Patents

Literature

2487 results about "N-Butyl acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

N-Butyl acetate, also known as butyl ethanoate, is an ester which is a colorless flammable liquid at room temperature. Butyl acetate is found in many types of fruit, where along with other chemicals it imparts characteristic flavors and has a sweet smell of banana or apple.

Waterproof zipper

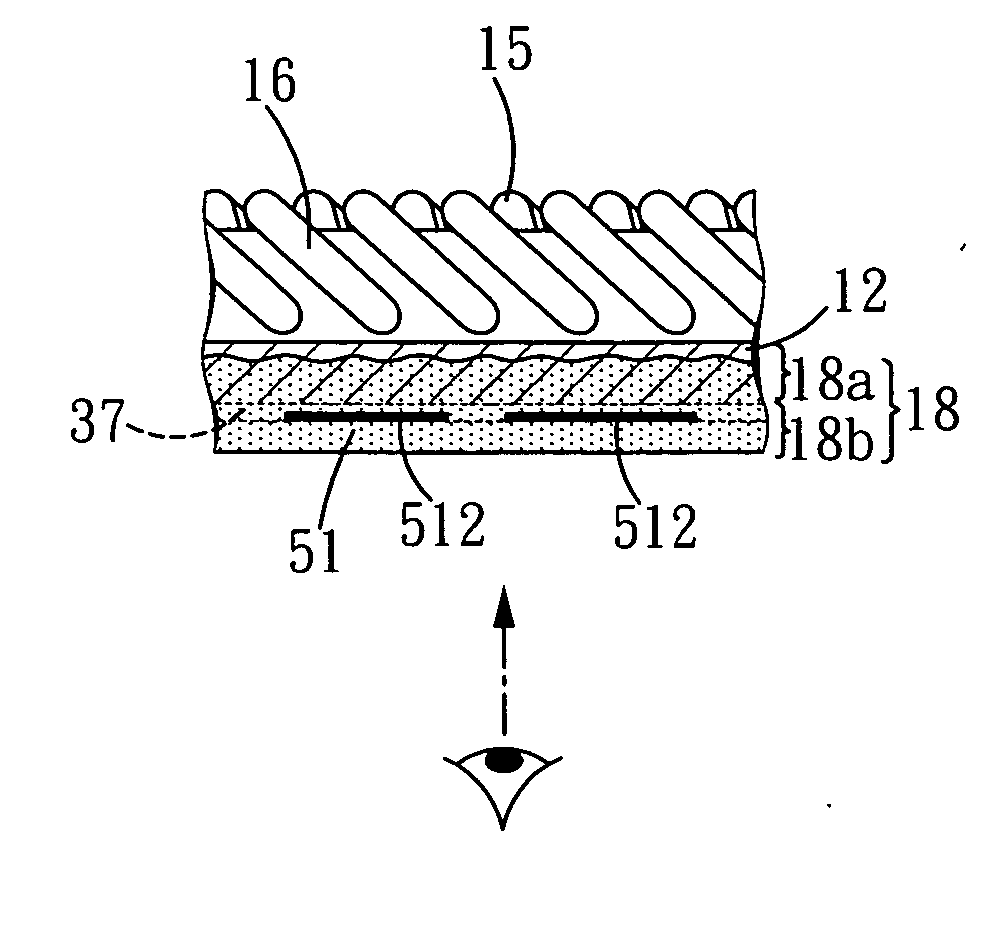

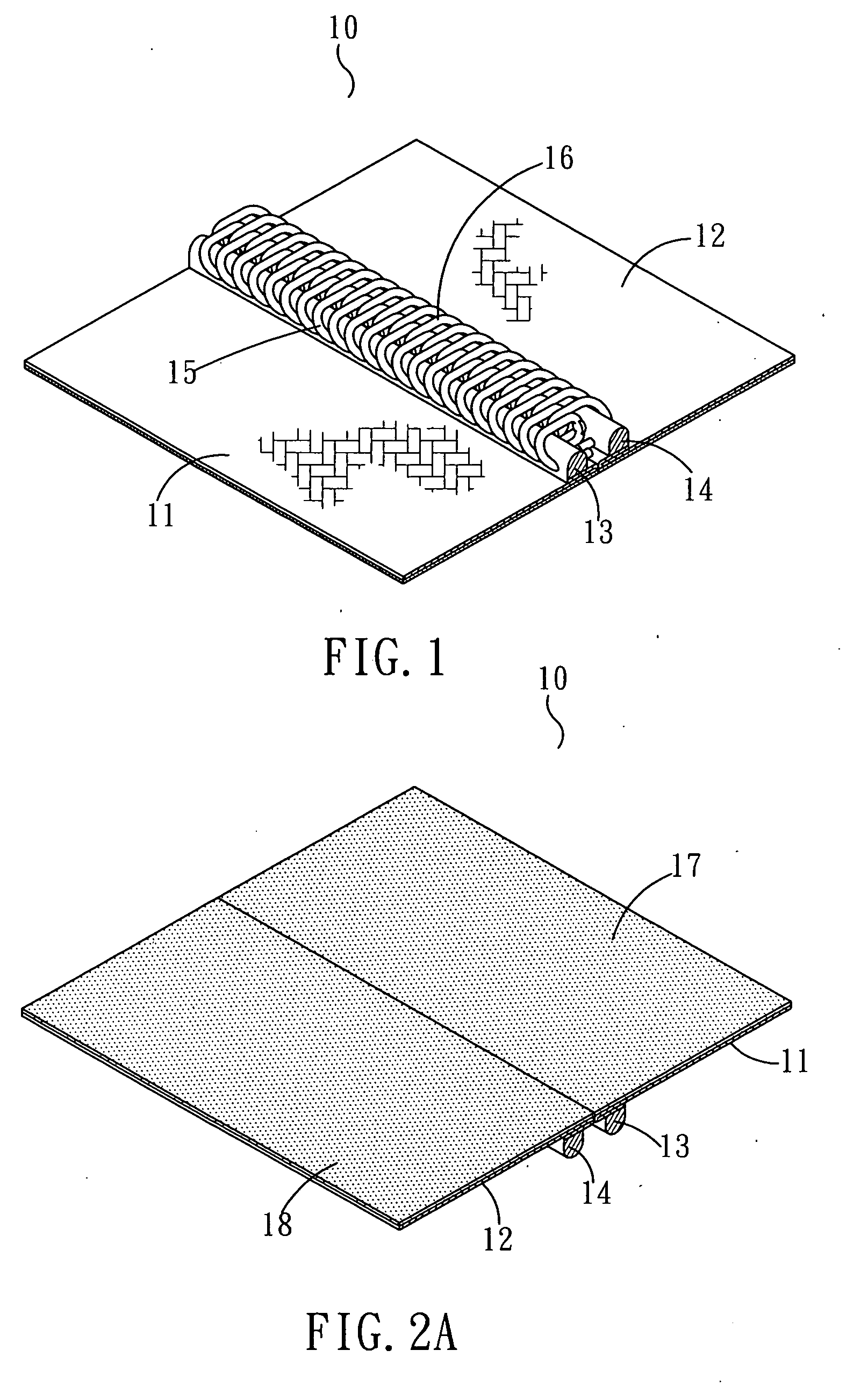

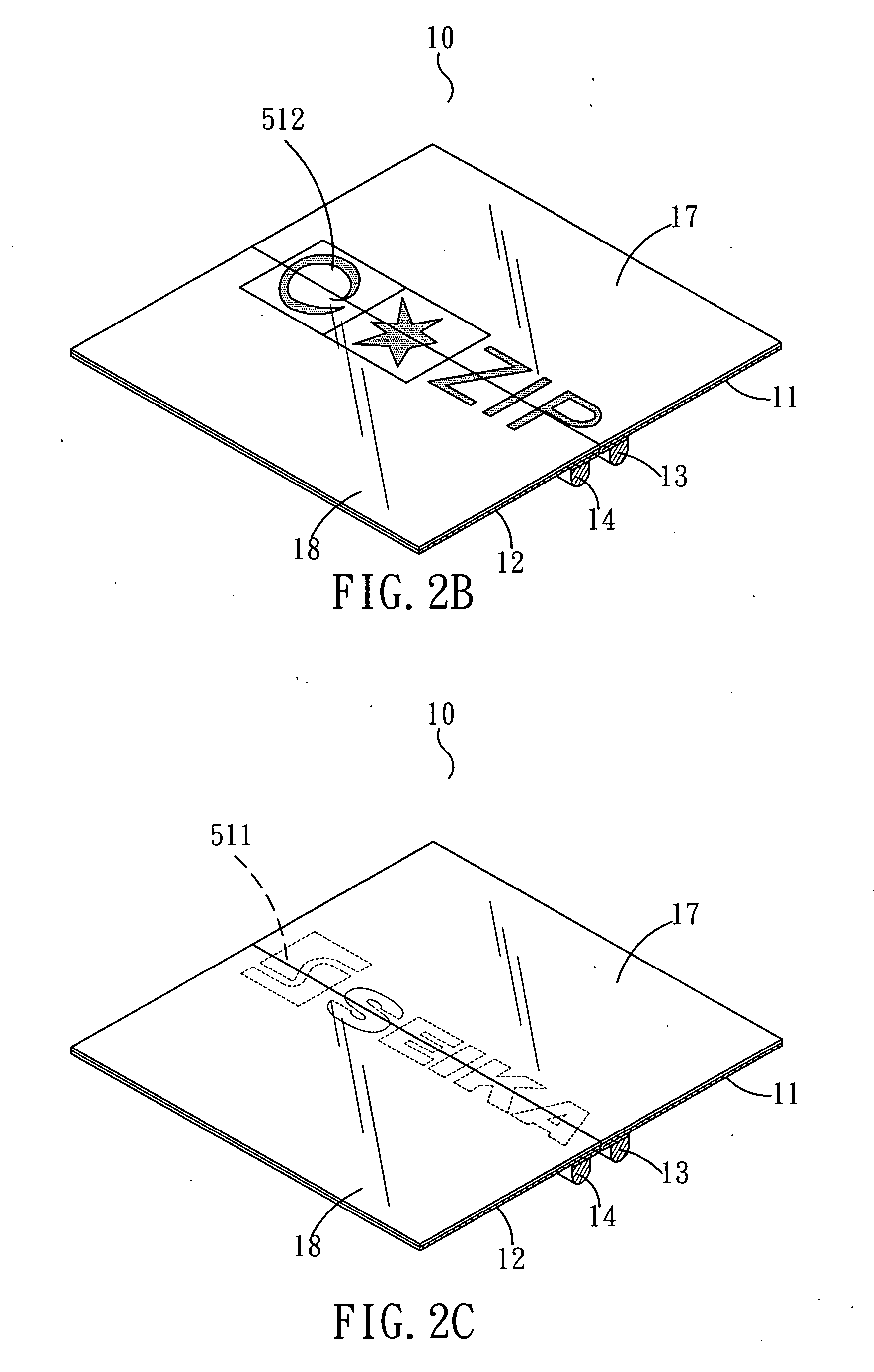

A waterproof zipper having a back surface of each fastener strip is permeated with solvent-based PU adhesive contains solid contents 34˜36% toluene or methyl-ethyl-ketone 64˜66% with a viscosity 60,000˜90,000 cps at 25° C. and hardener contains butyl-acetate 23˜27%, polyisocyanate 73˜77%; and then a PU film is adhered to the back surface by thermal plastic stage so as to be formed as a waterproof layer which includes an inner layer permeating into the fastener strips and an outer layer at an outer side of the fastener strips.

Owner:SUN YEN PING

High-fullness high-resolution environment protection polyureshane sublight uarnish

InactiveCN1483777AIncreased weight percentageReduce weightPolyurea/polyurethane coatingsKetoneSolvent

The present invention relates to a high-fullness high-distinctness environment-protecting type polyurethane matte varnish. Said varnish consists of the paint component, polyurethane solidifying agent component and diluting agent component according to the ratio of 1:0.5:0.6-0.8. The polyurethane solidifying agent component contains 50-70 wt% of tolylene diisocyanate trimer, and the rest is the affixture of 80% of tolylene diisocyanate and 20% of trimethylol propane, the paint component contains 15-25% of short oil soya alkyd resin whose solid content is 80%, 50-60% of modified saturated polyester resin, 0-5% of castor oil, 10-12% of aldehyde ketone resin whose solid content is 60%, 3-5% of flatting silica, 0.3-1.0% of teflon wax and 4%-10% of conventional adjuvant and solvent, and the diluting agent component contains 70-80% of butyl acetate, 10-20% of mixed diacid dimethyl ester and 10-15% of isophorone.

