Casting method for steel-copper composite cylinder

A composite cylinder and steel-copper technology, which is applied in the field of metal casting, can solve the problems of steel-copper composite cylinder oxidation and substandard composite performance, and achieve the effects of refining grains, avoiding cracking, and overcoming adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

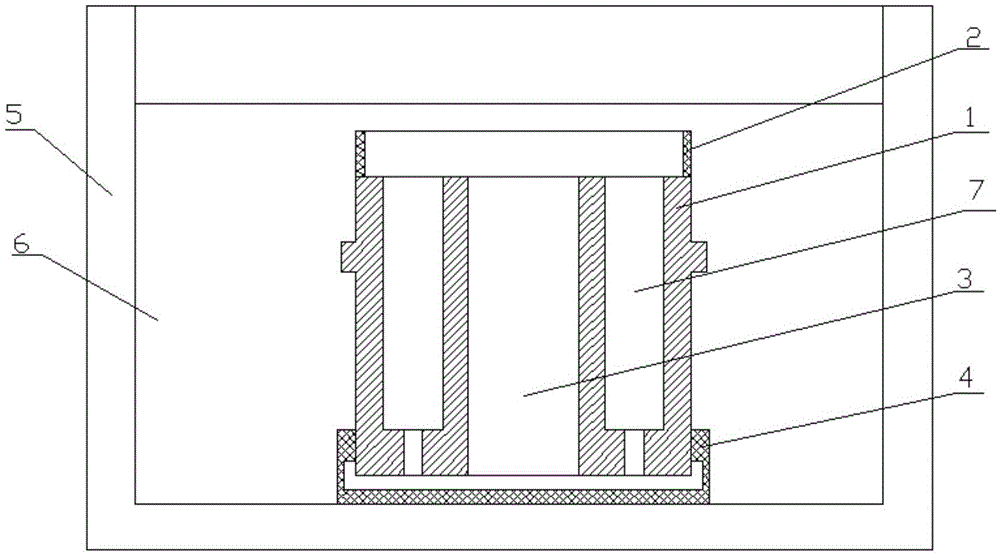

[0027] Depend on Figure 1-2 , a casting method of a steel-copper composite cylinder, comprising the following steps:

[0028] Step 1: Use UG to build a three-dimensional model, calculate the mass of the poured copper metal 7 to be 19.86kg, use CASTsoft to design and simulate the casting process, optimize the pouring process through process design and process simulation technology, and determine the initial temperature of the steel base 1 to be 1250 °C, the initial pouring temperature of copper metal 7 is 1250°C, the holding time is 9min, the pouring time is 15s, and the pouring speed is 1.5kg / s;

[0029] Step 2. Using a round steel billet as the steel base 1, perform heat treatment and annealing process on the steel base 1: slowly heating to 900° C. for 15 hours;

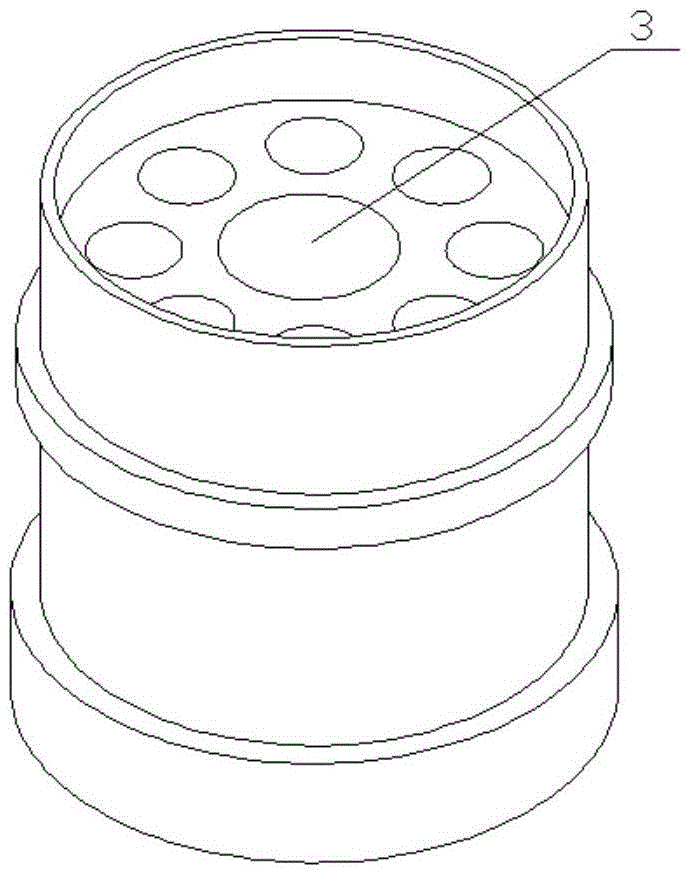

[0030] Step 3: Carry out milling, drilling, and boring on the heat-treated steel base 1 to form the center hole 3 and other feeding holes distributed around the center hole, and weld the riser 2 on the top of the ...

Embodiment 2

[0039] Depend on Figure 1-2 , a casting method of a steel-copper composite cylinder, comprising the following steps:

[0040] Step 1. Use PROE to build a three-dimensional model, calculate the mass of poured copper metal 7 to be 19.86kg, use MAGMA to design and simulate the casting process, optimize the pouring process through process design and process simulation technology, and determine the initial temperature of steel base 1 to be 1250 ℃, the initial pouring temperature of copper metal 7 is 1250°C, the holding time is 12min, the pouring time is 15s, and the pouring speed is 1.5kg / s;

[0041] Step 2: Using a round steel billet as the steel base 1, perform heat treatment and annealing process on the steel base 1: slowly heating to 1050°C for 20 hours;

[0042] Step 3: Carry out milling, drilling, and boring on the heat-treated steel base 1 to form the center hole 3 and other feeding holes distributed around the center hole, and weld the riser 2 on the top of the steel base...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com