Patents

Literature

227 results about "FLANGE CAP" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

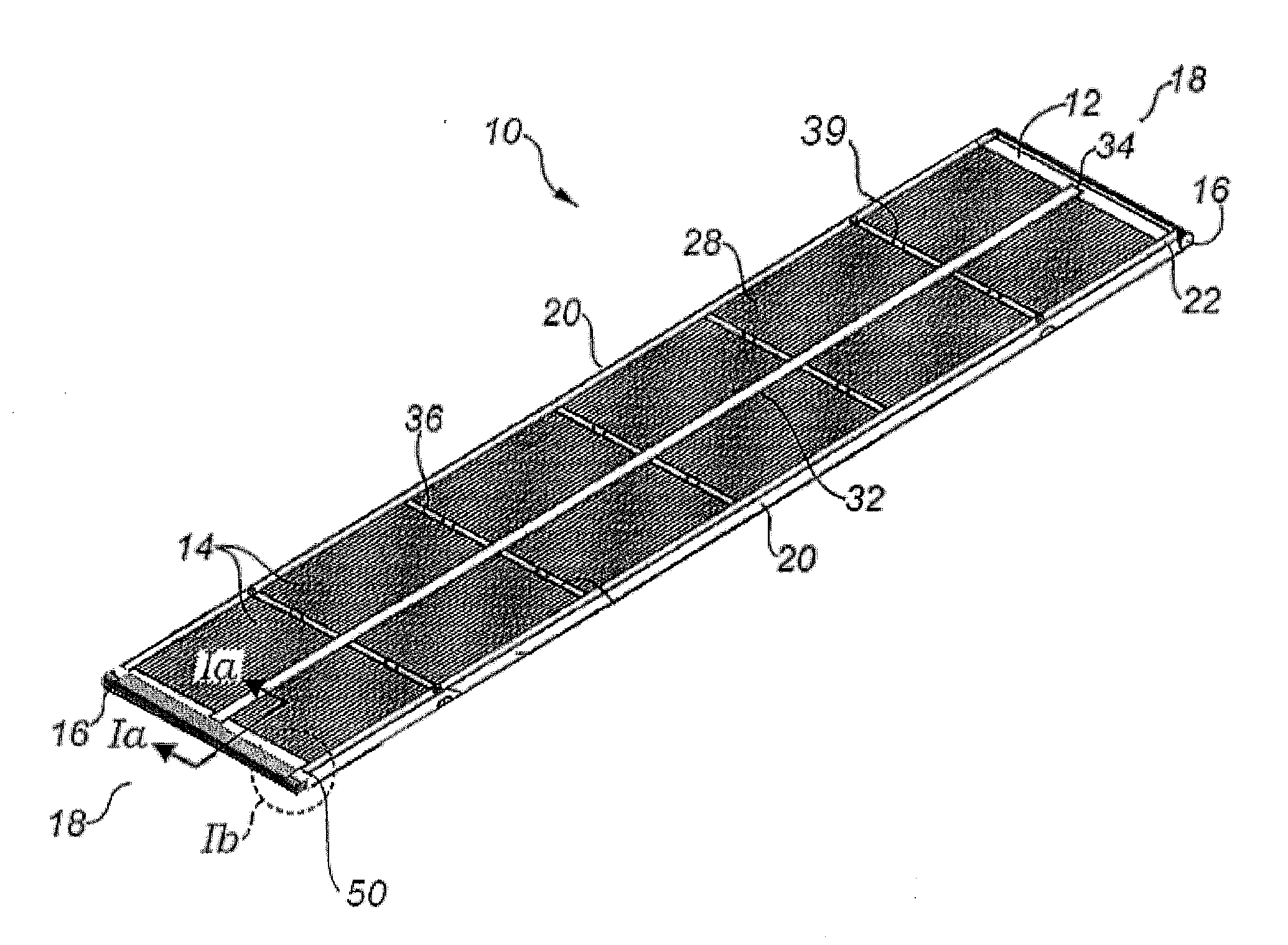

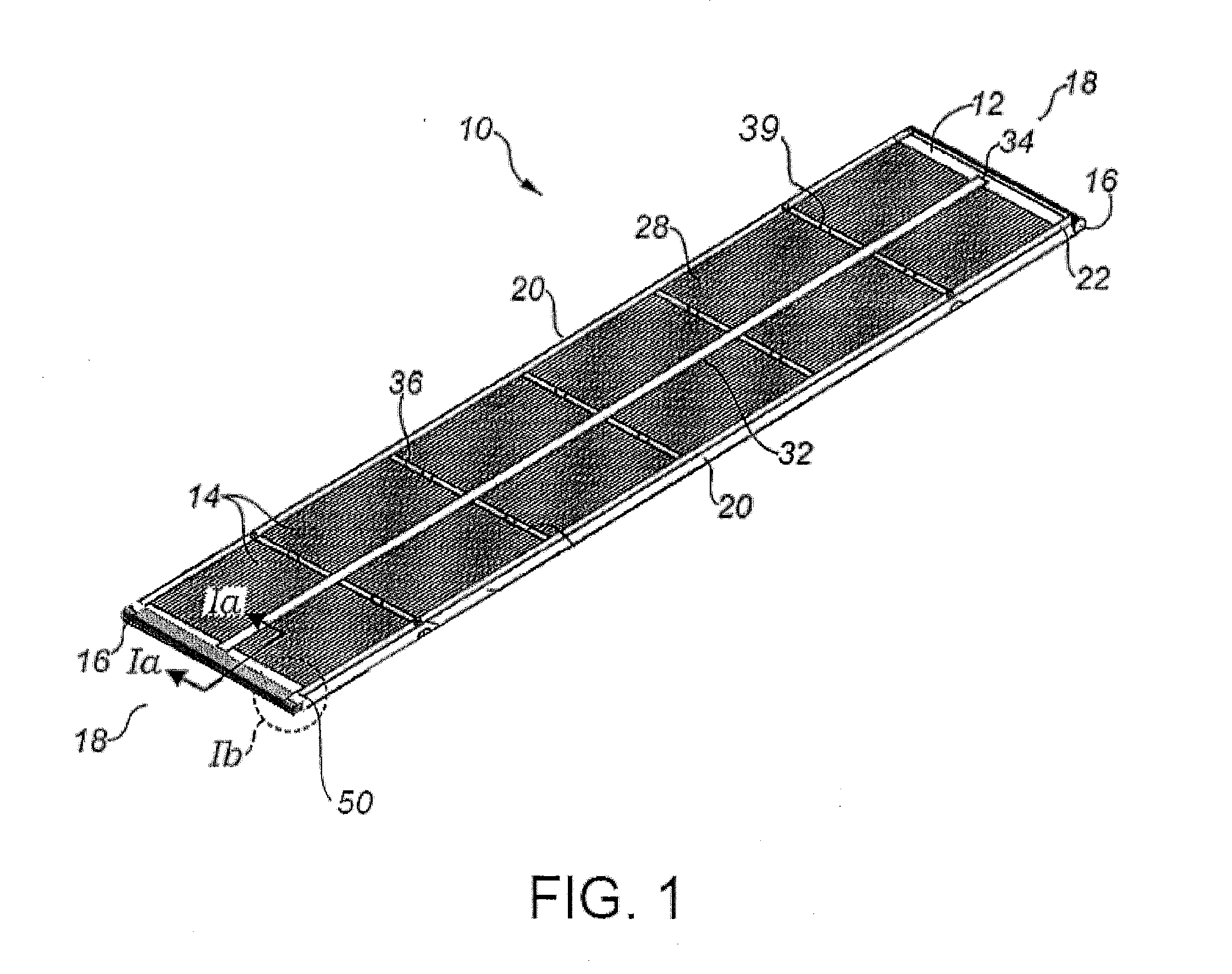

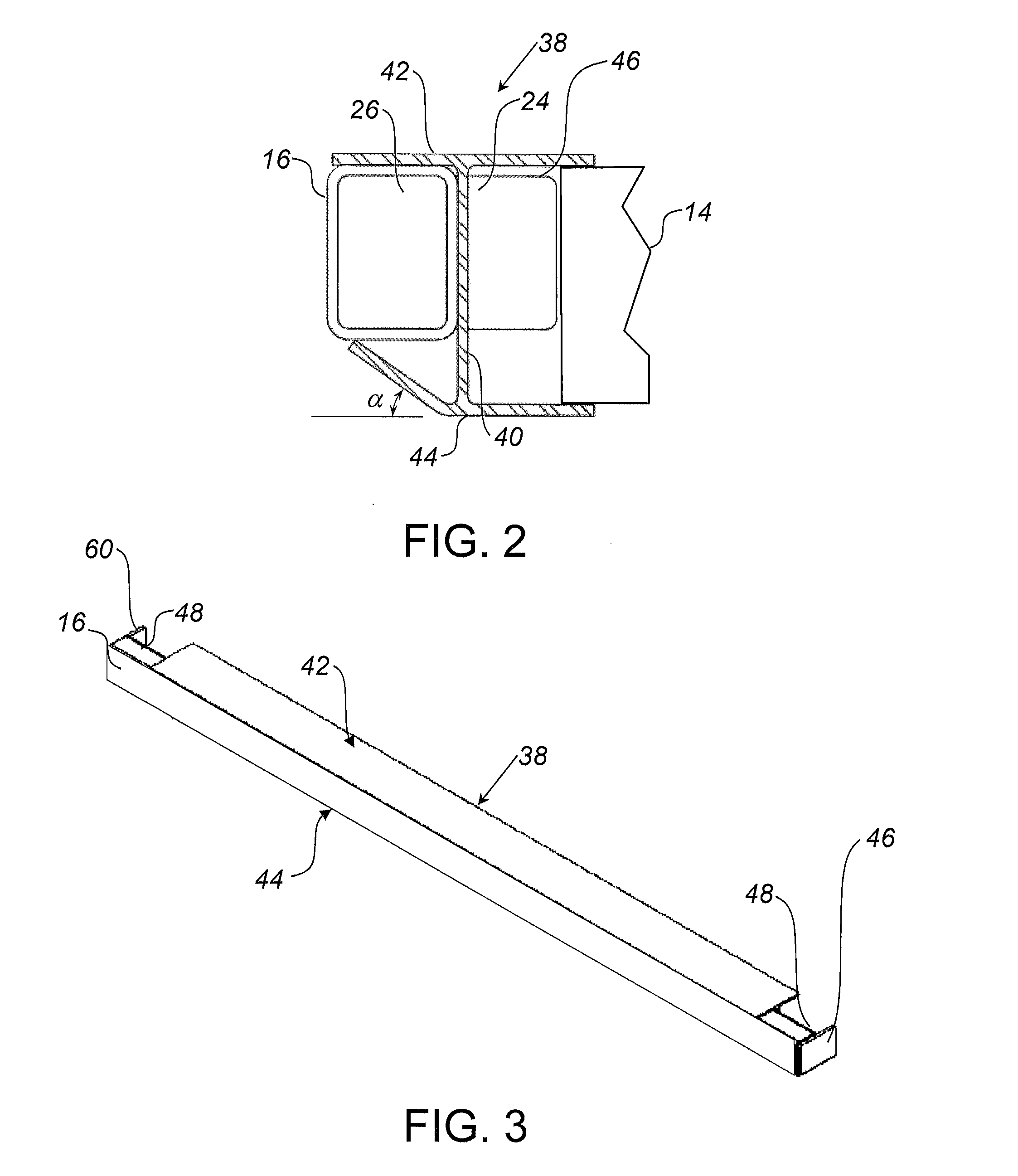

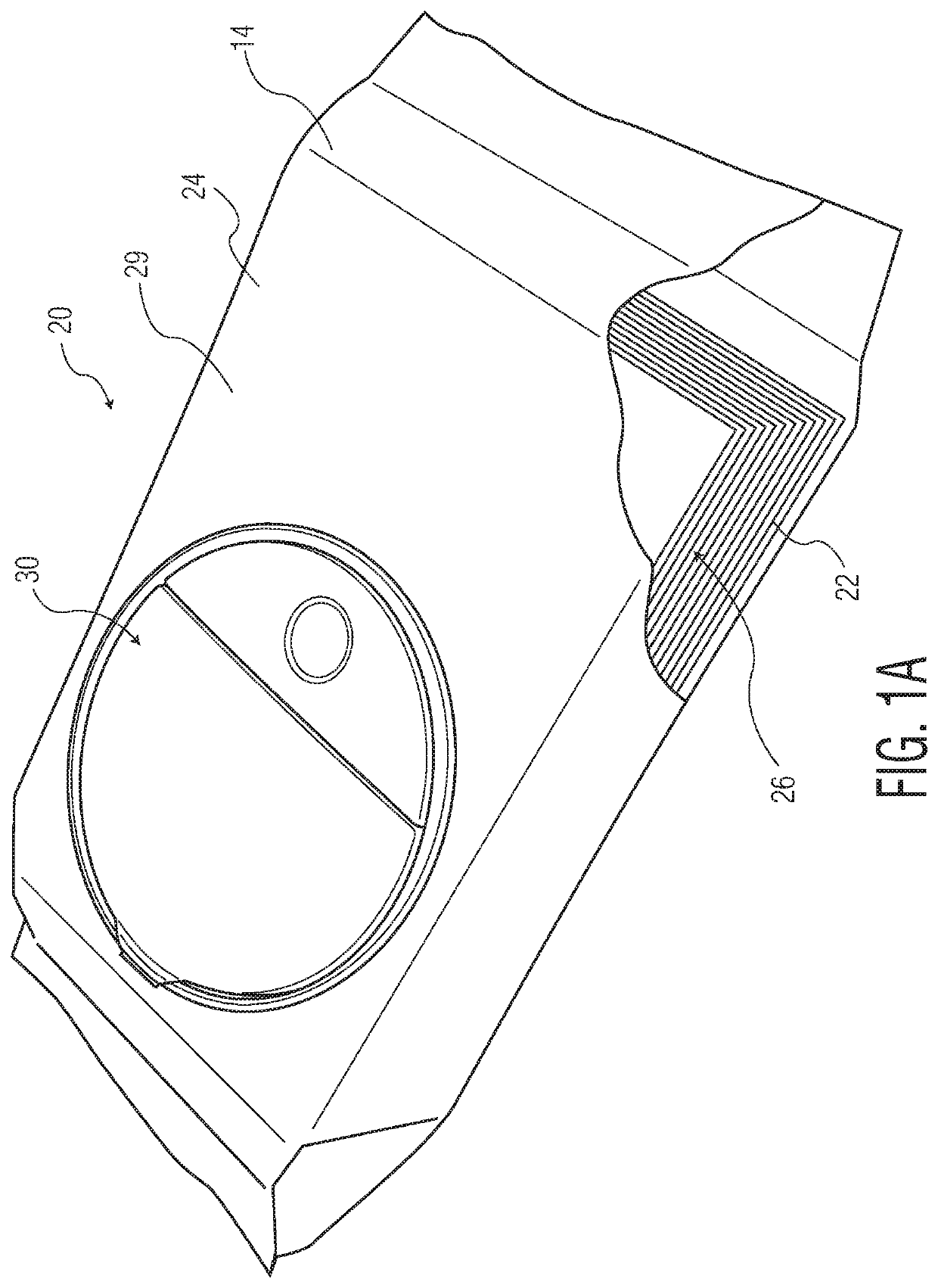

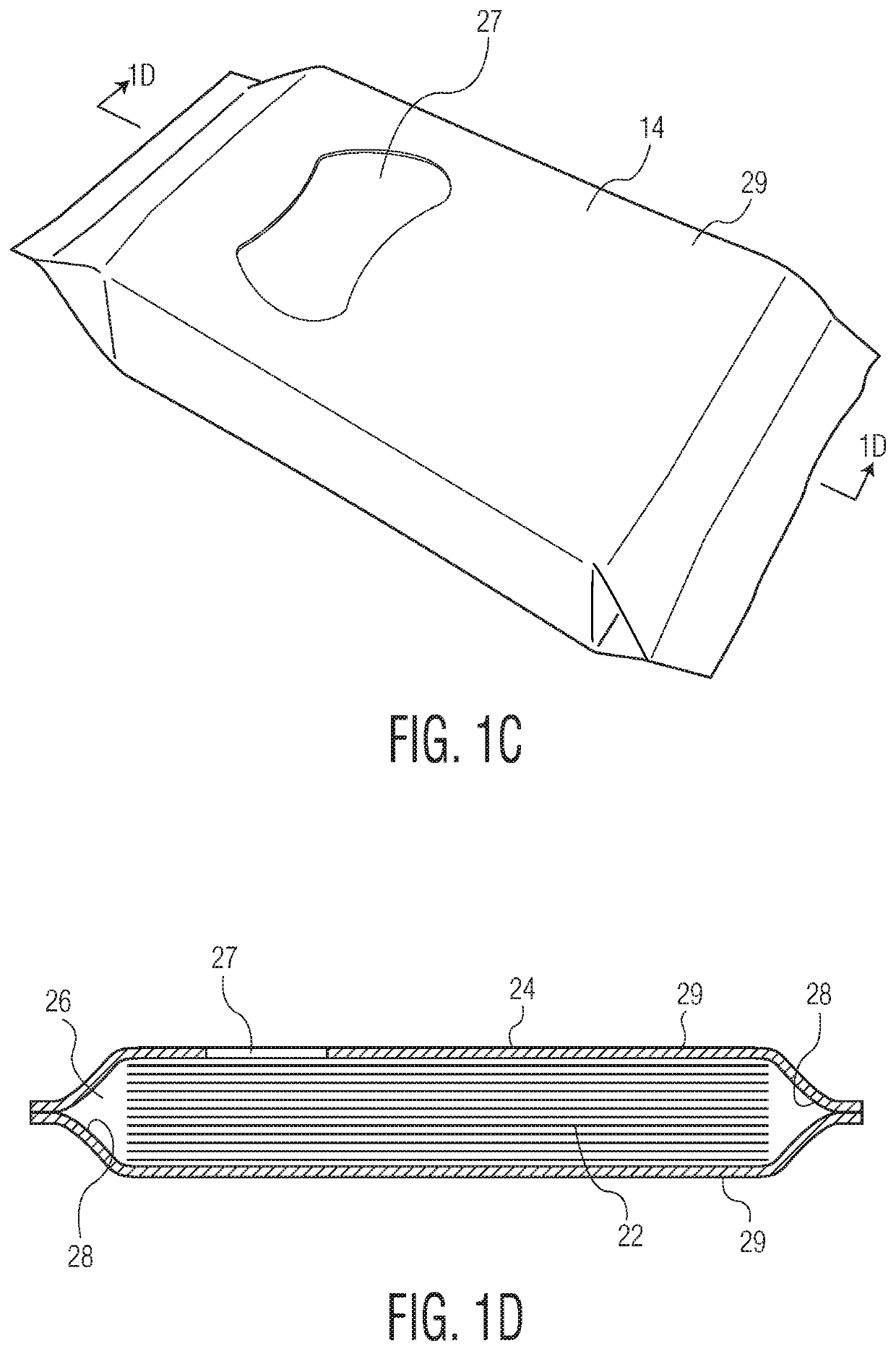

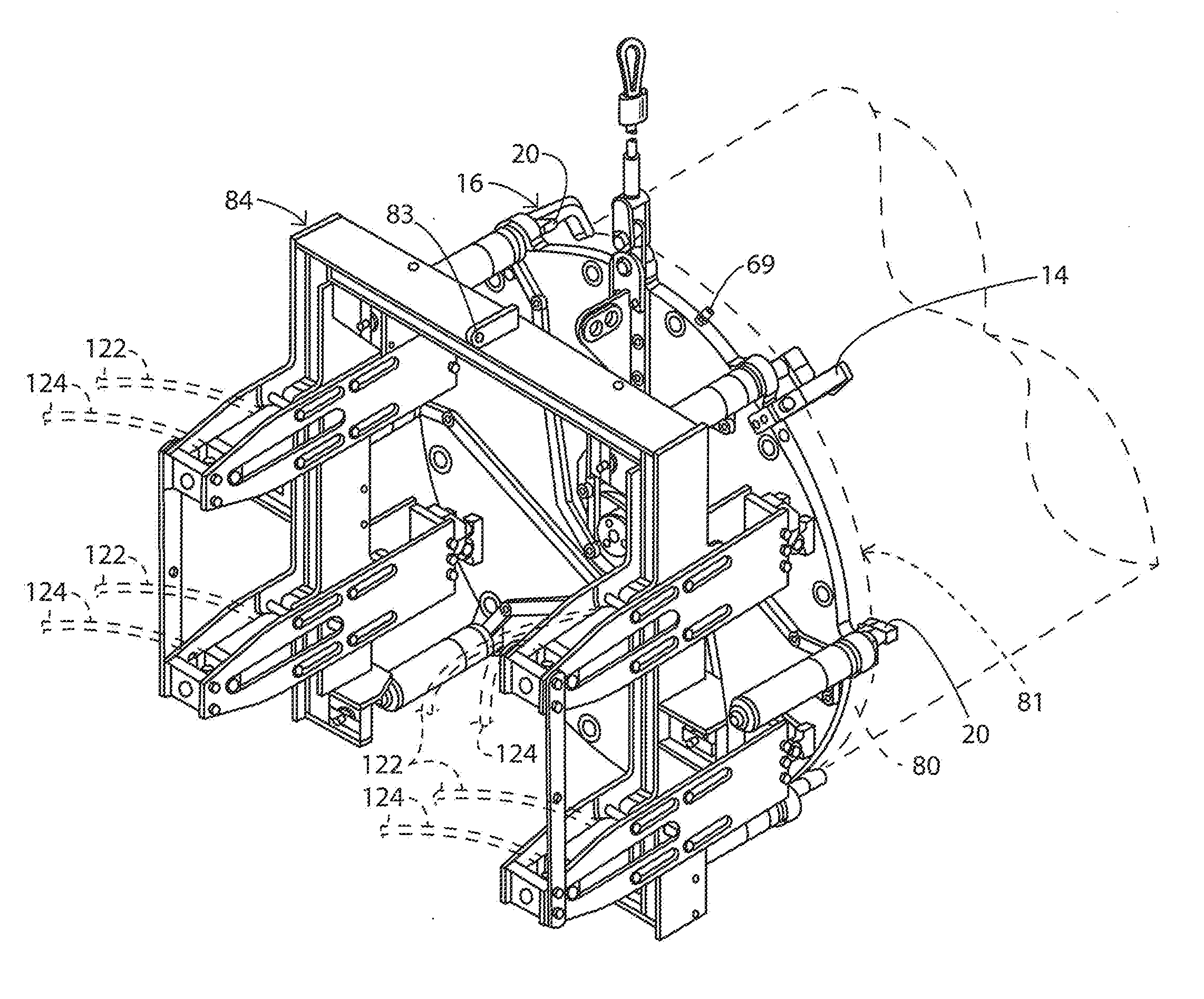

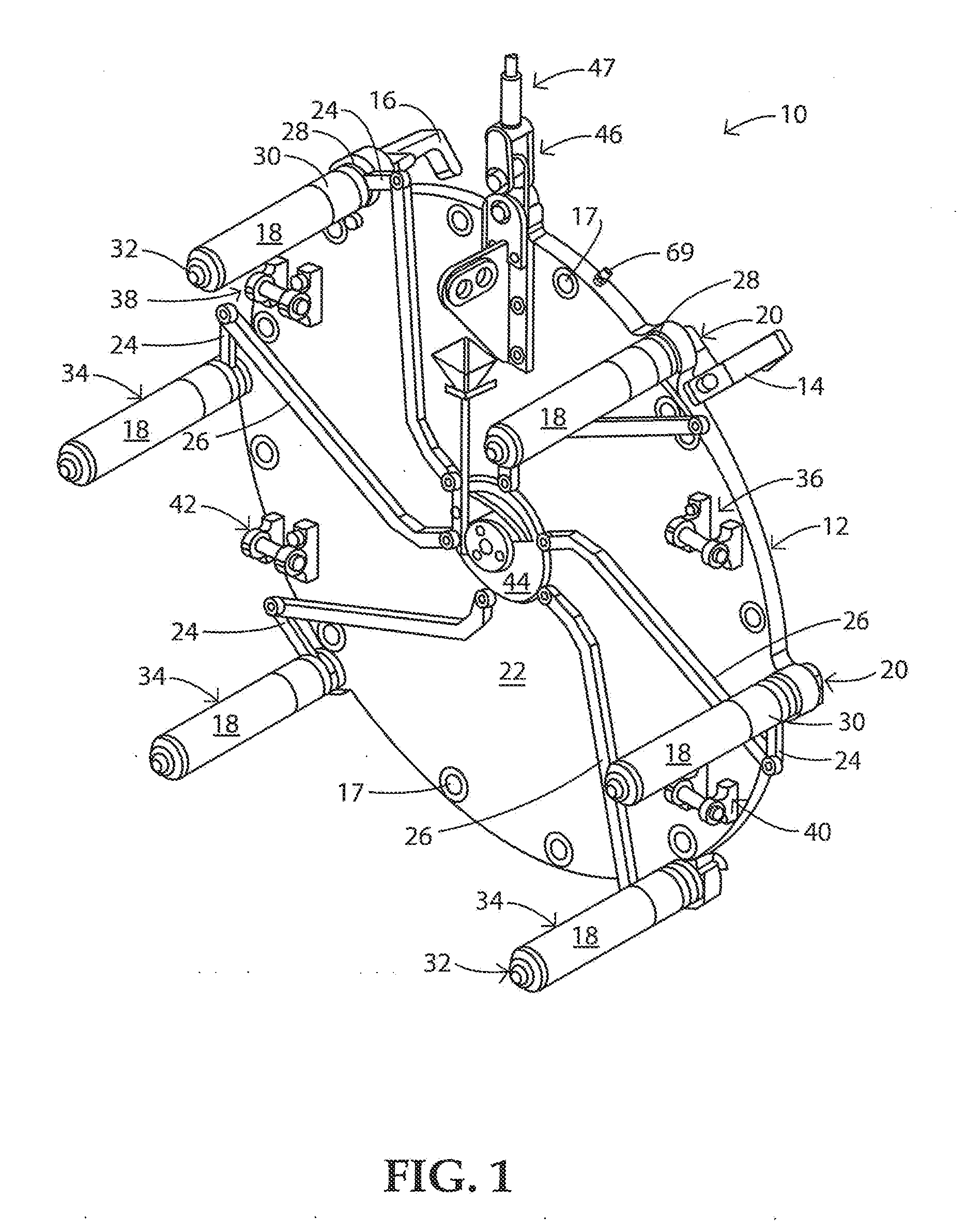

Ground cover mats with rectangular ends

Reinforced ground cover mats are used to facilitate the passage of heavy equipment and vehicles on wet or disturbed ground. The ground cover mats are comprised of boards contained within a peripheral metal frame having two substantially parallel opposing end members that are I-beams, the upper and lower horizontal flanges and vertical webs of which define an outer slot into which a reinforcing member is inserted such that the reinforcing member contacts the vertical web and upper and lower horizontal flanges. Flanged caps may be attached to the ends of the reinforcing member to retain a sling looped around the reinforcing member for pulling the mat.

