Patents

Literature

46results about How to "Solving intractable puzzles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

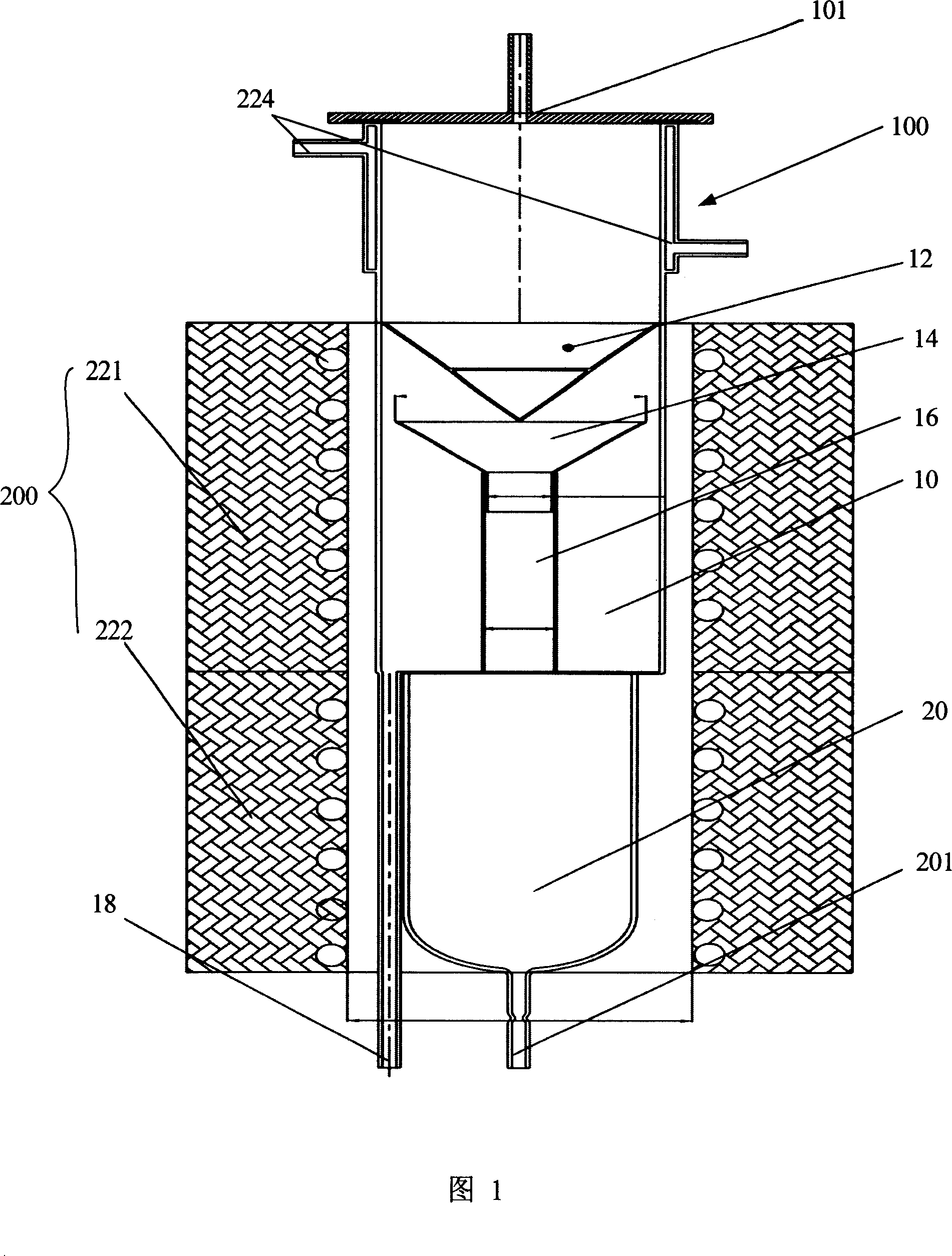

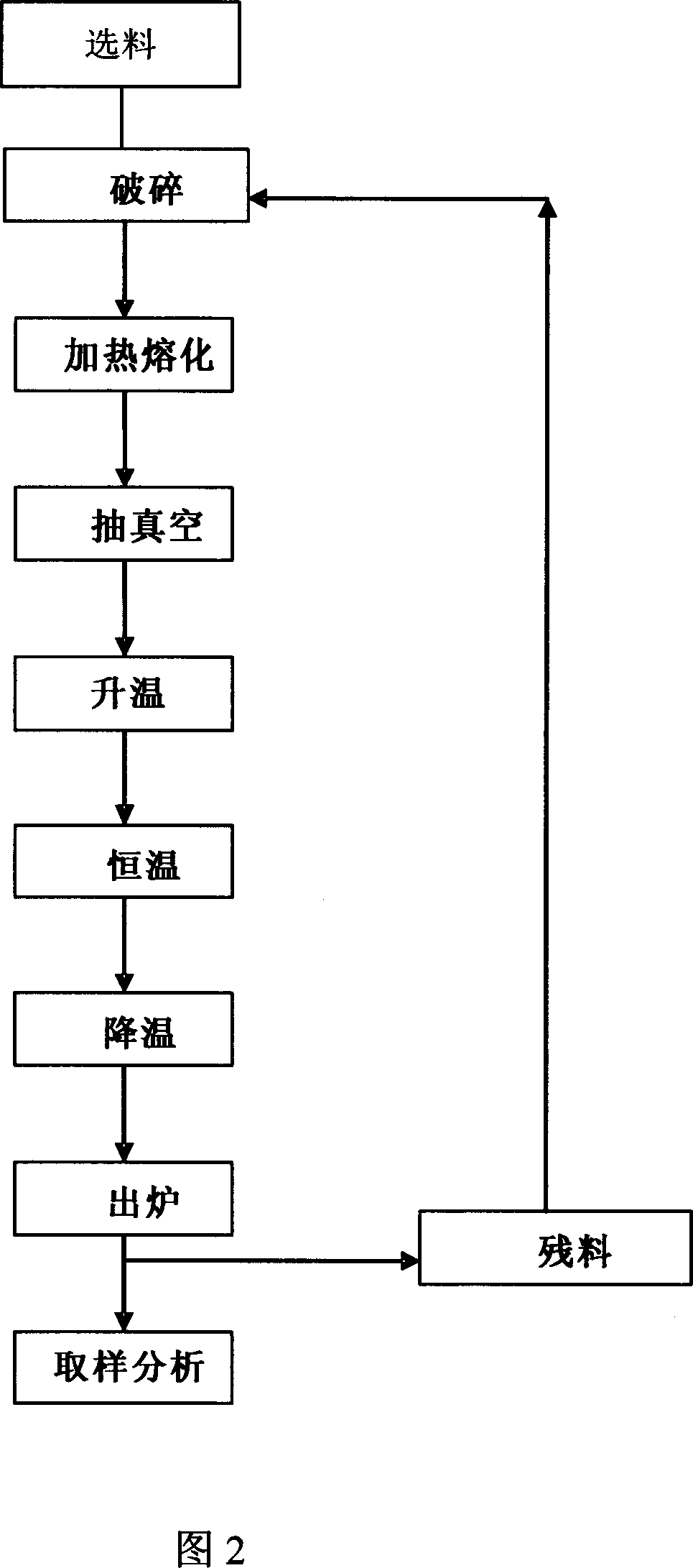

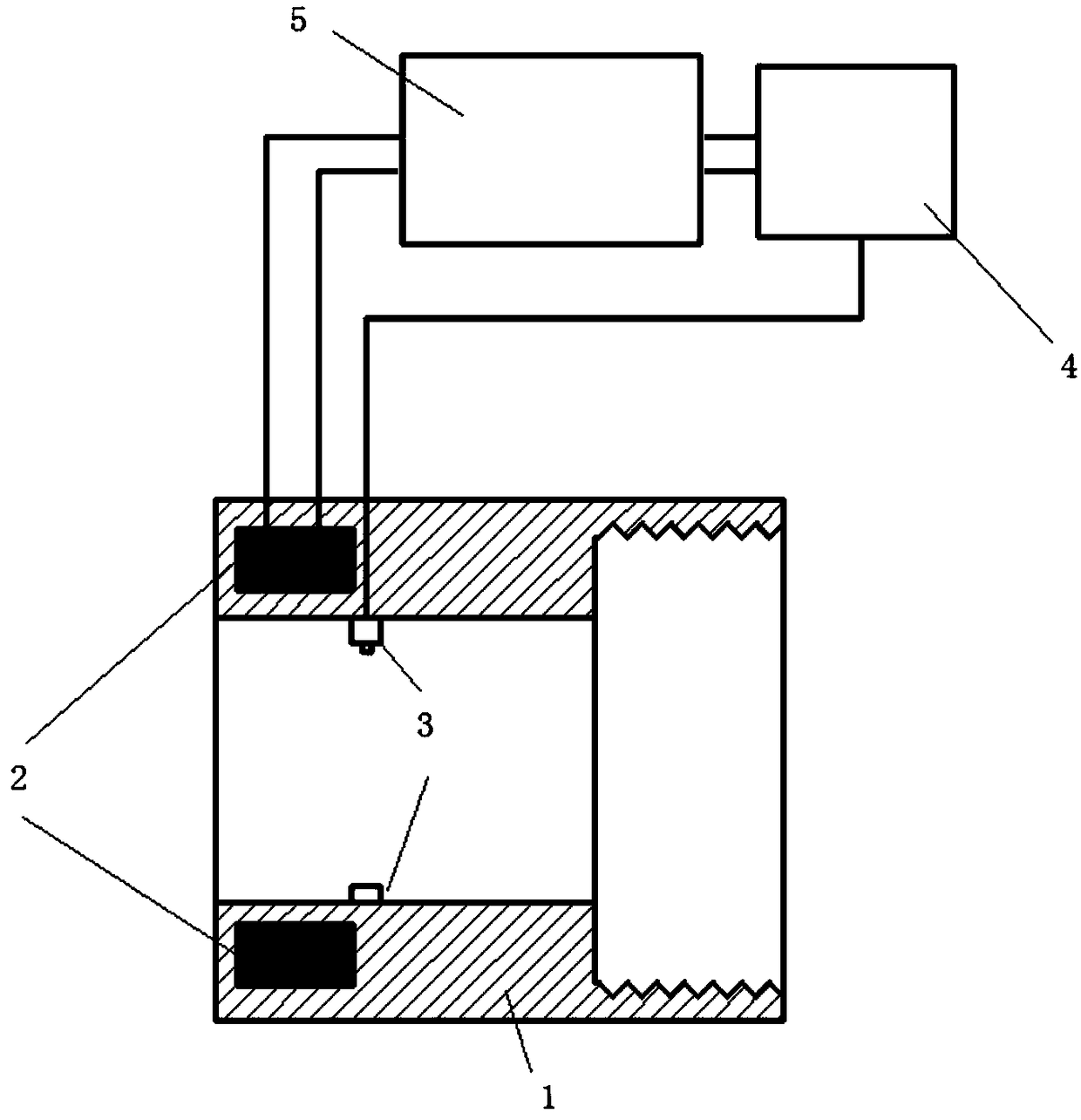

Producing device of high-purity selenium and producing process

ActiveCN1927701AEasy to collectHelp to separateElemental selenium/telluriumTemperature controlBoiling point

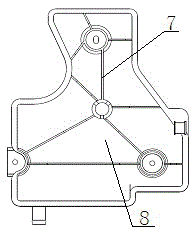

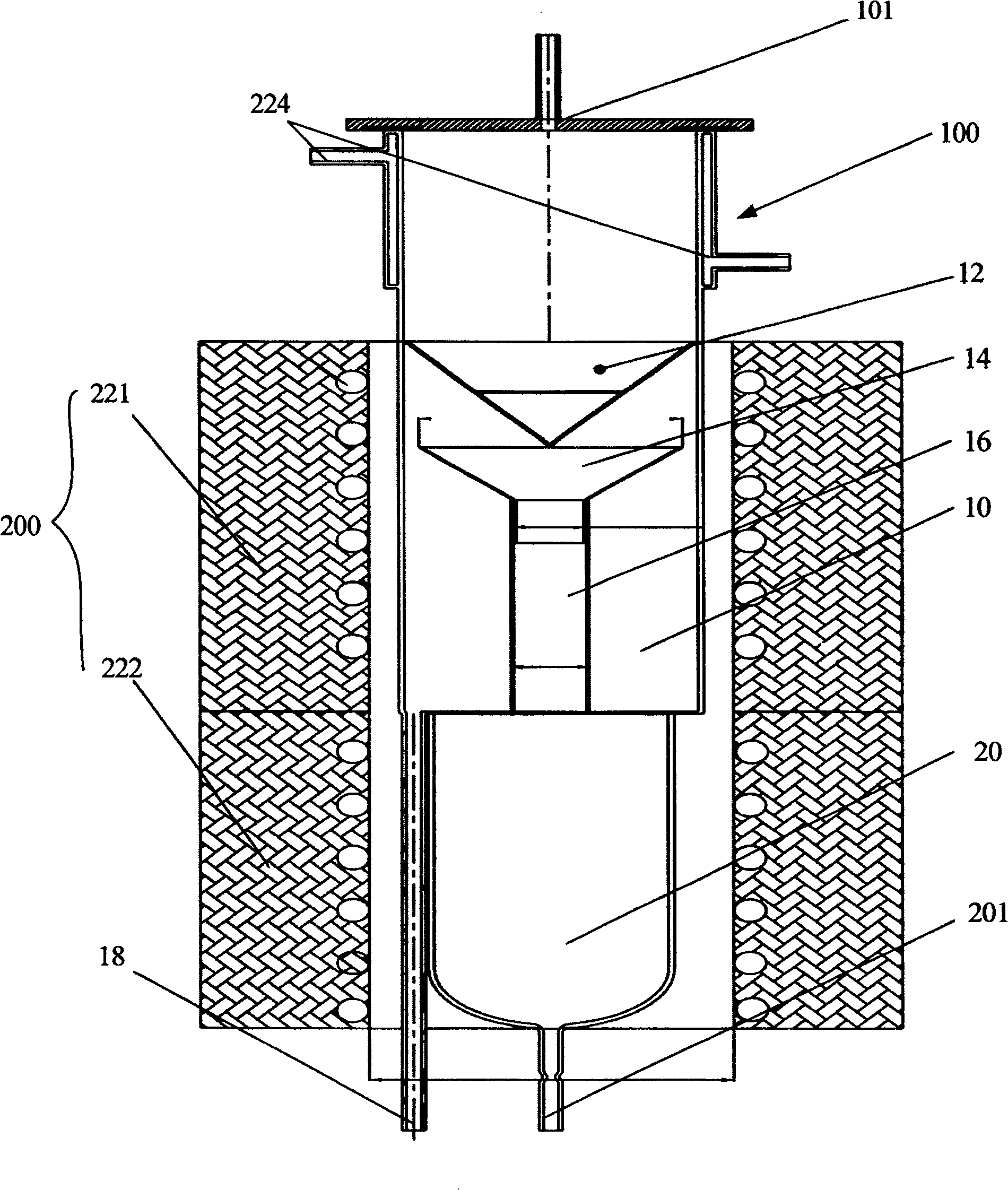

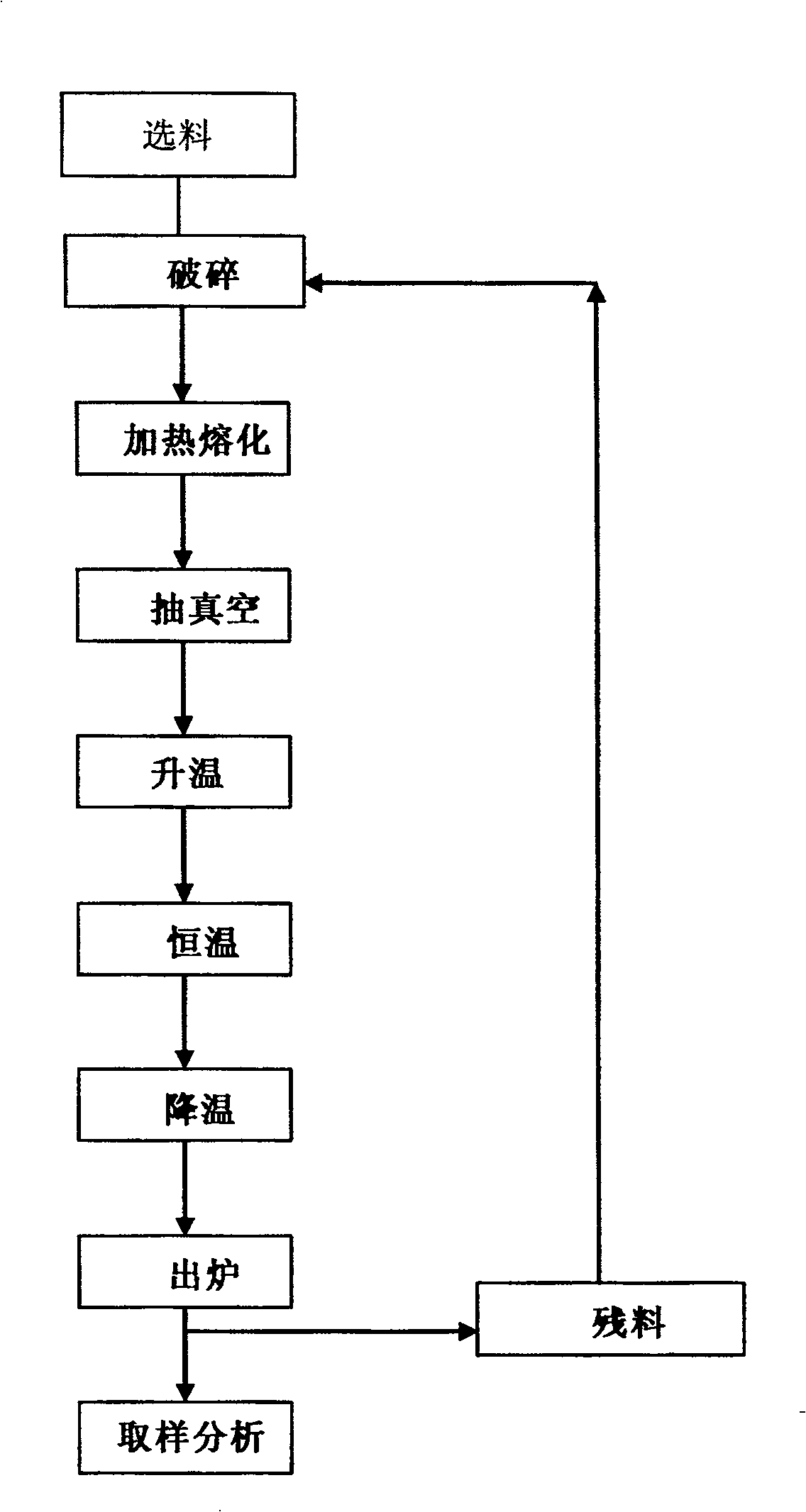

High purity selenium producing apparatus and process are disclosed. The producing apparatus includes one rectifying unit coated with heat insulating layer, one temperature controlling system and one vacuum system comprising one mechanical pump and one diffusion pump. The rectifying unit with vacuum gland in the upper part is divided into one material layer and one product layer communicated mutually. The material layer includes one conical condenser, one umbrella shaped material accepter and one connecting pipe vertically distributed successively; and the product layer is provided with one product kettle connected through the connecting pipe to the material accepter. The rectifying unit in inside multilayer structure is favorable to the separation of selenium from other impurity elements, and has high yield and high product purity.

