Patents

Literature

36 results about "Bunsen burner" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A Bunsen burner, named after Robert Bunsen, is a common piece of laboratory equipment that produces a single open gas flame, which is used for heating, sterilization, and combustion. The gas can be natural gas (which is mainly methane) or a liquefied petroleum gas, such as propane, butane, or a mixture of both.

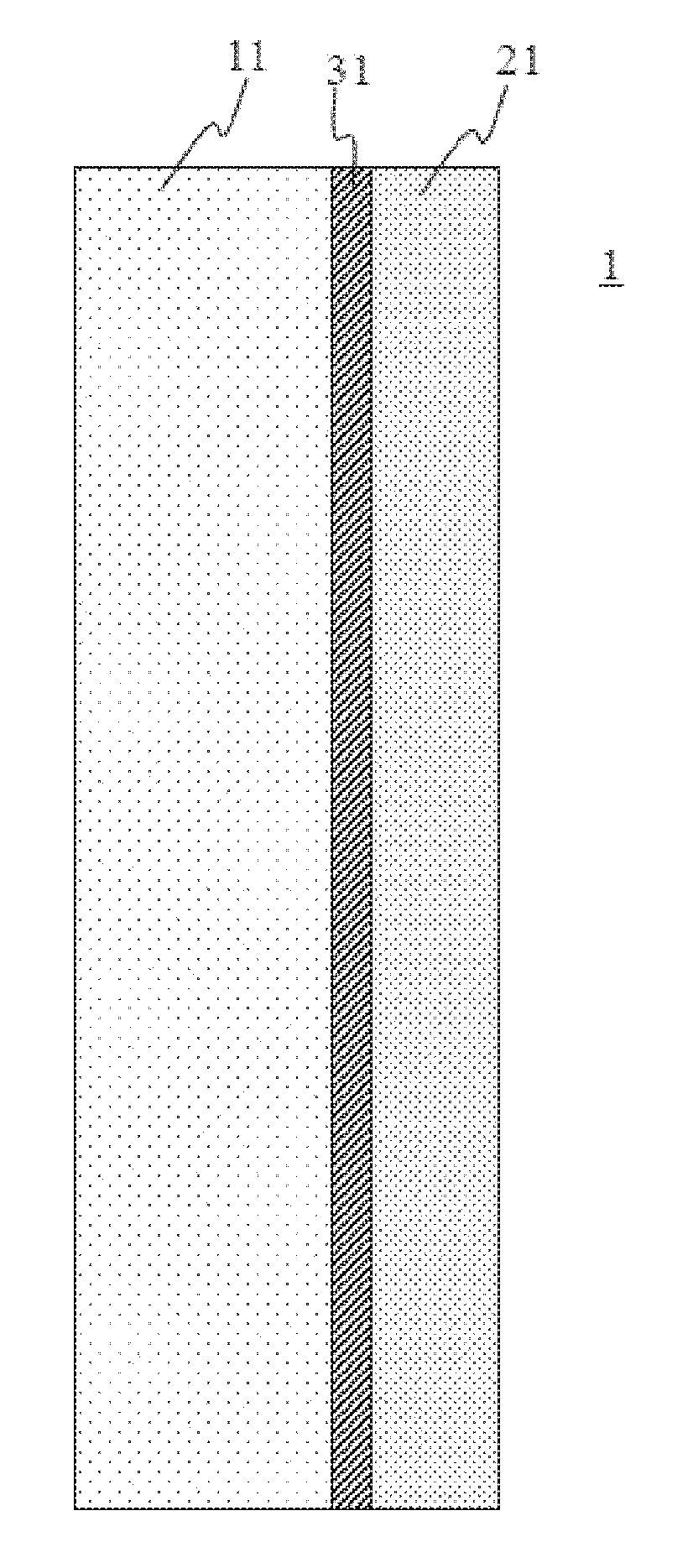

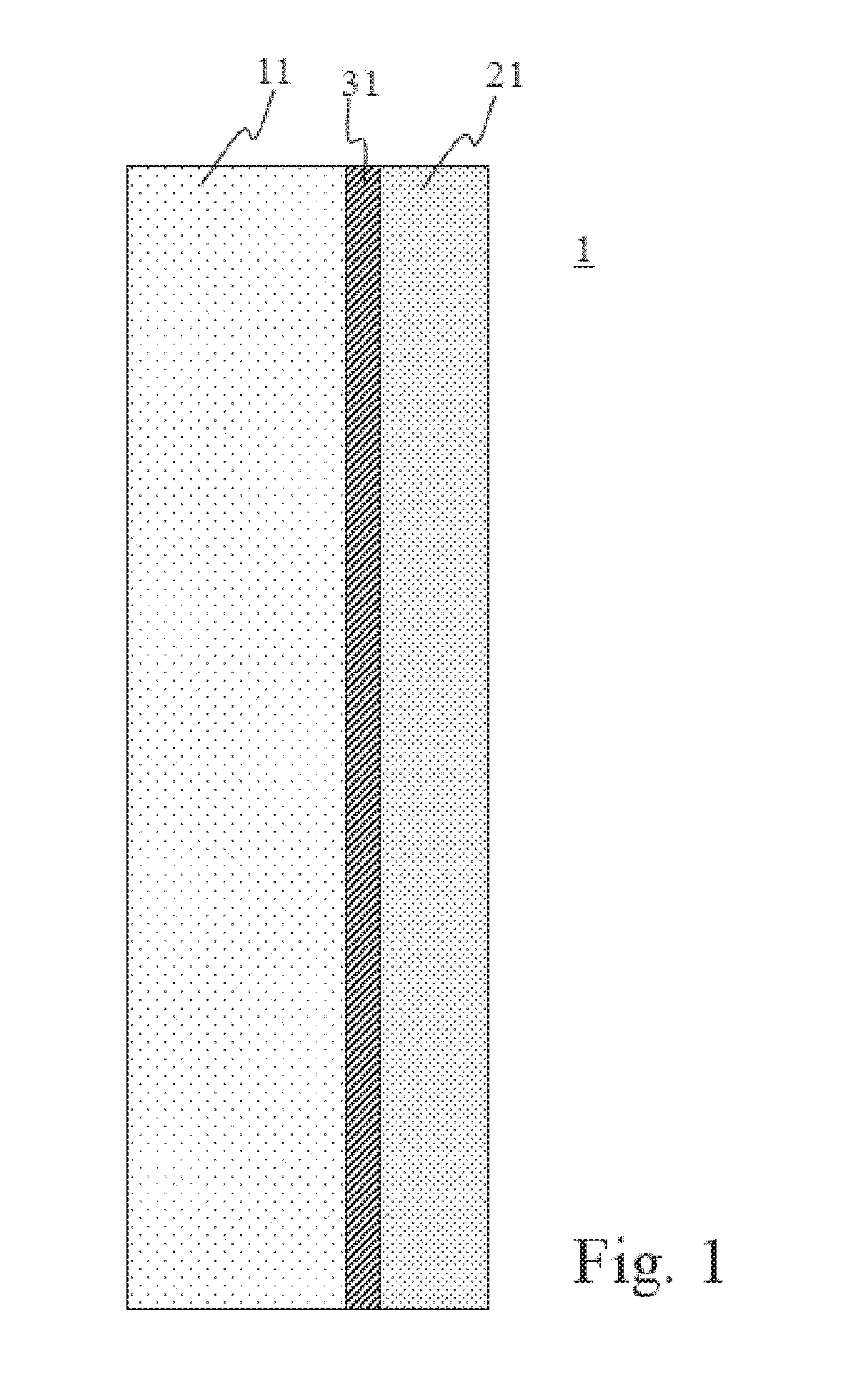

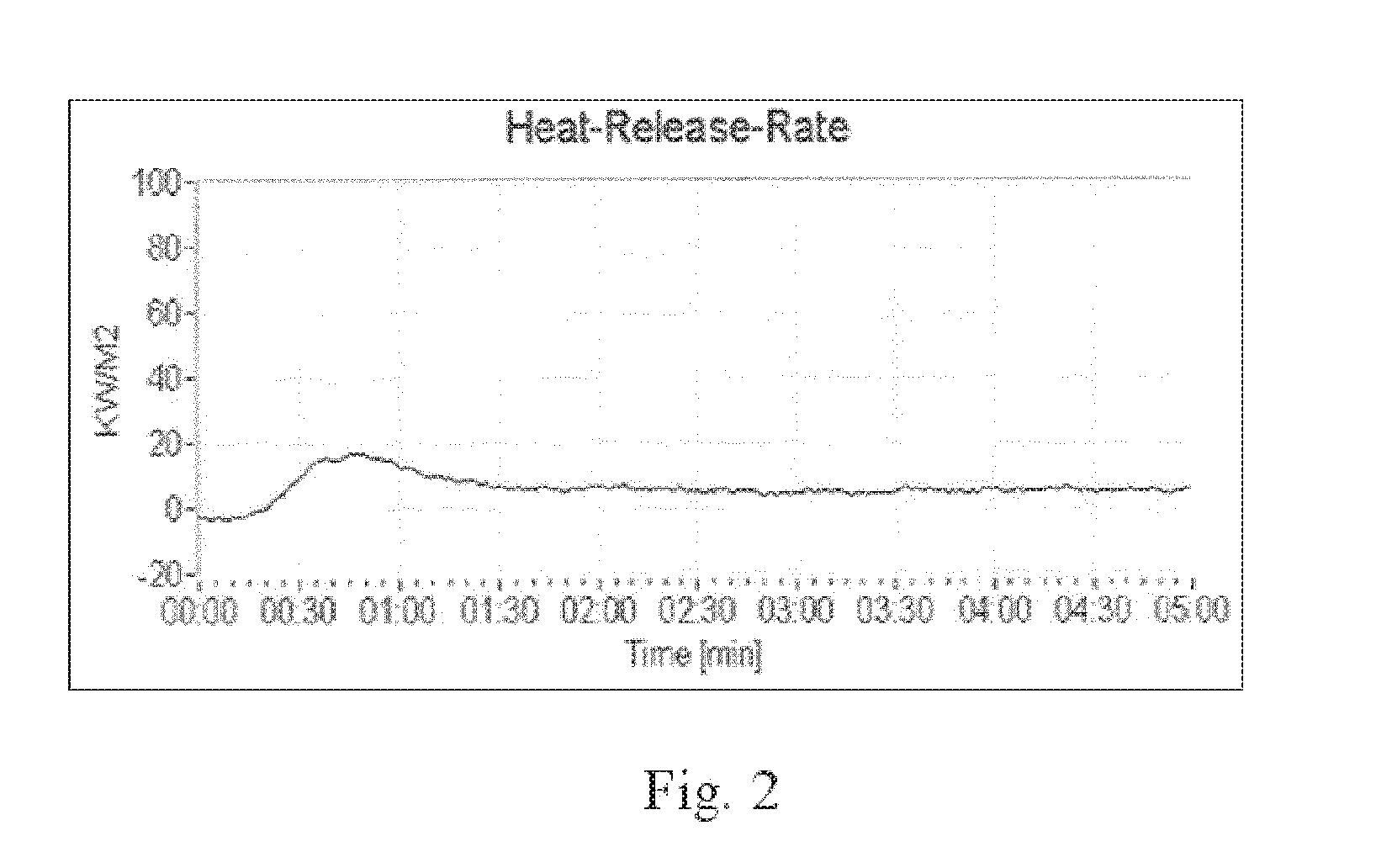

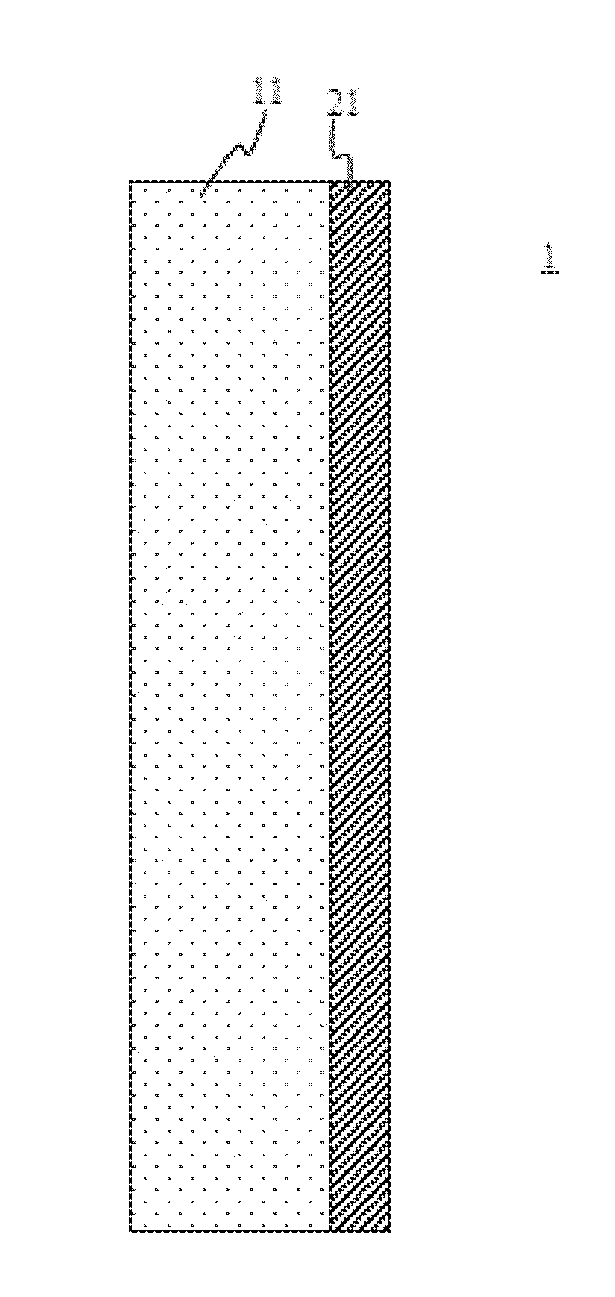

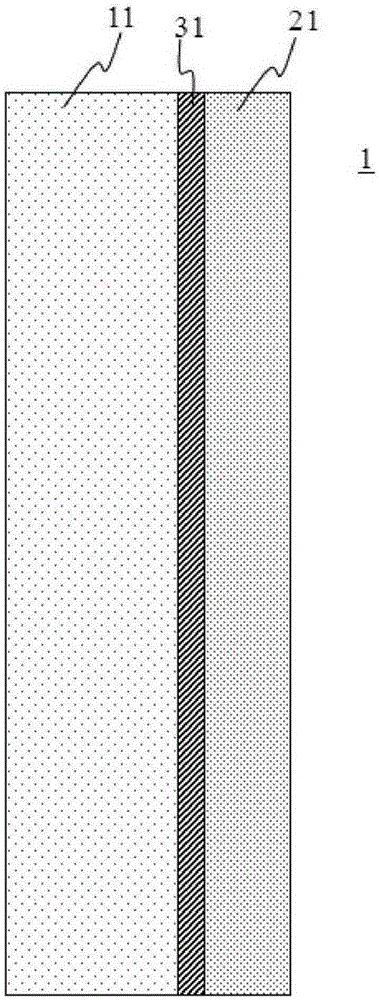

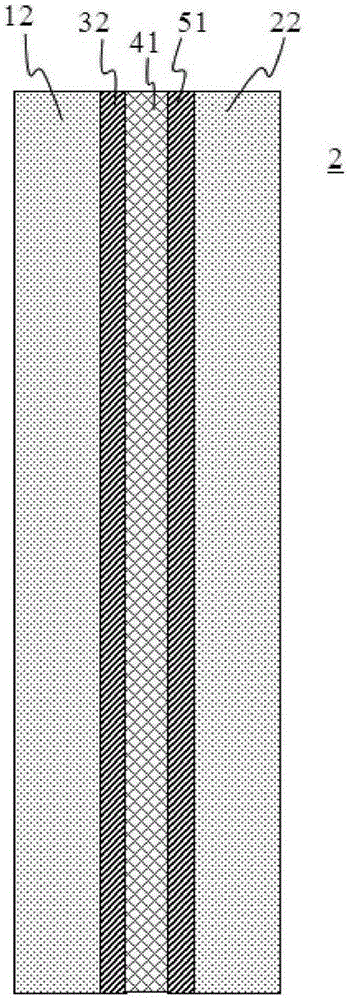

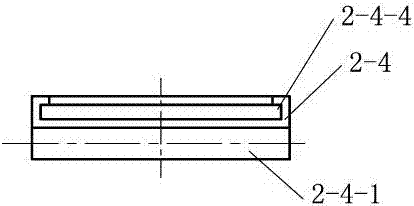

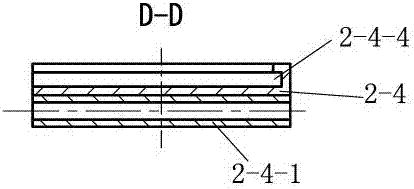

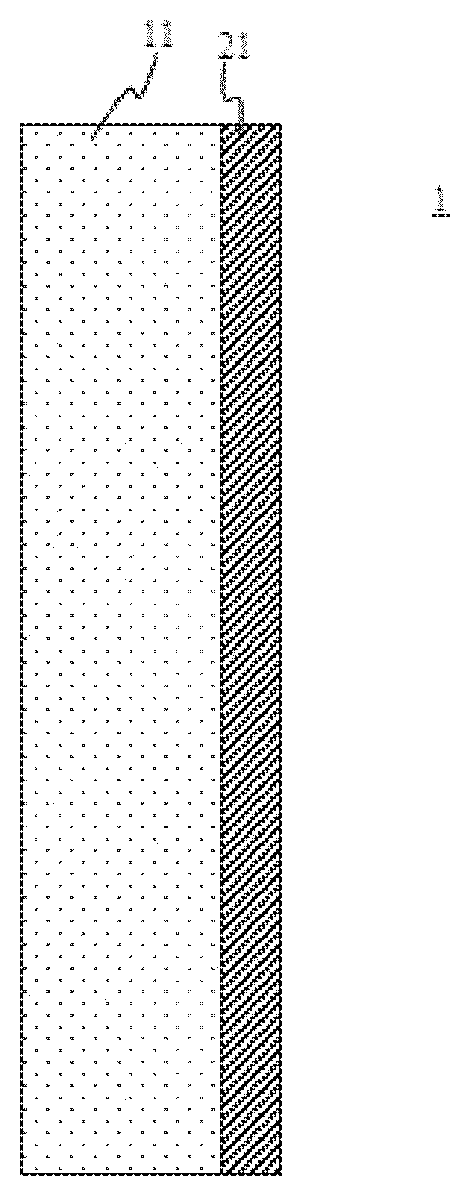

Composite Element and Use Thereof

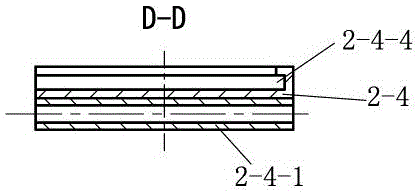

InactiveUS20160136929A1Avoid spreadingAvoid transmissionLamination ancillary operationsLayered product treatmentOrganic layerBunsen burner

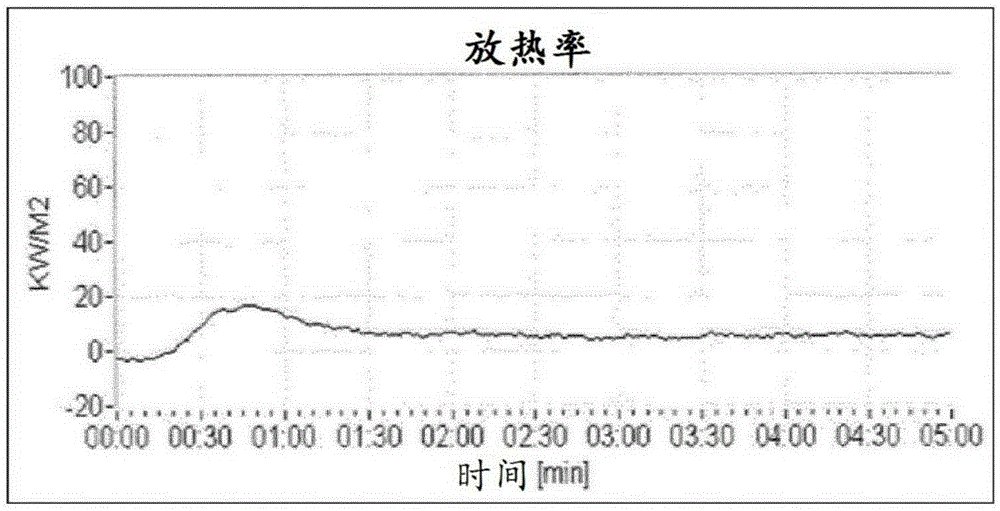

A lightweight composite panel is provided that includes at least one mineral glass or glass-ceramic panel and at least one organic layer. The weight per unit area of the lightweight composite panel is in the range from 0.5 kg / m2 to 5.5 kg / m2, the ratio of the total thickness of the one or more mineral glass or glass-ceramic panels to the total thickness of all of the organic layers is from 1:0.01 to 1:1 and the total thickness of all of the organic layers is less than or equal to 350 μm. The lightweight composite panel complies with the thermal safety requirements of the air travel authorities and its “Total Heat Release,” measured in accordance with JAR / FAR / CS 25, App. F, Part IV & AITM 2.0006, is less than 65 kW×min / m2 and its flame time after removal of the flame in the “Vertical Bunsen Burner Test”, measured in accordance with FAR / JAR / CS 25, App. F, Part 1 & AITM 2.0002A, is less than 15 s.

Owner:SCHOTT AG

Composite Element and Use Thereof

ActiveUS20160137549A1Low hazeGood optical performancePretreated surfacesRecord information storageBunsen burnerComposite element

A lightweight composite pane is provided that includes a mineral glass or glass-ceramic pane and an organic layer. The weight per unit area of the lightweight composite pane is in the range from 0.5 kg / m2 to 5.5 kg / m2, the ratio of the thickness of the mineral glass pane to the thickness of the organic layer is 1:0.01 to 1:1, and the thickness of the organic layer is less than or equal to 500 μm. The lightweight composite pane meets the thermal safety requirements of aerospace authorities and has a “Total Heat Release,” measured in compliance with JAR / FAR / CS 25, App. F, Part IV & AITM 2.0006, of less than 65 kW×min / m2 and a flame time, after removal of the flame in the “Vertical Bunsen Burner Test”, measured in compliance with FAR / JAR / CS 25, App. F, Part 1 & AITM 2.0002A, is less than 15 seconds.

