Patents

Literature

205 results about "Composite cylinder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Every composite cylinder design is different. Our patented manufacturing process starts with a seamless liner, which is then wrapped with composite fibers. This ensures a safer, stronger, more durable product. In addition, all composite cylinders undergo rigorous testing before leaving our factory.

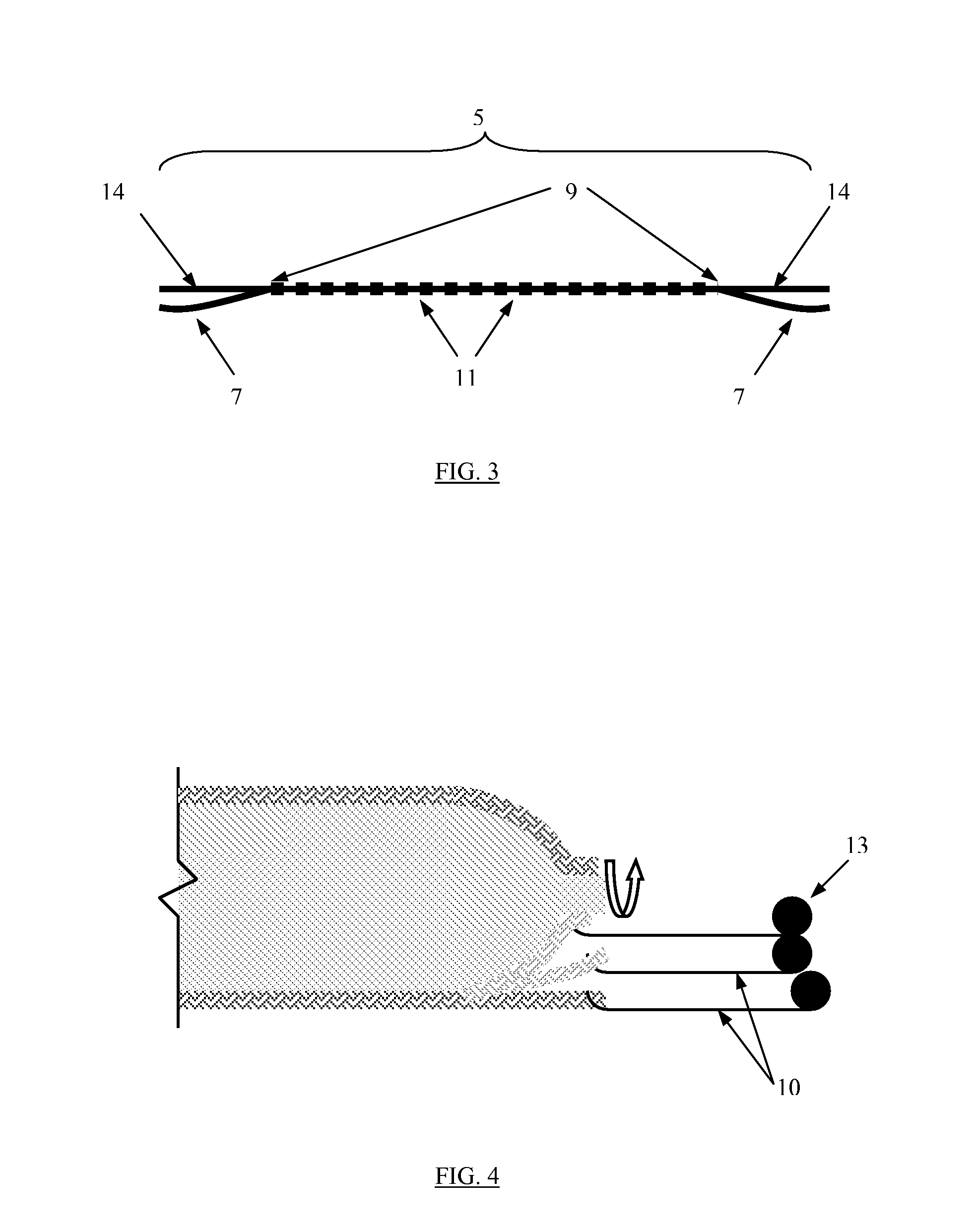

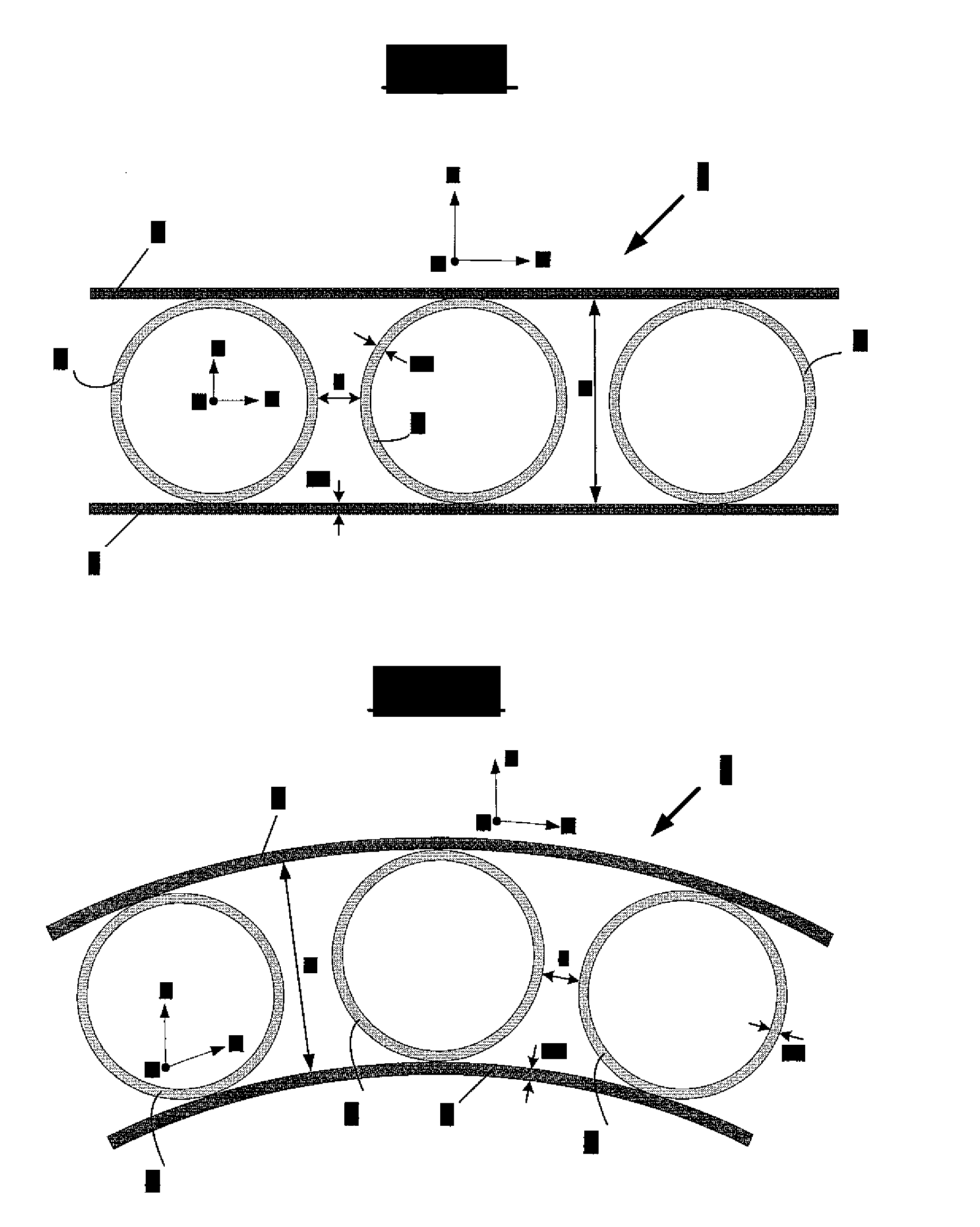

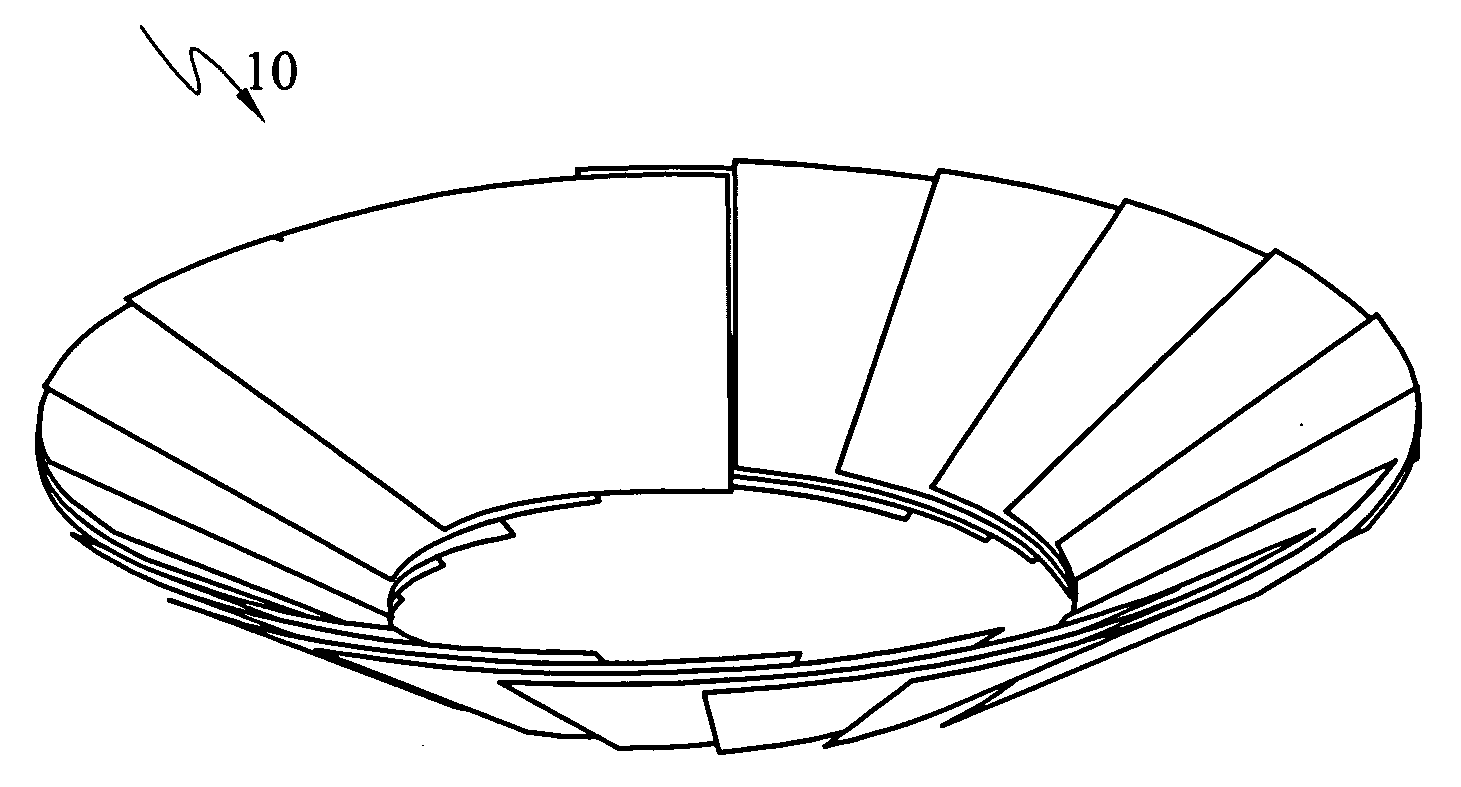

Non-Pneumatic Elastic Wheel

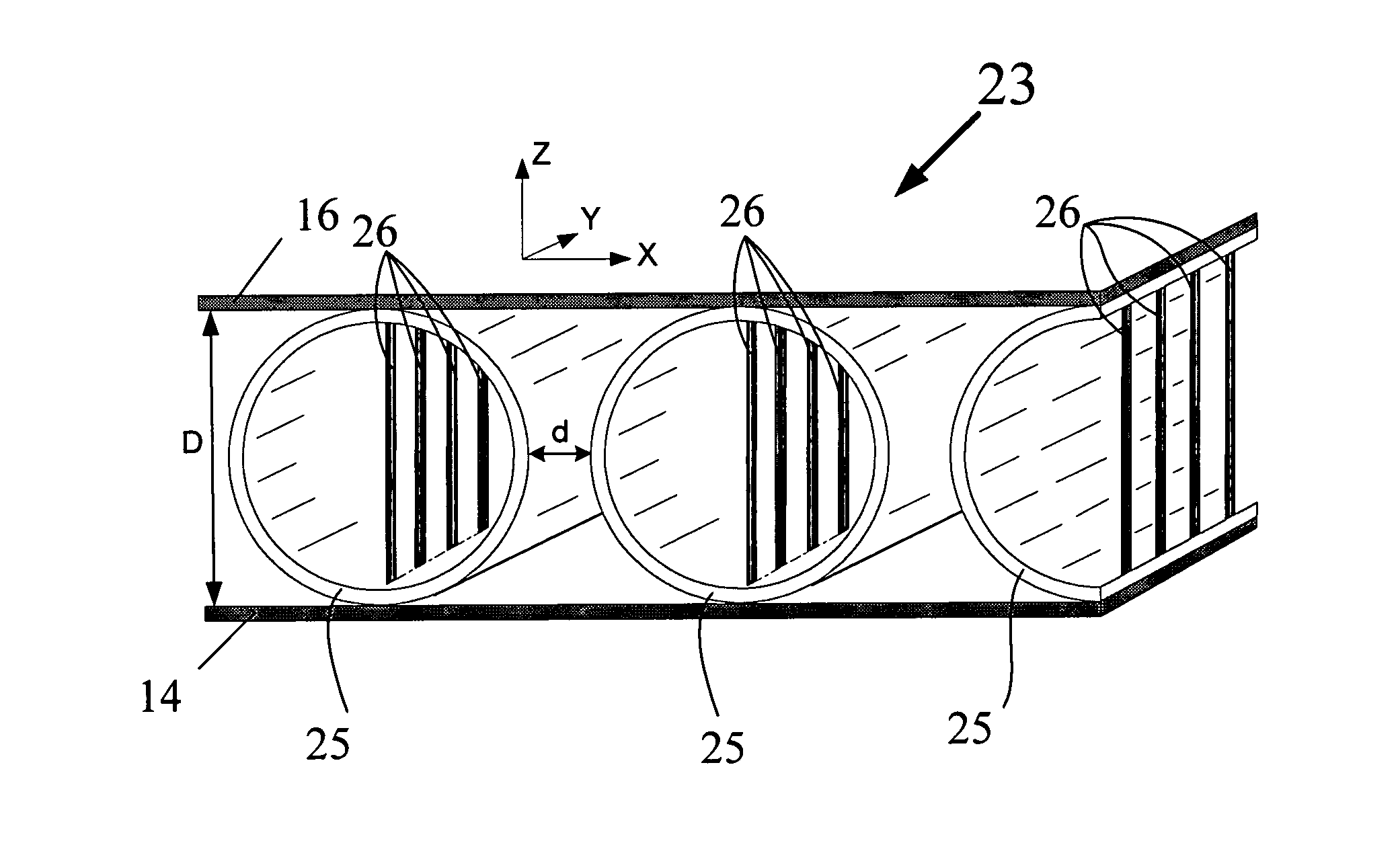

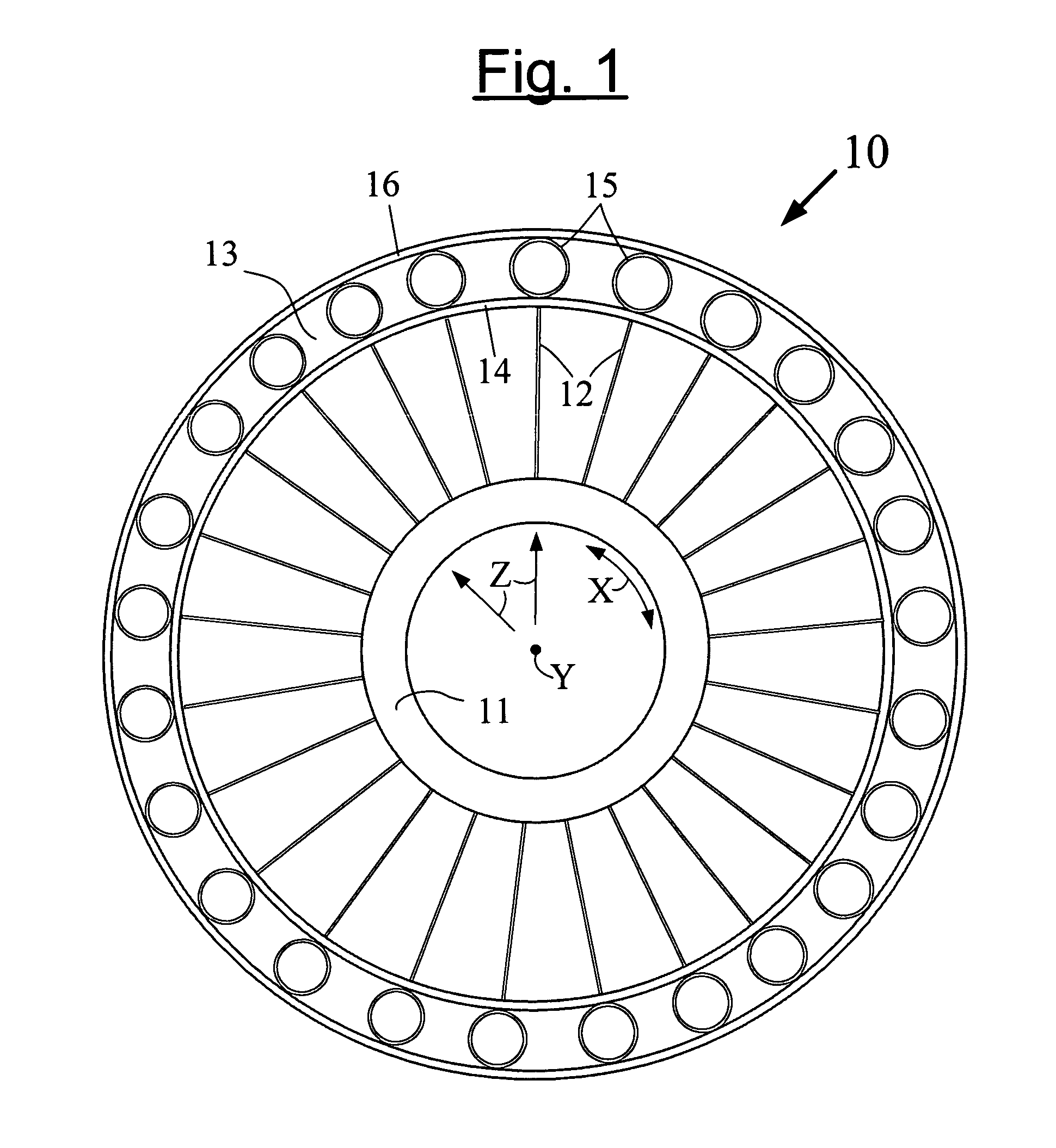

ActiveUS20100307653A1Improve staminaIncrease resistanceNon-inflatable tyresNon-metallic wheel bodyFiberResin matrix

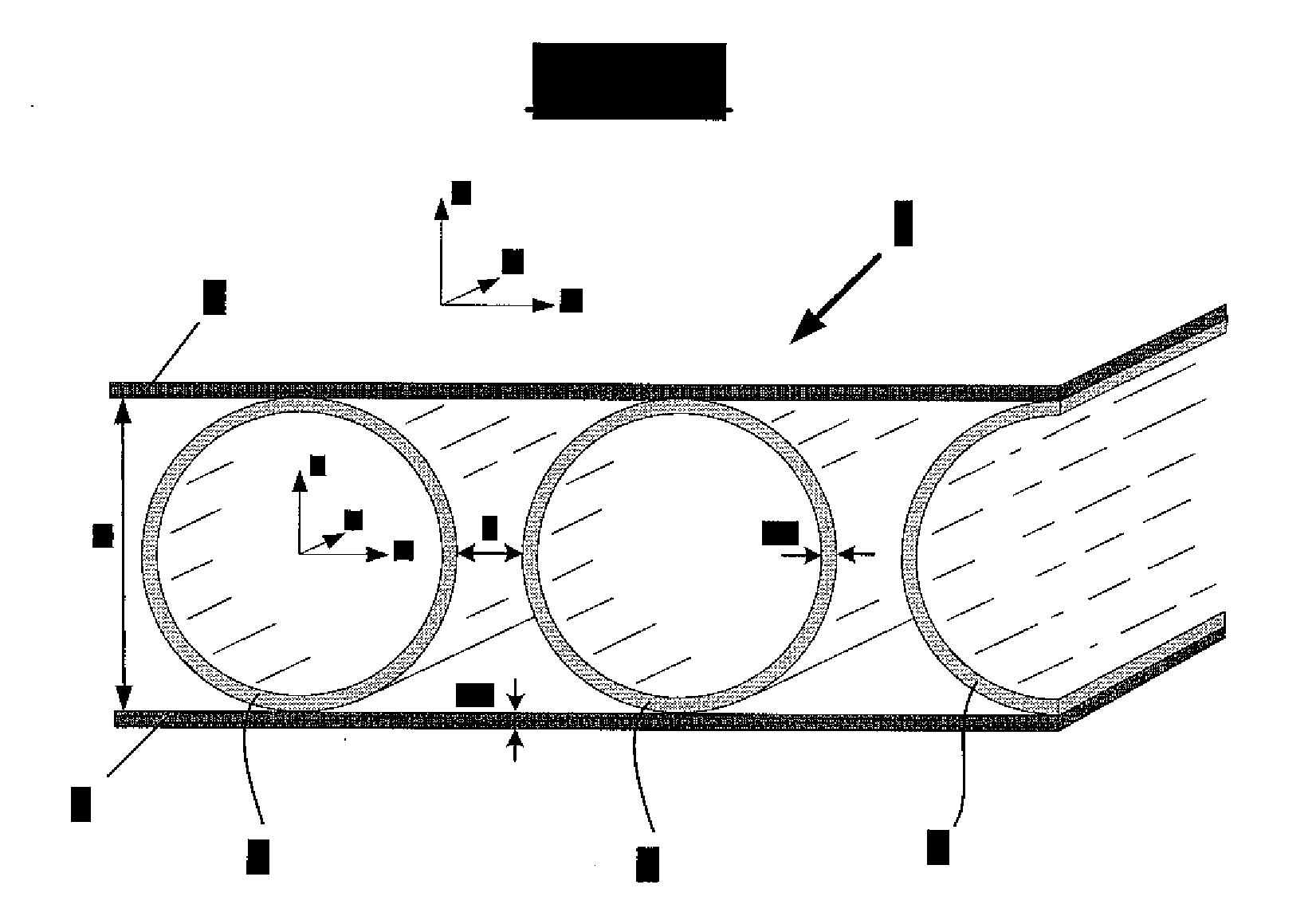

Non-pneumatic resilient wheel (10), that is supported structurally and defines three perpendicular directions, circumferential (X), axial (Y) and radial (Z), this wheel comprising: a hub (11); an annular band referred to as a shear band (13) comprising at least one inner circumferential membrane (14) and one outer circumferential membrane (16) that are oriented in the circumferential direction X; and a plurality of support elements (12) that connect the hub (11) to the inner circumferential membrane (14)U. The two membranes (14, 16) are connected to one another by means of a series, that extends in the circumferential direction (X), of cylinders (15) referred to as connection cylinders, said connection cylinders (15) being non-touching in the circumferential direction X and having their generatrix oriented in the axial direction Y. The connection cylinders (15) are composite cylinders comprising fibres embedded in a resin matrix.

Owner:MICHELIN RECH & TECH SA +1

Method for manufacturing aluminum liner of vehicular composite cylinder

The invention discloses a method for manufacturing an aluminum liner of a vehicular composite cylinder, which is used for manufacturing the aluminum liner of the vehicular composite cylinder. The aluminum liner consists of a thin-walled cylinder body of the aluminum liner, an end enclosure gradually thickening part and an opening part. The aluminum liner is manufactured by adopting a method of reducing the wall thickness of a thick-wall aluminum pipe by over 60 percent by one time of rotary pressing by a 450 strong spinning reduction machine, forming the end enclosure part and the opening part by using a 412 spinning necking machine, and machining the connecting threads on the opening part after solution ageing heat treatment. The aluminum liner of the vehicular composite cylinder has the advantages of high quality, large diameter, thin wall thickness, small weight capacity ratio (weight / capacity), high geometric dimensioning accuracy, high quality of inner and outer surfaces and the like, and has the excellent application and market prospects.

Owner:BEIJING TIANHAI IND

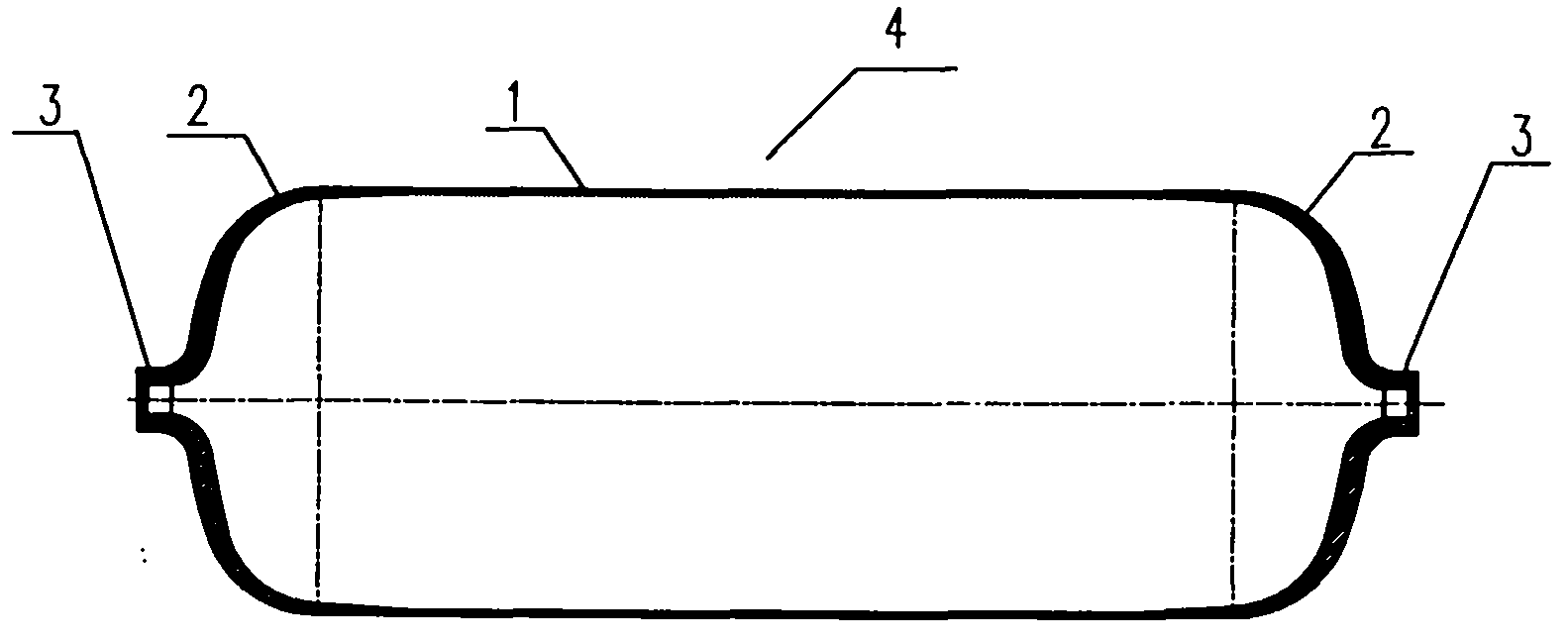

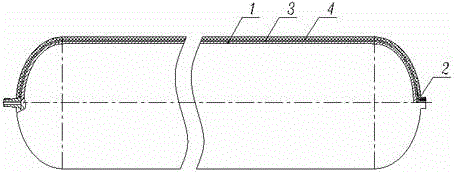

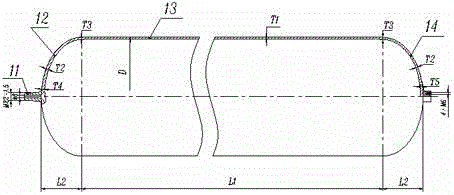

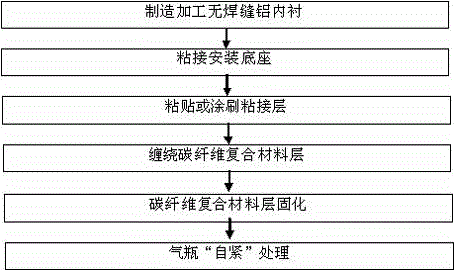

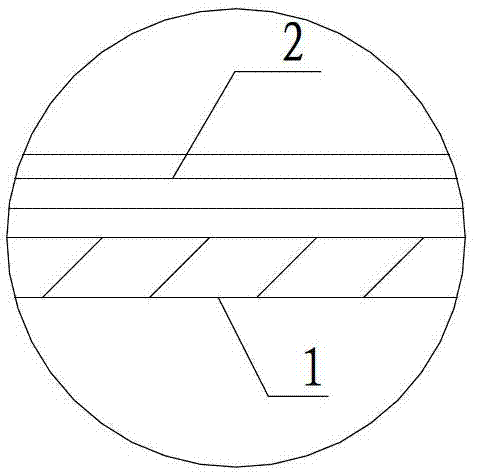

100 L carbon fiber wrapped aluminum-lined composite cylinder and manufacture method thereof

The present invention provides a 100 L carbon fiber wrapped aluminum-lined composite cylinder, including a weldless aluminum liner, a mounting base, an adhesive layer and a carbon fiber composite layer. The mounting base and the weldless aluminum liner form a smooth flattening winding mandrel; the external part of the mandrel is wound by the carbon fiber composite layer; and the adhesive layer is arranged between the mandrel and the carbon fiber composite layer and is used for firmly connecting the weldless aluminum liner and the carbon fiber composite layer. The composite cylinder has the advantages of large volume, high pressure resistance, high efficiency, light weight, high security, low cost and short manufacturing cycle. The present invention also provides a manufacture method of the carbon fiber wrapped aluminum-lined composite cylinder.

Owner:SHANGHAI INST OF SPACE PROPULSION

Composite cylinder jacket and manufacturing method

A composite cylinder jacket is featured as using alloy cast ¿C iron layer as internal layer of cylinder jacket and using cast ¿C steel layer as external layer, setting pure copper combination layer between alloy cast ¿C iron layer and cast ¿C steel layer for connecting these two layers. Its preparing method is the same to cold processing technology, heating and chemical treatment technique and outline size in method for preparing universal cylinder jacket in addition to casting technique.

