Patents

Literature

36results about How to "Reduce chance of defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon-base compound substrate and manufacturing method thereof

InactiveCN102208337AIncrease stressImprove coordinationSemiconductor/solid-state device manufacturingSemiconductor devicesTitanium nitrideEpitaxial material

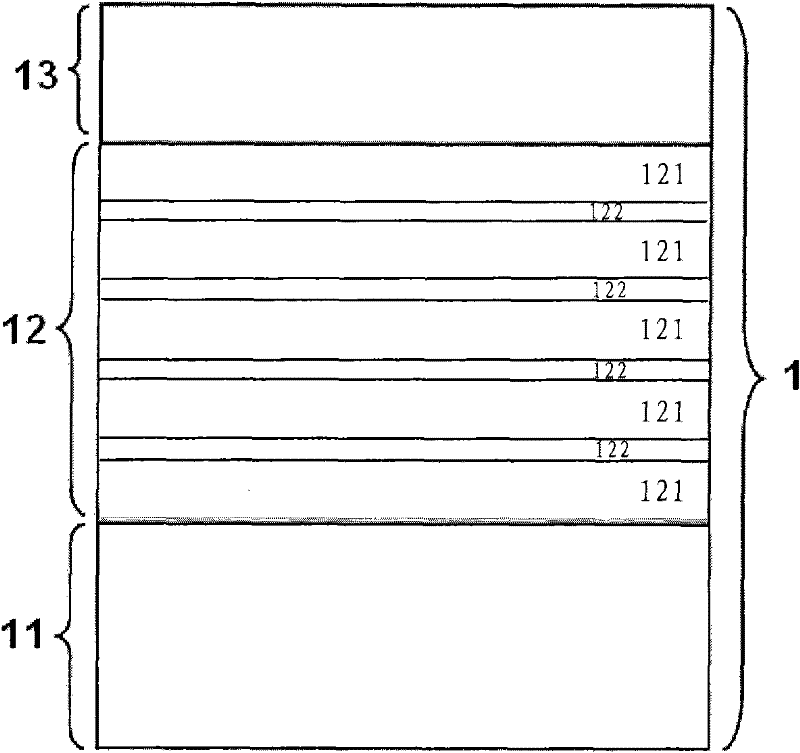

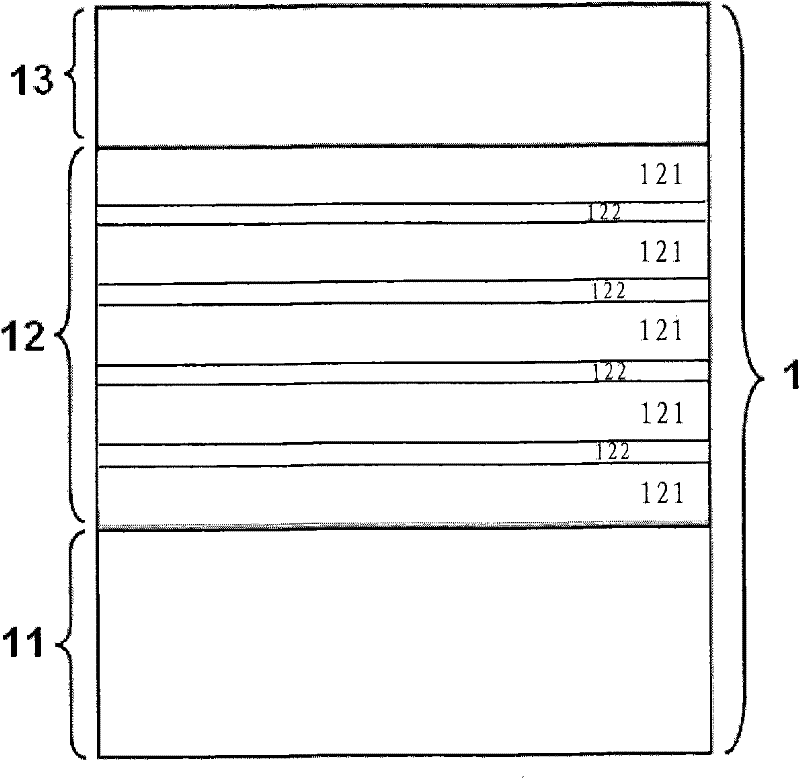

The invention provides a silicon-base compound substrate for preparing a nitride semiconductor epitaxial material, and a manufacturing method of the silicon-base compound substrate. The silicon-base compound substrate comprises a silicon monocrystal substrate, a compound stress covariant layer which is formed on the silicon monocrystal substrate and formed by frequently stacking aluminum nitride and a titanium nitride monocrystal thin film material, and a gallium nitride template layer which is formed on the compound stress covariant layer and consists of a gallium nitride monocrystal thin film material. By the silicon-base compound substrate, the crystal lattice and big heat mismatch problems of the silicon-base gallium nitride material are solved; therefore, the preparation cost of a gallium nitride light emitting diode (LED) epitaxial sheet can be reduced greatly; and the silicon-base compound substrate is suitable for application and market popularization.

Owner:杭州海鲸光电科技有限公司

Method for preparing polyacrylonitrile spinning stoste

InactiveCN1710159AStable concentrationSmall molecular weight distributionMonocomponent synthetic polymer artificial filamentYarnPolymer science

The poly-acrylonitrile spinning stost is prepared by mixing acrylonitrile, azobisisobutyronitrile and dimethyl sulfoxide according to a certain weight proportion, stirring uniformly, leading in nitrogen gas under the stirring speed of 230-290 turn / min., making them react under reaction temp. of 52-65 degree C, continuously feeding in acryamide solution to react for 8-13 hours in which the ratio of feed amount per min. to container volume is 2x10-5 -1x10-4 min-1 , then demonomorizing and defoaming. Advantages: obviously reduced poly-acrylonitrile molecular weight distribution, improved spinning property of polymer and the oxidisability of raw yarn and simple process etc..

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

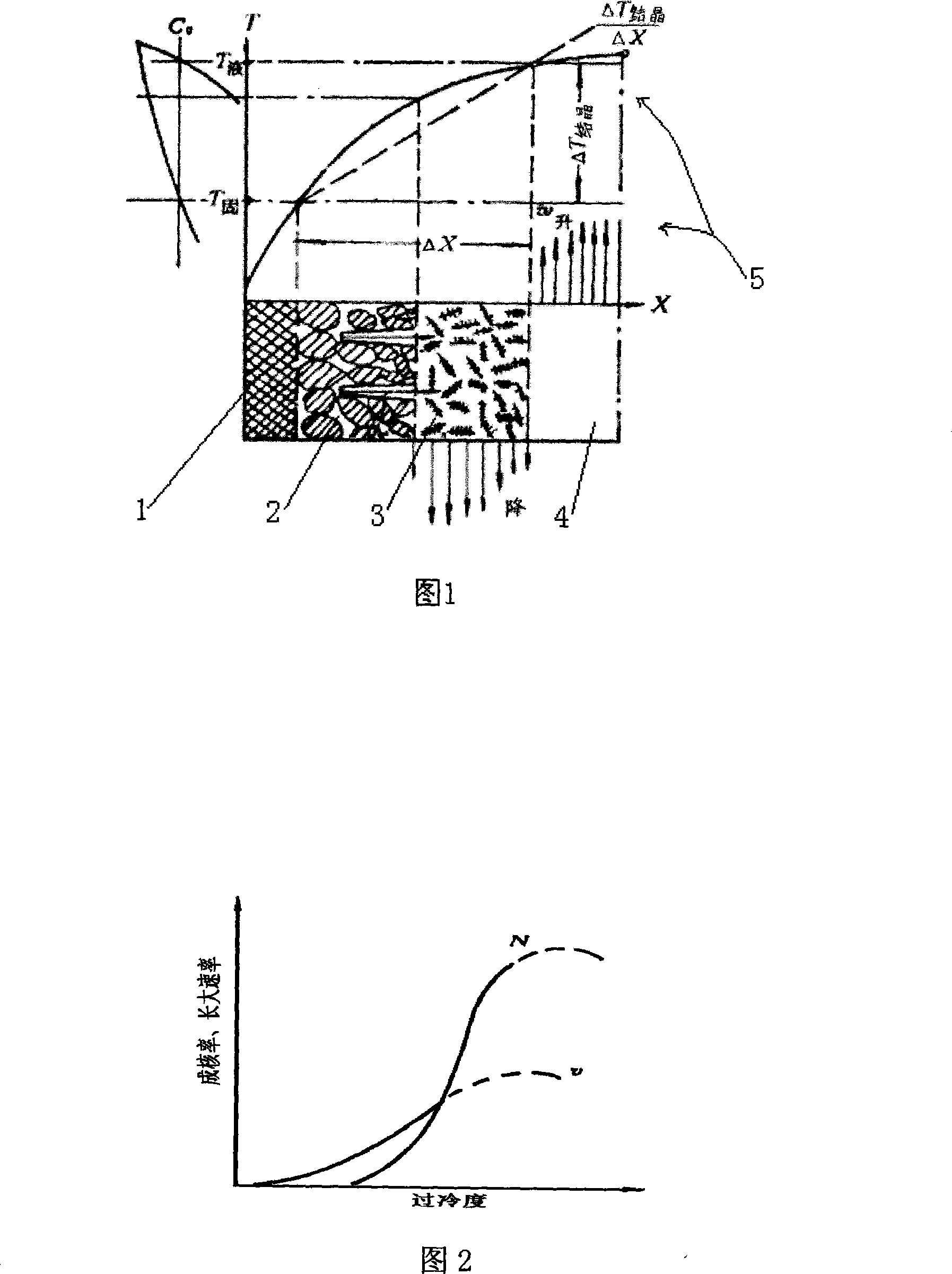

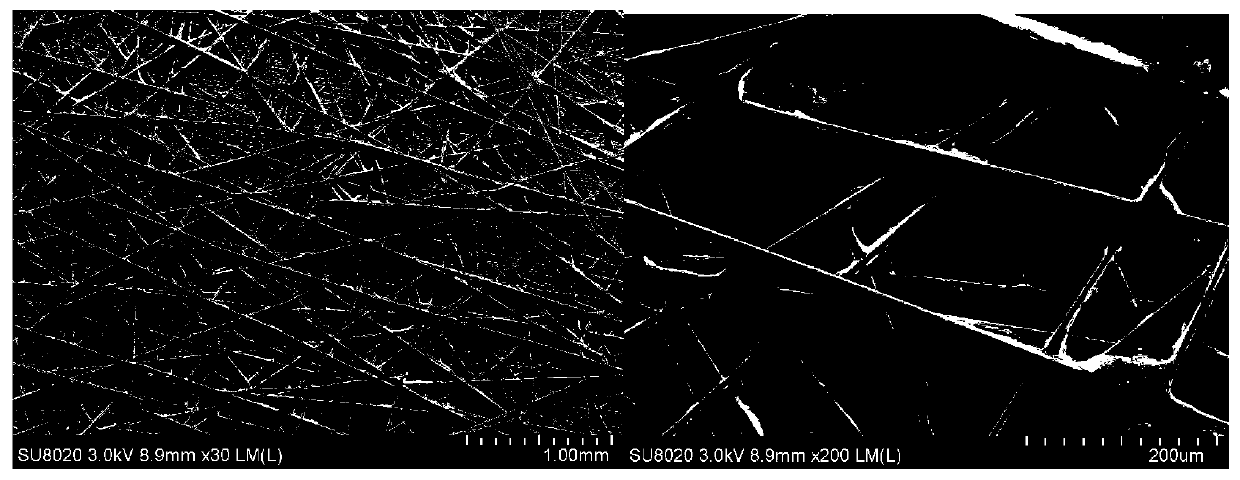

Continuous casting columnar crystallizer small square blank and its columnar crystal control method

InactiveCN101147966AIncrease productivityIncrease casting speedChemical compositionEquiaxed crystals

The present invention discloses a continuous cast columnar crystal square billet and its columnar crystal control method. It is characterized by that said square billet is continuously cast by using molten steel containing chemical components of screw-thread steel, carbon structure steel, alloy structure steel, spring steel, bearing steel, low-alloy high-strength steel, hard wire steel or cold-short steel. The columnar crystal rate in the central zone of said square billet is 90-100%, and its equiaxed crystal rate is 0-10%. Said invention utilizes forced cooling and thermal stress downwards compression of continuous casting process to raise uniformity of material components, reduce segregation value of material components and internal defect probability and raise columnar crystal rate of square billet, at the same time, said invention adopts forced cooling and high drawing speed so as to make continuous casting machine efficiency be raised by 10%-40%.

Owner:JIANGSU SHAGANG GROUP HUAIGANG SPECIAL STEEL CO LTD

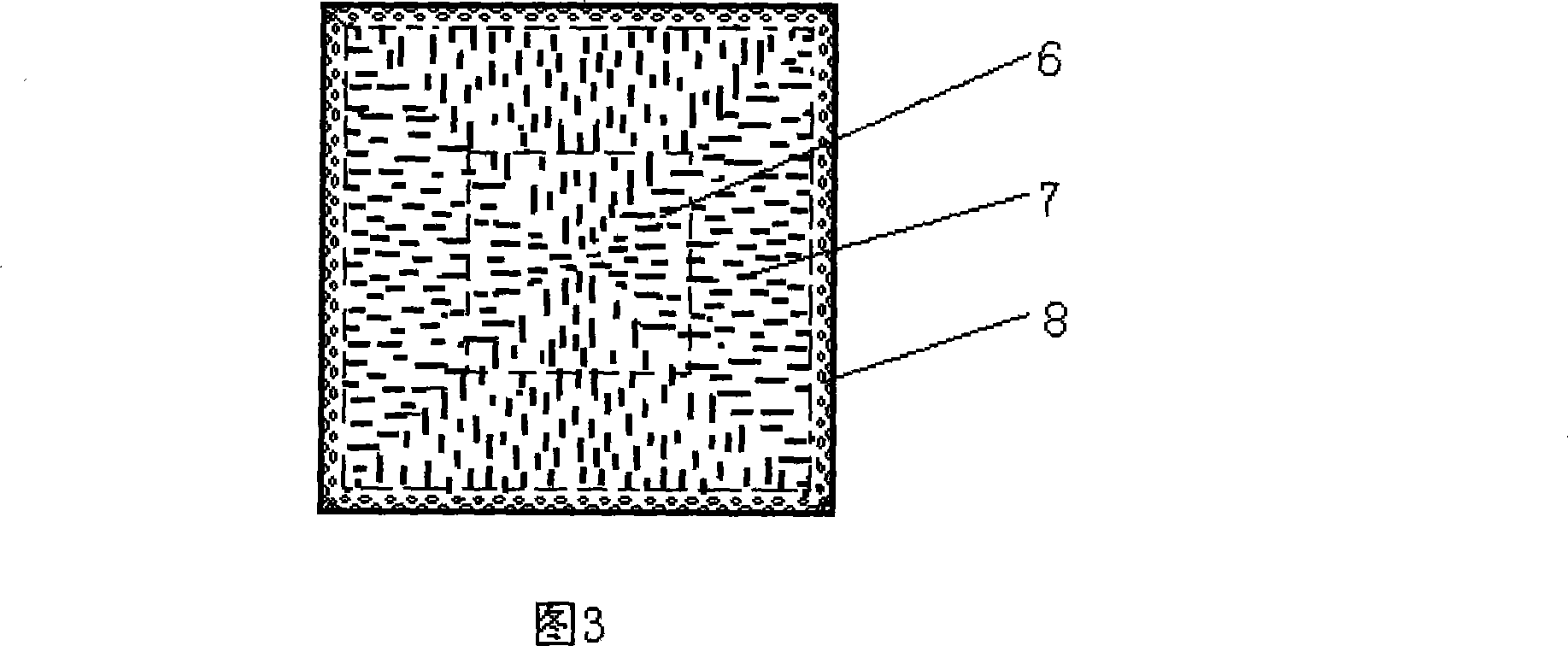

Technical method using low resin content prepreg for preparation of composite material

The invention belongs to the technical field of low-cost manufacturing of high performance composite materials, and relates to a technical method using a low resin content fiber-reinforced prepreg for preparation of a composite material. First of all, resin content in the prepreg can be regulated by precise control of the concentration of a resin solution in a wet-method prepreg preparing process, and under the premises of ensuring structural integrity and technical operability of the prepreg, fiber tows are partly wetted with resin to obtain the low resin content prepreg; then by combination with a mold-closing RTM (resin transfer molding) technology and in dependence on injection and flowing of low viscosity RTM resin, the reinforced fiber can be finally and completely wetted to obtain the high performance composite material which has good paving technical properties and high fiber collimation degree and fiber volume fraction of both the prepreg and the composite material and can combine manufacturing flexibility of the RTM technology.

Owner:AVIC COMPOSITES

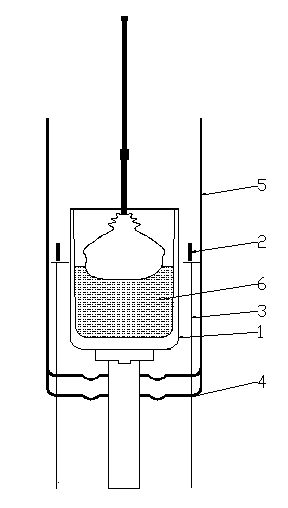

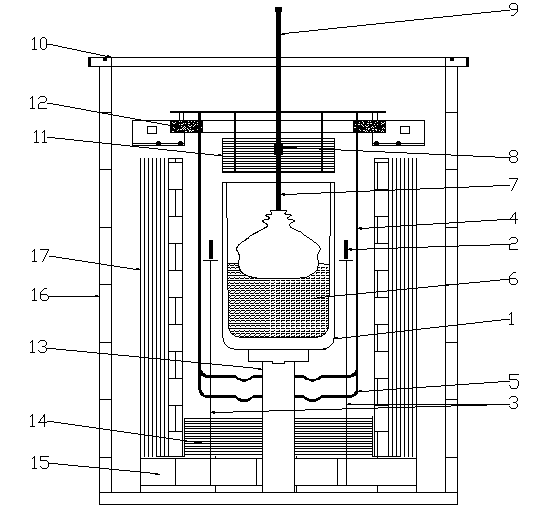

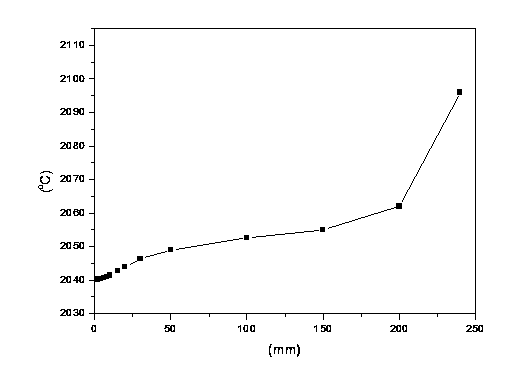

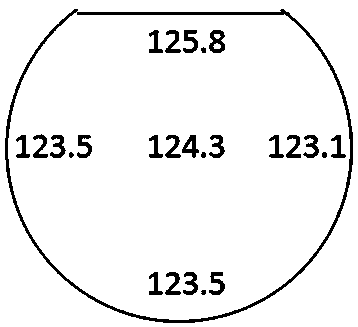

Dynamic-temperature-field preparation method for large-size C-axis sapphire crystal

InactiveCN104120488AAddressing Chance IncreasesNo Bubbles Low Defect DensityPolycrystalline material growthBy pulling from meltCrucibleCrystal growth

The invention relates to a dynamic-temperature-field preparation method for large-size C-axis sapphire crystal. An employed crystal growth furnace heating body comprises an auxiliary heating body at the upper part of the outer side of a crucible, an auxiliary heating body at the outer side and a main heating body at the lower part of the bottom. A tungsten filament of the auxiliary heating body at the upper part of the outer side of the crucible employs a left part and a right part which are in connection in a parallel way. The power of the auxiliary heating bodies and the main heating body are respectively independently controlled by corresponding temperature control systems. By independently controlling the power of the three heating bodies and utilizing the dynamic temperature field method during crystal growth, temperature fields adaptive to demands of expelling bubbles, expanding shoulder and constant-diameter growth of a crystal are formed in the hearth when the crystal grows. In the constant-diameter growth stage, a horizontal growth interface is employed, the crucible wall temperature is close to the melt temperature, and thus no defect is generated caused by impact of a melt convecting to the middle on the crystal growth solid-liquid interface because of high crucible wall temperature. Heat radiation of the crystal is uniform, and thus the center axis does not have too many defects caused by concentrated heat radiation at the center axis. Therefore, the crystal has less defects, and high-quality C-axis sapphire crystal can be grown and obtained.