Owner:SCHOTT AG

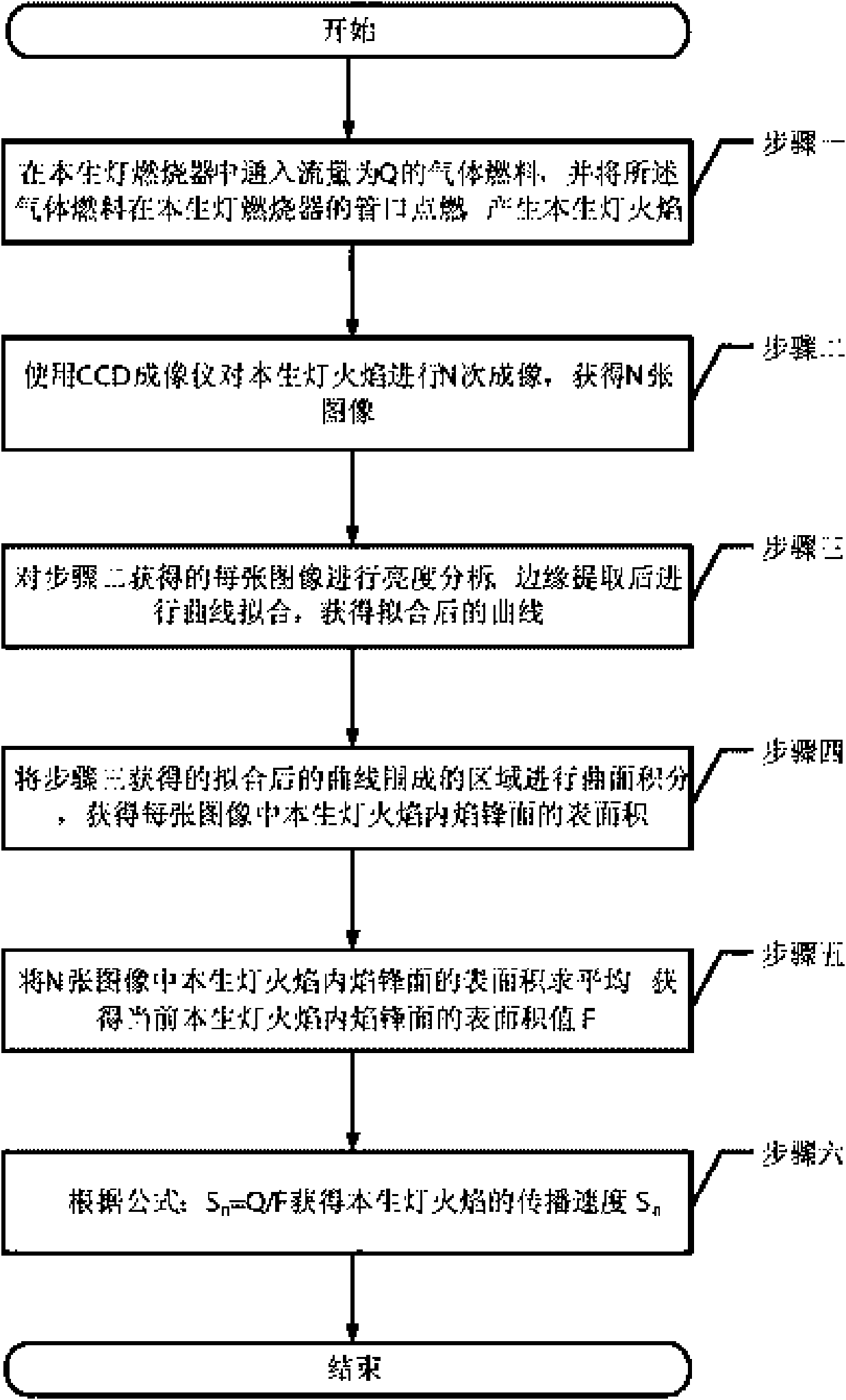

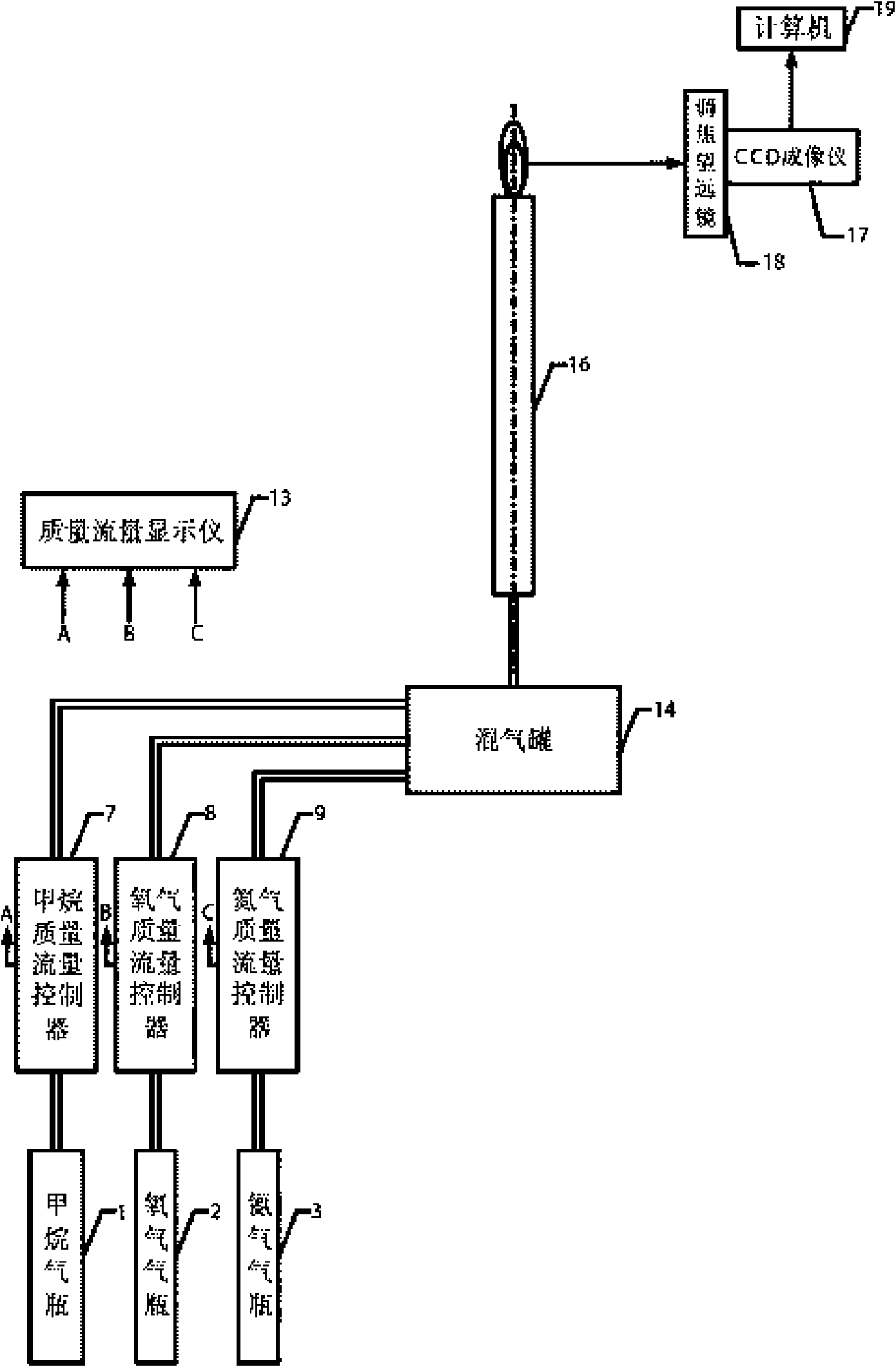

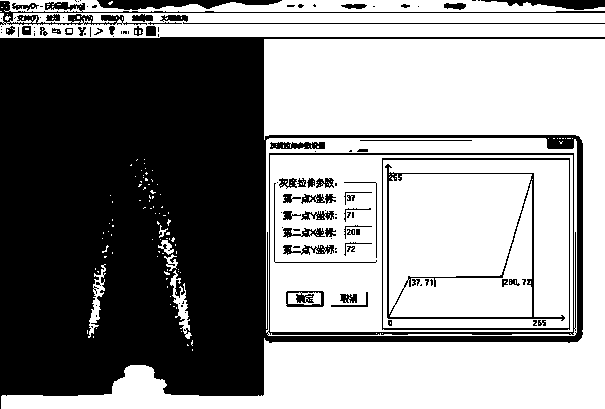

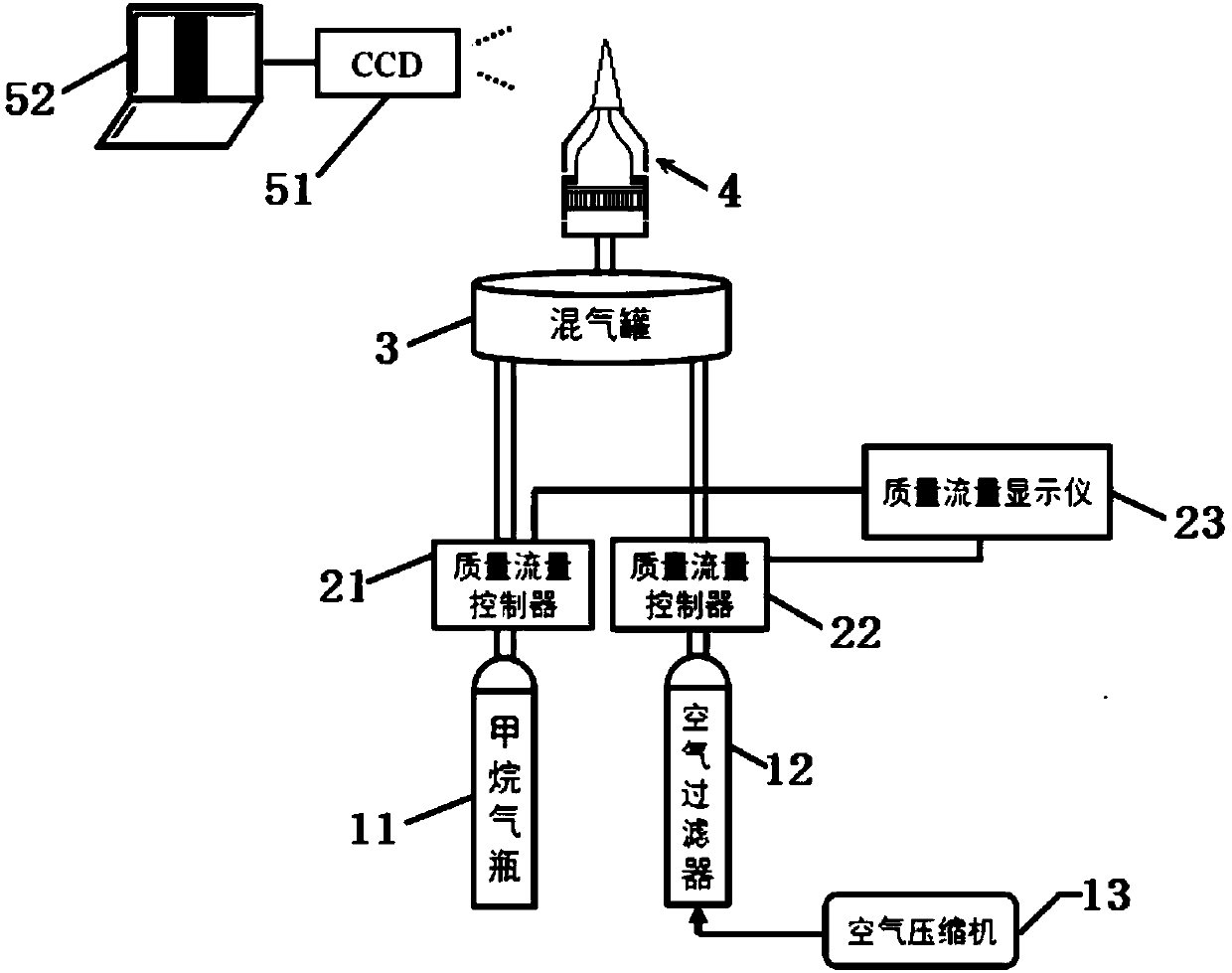

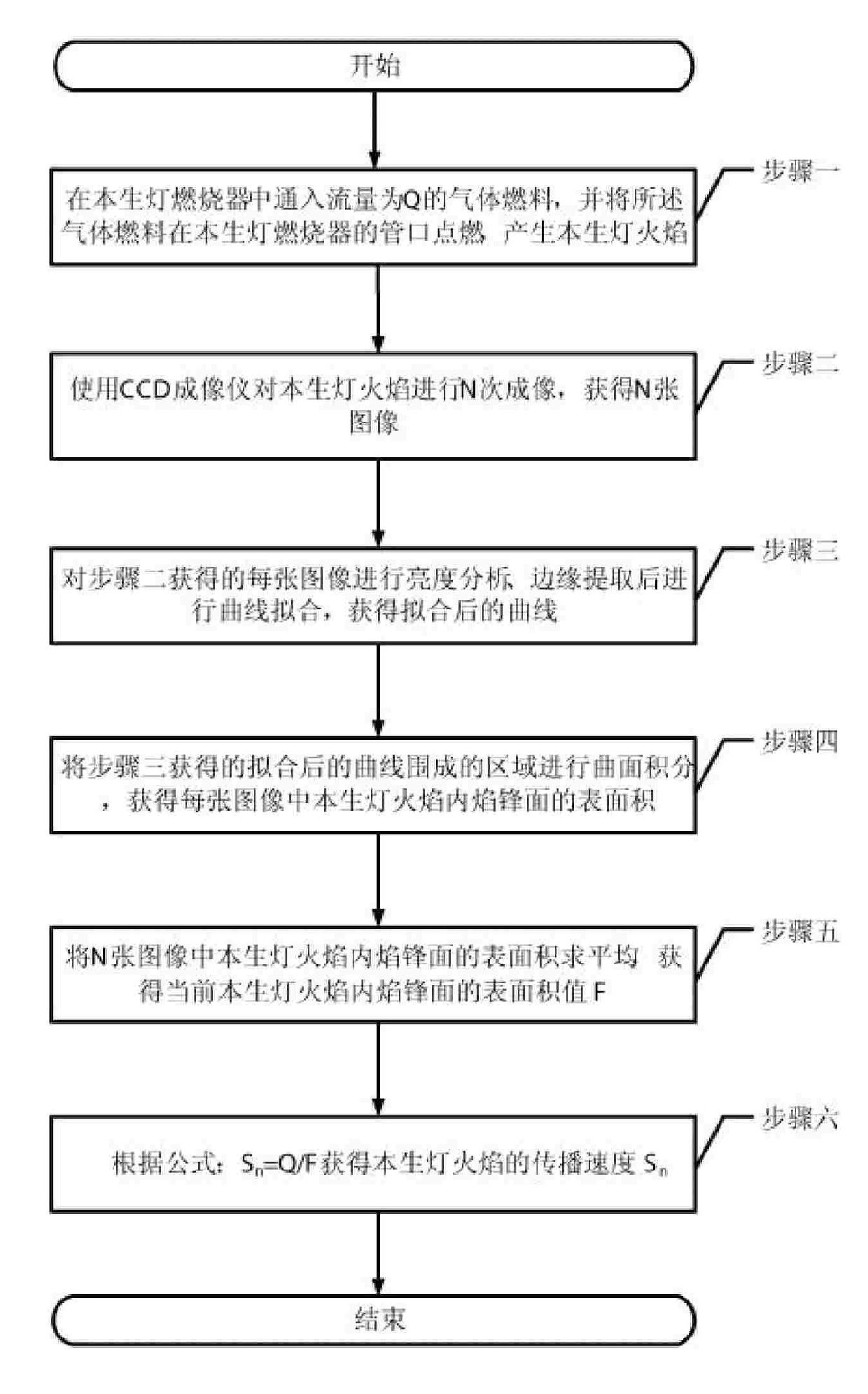

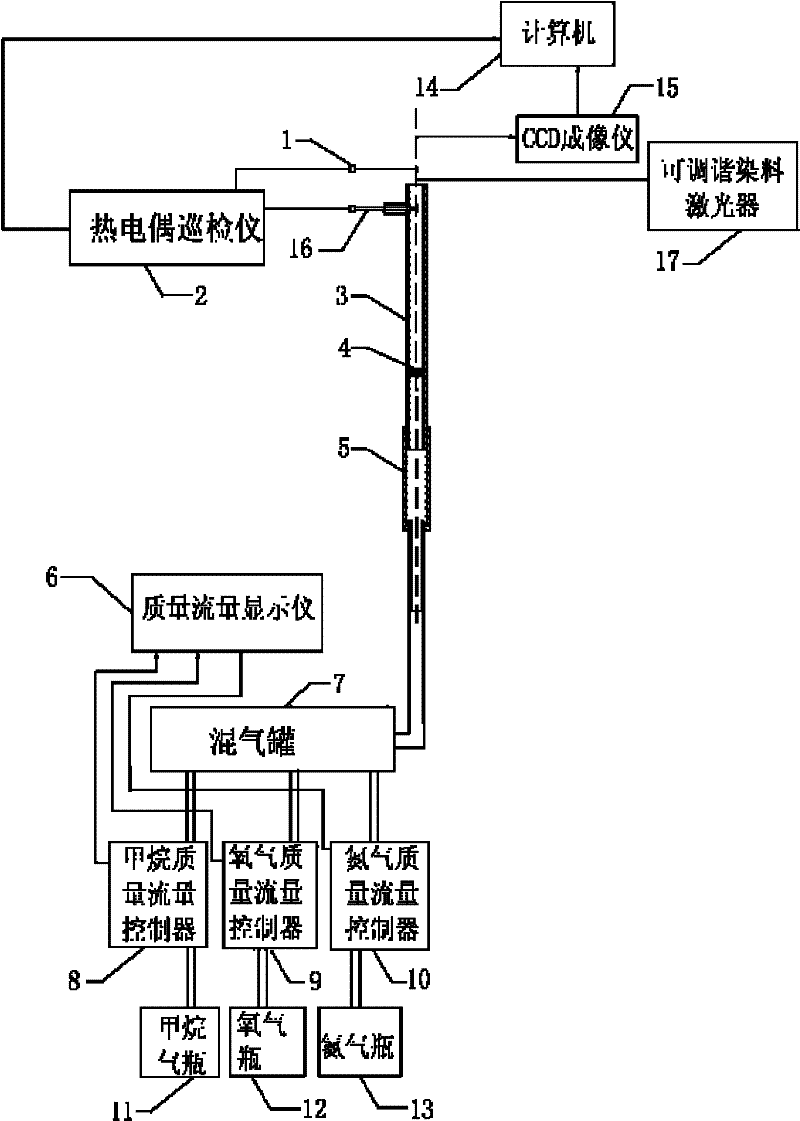

Method for measuring flame propagation velocity of Bunsen burner during combustion process of gaseous fuel

InactiveCN101672858AWon't breakImprove accuracyDevices using optical meansFlame propagationBunsen burner

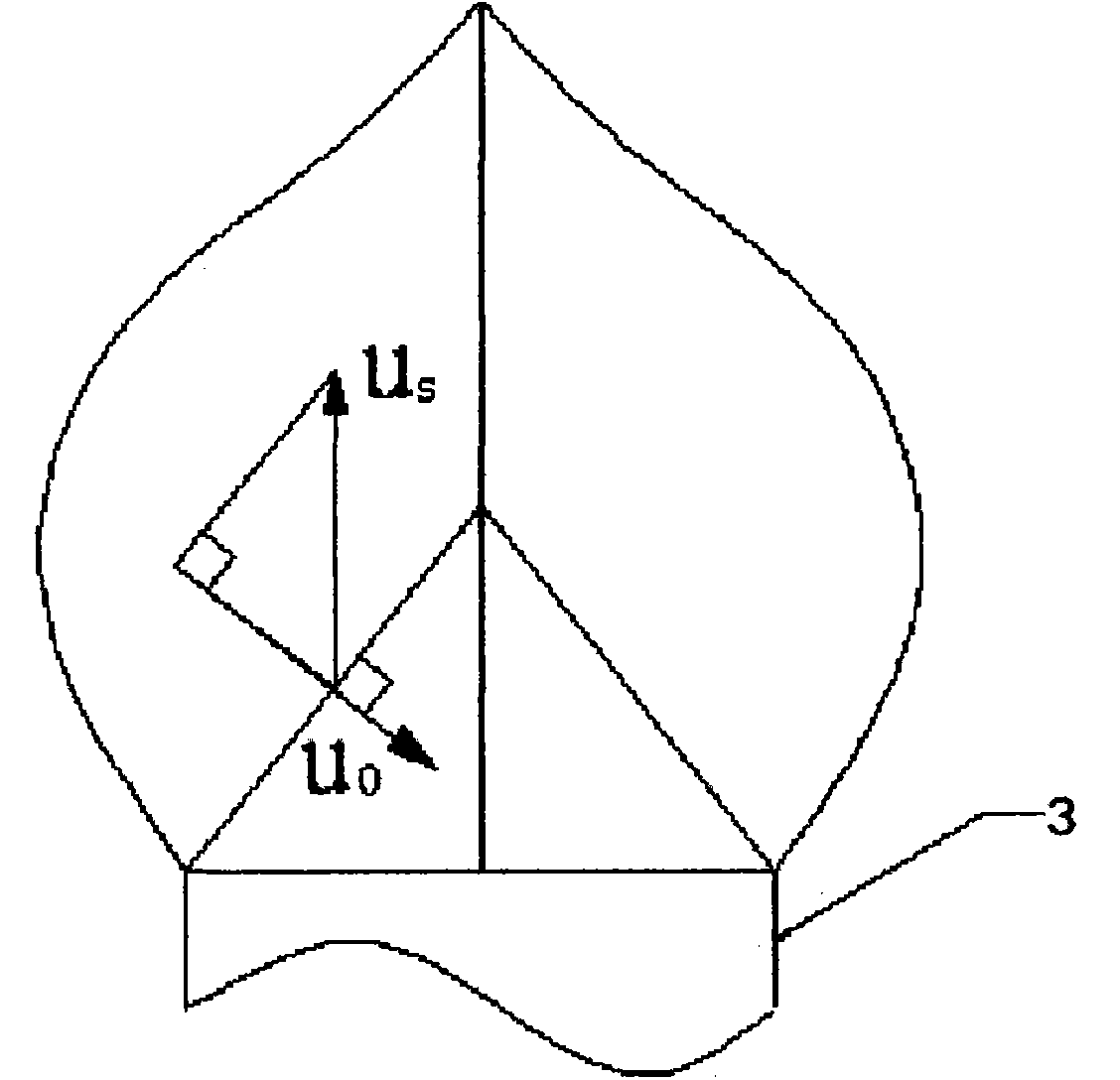

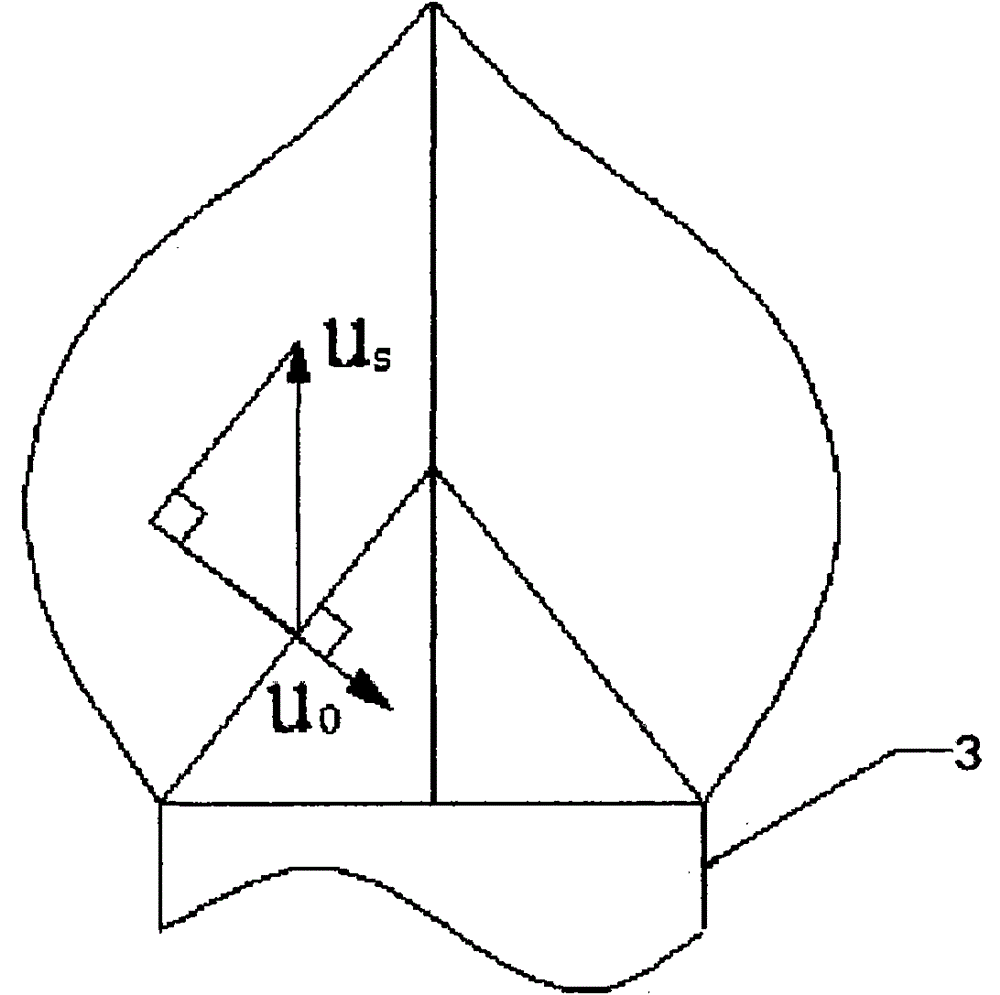

The invention relates to a method for measuring the flame propagation velocity of a Bunsen burner during the combustion process of gaseous fuel, relating to a method for measuring the flame propagation velocity. The method for measuring the flame propagation velocity of a Bunsen burner during the combustion process of gaseous fuel is realized by the following steps of: igniting gaseous fuel with aflow rate Q in the Bunsen burner to generate flame of the Bunsen burner; performing N times of imaging on the flame of the Bunsen burner by a CCD imaging device to obtain N images; performing brightness analysis and edge extraction on each image and then performing curve fitting; performing curve integration on the area surrounded by the fit curve to obtain the superficial areas of the inner flame frontal surfaces in the flame of the Bunsen burner in each image, averaging the superficial areas to obtain the current superficial area value of the inner flame frontal surface in the flame of theBunsen burner; and calculating the flame propagation velocity of the Bunsen burner according to the superficial area value of the inner flame frontal surface in the flame and the gas flow rate. The method for measuring flame propagation velocity of Bunsen burner during combustion process of gaseous fuel is suitably used for measuring the flame propagation velocity of the Bunsen burner during the combustion process of gaseous fuel.

