Patents

Literature

119results about How to "Increase casting speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

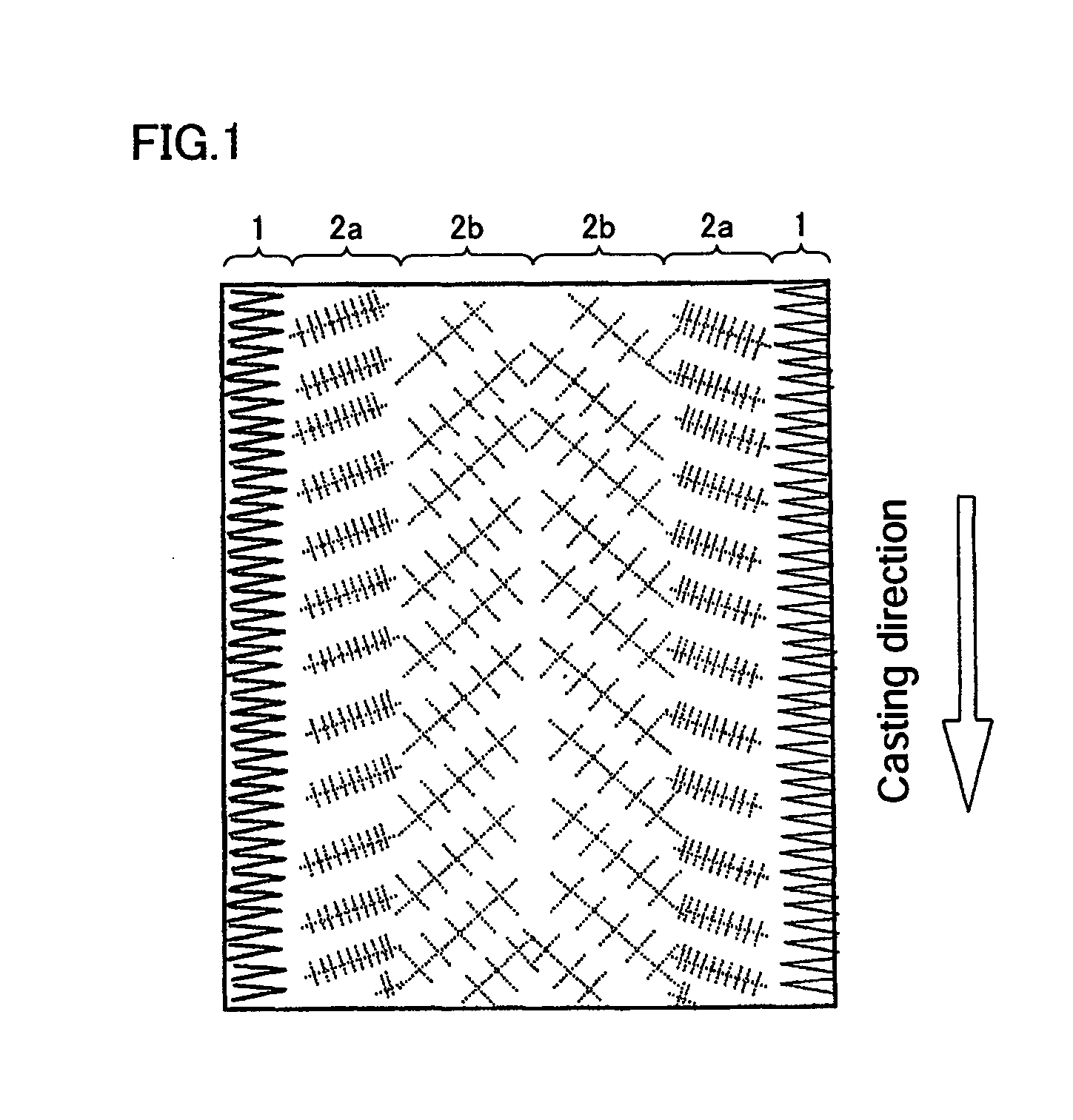

Continuous casting technique for aluminum alloy thin belt blank

InactiveCN101269406AImprove organizationComprehensive mechanical properties of high thin stripIngotMaterials science

The invention discloses a continuous casting process of an aluminum thin billet, which is characterized in that the following steps are included: aluminum alloy ingots are preheated and are melted in a melting furnace in the role of a flux; before casting, a side closure system is preheated to 400-450 DEG C, when the temperature of a melting body ranges from 650 DEG C to 680 DEG C, the aluminum alloy ingots are arranged into a tundish for 15 to 30 minutes in the role of the flux, then through a flux distributing device, the aluminum alloy ingots flow into an equant vertical twin-roll thin strip billet continuous caster, with a left forging seam gap being 0 mm and maintaining the height of a melting pool between 90 mm and 340 mm, the casting is carried out in a sinking way; when in casting, the casting speed of the casting machine ranges from 20 to 120m / min, the thin strip blank is sent into a pinch roll after leaving a casting roller, and the forged aluminum alloy thin strip has a thickness between 1.0 mm and 3.5 mm. The continuous casting process can directly make aluminum alloy thin strip blank from the liquid aluminum alloy, the forged thin strip blank has good quality on the surface, and the internal organizational structure is uniform, thereby being conducive to succeeding rolling processes. The continuous casting process for an aluminum thin blank has short process and low cost.

Owner:CHONGQING UNIV

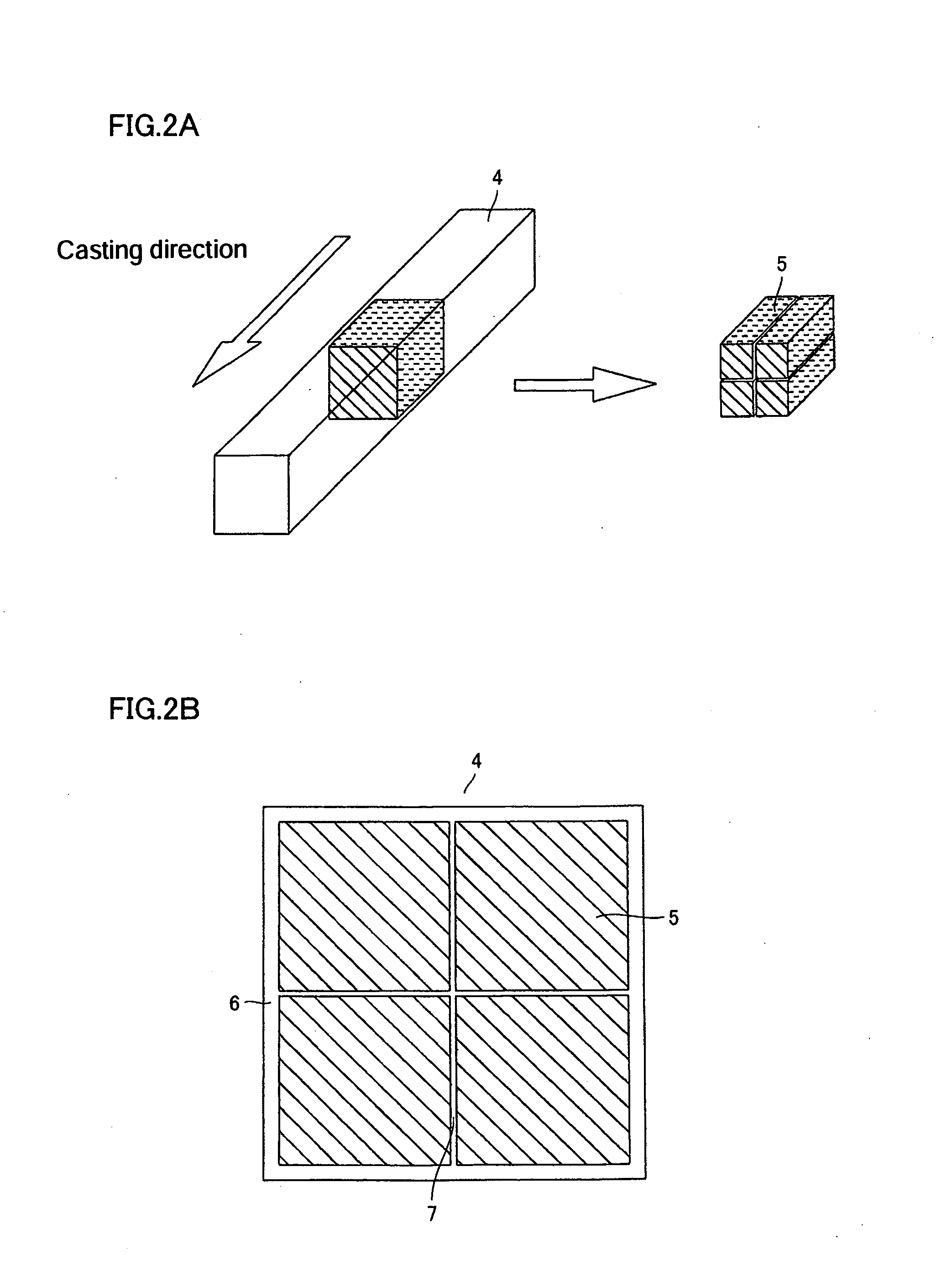

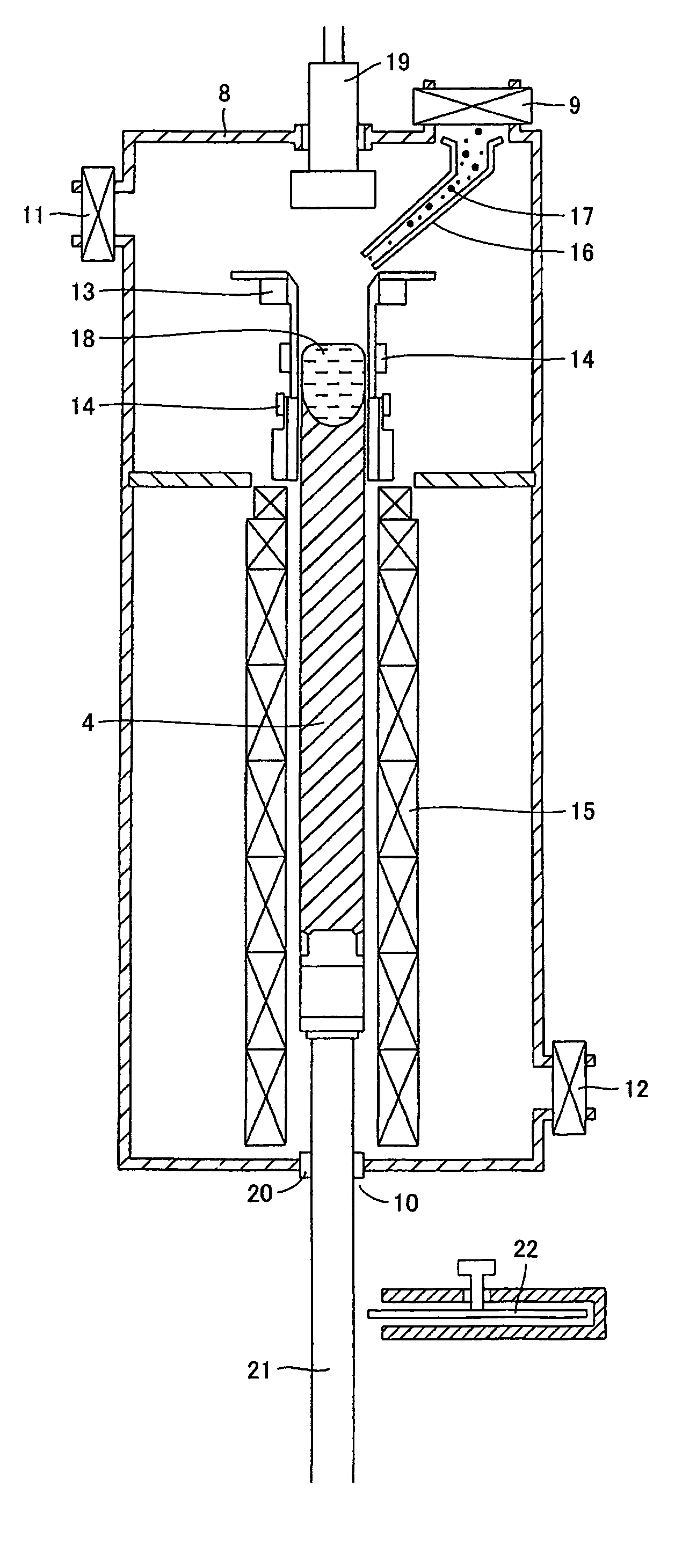

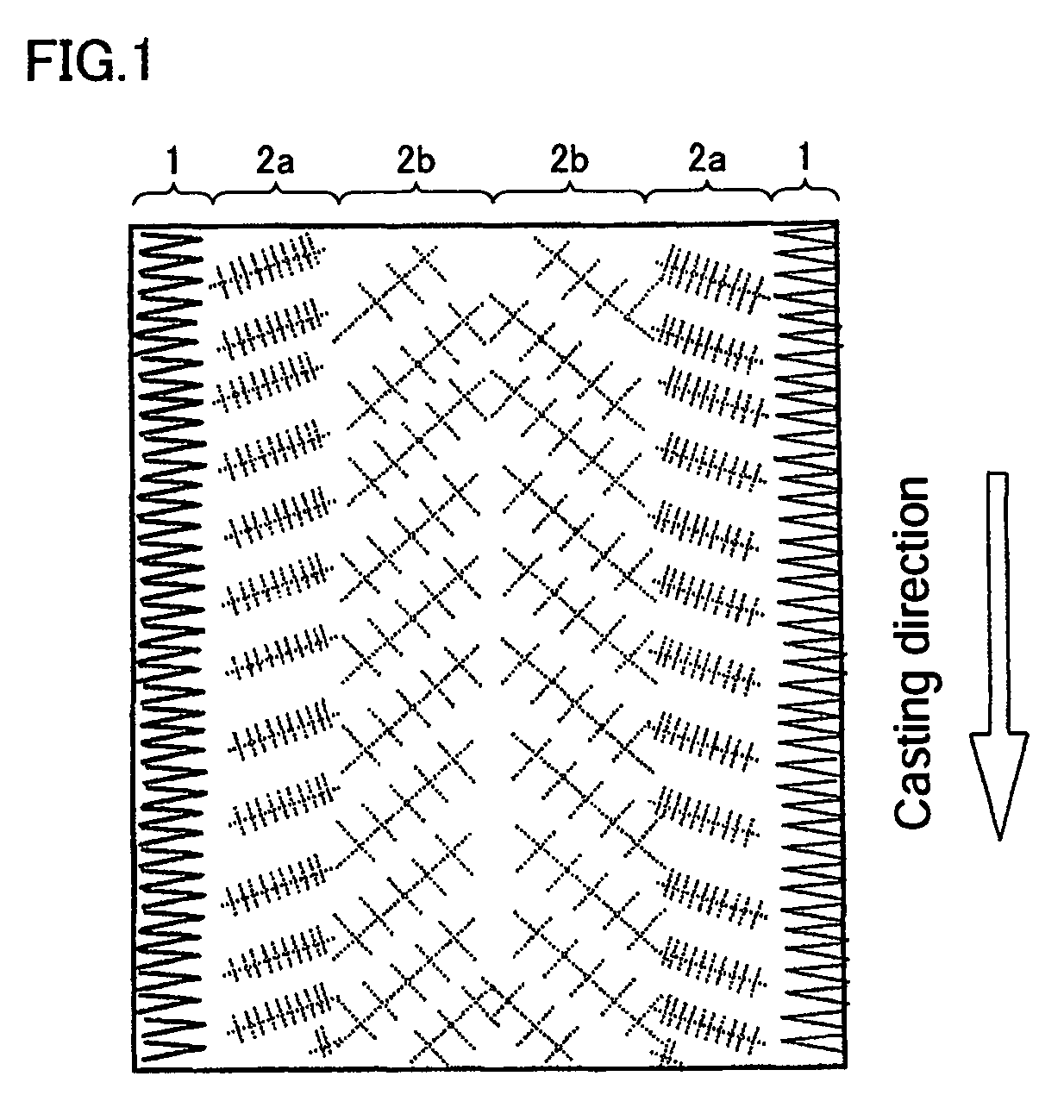

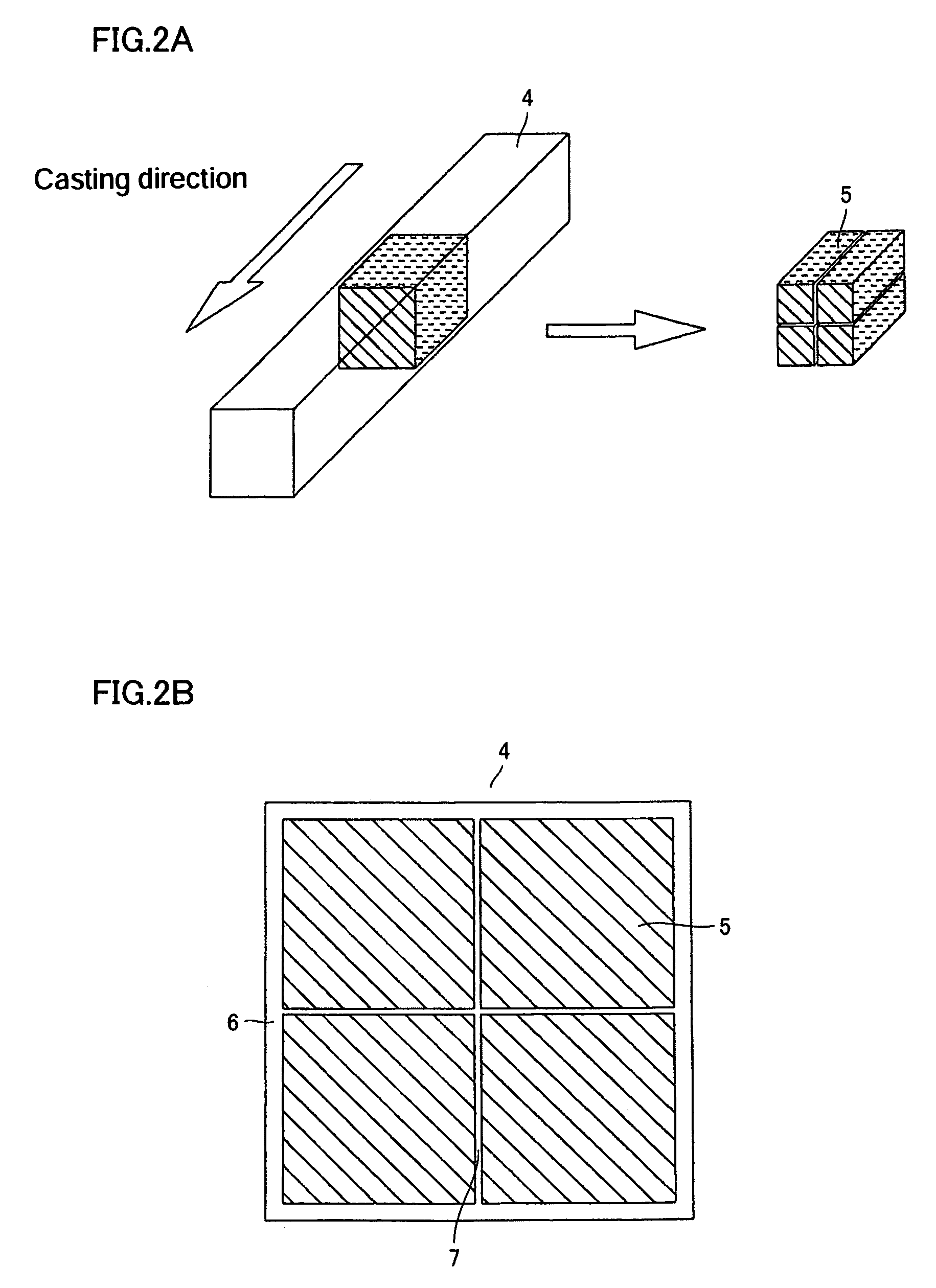

Casting method of silicon ingot and cutting method of the same

InactiveUS20080179037A1Improve production efficiencyReduce manufacturing costPolycrystalline material growthBy zone-melting liquidsIngotSolar battery

The present invention includes a method for casting a silicon ingot by using a continuous casting method by means of an electromagnetic induction, and a method for cutting the silicon ingot as a starting material into plural silicon blocks. When the silicon blocks with a square section are cut out, the sectional shape of the silicon ingot is set to be rectangular. Not less than 6 pieces of equal-sized silicon blocks are cut out from the silicon ingot, thereby enabling to enhance the manufacturing efficiency to a great extent. And since the amount of excision of the edge per silicon block is reduced, the production yield can be enhanced. Further, since the proportion of columnar crystals with large grain size inside the ingot can be increased, it becomes possible to enhance the conversion efficiency of a solar battery using the silicon block as a substrate material.

Owner:SUMCO CORP

Alloy ingot for automotive hub and production method thereof

The invention discloses an alloy ingot for an automotive hub and a production method thereof. The alloy ingot comprises the following components: 6.8-7.2% of Si, 0.28-033% of Mg, 0.10-0.15% of Ti, 0.015-0.030% of Sr, less than or equal to 0.10% of Fe, less than or equal to 0.05% of Mn, less than 0.01% of zinc, less than 0.01% of Cu, less than 0.003% of Ca, less than 0.002% of P, less than 0.02% of other single impurity content, less than 0.1% of total impurity content and the balance of aluminum. The production method of the alloy ingot for the automotive hub comprises the following steps of: adding 3303 industrial metallic silicon and electrolytic aluminum liquid for batching, heating at an appropriate temperature and melting, spreading a covering agent so as to reduce oxidation slagging, stirring so that the industrial metallic silicon rapidly melts, keeping uniform temperature, slagging off, keeping melt clean, spraying powder and refining by adopting high-purity N2 and a refined powder spraying agent, controlling the temperature of a smelting furnace to 740-750 DEG C, adding Al-Sr alloy to aluminium water, carrying out secondary degassing and slagging-off by adopting a powder spraying refinement method, filtering to remove slag, and casting the alloy ingot in line with requirements. The alloy ingot obtained by the method has the advantages of stable and uniform components, compact structure and clean surface; and the production method is the best production method for producing the A356.2 alloy ingot for the low-iron high-end automotive hub.