Owner:SHENZHEN FEIYANG JUNYAN TECH DEV

Polysiloxane coating composition

ActiveCN101525519AImprove interlayer adhesionGood weather resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyManufacturing technology

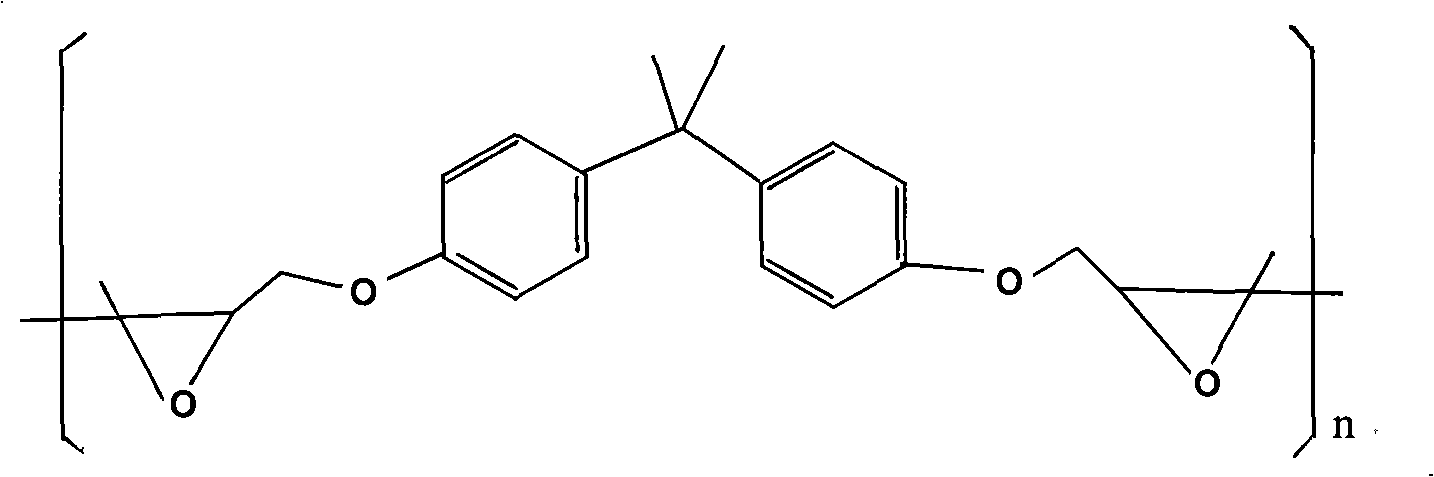

The invention relates to a polysiloxane coating composition belonging to a coating chemical manufacturing technology. The polysiloxane coating composition is obtained by reacting hydrogenated epoxide resin and amino-functionalized siloxane and combining acrylic resin with good coating performance and weatherability and polyetheramine resin with excellent flexibility and adhesion. The invention particularly relates to a polysiloxane coating composition applied to offshore oil platforms. The polysiloxane coating composition has weather-proof, water-proof and corrosion-resistant performances, good flexibility and excellent ply adhesion. The polysiloxane coating composition comprises the following ingredients of 12-50 of epoxide resin, 10-40 of acrylic resin, 0.5-1.5 of dispersant, 20-30 of titanium pigment, 5-25 of French chalk, 5-15 of mica powder, 0.5-1.5 of rheological agent, 0.5-2 of anti-settling agent, 2-10 of dimethyl benzene, 5-10 of butyl acetate, 15-40 of curing agent 1 and 5-25 of curing agent 2 according to the weight percent.

Owner:中山大桥化工集团有限公司

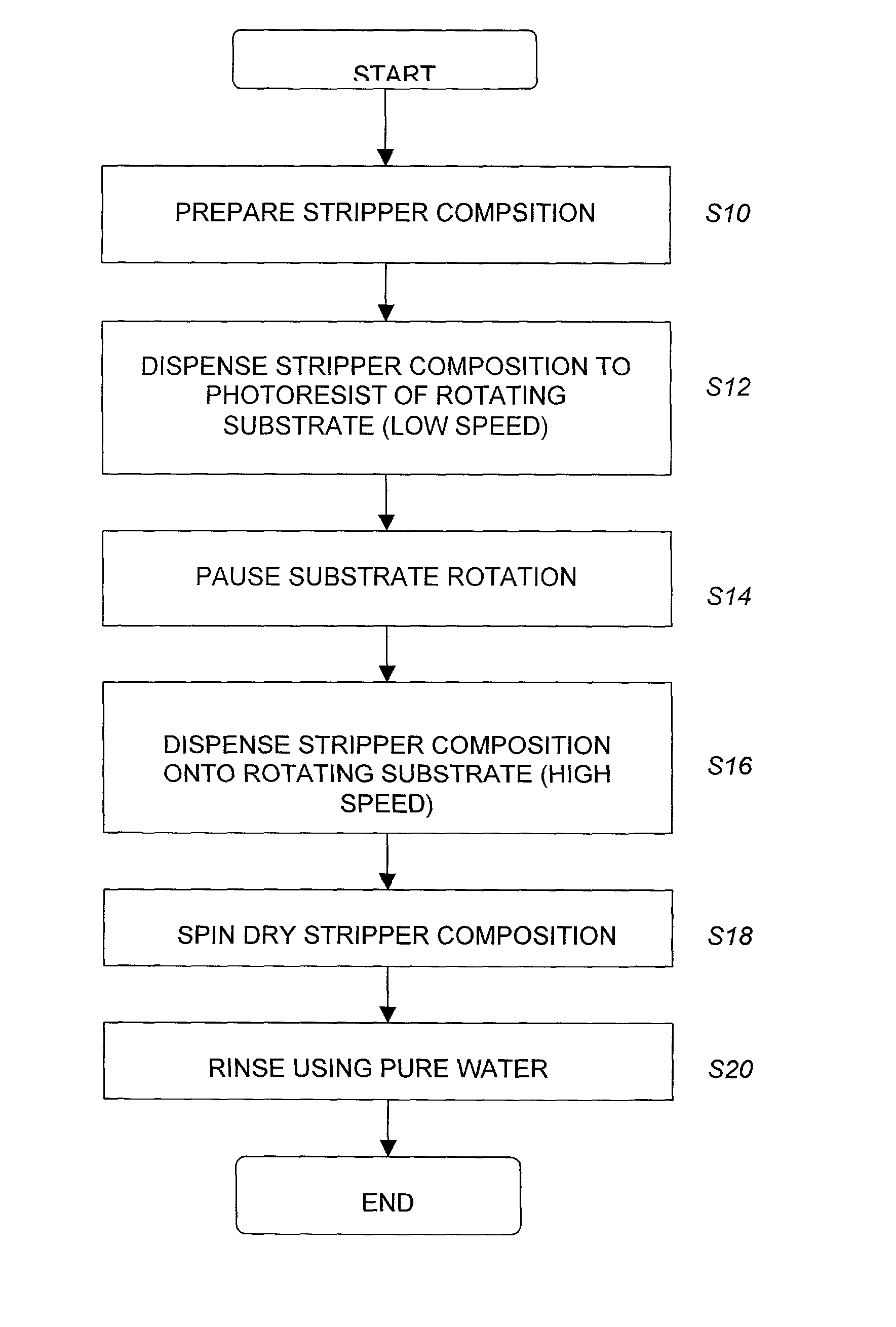

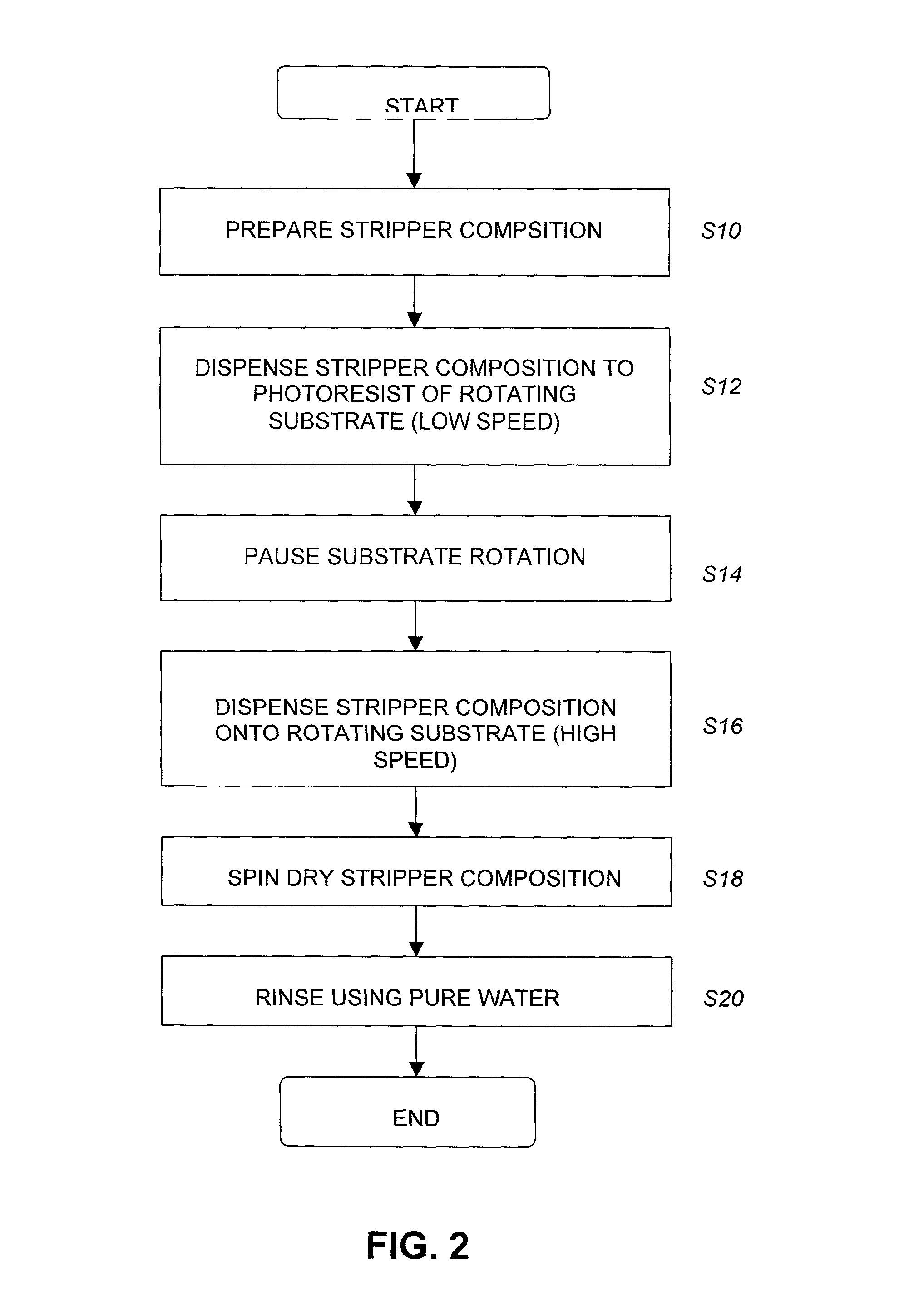

Photoresist stripper compositions

InactiveUS20030113673A1Semiconductor/solid-state device manufacturingPhotomechanical coating apparatusAmyl acetateMethyl group

A photoresist stripper composition is made up of a mixture of an acetic acid ester, gamma-butyrolactone (GBL), and a non-acetate ester or a poly alkyl alcohol derivative. The acetic acid ester may be at least one of n-butyl acetate, amyl acetate, ethyl aceto-acetate, and isopropyl acetate. The non-acetate ester may be at least one of ethyl lactate (EL), ethyl-3-ethoxy propionate (EEP) and methyl-3-methoxy (MMP). The poly alkyl alcohol derivative may be at least one of propylene glycol monomethyl ester (PGME) and propylene glycol monomethyl ester acetate (PGMEA).

