Patents

Literature

175results about How to "Good chemical and thermal stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aqueous emulsion polymerization of fluorinated monomers using a perfluoropolyether surfactant

The invention relates to an aqueous emulsion polymerization of fluorinated monomers using perfluoropolyethers of the following formula (I) or (II). In particular, the perfluoropolyether surfactants correspond to formula (I) or (II) CF3—(OCF2)m—O—CF2—X (I) wherein m has a value of 1 to 6 and X represents a carboxylic acid group or salt thereof, CF3—O—(CF2)3—(OCF(CF3)—CF2)z—O-L-Y (II) wherein z has a value of 0, 1, 2 or 3, L represents a divalent linking group selected from —CF(CF3)—, —CF2— and —CF2CF2— and Y represents a carboxylic acid group or salt thereof. The invention further relates to an aqueous dispersion of a fluoropolymer having the aforementioned perfluoropolyether surfactant(s).

Owner:3M INNOVATIVE PROPERTIES CO

Aqueous emulsion polymerization of fluorinated monomers using a fluorinated surfactant

InactiveUS20070015866A1Low toxicityGood chemical stabilityLiquid surface applicatorsFibre treatmentEmulsion polymerizationEther

The present invention provides an aqueous emulsion polymerization of fluorinated monomers including gaseous fluorinated monomers using a perfluoro ether surfactant as an emulsifier. The perfluoro ether surfactants correspond to formula (I) Rf—O—CF2CF2—X (I) wherein Rf represents a linear or branched perfluoroalkyl group having 1, 2, 3 or 4 carbon atoms and X represents a carboxylic acid group or salt thereof. In a further aspect, the invention also provides an aqueous fluoropolymer dispersion comprising the perfluoro ether surfactant and the use of such dispersion in the coating or impregnation of substrates.

Owner:3M INNOVATIVE PROPERTIES CO

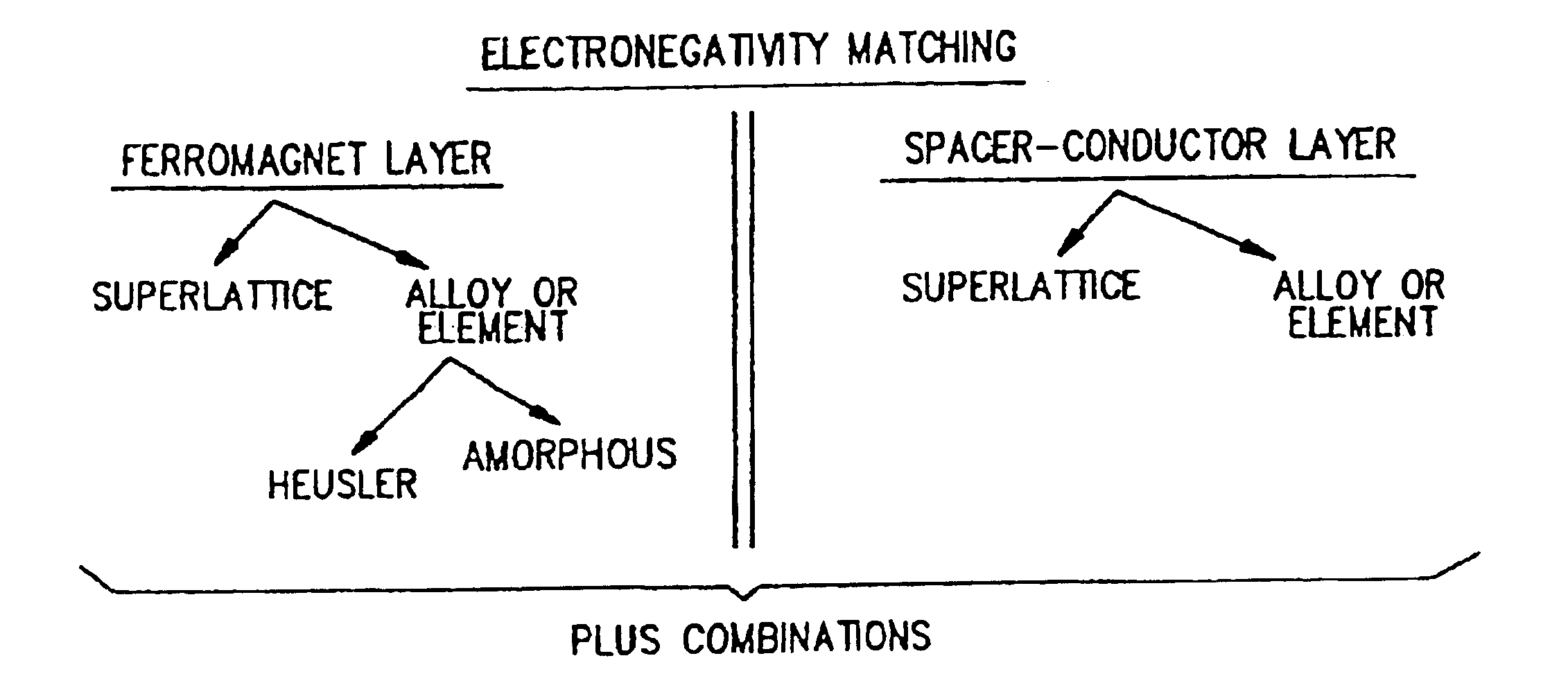

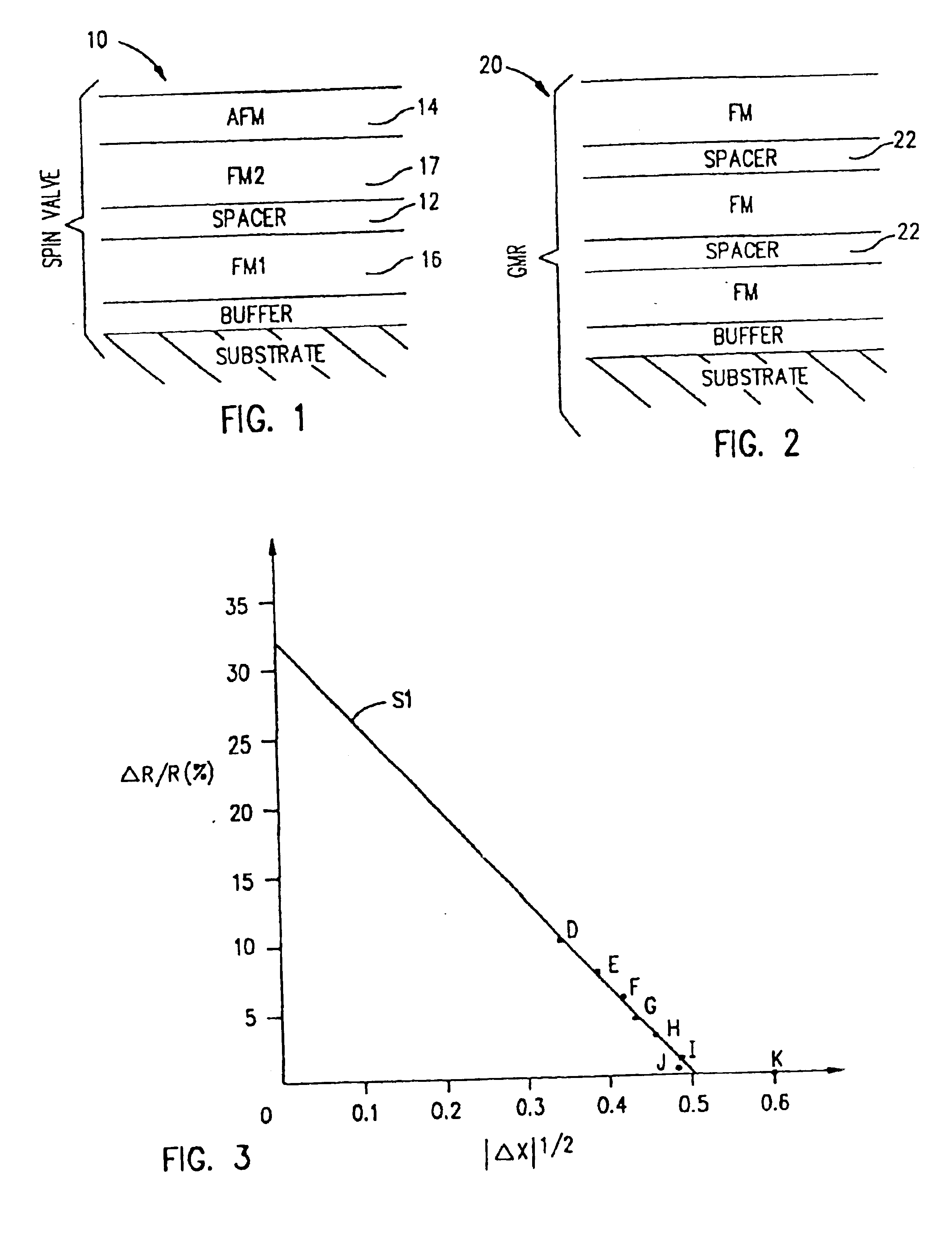

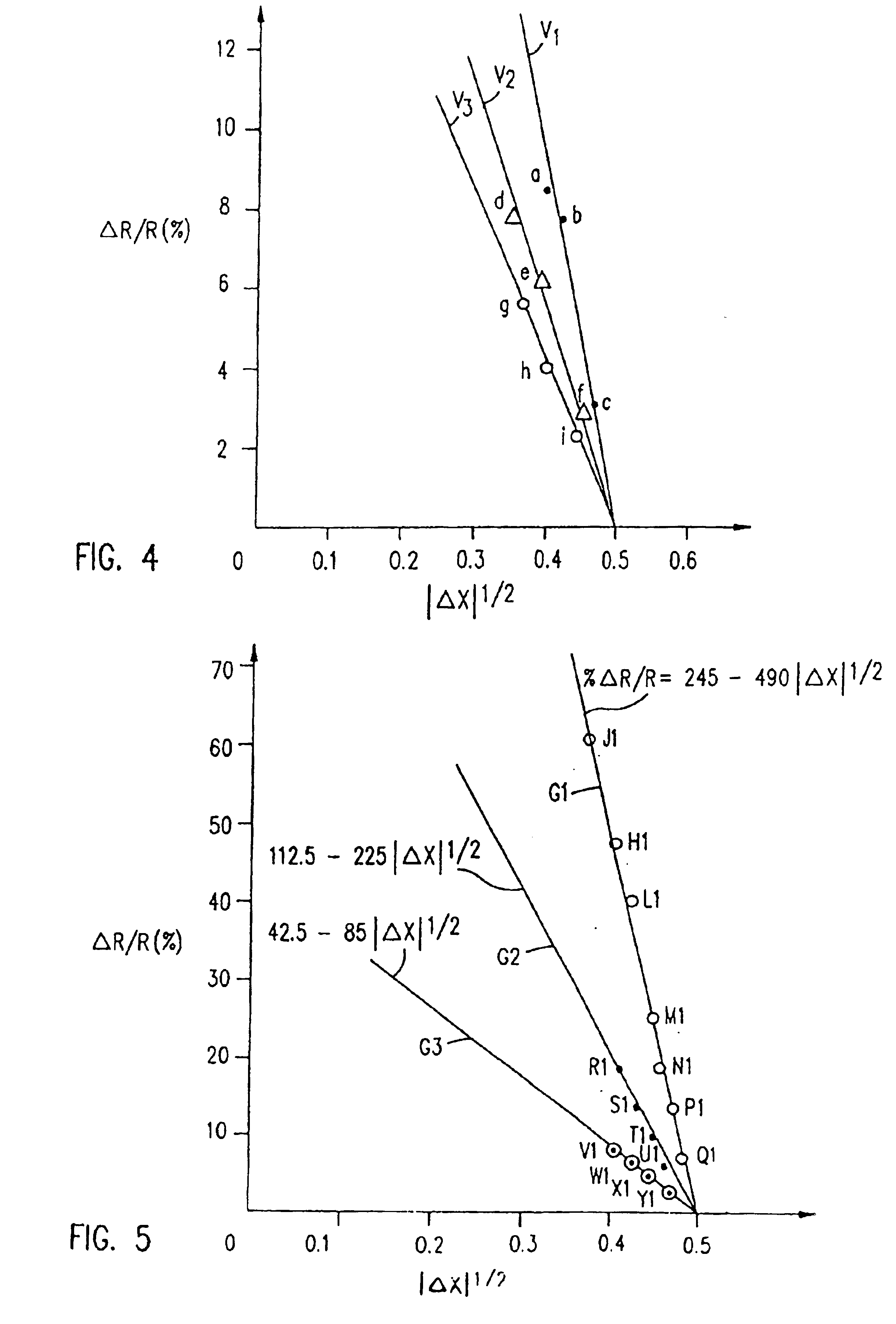

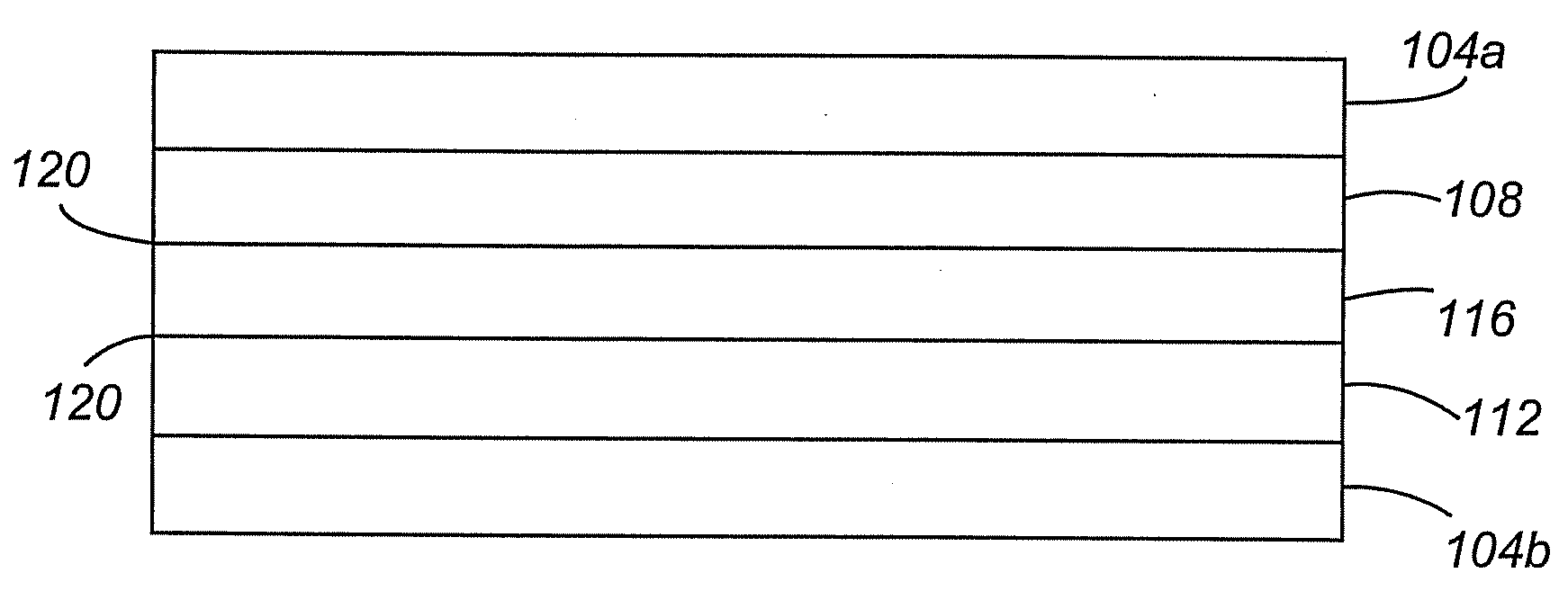

Methods and compositions for optimizing interfacial properties of magnetoresistive sensors

InactiveUS6828897B1Minimize electromigrationExtended service lifeNanomagnetismFixed microstructural devicesMean free pathElectronegativity

A method for maximizing the interfacial properties of magnetoresistive sensors, such as spin valve and GMR sensors used in storage devices, comprises selecting the materials for ferromagnetic layers and for electrically conductive spacers that are interposed between the ferromagnetic layers. The electronegativities of the selected materials are substantially matched so that an absolute value of the differences in electronegativities is minimized. The conductive spacer material provides a relatively low resistivity and a large mean free path. The sensors experience greater chemical and thermal stability, are corrosion resistant, and realize an increased signal output.

Owner:WESTERN DIGITAL TECH INC

High performance ultracapacitors with carbon nanomaterials and ionic liquids

InactiveUS20080192407A1Excellent electrolyte accessibilityImprove performanceHybrid capacitor electrolytesElectrolytic capacitorsSupercapacitorCarbon nanomaterials

The present invention is directed to the use of carbon nanotubes and / or electrolyte structures comprising ionic liquids in various electrochemical devices, such as ultracapacitors.

Owner:ADA TECH

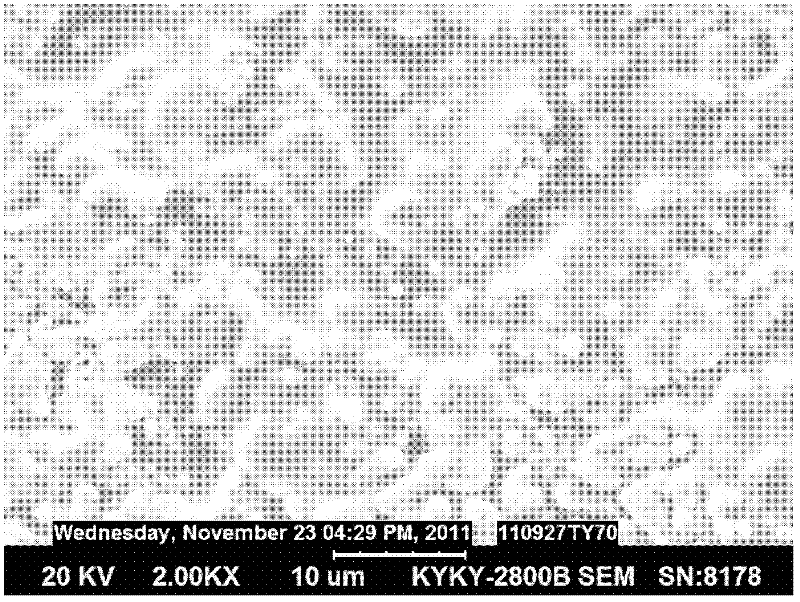

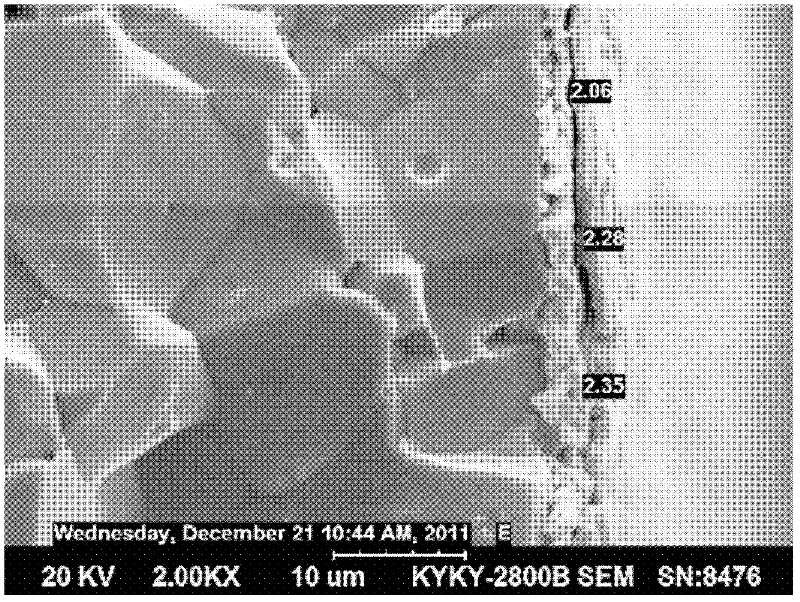

Microporous Aluminophosphate Molecular Sieve Membranes for Highly Selective Separations

InactiveUS20090114089A1High selectivityGood chemical and thermal stabilityPhosphatesPretreated surfacesChemical stabilityPolymer

The present invention discloses microporous aluminophosphate (AlPO4) molecular sieve membranes and methods for making and using the same. The microporous AlPO4 molecular sieve membranes, particularly small pore microporous AlPO-14 and AlPO-18 molecular sieve membranes, are prepared by three different methods, including in-situ crystallization of a layer of AlPO4 molecular sieve crystals on a porous membrane support, coating a layer of polymer-bound AlPO4 molecular sieve crystals on a porous membrane support, and a seeding method by in-situ crystallization of a continuous second layer of AlPO4 molecular sieve crystals on a seed layer of AlPO4 molecular sieve crystals supported on a porous membrane support. The microporous AlPO4 molecular sieve membranes have superior thermal and chemical stability, good erosion resistance, high CO2 plasticization resistance, and significantly improved selectivity over polymer membranes for gas and liquid separations, including carbon dioxide / methane (CO2 / CH4), carbon dioxide / nitrogen (CO2 / N2), and hydrogen / methane (H2 / CH4) separations.