Owner:广东先导稀贵金属材料有限公司

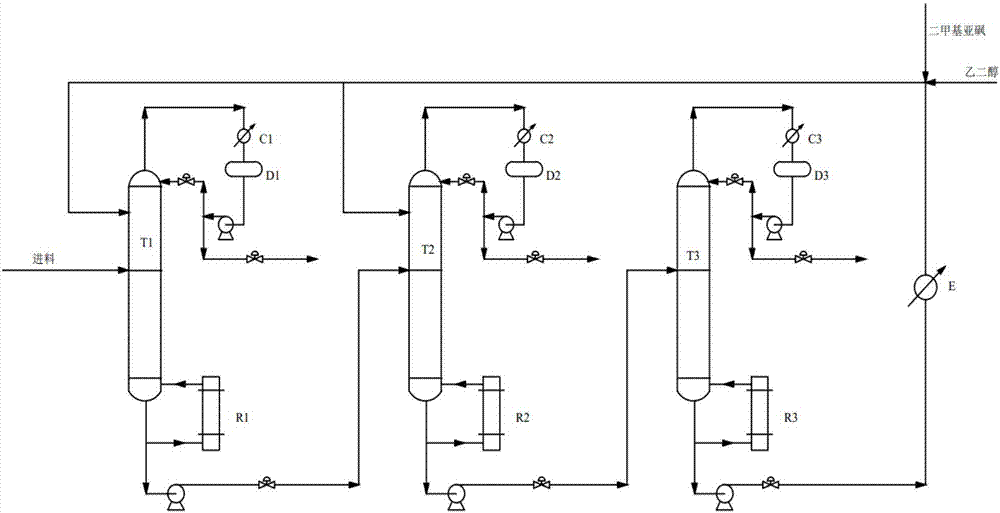

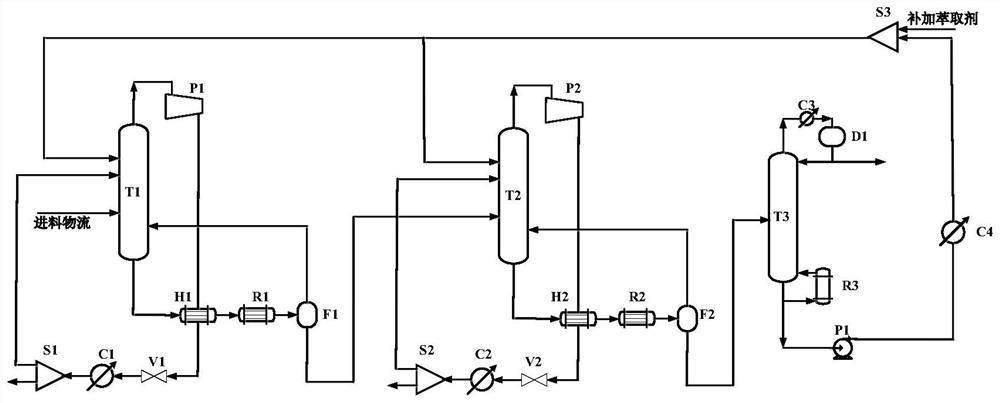

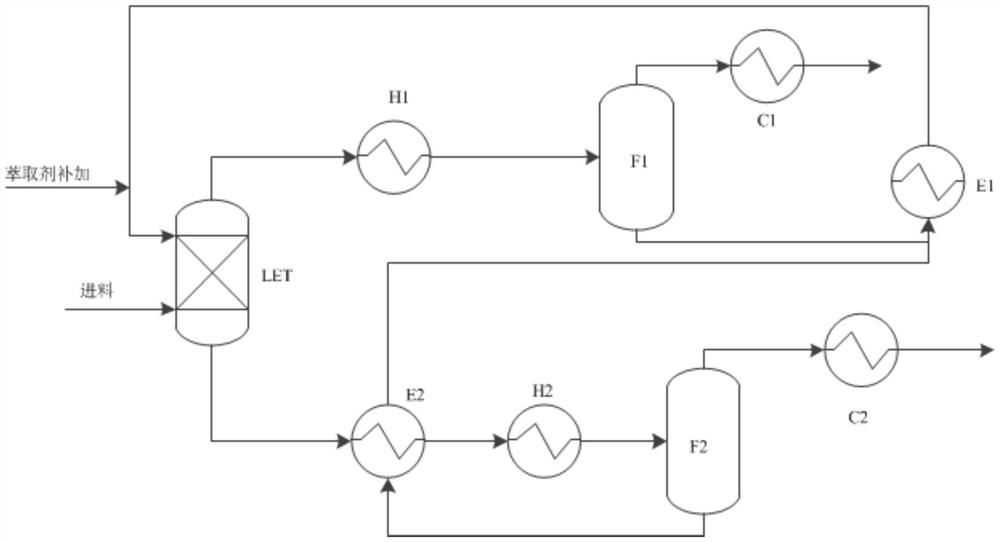

Method for separating tetrahydrofuran-ethyl alcohol-water mixture by mixed extraction agent

ActiveCN106967017ASolving intractable puzzlesEasy to separateOrganic compound preparationHydroxy compound preparationHeat stabilityAlcohol products

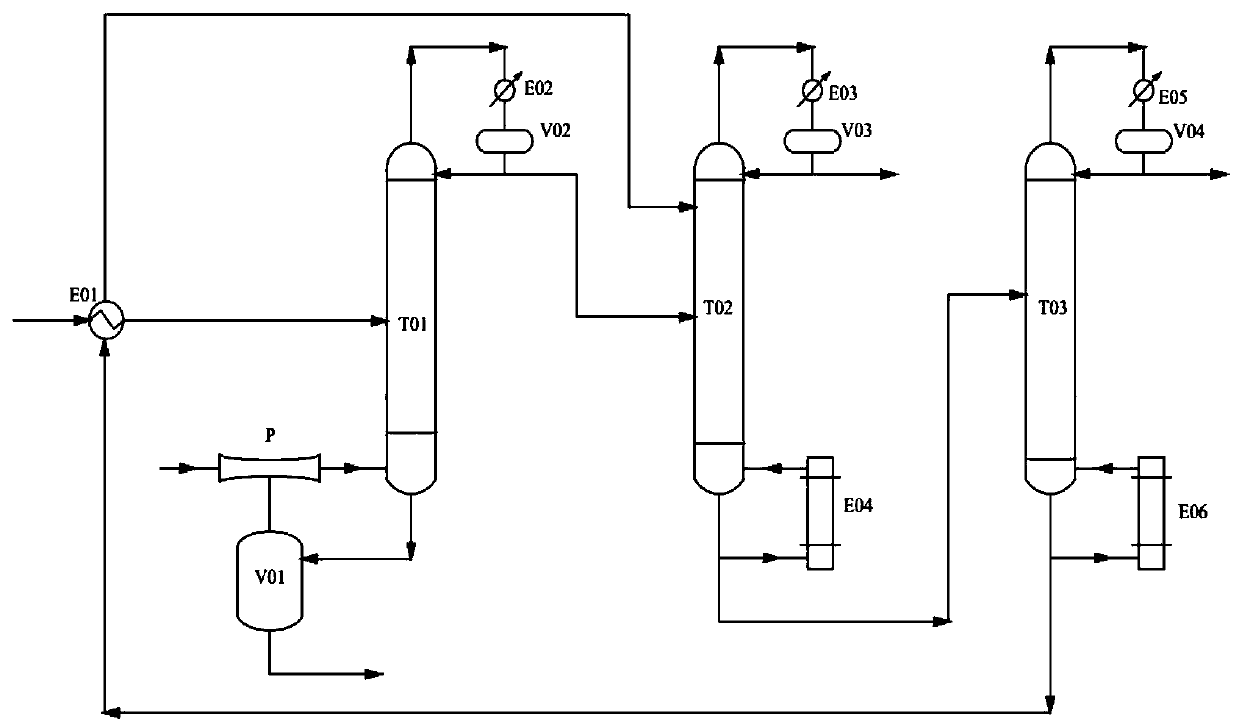

The invention relates to a method for separating a tetrahydrofuran-ethyl alcohol-water mixture by a mixed extraction agent and a device suitable for the method. According to the method, dimethyl sulfoxide and ethylene glycol are mixed into a mixed extraction agent in certain proportion, the tetrahydrofuran-ethyl alcohol-water mixture firstly enters a first extraction rectifying tower for separation, a tetrahydrofuran product is obtained at the tower top, tower bottom materials enter a second extraction rectifying tower for separation, an ethyl alcohol product is extracted from the tower top, a tower bottom extraction agent and water mixture enters an extraction agent recovery tower, water is extracted from the tower top, and the extraction agent is recycled after being extracted from the tower bottom. The method has the advantages that the energy consumption is low, the technology is simple, equipment investment is small, the product purity of the separated tetrahydrofuran and ethyl alcohol is high and the like, and the adopted ethylene glycol and dimethyl sulfoxide mixed extraction agent can break three binary azeotropes in the system simultaneously and is easy to recycle and good in chemical heat stability.

Owner:QINGDAO UNIV OF SCI & TECH

Method and device for separating acetic acid sec-butyl ester and sec-butyl alcohol

InactiveCN105111079AEasy to separateFulfil requirementsOrganic compound preparationCarboxylic acid esters preparationAcetic acidSolvent

The invention provides a method and device for separating acetic acid sec-butyl ester and sec-butyl alcohol. The method comprises the steps that 1, a mixture of the acetic acid sec-butyl ester and the sec-butyl alcohol is put into an extraction rectifying tower, an extraction agent is added, after extraction rectifying separation is performed, the acetic acid sec-butyl ester is steamed out from the tower top and condensed, then part of the acetic acid sec-butyl ester is used for reflux, part of the acetic acid sec-butyl ester is extracted to obtain the acetic acid sec-butyl ester, and a mixture of the sec-butyl alcohol and the extraction agent falls into the tower bottom; 2, the mixture of the sec-butyl alcohol and the extraction agent is extracted out from the tower bottom and then put into a solvent concentration tower, the sec-butyl alcohol is steamed out from the tower top and then condensed, then part of the sec-butyl ester is put into the solvent concentration tower for reflux, part of the sec-butyl ester is extracted to obtain the sec-butyl ester, and the extraction agent falls into the tower bottom; 3, the extraction agent is extracted out from the tower bottom and then returns to the extraction rectifying tower for cyclic utilization. According to the method, the problem that in the prior art, the acetic acid sec-butyl ester and the sec-butyl alcohol are difficult to separate is solved, the purity of the separated acetic acid sec-butyl ester is above 99 percent, and the purity of the separated sec-butyl ester is above 99.9 percent; meanwhile, the energy consumption of the separation process is low, the procedures are simple, and operation is easy.

Owner:HUNAN ZHONGCHUANG CHEM

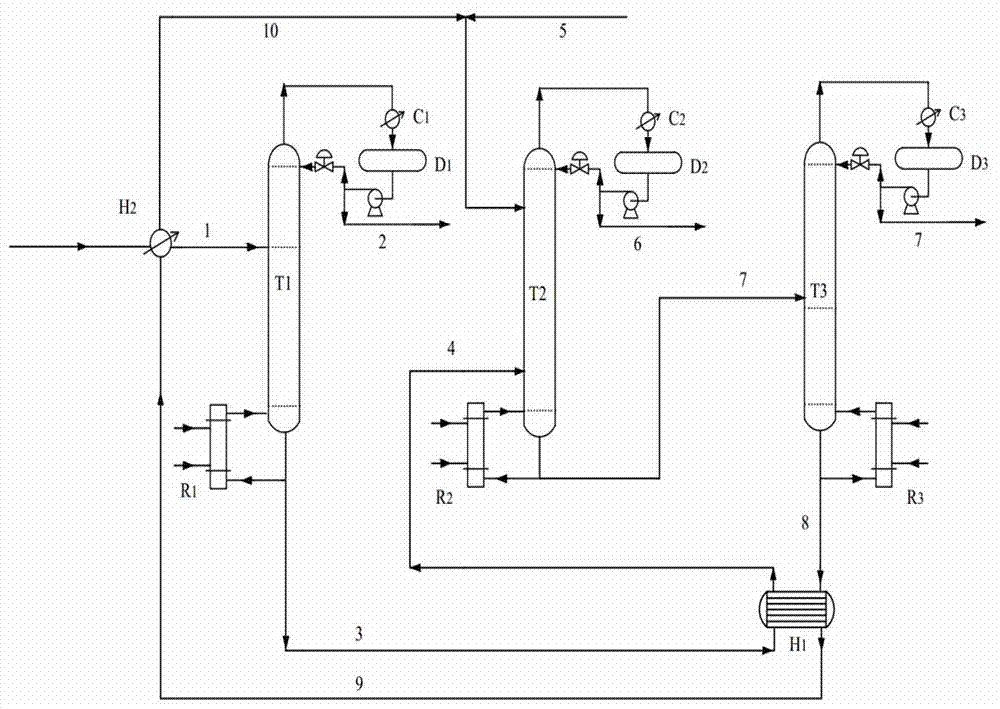

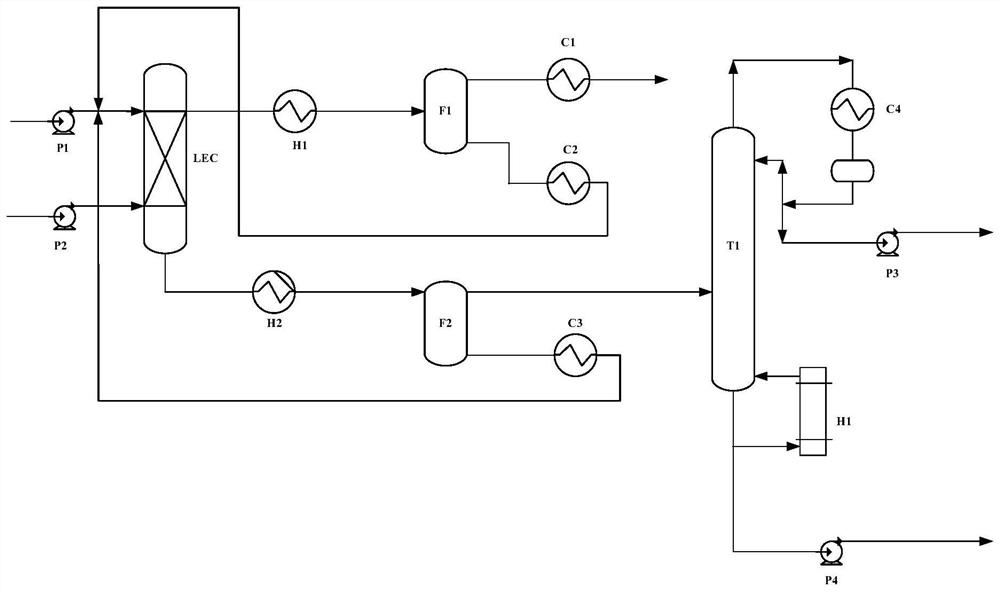

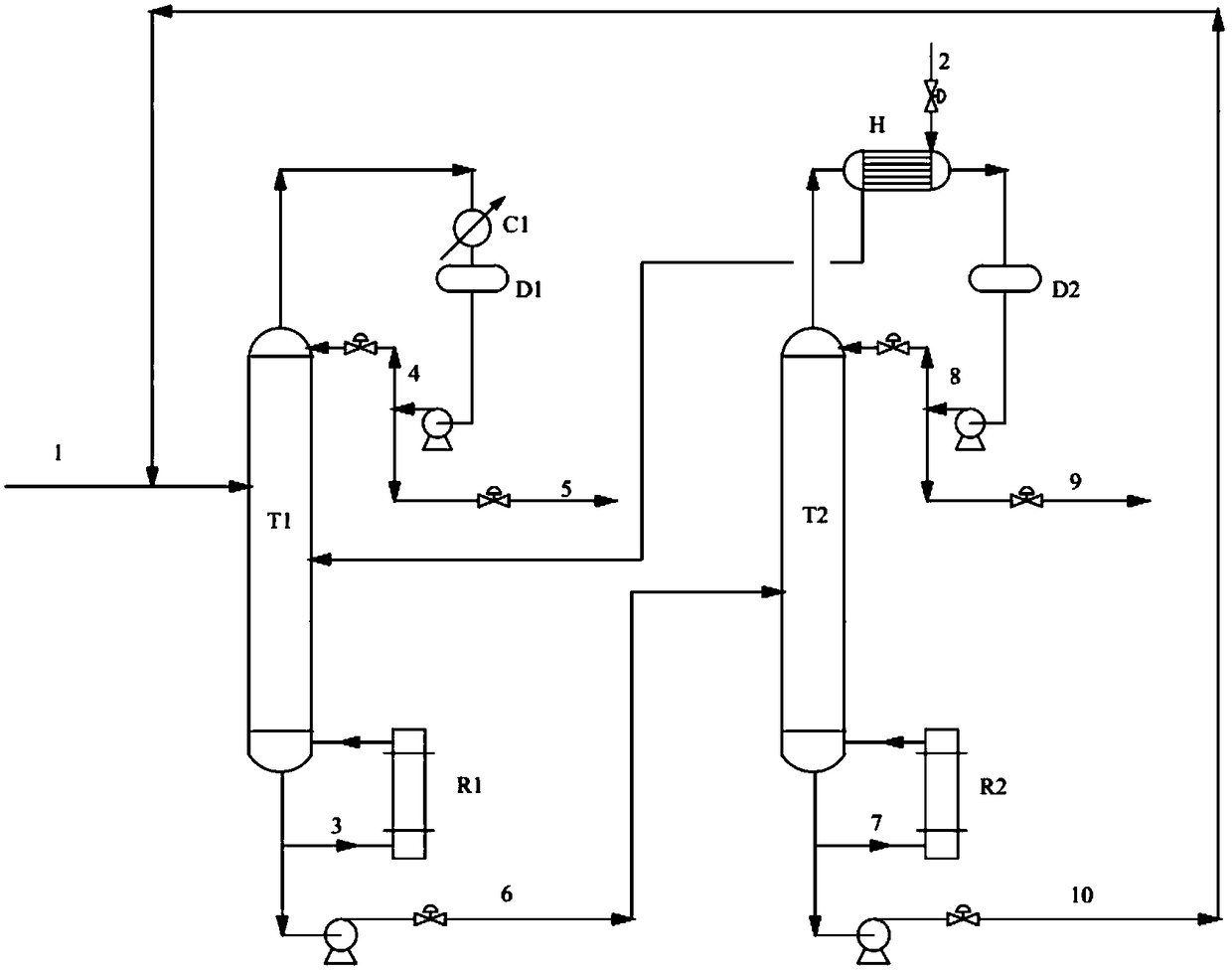

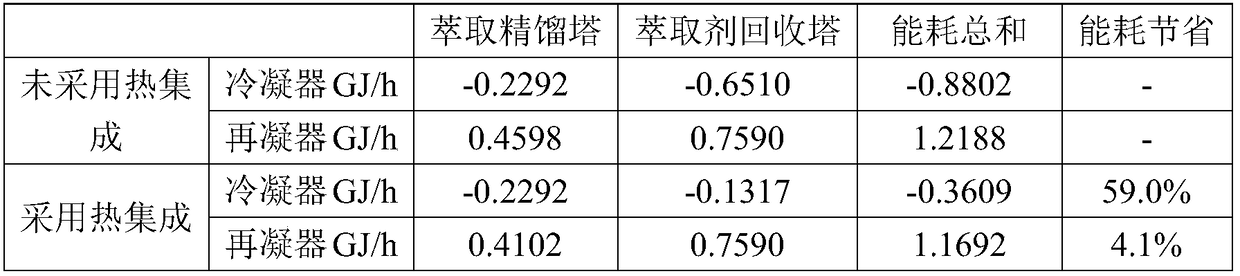

Method of separating acetone-isopropanol-water by three-tower heat-integrated extraction distillation

ActiveCN107473947AEmission complianceSolving intractable puzzlesOxygen-containing compound preparationOrganic compound preparationExtractive distillationEnergy conservation

The invention relates to a method of separating acetone-isopropanol-water by three-tower heat-integrated extraction distillation. A device mainly comprises an acetone tower T1, an isoprpanol tower T2, a solvent recovery tower T3, a heat exchanger H1 and a preheater H2. In the method provided by the invention, a tree-tower distillation way is adopted; acetone which has a lower boiling point is evaporated first; then an isopropanol-water binary azeotrope is separated by extraction distillation; and high-purity acetone and isopropanol are obtained. A second condensation method is used to cool the material flow of a circulating extracting agent, so that high-efficiency used of the material flow is realized; and the heat-integrated way is used to reach a goal of saving energy resources. The method solves the problems of complex process, large energy consumption and low product yield in the prior art, and increases the purity and yield of products.

