Patents

Literature

3042 results about "Aluminium nitride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium nitride (AlN) is a solid nitride of aluminium. It has a high thermal conductivity of up to 285 W/(m·K), and is an electrical insulator. Its wurtzite phase (w-AlN) has a band gap of ~6 eV at room temperature and has a potential application in optoelectronics operating at deep ultraviolet frequencies.

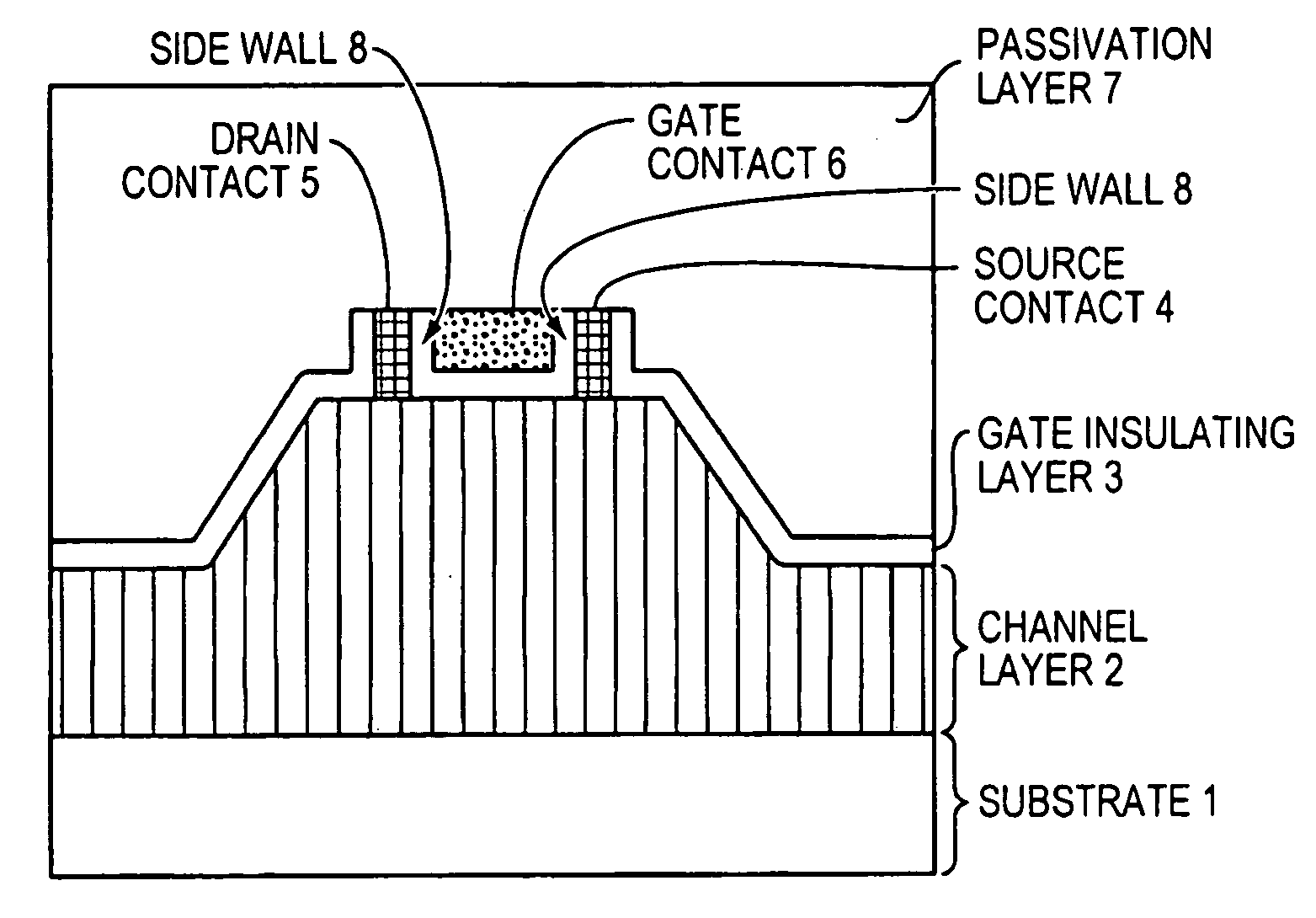

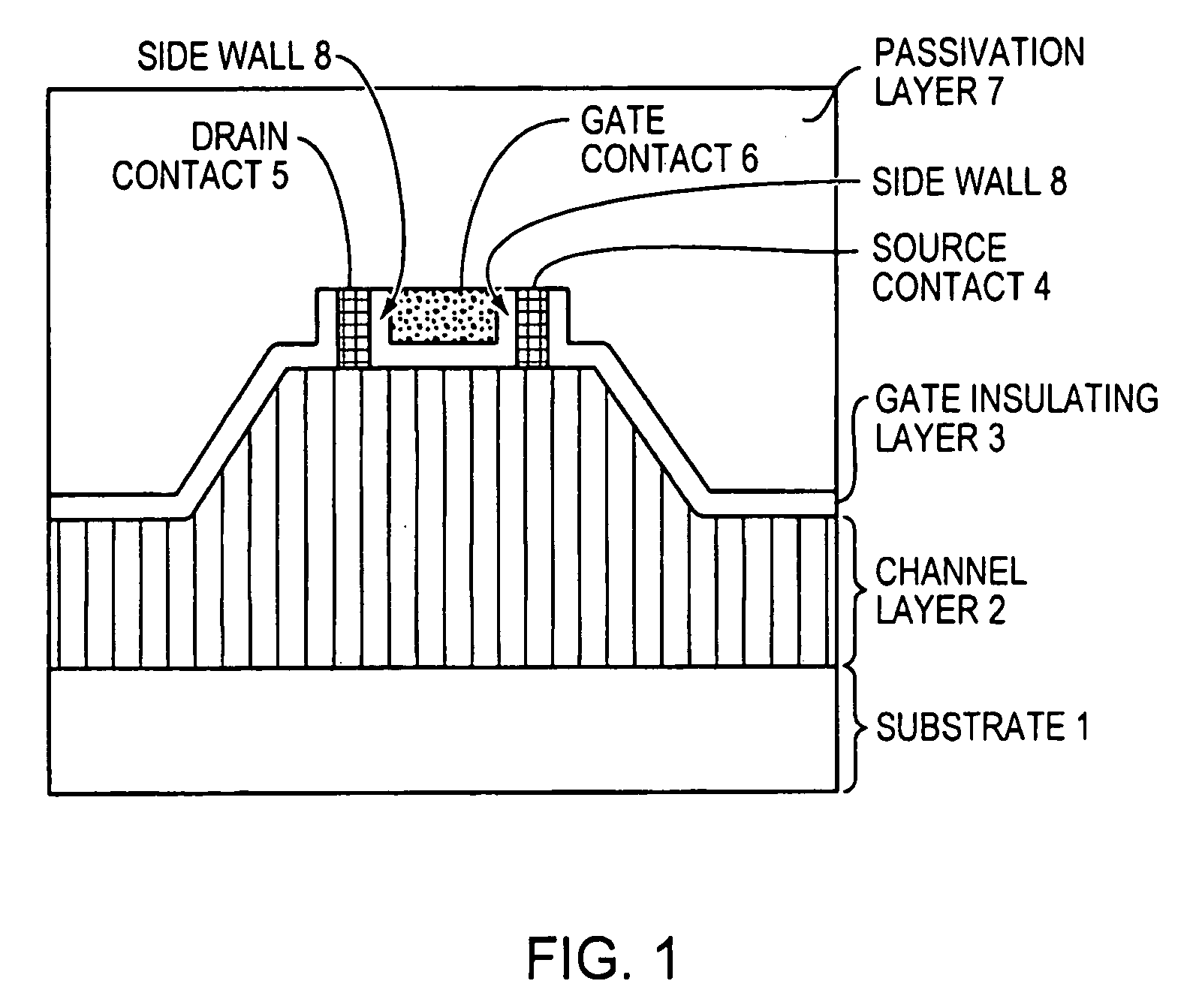

High-electron mobility transistor with zinc oxide

InactiveUS7105868B2Increase heightHigh electron mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesSchottky barrierField-effect transistor

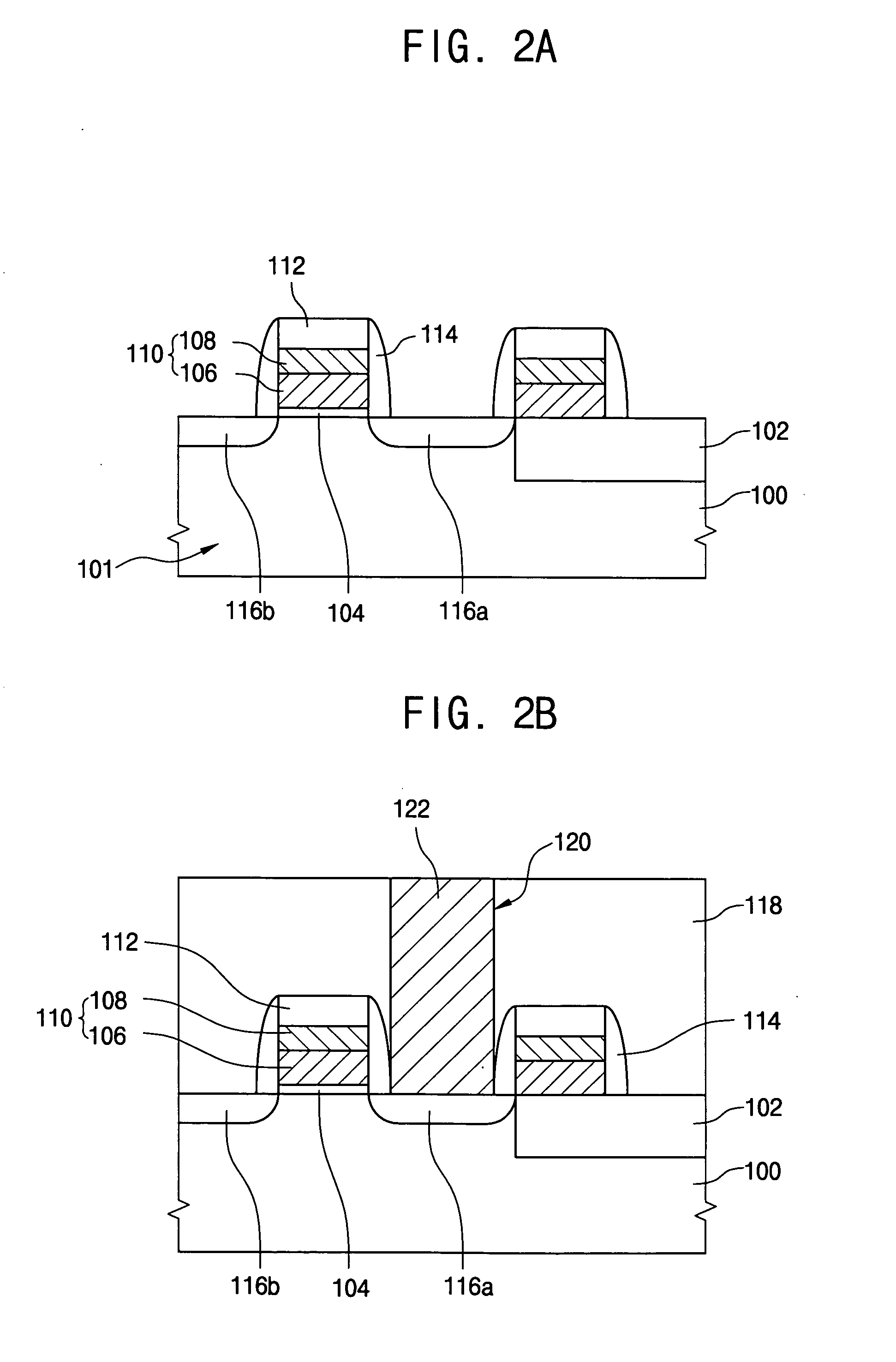

A zinc oxide (ZnO) field effect transistor exhibits large input amplitude by using a gate insulating layer. A channel layer and the gate insulating layer are sequentially laminated on a substrate. A gate electrode is formed on the gate insulating layer. A source contact and a drain contact are disposed at the both sides of the gate contact and are electrically connected to the channel layer via openings. The channel layer is formed from n-type ZnO. The gate insulating layer is made from aluminum nitride / aluminum gallium nitride (AlN / AlGaN) or magnesium zinc oxide (MgZnO), which exhibits excellent insulation characteristics, thus increasing the Schottky barrier and achieving large input amplitude. If the FET is operated in the enhancement mode, it is operable in a manner similar to a silicon metal oxide semiconductor field effect transistor (Si-MOS-type FET), resulting in the formation of an inversion layer.

Owner:NAUSE CATHERINE D

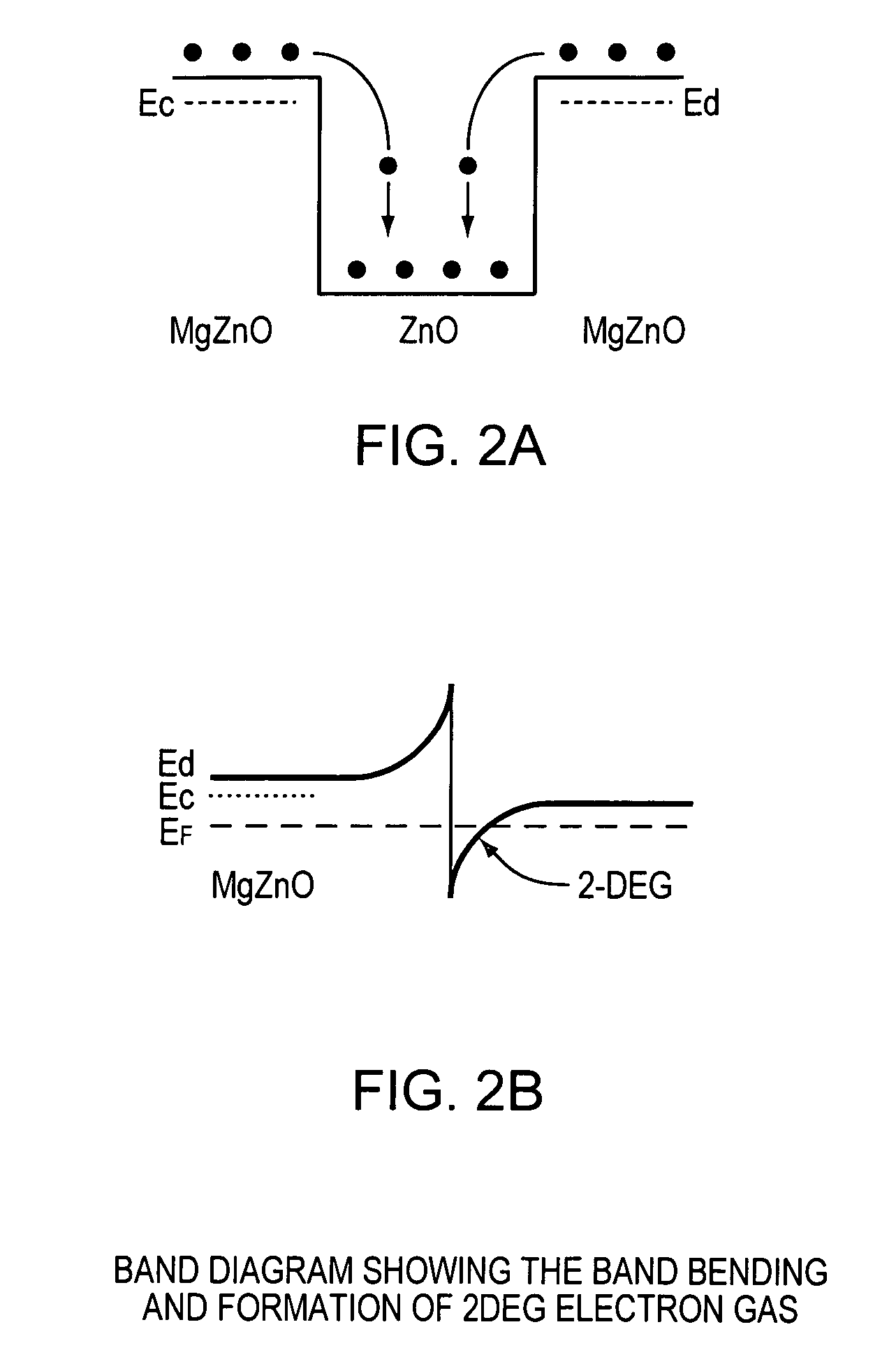

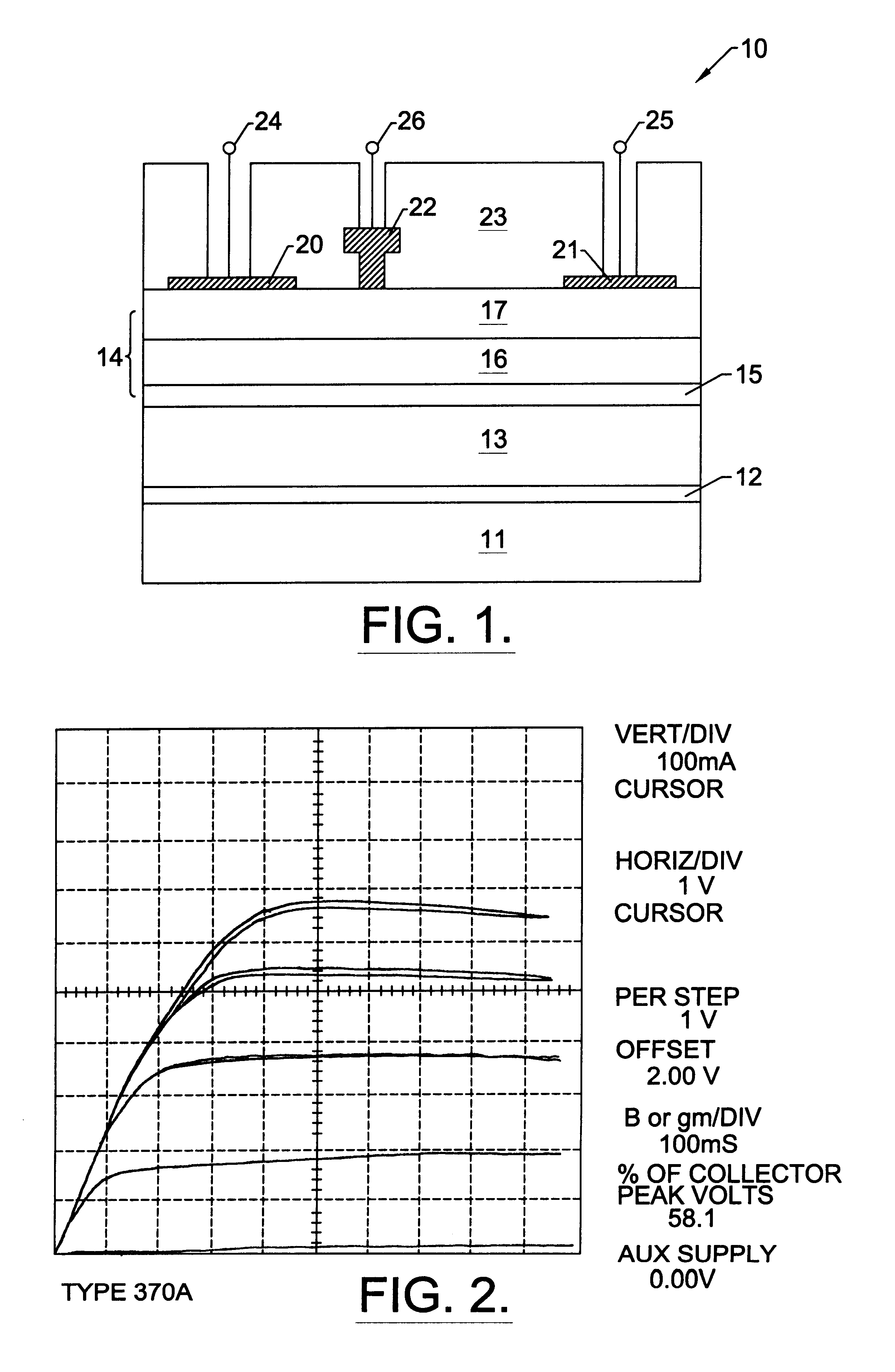

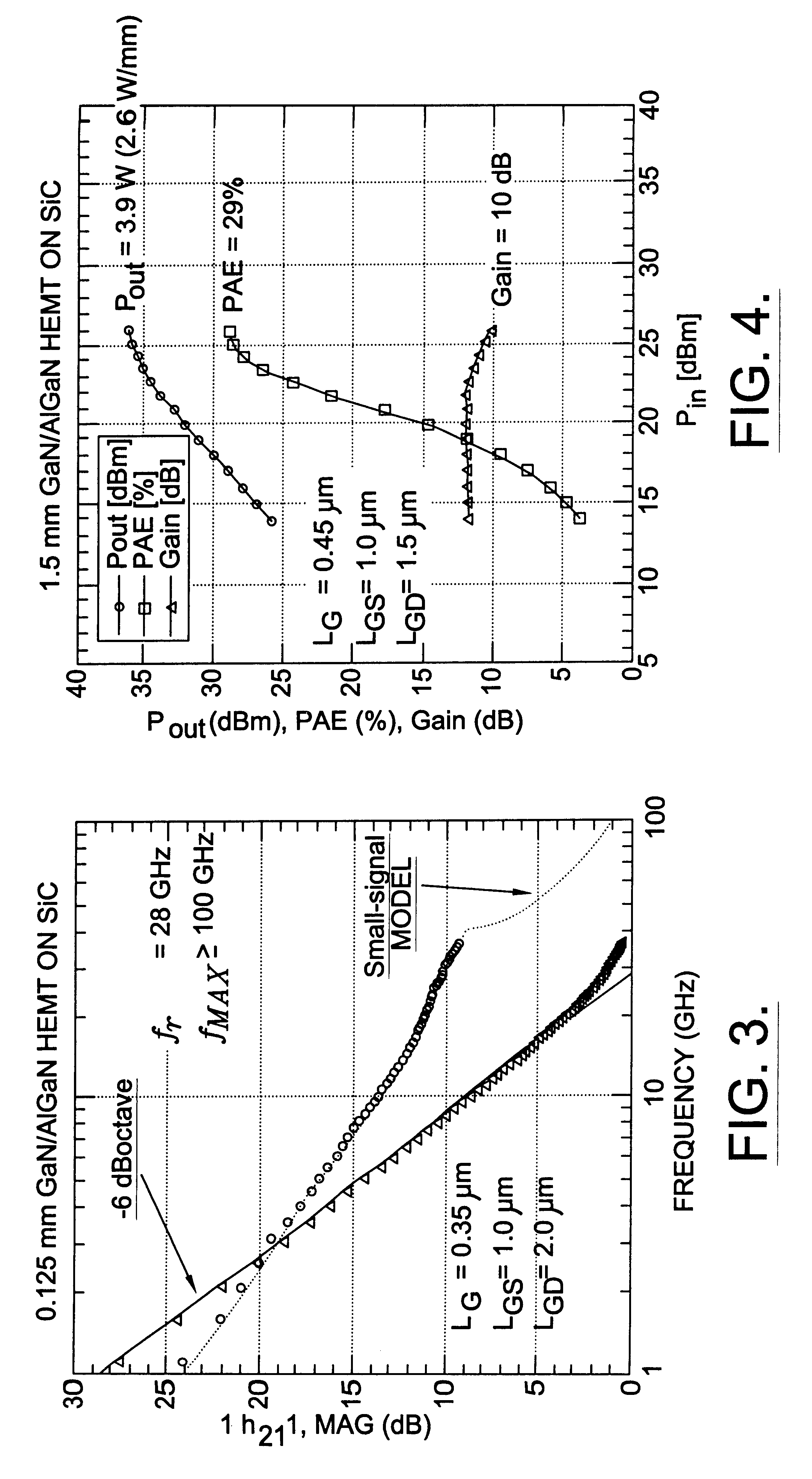

Nitride based transistors on semi-insulating silicon carbide substrates

InactiveUS6316793B1Quality improvementImprove thermal conductivitySemiconductor/solid-state device manufacturingSemiconductor devicesGallium nitrideMaterials science

A high electron mobility transistor (HEMT) is disclosed that includes a semi-insulating silicon carbide substrate, an aluminum nitride buffer layer on the substrate, an insulating gallium nitride layer on the buffer layer, an active structure of aluminum gallium nitride on the gallium nitride layer, a passivation layer on the aluminum gallium nitride active structure, and respective source, drain and gate contacts to the aluminum gallium nitride active structure.

