Patents

Literature

1396 results about "Stringer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stringers are filaments of slag left in wrought iron after the production process. In their correct proportions their presence is beneficial, as they help to control the ductility of the finished product, but when the proportion of slag is too high, or when the filaments run at right angles to the direction of tension, they can cause weakness.

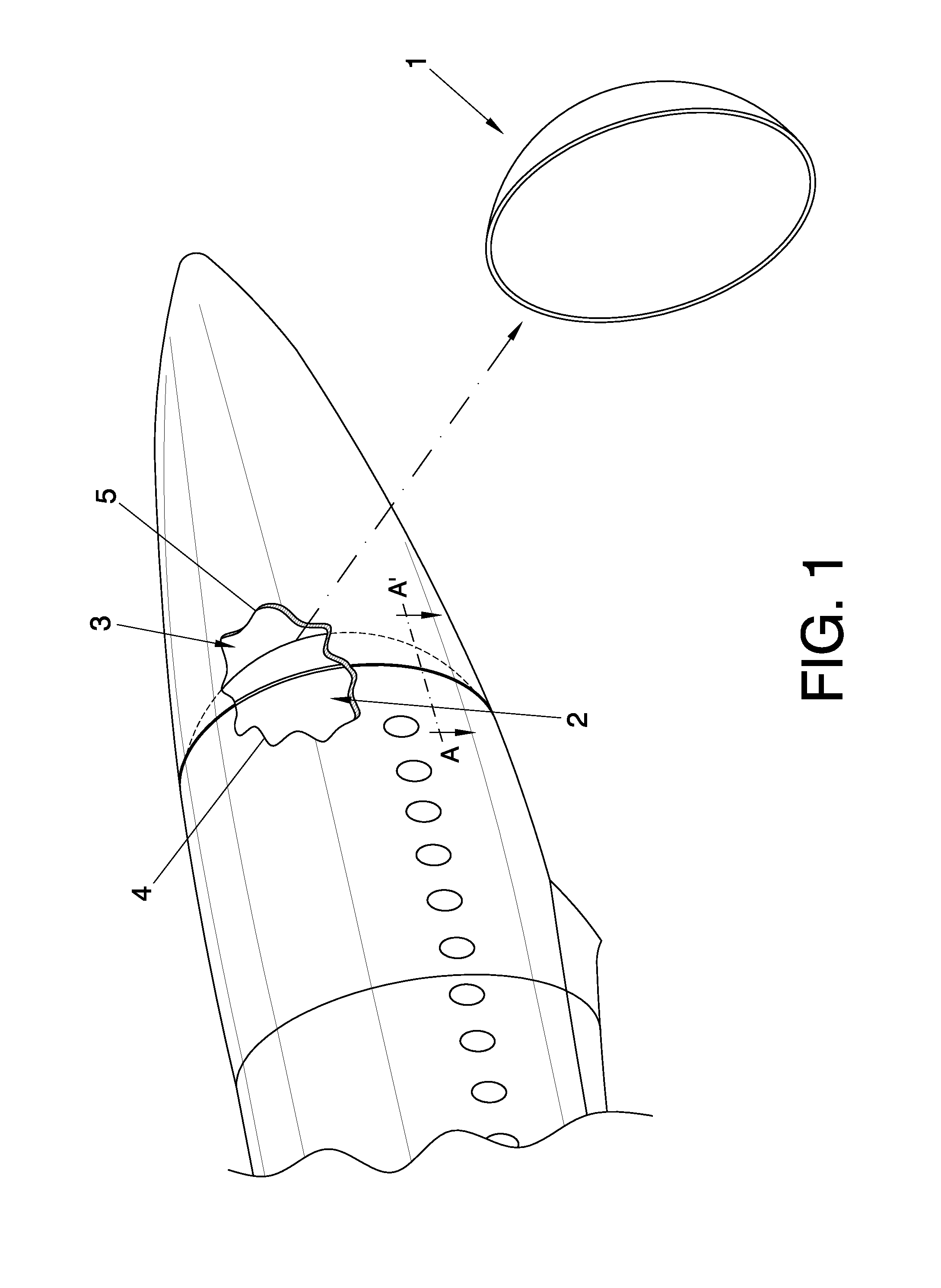

