Patents

Literature

144 results about "Isobutyl acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The chemical compound isobutyl acetate, also known as 2-methylpropyl ethanoate (IUPAC name) or β-methylpropyl acetate, is a common solvent. It is produced from the esterification of isobutanol with acetic acid. It is used as a solvent for lacquer and nitrocellulose. Like many esters it has a fruity or floral smell at low concentrations and occurs naturally in raspberries, pears and other plants. At higher concentrations the odor can be unpleasant and may cause symptoms of central nervous system depression such as nausea, dizziness and headache.

Silicon tungsten, phosphorus heteropoly tungstic acid load type catalyzer used for esterification reaction, manufacturing method and application thereof

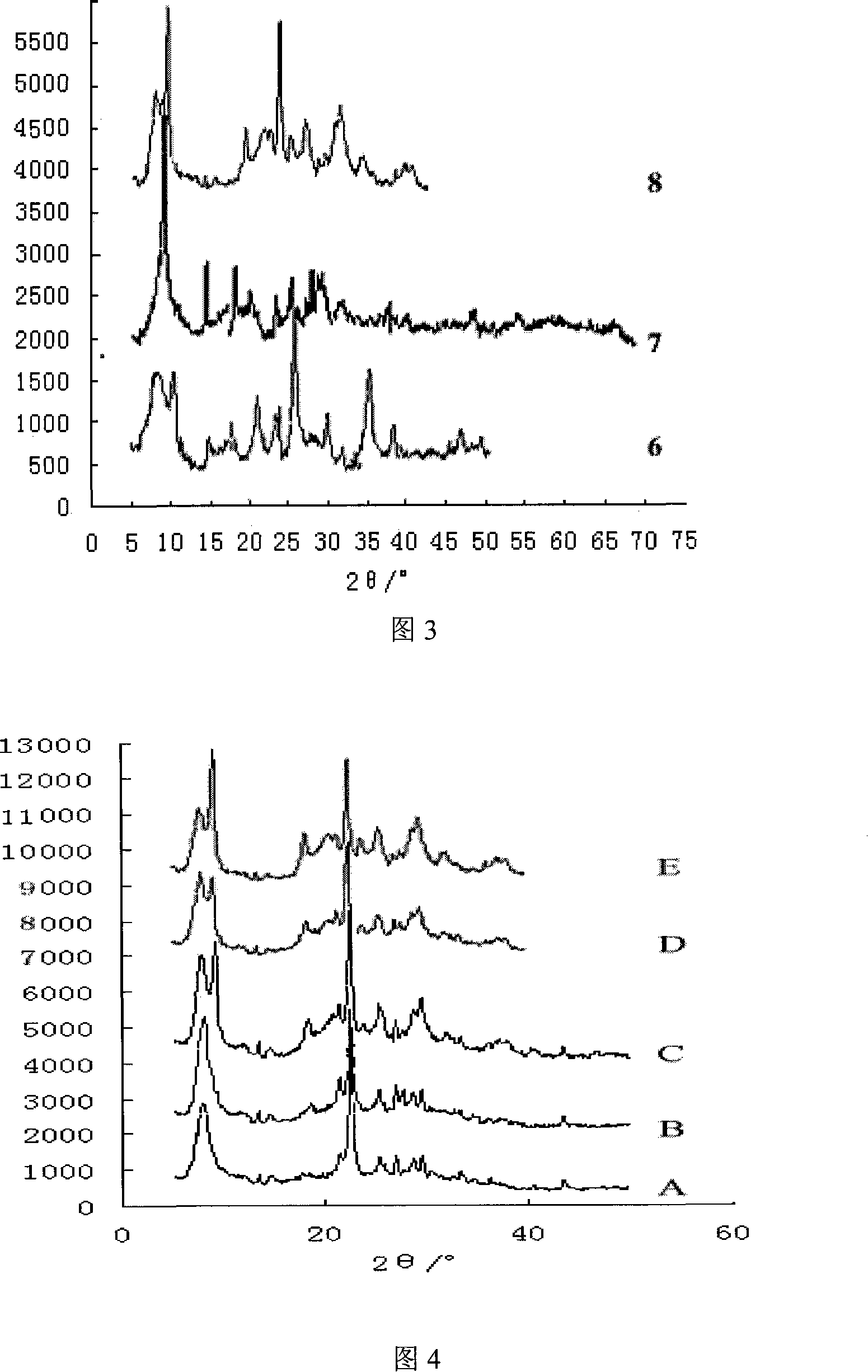

The invention is a silicotungstic and phosphotungstic heteropoly acid load catalyst used for esterification reaction, which comprises the following components: Keggin structure silicotungstic acid H3SiW12O40.xH2O and phosphotungstic H3PW12O40.xH20, the content occupies 10 to 50 quality per centage of the amount of the catalyst; the carrier is H Beta zeolite. The invention adopts soaking method to prepare the solid silicotungstic and phosphotungstic heteropoly acid catalyst load on the H Beta zeolite, which can be used for catalyzing the esterification reaction of etic acid, isobutanol, isobutanol and ethanol, but also can be used for catalyzing esterification reaction of lactic acid and isobutanol to synthesis n-butyl acetate, isobutyl acetate, ethyl acetate and N-Butyl Lactate. The invention has the advantages of good stability, high activity and good selectivity, but also can used as inhomogeneous catalyst which is easy to be separated with reaction product and can use the prepared and formed catalyst powder in the continuous operating fixed bed reactor. The invention is used in the techinics of esterification reaction catalyzing rectifying.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

