Patents

Literature

306 results about "Aluminum gallium nitride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

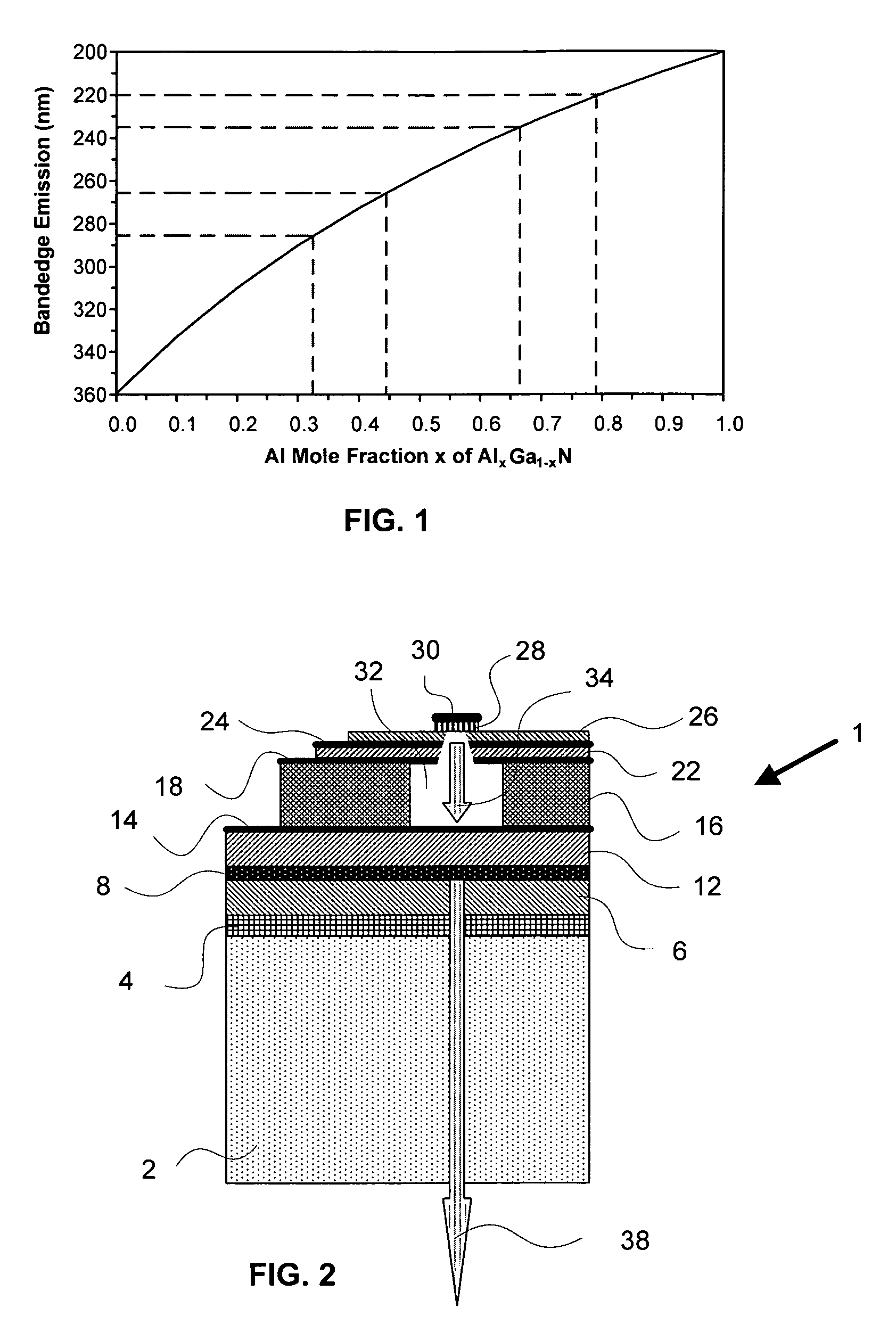

Aluminium gallium nitride. Aluminium gallium nitride (AlGaN) is a semiconductor material. It is any alloy of aluminium nitride and gallium nitride. The bandgap of AlxGa1−xN can be tailored from 3.4eV (xAl=0) to 6.2eV (xAl=1).

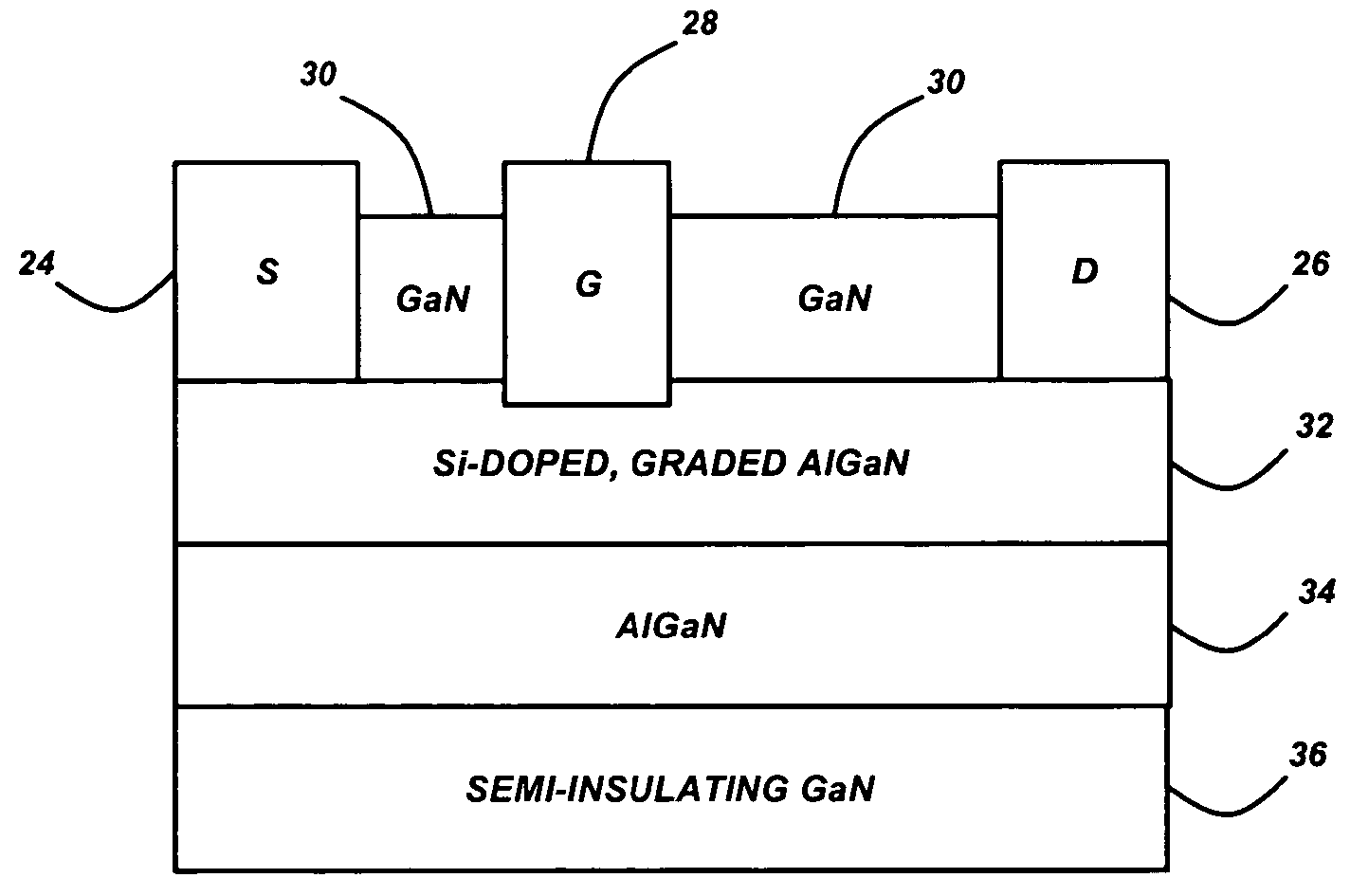

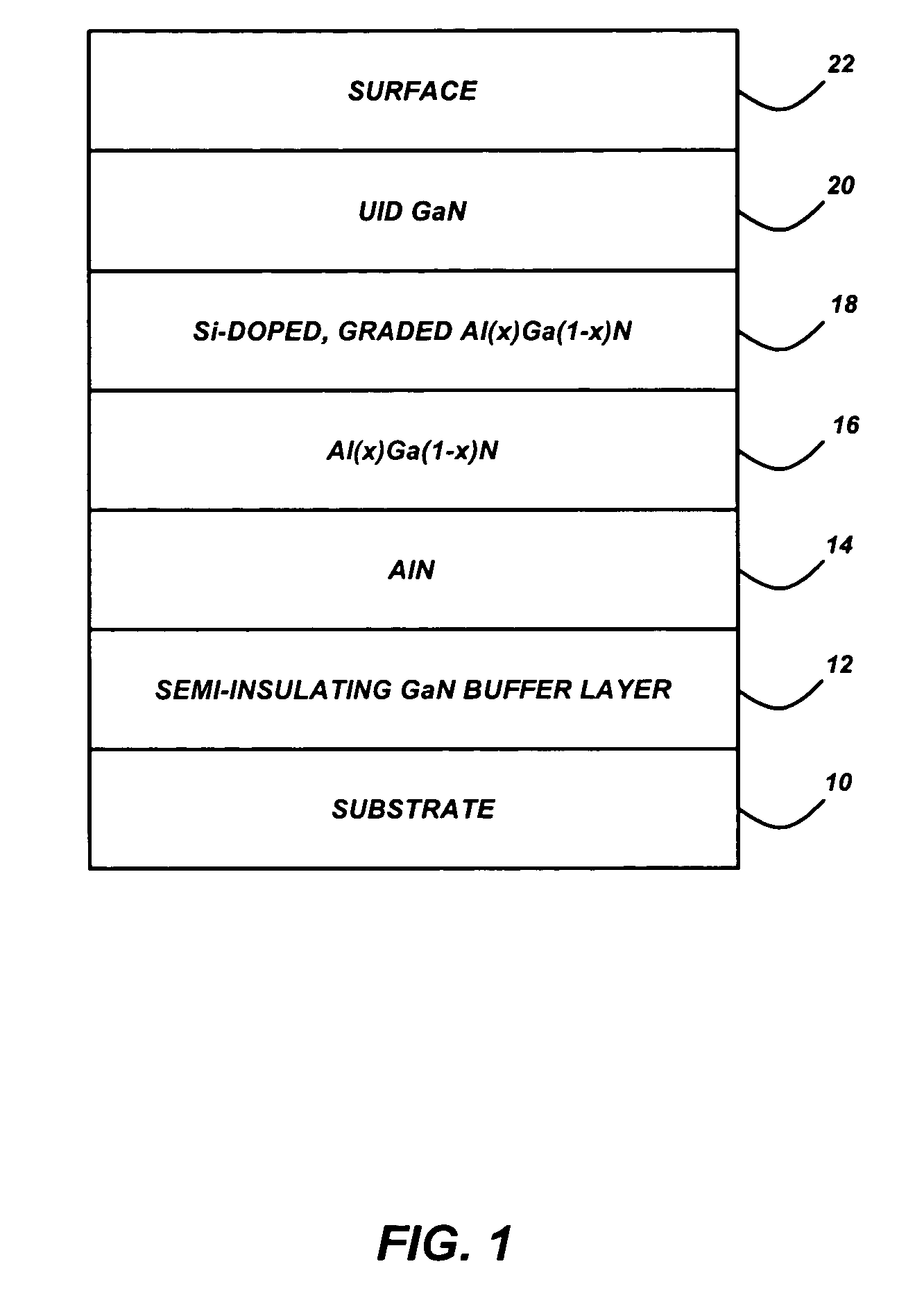

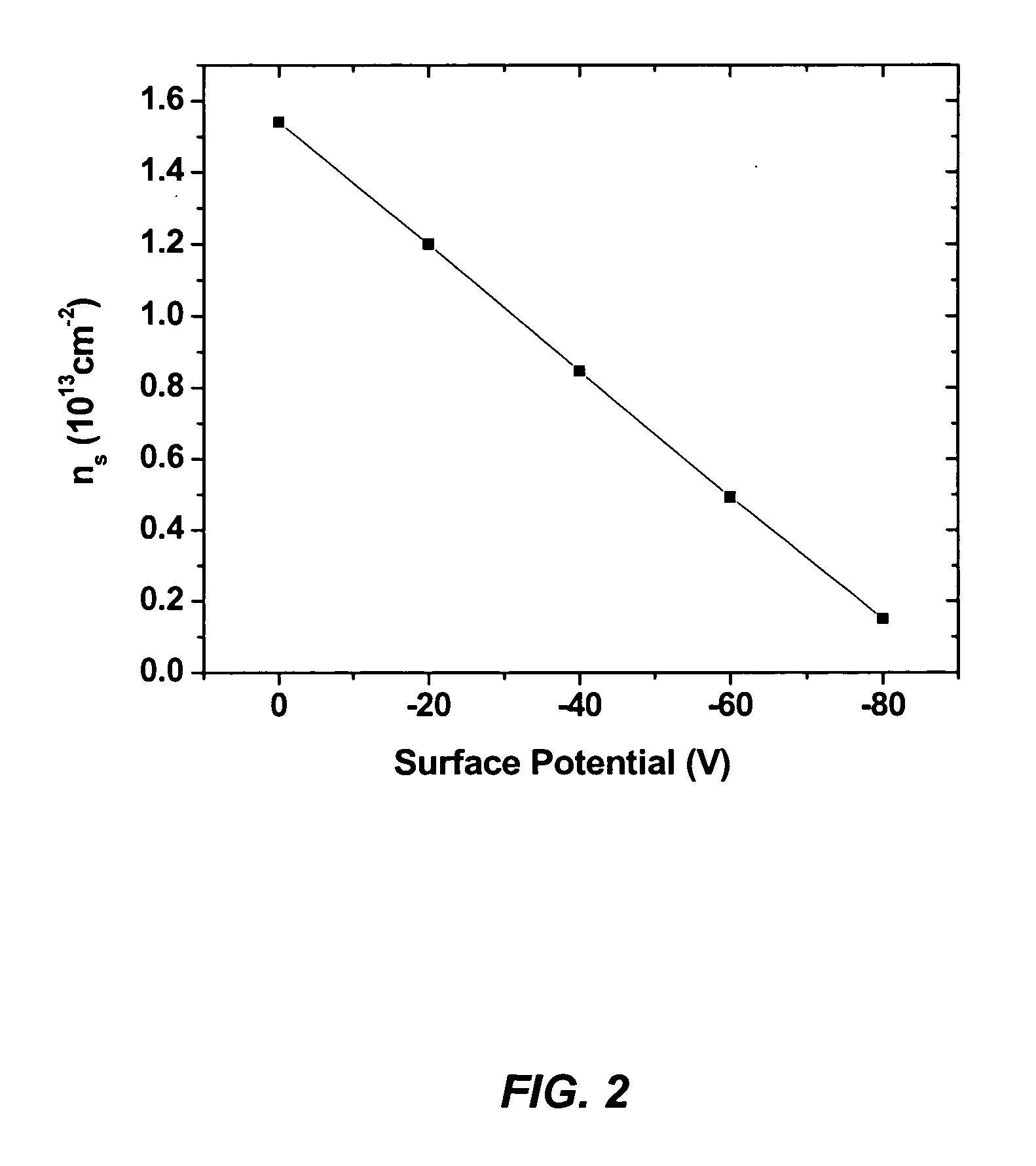

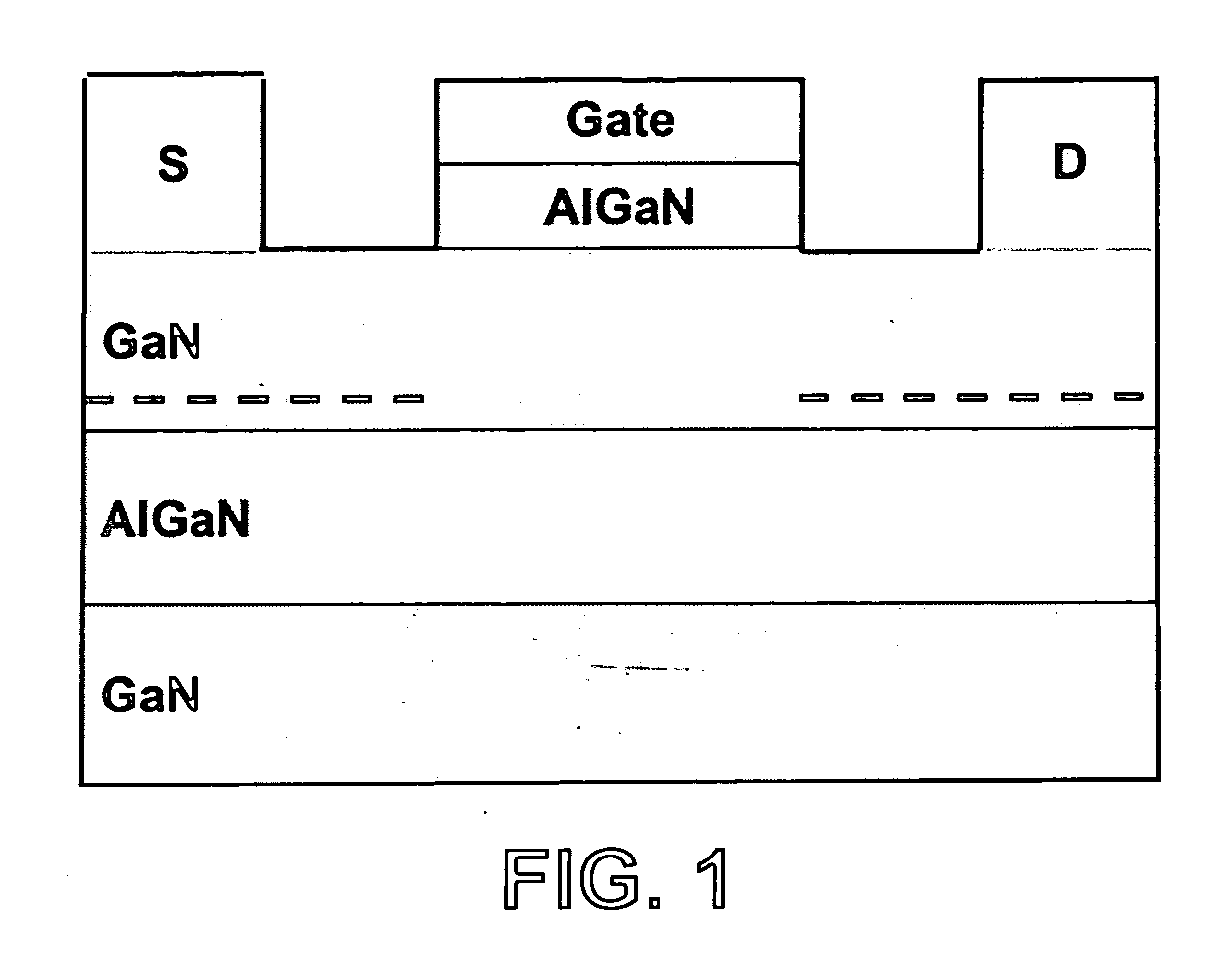

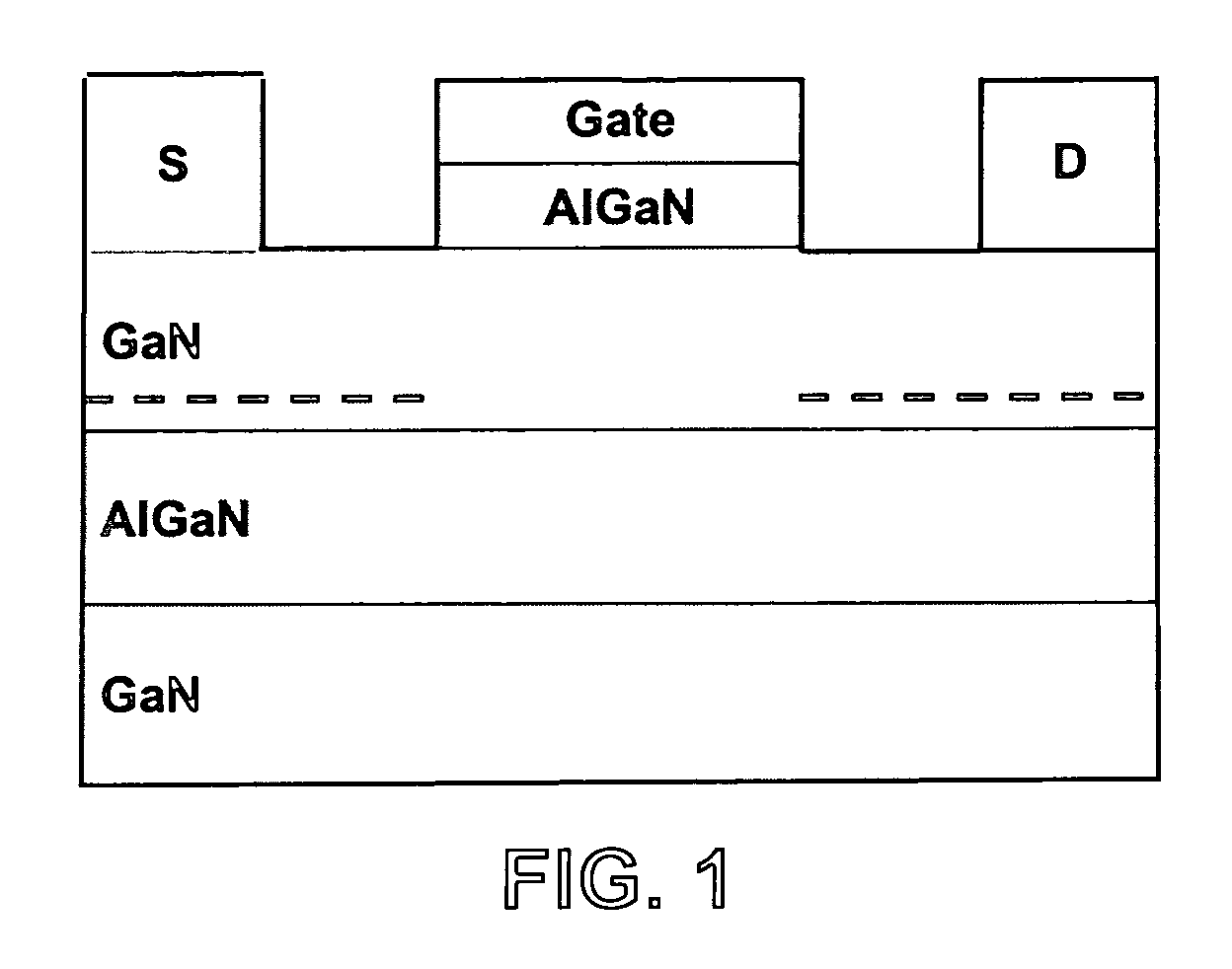

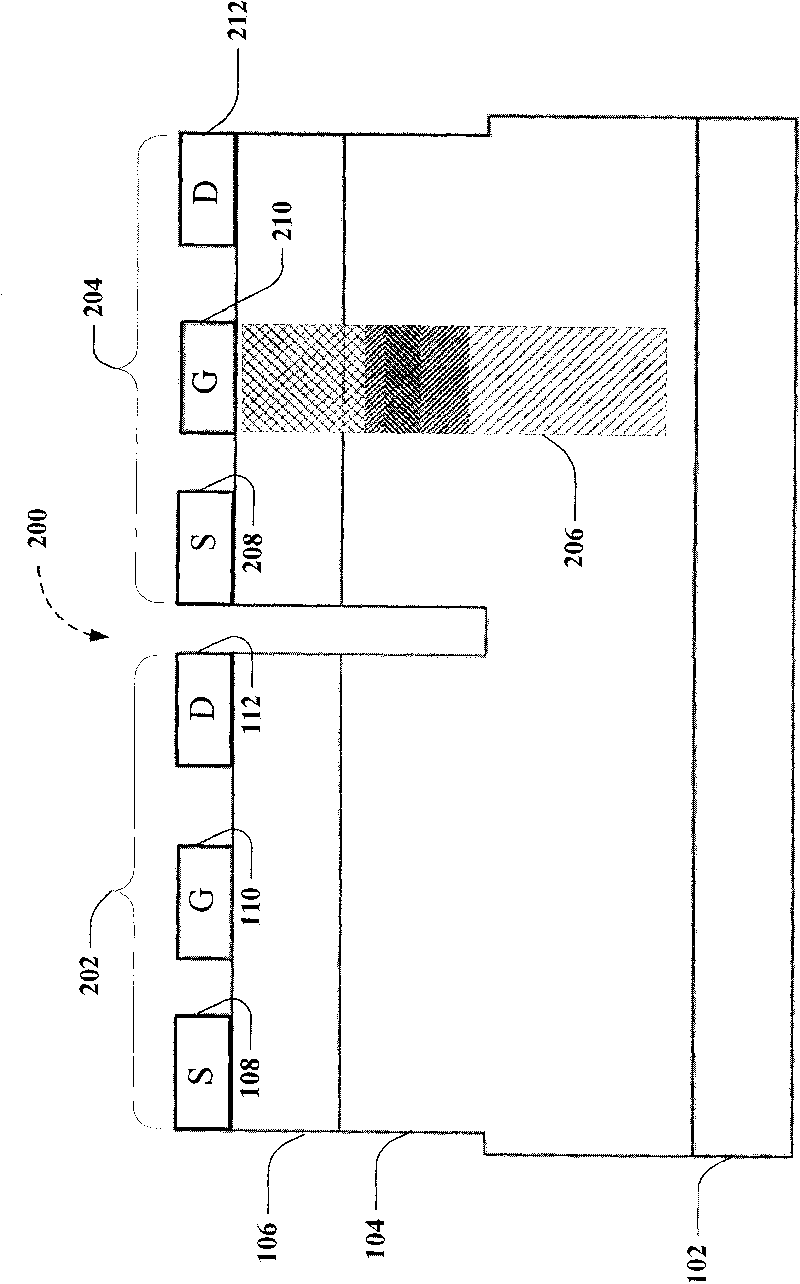

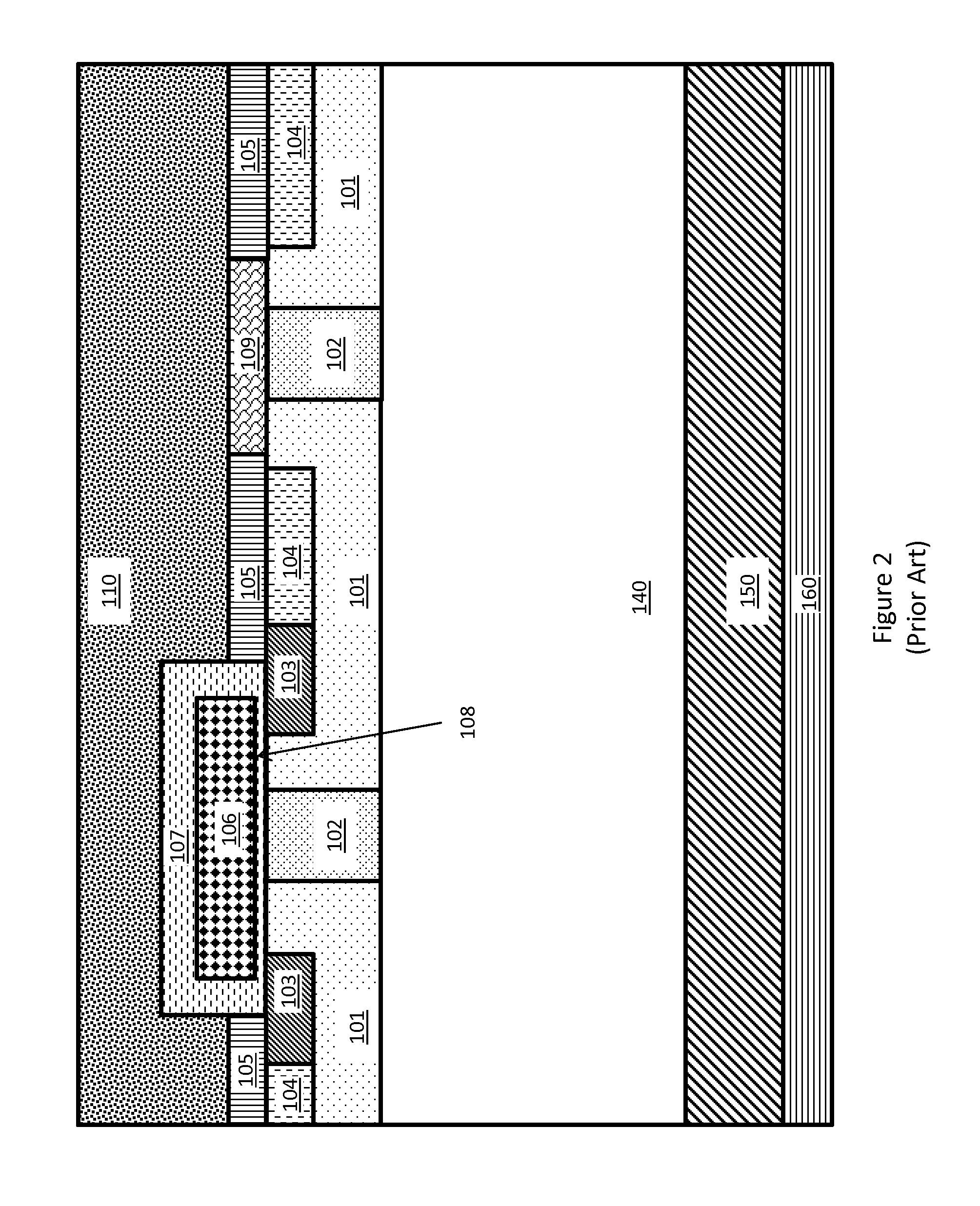

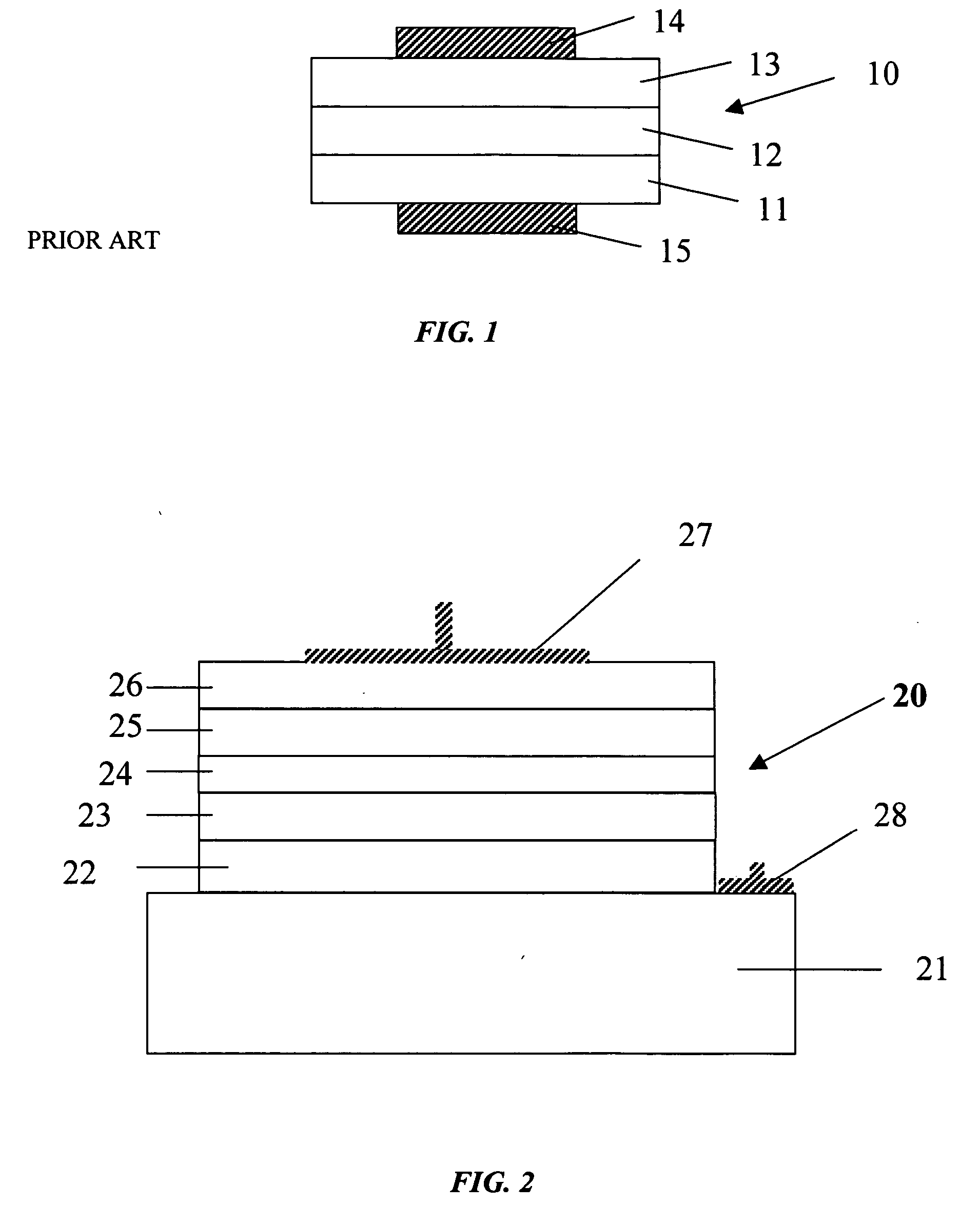

GaN/AIGaN/GaN dispersion-free high electron mobility transistors

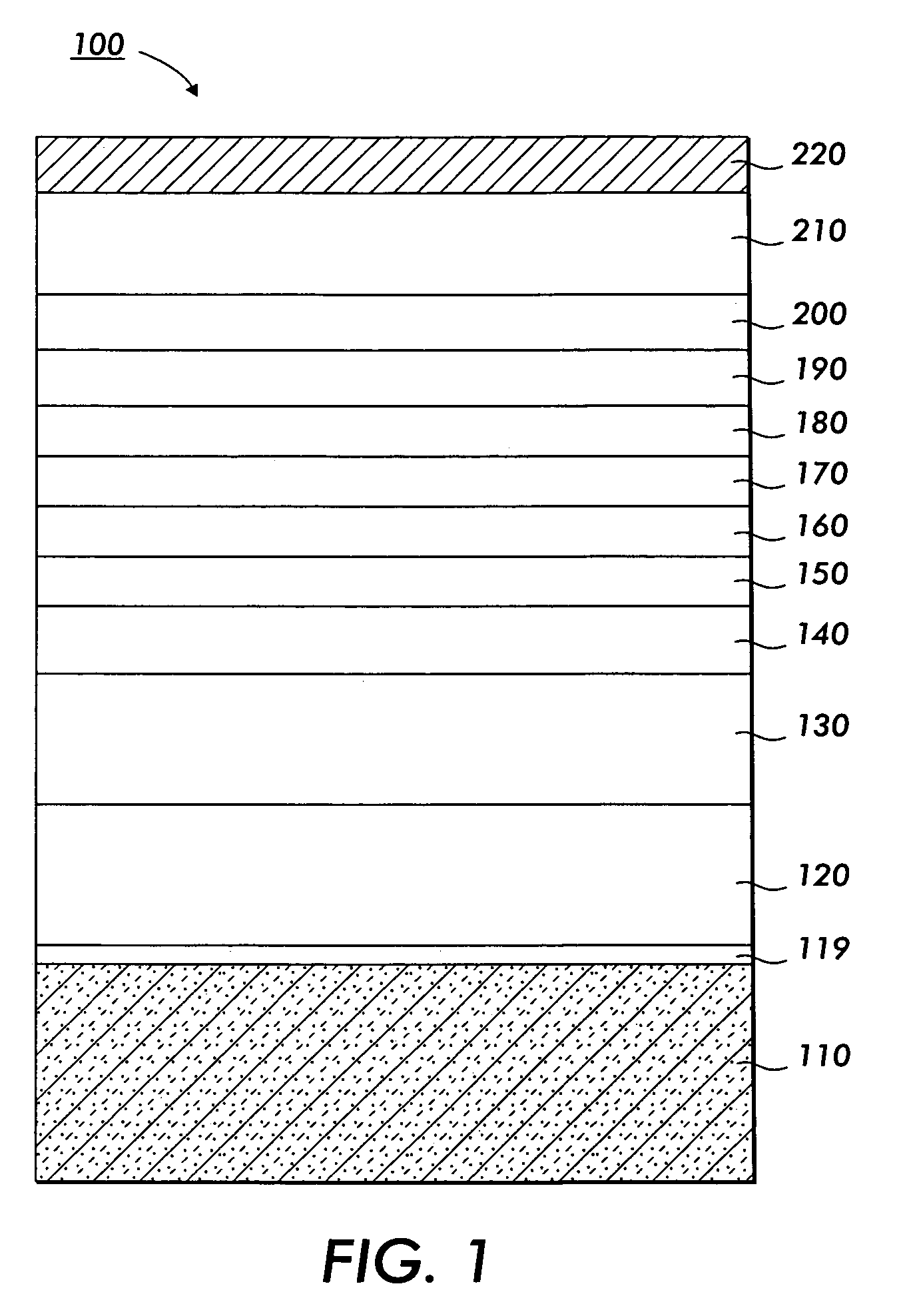

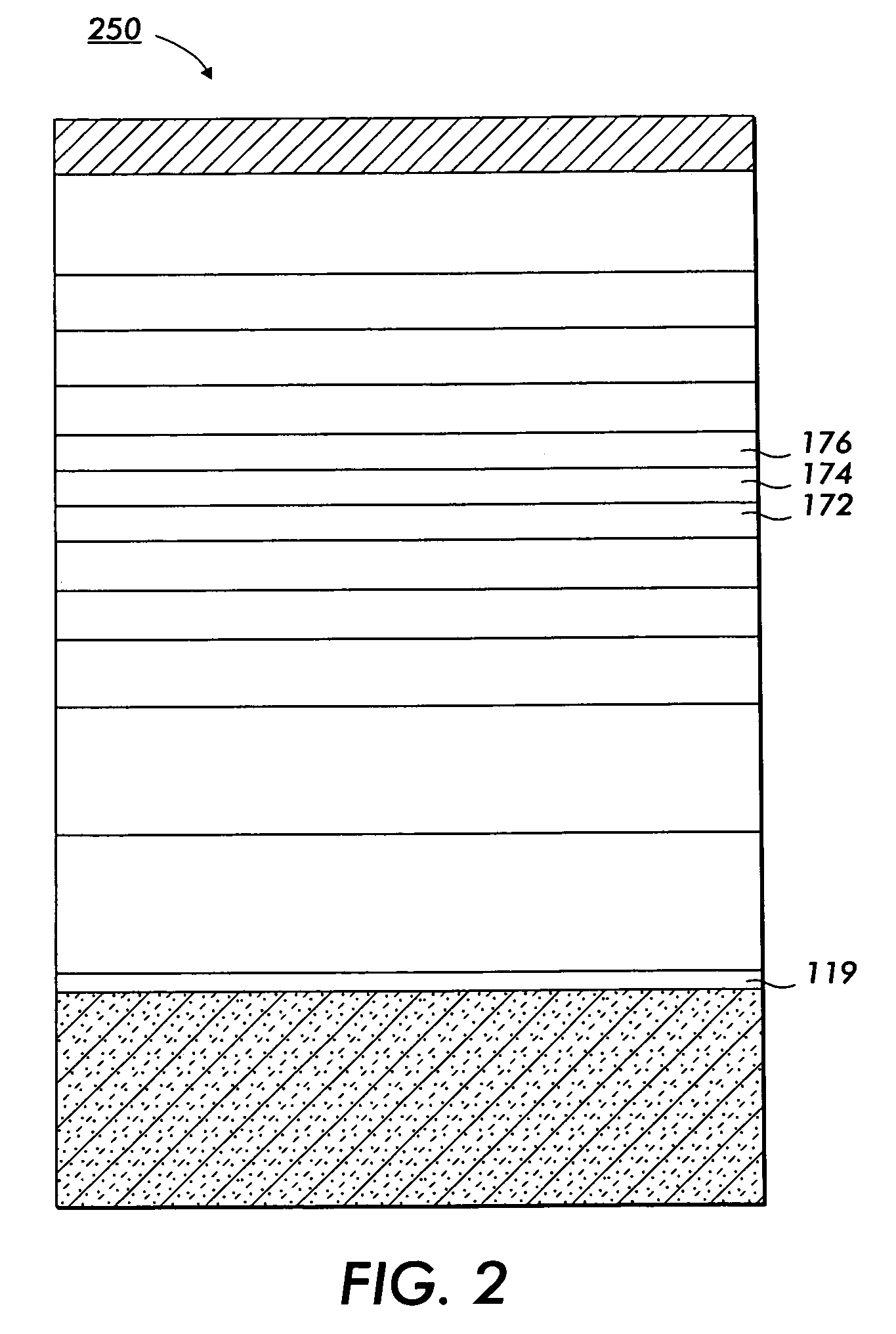

InactiveUS20050077541A1High electron mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesHigh electronGallium nitride