Owner:青岛三瑞节能环保技术有限公司

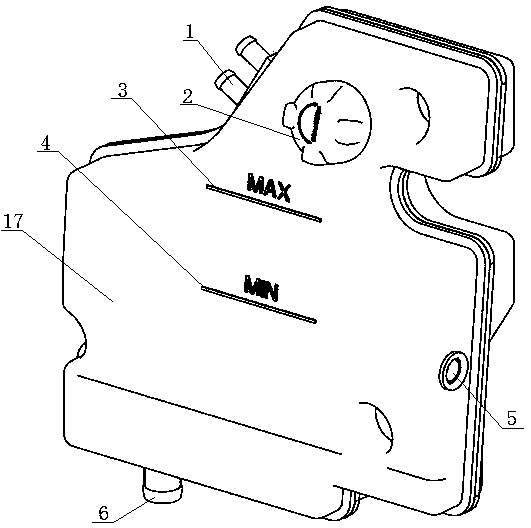

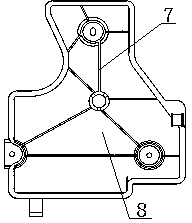

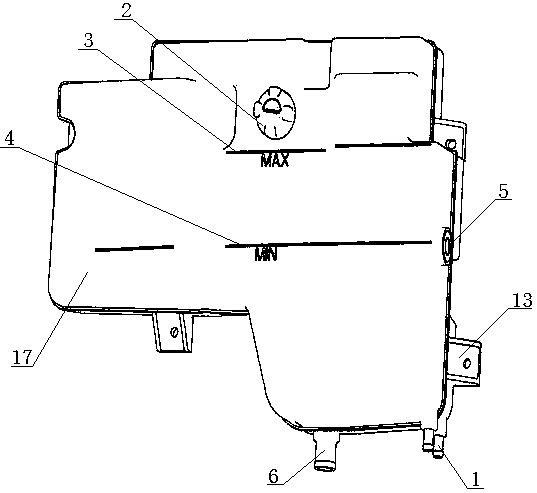

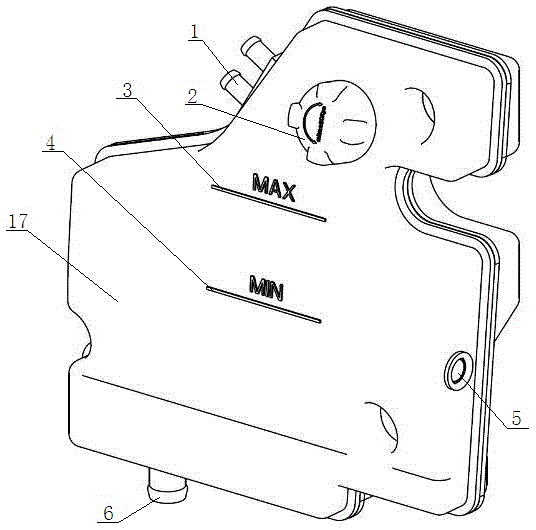

Expansion tank of automobile

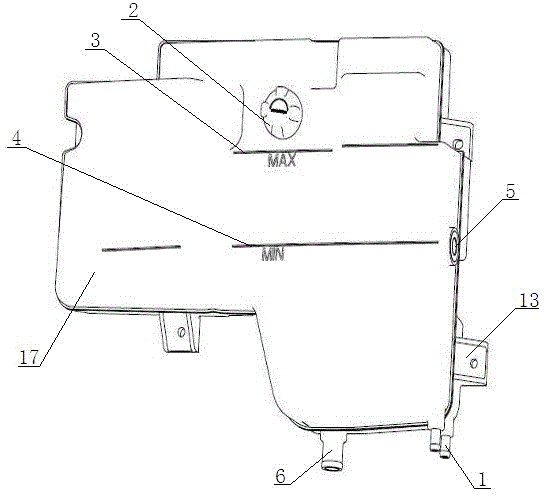

ActiveCN104018928ASolve layout difficultiesSmooth and beautifulMachines/enginesEngine cooling apparatusExpansion tankThermodynamics

An expansion tank of an automobile comprises a tank body (17). The tank body (17) is provided with two air removing pipe ports (1), an injection port, a liquid-level sensor connector (5) and a water returning pipe port (6). The two air removing pipe ports (1) are formed in the bottom of the tank body (17) side by side. A reinforcing rib separation portion (9) is vertically arranged in a tank body cavity (8) and is close to the outer wall of the edges, except for the sides with the two air removing pipe ports (1), of the tank body (17). The tank body cavity (8) is divided into a pressure-releasing cavity (10) and a working cavity (18) through the reinforcing rib separation portion (9). An upper pressure-releasing hole (12) and a lower pressure-releasing hole (19) are respectively formed in the upper end of the reinforcing rib separation portion (9) and are vertically distributed. The pressure-releasing cavity (10) is communicated with the two air-removing pipe ports (1). The cooling liquid overflowing and water-returning phenomenon caused by overlarge internal pressure of the tank body (17) is avoided.

Owner:DONGFENG COMML VEHICLE CO LTD

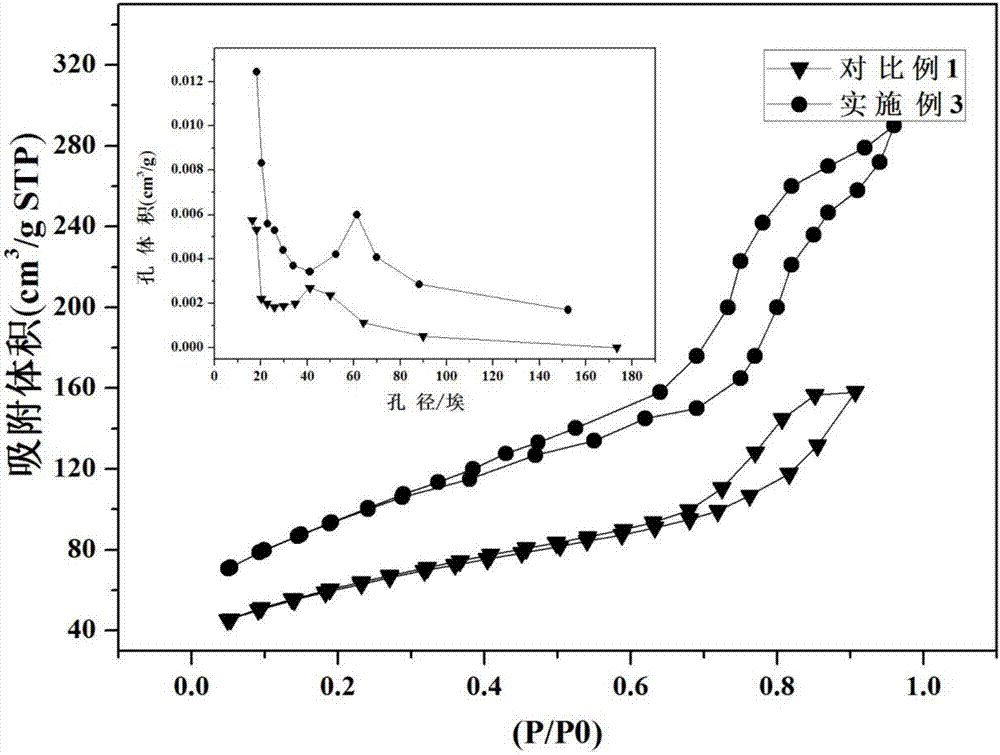

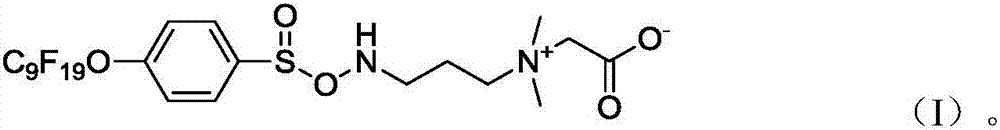

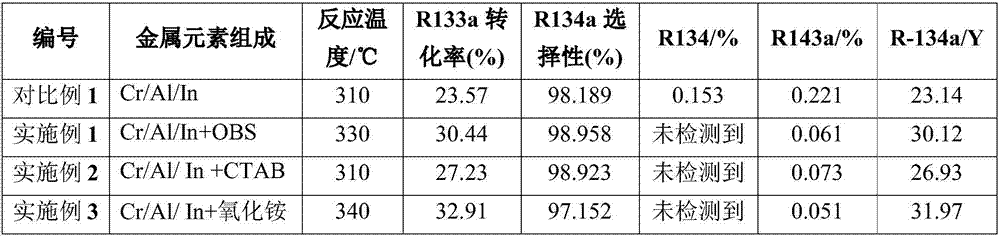

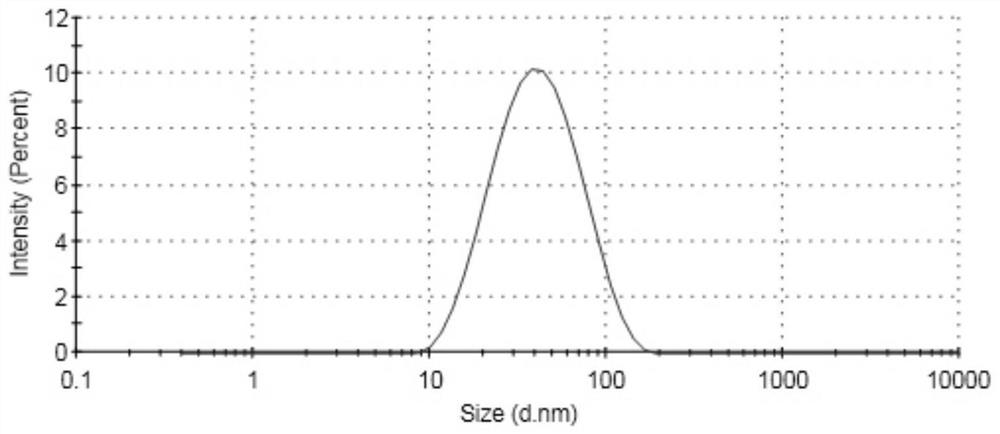

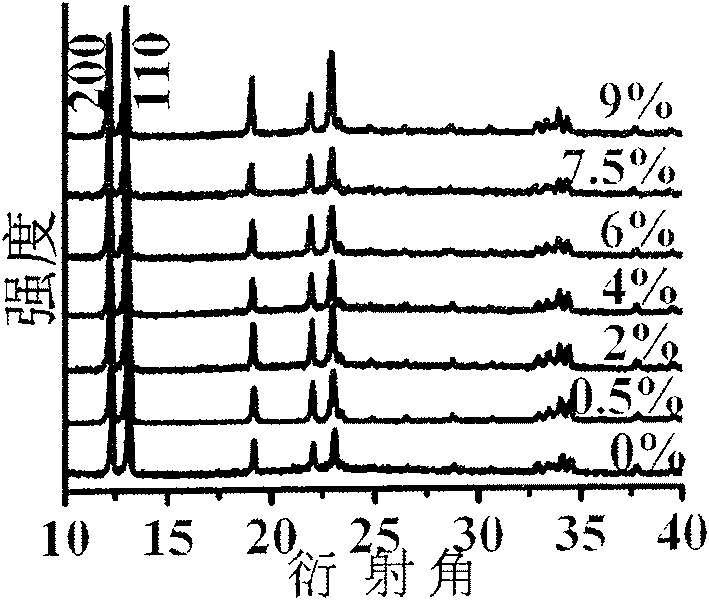

Mesoporous chromium-based fluorination catalyst and preparation method of same

ActiveCN107497461ALow selectivityReduce energy consumptionPhysical/chemical process catalystsPreparation by halogen replacementGas phasePore diameter

The invention relates to a mesoporous chromium-based fluorination catalyst and a preparation method of same. The fluorination catalyst includes chromium, aluminum and other metals according to the mass ratio of 40-80:20-30:0-20. A precursor of the fluorination catalyst is 6.0-8.0 nm in pore diameter and is 400-500 m<2> / g in specific surface area. The preparation method includes the steps of: dissolving chromium salt, aluminum salt, salts of other metals, and a surfactant in water; performing precipitation with ammonia water; moving the liquid to a crystallization tank, and performing crystallization to obtain a turbid liquid; filtering the turbid liquid, water-washing a solid, drying and roasting the solid, crushing and mixing the solid, and tabletting the solid to form a catalyst precursor; and fluorinating the precursor to obtain the fluorination catalyst. The mesoporous chromium-based fluorination catalyst has large specific surface area, excellent pore structure and high catalytic activity, and is suitable for application of gas-phase fluorination reaction; especially, the catalyst, when being applied to preparation of R134a, is good in control effect on byproducts.

Owner:RUYUAN DONGYANG LIGHT FLUORIDE CO LTD

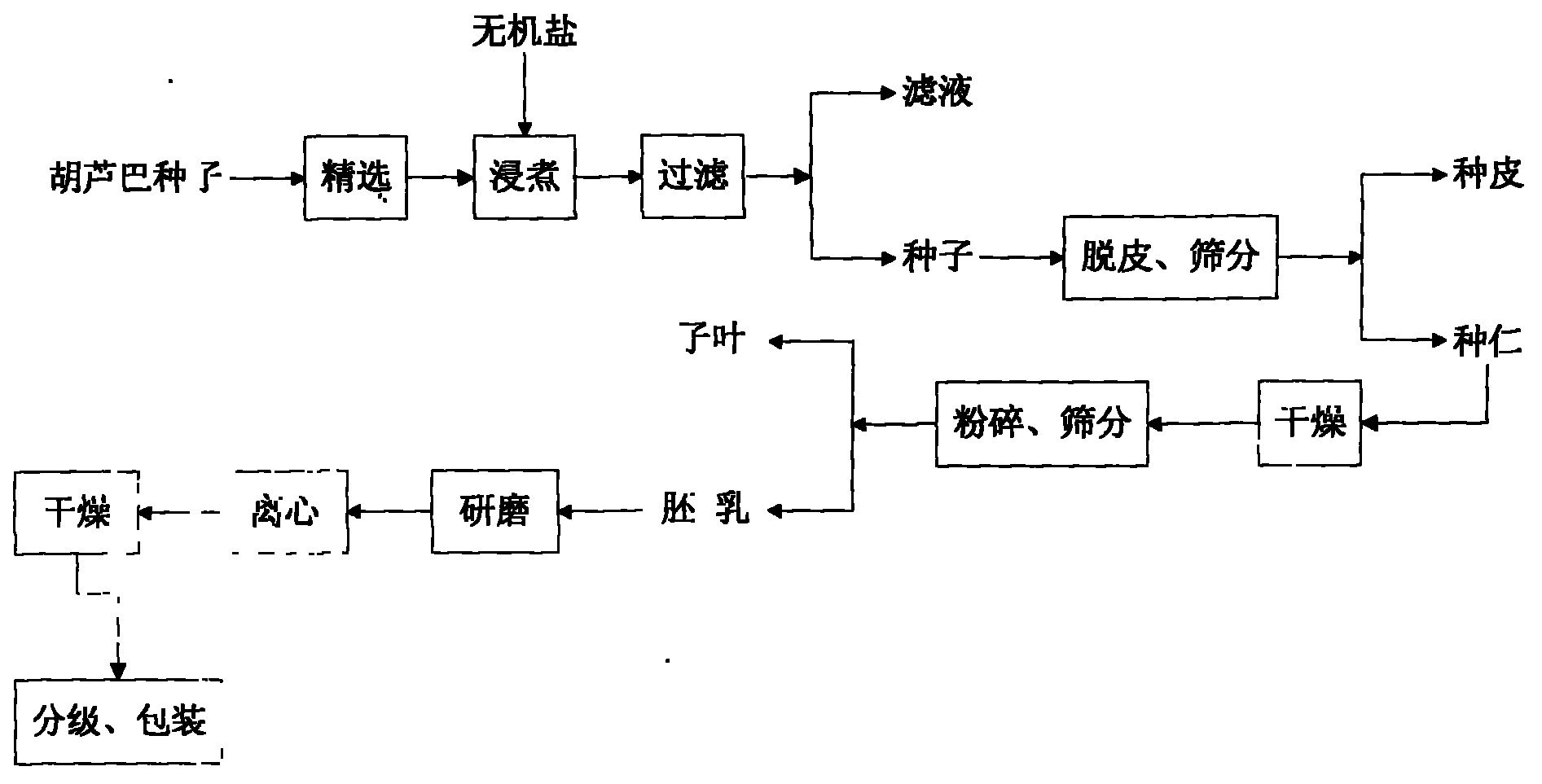

Production method of fenugreek gum

The invention discloses a production method of fenugreek gum. The production method comprises the following steps of a, cleaning and winnowing seeds; b, adding inorganic salt in selected seeds according to a proportion of seed weight to inorganic salt volume of 1:(10-50), digesting, and filtering to eliminate a digestion solution; c, peeling and screening the filtered seeds to obtain seed kernels; d, drying and dehumidifying the seed kernels obtained in the step c, and controlling the water content to be 8-25 percent; e, separating endosperms of the seed kernels obtained in the step d from cotyledons of the seed kernels, and collecting the endosperms and the cotyledons; f, grinding the cotyledons obtained in the step e in ethyl alcohol to obtain ground fenugreek gum; and g, centrifuging, drying and grading the ground fenugreek gum obtained in the step f, and packaging a finished product. According to the production method, the process is simplified, and the quality of the fenugreek gum is improved.

