Patents

Literature

241 results about "Composite element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite Element. Overview. The composite elements are a new kind of user created element introduced in Jaspersof Studio with the version 6.1.1. They allow to create a new element in the palette starting from one or more basic elements, and reuse them whenever you want in any report.

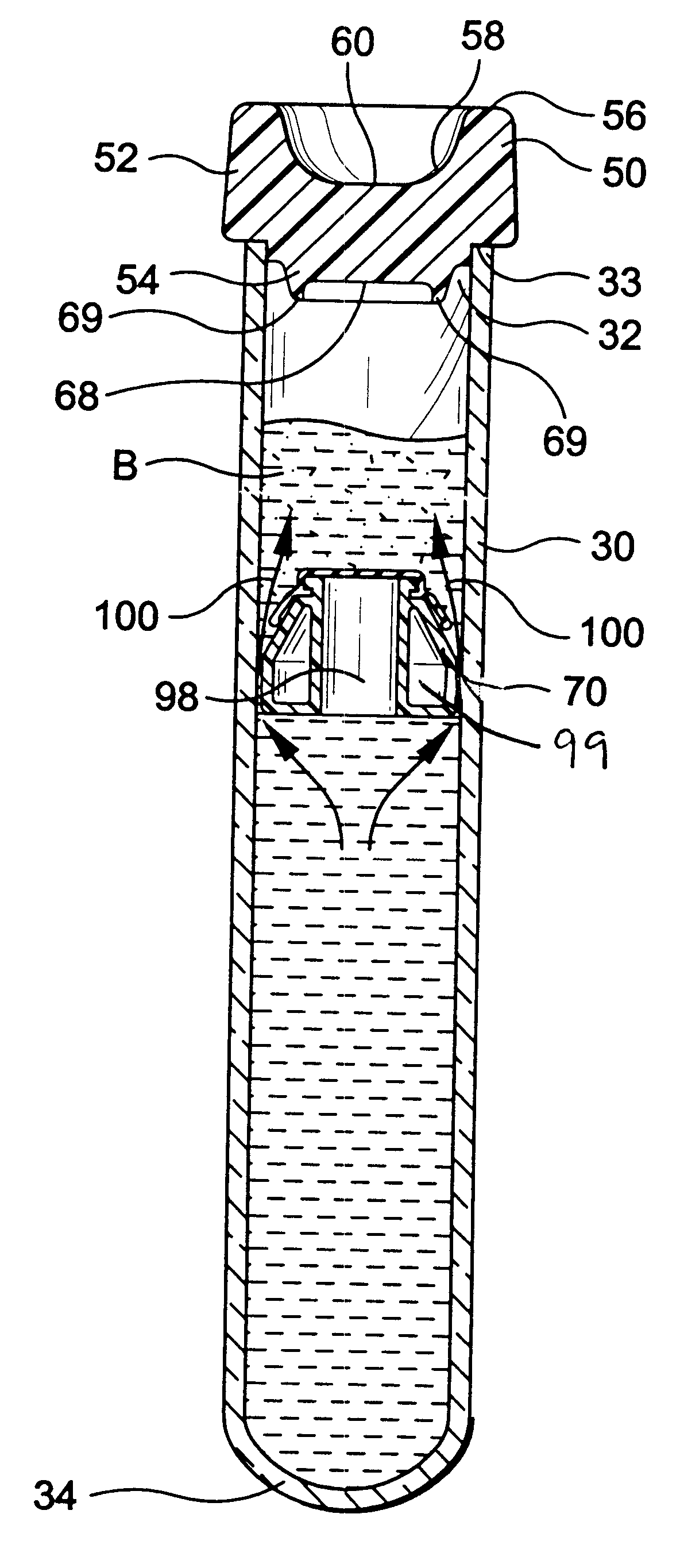

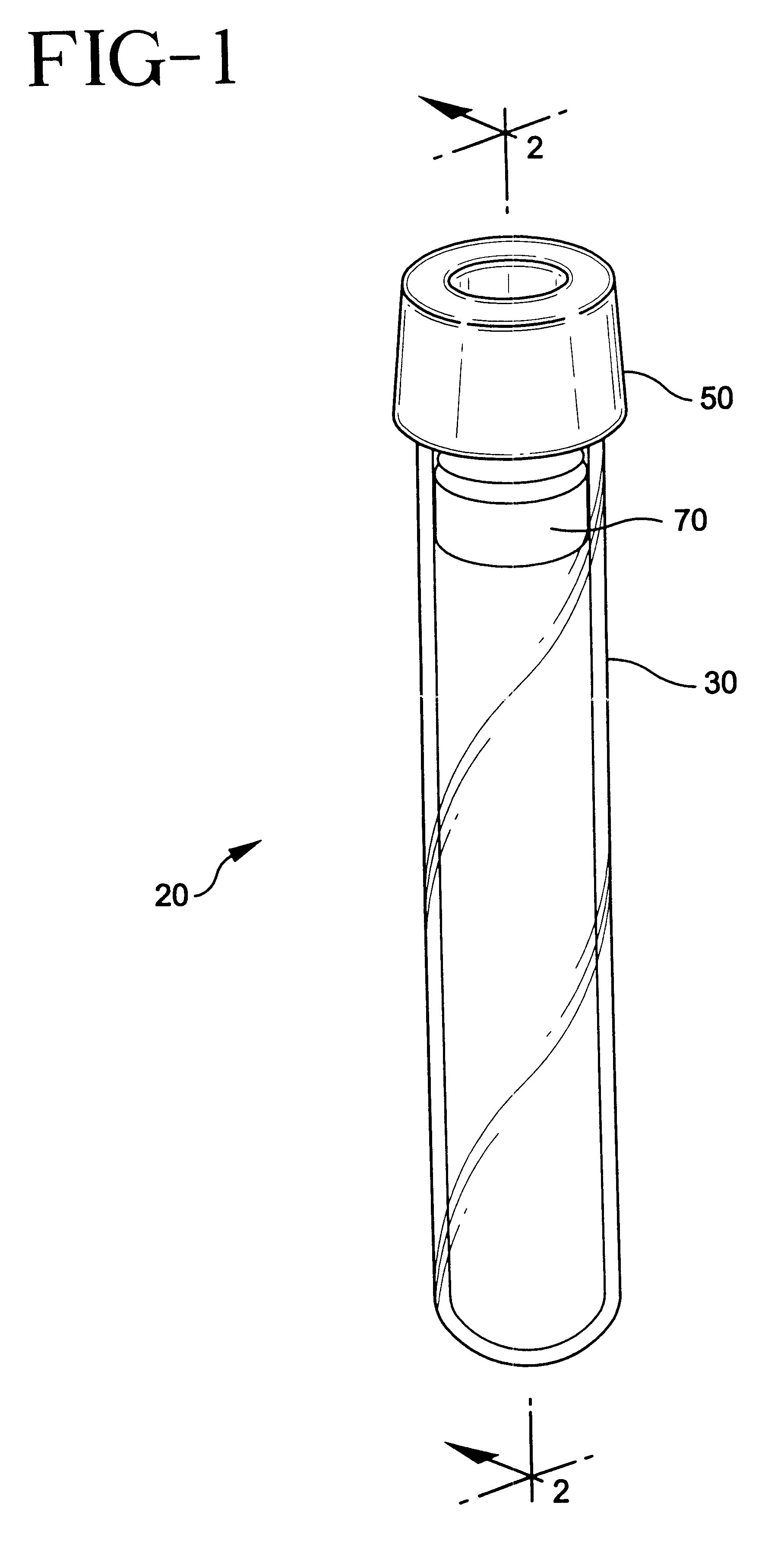

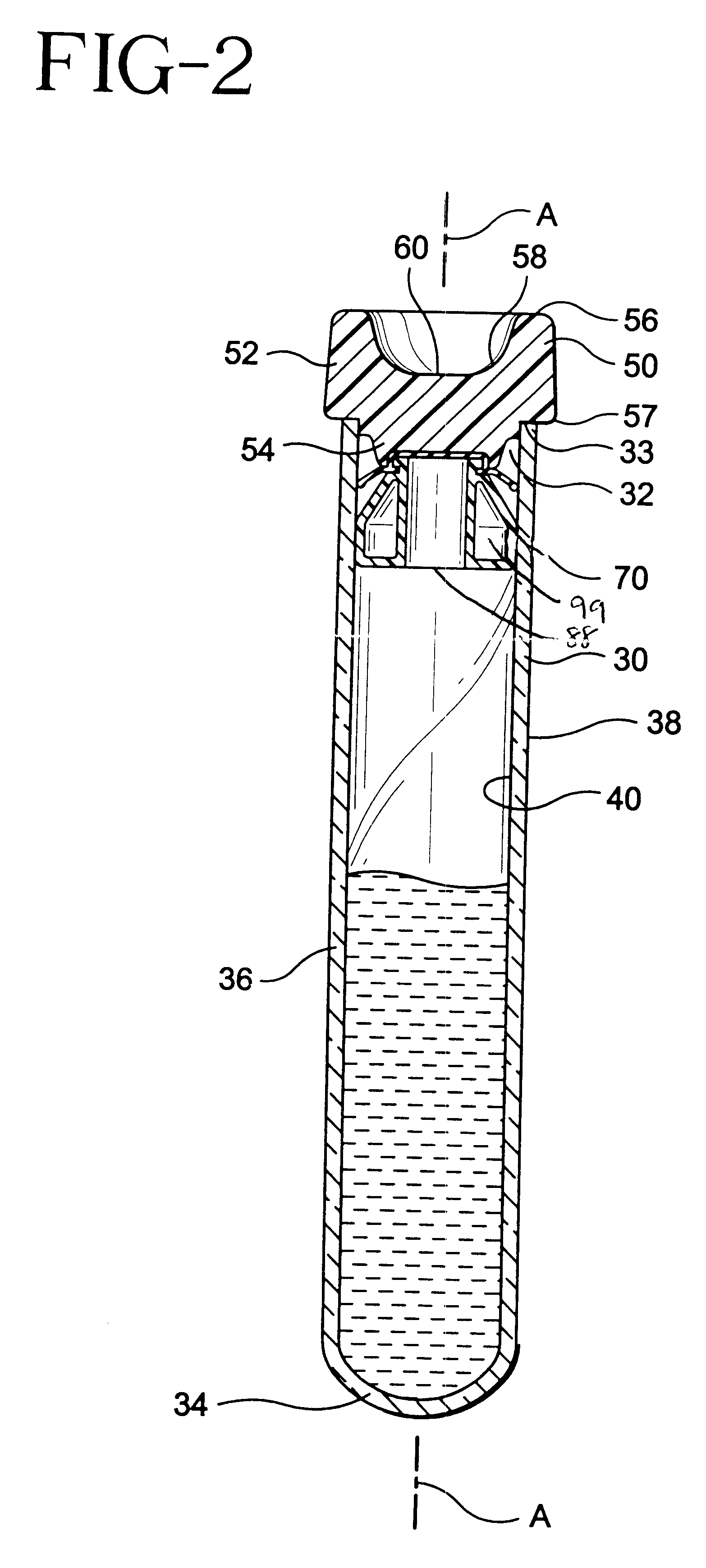

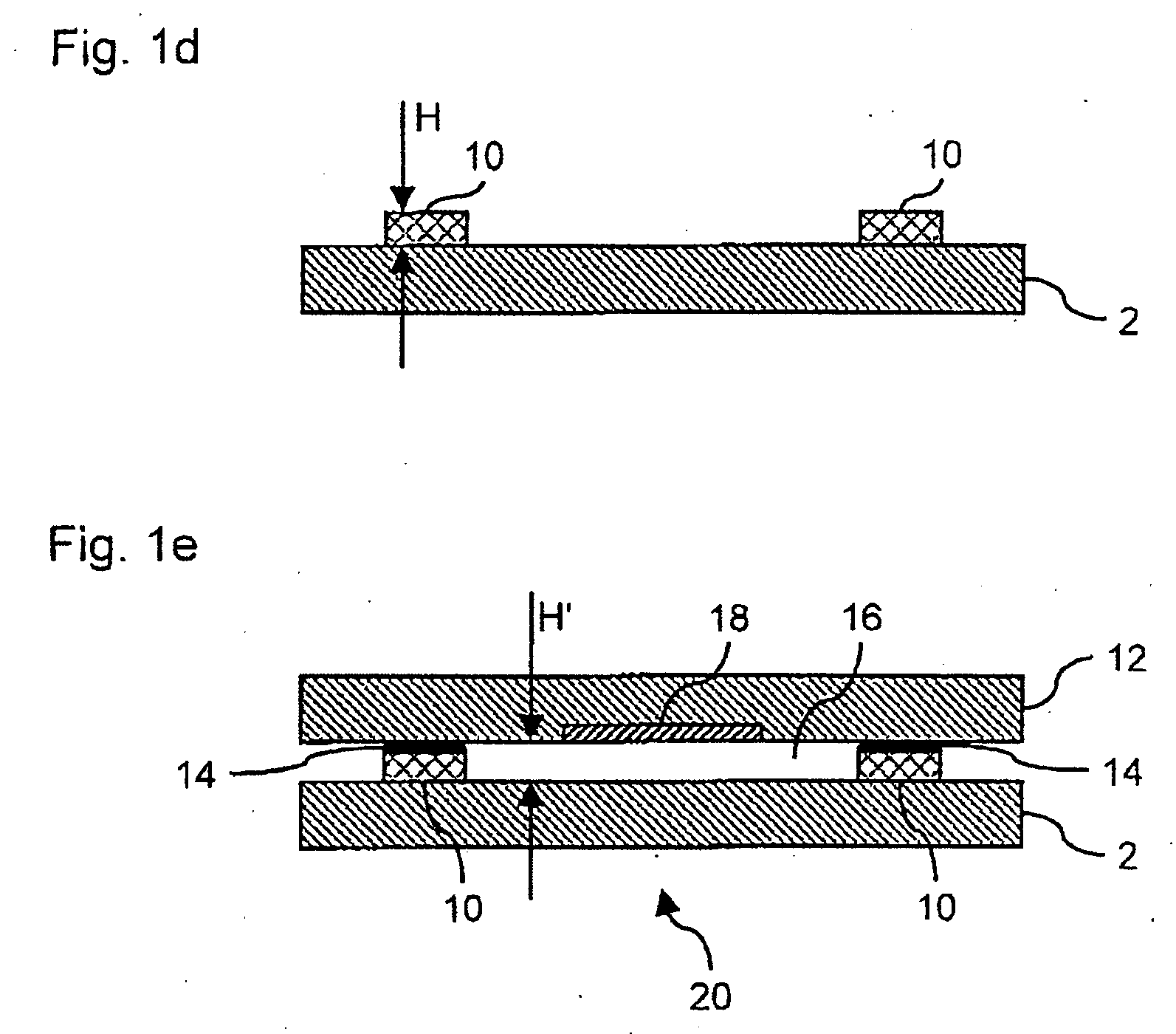

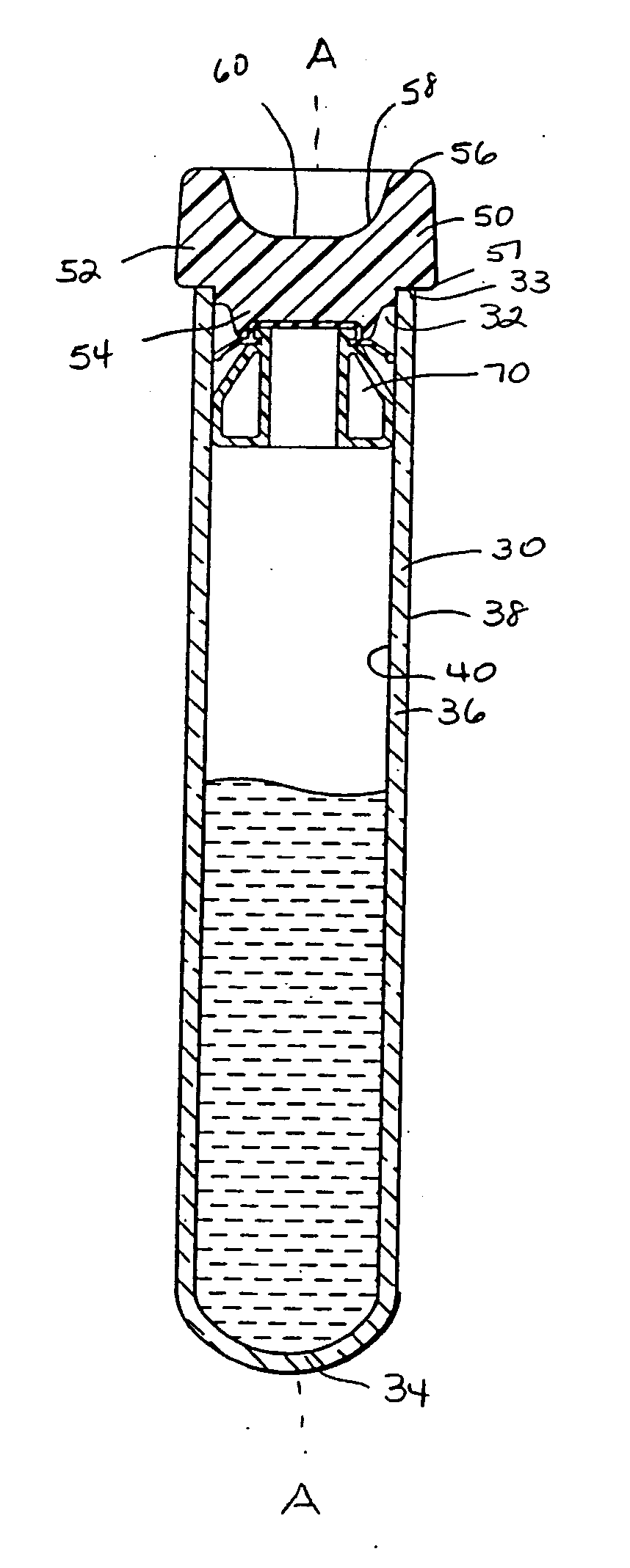

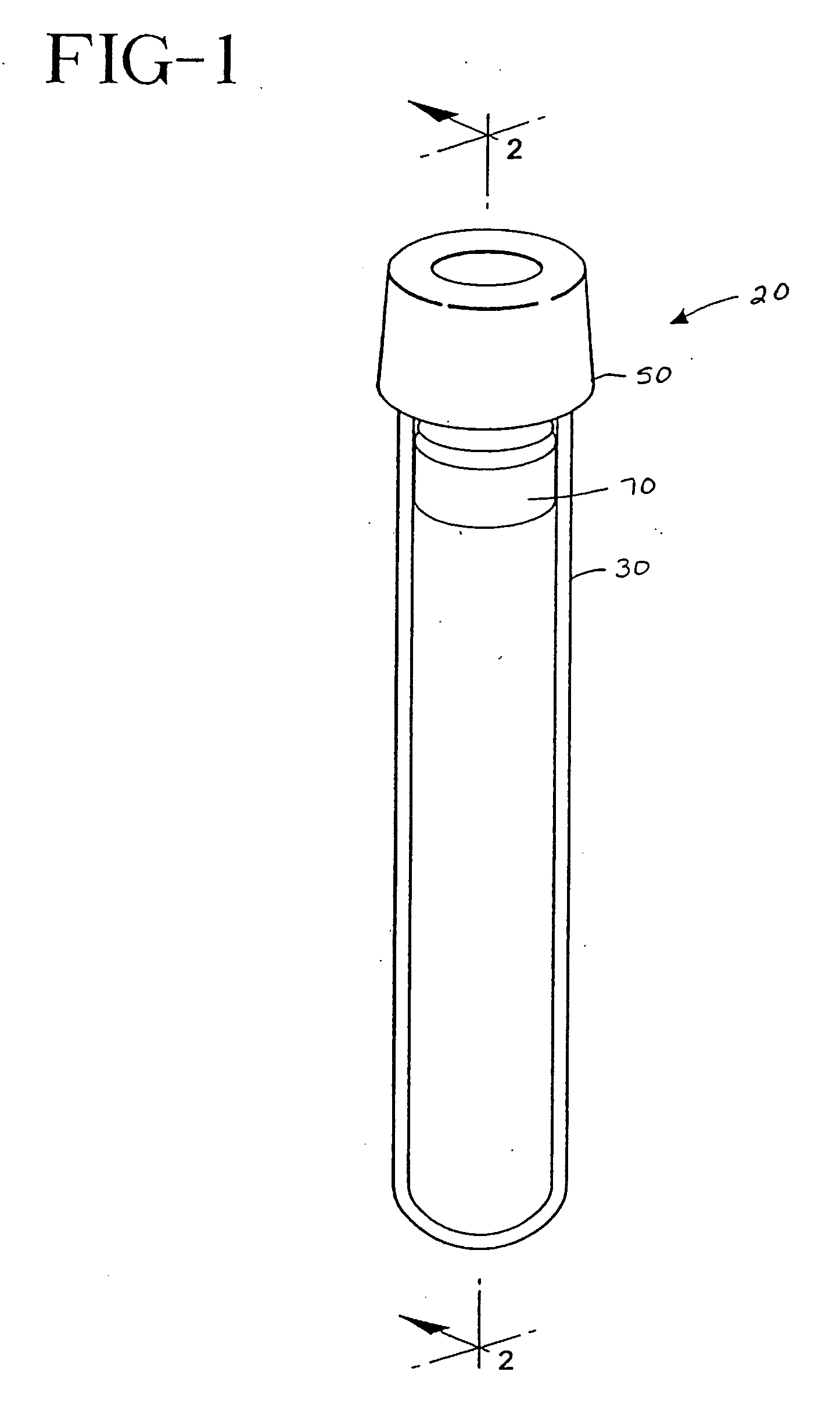

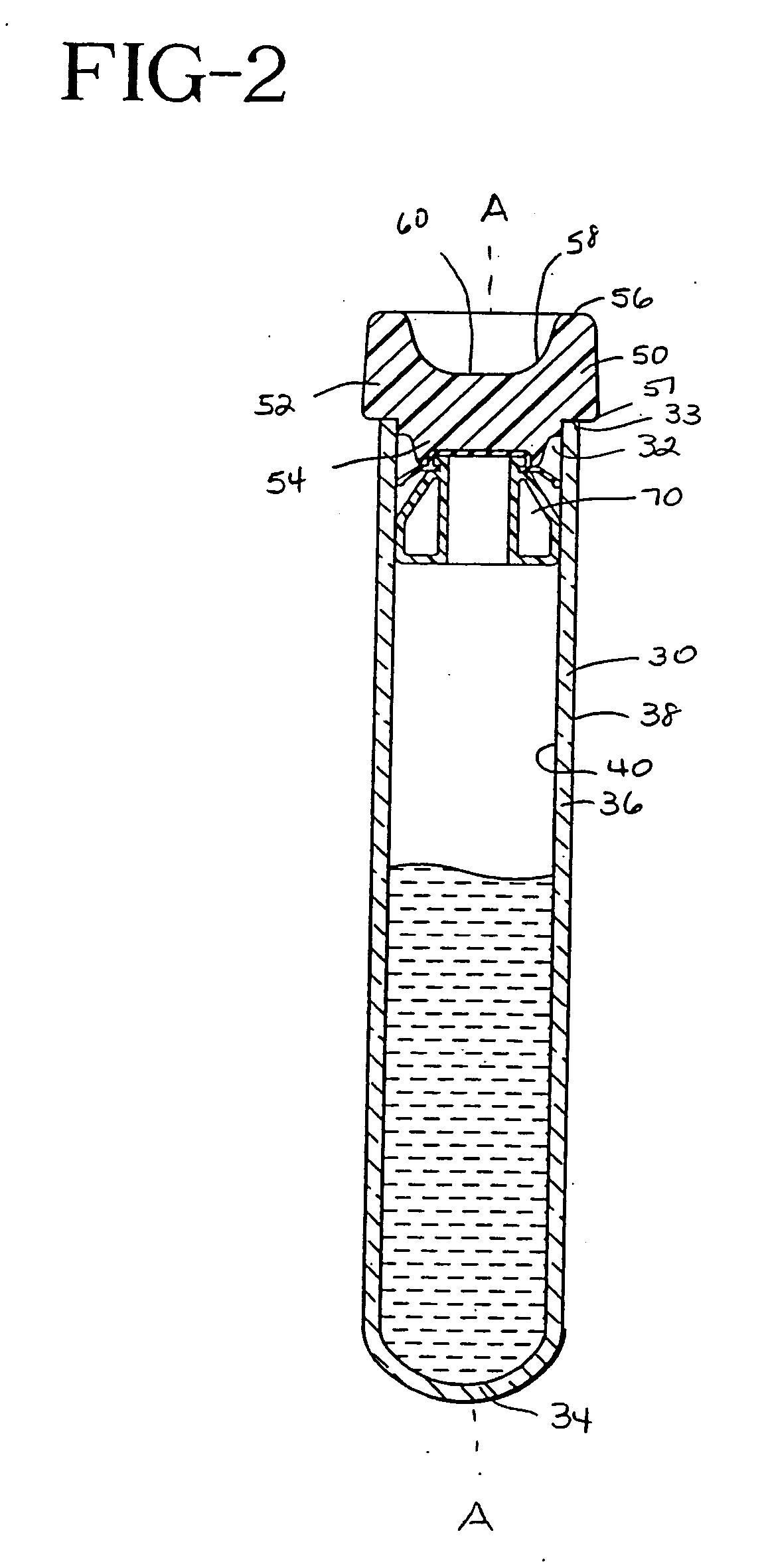

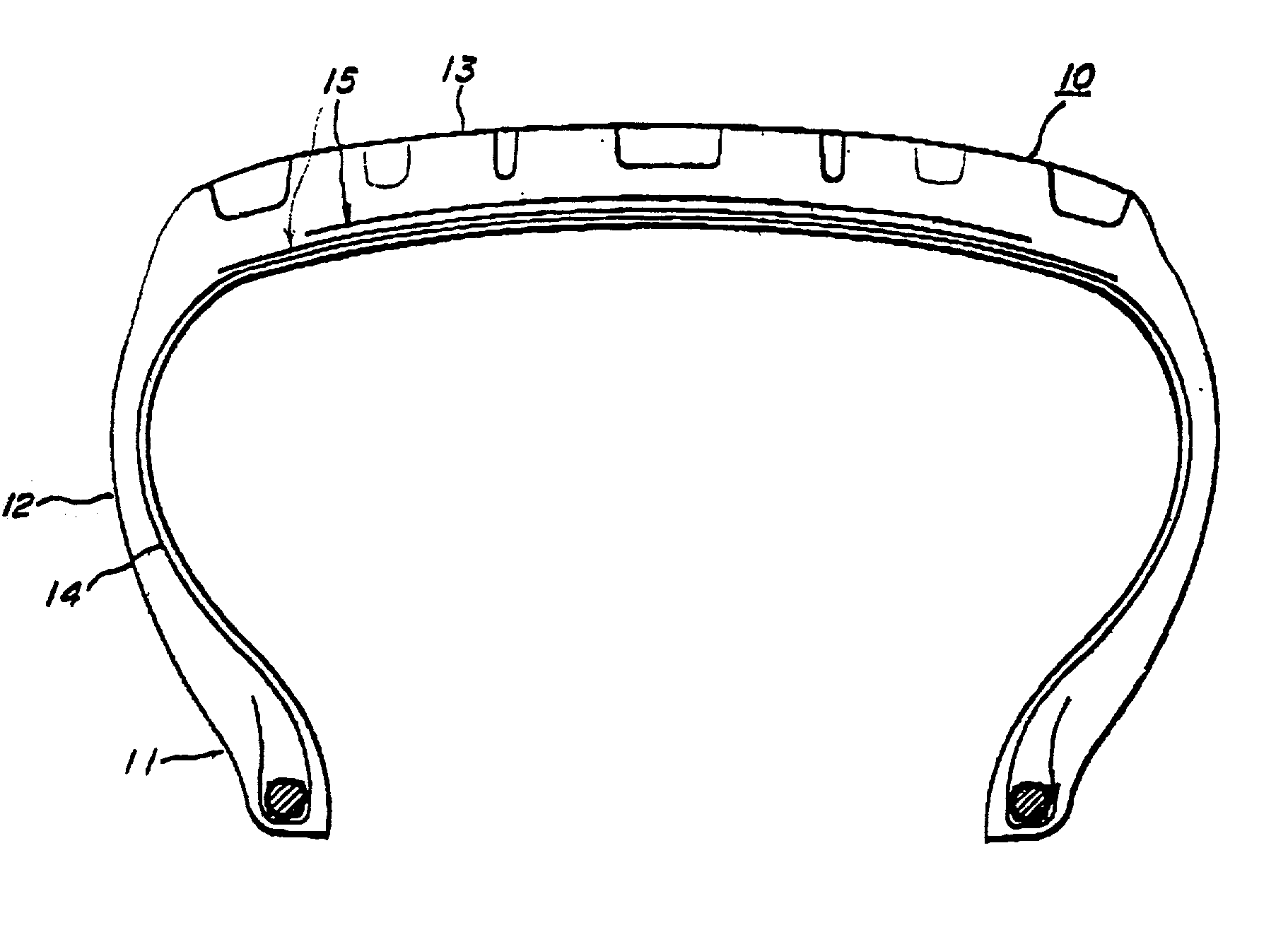

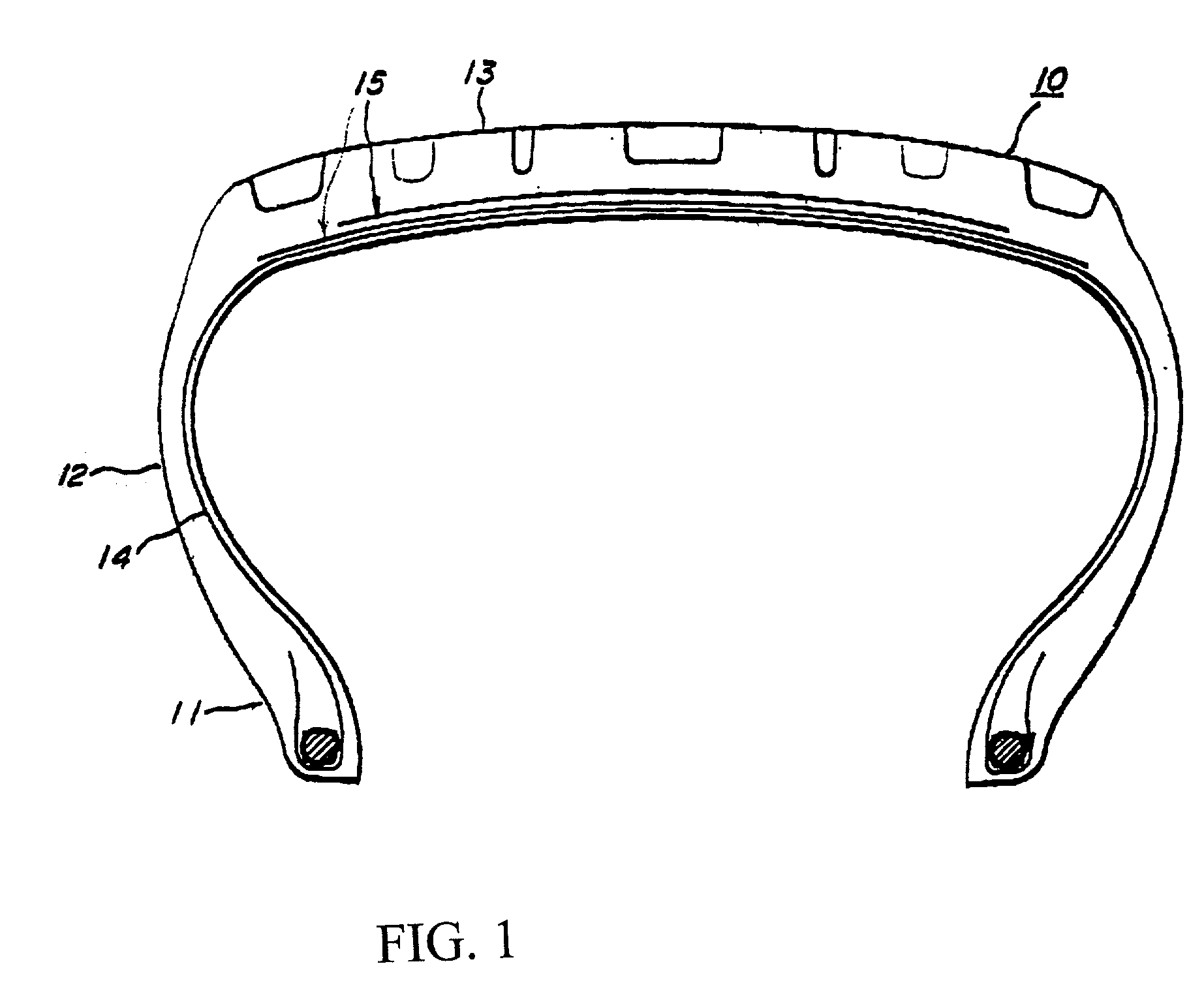

Device and method for separating components of a fluid sample

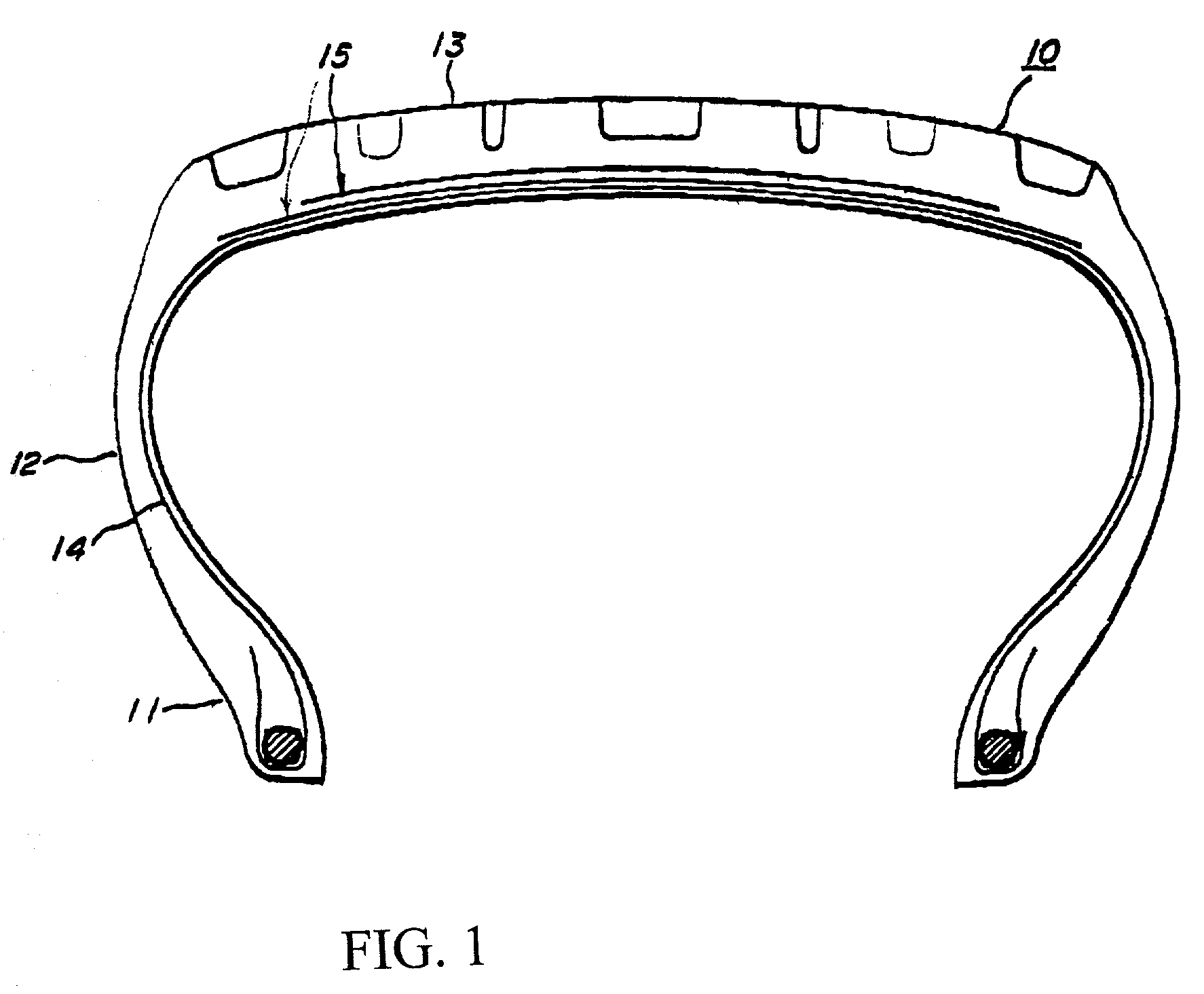

A device and method is provided for separating heavier and lighter fractions of a fluid sample. The device includes a plurality of constituents comprising a container and a composite element in the container. The composite element is a separator comprising at least two components and more particularly an elastic portion and a plug member. A fluid sample is delivered to the container and the device is subjected to centrifugation whereby the centrifugal load causes the elastic portion of the separator to deform so that the separator migrates into the fluid sample and stabilizes between the heavier and lighter fractions of the fluid sample. The elastic portion of the separator will resiliently return to its initial configuration upon termination of the centrifugal load such that the elastic portion sealingly engages the container and separates the heavier and lighter fractions of the fluid sample.

