Patents

Literature

279 results about "Copper cylinder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Printed circuit board and producing method of encapsulation base of integrated circuit

ActiveCN101286454AFinely craftedAvoid production capacity constraintsPrinted circuit aspectsSemiconductor/solid-state device manufacturingEngineeringInterconnection

The invention relates to a manufacturing method of a printed circuit board and an integrated circuit packaging substrate; based on the interconnection of electroplating pore filling and a semi-additive forming layer and a fine circuit, the method comprises the following steps: (1) a dielectric layer is manufactured on the substrate; (2) blind hole structure is manufactured on the dielectric layer; (3) after the blind hole structure is completed, a first conductive seed layer is manufactured; (4) a solid conductive via hole is manufactured by adopting the method of electroplating pore filling, and a copper layer grows and covers on the first seed layer in the process of electroplating pore filling; (5) the copper layer and the first seed layer are removed, and a solid copper cylinder in the solid conductive via hole is retained; (6) a second seed layer of semi-additive manufacturing circuit is manufactured; (7) a photosensitive thin film is glued, an anti-plating layer is formed by transferring diagram and the circuit diagram is exposed: (8) the circuit in the circuit diagram is thickened; (9) the photosensitive thin film and the exposed second seed layer are removed, the thickened circuit is retained, and a needed conductive diagram is formed; (10) all the steps from (1) to (9) are repeated on the new circuit surface, and the manufacture of fine circuits of following circuit layers and the connection of the solid conductive via holes in the layers are completed.

Owner:SHANGHAI MEADVILLE SCI & TECH

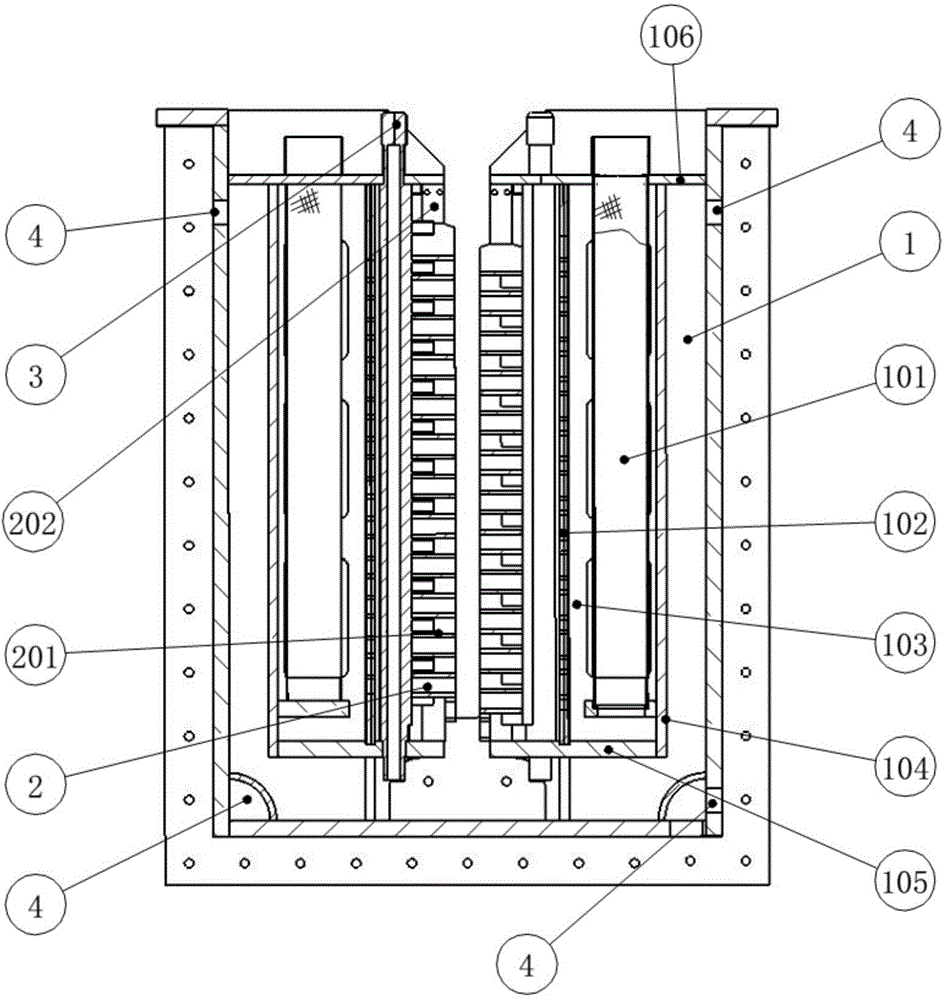

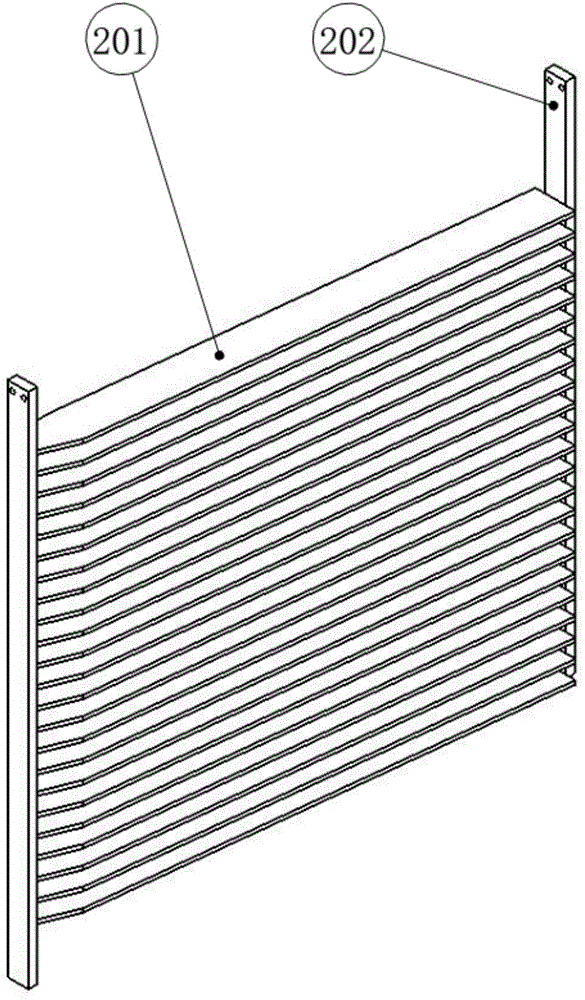

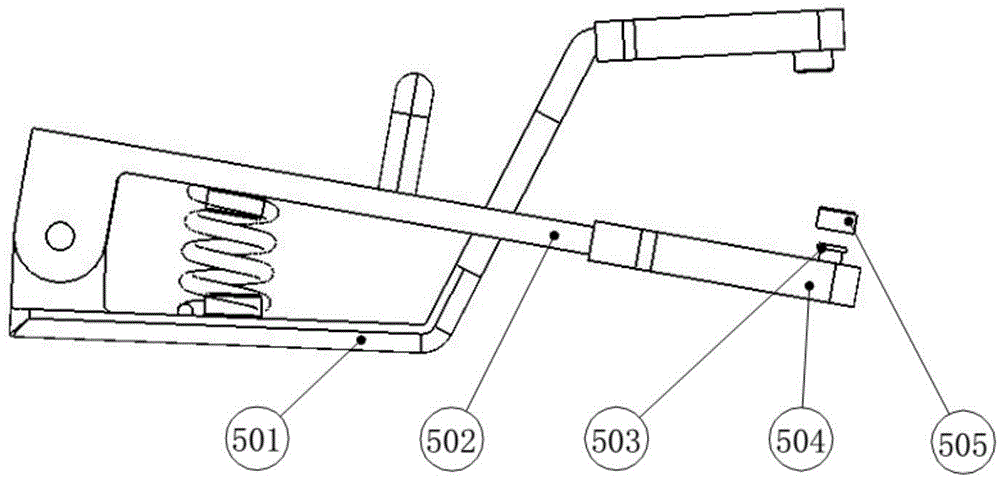

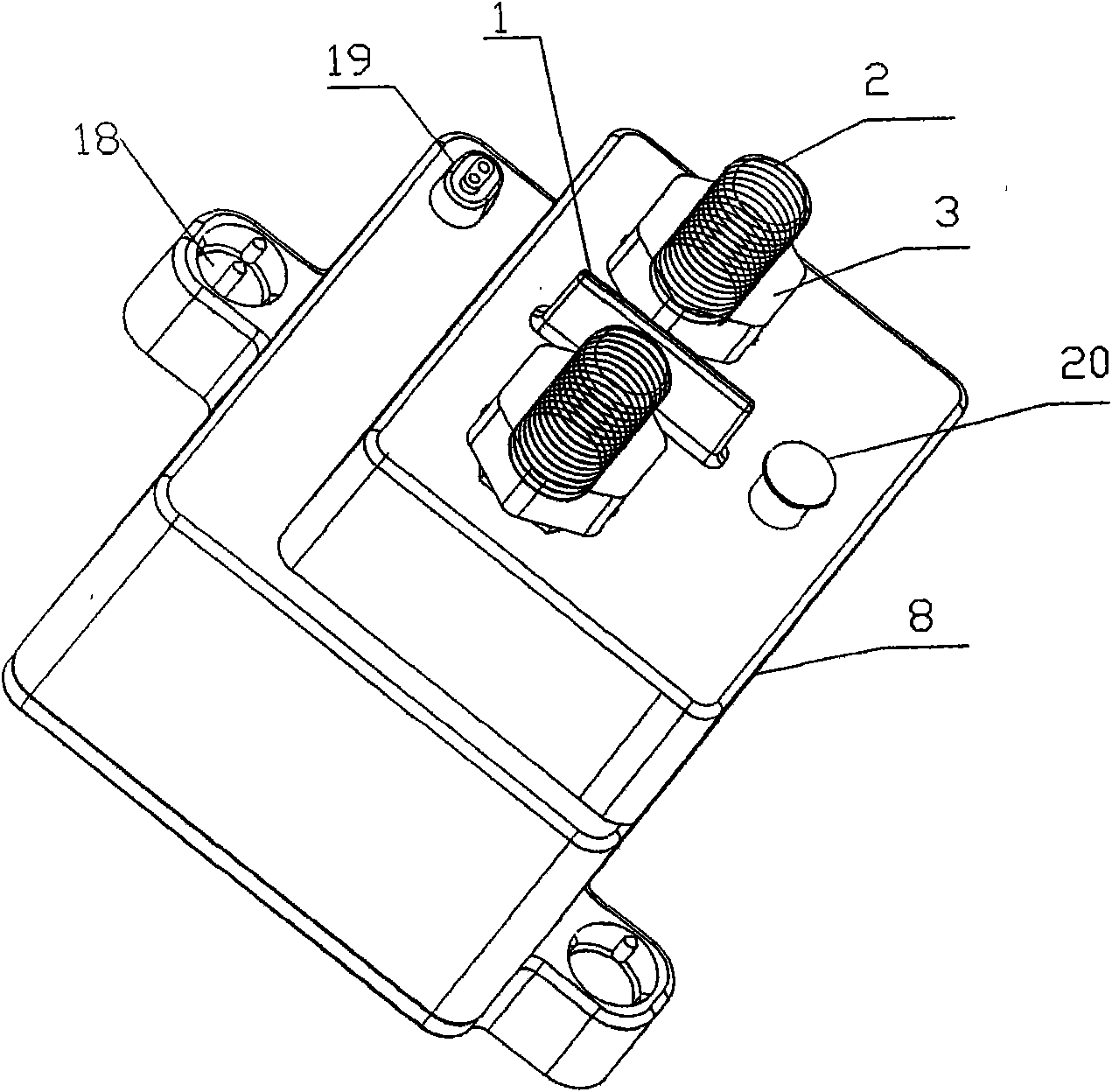

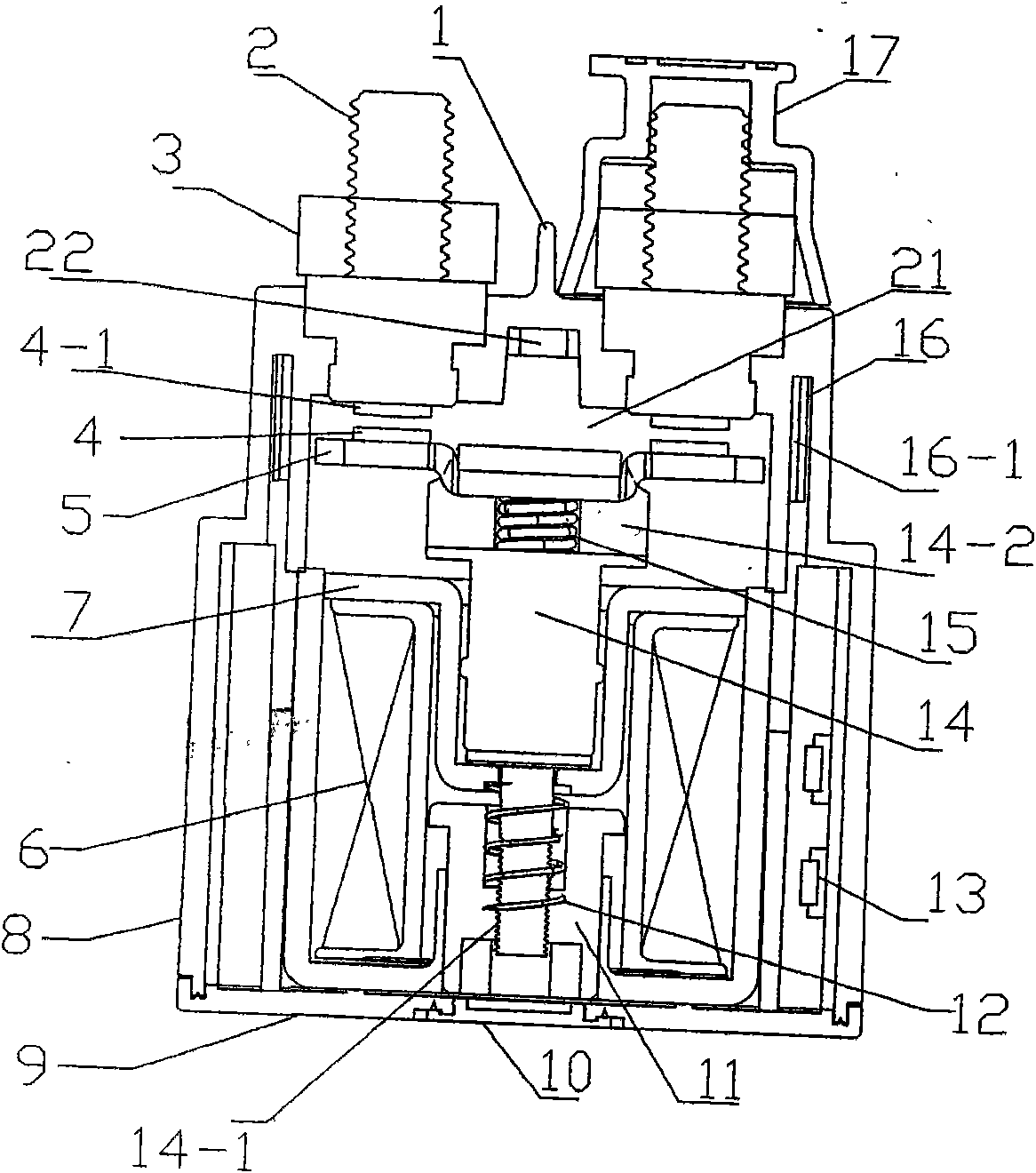

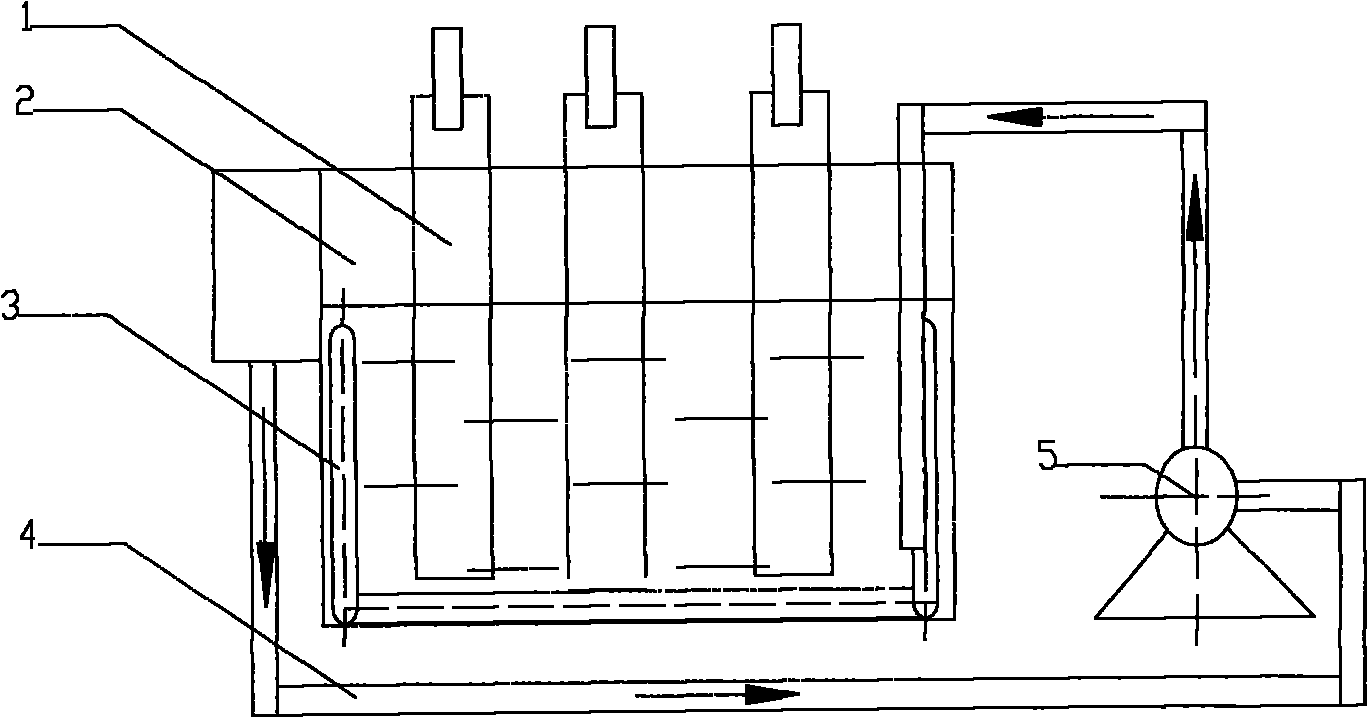

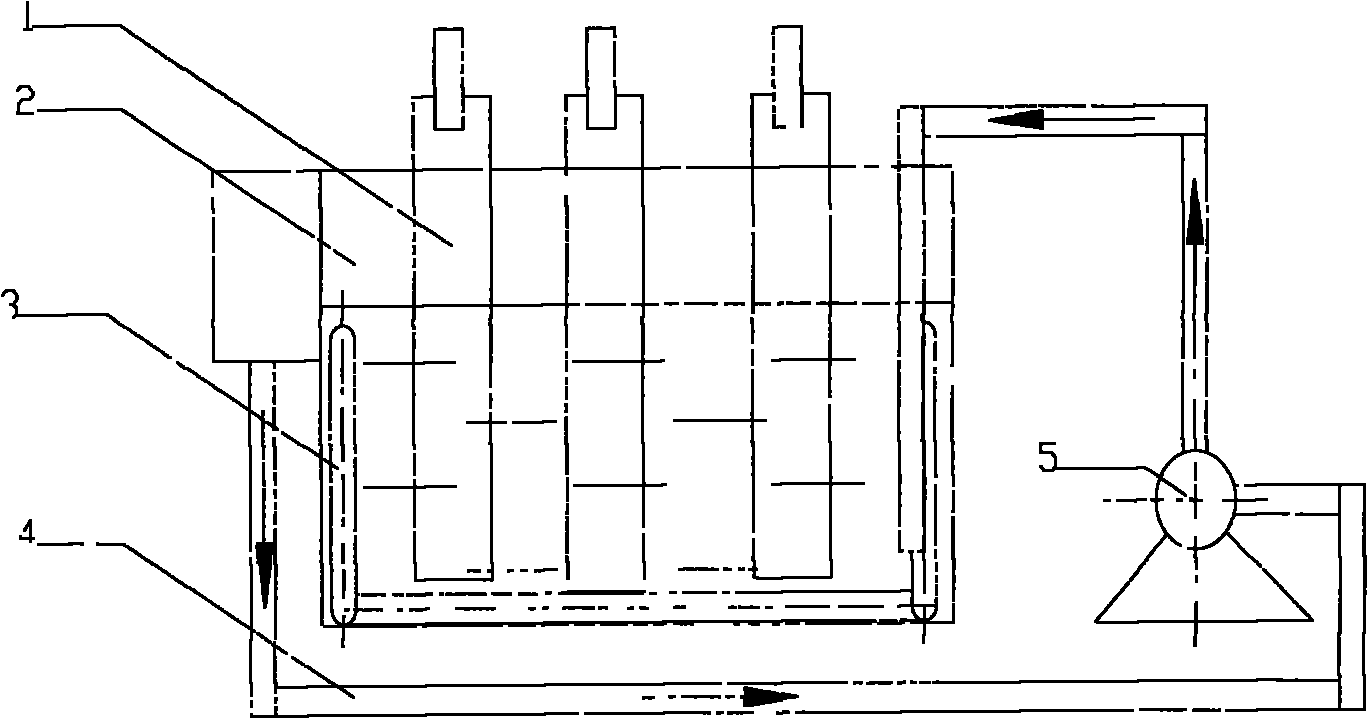

Novel full-automatic vertical and continuous electroplating device for PCB

ActiveCN104790022AReduce consumptionAvoid affecting the quality of platingElectrolysis componentsMetallurgyChain link

The invention discloses a novel full-automatic vertical and continuous electroplating device for a PCB. The novel full-automatic vertical and continuous electroplating device comprises the following steps: automatic loading, chain transmission, pre-treatment, electroplating, post-treatment and automatic unloading. An independent anode chamber structure, lower auxiliary chain clamping, side spraying, adjustable height bottom spray, a guide member, an independent slide block connecting clamp as a guide and conducting structure, and a rubber sealing conductive chuck without deplating are adopted by an electroplating copper cylinder; and push spring-loaded tension adjustment is adopted by chain transmission. The novel full-automatic vertical and continuous electroplating device has the beneficial effects that anode liquid is completely separated from cathode electroplate liquid by the independent anode chamber; anode mud is thoroughly prevented from entering the cathode electroplate liquid to avoid affecting the electroplating quality; the filtering burden is removed or significantly reduced; the consumption of an additive is greatly reduced; the process is simplified by the chuck without deplating; dual-row operation can be realized; and the capacity is improved.

Owner:栾善东

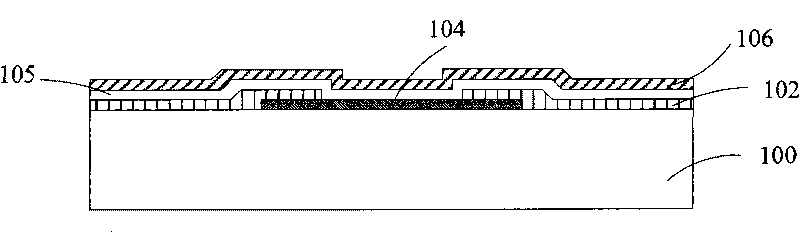

Manufacturing method of fan-out type packaging structure

ActiveCN105244307ASuitable for productionReduce package thicknessSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSingle chip

The invention provides a manufacturing method of a fan-out type packaging structure. A protection layer covers the front surface of a wafer and then the wafer is cut into single chips; the chips are positively adhered on a bearing piece on which a temporary bonding film is coated; then a first insulating resin layer covers the temporary bonding film and the chips, and the first insulating resin layer is higher than the protection layer on the chips; the first insulating resin layer is thinned; then the protection layer is removed and the front surfaces of the chips and electrodes are exposed; then a second insulating resin layer is coated and an opening is formed; a heavy wiring layer is manufactured; then a third insulating resin layer is coated and an opening is formed so that the welding disc of the heavy wiring layer is exposed; conductive columns are formed on the surface of the welding disc; and then the bearing piece and the temporary bonding film are removed, and a protective layer is formed on the first insulating resin layer and the back surfaces of the chips. The packaging structure has no bearing piece so that packaging thickness can be reduced, and application range of the technology can be extended; besides, copper cylinders are not manufactured in the chips so that cost can be reduced.

Owner:NAT CENT FOR ADVANCED PACKAGING

Method for testing processing residual stress of 'through-silicon via'-Cu structure

InactiveCN102818765AIntegrity guaranteedThe test result is accurateUsing mechanical meansApparatus for force/torque/work measurementCopper platingShear stress

The invention discloses a method for testing processing residual stress of a 'through-silicon via'-Cu structure, and belongs to the technical field of electronic information. The method includes downwardly squeezing a copper cylinder in a through-silicon via in a test sample by a pressure head, simultaneously recording the displacement and the pressure F when the pressure head acts downwardly to obtain a pressure F and displacement curve and a threshold value of the pressure F when the pressure F is reduced, and substituting the threshold value of the pressure F in a pressure and interfacial shear stress conversion formula to obtain a shear stress threshold value tau 0 when a copper and silicon interface in the TSV-Cu structure manufactured by a copper plating process slips; and computing to obtain the to-be-measured residual stress of the 'through-silicon via' TSV-Cu structure via the shear stress threshold value tau 0. The method has the advantages that completeness of the test sample is kept to the greatest extent, operation, such as cutting the test sample, which affects release of the residual stress, is omitted, and a test result is accurate; and a residual stress computing method is simple and reliable, and the positive or negative property of the residual stress can be visually judged.

Owner:BEIJING UNIV OF TECH

Through silicon hole structure with step and manufacture process of through silicon hole

InactiveCN102376689AReduce current densitySemiconductor/solid-state device detailsSolid-state devicesElectrical conductorInsulation layer

The invention discloses a through silicon hole structure with a step, which comprises a semiconductor substrate and a through hole penetrating through the semiconductor substrate and having the step, wherein an insulation layer, an adhesion layer and a barrier layer are sequentially deposited on the side wall of the step through hole; a metal conductor is filled in the through hole; an interconnecting structure formed by sequential deposition of the insulation layer, the adhesion layer, the barrier layer and a conductive layer is deposited on the surface of the semiconductor substrate; and the conductive layer in the interconnecting structure is connected with the metal conductor. The invention also provides a manufacture process of the through silicon hole structure. The step in the through silicon hole can allow copper cylinder protruding height difference caused by local electroplating rate difference in an electroplating hole-filling process, and avoids silicon wafer breakage caused by the problem in a chemical mechanical polishing (MCP) process and a bonding process.