Owner:SAMSUNG ELECTRONICS CO LTD

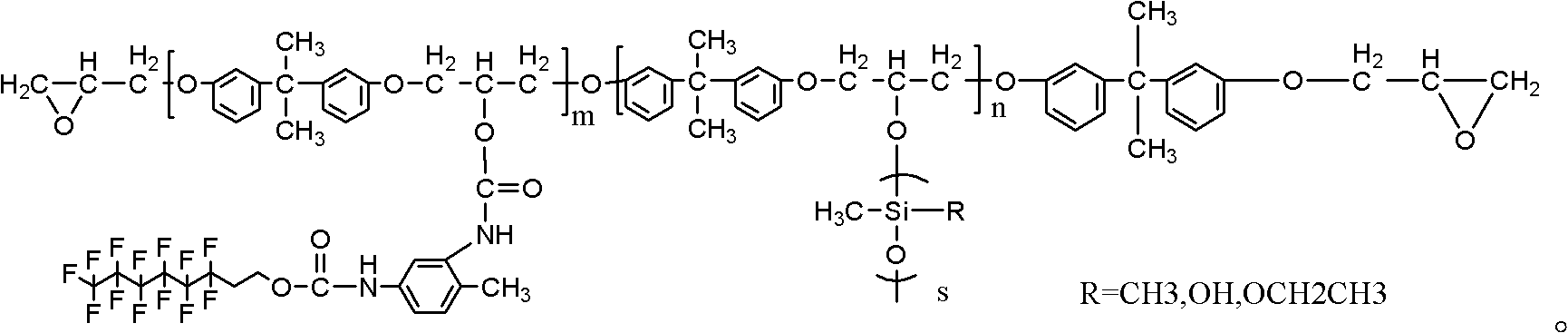

High-voltage power transmission line ice-covering-proof paint and preparation method thereof

InactiveCN102146249AImprove thermal conductivityImprove hydrophobicityEpoxy resin coatingsTransformerLow temperature curing

The invention discloses high-voltage power transmission line ice-covering-proof paint and a preparation method thereof. The preparation method comprises the following steps: using toluene diisocynate, tridecafluoro-octanol, butyl acetate, organosilicon modified epoxy resin, epoxy resin curing agent, organic solvent, nanographite and carbon nanotubes as raw materials to react and ensure that long-carbon-chain fluoro-alcohol is grafted in the molecular chain of epoxy resin, and adding nanographite and carbon nanotubes in the modified epoxy resin to prepare the paint with good hydrophobicity and thermal conductivity. The paint is mainly used in the coating of the high-voltage power transmission line and the coatings of equipment such as the insulator and the transformer case; and the paint has high coating adhesion, is ice-covering-proof and environmental friendly, has the advantages of corrosion resistance, ultraviolet resistance and aging resistance, and no pollution. Compared with the traditional acrylic paint, the paint has the advantages of simple preparation technology and excellent room temperature curing performance and low temperature curing performance, and is convenient to construct and operate.

Owner:甘肃省电力公司检修公司 +1

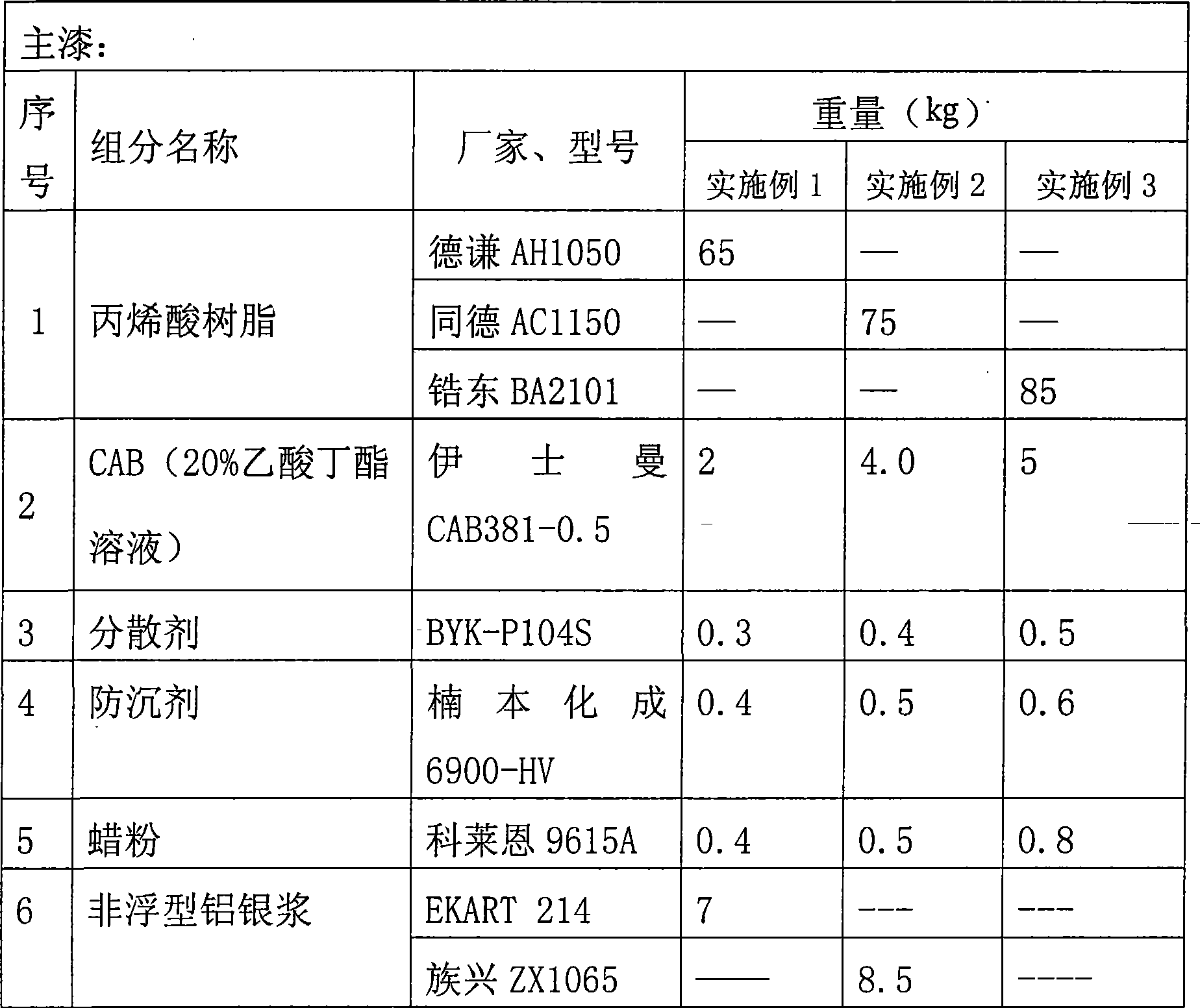

Elastic polyurethane silver paint and preparation method and use method thereof

ActiveCN101386771AGood room temperatureIncrease elasticityLiquid surface applicatorsPolyurea/polyurethane coatingsWaxWeather resistance

The invention discloses elastic polyurethane silver paint. Main paint of the elastic polyurethane silver paint is prepared from compositions according to the following weight proportion: 65 to 85 percent of a hydroxy acrylic acid resin, 2 to 5 percent of 20 percent CAB381-0.5, 0.3 to 0.5 percent of a dispersant, 0.4 to 0.6 percent of an anti-settling agent, 0.3 to 0.5 percent of a flatting agent, 0.4 to 0.8 percent of wax powder, 7 to 10 percent of non-leafing aluminum paste, 7 to 10 percent of dimethylbenzene, and 15 to 22 percent of mixed solvent; a curing agent of the elastic polyurethane silver paint is formed by mixing compositions according to the following weight percent: 75 percent of elastic HDI curing agent, and 25 percent of absolute butyl acetate; and the weight proportion of the main paint to the curing agent is calculated based on a hydroxyl value of acrylic acid resin and the NCO content of the curing agent, and OH / NCO is equal to 1 to (1.05-1.15). The elastic polyurethane silver paint has excellent weather resistance, stain resistance, scrubbing resistance and decoration property, is a coating variety with excellent performance which is second only to fluorocarbon paint, also has good elasticity at normal temperature and low temperature, can resist fine cracks, can prevent cracks on the surface of a coating caused by the fine cracks of a putty layer, and can also be used as finish for a complete anti-cracking aluminum-imitation plate coating system that flexible putty is matched with an elastic primer and an elastic middle coating.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Elastic handfeel paint

InactiveCN101921538AAvoid it happening againIncrease productivityPolyurea/polyurethane coatingsDibutyl tin dilauratePolyester resin

The invention relates to an elastic handfeel paint, comprising a hydroxy component A and a curing agent component B, wherein the hydroxy component A is prepared by the following raw materials by weight percent: 35-38% of hydroxy linear saturated polyester resin, 0.1-0.3% of dibutyltin dilaurate catalyst, 0.5-1% of levelling agent, 6.5-7% of extinction powder, 2-3% of polyurethane modified wetting and dispersing agent, 2-3% of nano pigment and 48-53% of mixed solvent; and the curing agent component B is prepared by the following raw materials by weight percent: 60-80% of HDI tripolymer and 20-40% of anhydrous butyl acetate. The hydroxy component A and the curing agent component B are mixed to obtain the polyurethane elastic handfeel paint, wherein the equivalent weight ratio of -NCO in the HDI tripolymer of the curing agent component B to -OH in the hydroxy linear saturated polyester resin of the hydroxy component A is 1.05:1.2. The elastic handfeel paint has an intrinsic color, thus being free of secondary spraying.

Owner:DONGGUAN PAINT KEY PRECISE INDAL

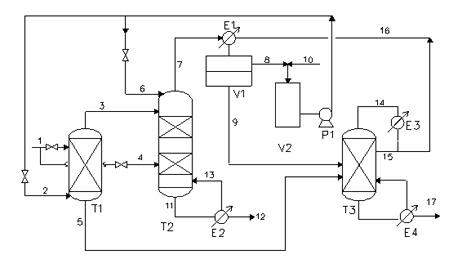

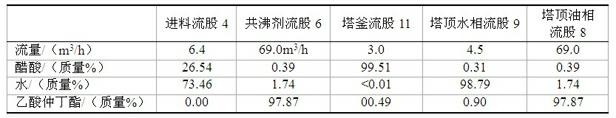

Method for recovering dilute acetic acid by virtue of extraction-azeotropic distillation of sec-butyl acetate

InactiveCN102153458AGood value for moneyReduce lossCarboxylic compound separation/purificationPhysical chemistryEthylic acid

The invention relates to a method for recovering dilute acetic acid by virtue of extraction-azeotropic distillation of sec-butyl acetate. In the method, the sec-butyl acetate is an extractant of an extraction tower and an entrainer of an azeotropic distillation tower. The method is characterized in that a part of dilute acetic acid is fed into the top of a filler extraction tower, a small portion of tower top reflux liquid of the azeotropic distillation tower is used as the extratant to be fed to the bottom of the extraction tower, and is subjected to room temperature counter current contact extraction together with the dilute acetic acid; an extraction phase containing the sec-butyl acetate, acetic acid and little water is obtained on the top of the extraction tower; raffinate water containing trace acetic acid is obtained at a tower kettle, and enters into a solvent recovering tower; and the extraction phase in the extraction tower is fed to the upper half part of the azeotropic distillation tower for further concentration, and the other part of sec-butyl acetate is fed to the tower top of the azeotropic distillation tower. The method has the characteristic of high separation efficiency; and the recovery of the acetic acid is more than 95%, and the content of the acetic acid in waste water is below 0.5%. By using the method, the defects of large reflux ratio, high energy consumption and the like which are caused by using a rectification method are directly overcome, and the production capability of dilute acetic acid recovery is enlarged.

Owner:FUZHOU UNIV

Transparent hydrophobic and oleophobic functional coating material and transparent hydrophobic and oleophobic functional coating layer formed thereby

InactiveCN106905807AWith super hydrophobic functionRealize hydrophobic and oleophobic treatmentPolyurea/polyurethane coatingsCyclohexanoneAcrylic resin

The invention provides a transparent hydrophobic and oleophobic functional coating material. The transparent hydrophobic and oleophobic functional coating material is prepared from fluorine-containing resin, silicon dioxide particles and a solvent, wherein the mass concentration of the fluorine-containing resin is 5 to 15%; the mass of the silicon dioxide particles accounts for 1 to 5% of the mass of the fluorine-containing resin; the fluorine-containing resin contains at least one of fluorine-containing acrylic resin, fluorocarbon resin, fluorine-containing acrylic modified polyurethane resin and fluorine-containing acrylic modified organic silicon resin; the fluorine content of the fluorine-containing resin is 10 to 50wt%, the particle size of the silicon dioxide particles is 10 to 40 nanometers, and a modifying solvent uses a fluoroalkyl silane coupling agent to modify; the solvent is prepared from ethyl acetate, butyl acetate, isoamyl acetate, ethyl butyrate, acetone, butanone, cyclohexanone, methylbenzene, xylene or nonafluorobutyl ether. The invention also provides a transparent hydrophobic and oleophobic functional coating layer which is made of the transparent hydrophobic and oleophobic functional material.