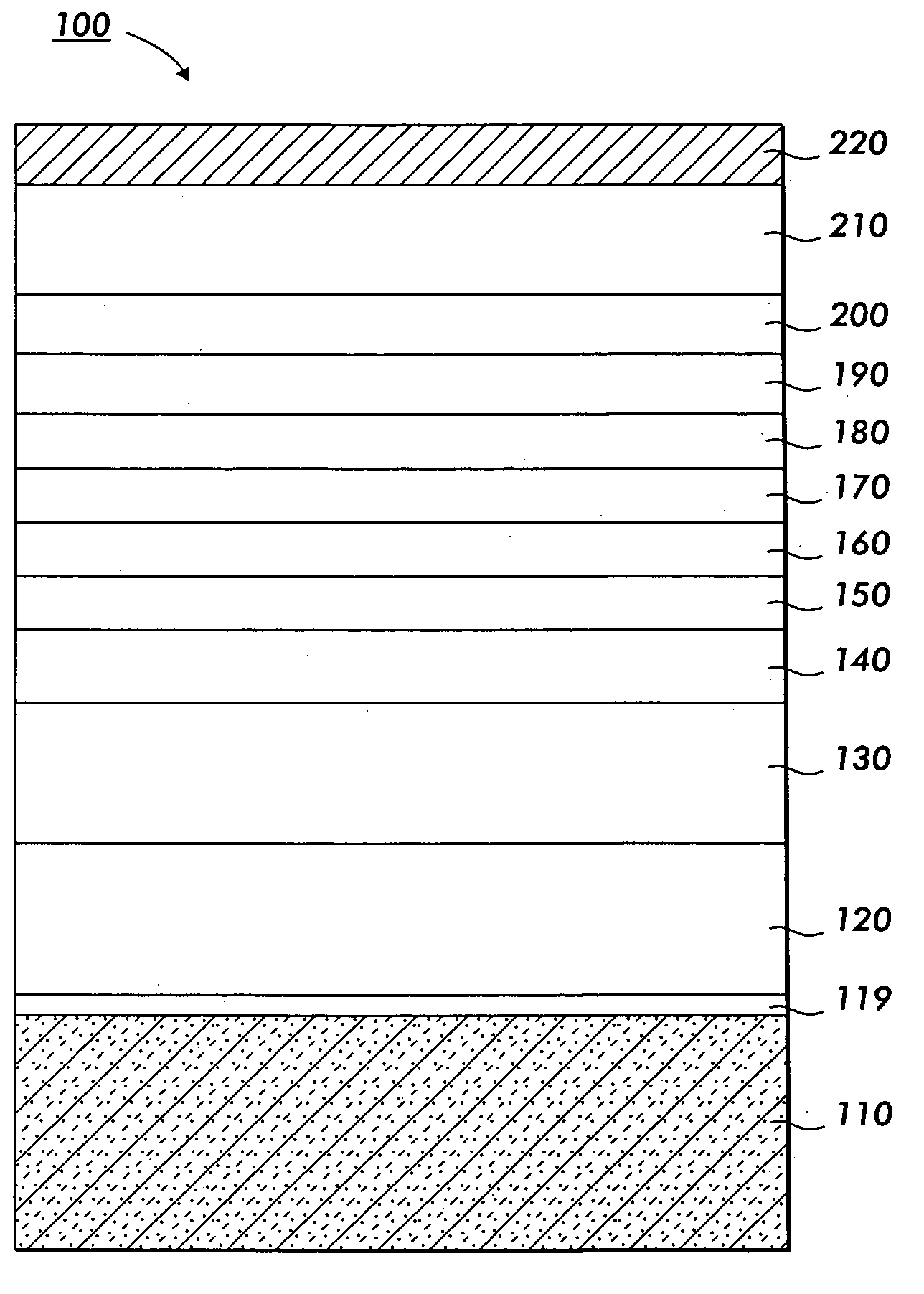

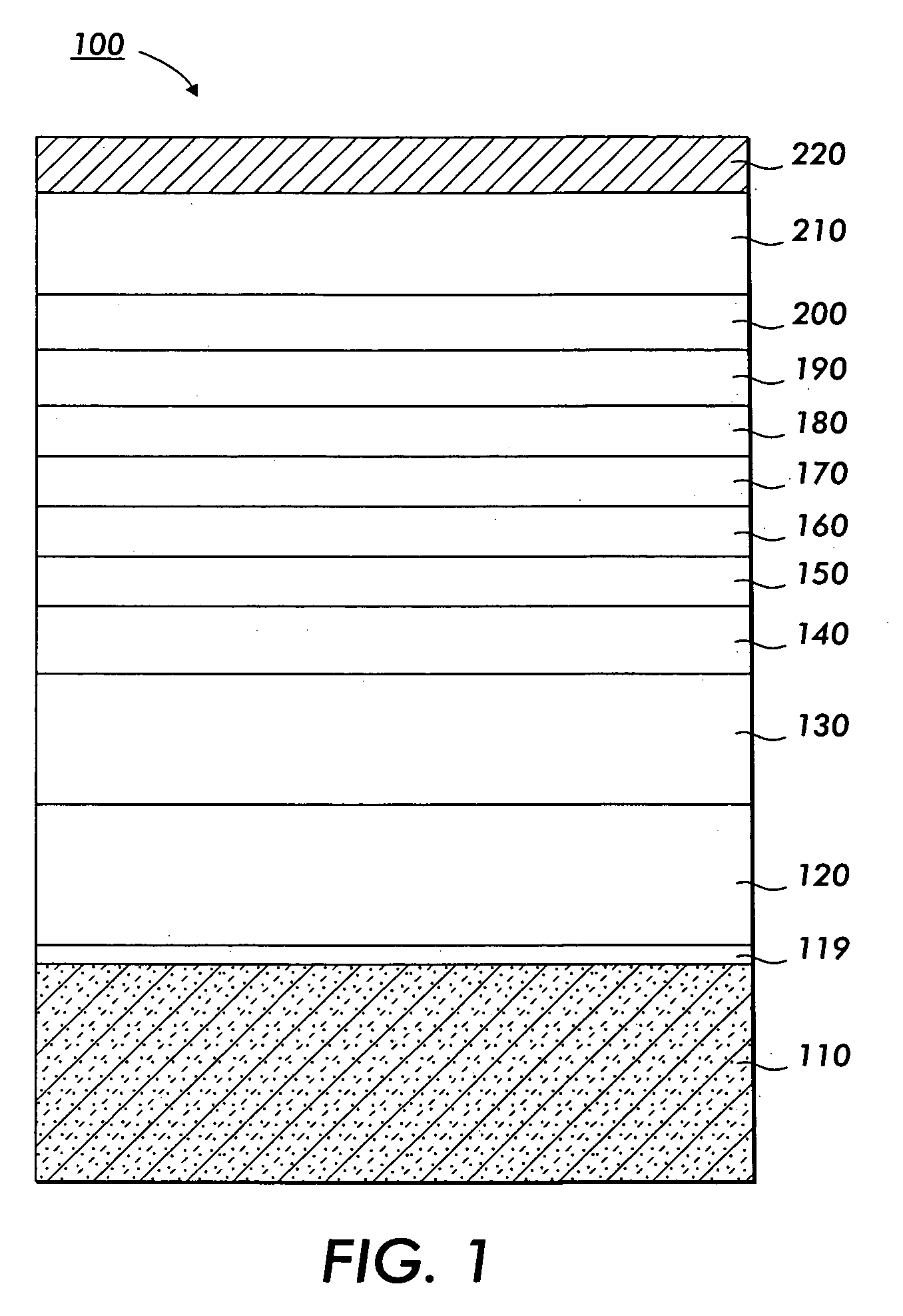

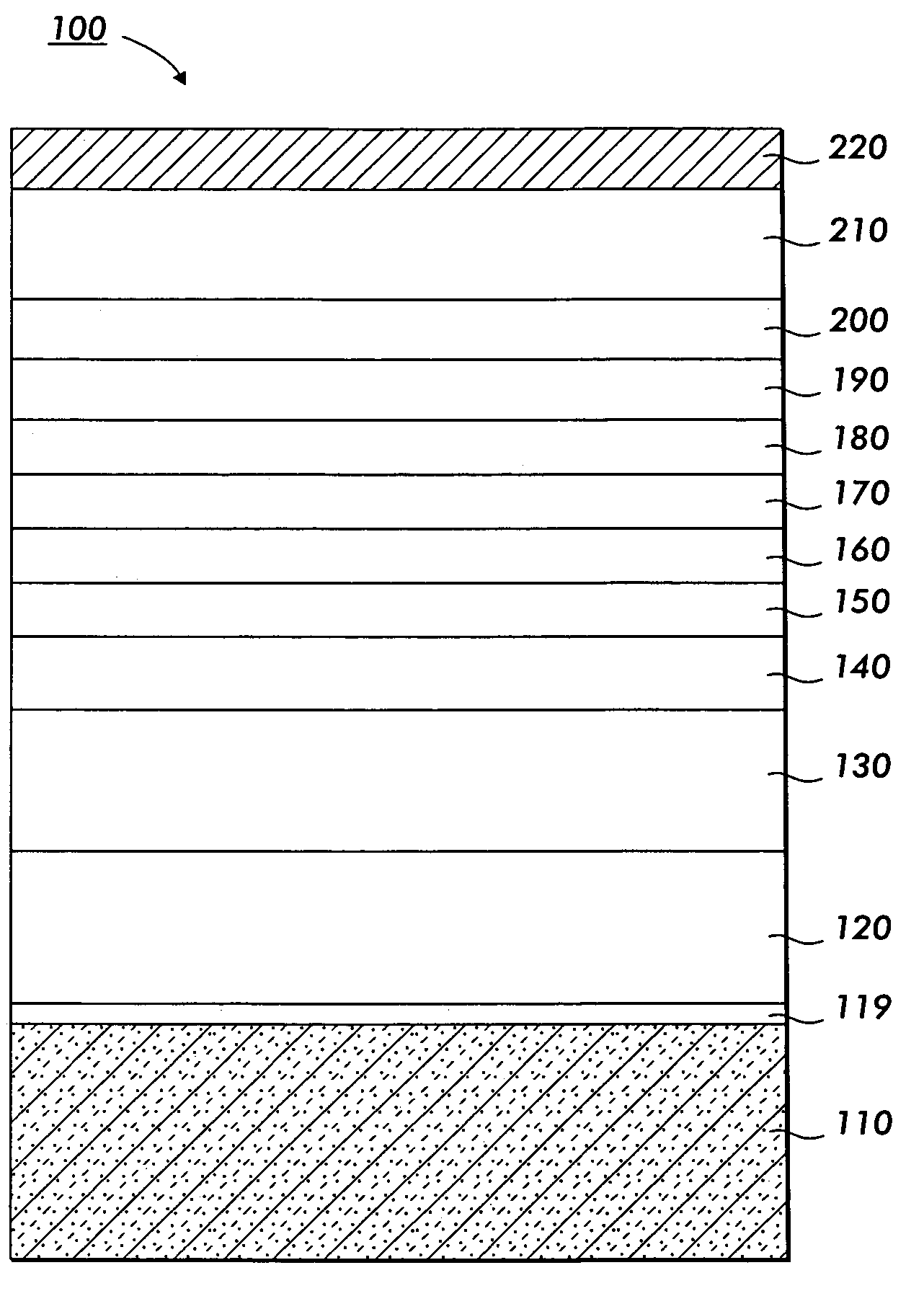

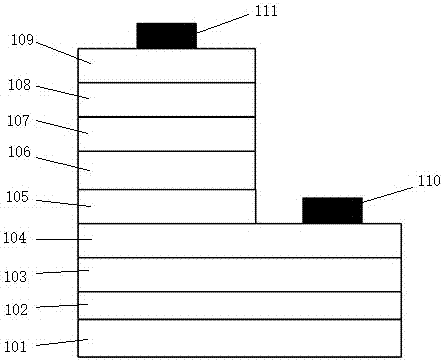

A dispersion-free high electron mobility transistor (HEMT), comprised of a substrate; a semi-insulating buffer layer, comprised of gallium nitride (GaN) or aluminum gallium nitride (AlGaN), deposited on the substrate, an AlGaN barrier layer, with an aluminum (Al) mole fraction larger than that of the semi-insulating buffer layer, deposited on the semi-insulating buffer layer, an n-type doped graded AlGaN layer deposited on the AlGaN barrier layer, wherein an Al mole fraction is decreased from a bottom of the n-type doped graded AlGaN layer to a top of the n-type doped graded AlGaN layer, and a cap layer, comprised of GaN or AlGaN with an Al mole fraction smaller than that of the AlGaN barrier layer, deposited on the n-type doped graded AlGaN layer.

Owner:RGT UNIV OF CALIFORNIA

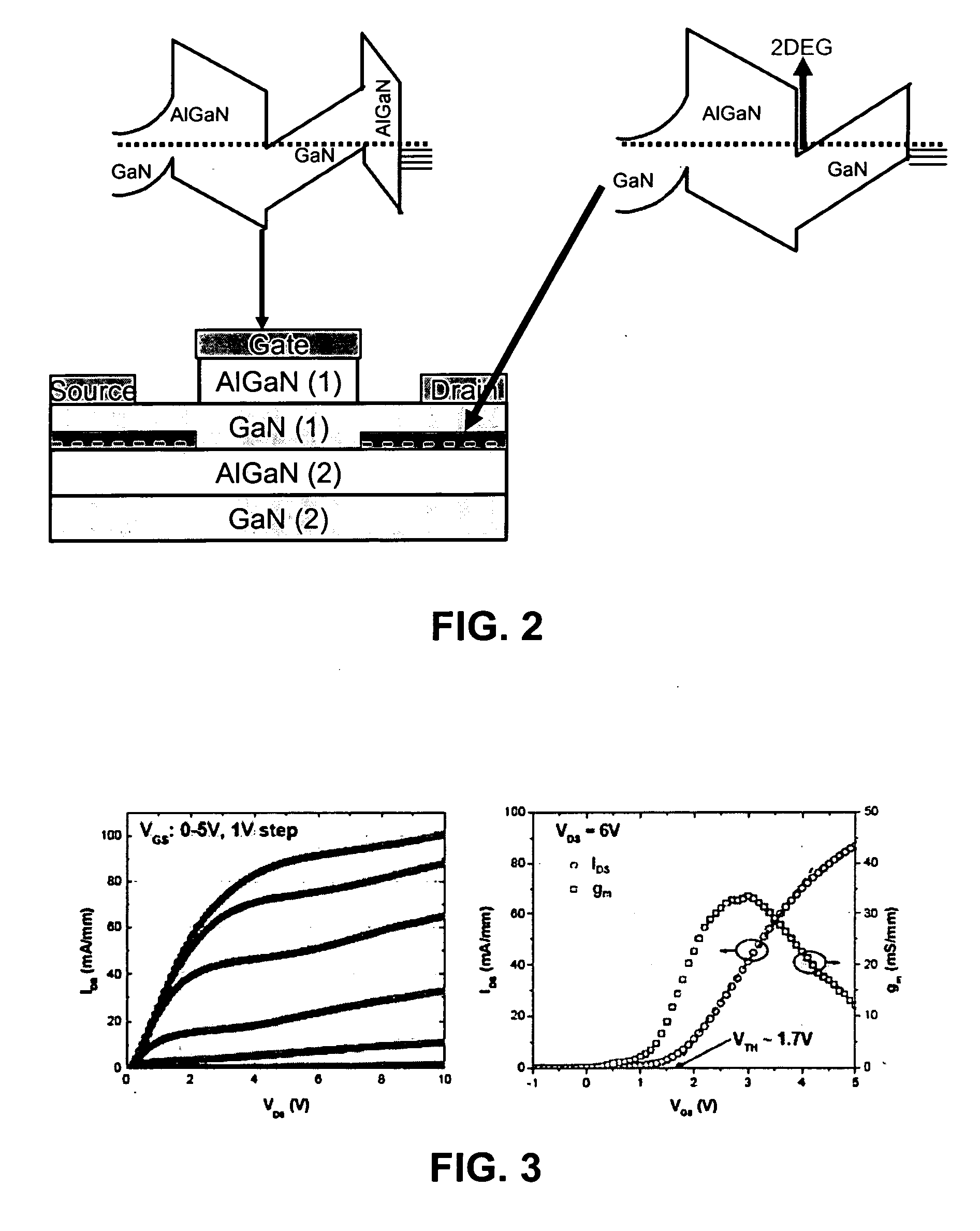

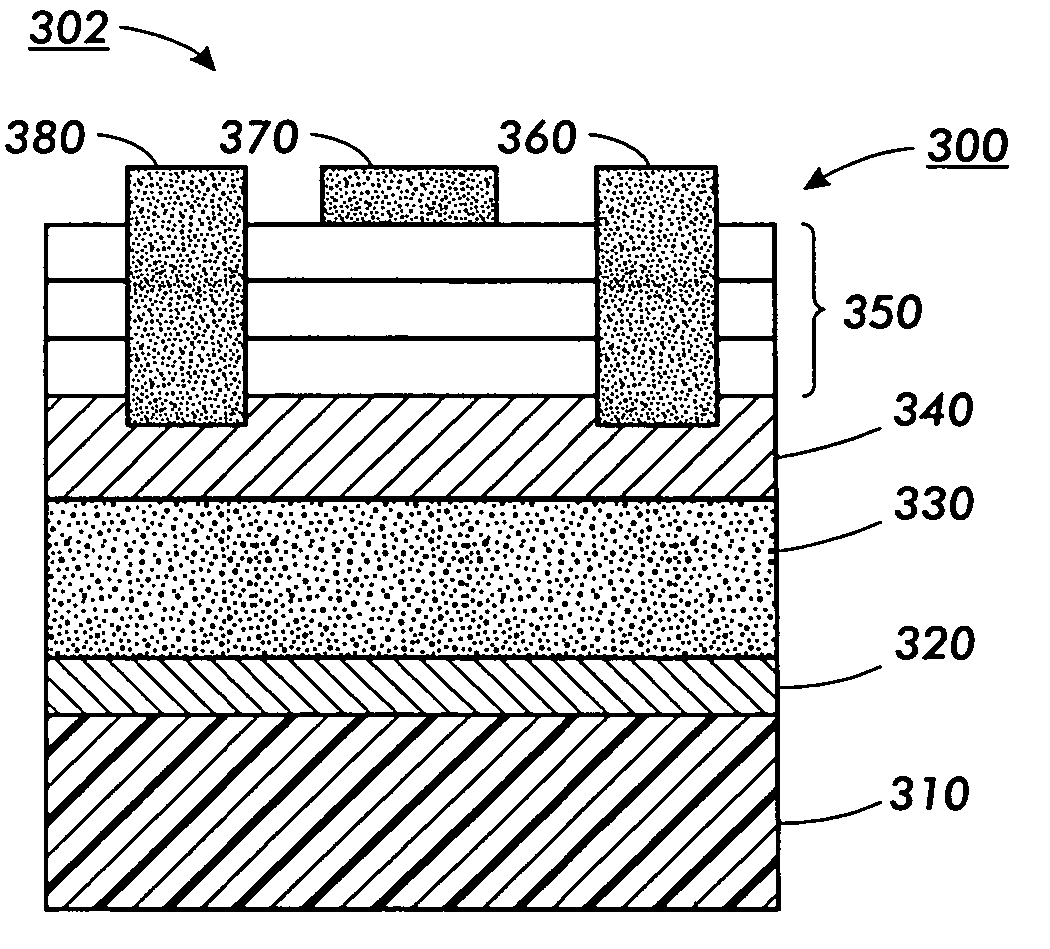

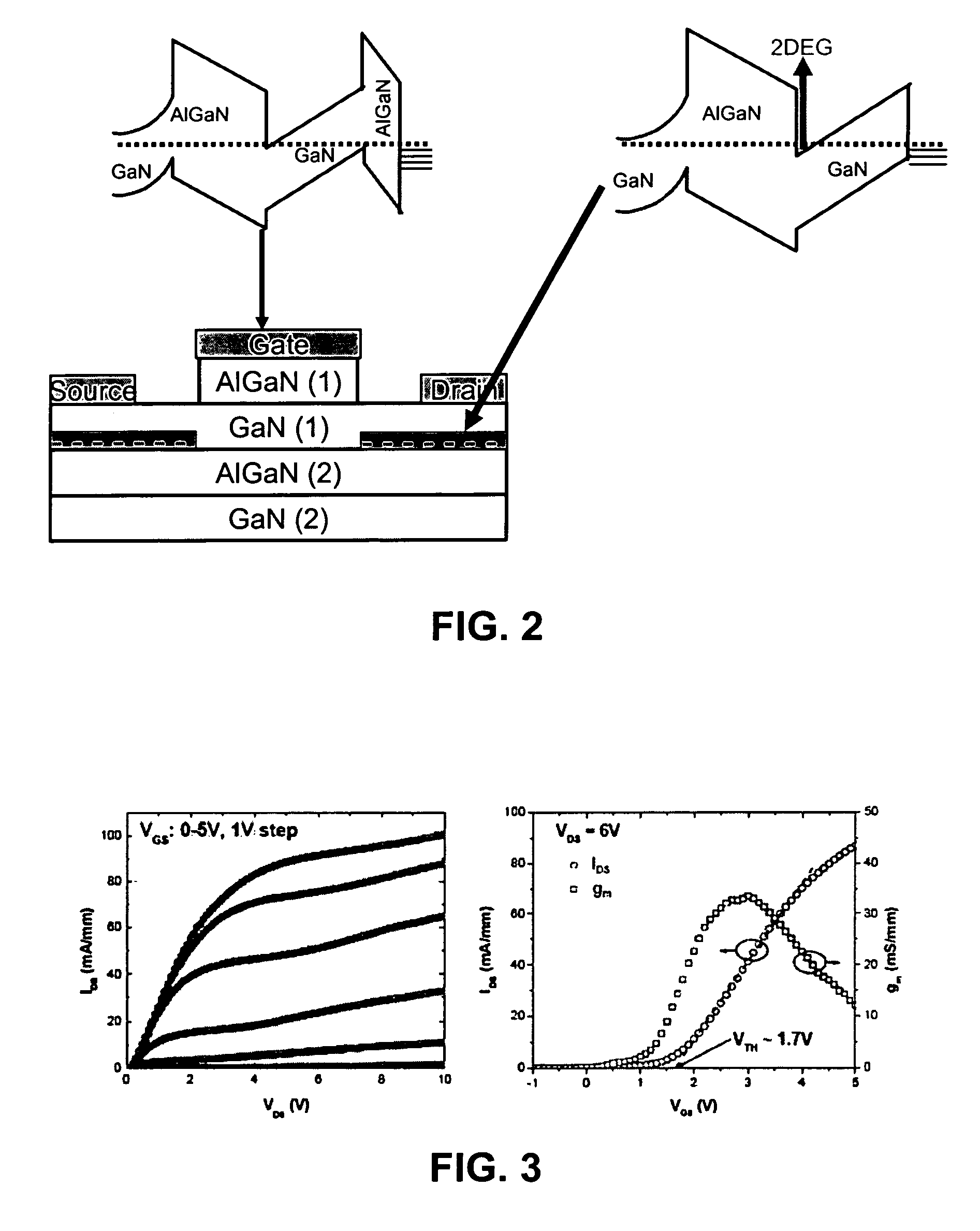

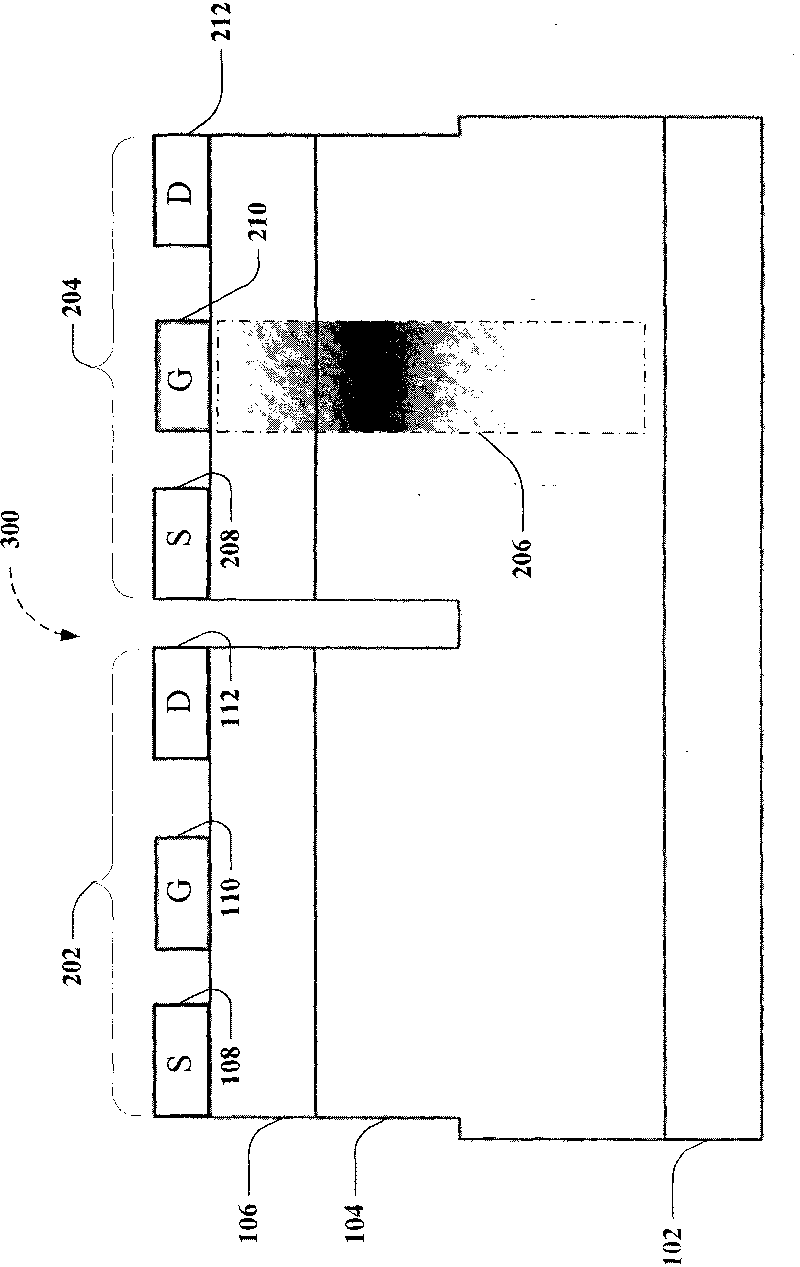

N-polar aluminum gallium nitride/gallium nitride enhancement-mode field effect transistor

ActiveUS20100264461A1High electron mobilityGood dispersionSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical polarityField effect

A novel enhancement mode field effect transistor (FET), such as a High Electron Mobility Transistors (HEMT), has an N-polar surface uses polarization fields to reduce the electron population under the gate in the N-polar orientation, has improved dispersion suppression, and low gate leakage.

Owner:RGT UNIV OF CALIFORNIA

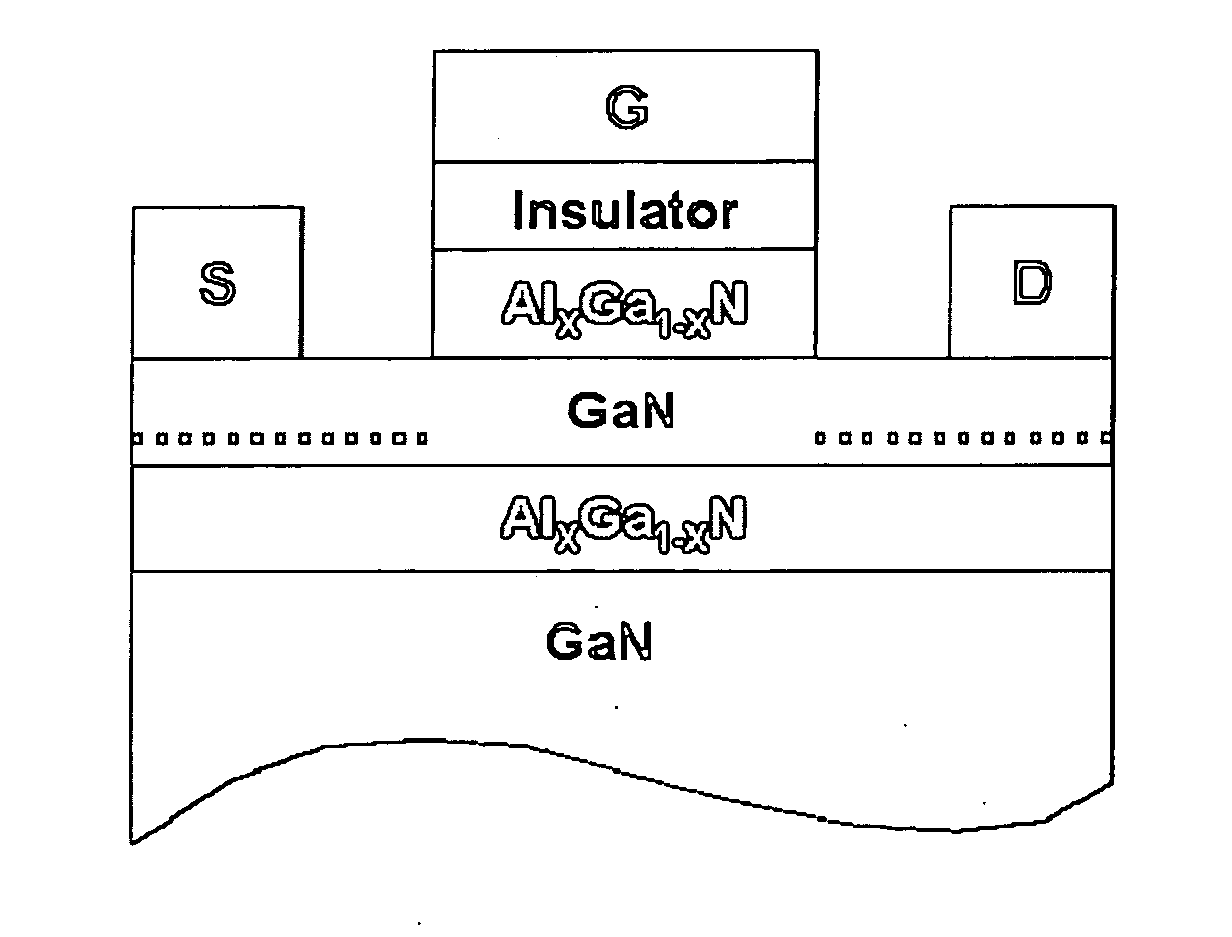

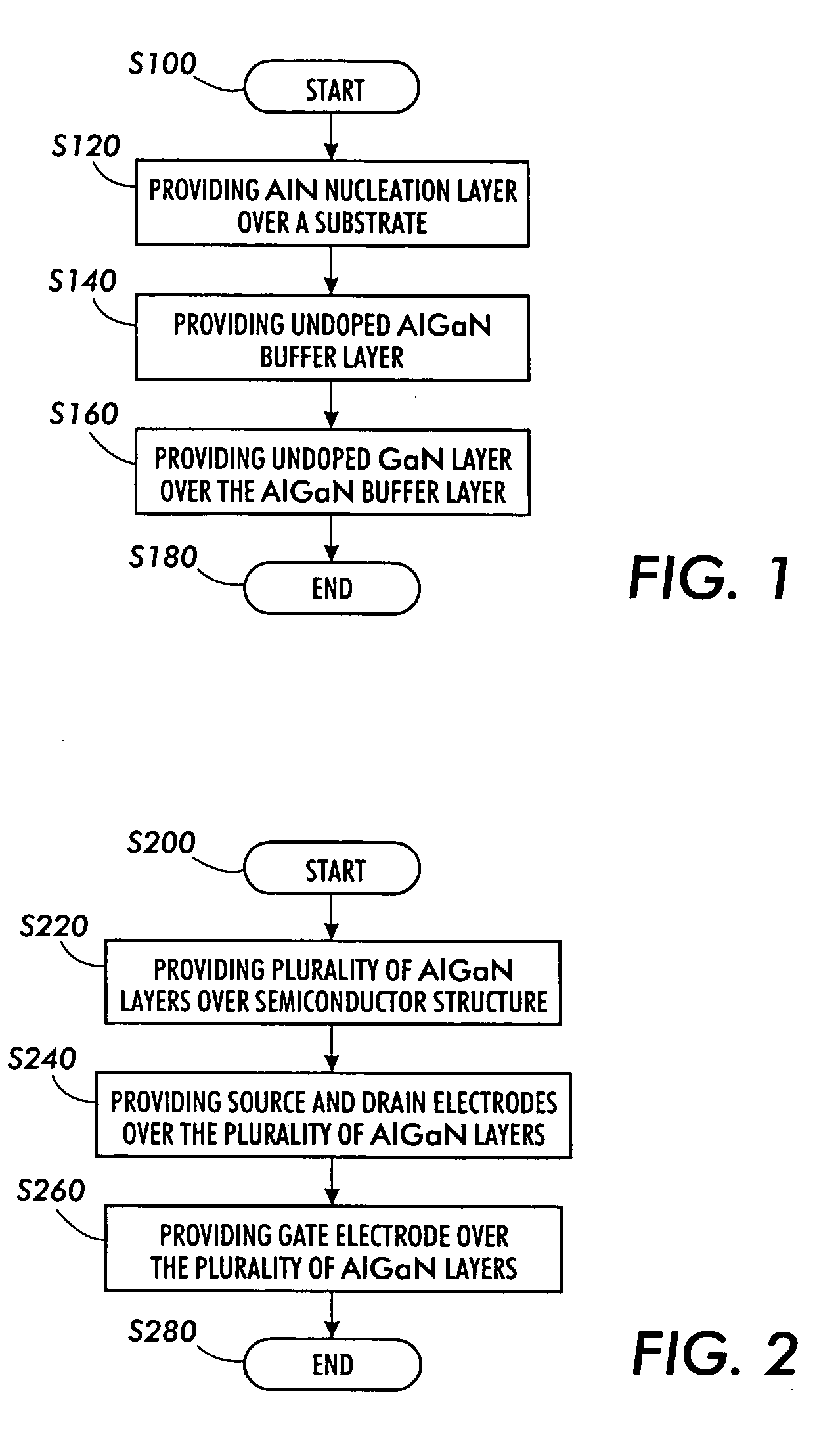

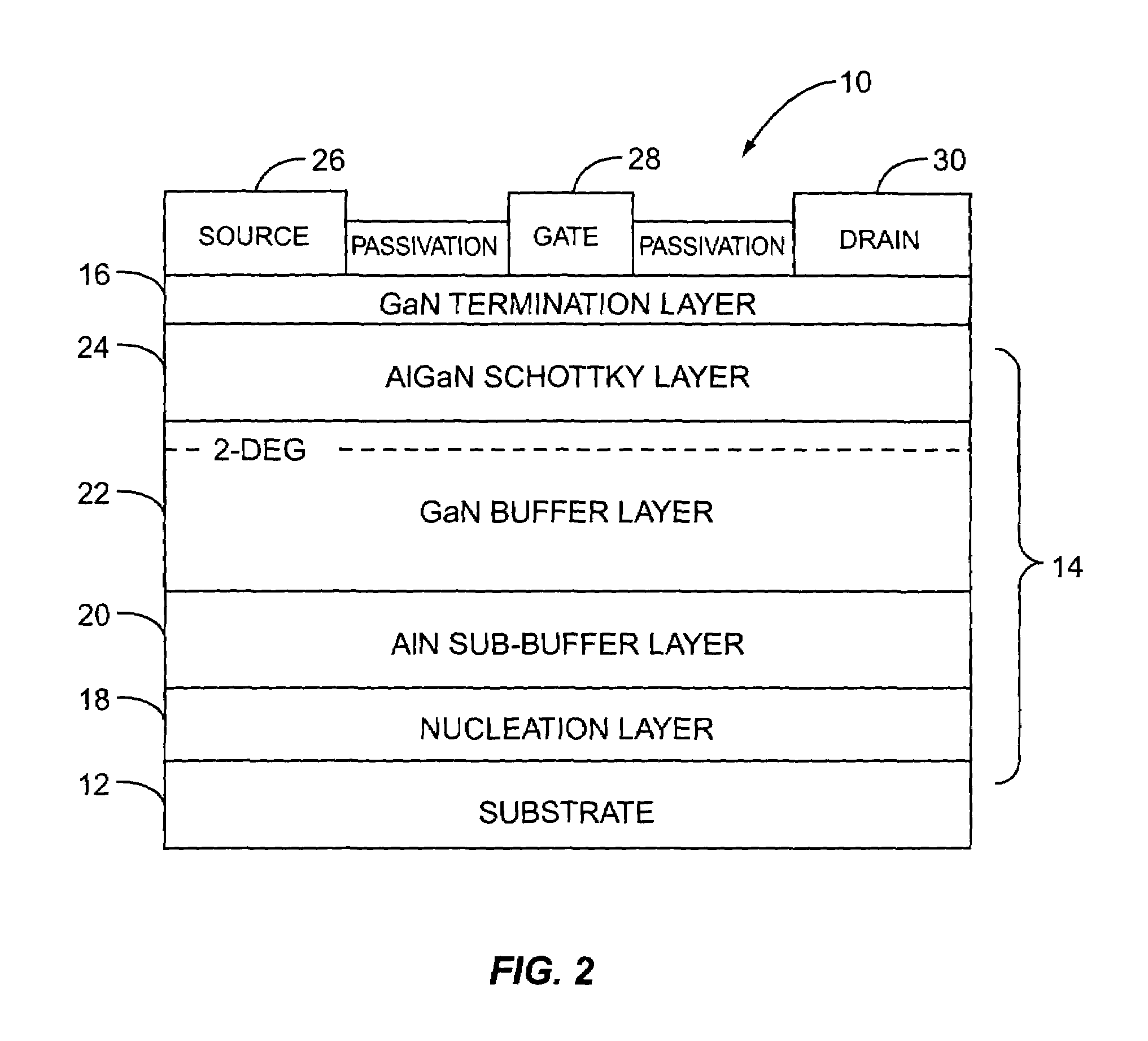

Group III-nitride based HEMT device with insulating GaN/AlGaN buffer layer

InactiveUS20060073621A1Semiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor structureGallium nitride