Owner:HUAZHONG UNIV OF SCI & TECH

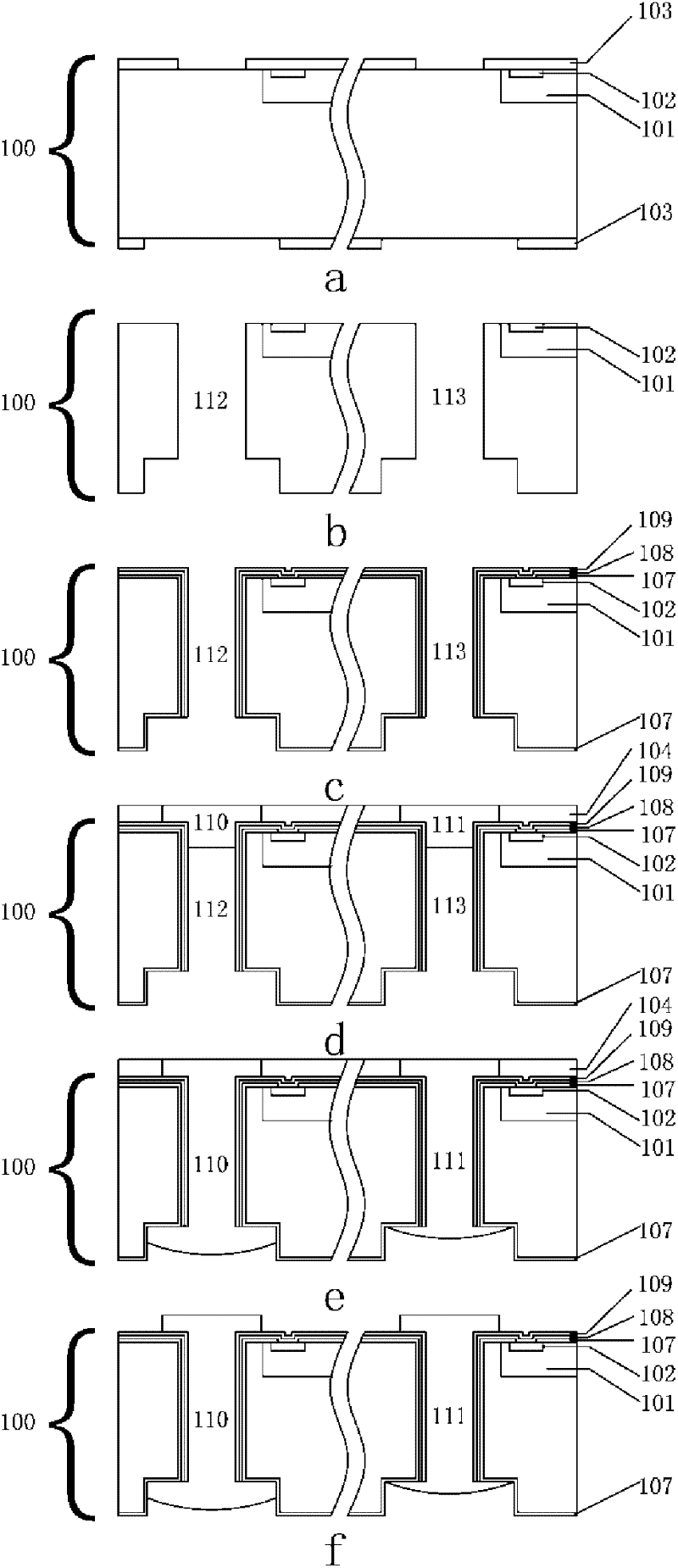

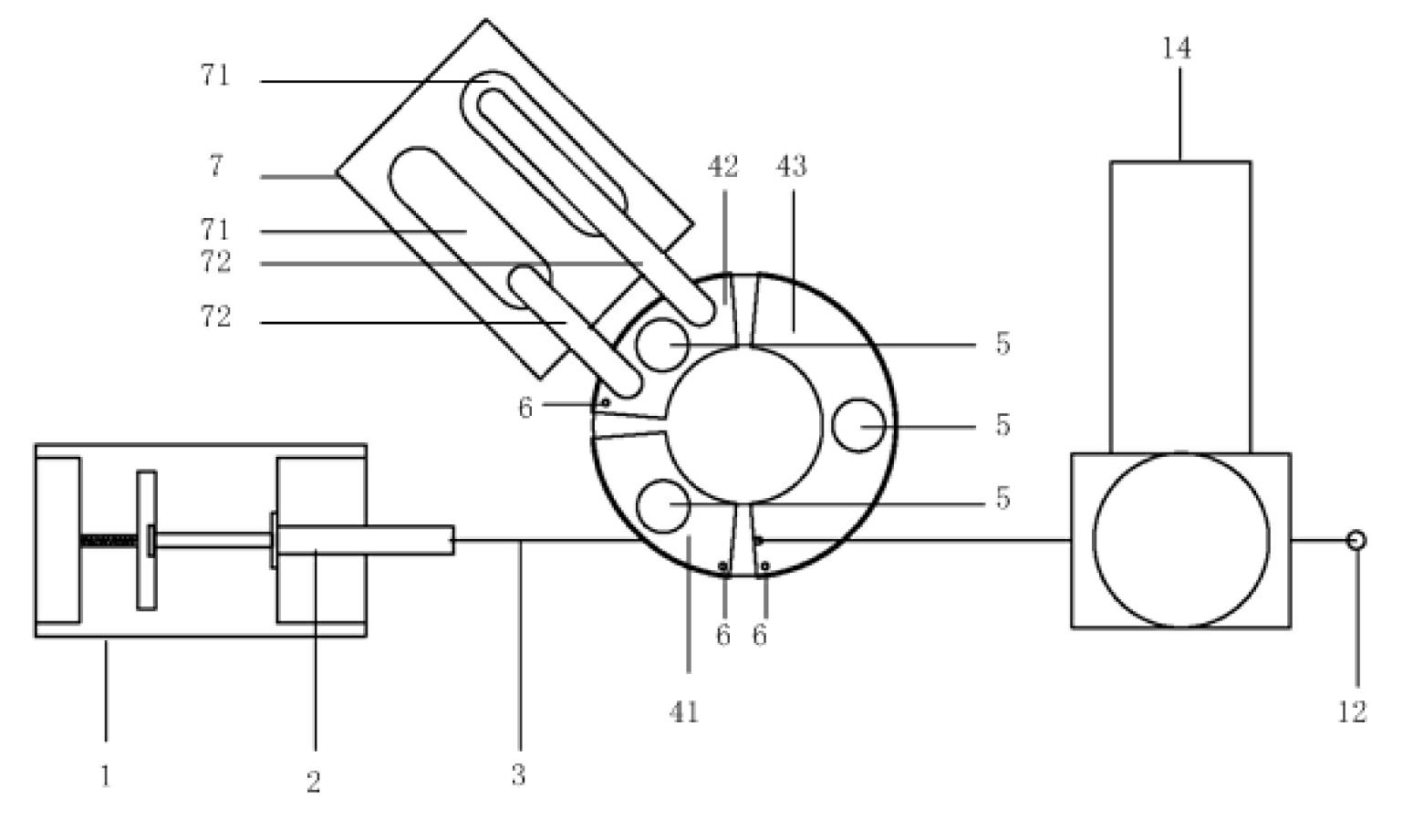

Continuously mobile nest type PCR (polymerase chain reaction) microfluidic method

InactiveCN102605065AQuick checkHigh sensitivity detectionMicrobiological testing/measurementMicrofluidicsA-DNA

The invention discloses a continuously mobile nest type PCR (polymerase chain reaction) microfluidic method. A nest type primer consisting of two pairs of primers is designed according to a DNA (deoxyribonucleic acid) sequence of a target detected object, after DNA of a to-be-detected sample is added into a PCR reaction system containing an outer primer the DNA of the to-be-detected sample and the PCR reaction system are mixed uniformly, the mixture is injected into a continuously mobile nest type PCR microfluidic device, PCR reaction liquid completes 20-35 PCR expansion circulations along capillary tubes spirally wound on three independent temperature-control constant-temperature copper cylinders, and fluorescence detection and analysis systems at the tail ends of the capillary tubes are used for acquiring and analyzing fluorescent images of expanded products. The expanded products are added into a PCR reaction system containing an inner primer, so that nest type PCR second-step expansion and product detection is completed as the above. By means of analyzing the intensity of the fluorescent images of the expanded products in two turns, whether the to-be-detected sample has the target detected object or not and the relative quantity of the target detected object can be determined. The continuously mobile nest type PCR microfluidic method can realize low-cost, high-sensitivity and fast detection for low-abundance DNA samples, detection limit can achieve 1 copy number / total volume, and consumed time is only 35-45min.

Owner:SOUTH CHINA NORMAL UNIVERSITY

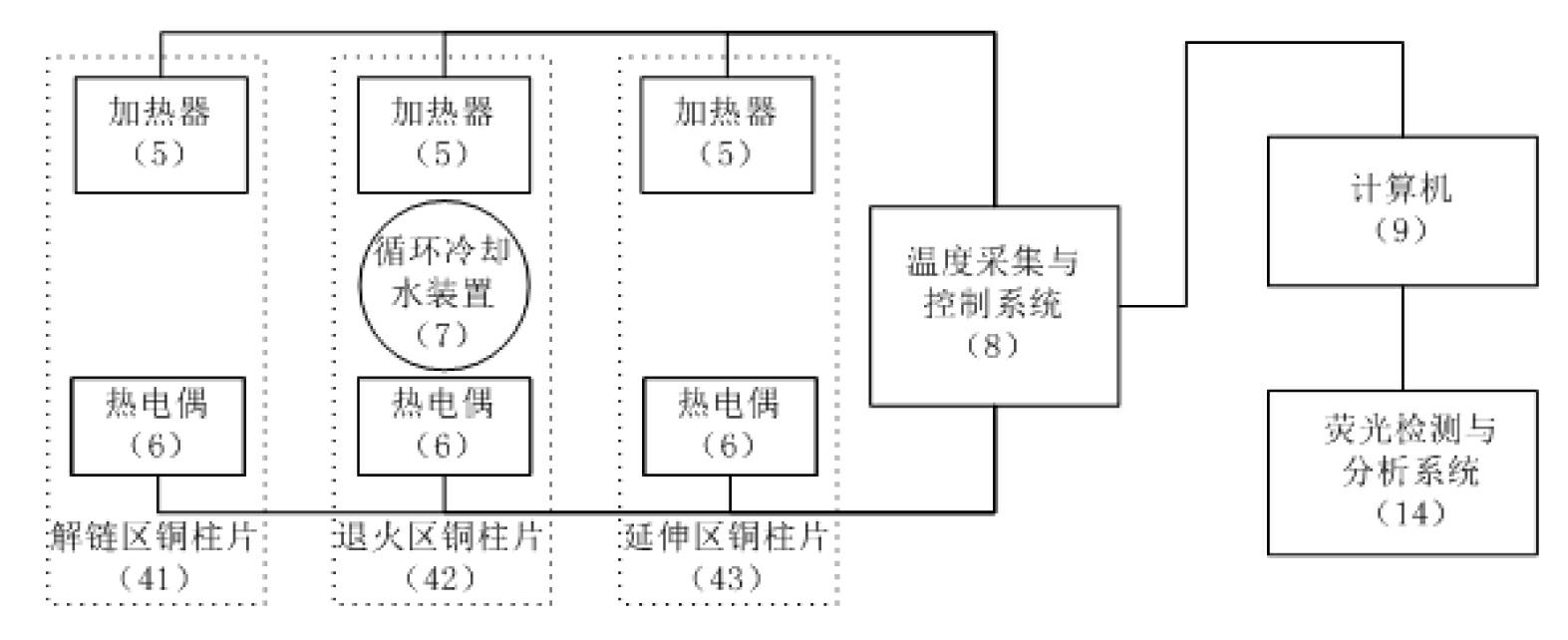

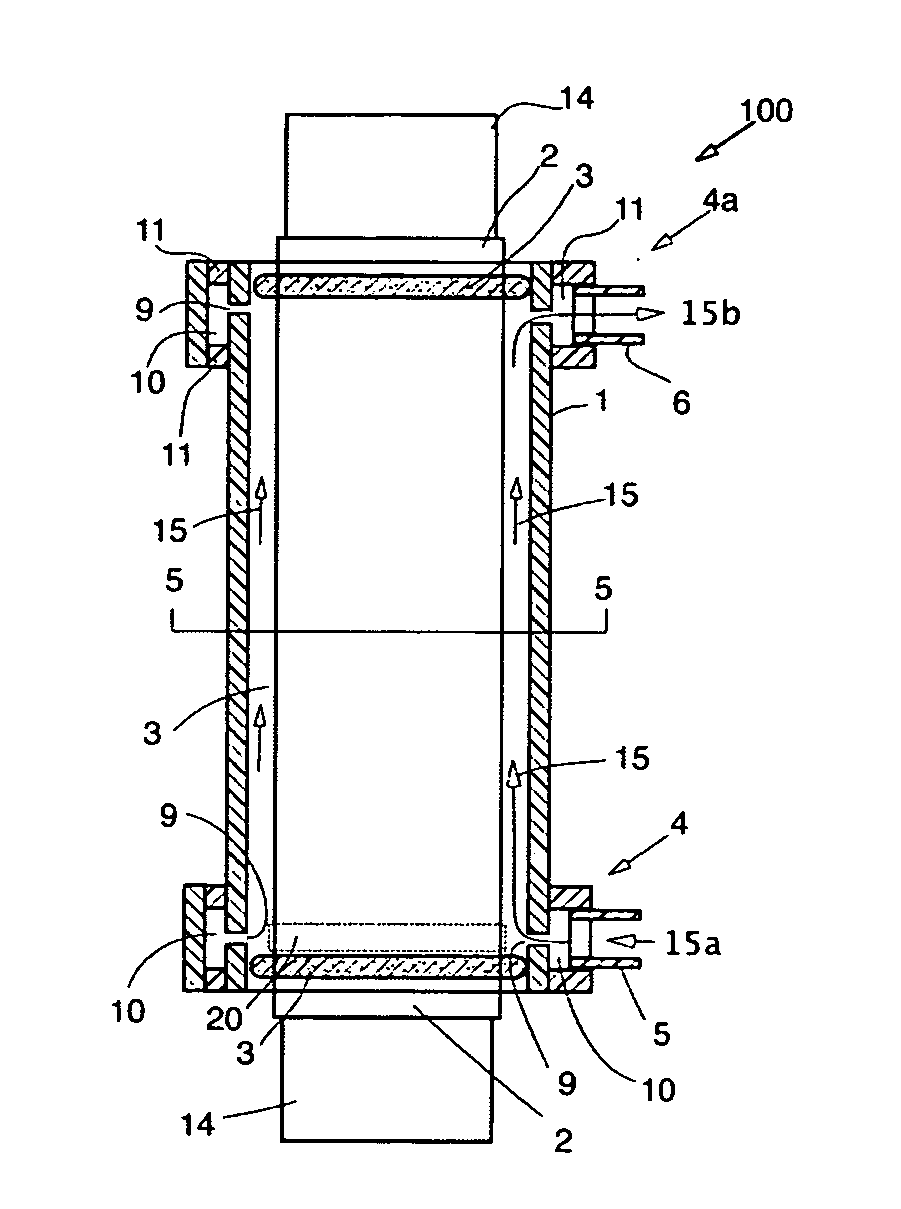

Hybrid vertical drainpipe heat exchanger

InactiveUS20130306290A1Area maximizationAffect performanceHeat recovery systemsRecuperative heat exchangersWater useEngineering

A low-cost hybrid heat exchanger uses sheet copper and rigid plastic tubing. Copper is used only where actual heat transfer takes place, adjacent the drainpipe wall. All other components are plastic to lower cost. It pre-heats fresh cold water using waste heat from the drain such as from a shower drain. The heat exchanger comprises an inner copper conduit or drainpipe, a rolled sheet copper cylinder, an outer plastic tube and manifolds, and O-ring. On assembly, inserting the drainpipe results in the O-ring being compressed between the copper cylinder and the plastic tube. The result is a sealed water chamber wherein heat transfer takes place. The ends of the plastic tube have radially spaced water distribution holes into the chamber and inlet and outlet manifolds, each with water connections to the building's cold water supply. A method of recovering heat from non-shower hot water uses using a separate reservoir is also disclosed.

Owner:MACKELVIE WINSTON

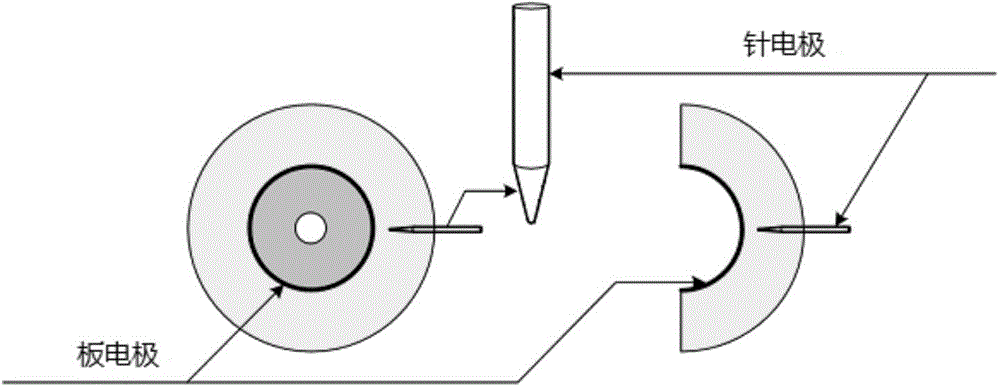

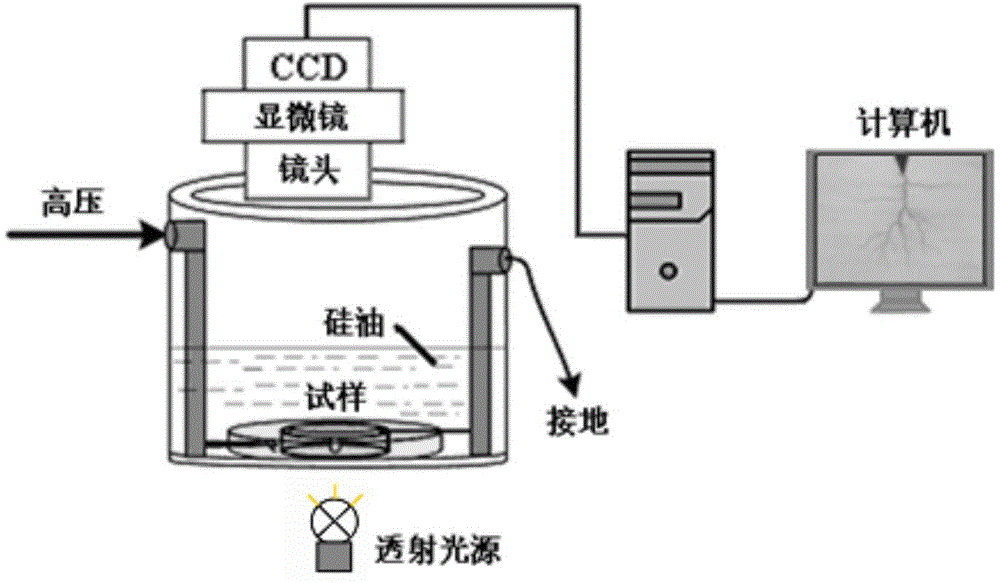

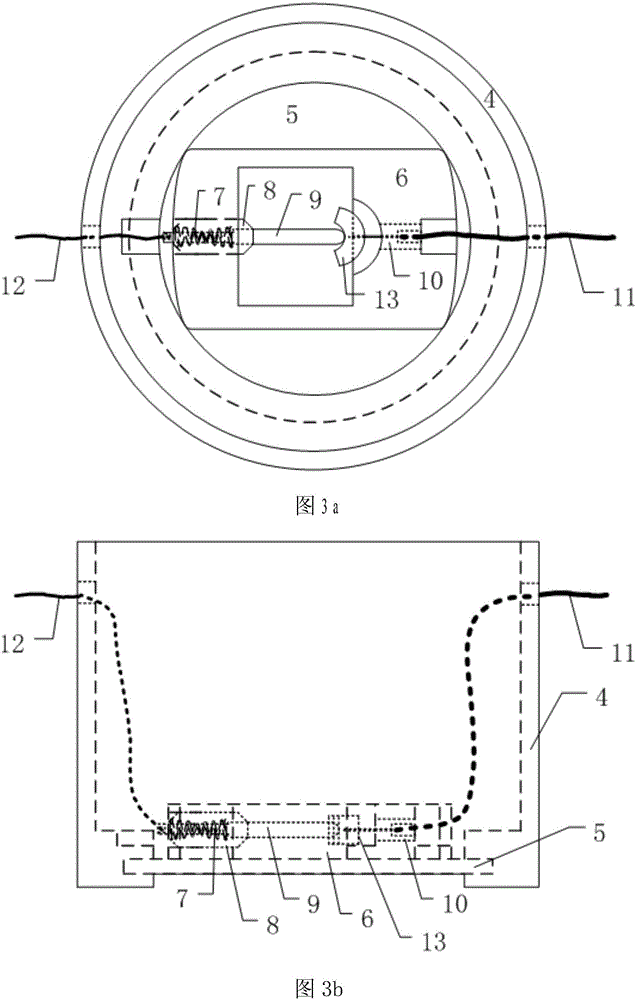

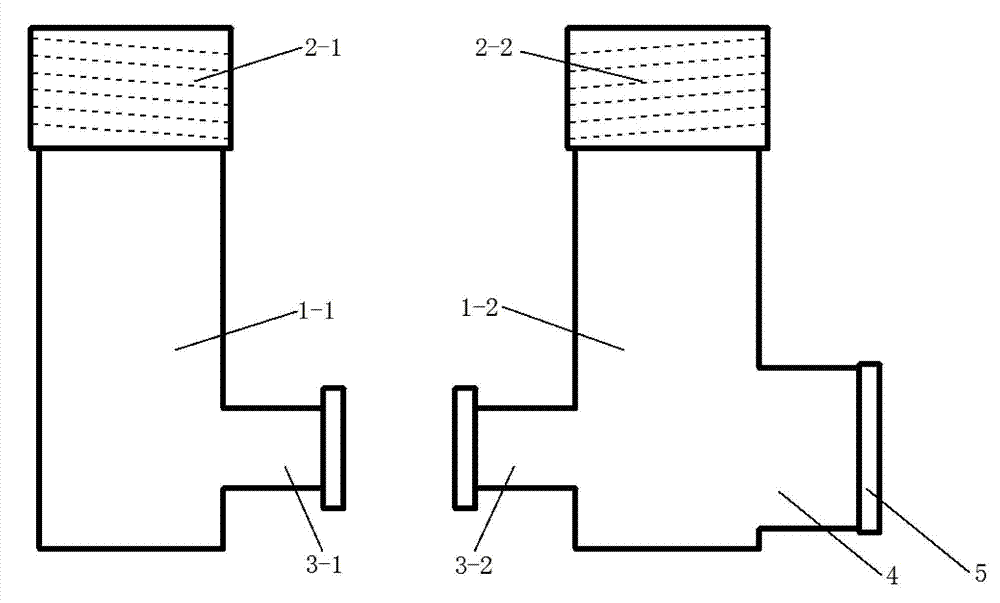

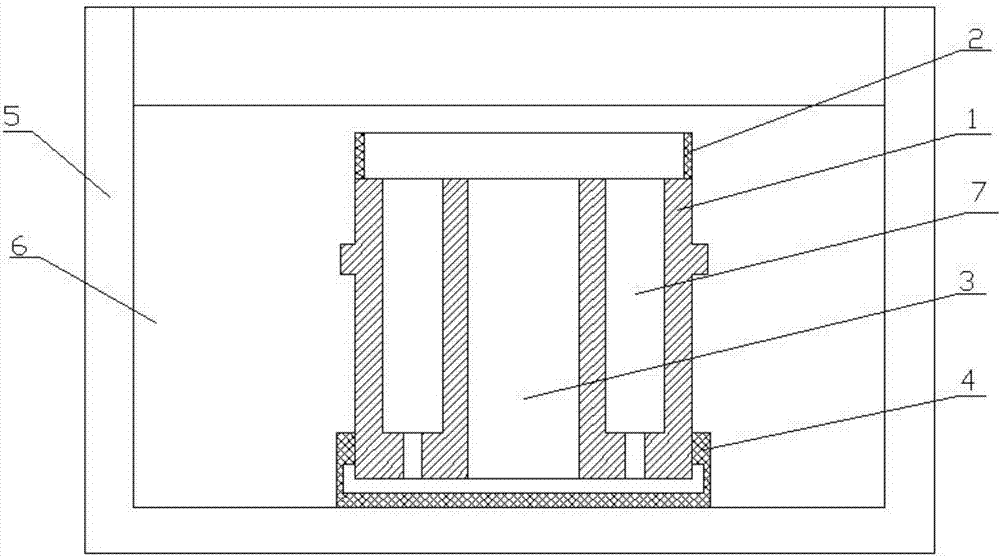

Real-time microscopic observation test system for electrical tree characteristics in solid insulation under DC voltage

ActiveCN104965162AAids in position fixationEasy to fixTesting dielectric strengthElectrical measurement instrument detailsMicroscopic observationLow voltage

The invention relates to a real-time microscopic observation test system for electrical tree characteristics in solid insulation under DC voltage, which comprises an open container, a supporting base is placed in the open container, a tested sample is placed on the supporting base, a pin electrode of the sample is connected with a high-voltage lead through a high-voltage copper cylinder, a plate electrode of the sample is connected with a low-voltage lead through a low-voltage copper rod, the low-voltage copper rod, a spring and the high-voltage copper cylinder are matched in design so as to be conducive to placement and position fixing of the sample, the open container is covered by a container cover, sloshing of silicon oil in an area above the sample can be effectively weakened through a microscopic observation column inserted at a hole in the container cover, and a direct observation window on the container cover is used for carrying out position observation and adjustment on the microscopic observation column. The real-time microscopic observation test system can fix the position of the tested sample effectively, is convenient for placing and taking the sample, can be applied to solid insulation electrical tree test samples with different shapes and sizes, can carry out real-time observation and photographic recording on a pinpoint area of the sample while applying the DC voltage, and does not need to cut off the power.