Owner:河南省银湖铝业有限责任公司

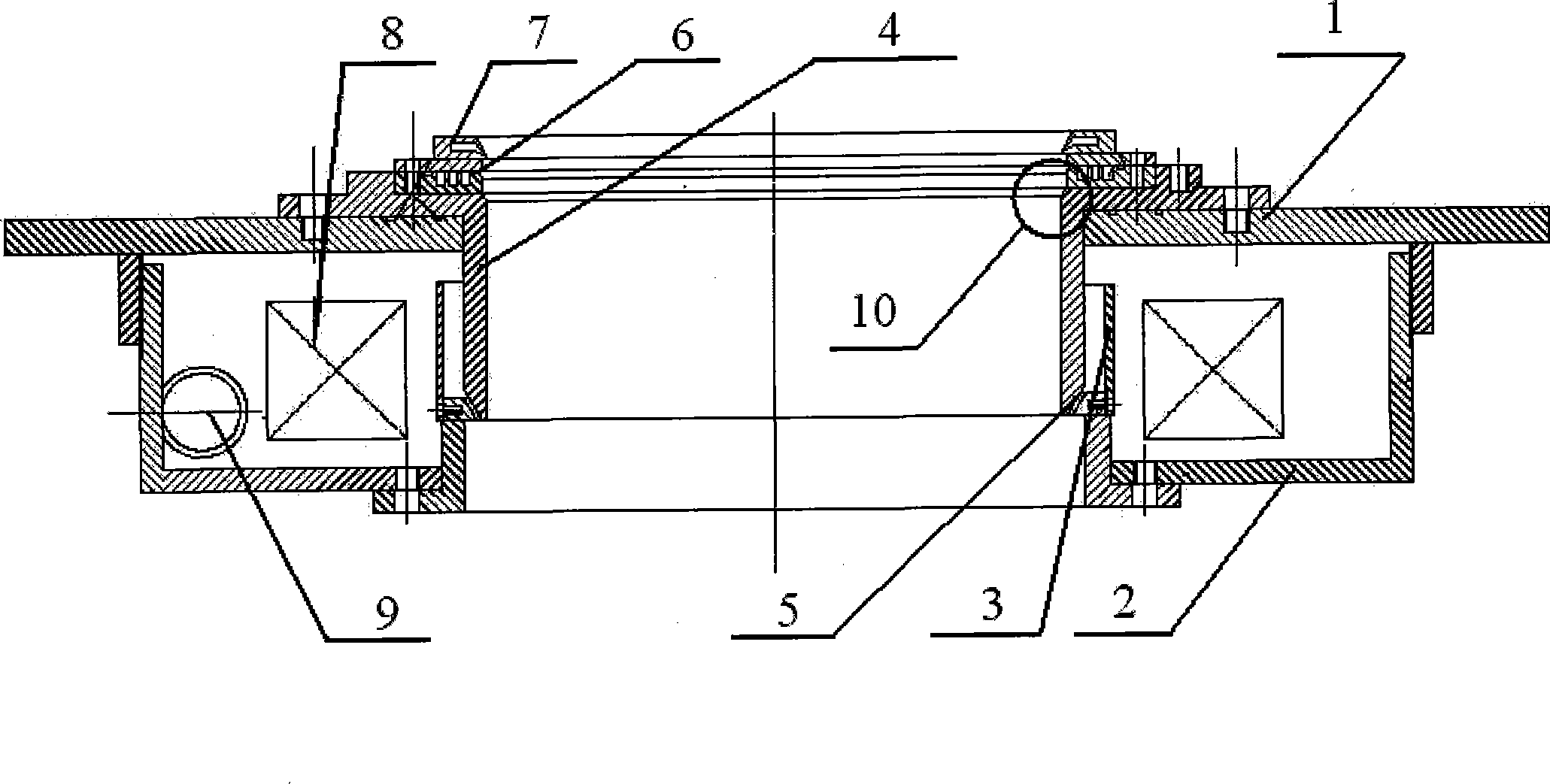

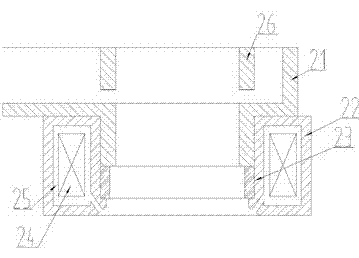

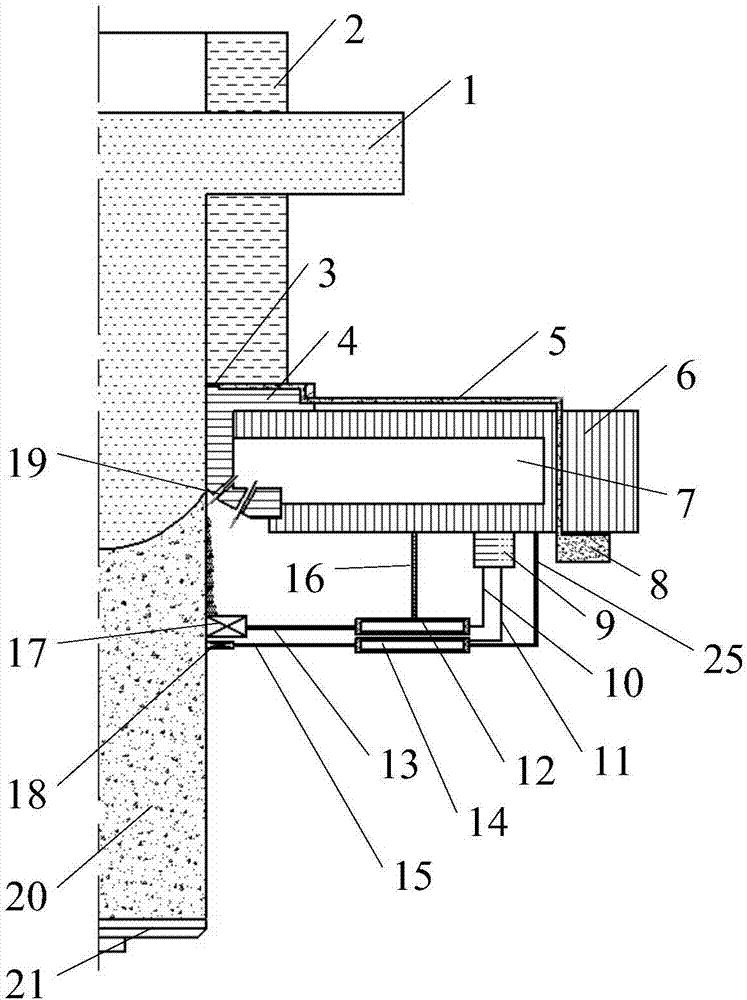

Oil lubricating electromagnetic vertical type semi-continuous casting method and crystallizer of magnesium alloy ingot blank

InactiveCN101239371AReduce interface contact pressureLow coefficient of sliding frictionThin layerConductor Coil

An oily electro-magnetism vertical type semi-continuous casting process for a magnesium alloy ingot blank and a crystallizer are disclosed. The crystallizer comprises a metal liner, a cooling system, an excitation winding, a splash ring and a cover gas ring. The metal liner is disposed at the center of crystallizer. A cavity cooling system is disposed out of the metal liner. The excitation winding is disposed at the lower part in the cooling water cavity. A splash ring is disposed at the upper edge of the crystallizer liner. A cover gas ring is disposed above the splash ring. The invented method comprises following steps: coating a thin layer of lubricant oil on the inner wall of the metal liner, starting the crystallizer cooling system; then starting the low frequency generation power source to supply low frequency alternating current to the excitation winding; inducing the magnesium alloy fluid into the shunting disk disposed in the center of the liner; opening the cover gas ring; starting the casting machine and adjusting the crystallizer liquid level to be stable after the magnesium alloy fluid fills the top of the dummy ingot head; enlarging the cooling water flow, opening and adjusting control valve for controlling the splash ring. The invented proves can improve the surface quality of the magnesium alloy ingot blank, reduce surface turning quantity thereof, and increase casting speed thereof.

Owner:NORTHEASTERN UNIV

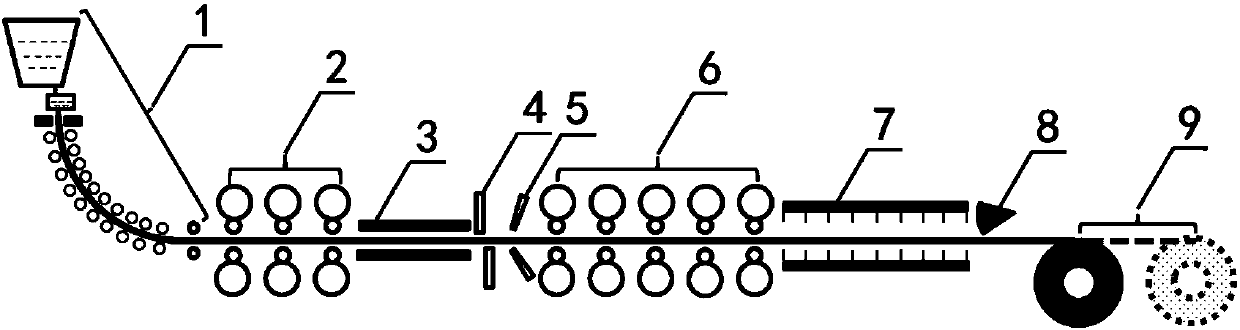

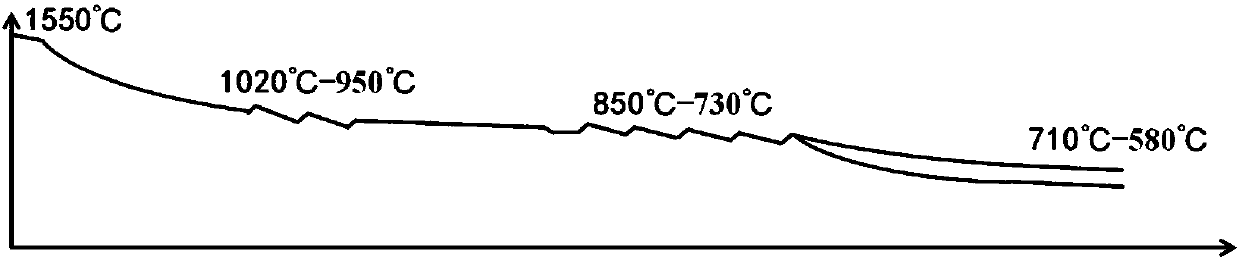

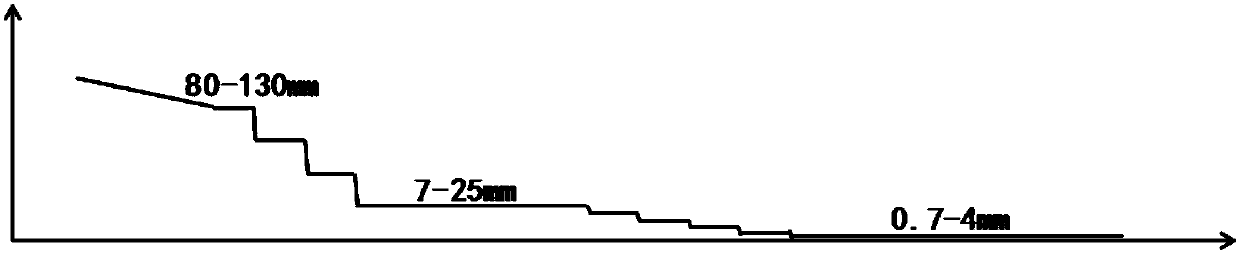

Headless continuous casting and rolling ferrite rolling method and device of low/micro-carbon steel coil for deep drawing

PendingCN107597844AReduce aging phenomenonPromote formationTemperature control deviceWork treatment devicesTemperature controlHigh pressure water

The invention discloses a headless continuous casting and rolling ferrite rolling method and device of a low / micro-carbon steel coil for deep drawing and belongs to the field of metallurgy steel rolling. According to the headless continuous casting and rolling ferrite rolling method and device of the low / micro-carbon steel coil for deep drawing, continuous casting for blank forming, rough rollingof a rough rolling unit, temperature control of a cooling channel, descaling of high-pressure water, ferrite rolling of a finishing mill group, cooling of a layer cooling device, high-speed flying shear and shunt winding and coiling of a reeling machine are carried out. By means of the method and device, the problems that heating / soaking of a heating furnace is needed before rough rolling of a conventional hot rolling process, and cooling with temperature retaining is needed due to the fact that the temperature difference of rough rolling of an austenite zone and finish rolling of a ferrite zone is large and the problems that for thin slab casting and rolling processes with CSP as a respective, heating / soaking or induction heating for temperature supplementing of a heating furnace is needed are solved, the advantages that the arrangement is compact, the investment is small, the production efficiency is high, safety and reliability are achieved, energy is saved, environmental friendliness is achieved, and the cost is reduced are achieved, and the low-carbon / micro-carbon steel coil for deep drawing is produced through headless continuous casting and rolling and ferrite rolling.

Owner:UNIV OF SCI & TECH BEIJING +1

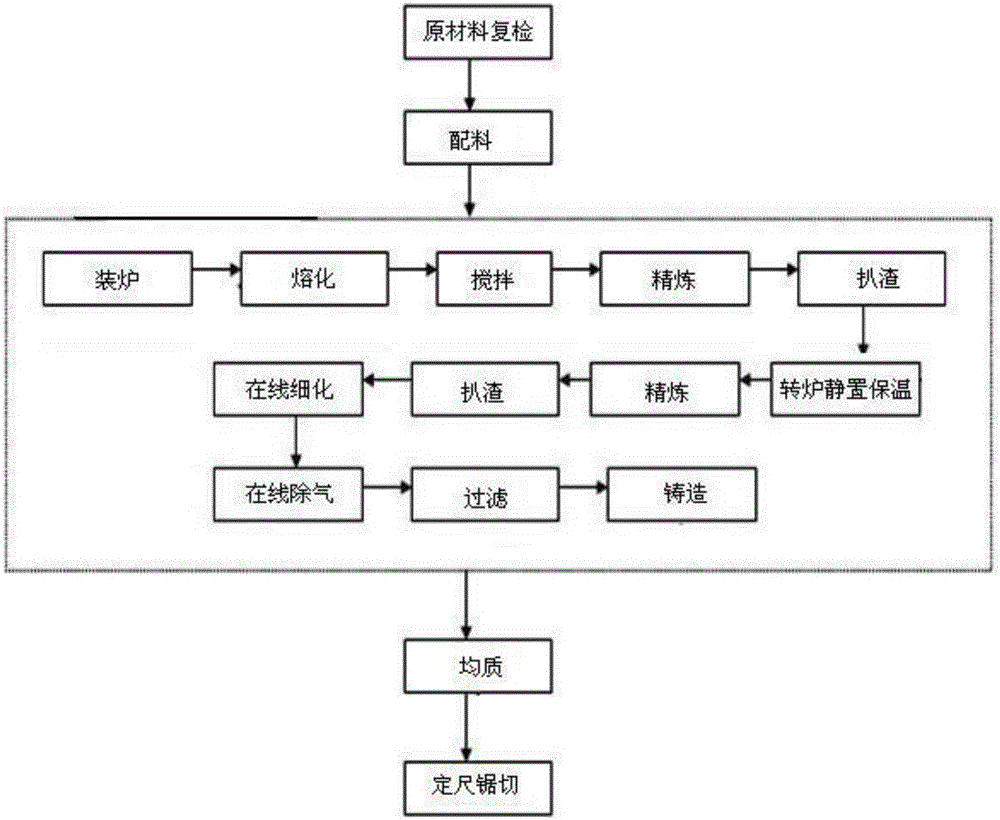

Hot top casting process for phi 784-mm 7xxx-series superhard aluminum alloy round bar

The invention discloses a hot top casting process for a phi 784-mm 7xxx-series superhard aluminum alloy round bar. The aluminum alloy round bar is composed of, by mass, 0.25% of Si, 0.4% of Fe, 1.55-1.65% of Cu, 0.25% of Mn, 2.55-2.65% of Mg, 0.19-0.25% of Cr, 5.6-5.7% of Zn, 0.15% of Ti, 0.03% of Zr and the balance Al. The manufacturing process comprises the steps of a, material preparation; b, smelting; c, stirring; d, refining; e, slagging-off; f, heat preservation and standing; g, online thinning; h, online degassing; i, filtration; j, casting; k, homogenizing. Through the process, the defects, such as cracks, component segregation, bright grains, thick grains and loose pores, which often appear when a direct condensation casting technology is adopted for large-diameter superhard aluminum alloy are overcome, and by the adoption of hot top casting, the defects of surface segregation tumors, thick coarse-grain layers and the like are overcome.

Owner:CHINA ZHONGWANG

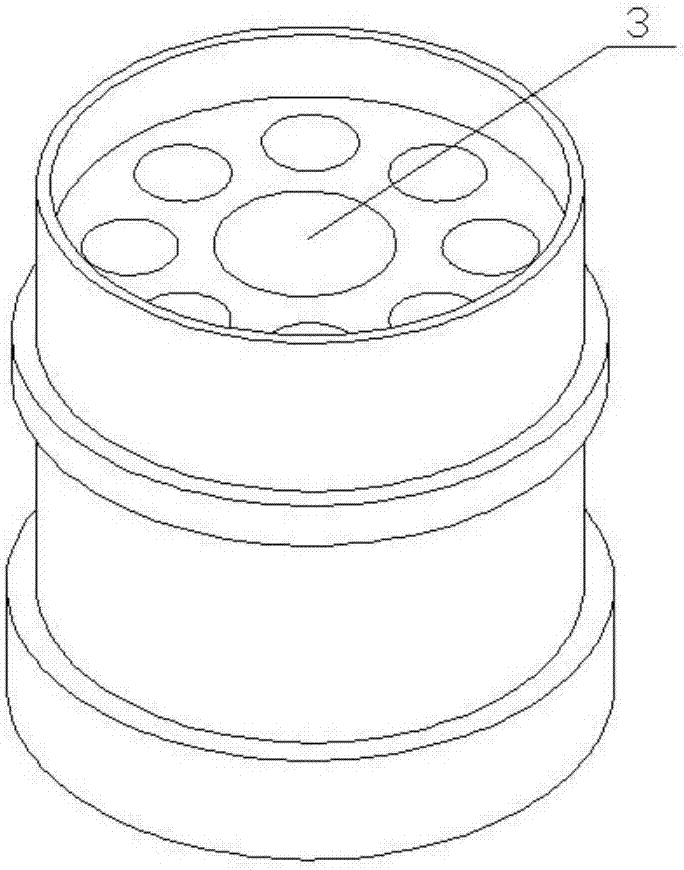

Equipment for producing aluminum alloy hollow casting ingot and method of equipment

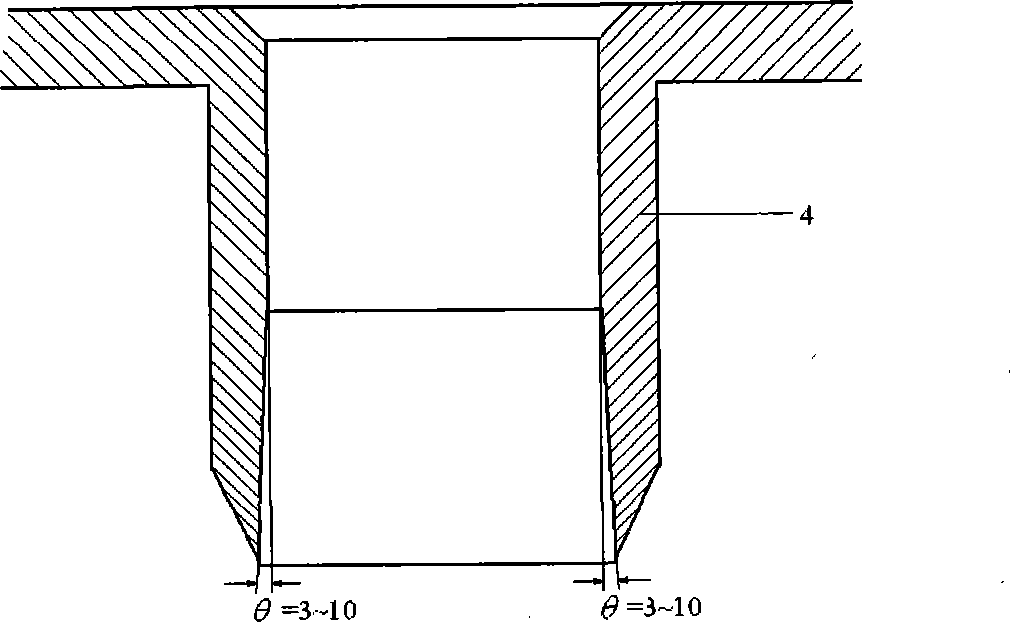

The invention relates to the technical field of aluminum alloys, in particular to equipment for producing an aluminum alloy hollow casting ingot and a method of the equipment. The equipment for producing the aluminum alloy hollow casting ingot comprises a core die, a crystallizer, a bracket and a dummy ingot, wherein the core die is positioned at the center of the crystallizer and is concentric with the crystallizer; the bracket arranged on the crystallizer is used for supporting the core die; the dummy ingot is arranged at the lower part of the core die; a space between the core die and the crystallizer is a die cavity; the core die is designed into a taper with a large upper part and a small lower part; and the size of the taper is 1-30 degrees; a cooling system and a lubricating system are arranged in the core die; a coil is arranged in a water chamber of an aluminum sleeve of the crystallizer; and a shunt and a stop block are arranged on the crystallizer. According to the equipment for producing the aluminum alloy hollow casting ingot and the method for the equipment disclosed by the invention, a friction force between the casting ingot and the die core in the hollow casting process of the aluminum alloy is reduced and the core locking and breakout are avoided.