Owner:WOLFSPEED INC

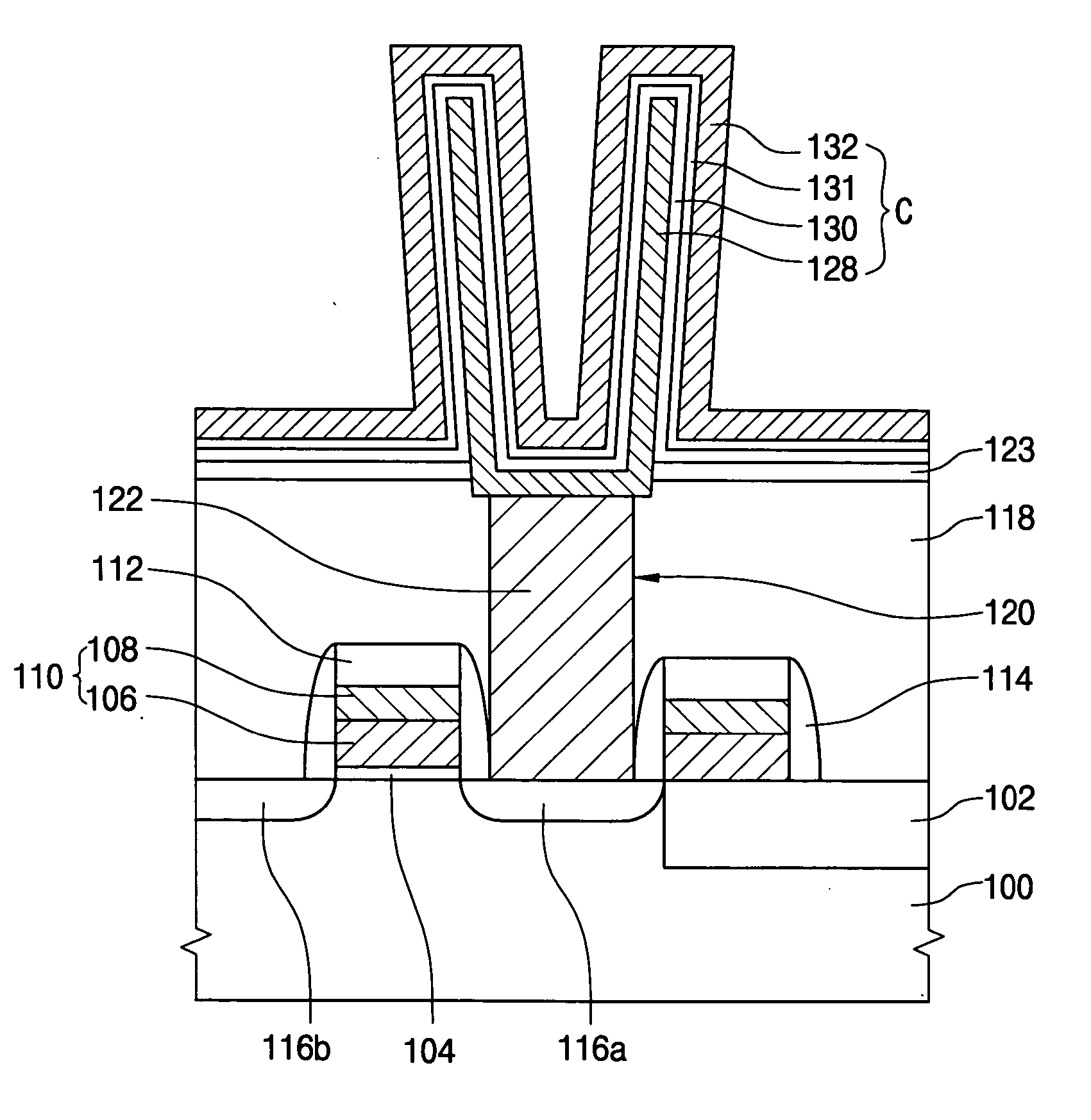

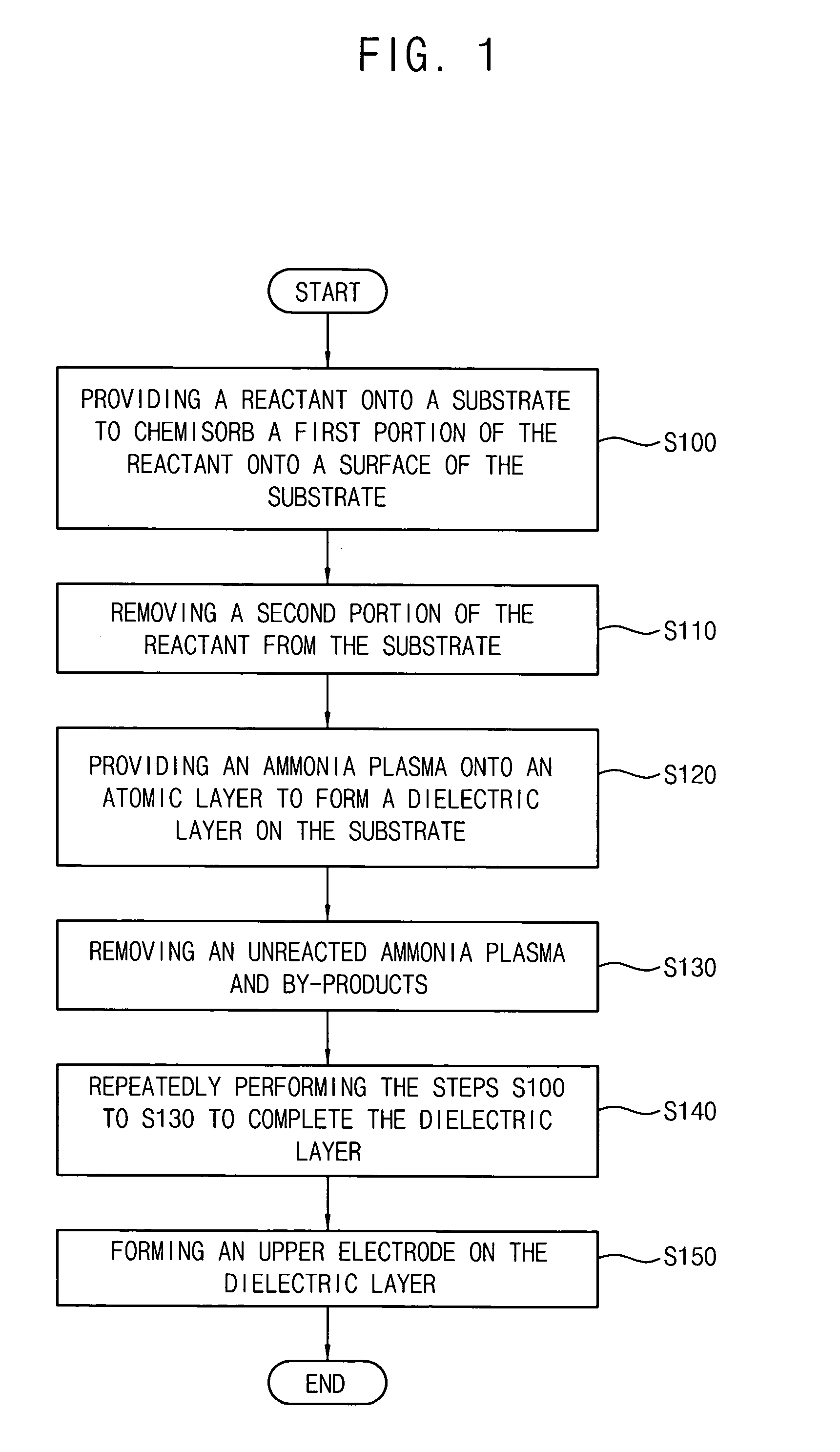

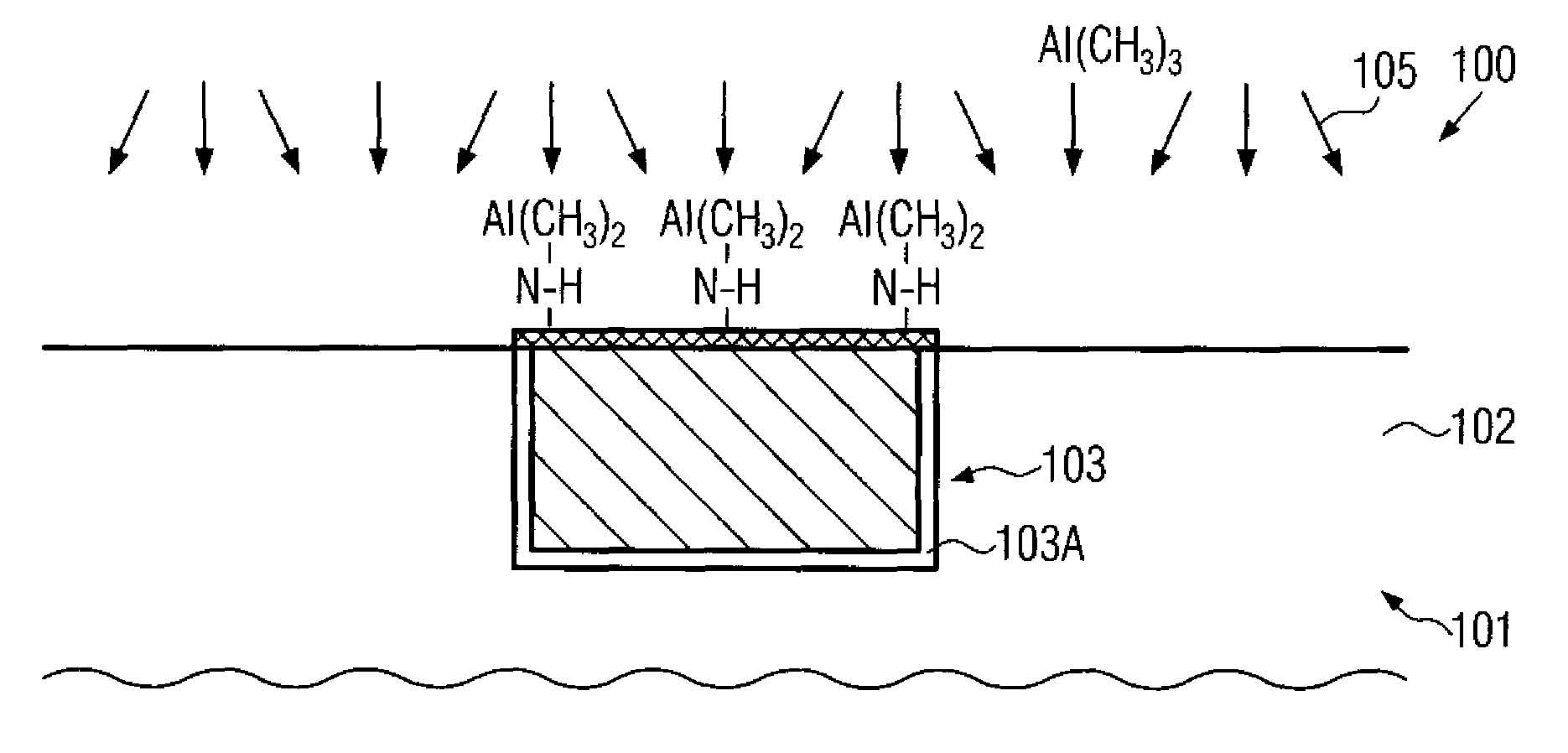

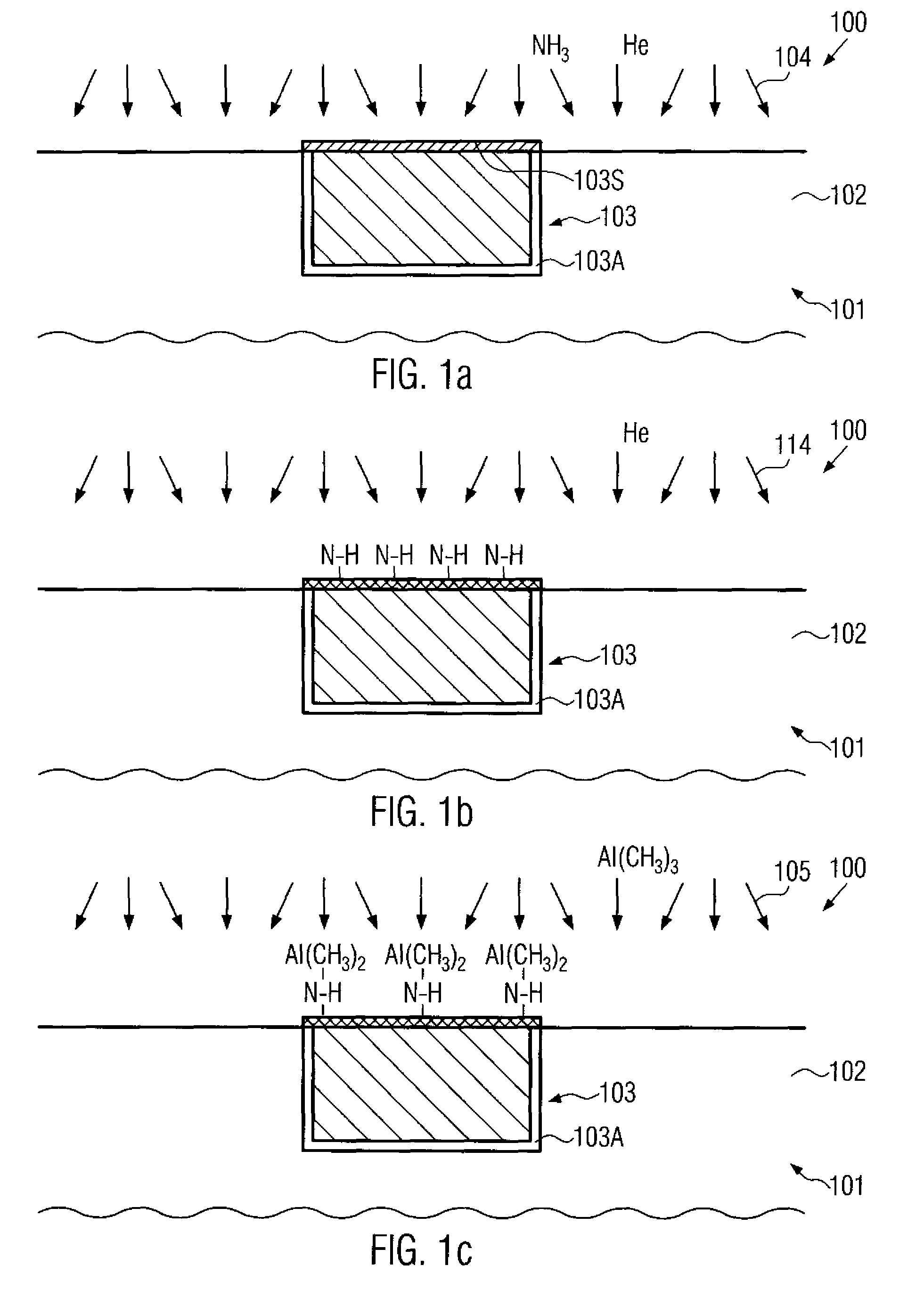

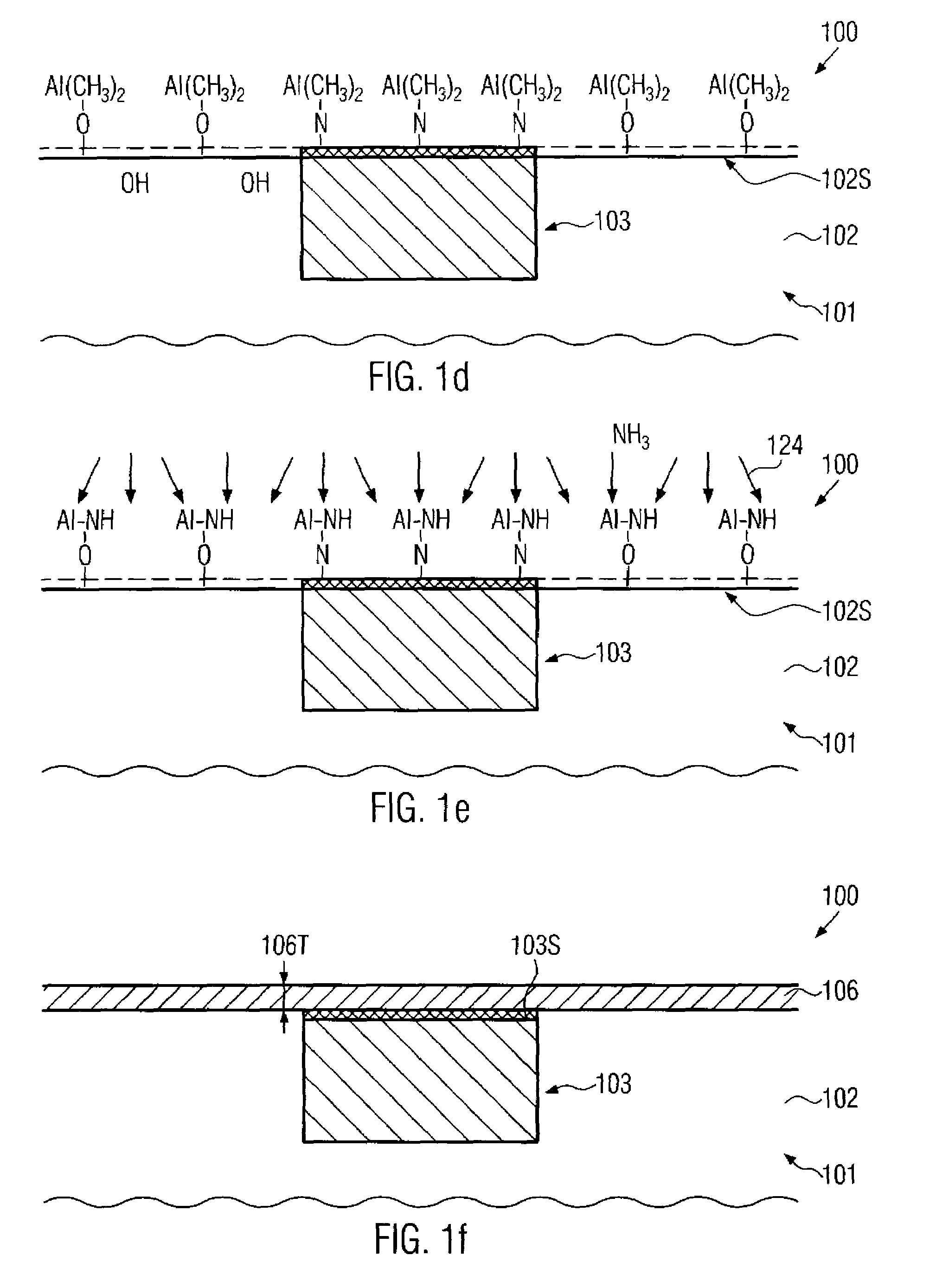

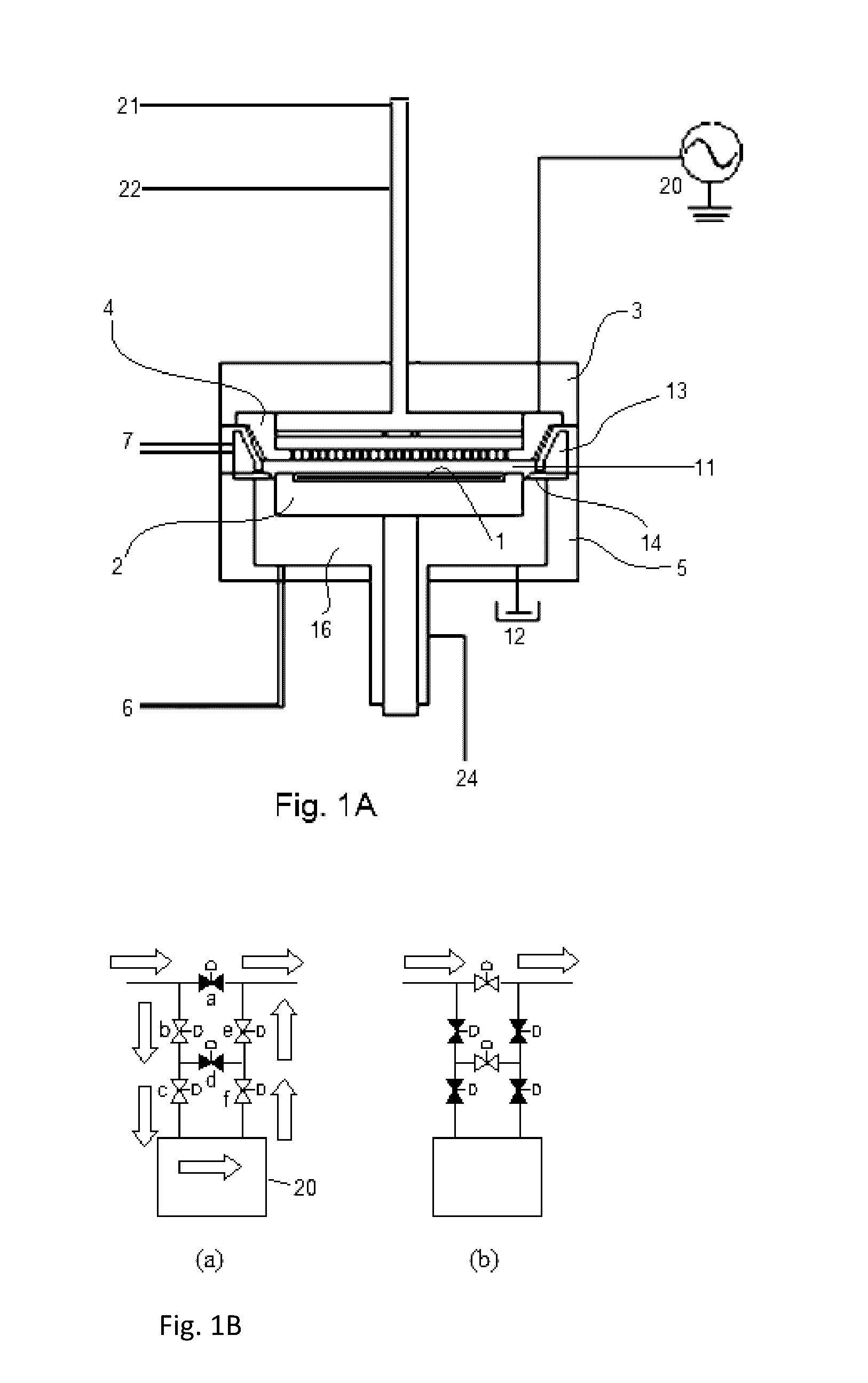

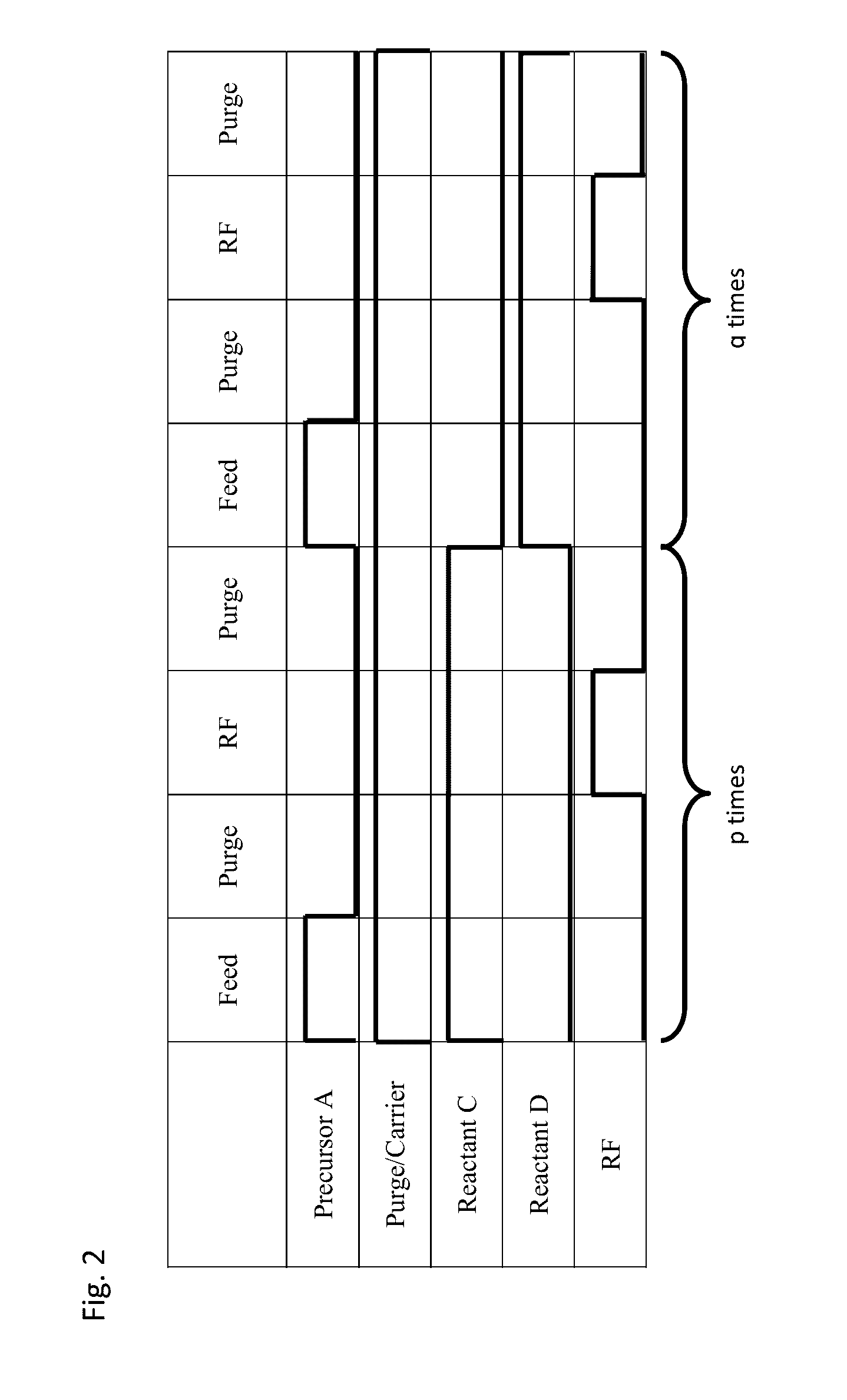

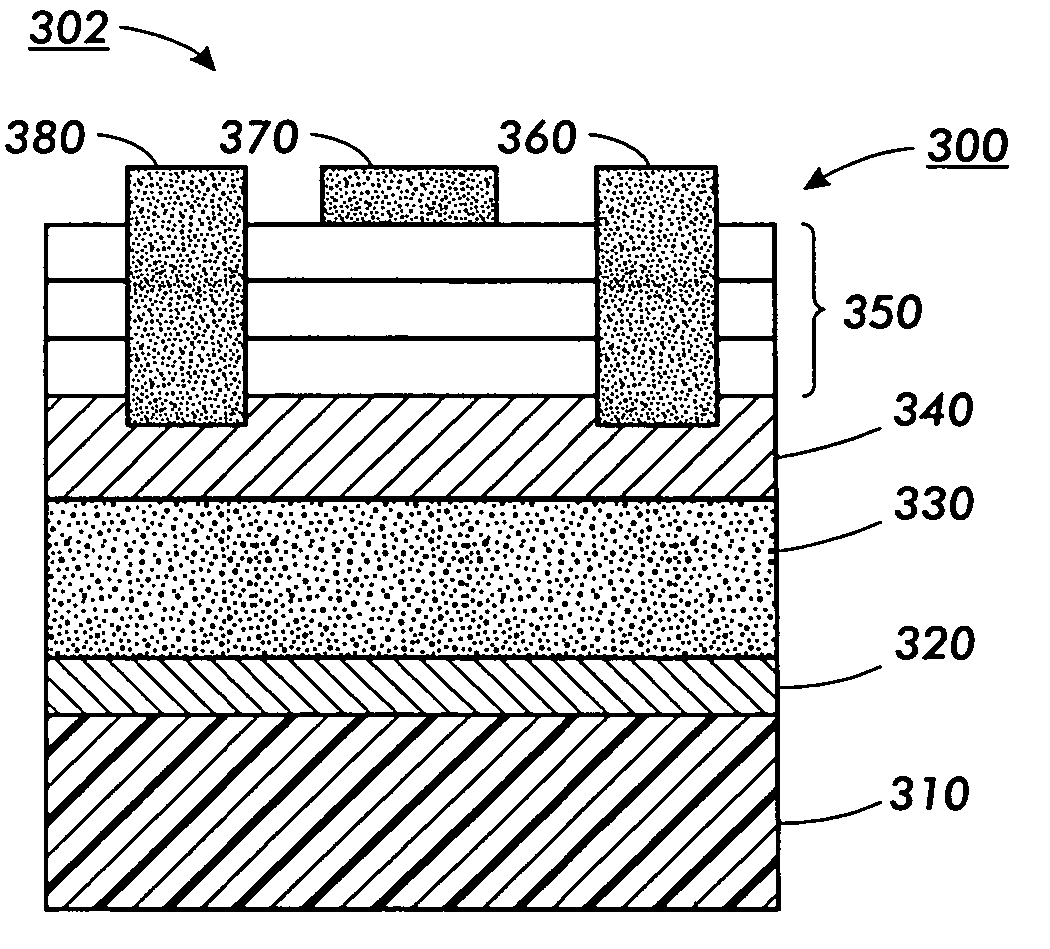

Methods of forming a capacitor using an atomic layer deposition process

Methods for forming a capacitor using an atomic layer deposition process include providing a reactant including an aluminum precursor onto a substrate to chemisorb a portion of the reactant to a surface of the substrate. The substrate has an underlying structure including a lower electrode. An ammonia (NH3) plasma is provided onto the substrate to form a dielectric layer including aluminum nitride on the substrate including the lower electrode. An upper electrode is formed on the dielectric layer. A second dielectric layer may be provided oil the first dielectric layer

Owner:SAMSUNG ELECTRONICS CO LTD

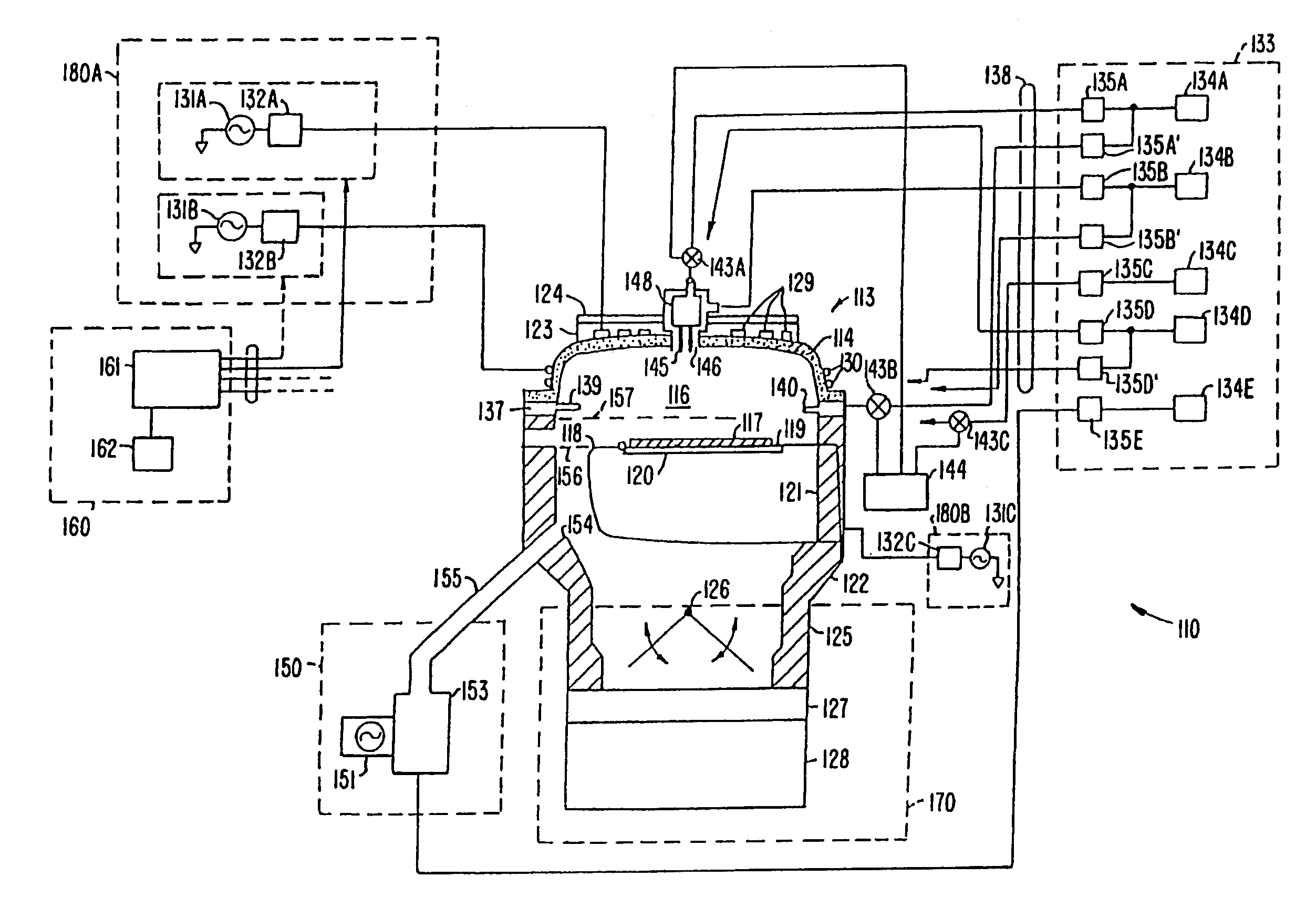

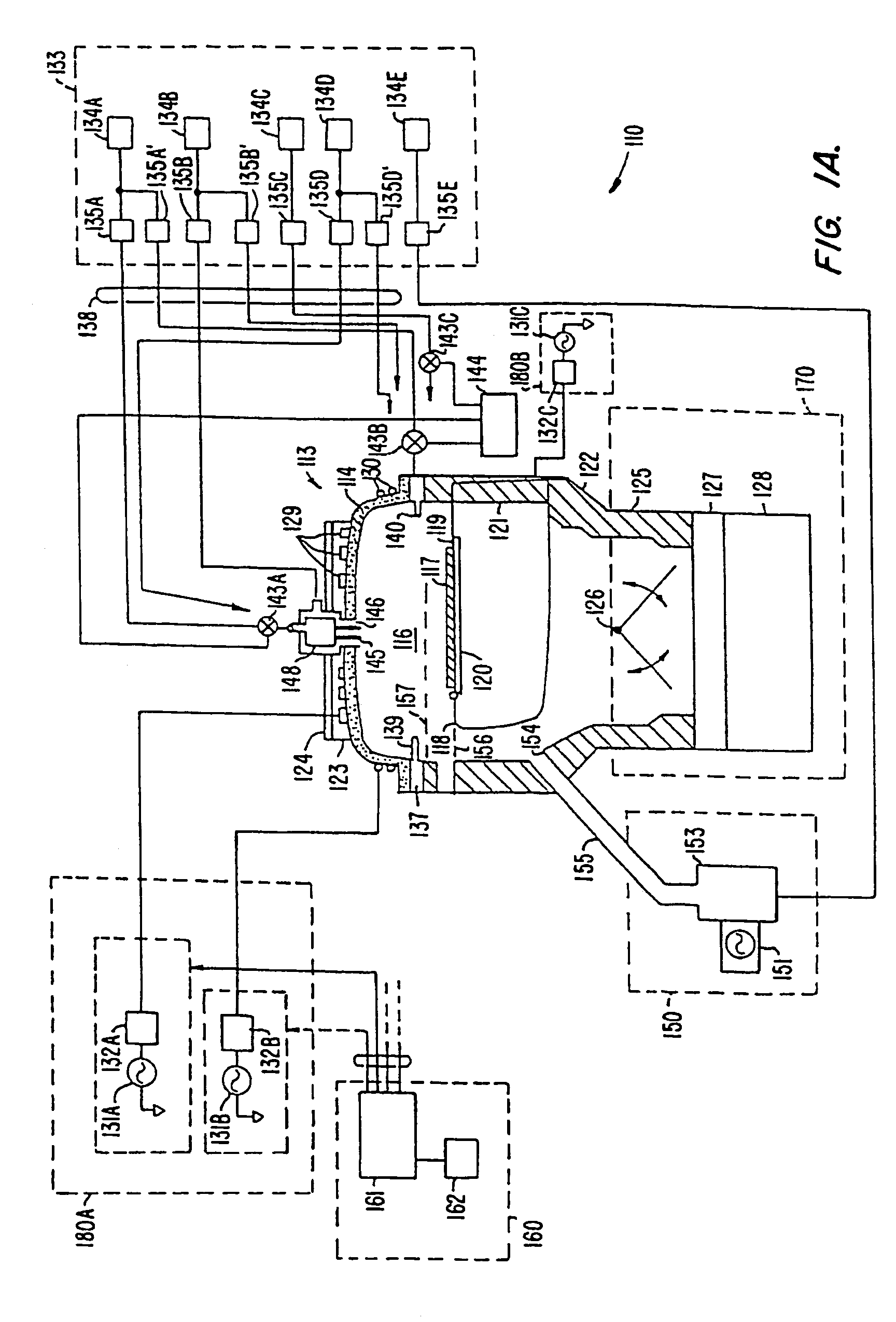

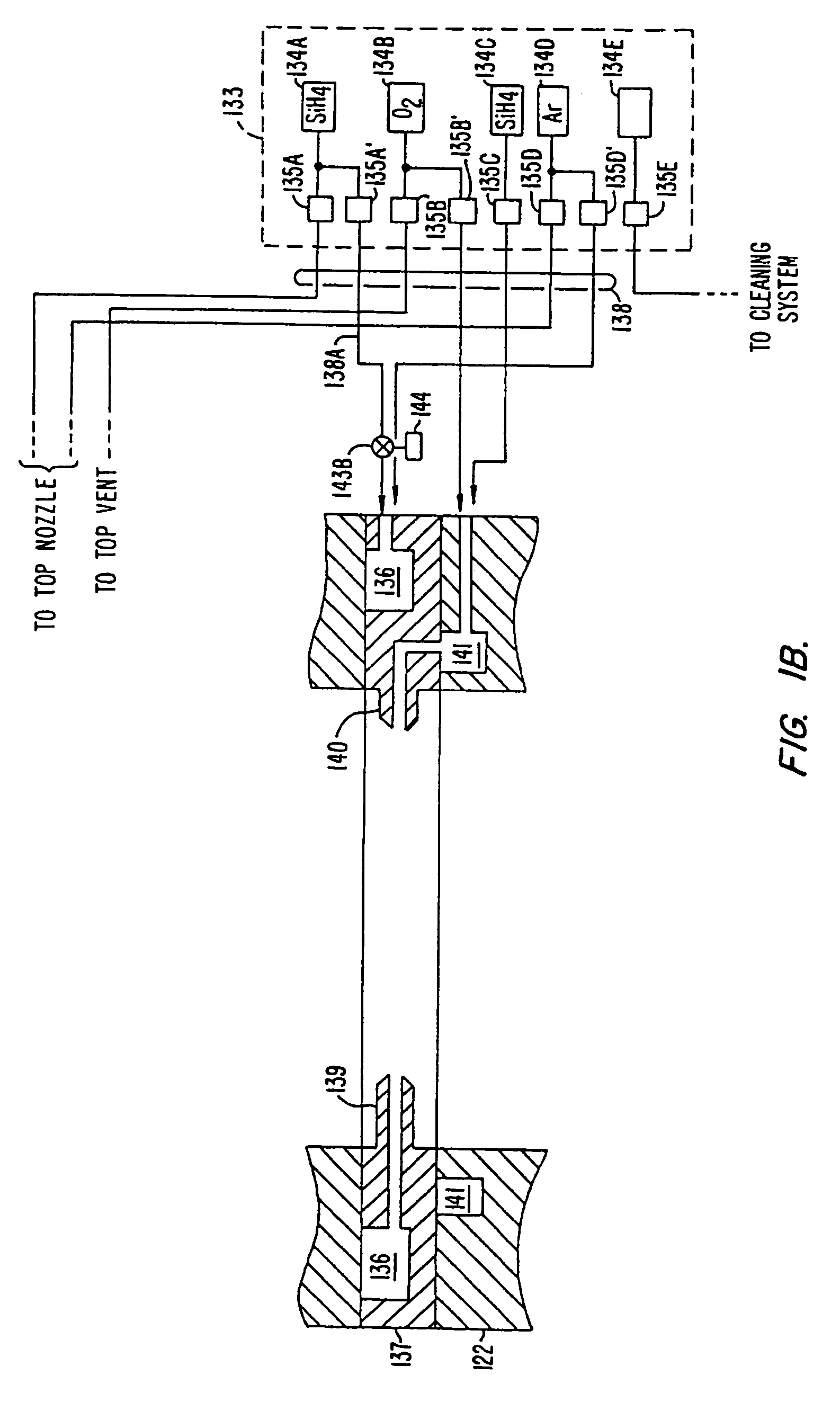

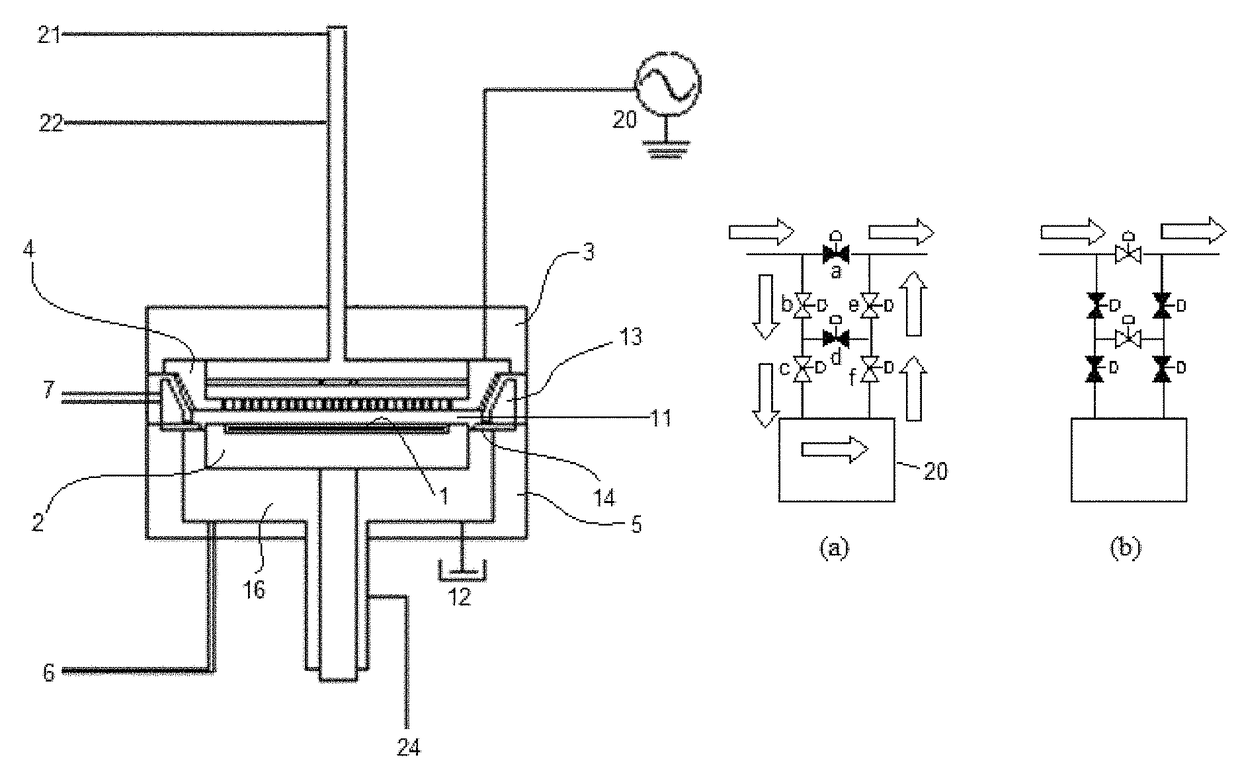

HDP-CVD seasoning process for high power HDP-CVD gapfil to improve particle performance

InactiveUS7109114B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSilanesSilicon oxide

A method of operating a substrate processing chamber that includes, prior to a substrate processing operation, flowing a seasoning gas comprising silane and oxygen into said chamber at a flow ratio of greater than or equal to about 1.6:1 oxygen to silane to deposit a silicon oxide film over at least one aluminum nitride nozzle exposed to an interior portion of the chamber. Also, a substrate processing system that includes a housing, a gas delivery system for introducing a seasoning gas into a vacuum chamber, where the gas delivery system comprises one or more aluminum nitride nozzles exposed to the vacuum chamber, a controller and a memory having a program having instructions for controlling the gas delivery system to flow a seasoning gas that has an oxygen to silane ratio greater than or equal to about 1.6:1 to deposit a silicon oxide film on the aluminum nitride nozzles.