Owner:XI AN JIAOTONG UNIV +1

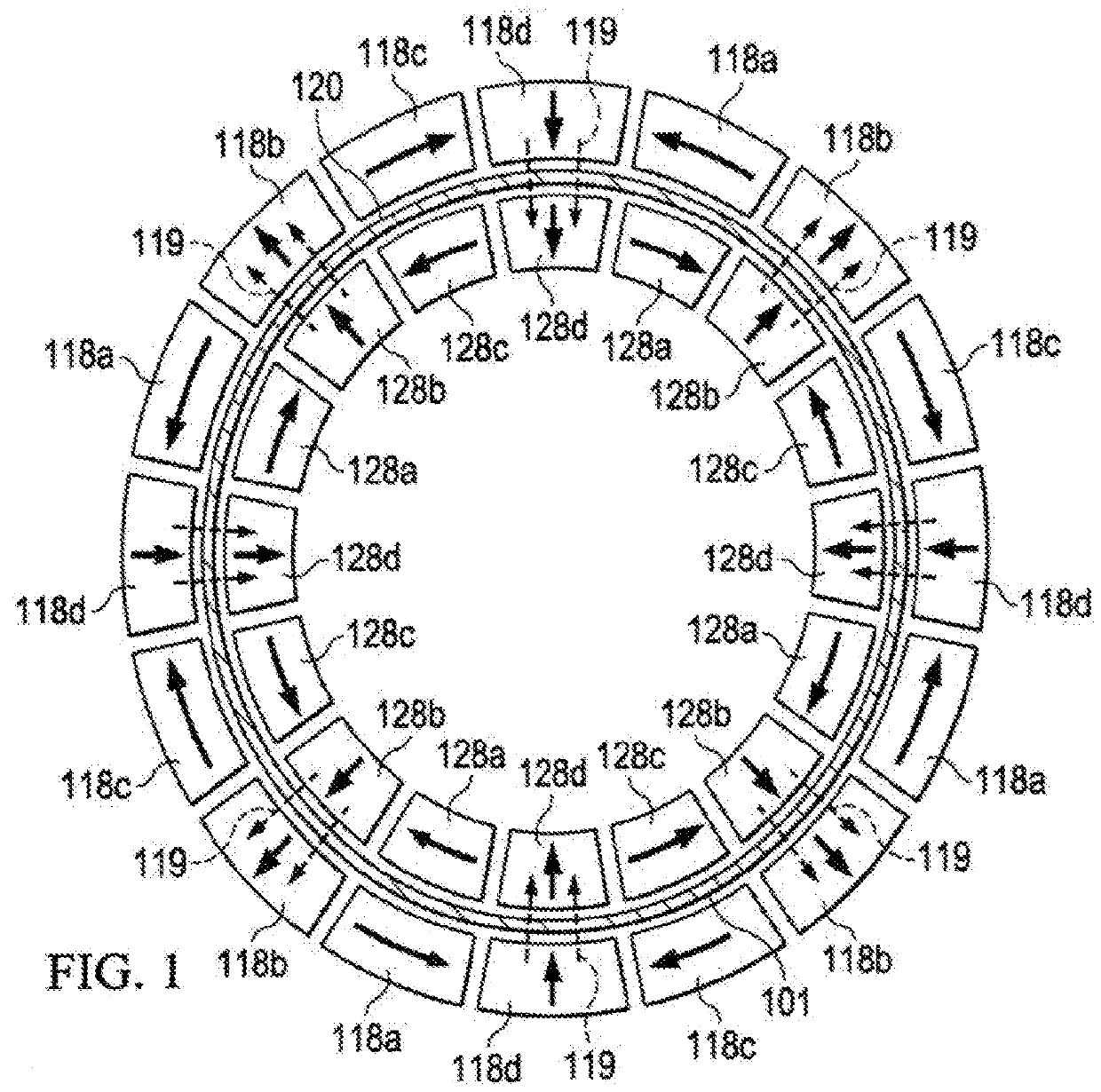

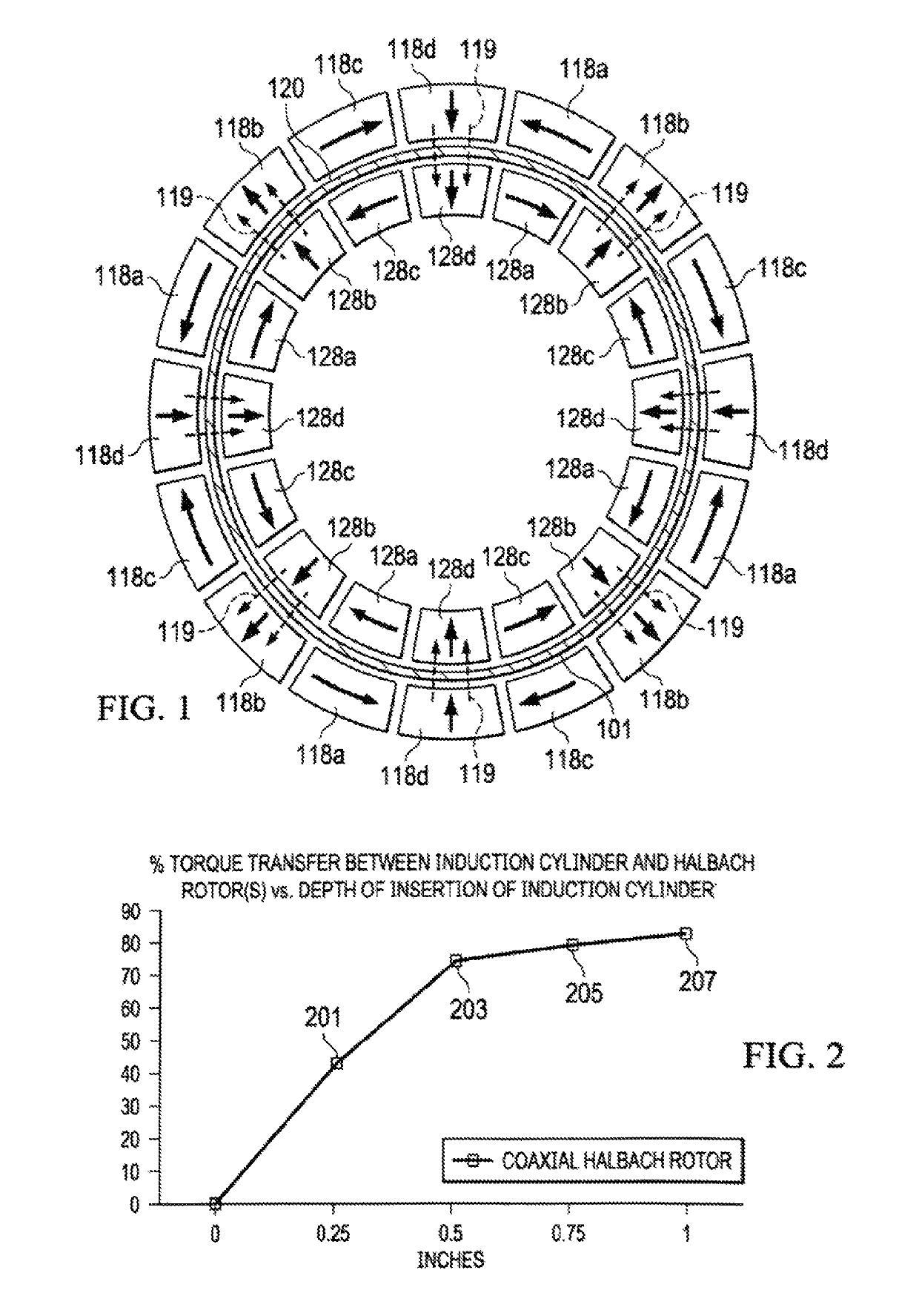

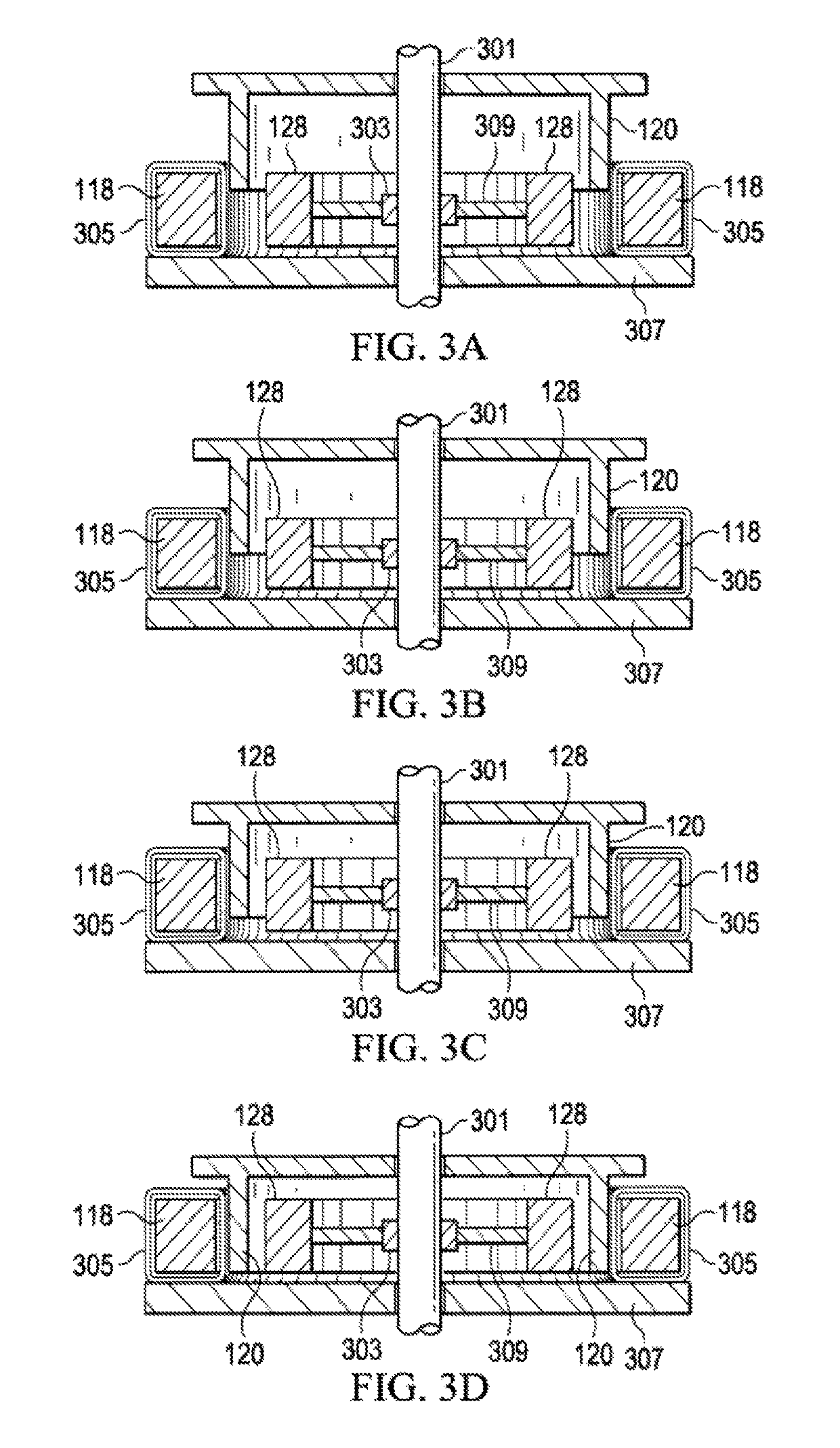

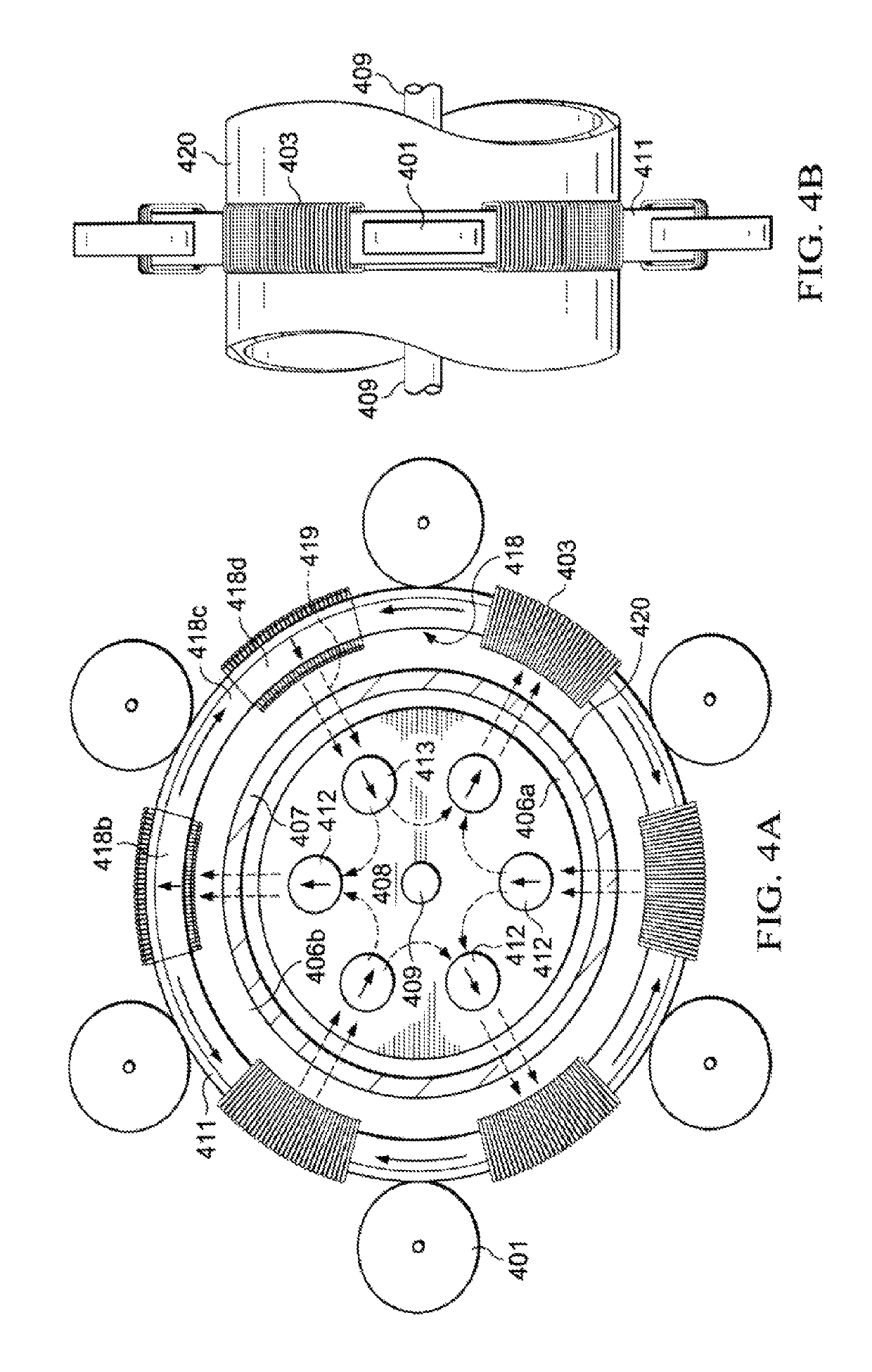

Flywheel energy storage device with induction torque transfer

InactiveUS20180166946A1Increase power generationPower generationEngine fuctionsEngine componentsMagnetic tension forceElectricity

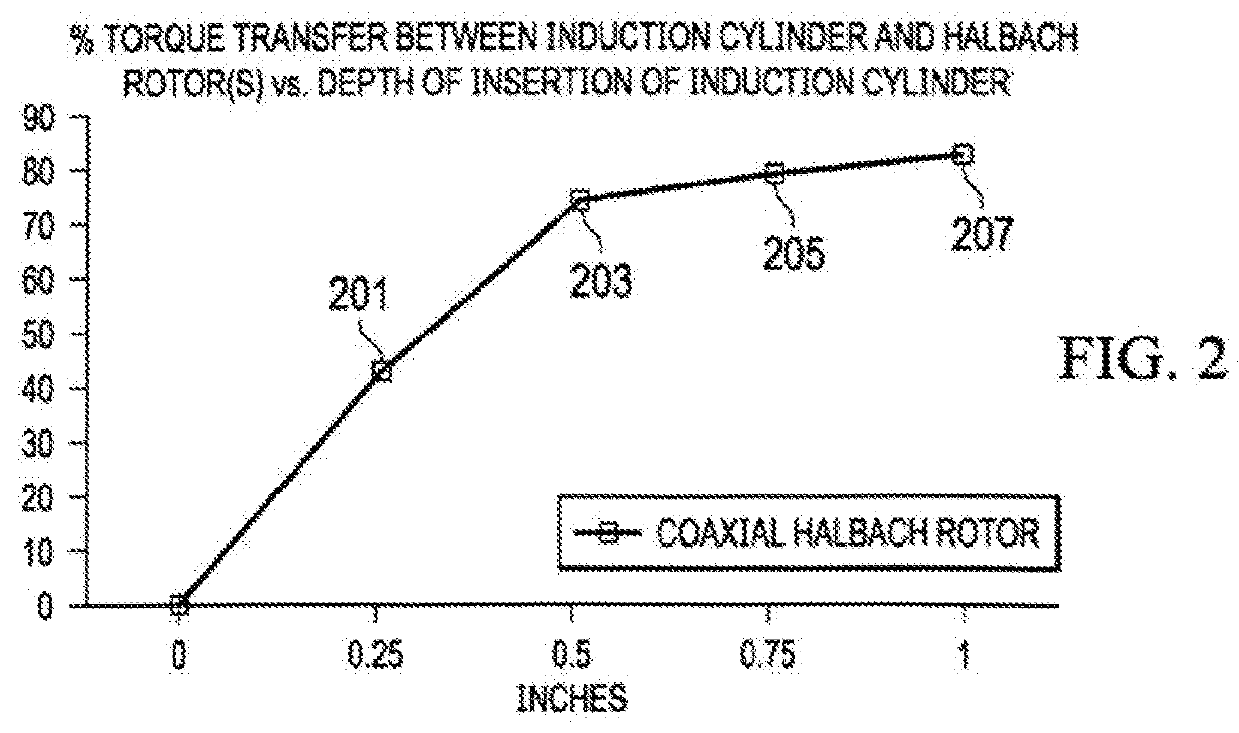

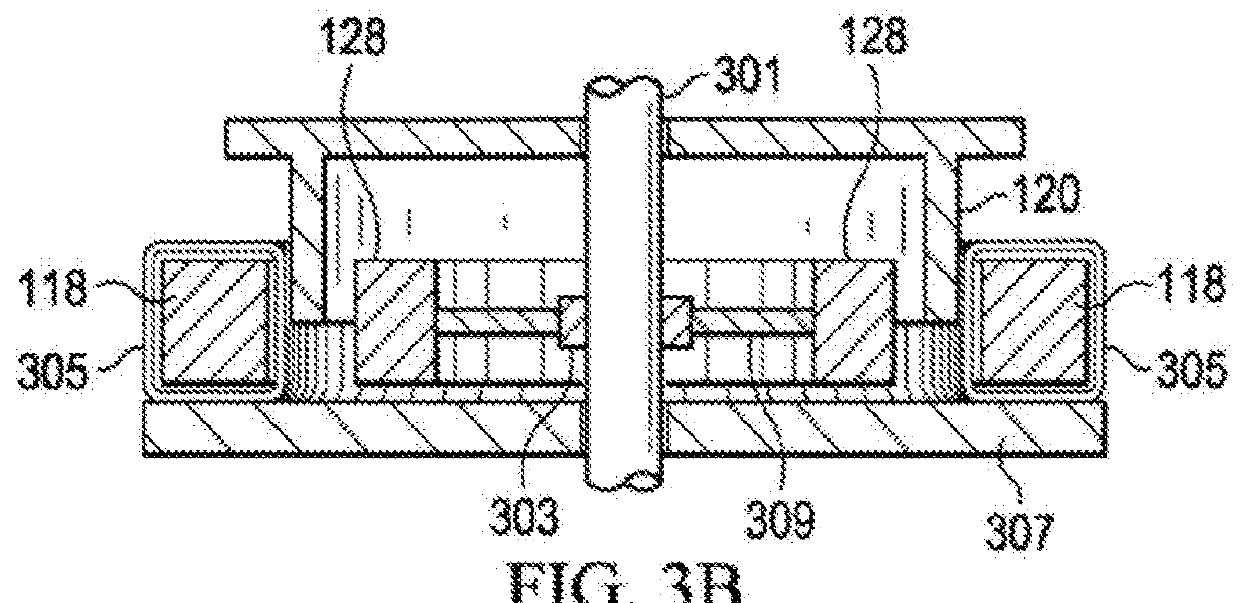

A flywheel energy storage device includes the Halbach Motor / Generator with rolling biphasic coil control, continuously variable torque transfer via magnetic induction and a reluctance magnetic levitation system known as the Axial-Loading Magnetic Reluctance Device. Electric energy input turns the magnetically coupled rotors of the Halbach motor, and torque is transferred to a flywheel through a copper cylinder variably inserted between the Halbach magnet rotors. In idle mode, the energy is stored kinetically in the spinning flywheel, which is levitated by a permanent magnet bearing. Electric energy output is achieved by transferring torque from the flywheel through the copper cylinder to the rotors of the Halbach Generator by magnetic induction. Rolling biphasic motor control includes dividing Halbach motor coils into increments, then energizing groups of contiguous increments into virtual coils, which revolve in tandem with the magnet rotors so to achieve continuous and optimal torque.

Owner:WALSH RAYMOND JAMES

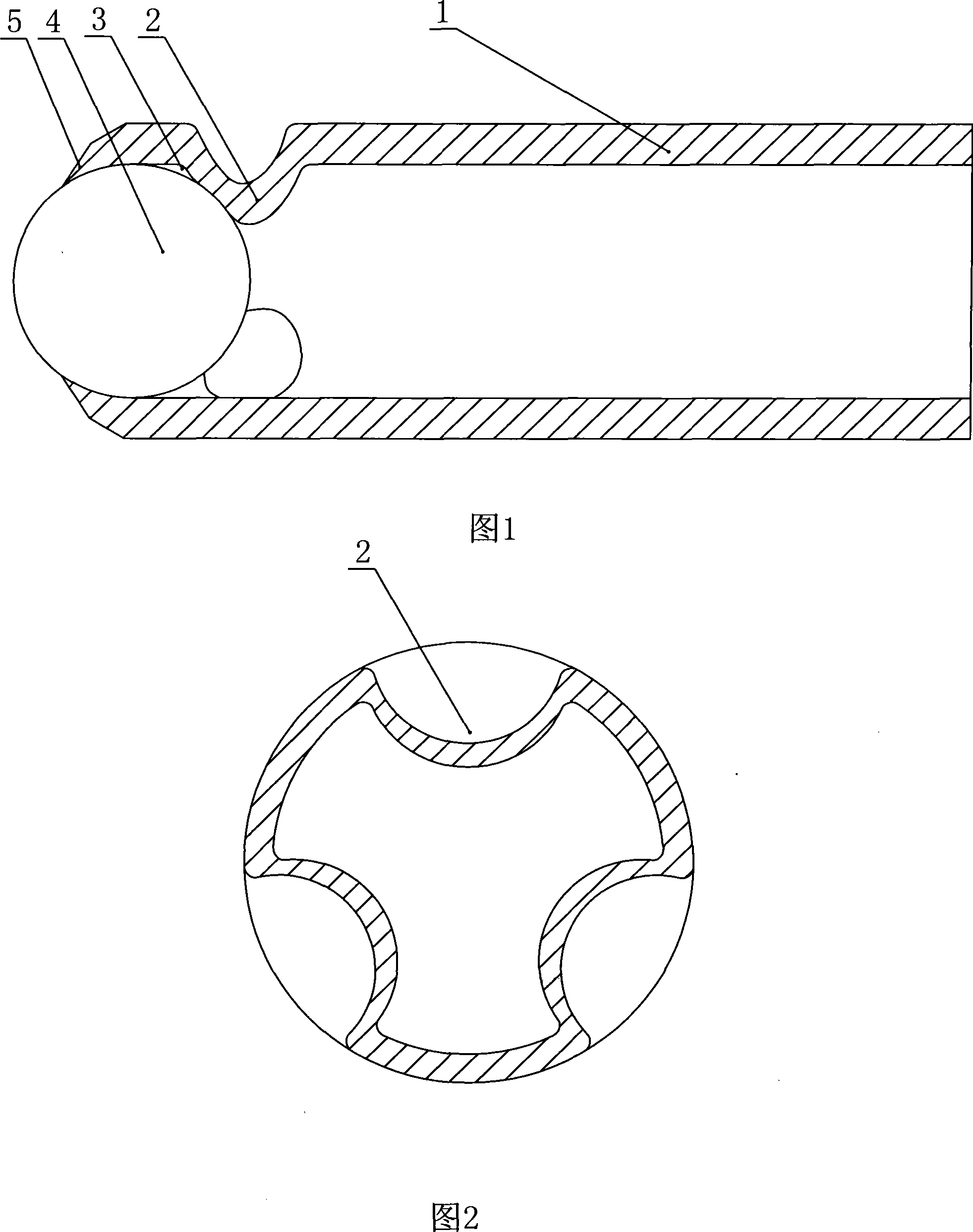

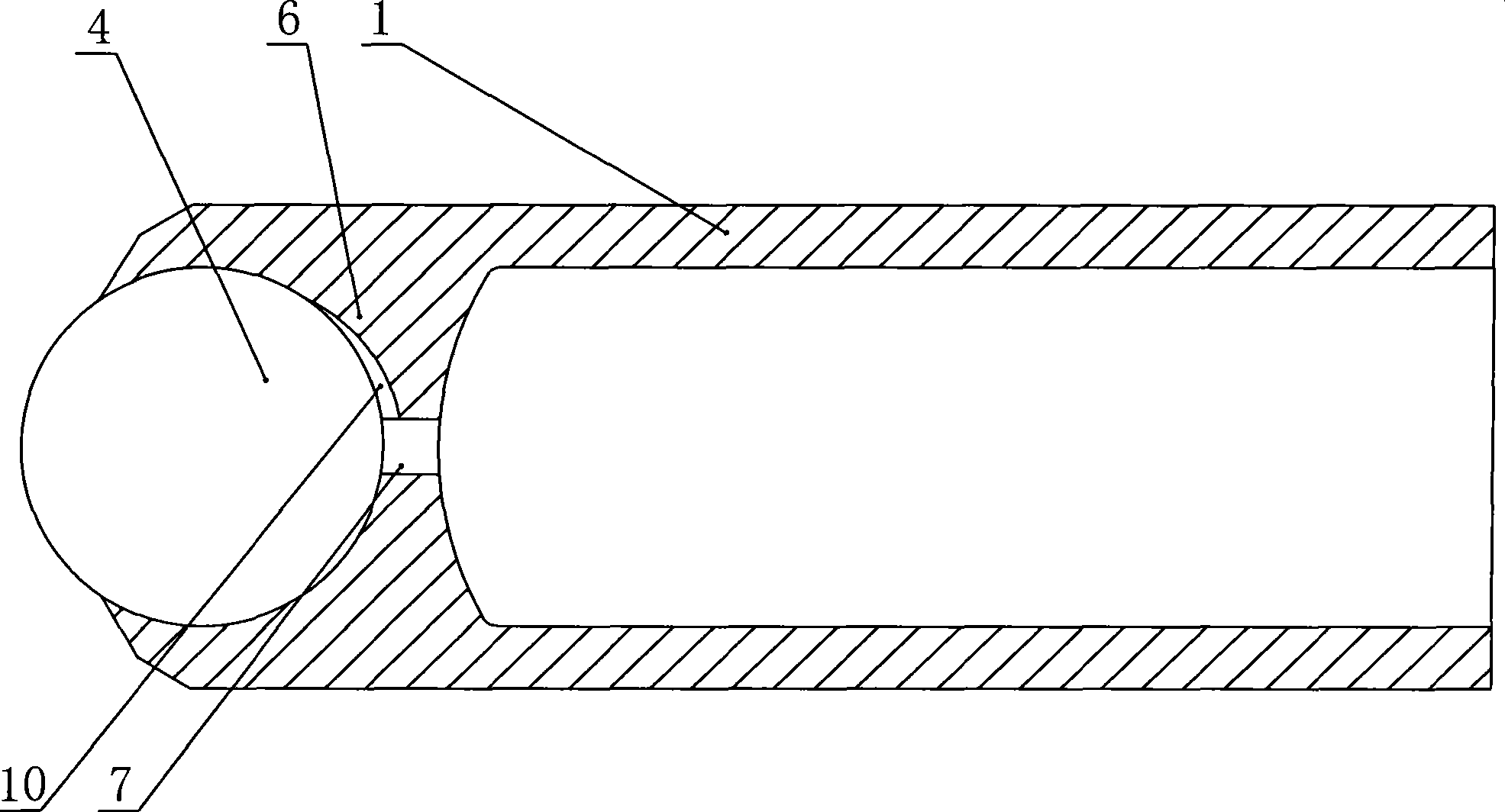

Copper full needle-tube pen-point and processing technique

The invention relates to a copper pen head with full needle tube and the processing technique thereof, solving the disadvantage in the prior art that stainless steel is used to make pen head, which increases the material cost and leads to difficult processing. The processing steps is as follows: 1.1 selecting a copper cylinder and cutting the cylinder into a length of the pen head; 1.2 clamping the cut copper cylinder firmly on a lathe and drilling hole on the cylinder by a drill needle with appropriate diameter and profile. 1.3 processing an internal treatment at one end of the copper cylinder and producing a hole concave cavity for placing a rolling ball; 1.4 putting the rolling ball into the processed hole concave cavity and fixing the rolling ball by closing the hole . Adopting the copper cylinder as the pen head can save material cost, the cost can be saved by 30% comparing with the stainless steel pen head; the hardness of copper is lower than that of stainless steel, and can suffice the writing requirements; the processing of copper is easier than processing of stainless steel; and the processing cost is reduced and the processing efficiency is increased.