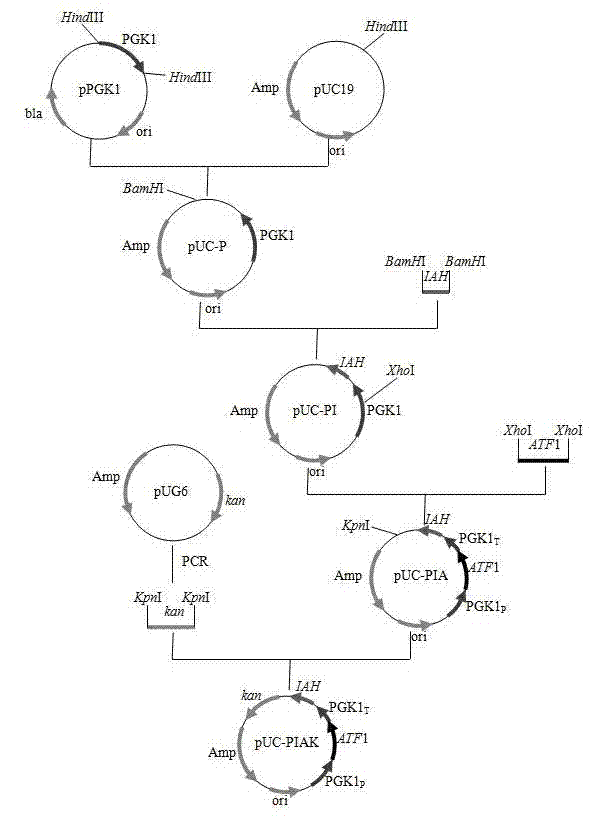

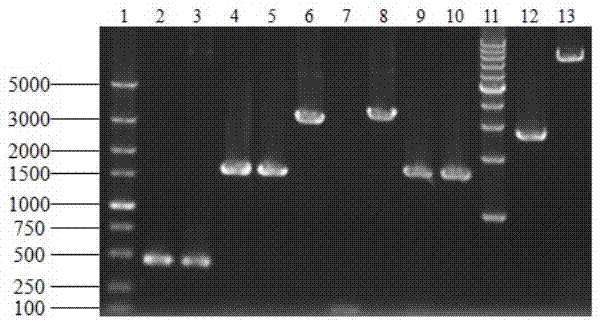

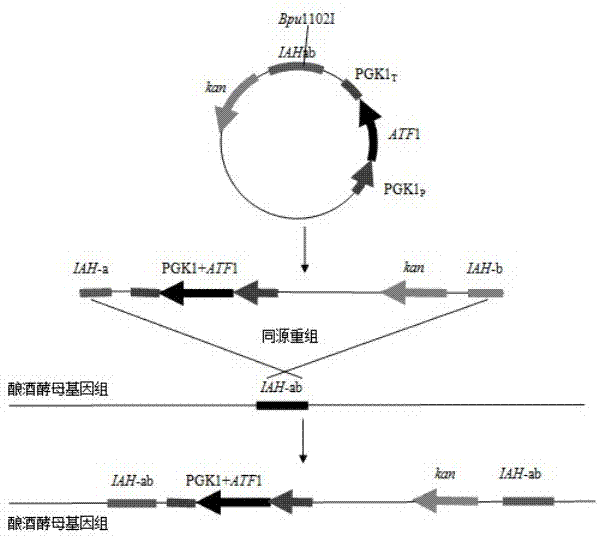

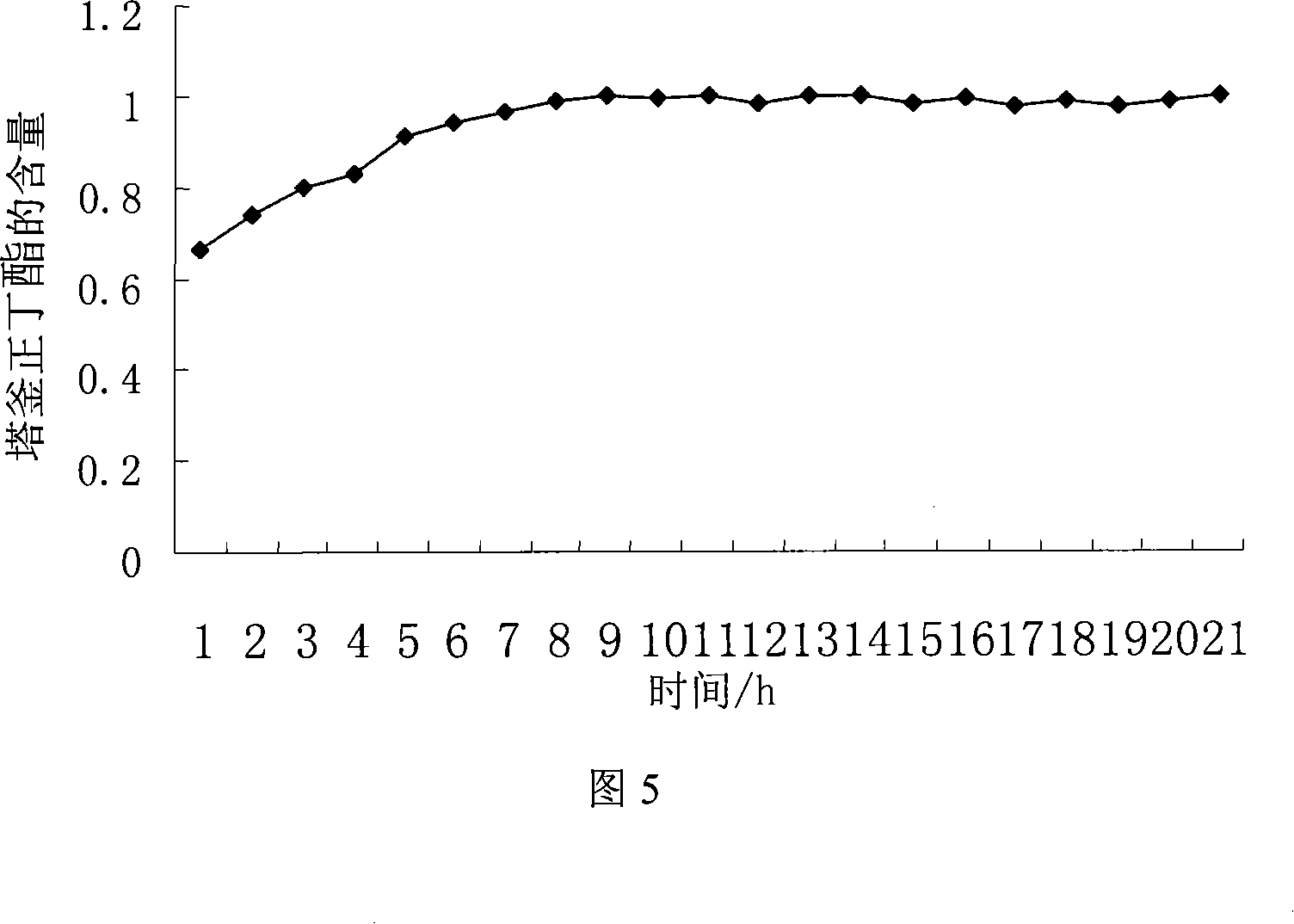

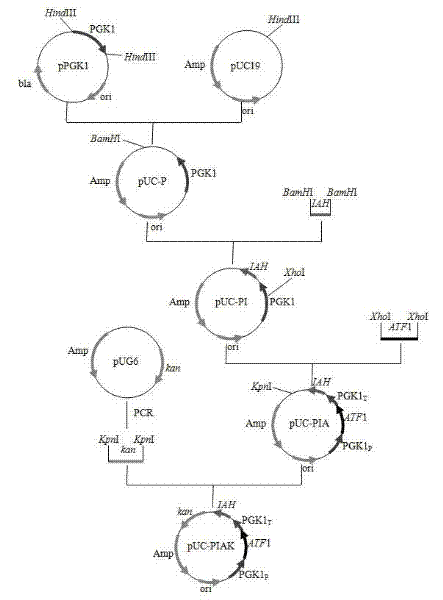

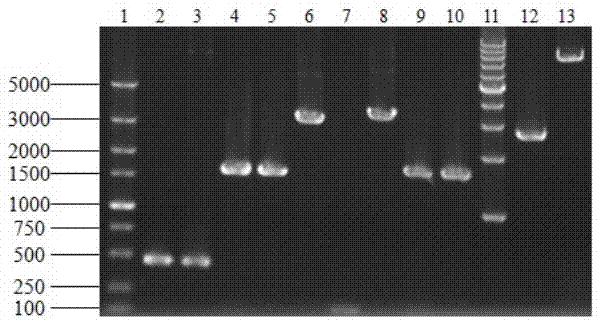

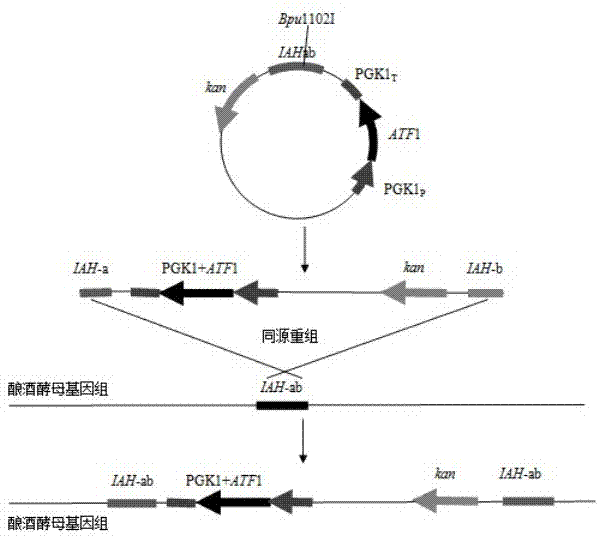

Saccharomyces cerevisiae genetic engineering bacteria with high ester yield and construction method thereof

ActiveCN102199556AReduce contentIncrease contentFungiAlcoholic beverage preparationEster hydrolaseGenetic engineering

The invention discloses Saccharomyces cerevisiae genetic engineering bacteria with high ester yield. The Saccharomyces cerevisiae genetic engineering bacteria EY-13 were collected in China General Microbiological Culture Collection Center on November 17, 2010, the collection number is CGMCC NO.4350, and the Saccharomyces cerevisiae genetic engineering bacteria are recommended to be named Saccharomyces cerevisiae. PGK1 derived from the Saccharomyces cerevisiae is selected as a promoter; and the construction method of the Saccharomyces cerevisiae genetic engineering bacteria with the high esteryield comprises a step of knocking-out an IAH1 gene for encoding ester hydrolase in a Saccharomyces cerevisiae genome when an ATF1 gene which is derived from the Saccharomyces cerevisiae and is used for encoding alcohol acetyltransferase is overexpressed. Compared with initial recipient bacteria, the Saccharomyces cerevisiae genetic engineering bacteria have the advantages that: after rice wine fermentation is simulated, the content of isoamylol is about one half, the content of ethyl acetate is improved by 20 times, the content of isoamyl acetate is 100mg / L, and the content of isobutyl acetate is 5 to 7mg / L; and after liquor fermentation is simulated, the content of total esters is improved by 4 times and the content of the ethyl acetate is improved by 35 times, so an excellent strain is provided for the production of brewing industry.

Owner:TIANJIN UNIV OF SCI & TECH

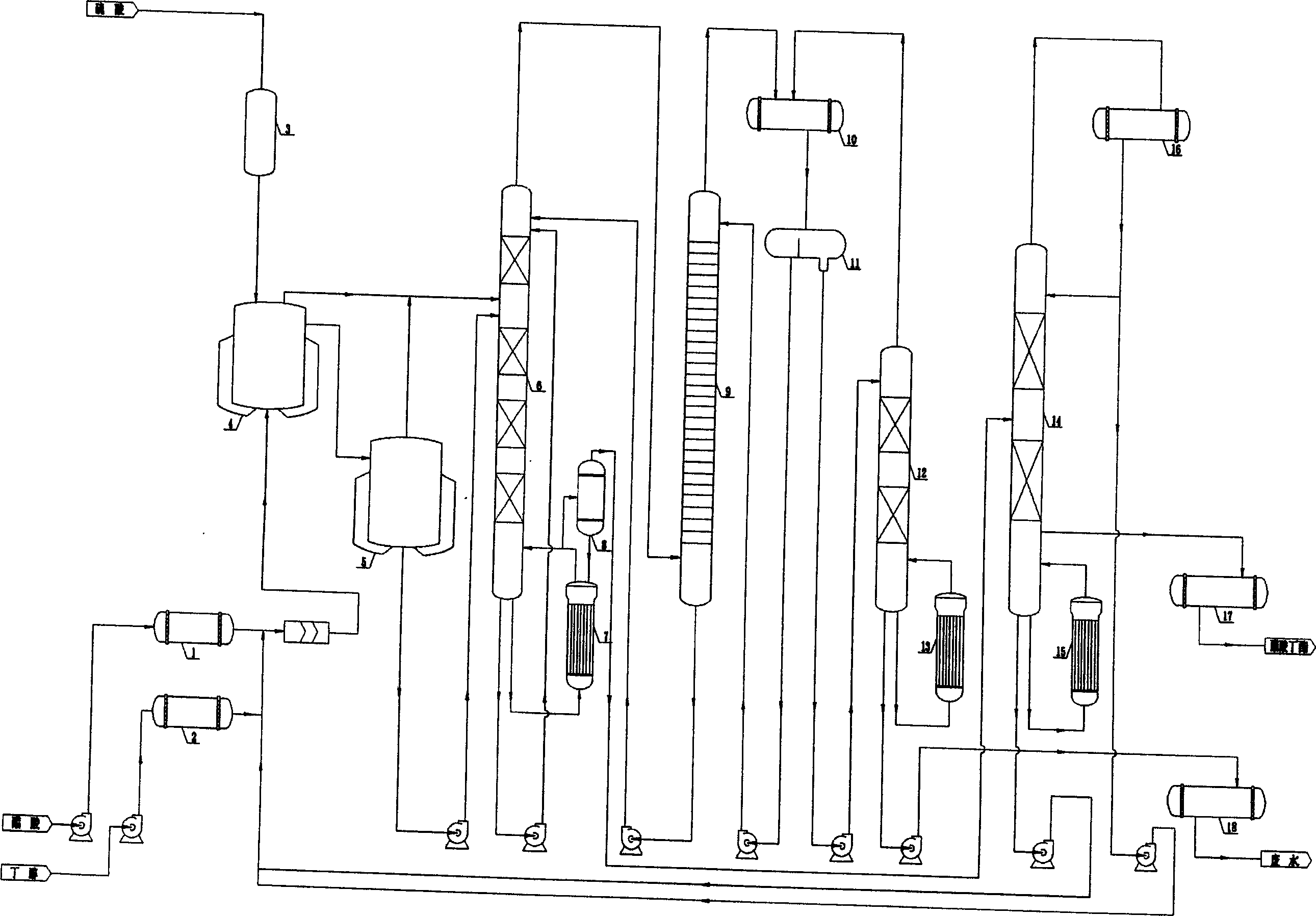

Method for mass producing butyl acetate by reactive distillation method and using sulfuric acid as catalyst

ActiveCN1844076AEasy to separateAvoid corrosionPhysical/chemical process catalystsOrganic compound preparationAcetic acidAlcohol

The refers to a mass production method of isobutyl acetate which uses hydric sulphate as accelerant by reaction fractional distillation, using ethyl acetate and butyl alcohol as raw material, concentrated sulfuric acid as accelerant, continue producing isobutyl acetate by reaction fractional distillation, the whole production system contains three towers, reaction fractionating tower, azeotropy tower and eater fractionating tower, the reaction fractionating tower, azeotropy tower are setted side by side. The ethyl acetate, butyl alcohol and concentrated sulfuric acid are drived into feeder column plate of reaction fractionating tower after esterification prereaction, the gas phase of prereactor going into feeding phase of reaction fractionating tower, the gas phase on top of reaction fractionating tower going into column plate of cellar of azeotropy towder, the liquid phase of towder bottom going into mesomere of eater fractionating tower, the butyl product is continue discharged from side tower. This invention combines the technique which using sulfuric as accelerant by mean improvement of reaction fractional distillation technique, not only ustilizing the advanced technology of reaction fractional distillation, but also making the liquid accelerant's characters of convenience to operate, easy to enlarge production scale getted adequate use.

Owner:NANTONG BAICHUAN NEW MATERIAL CO LTD +1

Ultraviolet light curing coating and production thereof

InactiveCN1778850AImprove wear resistanceHigh hardnessPolyurea/polyurethane coatingsUltraviolet lightsKetone

A ultraviolet curing coating and its production are disclosed. The coating consists of filming substance, diluent and light initiating agent or assistants. The diluent is a organic solvent which comprises one of several from toluene, acetic ether, acetate butyrin, isobutyl acetate, propyl acetate, alcohol, n-butyl alcohol, ethylene ketone, dimethyl benzene, methyl isobutyl ketone, acetone, methyl ethyl ketone, ethanediol butyl ester and propylene butyl ester. It costs low, has better abrasive-resistance, hardness and adhesion.

Owner:BYD CO LTD

Method for synthesizing diatomic alcohol ether acid ester

InactiveCN101475469ALow toxicityEasy to useOrganic compound preparationCarboxylic acid esters preparationSolubilityReaction temperature

The invention relates to a method for synthesizing glycol ether ester. The method comprises the following steps that: glycol ether and fatty acid as raw materials are directly esterified and synthesized into glycol ether acetic ester at a temperature of between 80 and 180 DEG C in the presence of an acidic catalyst and an azeotropic dehydrating agent; and the acidic catalyst is paratoluenesulfonic acid or methanesulfonic acid, and dosage of the catalyst is 0.05 to 1 percent of total weight of reaction materials. The method is characterized in that the mol ratio of the fatty acid to the glycol ether is 1.0:0.8-1.5; and the azeotropic dehydrating agent is isobutyl acetate or 2-butanol acetate, and dosage of the azeotropic dehydrating agent is 5 to 30 percent of the total weight of the reaction materials. The method has the advantages that compared with butyl acetate, the azeotropic dehydrating agent used in the reaction has a lower boiling point and a lower azeotropic point, smaller solubility and lower hydrolysis speed, so that energy consumption during reacting and reclaiming the azeotropic dehydrating agent can be reduced, the reaction speed is improved, and water entrainment of a side product is reduced.