Owner:NINGXIA UNIVERSITY

Method for separating cyclohexane and tert-butyl alcohol through liquid-liquid extraction-flash evaporation

PendingCN112225634AHigh puritySolving intractable puzzlesOrganic compound preparationHydrocarbon purification/separationPhysical chemistryEngineering

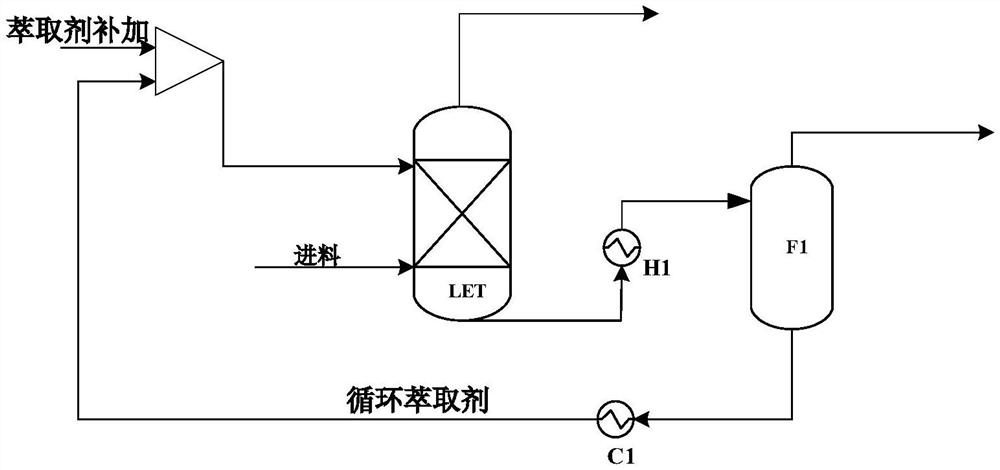

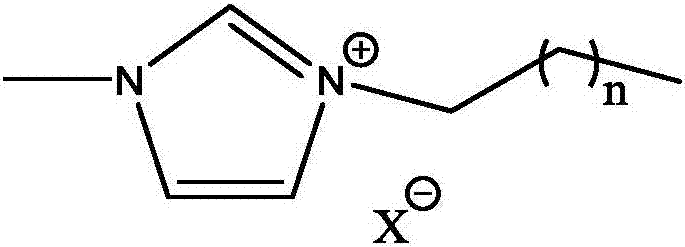

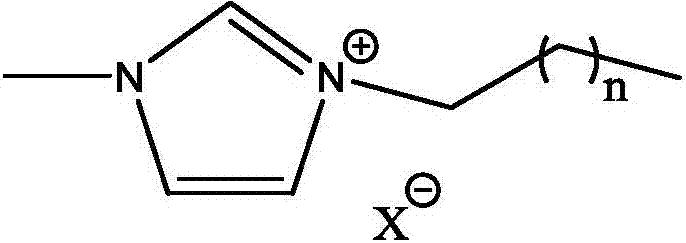

The invention relates to a method for separating cyclohexane and tert-butyl alcohol through liquid-liquid extraction flash evaporation and a device suitable for the method. According to the method, imidazole ionic liquid is used as an extraction agent, cyclohexane and tert-butyl alcohol firstly enter a liquid-liquid extraction tower to be extracted and separated, high-purity cyclohexane is obtained at the top of the liquid-liquid extraction tower, materials at the bottom of the liquid-liquid extraction tower enter a flash tank to be separated, and high-recovery-rate tert-butyl alcohol is obtained at the top of the flash tank. High-purity ionic liquid is extracted from the bottom of the flash tank for recycling. The method has the advantages of low energy consumption, simple process, high purity of cyclohexane after separation and the like, the adopted extracting agent imidazole ionic liquid is hardly volatilized, the loss of the extracting agent is reduced, and the method is easy to recover, good in chemical thermal stability, green and pollution-free.

Owner:洪泽县恒泰科工贸有限公司

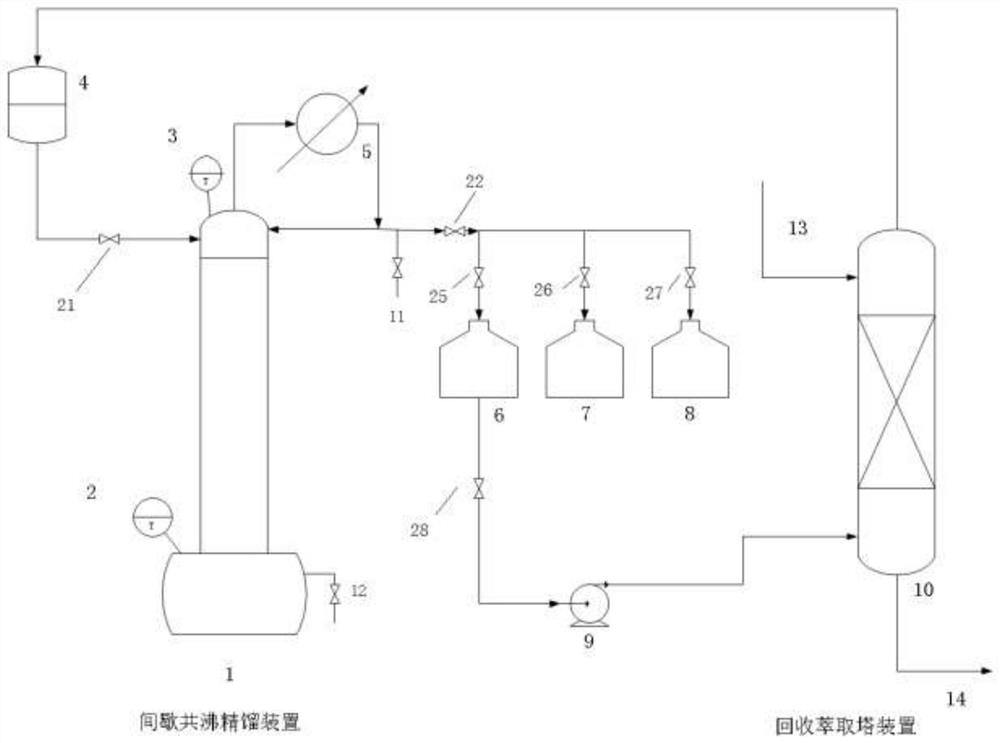

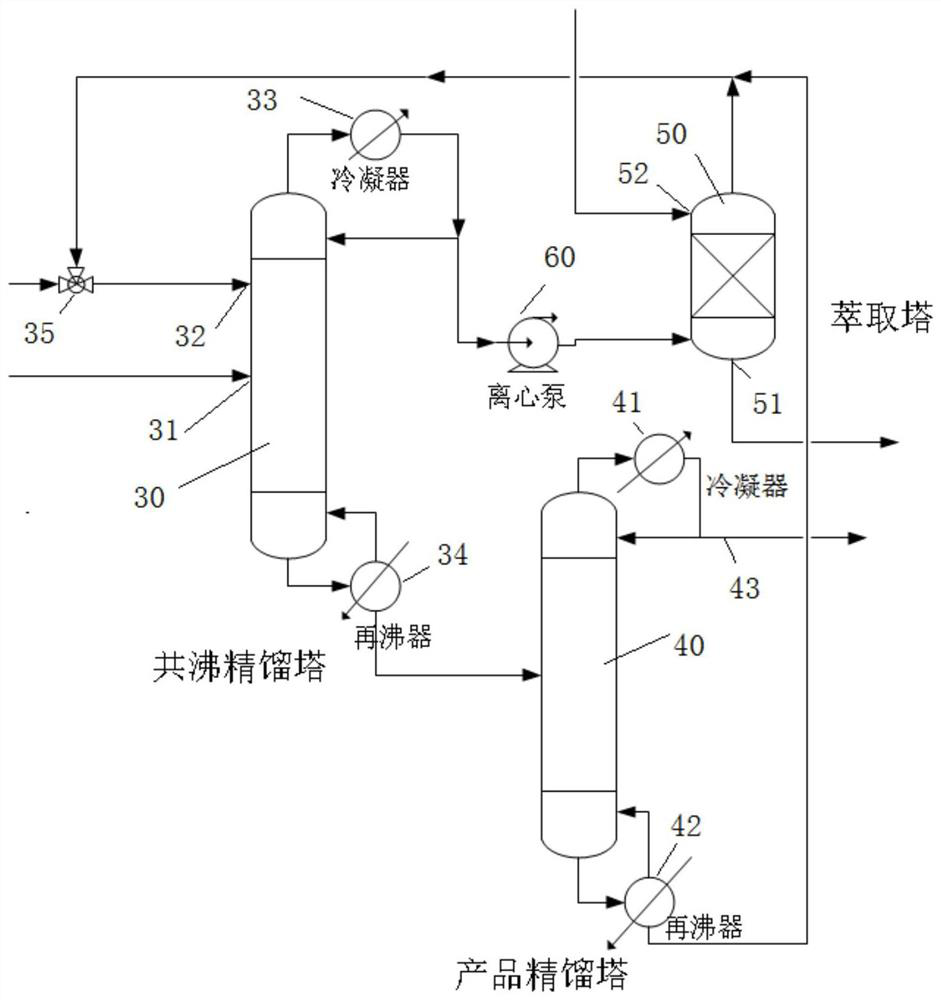

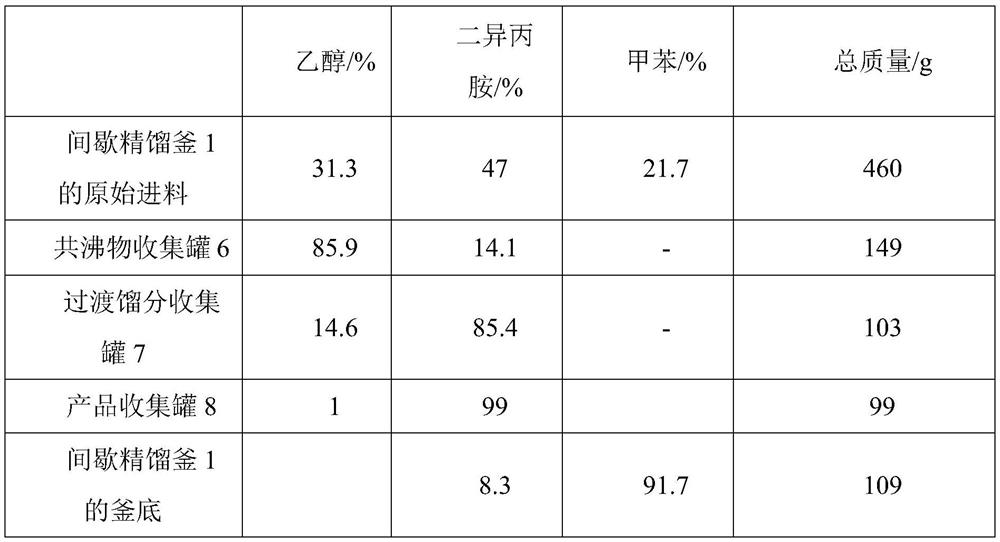

Method for separating mixture of diisopropylamine and ethanol through azeotropic distillation

ActiveCN112441929ASolving intractable puzzlesFlexible processAmino compound purification/separationOrganic compound preparationAlcohol ethylDiisopropylamine

The invention discloses a method for separating a mixture of diisopropylamine and ethanol by azeotropic distillation. According to the method, the mixture of diisopropylamine and ethanol taken as a raw material is a mixed solution mainly composed of diisopropylamine and ethanol and containing a small amount of water, firstly dehydration treatment is conducted on the mixed solution until a dewatered mixed solution with the water content of less than 1% is obtained; and a azeotropic agent and the dewatered mixed solution are rectified in an azeotropic rectification tower by adopting a batch rectification method or a three-tower continuous rectification method, and ethanol in the dewatered mixed solution is entrained out by the azeotropic agent, so that the aim of separating diisopropylamineand ethanol is fulfilled, wherein the azeotropic agent is toluene. According to the invention, water is used as an extractant to recover toluene, so addition of additional third components for separation and recovery of toluene is avoided, and energy consumption is reduced.

Owner:QUZHOU RES INST OF ZHEJIANG UNIV +1

Method for treating metronidazole wastewater

ActiveCN105776707AAchieve recyclingReduce pollutionOrganic compound preparationWater contaminantsInorganic saltsPre treatment

The invention belongs to the technical field of industrial wastewater treatment and recycling, and relates to a method for treating metronidazole wastewater. The method comprises the steps of pretreating and recycling salts and organic matters in metronidazole production wastewater, so that the content of polluting organic matters and inorganic salts in the metronidazole wastewater is reduced, and finally, the wastewater amount in every tonnage of metronidazole is reduced from the original 15 tons to about 1 tons.