Owner:北京奥润联创微电子科技开发有限公司

Polyurethane matt varnish for benzene-free odor-less furniture

ActiveCN101684388AImprove mechanical propertiesGood gloss and color retentionPolyurea/polyurethane coatingsCyclohexanoneFoaming agent

The invention provides a polyurethane matt varnish for benzene-free odor-less furniture, which is composed of a main agent, a curing agent and a diluent. The main agent comprises 66.5-75.5% of hydroxyacrylic resin, 16.0-25.0% of solvent, 0.1-0.3% of defoarming agent, 0.05-0.1% of flatting agent, 0.1-0.5% of anti-settling agent, 0.1-0.5% of dispersing agent, and 4-8% of delustering agent; the curing agent comprises40.0-50.0% of toluene diisocyanate tripolymer, 20.0-30.0% of toluene diisocyanate-trimethylolpropane affixture, and 20.0-30.0% of butyl acetate; the diluent comprises 60.0-70.0% of butyl acetate, 15.0-20.0% of cyclohexanone, and 15.0-25.0% of propylene glycol methyl ether acetate. The product of the invention is favorable for construction, and no odor exists after the construction of the previous night.

Owner:上海展辰涂料有限公司 +1

Method for preparing solid acid catalyst of esterification

InactiveCN101703940AHigh activityGood choiceOrganic compound preparationCarboxylic acid esters preparationSolid acidN-Butanol

The invention relates to a method for preparing a solid acid catalyst used in esterification. The method takes organic titanium ester and silicone ester as raw materials and prepares a SO42- / TiO2-SiO2 novel solid acid by a hydrothermal method. If the solid acid catalyst is used in a reflux device to catalyze acetic acid / n-butanol esterification reaction, the yield and selectivity of n-butyl acetate can reach 98.9 percent and 99.5 percent respectively. The catalyst is characterized in simple preparation process, low cost, high activity and selectivity, long lifespan and the like, overcomes the disadvantage that concentrated sulfuric acid used as the catalyst is poor in selectivity, low in esterification yield, severe in equipment corrosion, large amount of waste liquid produced, environmental pollution and the like, and has good industrial application prospect.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Silicon tungsten, phosphorus heteropoly tungstic acid load type catalyzer used for esterification reaction, manufacturing method and application thereof

The invention is a silicotungstic and phosphotungstic heteropoly acid load catalyst used for esterification reaction, which comprises the following components: Keggin structure silicotungstic acid H3SiW12O40.xH2O and phosphotungstic H3PW12O40.xH20, the content occupies 10 to 50 quality per centage of the amount of the catalyst; the carrier is H Beta zeolite. The invention adopts soaking method to prepare the solid silicotungstic and phosphotungstic heteropoly acid catalyst load on the H Beta zeolite, which can be used for catalyzing the esterification reaction of etic acid, isobutanol, isobutanol and ethanol, but also can be used for catalyzing esterification reaction of lactic acid and isobutanol to synthesis n-butyl acetate, isobutyl acetate, ethyl acetate and N-Butyl Lactate. The invention has the advantages of good stability, high activity and good selectivity, but also can used as inhomogeneous catalyst which is easy to be separated with reaction product and can use the prepared and formed catalyst powder in the continuous operating fixed bed reactor. The invention is used in the techinics of esterification reaction catalyzing rectifying.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

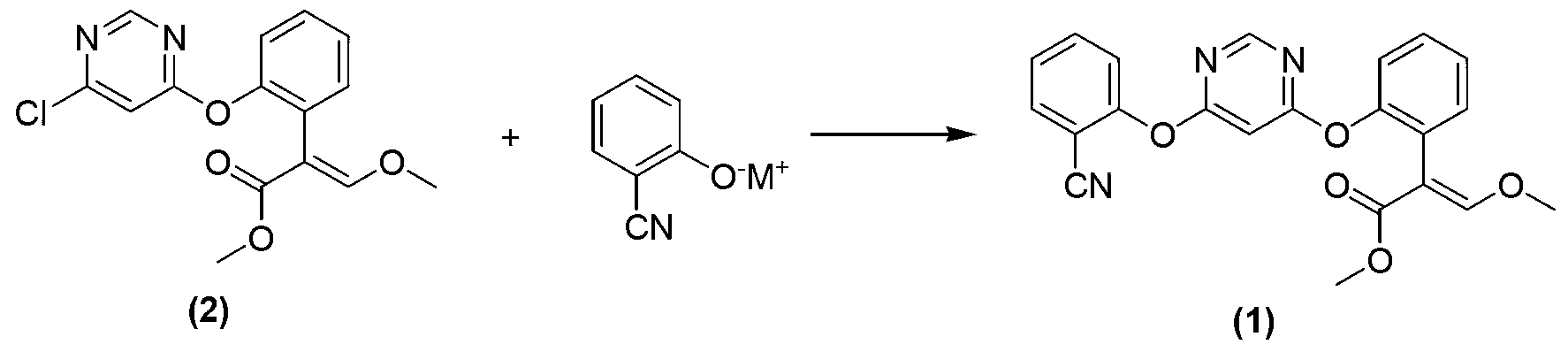

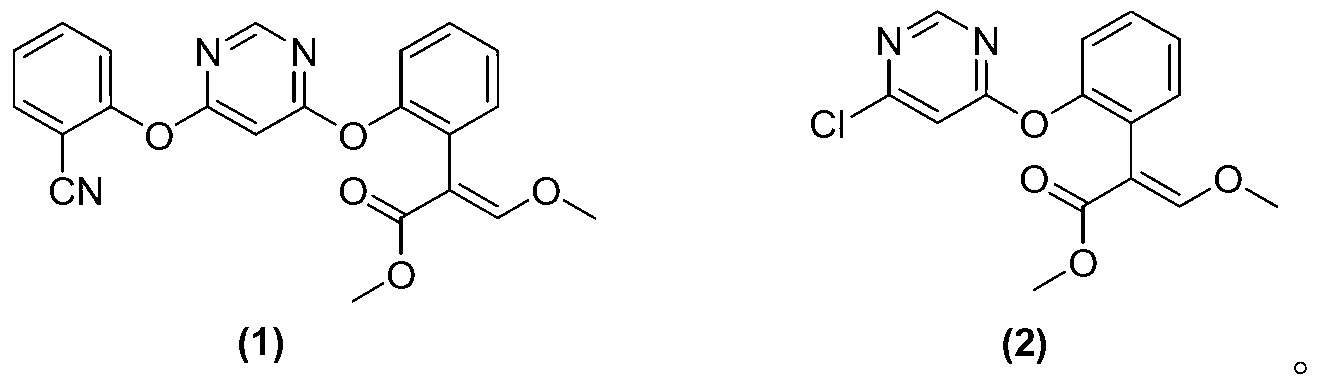

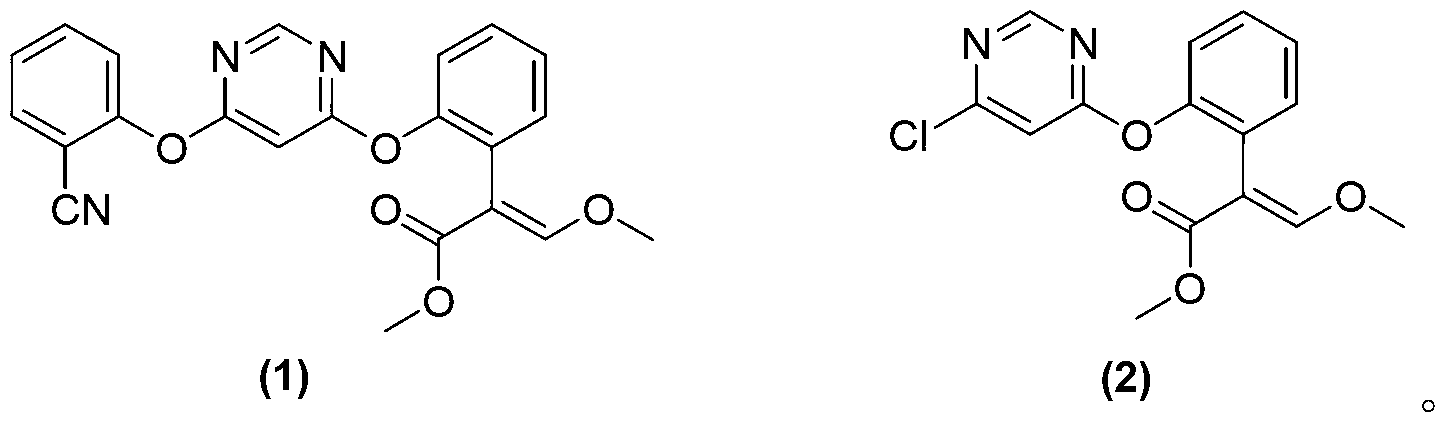

Preparation method of azoxystrobin

The invention discloses a preparation method of azoxystrobin disclosed as Formula (1), which comprises the following steps: a) under the catalytic action of aza-bicyclo-tertiary amines and / or salts thereof, carrying out etherification reaction on a compound disclosed as Formula (2) and 2-cyanophenol and / or salts thereof in a medium butyl acetate to obtain an azoxystrobin-containing butyl acetate solution; and b) cooling the azoxystrobin-containing butyl acetate solution to precipitate the azoxystrobin disclosed as Formula (1) from the butyl acetate. The method disclosed by the invention can obviously enhance the yield of azoxystrobin and obtain the higher-purity azoxystrobin product.

Owner:NUTRICHEM LAB CO LTD +1

Vacuum plating paint, and preparation and construction methods thereof

ActiveCN102167950AImprove reliabilityControl shrinkage of photocuring reactionSynthetic resin layered productsVacuum evaporation coatingPolyesterPhosphate

The invention discloses a vacuum plating paint, and preparation and construction methods thereof. The vacuum plating paint is composed of a priming coat, an undercoat and a finish coat, wherein the priming coat is prepared from polyurethane acrylate resin, acrylate, photoinitiator, organosiloxane leveling agent, butyl acetate, ethyl acetate and isopropanol; the undercoat is prepared from polyester-modified polyurethane acrylate resin, polyurethane acrylate resin, phosphate acrylate, photoinitiator, butyl acetate, ethyl acetate and isopropanol; and the finish coat is prepared from polyurethaneacrylate resin, acrylate, phosphate acrylate, photoinitiator, organosiloxane leveling agent, butyl acetate, ethyl acetate and isopropanol. By adopting imported environment-friendly raw materials, thevacuum plating paint has the advantage of low toxicity; no high-temperature high-pressure process is carried out in the production process, so the vacuum plating paint has the advantage of high safety; the vacuum plating paint does not need to be diluted, and thus, can be directly used conveniently; and the priming coat, undercoat and finish coat are cured under ultraviolet, so the vacuum platingpaint has the advantage of high production efficiency.

Owner:江西赐彩新材料股份有限公司

Novel high sealing property unsaturated polyester white primer, and preparation method thereof

The present invention discloses a novel high sealing property unsaturated polyester white primer, and a preparation method thereof. The unsaturated polyester white primer provided by the present invention comprises, by weight, 40-45% of unsaturated polyester PE resin, 0.2-0.3% of an antifoaming agent, 0.3-0.5% of a wetting dispersant, 0.2-0.3% of a polyacrylate leveling agent, 0.1-0.2% of an anti-green agent, 4-6% of organic bentonite pre-clotting slurry, 0.2-0.8% of fumed silica, 3-7% of zinc stearate, 3-9% of 1250 mesh pulvistalci, 7-11% of 800 mesh pulvistalci, 13-21% of ground calcium carbonate, 11-17% of rutile titanium dioxide, 2-5% of a nitrocellulose solution and 1-3% of n-butyl acetate. The unsaturated polyester PE primer provides especially good sealing property for the low density medium density fiberboard, wherein the low density medium density fiberboard is not subjected to a sealing treatment or is treated bad. In addition, the unsaturated polyester PE primer has characteristics of excellent caving resistance, excellent sagging resistance, short polishing time, good polishing property, strong interlayer adhesion, and can be applicable for the comprehensive primer solution schemes for different environments, various processes and plates.

Owner:恒昌涂料(惠阳)有限公司

Environment protective polyurethanes hammer paint

ActiveCN101353550AGood solvent resistanceGood acid and alkali resistancePolyurea/polyurethane coatingsOleoresinDimethyl siloxane

The invention discloses an environmental-protection polyurethane hammer paint which is applied to wood surface decoration and protection and consists of a component A, a component B and a component C; when in use, the component A, the component B and the component C can be evenly mixed by the weight ratio that component A: component B: component C is equal to 1: 0.4 to 0.6: 0.5 to 0.6; wherein, the component A consists of: short oil alkyd resin, 40 to 60 parts; long oleoresin, 2 to 5 parts; dispersing agent, 0.2 to 0.5 part; anti-sedimentation agent, 0.4 to 0.9 part; propylene glycol ether acetate 3 to 6 part; divalent ester 1 to 3 parts; pigment, 0 to 30 parts; defoamers, 0.2 to 0.5 part; leveling agent, 0.2 to 0.7 part; non-floating-type aluminum paste, 1 to 5 parts; n-butyl acetate 5 to 15 parts, polydimethylsiloxane, 0.1 to 0.5 part; the component B consists of the following materials by weight ratio: HDI trimer poly isocyanate: HDI-TDI trimer: n-butyl acetate is equal to 2 to 4: 3 to 5: 1 to 4; the component C consists of the following materials by weight ratio: n-butyl acetate: propylene glycol methyl ether acetate is equal to 7 to 9: 1 to 3. The invention has the advantagesof: 1. good paint film solvent resistance and acid and alkaline resistance, bright color, clear texture, and good hammer effective; 2. high paint film hardness and wide application range, not only being applicable to wood surface, but also being applicable to metal surface decoration and protection; and 3. triphenyl-free, low VOC, and high solid content, and meeting the requirements on environmental protection.