Owner:UOP LLC

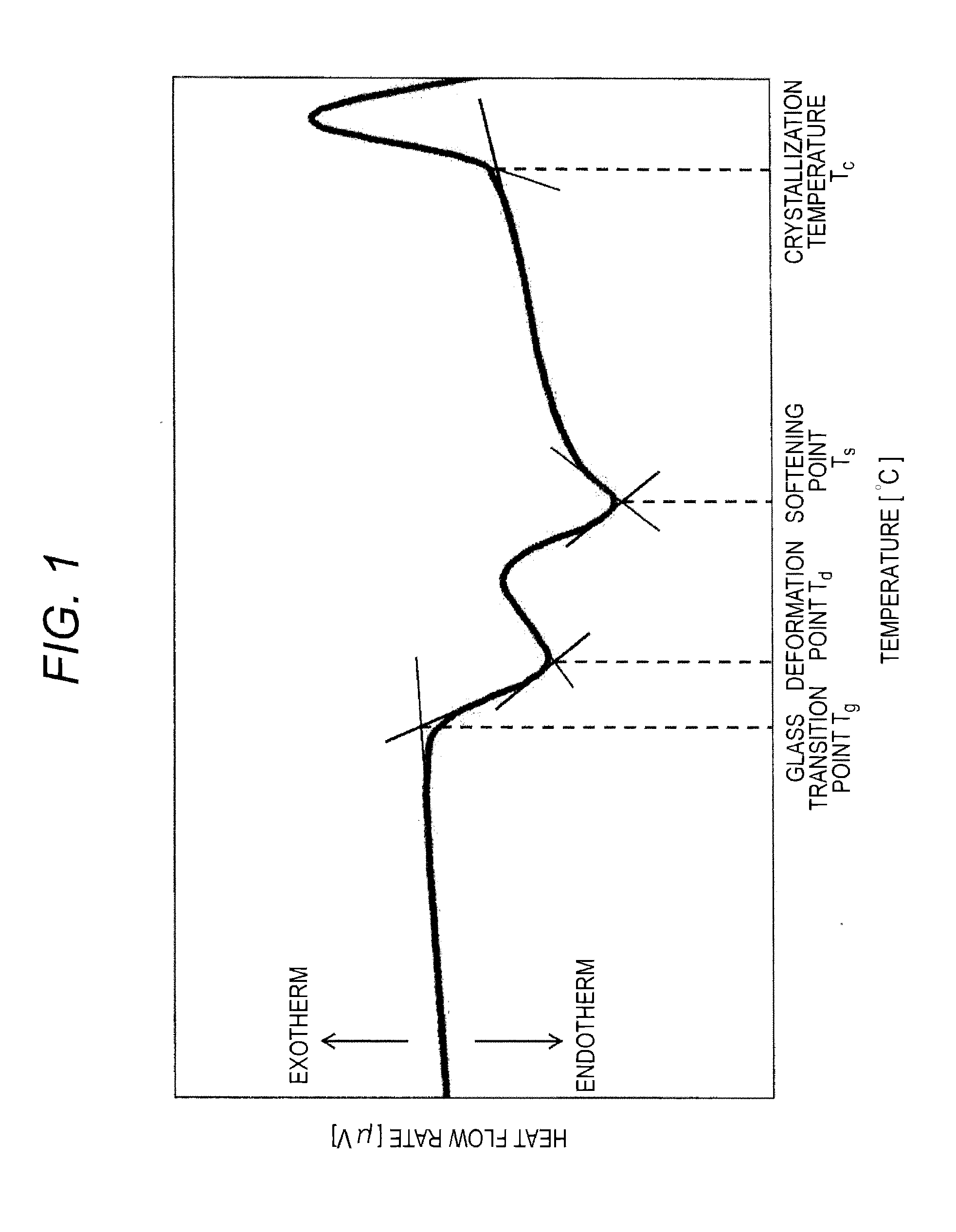

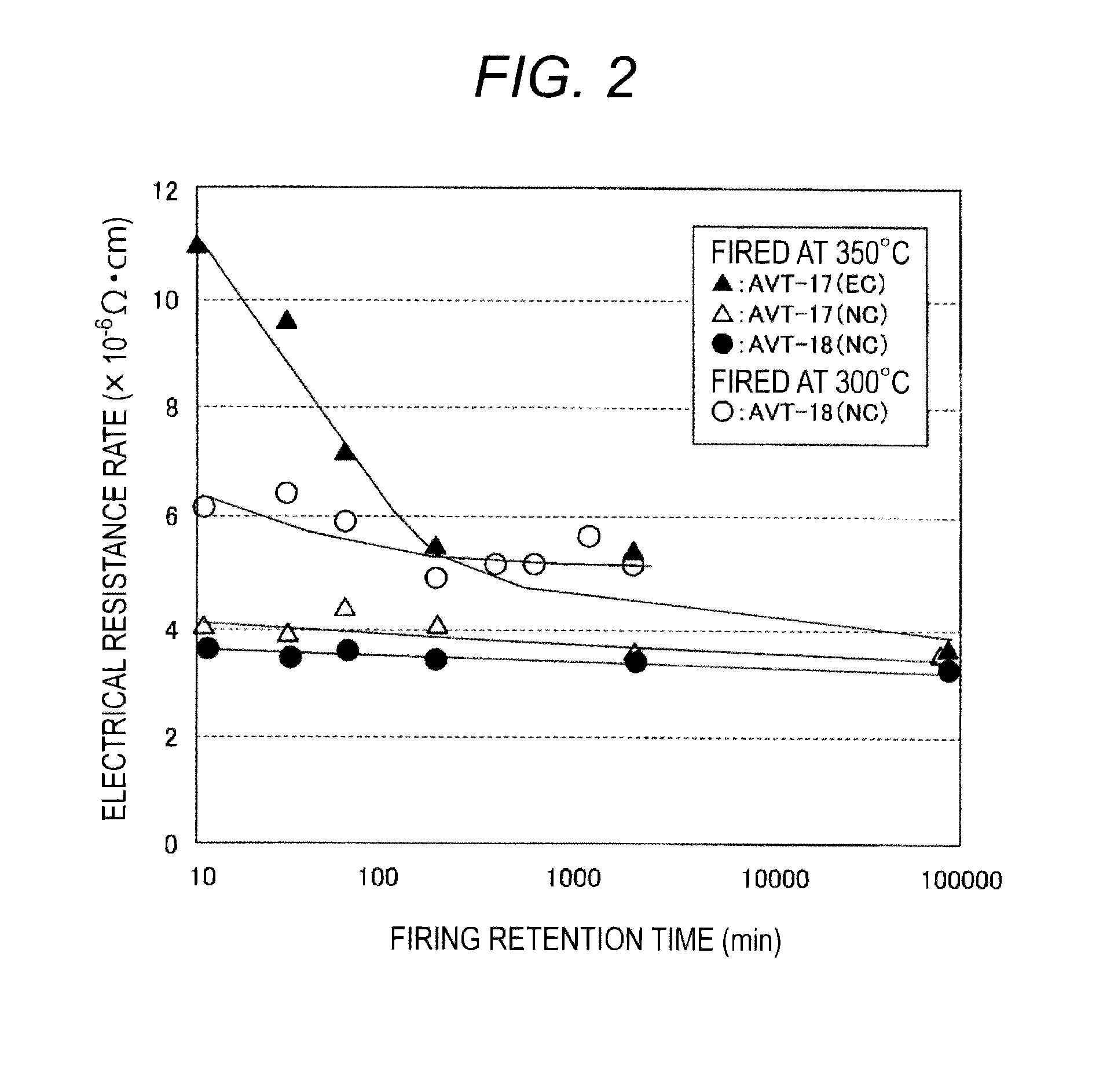

Glass composition, glass frit containing same, glass paste containing same, and electrical/electronic component obtained using same

ActiveUS20140145122A1Improve thermal stabilityGood chemical stabilityCathode-ray/electron-beam tube leading-in arrangementsSemiconductor/solid-state device detailsFritThermal stability

The present invention aims at providing a lead-free glass composition that can be soften and flowed at a firing temperature that is equal to or lower than that of conventional low melting point lead glass. Furthermore, the present invention aims at providing a lead-free glass composition having fine thermal stability and fine chemical stability in addition to that property. The lead-free glass composition according to the present invention is characterized by comprising at least Ag2O, V2O5 and TeO2 when the components are represented by oxides, wherein the total content ratio of Ag2O, V2O5 and TeO2 is 75 mass % or more. Preferably, the lead-free glass composition comprises 10 to 60 mass % of Ag2O, 5 to 65 mass % of V2O5, and 15 to 50 mass % of TeO2.

Owner:HITACHI LTD

Lubricating oil composition for chiller

ActiveUS20130012420A1Low global warming potentialGood chemical and thermal stabilityHeat-exchange elementsAdditivesEngineeringOrganic compound

It is to provide a lubricating oil composition for a refrigerating machine that has a low global warming potential, and that is used for a refrigerating machine using a refrigerant having a particular structure, such as an unsaturated fluorinated hydrocarbon compound, which is a refrigerant capable of being used for existing car air conditioner system, air conditioners and the like, and that has excellent compatibility with a refrigerant and excellent thermal and chemical stability, in which the lubricating oil composition is used for a refrigerating machine using a refrigerant containing at least one fluorine-containing organic compound selected from compounds represented by the following molecular formula (A), or a combination of the fluorine-containing organic compound and a saturated fluorinated hydrocarbon compound, and contains a base oil and a sulfur-containing aromatic compound: CpOqFrRs (A), wherein R represents any one of Cl, Br, I and H; p represents an integer of from 1 to 6; q represents an integer of from 0 to 2; r represents an integer of from 1 to 14; and s represents an integer of from 0 to 13, provided that when q is 0, p is from 2 to 6, and at least one carbon-carbon unsaturated bond is contained in the molecule.

Owner:IDEMITSU KOSAN CO LTD

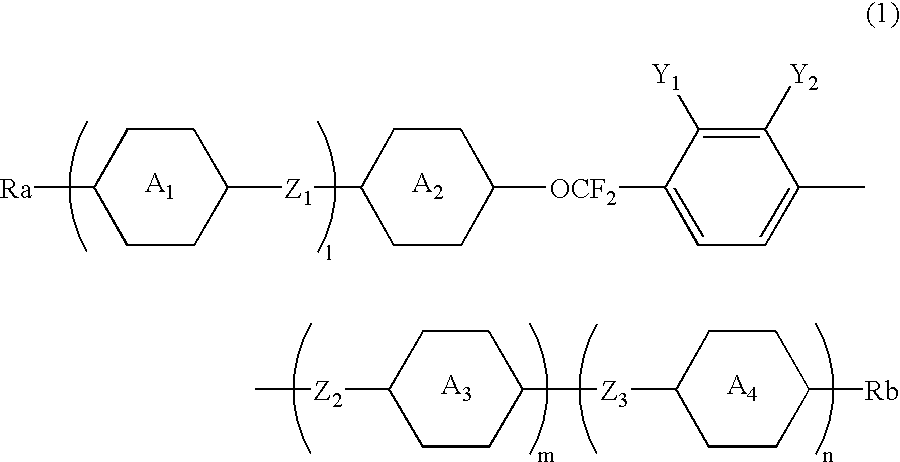

2,3-difluorophenyl derivative having negative dielectric anisotropy, liquid crystal composition, and liquid crystal display device

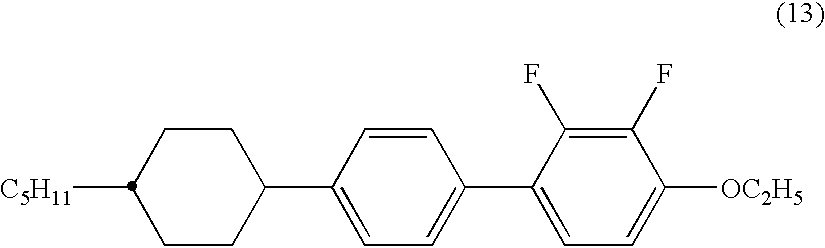

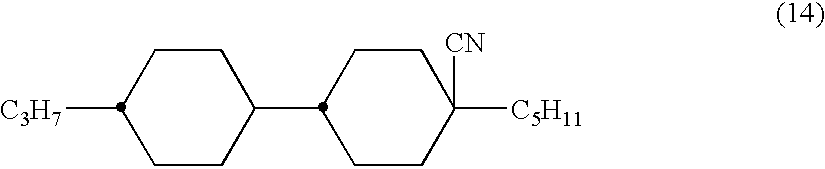

InactiveUS6548126B1Good compatibilityIncrease resistanceLiquid crystal compositionsOrganic chemistryLiquid crystallineCrystallography

The invention is to provide liquid crystalline compounds having a negative and extremely large dielectric anisotropy value and a small optical anisotropy value at the same time; liquid crystal compositions comprising the compound; and liquid crystal display devices fabricated by using the liquid crystal composition; the liquid crystalline compounds have 2,3-dihalogenophenylene moiety and are expressed by formula (1)wherein Ra and Rb each independently represents a linear or branched alkyl having 1 to 10 carbon, any methylene in the alkyl may be replaced by -O-, -S-, -CH=CH-, or -C=C-, but -O- is not successive, and any hydrogen in the alkyl may be replaced by halogen; rings A1 to A4 each independently represents trans-1,4-cyclohexylene, cyclohexene-1,4-diyl, pyridine-1,4-diyl, pyrimidine-2,5-diyl, or 1,4-phenylene, wherein at least one hydrogen in these rings may be replaced by halogen, and any nonadjacent methylene in cyclohexane ring may be replaced by -O-; Y1 and Y2 each independently represents F or Cl; Z1, Z2 and Z3 each independently represents a single bond, -CH2CH2-, -(CH2)4-, -COO-, -OCO-, -CH2O-, -OCH2-, -CF2O-, or -OCF2-; and l, m and n each independently is 0, 1 or 2, and the sum of l+m+n is 3 and less.

Owner:CHISSO CORP

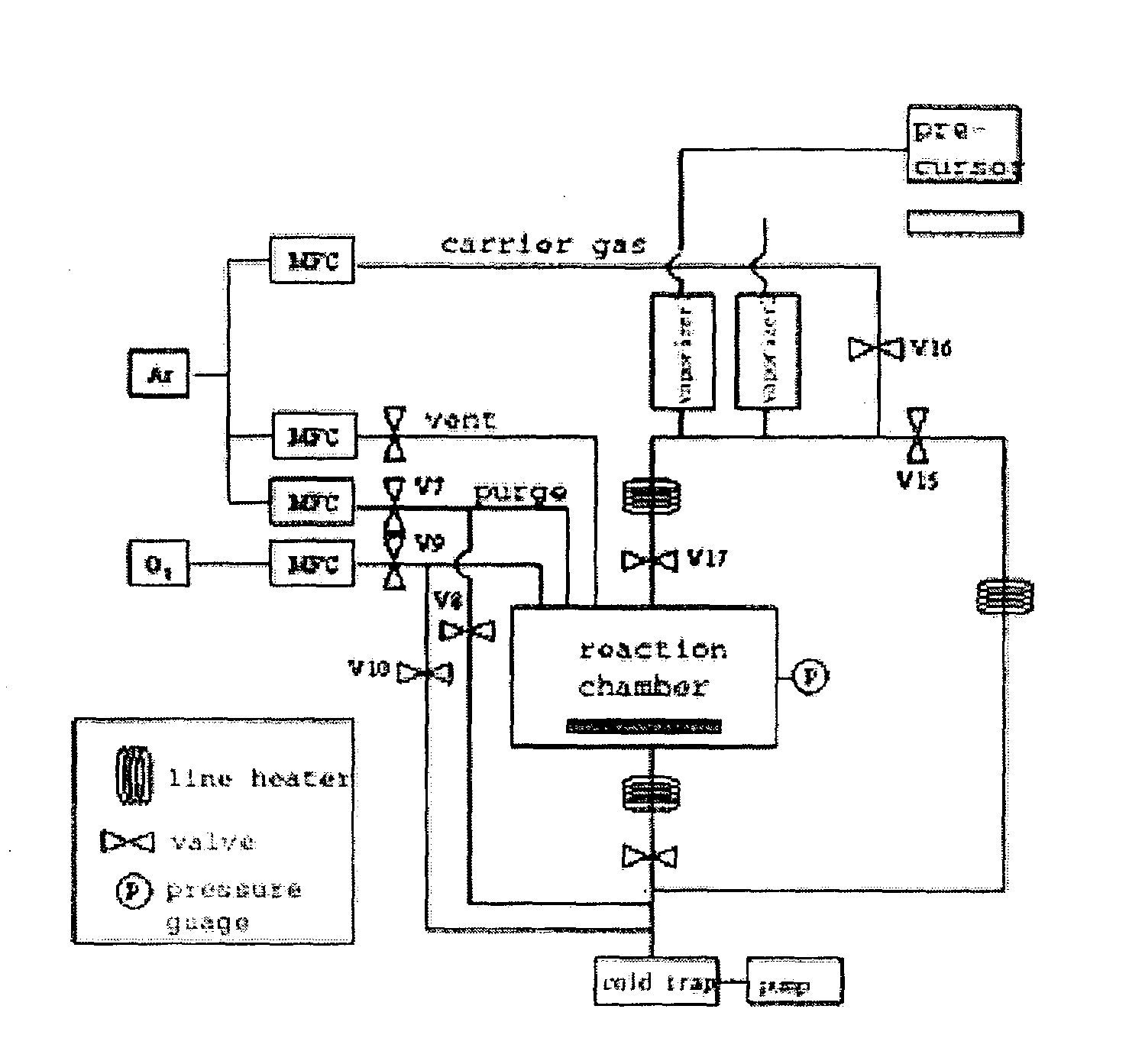

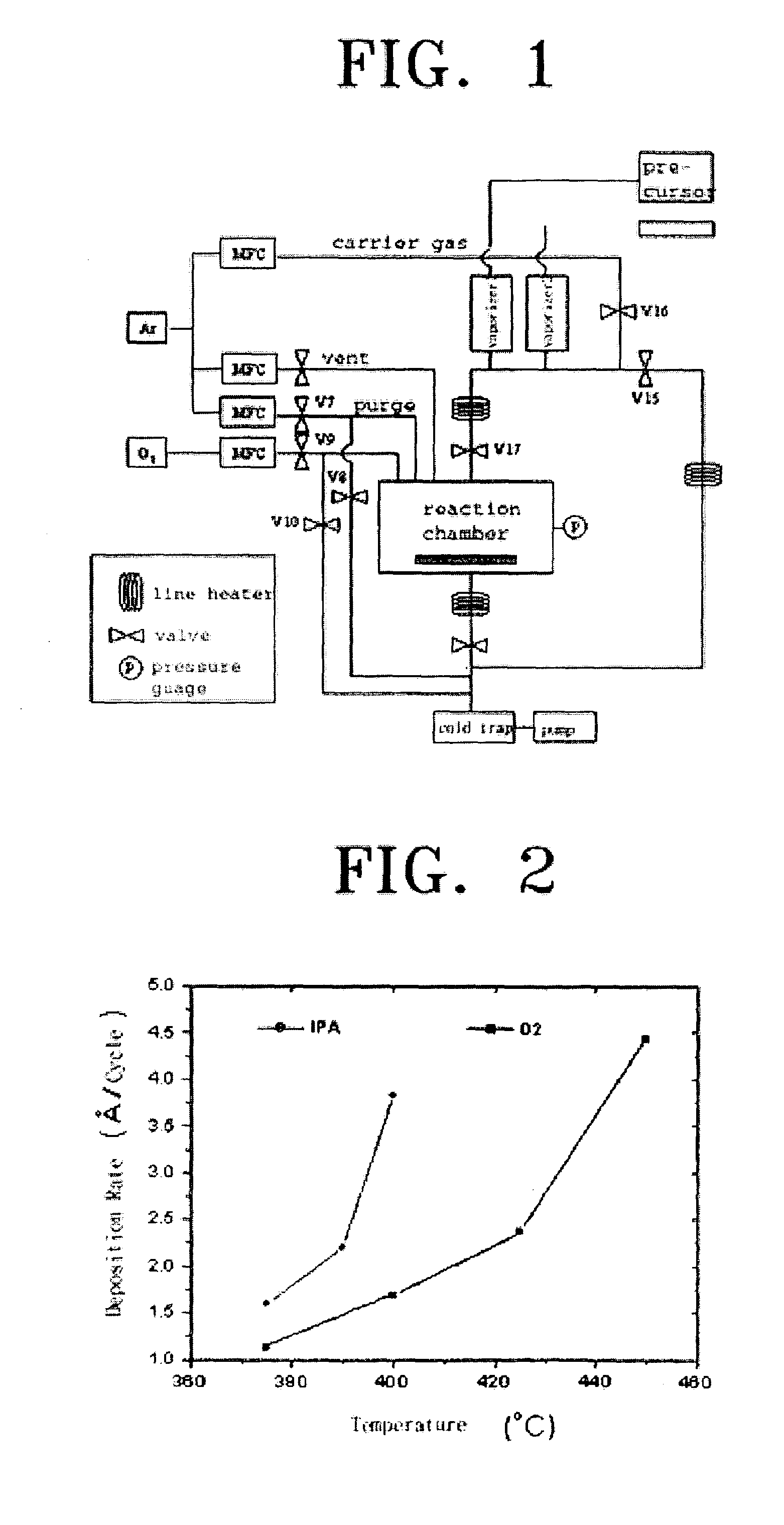

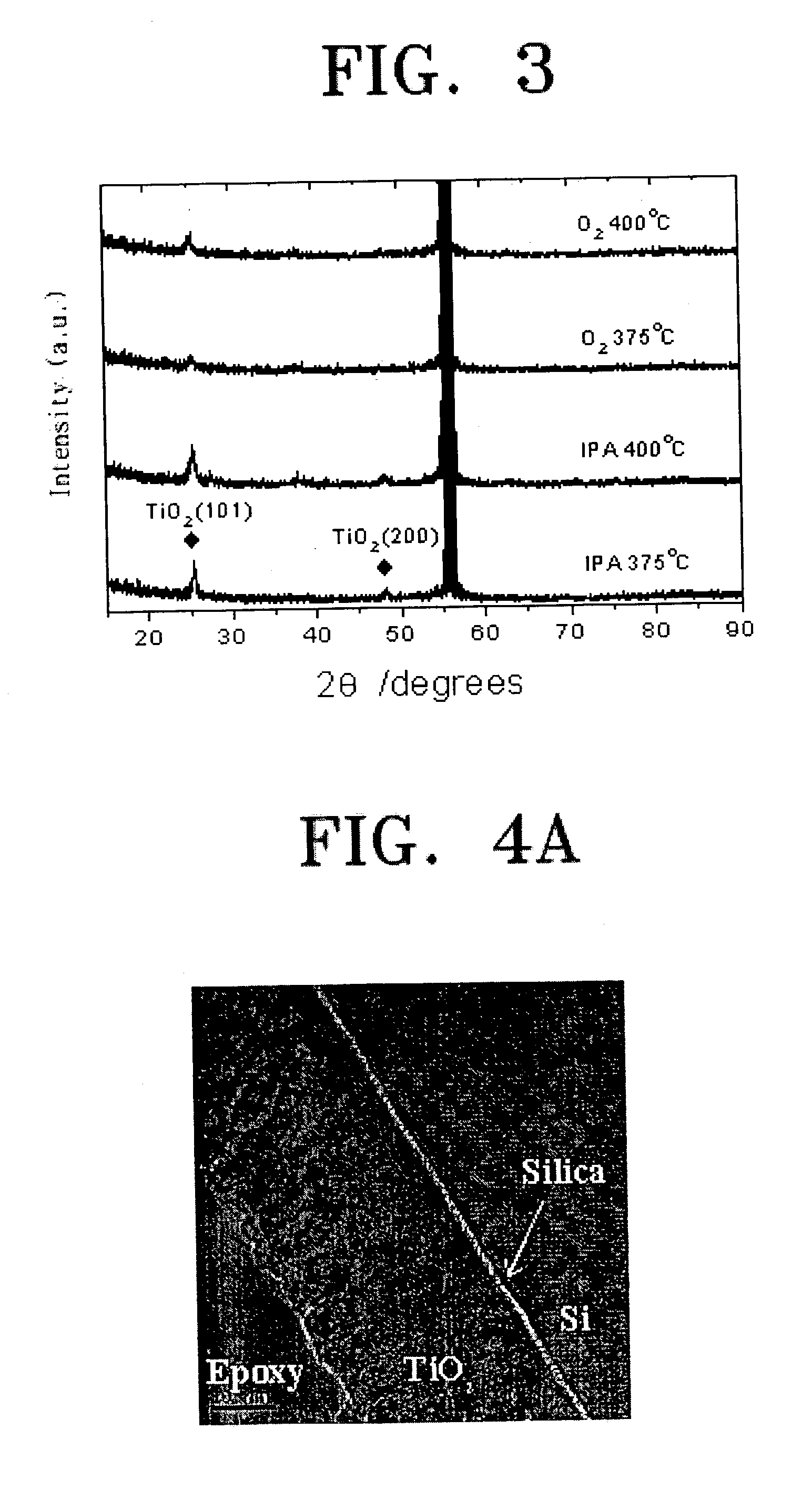

Chemical vapor deposition method using alcohol for forming metal oxide thin film

ActiveUS7135207B2Excellent leakage current characteristicFine microstructureFixed capacitor dielectricSemiconductor/solid-state device manufacturingLow leakageMicrostructure

Provided is a method for fabricating a metal oxide thin film in which a metal oxide generated by a chemical reaction between a first reactant and a second reactant is deposited on the surface of a substrate as a thin film. The method involves introducing a first reactant containing a metal-organic compound into a reaction chamber including a substrate; and introducing a second reactant containing alcohol. Direct oxidation of a substrate or a deposition surface is suppressed by a reactant gas during the deposition process, as it uses alcohol vapor including no radical oxygen as a reactant gas for the deposition of a thin film. Also, since the thin film is deposited by the thermal decomposition, which is caused by the chemical reaction between the alcohol vapor and a precursor, the deposition rate is fast. Particularly, the deposition rate is also fast when a metal-organic complex with β-diketone ligands is used as a precursor. Further, a thin film with low leakage current can be obtained as the metal oxide thin film fabrication method using a chemical vapor deposition or atomic layer deposition method grows a thin film with fine microstructure.