Owner:胡泰林

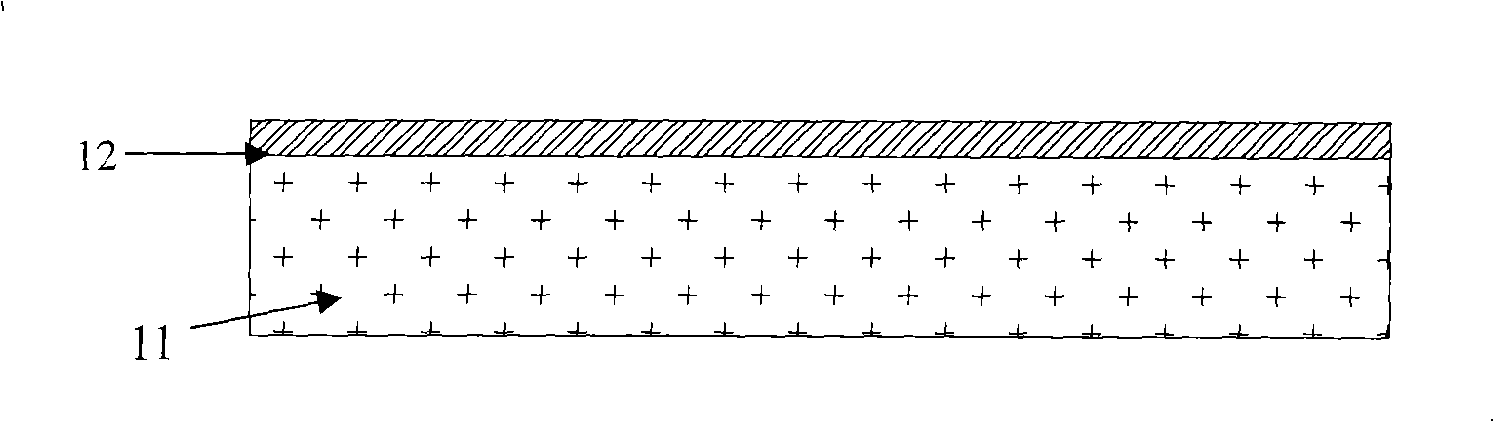

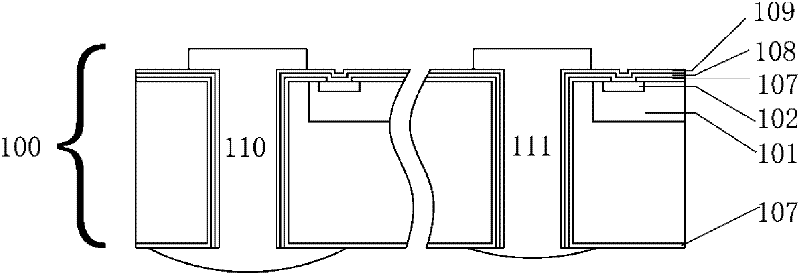

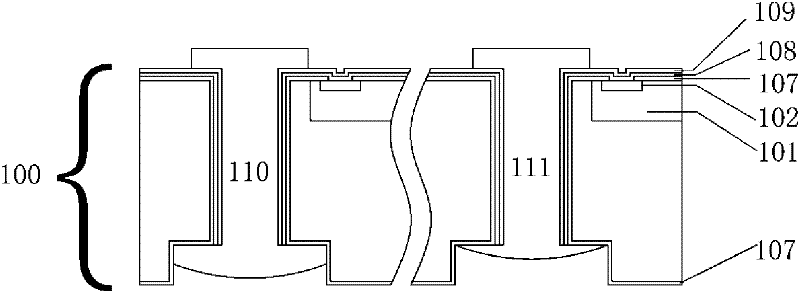

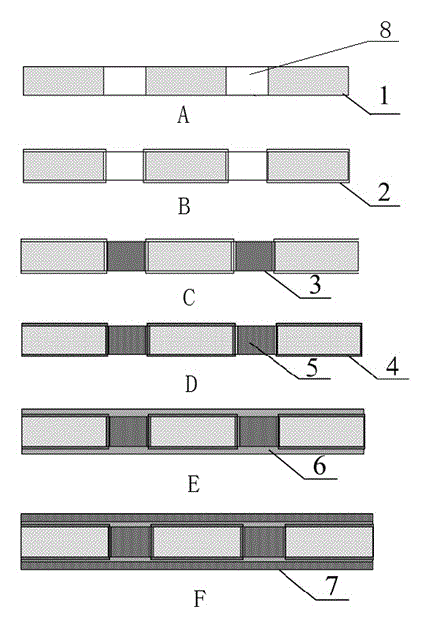

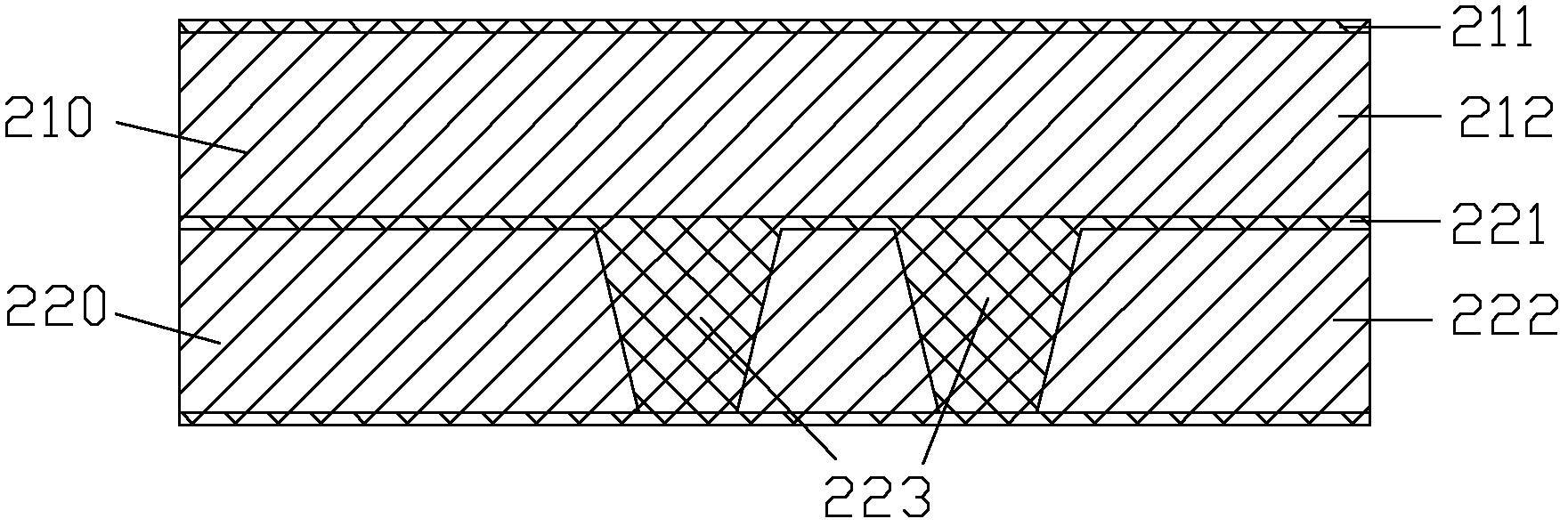

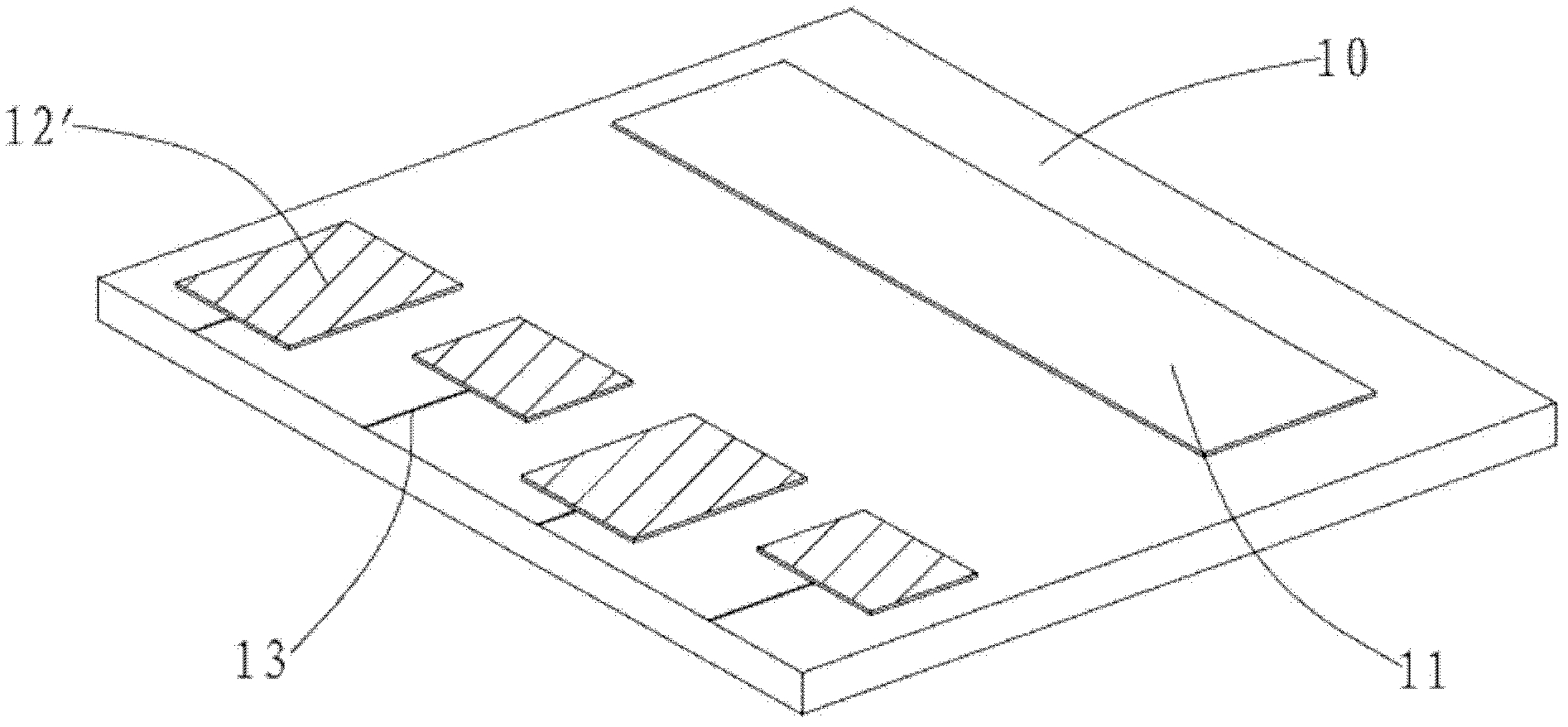

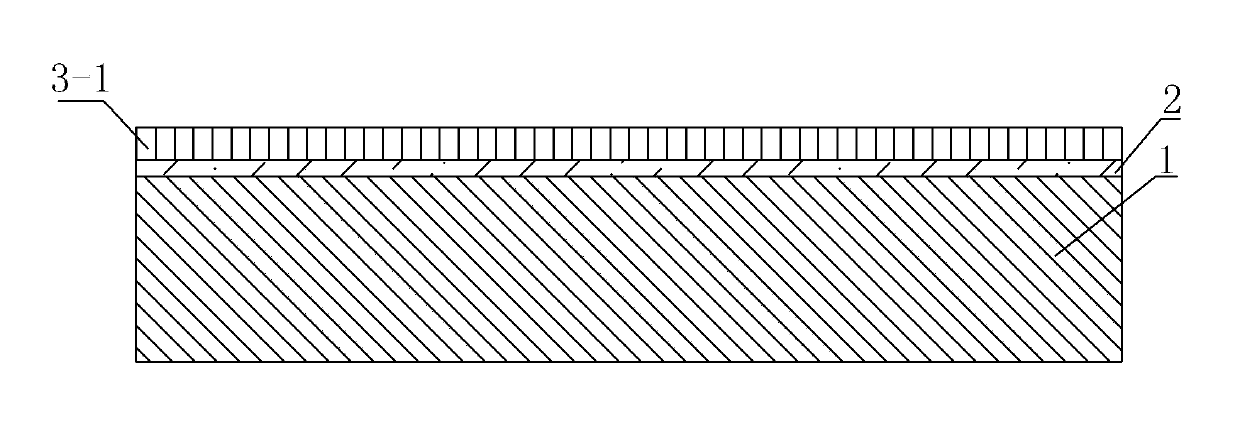

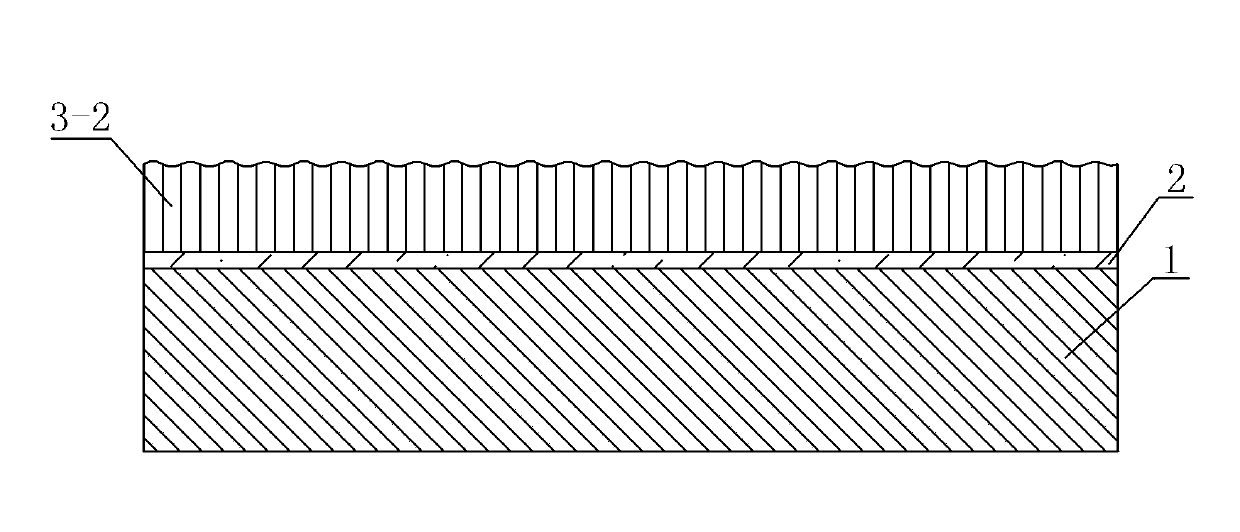

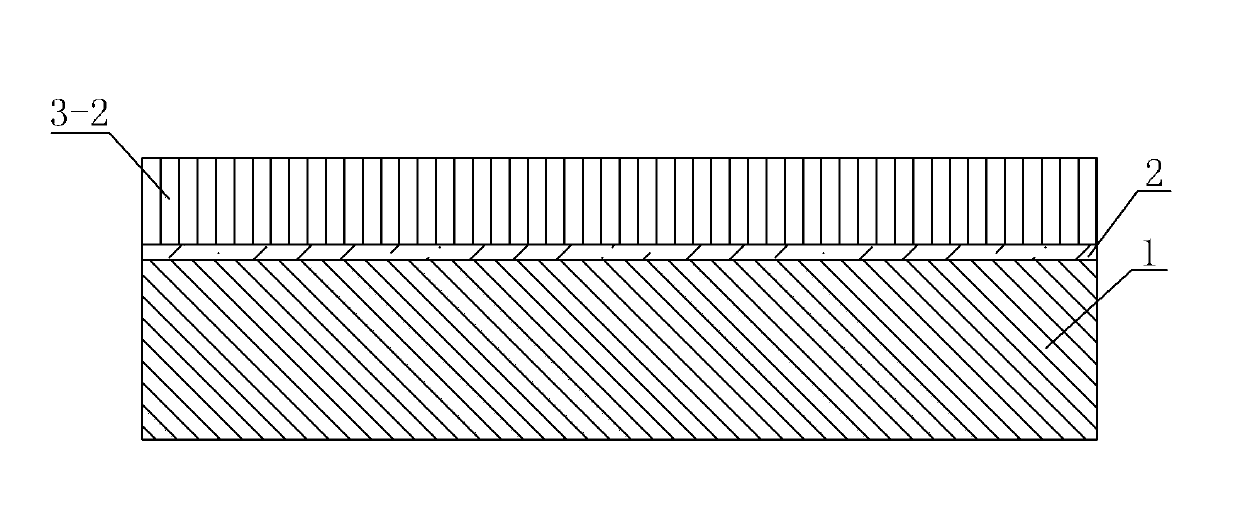

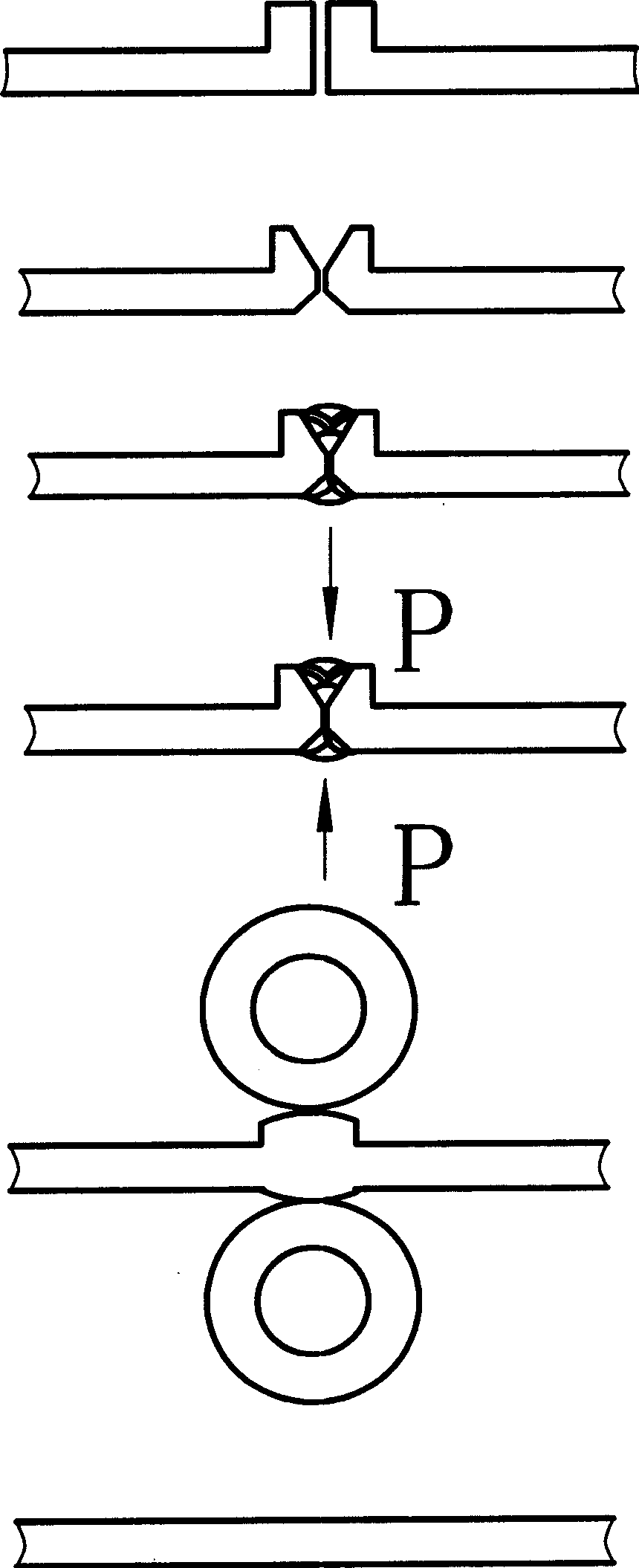

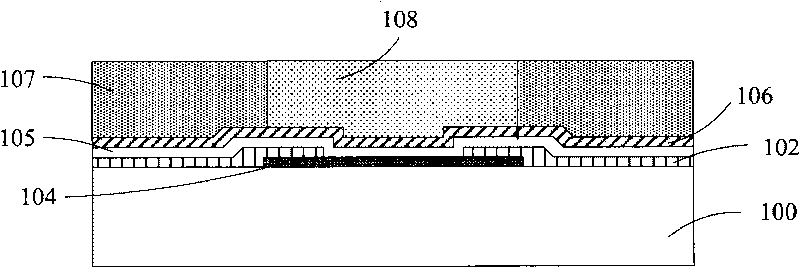

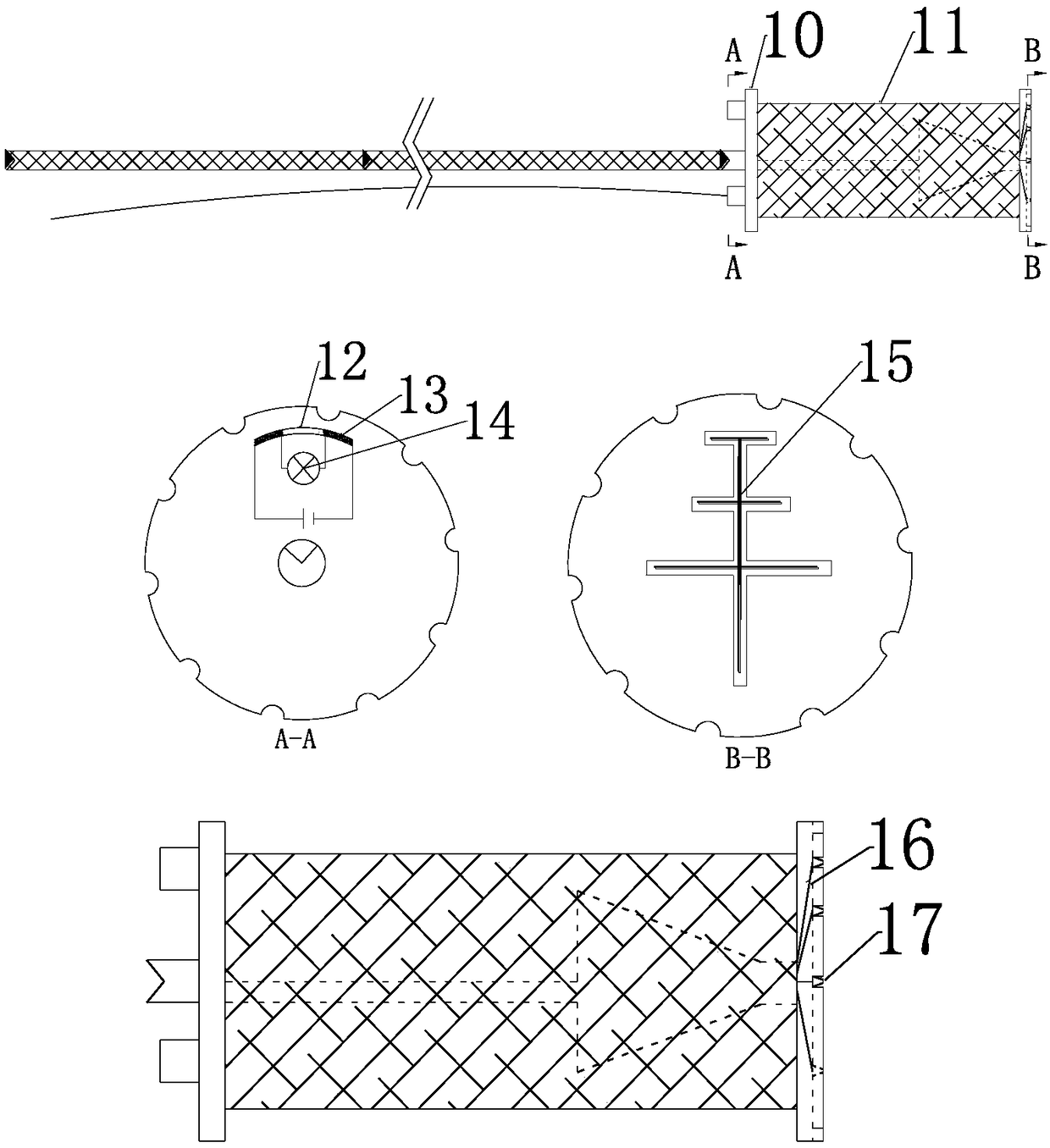

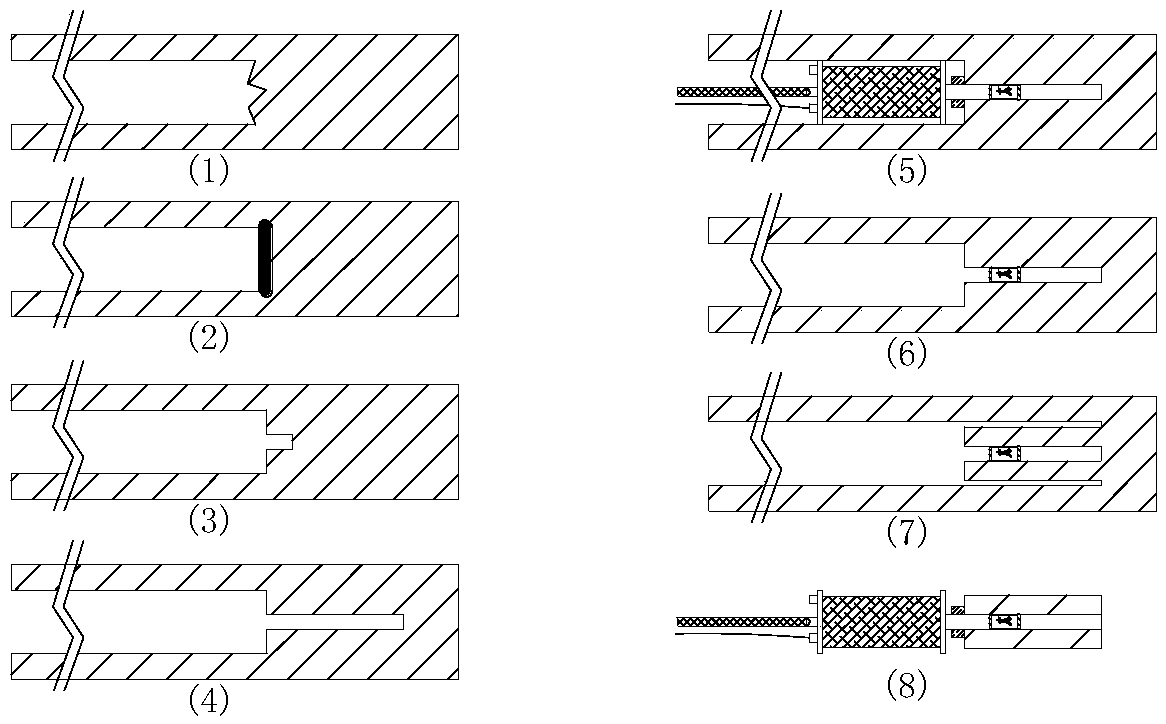

Manufacturing method for interconnected multilayer circuit board by copper cylinder method

InactiveCN101528011ASolve key technical issuesImprove production efficiencyMultilayer circuit manufacturePrinted element electric connection formationEngineeringCopper cylinder

The invention relates to a manufacturing method for an interconnected multilayer circuit board by a copper cylinder method, comprising the following steps: (1) manufacturing an interlayer wiring layer on a substrate; (2) manufacturing a copper cylinder on the interlayer wiring layer; (3) manufacturing an insulating layer; (4) manufacturing another wiring layer on the basis of the copper cylinder and the insulating layer, wherein the step (3) of manufacturing the insulating layer comprises the following concrete steps: a, sequentially carrying out oil removing, acid cleaning, pre-impregnation, brownification and plate baking to a circuit board in the step (2); b, screening resin by silk and solidifying the resin; and c, rubbing down the copper cylinder and the resin. The invention discloses a concrete processing technique for plating the copper cylinder first and then the insulating layer and solves the key technical problem of the prior interconnected multilayer circuit board by the copper cylinder method in the production process. By the invention, more than three orders of HDI circuit boards can be manufactured, such as 4+N+4. The invention has the characteristics of high manufacturing efficiency, short production period and further reduction of the volume and the weight of products.

