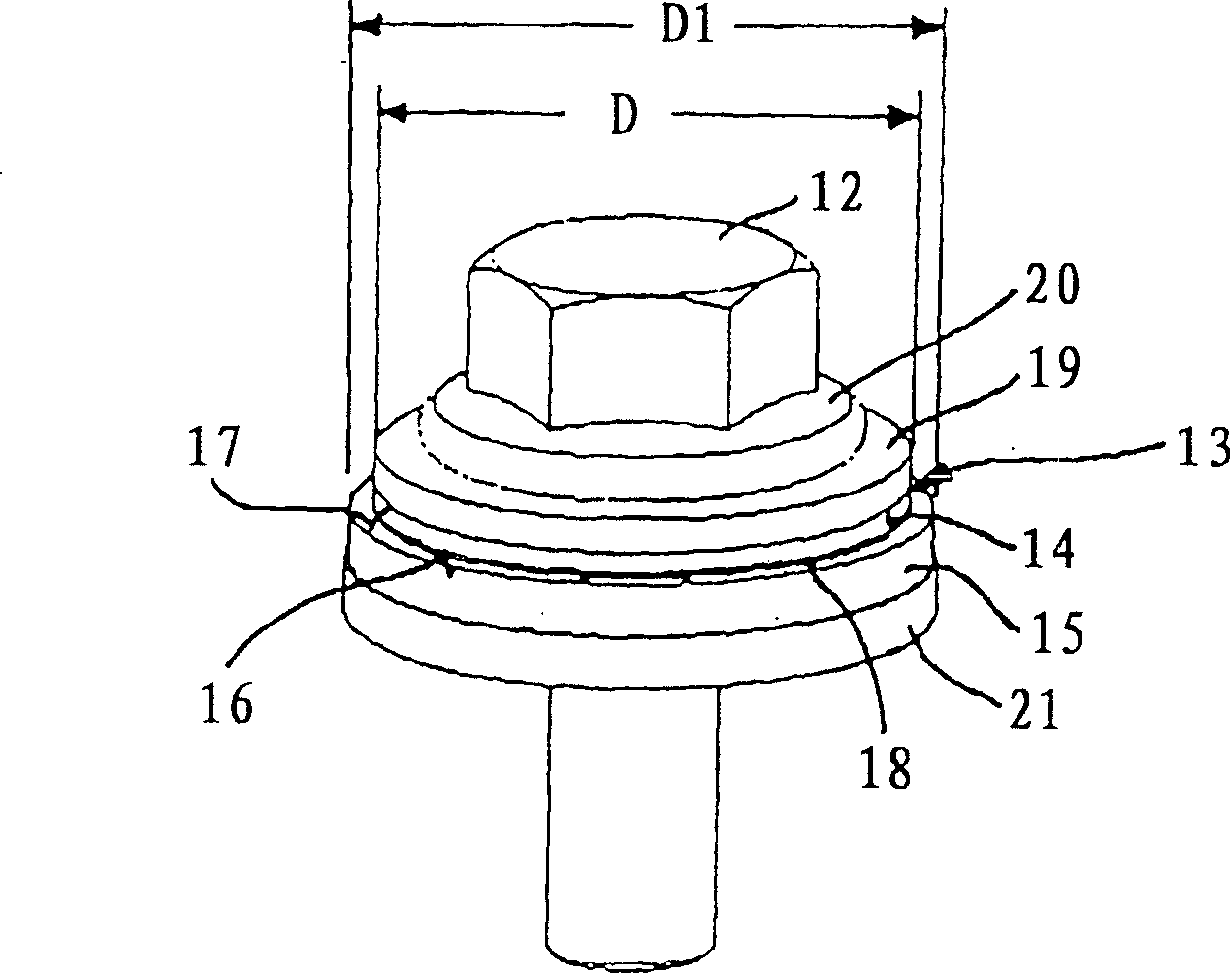

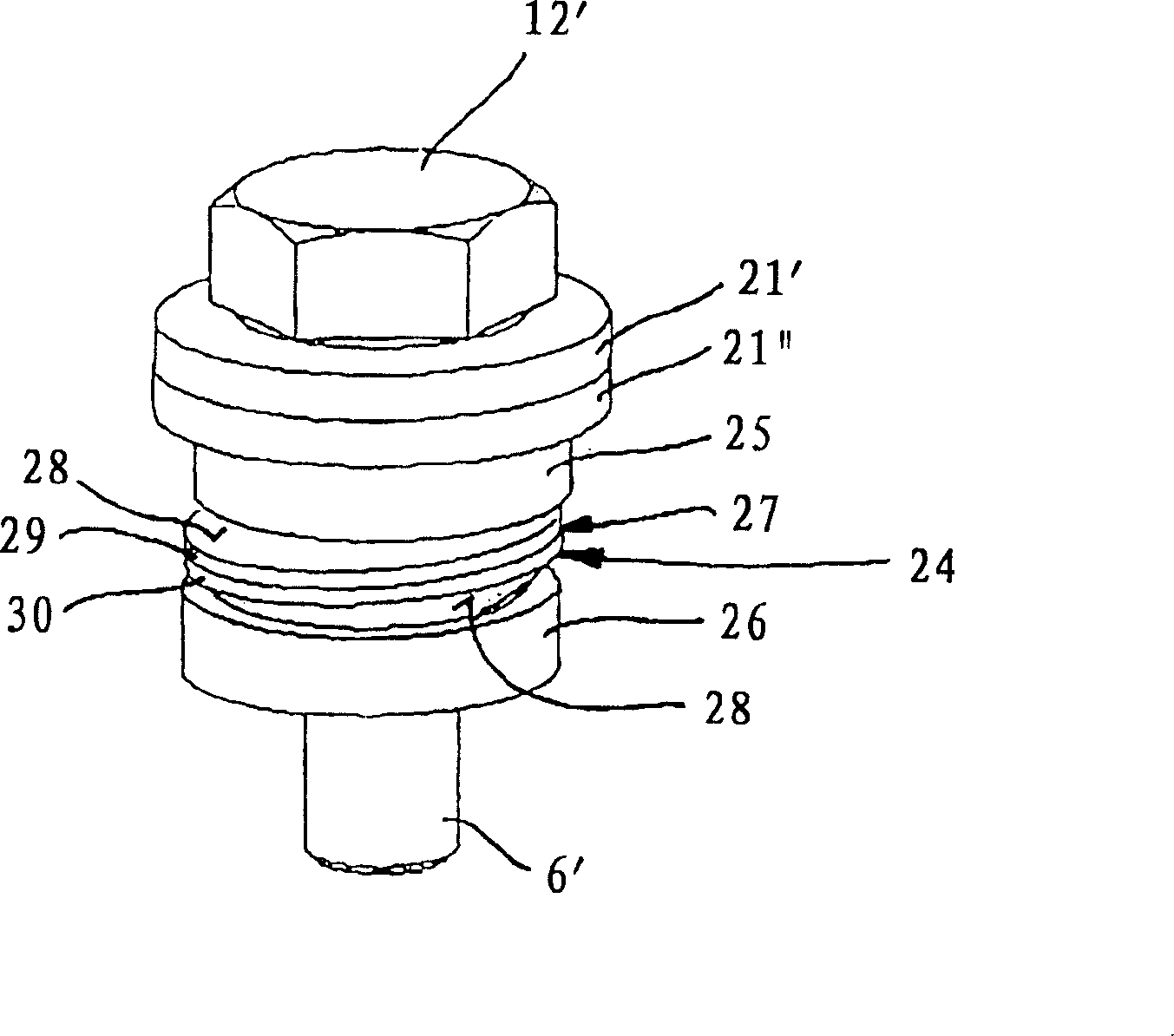

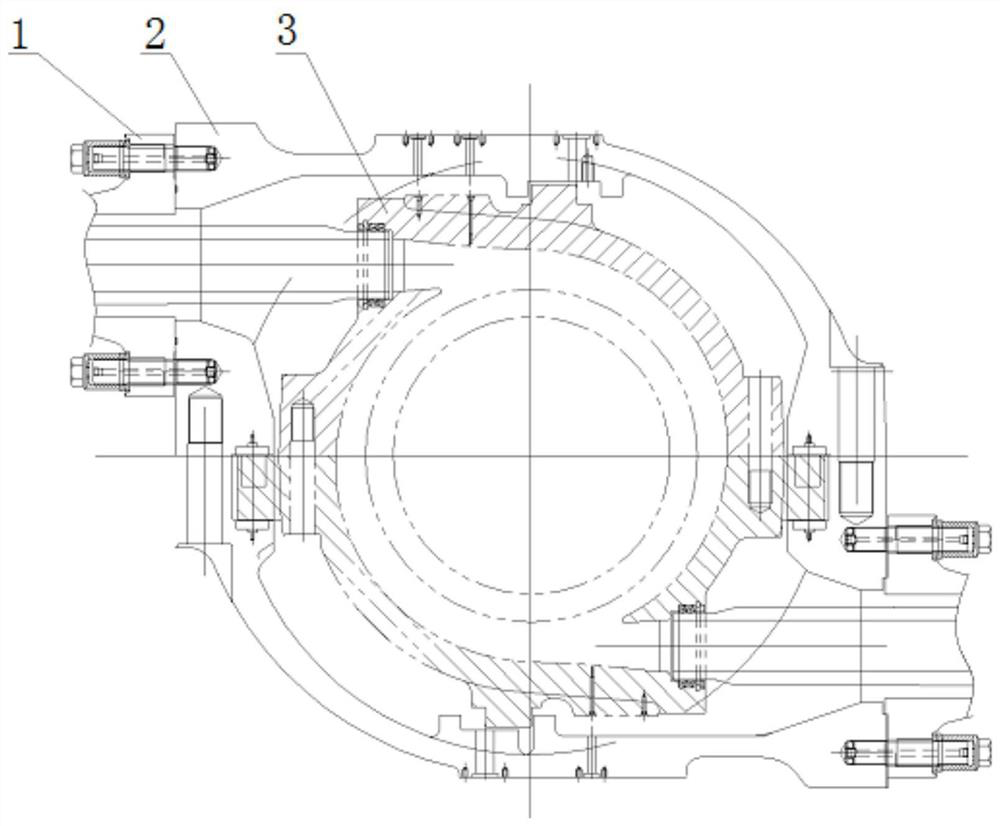

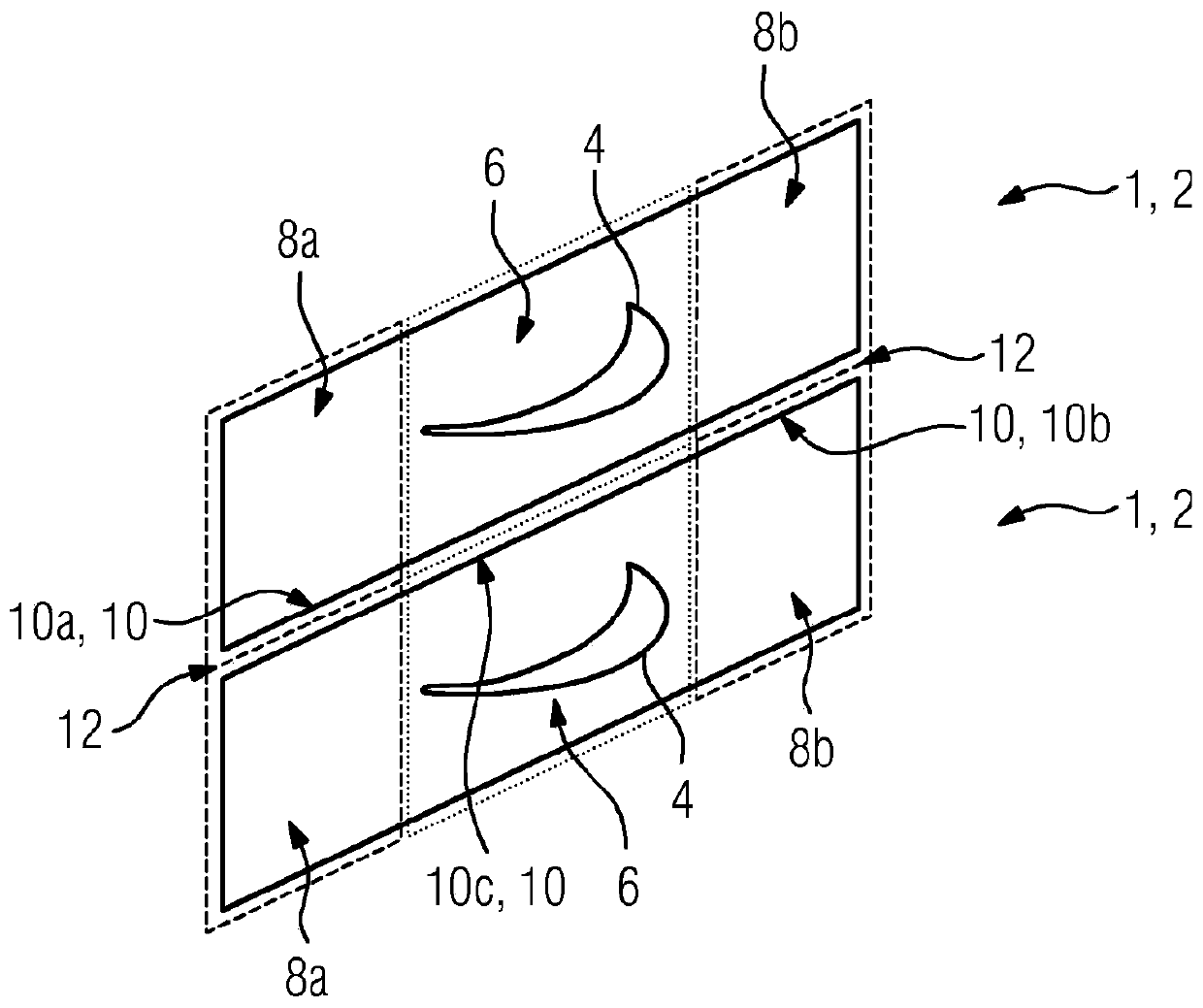

Liquid-cooled crystallizer for continaous casting of metals

A liquid-cooled mold for the continuous casting of metals, including mold plates made of copper or a copper alloy, which are supported at their rear on supporting plates by the use of a plurality of bolts. The bolts have bolt heads in the region of the backsides of the supporting plates facing away from the mold plates. Between the bolt heads and the supporting plate an articulation system making possible relative motion between the mold plate and the supporting plates is incorporated, having two articulation members, between which a sliding element is undetachably embedded.

