Waterproof zipper

a zipper and water-resistant technology, applied in the field of waterproof zippers, can solve the problem of not being able to maintain for a longer tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

[0036] In this embodiment, the performance is described in two stages. FIG. 3 shows the first stage and FIG. 5 shows the second stage. At first, referring to FIG. 3, the first stage includes the steps of feeding material 21, gluing 22, pressing 23, drying 24, and outputting 25.

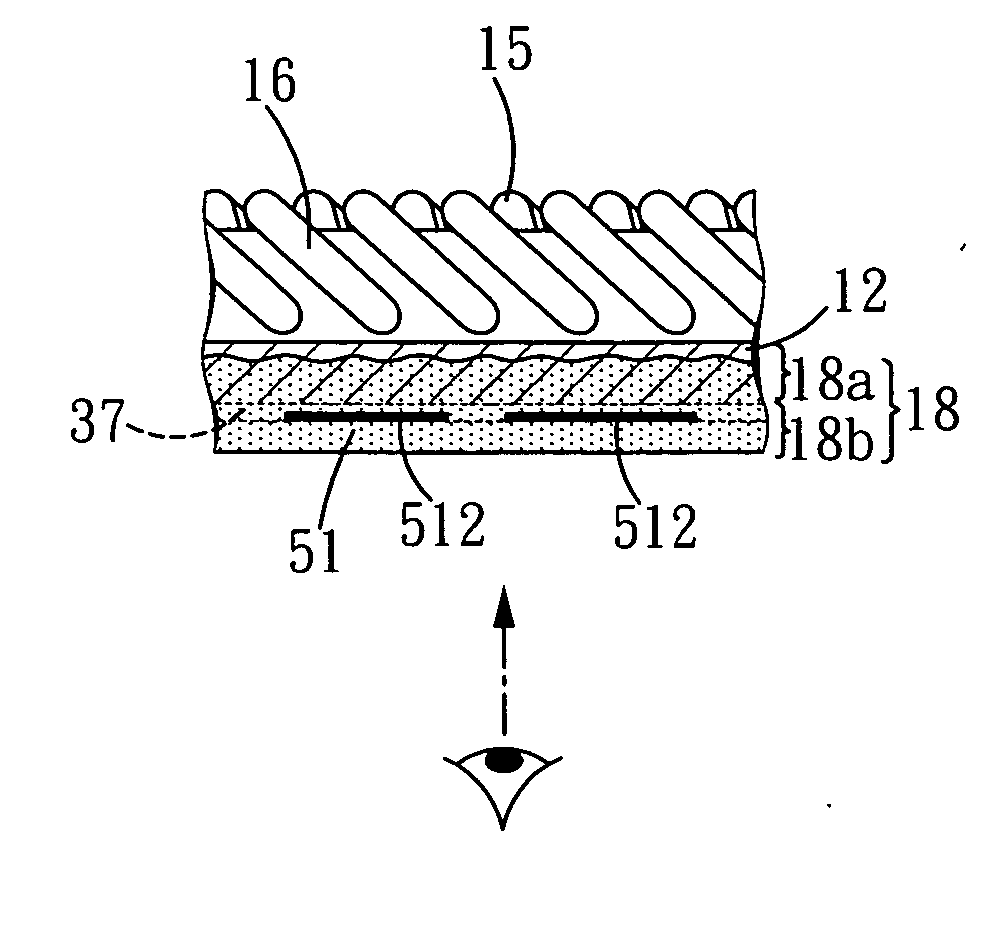

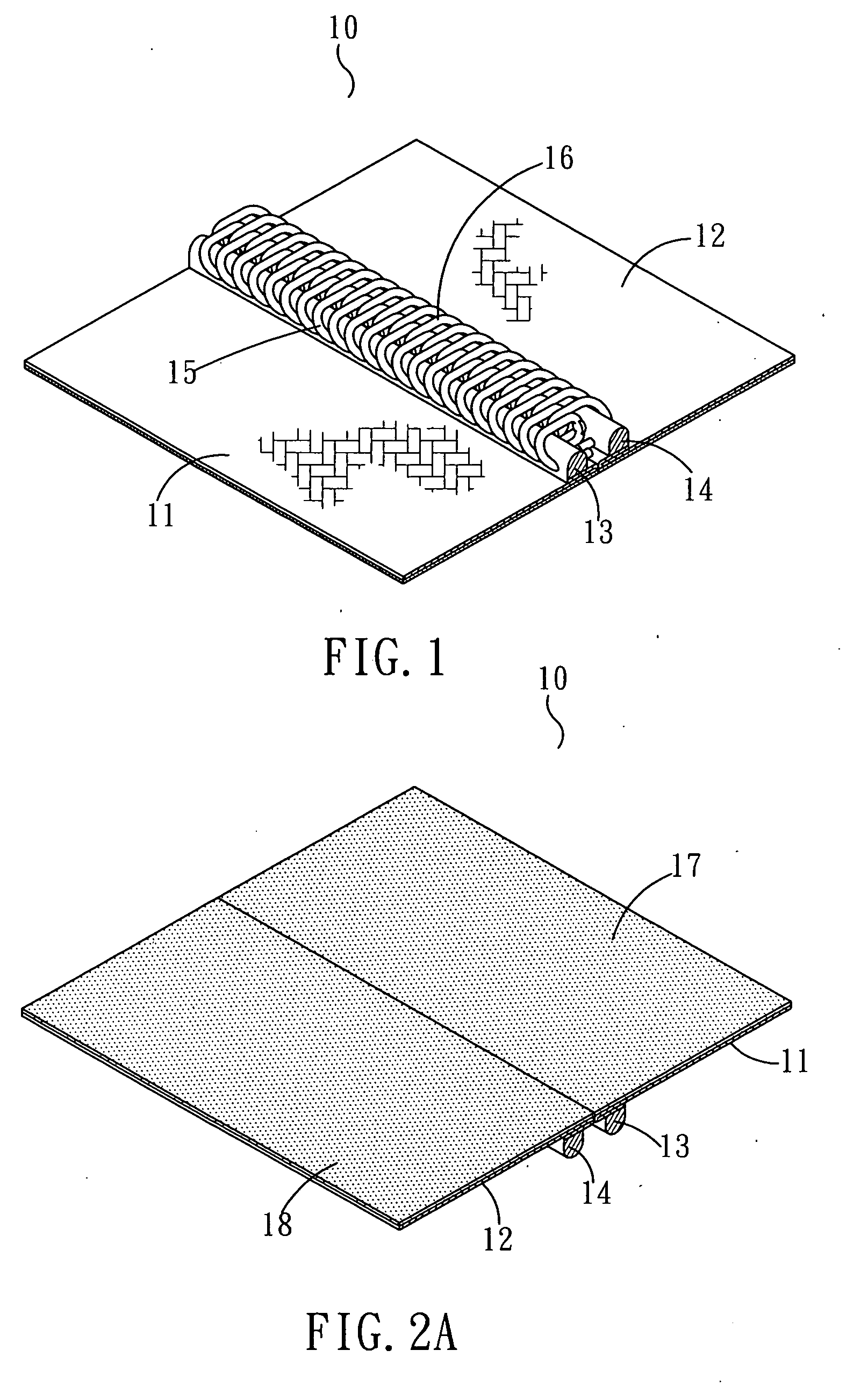

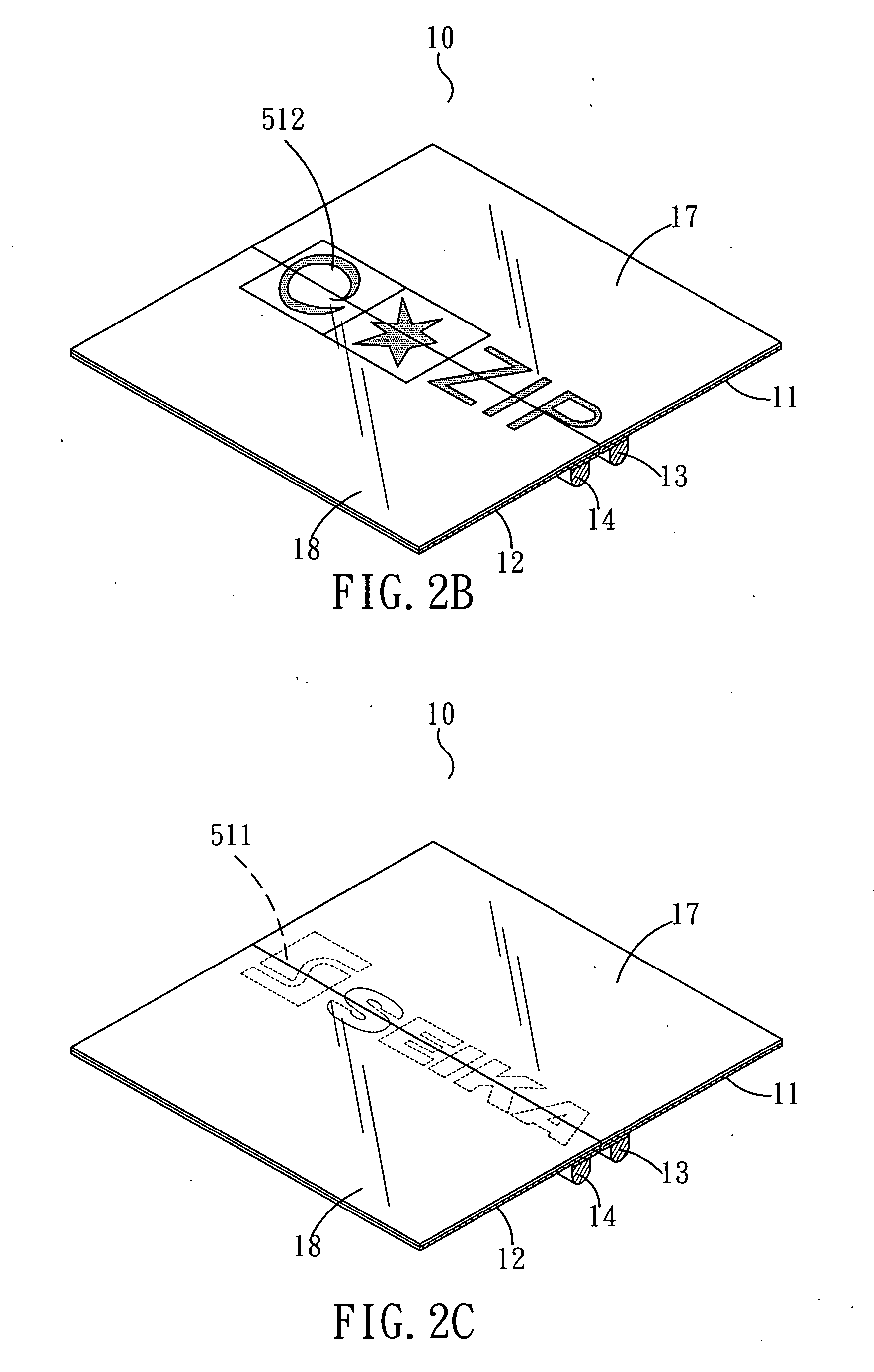

[0037] As shown in FIG. 4, in the feeding stage 21, the nylon zipper 10 passes through a feeding device (formed by an upper and a lower rollers 32, 33) and is taken