Owner:NORTHEASTERN UNIV

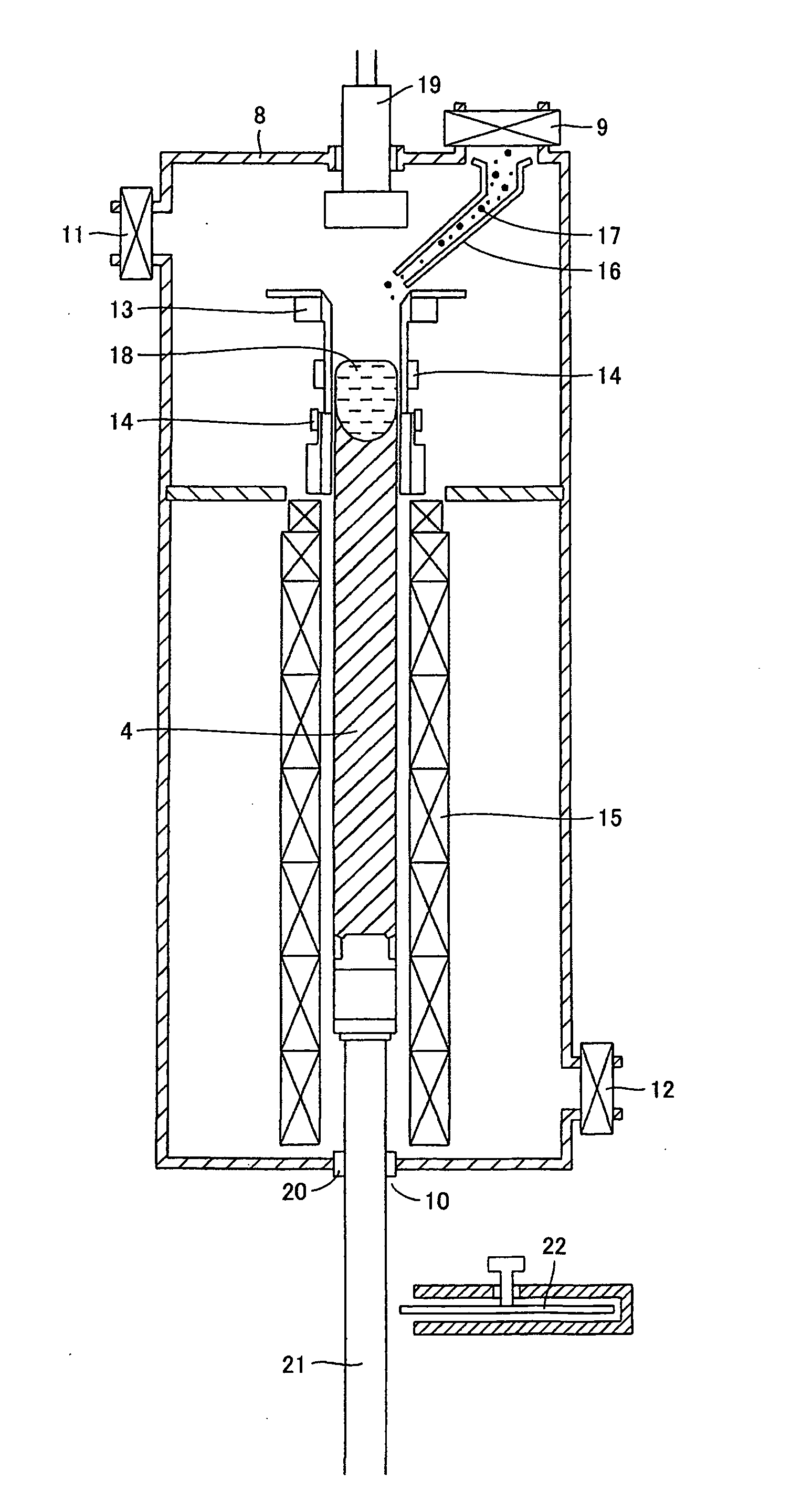

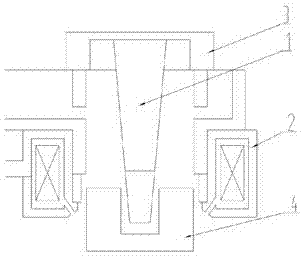

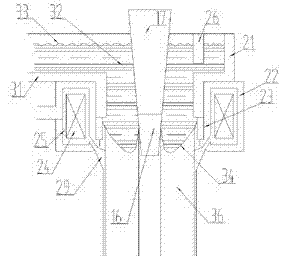

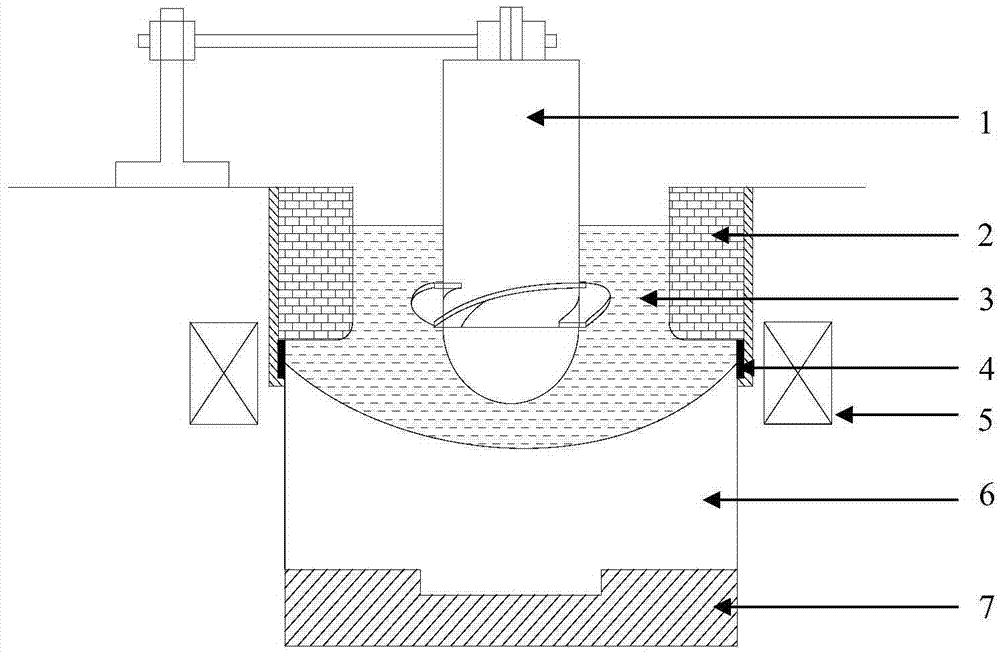

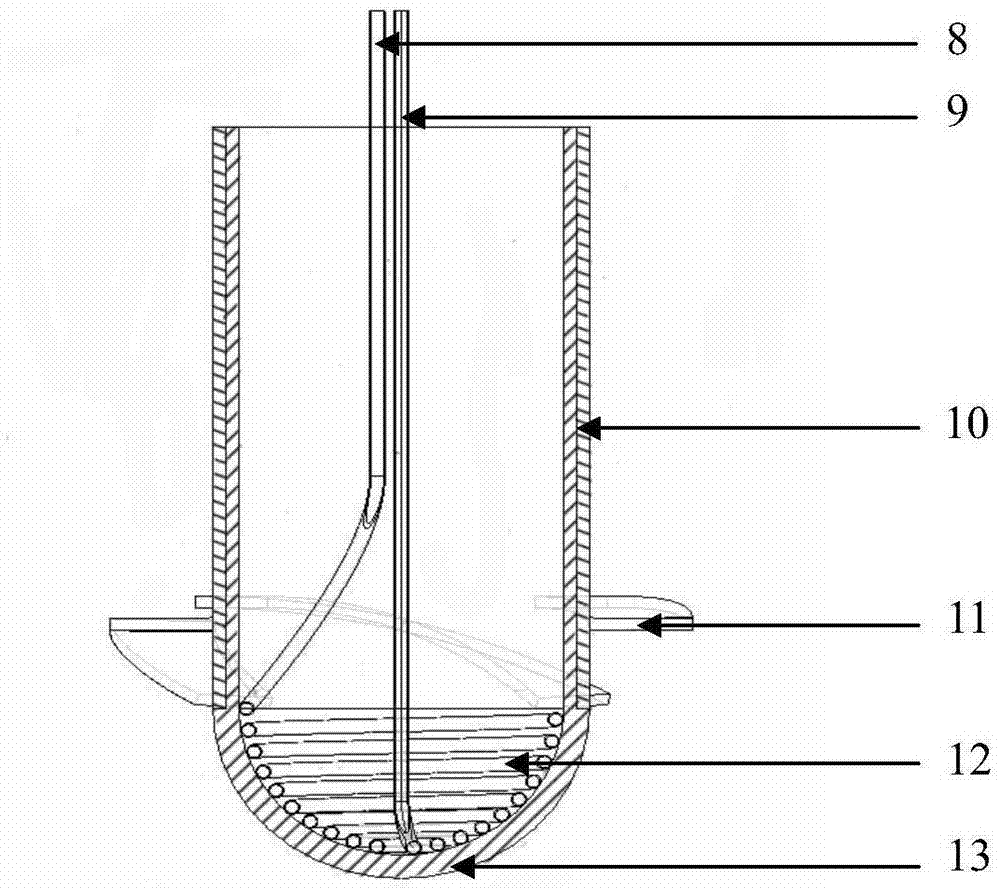

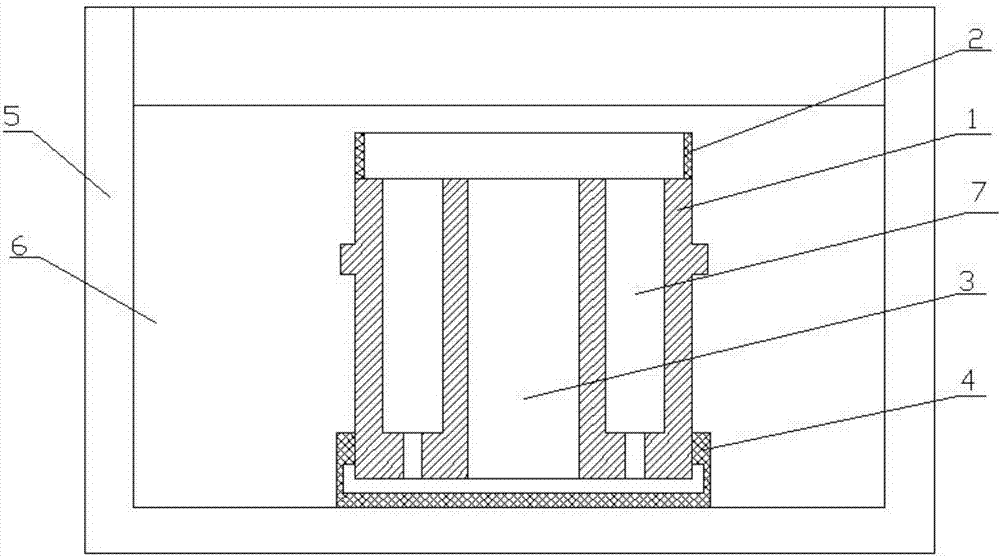

Manufacture device and method for large-size fine-grain homogeneous aluminum alloy cast ingot

The invention relates to a manufacture device and method for a large-size fine-grain homogeneous aluminum alloy cast ingot, belonging to the field of metal material machinery. The device mainly comprises a uniform cooler, a thermal ejector, an electromagnetic stirrer, a crystallizer and a dummy ingot, wherein the thermal ejector is arranged above the crystallizer; the electromagnetic stirrer is arranged on the periphery of the thermal ejector and the crystallizer; the dummy ingot is arranged below the crystallizer; the uniform cooler is arranged in the crystallizer; and the uniform cooler consists of an inner pipe and an outer pipe. According to the manufacture device and method, through special coupling treatment of uniform cooling in the crystallizer and electromagnetic stirring outside the crystallizer is applied to an alloy melt, so that effective control on uniformity of a temperature field and a component field of the large-size alloy melt is realized, and the large-size aluminum alloy cast ingot with uniform and fine structure and uniform components is manufactured. The manufacture device is simple in structure, feasible in method, obvious in effect, high in production efficiency and easy for combination with large-scale industrial production, and has a wide industrial application prospect in the fields of aerospace, rail transportation and manufacture of ships and the like.

Owner:有研金属复材技术有限公司

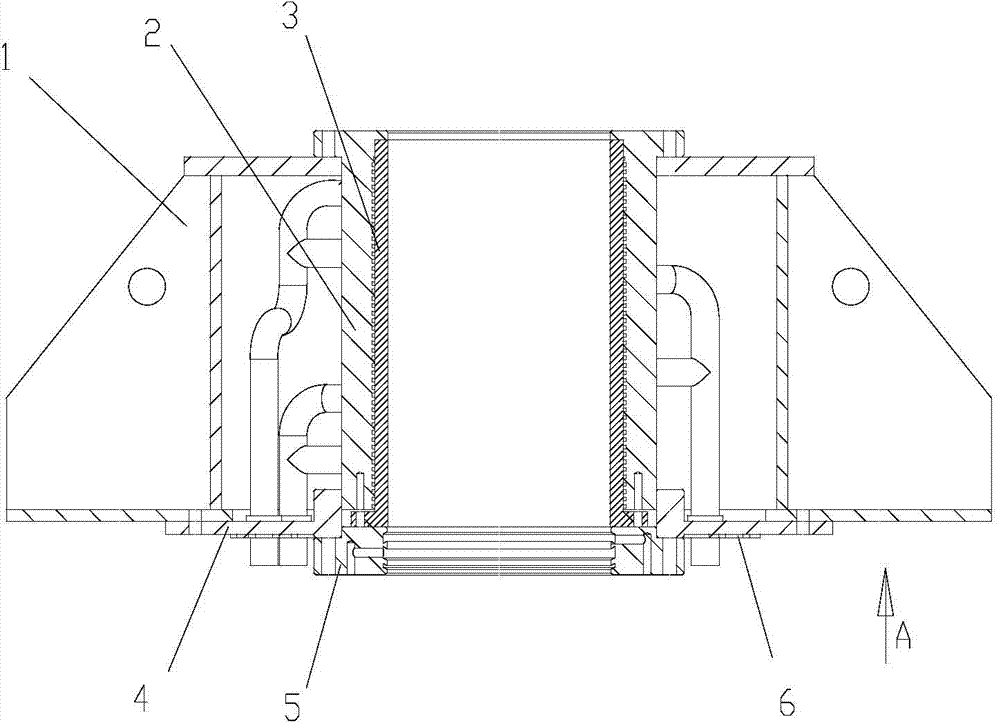

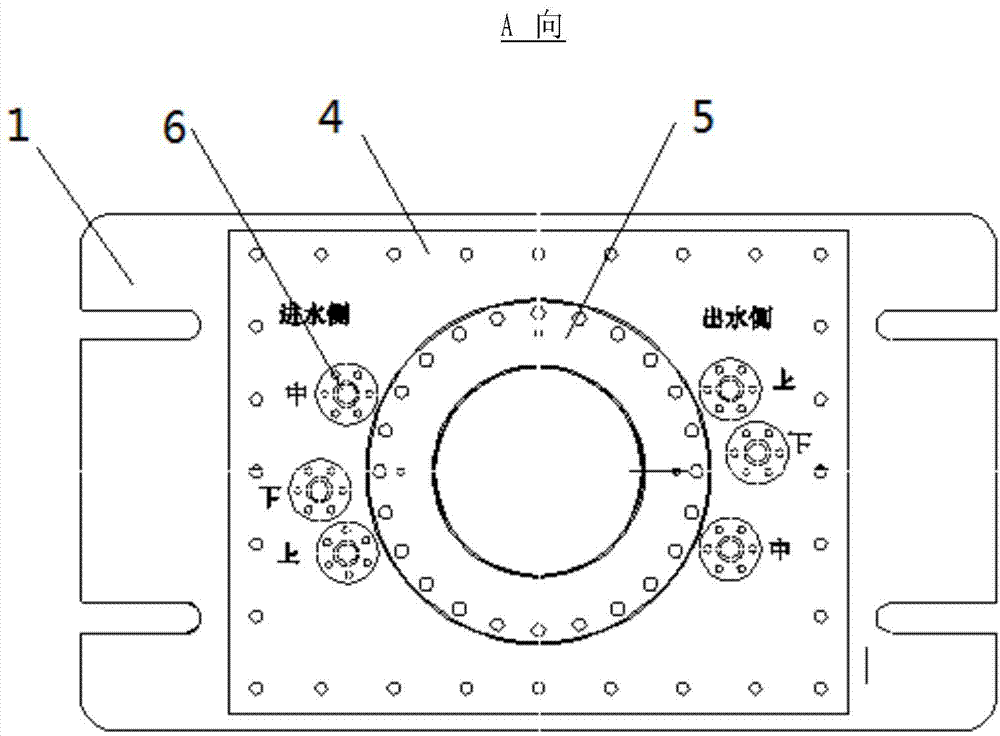

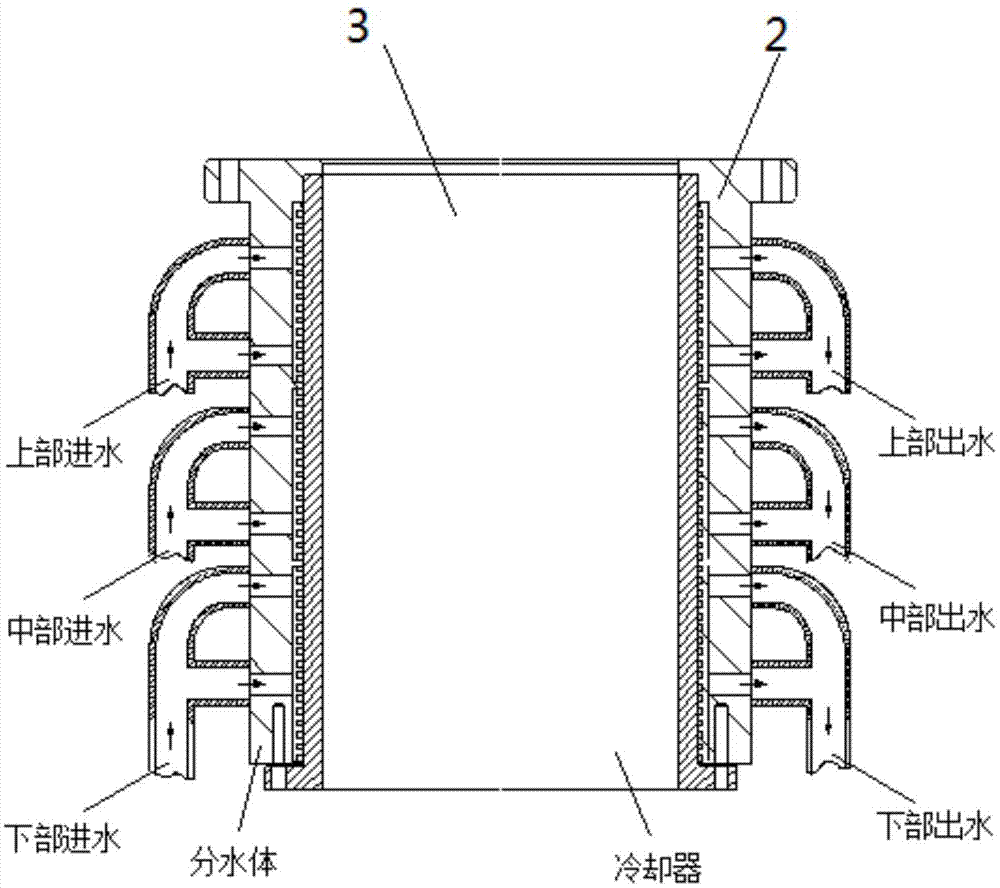

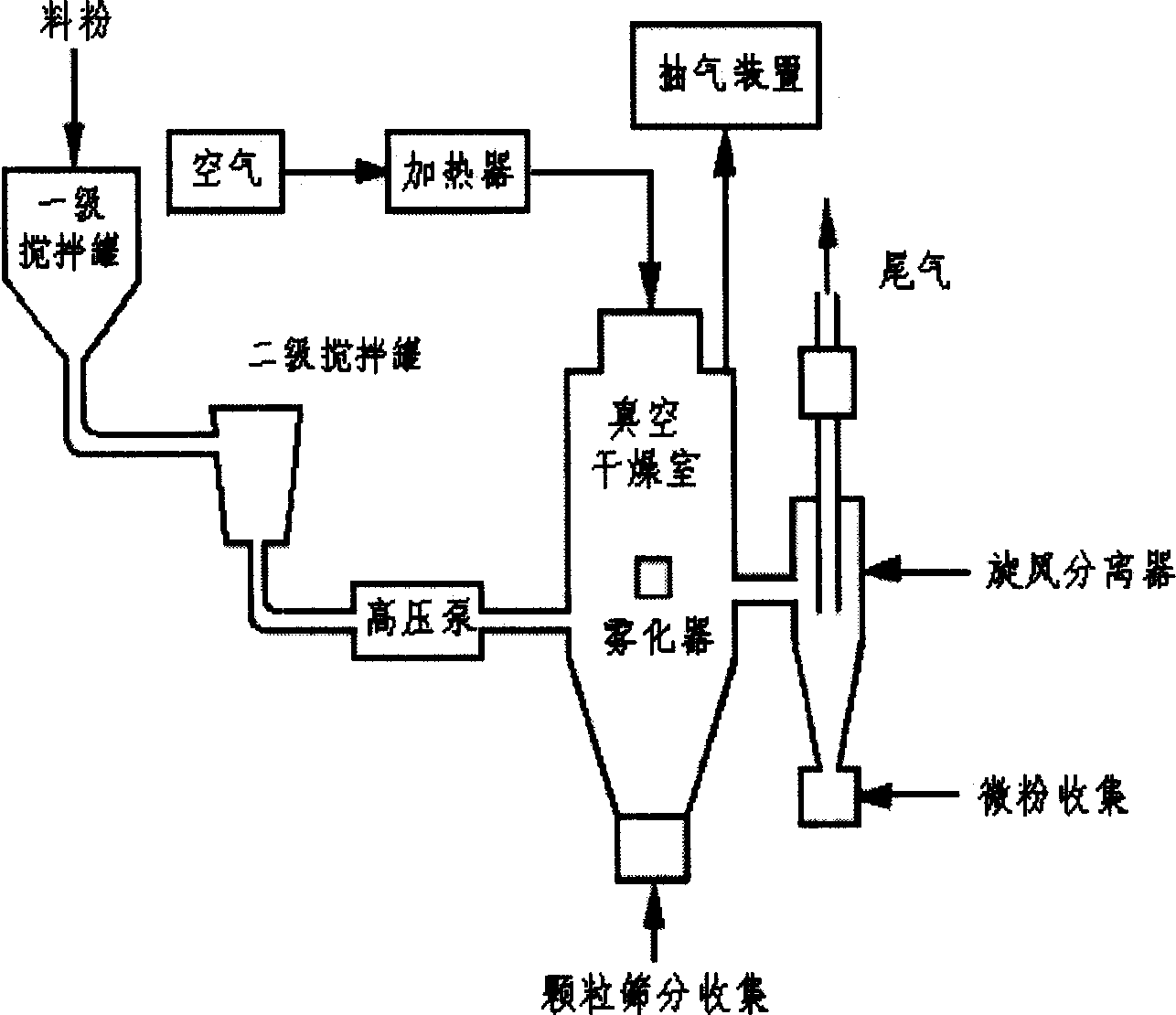

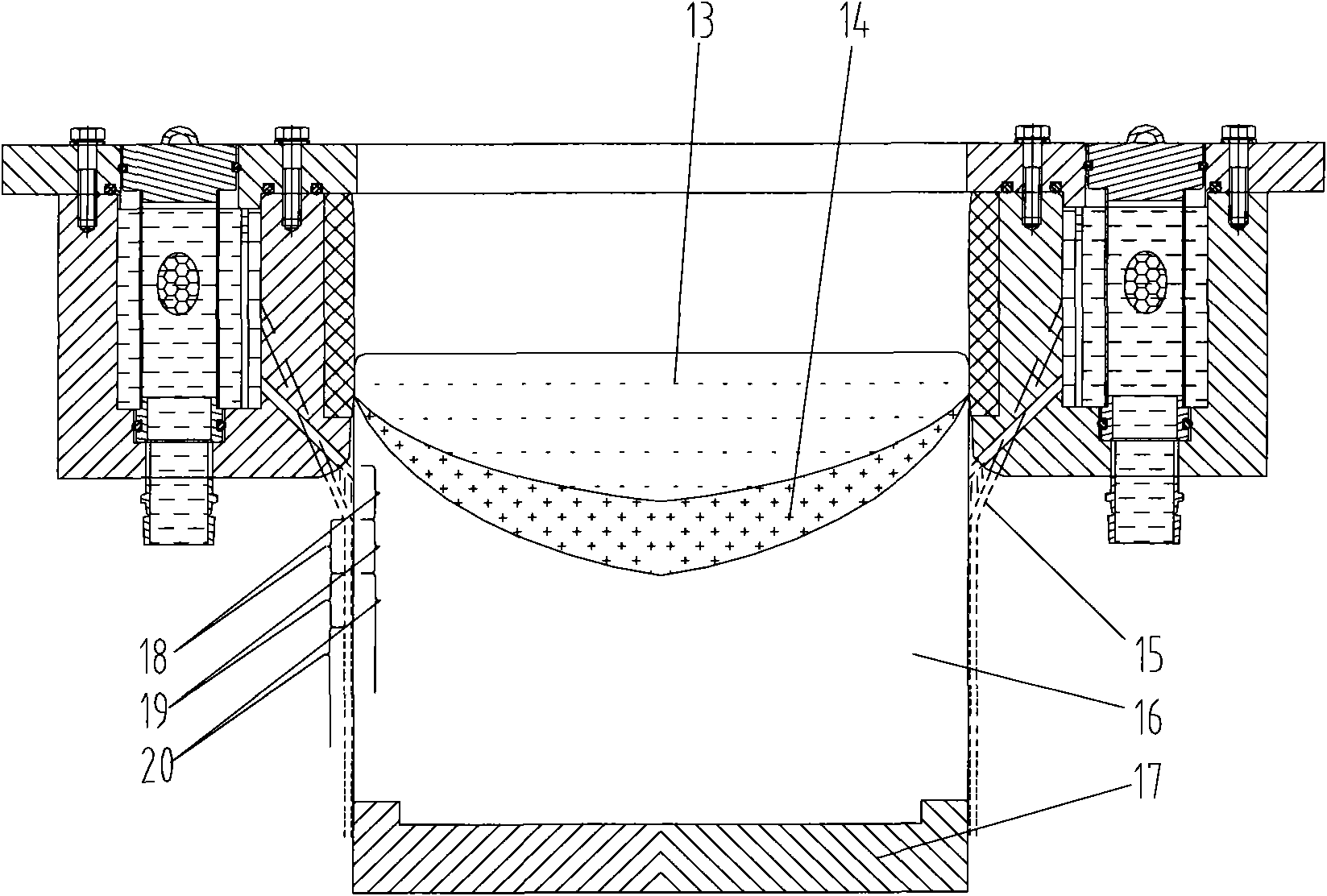

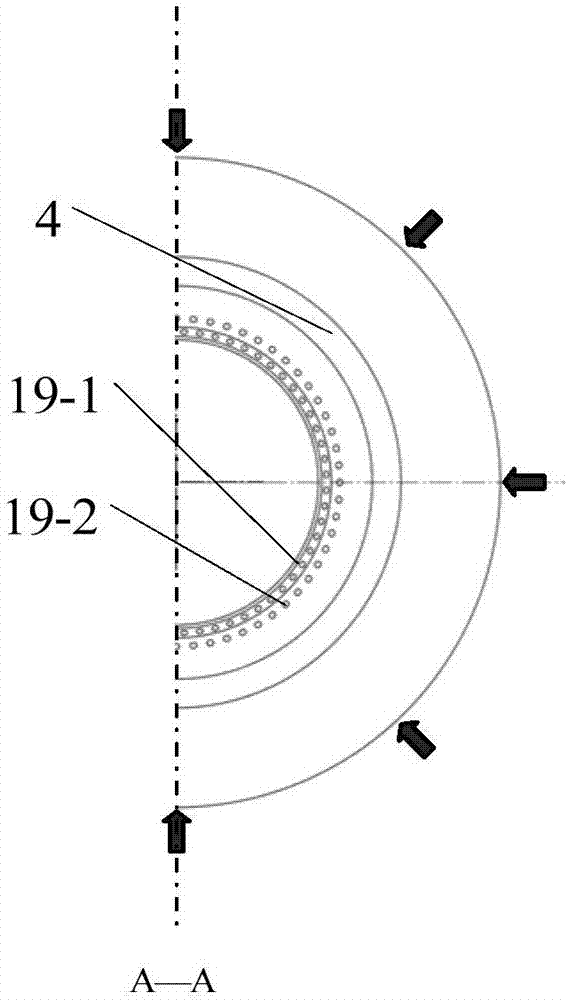

Magnesium alloy round billet continuous casting crystallizer

Disclosed is a magnesium alloy round billet continuous casting crystallizer. Water flowing grooves are distributed in the contact surface of a water tank water diversion body or a cooler along the periphery, and the water flowing grooves in the upper, middle and lower portions are connected with water inlet / outlet channels in respective areas respectively and enable the upper, middle and lower portions to supply different cooling media and flowing amounts according to needs, so that segmentation cooling control over the crystallizer is achieved. Medium inlet / outlet ports of the upper, middle and lower portions are communicated with corresponding water inlet / outlet flanges respectively, and the length of the crystallizer can be increased to 800 mm to the maximum extent. A cooling area of the inner wall of the crystallizer adopts independent cooling control with an upper section, a middle section and a lower section from top to bottom, and control flexibility of the crystallization and solidification intensity of molten magnesium alloy is improved. Inert gas is introduced to the lower portion of the crystallizer for protection, so that water steam is prevented from entering the inner wall of the crystallizer and causing combustion or explosion accidents of the molten magnesium alloy. The magnesium alloy round billet continuous casting crystallizer is an important breakthrough in improving the casting speed of the magnesium alloy, and fills the blank in the field of comprehensive design schemes of the magnesium alloy continuous casting crystallizer.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Casting method for steel-copper composite cylinder body

InactiveCN107096905AImprove corrosion resistanceImprove wear resistanceInternal combustion piston enginesCylindersCopper cylinderComposite cylinder

The invention discloses a casting method for a steel-copper composite cylinder body. The casting method comprises the steps of performing three-dimensional modeling, designing a casting technology and performing technology simulation and optimization, performing base steel heat treatment, performing machining, tool machining and welding, performing base steel surface treatment, performing pre-heating treatment before base steel production, smelting copper alloy, dipping the copper alloy, melting anhydrous borax, putting base steel into a borax solution, pouring the copper alloy into the base steel, putting the base steel into a water tank and cooling and solidifying the base steel to room temperature to obtain the steel-copper composite cylinder body. According to the casting method, the problems of the composite casting technology and the composite material composition of the steel-copper cylinder body can be solved; and the composite strength of the thermometal cylinder body can be high, the yield can be high, the cost can be low, the size of the cylinder body can not be limited, the forming process can be controlled easily, and the quality can be stable.

