Liquid level detector for magnesium electrolytic cell

A technology of liquid level detection and magnesium electrolyzer, which is applied in the direction of measuring device, lubrication indicating device, liquid/fluid solid measurement, etc., can solve the problems of not being able to withstand the high temperature of 720 ℃ and the health impact of operators, and achieve low price and lighten Worker labor intensity, simple maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

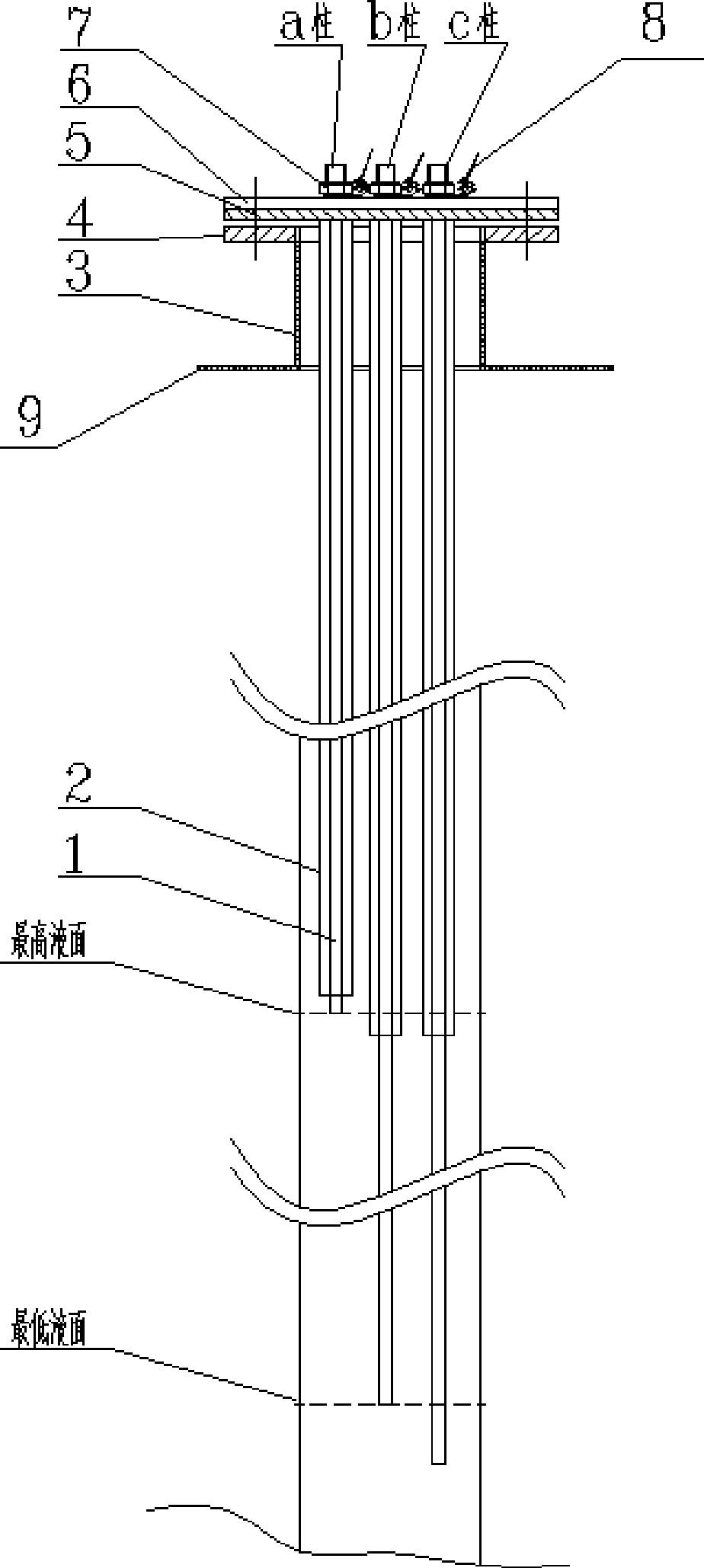

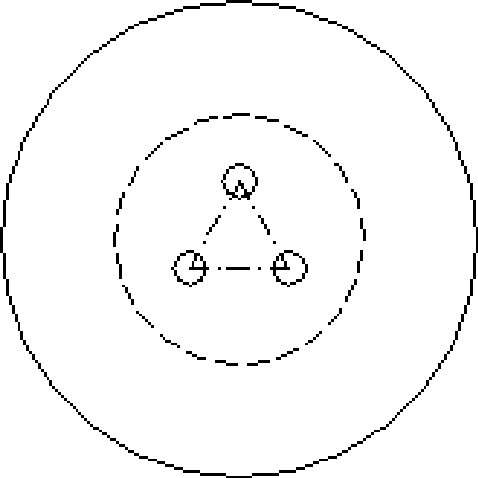

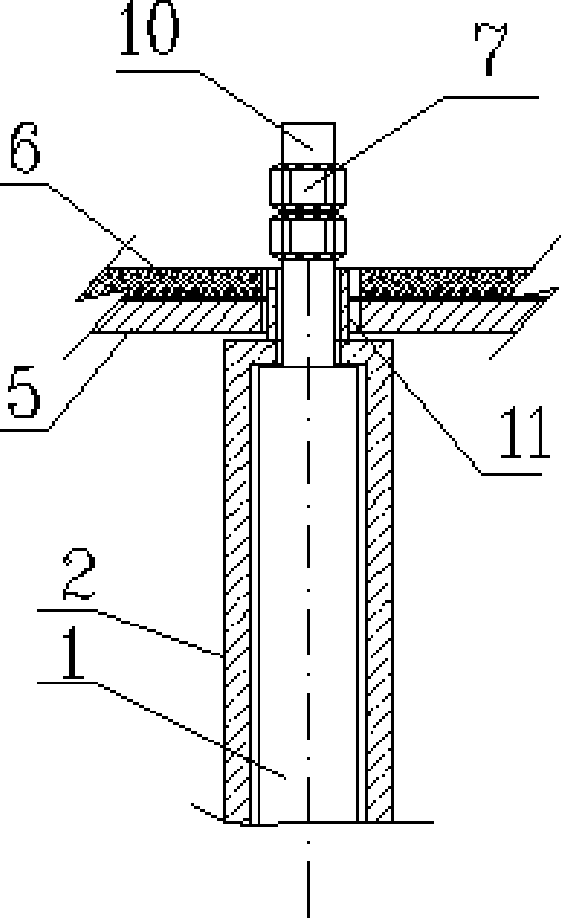

[0014] The embodiment of the present invention: as shown in the attached drawings, according to the position of the highest liquid level and the lowest liquid level in each electrolytic cell, a hole ¢150 is opened on the top of the cover plate 9 of the magnesium collecting chamber of the electrolytic cell, and a method of corresponding length is welded. Flange pipe 3, DN150, PN1.0 flange 4 is welded on flange pipe 3, flange 4 is connected with the stainless steel flange cover plate 5 and the PTFE partition plate 6 that have been opened, and the PTFE partition The plate 6 is covered on the flange cover plate 5 for insulation. The upper end of the stainless steel rod 1 has threads 10, and three stainless steel rods 1 with different lengths pass through the flange cover plate 5 and the PTFE partition plate 6 Fixed by thread 10 and nut 7, there is a silicon carbide protection tube 11 between the stainless steel flange cover 5, the PTFE separator 6 and the stainless steel rod 1; eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com