Owner:浙江特锐新能源有限公司

Preparation method of silicon epitaxial wafer for high-voltage power device

ActiveCN110379704AImprove crystal qualityReduce high temperature heating timeSemiconductor/solid-state device manufacturingChemical vapor deposition coatingReaction rateHigh pressure

The invention discloses a preparation method of a silicon epitaxial wafer for a high-voltage power device. According to the method, a reaction cavity of the epitaxial equipment is purified and the content of impurities accumulated in the cavity is reduced by long-time purging of large-flow hydrogen before epitaxial growth; the nonlinear gradient heating is adopted, so that the stress accumulated in the heating stage is released in time, and the generation probability of defects is reduced; and the reaction rate is significantly improved by shortening the distance between a quartz bell jar anda base of the reaction cavity of the epitaxial equipment and adopting a large-flow trichlorosilane and hydrogen proportioning mode, and high-speed epitaxial growth is realized under the premise of ensuring good crystallization quality of the silicon epitaxial wafer. The problem of comprehensive control on thickness, resistivity and crystallization quality in the existing preparation process is overcome by adopting the method of sectional growth of the silicon epitaxial wafer layer. the prepared silicon epitaxial wafer has a bright surface, is free from dislocation, staggered layers, slip linesand fog defects, realizes the controllability of material indexes such as thickness, resistivity and defects and meets the use requirements of the high-voltage power device.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

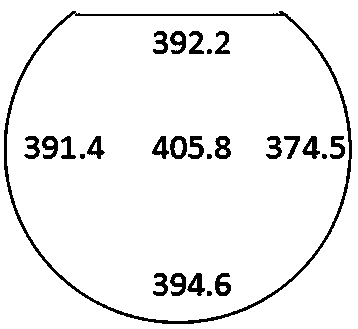

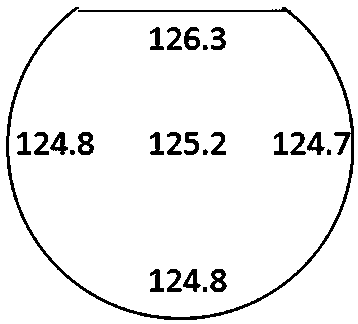

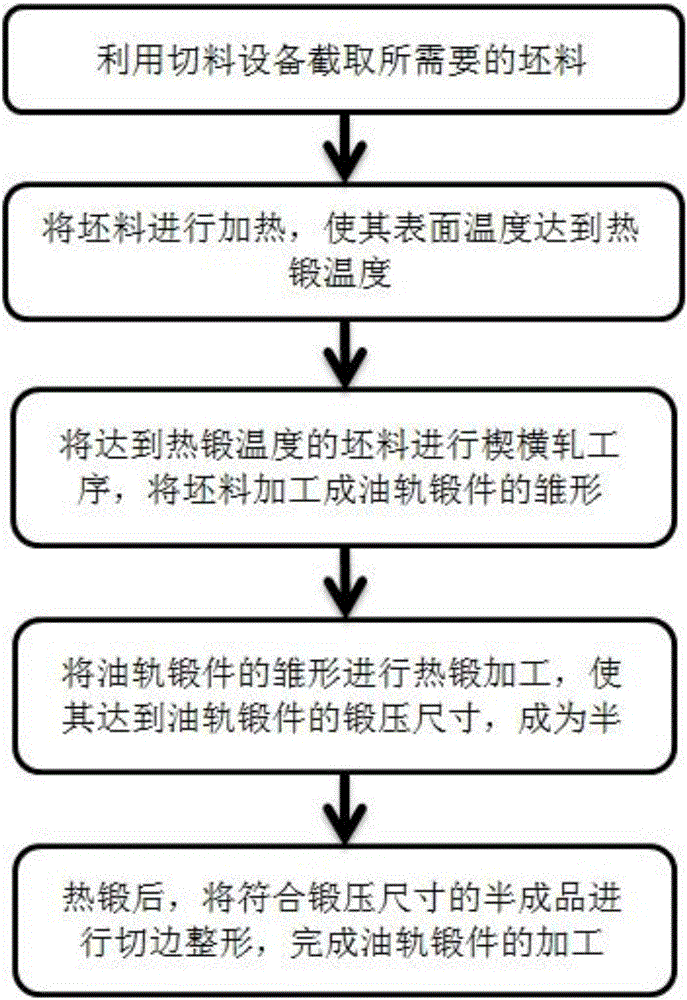

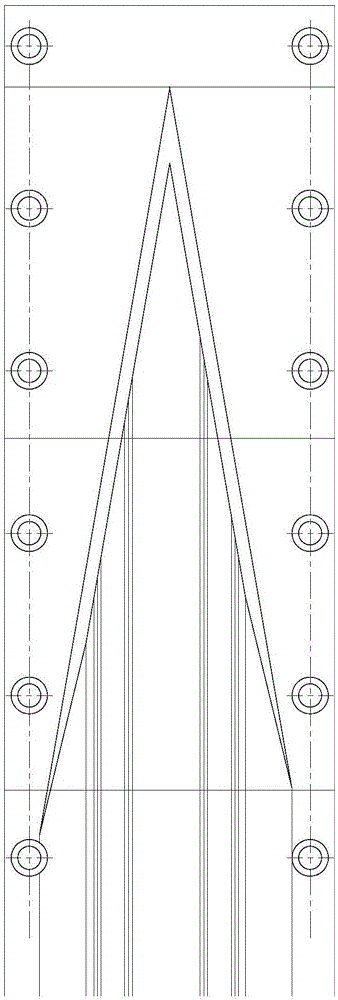

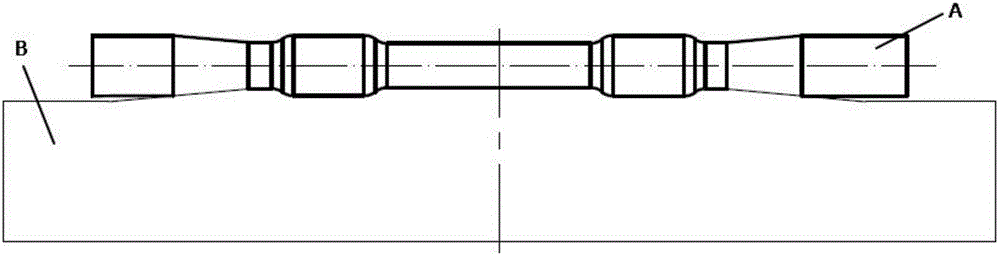

Machining method for fuel rail forge piece of engine

The invention belongs to the technical field of processing engine accessories, and discloses a processing method for an engine oil rail forging, which comprises the following steps: 1) using cutting equipment to cut the required blank; 2) heating the blank to make Its surface temperature reaches the hot forging temperature; Ⅲ) subjecting the billet reaching the hot forging temperature to a cross wedge rolling process, and processing the billet into a prototype of the oil rail forging; Ⅳ) performing hot forging on the prototype of the oil rail forging, Make it reach the forging size of the oil rail forging to become a semi-finished product; V) After hot forging, trim and shape the semi-finished product that meets the forging size to complete the processing of the oil rail forging. The invention adds a cross wedge rolling process before the existing hot forging processing method, improves material utilization rate, reduces processing time, improves production efficiency and increases operating income.

Owner:SHANGHAI JD CHUKYO FORGING & STAMPING +1

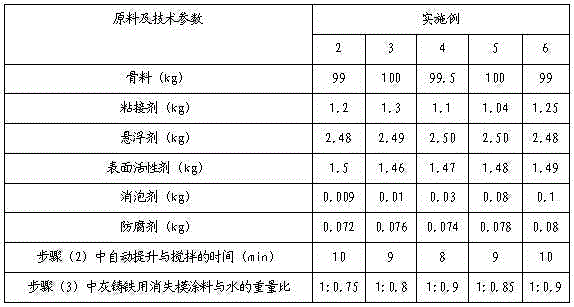

Lost foam casting coating for gray cast iron and preparation method of lost foam casting coating

InactiveCN104624922AVolume phase transition is stableReduce dosageFoundry mouldsFoundry coresDefoaming AgentsActive agent

The invention discloses a lost foam casting coating for gray cast iron and a preparation method of the lost foam casting coating. The lost foam casting coating comprises an aggregate, a binder, a suspending agent, a surfactant, a defoaming agent, water and a preservative, wherein recovered pill-cleaning dust is adopted as one part of the aggregate; the finally prepared coating is good in air permeability; a high-temperature gas can be rapidly and almost invariantly discharged out of a coat when a thick-walled casting is poured; carbon black and blowhole defects are reduced to the minimal extent; in addition, absence of an adhesive sand defect is also ensured; the lost foam casting coating can be mixed evenly by the preparation method disclosed by the invention; and later use is facilitated. The lost foam casting coating is suitable for preparation of the lost foam casting coating.

Owner:SHIJIAZHUANG MANDINGFU CASTING CO LTD

Welding process of water feed pump of nuclear power plant conventional island

InactiveCN104416259AIncrease productivitySave resourcesArc welding apparatusShielded metal arc weldingProcess engineering

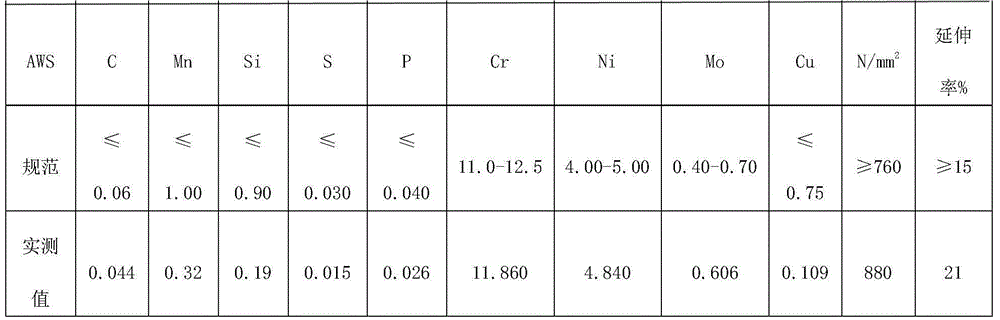

The invention discloses a welding process of a water feed pump of a nuclear power plant conventional island. The welding process comprises the following steps: (1) machining a bevel; (2) preheating before welding; (3) welding; (4) detecting after welding, wherein the preheating temperature before welding is 150-300 DEG C, wherein the welding step comprises the following sub-steps: a, welding the bevel of each component by using a manual welding rod, and stopping welding when the bevel is welded to 1 / 3 of the thickness; b, continuously welding the bevel of each component by using gas metal arc welding until the welding is finished. The production efficiency is greatly improved by using the manual arc welding and the gas metal arc welding method.