Owner:HARBIN INST OF TECH

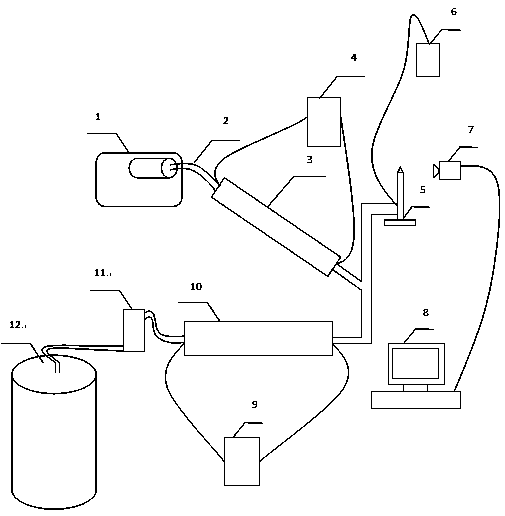

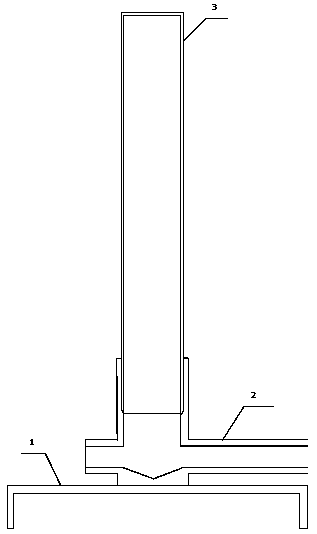

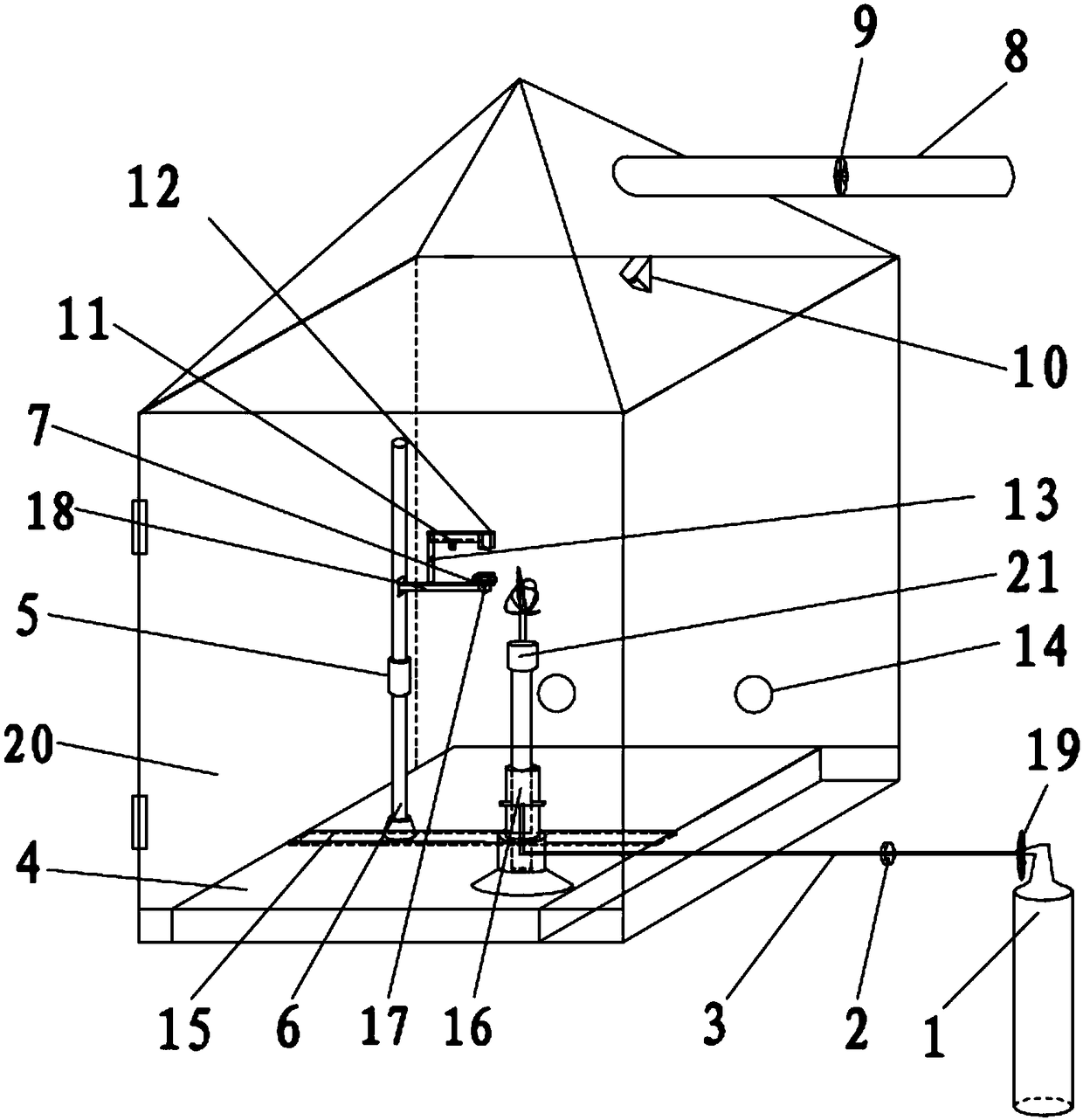

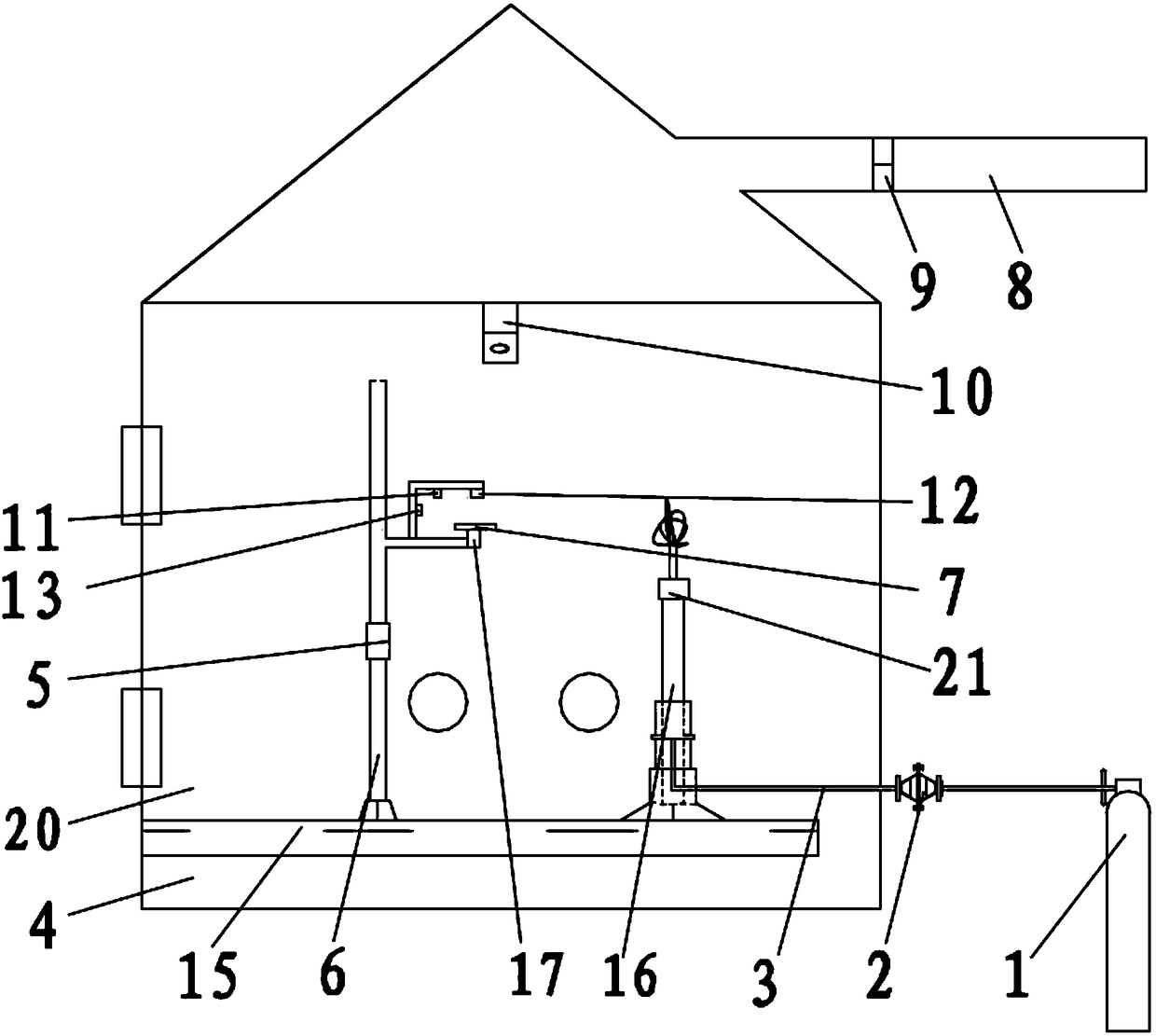

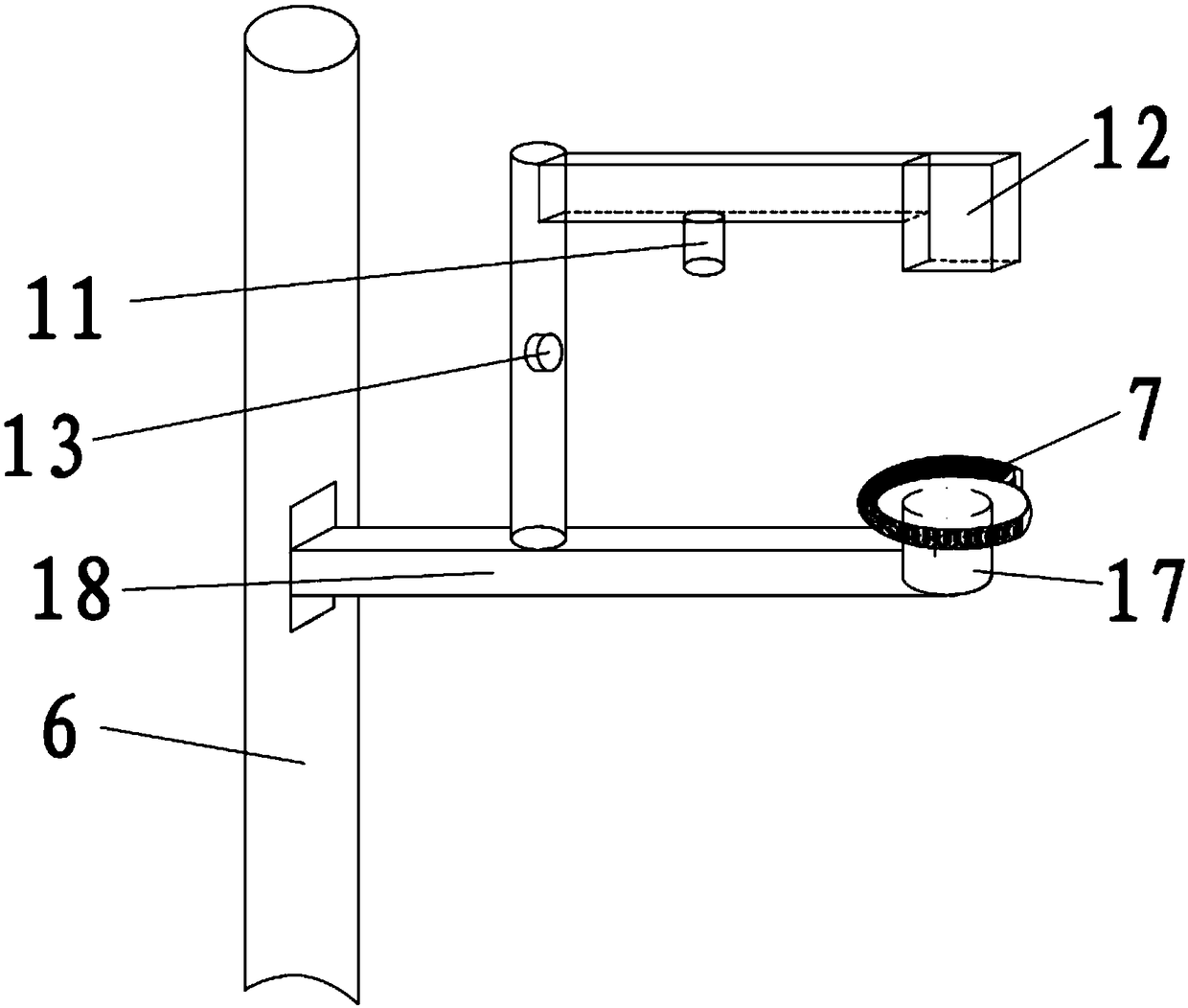

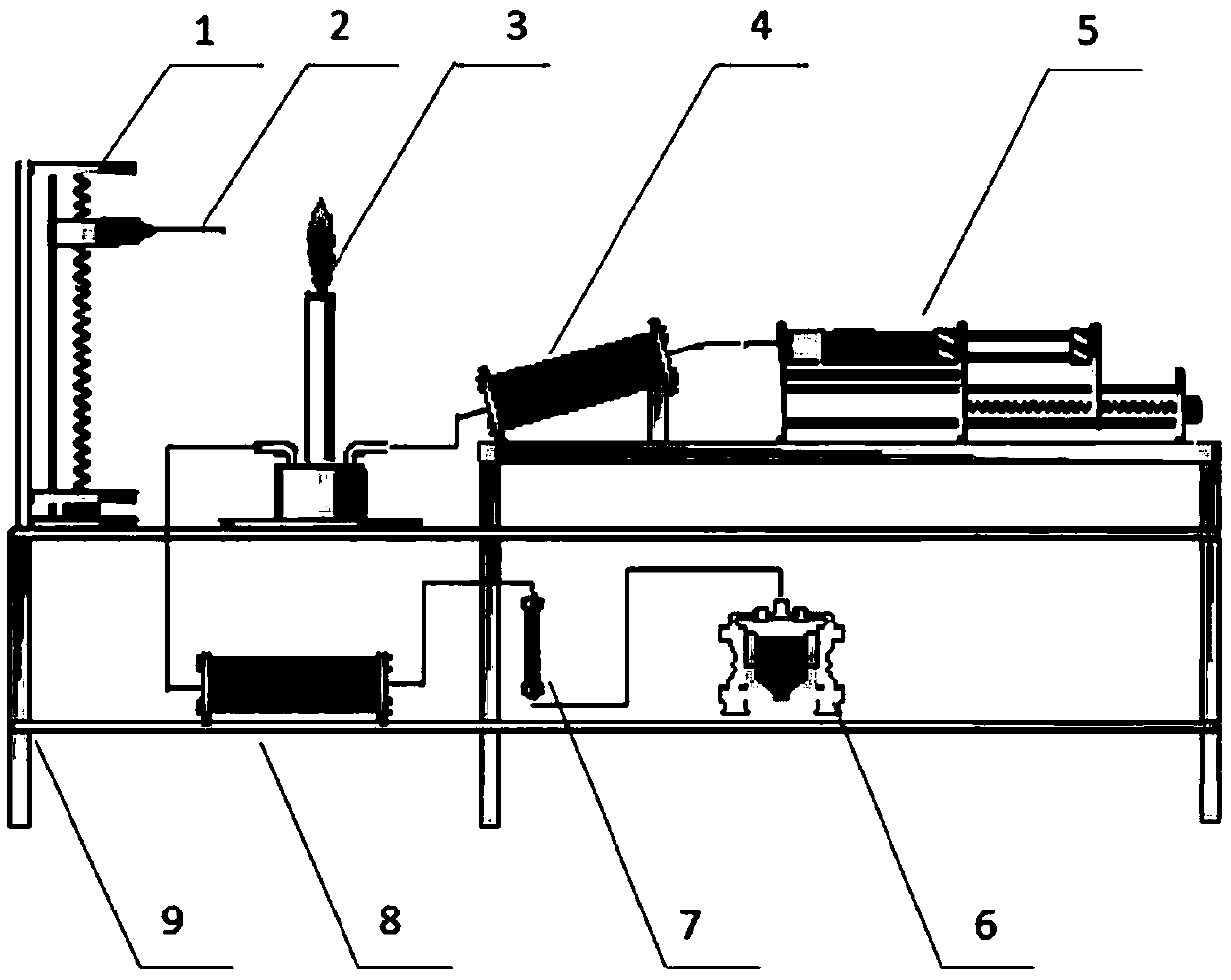

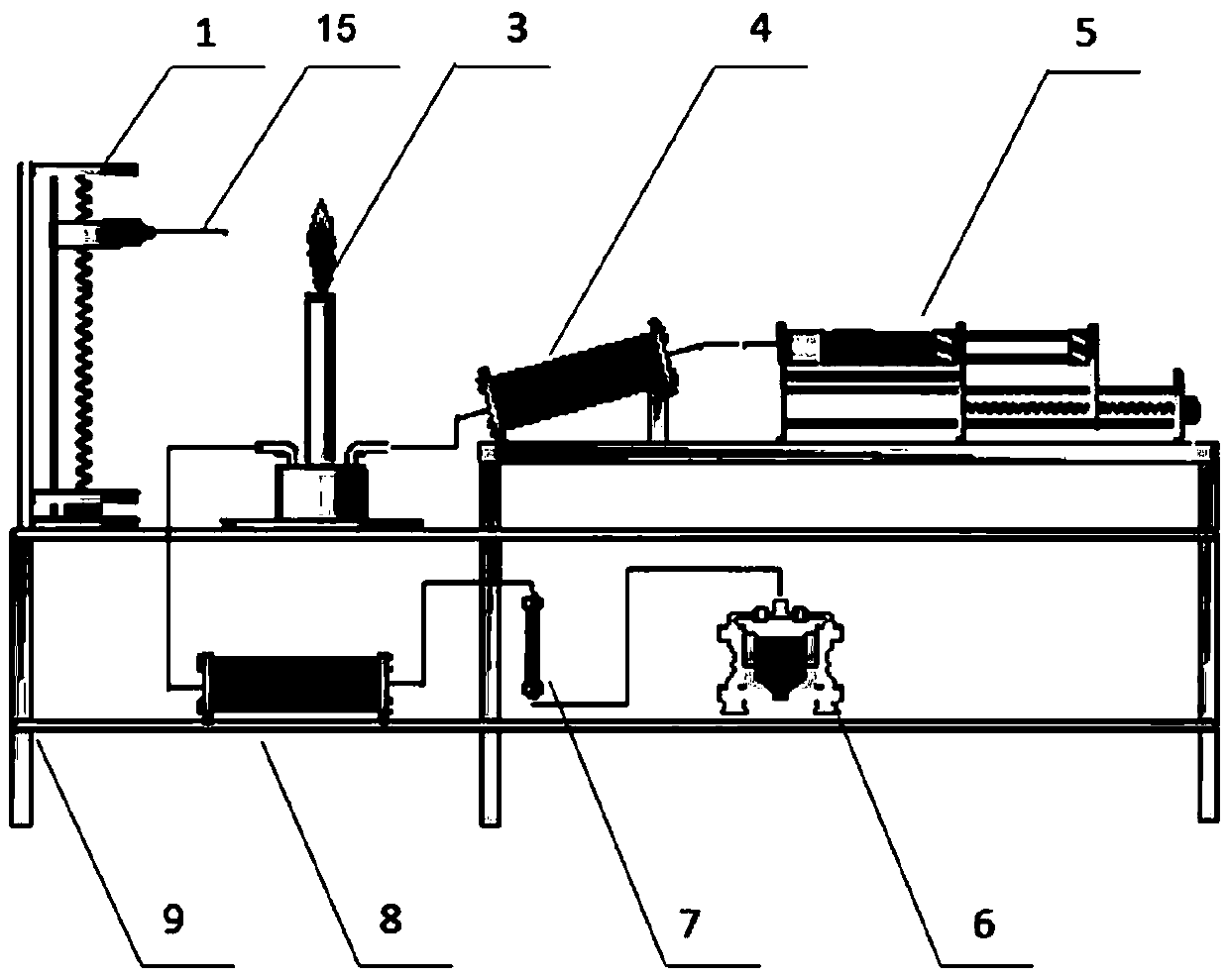

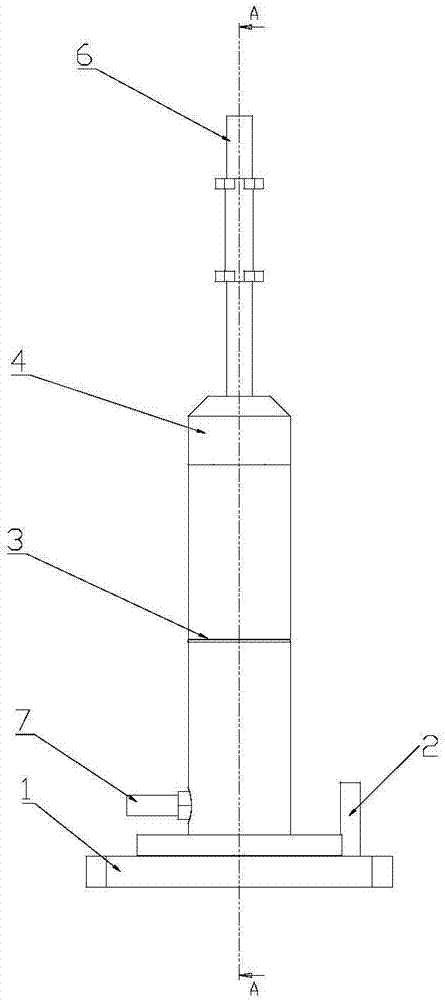

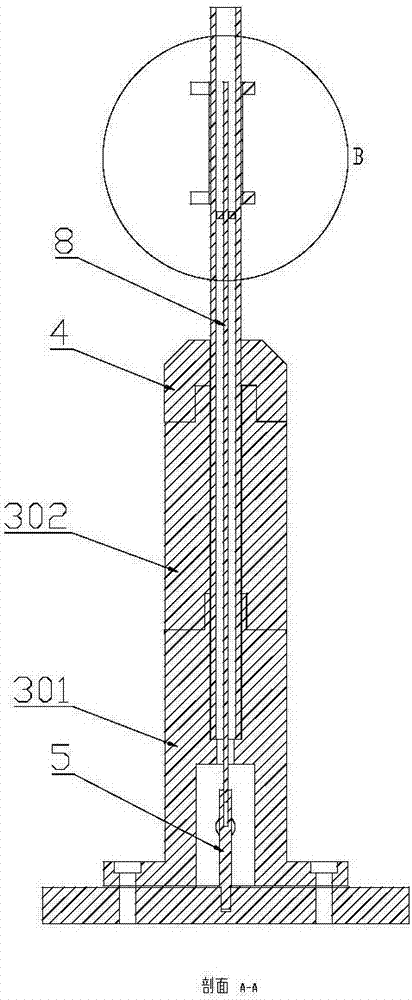

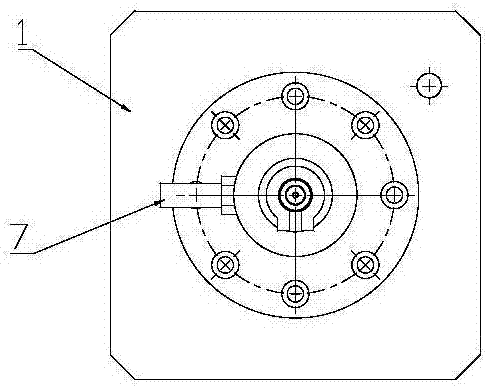

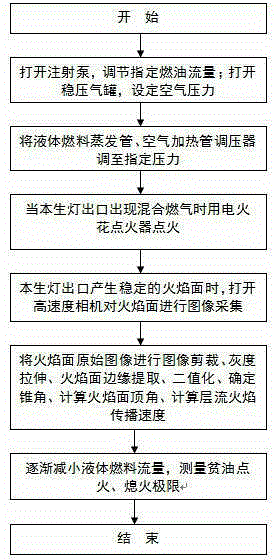

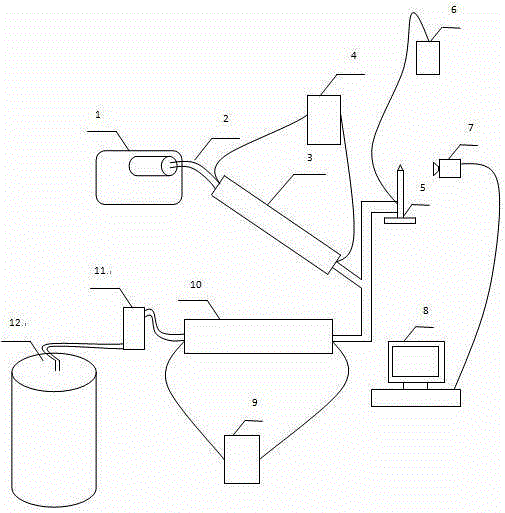

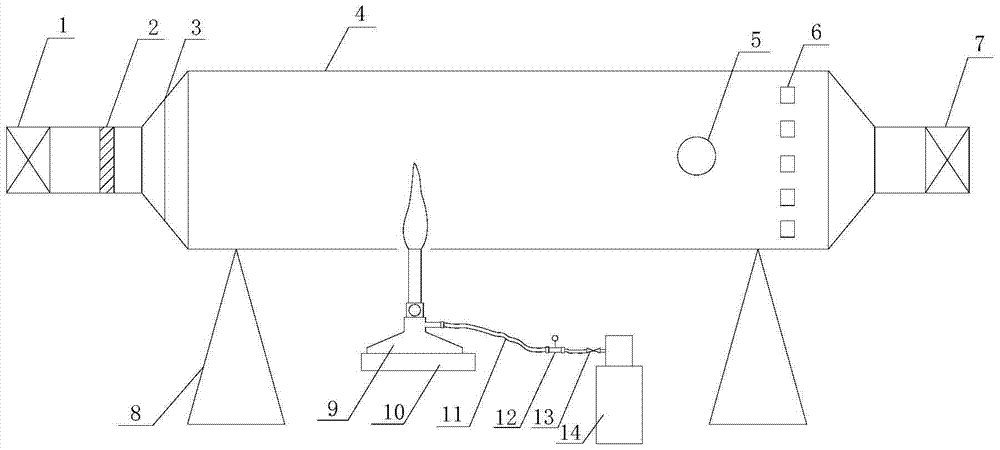

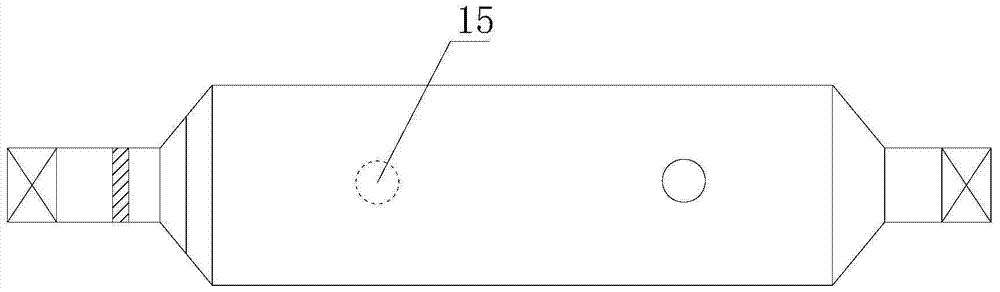

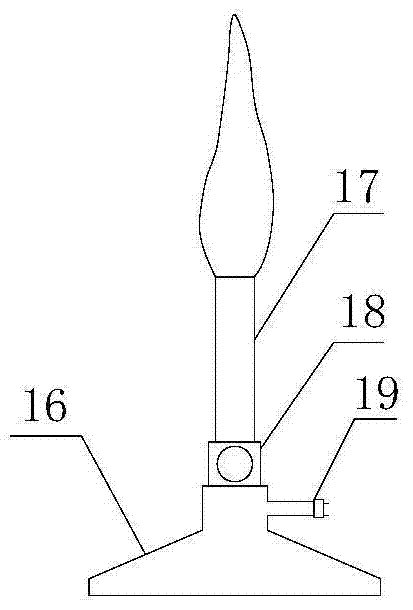

Gaseous-phase Bunsen burner laminar flame propagation speed measurement device and measurement method for liquid fuel

InactiveCN104062394AQuick pickEasy to operateChemical analysis using combustionBunsen burnerEvaporation