Owner:安徽恒利增材制造科技有限公司

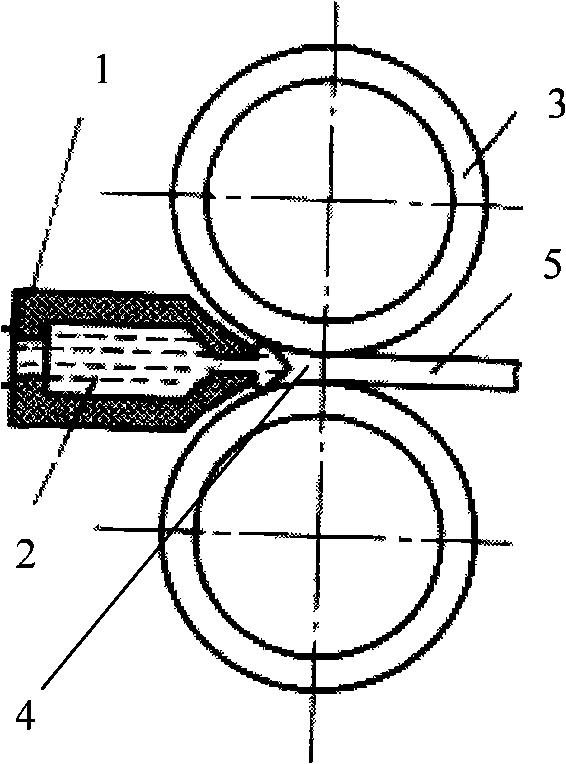

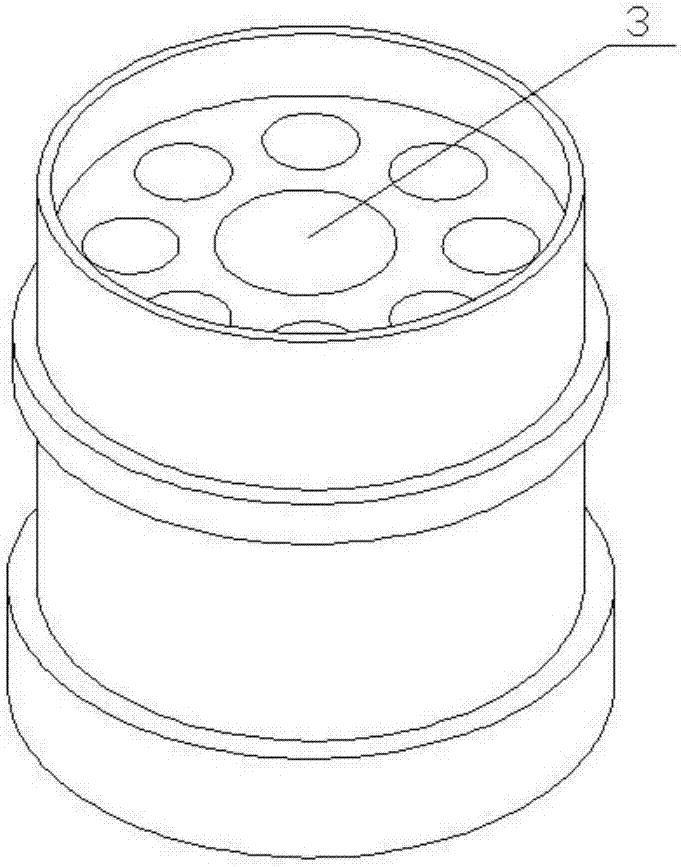

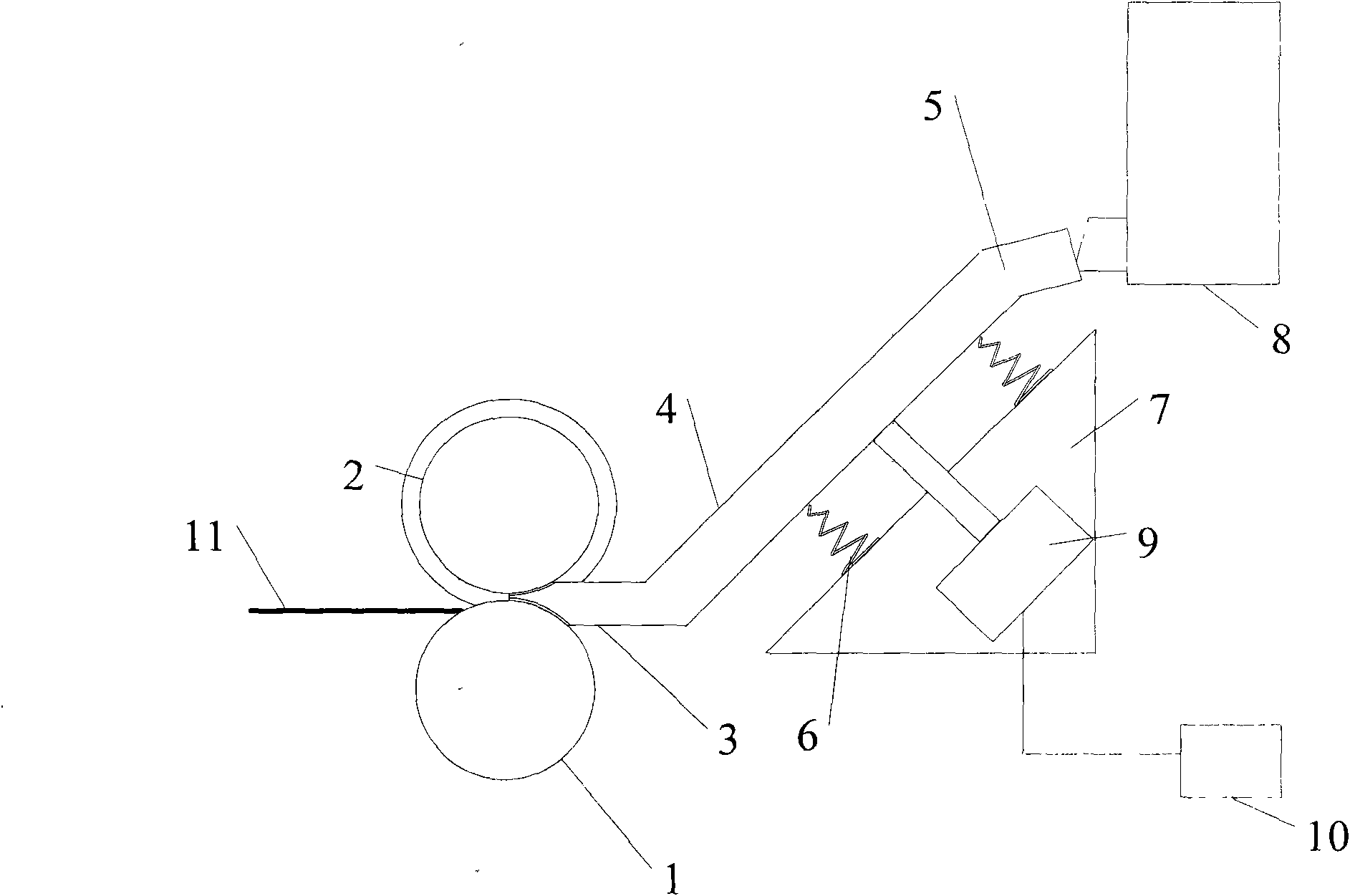

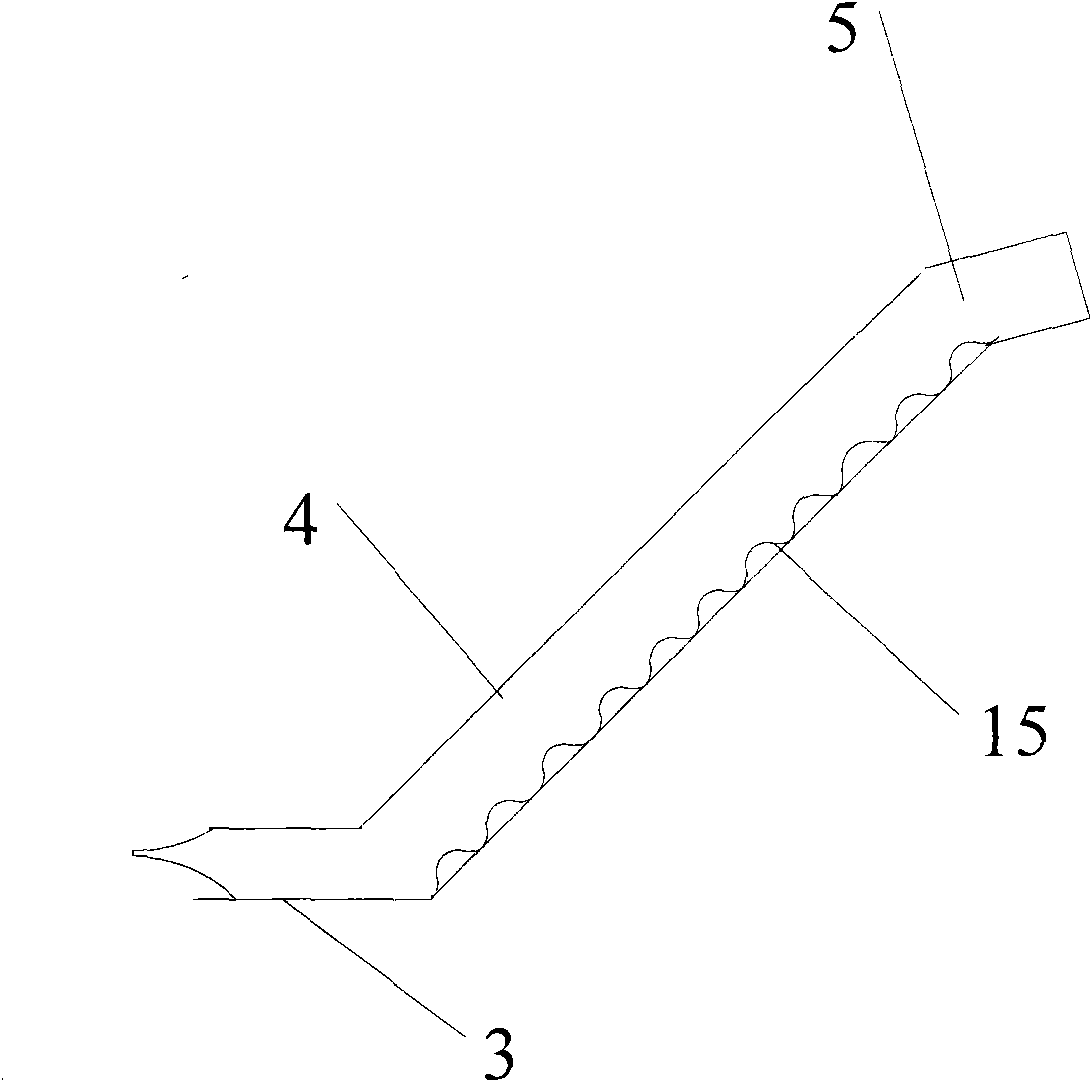

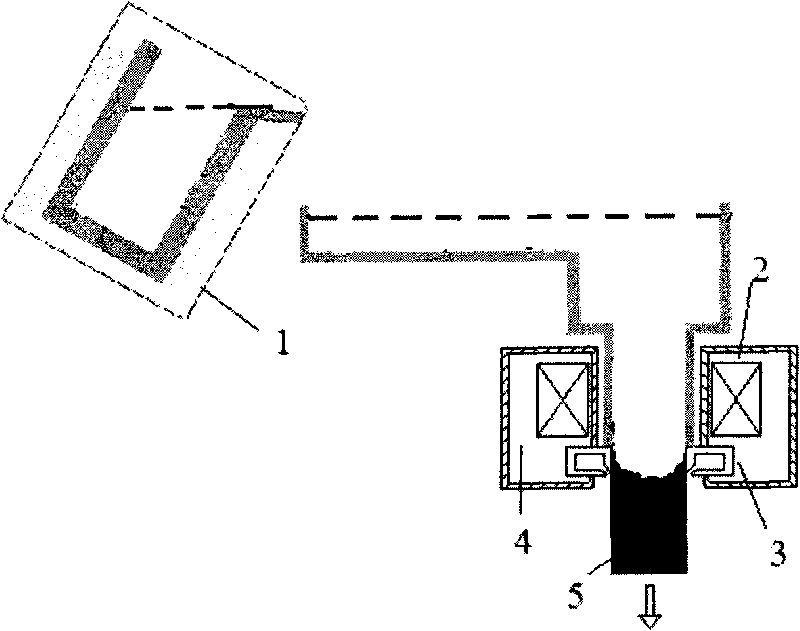

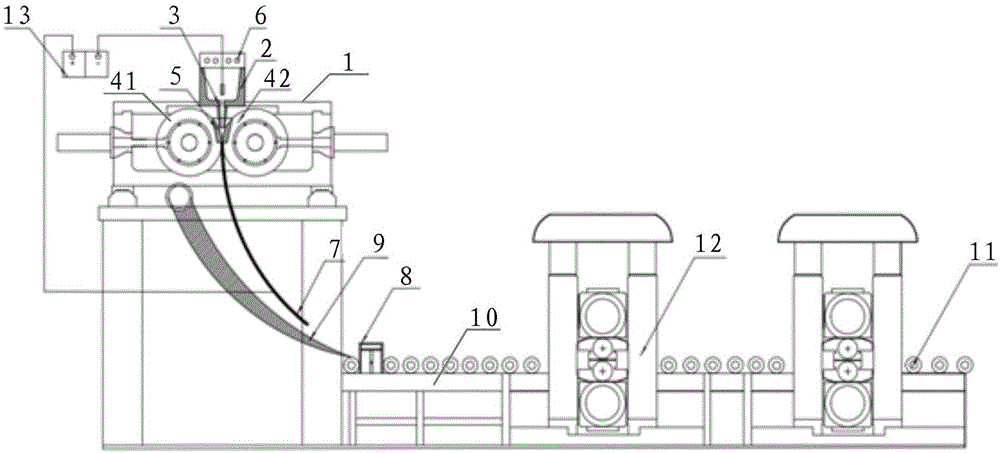

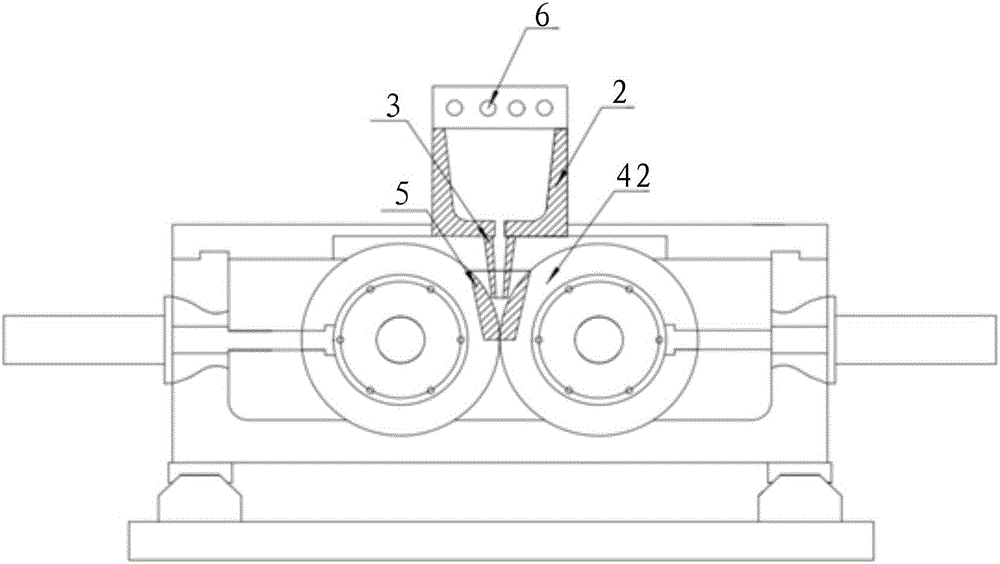

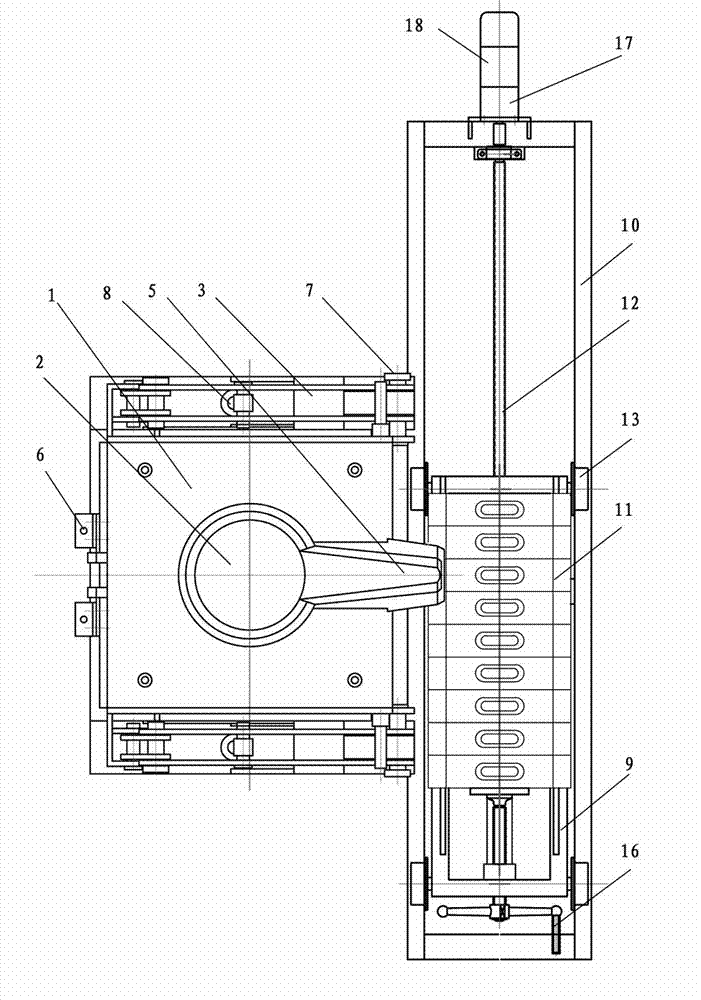

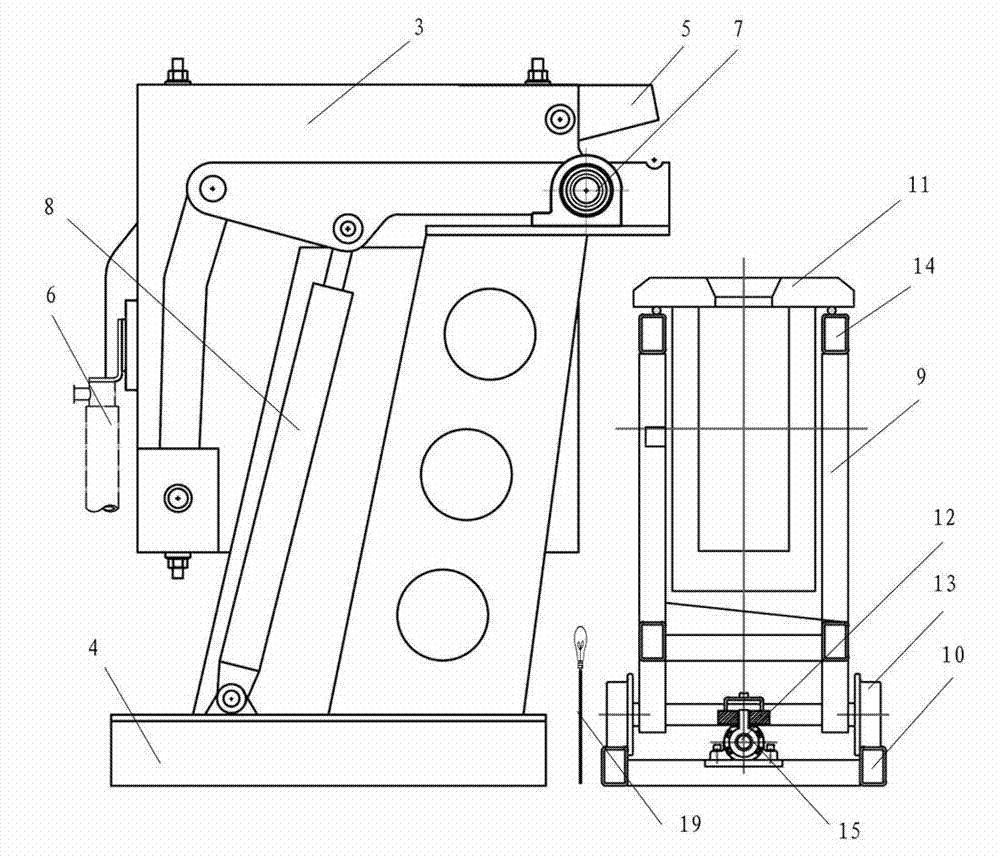

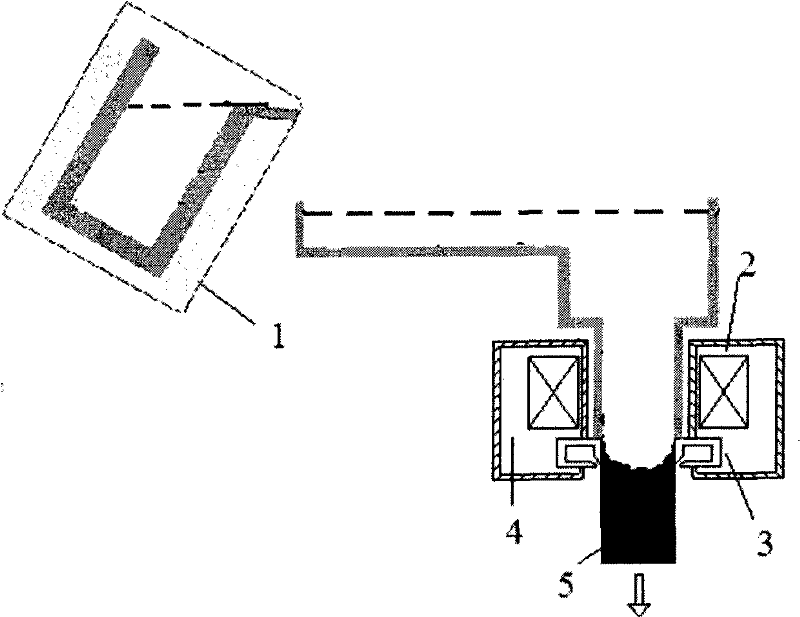

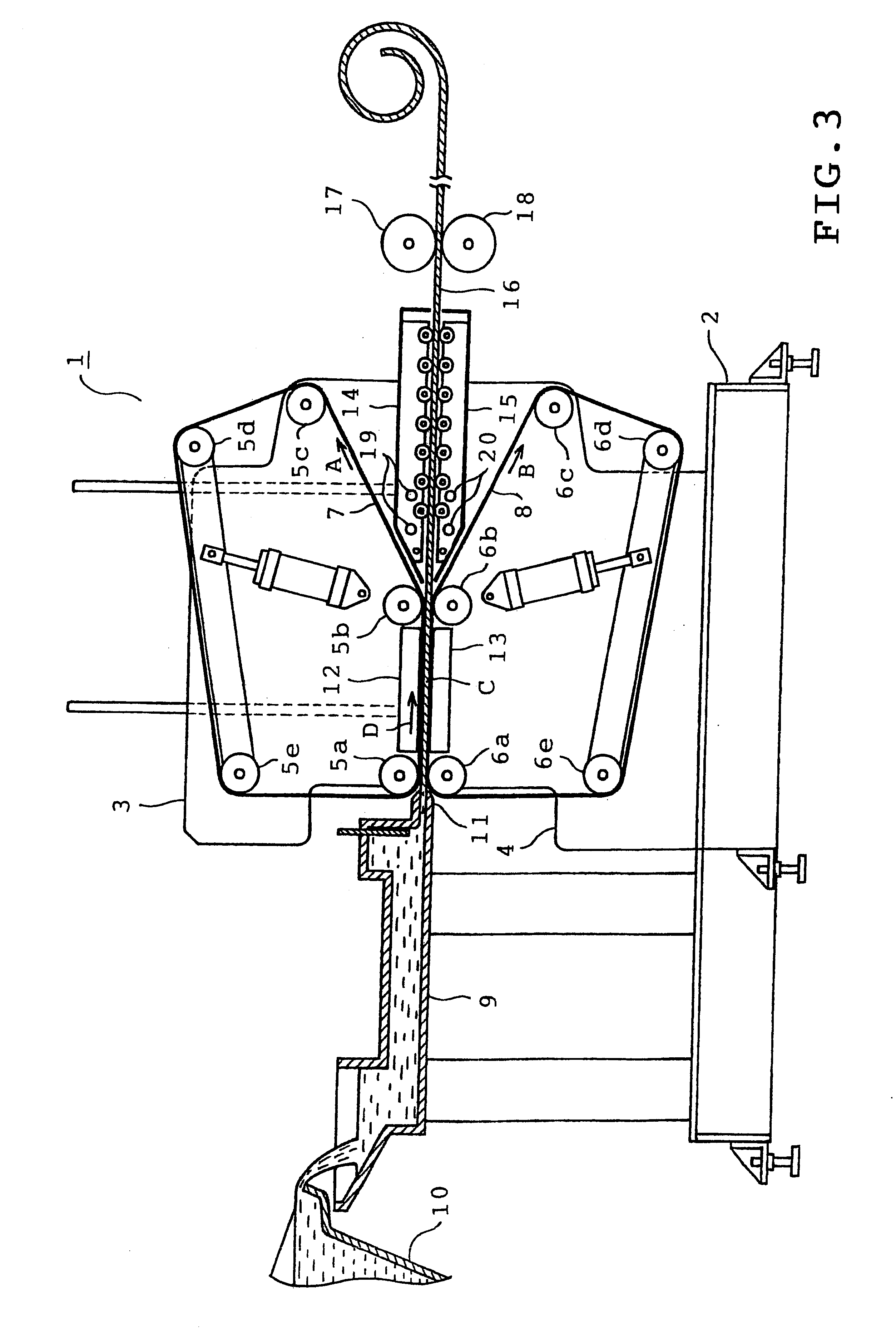

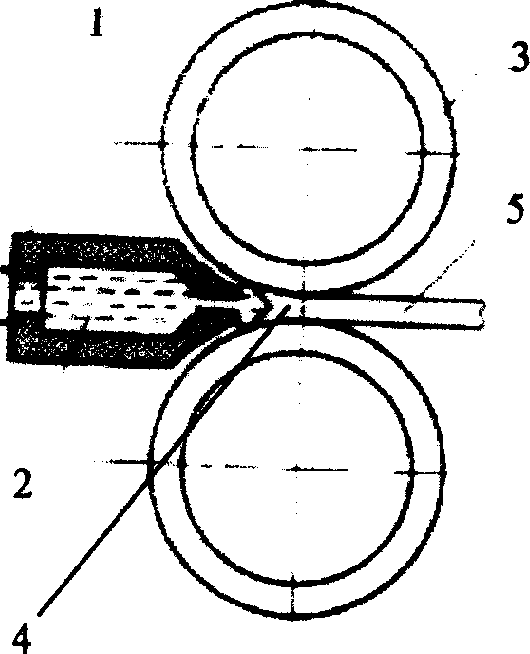

Continuous rheomolding device for manufacturing metal plate strips

InactiveCN101890431AIncreased speed of continuous rheological formingGood formabilityMetal rolling arrangementsEngineeringAlloy

The invention provides a continuous rheomolding device for manufacturing metal plate strips. The device comprises an inclined plate, a base, an electromagnetic vibration exciter and a double-roller rolling mill and is characterized by also comprising the double-roller rolling mill, wherein the inclined plate is formed by connecting a feeding section, a pulping section and a discharging section in turn; the lower side of a bottom plate of the pulping section is connected with the upper end of a spring; the lower end of the spring is fixed on the base; one end of the electromagnetic vibration exciter is fixed on the base, and the other end of the electromagnetic vibration exciter is connected with the lower side of the bottom plate of the pulping section; and gaps are formed between the bottom plate and two side plates of the discharging section and the roll surfaces of upper and lower rollers of the double-roller rolling mill. The range of vibration frequency which can be provided by the electromagnetic vibration exciter adopted by the device is expanded greatly and the vibration frequency is adjusted so that an alloy structure can be improved more effectively and molten metal is prevented from crusting on the surface of the inclined plate.