Owner:SHANGHAI KAIQUAN PUMP IND GROUP

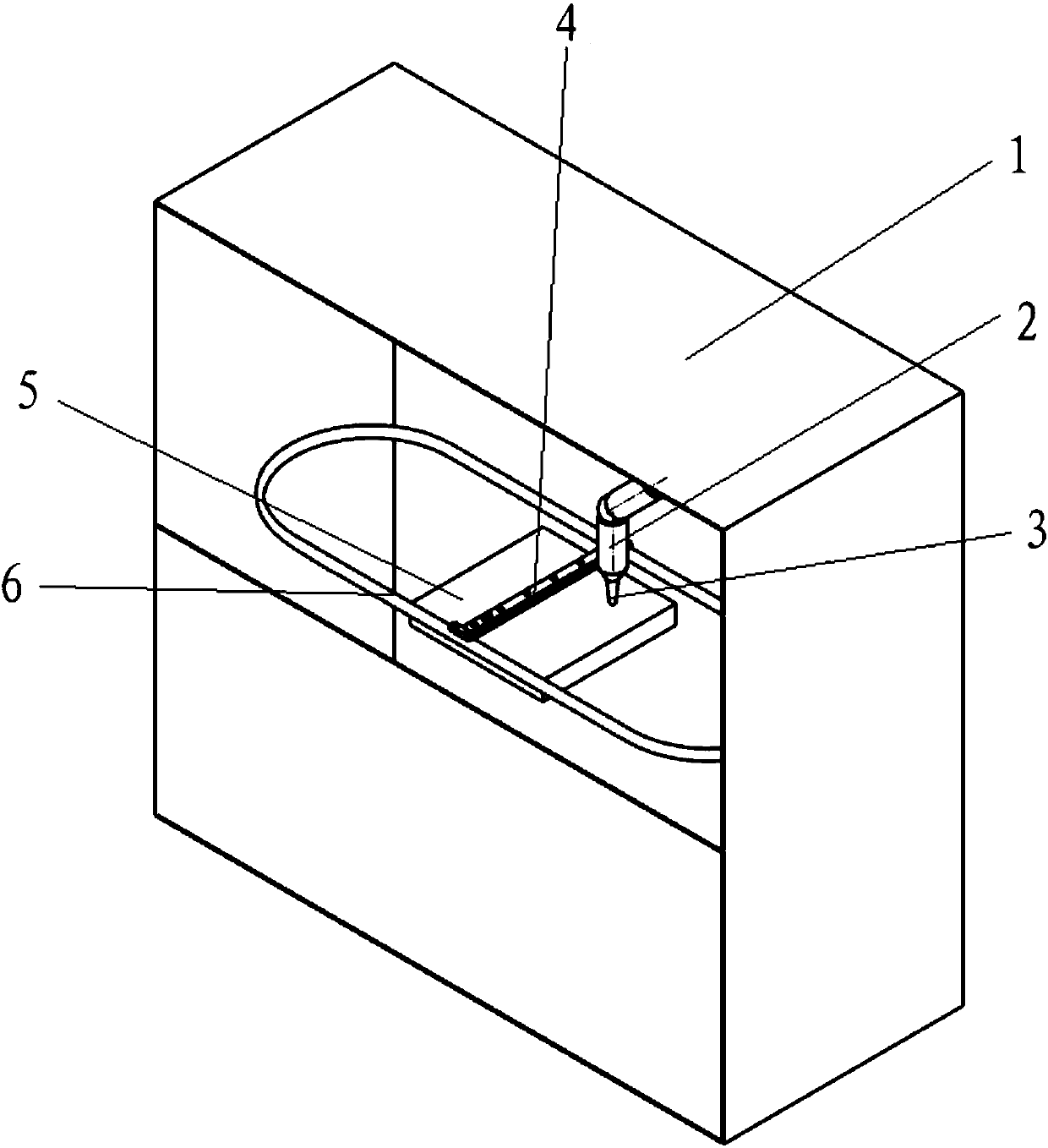

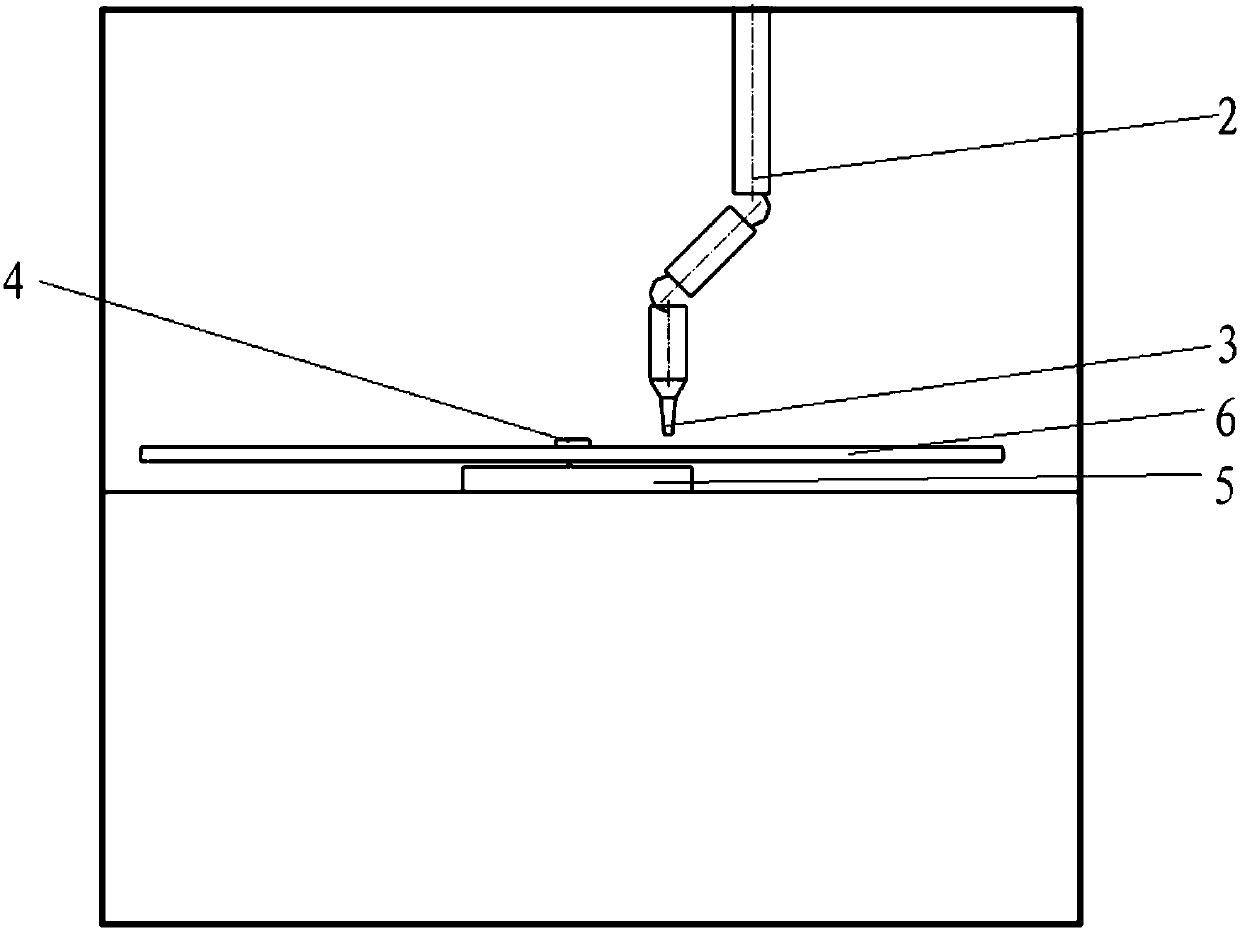

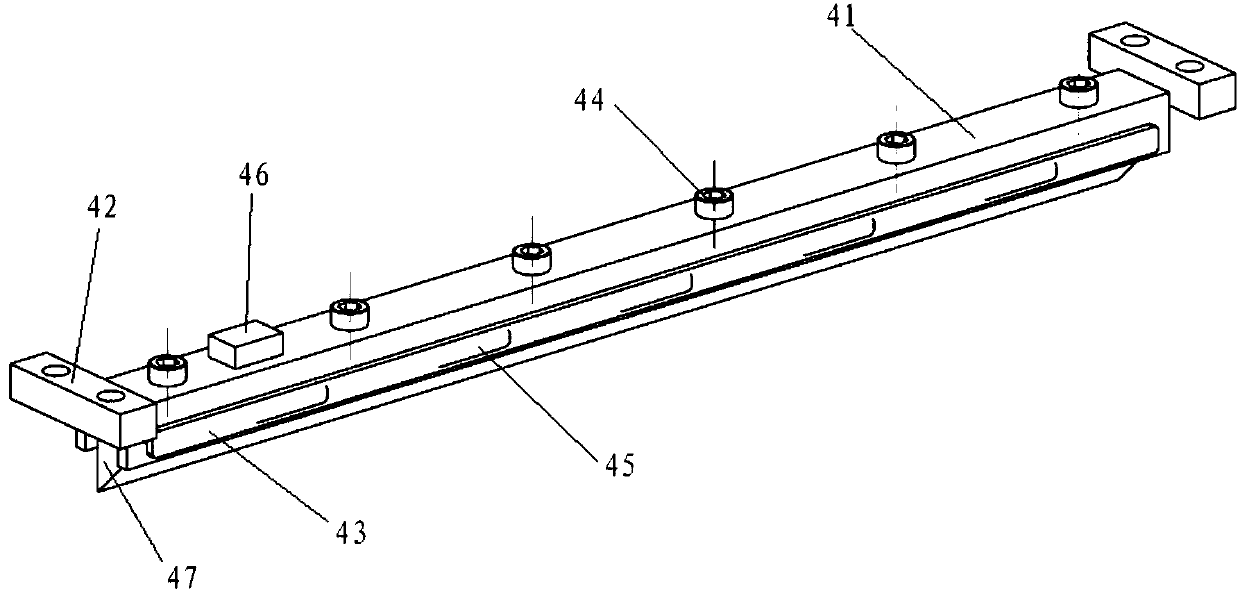

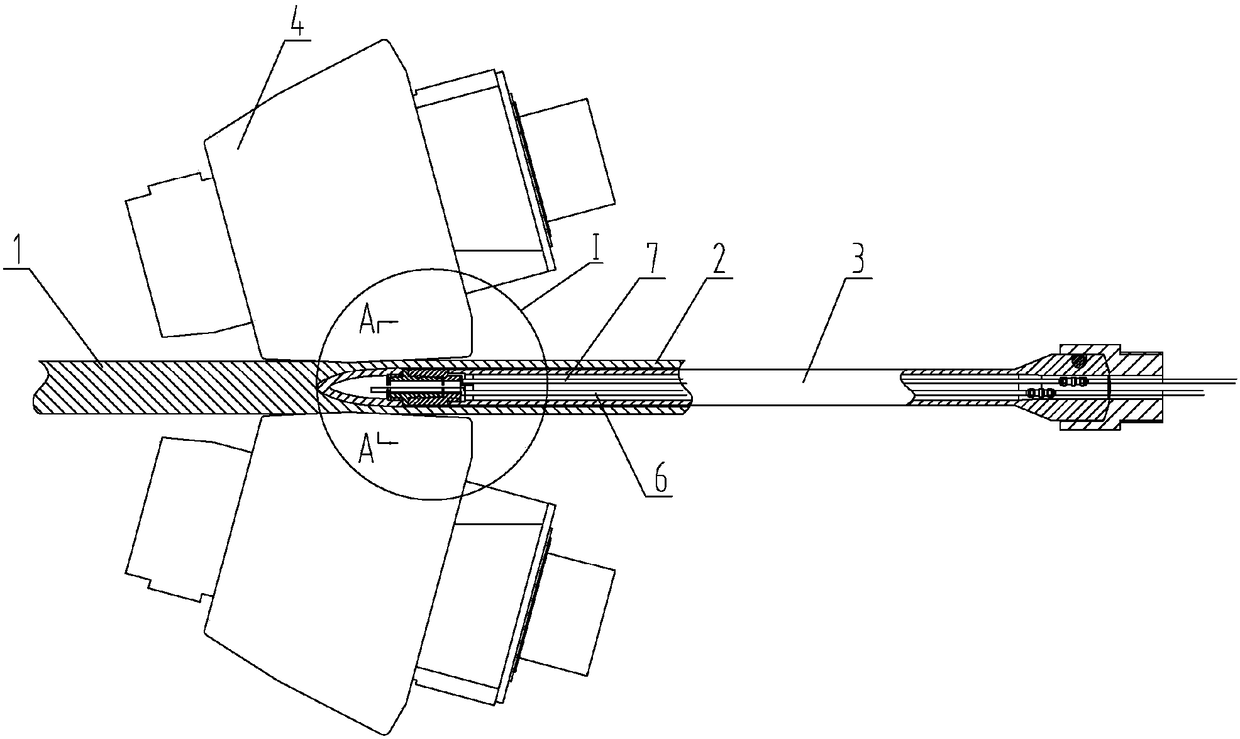

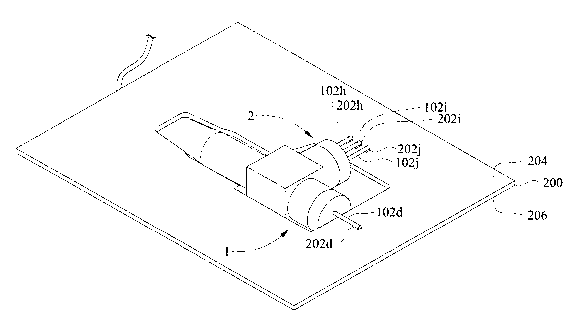

Selective laser melting device

PendingCN107626924AAchieve reductionGuaranteed accuracyAdditive manufacturing apparatusSelective laser meltingPower flow

The invention discloses a selective laser melting device. The selective laser melting device comprises a rigid powder laying device, a milling tool cutting device and a control device. The rigid powder laying device comprises a scraping knife mechanism, a guide rail mechanism, a power mechanism and an overcurrent detection mechanism. The power mechanism drives the scraping knife mechanism to movealong the guide rail mechanism. The overcurrent detection mechanism is arranged on the scraping knife mechanism and is connected with the control device. The milling tool cutting device comprises a mechanical arm and a milling tool. The control device is used for receiving and analyzing detection information transmitted by the overcurrent detection mechanism and controls the mechanical arm and themilling tool to realize the high point cutting action according to the detection information. The selective laser melting device conducts forced scraping on high points by means of the rigidity of ascraping knife in the powder laying process. If the high points are cut off by the scraping knife, the powder laying action can be completed smoothly. If the scraping knife gets stuck, cutting of thehigh points is realized through monitoring of the overcurrent detection mechanism and cutting of the milling tool cutting device. It is guaranteed that no high point exist in the manufacturing process. The defect rate of parts is greatly reduced. The precision of the parts is improved.

Owner:TSC LASER TECH DEV BEIJING CO LTD

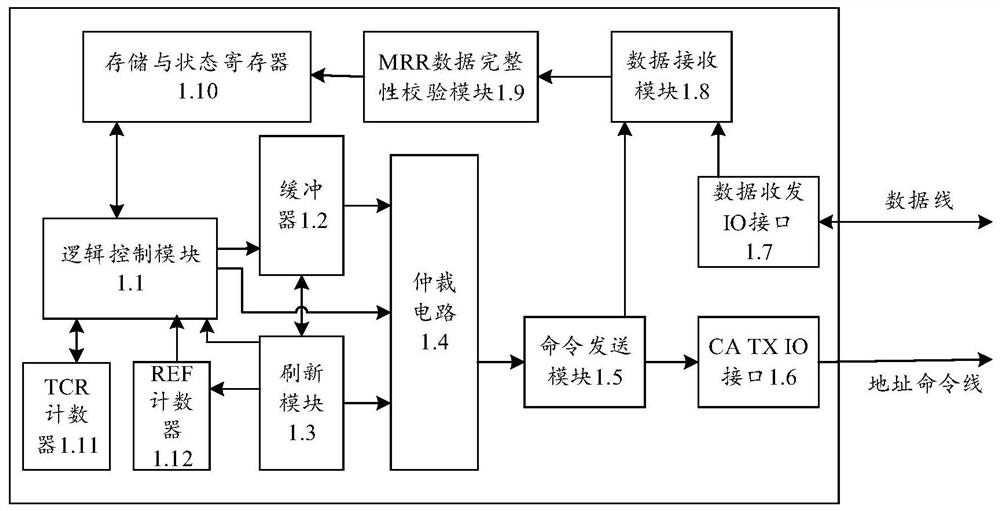

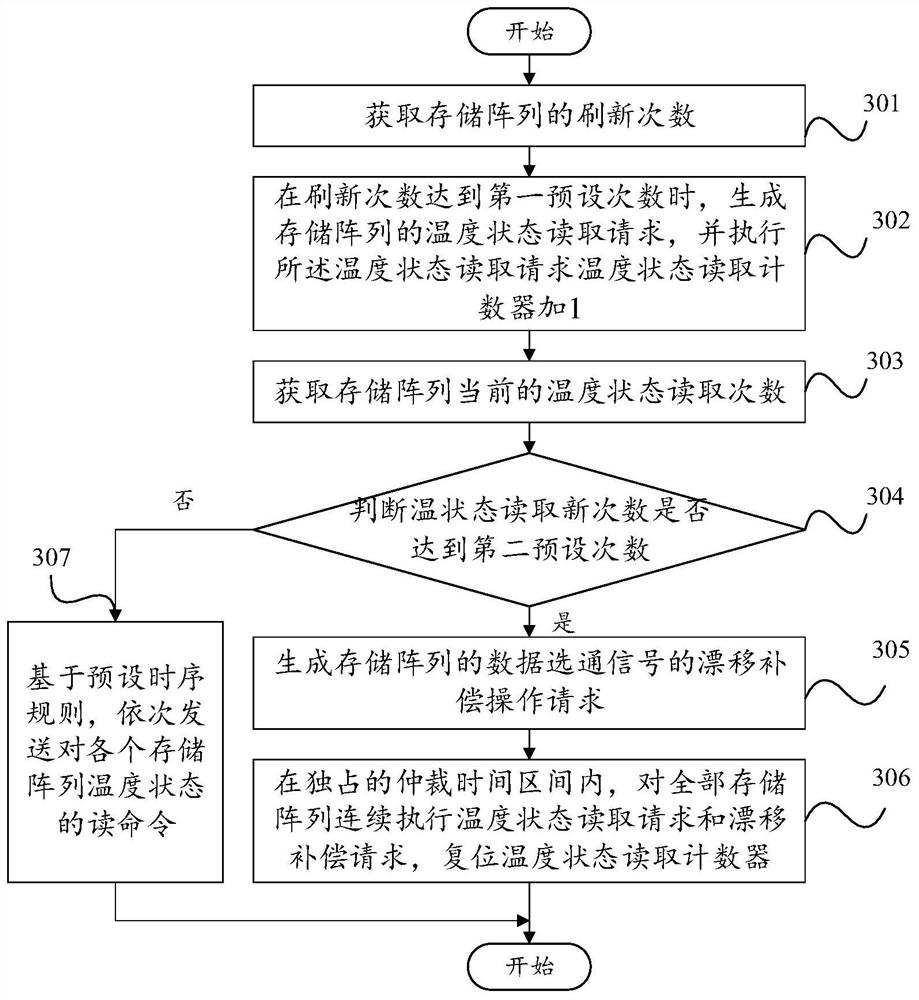

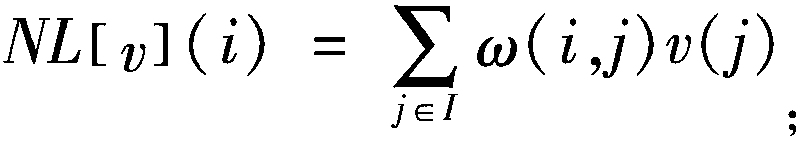

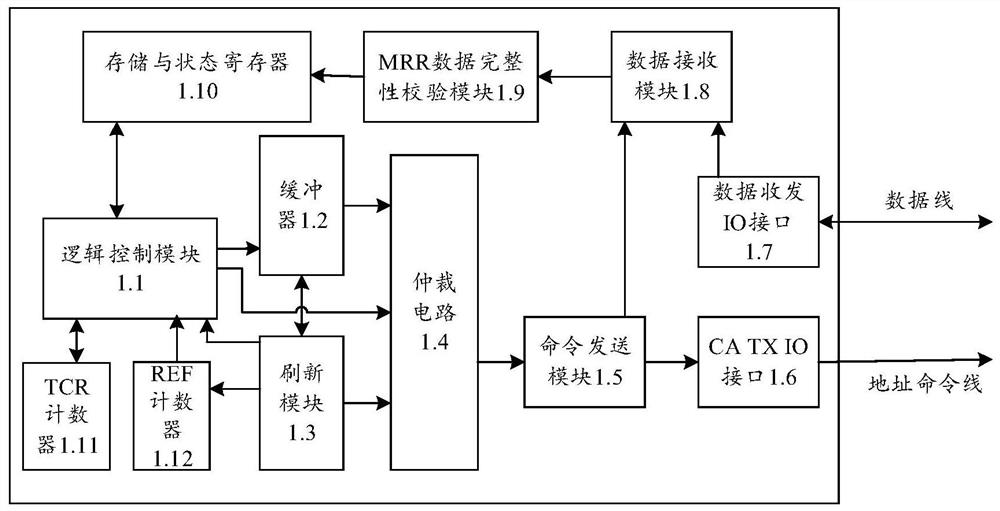

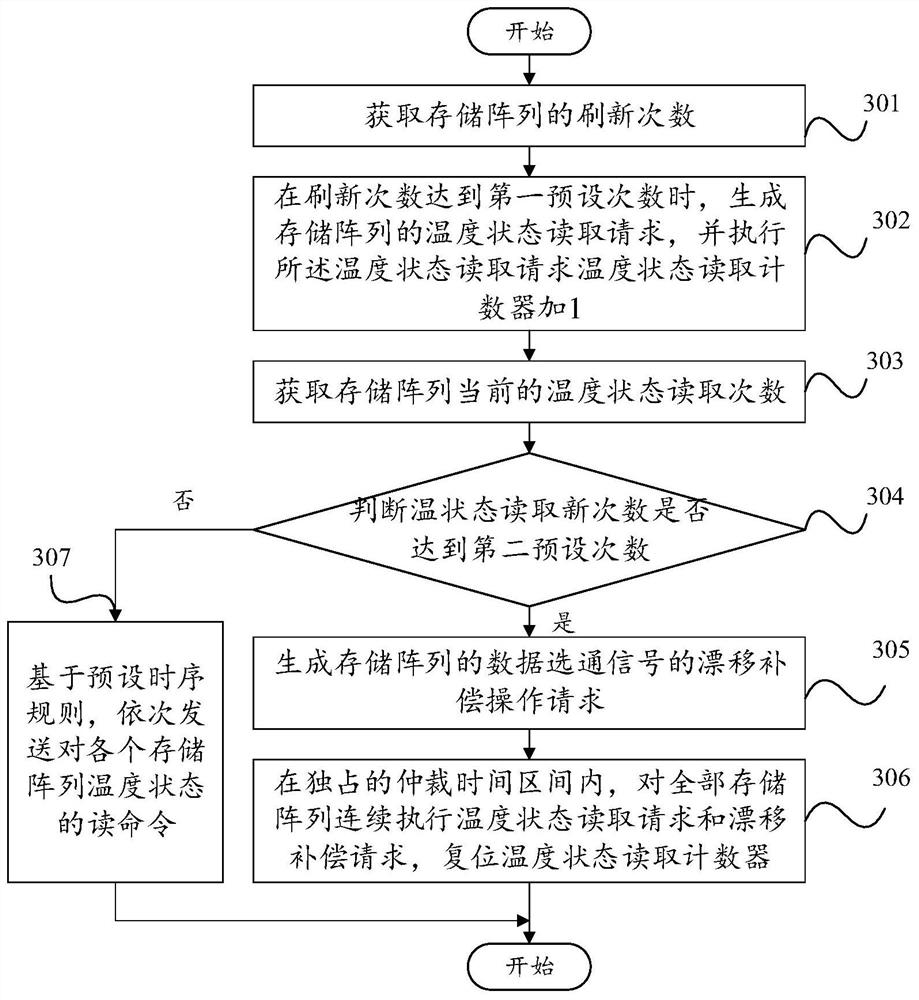

Command scheduling method, device and equipment and storage medium

ActiveCN112612596AReduce the numberReduce bit widthProgram initiation/switchingMemory adressing/allocation/relocationArbiterElectrical and Electronics engineering

The invention provides a command scheduling method, device and equipment, and a storage medium. The method comprises the steps of obtaining refreshing times of a storage array; when the refreshing frequency reaches a first preset frequency, generating a temperature state reading request of the storage array, and executing the temperature state reading request; obtaining the current temperature state reading frequency of the storage array; judging whether the temperature state reading frequency reaches a second preset frequency or not; if the temperature state reading frequency reaches the second preset frequency, generating a drift compensation operation request of a data gating signal of the storage array; and in an exclusive arbitration time interval, continuously executing the temperature state reading request or the temperature state reading request and the drift compensation operation request on all the storage arrays, and resetting the temperature state reading times. According to the invention, the number of bit widths of the counter is reduced, hardware resources are saved, and the complexity of the arbiter is reduced.