Owner:MAXXIMAT

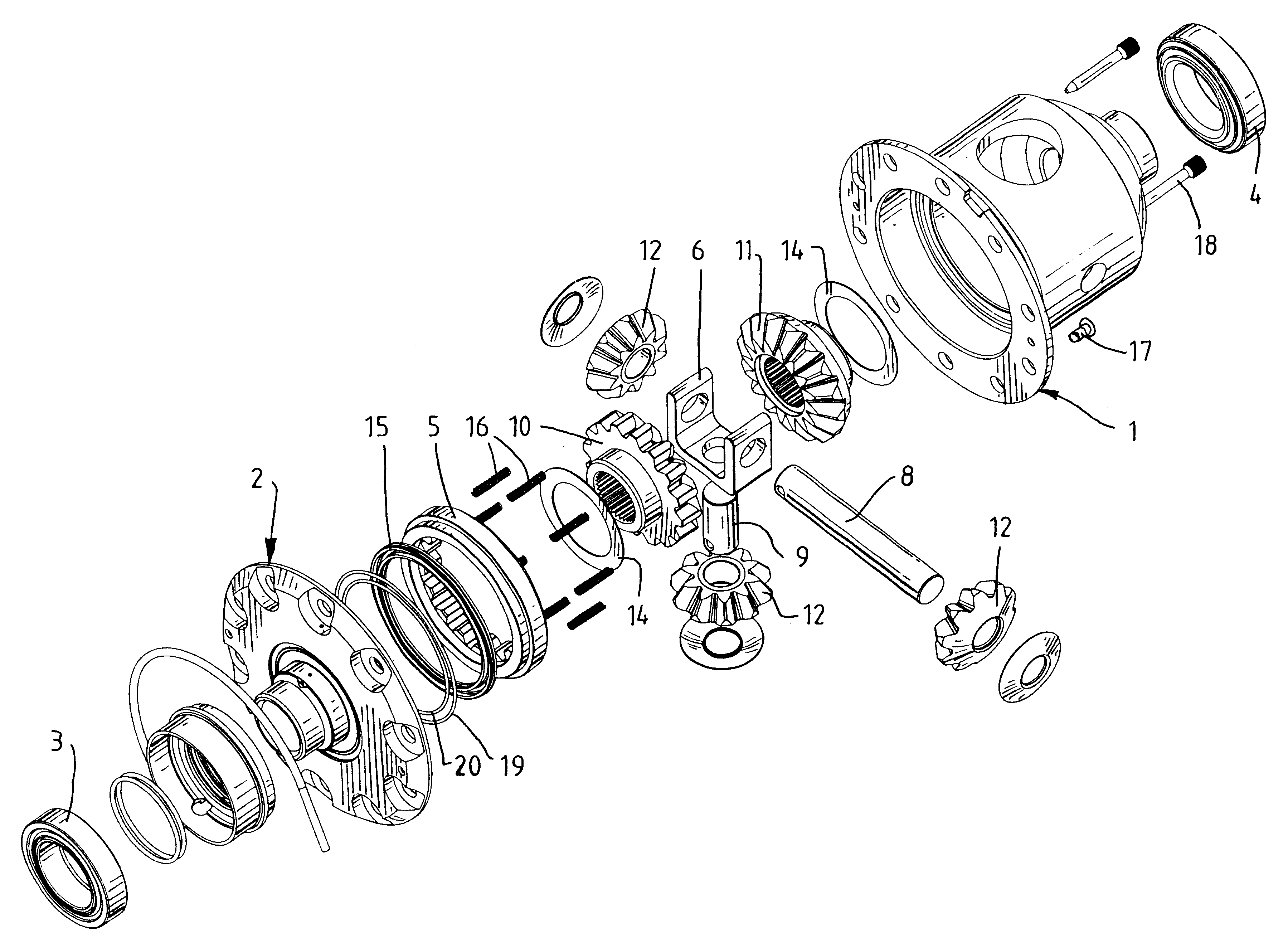

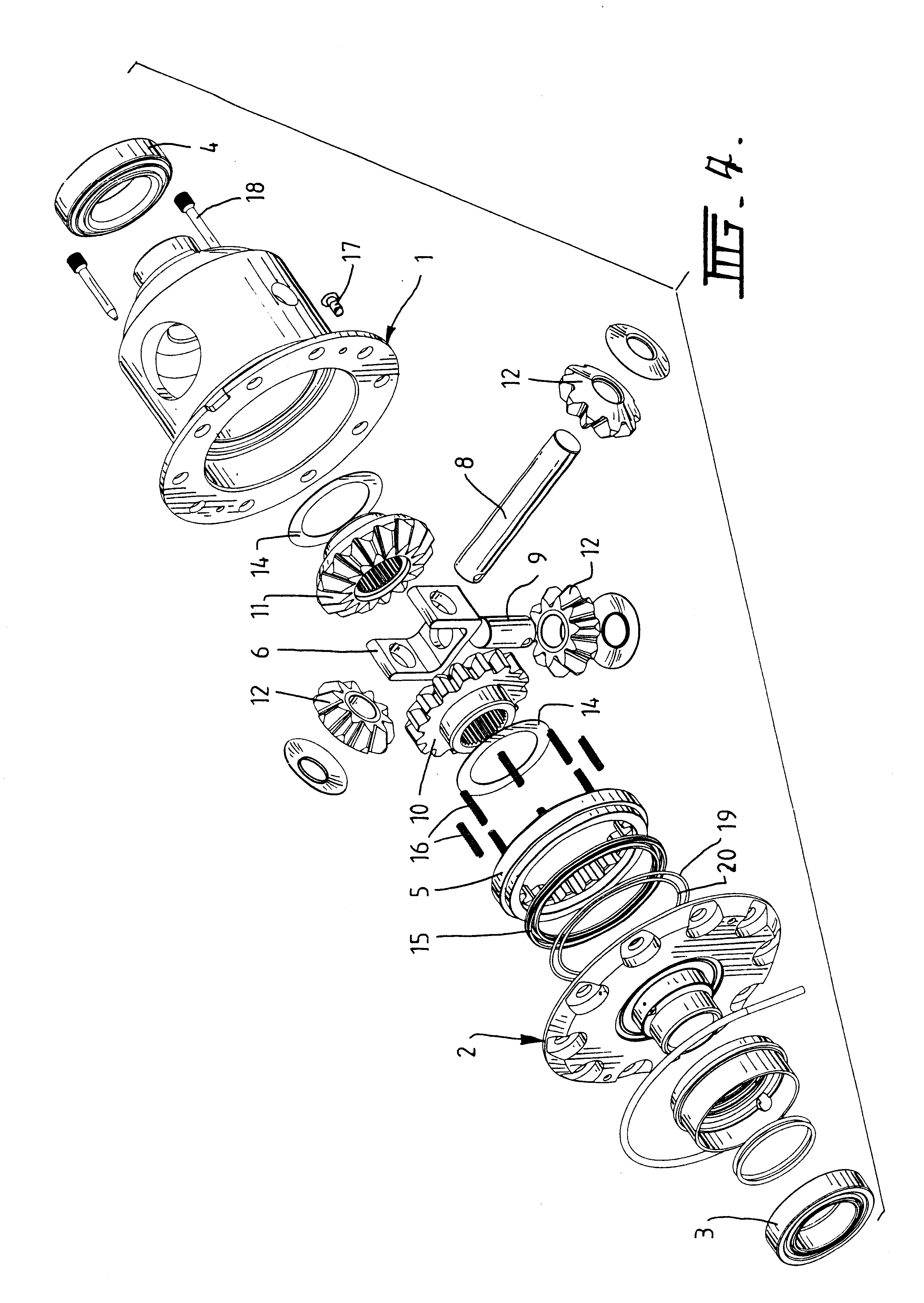

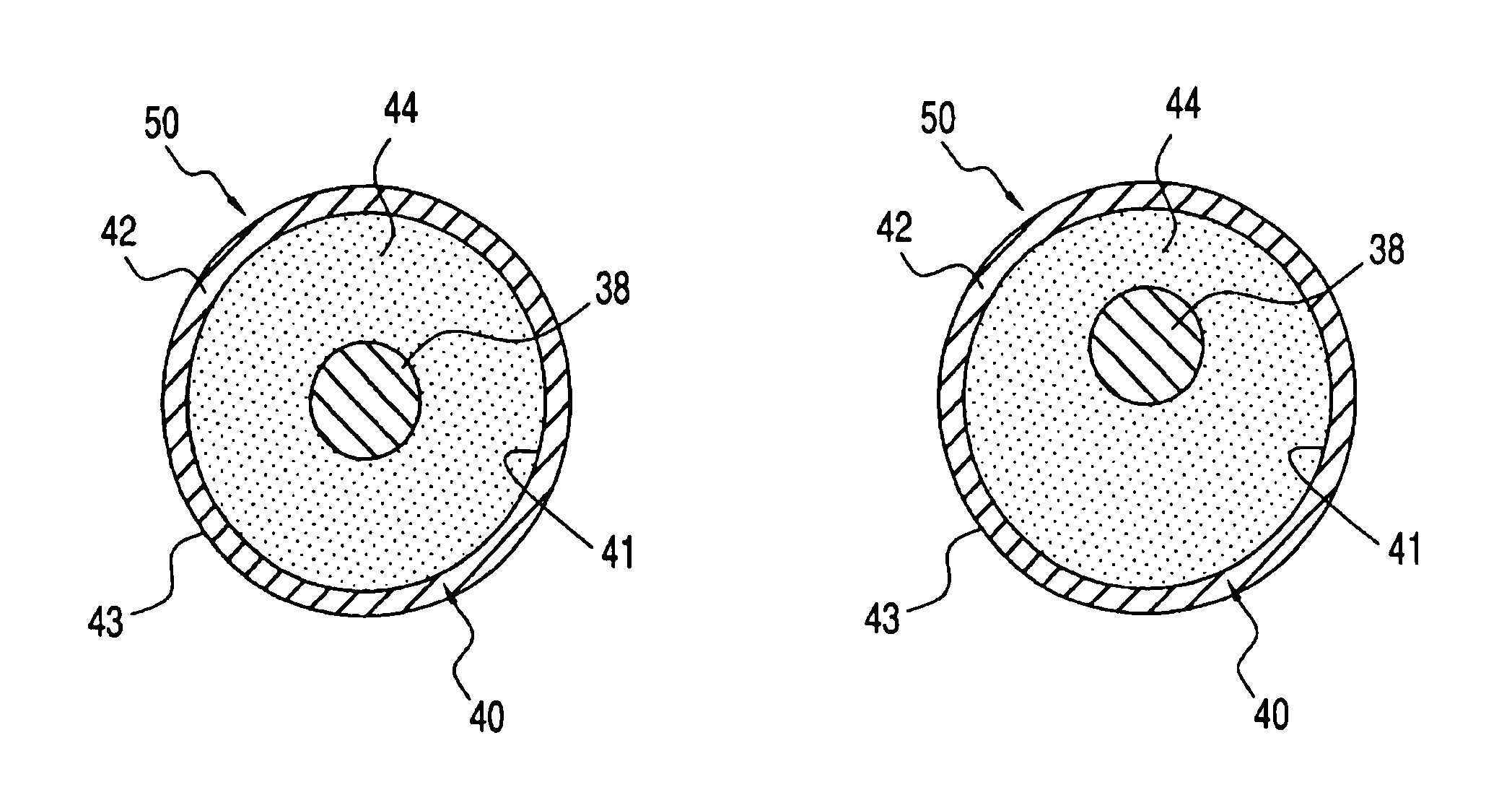

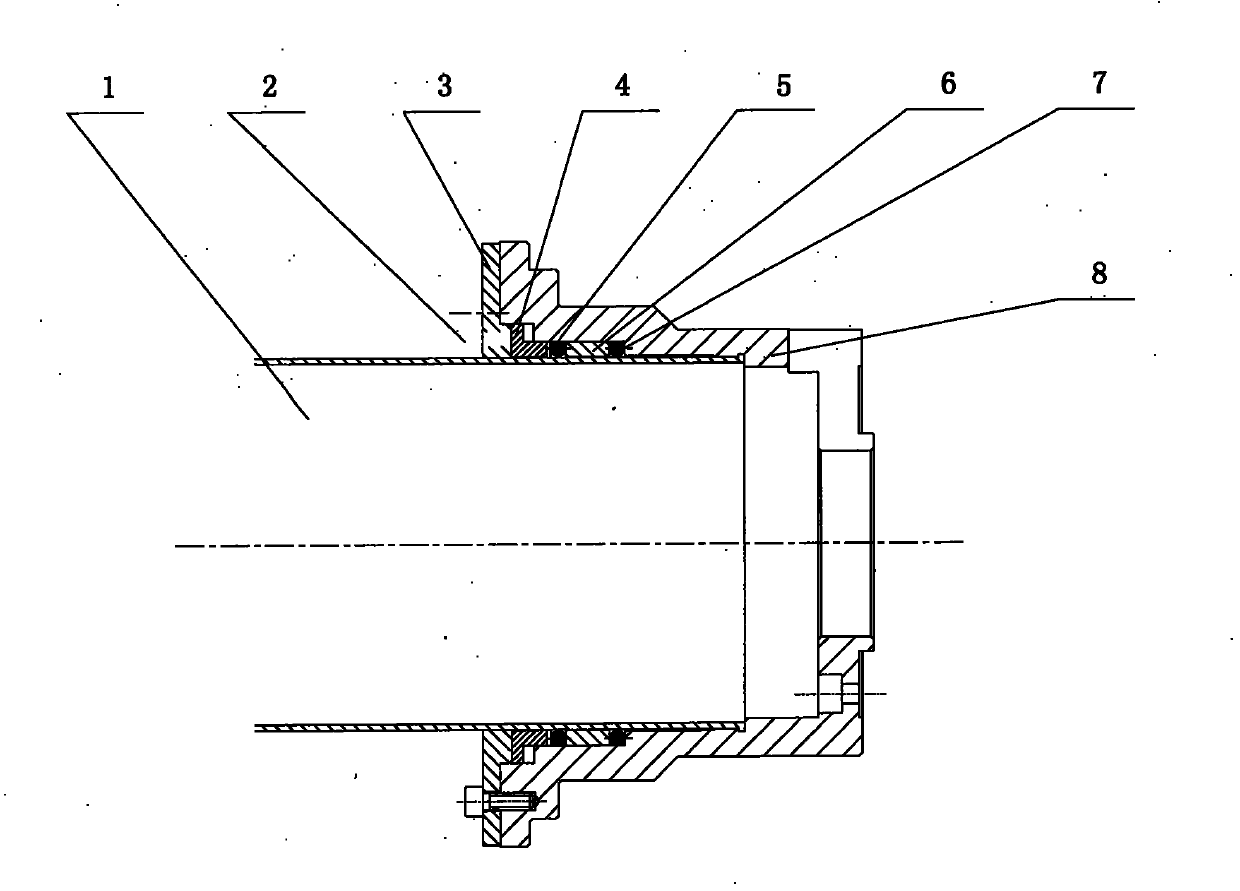

Locking differential with improved tooth meshing configuration

InactiveUS6394927B1Reduce the possibilityOptimizationTransmission elementsDifferential gearingsGear wheelEngineering

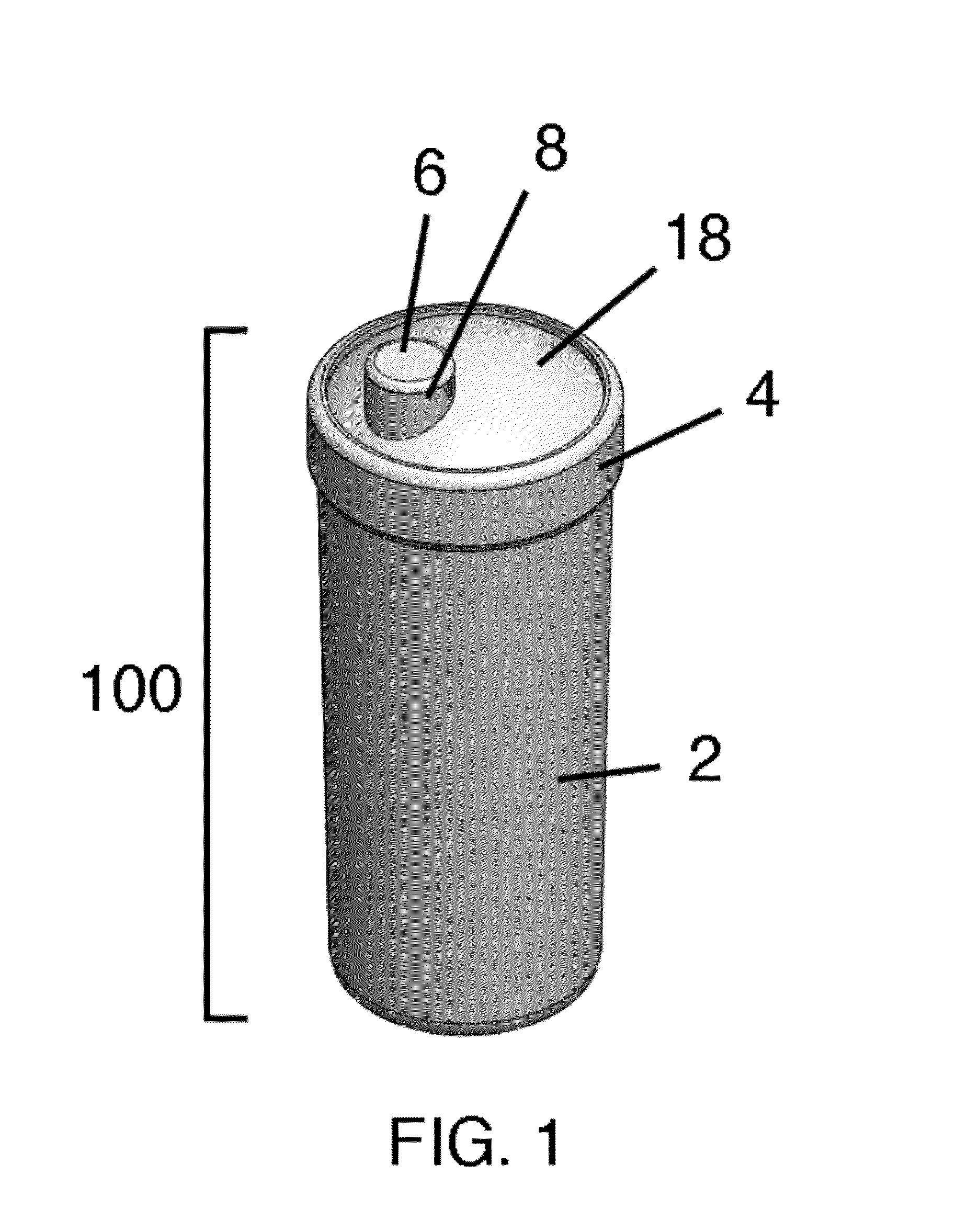

A locking differential including a differential carrier or housing 1 closed by a flange cap 2 engaging locking gear 2A, the housing 1 and flange cap 2 supporting side gears 10 and 11 which mesh with pinion gears 12 supported by cross shafts 8 and 9, the cross shafts engaging mounting holes in the housing 1, each pinion gear having an even number of teeth, and each side gear having a number of teeth which is a multiple of two where two pinions are at 180° to each other, three where three pinion gears are at 120° to each other, four where three or four pinion gears are at 90° to each other, or five where five pinions are at 72° to each other, the locking means further including a clutch gear 5 which slidably engages the locking gear 2A and the teeth on side gear 10 in the locked position, the cross shafts 8 and 9 being in a fixed relationship to the locking gear 2A.