Owner:BECTON DICKINSON & CO

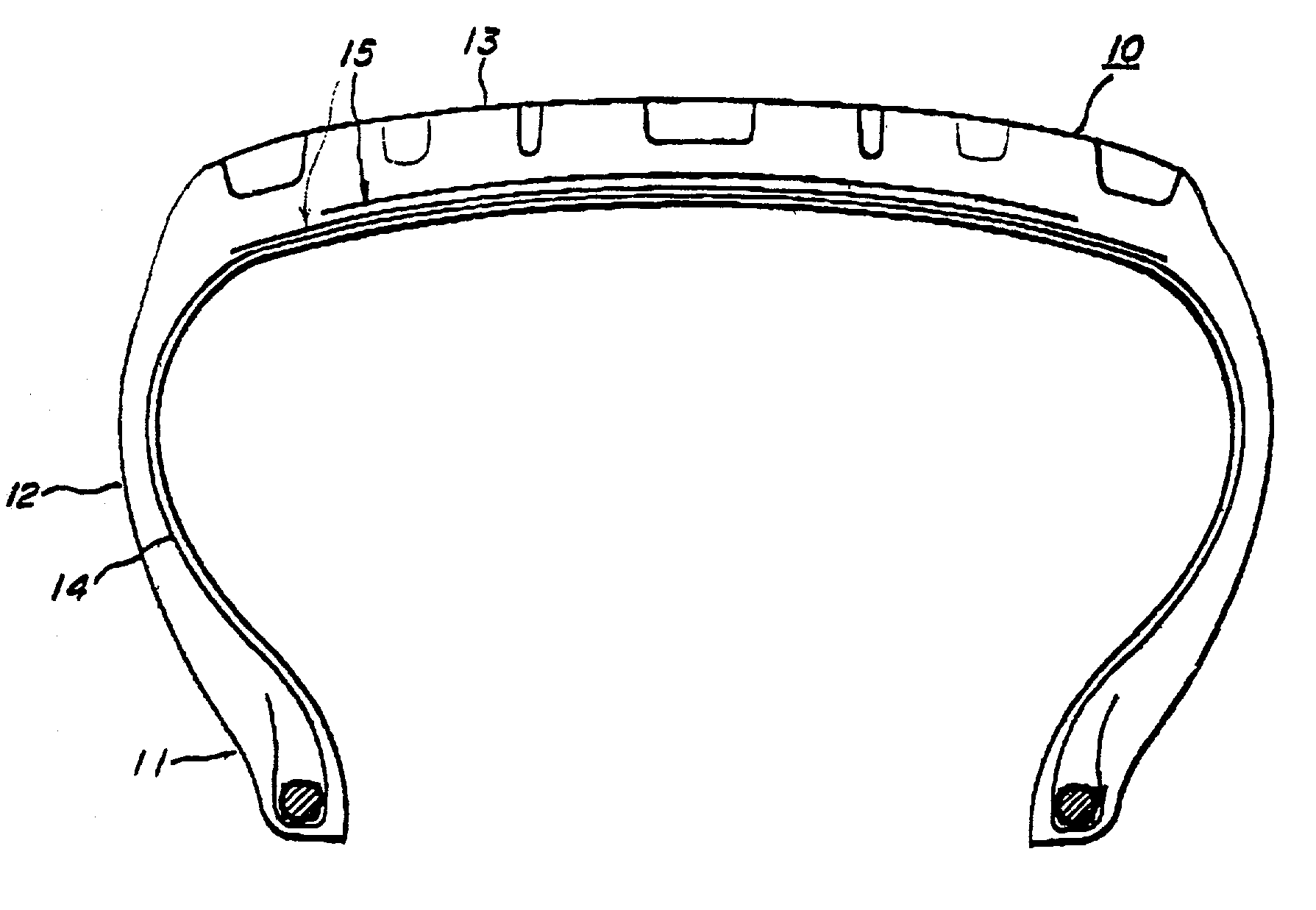

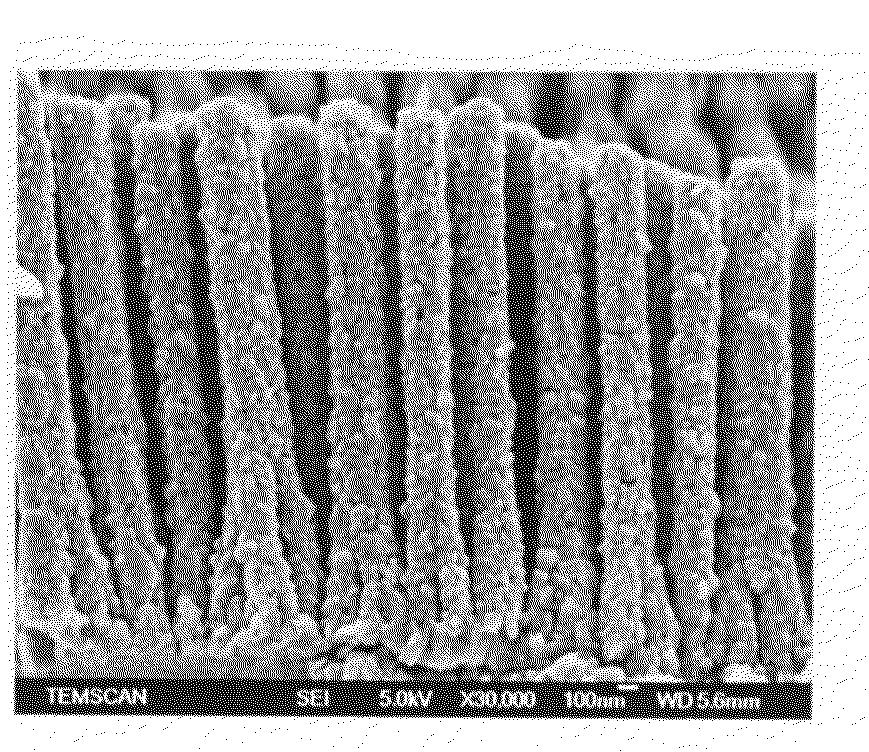

Tire reinforced by an elongate composite element of the monofilament type, and such element

A tire, in particular an elastomeric pneumatic tire, reinforced by lengths of a monofilament elongate composite element of long glass fibers impregnated in a thermoset resin having a glass transition temperature Tg greater than 130° C., in which the fibers are all parallel to each other, the elongate composite element having, under a bending stress an elastic deformation in compression of at least 2%, in flexion a breaking stress in compression greater than the breaking stress in extension.

Owner:CONCEPTION & DEV MICHELIN SA

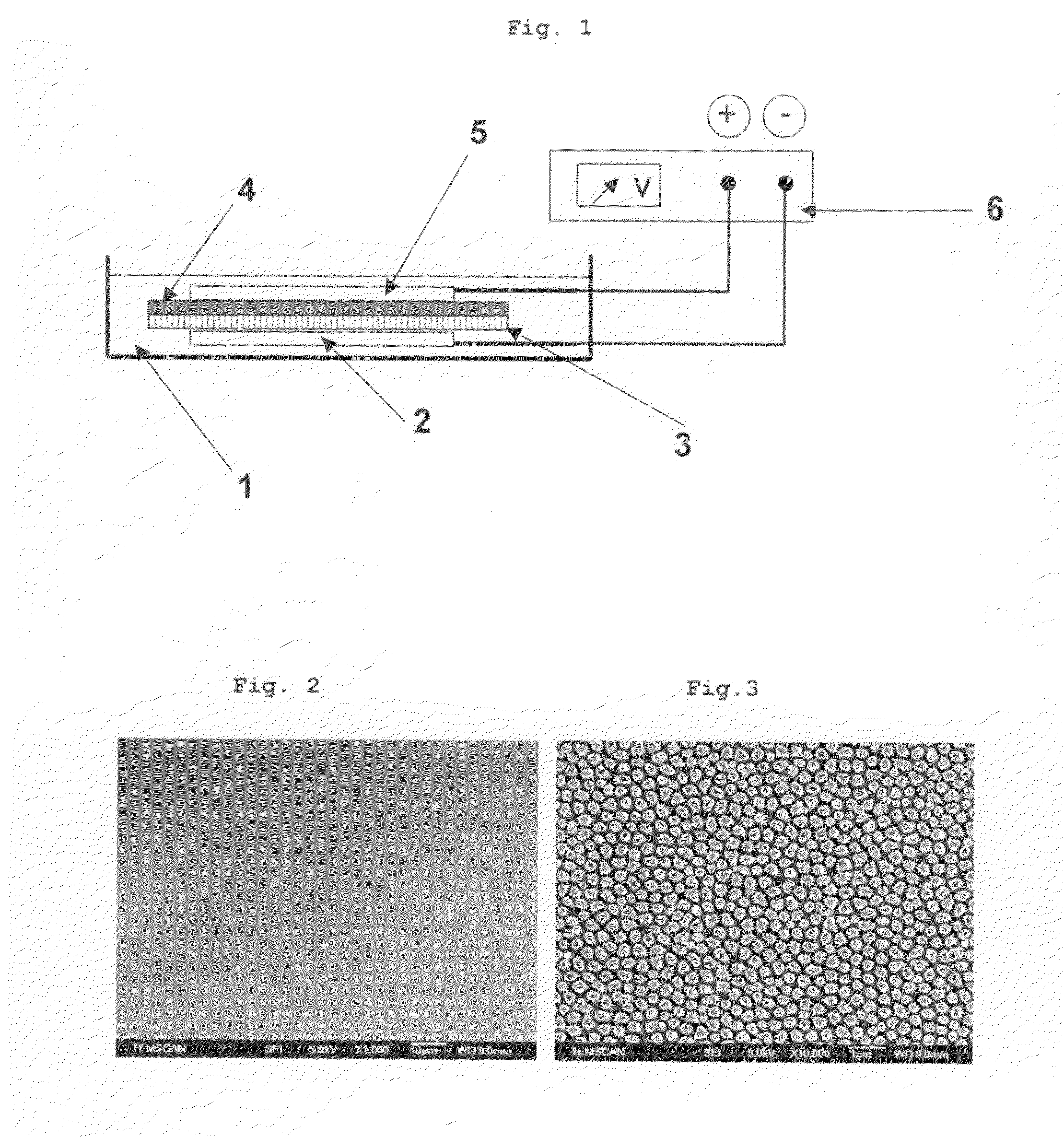

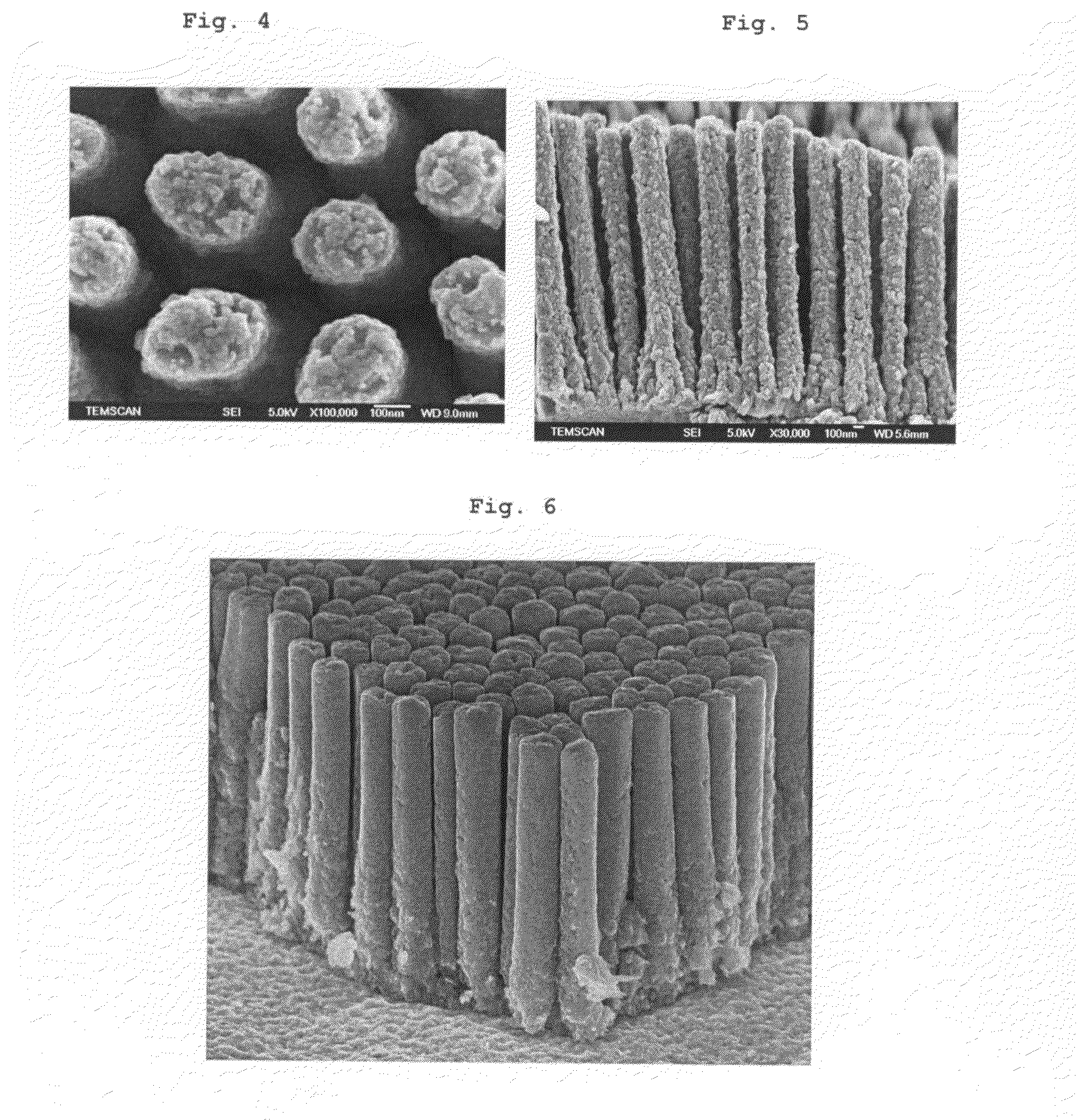

Method for the Electrolytic Production of Self-Supporting Conductive Nanocomposite Elements

InactiveUS20090316335A1Electrolytic capacitorsFinal product manufactureElectrolysisMetallic materials

The invention relates to a self-supporting composite element and to a method of producing same. The composite element comprises a substrate of electronic conductive material which is covered with metal nanowires that are essentially oriented along a plane that is perpendicular to the substrate. The element is produced in a cell comprising a cathode which is formed by the substrate to be covered, one or more anodes and an electrolyte which is formed by a solution of a precursor of the metal material and optionally containing a conductive ionic salt, a flat porous membrane which is placed between the cathode and each of the anodes and a spacer element between each membrane and the anode adjacent thereto, the different constituent parts of the cell being maintained in contact.

Owner:UNIV DE PICARDIE JULES VERNE +1

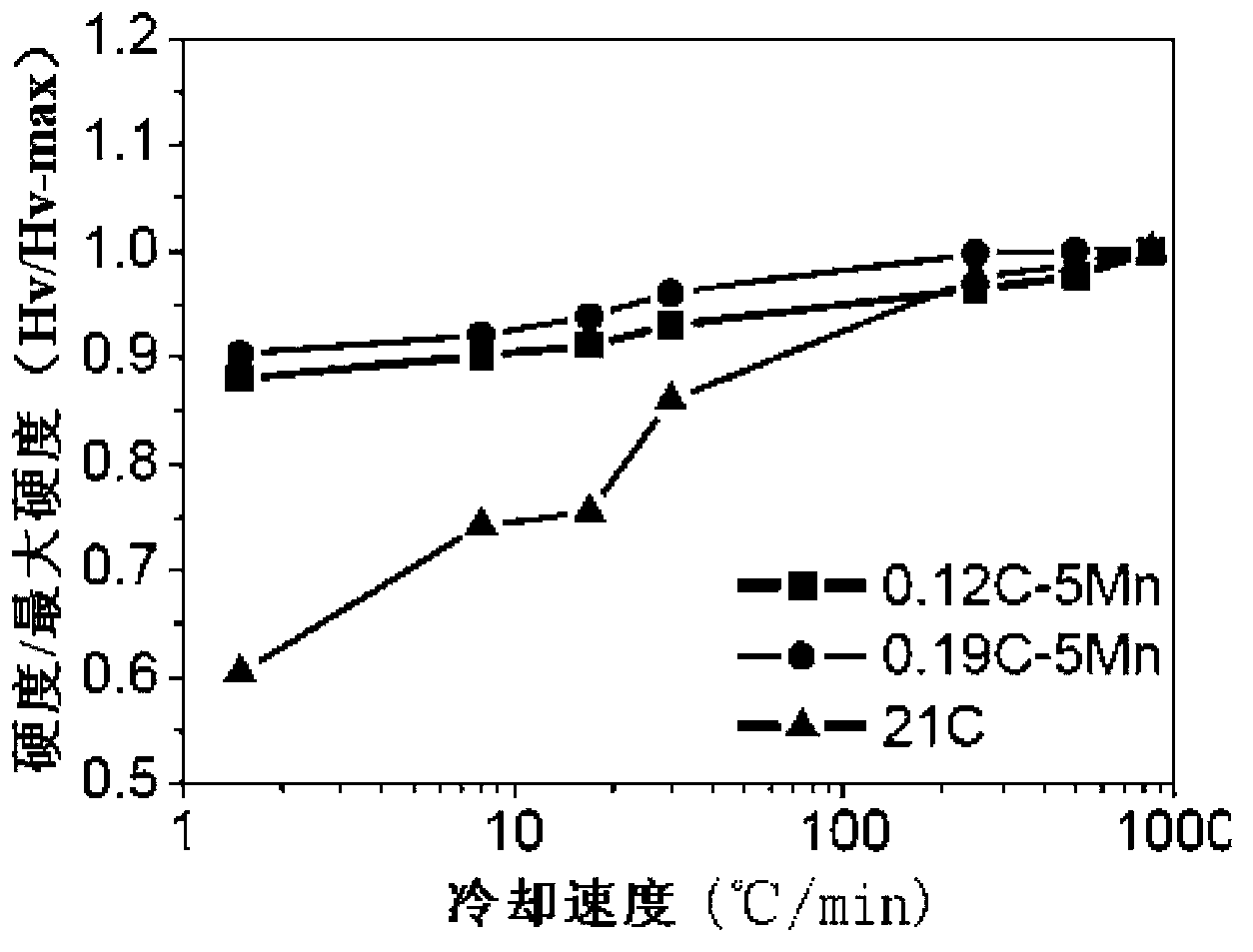

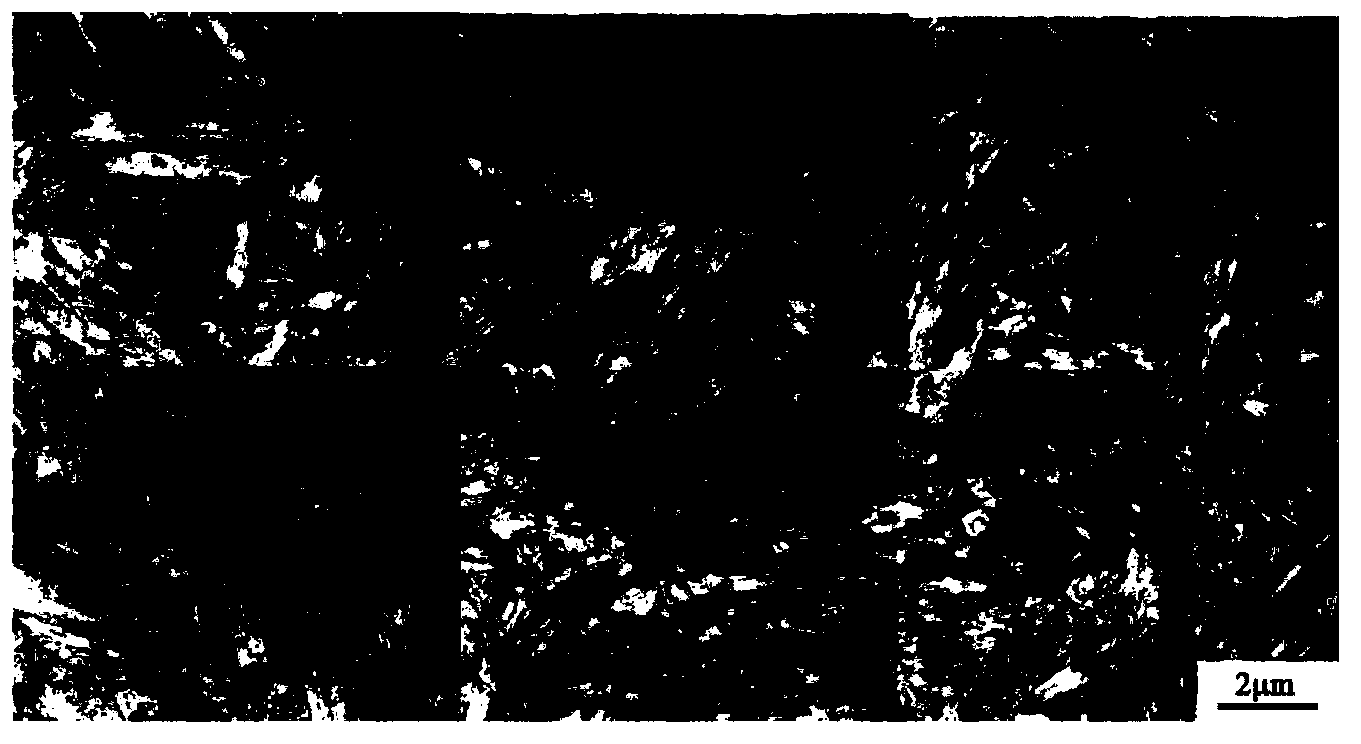

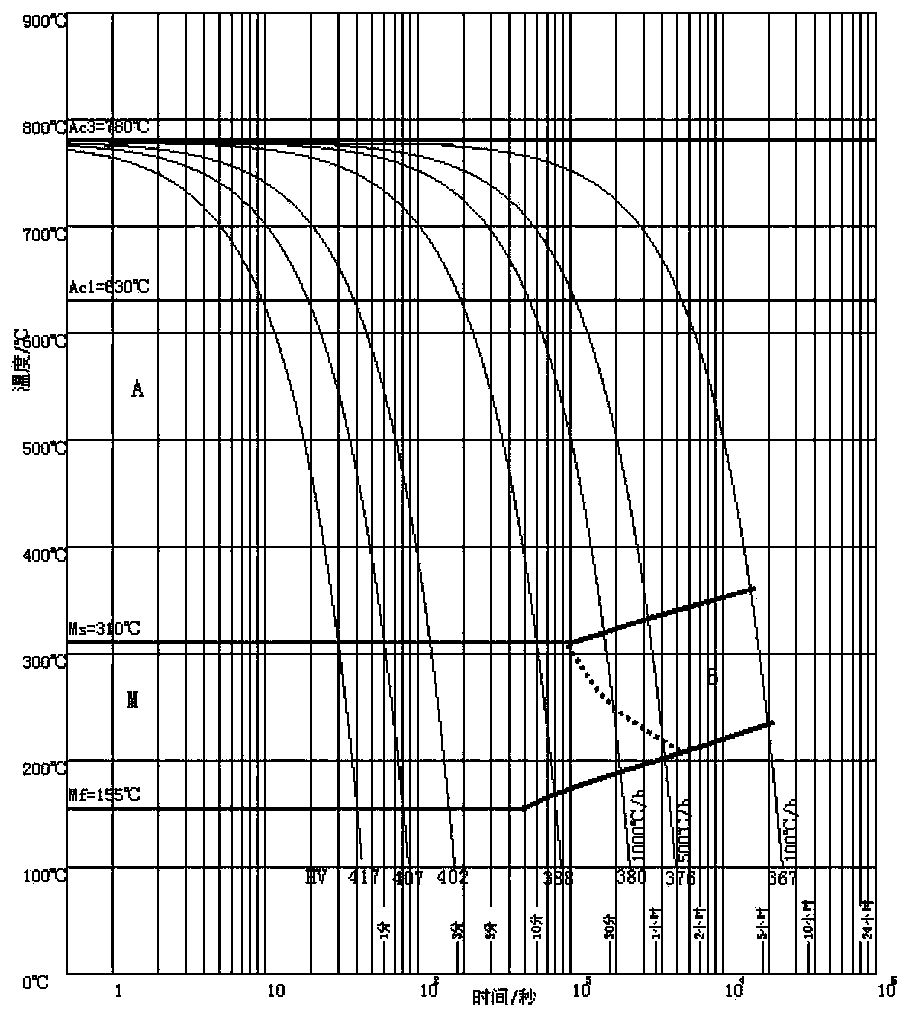

Martensite series wear-resistant steel and preparation method thereof

The invention relates to martensite series wear-resistant steel and a preparation method thereof, belonging to the technical field of wear-resistant steel. The steel comprises the following chemical components: 0.05-0.51wt% of C, 2.0-10wt% of Mn, 0-1.5wt% of Al, 0-1.5wt% of Si, 0-1.5wt% of Cr, 0-1.5wt% of Cu, 0-1.5wt% of Ni and the balance of Fe and inevitable impurities, wherein the Mn / C ratio is not less than 9. Based on this, the following one or more composite elements can be optionally added: 0.02-0.50wt% of Mo, 0.02-0.50wt% of V, 0.02-0.50wt% of Nb, 0.01-0.5wt% of Ti, 0.02-0.50wt% of B and 0.02-0.50wt% of RE. The wear-resistant steel provided by the invention is easy to produce, low in cost and high in performance. The invention is applicable to the technical field of wear-resistant materials for mines, energy, transportation, agricultural machinery, engineering machinery and other industries.

Owner:CENT IRON & STEEL RES INST

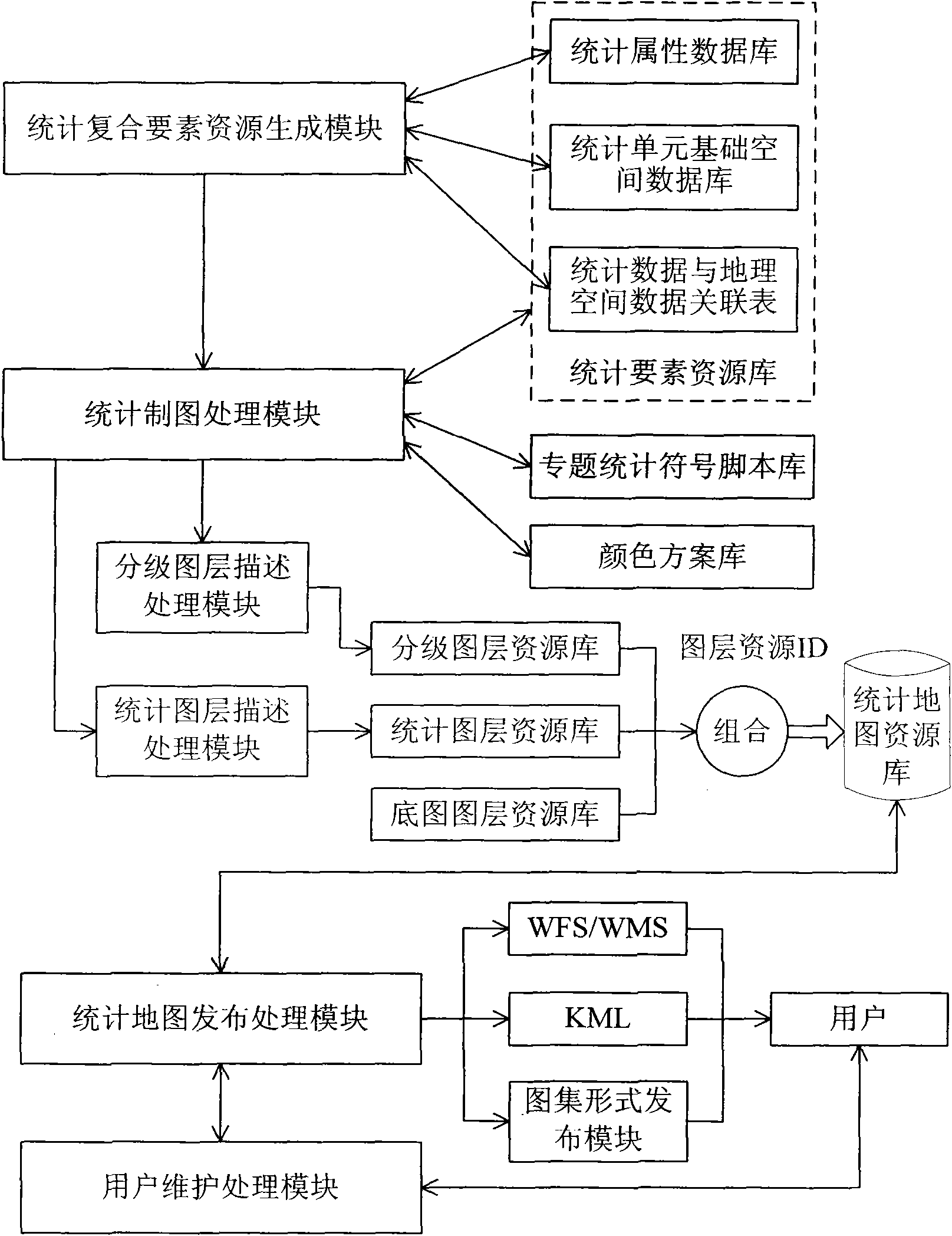

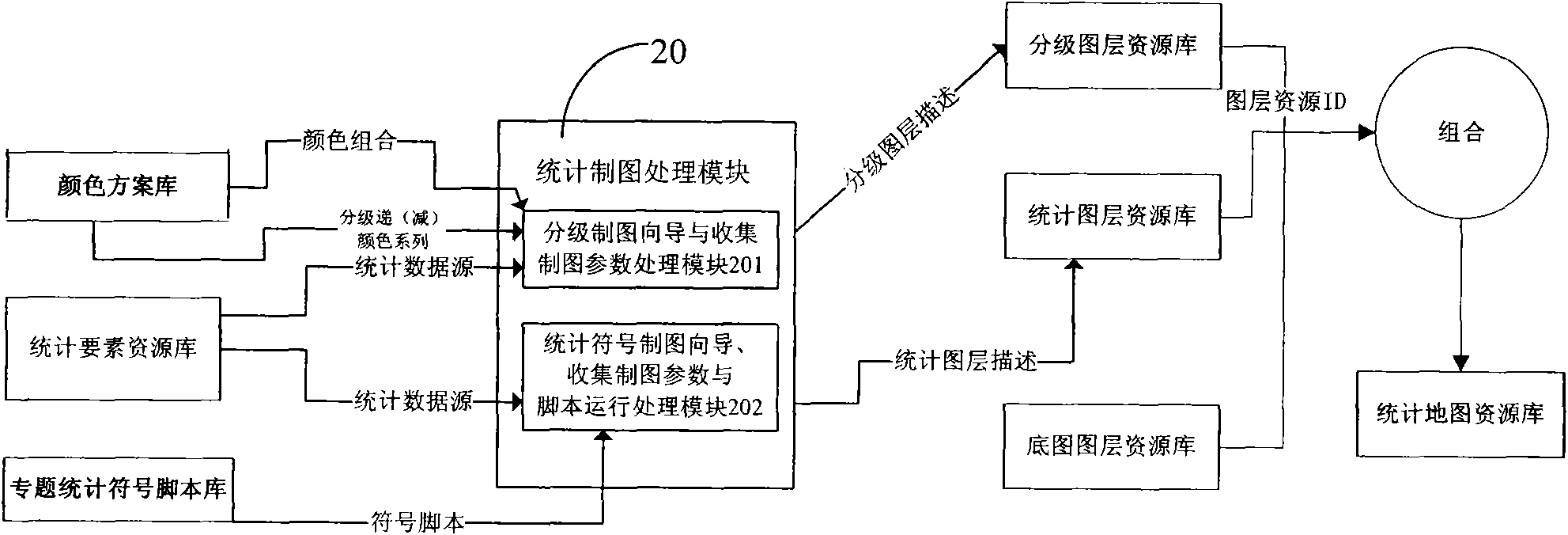

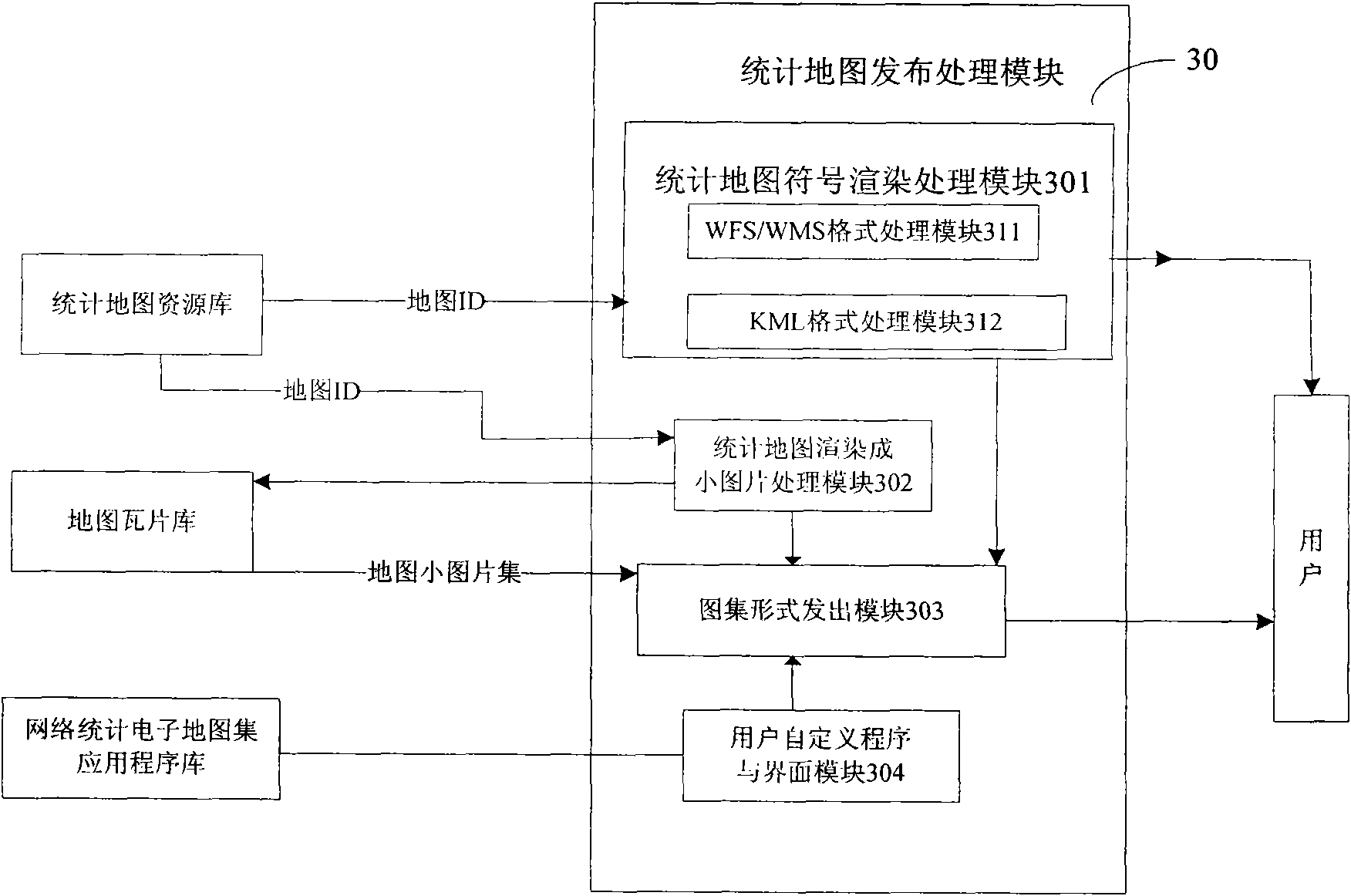

Alternating type online statistical map generation and releasing device and method thereof

InactiveCN101593209AEasy accessAdd depthMaps/plans/chartsSpecial data processing applicationsComposite elementData mining

The invention discloses an alternating type online statistical map generation and releasing device and a method thereof; the device comprises a statistical composite element resource generation module, a statistical graphic processing module and a statistical map release processing module, wherein the statistical composite element resource generation module is used for generating a statistical element resource library according to input statistical attribute data and statistical unit base spatial data; the statistical graphic processing module carries out hierarchical layer description and statistical layer description respectively according to data input by the statistical element resource library, a set thematic statistical symbol script library and a color scheme library and is combined with a base map layer resource library and uses a layer resource ID as an identifier to carry out combined processing so as to generate the statistical map resource library; and the statistical map release processing module is used for providing a user requirement customization input interface and generating and outputting statistical map data customized by a user according to data input by the user requirement customization input interface.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