Owner:HYGON INFORMATION TECH CO LTD

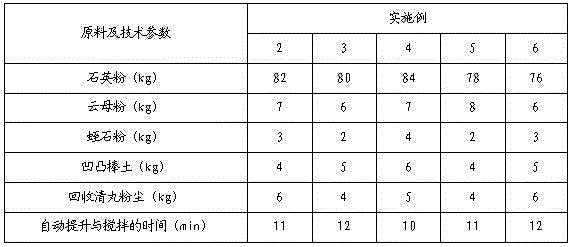

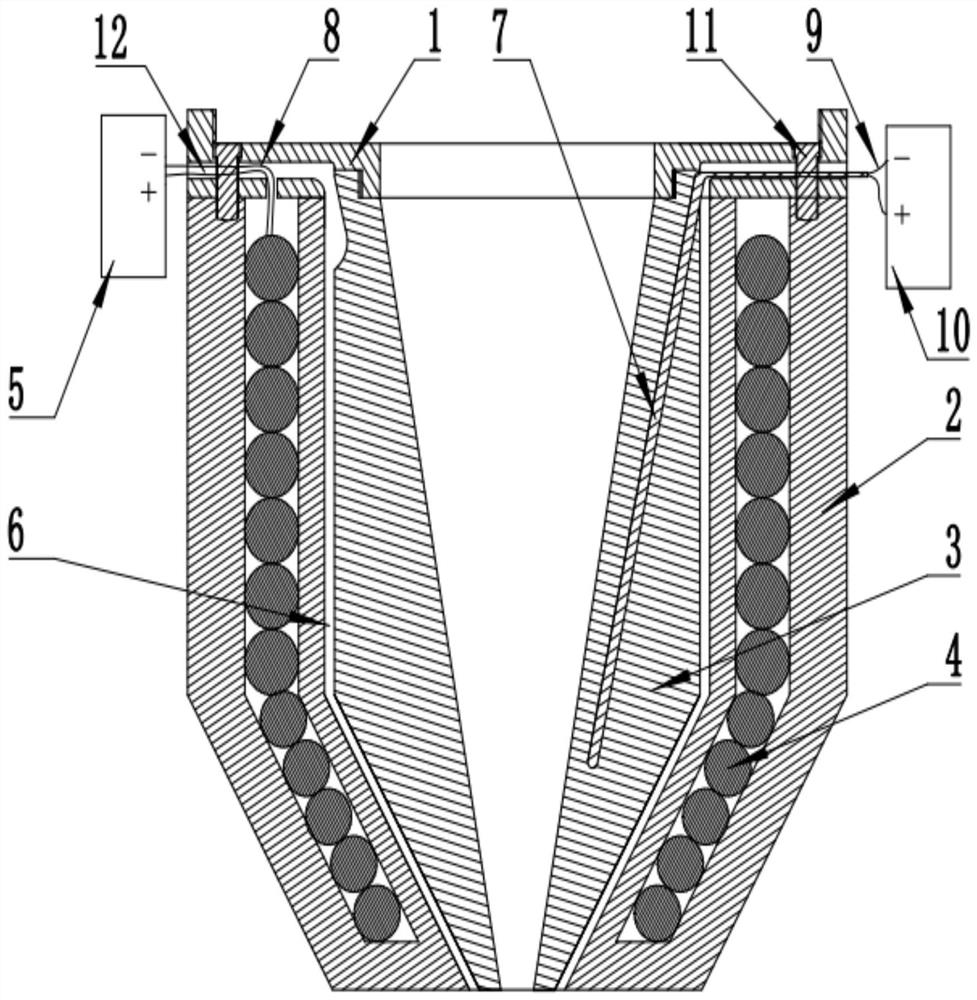

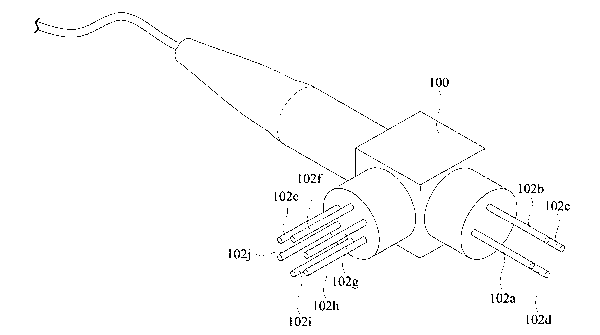

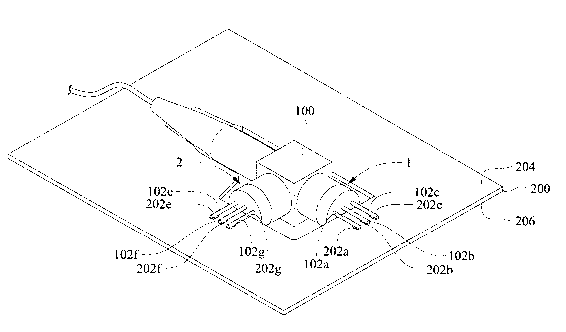

Electromagnetic induction annular heating laser cladding nozzle device and laser cladding device

PendingCN112080743AWith innovative technical effectQuality improvementMetallic material coating processesThermocouple deviceLaser beams

The invention provides an electromagnetic induction annular heating laser cladding nozzle device and a laser cladding device. The nozzle device comprises a connecting part, an induction coil fixing part, a ceramic inner ring, induction heating coils, an induction heating power supply, a thermocouple and a thermocouple power supply; the induction heating coils are arranged in the induction coil fixing part and is connected to the induction heating power supply; the ceramic inner ring is arranged in the induction coil fixing part, a powder flow channel is formed between the ceramic inner ring and the induction coil fixing part, a thermocouple mounting hole is formed in the ceramic inner ring, and a thermocouple is mounted in the thermocouple mounting hole and connected to the thermocouple power supply; and the connecting part is connected to the ceramic inner ring and the induction coil fixing part, a powder inlet channel communicated with the powder flow channel is formed in the connecting part, and a laser beam channel is formed in the center of the connecting part and the ceramic inner ring. According to the electromagnetic induction annular heating laser cladding nozzle device and the laser cladding device, laser cladding powder is preheated before the powder is converged into a laser beam focus area, and the laser cladding efficiency is improved.

Owner:SHAANXI TIANYUAN MATERIALS PROTECTION TECH

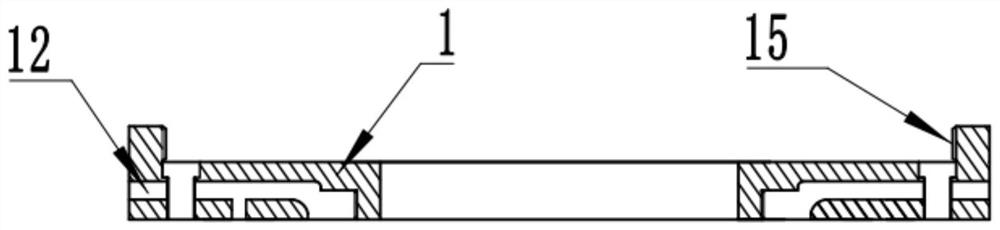

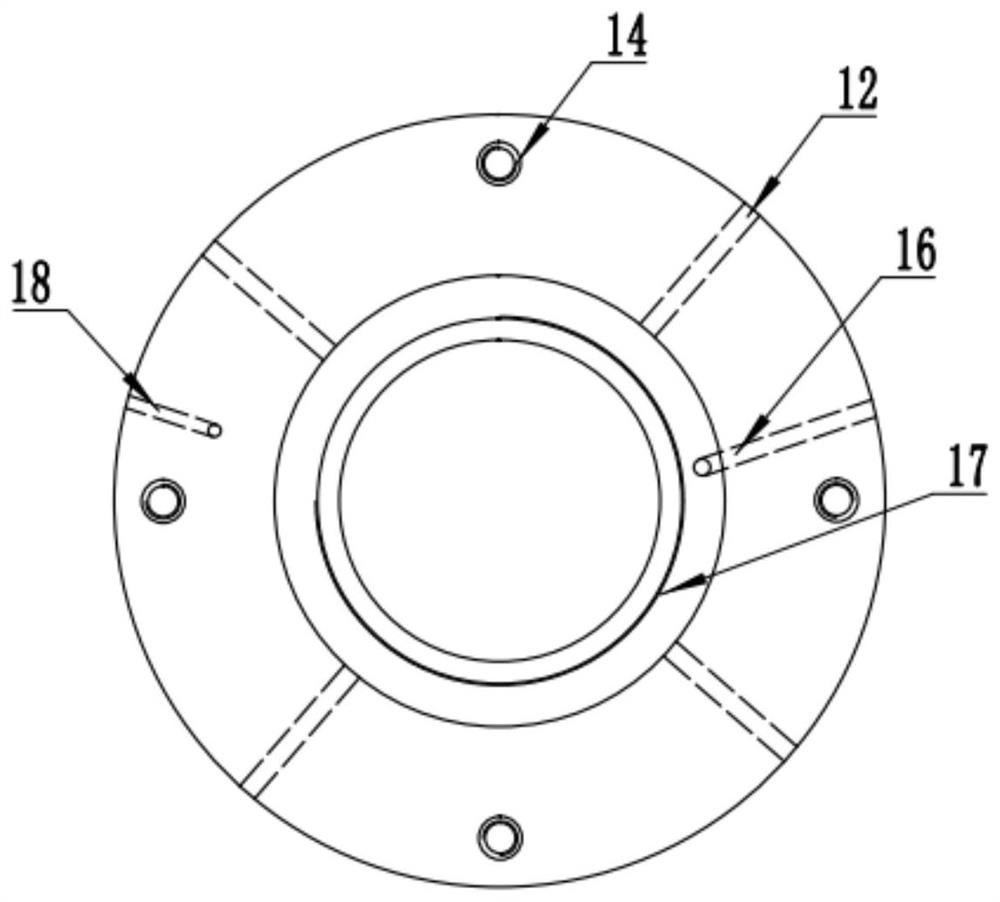

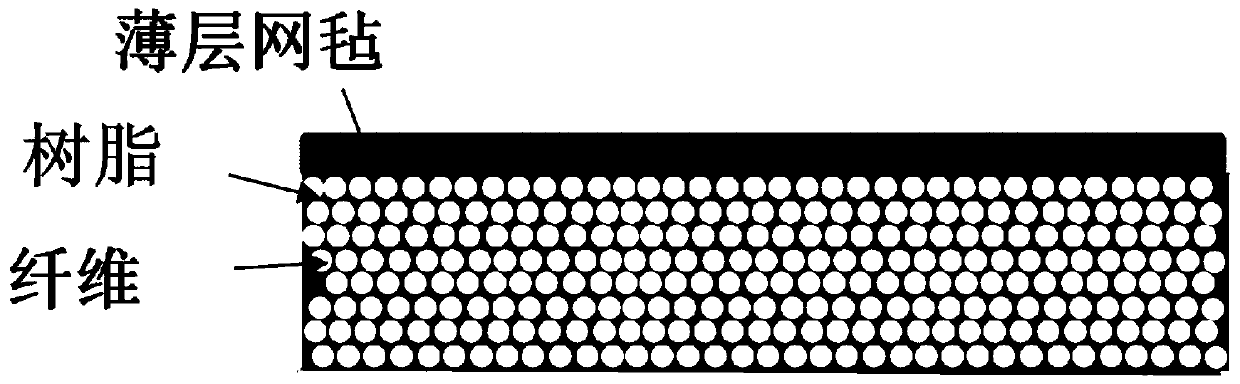

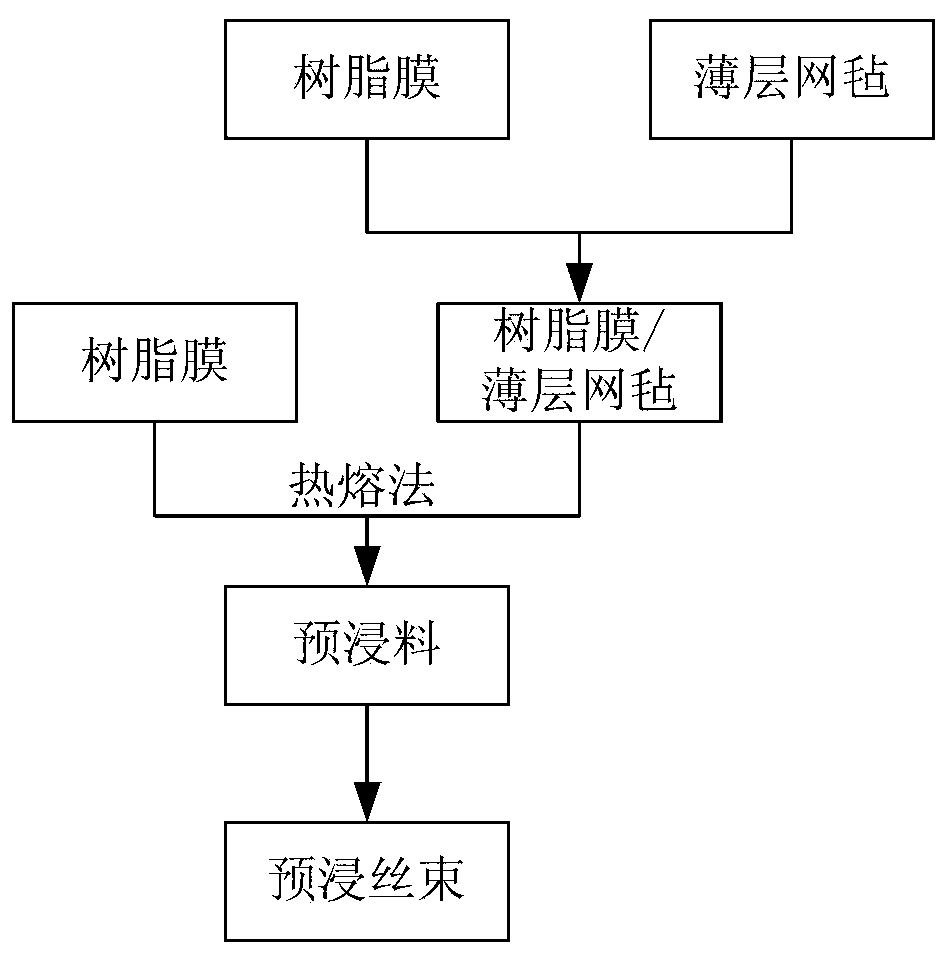

Prepreg and preparation method thereof

The invention provides a prepreg and a preparation method, the prepreg is composed of continuous reinforced fibers, a thin-layer mesh felt and resin, the prepreg is formed by compounding the continuous reinforced fibers and the thin-layer mesh felt by dipping in a double-sided resin film by a hot melting method, and the thin-layer mesh felt is located at one side of the continuous reinforced fibers, wherein the resin accounts for not more than 15% of the mass of the prepreg, the continuous reinforced fibers account for not less than 80% of the mass of the prepreg, and the balance is the thin-layer mesh felt. Through prepreg structure design and preparation process control, the prepreg meets the requirements of a subsequent slitting process and an RTM forming process, and is convenient to store and transport.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

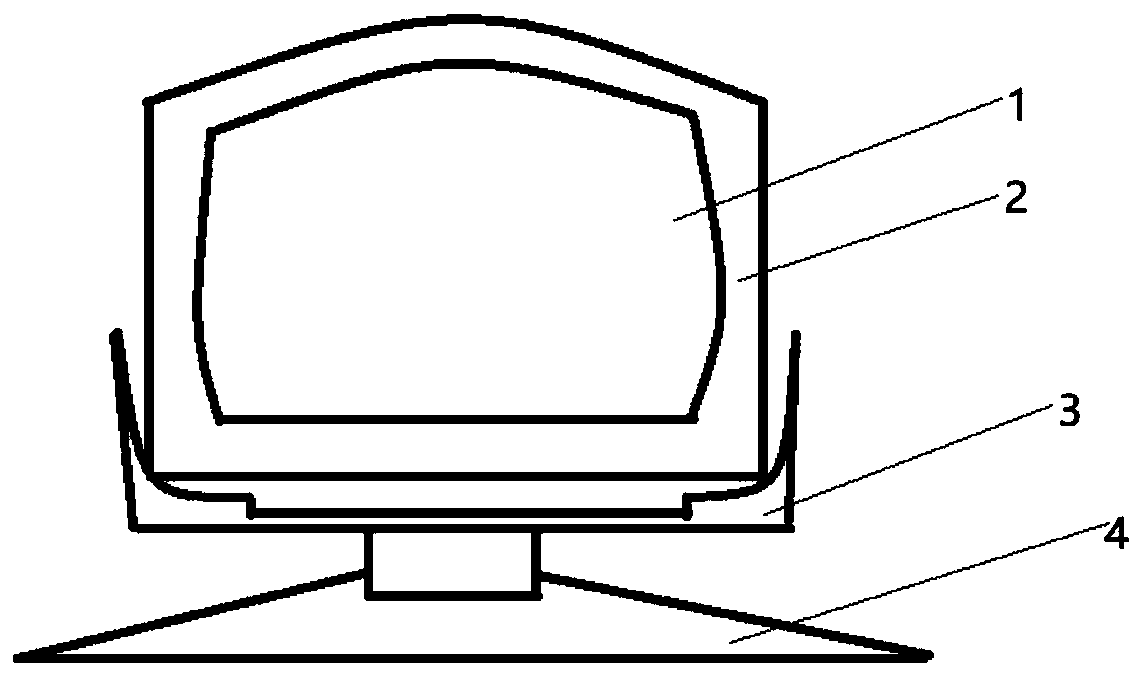

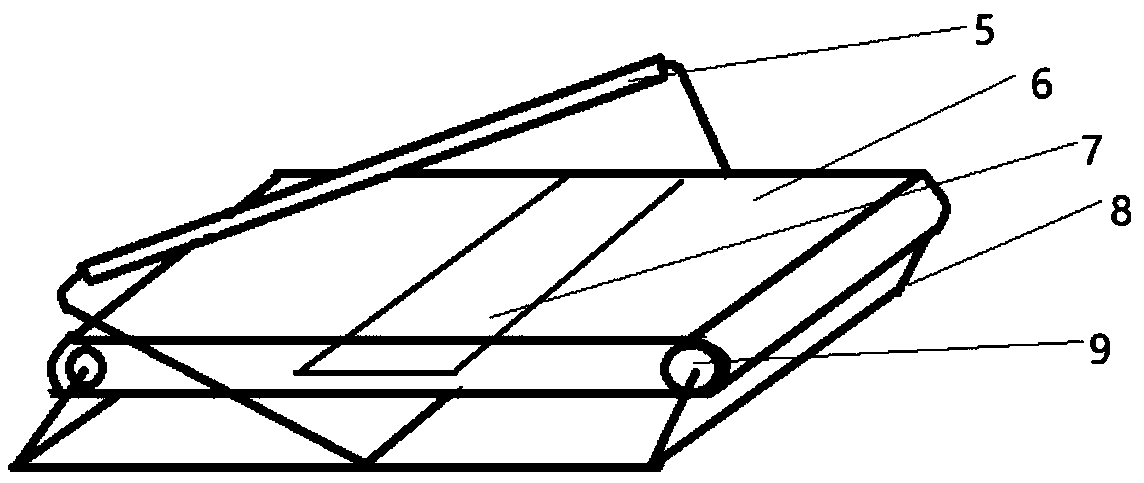

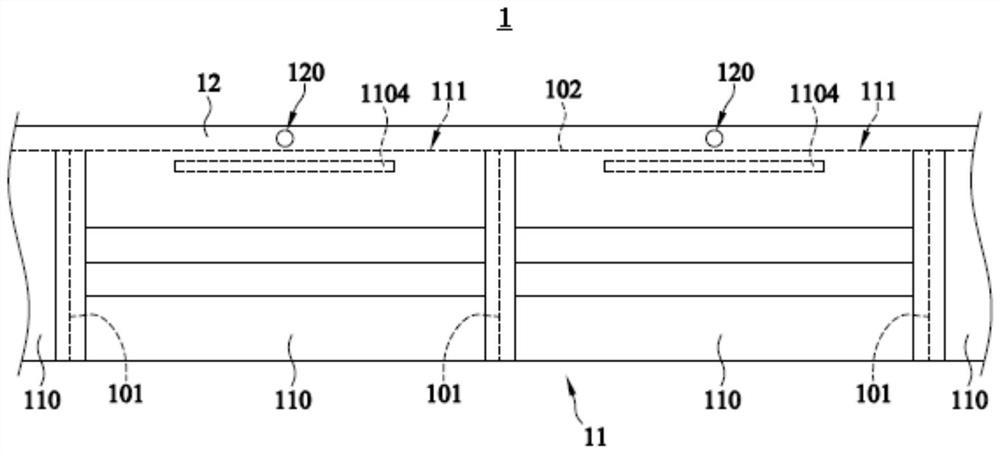

Intelligent custom furniture assembling component quality inspection system and method

ActiveCN109374042AReduce chance of defectsImprove the accuracy of quality inspectionMeasurement devicesInductorWorkload

The invention belongs to the custom furniture information production system technical field and discloses an intelligent custom furniture assembling component quality inspection system and method. A display screen, a shell, a tray, a pedestal, a gamma-ray lamp, a conveyor belt, an inductor, a support and a power shaft are arranged. The display screen is embedded in the shell. The shell is placed on the tray. The shell wraps the two ends of the tray. The tray is fixedly connected to the pedestal through a nut. The gamma-ray lamp is fixedly connected to the support through the nut. The conveyorbelt wraps the outer surface of a power output shaft. A sensor is placed at the middle portion of the power output shaft. The sensor is placed among the conveyor belt. The support is connected to thepower output shaft through the nut. The defect rate of custom furniture assembling components can be reduced, a condition that a custom furniture assembling component material, a processing technologyand a specification and dimension do not accord with a requirement and so on can be avoided, labor saving and time saving are achieved and the workload of people is mitigated.