Owner:ARB CORP LTD

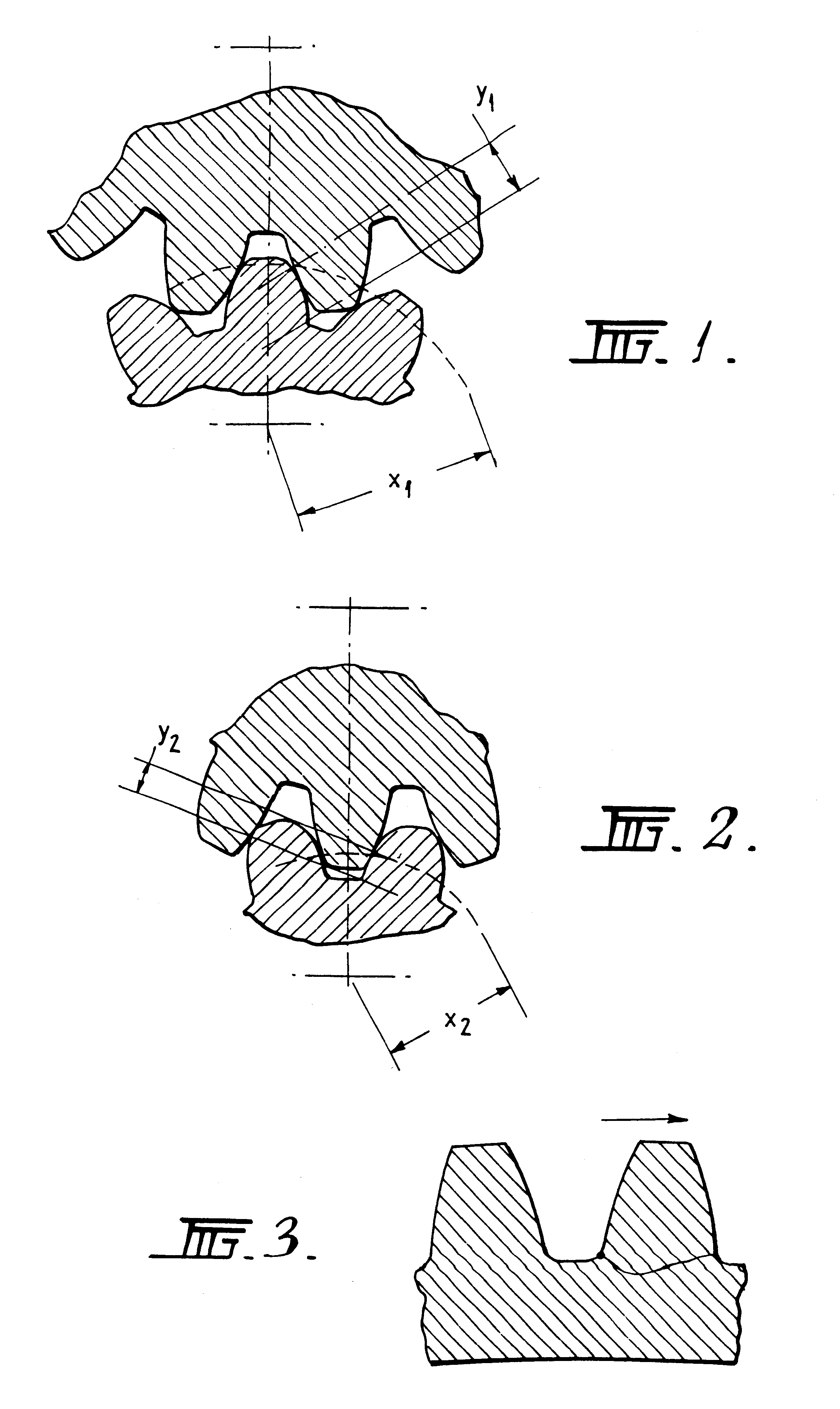

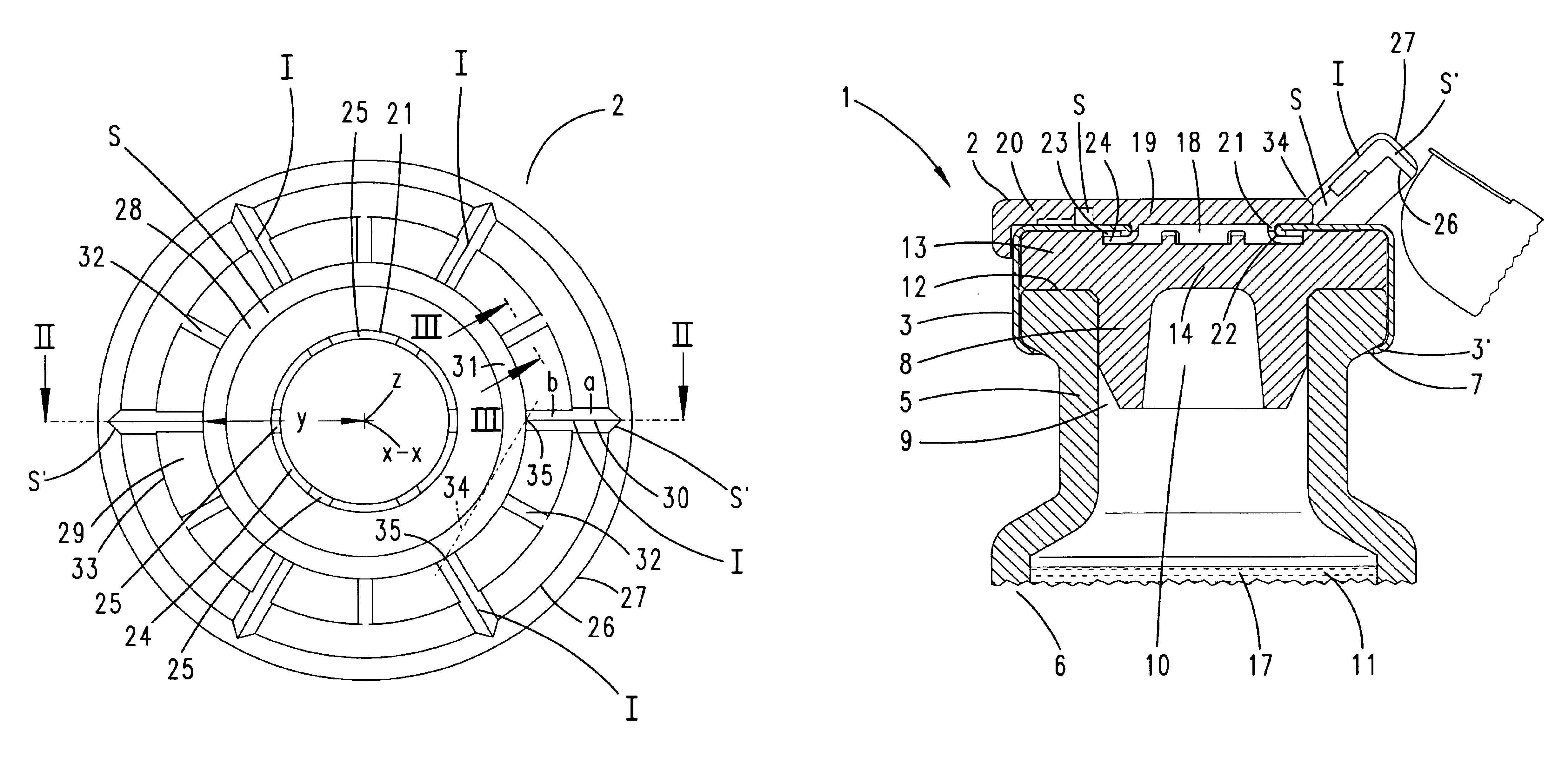

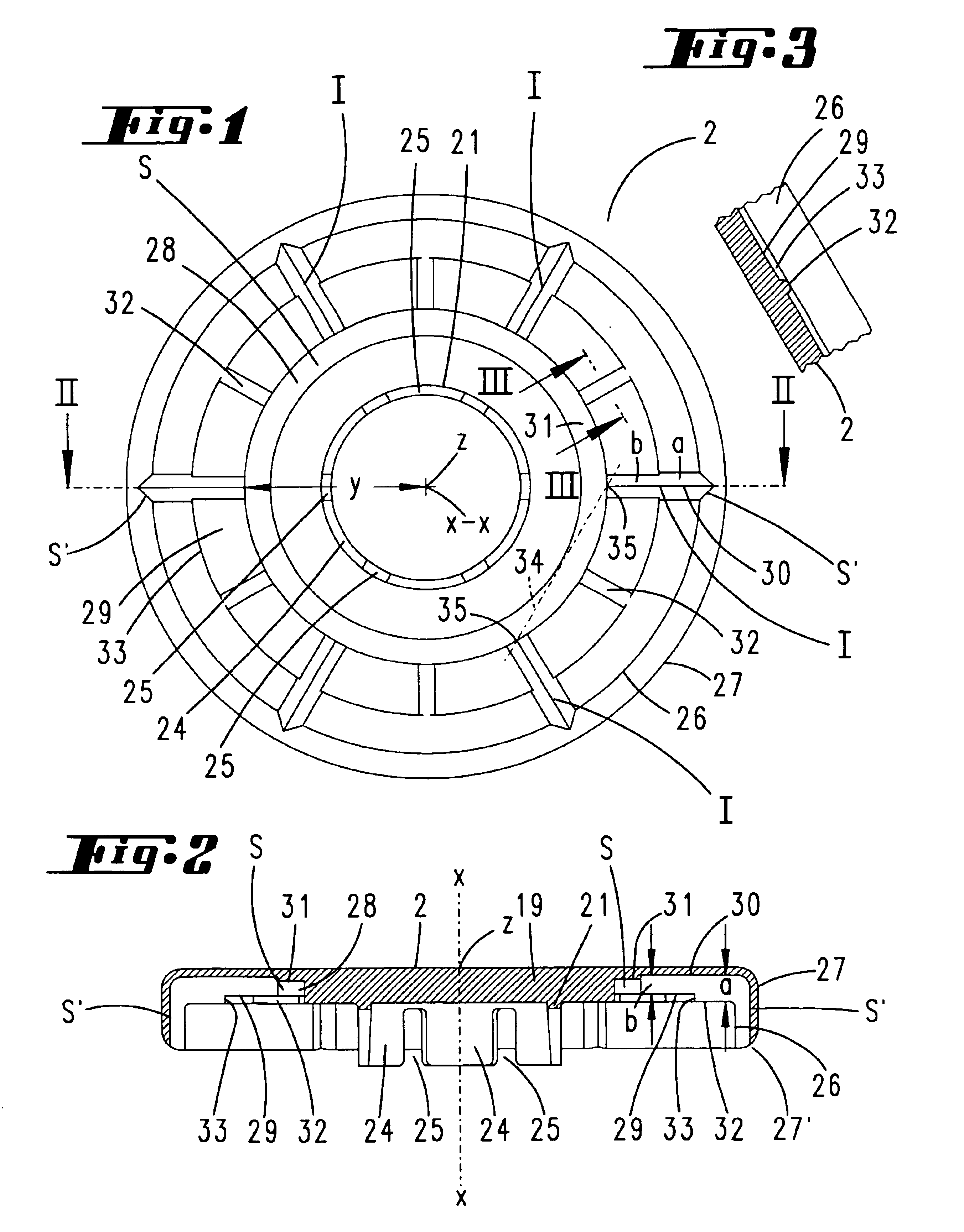

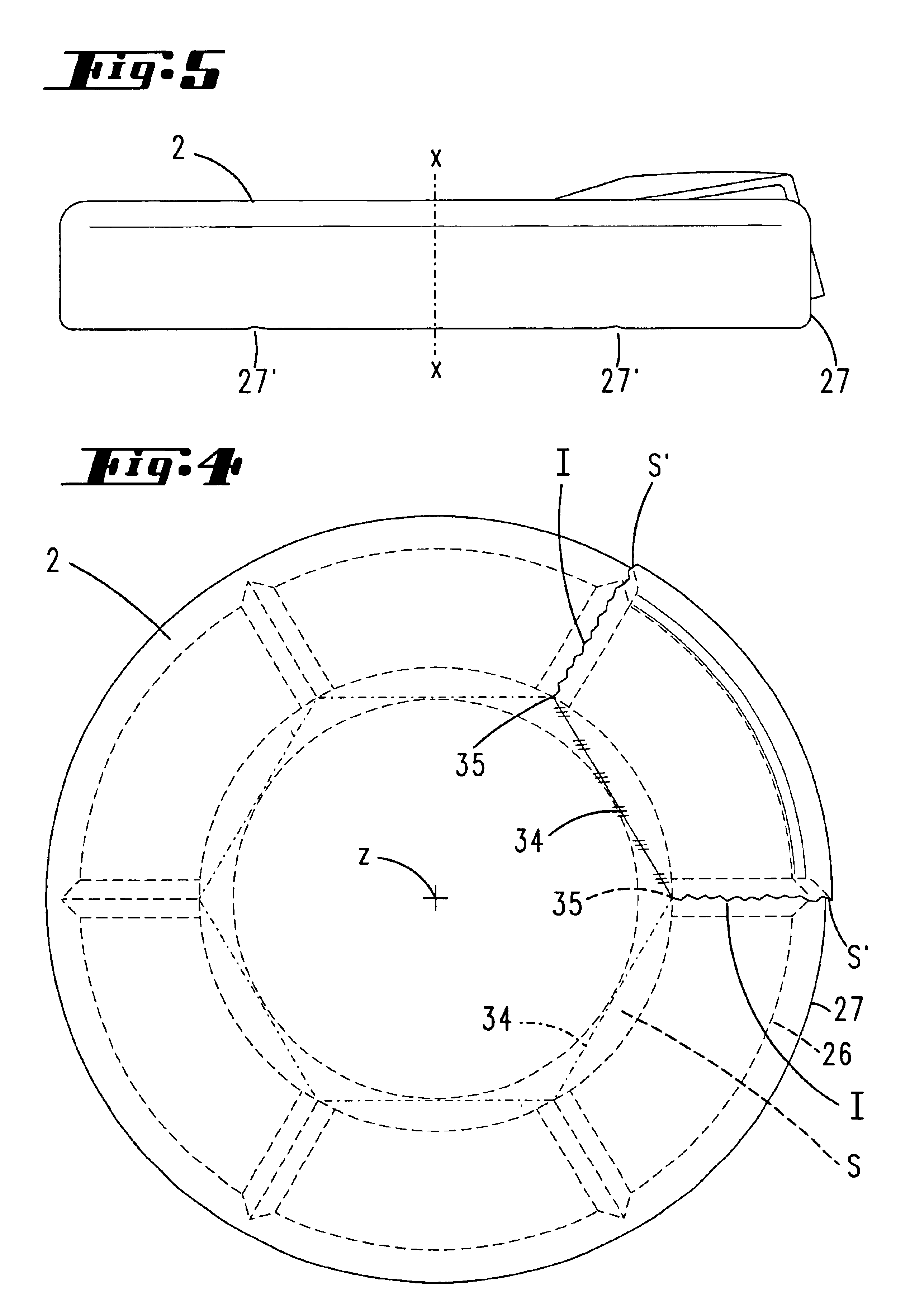

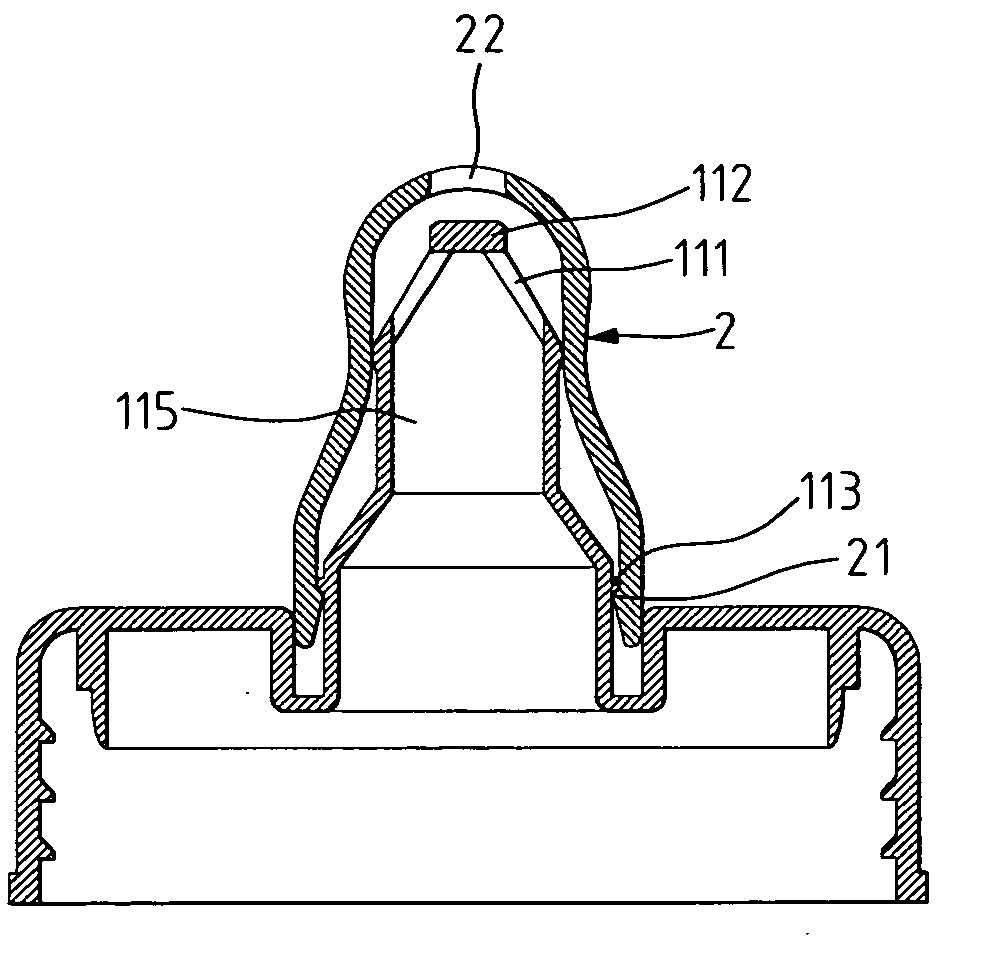

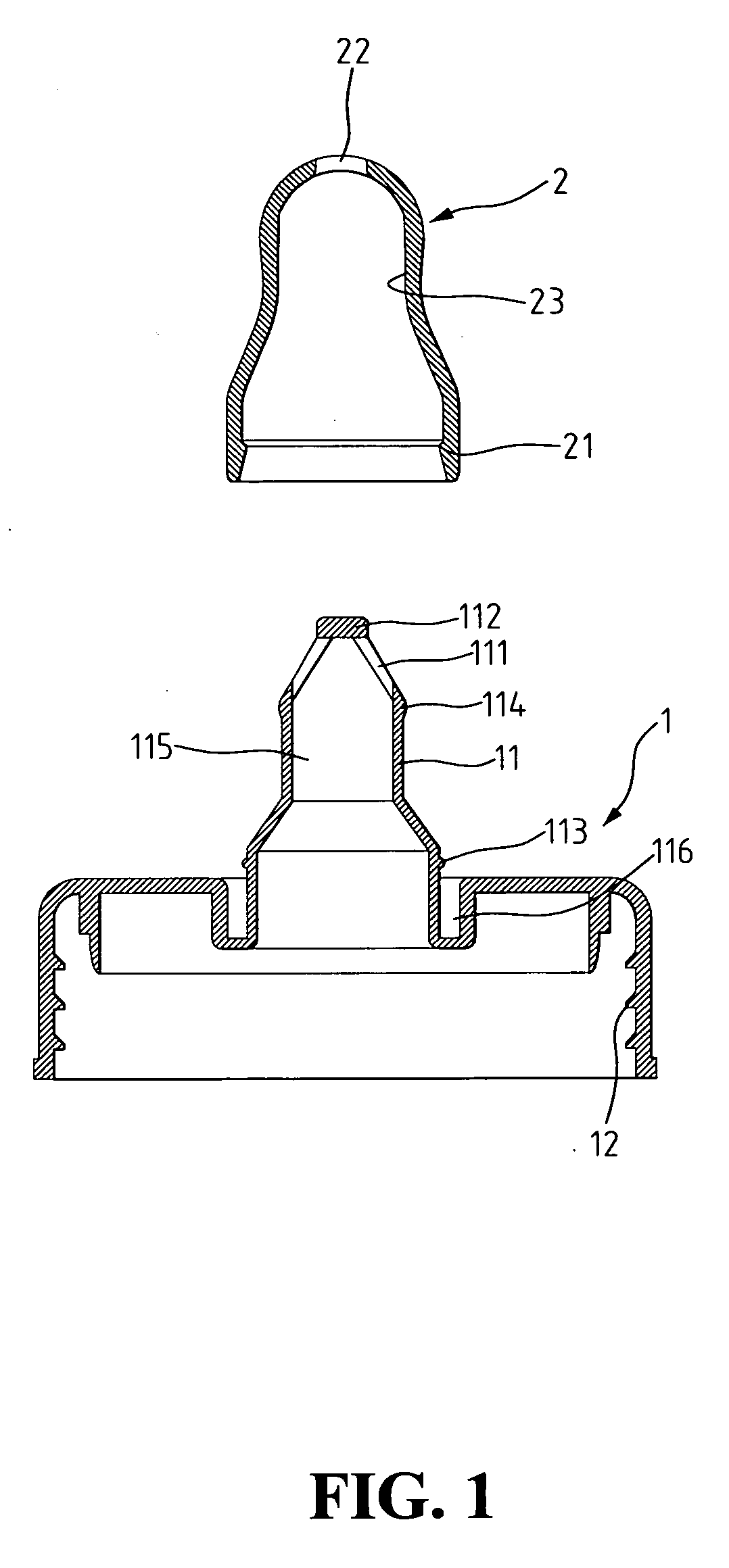

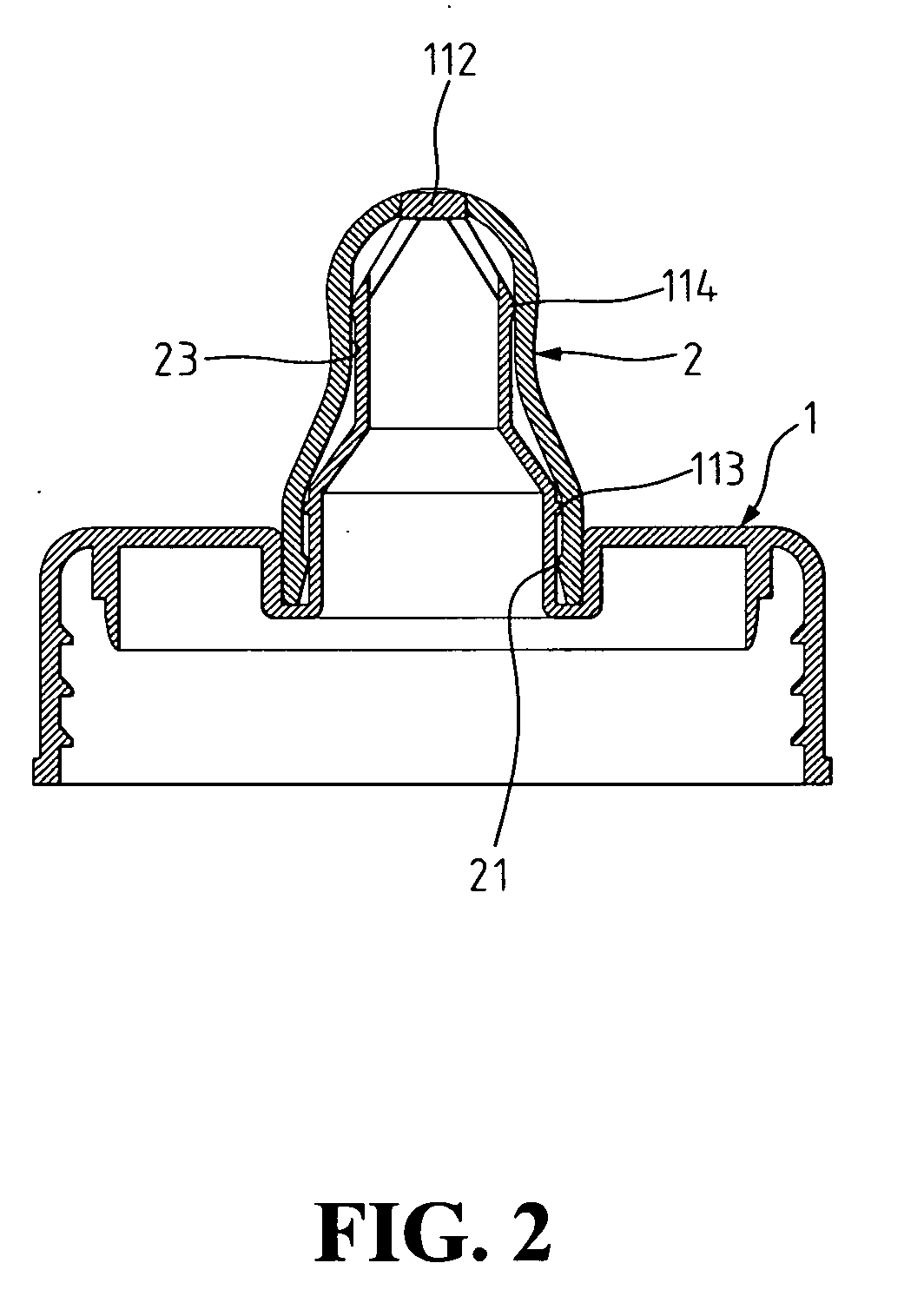

Closing cap for infusion and transfusion bottles

The invention relates to a closing cap for infusion and transfusion bottles. The inventive cap is provided with a flanged cap which encompasses a flanged neck of the bottle, secures a closing plug in the bottle and is provided with a middle recess that is closed by the middle region of a plastic lid in such a way that a ring zone (21) of the plastic lid (2) supports the edge of the middle recess from behind. At least one radially extending desired folding line (I) of the plastic lid (2) is embodied. Said line is formed by thinning the material. The aim of the invention is to indicate when said cap has been used. In an advantageous embodiment, the desired folding line (I) opens into a circumferential weakened area (S) that extends at a radial distance (y) from the center (z) of the plastic lid (2).