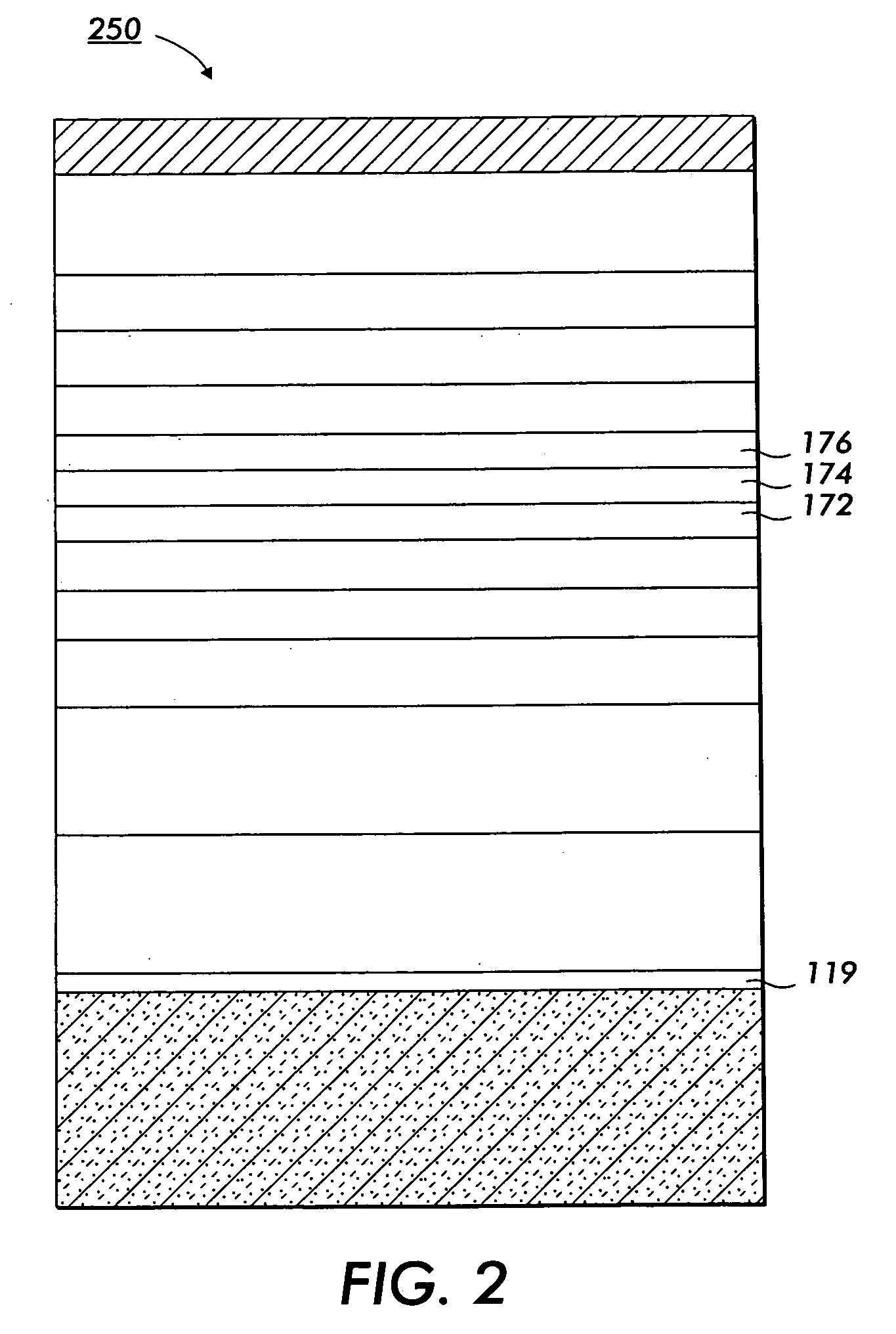

Various exemplary embodiments of the devices and methods for this invention provide for a semiconductor structure and a method of manufacturing a semiconductor structure that includes providing an aluminum nitride nucleation layer over a substrate, providing an undoped AlGaN buffer layer over the aluminum nitride nucleation layer, providing an undoped GaN over the AlGaN buffer layer, providing a plurality of AlGaN layers over the GaN layer wherein the plurality of aluminum GaN layers comprise a first layer provided over the undoped GaN layer, a second layer provided over the first layer and the third layer provided over the second layer, providing a source electrode and a drain electrode, through the first, second and third aluminum gallium nitride layers, the source electrode and the drain electrode being in electrical contact with the gallium nitride layer and providing a gate electrode over the third aluminum gallium nitride layer.

Owner:PALO ALTO RES CENT INC

N-polar aluminum gallium nitride/gallium nitride enhancement-mode field effect transistor

ActiveUS7948011B2High electron mobilityGood dispersionSemiconductor/solid-state device manufacturingSemiconductor devicesField effectHigh electron

A novel enhancement mode field effect transistor (FET), such as a High Electron Mobility Transistors (HEMT), has an N-polar surface uses polarization fields to reduce the electron population under the gate in the N-polar orientation, has improved dispersion suppression, and low gate leakage.

Owner:RGT UNIV OF CALIFORNIA

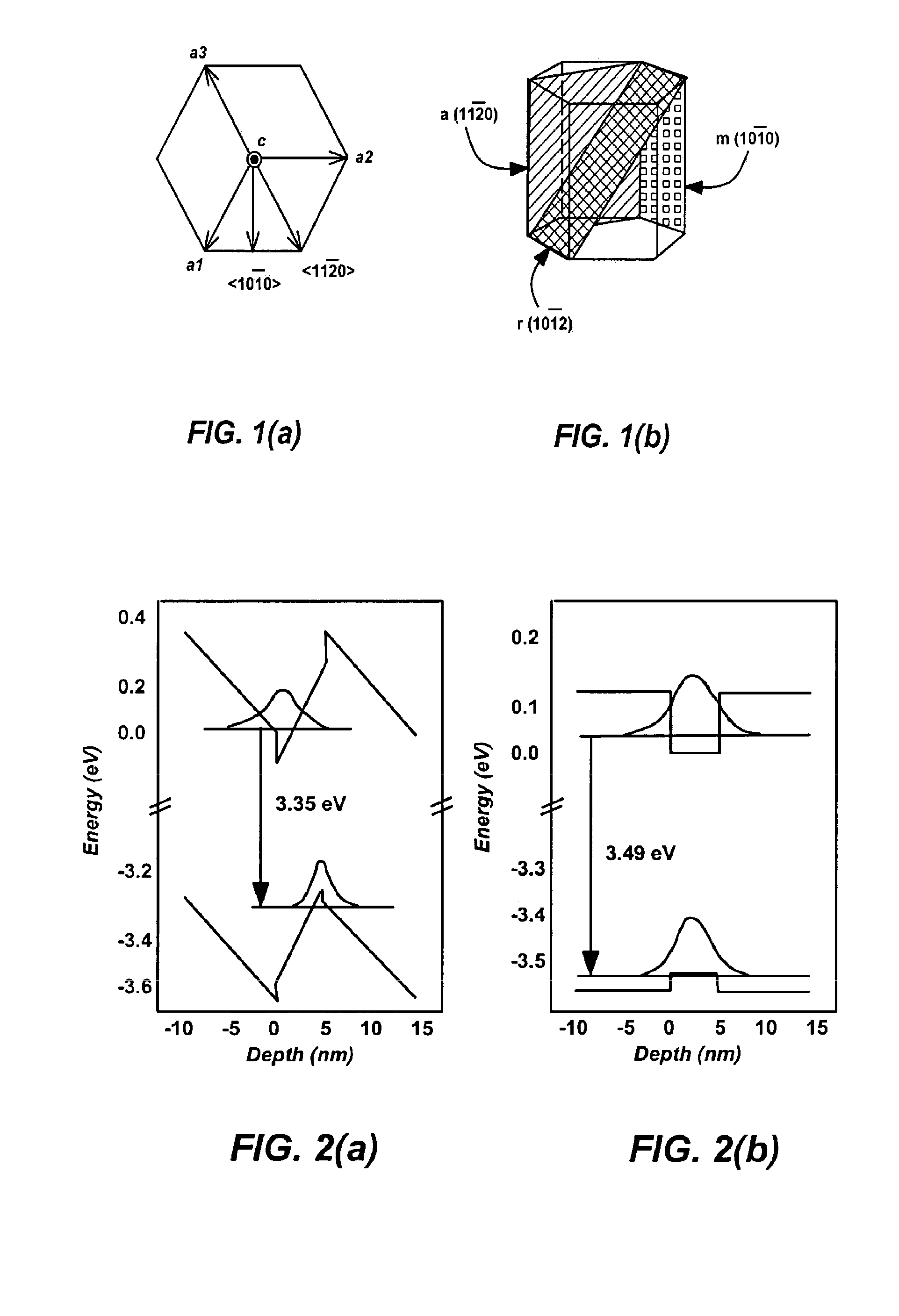

Ultraviolet group III-nitride-based quantum well laser diodes

InactiveUS20050224781A1Sufficient carrier confinementAvoid structural degradationOptical wave guidanceLaser detailsUltravioletGallium

A pair of undoped spacer layers are provided adjacent to, or near to, a single quantum well aluminum gallium nitride active region. In various exemplary embodiments, the undoped spacer layers are provided between the single quantum well aluminum gallium nitride active region and carrier confinement layers. The undoped spacer layers reduce the threshold current for the laser device and improve the output characteristics.

Owner:PALO ALTO RES CENT INC

Ultraviolet group III-nitride-based quantum well laser diodes

InactiveUS7138648B2Sufficient carrier confinementAvoid structural degradationOptical wave guidanceLaser detailsUltravioletGallium

A pair of undoped spacer layers are provided adjacent to, or near to, a single quantum well aluminum gallium nitride active region. In various exemplary embodiments, the undoped spacer layers are provided between the single quantum well aluminum gallium nitride active region and carrier confinement layers. The undoped spacer layers reduce the threshold current for the laser device and improve the output characteristics.

Owner:PALO ALTO RES CENT INC

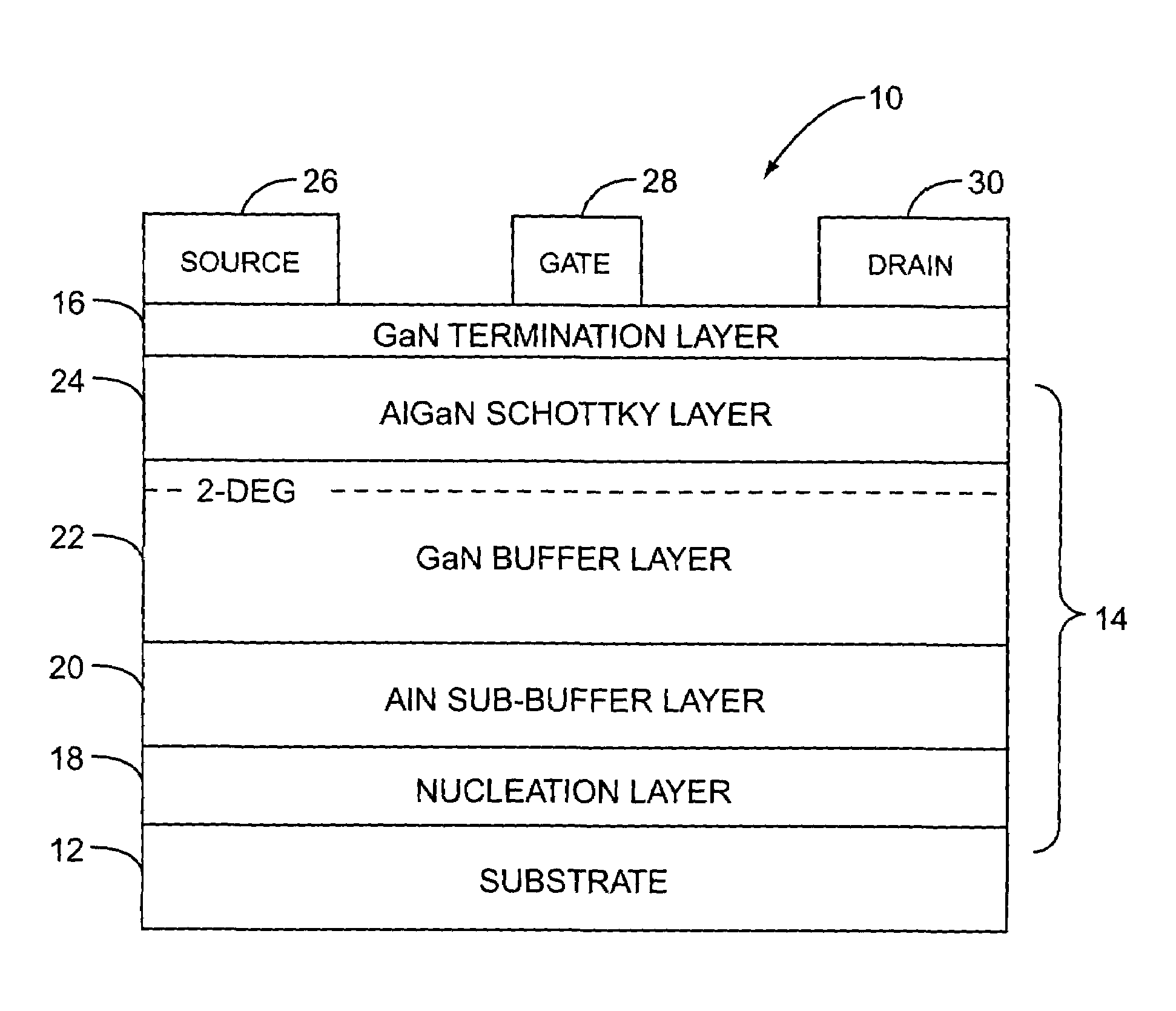

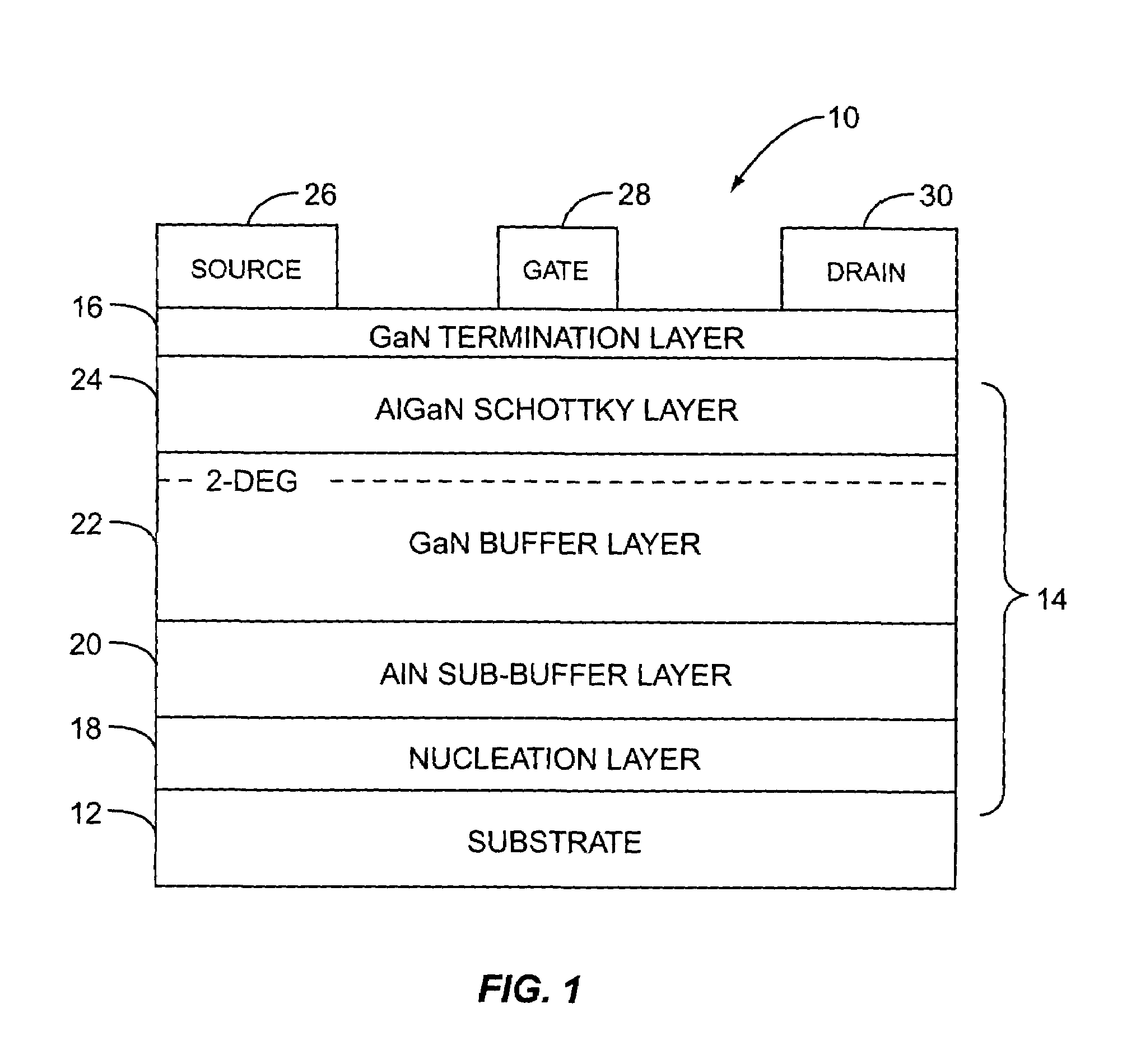

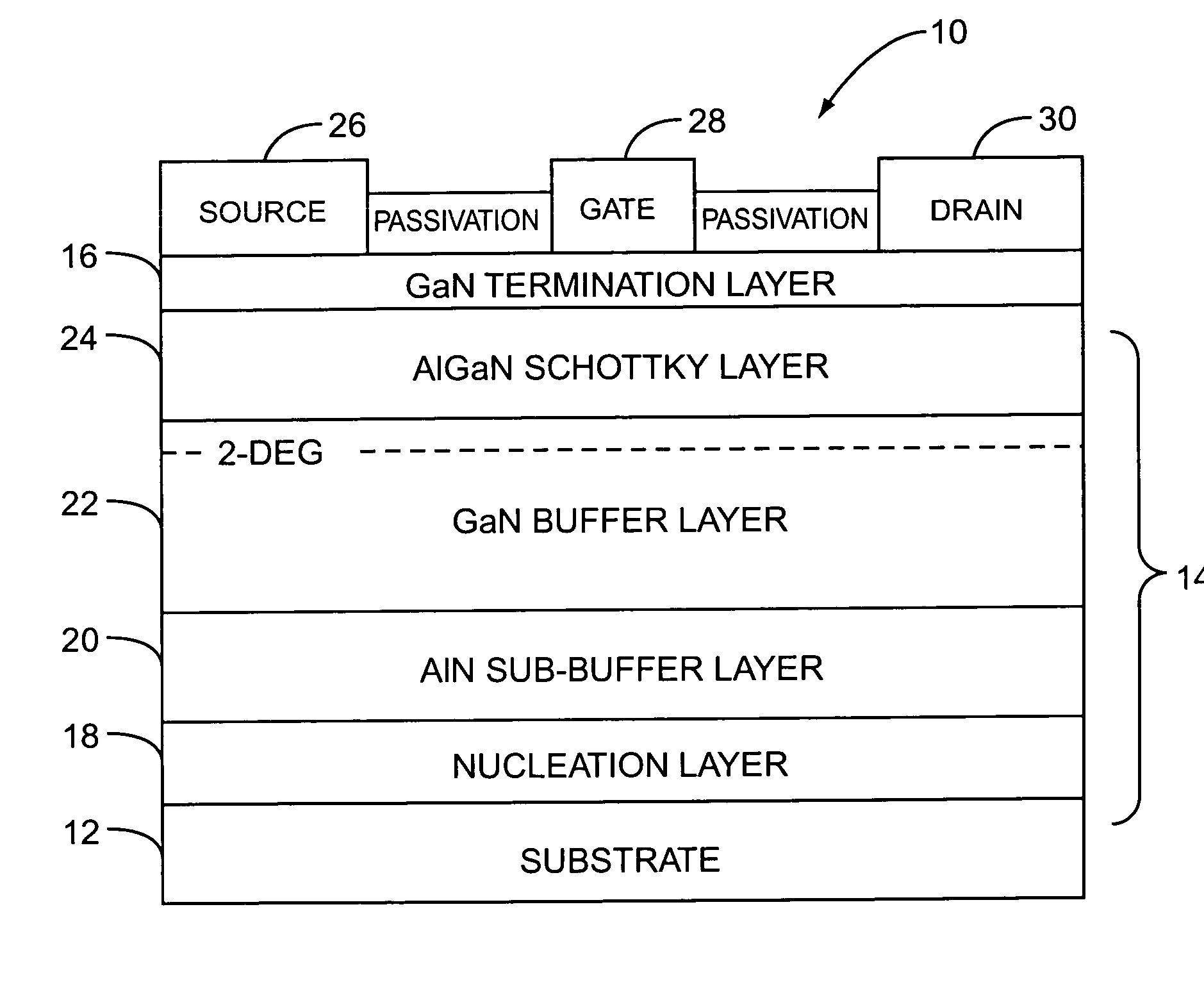

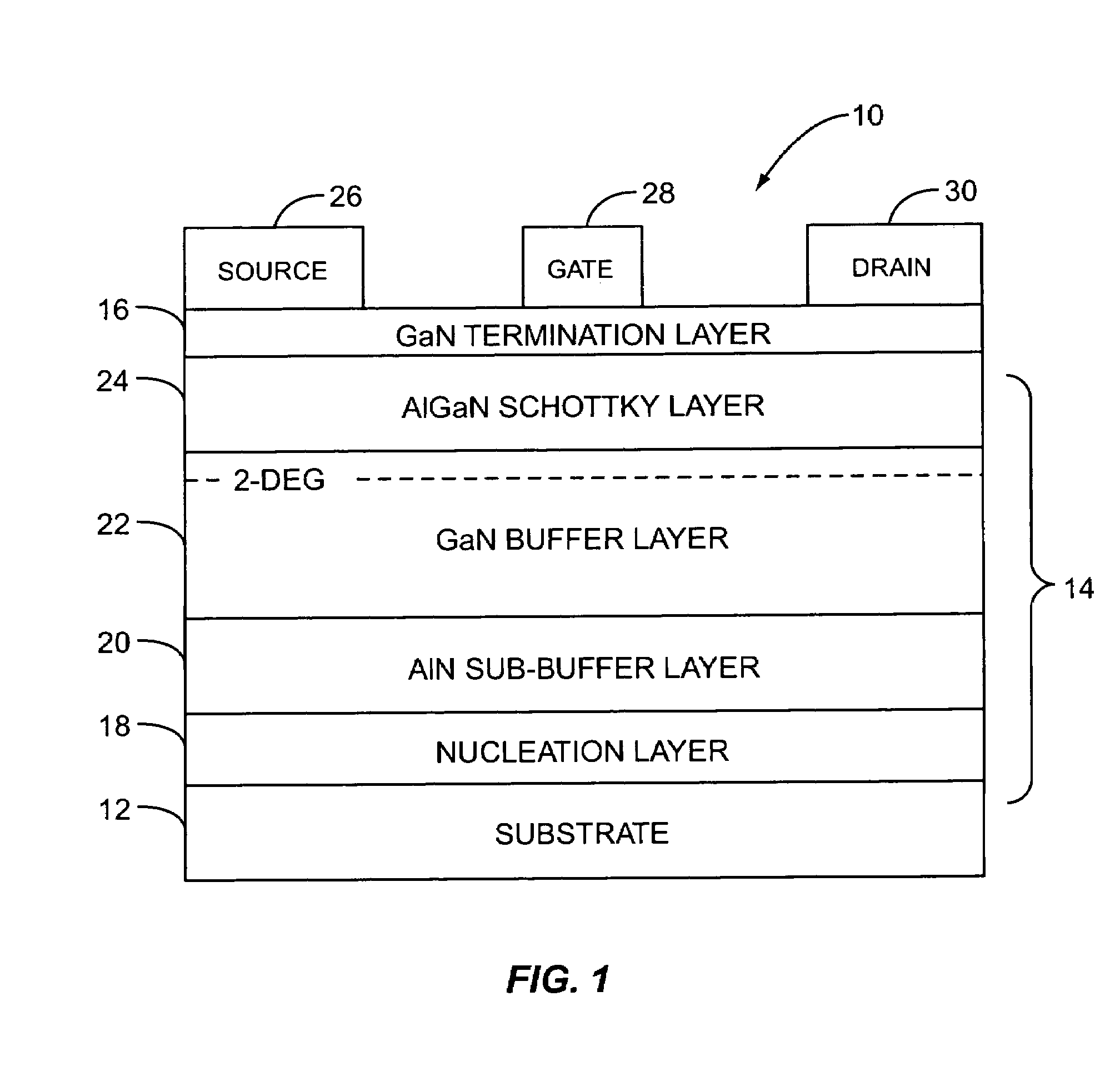

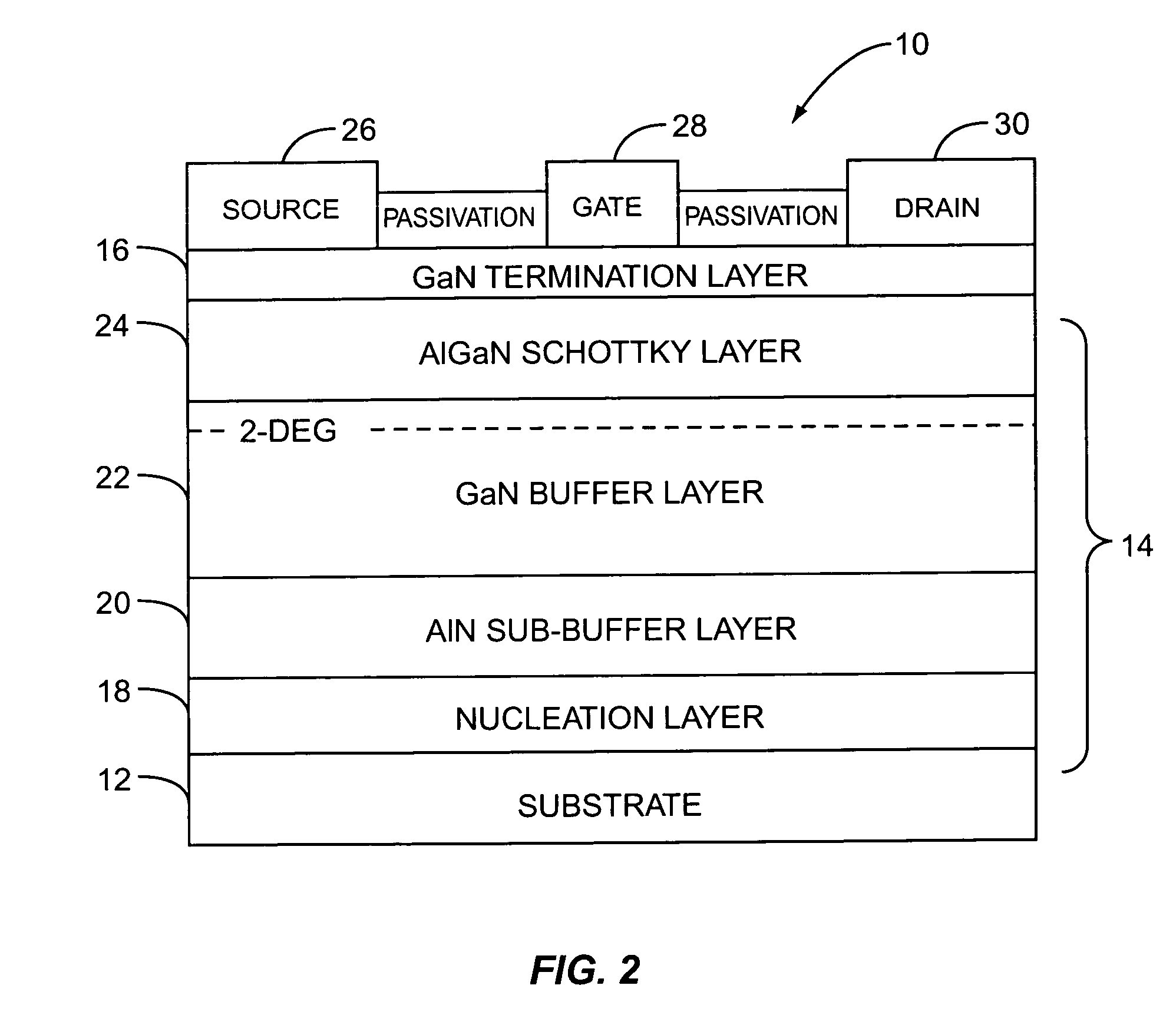

High voltage GaN-based transistor structure

ActiveUS7026665B1Improve performanceImprove passivation effectSemiconductor/solid-state device manufacturingSemiconductor devicesGallium nitrideHigh pressure

The present invention relates to a high voltage and high power gallium nitride (GaN) transistor structure. In general, the GaN transistor structure includes a sub-buffer layer that serves to prevent injection of electrons into a substrate during high voltage operation, thereby improving performance of the GaN transistor structure during high voltage operation. Preferably, the sub-buffer layer is aluminum nitride, and the GaN transistor structure further includes a transitional layer, a GaN buffer layer, and an aluminum gallium nitride Schottky layer.

Owner:QORVO US INC

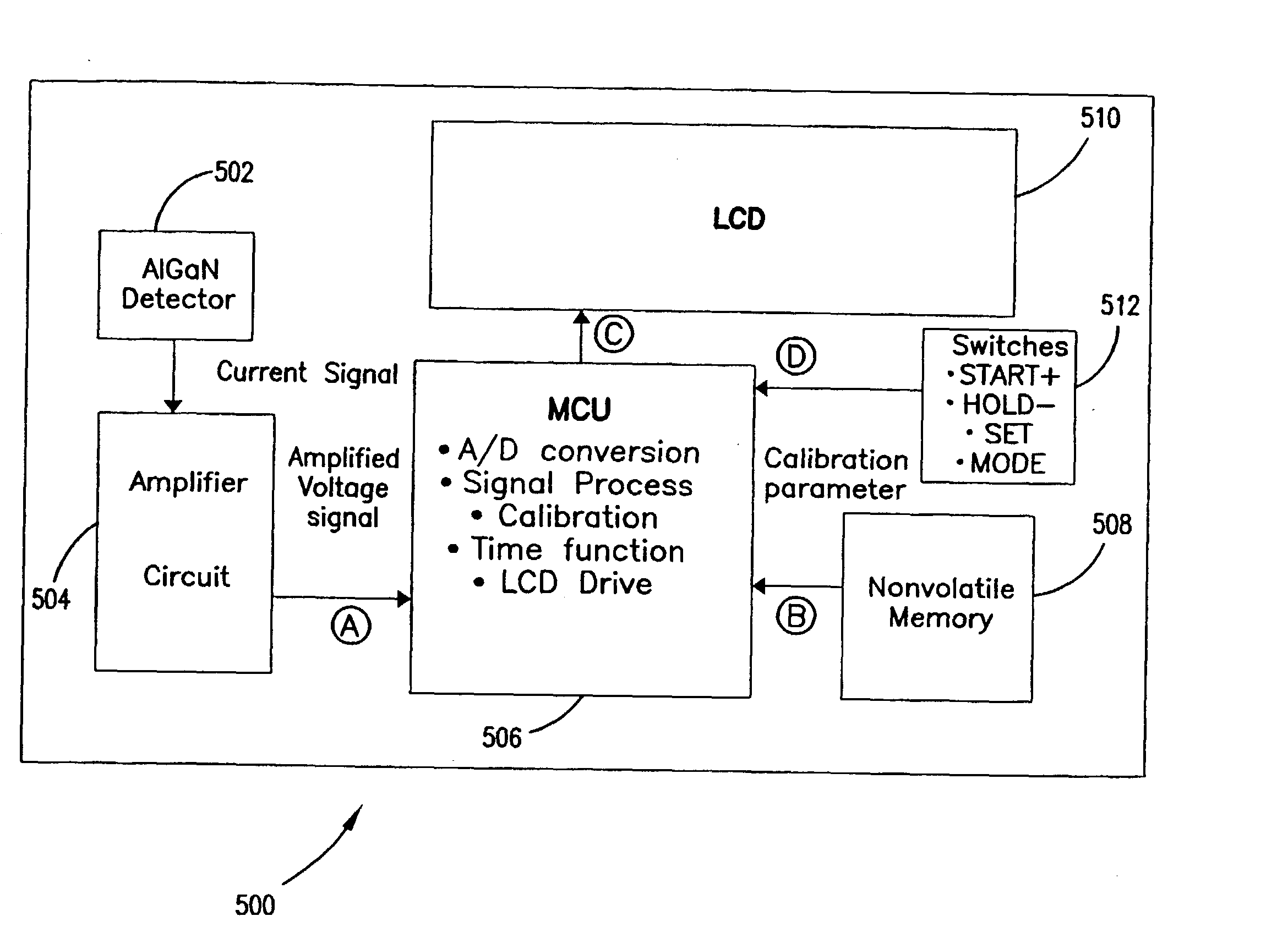

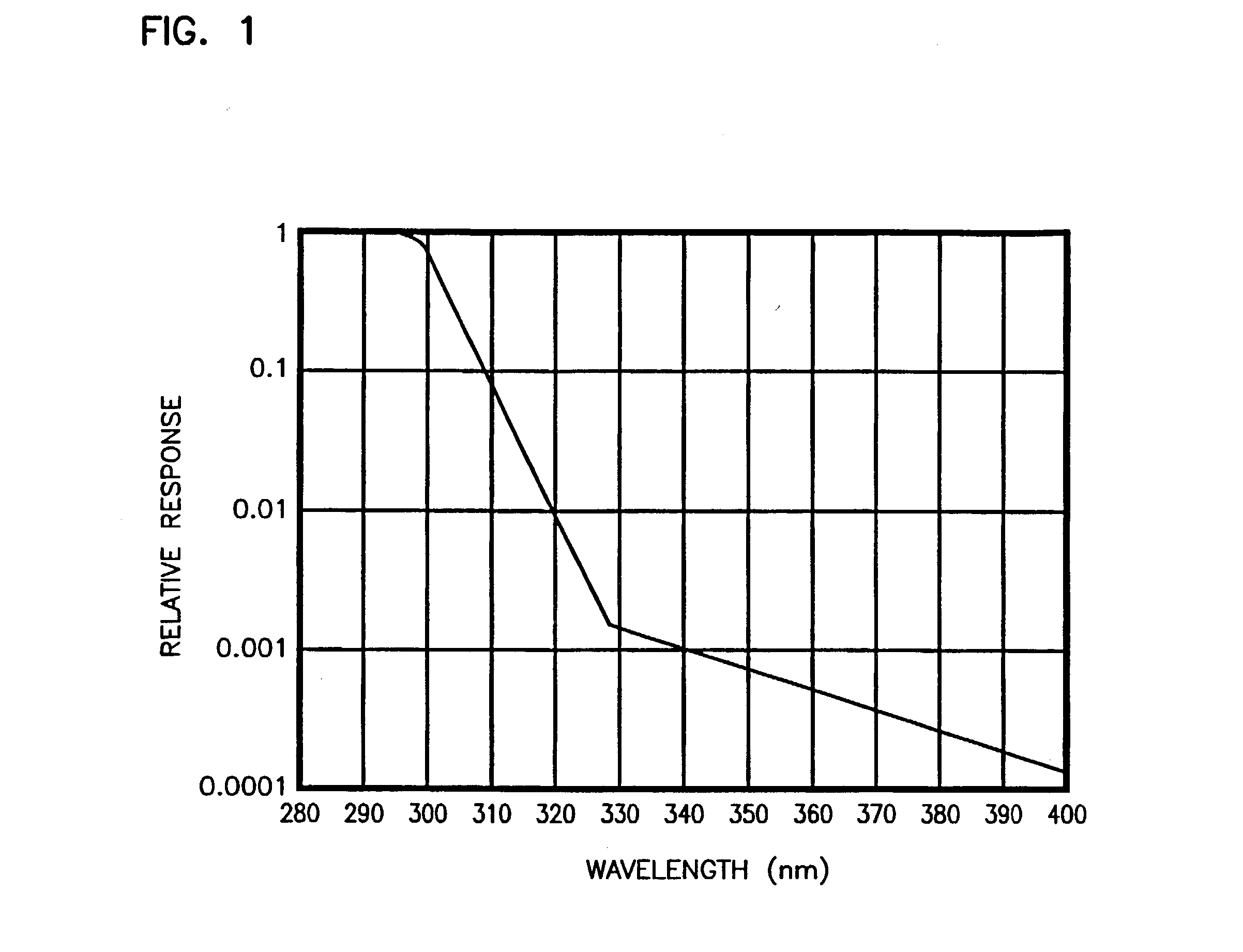

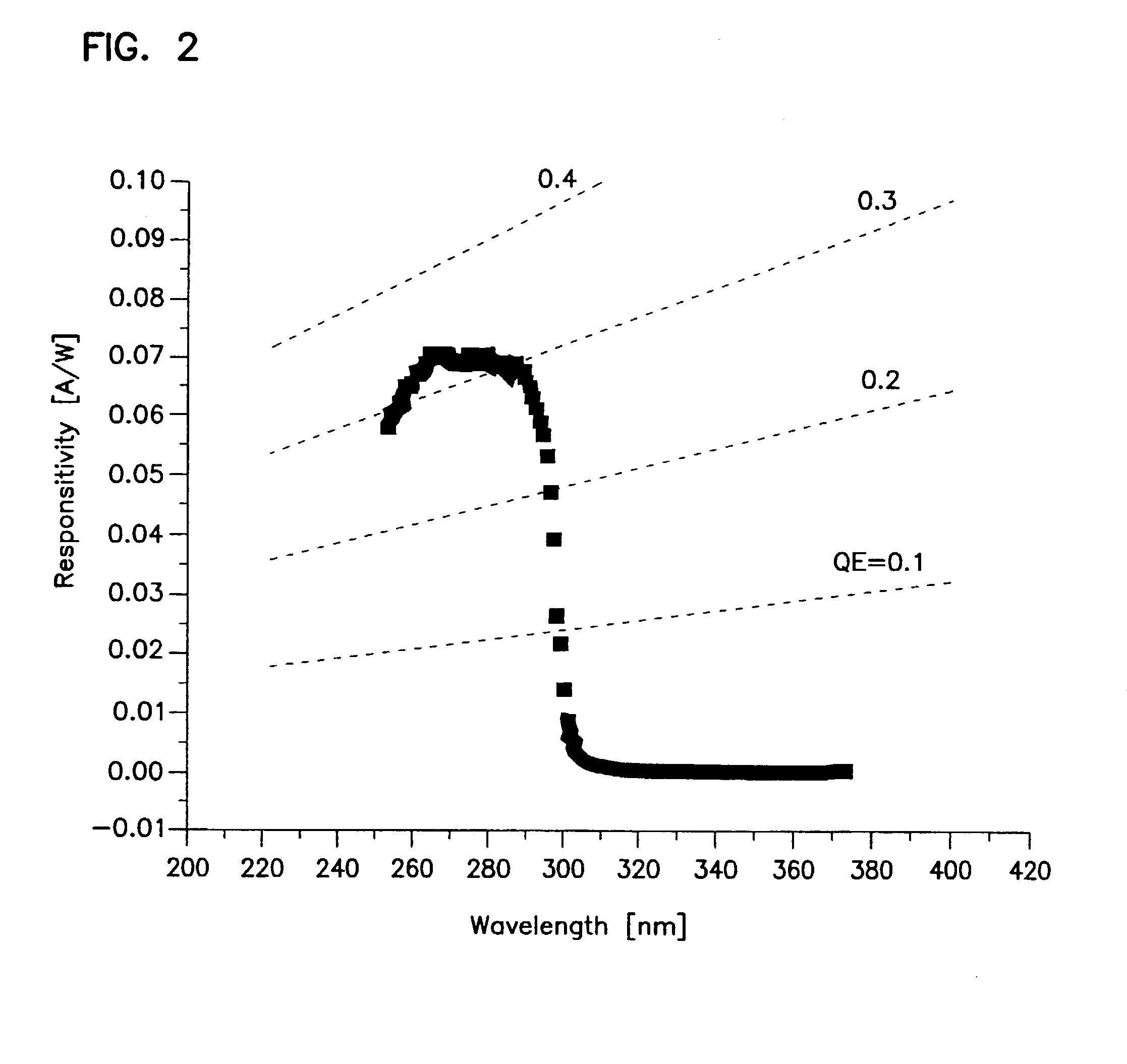

Device and method for ultraviolet radiation monitoring

InactiveUS20030150998A1Material analysis by optical meansPhotometry for measuring UV lightUser inputUltraviolet

An ultraviolet radiation monitor is disclosed. The monitor includes an aluminum gallium nitride-based detector, such as a Schottky junction fabricated with aluminum gallium nitride and a Schottky layer containing palladium, and a processor. The composition of the detector is tailored so that the detector is responsive substantially only to radiation of certain wavelengths, such as UV-B. The processor is adapted to receive user input of the user's skin type and ultraviolet-blocking power of any sunscreen the user is wearing. The processor is also adapted to read the signal generated by the detector and calculate the intensity of the ultraviolet radiation received by the detector. The processor is further adapted to calculate the maximum length ultraviolet exposure time for the user, based on the radiation intensity, skin type and sunscreen information.