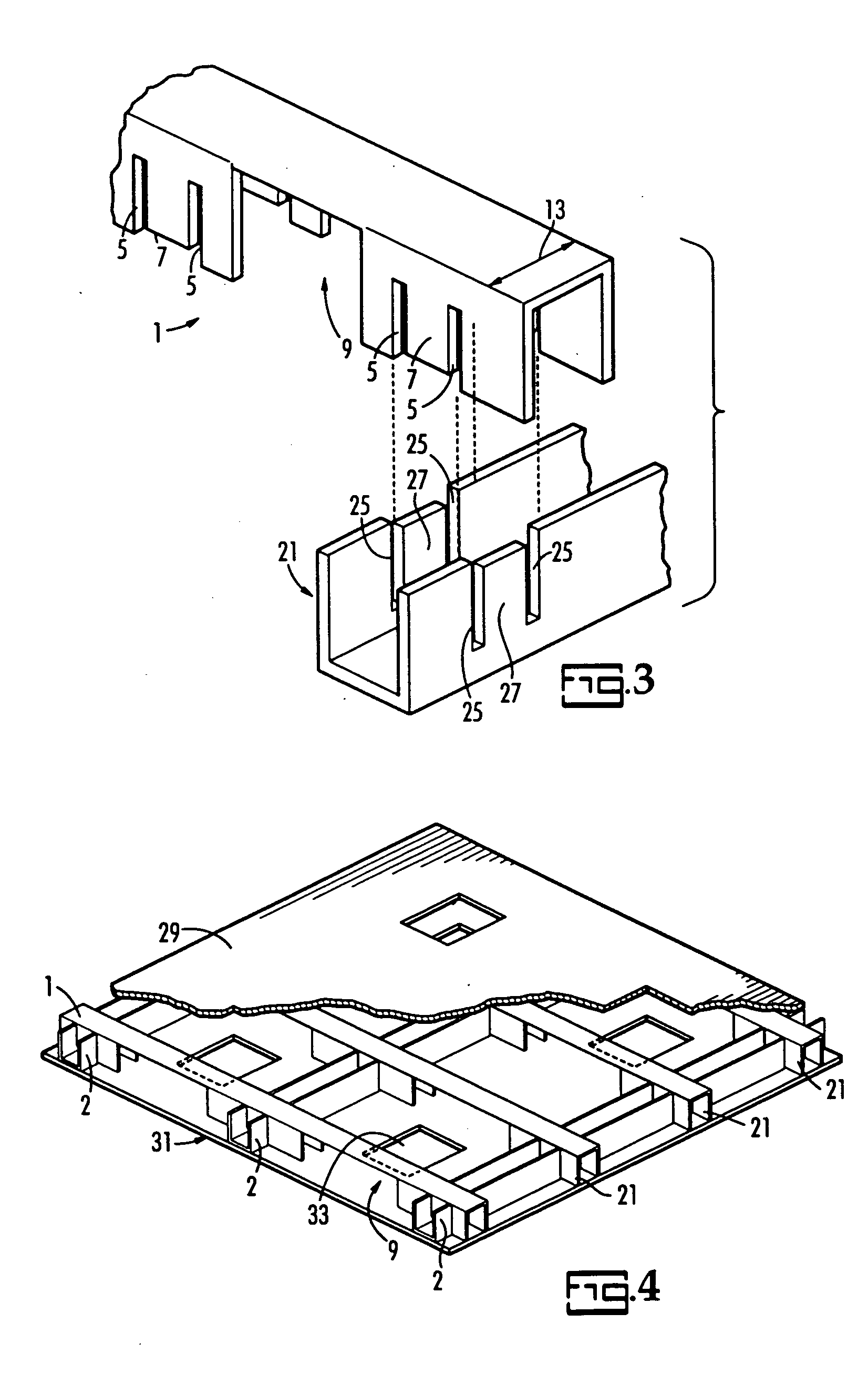

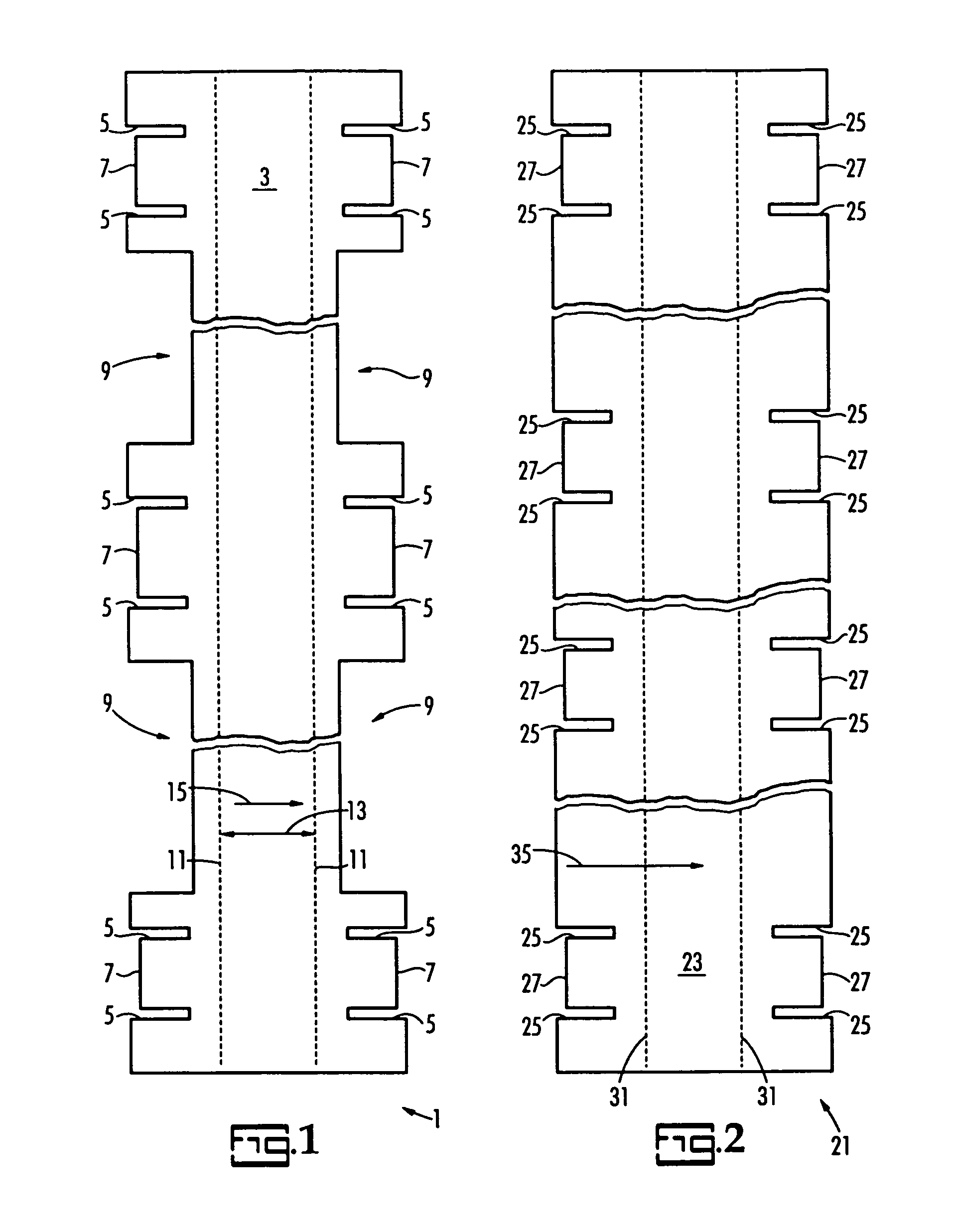

Shell component for an aircraft fuselage and method of manufacturing the same

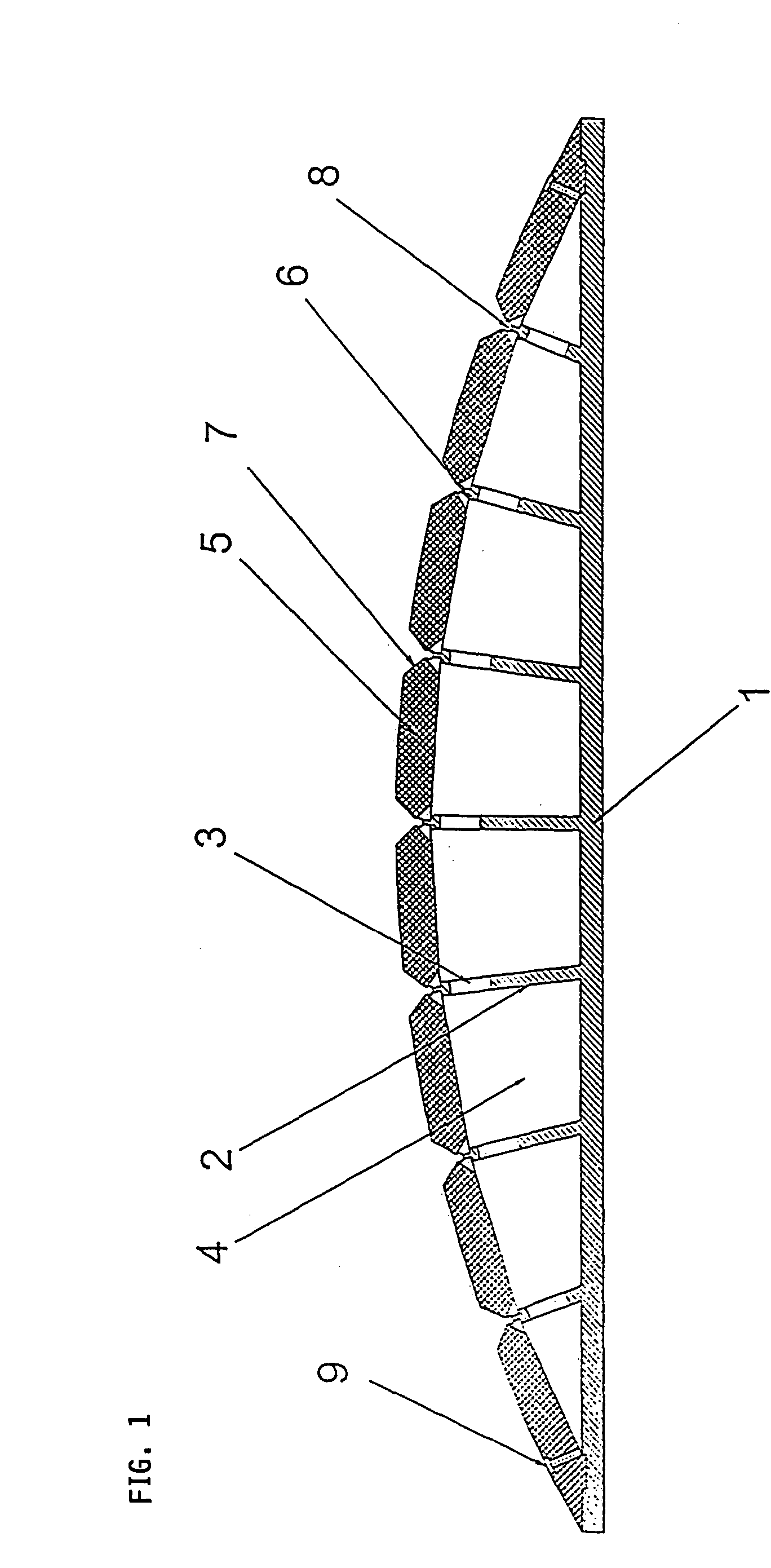