Owner:ZHONGSHAN POLYTECHNIC

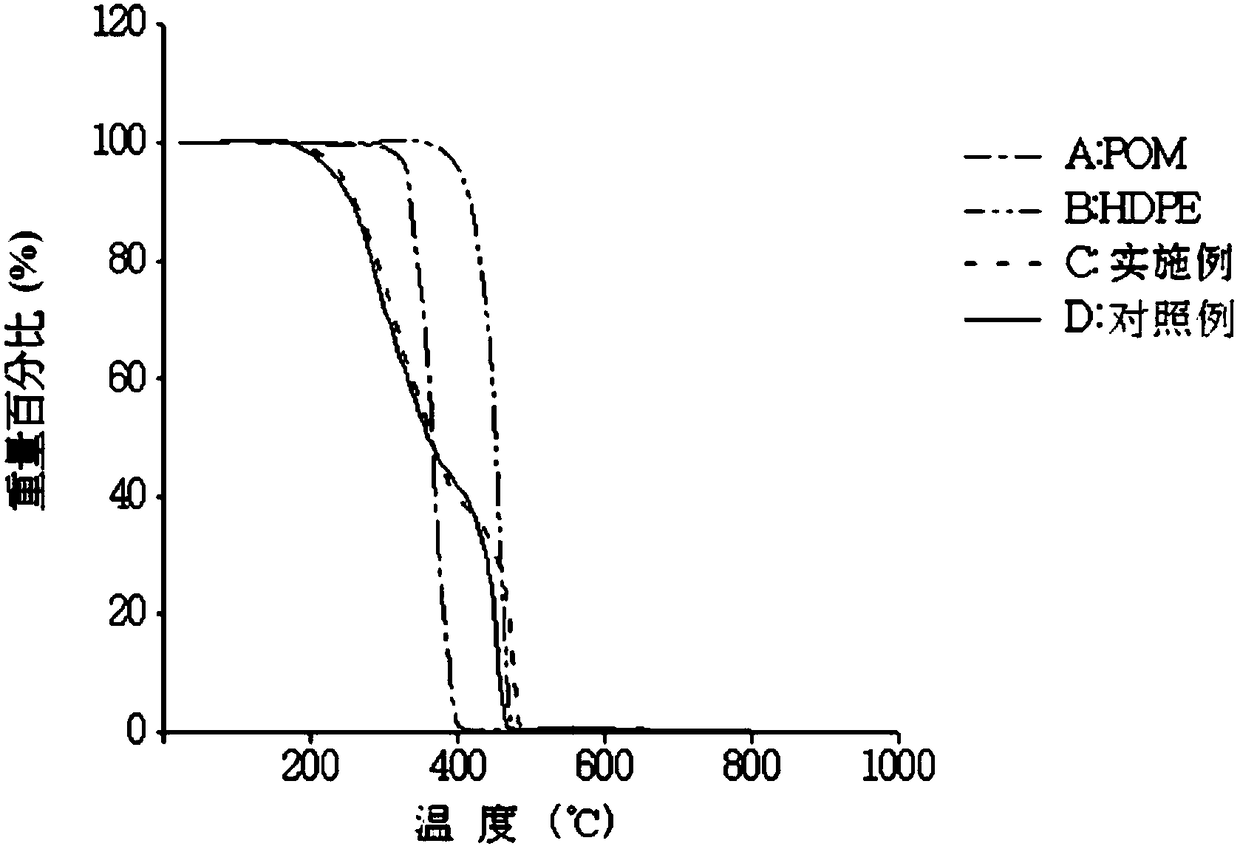

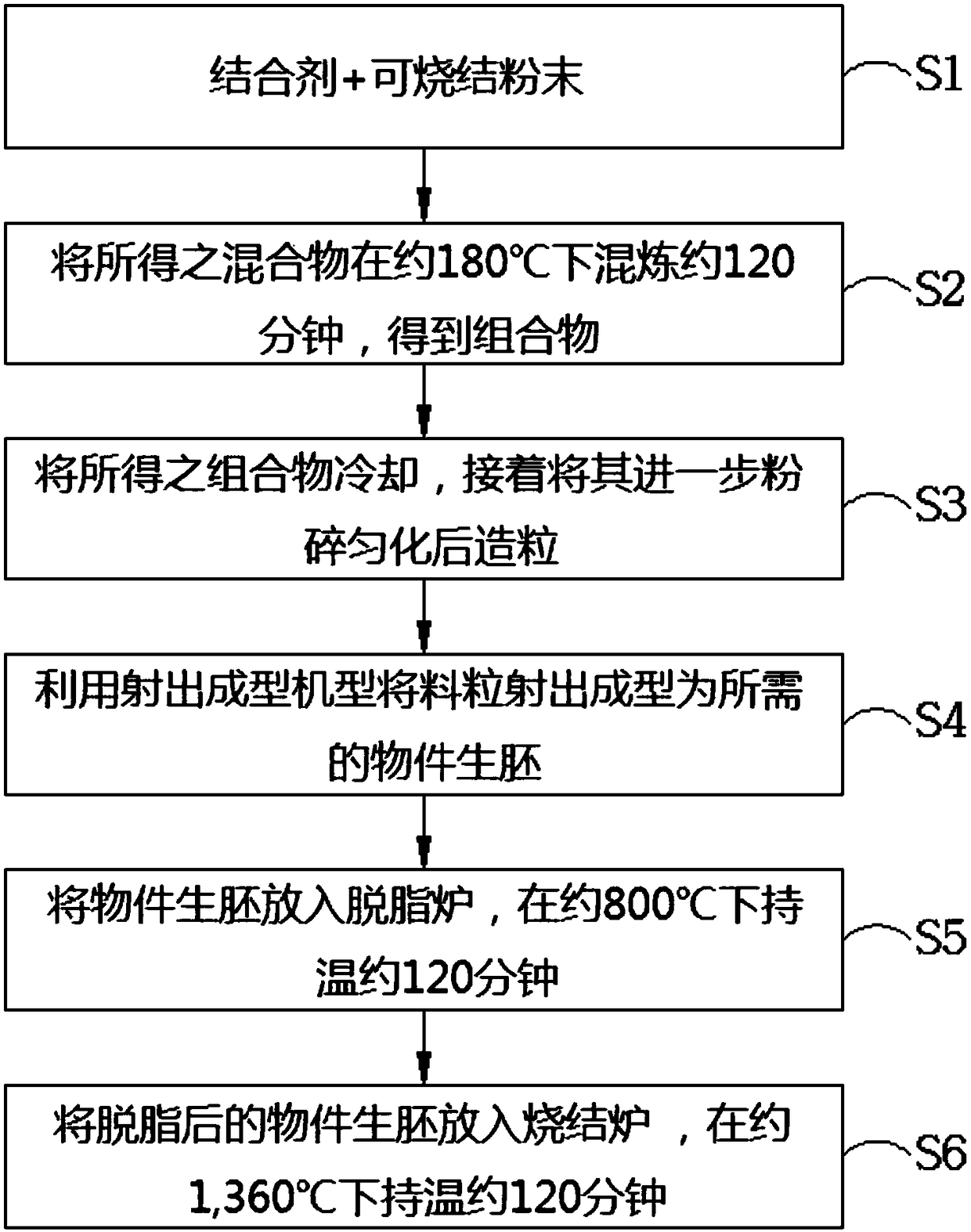

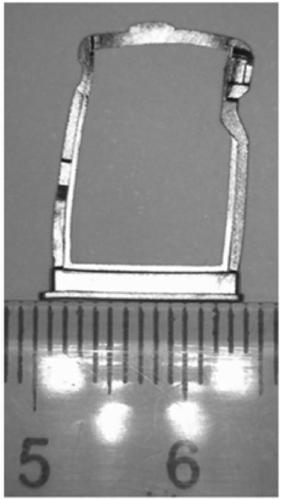

Binder for injection molding

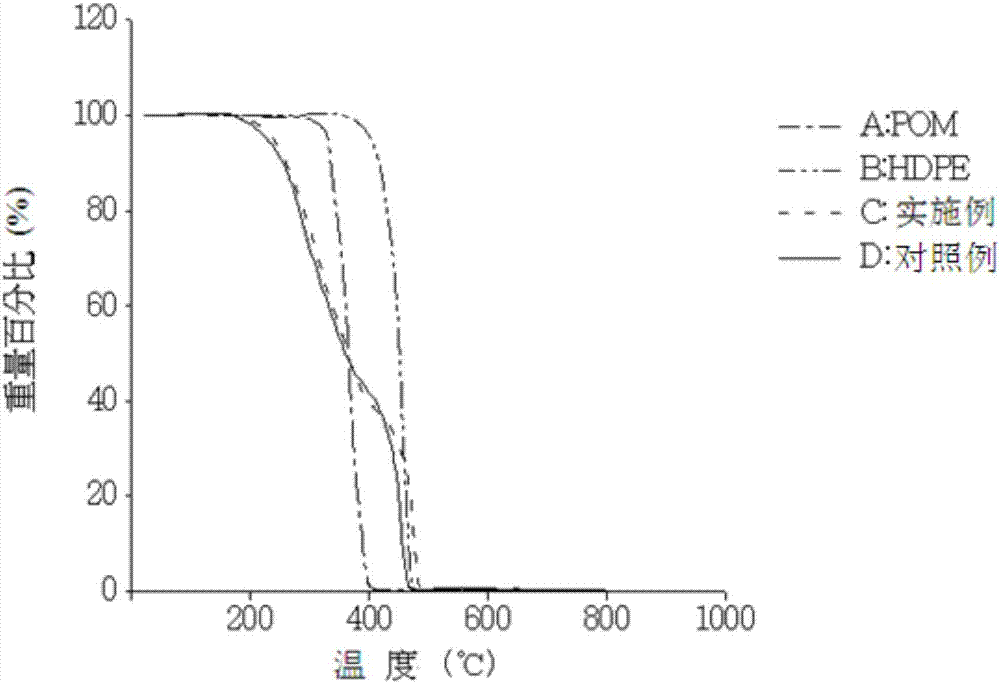

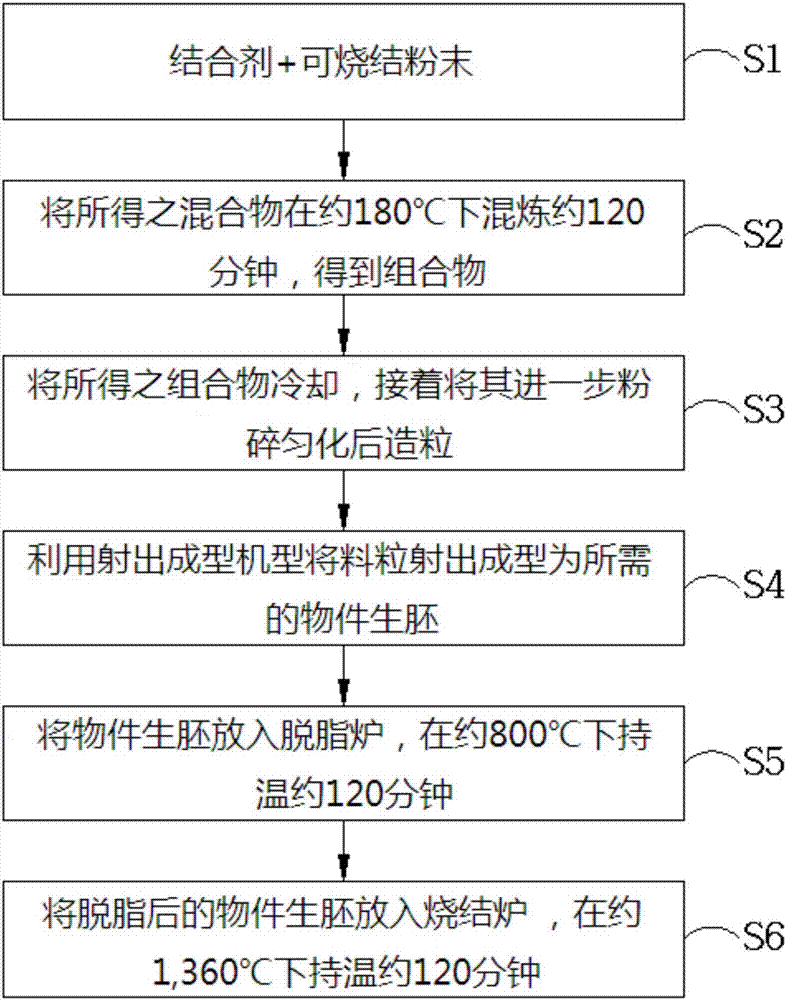

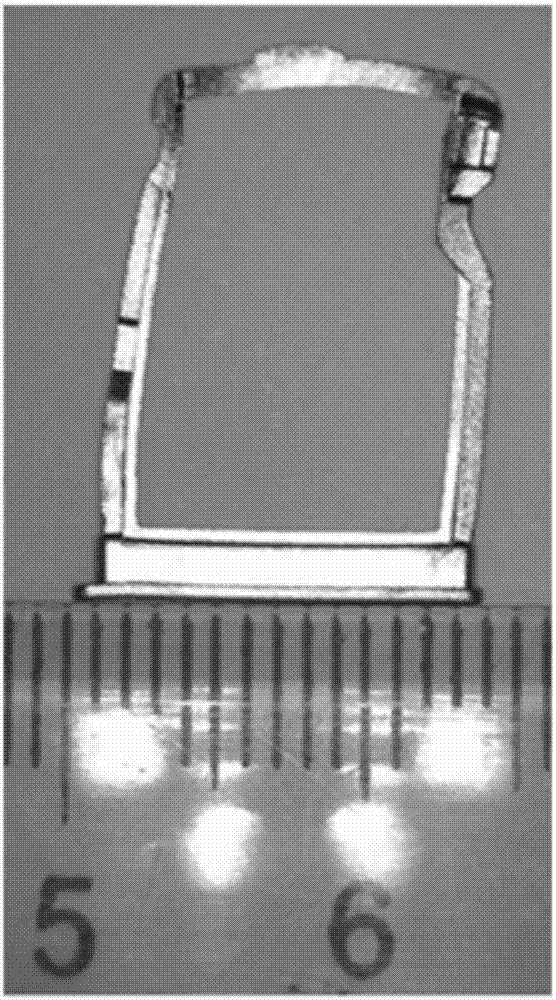

ActiveCN107309421AImprove compatibilityLarge temperature rangeTransportation and packagingMetal-working apparatusWaxPolyoxymethylene

The present invention provides a binder for injection molding which comprises from about 3 to about 20% by weight of a polyolefin with a maleic anhydride group, from about 30 to about 40% by weight of a polyolefin compound, from about 5 to about 20% by weight of polyoxymethylene, from about 1 to about 5% by weight of stearic acid and from about 35 to about 60% by weight of wax. The binder for injection molding of the present invention is characterized in that the polyolefin with the maleic anhydride group is bonded with the polyolefine compound and polyoxymethylene to improve the compatibility between the binder components and extend the thermal cracking time, to reduce the defects of the object to improve the accuracy of its size and consistency of the effect.