Owner:APA OPTICS

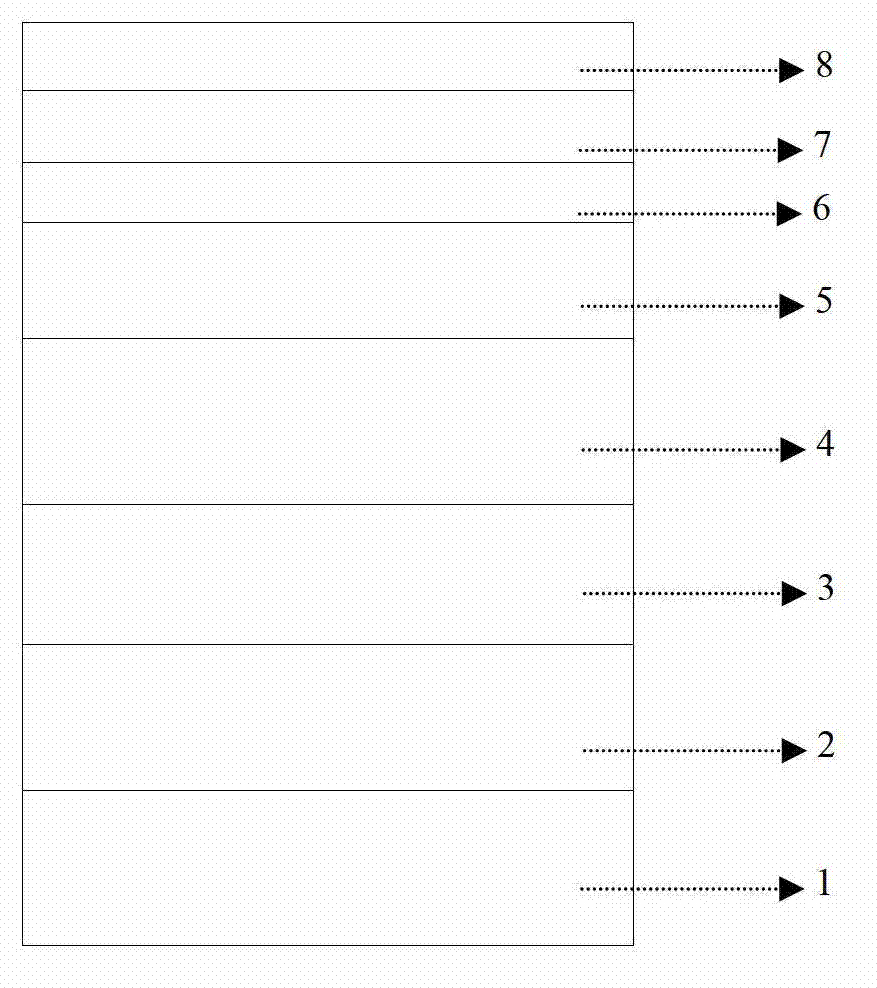

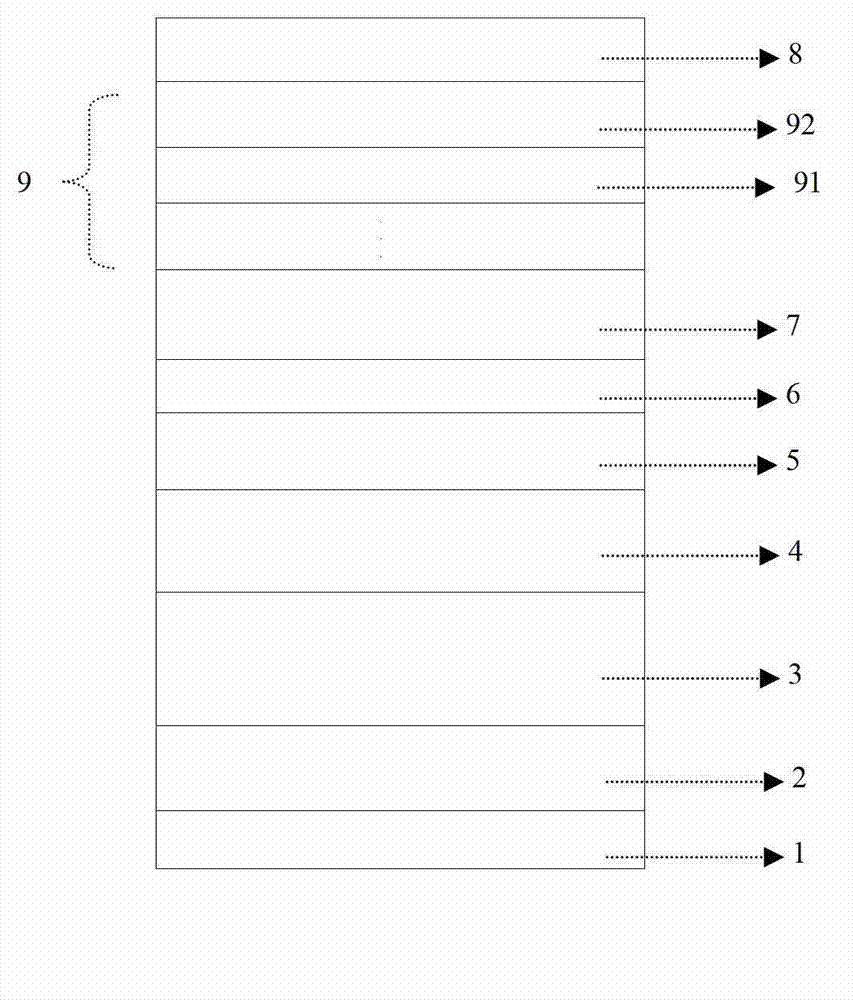

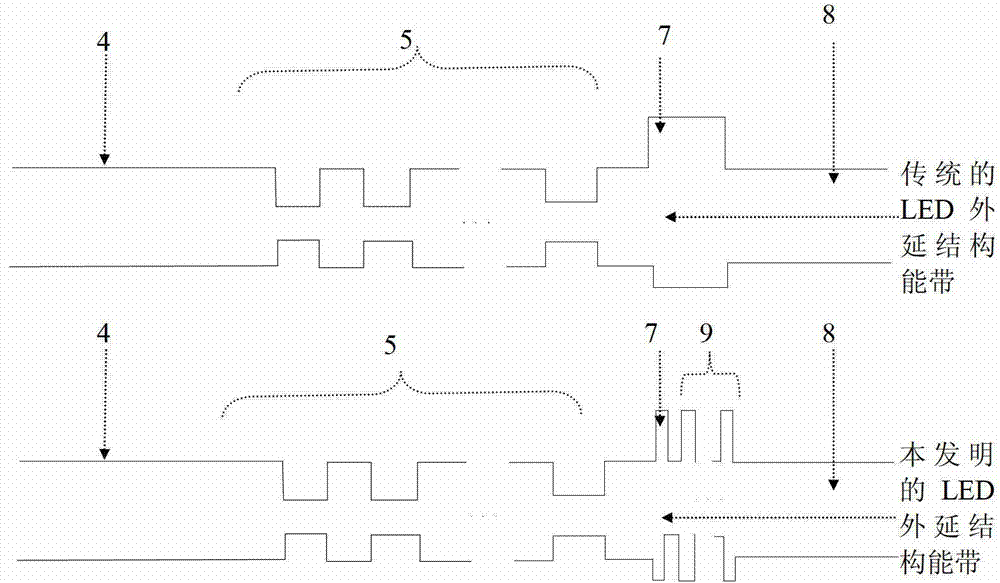

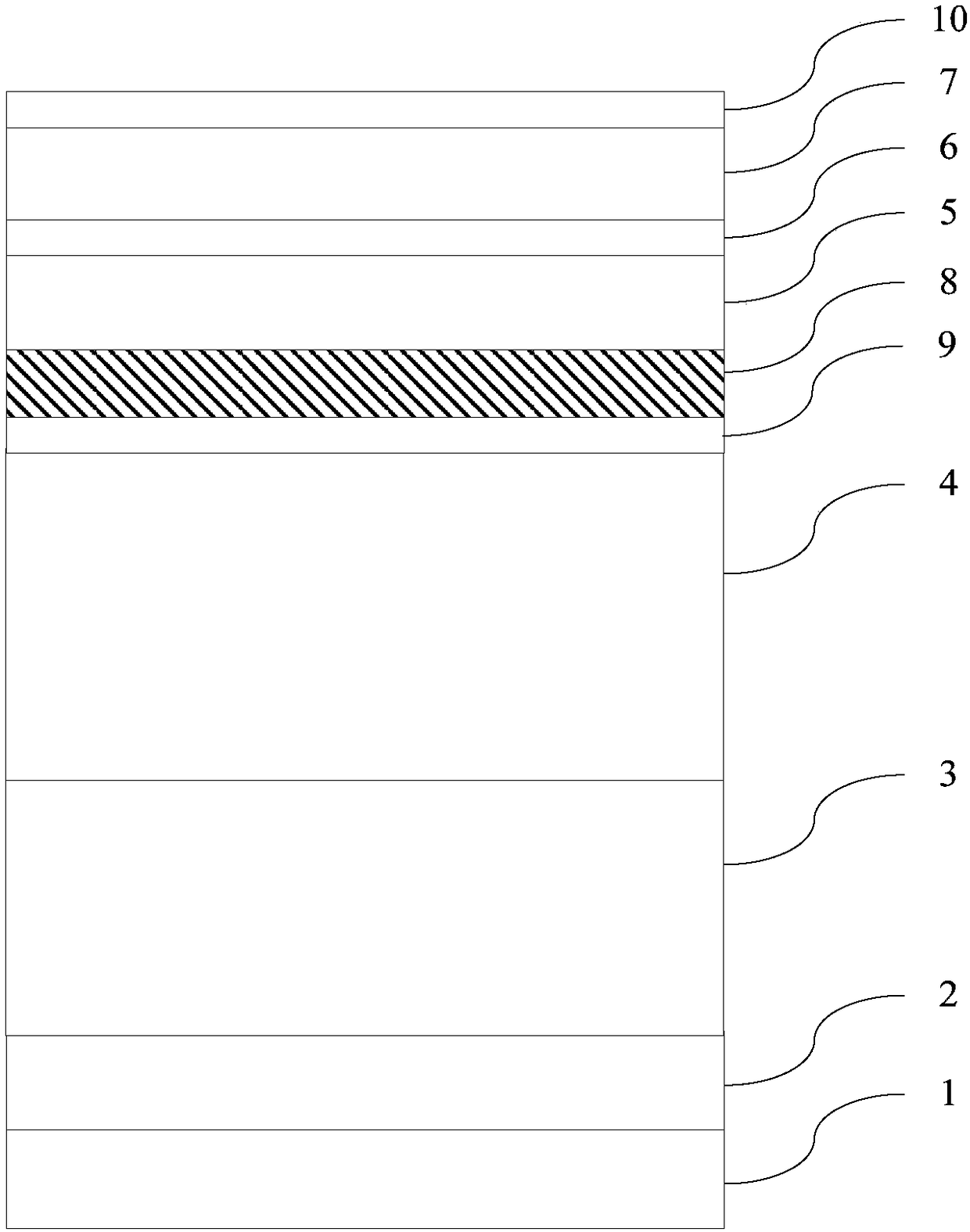

LED (Light Emitting Diode) epitaxial structure with P (Positive) type superlattice and preparation method thereof

ActiveCN103050592AStop SpillFacilitate horizontal expansionSemiconductor devicesPotential wellHigh density

The invention discloses an LED (Light Emitting Diode) epitaxial structure with a P (Positive) type superlattice and a preparation method thereof. The epitaxial structure comprises a substrate, wherein a GaN (Gallium Nitride) buffer layer, an undoped GaN layer, an n (negative) type GaN layer, a multi-quantum well luminous layer, a first P type GaN layer, a P type AlGaN (Aluminium Gallium Nitride) electronic blocking layer and a second P type GaN layer are sequentially arranged on the substrate from bottom to top, and the P type superlattice formed by a PInGaN (P type Indium Gallium Nitride) potential well layer and a PAlGaN potential barrier layer in a periodic interactive overlapping way is arranged between the P type AlGaN electronic blocking layer and the second P type GaN layer. The PInGaN potential well layer in the P type superlattice generates and constrains a great number of holes for the formation of a two-dimensional hole high-density state; the PAlGaN potential barrier layer hinders the escape of the holes; in such a way, the transverse spreading of the holes is improved, the electron overflow can be prevented, the hole injection efficiency is increased and the electron and hole recombination probability is improved; and therefore, the brightness of a chip can be improved by 5-10%.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

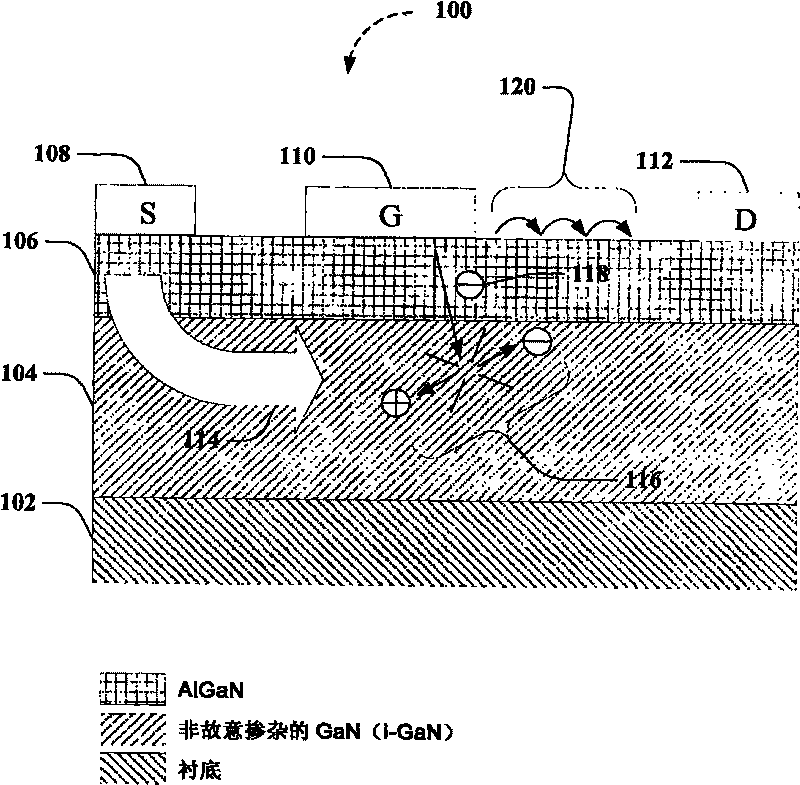

Aluminum gallium nitride/gallium nitride high electron mobility transistors

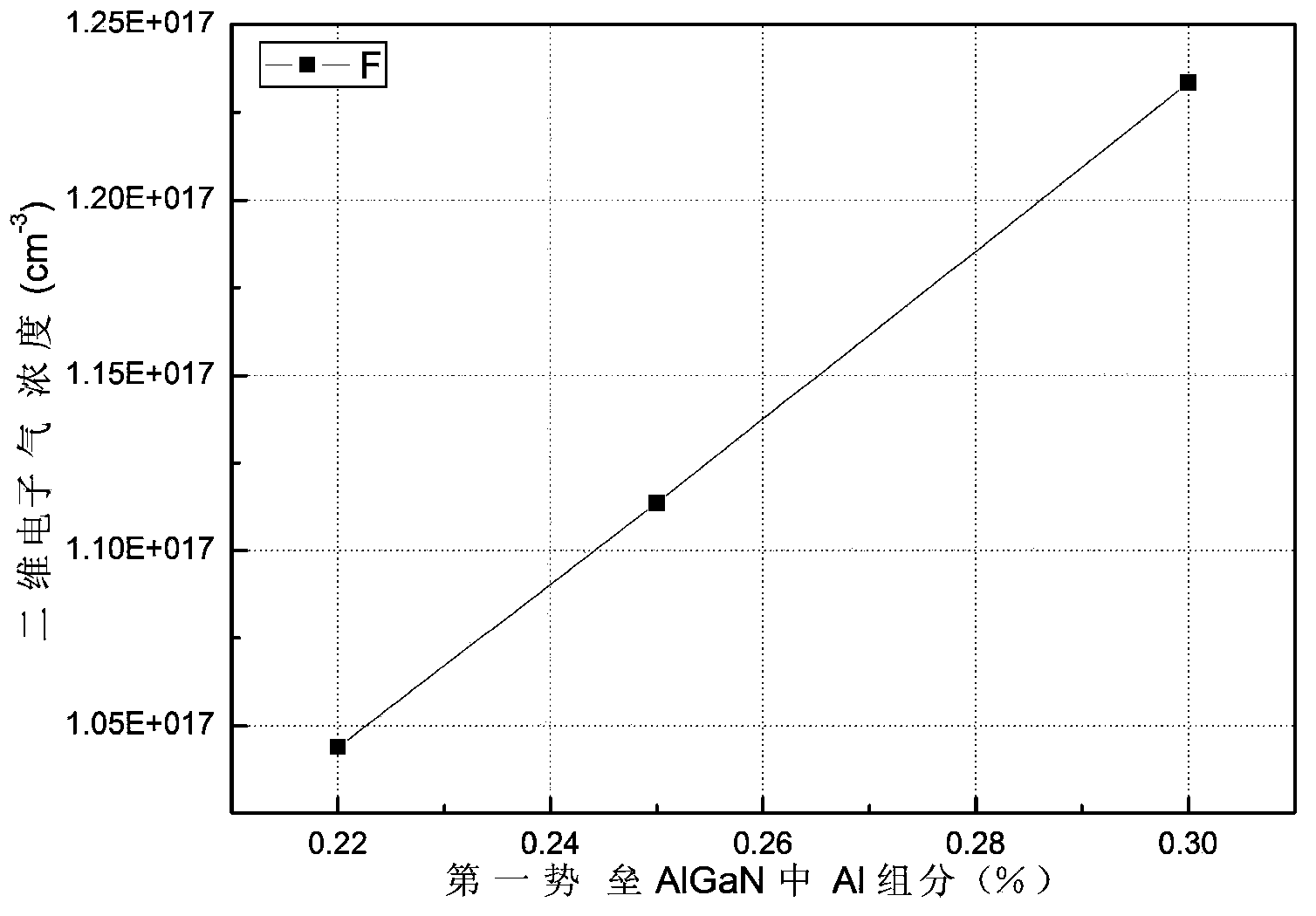

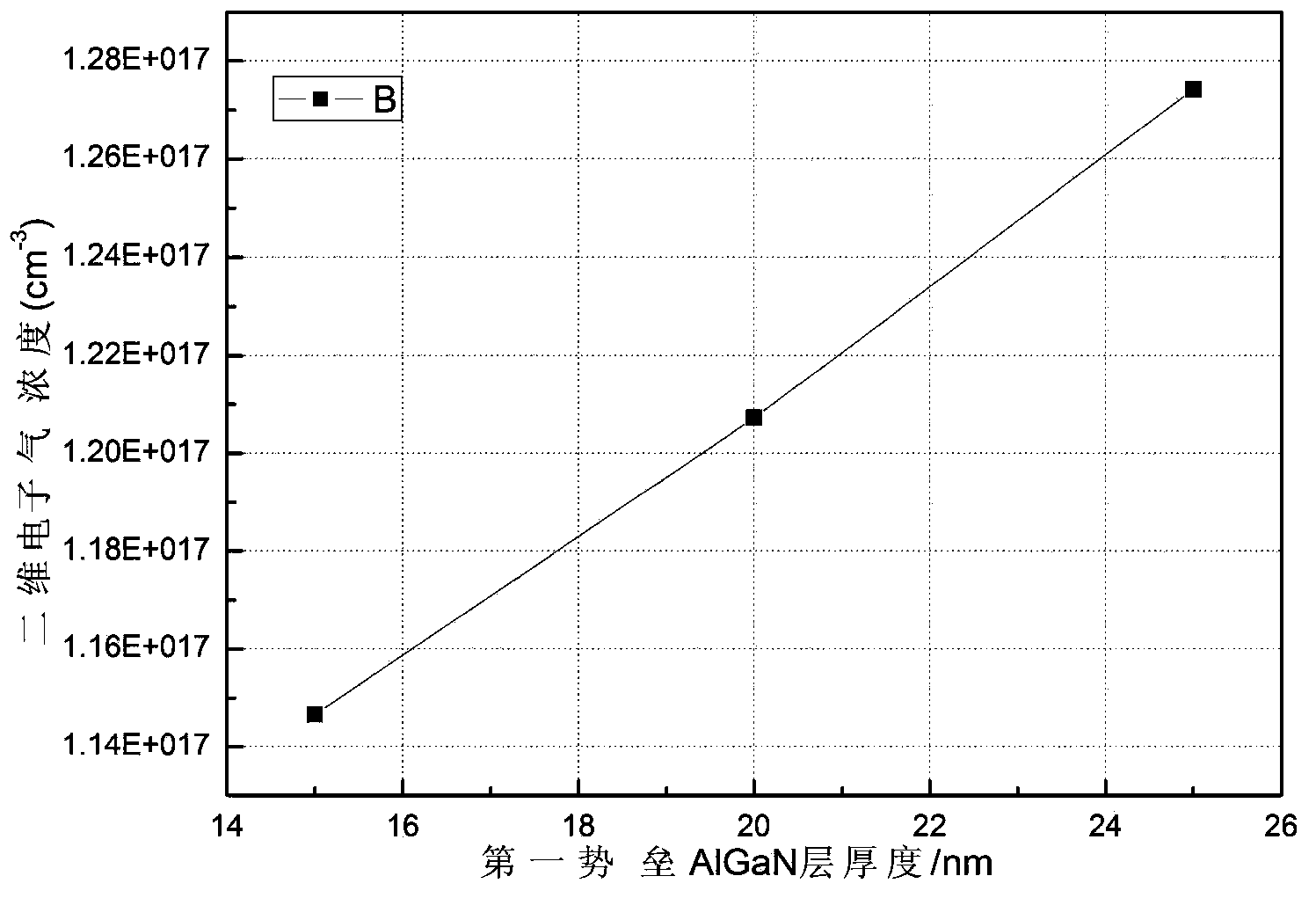

ActiveCN101714574ARaise the local barrierSemiconductor/solid-state device manufacturingSemiconductor devicesHigh energyHigh electron

Structures, devices and methods are provided for creating enhanced back barriers that improve the off-state breakdown and blocking characteristics in aluminum gallium nitride AlGaN / GaN high electron mobility transistors (HEMTs). In one aspect, selective fluorine ion implantation is employed when developing HEMTs to create the enhanced back barrier structures. By creating higher energy barriers at the back of the two-dimensional electron gas channel in the unintentionally doped GaN buffer, higher off-state breakdown voltage is advantageously provided and blocking capability is enhanced, while allowing for convenient and cost-effective post-epitaxial growth fabrication. Further non-limiting embodiments are provided that illustrate the advantages and flexibility of the disclosed structures.