Owner:珠海市科盈电子有限公司

Casting method for steel-copper composite cylinder

A casting method for a steel-copper composite cylinder comprises the steps that three-dimensional modeling, casting technology designing and technology simulating and optimizing, steel base heat treatment, machining and tool machining and welding and steel base surface treatment are sequentially carried out, preheat treatment on a steel base before production is carried out, anhydrous borax is melted, the steel base is placed into a borax solution, copper alloy is smelted, the copper alloy is cast into the steel base, the steel base is placed into a water trough and is cooled and solidified to the room temperature, and then the steel-copper composite cylinder is manufactured. The method solves the problems about the steel-copper cylinder composite casting technology and composite components. The bi-metal cylinder is high in composite strength, high in yield and low in cost, the size of the cylinder is not limited, the forming process is easy to control, and the quality is stable.

Owner:徐宏

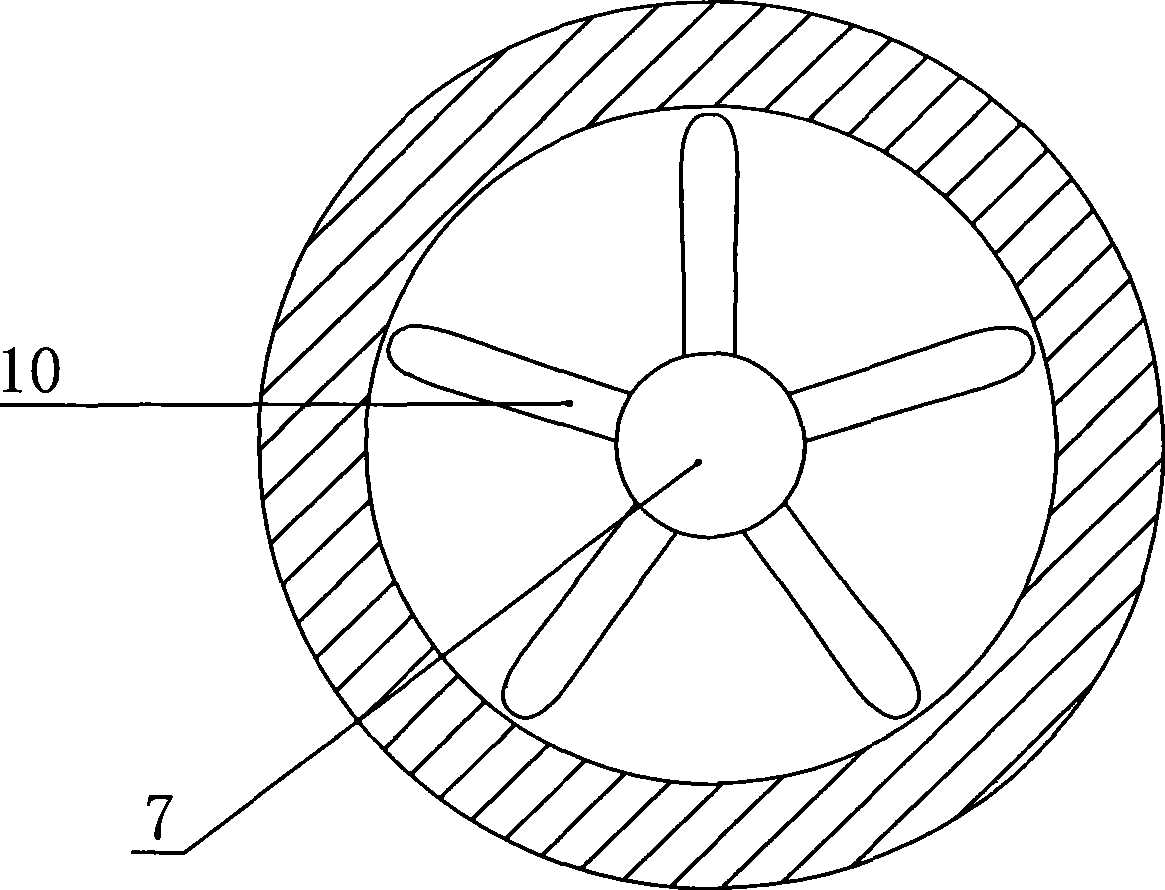

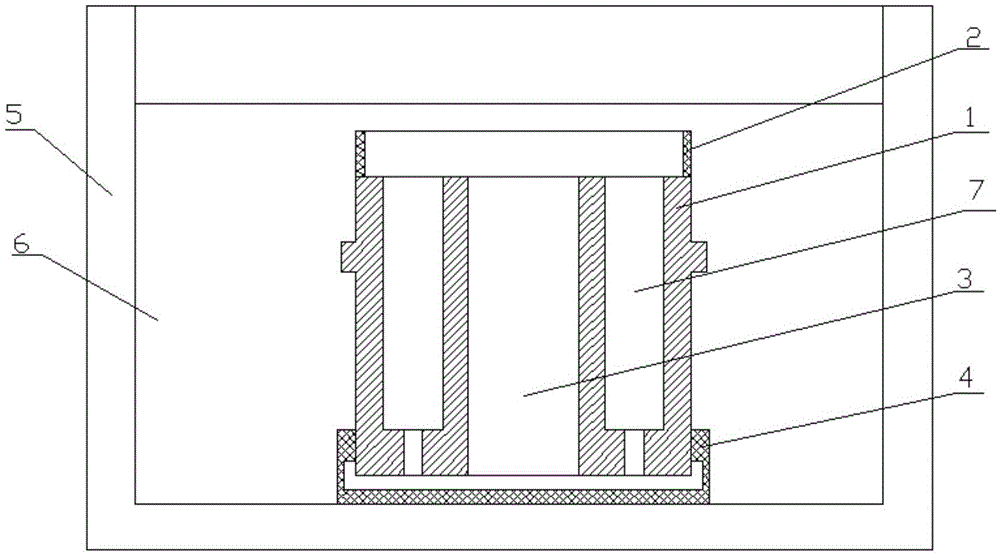

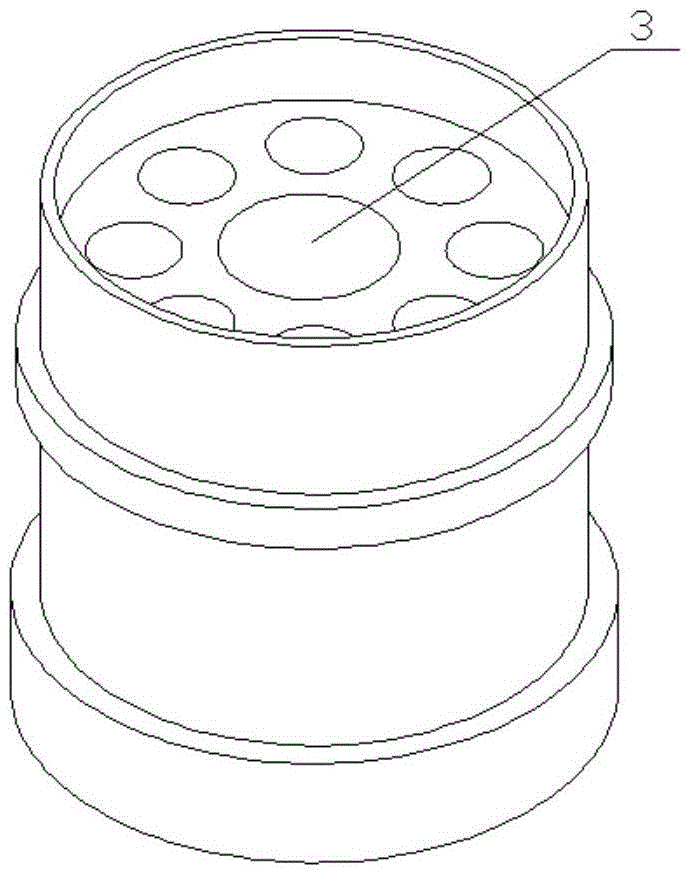

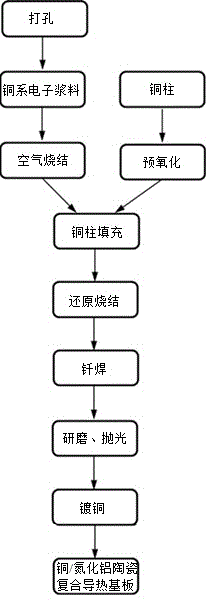

Preparation method for copper/aluminium nitride ceramic composite heat-conductive substrate

InactiveCN104064478AGuaranteed smoothGuaranteed flow capacitySemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingCopper platingCeramic composite

The invention discloses a preparation method for a copper / aluminium nitride ceramic composite heat-conductive substrate. The method comprises the following steps: 1) providing through holes in the surface of an aluminium nitride substrate; 2) coating copper electronic paste layers on the double surfaces of the aluminium nitride substrate; 3) filling the through holes with pre-oxidation copper cylinders; 4) carrying out overall sintering for 30 min; 5) carrying out brazing after the double surfaces of the aluminium nitride substrate being coated with tin silver copper solder materials; 6) carrying out surface polishing; and 7) carrying out copper plating processing directly and forming uniform copper layers, and thus, the copper / aluminium nitride ceramic composite heat-conductive substrate is obtained. The through holes in the copper / aluminium nitride ceramic composite heat-conductive substrate produced with the preparation method are communicated up and down; the combination between the metalized layers in the holes and the ceramic substrate is strong; the middle copper cylinders can realize the communication of the copper layers on the upper and lower surfaces; and the copper / aluminium nitride ceramic composite heat-conductive substrate helps the transmission of electrical signals and has the advantages of ideal heat-conductive effect, low thermal expansion coefficients and good conductivity and the like.

Owner:NANJING MING KUANG ELECTRONICS TECH

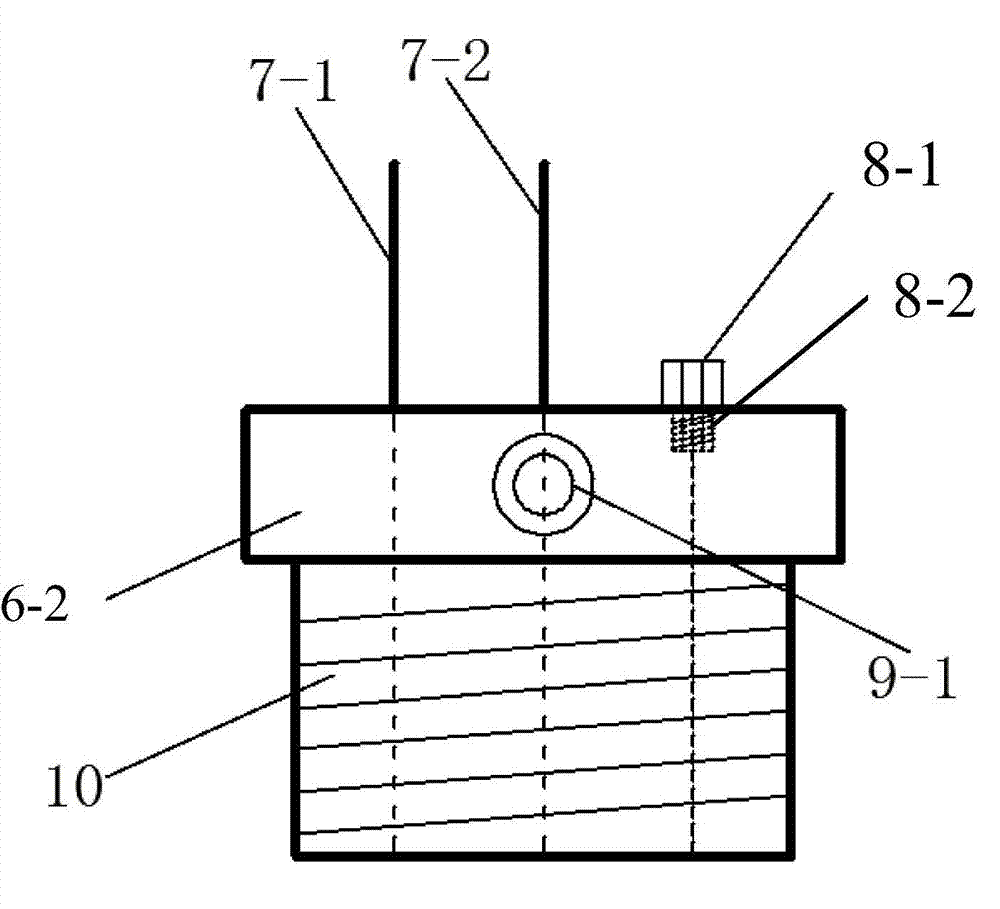

Photoelectric-catalytic carbon dioxide reduction device and application thereof

ActiveCN104492253ARapid and accurate quantitative analysis and detectionSimple structureComponent separationDispersed particle separationEngineeringSemiconductor

The invention provides a photoelectric-catalytic carbon dioxide reduction device and an application thereof. A reactor main body comprises two half-reactor main bodies of which one half-reactor main body is provided with an illumination window, wherein a sealing sheet is arranged at the window and two half-reactors are fixedly connected through a clamping device. A gas inlet and a gas outlet are respectively formed in both ends of a rotary cover, the rotary cover is hermetically connected with the reactor main body through a thread, electrode copper cylinders for respectively providing a bias for a working electrode, a counter electrode and a reference electrode are arranged on the rotary cover and a liquid phase sampling hole is formed in the rotary cover. Illumination can be applied to a semiconductor catalytic material by virtue of the illumination window so as to achieve the photoelectric-catalytic carbon dioxide reduction process. The photoelectric-catalytic carbon dioxide reduction device is simple in structure and convenient to implement, has compact size and can be conveniently connected with a gas detection system so as to quickly and accurately carry out quantitative analysis and detection on gas.