Owner:SAMSUNG ELECTRONICS CO LTD

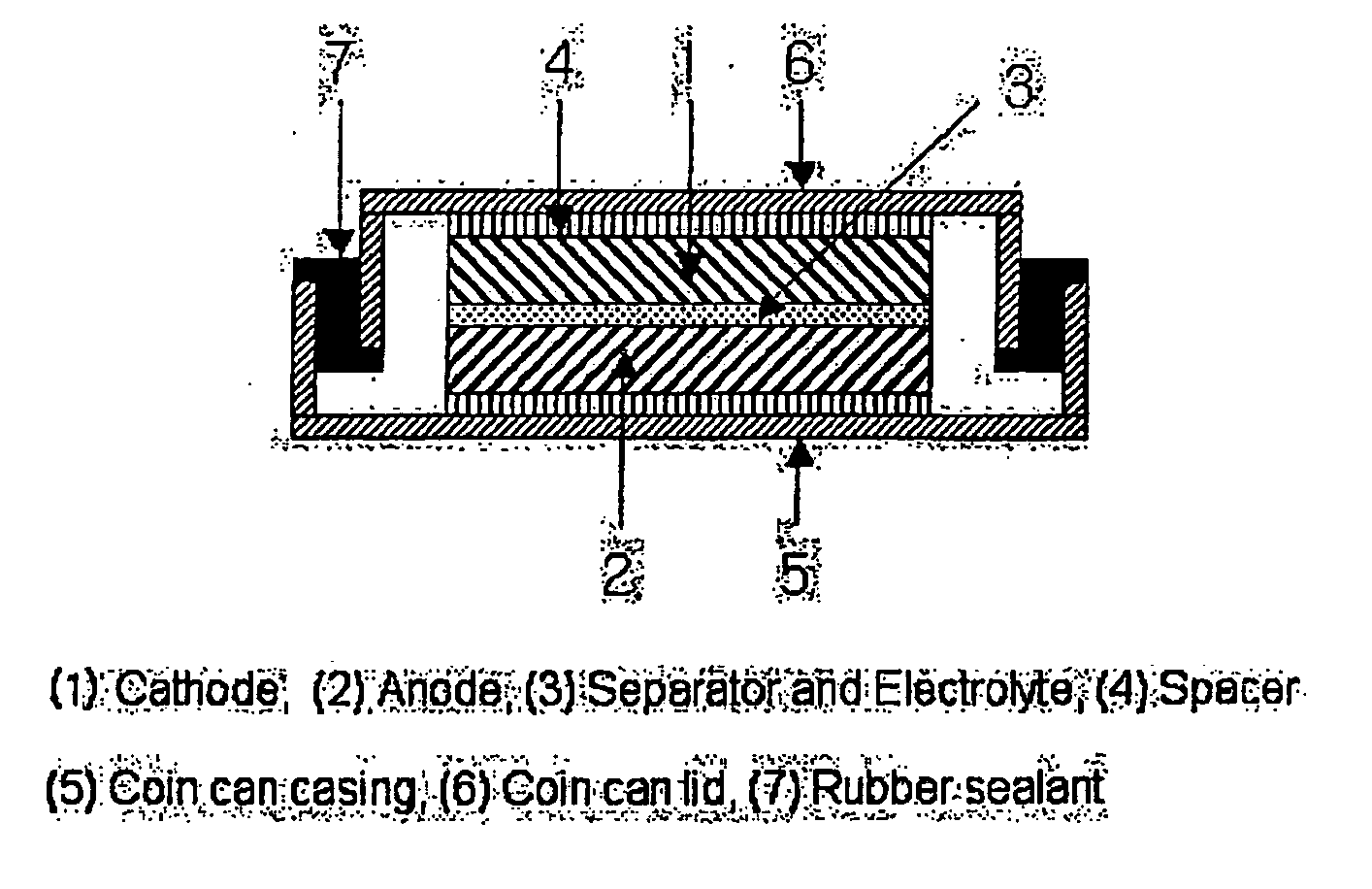

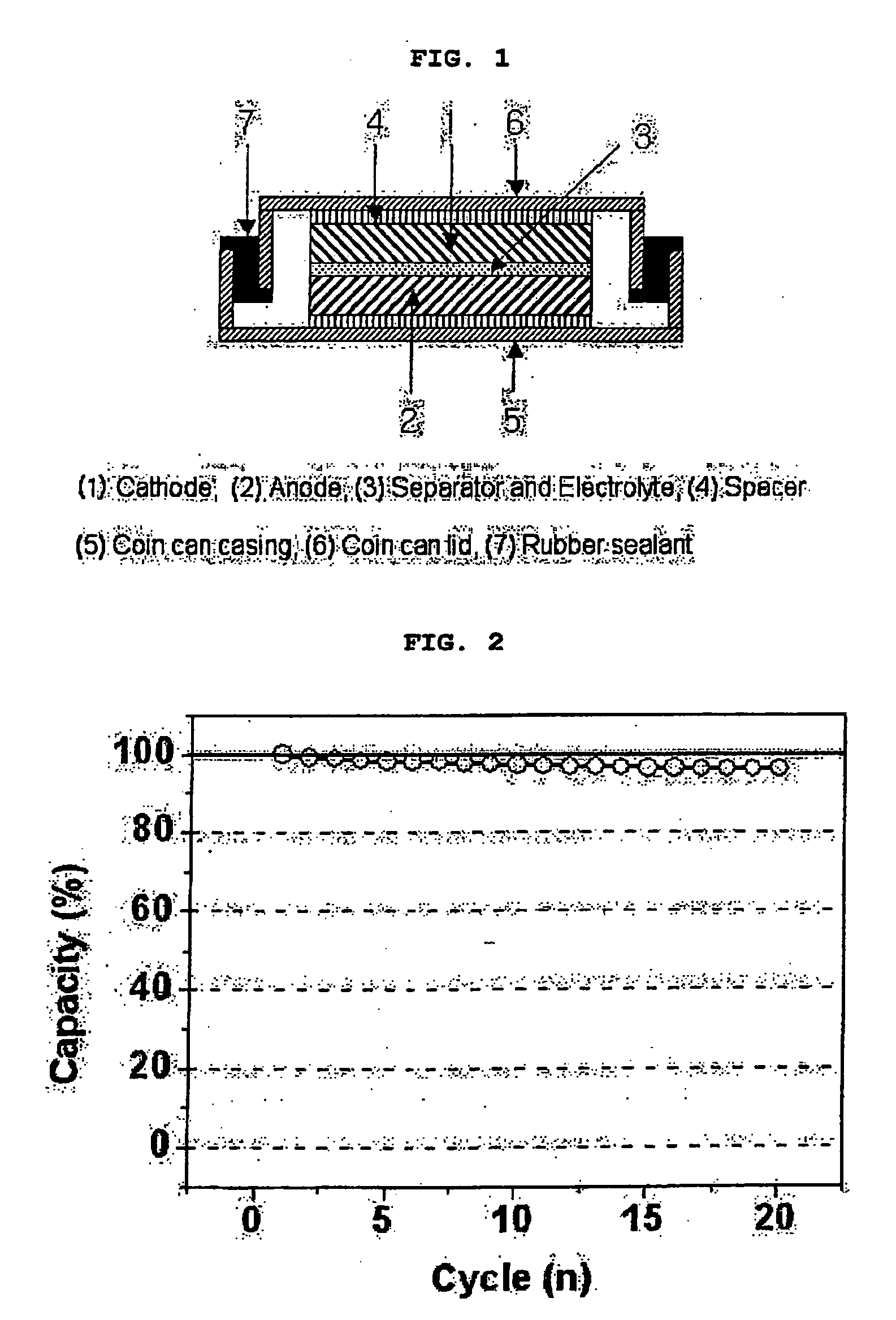

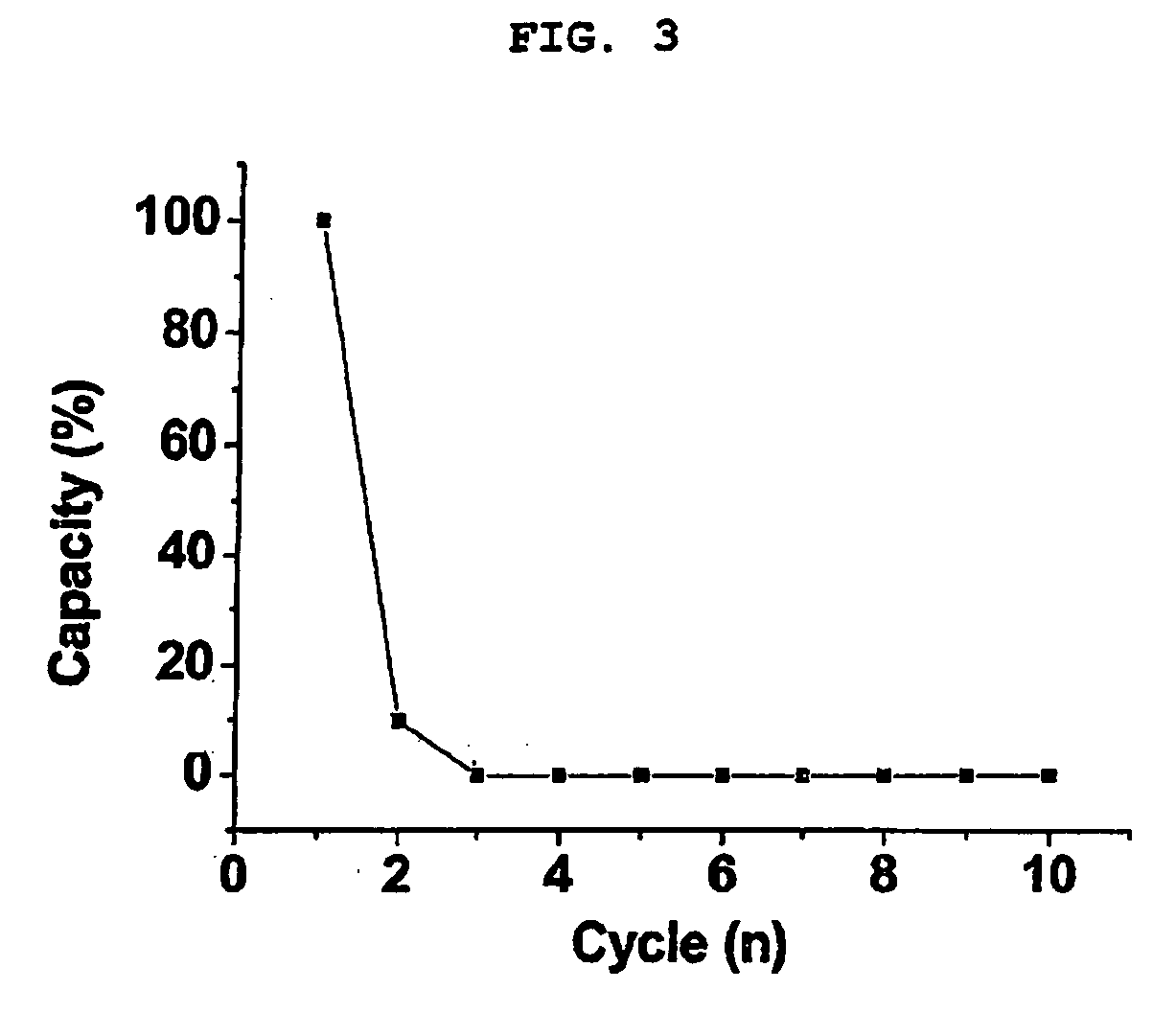

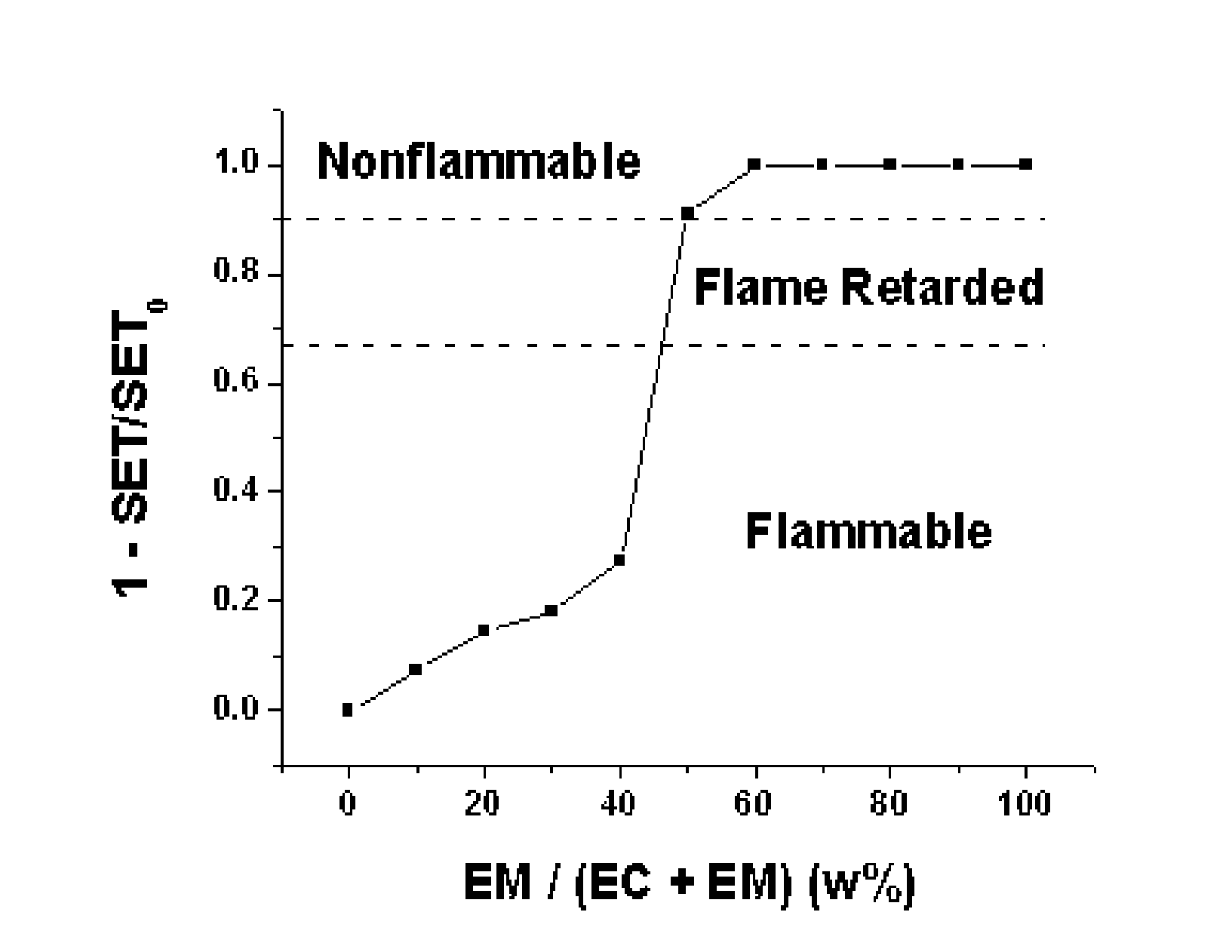

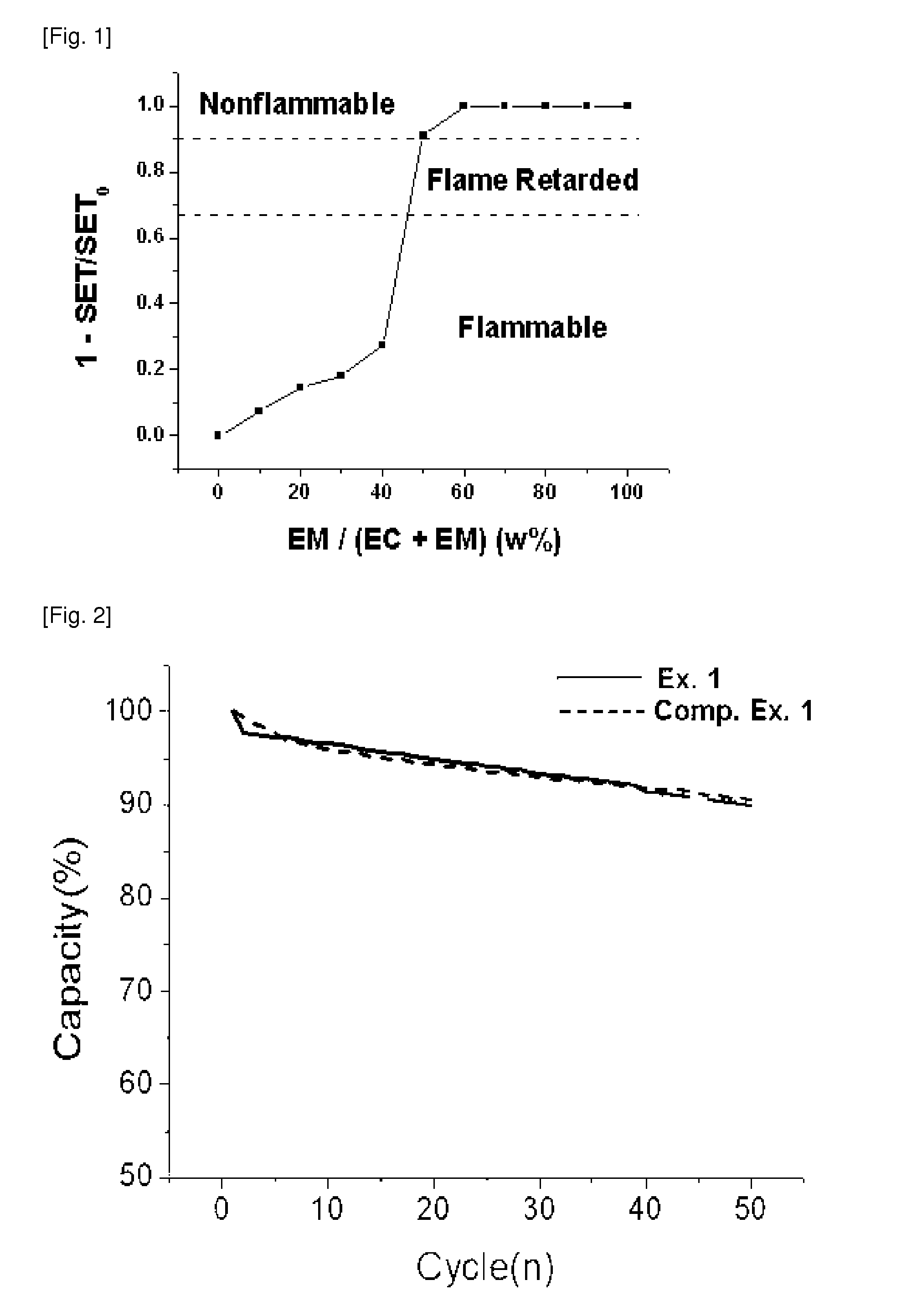

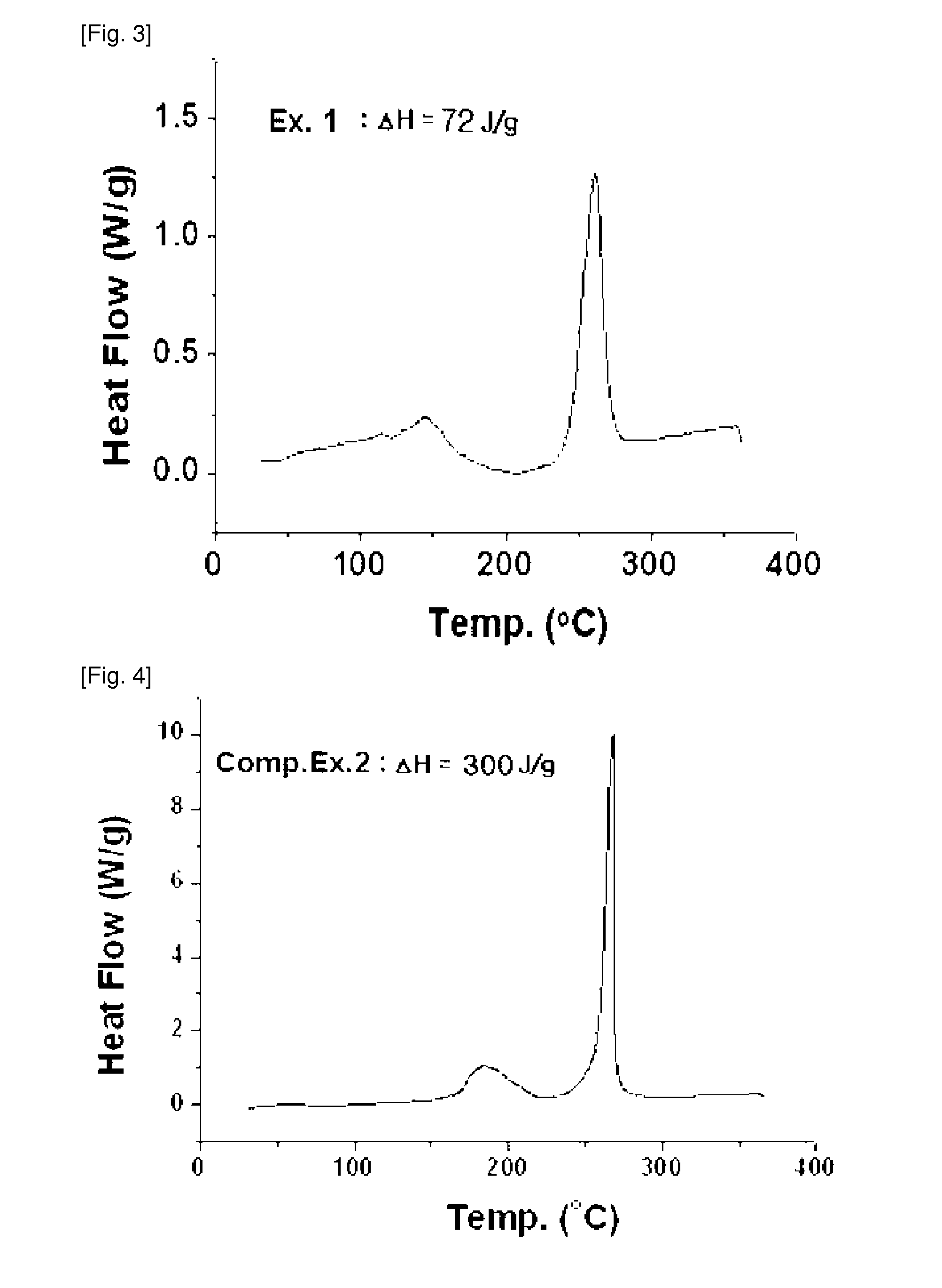

Secondary batteries comprising eutectic mixture and preparation method thereof

InactiveUS20100021815A1Good chemical and thermal stabilityQuality improvementAlkaline accumulatorsLead-acid accumulatorsLithiumLower limit

Disclosed is a secondary battery comprising a cathode, an anode, a separator and an electrolyte, wherein the electrolyte comprises: (a) a eutectic mixture; and (b) a first compound reduced at a higher potential vs. lithium potential (Li / Li+) than the lowest limit of the electrochemical window of the eutectic mixture. The electrolyte uses a eutectic mixture in combination with an additive reduced in advance of the eutectic mixture upon the initial charge to form a solid electrolyte interface (SEI) layer. Therefore, the electrolyte can solve the problem of electrolyte decomposition occurring when using a eutectic mixture alone as an electrolyte for a battery, and thus can prevent degradation of the quality of a battery.