Owner:KME GERMANY GMBH & CO KG

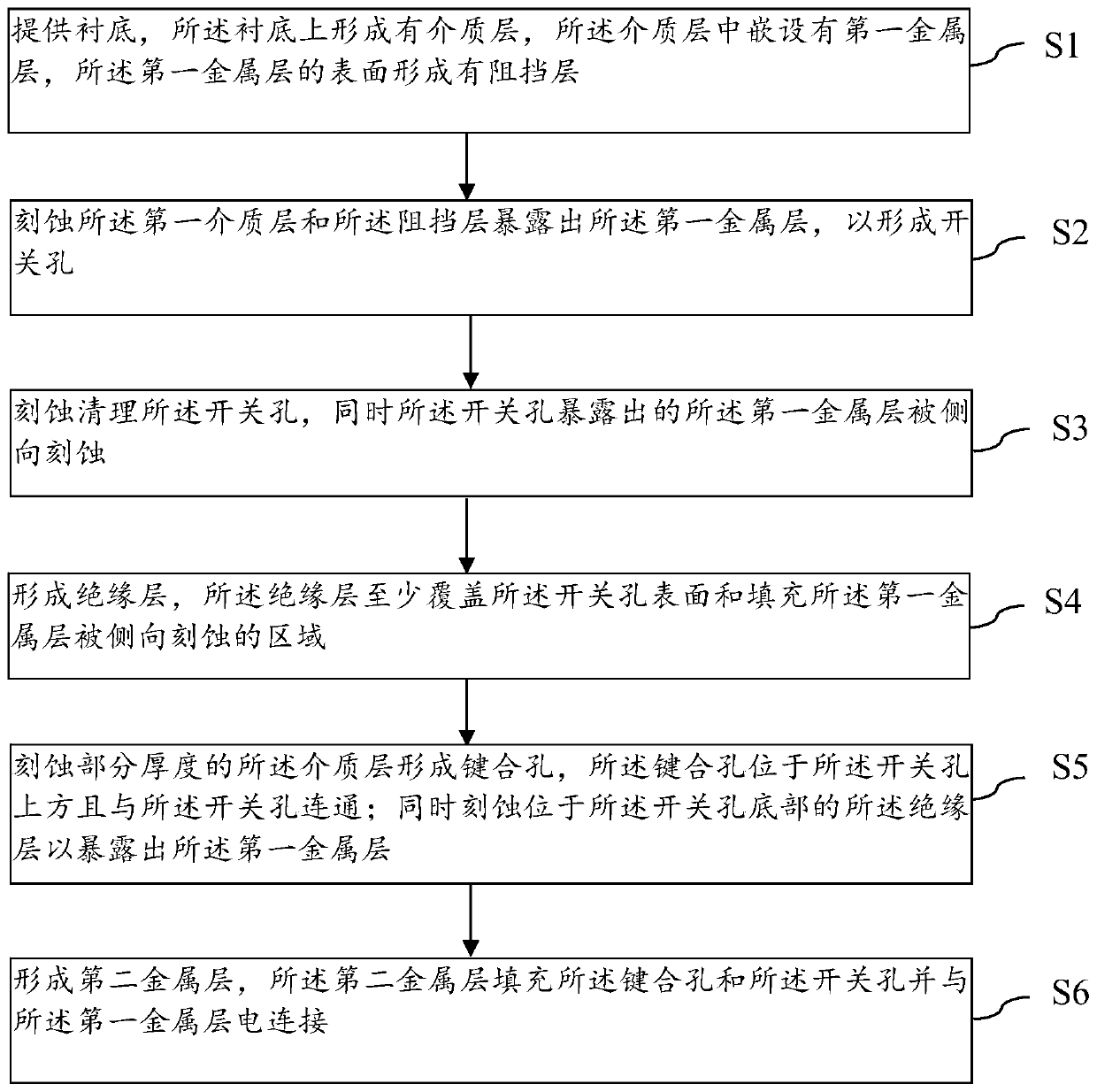

Semiconductor device and formation method thereof

ActiveCN110739269AImprove reliabilityImprove flatnessSemiconductor/solid-state device detailsSolid-state devicesPhysicsThin membrane

The invention provides a semiconductor device and a formation method thereof. The formation method comprises the following steps: providing a substrate; etching a first dielectric layer and a barrierlayer to expose a first metal layer so as to form a switch hole; etching and cleaning the switch hole, while the first metal layer exposed out of the switch hole is laterally etched; and forming an insulating layer which at least covers the surface of the switch hole and fills the area where the first metal layer is laterally etched. The area where the first metal layer is laterally etched is filled with the insulating layer, thus avoiding the formation of gaps and improving the stability and the reliability of the contact resistance in the switch hole. The insulating layer of the side wall ofthe switch hole separates the first metal layer of the bottom circumferential ring of the switch hole to prevent it from being damaged, and the insulating layer covers the side wall of the switch hole so that the flatness of the switch hole is high, the uniformity of film deposition in the switch hole and the metal layer filling the switch hole is improved and the thermal expansion and stress areenabled to be uniform.

Owner:WUHAN XINXIN SEMICON MFG CO LTD

Aluminosilicate efficient iron liquid slag removing heat preservation covering agent

The invention discloses an aluminosilicate efficient iron liquid slag removing heat preservation covering agent and relates to the technical field of steel liquid and iron liquid slag removing heat preservation covering agents in the metallurgy and casting production process. The chemical components comprise, by weight, 71%-75% of SiO2, 11%-14% of Al2O3, 4%-5% of Na2O, 3%-4% of K2O, 0.5%-1.5% of CaO, 1.0% or less of FeO, 1% or less of Fe2O3, 1% or less of microscale other oxides comprising MgO, P2O5, TiO2, MnO and the like, and 4%-7% of ignition loss, and the sum of the weight percentages of all the chemical components is 100%. By adopting the specified heat treatment process, the mass ignition loss of treated volcanic rock can be controlled to be within 2%-4%, the optimal expanding effect is obtained, capacity of adhering floating slag is strengthened greatly, and the efficient slag removing effect is achieved.

Owner:丹晟实业(上海)有限公司

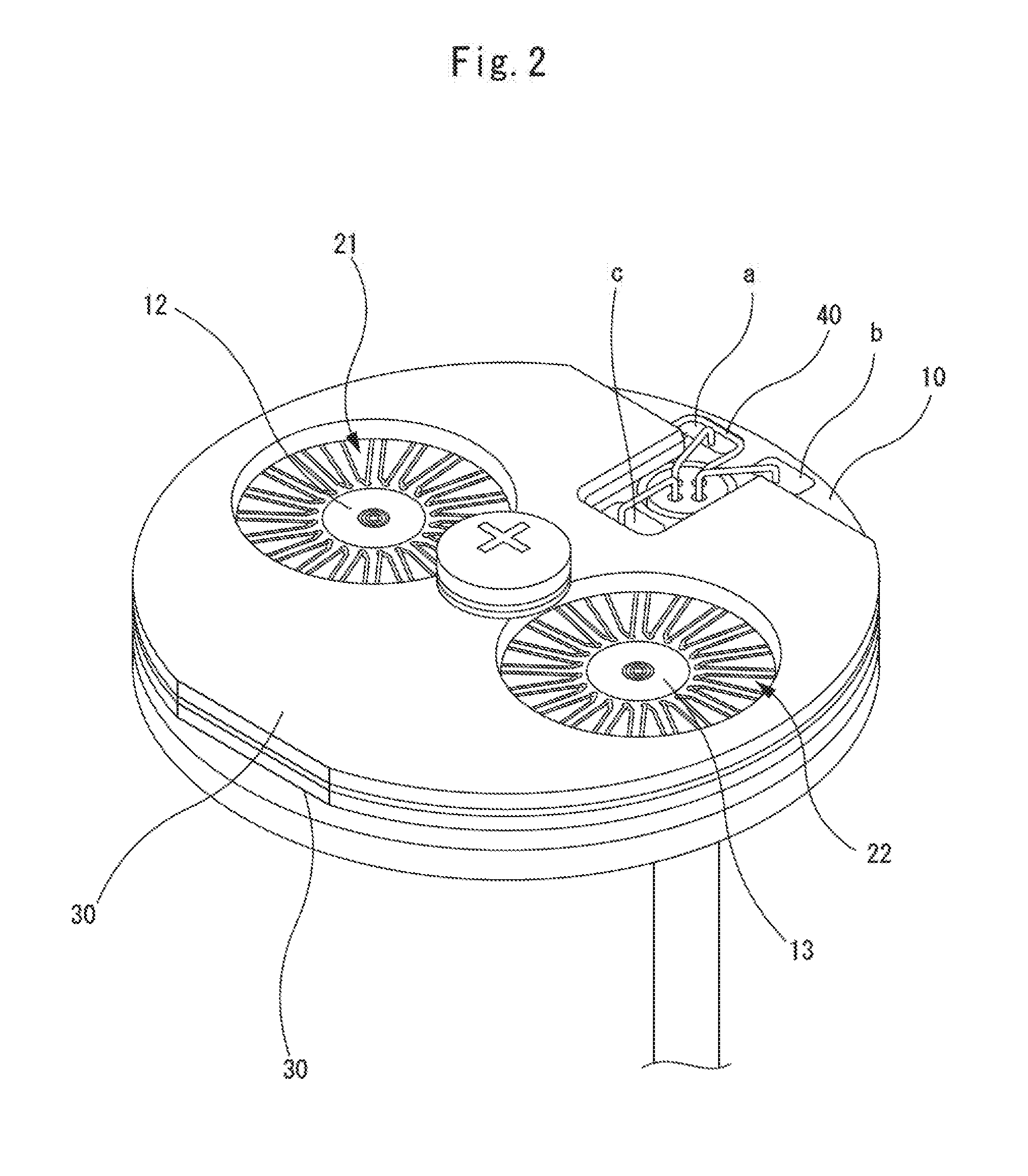

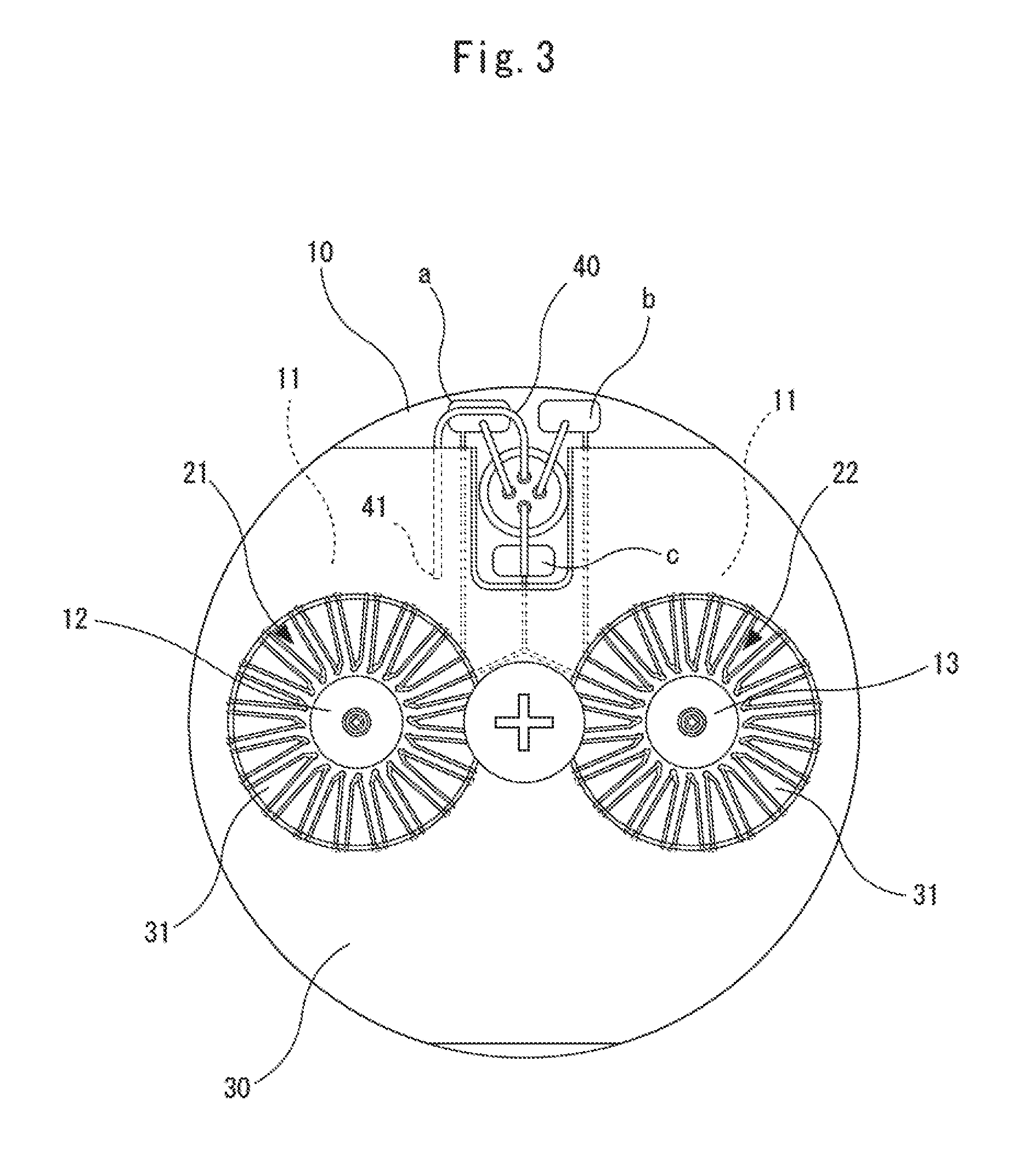

Gas turbine

InactiveCN105179029AUniform thermal expansionAvoid Axial MisalignmentEngine manufactureTurbine/propulsion engine coolingEngineeringGas turbines

A gas turbine configured to prevent eccentricity of a rotor (14) due to heat is installed with a strut (23), an outer diffuser (24), an inner diffuser (25), a strut cover (26), and a partition wall (28), wherein the gas turbine includes an inflow hole (31) for cooling air (W), a first flow passage (R1) formed between a casing wall (21) and the outer diffuser (24), a second flow passage (R2) formed between the strut (23) and the strut cover (26), a third flow passage (R3) formed between the inner diffuser (25) and the partition wall (28), and an outflow hole (51) installed in the inner diffuser (25).