Owner:WEICHAI POWER CO LTD

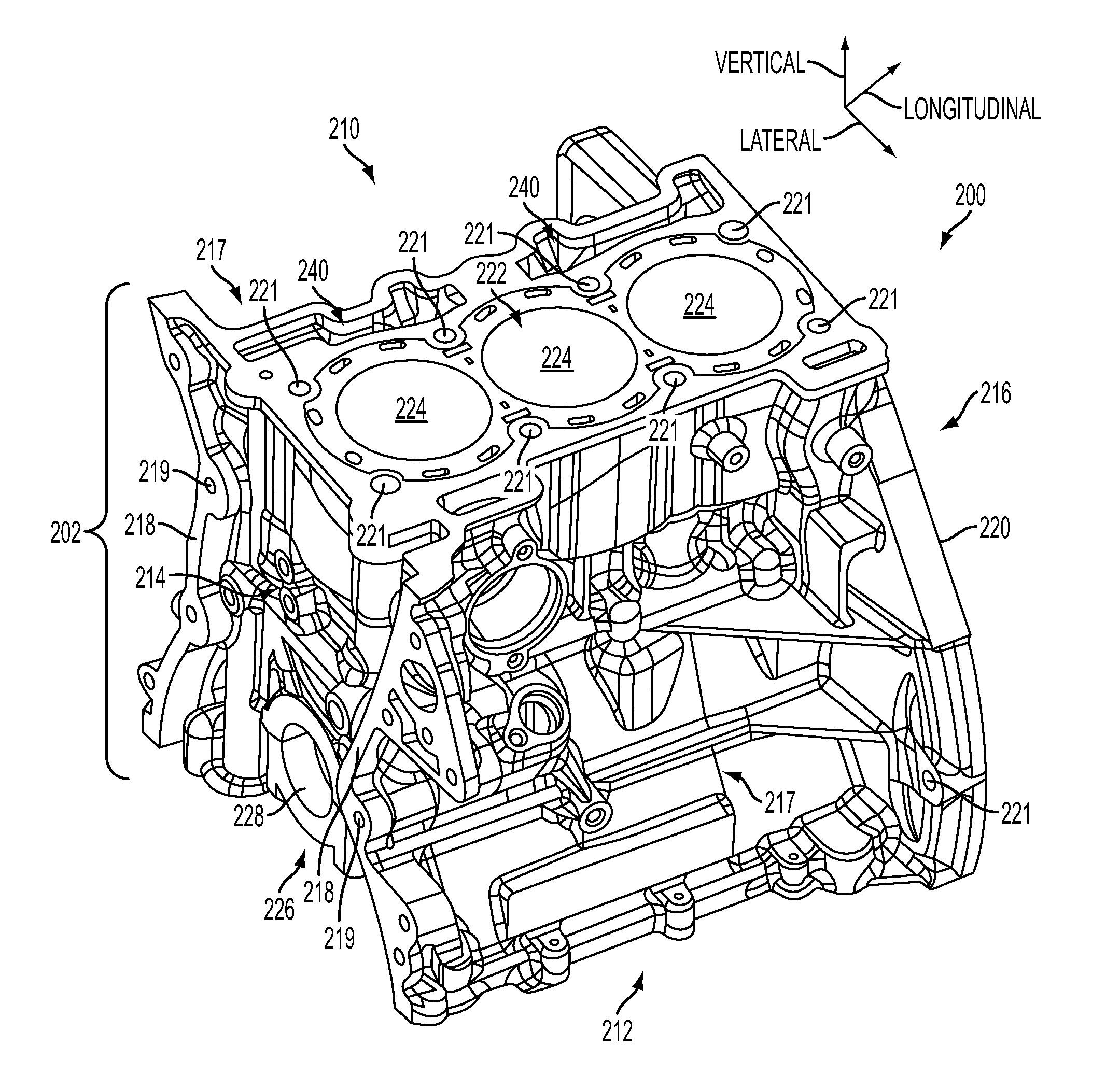

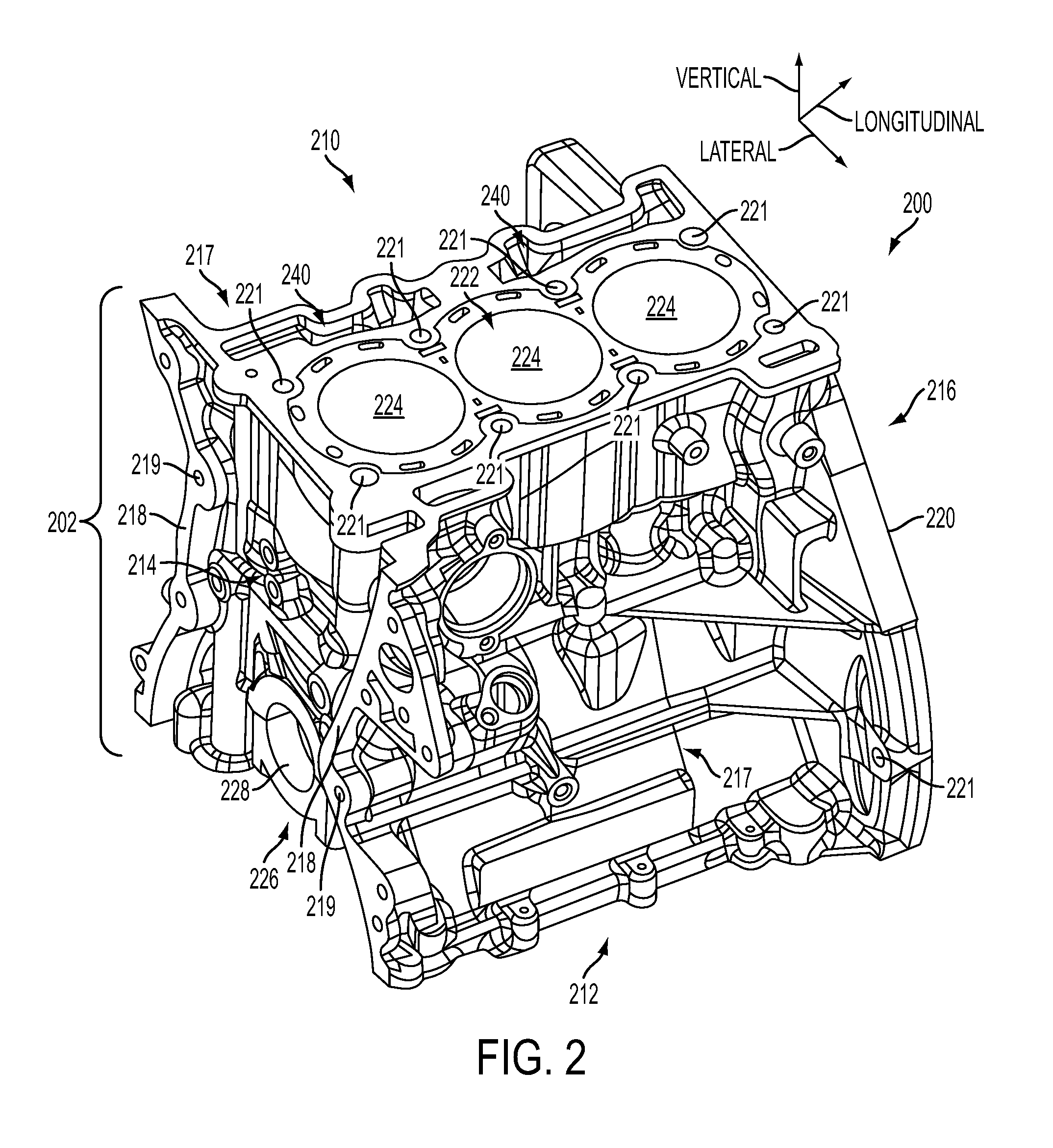

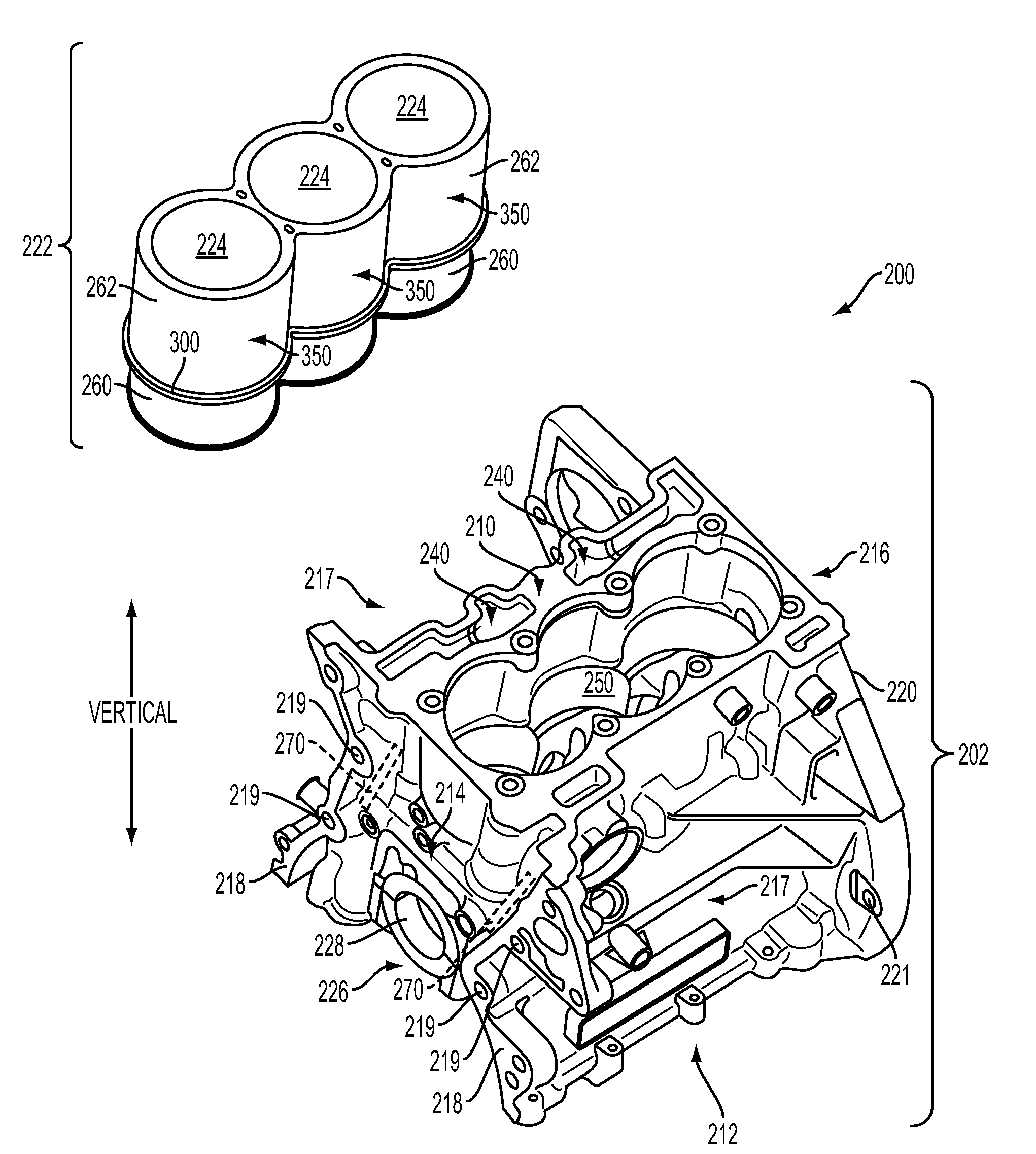

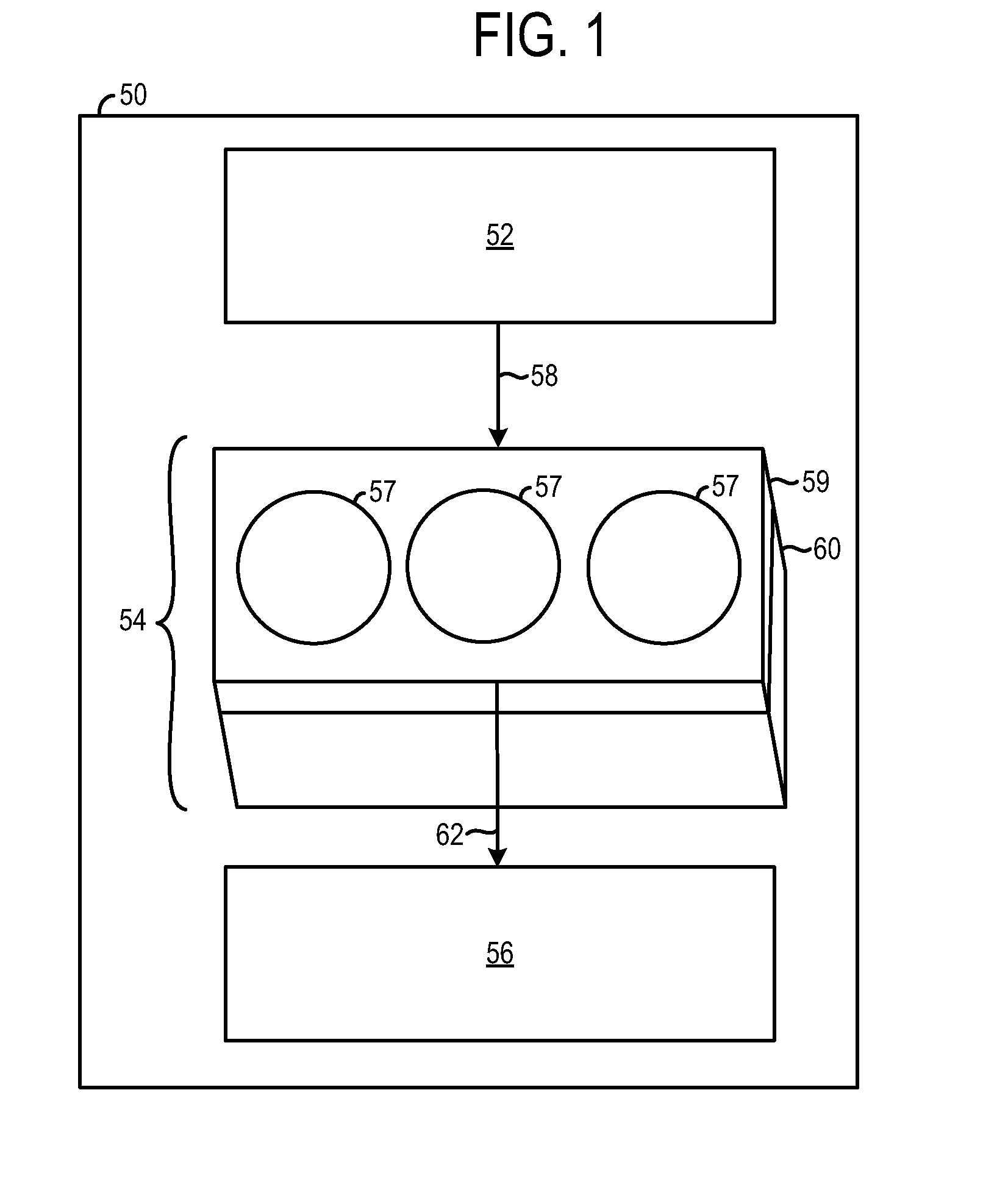

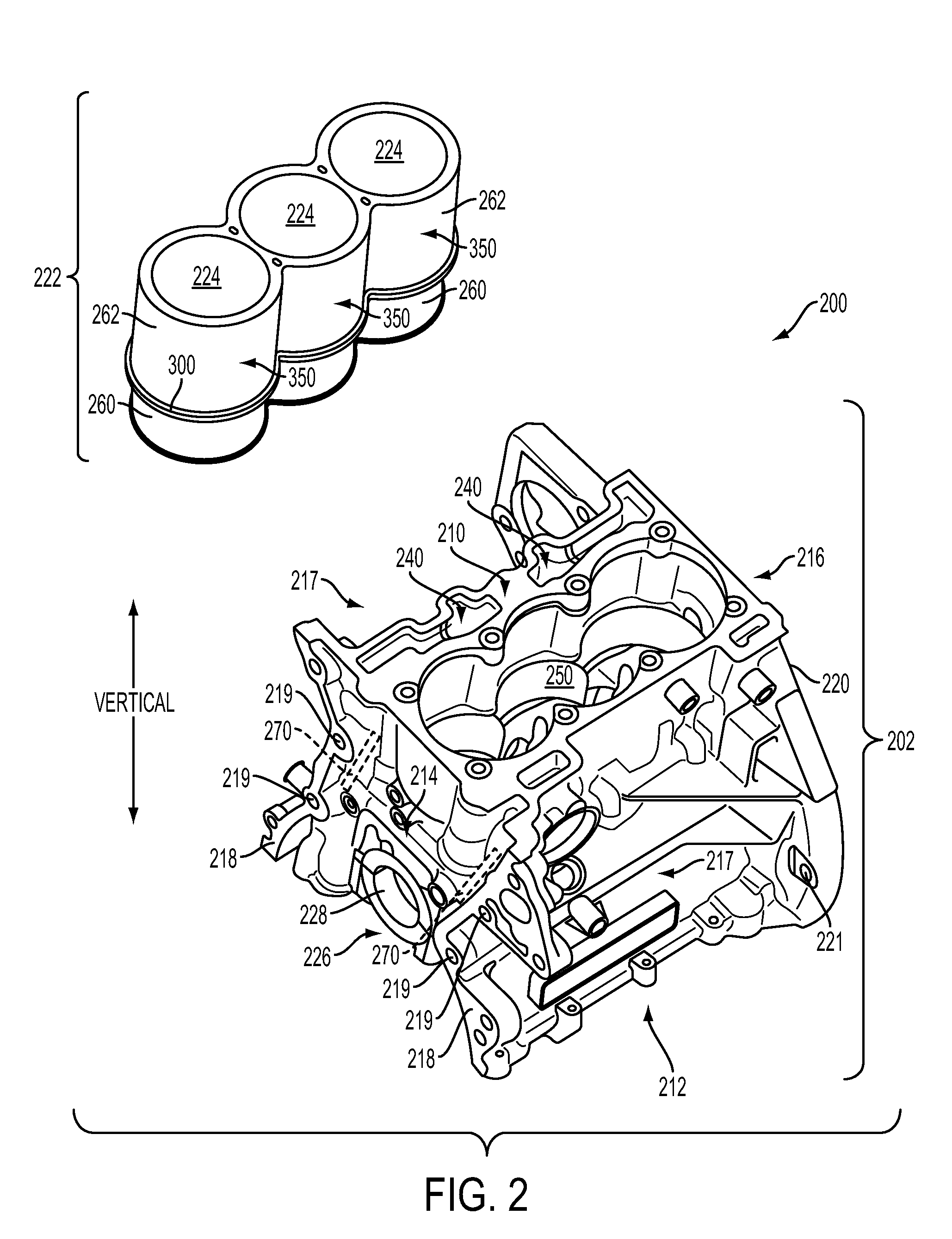

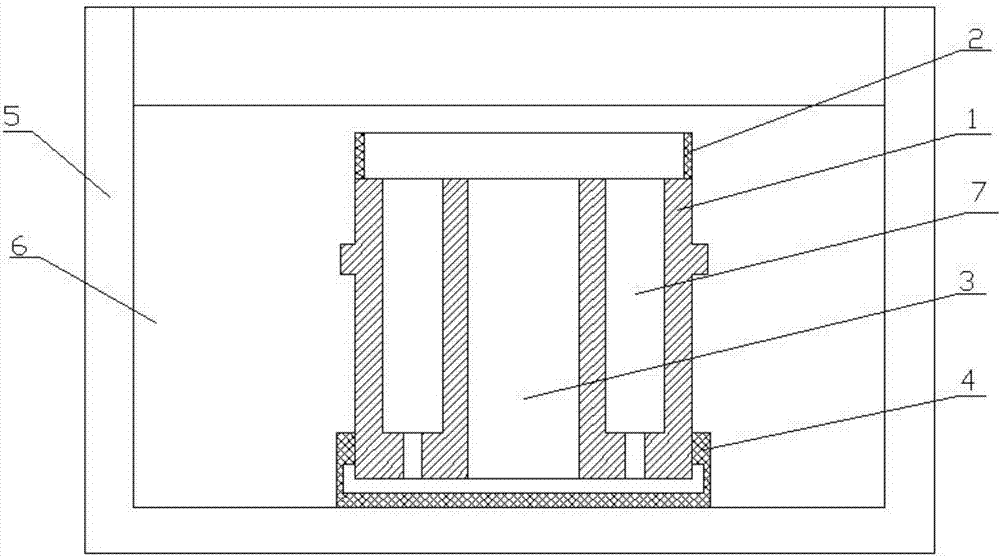

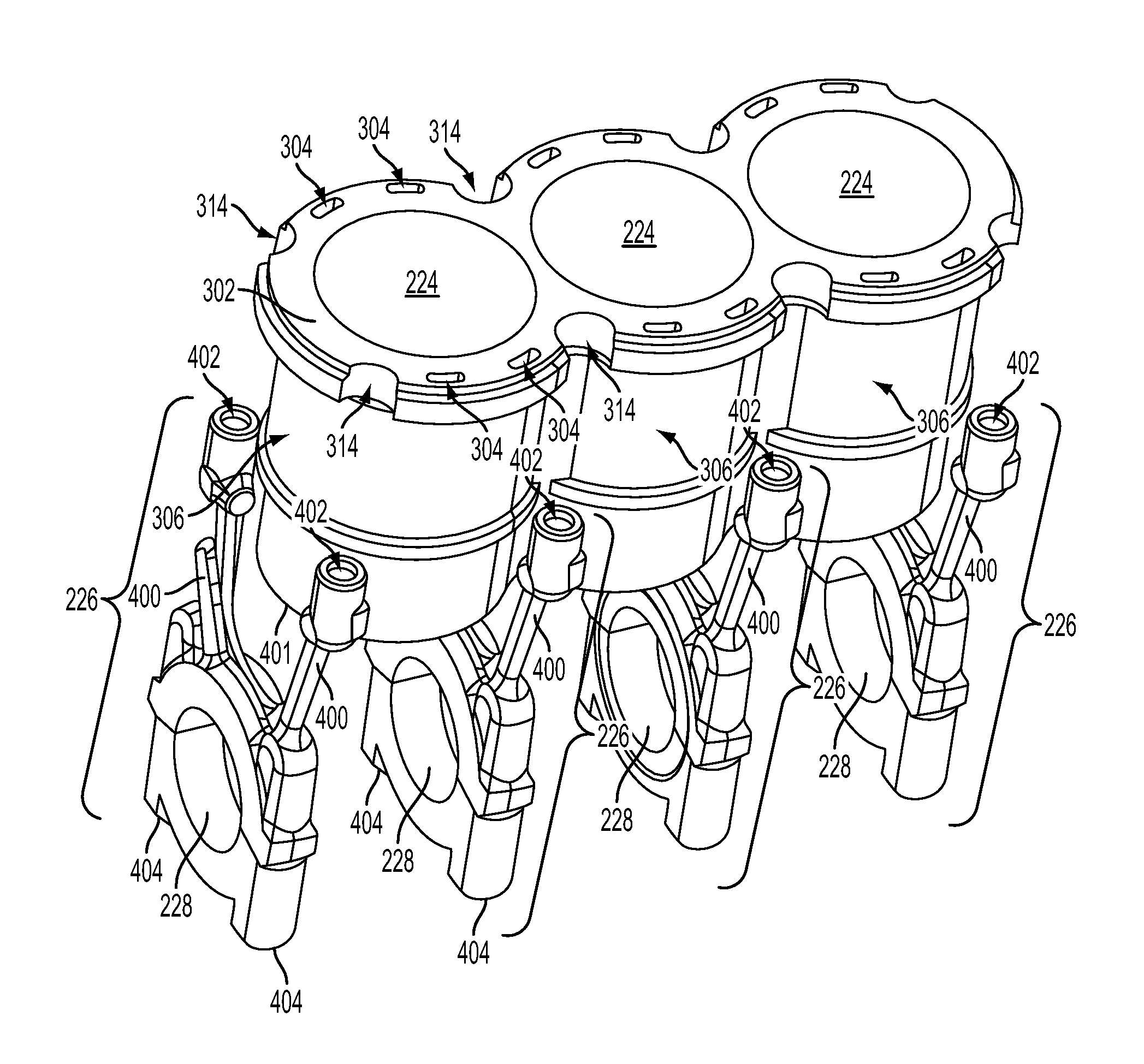

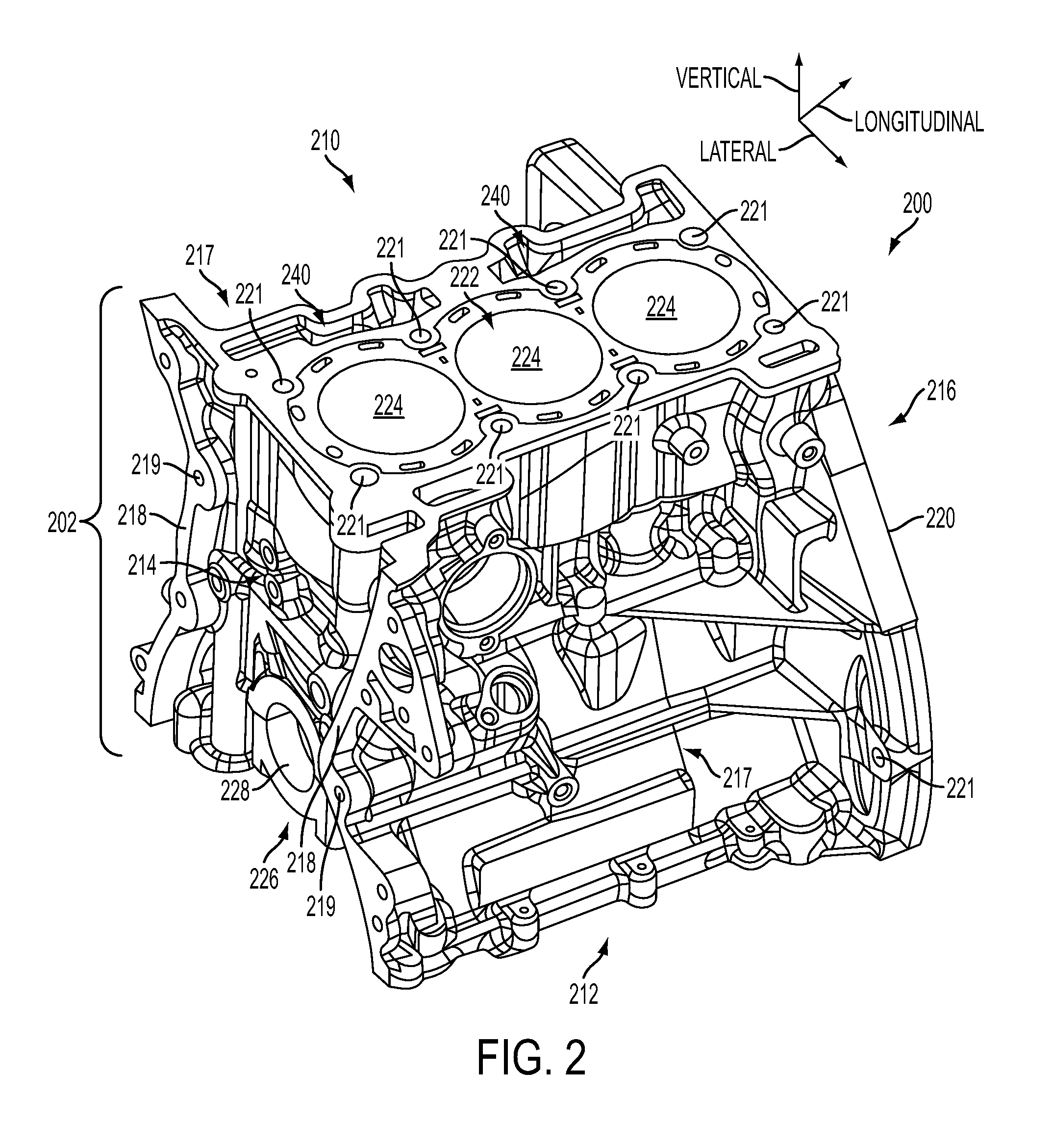

Engine having composite cylinder block

ActiveUS20150159581A1Strength to weight ratio is relatively lowMore susceptible to corrosionCasingsCylinder headsEngineeringWater jacket

An engine is provided. The engine includes a thermo-molded composite cylinder block including a front engine cover attachment interface and a transmission attachment interface. The engine further includes a cylinder liner comprising a different material than a composite cylinder block and integrally molded with the composite cylinder block, the cylinder liner defining a portion of a boundary of a cylinder and including a top deck at least partially extending across a water jacket cavity surrounding the cylinder.

Owner:FORD GLOBAL TECH LLC

Process for the rapid fabrication of composite gas cylinders and related shapes

ActiveUS20080264551A1Reduce tensionFast thermal responsePressure vesselsDomestic articlesGas cylinderPlastic materials

A method of fabricating a composite vessel encompassing rapid manufacturing that is applicable to composite hydrogen and other gas storage tanks, both for high-pressure cylinders, as well as low-pressure conformal tanks. The process of fabrication includes using a liner, of metal or plastic materials, over which a braided or developed preform is wrapped. The dry fiber wrapped liner is placed in a mold and resin injected into the cavity formed between the liner and the mold outer walls. The liner is flooded with heated and / or cooled pressurized fluid thus enabling complete and independent process control from within the liner for both the resin injection and the cure phases. Fiber placement control is determined through combined biaxial and triaxial braid / preform design, and by wrapping at controlled tension onto the supporting liner. Fiber tension control is further enhanced by the methodology of mold loading whereby tensioning forces are enacted during actual load and close. The process may use thermoset or thermoplastic resins and any of a variety of fibrous reinforcements such as carbon, boron, glass, natural, aramid or other fibers.

Owner:A&P TECH

Engine having composite cylinder block

ActiveUS20150159582A1Small volumeDecreasing engine 's sizeCasingsCylinder headsCylinder headEngineering

An engine is provided. The engine includes a thermal set composite cylinder block including a front engine cover attachment interface and a transmission attachment interface and a cylinder liner integrally molded with the composite cylinder block, the cylinder liner defining a portion of a boundary of a cylinder. The engine further includes a bulkhead insert extending through the thermal set composite cylinder block and is directly coupled to a cylinder head.

Owner:FORD GLOBAL TECH LLC

Casting method for steel-copper composite cylinder

A casting method for a steel-copper composite cylinder comprises the steps that three-dimensional modeling, casting technology designing and technology simulating and optimizing, steel base heat treatment, machining and tool machining and welding and steel base surface treatment are sequentially carried out, preheat treatment on a steel base before production is carried out, anhydrous borax is melted, the steel base is placed into a borax solution, copper alloy is smelted, the copper alloy is cast into the steel base, the steel base is placed into a water trough and is cooled and solidified to the room temperature, and then the steel-copper composite cylinder is manufactured. The method solves the problems about the steel-copper cylinder composite casting technology and composite components. The bi-metal cylinder is high in composite strength, high in yield and low in cost, the size of the cylinder is not limited, the forming process is easy to control, and the quality is stable.