Owner:APPLIED MATERIALS INC

Method of manufracturing increasing reliability of copper-based metallization structures in a microstructure device by using aluminum nitride

ActiveUS7829460B2Reduce parasitic capacitanceEasy to controlSemiconductor/solid-state device detailsSolid-state devicesSelf limitingPermittivity

Owner:GLOBALFOUNDRIES U S INC

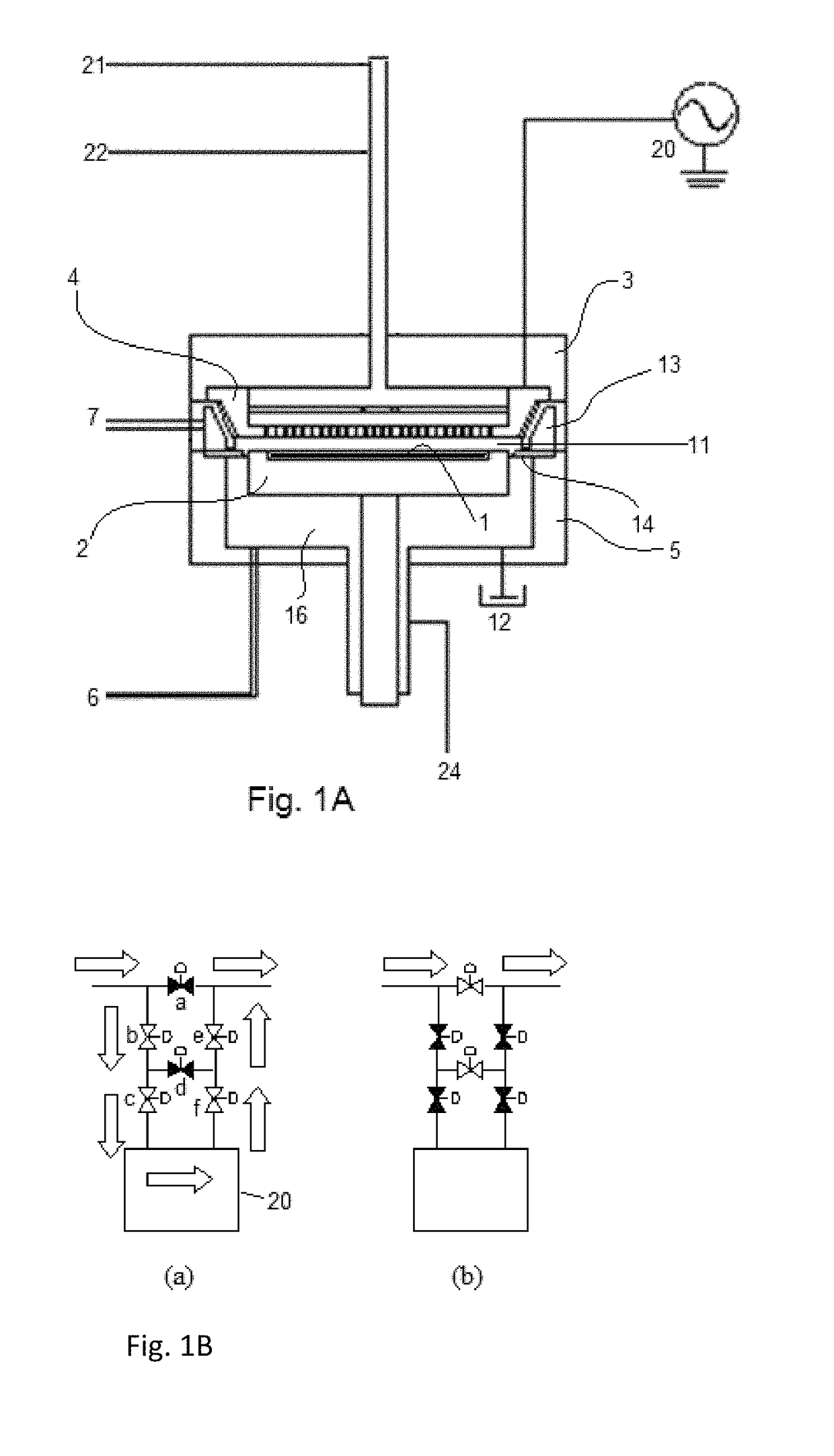

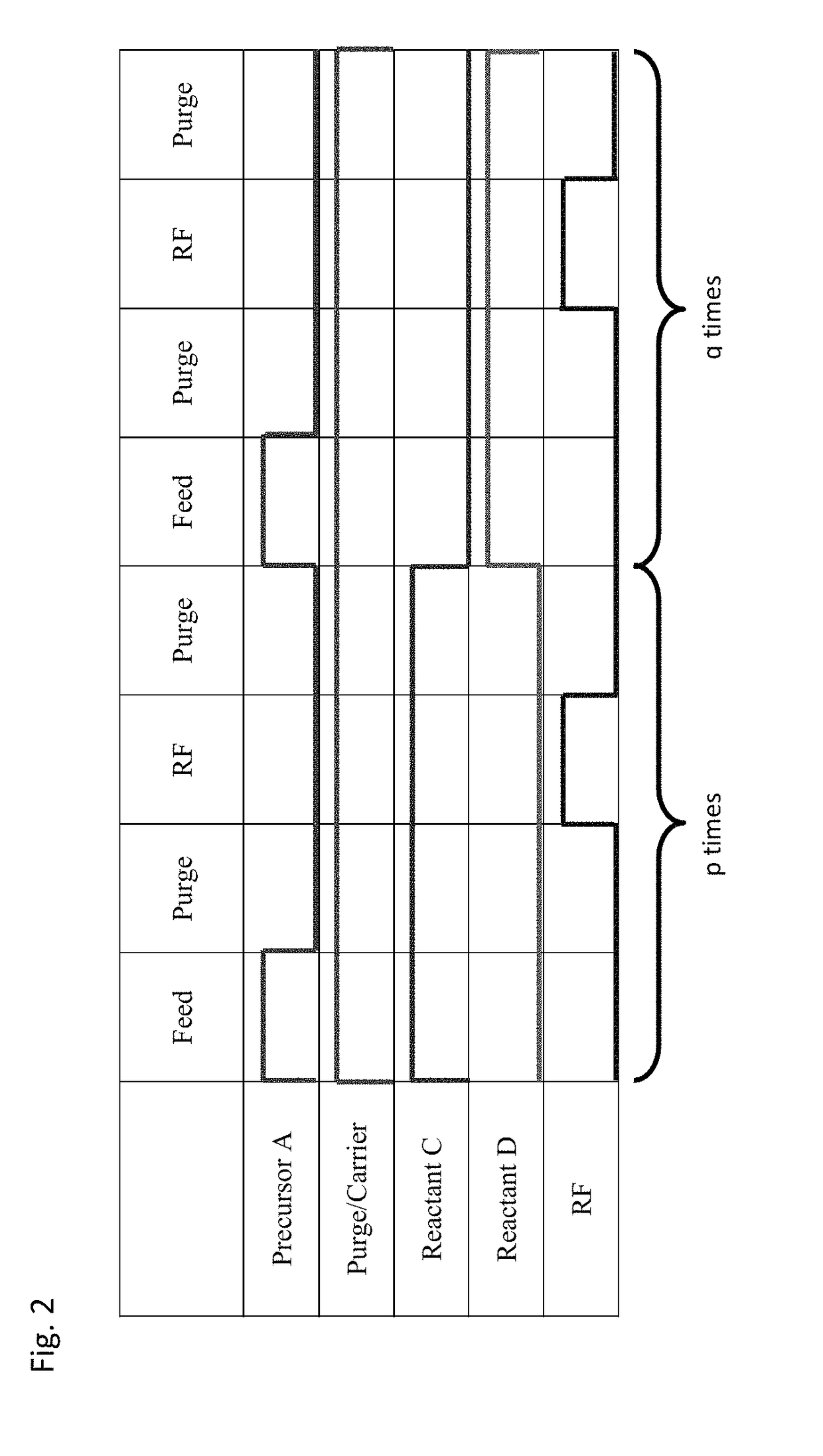

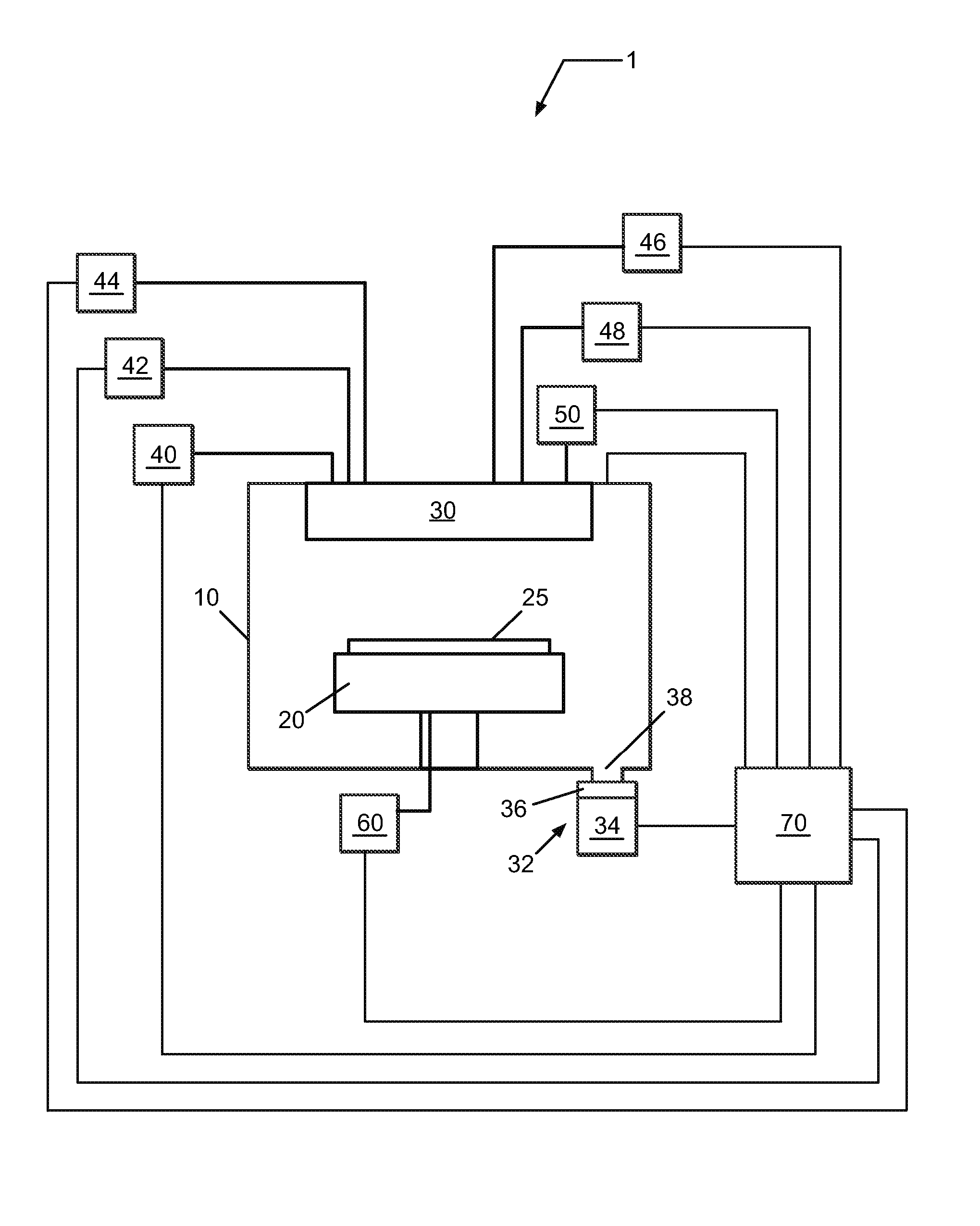

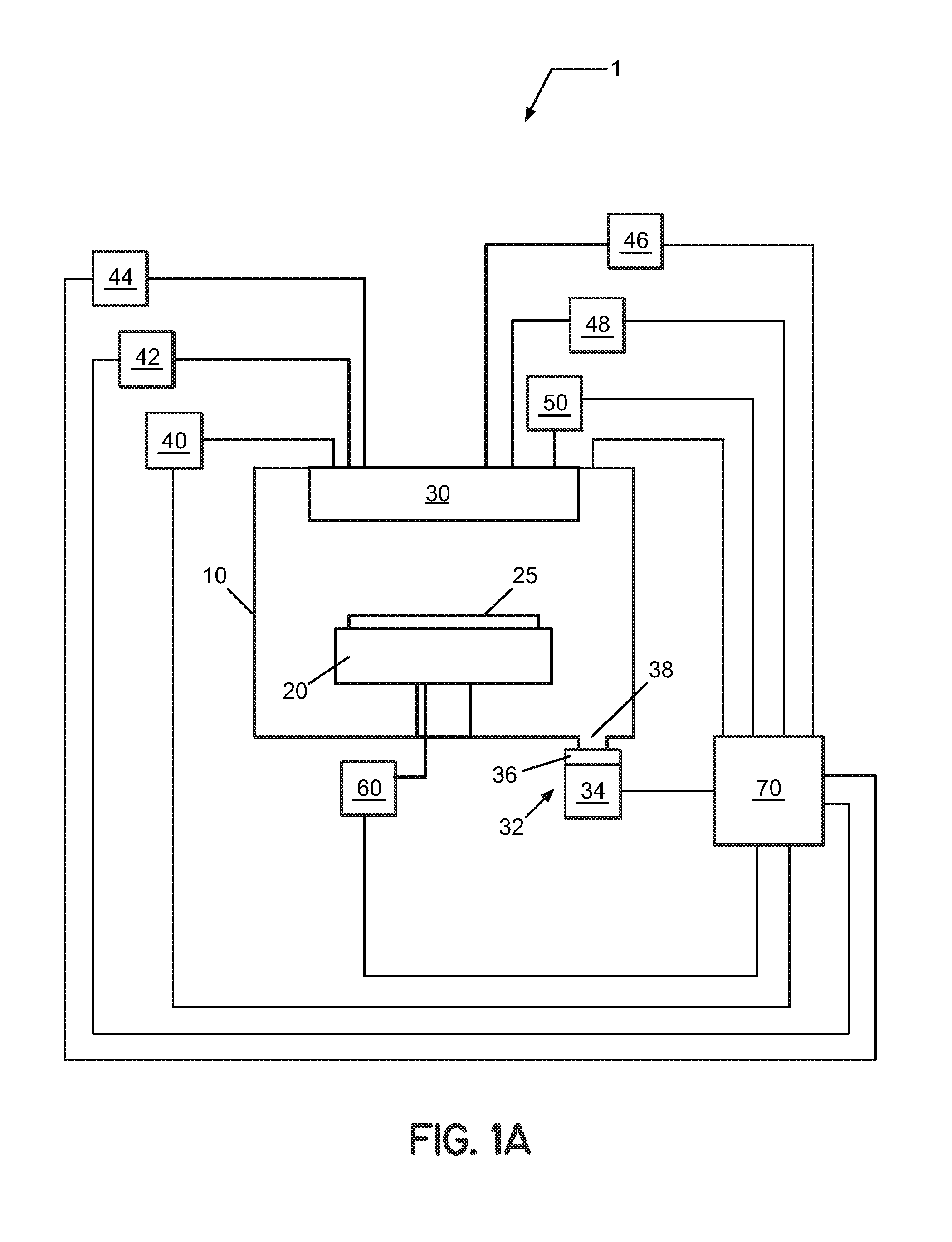

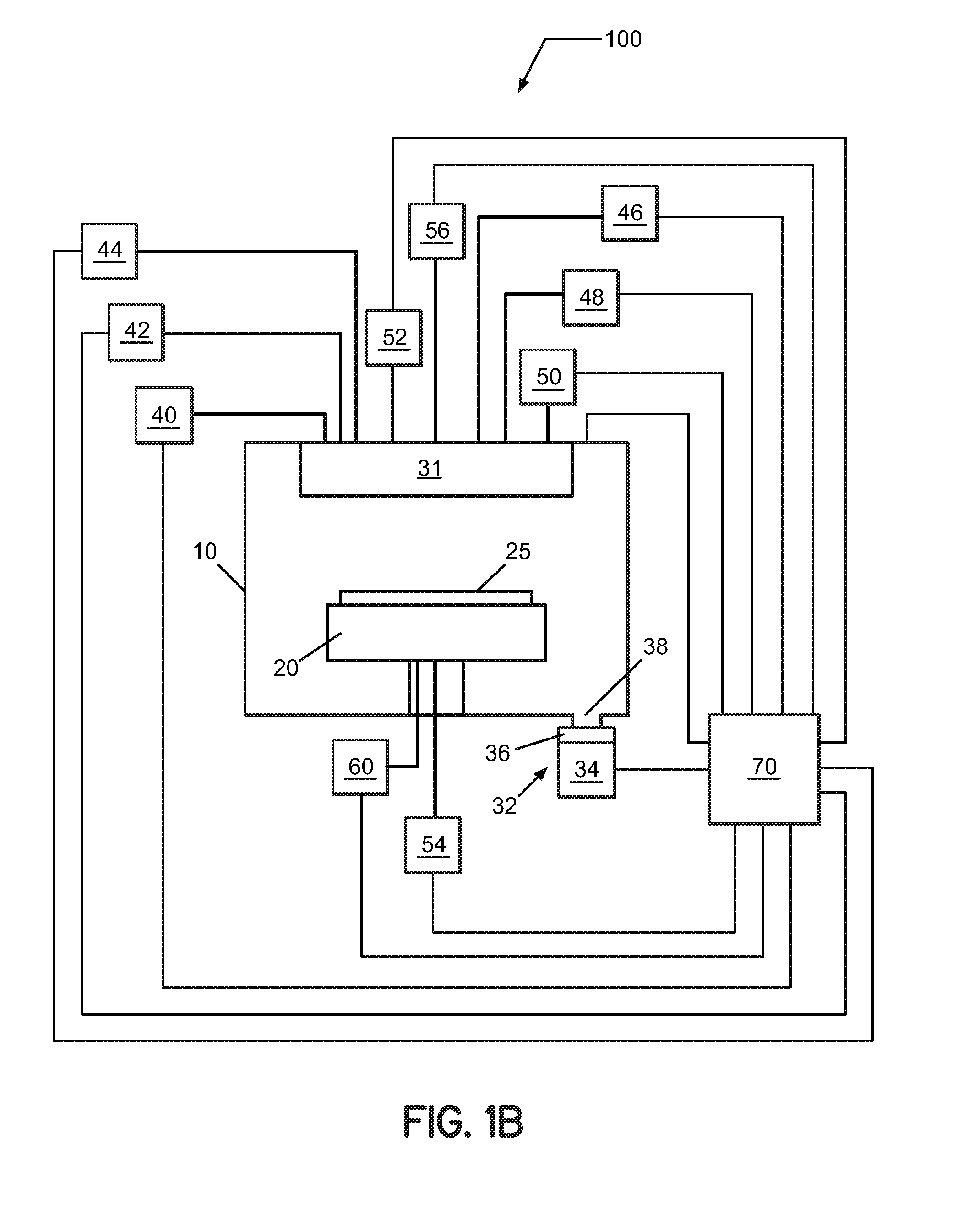

Method for forming aluminum nitride-based film by PEALD

ActiveUS9711345B2Improve leakage currentSemiconductor/solid-state device detailsSolid-state devicesPhysical chemistryThin membrane

Owner:ASM IP HLDG BV

Method of forming mixed rare earth nitride and aluminum nitride films by atomic layer deposition

InactiveUS20070237698A1Semiconductor/solid-state device manufacturingRare earth metal compoundsGate dielectricRare earth

A method is provided for depositing a gate dielectric that includes at least two rare earth metal elements in the form of a nitride or an aluminum nitride. The method includes disposing a substrate in a process chamber and exposing the substrate to a gas pulse containing a first rare earth precursor and to a gas pulse containing a second rare earth precursor. The substrate may also optionally be exposed to a gas pulse containing an aluminum precursor. Sequentially after each precursor gas pulse, the substrate is exposed to a gas pulse of a nitrogen-containing gas. In alternative embodiments, the first and second rare earth precursors may be pulsed together, and either or both may be pulsed together with the aluminum precursor. The first and second rare earth precursors comprise a different rare earth metal element. The sequential exposing steps may be repeated to deposit a mixed rare earth nitride or aluminum nitride layer with a desired thickness. Purge or evacuation steps may also be performed after each gas pulse.

Owner:TOKYO ELECTRON LTD

Method for forming aluminum nitride-based film by peald

ActiveUS20170062209A1Improve leakage currentSemiconductor/solid-state device detailsSolid-state devicesPhysical chemistryThin membrane

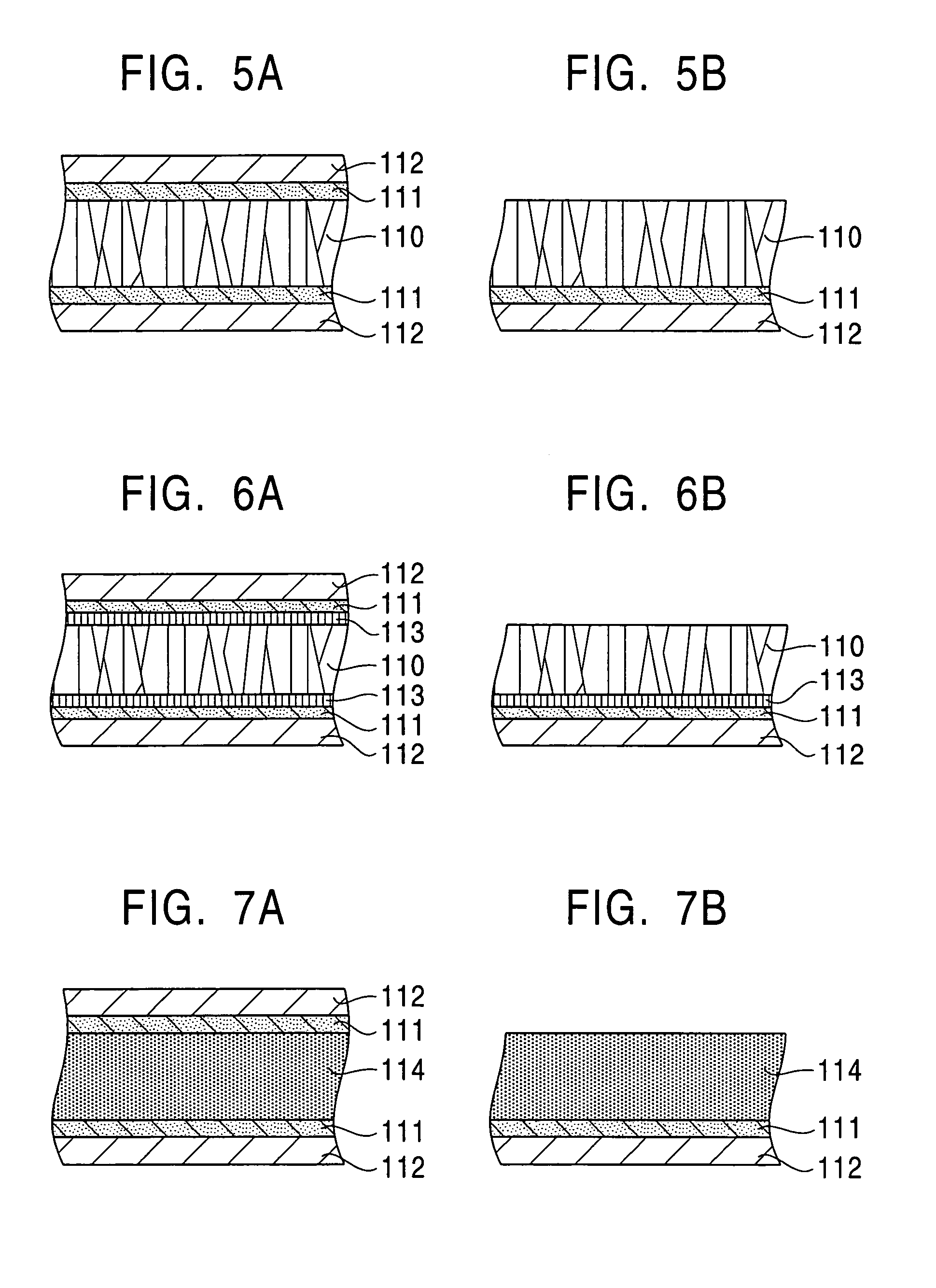

A method for forming an aluminum nitride-based film on a substrate by plasma-enhanced atomic layer deposition (PEALD) includes: (a) forming at least one aluminum nitride (AlN) monolayer and (b) forming at least one aluminum oxide (AlO) monolayer, wherein steps (a) and (b) are alternately conducted continuously to form a laminate. Steps (a) and (b) are discontinued before a total thickness of the laminate exceeds 10 nm, preferably 5 nm.