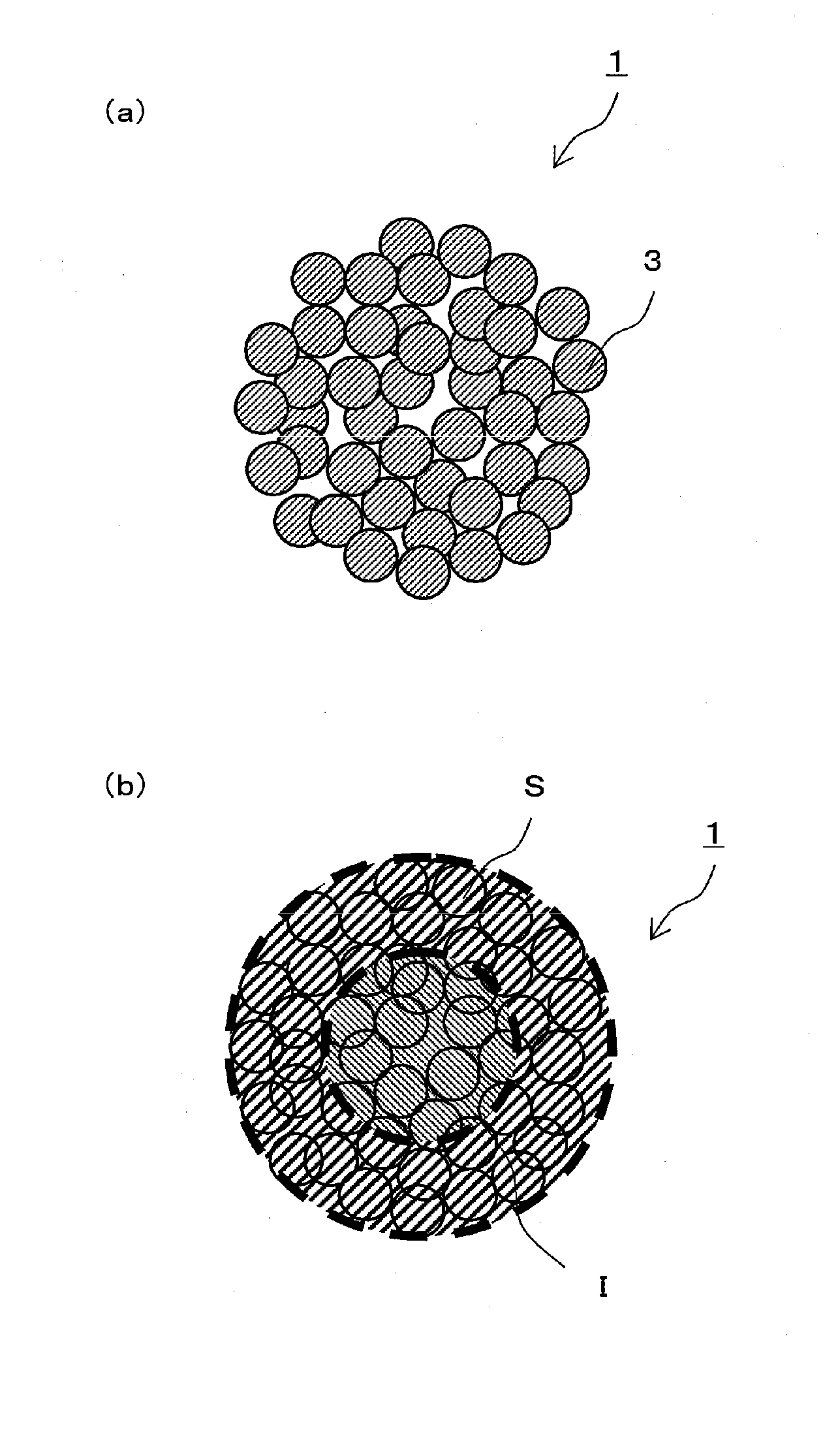

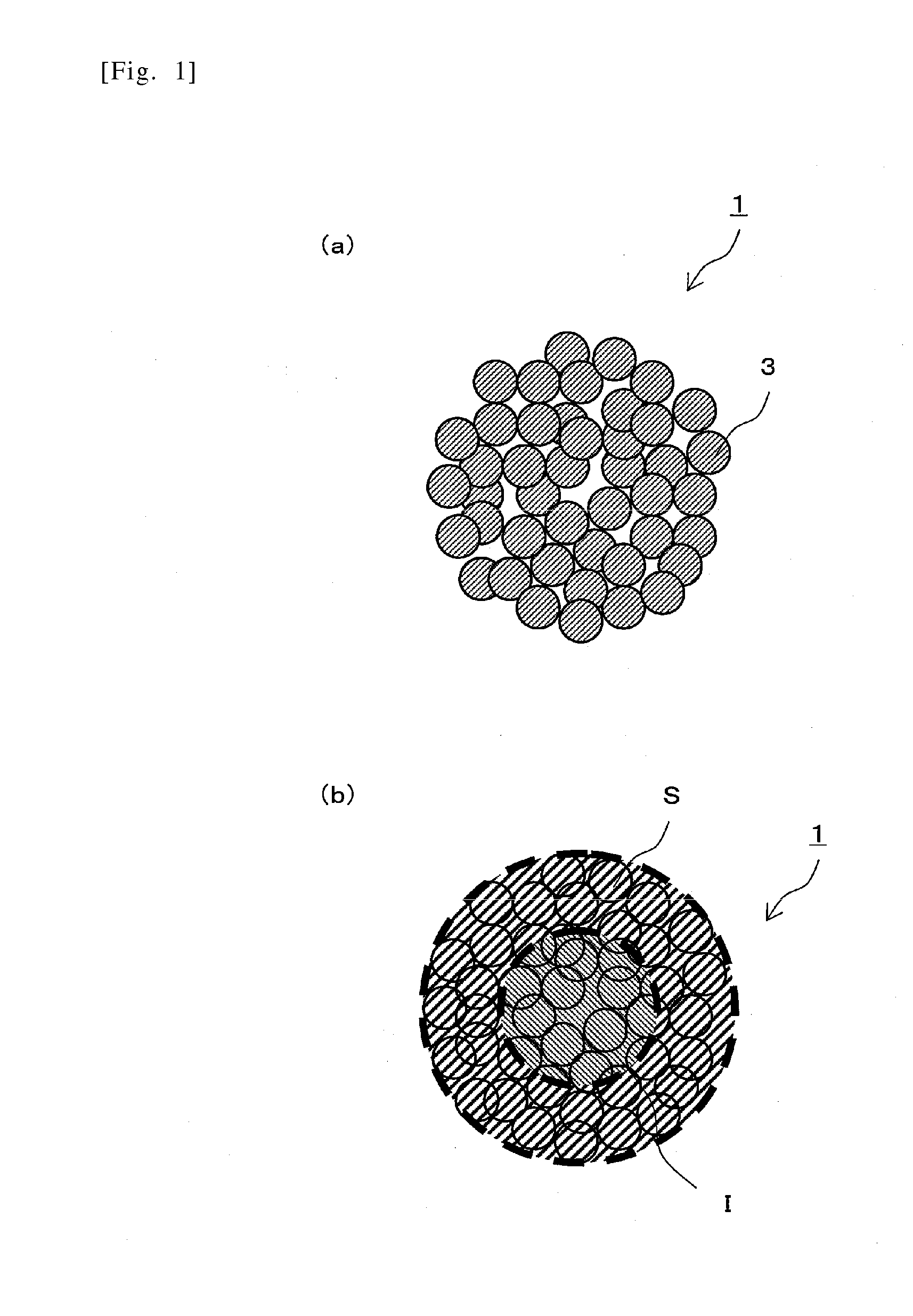

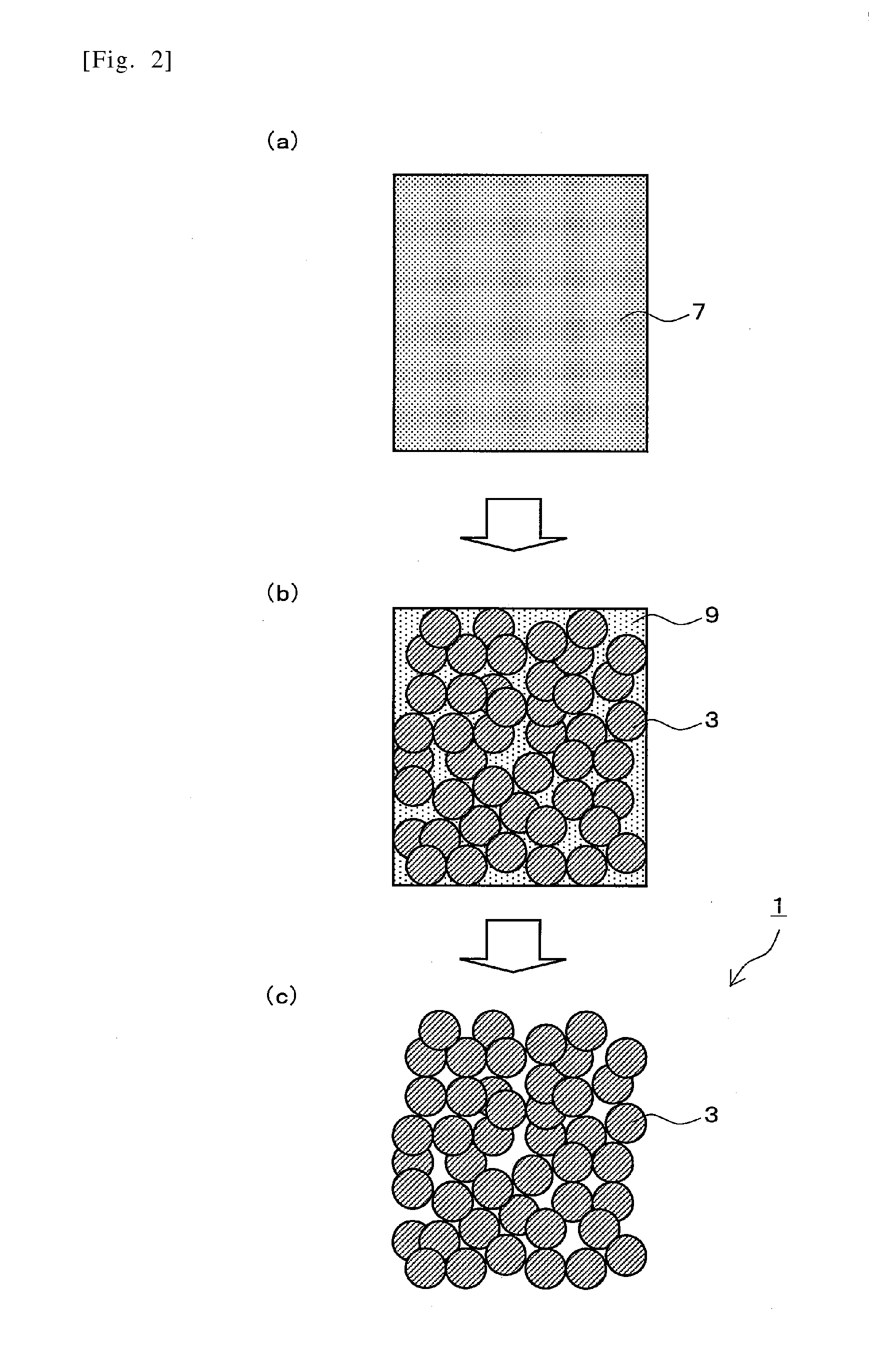

Porous silicon particles and complex porous silicon particles, and method for producing both

ActiveUS20130196158A1Large capacityImprove featuresElectrode manufacturing processesSiliconNetwork structureMicroparticle

Porous silicon particles and complex porous silicon particles suitable for negative electrode materials etc. for lithium-ion batteries, which achieve high capacity and good cycling characteristics, are provided. Porous silicon particles formed by the joining of a plurality of silicon microparticles, and having an average particle diameter of 0.1 μm to 1000 μm, a three-dimensional network structure having continuous gaps, an average porosity of 15 to 93%, and a structure in which the particles of a whole particle are uniform. Complex porous silicon particles formed by the joining of a plurality of silicon microparticles and a plurality of silicon compound particles, and characterized by containing a compound of silicon and composite elements, having an average particle diameter of 0.1 μm to 1000 μm, and having a three-dimensional network structure having continuous gaps.

Owner:FURUKAWA ELECTRIC CO LTD +1

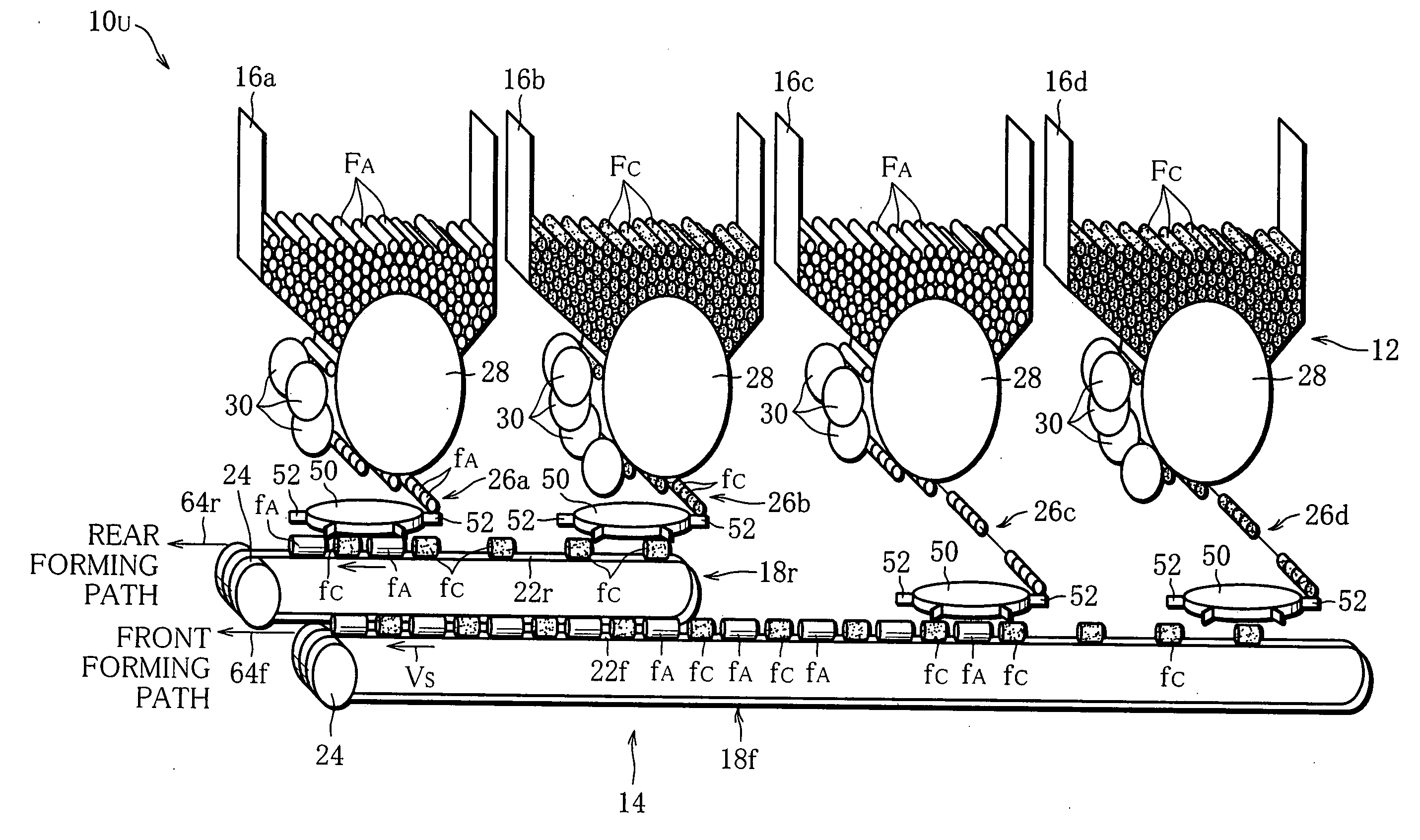

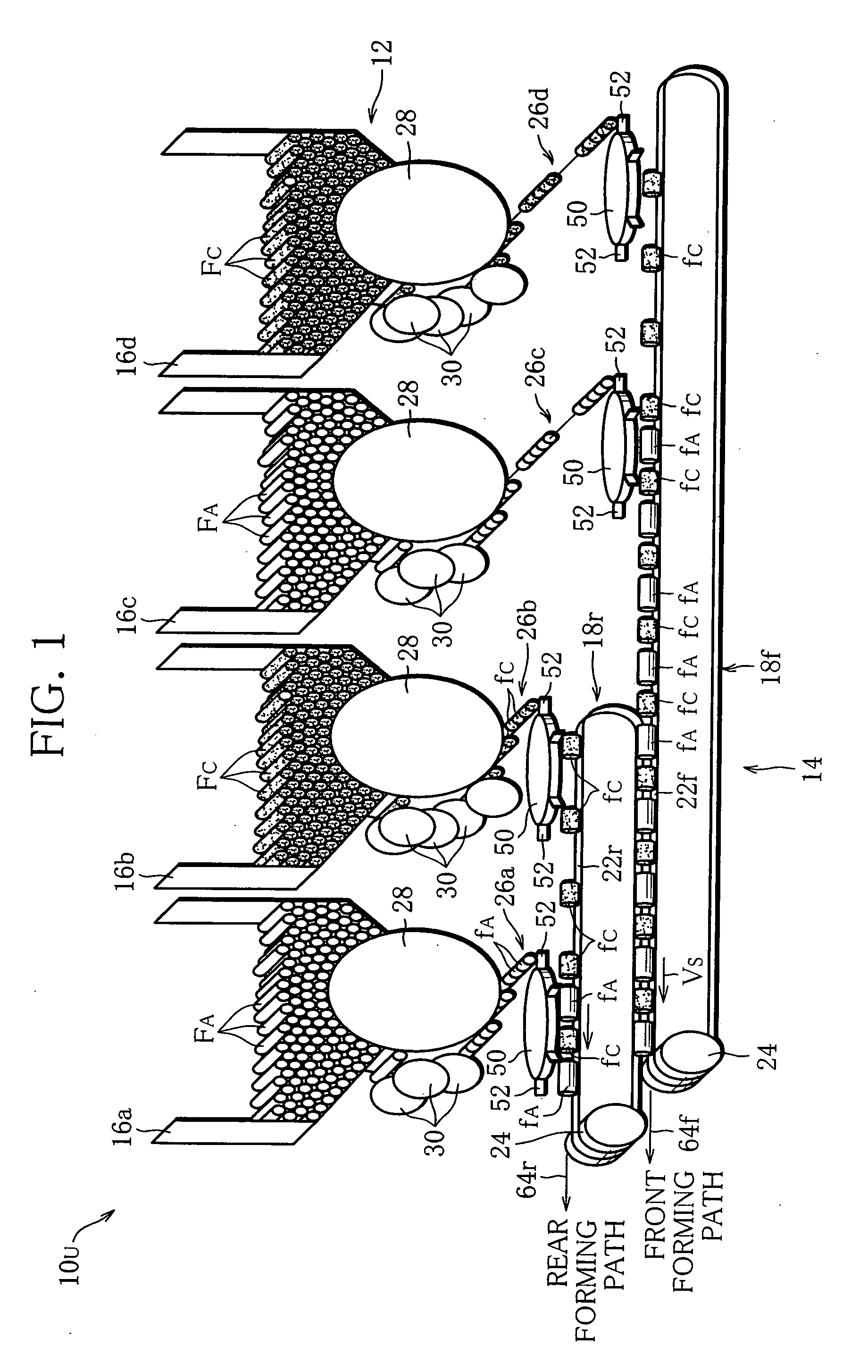

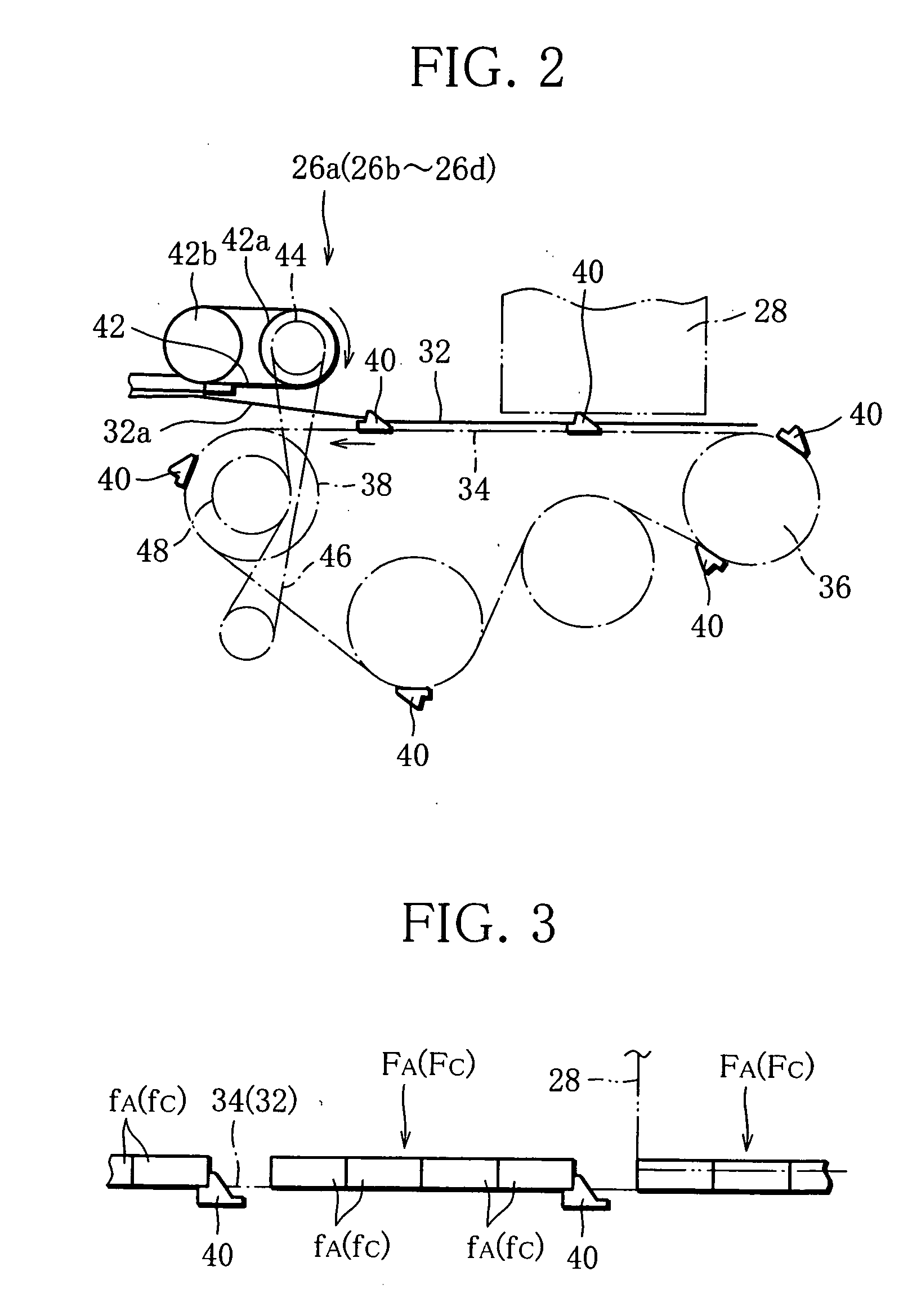

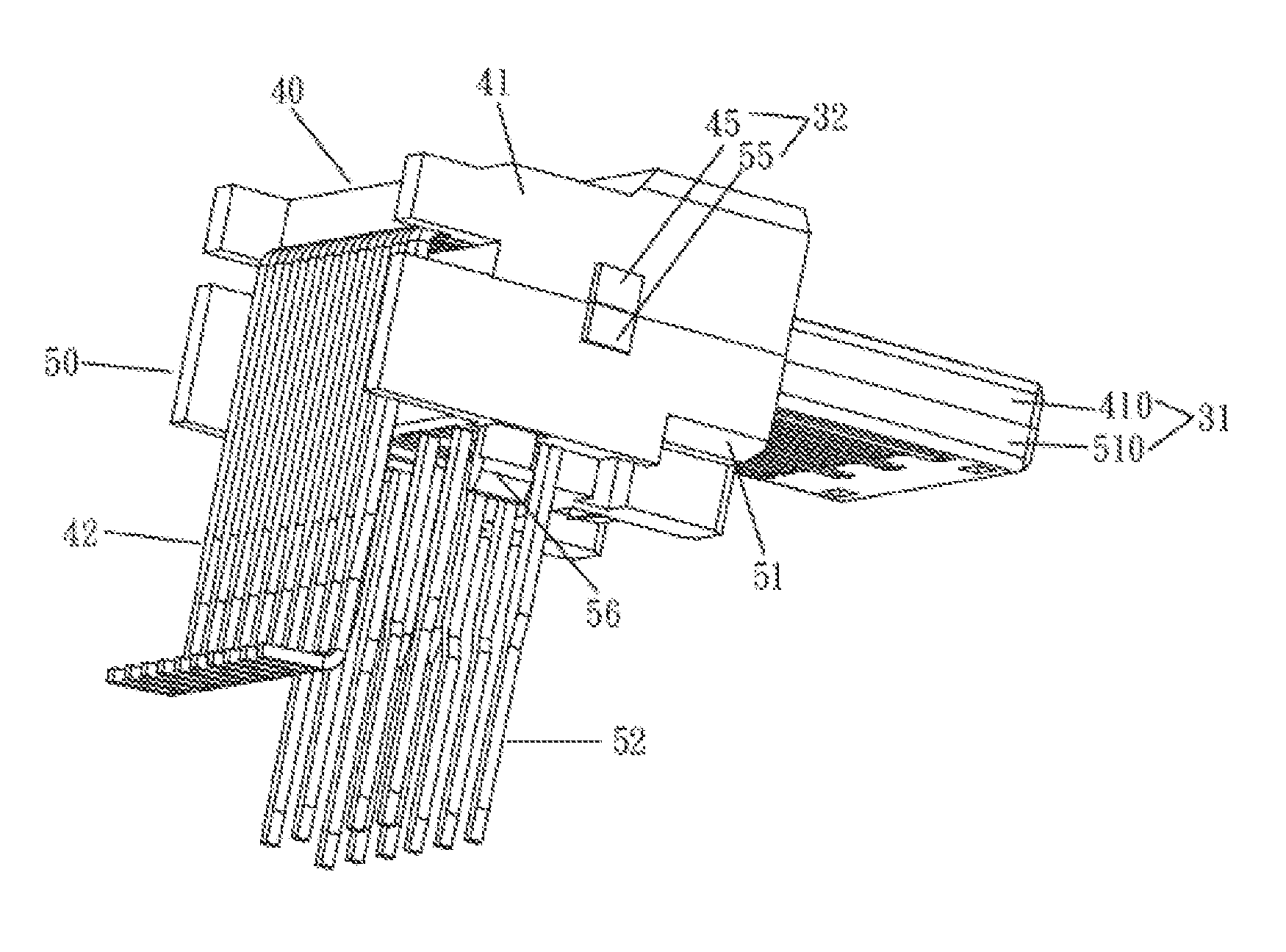

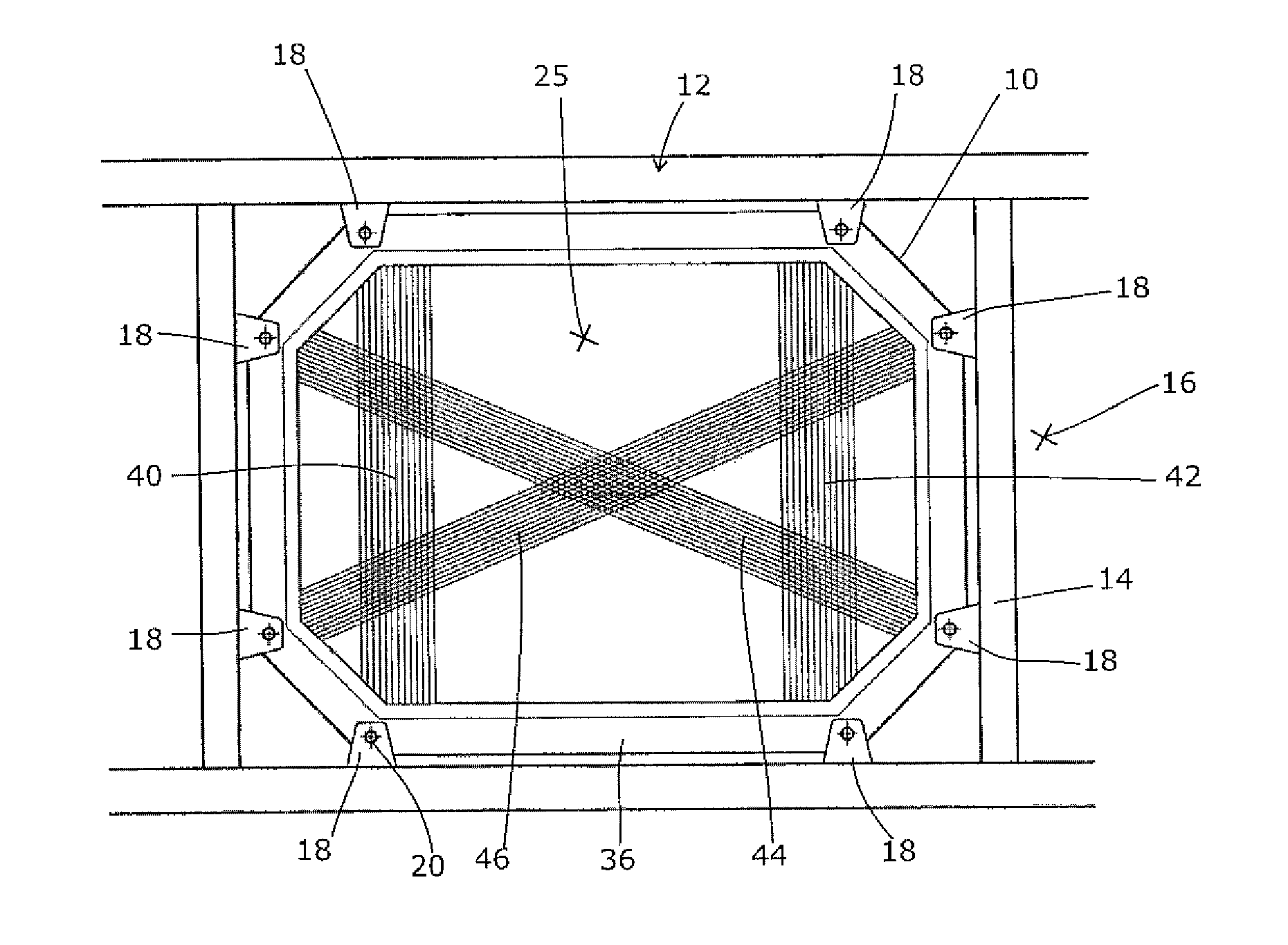

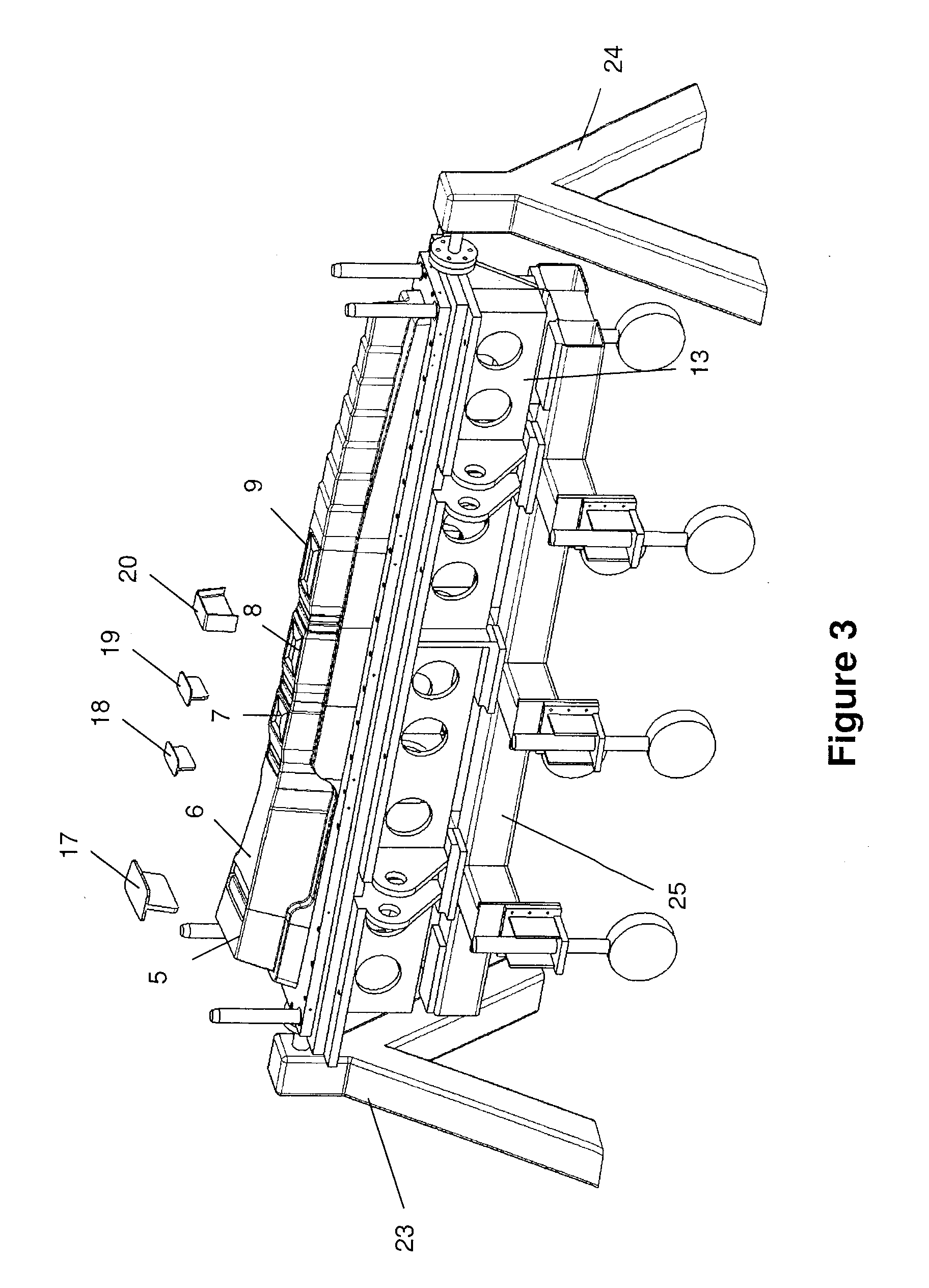

Filter rod making machine

InactiveUS20070117700A1Reduce positioningProduced in advancePaper/cardboard wound articlesTobacco smoke filtersEngineeringPhase change

A filter rod making machine comprises a plurality of feed wheels (50) for feeding filter elements (fA, fC) at intervals; a conveyor (18) for receiving the filter elements (fA, fC) from the feed wheels (50) and forming an element stream in which the filter elements (fA) and the filter element (fC) are arranged alternately; a wrapping apparatus (62) for forming the element stream into a composite element column (CE) in which the filter elements (fA, fC) are in close contact with each other, and then into a composite element rod (ER) by wrapping the composite element column (CE) in a paper web (W); a cutting apparatus (92) for cutting the composite element rod (ER) into individual filter rods (FR); and a phase change apparatus (112) for adjusting the rotation phase of the feed wheel (50) on the basis of information on the filter rod (FR) cut.

Owner:JAPAN TOBACCO INC

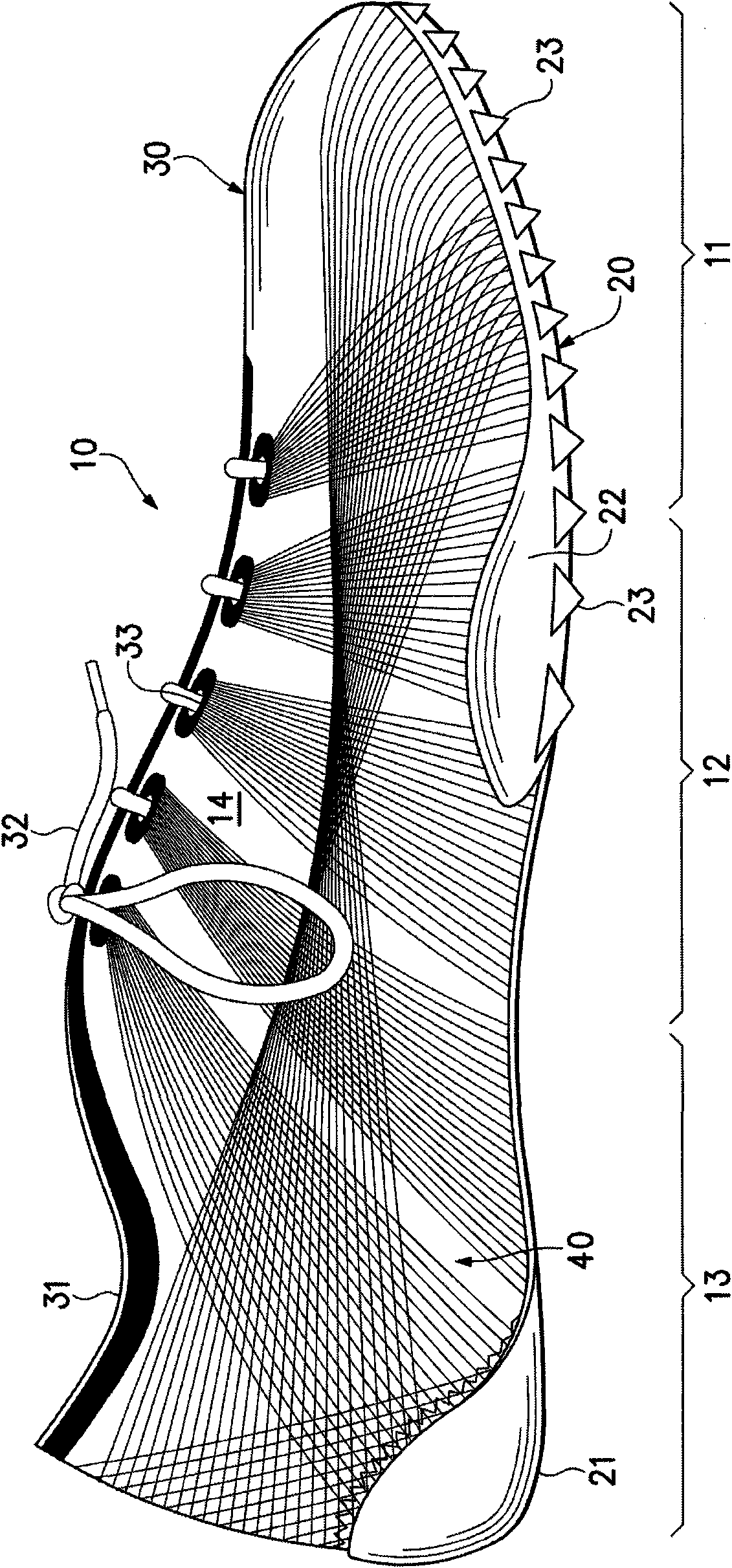

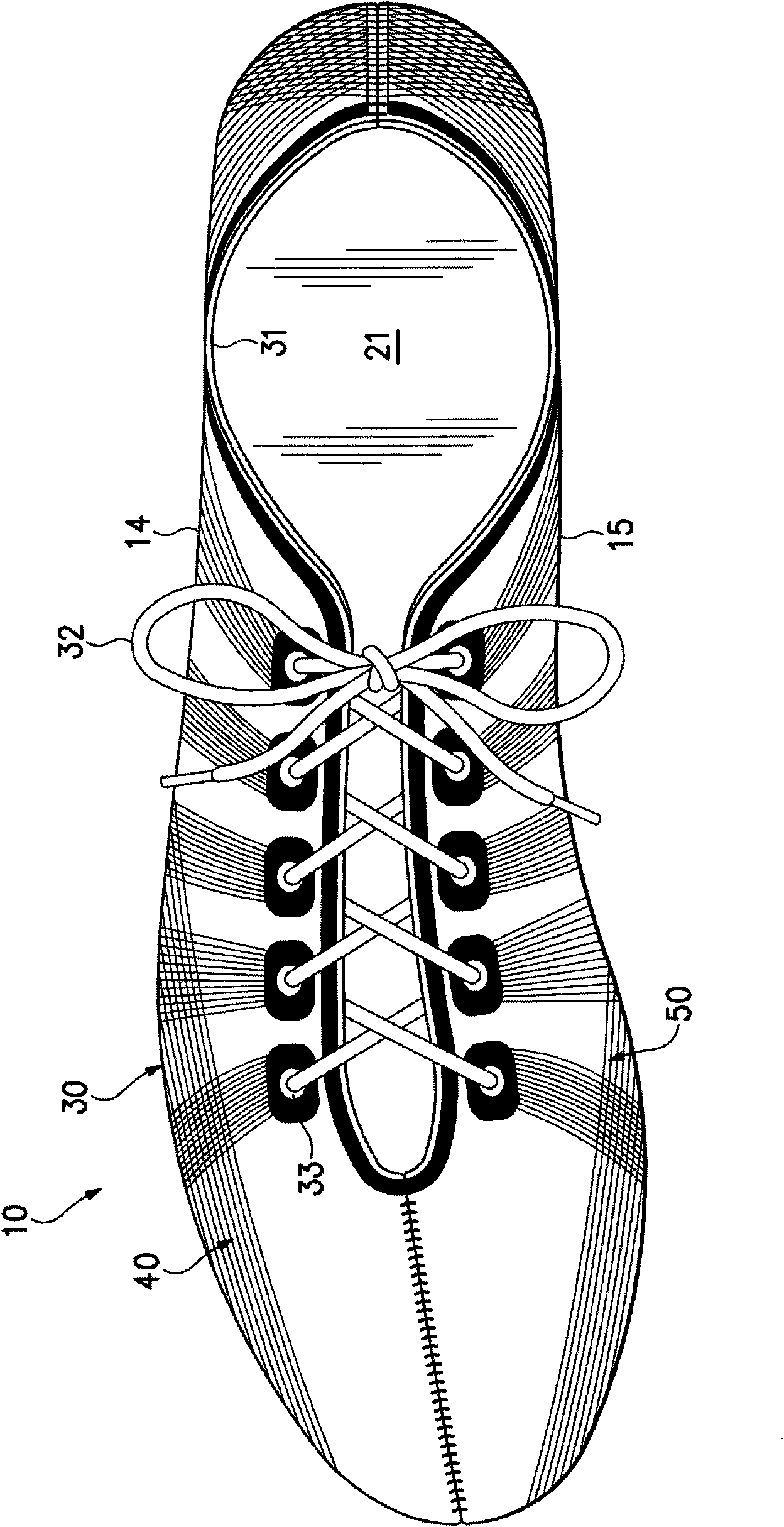

Composite element with a polymer connecting layer

A composite element includes a base layer, a thermoplastic polymer material, a thread, and a cover layer. The base layer has a first surface and an opposite second surface. The polymer material is separate from the base layer, extends into the base layer, and is at least partially located at the first surface. The thread has a section lying adjacent to the first surface layer and substantially parallel to the first surface throughout a distance of at least five centimeters, and the thread is bonded to the base layer with the polymer material. The cover layer is located adjacent to the first surface and bonded to the base layer with the polymer material, and the section of the thread is located between the cover layer and the base layer.