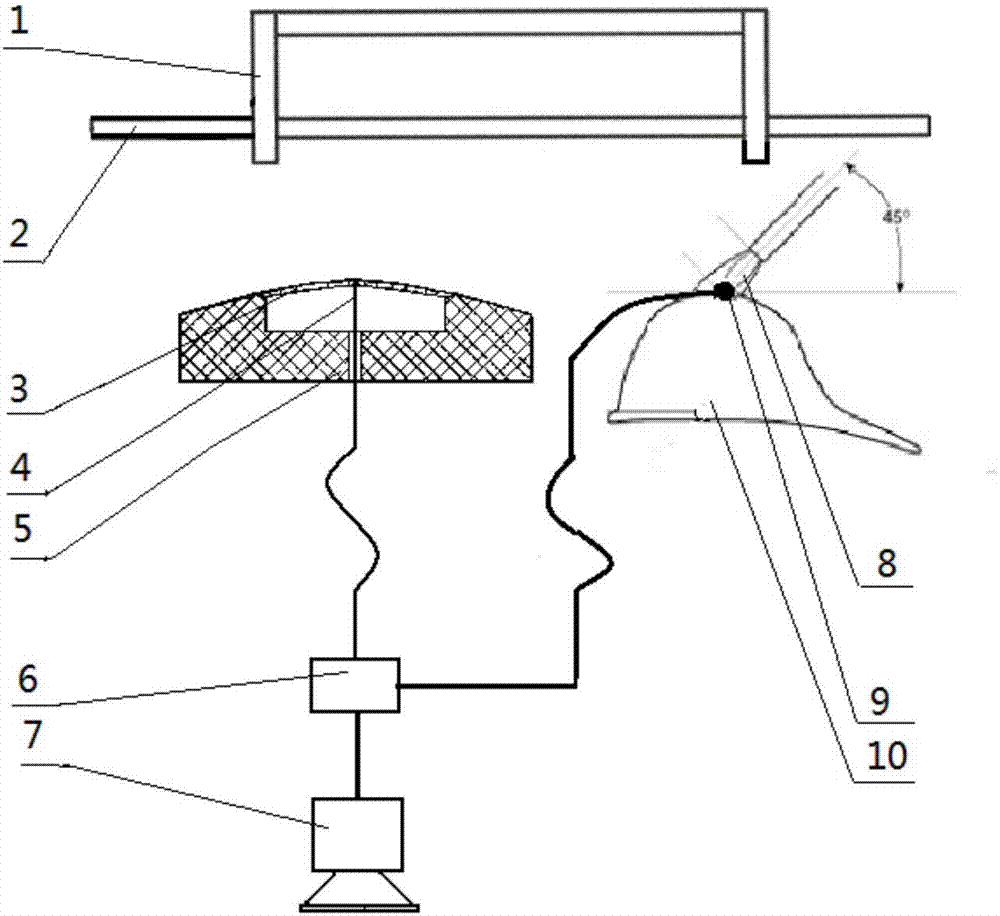

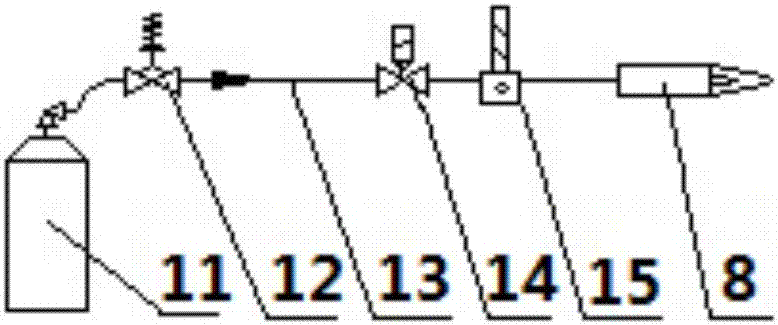

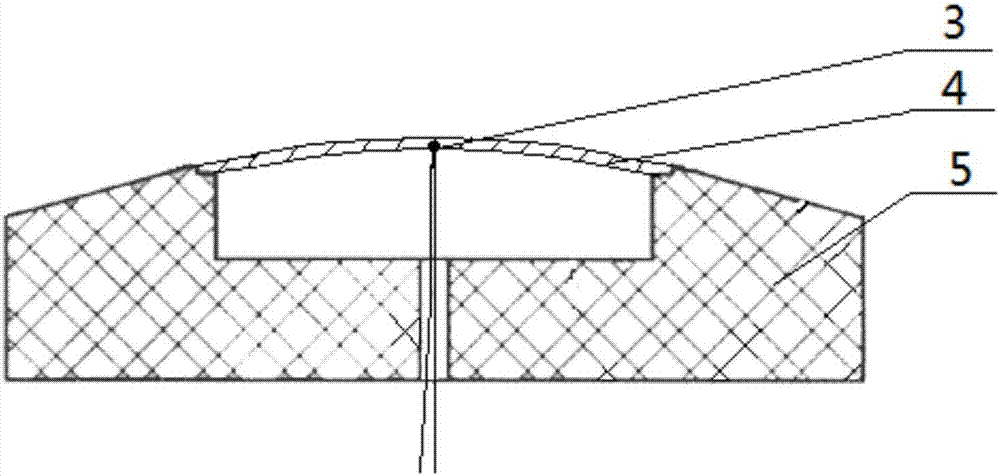

The invention provides a gaseous-phase Bunsen burner laminar flame propagation speed measurement device and a gaseous-phase Bunsen burner laminar flame propagation speed measurement method for a liquid fuel. The device comprises a Bunsen burner, wherein the Bunsen burner is connected with a temperature measurement display (thermocouple), a cold air heating system and a liquid fuel evaporation system respectively; the liquid fuel evaporation system is connected with an injection pump through a rubber pipeline; the cold air heating system is communicated with external air; a flame image acquisition and processing device is arranged beside the Bunsen burner. The device is simple, convenient to operate, low in cost and favorable for basic comparison between burning characteristics of different liquid fuels, and the rapid fuel selection of a spray burning system is supported. A high-speed digital camera is adopted for the measurement method, a flame conical surface can be continuously shot, a flame image cosine law method is used for calculating the gaseous-phase Bunsen burner laminar flame propagation speed of the liquid fuel according to current mixed gas speed, and the measurement method is directly provided based on the definition of the flame propagation speed, and is simple and effective.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