Owner:MITSUBISHI HITACHIPOWER SYST LTD

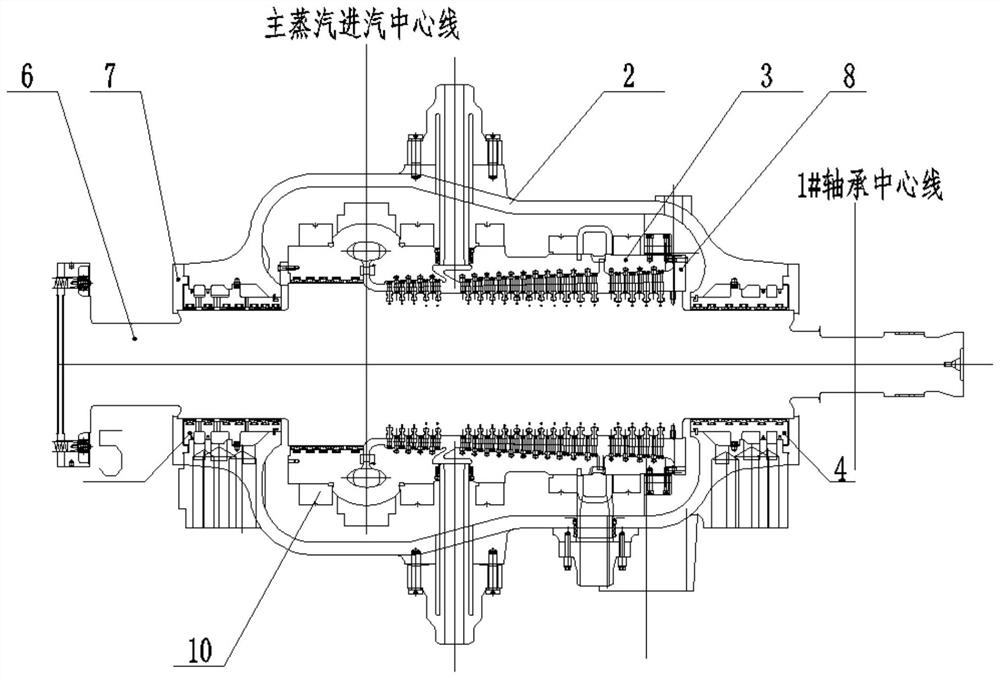

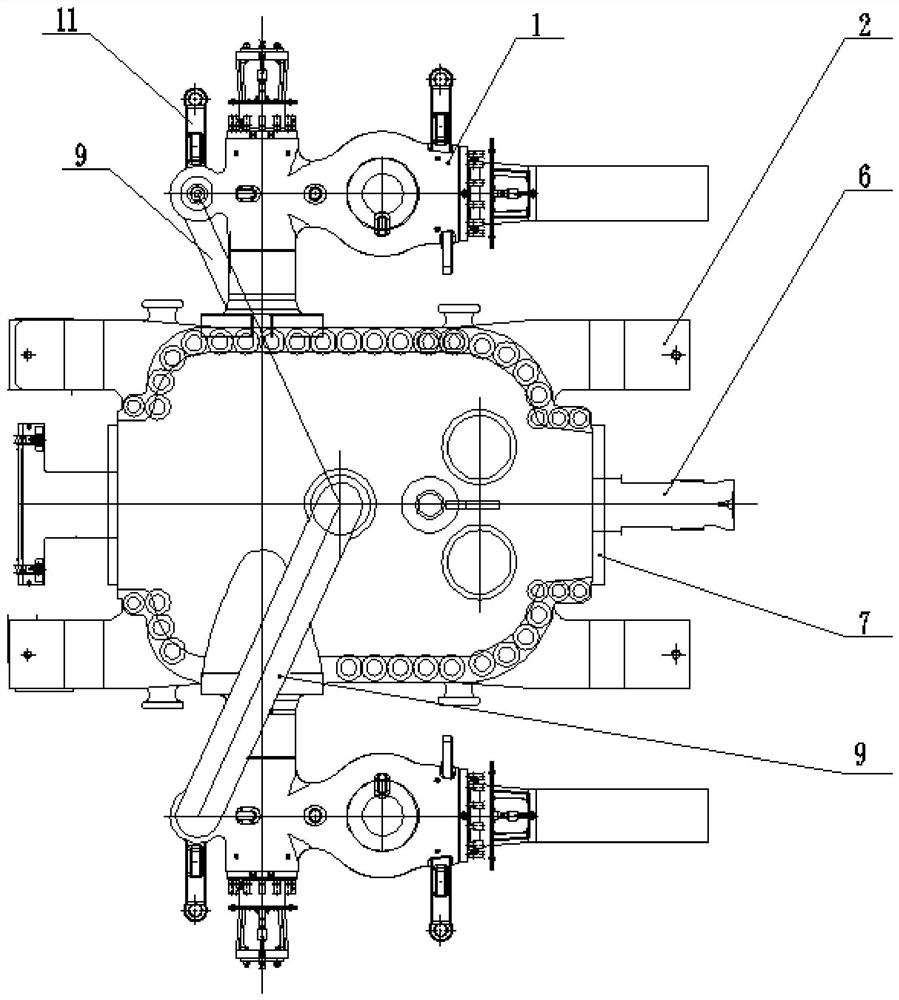

High-pressure module for supercritical 350MW three-cylinder steam turbine

PendingCN112746873AImprove thermal efficiencyHigh thermal efficiencyCombination enginesEngine componentsEngineeringSteam turbine

The invention relates to a high-pressure module, in particular to a high-pressure module for a supercritical 350MW three-cylinder steam turbine. The problems that an existing high-pressure module of a three-cylinder steam turbine is complex in steam inlet structure, high in weight and low in cylinder efficiency, thermal expansion of an inner cylinder split flange is uneven, and field installation is inconvenient are solved. Two high-pressure main steam adjusting combination valves are directly connected with a high-pressure outer cylinder through flanges, a high-pressure inner cylinder is installed in the high-pressure outer cylinder, a high-pressure rotor is rotatably installed in the high-pressure inner cylinder, the end of the high-pressure inner cylinder is connected with a high-pressure inner cylinder positioning plate through bolts, a high-pressure outer cylinder positioning plate is connected with the end of the high-pressure outer cylinder through bolts, a high-pressure cylinder adjusting end steam seal and a high-pressure cylinder electric end steam seal are installed on the two sides of the high-pressure outer cylinder respectively, a high-pressure steam supplementing valve is installed on each high-pressure main steam adjusting combination valve, one end of each steam supplementing guide pipe is connected with a corresponding high-pressure steam supplementing valve, and the other end of each steam supplementing guide pipe is connected with a connecting pipe structure of the high-pressure outer cylinder. The invention is used in the supercritical 350MW three-cylinder steam turbine.

Owner:济宁华源热电有限公司 +1

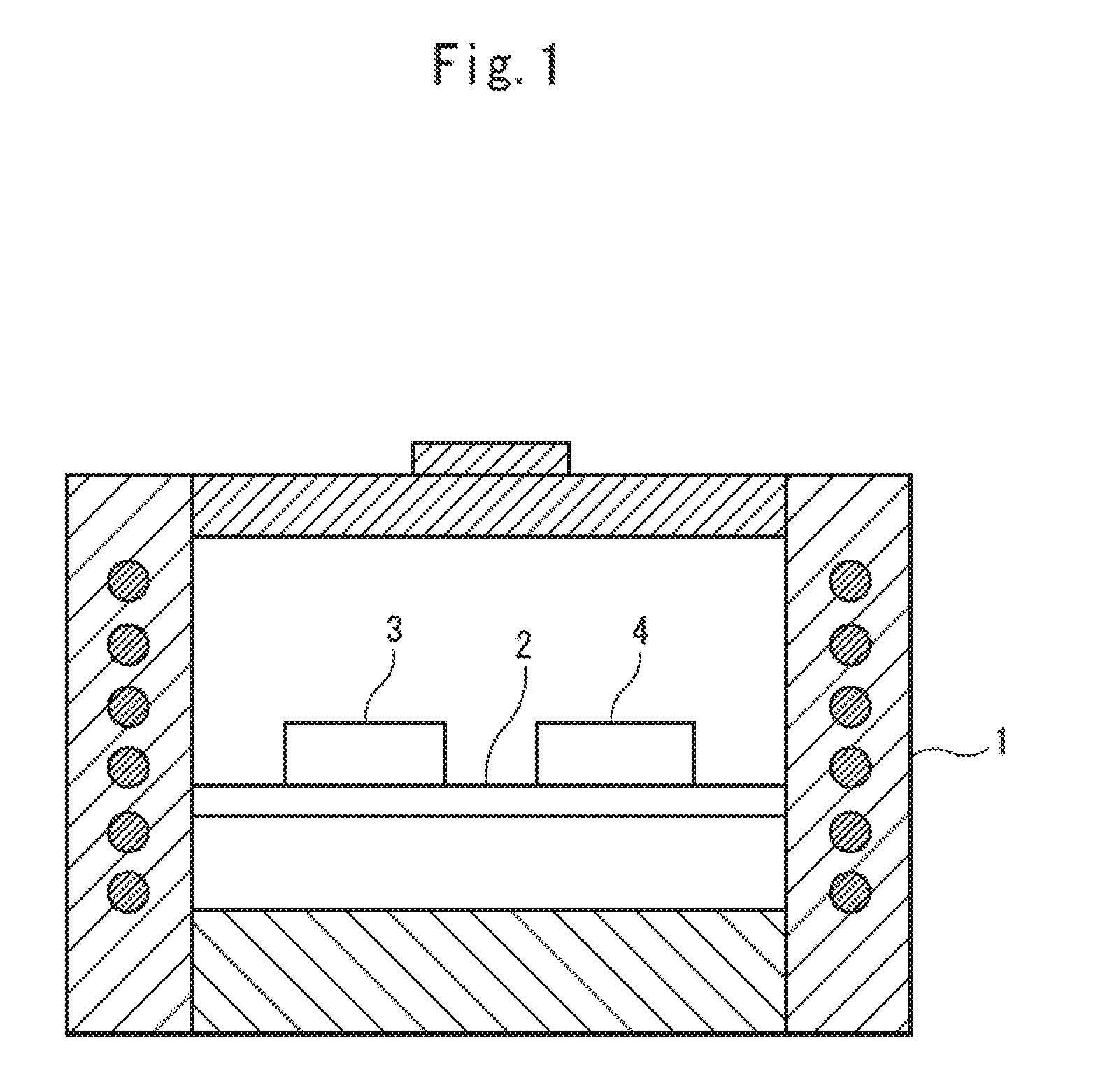

Sensor unit for thermal analysis equipment and thermal analysis equipment

InactiveUS20170045466A1Excellent thermal uniformityUniform thermal expansionThermometers using value differencesMaterial heat developmentThermal transmittanceThermal conductivity

First and second multi-pair thermocouples (21, 22) are formed on the upper surface of a heat-sensitive member (10), and a thermally uniformizing member (30) is adhesively attached to a base portion (11) of the heat-sensitive member (10). The thermally uniformizing member (30) is formed of a heat-resistant and electrically insulating material having a higher thermal conductivity than the heat-sensitive member (10) and a linear expansion coefficient approximate to the linear expansion coefficient of the heat-sensitive member (10). For example, the heat-sensitive member (10) is formed of mullite, and the thermally uniformizing member (30) is formed of aluminum nitride, whereby damage caused by thermal expansion can be prevented and at the same time the base portion (11) of the heat-sensitive member (10) can be thermally uniformalized.