Owner:HUBEI HONGYUAN PHARMA

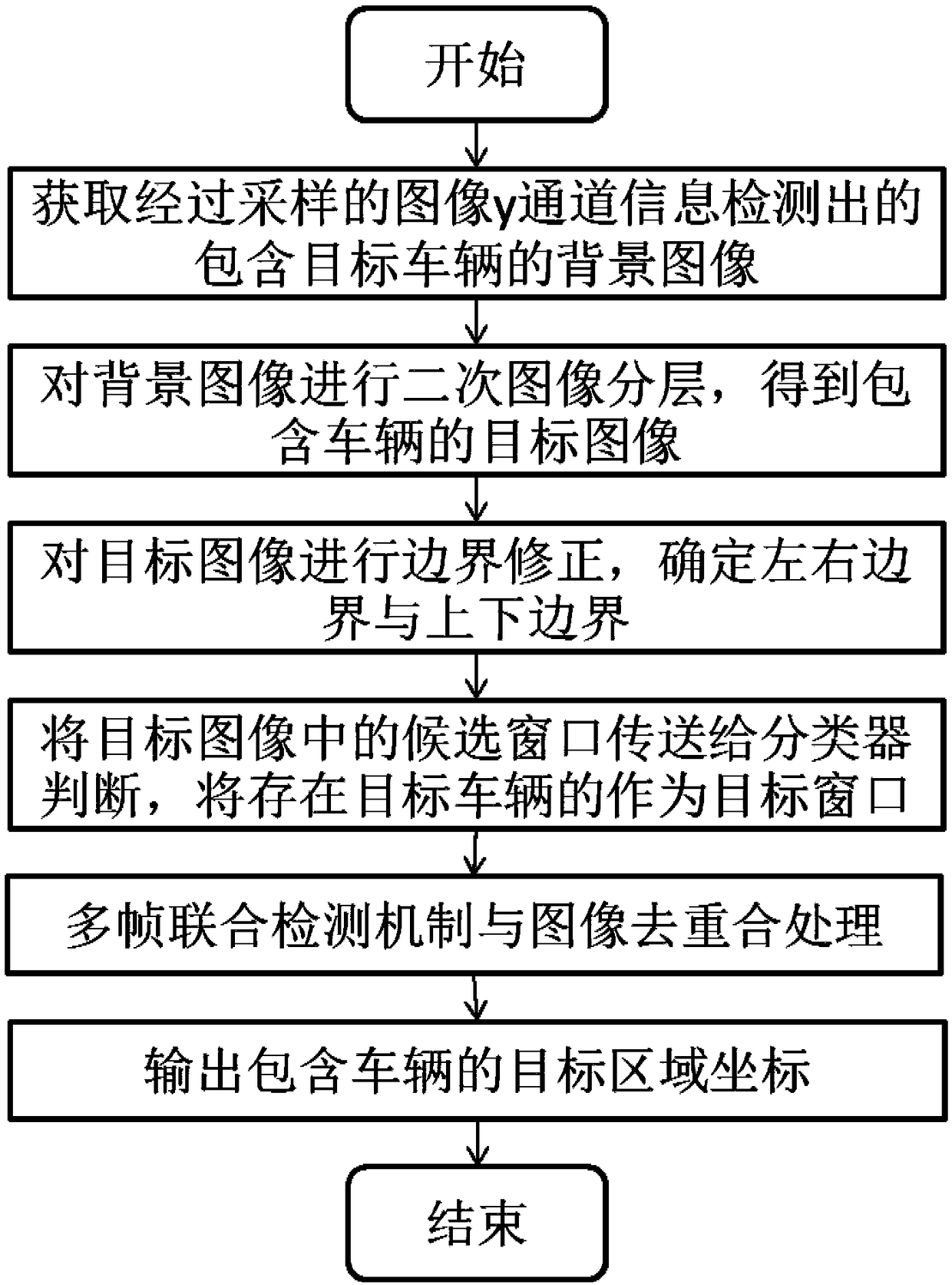

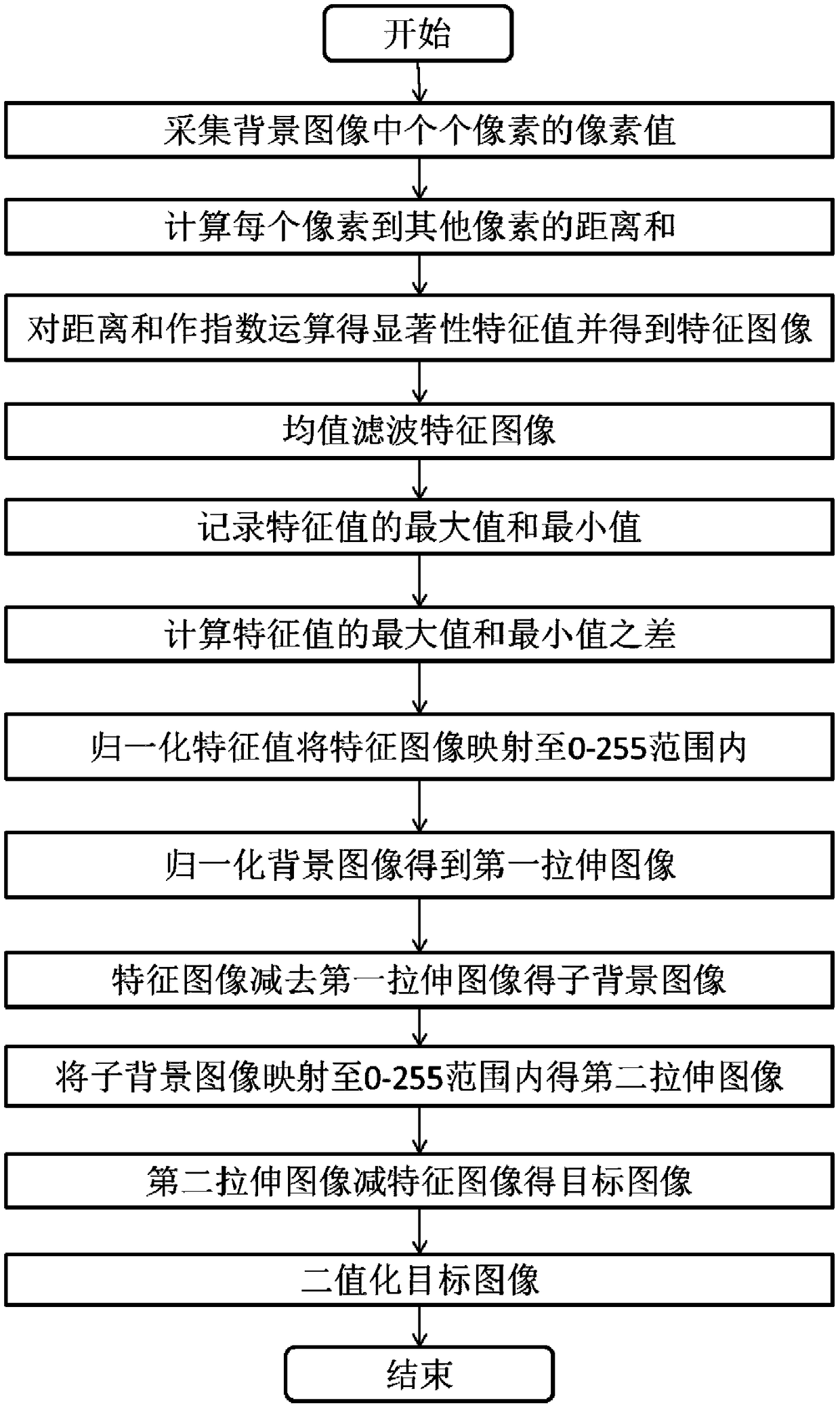

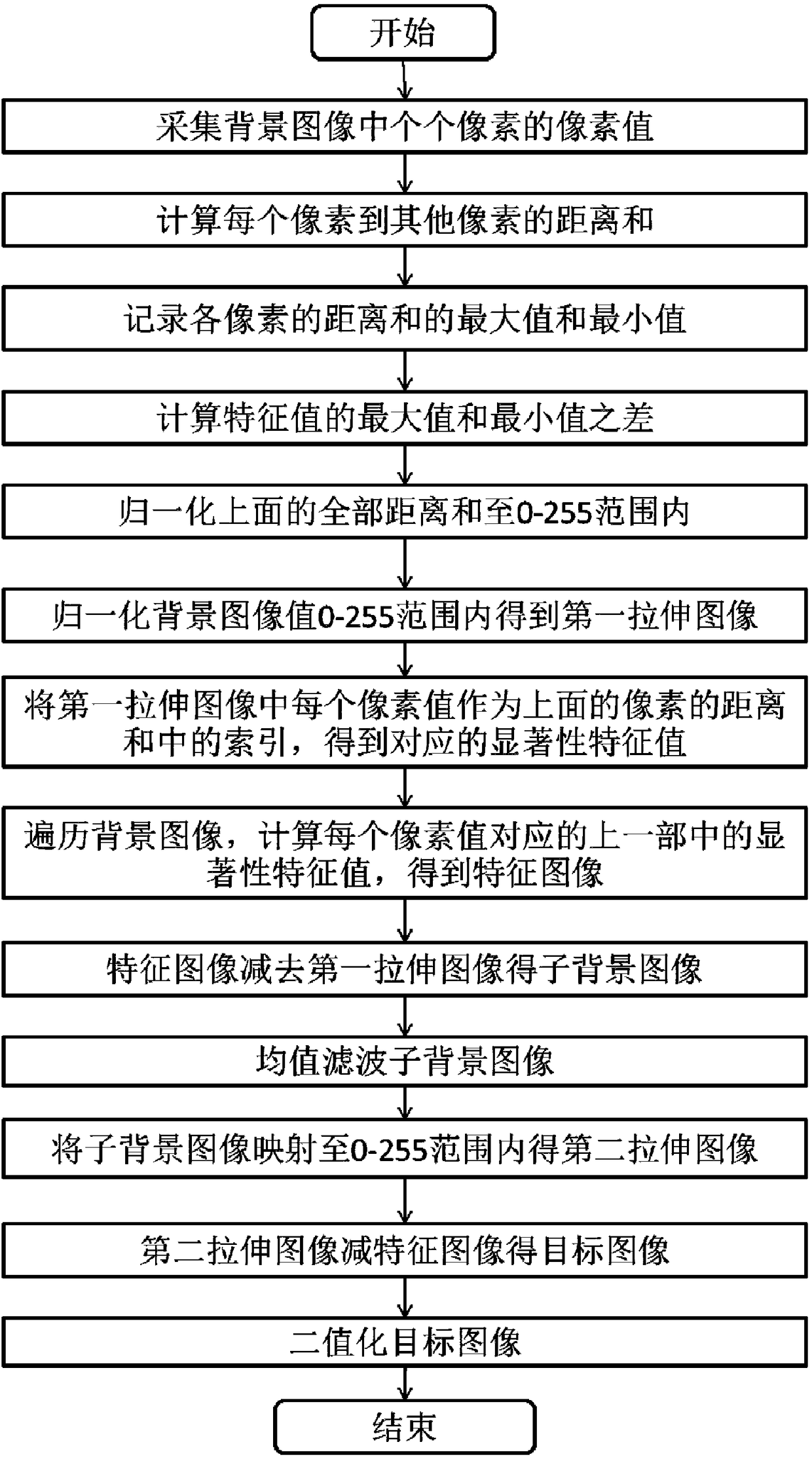

Vehicle detection method and system based on image segmentation technology

ActiveCN108629226ASolving intractable puzzlesReduce false alarmsImage enhancementImage analysisMultiple frameVehicle detection

The invention discloses a vehicle detection method based on image segmentation technology. The method comprises the following steps: collecting a background image comprising a vehicle; carrying out secondary image segmentation on the background image to obtain a target image comprising the vehicle; carrying out boundary correction on the target image; detecting candidate windows of a current framegenerated according to a neighborhood range, where the vehicle is detected, in multiple frames target images before the current frame through multi-frame joint, and serving the window, where the vehicle is detected, in the candidate windows as a target window; and carrying out image de-overlapping processing on all frames of target windows to obtain a target region comprising the vehicle; and outputting a target region coordinate. The invention also discloses a vehicle detection system based on the image segmentation technology. The system comprises an image acquisition module, an image segmentation module, an image de-overlapping module and an output module.

Owner:ZONGMU TECH SHANGHAI CO LTD

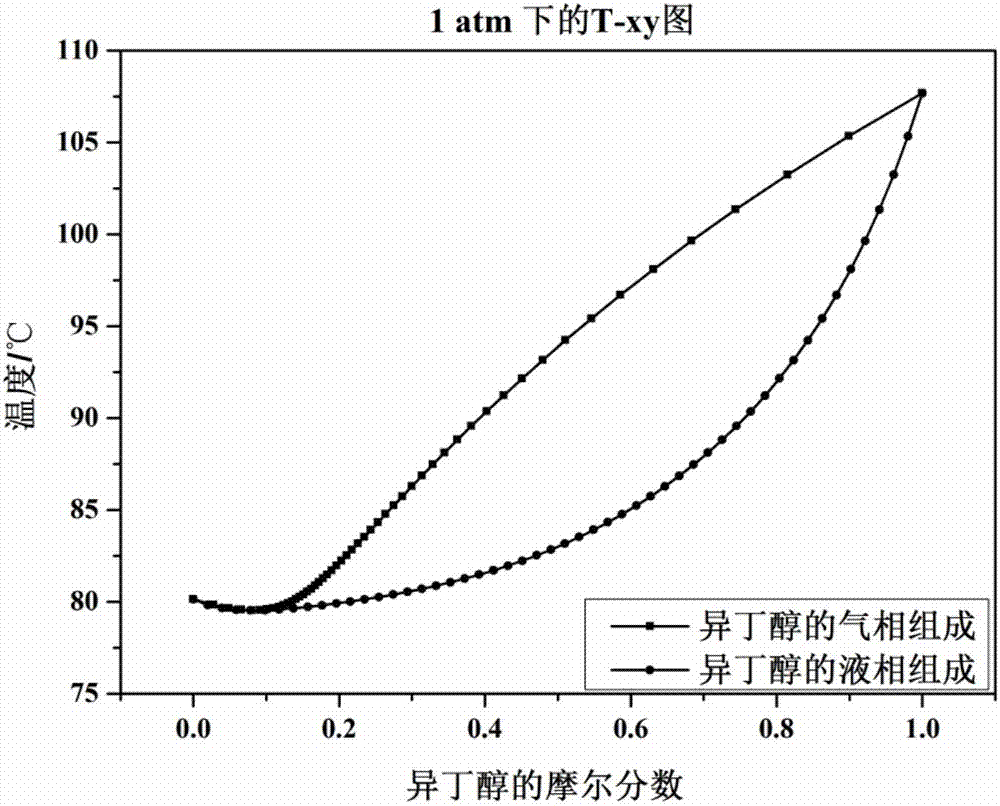

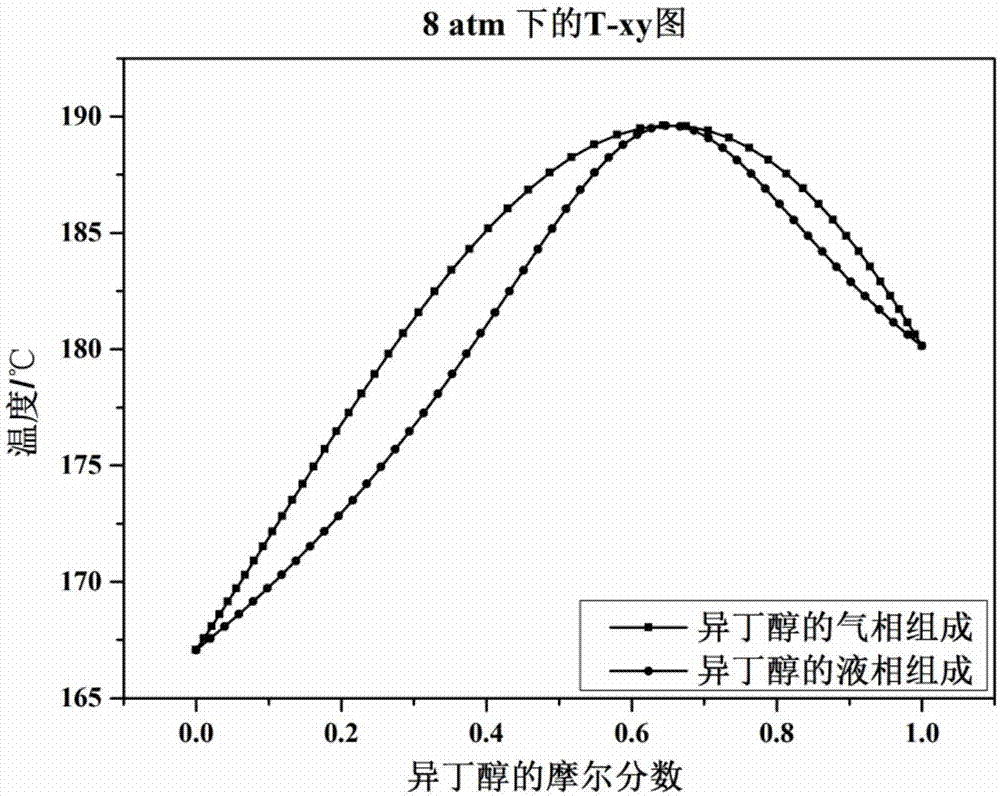

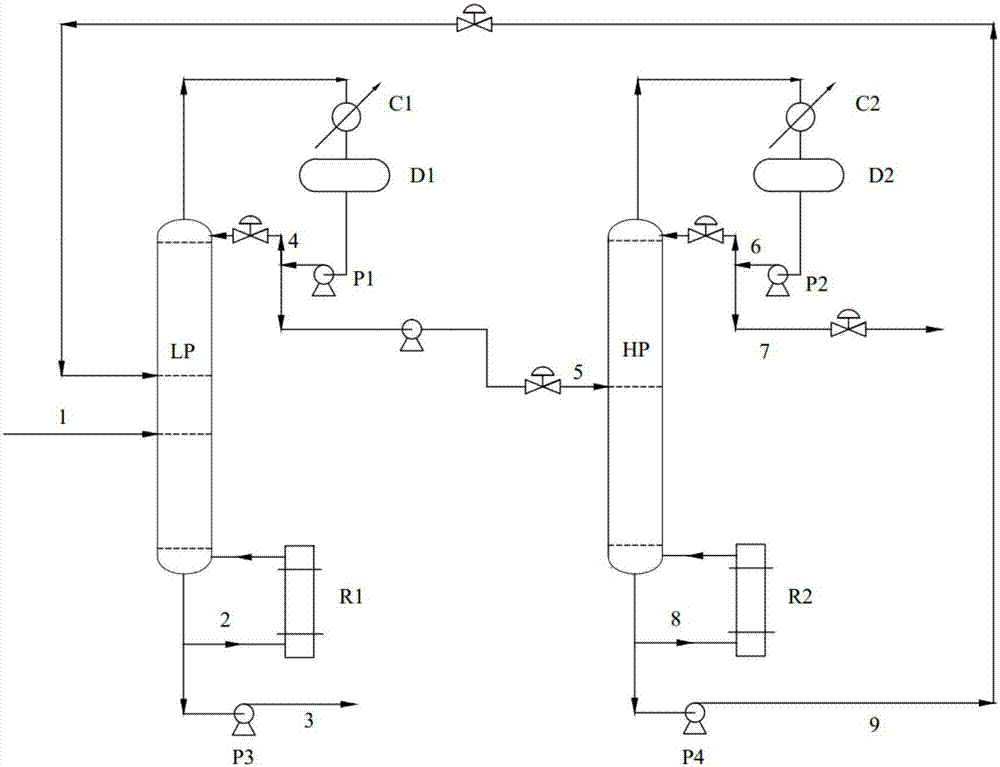

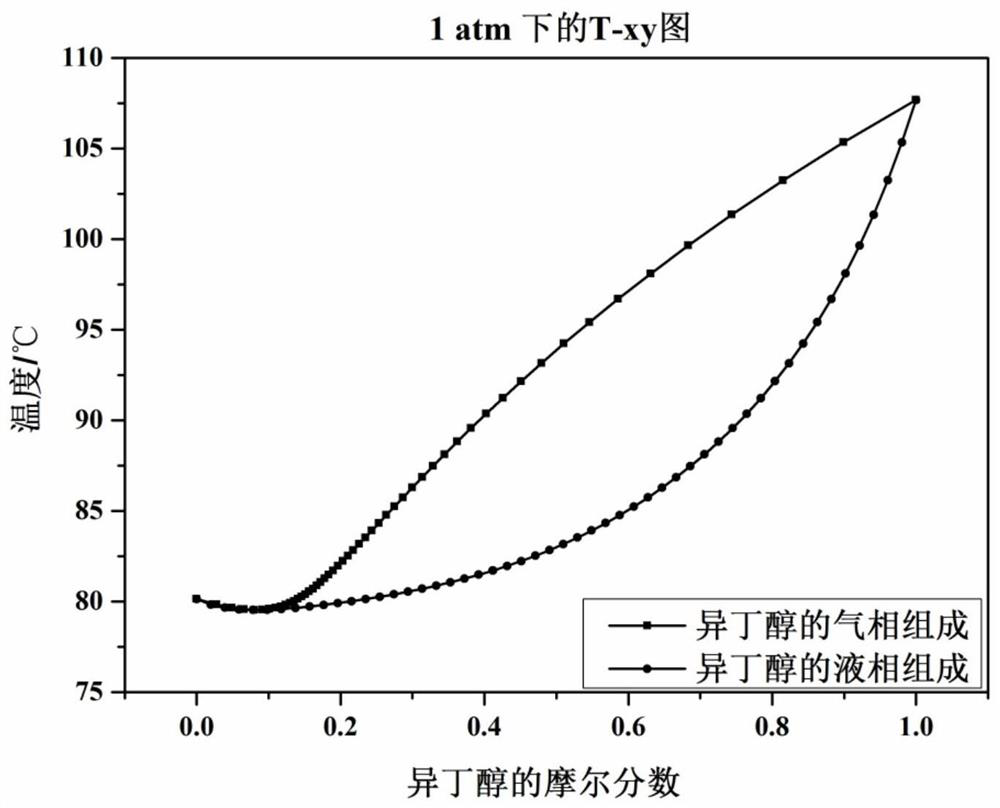

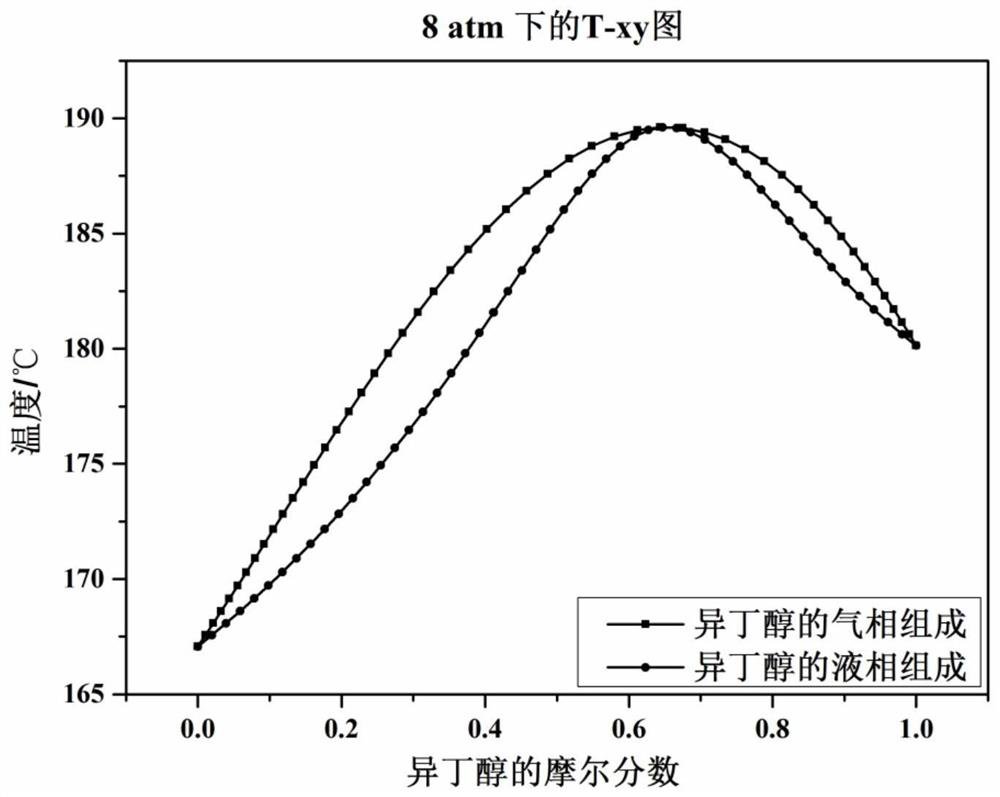

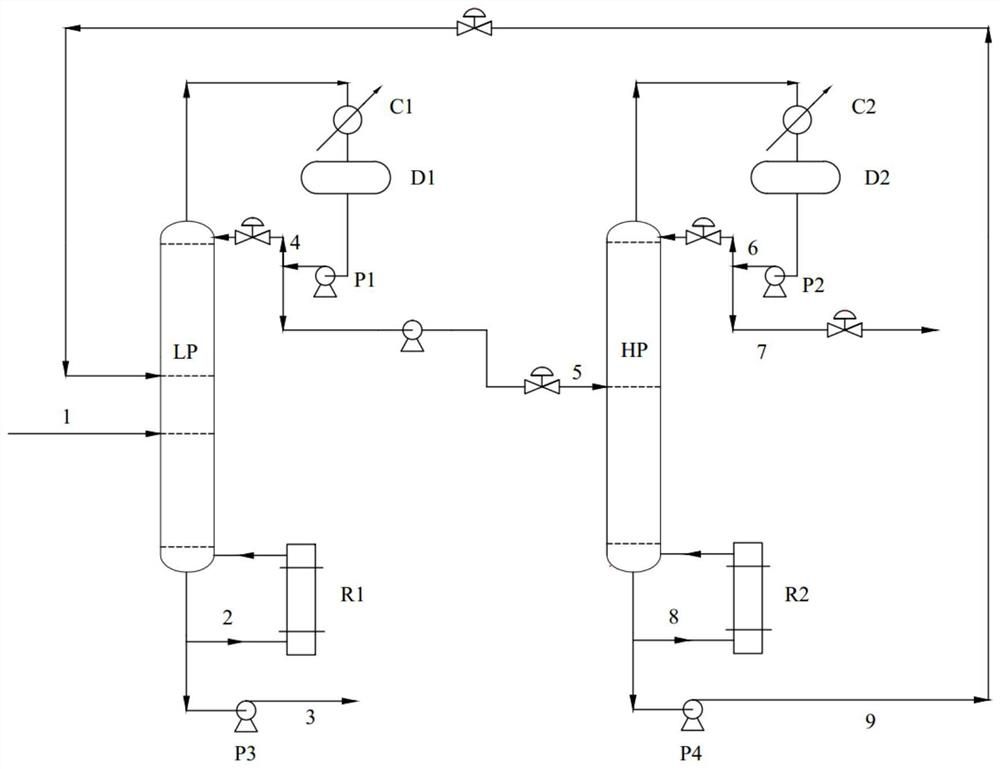

Method for separating azeotropic system of benzene and isobutanol by pressure swing distillation

ActiveCN107986928AHigh purityHigh yieldOrganic compounds purification/separation/stabilisationOrganic compound preparationBenzeneIsobutanol

The invention relates to a method for separating azeotrope of benzene and isobutanol by pressure swing distillation and a device suitable for the method. The device mainly comprises an atmospheric tower LP, a pressurization tower HP, condensers C1 and C2, reflux tanks D1 and D2 and reboilers R1 and R2, wherein the reboilers R1 and R2 are connected to bottoms of the atmospheric tower LP and the pressurization tower HP respectively, the condenser C1 and the reflux tank D1 are connected to the top of the atmospheric tower LP sequentially, and the condenser C2 and the reflux tank D2 are connectedto the top of the pressurization tower HP sequentially. According to the method for separating the azeotropic system of benzene and isobutanol by pressure swing distillation, two tower sequences are included, that is, sequence one: separating the lowest azeotrope in the atmospheric tower, and then separating the highest azeotrope in the pressurization tower; sequence two: separating the highest azeotrope in the pressurization tower, and then separating the lowest azeotrope in the atmospheric tower. The problem about separation caused by the fact that the azeotropic behavior of the system showsthe lowest and highest characteristics with the increase of pressure is solved, and the method has the advantages of low energy consumption and high product recovery rate.