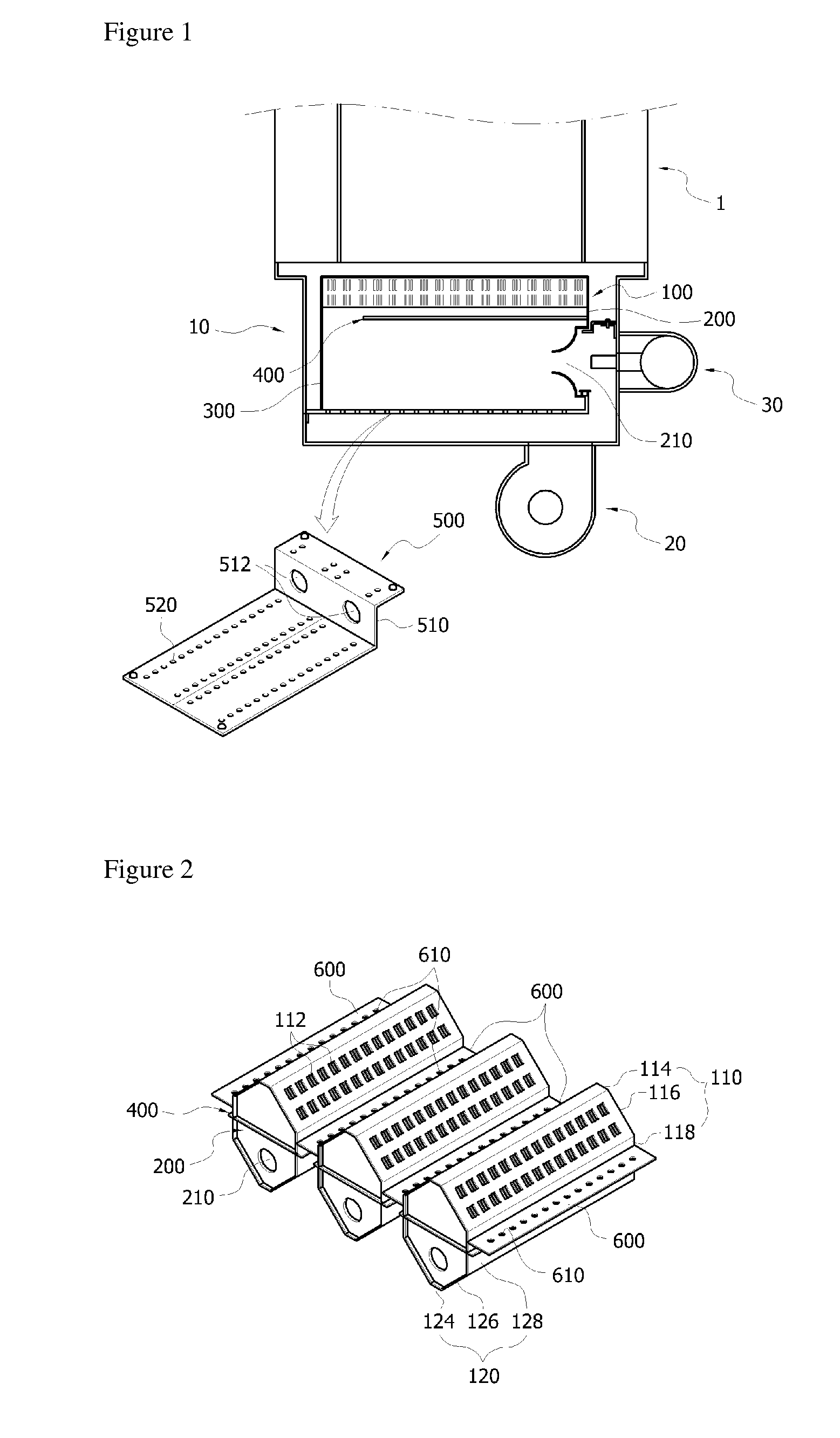

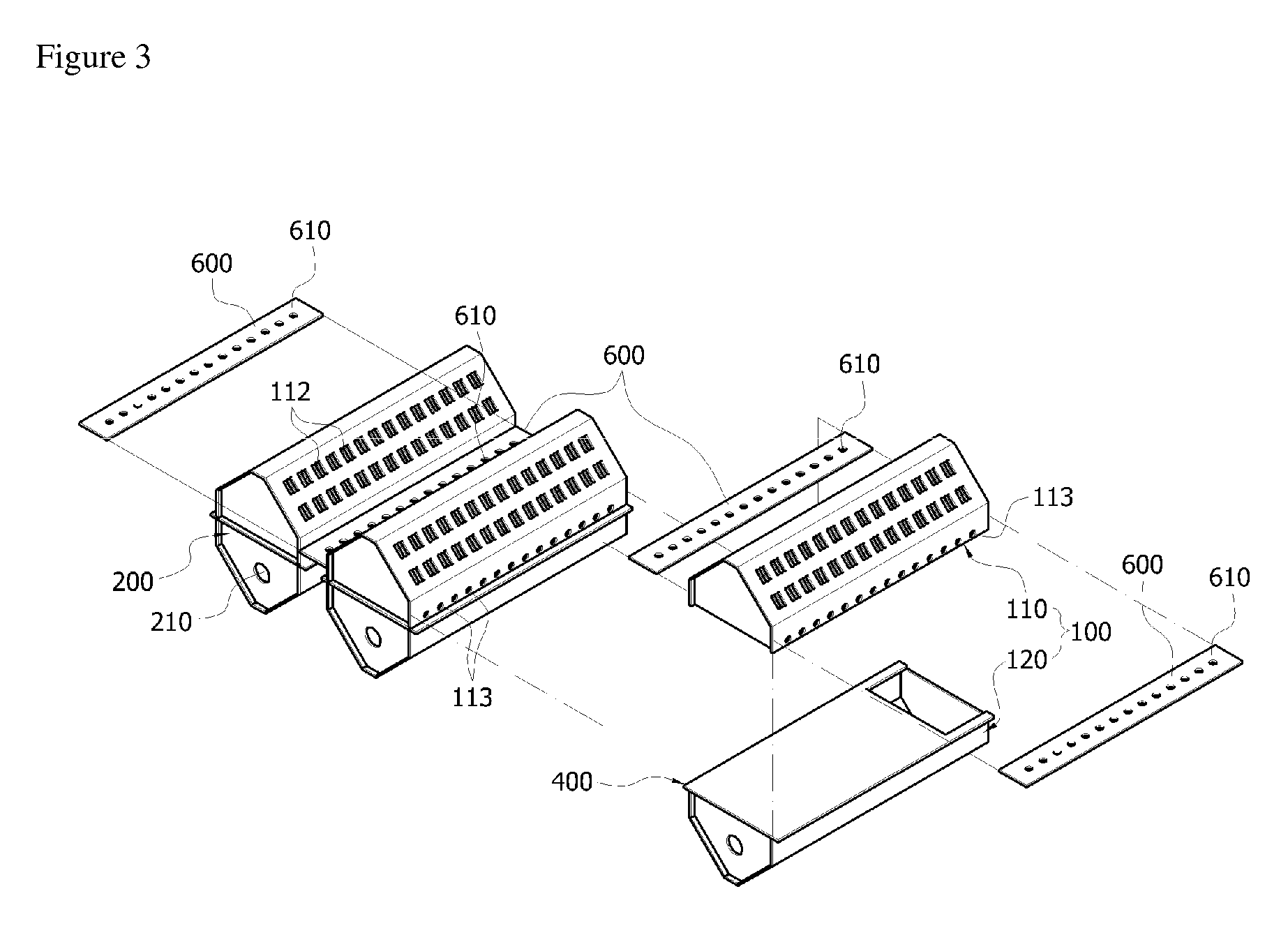

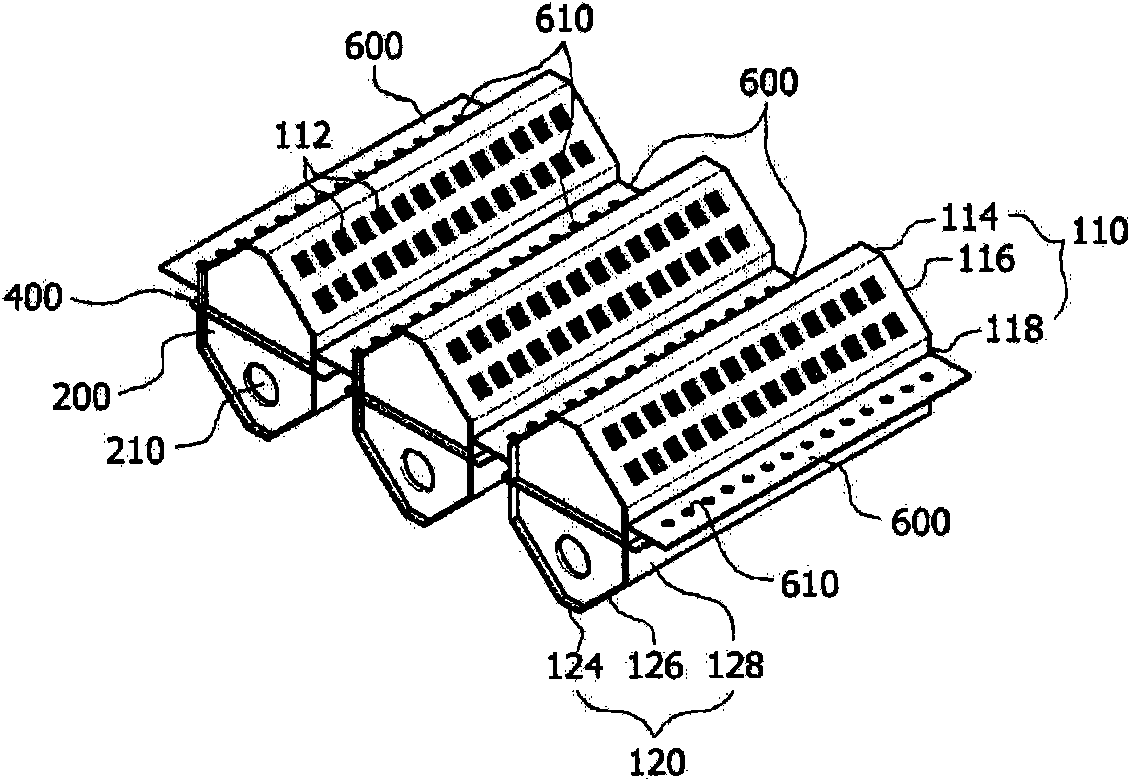

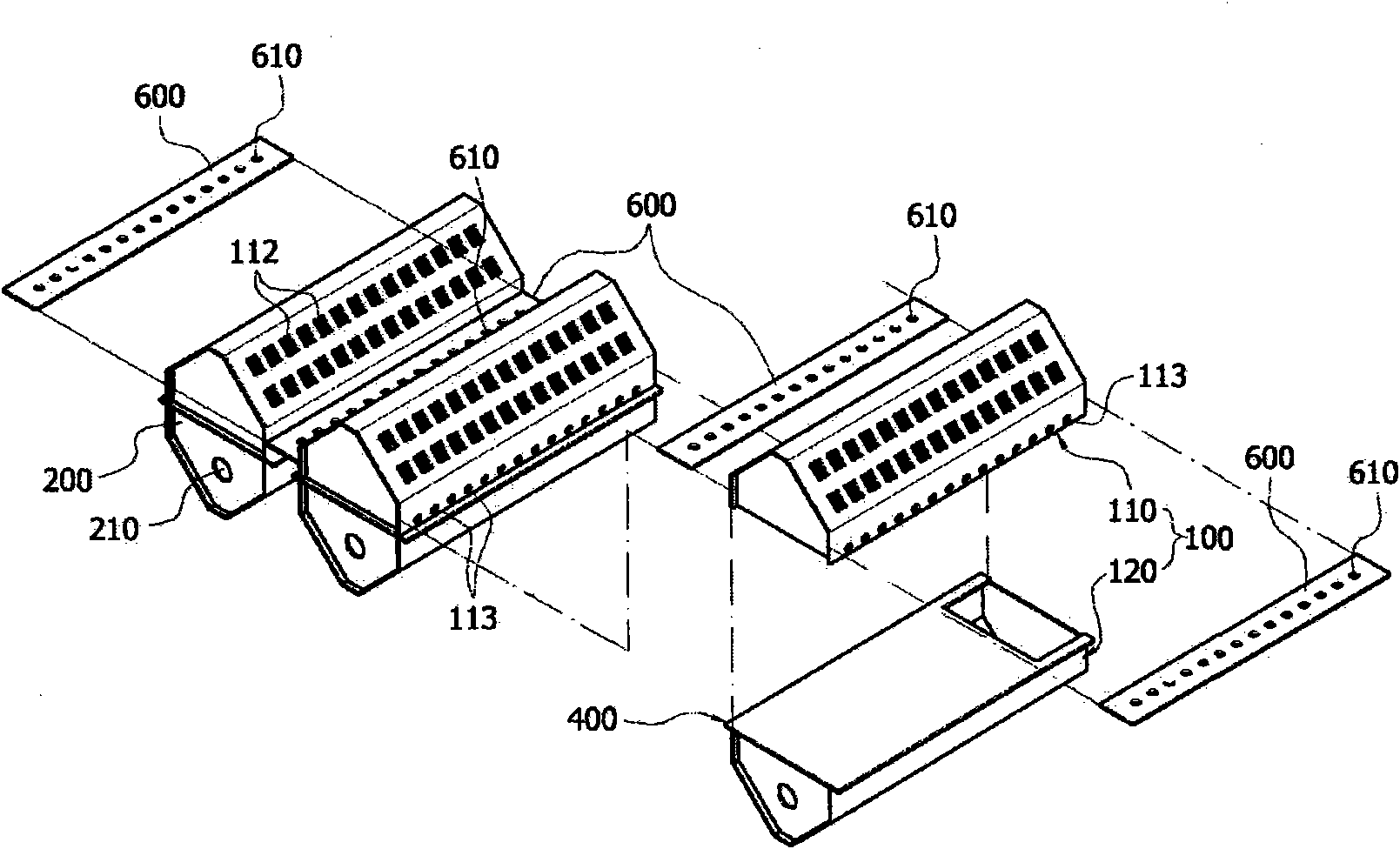

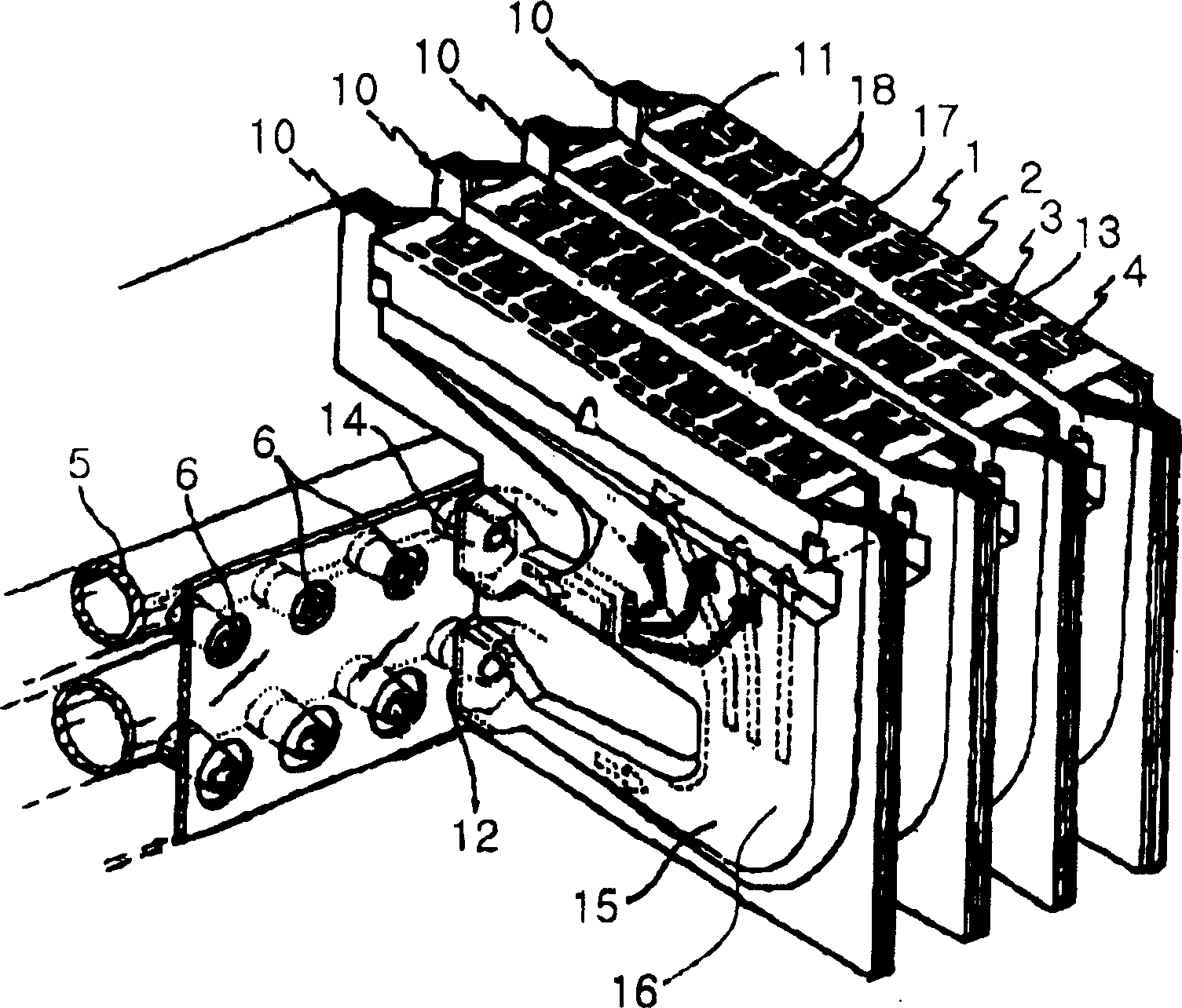

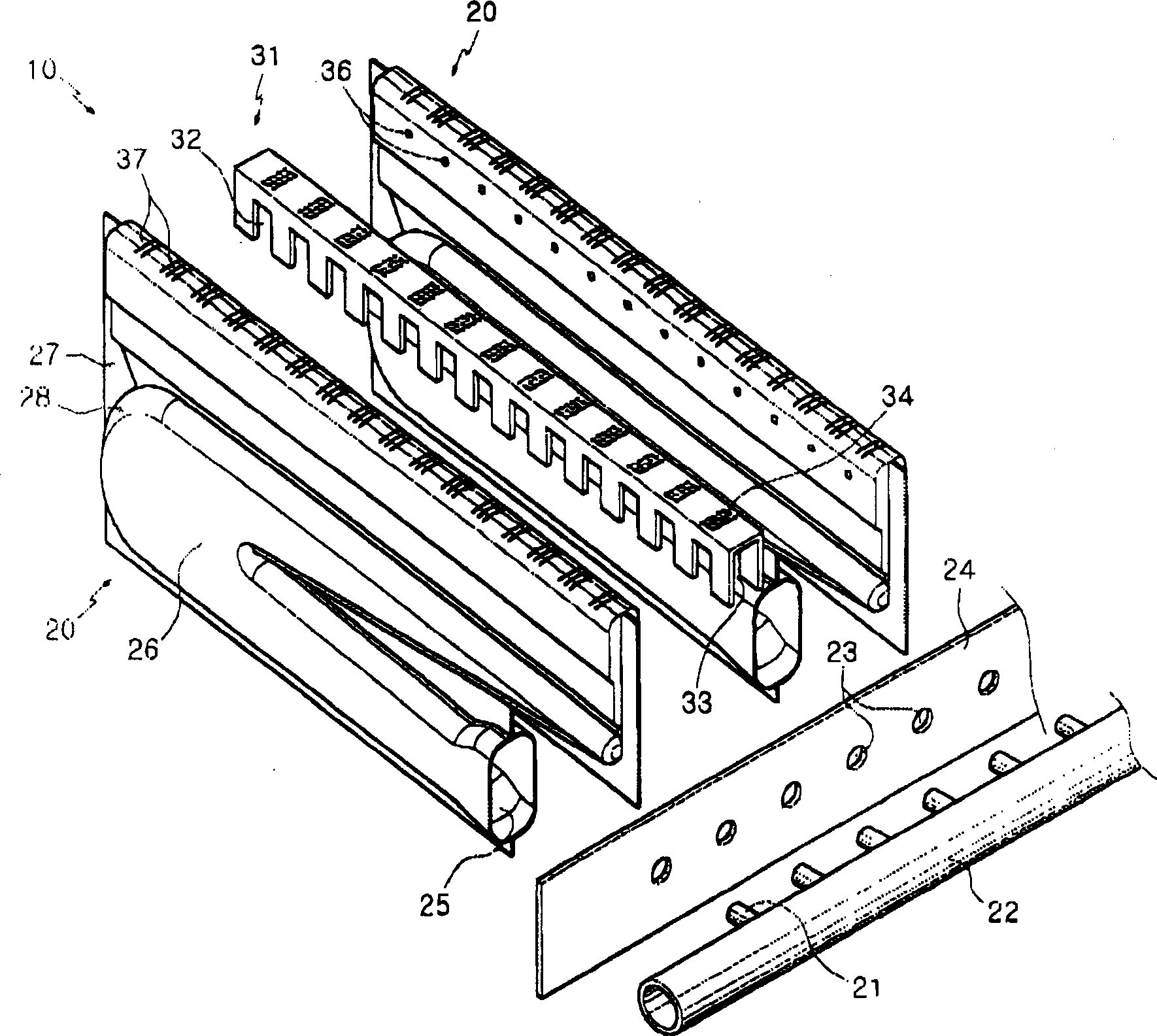

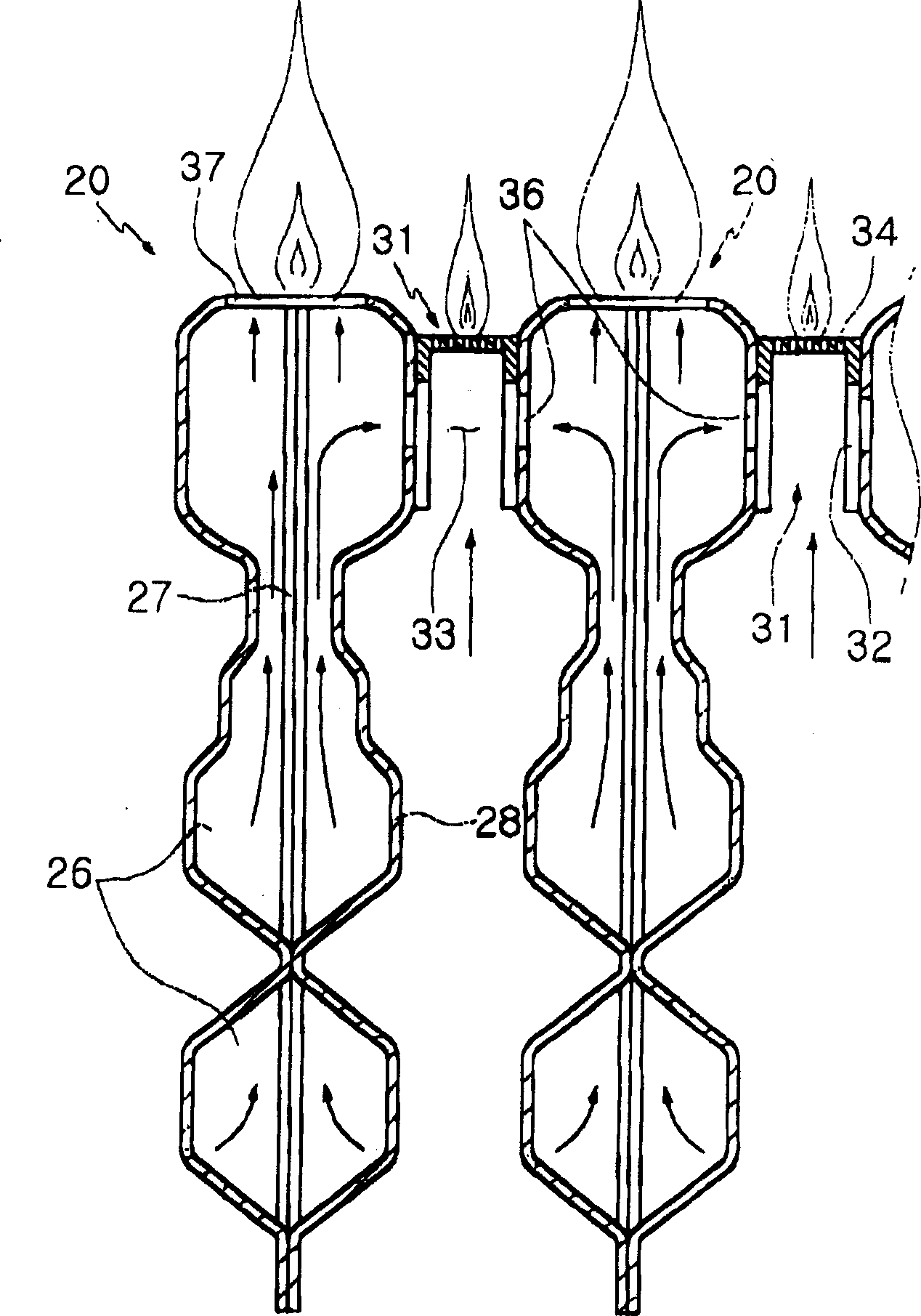

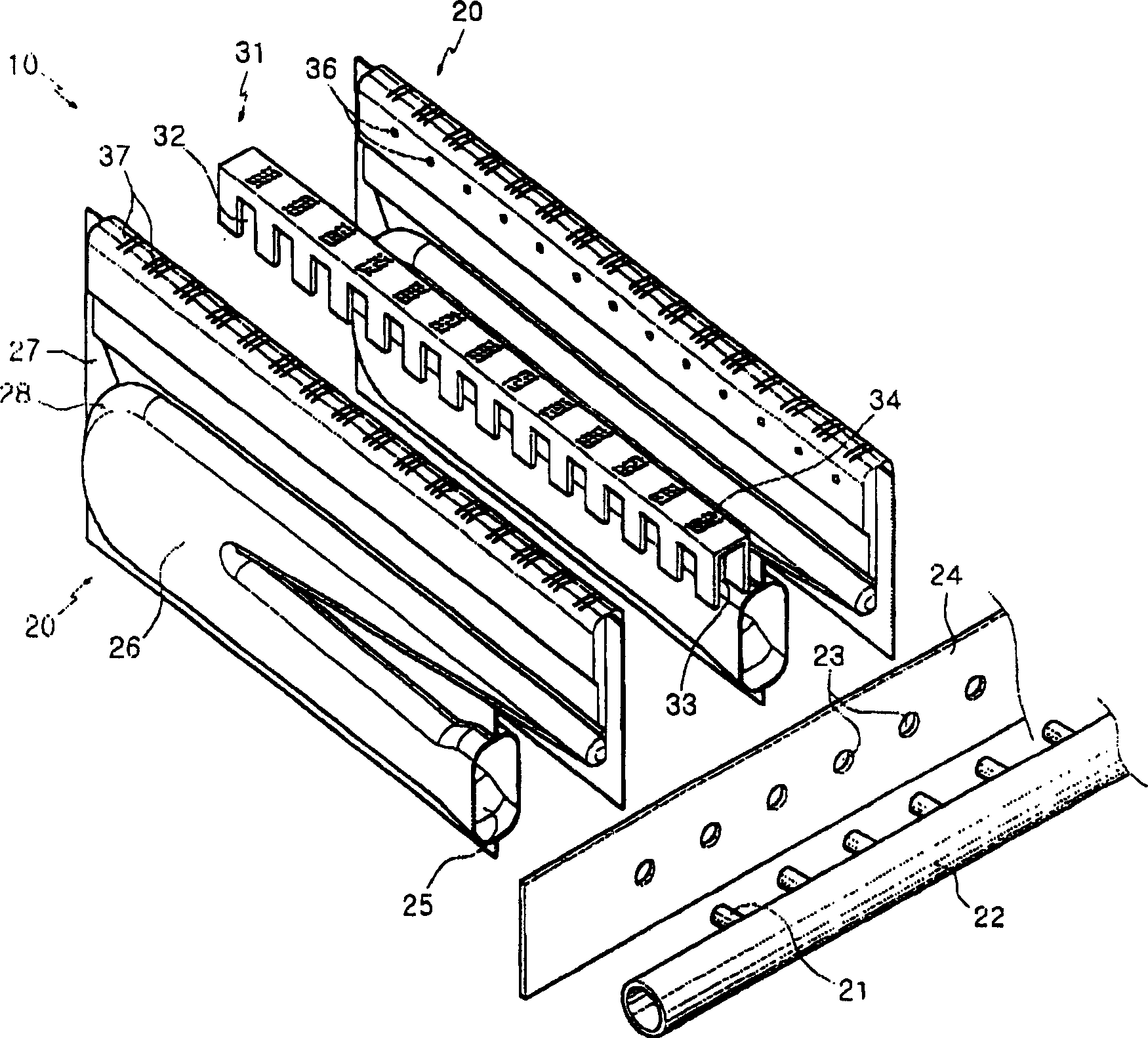

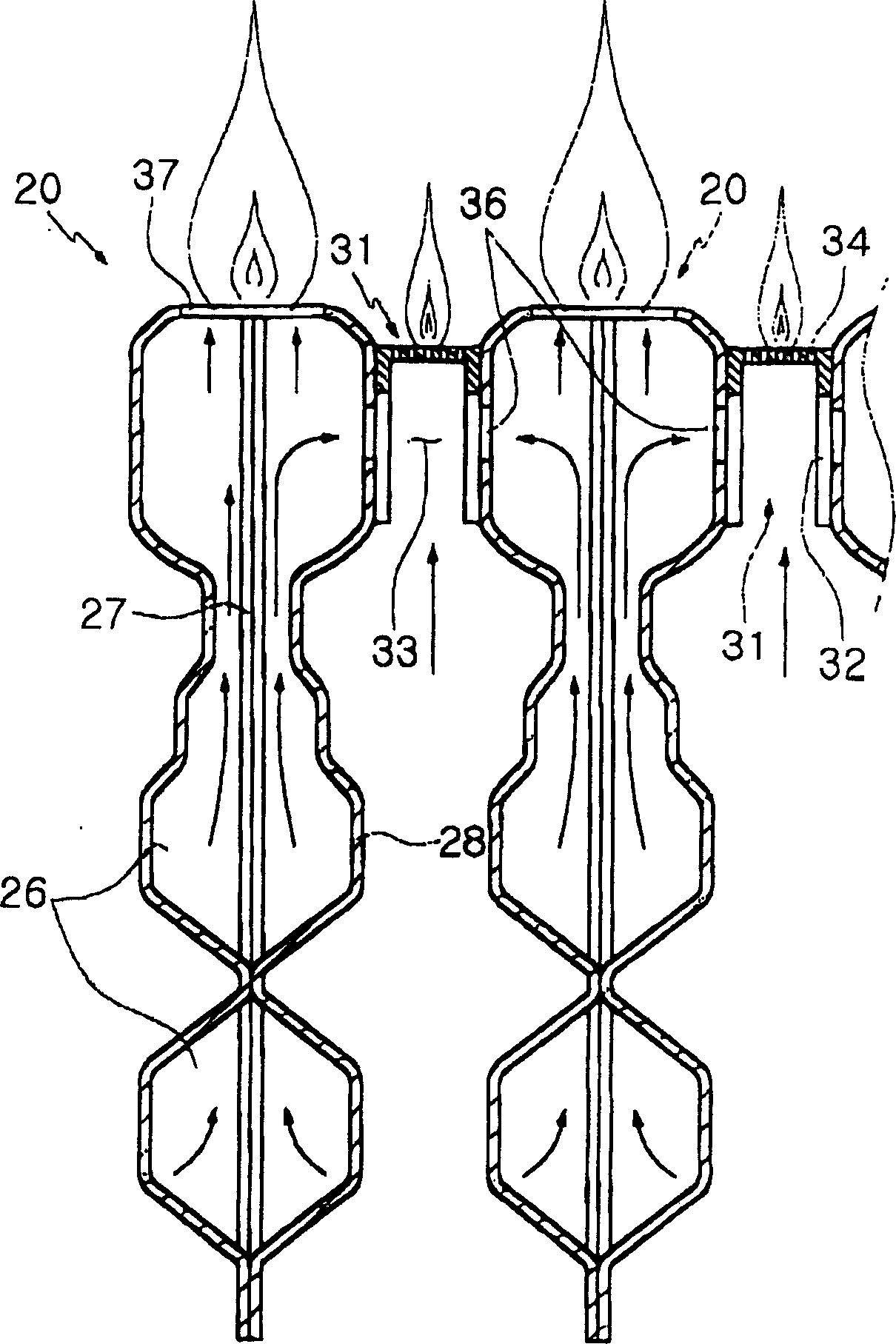

Bunsen burner using lean-rich combustion type

InactiveUS20110053105A1Stabilizing function is enhancedReduce widthGaseous fuel burnerCombustion chambersBunsen burnerEngineering

A Bunsen burner which reduces pollutant materials generated during combustion by adopting a lean combustion, enhancing combustion stability. The Bunsen burner includes burner bodies, each including: a venturi plate having a venturi hole through which a gas mixture is introduced, wherein air supplied from a fan is mixed with fuel jetted from a nozzle unit, a guide plate for guiding the gas mixture upward, an inclined portion having first flame holes for jetting the gas mixture at an oblique angle with respect to the vertical direction, a side portion that extends downward from a lower side of the inclined portion and includes through-holes through which some of the gas mixture passes, and a connection plate having opposed ends connected to the side portions of the burner bodies, respectively, and having second flame holes in which the gas mixture passing through the through-holes and secondary air, introduced by the fan and supplied along outer surfaces of the burner bodies, are mixed so that lean combustion occurs.