Owner:RIGAKU CORP

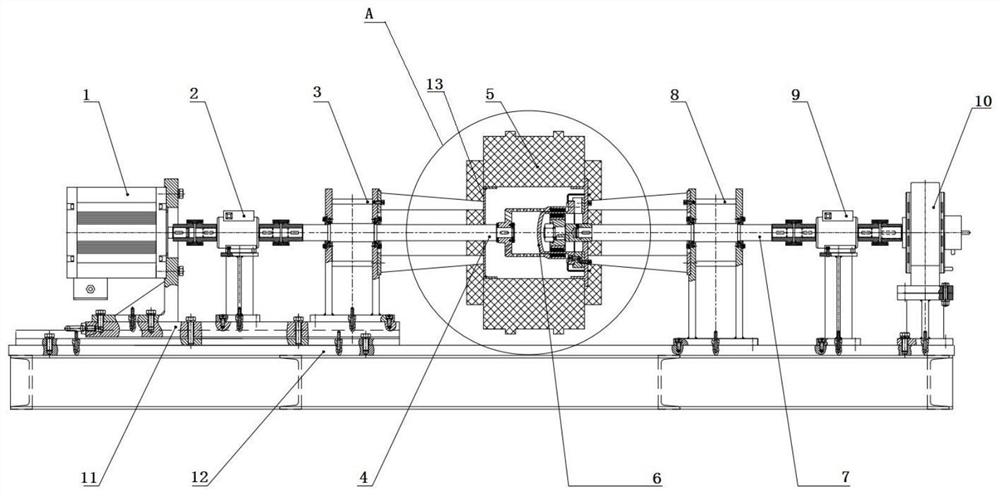

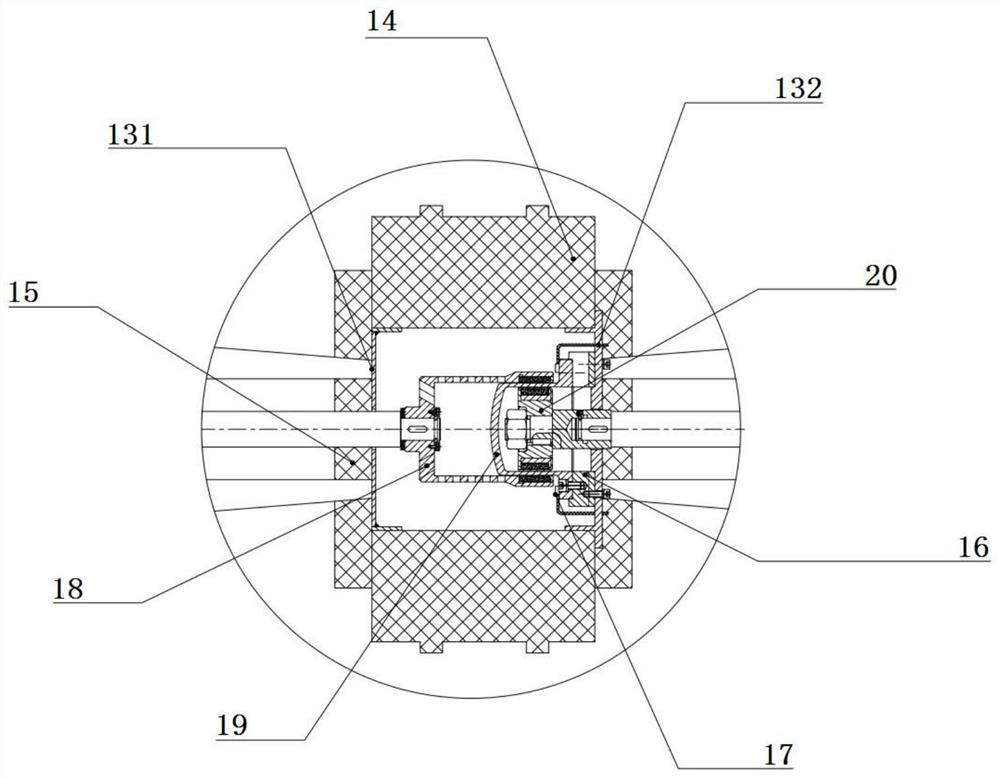

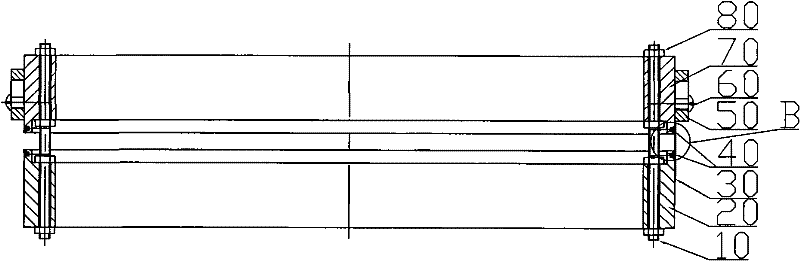

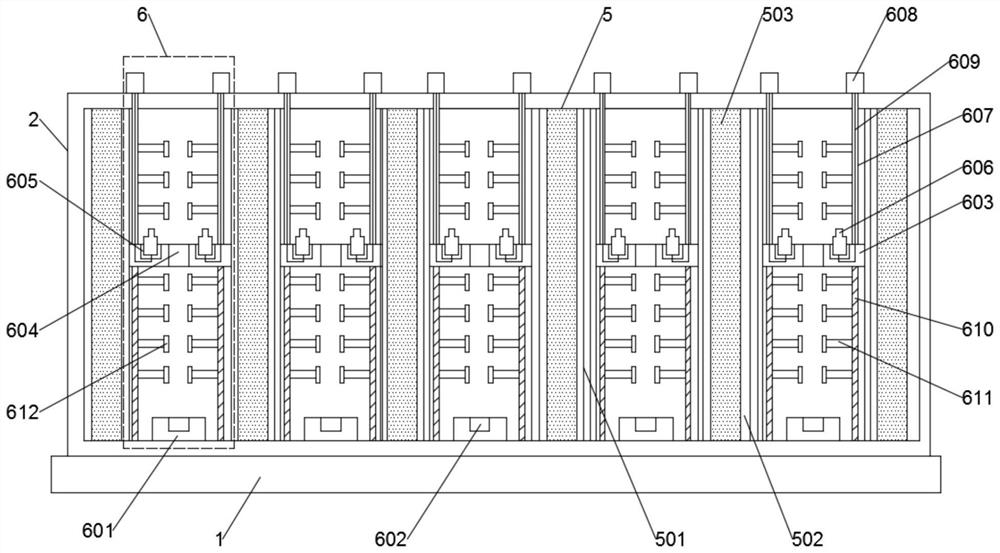

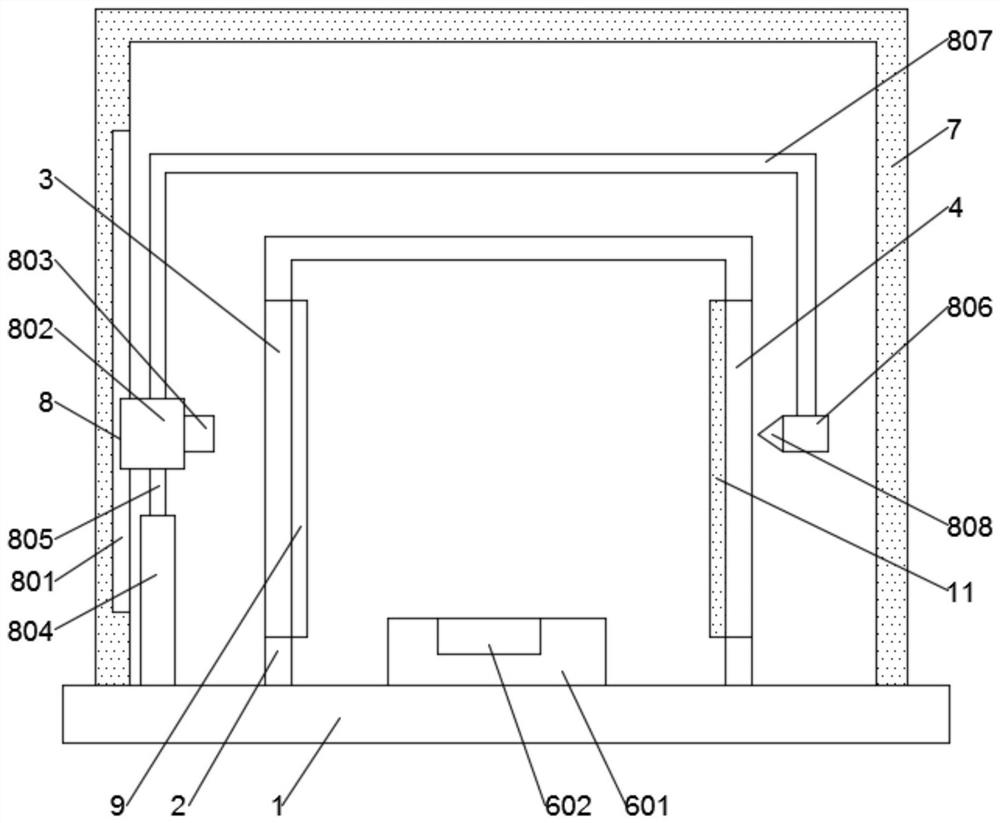

Magnetic coupling performance testing device

The invention discloses a coupling testing device, and aims to provide a magnetic coupling performance testing device capable of testing the maximum transmission torque and the transmission efficiency value at different temperatures. The device comprises an input shaft, a high-temperature test box, a coupling test piece and an output shaft, the coupling test piece is arranged in the hollow high-temperature test box, the left end and the right end of the coupling test piece are connected with the input shaft and the output shaft respectively, and flange supports used for fixing the input shaft and the output shaft are arranged on the two side walls of the high-temperature test box respectively. A gap exists between the coupling test piece and the inner surface of the high-temperature test box. The flange supports are adopted on the two side walls of the high-temperature test box to support the input shaft and the output shaft, the input shaft and the output shaft can axially and freely expand at a high temperature, and a gap exists between the circumference of the test piece and the high-temperature test box so that the test piece can be uniformly heated and expanded, the accuracy of performance test is improved, and local overheating is avoided. The design has a high practical value.

Owner:浙富控股集团股份有限公司

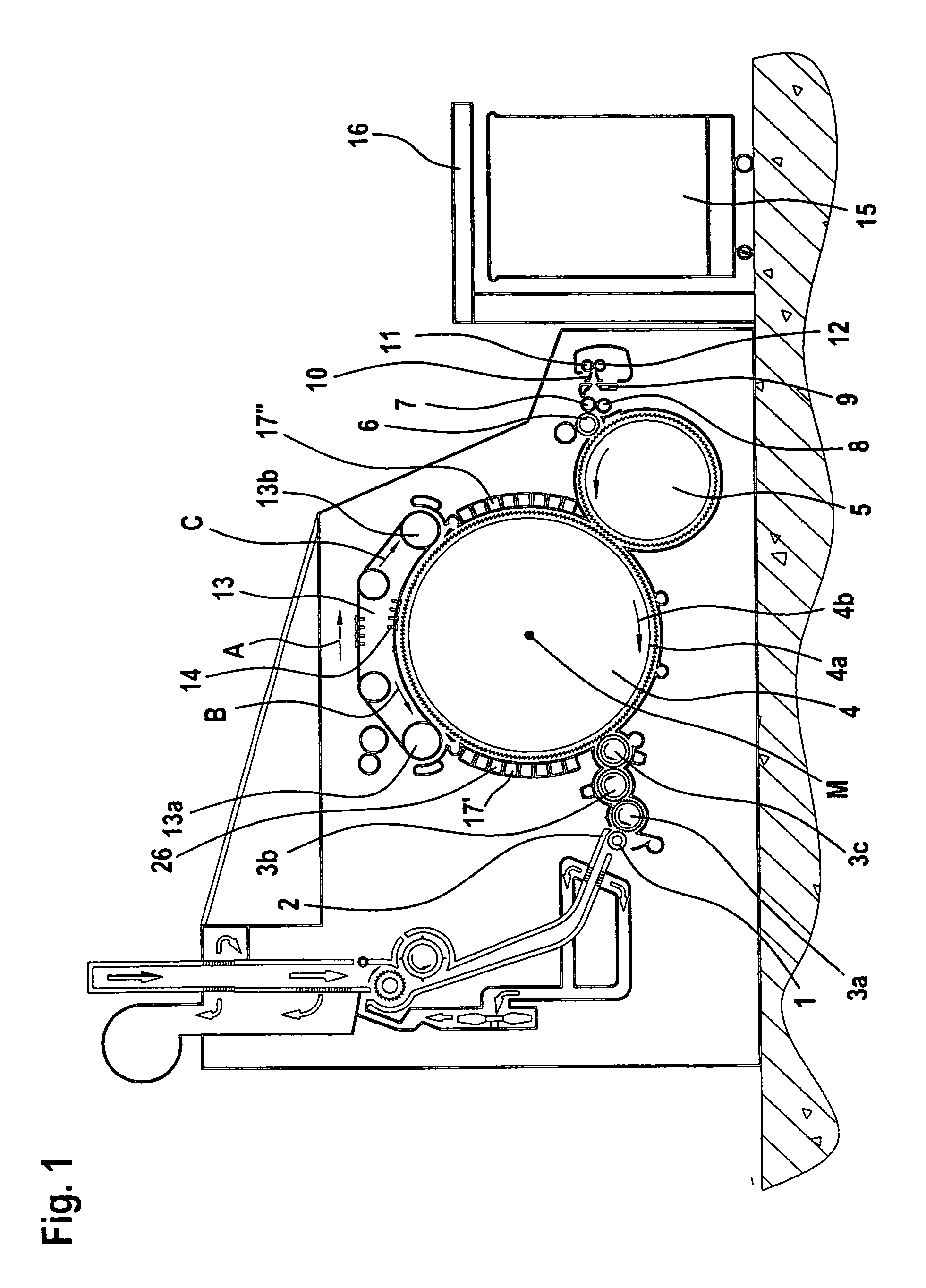

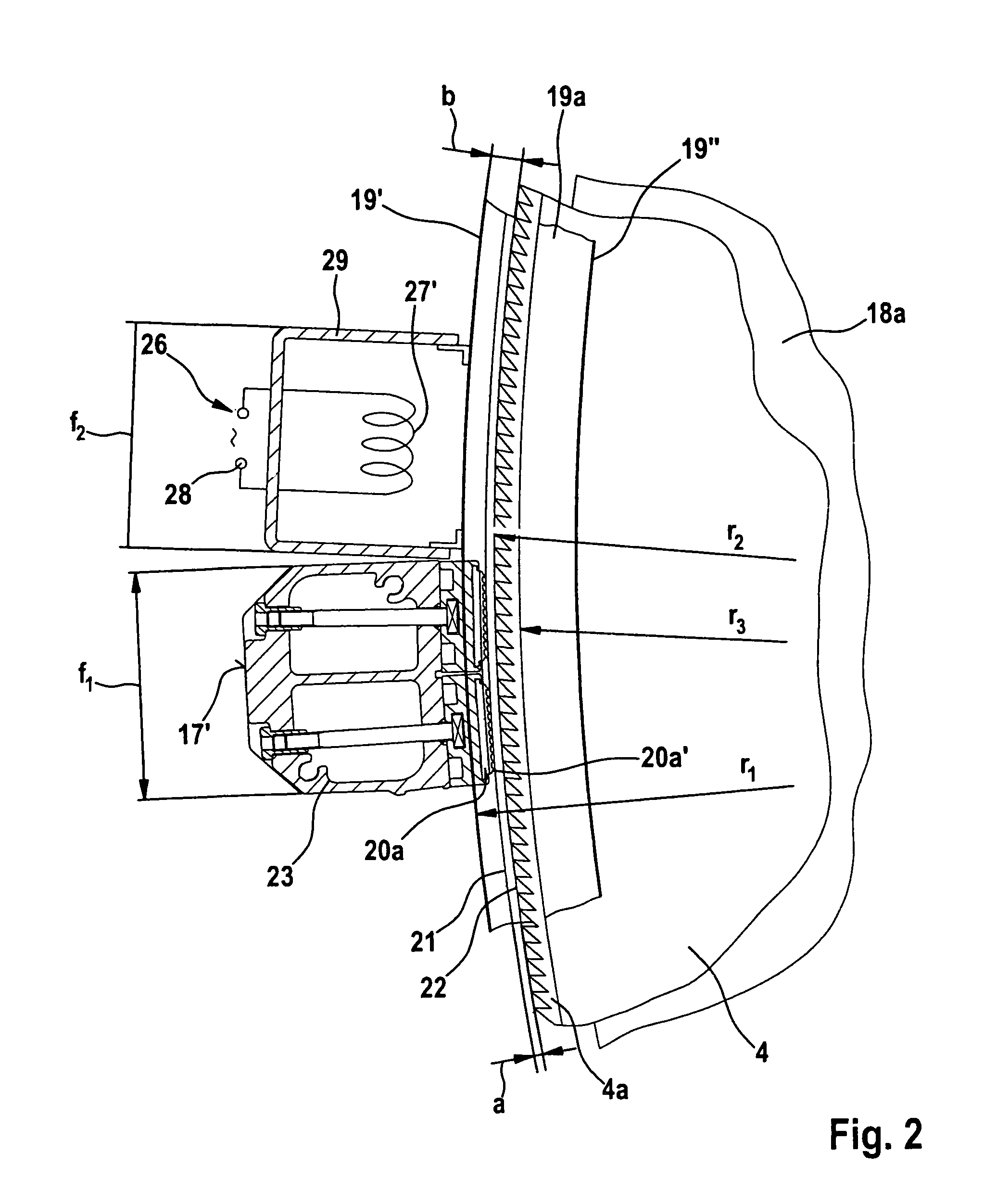

Apparatus on a spinning preparation machine, especially a flat card, roller card, or the like, for adjusting the carding clearance

An apparatus is provided on a spinning preparation machine for adjusting the carding clearance. A clothed roller has a cylindrical peripheral surface and a cladding facing and spaced therefrom, wherein between the peripheral surface of the roller and a part of the cladding there is a carding region with a carding clearance where carding work is performed and carding heat is generated, heat leading to an alteration across the width of the machine in the contour of at least one of the components lying opposite each other. In order in simple manner to allow a uniform carding clearance under different production and processing conditions, the carding clearance can be made smaller by external energy input to at least one of the components facing each other and / or can be enlarged by throttling the energy input and the energy input.

