Patents

Literature

50results about How to "Limit bloat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

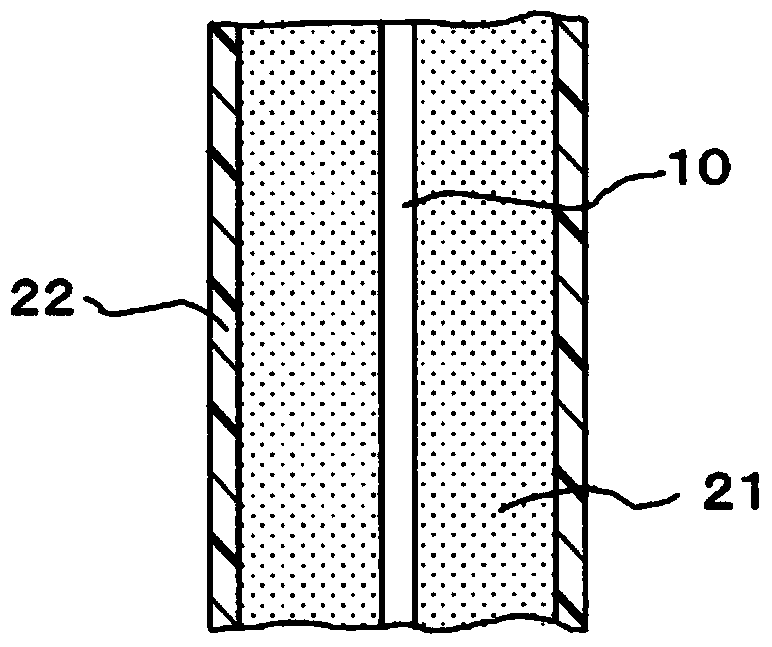

Elastic compound metal heat interface material and preparation method thereof

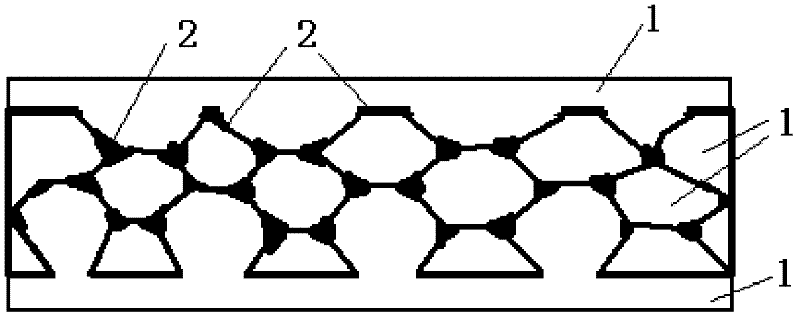

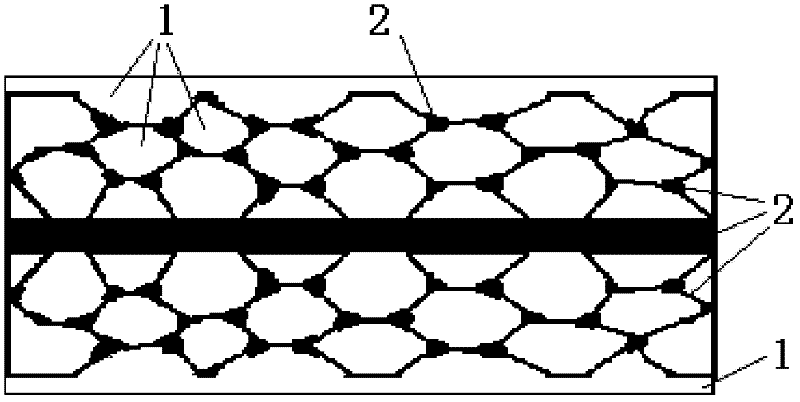

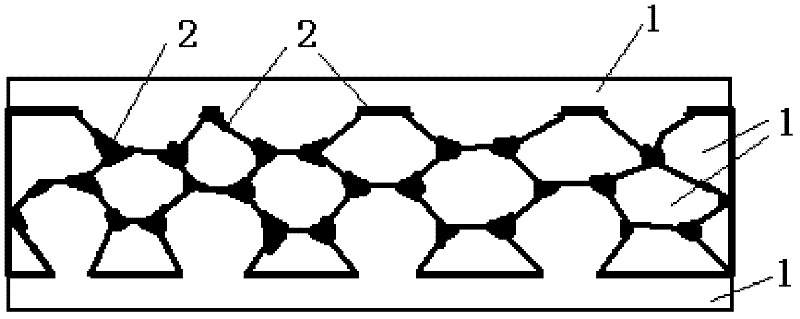

The invention belongs to the technical field of a heat interface material and discloses an elastic compound metal heat interface material. The elastic compound metal heat interface material is formed by compounding indium and a through-hole porous metal sheet, wherein the indium is filled in the through-hole porous metal sheet and covers the upper and lower surfaces of the through-hole porous metal sheet. The invention also discloses a preparation method of the elastic compound metal heat interface material. The method comprises the following steps: preparing the through-hole porous metal sheet at first; adding a proper amount of indium; heating for smelting indium so that smelted indium fills in the through-hole porous metal sheet and covers the upper and lower surfaces of the through-hole porous metal sheet; and finally cooling, thereby obtaining the elastic compound metal heat interface material. The two surfaces of the through-hole porous metal sheet are both through-hole porous metal and the middle core of the through-hole porous metal sheet is a metal solid. The compound material of the through-hole porous metal sheet and indium has higher elasticity and flexibility in the direction vertical to a mounting surface, so that the compound material can be quickly filled in bigger gaps caused by heat sink and an uneven silicon surface, the interface can be completely filled and the heat resistance of the interface can be kept.

Owner:SOUTHEAST UNIV

Battery, terminal and battery protection method

InactiveCN106816929AReasonable control voltageReasonable control currentSecondary cells charging/dischargingElectric powerElectricityStrain sensor

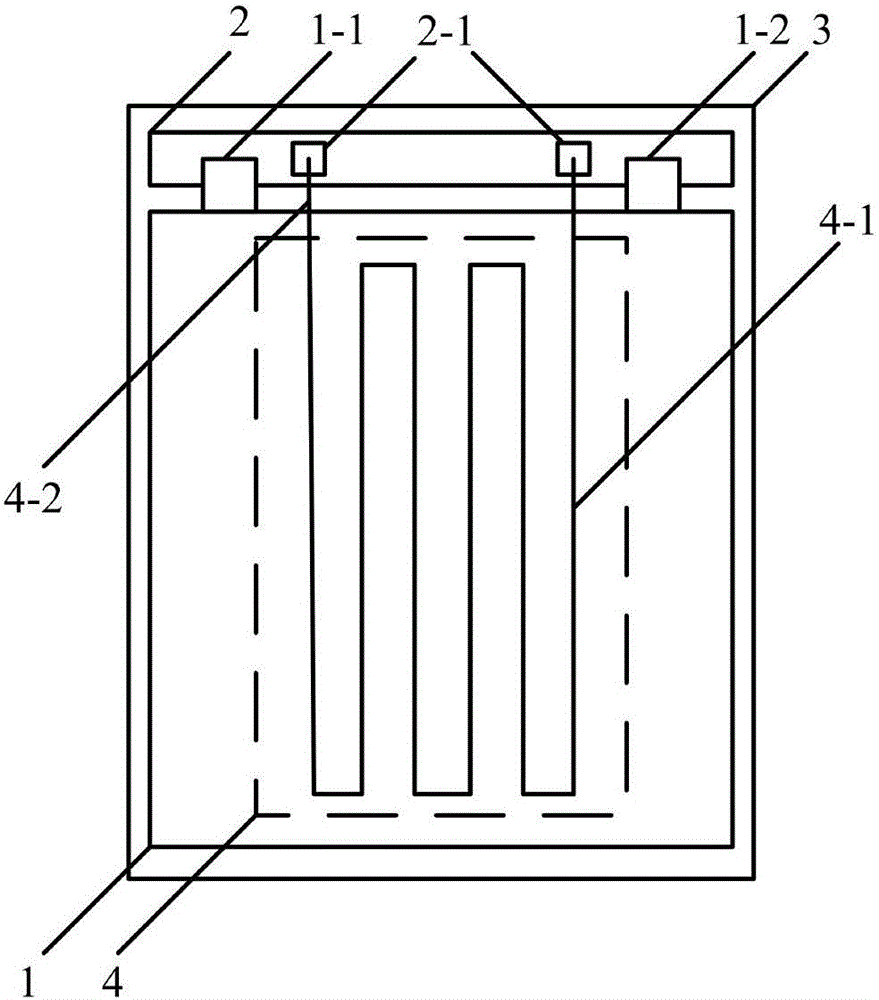

The embodiment of the invention relates to the technical field of electronics, and discloses a battery, a terminal and a battery protection method. The battery comprises a battery core, a battery protection board, a battery shell and a resistance strain sensor. The battery shell covers the battery core and the battery protection board. The battery protection board is electrically connected with the positive electrode lug and the negative electrode lug of the battery core. The battery protection board is provided with a control chip. The resistance strain sensor comprises a sensitive grid and pins led out of the sensitive grid. The sensitive grid is fixed within the area of the battery core. The pins are electrically connected with the control chip on the battery protection board. According to the technical scheme of the invention, the sensitive grid is fixed with the area of the battery core, and the pins are electrically connected with the control chip on the battery protection board. In this way, during the charging process of the battery, the variation of the battery itself can be detected according to the variation of the resistance value. Therefore, the voltage and the current of the battery during the charging process can be reasonably controlled. The over-expansion of the battery is avoided.

Owner:SHANGHAI YUDE COMM TECH

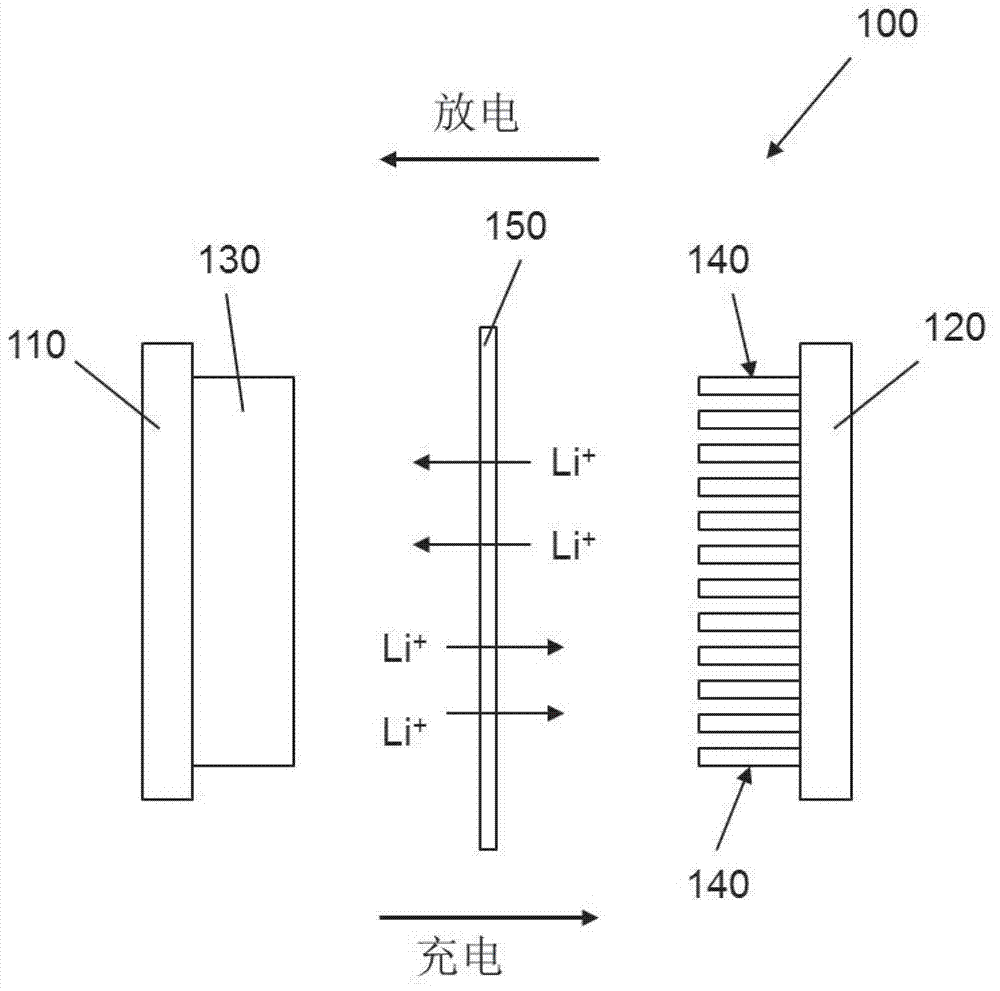

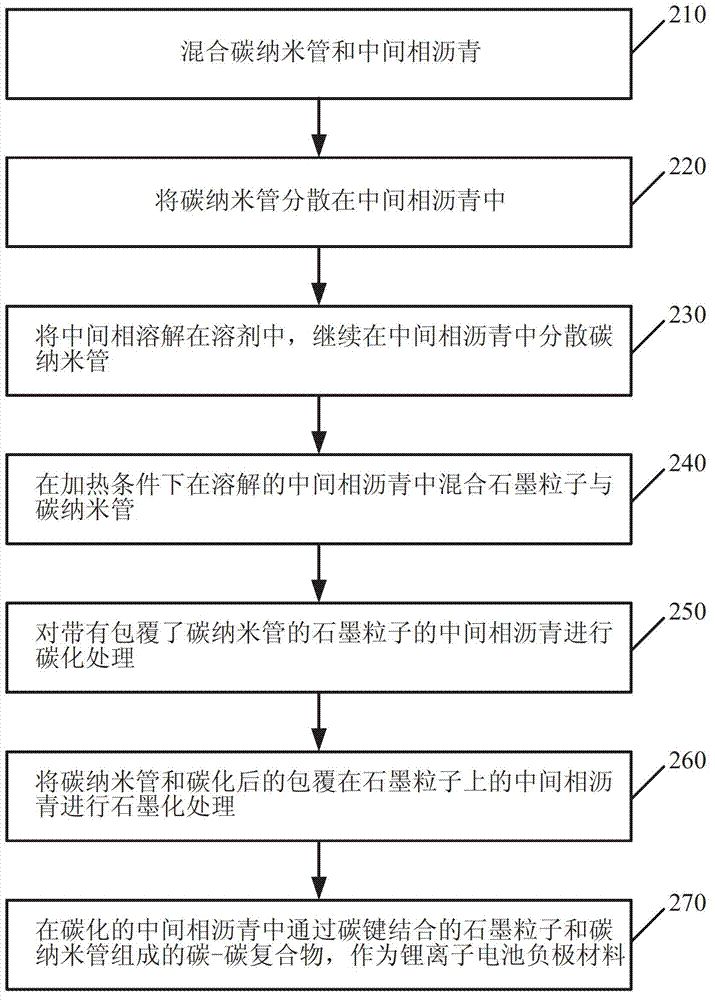

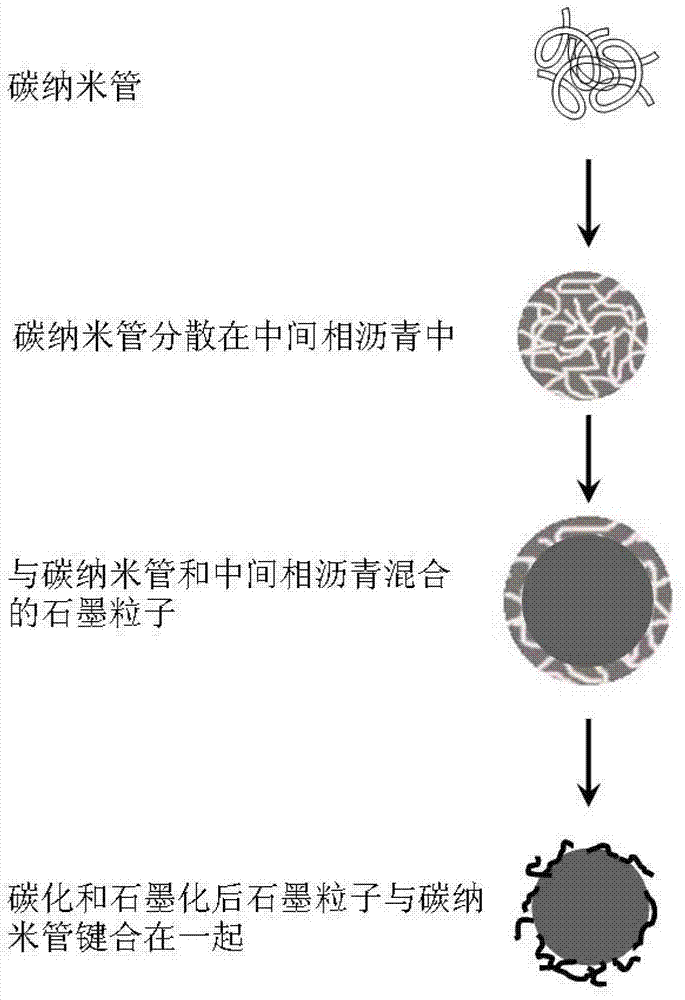

Modified battery anode with carbon nanotubes

ActiveCN103050670AHigh strengthHigh tensile strengthElectrode thermal treatmentSecondary cellsCarbonizationCarbon nanotube

A modified battery anode with carbon nanotubes is disclosed. The anode includes graphite particles and carbon nanotubes, the carbon nanotubes are bonded to the surfaces of the graphite particles through atom bonds. The method includes the steps as following: the carbon nanotubes are dispersed in a mixture formed by a binding material; the mixture is liquified to a mushy material, the graphite particles are mixed with the mushy material, the surfaces of the graphite particles are coated by the mushy material, the mushy material mixed with graphite particles is processed by carbonization, the carbon nanotubes and the graphite particles are processed by graphitization, carbon-carbon compounds are formed, the carbon nanotubes are bonded to the surface of the graphite particles, and the carbon-carbon compounds play as at least a part of the lithium ion battery anode. The improved anode material can improve both electric conductivity and the mechanical resilience of the anode, thus drastically increasing the lifetime of lithium ion batteries.

Owner:JIANGSU CNANO TECHNOLOGY CO LTD

Method for preparing thin-wall composite steel pipe with ceramic lining

Owner:南京金陶耐磨管道有限公司

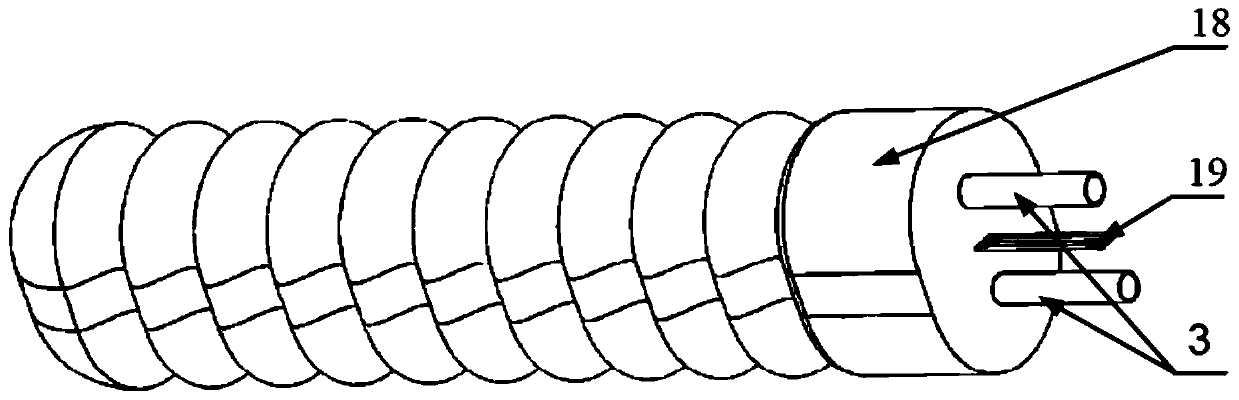

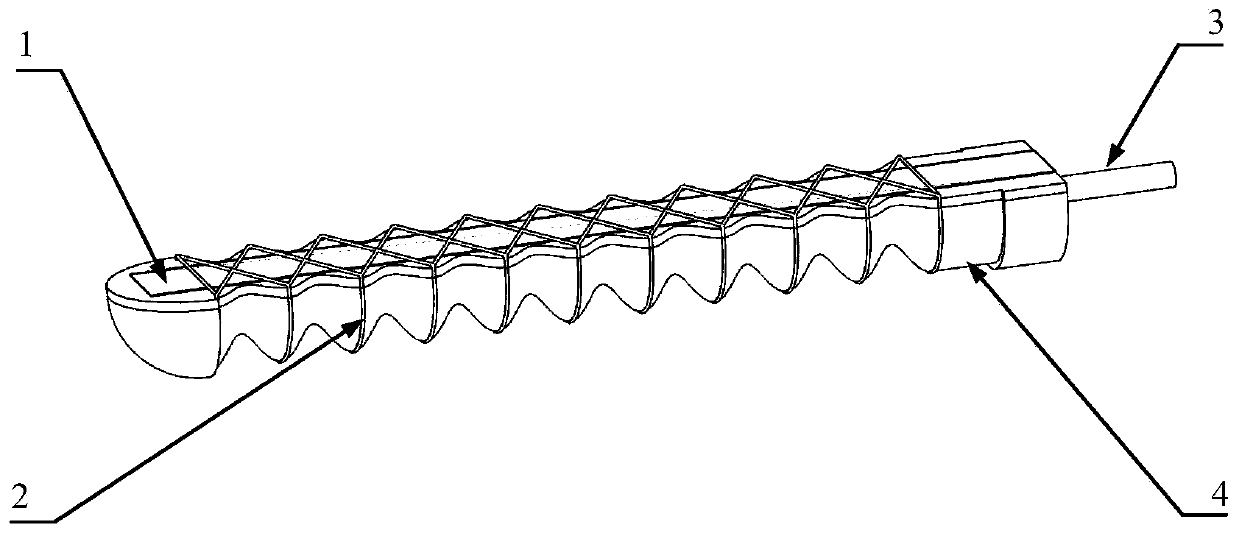

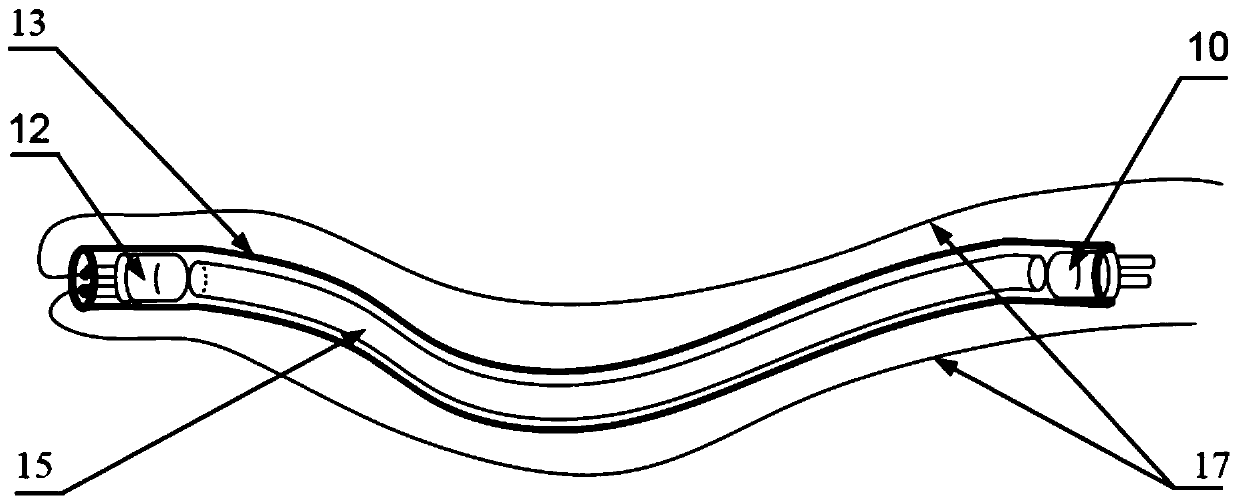

Flexible actuator based on optical fiber bending sensor

InactiveCN110193825AHas hardnessImprove measurement accuracyProgramme-controlled manipulatorChiropractic devicesEngineeringSilica gel

The invention belongs to the technical field of hand rehabilitation and flexible robots, and discloses a flexible actuator based on an optical fiber bending sensor. The flexible actuator is a cylinder-like body with a corrugated structure on the surface, and comprises a silica gel shell, two cavity mechanisms and the optical fiber bending sensor, wherein the cavity mechanisms and the optical fiberbending sensor are arranged in the silica gel shell; each cavity mechanism is semi-cylindrical and comprises a silica gel cavity, corrugated folds are formed on the portion, far away from the opticalfiber bending sensor, of the surface of the silica gel cavity, and Kevlar fiber wires are spirally wound around the largest part of the corrugated folds; and the optical fiber bending sensor comprises a PMMA plastic optical fiber, when the surface of the PMMA plastic optical fiber is subjected to pressure, axial deformation generated on the PMMA plastic optical fiber is larger than radial deformation, so that the optical fiber bending sensor is not influenced by the pressure when bending measurement is performed. Without being affected by the pressure, the flexible actuator improves measurement accuracy and has good flexibility.