Owner:QINGDAO UNIV OF SCI & TECH

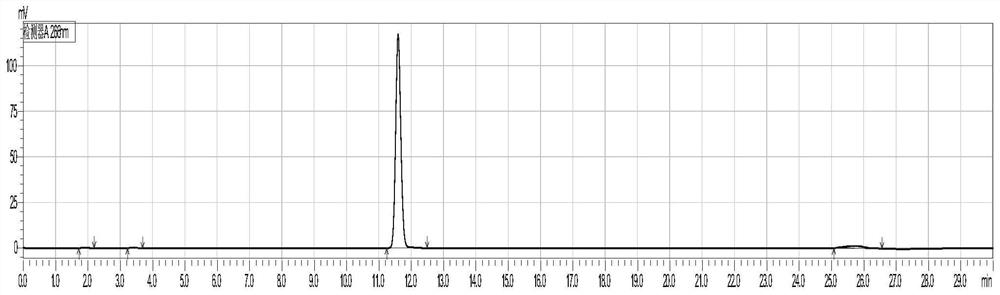

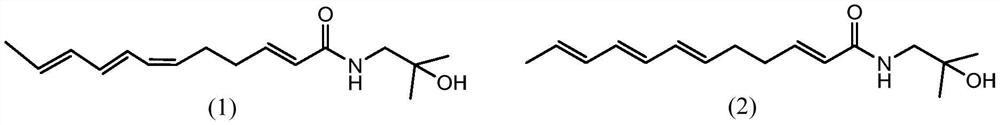

Preparation method of hydroxyl-alpha-sanshool single substance

ActiveCN112321450AGuaranteed stabilityLow technical requirementsCarboxylic acid amide separation/purificationAlcoholPharmaceutical drug

The invention provides a preparation method of a hydroxyl-alpha-sanshool single substance, and belongs to the technical field of natural medicine extraction and separation. The preparation method comprises the following steps: (1) conducting leaching with low alcohol to obtain a pepper extract total extract; (2) conducting extracting by adopting ethyl acetate, and enriching a hydroxysanshool mixture by column chromatography; (3) removing impurities by adopting a freezing crystallization method, and enriching hydroxyl-alpha-sanshool; and (4) separating and purifying the hydroxyl-alpha-sanshool.The preparation method of the hydroxyl-alpha-sanshool single substance is simple and convenient to operate and has low technical requirements on operators; the conditions in the preparation process are mild, so that the stability of the hydroxyl-alpha-sanshool is guaranteed, and the hydroxyl-alpha-sanshool is very safe; and meanwhile, the hydroxyl-alpha-sanshool single substance prepared by the preparation method is high in purity, the purity of the prepared hydroxyl-alpha-sanshool single substance can reach 99% or above, and the hydroxyl alpha-sanshool single substance can be used as a standard substance of the hydroxyl alpha-sanshool single substance. The preparation method is low in cost, suitable for large-scale industrial popularization and good in application prospect.

Owner:SOUTHWEST JIAOTONG UNIV

Method for rapidly extracting different sanshool monomers

PendingCN113816870AThe preparation process is stableHigh yieldAntipyreticAnalgesicsPolyamideColumn chromatography

The invention belongs to the technical field of natural medicine extraction and separation and local anesthesia medicine preparations, and particularly relates to a method for rapidly and simultaneously extracting hydroxyl-alpha-sanshool and hydroxyl-beta-sanshool and application of the hydroxyl-alpha-sanshool obtained through extraction in preparation of a nano-lipid carrier. The method comprises the following steps: (1) extracting with ethanol and n-hexane to obtain a crude sanshool product; and (2) respectively obtaining high-purity hydroxyl-alpha-sanshool and hydroxyl-beta-sanshool by adopting a column chromatography method and a freeze drying method. The preparation method disclosed by the invention is simple to operate, mild in condition, recyclable in polyamide and high in recovery rate, not only ensures the purity of the two sanshool, but also reduces the operation cost. Meanwhile, the invention discloses the hydroxyl-alpha-sanshool nanostructure lipid carrier and a preparation method thereof. The preparation is released through slow release and has a good analgesic effect.

Owner:SHENYANG PHARMA UNIVERSITY

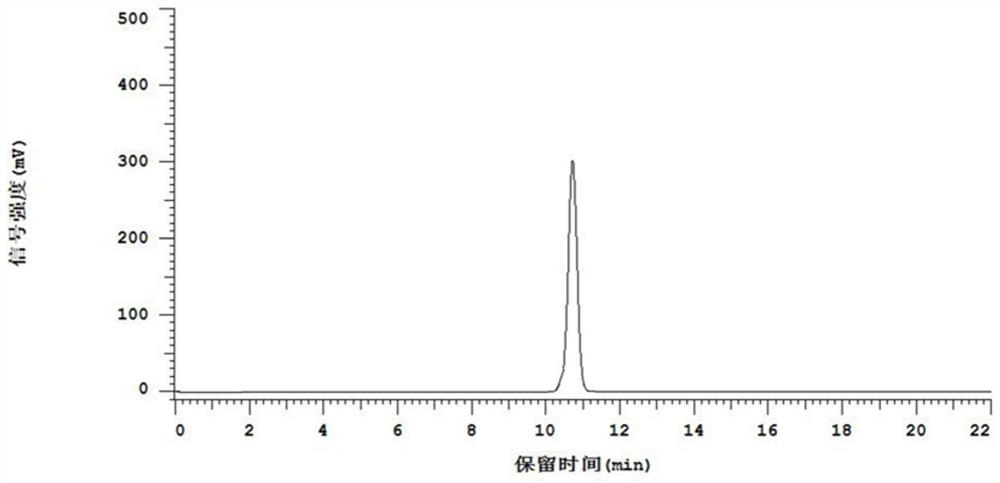

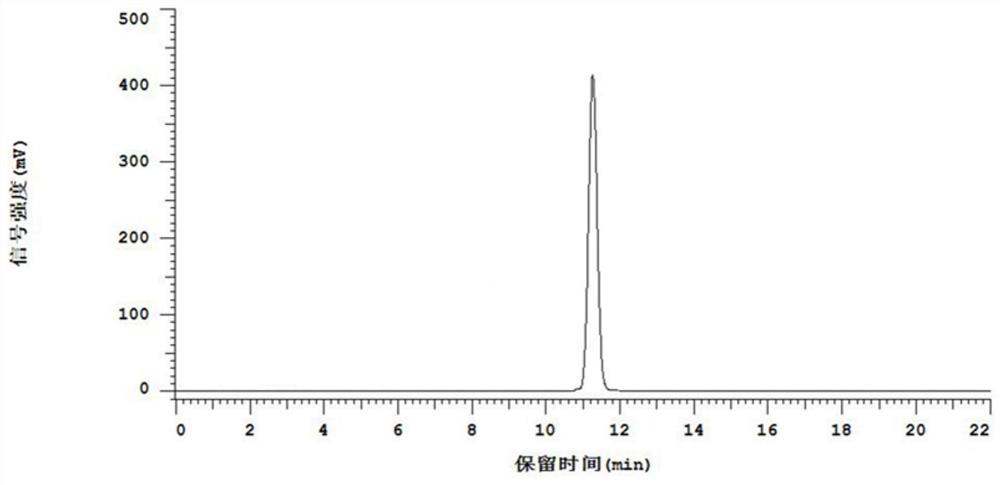

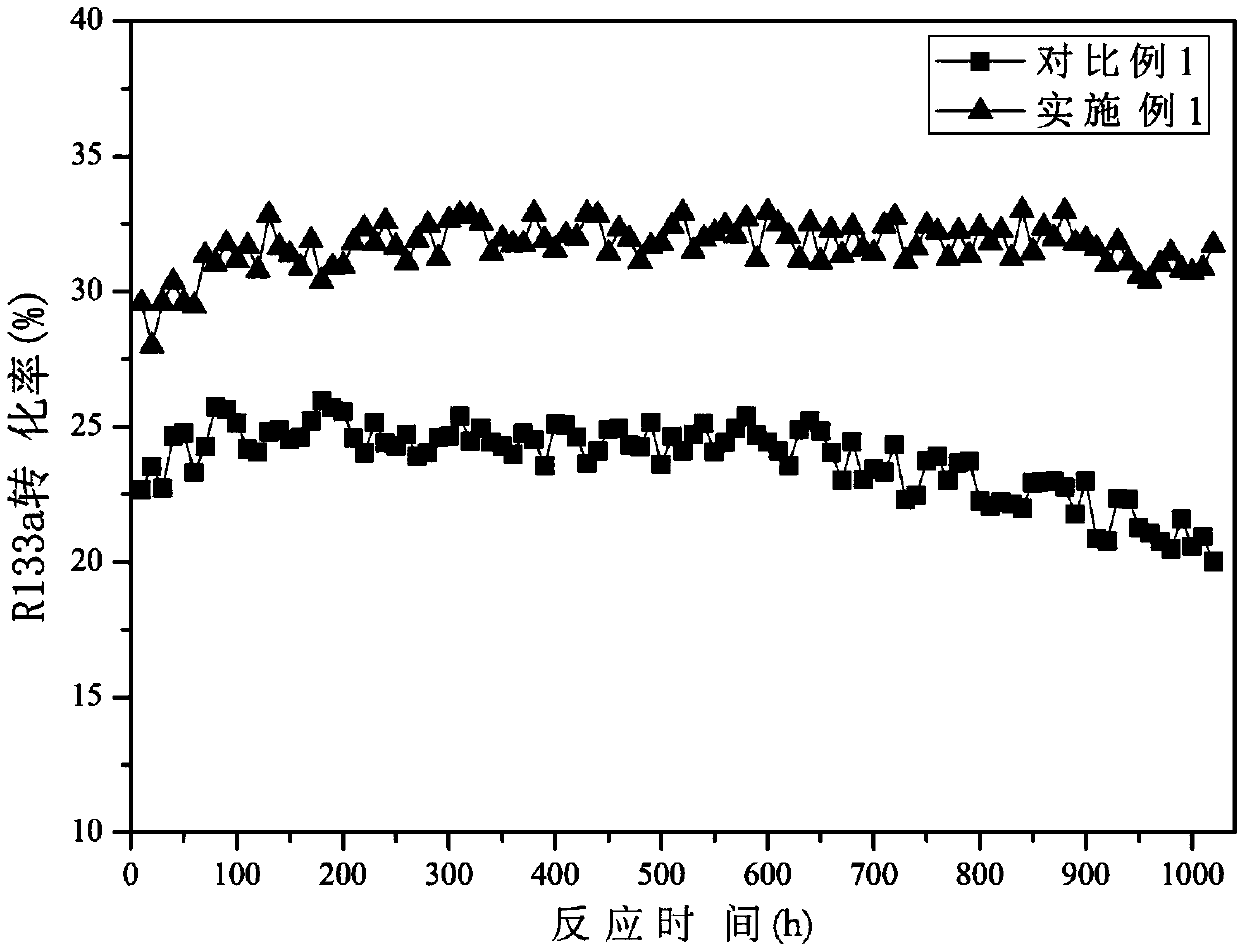

Fluorination catalyst and preparation method thereof

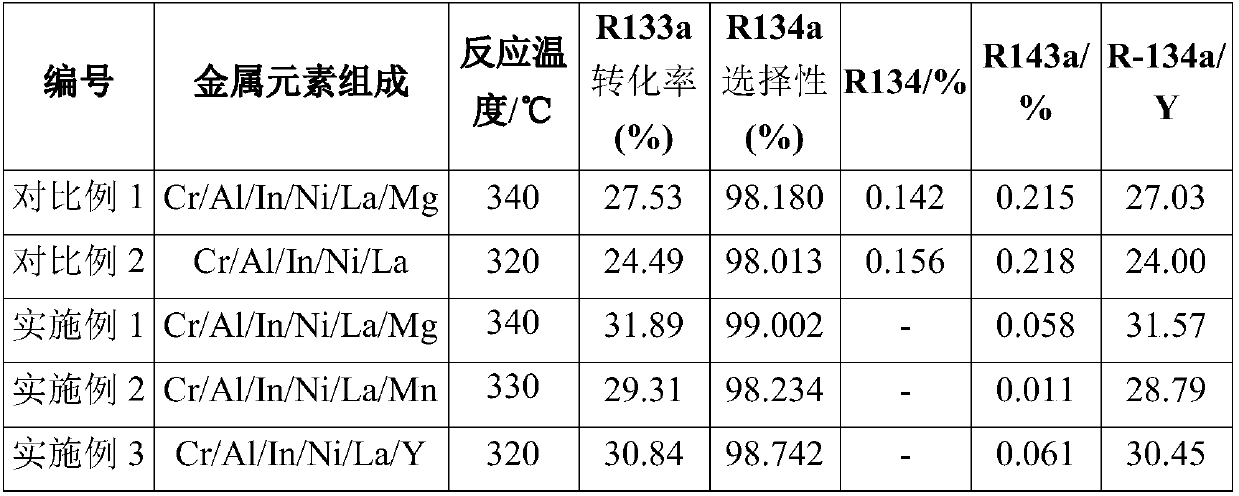

ActiveCN107552064AHigh activityHigh yieldPreparation by halogen replacementMetal/metal-oxides/metal-hydroxide catalystsCoprecipitationFluoride

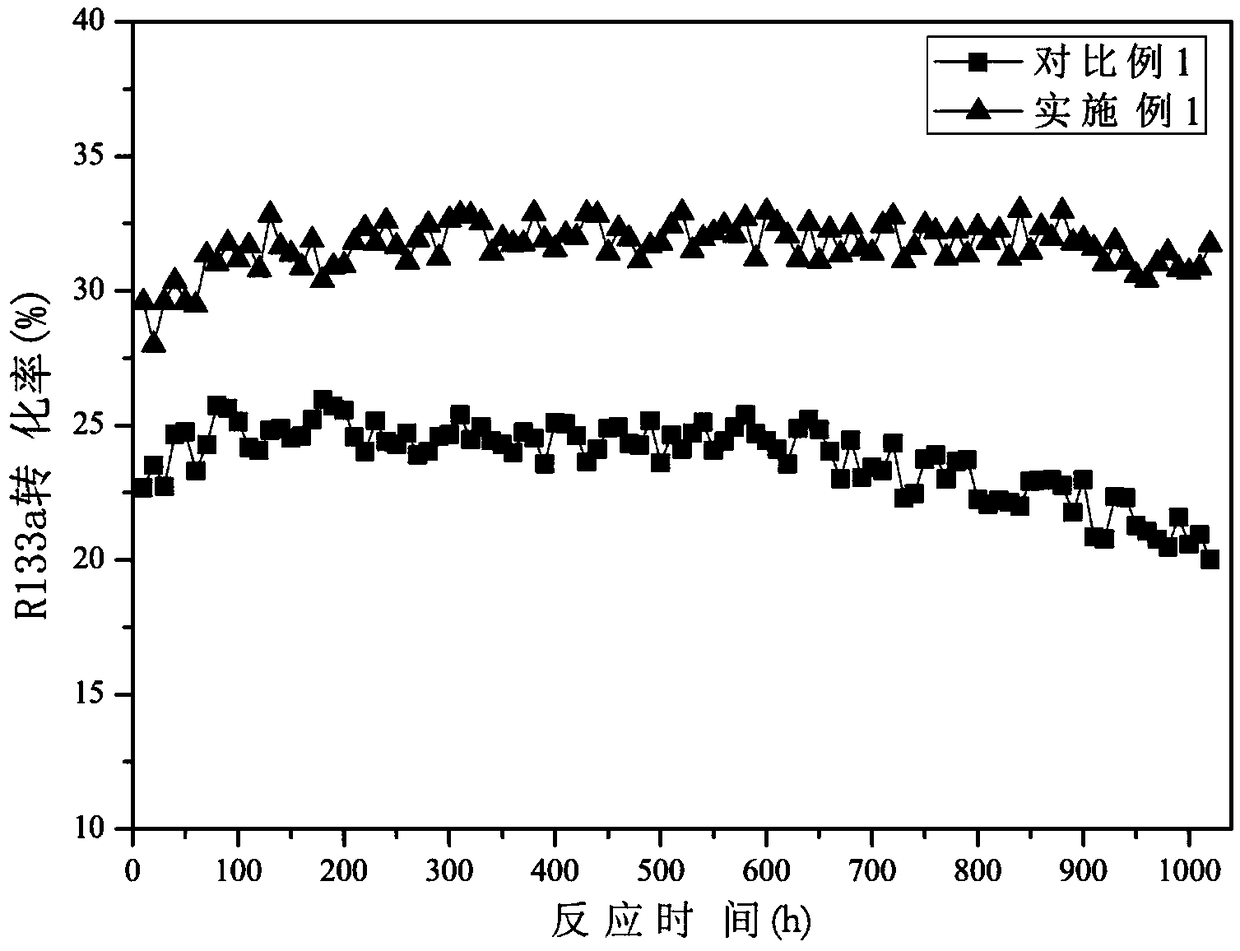

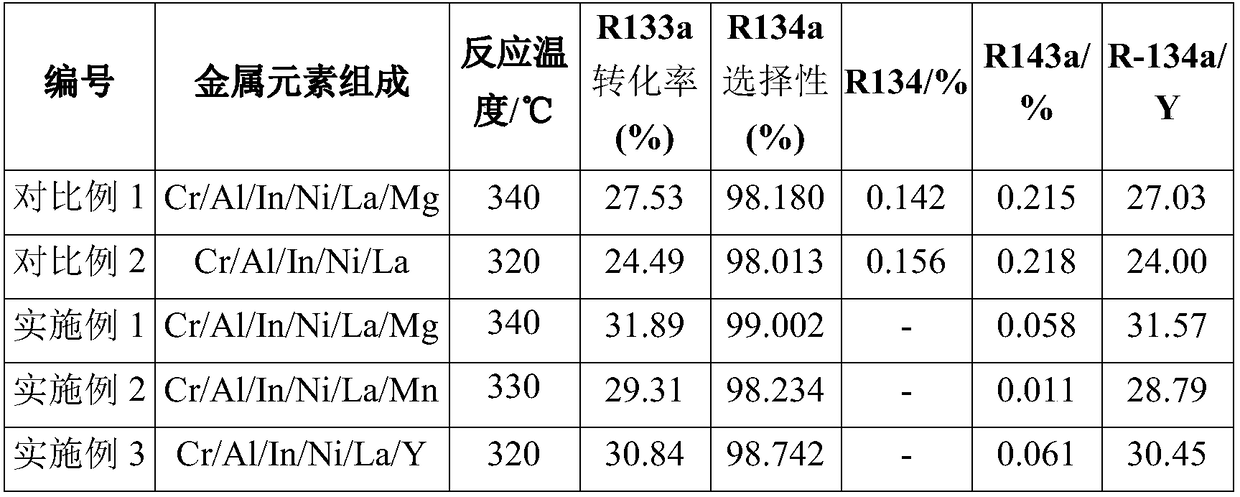

The invention relates to a fluorination catalyst and a preparation method and an application thereof. The fluorination catalyst contains Cr, Al, In, Ni, La and metallic element X, wherein the metallicelement X is at least one selected from Co, Mg, Ce, Fe, Mn, Cu, Y and Ga; the mass ratio of Cr, Al, In, Ni, La and the metallic element X in the fluorination catalyst is (70-90):(5-10):(1-3.5):(2-4.5):(0.5-3):(3-5.5). A precursor of the fluorination catalyst is prepared with a coprecipitation method, and ammonium salt as a pore expanding agent is added during preparation. The prepared precursor of the fluorination catalyst has large specific surface area, good pore structure and high catalytic activity, the precursor after being fluorinated is particularly suitable for catalyzing preparationof R134a, a byproduct control effect is good, and the service life is long.