Owner:TRUETZSCHLER GMBH & CO KG

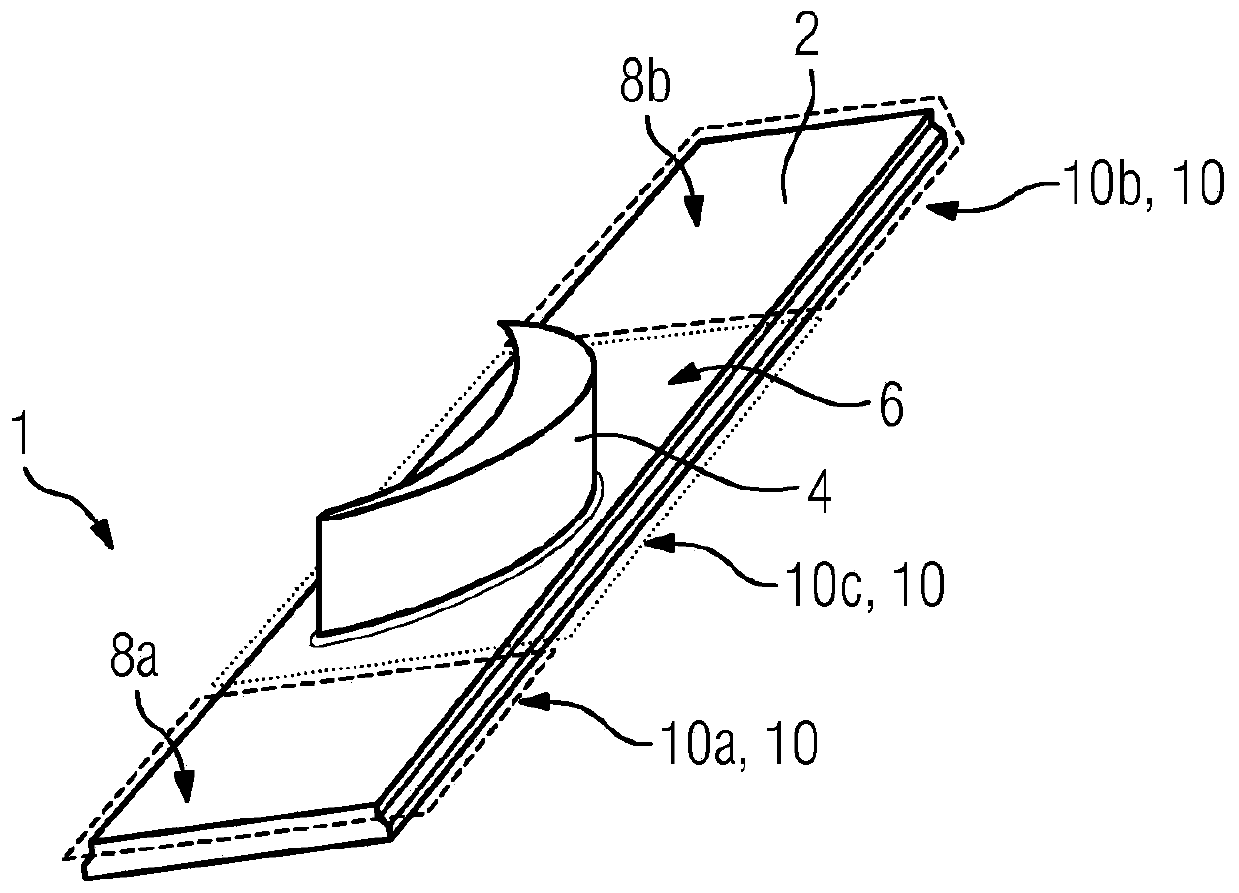

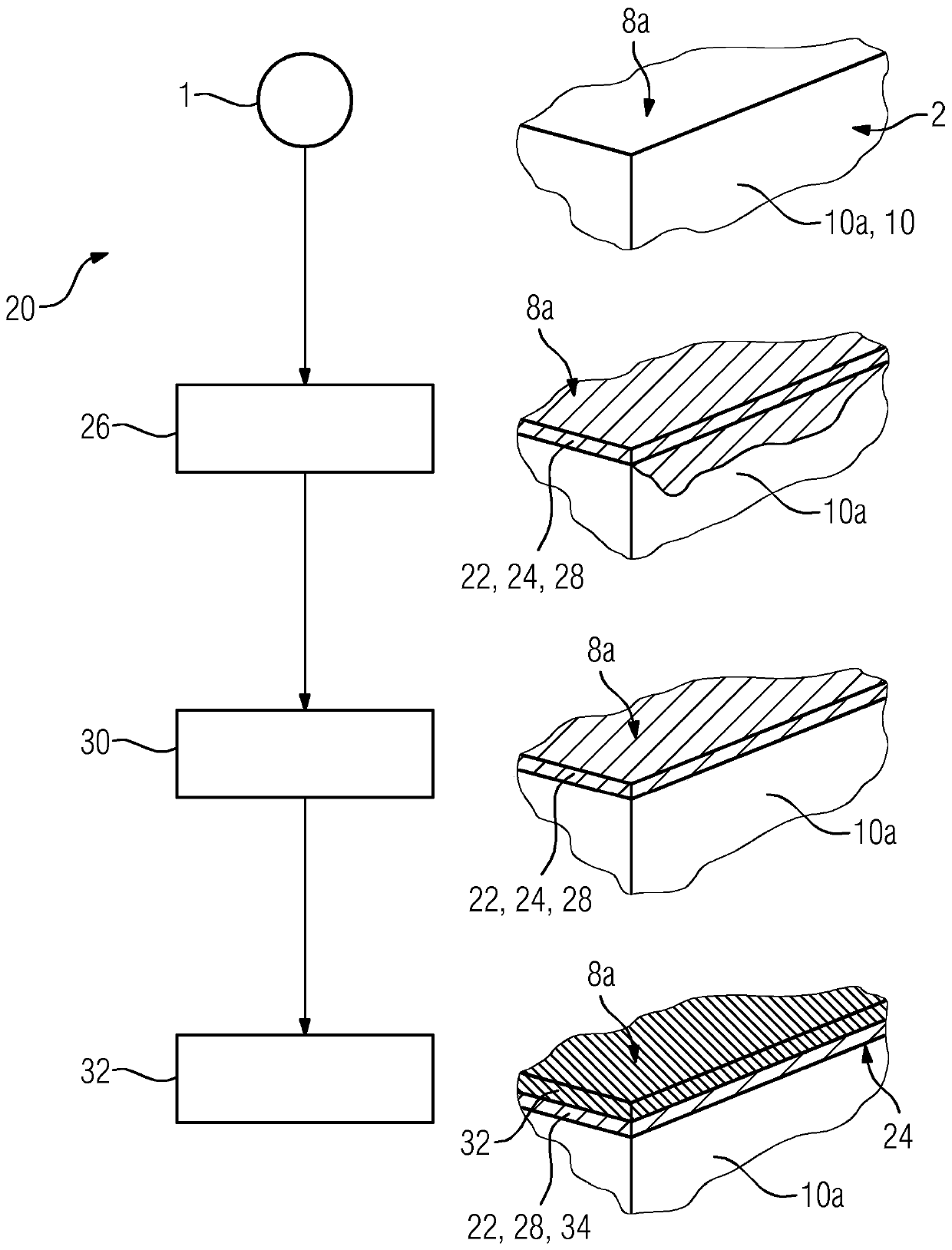

Method for coating turbine blades

ActiveCN107002214BReduced risk of partial separationReduce adhesionHot-dipping/immersion processesMolten spray coatingTurbine bladeEngineering

The invention proposes a method (2) for coating a turbine blade (1) comprising an airfoil (4) and at least one platform arranged at the end of the airfoil (4) (2), wherein the or each platform (2) has a contact region (6) and at least one planar raised region (8a, 8b) adjacent to the contact region (6), and the airfoil ( 4) terminating in the contact zone (6), with the following method steps: applying at least a first layer (22) of the coating (24) on the airfoil side on the platform (2), and applying the coating (24) ) of the at least first layer (22) remaining on the end face (10c) within the range of the contact zone (6), the at least first layer (22) of the coating (24) in the protruding zone (8a, 8b) are removed from at least one end face (10a, 10b) of the platform (2).