Owner:HUAZHONG UNIV OF SCI & TECH

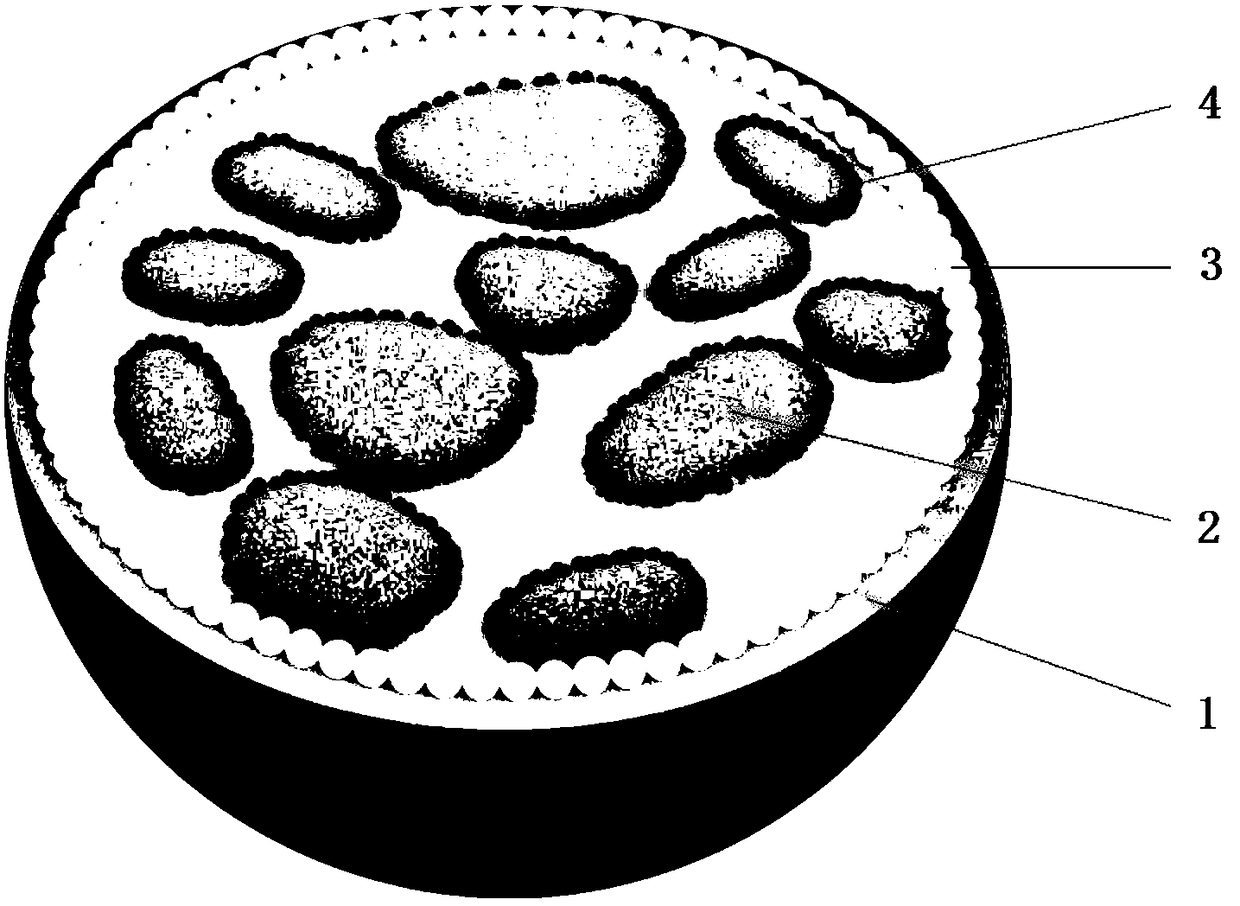

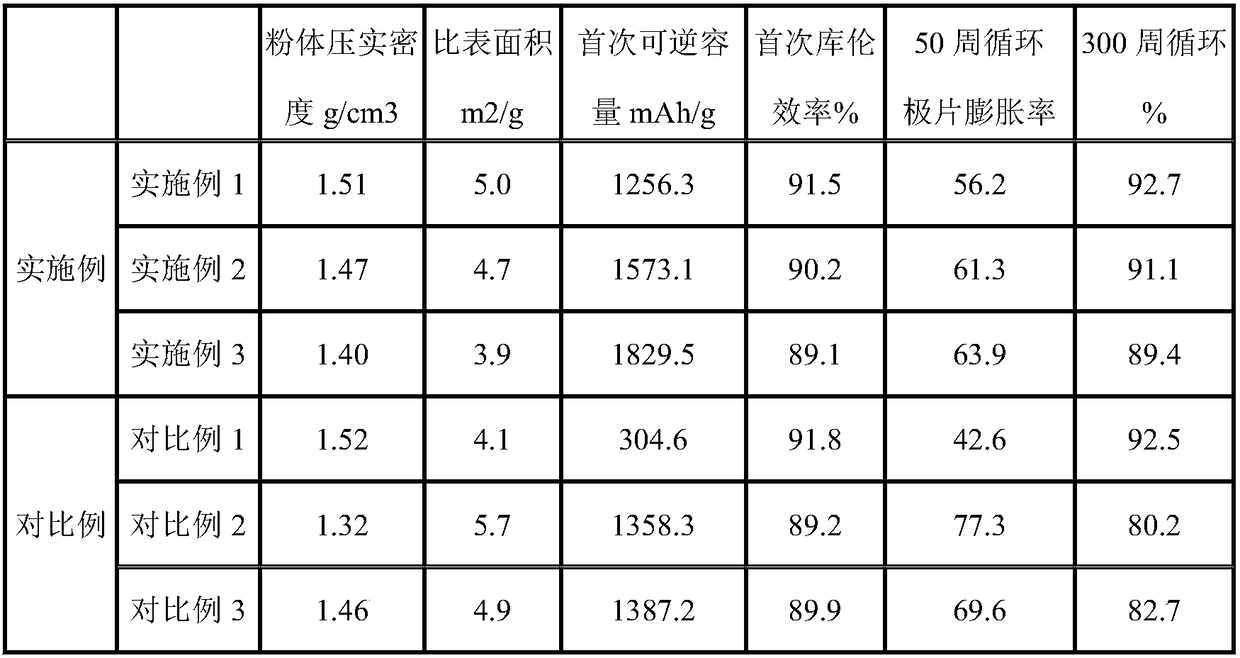

A double-layer coated core-shell negative electrode material for lithium ion battery and a preparation method thereof

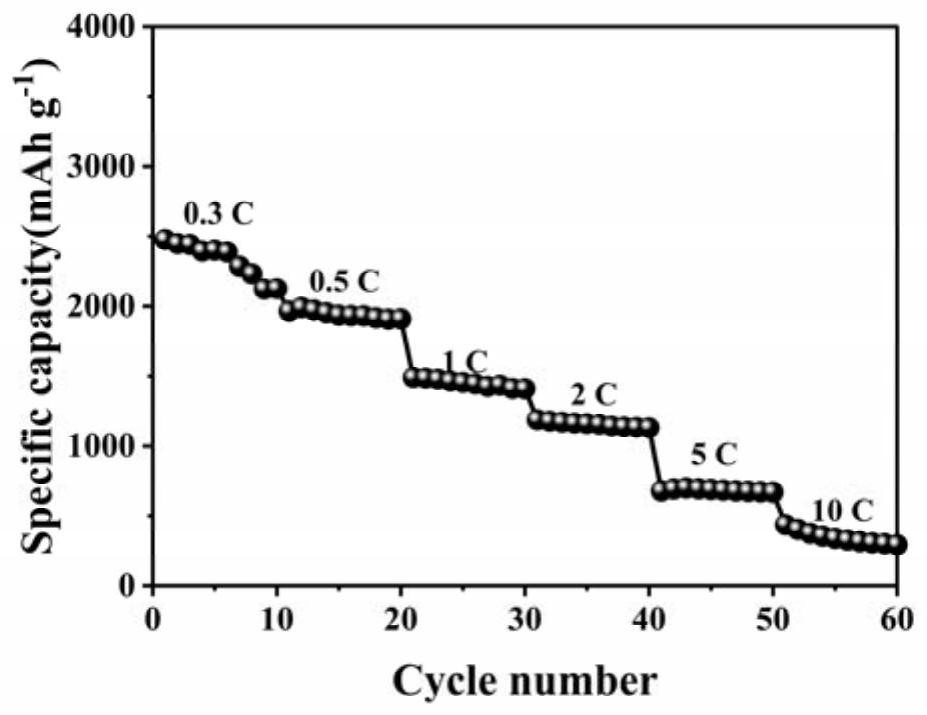

InactiveCN109119618AHigh magnificationExcellent long cycle performanceMaterial nanotechnologyCell electrodesHigh rateSodium-ion battery

The invention discloses a double-layer coated core-shell negative electrode material for lithium ion battery and a preparation method thereof. A CVD deposition method is used for depositing nano silicon on that graphite particle to obtain a precursor of a negative electrode material; The titanium dioxide, the lithium carbonate and the organic pyrolysis carbon source are dispersed in an organic solvent to prepare a gel; the precursor of anode material was added into the gel, and the core-shell structure anode material was prepared by low temperature treatment, homogeneous dispersion and high temperature reaction. The core of double-layer coated core-shell negative electrode material for the lithium ion battery is nano silicon and graphite, the nano silicon is deposited on the surface of graphite particles, the outer shell is an organic pyrolytic carbon layer, and the inner shell is formed by attaching lithium titanate to the inner wall of the organic pyrolytic carbon layer. The core-shell negative electrode material has high capacity, high rate and excellent cycling performance, and the preparation process is simple, green and pollution-free, suitable for large-scale production.

Owner:MAANSHAN KEDA PURUI ENERGY TECH CO LTD

Long-life lead acid secondary battery

InactiveCN107069044AHigh creepReduce distortionFinal product manufactureElectrode carriers/collectorsVulcanizationEngineering

The invention discloses a long-life lead acid secondary battery and intends to provide a long-life lead-acid battery which can effectively improve the problem of negative electrode vulcanization and reduce the occurrence of the negative electrode vulcanization failure, so as to effectively prolong the charging and discharging cycle life of the lead acid secondary battery. The long-life lead acid secondary battery comprises an electrode group, which comprises a plurality of positive and negative plates. The negative plates comprises a negative grid, which comprises a grid inner core made of highly conductive metal and a lead or lead alloy cladding layer cladding the surface of the grid inner core.

Owner:CHAOWEI POWER CO LTD

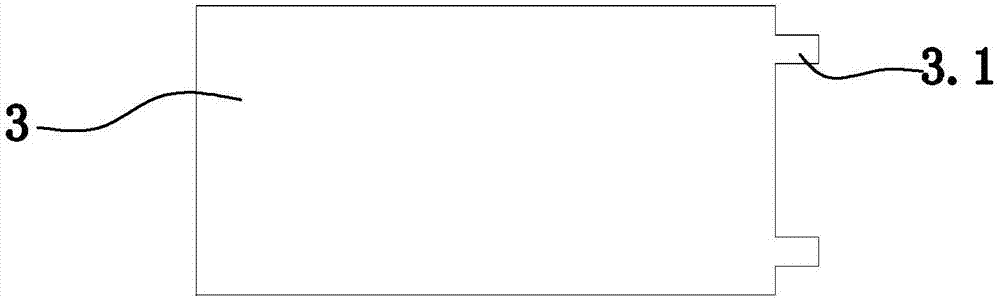

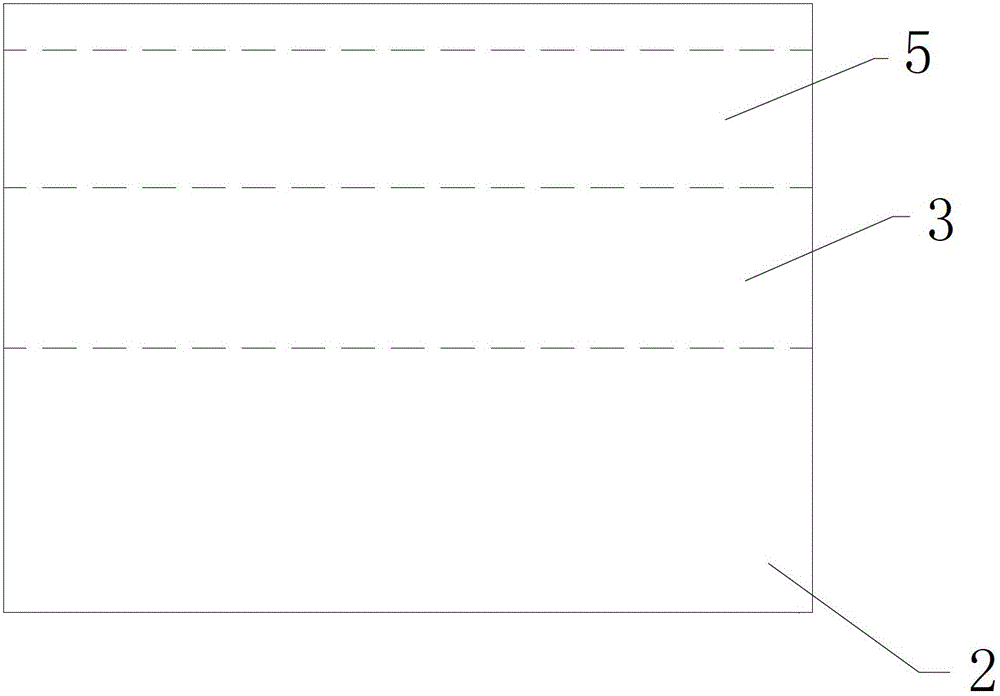

Zipper wire material and zipper tooth made of zipper wire material

ActiveCN102742981AImproves metal strengthImprove antioxidant capacitySlide fastenersEngineeringUltimate tensile strength

The invention relates to a zipper wire material, which is in a linear state. A main body of the zipper wire material comprises a head part and a pair of leg parts, wherein cross section leg parts of the linear main body are arranged at two sides of the main body and outsides extend so that the two leg parts are in an open state, the leg parts comprise leg claws, the leg claws are arranged at the end parts of the leg parts, the main body comprises an inner main body and a covering layer, and the covering layer for enhancing the metal intensity and the oxidation resistance capability of the zipper wire material is covered and pressed outside the inner main body. The invention also provides a zipper tooth made of the zipper wire material. The zipper tooth has the technical characteristics identical to that of the zipper wire material. Because the zipper wire material and the zipper tooth are provided with the covering layer, the covering layer has better metal intensity and oxidation resistance capability, and the physical performance and the oxidation resistance capability of the zipper wire material and the zipper tooth can be improved through the arrangement of the covering layer.

Owner:广州市东晨拉链服饰制造有限公司

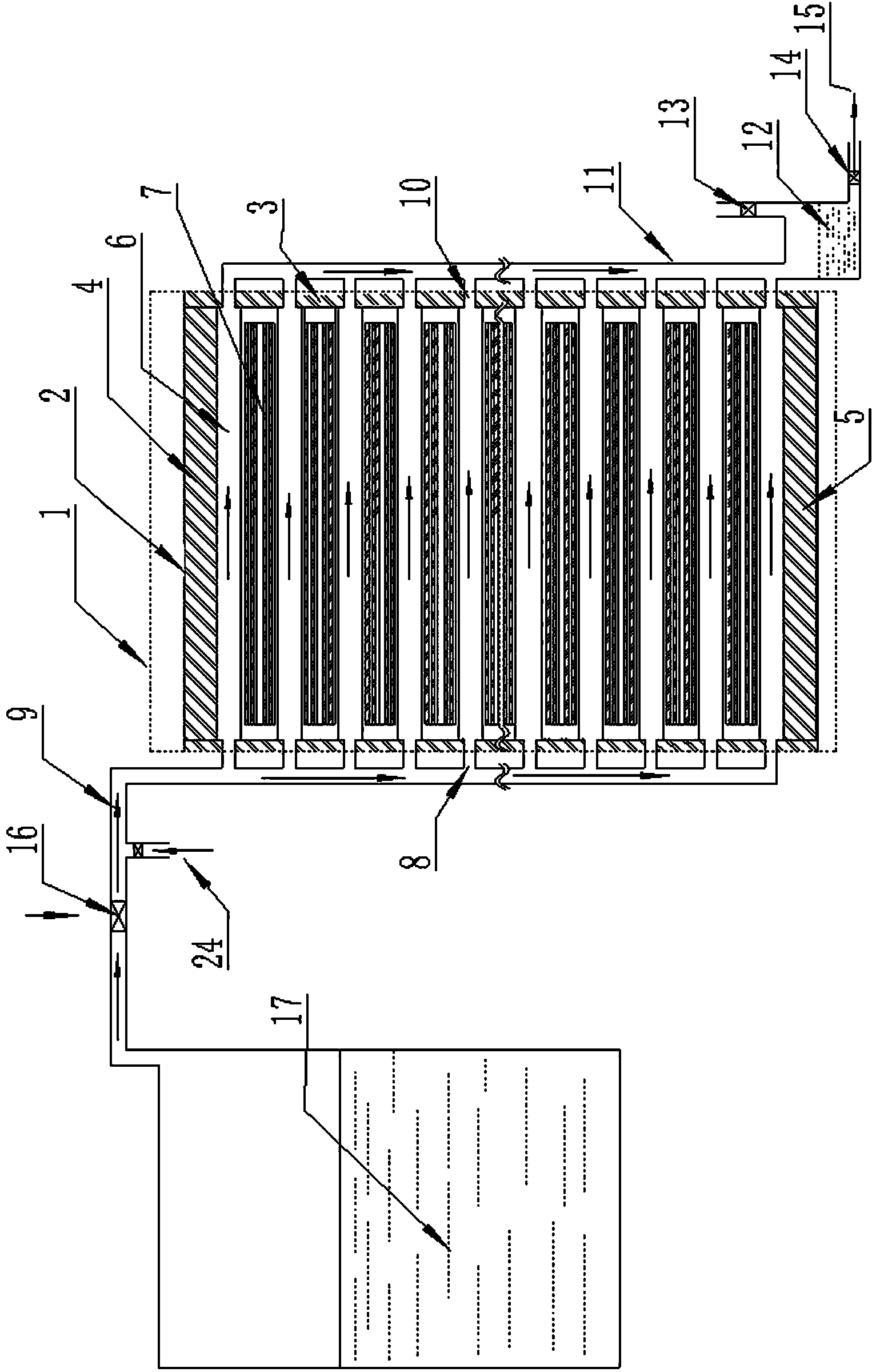

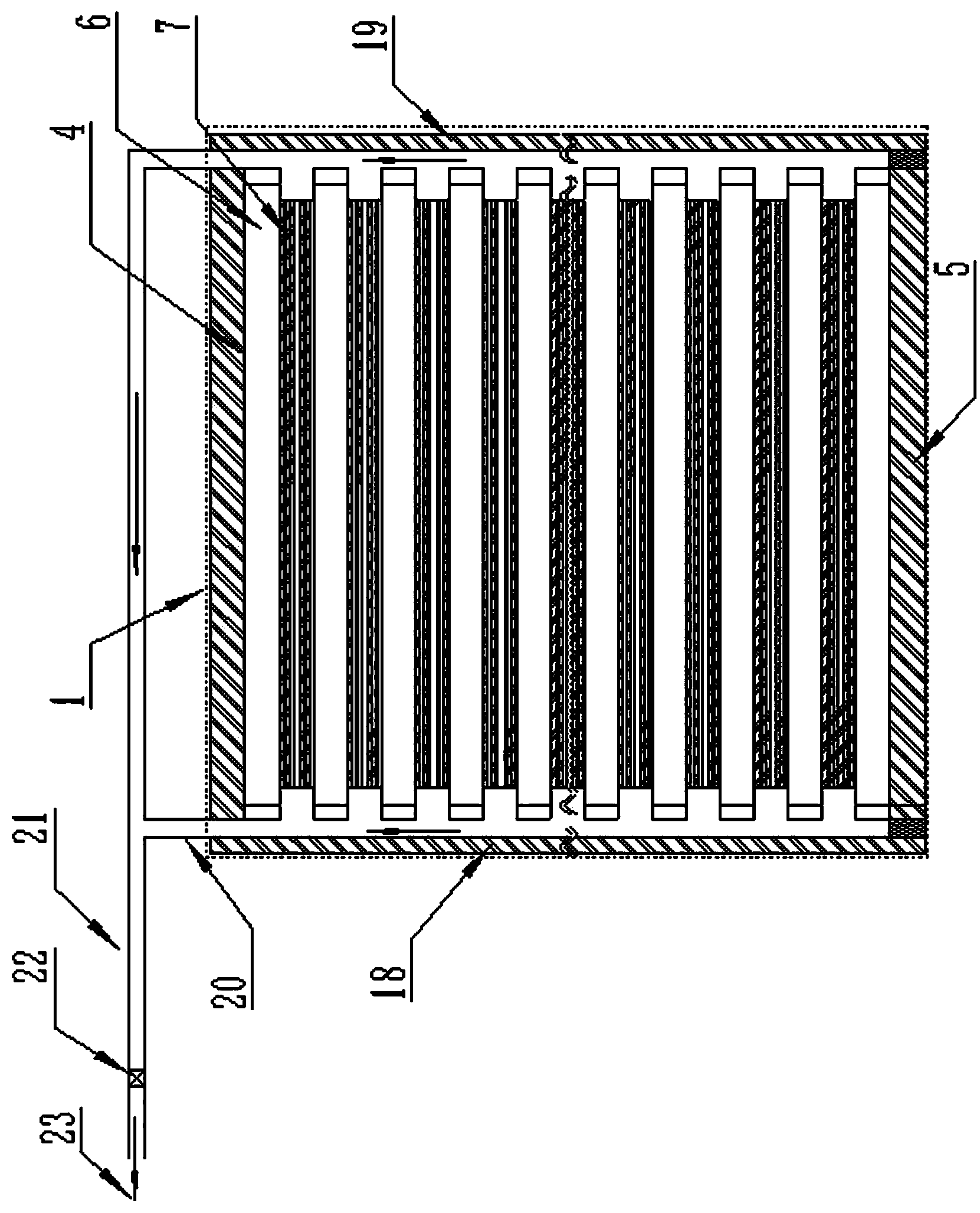

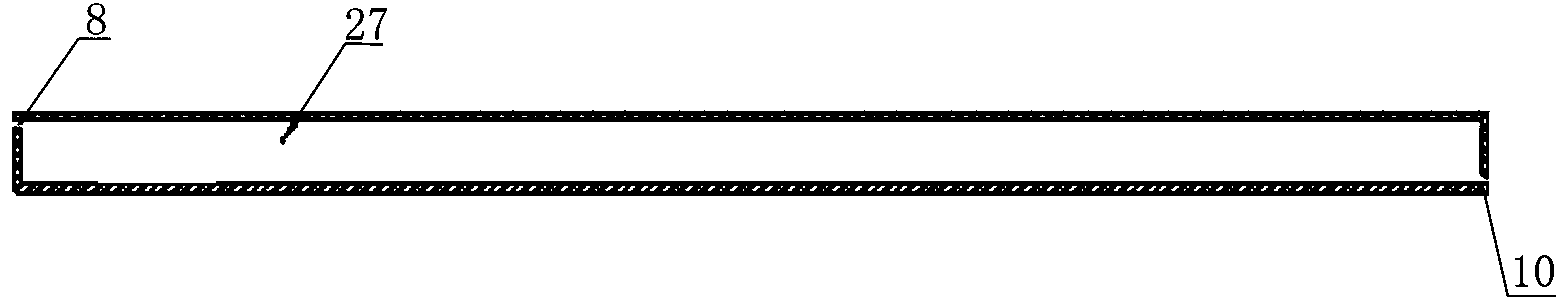

Steam direct pressure type drying device of veneer materials

InactiveCN104006634AFast dryingReduce heat lossDrying gas arrangementsDrying machines with local agitationLiquid waterWater storage tank

The invention discloses a steam direct pressure type drying device of veneer materials. The steam direct pressure type drying device of the veneer materials comprises a drying oven, a steam boiler and a steam air supply pipe connecting the drying oven and the steam boiler. A horizontally arranged drying frame is arranged in the drying oven, the top layer and the bottom layer of the drying frame are an upper pressure bearing limiting plate and a lower pressure bearing limiting plate which are made of steel plates respectively, a connecting rod is arranged between the limiting plates and fixedly connected with the limiting plates, enclosed hollow heating plates made of stainless steel sheets are arranged between the limiting plates at intervals in parallel, the side edges of all layers of heating plates are fixedly connected with the connecting rod, a steam inlet connecting pipeline is arranged on the same side face of the heating plates and is communicated with the boiler steam air supply pipe, a gas-liquid inlet connecting pipeline is arranged on the other side face of the heating plates and is communicated with a gas-liquid water outlet pipe, and the gas-liquid water outlet pipe is communicated with a water storage tank. According to the steam direct pressure type drying device of the veneer materials, the heat energy for drying the materials is transmitted to the materials through the steam and is separated from the materials only through a thin layer of stainless steel sheet, and pressure is directly provided by the steam, so that a mechanism for providing pressure and energy consumption are omitted, the device is compact in structure, and the defects that an existing device is high in manufacturing cost and large in energy consumption are overcome.