Owner:NIKE INNOVATE CV

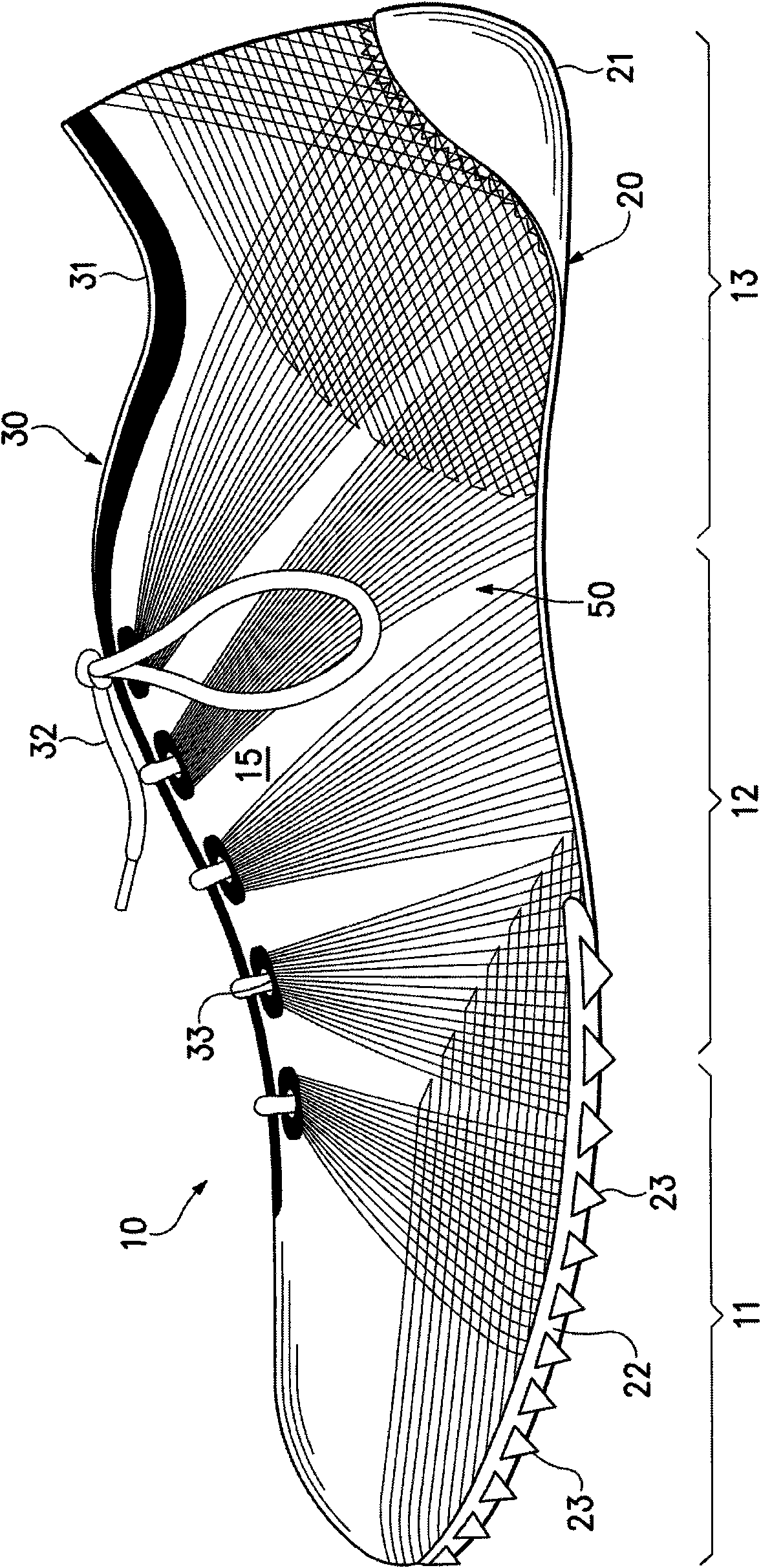

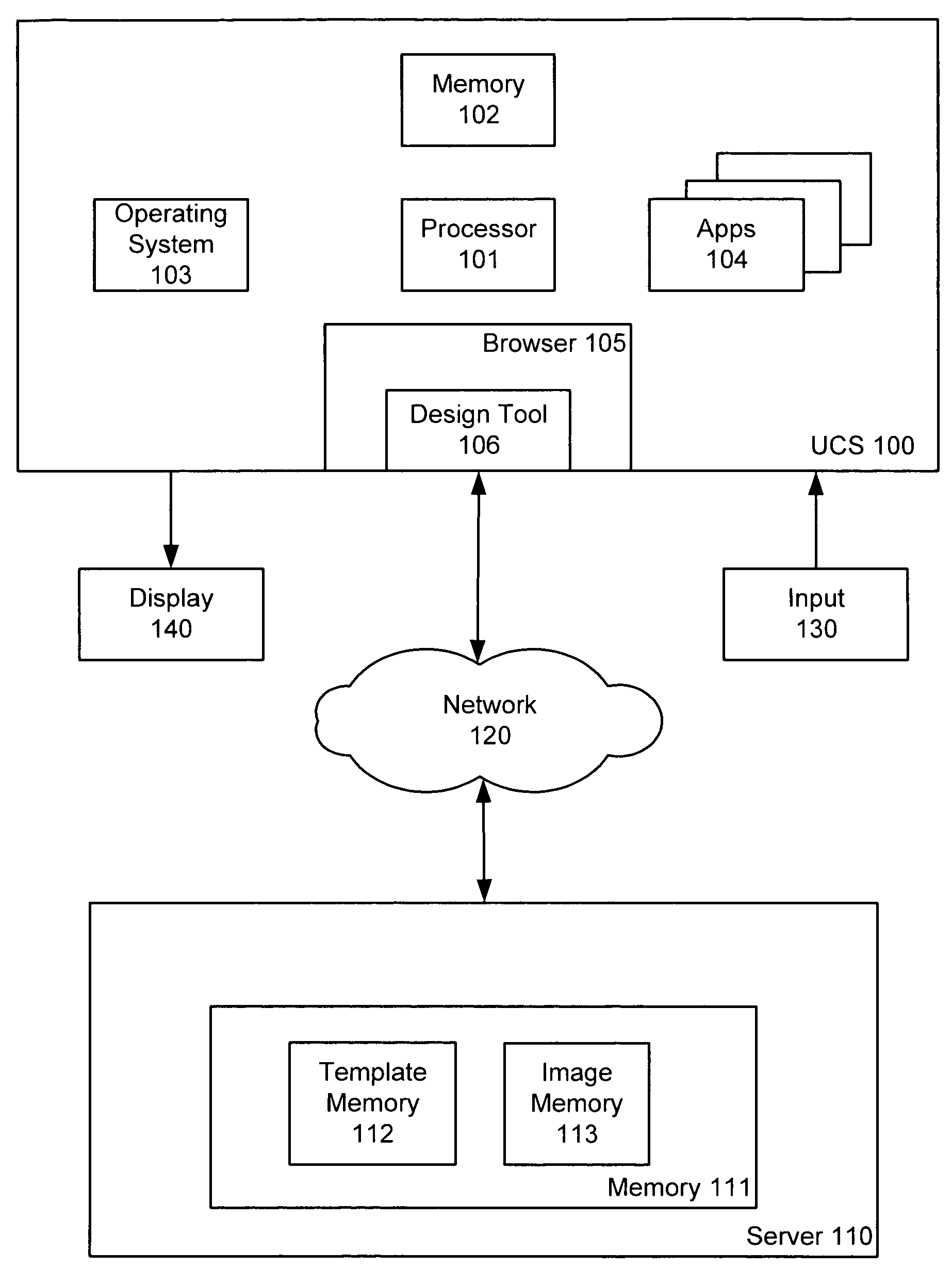

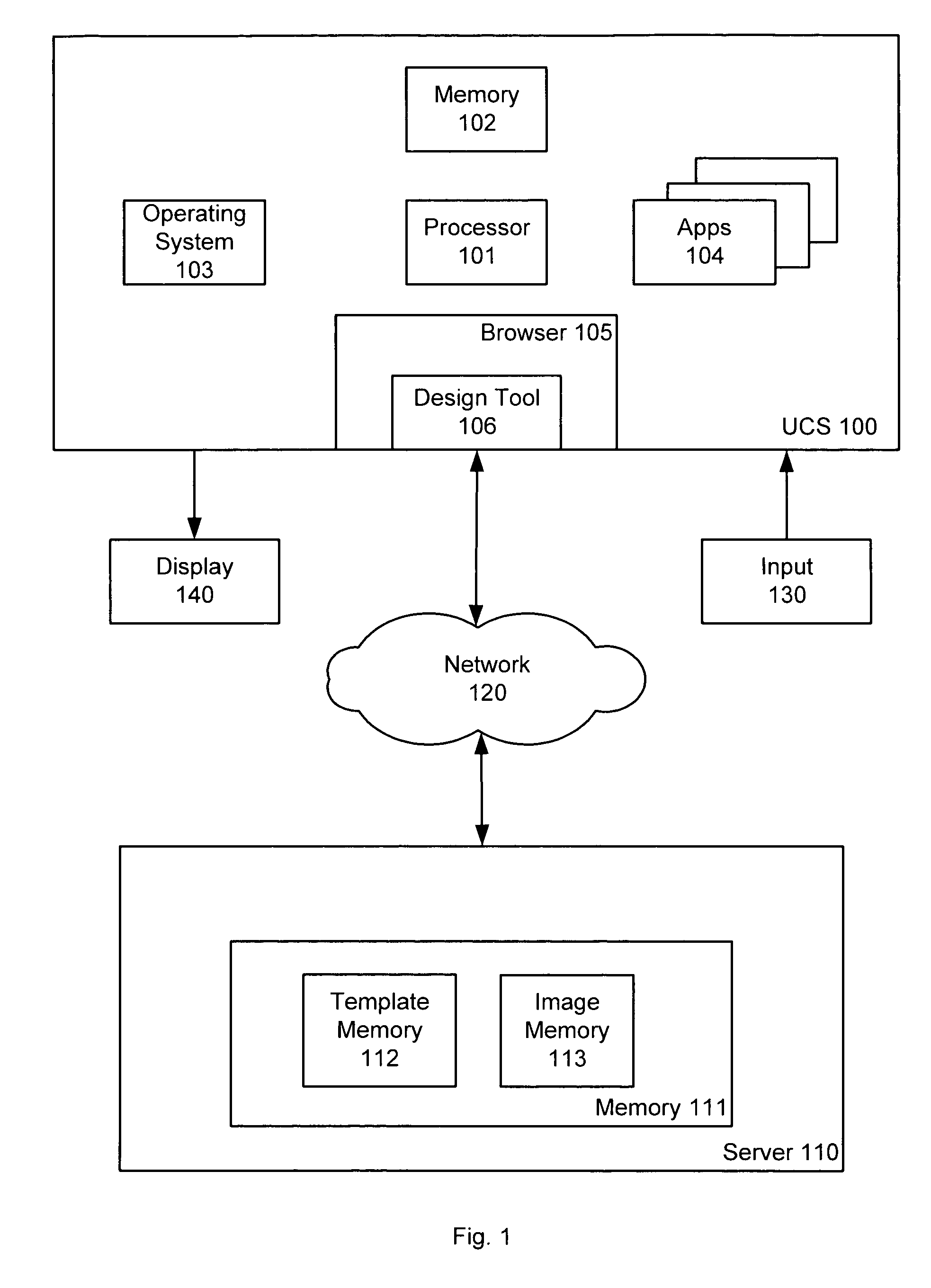

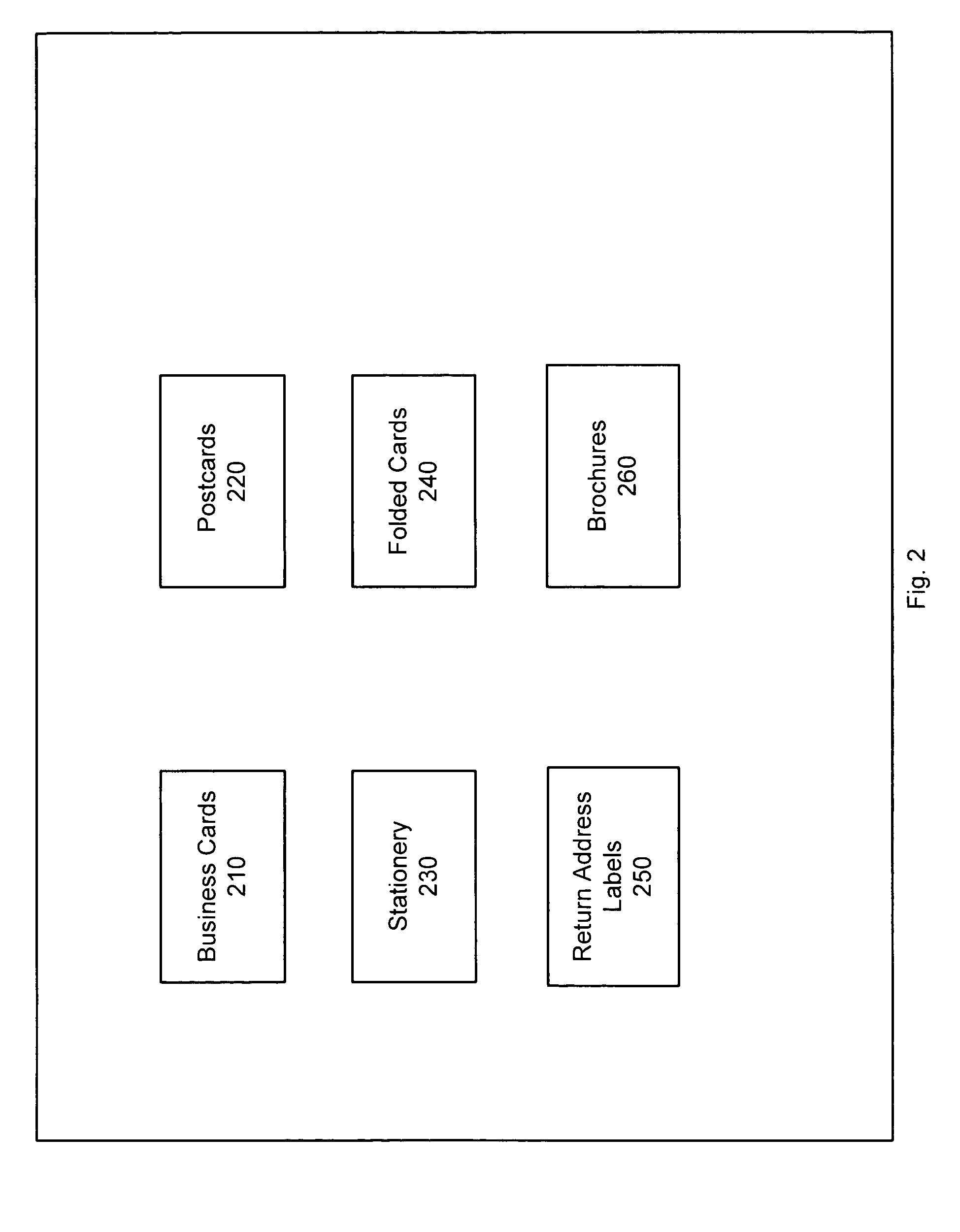

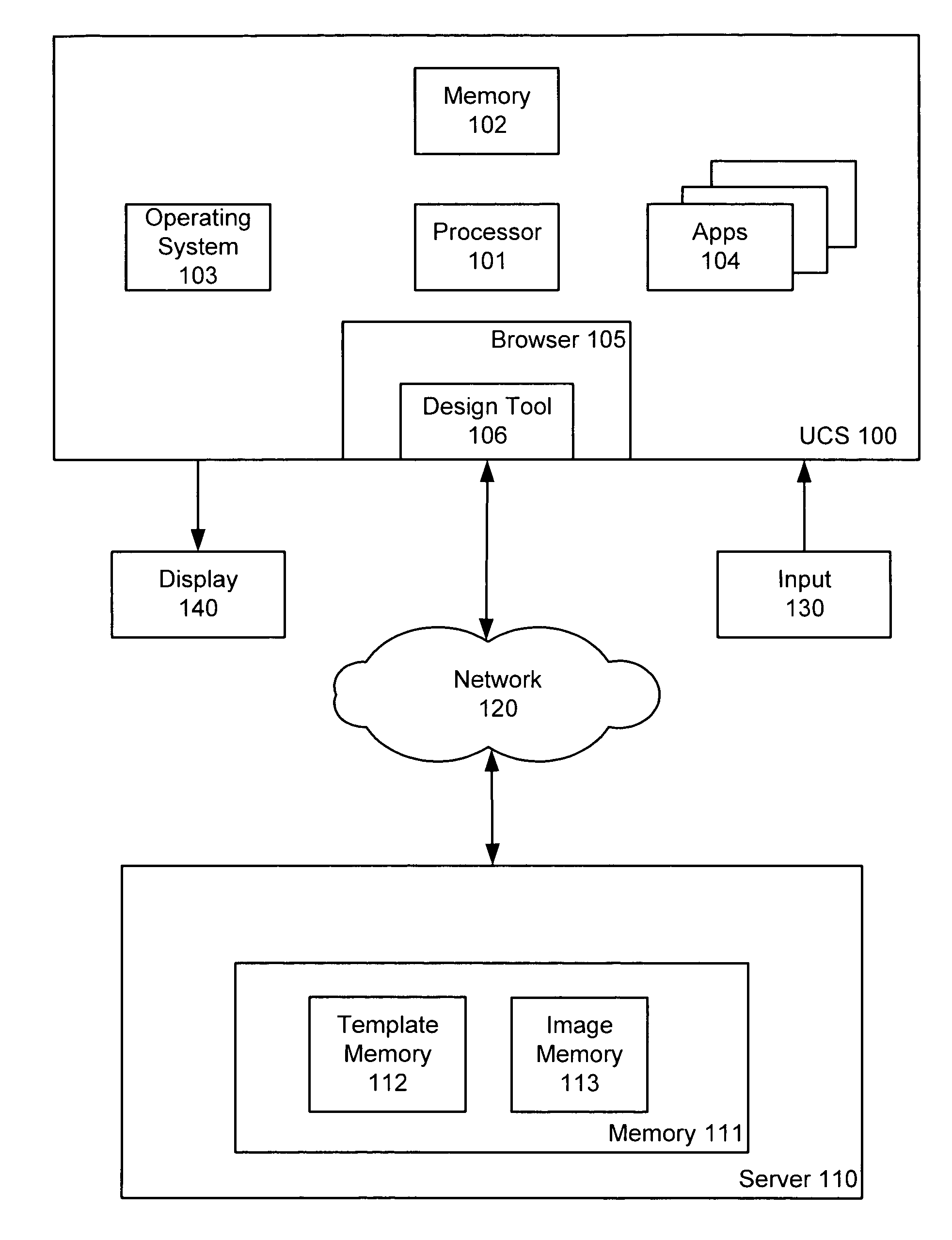

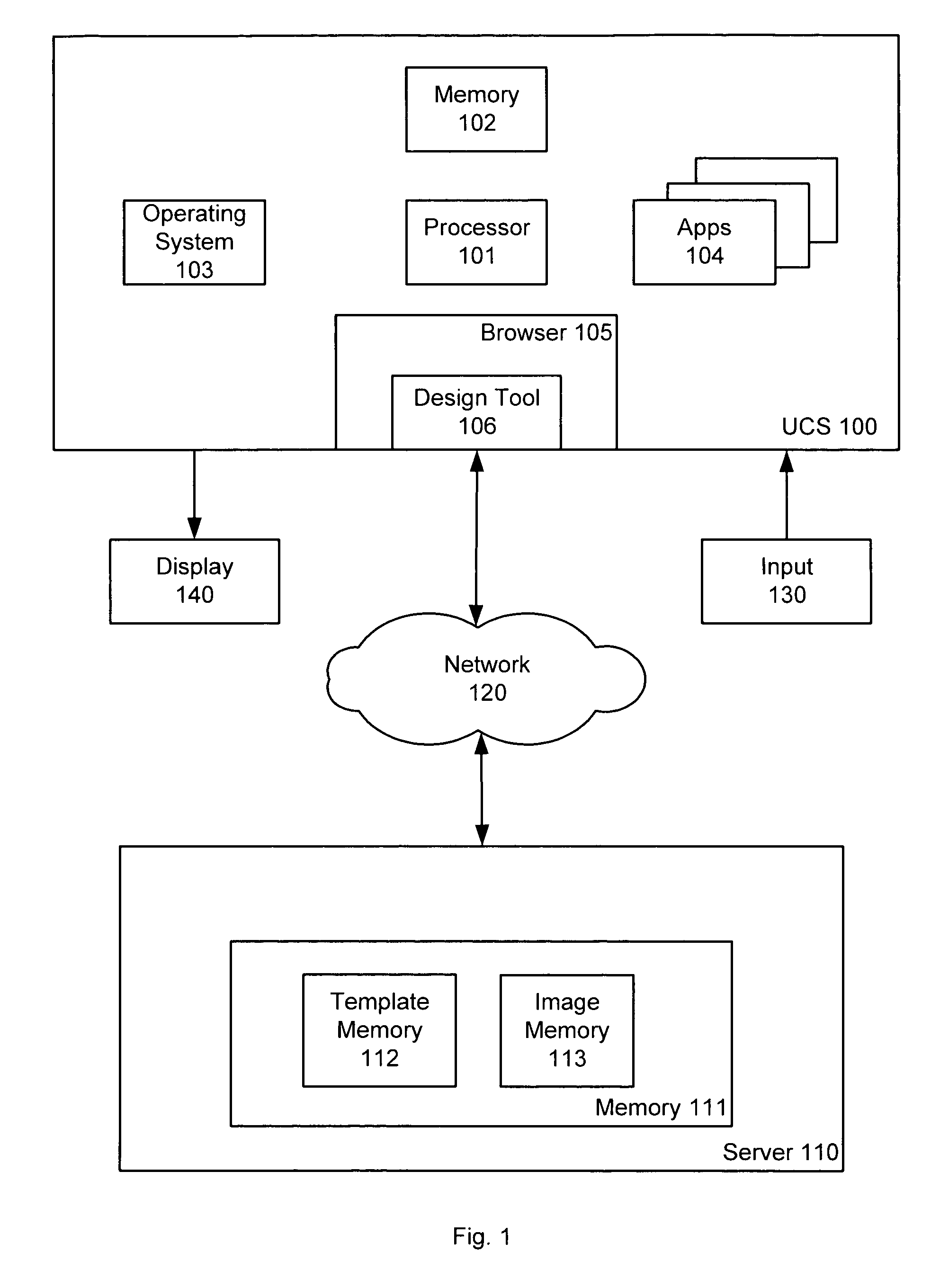

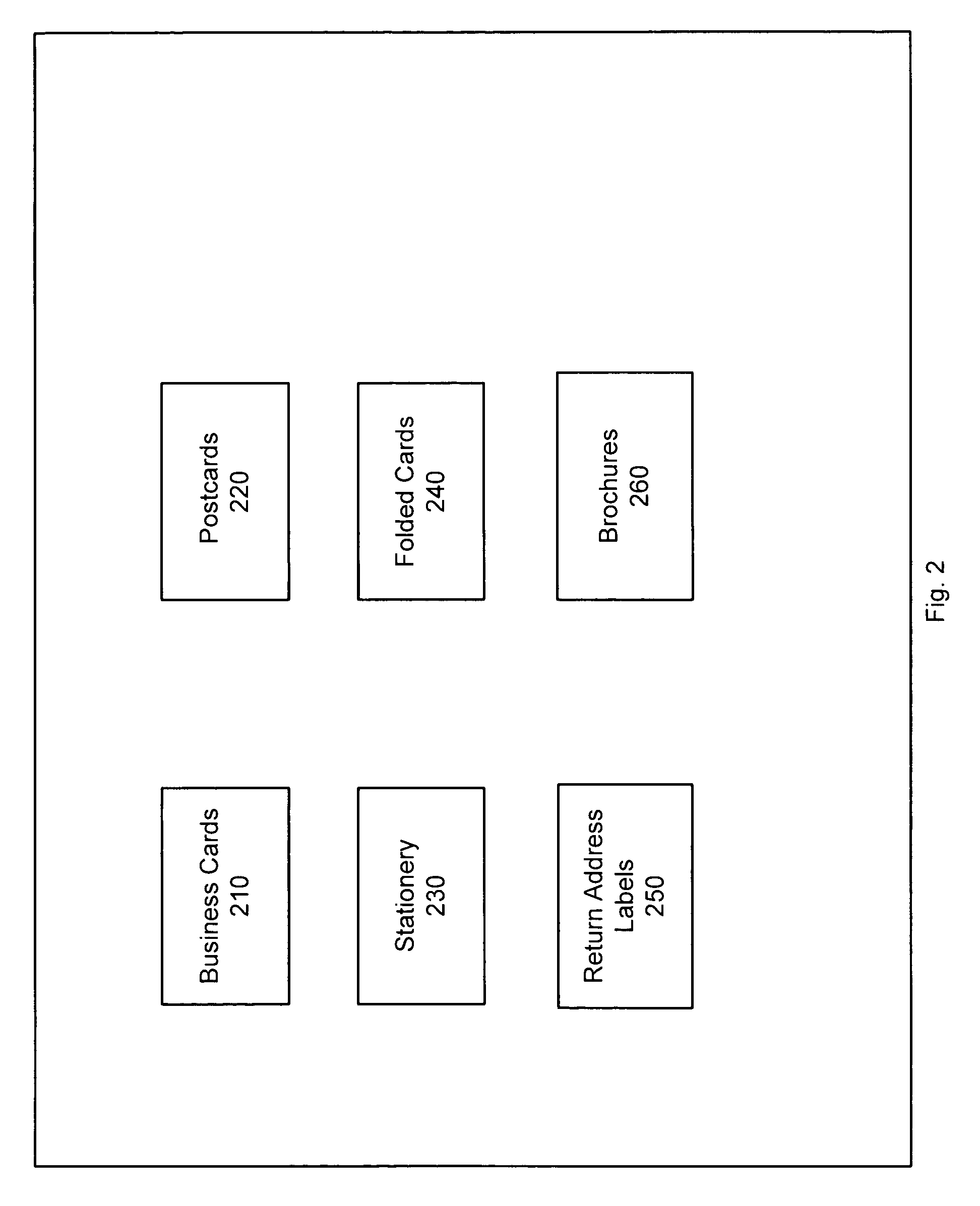

Electronic product design

ActiveUS20050075746A1Easy to mergeNatural language data processingSpecial data processing applicationsElectronic documentSoftware engineering

Automated electronic document design systems and method for designing and modifying product templates. When a user initiates a product design session, a product template is presented for user editing and a product description identifier is assigned to the product being designed. Document templates are assembled from individual composite elements. The individual identifiers of the component elements that make up the template being viewed by the user are associated with the description identifier. Tools are provided to allow a user to change one or more of the composite elements of the template. When a user changes an element, the identifier of the newly selected element is associated with the description identifier. Component elements of one template can be individually used, as appropriate, to prepare customized templates for another part of the same document or for different documents.

Owner:CIMPRESS SCHWEIZ

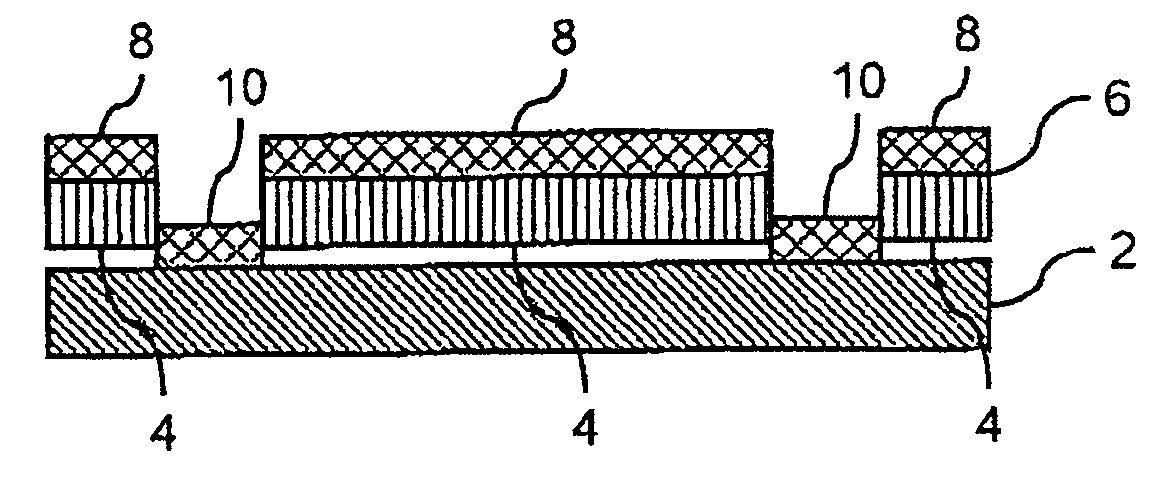

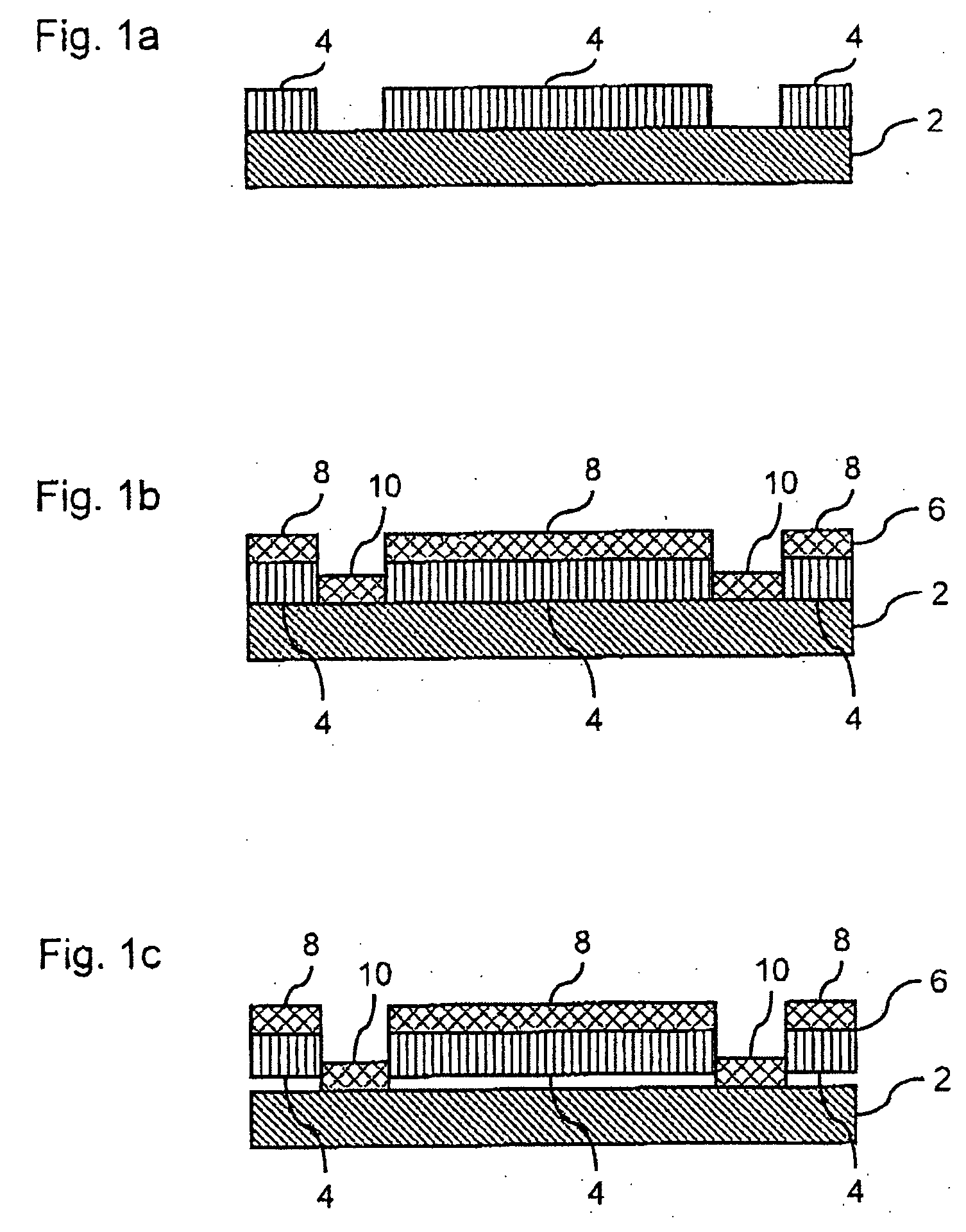

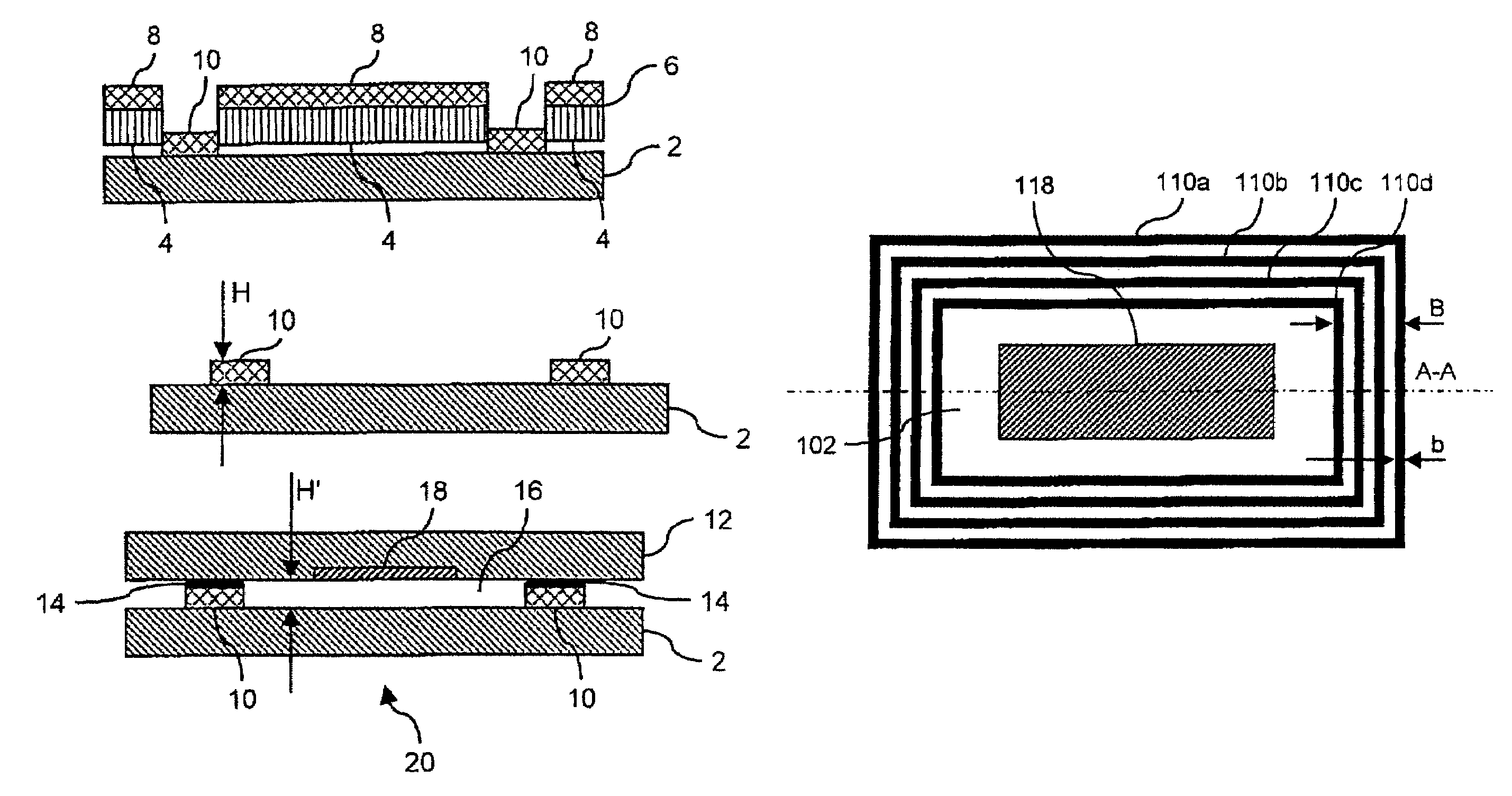

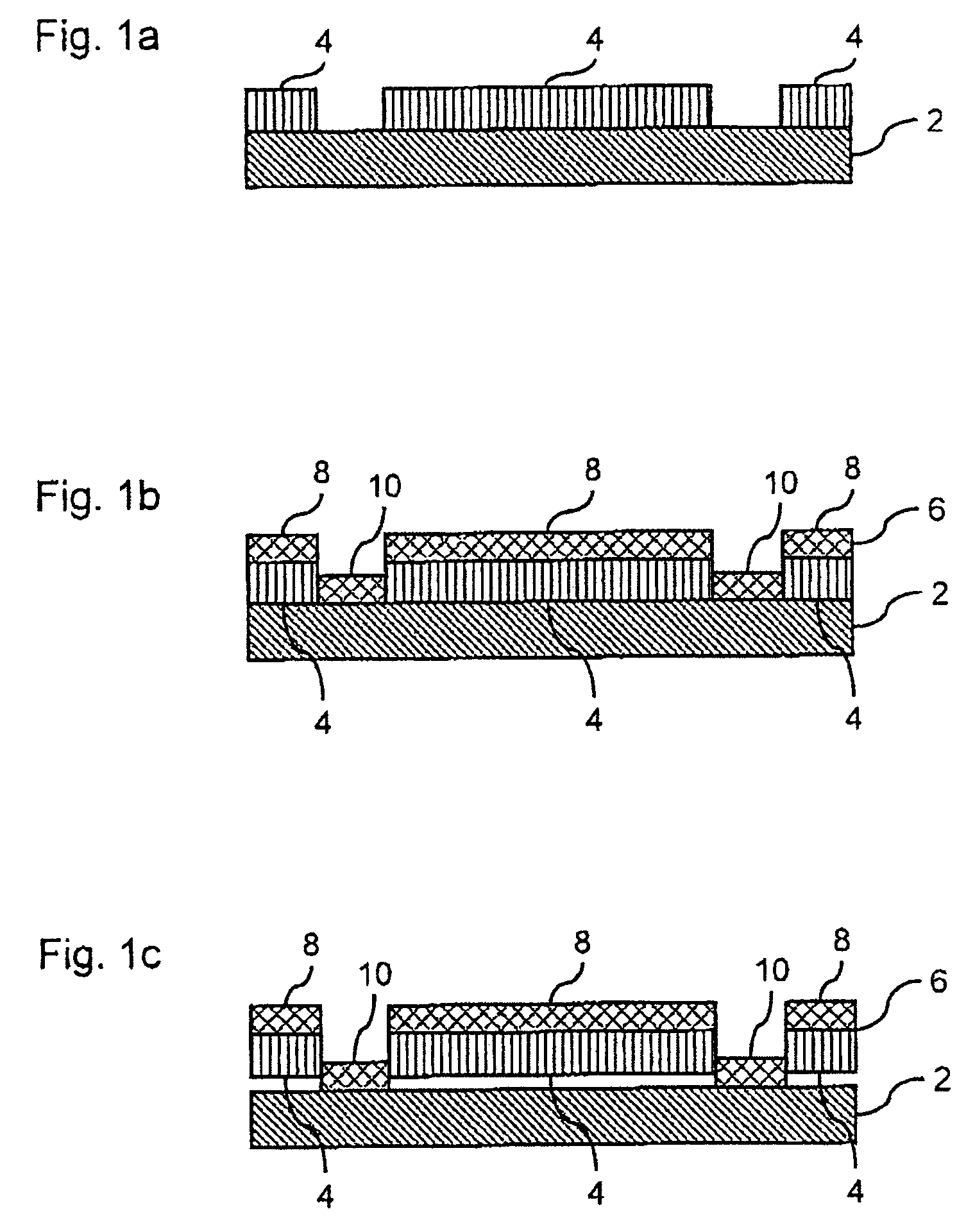

Method for connecting substrate and composite element

ActiveUS20060030074A1OpenSemiconductor/solid-state device detailsElectric lighting sourcesEvaporationCompound (substance)

The invention relates to a process for joining substrates having electrical, semiconducting, mechanical and / or optical components, and to a composite element. The process is to be suitable for the substrates which are to be joined substantially irrespective of material and in particular also for sensitive substrates, is to have a high chemical and physical stability and / or is to produce a hermetic cavity. According to the invention, a raised frame, in particular formed from anodically bondable glass, is applied by evaporation coating to one of the two substrates in order to serve as a joining element.