Owner:HELVOET PHARM BELGIUM NV

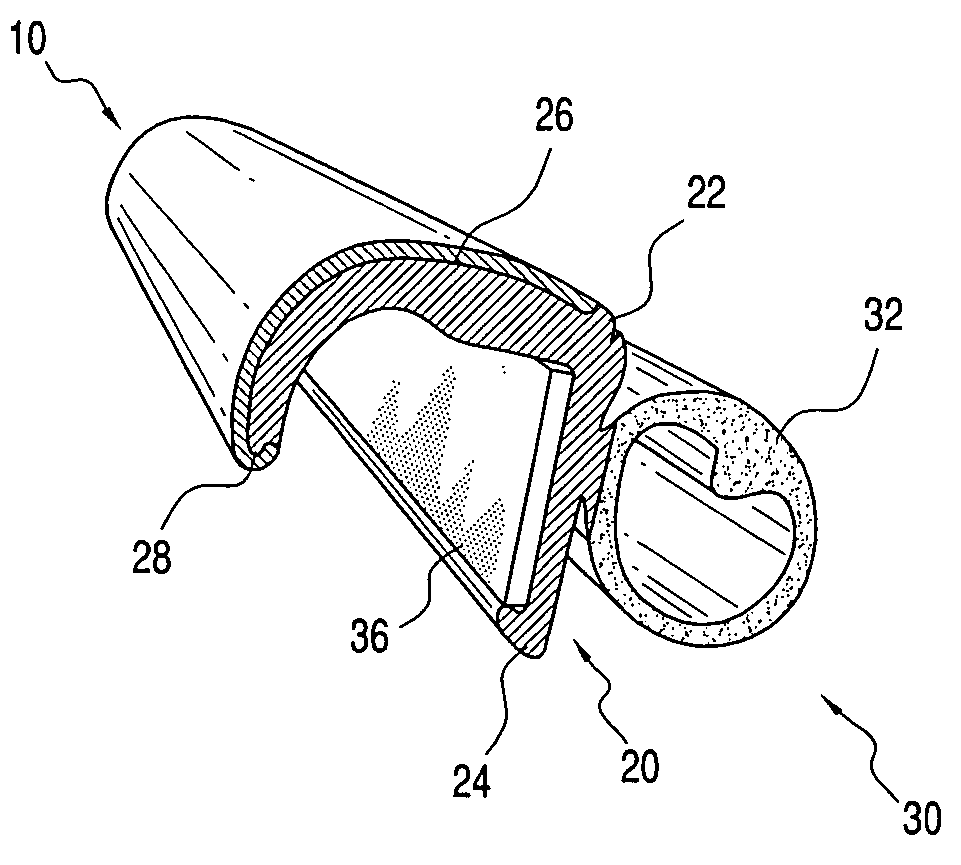

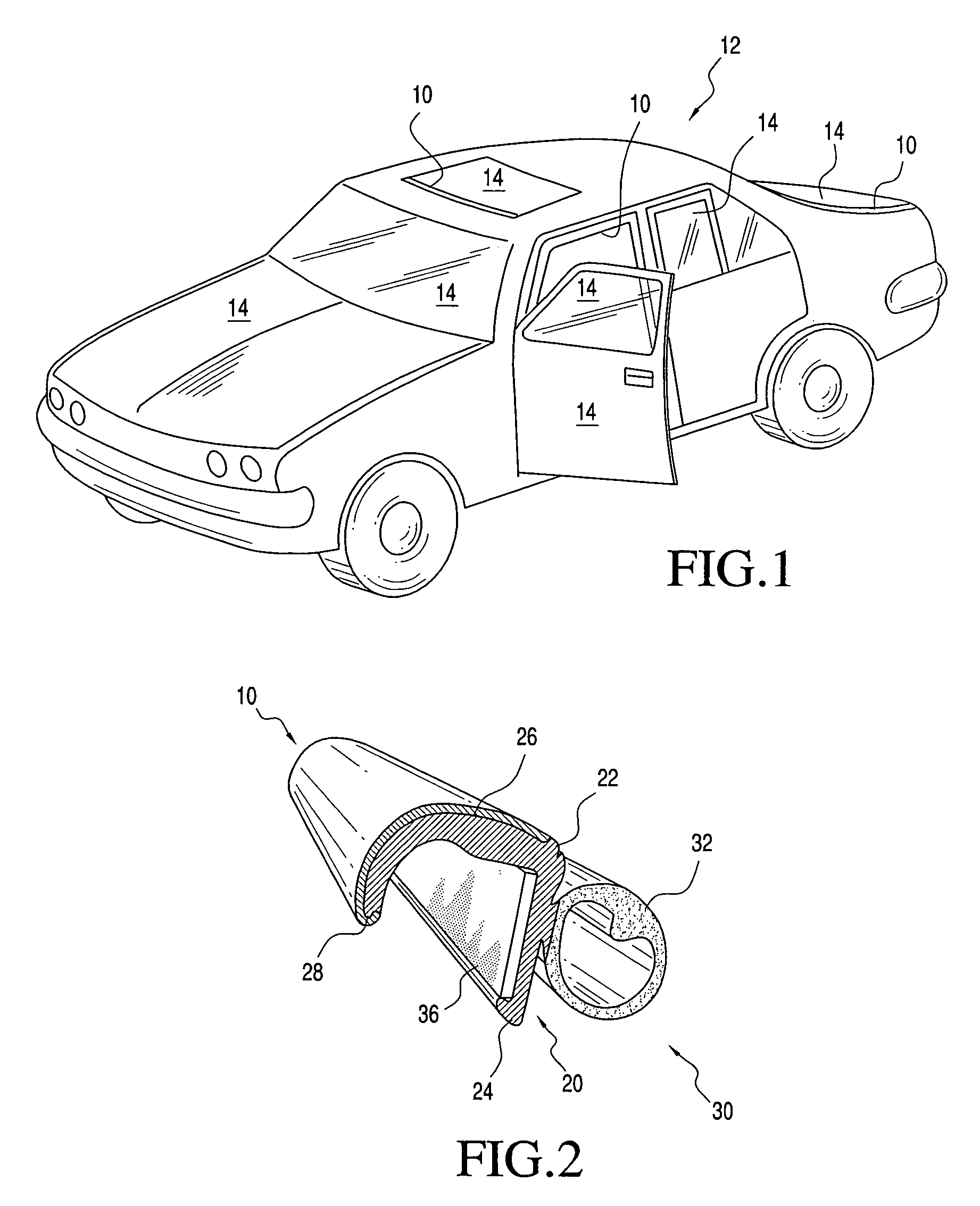

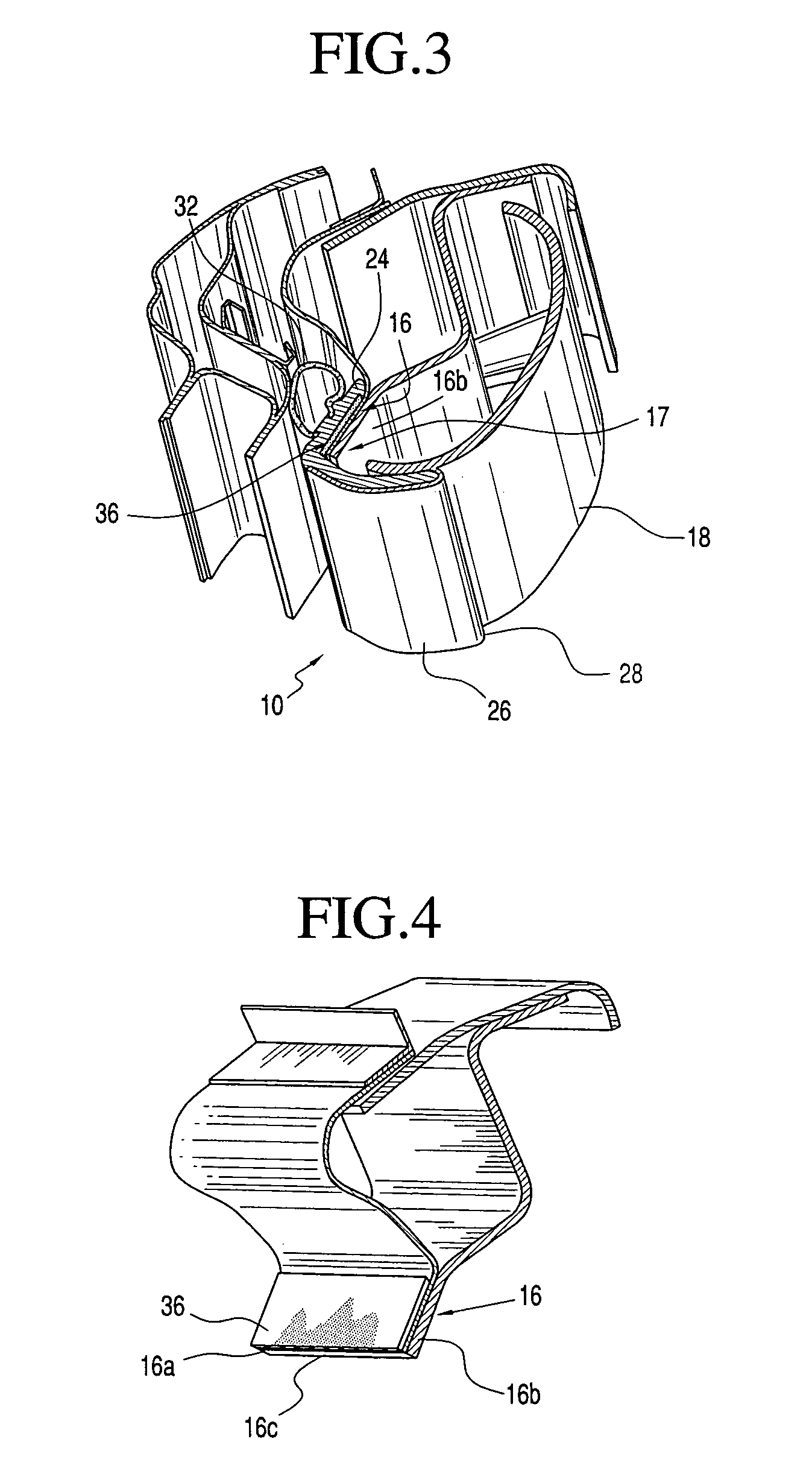

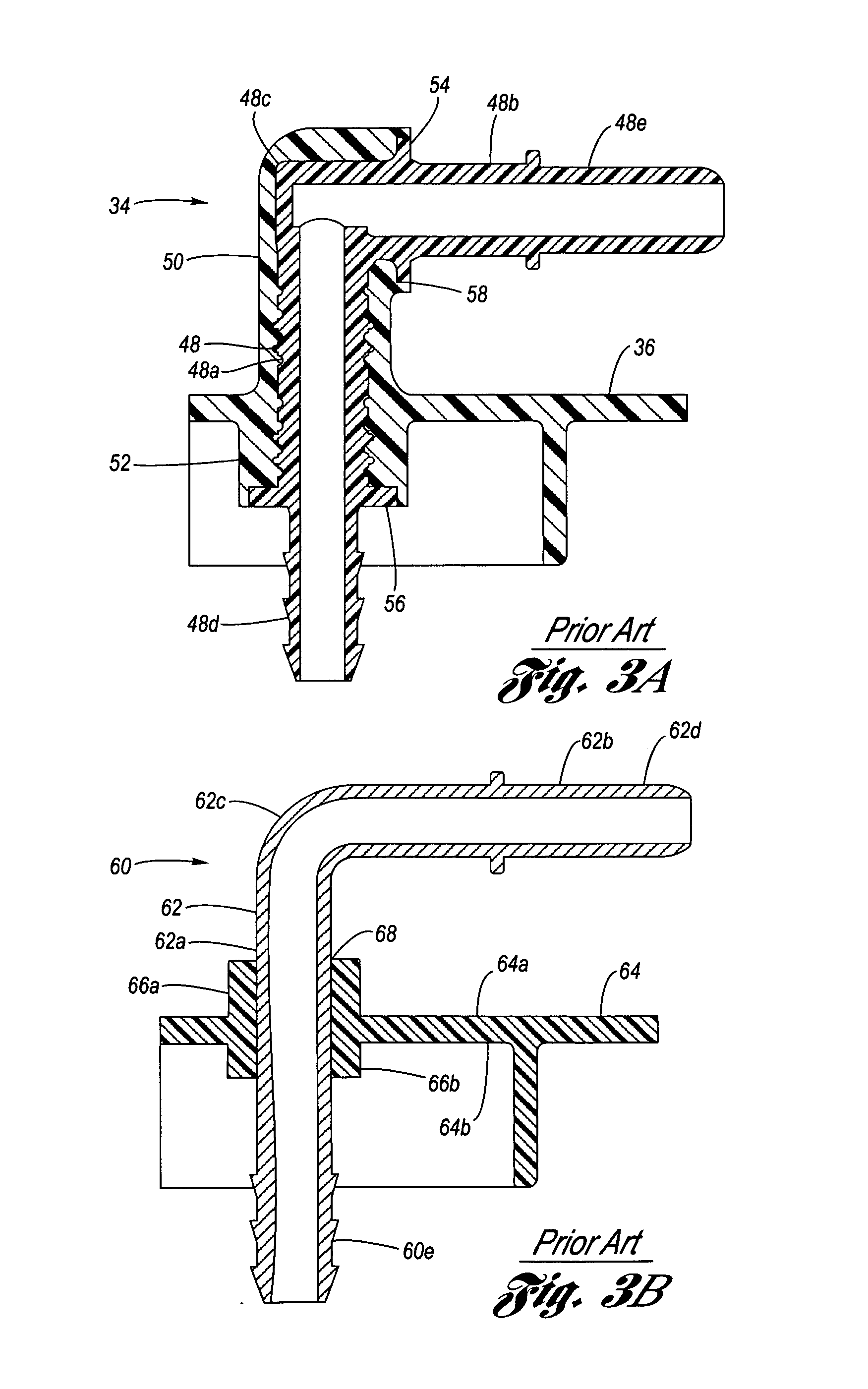

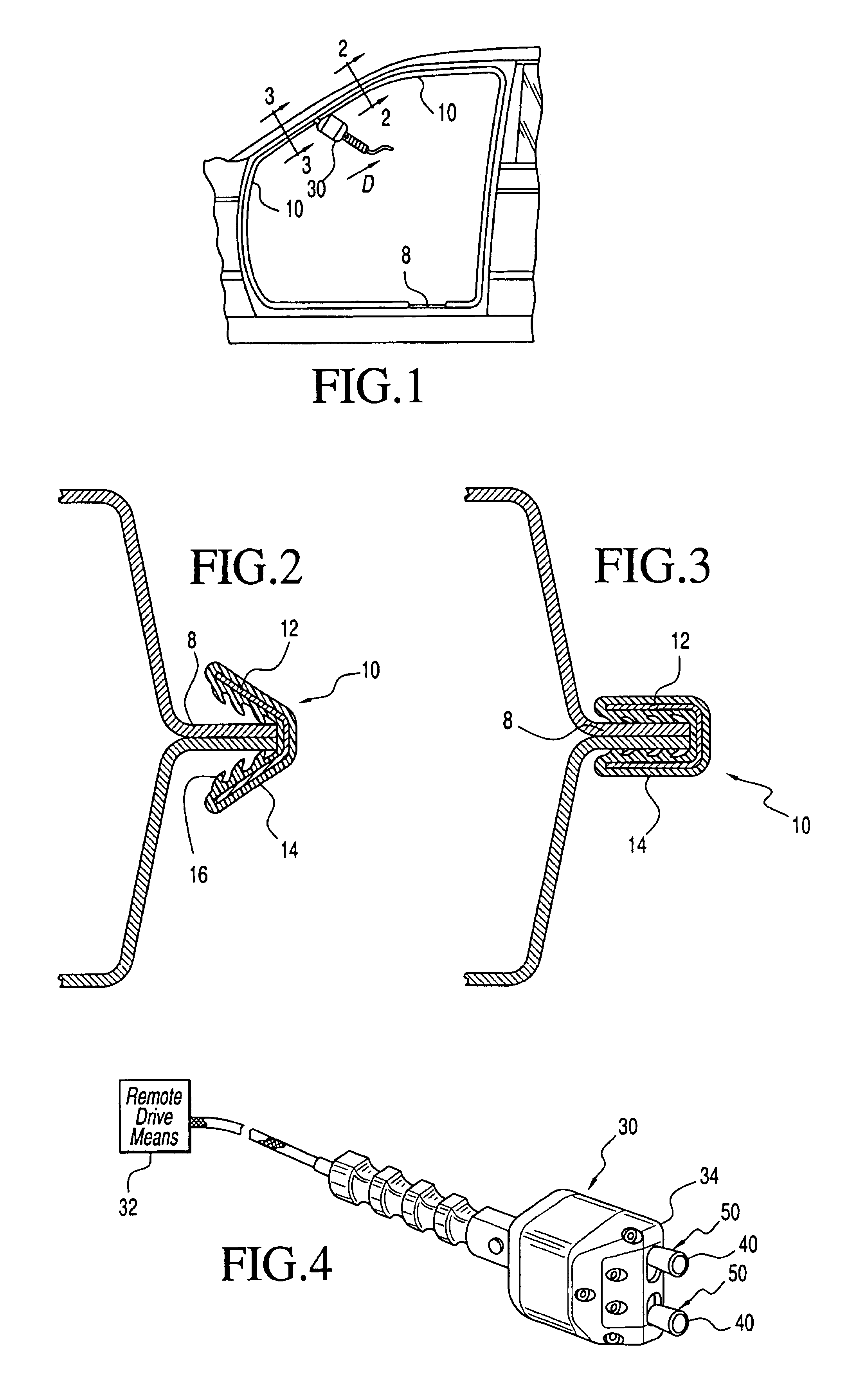

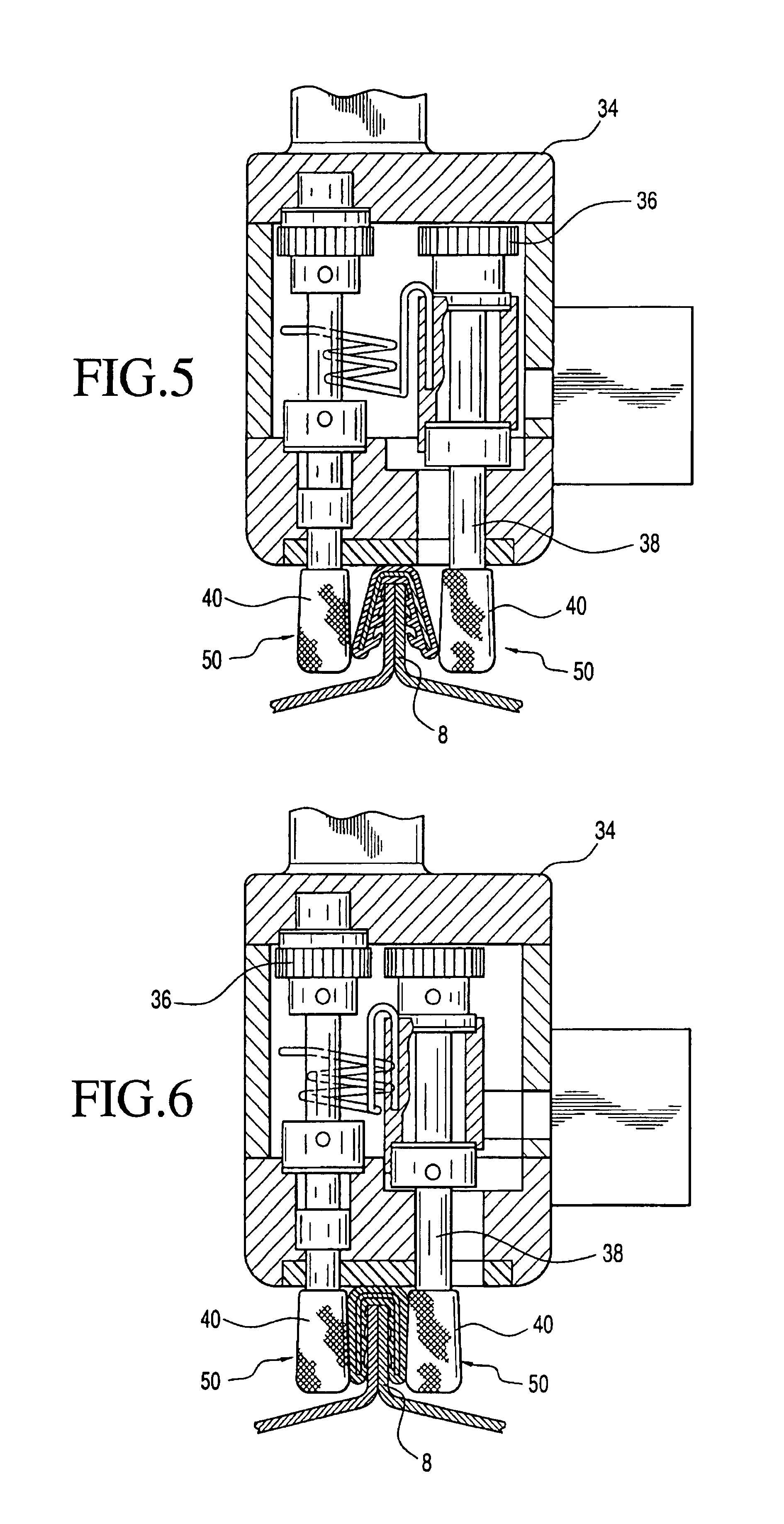

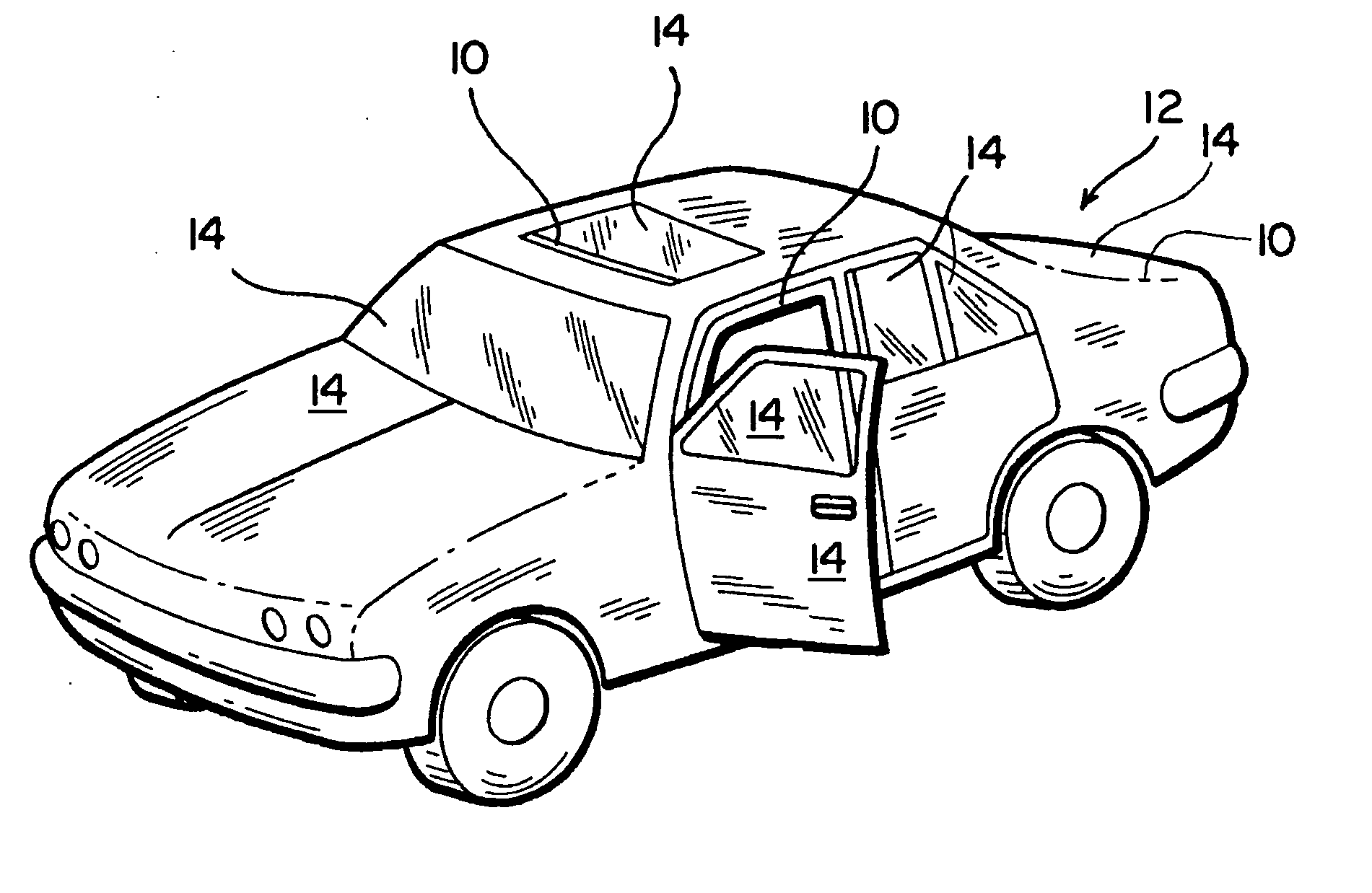

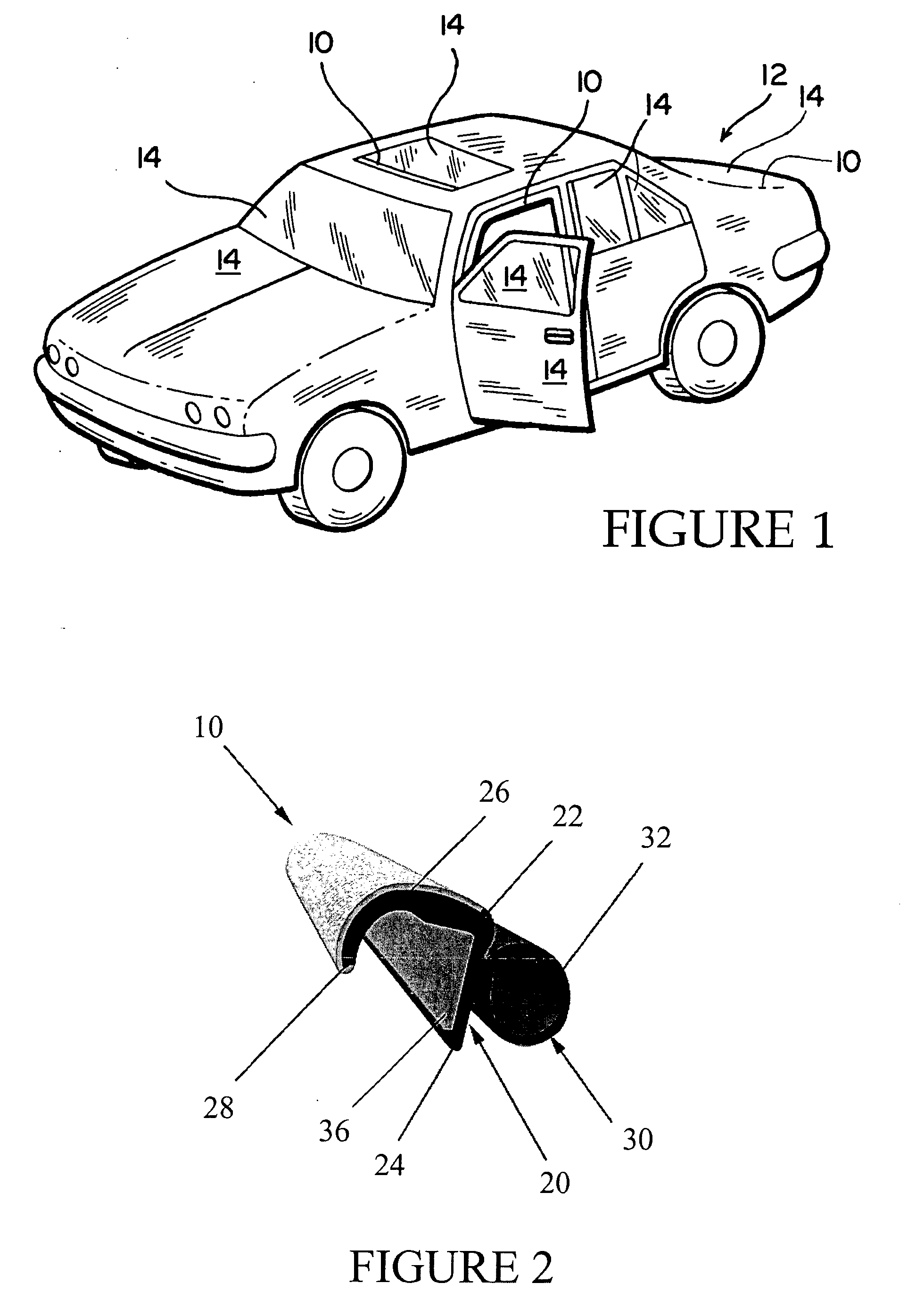

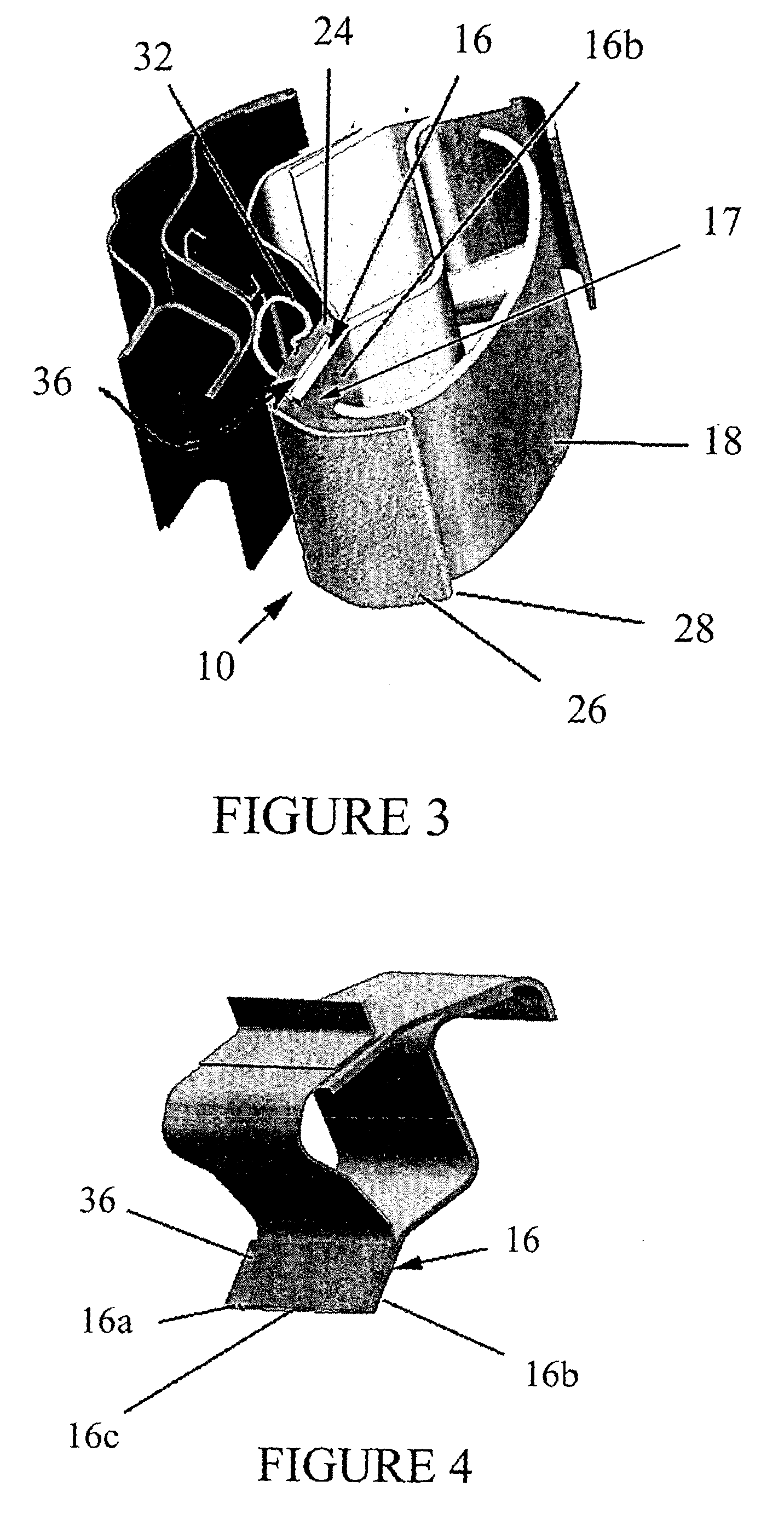

Carrierless flange cover with integral trim strip

InactiveUS6883847B2Reducing material requirement and hence weightUniform appearanceWindowsEngine sealsFLANGE CAPEngineering

A flange cover with a trim lip is provided for finishing a vehicle flange, wherein the flange cover can include a seal. The flange cover is affixed to a single side of the flange and the trip lip projects from an opposed side of the flange to be spaced from the flange. The trim lip can be sized to contact an interior trim piece of the vehicle to occlude a gap between the flange and the interior trim piece. A seal can be operably located on an outside surface of a flange engaging leg.

Owner:SCHLEGEL

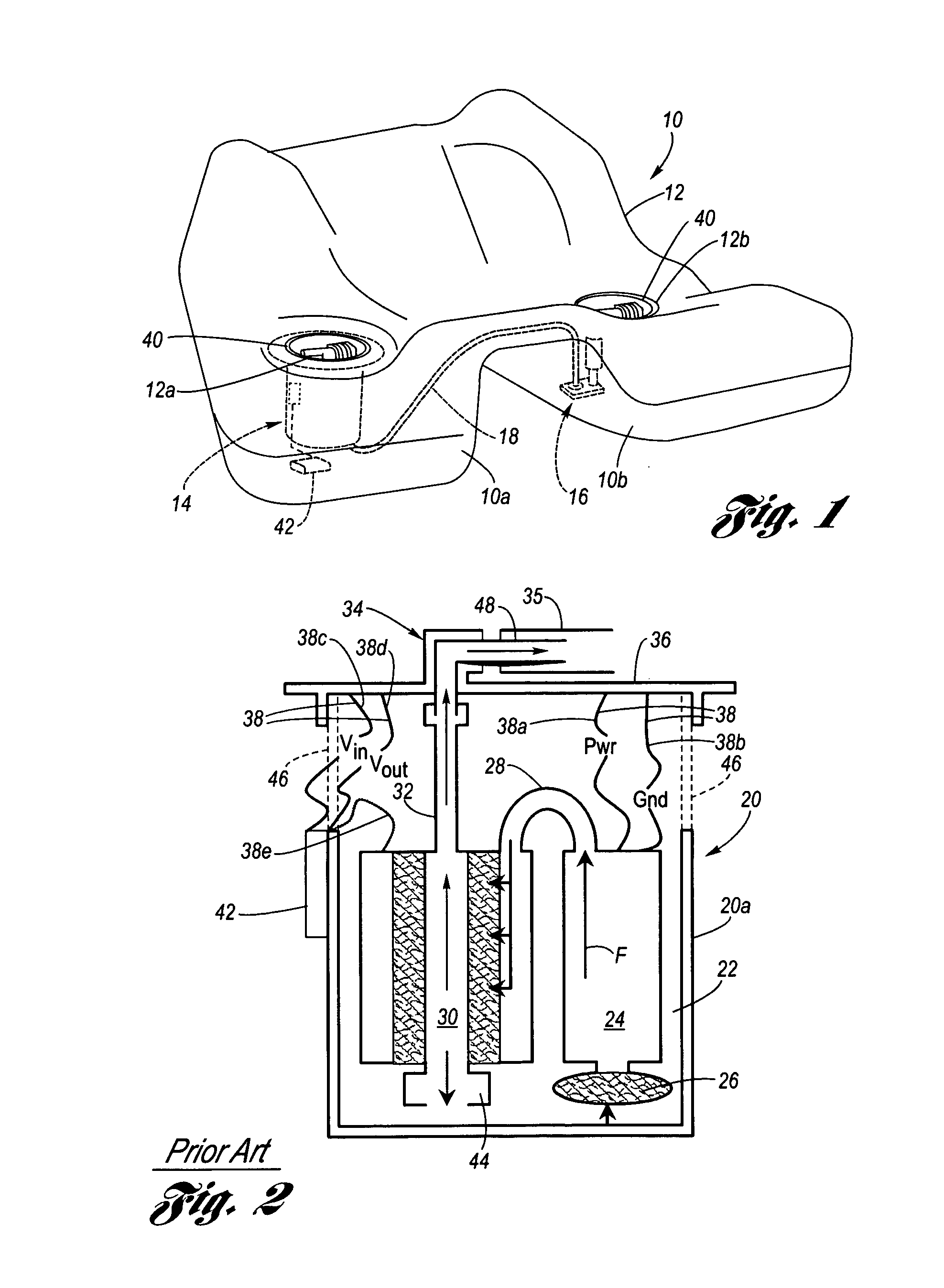

Fuel Port Elbow Having a Truncated Conductive Insert Tube

InactiveUS20090230674A1Minimizes insert tube material costMaterial removalEngine controllersMachines/enginesLine tubingEngineering

A fuel port elbow composed of a plastic port body overmolding an electrically conductive, truncated insert tube such that there is no external dissimilar materials boundary. The tube has a tube first segment, a tube elbow segment and a tube second segment truncated such that the dissimilar materials boundary at the tube truncation is internal to the port body. A port body is integral with the plastic of a flange cover, and overmolds part of the tube first segment and all of the tube elbow and second segments. The port body has a port body second segment having a port body passage communicating with the tube passage and extending remotely from the tube truncation, being adapted for connecting with a fuel line.

Owner:GM GLOBAL TECH OPERATIONS LLC

Container having a push-button activated, pop-open lid

A container for dispensing product includes a housing having an interior space. A rigid flip top assembly is disposed on the housing, and includes a lever, a lid, and a flange. The lid covers a dispensing orifice when in a closed position. The lever has a first end and a second end, and the lid is connected to the flange at a hinge proximate the second end. The lever longitudinally extends over a fulcrum. When a force is applied to the lever proximate the first end, the lever pivots at the fulcrum about a pivot axis, and the second end of the lever moves the lid from the closed position toward an open position.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Liquid tank liner connection

InactiveUS20050178768A1Easy to installLarge containersLinings/internal coatingsThreaded pipeEngineering

The connection employs a plate with at least one through hole for receipt of a liquid conduit tube and at least two projecting threaded studs. A portion of a flexible, non-molded removable liner is mounted between the plate and an inside surface a liquid containing tank having an annular opening. The liquid conduit tube passes through an annular opening in the flexible liner and a flange cap or threaded insert is engaged to either a tank head flange or threaded pipe welded to the tank adjacent to the annular opening. The flange cap or threaded insert receives the studs and nuts are tightened down over the studs tightly pressing the portion of the flexible liner to the inside surface of the tank.

Owner:AQUA TECH INC

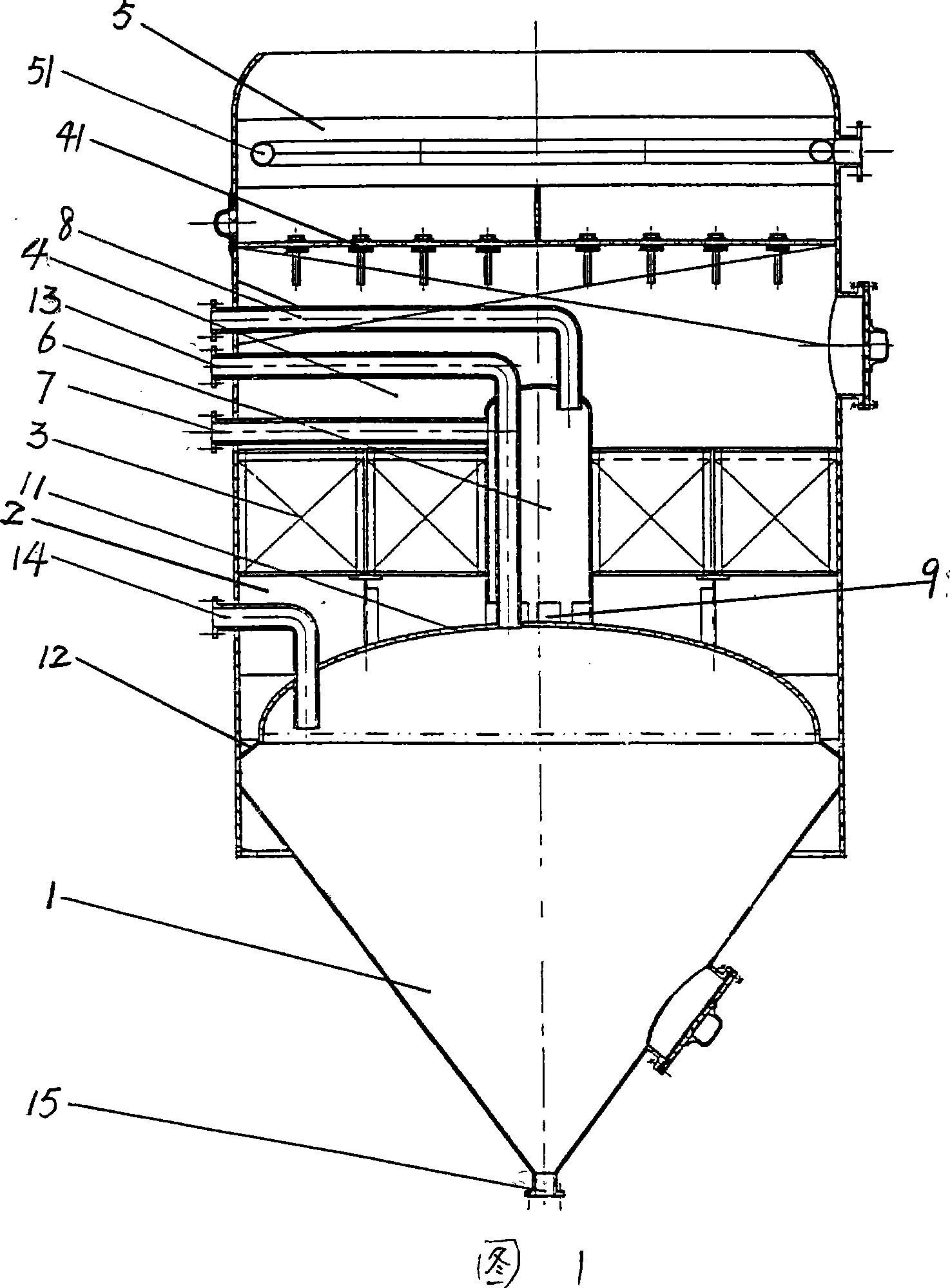

Precise filter

InactiveCN101066812AImprove filtering effectExtended service lifeMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationSludgeSlurry

The precise filter as one water purifying and recovering apparatus includes a casing, and a sludge collecting zone, a flocculating zone, a settling zone, a filtering zone and clear water zone communicated successively from the bottom to top. The sludge collecting zone is one conic sludge collecting bin with one flange cap, and one central liquid tank connected to the water inlet pipe is communicated to the flange cap. The precise filter is one multifunctional solid-liquid separator with integrated settling, filtering, slurry exhausting, washing and other functions, and has high sludge collecting capacity, smooth effluent, high filtering efficiency and other advantages.

Owner:宜兴市亿达工业成套设备有限公司

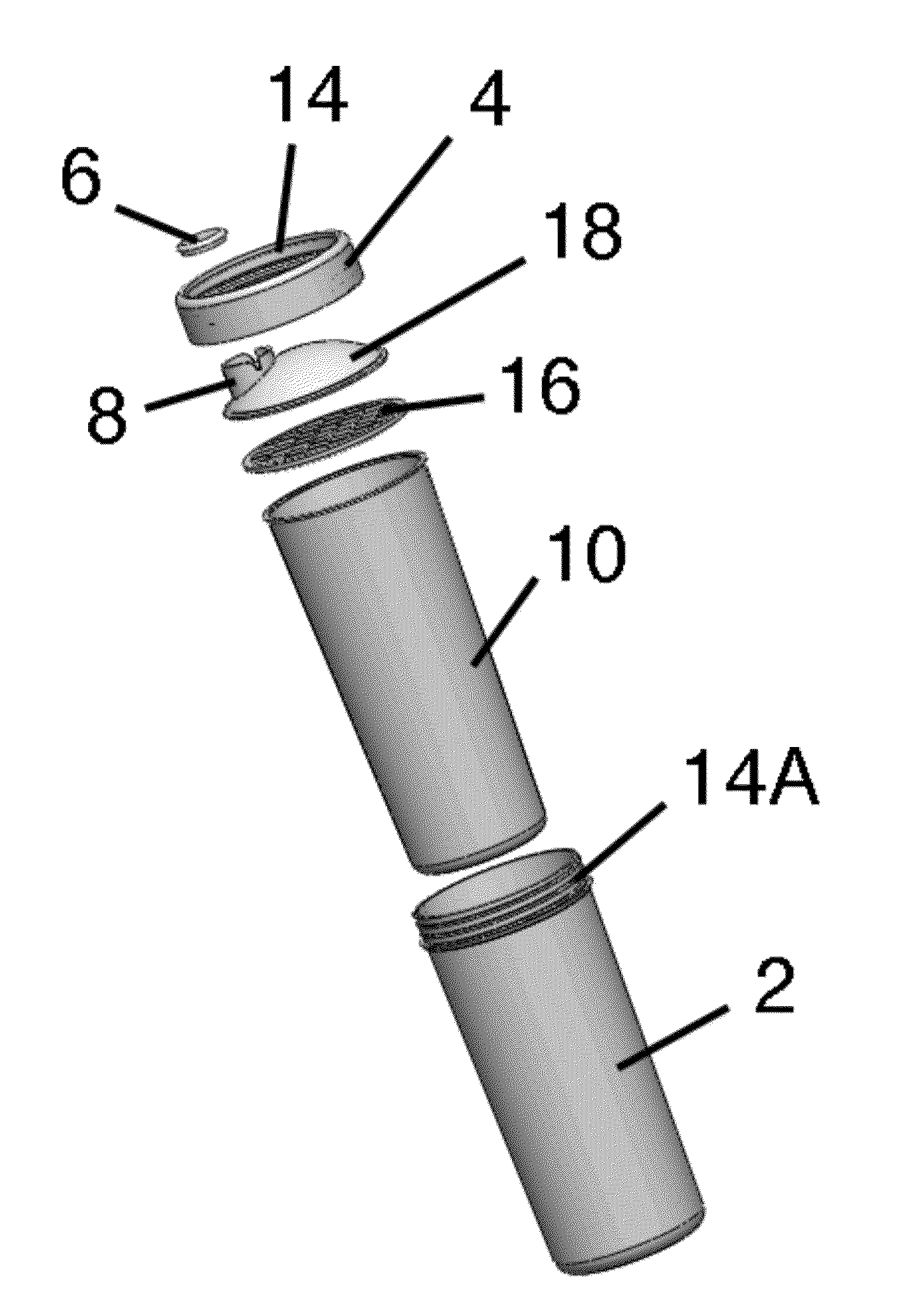

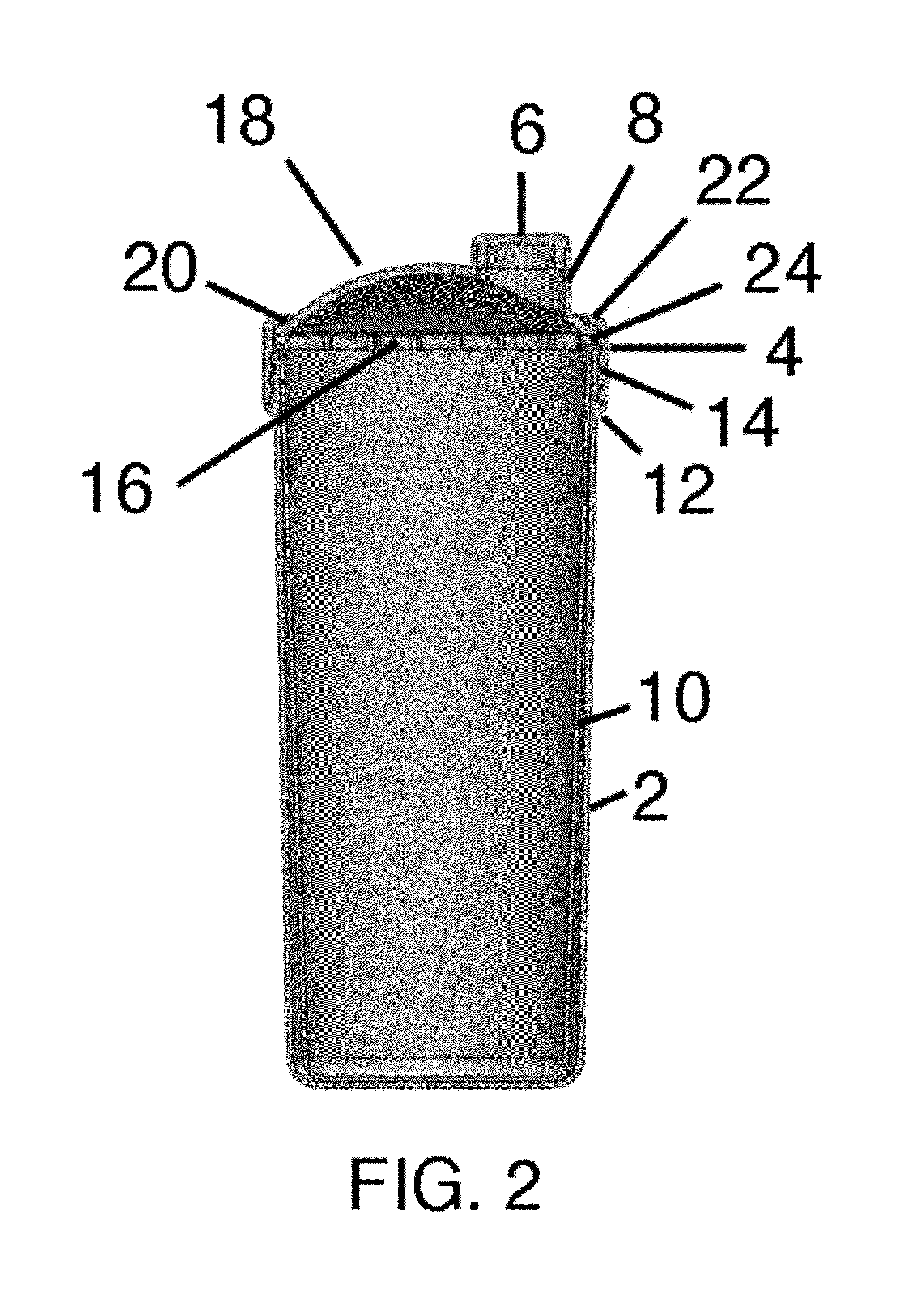

Disposable liner system for cup

A shaker cup with a main cup body, a disposable cup liner, a disposable mixing grid, a disposable lid member and a lid retaining ring. The disposable cup liner is inserted into the main cup body and has flange that fits over the top of the main cup body lip. The disposable mixing grid fits within the top area of the main cup body. The disposable lid member has a flange that matches the diameter of the disposable liner flange. The lid retaining ring capable screws onto the main cup body, and in the process, capturing the inner liner flange, the mixing grid flange and the lid member flange to hold them in a liquid retaining manner. A preferred embodiment includes the disposable cup liner, the disposable mixing grid, the disposable lid member and the disposable spout cap member are all made of biodegradable molded plastic.

Owner:MATTERI CHAD A

Flange cover plate overturning device for syringe fixation

ActiveCN107126602ANo structural damageInfusion syringesIntravenous devicesStructural engineeringMechanics

The invention discloses a flange cover plate overturning device for syringe fixation. The device comprises a body, a friction piece capable of rotating relative to the body, a fixing frame connected with the body in the hinging manner and used for accommodating a syringe and a protective sleeve arranged on the outer side of the syringe in a sleeving manner, wherein the friction piece comprises a cambered part, the circle center of the cambered part is concentric with the circle center of the body, and the body rotates relative to the fixing frame in a first direction, and is connected in a hinging manner in a second direction. According to the device, the body is ensured to rotate only 90 degrees relative to the fixing frame without separation, and the body is also prevented from being structurally damaged due to rapid falling under the action of gravity when being separated from the fixing frame.