Owner:黄达宏

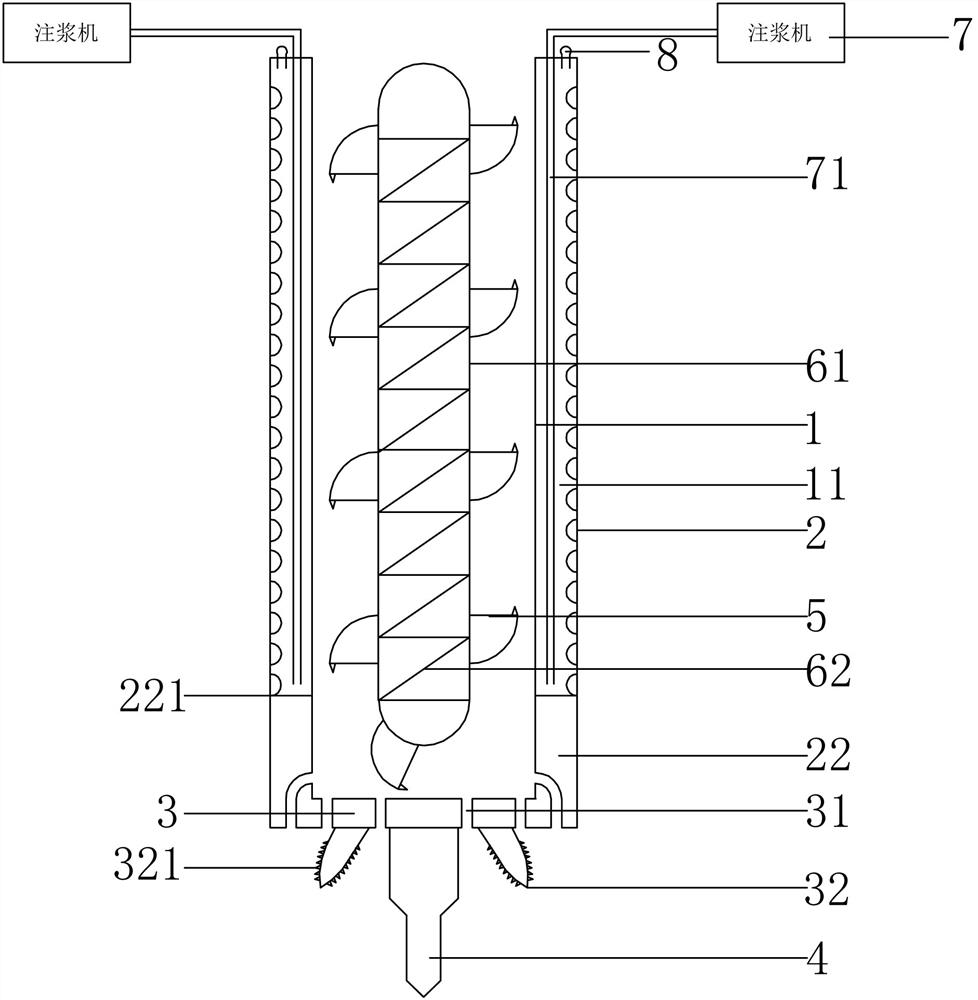

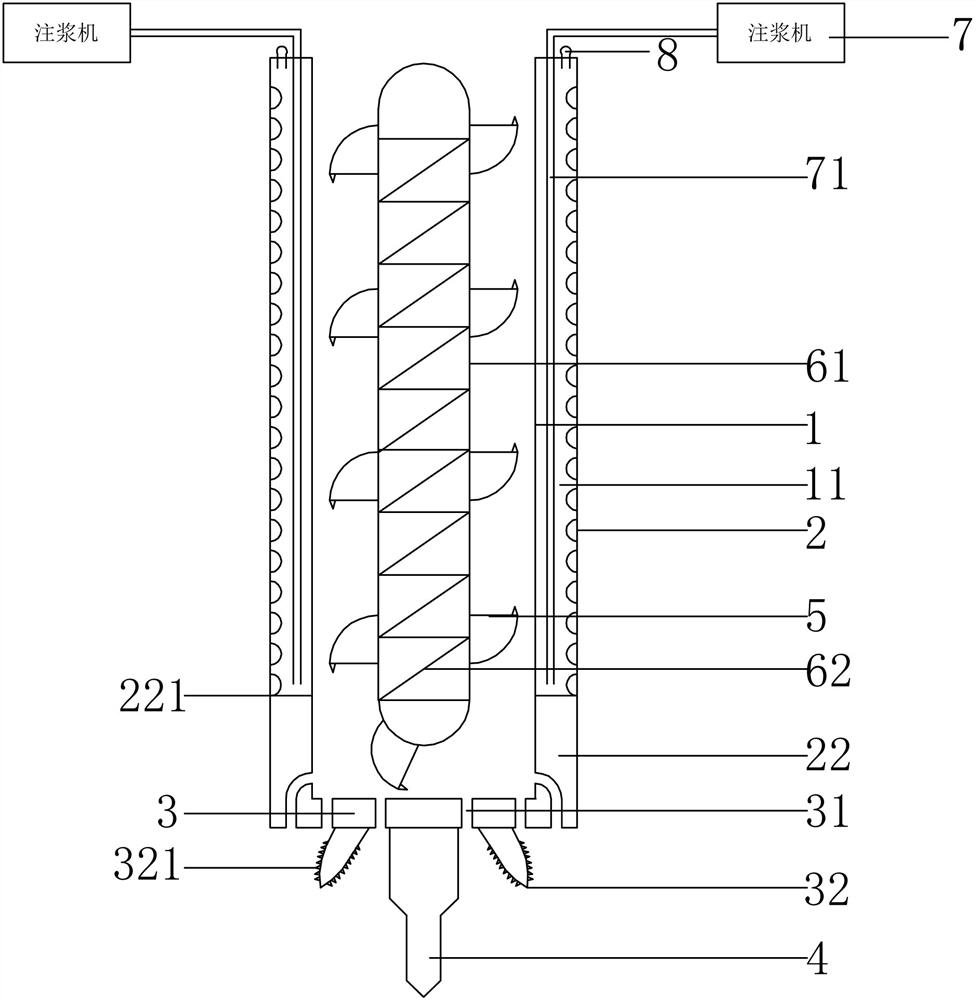

Rotary drilling type sand-pumping hole-forming side wall high-pressure grouting device and construction method

The invention provides a rotary drilling type sand-pumping hole-forming side wall high-pressure grouting device and a construction method. The rotary drilling type sand-pumping hole-forming side wall high-pressure grouting device is characterized in that an inner protection cylinder is sleeved with a floral tube in a wrapping mode, a steel protection cylinder is fixedly arranged on the portion, located on the lower portion, of the outer portion of the inner protection cylinder in a sleeving mode by a certain length, an annular cavity is formed between the inner protection cylinder and the floral tube, a grout storage layer is formed, an opening in the top end of the grout storage layer is blocked by a pressing sheet, the grout storage layer communicates with a grouting machine for grouting, a rotary type drawing disc is arranged in the bottom end of the inner protection cylinder in a spliced mode, a chain bucket device is arranged in the inner protection cylinder, and a plurality of evenly-distributed digging buckets used for digging sand are arranged on the chain bucket device. According to the rotary drilling type sand-pumping hole-forming side wall high-pressure grouting device, high-pressure grouting is conducted on the side wall of a pile hole while suction type drilling is conducted, and the foundation structure condition is improved through the technology in which the pile periphery is solidified through pressure grouting of the side wall of the pile hole.

Owner:CHINA THREE GORGES UNIV

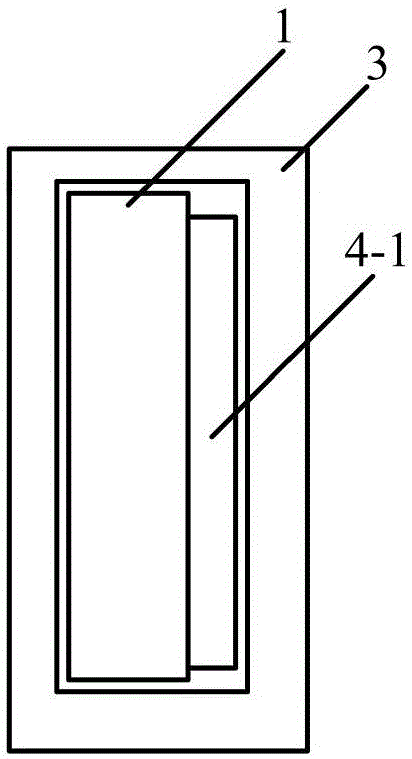

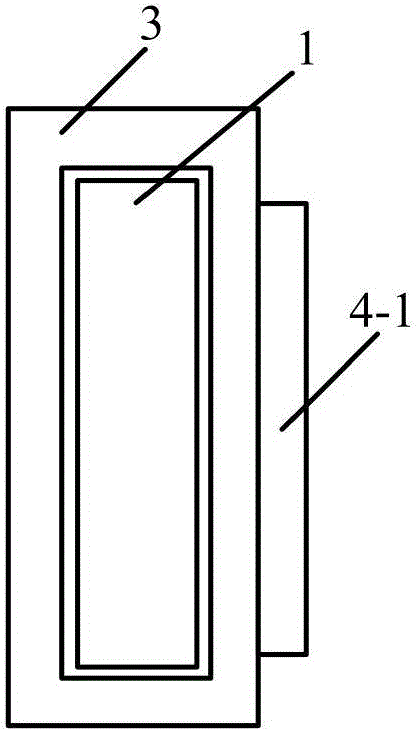

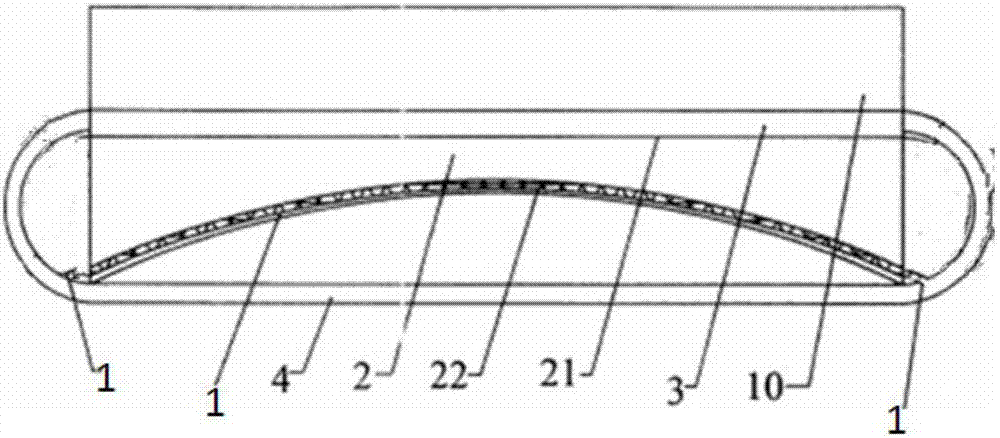

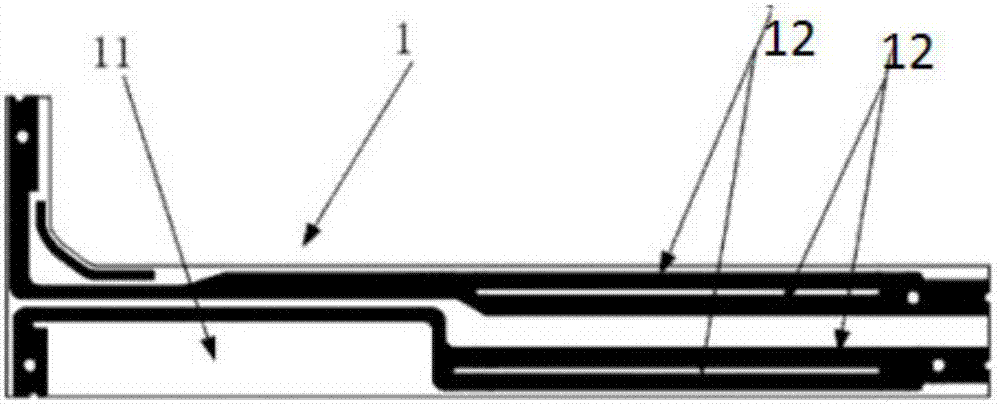

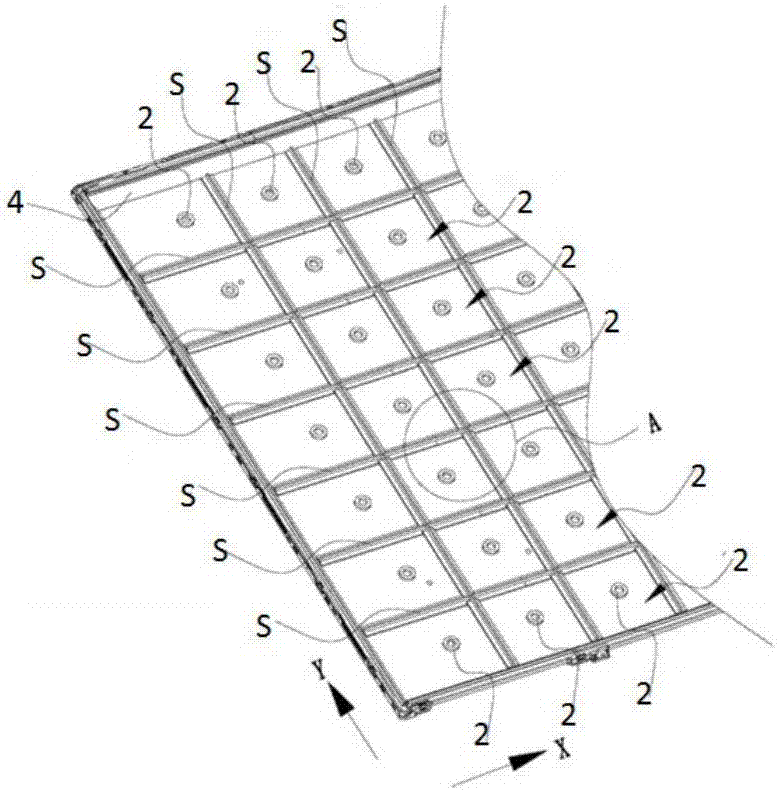

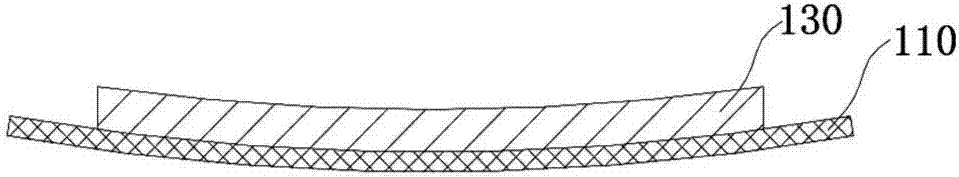

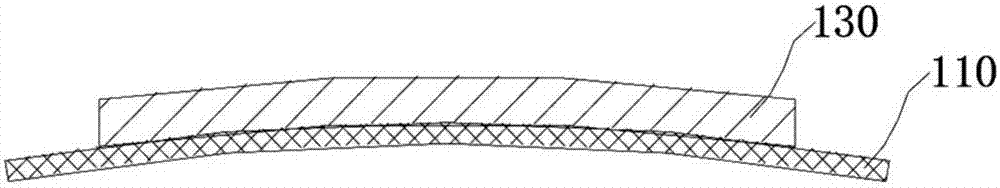

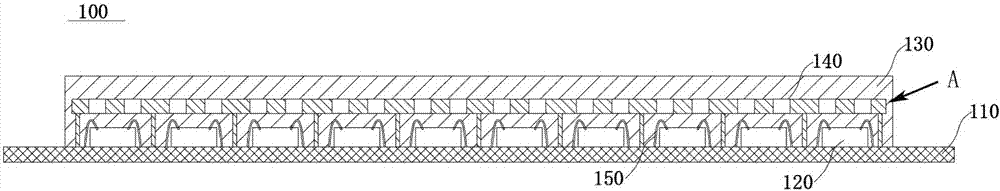

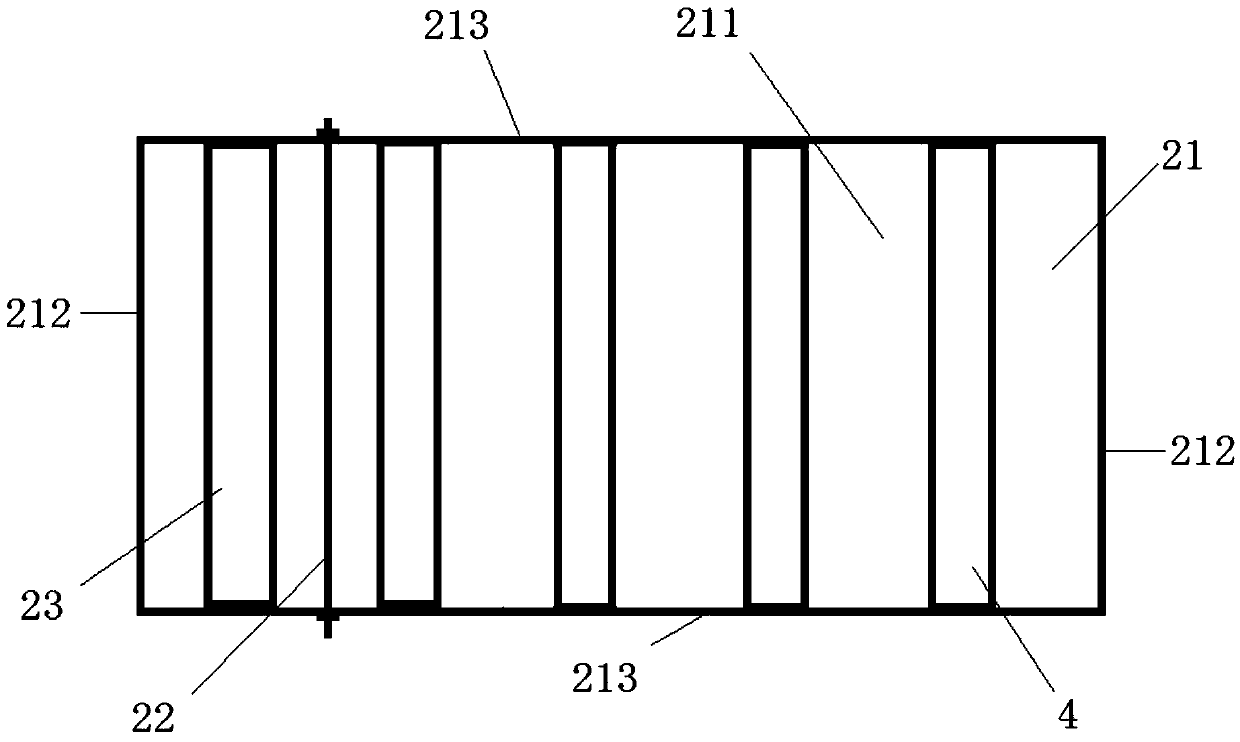

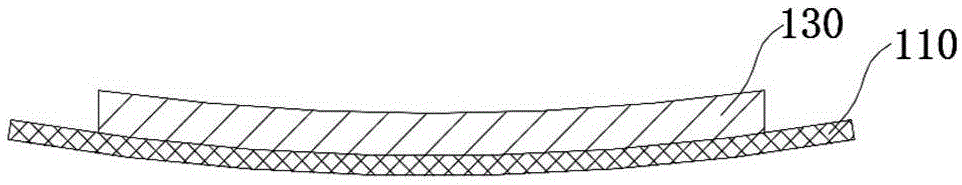

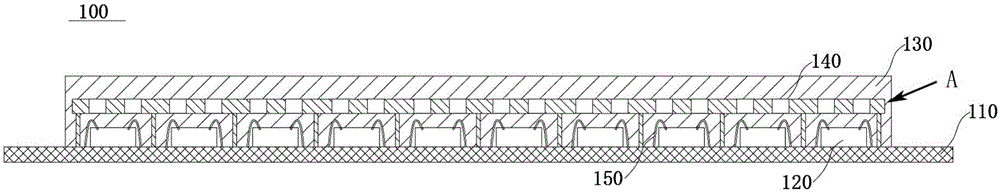

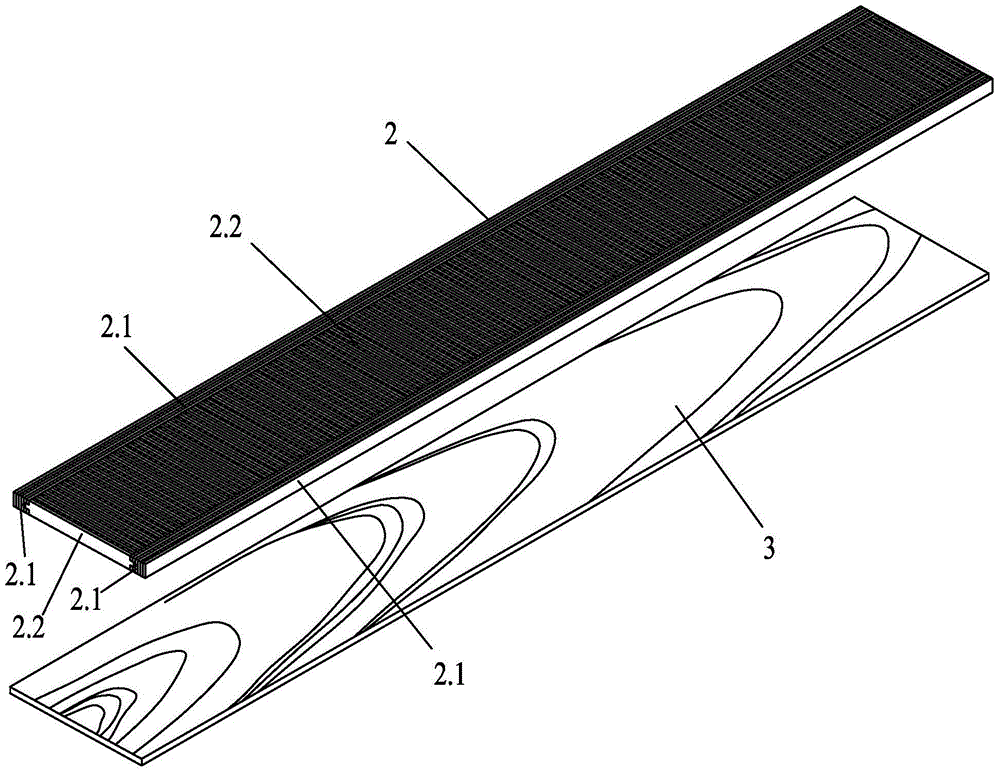

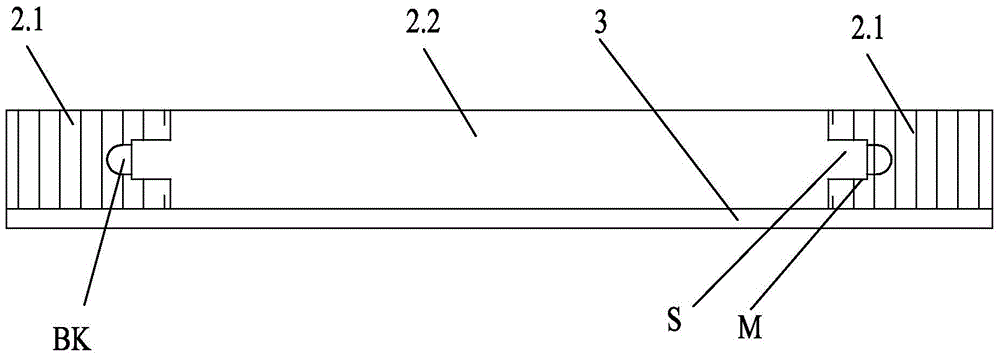

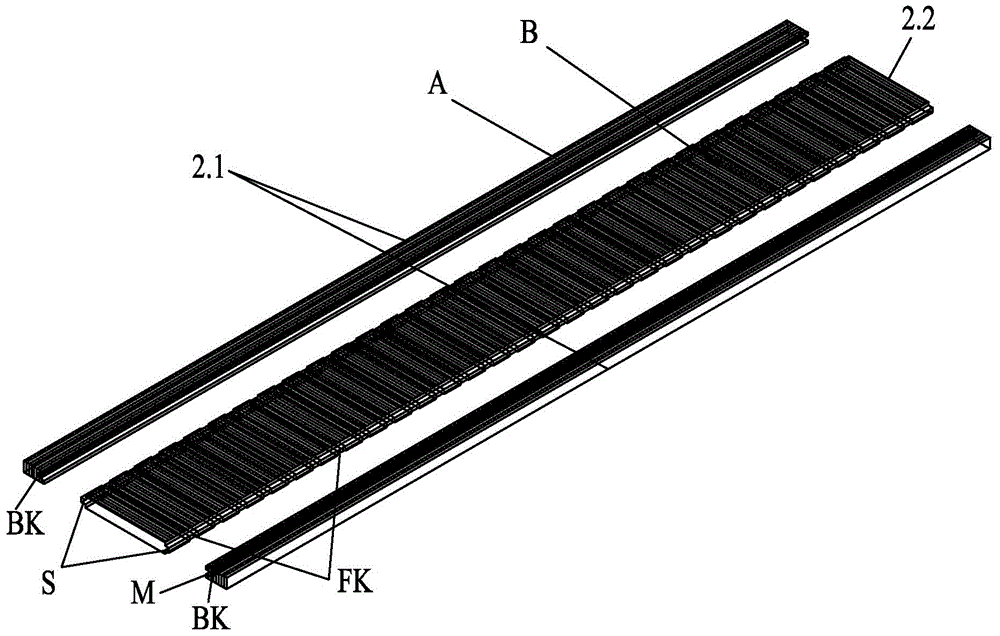

Flexible liquid crystal module and flexible liquid crystal display device

InactiveCN107331298ALimit bloatEliminate warpingStatic indicating devicesOptical light guidesElectrical conductorLiquid-crystal display

The invention provides a flexible liquid crystal module. The flexible liquid crystal module comprises a back plate, LED light strips, light guide plates and diffusion plates, wherein the LED light strips, the light guide plates and the diffusion plate are sequentially arranged on the back plate; the upper surface of each light guide plate is planar, the lower surface of each light guide plate is curved, each light guide plate is divided into multiple array modules in a horizontal direction, each light guide plate facing the vertical direction of the LED light strips is divided into two plates, the side surfaces of every two light guide plates in the vertical direction are attached to two reflective sheets respectively, a gap is formed between every two adjacent light guide plates, and every two reflective sheets are connected through at least two elastic components; each LED light strip comprises a flexible circuit board, and multiple groups of electric conductors and LED chips which are printed on the flexible circuit board and in parallel connection, and each flexible circuit board is provided with multiple micro-arrays, wherein the heights of the micro-arrays are different, but the arc shapes formed by the micro-arrays are equal to the lower surfaces of the light guide plates. Thus, the expansion and support problems during heating are well solved, the structure is simplified, and the cost is saved.