Owner:NANJING FORESTRY UNIV +1

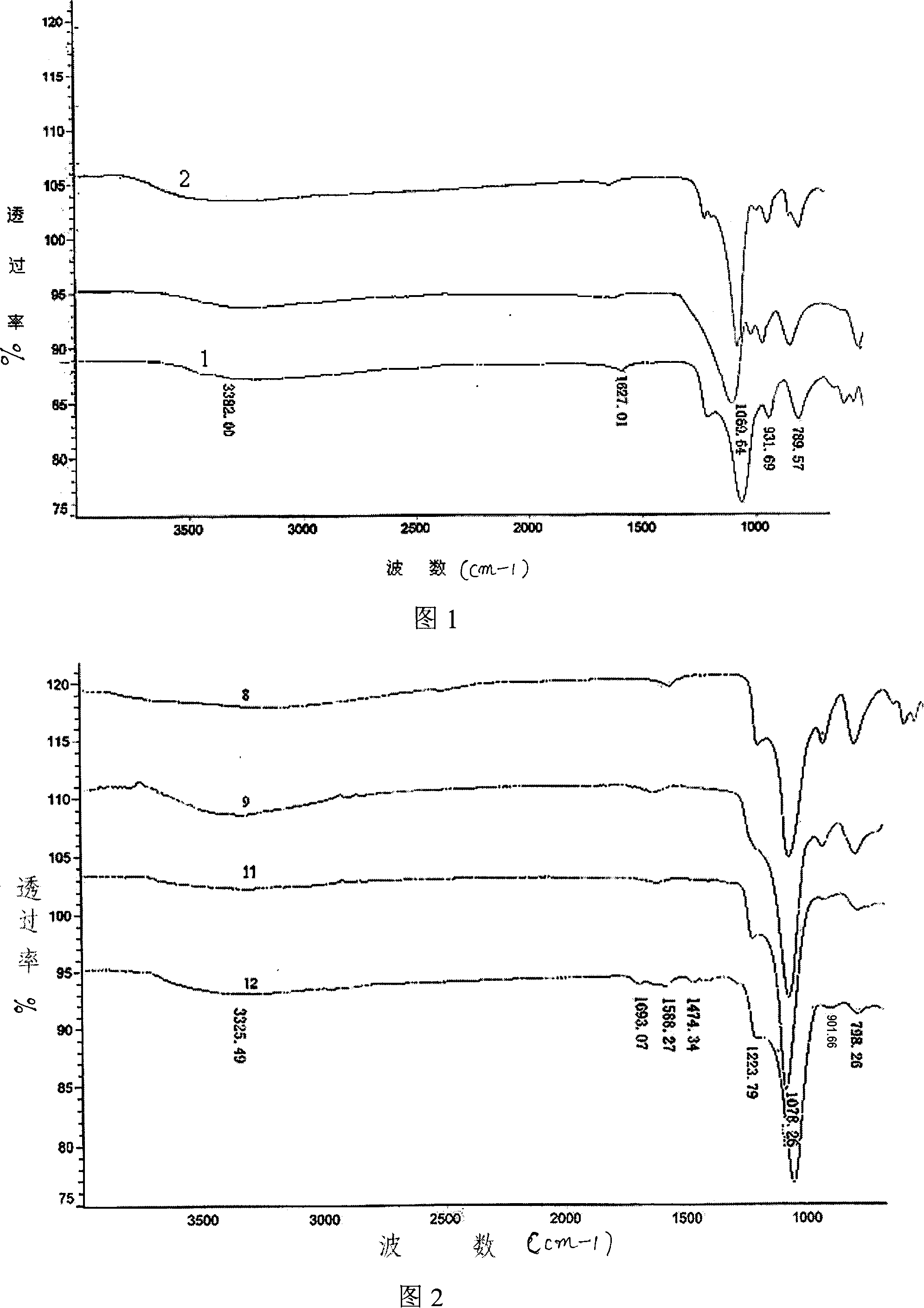

Porous adsorbent resin preparation method

InactiveCN103275258ALarge specific surface areaHigh adsorption selectivityOther chemical processesAlkali metal oxides/hydroxidesPolymer scienceDivinylbenzene

The invention discloses a porous adsorbent resin preparation method which comprises the following steps: by taking styrene and monophenol acrylate as polymerization monomers, divinylbenzene as a crosslinking agent and isobutyl acetate as a pore-forming agent, performing suspension polymerization to obtain spherical adsorbent resin. According to the invention, the polymer monomers containing phenolic hydroxyl groups are introduced onto a polymeric chain of a polymer, so that the framework of the polymer is provided with polar groups, thereby enhancing the adsorption capacity of adsorbed substances. Experimental results show that the adsorbent resin prepared by the invention has appropriate pore size, high specific area, high adsorption selectivity and better adsorption capacity on phenol-containing organic substances.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Method for reaction rectification coupling continuous preparation of and series acetate

ActiveCN1837183AReduce unit consumptionHigh selectivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIsobutanolDistillation

The invention discloses a reaction-distillation coupling preparing acetic acid series ester method, which comprises the following steps: using glacial acetic acid and alcohol with lower five carbons (alcohol, optal,alcohol isopropylicum, butanol, isobutanol, amyl alcohol and isoamyl alcohol ) for raw material; adopting modified strong acidic phenylethene series basic ion exchange resin for accelerant; preparing by reaction-distillation coupling; getting acetic acid ethyl ester, propyl acetate, isopropyl acetate, butyl acetate, isobutyl acetate, amyl acetate and iso-amyl acetate; making glacial acetic acid and alcohol with lower five carbons to carry on esterification reaction by solid acid catalysis in trickle bed reactor; adding reaction product (acetic acid ethyl ester, propyl acetate, isopropyl acetate, butyl acetate, isobutyl acetate, amyl acetate and iso-amyl acetate), water and cycle still liquor in fractionating tower; getting acetic acid ethyl ester, propyl acetate, isopropyl acetate, butyl acetate, isobutyl acetate, amyl acetate and iso-amyl acetate by separating at the top of the tower. The conversion rate of alcohol with lower five carbons is more than 96%, the recovery ratio of acetic acid ethyl ester (propyl acetate, isopropyl acetate, butyl acetate, isobutyl acetate, amyl acetate and iso-amyl acetate) is more than 95%. The invention has high alcohol conversion rate, which simplifies the operation.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

Orange essence

The invention provides an orange essence, consisting of the following components in parts by weight: 1-100 parts of an essence base, 10-50 parts of a solvent, 0-20 parts of a surfactant, 0-15 parts of a cosurfactant and 20-80 parts of a carrier, wherein the essence base consists of the following components in parts by weight: 10-40 parts of citral, 10-40 parts of linalool, 10-40 parts of terpineol, 0-10 parts of peach aldehyde, 5-10 parts of ethyl acetate, 1-30 parts of ethyl butyrate, 5-15 parts of dihydro jasmone, 5-20 parts of ethyl caproate, 5-20 parts of isobutyl acetate and 5-10 parts of lemon oil. The orange essence provided by the invention has a fresh fragrance of an orange juice, and enables consumers to feel the flavor of oranges.

Owner:顾明岐

Transparent acrylic acid intermediate-coating paint base stock and preparation method thereof

ActiveCN103254715AImprove boiling resistanceNo difference in high temperature and high humidity resistanceCoatingsCyclohexanonePolycarbonate plastic

The invention discloses a transparent acrylic acid intermediate-coating paint base stock and a preparation method thereof. The base stock comprises the following ingredients in percentage by weight: 40.0%-45.0% of polymethyl methacrylate, 35.0%-40.0% of iso-octyl methacrylate, 1.0%-5.0% of butyl acetate, 1.0%-5.0% of isobutyl acetate, 1.0%-5.0% of cyclohexanone, 1.0%-5.0% of methyl ethyl ketone, 1.0%-5.0% of methyl isobutyl ketone, and 0-3.5% of cellulose acetate. The transparent acrylic acid intermediate-coating paint base stock can meet the requirement of mobile phone industry on no halogen in paint. Transparent acrylic acid intermediate-coating paint produced by the base stock is additionally provided with a mating curing agent, spraying diluents, halogen-free acrylic acid primer and ultraviolet radiation curing finishing paint for use and then is sprayed onto polycarbonate ester plastics, and a dried and cured coating has excellent boiling resistance.

Owner:深圳市美丽华科技股份有限公司

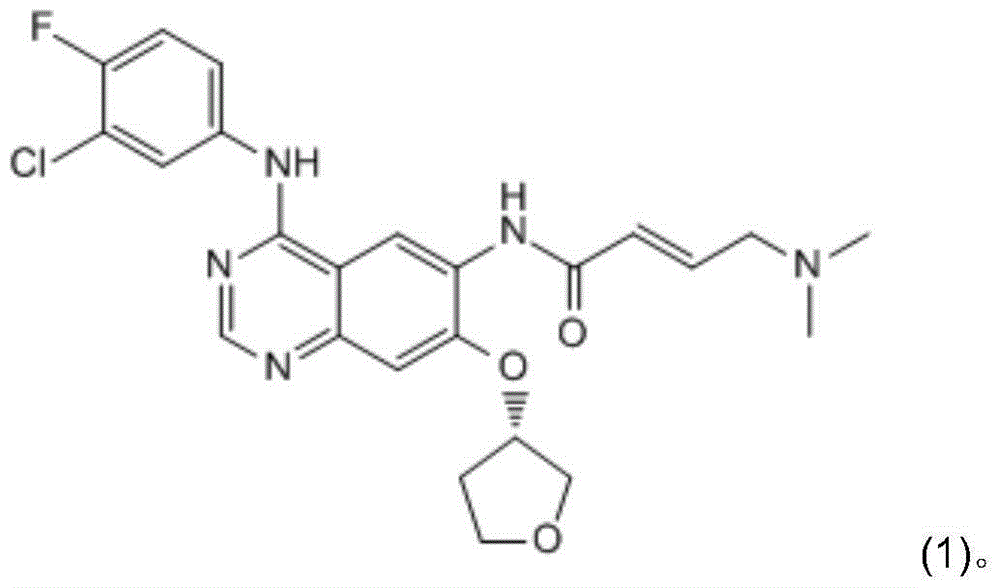

Crystallization purification method

Belonging to the field of pharmaceutical chemistry, the invention relates to a crystallization purification method for Afatinib. The method includes: mixing an Afatinib crude product with isobutyl acetate, conducting stirring and heating to obtain a clarified solution, then cooling the obtained clarified solution, carrying out stirring crystallization for certain period of time, and then performing solid-liquid separation to obtain the product Afatinib. Specifically, the Afatinib crude product and isobutyl acetate are in a mass ratio of 1:3-1:20. By using isobutyl acetate as the crystallization solvent and controlling the crystallization conditions, the cis-isomer impurities of Afatinib can be effectively reduced, the obtained product has high purity, and the operation is simple, thus being favorable of industrial production.