Owner:THE HONG KONG UNIV OF SCI & TECH

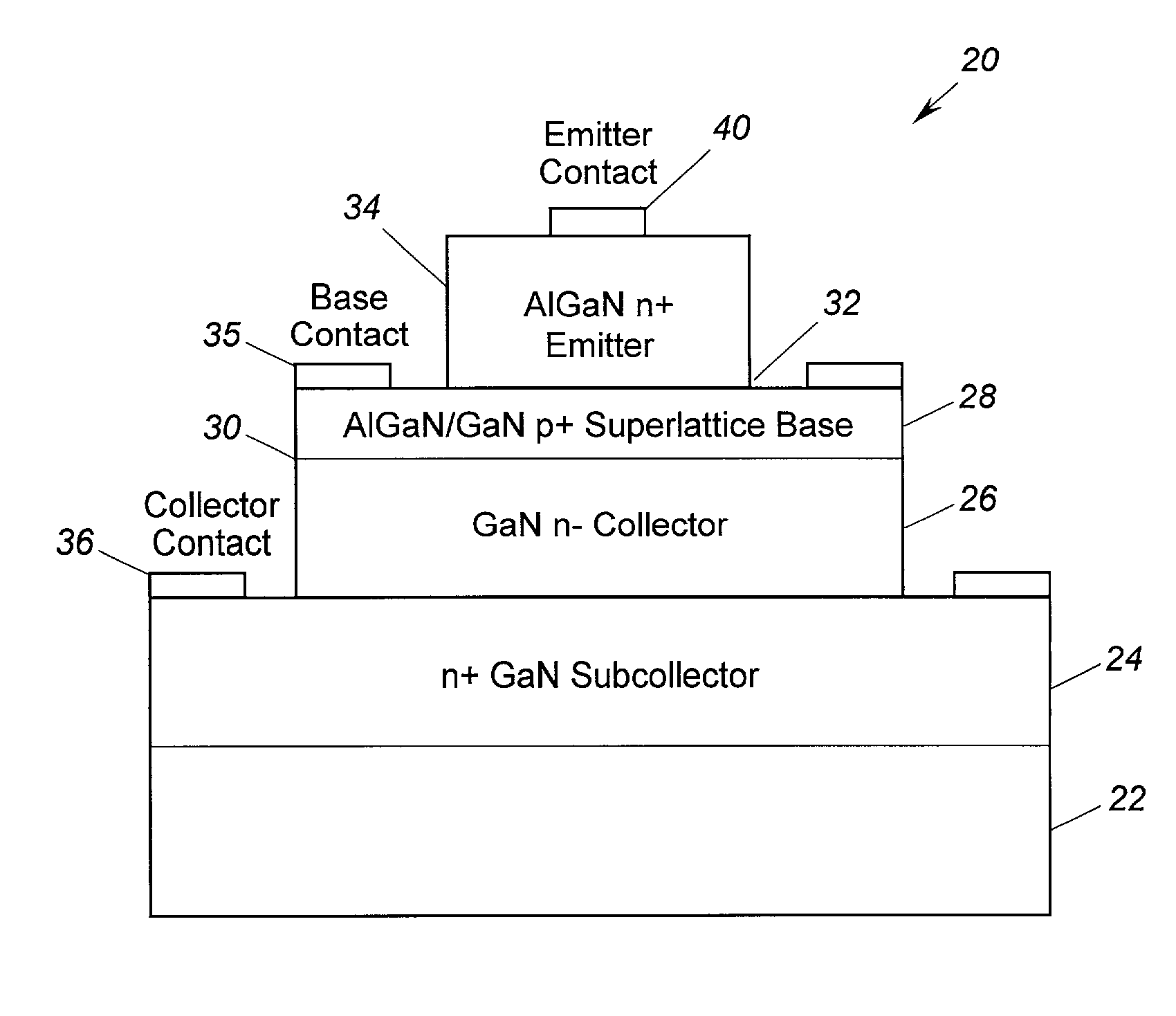

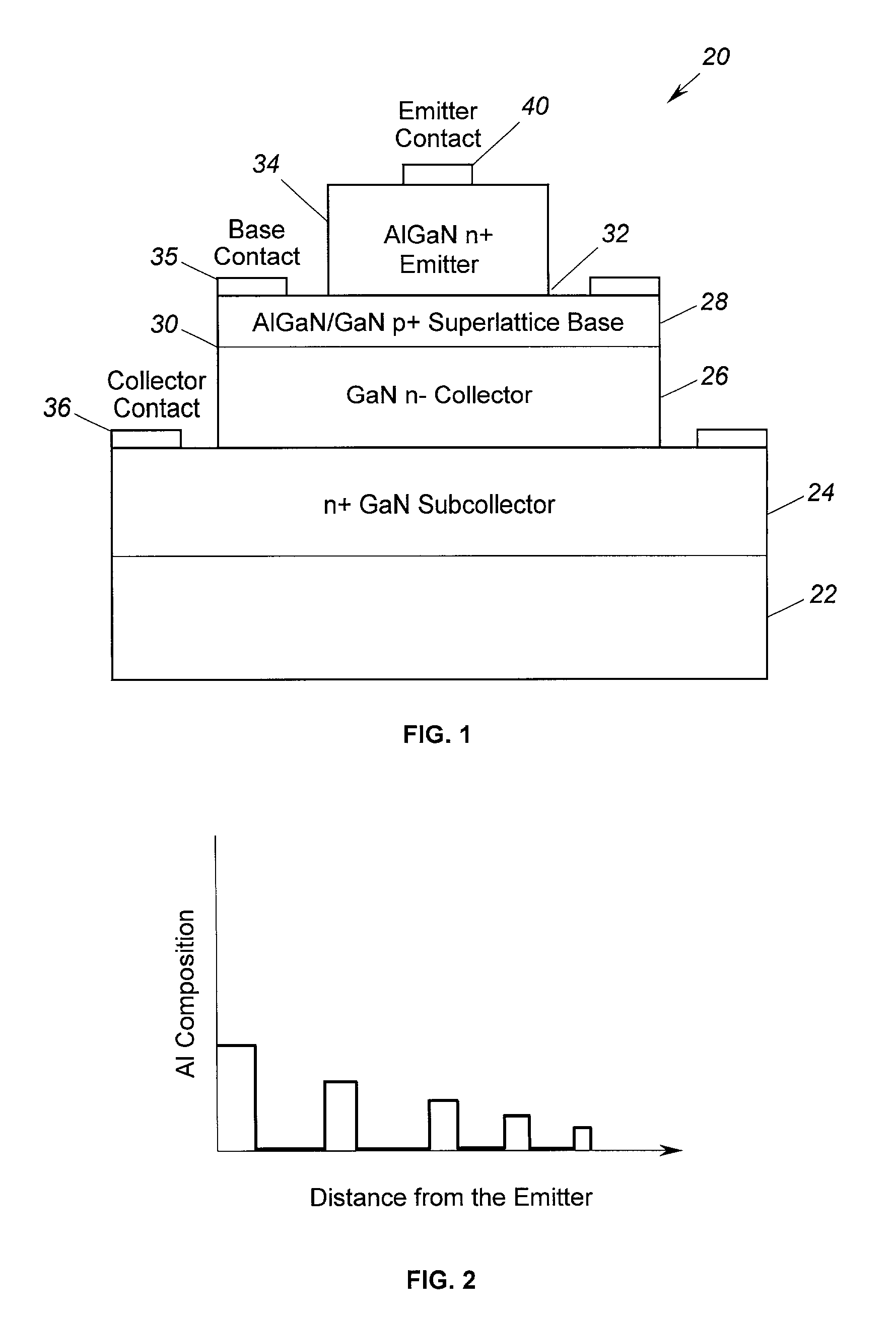

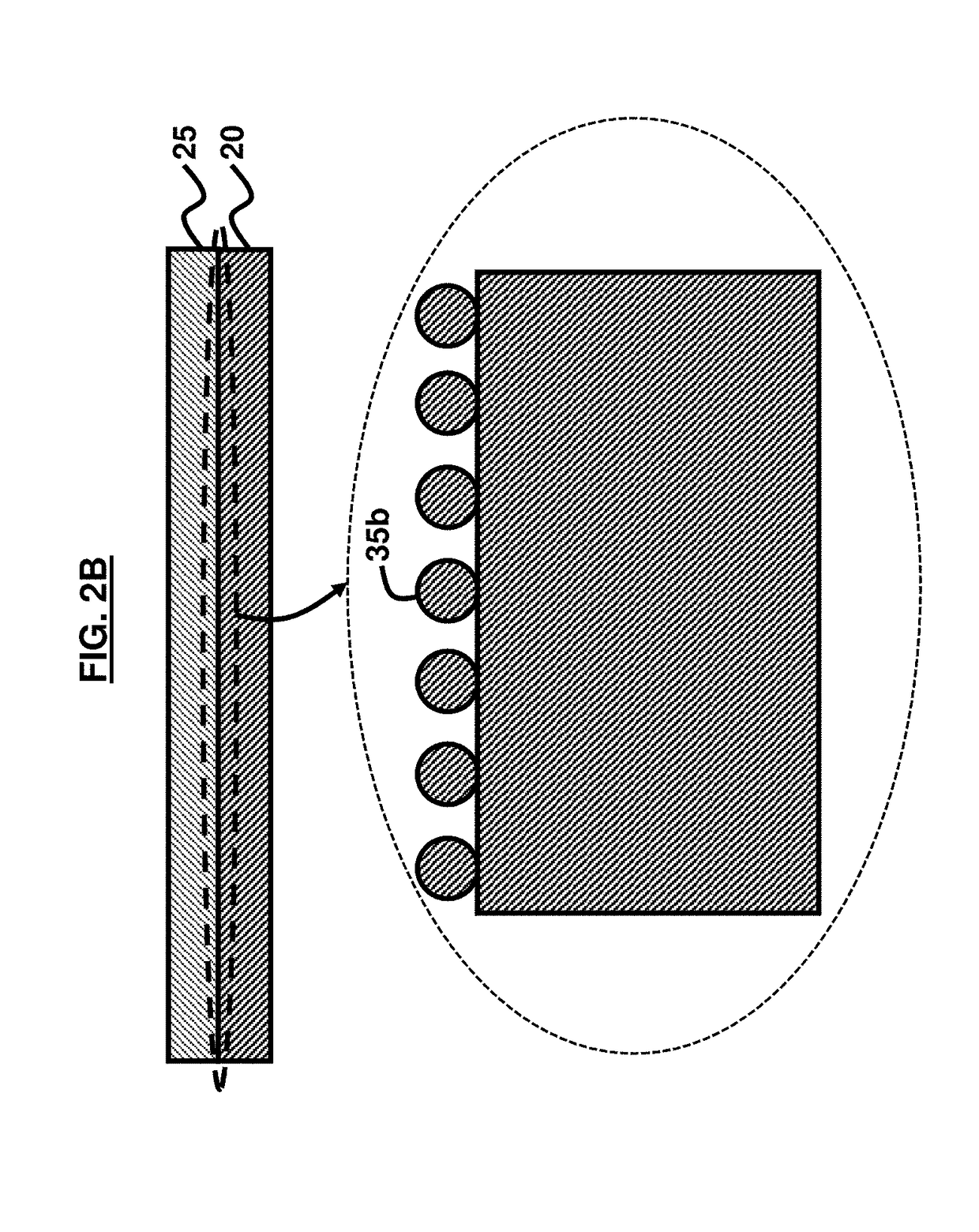

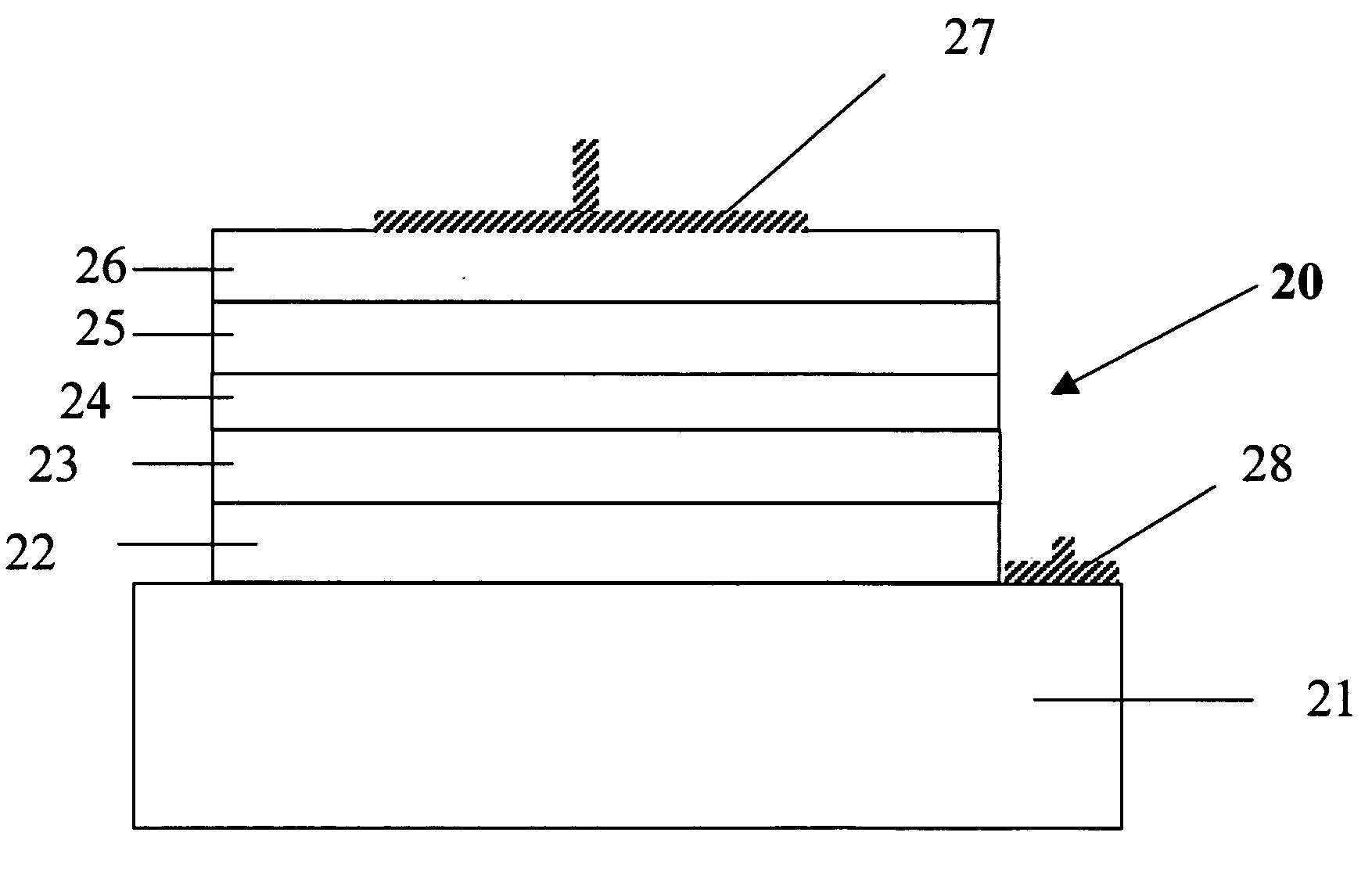

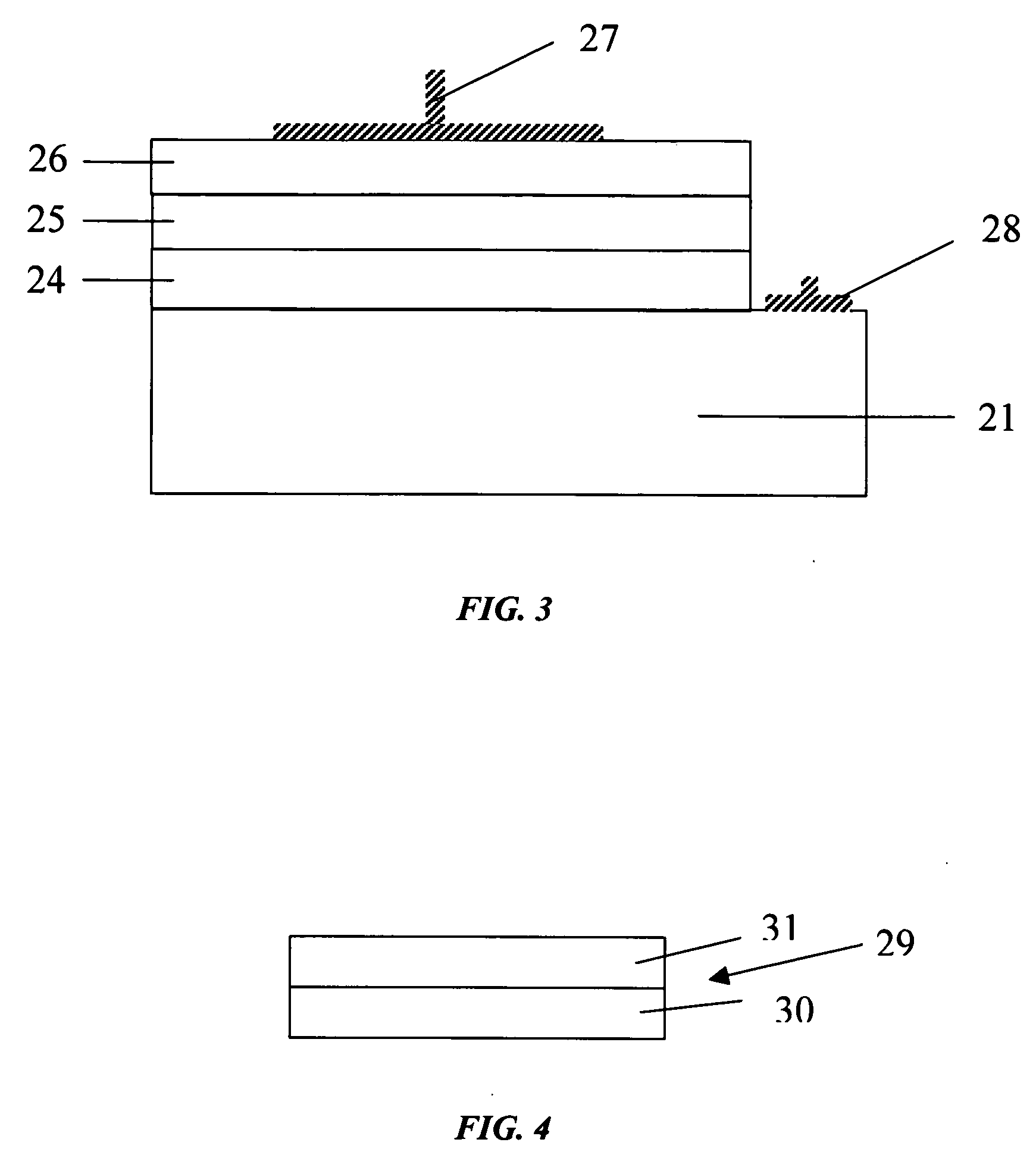

GaN HBT superlattice base structure

InactiveUS20020149033A1Semiconductor/solid-state device manufacturingSemiconductor devicesCharge carrierThin layer

A heterojunction bipolar transistor (HBT) (20) with alternating layers of gallium nitride (GaN) and aluminum gallium nitride (AlGaN) with varying Al composition forming a graded superlattice structure in the base layer (28) includes. The thin layers of AlGaN in the base layer (28) increases the base p-type carrier concentration. Grading of the Al composition in the thin AlGaN layers induces an electrostatic field across the base layer (28) that increases the carrier velocity and reduces the carrier transit time. The structure thus decreases the transit time and at the same time increases the p-type carrier concentration to improve the operating efficiency of the device.

Owner:NORTHROP GRUMAN CORP

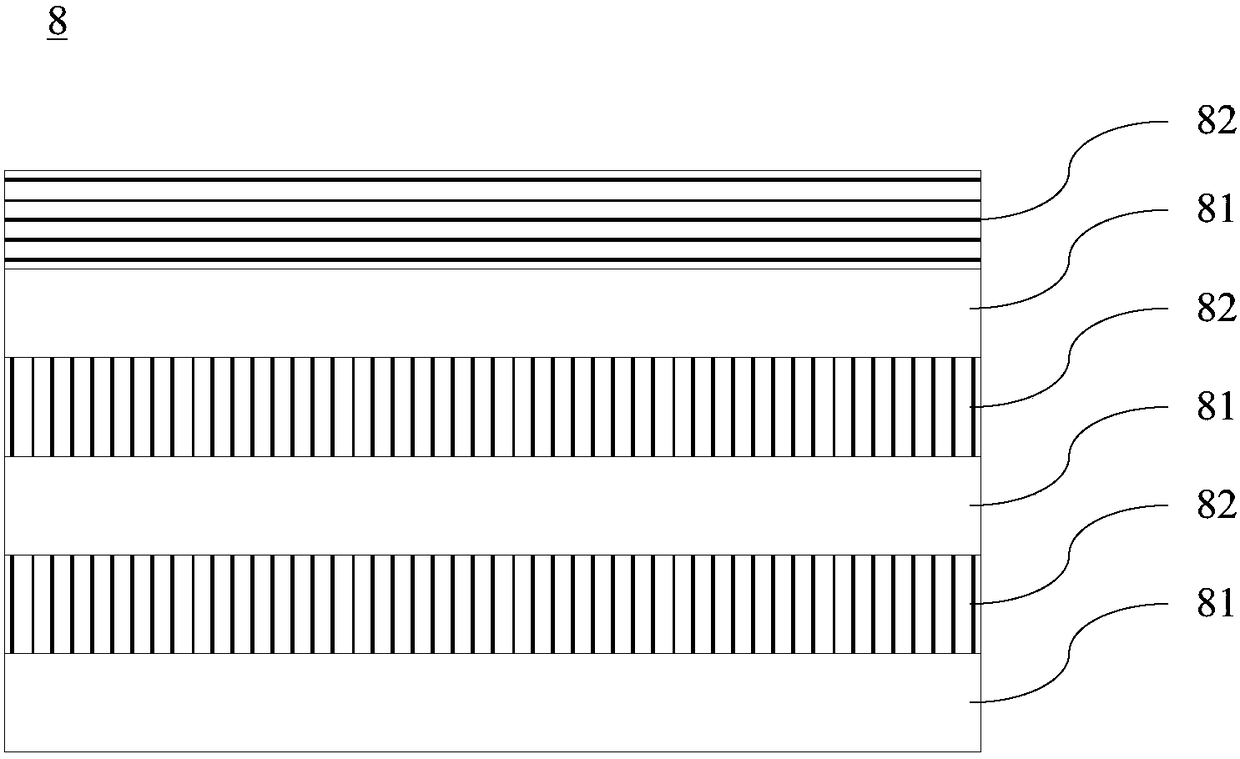

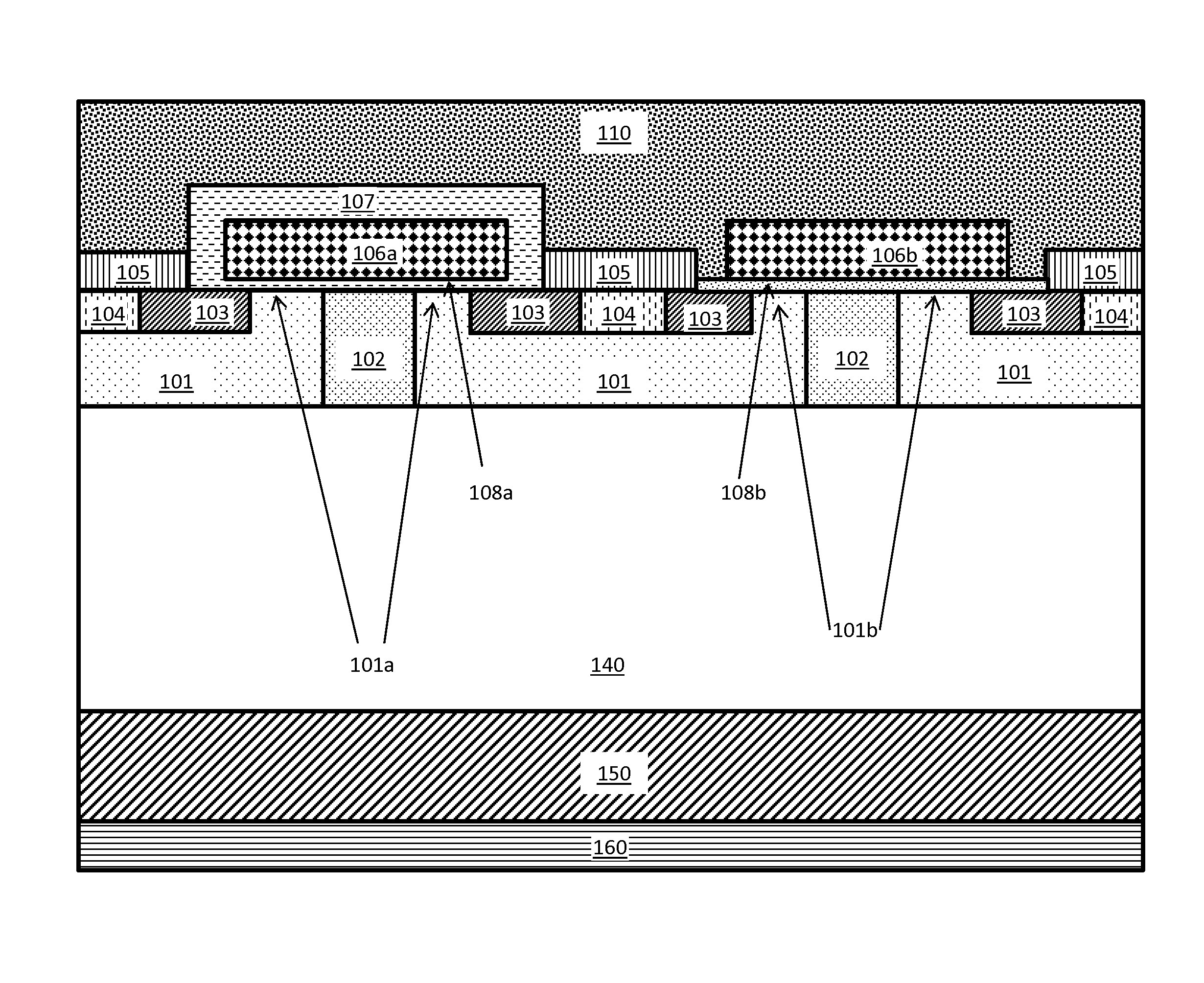

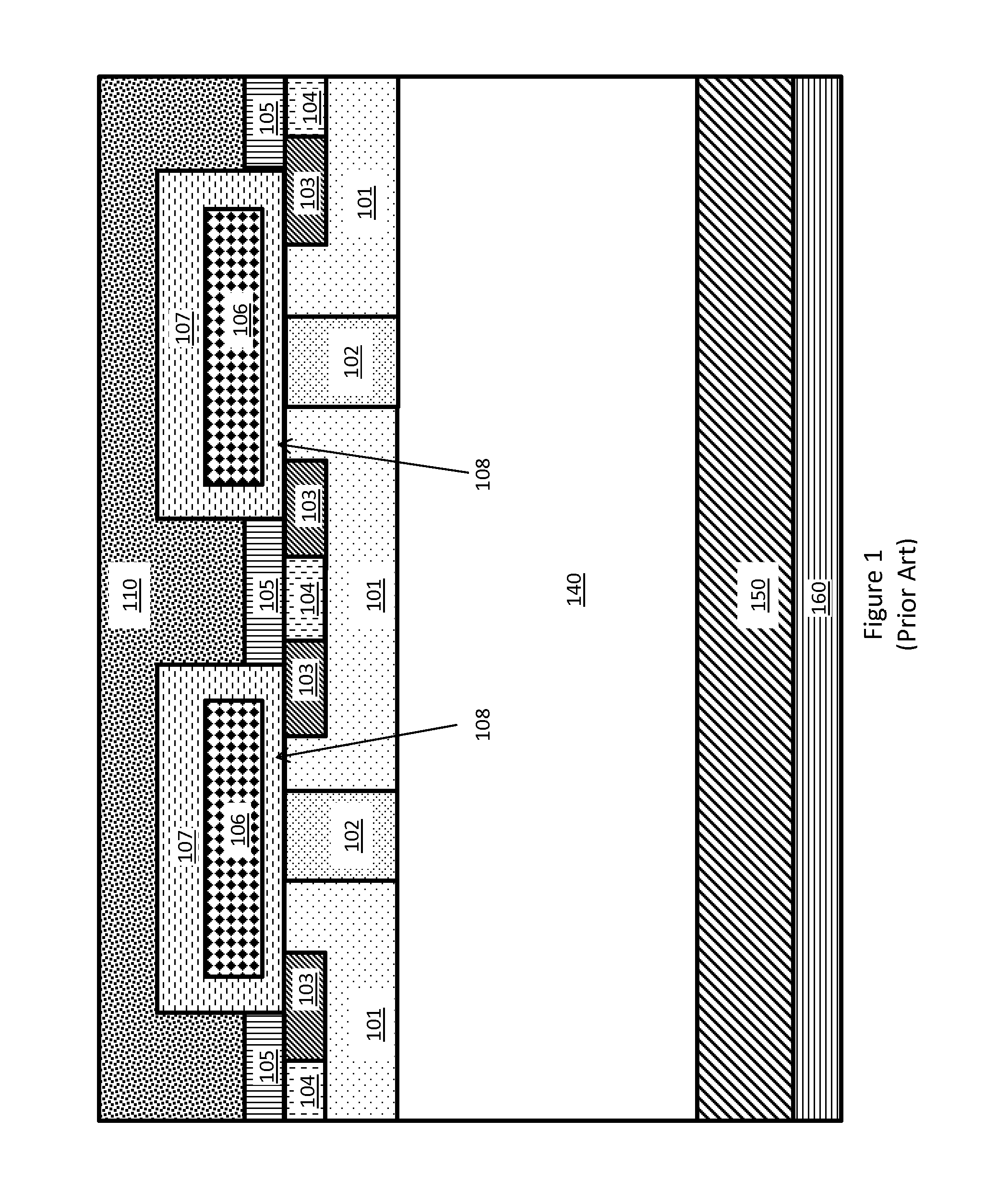

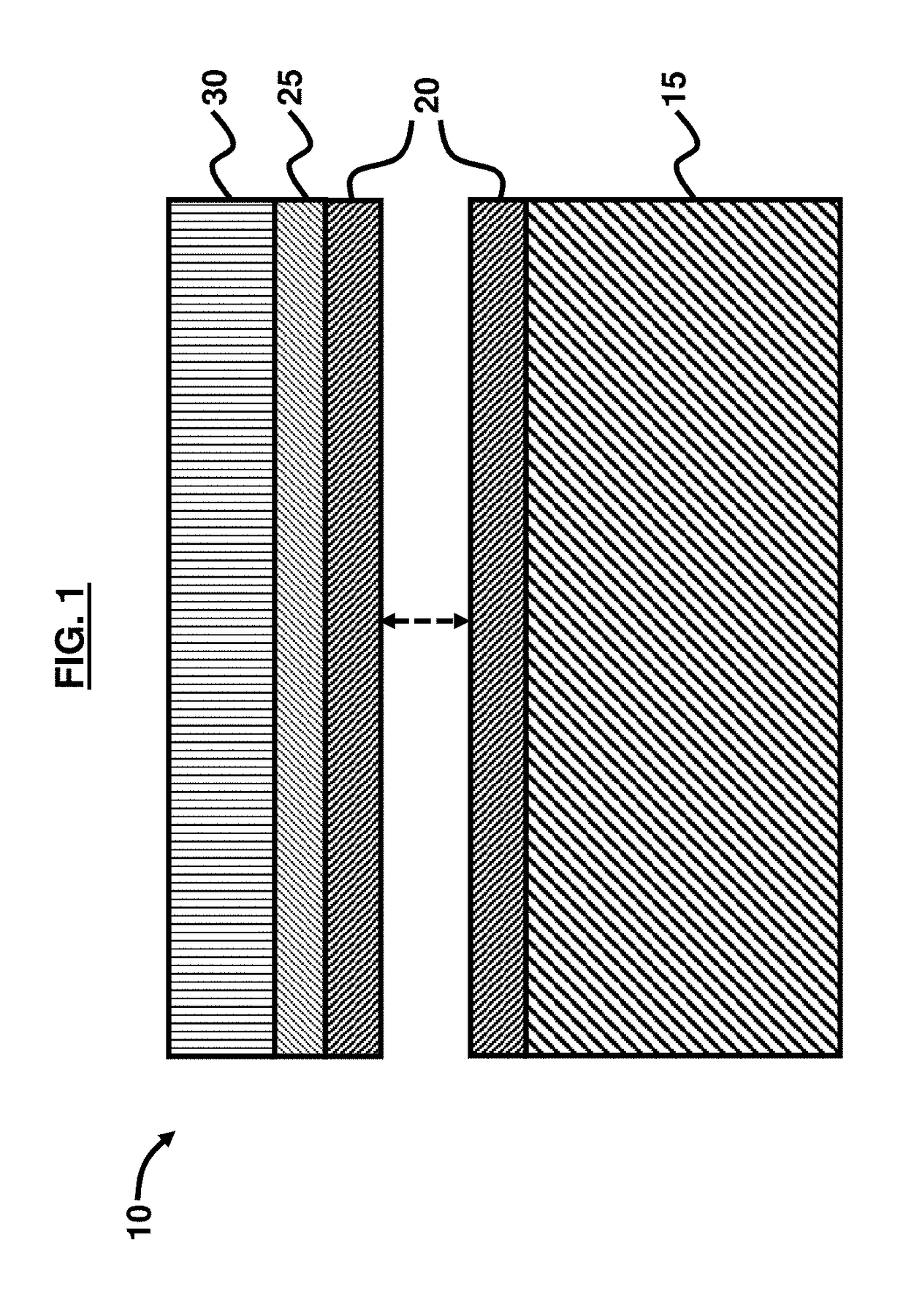

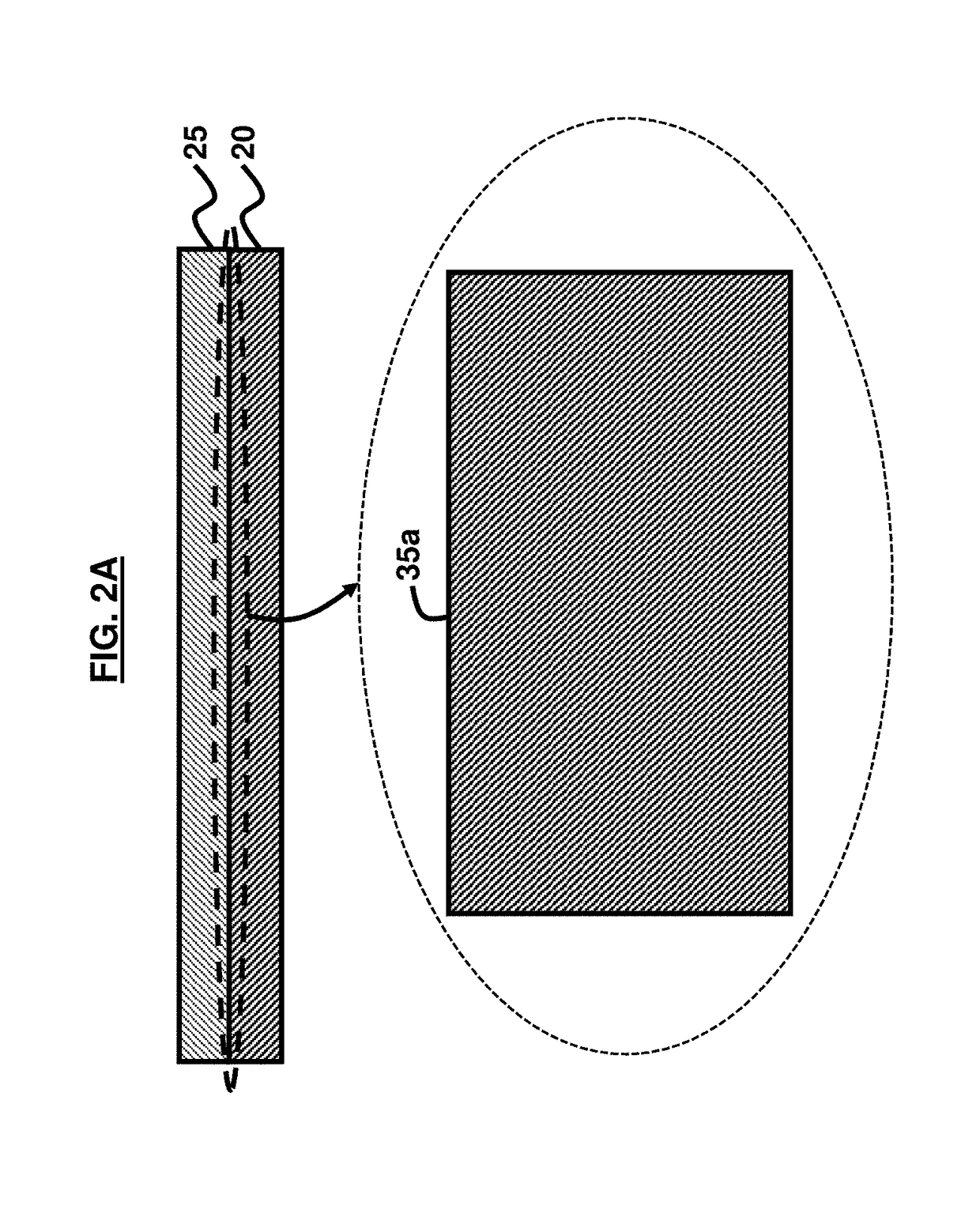

N-type gallium-nitride layer having multiple conductive intervening layers

ActiveUS20130032836A1Low costReduces lattice defect densitySolid-state devicesSemiconductor/solid-state device manufacturingInter layerGallium nitride

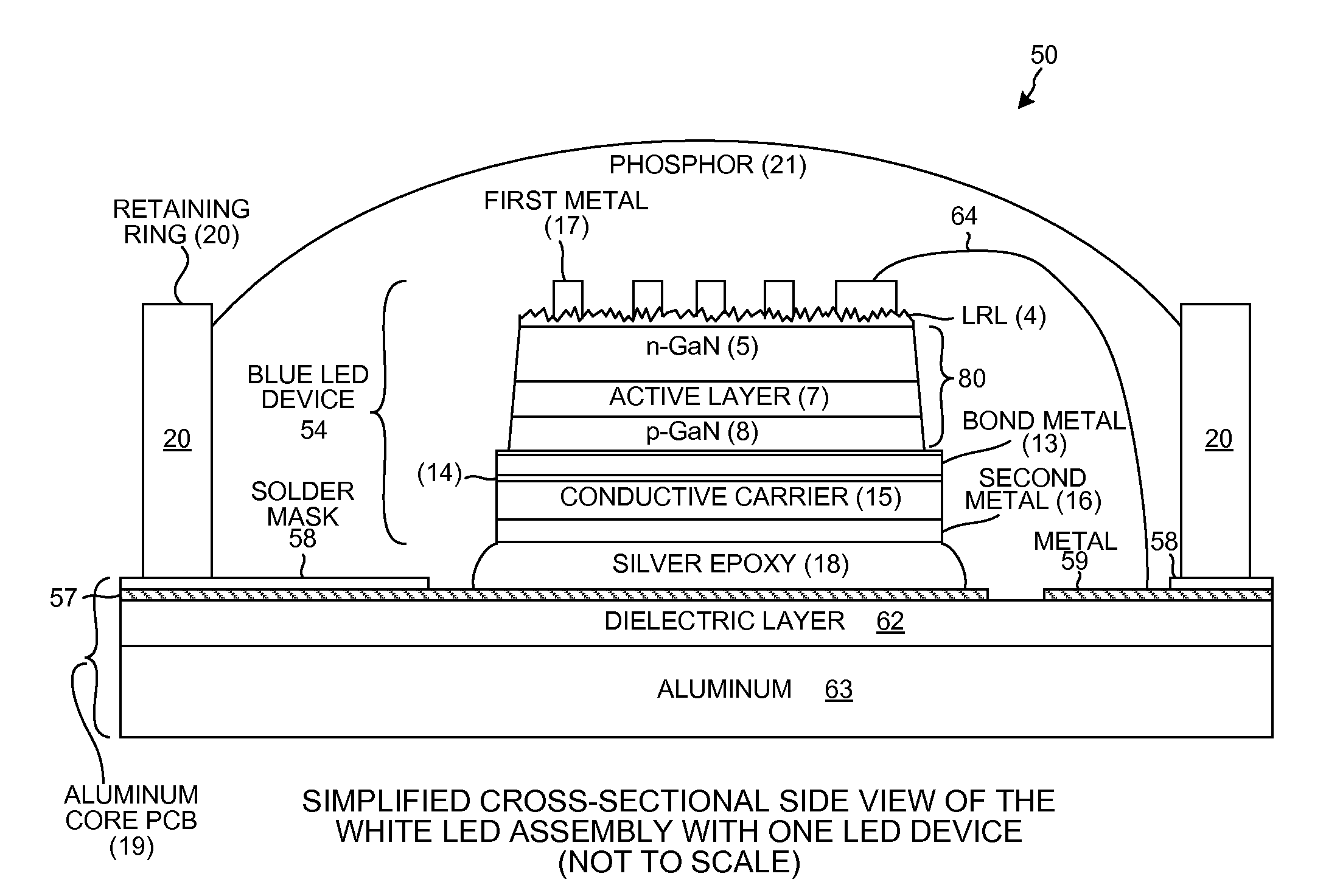

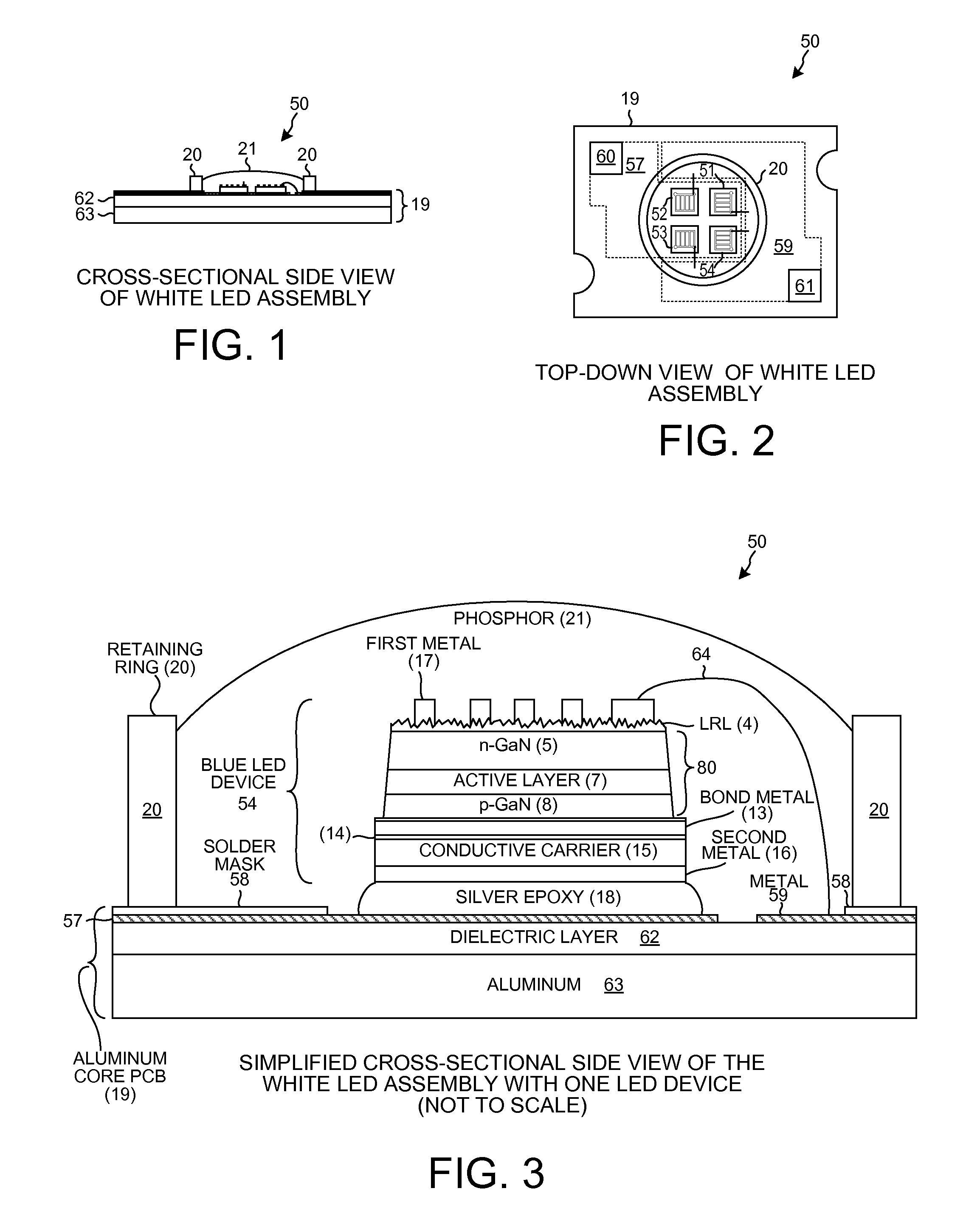

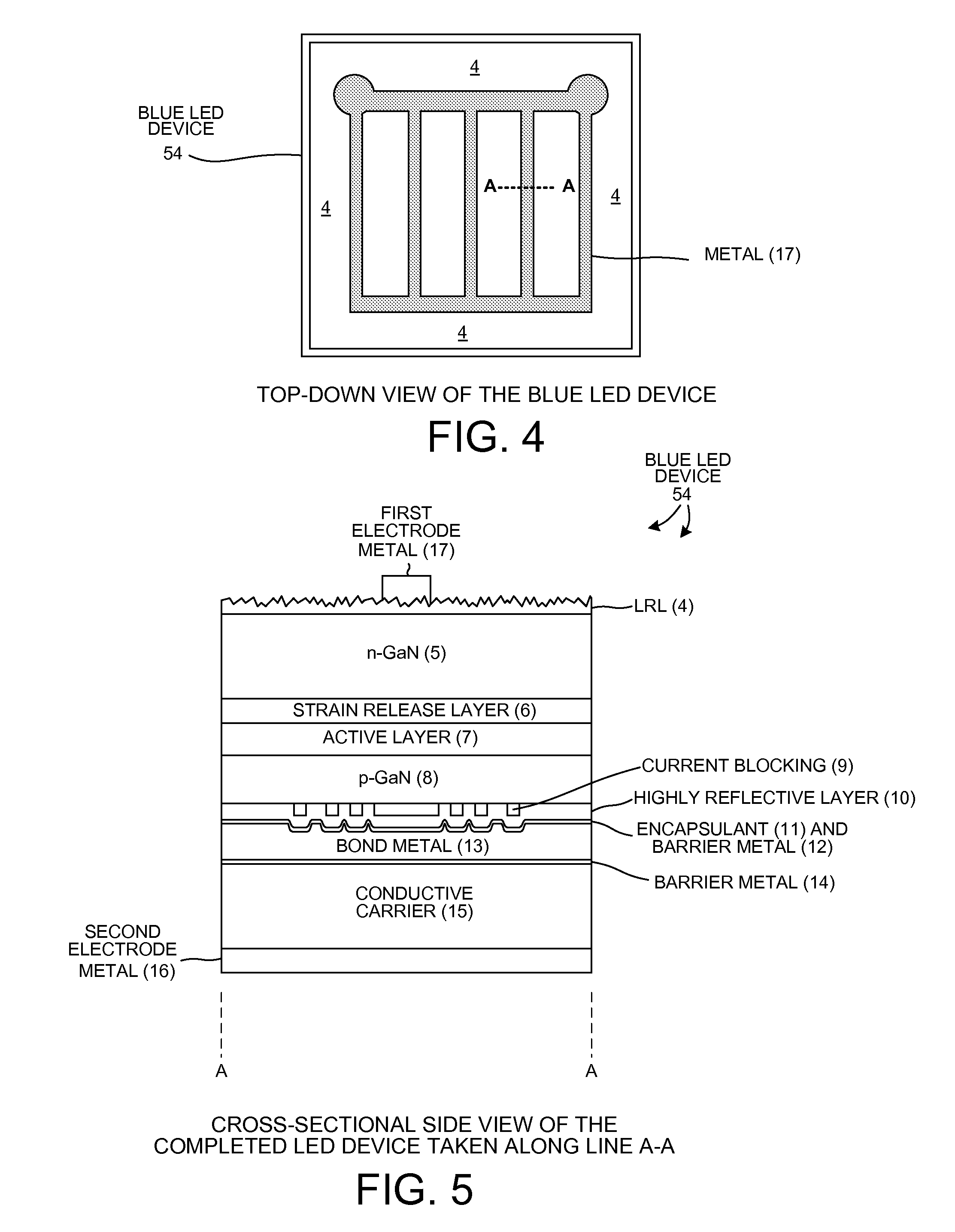

A vertical GaN-based blue LED has an n-type layer comprising multiple conductive intervening layers. The n-type layer contains a plurality of periods. Each period of the n-type layer includes a gallium-nitride (GaN) sublayer and a thin conductive aluminum-gallium-nitride (AlGaN:Si) intervening sublayer. In one example, each GaN sublayer has a thickness substantially more than 100 nm and less than 1000 nm, and each AlGaN:Si intervening sublayer has a thickness less than 25 nm. The entire n-type layer is at least 2000 nm thick. The AlGaN:Si intervening layer provides compressive strain to the GaN sublayer thereby preventing cracking. After the epitaxial layers of the LED are formed, a conductive carrier is wafer bonded to the structure. The silicon substrate is then removed. Electrodes are added and the structure is singulated to form a finished LED device. Because the AlGaN:Si sublayers are conductive, the entire n-type layer can remain as part of the finished LED device.