Owner:CHENMING MOLD IND CORP

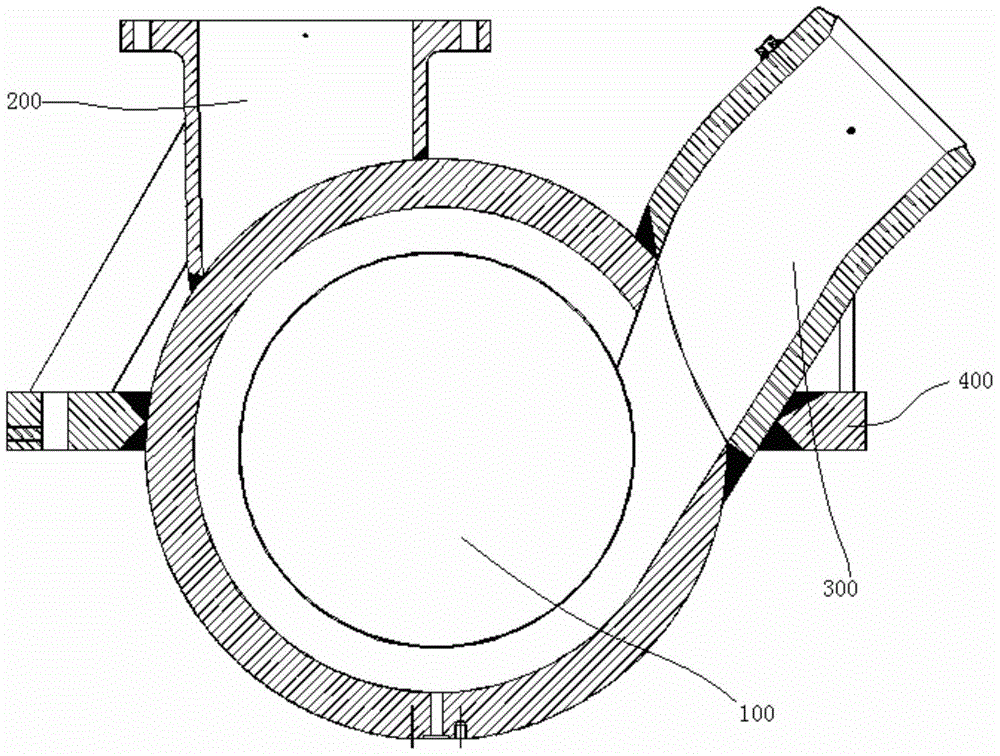

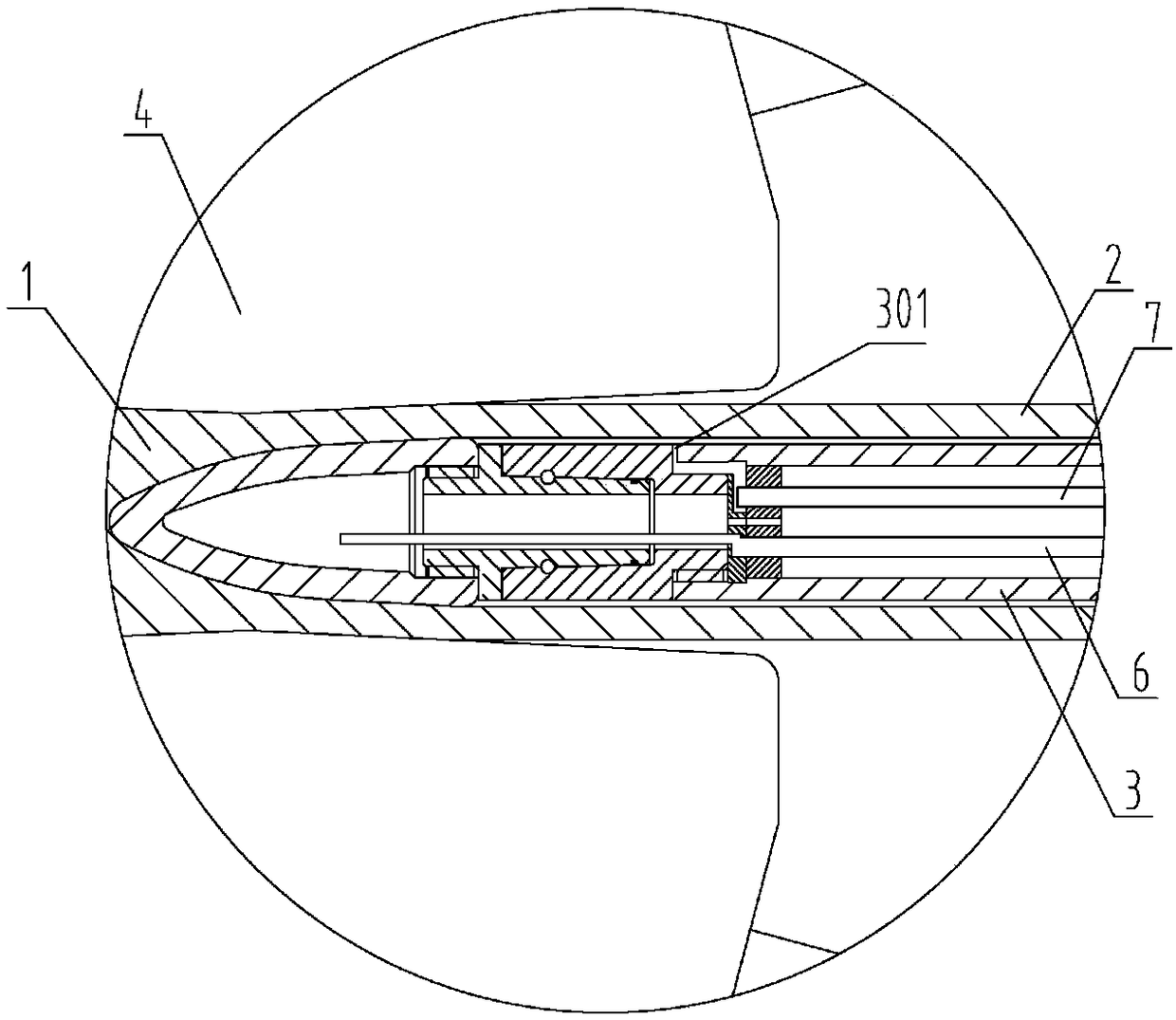

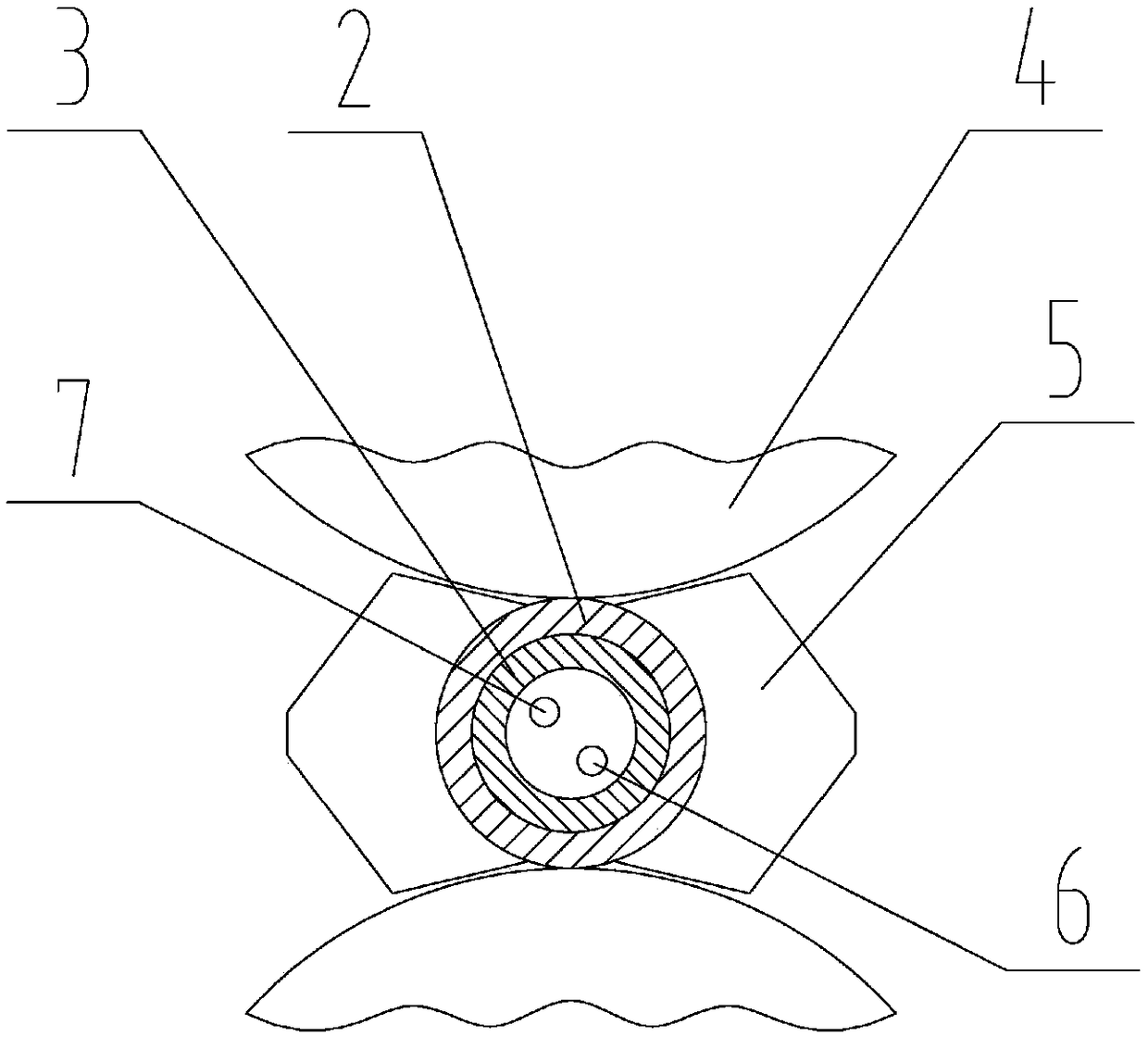

Antioxidant spraying device and process for seamless steel tube production

InactiveCN108080418AReduce chance of defectsReduce work stationsSpraying apparatusMandrelsPunchingAntioxidant

The invention discloses an antioxidant spraying device and an antioxidant spraying process for seamless steel tube production. The spraying device comprises an annular cavity punching machine, a firstpipeline and a second pipeline, wherein the annular cavity punching machine is formed by an ejection rod with an ejection head and a roller, the middle of the ejection rod is conducted, the first pipeline and the second pipeline are arranged in a through hole of the ejection rod, one of the first pipeline and the second pipeline is used as an antioxidant pipeline, the other pipeline is used as acooling water pipeline, an outlet of the antioxidant pipeline is opposite to the inner wall of a hollow capillary, and an outlet of the cooling water pipeline is opposite to the top end of the ejection rod. According to the antioxidant spraying device and the antioxidant spraying process for seamless steel tube production, the inner wall, on which an antioxidant is not sprayed, of the hollow capillary can be prevented from making contact with air, so that the probability of defects of the inner wall of the hollow capillary is reduced, the surface quality of the inner wall of a steel tube is increased, special stations for spraying the antioxidant are reduced, and the production rhythm is increased.

Owner:TAIYUAN HEAVY MACHINERY GRP ENG TECH R & D CO LTD

Electronic component pin regulating device

InactiveCN103140127AShorten the timeFast and correct alignmentElectrical componentsElectronic component

The invention discloses an electronic component pin regulating device. When the electronic component pin regulating device is used for assembling an electronic component onto a circuit board, connecting pins of the electronic component are regulated and fixed so as to be connected with multiple connecting points on the circuit board in para-position mode. The electronic component pin regulating device comprises an insulating body and multiple channels, wherein the channels penetrate through the insulating body, each channel is provided with an inlet end and an outlet end respectively, the inlet ends correspond to the positions of the connecting pins on the electronic component, the outlet end correspond to the positions of the connecting points, and the connecting pins are regulated and fixed through the channels. Therefore, the electronic component pin regulating device can enable the connecting pins to be quickly and rightly connected with the multiple connecting points in para-position mode, further can enable the time required by procedures for installing the electronic component on the circuit board to be remarkably decreased, and facilitates manual operation.

Owner:ASKEY TECH JIANGSU +1

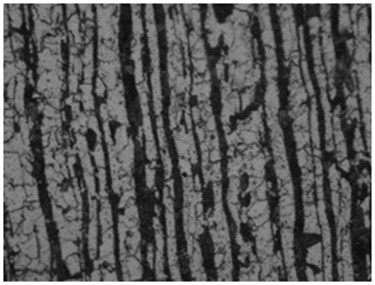

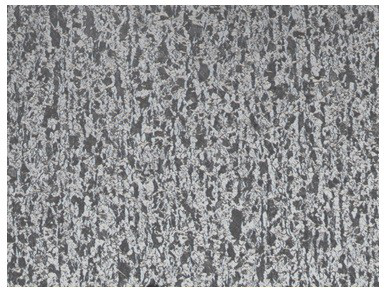

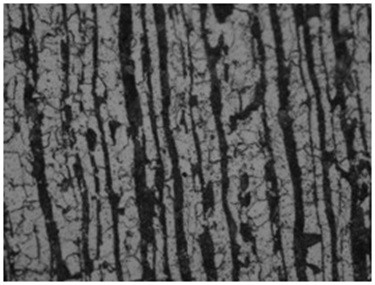

Method for improving banded structure of hot-formed steel plate

ActiveCN113755746AReduce the chance of banding defectsImprove band tissueProcess efficiency improvementSteel platesRare-earth element

The invention relates to a method for improving a banded structure of a hot-formed steel plate. The method comprises the steps of adjusting chemical components of the plate and optimizing the production process of the plate. The adjustment of the chemical components of the plate specifically comprises the step of adding a rare earth element RE into the plate. In addition, by controlling the content of harmful element components, the purity of molten steel, the controlled rolling and controlled cooling process, the cold rolling process and the annealing process, the generation probability of banded structure defects of the hot-formed steel product is further reduced. By adopting the technical scheme, the purity of molten steel can be improved, the structure of a steel plate can be refined, the generation of banded structure defects of a product can be reduced, and the requirements of high-quality steel types can be met without adding additional equipment and treatment means.

Owner:TANGSHAN IRON & STEEL GROUP +1

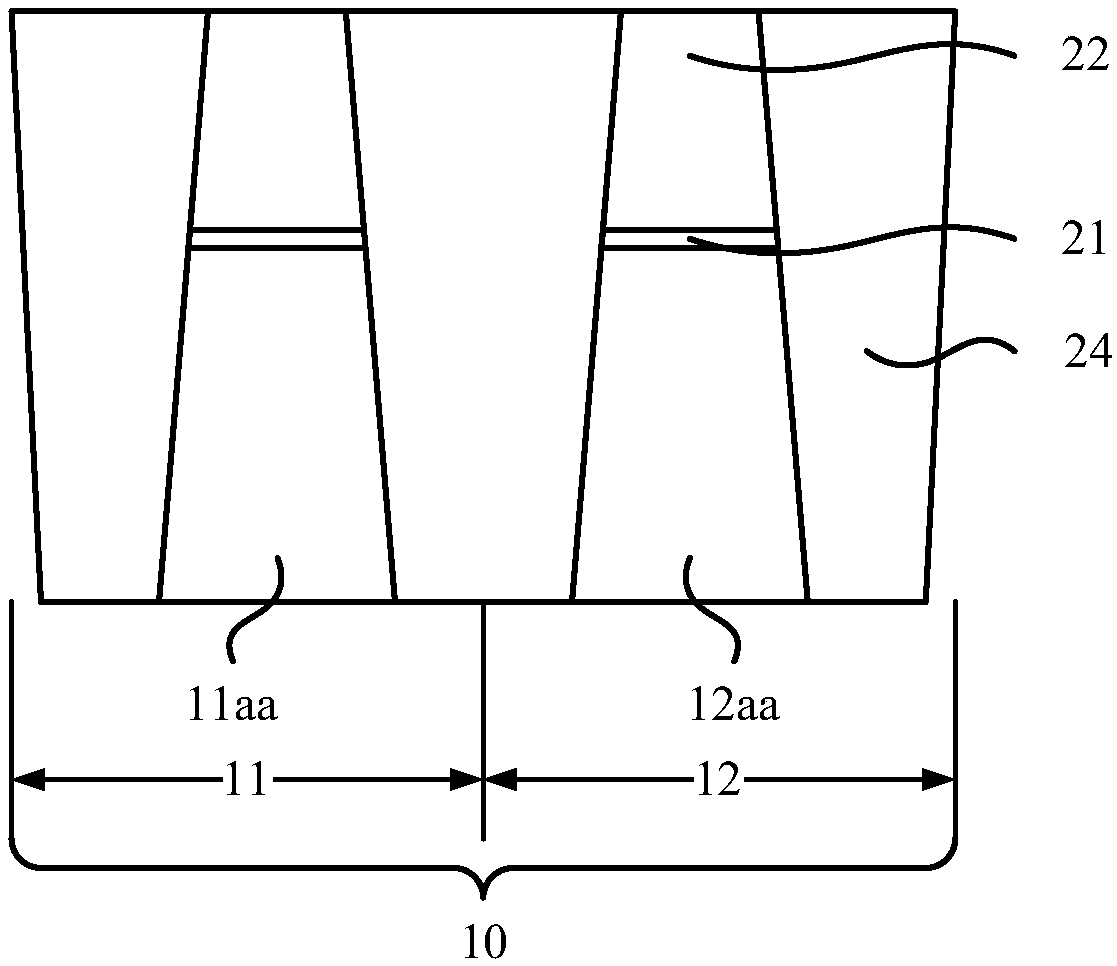

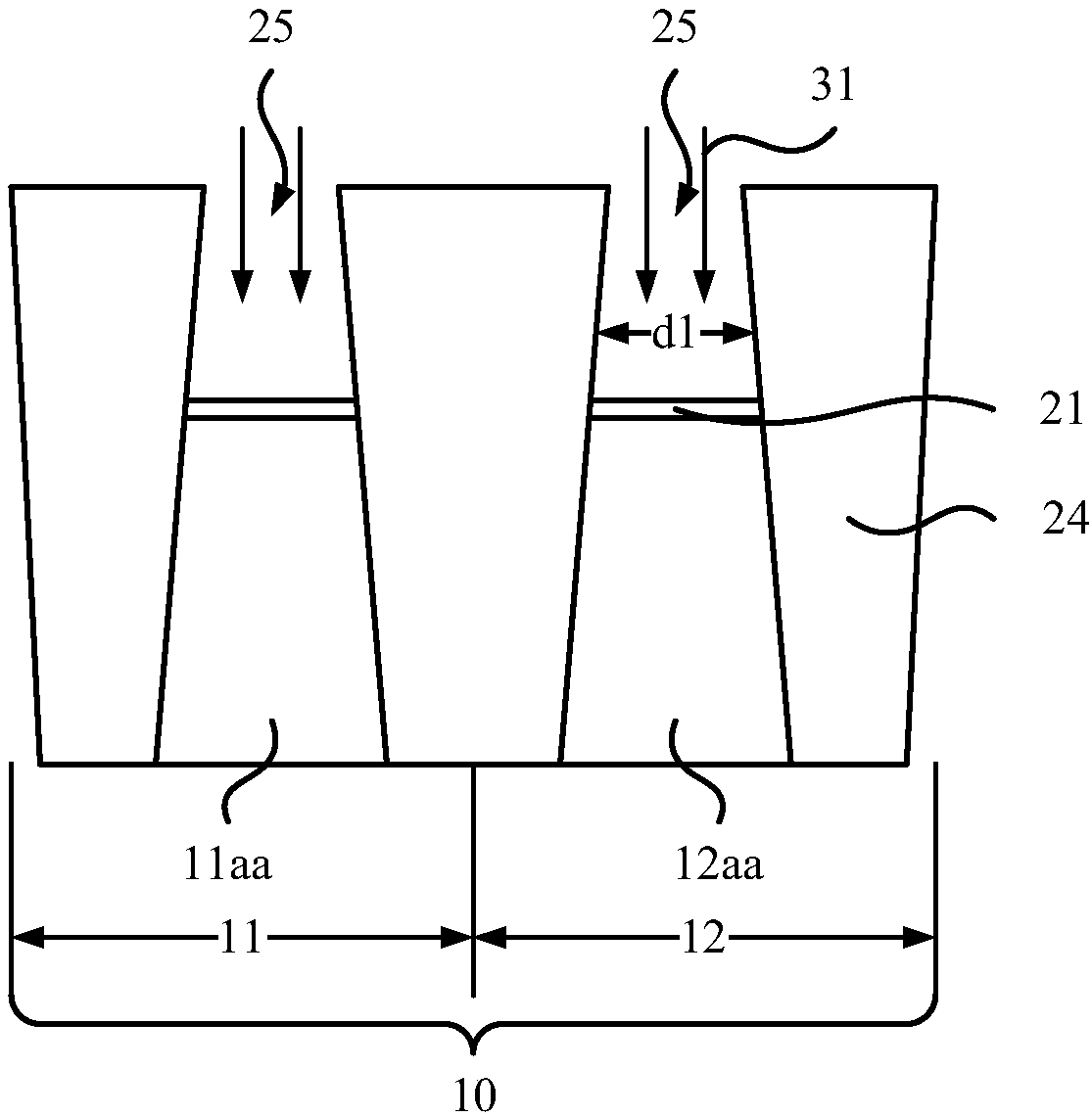

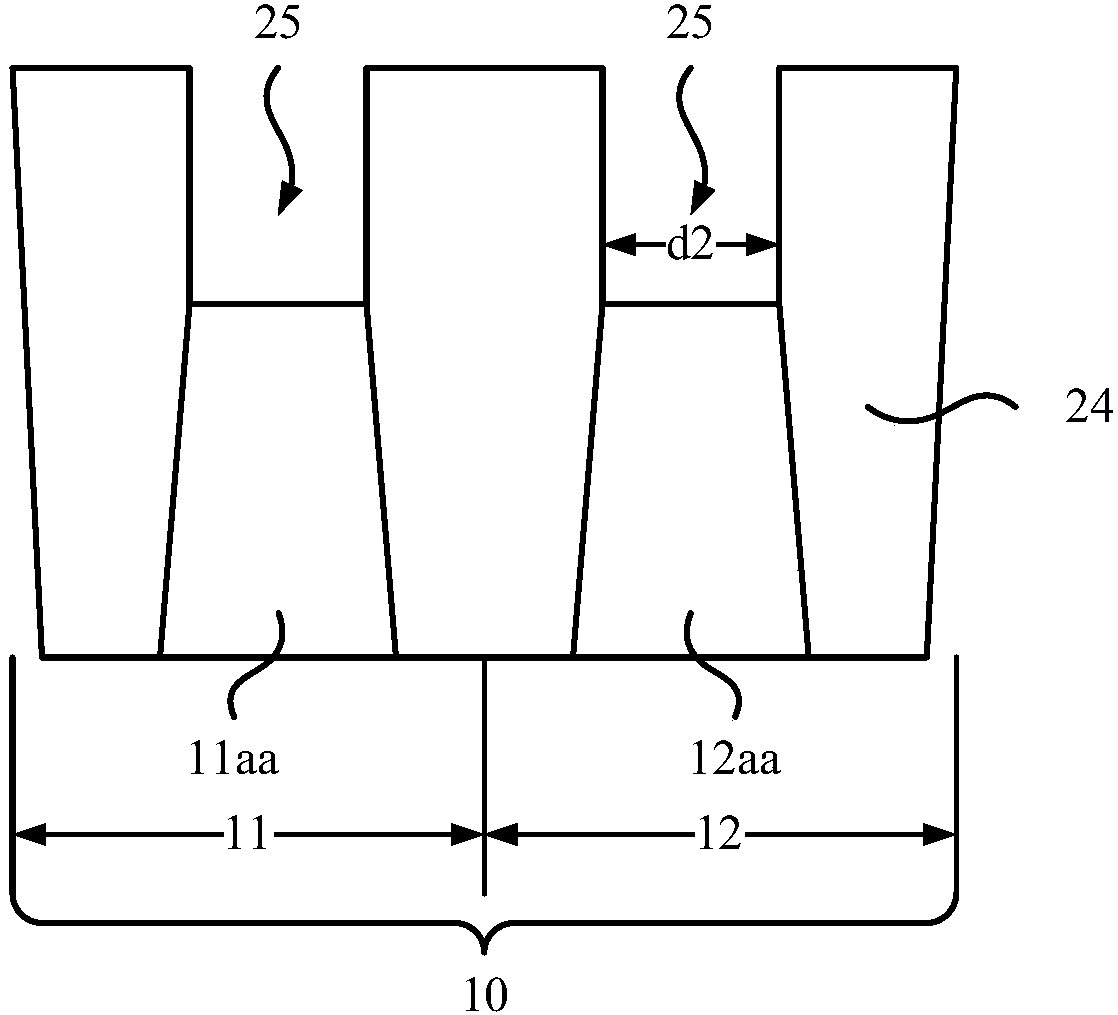

Semiconductor structure and method for forming semiconductor structure

ActiveCN109841626AReduce the impactImprove etch selectivitySolid-state devicesSemiconductor devicesEtchingSemiconductor structure