Owner:NORTHEASTERN UNIV

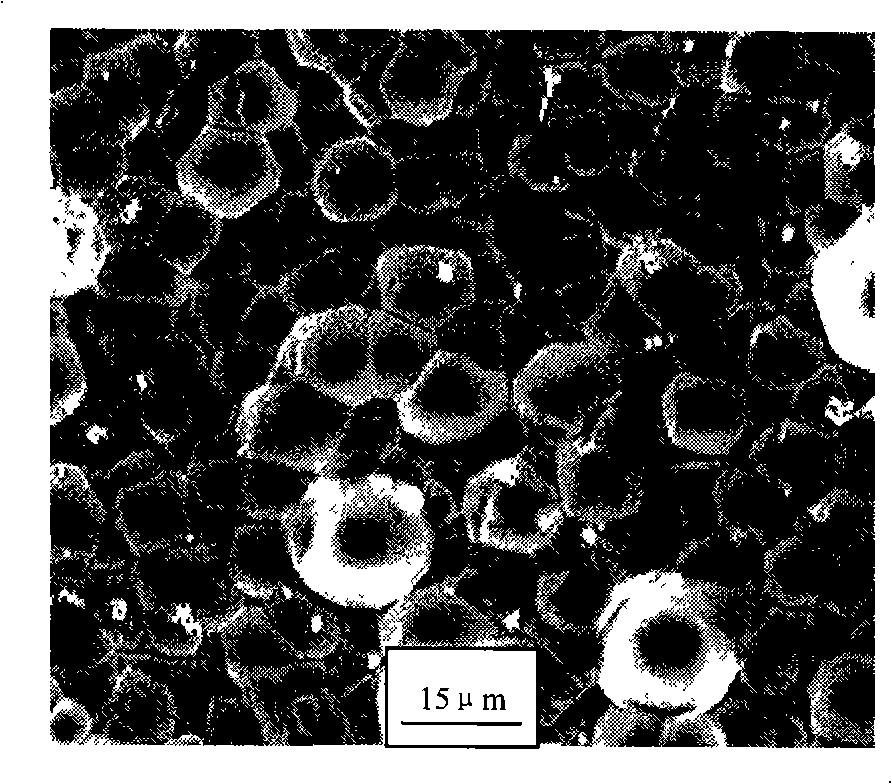

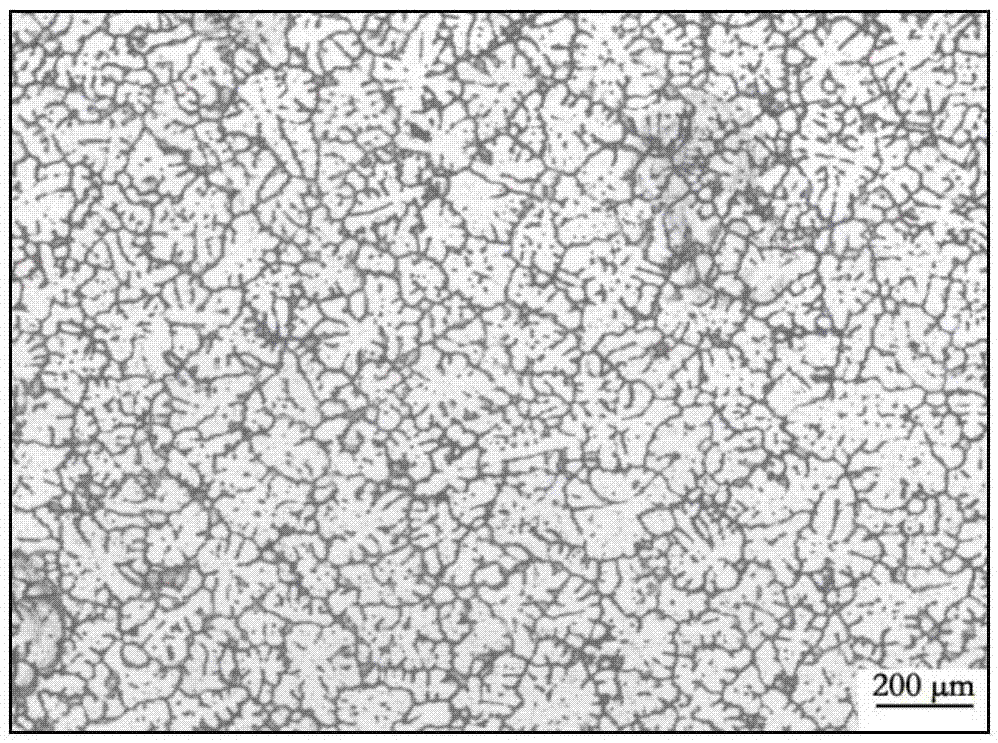

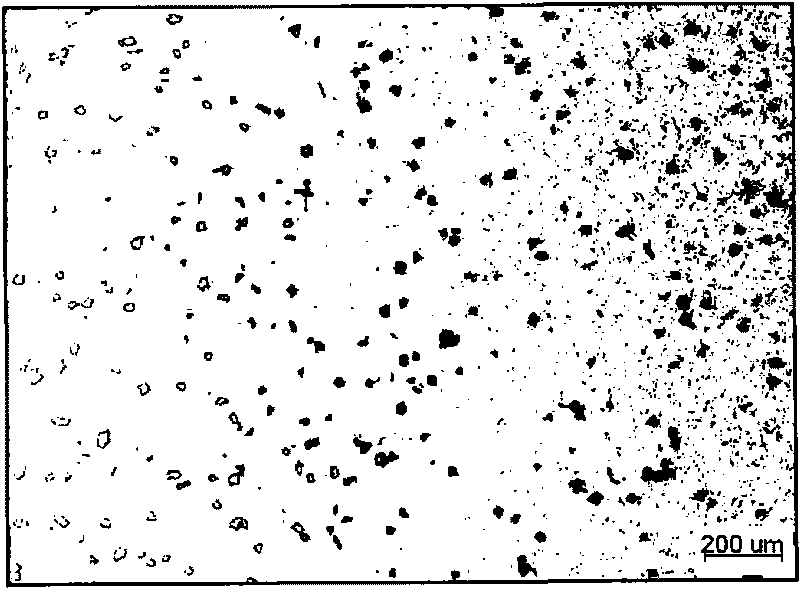

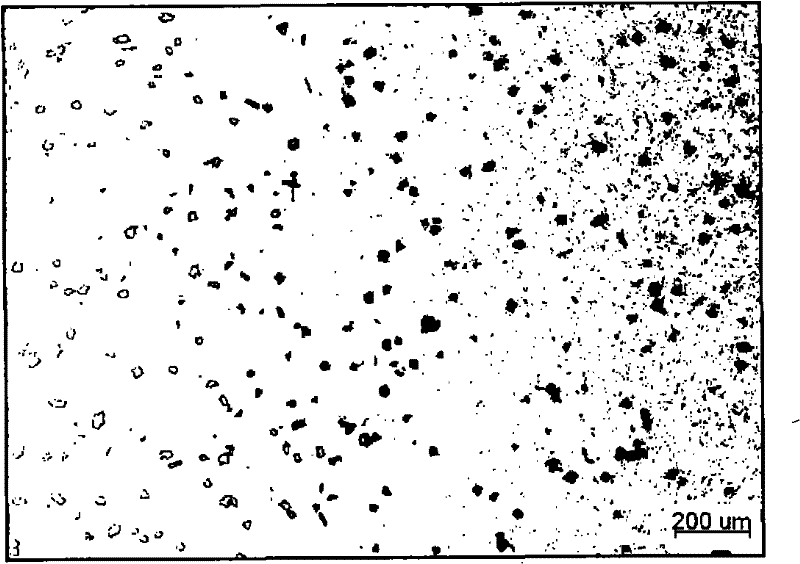

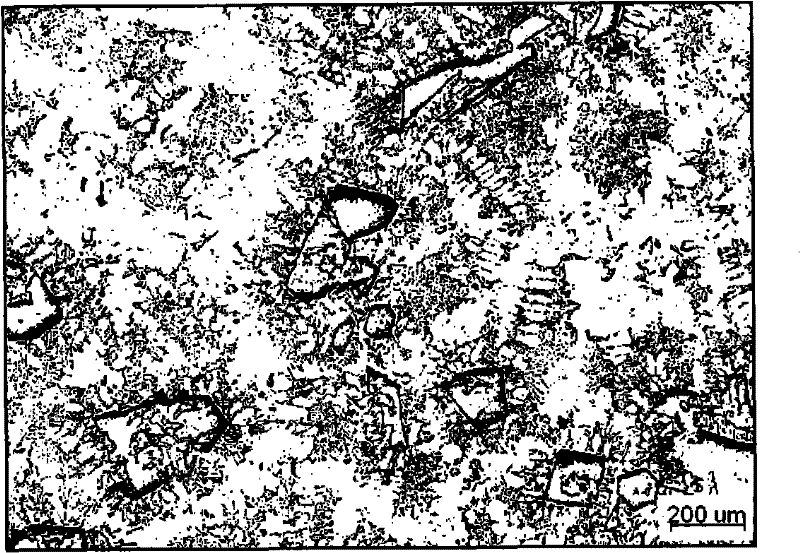

Method for quickly preparing hypereutectic Al-Si alloy bar billet at low cost

The invention discloses a method for quickly preparing a hypereutectic Al-Si alloy bar billet at low cost, and belongs to the technical field of metal material processing. The method comprises the following steps: smelting a hypereutectic Al-Si alloy under the protection of inert gas; refining melt by adopting multiple modification at high temperature; degassing the melt; and finally, performing quick semicontinuous casting by adopting an electromagnetic stirring method. The method can prepare the hypereutectic Al-Si alloy bar billet which has the advantages of high performance, large size, fine primary silicon grains, and uniform distribution of the silicon grains. The method has the advantages of simple process, low cost, high production efficiency and suitability for large-scale industrial production.

Owner:有研金属复材技术有限公司

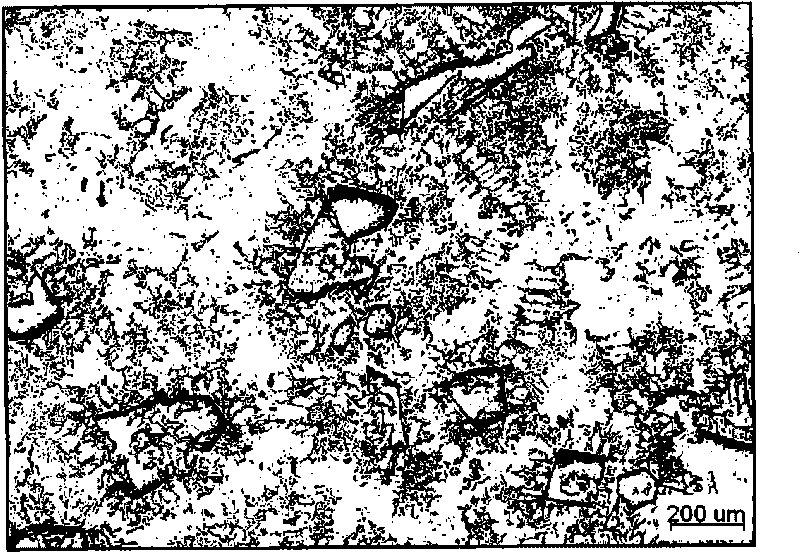

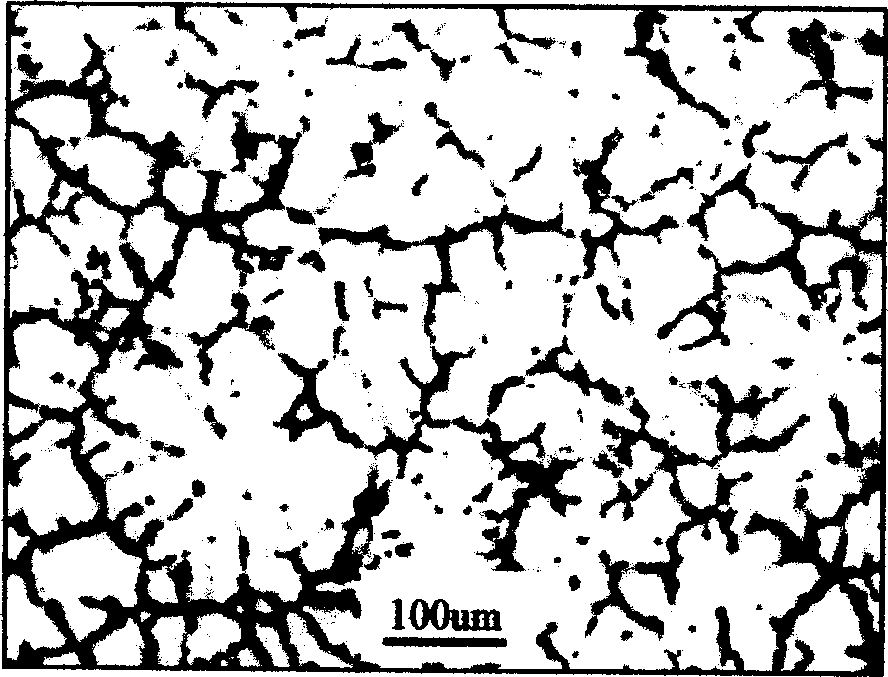

Continuous casting columnar crystallizer small square blank and its columnar crystal control method

InactiveCN101147966AIncrease productivityIncrease casting speedChemical compositionEquiaxed crystals

The present invention discloses a continuous cast columnar crystal square billet and its columnar crystal control method. It is characterized by that said square billet is continuously cast by using molten steel containing chemical components of screw-thread steel, carbon structure steel, alloy structure steel, spring steel, bearing steel, low-alloy high-strength steel, hard wire steel or cold-short steel. The columnar crystal rate in the central zone of said square billet is 90-100%, and its equiaxed crystal rate is 0-10%. Said invention utilizes forced cooling and thermal stress downwards compression of continuous casting process to raise uniformity of material components, reduce segregation value of material components and internal defect probability and raise columnar crystal rate of square billet, at the same time, said invention adopts forced cooling and high drawing speed so as to make continuous casting machine efficiency be raised by 10%-40%.