Owner:TIANJIN UNIV

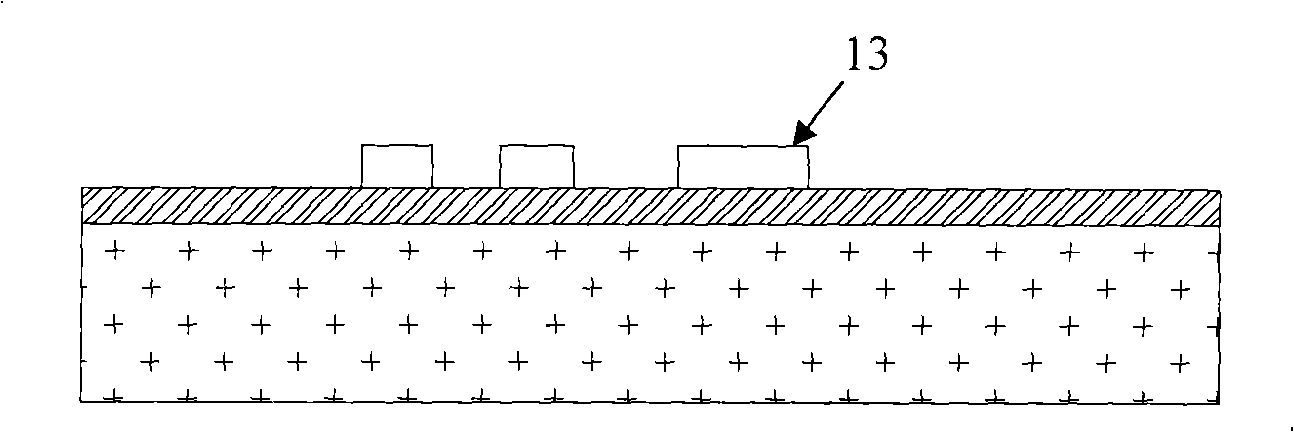

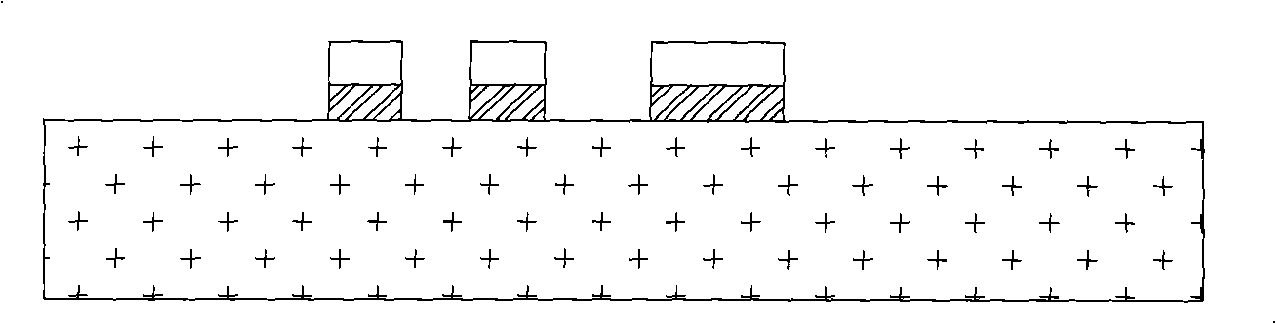

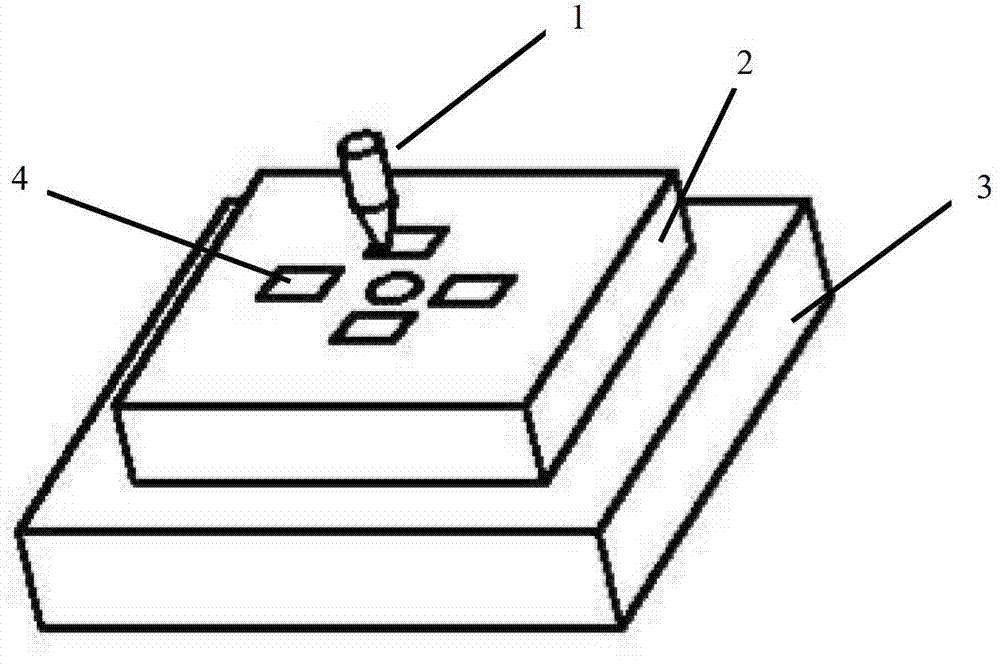

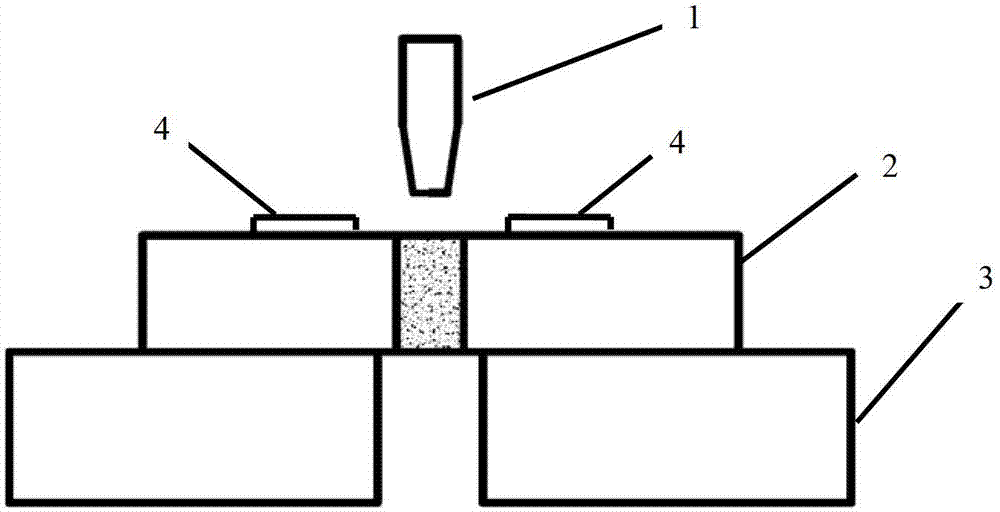

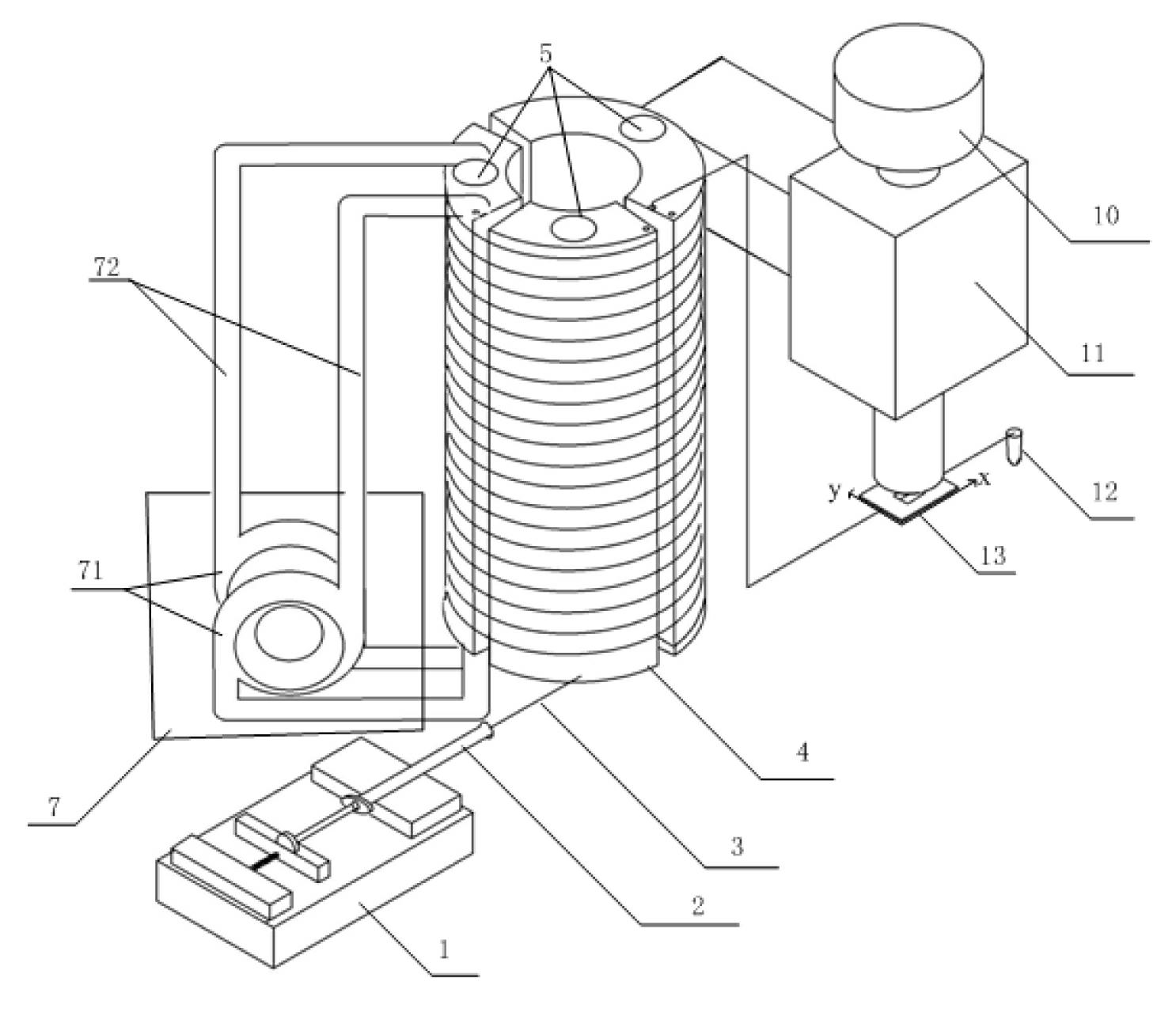

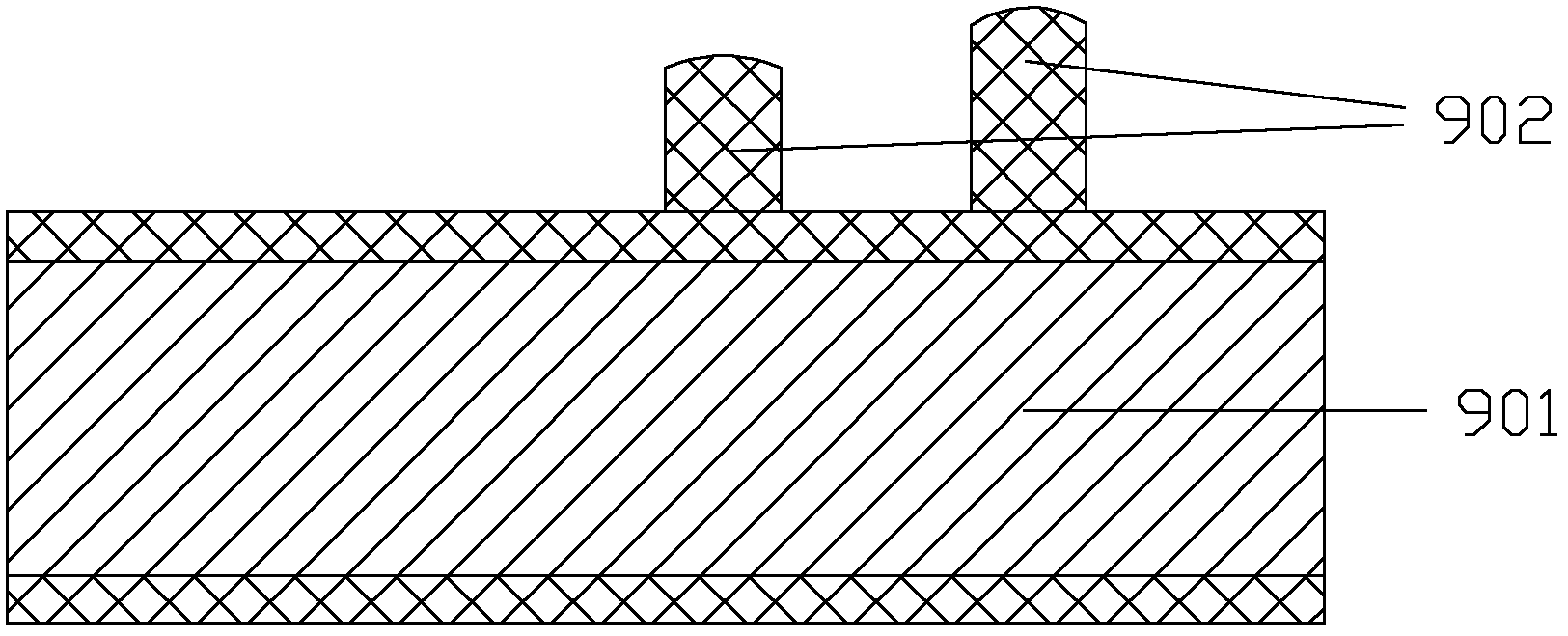

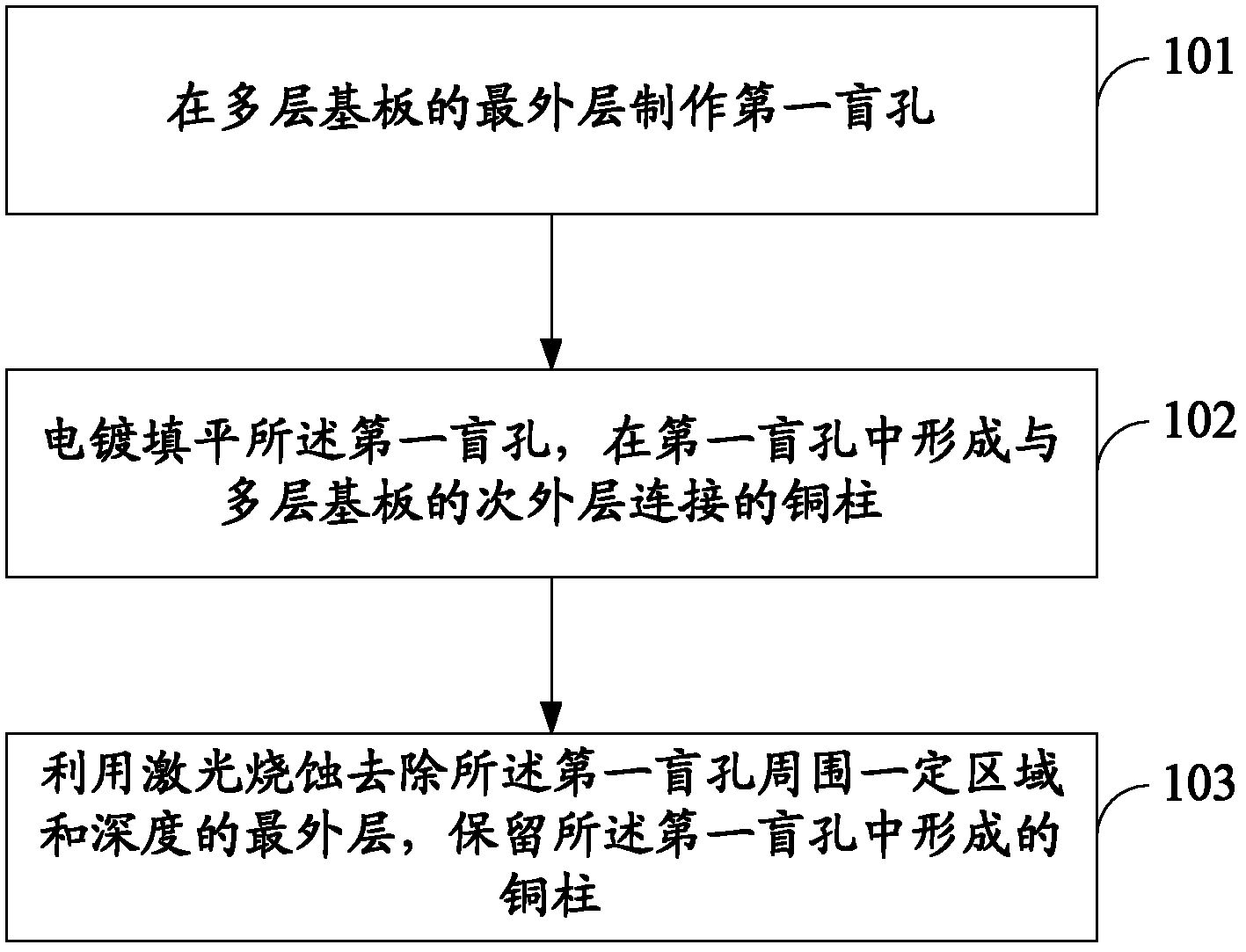

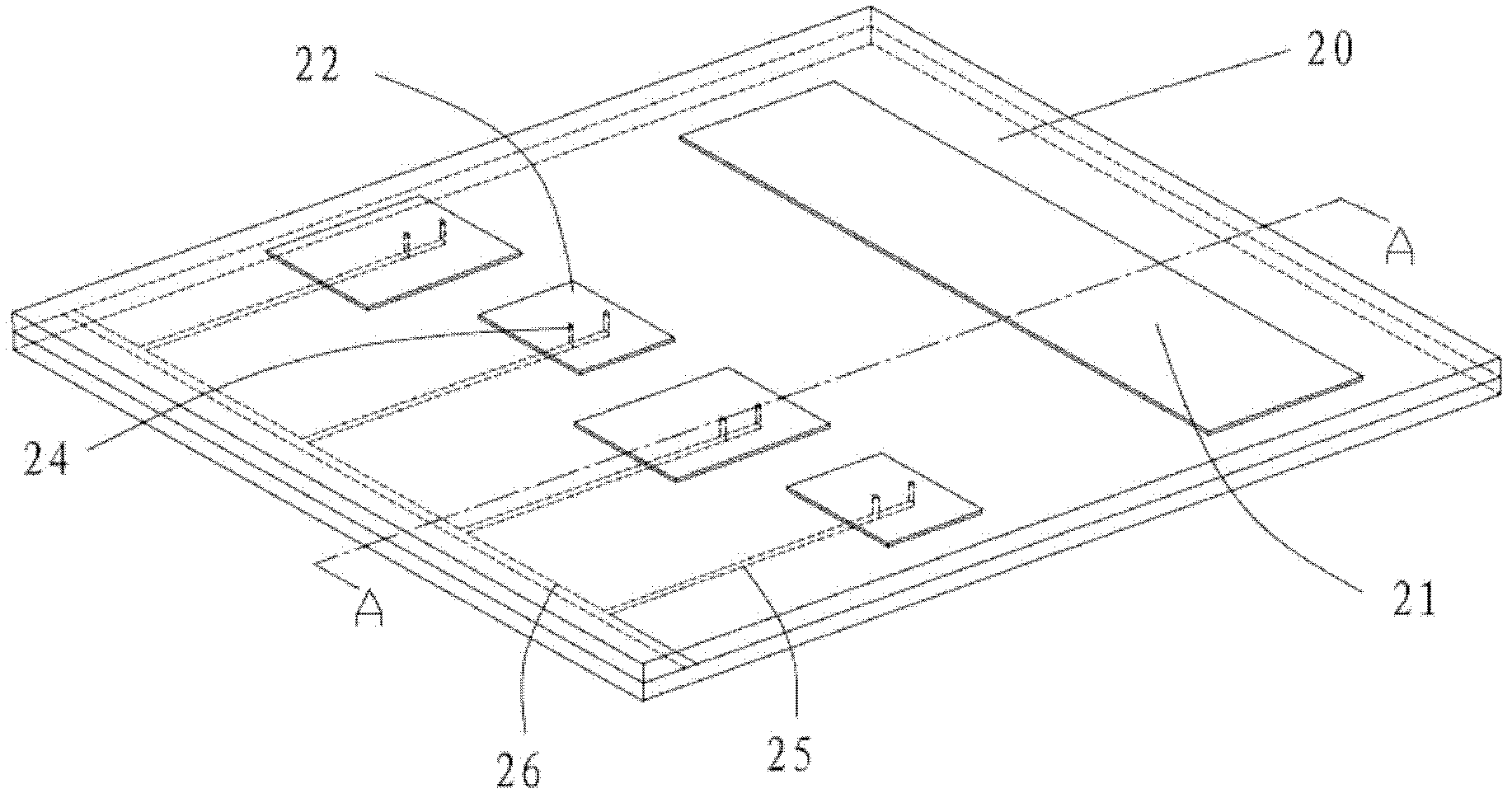

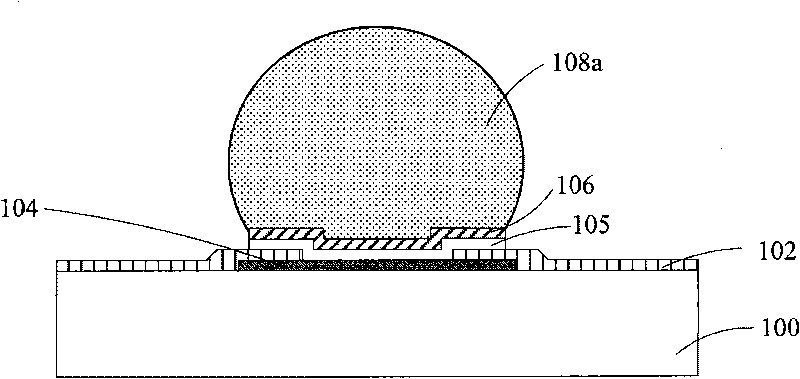

Method for making copper cylinder on circuit board and circuit board with surface copper cylinders

ActiveCN102325431ANot easy to break offElectrical connection printed elementsMultilayer circuit manufactureElectroplatingSubstrate surface

The embodiment of the invention discloses a method for making copper cylinders on a circuit board, comprising the following steps: making first blind holes on the outermost layer of a multilayer substrate; filling and leveling up the first blind holes through galvanizing so as to form the copper cylinders, which can be connected with the second outermost layer of the multilayer substrate, in the first blind holes; and removing the outermost layer at a certain area and depth around the first blind holes through laser ablation to keep the copper cylinders formed in the first blind holes. The embodiment of the invention also provides a corresponding circuit board with surface copper cylinders. By the method disclosed by the embodiment of the invention, the copper cylinders are formed on the outermost layer of the multilayer substrate, the height of the copper cylinders can be kept consistent, the copper cylinders are firm and reliable and cannot be broken or fall off easily, and the operation that a circuit graph is made on a substrate surface is not influenced.

Owner:SHENNAN CIRCUITS

Method for manufacturing gold finger circuit board

ActiveCN102427682ADoes not affect appearanceImprove aestheticsPrinted element electric connection formationEngineeringElectroplating

The invention relates to a method for manufacturing a gold finger circuit board. The method comprises the following steps of: providing a first laminate, forming a gold finger on a first side of the first laminate, and forming an electroplating lead corresponding to the gold finger on a second side of the first laminate; forming metalized copper cylinders in the first laminate, wherein each gold finger is electrically connected to the corresponding electroplating lead through a plurality of the metalized copper cylinders; electroplating the gold finger through the electroplating lead; and removing the redundant first laminate and electroplating lead. The gold finger circuit board manufactured by the circuit board manufacturing method has the advantages of attractive appearance and high electrical reliability.

Owner:SHENZHEN WUZHU TECH +1

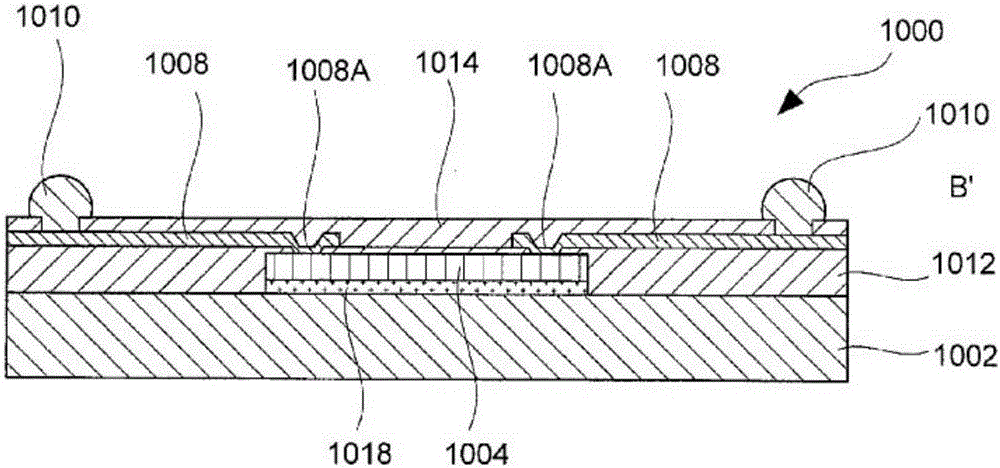

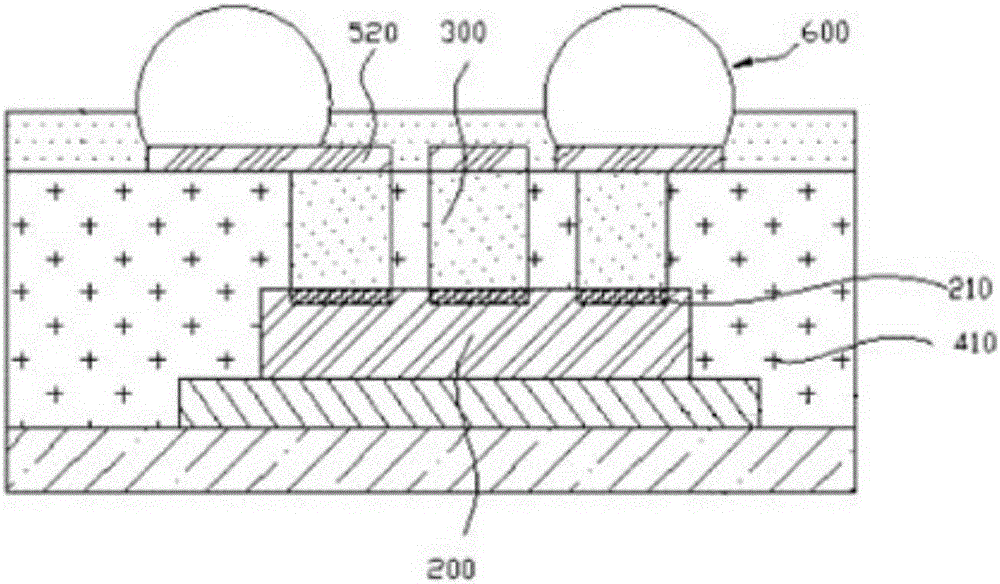

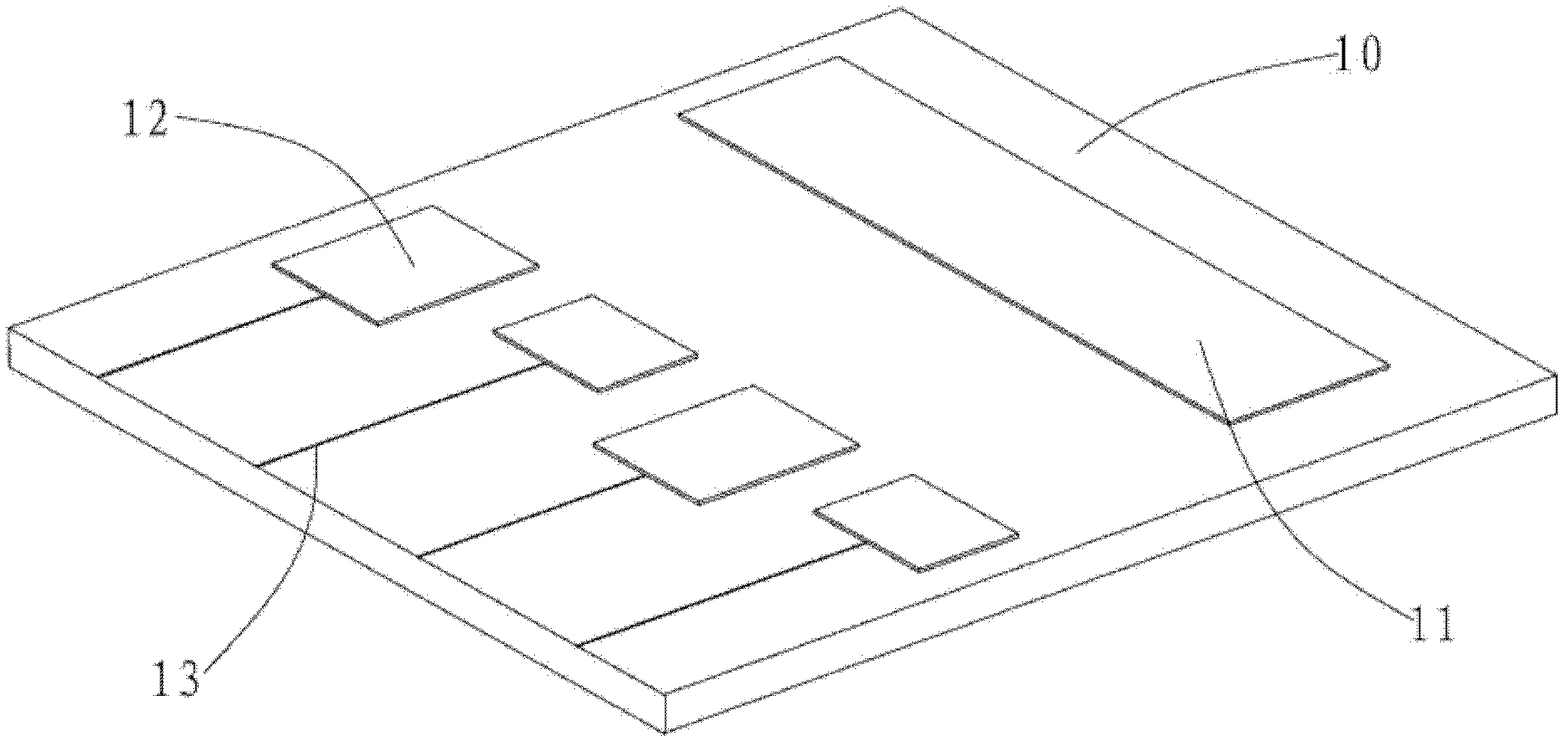

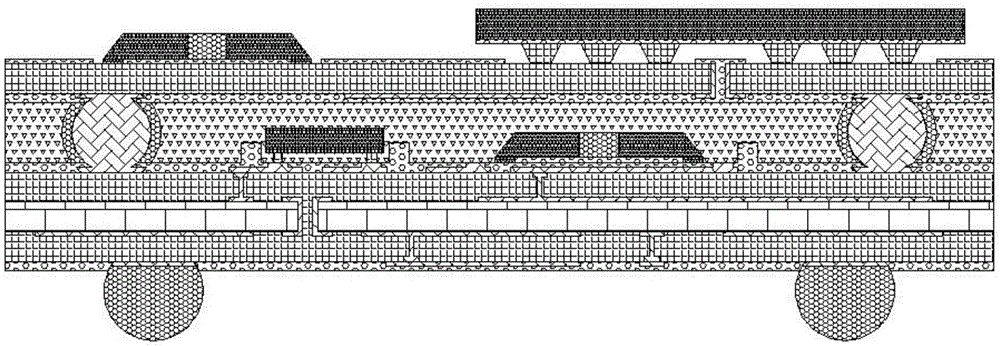

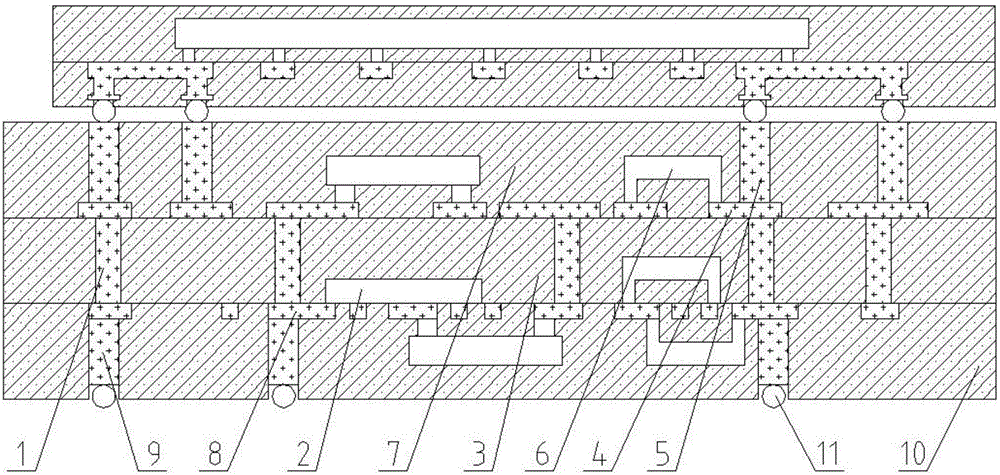

Two-way integrated embedded chip rerouting POP packaging structure and manufacturing method thereof

InactiveCN106129016AHighly integratedImprove performanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringMetal

The invention relates to a two-way integrated embedded chip rerouting POP packaging structure and a manufacturing method thereof. The structure comprises a first packaging body and a second packaging body, wherein the first packaging body comprises a second circuit layer (8); the front surface of the second circuit layer (8) is provided with first connecting copper cylinders (1) and first components (2); a first insulating material (3) packages the outside of the first connecting copper cylinders (1) and first components (2); the front surface of the first insulating layer (3) is provided with a first circuit layer (4); the front surface of the first circuit layer (4) is provided with second connecting copper cylinders (5) and second components (6); a second insulating material (7) packages the outside of the second connecting copper cylinders (5) and the second components (6); the back surface of the second circuit layer (8) is provided with third connecting copper cylinders (9); and the third connecting copper cylinders (9) are provided with metal balls (11). The two-way integrated embedded chip rerouting POP packaging structure can be embedded in multi-layer and two-way manners; the placement number of passive devices is larger; the substrate space is effectively saved; and the integration level of a packaging technology is improved.

Owner:江阴芯智联电子科技有限公司

Manufacturing method of copper-copper bonding salient points

ActiveCN103730382AHigh surface flatnessHighly consistentSolid-state devicesSemiconductor/solid-state device manufacturingElectricitySurface roughness

The invention provides a manufacturing method of copper-copper bonding salient points. The surface roughness of a copper cylinder is effectively reduced, the surface evenness of the micro salient points is improved, meanwhile, the consistency of the heights of the micro salient points in different areas of a wafer is guaranteed, and the requirements of a copper-copper bonding technology for the surface smoothness are met. The manufacturing method is characterized by including the following steps: (1) manufacturing an adhesion layer and a seed layer on the surface of the wafer, (2) depositing a copper layer on the surface of the wafer, (3) processing the copper layer on the surface of the wafer, and improving the surface roughness and the surface evenness of copper; (4) imaging the copper layer with a photolithography technique, (5) removing copper outside the positions of the micro salient points, and forming micro salient point structures on the wafer, (6) removing adhesion layer materials outside micro salient point areas of the surface of the wafer, and forming electrical isolation micro salient point structures, and (7) removing photoresist on the surface of the wafer, and obtaining the micro salient point structures with the even heights and the flat and smooth surfaces.

Owner:NAT CENT FOR ADVANCED PACKAGING

Making process of large titanium cathode roller cylinder and composite great current cathode roller

The present invention is making process of large titanium cathode roller cylinder and composite great current cathode roller. The making process includes the steps of: heating ends of titanium plate and molding to form flanges of certain height; winding the titanium plate into cylinder and butt welding the formed flanges; heating the weld seam, forging and rolling the weld seam, and heat treatment the whole titanium cylinder. The composite great current cathode roller with the titanium cylinder has main shaft inside the cylinder, conducting wheel, copper conducting plate, and steel-copper cylinder assembled together. The titanium cylinder has low cost and high quality, and the composite great current cathode roller has homogeneous current, no overheat and long service life.