Owner:LG CHEM LTD

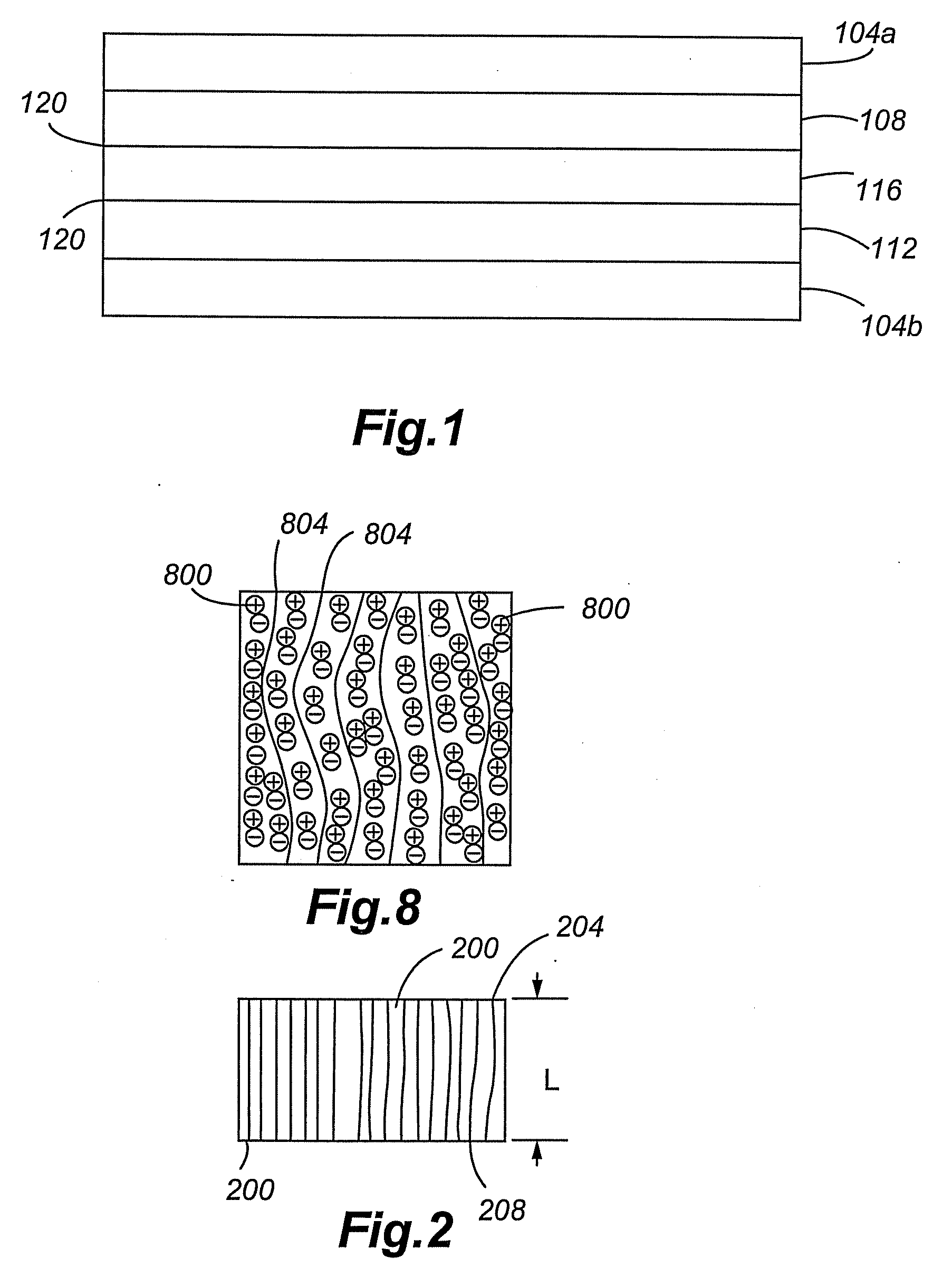

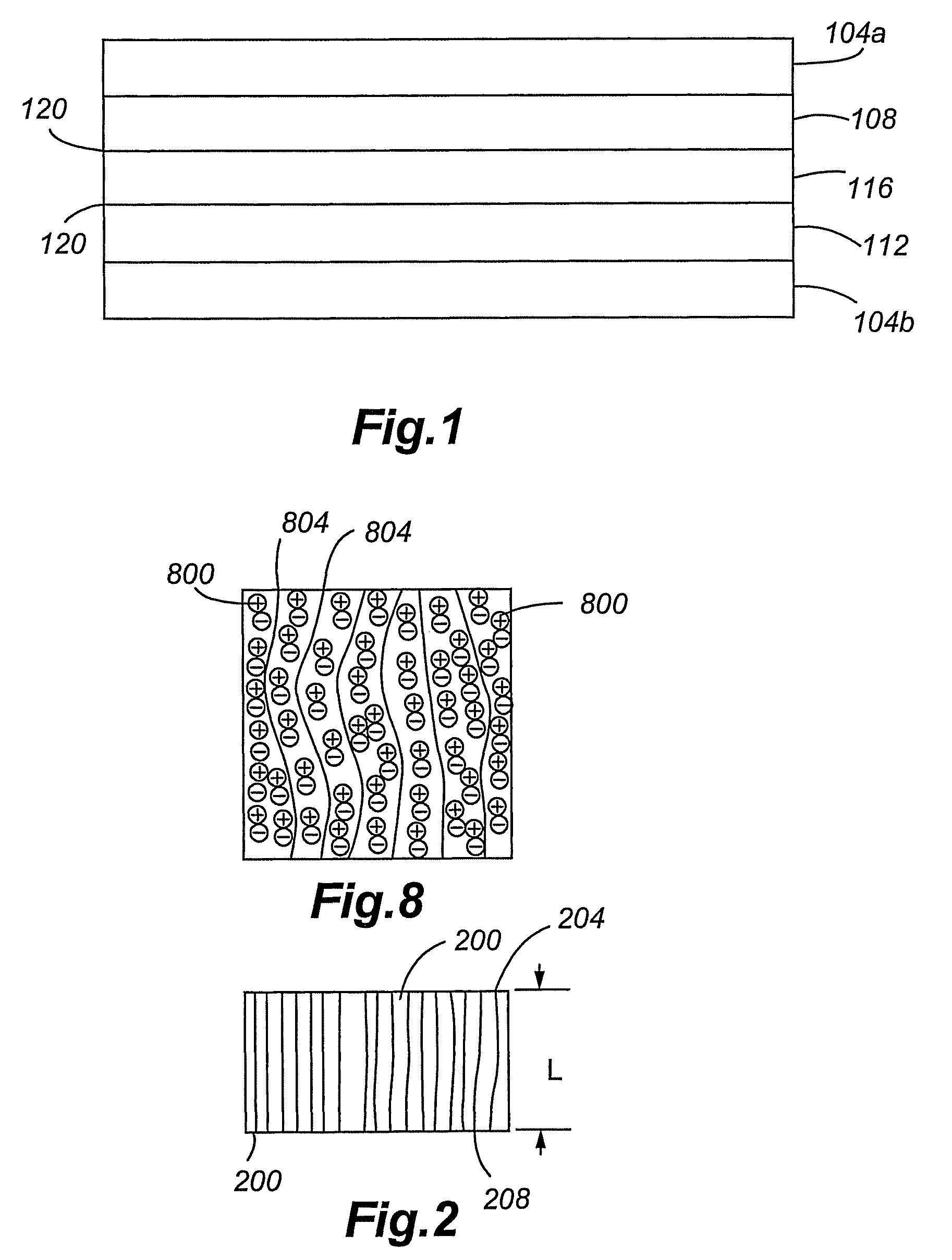

Separator for electrochemical devices

InactiveUS20060040175A1Improve performanceFast and efficient production speedCell seperators/membranes/diaphragms/spacersNon-aqueous electrolyte cellsElectrochemistryElectrochemical cell

A separator for a wound electrochemical device comprising an expanded polytetrafluoroethylene membrane having pores defining an internal surface area, the internal surface area being substantially coated with a pore coating agent, the separator having a longitudinal modulus of greater than 20,000 lbs / in2.

Owner:WL GORE & ASSOC INC

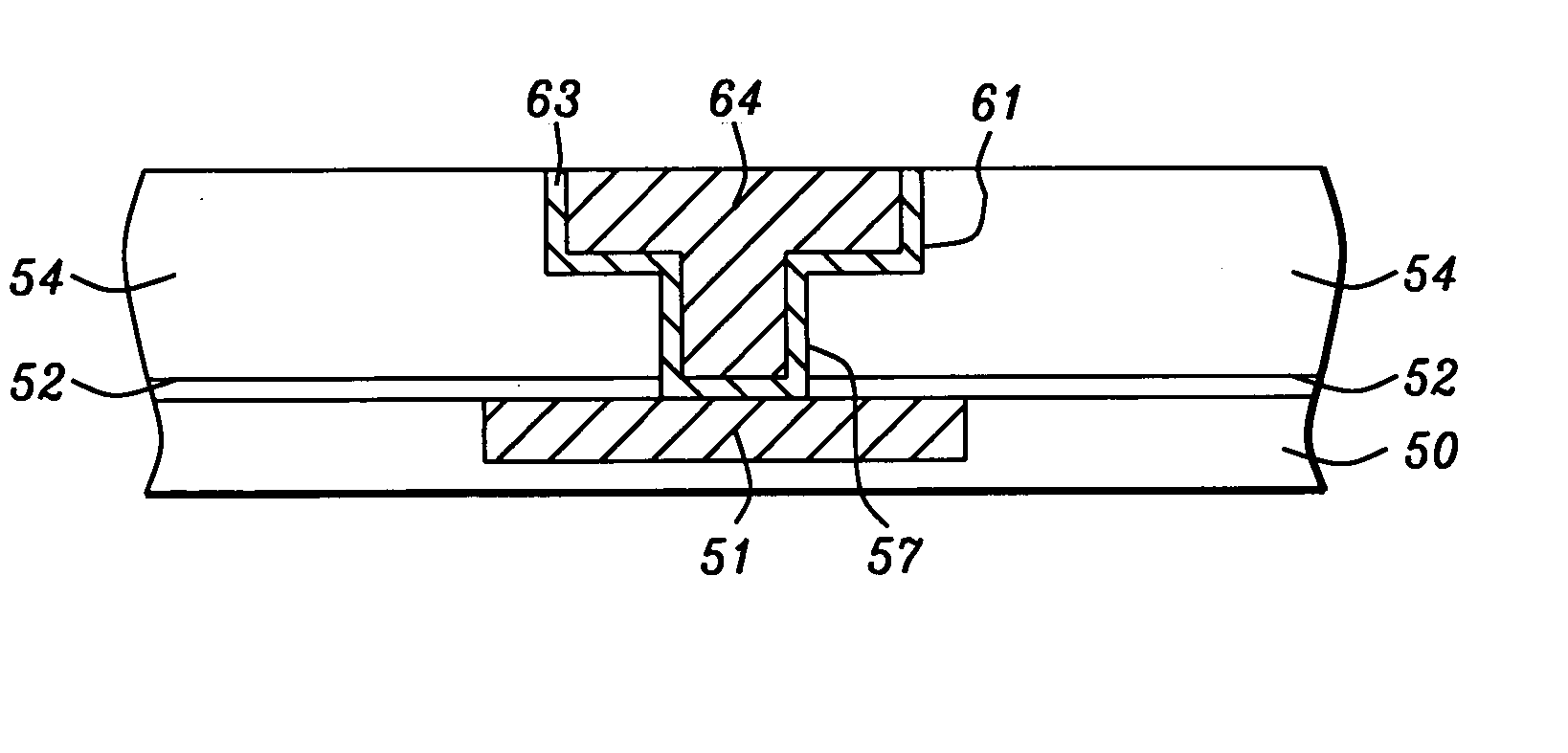

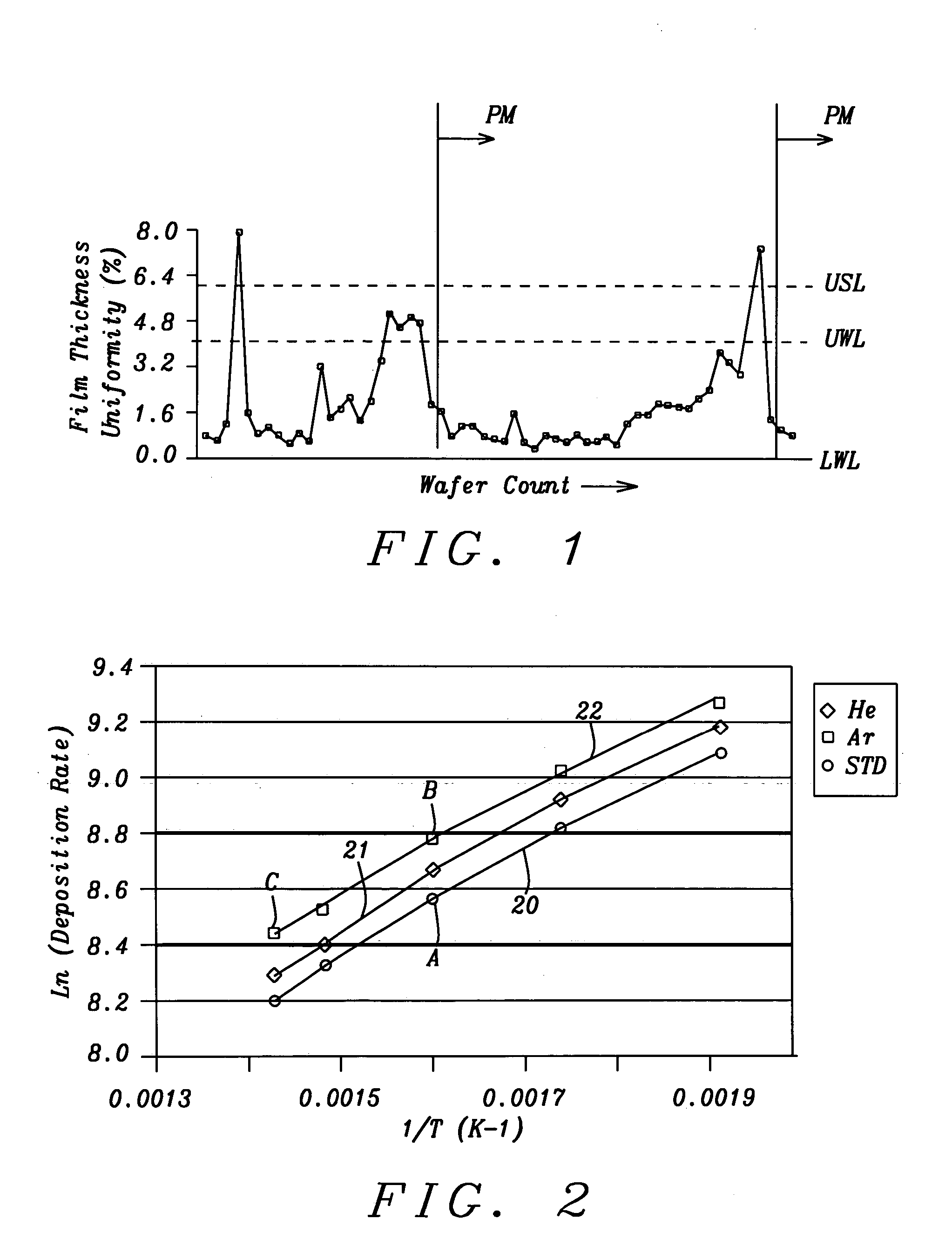

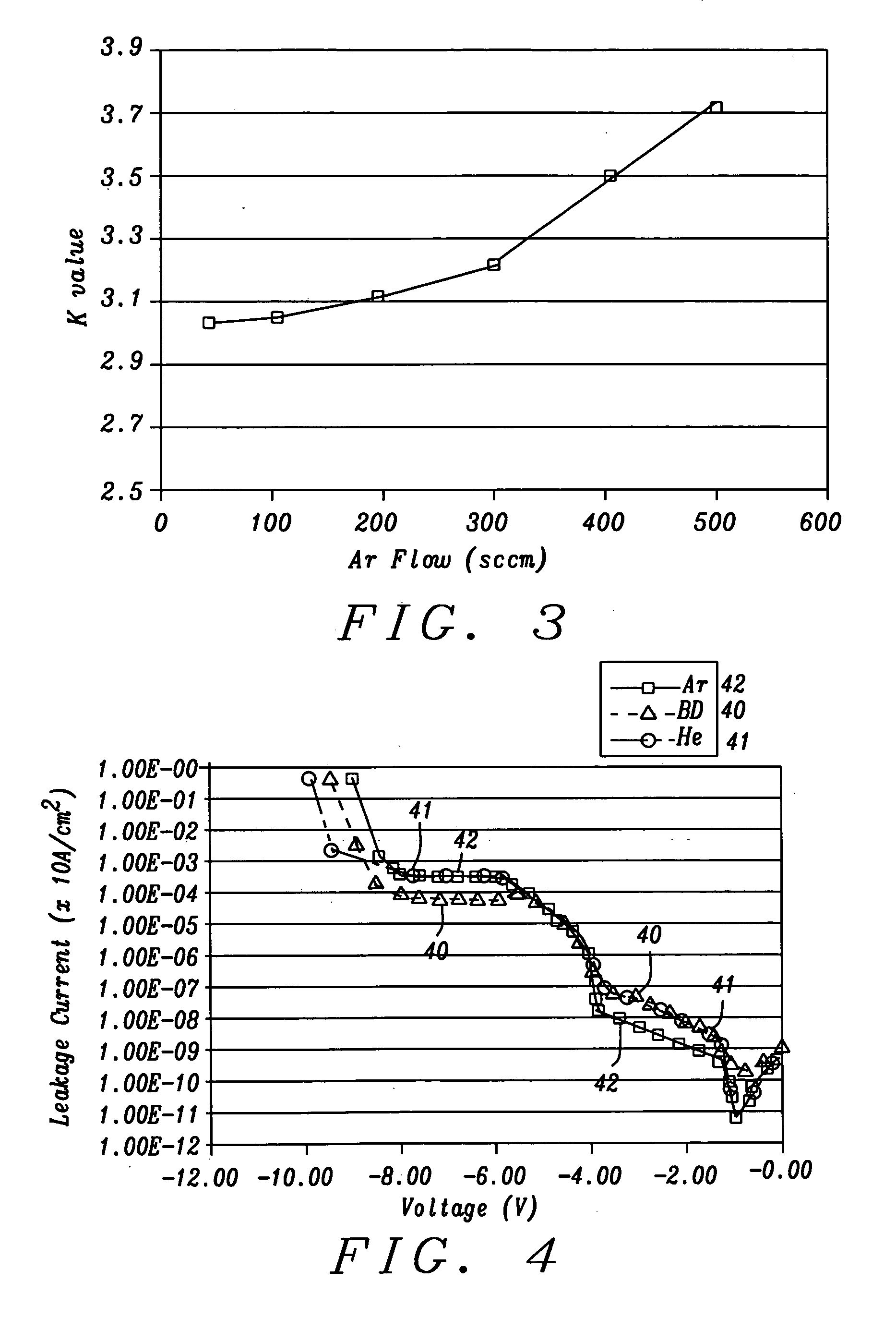

Novel method to deposit carbon doped SiO2 films with improved film quality

InactiveUS20050124151A1Increase deposition rateImprove film thickness uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingMetal interconnectLow leakage

A method is disclosed for depositing a Black Diamond layer in a CVD chamber. Trimethylsilane, O2, and Ar are flowed into the chamber at 300° C. to 400° C. with an O2:Ar:trimethylsilane flow rate ratio that is preferably 1:1.5:6. The resulting low k dielectric layer is formed with a higher deposition rate than when Ar is omitted and has a k value of about 3 that increases only slightly in O2 plasma. A higher density, hardness, and tensile strength are achieved in the Black Diamond layer when Ar is included in the deposition process. The addition of Ar in the deposition maintains film thickness uniformity below 2% for a longer period so that PM cleaning operations are less frequent and affords a lower fluorocarbon plasma etch rate to enable improved trench depth control in a damascene scheme. A lower leakage current and higher breakdown voltage in achieved in the resulting metal interconnect.

Owner:TAIWAN SEMICON MFG CO LTD

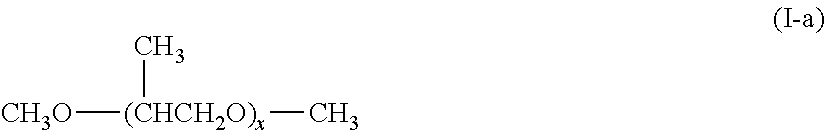

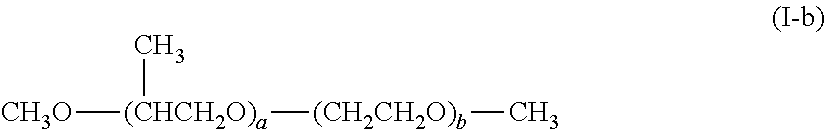

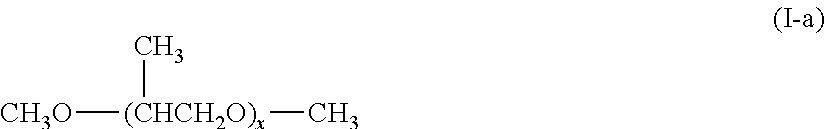

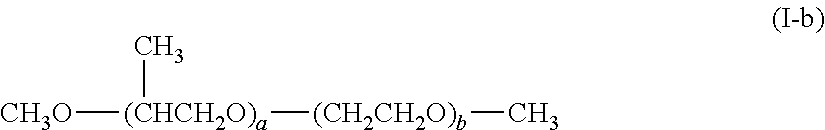

Lubricant oil composition for compression refrigerator

ActiveUS20140135241A1Good chemical and thermal stabilityReduce the numberHeat-exchange elementsAdditivesVinyl etherMethacrylate

The present invention is able to provide a lubricating oil composition for compression refrigerating machine having excellent thermal / chemical stability even when used for a compression refrigerating machine using a saturated fluorinated hydrocarbon refrigerant having a low carbon number and a low global warming potential, by using a refrigerant containing a saturated fluorinated hydrocarbon having from 1 to 3 carbon atoms, which uses, as a base oil, an oxygen-containing organic compound composed of at least one member selected from a polyoxyalkylene glycol, a polyvinyl ether, a copolymer of a poly(oxy)alkylene glycol and a polyvinyl ether, a copolymer of a poly(oxy)alkylene glycol monoether and a polyvinyl ether, and a polyol ester, each having a hydroxyl value of not more than 15 mgKOH / g.

