Method for separation of benzene and isobutanol azeotropic system by pressure swing rectification

A technology of pressure swing rectification and isobutanol, which is applied in the field of benzene and isobutanol binary azeotrope system, pressure swing rectification separation of benzene and isobutanol azeotrope system

- Summary

- Abstract

- Description

- Claims

- Application Information

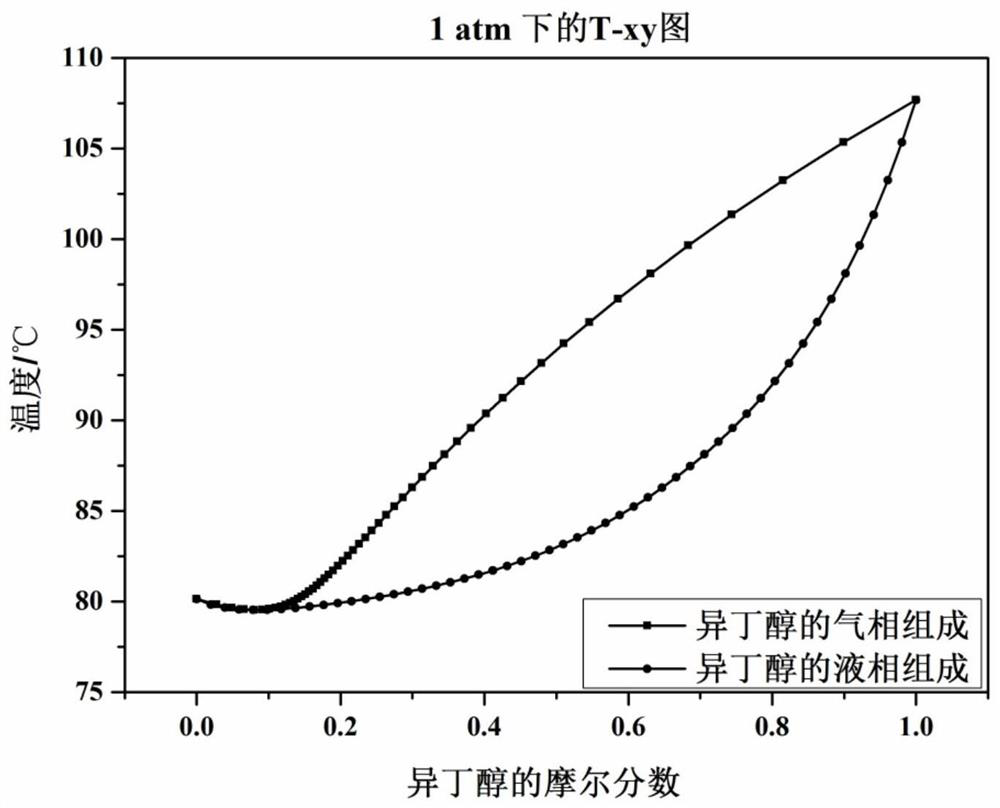

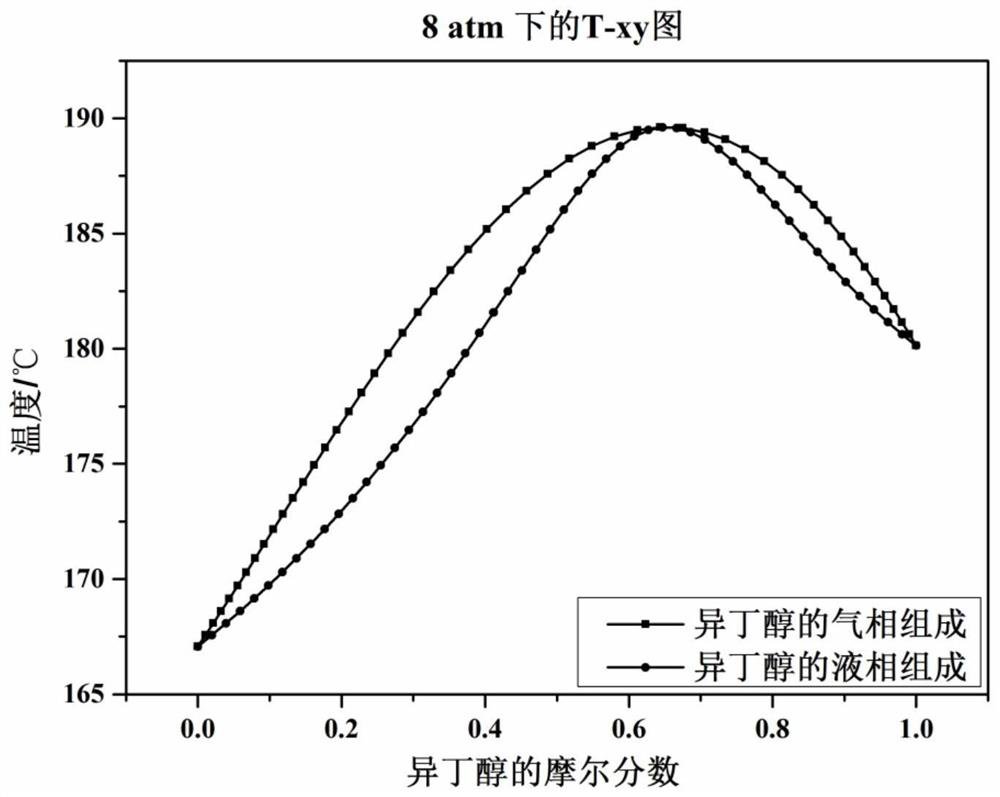

AI Technical Summary

Problems solved by technology

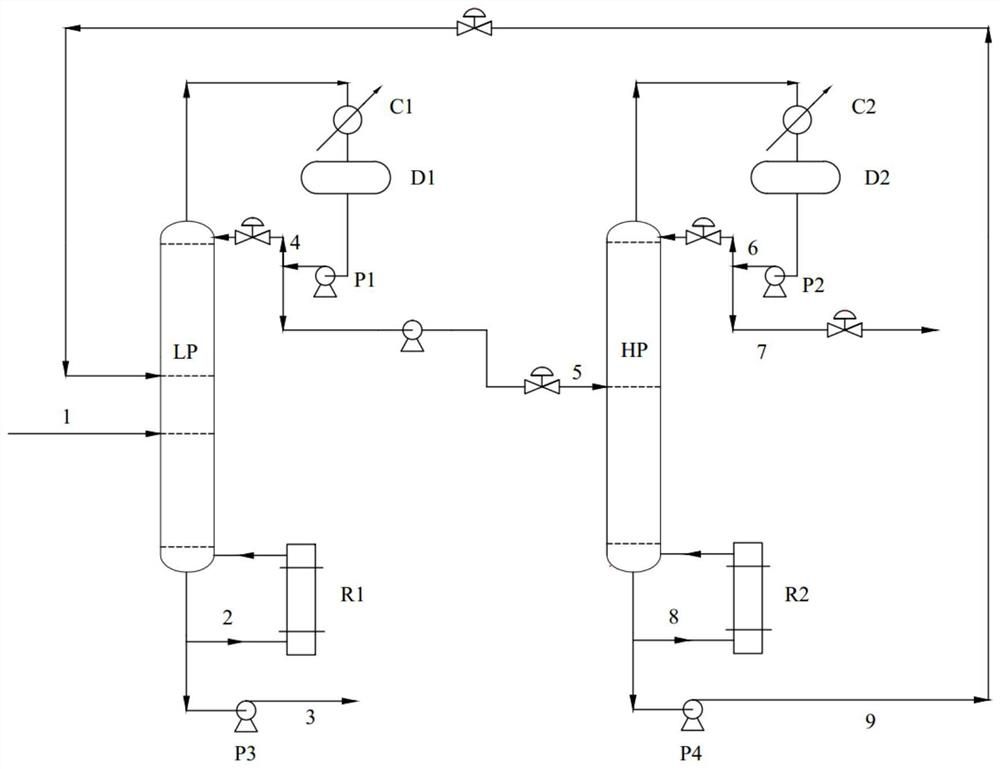

Method used

Image

Examples

Embodiment 1

[0046] The operating conditions and product quality of the feed and rectification tower are shown in the table below:

[0047] Separation of Benzene and Isobutanol Azeotropic System Sequence 1 by Pressure Swing Distillation

[0048]

[0049] Pressure swing rectification separation of benzene and isobutanol azeotropic system sequence two

[0050]

Embodiment 2

[0052] The operating conditions and product quality of the feed and rectification tower are shown in the table below:

[0053] Separation of Benzene and Isobutanol Azeotropic System Sequence 1 by Pressure Swing Distillation

[0054]

[0055] Pressure swing rectification separation of benzene and isobutanol azeotropic system sequence two

[0056]

Embodiment 3

[0058] The operating conditions and product quality of the feed and rectification tower are shown in the table below:

[0059] Separation of Benzene and Isobutanol Azeotropic System Sequence 1 by Pressure Swing Distillation

[0060]

[0061] Pressure swing rectification separation of benzene and isobutanol azeotropic system sequence two

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com