Owner:ASM IP HLDG BV

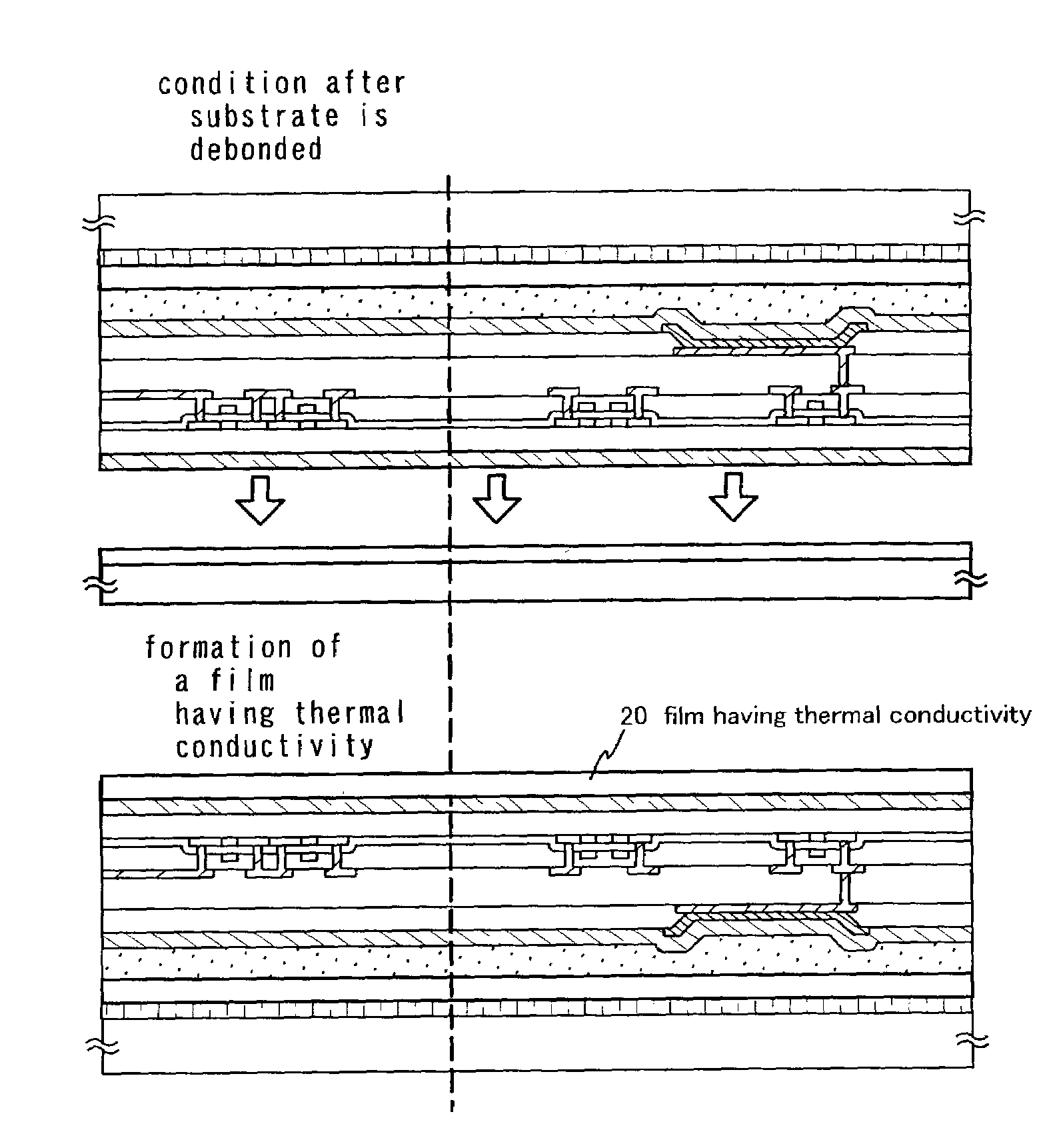

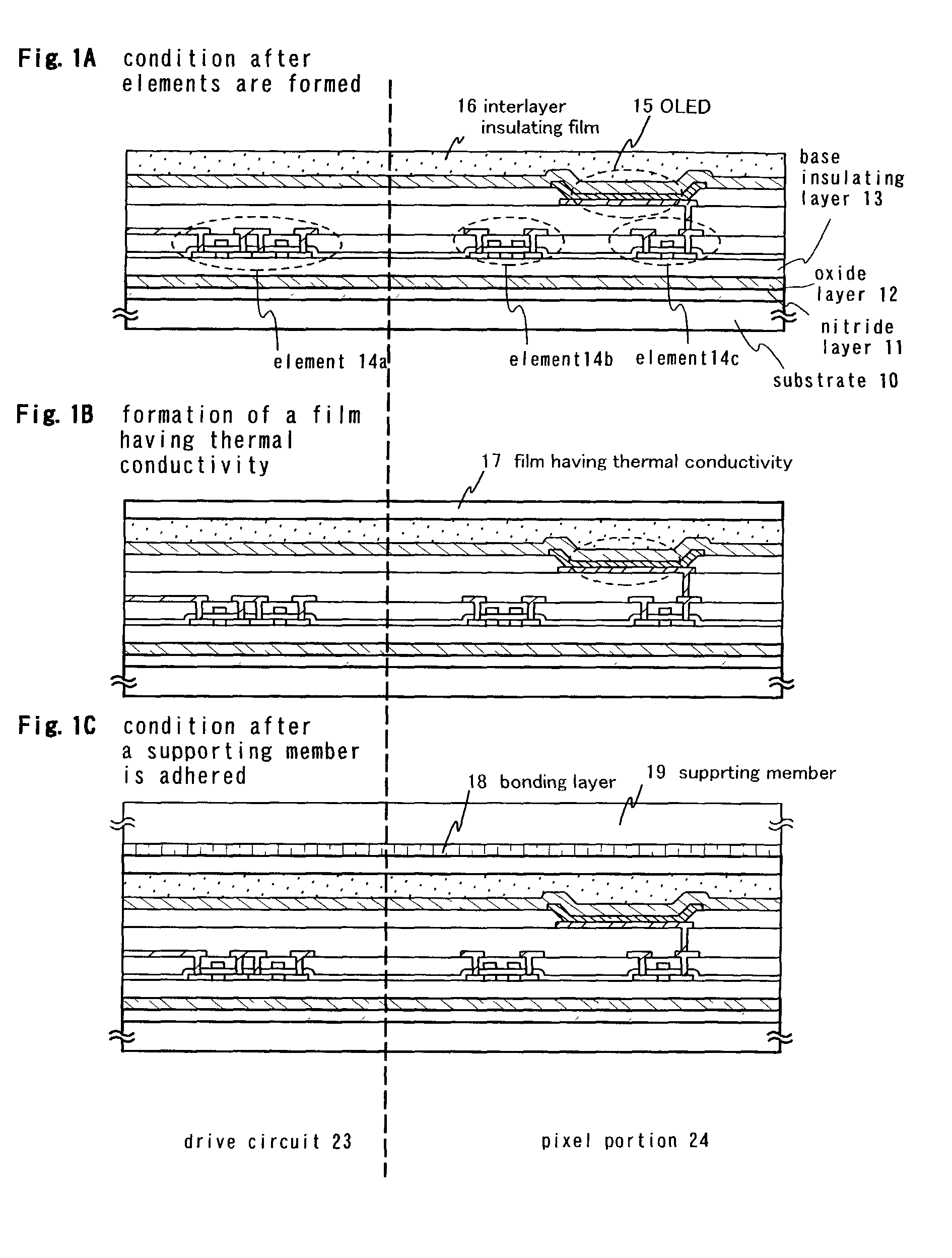

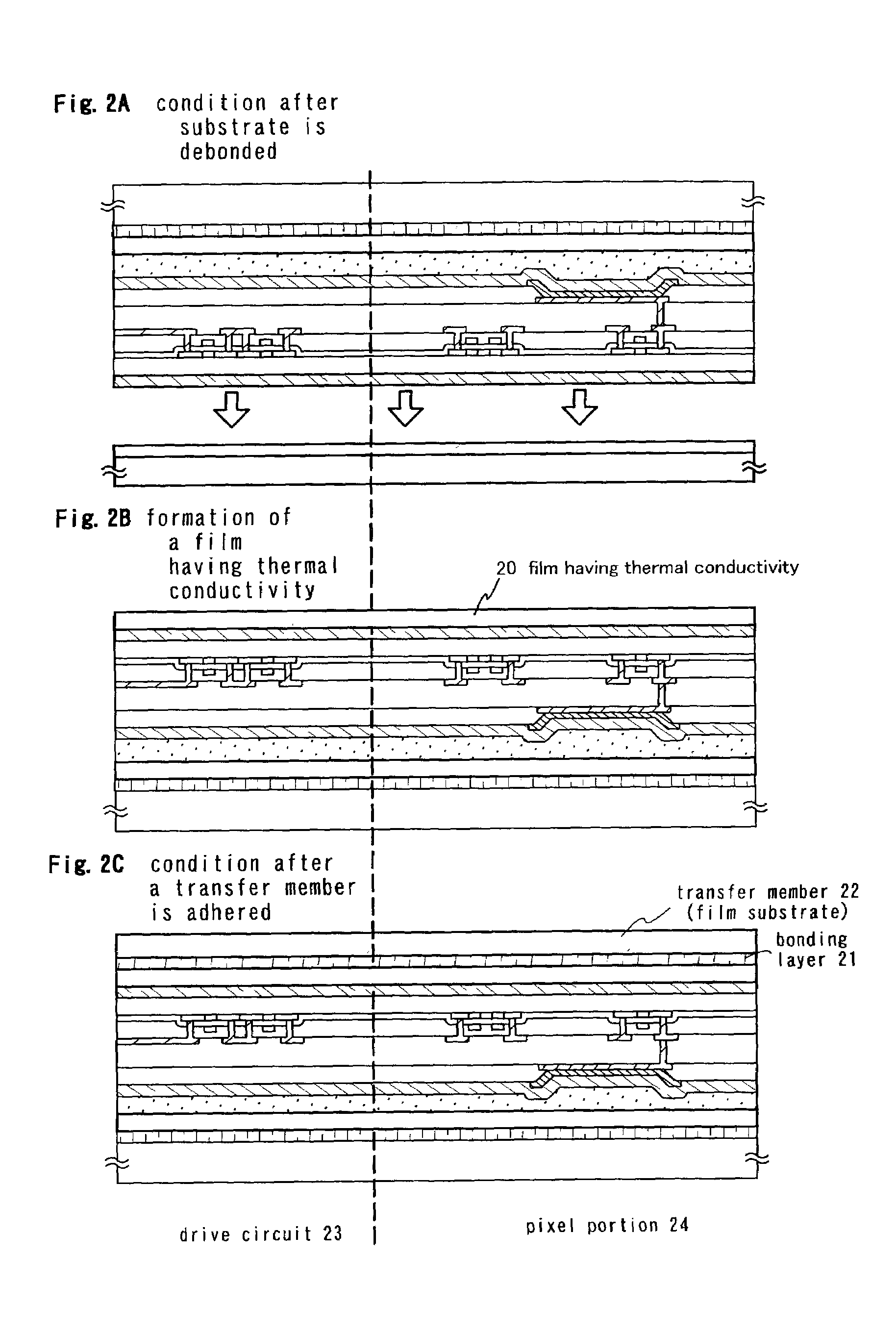

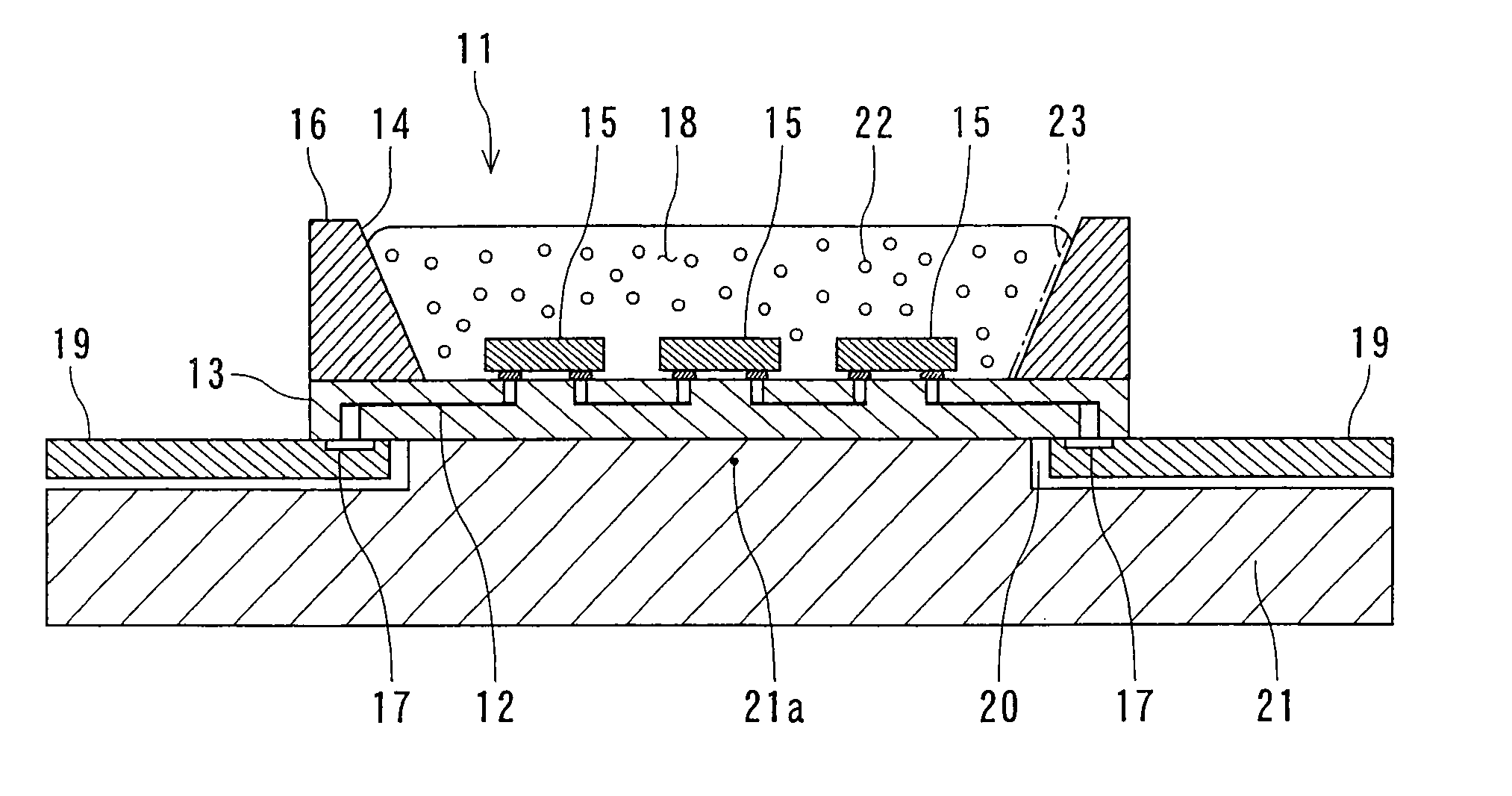

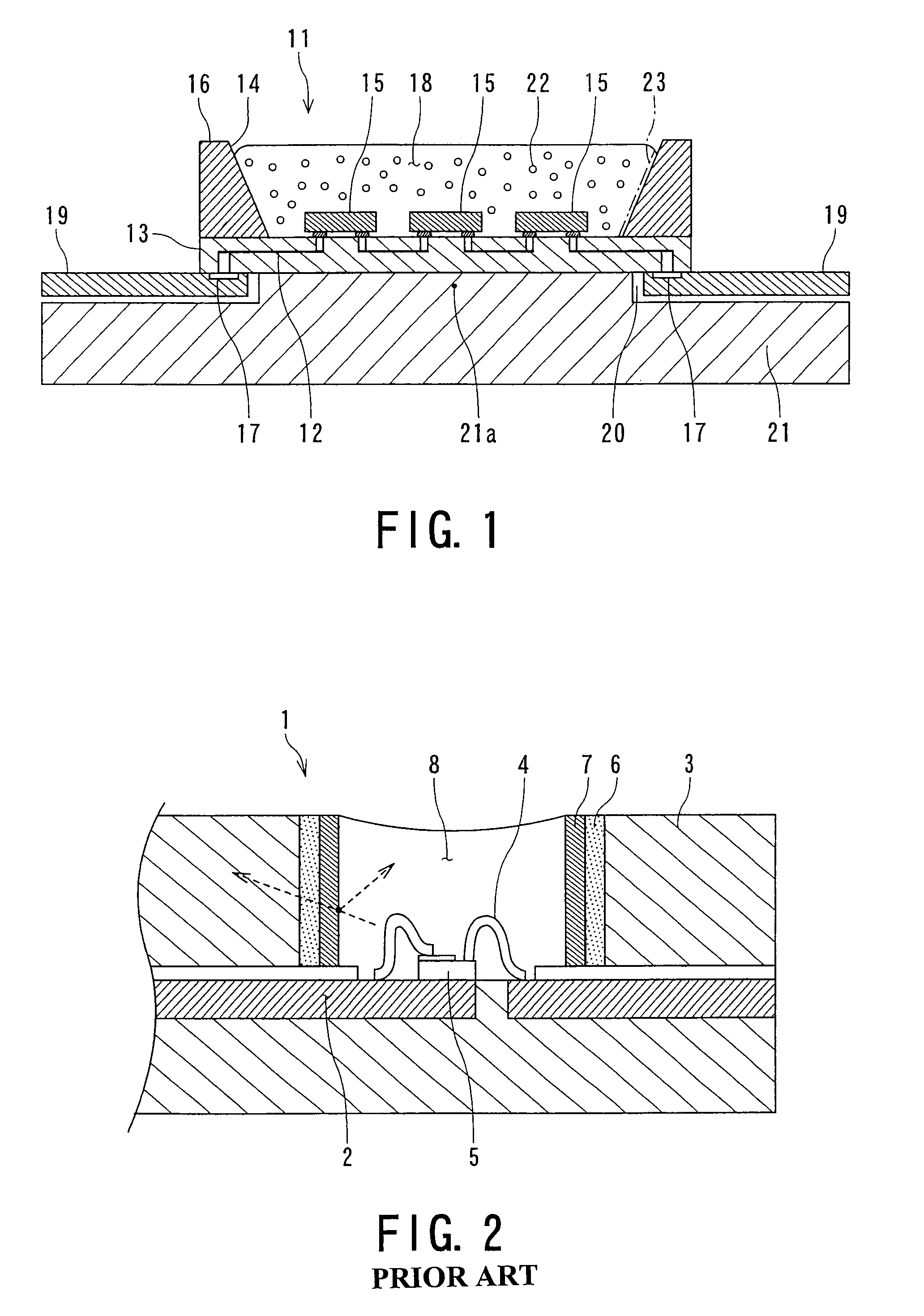

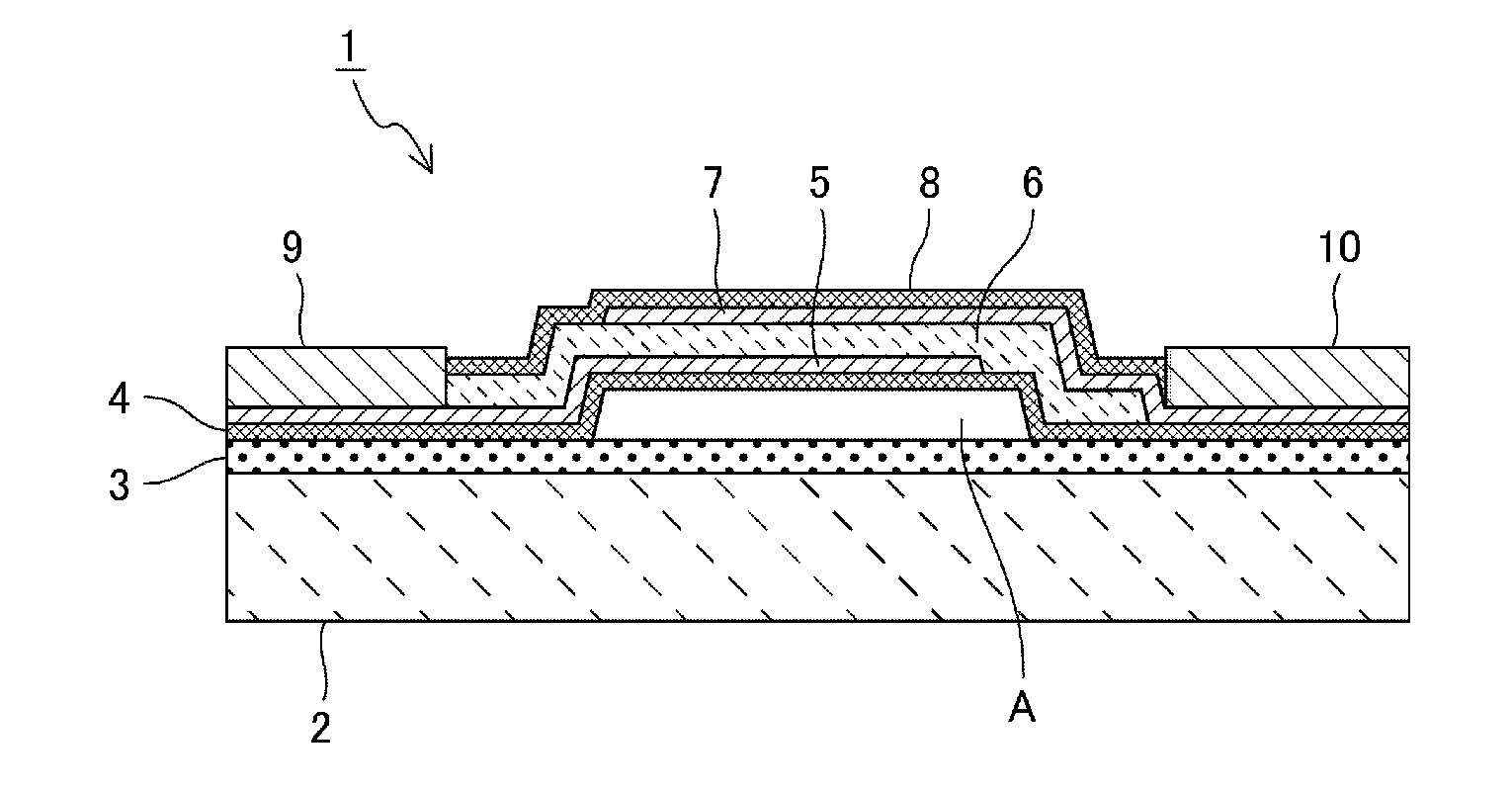

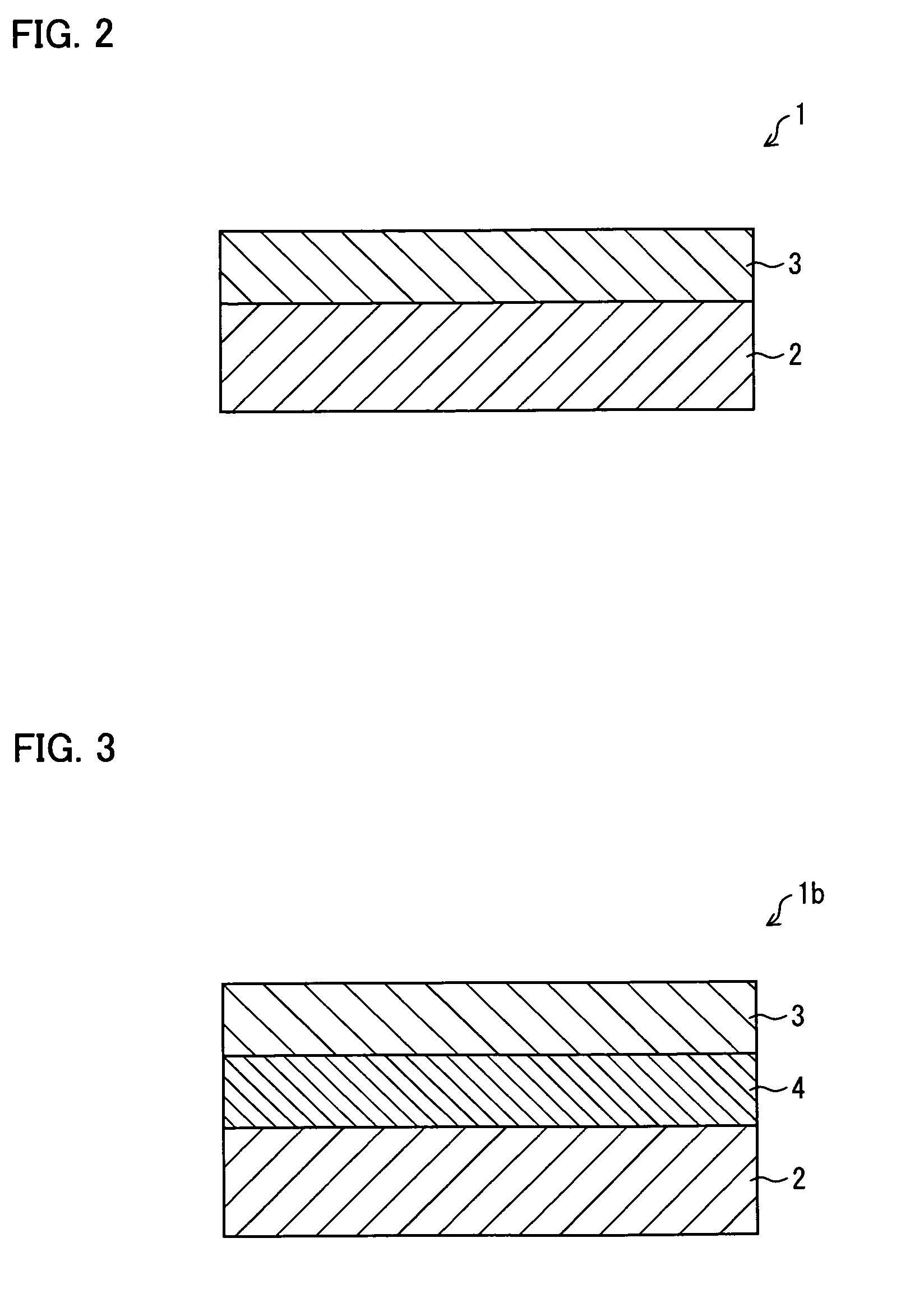

Light emitting device, semiconductor device, and method of fabricating the devices

InactiveUS7045438B2Prevent degradationPreventing deformation and change in qualityTransistorElectroluminescent light sourcesLiquid-crystal displayOrganic light emitting device

A semiconductor device in which degradation due to permeation of water and oxygen can be limited, e.g., a light emitting device having an organic light emitting device (OLED) formed on a plastic substrate, and a liquid crystal display using a plastic substrate. A layer to be debonded, containing elements, is formed on a substrate, bonded to a supporting member, and debonded from the substrate. A thin film is thereafter formed on the debonded layer. The debonded layer with the thin film is adhered to a transfer member. Cracks caused in the debonded layer at the time of debonding are thereby repaired. As the thin film in contact with the debonded layer, a film having thermal conductivity, e.g., film of aluminum nitride or aluminum nitroxide is used. This film dissipates heat from the elements and has the effect of preventing deformation and change in quality of the transfer member, e.g., a plastic substrate.