Owner:JIANGSU SHAGANG GROUP HUAIGANG SPECIAL STEEL CO LTD

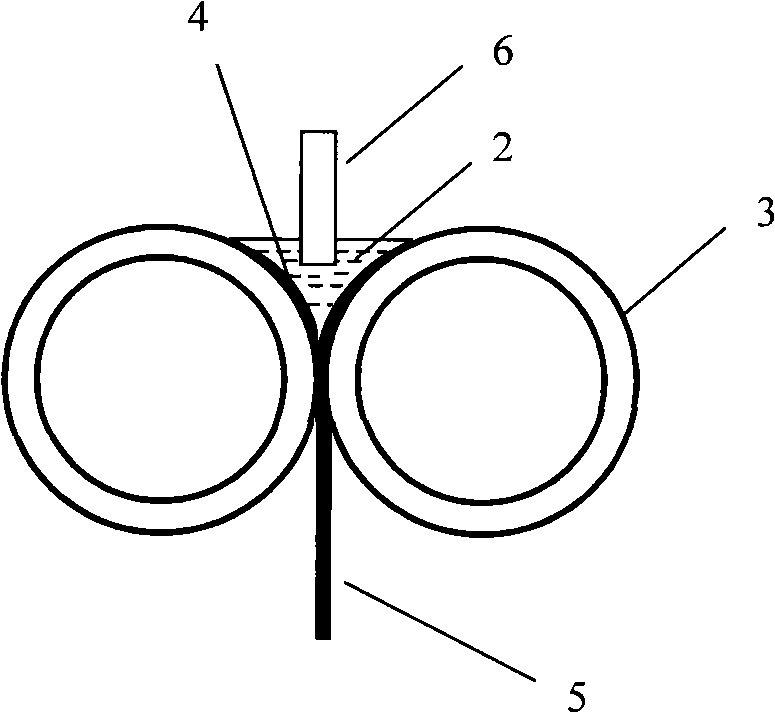

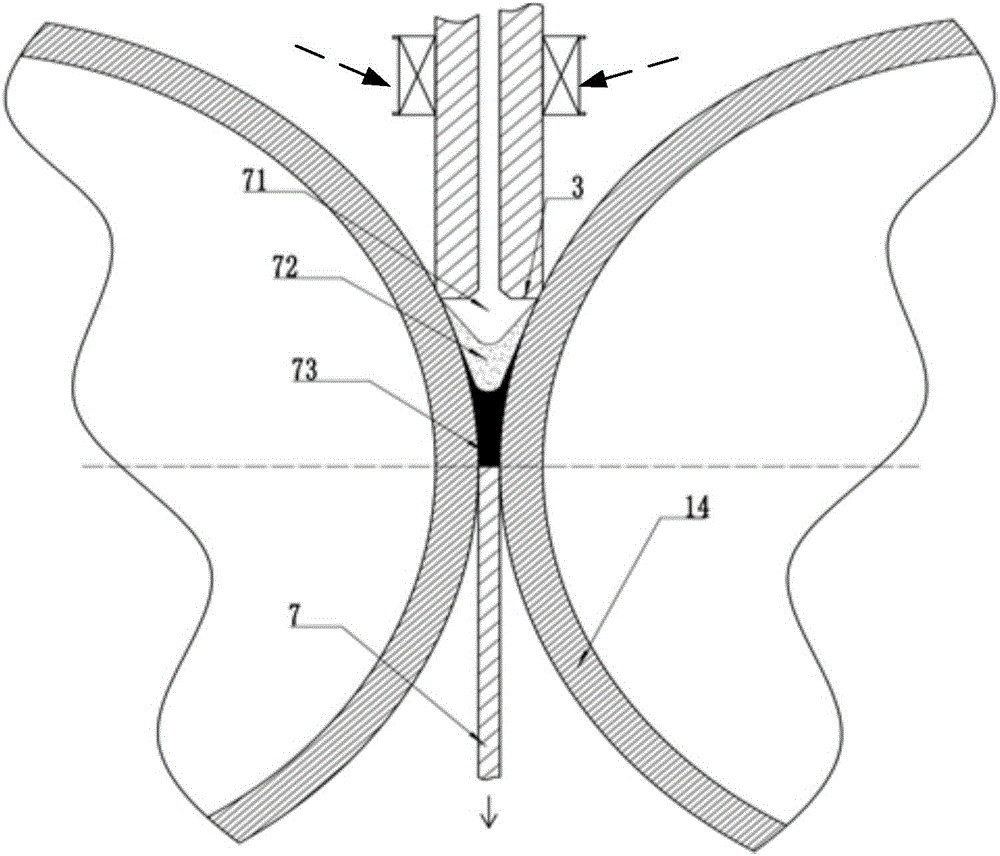

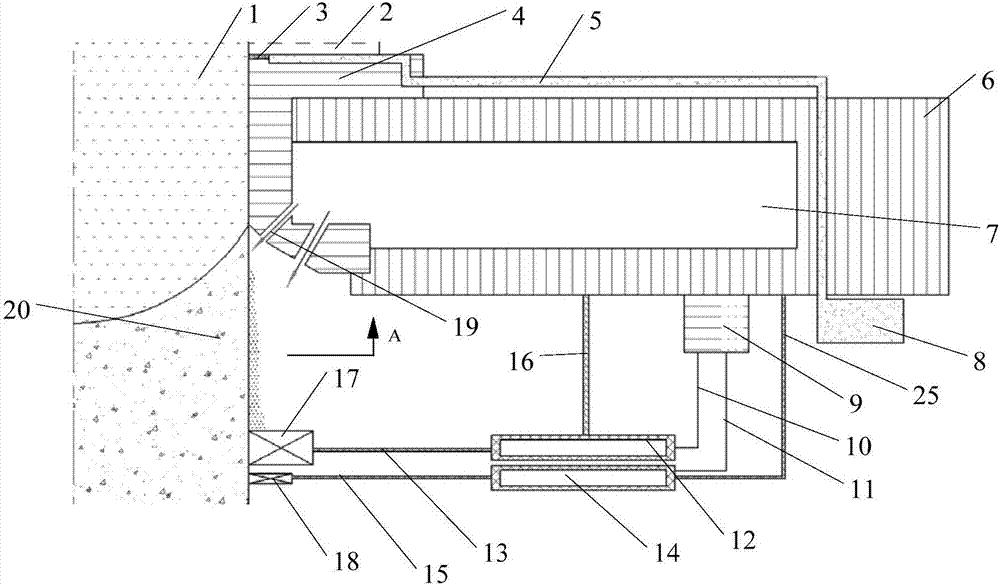

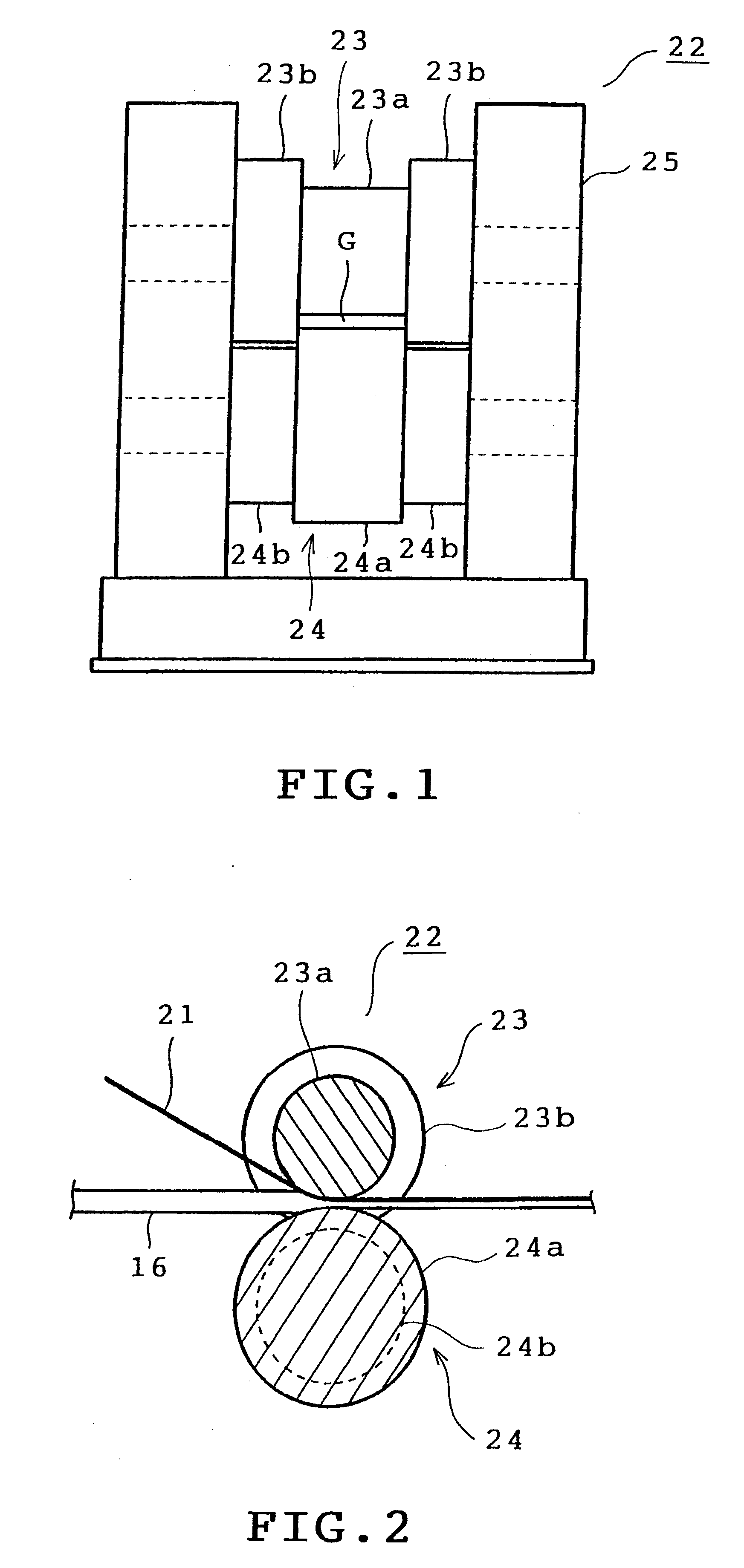

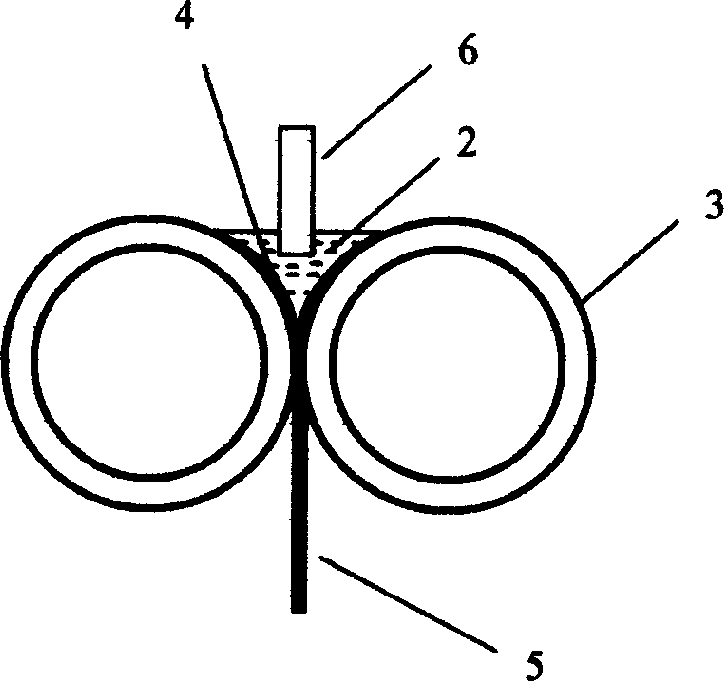

Vertical semi-solid state cast rolling device and method

The invention discloses a vertical semi-solid state cast rolling device and method and relates to aluminum alloy cast rolling equipment and the technical field of manufacturing in order to solve the technical problems that an existing cast rolling method is low in production efficiency, a casting nozzle is prone to blockage, and serious macro segregation and micro segregation defects exist. The vertical semi-solid state cast rolling device comprises a platform, and a launder is arranged at the upper end of the platform; the lower end of the platform is provided with a casting nozzle which is communicated with the launder; the outlet position of the casting nozzle is horizontally and symmetrically provided with a left cast rolling roller and a right cast rolling roller; an outlet of the casting nozzle is higher than a center line of the left cast rolling roller and the right cast rolling roller; a flow dividing block is arranged in the casting nozzle in the width direction; and cooling water is introduced in a roller sleeve of the left cast rolling roller and a roller sleeve of the right cast rolling roller.

Owner:NORTHEASTERN UNIV

Casting method of silicon ingot and cutting method of the same

InactiveUS7749324B2Improve production efficiencyReduce manufacturing costPolycrystalline material growthBy zone-melting liquidsIngotSolar battery

The present invention includes a method for casting a silicon ingot by using a continuous casting method by means of an electromagnetic induction, and a method for cutting the silicon ingot as a starting material into plural silicon blocks. When the silicon blocks with a square section are cut out, the sectional shape of the silicon ingot is set to be rectangular. Not less than 6 pieces of equal-sized silicon blocks are cut out from the silicon ingot, thereby enabling to enhance the manufacturing efficiency to a great extent. And since the amount of excision of the edge per silicon block is reduced, the production yield can be enhanced. Further, since the proportion of columnar crystals with large grain size inside the ingot can be increased, it becomes possible to enhance the conversion efficiency of a solar battery using the silicon block as a substrate material.

Owner:SUMCO CORP

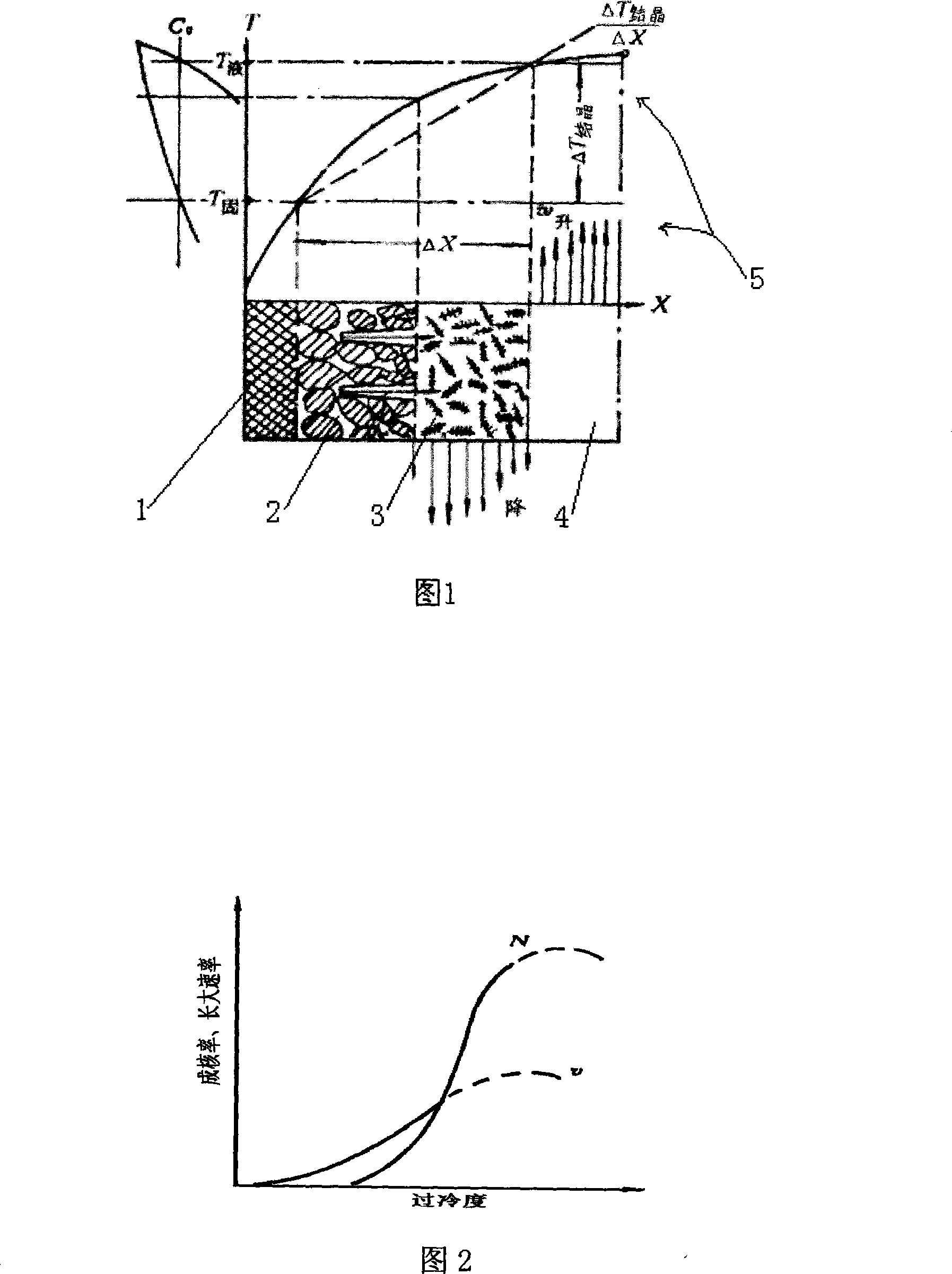

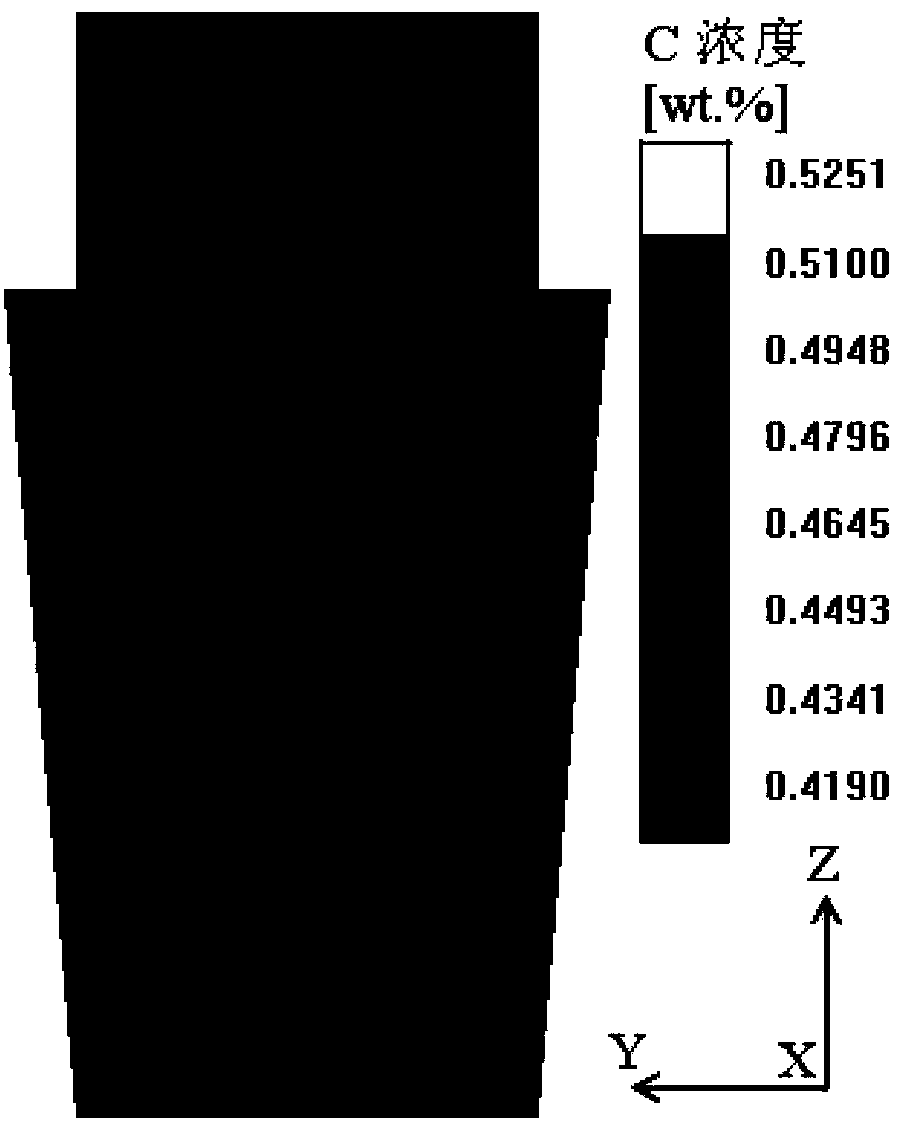

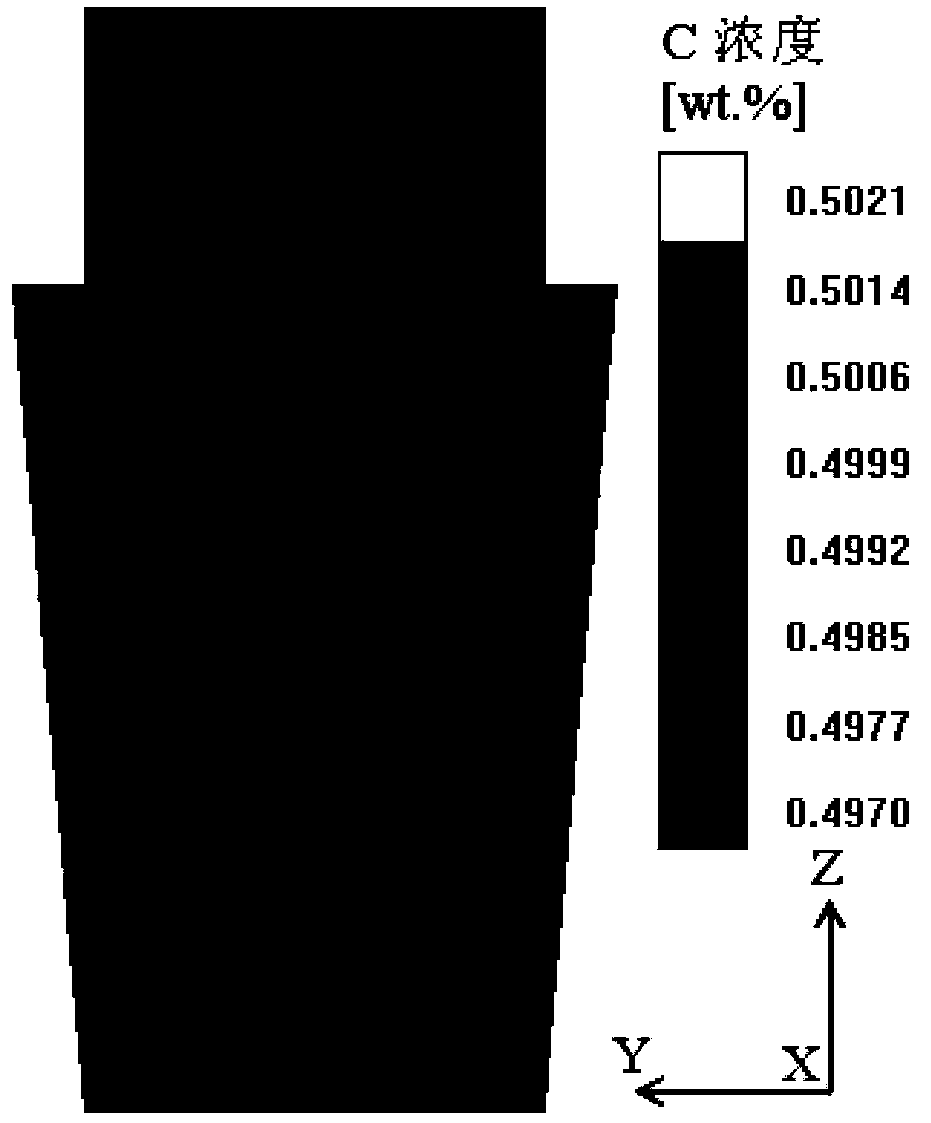

Casting method for reducing macroscopic segregation of cast ingot

InactiveCN103350219AReduce convectionConvection range reducedMolten metal pouring equipmentsIngot castingConvection

Disclosed is a casting method for reducing macroscopic segregation of a cast ingot. The method is characterized in that real casting time tp of the cast ingot is controlled to meet the following requirement: 1 / 10t<tp<t, wherein t is the time needed by the cast ingot to solidify completely in a common casting technique. The method includes the following concrete steps: step1, obtaining the time t needed by the cast ingot to solidify completely in the common casting technique through experimental determination or numerical simulation, step2, casting the cast ingot in a casting mould by using a casting ladle, and step3, controlling the real casting time tp to meet the requirement by adjusting casting speeds or adjusting the size, the position and the number of holes of the casting ladle till casting is finished. The method has the advantages that the casting speeds are low, solute convection is reduced, and local solidification speeds are improved; therefore, the method is beneficial to grain refinement and suppression on the macroscopic segregation, and suitable for casting various cast ingots, especially large-sized cast ingots.

Owner:SHANGHAI JIAO TONG UNIV

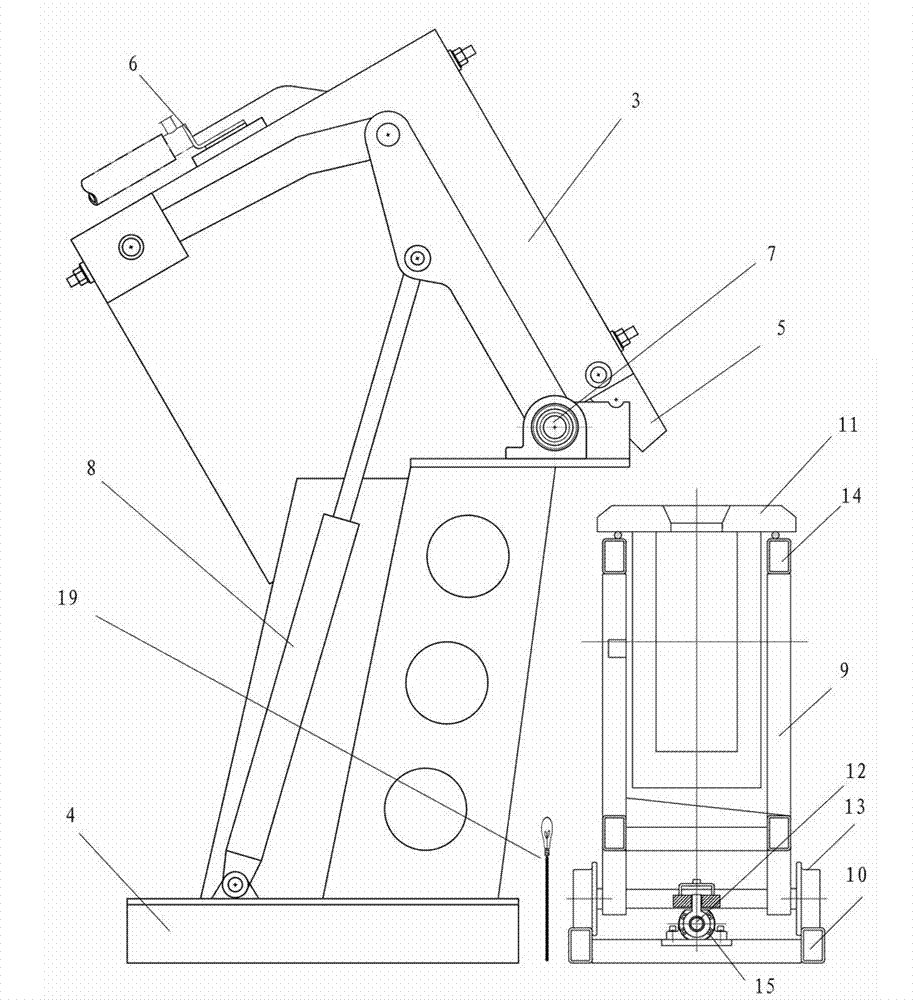

Automatic silver ingot casting system

InactiveCN103611923AAvoid pinch outExtend your lifeMolten metal supplying equipmentsControl systemIngot casting

The invention relates to an automatic silver ingot casting system which comprises a casting machine, an automatic mold positioning machine and a control system. The casting machine comprises an intermediate frequency furnace, a crucible in the furnace and a furnace frame. The intermediate frequency furnace is fixed on the furnace frame, the crucible is placed in the furnace, the crucible and the intermediate frequency furnace are built together through fire clay, a pair of hydraulic oil cylinders is arranged on the two sides of the furnace frame in a matched mode, the automatic mold positioning machine is arranged right ahead of the smelting furnace, and the control system is arranged in front of the automatic mold positioning machine. A traditional manual casting mode is changed, casting speed is greatly increased, labor intensity is relieved, and due to the fact that the crucible, the intermediate frequency furnace and the furnace frame are built into a whole, it is avoided that the crucible is clamped out through an iron stand when casting is performed each time, cold and hot impact and mechanical damage are reduced or avoided, service life of the crucible can be prolonged, and cost is lowered.

Owner:HUNAN JINWANG BISMUTH

Casting method for steel-copper compound cylinder

InactiveCN107199326AImprove corrosion resistanceImprove wear resistanceCylindersLiquid/solution decomposition chemical coatingMetal cylinderSurface finishing

A casting method for a steel-copper compound cylinder includes the steps of three dimensional modeling, casting technology design and technology simulation and optimization, steel base heat treatment, machining-tool machining and welding, steel base surface treatment, preheating treatment of the steel base before production, borax leaching, copper alloy smelting, pouring the copper alloy into the steel base, centrifugal treatment and cooling solidification to the room temperature, and obtaining the steel-copper compound cylinder. The casting method solves the difficult problems of compound casting technology and compound material elements of the steel-copper cylinder; and the compound strength of the bi-metal cylinder is high, the rate of finished products is high, the cost is low, the size of cylinders is not limited, the molding process is easy to control, and the quality is stable.

Owner:安徽恒利增材制造科技有限公司

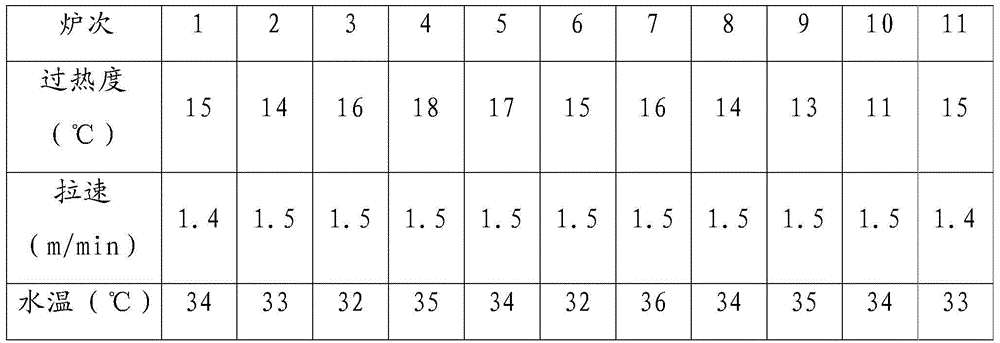

Method for reducing longitudinal division of weather-proof steel continuously cast slab

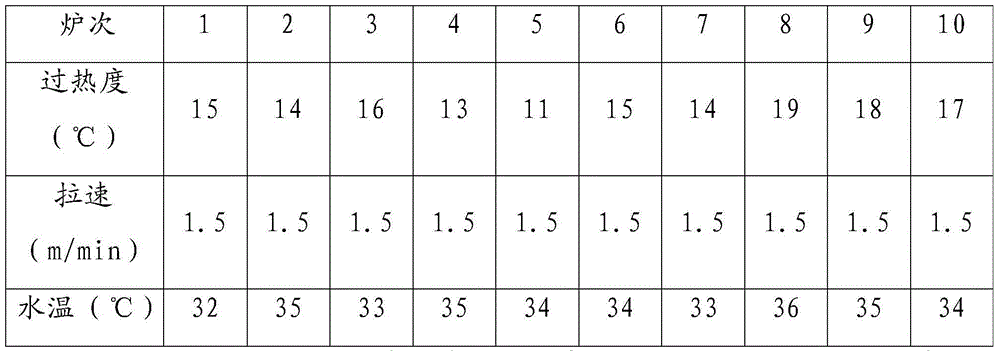

The invention provides a method for reducing longitudinal division of a weather-proof steel continuously cast slab. The control performed in a technological process is that casting is performed at a low molten steel superheat degree and a higher slab pulling rate, wherein the temperature of cooling water at an inlet of a crystallizer is improved in a casting process, and the taper of the crystallizer is increased; the alkalinity of covering slag is improved to be within a range of 1.40-1.50; the viscosity eta of the covering slag is reduced to be within the range of 0.70-0.80 at the temperature of 1,300 DEG C. According to the method for reducing the longitudinal division of the weather-proof steel continuously cast slab, the longitudinal division of the weather-proof steel continuously cast slab can be reduced to be below 0.82 percent from 2.75 percent, and considerable economic benefit can be achieved.