Owner:GUANGDONG SANVO CHEM IND TECH

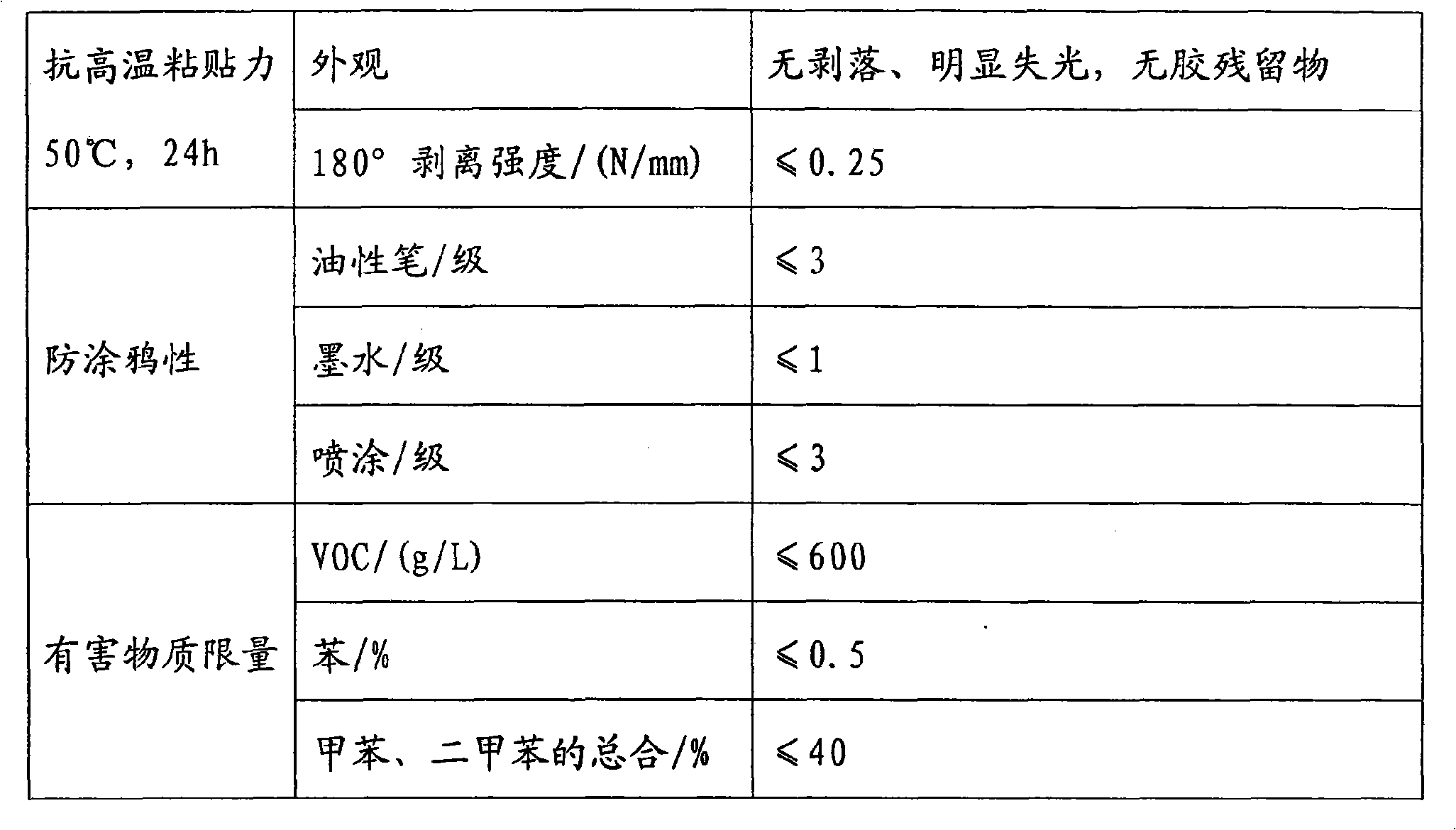

Oil-based anti-graffiti adhesion resistant paint and preparation method thereof

ActiveCN101585995AHigh hardnessImprove self-cleaningPolyurea/polyurethane coatingsAcrylic resinPolydimethyl siloxane

The invention discloses oil-based anti-graffiti adhesion resistant paint and a preparation method thereof, and belongs to paint and a preparation method thereof. Components A of the paint comprise hydroxy acrylic resin, fluorocarbon resin, modified polydimethyl siloxane resin, polyacrylate modified organic silicon resin, smooth flow agent, flatting agent, antifoaming agent, drier, dibutyl tin laurate, butyl acetate and dimethyl benzene; components B comprise hexamethylene diisocyanate, butyl acetate and ethylene glycol monoethyl ether acetate; and the mixture ratio of the components A to the components B is 3:1. The invention also discloses the preparation method thereof. The paint has the advantages of good anti-graffiti adhesion resistant function, super-strong scrubbing resistance, easy cleaning, and quick and convenient construction, has limited harmful substances, and achieves national requirement.

Owner:LANZHOU XUNMEI PAINT IND TECH

Process for covering water transfer printing on wood plastic, plastic and metallic products

The invention discloses a water-coated transfer printing process for wood, plastic, and metal products, which comprises the following steps: according to the necessary background color, spraying oil paint on the surfaces of the wood, the plastic, and the metal products; spreading a water-coated transfer printing film on the water surface by putting the surface with printing ink patterns to face upwards; spraying an activator on the water-coated transfer printing film evenly through a spray gun when the water-coated transfer printing film is softened and spread levelly; and according to the positions of the patterns floating on the water surface, pressing an obtained product downwards into the water for 2 to 10 seconds and taking out the product, and transferring the patterns on the water-coated transfer printing film to the surface of the product under the action of water pressure. The process further comprises the following steps: washing the obtained product clean by water and then putting the product into a drying furnace to be dried at a temperature between 50 and 70 DEG C; or using a blowing gun to blow off the water, drying the product at room temperature, spraying a layer of transparent oil paint on the surface of the product, putting the product in the drying furnace and curing the product at a temperature between 50 and 160 DEG C. The compositions of the activator are as follows according to percentage by weight: 33 percent of xylene, 15 percent of butyl acetate, 15 percent of methyl acetate, 10 percent of methyl isobutyl ketone, 5 percent of isobutanol, 8 percent of isophorone, 5 percent of methyl methacrylate, 7 percent of cyclo ethyl ketone, and 2 percent of nitrocellulose resin.

Owner:张艳 +1

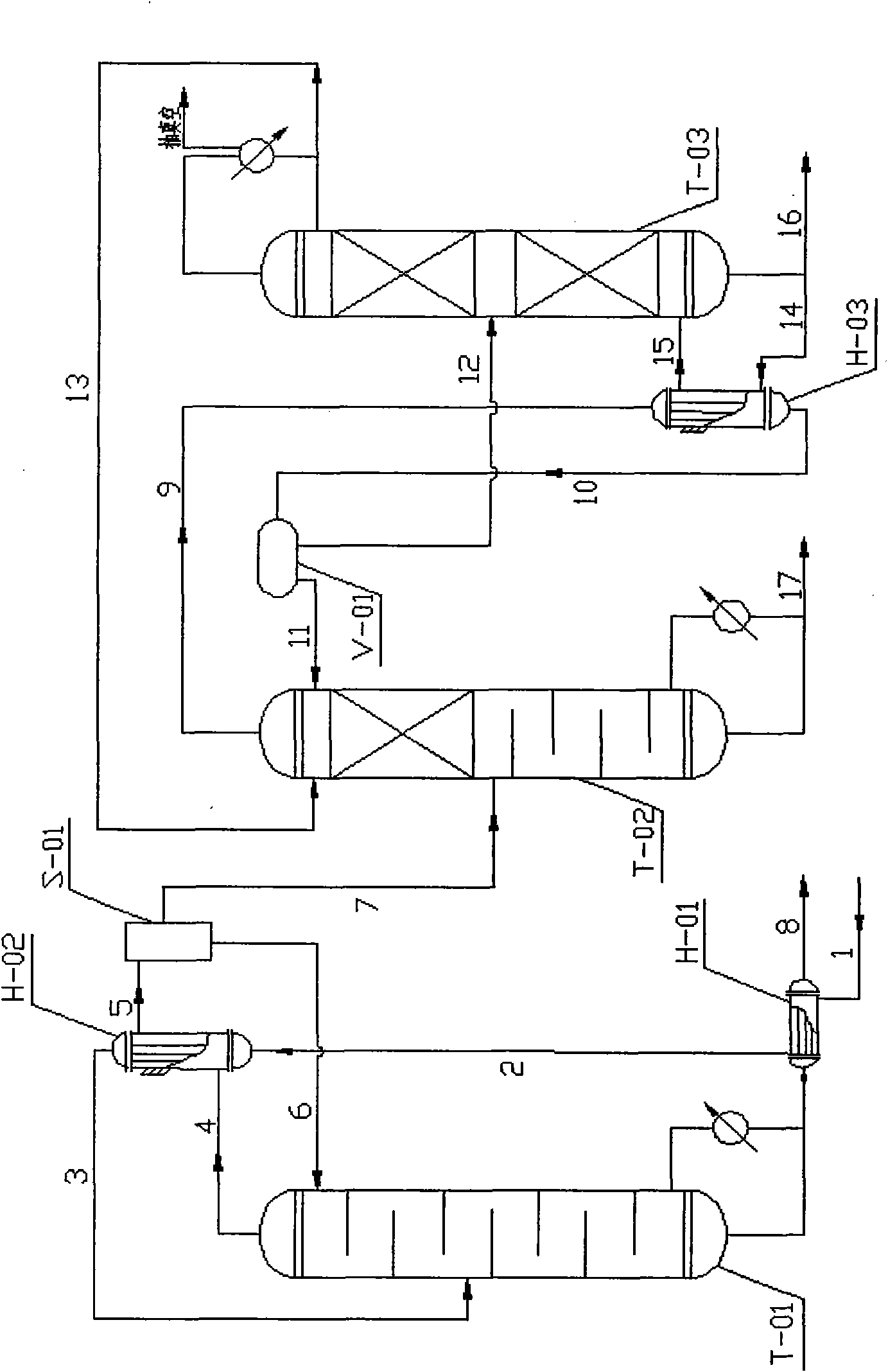

Process for separating and recovering butyl acetate and butyl alcohol in wastewater by using azeotropic rectification

ActiveCN101811965AHigh purityEasy to recycleOrganic compound preparationCarboxylic acid esters preparationAlcoholButyl acetate

The invention relates to a process for separating and recovering butyl acetate and butyl alcohol in wastewater by using azeotropic rectification, comprising the following steps of: carrying out normal-pressure distillation and thickening on the wastewater containing the butyl alcohol, the butyl acetate, water and organic residues in a first rectifying tower T-01 to obtain pure water and the organic residues through a tower kettle; delaminating condensed steam at a tower top, flowing a water layer back, and causing an organic layer to enter a second rectifying tower T-02 for pressurization and rectification under 120-200 Kpa so that the high-purity butyl acetate is extracted by the tower kettle and the steam with the alcohol ester ratio of 3 / 1-9 / 1 is obtained at the tower top; condensing to cause one part of a condensate to back flow and one part of the condensate to enter a third rectifying tower T-03 for pressure reduction and rectification under 3-15 KPa so that the high-purity butyl alcohol is extracted by the tower kettle and the steam with the alcohol ester ratio of 1 / 3-1 / 2 is obtained at the tower top; and after condensing and cooling, causing the steam with the alcohol ester ratio of 1 / 3-1 / 2 to enter the tower from a feed inlet of the second rectifying tower T-02 for continuous thickening and purification. The process has the advantages of environmental protection, low energy consumption, investment saving, no entrainer addition, high recovery rate (above 99%) of solvents and the like.