Owner:SCHOTT AG

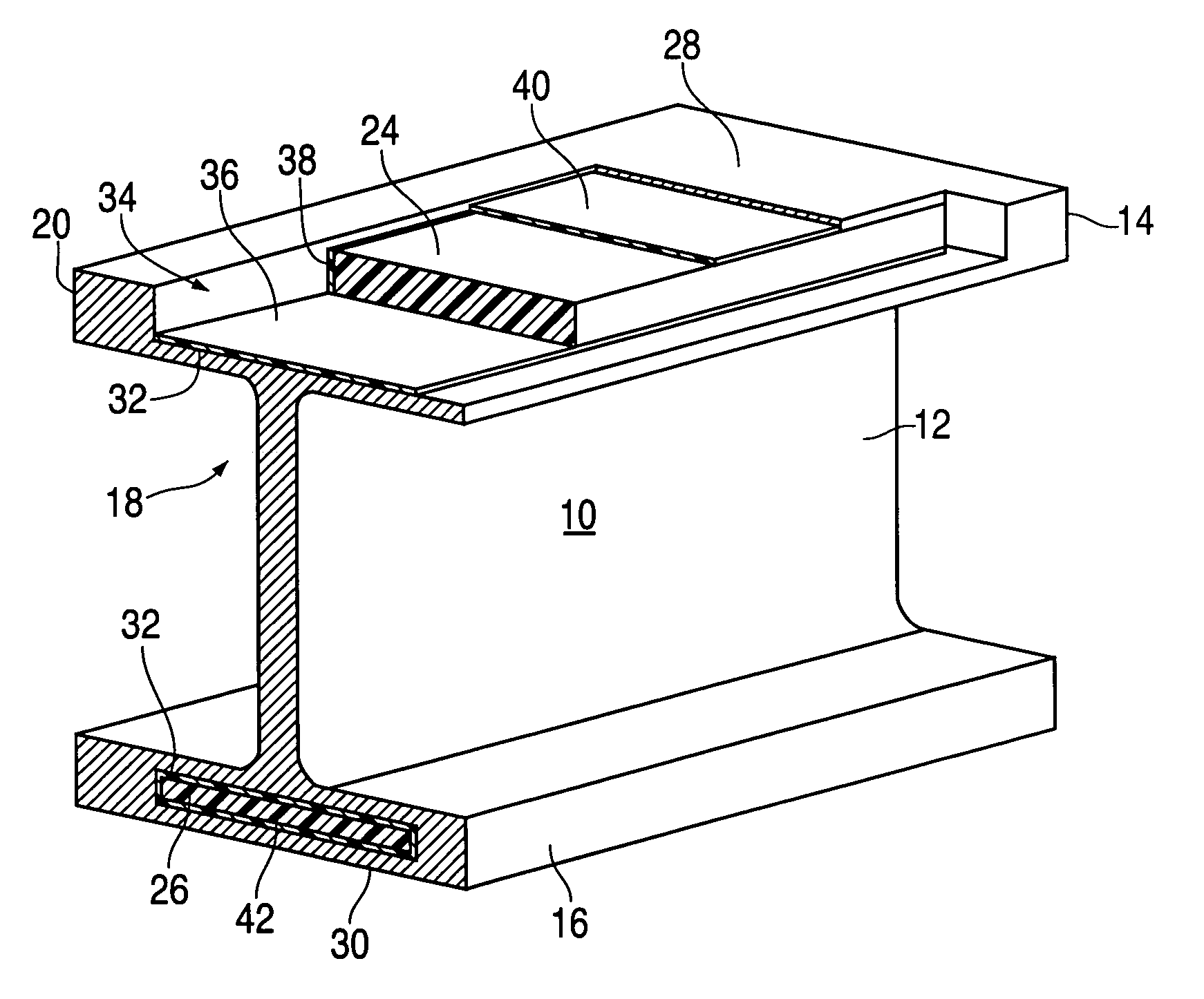

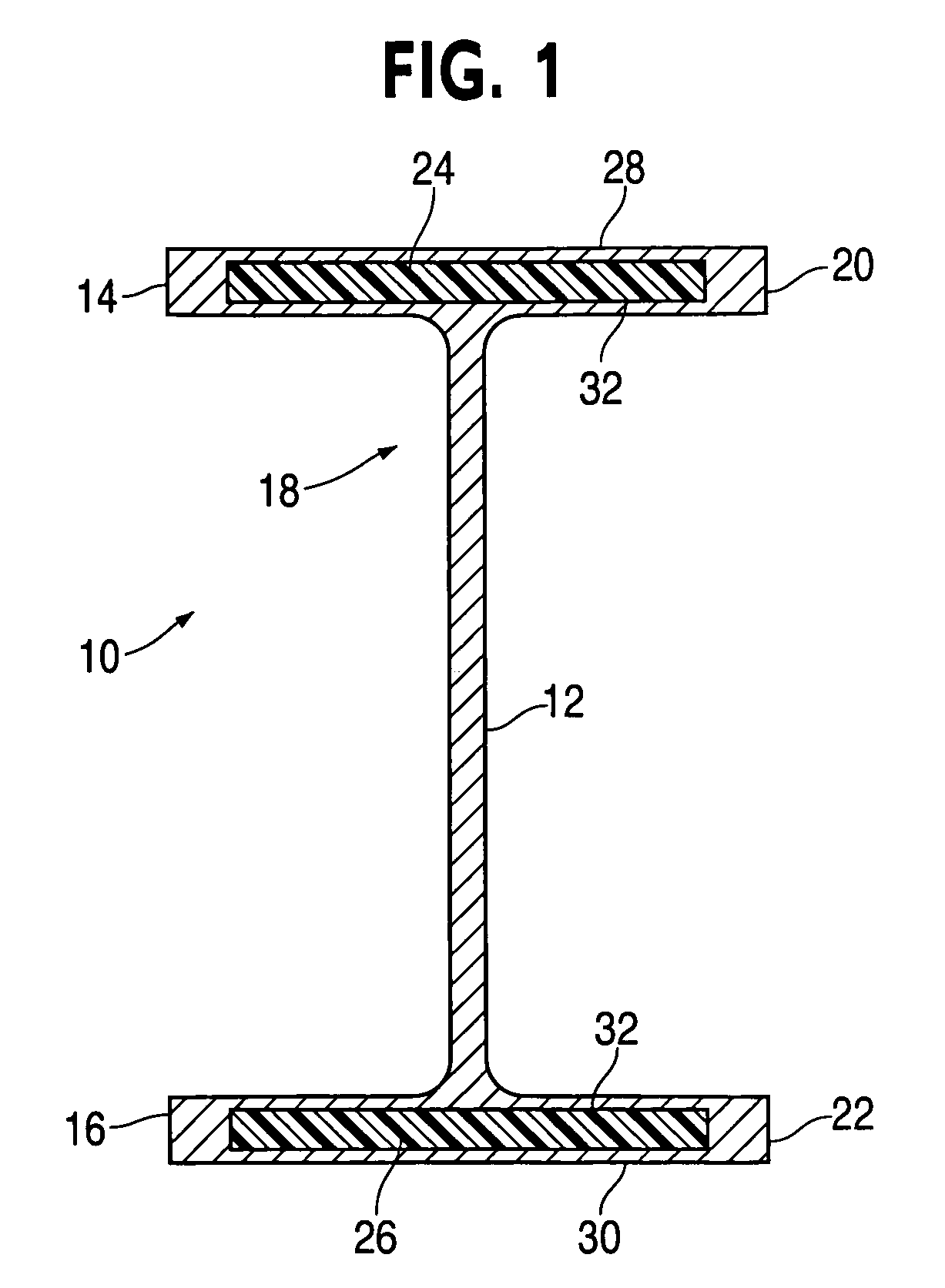

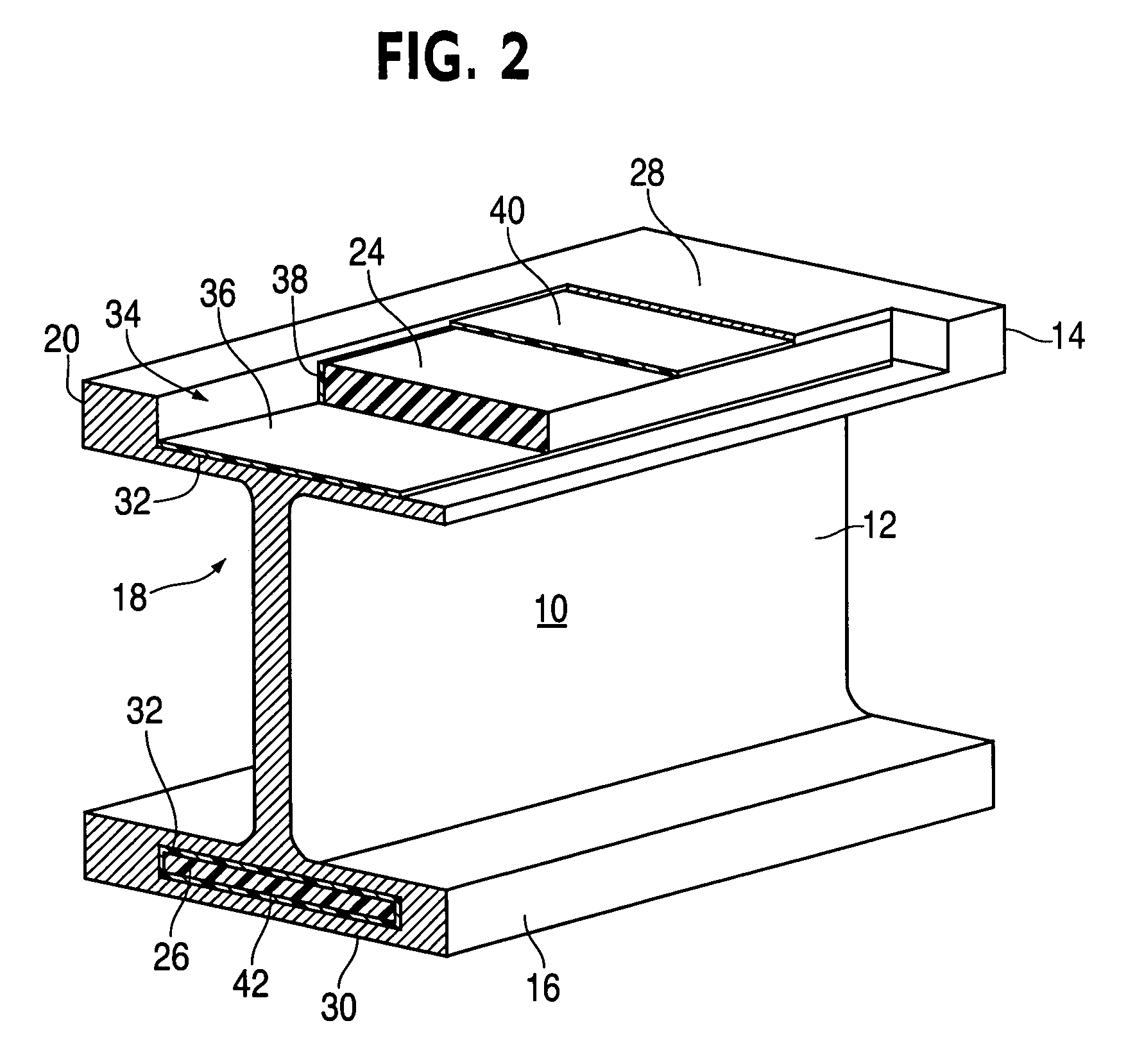

Composite reinforcement of metallic structural elements

A selectively reinforced hybrid metal-composite structural element can include a metal element and a composite material. The composite material can be bonded to the metal element by an adhesive layer including a polymer matrix using a radiation curing process, resulting in insubstantial or negligible residual stresses at the bond line between the metal element and the composite element. The structural element also can include a metal closeout cap to provide a barrier from a corrosive atmosphere, and the adhesive layer can encapsulate the composite element to provide a corrosion-resistant barrier between the composite element and the surrounding metal.

Owner:THE BOEING CO

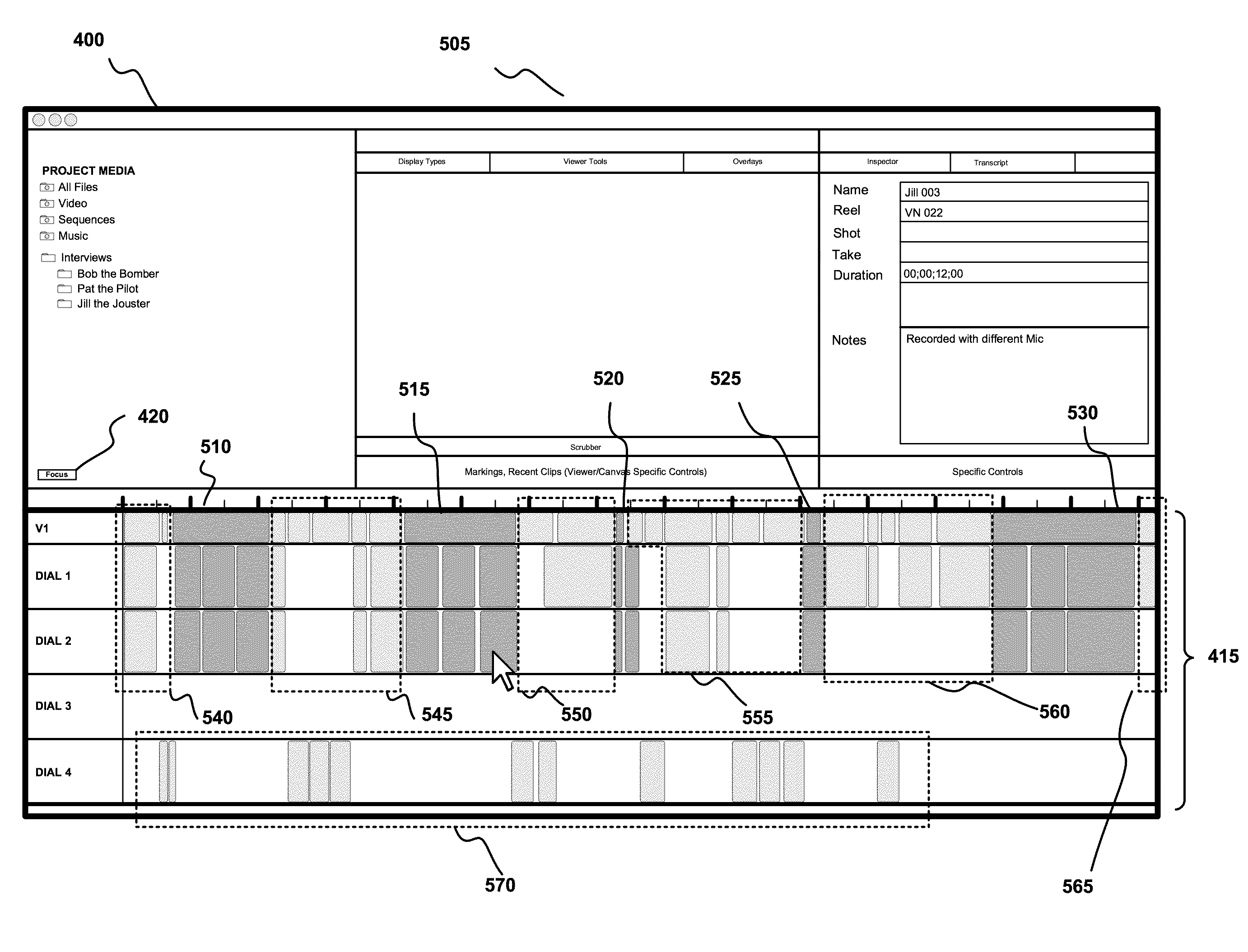

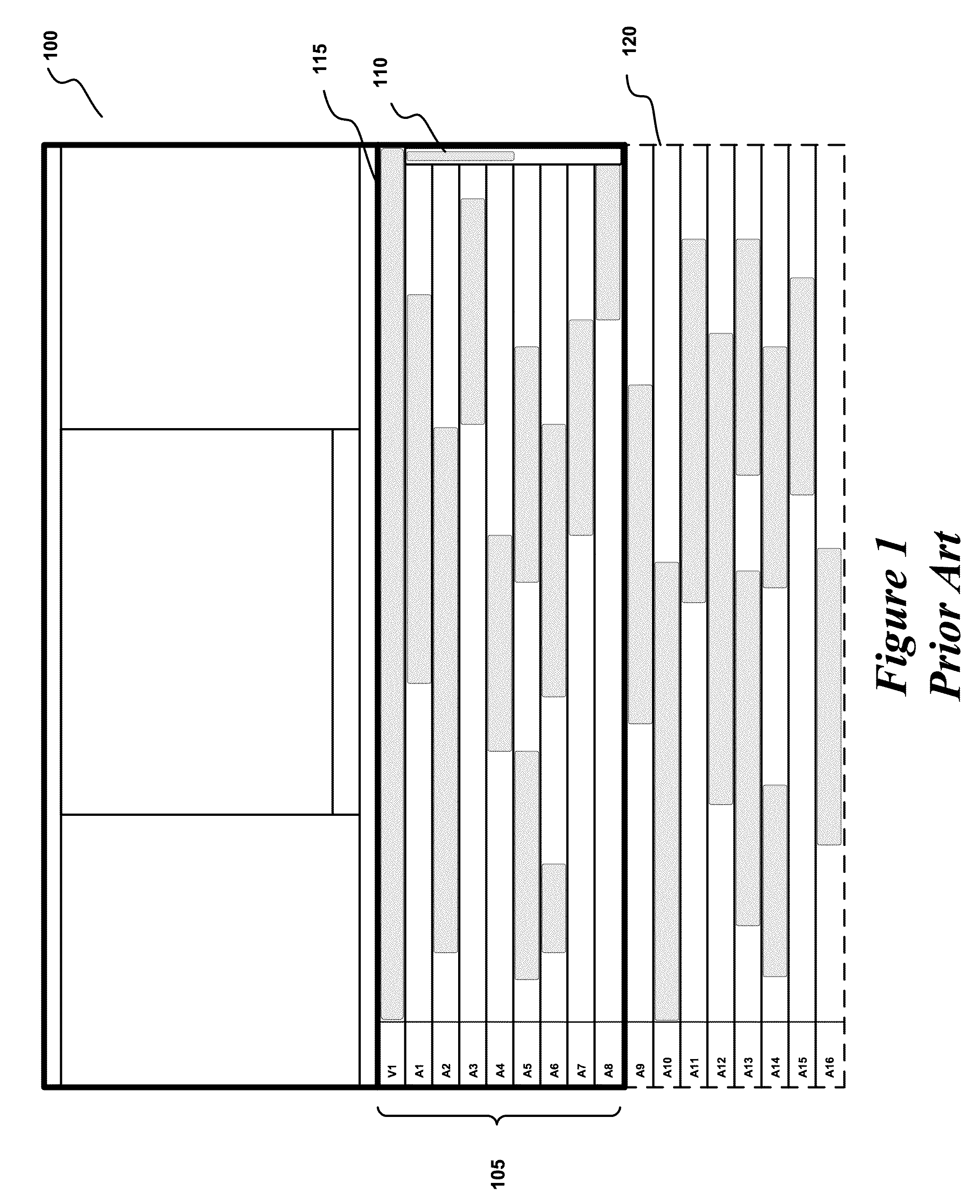

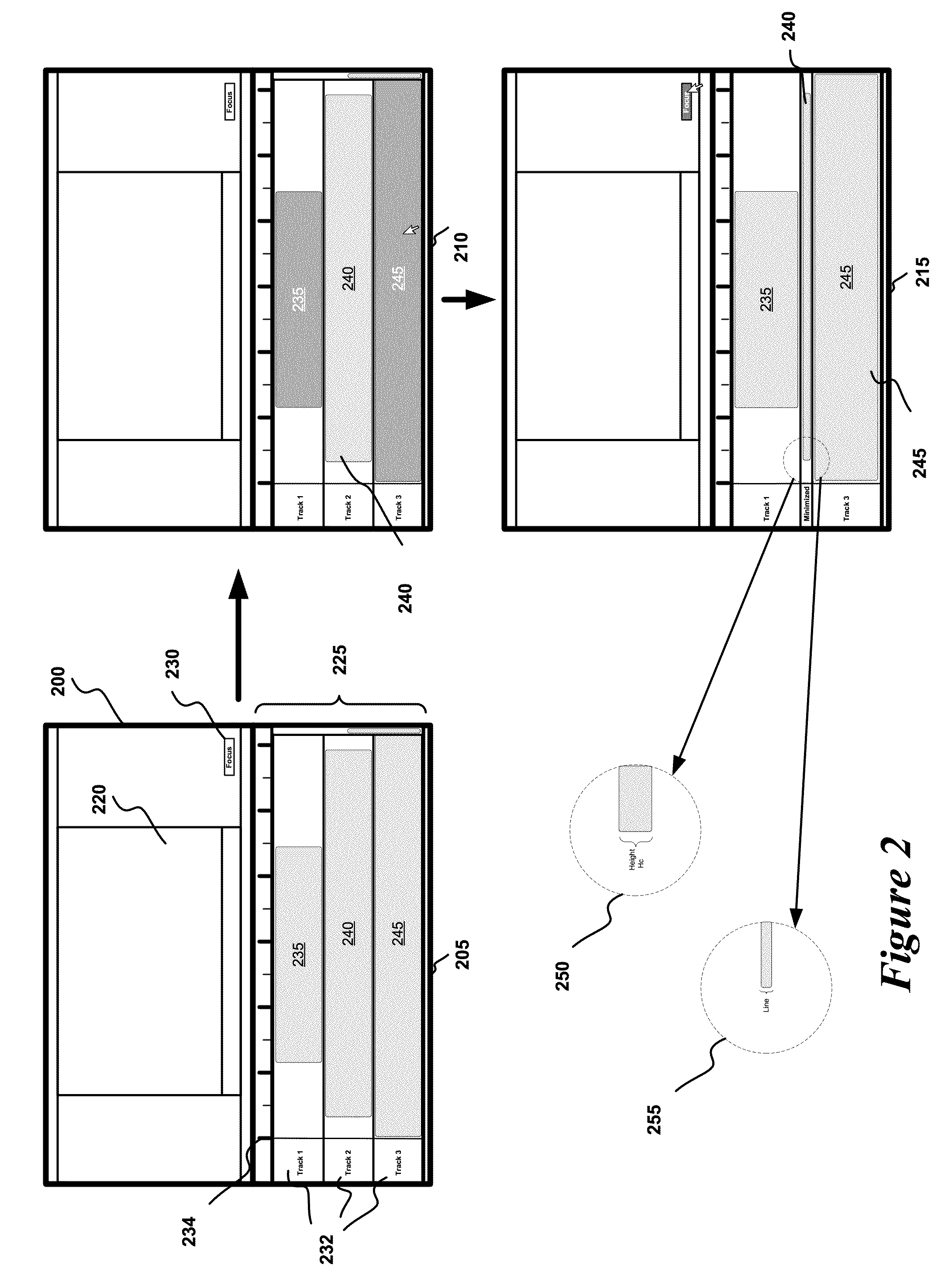

Media editing application with capability to focus on graphical composite elements in a media compositing area

ActiveUS20100281378A1Increase in sizeSmall sizeInput/output for user-computer interactionElectronic editing digitised analogue information signalsGraphicsComposite element

Some embodiments provide a media editing application that allows a user to focus on a subset of media clips that the application combines to create a composite presentation. The media editing application of some embodiments includes a display area for displaying the composite presentation that the application creates by compositing several media clips (e.g., audio clip, video clip). The multimedia editing application of some embodiments also includes a composite display area (e.g., an area with multiple tracks that span a timeline) for displaying graphical clips representations of media clips that are part of the composite presentation. To focus on a subset of clip representations in the composite display area, the application of some embodiments also includes a tool for causing a first emphasized subset of clip representations (also referred to as “in-focus clips”) to appear larger in the composite display area than a second de-emphasized subset of clip representations (also referred to as “out-of-focus clips”) that are being concurrently represented in the composite display area.

Owner:APPLE INC

Device and method for separating components of a fluid sample

A device and method is provided for separating heavier and lighter fractions of a fluid sample. The device includes a plurality of constituents comprising a container and a composite element in the container. The composite element is a separator comprising at least two components and more particularly an elastic portion and a plug member. A fluid sample is delivered to the container and the device is subjected to centrifugation whereby the centrifugal load causes the elastic portion of the separator to deform so that the separator migrates into the fluid sample and stabilizes between the heavier and lighter fractions of the fluid sample. The elastic portion of the separator will resiliently return to its initial configuration upon termination of the centrifugal load such that the elastic portion sealingly engages the container and separates the heavier and lighter fractions of the fluid sample.

Owner:BECTON DICKINSON & CO

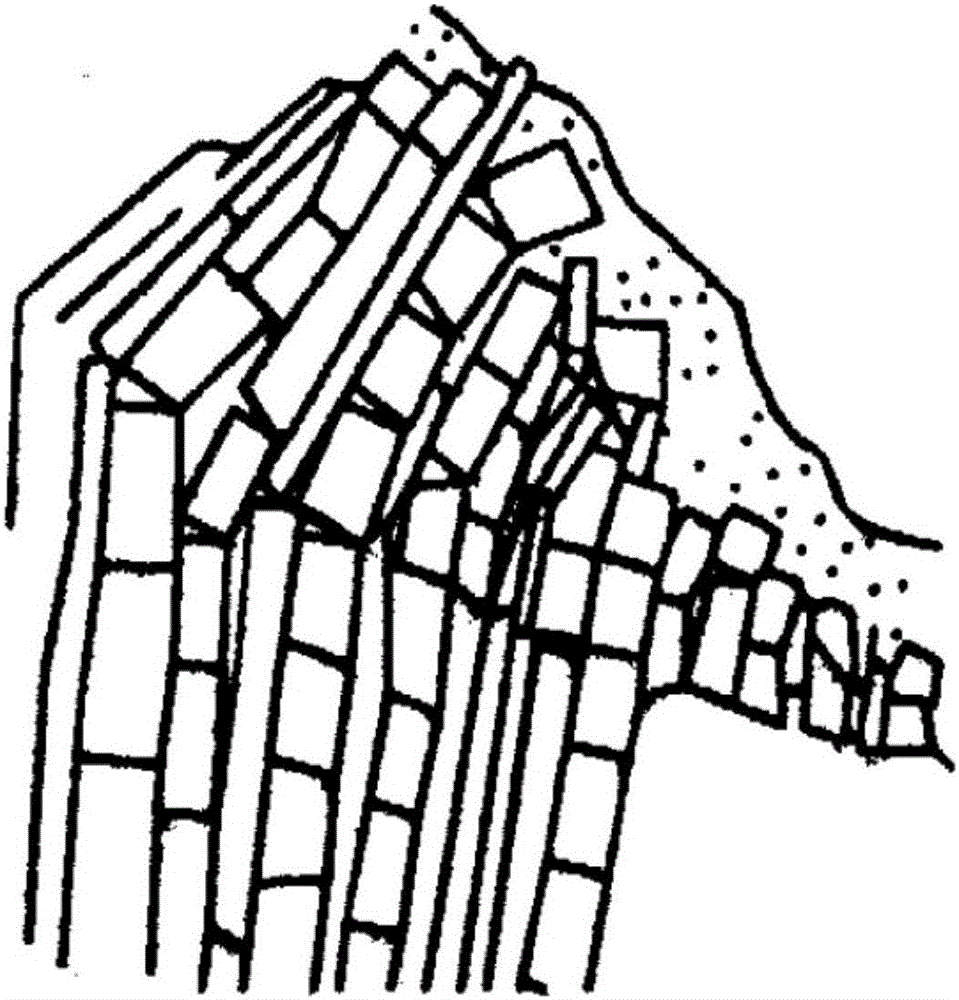

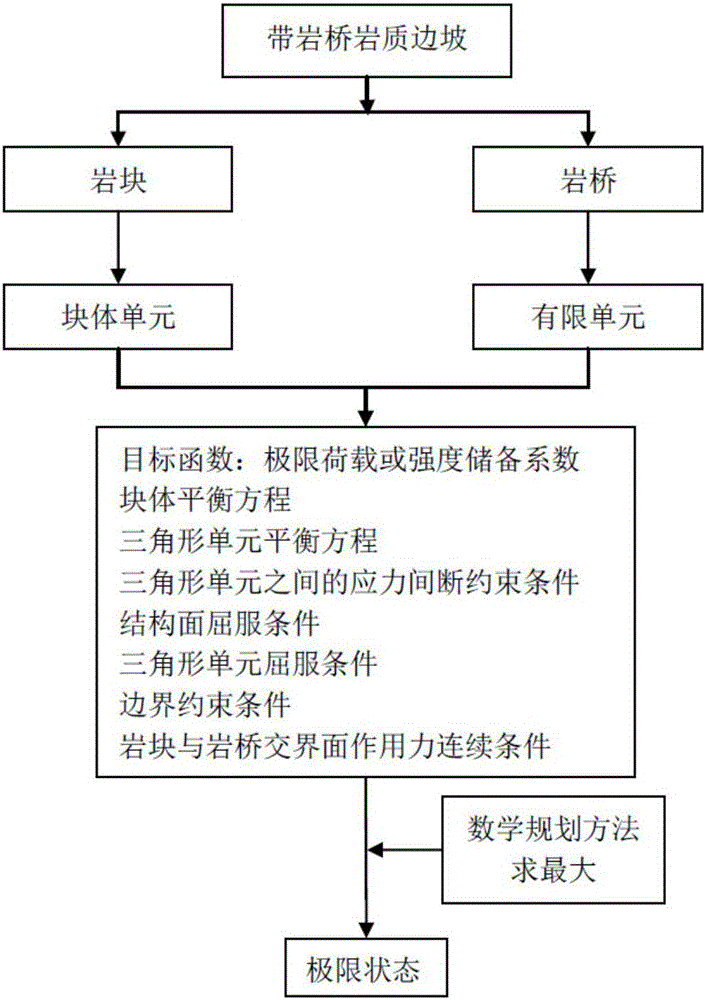

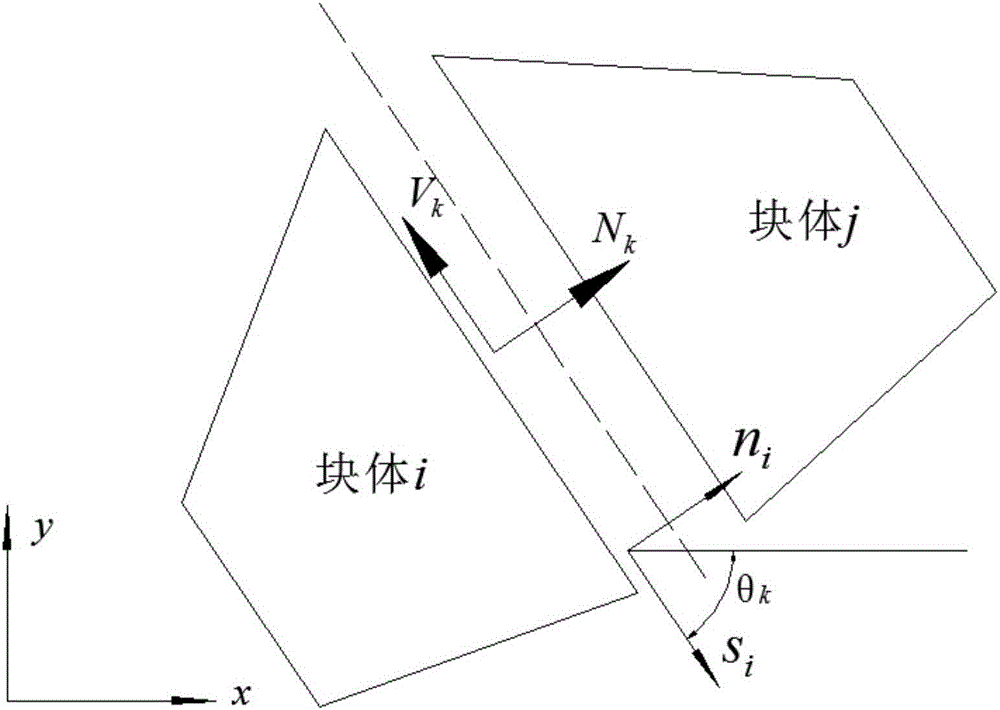

Plastic ultimate analysis lower limit method for ultimate bearing capacities of rock slopes with rock bridges

ActiveCN106126796AMethod concept is clearImprove calculation accuracyClimate change adaptationDesign optimisation/simulationLower limitSlope stability analysis

The invention relates to a calculation method for ultimate bearing capacities of rock slopes with rock bridges, and belongs to the field of rock slope stability analysis. The method comprises the following steps of: dispersing a rock slope with rock bridges by adoption of a composite element method on the basis of a theory of the plastic ultimate analysis lower limit method; establishing a nonlinear mathematic programming model for stability analysis of rock slopes with rock bridges by taking an ultimate load and a strength reserve coefficient of the rock slope as target functions; and solving maximum values of the ultimate load and the strength reserve coefficient by using a mathematic programming optimization algorithm. According to the method provided by the invention, the plastic ultimate analysis lower limit method, a composite element method dispersion technology and a mathematic programming measure are combined to establish a rock slope ultimate bearing capacity solution method which not only can simulate the continuous media characteristics of the rock bridges, but also can simulate the non-continuous media characteristics of rock blocks. The method provided by the invention has the characteristics of being clear in concept and high in calculation precision, and can be applied to the analysis of bearing capacities of the rock bridges in rock slopes.

Owner:KUNMING UNIV OF SCI & TECH

Formable composite films of plastic and composite elements of plastic coated with soft touch coating, and the production thereof

InactiveUS20060078745A1Synthetic resin layered productsPolyurea/polyurethane coatingsComposite filmComposite element

The present invention relates to composite plastic moldings containing A) a thermoplastically formable, heat-resistant composite film having A1) a carrier film of a thermoplastic resin and A2) a layer of a heat-resistant soft touch coating on one side of the carrier film (A1) and B) a thermoplastic layer on the side of the carrier film (A1) facing away from the soft touch coating, wherein the soft touch coating (A2) is obtained from a composition containing i) polyurethanes and / or polyurethane-ureas which are free from hydroxyl and / or amine groups, ii) ionically modified polyurethanes and / or polyurethane-ureas which contain hydroxyl and / or amine groups, iii) at least one crosslinking agent, iv) optionally film-forming resins other than A1) or A2), and v) optionally additives. The present invention also relates to a process for the production of these composite moldings and their use in telecommunications equipment and in vehicle, ship and aircraft construction.