Owner:徐宏

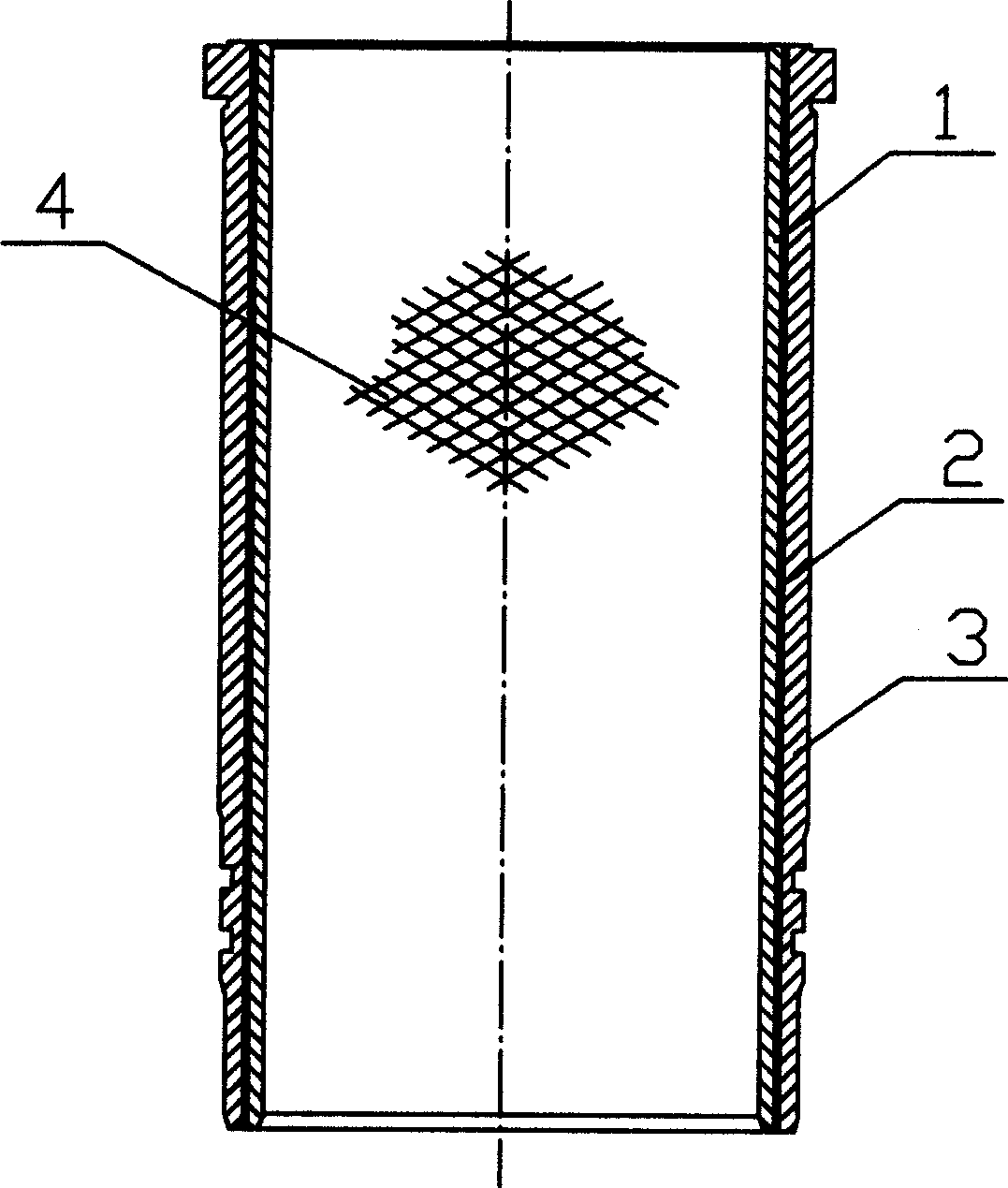

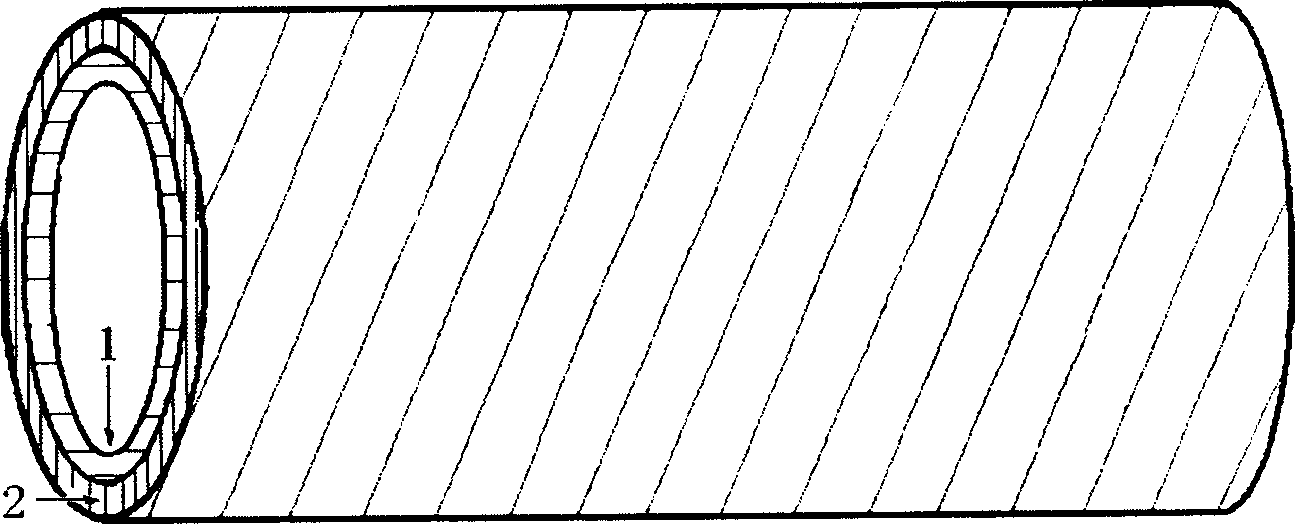

Hydraulic pressure resistant, corrosion resistant, light composite cylindrical thin-walled casing and manufacturing method thereof

InactiveCN1866405AUniform internal stressUniform wall thicknessLaminationLamination apparatusEpoxyCarbon fibers

The disclosed hydraulic-withstand corrosion-resisting light composite cylinder thin-wall shell is manufactured as: coating fiber reinforced thermosetting resin that is prepared by carbon fiber or glass fiber added epoxy resin, polyimide resin, phenol resin or polyurethane resin on cast hard Al alloy outside surface. Wherein, the composite structure with pre-stress has higher rigidness, better hydraulic-withstand and corrosion-resisting capacity. This invention has wide application.

Owner:北京诚恩电子材料有限责任公司 +1

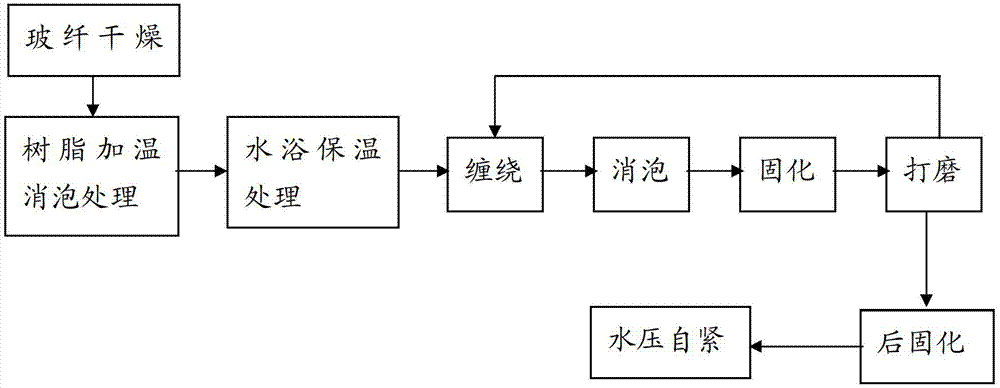

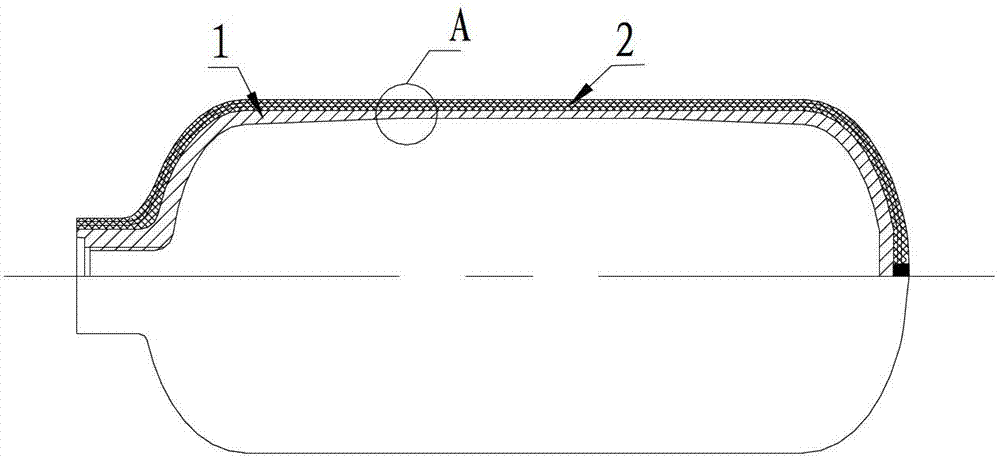

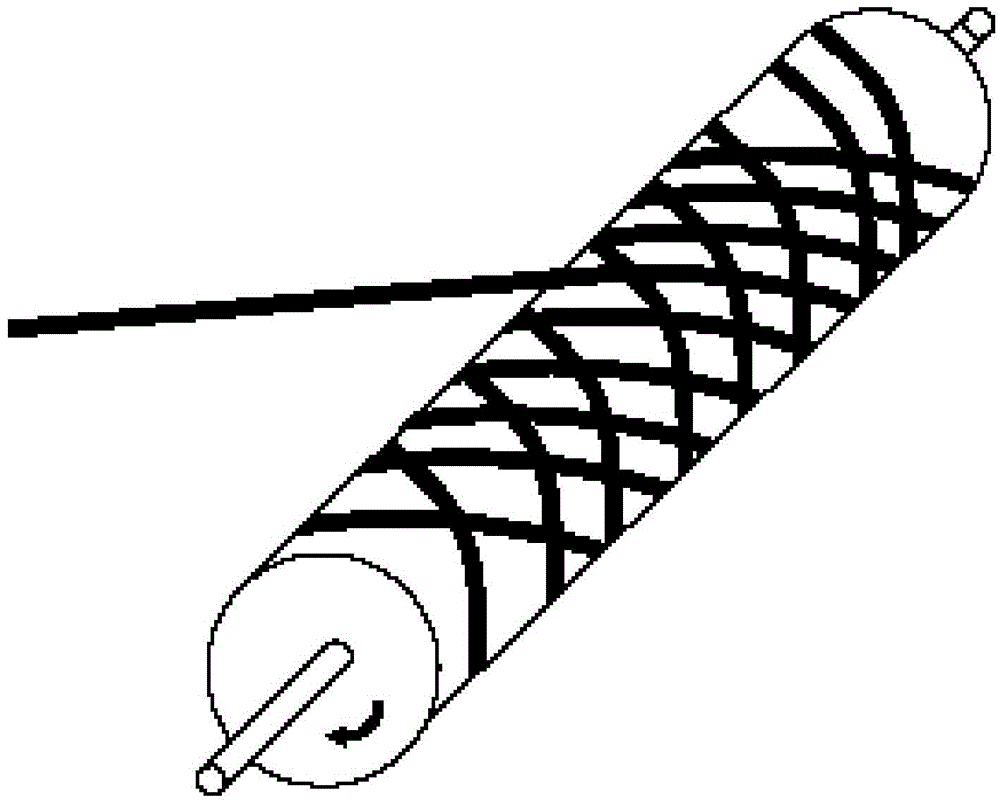

Glass fiber all-winding aluminum liner composite cylinder and manufacturing process thereof

The invention discloses a glass fiber all-winding aluminum liner composite cylinder and a manufacturing process thereof. The process comprises the following steps of: (1) carrying out drying treatment on the glass fiber, defoaming epoxy resin matrix, then uniformly mixing with a curing agent to obtain resin matrix, and carrying out water bath thermal insulation on the resin matrix; (2) soaking the glass fiber subjected to the drying treatment in the resin matrix of water bath thermal insulation to obtain a glass fiber reinforced resin matrix composite material; (3) winding the glass fiber reinforced resin matrix composite material for 2-5 layers on the surface of the aluminum alloy liner, and defoaming, curing and carrying out surface polishing after winding one layer; and (4) curing and carrying out water self-compacting treatment after winding the final layer. Compared with the production technology of a carbon fiber all-winding aluminum liner gas cylinder, the process has the advantages of saving the insulating layer of aluminum liner surface and the protective layer of the air cylinder surface, so that the forming process is simplified, and the efficiency is improved.

Owner:ZHEJIANG KAIBO PRESSURE VESSEL

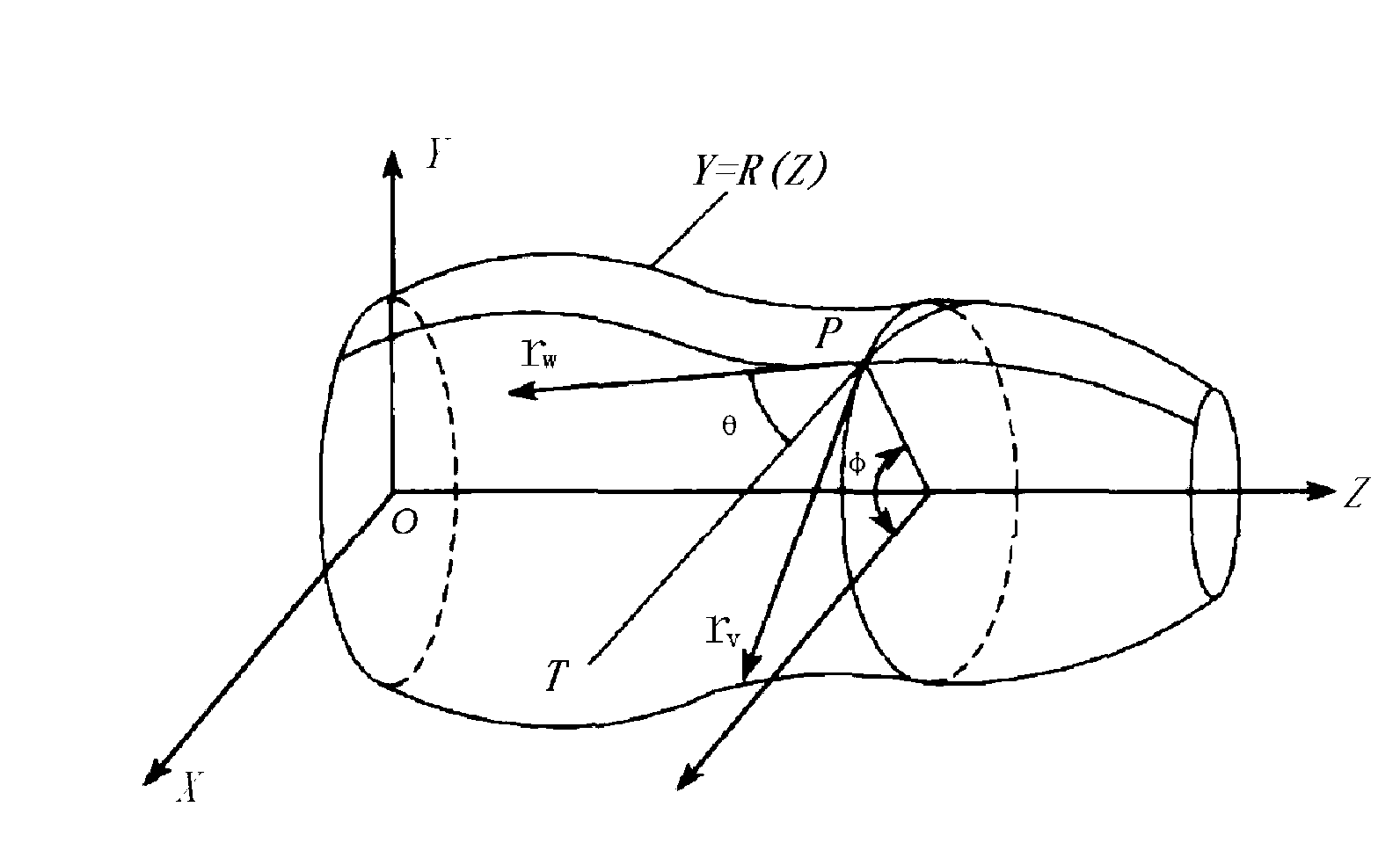

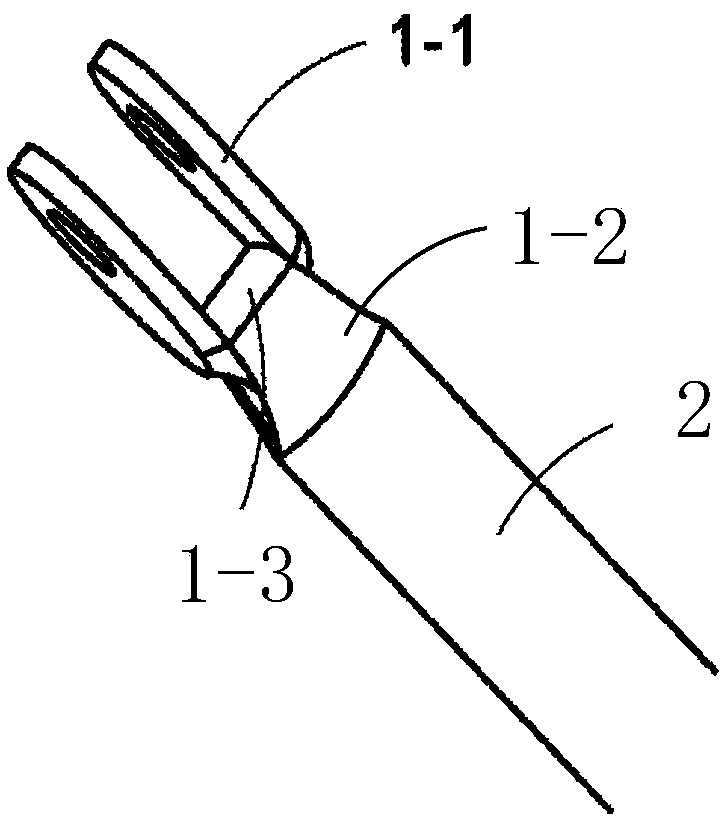

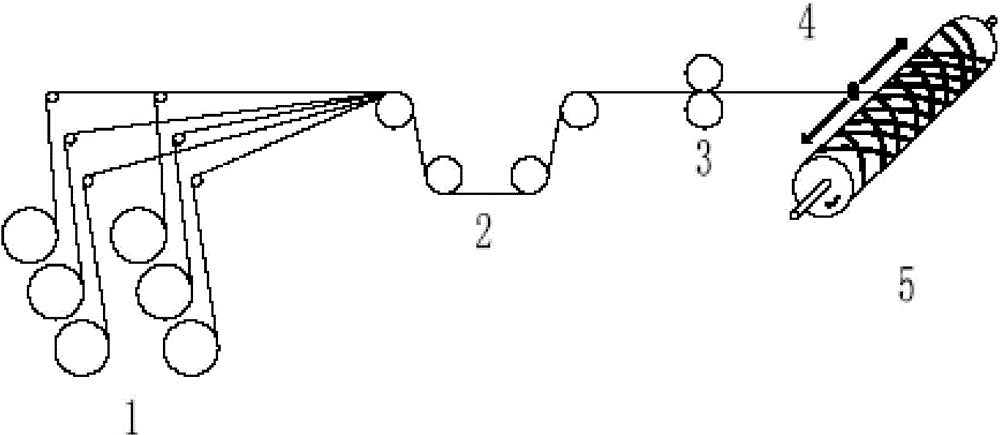

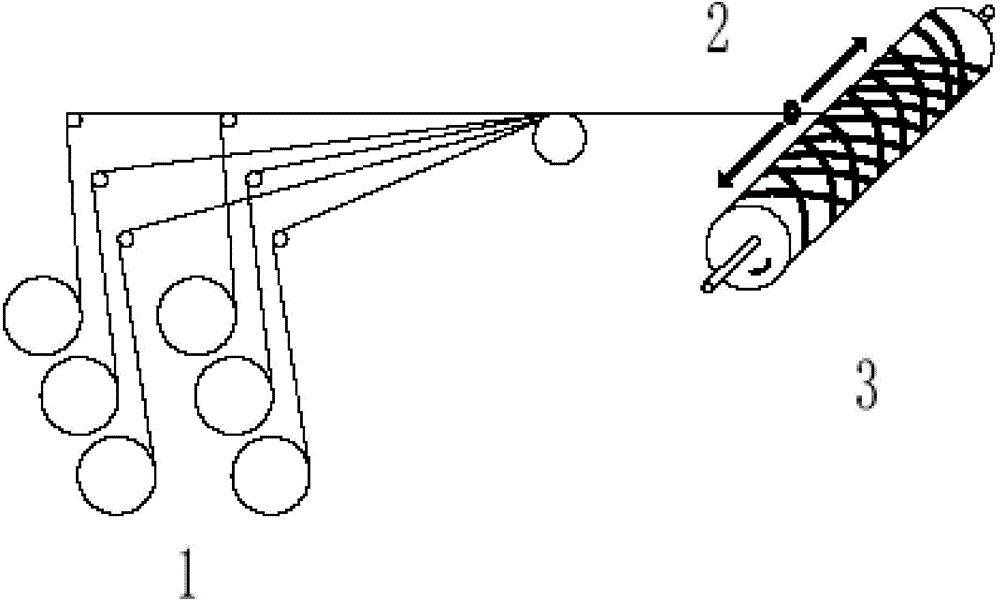

Wiring method for fibers for monitoring composite cylinder

ActiveCN103076331AAvoid entanglementAvoid failure damageMaterial analysis by optical meansWinding machineGas cylinder

The invention relates to a wiring method for fibers for monitoring a composite cylinder. The method comprises the steps as follows: (1) clamping a cylinder liner on a main shaft of a numerically controlled winding machine; (2) arranging the fibers on the surface of the cylinder liner; (3) forming in a winding way and solidifying a composite layer of the cylinder; and (4) performing a water pressure self-tightening test. According to the structural characteristics of the columnar composite cylinder, a winding geometric planning programming method of a geodesic line or a non-geodesic line of the composite cylinder is simulated, a geodesic line or a non-geodesic line fiber wiring method with the wiring direction changed gradually is adopted firstly, gradual change track wiring of the fibers for measuring stress, strain and temperature in any angle and direction is implemented, the fiber damage failure resulting from the relatively large stress difference between a winding layer fiber and a fiber is avoided in the winding forming process of the cylinder, the solidifying process of the cylinder and the water pressure test process after an optical fiber sensor is implanted, and the survival rate of the fibers implanting in a cylinder layer is greatly increased.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