Owner:NANJING UNIV

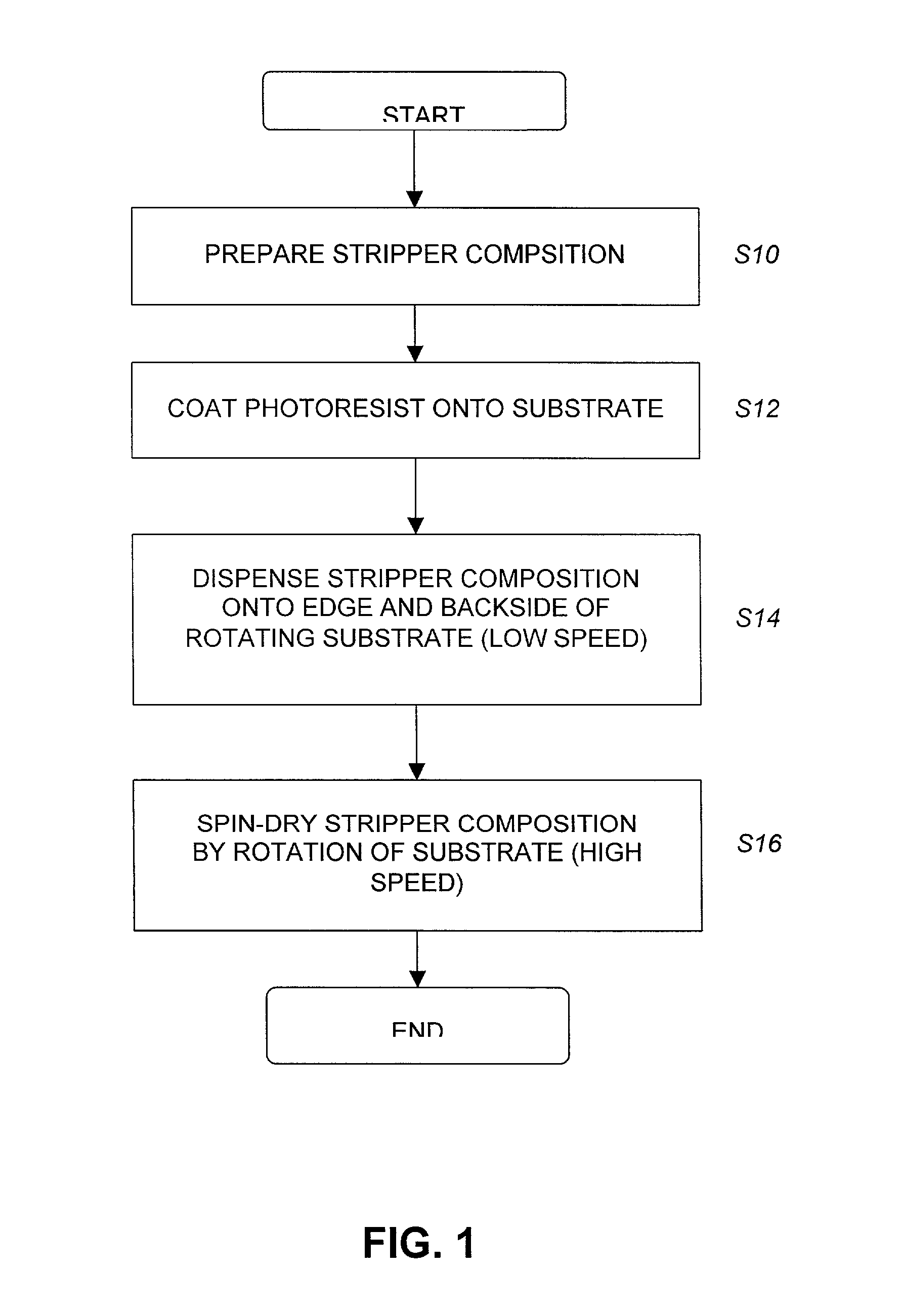

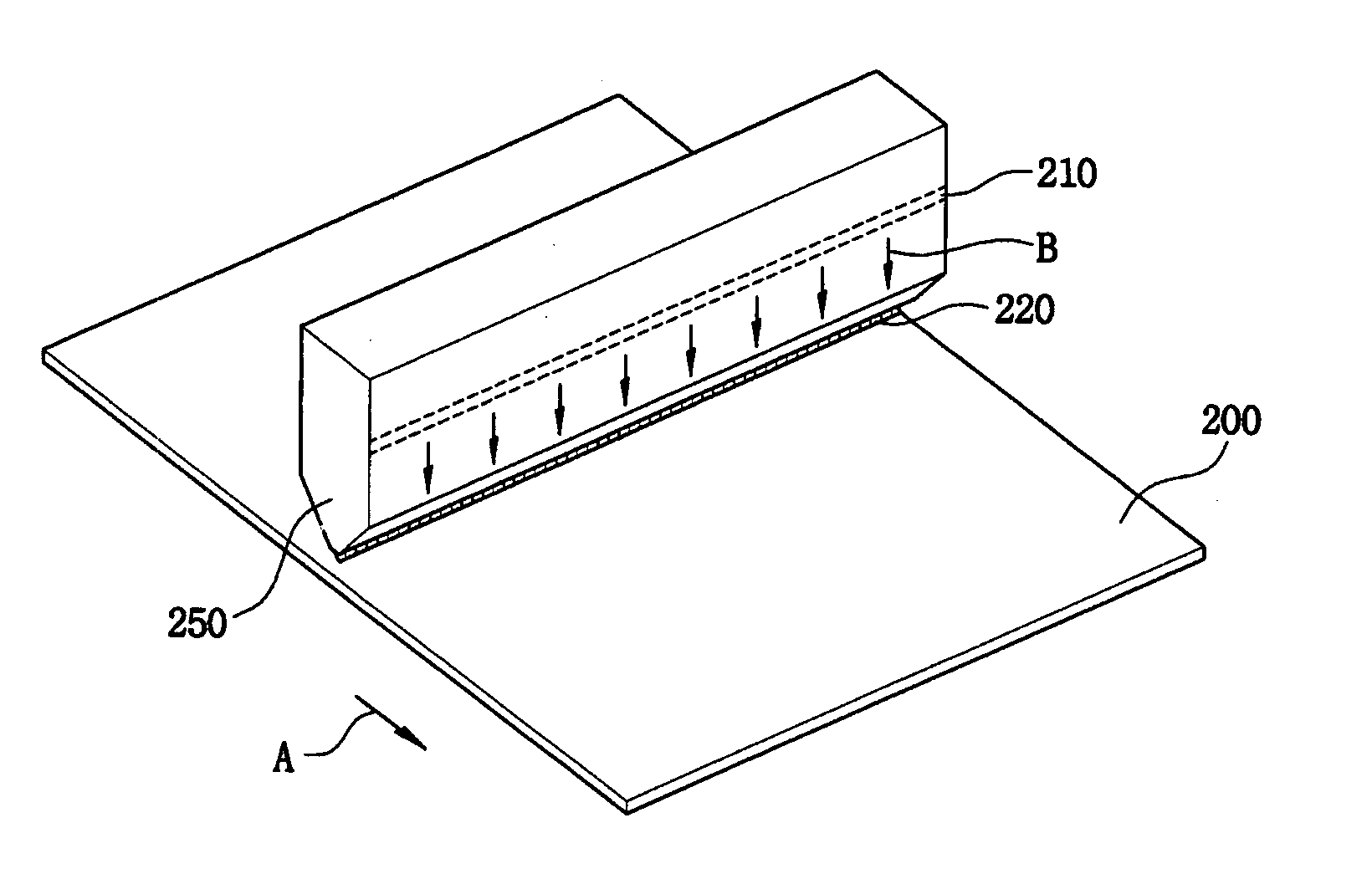

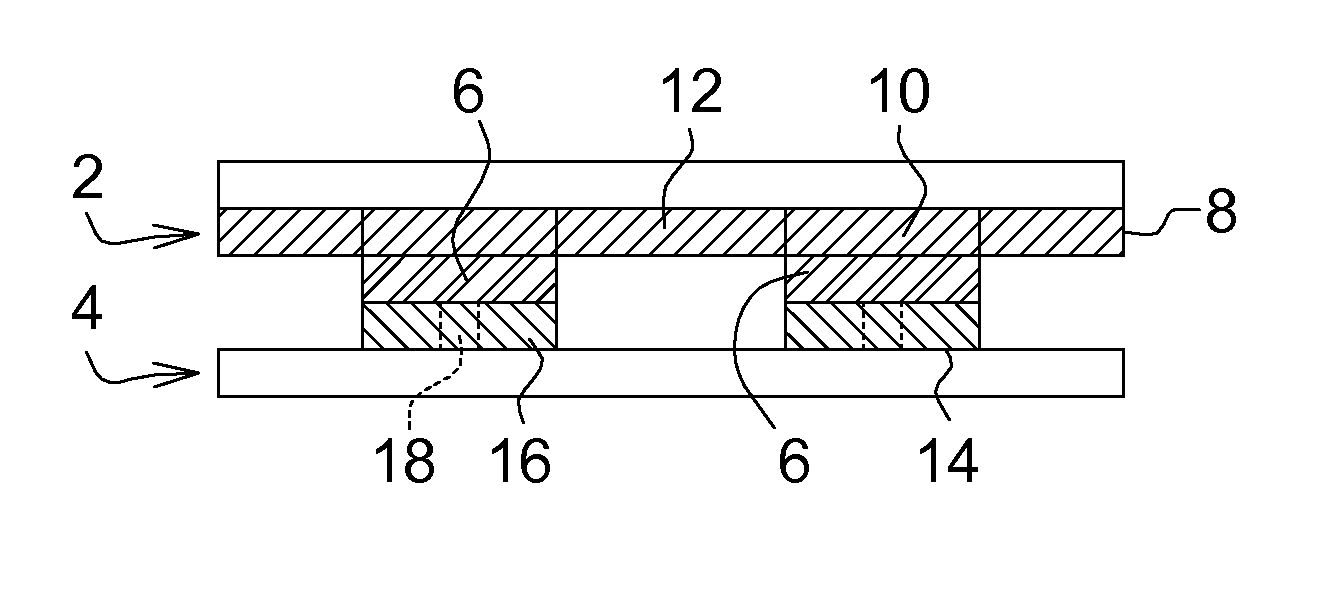

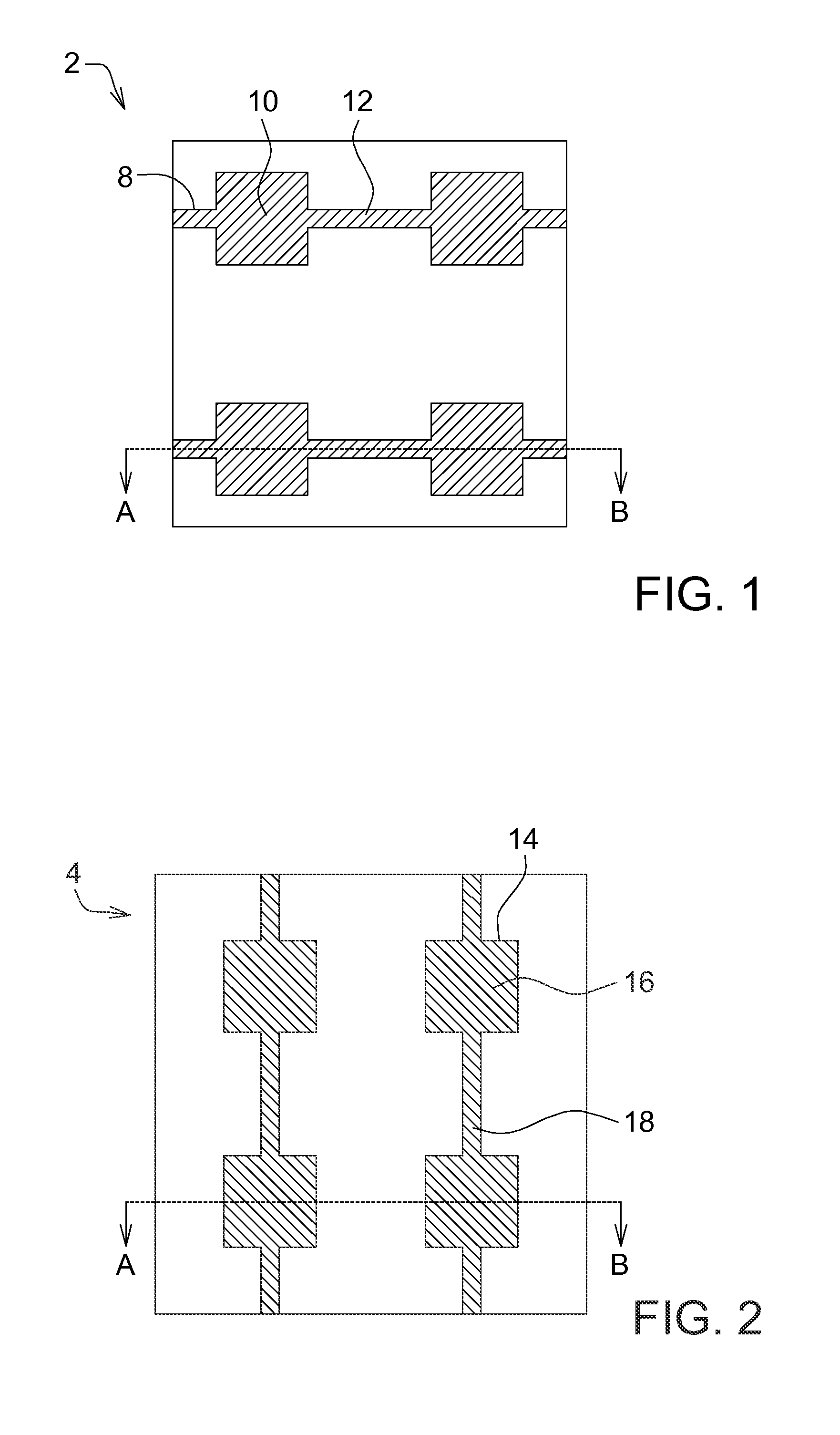

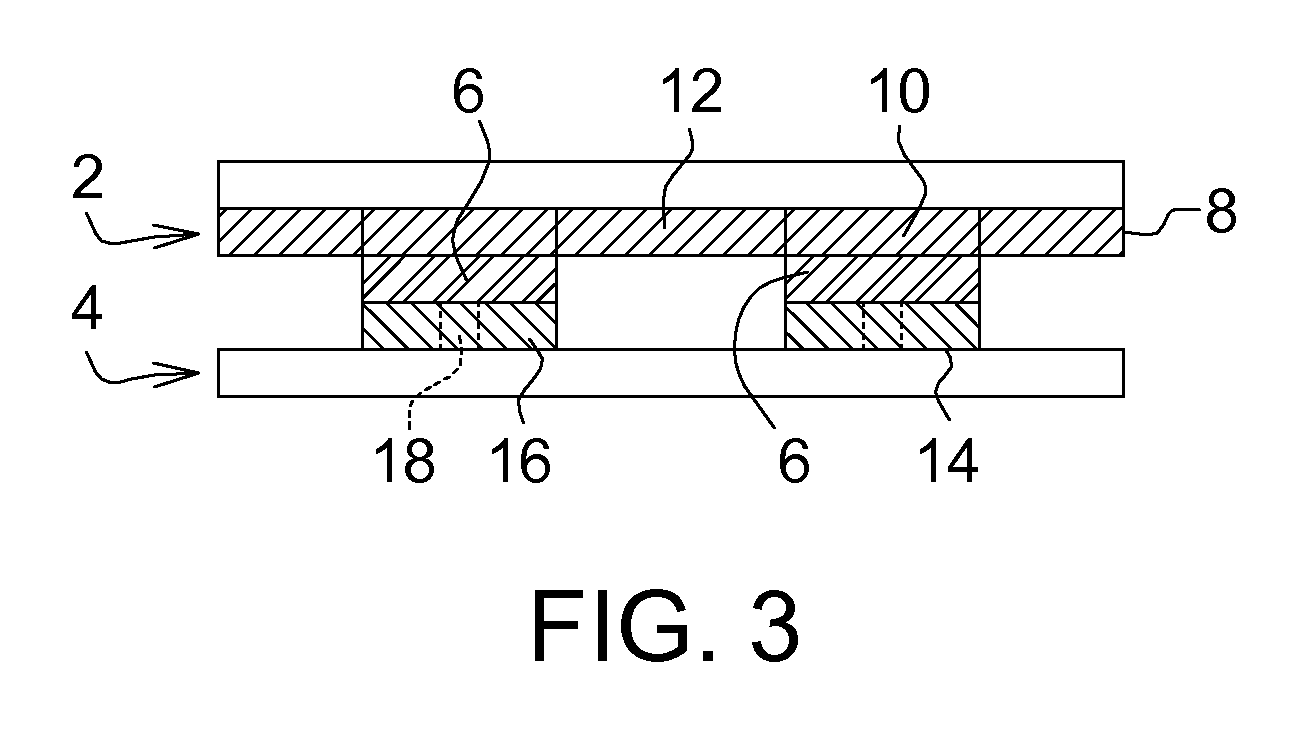

Photoresist composition for a spinless coater and method of forming a photoresist pattern using the same

InactiveUS20050089790A1Low costShorten the timePhotoprinting processesPhotosensitive materials for photomechanical apparatusLiquid-crystal displayOrganic solvent

A photoresist composition for a spinless coater includes a novolak resin having a weight average molecular weight of about 2,000 to about 15,000, a diazide based photosensitive compound and a volatile organic solvent. The photoresist composition is applied to a substrate of a liquid crystal display apparatus to reduce blots and enhance application uniformity. A highly volatile solvent, such as n-propyl acetate (nPAC) or n-butyl acetate (nBA) is used in the photoresist composition as the volatile organic solvent. The photoresist composition including the volatile organic solvent gives a photoresist film that has a uniform thickness. Hence, the generation of small resin blots and thick blots may be reduced.

Owner:SAMSUNG ELECTRONICS CO LTD

Methanol gasoline additive and process for producing methanol gasoline

The invention relates to a preparation method for a methanol oil additive and the methanol oil thereof. The compound additive consists of the components of the following weight percentages; 30 to 50 percent of isopropanol, 10 to 20 percent of tertiary butyl alcohol, 1 to 5 percent of butyl acetate, 1 to 5 percent of methyl ethyl ketone peroxide, 1 to 5 percent of peroxide, 1 to 5 percent of sherwood oil, 5 to 10 percent of dimethylbenzene, 1 to 4 percent of octane enhancing additive, 1 to 5 percent of dimethoxymethane, 0.1 to 0.5 percent of antioxidizing and antigum agent, 0.1 to 0.5 percent of antiseptic, 1 to 8 percent of antiwear agent, 3 to 6 percent of waterproofing agent, 1 to 5 percent of dispersant, 1 to 3 percent of fatty acid amine, 10 to 30 percent of 120# solvent oil as well as 5 to 10 percent of ethanol. The methanol oil consists of the components of the following weight percentages: 10 to 80 percent of methanol, 0 to 85 percent of diesel oil as well as 5 to 20 percent of methanol oil additive. The methanol oil has the advantages of low cost, excellent performance, good environment protection effect, remarkable economic benefit and convenient popularization.