Owner:宝钛特种金属有限公司

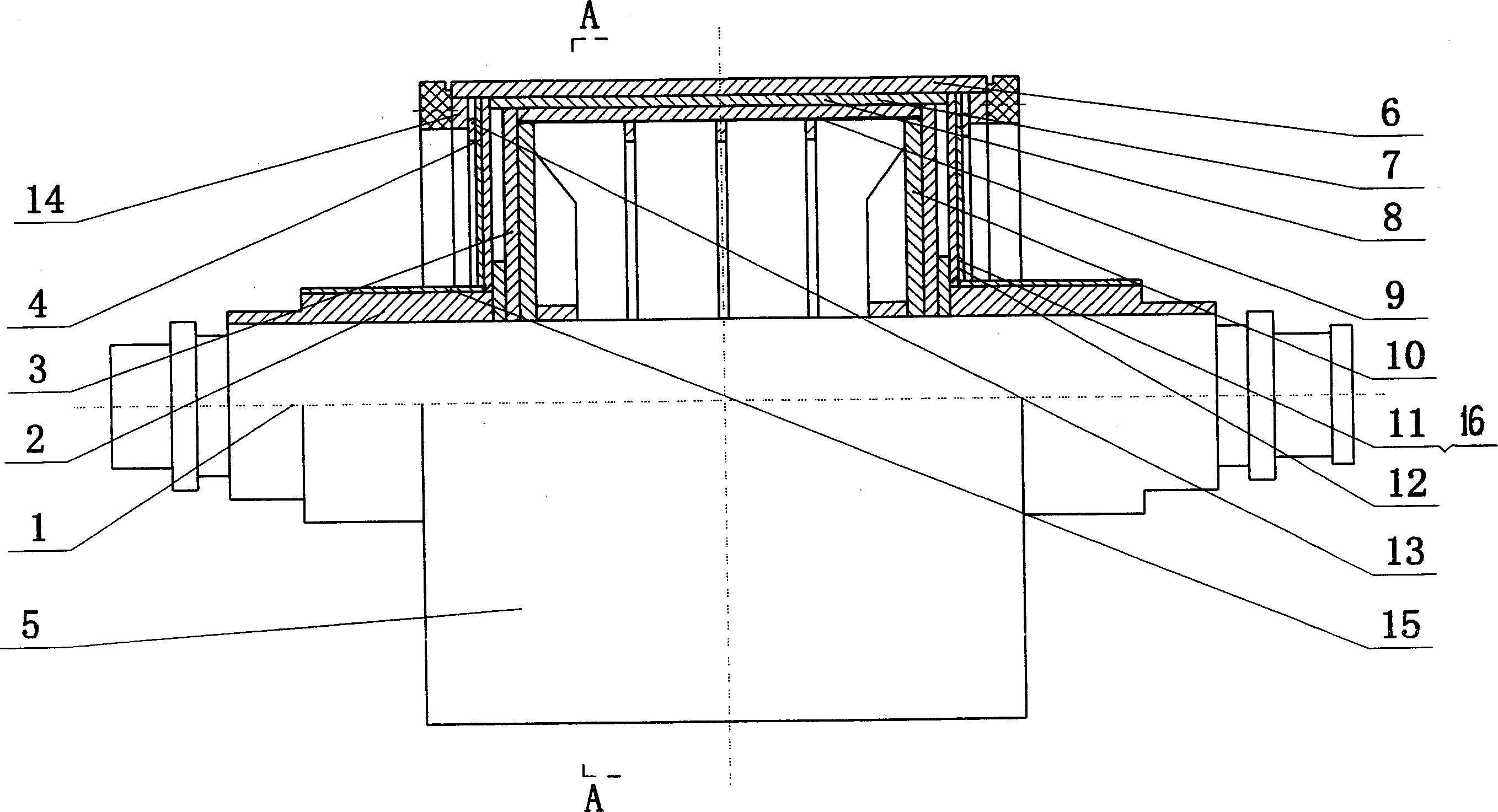

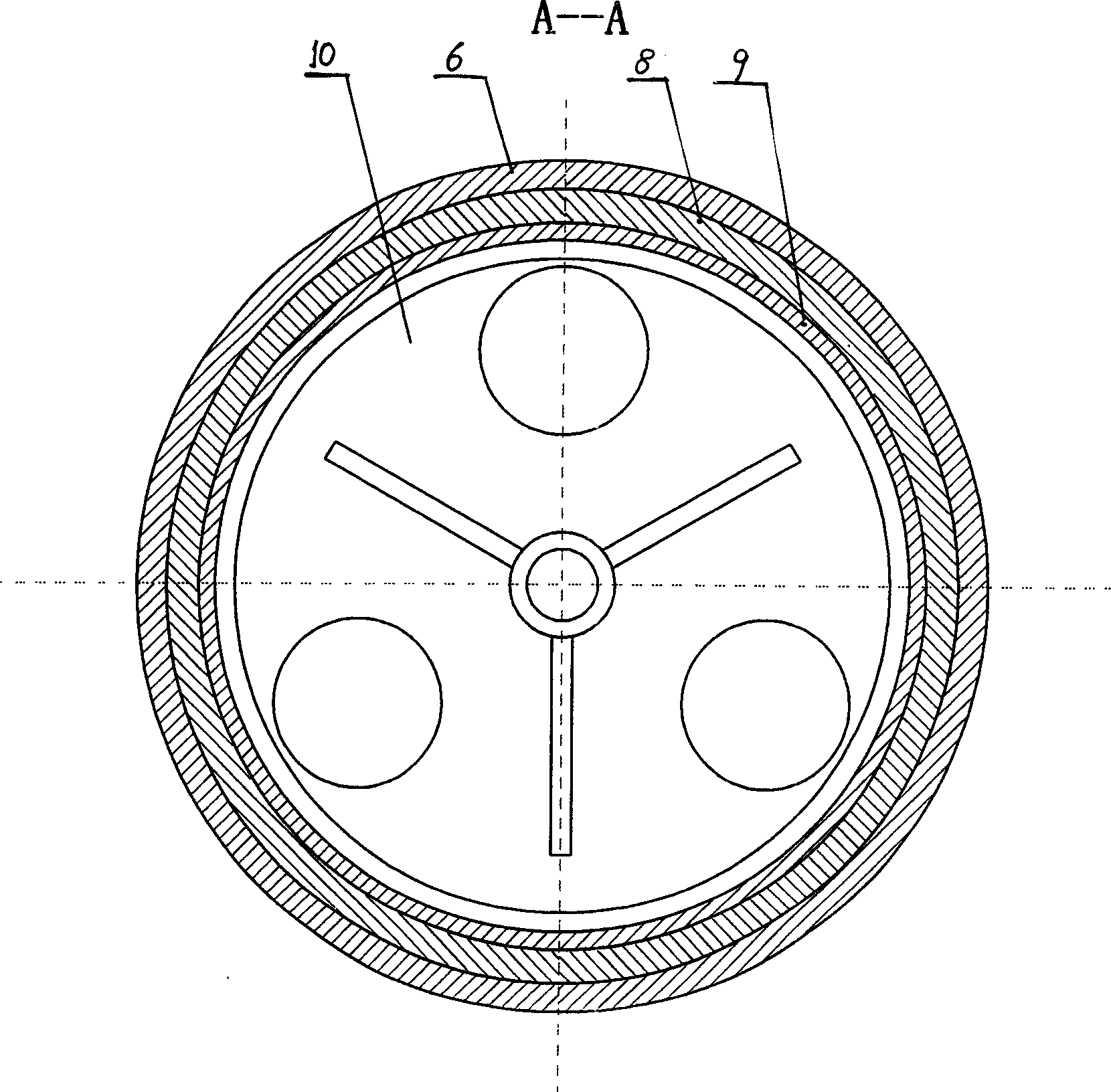

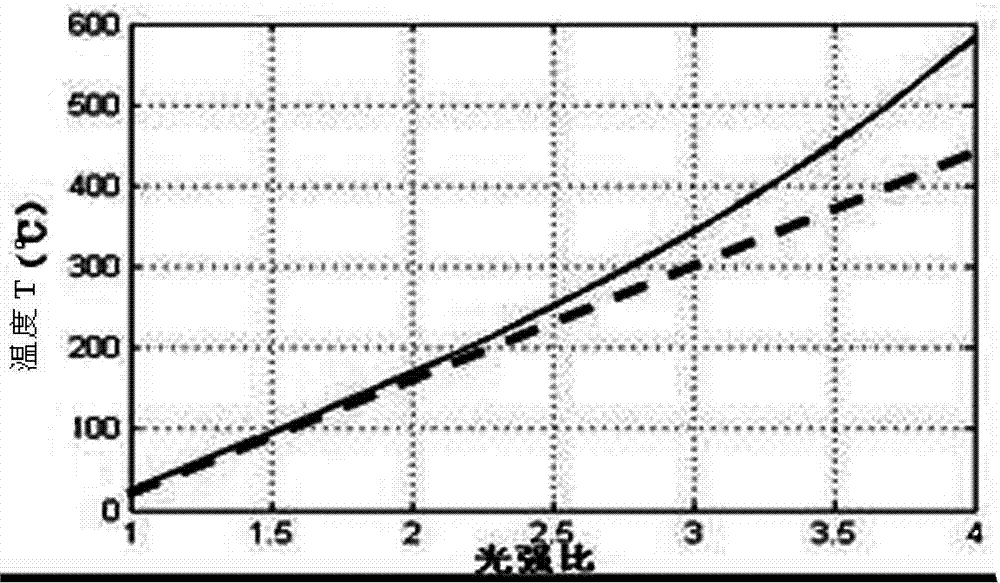

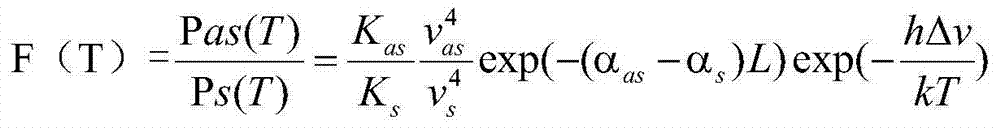

Multi-temperature zone calibration method based on internal hollow type temperature control member

InactiveCN104501996AFix bugsSolve problemsThermometers using physical/chemical changesThermometer testing/calibrationTemperature controlEngineering

The invention discloses a multi-temperature zone calibration method based on an internal hollow type temperature control member. A multi-segment broken line relationship of temperatures varying along with the light intensity ratio of anti-Stokes to Stokes is obtained by utilizing a segmentation calibration manner while adopting an internal hollow type copper cylinder as the main body of a temperature control system, so that a temperature calibration curve infinitely approaches an index changing curve of the light intensity ratio of anti-Stokes to Stokes and the temperature. Under the precondition that the method does not influence the system performance, the temperature measurement accuracy of a system is further improved, the applicable temperature measurement range of the system is extended, and the defects and disadvantages of an existing temperature calibration manner are better overcome.

Owner:TUOPU INTELLIGENT INSTR & GAUGE ZHUHAI

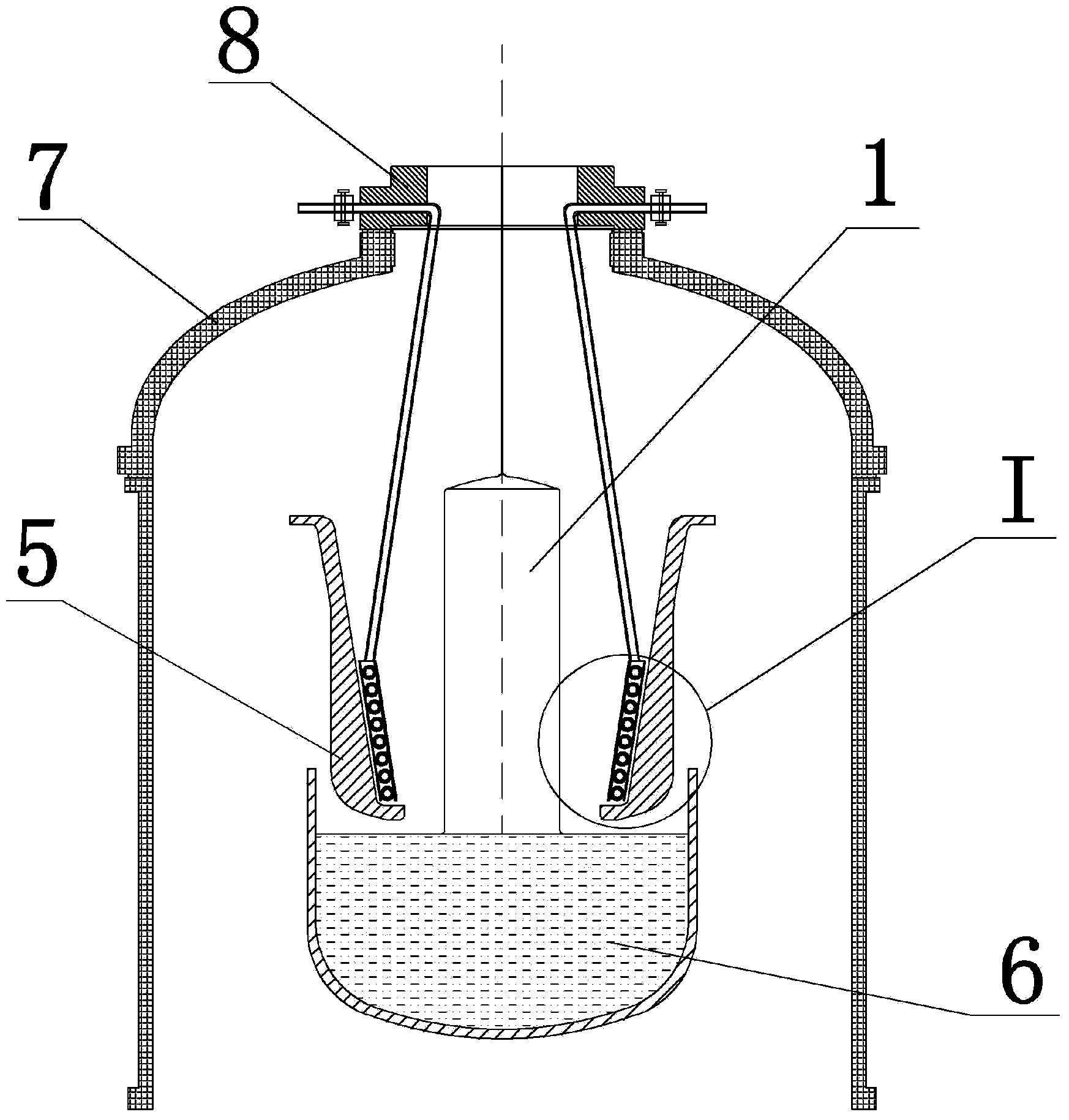

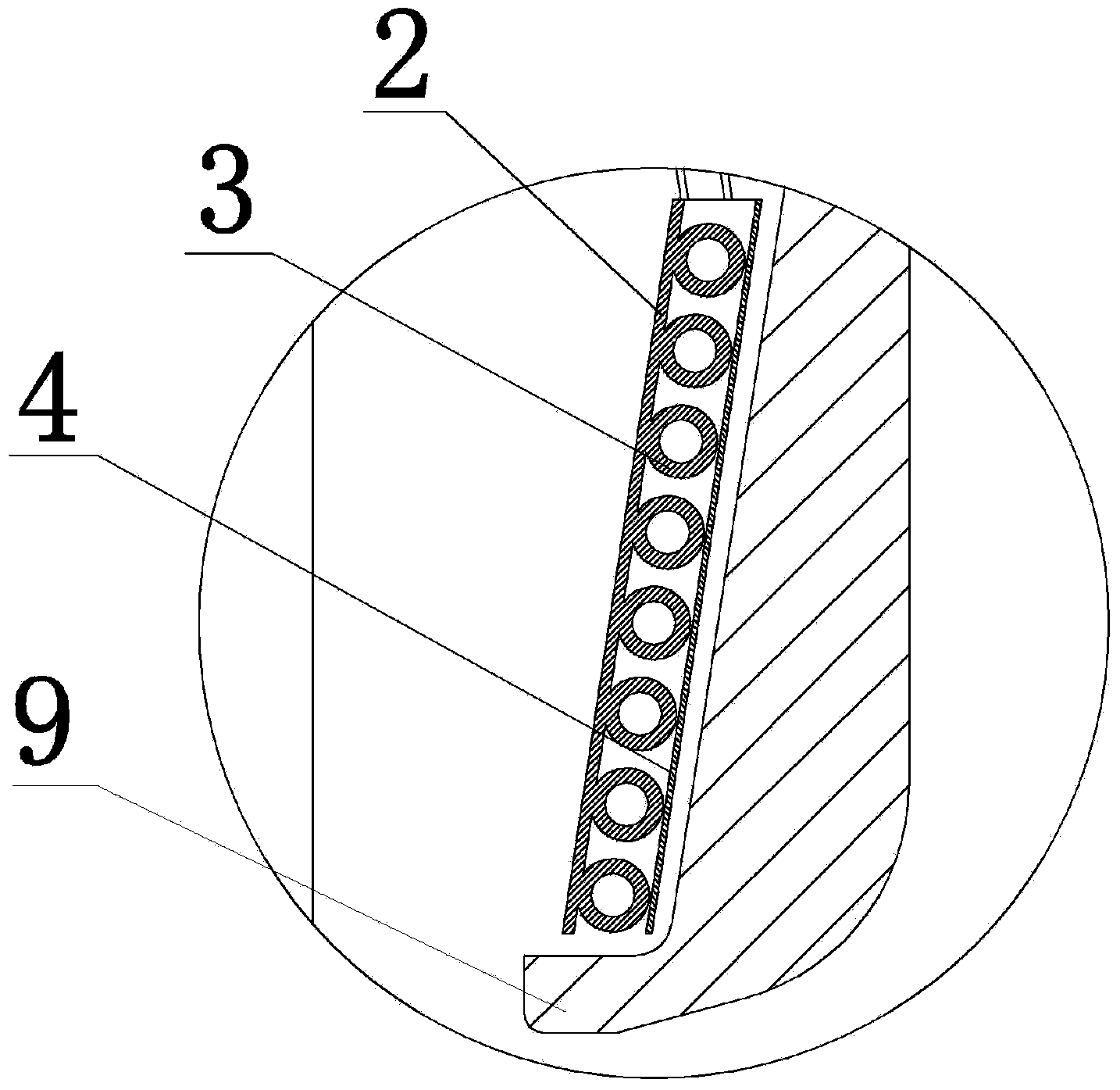

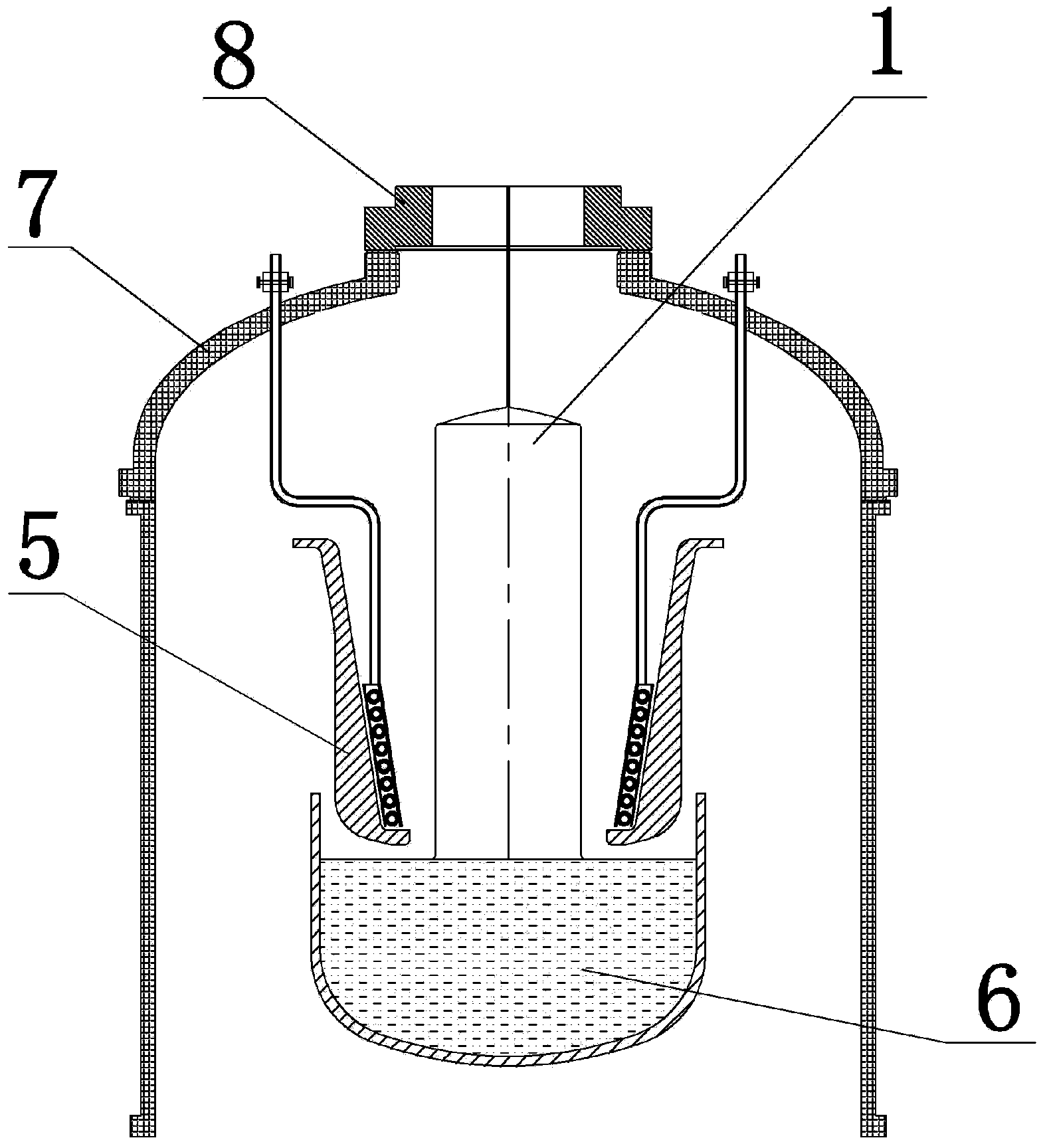

Single crystal furnace capable of improving czochralski-method single crystal growth speed

InactiveCN103710742APrevent leakageImprove cleanlinessBy pulling from meltCzochralski methodCooling effect

The invention discloses a single crystal furnace capable of improving a czochralski-method single crystal growth speed. The single crystal furnace comprises a draft tube, wherein a cooling device is arranged in the guide cylinder; the cooling device comprises a molybdenum cylinder encircling along the inner wall of the guide cylinder; a hollow copper tube is arranged in an encircling manner at the inner side of the molybdenum cylinder; the two ends of the copper tube extend to the outside of the single crystal furnace, and one end of the copper tube serves as an inlet for a cooling medium while the other end of the same serves as an outlet for the cooling medium; and the copper tube is full of the flowing cooling medium. Besides, a copper cylinder is connected at the inner side of the copper tube. The single crystal furnace is reasonable in structural design; the copper tube penetrates to the outside of the single crystal furnace after being wound by a certain taper; and therefore, the possibility of leakage of the cooling medium in the furnace is avoided. The guide cylinder is capable of preventing the melt from splashing to the cooling device. The device is adopted in the thermal field of the czochralski-method single crystal furnace so that the crystal cooling effect near the growth interface can be strengthened and the longitudinal temperature gradient of crystals can be increased; and as a result, the growth speed of crystals can be greatly increased. Besides, the purposes of quickly growing crystals and reducing the crystal processing cost are achieved.

Owner:SHANGHAI YONGZHEN MACHINERY +1

Casting method for steel-copper composite cylinder body

InactiveCN107096905AImprove corrosion resistanceImprove wear resistanceInternal combustion piston enginesCylindersCopper cylinderComposite cylinder

The invention discloses a casting method for a steel-copper composite cylinder body. The casting method comprises the steps of performing three-dimensional modeling, designing a casting technology and performing technology simulation and optimization, performing base steel heat treatment, performing machining, tool machining and welding, performing base steel surface treatment, performing pre-heating treatment before base steel production, smelting copper alloy, dipping the copper alloy, melting anhydrous borax, putting base steel into a borax solution, pouring the copper alloy into the base steel, putting the base steel into a water tank and cooling and solidifying the base steel to room temperature to obtain the steel-copper composite cylinder body. According to the casting method, the problems of the composite casting technology and the composite material composition of the steel-copper cylinder body can be solved; and the composite strength of the thermometal cylinder body can be high, the yield can be high, the cost can be low, the size of the cylinder body can not be limited, the forming process can be controlled easily, and the quality can be stable.

Owner:安徽恒利增材制造科技有限公司

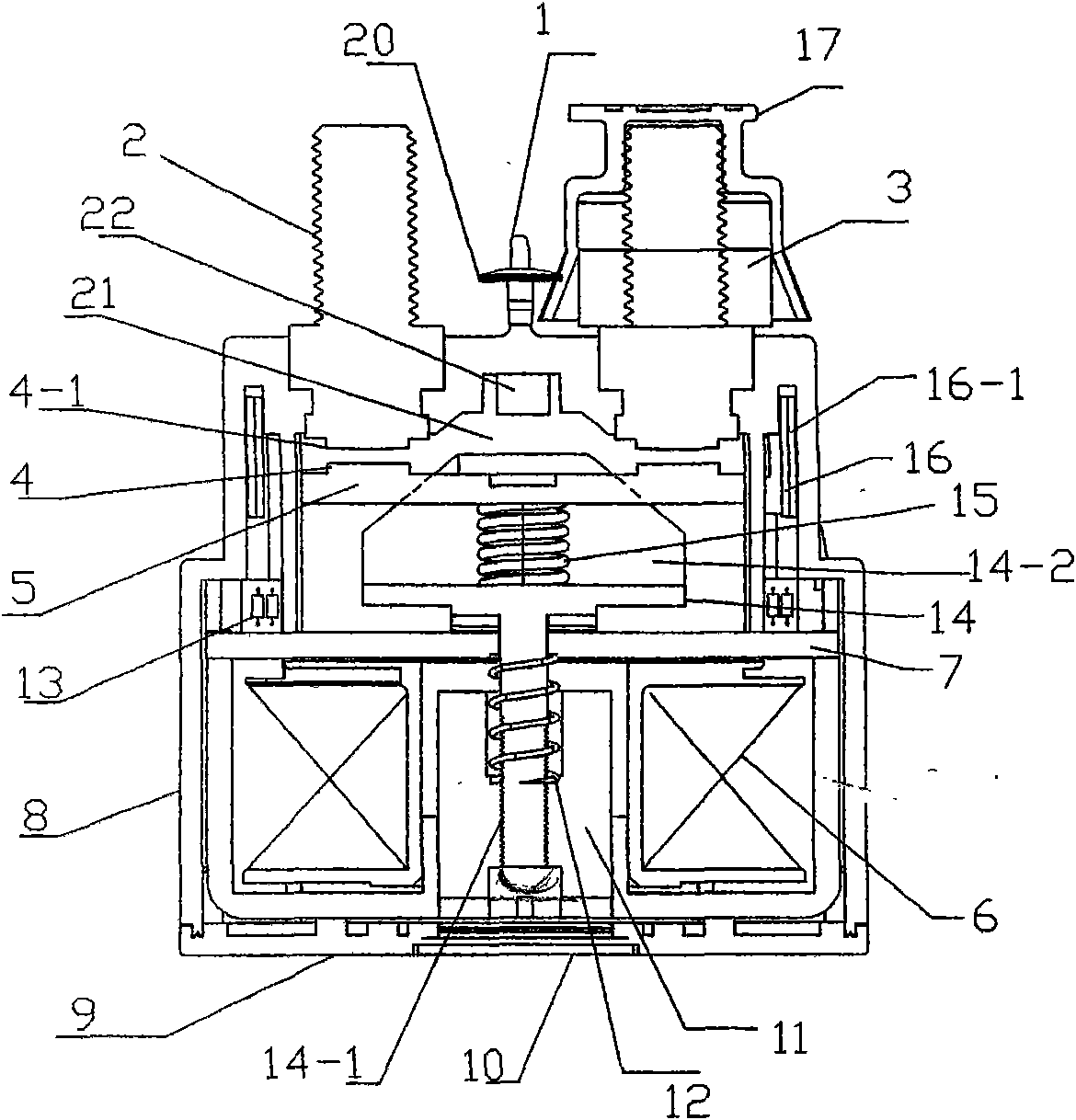

Energy-saving high-current electromagnetic relay

ActiveCN101593638AHigh insulation withstand voltage levelReduce weightElectromagnetic relay detailsNon-polarised relaysEngineering plasticEngineering

The invention relates to an energy-saving high-current electromagnetic relay, which is provided with two copper cylinder bolts fixed on a step-shaped shell made from engineering plastics through parallel injection molding, wherein each bolt head is provided with a protective cap respectively, an isolation wall is arranged between the protective caps, a magnetic yoke which comprises a coil enwrapped inside and a sunken cylindrical bottom surface is arranged below a step in the shell, a concave cylinder of a lower magnetic yoke is filled with a moving iron of which the upper surface is a concave cylinder, a pushing frame is arranged above the lower magnetic yoke, an adjusting push rod below the pushing frame passes through the center of the lower magnetic yoke and the center of a return spring arranged in the concave cylinder of the moving iron and is in spiral connection with the moving iron, a blocking frame is arranged above the pushing frame, a red copper open-close plate is supported in a center hole on the blocking frame by a pressure overshoot spring, two sides on the open-close plate are provided with a movable silver contact respectively, the bottoms of the copper cylinder bolts are provided with fixed silver contacts, a temperature sensor is arranged in an open-close chamber between the movable contacts and the fixed contacts, a pair of strong magnets are arranged on the inner walls of the shell on two sides of the open-close chamber by an upper magnetic yoke, and a circuit control board is arranged on the inner wall of the shell. The energy-saving high-current electromagnetic relay is particularly applicable to automotive vehicles.