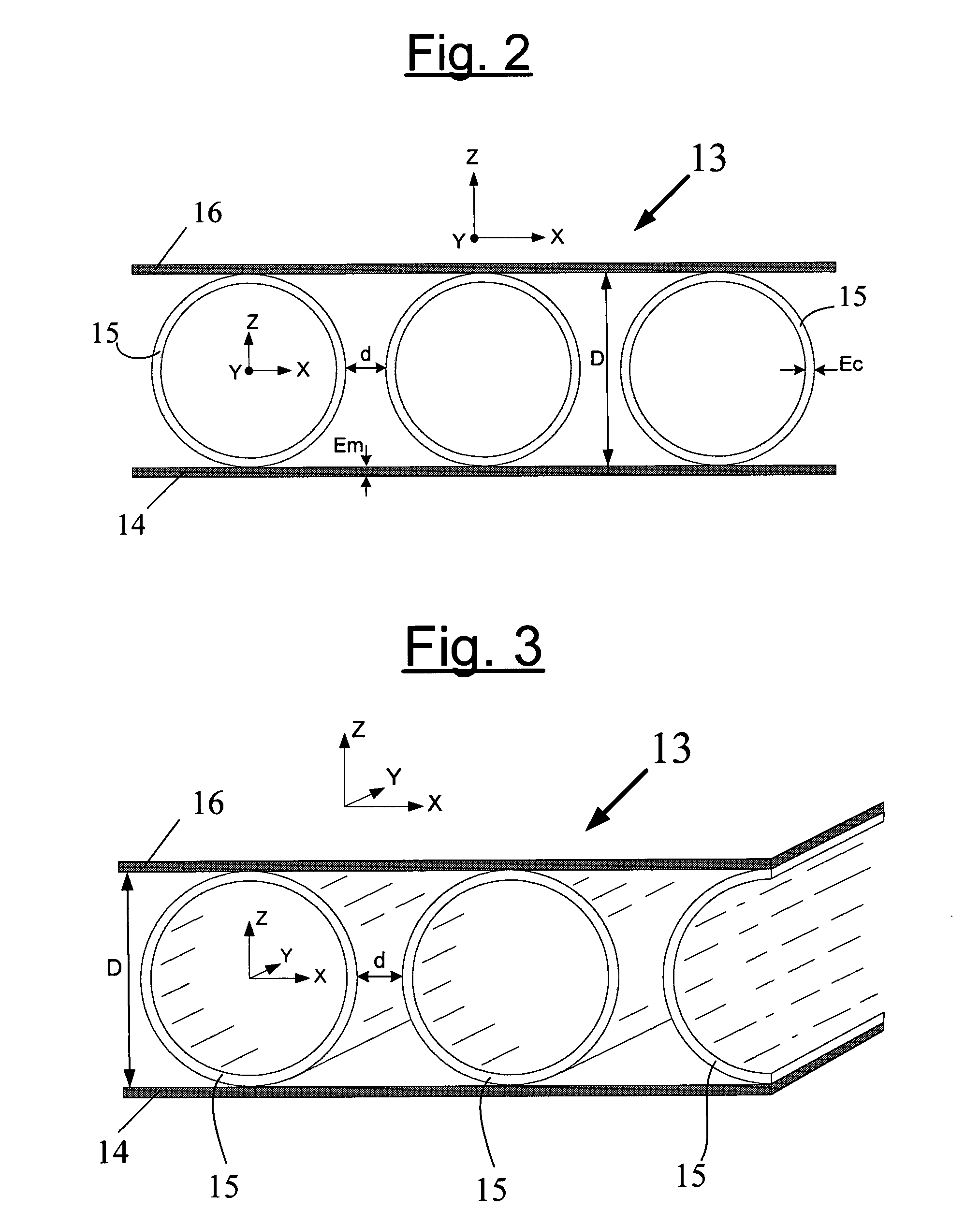

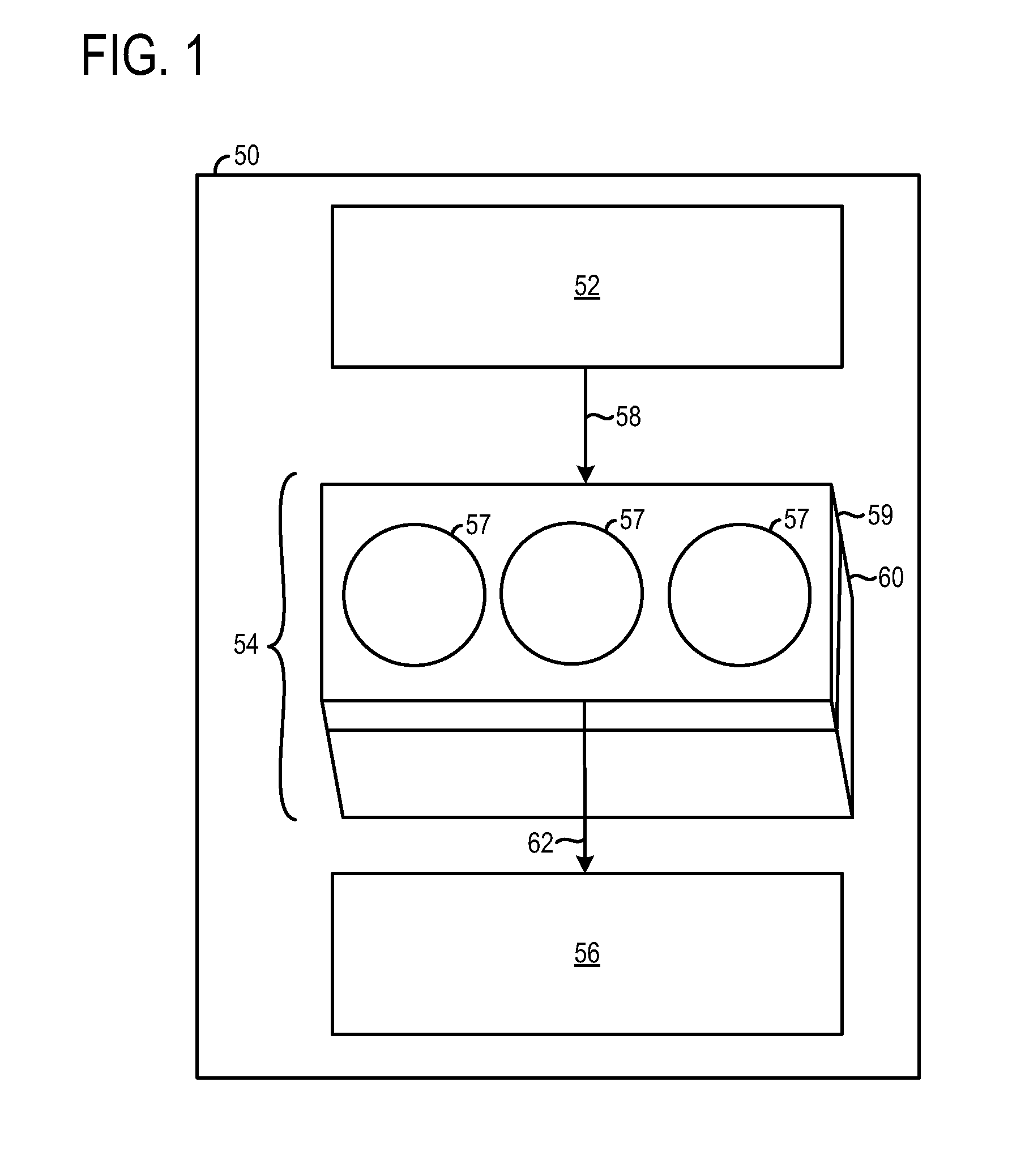

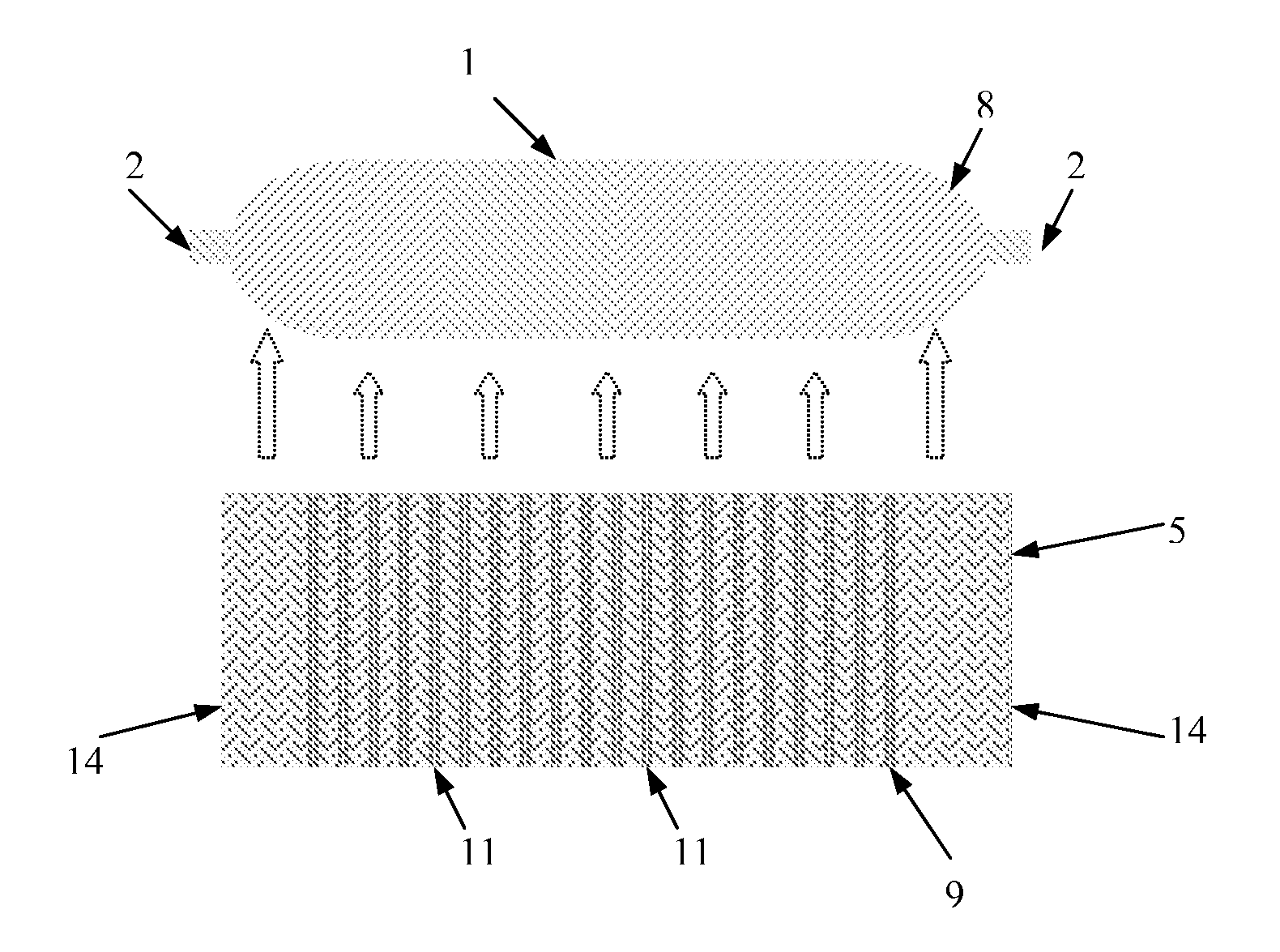

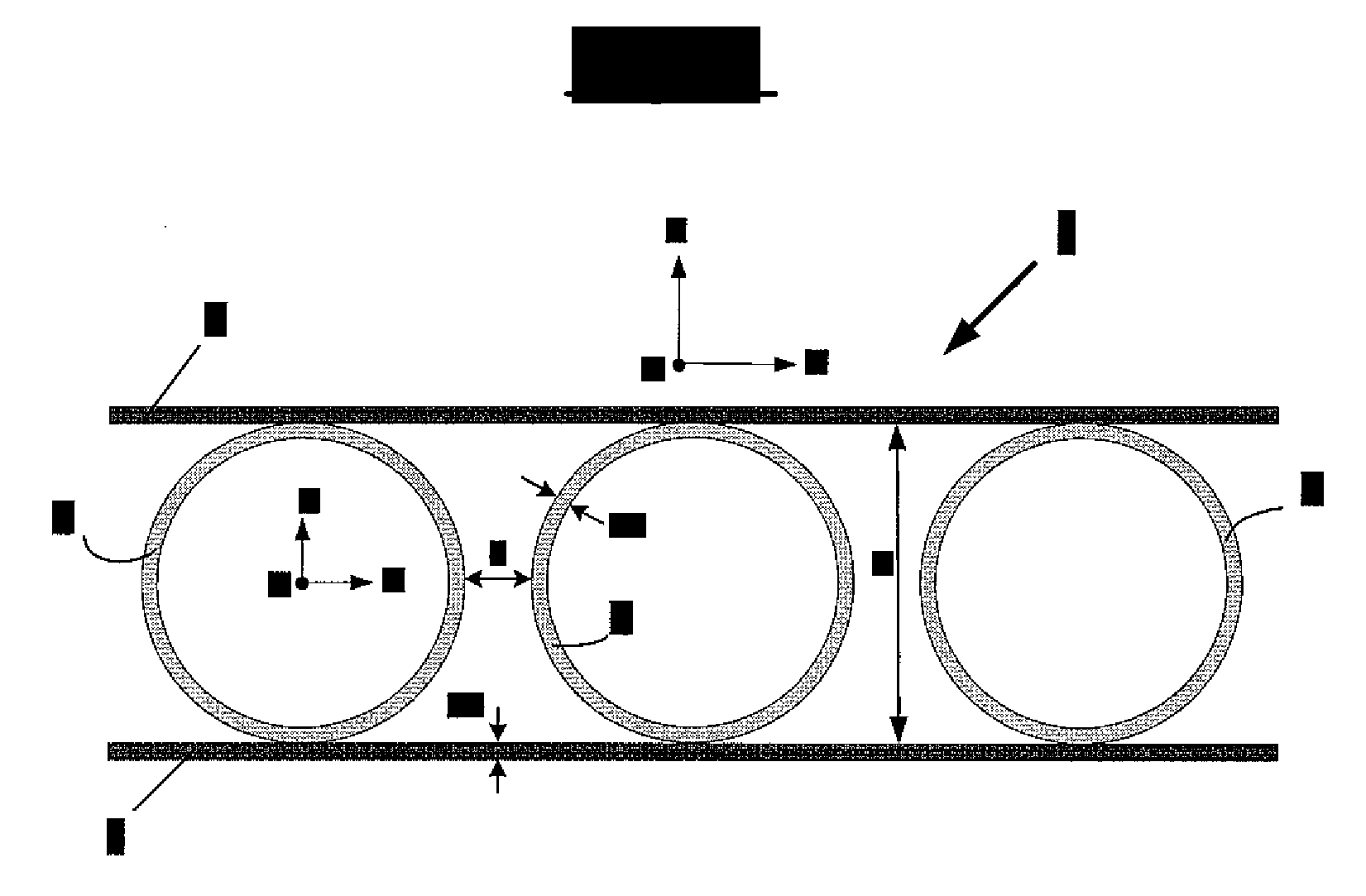

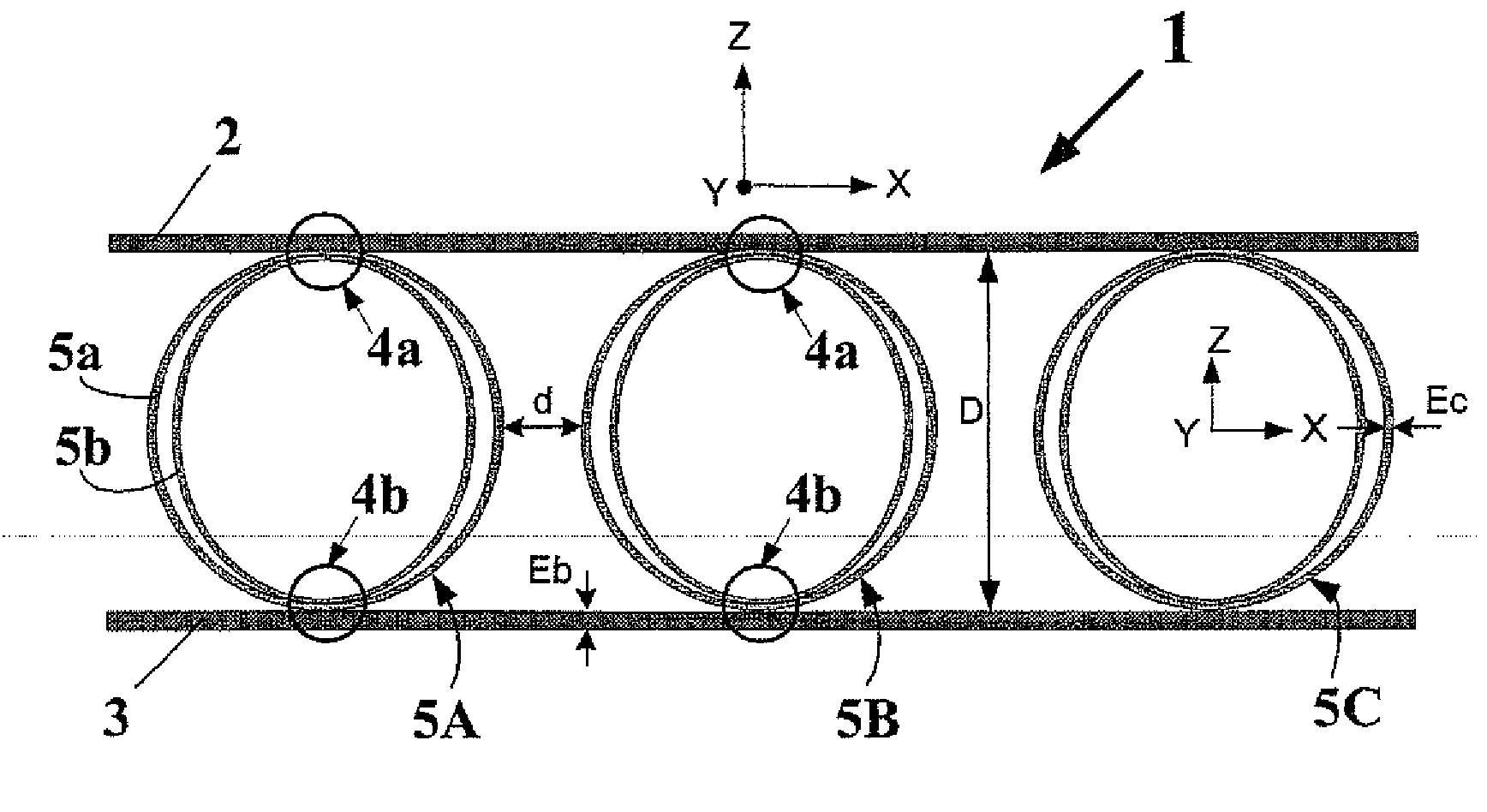

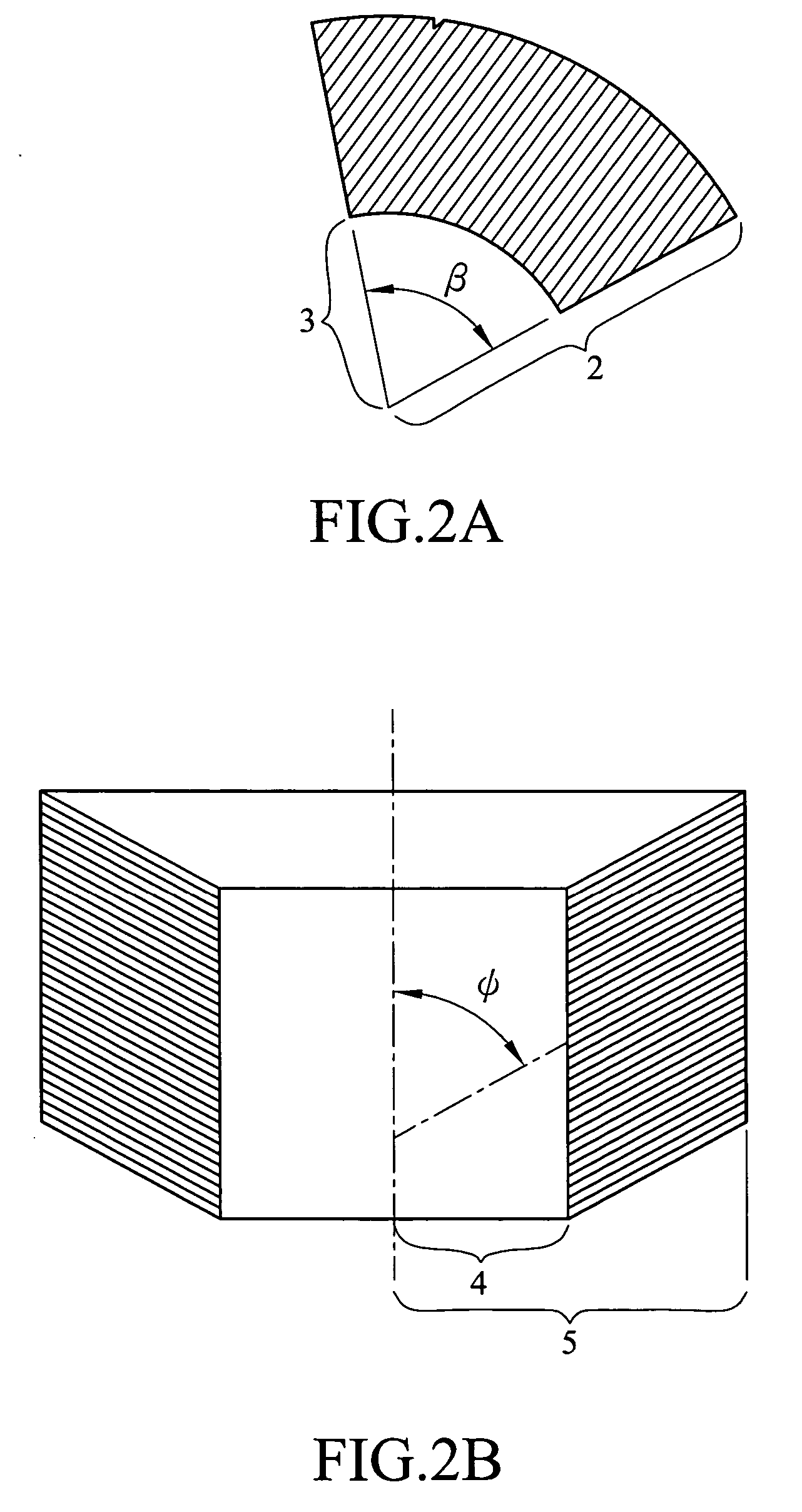

Composite Laminated Product

ActiveUS20100260967A1Overcomes drawbackWide temperature rangeLayered productsNon-inflatable tyresFiberHigh resistance

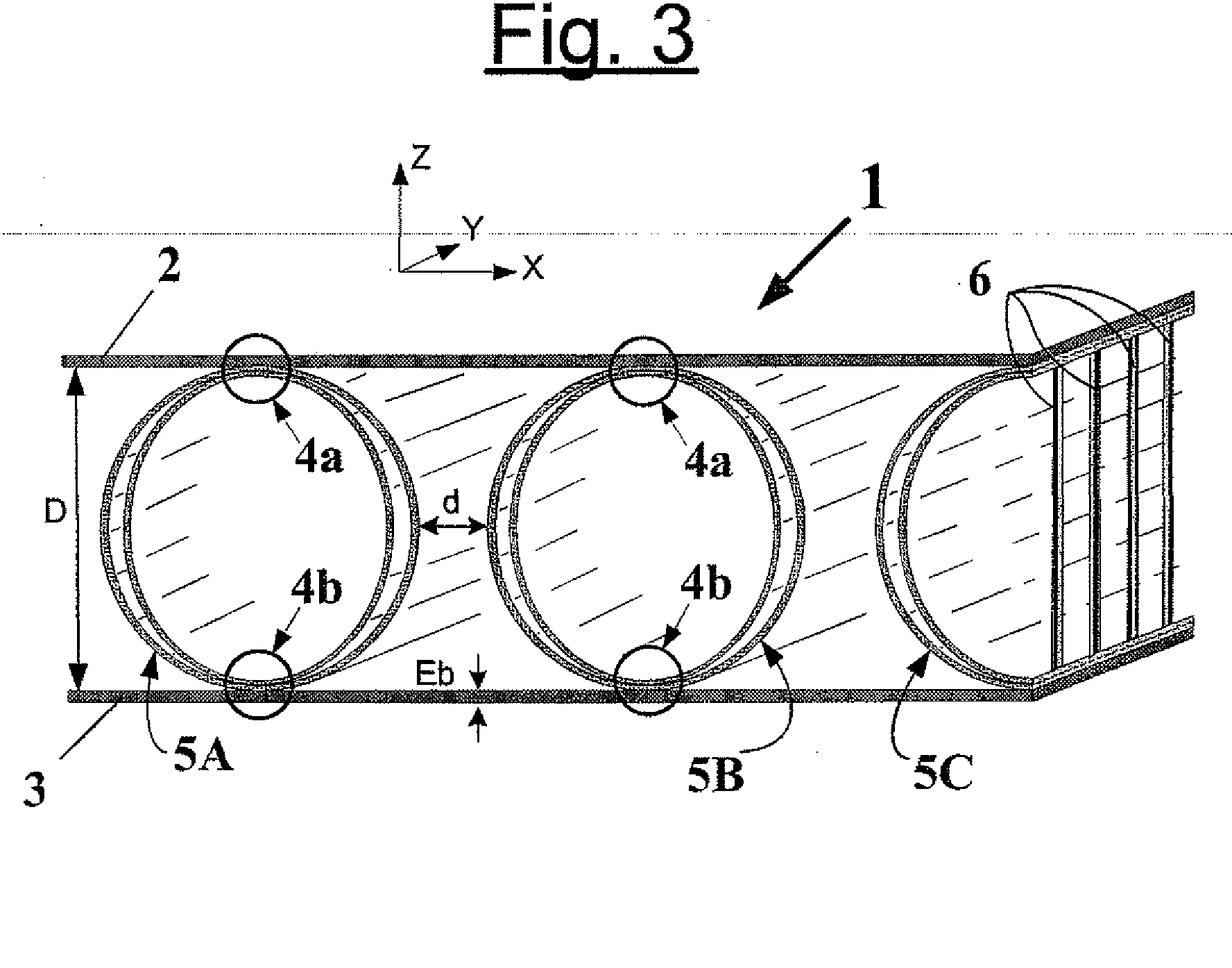

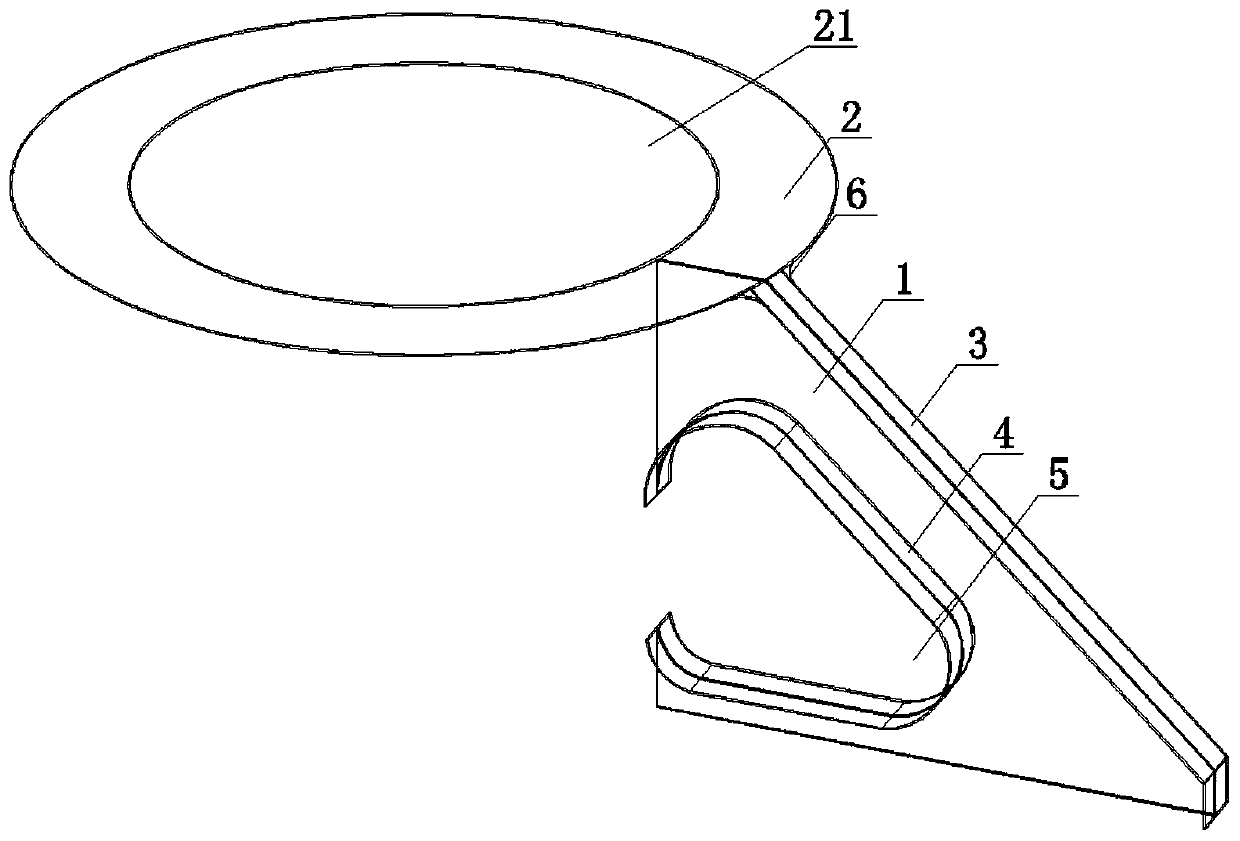

Composite laminated product (1) that forms a deformable cellular structure, comprising: an upper band (2) and a lower band (3) both oriented in the same main direction (X); and between the two bands (2, 3) and connecting the latter, a series that extends in the direction X, of cylinders (4) referred to as connection cylinders, said connection cylinders (4) being non-touching in the direction X and having their generatrix oriented along an axis Y perpendicular to the direction X. The connection cylinders are composite cylinders comprising fibres embedded in a resin matrix. Such a laminated product can be used as an elastic beam having a high resistance to flexural / compressive stresses and having a high endurance to such repeated or alternated stresses, in particular as a shear band in a non-pneumatic resilient wheel.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