Owner:SUNSHINE LAKE PHARM CO LTD

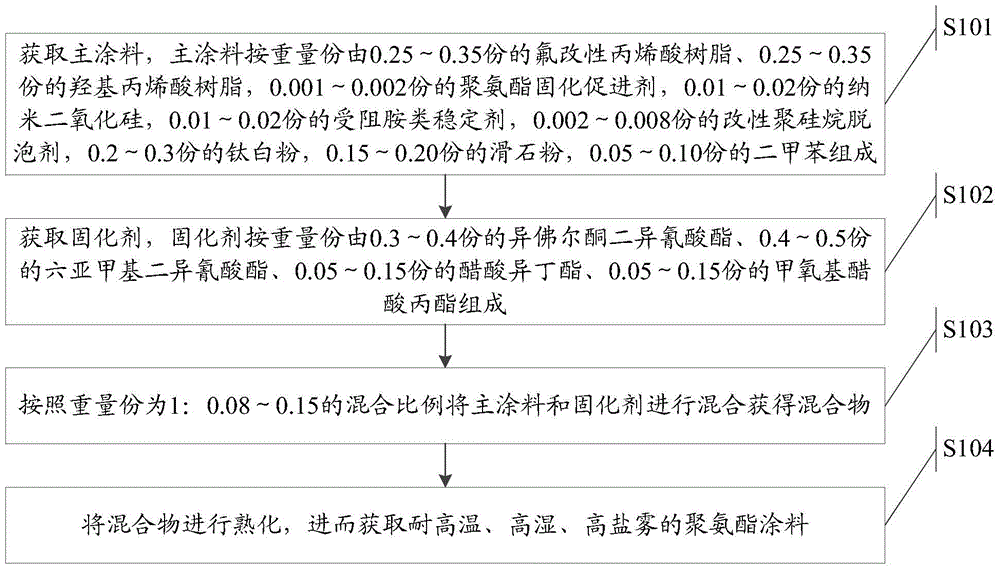

High-temperature, high-humidity and high-salt mist-resistant polyurethane coating and preparation method thereof

InactiveCN104449335AImprove high temperature resistanceImprove anti-corrosion performanceAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylic resinTalc

The invention relates to the chemical technical field and discloses a high-temperature, high-humidity and high-salt mist-resistant polyurethane coating and a preparation method thereof, so as to solve the technical problem that in the prior art, the steel structure is relatively poor in preservative effect. The polyurethane coating is prepared from 1 part by weight of a main coating and 0.08-0.15 part by weight of a curing agent; the main coating is prepared from the following components in parts by weight: 0.25-0.35 part of fluorine-modified acrylic resin, 0.25-0.35 part of hydroxy acrylic resin, 0.001-0.002 part of a polyurethane curing accelerator, 0.01-0.02 part of nanosilicon dioxide, 0.01-0.02 part of a hindered amine stabilizer, 0.002-0.008 part of a modified polysilane defoaming agent, 0.2-0.3 part of titanium dioxide, 0.15-0.20 part of talcum powder and 0.05-0.10 part of dimethylbenzene; the curing agent is prepared from the following components in parts by weight: 0.3-0.4 part of isophorone diisocyanate, 0.4-0.5 part of hexamethylene diisocyanate, 0.05-0.15 part of isobutyl acetate and 0.05-0.15 part of methoxy propyl acetate. Furthermore, the preservative effect of the steel structure is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

Tylosin extraction menstruum and extraction method

ActiveCN102584921AHigh extraction yieldSugar derivativesSugar derivatives preparationButyl acetateIsobutyl acetate

The invention relates to a compound menstruum for extracting tylosin and an extraction method. According to the invention, the compound menstruum formed by mixing butyl acetate, isobutyl acetate and butanol according to the volume ratio of 6:3 to 3.2 to 0.8-1 is used for extracting tylosin in fermentation filtrate through a secondary counter-current extraction method. The method has the advantages of low consumption of organic menstruum, low loss of tylosin, short extraction time, high extraction yield and the like.

Owner:宁夏泰瑞制药股份有限公司

Environment-friendly nontoxic wood paint formula

InactiveCN104263174AImprove waterproof performanceGood alkali resistanceAntifouling/underwater paintsAnti-corrosive paintsEpoxySodium Bentonite

The invention relates to an environment-friendly nontoxic wood paint formula which comprises 25 parts of polyacrylate emulsion, 20 parts of cerium oxide, 5 parts of sodium silicate, 10 parts of talcum powder, 16 parts of turpentine, 12 parts of bentonite, 5 parts of urea-formaldehyde resin, 12 parts of cellaburate, 8 parts of triethyl citrate, 8 parts of isobutyl acetate, 15 parts of methyl isoamyl ketone, 2 parts of silicon oil, 6 parts of silicon dioxide, 5 parts of ethanol, 8 parts of epoxy resin, 5 parts of triethanolamine and 1 part of alkali lignin. The paint has the advantages of favorable water resistance, favorable alkali resistance, favorable scrub resistance, excellent color retention, excellent weather resistance, excellent resistance to ultraviolet radiation, excellent pollution resistance and mold resistance, and can be used for applying side walls and the like of offices, classrooms and families; and the ink, sewage and the like sprayed on the wall can be easily cleaned.

Owner:QINGDAO HI TECH PATENT TECH TRANSFER PLATFORM

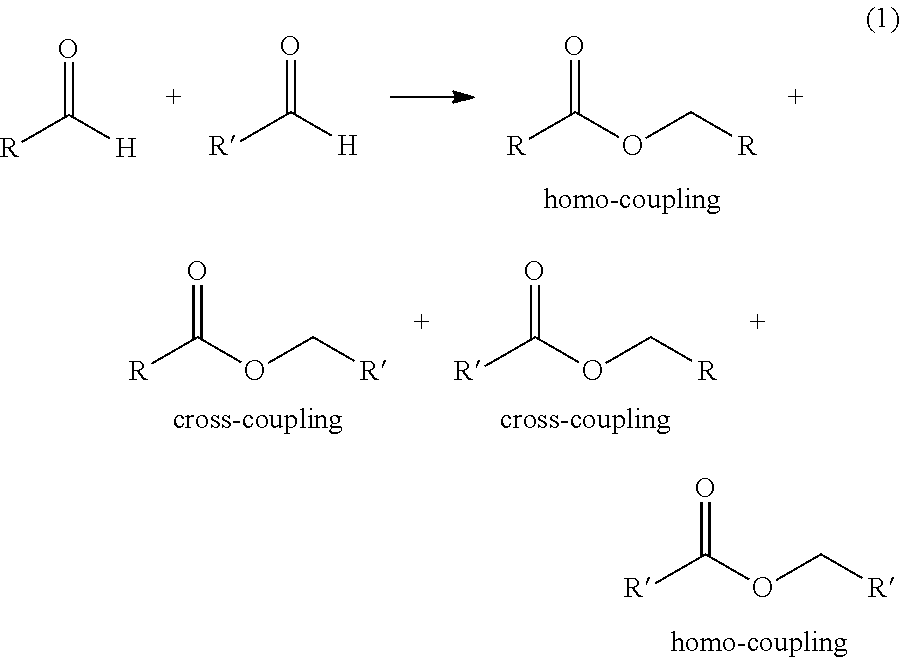

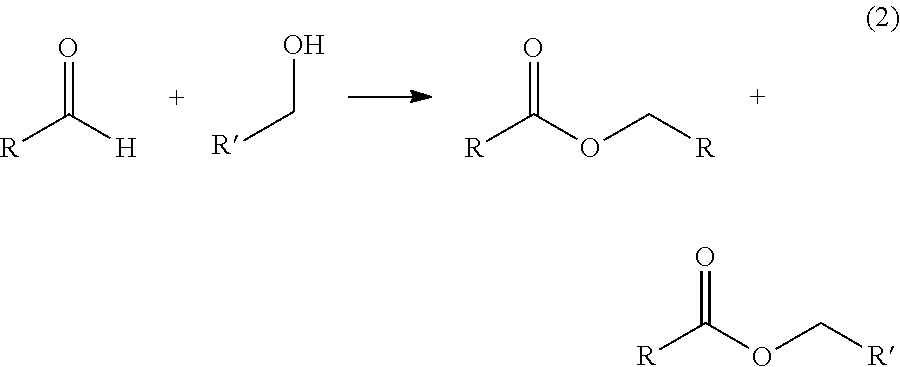

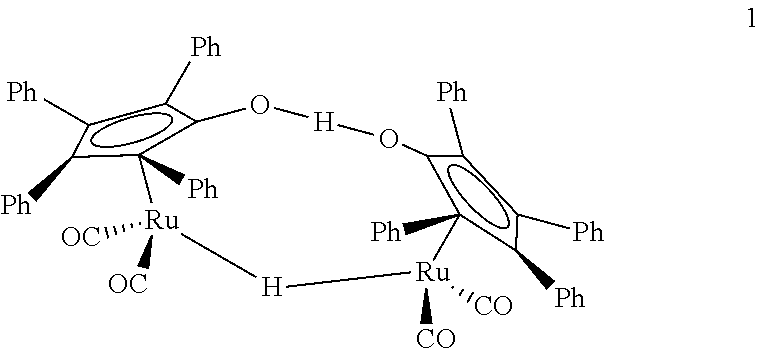

Production of two esters using homogeneous catalyst

ActiveUS9493395B2Speed up the conversion processOrganic compound preparationPreparation by aldehyde oxidation-reductionPtru catalystEthyl group

Owner:EASTMAN CHEM CO

Culture medium for fermenting and producing tylosin with streptomyces fradiae, and fermentation method

InactiveCN102584920AHigh extraction yieldSugar derivativesSugar derivatives preparationButyl acetateIsobutyl acetate

The invention relates to a compound menstruum for extracting tylosin and an extraction method. According to the invention, the compound menstruum formed by mixing butyl acetate, isobutyl acetate and butanol according to the volume ratio of 6:3 to 3.2 to 0.8-1 is used for extracting tylosin in fermentation filtrate through a secondary counter-current extraction method. The method has the advantages of low consumption of organic menstruum, low loss of tylosin, short extraction time, high extraction yield and the like.

Owner:宁夏泰瑞制药股份有限公司

Jacquard coating material

The present invention discloses a jacquard coating material, which comprises the following raw materials by mass: 20-50 parts of a propylene pigment, 30-50 parts of an organic pigment, 10-30 parts of a polystyrene polydiphenylsiloxane graft copolymer, 20-30 parts of a cyanate ester epoxy resin copolymer, 15-20 parts of an ethylene acrylate copolymer, 100-150 parts of toluene, 100-120 parts of styrene, 100-150 parts of acetone, 100-120 parts of xylene, 60-80 parts of cyclohexylamine, 30-60 parts of ethyl acetate, 20-50 parts of isobutyl acetate, 30-60 parts of hydroxypropyl methyl cellulose, 20-40 parts of hydroxypropyl cellulose, 10-30 parts of lignocellulose, and 15-30 parts of polypropylene fibers. The jacquard fabric prepared from the jacquard coating material of the present invention has characteristics of soft, fine, smooth and unique texture, good gloss, good drapability, good air permeability, high color fastness, smooth and delicate fabric surface, no pilling, fading resistance, firm and stiff texture, and smooth surface.