Owner:SEMICON ENERGY LAB CO LTD

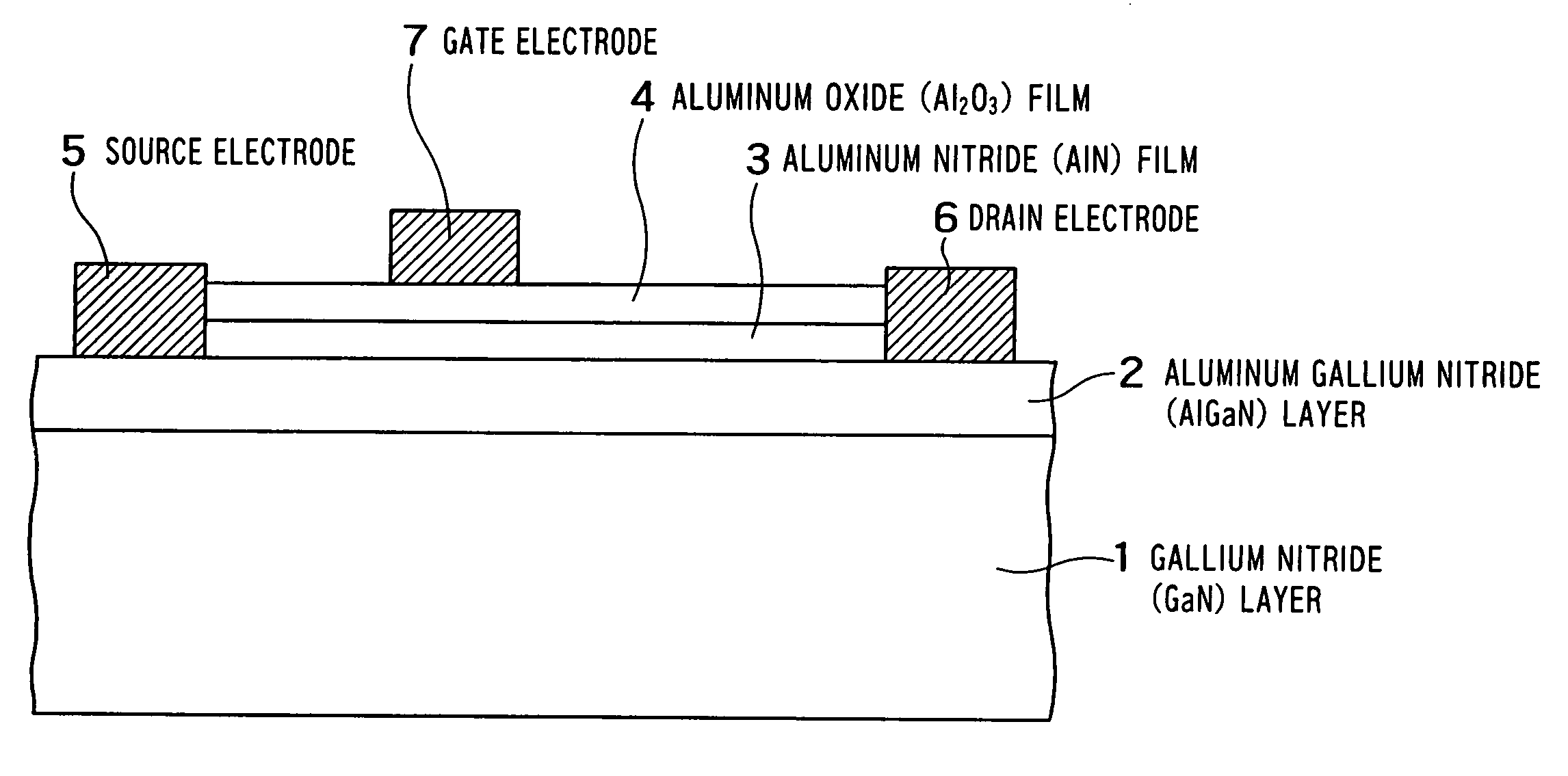

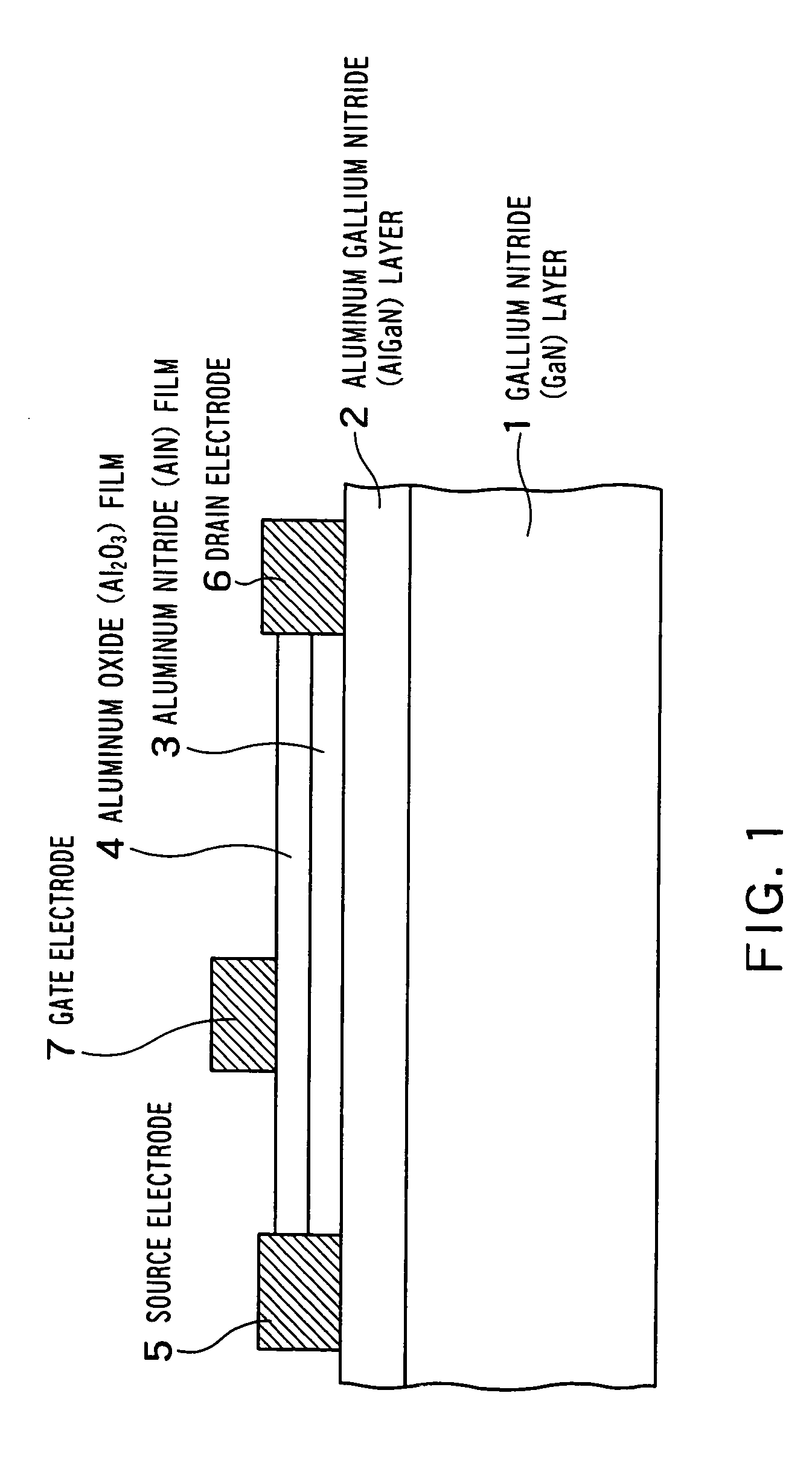

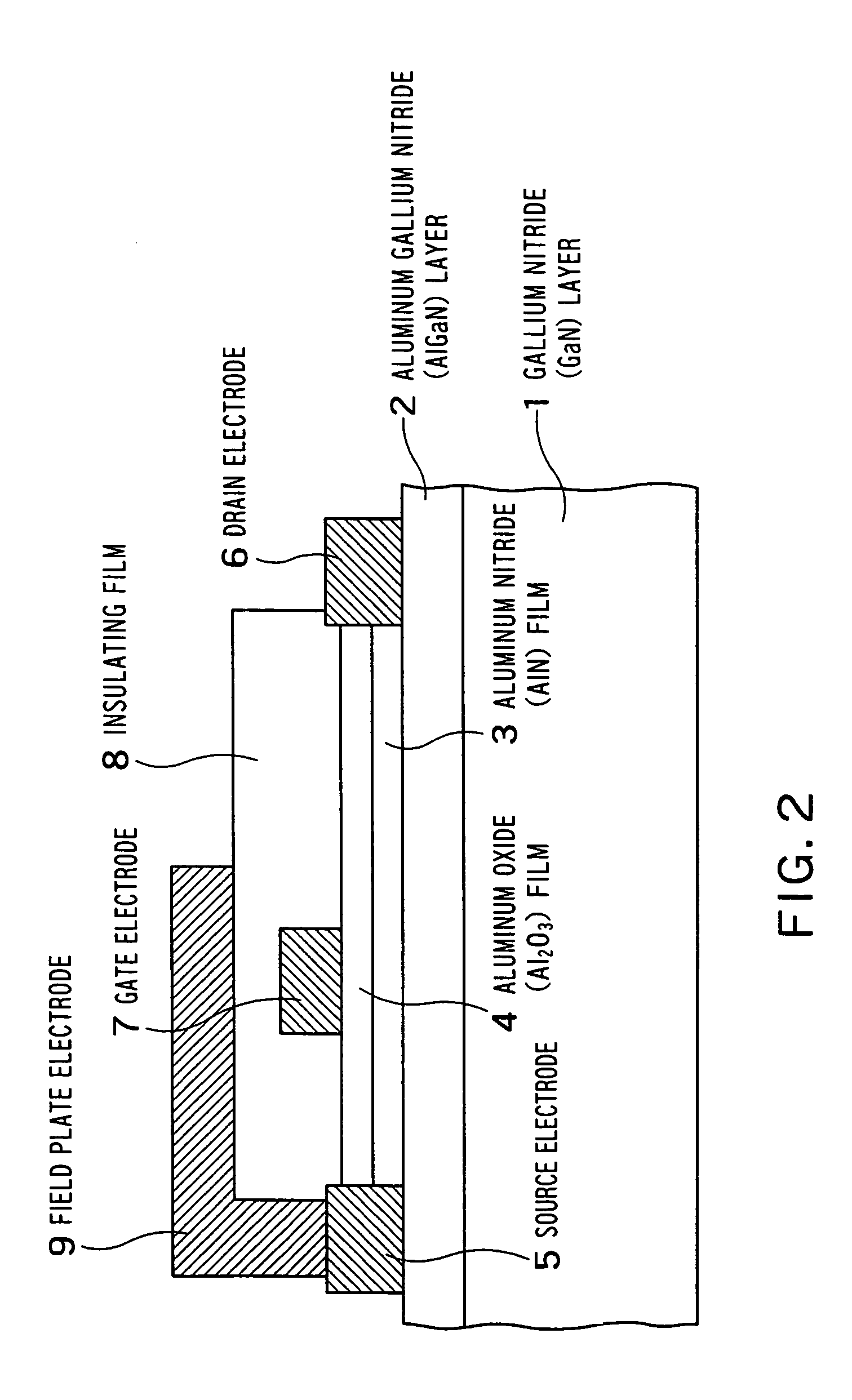

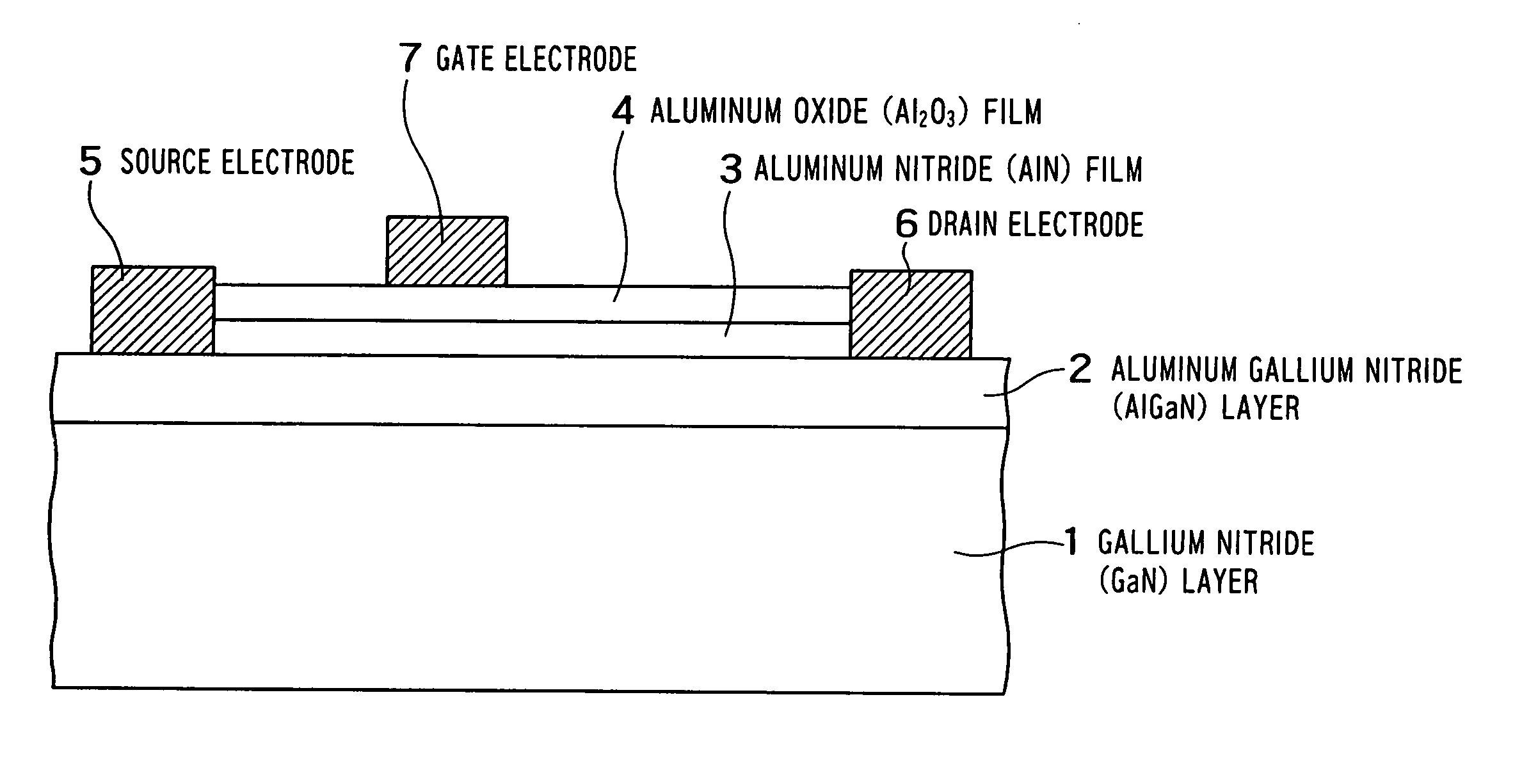

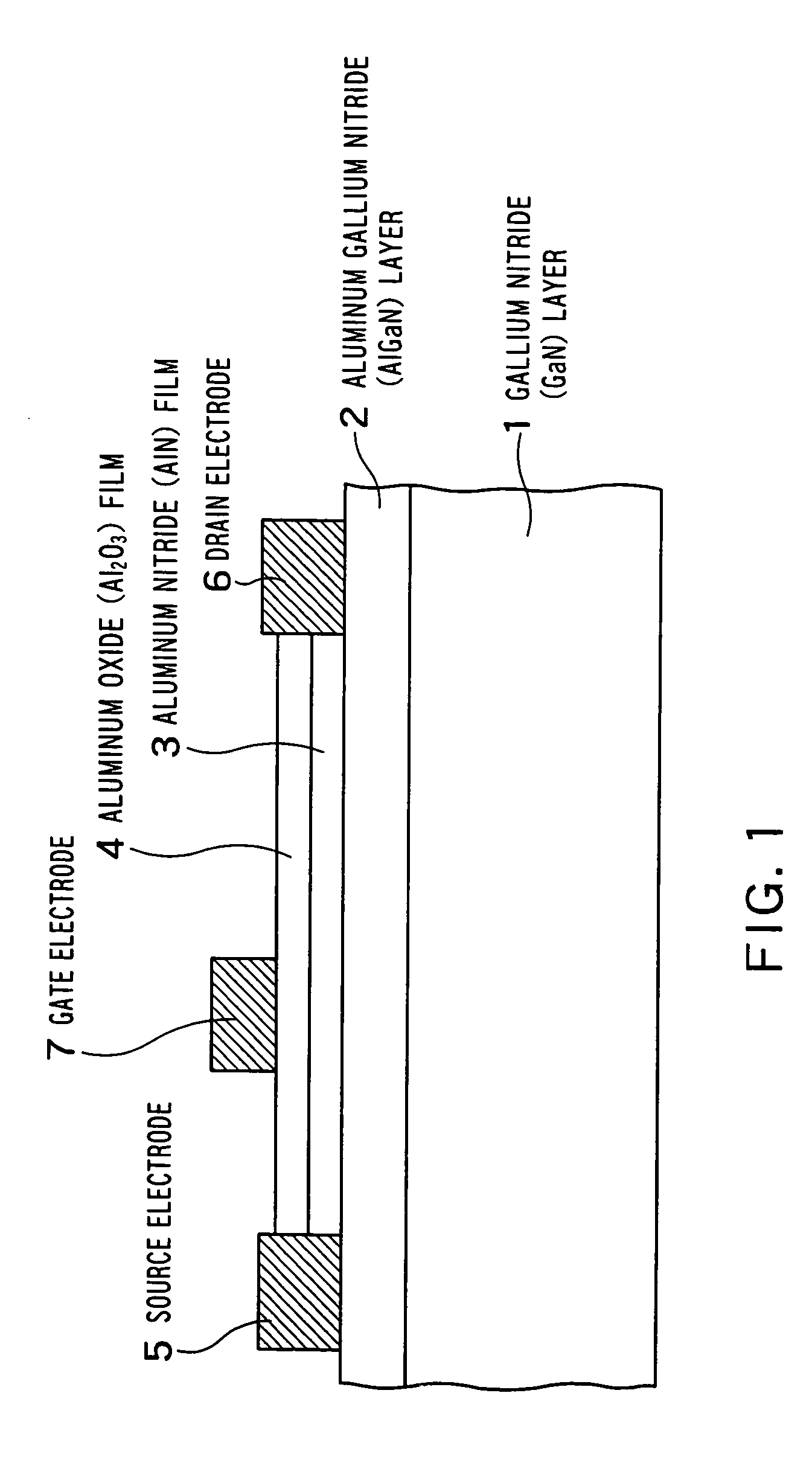

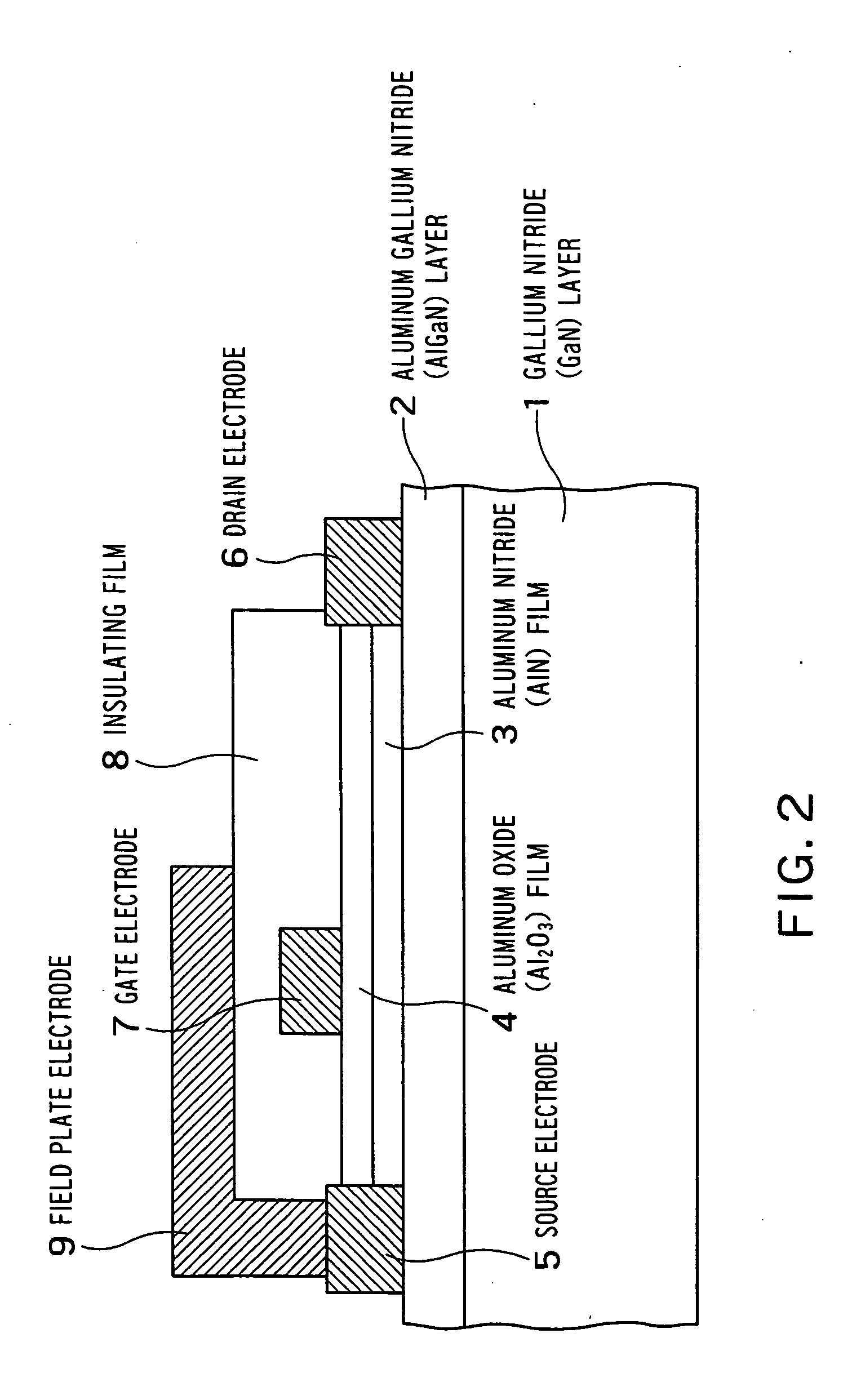

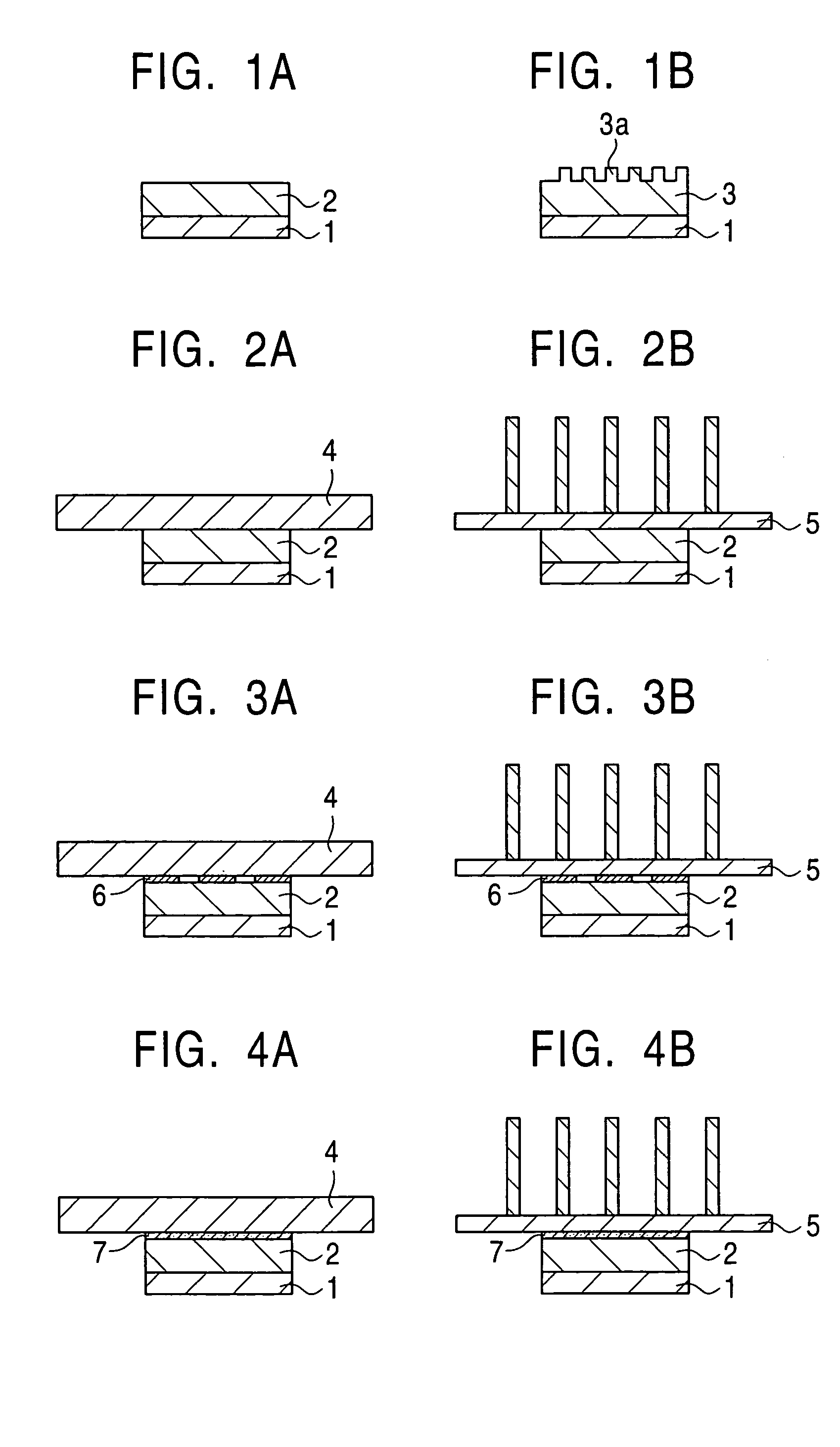

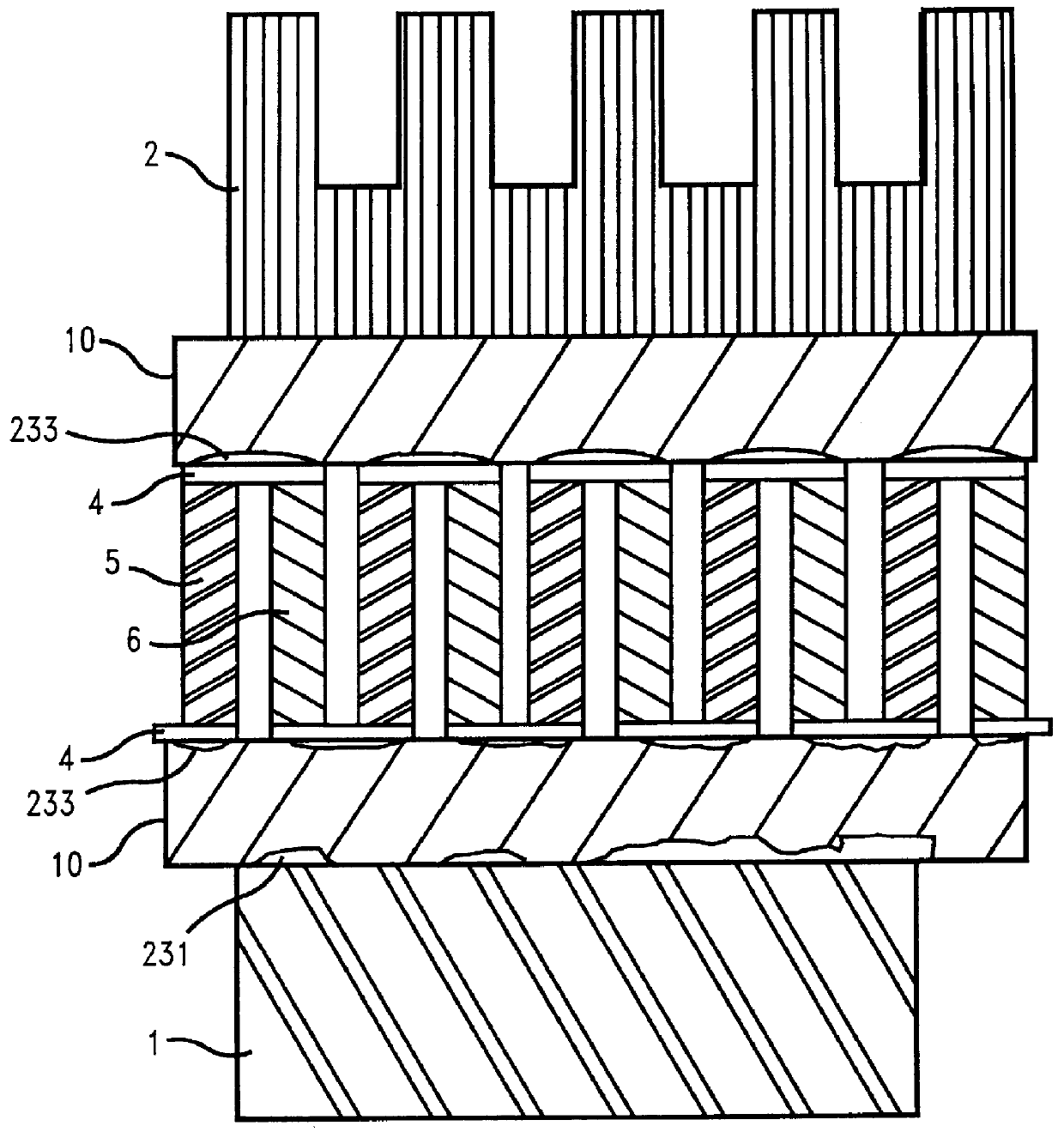

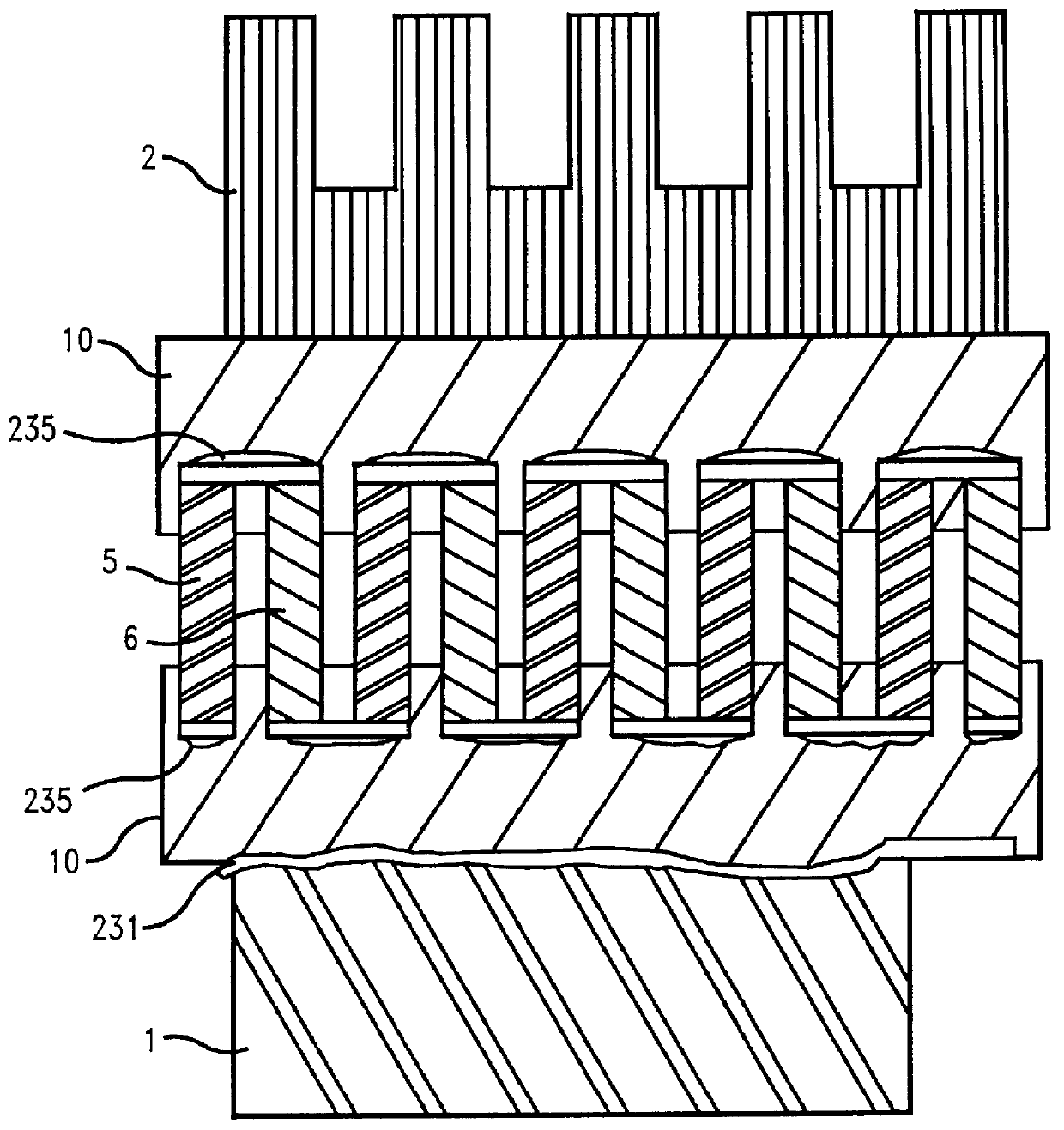

Nitride semiconductor device such as transverse power FET for high frequency signal amplification or power control

InactiveUS7304331B2Semiconductor/solid-state device manufacturingSemiconductor devicesNon dopedSignal amplification

A nitride semiconductor device according to one embodiment of the present invention includes: a non-doped first aluminum gallium nitride (AlxGa1-xN (0≦x≦1)) layer which is formed as a channel layer; a non-doped or n type second aluminum gallium nitride (AlyGa1-yN (0≦y≦1, x <y)) layer which is formed on the first aluminum gallium nitride layer as a barrier layer; an aluminum nitride (AlN) film which is formed on the second aluminum gallium nitride layer as a gate insulating film lower layer; an aluminum oxide (AL2O3) film which is formed on the aluminum nitride film as a gate insulating film upper layer; a source electrode and a drain electrode which are formed as first and second main electrodes to be electrically connected to the second aluminum gallium nitride layer, respectively; and a gate electrode which is formed on the aluminum oxide film as a control electrode.

Owner:KK TOSHIBA

Nitride semiconductor device

InactiveUS20060011915A1Semiconductor/solid-state device manufacturingSemiconductor devicesNon dopedNitride semiconductors

A nitride semiconductor device according to one embodiment of the present invention comprises: a non-doped first aluminum gallium nitride (AlxGa1-xN (0≦x≦1)) layer which is formed as a channel layer; a non-doped or n type second aluminum gallium nitride (AlyGa1-yN (0≦x≦1,x<y)) layer which is formed on the first aluminum gallium nitride layer as a barrier layer; an aluminum nitride (AlN) film which is formed on the second aluminum gallium nitride layer as a gate insulating film lower layer; an aluminum oxide (Al2O3) film which is formed on the aluminum nitride film as a gate insulating film upper layer; a source electrode and a drain electrode which are formed as first and second main electrodes to be electrically connected to the second aluminum gallium nitride layer, respectively; and a gate electrode which is formed on the aluminum oxide film as a control electrode.

Owner:KK TOSHIBA

Fused aluminum oxycarbide/nitride-Al2O3.rare earth oxide eutectic materials

Fused, crystalline eutectic material comprising aluminum oxycarbide / nitride-Al2O3.rare earth oxide eutectics. Examples of useful articles comprising the fused eutectic material include fibers and abrasive particles.

Owner:3M INNOVATIVE PROPERTIES CO

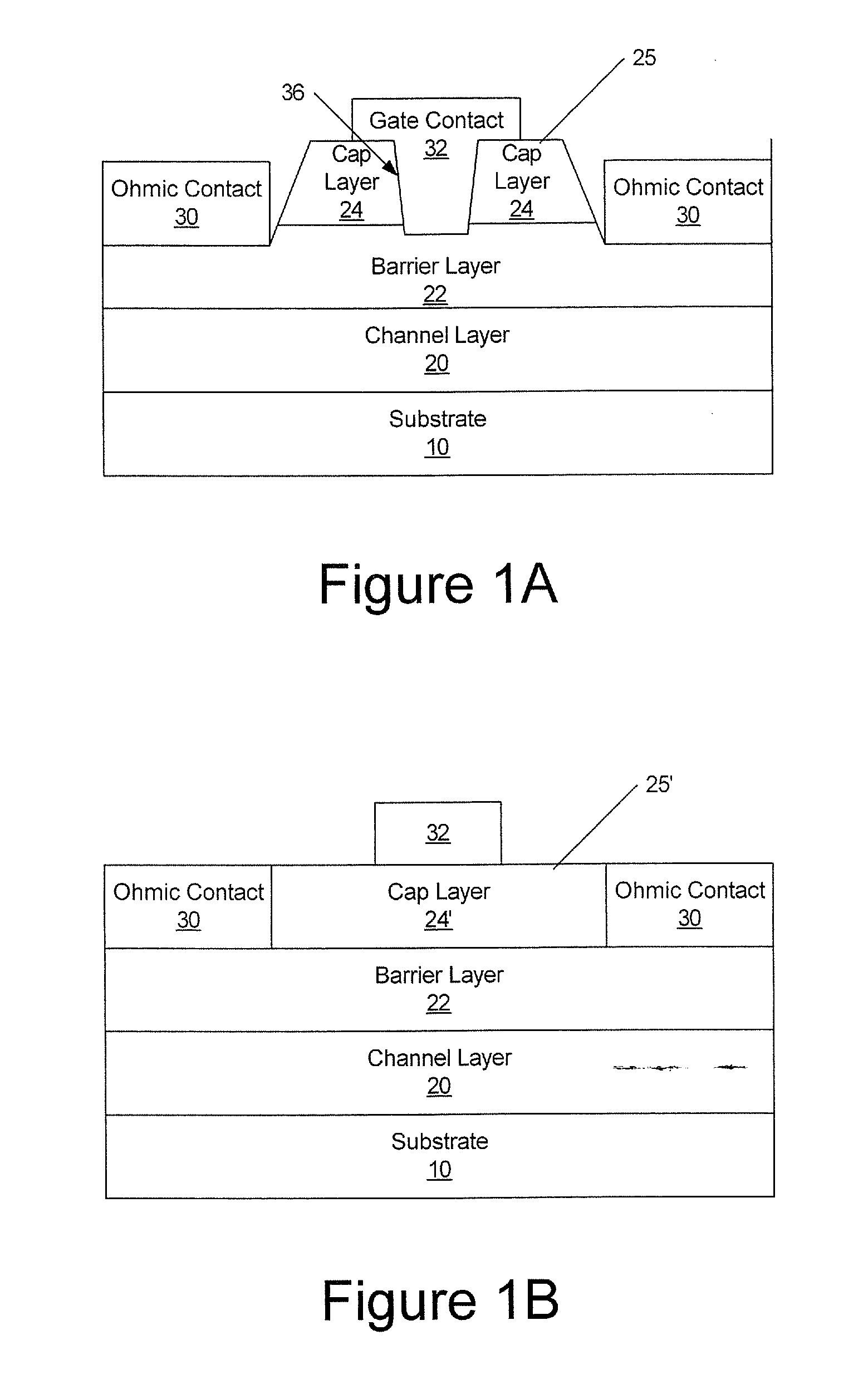

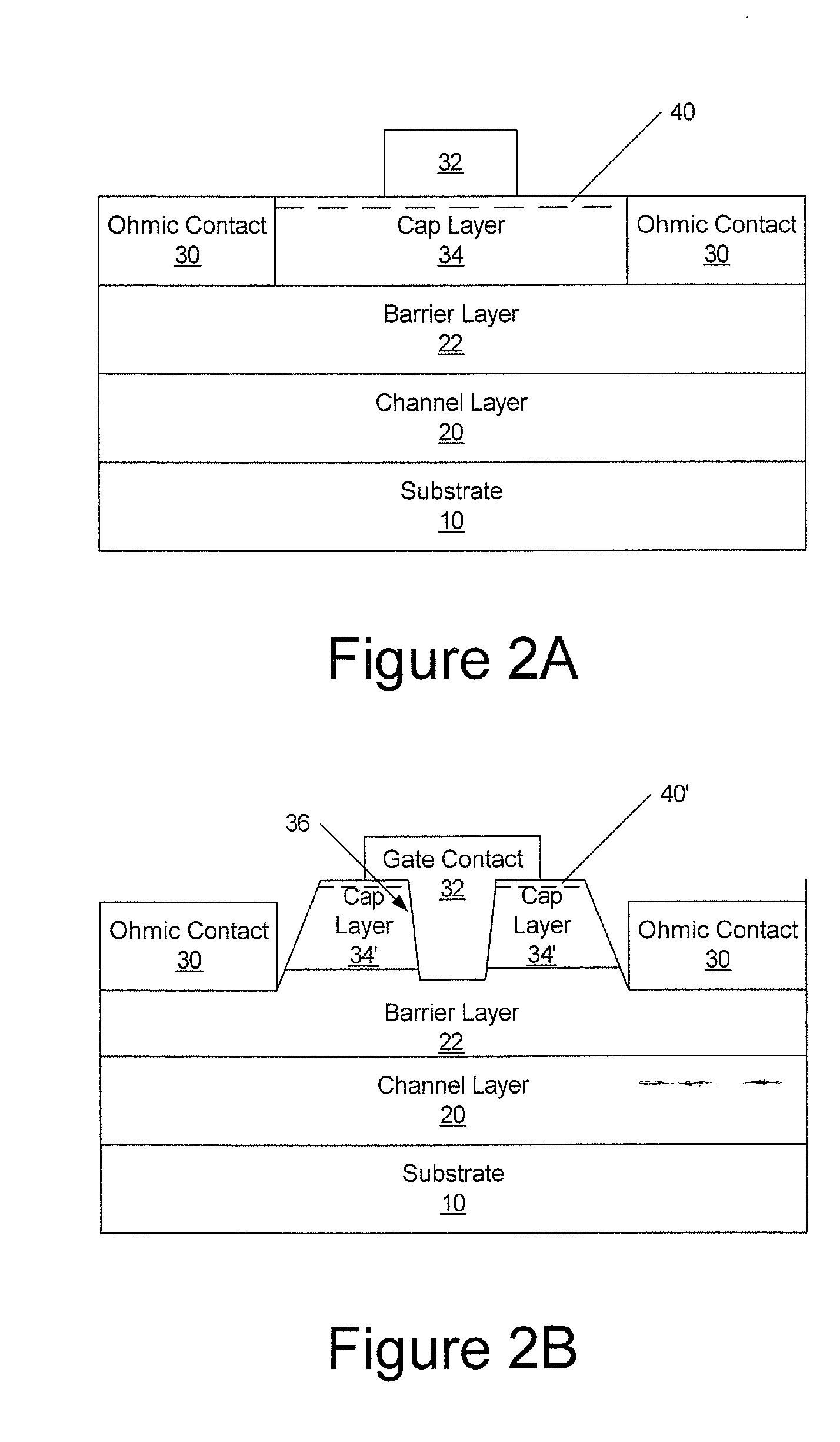

Cap Layers Including Aluminum Nitride for Nitride-Based Transistors and Methods of Fabricating Same

ActiveUS20070164315A1Increase concentrationSemiconductor/solid-state device detailsSolid-state devicesOhmic contactGraphite

High electron mobility transistors are provided that include a non-uniform aluminum concentration AlGaN based cap layer having a high aluminum concentration adjacent a surface of the cap layer that is remote from the barrier layer on which the cap layer is provided. High electron mobility transistors are provided that include a cap layer having a doped region adjacent a surface of the cap layer that is remote from the barrier layer on which the cap layer is provided. Graphitic BN passivation structures for wide bandgap semiconductor devices are provided. SiC passivation structures for Group III-nitride semiconductor devices are provided. Oxygen anneals of passivation structures are also provided. Ohmic contacts without a recess are also provided.

Owner:CREE INC

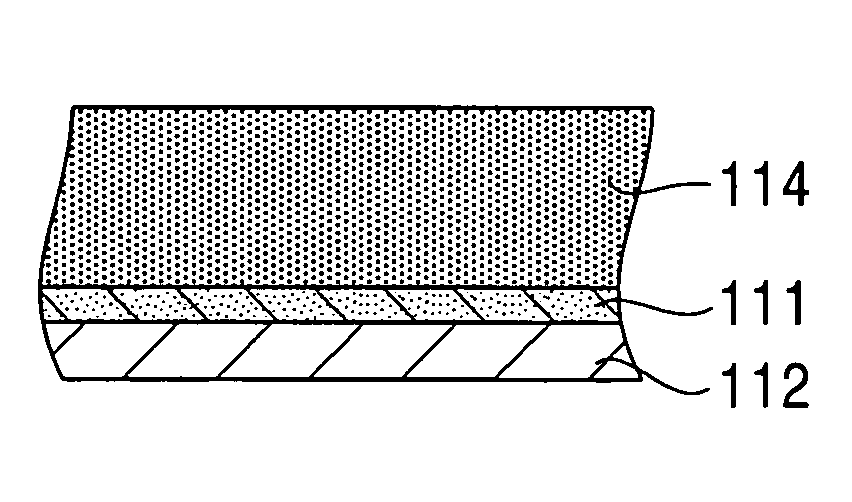

Heat spreader and semiconductor device and package using the same

InactiveUS7067903B2Improve thermal conductivityLarge thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesPolymer adhesiveCeramic

A semiconductor device and package has a heat spreader directly disposed on the reverse surface of the semiconductor device. This heat spreader includes a diamond layer or a layer containing diamond and ceramics such as silicon carbide and aluminum nitride. The heat spreader is directly formed on a substrate for the semiconductor device. In particular, the heat spreader is composed of a diamond layer and one or two metal or ceramic members, which are bonded to the diamond layer with one or two polymer adhesive layers. This diamond layer has a fiber structure across the thickness or a microcrystalline structure. Cilia are formed on a surface of the diamond layer facing the one or two metal or ceramic members.

Owner:KOBE STEEL LTD

Light emitting device, lighting equipment or liquid crystal display device using such light emitting device

ActiveUS7812360B2Improve cooling effectIncrease currentSolid-state devicesSemiconductor devicesLiquid-crystal displayLight equipment

Owner:KK TOSHIBA +1

Short fiber-particle synergetically-reinforced copper-based composite material and preparation method thereof

The invention relates to a copper-based composite material, and particularly relates to a short fiber-particle synergetically-reinforced copper-based composite material which is prepared through powder metallurgy. Short fibers and particles are used as reinforced phases, the content of the short fiber is 0.1-0.1 wt%, and the content of reinforcement particles is 0.1-10 wt%. The short fibers can be carbon nanotubes, carbon nanofibers, ceramic short fibers, and the like, and the particles used as reinforced phases can be aluminum oxide, zirconium oxide, magnesium oxide, titanium dioxide, silicon carbide, titanium carbide, tungsten carbide, silicon nitride, aluminum nitride, titanium nitride, titanium diboride, Ti3SiC2, and the like. The composite material is prepared through the steps of mixing, forming, sintering and processing, and the room temperature and the high temperature strength of the composite material can be increased by more than 3 times in comparison with those of pure copper; the electrical conductivity of the composite material can reach more than 80% of that of pure copper; the thermal conductivity of the composite material can reach more than 70% of that of pure copper; the coefficient of friction of the composite material can be reduced to be below 70% of that of pure copper; and the wear rate of the composite material can be reduced to be below 50% of that of pure copper.

Owner:UNIV OF SCI & TECH BEIJING

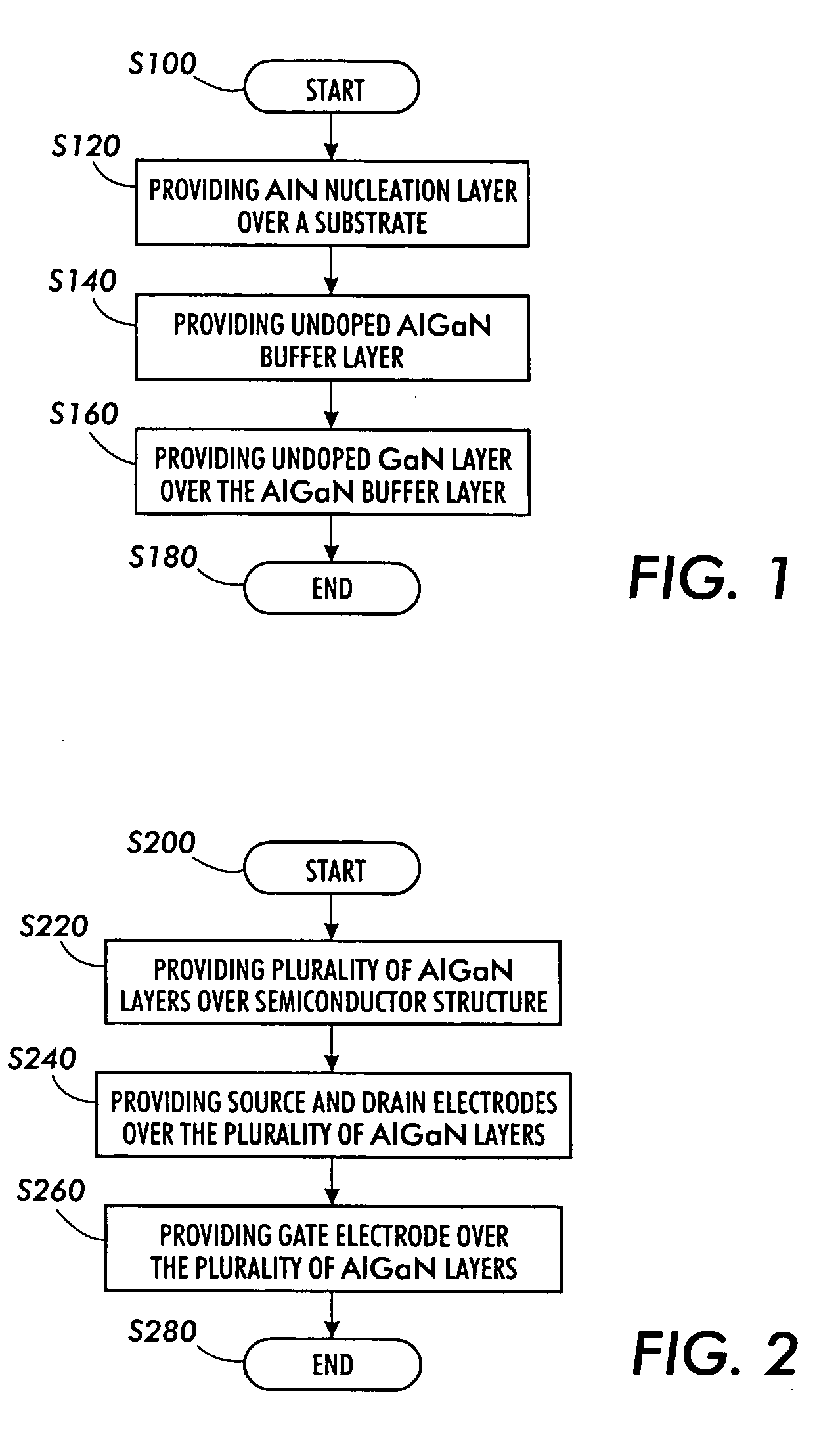

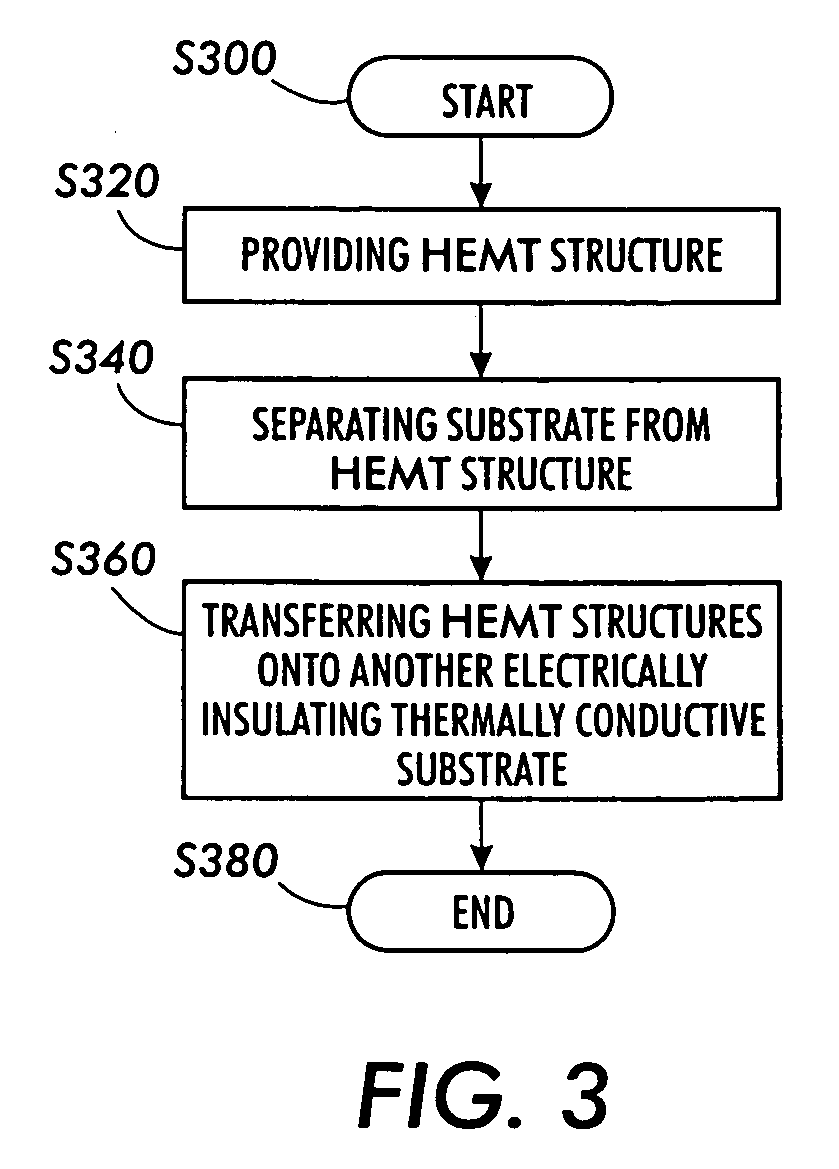

Group III-nitride based HEMT device with insulating GaN/AlGaN buffer layer

InactiveUS20060073621A1Semiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureGallium nitride

Various exemplary embodiments of the devices and methods for this invention provide for a semiconductor structure and a method of manufacturing a semiconductor structure that includes providing an aluminum nitride nucleation layer over a substrate, providing an undoped AlGaN buffer layer over the aluminum nitride nucleation layer, providing an undoped GaN over the AlGaN buffer layer, providing a plurality of AlGaN layers over the GaN layer wherein the plurality of aluminum GaN layers comprise a first layer provided over the undoped GaN layer, a second layer provided over the first layer and the third layer provided over the second layer, providing a source electrode and a drain electrode, through the first, second and third aluminum gallium nitride layers, the source electrode and the drain electrode being in electrical contact with the gallium nitride layer and providing a gate electrode over the third aluminum gallium nitride layer.

Owner:PALO ALTO RES CENT INC

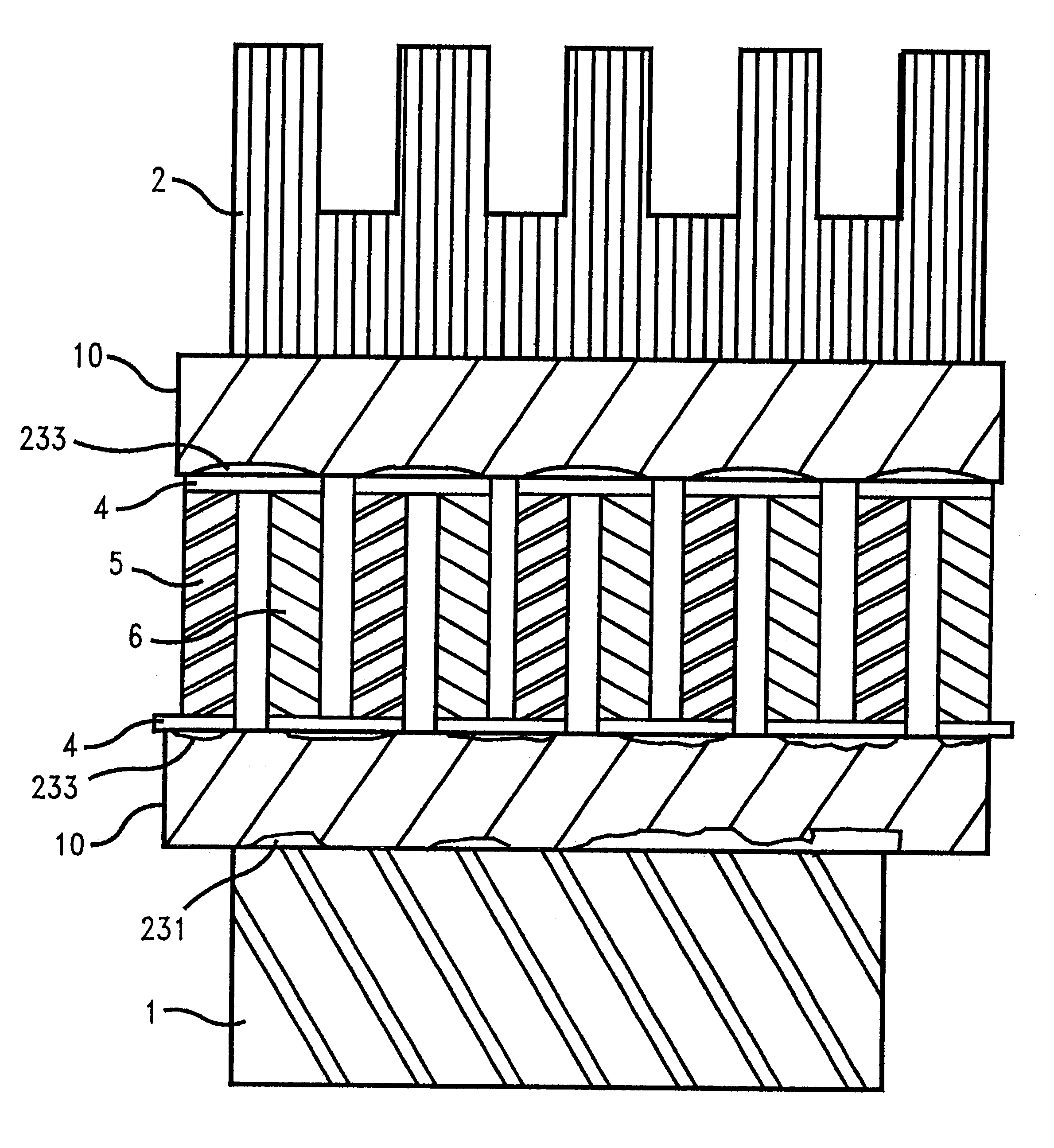

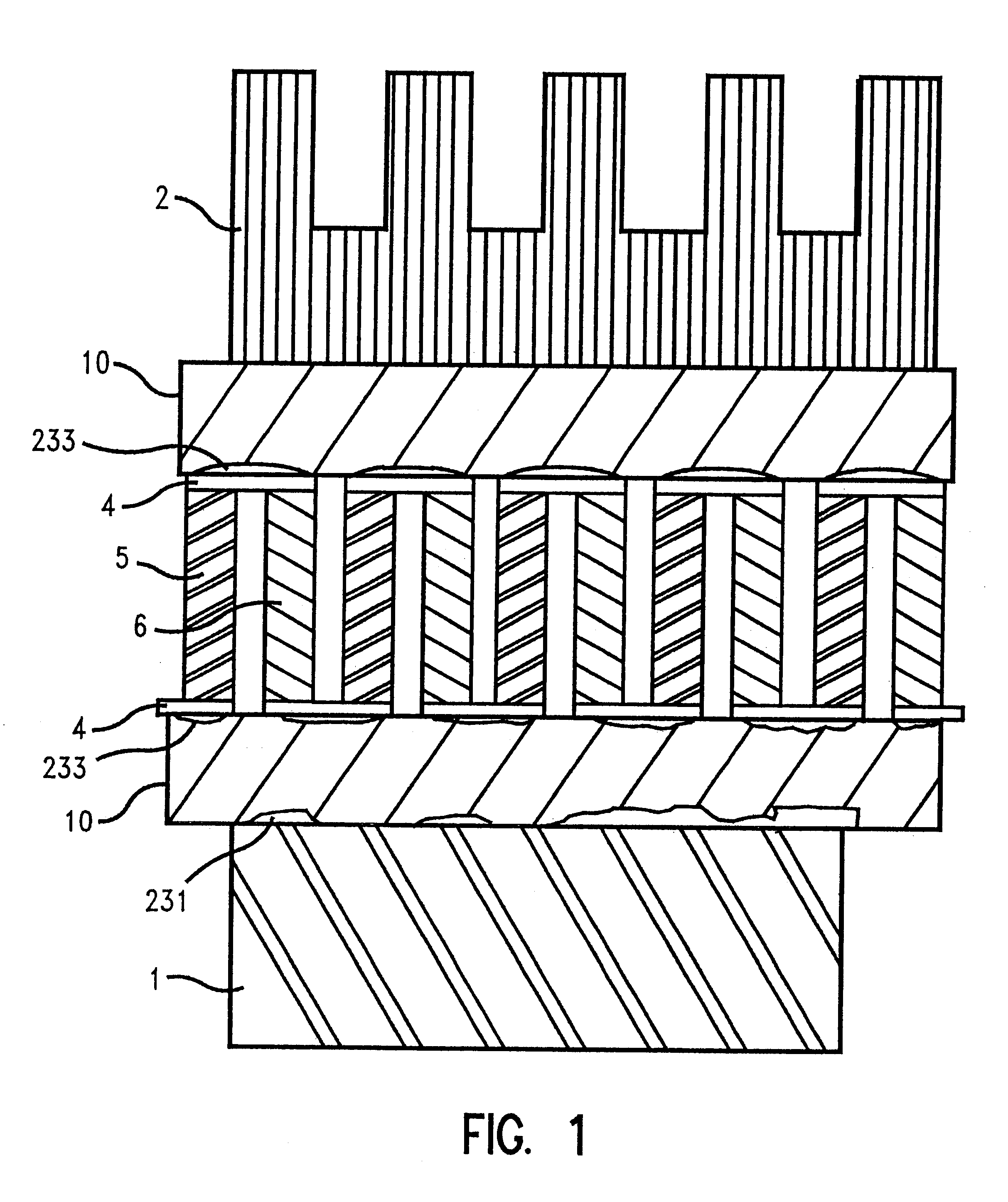

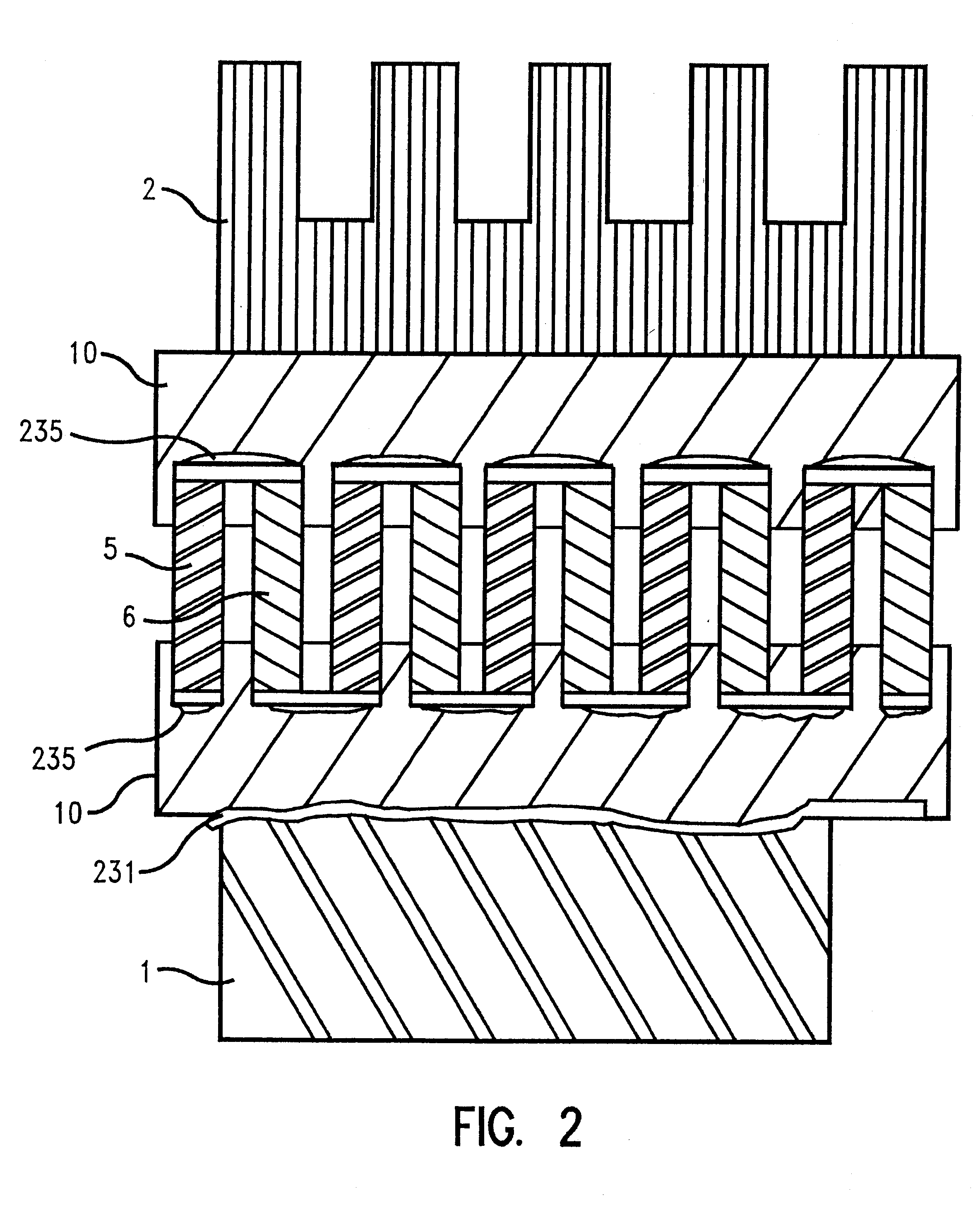

Thermoelectric devices and methods for making the same

InactiveUS6121539AMaximize heat flowMaximize flowThermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsScreening techniquesThermal energy