Owner:RUYUAN DONGYANG LIGHT FLUORIDE CO LTD

Method for separating benzene-n-propyl alcohol-water mixture through heat pump extractive distillation

ActiveCN113214038AHigh puritySolving intractable puzzlesOrganic compound preparationChemical industryPropanolBenzene

The invention relates to a method for separating a benzene-n-propyl alcohol-water mixture through heat pump extractive distillation and a device suitable for the method. According to the method, glycerin is used as an extraction agent, water containing benzene and n-propanol enters an extractive distillation tower for extractive distillation separation, benzene with the purity of 99.9% is extracted from the upper portion of the extractive distillation tower, materials on the lower portion of the extractive distillation tower enter another extractive distillation tower for separation, high-purity n-propanol is obtained at the top of the extractive distillation tower, the extraction agent and water are extracted from the bottom of the extractive distillation tower and then separated through a common distillation tower, and the high-purity extraction agent is obtained and then recycled. The method has the advantages of low energy consumption, simple process, high purity of benzene and n-propanol and the like, the adopted extraction agent glycerol is almost non-volatile, the loss of the extraction agent is reduced, and the method is easy to recover, good in chemical thermal stability, green and pollution-free.

Owner:QINGDAO UNIV OF SCI & TECH

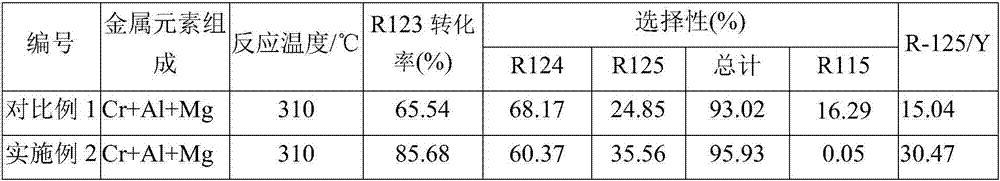

Method for preparing mesoporous chromium-based gaseous fluorinated catalyst

ActiveCN107456982AHigh mechanical strengthHigh activityPhysical/chemical process catalystsHalogenated hydrocarbon preparationSalt solutionChromium

The invention relates to a method for preparing a mesoporous chromium-based gaseous fluorinated catalyst. The method comprises the steps of taking SBA-16 as a hard template, adding chromium-based metal salt solution dropwise, and performing roasting; adding other metal salt solutions dropwise, and performing drying, roasting, smashing and tabletting to obtain a catalyst precursor; fluoridizing the precursor and removing the SBA-16 template, and obtaining the mesoporous chromium-based gaseous fluorinated catalyst. The prepared mesoporous chromium-based gaseous fluorinated catalyst has a specific surface area of 300-350 m<2> / g and an average pore size of 10-13 nm. The mesoporous chromium-based gaseous fluorinated catalyst is high in catalytic activity and suitable for being applied to gaseous fluoridation, and particularly when the mesoporous chromium-based gaseous fluorinated catalyst is applied to R125 preparation, a by-product control effect is very good.

Owner:RUYUAN DONGYANG LIGHT FLUORIDE CO LTD

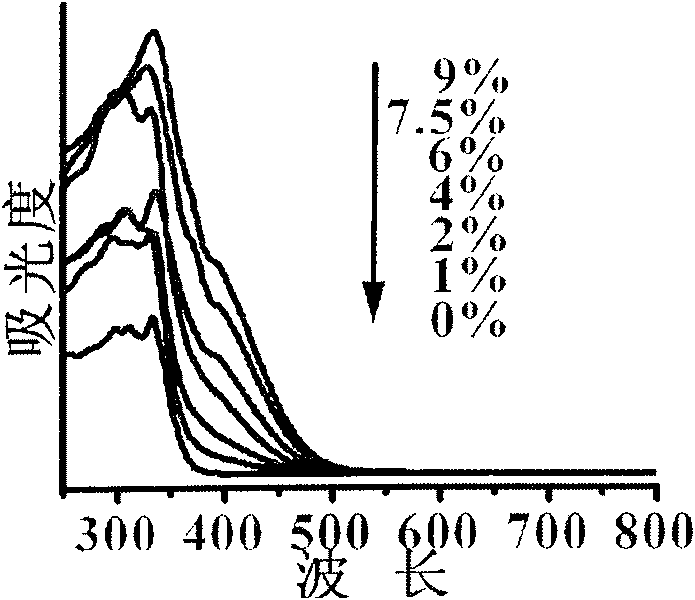

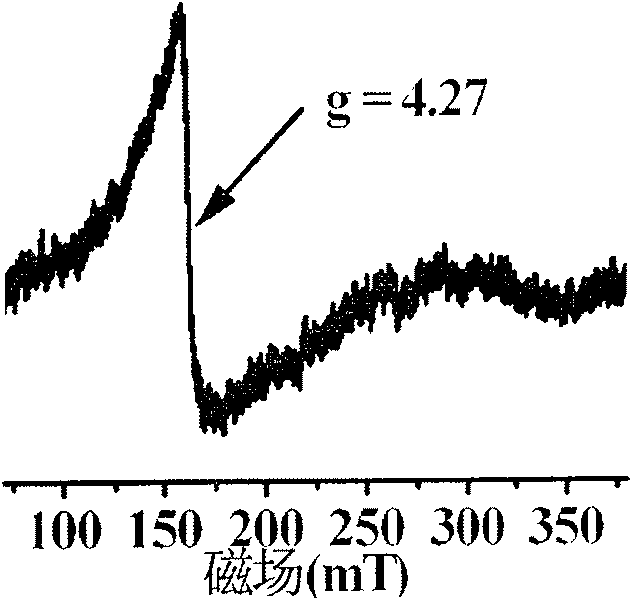

Method for preparing porous iron-doped titanic oxide photocatalyst

InactiveCN101347732BReduce pollutionLarge mesoscopic scaleMetal/metal-oxides/metal-hydroxide catalystsSolventEthanol

The invention relates to a preparation method of a porous iron-doped titanium dioxide photocatalyst, the preparation method belongs to the technical field of photocatalyst and comprises the followingsteps: solid hexahydrated ferric chloride FeCl3. 6H2O and tetrabutyl titanate Ti(OC4H9)4 are sequentially added in an ethylene glycol solvent for carrying out the stirring and the reflux, and solutionis further cooled to the room temperature; the solution after the cooling is arranged in a centrifuge for carrying out the separation, then the solution is arranged in anhydrous ethanol for carryingout a plurality of times of dispersion and washing, thereby obtaining metal alkoxide solids; the drying treatment and the heating treatment are further carried out to obtain solid powder of the porousiron-doped titanium dioxide photocatalyst. The porous iron-doped titanium dioxide photocatalyst which is prepared and obtained by the preparation method of the invention has high photocatalytic activity in the reaction of the degradation of molecules of organic pollutants, the activity thereof is higher than an industrial product of nano-titanium dioxide photocatalyst P25, the porous iron-doped titanium dioxide photocatalyst also has high stability and can be recycled; compared with the catalysts in the prior art, the activity is more durable.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Method for extracting and separating n-heptane-dimethyl carbonate by ionic liquid

ActiveCN113185409AHigh puritySolving intractable puzzlesDistillation purification/separationHydrocarbonsIonic liquidChemical engineering

The invention relates to a method for extracting and separating n-heptane and dimethyl carbonate by using ionic liquid and a device suitable for the method. According to the method, imidazolium ionic liquid is used as an extracting agent, n-heptane and dimethyl carbonate firstly enter a liquid-liquid extraction tower to be extracted and separated, materials on the upper portion of the liquid-liquid extraction tower enter a flash evaporation tank to be separated, high-purity n-heptane is obtained at the top of the flash evaporation tank, materials on the lower portion of the liquid-liquid extraction tower enter another flash tank to be separated, the material flow at the top of the flash evaporation tank enters rectification tower for separating, high-purity n-heptane is obtained from the top of the rectification tower, high-purity dimethyl carbonate is obtained from the bottom of the rectification tower, and the extracting agent is recycled after being extracted from the bottoms of the two flash evaporation tanks. The method has the advantages of low energy consumption, simple process, high purity of n-heptane and dimethyl carbonate after separating and the like, the adopted extracting agent imidazole ionic liquid is almost non-volatile, the loss of the extracting agent is reduced, and the method is easy to recover, good in chemical thermal stability, green and pollution-free.

Owner:QINGDAO UNIV OF SCI & TECH

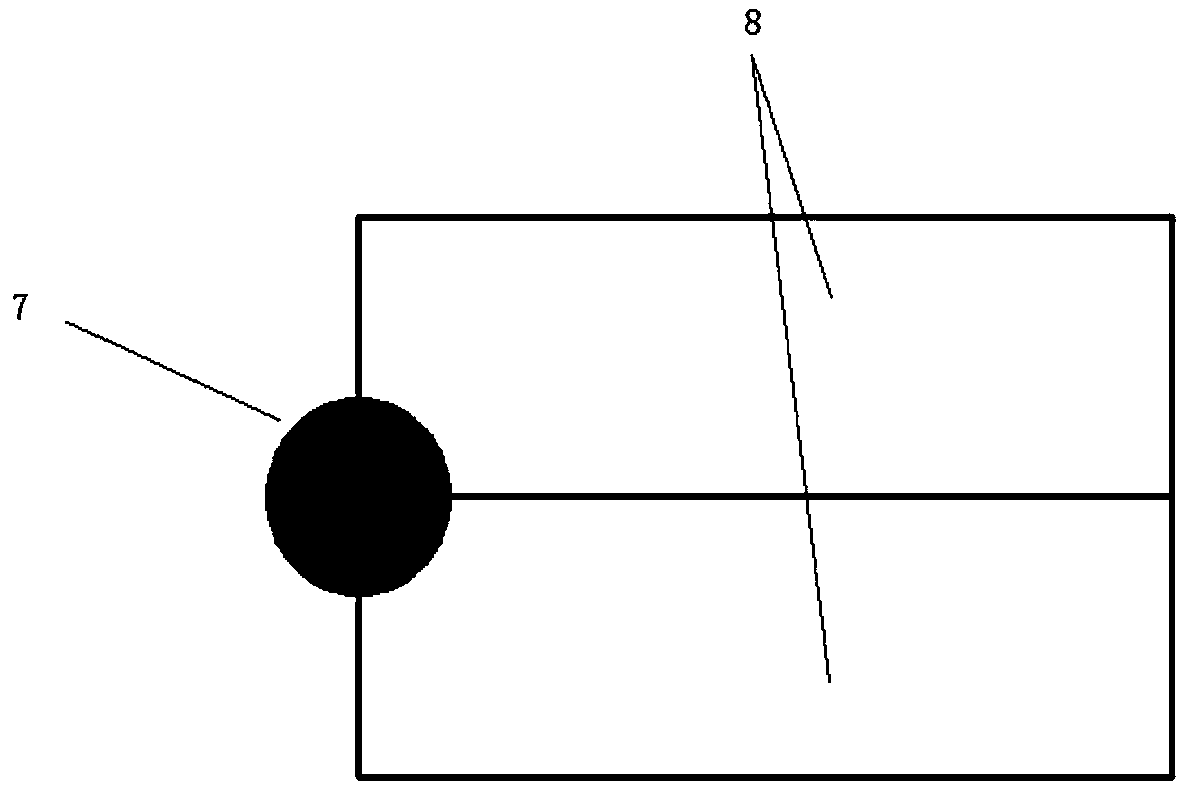

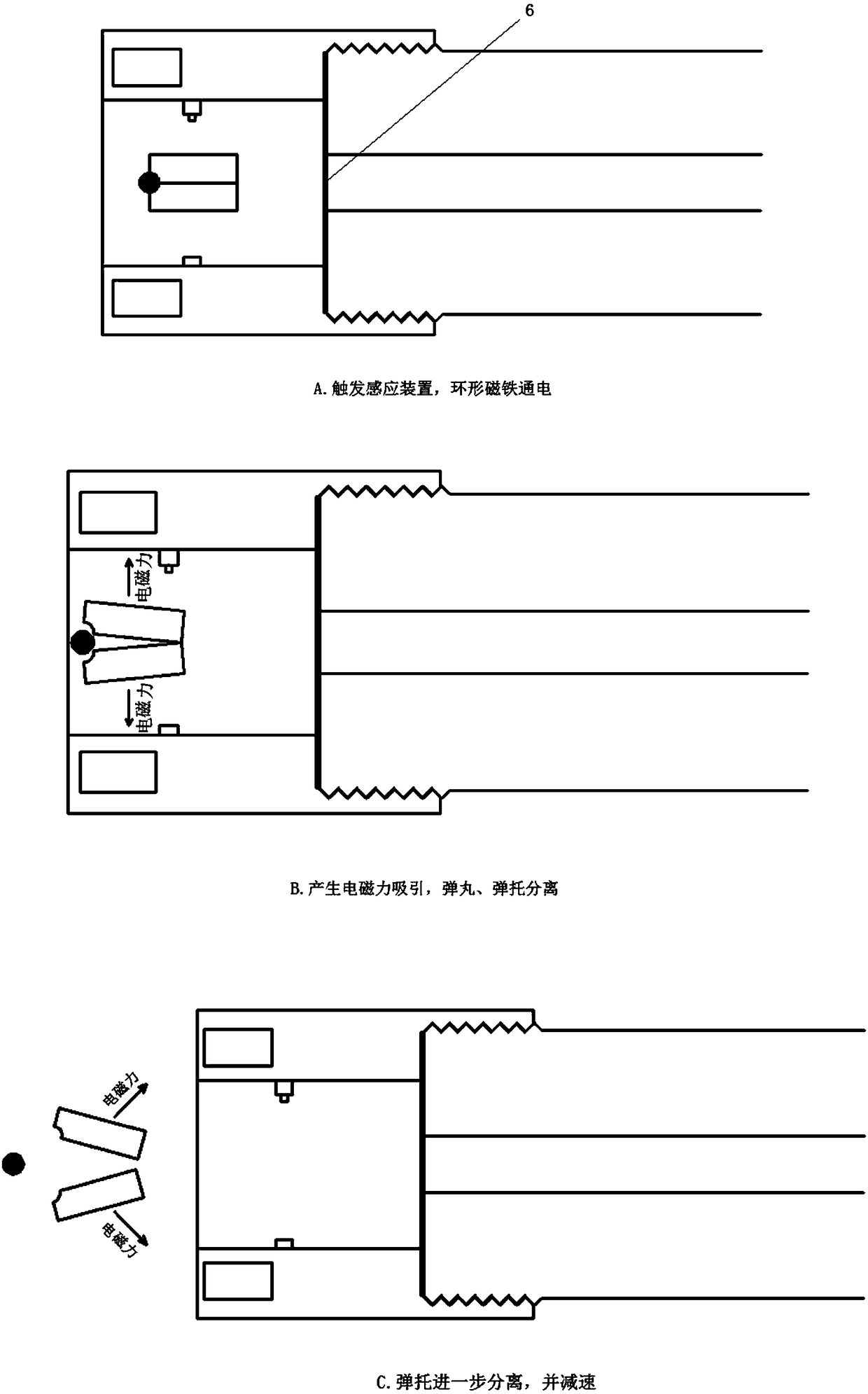

Electromagnetic sabot separation device for light-gas gun

ActiveCN108955371ASolving intractable puzzlesHigh strengthCompressed gas gunsPower flowHypervelocity

The invention relates to the technical field of hypervelocity impact loading tests, in particular to a sabot separation device. The electromagnetic sabot separation device for a light-gas gun comprises an annular casing, annular electromagnets, a sensing device, a controller and an electric storage device, wherein a projectile and the sabot are accelerated by the light-gas gun to enter an electromagnetic separation device connected with a gun muzzle, and when the projectile and the sabot pass through the sensing device located on the inner wall of the electromagnetic separation device, the sensing device triggers the controller to control the electric storage device to produce strong current to power on the annular electromagnets and the annular electromagnets produce strong attraction force on the sabot made of a ferromagnetic high-polymer material. The sabot with a split structure is separated towards the lateral direction under the action of uneven electromagnetic attraction force,and meanwhile, after the sabot flies over the positions of the electromagnets, the annular electromagnets produce backward electromagnetic force on the sabot to slow down the sabot, so that the sabotand the projectile are separated. The sabot is separated from the projectile stably and smoothly without impact.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for separating n-hexane and acetone by liquid-liquid extraction-flash evaporation of ionic liquid

PendingCN112225636ASimple processLess investment in equipmentHydrocarbonsExtraction purification/separationAnalytical chemistryAcetone

The invention relates to a method for separating a mixture of n-hexane and acetone by liquid-liquid extraction-flash evaporation of ionic liquid and a device suitable for the method. According to themethod, imidazole ionic liquid is used as an extraction agent, n-hexane and acetone firstly enter a liquid-liquid extraction tower to be extracted and separated, materials at the upper part of the liquid-liquid extraction tower enter a flash tank to be separated, high-purity n-hexane is obtained at the top of the flash tank, and materials at the lower part of the liquid-liquid extraction tower enter another flash tank to be separated; high-purity acetone is obtained at the tops of the flash tanks, and the extracting agent is recycled after being extracted from the bottoms of the two flash tanks. The method has the advantages of low energy consumption, simple process, high purity of n-hexane and acetone after separation and the like, the adopted extracting agent imidazolium salt ionic liquid is hardly volatilized, the loss of the extracting agent is reduced, and the method is easy to recover, good in chemical thermal stability, green and pollution-free.