Owner:黄慧娟

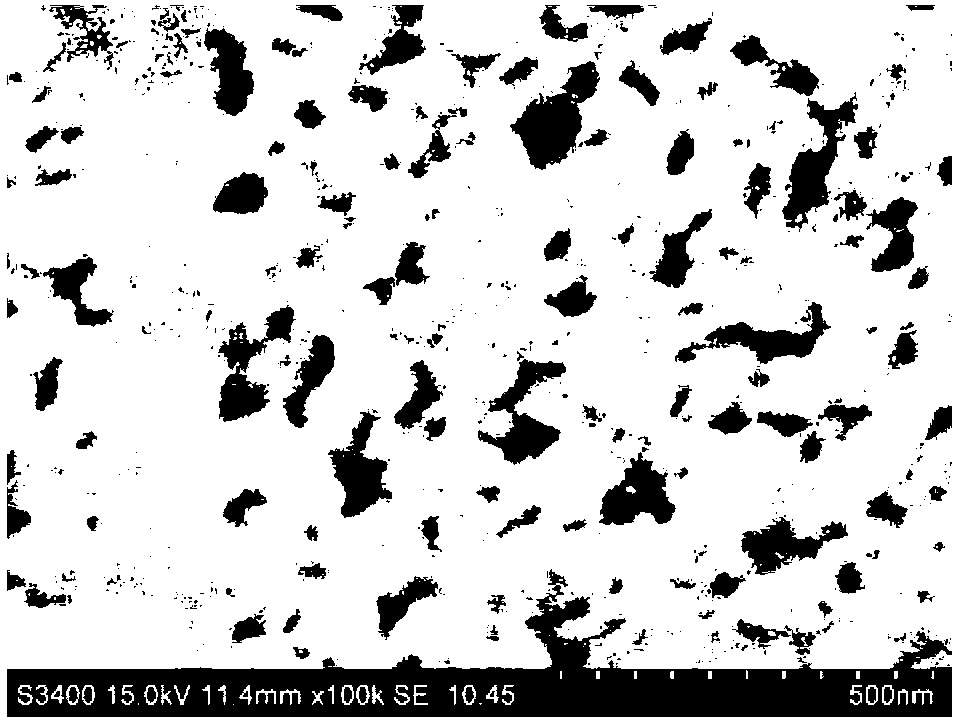

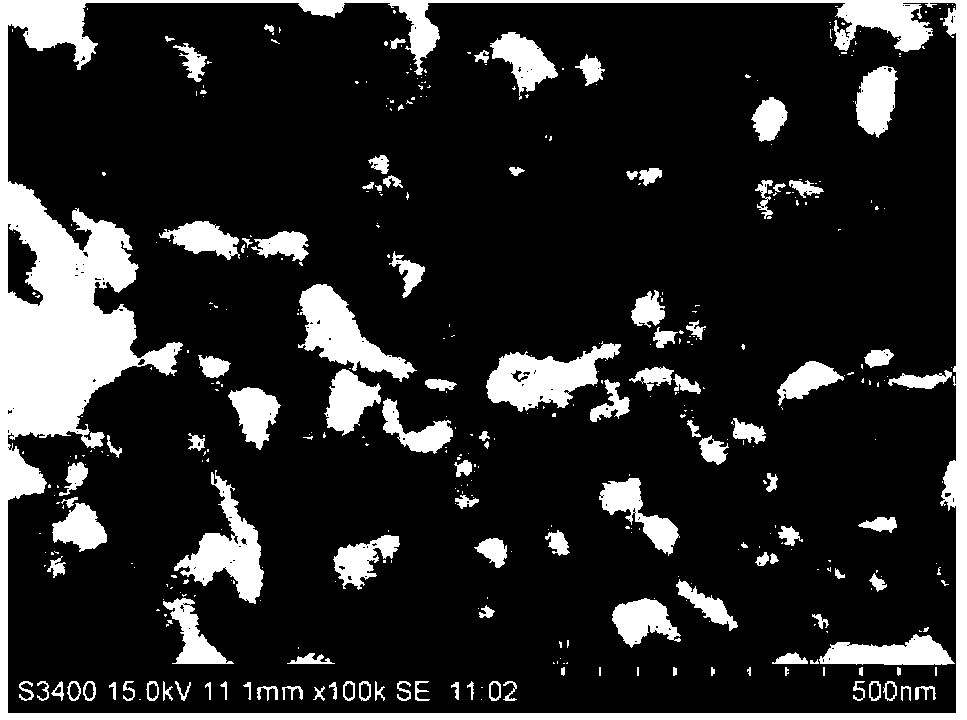

Method for preparing grease hydrogenation catalyst in organic-aqueous system

ActiveCN104399467AUniform particle sizeHigh reactivityFatty acid hydrogenationMetal/metal-oxides/metal-hydroxide catalystsDistillationHydrogenation reaction

The invention discloses a method for preparing a grease hydrogenation catalyst in an organic-aqueous system. According to the method, isobutyl acetate and water are employed as mediums for performing a co-precipitation reaction, and then distillation modification is performed, so that the grease hydrogenation catalyst, which employs nickel as an active composition, zirconium, magnesium or iron as an auxiliary agent and aluminium oxide as a carrier, is prepared. Calculated based on the total weight of the catalyst, nickel accounts for 10-30 wt%, the aluminium oxide carrier accounts for 50-85 wt%, and the auxiliary agent zirconium, magnesium or iron accounts for 0.01-10 wt%. The specific surface area of the aluminium oxide carrier is 120-450 cc / g, and the pore volume is 1-2.7 mm / g. The prepared catalyst is high in activity, safe to use and applicable to grease hydrogenation reaction.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

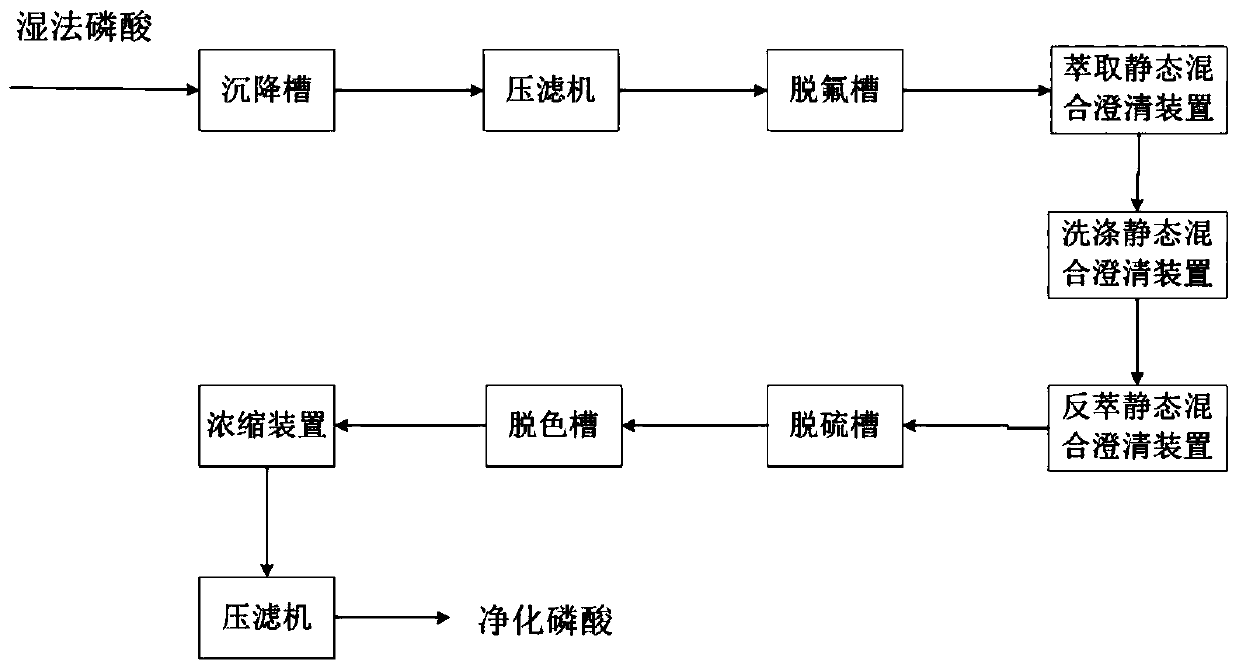

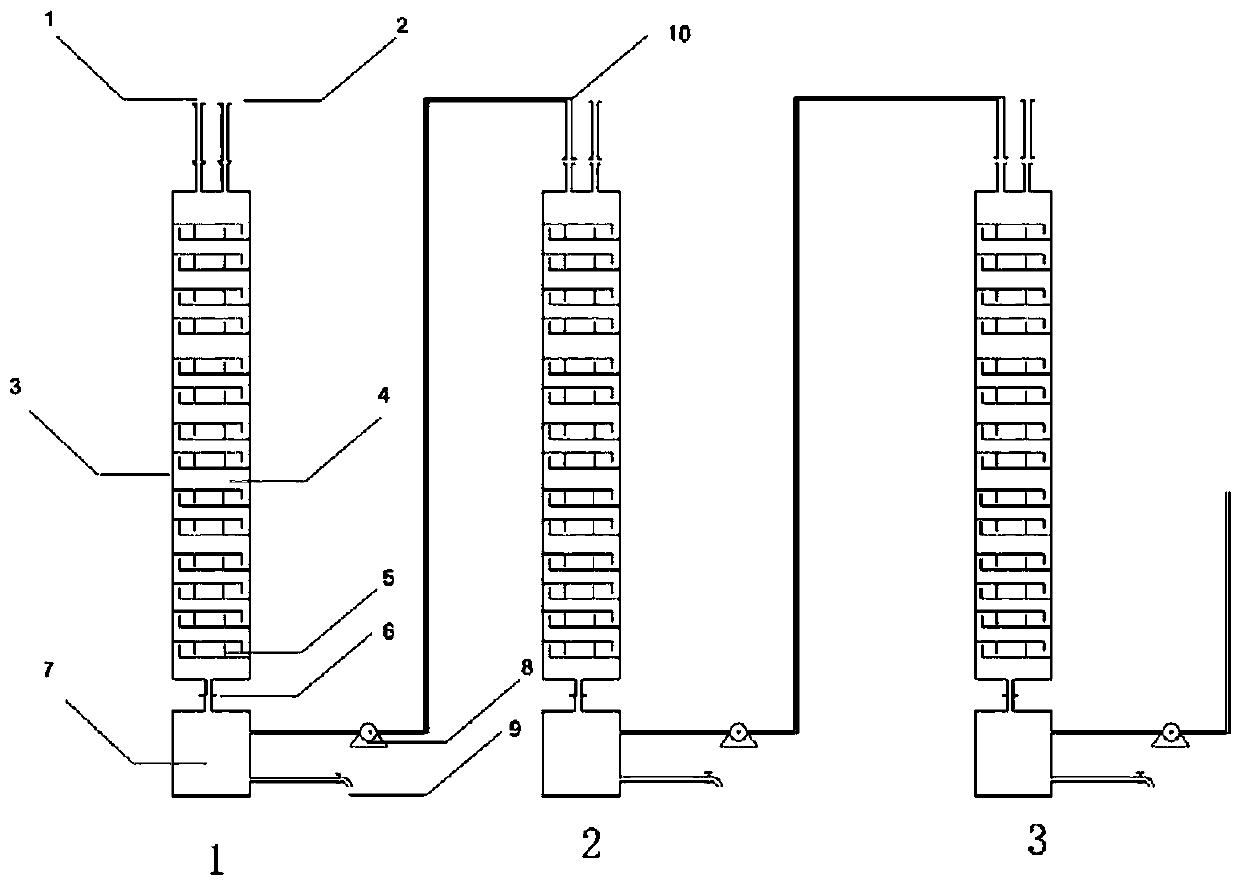

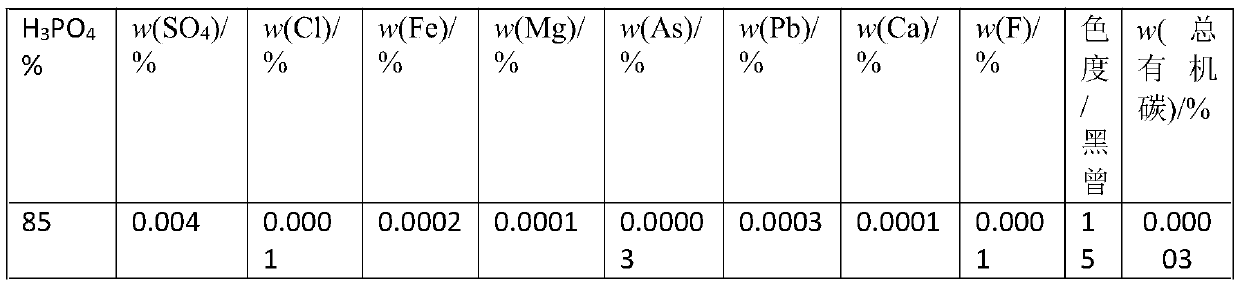

Production method and device for purification of low-concentration wet-process phosphoric acid by solvent extraction

InactiveCN109928373AGood effectIncrease economic value addedPhosphorus compoundsCyclohexanoneIsooctyl alcohol

The invention relates to a production method and device for purification of low-concentration wet-process phosphoric acid by solvent extraction. The technology utilizes solvent extraction to realize preparation of food-grade phosphoric acid from low-concentration wet-process phosphoric acid. The method adopts one or more of trioctyl phosphate, cyclohexanol, isooctyl alcohol, butyl ether, cyclohexanone, isobutyl acetate and ethylene glycol diethyl ether as the extraction agent; extraction, washing and reverse extraction are accomplished by a multistage static mixer; and in the washing process,the quaternary ammonium salt cation [N(CH3)4]<+> is added into a washing solution. The static mixer used in the invention is special equipment designed and developed by self according to the process requirements and practical production practice experience, and is the key production device of the invention. The method and equipment provided by the invention can be applied to the industrial production of food grade phosphoric acid from wet-process phosphoric acid, and can significantly shorten the purification process, reduce consumption and ultimately lower the purification cost of the whole process.