Owner:王宇

Weather-resistant epoxy polyurethane anticorrosive paint and preparation thereof

InactiveCN101298535AGood weather resistanceStrong adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsGas phaseSiloxane

The invention relates to a weather resistant epoxy-polyurethane anti-corrosion coating and a manufacturing method thereof, which adds phenol-A epoxy resin, bisphenol-F epoxy resin, hydroxyl contained saturated polyester resin and fluorocarbon resin into the mixed solvent of dimethylbenzene, n-butyl acetate, methyl isobutyl ketone and butanone; then adds rutile type titanium pigment, saponite, sericite in powder, polyacrylate co-polymer, polymethyl alkyl siloxane, benzotriazole, gas phase silica and iso-caprylic acid znic to make the fluid A of the weather resistant epoxy-polyurethane anti-corrosion coating while adds fatty group polyisocyanate into the mixed liquor of anhydro-dimethylbenzene and the n-butyl acetate to make fluid B, and mix the two components during application. The invention can be applied to the preservation of the surfaces of outdoor steel structures, pipes and concrete requiring weather resistance, light aging resistance and acid, alkali and salt corrosion resistance.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +1

Method for manufacturing piezoresistive material, piezoresistive composition and pressure sensor device

A method for manufacturing a piezoresistive material, a piezoresistive composition and a pressure sensor device are provided. The piezoresistive composition includes a conductive carbon material, a solvent, a dispersive agent, an unsaturated polyester and a crosslinking agent. The conductive carbon material is selected from a group consisting of multi-wall nanotube, single-wall carbon nanotube, carbon nanocapsule, graphene, graphite nanoflake, carbon black, and a combination thereof. The solvent is selected from a group consisting of ethyl acetate, butyl acetate, hexane, propylene glycol mono-methyl ether acetate and a combination thereof. The dispersive agent includes block polymer solution with functional groups providing the affinity. The unsaturated polyester is selected from a group consisting of an ortho-phthalic type unsaturated polyester, an iso-phthalic type unsaturated polyester, and a combination thereof. The crosslinking agent is selected from a group consisting of ethyl methyl ketone peroxide, cyclohexanone diperoxide, dibenzoyl peroxide, tert-butyl peroxybenzoate and a combination thereof.