Owner:BAYER MATERIALSCIENCE AG

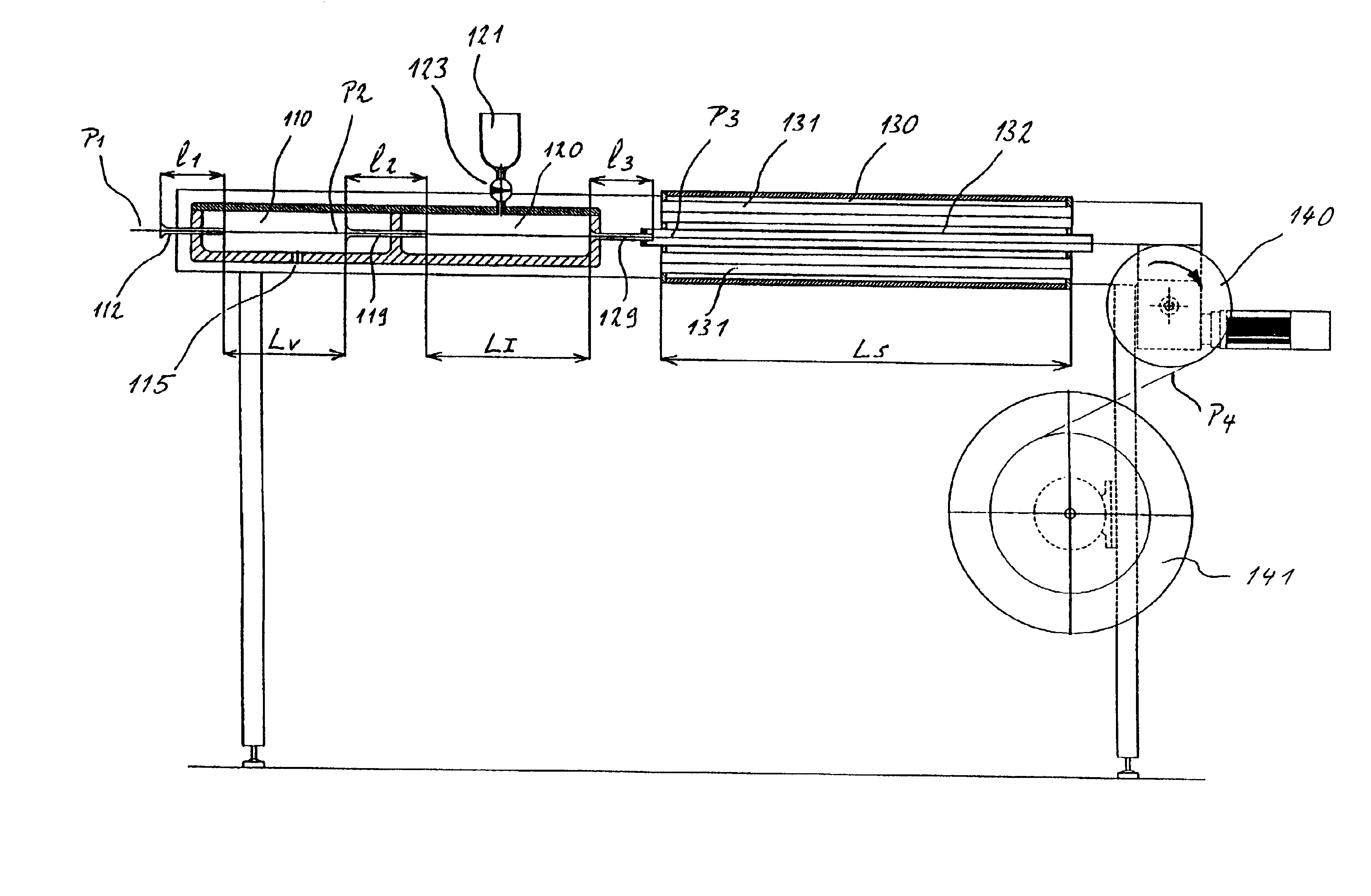

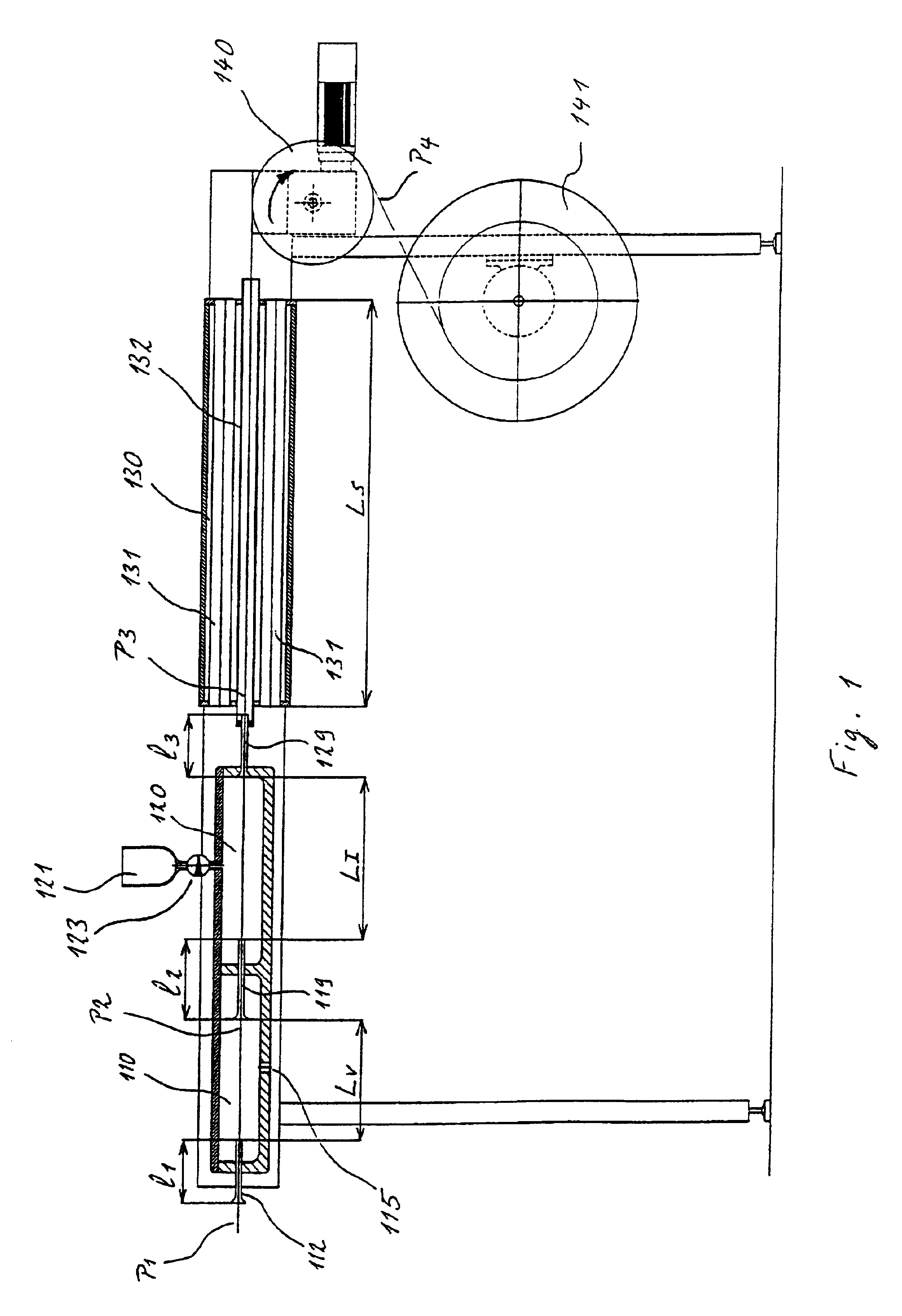

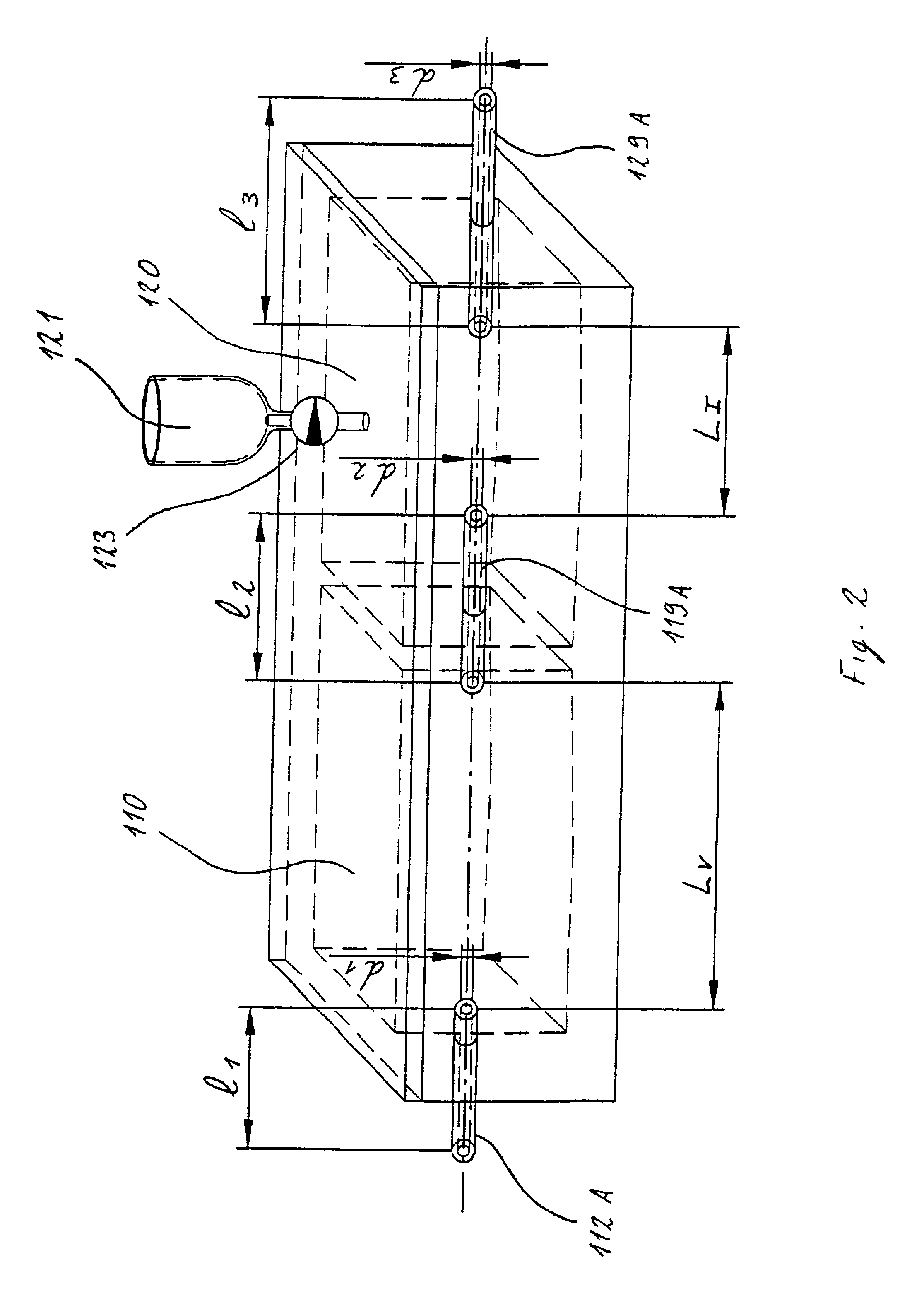

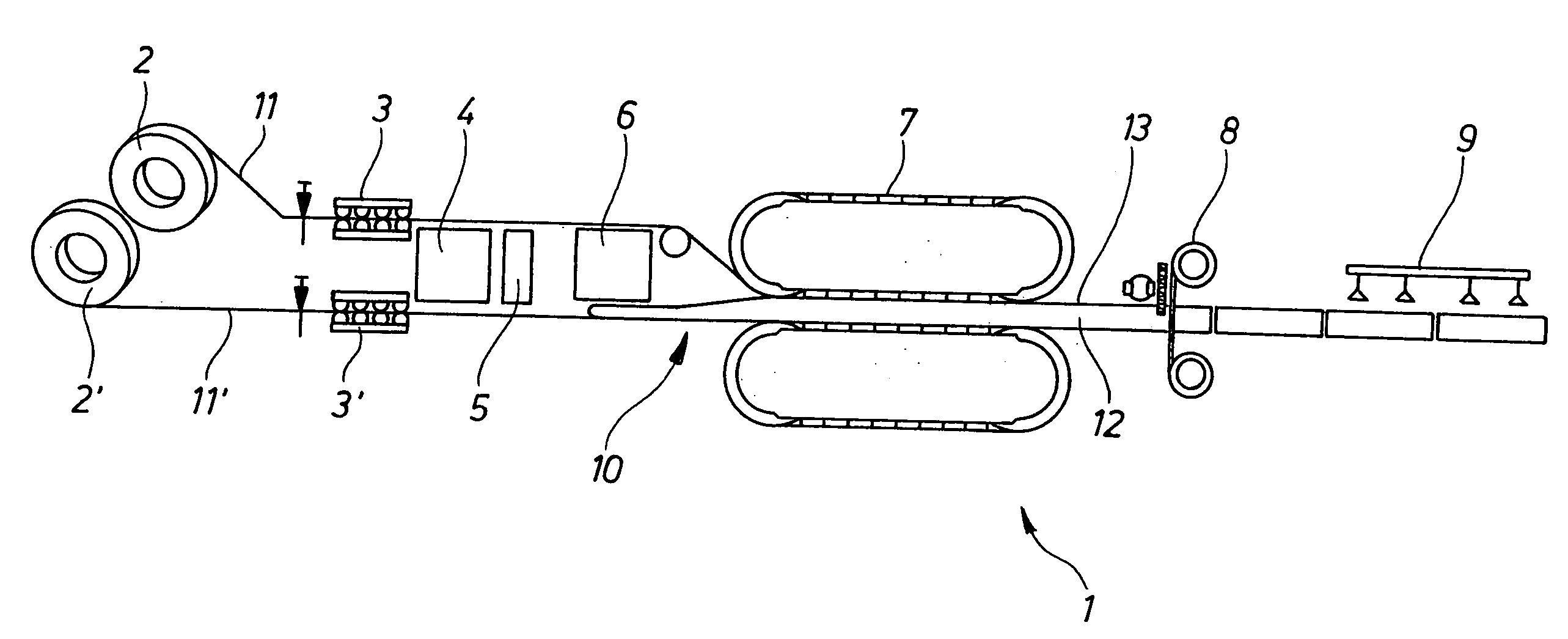

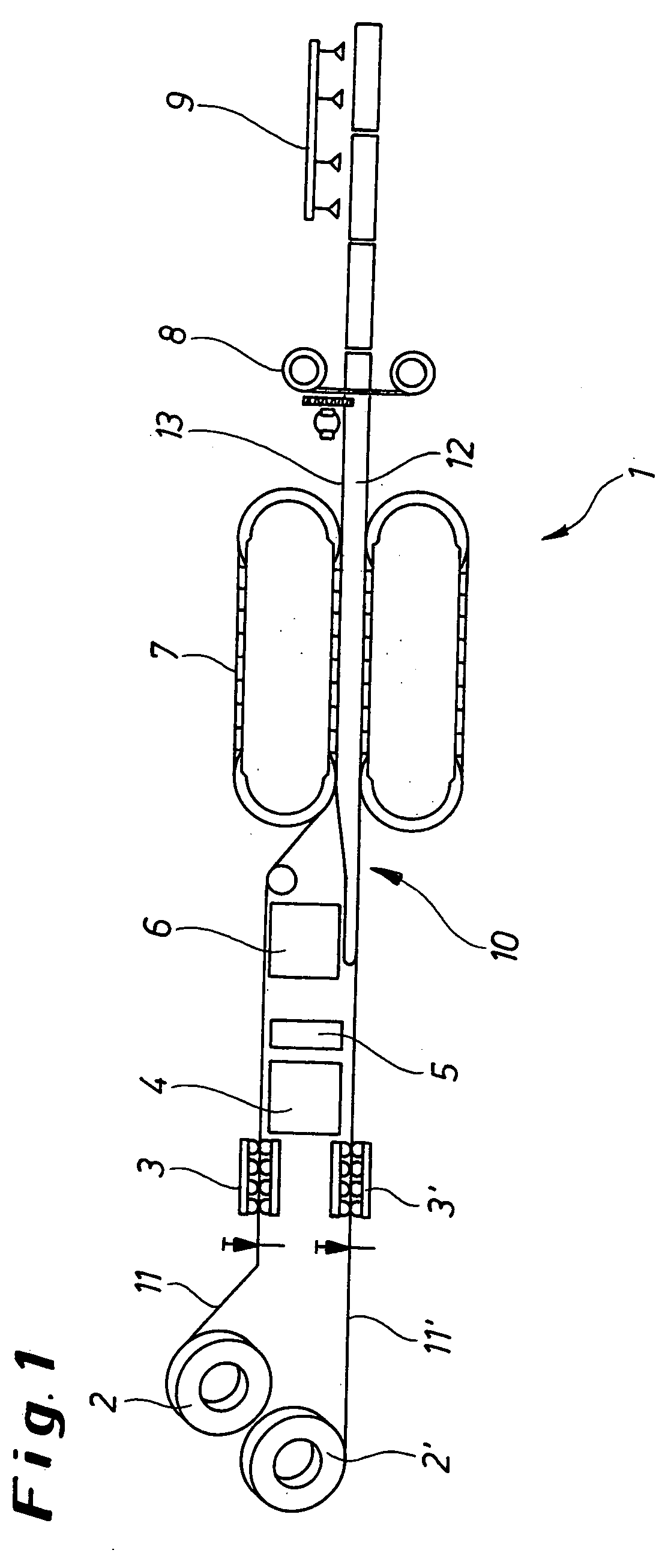

Continuous impregnation of long fibers with resin for manufacturing elongate composite elements

InactiveUS6926853B2Improve productivityPrevent outflowTailstocks/centresElectric discharge tubesFiberRigid wall

An apparatus for manufacturing an elongate composite element in undefined lengths, the composite element containing reinforcement fibers embedded in a matrix based on a composition containing a curable resin, including a vacuum chamber, rigid-walled inlet tubing, an impregnation chamber, rigid-walled transfer tubing between the vacuum chamber and the impregnation chamber, a sizing die and, downstream of the sizing die, irradiation tubes providing radiation in the ultraviolet-visible spectrum to prepolymerize the resin.

Owner:CONCEPTION & DEV MICHELIN SA

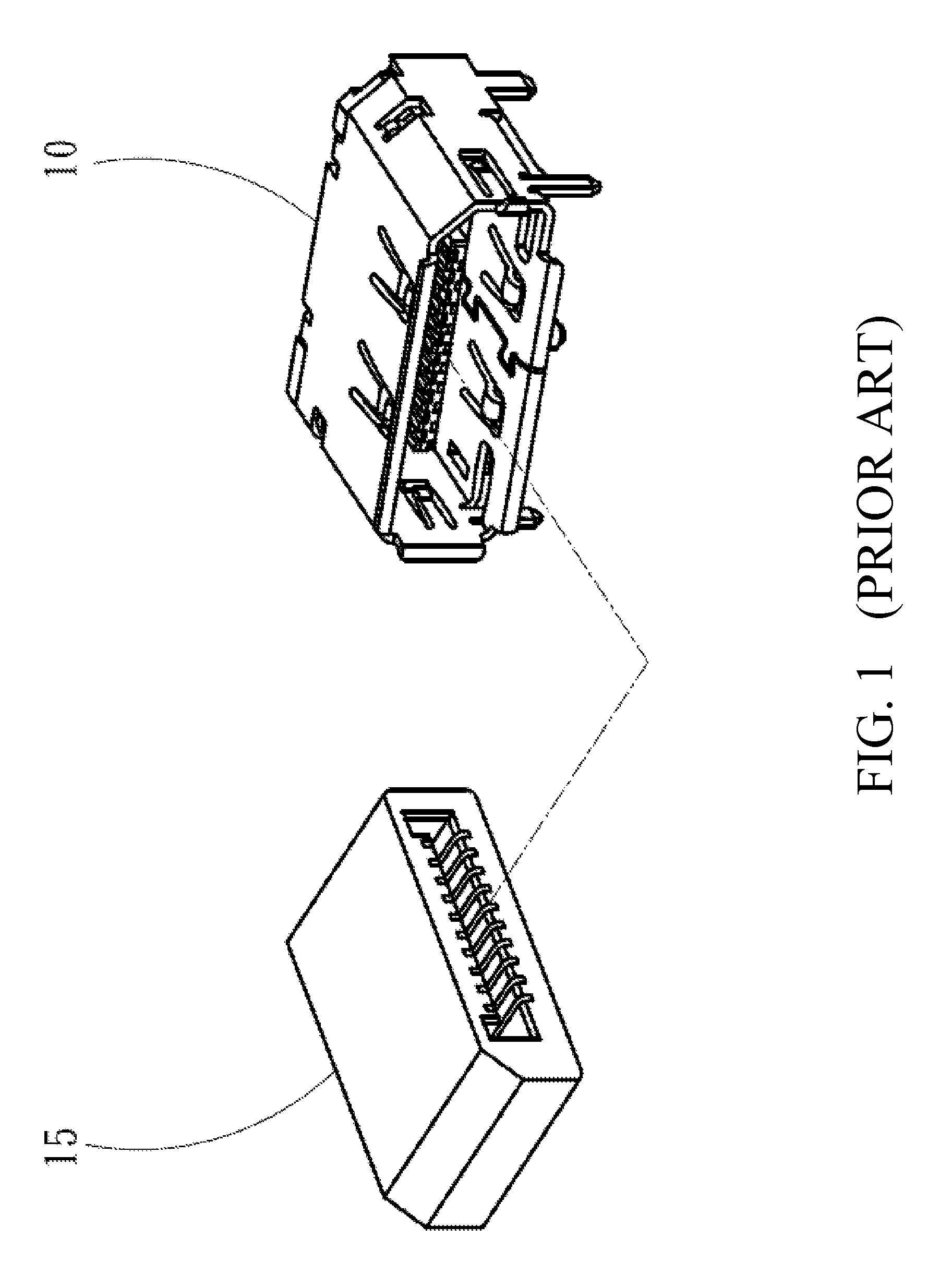

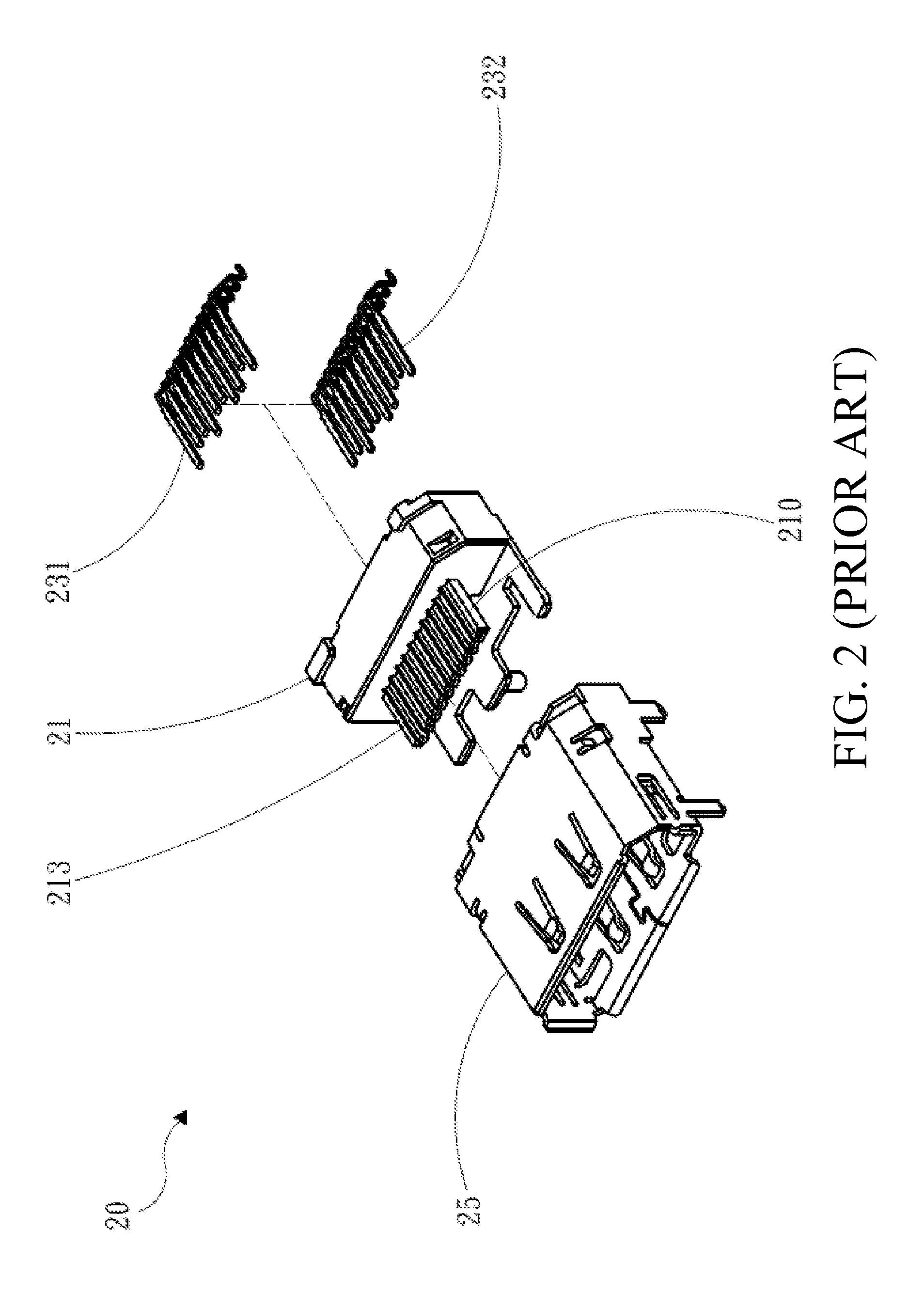

Display port socket

InactiveUS7845982B1Cover tightlyStable positionTwo-part coupling devicesFixed connectionsCouplingComposite element

A DisplayPort socket includes a first composite element and a second composite element. The first composite element includes a first insulating body partially and tightly covering plural terminals so that the terminals are exposed on a plate of the first insulating body and form plural conduction zones. The second composite element includes a second insulating body partially and tightly covering plural terminals so that the terminals are exposed on a plate of the second insulating body and form plural conduction zones. The plates of the first and second composite elements are stacked flat on each other to form a coupling plate for coupling buttingly with a DisplayPort connector. By integrating the first and second insulating bodies with their corresponding terminals to form the first and second composite elements and then assembling the first and second composite elements together, the terminals are securely positioned, thus increasing the reliability of the socket.

Owner:COMPUPACK TECH

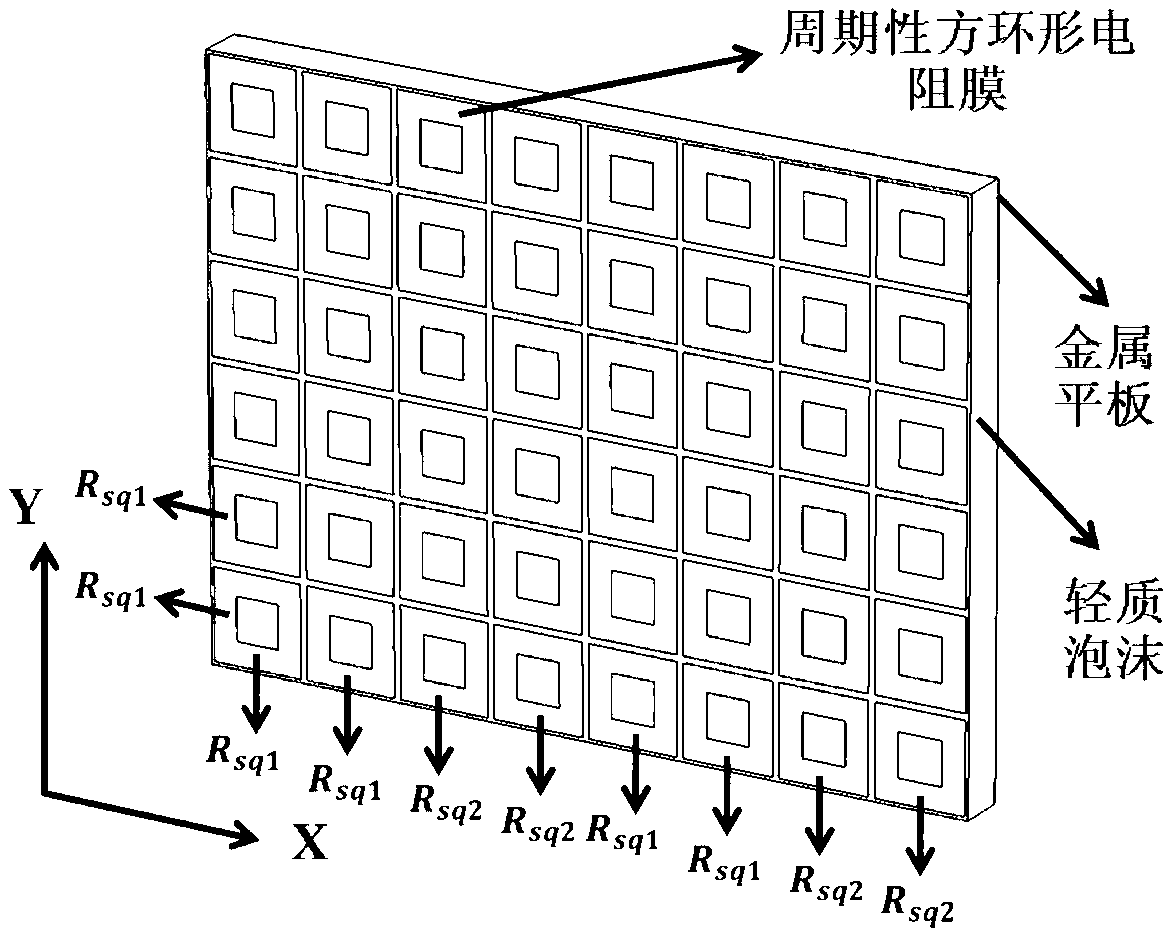

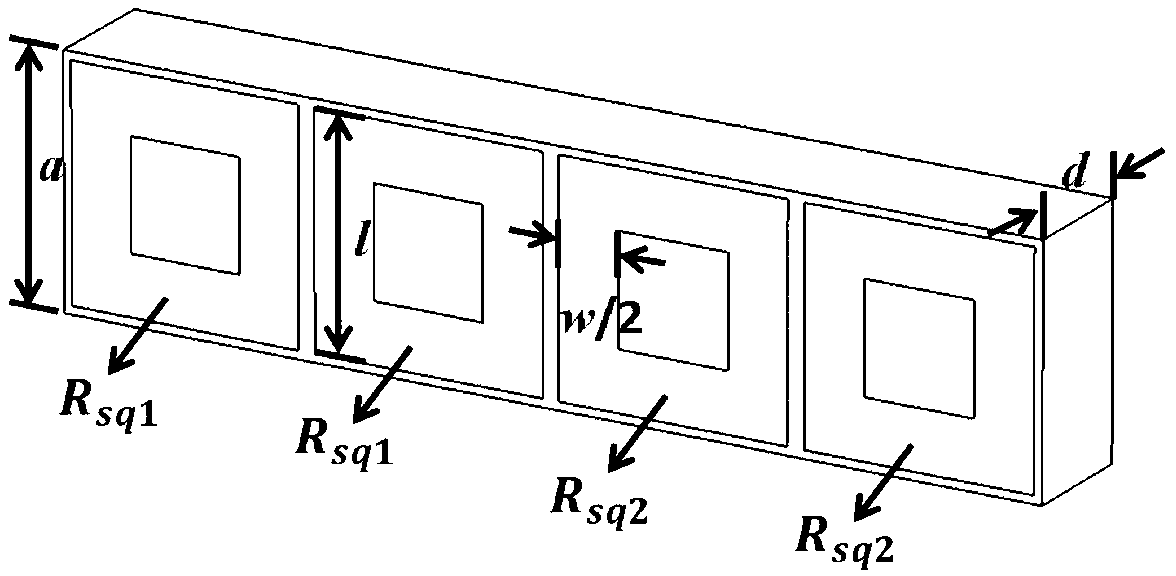

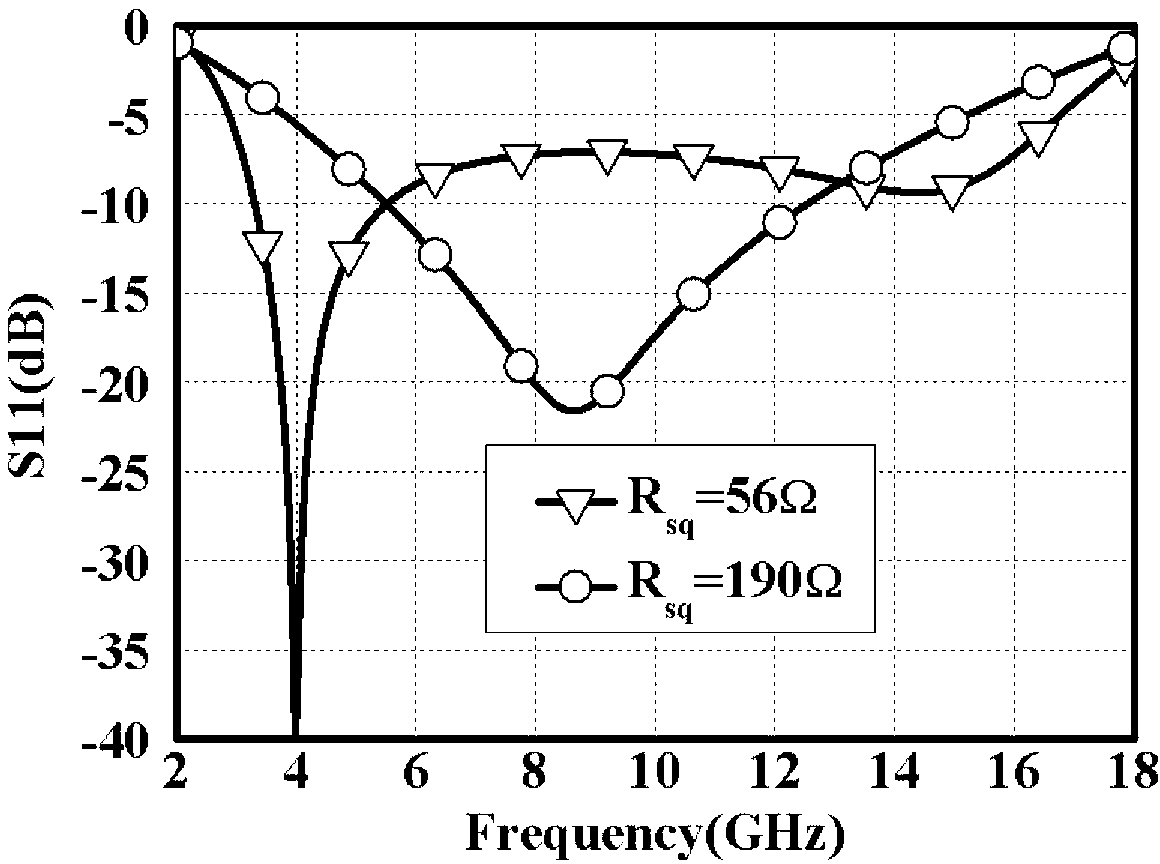

Single-layered composite element wideband periodic wave-absorbing structure

InactiveCN103249290AStructural absorbing performance controllable adjustmentTo achieve the effect of broadband absorptionMagnetic/electric field screeningEngineeringWide band

The invention discloses a single-layered composite element wideband periodic wave-absorbing structure, and belongs to the technical field of electronic materials. According to the invention, a dielectric layer printed with periodic array resistance patterns is arranged on a metal flat plate, the dielectric layer comprises a foam layer and periodic square ring-shaped resistive films arranged on the foam layer, and the periodic square ring-shaped resistive films consist of two kinds of resistive films of different sheet resistances.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Catalytic cracking auxiliary agent for increasing heavy oil conversion performance and preparation method thereof

The invention provides a catalytic cracking additive for improving the transformation ability of heavy oil and the preparation method. The catalytic cracking additive is produced by spray shaping, roasting, in-situ crystallization and composite elements modification after natural sepiolite is mixed with natural kaolinite mineral or with one or two roasting kaolinite mineral. Provided with high activity, high heavy metal resistance and good selectivity in cracking reaction, the additive can improve the transformation ability of heavy oil and reduce the olefin content and increase gasoline octane number.