Owner:广西川金诺化工有限公司

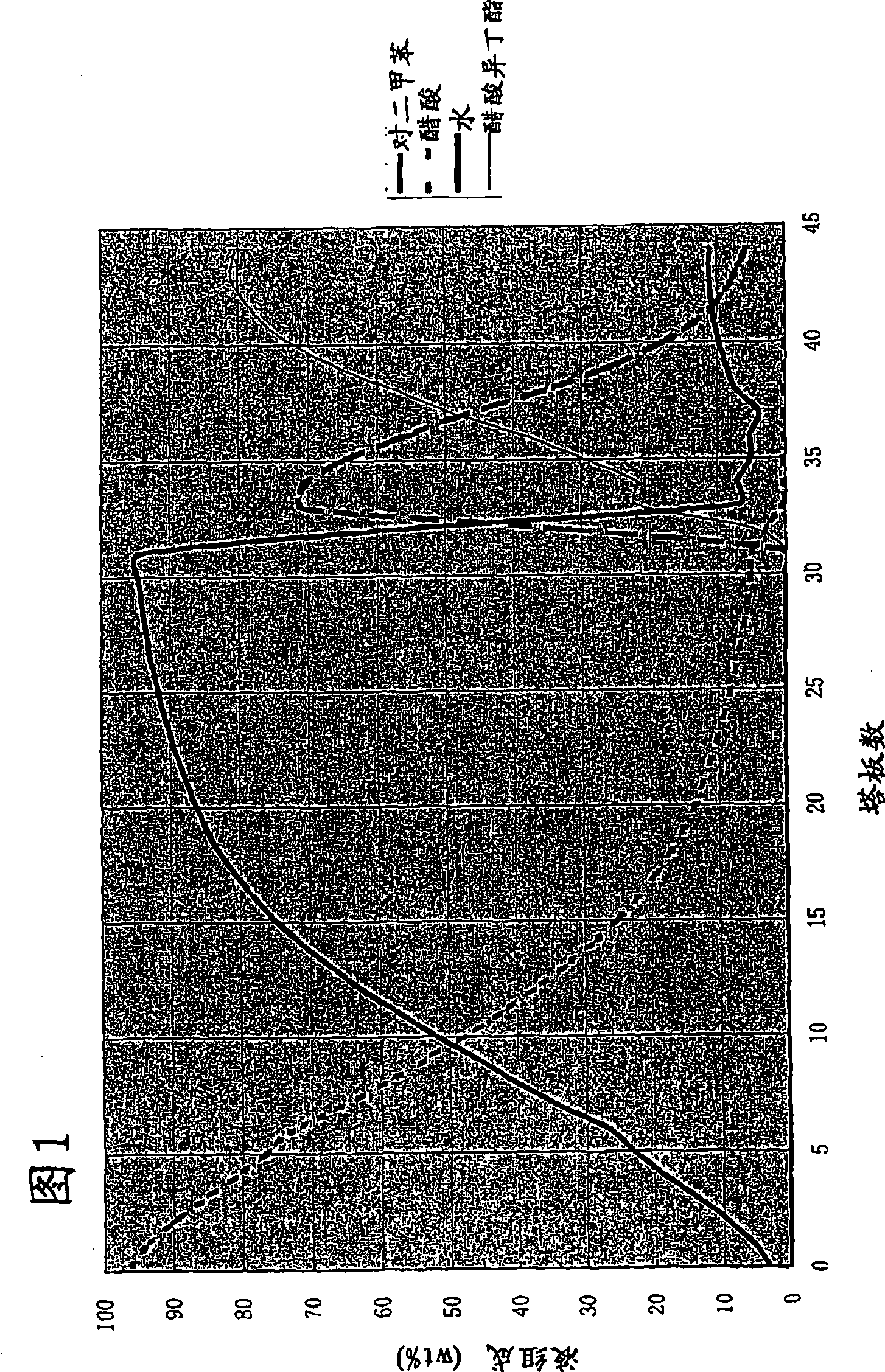

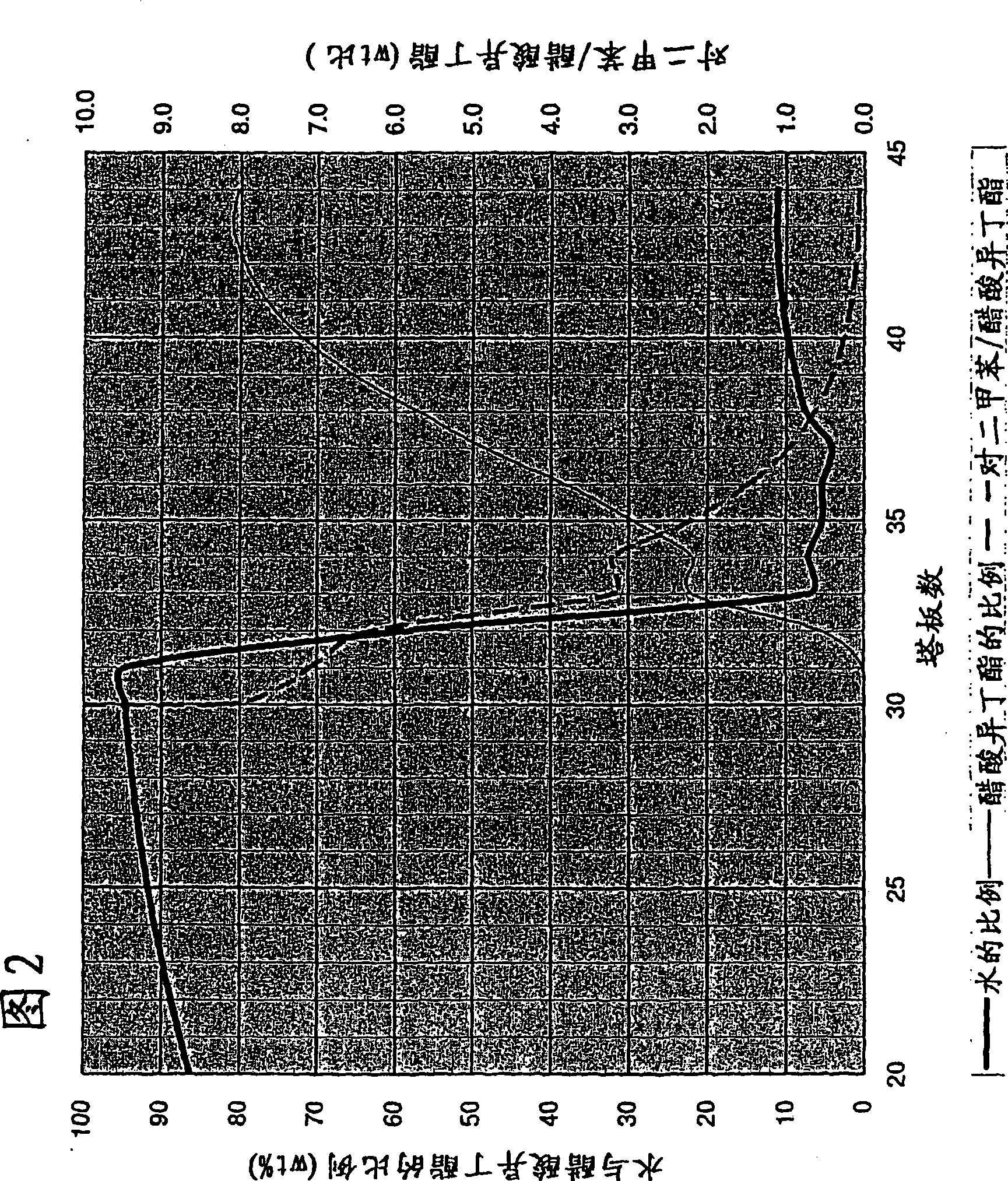

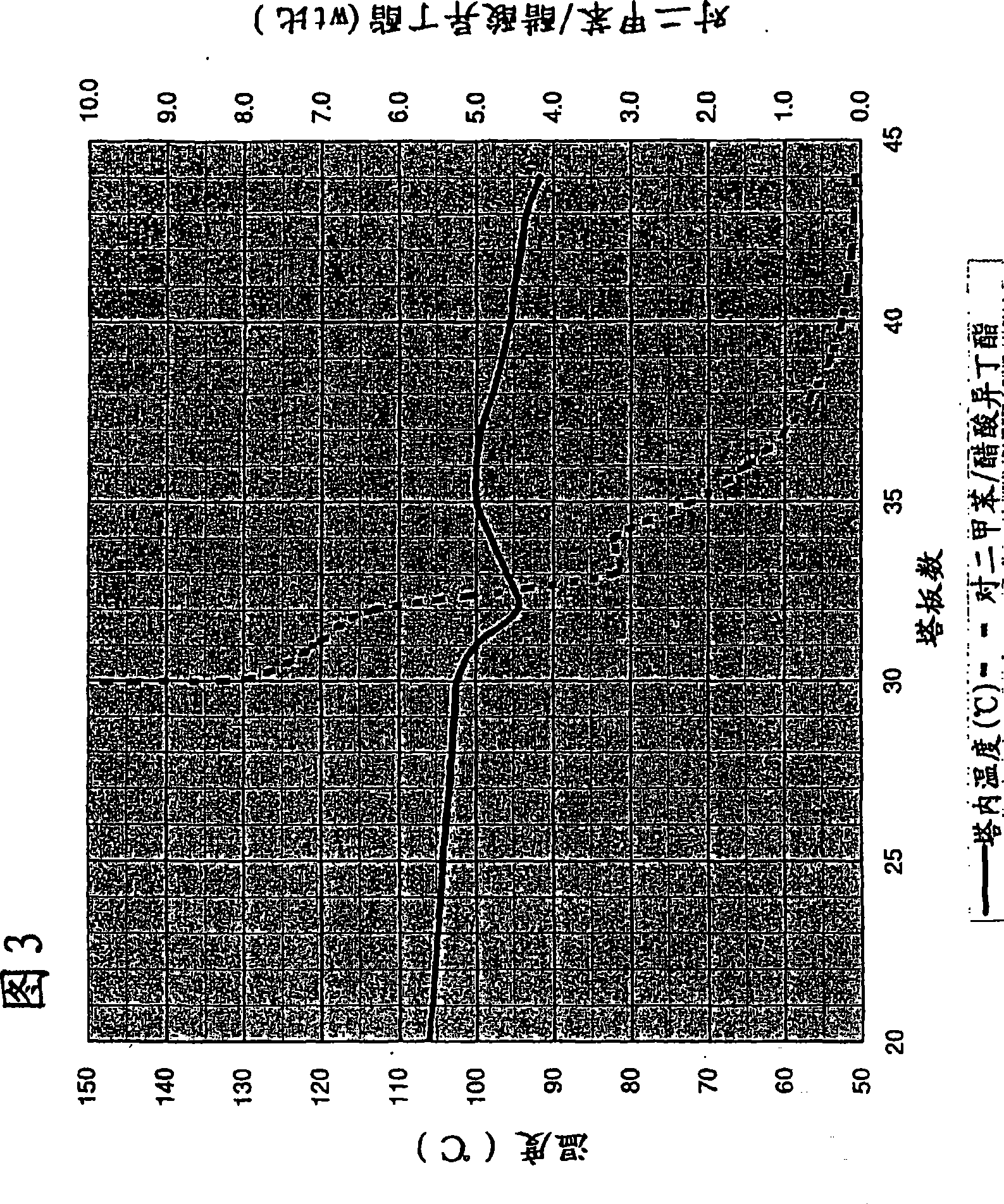

Azeotropic distillation method for water-containing acetic acid containing aromatic hydrocarbon