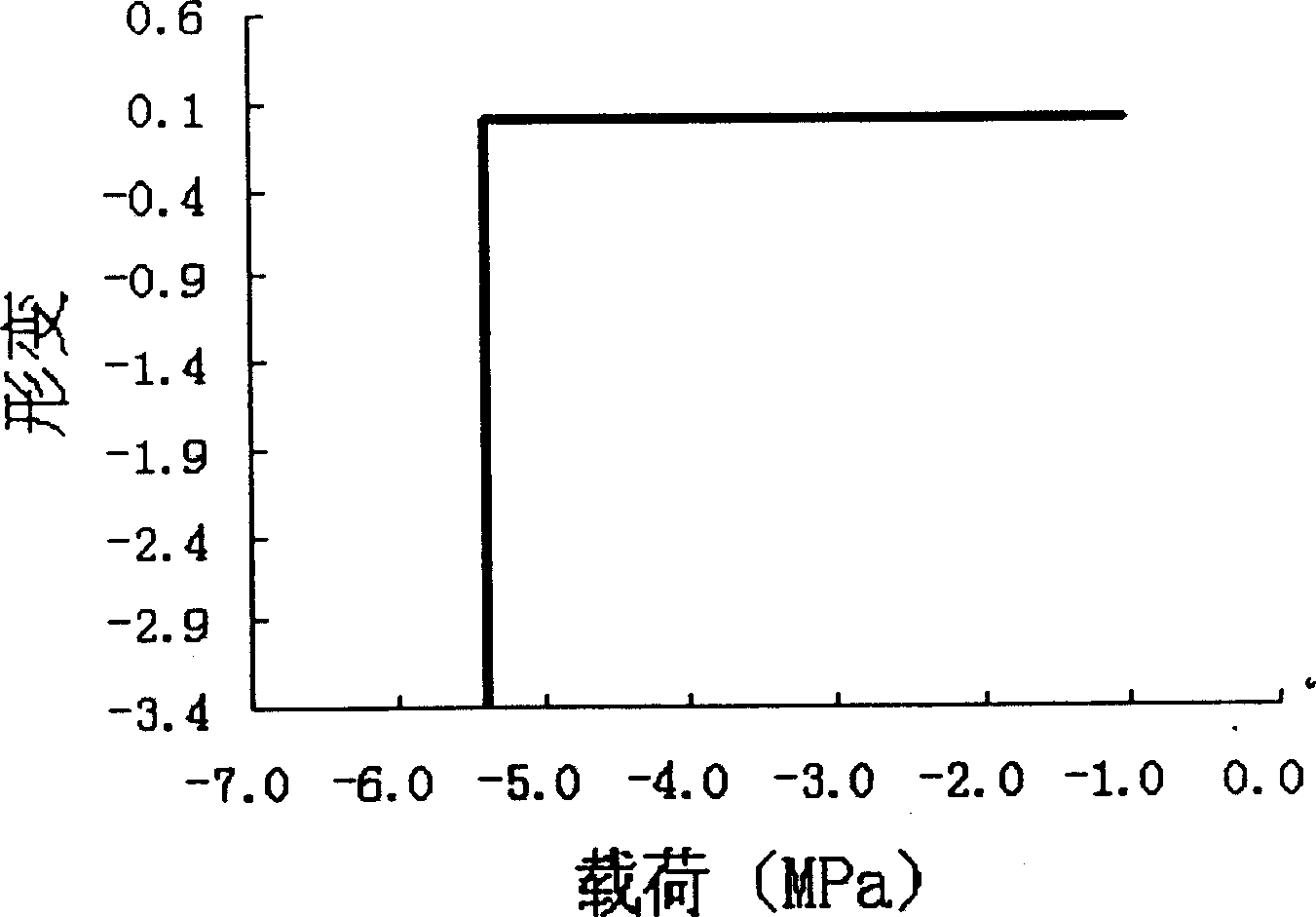

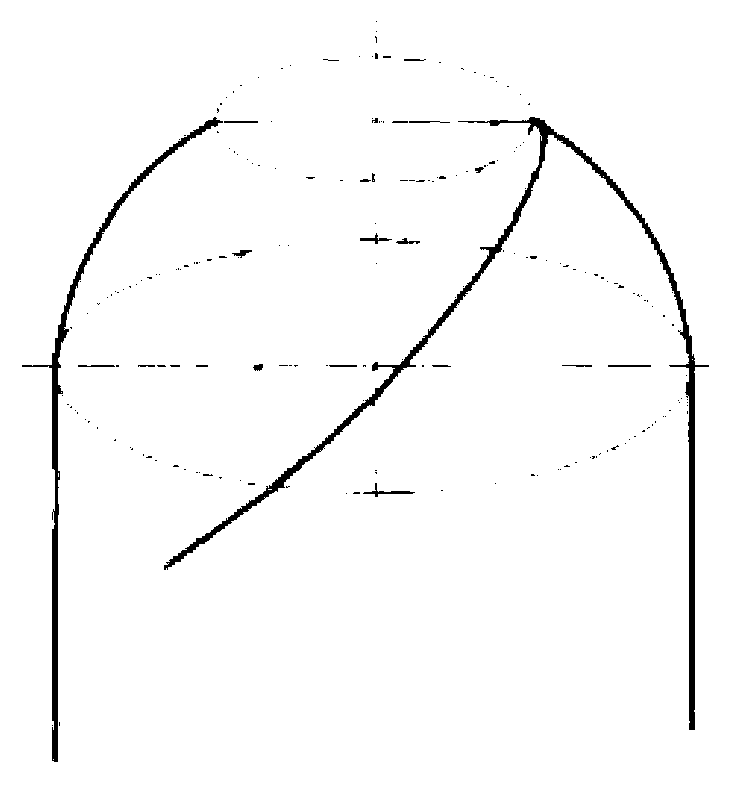

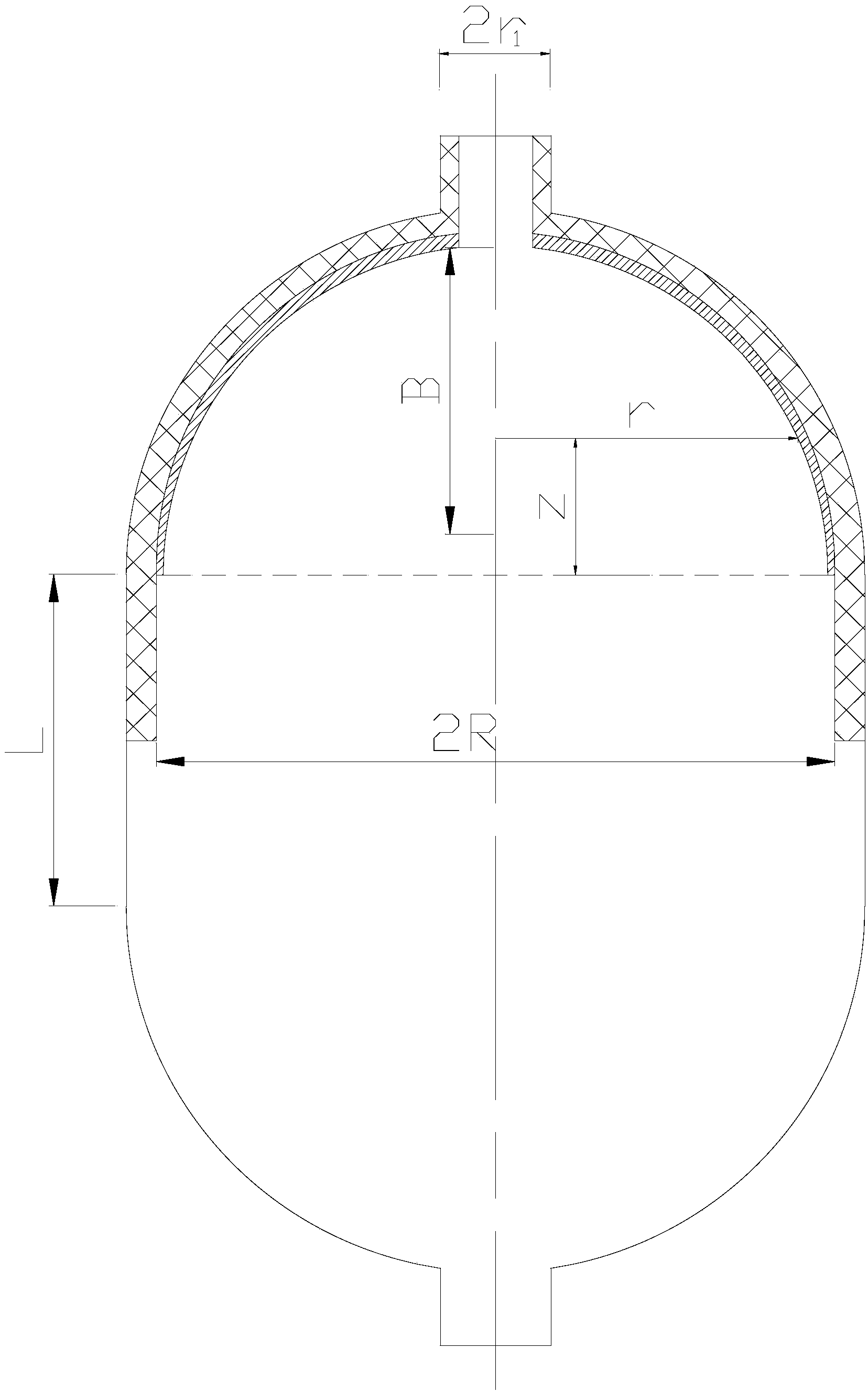

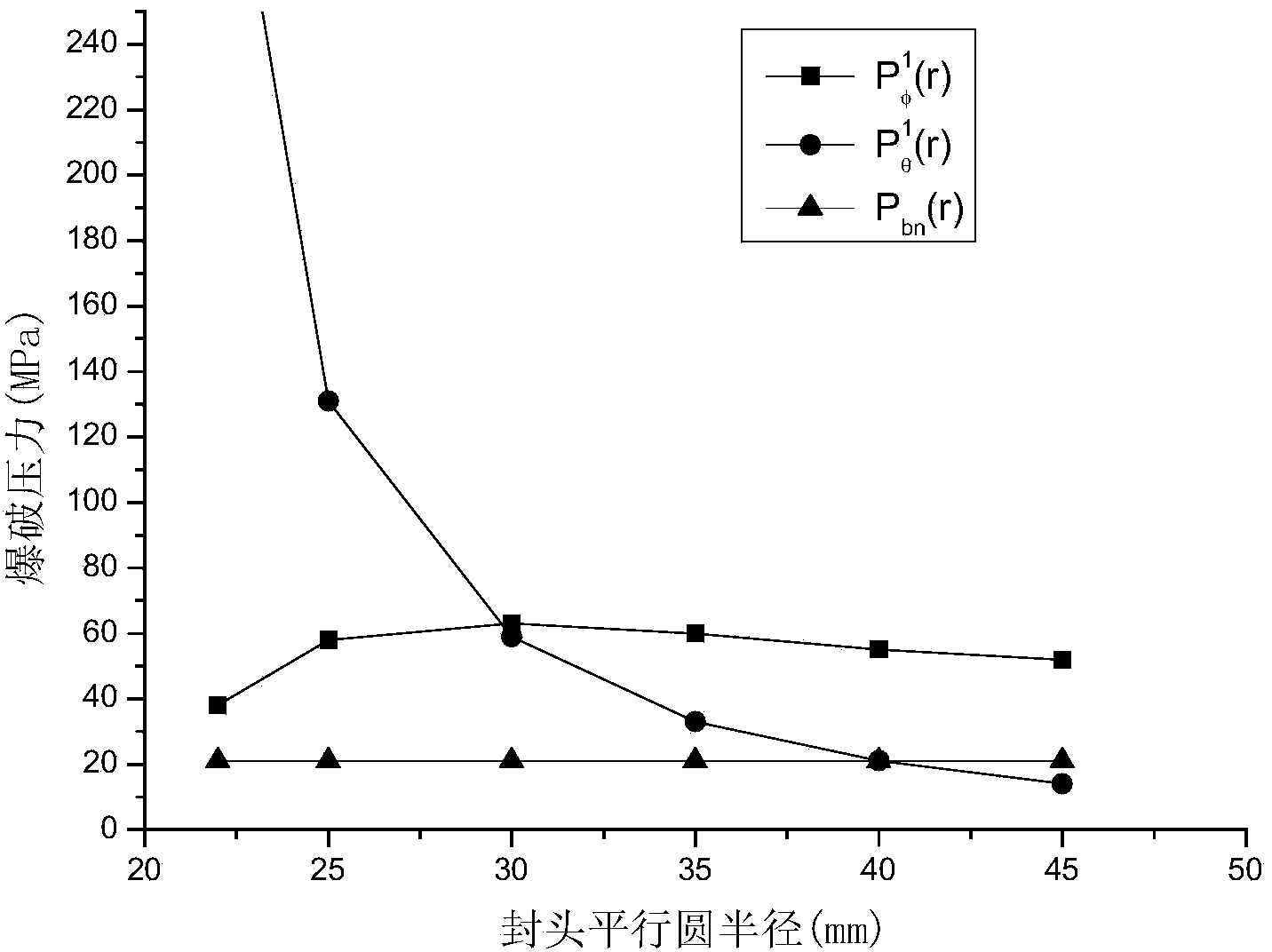

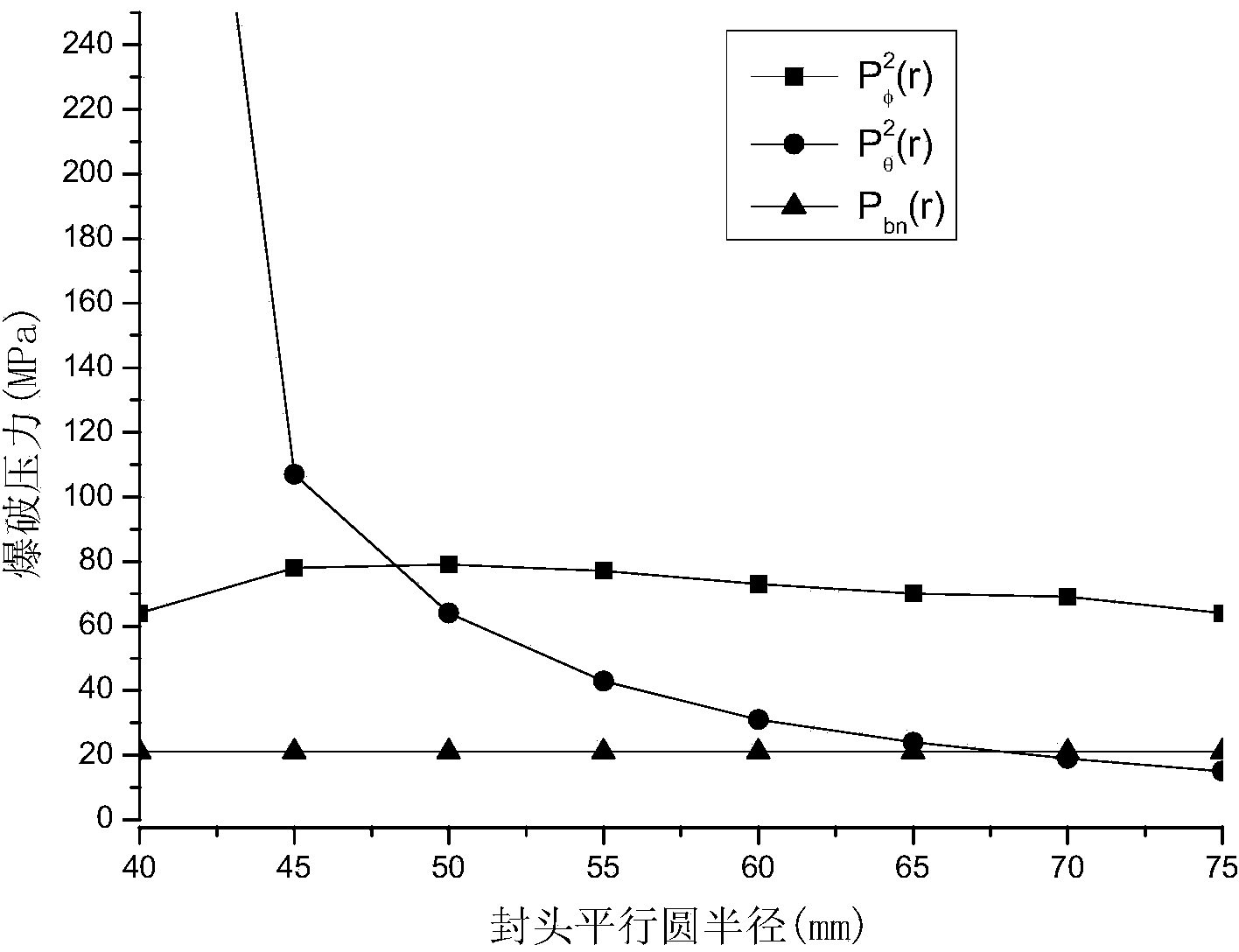

Design method of head-tube body integration filament-wound composite cylinder

ActiveCN103672388ARapid Design OptimizationReduce repetitionPressure vesselsGas cylinderNatural gas storage

The invention relates to a design method of a head-tube body integration filament-wound composite cylinder. The composite cylinder can be used as high-pressure cylinders of rockets and missiles, vehicular natural gas storage pressure vessels and the like. According to the method, the quick and optimized design of the composite high-pressure cylinder winding and laying can be realized, and the repeatability of cylinder design, analysis and verification is reduced or even avoided.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG +1

Casting method for steel-copper composite cylinder body

InactiveCN107096905AImprove corrosion resistanceImprove wear resistanceInternal combustion piston enginesCylindersCopper cylinderComposite cylinder

The invention discloses a casting method for a steel-copper composite cylinder body. The casting method comprises the steps of performing three-dimensional modeling, designing a casting technology and performing technology simulation and optimization, performing base steel heat treatment, performing machining, tool machining and welding, performing base steel surface treatment, performing pre-heating treatment before base steel production, smelting copper alloy, dipping the copper alloy, melting anhydrous borax, putting base steel into a borax solution, pouring the copper alloy into the base steel, putting the base steel into a water tank and cooling and solidifying the base steel to room temperature to obtain the steel-copper composite cylinder body. According to the casting method, the problems of the composite casting technology and the composite material composition of the steel-copper cylinder body can be solved; and the composite strength of the thermometal cylinder body can be high, the yield can be high, the cost can be low, the size of the cylinder body can not be limited, the forming process can be controlled easily, and the quality can be stable.

Owner:安徽恒利增材制造科技有限公司

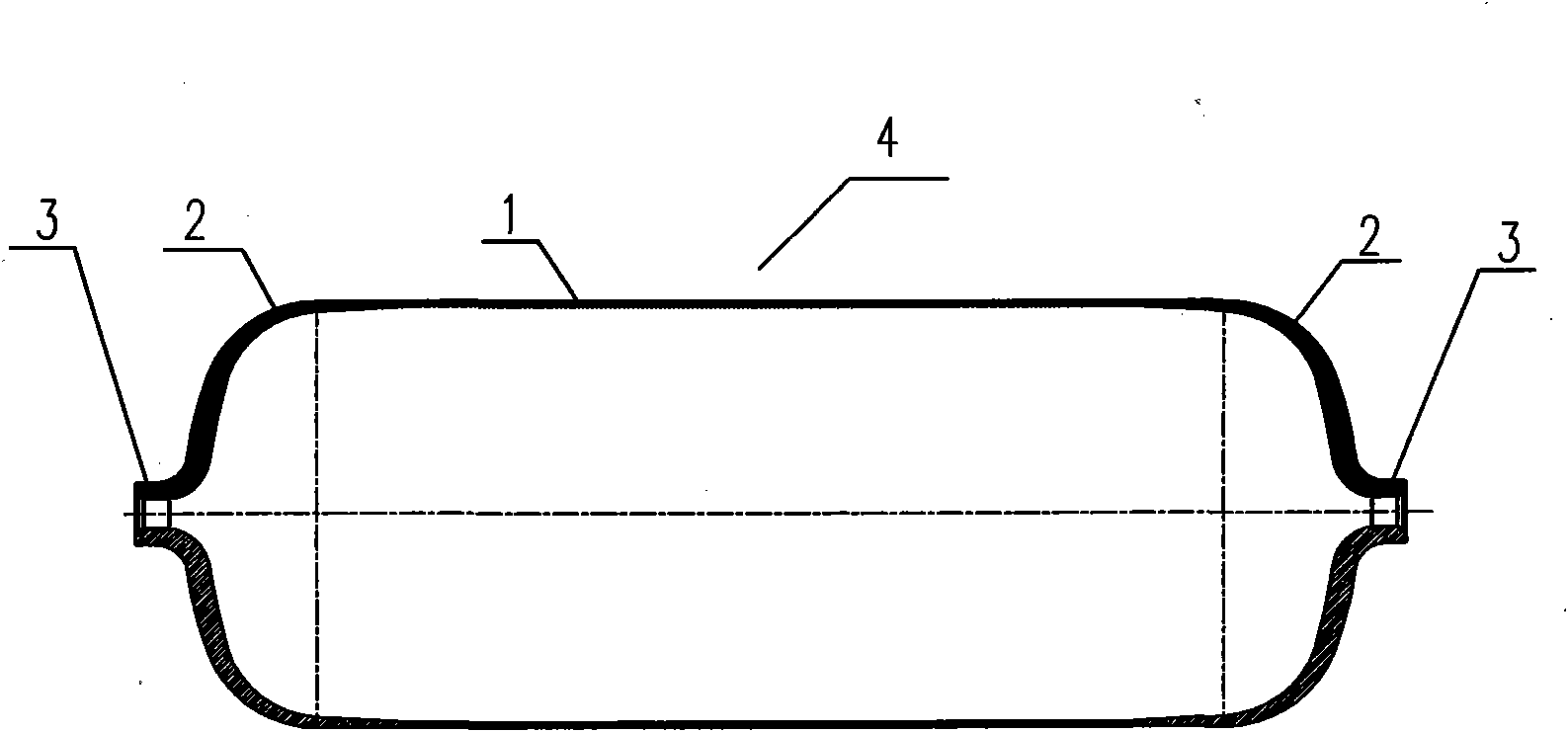

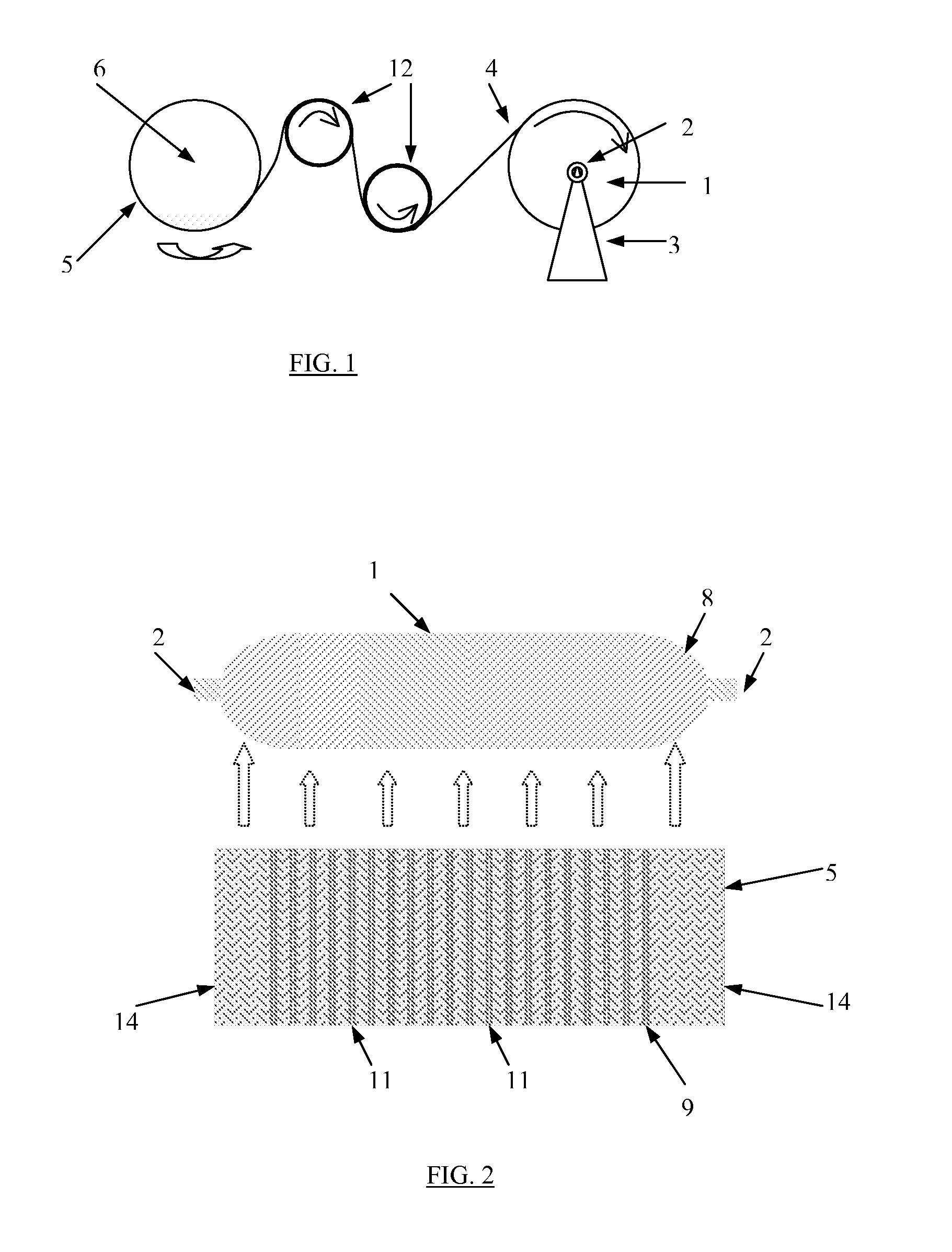

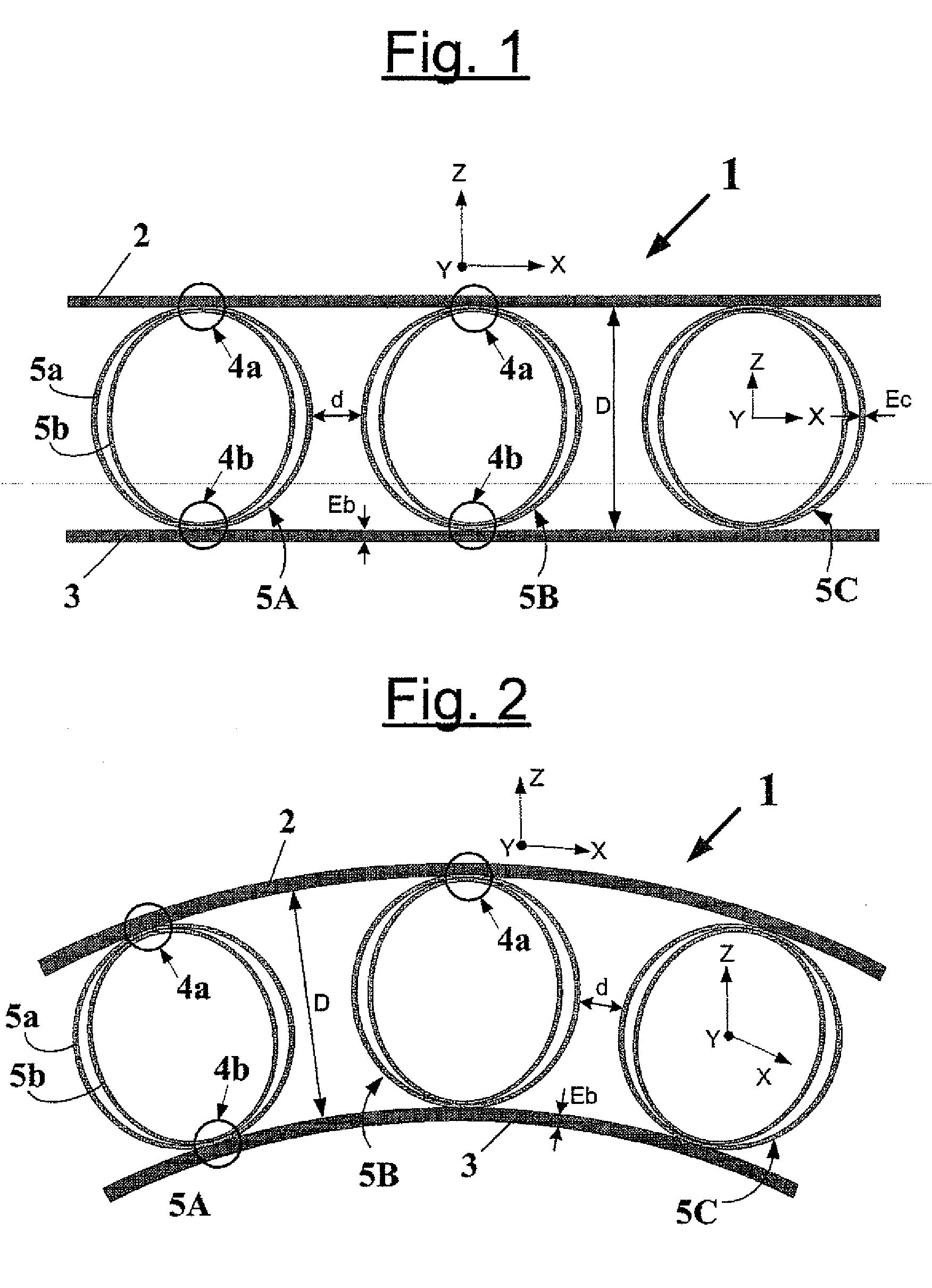

Composite Laminate Product

ActiveUS20110104428A1Overcomes drawbackSynthetic resin layered productsNon-inflatable tyresFiberHigh resistance

A laminated product (1) that forms a deformable cellular structure, comprising: an upper band (2) and a lower band (3) both oriented in the same main direction (X); and between the two bands and connecting the latter in zones (4a, 4b) referred to anchoring zones, a series (5A, 5B, 5C) that extends in the direction X, of cylindrical structures (5) referred to connecting cylindrical structures that are non-touching in the direction X. Each connecting cylindrical structure (5) comprises a plurality of preferably concentric elementary cylinders (5a, 5b) having their generatrix oriented along an axis Y perpendicular to the direction X, said elementary cylinders being fitted one inside the other and interconnected to one another in each anchoring zone (4). Said elementary cylinders are especially composite cylinders comprising fibres embedded in a resin matrix. Such a laminated product can be used as an elastic beam having a high resistance to flexural / compressive stresses and having a high endurance to such repeated or alternated stresses, in particular as a shear band in a non-pneumatic resilient wheel.

Owner:MICHELIN RECH & TECH SA +1

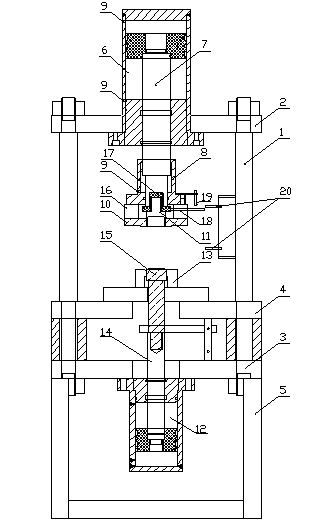

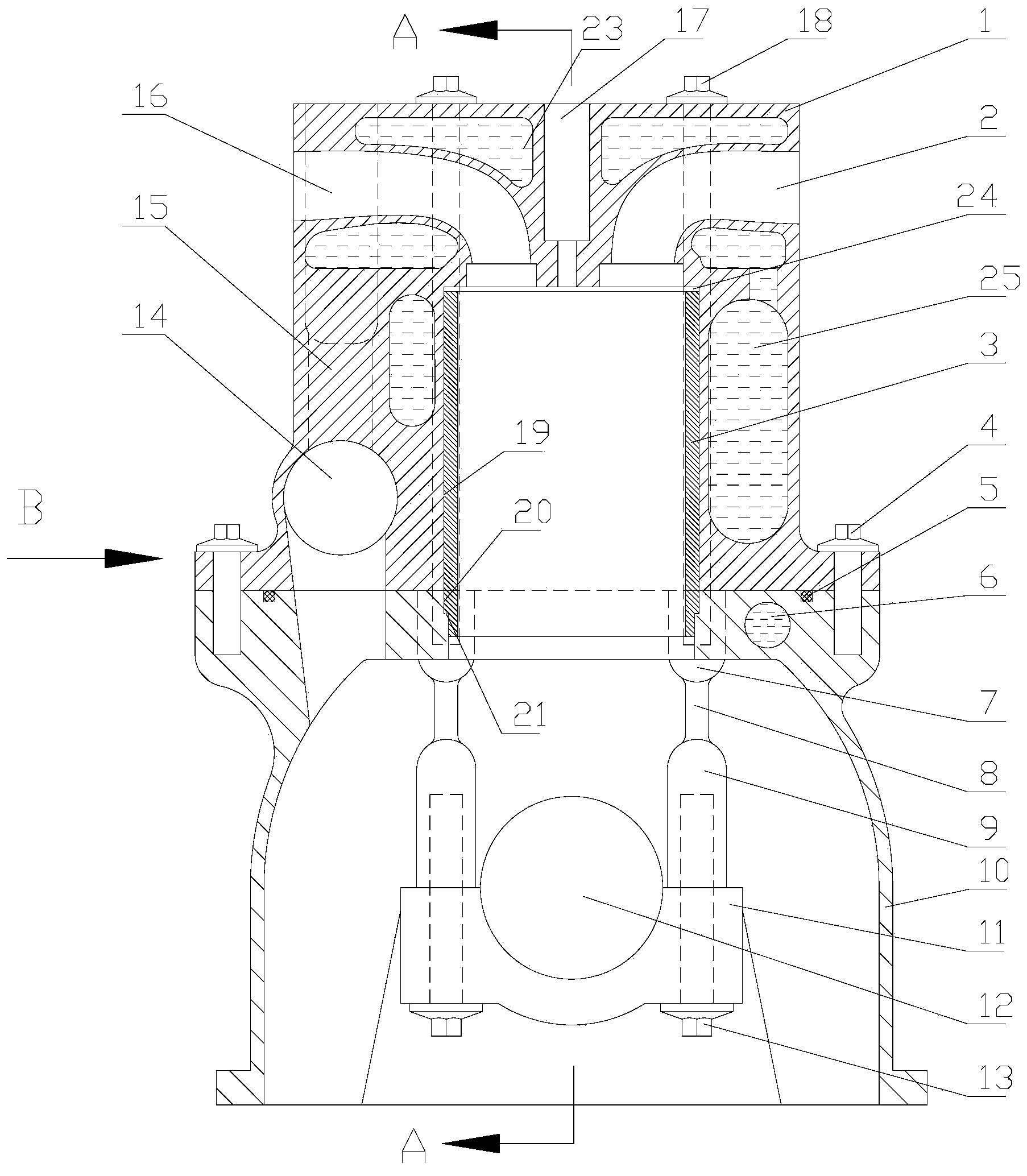

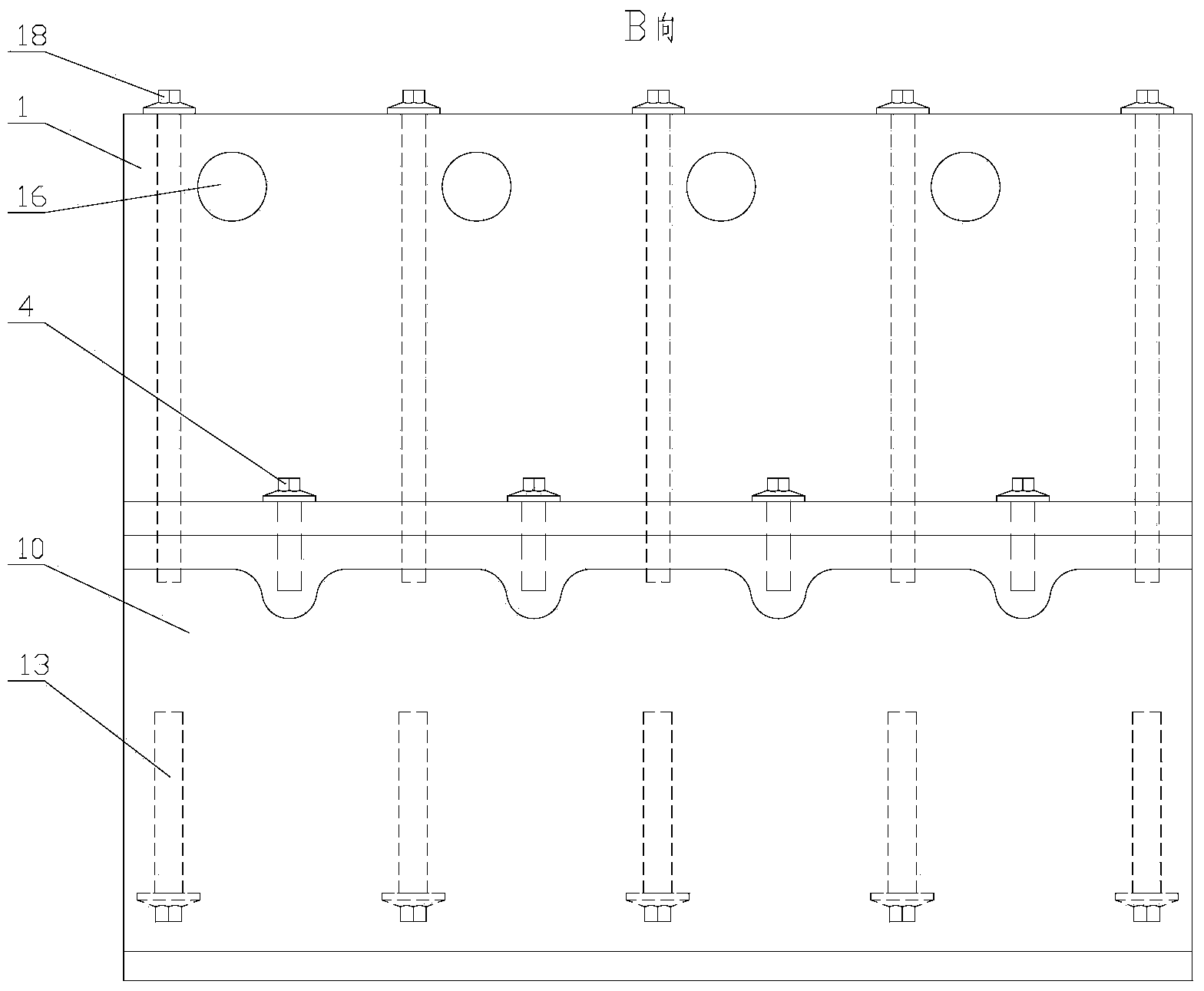

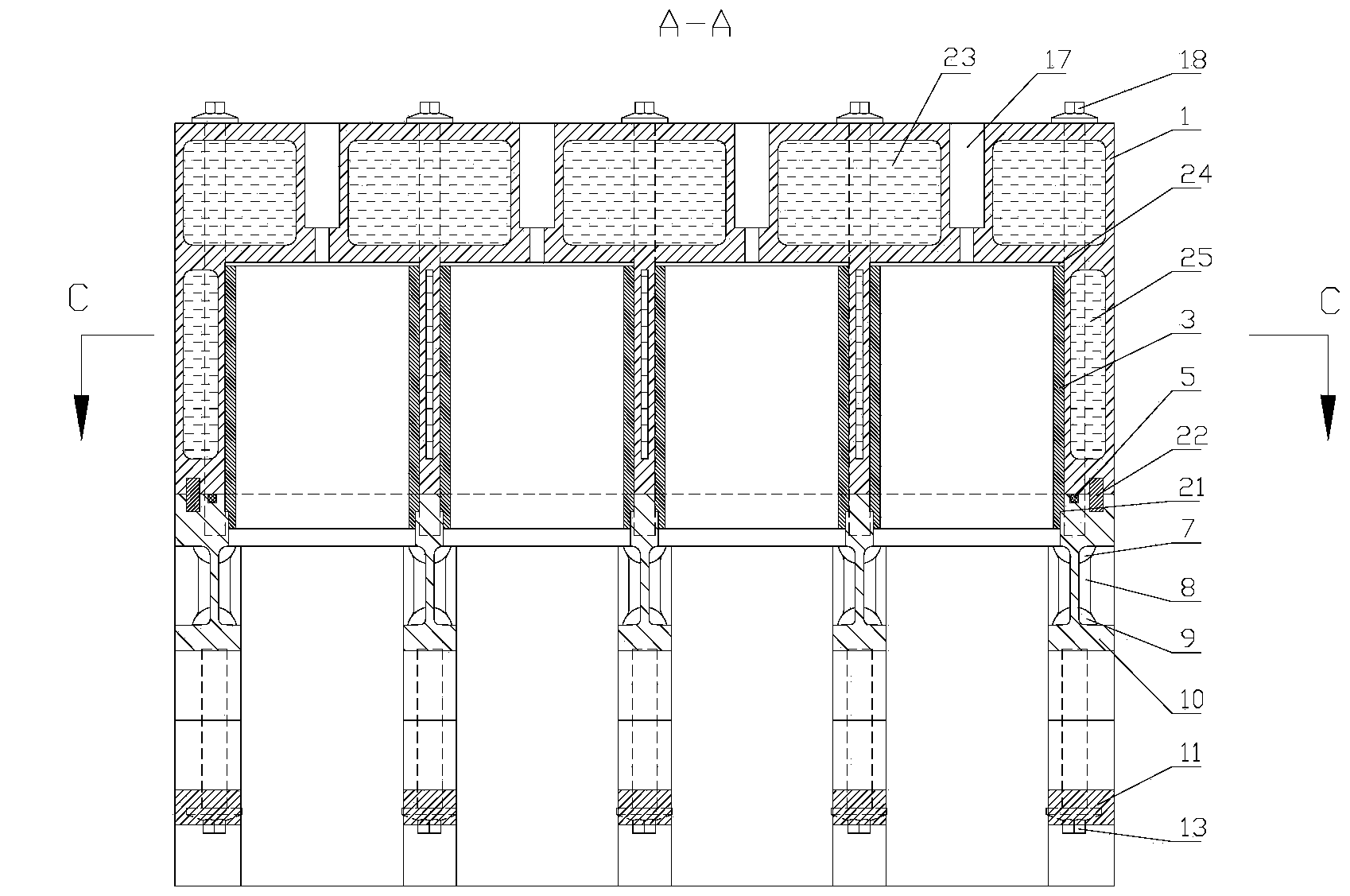

Double-acting hydraulic stretcher for composite cylinder

The invention relates to a double-acting hydraulic stretcher for a composite cylinder, and belongs to the technical field of the plate material extending equipment. The double-acting hydraulic stretcher for the composite cylinder comprises four parallel stand columns and a rack, wherein the rack consists of an upper fixed plate, a lower fixed plate, a workbench and a base; the upper fixed plate is provided with a bidirectional hydraulic cylinder as a main cylinder hydraulic cylinder; the lower end of the piston rod of the main cylinder hydraulic cylinder penetrates through a blank pressing cylinder jacket to form a blank pressing hydraulic cylinder; an oil delivery hole is formed in the blank pressing cylinder jacket; the lower end of the blank pressing cylinder jacket is connected with an upper blank pressing die via a screw; the head part of the lower end of the piston rod of the main cylinder hydraulic cylinder is provided with an upper die; a bidirectional hydraulic cylinder is installed below the lower fixed plate to serve as an ejection hydraulic cylinder; the workbench is provided with a lower die corresponding to the upper die; the head part of the piston rod of the ejection hydraulic cylinder is provided with a lower blank pressing die. The double-acting hydraulic stretcher for the composite cylinder disclosed by the invention has the advantages of simple structure, small size, convenience in use, low cost and stable performance.