Owner:IDEMITSU KOSAN CO LTD

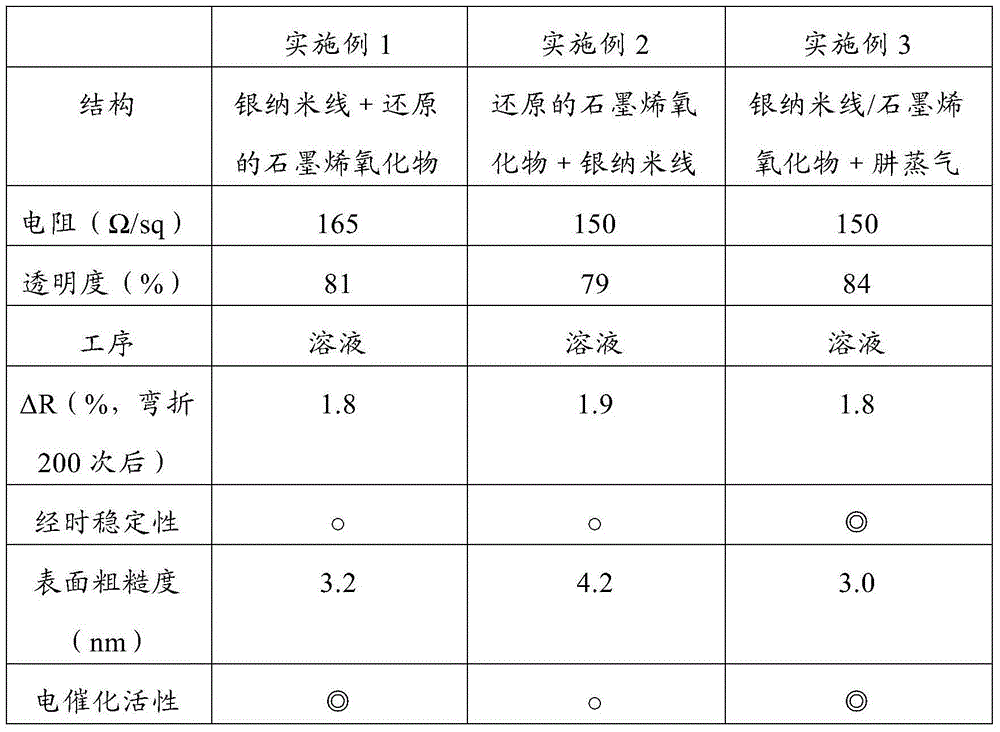

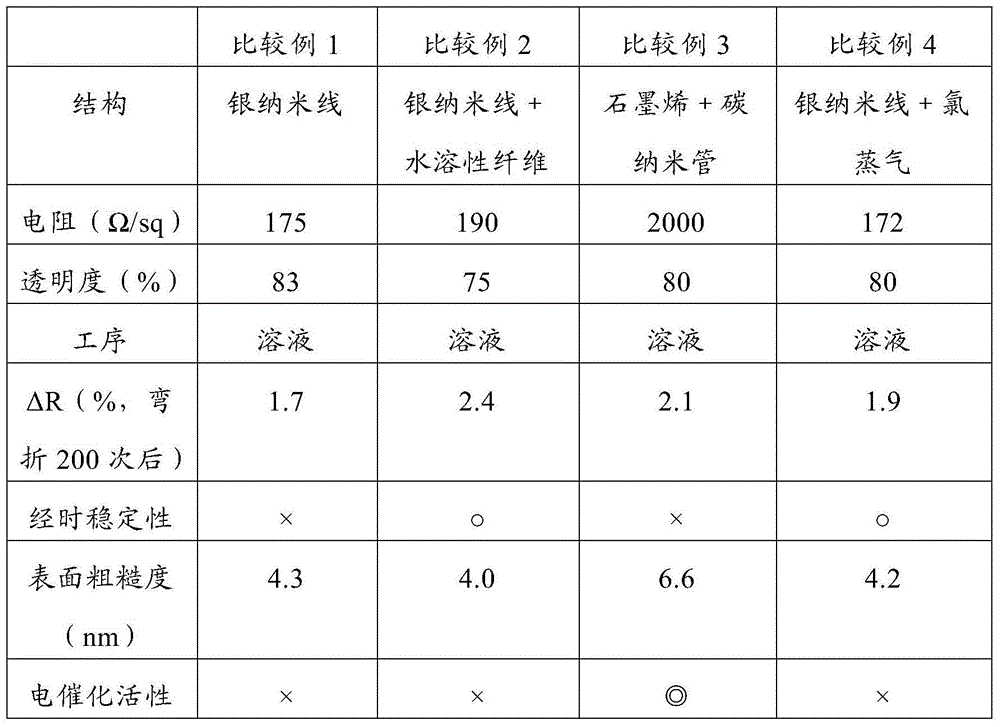

Hybrid electrode using silver nanowires and graphene, and preparation method thereof

ActiveCN104412335AHigh light transmittanceHigh surface resistanceConductive layers on insulating-supportsFinal product manufactureElectricityTransmittance

The present invention relates to a hybrid electrode using silver nanowires and graphene, and a preparation method thereof, and more specifically, provides: a hybrid electrode comprising a silver nanowire network and graphene so as to have high light transmittance, improved surface resistance and electrocatalytic reactivity, and flexibility; and a preparation method thereof.

Owner:国立韩国交通大学校产学协力团

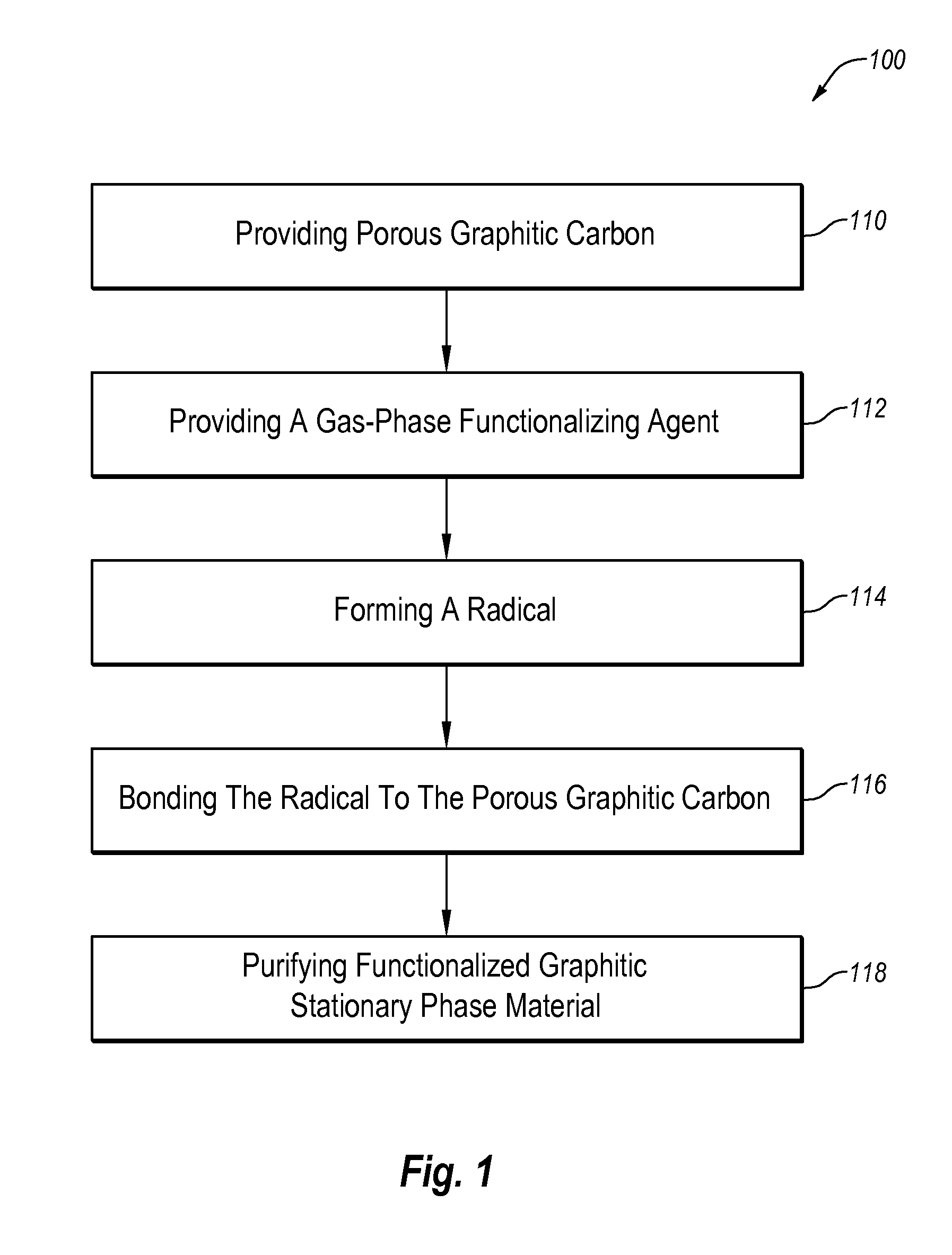

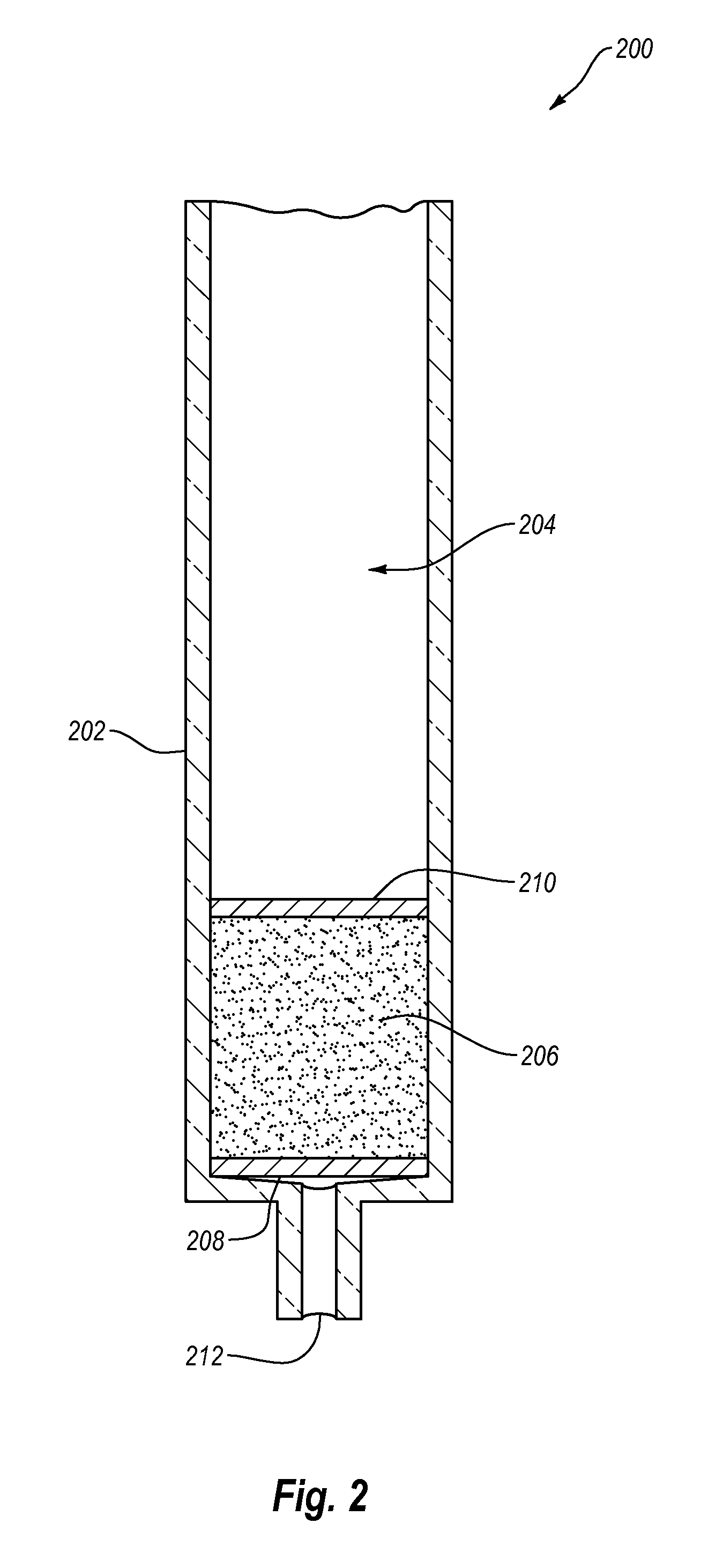

Gas phase approach to in-situ/ex-situ functionalization of porous graphitic carbon via radical-generated molecules

InactiveUS20110210056A1Extended retention timeLess tailingGraphiteIon-exchanger regenerationSolid phase extractionCovalent bond

Embodiments disclosed herein include graphitic stationary phase materials functionalized through a gas-phase functionalization reaction, as well as and methods for making and using these materials, including the use of these materials in separation technologies such as, but not limited to, chromatography and solid phase extraction. In an embodiment, a functionalized graphitic stationary phase material may be prepared from high surface area porous graphitic carbon and a radical forming volatilized functionalizing agent. The radical forming volatilized functionalizing agent produces an intermediate that forms a covalent bond with the surface of the porous graphitic material and imparts desired properties to the surface of the graphitic carbon.

Owner:US SYNTHETIC CORP +1

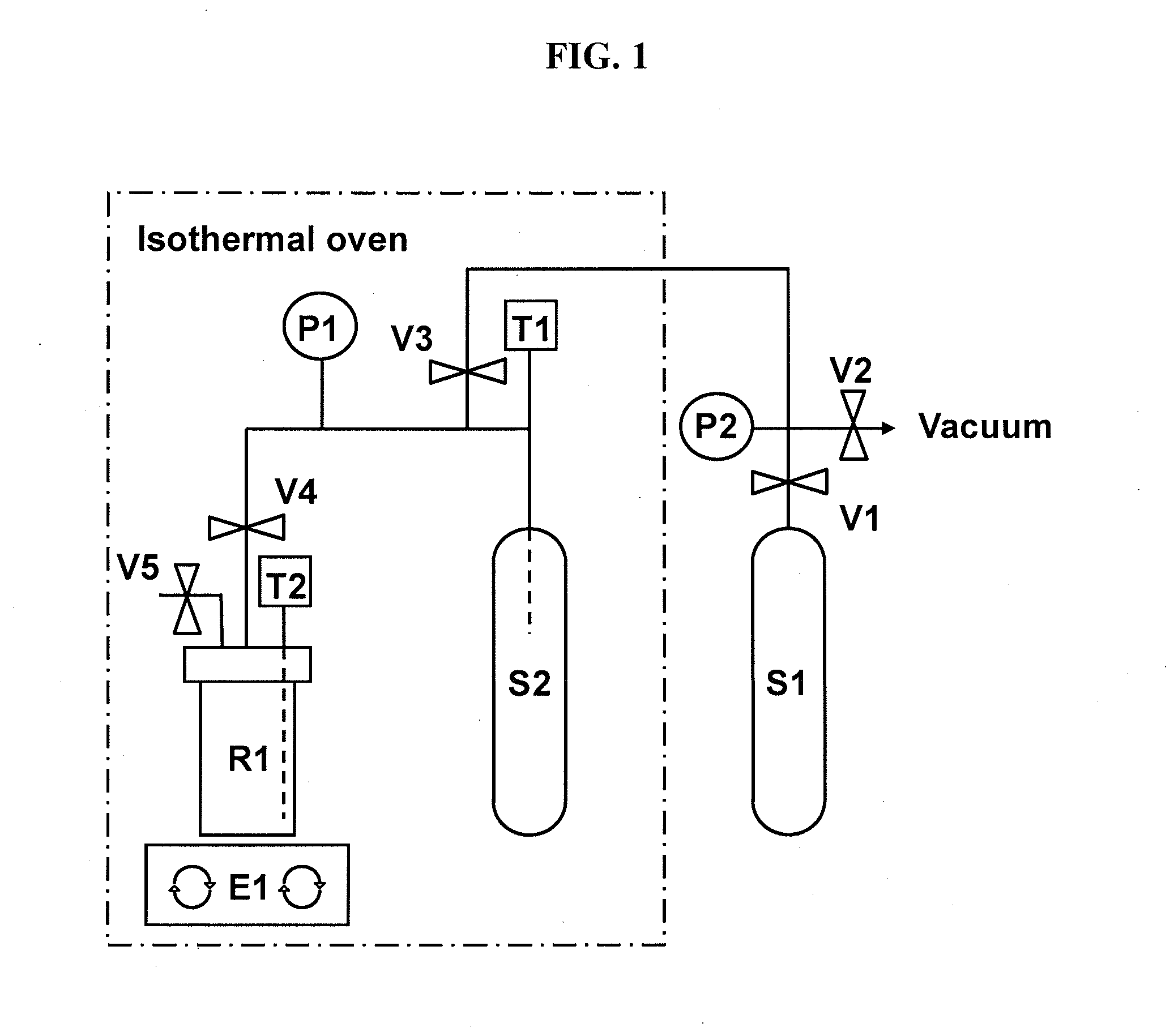

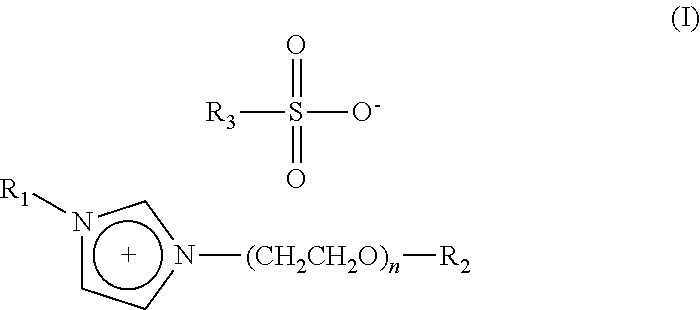

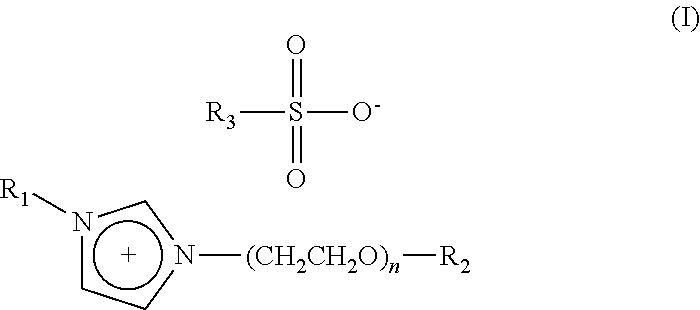

Sulfur dioxide absorbent comprising ionic liquid

InactiveUS20120042778A1High thermal/chemical stabilityPromote regenerationLiquid degasificationOrganic chemistryCombustionAbsorption rate

A sulfur dioxide absorbent comprising an ionic liquid comprised of alkyl ether-substituted imidazolium cation and an alkanesulfonate anion moieties possesses a high thermal / chemical stability, high SO2 absorption rate and low regeneration temperature, and is useful for an effective separation of SO2 from a combustion exhaust gas mixture or the like.

Owner:KOREA INST OF SCI & TECH

Microporous aluminophosphate molecular sieve membranes for highly selective separations

ActiveUS20100311565A1High selectivityGood chemical and thermal stabilitySolid sorbent liquid separationPretreated surfacesMolecular sieveIn situ crystallization

The present invention discloses microporous aluminophosphate (AlPO4) molecular sieve membranes and methods for making and using the same. The microporous AlPO4 molecular sieve membranes, particularly small pore microporous AlPO-14 and AlPO-18 molecular sieve membranes, are prepared by three different methods, including in-situ crystallization of a layer of AlPO4 molecular sieve crystals on a porous membrane support, coating a layer of polymer-bound AlPO4 molecular sieve crystals on a porous membrane support, and a seeding method by in-situ crystallization of a continuous second layer of AlPO4 molecular sieve crystals on a seed layer of AlPO4 molecular sieve crystals supported on a porous membrane support. The microporous AlPO4 molecular sieve membranes have superior thermal and chemical stability, good erosion resistance, high CO2 plasticization resistance, and significantly improved selectivity over polymer membranes for gas and liquid separations, including carbon dioxide / methane (CO2 / CH4), carbon dioxide / nitrogen (CO2 / N2), and hydrogen / methane (H2 / CH4) separations.

Owner:UOP LLC

Secondary battery comprising ternary eutectic mixtures and preparation method thereof

ActiveUS20100196766A1Good chemical and thermal stabilityAlkaline accumulatorsElectrode manufacturing processesLithiumElectrochemical window

Disclosed is a secondary battery including a cathode, an anode, a separator, and an electrolyte, wherein the electrolyte includes a ternary eutectic mixture prepared by adding (c) a carbonate-based compound to a eutectic mixture containing (a) an amide group-containing compound and (b) an ionizable lithium salt, and the carbonate-based compound is included in an amount of less than 50 parts by weight based on 100 parts by weight of the electrolyte. The use of the disclosed ternary eutectic mixture having flame resistance, chemical stability, high conductivity, and a broad electrochemical window, as the electrolyte material, improves both the thermal stability and quality of the battery.

Owner:LG ENERGY SOLUTION LTD

Selective hydrogenation catalyst for pyrolysis gasoline

InactiveUS6576586B2Improve and increase utilization factorReduce lossesRefining by selective hydrogenationMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalCrystal structure

A selective hydrogenation catalyst for pyrolysis gasoline. The catalyst mainly consists of a support of delta, alpha mixed alumina covered by palladium and alkali metal and / or alkaline-earth metal which are distributed on the support surface, and the support has 0.5 to 09. ml / g of specific pore volume. 40 to 200 Å pores account for more than 85% of the total pore volume. The specific surface area is 70 to 140 m2 / g, and alpha crystal structure in the alumina support is 0.5 to 5% based on the weight percentage of delta, alpha mixed alumina support. The catalyst includes palladium in amount of 0.05 to 0.4 wt %, alkali metal and / or alkaline-earth metal in amount of 0.05 to 2.0 wt %.