InactiveCN101445442AStable recyclingInhibition lossOrganic compound preparationDistillation purification/separationHigh concentrationConcentration ratio

In a recovery system for preparing the acetic acid solvent in aromatic dicarboxylic acid, the unreacted dialkyl benzene is stably recovered from an acid dehydrate tower for azeotropic distillation with high concentration, and the reutilization is carried out. The invention adopts the method that during the process of recovering the acetic acid for preparing the aromatic carboxylic acid, the unreacted dialkyl benzene is recovered by an azeotropic distillation tower taking the isobutyl acetate as an entrainer during the dehydration of the acetic acid, wherein, the alkyl benzene-containing fraction is delivered to a distillate storage tank in the azeotropic area of the azeotropic distillation tower at the temperature of ranging from 94-100 DEG C, after the aqueous phase is separated from thebottom part of the distillate storage tank, the organic phase fraction at the upper part of the distillate storage tank is circulated to the azeotropic area, the organic phase fraction is accumulatedin the azeotropic distillation tower until the concentration ratio of the alkyl benzene and the entrainer reaches the target coverage with about 0.5 weight ratio to about 6 weight ratio, and the accumulated organic-phase fraction is intermittently recovered from the distillate storage tank.

Owner:HITACHI LTD

Colorful quick-drying nitrocellulose paint

Colorful quick-drying nitrocellulose paint comprises raw materials in parts by weight as follows: 100 parts of nitrocellulose, 5-15 parts of ethylene glycol monoethyl ether, 10-20 parts of methoxy methylpentanone, 20-30 parts of rutile type titanium dioxide, 1-10 parts of ethylene glycol monobutyl ether, 5-25 parts of polysiloxane, 80-90 parts of deionized water, 15-25 parts of hydroxyethyl methylacrylate, 10-20 parts of pigment, 15-35 parts of isobutyl acetate, 25-35 parts of methyl isobutyl carbinol, 10-30 parts of methyl amylketone, 5-10 parts of a plasticizer, 35-45 parts of cellulose acetate butyrate, 20-40 parts of naphtha and 20-30 parts of benzophenone; the pH value of a product is 7-9, and surface dry is performed for 30-60 minutes; the adhesive force is 100%, and the paint doesn't bubble and come off after soaked in water for 10-20 days; hard dry is performed for 6-10 hours, and the loss is 0.004-0.006g / cm<2> after the paint is tested by a reciprocating tester for 1,000 times; and the paint can be washed for 300-500 times, can be widely produced and can continuously replace a conventional material.

Owner:盐城市盐龙水务有限公司

Extraction method for increasing tylosin A component

ActiveCN103709218AHigh purityIncrease risk resistanceSugar derivativesCarboxylic acid salt preparationBiotechnologyButyl acetate

The present invention relates to a tylosin extraction technology, and specifically discloses an extraction method for increasing a tylosin A component, wherein a composite solvent is adopted to extract tylosin from a tylosin fermentation filtrate, the composite solvent comprises toluene and butyl acetate or isobutyl acetate, and the proportion of toluene in the composite solvent is 70-95% (V / V). According to the extraction method, the product yield is increased, the solvent loss problem is solved, and the abnormal tylosin fermentation problem is solved.

Owner:浙江普洛生物科技有限公司 +1

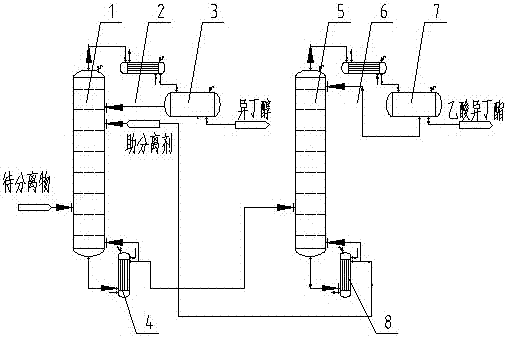

Method for separating isobutanol from isobutyl acetate

ActiveCN107337601AEasy to separateHigh purityOrganic compound preparationCarboxylic acid esters preparationIsobutanolIsobutyl acetate

The invention discloses a method for separating isobutanol from isobutyl acetate. According to the method, a screening separation promoter is added, an extraction distillation method is implemented to separate isobutanol from isobutyl acetate, the relative volatility of isobutanol and isobutyl acetate is changed, separation of isobutanol from isobutyl acetate is achieved, isobutanol and isobutyl acetate of relatively high purity are prepared, the added separation promoter can be recycled, and high-efficiency and high-purity separation of isobutanol from isobutyl acetate is achieved.

Owner:济南信兆昌化工科技有限公司

Synthesis method of 2-[2-(4-fluorophenyl)-2-oxa-1-phenylethyl]-4-methyl-3-oxa-N-phenylpentanamide

InactiveCN102382006AEasy to operateLow costOrganic compound preparationCarboxylic acid amides preparationSynthesis methodsAcetophenone

The invention discloses a synthesis method of 2-[2-(4-fluorophenyl)-2-oxa-1-phenylethyl]-4-methyl-3-oxa-N-phenylpentanamide. The method is characterized by comprising the following steps: firstly preparing methyl isobutyryl acetate from toluene, sodium hydride, dimethyl cabonate, methyl isopropyl ketone and the like as raw materials; then preparing isobutyryl acetanilide from toluene, methyl isobutyl acetate, HCl, sodium bicarbonate and the like as raw materials; preparing 4-fluorophenylacetophenone from aluminium choride, phenylacetyl chloride and the like as raw materials; preparing 2-chloro-1-(4-fluorophenyl)-acetophenone from 4-fluorophenylacetophenone, dichloromethane, chlorine and the like as raw materials; and finally preparing the finished product from isobutyryl acetanilide, potassium carbonate and 2-chloro-1-(4-fluorophenyl)-acetophenone. The raw materials of the synthesis method are inexpensive and easily available, the reaction has five steps and the yield of each step is high, thus the production cost can be greatly reduced; and the reaction conditions are mild, the method can be controlled easily, the process is simple, the pollution is low and the method is suitable for industrial production.

Owner:LIANYUNGANG HONGYE CHEM

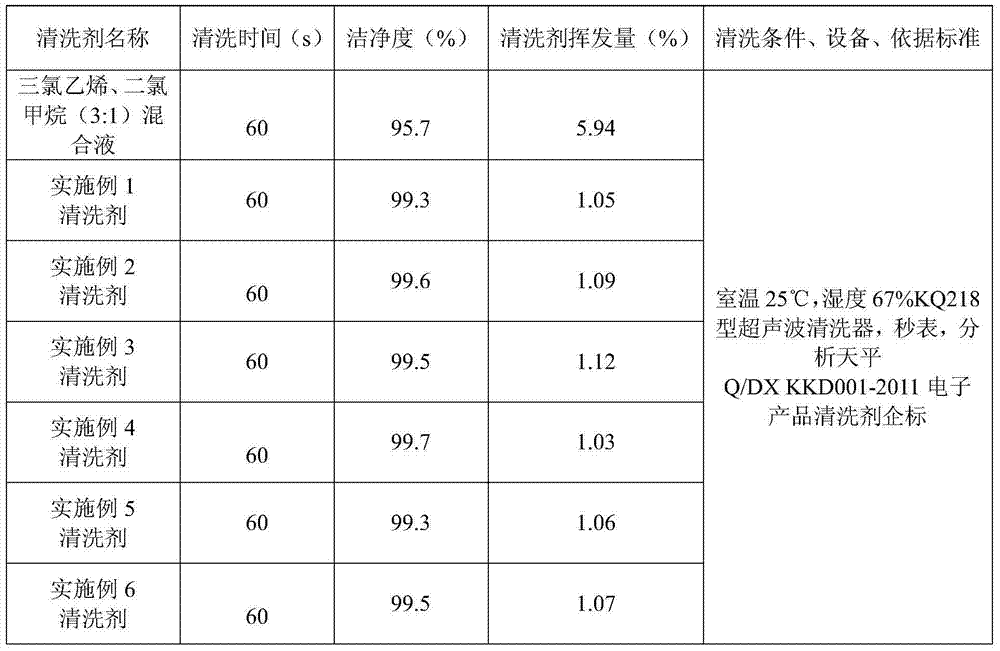

Cleaning agent for chip capacitors

InactiveCN103937627AIncrease cleaning powerImprove wettabilitySurface-active non-soap compounds and soap mixture detergentsDiethylene glycol monobutyl etherIsobutyl acetate

The invention provides a cleaning agent for chip capacitors. The cleaning agent consists of the following components in percentage by weight: 40-60% of ethanol, 20-30% of diethyl glutarate, 10-20% of diethylene glycol monobutyl ether, 5-15% of isobutyl acetate, 3-8% of surfactant and 2-5% of dispersing agent. The cleaning agent solves the problems that an existing clip capacitor cleaning agent is high in volatility and is not environment-friendly.

Owner:张海鹏

Anticorrosive paint for copper

ActiveCN103436140AGood waterproof and corrosion resistanceAchieve passivationAnti-corrosive paintsEpoxy resin coatingsEpoxyPolystyrene

The invention discloses an anticorrosive paint for copper, which is prepared by stirring the following raw materials in parts by weight: 80-85 parts of epoxy resin, 20-25 parts of polystyrene resin, 10-15 parts of 424 resin, 10-14 parts of silicon dioxide emulsion, 8-16 parts of dimethylbenzene, 3-9 parts of isobutyl acetate, 4-6 parts of polybenzimidazole, 8-10 parts of KH-560, 10-14 parts of talcum powder, 3-7 parts of tributyl phosphate, 6-8 parts of cobalt oxide, 11-14 parts of sodium petroleum sulfonate and 50-70 parts of water. The commercial test proves that the prepared paint has the advantages of excellent water resistance and excellent corrosion resistance, can implement passivation and corrosion inhibition of the metal substrate, avoids using chrome and other heavy metals capable of causing environmental pollution, is simple to prepare and low in cost, and can being easily put into industrial production.