Owner:NANJING JUSHA DISPLAY TECH +1

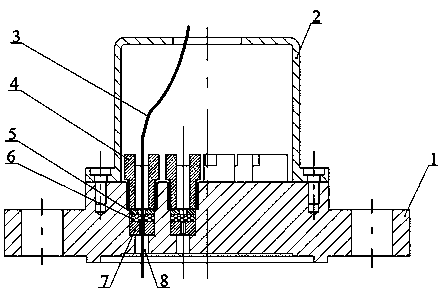

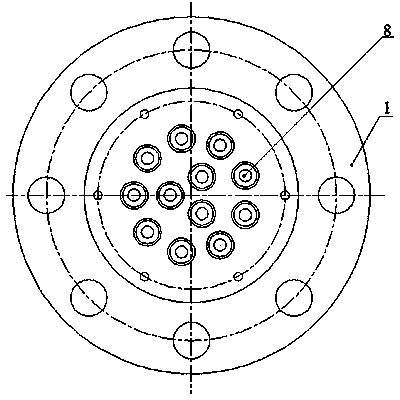

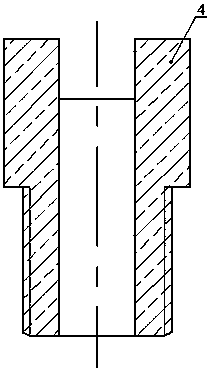

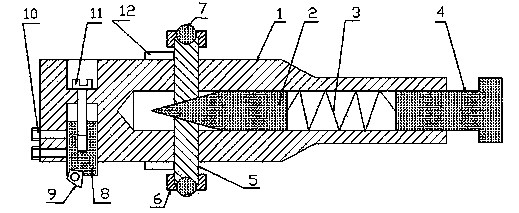

High pressure land-submersible dual-purpose explosion-proof outlet device

InactiveCN102290909AReasonable structural designEasy wiringSupports/enclosures/casingsDual purposeMechanics

The invention relates to a land and submerged high-pressure resistant explosion-proof wire outlet device, which comprises a bed plate, wherein the bottom of the bed plate is provided with a flange inside which an outlet hole is formed; a lead wire has a tapered structure; a tapered high-pressure resistant explosion-proof sealing ring is sleeved in the tapered hole; a jointing face between the bedplate and a wire outlet device of a motor is provided with a high-pressure resistant sealing ring and an explosion-proof face; a flange cover is fixed on the upper part of the bed plate; and the part, outside an outlet, of an outgoing line is sleeved with a high pressure sealed hose. The high-pressure resistant explosion-proof wire outlet device has a rational structural design, high sealing properties, high pressure resistance and explosion-proof performance, is quick and convenient to wire, can effectively fulfill the aim of sealing the outgoing line and bear the water pressure of 8MPa without leakage to achieve good sealing effects, and is particularly suitable for use in explosion-proof occasions with high pressure media.

Owner:WOLONG ELECTRIC NANYANG EXPLOSION PROTECTION GRP CO LTD

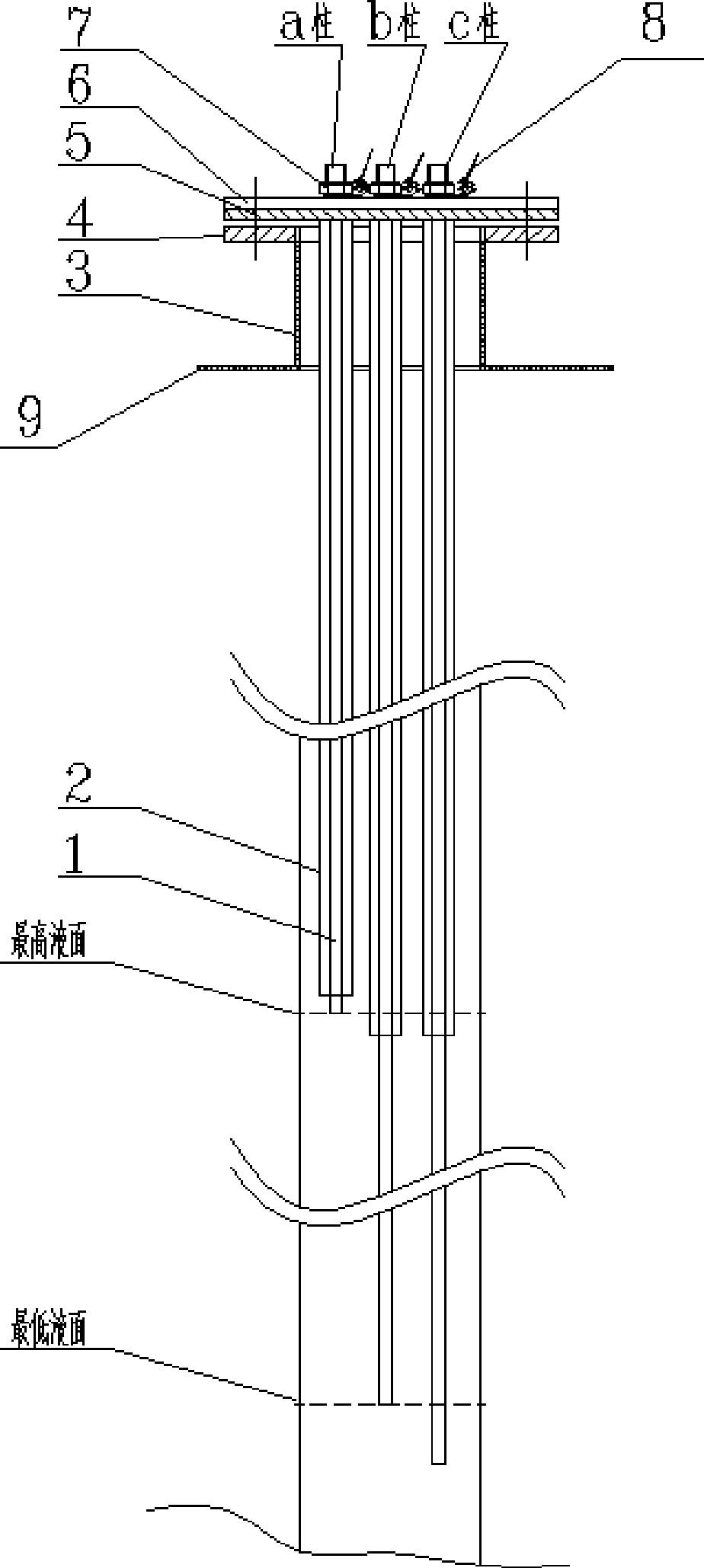

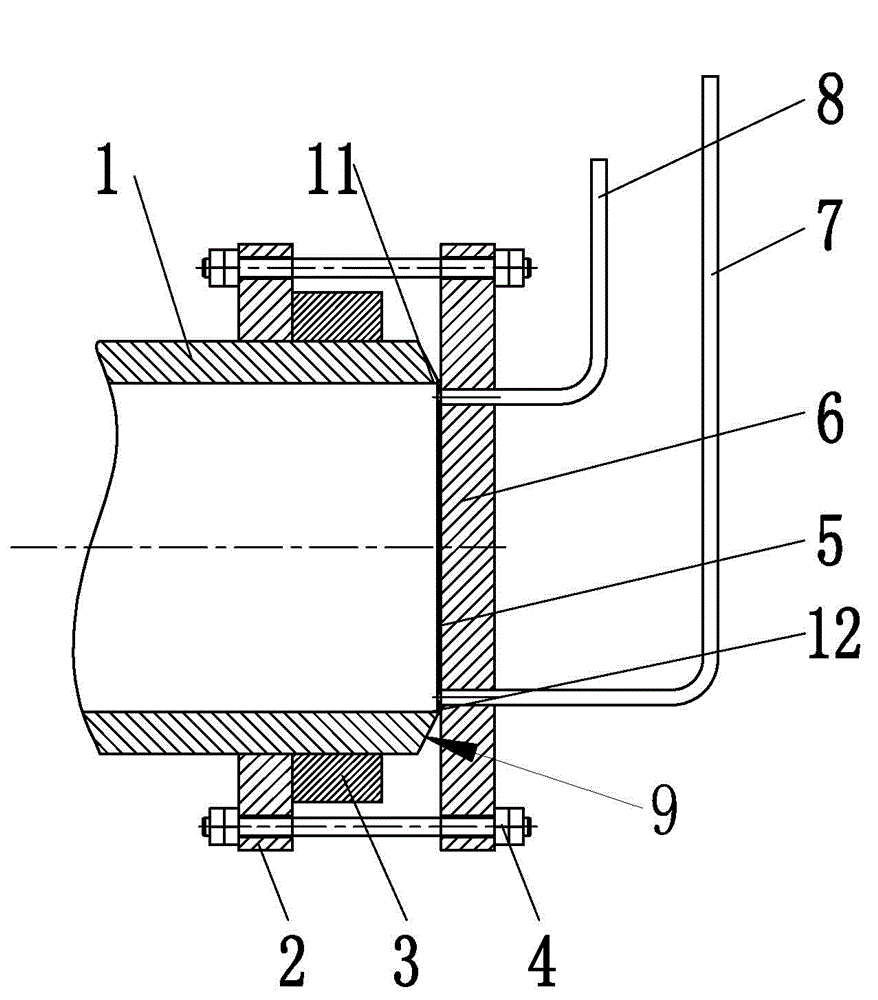

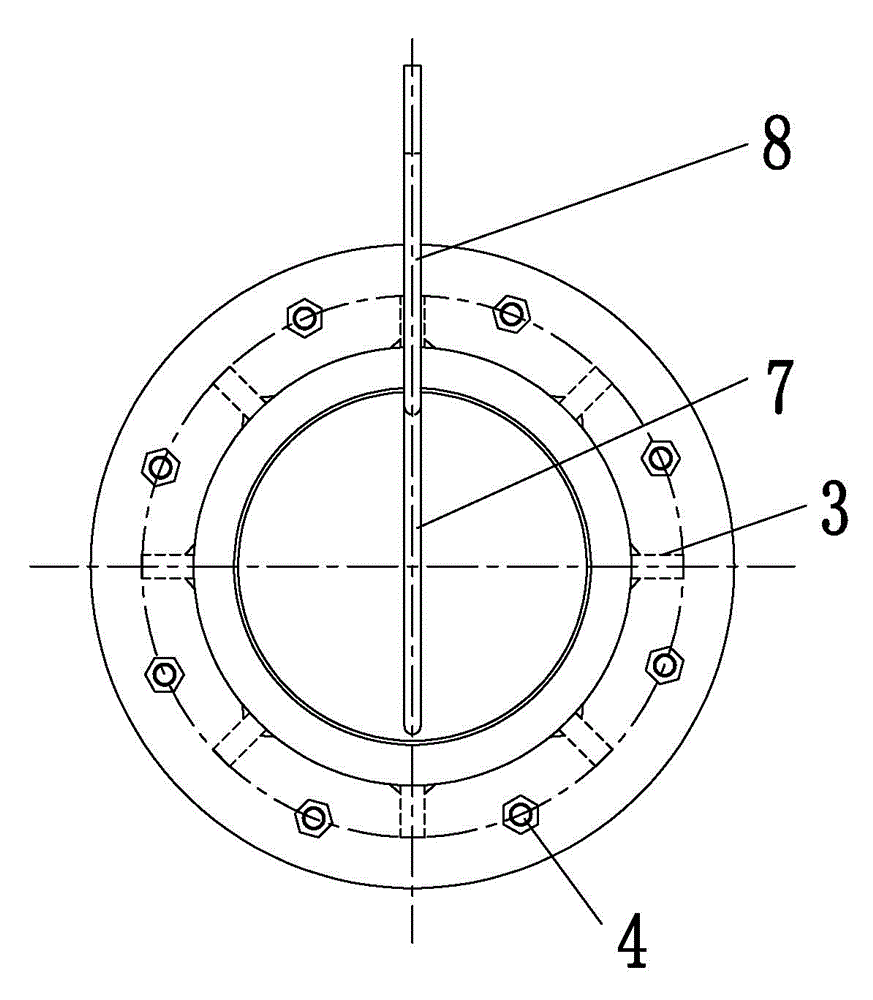

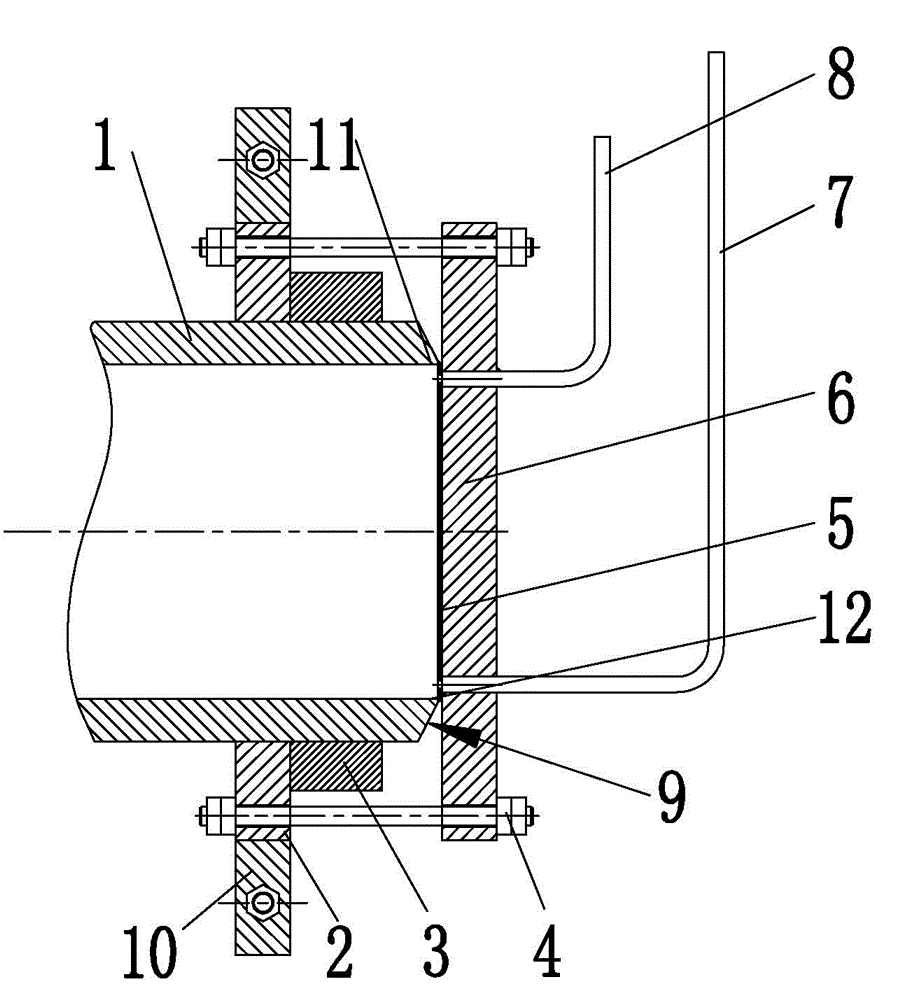

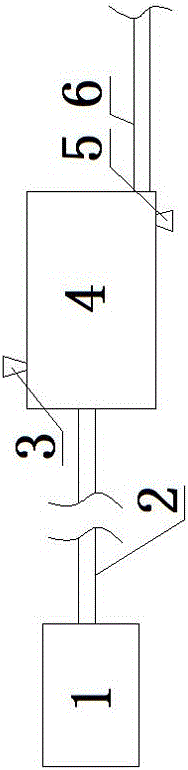

Liquid level detector for magnesium electrolytic cell

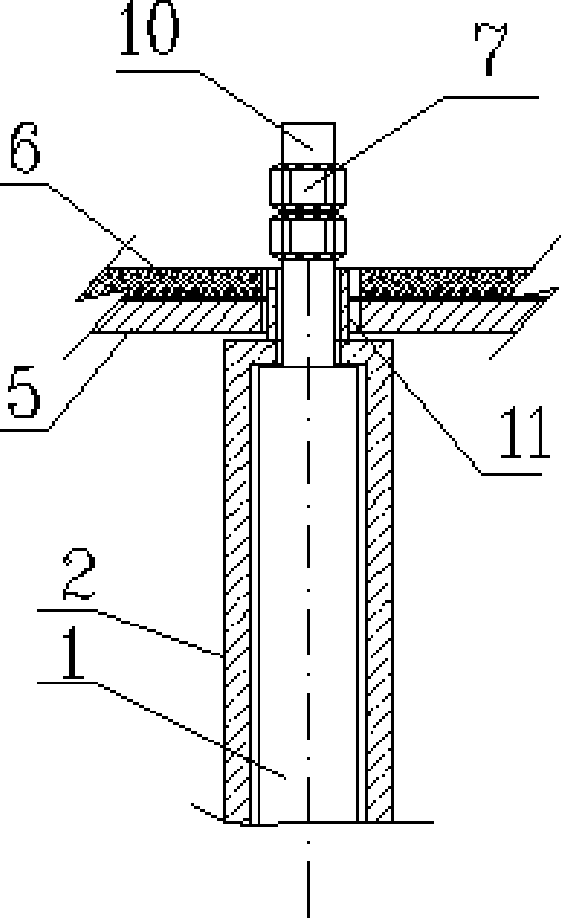

InactiveCN101463489ASolve technical problems that cannot be measuredReduce labor intensityMachines/enginesLevel indicatorsControl systemSteel bar

The invention discloses a device for detecting the liquid level of a magnesium electrolysis bath. The top of a cover board (9) of a magnesium collecting room of the electrolysis bath is provided with a hole. A flange joint pipe (3) is welded correspondingly to the hole and is welded with a flange (4) which is connected with a stainless steel flange cover board (5) with a hole and a polyfluortetraethylene clapboard (6). Three stainless steel bars (1) with different length pass through the flange cover board (5) and the polyfluortetraethylene clapboard (6) and are connected by a nut (7). Every stainless steel bar (1) leads out a lead wire (8) which is connected with a relay loop and a control system; wherein, the lower end of one stainless steel bar (1) is flush with the set highest liquid level; the lower end of another stainless steel bar (1) is flush with the set lowest liquid level; the lower end of the other stainless steel bar (1) is lower than the lowest liquid level. A carborundum protection tube is arranged among the flange cover board, the polyfluortetraethylene clapboard and the stainless steel bars.