Owner:PETROCHINA CO LTD

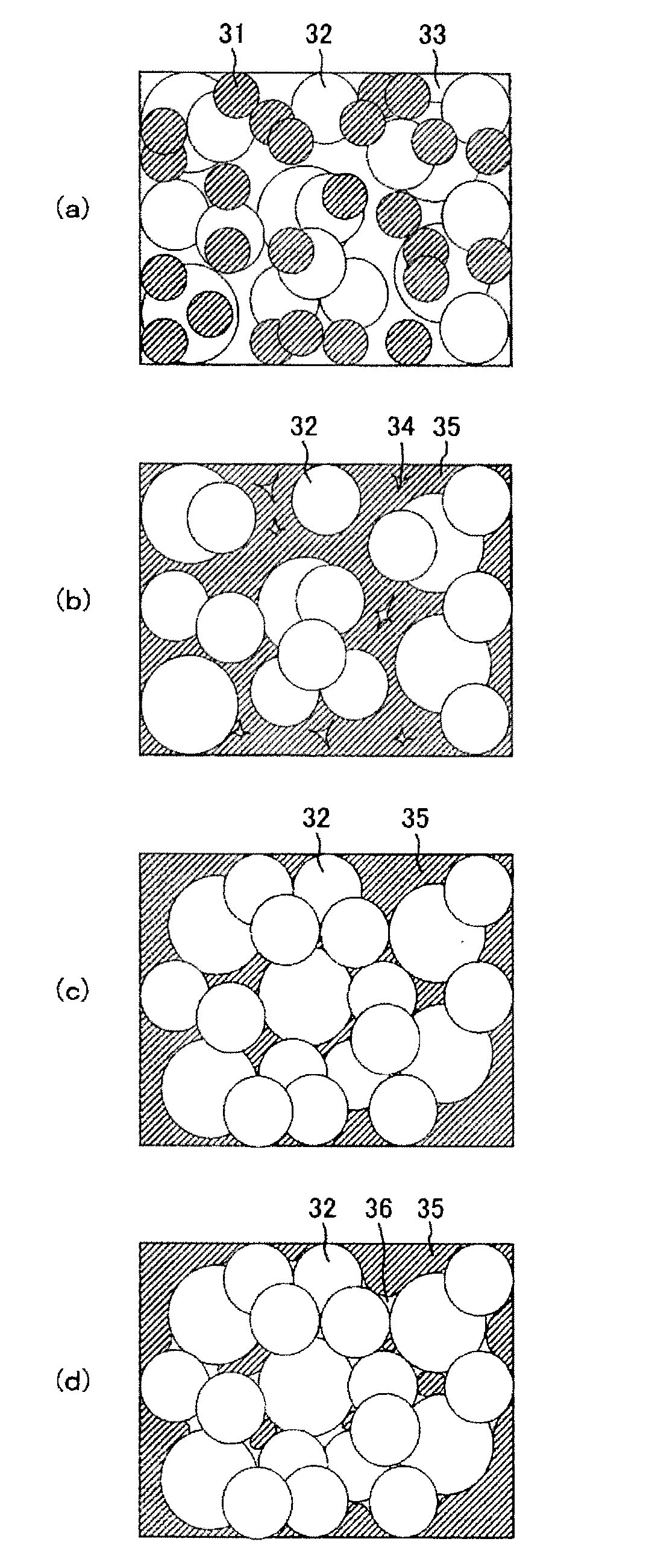

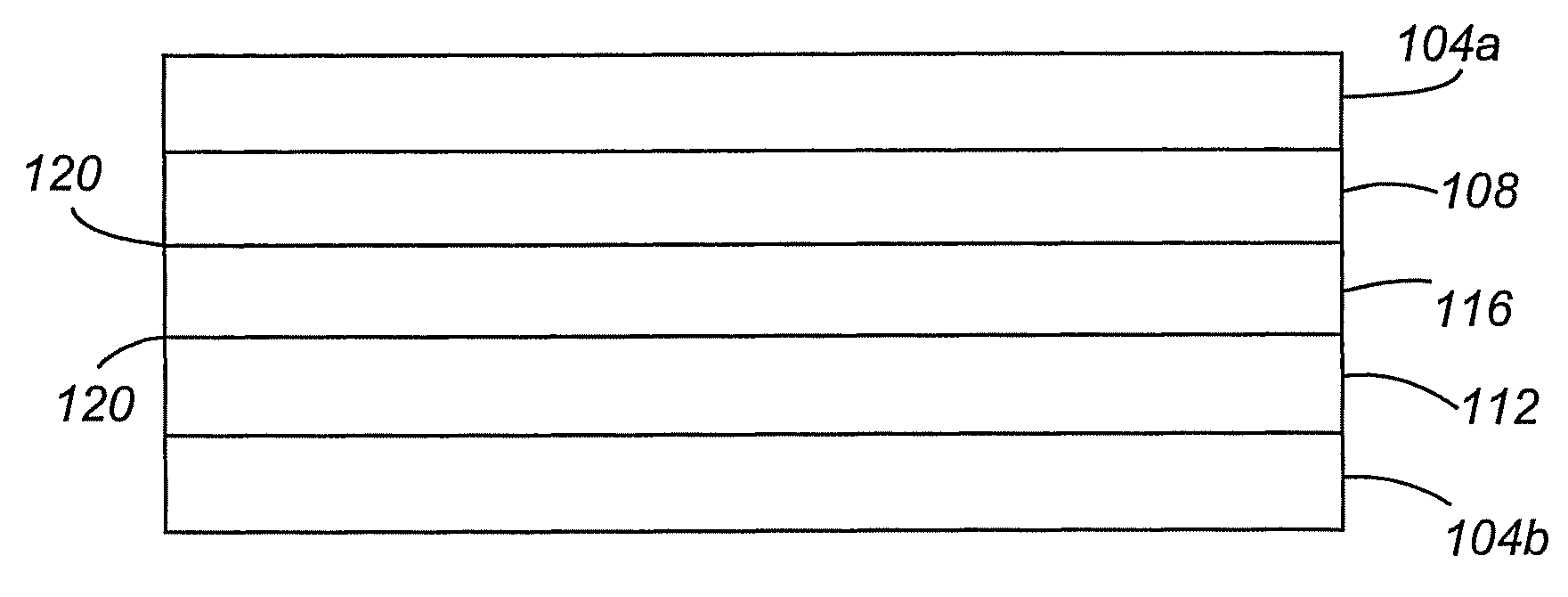

Porous separator coated with organic/inorganic complex using aqueous coating solution, method for manufacturing same, and electrochemical device using same

ActiveCN104272501AFix damageSolve for ionic conductivityLi-accumulatorsCell component detailsPorous substrateInorganic compound

The present invention relates to a separator used in an electrochemical device, and more particularly, to a porous separator obtained by applying an organic / inorganic complex coating layer on a porous substrate, to a method for manufacturing same, and to an electrochemical device using same.

Owner:HANWHA TOTAL PETROCHEMICAL CO LTD

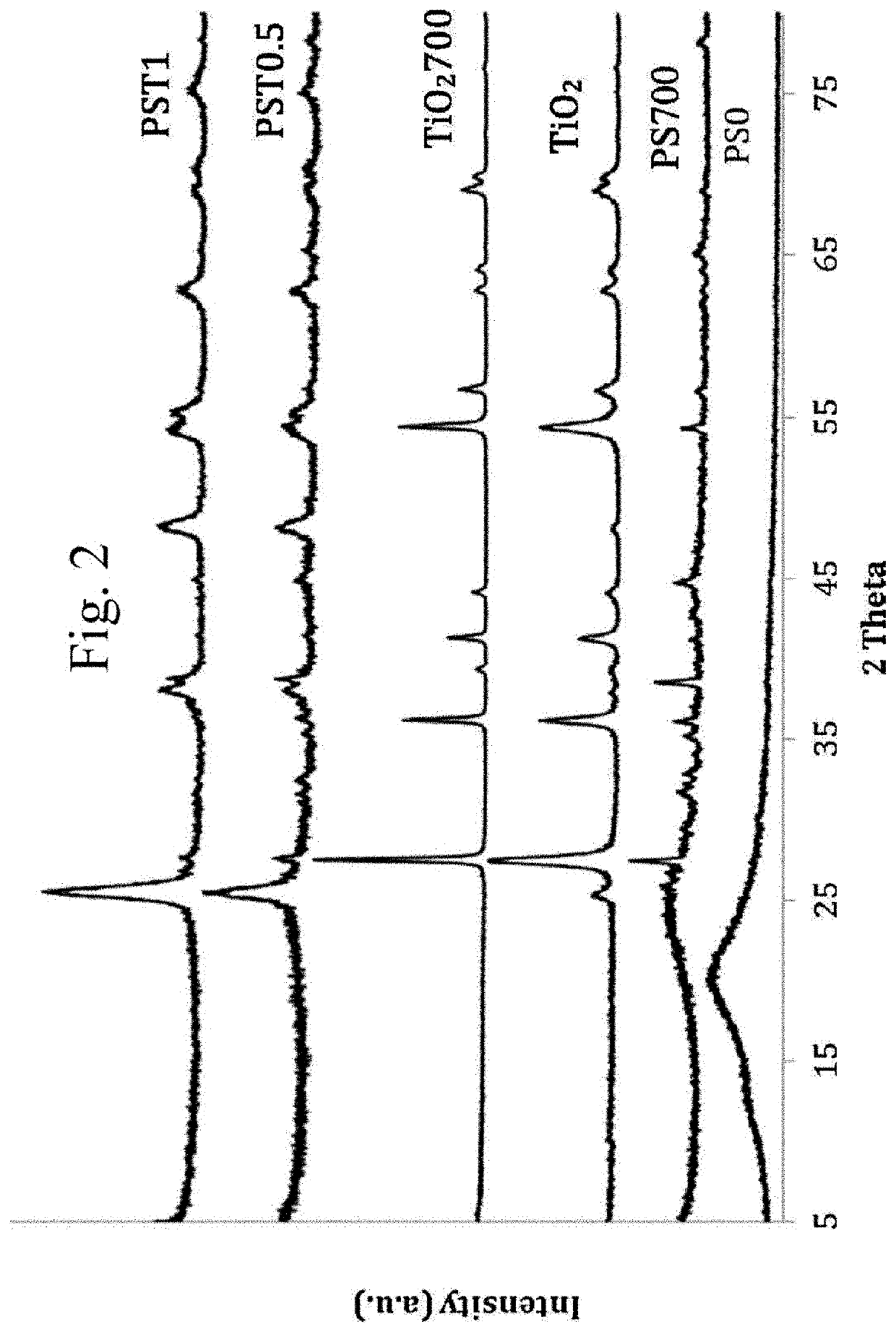

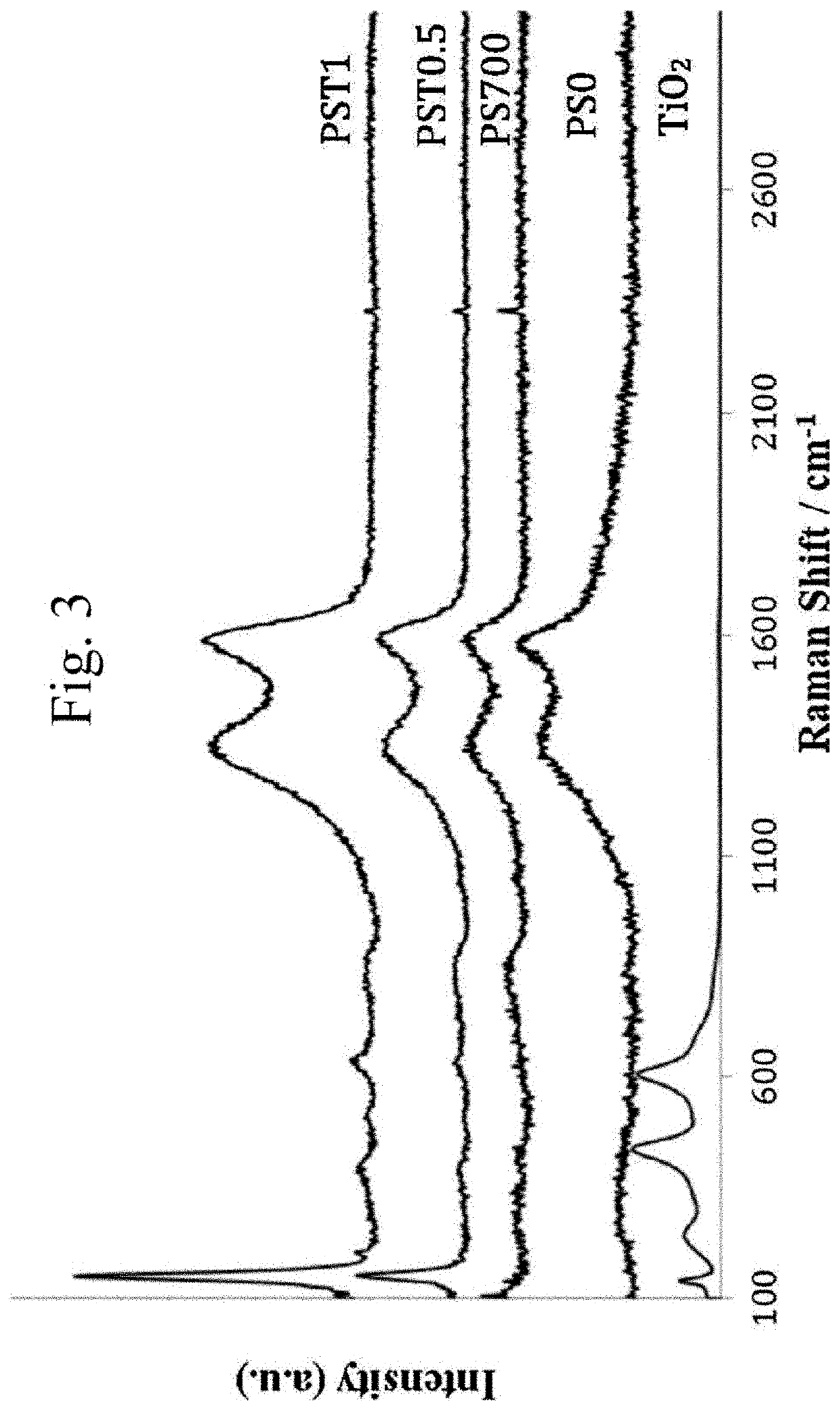

Titania-carbon dot-reduced graphene oxide composites, their make, and use

ActiveUS20200346187A1Extraordinary electrical propertiesEasy to transportWater/sewage treatment by irradiationWater treatment compoundsCatalytic pyrolysisPtru catalyst

Catalytic pyrolysis can upcycle waste, e.g., car bumpers, to carbon nanomaterials, preferably using synthetic TiO2 nanoparticles as catalyst during pyrolysis. Analysis of the carbon nanomaterials shows that, while RGO is produced from thermal pyrolysis of car bumper waste absent TiO2, RGO spotted with carbon dots is produced in presence of TiO2 catalyst. Rutile to anatase TiO2 phase transformation and carbon nanomaterial formation can simultaneously occur during the pyrolysis. Anatase to rutile transformation may occur while TiO2 absent the bumper material. Such TiO2-CD-RGO can be used, for example in photocatalytic degradation of organic compounds, such as methylene blue.

Owner:IMAM ABDULRAHRNAN BIN FAISAL UNIVERSITY

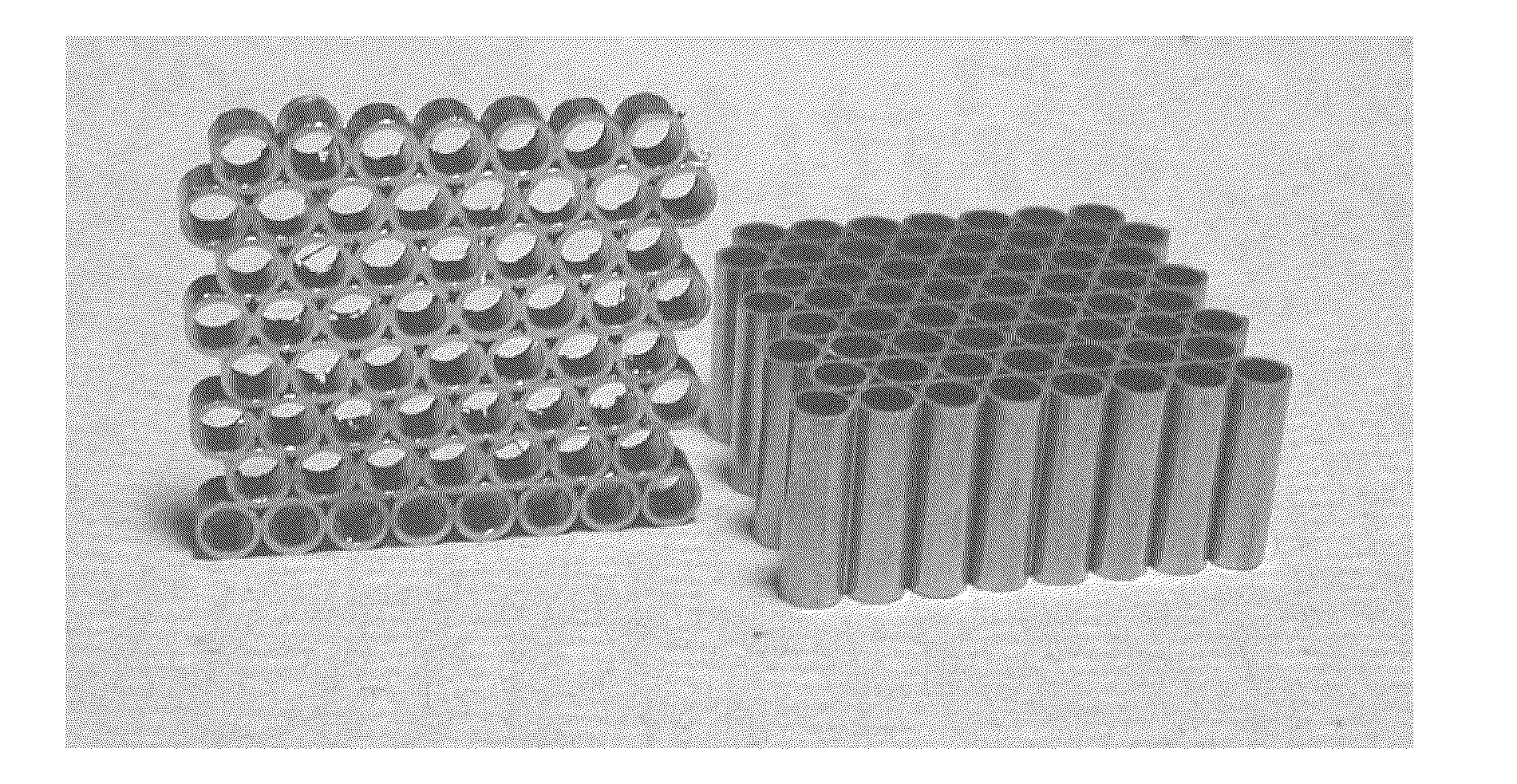

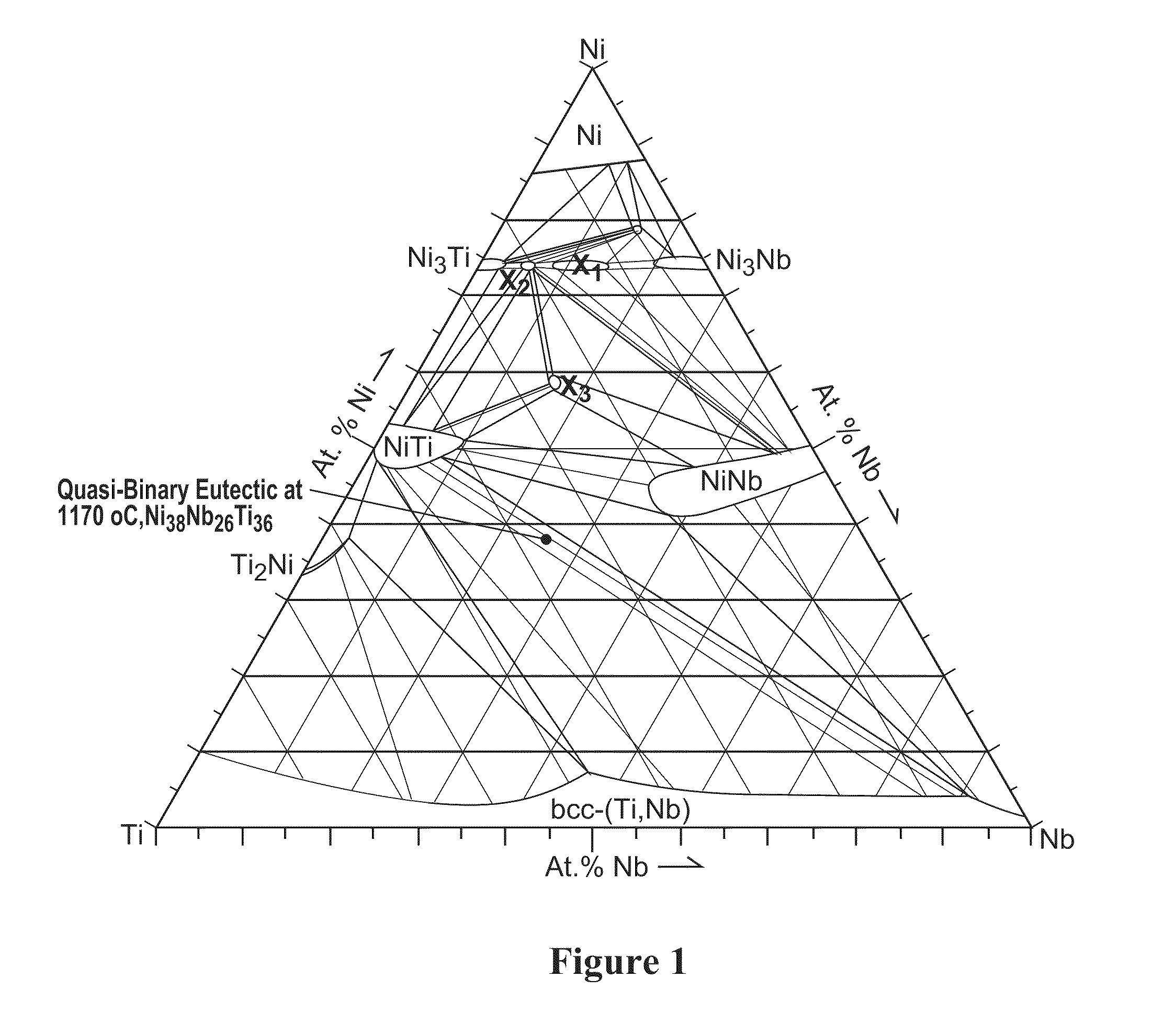

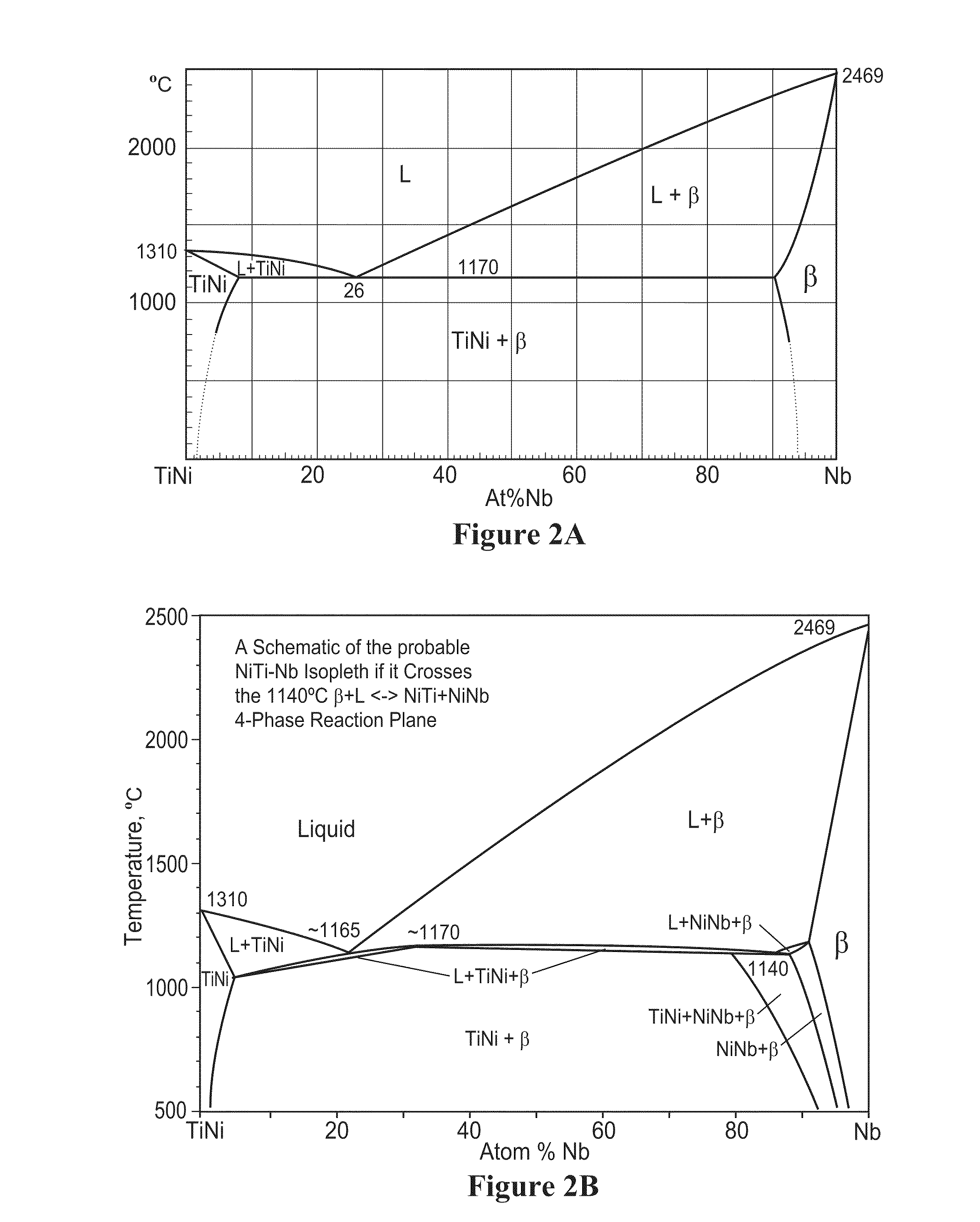

Manufacture of Shape-Memory Alloy Cellular Materials and Structures by Transient-Liquid Reactive Joining

ActiveUS20110008643A1Constant gainFine surfaceThermometers using material expansion/contactionSoldering apparatusNiobiumHoneycomb structure

This invention discloses a method, using pure niobium as a transient liquid reactive braze material, for fabrication of cellular or honeycomb structures, wire space-frames or other sparse builtup structures or discrete articles using Nitinol (near-equiatomic titanium-nickel alloy) and related shape-memory and superelastic alloys. Nitinol shape memory alloys (SMAs), acquired in a form such as corrugated sheet, discrete tubes or wires, may be joined together using the newly discovered joining technique. Pure niobium when brought into contact with nitinol at elevated temperature, liquefies at temperatures below the melting point and flows readily into capillary spaces between the elements to be joined, thus forming a strong joint.

