Silicon-base compound substrate and manufacturing method thereof

A composite substrate, silicon-based technology, applied in the manufacture of semiconductor/solid-state devices, electrical components, circuits, etc., can solve the problems of complex process, difficult to obtain no cracks and bends, interface chemistry problems, etc., and achieve a simple and good preparation process. Lattice mismatch stress and thermal stress transfer coordination and the effect of reducing fabrication cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

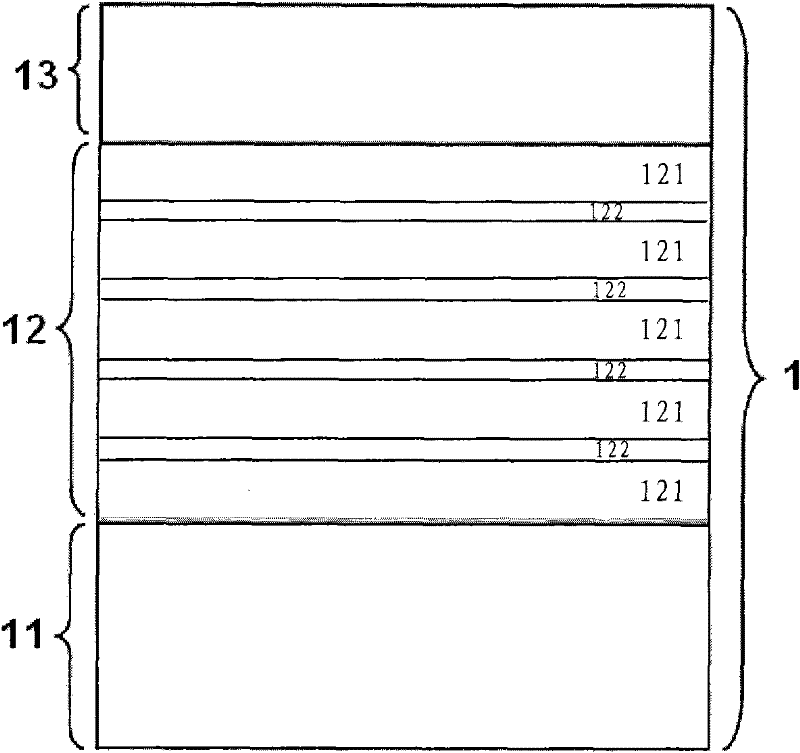

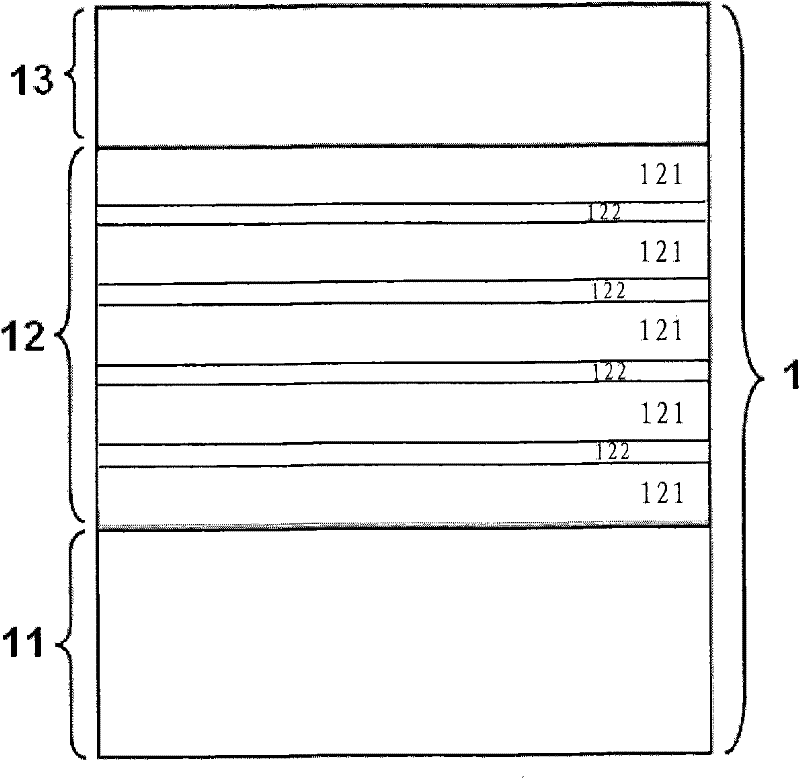

[0034] The technological process for preparing a silicon (Si)-based composite substrate for the preparation of gallium nitride (GaN) LED epitaxial wafer materials by metal-organic chemical vapor deposition (MOCVD) is as follows.

[0035] Step 1: Take a 4-inch Si single crystal substrate 11 with a Si(111) plane;

[0036] Step 2: Put the cleaned Si(111) single crystal substrate 11 into the MOCVD equipment reaction chamber;

[0037] Step 3: Prepare and grow a thin AlN single crystal film material 121 with a thickness of 50 nm on the Si(111) single crystal substrate 11 by MOCVD process as a barrier layer and a lattice mismatch stress covariant layer;

[0038] Step 4: Prepare and grow a 10nm-thick ultra-thin TiN single crystal thin film material 122 on the 50nm-thick AlN layer 121 by MOCVD process as a thermal stress covariant layer.

[0039] Step 5: Repeat steps 3 and 4 to prepare a composite stress-conforming layer material 12 composed of five overlapping 50nm thin AlN layers 12...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com