Ultraviolet group III-nitride-based quantum well laser diodes

a quantum well and laser diode technology, applied in the field of semiconductor laser diodes, can solve the problems of polarization effects, uneven carrier distribution, and unique problems of gan materials systems in the realization of uv lasers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

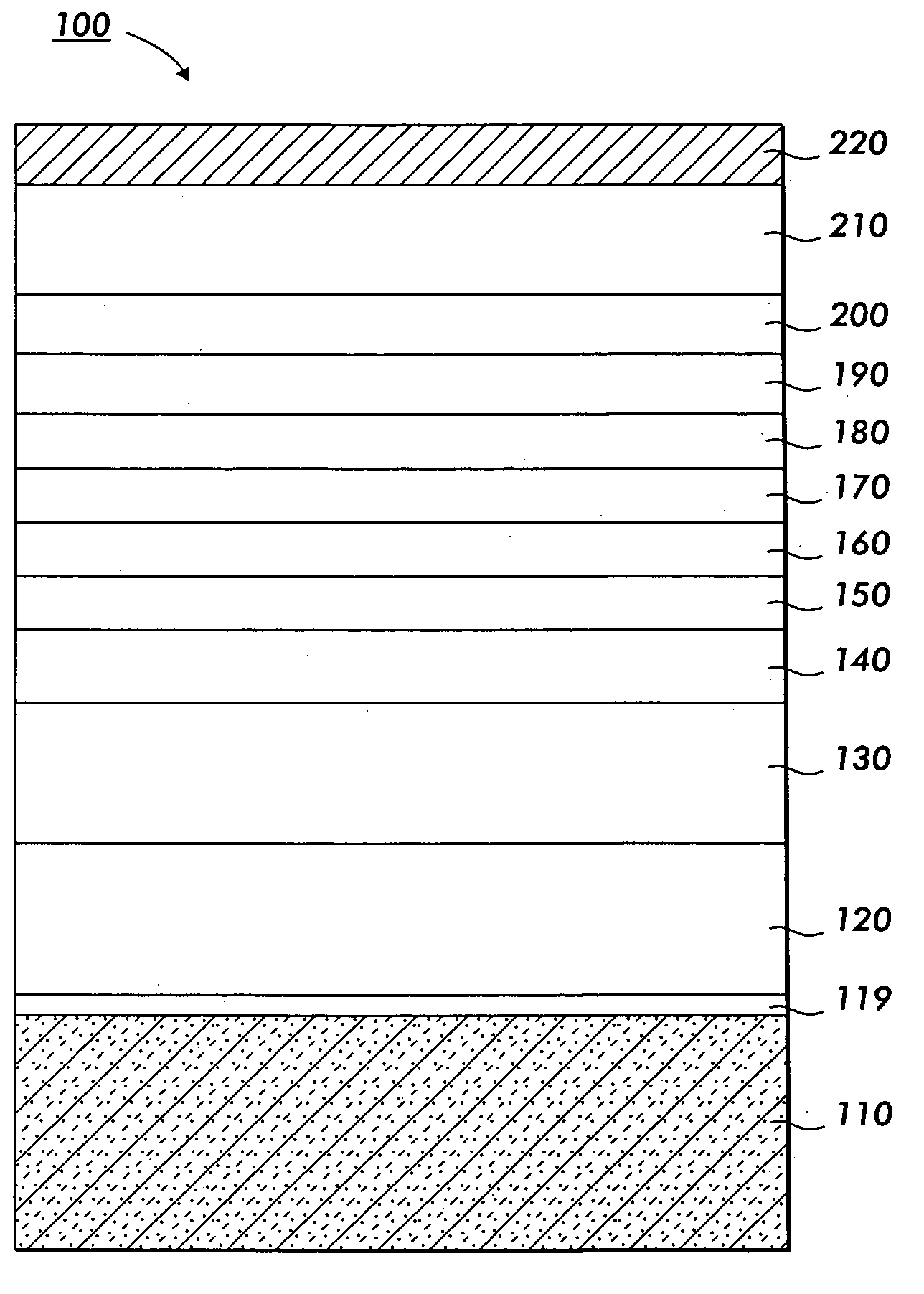

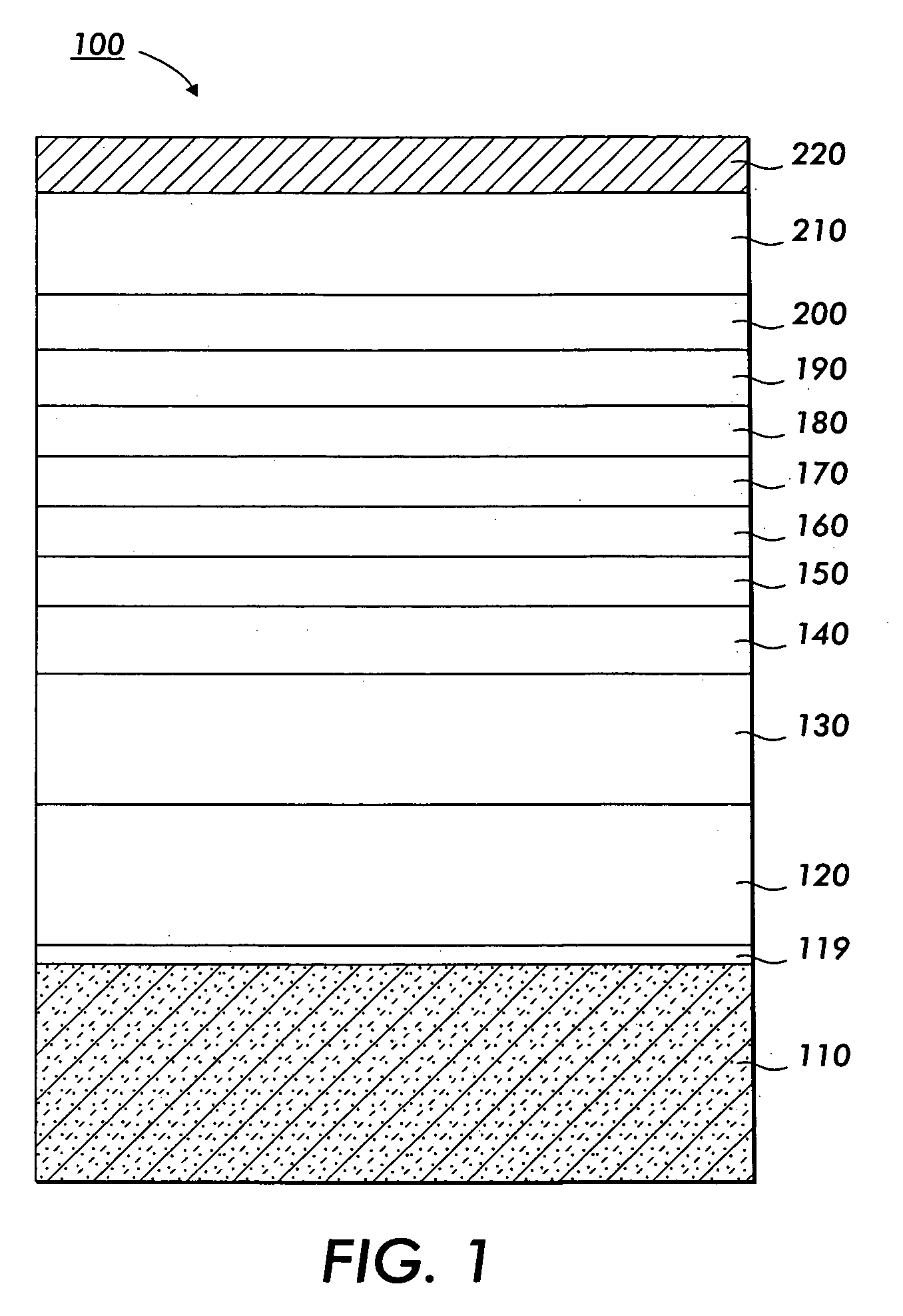

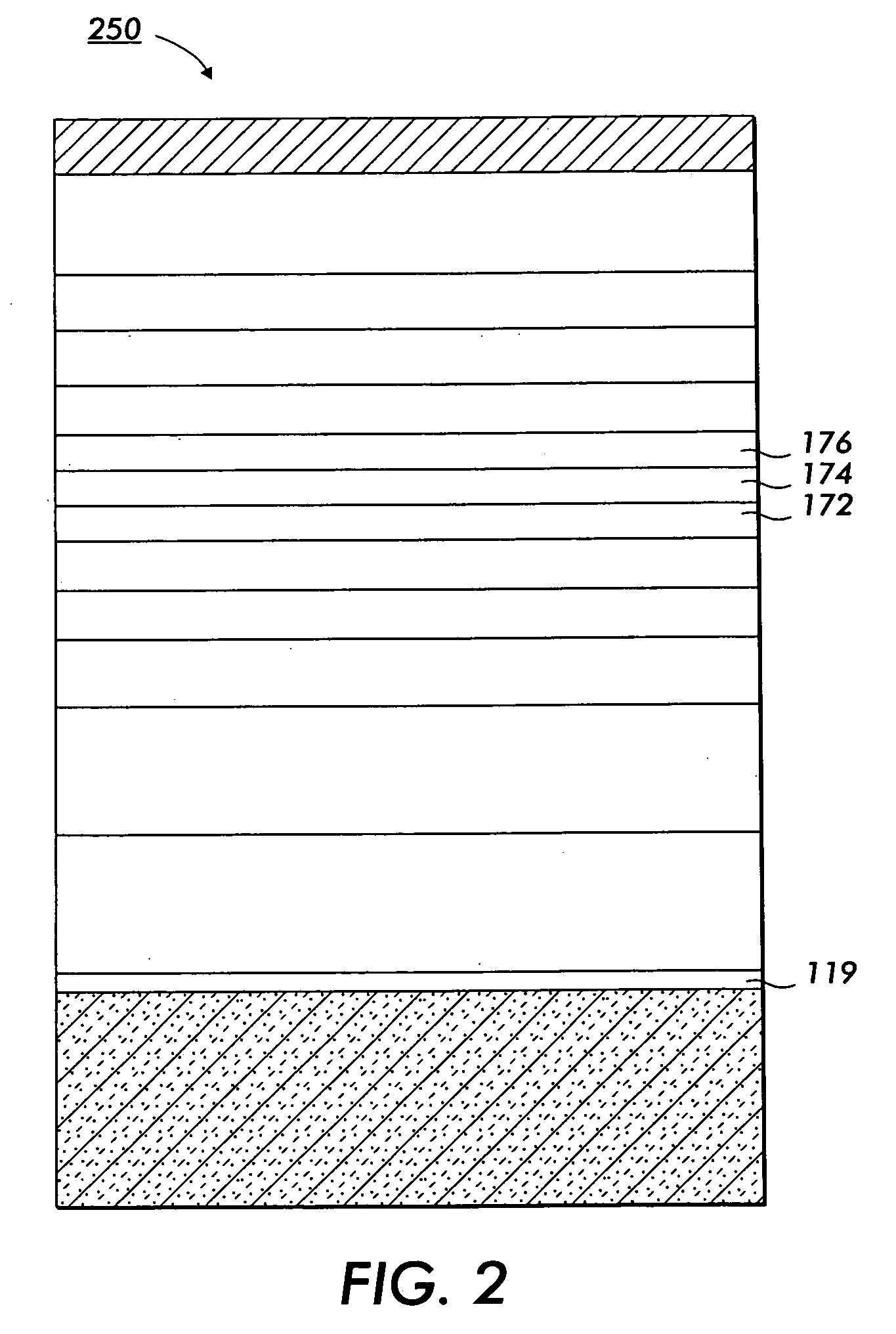

Image

Examples

Embodiment Construction

[0037] The short diffusion length of carriers in gallium nitride heterostructures requires that the carrier donor sites be located very near the quantum well active region, so that the carriers reach the active region before recombining. However, magnesium doping of a GaN heterostructure, which provides the positively-charged carriers (i.e., holes), has a very high ionization energy. For example, the ionization energy for Mg acceptor atoms in GaN is about 200 meV. As a result, for an Mg acceptor concentration of about 1020 atoms per cm3, only 1018 holes per cm3 are obtained. Furthermore, the Mg ionization energy in AlGaN compounds increases with increasing Al content at a rate of about 3 meV per percent mole fraction of aluminum, requiring even more donor atoms per generated carrier. Because only 1% of the donor atoms are ionized to produce a charge carrier, very high doping levels must be implemented in GaN or AlGaN films to generate sufficient carrier densities to produce gain.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com