Owner:青岛三瑞节能环保技术有限公司

A kind of automobile expansion water tank

ActiveCN104018928BSolve layout difficultiesSmooth and beautifulMachines/enginesEngine cooling apparatusExpansion tankEngineering

An automobile expansion water tank, comprising a tank body (17), on which two degassing pipe ports (1), a filling port, a liquid level sensor port (5) and a return pipe port (6) are arranged, two Two degassing pipe ports (1) are arranged side by side at the bottom of the box body (17), and a reinforcing rib partition (9) is vertically arranged in the box inner cavity (8), and the reinforcing rib partition (9) is close to the two degassing pipe ports (1 ) side of the outer wall of the box (17), and the rib partition (9) separates the box cavity (8) into two cavities, the pressure relief chamber (10) and the working chamber (18), and the rib partition (9) The upper end is respectively provided with an upper pressure relief hole (12) and a lower pressure relief hole (19). The upper pressure relief hole (12) and the lower pressure relief hole (19) are distributed along the vertical direction. (1) Connected. Have avoided the overflow of the cooling fluid that the internal pressure of casing (17) is excessively caused? "Backwater" phenomenon.

Owner:DONGFENG COMML VEHICLE CO LTD

Producing device of high-purity selenium and producing process

ActiveCN100411975CEasy to collectHelp to separateElemental selenium/telluriumTemperature controlInsulation layer

Owner:广东先导稀贵金属材料有限公司

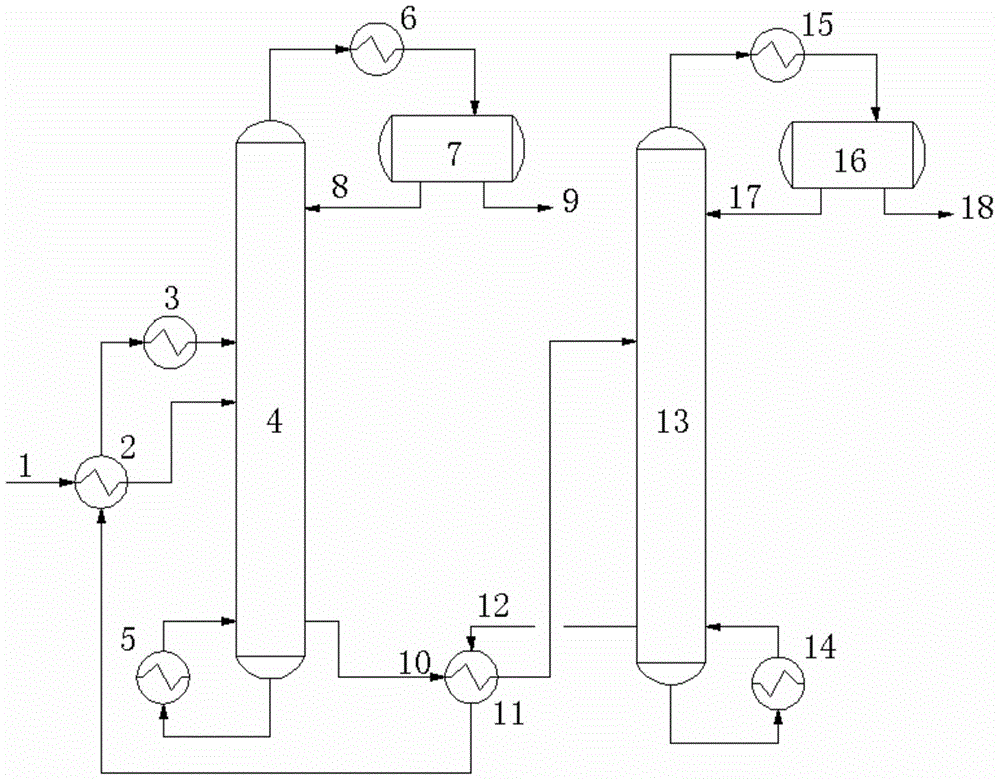

An energy-saving process for separating diethylamine-acetone wastewater by stripping-extractive distillation

ActiveCN107501064BSolving intractable puzzlesReduce consumptionAmino compound purification/separationChemical industryExtractive distillationProcess engineering

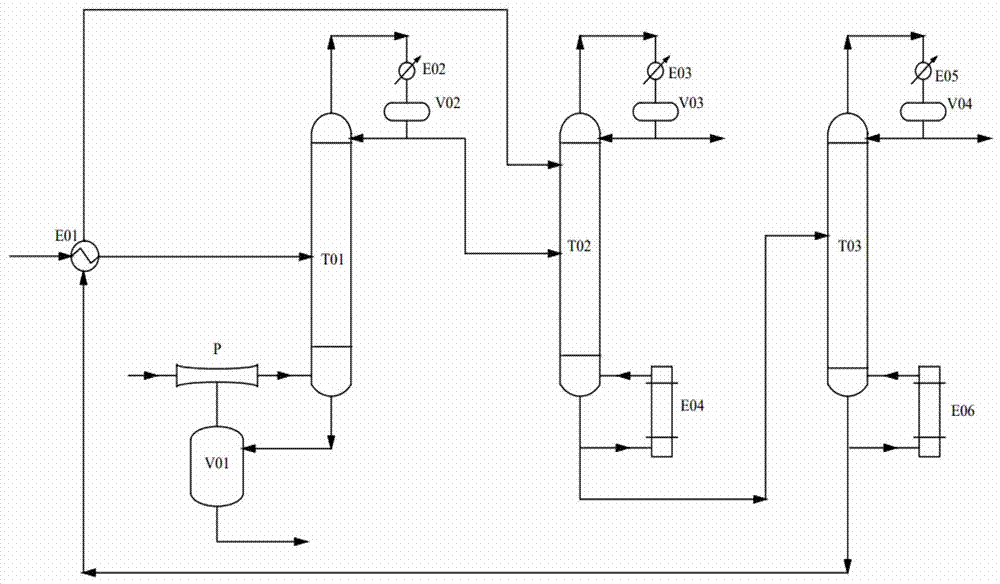

The invention relates to an energy-saving technology for separation of diethylamine-acetone wastewater by steam stripping-extractive distillation. The technology combines steam stripping and extractive distillation, firstly diethylamine and acetone in wastewater are separated by a stripping tower, the separated water can be discharged directly, the diethylamine and acetone mixture separated from the stripping tower enters an extractive distillation tower, ethylene glycol is used as the extractant, and extractive distillation is utilized for separation, diethylamine is recovered from the top of the extractive distillation tower, the extractant and acetone mixture enters an extractant recovery tower from the bottom of the extractive distillation tower, after effective separation, acetone is recovered from the top of the extractant recovery tower, and the extractant is recovered from the bottom of the extractant recovery tower for recycling. The technology utilizes an injection pump and a flash tank to recover a part of steam, and also utilizes the extractant circulating material flow to preheat the feed material flow, thus achieving the purpose of energy saving. According to the invention, the process is simple, the separated products have high purity, and the adopted extractant is easily recoverable and has good chemical thermal stability.

Owner:青岛三瑞节能环保技术有限公司

Energy-saving technology for separation of diethylamine-acetone wastewater by steam stripping-extractive distillation

ActiveCN107501064ASolving intractable puzzlesReduce consumptionAmino compound purification/separationChemical industryExtractive distillationWastewater

The invention relates to an energy-saving technology for separation of diethylamine-acetone wastewater by steam stripping-extractive distillation. The technology combines steam stripping and extractive distillation, firstly diethylamine and acetone in wastewater are separated by a stripping tower, the separated water can be discharged directly, the diethylamine and acetone mixture separated from the stripping tower enters an extractive distillation tower, ethylene glycol is used as the extractant, and extractive distillation is utilized for separation, diethylamine is recovered from the top of the extractive distillation tower, the extractant and acetone mixture enters an extractant recovery tower from the bottom of the extractive distillation tower, after effective separation, acetone is recovered from the top of the extractant recovery tower, and the extractant is recovered from the bottom of the extractant recovery tower for recycling. The technology utilizes an injection pump and a flash tank to recover a part of steam, and also utilizes the extractant circulating material flow to preheat the feed material flow, thus achieving the purpose of energy saving. According to the invention, the process is simple, the separated products have high purity, and the adopted extractant is easily recoverable and has good chemical thermal stability.

Owner:青岛三瑞节能环保技术有限公司

A kind of fluorination catalyst and preparation method thereof

ActiveCN107552064BHigh activityHigh yieldPreparation by halogen replacementMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPhysical chemistry

The invention relates to a fluorination catalyst and a preparation method and an application thereof. The fluorination catalyst contains Cr, Al, In, Ni, La and metallic element X, wherein the metallicelement X is at least one selected from Co, Mg, Ce, Fe, Mn, Cu, Y and Ga; the mass ratio of Cr, Al, In, Ni, La and the metallic element X in the fluorination catalyst is (70-90):(5-10):(1-3.5):(2-4.5):(0.5-3):(3-5.5). A precursor of the fluorination catalyst is prepared with a coprecipitation method, and ammonium salt as a pore expanding agent is added during preparation. The prepared precursor of the fluorination catalyst has large specific surface area, good pore structure and high catalytic activity, the precursor after being fluorinated is particularly suitable for catalyzing preparationof R134a, a byproduct control effect is good, and the service life is long.

Owner:RUYUAN DONGYANG LIGHT FLUORIDE CO LTD

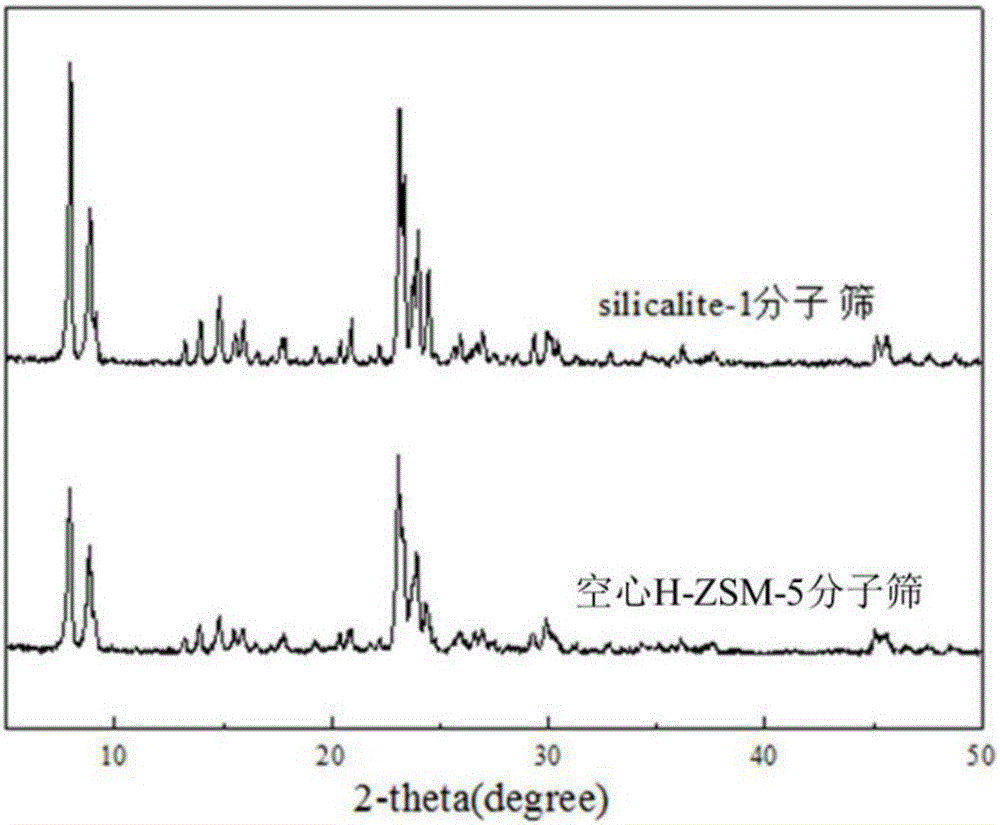

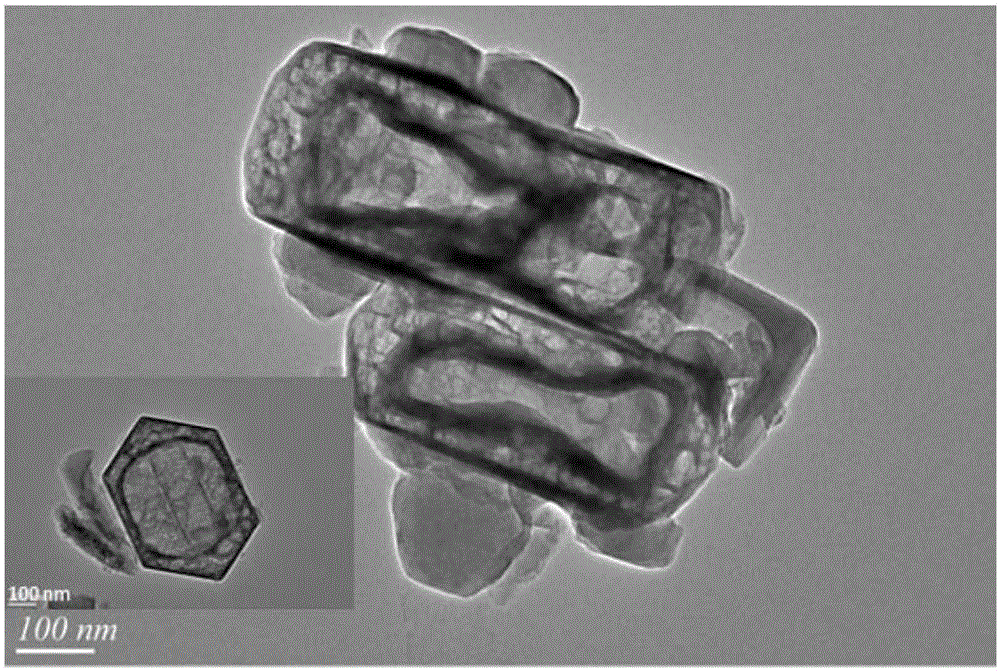

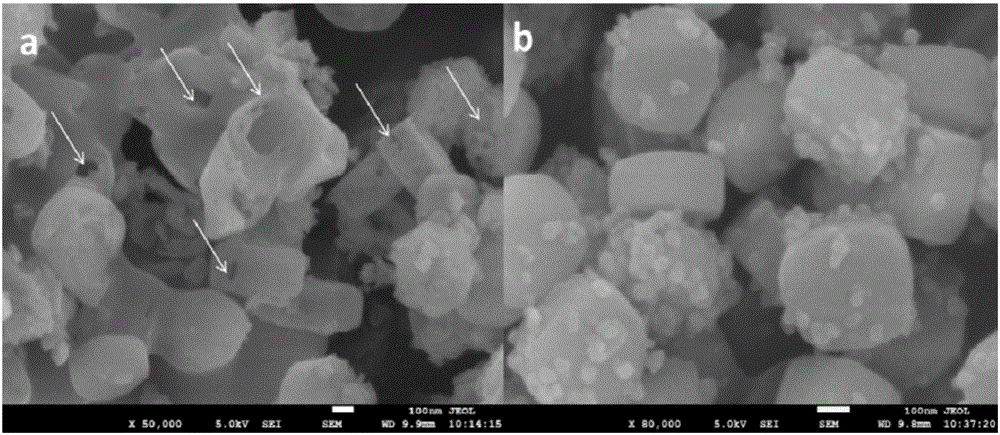

A kind of hollow h-zsm-5 molecular sieve and preparation method and application

ActiveCN105036152BImprove diffusion abilityInhibit carbon depositionPentasil aluminosilicate zeolitePore diameterZSM-5

The invention provides a hollow H-ZSM-5 molecular sieve of which the particle diameter is 70 to 2600 nm, the shell thickness is 20 to 300 nm, and the silica-alumina ratio is 20 to 200; the average pore diameter of holes distributed in shells of the molecular sieve is 10 to 200 nm. The molecular sieve has the advantages that the limitation problem on ZSM-5 diffusion can be solved effectively; the raw material cost is low; the preparation process is simple and easy to control; the product yield is high.

Owner:TAIYUAN UNIV OF TECH

Method for separation of benzene and isobutanol azeotropic system by pressure swing rectification

ActiveCN107986928BHigh purityHigh yieldOrganic compounds purification/separation/stabilisationOrganic compound preparationBenzeneIsobutanol

The invention is a method for separating benzene and isobutanol azeotrope by pressure swing rectification and a device suitable for the method. The device mainly includes: atmospheric column LP, pressurized column HP, condensers C1 and C2, reflux tanks D1 and D2, reboilers R1 and R2; wherein reboilers R1 and R2 are respectively connected to the atmospheric column LP and the The bottom of the pressure column HP, the condenser C1 and the reflux tank D1 are sequentially connected to the top of the atmospheric column LP, and the condenser C2 and the reflux tank D2 are sequentially connected to the top of the pressurization column HP. The method for separating the azeotrope system of benzene and isobutanol by pressure swing rectification has two column sequences, that is, sequence one: the lowest azeotrope is separated in the atmospheric column first, and the highest azeotrope is separated in the high pressure column, sequence two : The highest azeotrope is separated in the high pressure column first, and then the lowest azeotrope is separated in the atmospheric pressure column. The invention solves the separation problem brought about by the azeotropic behavior of the system showing the lowest and highest characteristics respectively as the pressure rises, and has the advantages of low energy consumption and high product recovery rate.

Owner:QINGDAO UNIV OF SCI & TECH

A method for extracting and rectifying separation of acetone and isopropyl ether mixture

ActiveCN106242958BSolving intractable puzzlesReduce dosageEther separation/purificationChemical industryExtractive distillationTower

Owner:QINGDAO UNIV OF SCI & TECH

Method for extracting and separating alkaloid by utilizing ionic liquid and inorganic salt mixed extracting agent

InactiveCN107320998ASolving intractable puzzlesNot volatileSolid solvent extractionPlant ingredientsInorganic saltsSteam pressure

The invention relates to a method for extracting and separating alkaloid by utilizing an ionic liquid and inorganic salt mixed extracting agent. The method takes the ionic liquid and inorganic salt mixed extracting agent as an extracting agent, and ionic liquid has extremely low steam pressure, has a wide liquid-state range and high stability, and is easy to recycle; an ionic liquid structure can be designed according to different requirements, and novel ionic liquid with different functions is synthesized. In an extraction and separation process, the ionic liquid with different types is selected or synthesized according to different separation systems and can be efficiently separated. The ionic liquid and inorganic salt mixed extracting agent is used as the extracting agent so that the selectivity of the ionic liquid can be improved and the viscosity of the ionic liquid can be reduced, and the separation efficiency is easy to improve. According to the method provided by the invention, the ionic liquid and inorganic salt mixed extracting agent is used for extracting and separating the alkaloid, and an application range of the ionic liquid is expanded; a novel method for separating the alkaloid is improved, the content of the obtained alkaloid is high, and the ionic liquid has little dosage and can be circularly utilized.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com