Owner:SHOUGANG CORPORATION

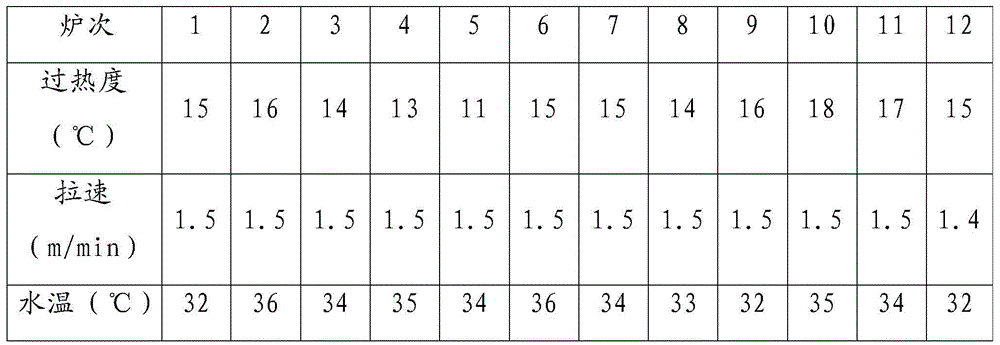

Method for producing high thermokeeping continuous casting protective slag

The invention discloses a method for producing the high heat-insulating continuous casting protective dregs, comprising: (a), material selection: limestone powder, sodium carbonate powder, carbon black, graphite, wollastonite in lump, emery, magnesite , fluor powder, iron ore powder, and binding agent; (b) material mixing and milling; (3) mixing the milled powder and water; (d) spraying granulation to form the hollow continuous casting protective dregs; (e) filtration and package that exhausting the waste gas whose micro-powder is separated by cyclone filter. The invention adds the material as carbonic acid salt into the material of continuous casting protective dreg, and the carbonic acid salt can decompose to form the CO2 gas in the spraying granulation process to enlarge the inter-space of continuous casting protective dregs; and processes the spraying granulation in vacuum to enlarge said inter-space more. The invention can improve the heat-insulating property of continuous casting protective dregs; stabilize the layer of continuous casting protective dregs and the meniscus shape of continuous casting blank; improve the surface quality of continuous casting blank; reduce the dreg consumption of continuous casting protective dregs; and improve the continuous casting of continuous casting.

Owner:UNIV OF SCI & TECH LIAONING

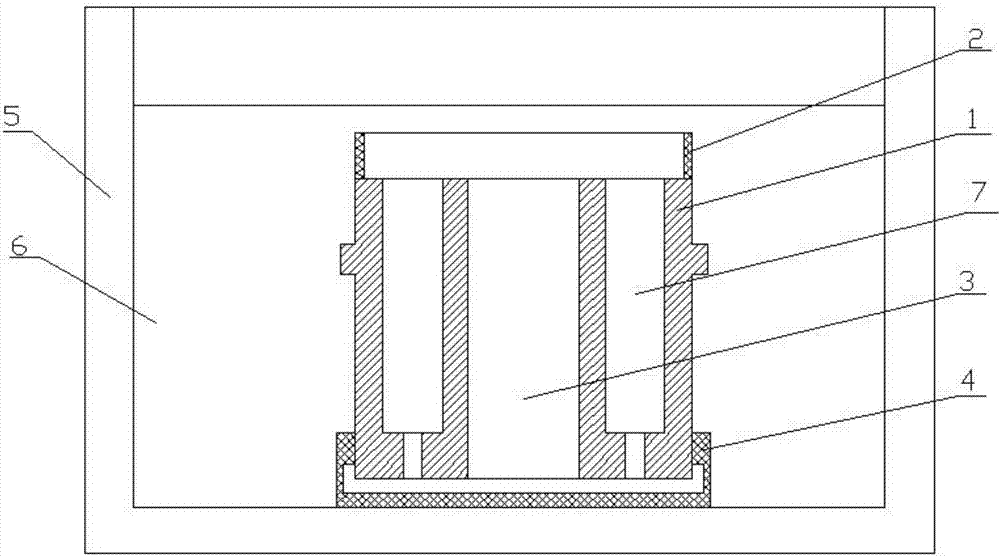

Crystallizer for semi-continuous casting of aluminum alloy

InactiveCN101829766AGuaranteed anti-deformation effectImprove deformation resistanceIngot castingGraphite

The invention relates to a crystallizer for semi-continuous casting of aluminum alloy. A graphite lining is embedded in a cavity of a body; the body is provided with a water cavity; an upper cover is connected on the body, the bottom of the upper cover is provided with a lug boss, and the lug boss on the upper cover is matched with the water cavity of the body; the water cavity of the body is provided with two groups of cooling water holes, and the two groups of cooling water holes are distributed across; a filter is arranged in the water cavity of the body, and the upper end of the filter is fixed with the upper cover; and the bottom of the body is provided with a water inlet pipe head which is communicated with the filter. After the lug boss designed on the upper cover is assembled, the upper cover extends to the interior of the water cavity, so the crystallizer has good deformation resistance, and the service life of the whole crystallizer is prolonged; the water cavity is designed with the two groups of cooling water holes, and double rows of cross cooling water cool the ingots so as to increase watering points and cooling active regions of the cooling water on the ingots; and the filter ensures that the cooling water enters the cavity after filtering, and the filter can be directly detached on the upper cover, so the cleaning operation is simple and convenient.

Owner:苏州有色金属研究院有限公司

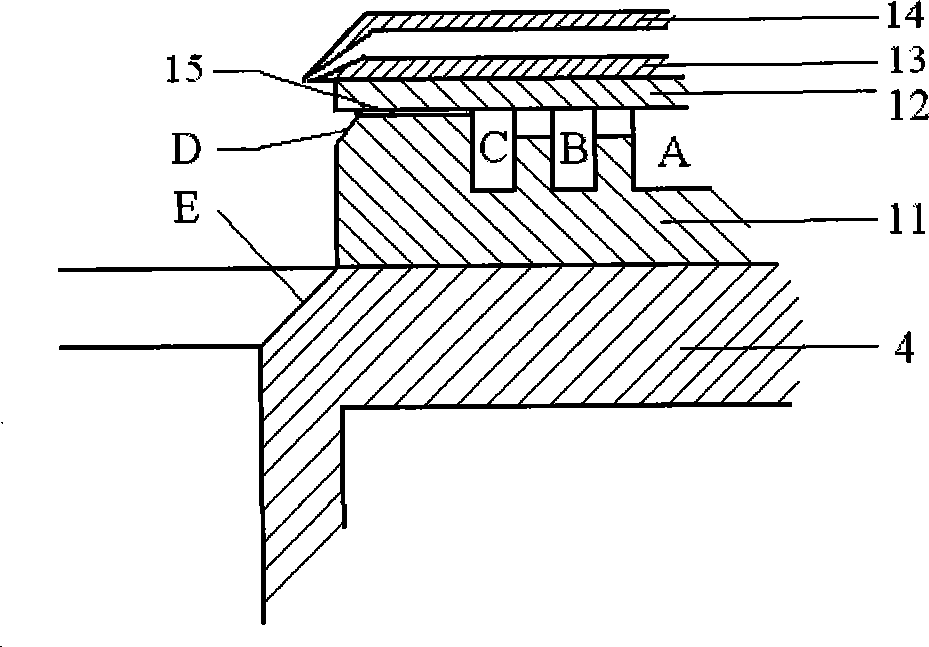

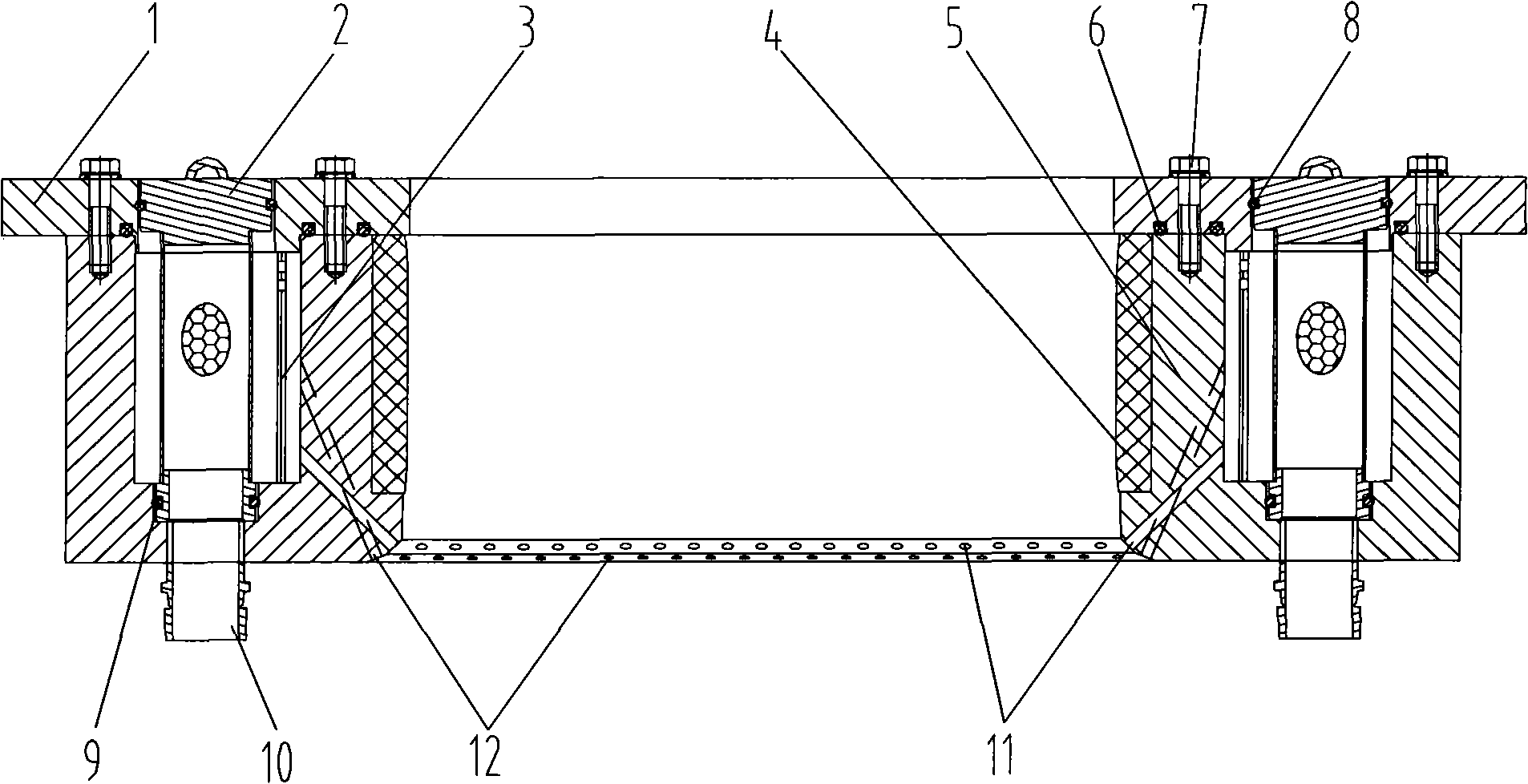

High-speed semicontinuous casting device and method of aluminum alloy cast ingot

The invention discloses a high-speed semicontinuous casting device of an aluminum alloy cast ingot, and belongs to the technical field of aluminum alloy casting. The device comprises a hot top, a crystallizer inner sleeve, a crystallizer outer sleeve, a cooling water cavity and a dummy bar head. A secondary cooling water cut-off device is arranged below the crystallizer inner sleeve, and a grease metering valve is arranged at an inlet of each oil conveying pipe below the crystallizer outer sleeve. A method comprises the steps that aluminum alloy melt is cast for semicontinuous casting, and lubricating oil is conveyed; (2) the semicontinuous casting speed is controlled to range from 200 mm / min to 400 mm / min, secondary cooling water is sprayed to the surface of the cast ingot, and the conveying amount of the lubricating oil is increased along with the casting speed; (3) the surface temperature of the cast ingot is detected; (4) the secondary cooling water cut-off device is controlled according to the surface temperature of the cast ingot; and (5) operation of the step (4) is repeated till casting is completed. According to the device and the method, the casting speed is greatly increased, the surface quality of the cast ingot is improved, the cast ingot has no casting defect, and the microstructure is uniform.

Owner:NORTHEASTERN UNIV

Aluminum alloy round ingot casting for computer hard disk drive arm and production method of ingot casting

The invention discloses an aluminum alloy round ingot casting for a computer hard disk drive arm. The ingot casting comprises 0.60 to 0.80% of Si, 0.10 to 0.20% of Fe, 0.90 to 1.1% of Mg, 0.10 to 0.30% of Cu, 0.10 to 0.20% of Mn, 0.10 to 0.30% of Cr, smaller than 0.03% of single impurities and the balance Al. The production method comprises the steps that pure aluminum ingot solid cold charge andelectrolytic aluminum liquid are burdened, heating and melting are carried out at the proper temperature, an electromagnetic stirrer is started to rapidly melt the cold charge, temperature uniformityand component uniformity are kept, according to the chemical components in aluminum melt, alloying treatment is carried out, slagging-off is carried out to kept melt clean, high-purity N2 and a refined powder spraying agent are adopted to carry out powder spraying refining, online filtering, slag removal and gas removal are achieved, and through casting production and uniform heating treatment, the aluminum alloy round ingot casting meeting the requirement is produced. The ingot casting is stable and uniform in component, compact in internal structure, smooth and clean in surface, excellent inmechanical performance, and high in product interior cleanness, and the method is an optimal method for producing the aluminum alloy round ingot casting for the computer hard disk drive arm.

Owner:HENAN ZHONGFU ALUMINUM ALLOY

Method for quickly preparing hypereutectic Al-Si alloy bar billet at low cost

The invention discloses a method for quickly preparing a hypereutectic Al-Si alloy bar billet at low cost, and belongs to the technical field of metal material processing. The method comprises the following steps: smelting a hypereutectic Al-Si alloy under the protection of inert gas; refining melt by adopting multiple modification at high temperature; degassing the melt; and finally, performing quick semicontinuous casting by adopting an electromagnetic stirring method. The method can prepare the hypereutectic Al-Si alloy bar billet which has the advantages of high performance, large size, fine primary silicon grains, and uniform distribution of the silicon grains. The method has the advantages of simple process, low cost, high production efficiency and suitability for large-scale industrial production.

Owner:有研金属复材技术有限公司

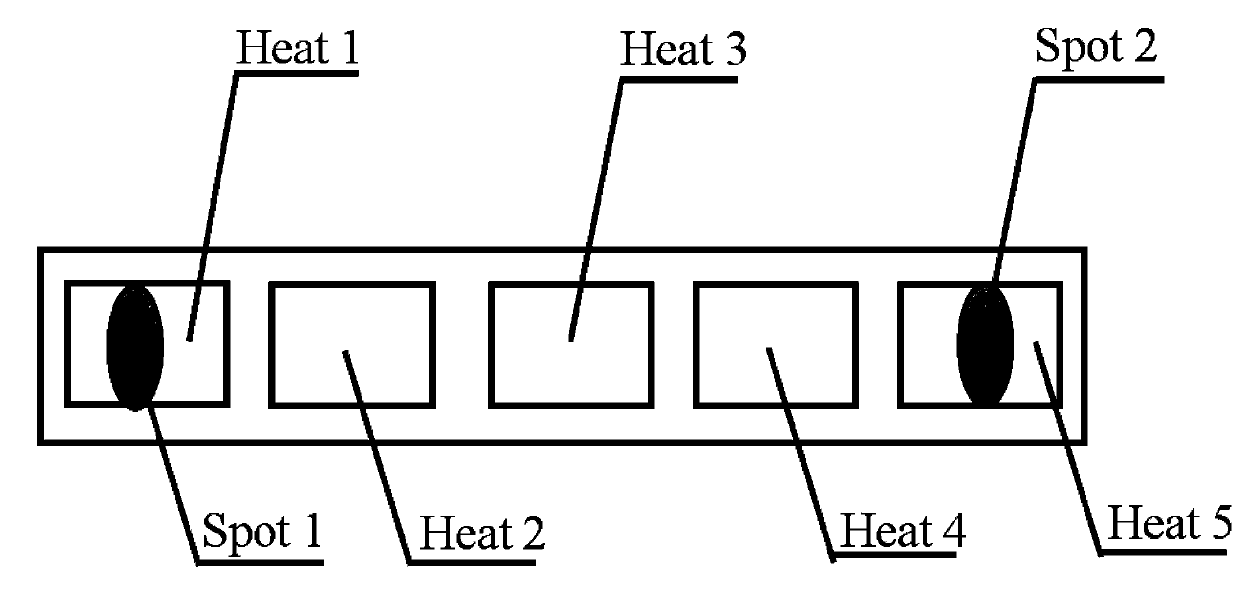

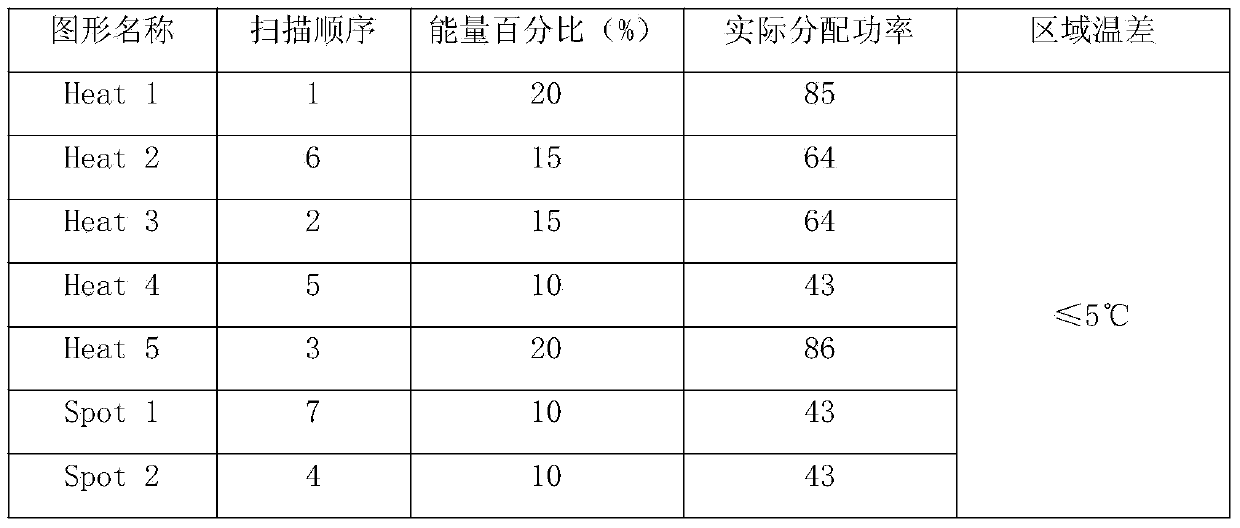

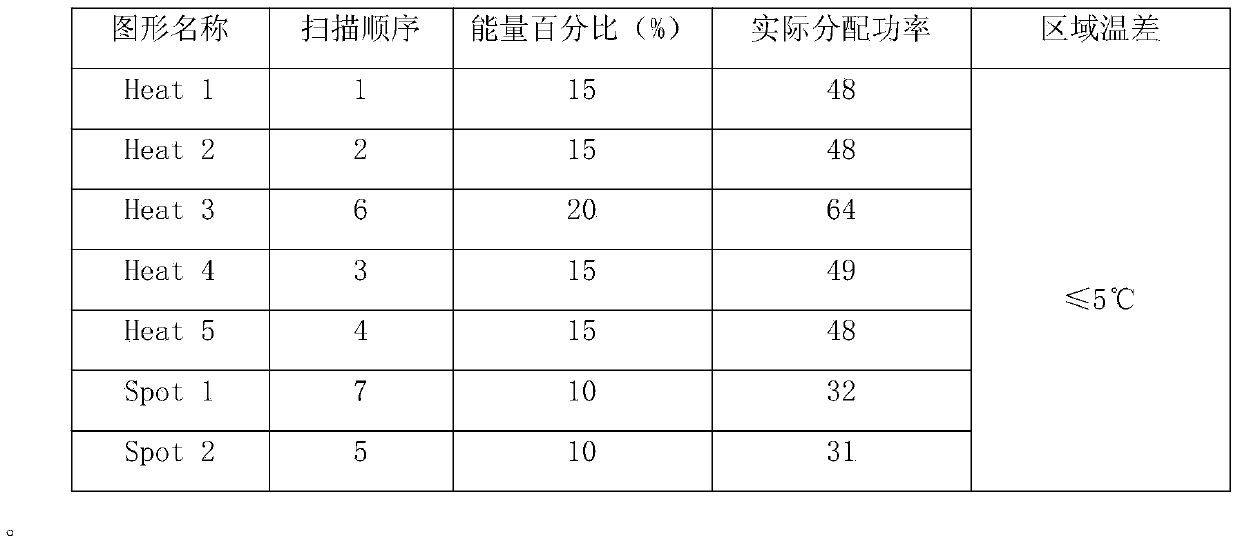

Scanning method for keeping uniform temperature of electron beam cold bed furnace rectangular crystallizer

The invention discloses a scanning method for keeping the uniform temperature of an electron beam cold bed furnace rectangular crystallizer. The scanning method includes the following steps that the size of the crystallizer is confirmed, the crystallizer is divided into five equal parts in the length direction, and equal dividing marks convenient to observe are arranged on the outer side of the crystallizer, the crystallizer is installed on a dummy ingot system to be leveled and well fixed, after normal work of a water cooling system, a dummy ingot system and a vacuum system is confirmed, an electron beam responsible for scanning the crystallizer is arranged for scanning a pattern, virtual thermal imaging is conducted on the set patterns, thermal uniformity of the scanned pattern is confirmed, and smelting can be conducted after vacuum reaches a preset value. The scanning method is simple in design, convenient to operate, good in using effect, capable of effectively overcoming the defects such as layer folding, cold isolating, scabbing, waisting and hole shrinking on the surface of a rectangular slab, and capable of effectively improving the quality of the surface of the slab, reducing the face milling amount and improving the one-time yield.

Owner:YUNNAN TITANIUM IND

Method of making aluminum alloy plate for bearing

InactiveUS6439451B1Preventing widthwise extension of each plateBonding strengthConnecting rod bearingsCrankshaft bearingsMaterials scienceAluminium alloy

A method of making an aluminum alloy plate for bearing which is made by cladding a bonding layer comprising a pure aluminum or an aluminum alloy excluding Sn onto a bearing alloy layer comprising an aluminum alloy containing Sn. The method includes the steps of fitting a concave portion of a first roll in a convex portion of a second roll, the first roll having both axial ends with large diameter portions respectively, the second roll having both axial ends with small diameter portions respectively, and passing superposed plates formed into the bearing alloy layer and the bonding layer respectively through a roll gap defined between the concave and convex portions and closed by the large diameter portions of the first roll so that the plates are rolled down at a reduction ratio not less than 50% while both widthwise ends of each plate is restricted by the large diameter portions of the first roll respectively such that the bonding layer is cladded onto the bearing alloy layer.