Owner:扬州市江洋塑料冲压配件厂

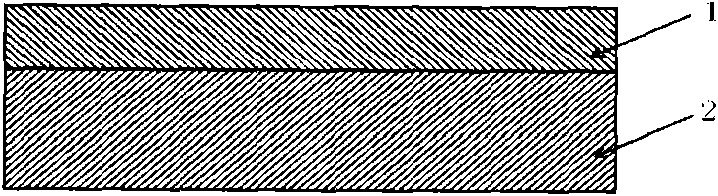

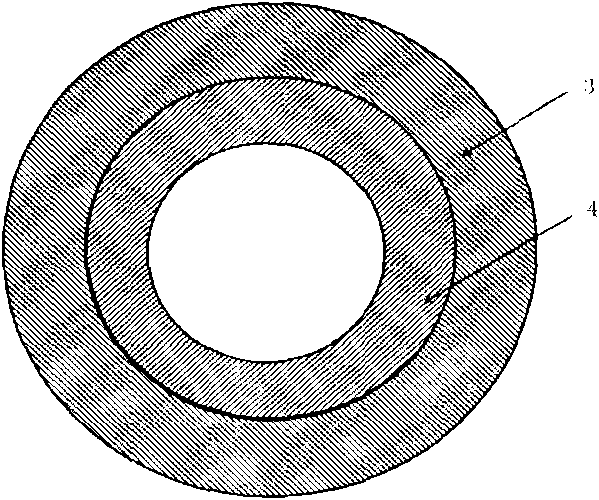

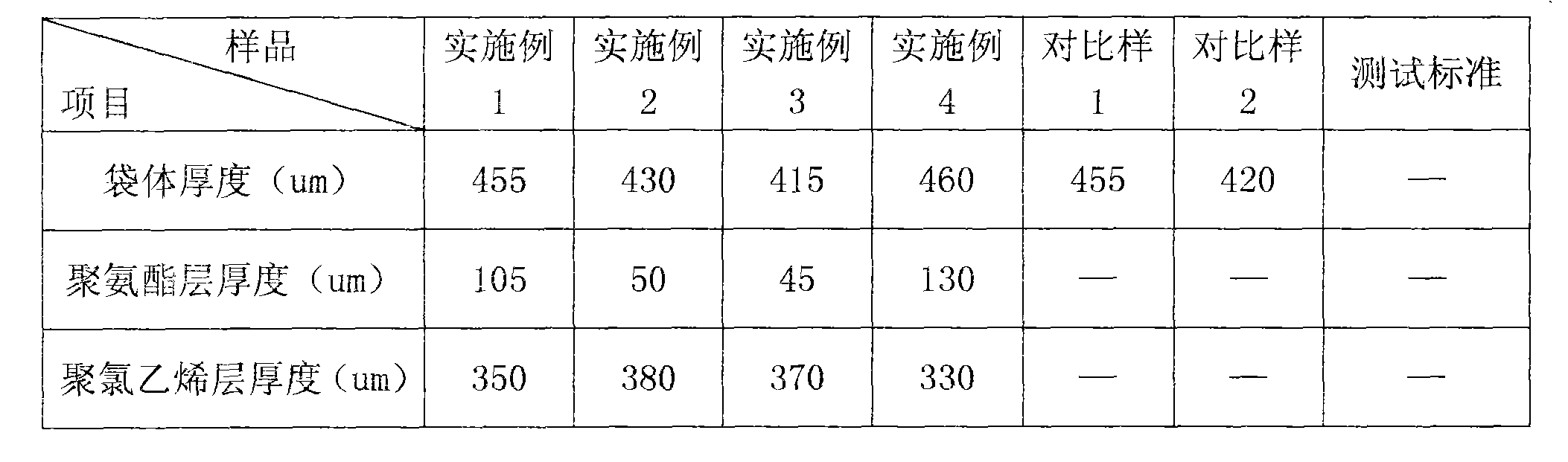

Safe blood or blood component storage container and preparation method thereof

ActiveCN101536961AGood blood compatibilityLow hemolysis ratePharmaceutical containersMedical packagingPolyvinyl chlorideEngineering

The invention provides a safe blood or blood component storage container and a preparation method thereof. The storage container comprises a storage bag and a tube; wherein, the storage bag is made of a polyurethane / polyvinyl chloride double-layer composite cylinder film; the tube is made of a polyurethane / polyvinyl chloride double-layer composite tube; the inner layer of the polyurethane / polyvinyl chloride double-layer composite cylinder film is made of polyurethane, and the corresponding outer layer thereof is polyvinyl chloride; the inner surface of the polyurethane / polyvinyl chloride double-layer composite tube is a polyurethane layer, and the outer surface thereof is a polyvinyl chloride layer. The polyurethane / polyvinyl chloride double-layer composite cylinder film is prepared by a co-extrusion blow molding method, and the polyurethane / polyvinyl chloride double-layer composite tube is prepared by a co-extrusion method. The storage container has excellent blood compatibility, can avoid micromolecules such as phthalate di (2- ethylhexyl), plasticizer and the like to pollute the blood, meets the requirements of humid hot sterilization on heat resistance, has the advantages of high mechanical strength, easy bonding and low manufacturing cost, and is suitable for high frequency soldering.

Owner:SHANDONG WEIGAO GROUP MEDICAL POLYMER +1

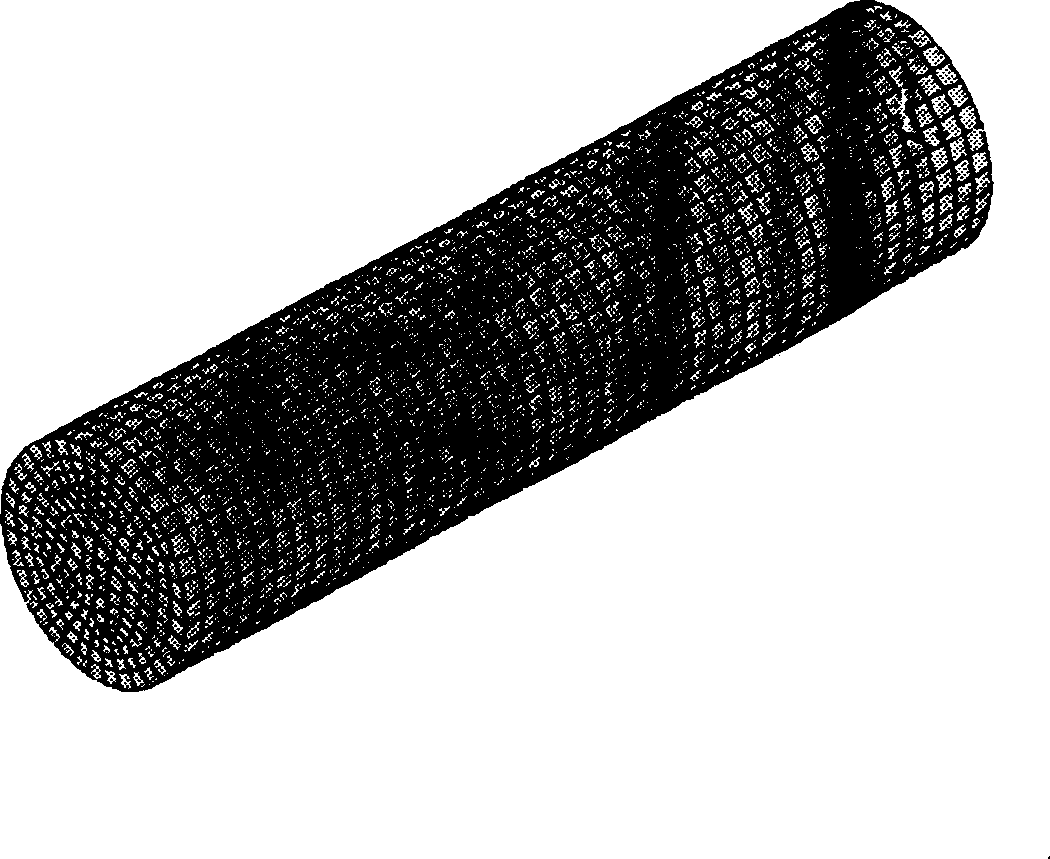

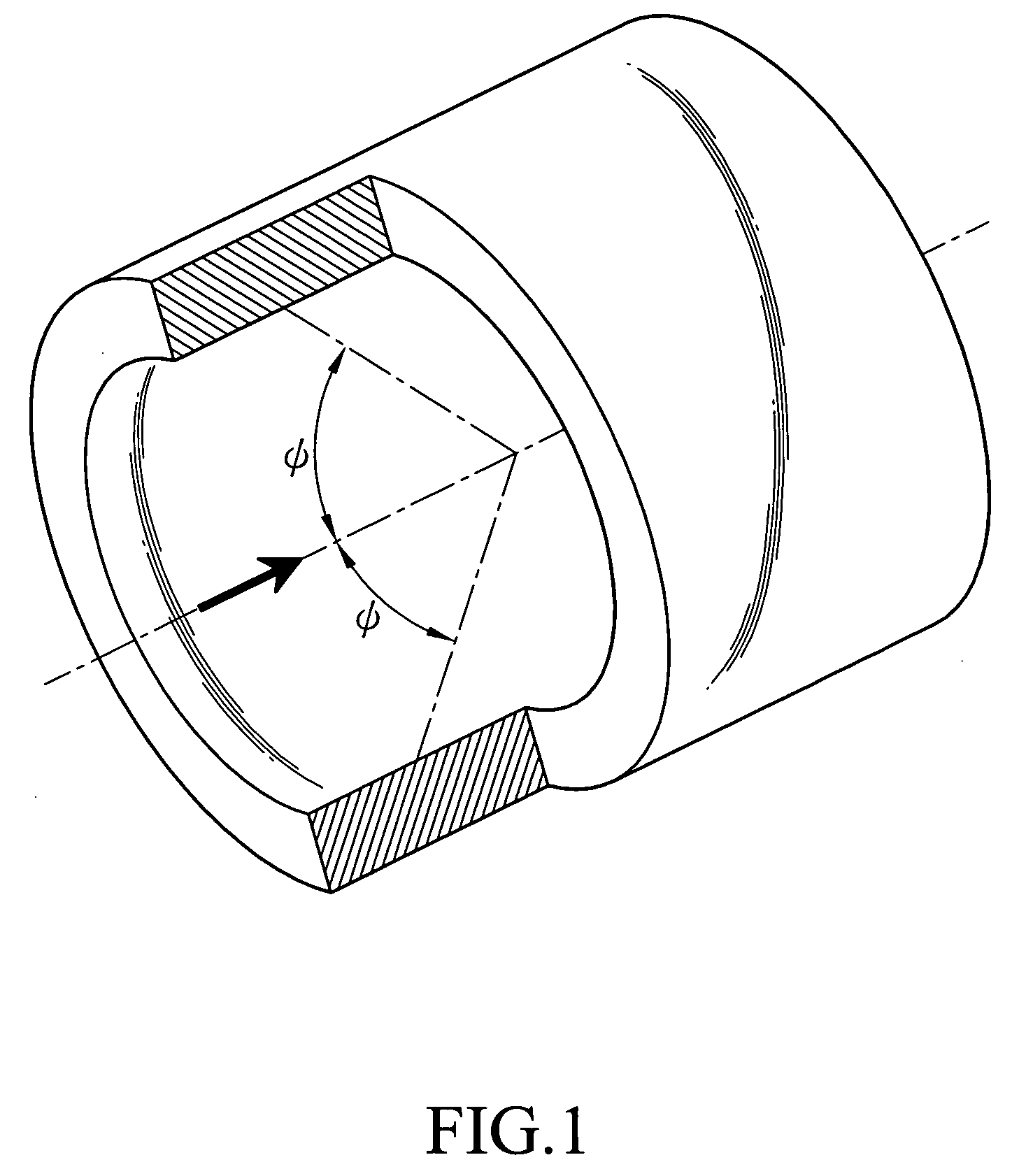

Process of fabricating a laminated hollow composite cylinder with an arranged ply angle

A manufacture method of a laminated hollow composite cylinder with an arranged ply angle is disclosed. The fiber in the hollow composite cylinder can be arranged in an angle Φ between 30° and 60° according the applications. Prepregs were cut into fan-shaped pieces and laminated in a metal mold to form an annular lamina assembly. The metal mold comprises a concave female mold and a convex male mold that both have a tapered angle complying with the ply angle Φ. Hot press molding with pressure over 140.6 kg / cm2 was then used for solidifying the lamina assembly to produce the composite hollow cylinders with the ply angle Φ. The laminated hollow composite cylinder can achieve excellent thermal and mechanical properties to meet design requirements.

Owner:NAT CHUNG SHAN INST SCI & TECH

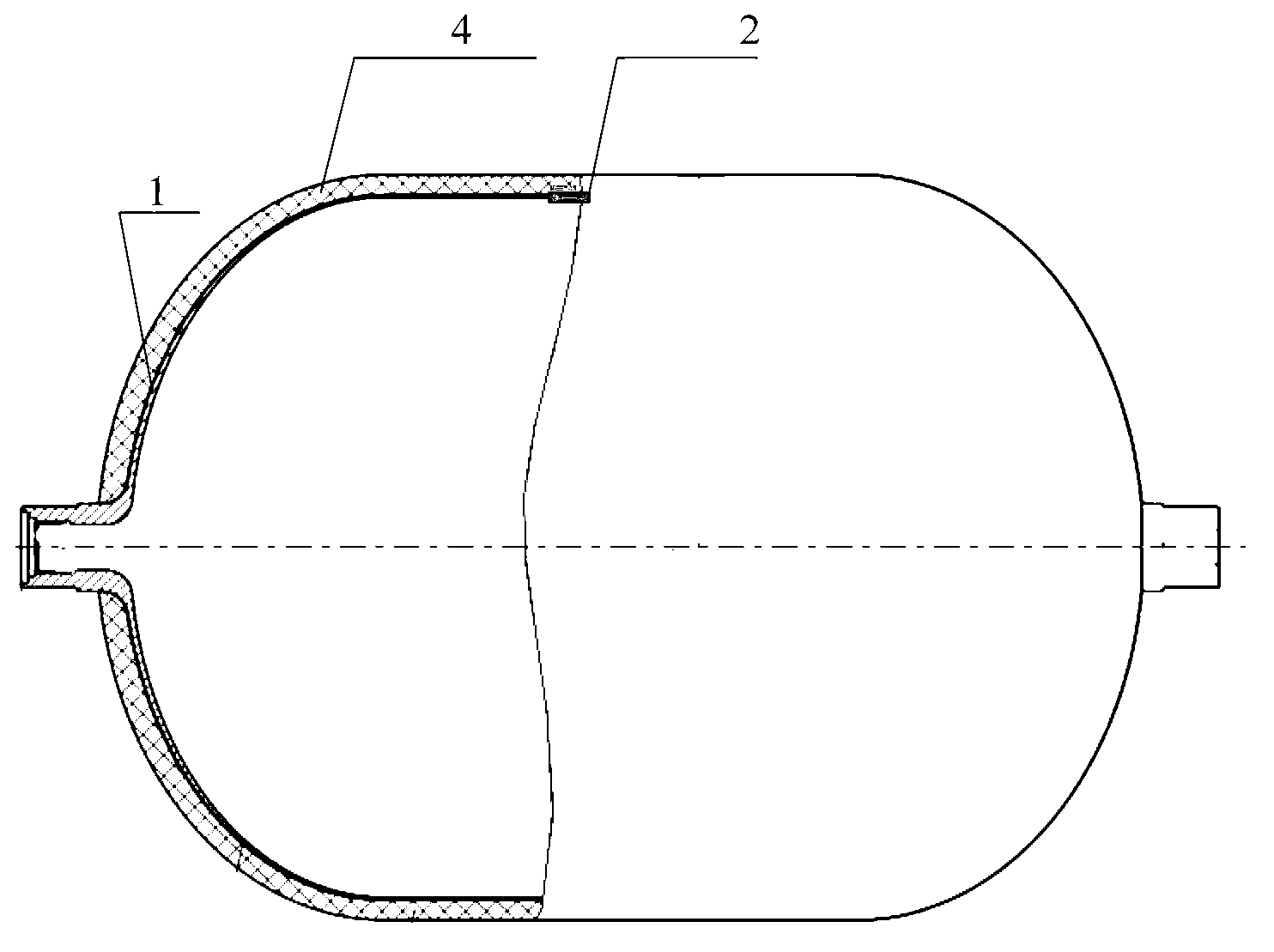

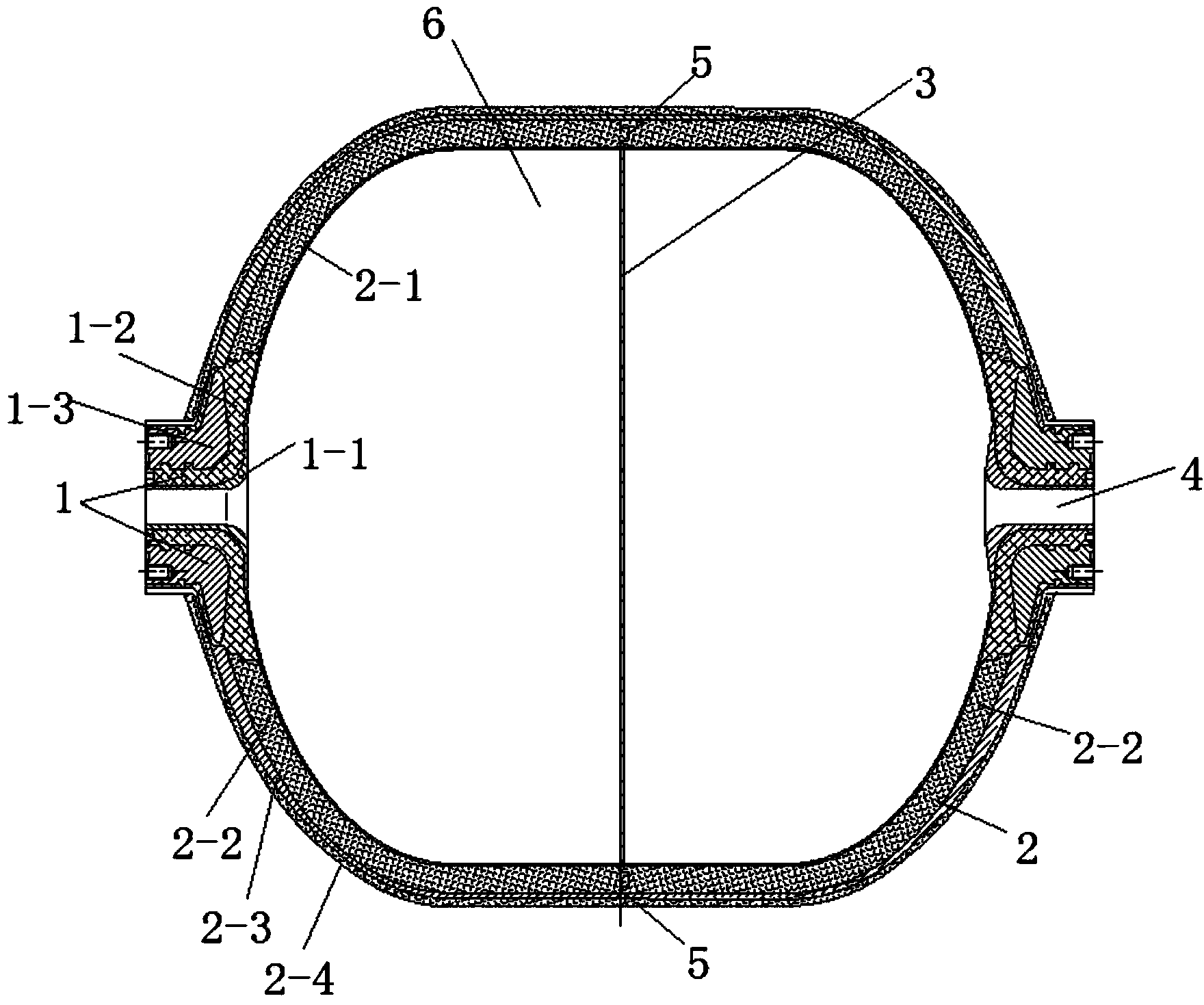

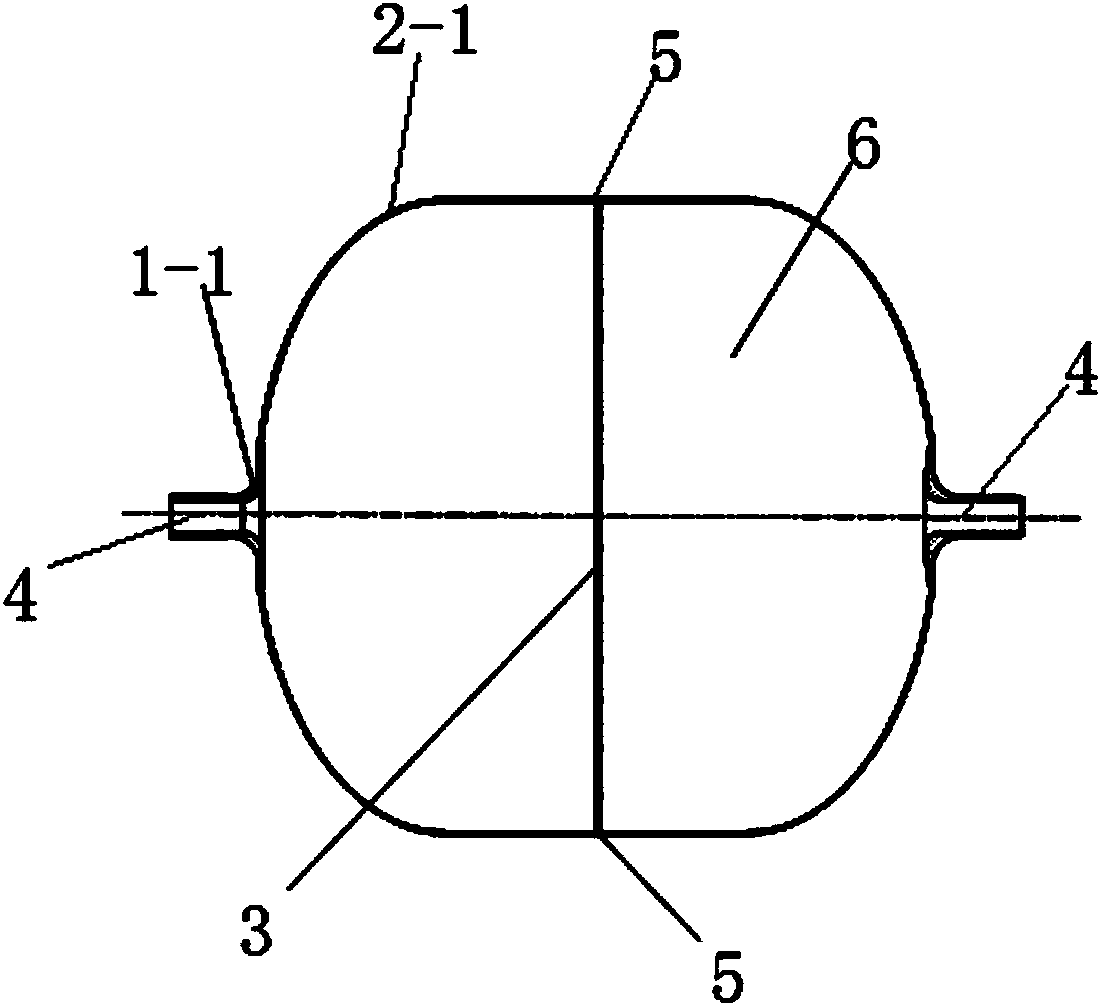

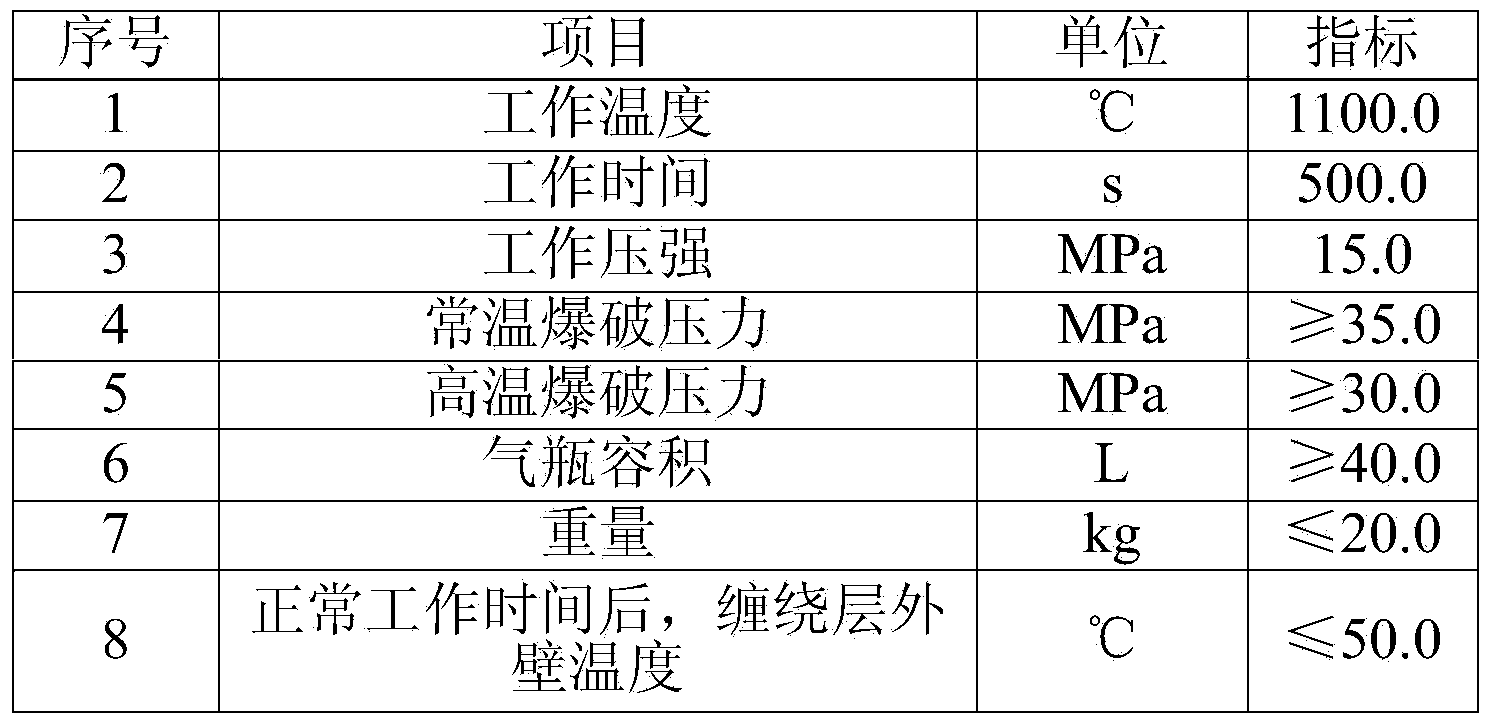

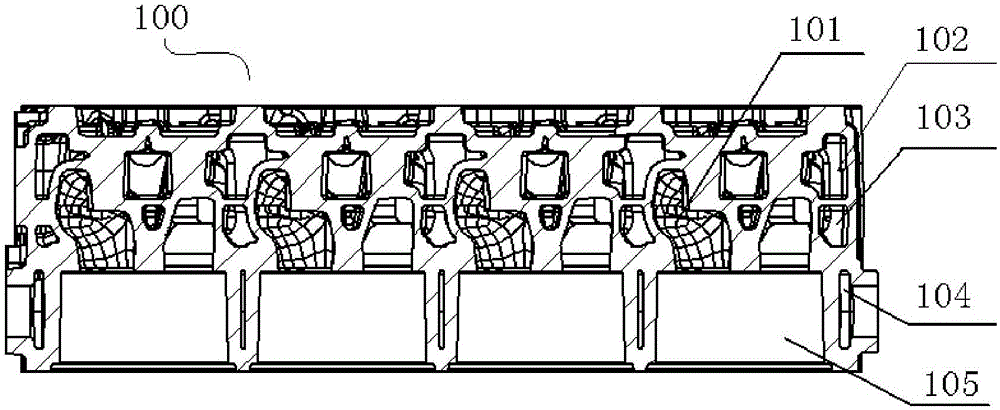

Lightened high-temperature and high-pressure composite cylinder and manufacturing method thereof

ActiveCN103883871AReduce weightImprove work efficiencyContainer filling methodsPressure vesselsCarbon fibersThermal insulation

The invention discloses a lightened high-temperature and high-pressure composite cylinder and a manufacturing method of the lightened high-temperature and high-pressure composite cylinder. The composite cylinder comprises filler necks and a bottle body, wherein the filler necks are arranged at two ends of the composite cylinder, the bottle body is arranged in the middle of the bottle body and sequentially comprises an ablation-resistant thin-wall metal liner, a ceramic tile thermal-insulation layer, a rubber thermal-insulation layer and a winding layer from inside to outside, and the winding layer is made of carbon-fiber-reinforced-resin-base composite materials. The manufacturing method comprises the following steps: (1) spheroid forming, (2) sand core forming, (3) metal liner forming, (4) thermal-insulation layer forming, (5) winding layer forming and (6) demolding and sand core dissolving. The composite cylinder has the advantages that a thin-wall metal material is taken as a liner, the light and high-temperature-resistant ceramic tile-rubber composite thermal-insulation layer is creatively utilized, and a ceramic tile in a quartz-fiber porous skeleton structure is taken as a main thermal-insulation material and is externally supplemented with a layer of rubber to be taken as an airtight layer, so that the weight of the thermal-insulation layer is reduced by 70-80% when the long-time high temperature resistance and ablation resistance are guaranteed, the working efficiency of an engine is substantially increased, and the requirements of a power system for the high total impulse and the high thrust are met.