Owner:SEOUL SEMICONDUCTOR

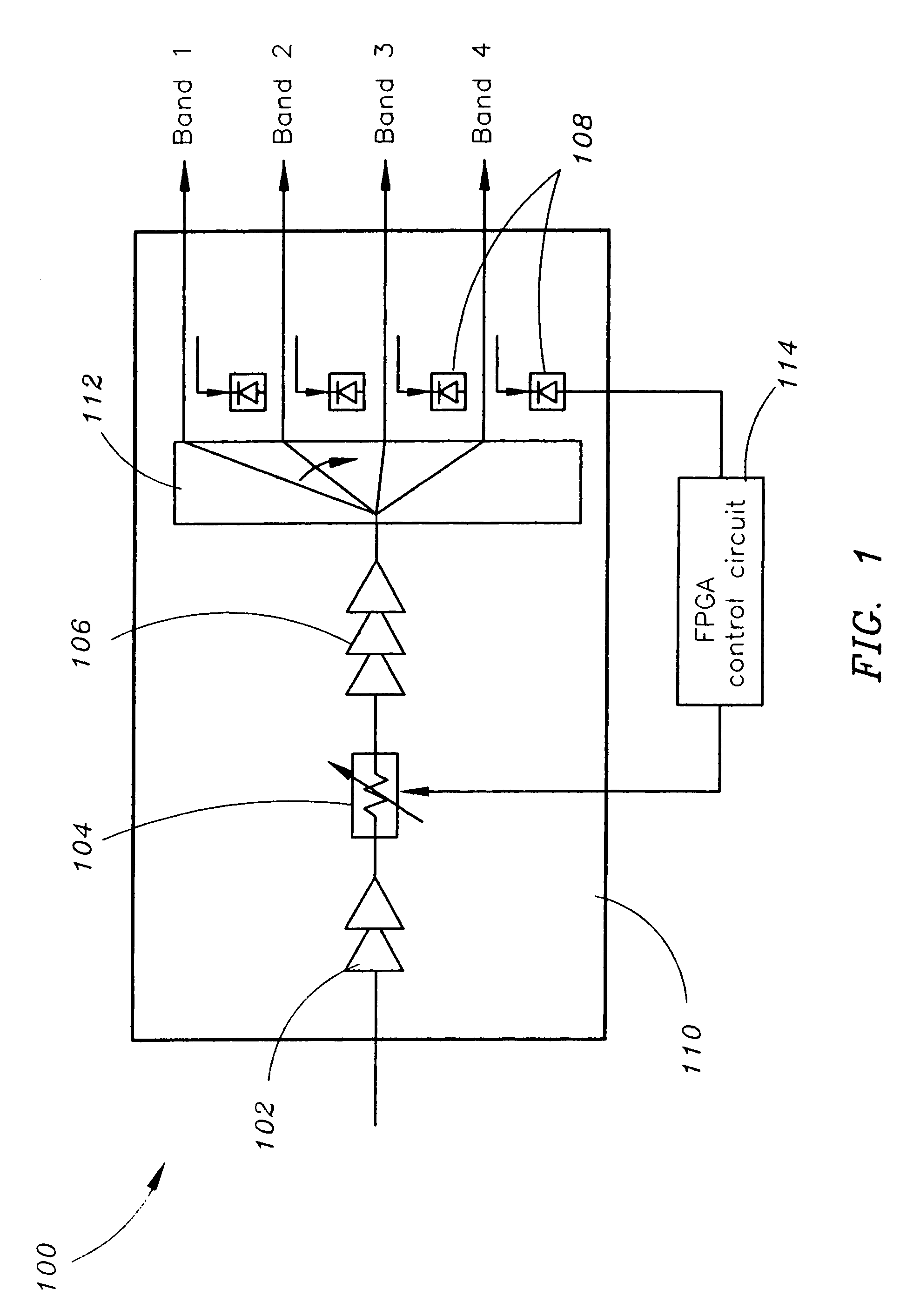

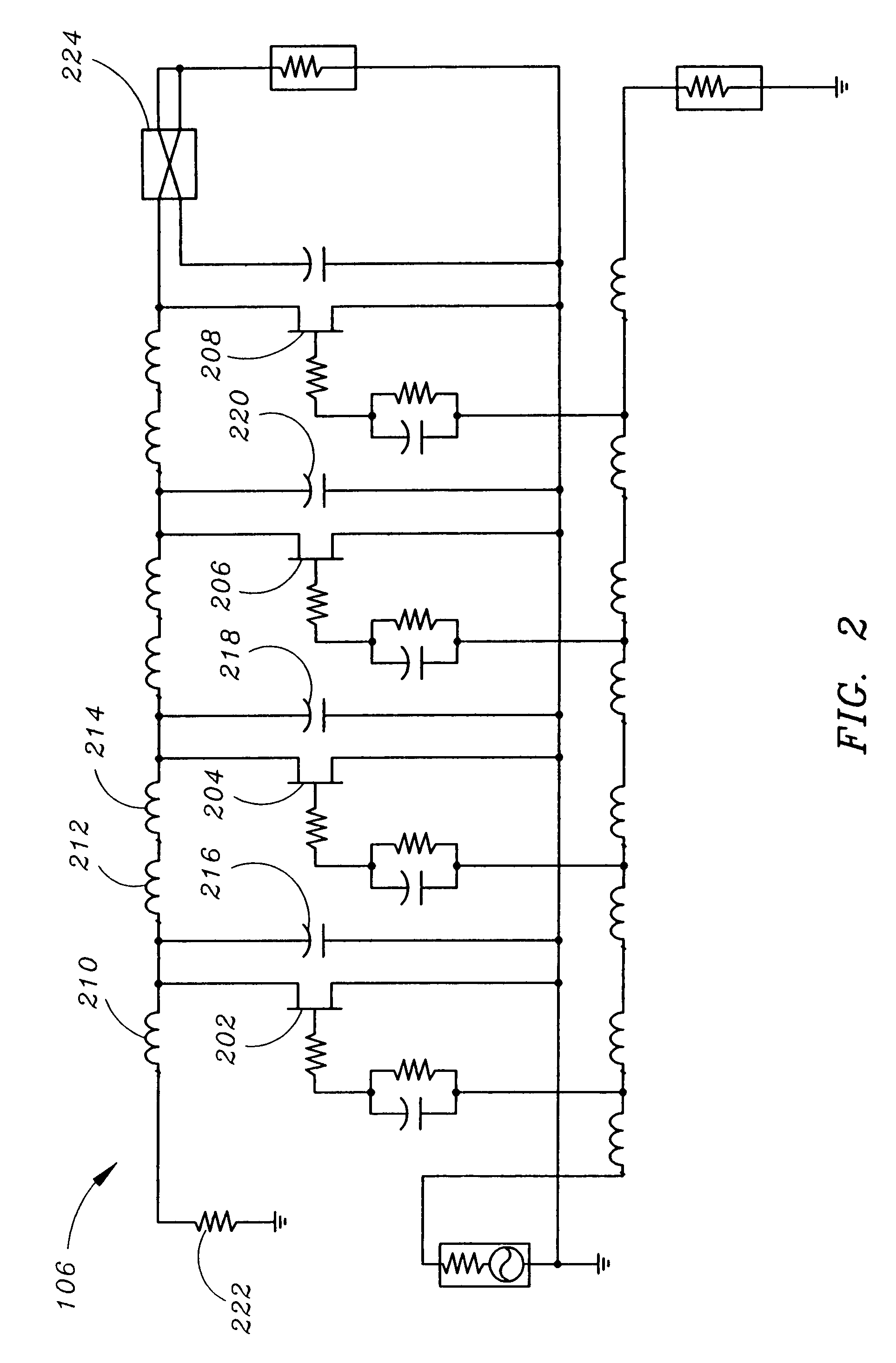

GaN based digital controlled broadband MMIC power amplifier

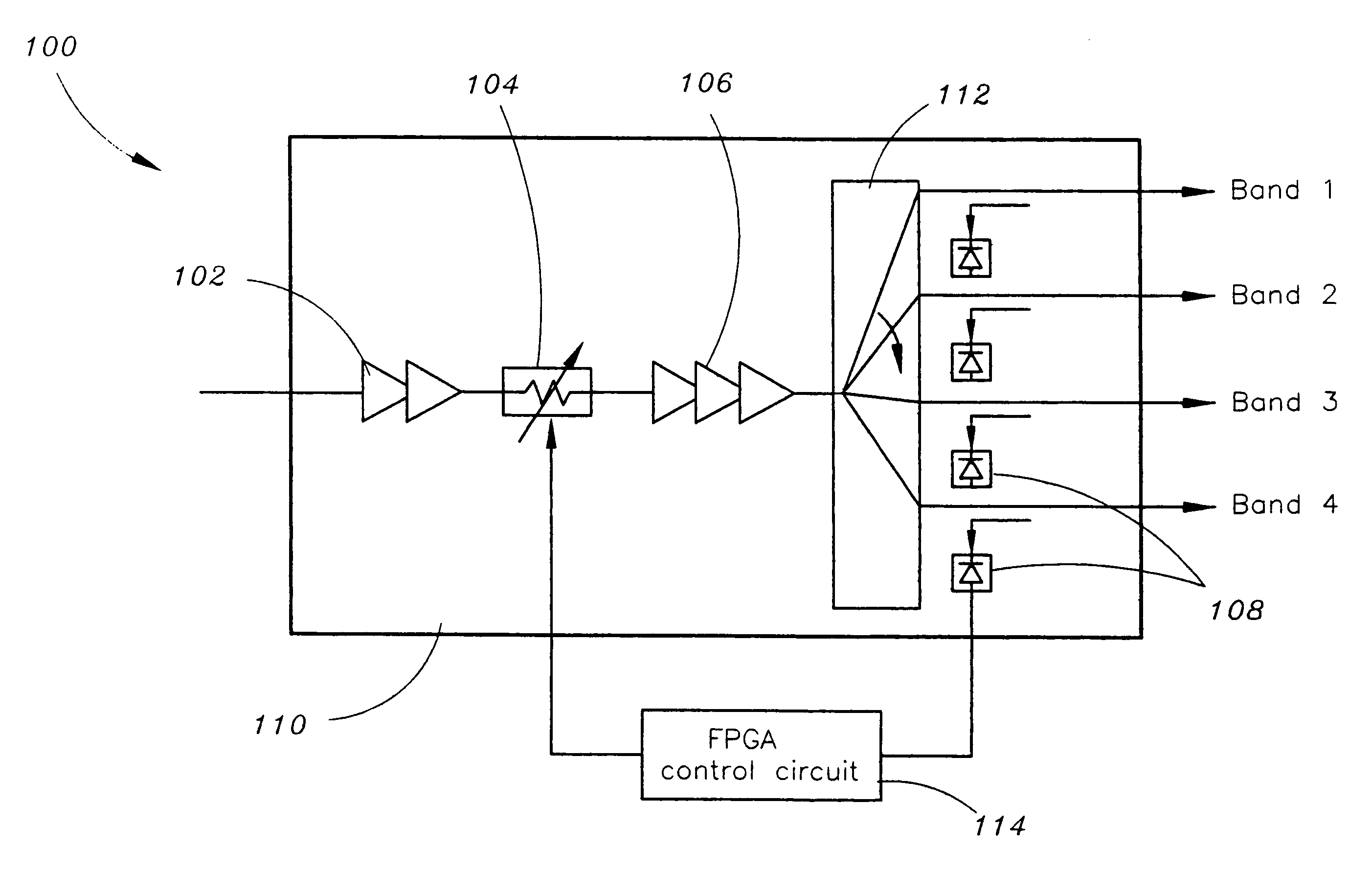

ActiveUS7508267B1Improve linearityAmplifiers wit coupling networksRF amplifierAudio power amplifierBroadband

A power amplifier comprises a distributed pre-driver, digital signal adjuster, a distributed high power amplifier; and an integrated coupler-detector unit. The distributed pre-driver, the digital signal adjuster, the distributed high power amplifier and the integrated coupler-detector unit are formed at an interface of a Gallium Nitride layer and an Aluminum Gallium Nitride layer of a monolithic microwave integrated circuit device.

Owner:ROCKWELL COLLINS INC

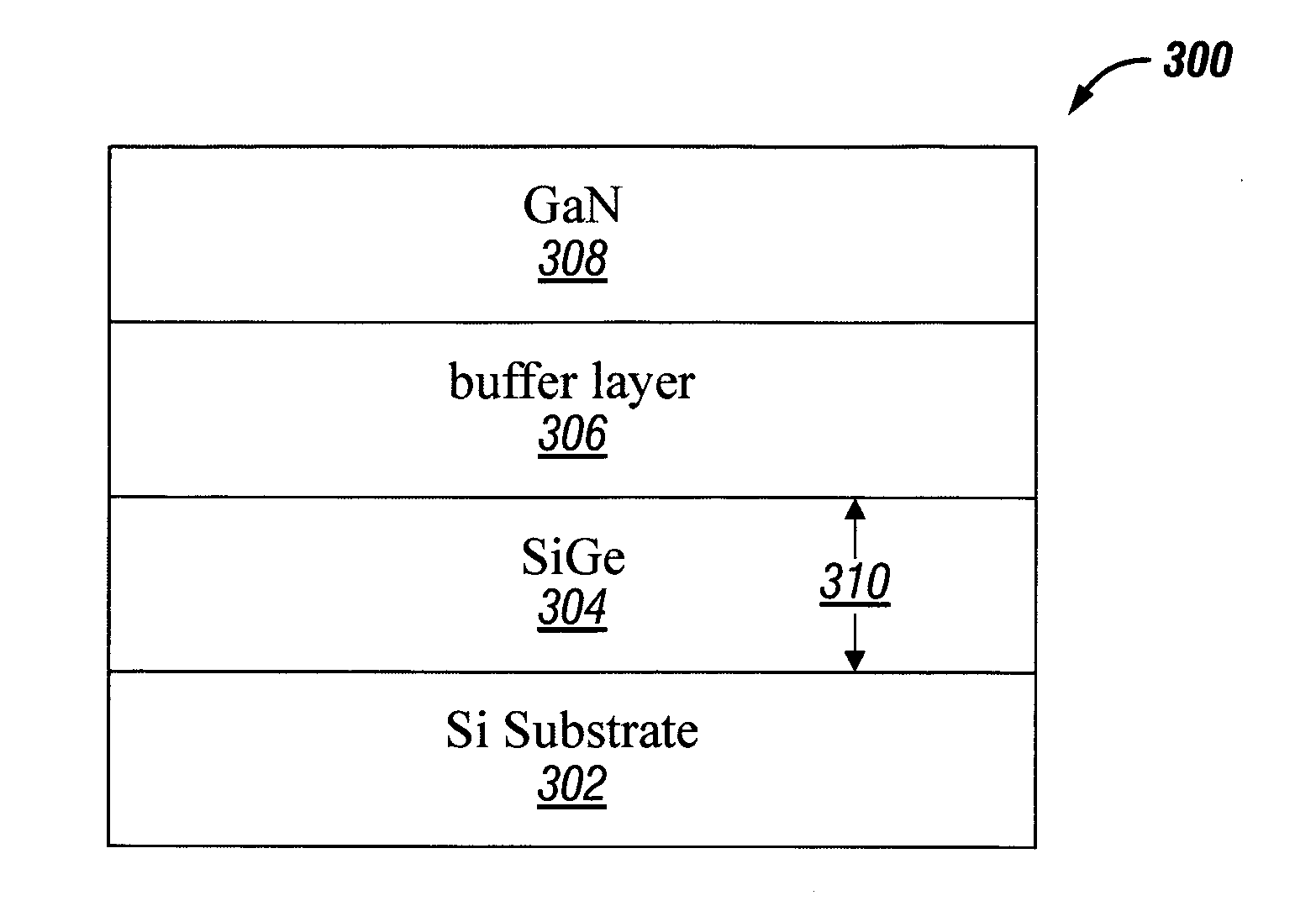

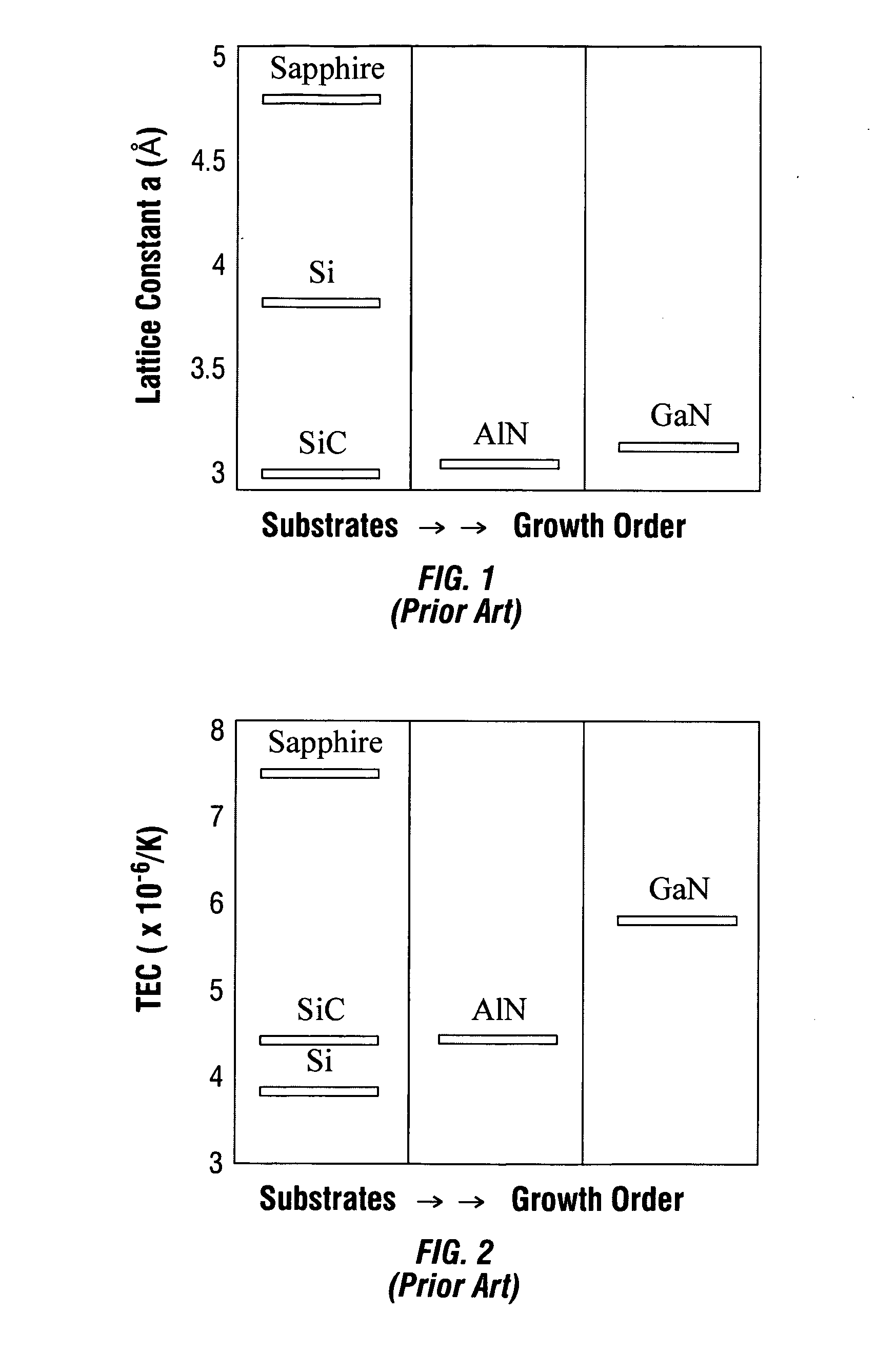

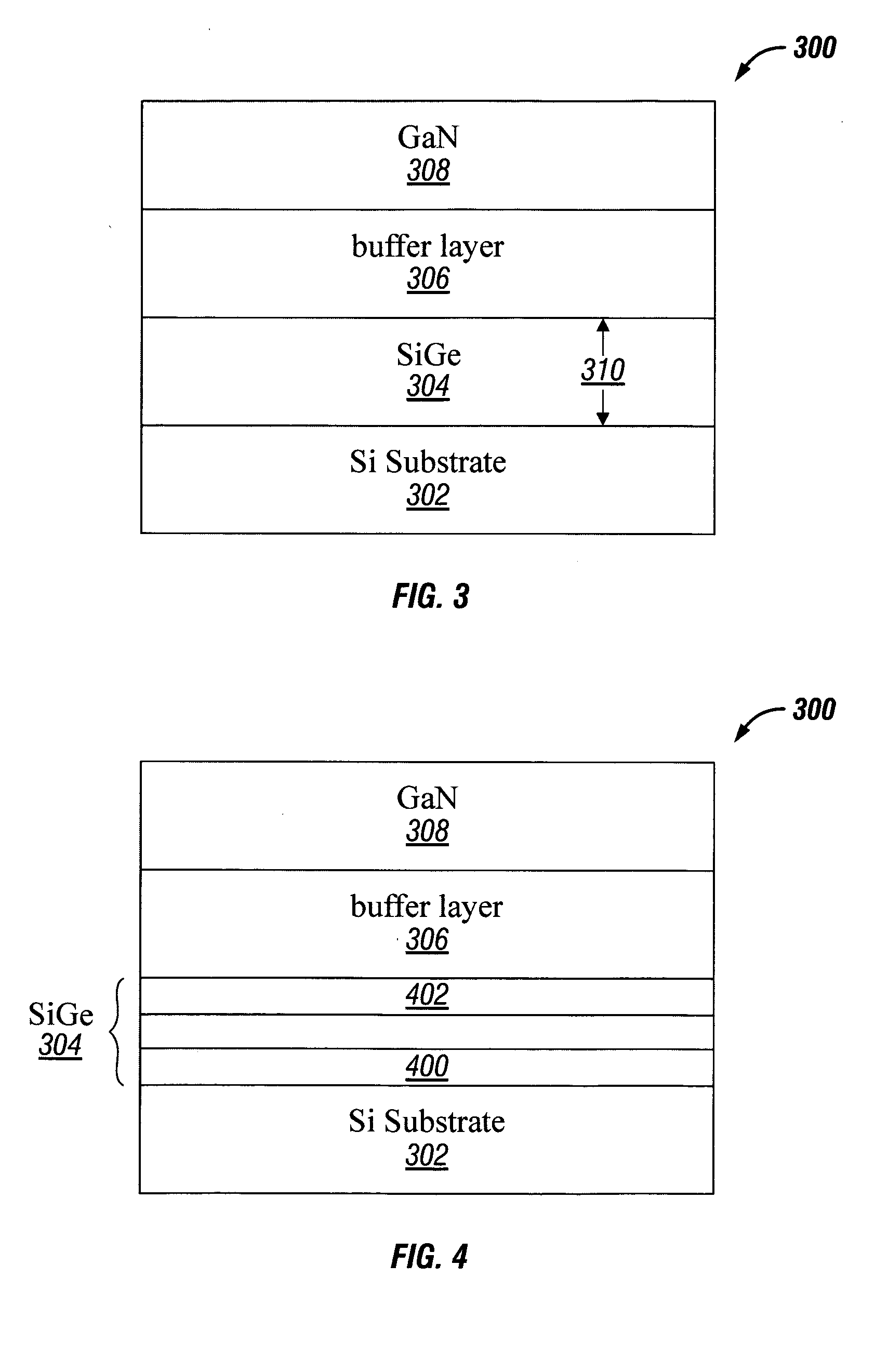

Gallium nitride on silicon with a thermal expansion transition buffer layer

InactiveUS20080173895A1Semiconductor/solid-state device manufacturingSemiconductor devicesThermal expansionGallium nitride

A method is provided for forming a matching thermal expansion interface between silicon (Si) and gallium nitride (GaN) films. The method provides a (111) Si substrate with a first thermal expansion coefficient (TEC), and forms a silicon-germanium (SiGe) film overlying the Si substrate. A buffer layer is deposited overlying the SiGe film. The buffer layer may be aluminum nitride (AlN) or aluminum-gallium nitride (AlGaN). A GaN film is deposited overlying the buffer layer having a second TEC, greater than the first TEC. The SiGe film has a third TEC, with a value in between the first and second TECs. In one aspect, a graded SiGe film may be formed having a Ge content ratio in a range of about 0% to 50%, where the Ge content increases with the graded SiGe film thickness.

Owner:SHARP LAB OF AMERICA

High voltage GaN-based transistor structure

ActiveUS7459356B1Improve performanceSemiconductor/solid-state device manufacturingSemiconductor devicesElectron injectionEngineering

Owner:QORVO US INC

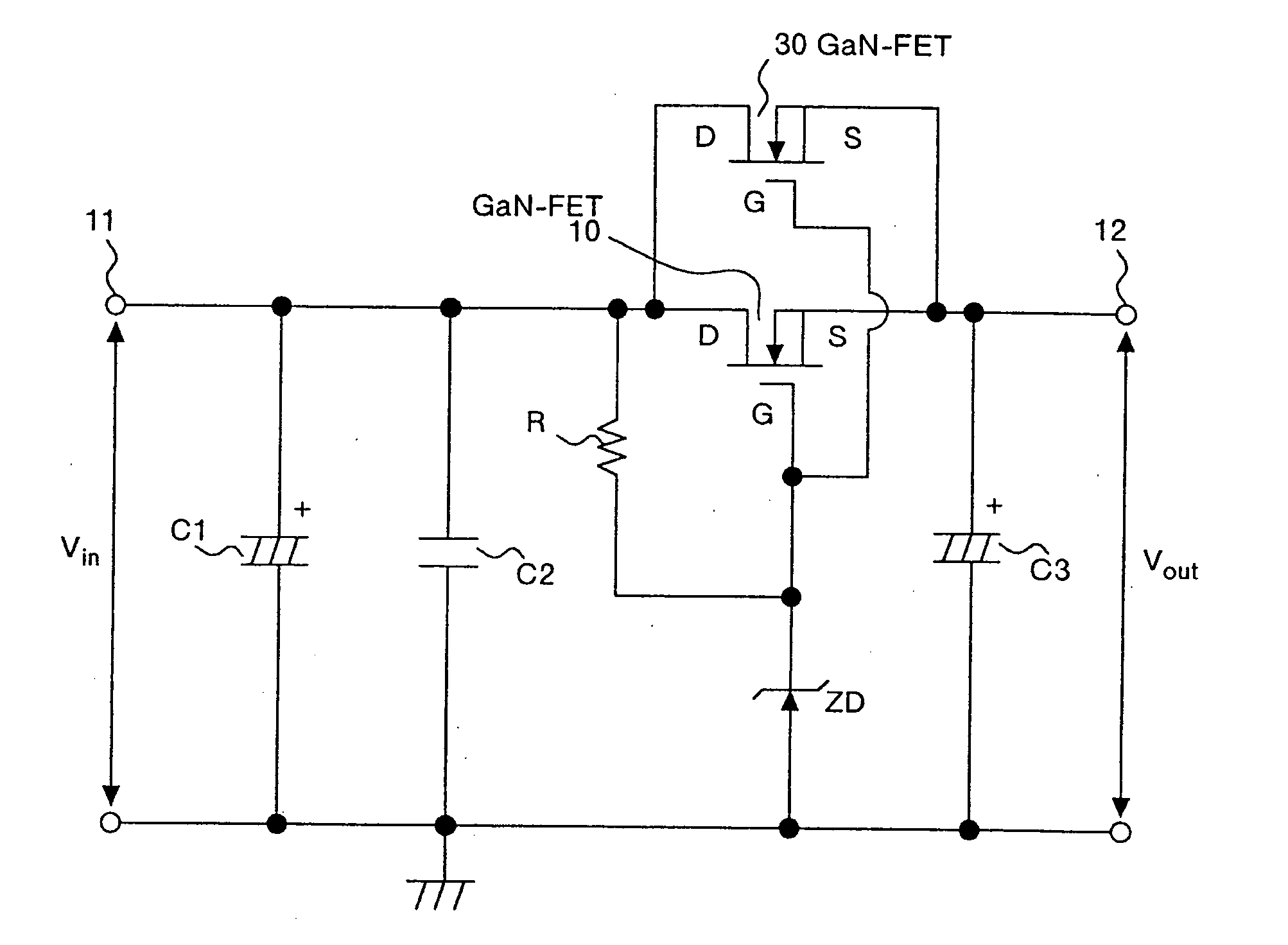

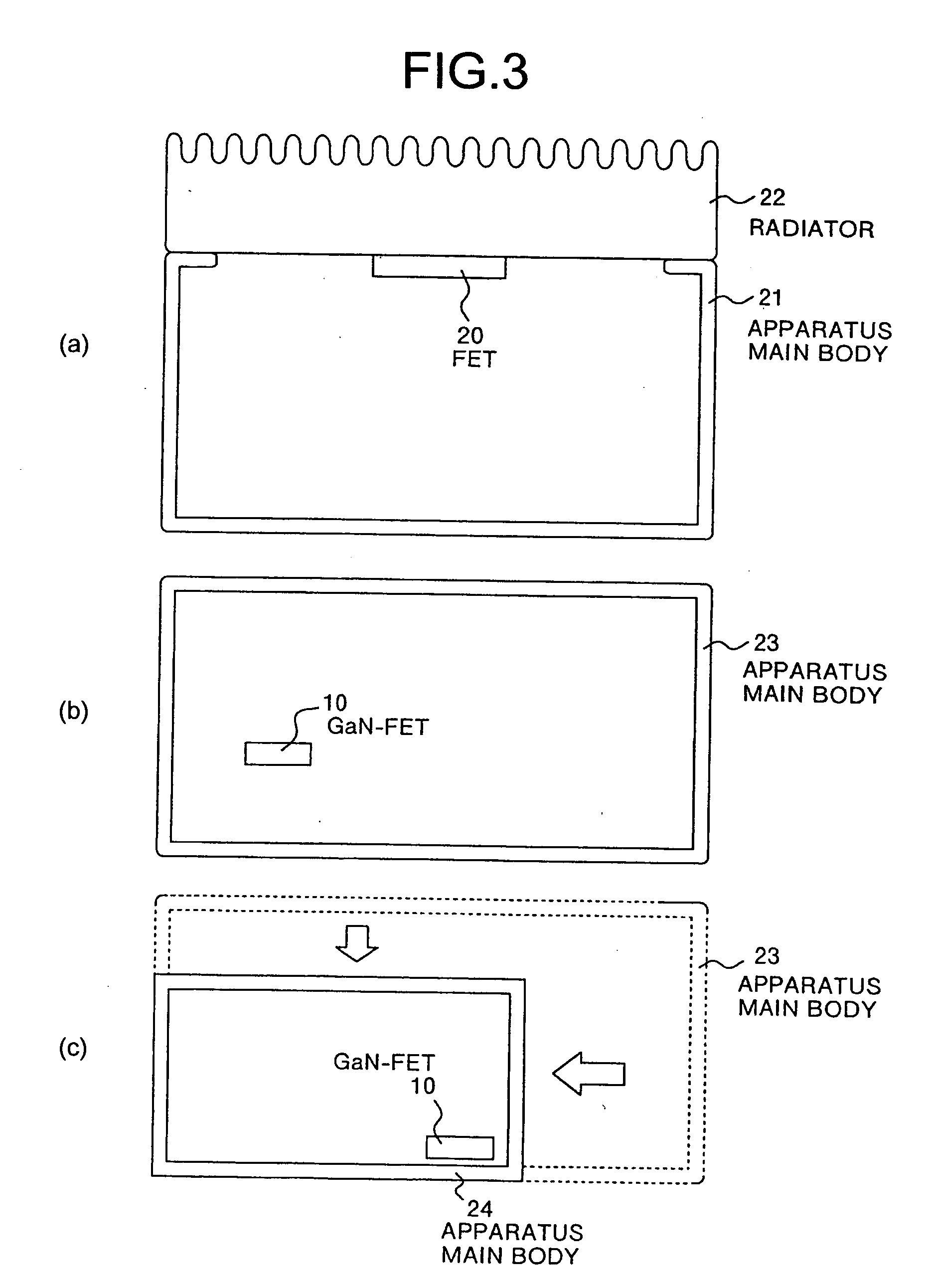

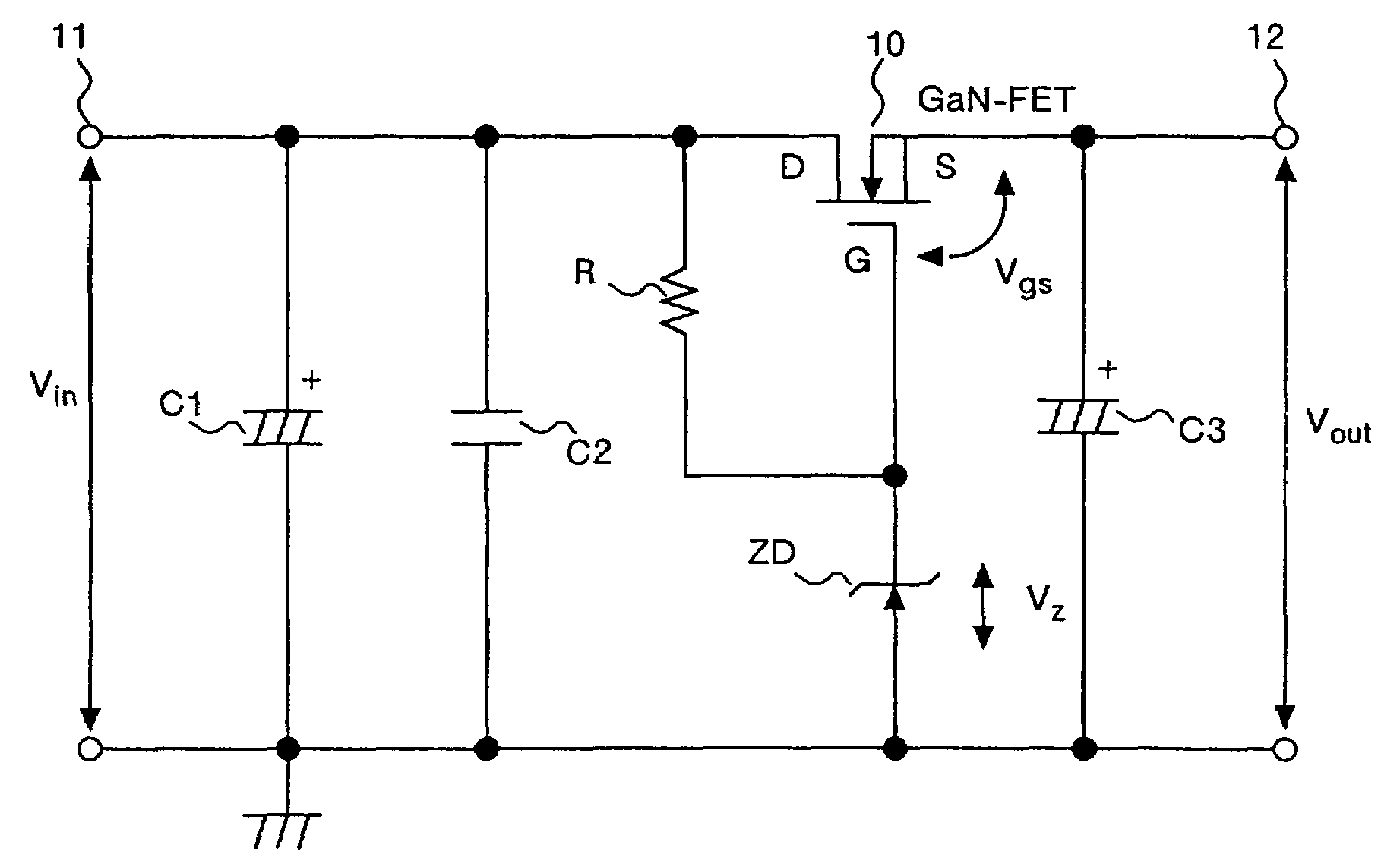

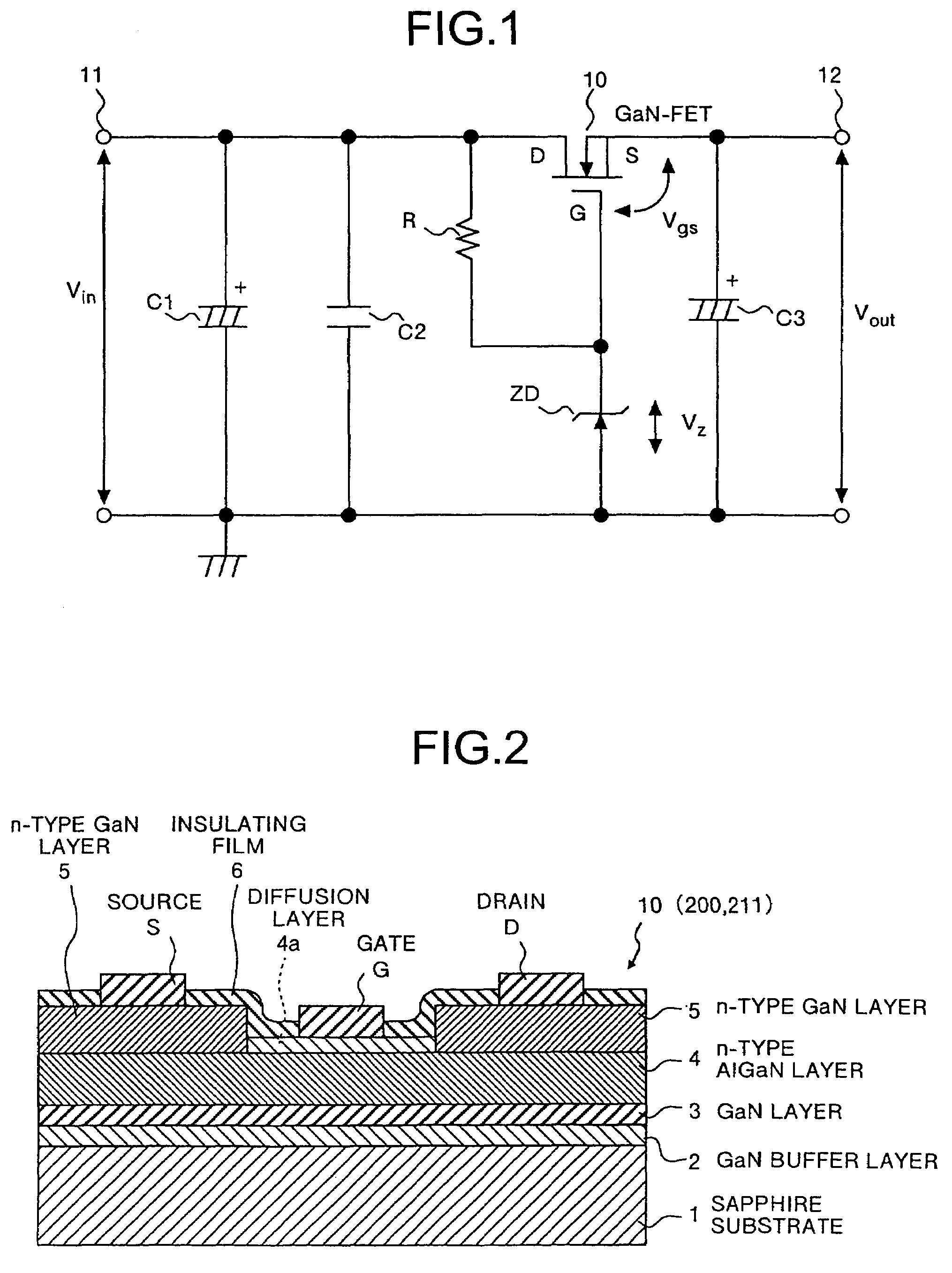

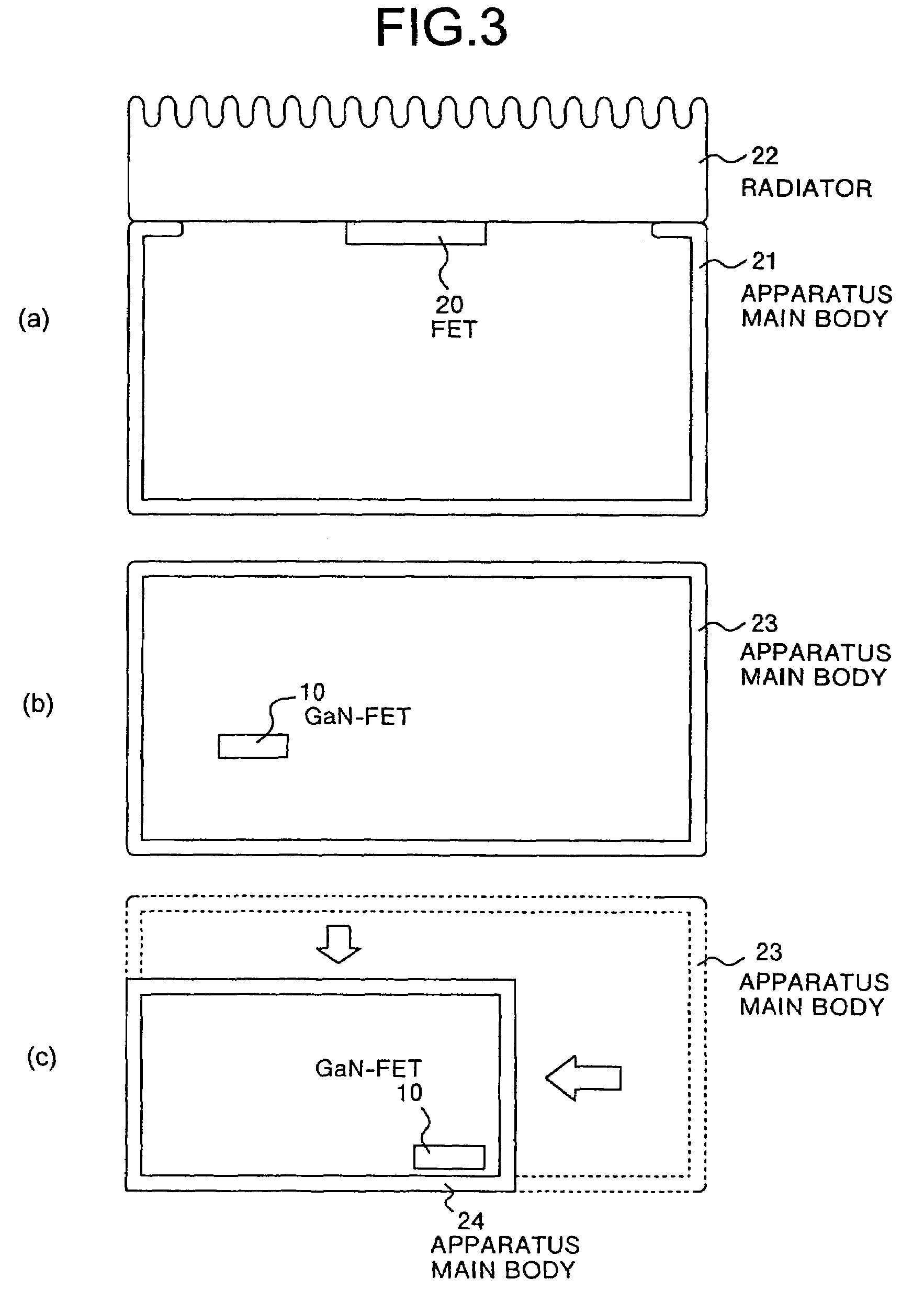

Apparatus and circuit for power supply, and apparatus for controlling large current load