Owner:RGT UNIV OF MICHIGAN +1

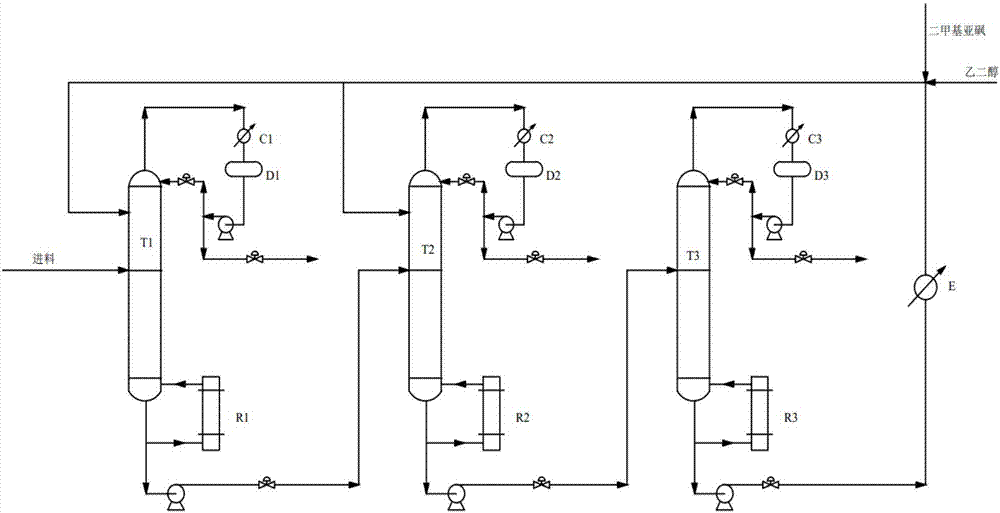

Method for separating tetrahydrofuran-ethyl alcohol-water mixture by mixed extraction agent

ActiveCN106967017ASolving intractable puzzlesEasy to separateOrganic compound preparationHydroxy compound preparationHeat stabilityAlcohol products

The invention relates to a method for separating a tetrahydrofuran-ethyl alcohol-water mixture by a mixed extraction agent and a device suitable for the method. According to the method, dimethyl sulfoxide and ethylene glycol are mixed into a mixed extraction agent in certain proportion, the tetrahydrofuran-ethyl alcohol-water mixture firstly enters a first extraction rectifying tower for separation, a tetrahydrofuran product is obtained at the tower top, tower bottom materials enter a second extraction rectifying tower for separation, an ethyl alcohol product is extracted from the tower top, a tower bottom extraction agent and water mixture enters an extraction agent recovery tower, water is extracted from the tower top, and the extraction agent is recycled after being extracted from the tower bottom. The method has the advantages that the energy consumption is low, the technology is simple, equipment investment is small, the product purity of the separated tetrahydrofuran and ethyl alcohol is high and the like, and the adopted ethylene glycol and dimethyl sulfoxide mixed extraction agent can break three binary azeotropes in the system simultaneously and is easy to recycle and good in chemical heat stability.

Owner:QINGDAO UNIV OF SCI & TECH

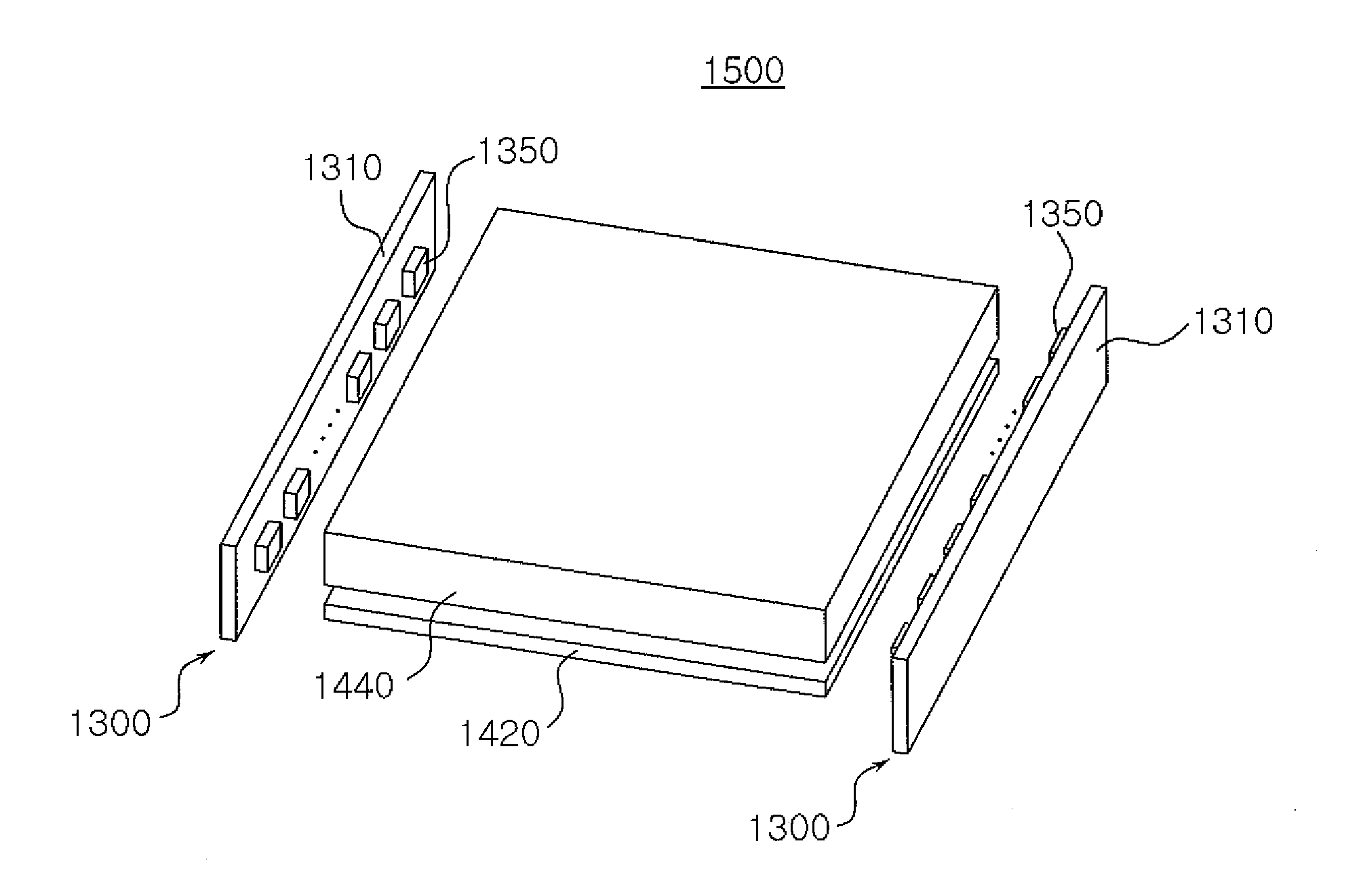

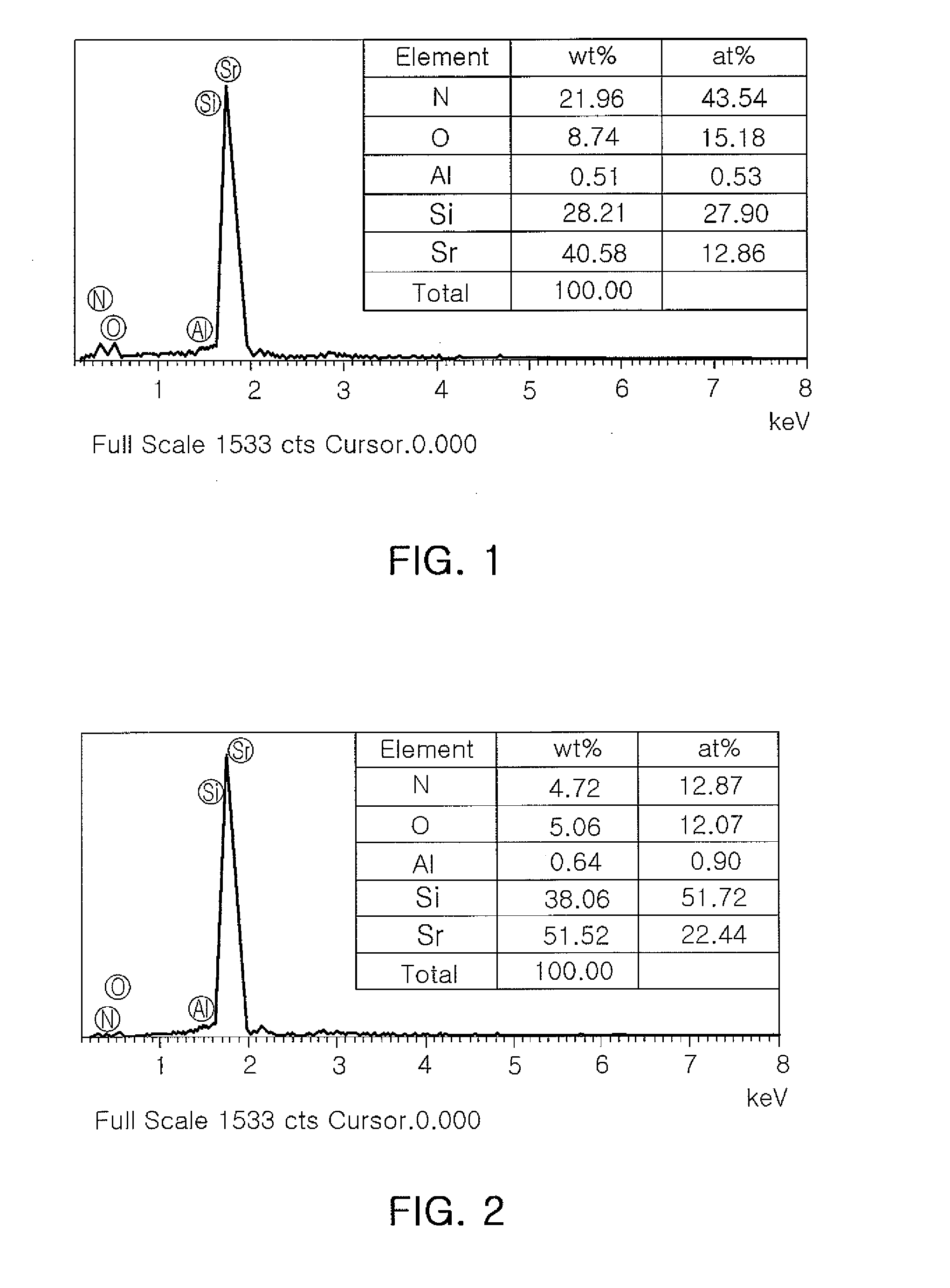

Complex Crystal Phosphor, Light Emitting Device, Surface Light Source Apparatus, Display Apparatus, and Lighting Device

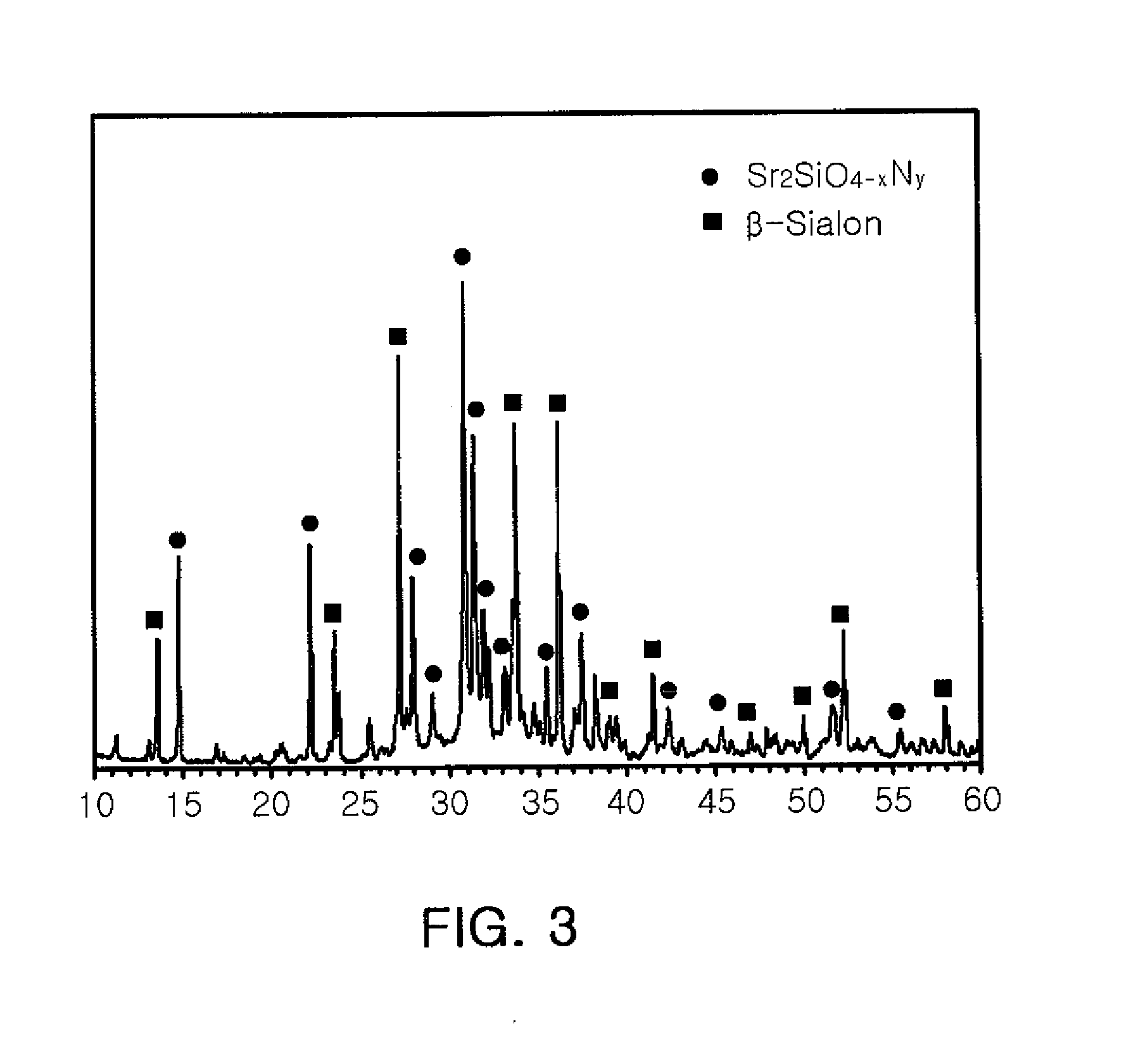

ActiveUS20110234118A1Good chemical stabilityImprove thermal stabilityElectric light circuit arrangementLuminescent compositionsOxygenLight emitting device

A complex crystal phosphor is an inorganic composition containing at least an M element, an Al element, silicon, oxygen, and nitrogen. The inorganic composition has particles having at least two types of crystal phase, and the at least two types of crystal phase include a first crystal phase which is the same as a M2SiO4 crystal and a second crystal phase as a β-sialon crystal. Here, M is at least one element selected from the group consisting of (Mg), calcium (Ca), strontium (Sr), and barium (Ba).

Owner:SAMSUNG ELECTRONICS CO LTD

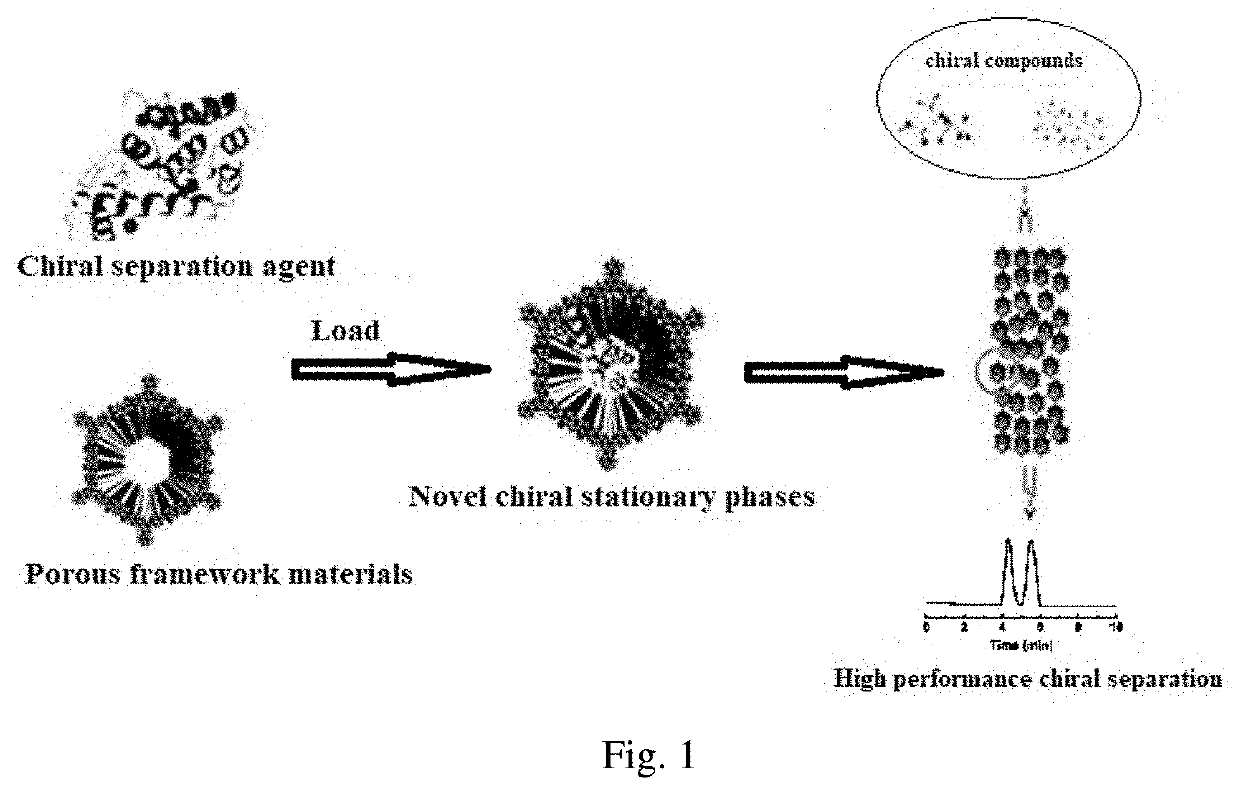

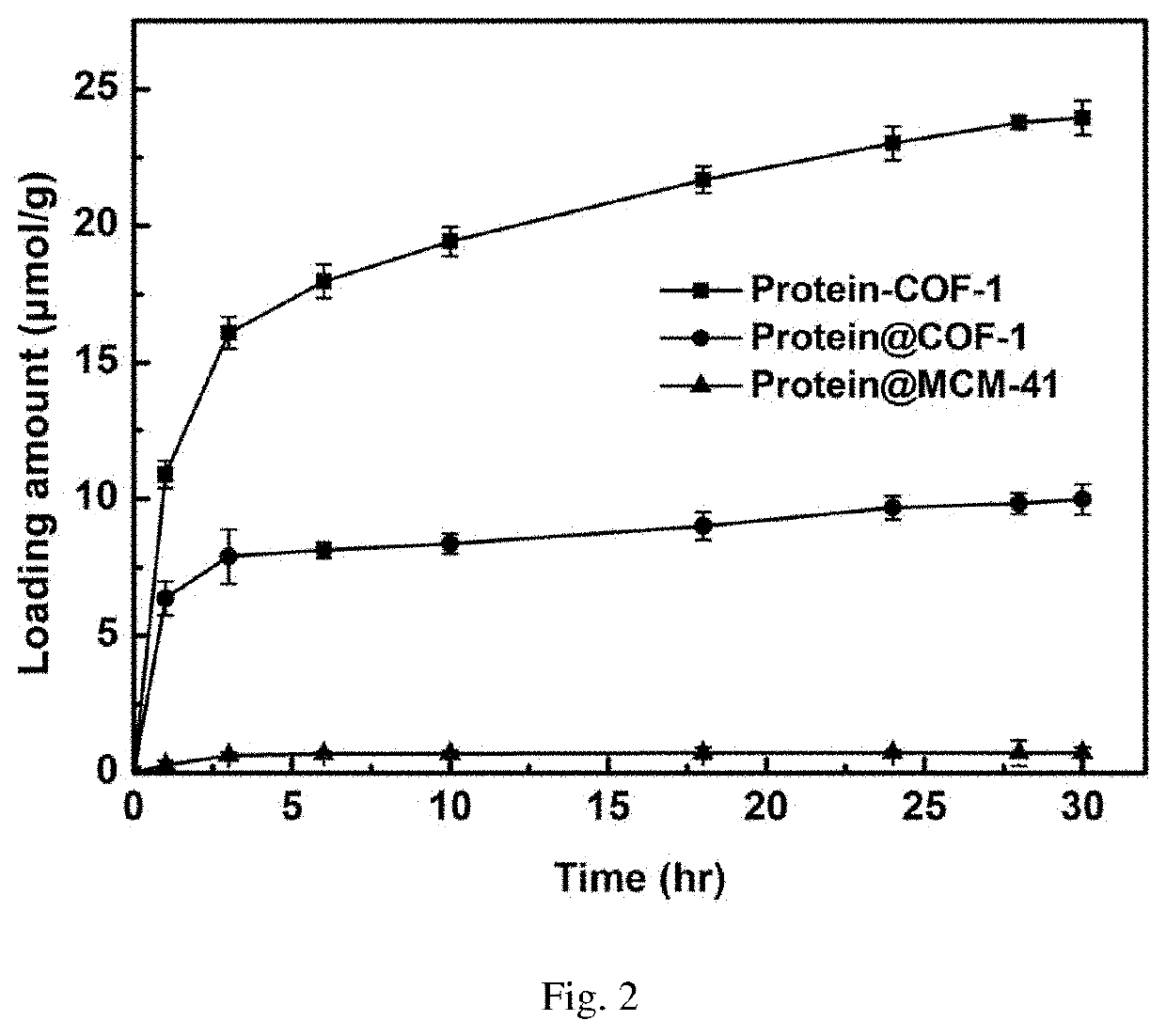

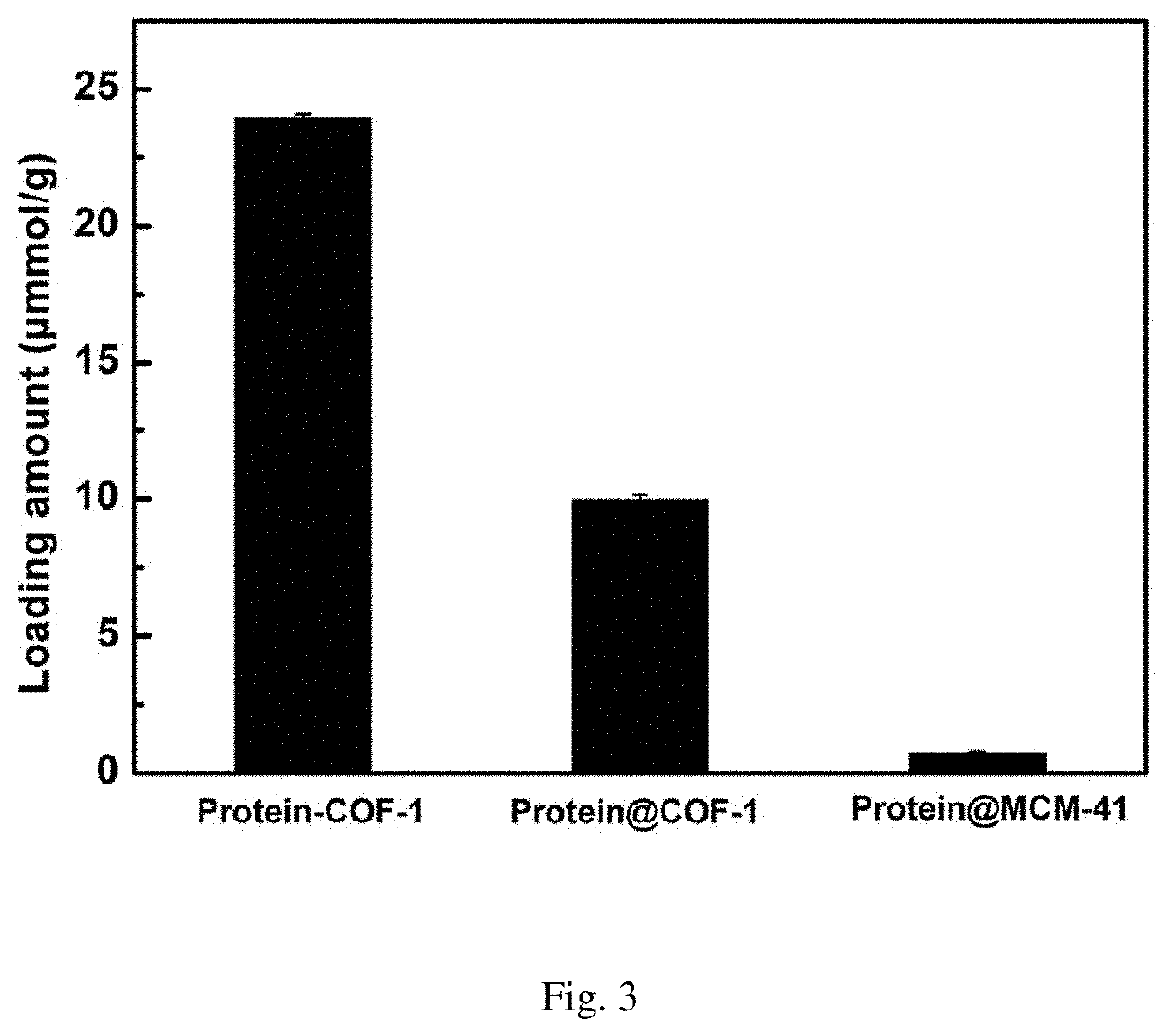

Preparation of chromatographic stationary phase having porous framework material as matrix for chiral separation