Owner:姚华

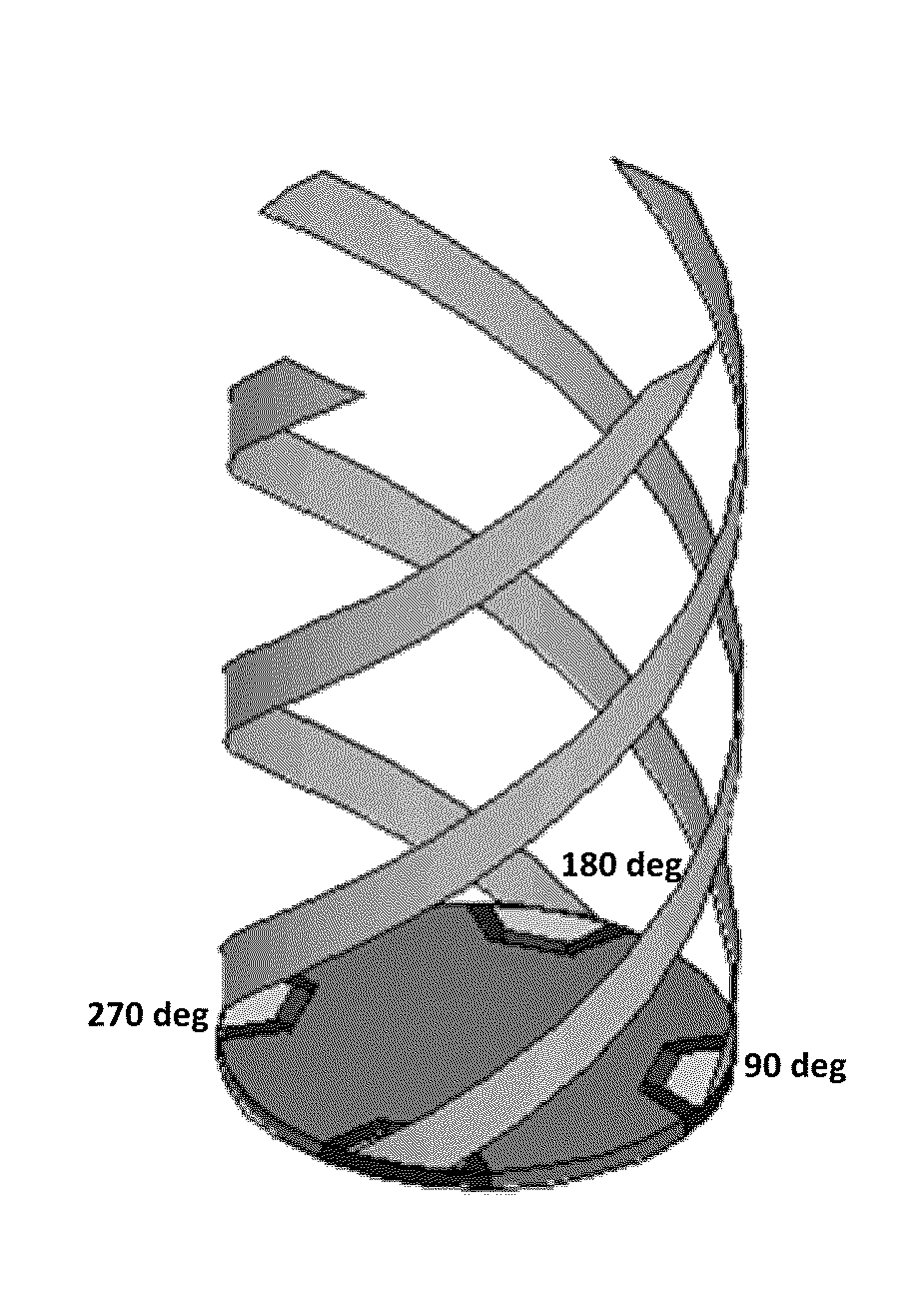

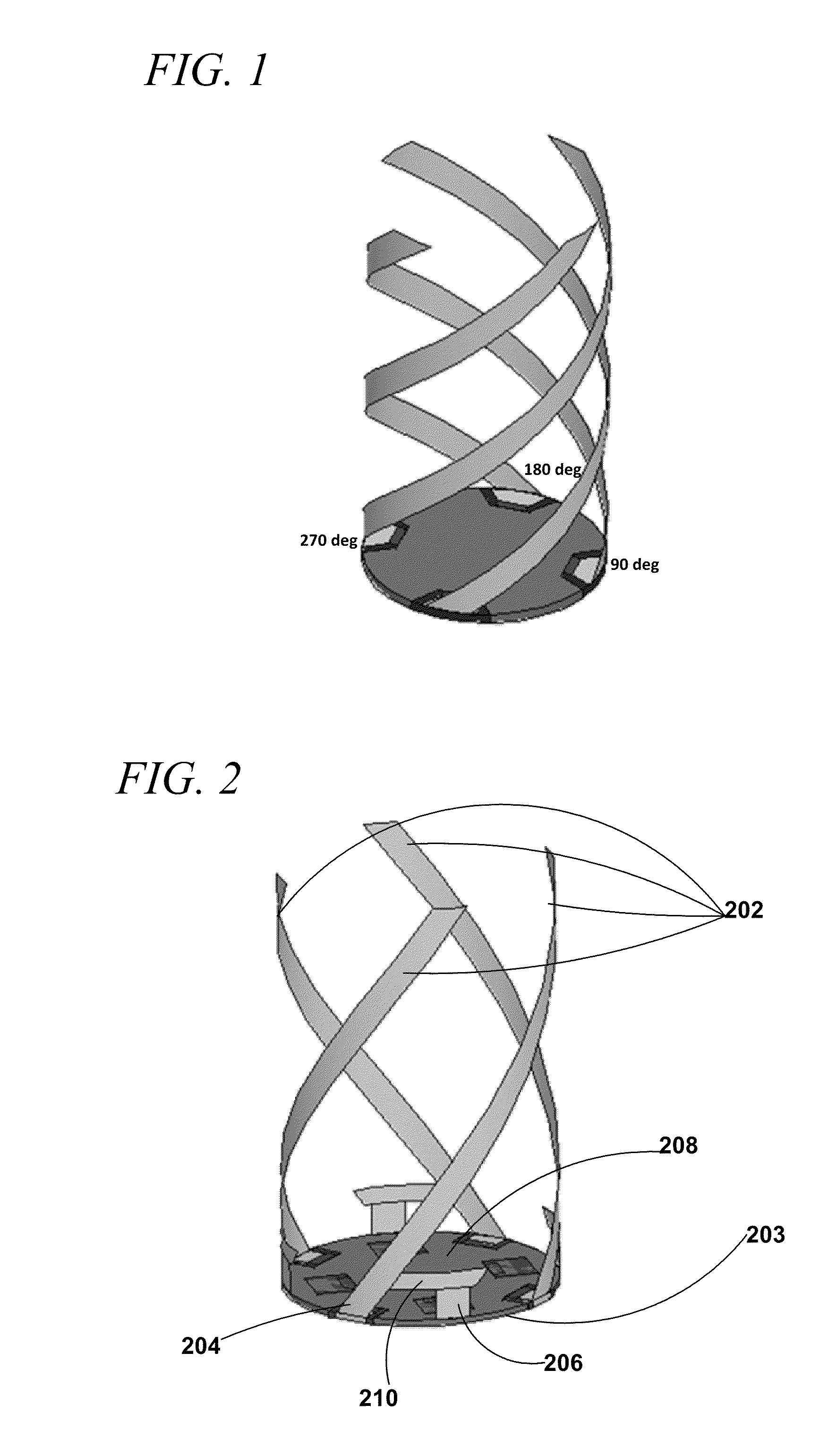

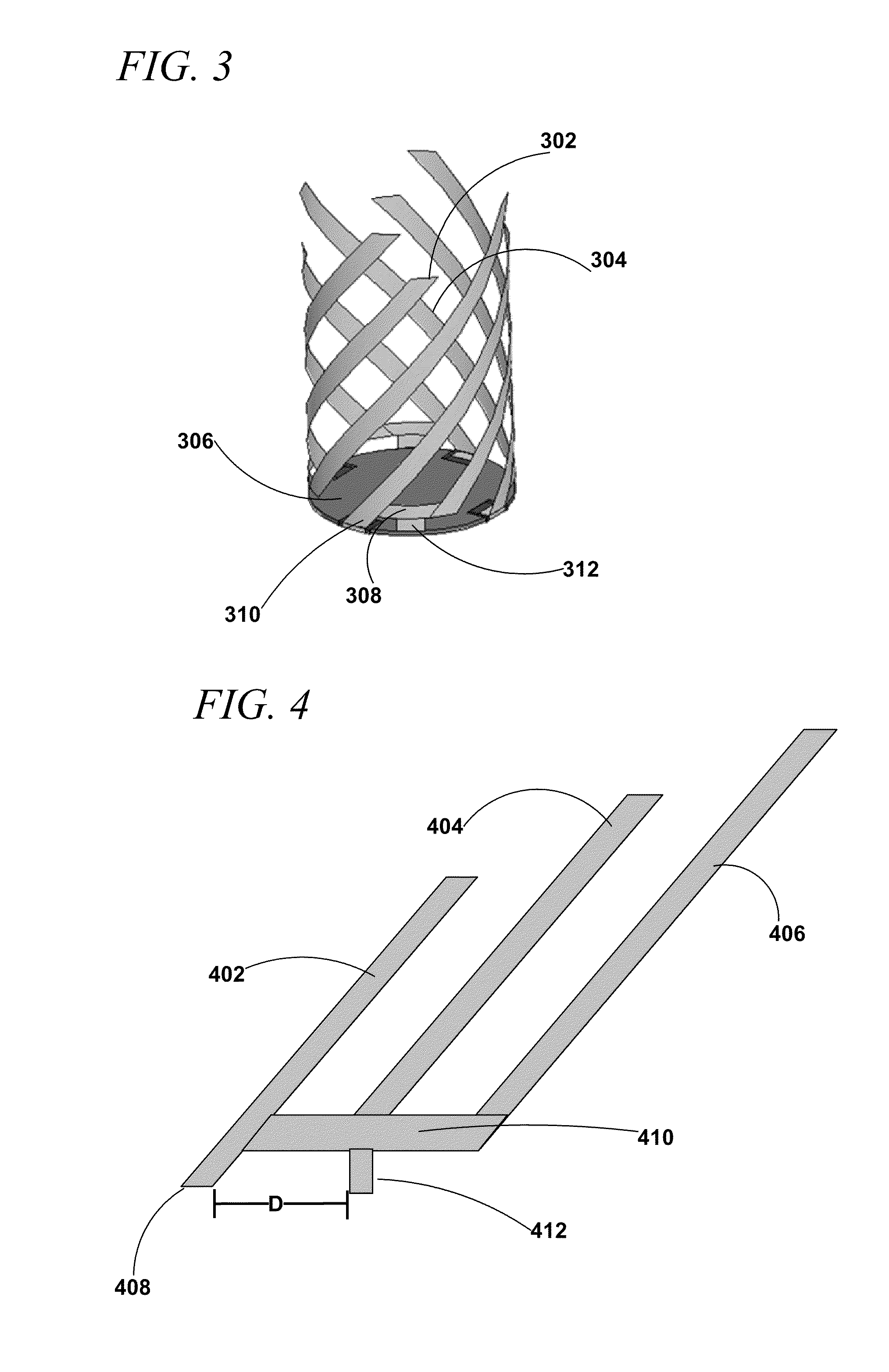

Multiband multifilar antenna

Multi-band quadrifilar antennas that are suitable for satellite communication include composite elements each of which include multiple conductors operating at different frequencies connected to a bus bar. Each composite element is coupled to a signal feed and to a ground structure.

Owner:MAXTENA

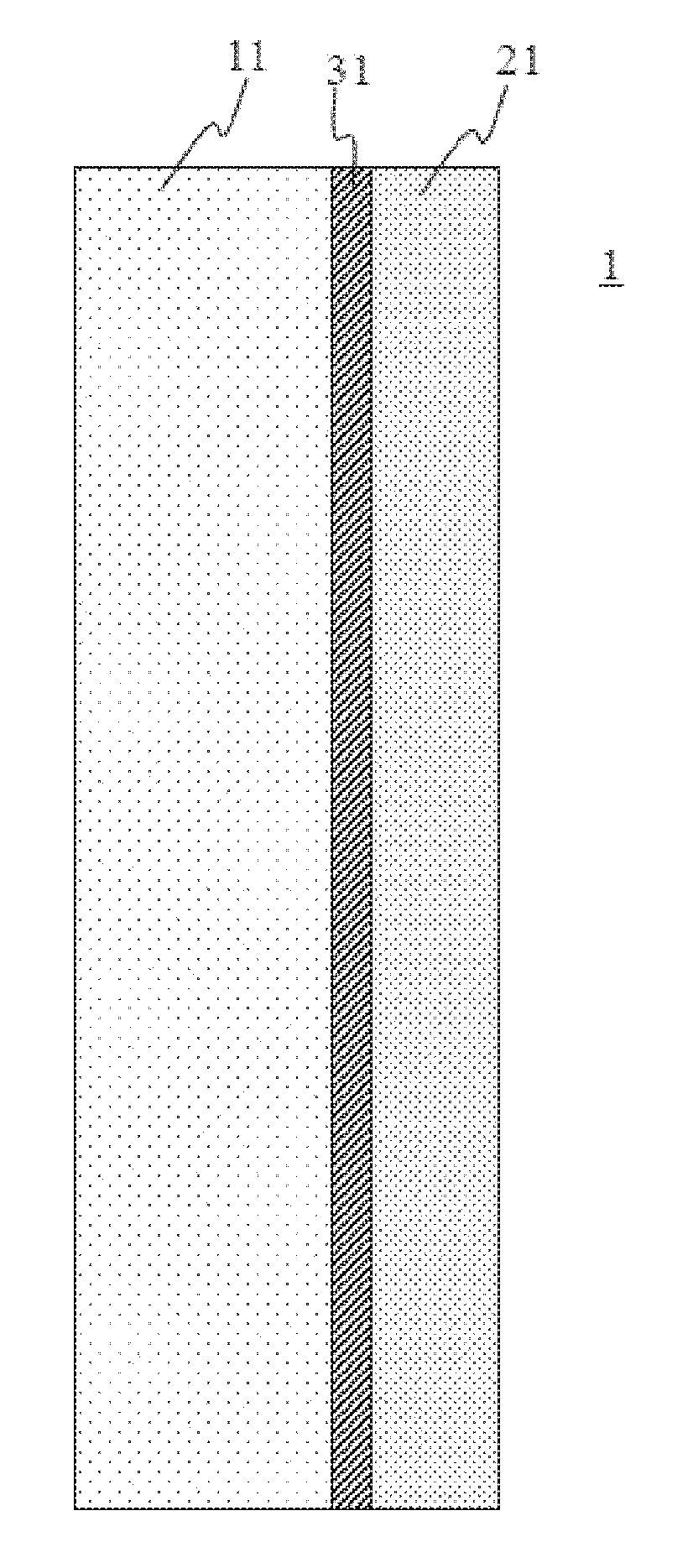

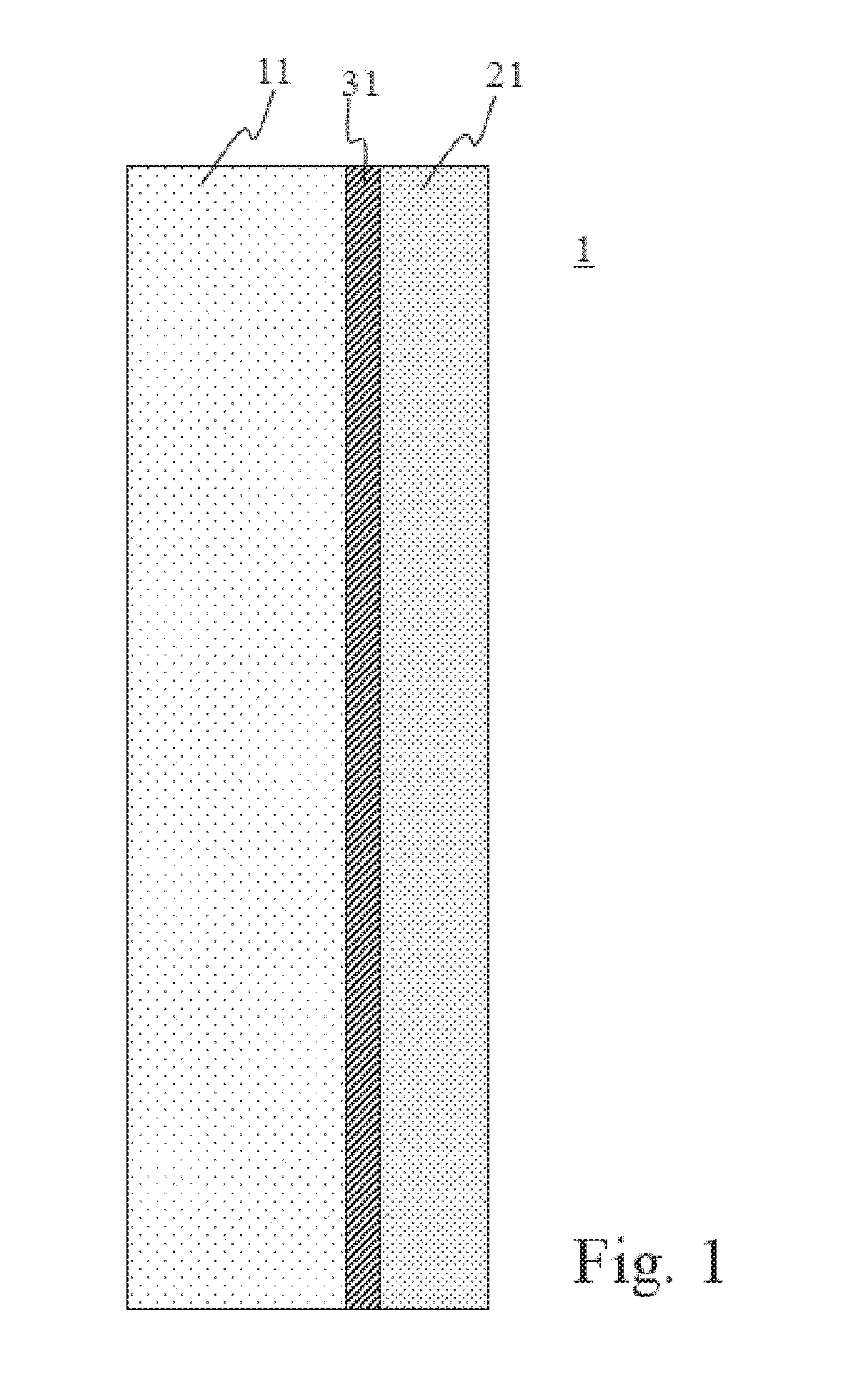

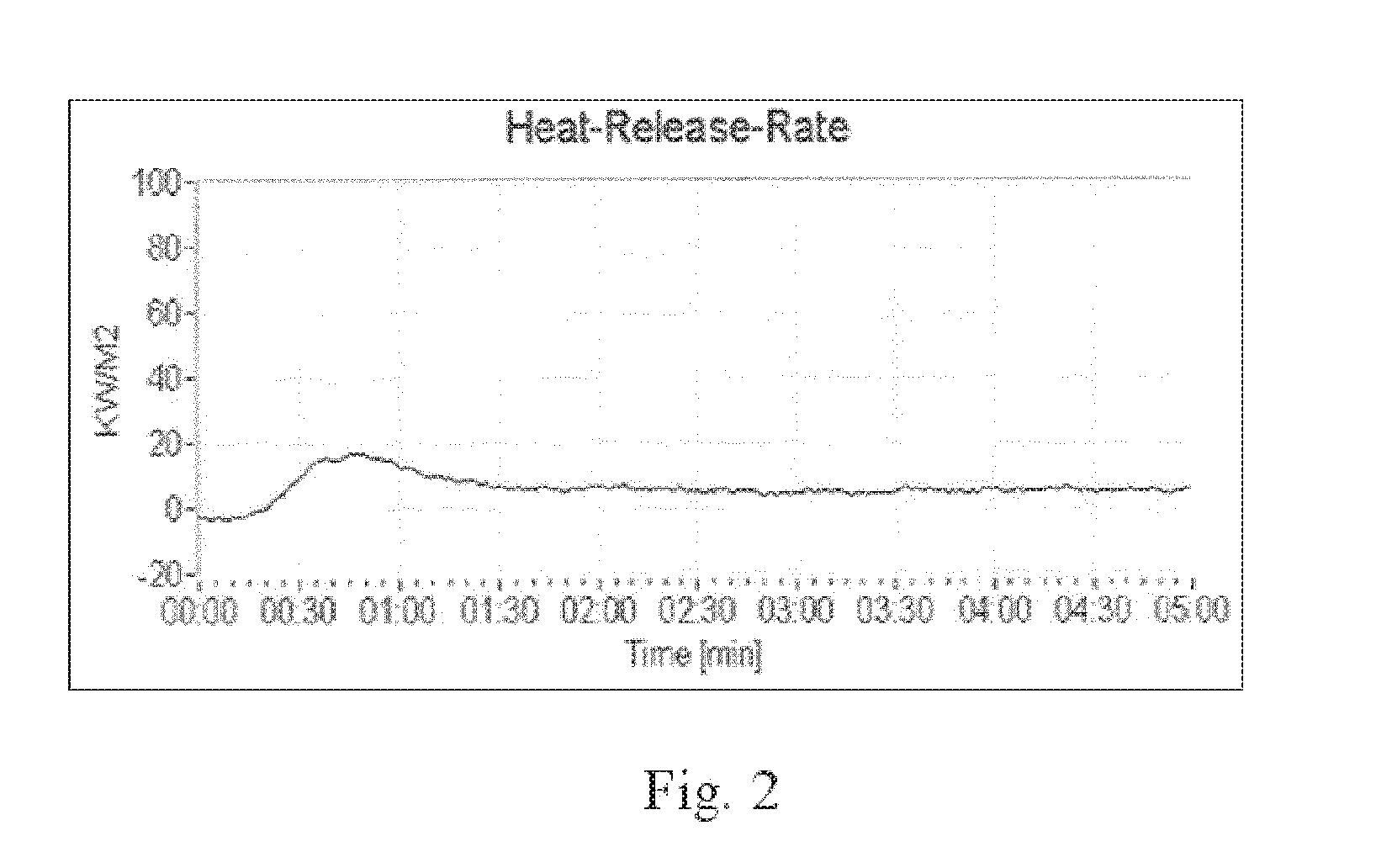

Composite Element and Use Thereof

InactiveUS20160136929A1Avoid spreadingAvoid transmissionLamination ancillary operationsLayered product treatmentOrganic layerBunsen burner

A lightweight composite panel is provided that includes at least one mineral glass or glass-ceramic panel and at least one organic layer. The weight per unit area of the lightweight composite panel is in the range from 0.5 kg / m2 to 5.5 kg / m2, the ratio of the total thickness of the one or more mineral glass or glass-ceramic panels to the total thickness of all of the organic layers is from 1:0.01 to 1:1 and the total thickness of all of the organic layers is less than or equal to 350 μm. The lightweight composite panel complies with the thermal safety requirements of the air travel authorities and its “Total Heat Release,” measured in accordance with JAR / FAR / CS 25, App. F, Part IV & AITM 2.0006, is less than 65 kW×min / m2 and its flame time after removal of the flame in the “Vertical Bunsen Burner Test”, measured in accordance with FAR / JAR / CS 25, App. F, Part 1 & AITM 2.0002A, is less than 15 s.

Owner:SCHOTT AG

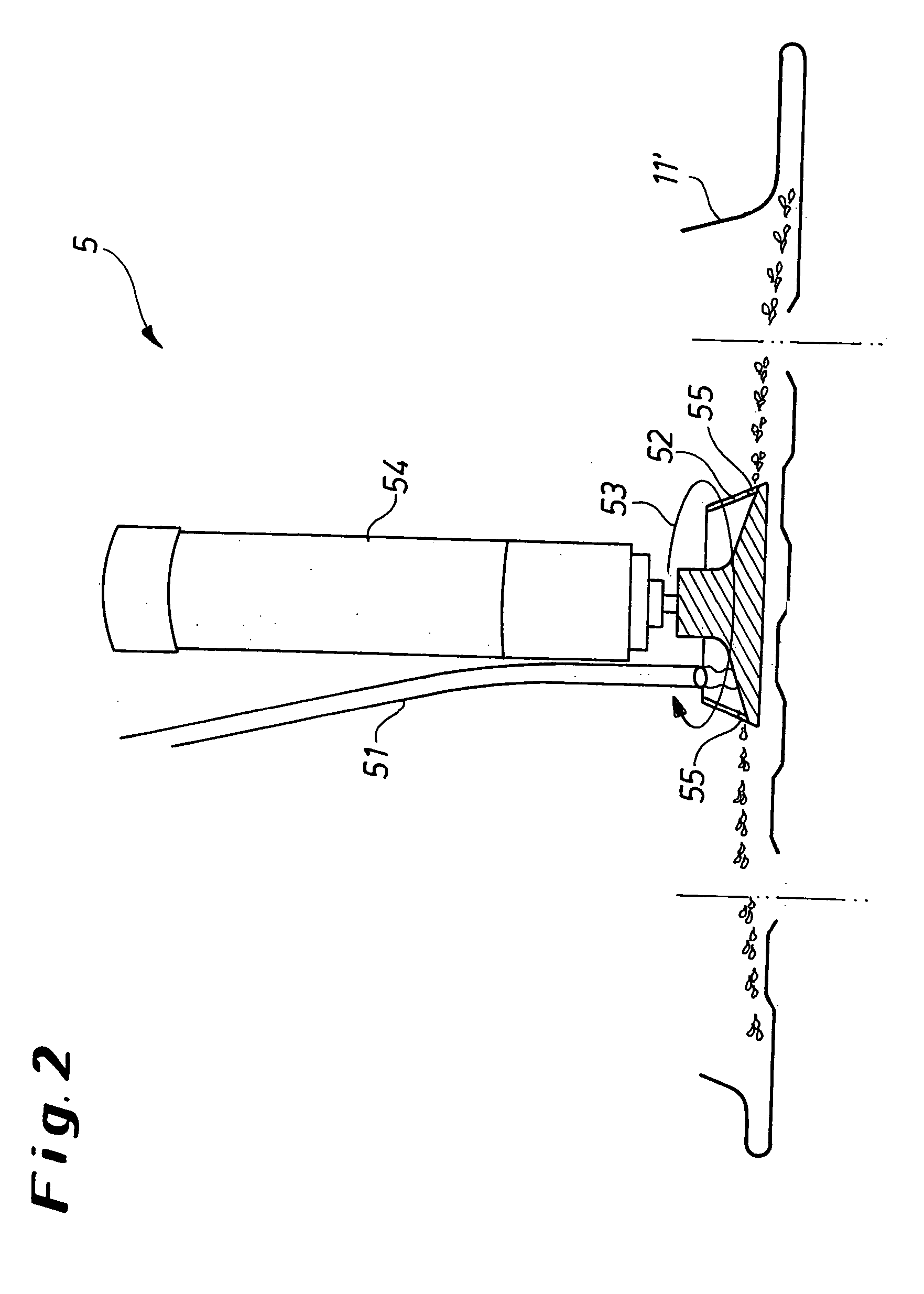

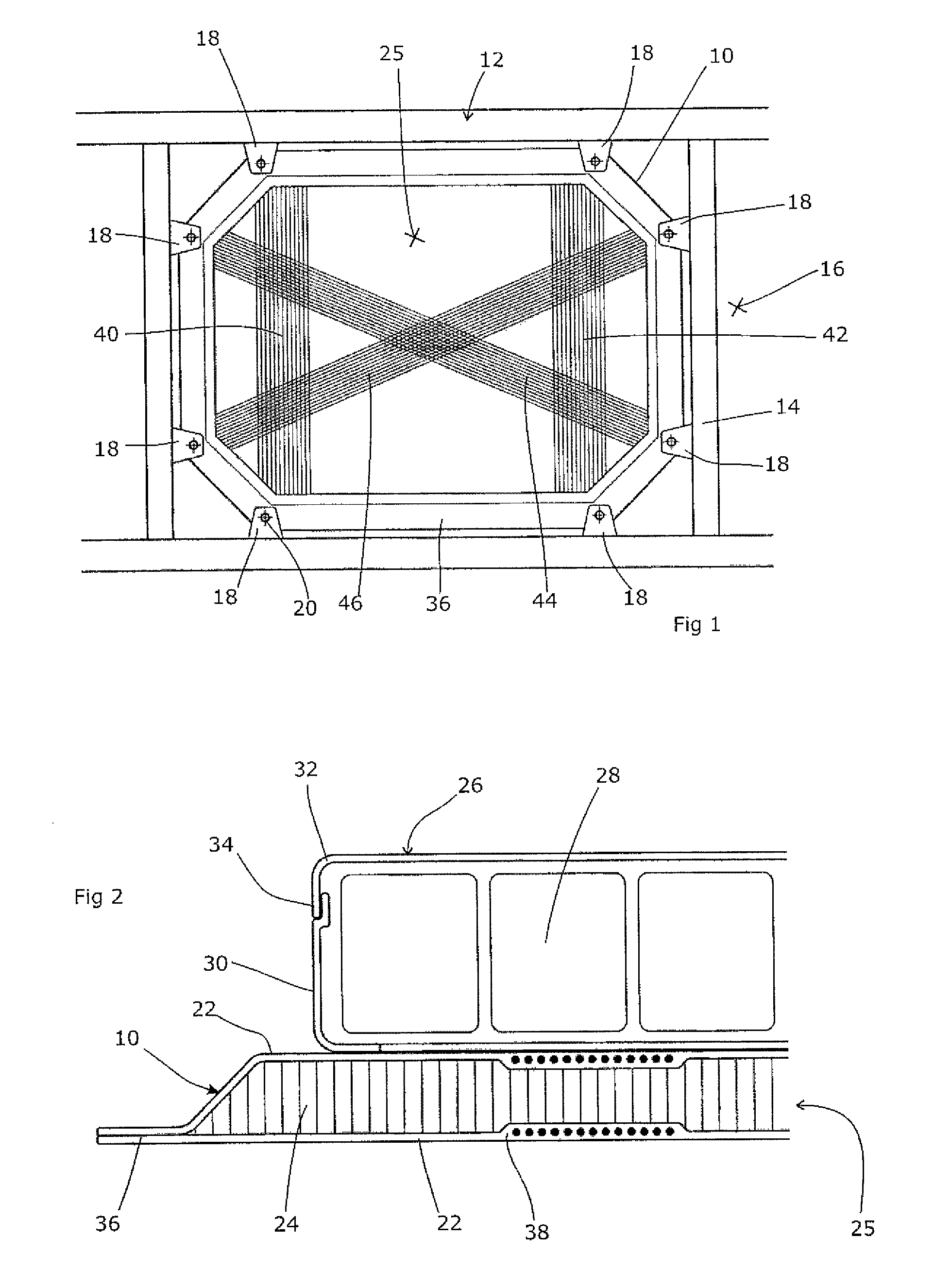

Apparatus and process for the production of sandwich composite elements

ActiveUS20050257893A1Avoid disadvantagesLiquid surface applicatorsLamination ancillary operationsLine tubingComposite element

An apparatus for the production of sandwich composite elements which includes at least two feed apparatus for facings, to which an application apparatus for an adhesion promoter, an application apparatus for a core layer, a conveying apparatus and a cutting apparatus are connected one after the other. The application apparatus for the adhesion promoter includes at least one feed line for the adhesion promoter, a rotary table with at least one lateral outlet orifice and a drive for the rotary table.