out from the feeding tank 31 so that the nylon zipper 10 is extended properly to be in flat state. The cross section view thereof is shown in FIG. 4A.

[0038] Next, a gluing step 22 is performed. In this step, the fastener strips 11, 12 are gluing so that the back sides of the fastener strips 11, 12 are coated with a layer of solvent-based PU adhesive contains solid contents 34˜36% toluene or methyl-ethyl-ketone 64˜66% with a viscosity 60,000˜90,000 cps at 25° C. and hardener contains butyl-acetate 23˜27%, polyisocyanate 73˜77%. Thereby, the back s...

second embodiment

[0052] In this embodiment, the first and second manufacturing stages are integrated as a continuous production line, as shown in FIGS. 7 and 8. The steps are feeding step 21, gluing step 22, pressing step 23, drying step 24, adhesion step 27, heating step 28, cutting step 29, guide step 30. In this embodiment, the guide device 25 in the first step and the feeding step 26 in the second stage can be reduced.

third embodiment

[0053] To simplify the manufacturing lines in FIGS. 7 and 8, the block diagram in FIG. 9 can be performed. The stages includes the step of feeding step 21, gluing step 22, adhesion step 27, heating step 28, cutting step 29 and guide step 30, as shown in FIG. 10. In this embodiment, not only the manufacturing stage is simplified, but also a batch of small amount in manufacturing can be performed easily. From above description, it is known that the embodiments in FIGS. 9 and 10 are basic and simple manufacturing method in the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com