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

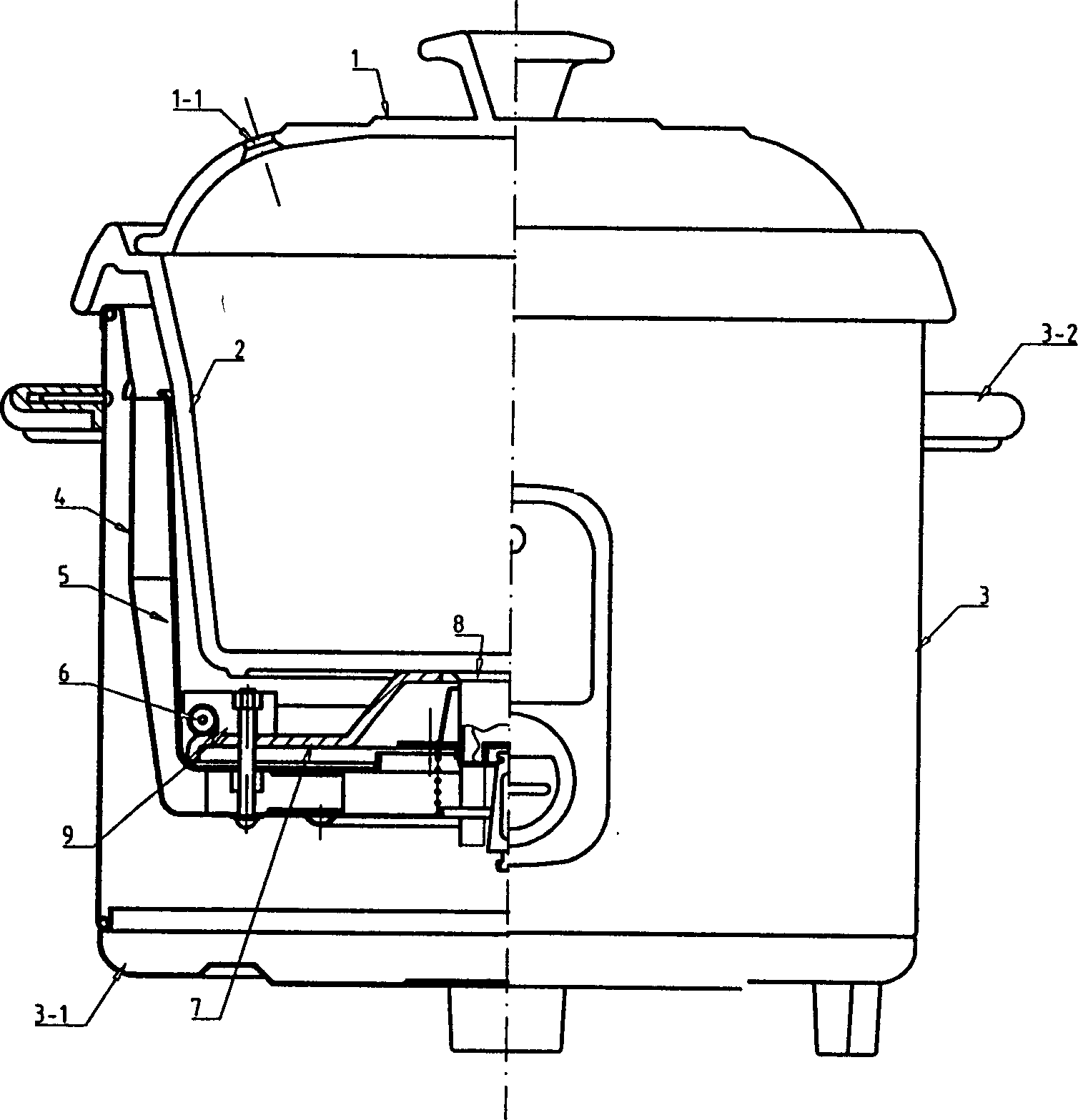

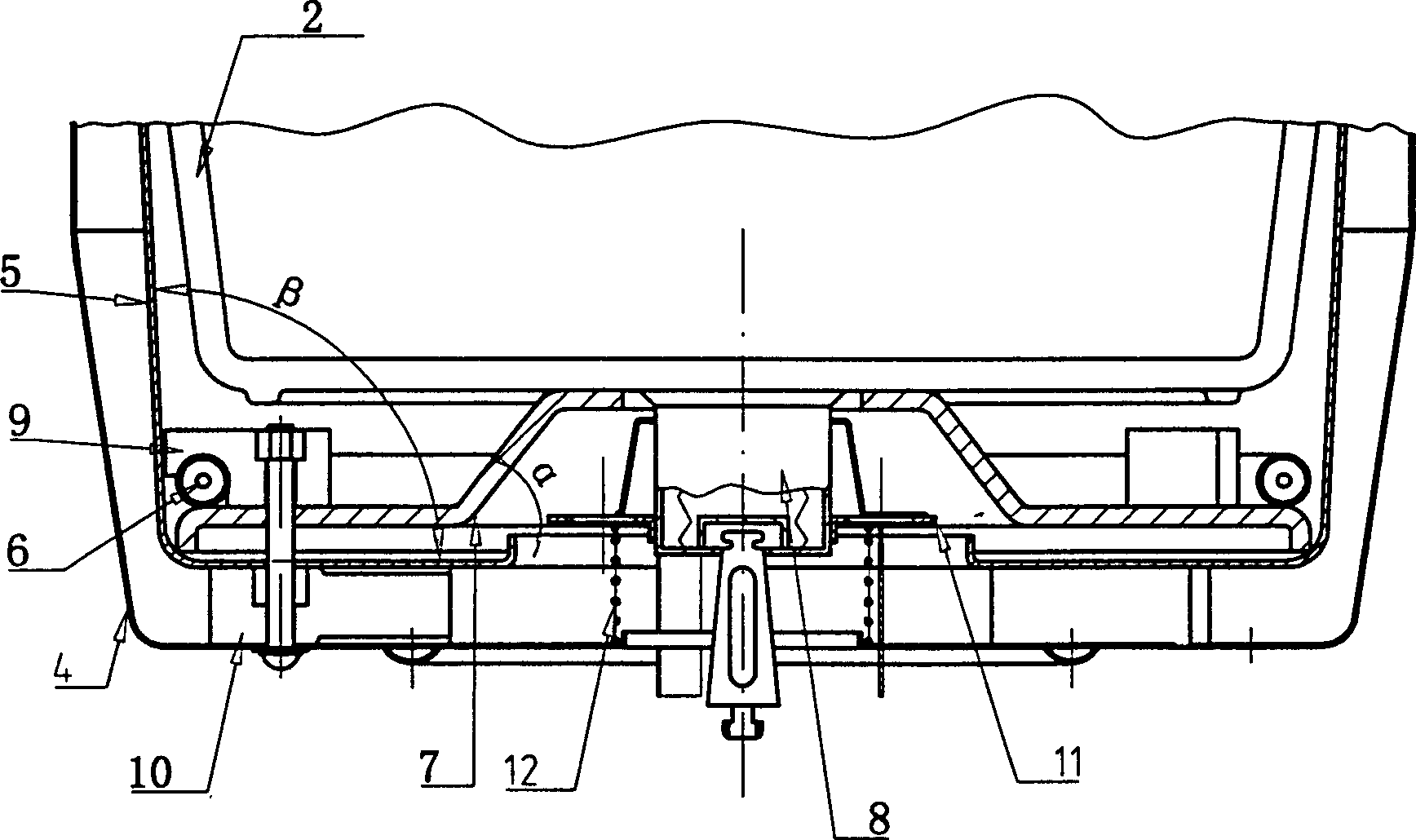

Fast energy saving electrothermal dark red pottery cooker

InactiveCN1121840CUniform thermal expansionWon't burstCooking vesselsTemperature controlHeat conducting

A fast and energy-saving purple sand ceramic electric heating pot, which is composed of an upper cover 1, a pot liner 2, a casing 3, a convection cooling cover 4, a heat insulating cover 5, an electric heating tube 6, a heat conducting plate 7, etc., and the heat conducting plate is placed in the heat insulating cover Inside, the exposed electric heating tube is installed on the board, and there is a raised platform on the board. The boss 7-1 and the temperature limiter 8 form a temperature limiting control mechanism. The pot liner 2 is placed on the boss. The distance between the bottom of the pot and the electric heating tube is Above 5mm, the space distance between the pot liner and the heat insulation jacket is less than 10mm, and the distance between the heat insulation jacket and the convection cooling jacket is greater than 2mm, during which air convection is formed from bottom to top, which greatly reduces the temperature of the shell, and can improve the heating temperature and efficiency. Dry burning to 350°C without cracking, saving 30-40% of electricity, and accurate temperature limit, has opened up a wide range of uses for purple sand ceramic cookware.

Owner:JIANS HOUSEHOLD ELECTRICAL APPLIANCE FACTORY SHUNDE DISTRICT FOSHAN CITY

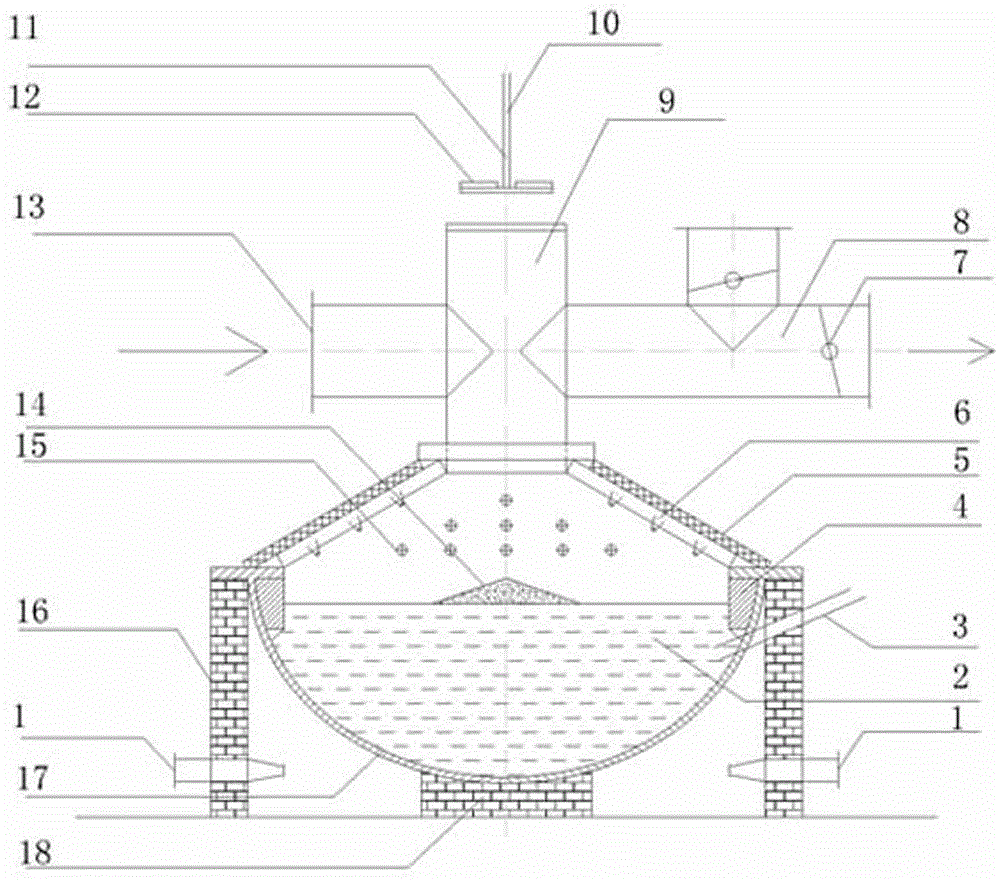

A long-life and durable lead-antimony alloy high-grade antimony white volatilization furnace

ActiveCN104495923BUniform thermal expansionExtended service lifeAntimony compoundsCharge manipulationVolatilesSlag

The invention relates to a durable lead-antimony alloy top-grade antimony white volatilization furnace with long service life. The durable lead-antimony alloy top-grade antimony white volatilization furnace comprises a furnace body (17), wherein the furnace body is a semispherical pot body formed by a furnace body wall (16) and a furnace bottom substrate (18), the furnace body wall is provided with a flame nozzle (1) facing the bottom of the furnace body and a feed opening (3) which is communicated with an inner cavity of the furnace body; a high temperature refractory material layer (4) with high slag invasion resistance is embedded nearby a slag line of the inner cavity of the furnace body; a gas collection cover (5) is arranged on the top of the furnace body in a covering manner, the gas collection cover is of a conical structure, a plurality of primary gas inlet nozzles (6) which incline towards the liquid surface in the furnace body are arranged on the gas collection cover, and a central slag fishing opening (9) which can be opened and closed is formed in the middle part of the gas collection cover; and a secondary gas inlet (13) and a gas outlet (8) with a valve (7) are formed in the central slag fishing opening. The furnace body is long in service life, unlikely to damage and simple and convenient to operate.

Owner:LEIYANG YANXIN NON FERROUS METALS

Adjustable strip-plating die

The invention discloses an adjustable strip-plating die which comprises an upper annular die and a lower annular die with same diameter as the upper annular die, wherein one side of the upper annular die, which is in contact with the lower annular die, is provided with a convex ring, a circle of water through holes are arranged on the convex ring, the outer side of each water through hole is provided with a threaded hole, one side of the lower annular ring, which is in contact with the upper annular die, is provided with a concave ring, the lower annular die is provided with an axial long regulating hole opposite to the thread holes, the upper annular die and the lower annular die are sleeved through the convex ring and the concave ring in transition matching manner, and screws are screwed in the threaded holes after passing through the long regulating hole so as to fixedly connect the lower annular die with the upper annular die together. Because the upper annular die and the lower annular die are embedded and matched, the rigidity of the die is greatly increased; meanwhile, the adjustable strip-plating die with critical dimension can be processed by once clamping so that the precision is improved.

Owner:曲悦峰

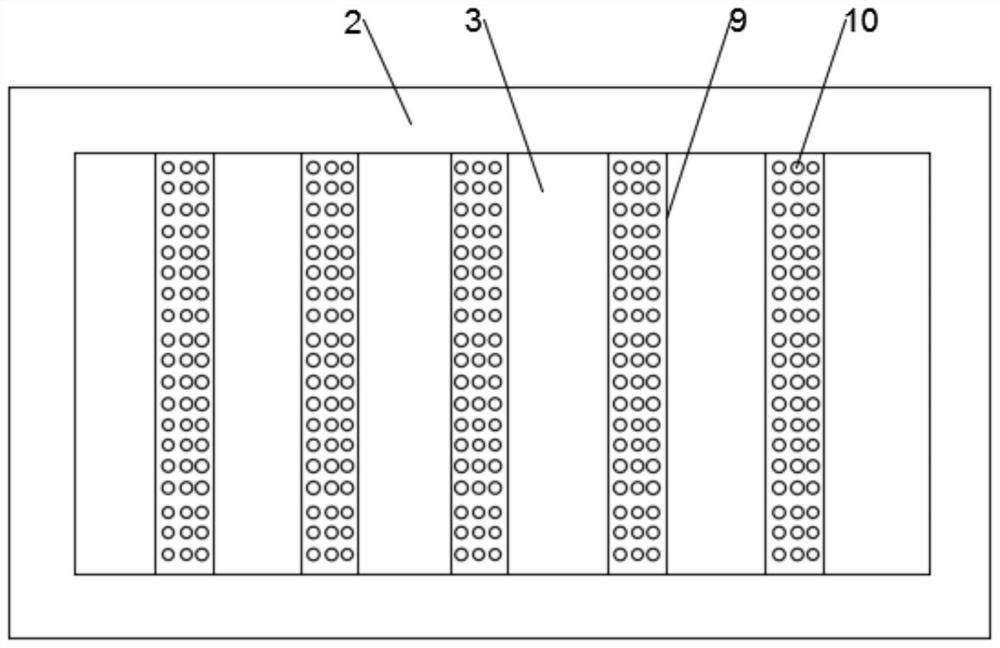

A thermal expansion coefficient measurement device based on engineering thermophysics

ActiveCN108614003BHigh measurement accuracyUniform thermal expansionMaterial thermal coefficient of expansionThermal dilatationMeasurement device

The invention discloses a thermal expansion coefficient measuring device based on engineering thermophysics. The thermal expansion coefficient measuring device comprises a support base, wherein a measuring shell is mounted at the top of the support base; a front transparent glass layer and a rear transparent glass layer are respectively arranged at the front end and the rear end of the measuring shell; a uniform heating mechanism is arranged inside the measuring shell; the uniform heating mechanism comprises heat conduction blocks which are arranged inside the measuring shell and are uniformlydistributed; holding cavities are formed inside the heat conduction blocks; electric heating plates are arranged inside the holding cavities; thermal expansion coefficient measuring mechanisms are arranged inside adjacent heat conduction blocks; a gantry is arranged outside the measuring shell; an adjusting photographing mechanism is arranged on the gantry. By adopting the thermal expansion coefficient measuring device, measurement of an object to be measured can be prevented from being affected by a measuring structure, meanwhile, temperatures inside the device can be uniformly distributed,the precision of measurement results can be ensured, in addition, thermal expansion coefficients of multiple objects can be simultaneously measured, multiple times of measurement can be carried out toobtain an average value, and thermal expansion coefficients of multiple objects can be simultaneously measured.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