Owner:GUIYANG AL-MG DESIGN & RES INST

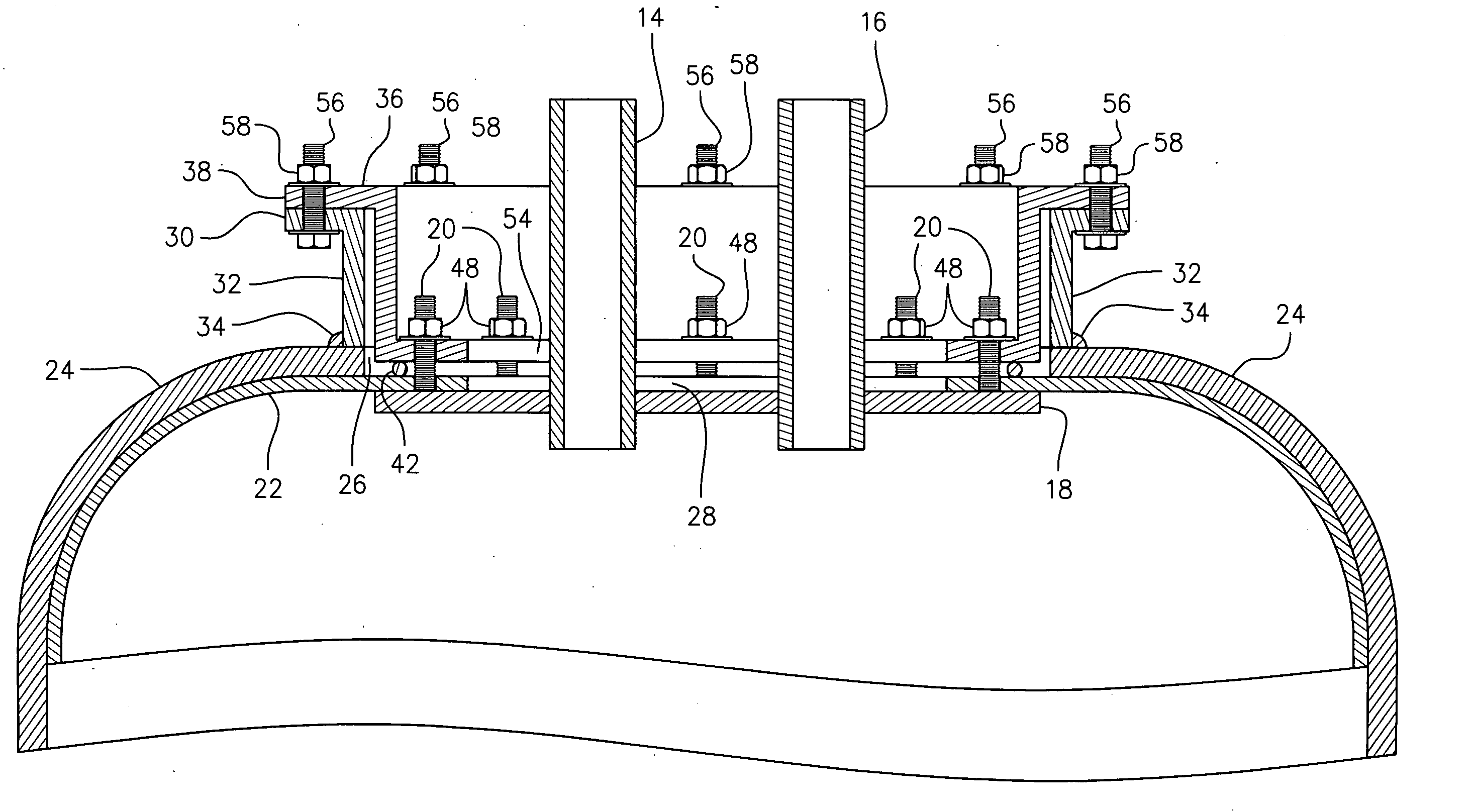

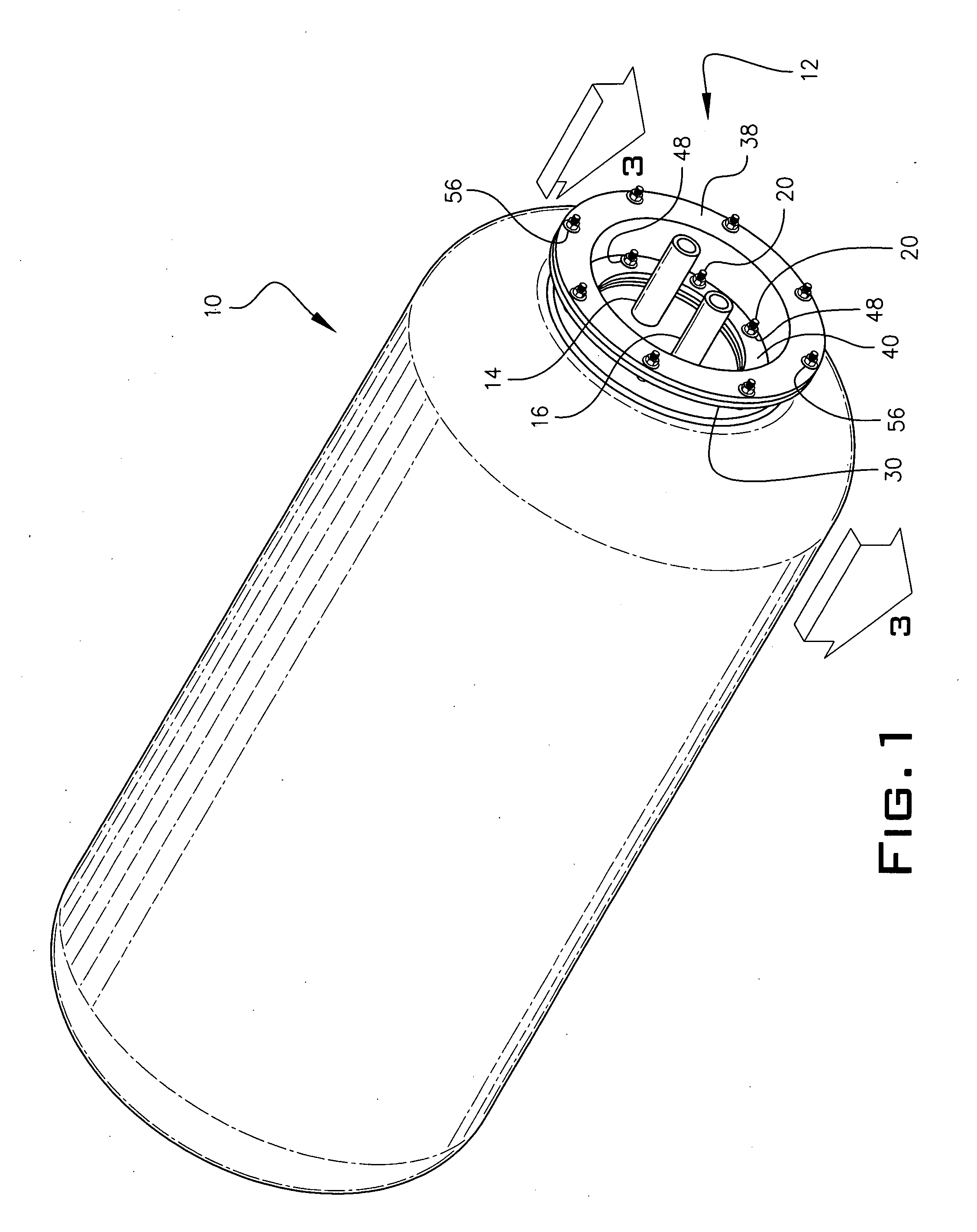

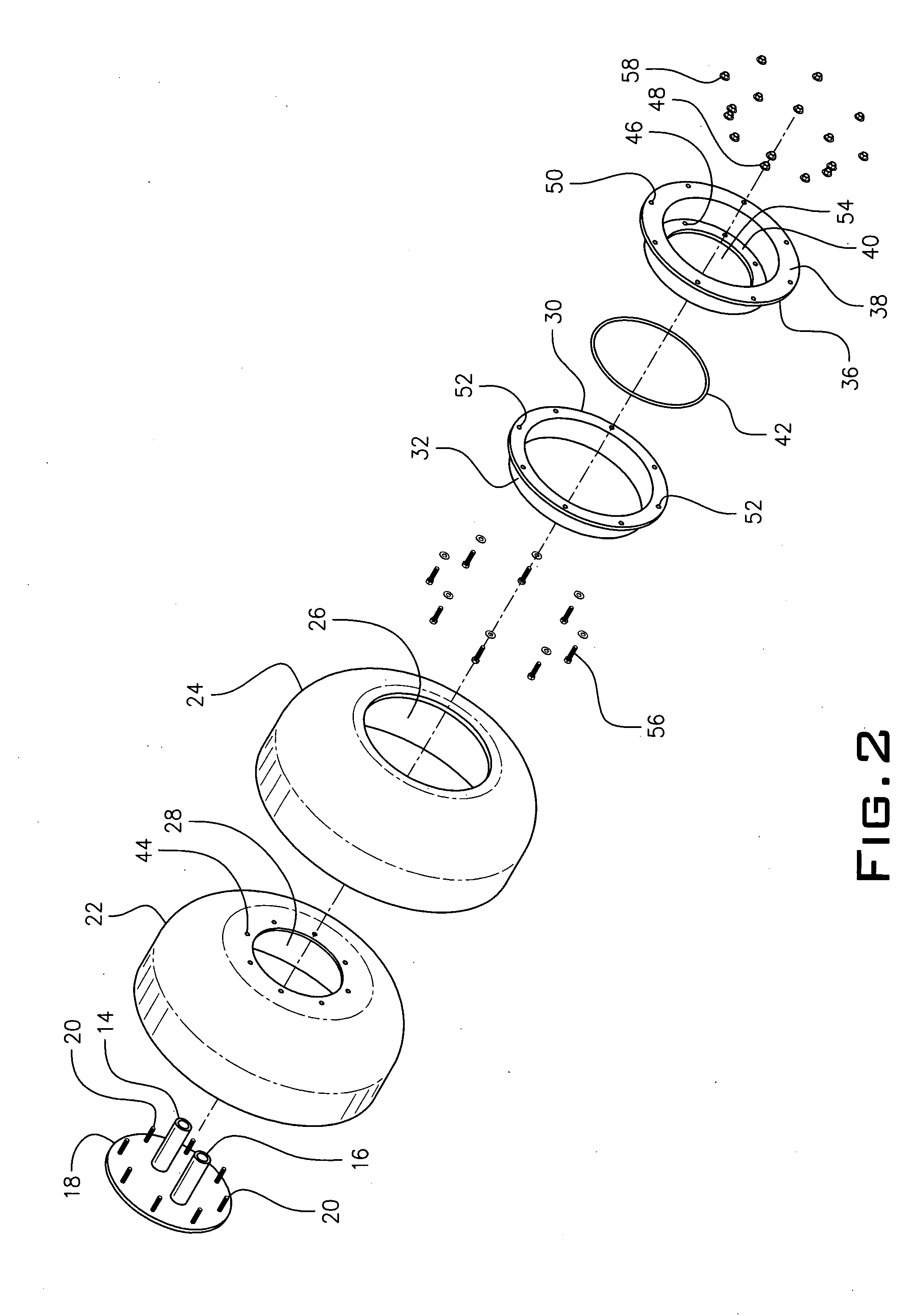

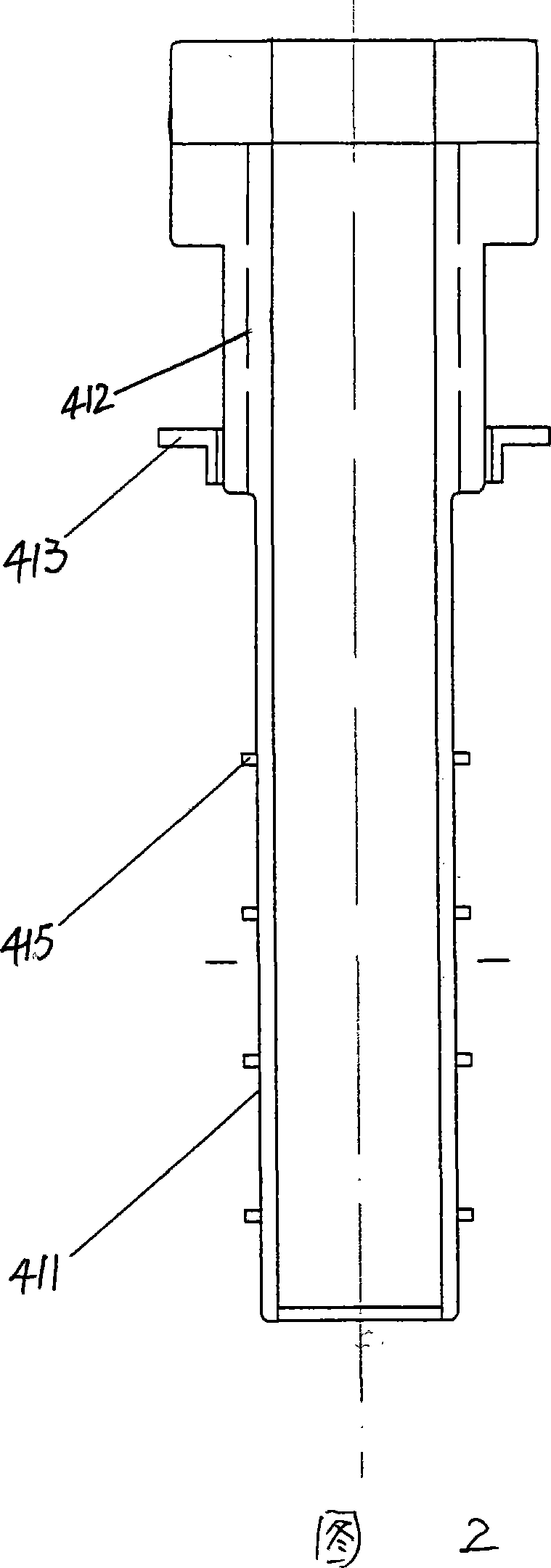

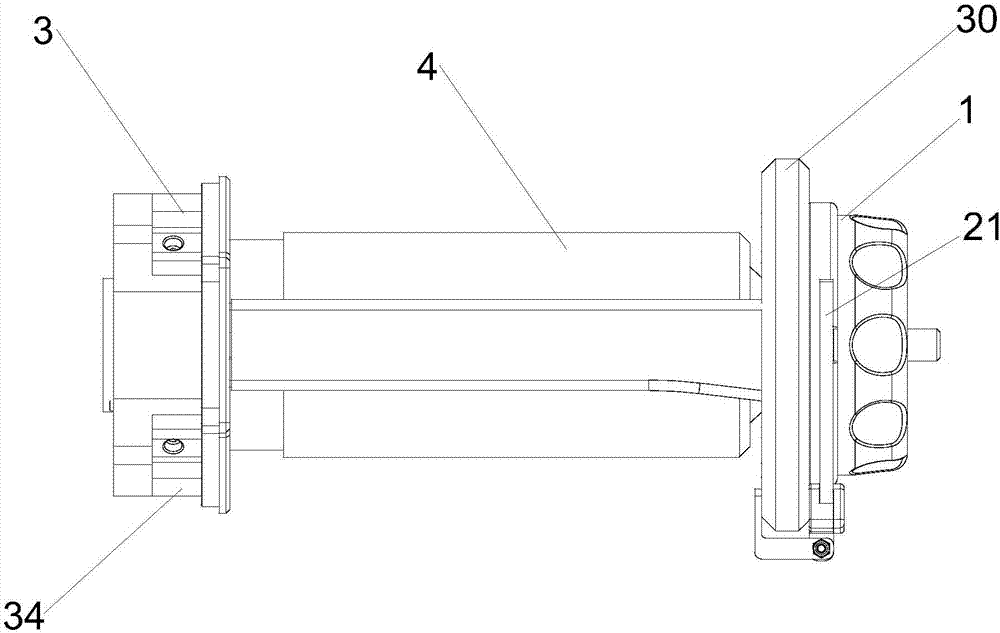

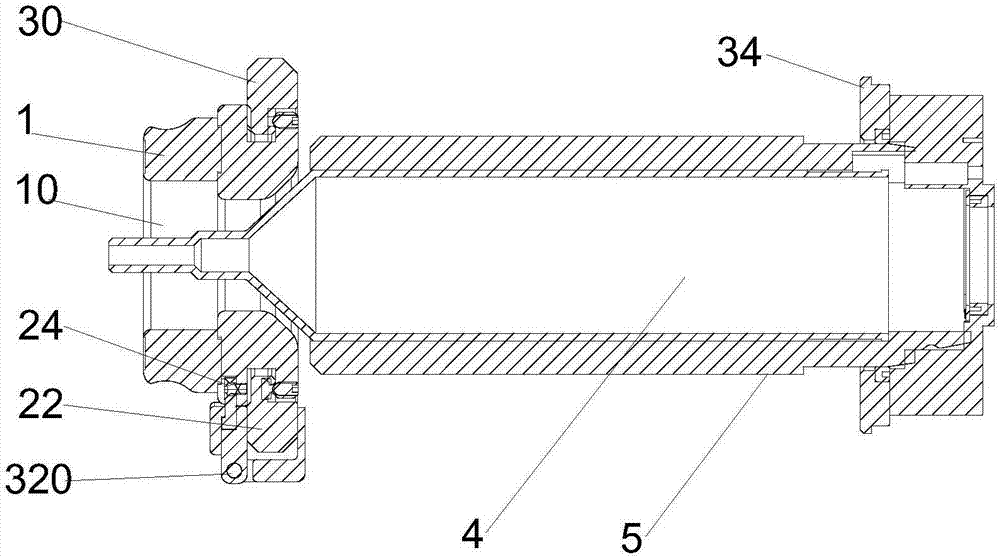

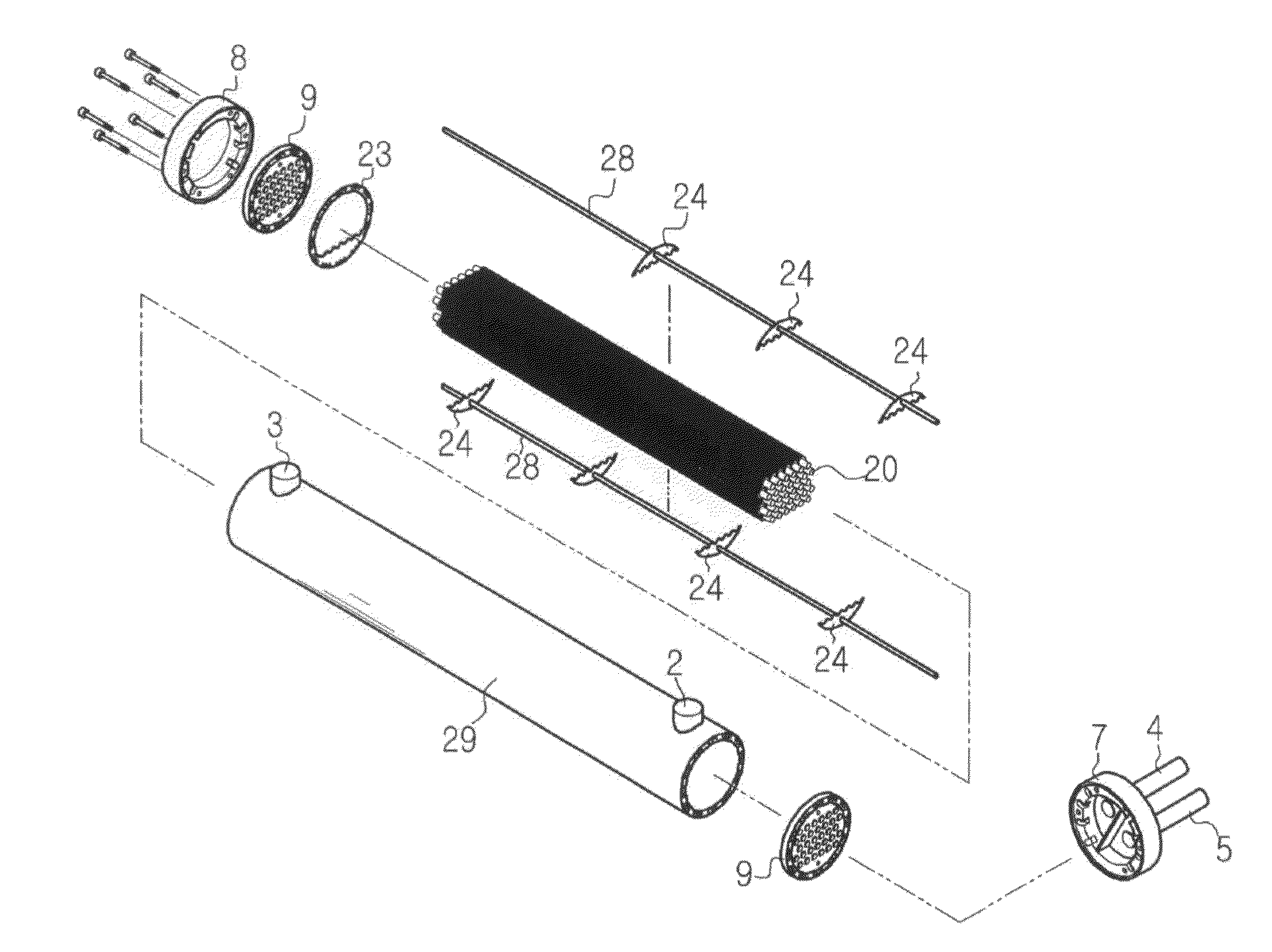

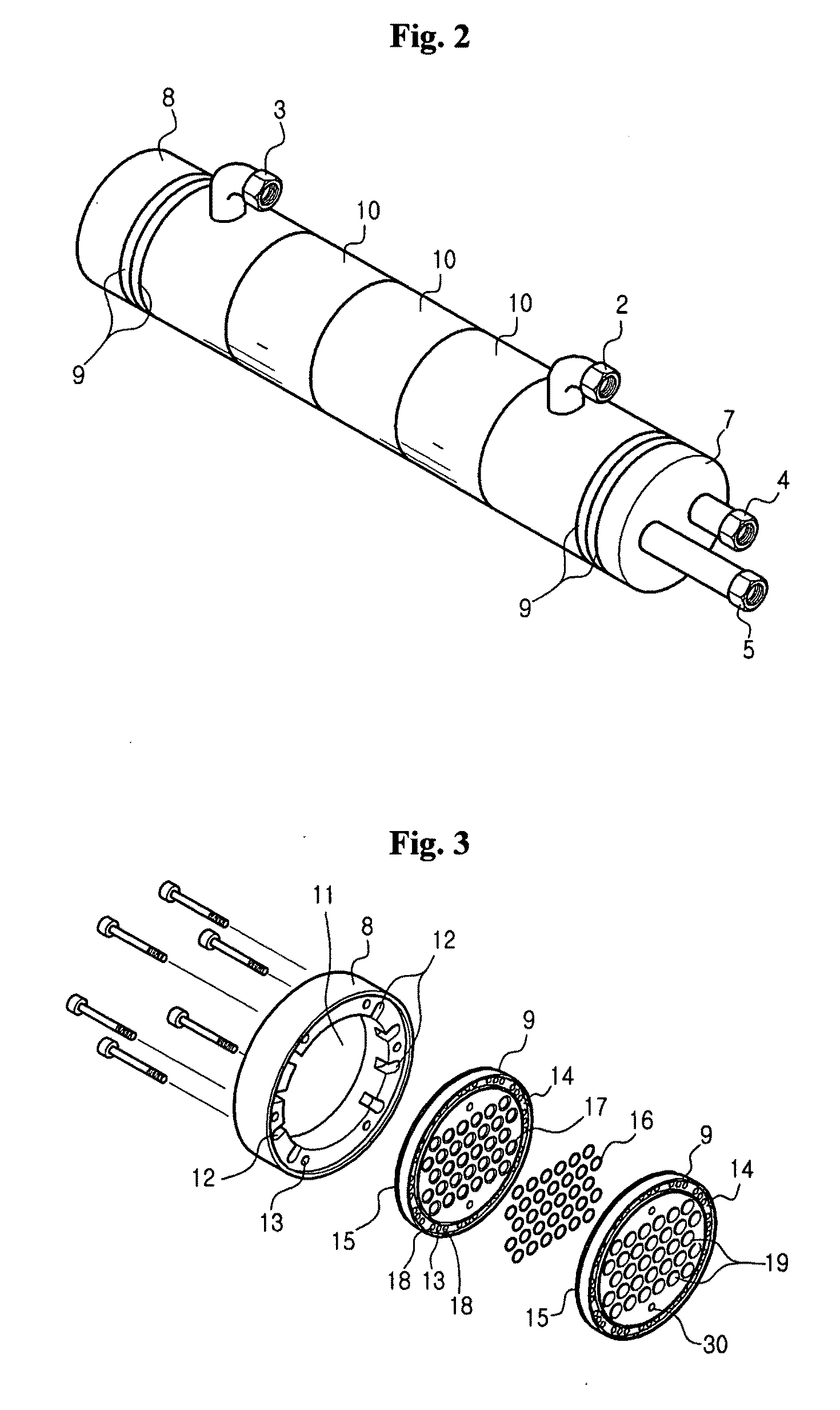

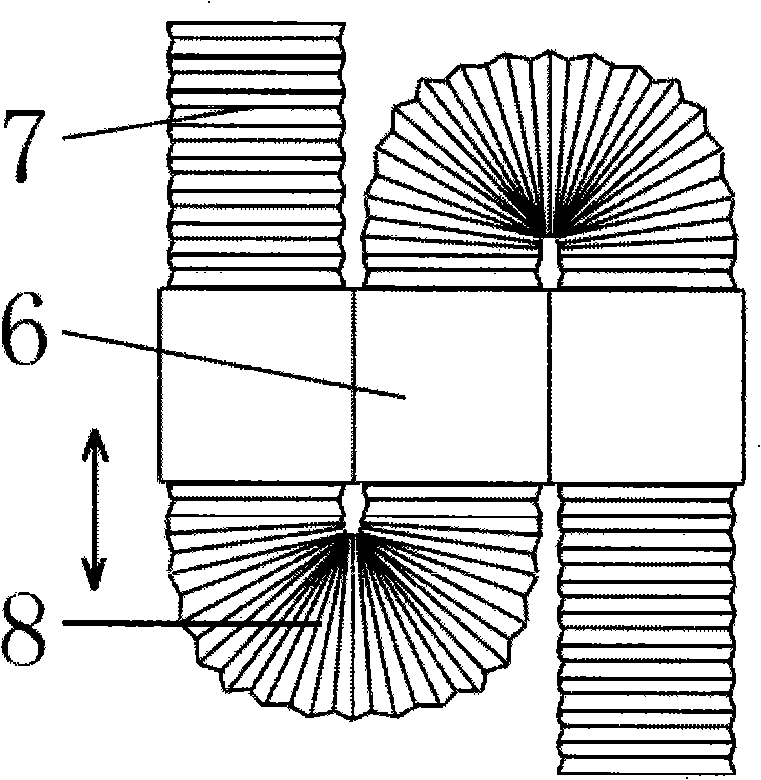

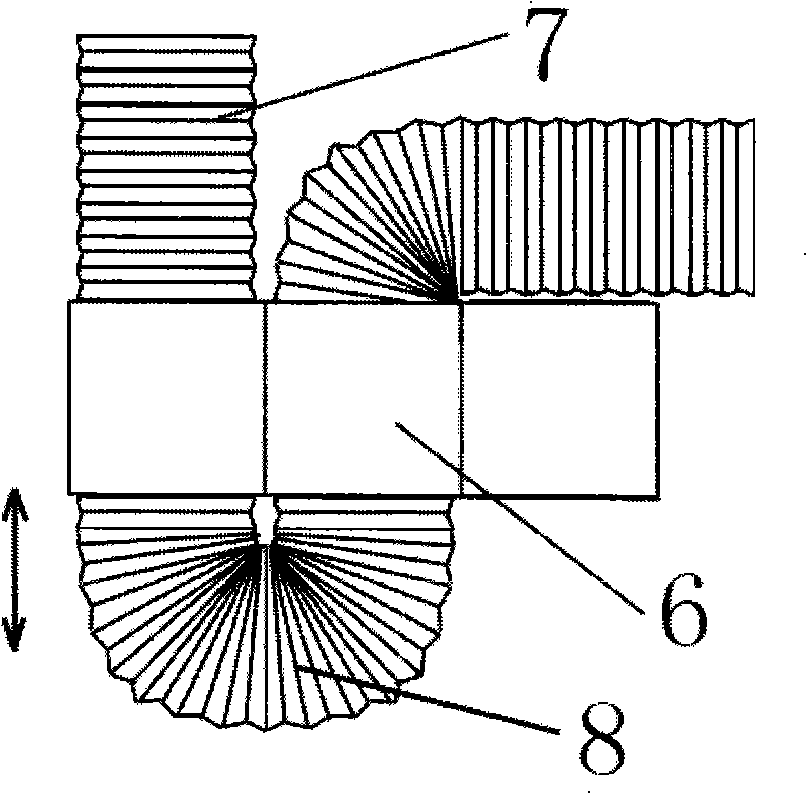

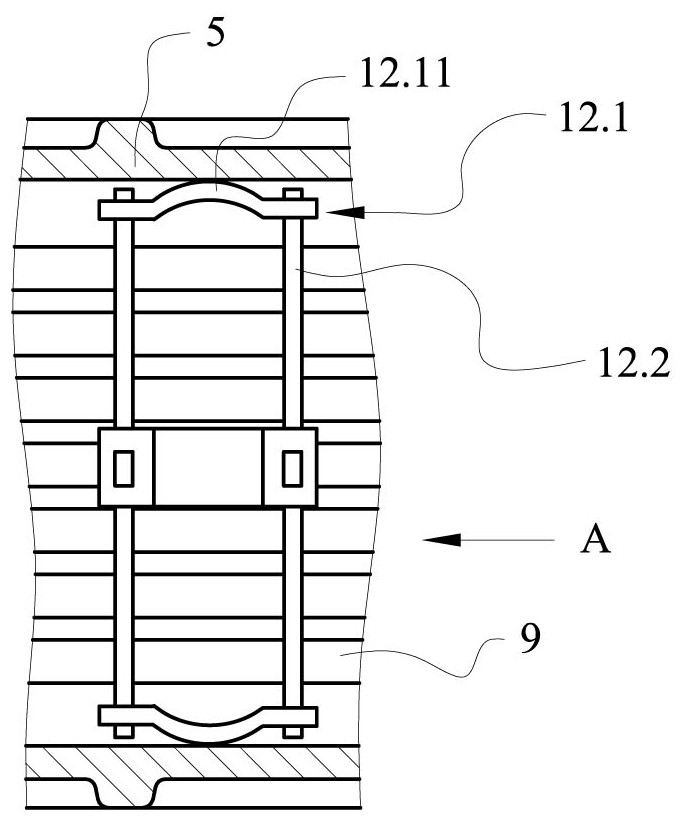

Assembly type oil cooler for intensively cooling hydraulic machinery

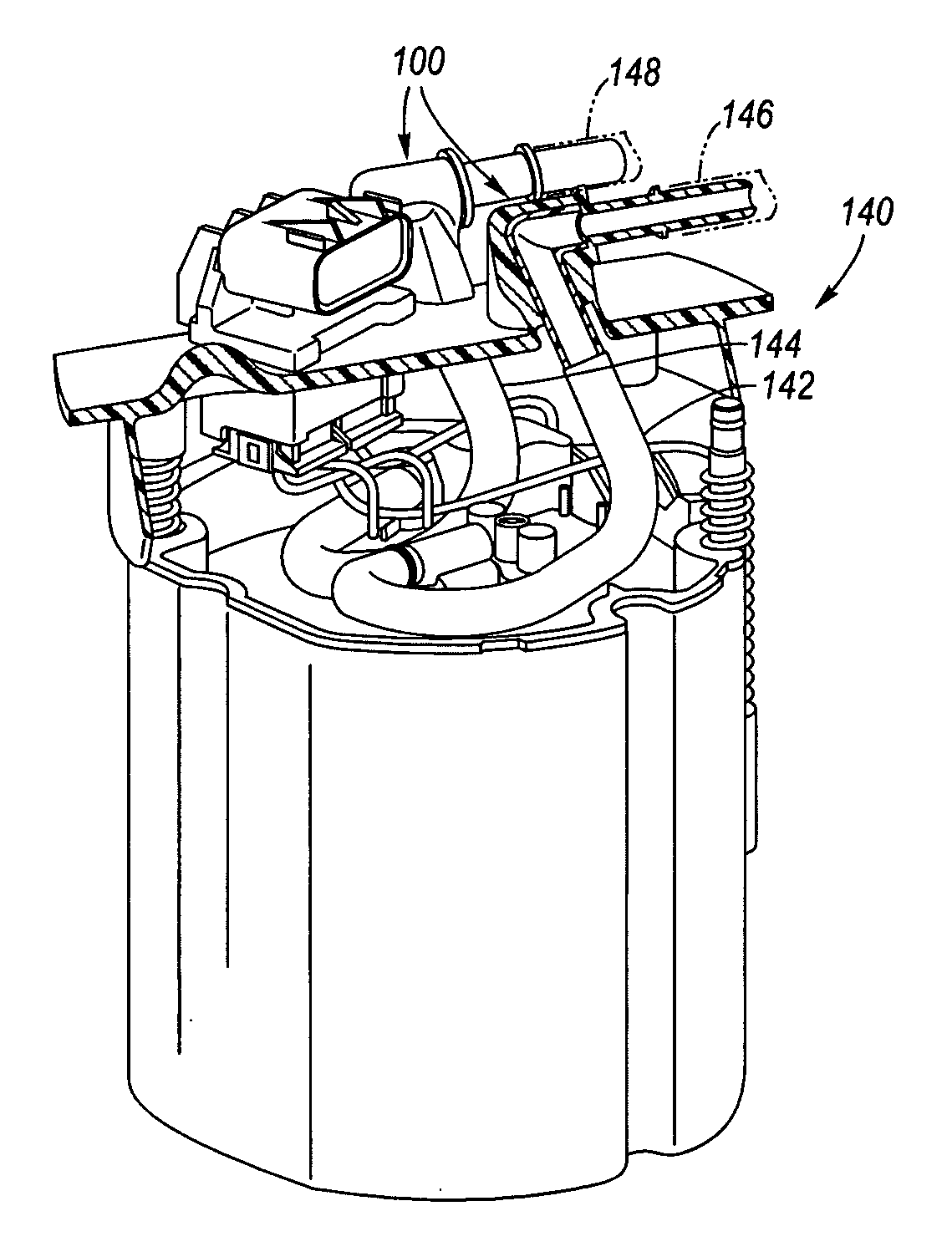

InactiveUS20100122797A1Easy and simple to maintain/repairReduce manufacturing costHeat exhanger finsStationary conduit assembliesHydraulic machineryEngineering

An assembly type oil cooler has developed for intensively cooling the various kinds of hydraulic machineries. The oil cooler comprises a main body assembled with a plurality of the body units having a plurality of bolt-holes for assembling and water passages disposed circumferentially for cooling, a plurality of annular-sealing having arched sectors, an oil inlet and an oil outlet are installed at the front and rear of the body units, a pair of front and rear flange plates installed at both end-sides of the body units, a plurality of heat exchange pipes and supporting rods inserted to supporting rod engaging holes through supporting rod holes, a front flange-cap having two compartments to connect a cooling water inlet and an outlet and the body cooling water inlets, and a rear flange-cap having the body cooling water inlets arranged around the body unit for connecting the water passages of the rear flange plate.

Owner:SEO DONG SOONG +1

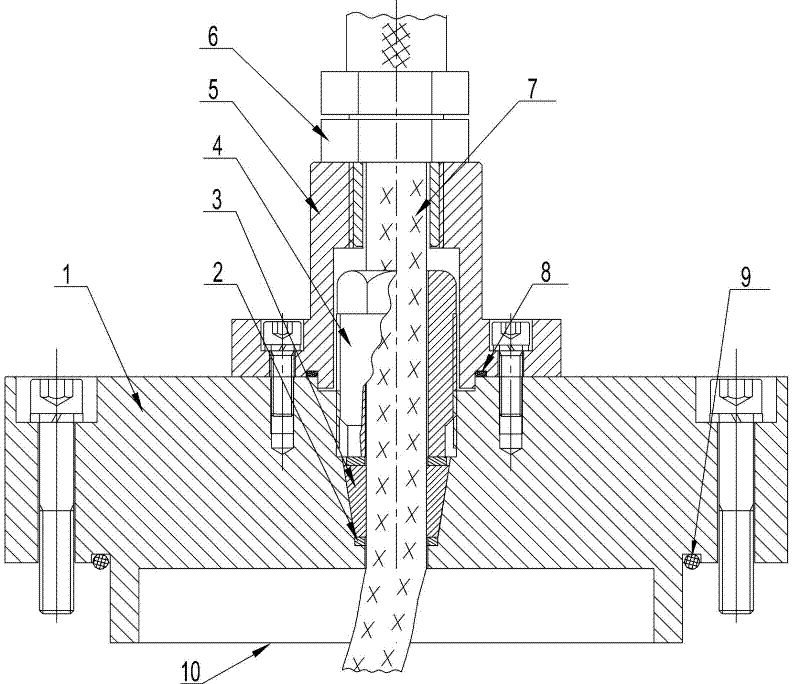

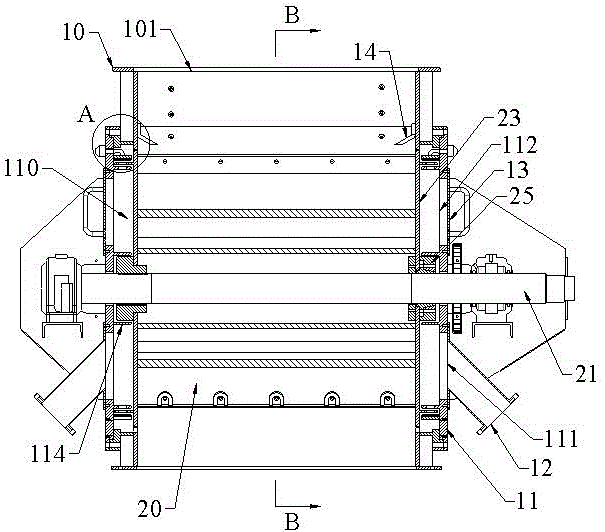

Star-shaped discharging valve with protecting structure

ActiveCN105923356AReduce contentAvoid accumulationCleaningLoading/unloadingStructural engineeringEquipment use

The invention relates to a star-shaped discharging valve with a protecting structure. The star-shaped discharging valve with the protecting structure comprises a shell, a rotor and a flange cover, wherein the rotor comprises a rotating shaft; a plurality of blades with U-shaped cross sections are arranged on the periphery of the rotating shaft; circular side plates are arranged at the left side and right side of each blade; an expansion sleeve matched with the rotating shaft is arranged in the center of each side plate; a buffering cavity is arranged between each side plate and the flange cover; a cylindrical inner protecting sleeve is arranged in the buffering cavity; a cylindrical upper protecting sleeve is arranged at the outer side of the inner protecting sleeve; a cylindrical lower protecting sleeve is arranged at the inner side of the inner protecting sleeve; a mounting hole matched with the rotating shaft is arranged in the center of the flange cover; and a shaft sleeve matched with the expansion sleeve is arranged at the outer side of the mounting hole. The star-shaped discharging valve with the protecting structure has the beneficial effects that dust and powdery materials on the discharging valve are convenient and fast to clean through matching of an air bag and a hairbrush layer under the multiple protection effect of a material blocking plate, the upper protecting sleeve, the lower protecting sleeve, the inner protecting sleeve and the shaft sleeve, the cleaning efficiency is high, the implementation effect is good, the rotor is prevented from being locked up, and the service life of equipment is prolonged.

Owner:TONGLING NONFERROUS XINGTONG ELECTROMECHANICAL MFG CO LTD

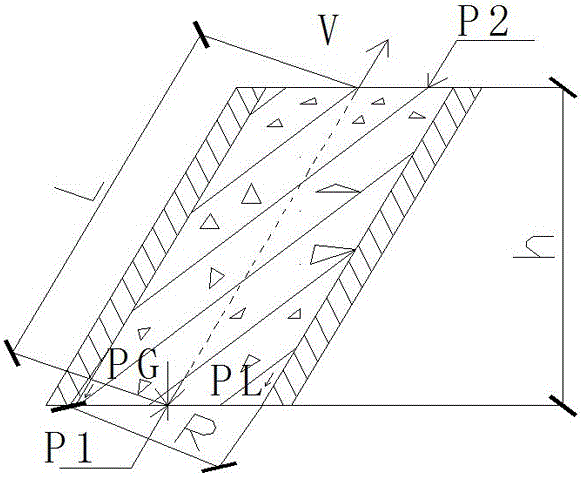

Contact surface for a crimping roller in a roll forming tool

A roll-forming tool for deforming a flange cap from a splayed configuration to engage a vehicle flange, the tool includes a polymeric contact surface disposed about a rigid drum. The polymeric contact surface can be in the form of a sleeve and integrally formed to the metal drum, or alternatively, the sleeve can be removeably attached to the drum for allowing replacement. The drums can be metal and configured for eccentric rotation relative to a corresponding drive shaft, thereby accommodating further variations in flange thickness.

Owner:SCHLEGEL

Leak-proof bottle cap

InactiveUS20070062905A1Highly resilient and durable structureEnsure tightClosuresLiquid flow controllersEngineeringBottle cap

A leak-proof bottle cap comprises a main body and a flanged cap. The main body has a flanged column vertically connected to a circular base, comprising an upper neck with an upper flange, an lower neck with a lower flange, a fixed plug at a tip, and multiple through holes surrounding the plug. The flanged cap is releasably attached onto the flanged column allowing a mouth end of the flanged cap to be lodged in a circle ditch. The outer rim of the upper flange is in close contact with the inner rim of the flanged cap, and the lower flange acts to block the upward movement of a catch ring on an inner wall of the flanged cap when the flanged cap is pulled up, so the mouth of the flanged cap is always covered by the circle ditch. This structural design can ensure tight sealing of the bottle to prevent spilling in any conditions.