Thermoelectric devices having enhanced thermal characteristics are fabricated using multilayer ceramic (MLC) technology methods. Aluminum nitride faceplates with embedded electrical connections provide the electrical series configuration for alternating dissimilar semiconducting materials. Embedded electrical connections are formed by vias and lines in the faceplate. Methods are employed for forming tunnels through lamination and etching. A portion of the dissimilar materials are then melted within the tunnels to form a bond. Thermal conductivity of the faceplate is enhanced by adding electrically isolated vias to one surface, filled with high thermal conductivity metal paste. A low thermal conductivity material is also introduced between the two high thermal conductivity material faceplates. Alternating semiconducting materials are introduced within the varying thermal conductivity layers by punching vias within greensheets of predetermined thermal conductivity and filling with n-type and p-type paste. Alternating semiconducting materials may also be patterned in linear or radial fanout patterns through screening techniques and lamination of wire structures. A liquid channel within the faceplate is used to enhance thermal energy transfer. Thermoelectric devices are physically incorporated within the IC package using MLC technology.

Owner:IBM CORP

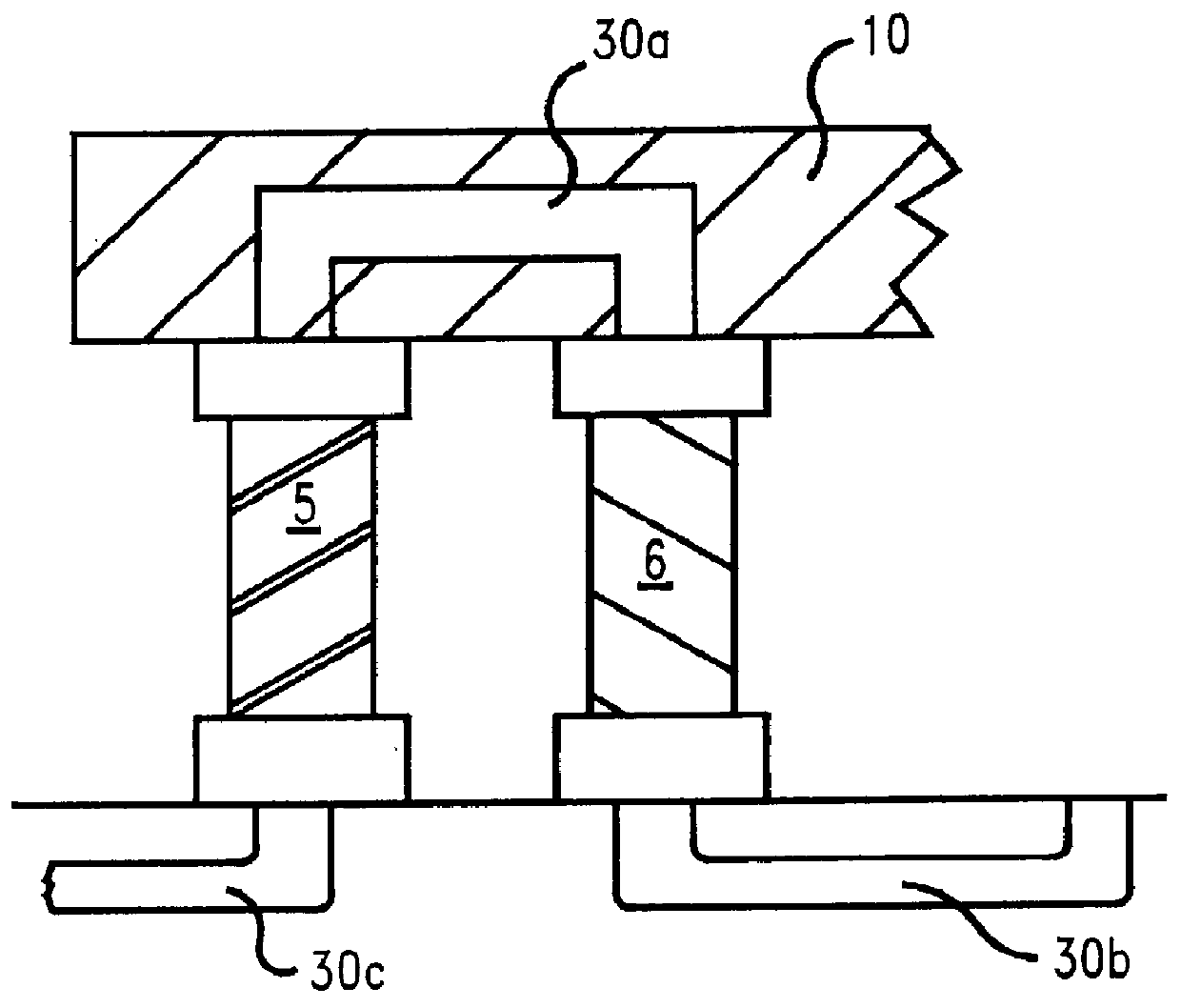

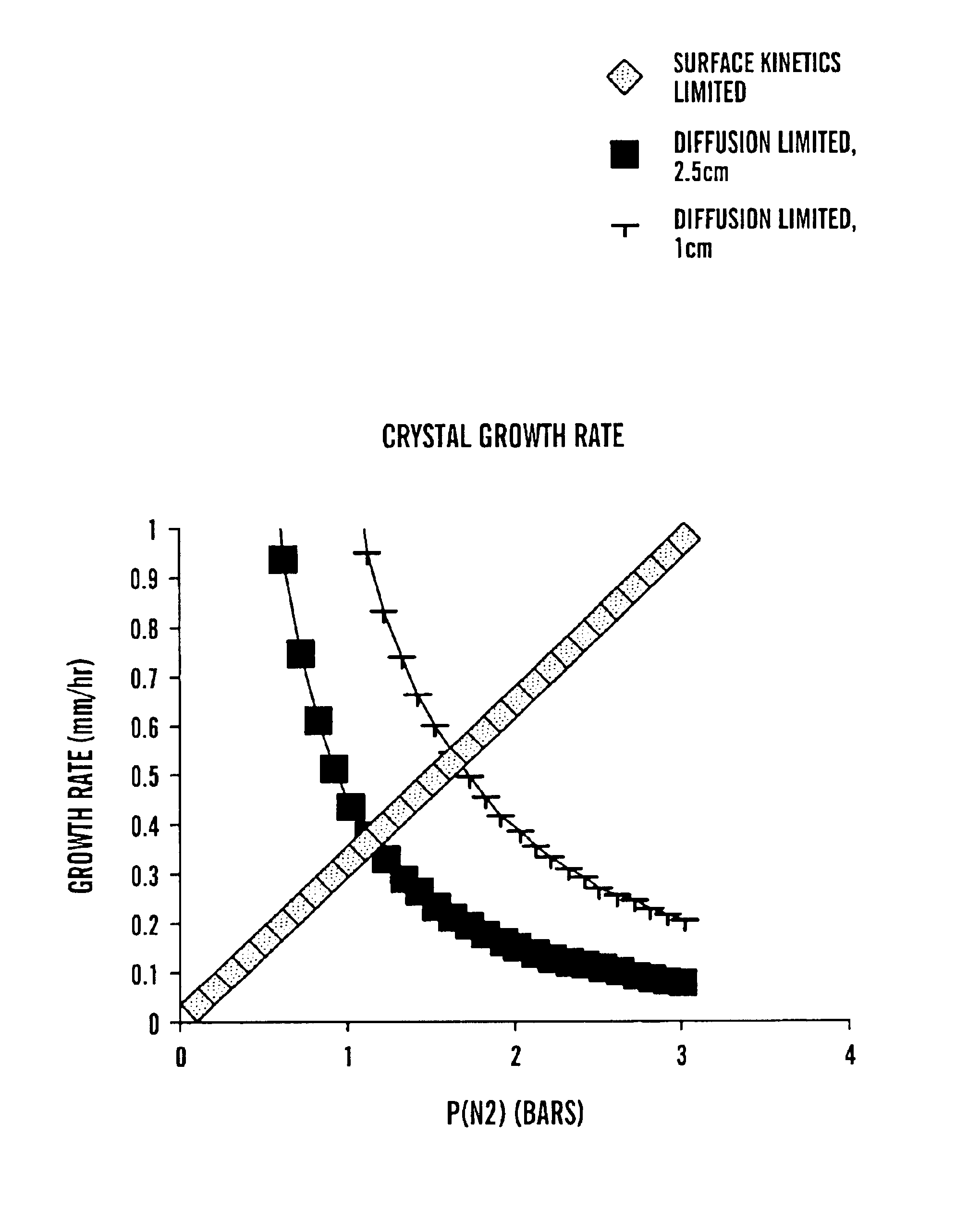

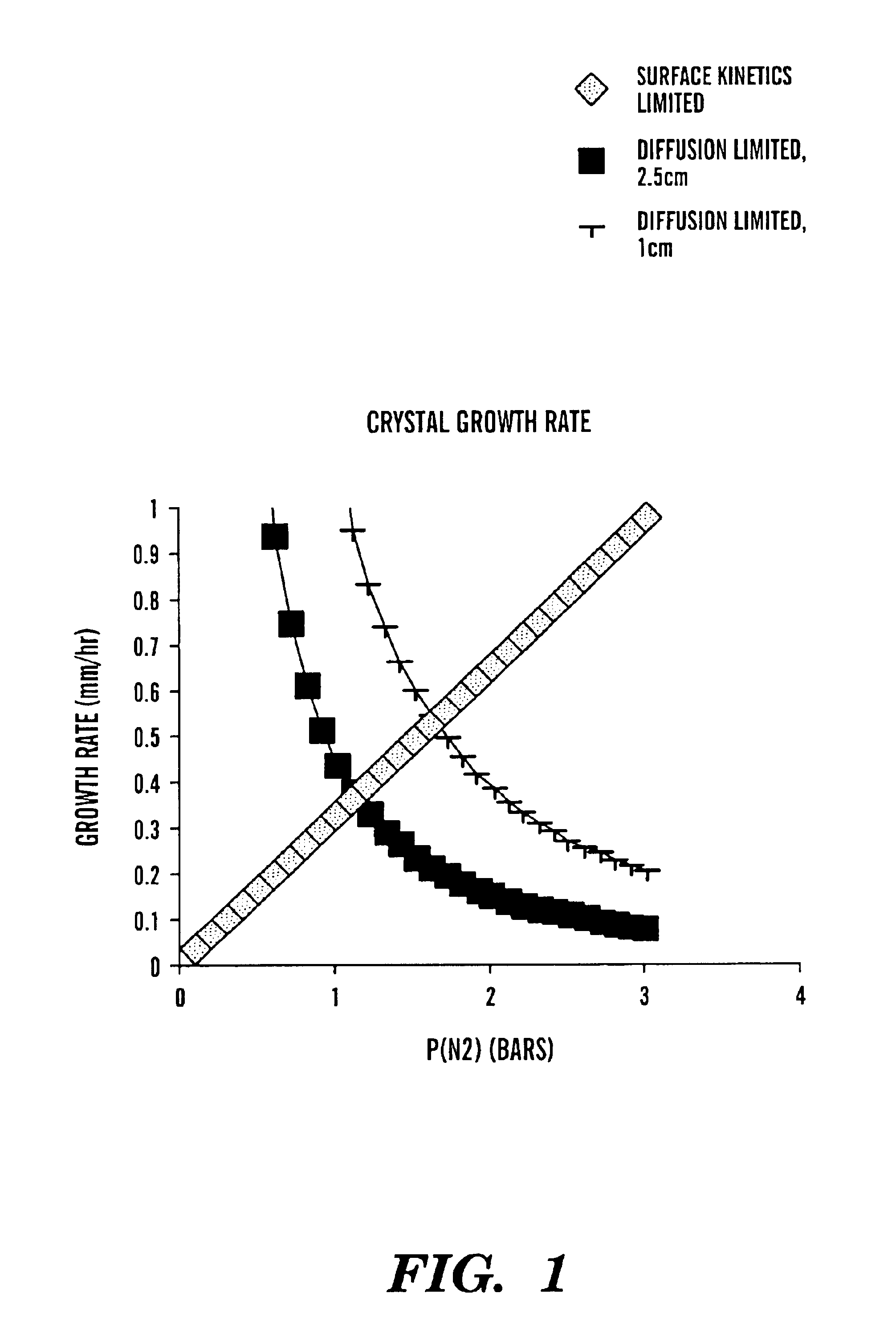

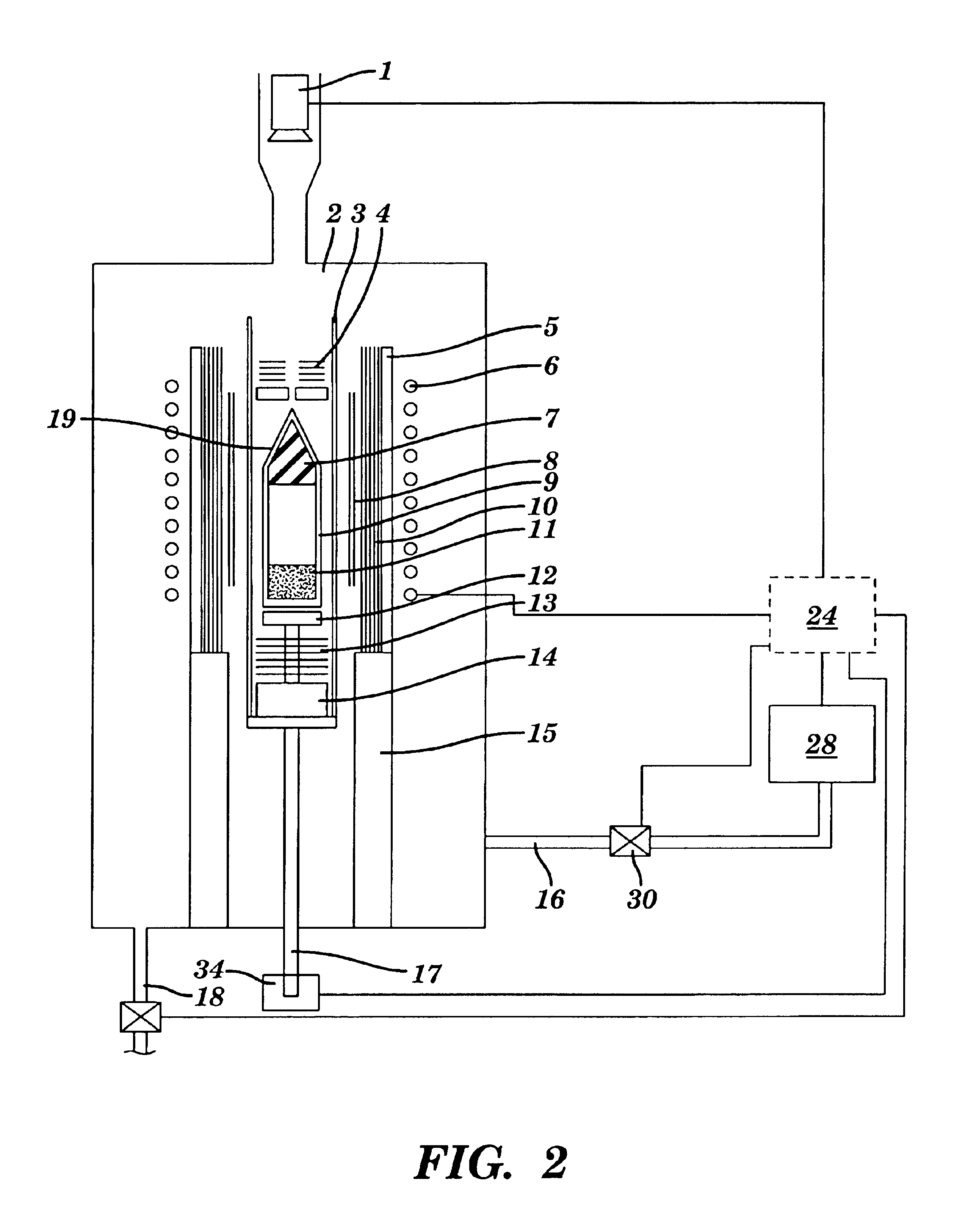

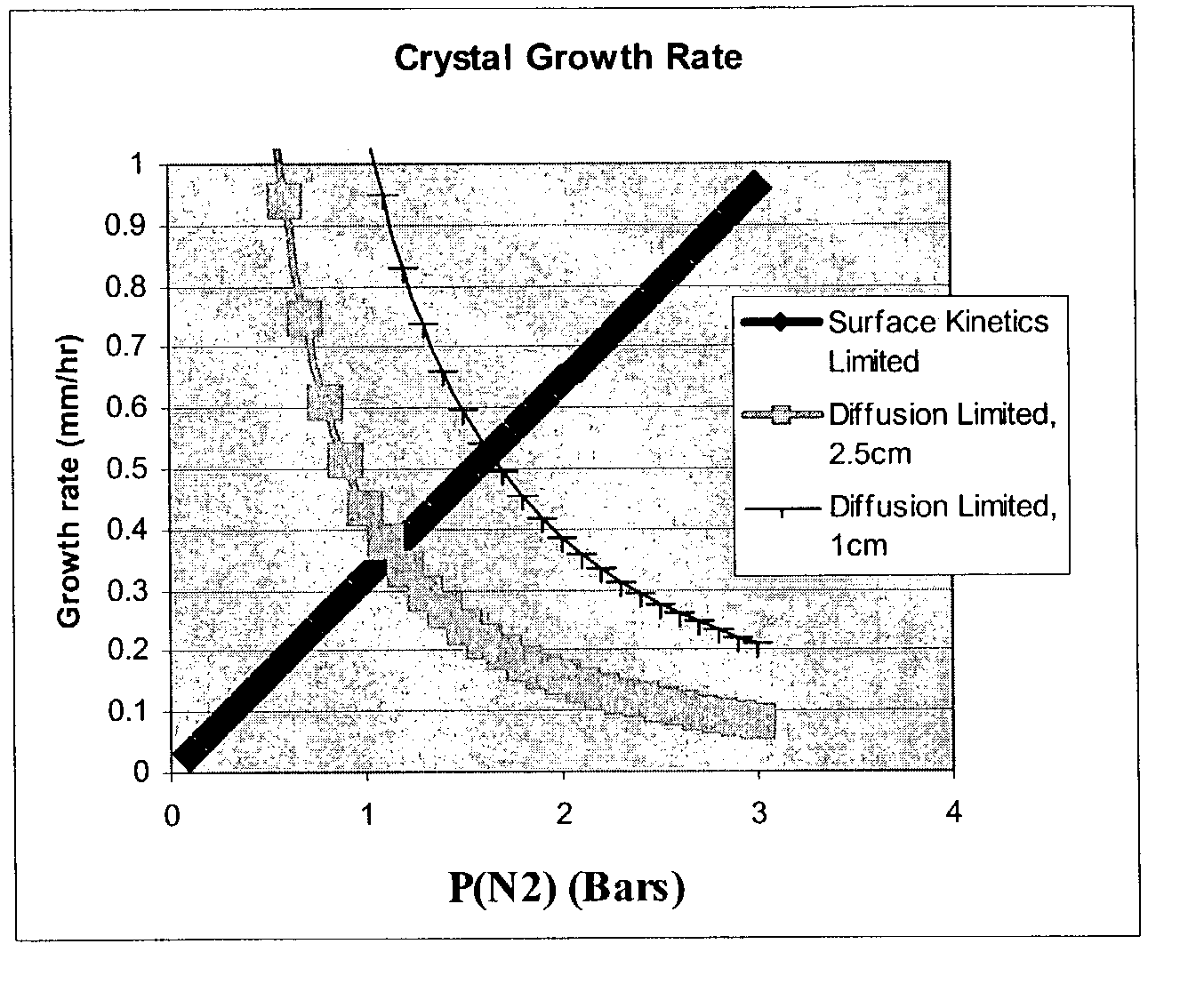

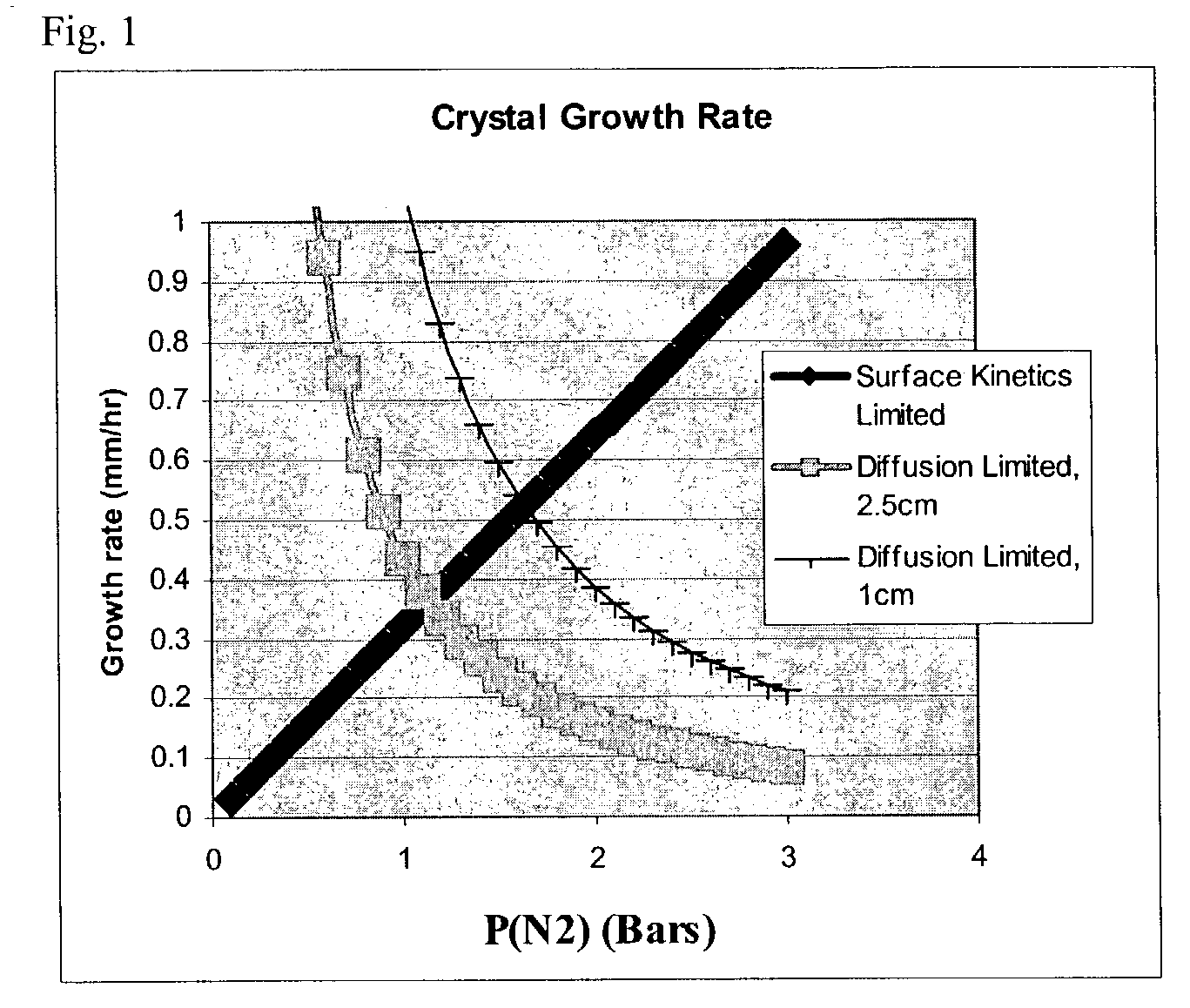

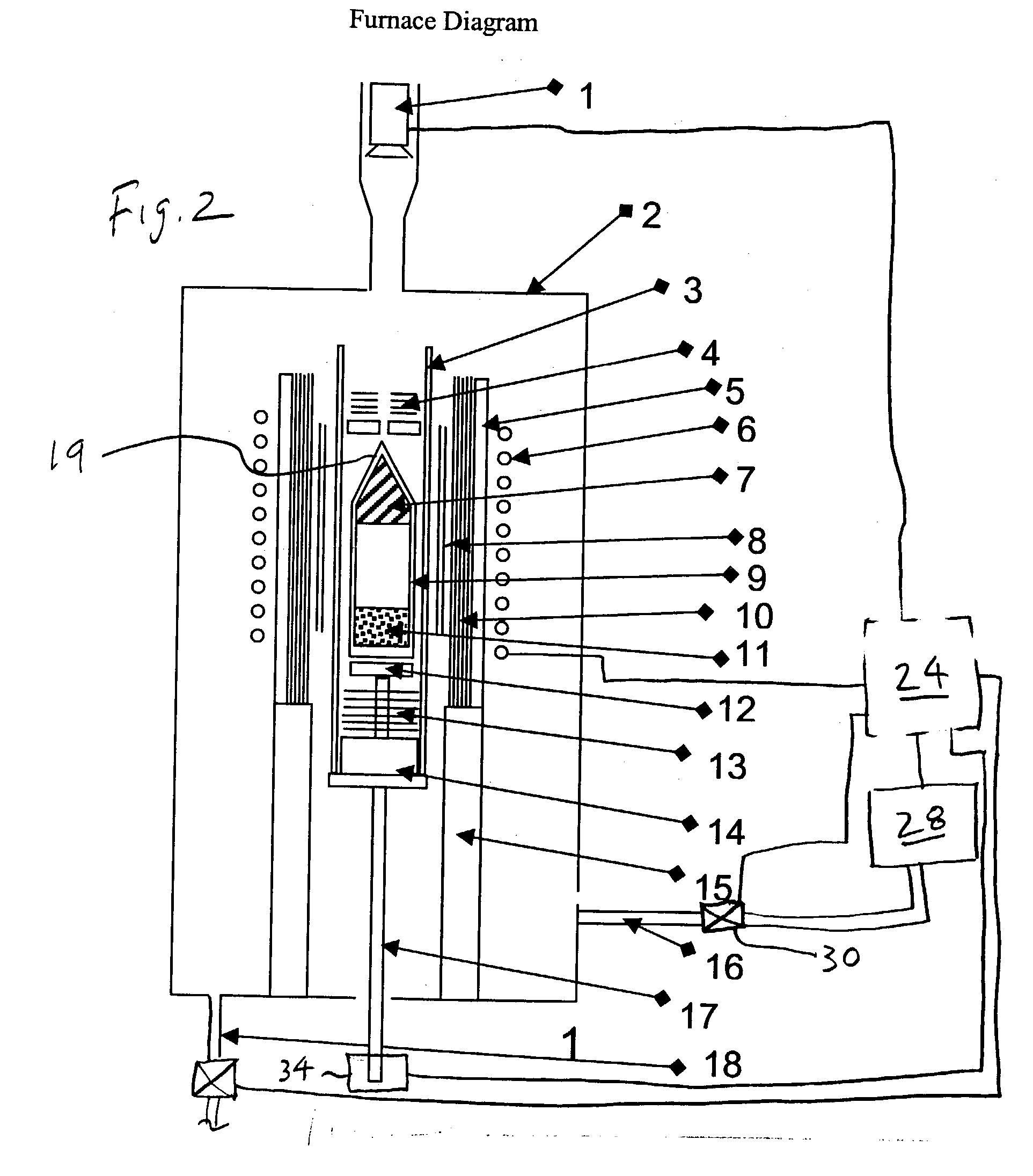

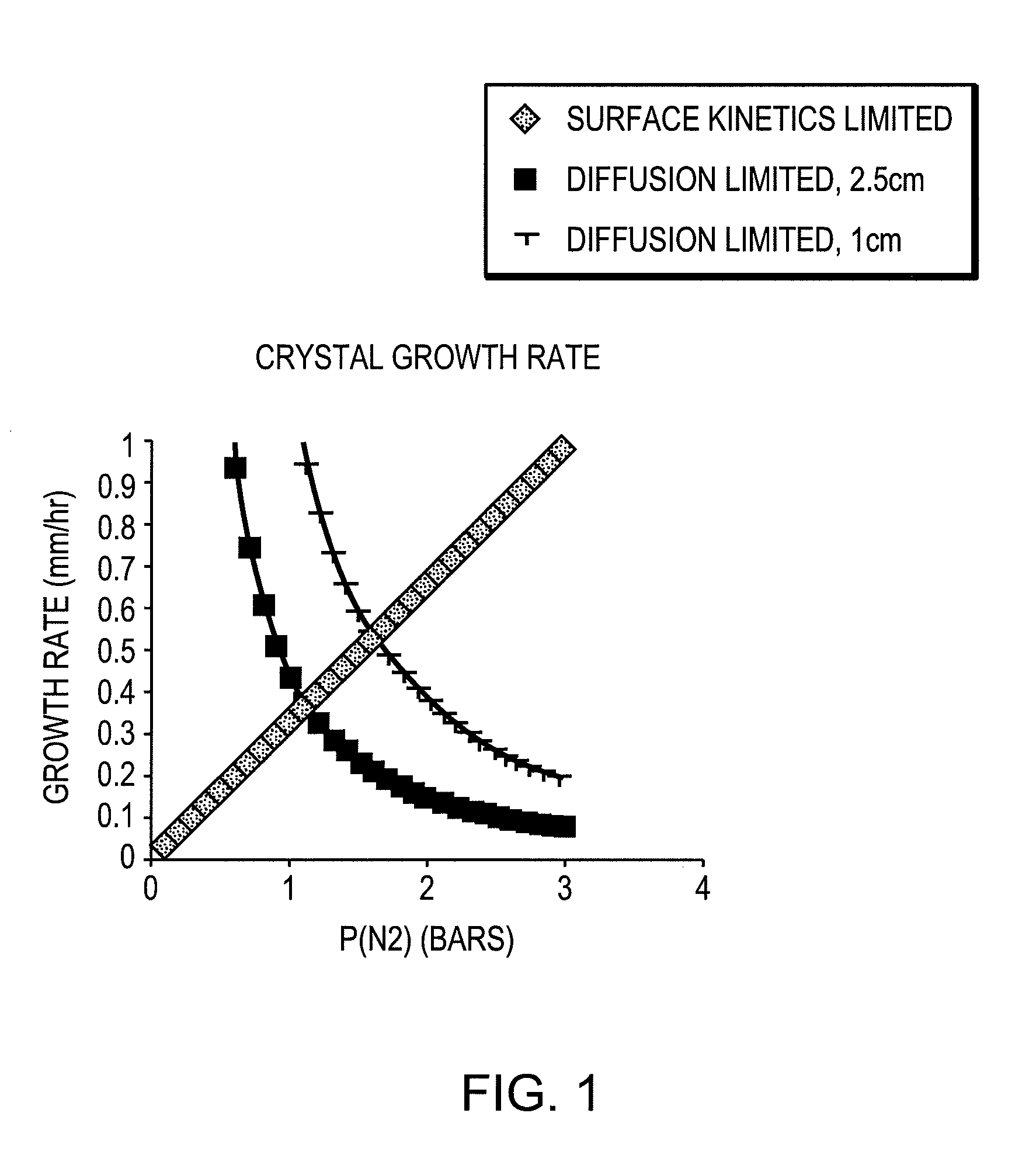

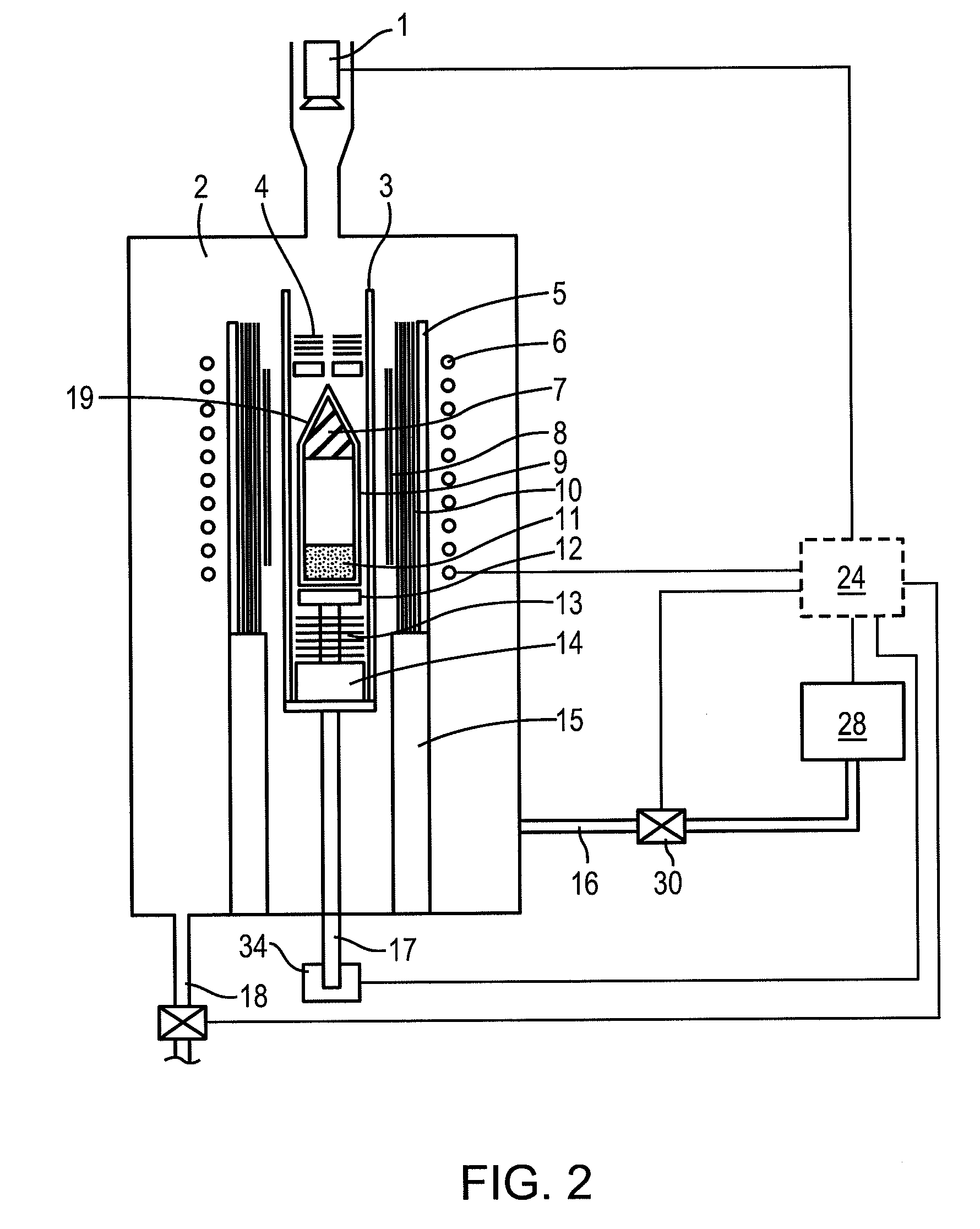

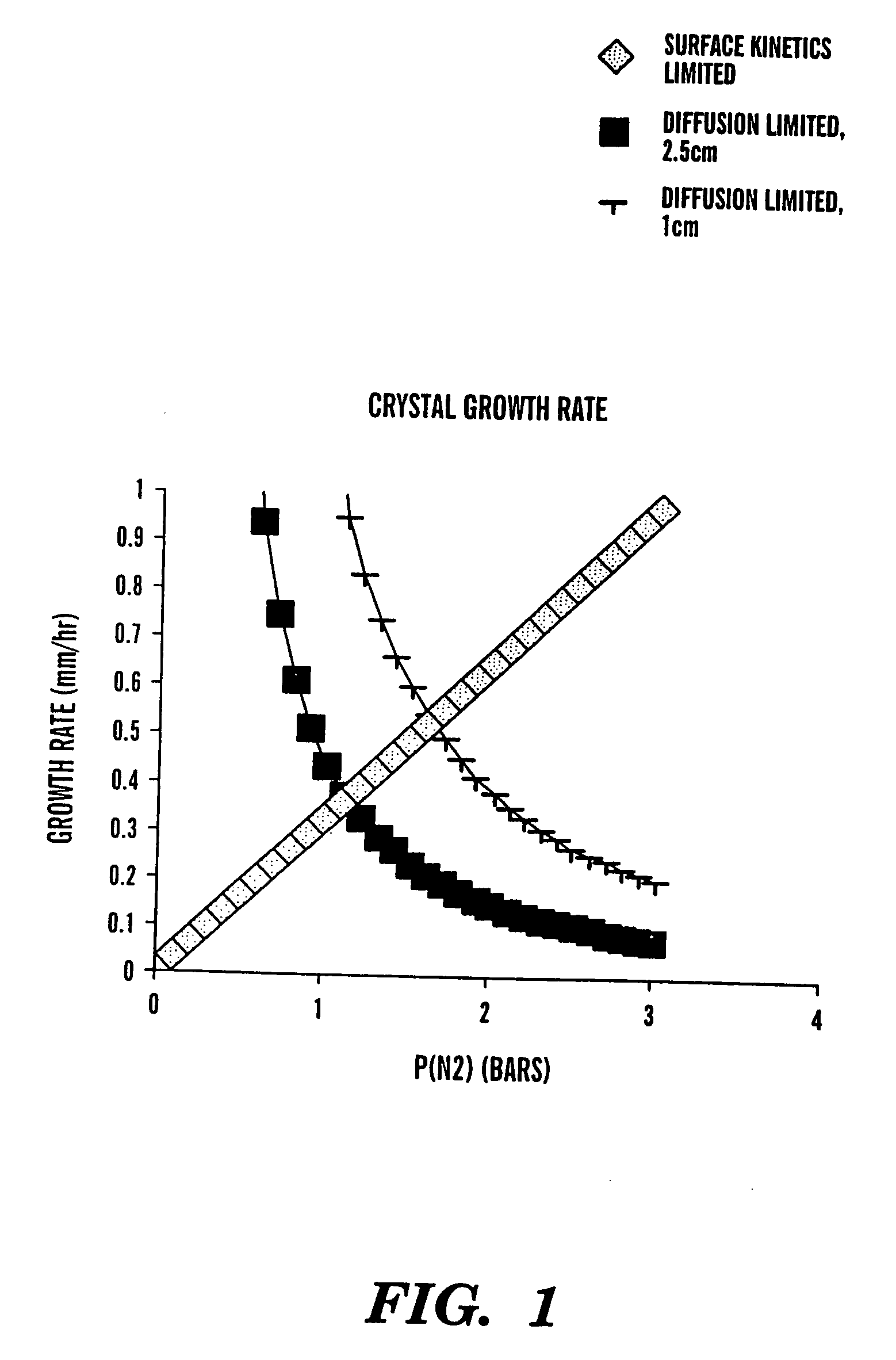

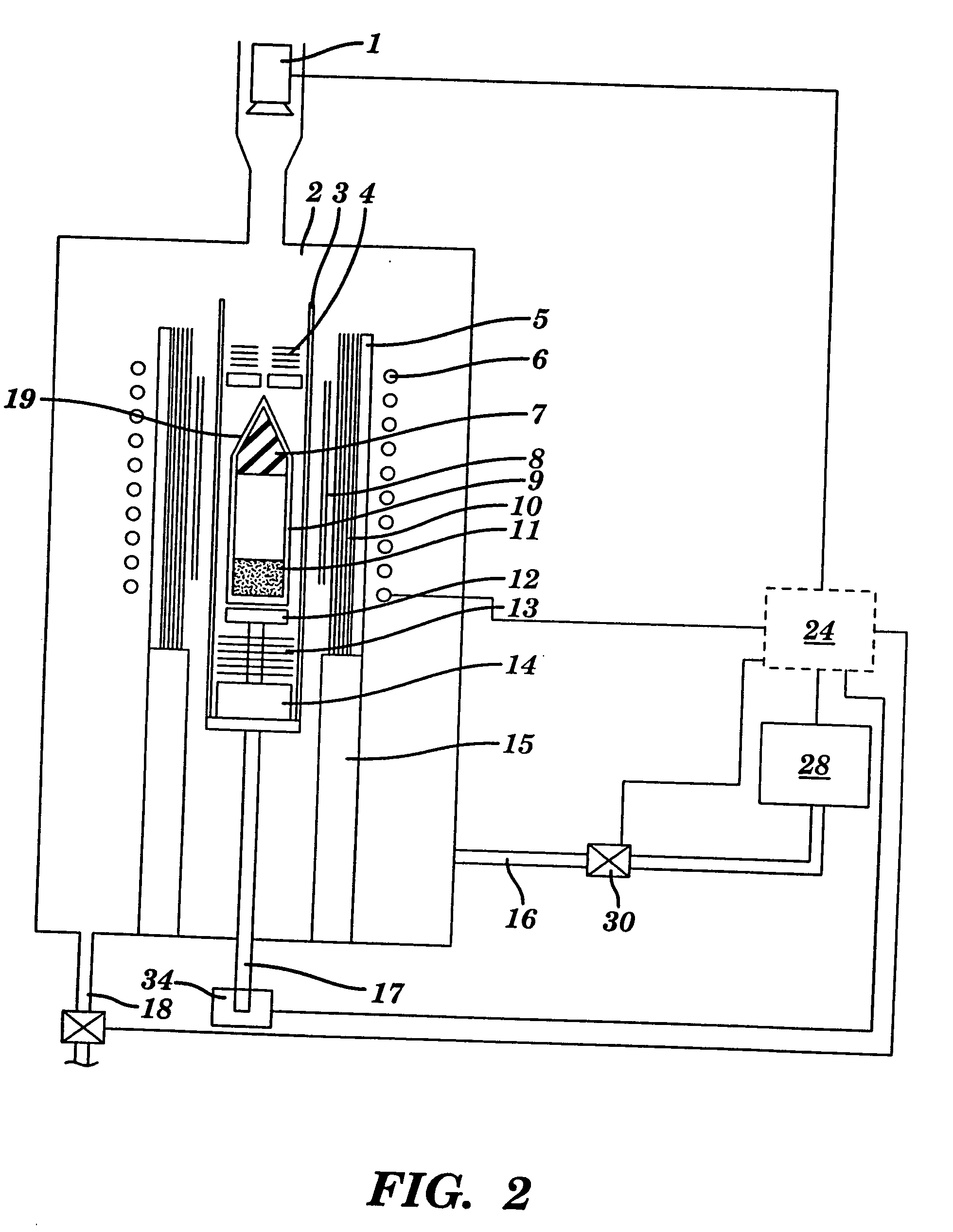

Method and apparatus for producing large, single-crystals of aluminum nitride

InactiveUS6770135B2After-treatment apparatusPolycrystalline material growthBulk crystalSource material

A method and apparatus for producing bulk single crystals of AlN includes a crystal growth enclosure with Al and N2 source material therein, capable of forming bulk crystals. The apparatus maintains the N2 partial pressure at greater than stoichiometric pressure relative to the Al within the crystal growth enclosure, while maintaining the total vapor pressure in the crystal growth enclosure at super-atmospheric pressure. At least one nucleation site is provided in the crystal growth enclosure, and provision is made for cooling the nucleation site relative to other locations in crystal growth enclosure. The Al and N2 vapor is then deposited to grow single crystalline AlN at the nucleation site.

Owner:CRYSTAL

Thermoelectric devices and methods for making the same

InactiveUS6262357B1Maximize heat flowMaximize flowThermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsThermal energyScreening techniques

Thermoelectric devices having enhanced thermal characteristics are fabricated using multilayer ceramic (MLC) technology methods. Aluminum nitride faceplates with embedded electrical connections provide the electrical series configuration for alternating dissimilar semiconducting materials. Embedded electrical connections are formed by vias and lines in the faceplate. Methods for forming tunnels through lamination and etching are employed. A portion of the dissimilar materials are then melted within the tunnels to form a bond. Thermal conductivity of the faceplate is enhanced by adding electrically isolated vias to one surface, filled with high thermal conductivity metal paste. A low thermal conductivity material is also introduced