Owner:YANCHENG HUAXU OPTOELECTRONICS TECH CO LTD

Semiconductor package and manufacturing method thereof

ActiveCN106910723AReduce warpageReduce signal interferenceSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

The invention provides a semiconductor package and a manufacturing method thereof. The semiconductor package comprises a substrate, at least one chip arranged on the substrate, an encapsulation layer which is arranged on the substrate and encloses at least one chip, at least one grid portion which is arranged in the encapsulation layer, and a number of open main body parts which are defined by a first rib and a second rib.

Owner:SAMSUNG SEMICON CHINA RES & DEV +1

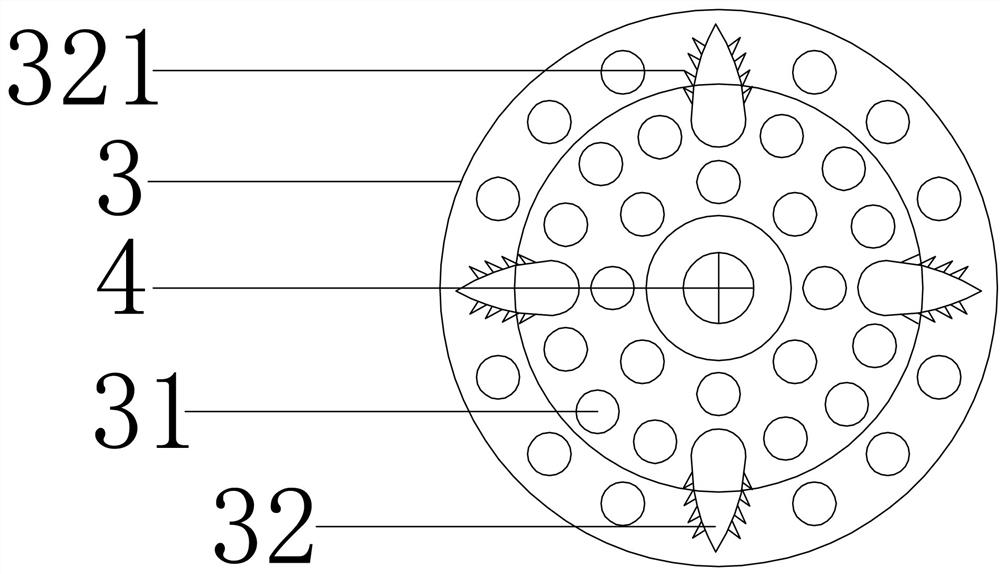

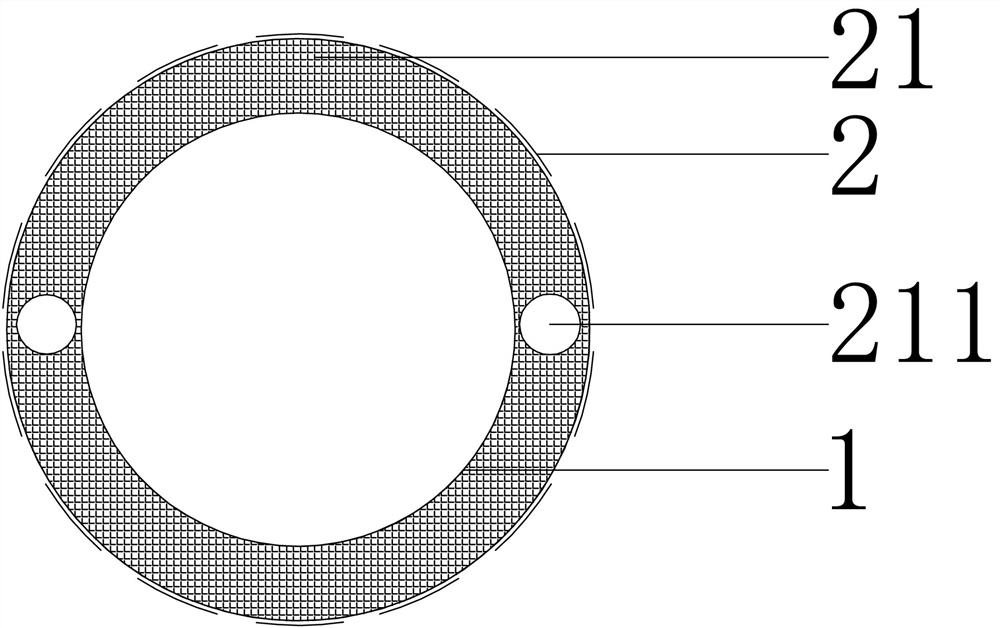

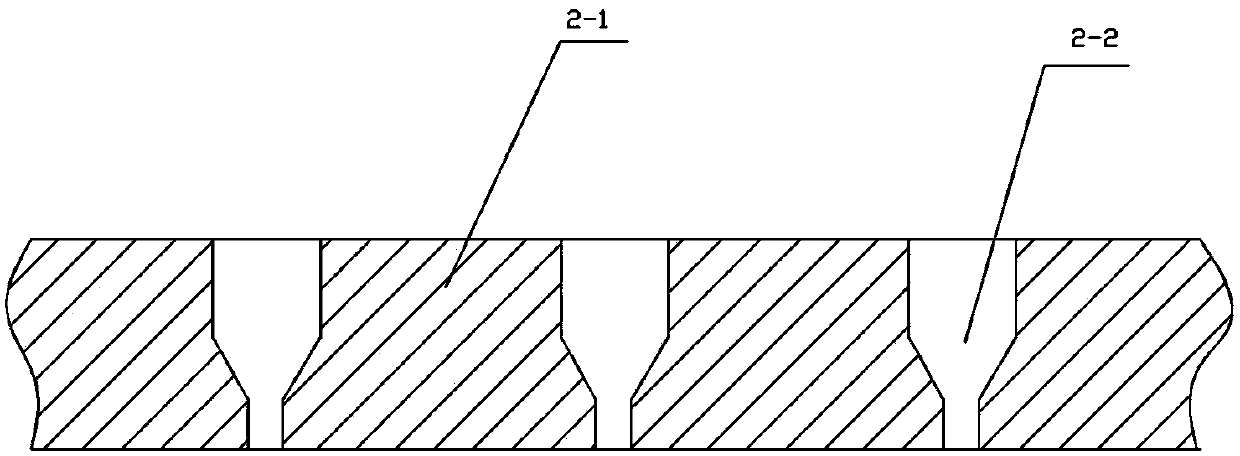

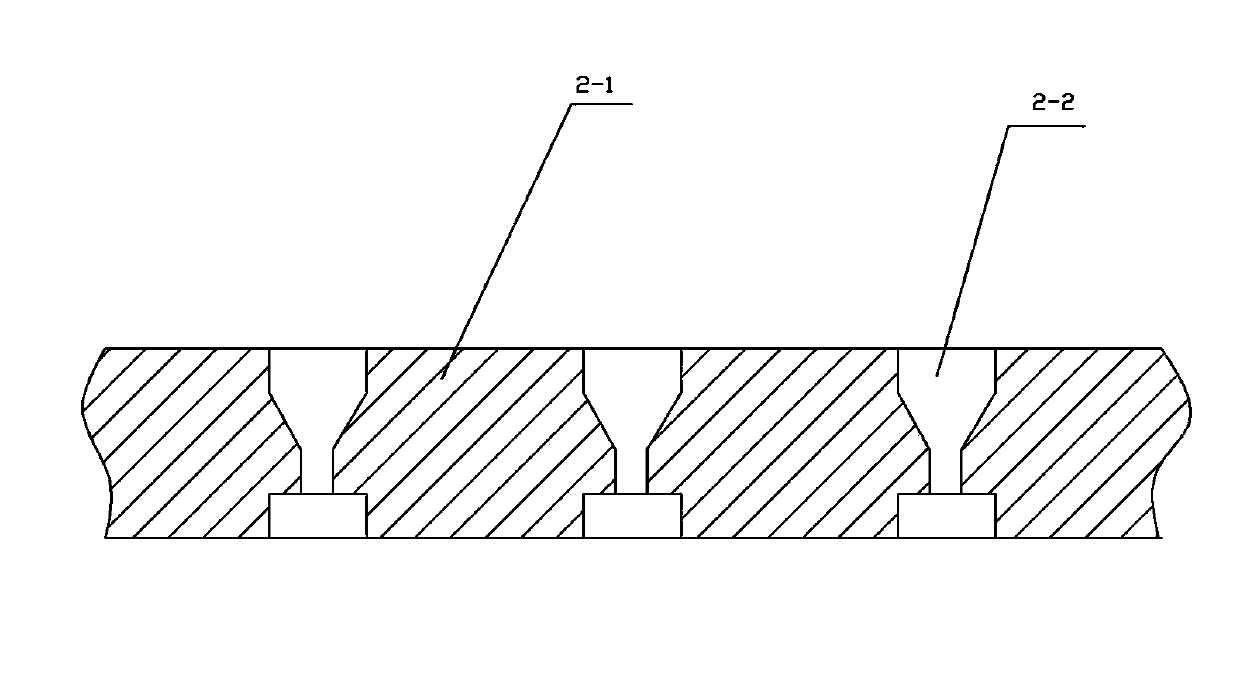

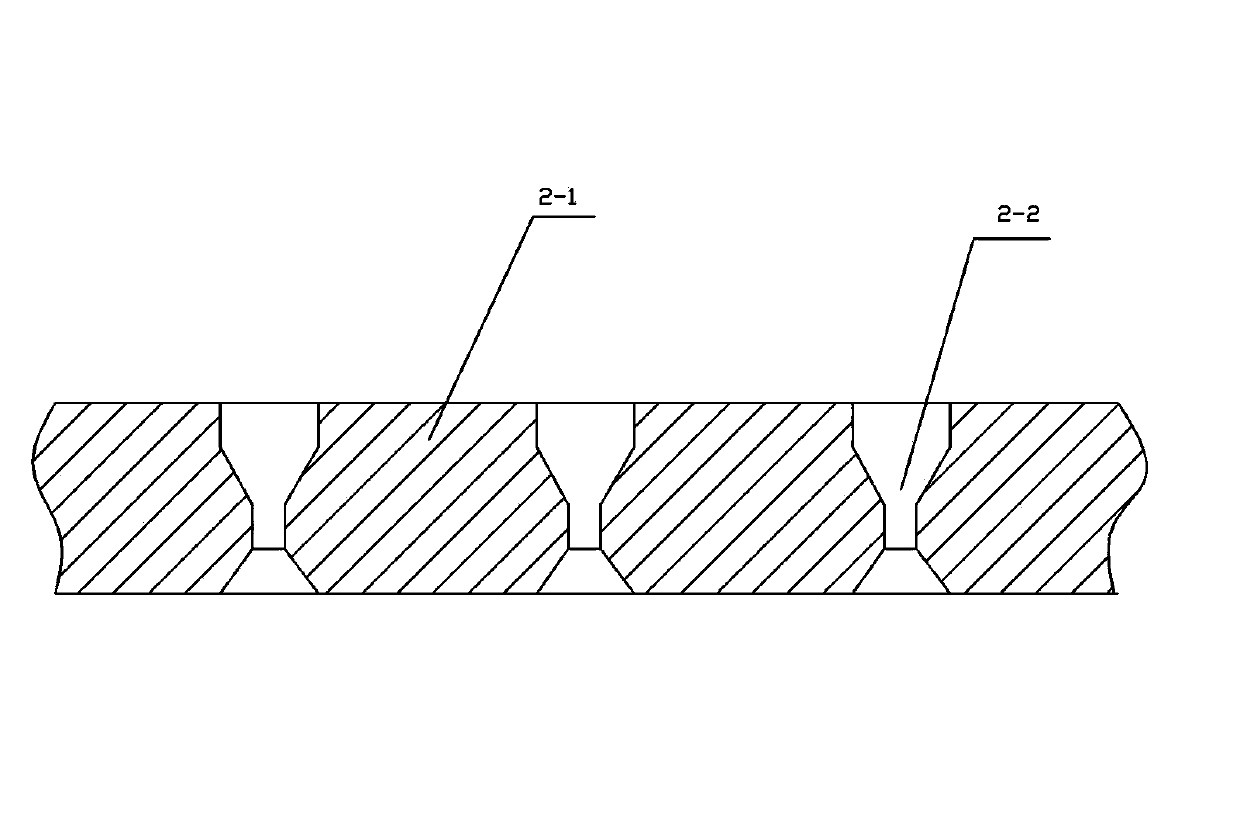

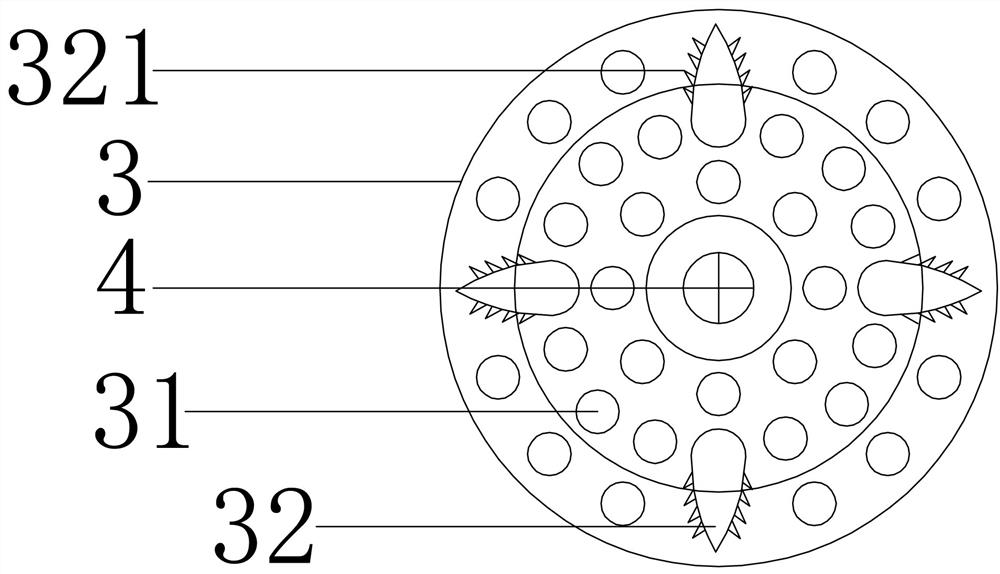

Spinneret plate for producing non-woven matrixes and cooling and shaping device of spinneret plate

ActiveCN103966674ALimit bloatLimit brokenSpinnerette packsFilament/thread formingFiberPolymer science

The invention relates to the field of fiber production, in particular to a spinneret plate for producing non-woven matrixes and a cooling and shaping device of the spinneret plate. Stepped cylindrical holes or positive frustum holes are additionally formed at the lower ends of spinneret orifices of the spinneret plate for producing the non-woven matrixes. The cooling and shaping device of the spinneret plate comprises a spinneret die head, netting licker-ins, a cooling mechanism, drying mechanisms, a glue spraying mechanism and a shaping mechanism, the cooling mechanism, the drying mechanism glue spraying mechanism and the shaping mechanism are sequentially mounted, semi-products of the matrixes are revolved via support rollers, power roller pairs and guide rollers, and the spinneret plate is mounted at the lower end of the spinneret die head. Expansion and crushing of melt can be limited after the melt flows out of the spinneret orifices, adhesion between two adjacent two spinneret orifices or among multiple spinneret orifices is eliminated, the produced non-woven matrixes are smooth in surface and less in bulk particles, defects of a traditional technology are overcome, improvement of production efficiency is facilitated, and production cost is saved.