Owner:KYUNGDONG NAVIEN

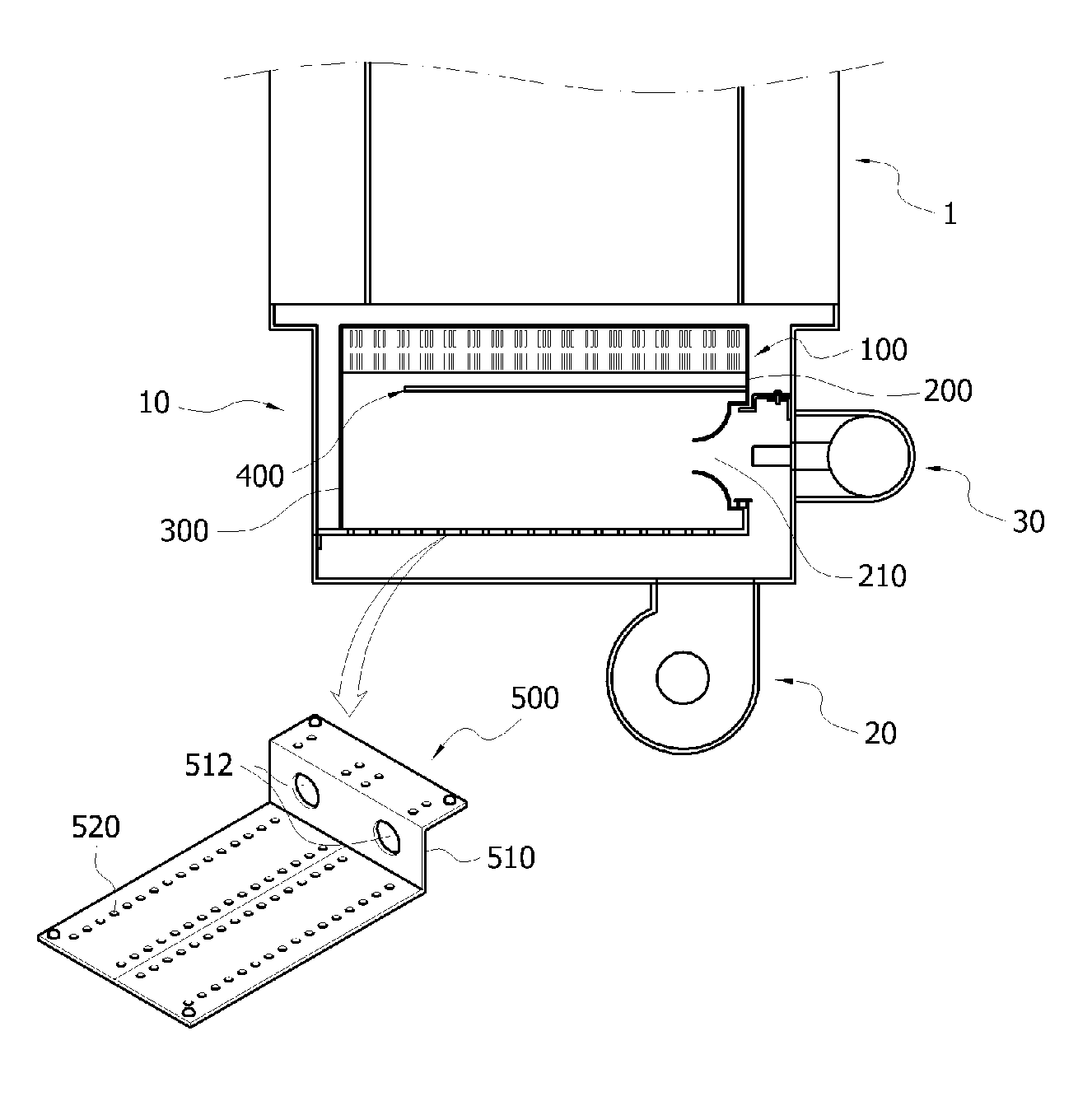

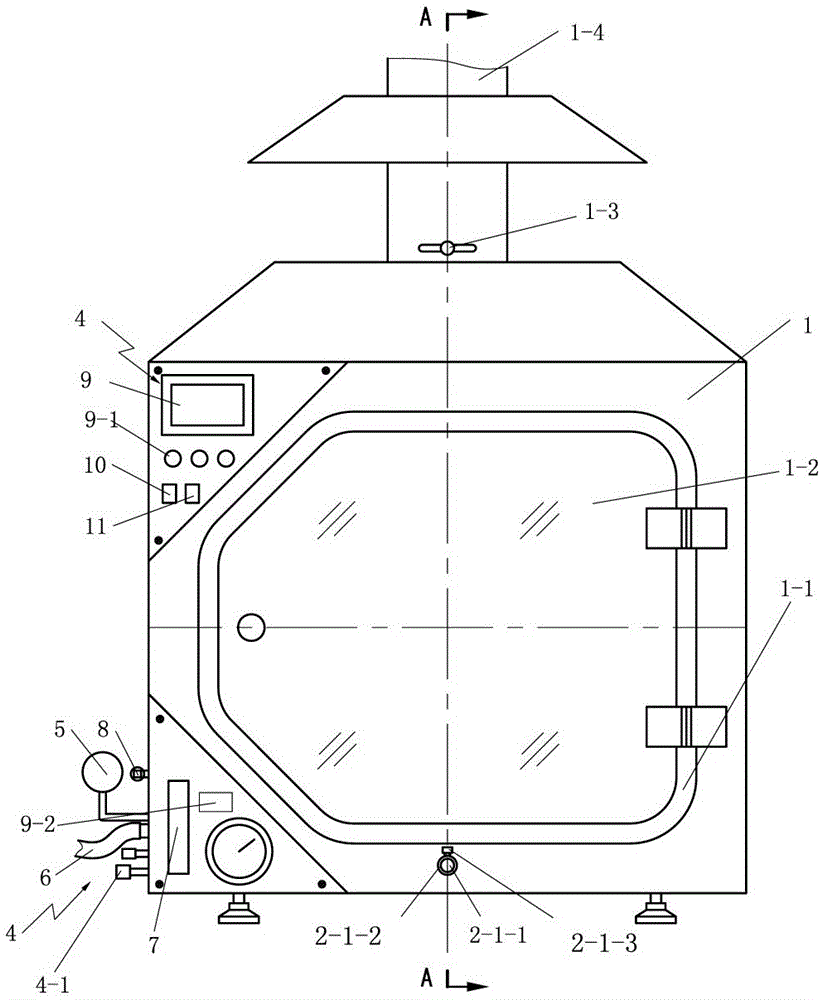

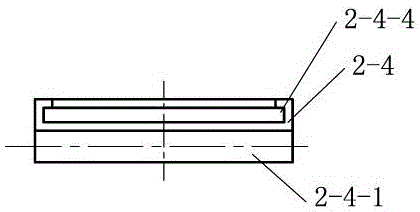

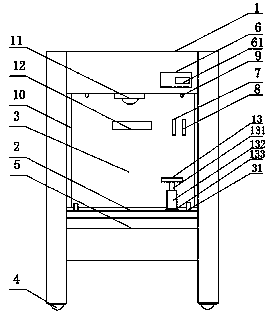

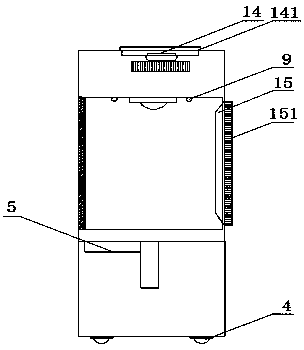

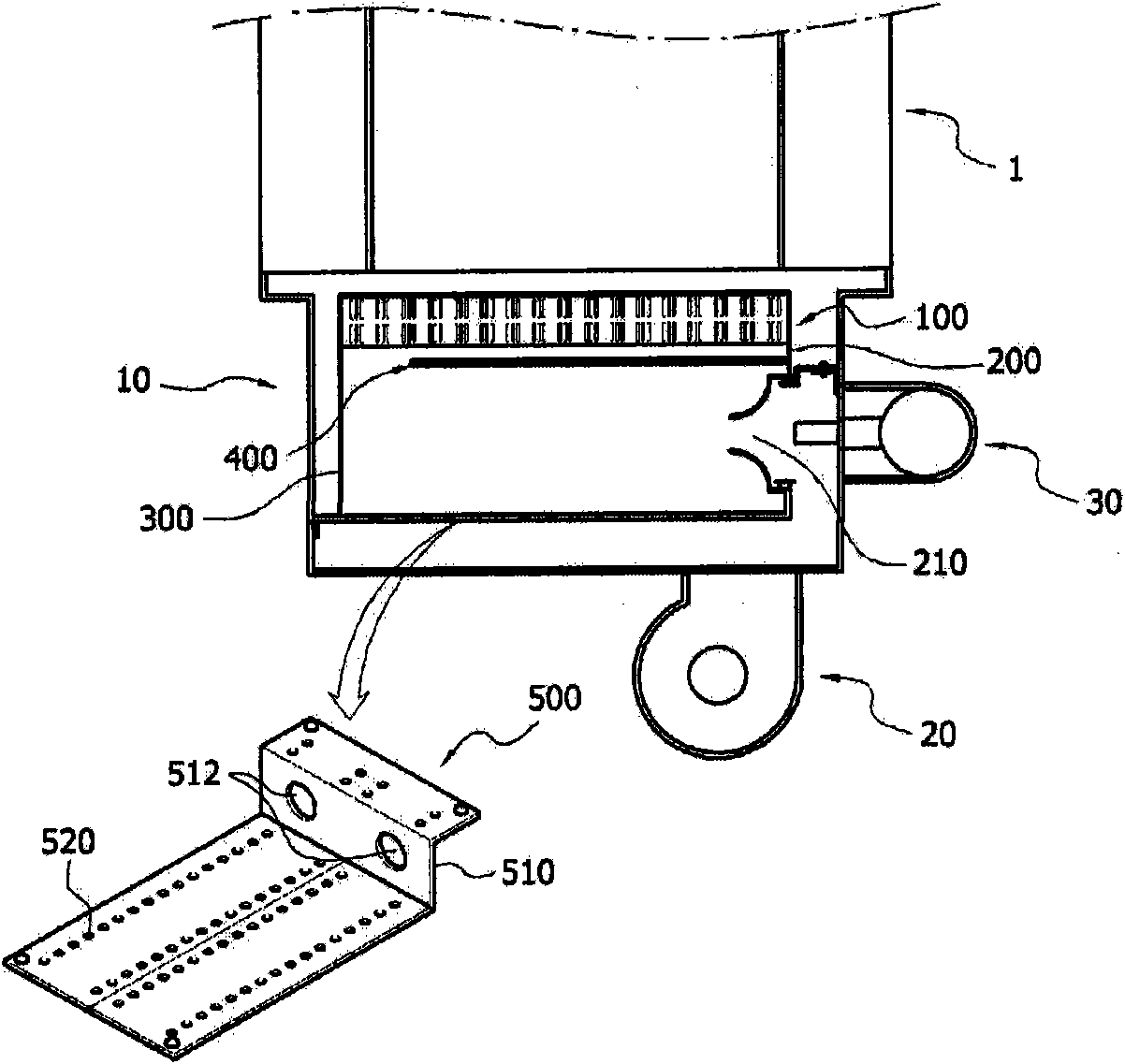

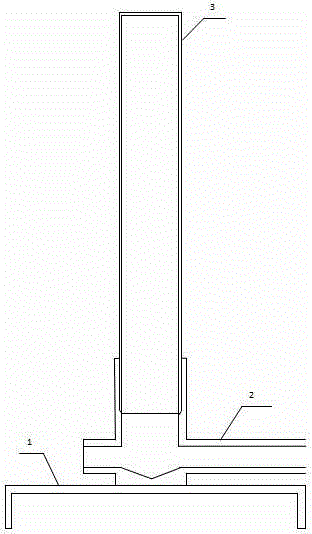

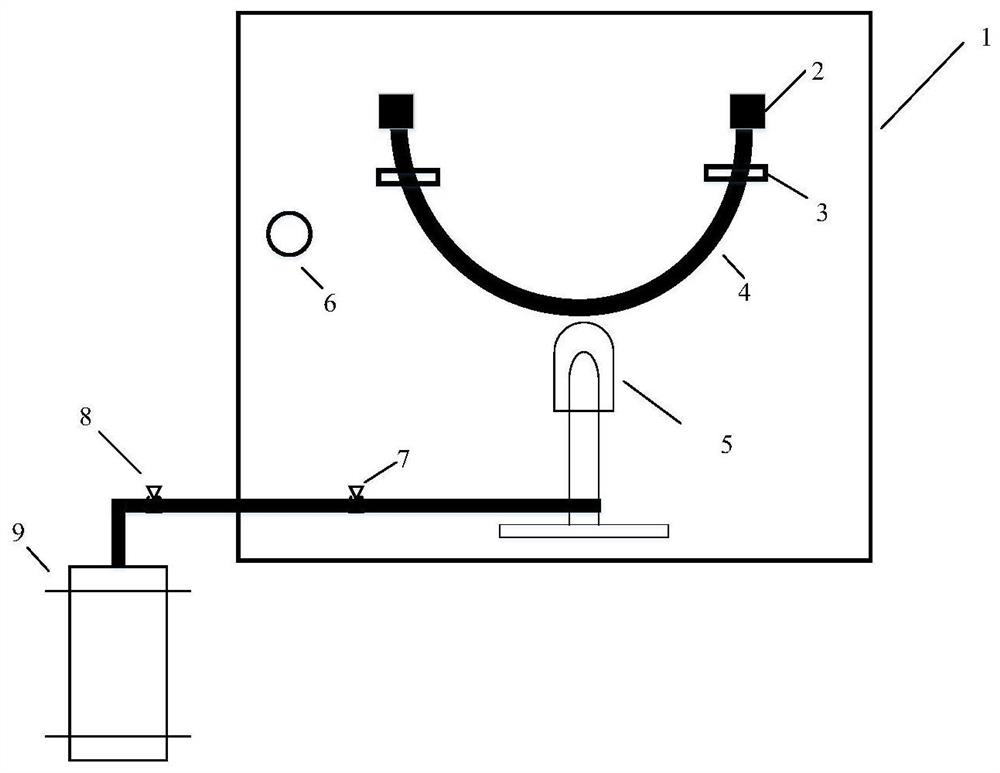

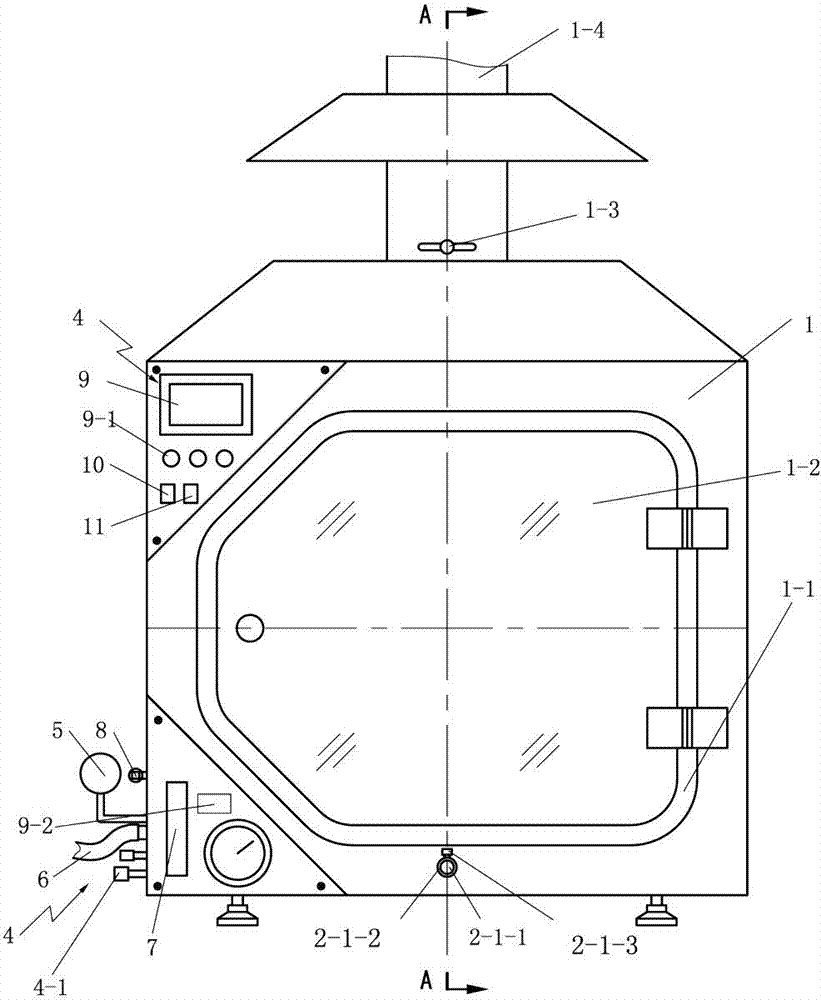

Non-metallic material combustion performance testing apparatus

ActiveCN105004750AEasy to adjust the angleEasy to adjust the distanceMaterial thermal analysisTest samplePush pull

The present invention relates to a non-metallic material combustion performance testing apparatus, which comprises a combustion box body, a flaming device, a sample fixing device and a combustion gas control mechanism. The flaming device and the sample fixing device are connected with the internal bottom plate of the combustion box body. The combustion gas control mechanism comprises a gas flow and pressure control part, and a gas switch and timing control part. The flaming device is connected with the pipeline of the gas flow and pressure control part and is electrically connected with the gas switch and timing control part. The flaming device comprises a sliding block, a guide rail, a 45-degree bracket, a Bunsen burner installation plate, a Bunsen burner base, a Bunsen burner lamp tube and a Bunsen burner nozzle. The guide rail is fixedly mounted onto the internal bottom plate of the combustion box body and is connected with the internal bottom plate. The sliding block is in sliding fit with the guide rail and is connected with the guide rail. One side surface of the sliding block is provided with a push-pull rod. Based on the above structure, the included angle and the distance of a flame nozzle relative to a test sample can be conveniently adjusted. Meanwhile, the test cost is lowered, and the operation flow is facilitated.

Owner:南德西交轨道交通技术(江苏)有限公司

Test device for combustion characteristics of coal sample under thermal radiation of jet flames in different strengths

ActiveCN108982745AReduce heat transferReduce the temperatureChemical analysis using combustionBunsen burnerFuel tank

The invention relates to a test device for combustion characteristics of a coal sample under thermal radiation of jet flames in different strengths. The device can be used for researching the coal sample ignition with non-contact flames. The test device comprises a box, a flame heating component, a coal sample placing component and a detecting component; an experimental platform, a gas-guide portand a fume exhausting pipeline are arranged on the box; the flame heating component comprises a fuel tank and a Bunsen burner; the Bunsen burner is connected with the fuel tank through a conduit; thecoal sample placing component comprises an expansion link, a support rod, a rail and a sample vessel; a rail is arranged on the experimental platform; the expansion link is arranged on the experimental platform; the support rod is arranged on the expansion link; the sample vessel is placed on the tail end of the support rod; the detecting component is arranged in the box and comprises a mass sensor, a photoelectric thermocouple, a radiation heat-flow meter, a gas sensor and a camera; the mass sensor is arranged on the tail end of the support rod; the photoelectric thermocouple, the radiation heat-flow meter and the gas sensor are all arranged on the support rod; a camera is arranged above the box.

Owner:XIAN UNIV OF SCI & TECH

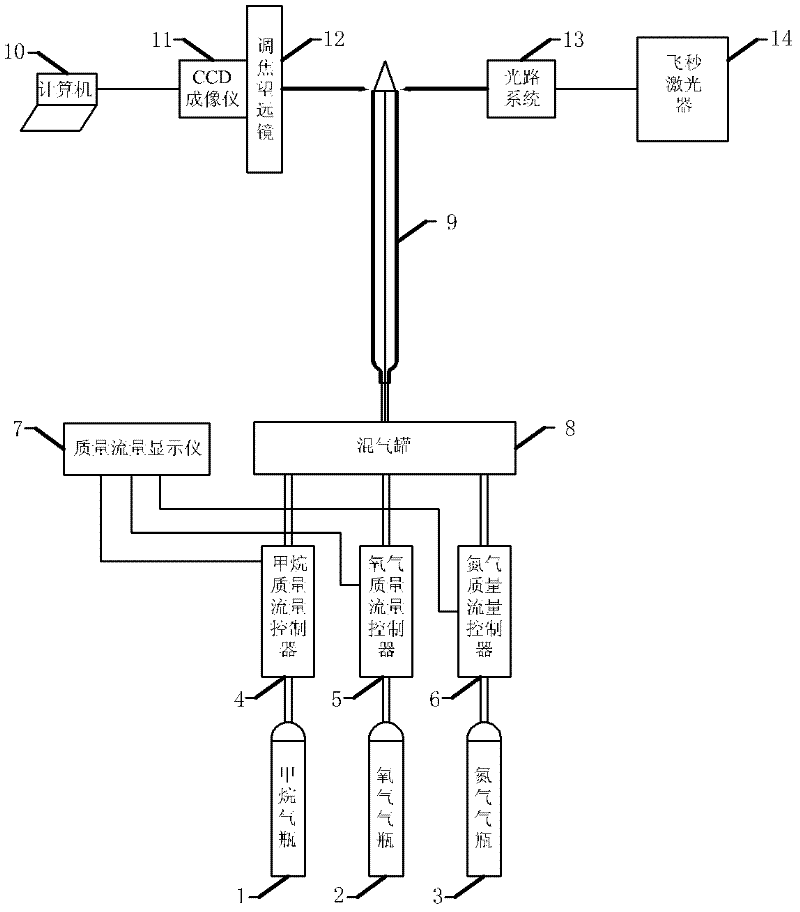

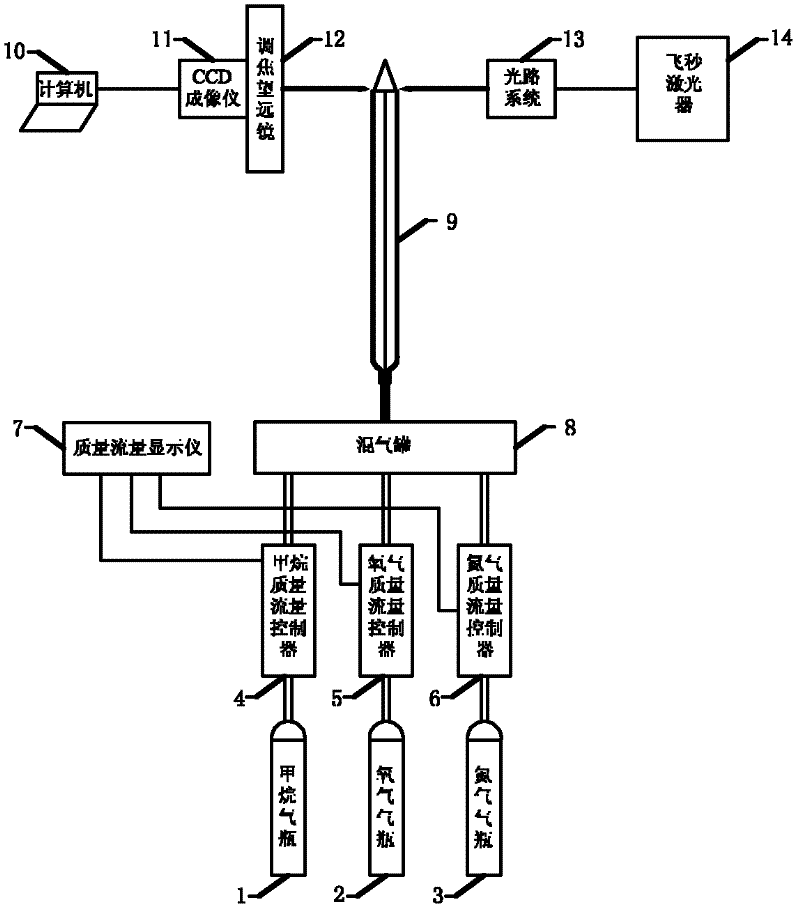

Femtosecond laser-induced plasma method for increasing gaseous hydrocarbon fuel stability limit and device for realizing the method

InactiveCN102287349AIncrease temperatureImprove combustion efficiencyMachines/enginesUsing plasmaCombustion instabilityBunsen burner

The invention discloses a method for increasing the stable combustion limit of gaseous hydrocarbon fuels by femtosecond laser-induced plasma and a device for realizing the method, relating to a method for improving the stable combustion limit of gaseous hydrocarbon fuels and a device for realizing the method. It solves the problems of unstable combustion and easy extinguishment of flames existing in the existing air velocity supercritical combustion system. Method: ignite the mixed gas at the nozzle of the quartz glass circular tube to form a Bunsen burner flame, and make the speed of the mixed gas supercritical; use a femtosecond laser to emit a femtosecond laser beam, and turn the femtosecond laser The beam is focused on the unburned area of the mixed gas to induce the mixed gas to generate plasma, so as to improve the flame stability limit. Device: The gas outlet of the gas mixing tank is connected to the inlet of the quartz glass circular tube; a flame is generated at the top of the quartz glass circular tube, and the femtosecond laser beam generated by the femtosecond laser is focused on the unburned area of the mixed gas. The invention can be widely used in the design of combustion systems with various supercritical airflow speeds.

Owner:HARBIN INST OF TECH

Clean bench for laboratory department

InactiveCN108855279AFree from pollutionAvoid pollutionGas treatmentDispersed particle separationAlcoholAir filter

The invention discloses a clean bench for laboratory department, comprising a box, a glass door, a workbench and a micro operating bench, wherein the glass door is arranged at the front end of the boxthrough a hinge, an air inlet unit is arranged above the box, an inlet air filtering device is arranged above the air inlet unit, an air diffuser cover is arranged outside the rear end of the box, and the interior of the air diffuser cover is provided with a high efficiency filter. The air inlet unit provided by the invention adopts a three-phase motor as a blowing power, and can effectively prevent the air nearby from disturbing and polluting the inside of the box through an inlet air filtering device without hindering burning disinfection of a alcohol lamp or a Bunsen burner and the like oninstruments. In addition, the micro operating bench is set as a rotatable mechanism, so that the laboratory personnel can carry out multi-angle observation on the objects to be tested in more convenient manner. A micro-camera is used to record the testing work in the box in real time, which facilitates the concentration of laboratory personnel, effectively improving the work efficiency.

Owner:王名民

Bunsen burner using lean-rich combustion type

InactiveCN101910725AReduce widthEasy supplyGaseous fuel burnerCombustion chambersBunsen burnerEngineering

Owner:KYUNGDONG NAVIEN

Composite element and use thereof

InactiveCN105408107AReduce static loadAvoid spreadingLamination ancillary operationsLayered product treatmentBunsen burnerComposite plate

Owner:SCHOTT AG

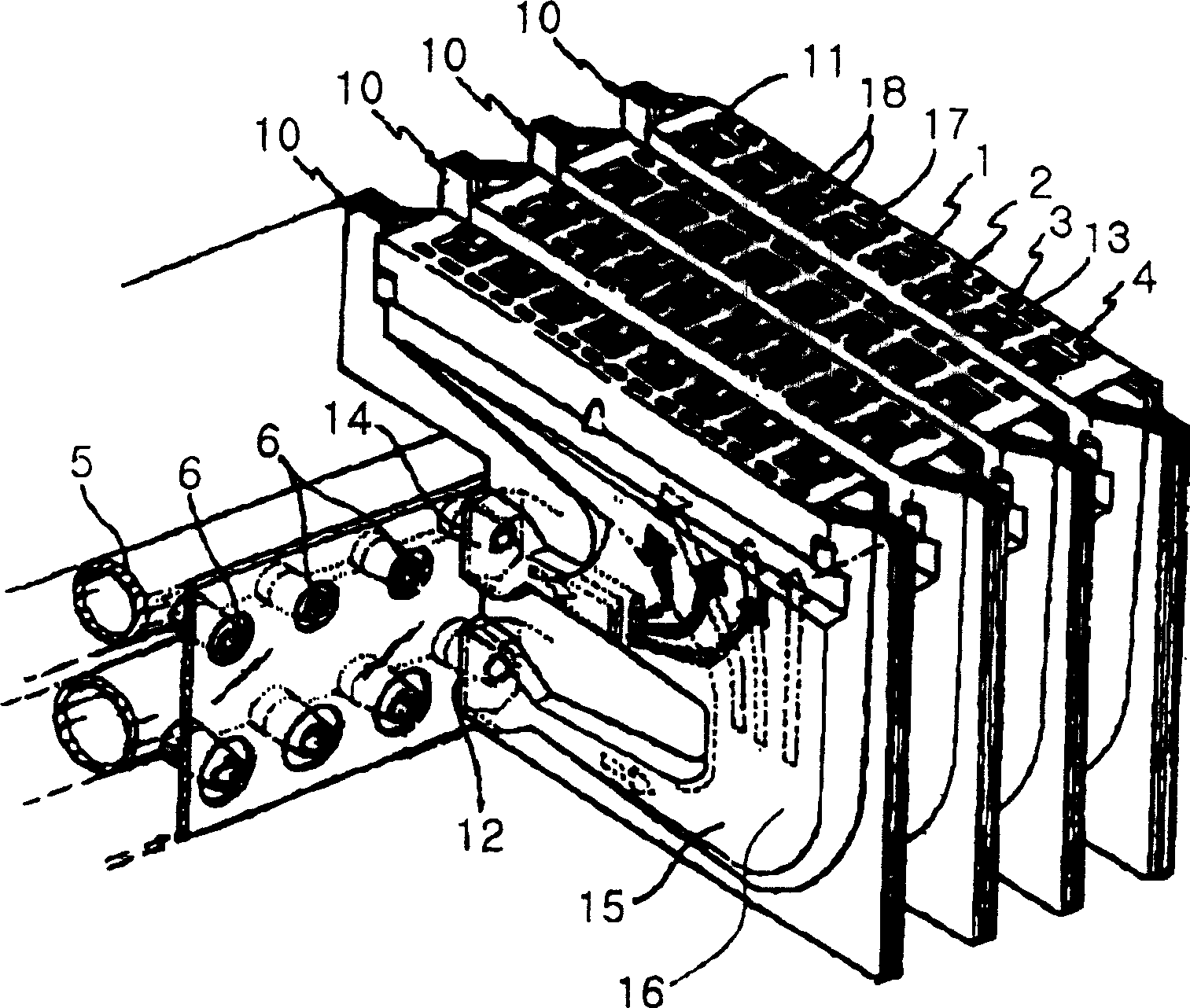

Gas burner with space by mixing gas fuel with sucked air

InactiveCN1431425AIncrease the combustion ratioShorten the lengthGaseous fuel burnerBunsen burnerProduct gas

The present invention provides a gas combustion burner having a mixing space for gas fuel and air. An intermediate burner which has gas suction holes, air suction holes and upper gas discharge holes is disposed among the side burner assembly in a Bunsen burner used for gas boiler. The air-fuel burning rate is improved at the gas discharging holes in order to improve the burning performance. Therefore, the whole length of the flame is reduced, the flame temperature is lowered, thereby the load in same area is reduced and the generating amount of pollutants such as carbon monoxide and nitric oxide can be reduced.

Owner:KYUNGDONG NAVIEN

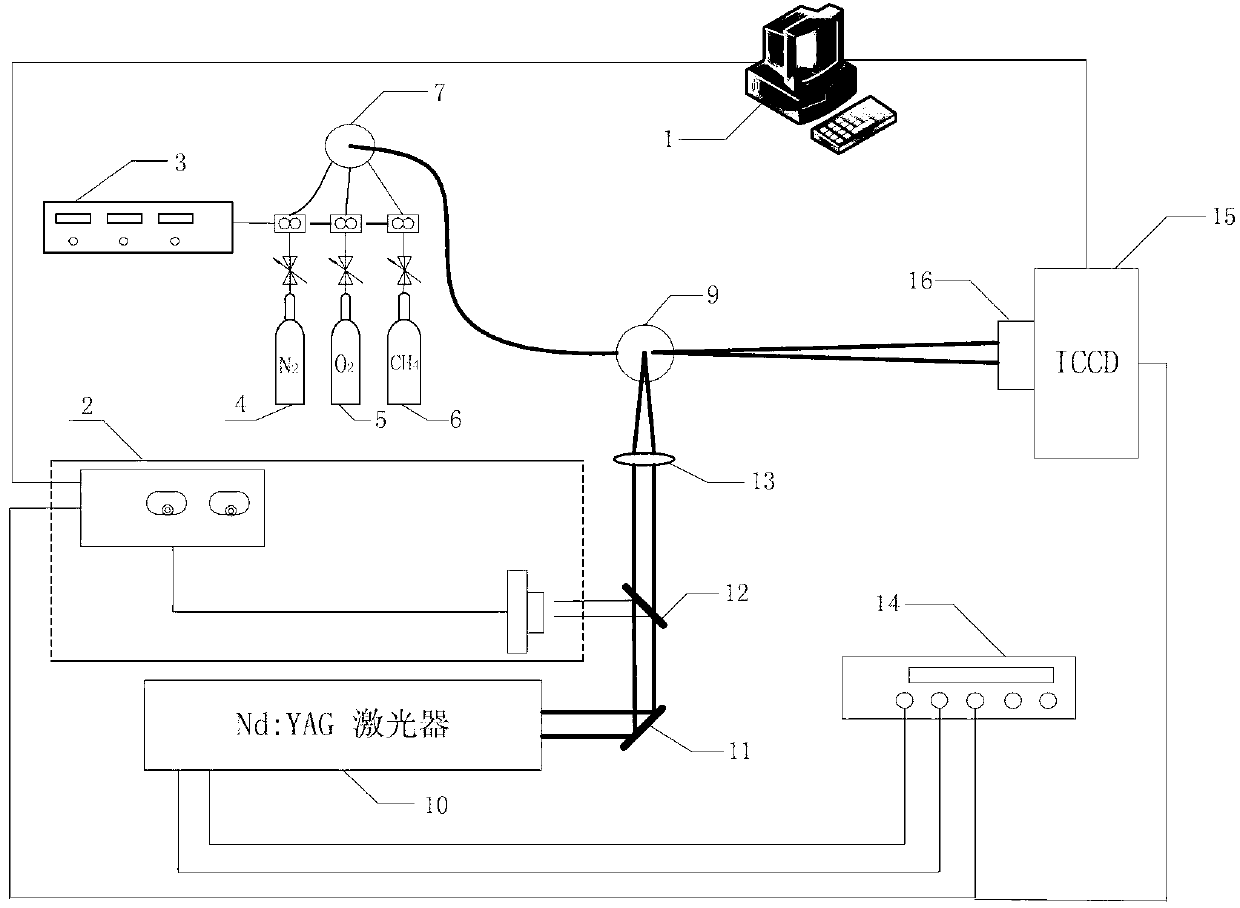

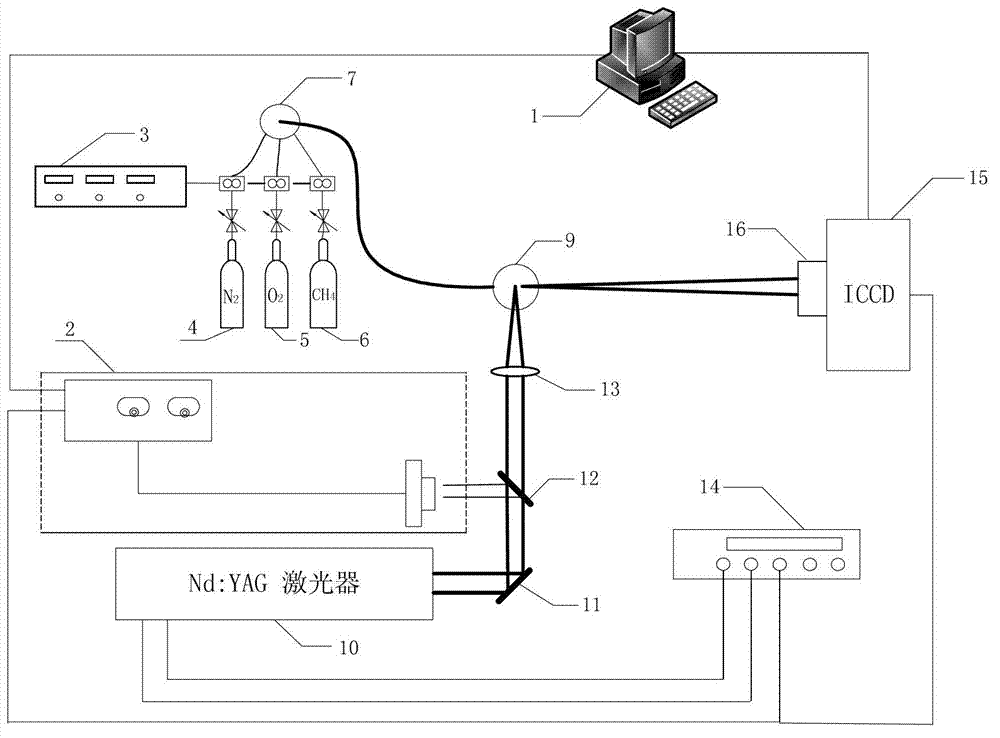

Method for nanosecond laser to induce plasma to improve stable combustion limit of gas hydrocarbon fuel and device for achieving method

ActiveCN103343735AIncrease temperatureImprove combustion efficiencyMachines/enginesUsing plasmaBunsen burnerNd:YAG laser

The invention discloses a method for a nanosecond laser to induce plasma to improve a stable combustion limit of gas hydrocarbon fuel and a device for achieving the method, and relates to the method for improving the stable combustion limit of the gas hydrocarbon fuel and the device for achieving the method. The problems that in an existing combustion system with supercritical airflow velocity, combustion is not stable, and flames are easy to blow out are solved. The method comprises the steps of filling mixed combustible gas in a pre-mixing pot in a quartz tube, igniting the mixed gas at the mouth of the quartz tube, forming a Bunsen burner flame, enabling the flow velocity of the mixed combustible gas to be in a supercritical state, adopting the nanosecond laser to emit laser beams, focusing the laser beams of the nanosecond laser on a non-combustion area of the mixed combustible gas, inducing the mixed combustible gas to generate the plasma, and achieving the improvement of the stable limit of the flame. According to the device, the air outlet of the pre-mixing pot is communicated with the tail end of the quartz tube, and lasers generated by an Nd:YAG laser are focused on the gas outlet of the quartz tube. The method for the nanosecond laser to induce the plasma to improve the stable combustion limit of the gas hydrocarbon fuel and the device for achieving the method are suitable for improving the stable combustion limit of the gas hydrocarbon fuel.