Owner:XINXIANG GUANGMING ELECTRIC APPLIANCE CO LTD

Process and special equipment for plating copper on special steel piece with deep/blind hole

InactiveCN101942682AImprove stabilitySimple and fast operationElectrolysis componentsCopper platingAlcohol

The invention discloses a process for plating copper on a special steel piece with a deep / blind hole, namely render copper. The process comprises the following steps of: chemical deoiling, washing with hot water, electrolytic deoiling, washing with hot water, washing with cold water, acid washing, secondary washing with cold water, neutralizing, washing with cold water, plating copper without cyanide, secondary washing with cold water, plating tin, secondary washing with cold water, neutralizing, washing with hot water, passivating, secondary washing with hot water, washing with hot pure water, dehydrating with alcohol, removing the residual water, drying and inspecting, wherein electroplate liquid used in the step of plating copper without cyanide has the following formula: 400 to 600ml / L of BH-580 non-cyanide alkaline copper cylinder plating bath solution, 1 to 2ml / L of BH-580 non-cyanide alkaline copper brightening agent and 7.5 to 12g / L of metal copper; and the pH value is 9.2 to 9.8. The process has the advantages of good stability of a plating liquid, simple and convenient operation, good dispersibility and good covering capability; the formed plating layer has the advantages of fine and compact crystallization, good adhesive force, stable and reliable production; and the method can effectively protect environment and the physical and psychological health of operators.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

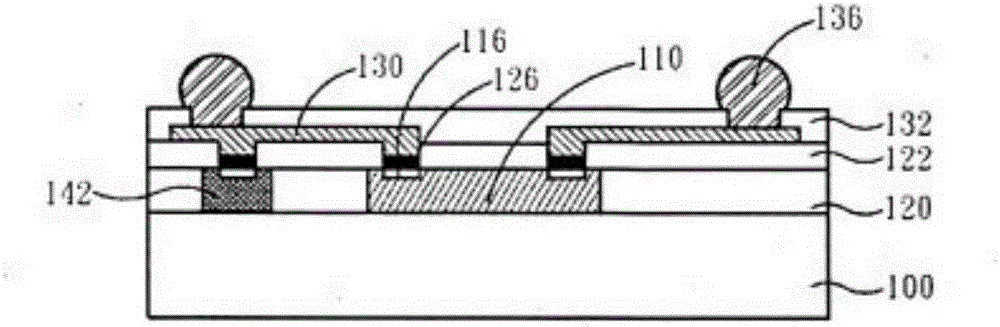

Preparation method and structure of welding spot

InactiveCN103187324ALow costImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesSputteringPhotoresist

The invention provides a preparation method and a structure of a welding spot. The preparation method of the welding spot comprises the following steps that firstly, a metal layer (2) is sputtered on the front face of a silicon wafer (1) to serve as an electroplating seed layer; secondly, photoresist (3) is coated on the metal layer (2) and pre-baked; thirdly, the photoresist is imaged and then is post-baked; fourthly, the imaged photoresist is used as a covering film, copper is electroplated to form a copper layer until the thickness of the copper layer exceeds the thickness of the photoresist layer, and an umbrella-shaped copper cylinder structure (4) is formed; fifthly, the photoresist (3) is still used as the covering film, and tin is electroplated to form a tin layer (5) covering the umbrella-shaped copper cylinder structure (4); and sixthly, return flow is carried out, and a welding spot structure covering an umbrella-shaped copper cylinder is formed. The structure of the welding spot has the advantages of being low in cost, and high in reliability of shearing force and thermal machinery.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Flywheel energy storage device with induction torque transfer

InactiveUS10340768B2Improve the forcePromote generationEngine fuctionsEngine componentsElectricityFlywheel energy storage

A flywheel energy storage device includes the Halbach Motor / Generator with rolling biphasic coil control, continuously variable torque transfer via magnetic induction and a reluctance magnetic levitation system known as the Axial-Loading Magnetic Reluctance Device. Electric energy input turns the magnetically coupled rotors of the Halbach motor, and torque is transferred to a flywheel through a copper cylinder variably inserted between the Halbach magnet rotors. In idle mode, the energy is stored kinetically in the spinning flywheel, which is levitated by a permanent magnet bearing. Electric energy output is achieved by transferring torque from the flywheel through the copper cylinder to the rotors of the Halbach Generator by magnetic induction. Rolling biphasic motor control includes dividing Halbach motor coils into increments, then energizing groups of contiguous increments into virtual coils, which revolve in tandem with the magnet rotors so to achieve continuous and optimal torque.

Owner:WALSH RAYMOND JAMES

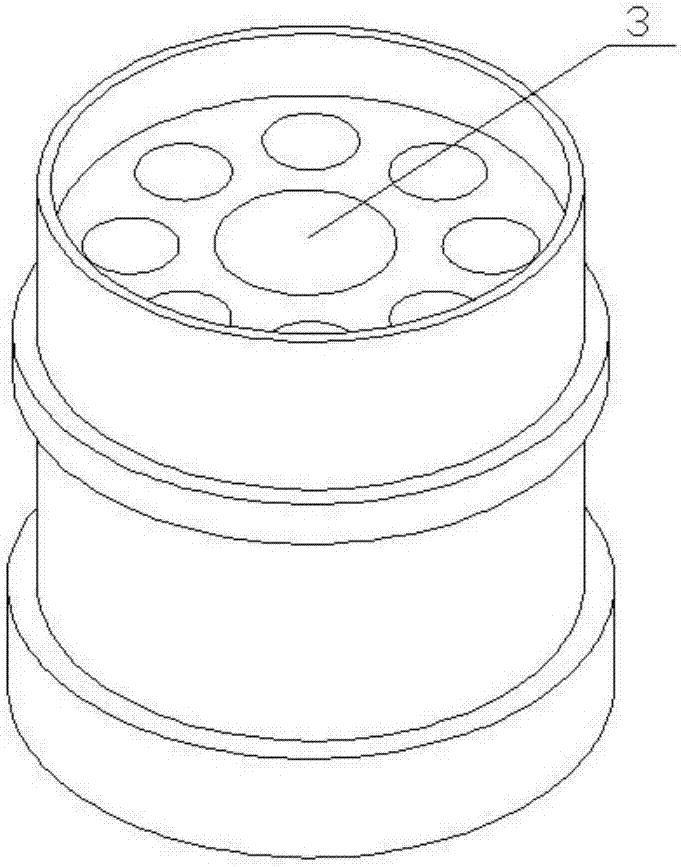

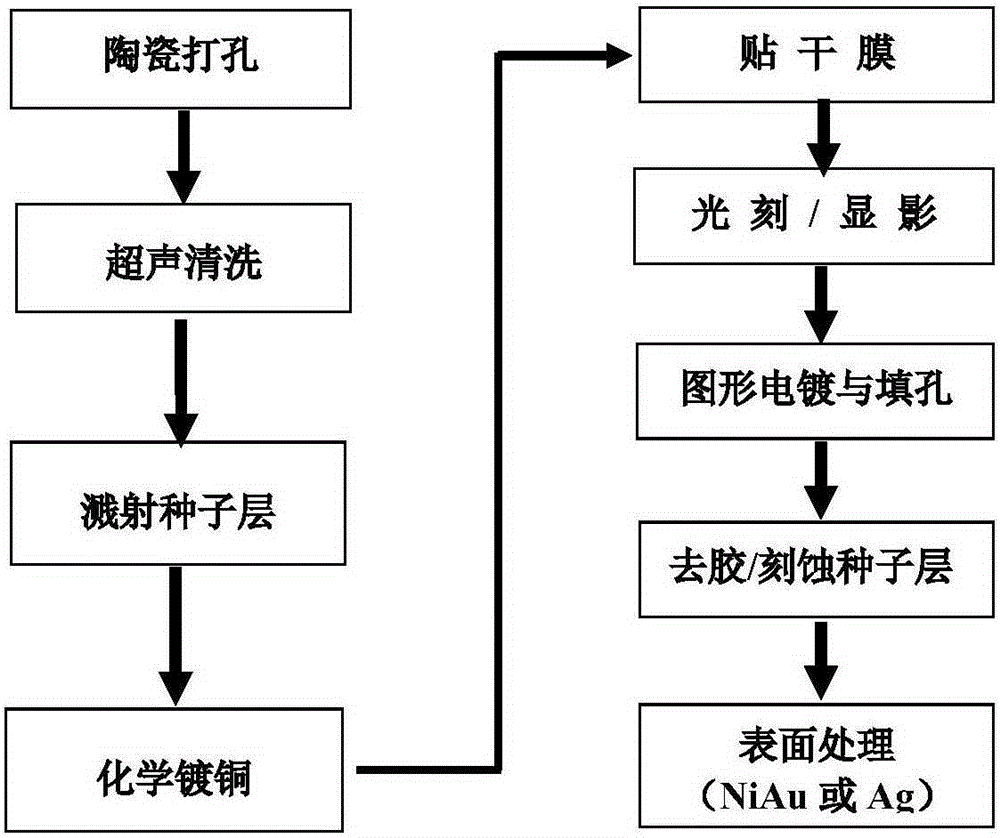

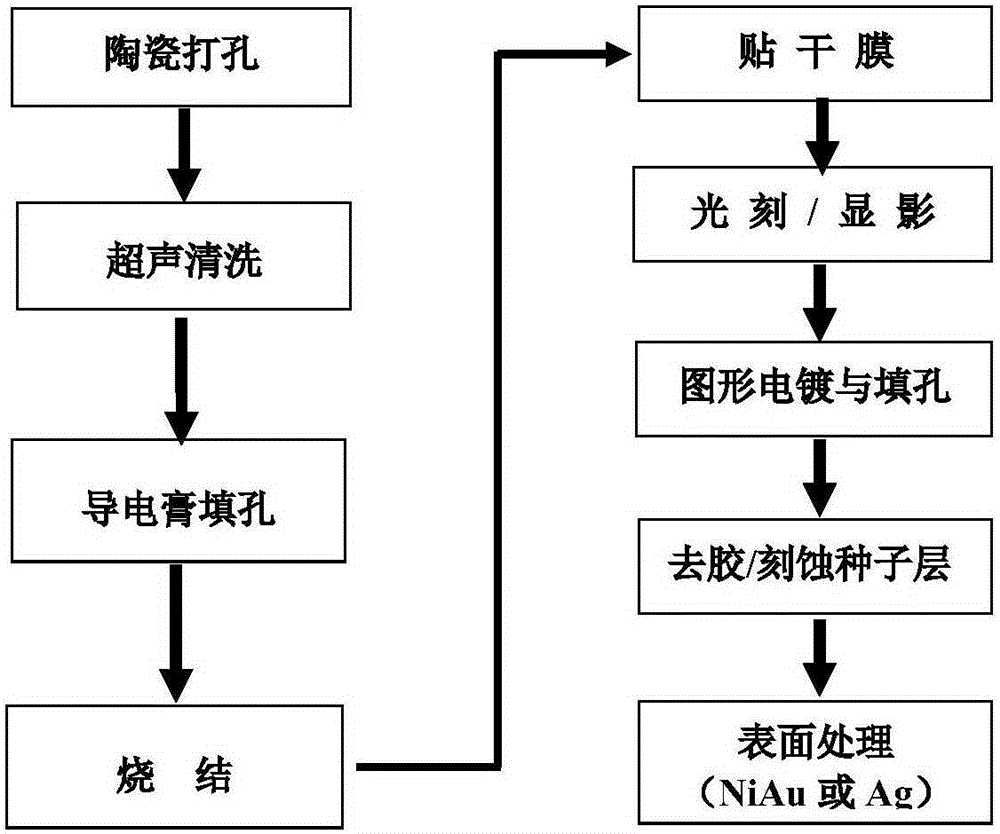

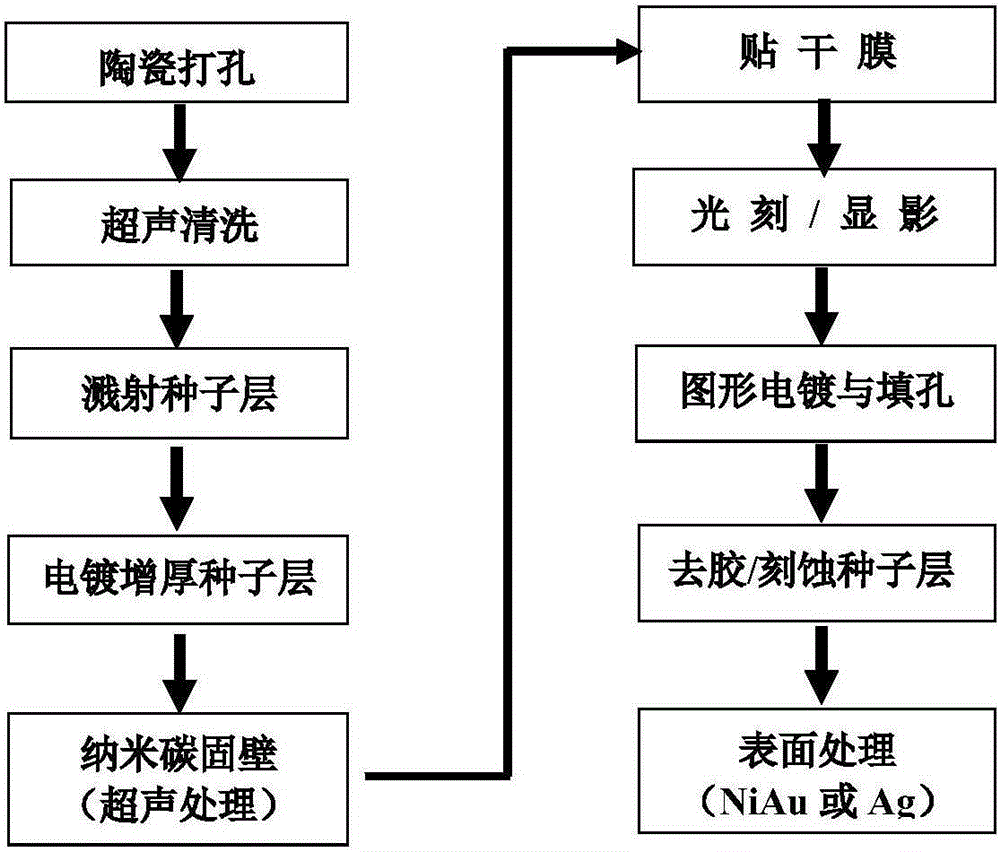

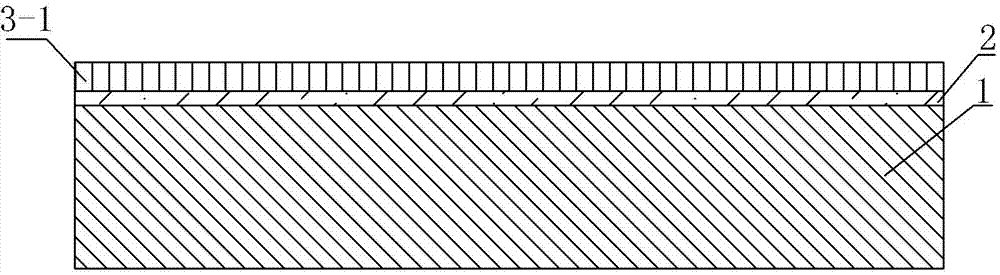

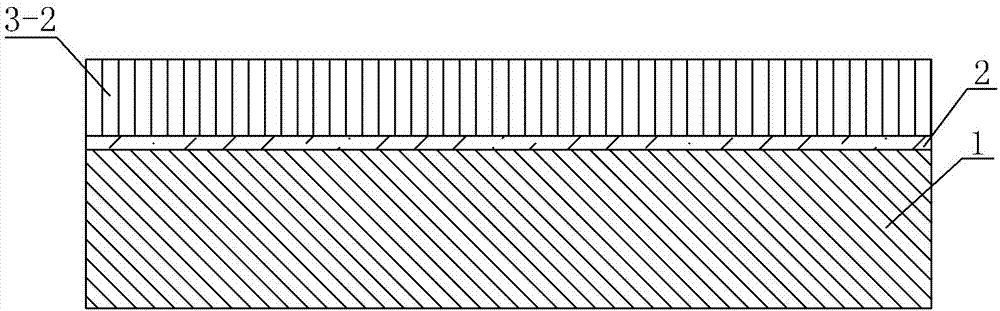

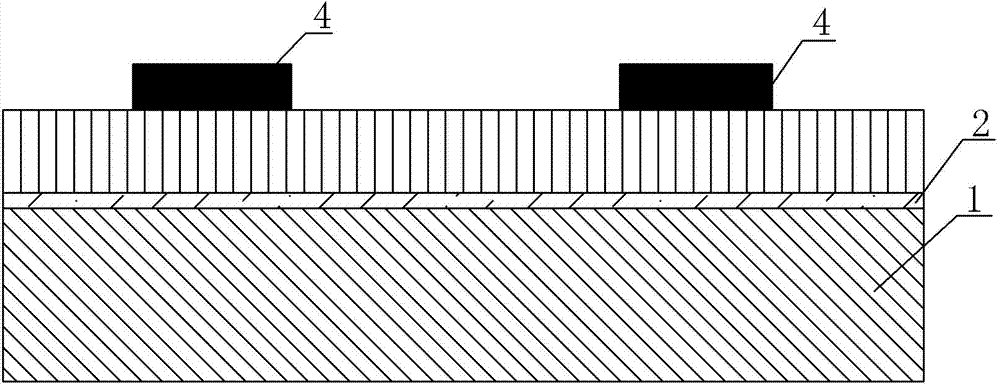

Method for preparing ceramic substrate containing conductive copper cylinder

ActiveCN105198491AImprove performanceImprove yieldSemiconductor/solid-state device manufacturingChemical platingConductive polymer

The invention provides a method for preparing a ceramic substrate containing a conductive copper cylinder. The method includes the steps that first, through holes are prepared in the ceramic substrate through a laser boring technology; then a metal seed layer is deposited on the surface of the substrate through a sputtering technology, and the thickness of the seed layer is increased through electroplating; afterwards, the substrate is soaked in a wall bracing solution made of a carbon nanomaterial, and a conducting film is formed on each hole wall under the action of ultrasound or jet; at last, the ceramic substrate with the surface being provided with a metal circuit and internally provided with the conductive copper cylinder is prepared through the pattern electroplating and corrosion technology. Due to the facts that the carbon nanomaterial is good in electricity-conducting and heat-conducting property and the binding force of the carbon nanomaterial and ceramic is high, the performance and reliability of the ceramic substrate are improved. Meanwhile, the nanocarbon wall bracing technology is adopted for preparing the conductive copper cylinder. Compared with an existing chemical plating and conducting polymer hole-filling technology, the method has the advantages of being simple in technology, environmentally friendly in material, low in cost, suitable for mass production and the like.

Owner:武汉利之达科技股份有限公司

Method for manufacturing novel Damascus copper and copper bonding structure

ActiveCN103762197AImprove reliabilityReduce process complexitySolid-state devicesSemiconductor/solid-state device manufacturingSurface roughnessProcess complexity

The invention provides a method for manufacturing a novel Damascus copper and copper bonding structure. The surface roughness of a copper cylinder is effectively reduced, the surface evenness of micro convex points is improved, the heights of the micro convex points in different areas of a wafer can be the same, the requirement for the surface evenness of the copper and copper bonding technology is met, the bottom filling technology is not needed in the following micro packaging technology, and the reliability of the bonding structure is improved while the technology complexity is reduced. The method is characterized by comprising the following steps that firstly, an adhesion layer and a seed layer are manufactured on the surface of the wafer; secondly, a copper layer is deposited on the surface of the wafer; thirdly, the copper layer is imaged; fourthly, copper not located in the micro convex point area is removed to form a micro convex point structure; fifthly, the adhesion layer not in the micro convex point area is removed to form an electric isolated micro convex point structure; sixthly, photoresist is removed to form a micro convex point structure; seventhly, parts between the micro convex points are filled and coated with a dielectric layer; eighthly, the surface of the wafer is processed to obtain highly-even dielectric layer with the flat and smooth surface and exposed micro convex point structures.

Owner:NAT CENT FOR ADVANCED PACKAGING

Method for fabricating bump

InactiveCN101740422ANo bridgingGuaranteed reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingCopper metalCopper cylinder

The invention discloses a method for fabricating a bump. The method comprises the following steps of: providing a chip on which a solder layer is formed; placing the chip in a refluxing device, wherein the solder layer is positioned below the surface of the chip; and refluxing the solder layer to form the bump. The method for fabricating the bump ensures the reliability of a metal layer below the bump; the bump does not cause a bridging phenomenon so as to avoid a short circuit; and the electrical property of a copper metal layer is improved in the fabricating process of the bump of a copper cylinder.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

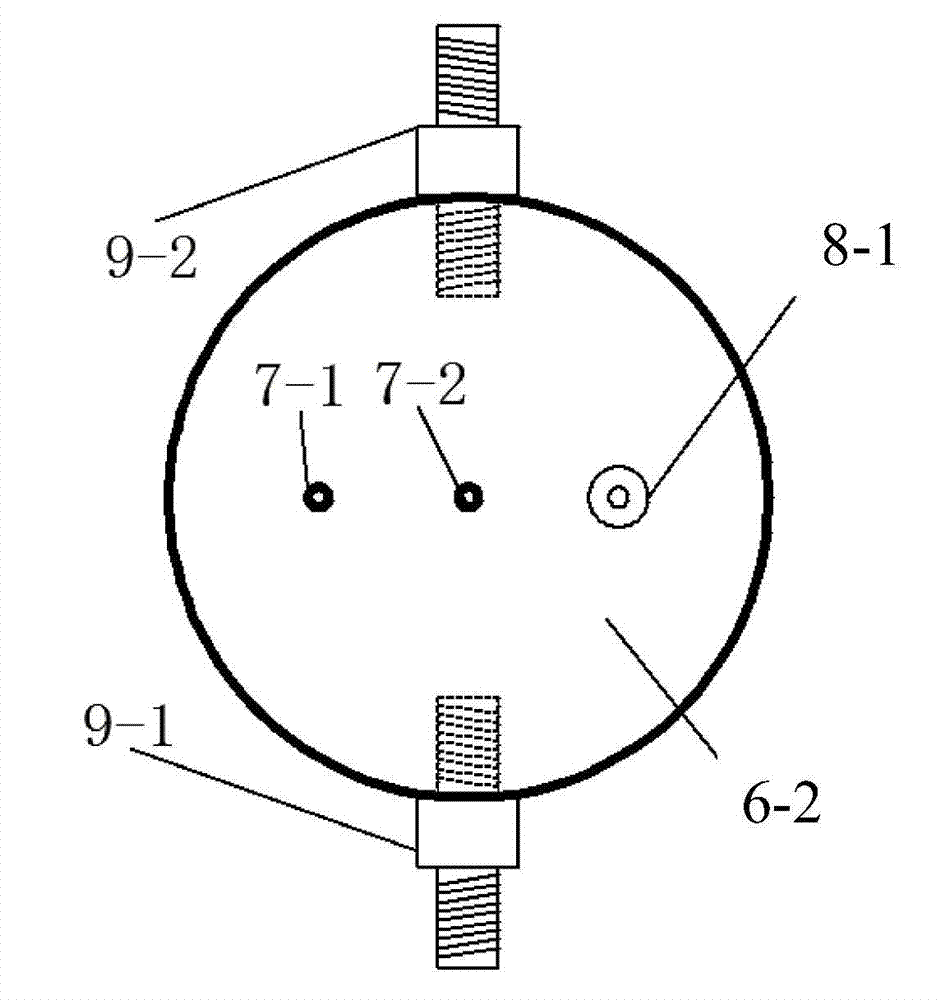

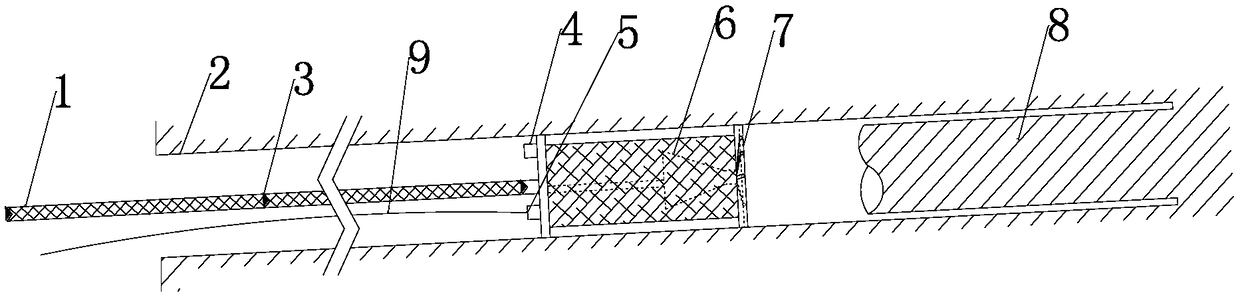

Spatial orientation device for rock core in hole and verification method for stress relief method by overcoring

ActiveCN109025984ADoes not affect production drillingHigh precisionSurveySpatial OrientationsRock core

The invention discloses a spatial orientation device for a rock core in a hole. A thick-walled copper cylinder 11 is equipped with a high pressure air duct interface 5 at the rear end thereof. The high pressure air duct interface 5 is connected with a high pressure air duct 9. A marking liquid holding box 6 is disposed in the thick-walled copper cylinder 11. The rear end of the marking liquid holding box 6 is connected with the high pressure air duct interface 5. The front end of the marking liquid holding box 6 is connected with marking liquid conveying tubes 16. Each marking liquid conveyingtube 16 is provided with a marking liquid nozzle 17 at the tail end thereof. The marking liquid nozzles 17 are sprayed with a waterproof orientation mark having the shape of a Chinese character "Feng". The thick-walled copper cylinder 11 is also provided with a horizontal orientation device 4 at the rear end thereof. Also disclosed is a verification method for the accuracy of a stress relief method by overcoring. In the method, the ground stress test results measured by a wave velocity analysis method, a differential strain analysis method and an AE method are compared with the results measured by the stress relief method, and if the consistency can be verified in many aspects, the accuracy of the test results by the stress relief method can be verified.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com