Owner:HUNG MING HUA

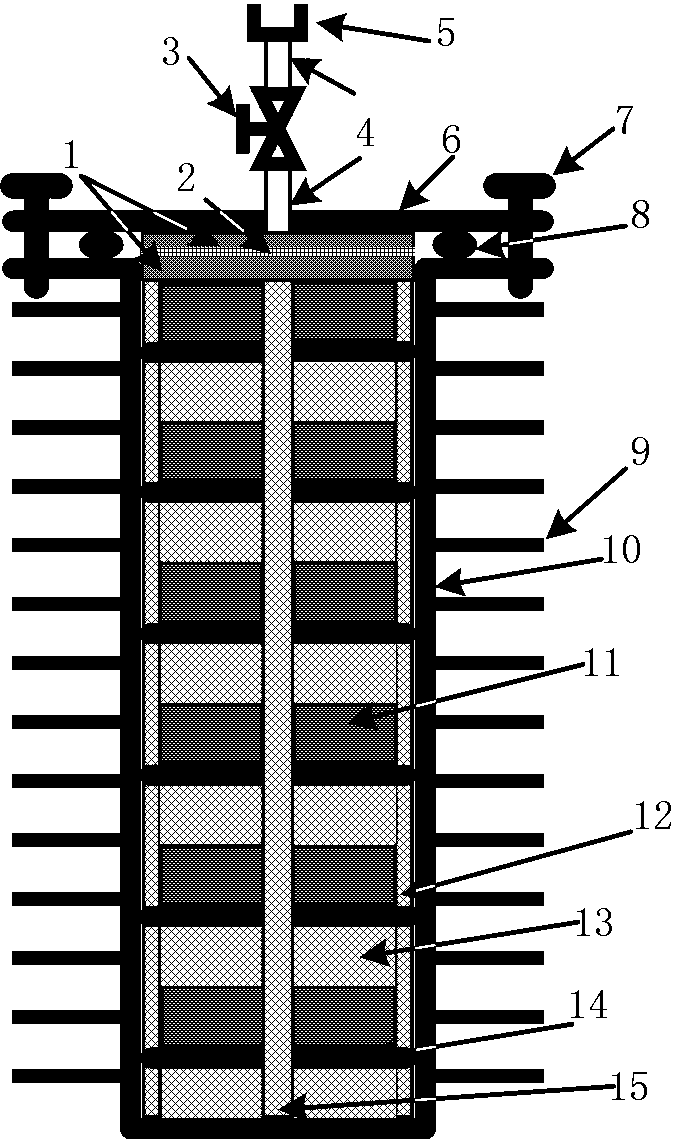

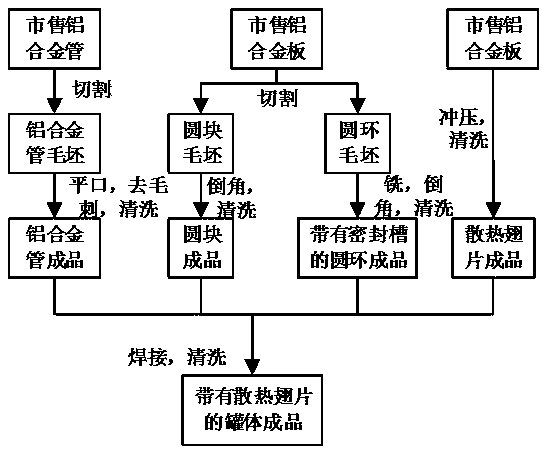

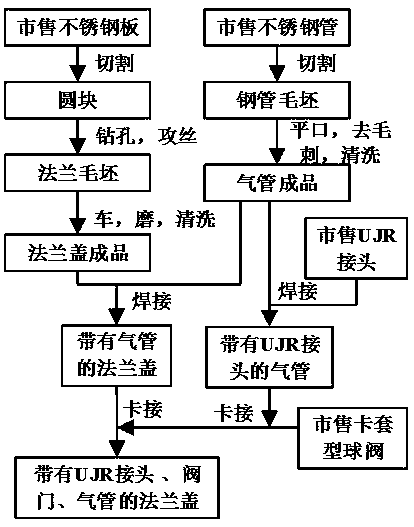

Manufacturing method of metal-hydride hydrogen storage tank

ActiveCN111195808ASimple structureImprove space utilizationVessel manufacturingVessel wallsCircular discMetallic hydrogen

The invention relates to a manufacturing method of a metal-hydride hydrogen storage tank. The method includes the steps of machining of a tank body, machining of a flange cover, machining of foam copper elements, preparation of hydrogen storage alloy powder and assembly line assembling and production of the hydrogen storage tank. The hydrogen storage tank comprises parts including a round foam copper cover, a mat type copper net, a clamping sleeve type ball valve, an air pipe, a UJR joint, the flange cover, bolts, an O-shaped sealing ring, cooling fins, the tank body, the hydrogen storage alloy powder, a foam copper drum, a foam copper disk, a copper-water heating pipe, a foam copper cylinder and the like. The manufacturing method is high in production efficiency, high in yield and low inmanufacturing cost, the metal-hydride hydrogen storage tank manufactured with the method is simple in structure, high in space utilization rate, large in hydrogen storage amount, good in sealing performance, excellent in heat and mass transfer performance, high in hydrogen absorption and release speed and good in long-time use safety, breakage of the tank body due to hydrogen absorption expansionof a hydrogen storage material can be avoided, no cooling media are required to be introduced, repeated recycling can be realized, and the use cost is low.

Owner:YANGZHOU UNIV

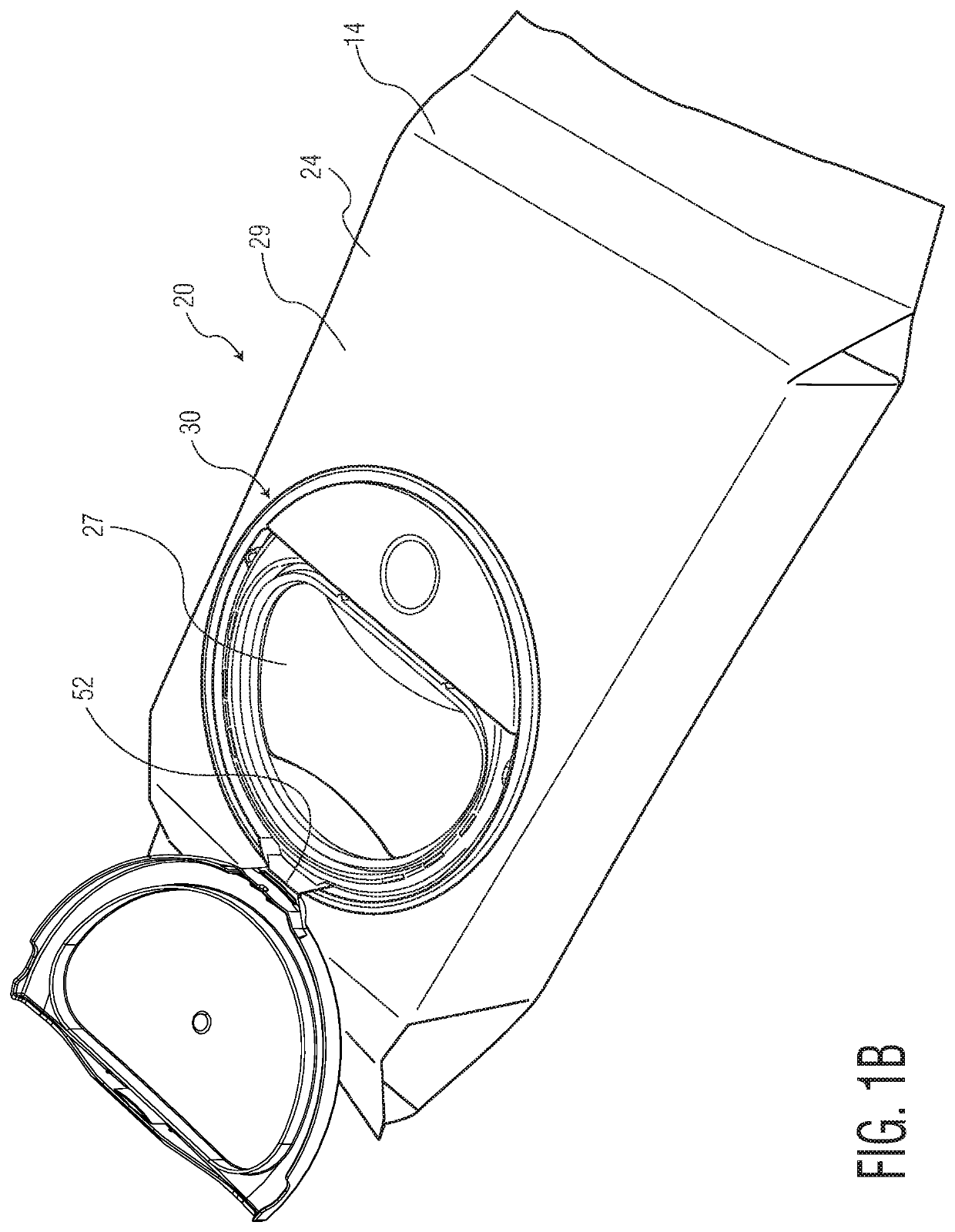

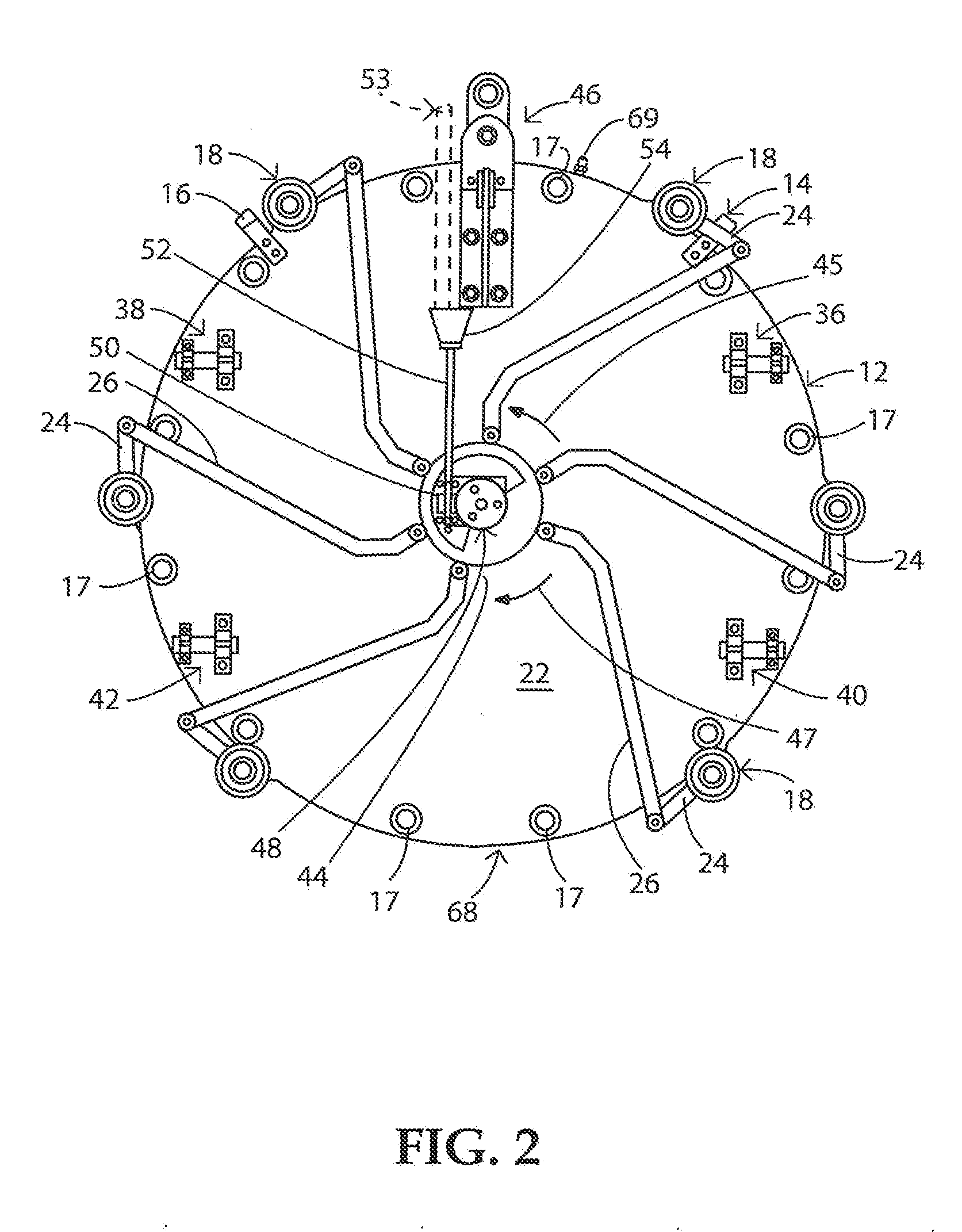

Remotely Installed Fuel Transfer Tube Closure System

A system, method and apparatus for remotely installing a flange cover assembly on a fuel transfer tube fixed flange in a containment pit in a nuclear power plant is presented. In one example, the flange cover assembly includes J-bolt spring assemblies in which the feet of the J-bolt are rotated between a clamping and non-clamping orientation to engage with the rear face of the fixed flange. A tool frame is lowered into the containment pit to engage with the flange cover assembly to compress the J-bolt springs and extend the J-bolt foot toward and away from the flange cover. Dual acting cylinders move a spring compression frame on the frame tool to compress and relax the J-bolt spring assemblies.

Owner:PREFERRED UTILITIES MFG

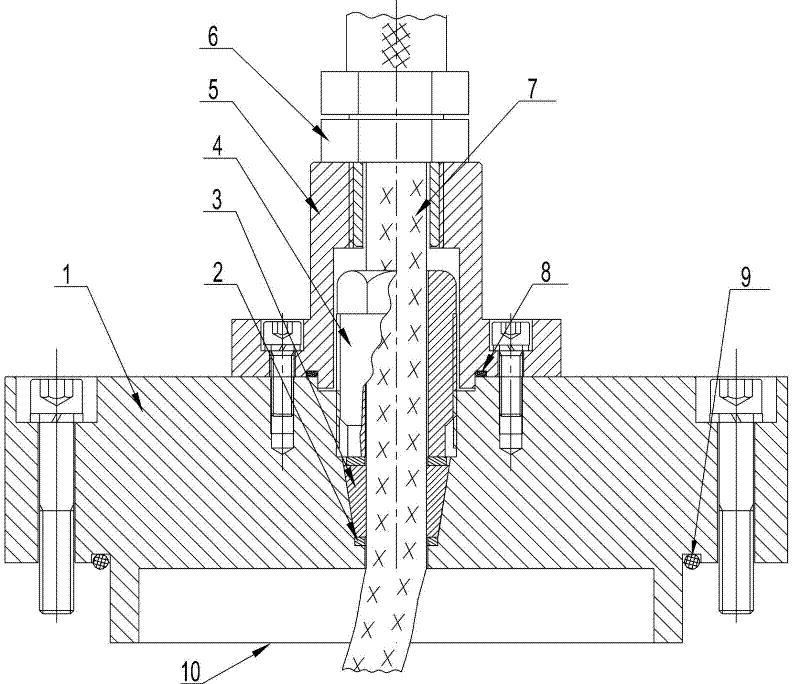

Testing cable sealing device for container for simulating deepwater environment explosion test

InactiveCN103822028AAchieving multiple longitudinal sealsImprove sealingPipesBlastingClassical mechanicsWasher

The invention relates to a testing cable sealing device for a container for simulating a deepwater environment explosion test. According to the technical scheme, two to fifteen cable holes (8) are formed around the center of a flange cover plate (1) and located in a protection cover (2); each cable hole (8) is a through hole which is formed by three sections, the hole diameter of the upper portion is larger than the hole diameter of the lower portion, a sprue (7), sealant (6) and a ring washer (5) are concentrically arranged on the middle section of each cable hole (8) from bottom to top, each compression bolt (4) is fixedly connected with the upper section of the corresponding cable hole (8) through threads, and the lower end of each compression bolt (4) is tightly pressed on the upper plane of the corresponding ring washer (5); a testing cable (3) sequentially penetrates through the protection cover (2), the corresponding compression bolt (4), the corresponding ring washer (5), the corresponding sealant (6) and the lower section of the corresponding cable hole (8) to be connected with an underwater impact wave pressure sensor. The testing cable sealing device is high in compression resistance, good in sealing performance, easy to assemble, wide in application range, and capable of meeting the requirement for simulating the 0.01-Kg TNT equivalent explosion test at the 200 m underwater environment.

Owner:WUHAN UNIV OF SCI & TECH

Special testing device for small measuring chamber of nuclear power plant reactor cavity

ActiveCN102842347AReasonable structureEasy to manufactureNuclear energy generationNuclear monitoringCircular coneEngineering

The invention relates to a small measuring chamber of a nuclear power plant reactor cavity and also relates to a special testing device, which belong to the technical field of nuclear power plant engineering. The lower surface of a flange ring of the small measuring chamber is fixedly connected with a supporting ring; the lower end of the supporting ring extends out of a groove bottom ring inwards in a radial direction; the inner circle of the groove bottom ring is fixedly connected with a lifting basket protective cylinder; an inner hole of the flange ring is a conical hole with the big upper part and the small lower part; one side of the upper surface of the flange ring is hinged with one end of a flange cover; a pressing bolt penetrating through a through hole in the other end of the flange cover is mounted in a screw hole in the other side of the upper surface of the flange ring; the middle part of the flange cover extends out of a cone frustum matched with the conical hole downwards; a recess, side walls of which in at least two rings are vertical to the conical surface, is formed in the conical surface of the cone frustum; a circular-section sealing ring is embedded into the recess; the diameter of the sealing ring is matched with the width of the recess; and the ratio between the depth of the recess and the width of the recess is 0.7-0.9. After a lifting basket is put and the flange cover is covered, the conical surface can be enabled to generate a tendency of sticking to the surface of the conical hole, so that the sealing ring slightly protruding out of the recess is pressed to generate an ideal anti-leakage sealing effect.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

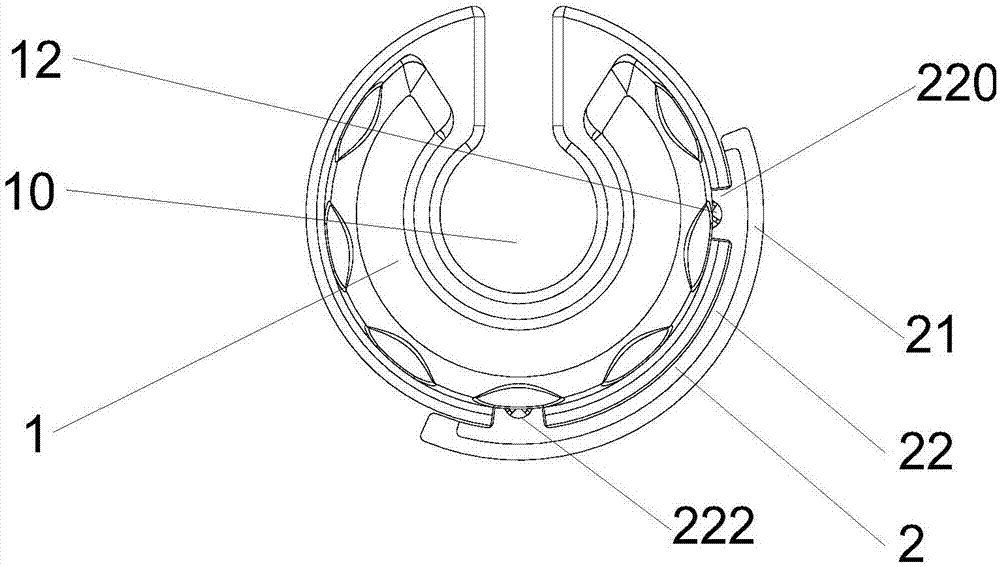

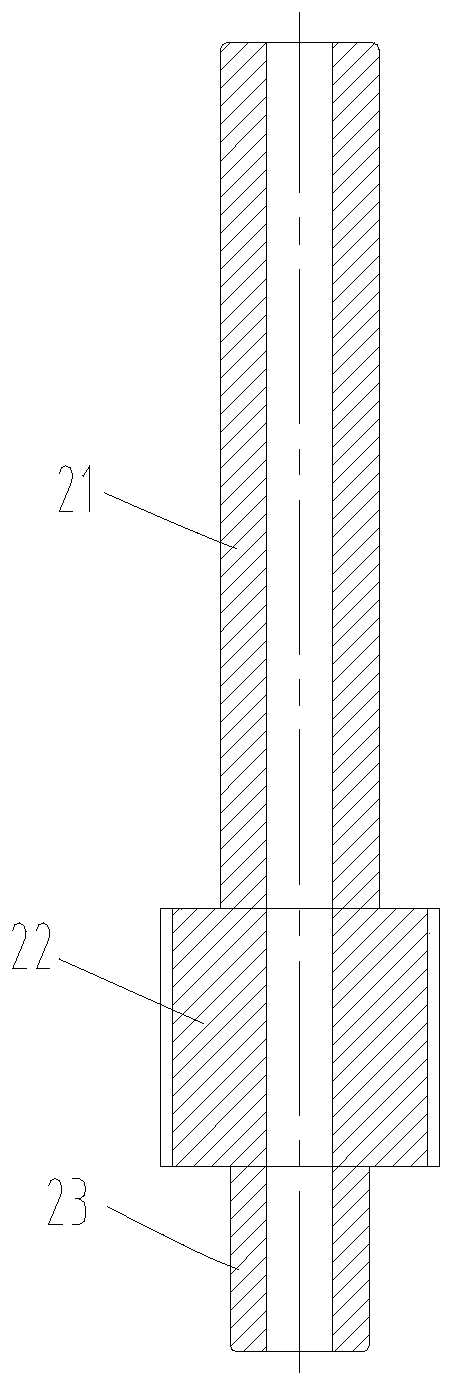

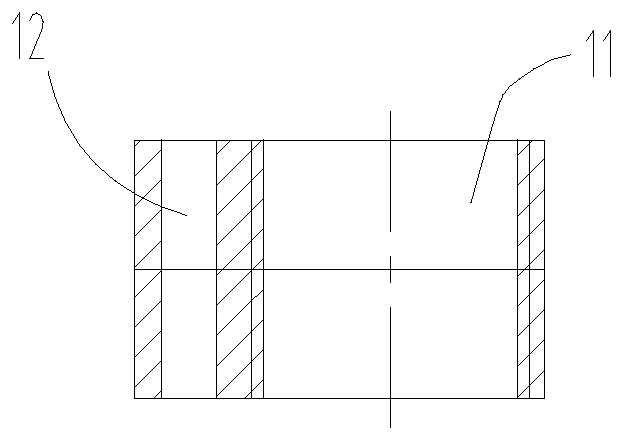

Clamping device for thin-wall parts

InactiveCN102886752AImprove the positioning accuracy of the center of the circleClamp evenlyWork holdersFLANGE CAPClip device

The invention relates to a clamping device for solving the clamping of thin-wall parts, and provides a clamping device for thin-wall parts. The clamping device for thin-wall-parts structurally comprises a blind flange, sealing rings, a pressing ring, a space ring and chuck sleeve, wherein the blind flange is fixedly connected with the chuck sleeve; the pressing ring, one sealing ring, the space ring and the other sealing ring are arranged in a hole of the chuck sleeve in sequence from the inside out; and the pressing ring is located at one end of the blind flange. By utilizing the flexible deformation of the sealing rings, the outer circles of the thin-wall parts are clamped. Compared with the prior art, the clamping device for thin-wall parts has the advantages and beneficial effects of improving the circle center positioning precision of the thin-wall parts, evenly clamping the thin-wall parts and ensuring that the outer circles of the thin-wall parts are free of clamping mark and deformation. The clamping device is capable of solving the clamping of the outer circles of the thin-wall parts with the wall thickness of 1mm.

Owner:SHANGHAI XINYUE METER FACTORY

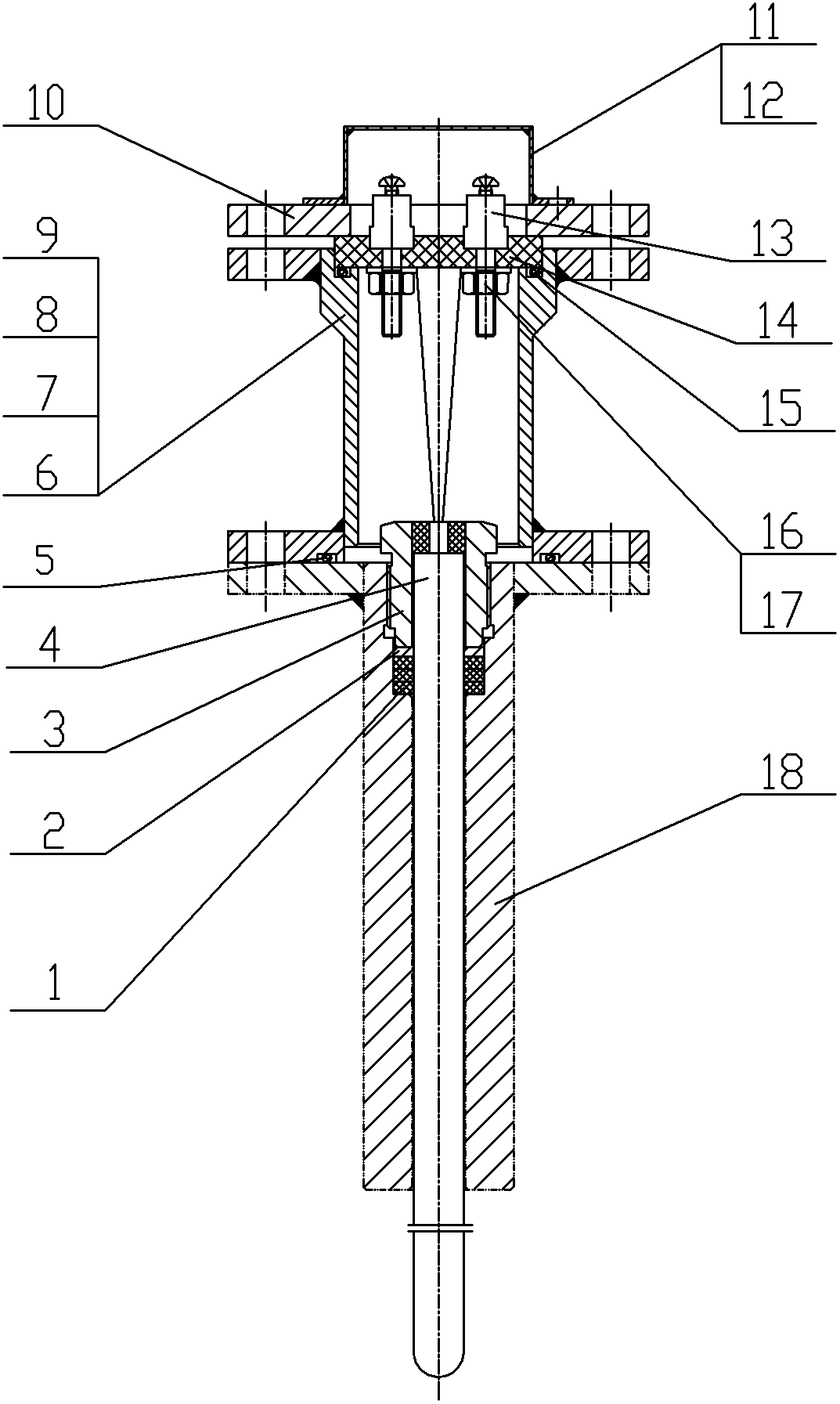

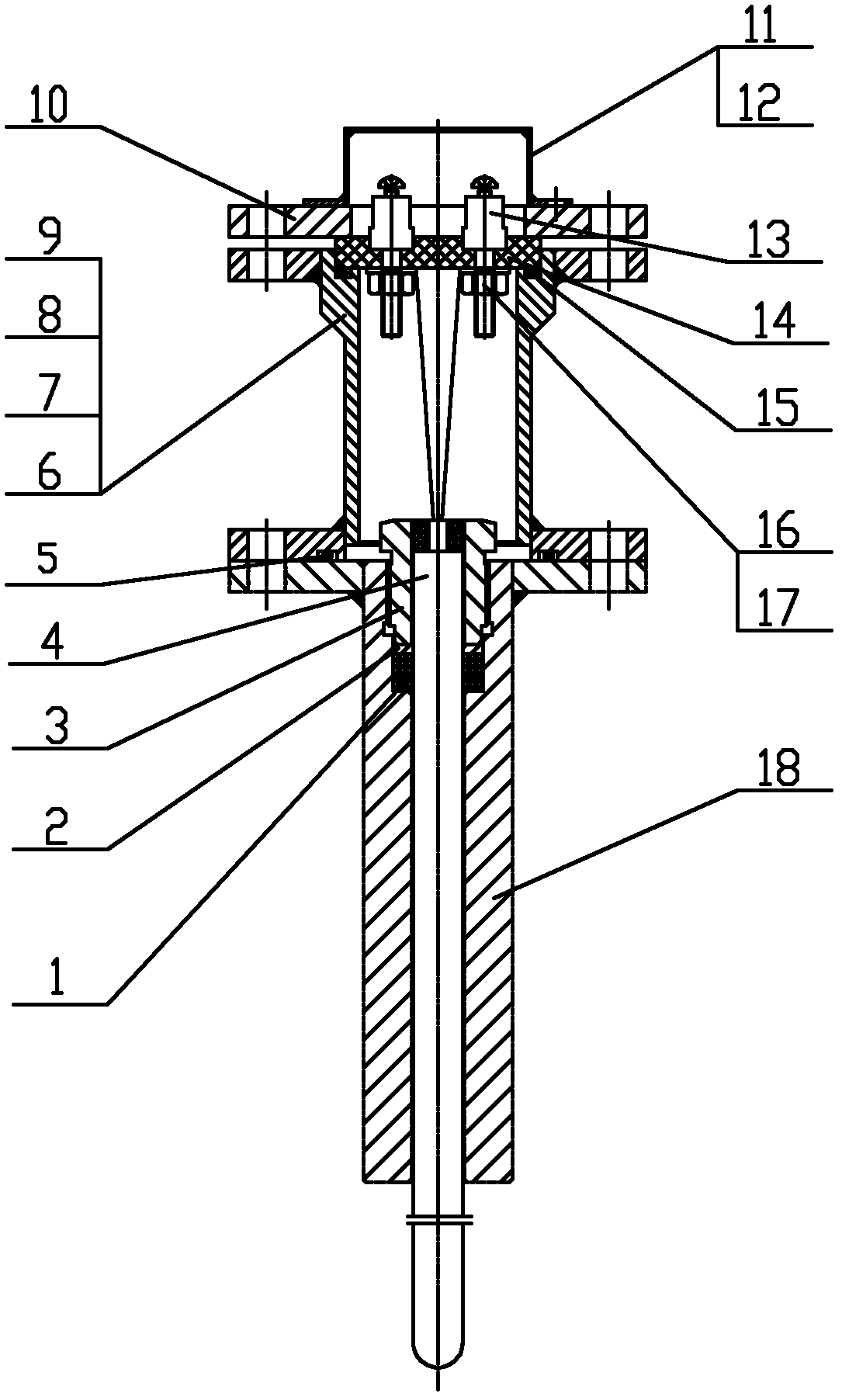

Thermocouple leading device

InactiveCN102331310AImprove sealingSolve the sealing problemThermometers using electric/magnetic elementsUsing electrical meansPlatinumThermocouple device

The invention relates to a thermocouple leading device which comprises a thermocouple connecting base, wherein the lower end of the thermocouple connecting base is provided with a thermocouple, an insulating base is arranged at the upper end of the thermocouple connecting base, and a wiring pole is arranged on the insulating base. The thermocouple leading device is characterized in that a flange cover and a protective cover fixed on the flange cover are covered on the insulating base, and the thermocouple is fixed at the lower end of the thermocouple connecting base through a compression screw and sealed by a seal pad and a gasket; a second O-shaped seal ring for sealing is arranged between the insulating base and the thermocouple connecting base, and a first O-shaped seal ring is arranged on the contact surface of the thermocouple connecting base with a furnace body. The thermocouple connecting base is respectively fixed with the furnace body and the flange cover by a hexagon bolt, a first hexagon nut and a first gasket. The thermocouple is a twin platinum-rhodium10-platinum thermocouple. With the thermocouple leading device, better seal property can be obtained, and the seal problem can be better solved.