InactiveUS20060113971A1Efficient power electronics conversionConversion constructional detailsCurrent loadGallium nitride

A power supply apparatus includes a diode that is disposed in the path of a main current that is a subject of power control. The diode includes a substrate; a gallium-nitride buffer layer formed on the substrate; a gallium-nitride layer formed on the gallium-nitride buffer layer; and an n-type aluminum-gallium-nitride layer formed on the gallium-nitride layer.

Owner:FURUKAWA ELECTRIC CO LTD

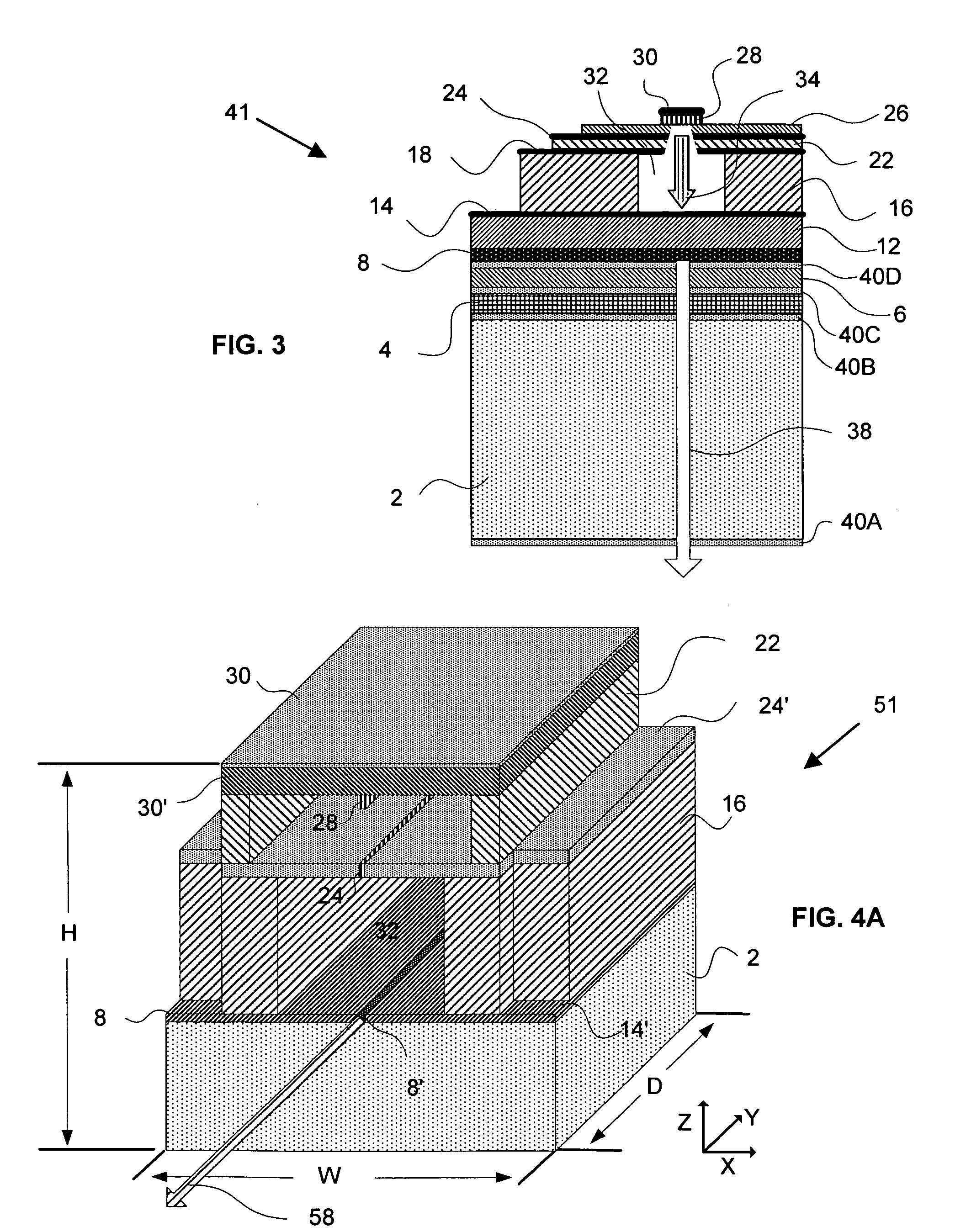

Electron beam pumped semiconductor laser

InactiveUS7590161B1Spectrum investigationExcitation process/apparatusVertical-cavity surface-emitting laserDiamond-like carbon

Electron-beam-pumped semiconductor ultra-violet optical sources (ESUVOSs) are disclosed that use ballistic electron pumped wide bandgap semiconductor materials. The sources may produce incoherent radiation and take the form of electron-beam-pumped light emitting triodes (ELETs). The sources may produce coherent radiation and take the form of electron-beam-pumped laser triodes (ELTs). The ELTs may take the form of electron-beam-pumped vertical cavity surface emitting lasers (EVCSEL) or edge emitting electron-beam-pumped lasers (EEELs). The semiconductor medium may take the form of an aluminum gallium nitride alloy that has a mole fraction of aluminum selected to give a desired emission wavelength, diamond, or diamond-like carbon (DLC). The sources may be produced from discrete components that are assembled after their individual formation or they may be produced using batch MEMS-type or semiconductor-type processing techniques to build them up in a whole or partial monolithic manner, or combination thereof.

Owner:PHOTON SYST

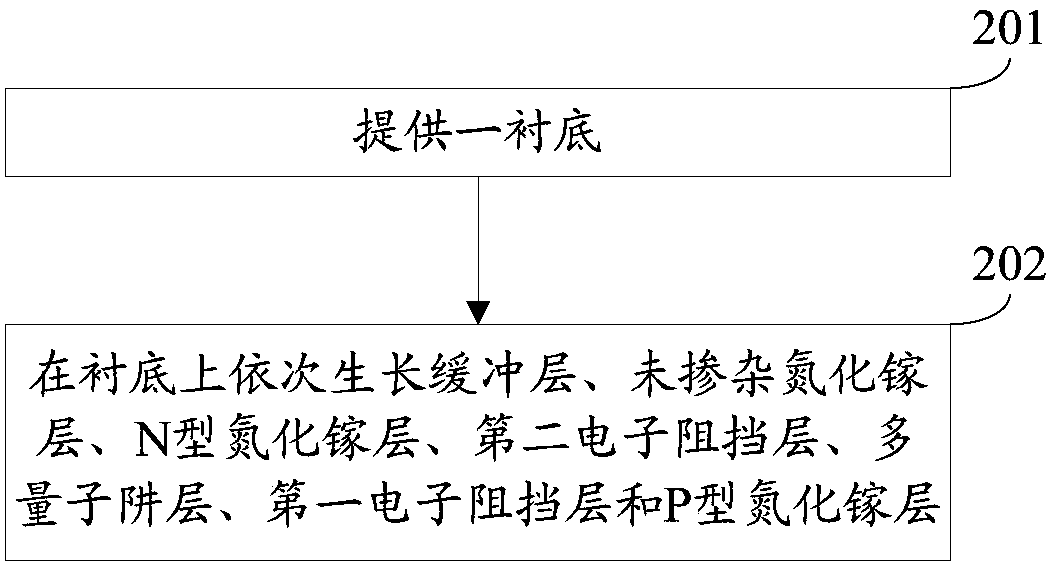

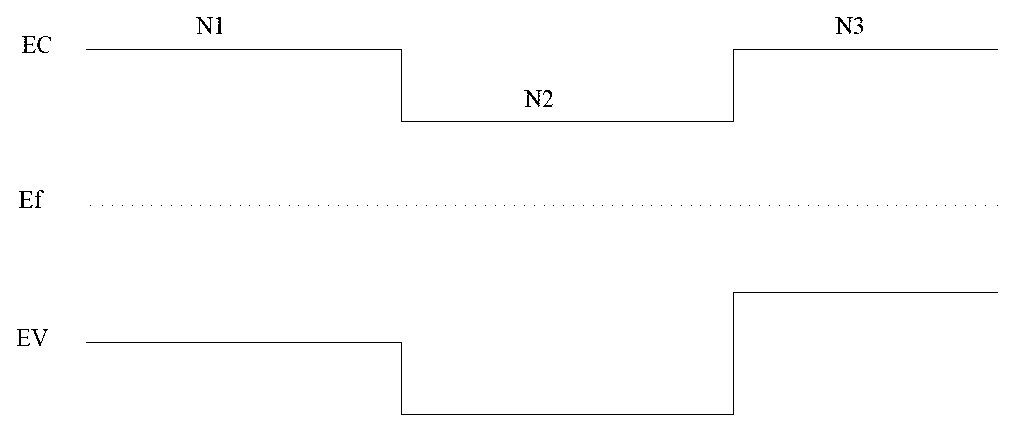

Light emitting diode epitaxial wafer and manufacturing method thereof

ActiveCN108091736AEffect of Luminous EfficiencyImprove luminous efficiencySemiconductor devicesDopantGallium nitride

The invention discloses a light emitting diode epitaxial wafer and a manufacturing method thereof, belonging to the technical field of semiconductors. The epitaxial wafer includes a substrate, a buffer layer, an undoped GaN layer, an N-type GaN layer, a second electron blocking layer, a multiple quantum well layer, a first electron blocking layer, and a P-type GaN layer. The electron blocking layer includes a plurality of first sub-layers and a plurality of second sub-layers that are alternately stacked. Each first sub-layer is an undoped indium gallium nitride layer, a second sub-layer of theplurality of second sub-layers closest to the multiple quantum well layer is a first aluminum gallium nitride layer, the first aluminum gallium nitride layer is an undoped aluminum gallium nitride layer, and each second sub-layer among the second sub-layers except the second sub-layer closest to the multiple quantum well layer is a second aluminum gallium nitride layer, the second aluminum gallium nitride layer is a P-type doped aluminum gallium nitride layer, and the doping concentration of a P-type dopant in each second aluminum gallium nitride layer is smaller than the doping concentrationof a P-type dopant in the GaN layer. The luminous efficiency can be improved.

Owner:HC SEMITEK ZHEJIANG CO LTD

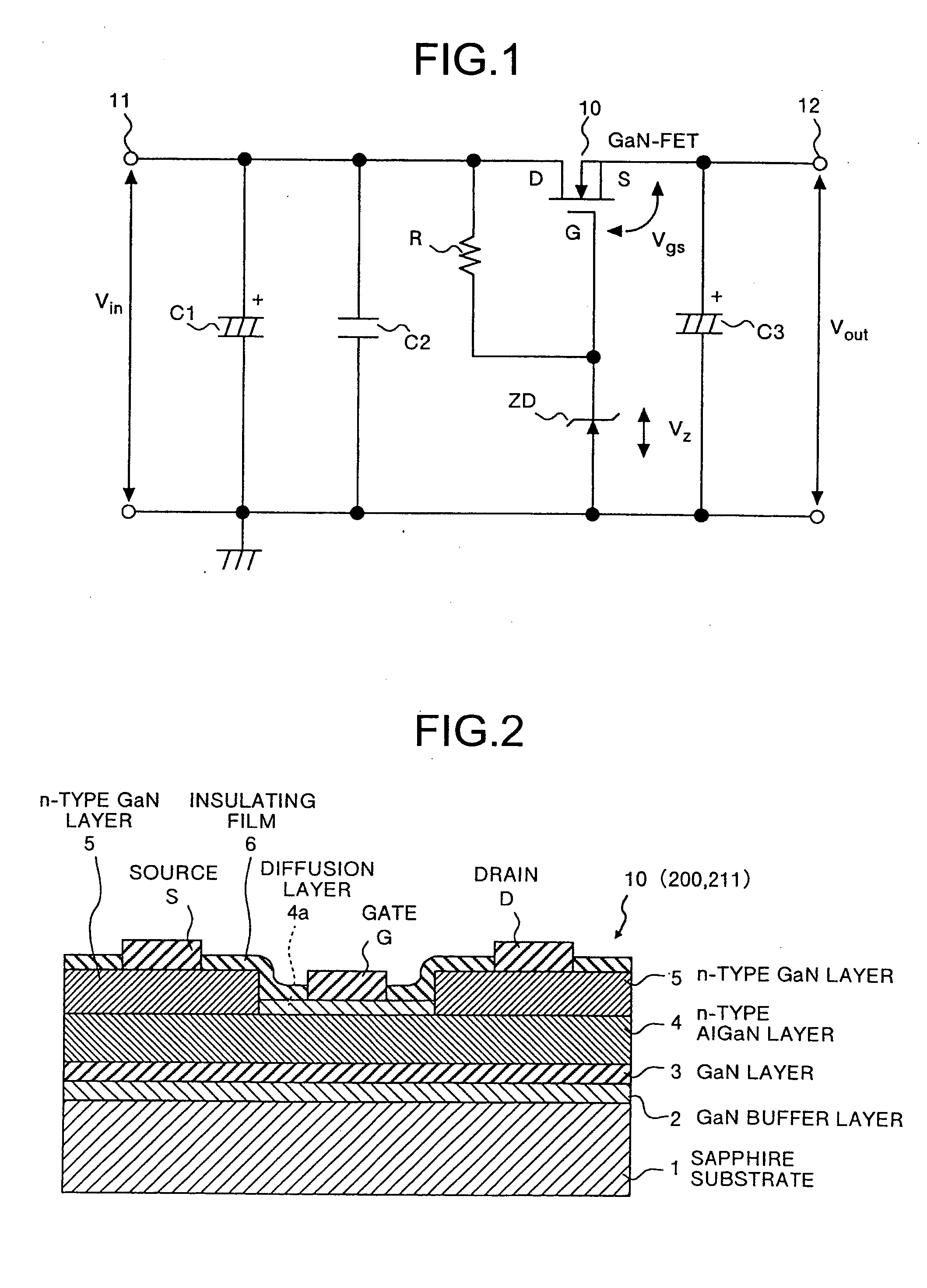

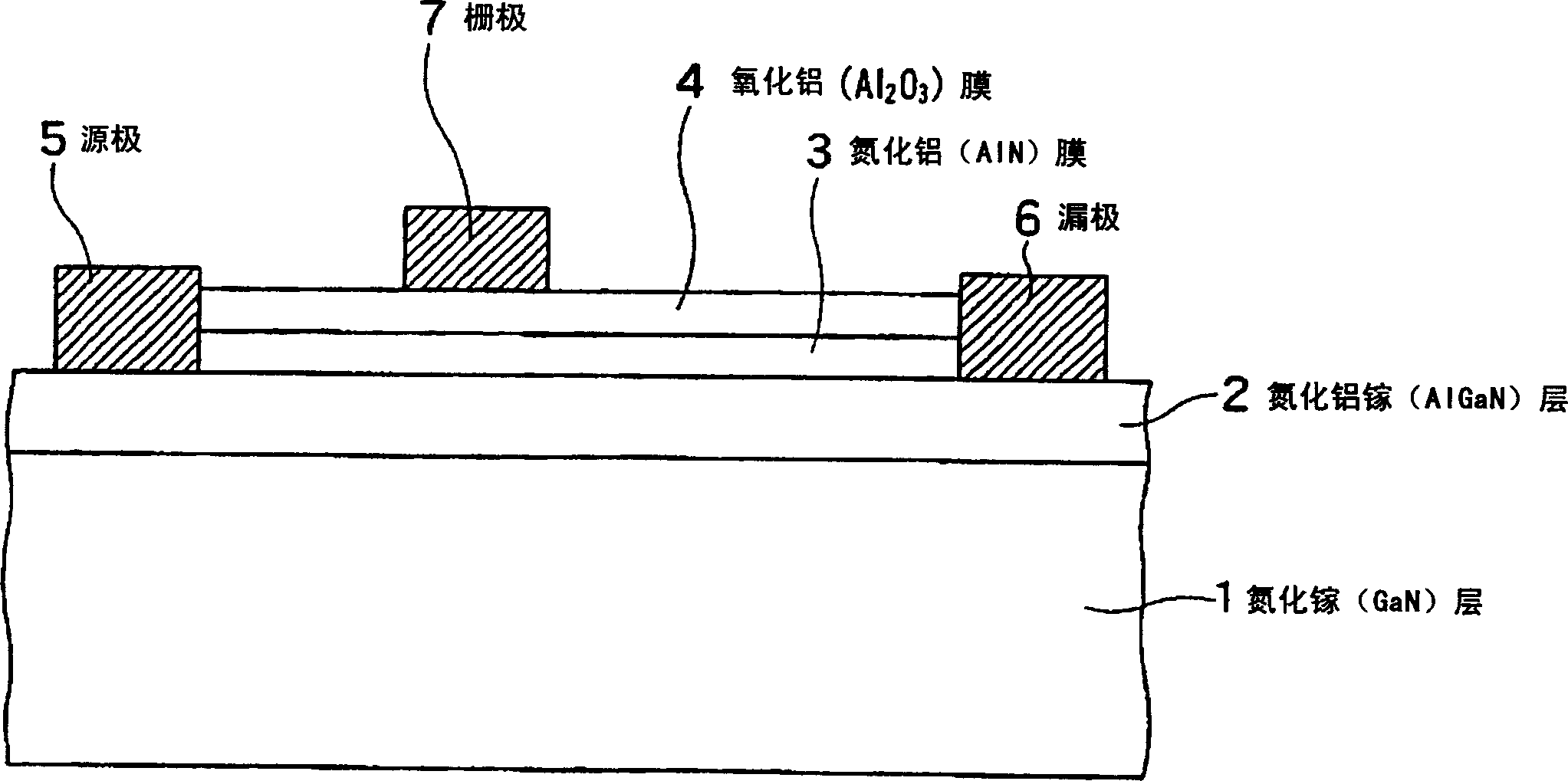

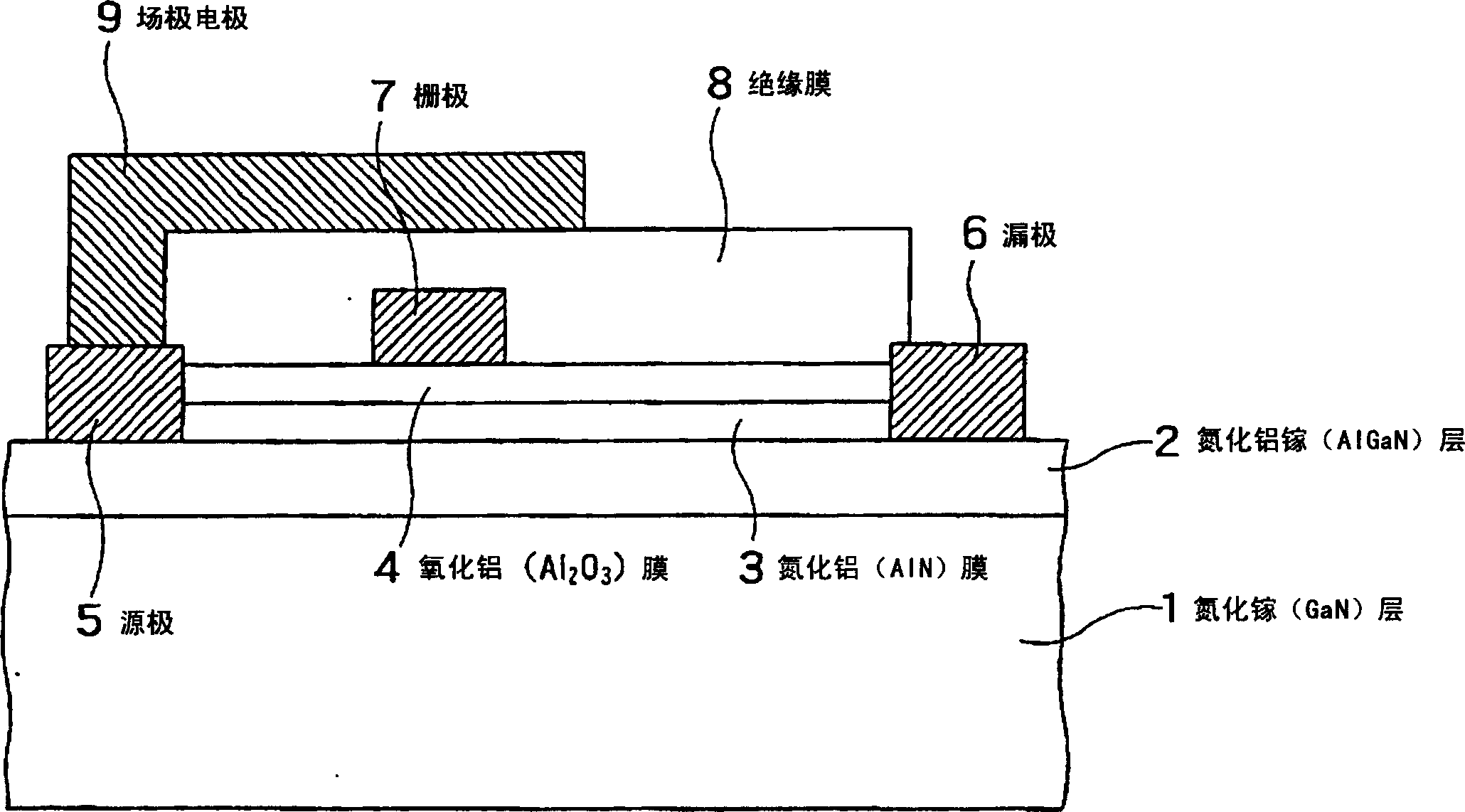

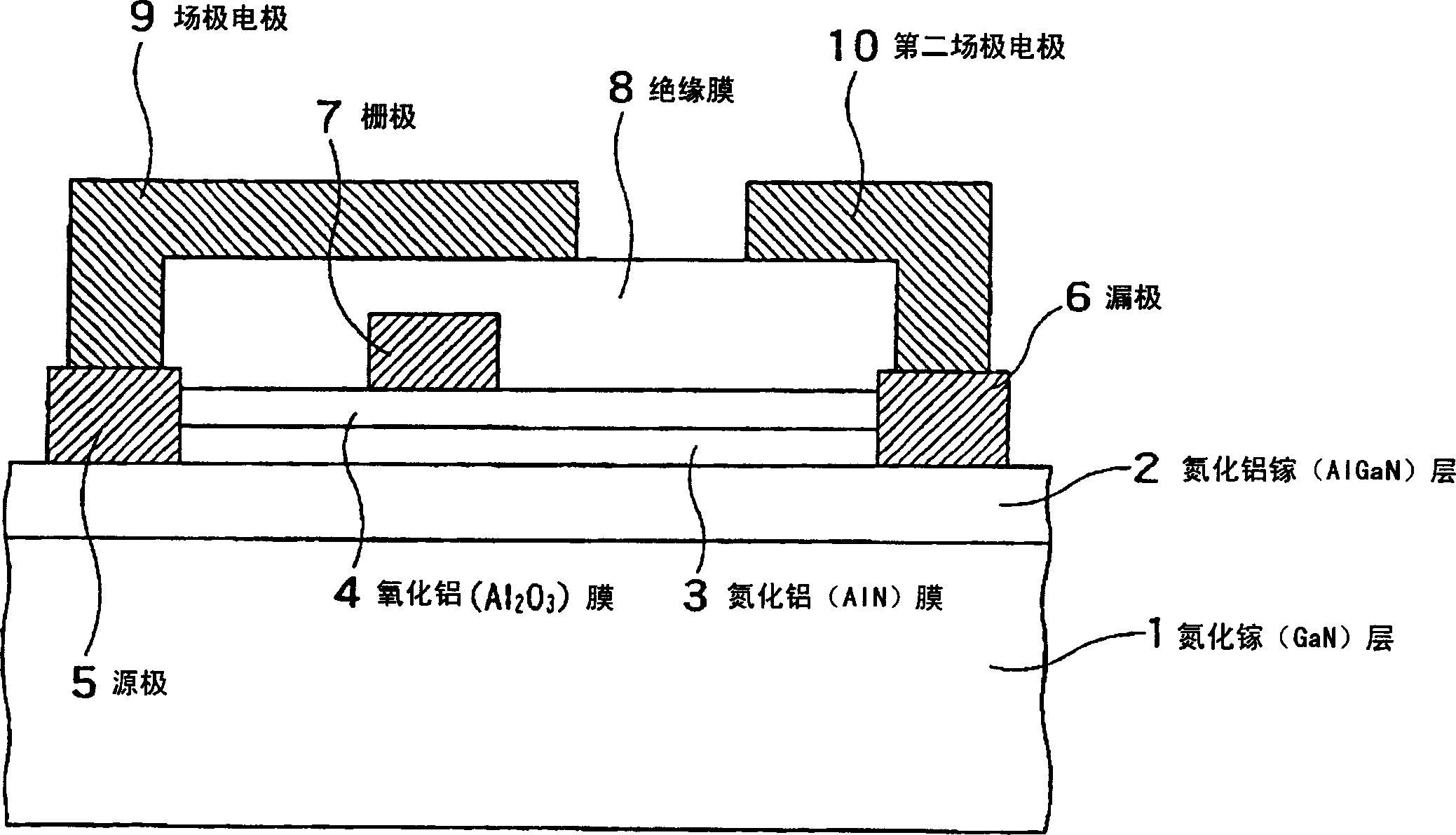

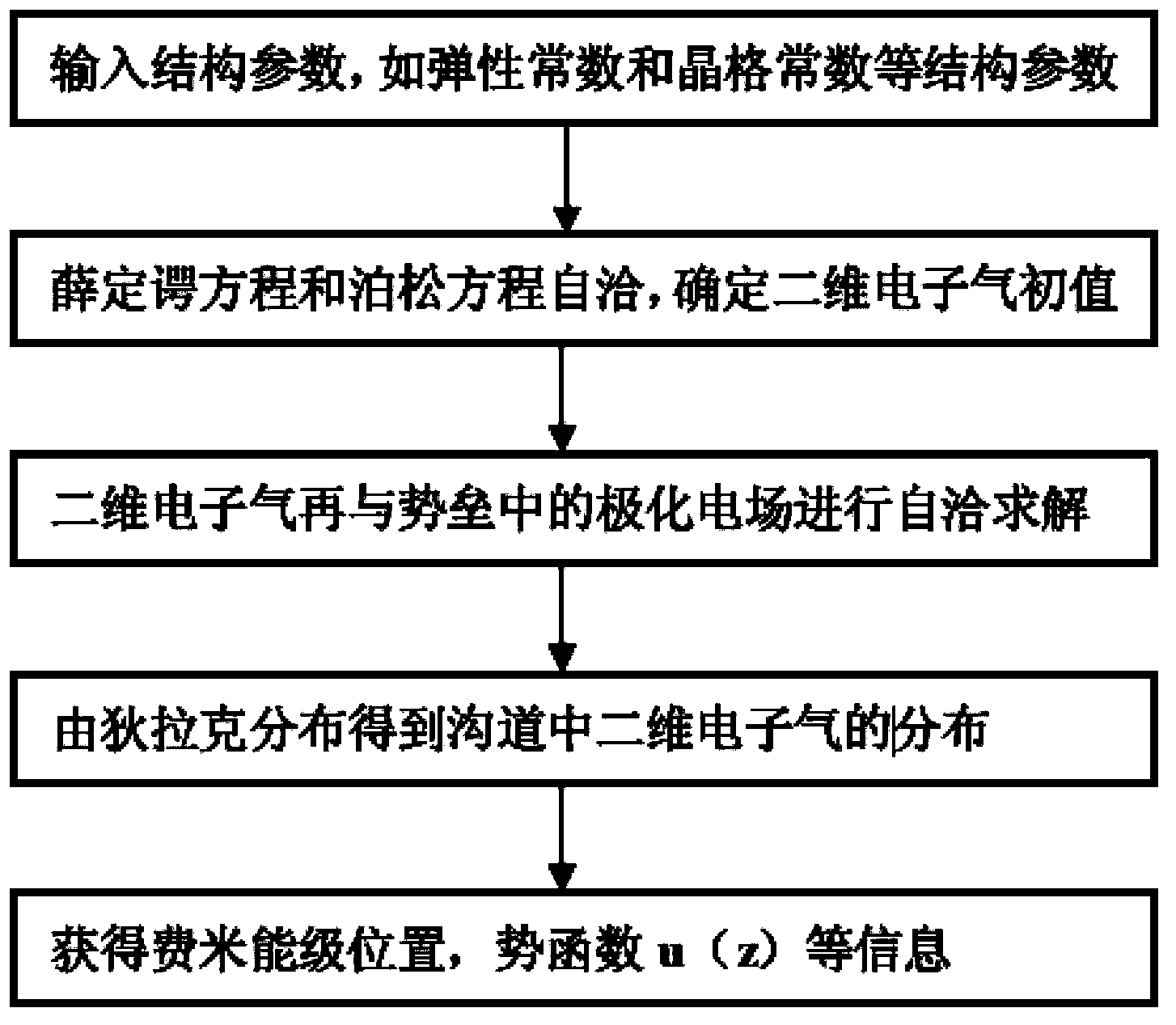

Nitride semiconductor device

InactiveCN1722465ASemiconductor/solid-state device manufacturingSemiconductor devicesNon dopedNitride semiconductors

A nitride semiconductor device according to one embodiment of the present invention comprises: a non-doped first aluminum gallium nitride (AlxGa1-xN (0<=x<=1)) layer which is formed as a channel layer; a non-doped or n type second aluminum gallium nitride (AlyGa1-yN (0<=x<=1,x H01L 29 / 78 11 16 3 2005 / 7 / 13 1722465 2006 / 1 / 18 000000000 Tokyo Shibaura Electric Co. Japan Saito Wataru Omura Ichiro yu hui 72002 NTD Patent & Trademark Agency Ltd. Units 1805-6, 18th Floor, Greenfield Tower, Concordia Plaza, No.1 Science Museum Road, Tsimshatsui, east, Kowloon, Hong Kong 100045 Japan 2004 / 7 / 14 207409 / 2004

Owner:KK TOSHIBA

Apparatus and circuit for power supply, and apparatus for controlling large current load

InactiveUS7298123B2Efficient power electronics conversionConversion constructional detailsCurrent loadEngineering

A power supply apparatus includes a diode that is disposed in the path of a main current that is a subject of power control. The diode includes a substrate; a gallium-nitride buffer layer formed on the substrate; a gallium-nitride layer formed on the gallium-nitride buffer layer; and an n-type aluminum-gallium-nitride layer formed on the gallium-nitride layer.