Owner:COVESTRO DEUTSCHLAND AG

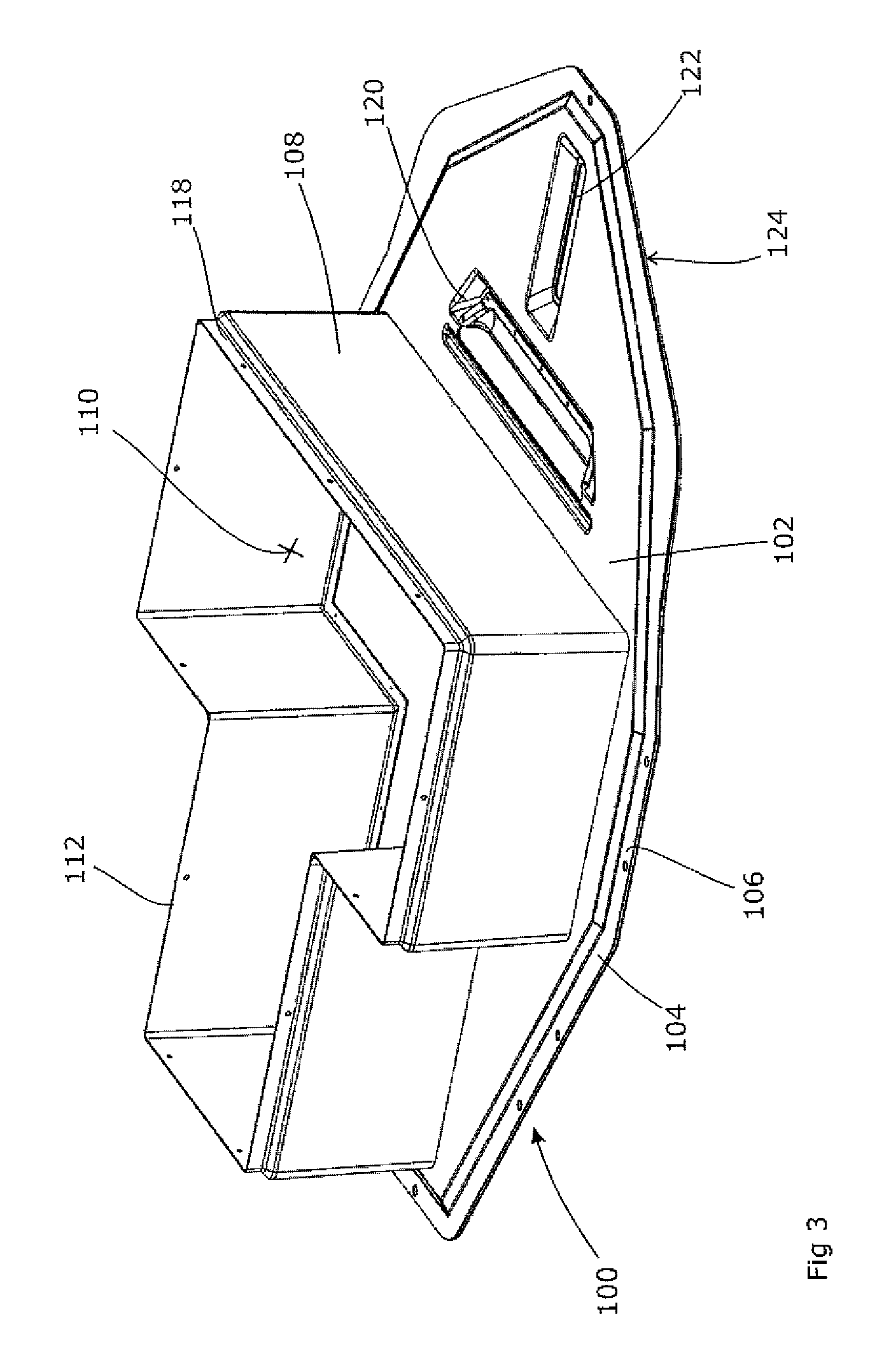

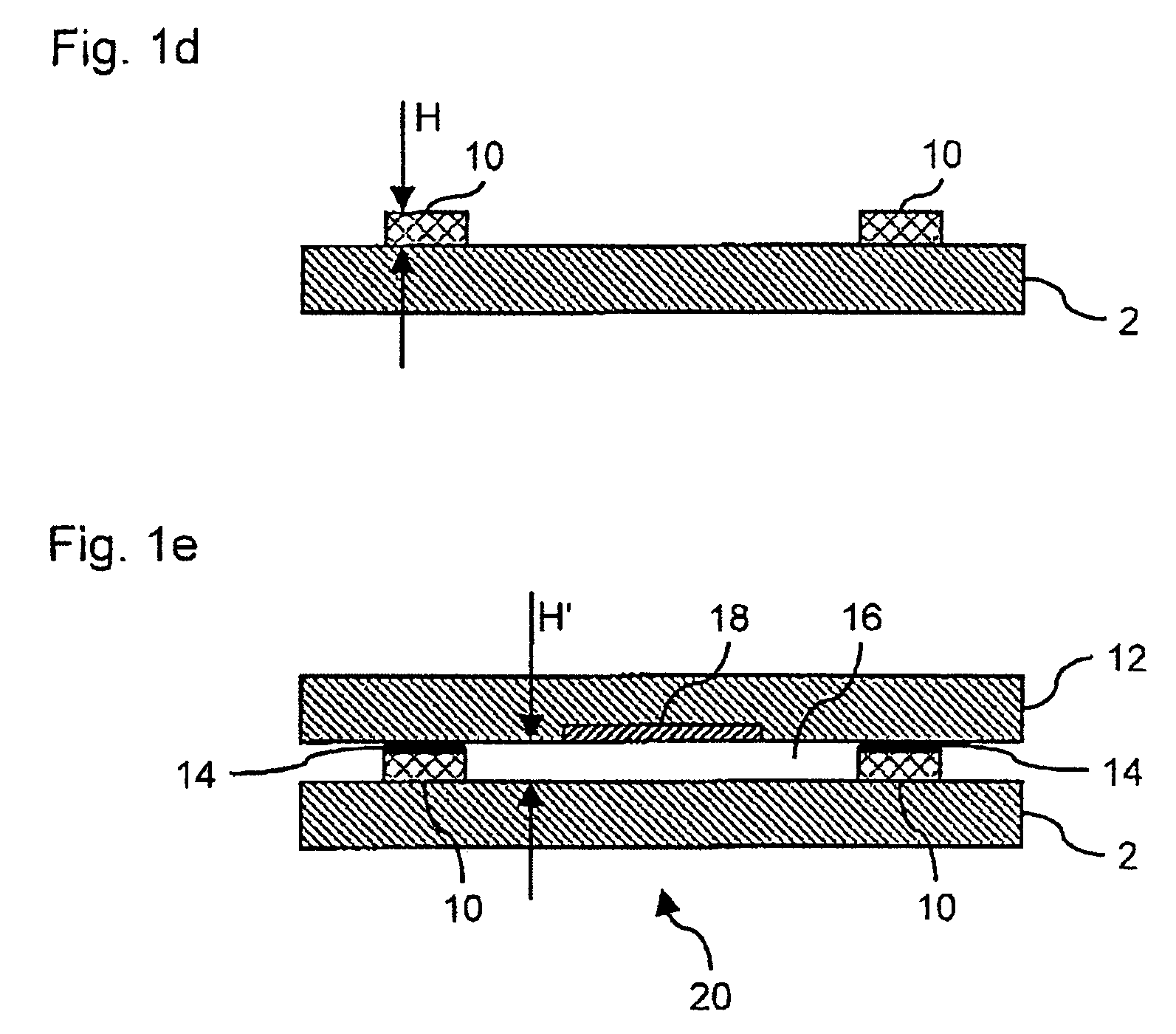

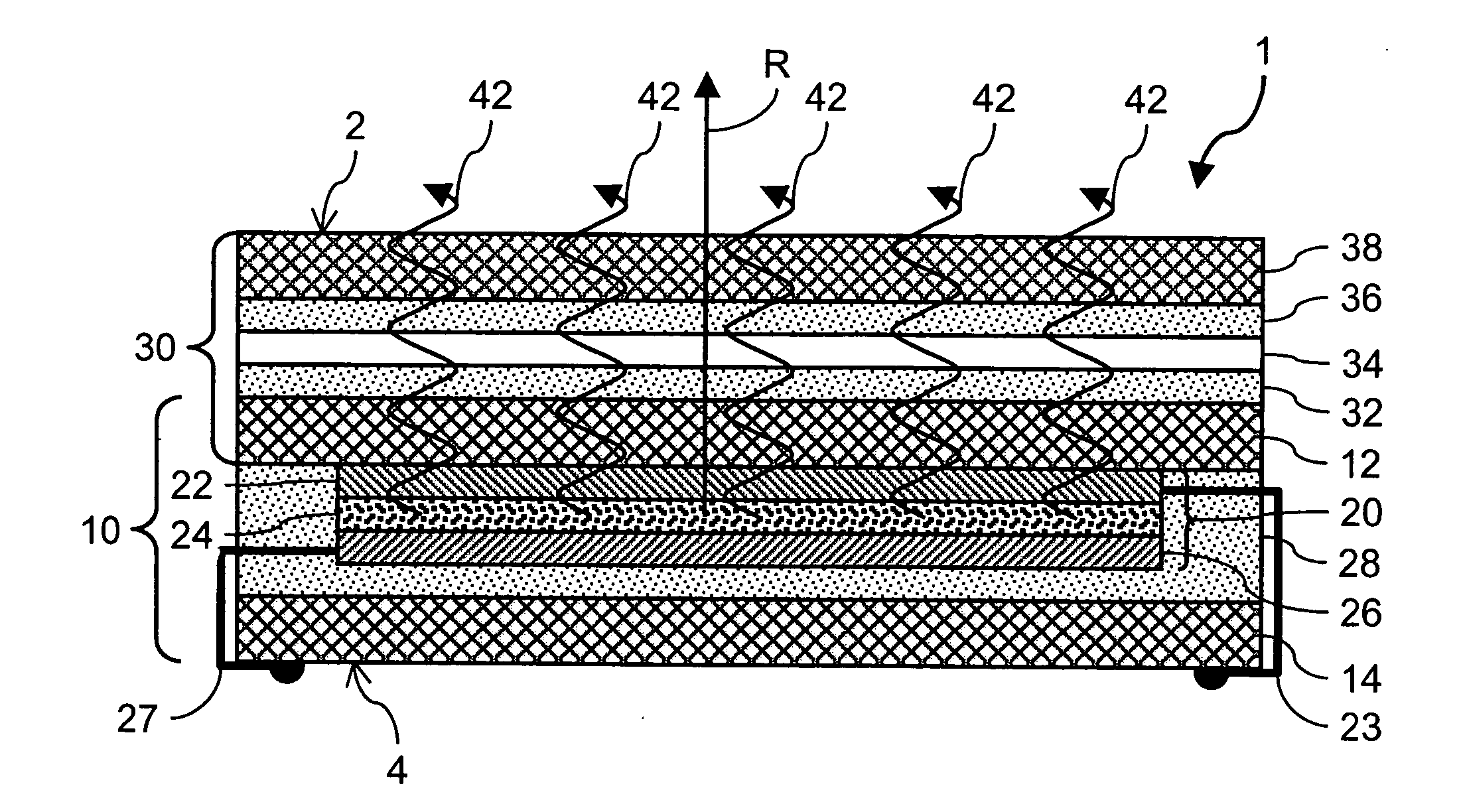

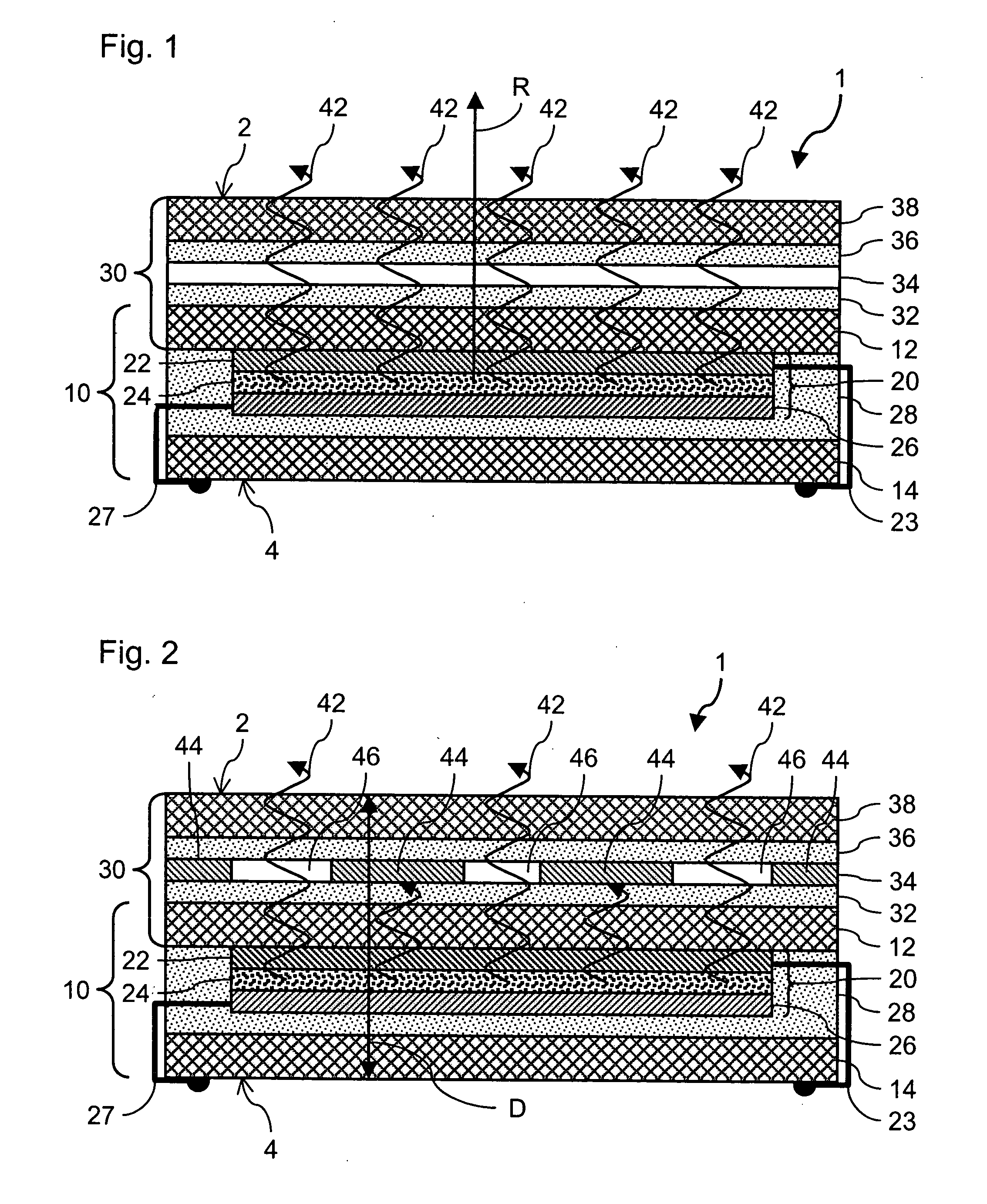

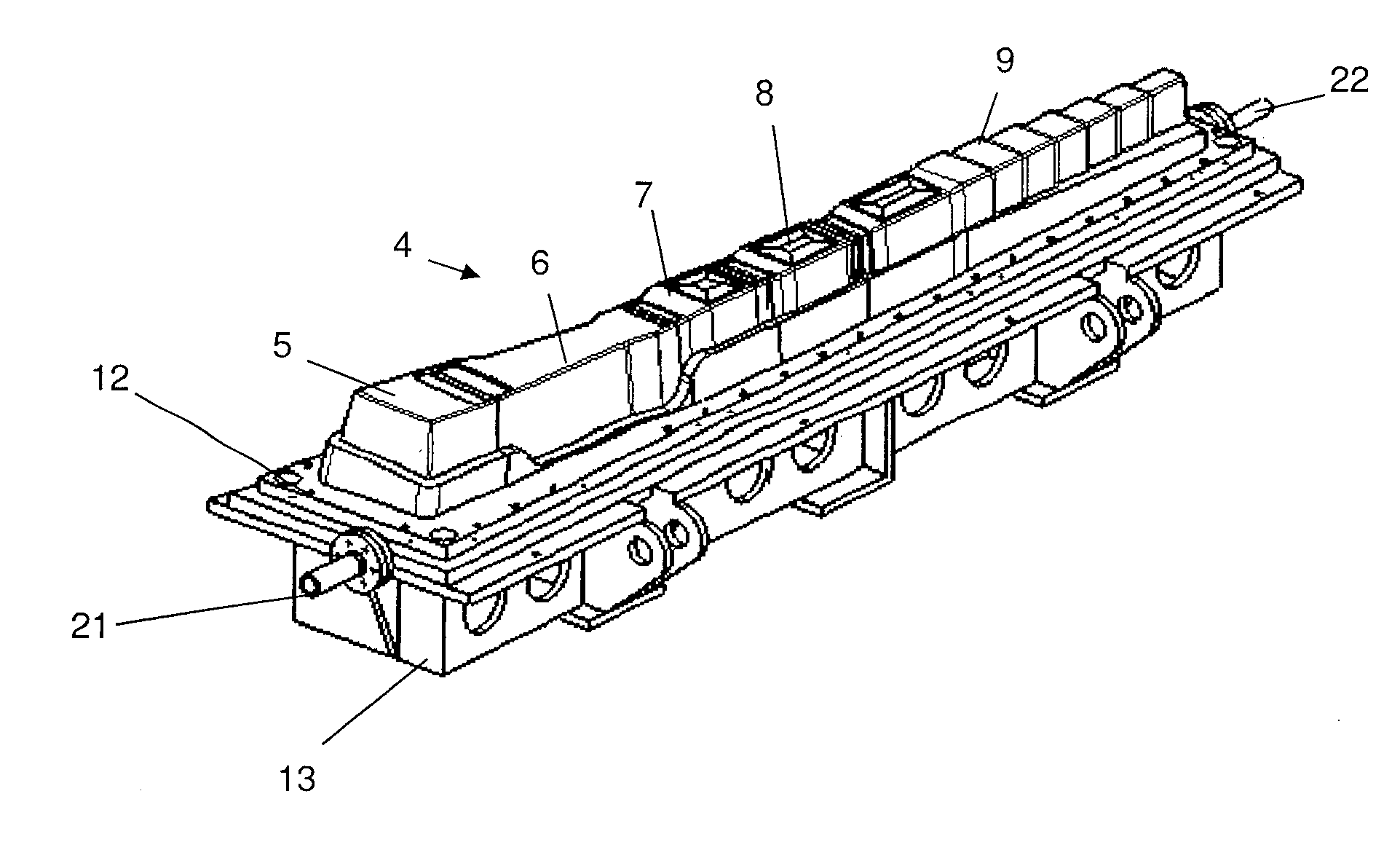

Chassis for electric vehicle

ActiveUS9346346B2Reduce weightImprove performanceCharging stationsElectric propulsion mountingFiberElectrical battery

Owner:GORDON MURRAY TECH LTD

Tire reinforced by an elongate composite element of the monofilament type, and such element

A tire, in particular an elastomeric pneumatic tire, reinforced by lengths of a monofilament elongate composite element of long glass fibers impregnated in a thermoset resin having a glass transition temperature Tg greater than 130° C., in which the fibers are all parallel to each other, the elongate composite element having, under a bending stress an elastic deformation in compression of at least 2%, in flexion a breaking stress in compression greater than the breaking stress in extension.

Owner:CONCEPTION & DEV MICHELIN SA

Electronic product design

ActiveUS7607084B2Easy to mergeNatural language data processingMarketingElectronic documentComposite element

Automated electronic document design systems and method for designing and modifying product templates. When a user initiates a product design session, a product template is presented for user editing and a product description identifier is assigned to the product being designed. Document templates are assembled from individual composite elements. The individual identifiers of the component elements that make up the template being viewed by the user are associated with the description identifier. Tools are provided to allow a user to change one or more of the composite elements of the template. When a user changes an element, the identifier of the newly selected element is associated with the description identifier. Component elements of one template can be individually used, as appropriate, to prepare customized templates for another part of the same document or for different documents.

Owner:CIMPRESS SCHWEIZ

Method for connecting substrate and composite element

InactiveUS7396741B2Semiconductor/solid-state device detailsElectric lighting sourcesEvaporationEngineering

A process for joining substrates having electrical, semiconducting, mechanical and / or optical components, and to a composite element is provided. The process is to be suitable for substrates that are to be joined substantially irrespective of material and for sensitive substrates. According to the process, a raised frame, in particular formed from anodically bondable glass, is applied by evaporation coating to one of the two substrates in order to serve as a joining element.

Owner:SCHOTT AG

Organic light emitting device

InactiveUS20070273281A1Easy to produceCost-effectiveDischarge tube luminescnet screensLamp detailsOrganic light emitting deviceEngineering

The invention relates to an OLED and a method for producing it. It is an object to improve the OLED with regard to its safety properties and, if appropriate, to pattern it. According to the invention, an antishatter protective layer is applied to the OLED, which is photopatterned, in particular, thereby fulfilling a multiple function. The formation of an antishatter protective composite element with a glass-plastic-glass layer sequence is particularly advantageous.

Owner:SCHOTT AG

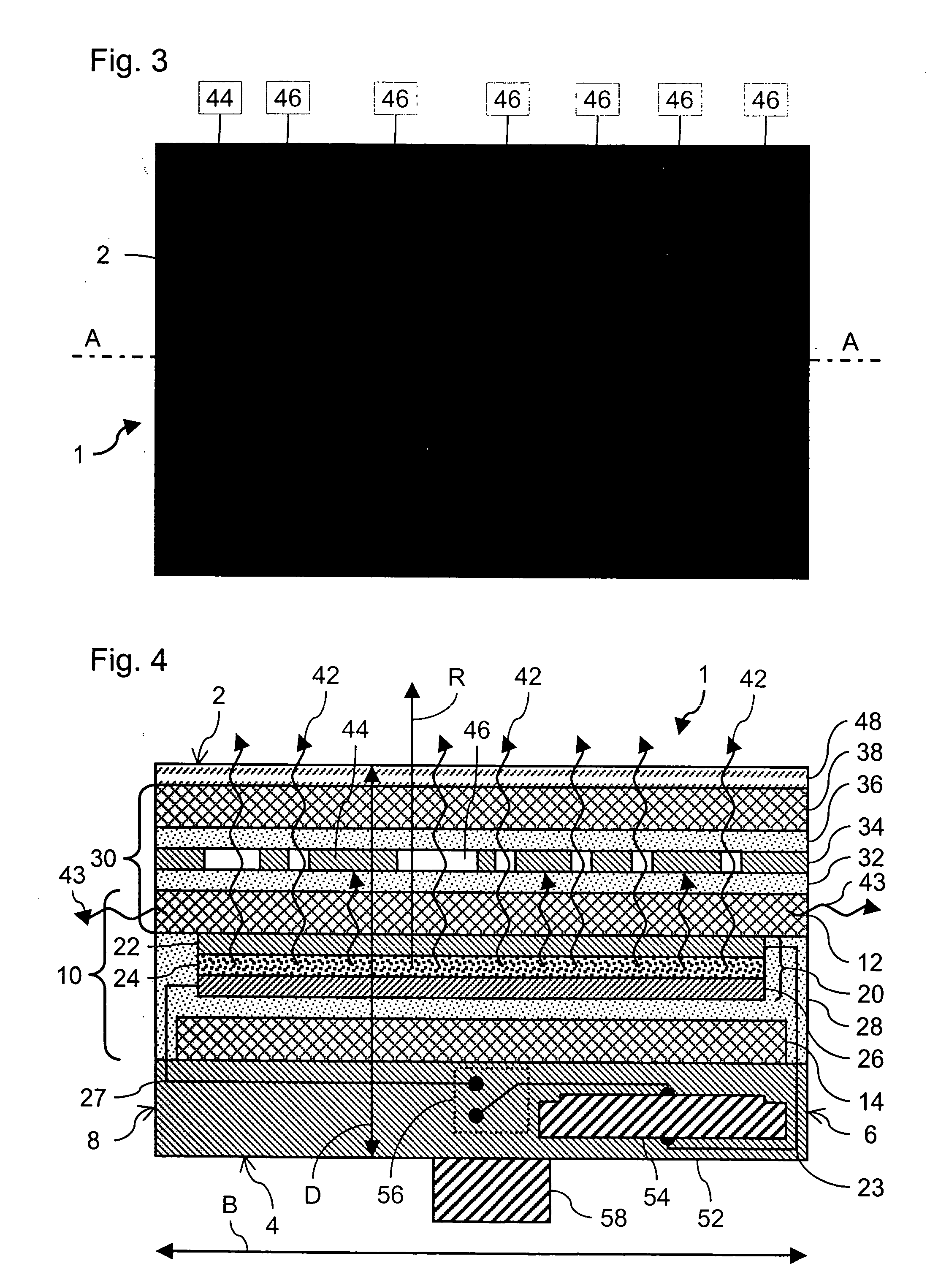

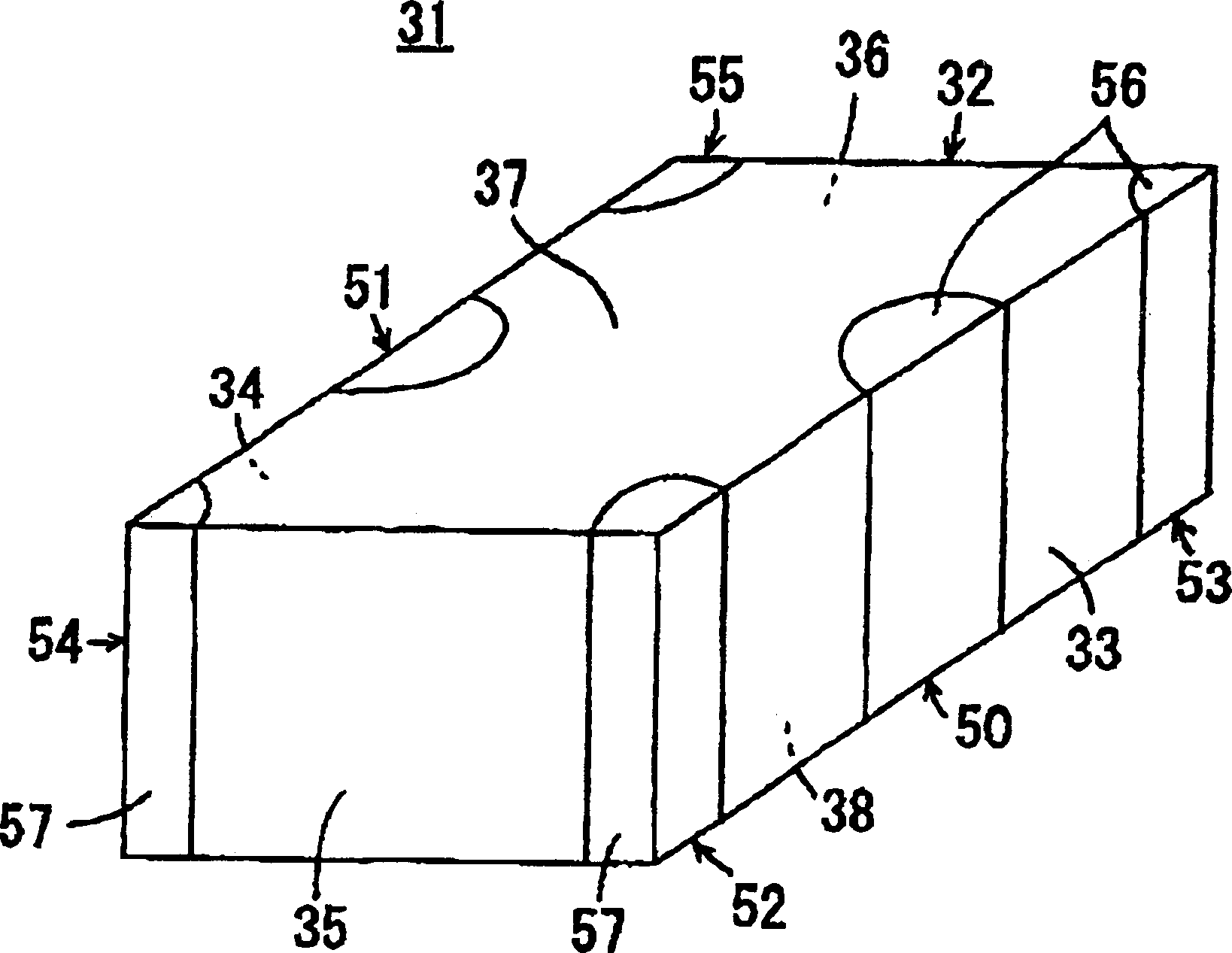

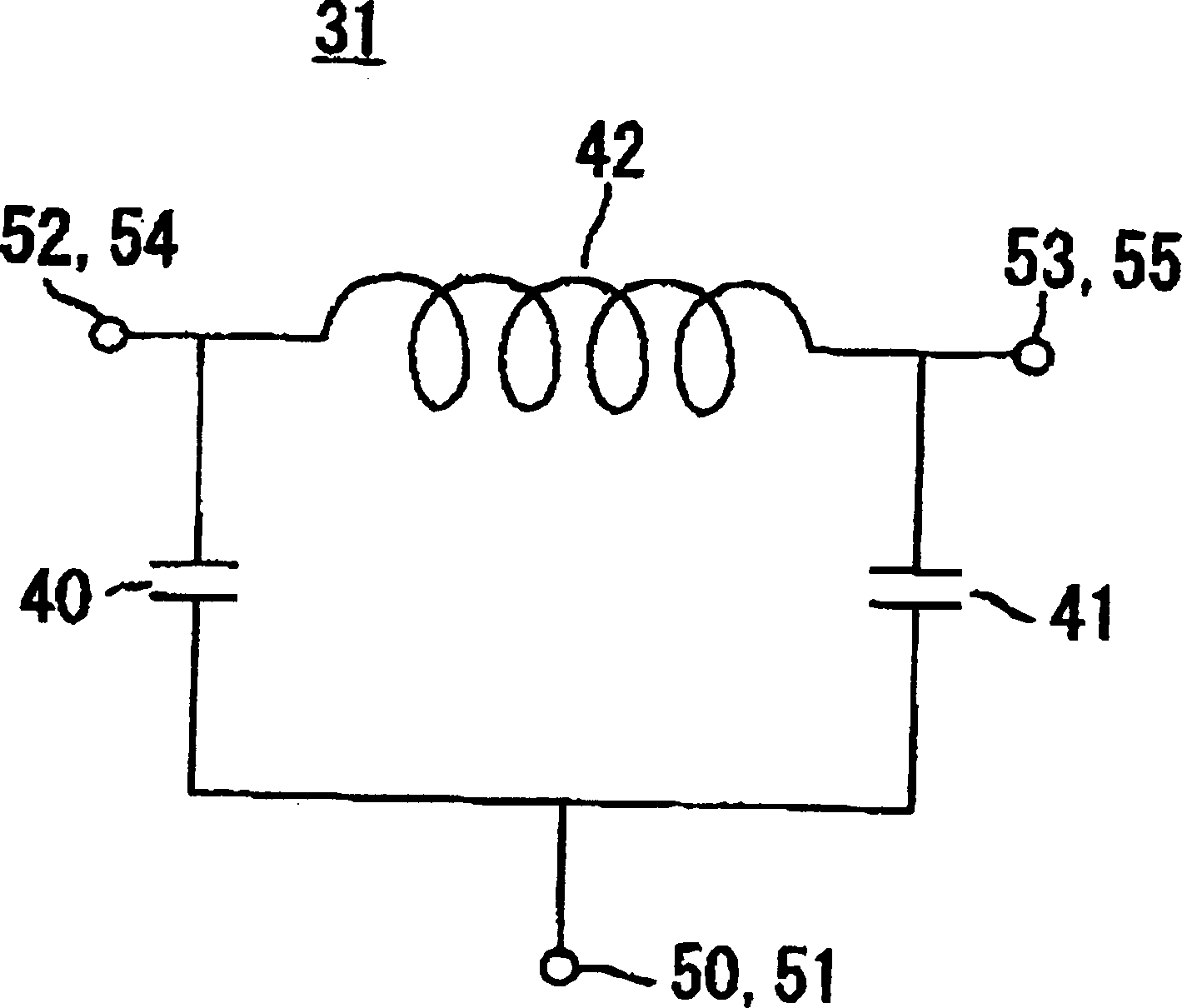

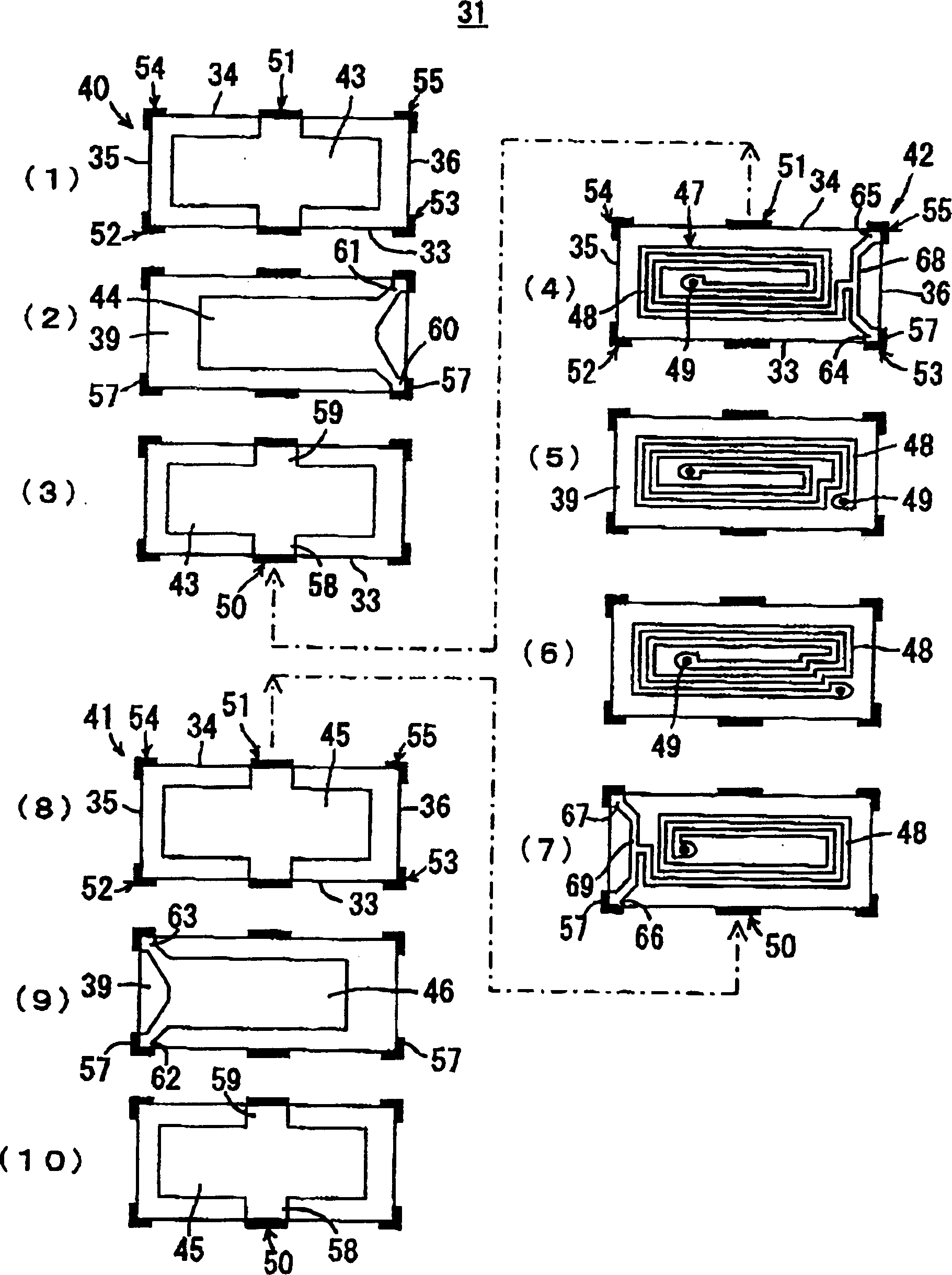

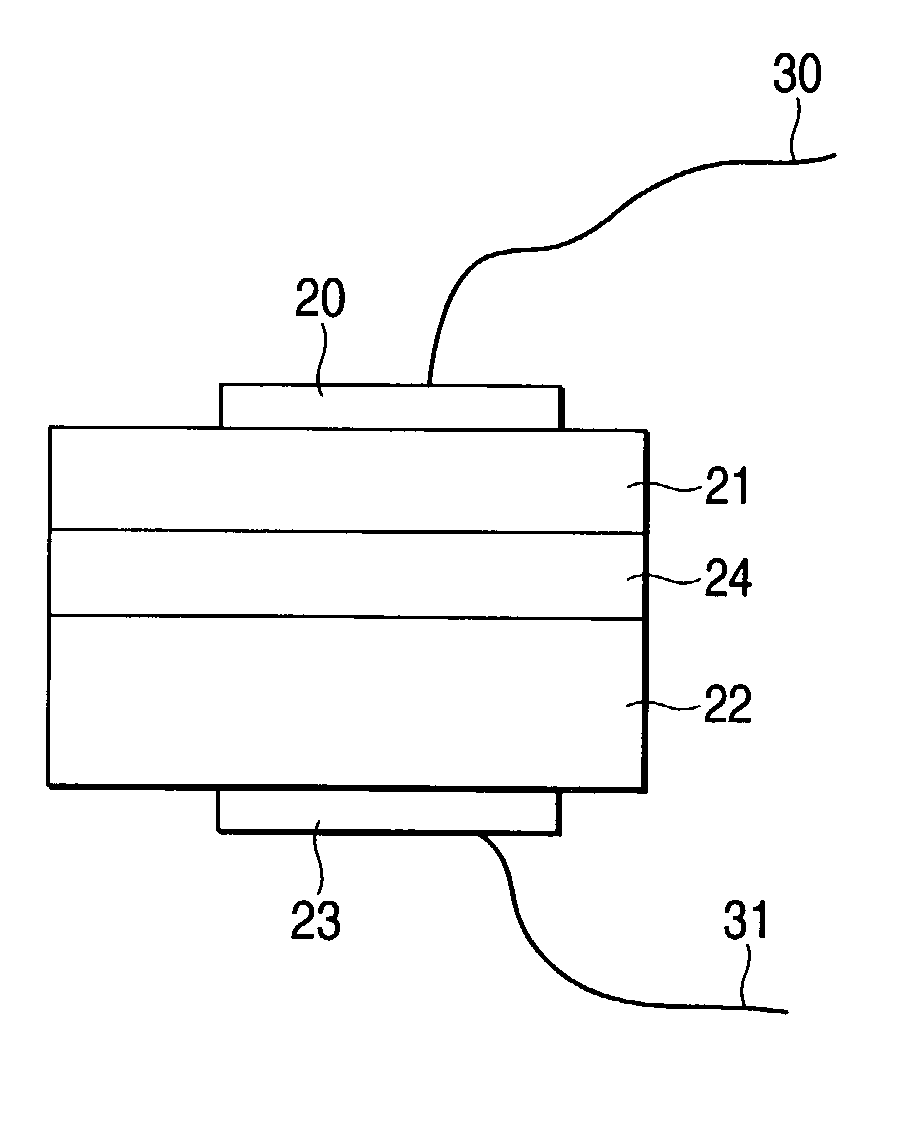

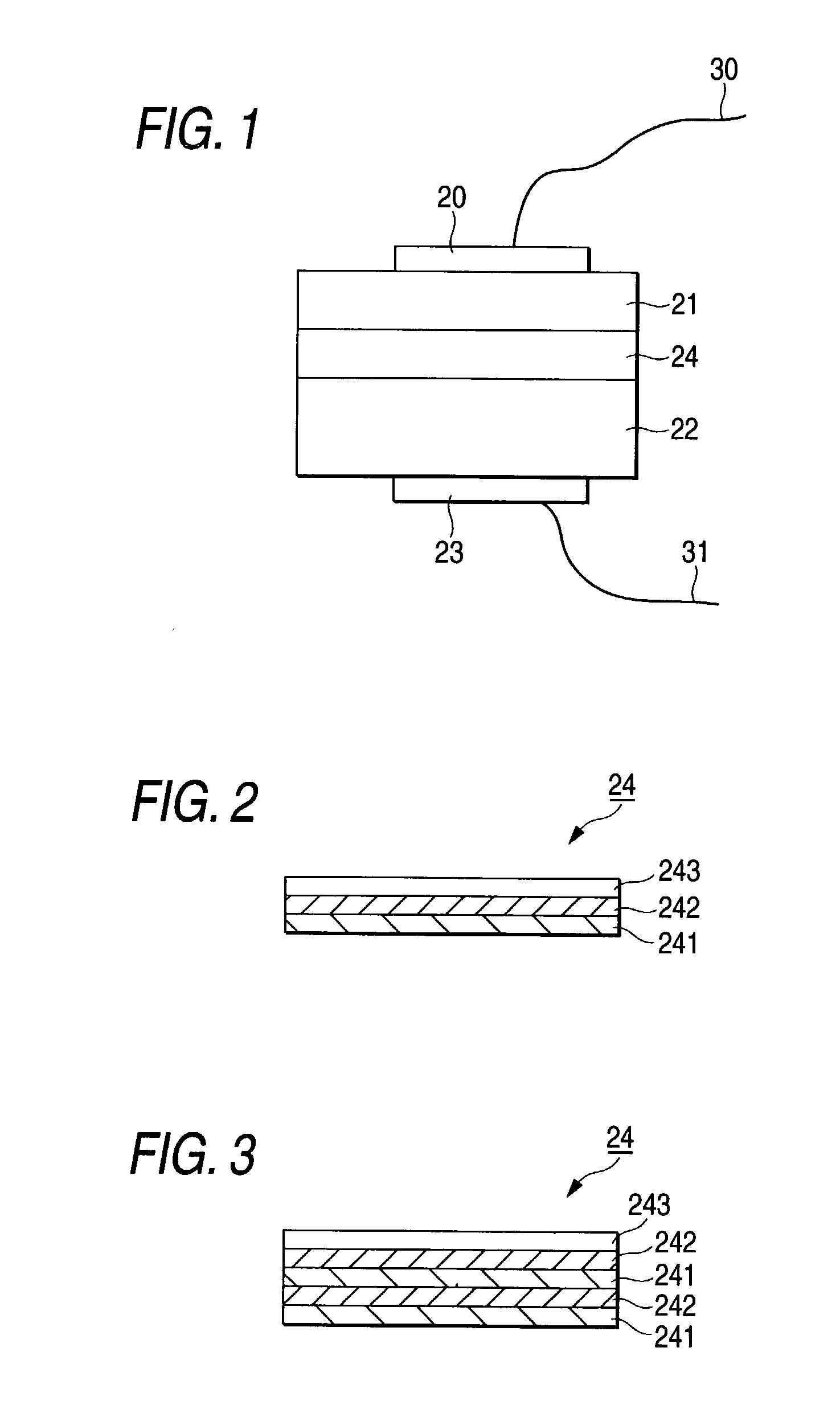

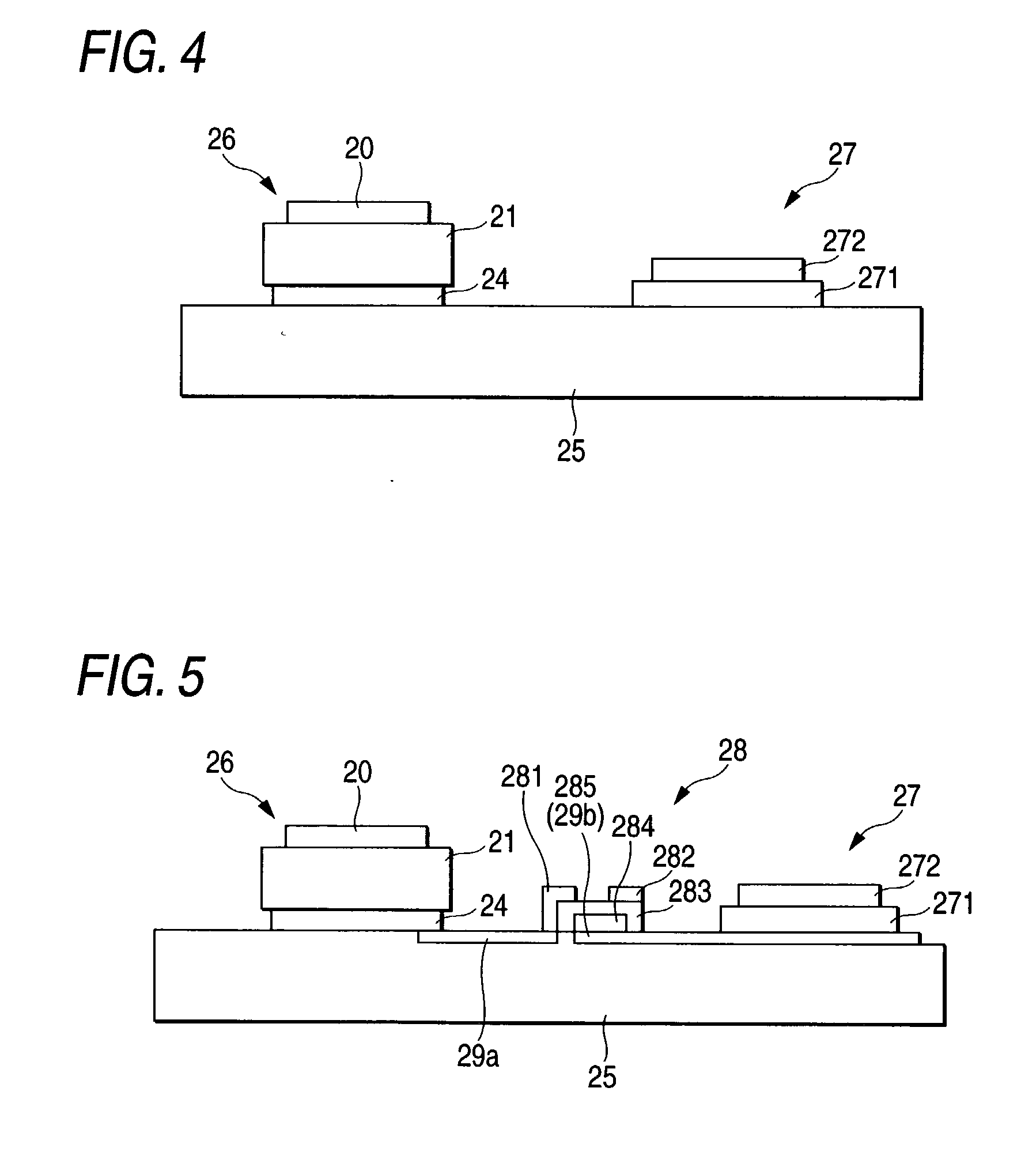

Multi-layer LC composite element and mfg. method thereof

Owner:MURATA MFG CO LTD

Semiconductor light emission element, semiconductor composite element and process for producing semiconductor light emission element

InactiveUS20030178629A1Solid-state devicesSemiconductor/solid-state device manufacturingComposite elementLight emission

A simple and low cost semiconductor light emission element exerting high performance and a process for producing the same are provided. The semiconductor light emission element contains a nitride semiconductor layer containing at least one or more element selected from Group IIIA elements and one or more element selected from Group VA element, a dissimilar semiconductor having a polarity different from the nitride semiconductor layer, and a light emission layer provided between the dissimilar semiconductor and the nitride semiconductor, in which electrons or positive holes are injected from semiconductors of the dissimilar semiconductor and the nitride semiconductor layer to the light emission layer to carry out light emission.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Method of manufacturing a composite element

InactiveUS20110121487A1Easy to assembleEasy to shapeConfectioneryAnimal feeding stuffEngineeringComposite element

A method of manufacturing a composite element. A stack of plies is assembled on a lay-up table, each ply comprising a plurality of reinforcement elements such as dry-fibres. A first part of the stack of plies is bound to form a partially bound stack of plies, a second part of the stack of plies remaining unbound. The partially bound stack of plies is press-formed in a mould cavity between a pair of mould tools to form a shaped pre-form, plies in the second part of the stack sliding against each other during the press-forming. A liquid matrix material is injected into the shaped pre-form in the mould cavity and subsequently cured.

Owner:AIRBUS OPERATIONS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com