Owner:佳研新材料科技(重庆)有限公司

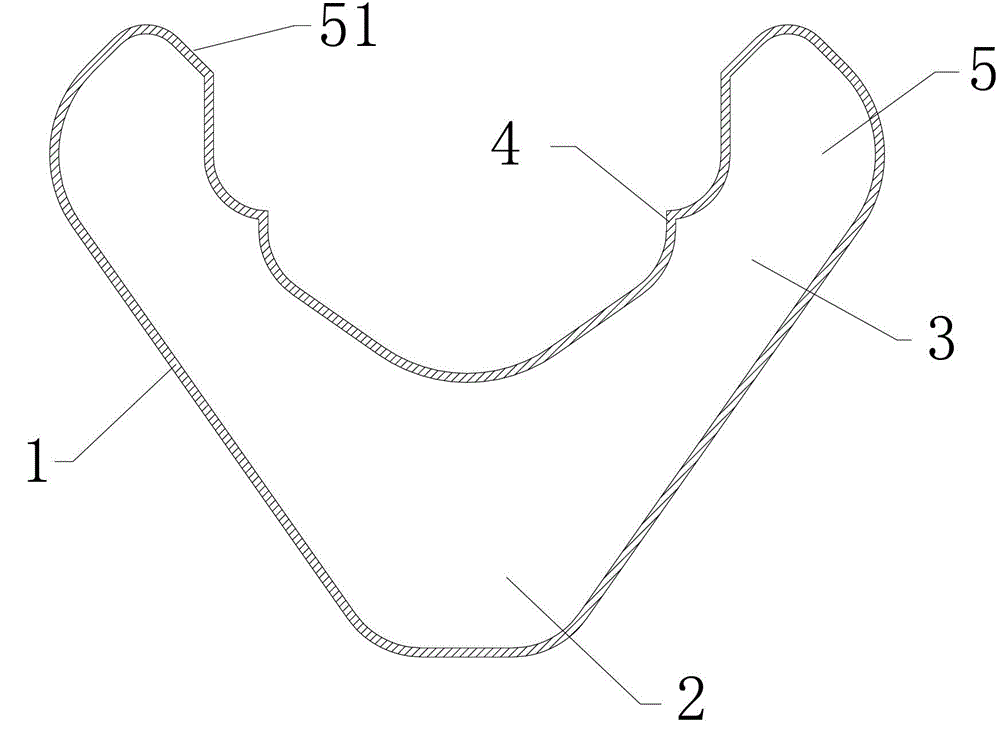

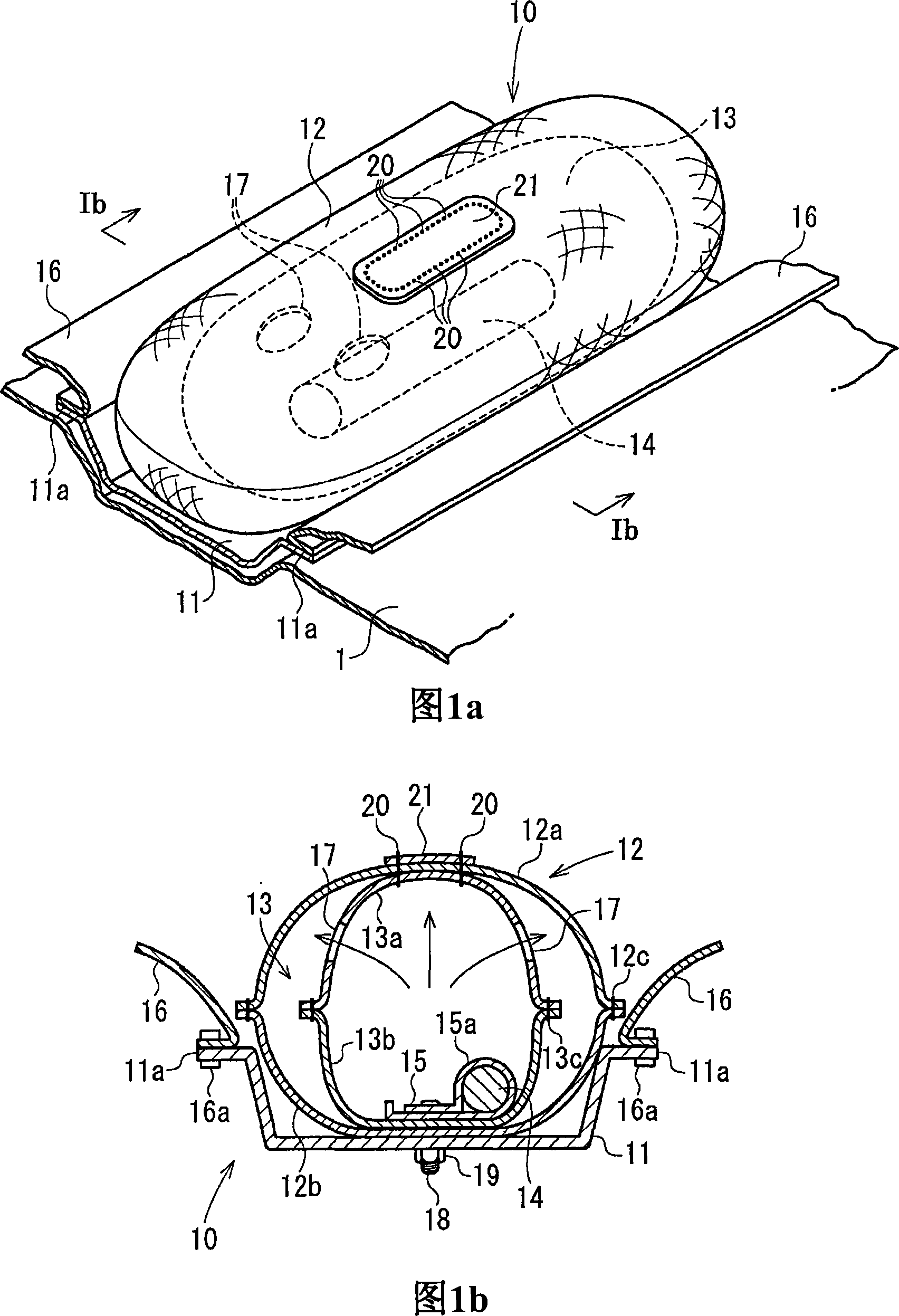

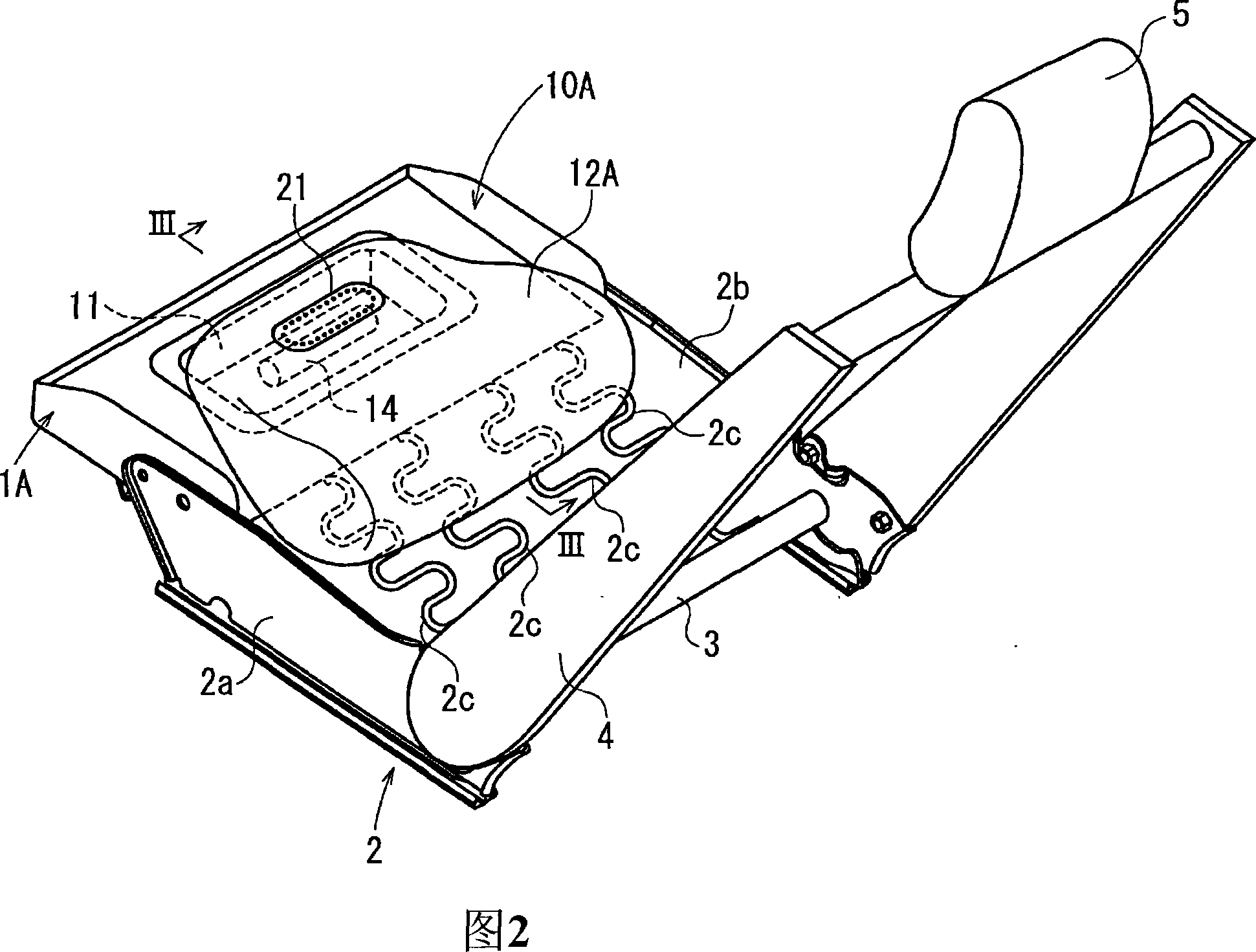

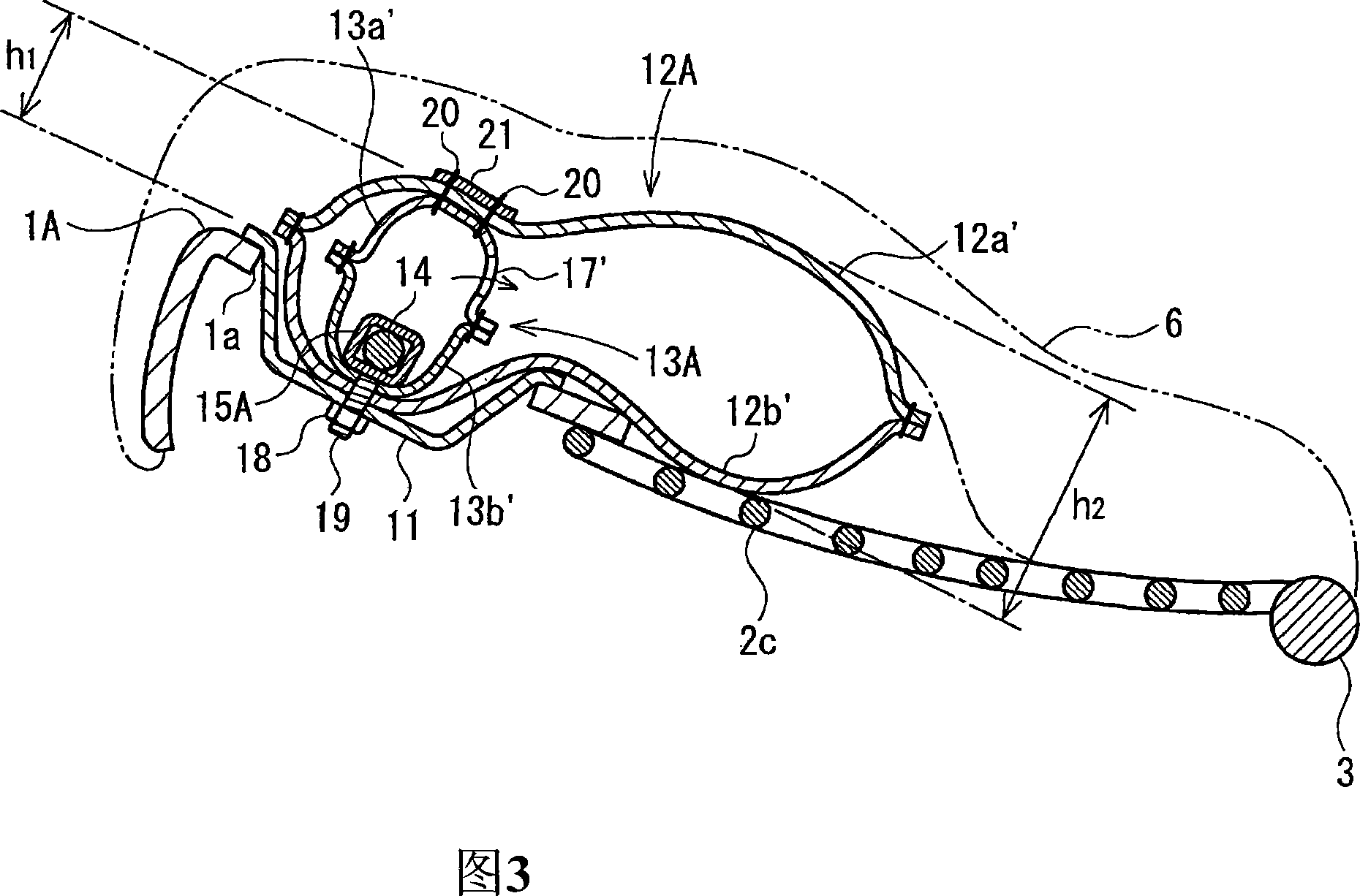

Occupant restraint device

InactiveCN101213117ALimit bloatVehicle seatsPedestrian/occupant safety arrangementEngineeringCushion

An occupant restraint device in which the amount of upward inflation of a seat bag is limited. The occupant restraint device (10) has the seat bag (12) extending in the direction of left-right width direction of a seat and inflatable to press a seat cushion from the underside; a retainer (11) placed on a seat pan (1); an inner bag (13) placed in the seat bag (12); and an inflator (14) for inflating the seat bag (12) and the inner bag (13). The inner bag (13) is connected at its lower part to the retainer (11) and at its upper part to the upper part of the seat bag (12).

Owner:TAKATA CORPORATION

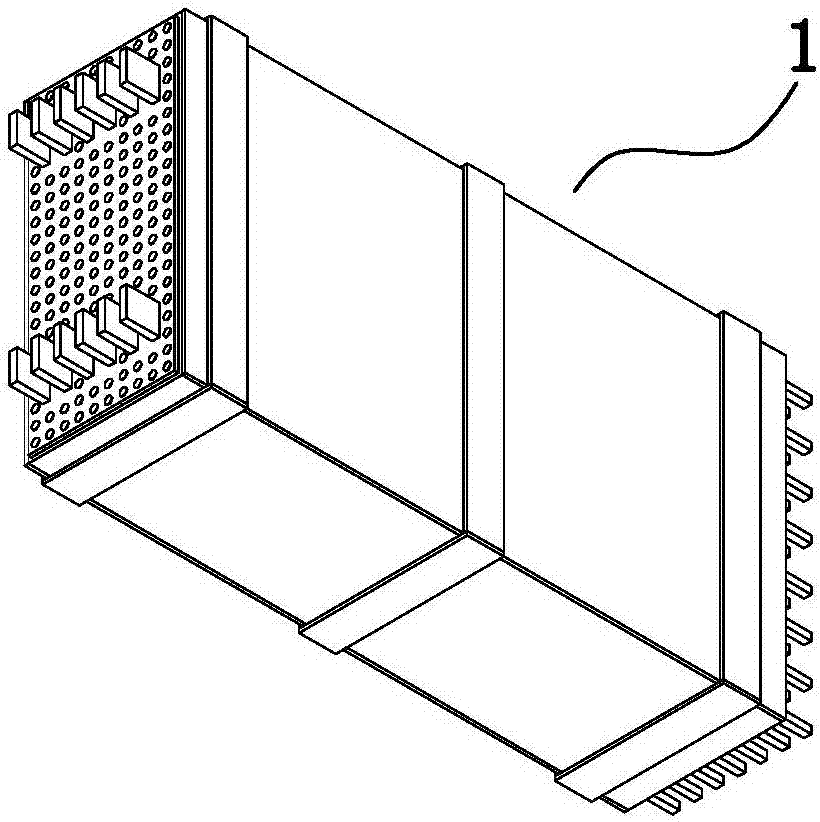

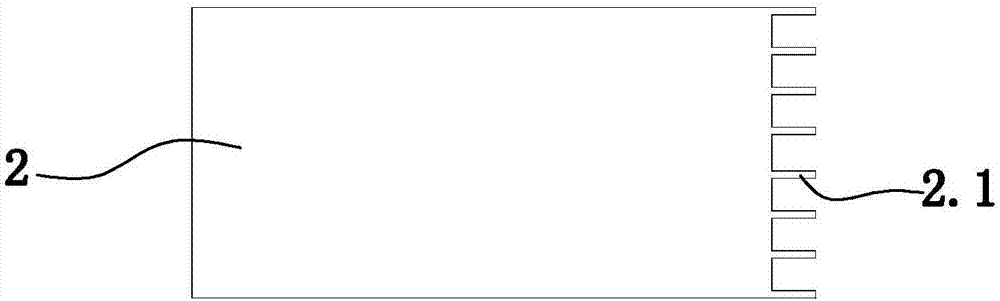

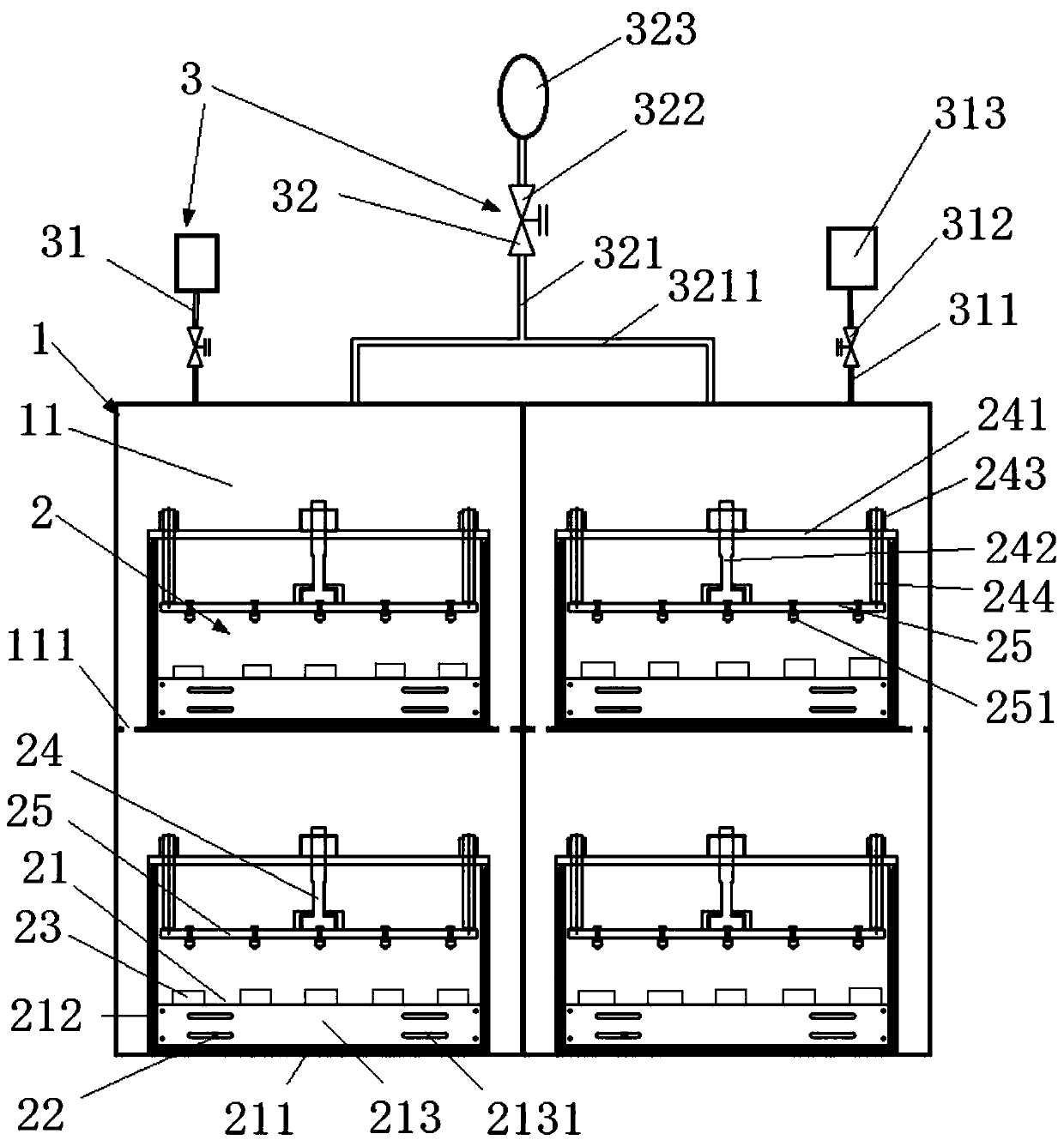

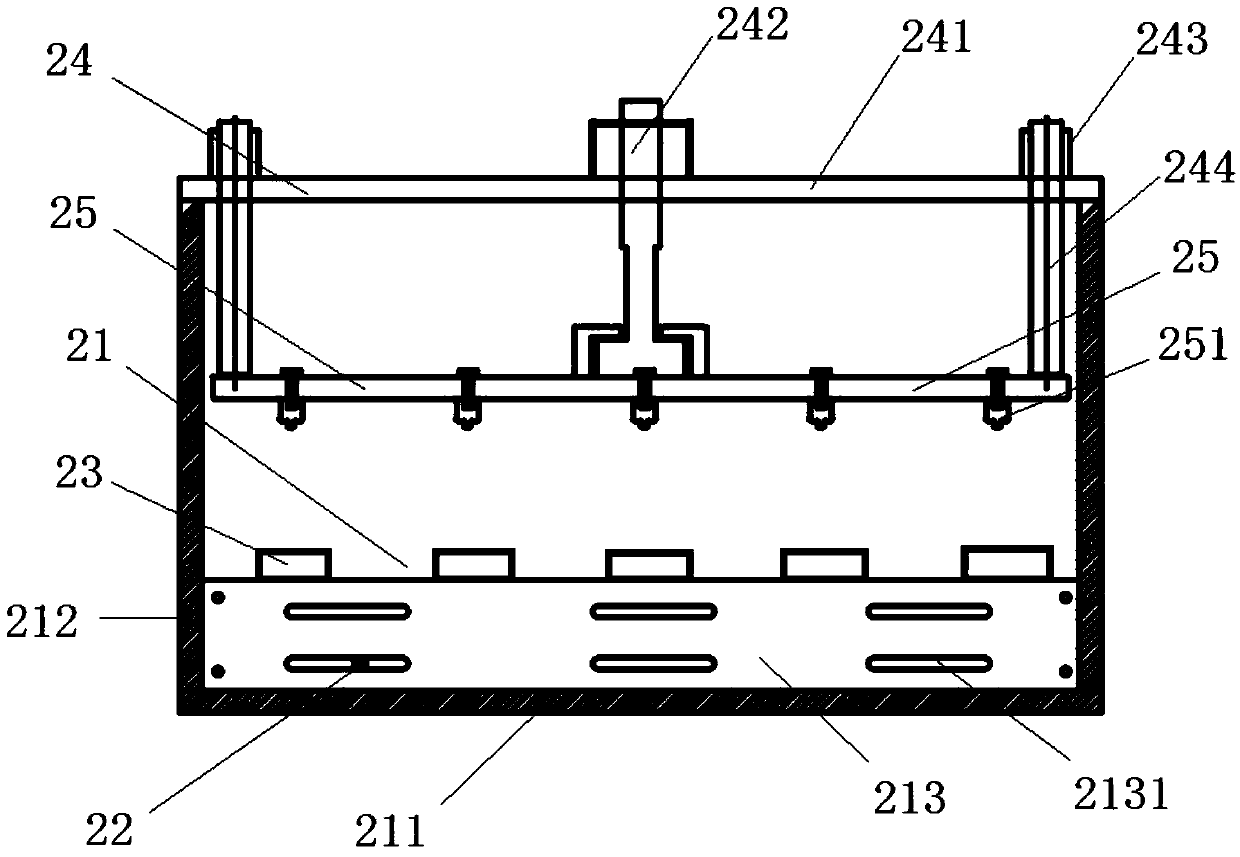

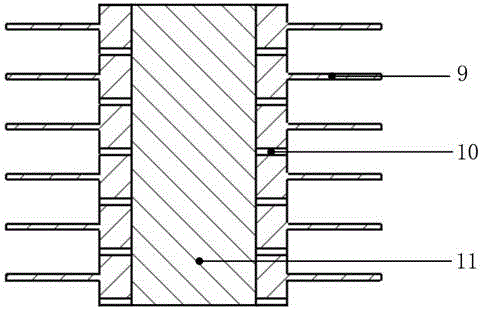

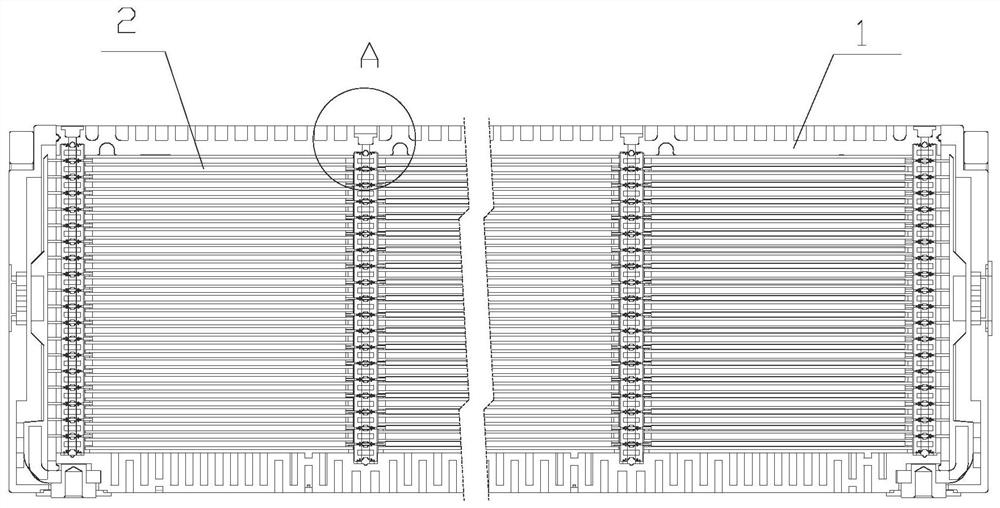

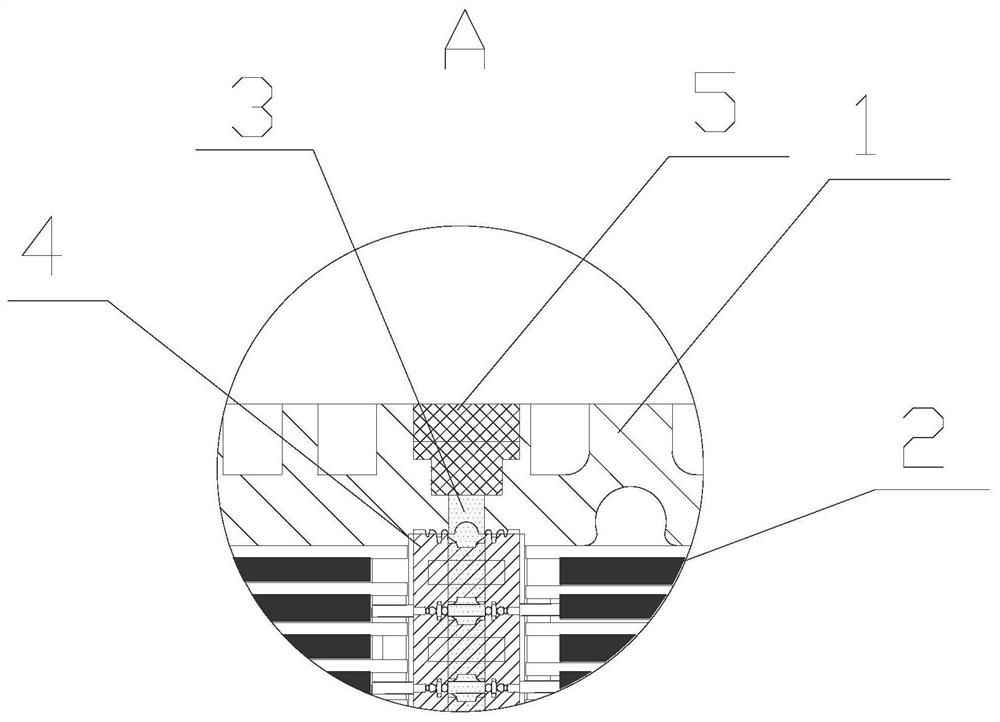

Lithium ion battery parallel formation system and process

InactiveCN107834114ALimit bloatEasy dischargeFinal product manufactureElectrolyte accumulators manufacturePhysical well beingLithium-ion battery

The invention discloses a lithium ion battery parallel formation system. The lithium ion battery parallel formation system comprises a formation cabinet, a formation device and a gas circulating piece, wherein the formation device comprises a formation tank, an adjusting rod, an electrode plate, a lifting piece and a clamping plate; the formation device is placed in the formation cabinet; to-be-formed batteries are placed in the formation tank and are matched with the rest components of the formation device so that the to-be-formed batteries are in parallel connection with the rest componentsof the formation device; and by a gas circulating system, gas generated by formation of the batteries is continuously discharged from the formation cabinet. By the lithium ion battery parallel formation system, the to-be-formed batteries are in parallel connection, a plurality of batteries can be formed at a time, formation space is saved, operation steps are reduced, by the formation cabinet andthe gas circulating piece, the gas generated by formation of the batteries is discharged rapidly, SEI films are formed uniformly, the formation is good, moreover, workers are not in direct contact with the gas discharged by formation, health of the workers is ensured, by the adjusting rod, positive and negative tabs of the formed batteries are separately maintained on a straight line, and thus, the battery formation consistency is high.

Owner:HUIZHOU JIMEITAI ELECTRONICS TECH CO LTD

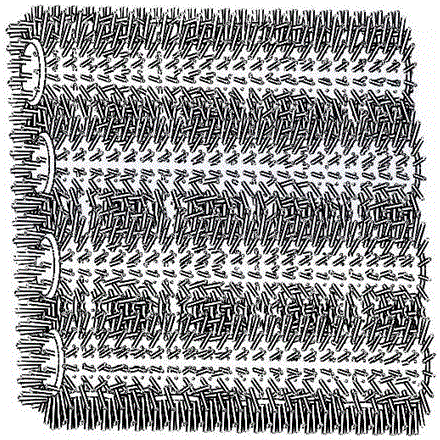

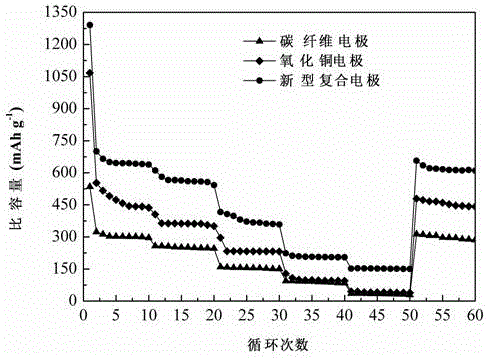

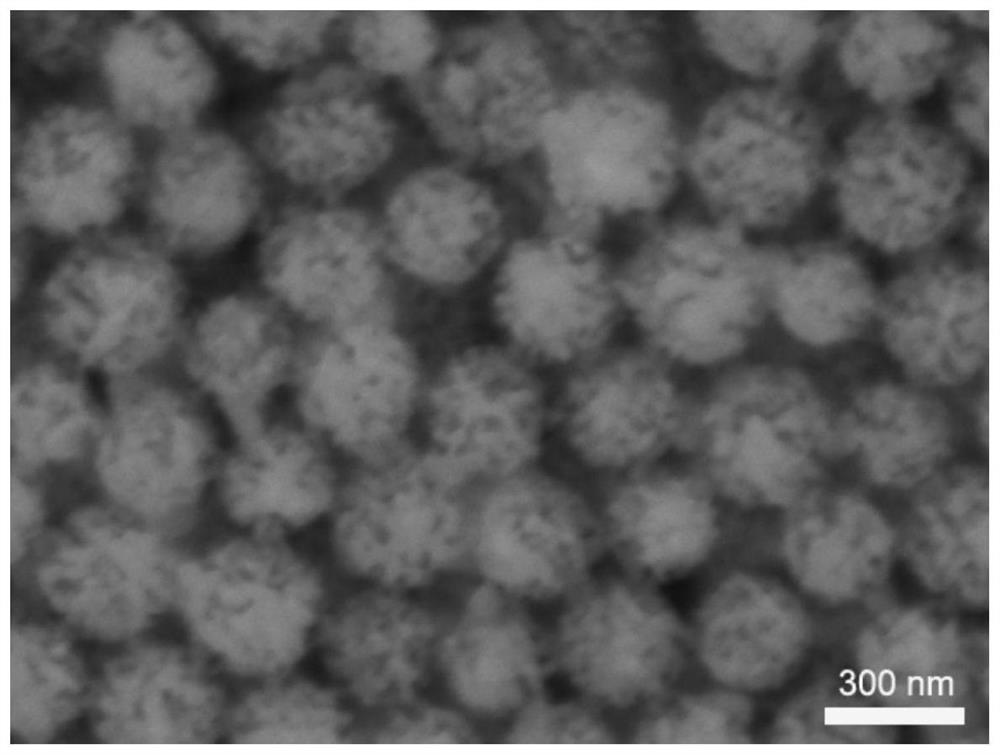

Carbon core/copper oxide housing composite electrode for lithium ion battery and preparation method thereof

PendingCN106602036AHigh charge and discharge capacityThe degree of buffer volume changeMaterial nanotechnologyCell electrodesFiberCopper plating

The invention discloses a carbon core / copper oxide housing composite electrode for a lithium ion battery and a preparation method thereof. A core part of the carbon core / copper oxide housing composite electrode is formed by carbon fibers, and a housing of the carbon core / copper oxide housing composite electrode is a copper oxide thin layer; and the copper oxide thin layer is provided with nano needle-shaped structures and nano pore-shaped structures, which are arranged in an array mode. The preparation method of the carbon core / copper oxide housing composite electrode comprises the following steps of: (1) preparation of copper-coated carbon fibers; (2) sintering moulding of the copper-coated carbon fibers; and (3) surface oxidation treatment of a formed copper-coated carbon fiber felt. According to the carbon core / copper oxide housing composite electrode disclosed by the invention, charging and discharging capacity of the lithium ion battery is improved, and electrochemical properties of a cycle life, coulombic efficiency, cycling stability and the like of the lithium ion battery are improved.