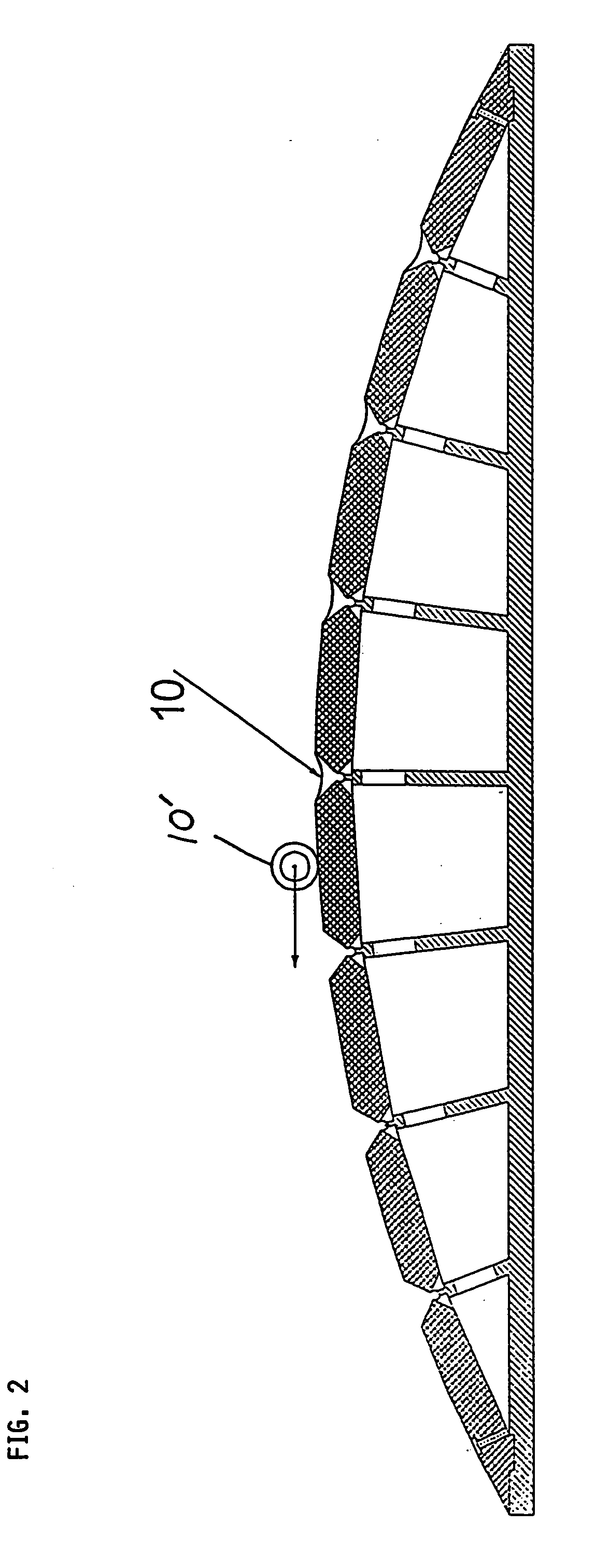

A shell component for an aircraft fuselage includes a fuselage skin panel, a plurality of stringers extending in an aircraft lengthwise direction, and a plurality of frames extending crosswise relative to the