Owner:江苏悠谷未来科技有限公司

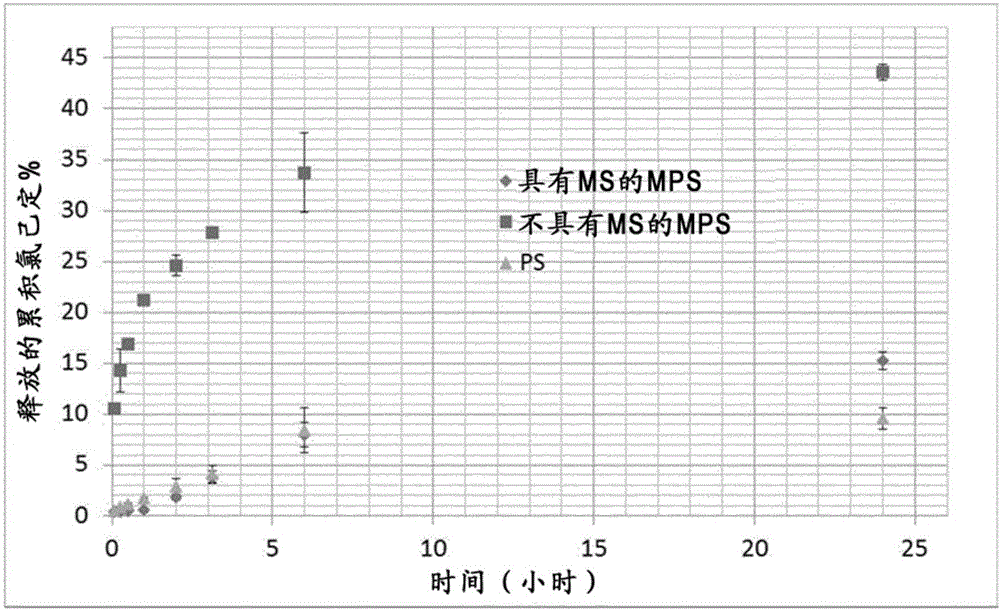

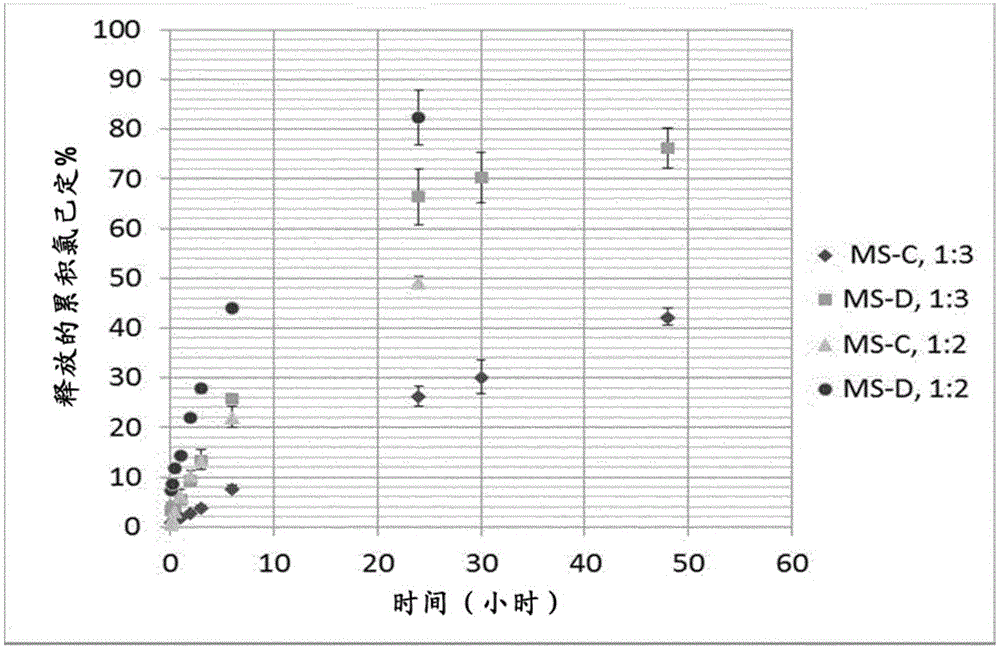

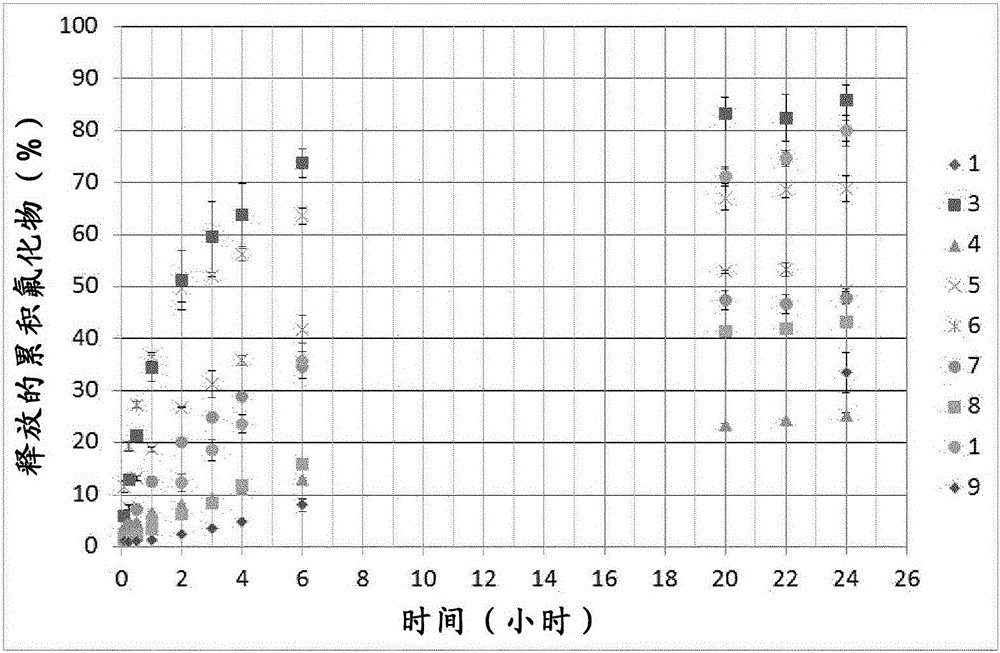

Encapsulation of oral care active agents

Disclosed is a process for encapsulating a water-soluble oral care active agent by a shell comprising a hydrophobic polymer. Two routes are described, both of which involve providing a system comprising a hydrophobic polymer, a solvent selected from the group consisting of ethyl formate, ethyl acetate, methyl acetate, propyl acetate, butyl acetate, isobutyl acetate, isopropyl acetate, isoamyl acetate, and mixtures thereof, an oral care active agent, and an oily liquid such as liquid paraffin. In the first route one first has separate phases (viz. the O / O emulsion) from which one allows precipitation by solvent removal. In the other route, the separate phases are created so as to trigger precipitation. In both routes a temperature rise takes place so as to force solvent removal, resulting in solidification.

Owner:KONINKLJIJKE PHILIPS NV

Coating capable of replacing electroplated decorative chromium layer

The invention discloses a coating capable of replacing an electroplated decorative chromium layer, which comprises the following components in percentage by weight: 20 to 30 percent of acrylic resin, 5 to 10 percent of melamine resin, 29 percent of dimethylbenzene, 3 to 8 percent of diacetone alcohol, 3 to 8 percent of n-butyl alcohol, 1 to 5 percent of alcohol, 1 to 5 percent of butyl acetate, 1 to 5 percent of isobutyl acetate, 1 to 5 percent of ethylene glycol monobutyl ether, 1 to 5 percent of silicon dioxide, 1 to 5 percent of epoxy resin and 5 to 10 percent of other components. The invention aims to overcome the disadvantages in the prior art and provide a coating with simple components and capable of replacing the electroplated decorative chromium layer. The decorative effect of the coating is very similar to that of electroplated chromium and can replace the apparent effect of the electroplated chromium; when coated and applied to products, the coating has good adhesive force, rigidity, wear resistance, corrosion resistance and anti-scraping performance; and the coating is coated on the metal surface after the polishing treatment, and an appearance similar to the electroplated chromium can be generated by mixing the coating with the own gloss of the metal.

Owner:中山市三民金属处理有限公司

Fine processing machine tool for foods

The invention discloses a fine processing machine tool for foods. The fine processing machine tool is in direct contact with a mixture of a solvent and an additive for a mixture of a food material, isopropyl acetate and isobutyl acetate and is made of stainless steel which is 0Cr18Ni12Mo2Ti, wherein the content of C is less than or equal to 0.08%, the content of Cr is 16-19%, the content of Ni is 11-14%, the content of Mo is 1.80-2.50%, and the content of Ti is 5 times as much as that of C and is less than or equal to 0.7%. The machine tool is suitable for finely machining the food material and is favorable in wear resistance, convenient to clean and capable of avoiding polluting food raw materials.

Owner:常熟市新洲机械制造厂

Cigarette anti-counterfeiting ink

The invention discloses a cigarette anti-counterfeiting ink. The cigarette anti-counterfeiting ink comprises the following raw materials by weight percent: 10-20% of a resin, 25-50% of methacrylate, 10-25% of a light resin type offset printing ink, 1-8% of propylene glycol methyl ether acetate, 5-9% of a temperature-varied pigment. 1-5% of a pearlescent pigment, 10-25% of a solvent, 0.1-1% of a leveller and 0.5-3% of a dispersant, wherein the resin is selected from acrylic resin or polyurethane resin; the solvent is selected from the composition composed of one of n-propyl acetate, ethyl acetate, n-butyl acetate and isobutyl acetate, and one of ethanol, isopropanol and n-butyl alcohol; the leveller is one of acrylic acids, organosilicones and fluorocarbons; and the dispersant is selected from one of reactants of carboxylates, sulphates, polyethylene glycol type polyalcohols, polyethyleneimine derivatives, polycaprolactone polyol-polyethylenimine segmented copolymers, polycaprolactone and triethylene tetramine. The cigarette anti-counterfeiting ink provided by the invention is low in cost, good in stealthiness, bright in colour and convenient to inspect.

Owner:NANJING TAMPER RESISTANT SECURITY TECH

Saccharomyces cerevisiae genetic engineering bacteria with high ester yield and construction method thereof

ActiveCN102199556BReduce contentIncrease contentFungiMicroorganism based processesEster hydrolaseGenetic engineering

The invention discloses Saccharomyces cerevisiae genetic engineering bacteria with high ester yield. The Saccharomyces cerevisiae genetic engineering bacteria EY-13 were collected in China General Microbiological Culture Collection Center on November 17, 2010, the collection number is CGMCC NO.4350, and the Saccharomyces cerevisiae genetic engineering bacteria are recommended to be named Saccharomyces cerevisiae. PGK1 derived from the Saccharomyces cerevisiae is selected as a promoter; and the construction method of the Saccharomyces cerevisiae genetic engineering bacteria with the high ester yield comprises a step of knocking-out an IAH1 gene for encoding ester hydrolase in a Saccharomyces cerevisiae genome when an ATF1 gene which is derived from the Saccharomyces cerevisiae and is used for encoding alcohol acetyltransferase is overexpressed. Compared with initial recipient bacteria, the Saccharomyces cerevisiae genetic engineering bacteria have the advantages that: after rice wine fermentation is simulated, the content of isoamylol is about one half, the content of ethyl acetate is improved by 20 times, the content of isoamyl acetate is 100mg / L, and the content of isobutyl acetate is 5 to 7mg / L; and after liquor fermentation is simulated, the content of total esters is improved by 4 times and the content of the ethyl acetate is improved by 35 times, so an excellent strain is provided for the production of brewing industry.

Owner:TIANJIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthesis method of 2-[2-(4-fluorophenyl)-2-oxa-1-phenylethyl]-4-methyl-3-oxa-N-phenylpentanamide Synthesis method of 2-[2-(4-fluorophenyl)-2-oxa-1-phenylethyl]-4-methyl-3-oxa-N-phenylpentanamide](https://images-eureka.patsnap.com/patent_img/3b82a23d-51dc-4945-890c-a169aa31ba8f/2011103568037100002DEST_PATH_IMAGE001.PNG)