Continuous casting columnar crystallizer small square blank and its columnar crystal control method

A control method and columnar crystal technology, applied in the iron and steel industry, can solve the problems that limit the high efficiency of continuous casting, achieve the effects of less pores, small shrinkage internal stress, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Use a conventional electric furnace, converter or other non-vacuum melting furnace for smelting (in this embodiment, converter smelting is used), measure the chemical composition before tapping, and carry out initial adjustment of the composition, and then put the ladle containing molten steel into the refining furnace Carry out refining, and finally take a sample to determine the chemical composition, and use it after meeting the design requirements (obtaining the third furnace steel). The chemical composition (%) of GCr15 bearing steel is shown in Table 1.

[0030] Table 1 Chemical composition of GCr15 bearing steel (%)

[0031] Preface

Number

C

Si

mn

Cr

P

S

Aloxy

Cu

T.[0]

1

0.98

0.23

0.34

1.49

0.012

0.005

0.001

0.04

0.0007

2

1.00

0.27

0.37

1.50

0.015

0.006

...

Embodiment 2

[0057] Still get the molten steel with the chemical composition contained in No. 2 in Table 1 for continuous casting. The process parameters of GCr15 bearing steel continuous casting slab are shown in Table 5.

[0058] Table 5 Process parameters of GCr15 bearing steel continuous casting slab

[0059] crystallization per flow

Secondary cooling section ratio

set pull speed

Water ratio of each stage of secondary cooling

[0060] Container water volume (L

/ min)

amount of water

(L / kg)

(m / min)

Foot roller section: movable section: fixed I section: fixed II

part

2000

1.6

2.4

2∶2∶5∶5

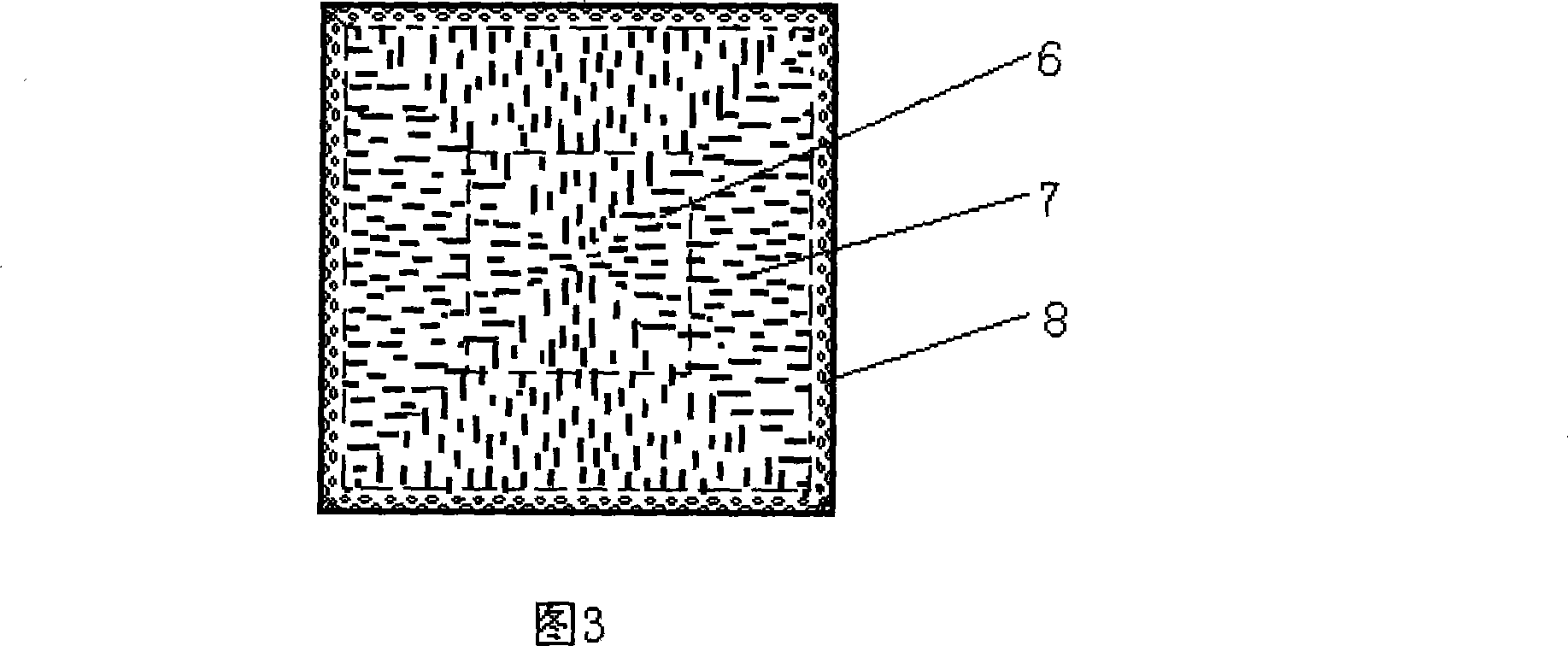

[0061] Obtain 150 square billets of GCr15 bearing steel. The low-magnification inspection of 150 square billets of GCr15 bearing steel shows that the proportion of columnar crystals in the central area of the billet is 95%, and the rest are equiaxed crystals.

[0062] All the other implementations...

Embodiment 3

[0064] Still get the molten steel with the chemical composition contained in No. 2 in Table 1 for continuous casting. The process parameters of GCr15 bearing steel continuous casting slab are shown in Table 6.

[0065] Table 6 Process parameters of GCr15 bearing steel continuous casting slab

[0066] crystallization per flow

Container water volume (L

/ min)

Secondary cooling section ratio

amount of water

(L / kg)

set pull speed

(m / min)

Water ratio of each stage of secondary cooling

Foot roller section: movable section: fixed I section: fixed II

part

2500

1.9

2.5

4∶4∶3∶3

[0067] Obtain 150 square billets of GCr15 bearing steel. The low-magnification inspection of the 150 billet of GCr15 bearing steel shows that the proportion of columnar crystals in the central area of the billet is 98%, and the rest are equiaxed crystals.

[0068] All the other implementations are as in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com