Owner:SOUTH CHINA UNIV OF TECH

Method for plating piezoelectric composite

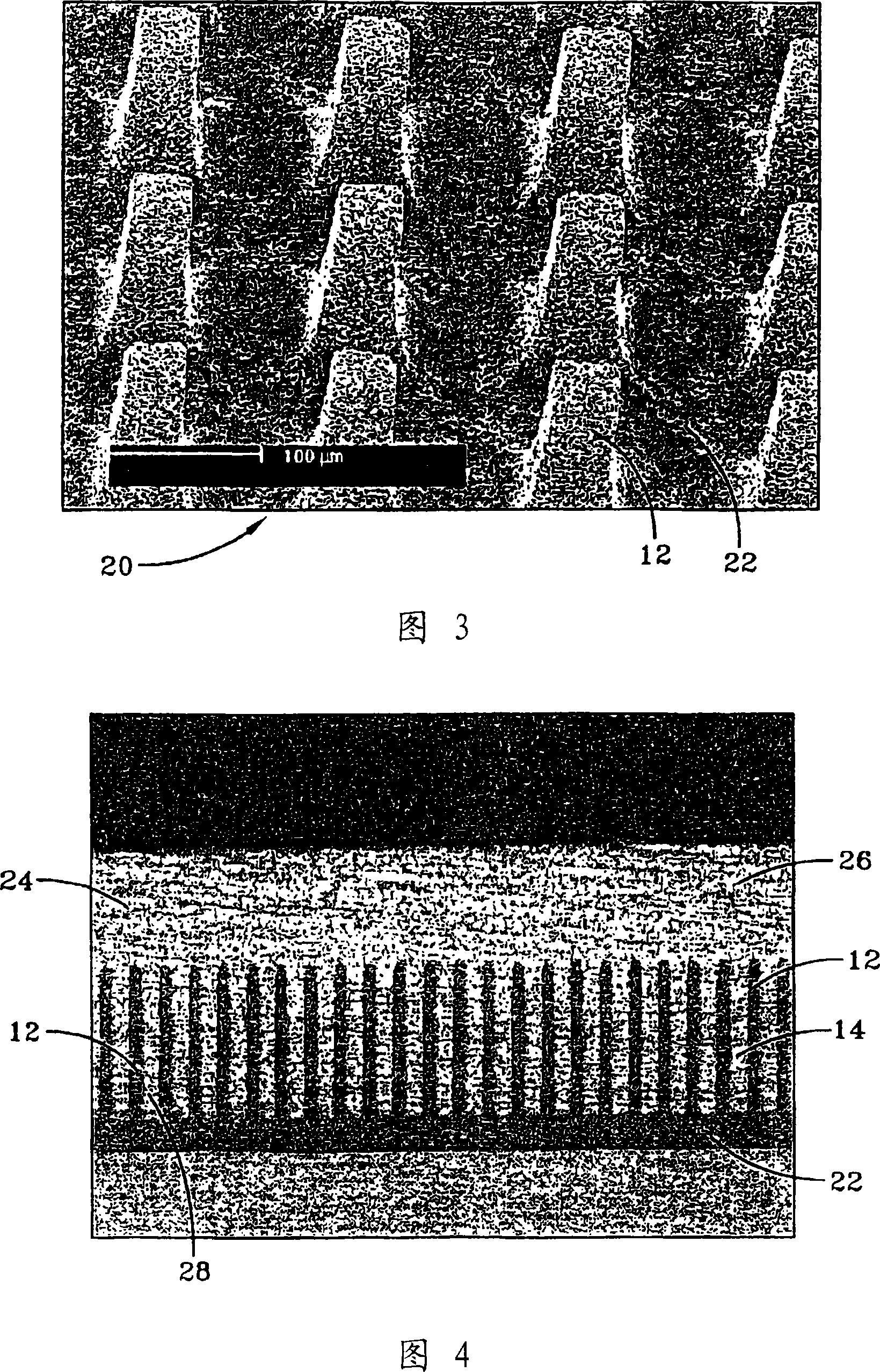

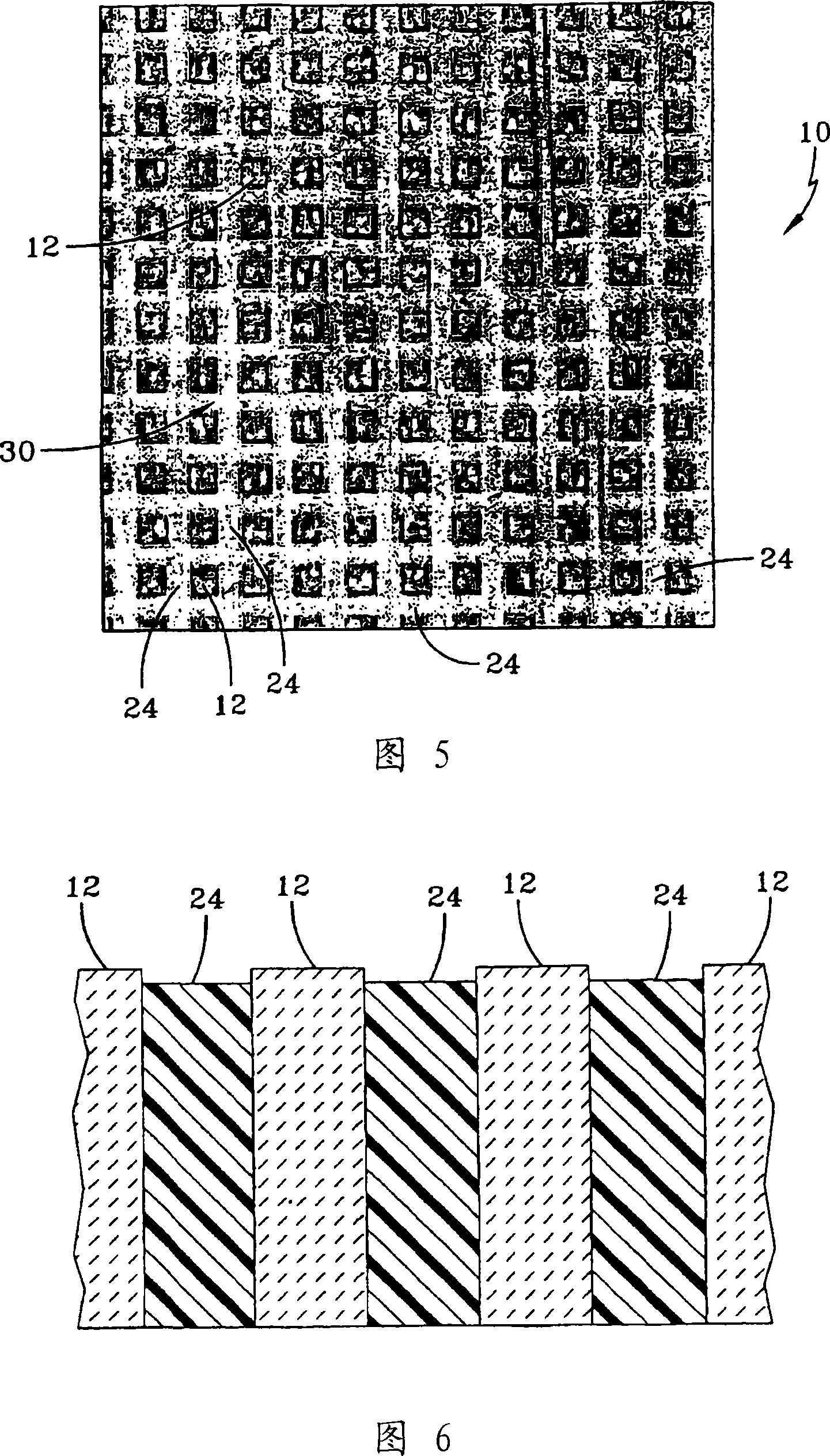

InactiveCN101115572AEasy to manufactureImprove reliabilityPiezoelectric/electrostrictive device manufacture/assemblyMechanical vibrations separationEpoxyAcid etching

A method of manufacturing a piezo-composite element comprising a ceramic element (12) embedded in a polymer (14) such as epoxy for use in an ultrasonic transducer (10) includes first grinding the face of the composite and removing damaged ceramic (12) by acid etching the ceramic (12). The epoxy is then removed by plasma etching so that the ceramic (12) is slightly elevated above the epoxy. The composite is sputter plated so that a maximum temperature that could damage the p1a ting is not exceeded. The ceramic (12) is then poled so that a maximum temperate re that could damage the plating is not exceeded. Contacts (16) are then attached to the plating adjacent the ceramic (12). In an array, the ceramic elements (1 2) may be in the form of posts. The plurality of ceramic elements (12) is in staggered arrangement with the polymer (14).

Owner:GE INSPECTION TECH LP

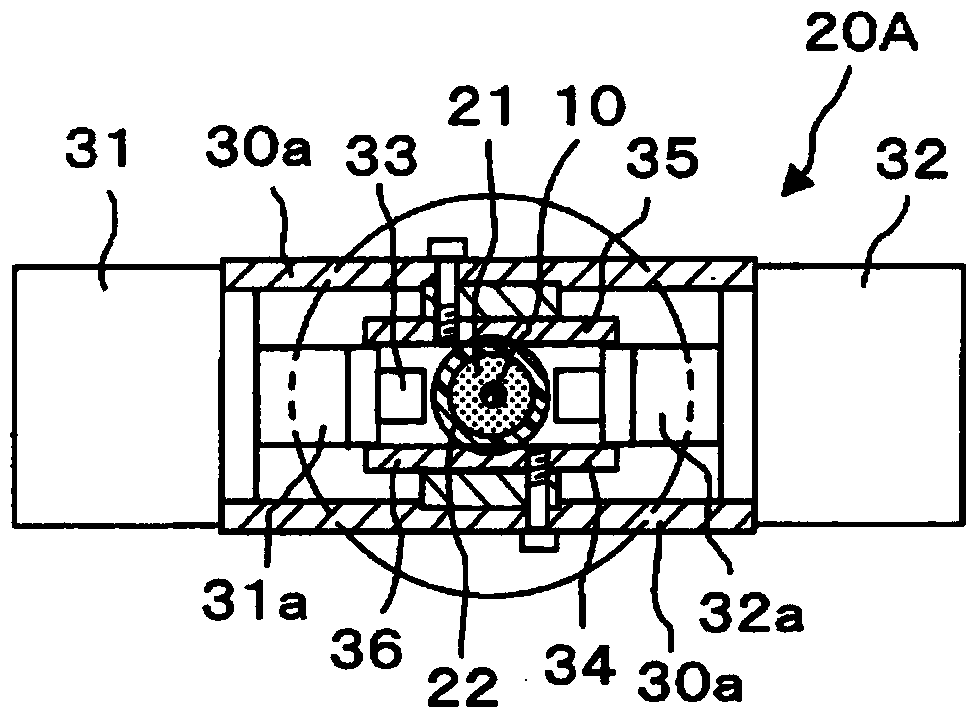

Surface treatment device and surface treatment method for long linear articles

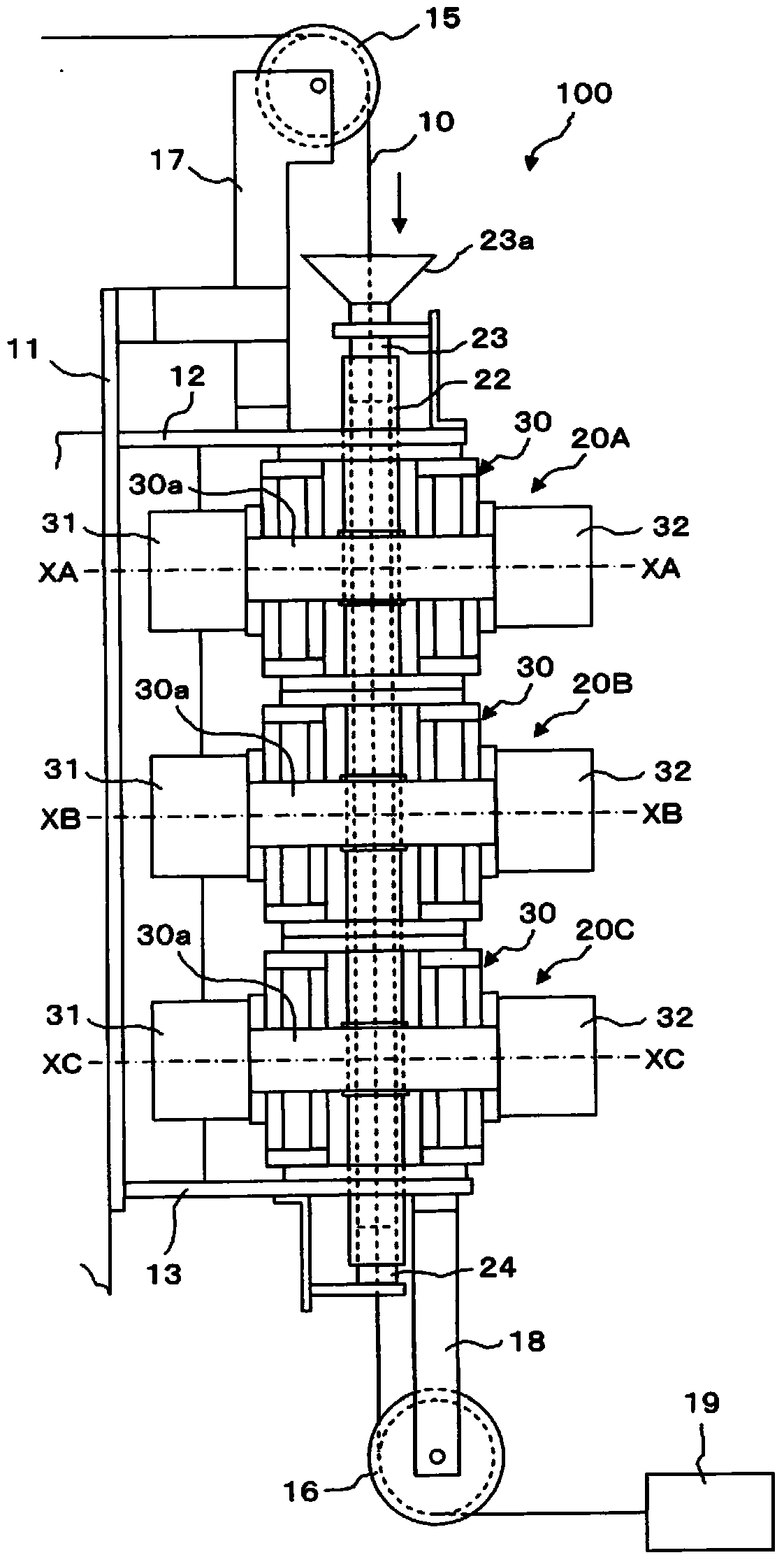

InactiveCN103889658AEfficient grindingImprove liquidityPolishing machinesAbrasive feedersBiomedical engineeringTreatment unit

Provided are a surface treatment device and surface treatment method for long linear articles, the device and method being configured so as to be able to polish the surface of long linear articles efficiently using a powder by cyclically repeating the pressurization and depressurization of an elastic tube filled with the powder. To that end, the device comprises at least one surface treatment unit (20A-20C, 120) and the surface treatment unit is provided with: a tube (22) which is filled with a powder (21) so as to allow supply and discharge and in which a long linear article (10) is movably inserted in the powder; pressurizing means (31, 32) that cyclically pressurize and depressurize the tube; and a feed means (19) for moving the long linear article inserted in the powder.

Owner:FUJI SHOJI

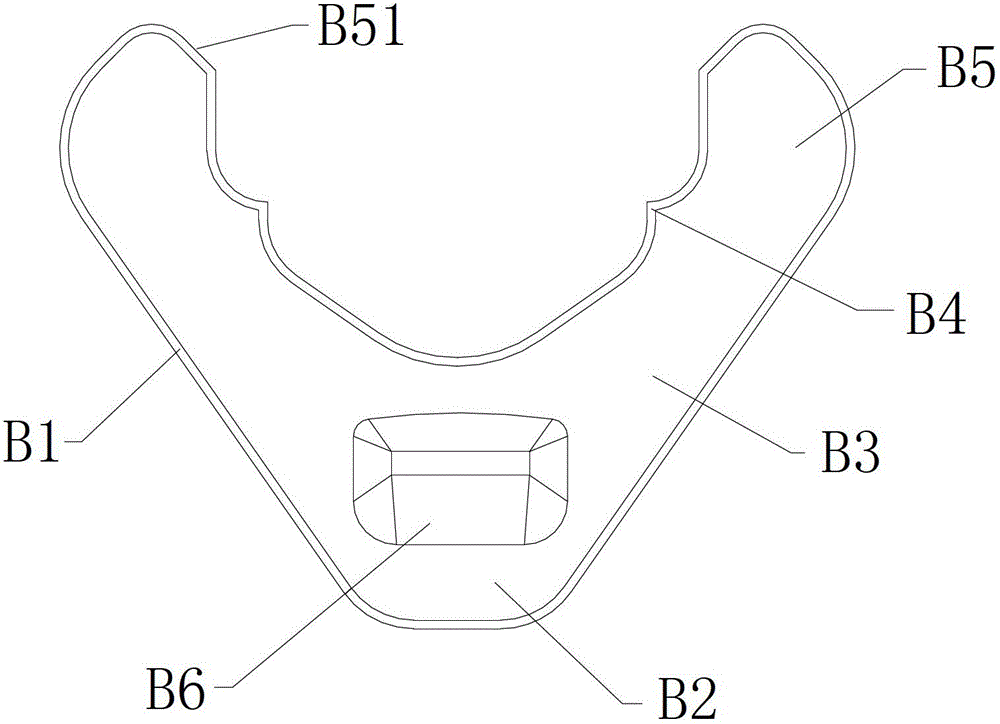

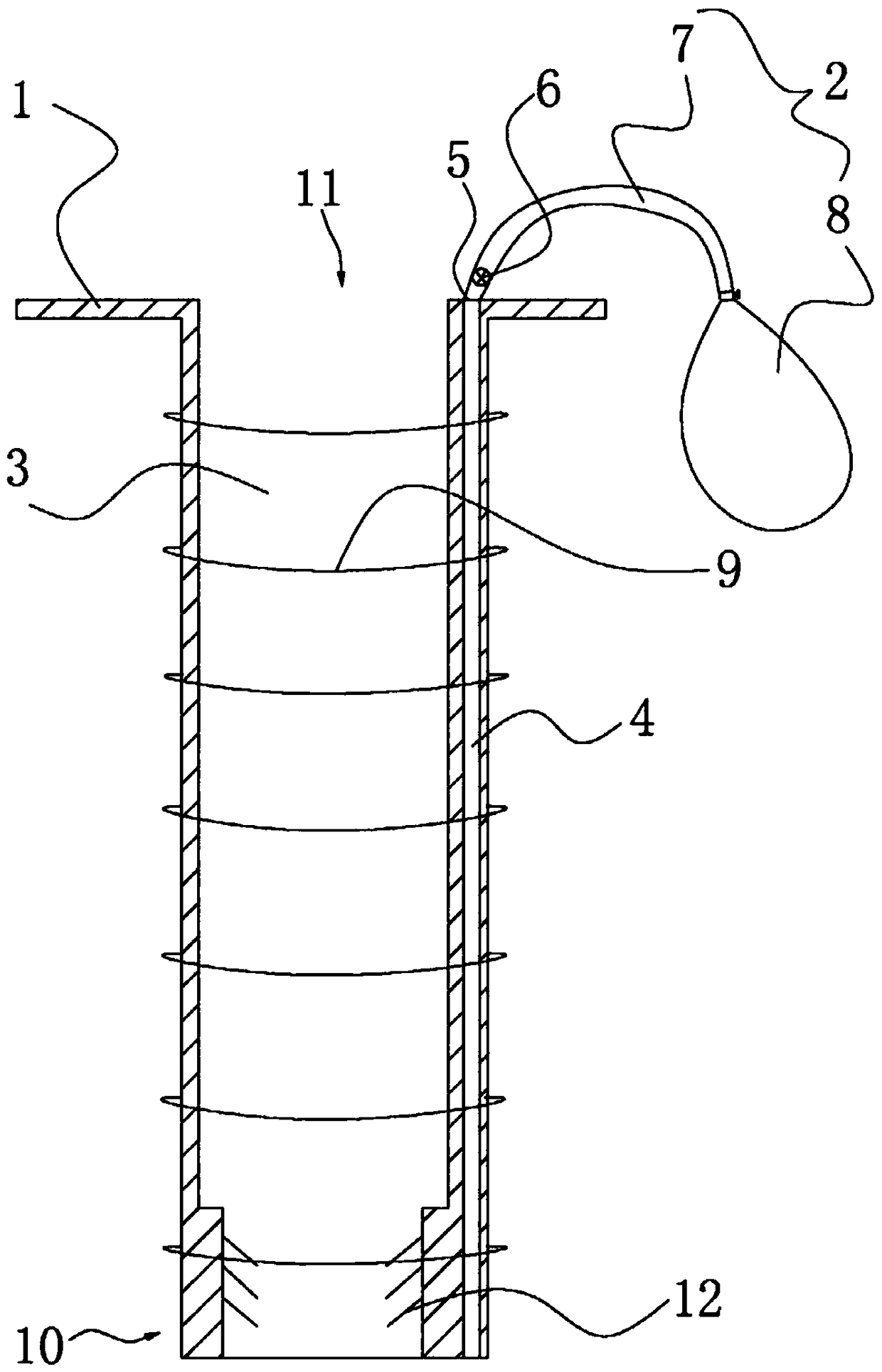

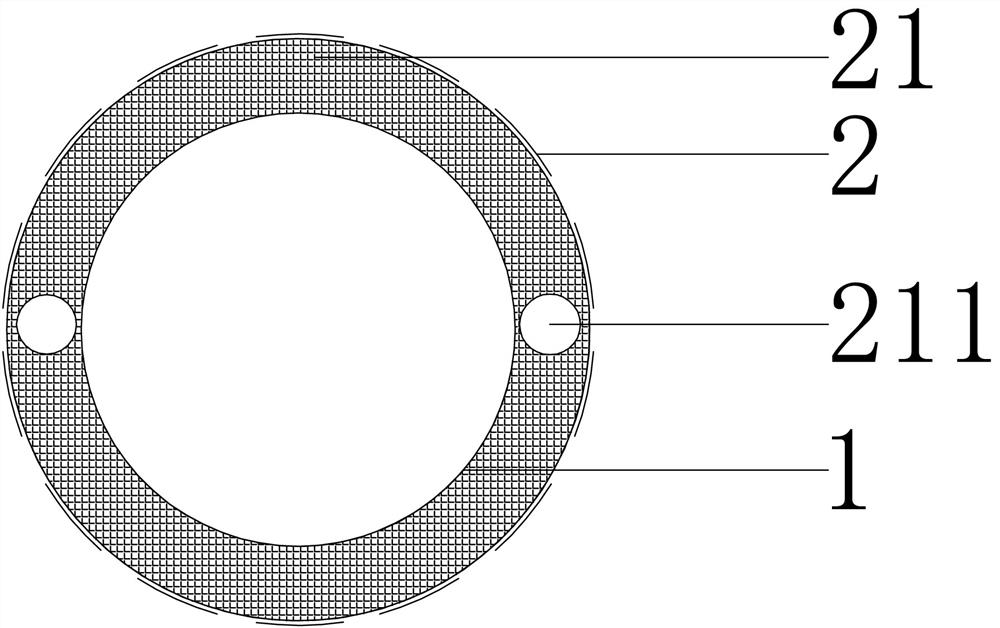

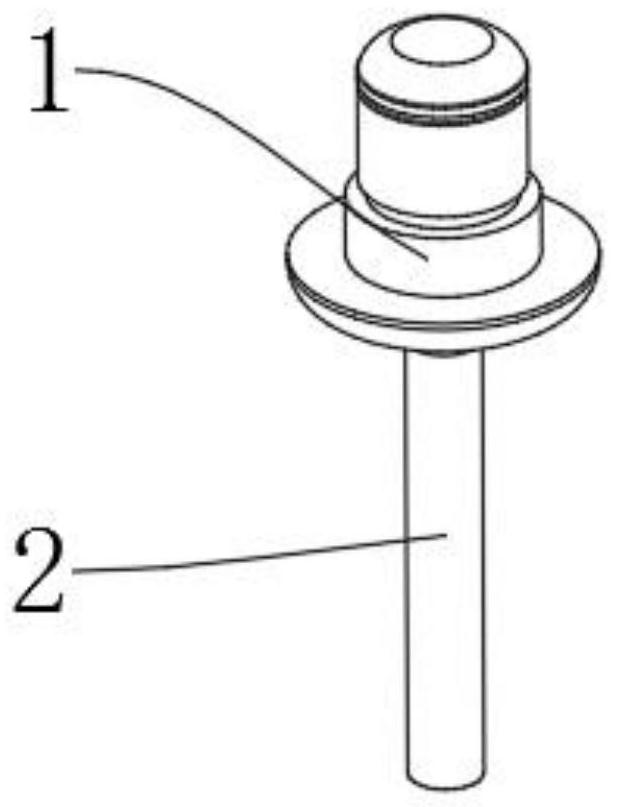

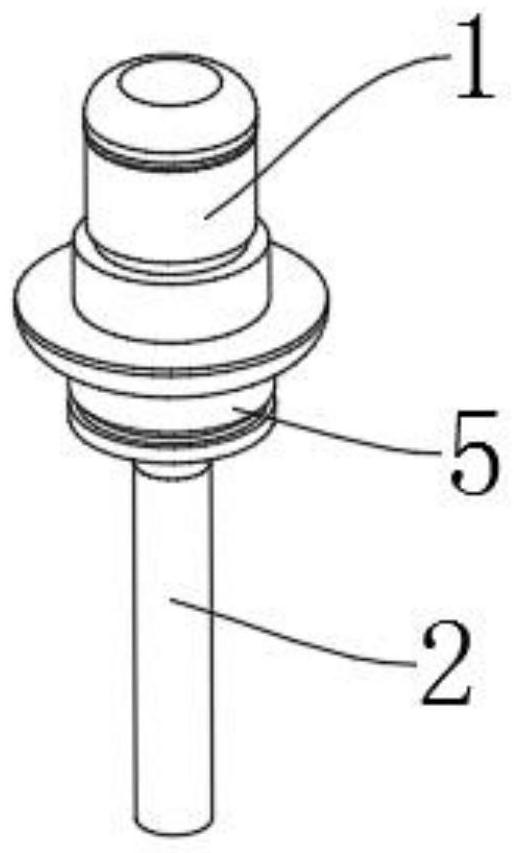

Anorectal endoscope protection sleeve

The invention provides an anorectal endoscope protection sleeve, and belongs to the field of medical instruments. The sleeve solves the problems that existing air supply devices are not once progressive and difficult to disinfect, and when the inflation is stopped, the gas and intestinal fluid which enter an intestinal cavity of a patient may flow back into the air supply devices, which may causea cross-infection of the patient. The anorectal endoscope protection cover comprises a housing and the gas supply devices connected to the housing, the housing is provided with an inner cavity for anendoscope to penetrate, the housing is provided with an inflation duct, an air inlet is formed in one end of the inflation duct, the air inlet is connected with the gas supply devices for inflating the intestinal cavity, and a check valve is arranged between the air inlet and the air supply devices. The sleeve has the advantages of preventing the backflow of the intestinal fluid from polluting thegas supply devices.

