Multi-layer LC composite element and mfg. method thereof

A composite component and component technology, applied in the field of multi-layer LC composite components and their manufacturing, can solve the problems of deteriorating high-frequency characteristics, large parasitic capacitance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

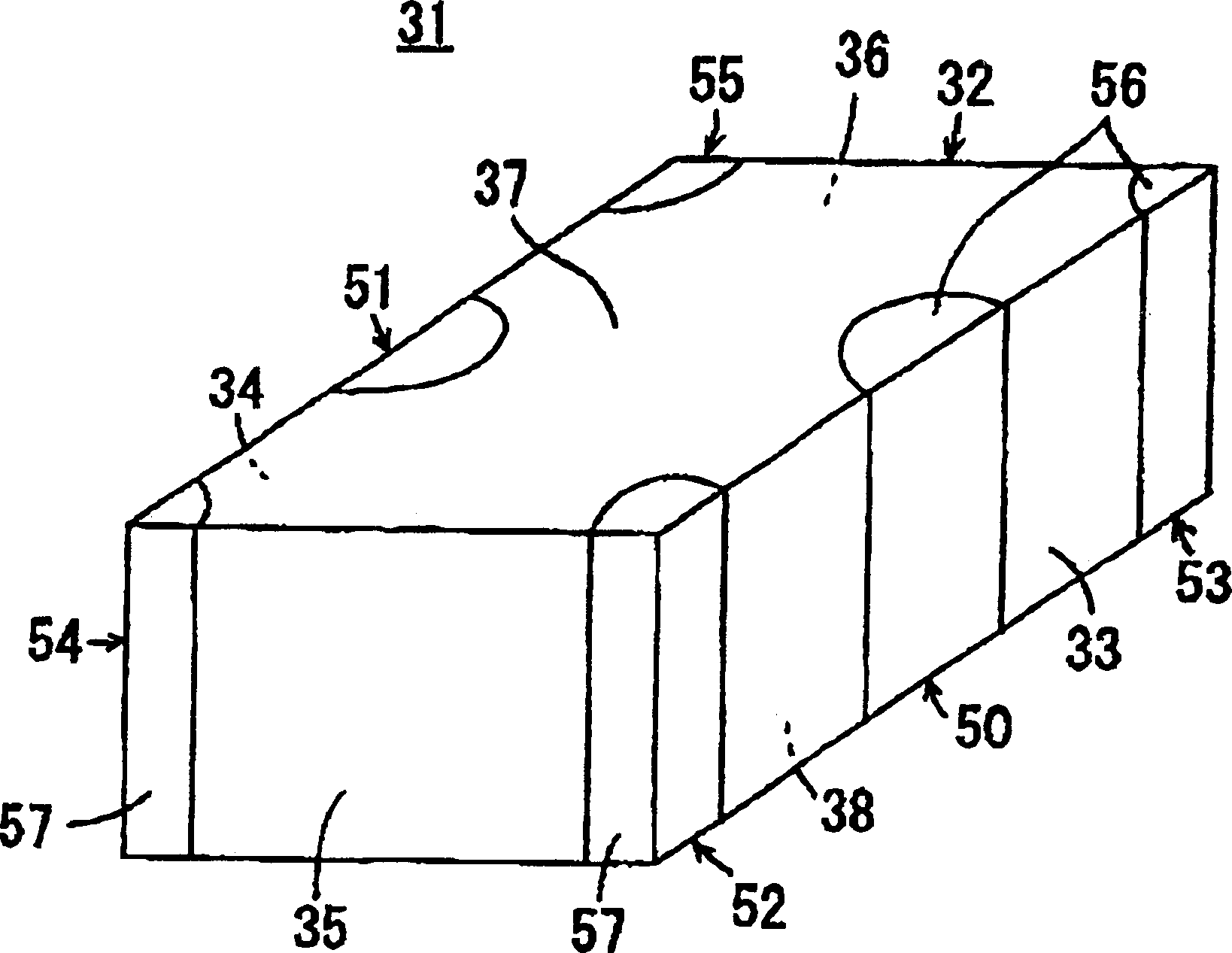

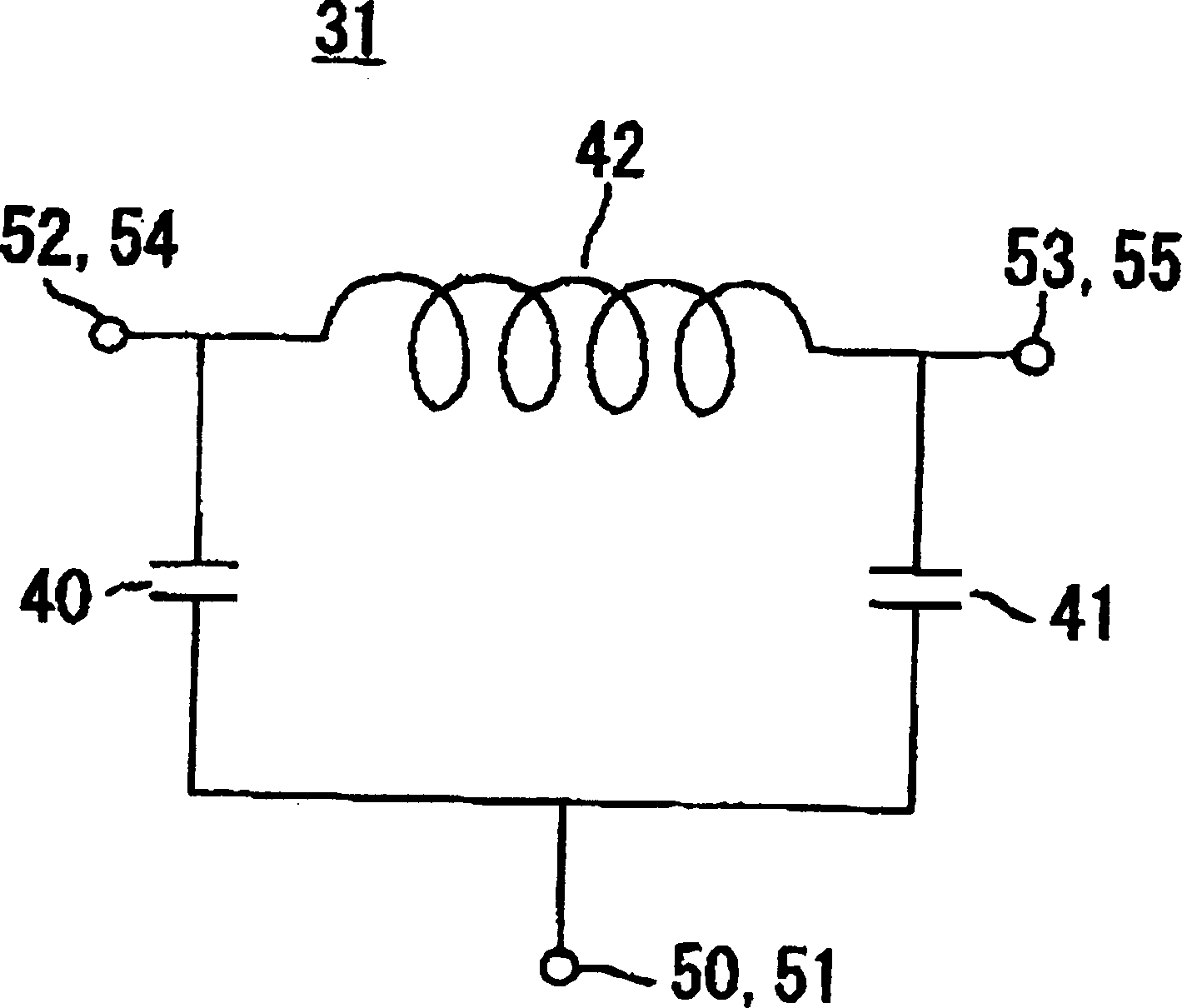

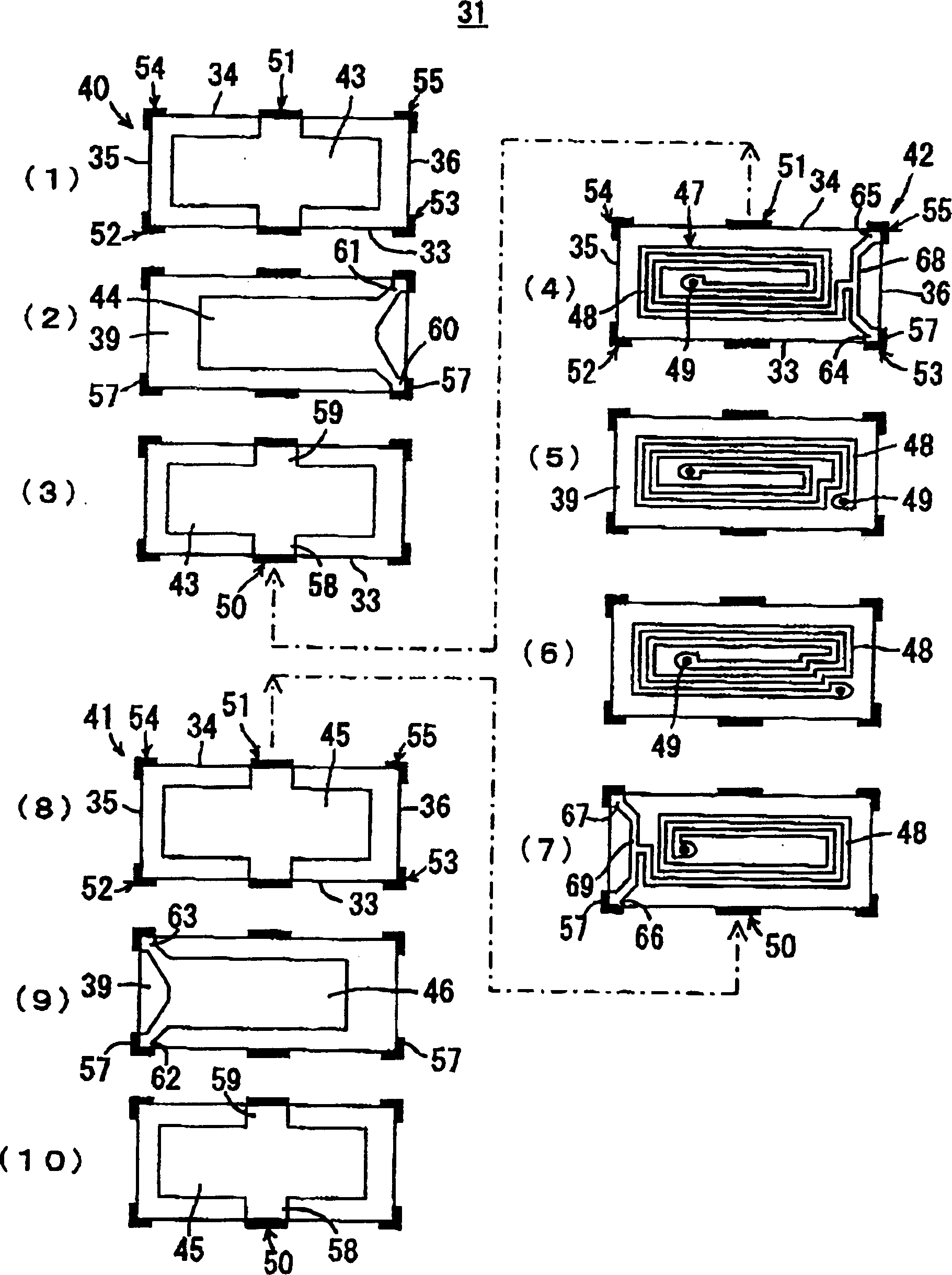

[0042] figure 1 is a perspective view showing the multilayer LC composite element 31 according to the first embodiment of the present invention. figure 2 is as figure 1 The equivalent circuit diagram of the multilayer LC composite element 31 is shown. image 3 Including showing decomposition such as figure 1 A plan view of the multilayer LC composite element 31 is shown.

[0043] The multilayer LC composite element 31 comprises a substantially rectangular body 32 . The main body 32 includes a pair of side surfaces 33 and 34 facing each other, a pair of end surfaces 35 and 36 facing each other, and upper and lower surfaces 37 and 38 facing each other.

[0044] For example, the body 32 is about 1.6 mm long, about 0.8 mm wide, and about 0.6 mm high.

[0045] like image 3 As shown, the body 32 has a multilayer structure including a plurality of electrically insulating layers 39 . The main body 32 includes as image 3 The capacitor element 40 shown in (1) to (3), as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com