between the two high thermal conductivity material faceplates.Alternating semiconducting materials are introduced within the varying thermal conductivity layers by punching vias within greensheets of predetermined thermal conductivity and filling with n-type and p-type paste. Alternating semiconducting materials may also be patterned in linear or radial fanout patterns through screening techniques and lamination of wire structures. A liquid channel within the faceplate is used to enhance thermal energy transfer.Thermoelectric devices are physically incorporated within the IC package using MLC technology.

Owner:INT BUSINESS MASCH CORP

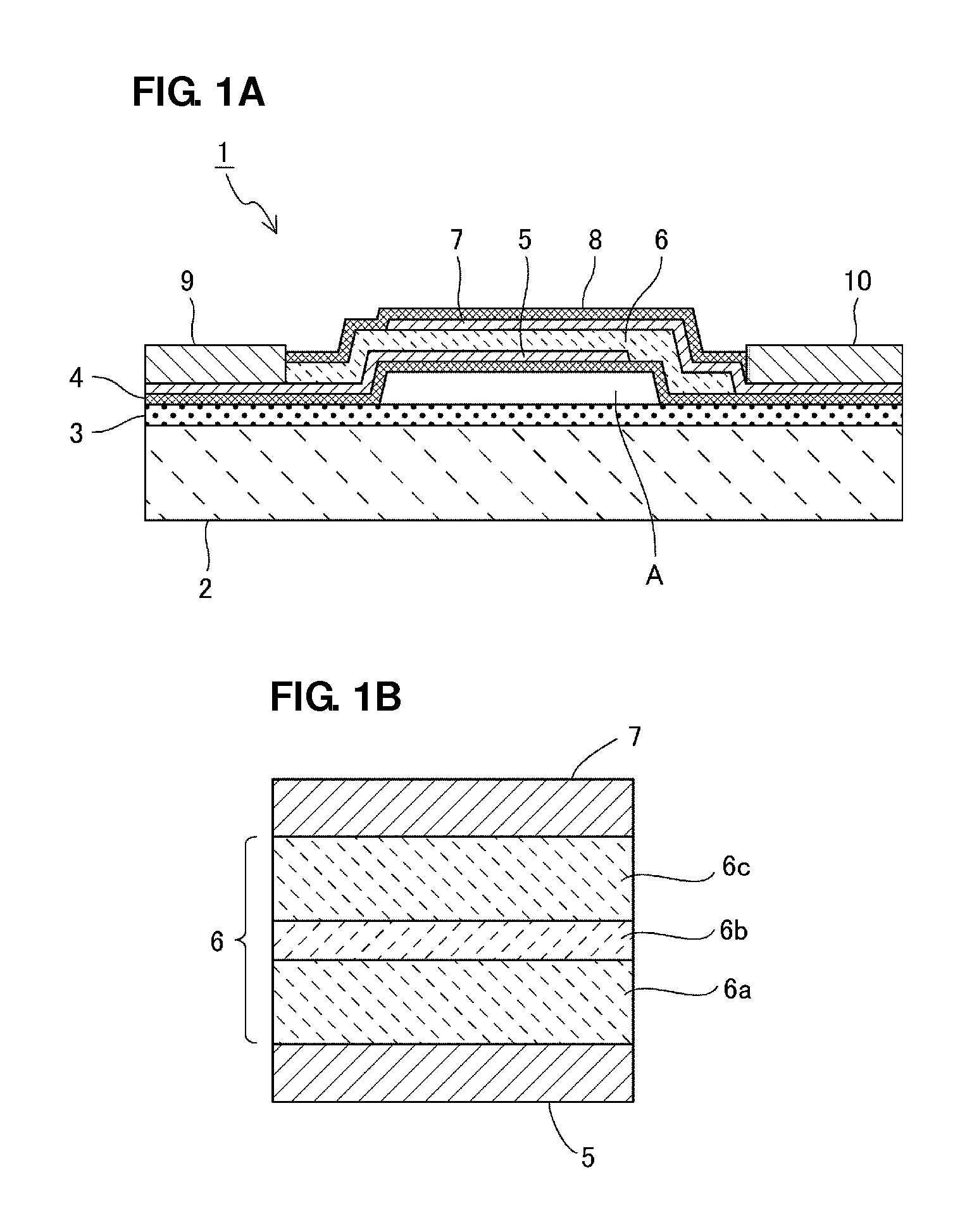

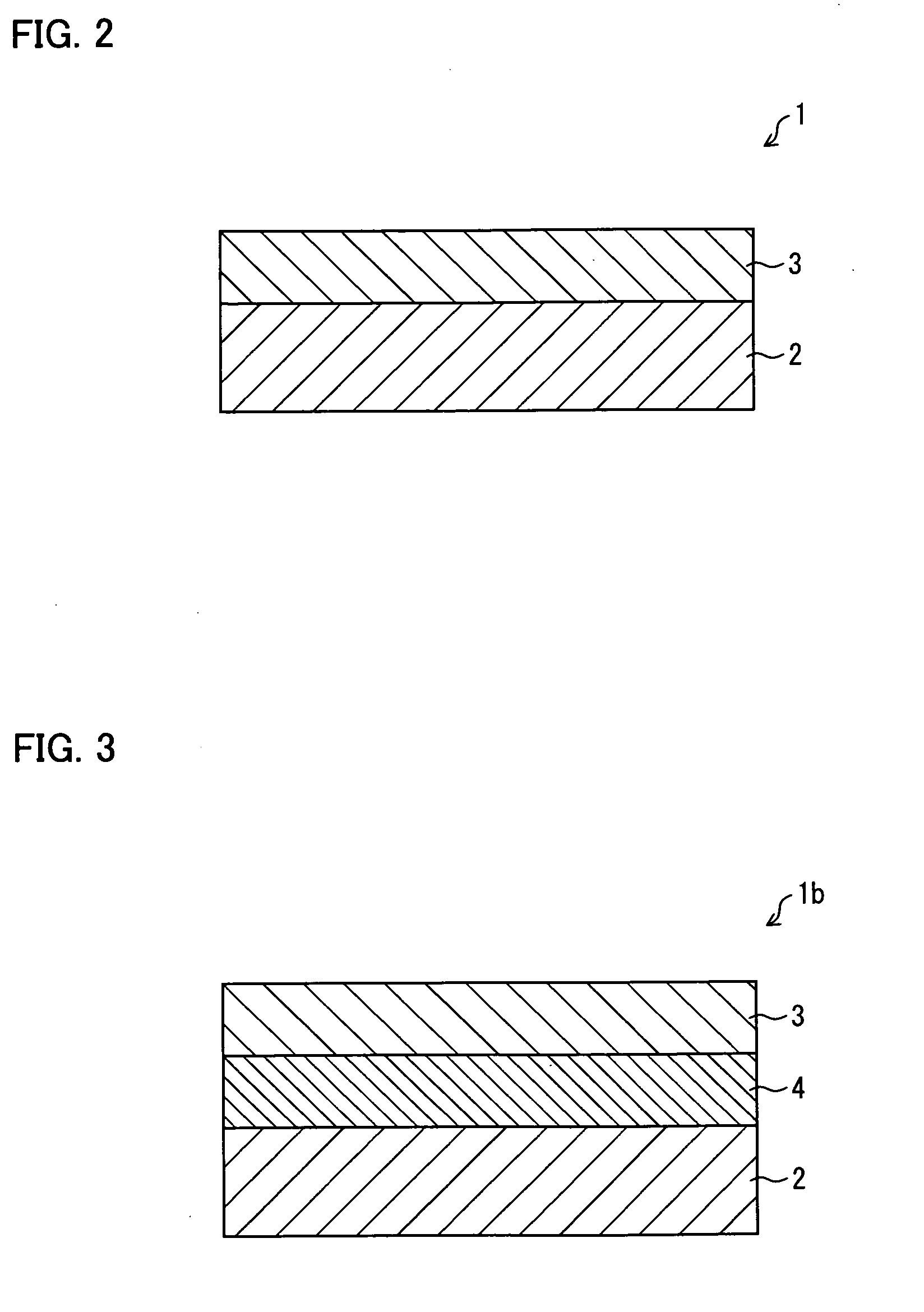

Piezoelectric thin-film resonator and method for producing piezoelectric thin film

ActiveUS20130127300A1Increase freedomExpand the scope ofImpedence networksPiezoelectric/electrostriction/magnetostriction machinesThin membranePiezoelectric thin films

A piezoelectric thin-film resonator includes a piezoelectric thin film which includes aluminum nitride containing Sc and which has a concentration distribution such that the concentration of Sc is non-uniform in a thickness direction of the piezoelectric thin film; a first electrode; a second electrode facing the first electrode across the piezoelectric thin film; and a substrate supporting a piezoelectric vibrating section defined by the piezoelectric thin film and the first and second electrodes.

Owner:MURATA MFG CO LTD

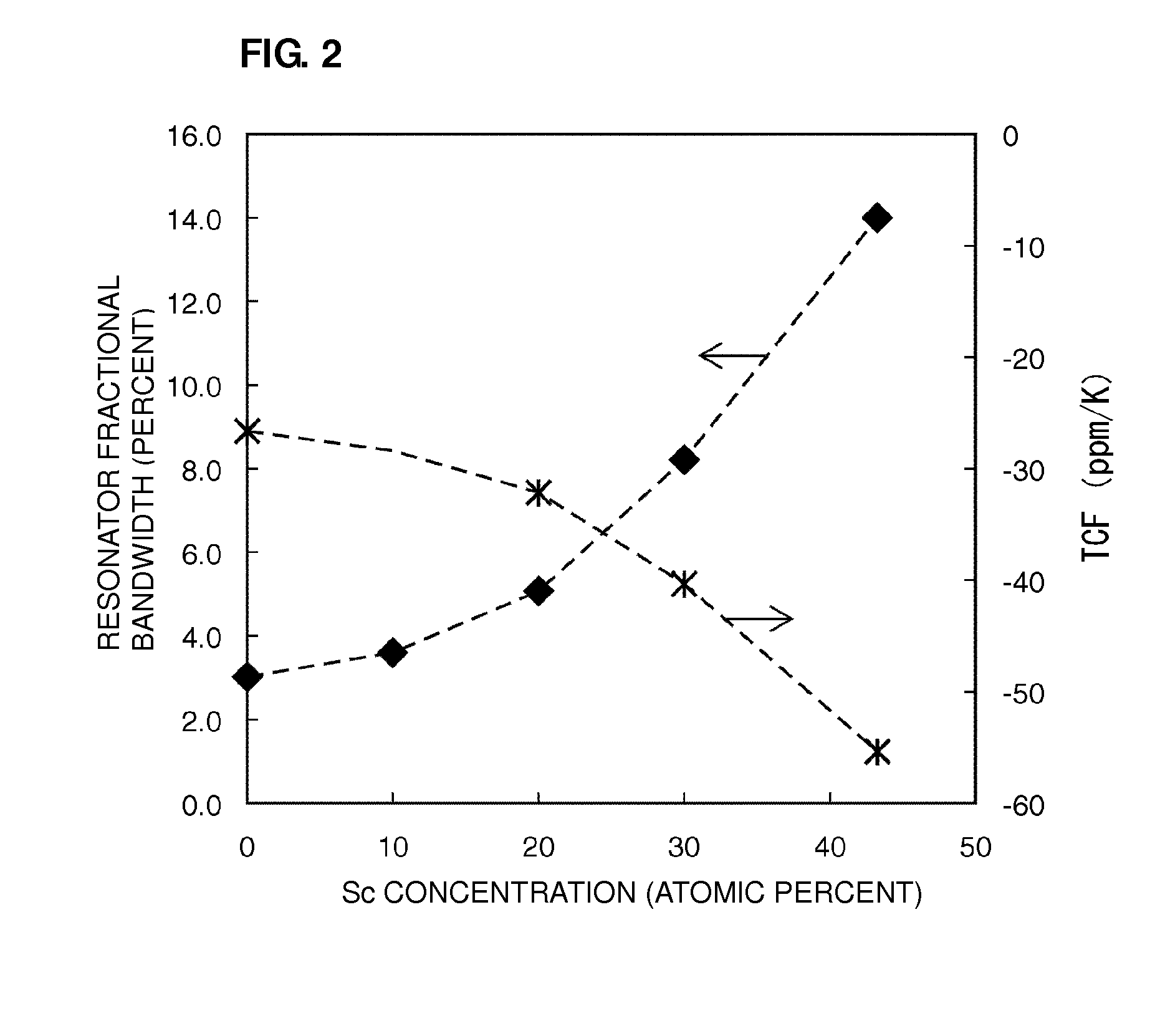

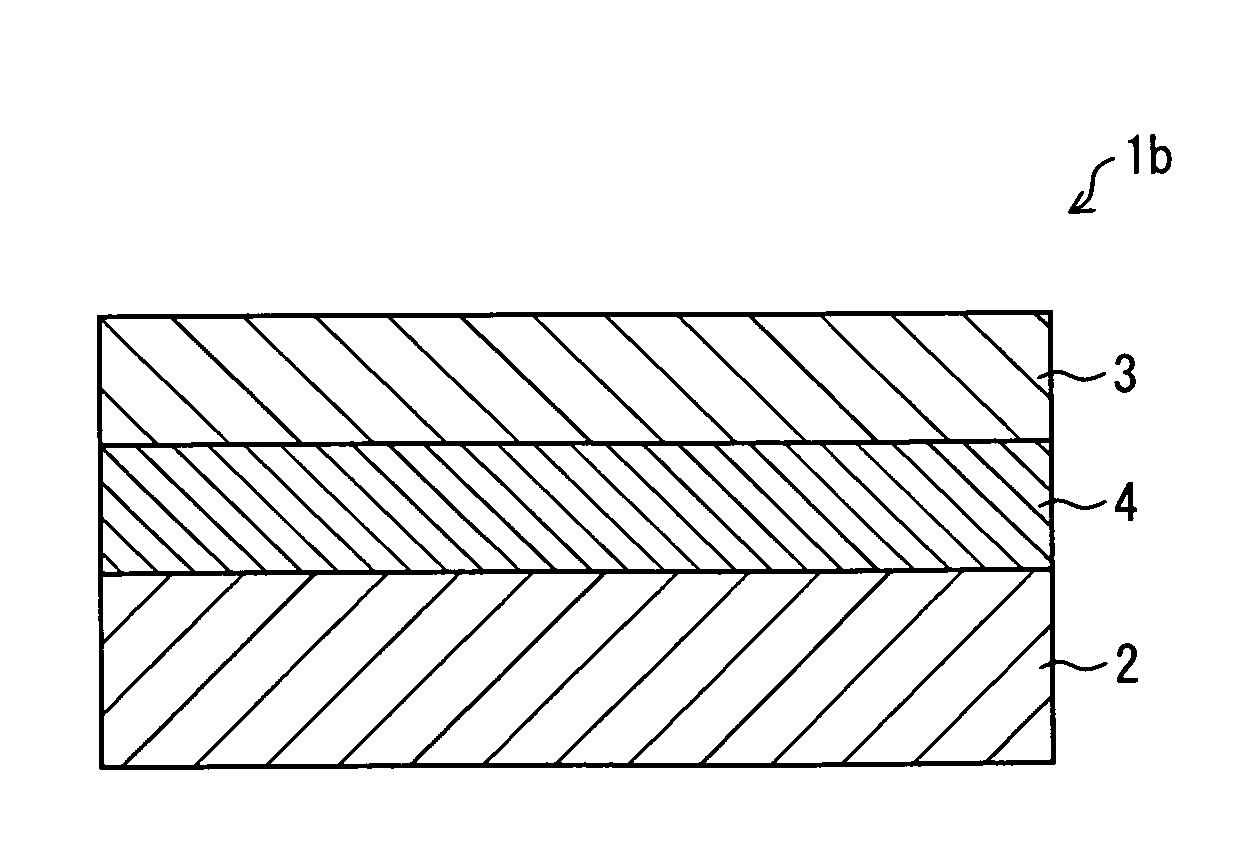

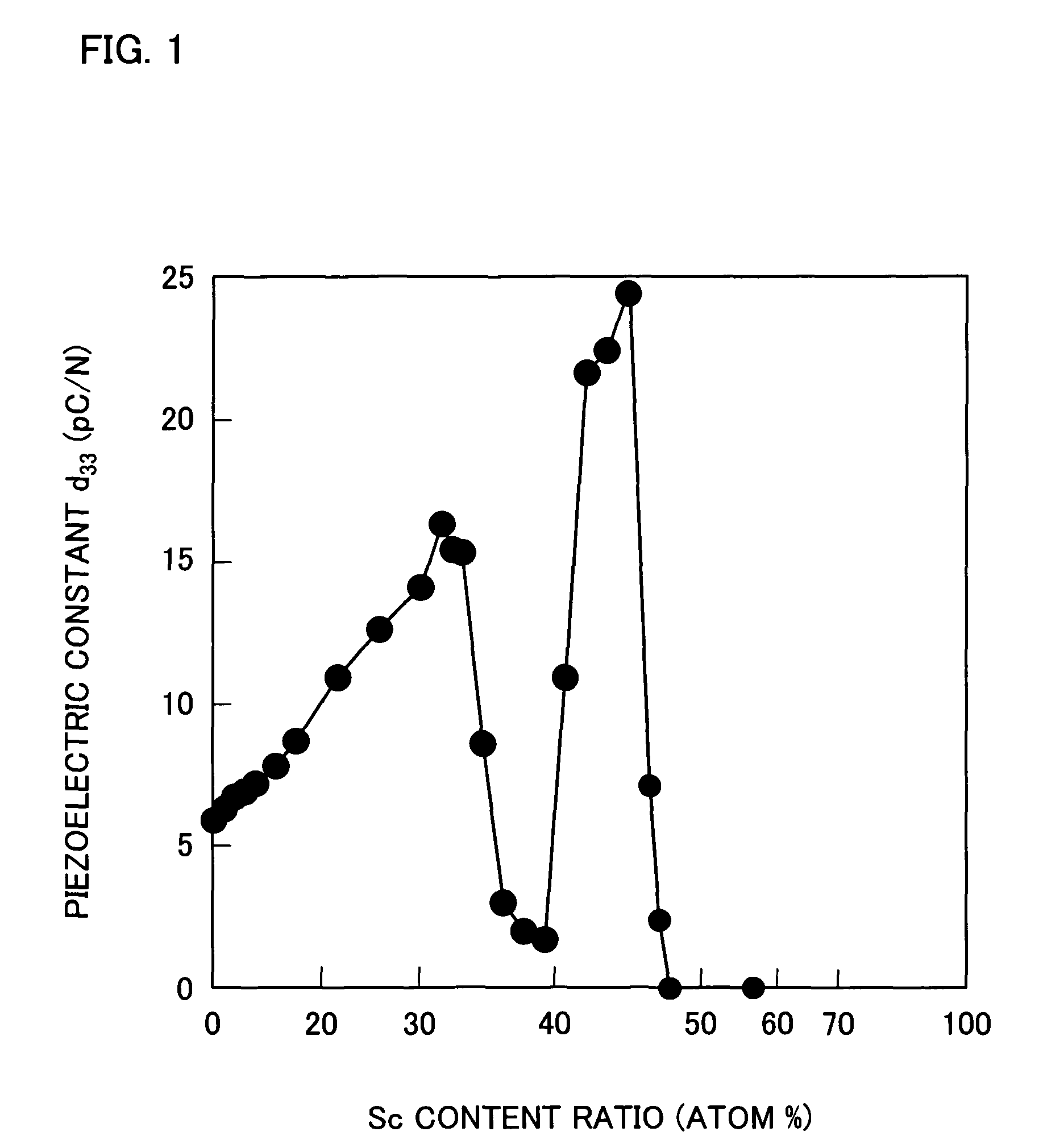

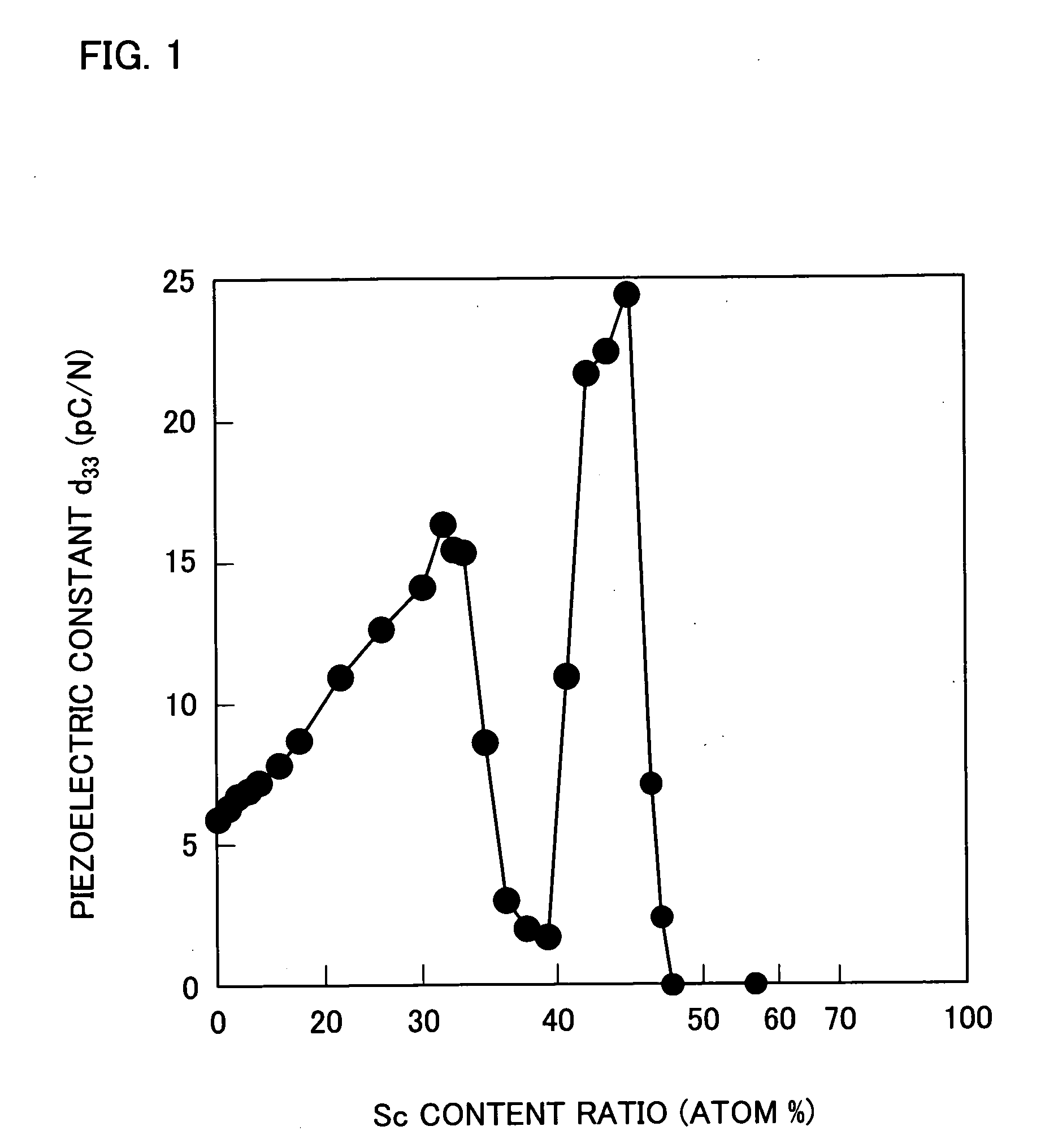

Piezoelectric thin film, piezoelectric material, and fabrication method of piezoelectric thin film and piezoelectric material, and piezoelectric resonator, actuator element, and physical sensor using piezoelectric thin film

ActiveUS7758979B2Improved piezoelectric responsePiezoelectric response of the aluminum nitride thin film that contains scandium can be further improvedImpedence networksNatural mineral layered productsActuatorTemperature coefficient

A piezoelectric thin film of the present invention includes an aluminum nitride thin film that contains scandium. A content ratio of scandium in the aluminum nitride thin film is 0.5 atom % to 50 atom % on the assumption that a total amount of the number of scandium atoms and the number of aluminum atoms is 100 atom %. According to this arrangement, the piezoelectric thin film of the present invention can improve a piezoelectric response while keeping characteristics of elastic wave propagation speed, Q value, and frequency-temperature coefficient that the aluminum nitride thin film has.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

Method and apparatus for producing large, single-crystals of aluminum nitride

InactiveUS20030168003A1After-treatment apparatusPolycrystalline material growthBulk crystalSource material

A method and apparatus for producing bulk single crystals of AlN includes a crystal growth enclosure with Al and N2 source material therein, capable of forming bulk crystals. The apparatus maintains the N2 partial pressure at greater than stoichiometric pressure relative to the Al within the crystal growth enclosure, while maintaining the total vapor pressure in the crystal growth enclosure at super-atmospheric pressure. At least one nucleation site is provided in the crystal growth enclosure, and provision is made for cooling the nucleation site relative to other locations in crystal growth enclosure. The Al and N2 vapor is then deposited to grow single crystalline AlN at the nucleation site.