Owner:DAIDO METAL CO LTD

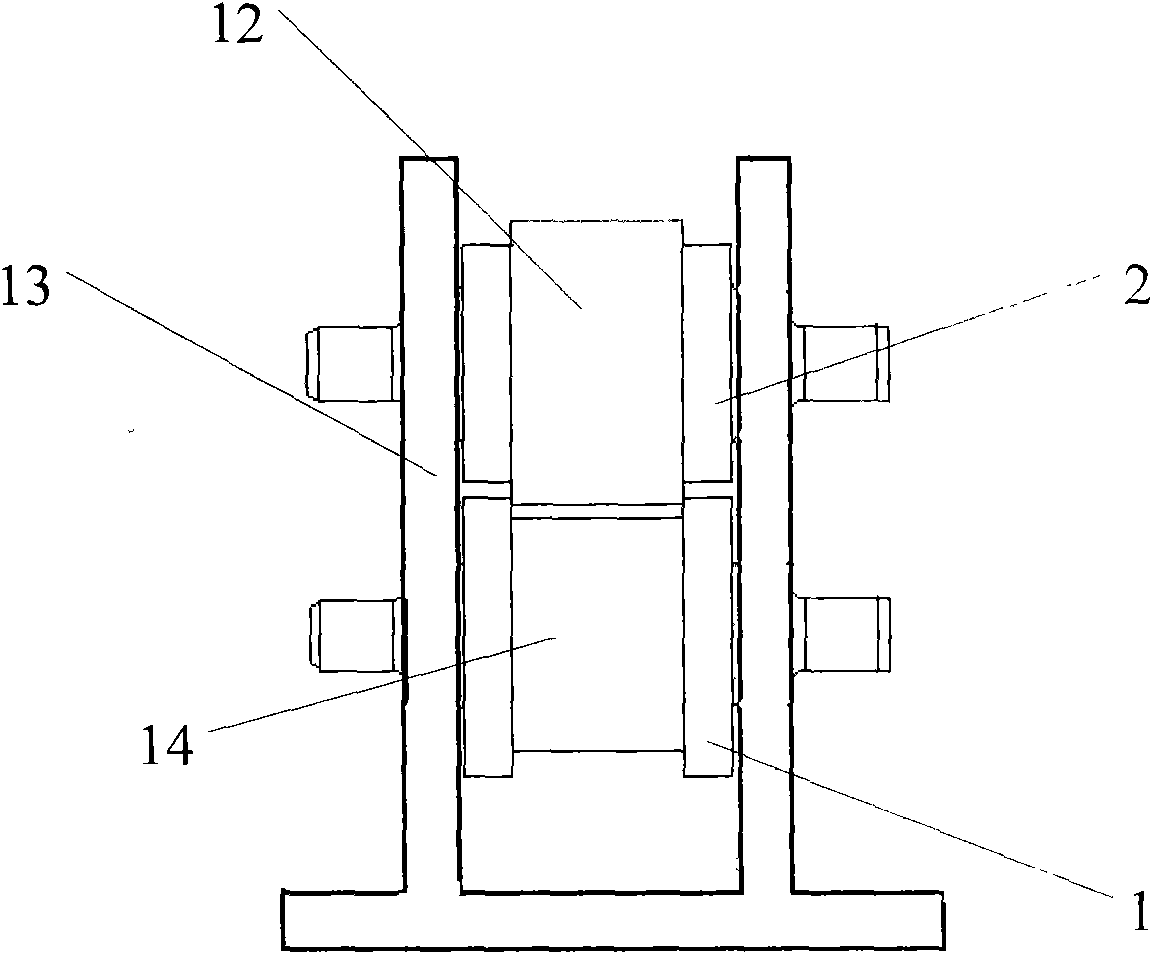

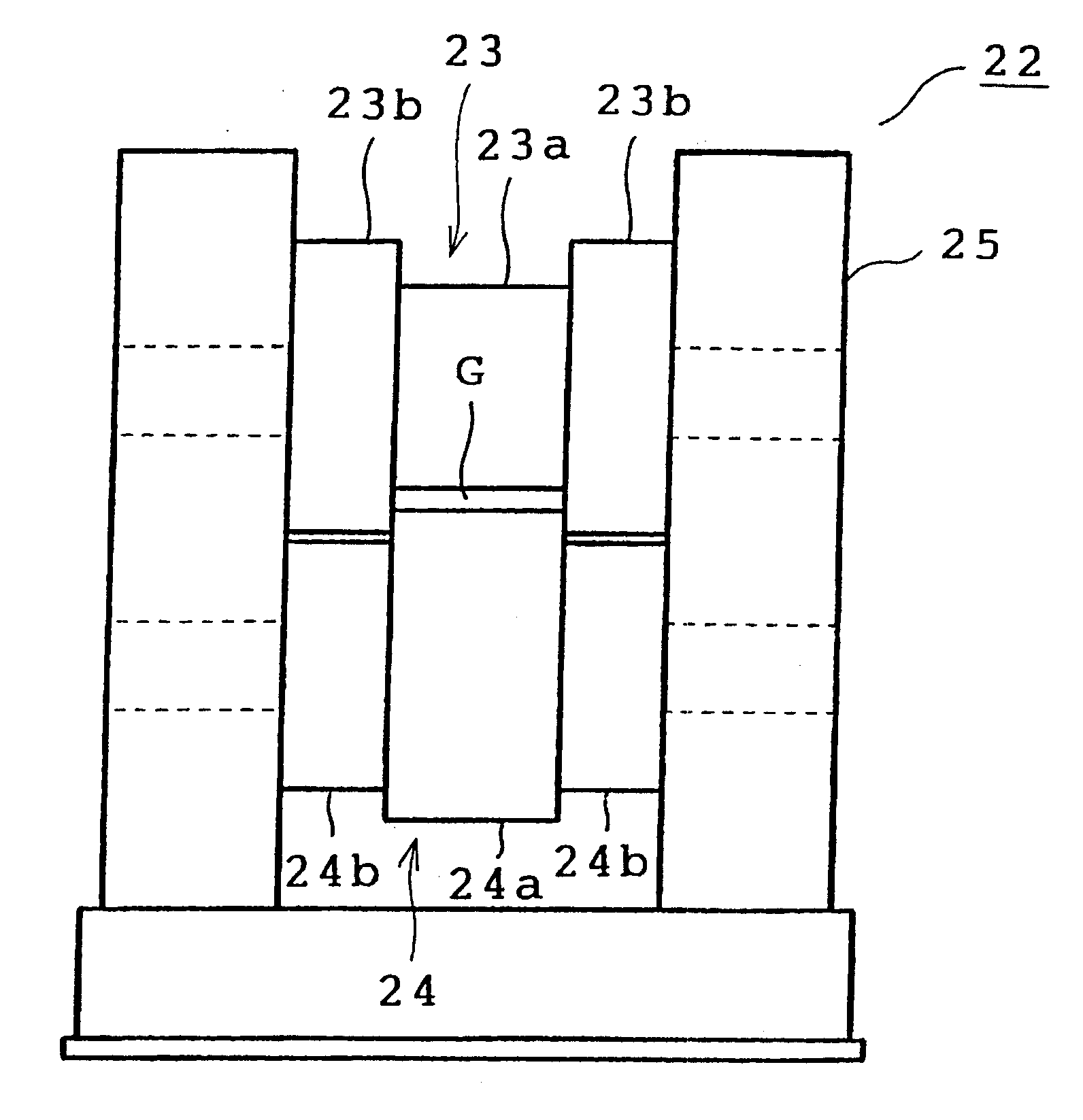

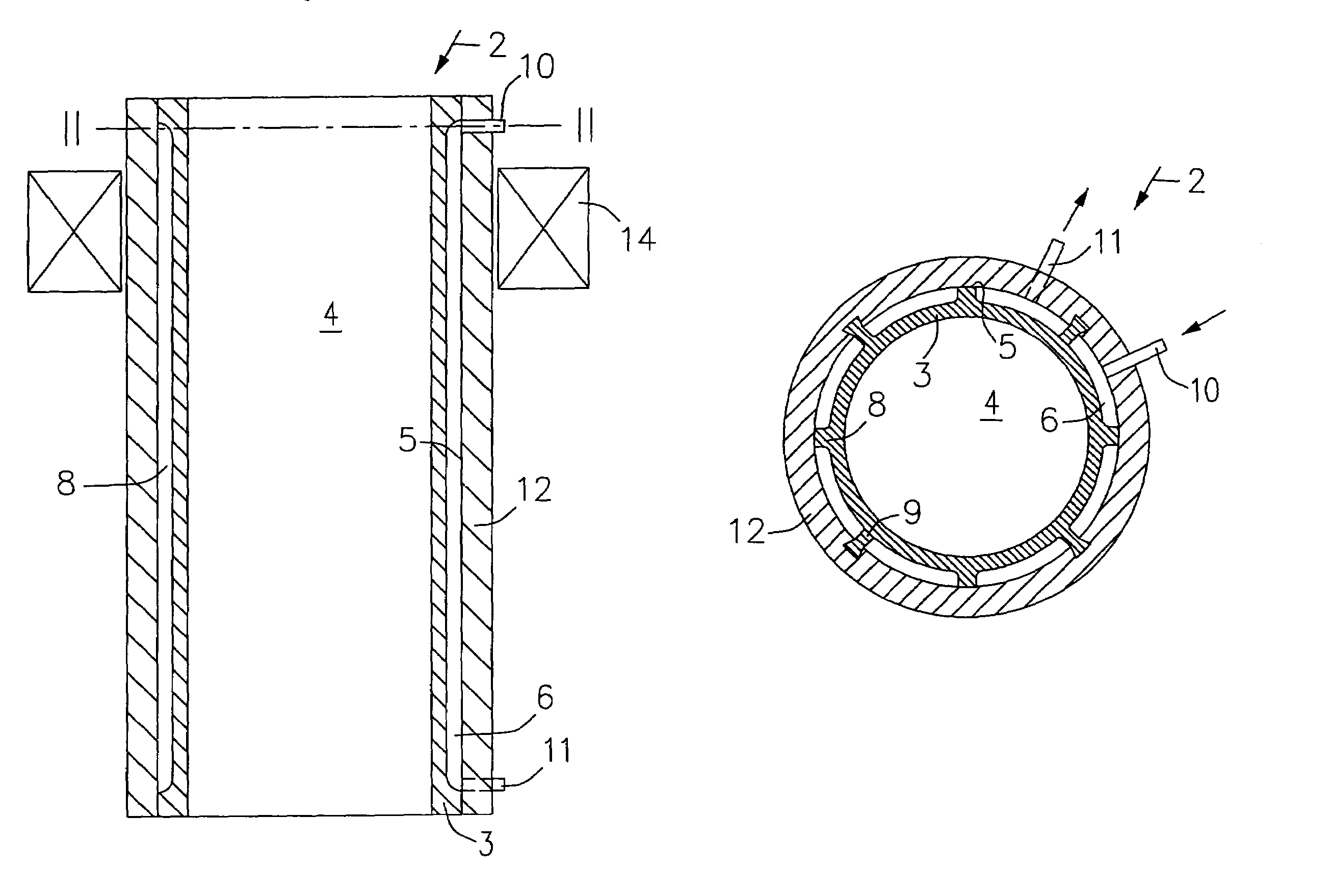

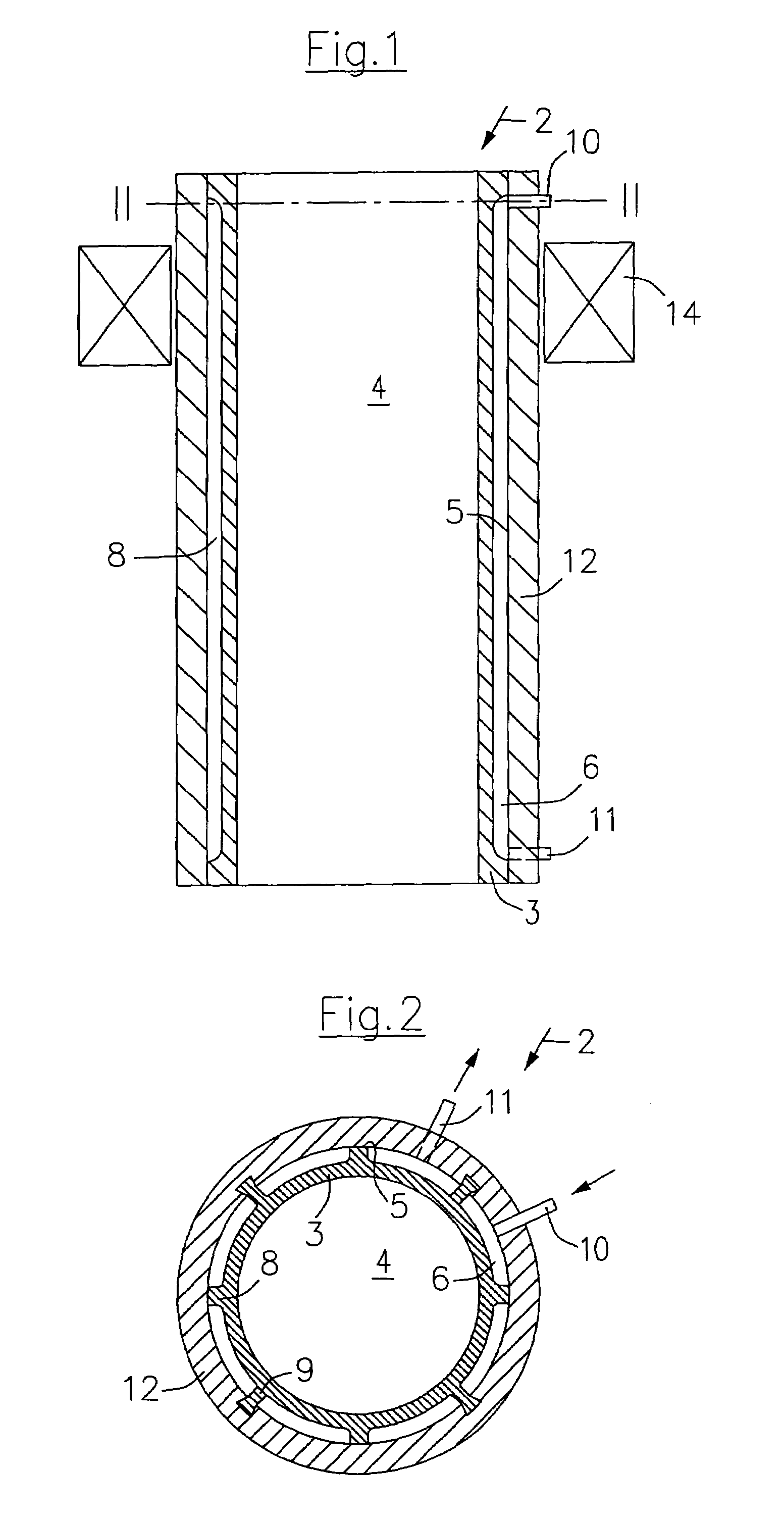

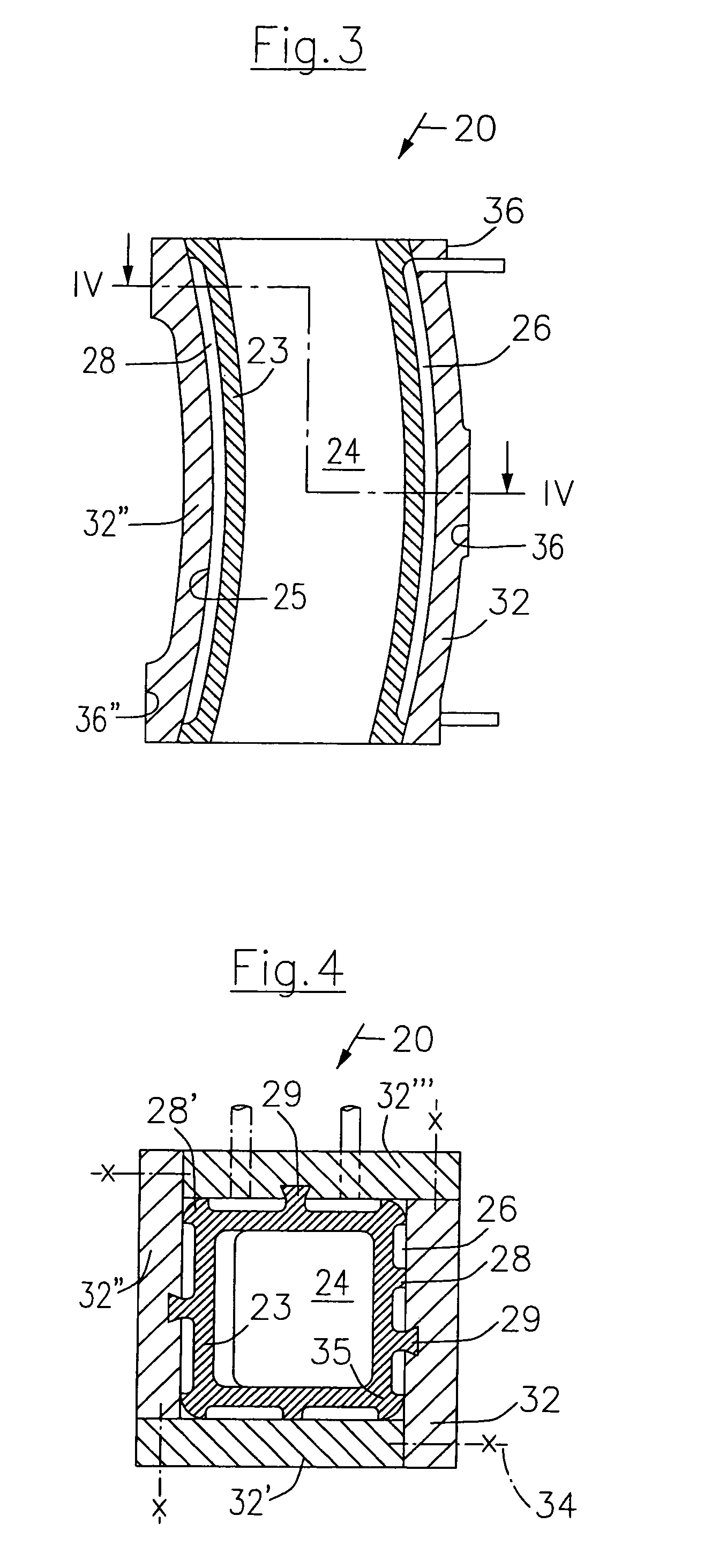

Tubular mould for continuous casting

ActiveUS7422049B2Prevent electrolytic corrosionGood dimensional stabilityPermanent magnetsElectromagnetsWater circulationCooling capacity

In the continuous casting of round or polygonal billet and bloom formats, use is made of moulds the mould cavity of which comprises a copper tube (3) which is intensively cooled by means of water-circulation cooling. In order to increase the cooling capacity on the one hand and the dimensional stability of the mould cavity (4) on the other hand, and also extend the total service life of the copper tube (3), it is proposed to provide the copper tube (3) with a supporting shell (12) or supporting plates over the entire circumference at the tube outer lateral surface (5). For the cooling of the copper tube (3), cooling ducts (6) for guiding the cooling water are arranged on the copper tube (3) or on the supporting shell (12). The cooling ducts (6) are distributed over the entire circumference at the tube outer lateral surface (5) and extend substantially over the entire mould length.

Owner:CONCAST AG

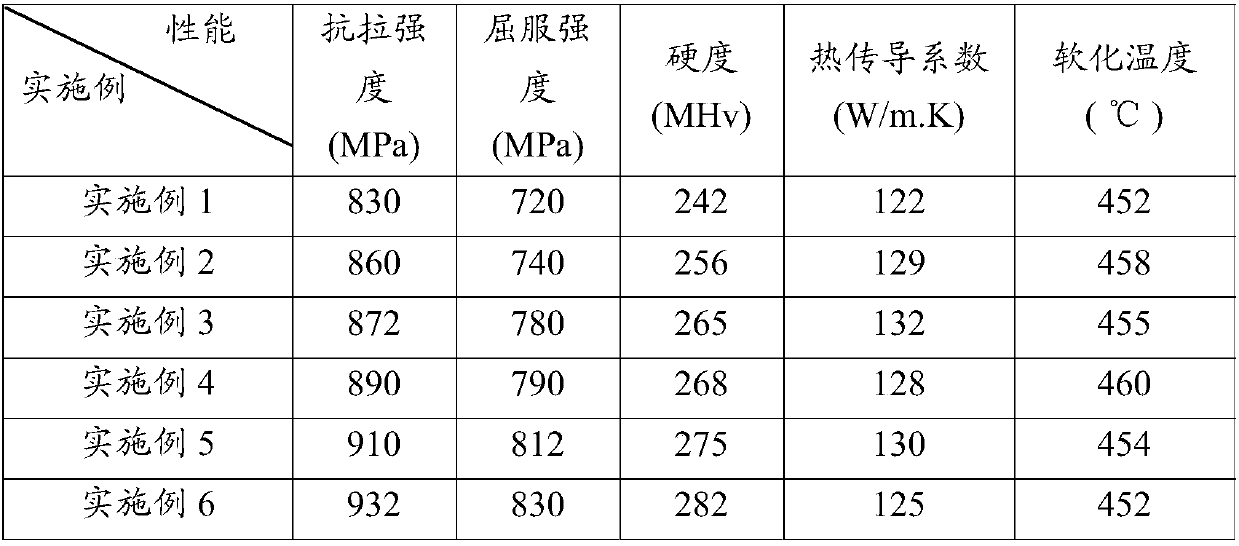

High-strength high-thermal conductivity copper alloy and preparation method thereof

InactiveCN107760920AImprove thermal conductivityImprove thermal fatigue resistanceThermal fatigueHeat conducting

The invention discloses a high-strength high-thermal conductivity copper alloy and a preparation method thereof. The copper alloy disclosed by the invention is composed of the following components inpercentage by mass: 3.5-4.0% of Ni, 2.0-2.5% of Co, 1.0-2.0% of Si, 0.5-1.0% of Be and the balance of Cu and inevitable impurities. According to the copper alloy disclosed by the invention, due to anappropriate preparation process, heat resistance in each heat-conducting link is reduced, the advantages of various elements are fully achieved, and the prepared material has high strength, excellentheat-conducting property and thermal fatigue resistance under the condition that the beryllium content is low. The excellent overall performance can meet the practical requirement of a cast roll shellmaterial.

Owner:HENAN UNIV OF SCI & TECH

Special continuous casting crystallizer casting powder for ESP low carbon

The invention relates to special continuous casting crystallizer casting powder for ESP low carbon, and belongs to the field of metallurgy accessories. The casting powder comprises chemical componentsincluding, by weight, 28-33 parts of CaO, 22-29 parts of SiO2, 4.5-7.5 parts of MgO, 4.5-7 parts of Al2O3, 7-10 parts of Na2O, 8-11 parts of F, 0.3-1.5 parts of B2O3, 0.5-1 part of Li2O and 1-3.5 parts of C. The casting powder has the low melting temperature, low viscosity and high melting speed, the casting powder can be rapidly consumed when the continuous casting pulling rate is 5-7 m / min, andaccordingly heat transfer and lubricating performance between a continuous casting blank shell and a crystallizer copper plate are guaranteed.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

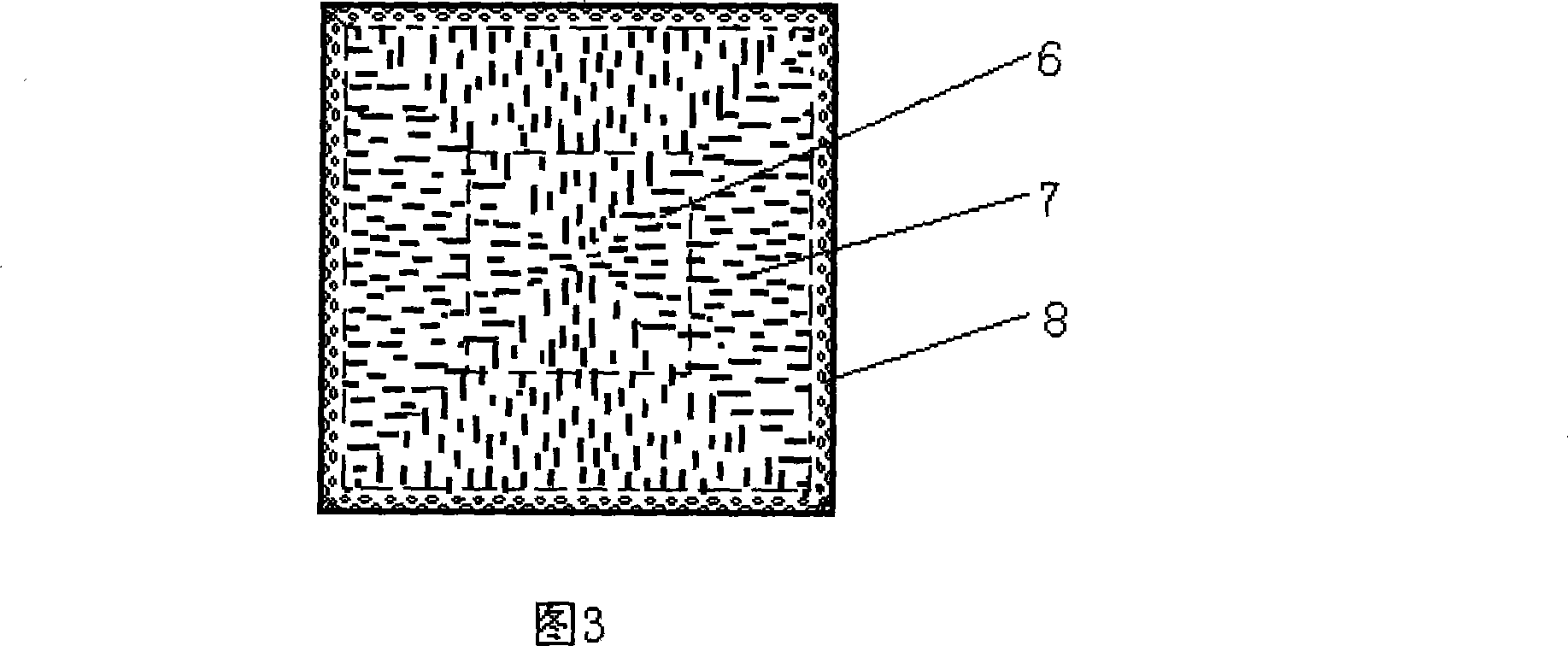

Process for continuously casting magnesium alloy thin strip blank

InactiveCN1748907AUniform and symmetrical coolingConsistent surface morphologyMelting tankShielding gas

The continuously casting process of thin magnesium alloy strip plate includes the following steps: preheating and smelting alloy blank in melting furnace with flux; preheating the side sealing system to 400-450 deg c before casting, transferring the melt at 650-680 deg c to pouring basket and maintaining for 15-30 min under the action of flux, feeding via melt distributor to equal diameter double roller vertical continuous casting machine under the action of protective gas, casting in immersion mode and casting speed of 20-100m / min for casting-rolling, and feeding the strip plate from the casting rollers to the pinch rollers under protecting gas action. The cast thin magnesium alloy strip plate has thickness of 1.0-3.5mm. The present invention produces thin magnesium alloy strip plate directly with molten magnesium alloy, and has the advantages of high product quality, homogeneous inner structure, being favorable to subsequent processing, short technological process and low cost.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com