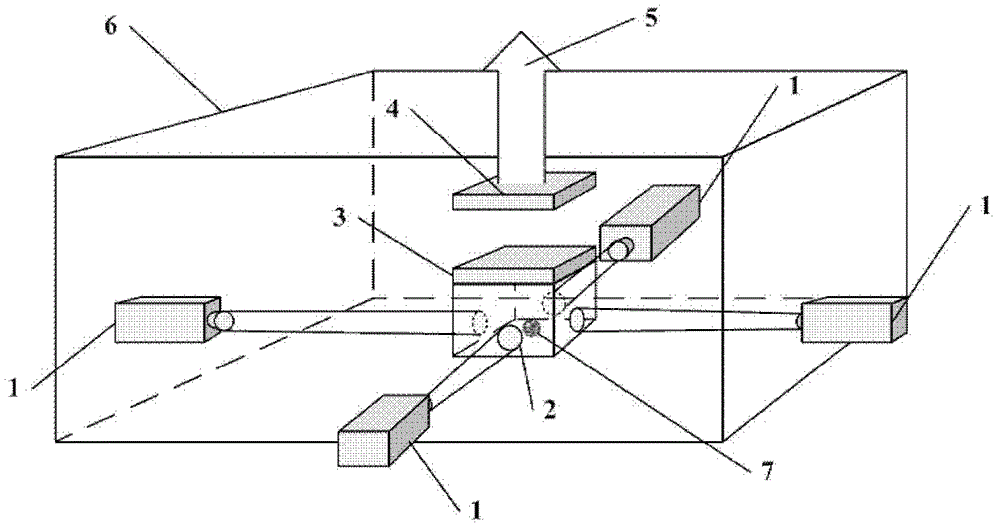

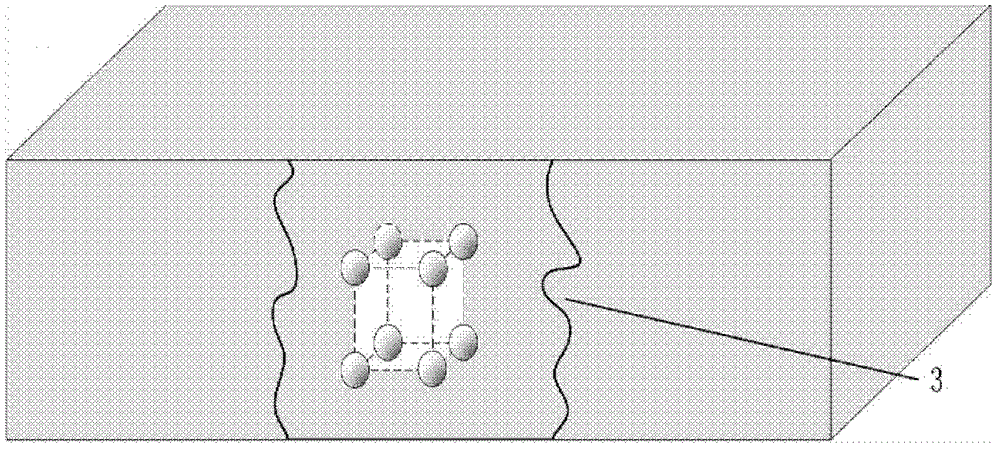

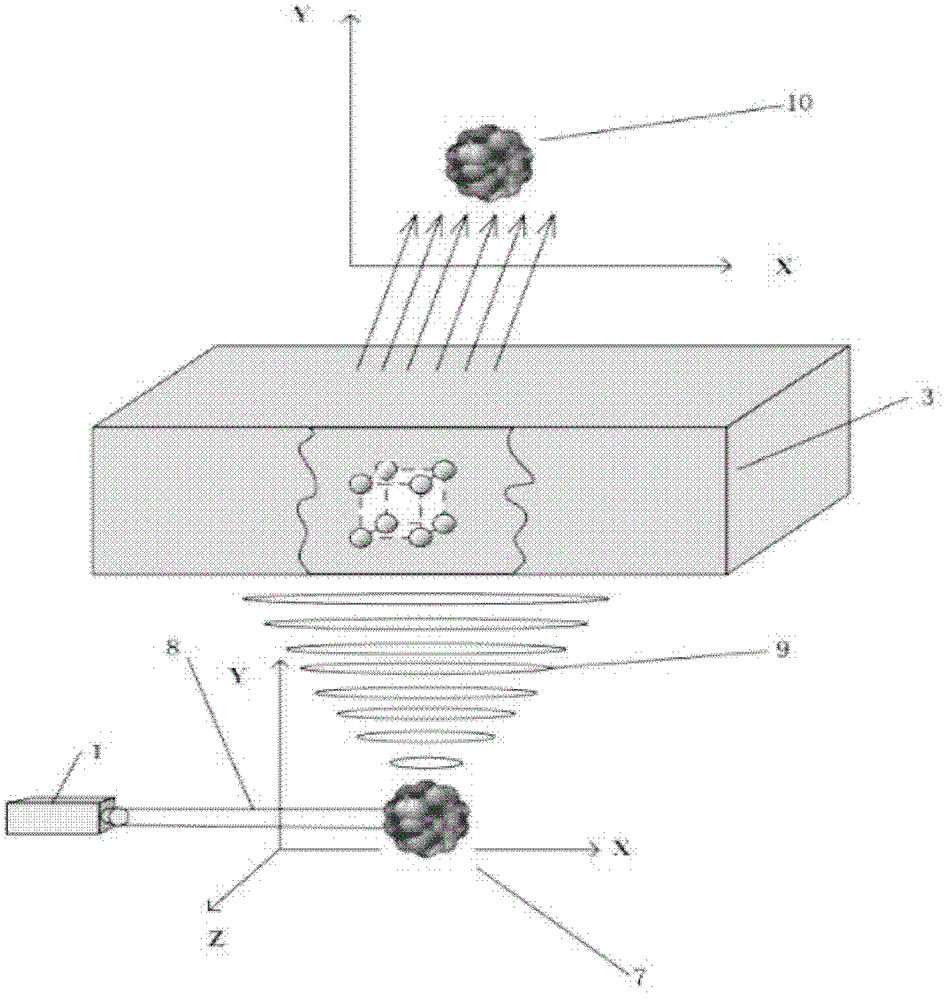

Three-dimensional opto-acoustic imaging system based on acoustic lens and sensor array and method

InactiveCN102608036BUniform thermal expansionAccurate recordMaterial analysis by optical meansSensor arrayDisplay device

The invention relates to a three-dimensional opto-acoustic imaging system based on an acoustic leans and a sensor array and a method. The system is a cube experimental table and mainly comprises a laser device, a beam expander, the phonon crystal lens, the opto-acoustic sensor array, a data bus, a ground glass container, a data acquisition module and a computer for image processing, center points of four side surfaces of the cube ground glass container are irradiated by laser, so that a sample is uniformly irradiated by the laser via dispersion of ground glass, and is uniformly heated and expanded, acoustic signals generated by expansion of the sample focus to form a beam, the opto-acoustic sensor array, the data acquisition module and the computer for image processing acquire and record opto-acoustic three-dimensional imaging data in real time, and a three-dimensional light absorption distribution image of the detected sample can be directly seen from a display via image processing. The three-dimensional opto-acoustic imaging system has the advantages of complete functions, stable performance, low cost and the like, and can be widely applied to the fields of biology, medical science, material analysis and the like.

Owner:ZHONGBEI UNIV

A kind of cold-resistant insulating resin composition and preparation method thereof

The invention belongs to the technical field of high polymer material and specifically relates to a cold-resistant insulating resin composition and a preparation method thereof. The cold-resistant insulating resin composition is prepared from the following raw materials (by weight): 70-85 parts of EPDM rubber, 10-23 parts of BR, 22-34 parts of Styrene Butadiene Rubber, 5-15 parts of wood fiber, 5-8 parts of a fire retardant, 80-100 parts of a filler, 3-6 parts of an anti-aging agent, 4-8 parts of a vulcanizing agent, 1-2 parts of a cross-linking agent, 12-25 parts of a softener and 4-10 parts of an accelerant. Through cooperation of the various raw materials, the insulating resin composition has excellent tensile property, aging resistance, oil resistance, cold resistance and flame retardant property.

Owner:国网河南省电力公司社旗县供电公司

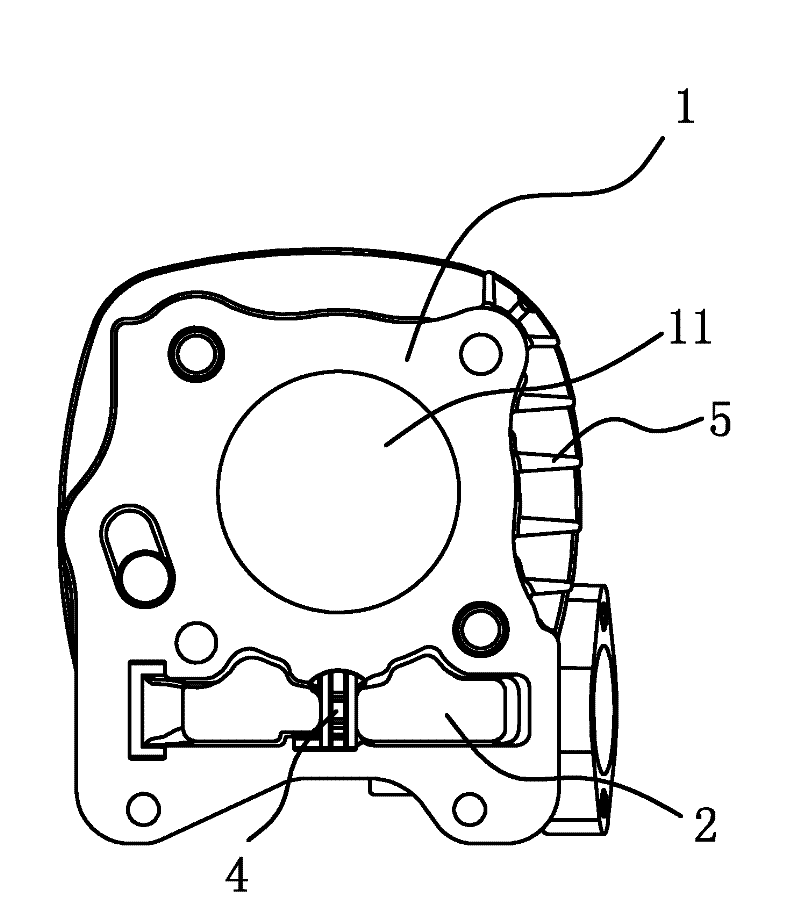

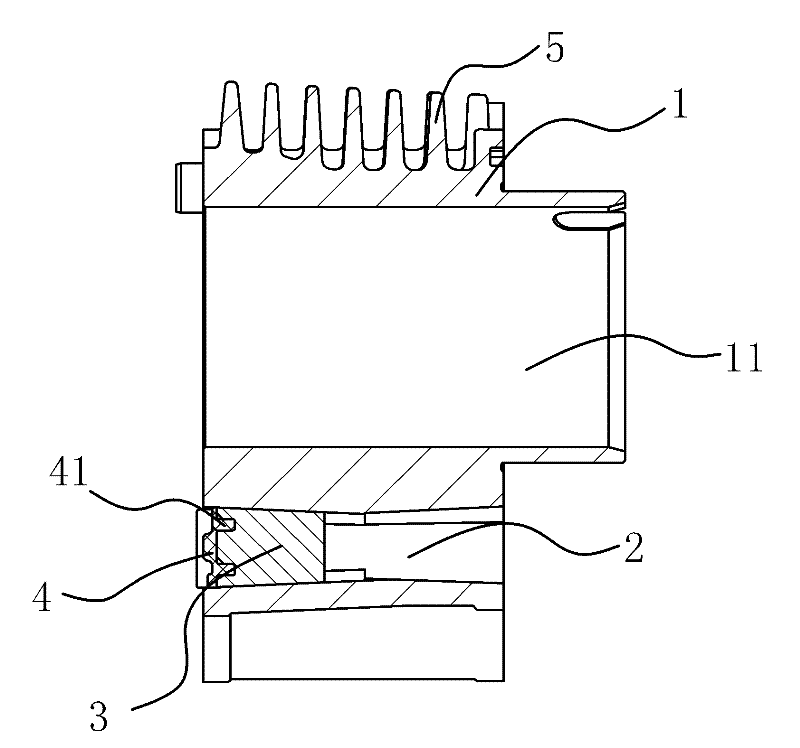

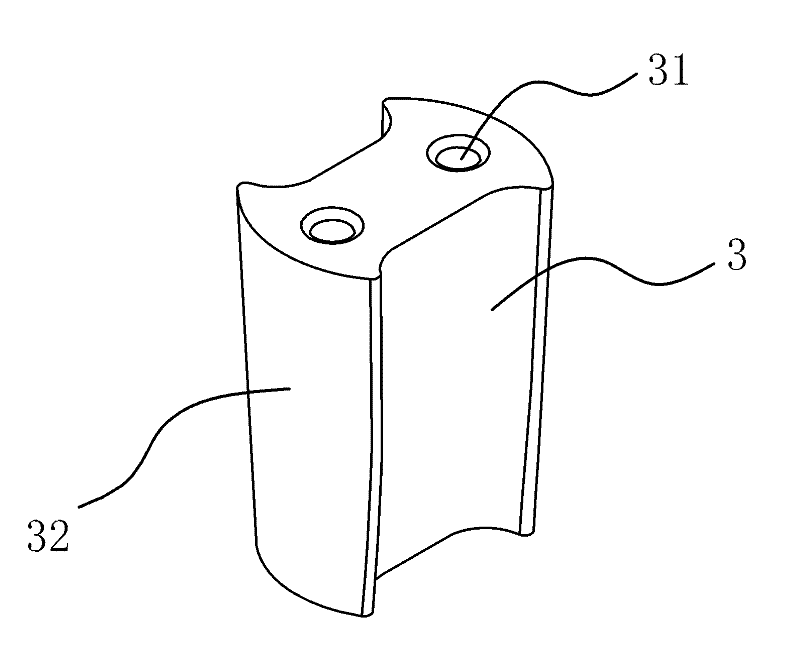

Cooling system of engine cylinder

ActiveCN101943047BEasy to fixEasy to replaceAir coolingCylinder headsHeat conductingMetallic materials

The invention provides a cooling system of an engine cylinder, belonging to the technical field of motorcycle engines and solving the problems of complicated structure, difficult processing, poor stability, and the like of the cooling system of a traditional engine cylinder. The cooling system of the engine cylinder comprises an engine cylinder body with a cylinder hole, one side of the engine cylinder body is provided with a cam chain chamber for mounting a cam chain, heat radiating ribs are arranged at other sides of the engine cylinder body, the cam chain chamber is internally provided with a heat-conducting piece, both outer walls of the heat-conducting piece are respectively attached to the outer lateral wall of the engine cylinder body and the inner lateral wall of the cam chain chamber, and the heat-conducting piece is made from a metal material. The invention has the advantages of good radiation effect, convenient processing and mounting and engine vibration and noise reduction.