Owner:HANGZHOU FIRST PEOPLES HOSPITAL

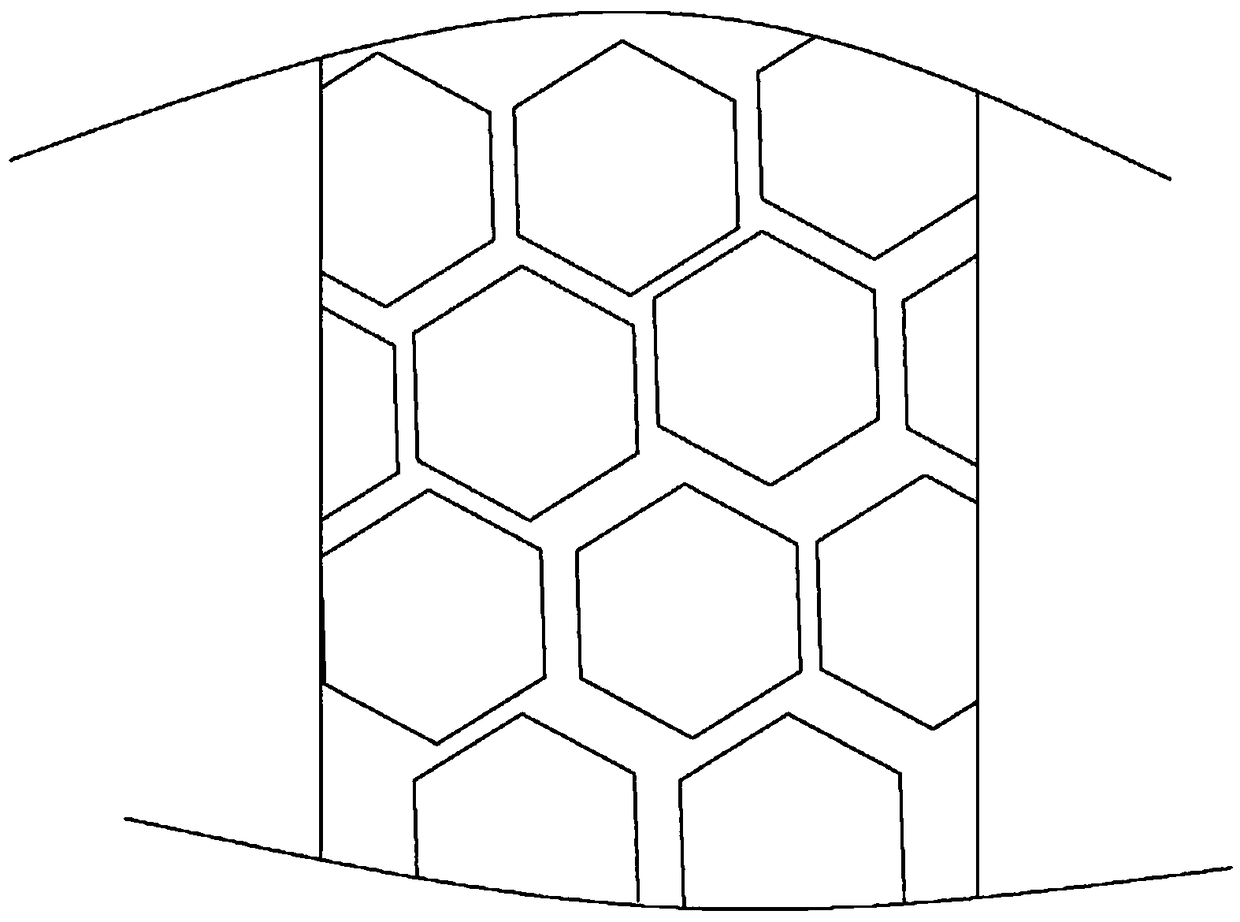

Semiconductor package element and method for manufacturing same

InactiveCN105140190AReduce warpageReduce signal interferenceSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageEngineering

The invention provides a semiconductor package element and a method for manufacturing the same. The same semiconductor package element comprises a substrate, at least one chip, an encapsulation layer and at least one grid part, wherein the at least one chip is arranged on the substrate, the encapsulation layer is arranged on the substrate and encapsulates the at least one chip, and the at least one grid part is arranged in the encapsulation layer and comprises a plurality of main body parts, wherein the main body parts are opened and limited by a first rib and a second rib.

Owner:SAMSUNG SEMICON CHINA RES & DEV +1

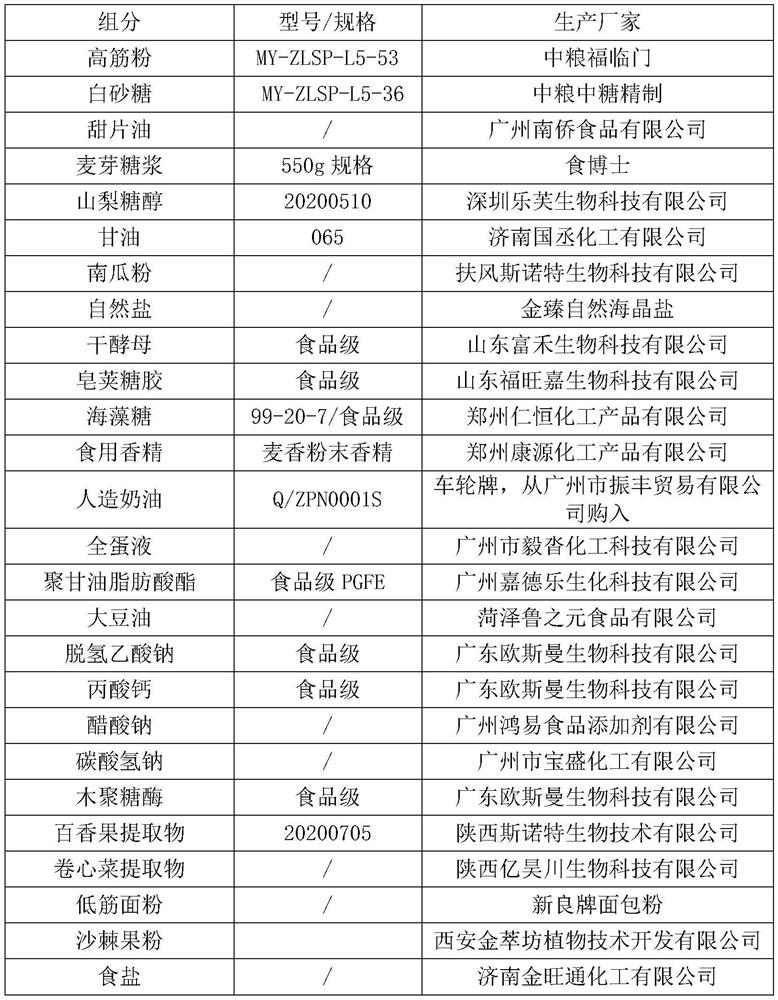

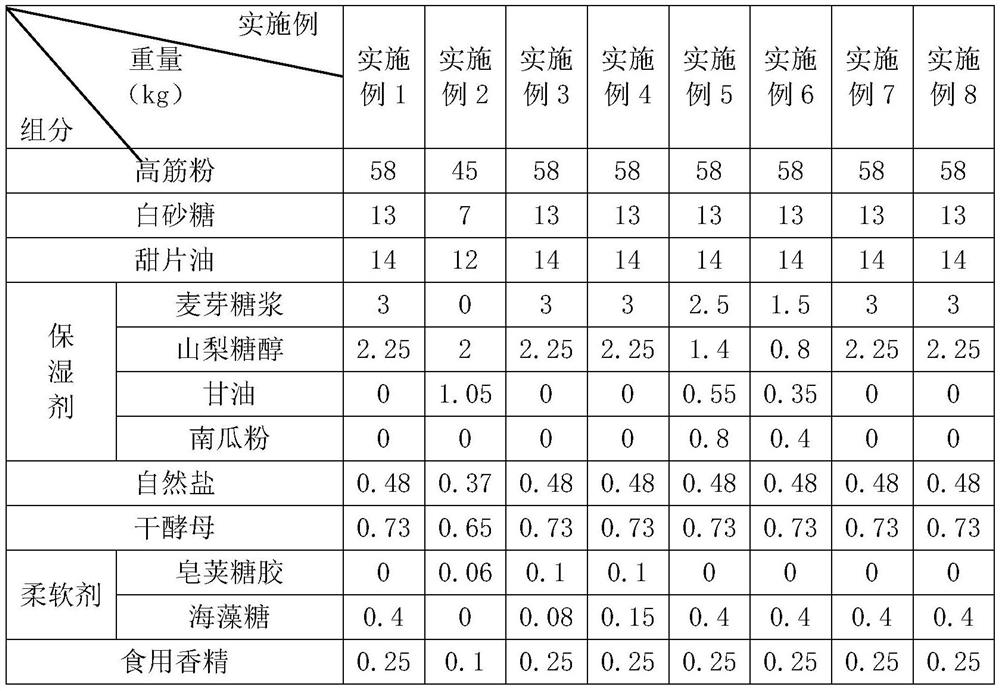

Soft and elastic bread and fermentation process thereof

PendingCN113475552ALimit bloatReduce moistureDough treatmentDough/pre-mixesBiotechnologyPreservative

The invention relates to the technical field of food preparation, and particularly discloses soft and elastic bread and a fermentation process thereof. The bread is prepared from the following raw materials in parts by weight: 45 to 58 parts of high gluten flour, 7 to 13 parts of white granulated sugar, 12 to 14 parts of sweet slice oil, 3.05 to 5.25 parts of humectant, 0.37 to 0.48 part of natural salt, 0.65 to 0.73 part of dried yeast, 0.06 to 0.4 part of softening agent, 0.1 to 0.25 part of edible essence, 3.25 to 4.45 parts of margarine, 1 to 1.5 parts of whole egg liquid, 0.65 to 0.9 part of emulsifying paste, 1 to 1.6 parts of soybean oil, 0.1 to 0.4 part of preservative and 21 to 24.5 parts of deionized water. The softening agent comprises at least one of gleditsia sinensis lam gum and trehalose; the fermentation process comprises the steps: after uniformly mixing, overturning and kneading the high gluten flour, the white granulated sugar, the dry yeast and the deionized water, adding natural salt, after uniformly overturning and kneading, adding the whole egg liquid, the sweet slice oil, the soybean oil, the margarine and the emulsifying paste, and after uniformly overturning and kneading, adding the humectant, the softening agent, the edible essence and the preservative to uniformly overturn and knead to obtain a dough; and after standing the dough for 50-80 minutes, cutting, baking and cooling to obtain a finished product. The bread provided by the invention has lasting softness and elasticity.

Owner:YOUCHEN FUJIAN FOOD

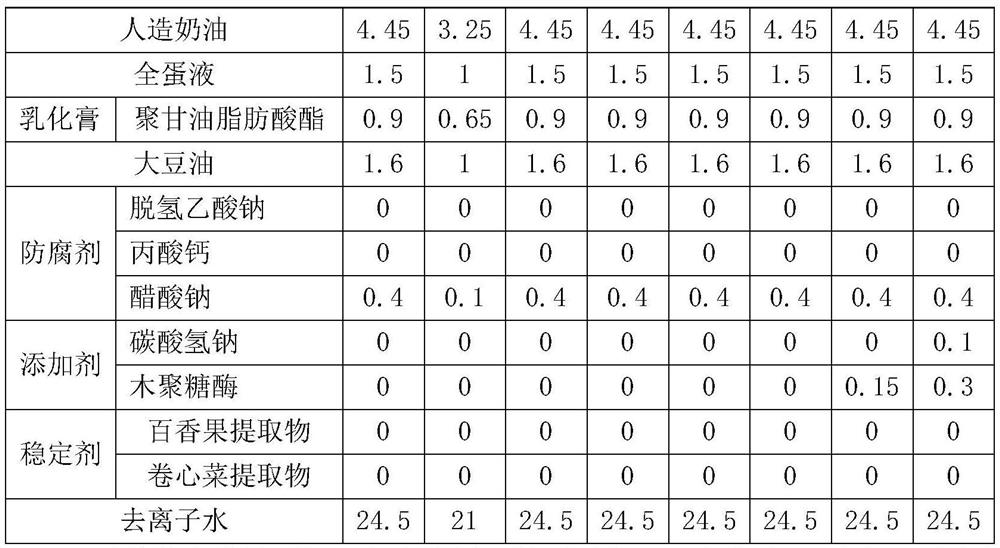

Preparation method of nano silicon-carbon negative electrode material

PendingCN114400327ASimple processLow costMaterial nanotechnologyCell electrodesCarbon layerMicrosphere

The invention relates to a preparation method of a nano silicon-carbon negative electrode material, which comprises the following steps: preparing nano SiO2 microspheres from tetraethoxysilane, and uniformly coating the surfaces of the nano SiO2 microspheres with a polymer or an organic matter layer to form a nano silicon-carbon precursor; under the protection of argon, the nanometer silicon carbon precursor and magnesium powder are pyrolyzed, a polymer on the surface of the nanometer silicon carbon precursor is carbonized to form a carbon shell coating the surface of SiO2, meanwhile, the magnesium powder is volatilized into magnesium steam, the magnesium steam permeates the carbon shell and enters the interior to react with nanometer SiO2, and the nanometer silicon carbon negative electrode material is prepared. Compared with the prior art, the prepared nano silicon-carbon negative electrode material is of a core-shell structure, silicon in the nano silicon-carbon negative electrode material is a core, the particle size of the nano silicon-carbon negative electrode material is all nanoscale, the size of the silicon is uniform, and the content of the silicon is 5wt%-60wt%; the surface of nano Si is coated with a carbon layer, and nano silicon is protected by the carbon layer, so that the capacity of the lithium ion battery is improved, and the cycle life of the lithium ion battery is prolonged.

Owner:SHANGHAI JIAO TONG UNIV

Horizontal lead-acid battery with filler and assembly method thereof

PendingCN112018455AExtend your lifeImprove performanceFinal product manufactureLead-acid accumulators constructionLiquid stateStructural engineering

The invention provides a horizontal lead-acid battery with filler and an assembly method thereof, the horizontal lead-acid battery comprises a battery shell and a battery pole group consisting of a positive plate, a negative plate and a diaphragm, and the horizontal lead-acid battery is characterized in that the filler which is injected in a liquid form at normal temperature, cured and converted into a solid state is arranged around the positive plate and the negative plate. The filler can fill all polar plate gaps, tightly wraps polar plates, limits polar plate expansion, can only expand towards the vertical direction of the polar plate plane, avoids short circuit of positive and negative polar plates, limits expansion of active substances due to extremely high assembly pressure of the horizontal battery, ensures completeness of the active substances, and greatly prolongs the service life of the horizontal lead-acid battery.

Owner:浙江图兰特储能科技有限公司

Deformation-preventing solid-wood floor-heating-resistant floor base material, manufacturing method of deformation-preventing solid-wood floor-heating-resistant floor base material and floor manufactured with deformation-preventing solid-wood floor-heating-resistant floor base material

InactiveCN104594607AReduce moistureBalance moistureWood working apparatusFlooringSolid woodHigh pressure

The invention discloses a deformation-preventing solid-wood floor-heating-resistant floor base material, a manufacturing method of the deformation-preventing solid-wood floor-heating-resistant floor base material and a floor manufactured with the deformation-preventing solid-wood floor-heating-resistant floor base material, and belongs to the field of solid-wood composite floors. The deformation-preventing solid-wood floor-heating-resistant floor base material, the manufacturing method and the floor aim at solving the problems that a current solid-wood floor is high in cost, is deformed, warped and cracked, is not environmentally friendly, is not resistant to moisture and can not be used on a floor-heating ground. A base plate is pasted to the bottom of a middle layer of the base material; edge strips are arranged on the two lateral sides of a core, the edge strips and the core are composed of veneers in a spliced mode, wood grains of the edge strips are perpendicular to wood grains of the core, and the wood grains of the edge strips and the wood grains of the core are perpendicular to wood grains of the base plate. The floor is composed of the base material and a famous-and-precious-wood face plate in a spliced mode. The method includes the steps that raw wood is boiled to be softened and cut into the veneers and the base plate, and drying is carried out; edge strip blank plates and a core blank plate are formed in a spliced mode, high-temperature and high-pressure pressing processing is carried out, conditioning, edge cutting, sanding and thickness fixing are carried out, the materials are spliced together to be pressed and sanded, and the base material is obtained. According to the deformation-preventing solid-wood floor-heating-resistant floor base material, the manufacturing method and the floor, energy emitted by a floor heating tube can be stored through a cavity groove of the core, and resources are saved; meanwhile, the internal stress of the wood is eliminated, and the floor can be prevented from being deformed. The deformation-preventing solid-wood floor-heating-resistant floor base material, the manufacturing method and the floor are particularly suitable for floor heating pavement.

Owner:张福贵

A preparation method of a through-hole type lithium battery negative electrode material

InactiveCN109192947AGuaranteed uniformityAvoid reunionCell electrodesLi-accumulatorsNew energyReaction temperature

The invention discloses a preparation method of a through-hole type lithium battery negative electrode material, belonging to the technical field of new energy materials. At first, that gelatin is dissolve in glycerol, then titanate and silicate are added, aft heating and stirring reaction for 3-5h, the gelatin is concentrated unde reduced pressure, the residual glycerol is removed, and the gelatin is cooled to obtain a refined concentrate; 3 to 5 hour after that refine concentrate and the sulfuric acid solution are mixed, the hydrothermal reaction is carried out, the material is discharged, is and dried to obtain a hydrothermal carbonized material. Then the hydrothermal carbonized material is dispersed in water, nanometer magnesium powder, nanometer iron powder and sodium fluoride are added, and after ultrasonic impregnation, the hydrothermal carbonized material is filtered and dried to obtain the impregnated hydrothermal carbonized material. The impregnated hydrothermal carbonized material is transferred into a vacuum furnace, the temperature is programmed to be 1480-1500 DEG C, the reaction temperature is preserved and vacuum reacted, then the material is cooled, discharged, washed with dilute hydrochloric acid, washed with water and dried to obtain a through-hole type lithium battery negative electrode material. The through-hole type lithium battery negative electrode material obtained by the invention has excellent cycle performance.