Owner:FURUKAWA ELECTRIC CO LTD

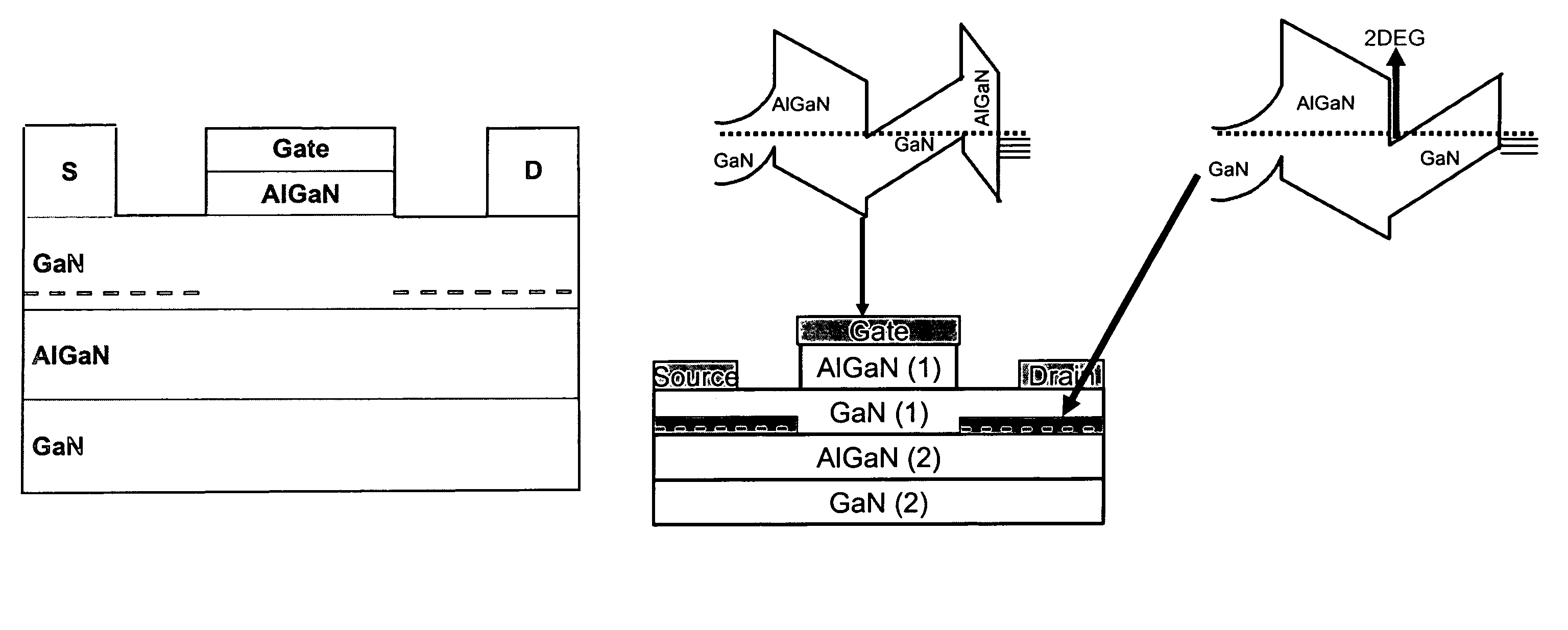

Double-channel transistor and preparation method for double-channel transistor

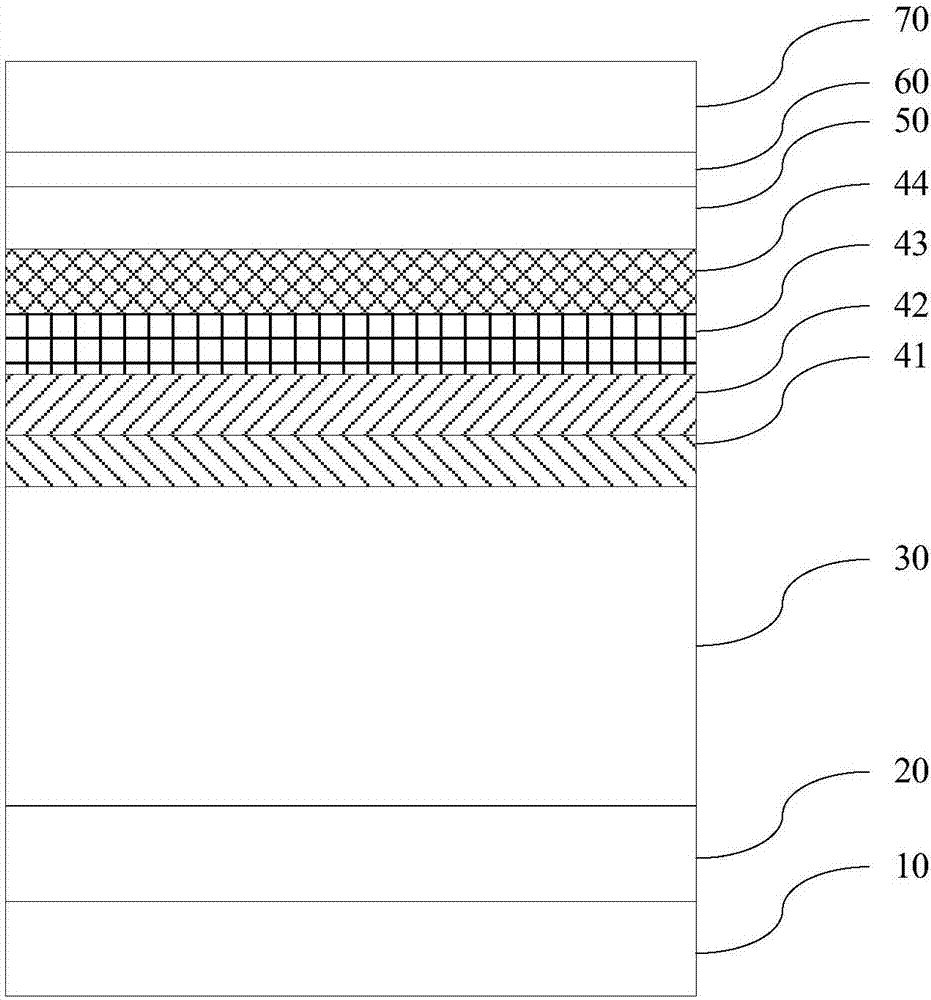

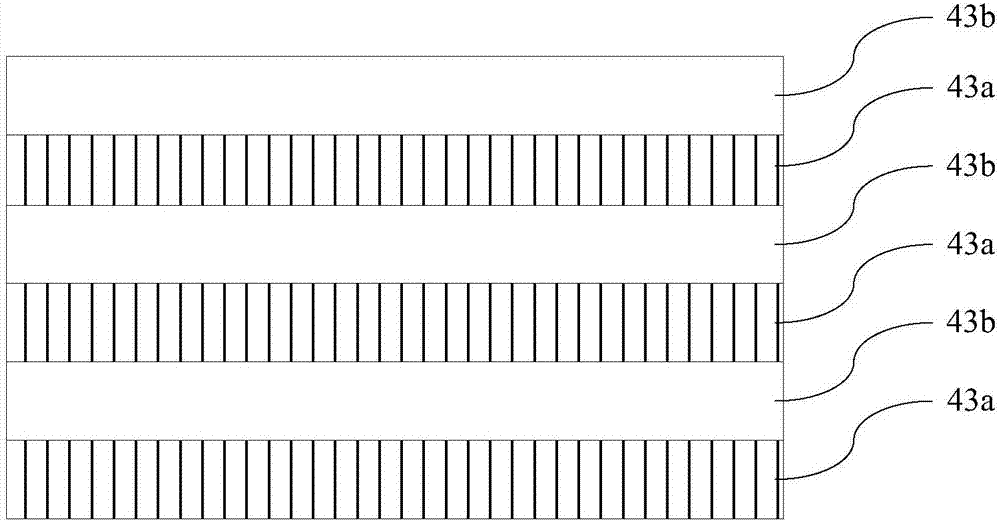

ActiveCN103681830AEnhanced 2DEG localizationImprove reliabilityTransistorSemiconductor/solid-state device manufacturingNitrogenGallium

The invention discloses a double-channel transistor. The double-channel transistor is made of GaN (gallium nitride), and includes two channels, i.e. a first channel and a second channel, wherein the first channel serves as an interface of a barrier layer and a GaN channel layer, the second channel serves as an interface of a back barrier layer and the GaN channel layer, and the barrier layer and the back barrier layer are both made of AlGaN (aluminum gallium nitride); the thickness of the AlGaN back barrier layer is 20 nm, and the aluminum content is 30 percent; the thickness of the AlGaN barrier layer is 20 nm, and the aluminum content is 30 percent; a substrate of the transistor is a silicon carbide substrate. The double-channel transistor and a preparation method for the double-channel transistor have the advantages that AlGaN with a certain aluminum content and a certain thickness serves as the back barrier layer, so as to form an AlGaN / GaN / AlGaN double heterostructure; a two-dimensional electron gas (2DEG) in the channels is confined in two extremely high barriers through a strong polarization electric field to form the two channels, which improves the 2DEG carrier confinement in the channels and the device reliability.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

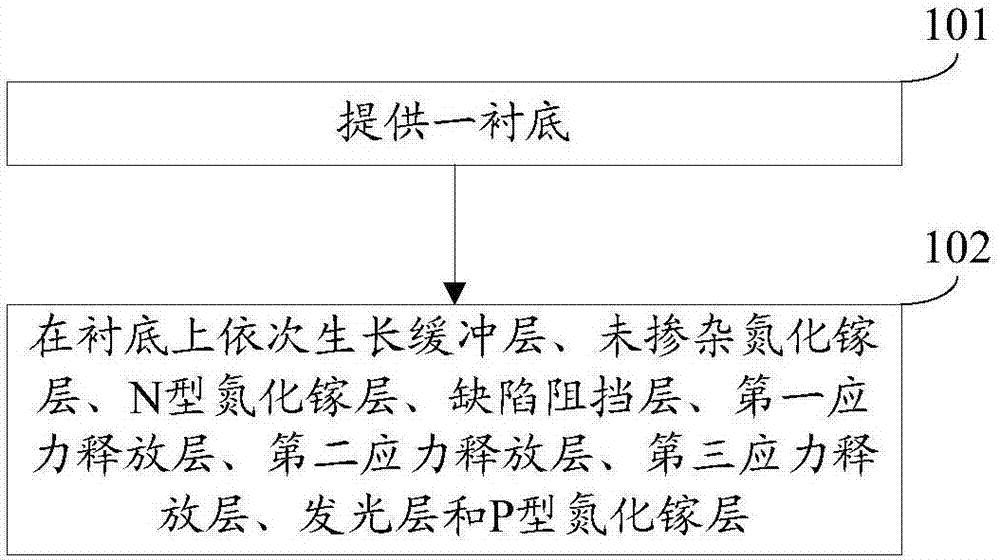

Epitaxial wafer of light-emitting diode and preparation method thereof

ActiveCN107331745AReduce stressReduce mismatchSemiconductor devicesGallium nitrideLight-emitting diode

The invention discloses an epitaxial wafer of a light-emitting diode and a preparation method thereof, and belongs to the technical field of semiconductors. The epitaxial wafer comprises a substrate, a buffer layer, an undoped gallium nitride layer, an N-type gallium nitride layer, a defect blocking layer, a first stress release layer, a second stress release layer, a third stress release layer, a light emitting layer and a P-type gallium nitride layer, and is characterized in that the buffer layer, the undoped gallium nitride layer, the N-type gallium nitride layer, the defect blocking layer, the first stress release layer, the second stress release layer, the third stress release layer, the light emitting layer and the P-type gallium nitride layer are sequentially laminated on the substrate, the defect blocking layer is a silicon-doped aluminum gallium nitride layer, the first stress release layer is a silicon-doped gallium nitride layer, the second stress release layer comprises a plurality of first sub-layers and a plurality of second sub-layers which are arranged in an alternately laminating manner, the first sub-layers are undoped InGaN layers, the second sub-layers are silicon-doped gallium nitride layers, and the third stress release layer is a silicon-doped InGaN layer; and the doping concentration of silicon in the defect blocking layer is lower than that of the first stress release layer, the doping concentration of silicon in the first stress release layer is higher than that of each second sub-layer, and the doping concentration of silicon in each second sub-layer is lower than that of the third stress release layer. The light emitting efficiency can be improved according to the invention.

Owner:HC SEMITEK ZHEJIANG CO LTD

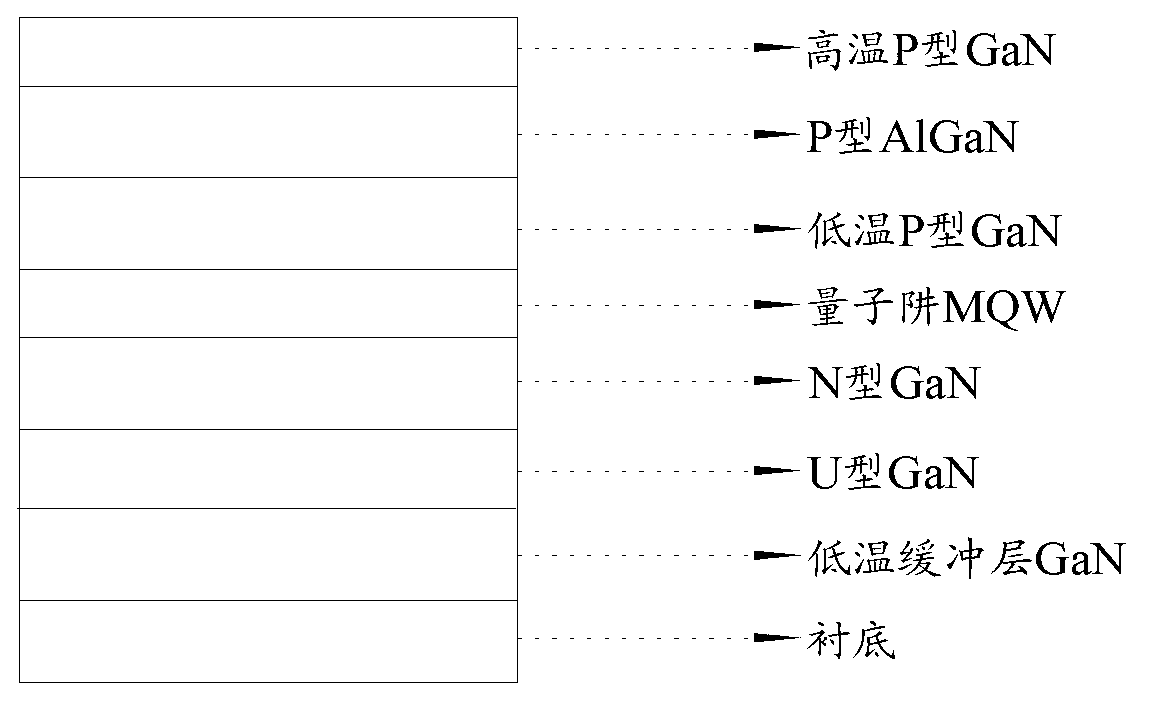

Light-emitting diode (LED) epitaxial wafer

ActiveCN103107256AReduce dosageImprove horizontal scalabilitySemiconductor devicesDopantGallium nitride

Disclosed is a light-emitting diode (LED) epitaxial wafer. The LED epitaxial wafer sequentially comprises a substrate, a gallium nitride (GaN) buffering layer, a non-dopant GaN layer, a doped N type GaN layer with silicon (Si), an indium gallium nitride (InGaN) / GaN multiple quantum well layer, a P type aluminum gallium nitride (AlGaN) layer and a P type doped GaN layer with magnesium (Mg), wherein the doped GaN layer with Si comprises a first doped N type GaN layer with Si, a second doped N type GaN layer with Si and at least one alternate structure layer composed of a third doped N type GaN layer with Si and an undoped U type GaN layer with no Si. According to the alternate structure layer composed of the third doped N type GaN layer with Si and the undoped U type GaN layer with no Si, usage amount of dopant is reduced, a driving voltage is reduced, and luminance and a lighting effect are improved.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

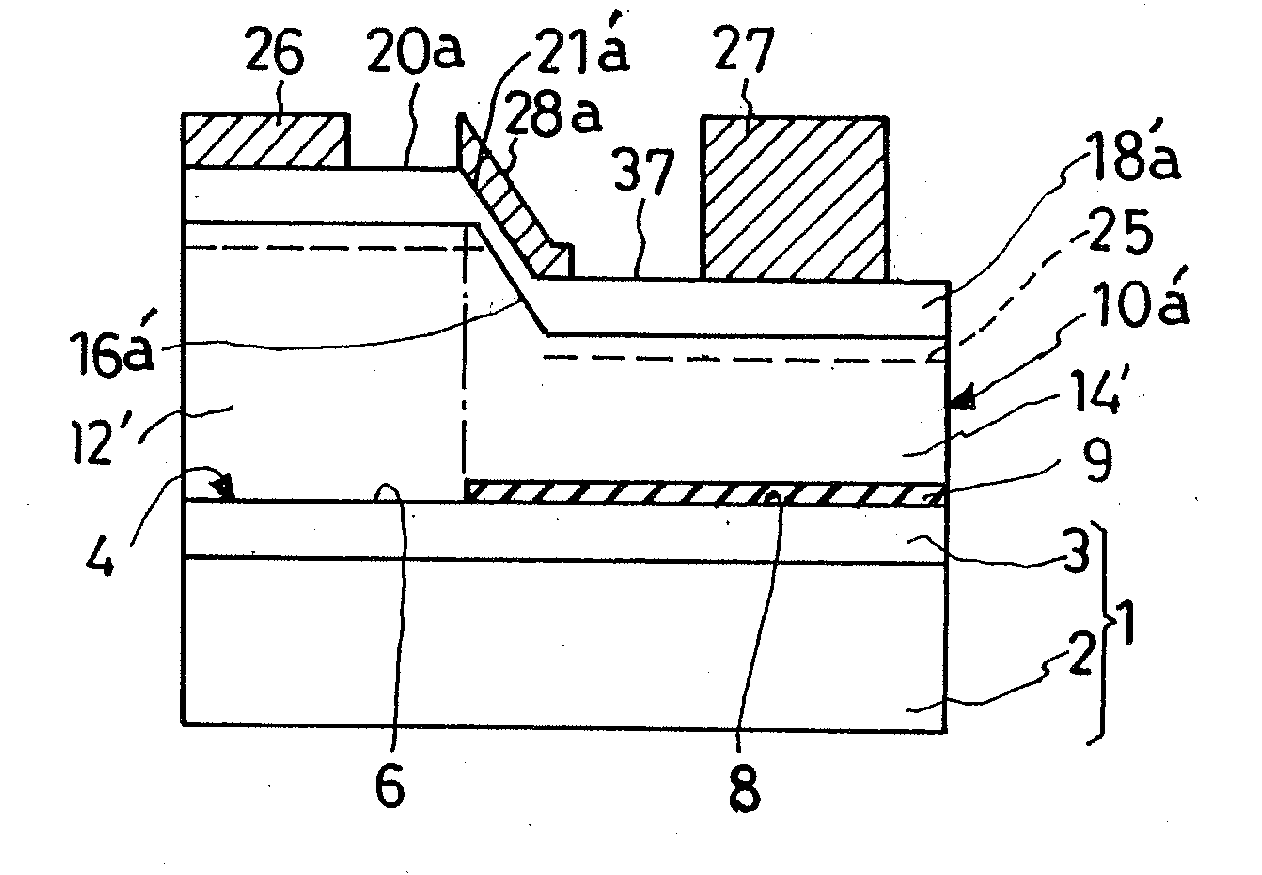

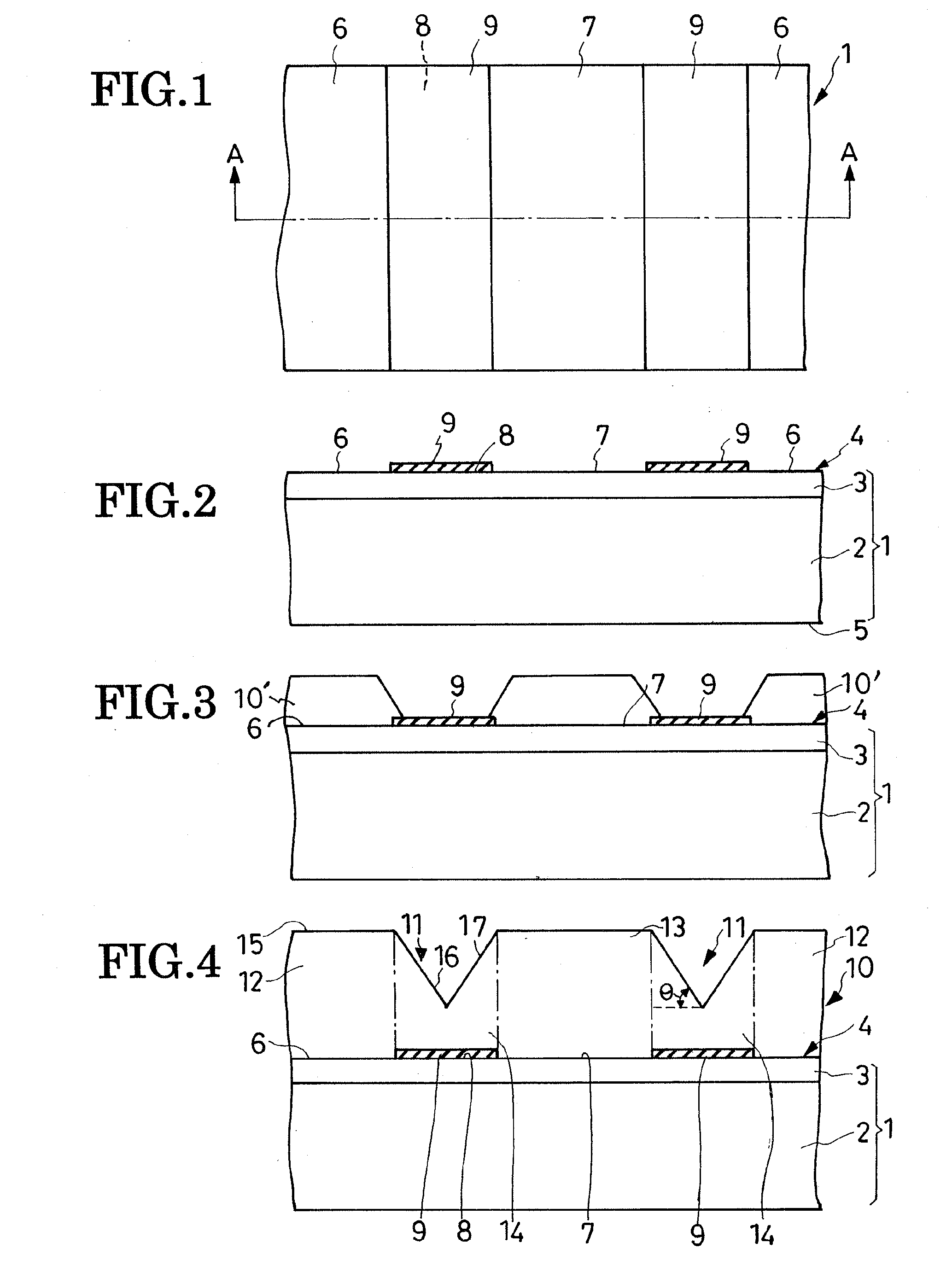

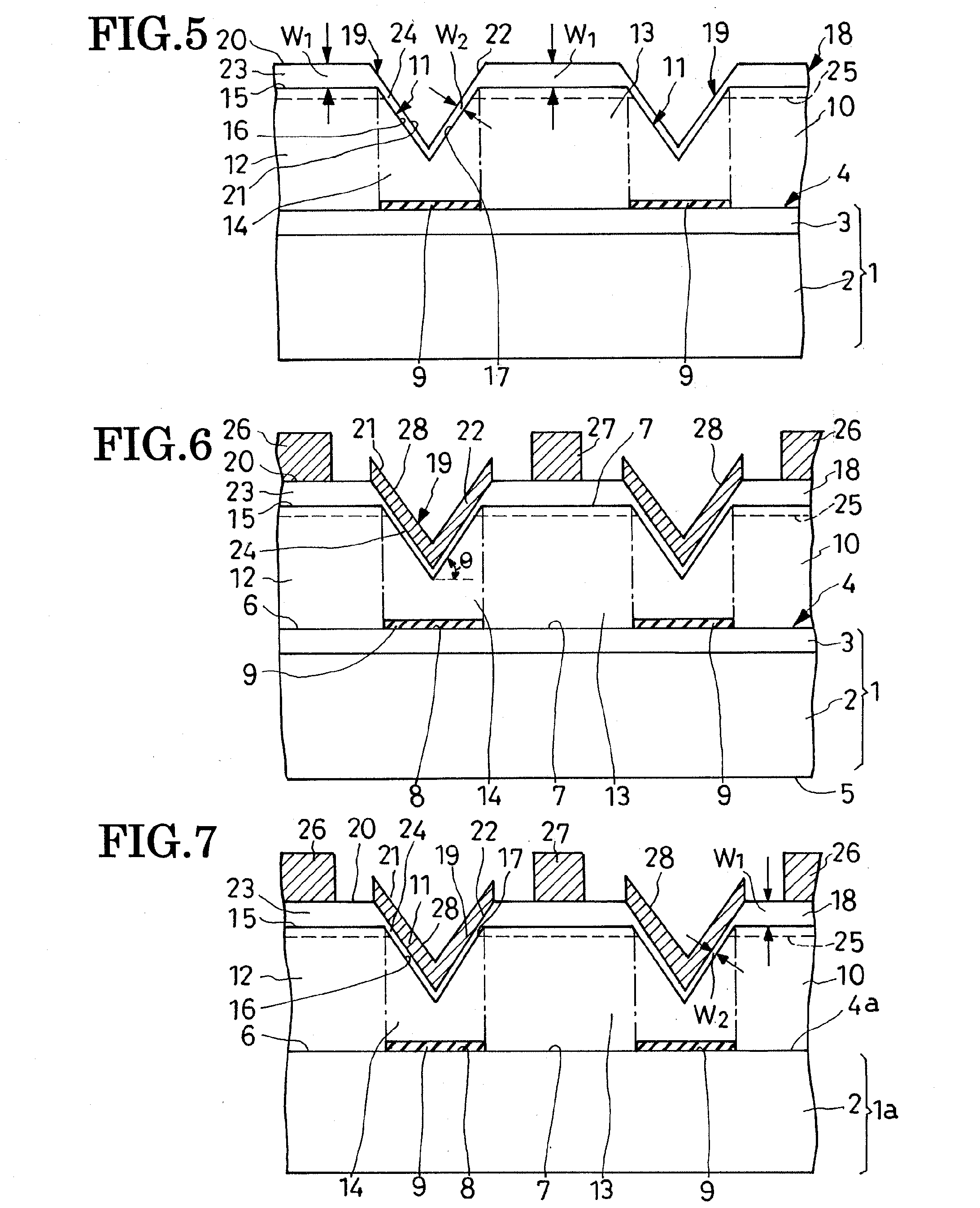

Normally-off field-effect semiconductor device, and method of fabrication

InactiveUS20090008676A1Easily and finely be adjustedLower turn-on resistanceSemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionLateral overgrowth

A normally-off HEMT is made by first providing a substrate having its surface partly covered with an antigrowth mask. Gallium nitride is grown by epitaxy on the masked surface of the substrate to provide an electron transit layer comprised of two flat-surfaced sections and a V-notch-surfaced section therebetween. The flat-surfaced sections are formed on unmasked parts of the substrate surface whereas the V-notch-surfaced section, defining a V-sectioned notch, is created by lateral overgrowth onto the antigrowth mask. Aluminum gallium nitride is then deposited on the electron transit layer to provide an electron supply layer which is likewise comprised of two flat-surfaced sections and a V-notch-surfaced section therebetween. The flat-surfaced sections of the electron supply layer are sufficiently thick to normally generate two-dimensional electron gas layers due to heterojunctions thereof with the first and the second flat-surfaced section of the electron transit layer. The V-notch-surfaced section of the electron supply layer is not so thick, normally creating an interruption in the two-dimensional electron gas layer.

Owner:SANKEN ELECTRIC CO LTD

Silicon carbide MOSFET with integrated MOS diode

ActiveUS9324807B1Reduce knee voltageLow field mobilityTransistorSolid-state devicesCapacitanceElectrical conductor

A monolithically integrated MOS channel in gate-source shorted mode is used as a diode for the third quadrant conduction path for a power MOSFET. The MOS diode and MOSFET can be constructed in a variety of configurations including split-cell and trench. The devices may be formed of silicon carbide, gallium nitride, aluminum nitride, aluminum gallium nitride, diamond, or similar semiconductor. Low storage capacitance and low knee voltage for the MOS diode can be achieved by a variety of means. The MOS diode may be implemented with channel mobility enhancement materials, and / or have a very thin / high permittivity gate dielectric. The MOSFET gate conductor and MOS diode gate conductor may be made of polysilicon doped with opposite dopant types. The surface of the MOS diode dielectric may be implanted with cesium.

Owner:UNITED SILICON CARBIDE

Epitaxial growth method for gallium-nitride-based (GaN-based) light-emitting diode (LED)

InactiveCN102842661AQuality improvementReduce generationPolycrystalline material growthFrom chemically reactive gasesWorking lifeRoom temperature

The invention relates to an epitaxial growth method for a gallium-nitride-based (GaN-based) light-emitting diode (LED), comprising the following steps of: annealing a substrate, then nitriding; cooling to grow a low temperature GaN buffer layer; rising the temperature of the substrate, thermally annealing the low temperature GaN baffer layer, epitaxially growing the high temperature GaN buffer layer; then growing a layer of an N-type GaN layer with stable doping concentration; growing light quantum well; growing multiple quantum wells of luminescent layer; seventhly, growling a P-type GaN layer with nitrogen (N2) as carrier gas; growing a P-type aluminum gallium nitride (AlGaN) layer; growing the P-type GaN layer; growing a P contact layer; reducing the temperature of a reaction chamber, annealing, then reducing to the room temperature. The method provided by the invention comprises high pressure growth of the P-type GaN layer after the P-type AlGaN layer, a high pressure growth condition can decrease the carbon generated in the epitaxial deposition process, decrease yellow belt and be capable of obtaining high-quality crystal, thereby obtaining a high-quality LED device and improving luminous efficiency and a working life of the device.

Owner:合肥彩虹蓝光科技有限公司

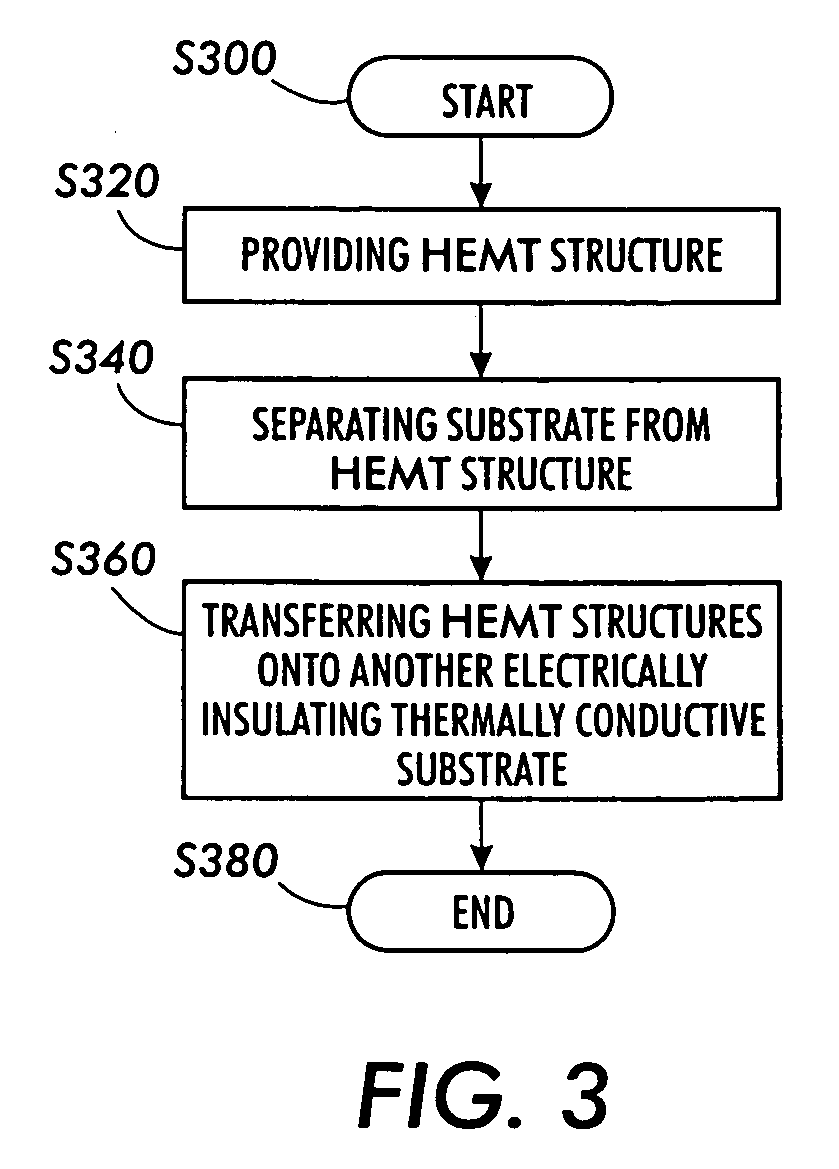

Growth of iii-nitride semiconductors on thin van der waals buffers for mechanical lift off and transfer

ActiveUS20190035624A1Semiconductor/solid-state device manufacturingDevice materialCondensed matter physics

A semiconductor device includes a mechanical release layer, such as a van der Waals buffer layer, with a predetermined material roughness and thickness adjacent to a first substrate; a nucleation layer adjacent to the mechanical release layer; and a first semiconductor layer attached to the nucleation layer. The first semiconductor layer, the nucleation layer, and a portion of the mechanical release layer are releasably connected to the first substrate. The predetermined material roughness and thickness of the mechanical release layer determines a bonding strength of the first semiconductor layer to the first substrate. The semiconductor device may include an aluminum nitride insert layer adjacent to the first semiconductor layer; an aluminum gallium nitride barrier layer adjacent to the aluminum nitride insert layer; and a second semiconductor layer adjacent to the aluminum gallium nitride barrier layer. The semiconductor device may include a second substrate attached to the released first semiconductor layer.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

Diamond based blue/UV emission source

A diamond based Blue / UV light emitting source is disclosed. The source includes a diamond substrate having a first conductivity type, a first aluminum gallium nitride layer above the diamond substrate having the same conductivity type as the substrate, a bulk or a quantum well structure on the AlGaN layer formed of a plurality of repeating sets of alternating layers selected from among GaN, InGaN, and AlInGaN, a second AlGaN layer on the quantum well or the bulk active layer having the opposite conductivity type as the first AlGaN layer, a contact structure on the second AlGaN layer having the opposite conductivity type from the substrate and the first AlGaN layer, an ohmic contact to the diamond substrate, and an ohmic contact to the contact structure.

Owner:INPHOT

Aluminum gallium nitride (AlGaN)base solar-blind ultraviolet detector and preparation method thereof

ActiveCN106960887AIncreased avalanche multiplication factorImprove quantum efficiencyFinal product manufacturePhotovoltaic energy generationUltraviolet detectorsNucleation

The invention discloses an aluminum gallium nitride (AlGaN) base solar-blind ultraviolet detector. The aluminum gallium nitride (AlGaN) base solar-blind ultraviolet detector comprises a sapphire substrate, an A1N nucleation layer, an Alx1Ga1-x1N buffer layer, an n-type Alx2Gal-x2N layer, a non-doped i-type Zny1Mg1-y1O absorption layer, an n-type ZnO / Zny2Mg1-y2O superlattice separation layer, a non-doped i-type Zny3Mg1-y3O multiplication layer, a p-type Alx3Ga1-x3N layer, and a p-type GaN layer. An n-type ohmic electrode is led out from the n-type Alx2Gal-x2N layer, and a p-type ohmic electrode is led out from the p-type GaN layer. The invention also discloses the preparation method the aluminum gallium nitride (AlGaN)base solar-blind ultraviolet detector. The aluminum gallium nitride (AlGaN) base solar-blind ultraviolet detector is capable of improving the solar-blind ultraviolet detector avalanche multiplication factor and the responsibility of the detector.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

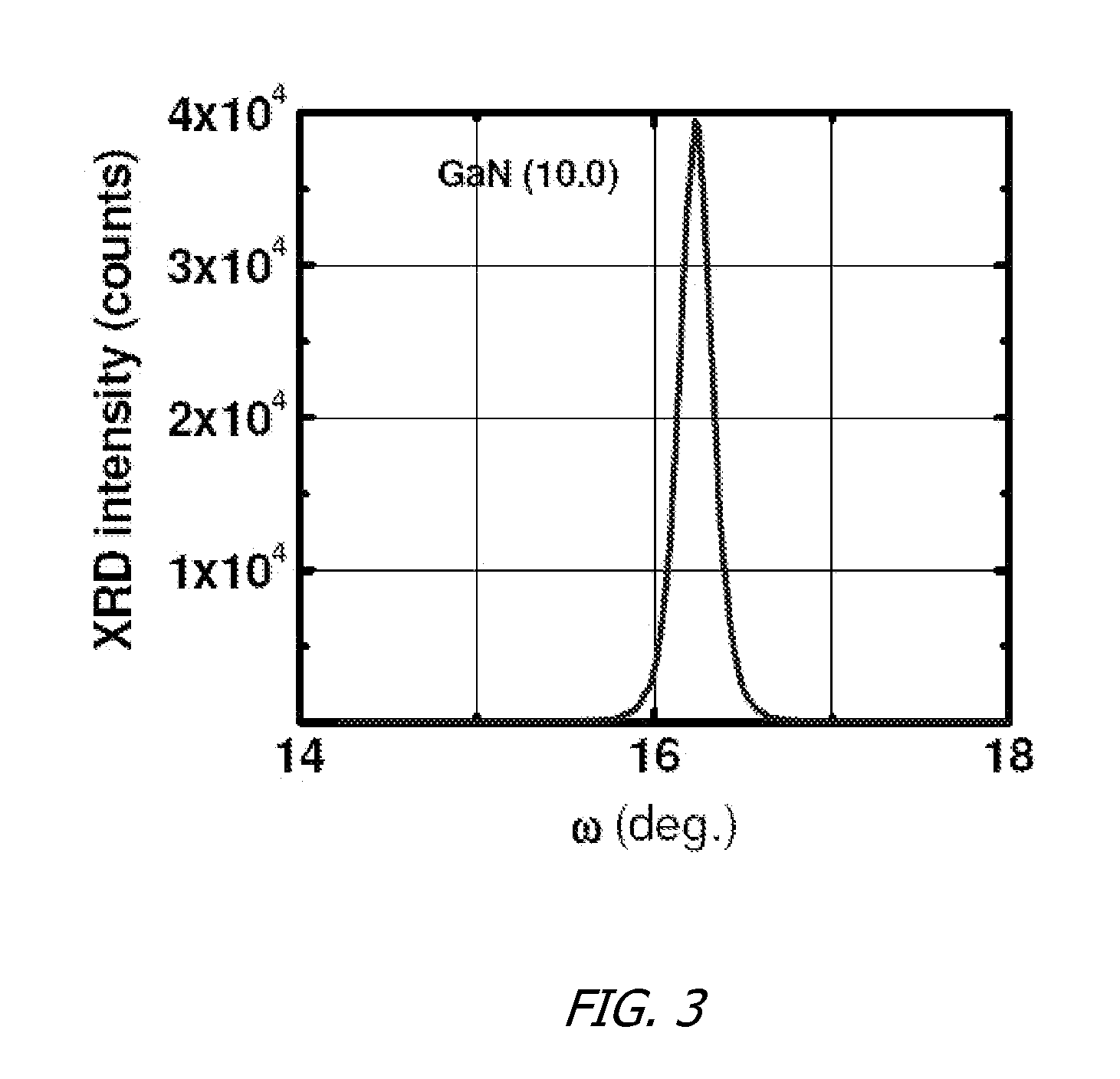

Growth of Planar Non-Polar M-Plane Gallium Nitride With Hydride Vapor Phase Epitaxy (HVPE)

ActiveUS20110108954A1Polycrystalline material growthSemiconductor/solid-state device manufacturingAlternative methodsGallium nitride

A method of growing planar non-polar m-plane III-Nitride material, such as an m-plane gallium nitride (GaN) epitaxial layer, wherein the III-Nitride material is grown on a suitable substrate, such as an m-plane Sapphire substrate, using hydride vapor phase epitaxy (HVPE). The method includes in-situ pretreatment of the substrate at elevated temperatures in the ambient of ammonia and argon, growing an intermediate layer such as an aluminum nitride (AlN) or aluminum-gallium nitride (AlGaN) on the annealed substrate, and growing the non-polar m-plane III-Nitride epitaxial layer on the intermediate layer using HVPE. Various alternative methods are disclosed.

Owner:OSTENDO TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com