Owner:HARBIN INST OF TECH

Premixed pre-evaporation Bunsen burner combustion test device using aviation kerosene as fuel

The invention discloses a premixed pre-evaporation Bunsen burner combustion test device using aviation kerosene as fuel, which belongs to the field of energy and environment. Two electric heating devices are added respectively before the fuel inlet and air inlet of a Bunsen burner. Through stored program control of the power of a fuel electric heater, liquid aviation kerosene is fully heated intogaseous fuel, and the gaseous fuel is thoroughly mixed with heated air in the mixing chamber of the Bunsen burner to form flammable mixed gas. Premixed pre-evaporation combustion flame is acquired atthe outlet of the Bunsen burner. The flame temperature or gas composition is measured by a designed thermocouple or sample tube. At the same time, the system uses an air pump and a program-controlledmicro-injection pump to precisely control the air flow and fuel flow. By adjusting the flow ratio of two pumps and by controlling the Reynolds number of the outlet of a lamp tube, two different formsof combustion flames: laminar flame or turbulent flame can be acquired. Diversified flame compensates for the shortcoming of singular flame of the existing Bunsen burner.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

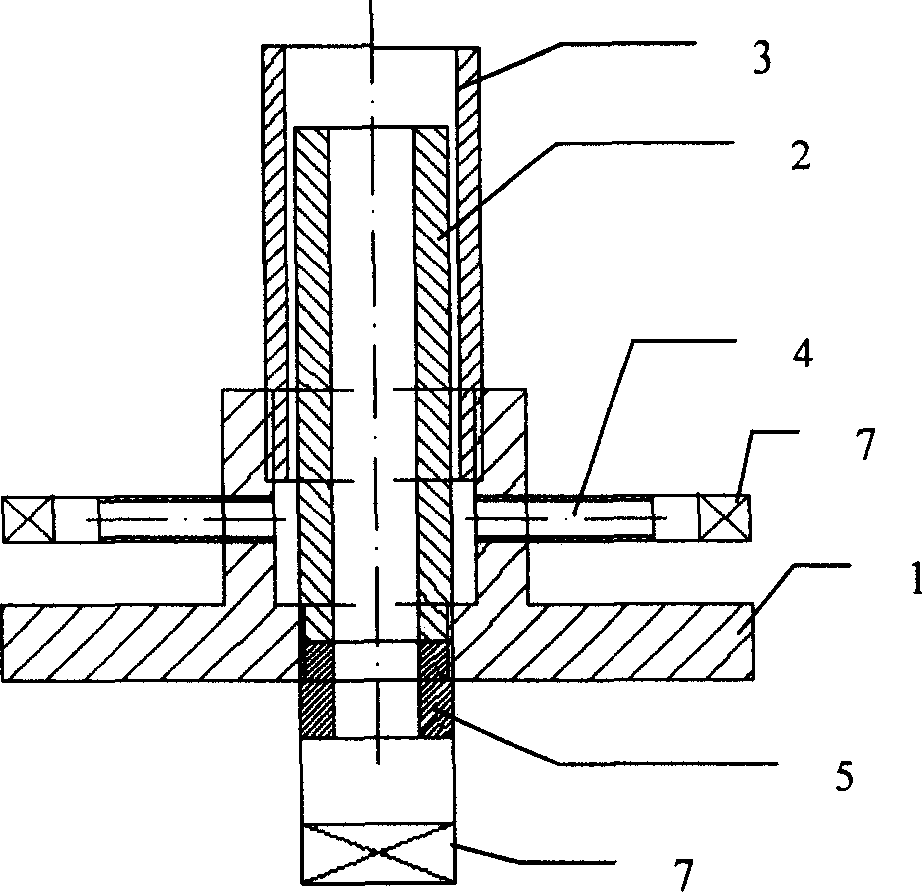

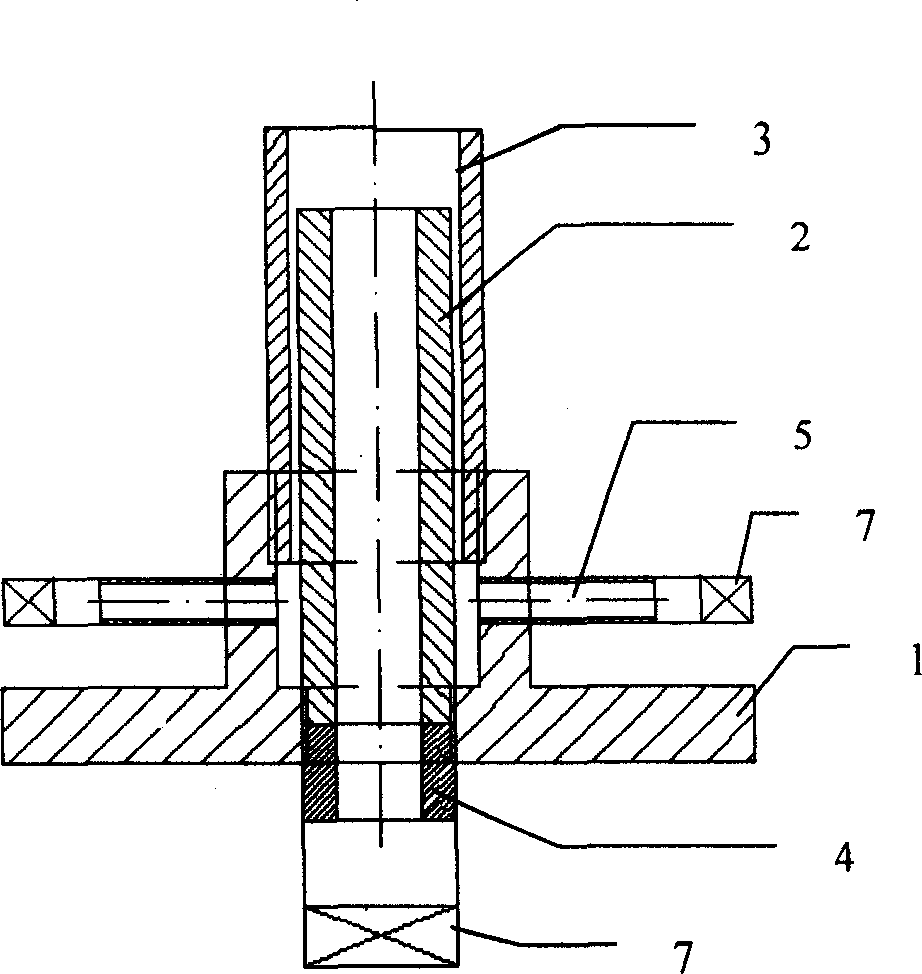

Bunsen burner capable of realizing multi-flame forms

The Bunsen burner capable of realizing several kinds of flame forms is one kind of gas burner. The Bunsen burner includes seat, burner pipe, fuel gas inlet pipe and combustion-supporting gas inlet pipe. The burner pipe is one concentric pipe comprising inner pipe of 2-50 mm inner diameter and outer pipe, the interval between the inner pipe and the outer pipe is 1-100 mm, and the length difference between the inner pipe and the outer pipe is -200 mm to +1000 mm. By means of selecting the different lengths and diameters of both the inner pipe and the outer pipe, the present invention can obtain various flames in different forms and this perfects further the teaching demonstration and heat science research one Bunsen burner.

Owner:TSINGHUA UNIV

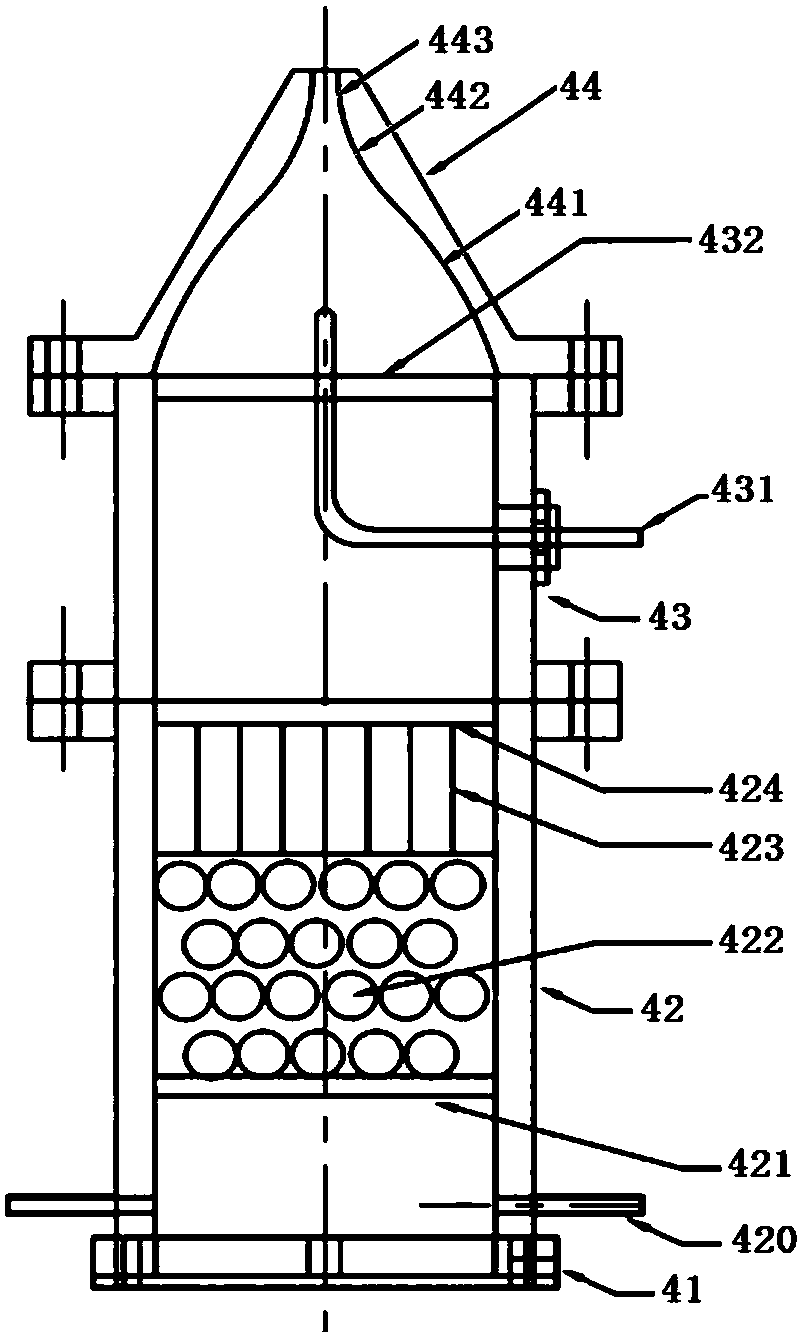

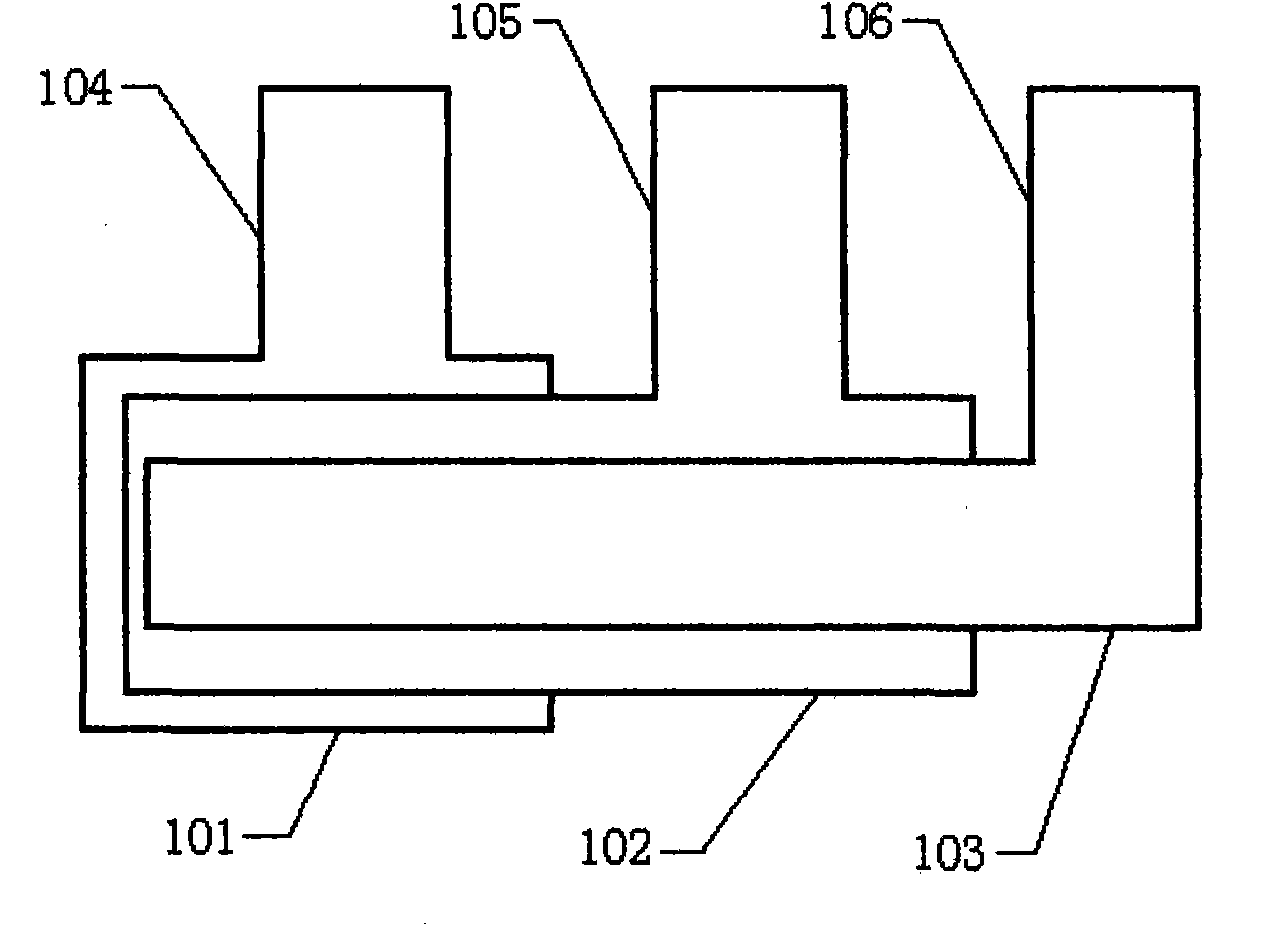

Bunsen burner with tapered flame burned and flame propagation speed measuring method

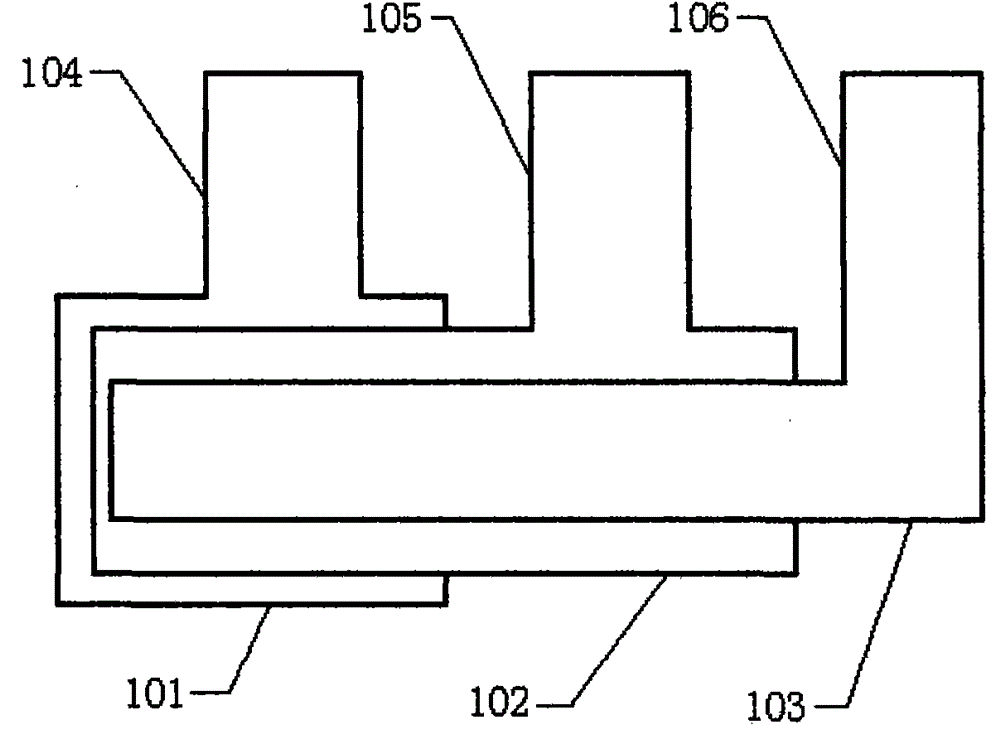

PendingCN108443881APlay a role in steady flowWell mixedFluid speed measurementGaseous fuel burnerFlame propagationBunsen burner

The invention discloses a Bunsen burner with a tapered flame burned and a flame propagation speed measuring method, and belongs to the field of flame detection. The Bunsen burner comprises the Bunsenburner body, the Bunsen burner body is mainly formed by connecting a burner body section and a burner nozzle, the inner cavity of the burner body section is provided with a packing layer, a flow equalizing plate and a first sintering net from bottom to top, the packing layer and the flow equalizing plate are located between a second sintering net on the upper side and a third sintering net on thelower side, and the first sintering net is arranged above the second sintering net by an interval. According to the Bunsen burner and the method, the inner cavity and the burner nozzle of the Bunsen burner body are improved, so that the flow stabilization effect is applied on the passing mixed gas, the flame emitted from the burner nozzle is approximately tapered, and then the detection precisionof the flame propagation speed can be improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

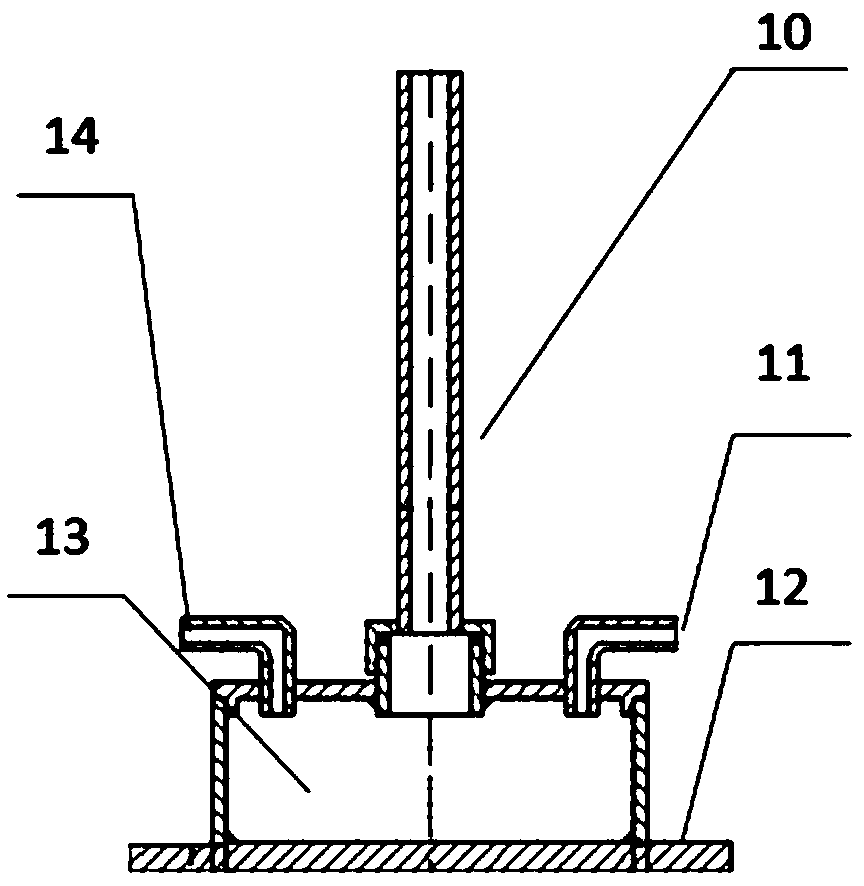

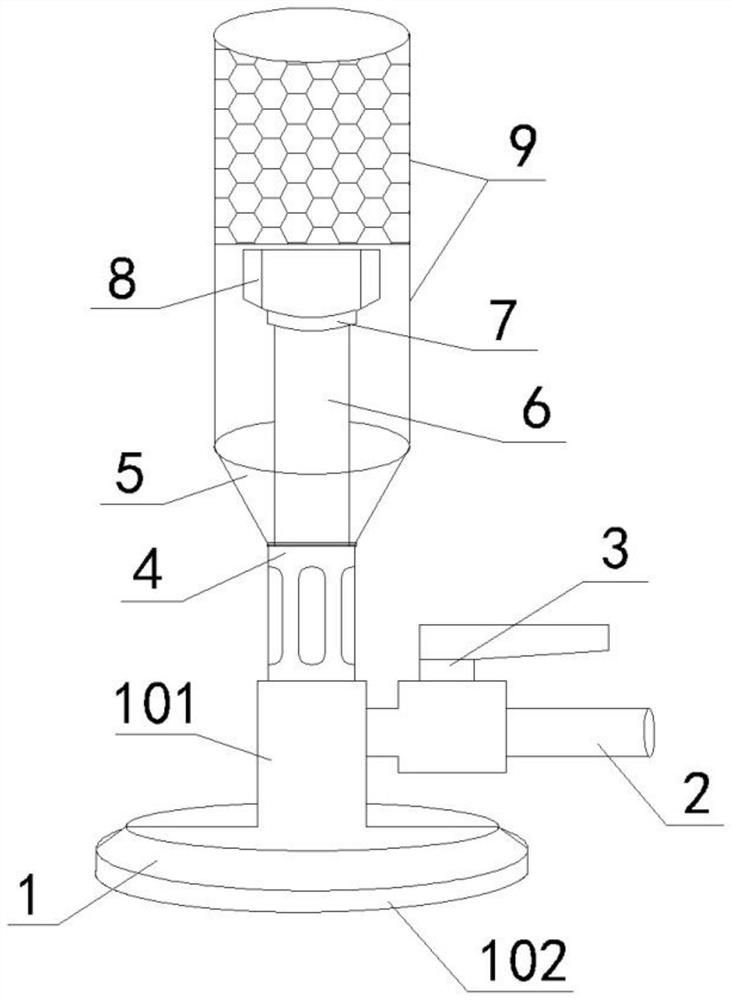

Bunsen burner type low-temperature plasma auxiliary burning device

ActiveCN106989390APromote combustionIncrease the propagation speedIon beam tubesGaseous fuel burnerBunsen burnerProduct gas

The invention relates to a Bunsen burner type low-temperature plasma auxiliary burning device. The Bunsen burner type low-temperature plasma auxiliary burning device comprises a base, a gas buffer unit and a plasma reaction unit, wherein the gas buffer unit comprises a fixed flange and a fixed rod; the plasma reaction unit comprises an outer electrode, an inner electrode and a quartz glass tube; the bottom of the fixed flange is fixed to the center of a bottom plate, a gas collection chamber and a stepped hole which are communicated are formed in the center of the fixed flange from bottom to top, and an air inlet which communicates with the gas collection chamber is formed in the side wall of the fixed flange; the bottom of the quartz glass tube is fixed to the stepped hole, and the top of the quartz glass tube protrudes to the outside of the fixed flange; the bottom of the fixed rod is fixed to the center of the bottom plate, and a flange cap sleeve is installed on the quartz glass tube and is connected to the top of the fixed flange; and the bottom of the inner electrode is fixed to the top of the fixed rod, and the outer electrode sleeves the quartz glass tube which is opposite to the inner electrode. The Bunsen burner type low-temperature plasma auxiliary burning device can be removed to replace and has the advantage of convenience in use and later maintenance. Low-temperature plasma which is generated by discharge is rich in various active particles, and an obvious strengthening effect is achieved on burning.