Owner:无锡四方集团真空炉业有限公司

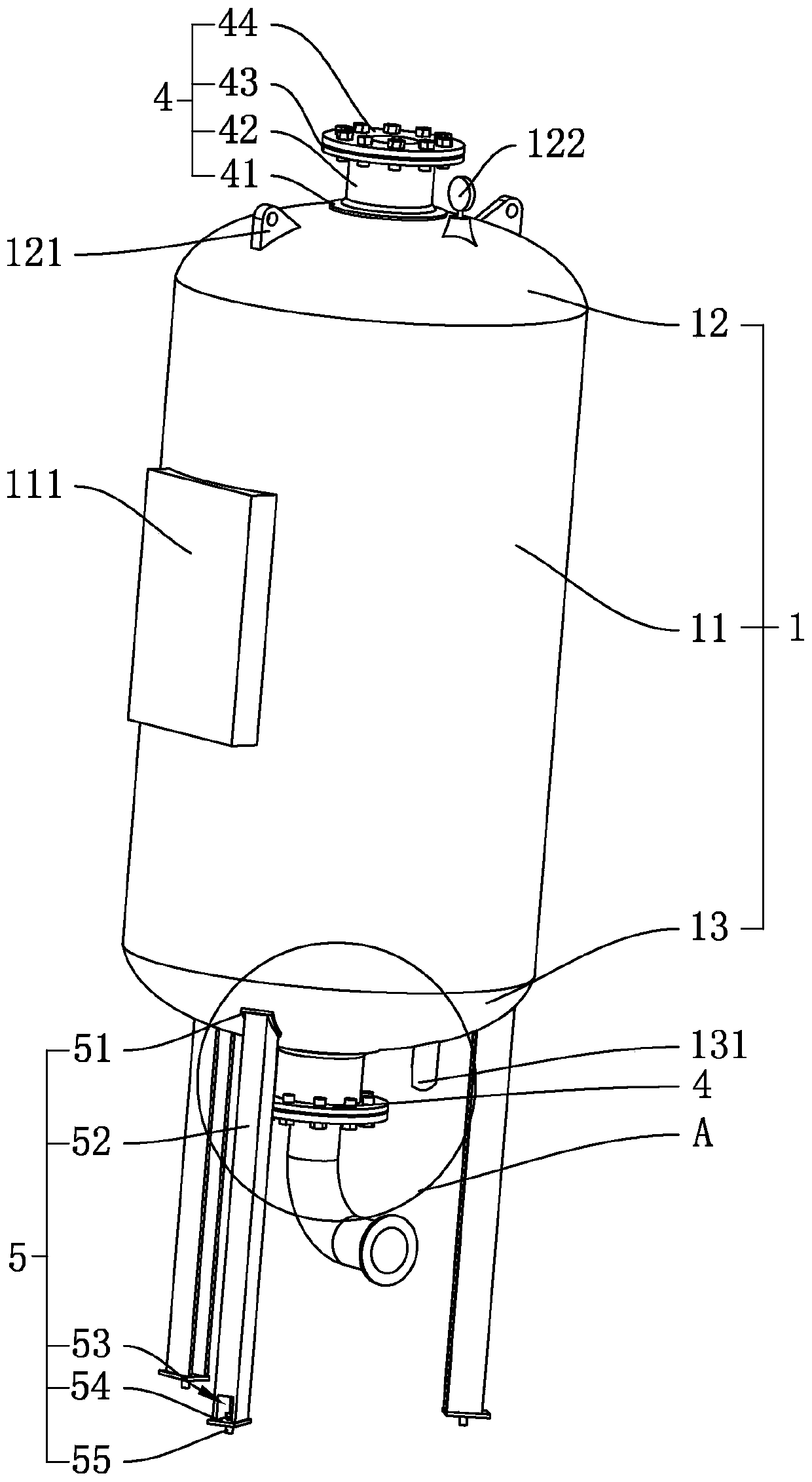

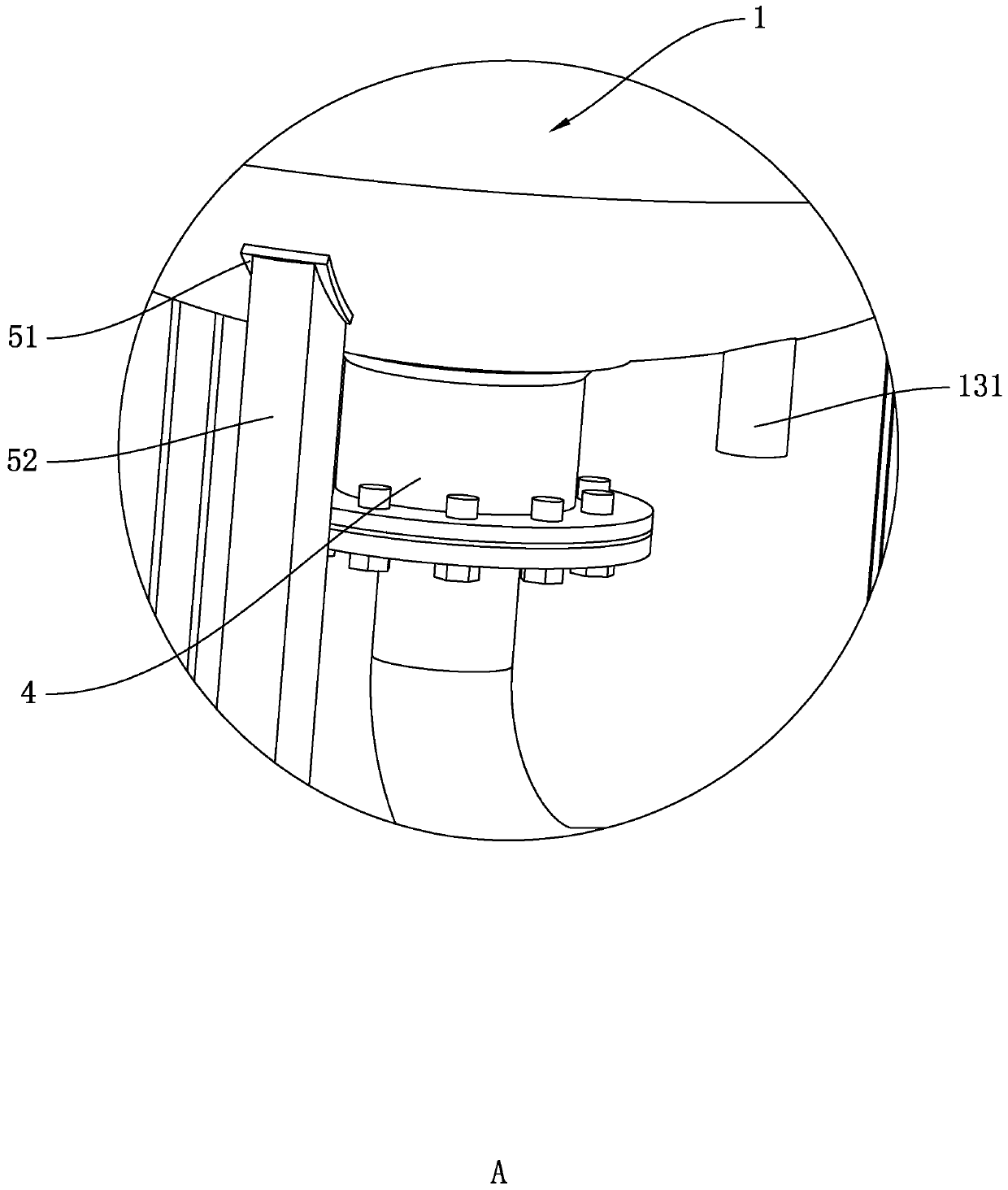

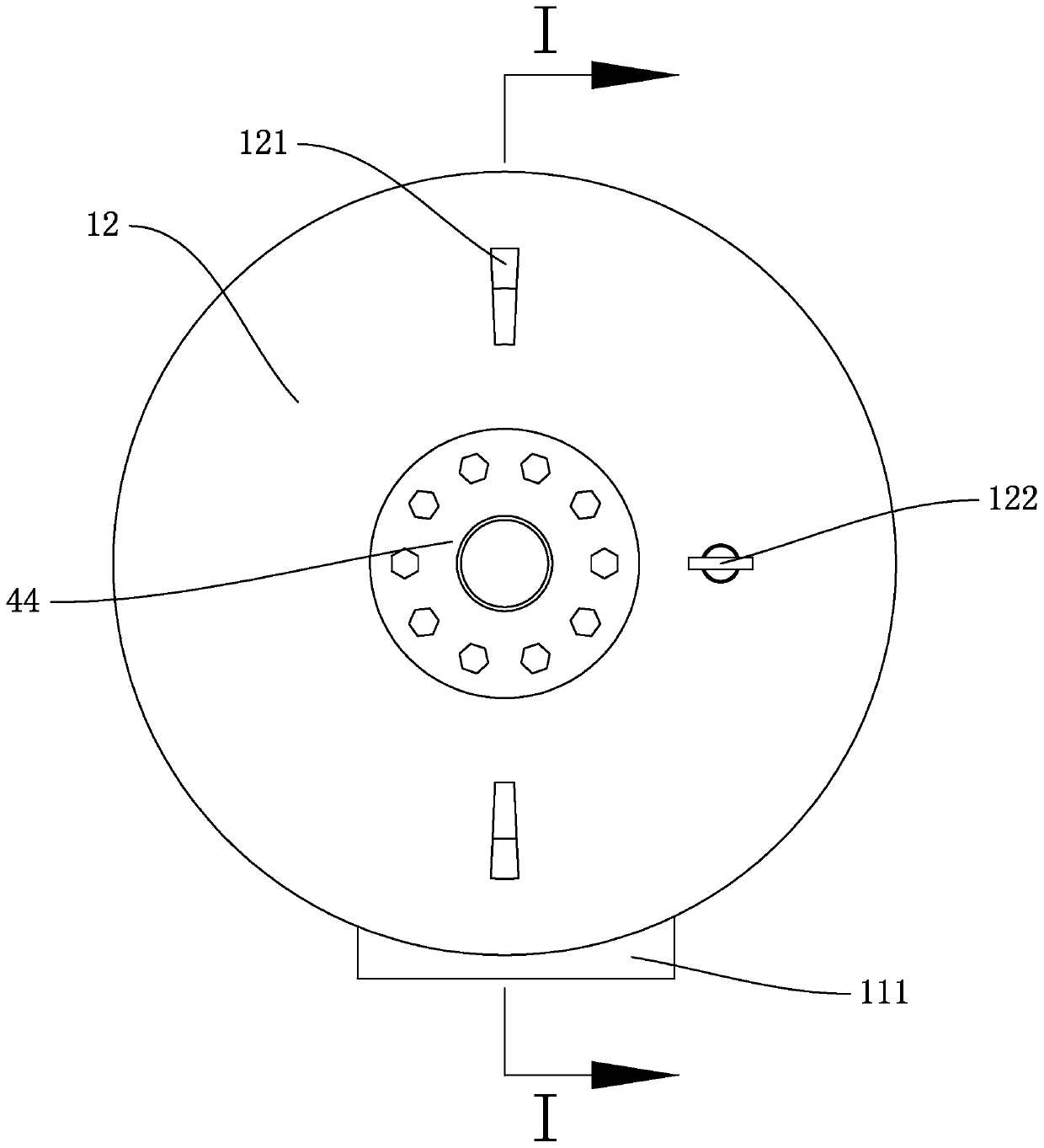

Diaphragm air pressure tank and processing technology thereof

ActiveCN111501913AImprove sealingStructural Strength EffectWater supply tanksWater conservationWater storageEngineering

The invention relates to the technical field of manufacturing and production of pressure containers, in particular to a diaphragm air pressure tank and a processing technology thereof. The diaphragm air pressure tank comprises a steel air tank body and a rubber air bag; the rubber air bag is located inside the steel air tank body, a pressure chamber is formed between the steel air tank body and the rubber air bag, a water storage chamber is formed by the rubber air bag, a fixing structure for fixing the rubber air bag is arranged on the steel air tank body, the fixing structure comprises a flange plate and a flange cover, the rubber air bag is located between the flange plate and the flange cover, a sealing structure for sealing a gap between the fixing structure and the rubber air bag isarranged in the fixing structure, the sealing structure comprises an air sealing layer used for sealing a gap of the pressure chamber at the fixing structure and a water sealing layer used for sealinga gap of the water storage chamber at the fixing structure, and the water sealing layer is fixedly connected between the rubber air bag and the flange cover. The diaphragm air pressure tank and the processing technology thereof have the effect of being good in sealing performance.

Owner:上海南汇压力容器厂有限公司

Telescoping tube water sealing clamper of water drain

A basin and a vegetable-washing basin are usually used in the rooms of present buildings, like toilet (bathroom), kitchen and the like. The drainage way thereof is that an S-shaped or a U-shaped water-sealing elbow, commonly called as water-sealing bend, is first connected to drainage holes of the basin and the vegetable-washing basin. An extension tube is then connected to a ground sewage hole. The defect of the water-sealing bend is the easiness for blockage. If the blockage occurs, the common method is to disassemble a flange at the bottom of the elbow at the underside for dredging, or to use a flexible shaft pipe cleaner for dredging, however, the dredging effect is unsatisfactory. In order to overcome the deficiency of the present water-sealing elbow structure, the invention provides a sewer extension pipe water-sealing clamp, with which an S-shaped or a U-shaped water-sealing structure can be formed on the extension pipe so as to facilitate and simplify the dredging of the water-sealing elbow.

Owner:BEIJING JIAOTONG UNIV

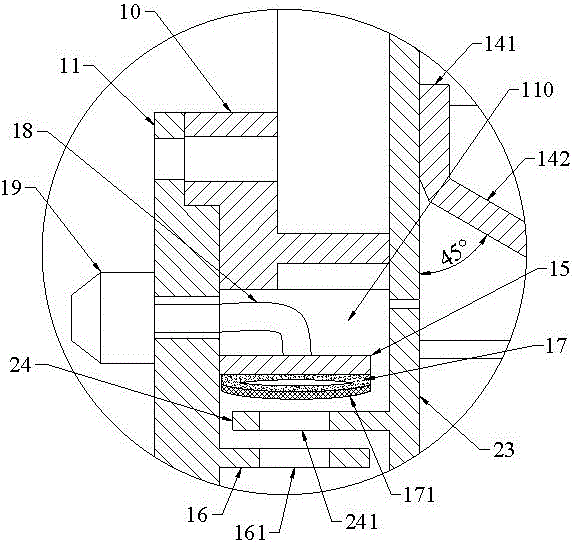

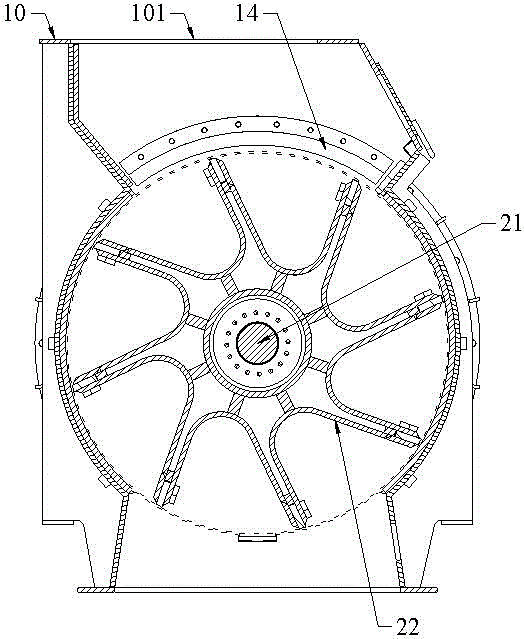

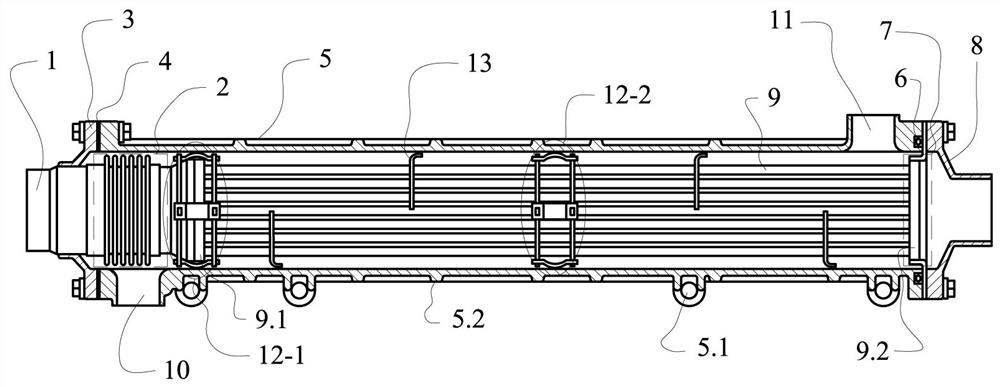

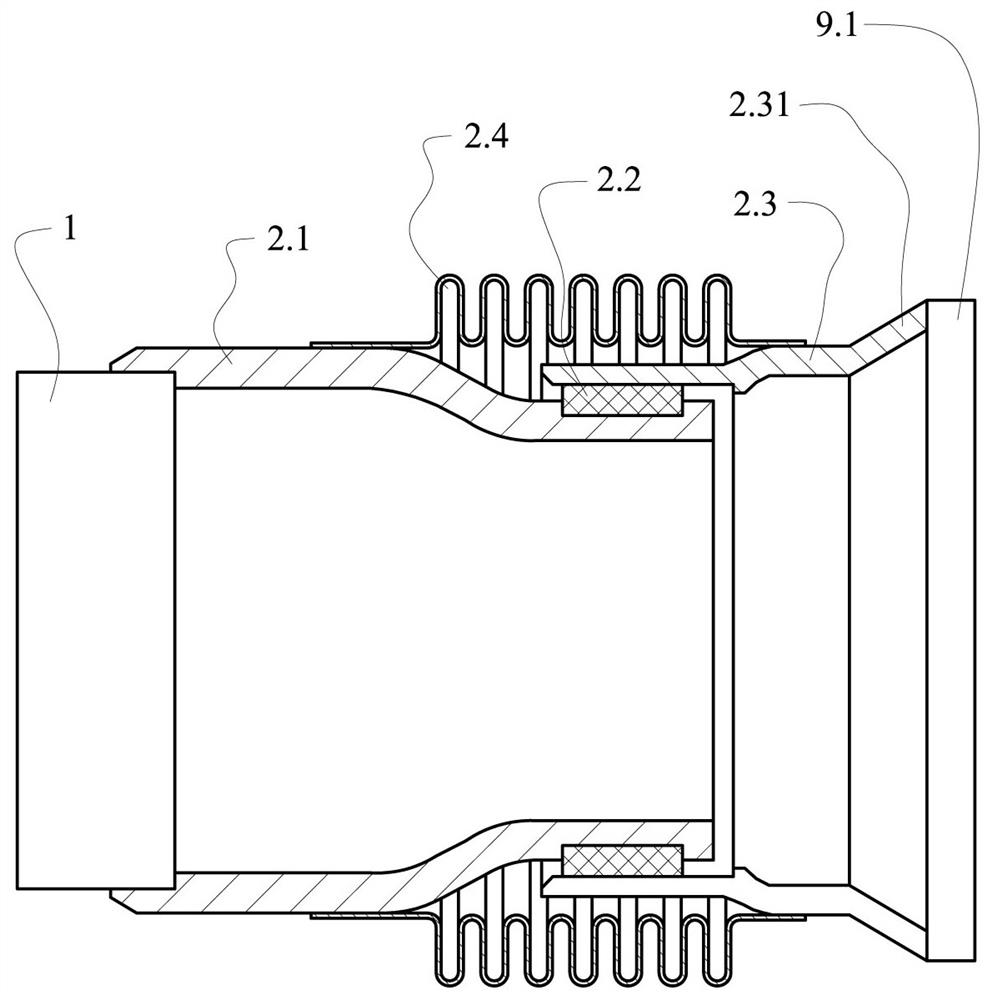

Cast shell type EGR cooler

PendingCN112577341ARaise the natural frequencyPlay the role of radial supportHeat exhanger sealing arrangementHeat exchanger casingsWater flowPipe

The invention relates to a cast shell type EGR cooler. An air inlet connector is connected with a telescopic structure with a corrugated pipe and a sleeve, the outer circumference of the telescopic structure is fixedly connected with an input end flange cover, and the input end flange cover is in bolted connection with one end of a cast pipe shell through an input end sealing gasket. The other endof the pipe shell is in bolted connection with a fixing structure and an output end flange cover with an output pipe connector through an output end sealing ring. The telescopic structure is welded to and connected with a pipe plate at one end of a pipe bundle, and a pipe plate at the other end of the pipe bundle is welded to and connected with the fixing structure. According to the cast shell type ERG cooler, the fixing structure is arranged at one end of the pipe bundle, the telescopic structure is arranged at the other end of the pipe bundle, the problem of dislocation between the pipe shell and the pipe bundle due to thermal expansion and cold contraction is solved, axial displacement compensation is conducted on a heat exchange core through a flexible structure of a double-layer corrugated pipe in the telescopic structure, the influence of thermal expansion and cold contraction on the heat exchange core is reduced, the double-layer corrugated pipe is placed at an air inlet end and combined with a shell water inlet structure, the water flow space is increased, and water flow uniformity is guaranteed.

Owner:渭南美益特发动机减排技术有限公司

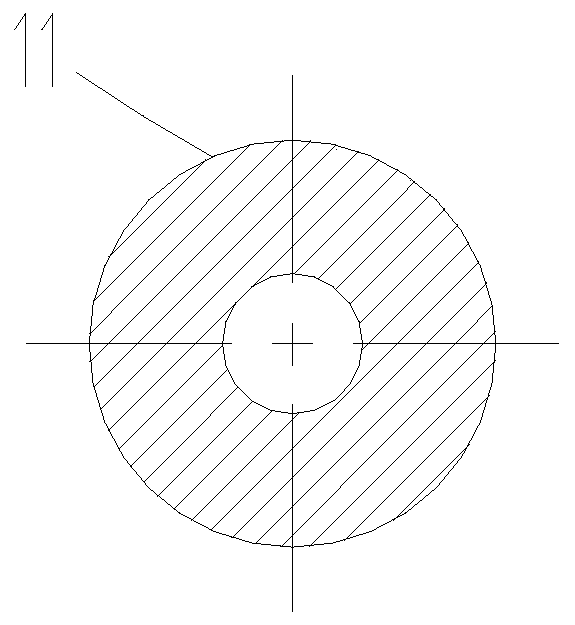

Hole boring device

InactiveCN103447562ASmall amount of expansion and contractionHigh strengthBoring barsTurning toolsConical formsCircular cone

The invention discloses a hole boring device. A conehead rod is arranged at the inner end inside a middle blind hole positioned at the tail of a knife bar, the front end of the conehead rod is of a cone-shaped structure, supporting pillars are symmetrically installed on the waist of the knife bar, the inner end of every supporting pillar is of an inclined-plane-shaped structure, the inclined plane of every supporting pillar is contacted with the conical surface of the conehead rod, the central axis of every supporting pillar is perpendicular to the central axis of the knife bar, steel balls are fixed at the upper ends and the lower ends of the supporting pillars respectively through flange caps, a top thread is installed on an opening part of the middle blind hole of the knife bar, and a plurality of bolts are arranged at the head of the knife bar and tighten and loosen a knife holder. The hole boring device is not subjected to the influence of eccentric acting force easily in cutting, the knife bar does not vibrate easily, workpiece quality is good, and knife collapse can be reduced simultaneously.

Owner:XUZHOU SILK FIBER TECH

Compressor and air conditioner

PendingCN110701044AStable jobReduce noiseRotary piston pumpsRotary piston liquid enginesEngineeringMechanical engineering

The invention provides a compressor and an air conditioner. The compressor comprises a rotating shaft and an air cylinder. The rotating shaft penetrates through the air cylinder, the rotating shaft issleeved with a first flange, a second flange and a roller, the roller is located in the air cylinder, the first flange is arranged at the first end of the air cylinder in a covering manner, the second flange is arranged on the second end of the air cylinder in a covering manner, the roller is limited inside through the air cylinder, the first flange and the second flange, the roller is provided with a first limiting part, a crankshaft is provided with a second limiting part, the first limiting part and the second limiting part are matched, and a rotating shaft and the roller are fixed in theaxis direction of the rotating shaft. According to the compressor, moving of the crankshaft during work in the axial direction can be reduced, the compressor can more stably work, friction between parts can be reduced, and meanwhile, noise generated during work of the compressor can be reduced.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

Pressure testing tool for opening connecting tubes without flange seal

ActiveCN102721605AReduce the amount of sandingChange lengthMeasurement of fluid loss/gain rateMaterial strength using tensile/compressive forcesLine tubingEngineering

A pressure testing tool for opening connecting tubes without flange seal comprises a pressure testing ring, a sealing sheet, a blind flange, an exhaust pipe, a water inlet pipe and a plurality of fixing rib plates. The pressure testing ring is sleeved on the outer wall of a pipe, the sealing sheet is welded at a pipe orifice, the blind flange is in close compression joint with the sealing sheet and is connected with the pressure testing ring by locking parts, one end of the exhaust pipe is penetratingly arranged on the blind flange and the sealing sheet and is communicated with an inner cavity of the pipe, the other end of the exhaust pipe is bent upwards, one end of the water inlet pipe is penetratingly disposed on the blind flange and the sealing sheet and is communicated with the inner cavity of the pipe, the other end of the water inlet pipe is bent upwards, and the fixing rib plates are peripherally arranged along the outer wall of the pipe and used for supporting the pressure testing ring. Compared with the prior art, the pressure testing tool is low in welding load, cutting and grinding workload for the pipe orifice is low after pressure testing, a groove is not damaged, the length of the pipe is ensured to be unchanged, and the pressure testing tool is particularly applicable to pressure tests for equipment and pipelines with machined grooves and opening connecting pipes made of pure materials.

Owner:THE CHALLENGE PETROCHEM MACHINERY CORP

Carrierless flange cover with integral trim strip

ActiveUS20050057058A1Uniform aesthetic appearanceReduce material requirementsWindowsEngine sealsFLANGE CAPEngineering

A flange cover with a trim lip is provided for finishing a vehicle flange, wherein the flange cover can include a seal. The flange cover is affixed to a single side of the flange and the trip lip projects from an opposed side of the flange to be spaced from the flange. The trim lip can be sized to contact an interior trim piece of the vehicle to occlude a gap between the flange and the interior trim piece. A seal can be operably located on an outside surface of a flange engaging leg.

Owner:SCHLEGEL

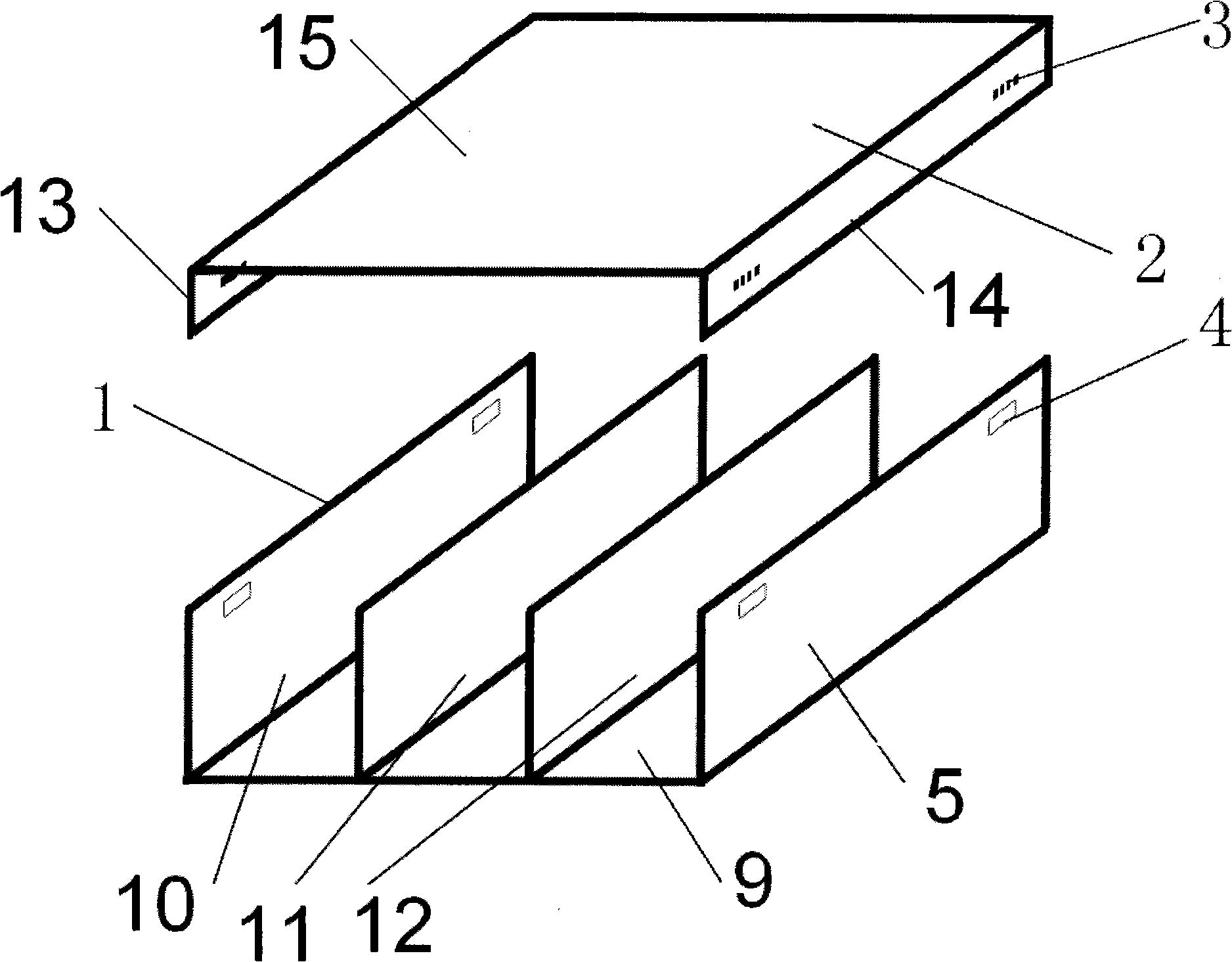

Novel constructional column concrete pumping system

ActiveCN106150097AImprove construction efficiencyQuality assuranceBuilding material handlingEngineeringAtmospheric pressure

The invention discloses a novel constructional column concrete pumping system which comprises a pneumatic power device. The pneumatic power device is connected with the front end of a concrete container through a power delivery pipe, and a concrete delivery pump pipe is arranged on the lower portion of the back end of the concrete container; the top of the concrete container is provided with a feeding port sealed by a flange cover, the lower portion of the concrete container is provided with a cleaning port sealed by a flange cover, and a pressure discharge device which is additionally provided with a ball valve is arranged beside the feeding port. By means of the novel constructional column concrete pumping system, pouring can be completed at a time, chiseling and column head repairing are not needed, therefore, the quality is effectively guaranteed, and work and labor are saved; when two persons operate a pumping machine, 80 constructional columns can be poured in a day, and when a traditional method is adopted, only 20 constructional columns can be poured by two persons in a day; the cost for producing the pumping machine through experimental machining in a matched mode is only 5,000 yuan. Pipeline lengthening and pumping air pressure mechanomotive force designing can be conduced on the pumping machine according to a specific construction calculation method, therefore, the construction efficiency of a construction enterprise is greatly improved, the construction quality is improved, and enterprise competitiveness is enhanced.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com