Owner:湖北三江航天江北机械工程有限公司

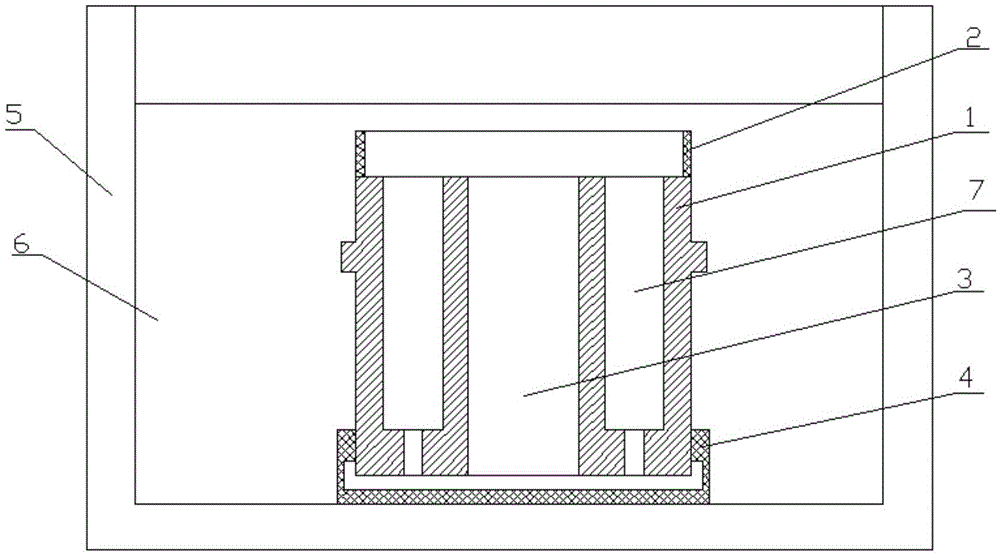

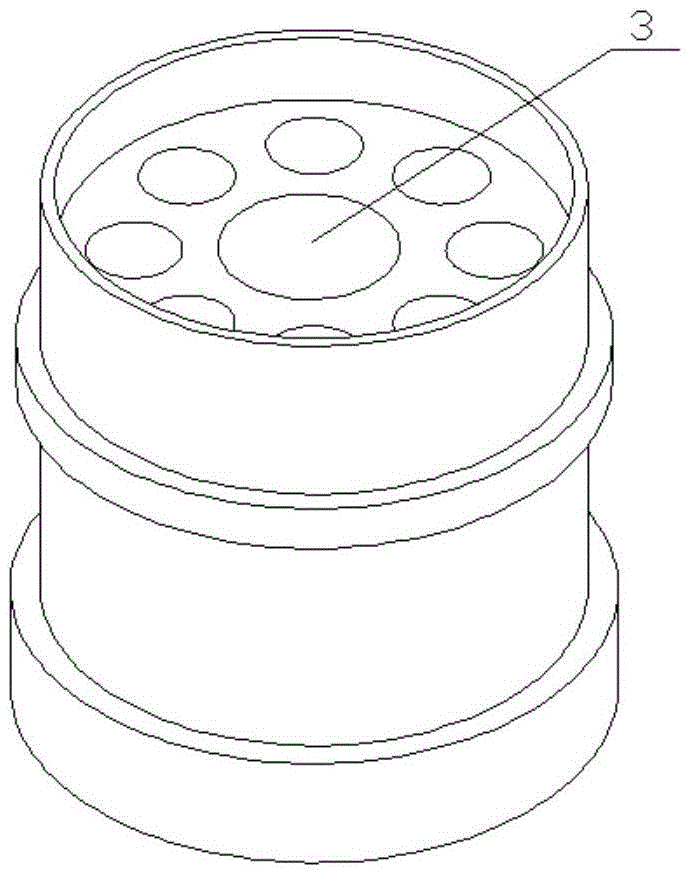

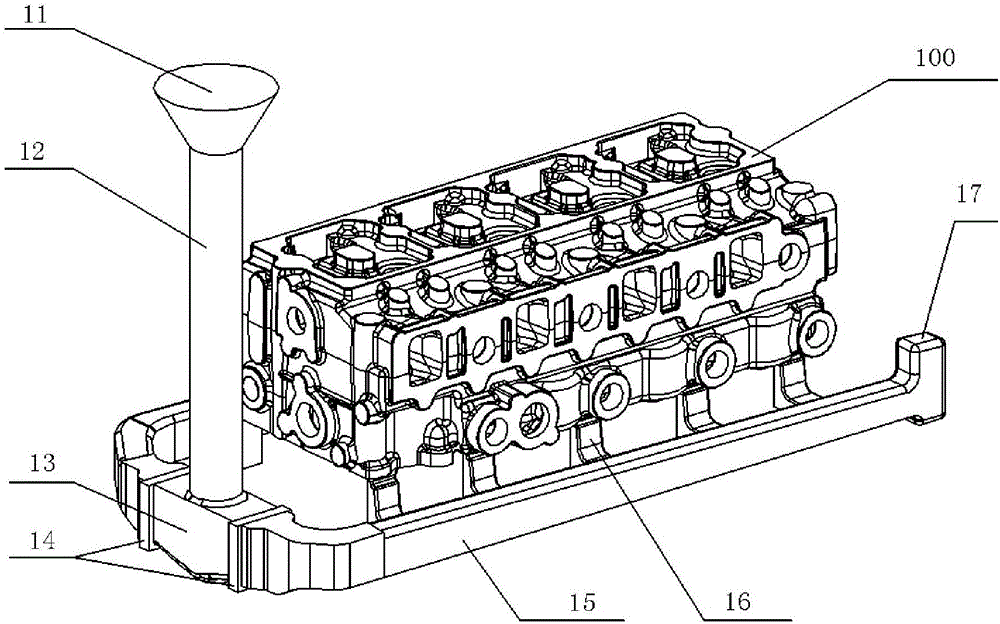

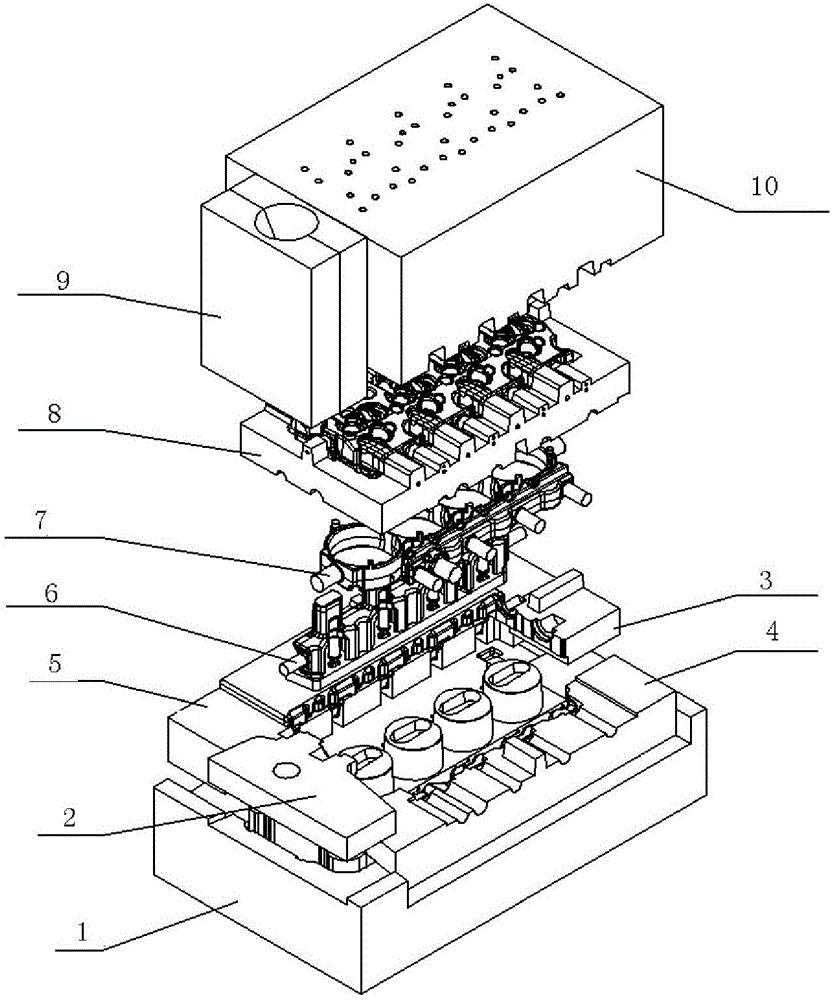

Sand core set for casting integrated composite cylinder cover

ActiveCN106111912AUniform wall thicknessSimple and accurate wall thicknessFoundry mouldsFoundry coresWater jacketCam

The invention discloses a sand core set for casting an integrated composite cylinder cover. The sand core set comprises a temporary sand core set, a cylinder hole water jacket sand mold, a combined sand mold, a cover disc sand mold and a pouring sand mold; the temporary sand core set is formed by assembling an integral chassis sand mold, a front sand mold, a back sand mold, a right sand mold, a cam tappet sand mold and a left sand mold; the integral chassis sand mold is integrated with a cylinder hole molding part of a cylinder hole; a gap between the cylinder hole water jacket sand mold and the cylinder hole molding part of the cylinder hole is adjustable; the pouring sand mold includes a straight sprue, a main cross gate, two branch cross gates and multiple L-shaped ingates; the lower section part of the straight sprue is formed in the front sand mold, and the upper section part of the straight sprue is provided by the pouring sand mold; the main cross gate is formed in the front end of the integral chassis sand mold; and the two branch cross gates and the multiple L-shaped ingates are respectively formed in the left sand mold and the right sand mold. The sand core set is used for successfully casting the integrated composite cylinder cover with high part complexity.

Owner:GUANGXI YUCHAI MASCH CO LTD

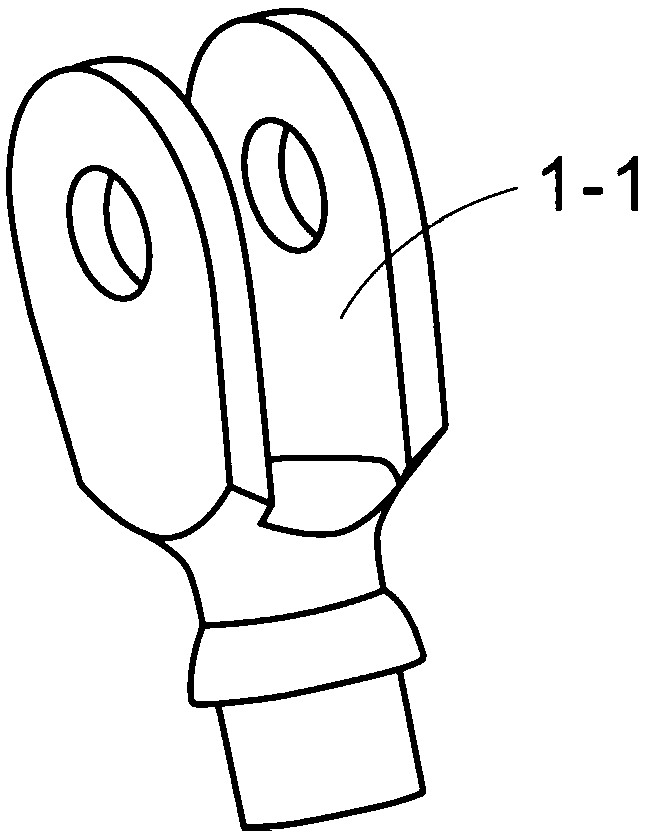

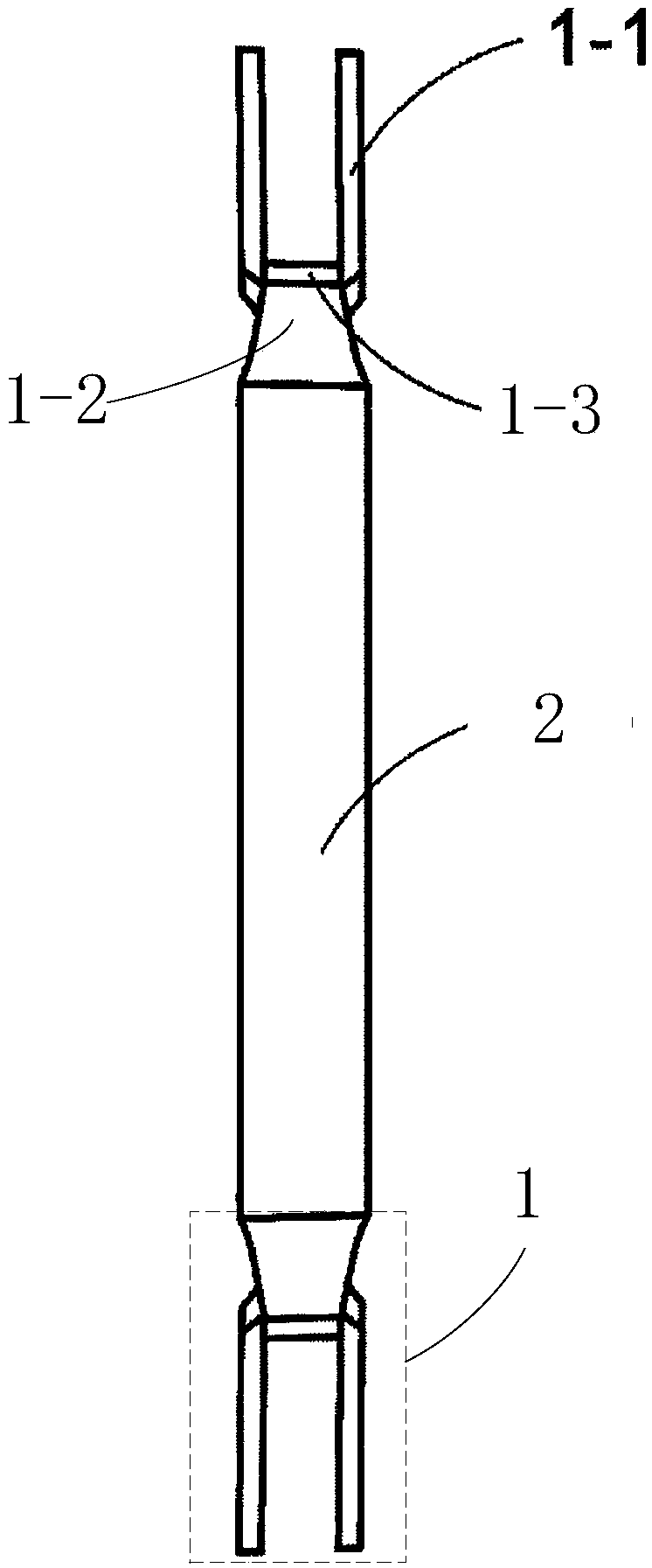

Connecting rod structure for combining composite material with metal

In view of a problem of poor durability of a barrel body and a metal connector of an existing composite connecting rod, the invention provides a connecting rod structure for combining a composite material with metal, and belongs to the technical field of aircraft weight reduction. The connecting rod structure provided by the invention comprises two metal connectors and a composite barrel body, wherein the two metal connectors are respectively connected with two ends of the composite barrel body; each metal connector comprises two metal lugs and one metal connecting structure; the two metal lugs are arranged at a first end of the metal connecting structure; the two metal lugs and the metal connecting structure form an integrated structure; the composite barrel body is an inner-outer double-cylinder structure; a tail end of the metal connecting structure of the two metal connectors is respectively connected with two end parts of an inner cylinder of the composite cylinder body; in an axial direction of the connecting rod, the metal connecting structure of the two metal connectors and the inner cylinder of the composite cylinder body are wound together by a composite material; and anouter cylinder of the composite cylinder body is formed on outer surfaces of the inner cylinder and the metal connecting structure.

Owner:HARBIN INST OF TECH

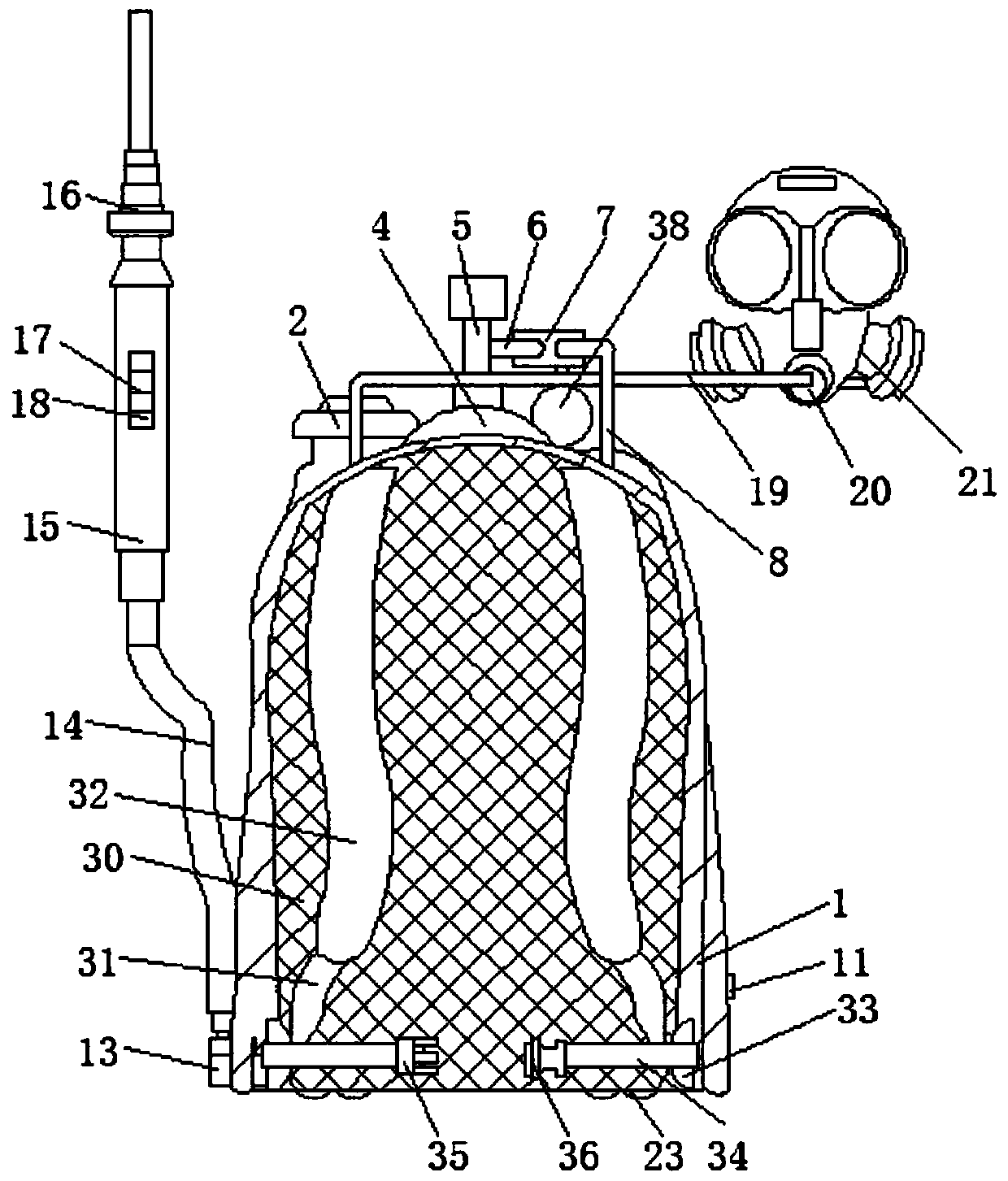

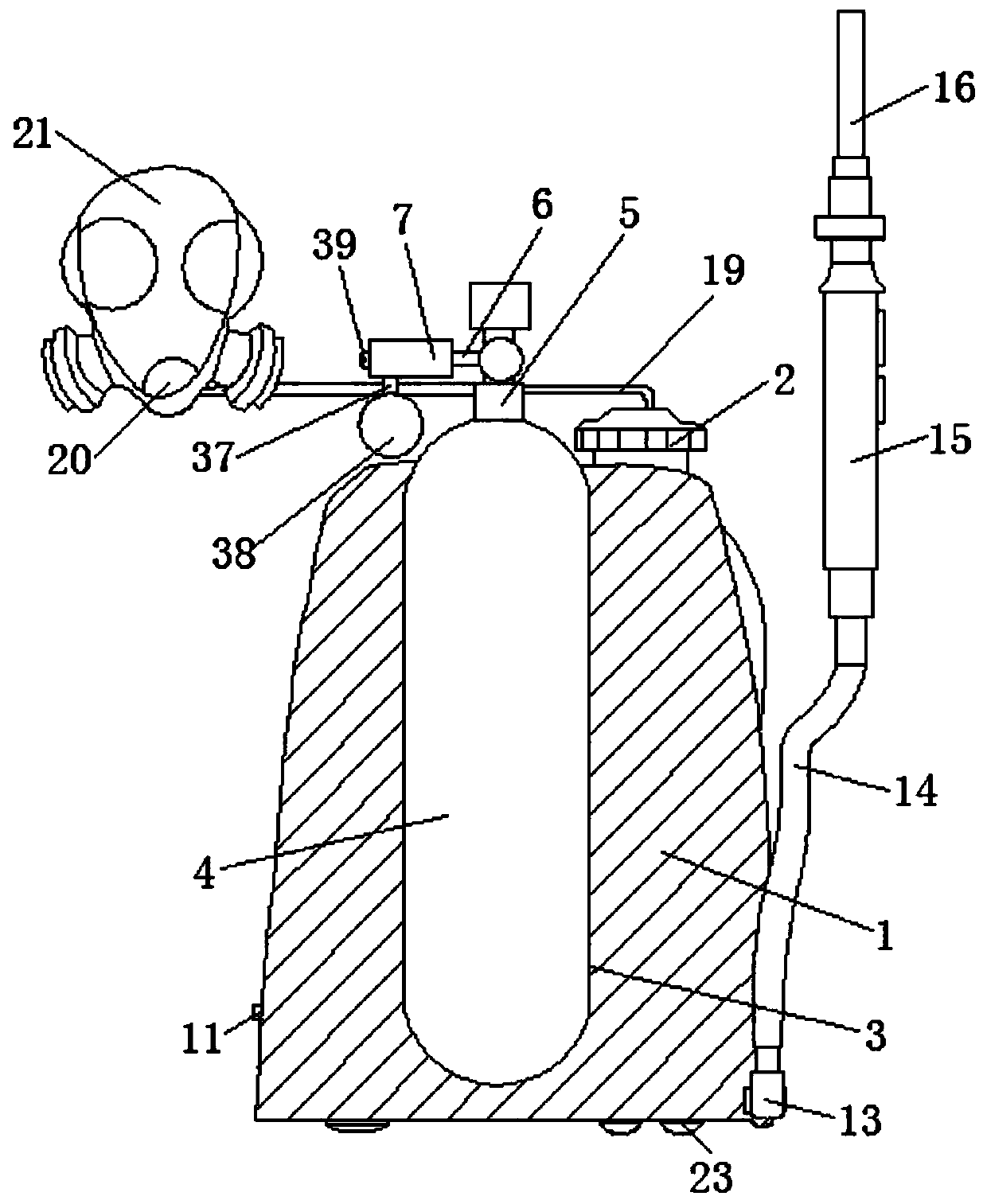

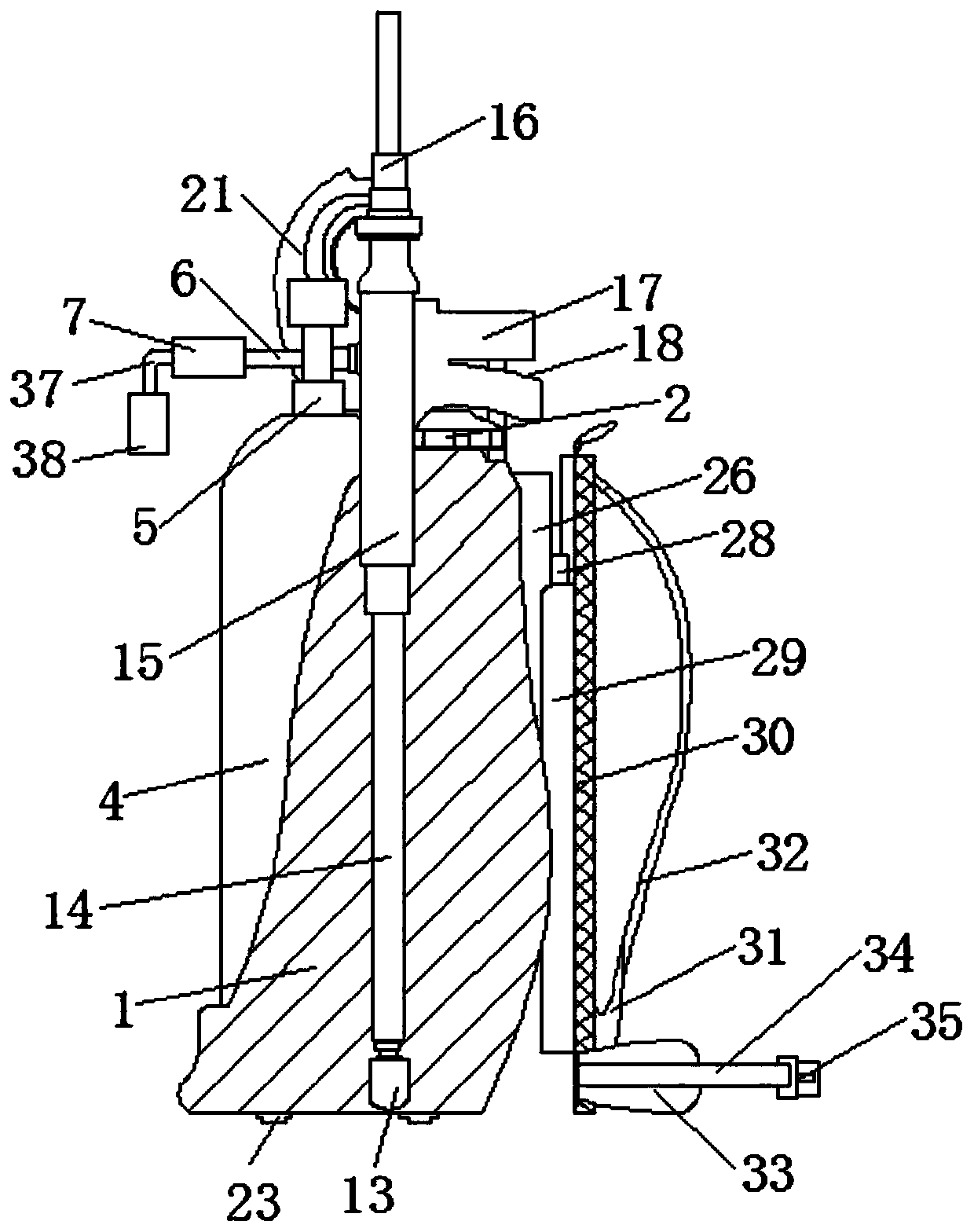

Backpack type multifunctional security protection fire extinguishing device

PendingCN110251865AEasy dischargeAvoid damageFire rescueRespiratory apparatusEngineeringHigh pressure

The invention relates to the technical field of security protection fire extinguishing, and particularly relates to a backpack type multifunctional security protection fire extinguishing device. The device comprises a high pressure assembly, a breathing protecting assembly, a foam generating assembly, an injecting assembly and a suspending backpack assembly, wherein the high pressure assembly comprises a composite cylinder which is connected to a first connecting pipe through a connecting valve; a pressure reduction valve is connected to the outer side of the first connecting pipe; the foam generating assembly comprises a material barrel; and a barrel cover is screwed to the upper end of the material barrel. The device is compact in structure design, small in size, high in practicability, and multifunctional; the body pressure due to load borne by users can be conveniently effectively relieved; the fire extinguishing and nuclear-biological-chemical washing and removing responding speed is increased; the effect is maximized; the use effect is effectively improved; in addition, the device is applicable to counter-terrorism explosion-proof activity based on different liquid mixing components and different ratio; gangsters can be remotely controlled; the life security of the users can be conveniently protected; in addition, the device is convenient to pick and use.

Owner:惠州市恒钛机械自动化有限公司

Engine having composite cylinder block

ActiveUS9416749B2Strength to weight ratio is relatively lowMore susceptible to corrosionCasingsCylinder headsEngineeringWater jacket

An engine is provided. The engine includes a thermo-molded composite cylinder block including a front engine cover attachment interface and a transmission attachment interface. The engine further includes a cylinder liner comprising a different material than a composite cylinder block and integrally molded with the composite cylinder block, the cylinder liner defining a portion of a boundary of a cylinder and including a top deck at least partially extending across a water jacket cavity surrounding the cylinder.