The invention provides a semiconductor structure and a method for forming the semiconductor structure. The method comprises a step of providing a substrate which comprises a core region and a high-voltage region, wherein a pad oxide layer is on the core region and the high-voltage region, a step of removing the pad oxide layer, a step of forming a first dielectric layer at least on the high-voltage region after removing the pad oxide layer, a step of forming a hard mask layer on the first dielectric layer, and a step of forming isolation structures in the core region and the high-voltage region with the hard mask layer as a mask. The pad oxide layer is removed before forming the isolation structures, the number of times of the wet etching process after the subsequent formation of the isolation structures can be effectively reduced, the reduction of the probability of the occurrence of bridging and short circuit problems is facilitated, the probability of defects in a subsequently formed gate structure is reduced, and the improvement of the performance of the formed semiconductor structure is facilitated.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

A method for improving strip structure of hot-formed steel sheet

ActiveCN113755746BReduce chance of defectsMeet the requirements of high-quality steel gradesProcess efficiency improvementRare-earth elementChemical composition

The invention relates to a method for improving the band-like structure of a hot-formed steel sheet, which includes adjusting the chemical composition of the sheet and optimizing the sheet production process; wherein, adjusting the chemical composition of the sheet is specifically adding rare earth element RE into the sheet. In addition, by controlling the content of harmful elements, the purity of molten steel, the controlled rolling and controlled cooling process, and the cold rolling and annealing processes, the probability of band-like structure defects in hot-formed steel products is further reduced. Using the technical solution provided by the present invention can not only improve the purity of molten steel, refine the structure of the steel plate, but also reduce the occurrence of product band-shaped structure defects, and can meet the requirements of high-quality steel grades without adding additional equipment and processing means. .

Owner:TANGSHAN IRON & STEEL GROUP +1

Photoresist processing system

ActiveCN110858542AReduce the chance of defectsEffective lift offSemiconductor/solid-state device manufacturingPhotoresistMaterials science

A photoresist processing system for processing a magnetic photoresist carried by a substrate, including a holding device and a magnetic device is disclosed. The holding device includes at least one combining section arranged to hold the substrate; the magnetic device is positioned on a specific position away from the combining section, wherein a magnetic field generated by the magnetic device hasa magnetic effect on the photoresist.

Owner:TAIZHOU GUANYU TECH CO LTD

Command scheduling method, apparatus, device and storage medium

ActiveCN112612596BReduce the numberSave resourcesProgram initiation/switchingMemory adressing/allocation/relocationEngineeringArbiter

The present application provides a command scheduling method, apparatus, device and storage medium, the method includes: acquiring the refresh count of a storage array; and generating a temperature state reading of the storage array when the refresh count reaches a first preset count request, and execute the temperature status reading request; obtain the current temperature status reading times of the storage array; determine whether the temperature status reading times reach a second preset number; if the temperature status reading times reach the For a second preset number of times, a drift compensation operation request of the data strobe signal of the storage array is generated; within the exclusive arbitration time interval, the temperature status read request is continuously executed for all the storage arrays, or the temperature status read request is executed. fetch request and the drift compensation operation request, and reset the temperature status read count. The present application reduces the number of bits of the counter, saves hardware resources, and reduces the complexity of the arbiter.

Owner:HYGON INFORMATION TECH CO LTD

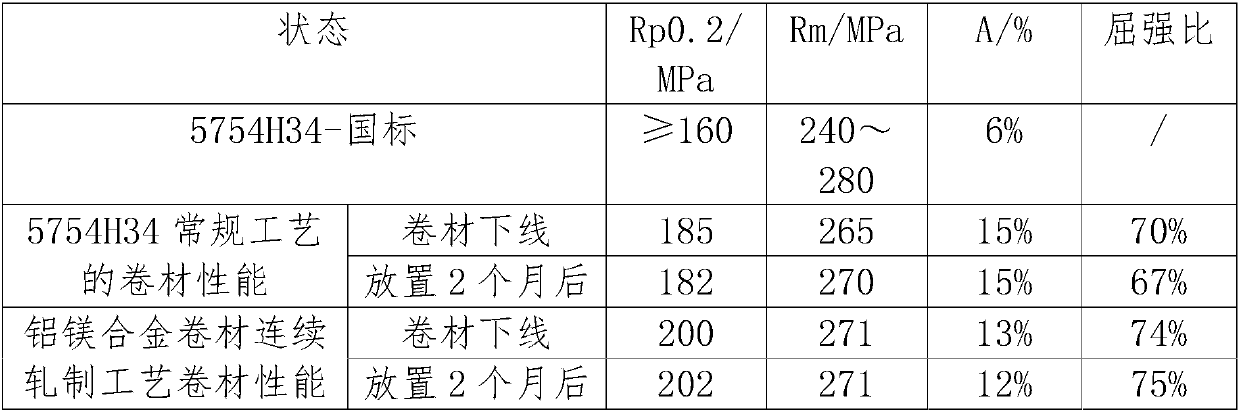

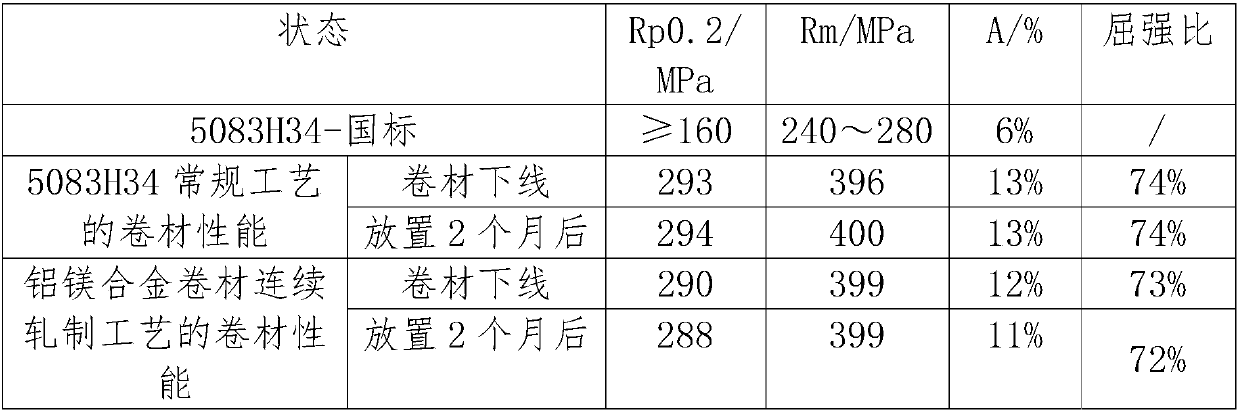

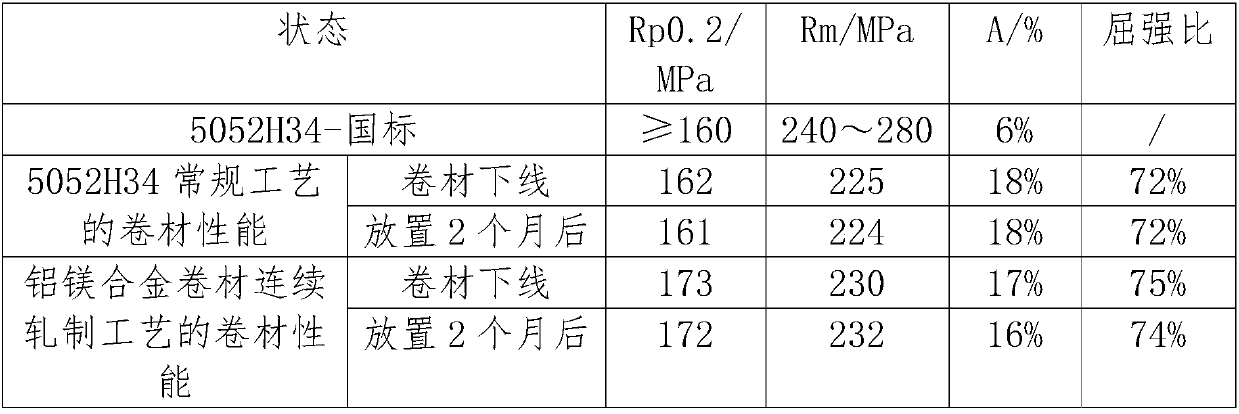

A kind of production method of aluminum-magnesium alloy coil

The invention discloses a production method of an aluminum-magnesium alloy coil. The weight percentage of the aluminum-magnesium alloy coil is Mg2.2-5.5%, Mn0.1-1.0%, Cr0.15-0.35%, Fe<0.4%, Si<0.4%, Ti<0.25%, Cu<0.1%, Zn<0.1%, the content of other individual elements is ≤0.05%, and the balance is Al. The method includes smelting, ingot casting, hot rolling, cold rolling, cleaning, intermediate annealing, high-speed two-pass continuous cold rolling, finishing and packaging. The method simplifies the production process, shortens the production cycle, reduces the production cost and the probability of defects in the aluminum-magnesium alloy coil.

Owner:广西南南铝加工有限公司

Binder for injection molding and composition containing same for manufacturing molding objects

ActiveCN107309421BImprove compatibilityLarge temperature rangeTransportation and packagingMetal-working apparatusWaxPolymer science

The present invention proposes a binder for injection molding, which comprises a polyolefin with maleic anhydride groups accounting for about 3 to about 20% by weight, a polyolefin compound accounting for about 30 to about 40% by weight, The polyoxymethylene accounts for about 5 to about 20% by weight, the stearic acid accounts for about 1 to about 5% by weight, and the wax accounts for about 35 to about 60% by weight. The bonding agent for injection molding of the present invention is characterized in that polyolefins with maleic anhydride groups are bonded with polyolefin compounds and polyoxymethylene to improve the compatibility between the components of the bonding agent and prolong its thermal cracking time. Achieve the effect of reducing the defect of the object and improving the accuracy and consistency of its size.

Owner:CHENMING MOLD IND CORP

A quality inspection system and method for intelligent customized furniture assembly parts

ActiveCN109374042BReduce chance of defectsReduce workloadMeasurement devicesMaterials processingConveyor belt

The invention belongs to the technical field of customized furniture information production systems, and discloses a quality inspection system and method for intelligent customized furniture assembly parts, which are equipped with a display screen, a shell, a tray, a base, a gamma ray lamp, a conveyor belt, an inductor, a bracket, a power axis. The display screen is embedded in the casing, the casing is placed on a tray, the two ends of the tray are wrapped with the casing, the tray is fixedly connected to the base through nuts, the gamma ray lamp is fixedly connected to the bracket through nuts, and the conveyor belt is wrapped around the power output shaft. Outside, a sensor is placed in the middle of the power take-off shaft, the sensor is placed between the conveyor belts, and the bracket is connected to the power take-off shaft through a nut. The invention can reduce the defect probability of customized furniture assembly parts, avoid the occurrence of materials, processing technology and specifications and sizes of customized furniture assembly parts that do not meet the requirements, save time and labor, and reduce people's workload.