Owner:IND TECH RES INST

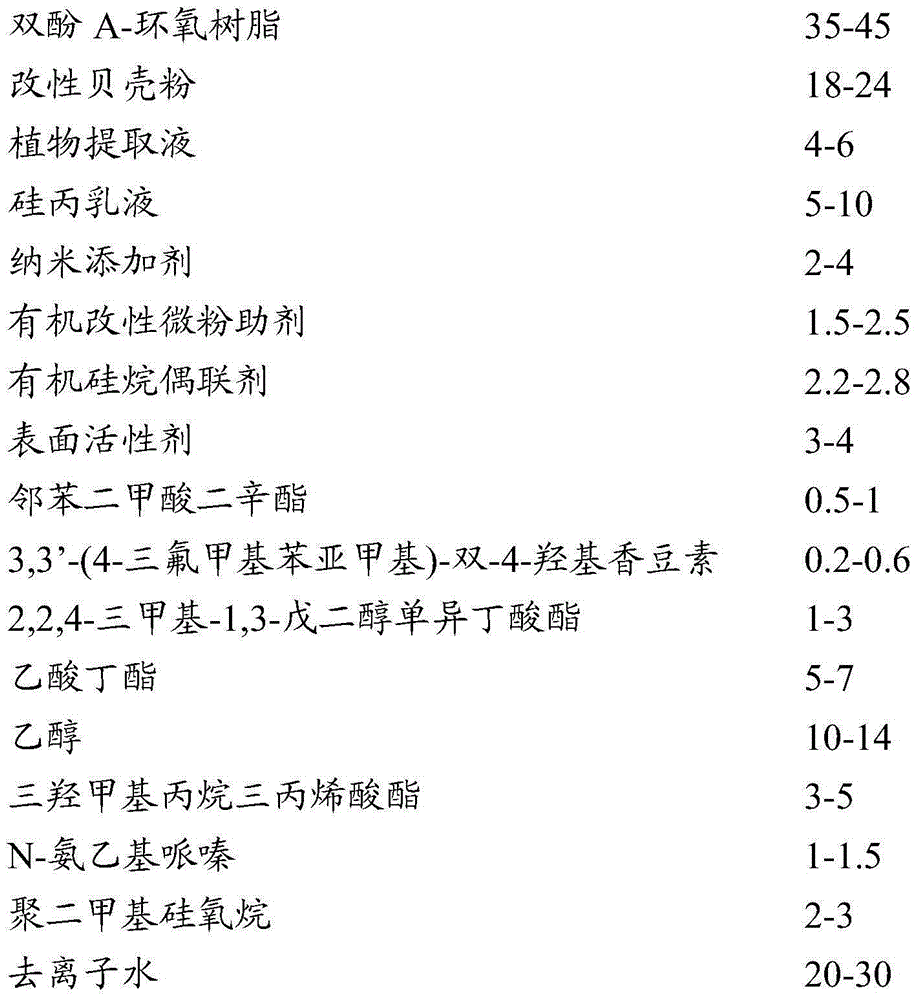

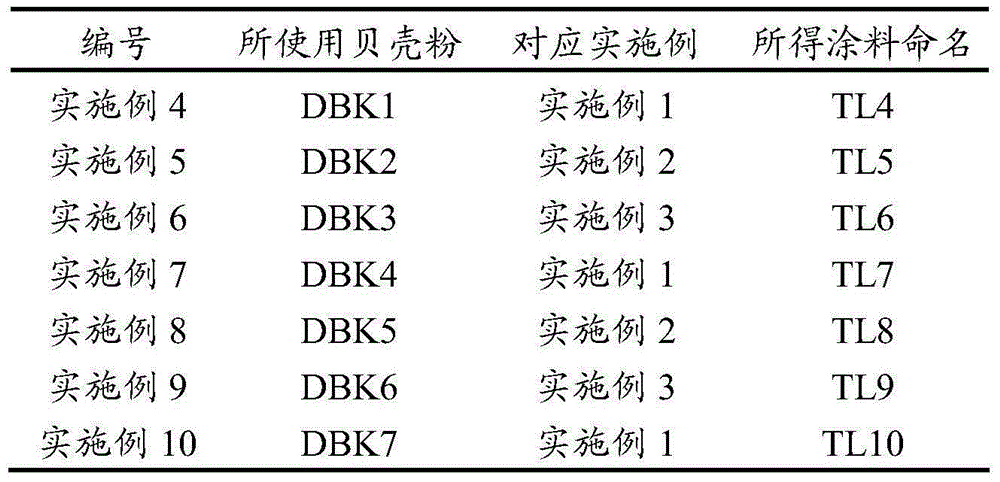

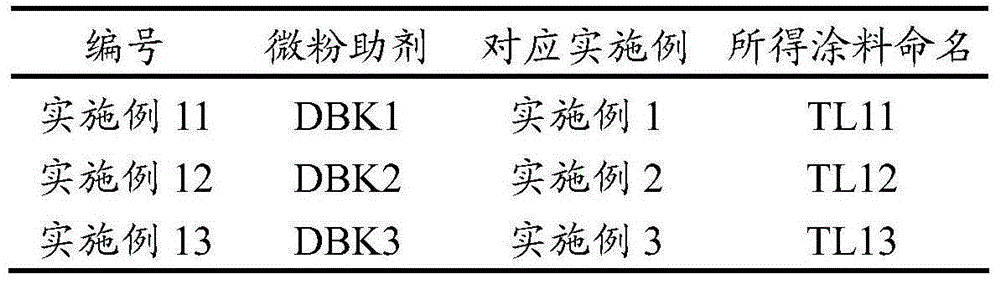

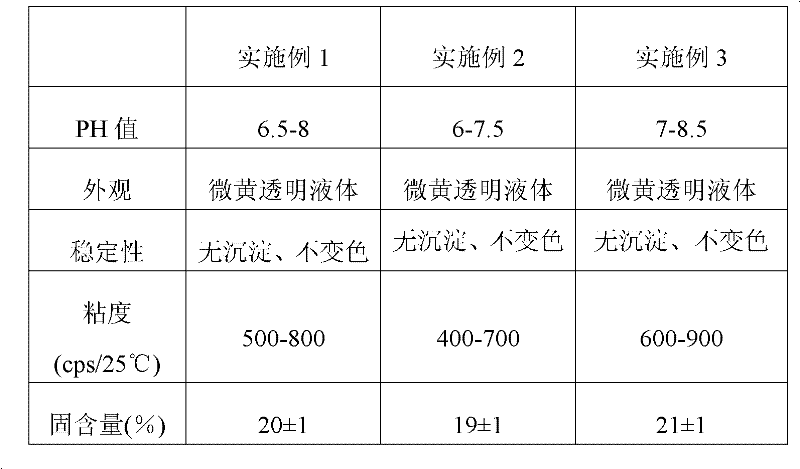

Environmentally friendly shell powder functional coating and preparation method therefor and uses thereof

ActiveCN104987808AImprove performancePractical application value is greatEpoxy resin coatingsDimethyl siloxaneIsoprene

The present invention relates to an environmentally friendly shell powder functional coating, a preparation method therefor and uses thereof. The coating comprises: bisphenol A-epon, modified shell powder, vegetable extract, propyl silicone emulsion, a nano additive, a modified organic micro powder agent, a surfactant, dioctylphthalate, 3, 3'-(4-trifluoromethyl methyl)-bi-4-hydroxy coumarin, 2,2,4-amino trimethyl-1,3-isoprene glycol mono iso-butyl methacrylate, butyl acetate, ethanol, trimethylol propane triacrylate, N-ammonia amino ethyl piperazine, polydimethylsiloxane and deionized water. In the present invention, by modification of a variety of components and materials, selection and collocation of specific components and a specific preparation method, the variety of components exert a synergistic effect, so as to make the prepared coating have significant antimicrobial, environmental-cleaning and wear-resisting properties. The coating has a huge application potential and extensive value in industrial production.

Owner:广西世家丽环保投资有限公司

Automobile trim PU (Poly Urethane) double-component plastic paint as well as preparation method and construction method thereof

InactiveCN103555172ALiquid surface applicatorsPolyurea/polyurethane coatingsLaser etchingPolymer science

The invention belongs to the field of paint, relates to PU (Poly Urethane) double-component plastic paint, and in particular relates to PU double-component plastic paint which is applied to automobile trim plastic and rubber components. The automobile trim PU double-component plastic paint consists of a component A and a component B, wherein the component A comprises resin, 2-4 parts of high pigment carbon black dye, 3-5 parts of carbon black dispersing agent, 0.5-1 part of anti-settling agent, 0.02-0.05 part of drying agent, 0.5-1 part of flatting agent, 0.2-0.5 part of defoaming agent, 5-7 parts of matting agent, 1-2 parts of wax powder and 20-25 parts of a solvent, and the resin is a mixture consisting of 10-15 parts of high-hydroxy acrylic acid resin, 20-25 parts of low-hydroxy acrylic acid resin and 20-30 parts of quick-drying hydroxy acrylic acid resin; the component B consists of 70-90 parts of aliphatic polyisocyanate and 10-30 parts of n-butyl acetate. The paint can meet the property requirements (good adhesion capability, good chemical product resistance and laser etching possibility) of automobile trim plastic products.

Owner:HUIZHOU KAIHUI CHEM

Preparation method of 2-butyl alcohol

InactiveCN102992956AHigh selectivityImprove conversion rateChemical industryPreparation by alcoholysisAlcoholN-Butyl acetate

The invention relates to a preparation method of 2-butyl alcohol. The method comprises the following steps: carrying out an ester exchange reaction of 2-butyl acetate and low-carbon alcohol in a catalytic rectifying tower in the presence of an ester exchange catalyst, and collecting the 2-butyl alcohol from tower bottoms, wherein the low-carbon alcohol is C1-C3 alcohol. The method has the advantages of high 2-butyl acetate conversion rate and high 2-butyl alcohol selectivity.

Owner:HUNAN CHANGLING PETROCHEM SCI & TECH DEV CO LTD

Strippable protective polyvinyl butyral coating film and its production process

The strippable protective polyvinyl butyral coating is produced with polyvinyl butyral, ethanol, methanol, ethyl acetate, butyl acetate, n-butanol and butanone as material. Modified polyvinyl butylral liquid is painted to the surface of automobile, furniture, electric appliance and other objects to form protective coating at normal temperature. The coating is continuous, homogeneous, tough and transparent and can be stripped for recovery. The coating is sun-proof, water, oil, alkali, salt solution and dilute acid resistant, and has wide application and no environmental pollution.

Owner:JILIN AOJIE SCI & TECH

Super black flock oil wax sense polishing treatment agent for synthetic leather and preparation method thereof

The invention relates to a super black flock oil wax sense polishing treatment agent for synthetic leather, which comprises nitrocotton resin, alkyd resin, cyclohexanone, butyl acetate, isopropanol, silicon dioxide extinction powder, hydrophilic silicon oil, castor oil, erucamide and an organic silicon flatting agent. The invention also relates to a preparation method of the super black flock oil wax sense polishing treatment agent for synthetic leather. Compared with the traditional common black flock leather surface treatment agent, the super black flock oil wax sense polishing treatment agent for synthetic leather, disclosed by the invention, obviously ensures that the synthetic leather has better mist glossy effect after being polished and has special flock sense and strong leather dermis effect; and the synthetic leather applying the super black flock oil wax sense polishing treatment agent has flock oil wax hand feeling and good comprehensive effect.

Owner:JIANGSU BAOZE POLYMER MATERIAL

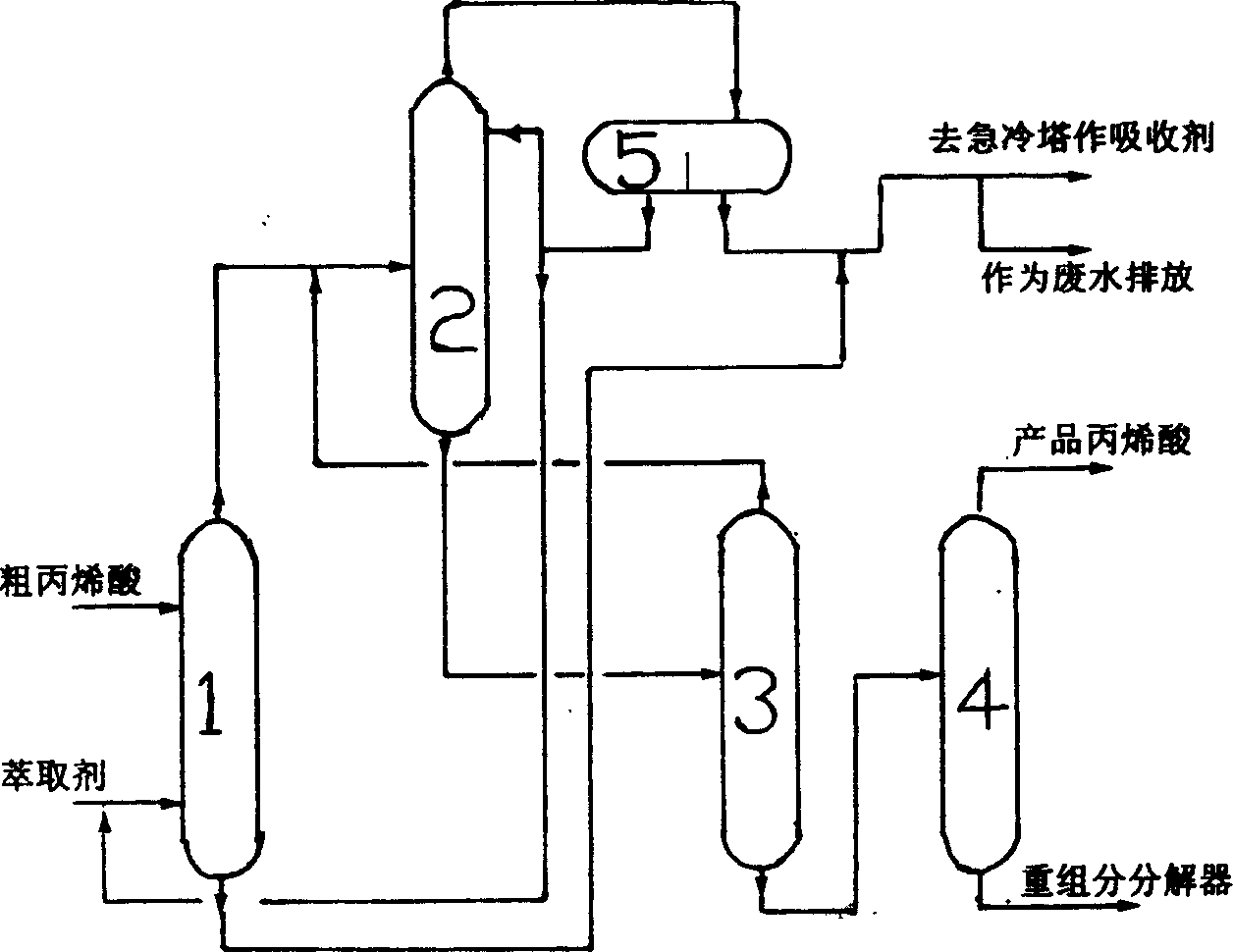

Method for purifying acrylic acid

The invention relates to the process for purifying acrylic acid which comprises using novel organic extracting agent to separate acrylic acid from its water solution, then removing light compositions such as water and acetic acid by azeotropic fractional distillation, wherein the organic extracting agent comprises toluene, acetic ether, butyl acetate, butyl acetate, propionic ether, diisobutyl ketone, isophorone, methyl phenyl ether or their mixture, preferably the composite compound of toluene with isobutyl phenylacetate, the mass ratio of toluene and isobutyl phenylacetate is between 1:1-1:50, preferably 1:2-1:12. The process according to the invention can realize high acetic acid removing ratio.

Owner:SHANGHAI HUAYI NEW MATERIAL

Fabric desizing agent

InactiveCN102965902AHigh whitenessImprove water absorptionDry-cleaning apparatus for textilesFiberAmylase

The invention discloses a fabric desizing agent. The fabric desizing agent consists of the following components in parts by weight: 10-20 parts of amylase, 3-5 parts of sodium persulfate, 2-6 parts of methyl cellulose, 0.2-0.6 part of sodium hydroxide, 10-20 parts of butyl acetate, 20-40 parts of isopropyl alcohol, 1-3 parts of butyl phthalate and 100-160 parts of water. Compared with the prior art, the fabric desizing agent has the following beneficial effects of (1) being good in desizing effect and enabling size to be fully hydrolyzed without damaging a fabric, and (2) removing impurities and minerals on the fiber, and improving the whiteness and hydroscopicity of a semi-finished product of the fabric.

Owner:吴江红蔷薇纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com