Owner:XI AN JIAOTONG UNIV

Liquid fuel gas phase Bunsen burner laminar flame propagation velocity measurement device and its measurement method

InactiveCN104062394BQuick pickEasy to operateChemical analysis using combustionBunsen burnerEvaporation

The invention provides a gaseous-phase Bunsen burner laminar flame propagation speed measurement device and a gaseous-phase Bunsen burner laminar flame propagation speed measurement method for a liquid fuel. The device comprises a Bunsen burner, wherein the Bunsen burner is connected with a temperature measurement display (thermocouple), a cold air heating system and a liquid fuel evaporation system respectively; the liquid fuel evaporation system is connected with an injection pump through a rubber pipeline; the cold air heating system is communicated with external air; a flame image acquisition and processing device is arranged beside the Bunsen burner. The device is simple, convenient to operate, low in cost and favorable for basic comparison between burning characteristics of different liquid fuels, and the rapid fuel selection of a spray burning system is supported. A high-speed digital camera is adopted for the measurement method, a flame conical surface can be continuously shot, a flame image cosine law method is used for calculating the gaseous-phase Bunsen burner laminar flame propagation speed of the liquid fuel according to current mixed gas speed, and the measurement method is directly provided based on the definition of the flame propagation speed, and is simple and effective.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

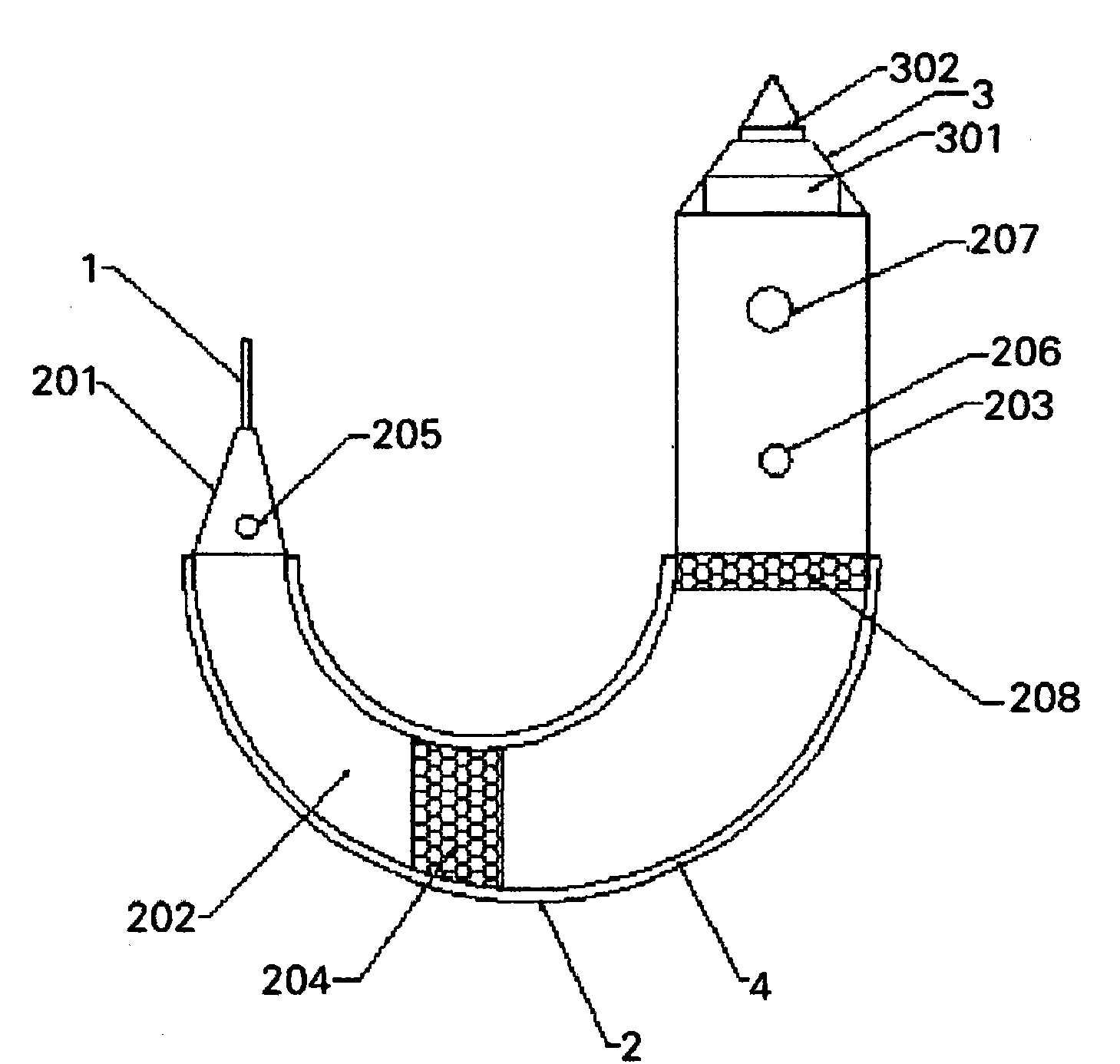

Liquid Bunsen burner

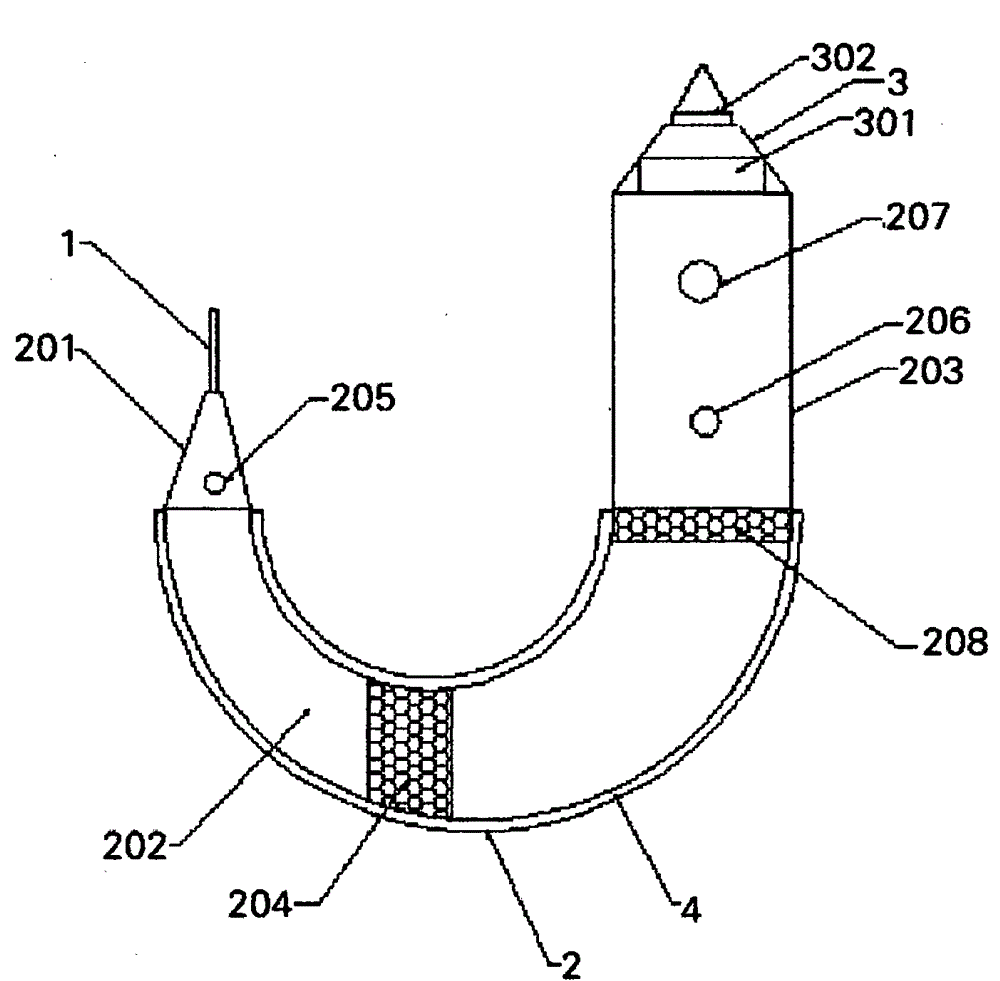

The invention discloses a liquid Bunsen burner which comprises a nozzle, a mixing tube and a lamp holder. The nozzle, the mixing tube and the lamp holder are sequentially connected. The nozzle comprises an inner air tube, a liquid tube and an outer air tube, wherein the inner air tube, the liquid tube and the outer air tube are coaxially installed, the inner air tube is located on an inner ring and used for spraying air or combustion-supporting gas, the liquid tube is located on a middle ring and used for spraying liquid, and the outer air tube is located on an outer ring and used for spraying air. The mixing tube is a U-shaped tube and is gradually expanded from one end to the other end. The lamp holder is a conical tube with the bottom diameter equal to the diameter of the mixing tube. A burner port for burning liquid is formed in an opening of the conical tube of the lamp holder. According to the liquid Bunsen burner, stabilized atomization of liquid fuel is achieved under the situation that the pressure of the liquid fuel and the pressure of feeding air are slightly higher than atmospheric pressure, the cost of the design of the whole liquid Bunsen burner is small compared with other experimental facilities, the amount of the required fuel for the experiment is only about 10 ml, the experimental expense is reduced, and the flame propagation velocity is conveniently measured.

Owner:TSINGHUA UNIV

Helmet flame resistance testing device and testing method

InactiveCN107290385AIngenious designEasy to useMaterial heat developmentThermometers using electric/magnetic elementsBunsen burnerData acquisition

The invention relates to a helmet flame resistance testing device which comprises a combustion heat source, a radiation heat source, a copper sheet calorimeter, a first temperature thermocouple, a second temperature thermocouple, a data acquisition device and a data processing system, wherein the radiation heat source comprises a support, and a plurality of quartz heating pipes which are arranged in parallel are fixed on the support; the copper sheet calorimeter comprises a structure which is formed by copper sheets and assembly blocks and is provided with a hollow cavity, the top of the inner side of the hollow cavity is connected with the first temperature thermocouple, and the other end of the first temperature thermocouple is connected with a data acquisition system; one end of the second temperature thermocouple is connected with a helmet with the temperature to be tested, and the other end of the second temperature thermocouple is connected with the data acquisition system; and the data acquisition device is connected with the data processing system. The helmet flame resistance testing device considers the testing accuracy and stability simultaneously; the quartz heating pipes serve as heat sources, so that the calorific value is high; a fuel gas Bunsen burner serves as the combustion heat source, so that the testing condition is stable; and the complete set of device has the characteristics of reasonable structure, accurate testing and strong operability and can simulate the actual use environment of a fire fighting helmet.

Owner:SHANGHAI FIRE RES INST OF THE MIN OF PUBLIC SECURITY +1

Device and method for testing combustion performance of rubber hose for conveying liquefied petroleum gas

PendingCN112782339AFine adjustment distanceBurn fullyChemical analysis using combustionCombustionBunsen burner

The invention discloses a device for testing the combustion performance of a rubber hose for conveying liquefied petroleum gas. The main body of the testing device is of a box body structure, and the testing device comprises a hose fixing tool for fixing the rubber hose to be tested and enabling the rubber hose to be bent, wherein the rubber hose is filled with the liquefied petroleum gas, and the two ends of the rubber hose are blocked; a Bunsen burner which is located under the rubber hose, wherein the inner diameter of a flame opening of the Bunsen burner is 10 mm; and a fuel pipeline which is used for supplying fuel to the Bunsen burner, wherein a pressure regulating valve is arranged on the fuel pipeline. The invention further discloses a method for testing the combustion performance of the rubber hose for conveying the liquefied petroleum gas. According to the testing device and the testing method, the combustion performance of the rubber hose can be effectively tested, so that the safety requirement in the liquefied petroleum gas conveying process is fully met, and accidents are avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

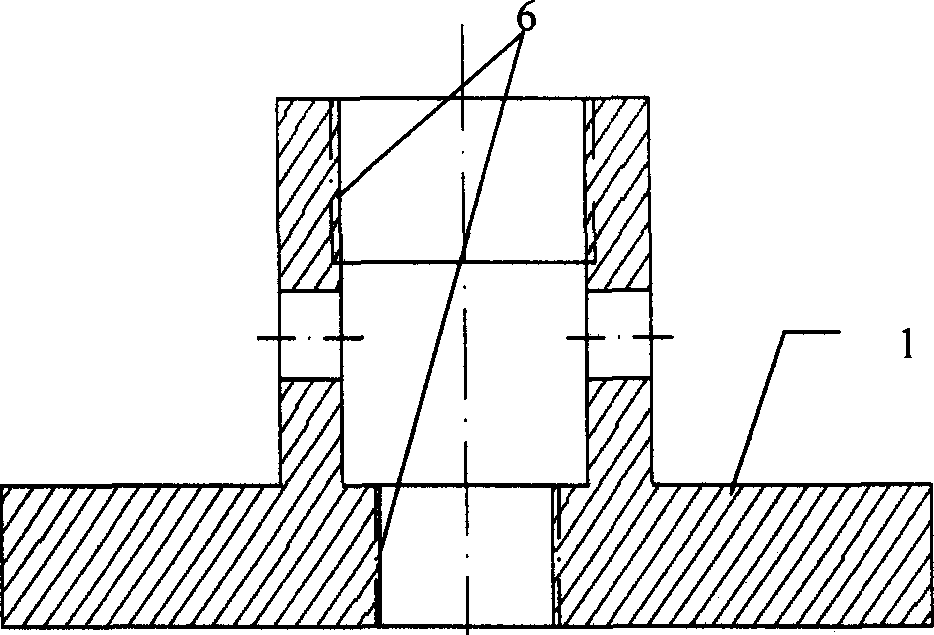

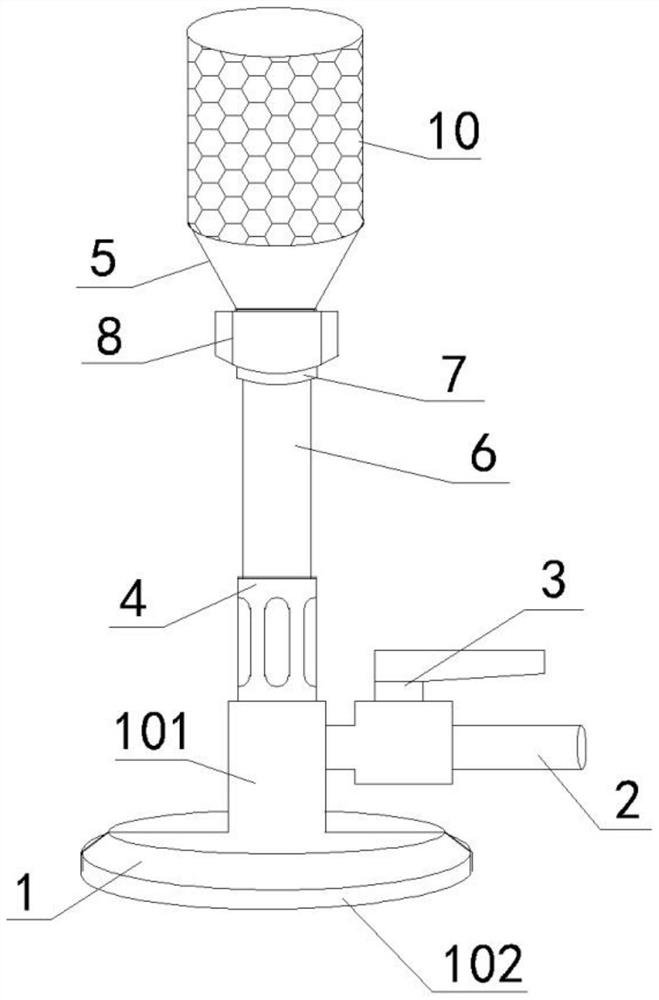

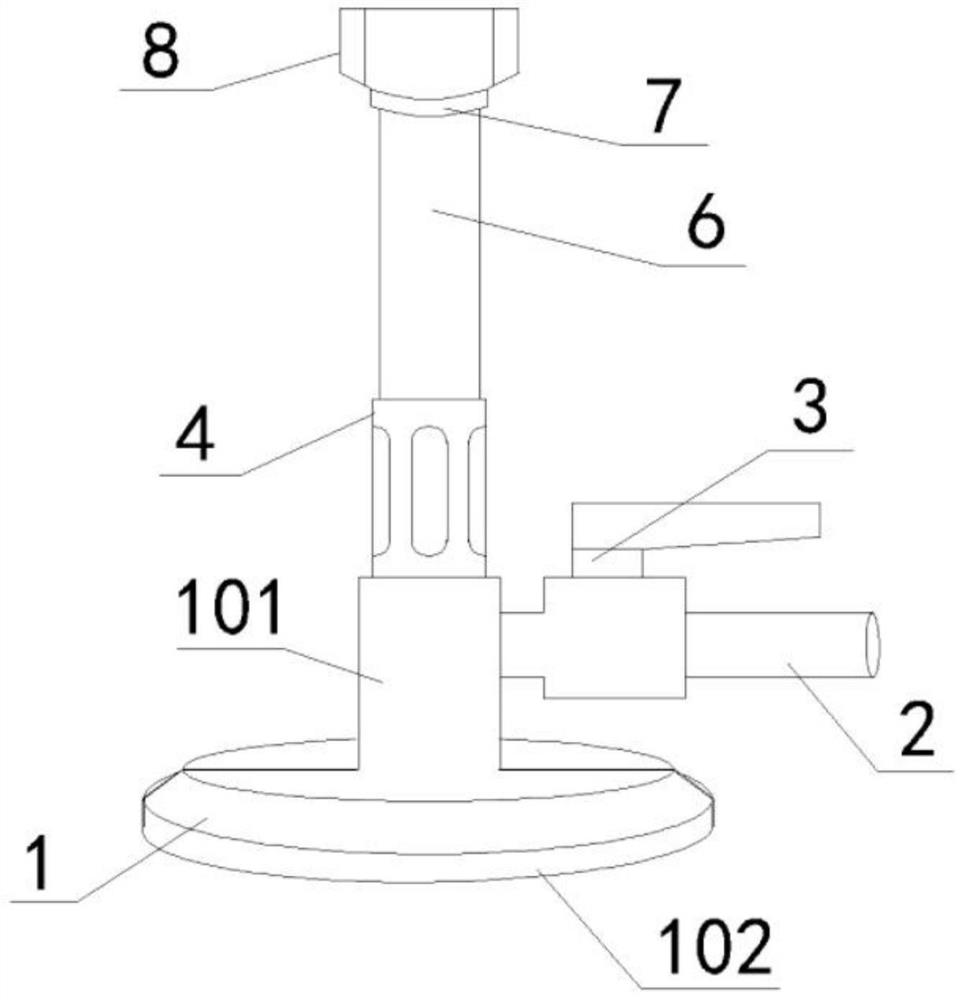

Dustproof surrounding-air-inlet Bunsen burner

PendingCN111637460ASolve the problem that the length of the combustion flame cannot be adjustedSolve the problem of being easily blown by the wind,Gaseous fuel burnerBunsen burnerLight head

The invention discloses a dustproof surrounding-air-inlet Bunsen burner. The dustproof surrounding-air-inlet Bunsen burner is characterized by comprising a lamp holder, a fuel gas input pipe, a valve,an air flow rate adjusting sleeve, a modulator tube, an adjustable lamp cap, an adjustable nut, a hopper saddle and a dustproof cover. The fuel gas input pipe is screwed into the side face of the upper side of the lamp holder. The valve is installed on the fuel gas input pipe. The air flow rate adjusting sleeve is screwed into the lower portion of the modulator tube. The bottom of the adjustablelamp cap and the bottom of the adjustable nut are both screwed into the upper portion of the modulator tube. A through hole is formed in the middle of the hopper saddle. The hopper saddle sleeves theouter side of the modulator tube through the through hole in the middle. The dustproof cover is installed on the upper face of the hopper saddle. By means of the dustproof surrounding-air-inlet Bunsenburner, the air inlet amount can be adjusted, it is ensured that air and fuel gas are sufficiently mixed in the modulator tube, the lamp cap can be adjusted according to actual demands, the length ofcombusting flames is adjusted, the dustproof cover has windproof, dustproof and high-temperature resistant performance, and the dustproof surrounding-air-inlet Bunsen burner is high in stability, safe, environmentally friendly and suitable for use as a high-temperature heating tool in experiments or other product production processes.

Owner:苏州忻智铭传感电子科技有限公司

A liquid bunsen burner

The invention discloses a liquid Bunsen burner which comprises a nozzle, a mixing tube and a lamp holder. The nozzle, the mixing tube and the lamp holder are sequentially connected. The nozzle comprises an inner air tube, a liquid tube and an outer air tube, wherein the inner air tube, the liquid tube and the outer air tube are coaxially installed, the inner air tube is located on an inner ring and used for spraying air or combustion-supporting gas, the liquid tube is located on a middle ring and used for spraying liquid, and the outer air tube is located on an outer ring and used for spraying air. The mixing tube is a U-shaped tube and is gradually expanded from one end to the other end. The lamp holder is a conical tube with the bottom diameter equal to the diameter of the mixing tube. A burner port for burning liquid is formed in an opening of the conical tube of the lamp holder. According to the liquid Bunsen burner, stabilized atomization of liquid fuel is achieved under the situation that the pressure of the liquid fuel and the pressure of feeding air are slightly higher than atmospheric pressure, the cost of the design of the whole liquid Bunsen burner is small compared with other experimental facilities, the amount of the required fuel for the experiment is only about 10 ml, the experimental expense is reduced, and the flame propagation velocity is conveniently measured.

Owner:TSINGHUA UNIV

Nanosecond laser-induced plasma method for improving gaseous hydrocarbon fuel stability limit and device for realizing the method

ActiveCN103343735BIncrease temperatureImprove combustion efficiencyMachines/enginesUsing plasmaCombustion systemNanosecond laser

The invention discloses a method for a nanosecond laser to induce plasma to improve a stable combustion limit of gas hydrocarbon fuel and a device for achieving the method, and relates to the method for improving the stable combustion limit of the gas hydrocarbon fuel and the device for achieving the method. The problems that in an existing combustion system with supercritical airflow velocity, combustion is not stable, and flames are easy to blow out are solved. The method comprises the steps of filling mixed combustible gas in a pre-mixing pot in a quartz tube, igniting the mixed gas at the mouth of the quartz tube, forming a Bunsen burner flame, enabling the flow velocity of the mixed combustible gas to be in a supercritical state, adopting the nanosecond laser to emit laser beams, focusing the laser beams of the nanosecond laser on a non-combustion area of the mixed combustible gas, inducing the mixed combustible gas to generate the plasma, and achieving the improvement of the stable limit of the flame. According to the device, the air outlet of the pre-mixing pot is communicated with the tail end of the quartz tube, and lasers generated by an Nd:YAG laser are focused on the gas outlet of the quartz tube. The method for the nanosecond laser to induce the plasma to improve the stable combustion limit of the gas hydrocarbon fuel and the device for achieving the method are suitable for improving the stable combustion limit of the gas hydrocarbon fuel.

Owner:HARBIN INST OF TECH

Method for measuring flame propagation velocity of Bunsen burner during combustion process of gaseous fuel

InactiveCN101672858BWon't breakImprove accuracyDevices using optical meansFlame propagationImaging processing

The invention discloses a method for measuring the flame propagation velocity of a Bunsen burner during the combustion process of gaseous fuel based on a surface integral image processing technology, relating to a method for measuring the flame propagation velocity. The invention overcomes the problem that the gas fuel has low accurate measurement result when the flame propagation velocity is measured during the Bunsen flame process by the prior binary image processing technology. The method for measuring the flame propagation velocity of a Bunsen burner during the combustion process of gaseous fuel is realized by the following steps of: igniting gaseous fuel in the Bunsen burner to generate flame of the Bunsen burner; performing N times of imaging on the flame of the Bunsen burner by a CCD imaging device; performing brightness analysis and edge extraction on each image and then performing curve fitting; performing curve integration on the area surrounded by the fit curve to obtain the superficial areas of the inner flame frontal surfaces in the flame of the Bunsen burner in each image, averaging the superficial areas to obtain the current superficial area value of the inner flame frontal surface in the flame of the Bunsen burner; and calculating the flame propagation velocity of the Bunsen burner according to the superficial area value of the inner flame frontal surface in the flame and the gas flow rate. The method for measuring flame propagation velocity of Bunsen burner during combustion process of gaseous fuel is suitably used for measuring the flame propagation velocity of the Bunsen burner during the combustion process of gaseous fuel.

Owner:HARBIN INST OF TECH

Apparatus and method for studying the influence of external wind speed on flame propagation and stability

InactiveCN105067026BReduce research costsSimple structureMeasurement devicesFlame propagationGas cylinder

The invention provides a device and a method for studying the influence of external wind speed on flame propagation and stability. The device comprises a fan, a wind quantity adjusting panel, a wind speed uniform distribution panel, an experiment tunnel, a wind speed measurement window, a smoke measurement window, a draught fan, a support, a Bunsen burner, a height adjusting stand, a rubber tube, a flow meter, a valve and a gas cylinder. One end of the experiment tunnel is used for wind supply and the other end is used for wind inducing, so that the propagation characteristic and the stability of flames of a fixed fire source can be studied on the condition of uniform external wind speed. The device is low in manufacture cost, simple in structure, convenient to operate and flexible to control; experimental phenomena are easy to observe and measure; obtained data are real and reliable; experimental basis can be provided for studying the flame structure and the burning characteristics under the condition of relative motion and analyzing the propagation characteristic and the stability of flames.

Owner:SOUTH CHINA UNIV OF TECH

Non-metallic material combustion performance test device

ActiveCN105004750BEasy to adjust the angleEasy to adjust the distanceMaterial thermal analysisTest sampleMetallic materials

Owner:南德西交轨道交通技术(江苏)有限公司

Composite element and use thereof

ActiveUS10532946B2Low hazeGood optical performanceAircraft accessoriesGlass/slag layered productsBunsen burnerOrganic layer

A lightweight composite pane is provided that includes a mineral glass or glass-ceramic pane and an organic layer. The weight per unit area of the lightweight composite pane is in the range from 0.5 kg / m2 to 5.5 kg / m2, the ratio of the thickness of the mineral glass pane to the thickness of the organic layer is 1:0.01 to 1:1, and the thickness of the organic layer is less than or equal to 500 μm. The lightweight composite pane meets the thermal safety requirements of aerospace authorities and has a “Total Heat Release,” measured in compliance with JAR / FAR / CS 25, App. F, Part IV & AITM 2.0006, of less than 65 kW×min / m2 and a flame time, after removal of the flame in the “Vertical Bunsen Burner Test”, measured in compliance with FAR / JAR / CS 25, App. F, Part 1 & AITM 2.0002A, is less than 15 seconds.

Owner:SCHOTT AG

Gas burner with space by mixing gas fuel with sucked air

InactiveCN1189697CIncrease the combustion ratioShorten the lengthGaseous fuel burnerBunsen burnerProduct gas

The present invention provides a gas combustion burner having a mixing space for gas fuel and air. An intermediate burner which has gas suction holes, air suction holes and upper gas discharge holes is disposed among the side burner assembly in a Bunsen burner used for gas boiler. The air-fuel burning rate is improved at the gas discharging holes in order to improve the burning performance. Therefore, the whole length of the flame is reduced, the flame temperature is lowered, thereby the load in same area is reduced and the generating amount of pollutants such as carbon monoxide and nitric oxide can be reduced.

Owner:KYUNGDONG NAVIEN

Combustion-supporting method by activating oxygen molecules by using laser

The invention provides a combustion-supporting method by activating oxygen molecules by using laser, which relates to a combustion-supporting method, and solves the problem that fuel has unstable combustion and low efficiency during the burning in the prior engine art. The method has the following implementation steps of: 1, introducing mixed gas into a quartz round tube, and igniting the mixed gas at an outlet of the quartz round tube to generate Bunsen flame, wherein the mixed gas is mixture of oxygen and other combustible gases; and 2, transmitting a laser beam to an unburnt gas area underthe Bunsen flame in the step 1 by adopting a tunable dye laser to realize laser combustion supporting. The method can be widely applied to the design of aerospace engine technology.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com