Owner:ZHONGSHAN POLYTECHNIC

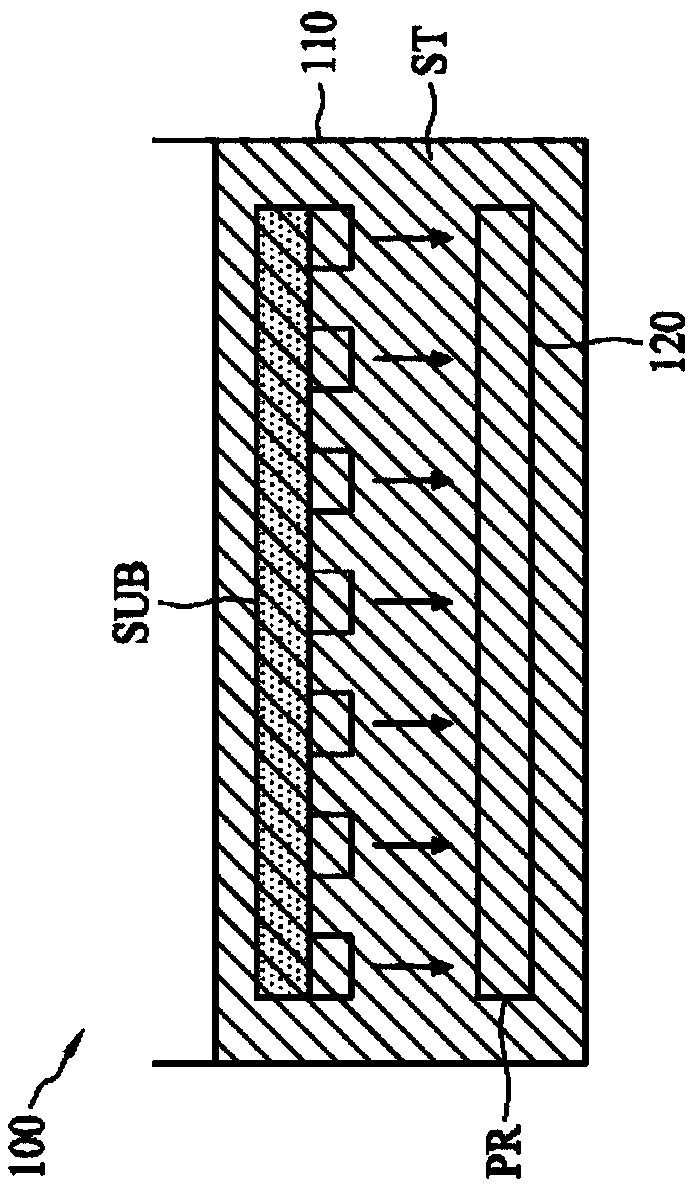

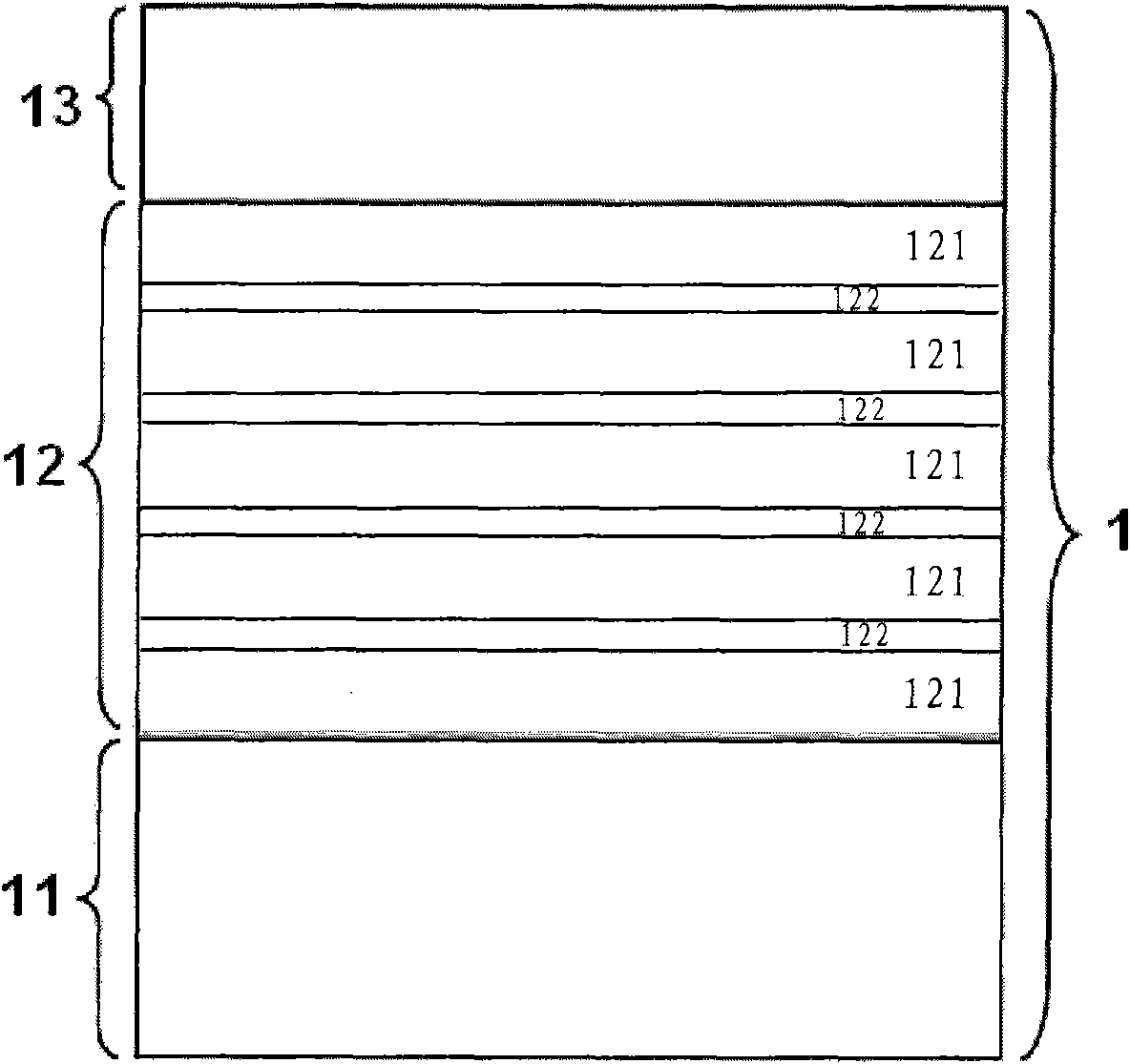

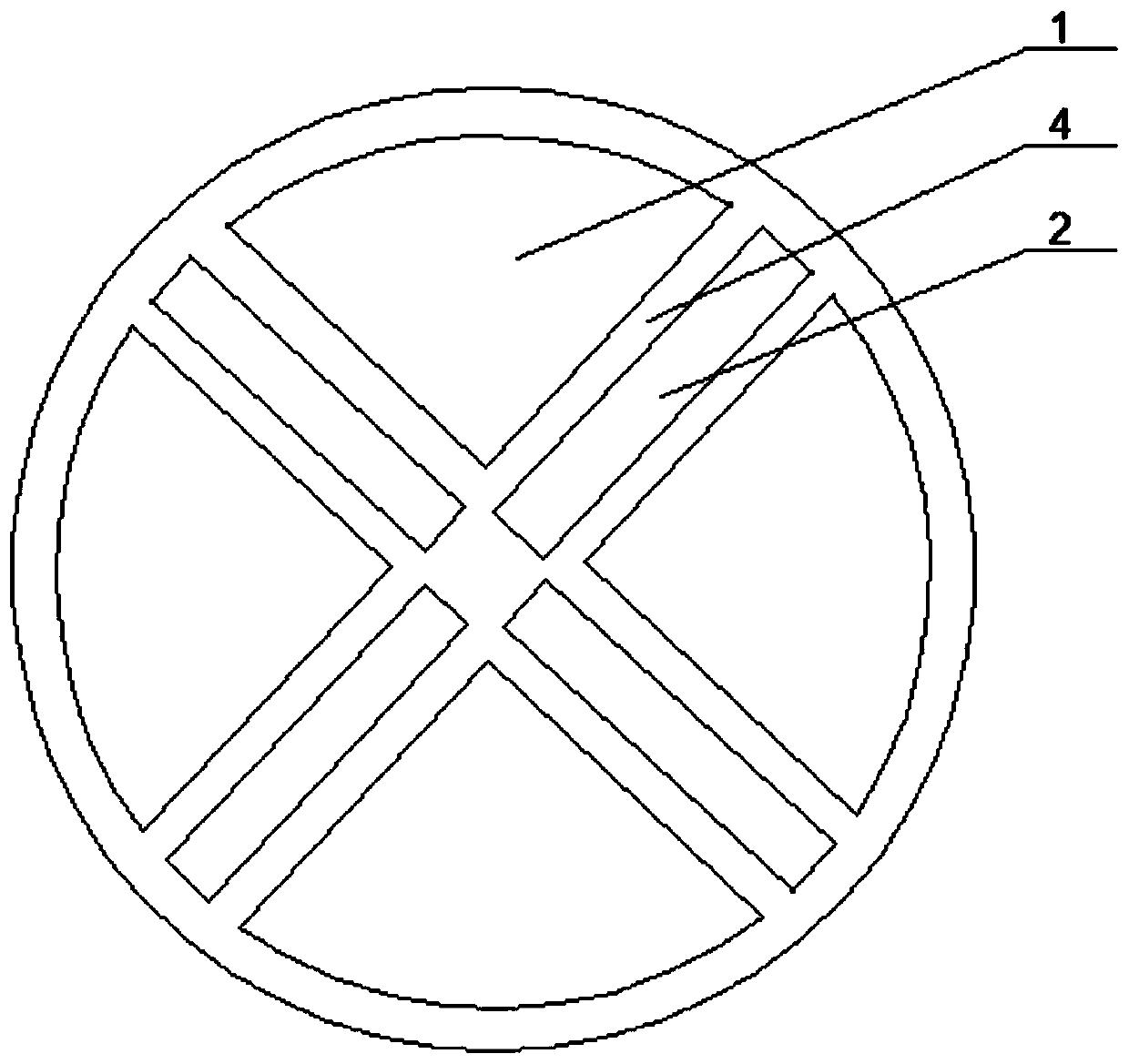

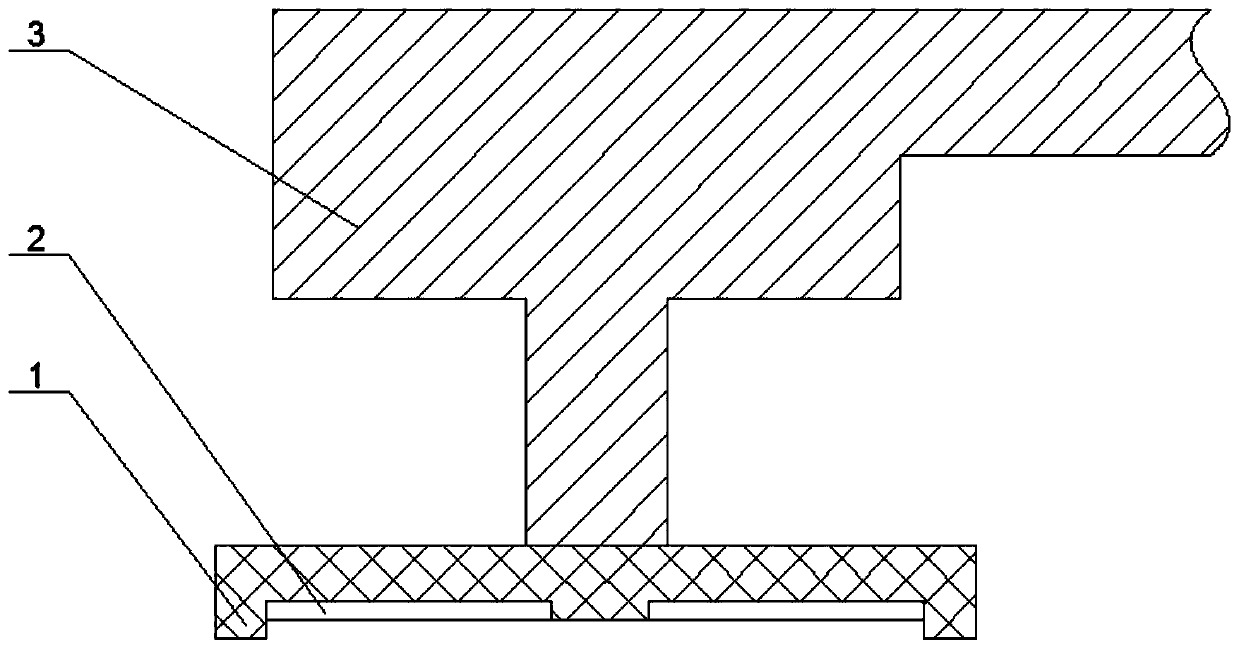

Silicon-base compound substrate and manufacturing method thereof

InactiveCN102208337BReduce chance of defectsPrevent threading dislocations from proliferating upwardSemiconductor/solid-state device manufacturingSemiconductor devicesTitanium nitrideEpitaxial material

The invention provides a silicon-base compound substrate for preparing a nitride semiconductor epitaxial material, and a manufacturing method of the silicon-base compound substrate. The silicon-base compound substrate comprises a silicon monocrystal substrate, a compound stress covariant layer which is formed on the silicon monocrystal substrate and formed by frequently stacking aluminum nitride and a titanium nitride monocrystal thin film material, and a gallium nitride template layer which is formed on the compound stress covariant layer and consists of a gallium nitride monocrystal thin film material. By the silicon-base compound substrate, the crystal lattice and big heat mismatch problems of the silicon-base gallium nitride material are solved; therefore, the preparation cost of a gallium nitride light emitting diode (LED) epitaxial sheet can be reduced greatly; and the silicon-base compound substrate is suitable for application and market popularization.

Owner:杭州海鲸光电科技有限公司

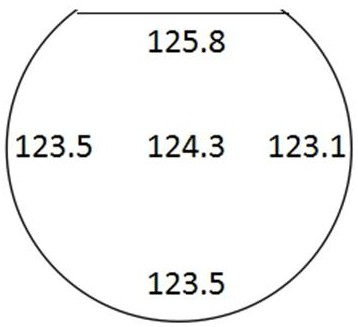

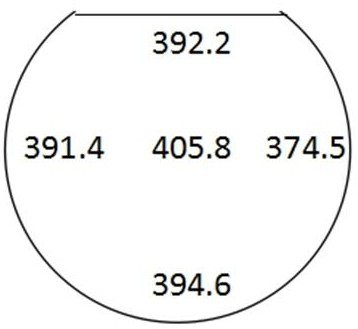

A method for preparing silicon epitaxial wafers for high-voltage power devices

ActiveCN110379704BImprove crystal qualityReduce high temperature heating timeSemiconductor/solid-state device manufacturingChemical vapor deposition coatingStacking faultPhysical chemistry

The invention discloses a method for preparing a silicon epitaxial wafer for a high-voltage power device. This method purifies the reaction chamber of the epitaxial equipment by long-time purging of large flow of hydrogen before epitaxial growth, and reduces the content of impurities accumulated inside the chamber; the non-linear gradient heating is adopted to release the stress accumulated in the heating stage in time, reducing the The probability of defect generation; by shortening the distance between the quartz bell jar and the pedestal of the reaction chamber of the epitaxial equipment, and adopting a large-flow ratio of trichlorosilane and hydrogen, the reaction rate is significantly improved, and the crystallization quality of the silicon epitaxial wafer is guaranteed. Realize high-speed epitaxial growth under the premise; by adopting the method of segmented growth of silicon epitaxial layer, the comprehensive control problems of thickness, resistivity and crystal quality in the existing preparation process are overcome; the surface of the silicon epitaxial wafer produced is bright and free of dislocations , stacking fault, slip line and fog defects, realize the controllability of material indicators such as thickness, resistivity and defects, and meet the use requirements of high-voltage power devices.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

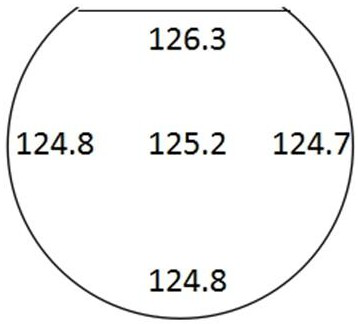

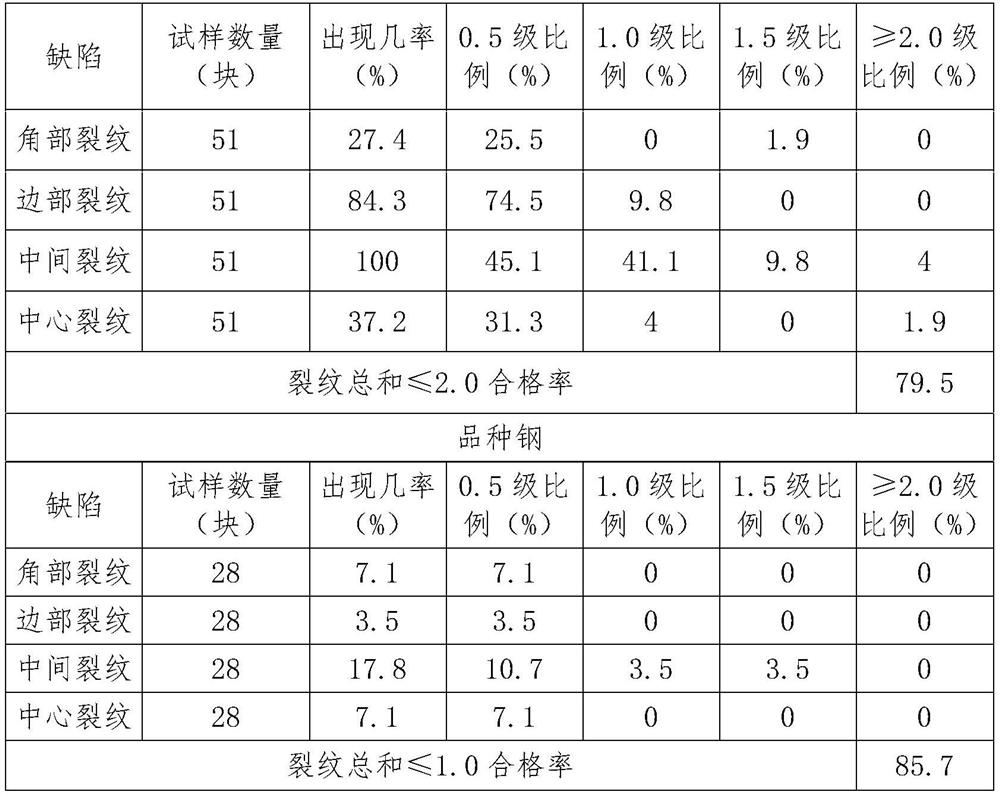

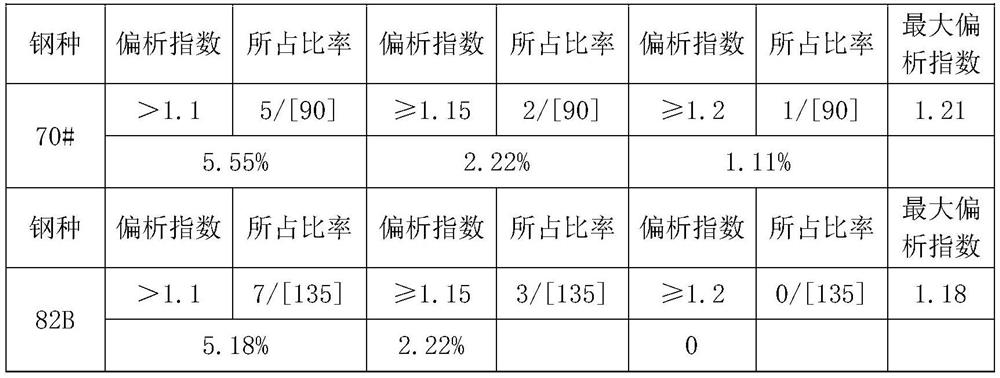

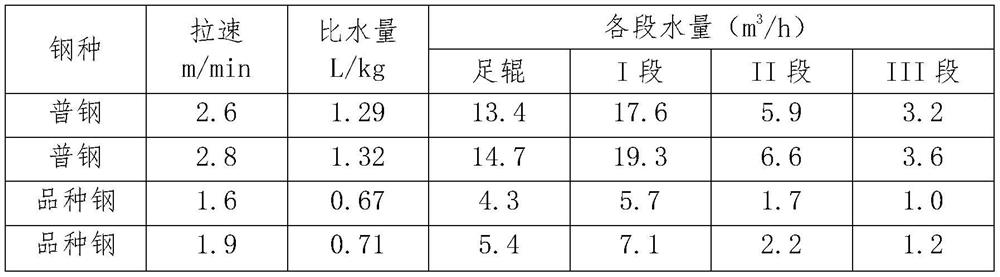

Method for improving quality of casting blank

The invention discloses a method for improving the quality of a casting blank. The method comprises the following steps that the cooling water flow of a crystallizer is adjusted to 130 m<3> / h-140 m<3> / h; (2), according to the atomization effect, the nozzle model of each section is selected, wherein the nozzle model of a foot roller section is 3 / 8PZ10067QZ5, the nozzle model of a section I of a spraying section is 3 / 8PZ4565QZ2, the nozzle model of a section II of the spraying section is HPZ2.5-65QZ2, and the nozzle section of a section III of the spraying section is HPZ2.5-65QZ2; (3), the casting speed of 70# and 82B high-carbon steel is set to be 1.75+ / -0.02 m / min; (4), electromagnetic stirring parameters of the crystallizer of the 70# and 82B high-carbon steel are set as follows that the current is 320 A, the frequency is 3.5 Hz, and the specific water flow is 0.78 L / kg; and (5), secondary cooling water distribution is conducted, specifically, section III water supply is closed, section II water is reduced to 5 m<3> / h-6 m<3> / h, and section I water is reduced to 10 m<3> / h-11 m<3> / h. According to the method, after processes such as casting machine secondary cooling nozzles, electric stirring parameters and water distribution are optimized, internal cracks and center segregation defects are effectively controlled, and the internal quality of the casting blank is further improved.

Owner:SHOUGANG SHUICHENG IRON & STEEL GRP

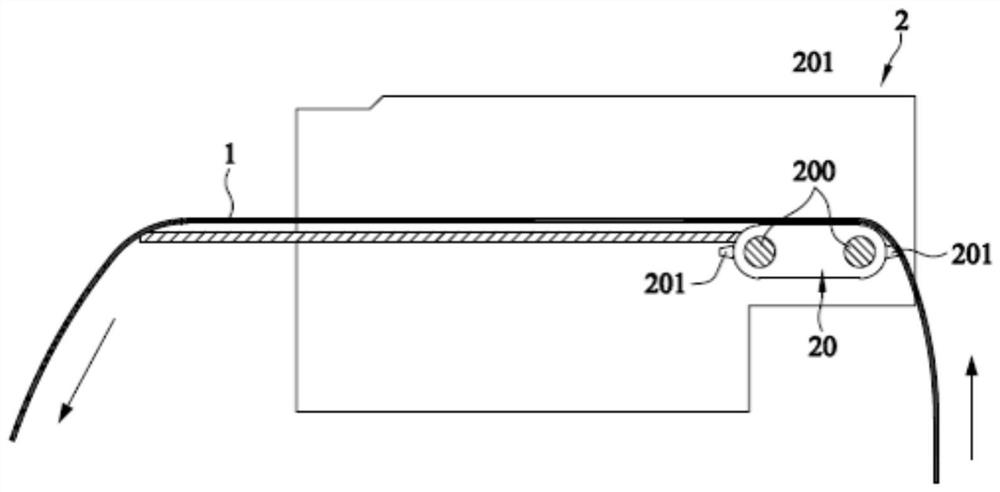

Mask group structure

PendingCN112890331AEasy to carryNot easy to slip and misalignProtective garmentClothes making applicancesEngineeringStructural engineering

The embodiment of the invention provides a mask group structure. The mask group structure comprises a mask group body and a first positioning part, the mask set body comprises a plurality of mask bodies which are connected with one another, and a first easy-to-tear line is arranged between every two adjacent mask bodies in the mask bodies. The first positioning part is connected to the first side edge of the mask set body, a second easy-to-tear line is arranged between the first positioning part and the first side edge, the first positioning part comprises at least two holes, and the second easy-to-tear line and the first easy-to-tear line are not parallel to each other. The mask group structure is arranged on a traction device of a mask manufacturing machine table in a penetrating mode through the at least two holes of the first positioning part. The first positioning part is guided by the traction device, and then the mask set body is driven to be guided out of the mask manufacturing machine table.

Owner:HOKI INVESTMENT INC

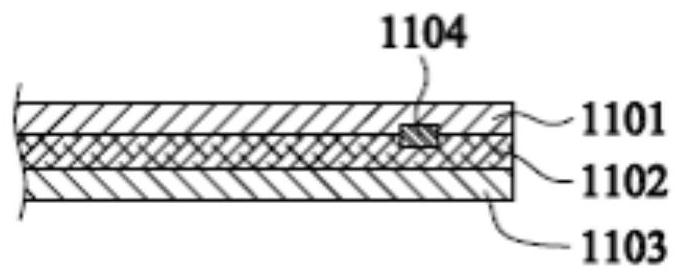

Grinding pad finishing unit and device

InactiveCN111571443AReduce scratchesReduce chance of defectsAbrasive surface conditioning devicesCleaning using liquidsSlagSilicon chip

The invention provides a grinding pad finishing unit. The unit comprises a finishing disc used for carrying out finishing on the surface property of a grinding pad, and at least one nozzle mounted onthe finishing disc and used for spraying cleaning media. According to the grinding pad finishing unit, the finishing disc is used for grinding grinding slag stacked on the surface of the grinding pad,meanwhile, the nozzle sprays the cleaning media, when the grinding slag is ground down, the grinding slag is immediately cleaned by the cleaning media sprayed by the nozzle, the good cleaning effectcan be provided, and the probability of scratch and defect appearing in a ground silicone wafer can be greatly reduced.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com