Owner:合肥哈工安循环保科技有限公司

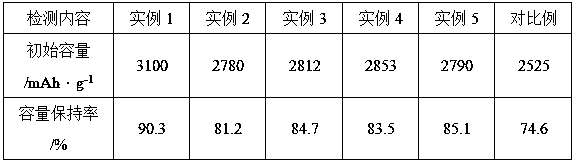

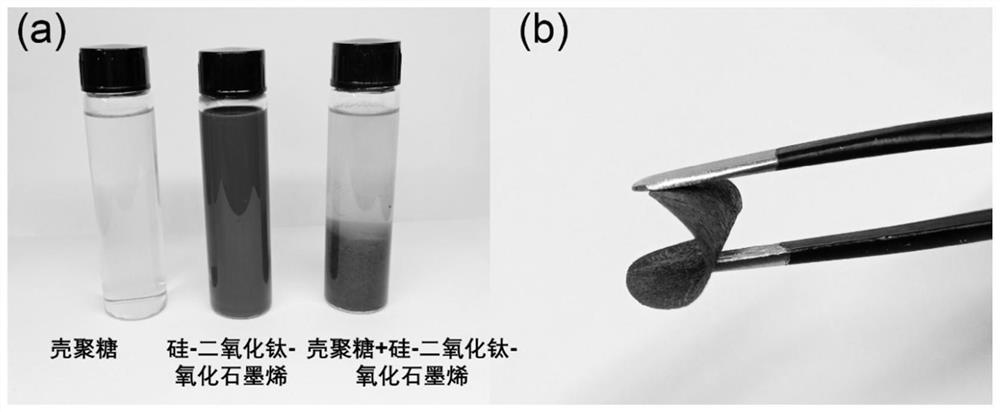

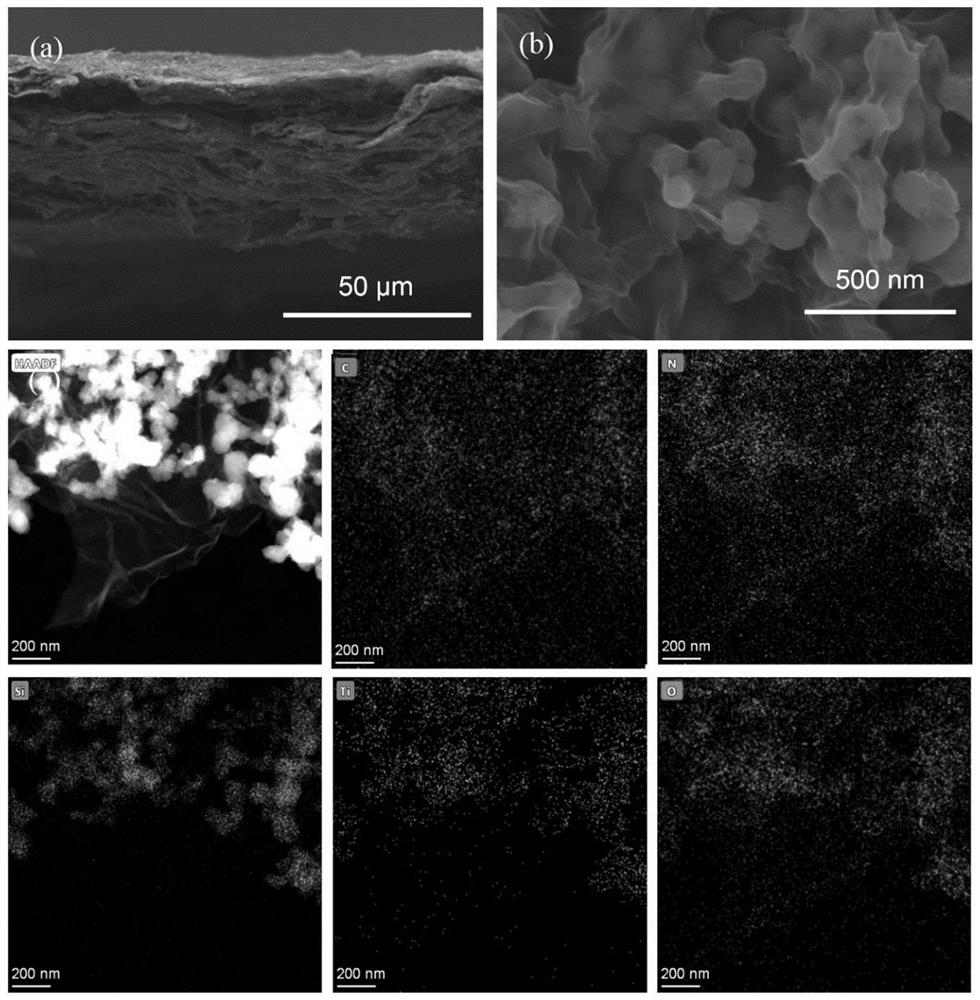

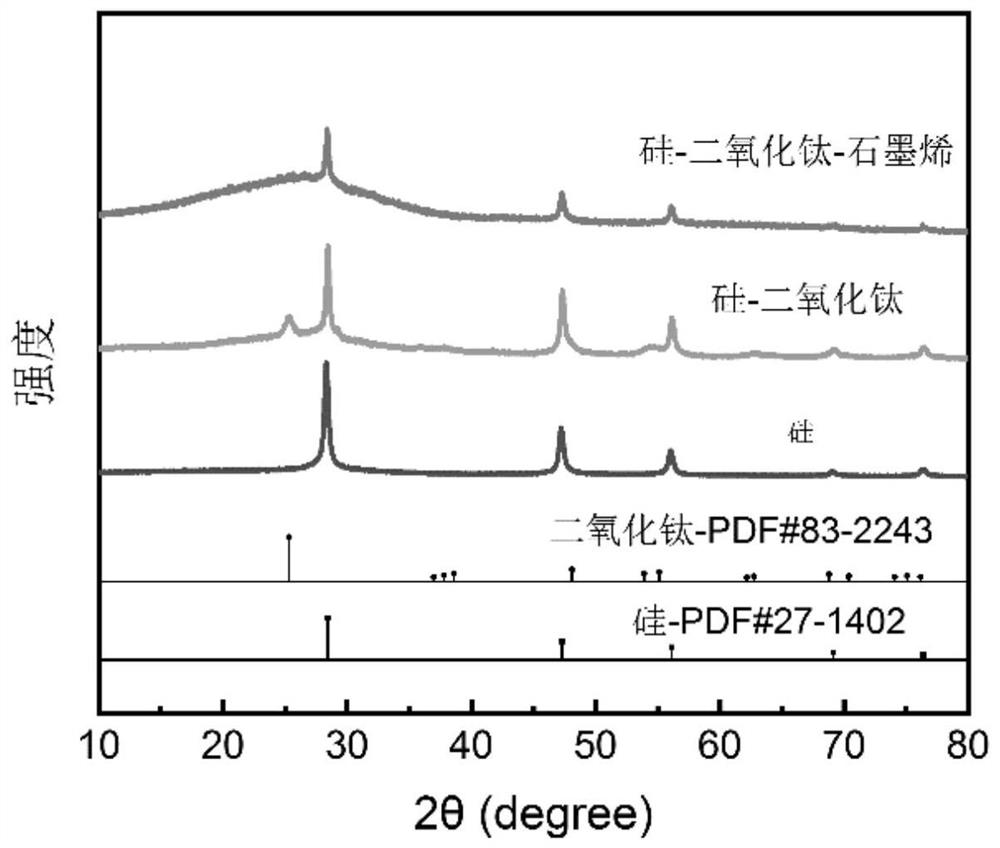

Preparation method of silicon-titanium dioxide-graphene flexible self-supporting electrode

PendingCN114725322AImprove electrical conductivityImprove mechanical propertiesNegative electrodesSecondary cellsSilicon particleSol-gel

The invention discloses a preparation method of a silicon-titanium dioxide-graphene flexible self-supporting electrode, which comprises the following steps: by taking large-size graphene oxide, titanium tetraisopropylate and nano silicon powder as raw materials, firstly coating a layer of titanium dioxide on the surface of silicon particles by a simple sol-gel method, dispersing silicon-titanium dioxide in graphene oxide dispersion liquid, and preparing a silicon-titanium dioxide-graphene flexible self-supporting electrode; performing ultrasonic treatment to form uniform dispersion liquid; the preparation method comprises the following steps: adding graphene into a chitosan coagulating bath, carrying out vacuum suction filtration, collecting a filter cake, flattening the filter cake, carrying out liquid nitrogen freezing, carrying out freeze drying, carrying out physical pressurization, and carrying out high-temperature treatment in a mixed atmosphere of argon and ammonia gas to obtain the silicon-titanium dioxide-graphene flexible self-supporting electrode. Titanium dioxide and graphene provide dual protection for silicon, titanium dioxide is tightly adhered to the surface of silicon, expansion of silicon is effectively limited, graphene is arranged on the outer layer, the overall conductivity of the material is improved, and the overall mechanical performance is improved while protection is achieved.

Owner:NANJING UNIV OF TECH

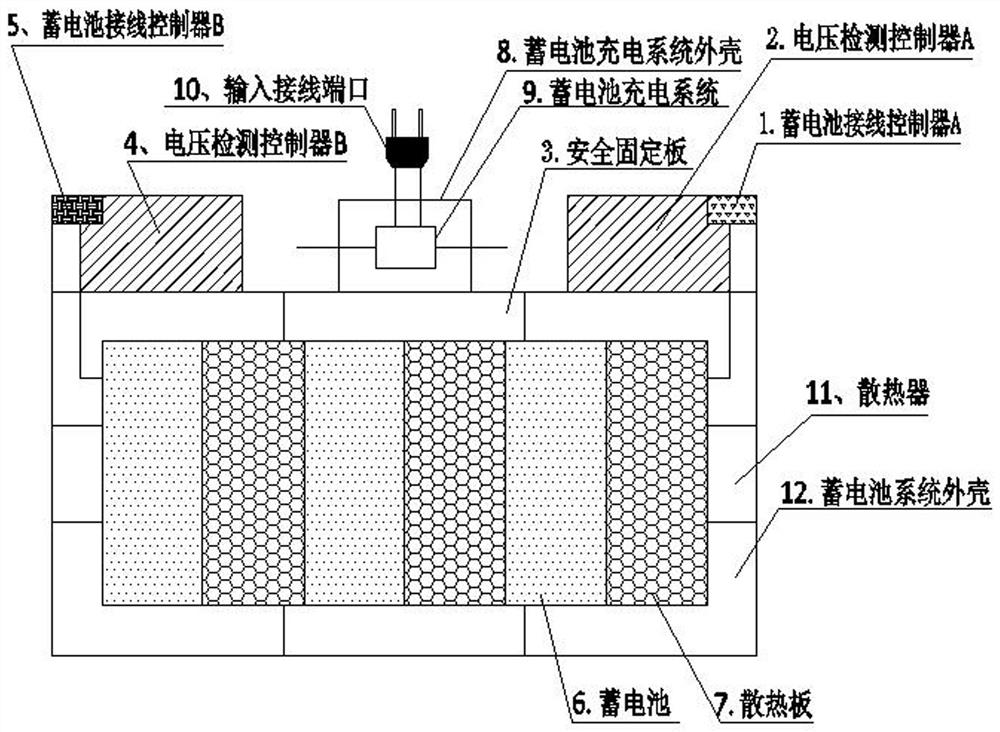

Safe and anti-expansion heat dissipation type storage battery system

InactiveCN112563589AExtended service lifeLimit bloatCell component detailsSecondary cells servicing/maintenanceBattery chargeEngineering

The invention discloses a safe anti-expansion heat dissipation type storage battery system which comprises a storage battery body and is characterized by further comprising a storage battery wiring controller, a voltage detection controller, a safe fixing plate, a heat dissipation plate, a storage battery charging system and a heat dissipation device which are arranged on the storage battery body.The heat dissipation plate is arranged on the inner side of the safety fixing plate; the storage battery is spaced at a certain distance; the storage battery charging system is connected with the endof the storage battery body through an input wiring port, the storage battery wiring controller and the voltage detection controller are connected with the storage battery body through the storage battery charging system, and the heat dissipation device is connected with the heat dissipation plate and the storage battery charging system. The system has the advantages that the expansion of activesubstances can be limited in the charging and discharging process of the battery, the contact short circuit of positive and negative active substances and the softening and falling of positive activesubstances are not easy to occur, the stable and reliable performance of the storage battery is ensured, and the service life of the battery is prolonged.

Owner:杨雨

A rotary drilling type high-pressure grouting device and construction method for the side wall of the hole formed by pumping sand

The invention provides a rotary drilling type sand pumping hole-forming side wall high-pressure grouting device and construction method. The outer casing of the inner casing is wrapped with flower tubes. A steel casing is set, an annular cavity is formed between the inner casing and the flower tube, and a slurry storage layer is formed, and the top opening of the slurry storage layer is sealed with a pressing sheet; the slurry storage layer is used for The grouting machines for grouting are connected; the bottom of the inner casing is spliced with a rotary drawer, and the inside of the inner casing is provided with a chain bucket device, and the chain bucket device is provided with multiple Evenly spaced buckets for digging sand. The device realizes high-pressure grouting on the side wall of the pile hole while suction drilling, and improves the foundation structure condition through the pressure grouting on the side wall of the pile hole to solidify the pile circumference.

Owner:SHENZHEN LOTUT INNOVATION DESIGN CO LTD

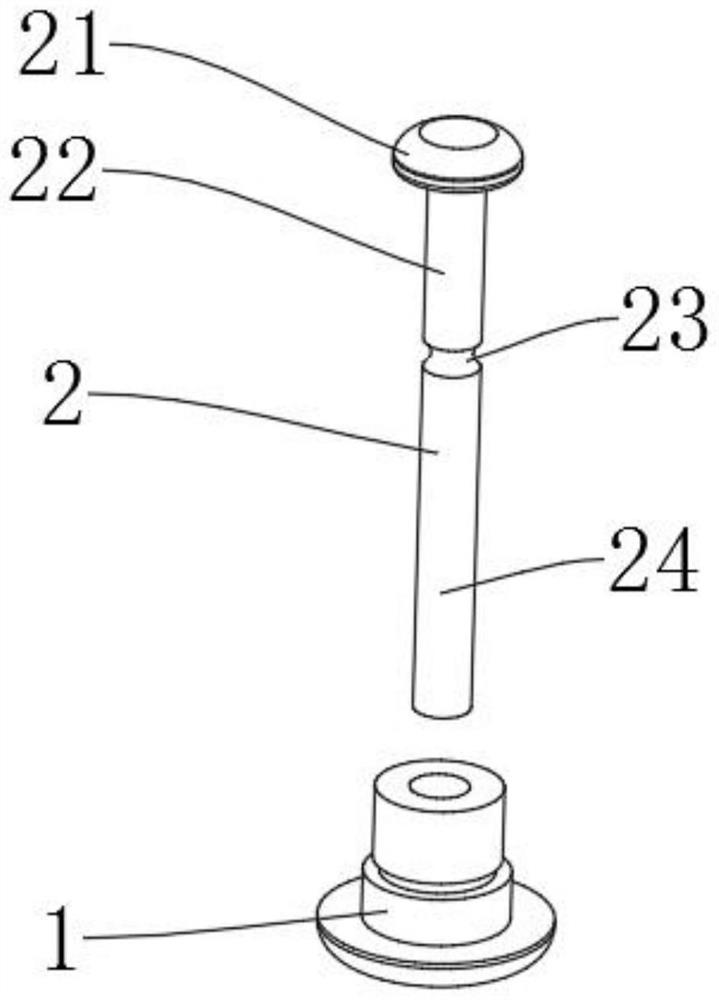

CFRP single-side core-pulling lossless riveting fastener and method

The invention discloses a CFRP single-side core-pulling lossless riveting fastener and a method. The CFRP single-side core-pulling lossless riveting fastener comprises a shear-resistant riveting fastener body and a tensile riveting fastener body. Wherein the shear-resistant riveting fastener is composed of a rivet with a hole and a shear-resistant core rod, and the tensile riveting fastener is composed of a rivet with a hole, a tensile core rod and a fastening nut; a central through hole is formed in the middle of the rivet with the hole, an upset head section is arranged above the rivet, a rivet rod section is arranged in the middle of the rivet, the diameter of the upset head section is smaller than that of the rivet rod section, a groove is designed between the upset head section and the rivet rod section, and a rivet head is arranged below the rivet. On the basis of a rivet pulling method, through the design of the rivet with the hole, the groove is formed, the diameter of the rivet rod section is larger than that of the upset head section, a buffering and restraining area is provided for deformation of the upset head part, a large amount of deformation acting force of the rivet acts in the groove, and damage to a composite material riveting component is avoided; the anti-shearing capability of the composite material riveting component is improved; and meanwhile, the tensile core rod is designed to be provided with a threaded section and is matched with the fastening nut, so that the tensile performance of the composite material riveting component is improved.

Owner:SICHUAN UNIV

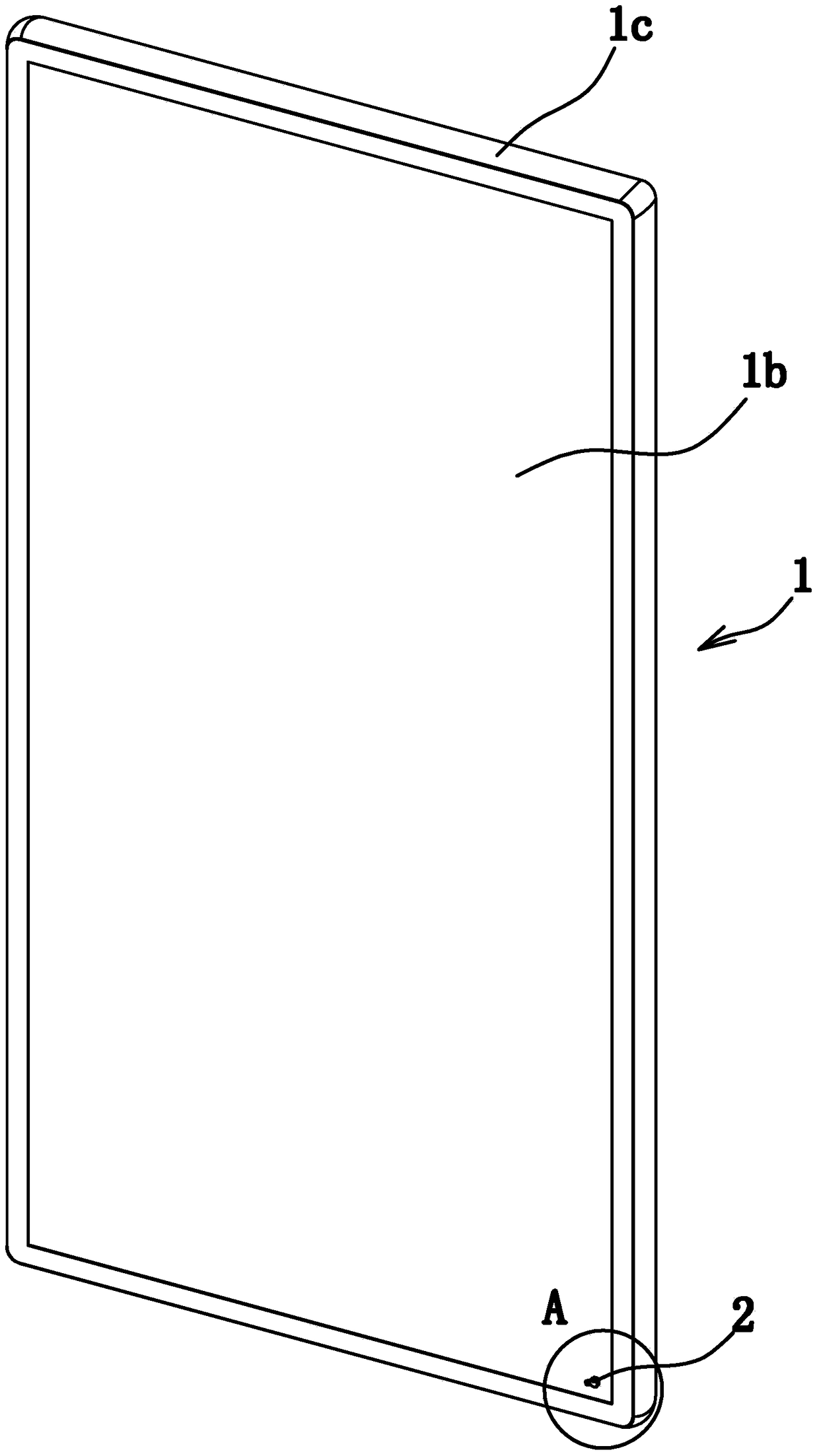

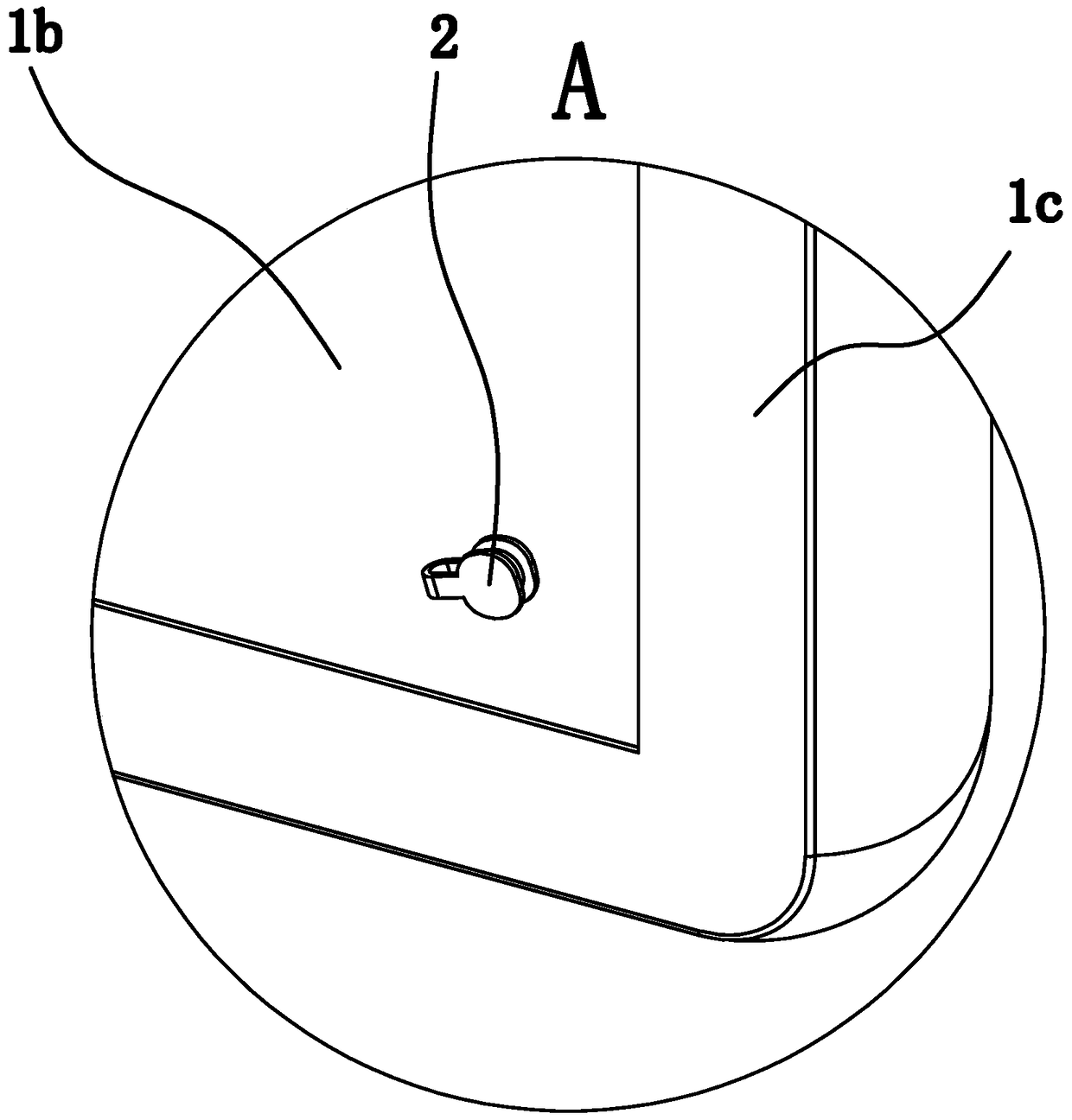

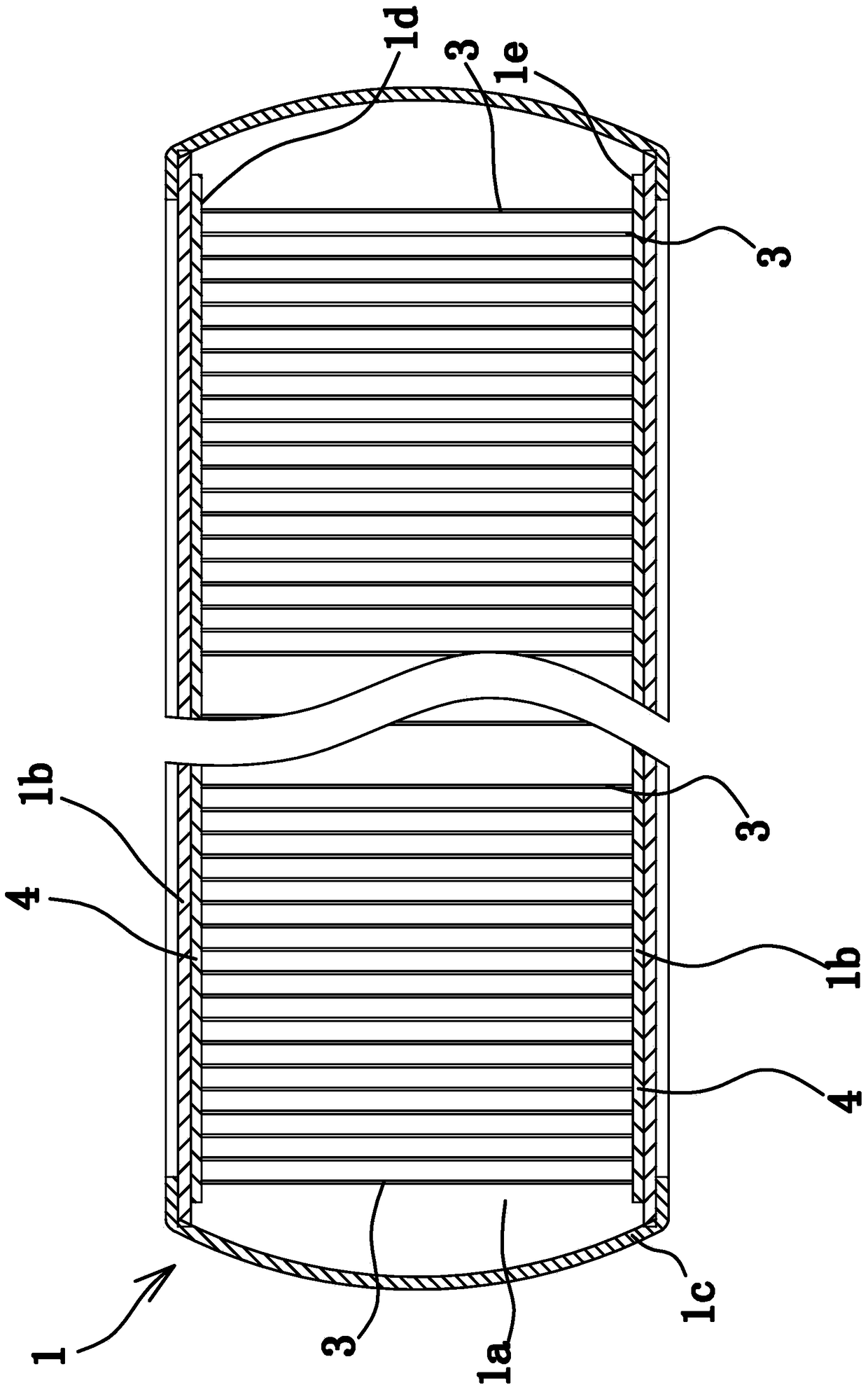

Heat-insulating airbag for a van

The invention provides a heat-insulating airbag for a van, which belongs to the technical field of machinery. It solves the problem of poor heat insulation effect of the existing heat insulation airbags. The heat-insulating airbag used on the van includes a body with a closed air chamber, and the body is provided with an air nozzle communicating with the air chamber. It is characterized in that the body is in the shape of a rectangular plate Shape, the said inflatable cavity is provided with a plurality of flexible parts of approximately equal length, and the plurality of flexible parts are parallel to each other, and the two ends of the flexible parts are connected with the front side of the body and the The rear side is fixed. The heat insulating air bag used on the van has the advantages of good heat insulation and heat preservation effects.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com