Owner:FORD GLOBAL TECH LLC

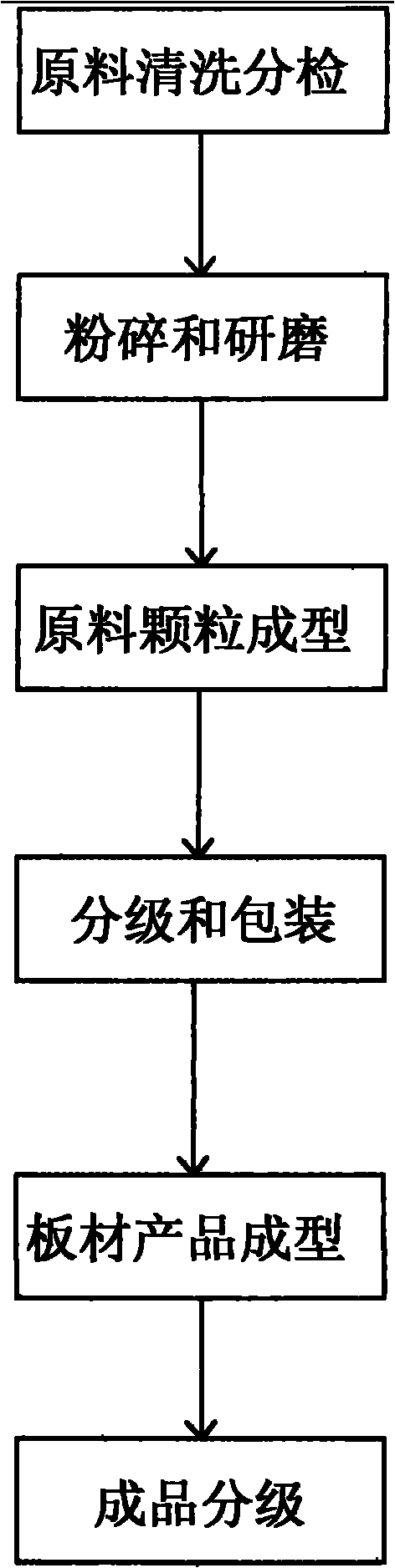

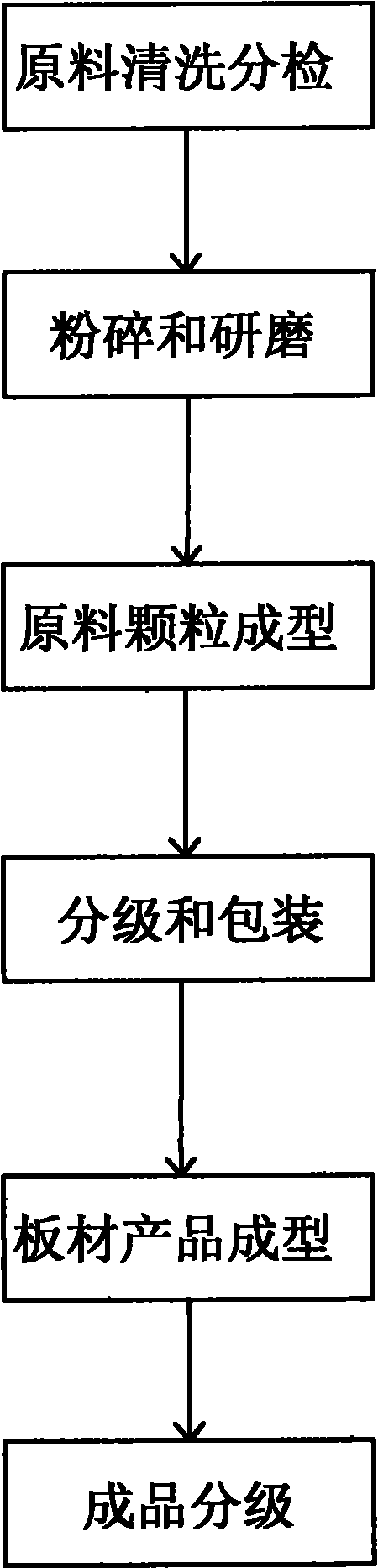

Silicon-plastic composite cylindrical particles prepared from power plant waste and method for preparing plastic plate thereof

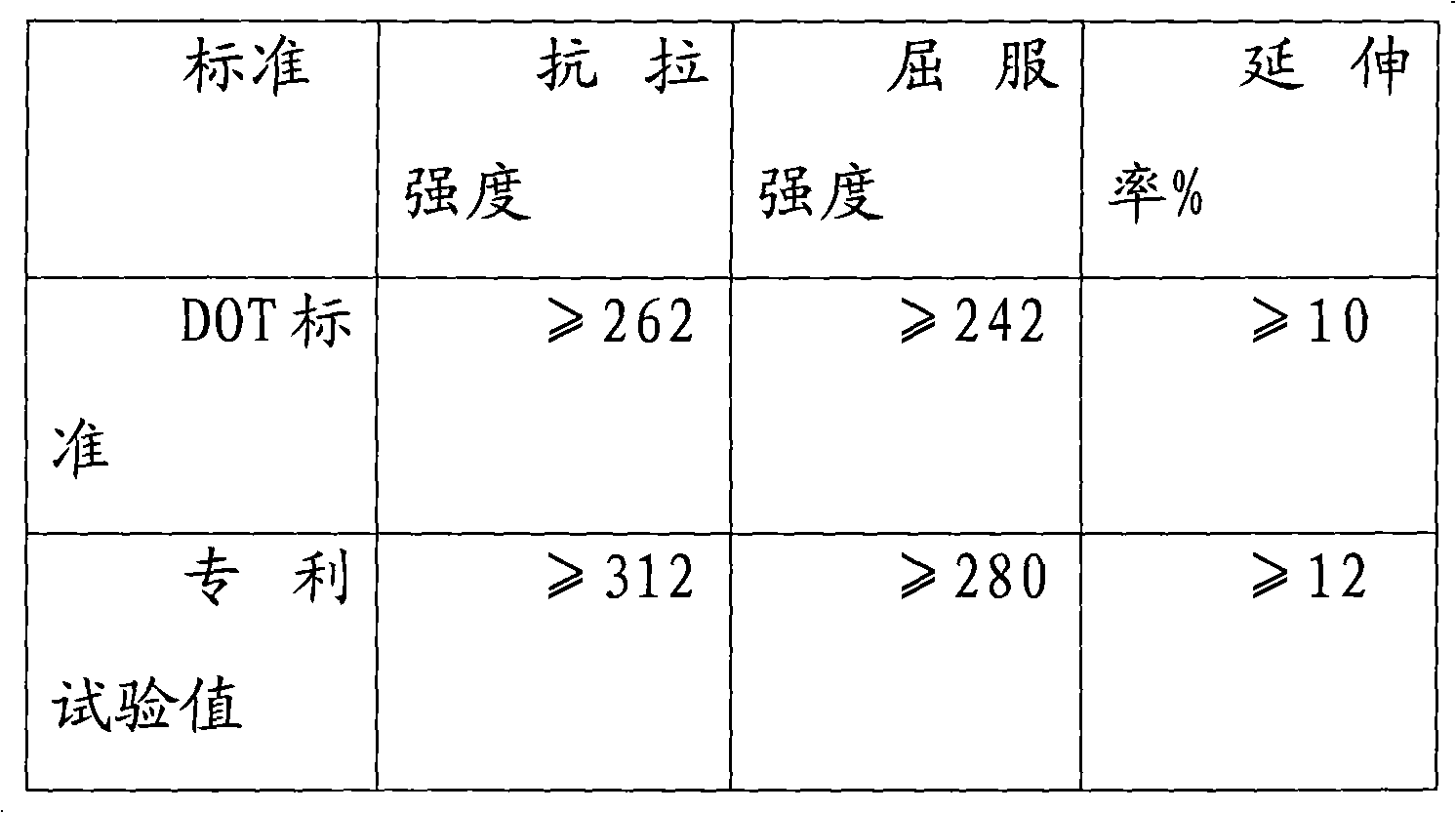

InactiveCN101817987AReduce or eliminate the occurrence ofReasonable workmanshipPlastic recyclingAging resistanceUltimate tensile strength

The invention discloses silicon-plastic composite cylindrical particles prepared by using power plant waste, such as coal ash, waste plastics, calcium carbonate and the like, as raw materials through a plastic extruder, wherein the silicon-plastic composite cylindrical particles are prepared from the following raw materials in percentage by weight: 50%-60% of waste plastics, 30%-40% of coal ash and 5%-15% of calcium carbonate. A method for preparing a plastic plate of the silicon-plastic composite cylindrical particles comprises the steps of: (1) crushing and grinding the raw materials; (2) forming particles; (3) classifying and packaging cylindrical particles; and (4) forming a plate product. By using the method, the process is reasonable and simple, the process flow is shortened greatly, the production cost is reduced, high yield is achieved, the surfaces of the particles are smooth, dust is reduced or avoided in the processes of charging and blending in production, and no secondary pollution is caused in the production process. The product has the advantages of no toxicity, no smell, ageing resistance, less environmental pollution, ecological balance friendliness, shock resistance, crushing resistance and high strength, and can be used as templates, green belt cover plates, and the like.

Owner:吉林市大成广盛塑业有限公司

TiC-Cr3C2 base cermet composite cylinder jacket

The invention discloses a making method of TiC-Cr3C2 based metal ceramic composite cylinder liner, which comprises the following steps: adopting TiC as base; adding Cr3C2 powder, metal nickel powder and metal molybdenum powder; milling raw material; blending raw materials in the blender; graining; moulding under high pressure; insulating under 1430-1520 deg.c for 2-3h; sintering into metal ceramic blank in the vacuum or protective atmosphere; manufacturing periphery of metal ceramic blank; placing metal ceramic blank in the metal sleeve to heat completely with retaining shrink range at 0.25-0.40mm; refining internal blank; polishing to the roughness at 0.1-0.2um; making the product for cement slurry pump.

Owner:范兴宽

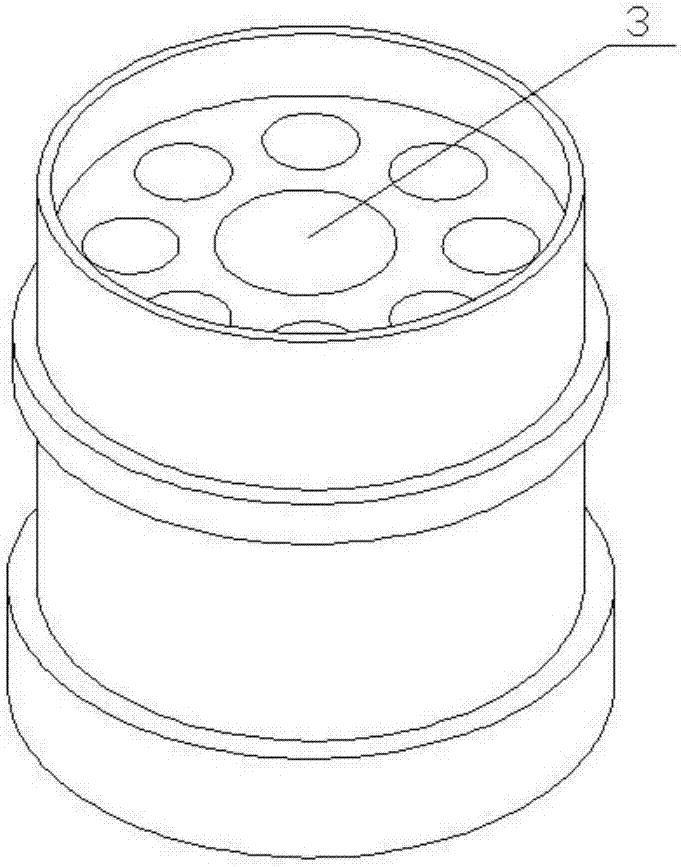

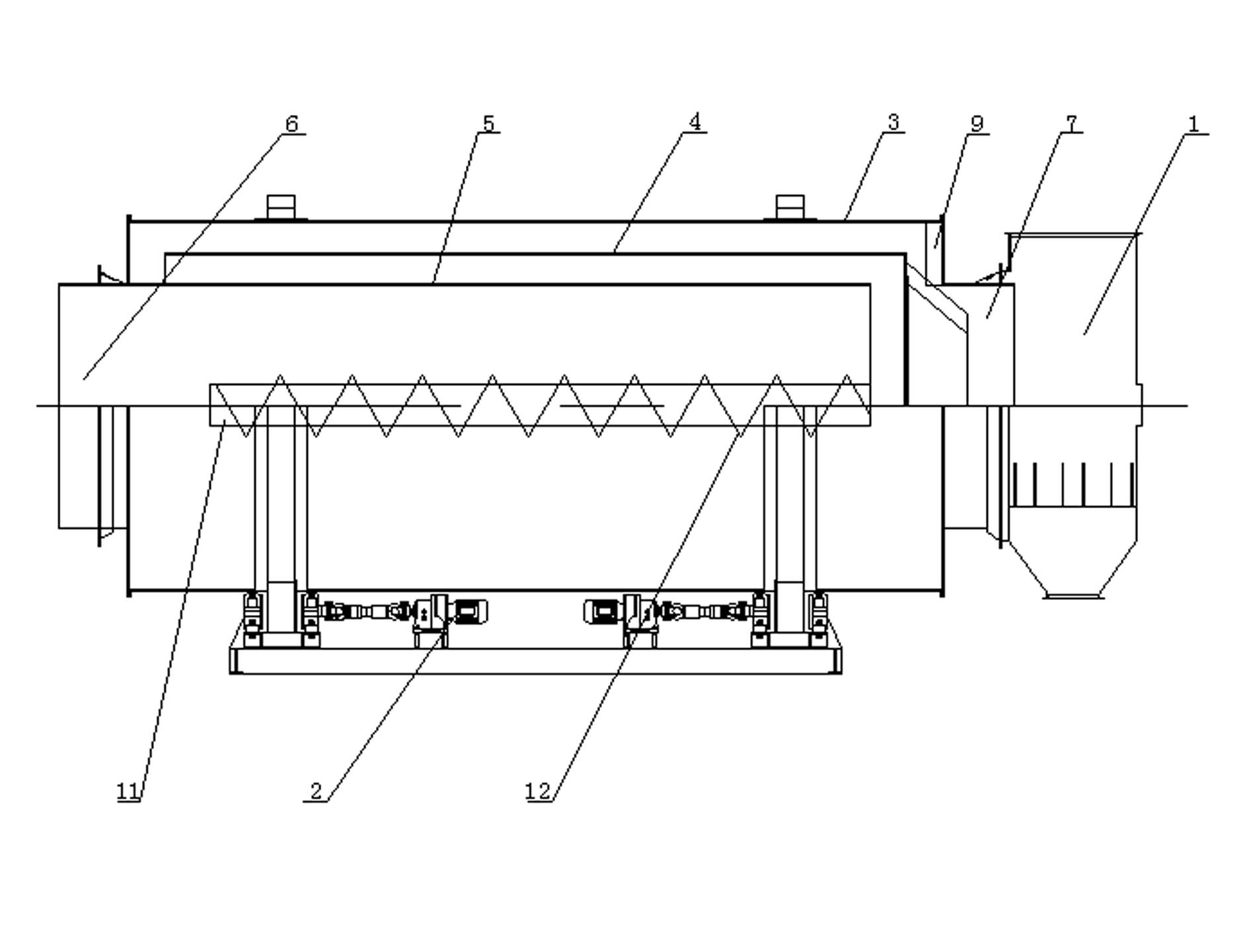

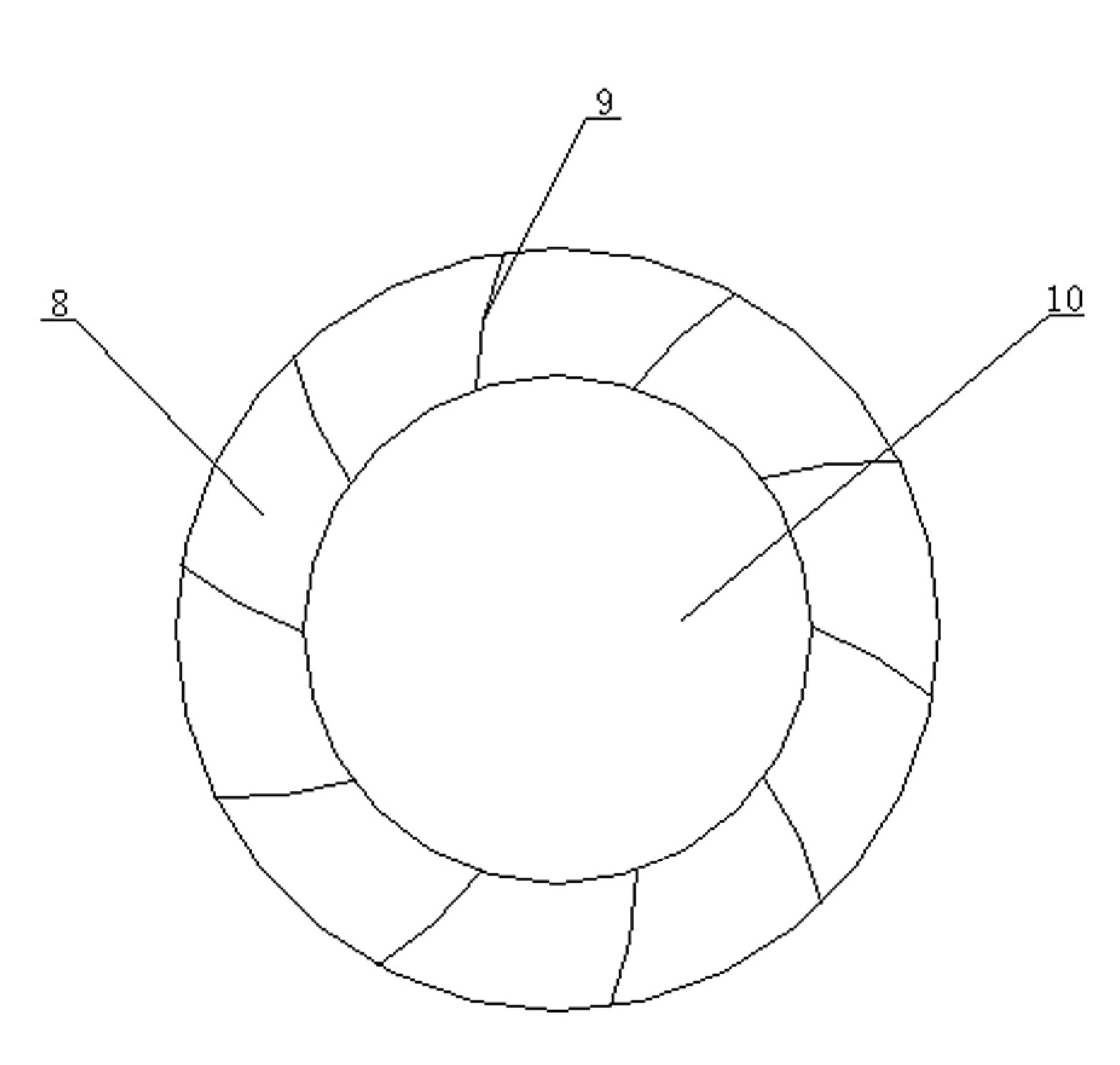

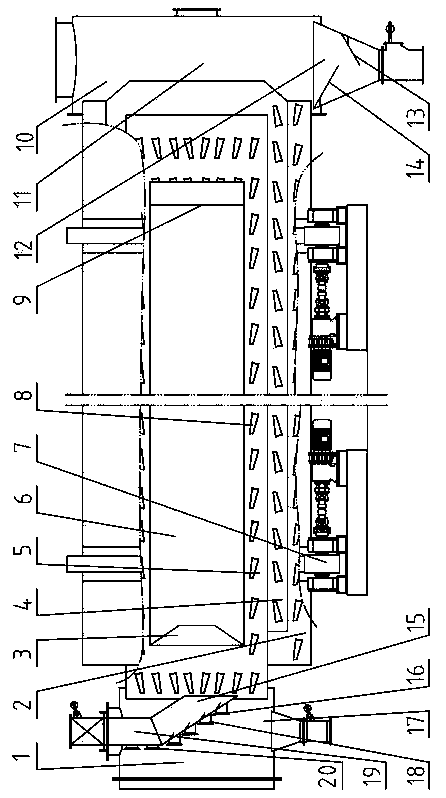

Material guide device of three-barrel drying machine

InactiveCN102200386ASmooth dischargeSimple structureDrying solid materialsPulp and paper industryComposite cylinder

The invention discloses a material guide device of a three-barrel drying machine. The material guide deice comprises a composite cylinder body, a blanking device and a transmission device, wherein the blanking device is arranged at one side of the composite cylinder body; the transmission device is arranged at the lower end of the composite cylinder body; the composite cylinder is sleeved by an outer cylinder body, a middle cylinder body and an inner cylinder body which are of different diameters from large to small in a concentric mode; the inner wall of the outer cylinder body, the middle cylinder body and the inner cylinder body are respectively provided with a screw-type lifting blade; the outer wall of the middle cylinder body and the inner cylinder body are respectively provided with a radial lifting blade; one end of the inner cylinder body is provided with a feed inlet; the other end of the inner cylinder body is provided with a discharge outlet; the discharge outlet is communicated with the feed inlet at one end of the middle cylinder body; a discharge outlet of the middle cylinder body is connected with a feed inlet of the outer cylinder body; the other end of the outer cylinder body is provided with a discharge outlet; and the discharge outlet of the outer cylinder body is provided with the material guide device. The material guide device provided by the invention has the advantages that the discharging is more smooth, the structure is simple, the material guide device is convenient to use, the material can be delivered well by the material guide device in the drying process, and the problem of material blocking for the three-barrel drying machine is solved.

Owner:JIANGSU RONGDALI MACHINE

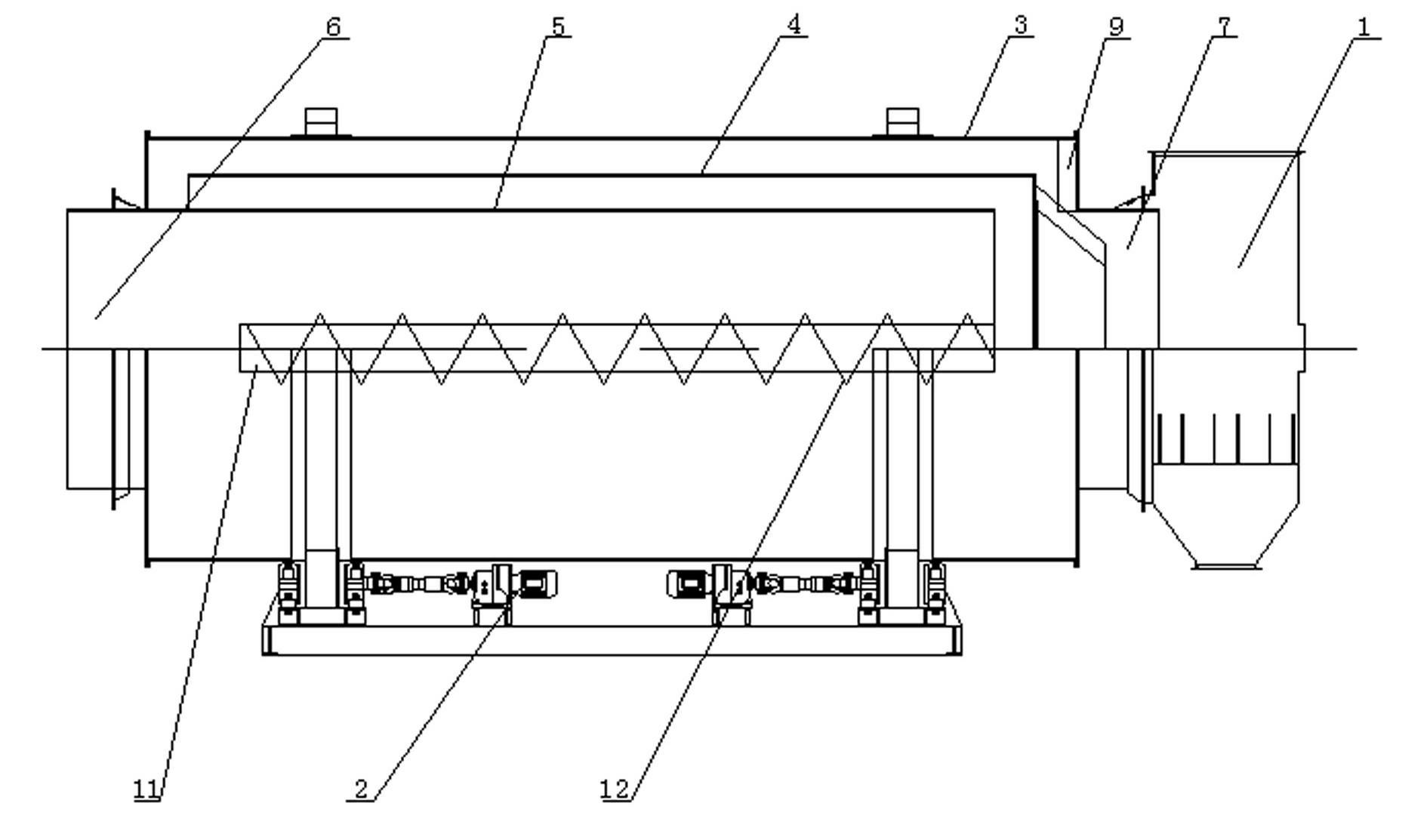

Semi-coke three-cylinder dryer

InactiveCN103471356AReduce dropReduce breakage rateDrying gas arrangementsDrying machines with non-progressive movementsComposite cylinderBreathing

The invention discloses a semi-coke three-cylinder dryer. The semi-coke three-cylinder dryer comprises a composite cylinder, a transmission device, a feeding device, a discharge device and a preheating cylinder, wherein the preheating cylinder is arranged in an inner cylinder through a bracket rod; the front end of the preheating cylinder is provided with an opening; a choke plate is arranged in the rear end of the preheating cylinder and is provided with at least one ventilation hole; the front end of the preheating cylinder is positioned in the front end of the composite cylinder; an upper pipe of a feed pipe of the feeding device is provided with an upper ventilation hole; an upper air inlet pipe is arranged on the upper ventilation hole and is positioned on the outer side of the upper pipe; a lower pipe of the feed pipe of the feeding device is provided with a lower ventilation hole; a lower air inlet pipe is arranged on the lower ventilation hole and is positioned on the outer side of the lower pipe; a stopping plate is arranged on the lower ventilation hole, is positioned in the lower pipe and stops a material from entering the lower ventilation hole; a left guide plate is arranged on the left side of the inner surface of a lower cone of the discharge device; a right guide plate is arranged on the right side of the inner surface of the lower cone of the discharge device.

Owner:盐城市成功机械制造有限公司

Composite cylinder cover

ActiveCN103925102AImprove cooling effectEliminate ablation failureCylinder headsCylindersInlet channelExternal combustion engine

The invention discloses a composite cylinder cover and an engine body of an internal combustion engine. The composite cylinder cover is provided with a gas inlet channel, an exhaust channel and an oil injector installation hole, the composite cylinder cover is further integrated with a cam shaft hole, a tappet hole and a cylinder hole, the cam shaft hole and the tappet hole are formed in the same side of the composite cylinder cover, the cylinder hole is formed in the middle of the composite cylinder cover, and the composite cylinder cover can be directly installed on a crankcase so that a piston can directly extend into the cylinder hole and moves in a reciprocating mode. The engine body of the internal combustion engine comprises the composite cylinder cover and the crankcase. By means of the composite cylinder cover and the engine body of the internal combustion engine, the faults of cylinder gasket pushing and cylinder gasket ablation of a traditional cylinder cover structure can be fundamentally avoided, meanwhile, the complex structure of a cooling water cavity in the cylinder cover is changed, the structure is simplified, and manufacturing requirements are low.

Owner:GUANGXI YUCHAI MASCH CO LTD

Tow prepreg tape winding laying process

InactiveCN106313582AEliminate the many disadvantages of windingImprove work efficiencyGlass fiberConductor Coil

The invention discloses a tow prepreg tape winding laying process suitable for winding and laying of a tow prepreg tape using carbon fiber, glass fiber, aramid fiber, ultra-high molecular polyethylene fiber and other special fiber for producing rotary parts. According to the process, a tow prepreg tape and modified fiber winding process is used to form a new winding and laying process to replace a traditional wet winding process, efficiency, workshop cleanness, product performance and quality of the winding process are greatly enhanced, performance, quality and production efficiency of various types of products(such as various types of composite cylinders and composite material pipes) prepared by the fiber winding process can be enhanced, and the zero angle laying function which cannot be achieved by a traditional winding process can be realized.

Owner:ATA CARBON FIBER TECH GUANGZHOU

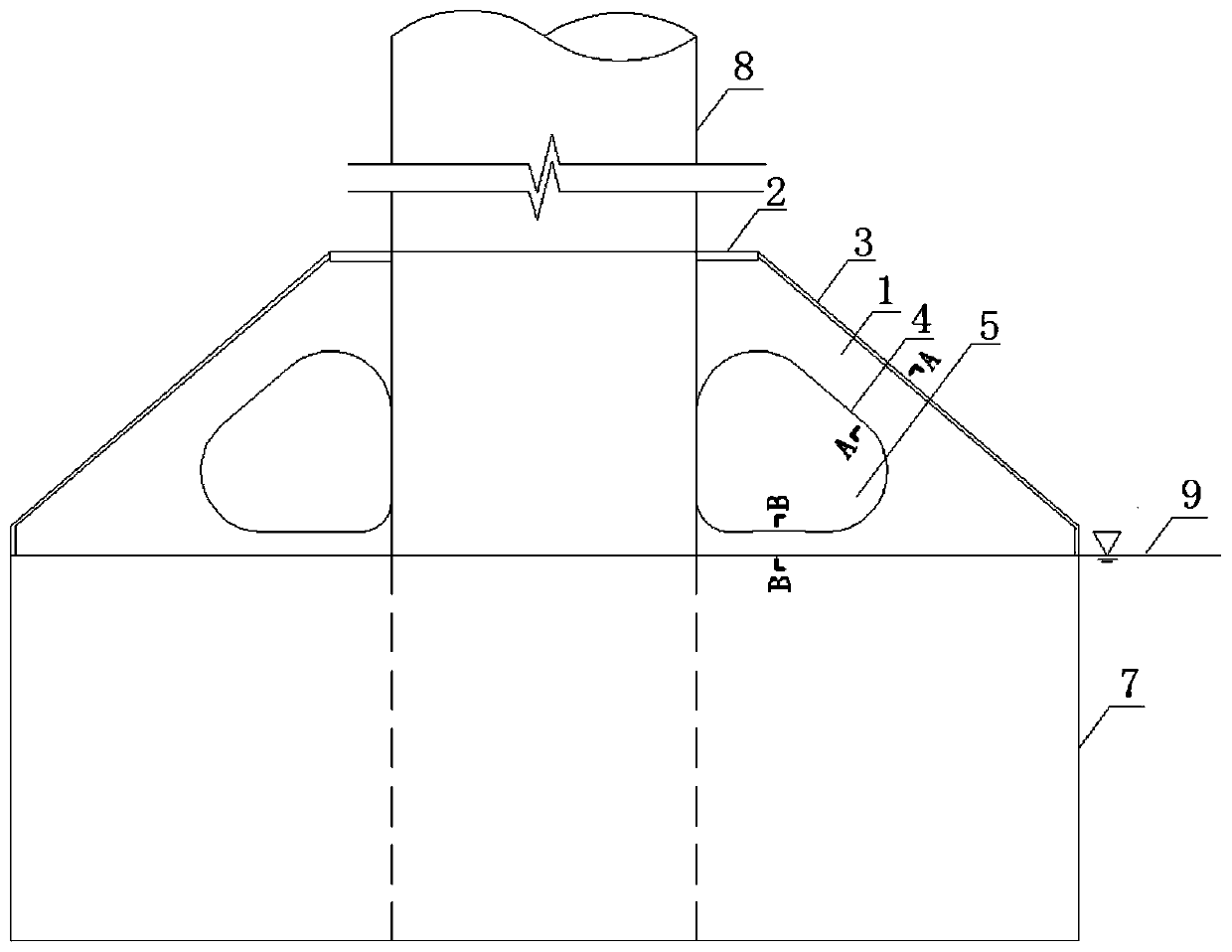

Connecting tooling used for single column and composite cylinder combined foundation

PendingCN110607802AAvoid sudden changes in stiffnessEasy and firm weldingFoundation engineeringEngineeringMotherboard

The invention relates to a connecting tooling used for a single column and composite cylinder combined foundation. A single column is inserted into a composite cylinder. The top end of the composite cylinder is provided with a fixed top cover plate. The connecting tooling comprises a connecting main plate and a plurality of stiffening webs fixedly connected to the lower plate surface of the connecting main plate. A connecting through hole adapting to the single column is arranged on the plate surface of the connecting main plate. The multiple stiffening webs are arranged around the connectingthrough hole, and the upper lateral sides of the stiffening webs are fixedly connected to the lower plate surface of the connecting main plate. The connecting main plate is connected to the single column in a sleeving mode, and the inner wall of the connecting through hole is welded to the single column. The inner lateral sides, facing the connecting through hole, of the stiffening webs are attached and welded to the columnar surface of the single column, and the lower lateral sides of the stiffening webs are attached and welded to the top cover plate. The connecting tooling related by the invention is simple in structure and convenient to mount and operate, the single column and the composite cylinder are stably connected and form an integrated structure, and big bending moment transmitted from the single column is transmitted to the whole composite cylindrical surface.

Owner:SHANGHAI INVESTIGATION DESIGN & RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com