ActiveUS20210023528A1Improve stabilityImprove comprehensive applicabilityOther chemical processesSolid sorbent liquid separationChromatographic separationMetal-organic framework

The novel porous framework materials (such as metal organic frameworks or covalent organic frameworks) having a wide range of applications, which was designed and developed in an inventive manner to resolve issues with respect to a carrier material in a stationary phase of a conventional chiral chromatographic column in which the carrier material has poor stability, a chiral resolving agent has a low loading rate, and the chiral resolving agent is prone to loss or is applied in a restricted manner. The porous framework material efficiently loads a chiral resolving agent (such as proteins, enzymes, or macrocyclic antibiotics) by means of covalent bonding, adsorption, embedding, and crosslinking, such that a variety of efficient and durable chiral stationary phases are prepared to serve as a novel high-performance chromatographic column filler used for chromatographic chiral separation (such as high-performance liquid chromatography or capillary chromatography). The various chiral stationary phases prepared by applying the above technique have high separation efficiency, high stability, and durability, and have been successfully applied to perform efficient separation of different kinds of chiral materials such as chiral amino acids and a chiral drug. The technique greatly widens the application range and extends the service life of a chiral chromatographic separation column.

Owner:NANKAI UNIV

Conductive silver paste for ferrite core inductance and method for producing same

ActiveCN102610326AAvoid crackingNot easy to electroplateTransformers/inductances coils/windings/connectionsNon-conductive material with dispersed conductive materialSilver pasteInductance

The invention discloses a conductive silver paste for a ferrite core inductance and a method for producing the same, wherein the method comprises the following steps that: (1) lead-free glass powder is produced and contains an inorganic additive I which occupies 1-4% of the total quantity of the lead-free glass powder; (2) an organic carrier is produced; (3) superfine silver powder, silver flake, the lead-free glass powder and an inorganic additive II are mixed to produce the powder, the powder is uniformly stirred and then added into the organic carrier, after high-speed stirring and dispersion, the powder is rolled by a three-roller mill to the fineness of lower than 10mum, and is screened by a screen of 200 meshes for producing the conductive silver paste for the ferrite core inductance. The ferrite conductive silver paste can effectively solve the defects of the silver paste for the ferrite core inductance on corrosion resistance, adhesive force and electroplating performance, has good quality, is low in cost, and is an ideal substitute product for lead-bearing paste. The adopted technology can ensure the stability and consistency of the silver paste.

Owner:广东羚光新材料股份有限公司

Zirconia honeycomb ceramic body

InactiveCN101323537AImprove thermal stabilityImprove crack resistanceCeramicwareCelluloseSocial benefits

The invention discloses a zirconia honeycomb ceramic body which comprises the raw materials as follows: ceramic raw material, alpha-Al2O3 powder, clay, Mgo, organic cellulose, a binder and ZrO2 powder. The raw materials are mixed evenly by weight percentage and then the binder and moderate amount of water are added, and ball milling, mixed milling and staleness are carried out to prepare pug; the pug is put into a vacuum pugmill for pug milling, and then extrusion molding wet honeycomb ceramic body is put into a far-infrared kiln for drying and shaping into a dry blank; the honeycomb ceramic body is calcined at 1500 DEG C to 1700 DEG C and then cooled and taken out from the kiln. The zirconia honeycomb ceramic body is not only applicable to be used under high temperature environment being over 1500 DEG C in a heating kiln; besides, the heat exchange of the heating kiln is fast and even, thus saving the fuel of the regenerative heating kiln by about 40 percent to 70 percent, promoting yield by more than 15 percent, reducing the emission of NOX gas to be lower than 100ppm and resulting in lower than 150 DEG C gas emission temperature; therefore, the zirconia honeycomb ceramic body greatly improves the burning effect of the regenerative heating kiln, saves fuel and energy, reduces the emission of harmful gases, prolongs the service life of the regenerative heating kiln, improves environment and promotes both economic and social benefits.

Owner:朱根源

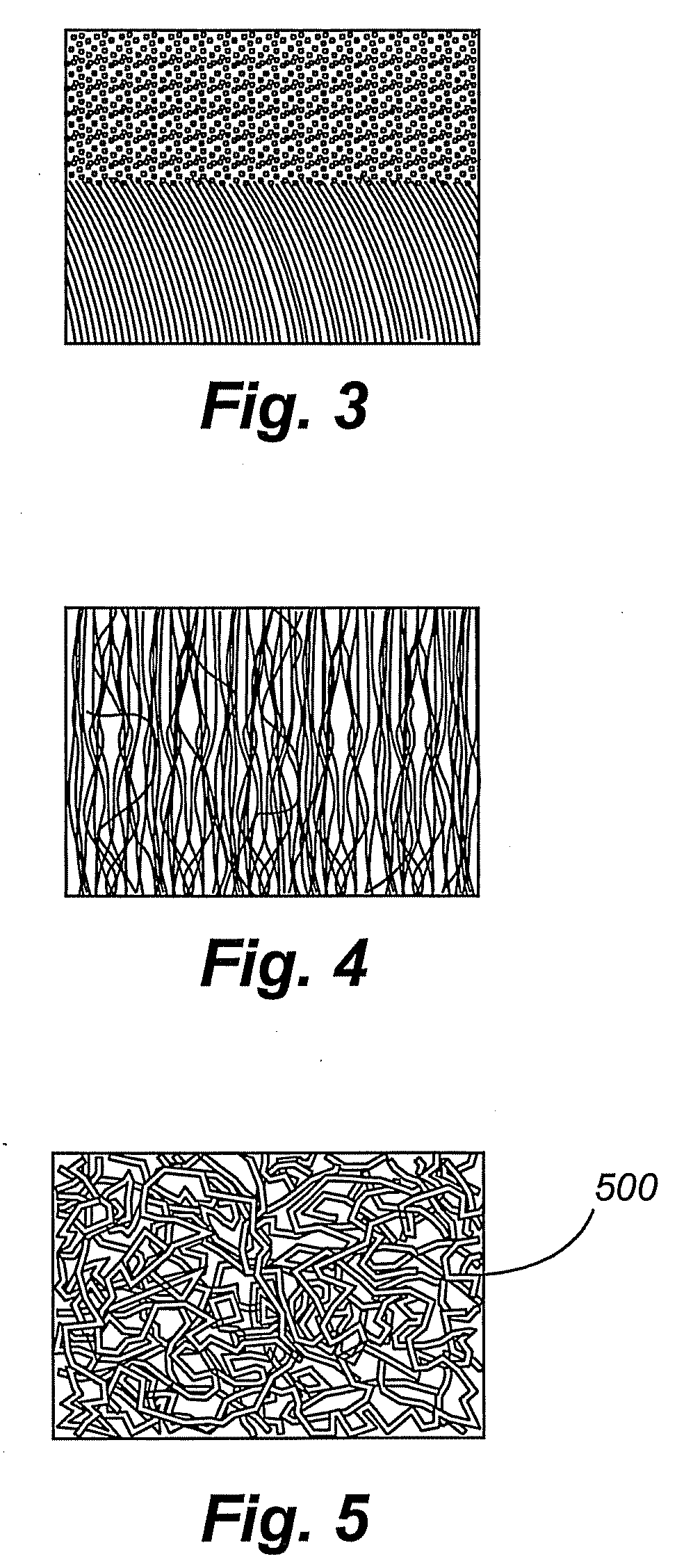

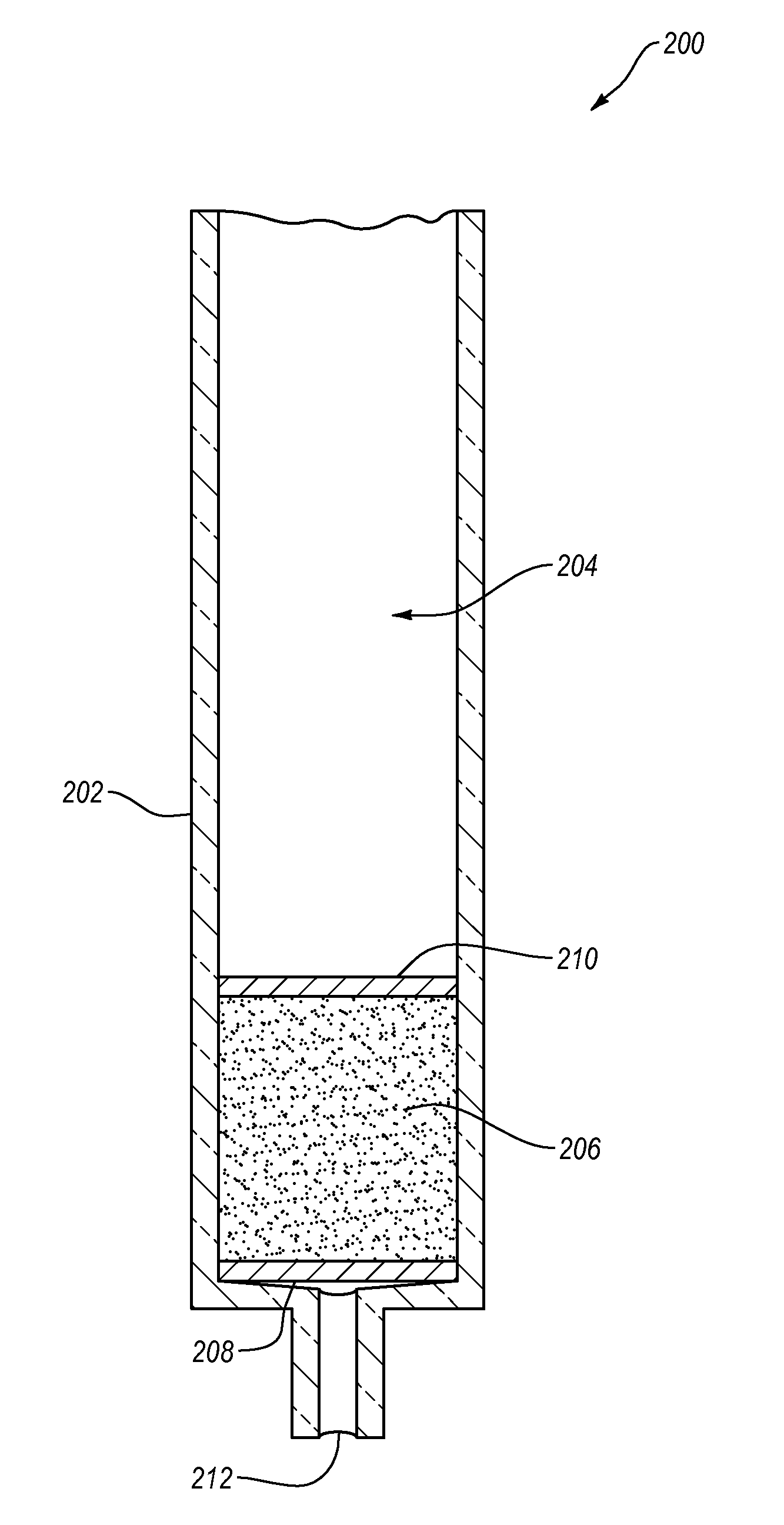

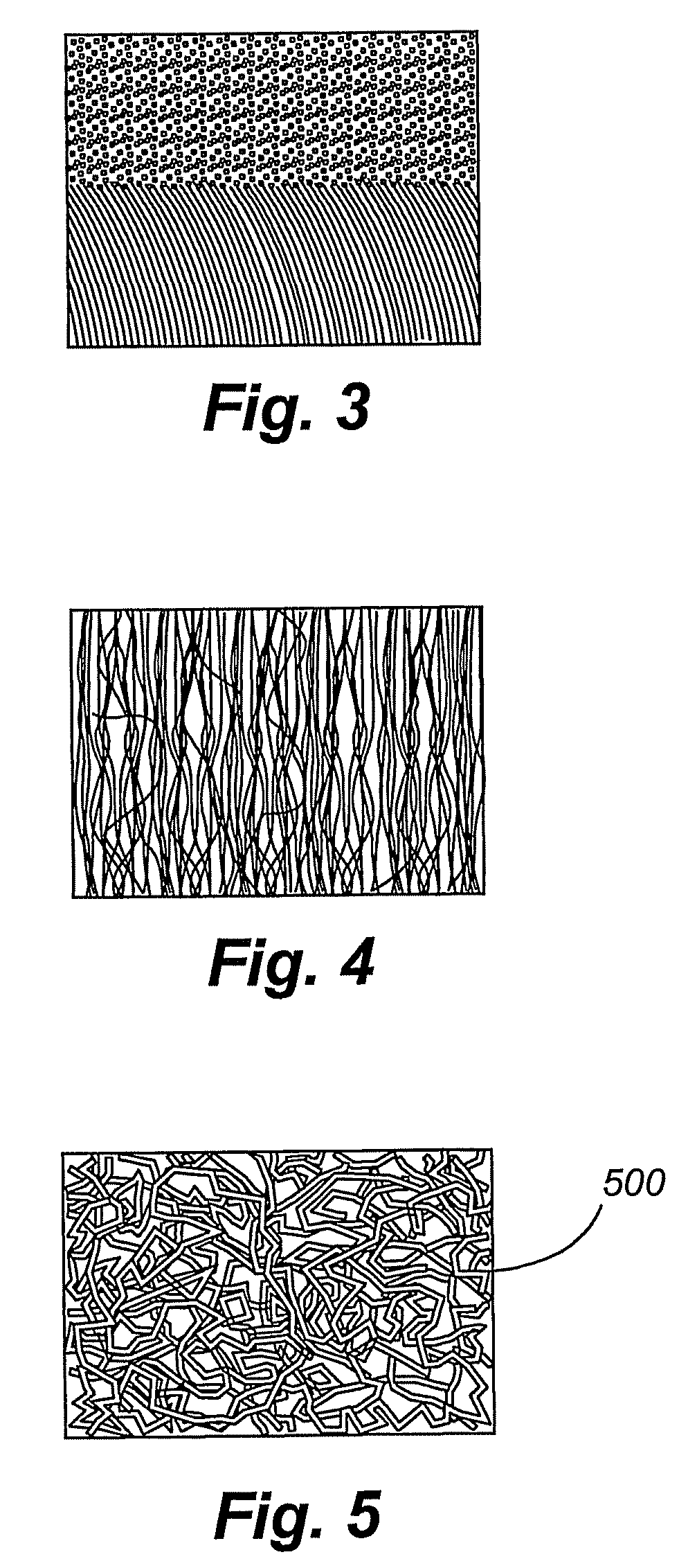

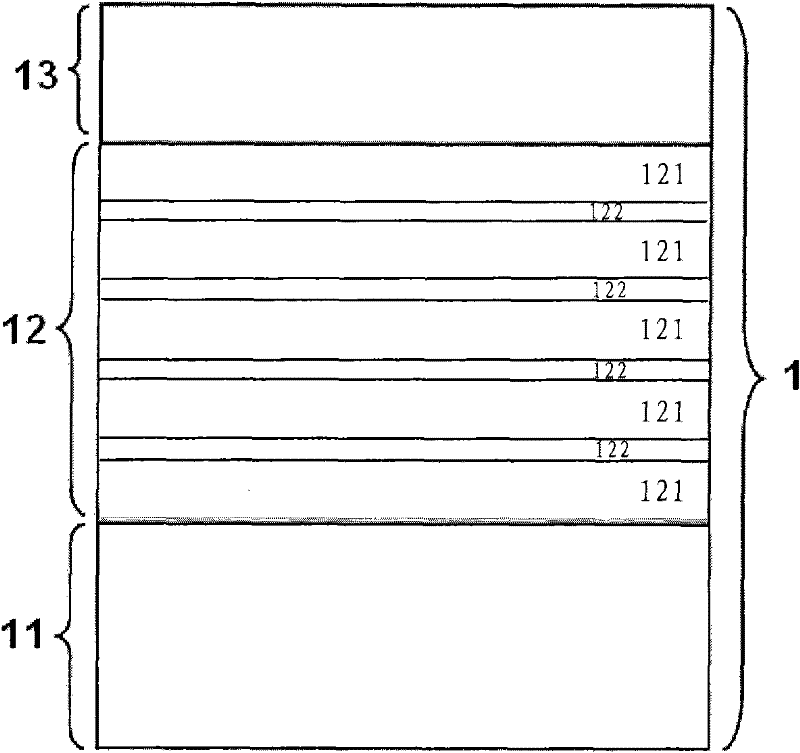

High performance ultracapacitors with carbon nanomaterials and ionic liquids

InactiveUS8284539B2Excellent electrolyte accessibilityImprove performanceHybrid capacitor electrolytesElectrolytic capacitorsSupercapacitorCarbon nanomaterials

The present invention is directed to the use of carbon nanotubes and / or electrolyte structures in various electrochemical devices, such as ultracapacitors having an ionic liquid electrolyte. The carbon nanotubes are preferably aligned carbon nanotubes. Compared to randomly entangled carbon nanotubes, aligned carbon nanotubes can have better defined pore structures and higher specific surface areas.

Owner:ADA TECH

Aqueous emulsion polymerization of fluorinated monomers using a fluorinated surfactant

InactiveUS7776946B2Low toxicityGood chemical and thermal stabilityLiquid surface applicatorsFibre treatmentEmulsion polymerizationEther

The present invention provides an aqueous emulsion polymerization of fluorinated monomers including gaseous fluorinated monomers using a perfluoro ether surfactant as an emulsifier. The perfluoro ether surfactants correspond to formula (I)Rf—O—CF2CF2—X (I)wherein Rf represents a linear or branched perfluoroalkyl group having 1, 2, 3 or 4 carbon atoms and X represents a carboxylic acid group or salt thereof. In a further aspect, the invention also provides an aqueous fluoropolymer dispersion comprising the perfluoro ether surfactant and the use of such dispersion in the coating or impregnation of substrates.

Owner:3M INNOVATIVE PROPERTIES CO

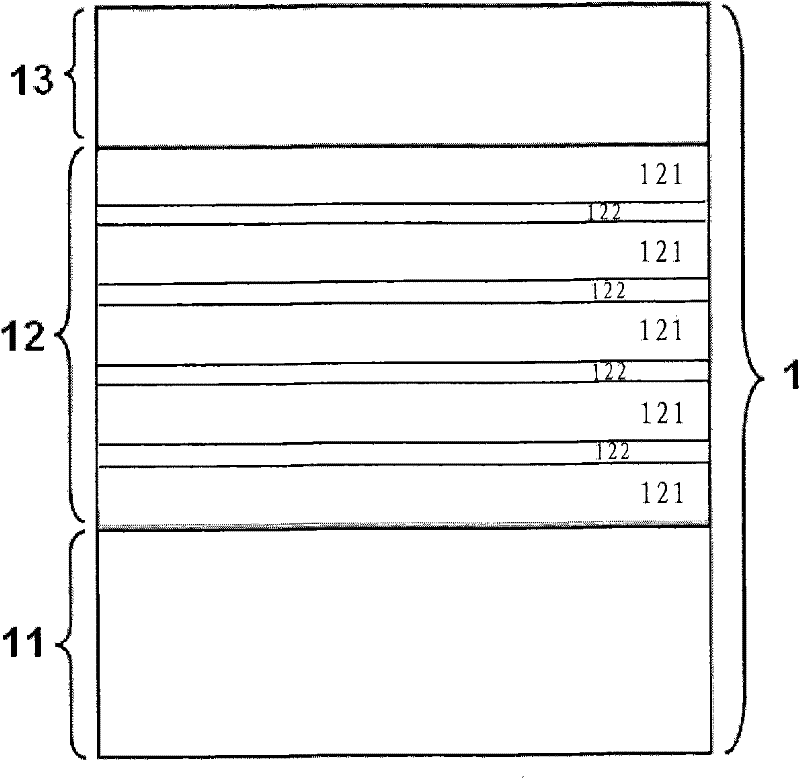

Silicon-base compound substrate and manufacturing method thereof

InactiveCN102208337AIncrease stressImprove coordinationSemiconductor/solid-state device manufacturingSemiconductor devicesTitanium nitrideEpitaxial material

The invention provides a silicon-base compound substrate for preparing a nitride semiconductor epitaxial material, and a manufacturing method of the silicon-base compound substrate. The silicon-base compound substrate comprises a silicon monocrystal substrate, a compound stress covariant layer which is formed on the silicon monocrystal substrate and formed by frequently stacking aluminum nitride and a titanium nitride monocrystal thin film material, and a gallium nitride template layer which is formed on the compound stress covariant layer and consists of a gallium nitride monocrystal thin film material. By the silicon-base compound substrate, the crystal lattice and big heat mismatch problems of the silicon-base gallium nitride material are solved; therefore, the preparation cost of a gallium nitride light emitting diode (LED) epitaxial sheet can be reduced greatly; and the silicon-base compound substrate is suitable for application and market popularization.

Owner:杭州海鲸光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com