Owner:浙江美可达摩托车有限公司

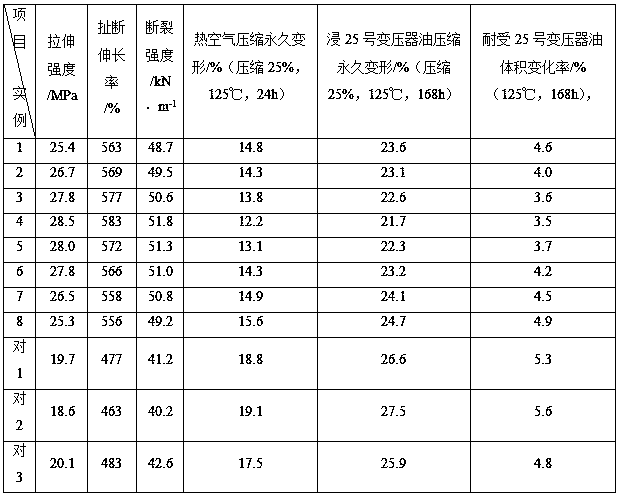

Phosphogypsum fireproof door core filler and preparation method thereof

PendingCN114409436ASolve the mechanical propertiesWith sound insulationFireproof doorsCement mixing apparatusPolyesterFiber

The invention discloses ardealite fireproof door core filler and a preparation method thereof, belongs to the technical field of door core filler processing, and aims at solving the problems that an existing fireproof door core plate is poor in mechanical property and tedious in door core plate installation. The preparation method comprises the following steps: weighing alpha type phosphogypsum, polyester fiber, redispersible latex powder, expanded foaming microbeads, fly ash microbeads, a waterproof agent, aluminum powder and lime according to component amounts, mixing to obtain composite phosphogypsum powder, mixing the composite phosphogypsum powder with water according to a mass ratio of 1: 2 to obtain a component A, mixing the aluminum powder with the lime to obtain a component B, mixing the component A with the component B according to a mass ratio of 1: 1 to obtain a liquid slurry filler, and mixing the liquid slurry filler with water according to a mass ratio of 1: 1 to obtain the waterproof material. And the liquid slurry filler is poured into the door plate cavity, the liquid slurry filler is naturally foamed for 1.5-2 h, and the liquid slurry filler is in a solid state after being foamed. The problems that a fireproof door core plate is poor in mechanical property and tedious in door core plate installation are solved, and the fireproof door core plate has the advantages of sound insulation, heat insulation, heat preservation, fire prevention, light volume weight and the like.

Owner:GUIZHOU ZHENGHE AERATED CONCRETE CO LTD

Rubber material for transformer sealing ring and preparation method thereof

ActiveCN106883472BGood oil resistanceImprove wear resistanceBuilding insulationsRubber materialFiber

The invention belongs to the technical field of sealing materials and particularly relates to a rubber material for a sealing ring of a transformer and a preparation method of the rubber material. The rubber material is prepared from the following raw material in parts by weight: 50-70 parts of nitrile rubber, 20-30 parts of acrylic rubber, 5-10 parts of epichlorohydrin rubber, 3-8 parts of wood fibers, 5-10 parts of nanometer titania, 15-25 parts of a fortifier, 1-5 parts of an anti-aging agent, 1-3 parts of an accelerate, 1-3 parts of sulfur, 3-6 parts of zinc oxide, 4-8 parts of stearic acid, 3-6 parts of asphalt, 1-3 parts of chlorinated paraffin, 10-15 parts of a plasticizer and 5-15 parts of a cross-linking agent. The rubber material for the sealing ring of the transformer is high in strength, small in compressive deformation and excellent in anti-aging performance.

Owner:国网河南省电力公司方城县供电公司

Condensing turbonator starting method

InactiveCN111140292ASmooth vibrationUniform thermal expansionMachines/enginesEngine startersThermal dilatationEngineering

The invention discloses a condensing turbonator starting method. The method comprises the steps that at time of impulse starting, a unit vacuum breaking valve is adjusted when the rotor speed reachesa medium speed of 900-1000 r / min for warming-up, the exhaust steam temperature is increased uniformly to 60-70 DEG C with the speed increase not higher than 5 DEG C / min, warming-up is performed for 30-40min at the exhaust steam temperature, vibration is checked, and if the sound is normal, a unit surpasses a critical point at the speed of 200 r / min; after the unit surpasses the critical point, thespeed of the unit rises uniformly to 300 r / min from 100 r / min; after grid-connection is completed and the thermal expansion value reaches 70%-80% of the value at full load, the vacuum breaking valveis closed, it is noted that the exhaust steam temperature decreasing amplitude should not exceed 5 DEG C / min when the valve is closed, and at the moment, a condensing turbonator is started. By adopting the technical scheme provided by the invention, the exhaust steam temperature is high during warming-up of a turbine, unit thermal expansion is uniform, the differential expansion is small, the unitis free of severe vibration when surpassing the critical point, the unit vibrates stably in a loading process after grid-connection, and the load can become full in a short time.

Owner:TIANJIN IRON WORKS CO LTD

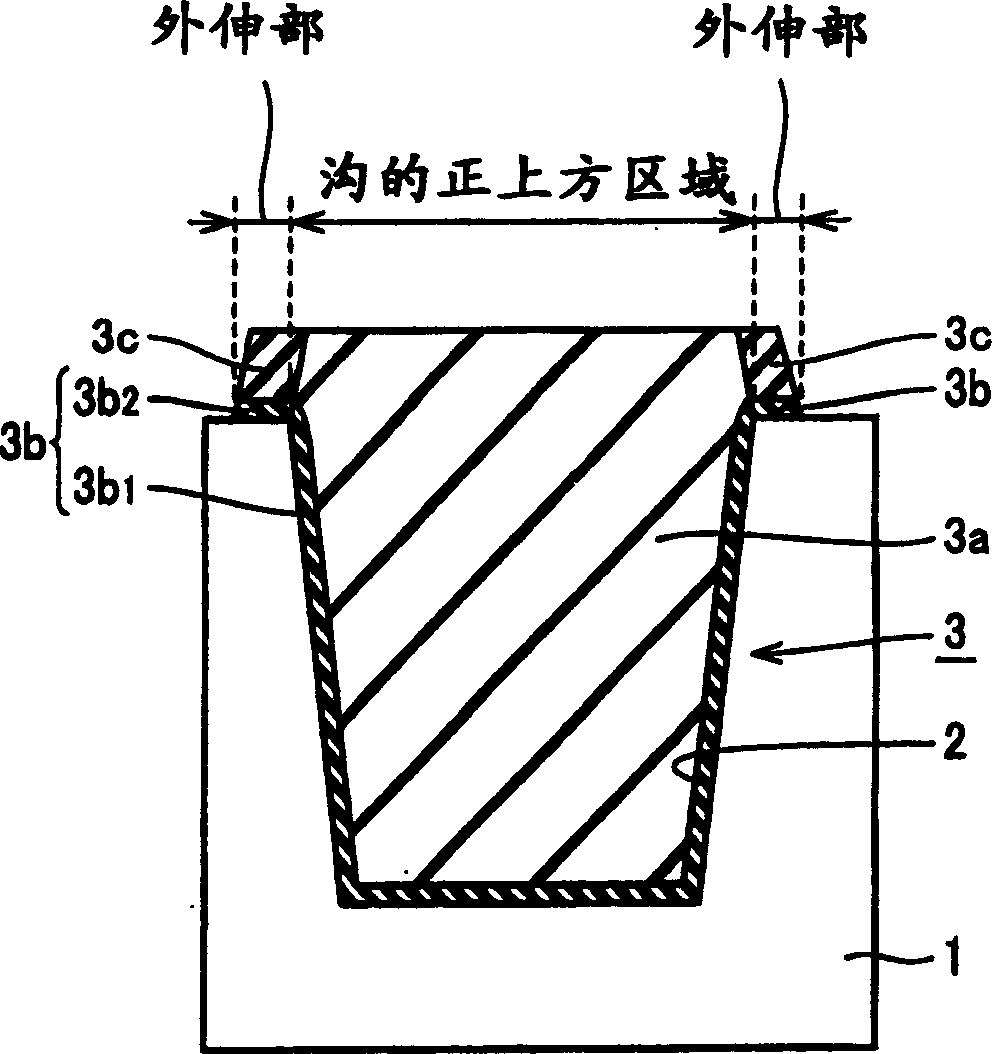

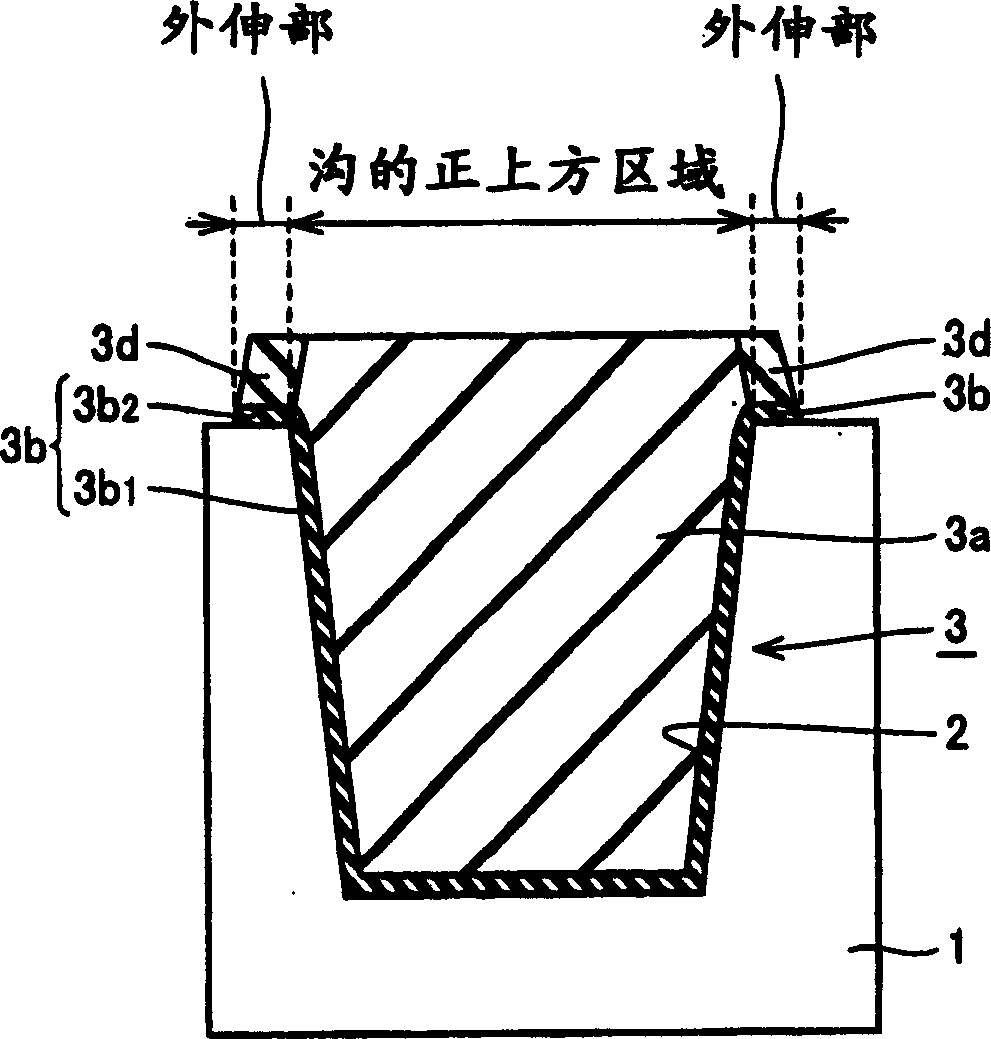

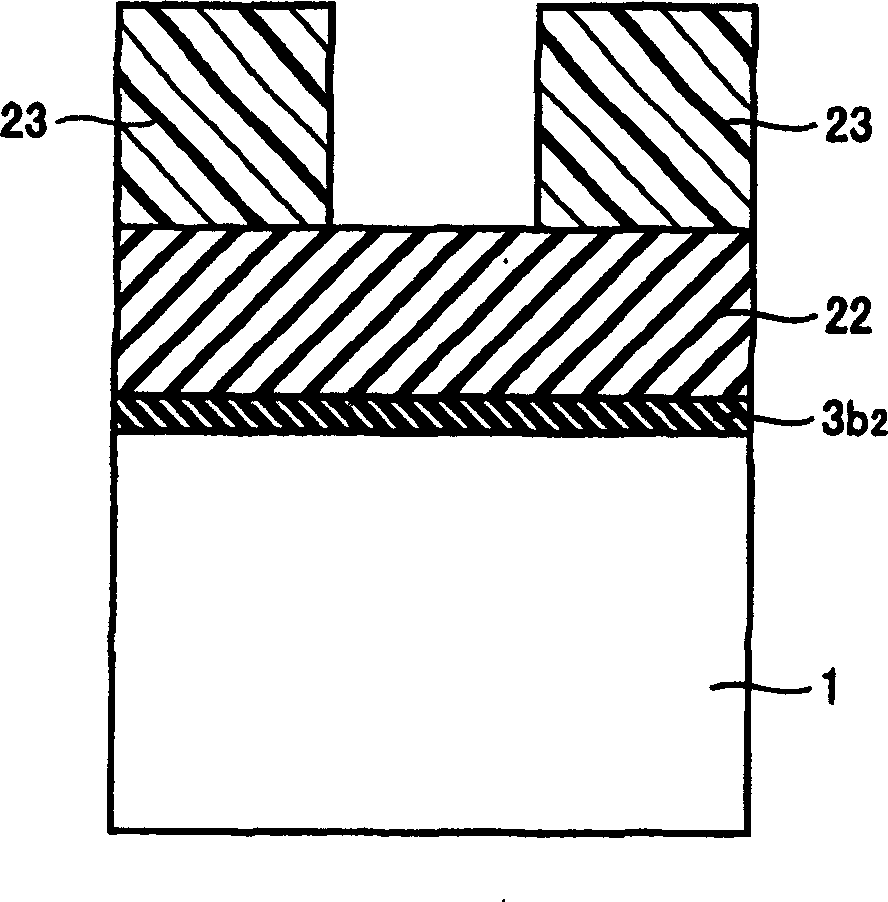

Semiconductor device having trench isolation

InactiveCN1574276APrevent Reliability DeteriorationPrevent collapseTransistorVehicle cranksSemiconductorNarrow channel

A semiconductor device with trench isolation is provided to restrain reverse narrow-channel effect and to obtain improved reliability from a gate insulating layer by forming a protrusion with a double insulating layer structure at both upper sidewalls of a burial insulating layer. A trench(2) is formed in a semiconductor substrate(1). A burial insulating layer(3) is filled in the trench. At this time, an upper surface of the burial insulating layer is higher than that of the substrate, so that both sidewalls of the burial insulating layer are partially exposed to the outside. A protrusion(3b2,3c) is formed at both exposed sidewalls of the burial insulating layer by stacking at least two insulating layers with each other.

Owner:RENESAS TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com