Owner:CRYSTAL

Repair process for aluminum nitride substrates

A method to repair Aluminum Nitride (AlN) substrates is disclosed wherein a frequency doubled Q-switched Nd:YAG laser is used to remove unwanted metallurgy. The substrate is place in a liquid filled work chamber which acts to prevent metallic species of AlN from forming. The repair site can be sealed with a novel polymer coating to prevent contamination or corrosion. Repairs can be made to buried or surface metallurgy.

Owner:IBM CORP

Thermocured, heat conductive and heat radiating paint for LED lamp and preparation method thereof

InactiveCN103555094AExtended service lifeImprove fullnessPolyurea/polyurethane coatingsEthyl acetateColor changes

A thermocured, heat conductive and heat radiating paint for an LED lamp is prepared by the following raw materials by weight: 40-45 parts of polyacrylic resin, 5-8 parts of polyurethane resin, 4-6 parts of polyacrylamide, 6-8 parts of isophorone diamine IPDA, 20-24 parts of xylene, 2-3 parts of silane coupling agent KH550, 1-2 parts of aluminium powder, 8-12 parts of ethyl acetate, 2-4 parts of benzyltrimethylammonium tribromide, 10-12 parts of aluminium nitride, 2-3 parts of beryllia, and 4-5 parts of film forming auxiliary agent. Aluminium nitride powder, the beryllia and the aluminium powder are added, so as that the paint has high heat conduction rate and good heat radiation effect, and can be long-term used under 200 DEG C without change of mechanical property; polyacrylic resin is used, so as that the paint has advantages of excellent fullness, glossiness, hardness, solvent resistance and weatherability, without color change and brightness reversion when high temperature baked; and the paint has advantages of large adhesion stress, not-easy shedding, aging resistance and long usage life.

Owner:天长市天泰光电科技有限公司

Piezoelectric thin film, piezoelectric material, and fabrication method of piezoelectric thin film and piezoelectric material, and piezoelectric resonator, actuator element, and physical sensor using piezoelectric thin film

ActiveUS20080296529A1Improved piezoelectric responsePiezoelectric response of the aluminum nitride thin film that contains scandium can be further improvedImpedence networksPiezoelectric/electrostrictive device material selectionActuatorTemperature coefficient

A piezoelectric thin film of the present invention includes an aluminum nitride thin film that contains scandium. A content ratio of scandium in the aluminum nitride thin film is 0.5 atom % to 50 atom % on the assumption that a total amount of the number of scandium atoms and the number of aluminum atoms is 100 atom %. According to this arrangement, the piezoelectric thin film of the present invention can improve a piezoelectric response while keeping characteristics of elastic wave propagation speed, Q value, and frequency-temperature coefficient that the aluminum nitride thin film has.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

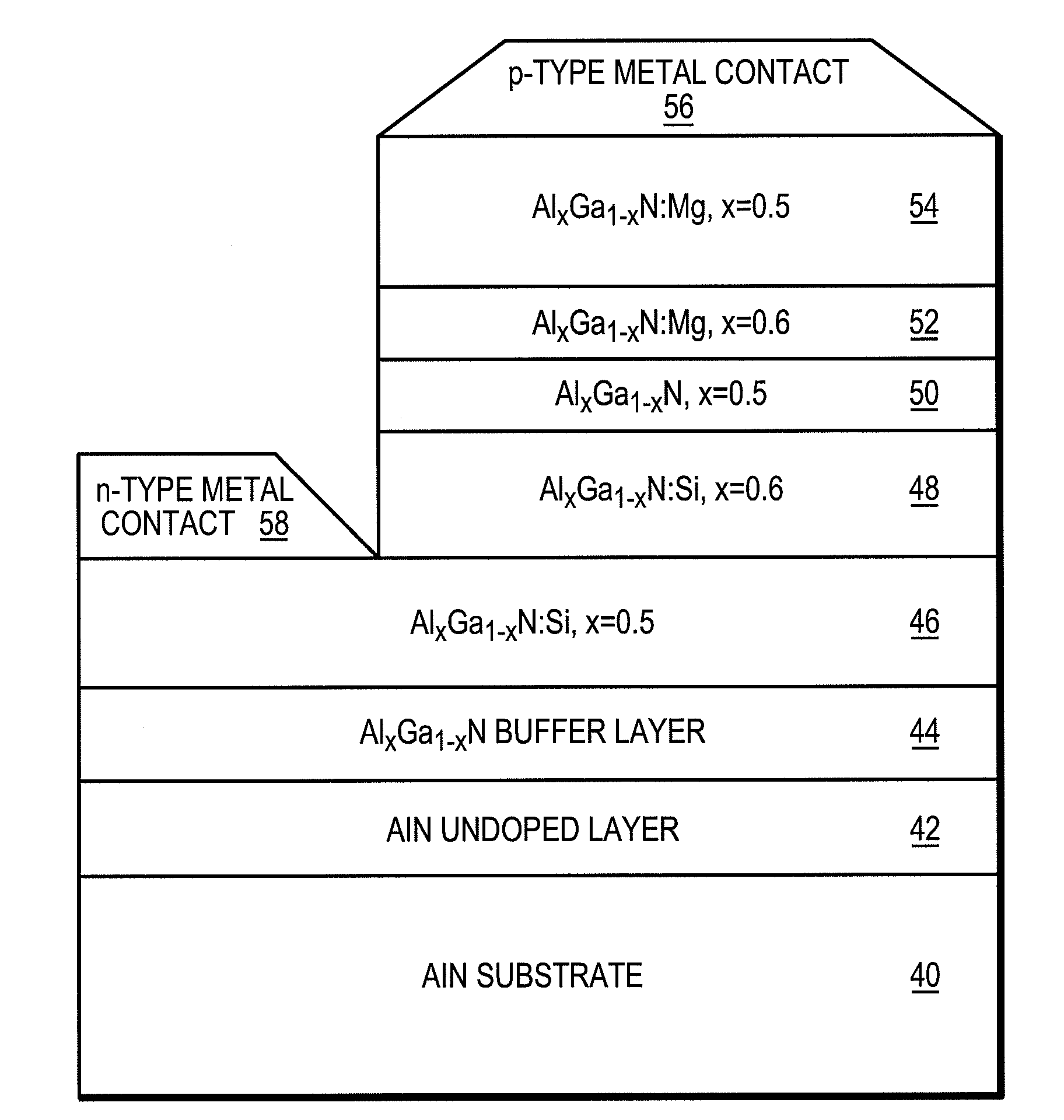

Nitride semiconductor heterostructures and related methods

InactiveUS20090283028A1Easy to manufactureGood chemical compatibilityFrom gel statePolycrystalline material growthSemiconductor structureSemiconductor heterostructures

Semiconductor structures and devices based thereon include an aluminum nitride single-crystal substrate and at least one layer epitaxially grown thereover. The epitaxial layer may comprise at least one of AlN, GaN, InN, or any binary or tertiary alloy combination thereof, and have an average dislocation density within the semiconductor heterostructure is less than about 106 cm−2.

Owner:CRYSTAL

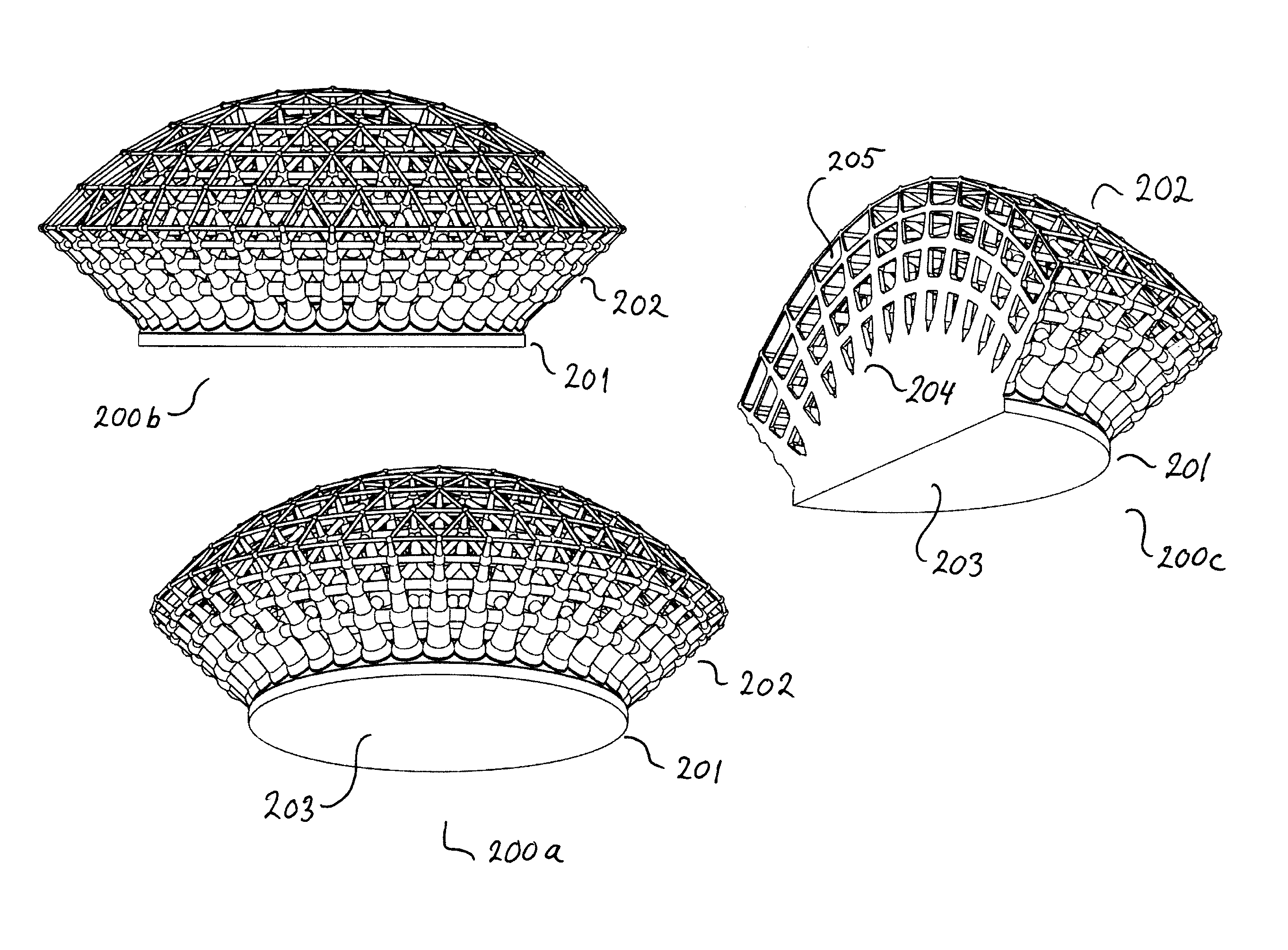

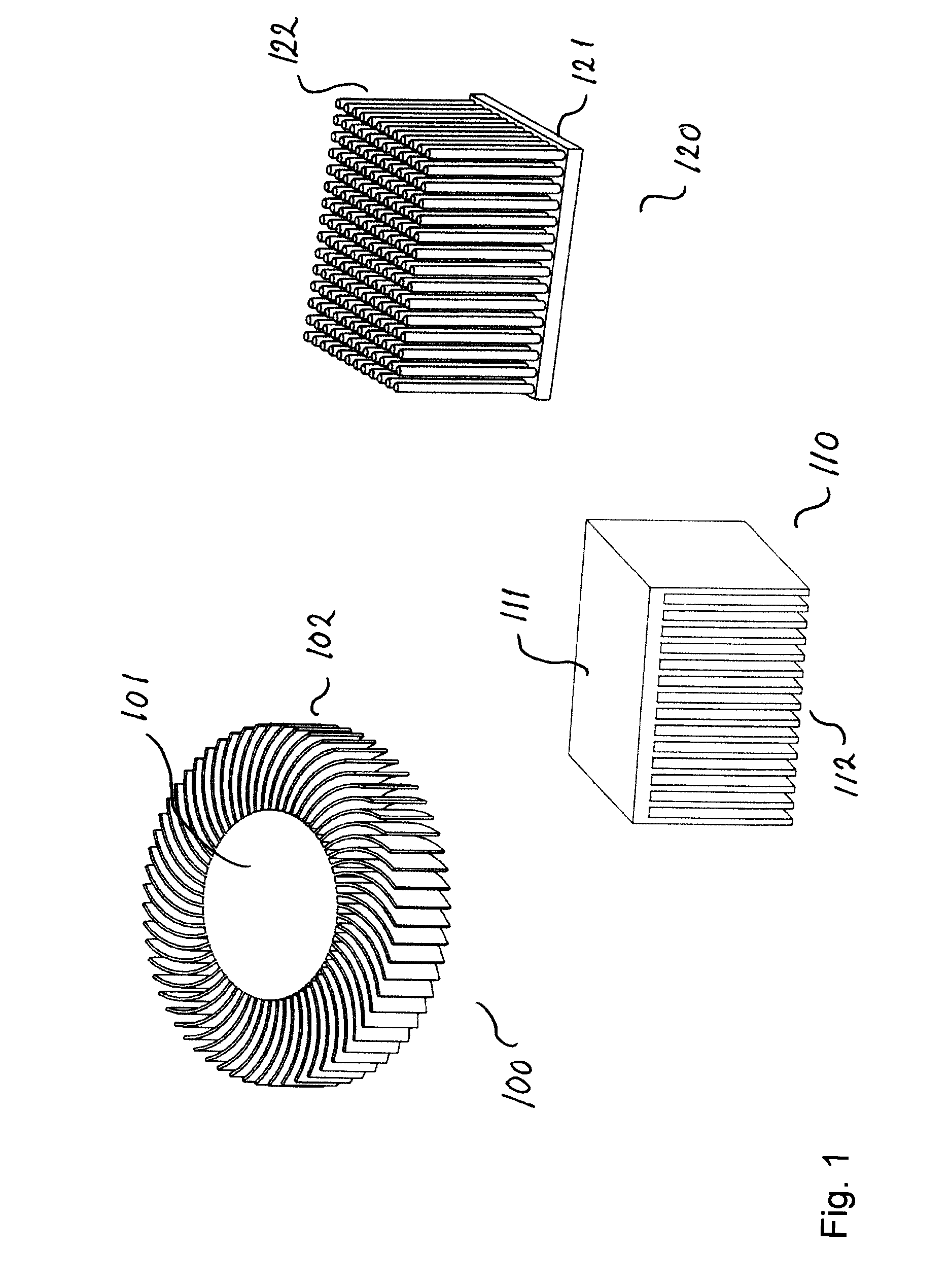

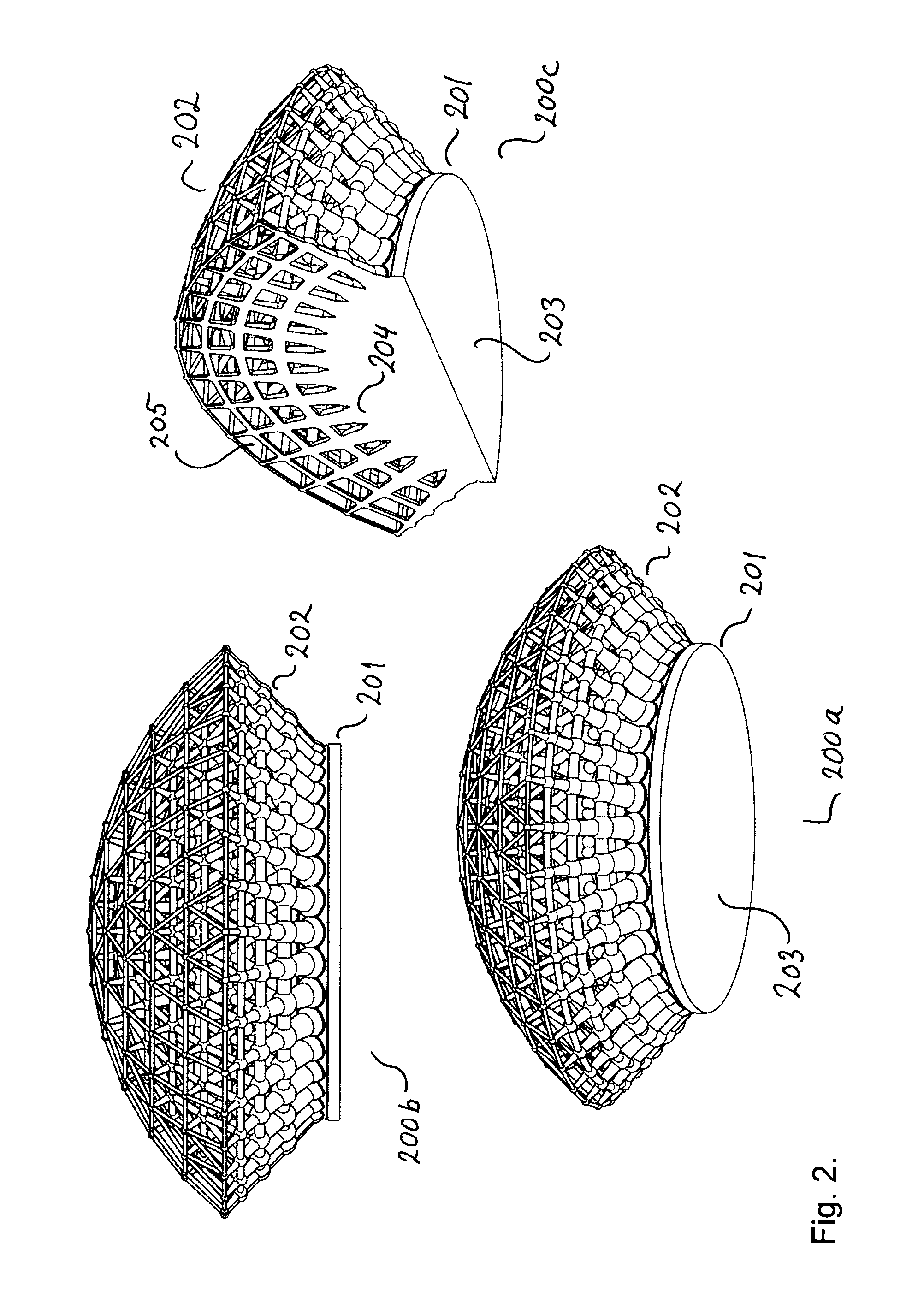

Heat Sink Having a Cooling Structure with Decreasing Structure Density

InactiveUS20160069622A1Increase distanceReduce material densityLighting support devicesDigital data processing detailsSelective laser meltingCarbon nanotube

A heat sink for cooling a heat generating device comprises a body part with a first surface for contacting the heat generating device, and a second surface contacting a cooling part, and the cooling part including a cooling structure. The structure density of the cooling structure decreases with increasing distance to body part. The cooling structure may be a three dimensional structure e.g. a grid or a lattice, but the cooling structure may also be fins projecting or extending from the second surface of the body part. The heat sink can be manufactured using additive manufacturing e.g. selective laser melting process (SLM). The heat sink can be made of metals e.g. aluminum, copper, ceramics e.g. aluminium nitride (AlN), silicon carbide or a composite containing graphite, graphene or carbon nanotubes.

Owner:ALEXIOU & TRYDE HLDG APS

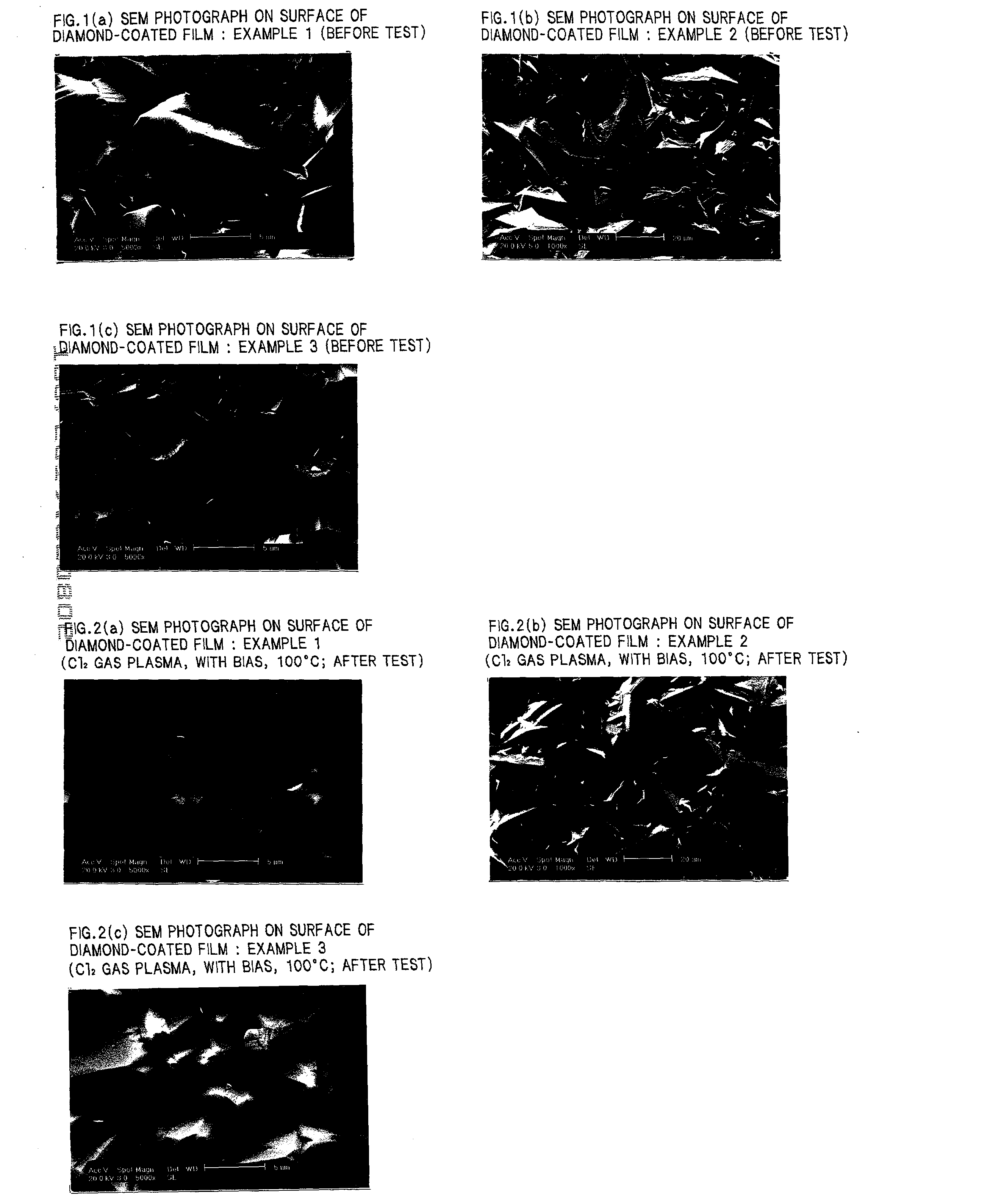

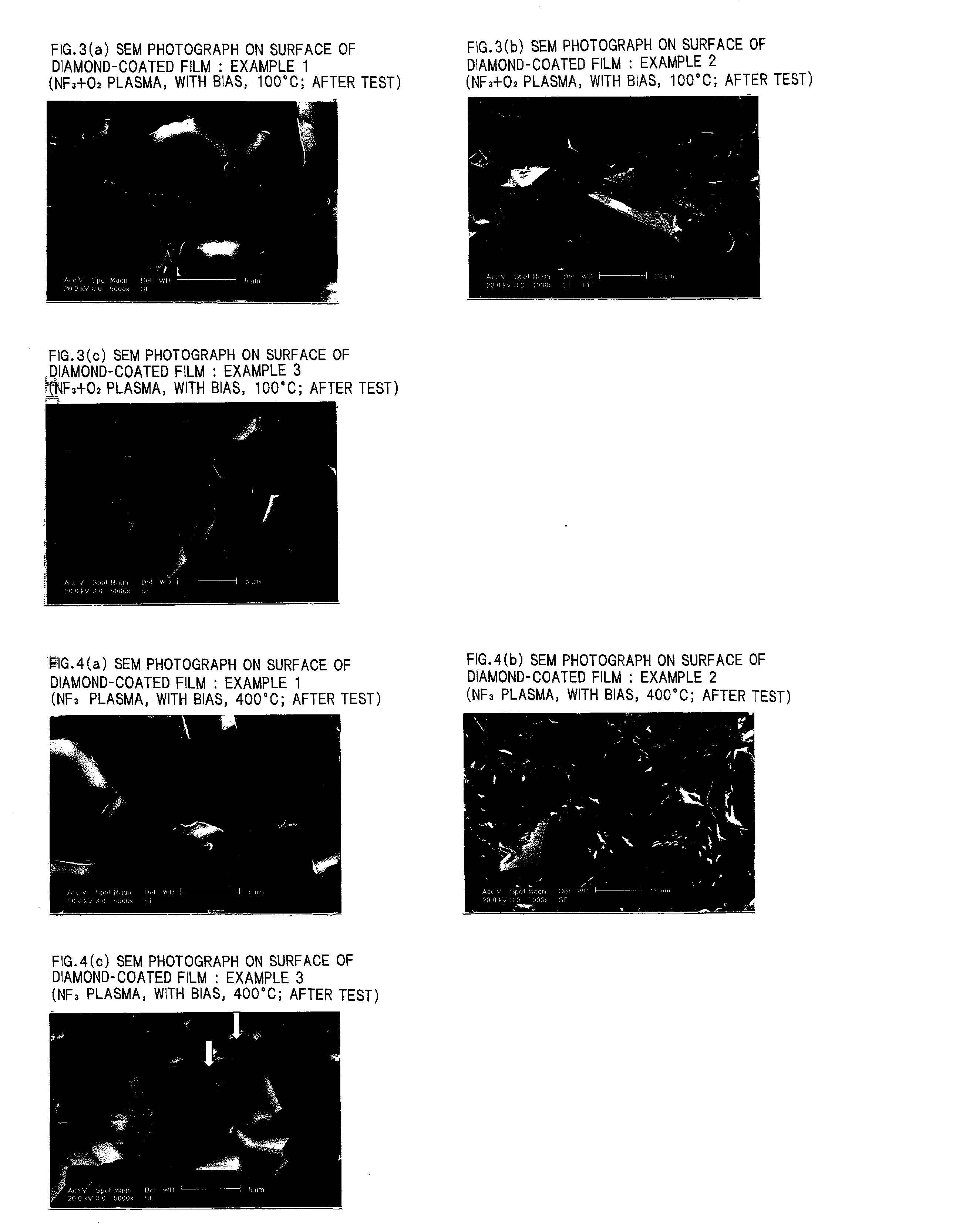

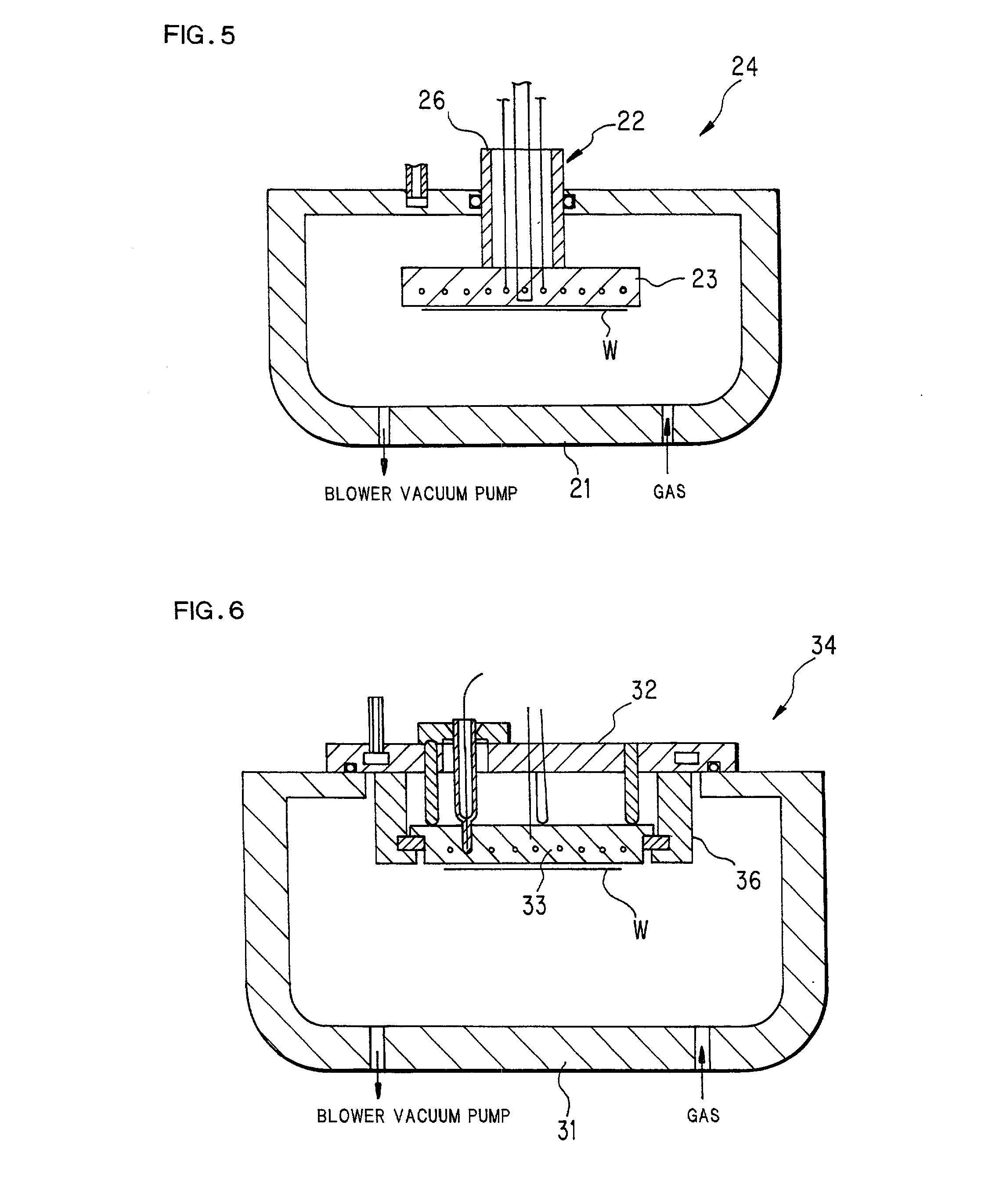

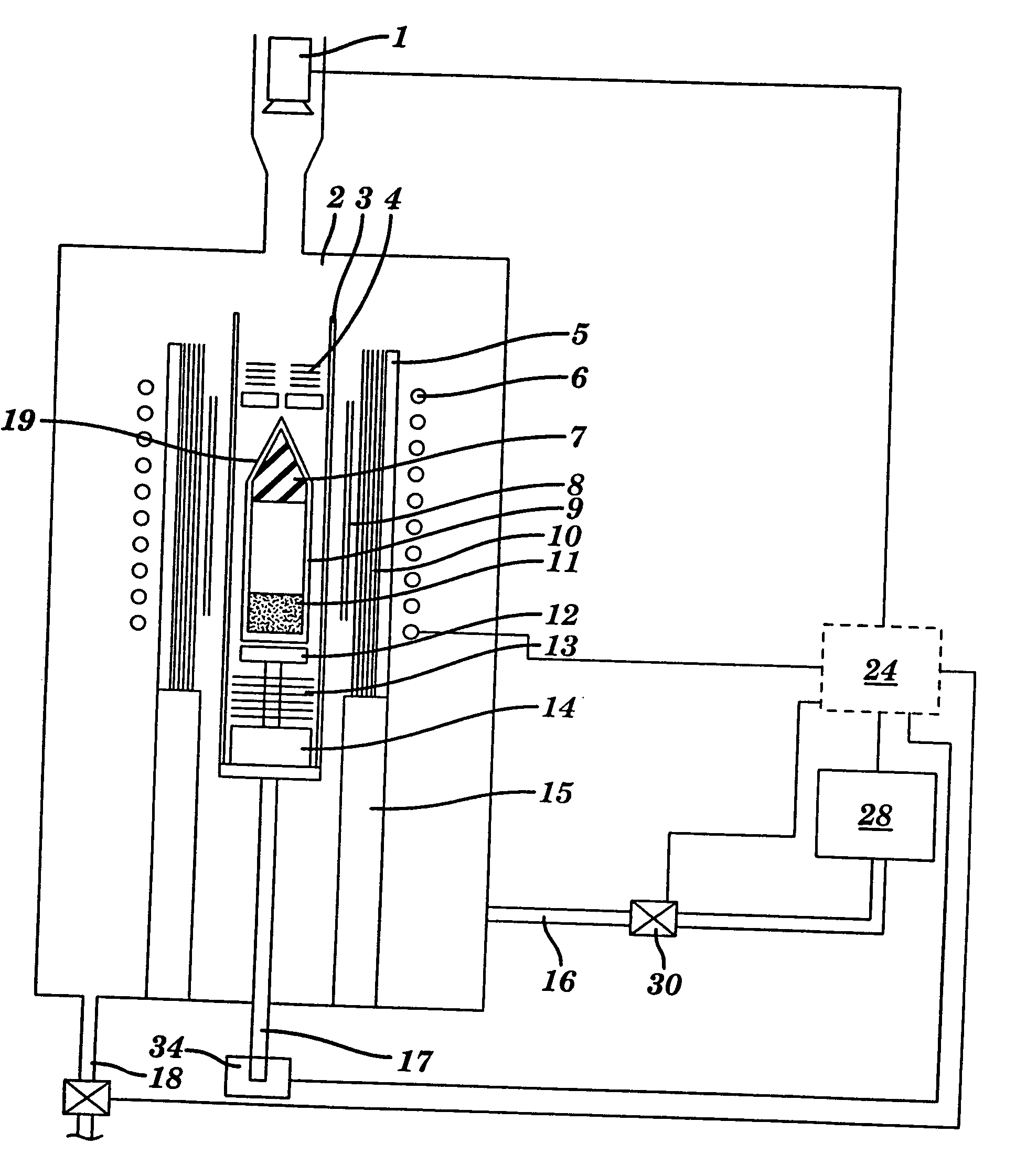

Diamond-coated member

InactiveUS20030064225A1Polycrystalline material growthElectric discharge tubesSusceptorAdhesion strength

A diamond-coated member includes a basal material such as aluminum nitride, and a diamond thin film coating at least one part of a surface of the basal material, being adhered thereto, and has corrosion-erosion resistance. Adhesion strength between the thin film and the basal material is 15 MPa or more. Or, in diamond thin film, degree of orientation of diamond {220} plane present in faces parallel to the basal material is expressed by following formula: [Im220 / (Im220+Im111)] / [Ip220 / (Ip220+Ip111)]<1. The diamond-coated corrosion-erosion resistant member has excellent corrosion-erosion resistance, and is used mainly for a semiconductor producing apparatus; being preferably applied as a member inside a reaction chamber where a substrate, represented by silicon wafer, is exposed to plasma, corrosion gas or the like, inclusive of rings, a chamber inner lining, a gas shower plate, nozzles, a susceptor, an electrostatic chuck, a heater, or the like.

Owner:NGK INSULATORS LTD

Method and apparatus for producing large, single-crystals of aluminum nitride

InactiveUS20060005763A1Polycrystalline material growthSolid-state devicesBulk crystalSource material

A method and apparatus for producing bulk single crystals of AlN having low dislocation densities of about 10,000 cm−2 or less includes a crystal growth enclosure with Al and N2 source material therein, capable of forming bulk crystals. The apparatus maintains the N2 partial pressure at greater than stoichiometric pressure relative to the Al within the crystal growth enclosure, while maintaining the total vapor pressure in the crystal growth enclosure at super-atmospheric pressure. At least one nucleation site is provided in the crystal growth enclosure, and provision is made for cooling the nucleation site relative to other locations in the crystal growth enclosure. The Al and N2 vapor is then deposited to grow single crystalline low dislocation density AlN at the nucleation site. High efficiency ultraviolet light emitting diodes and ultraviolet laser diodes are fabricated on low defect density AlN substrates, which are cut from the low dislocation density AlN crystals. Bulk crystals of ZnO may also be produced using the method.

Owner:CRYSTAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com