stringers. The stringers and the frames are respectively welded onto the skin panel with the addition of a weld filler material. Each frame includes a frame root portion and a frame profile portion connected to each other. The frame root portion has cut-out notches receiving the stringers passing therethrough. The frame root portion is welded to the skin panel at the areas between the cut-out notches, and may be welded to the respective stringer in each cut-out notch. The stringers and frames are fabricated from webs and flanges, whereby a premanufactured grid of flanges may be used. The result is a very strong, yet simple shell component structure, that may be manufactured with a simple welding process, at a low cost and with low effort.

Owner:DAIMLER CHRYSLER AEROSPACE AIRBUS

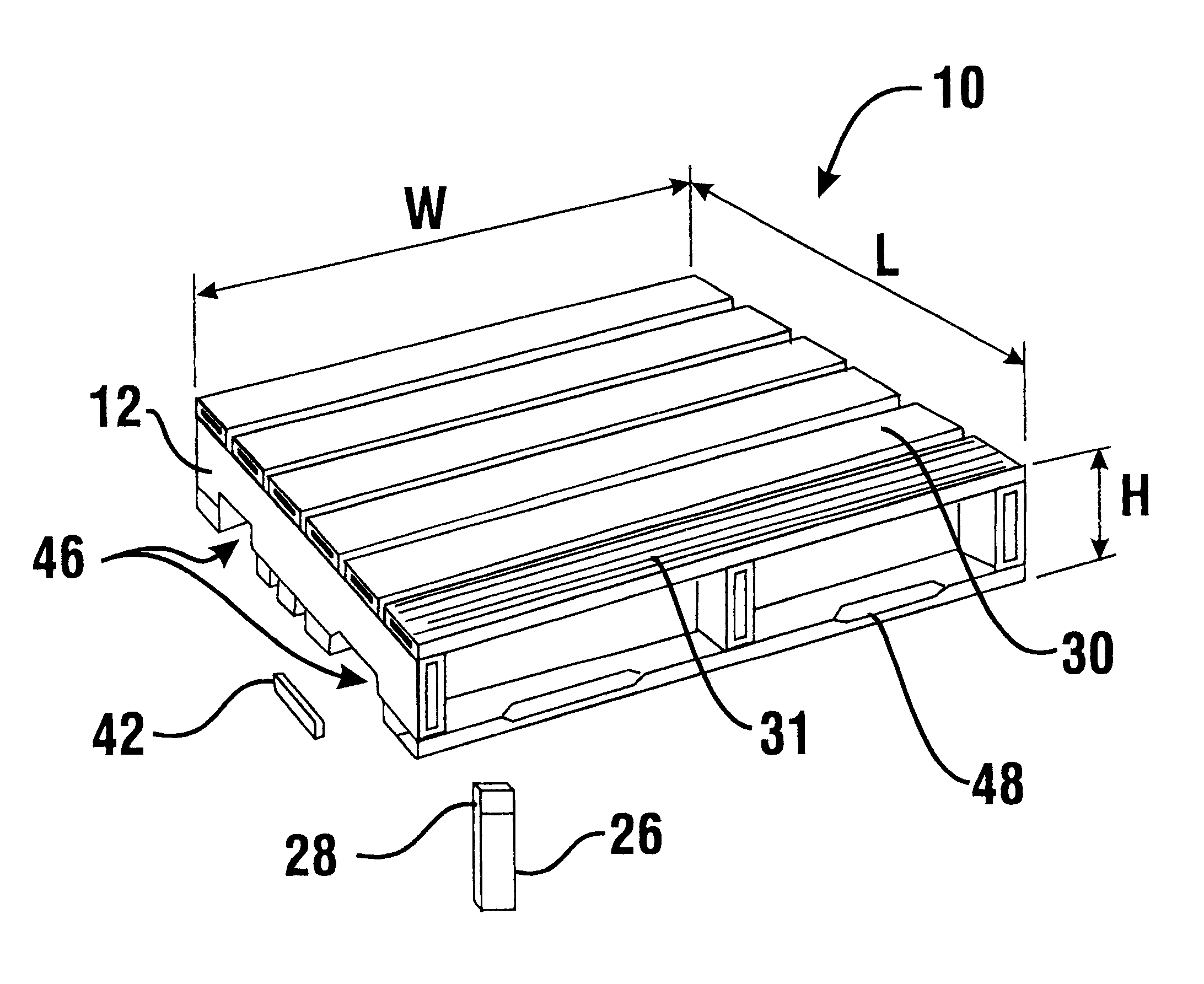

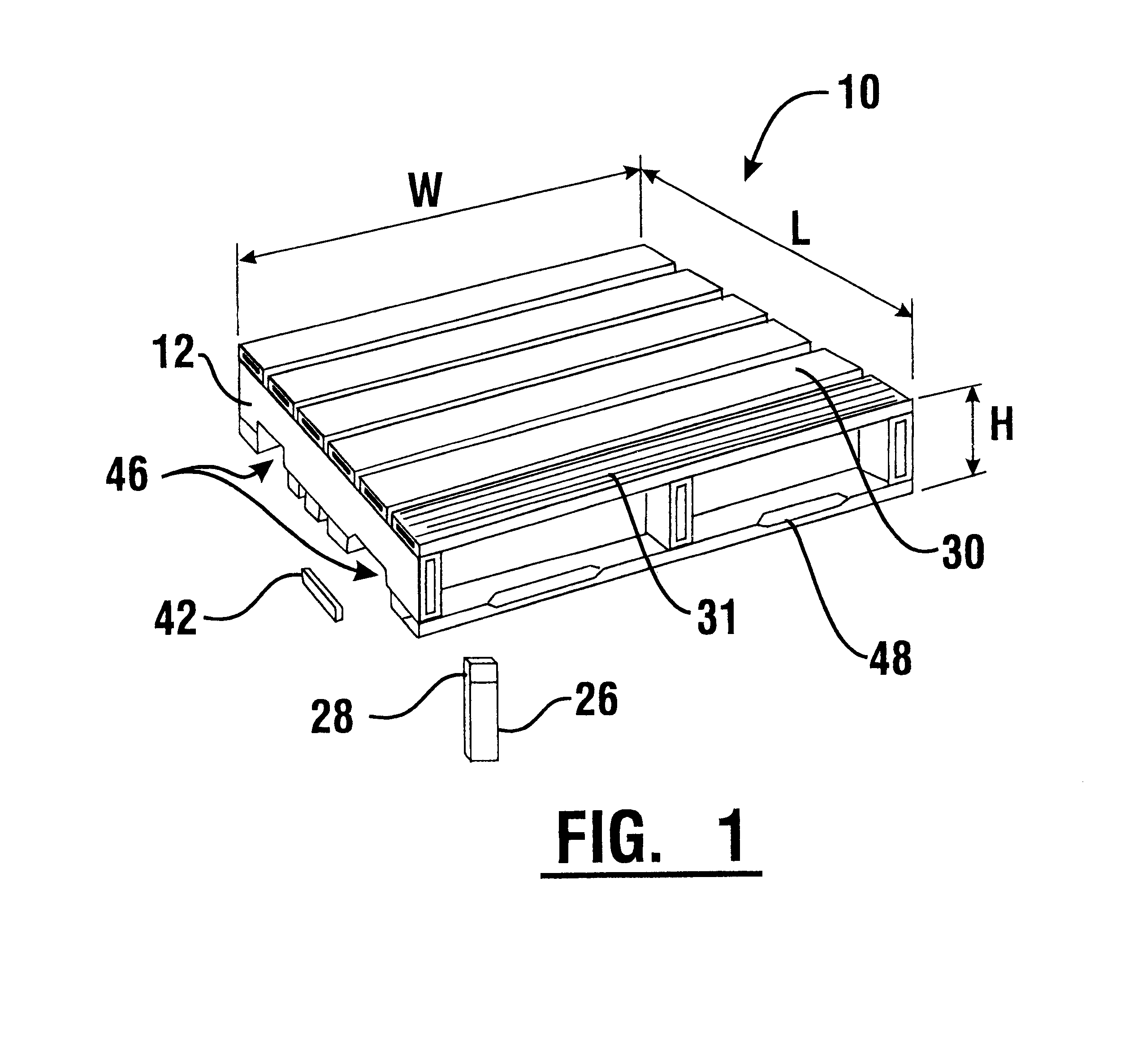

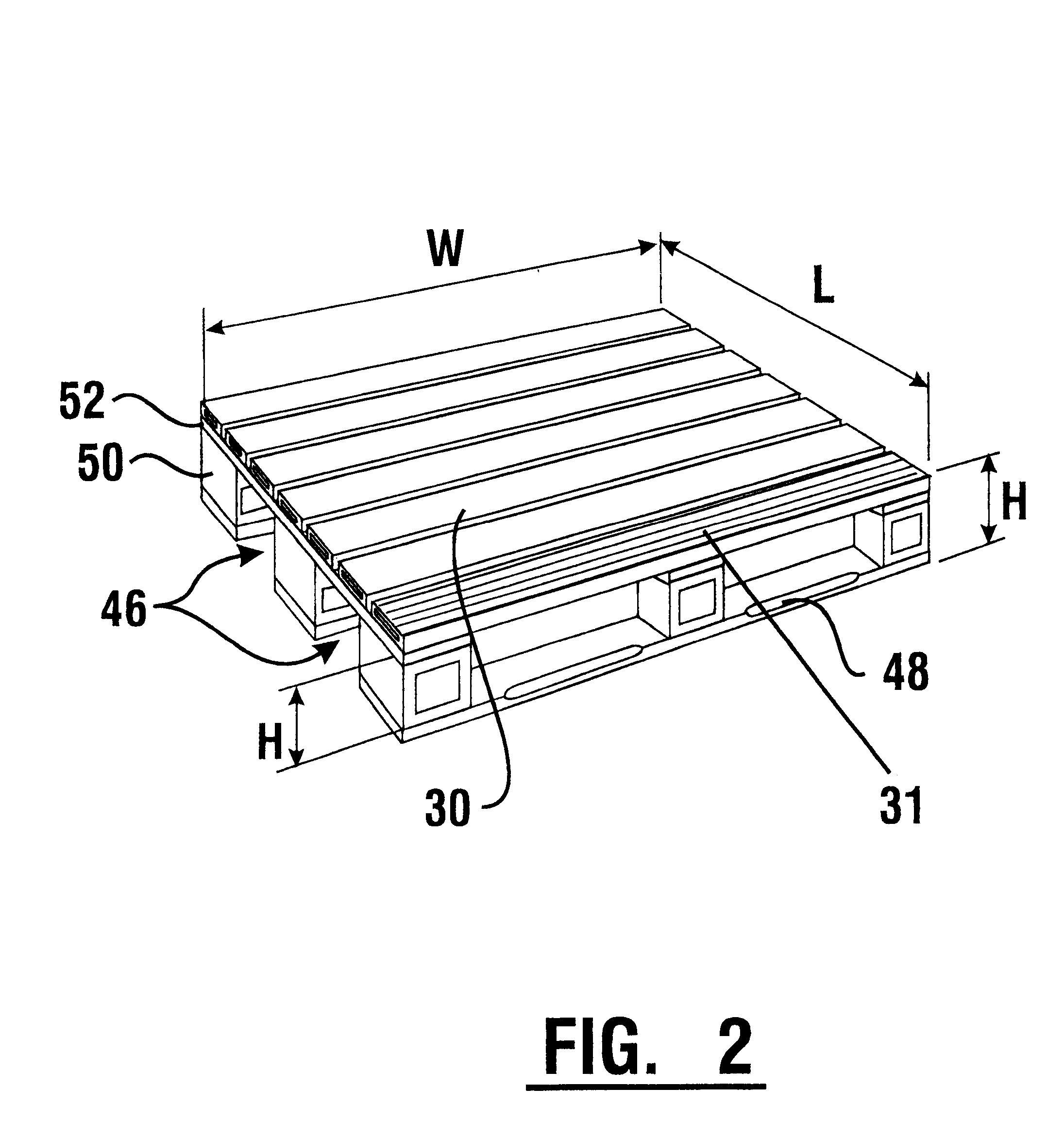

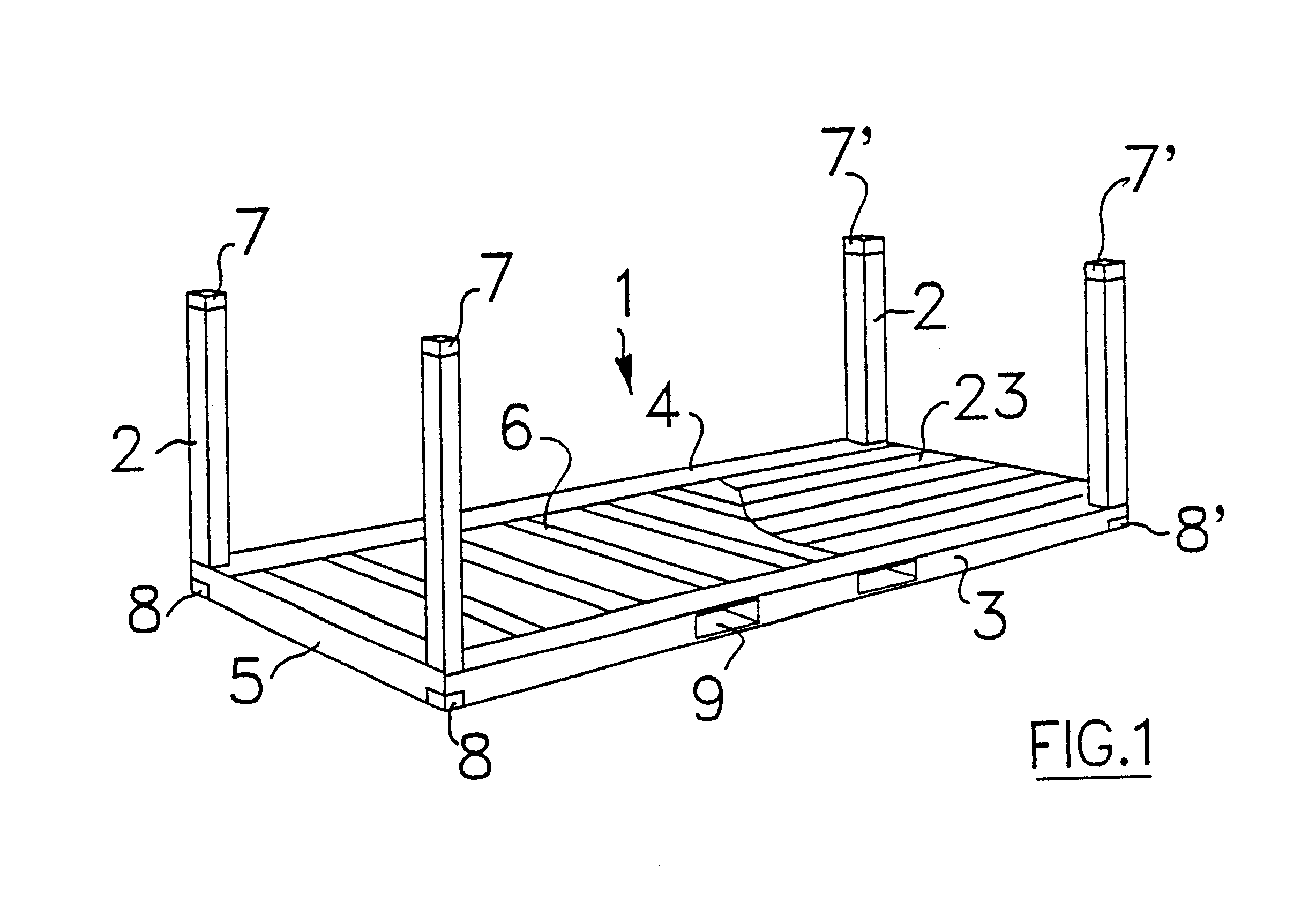

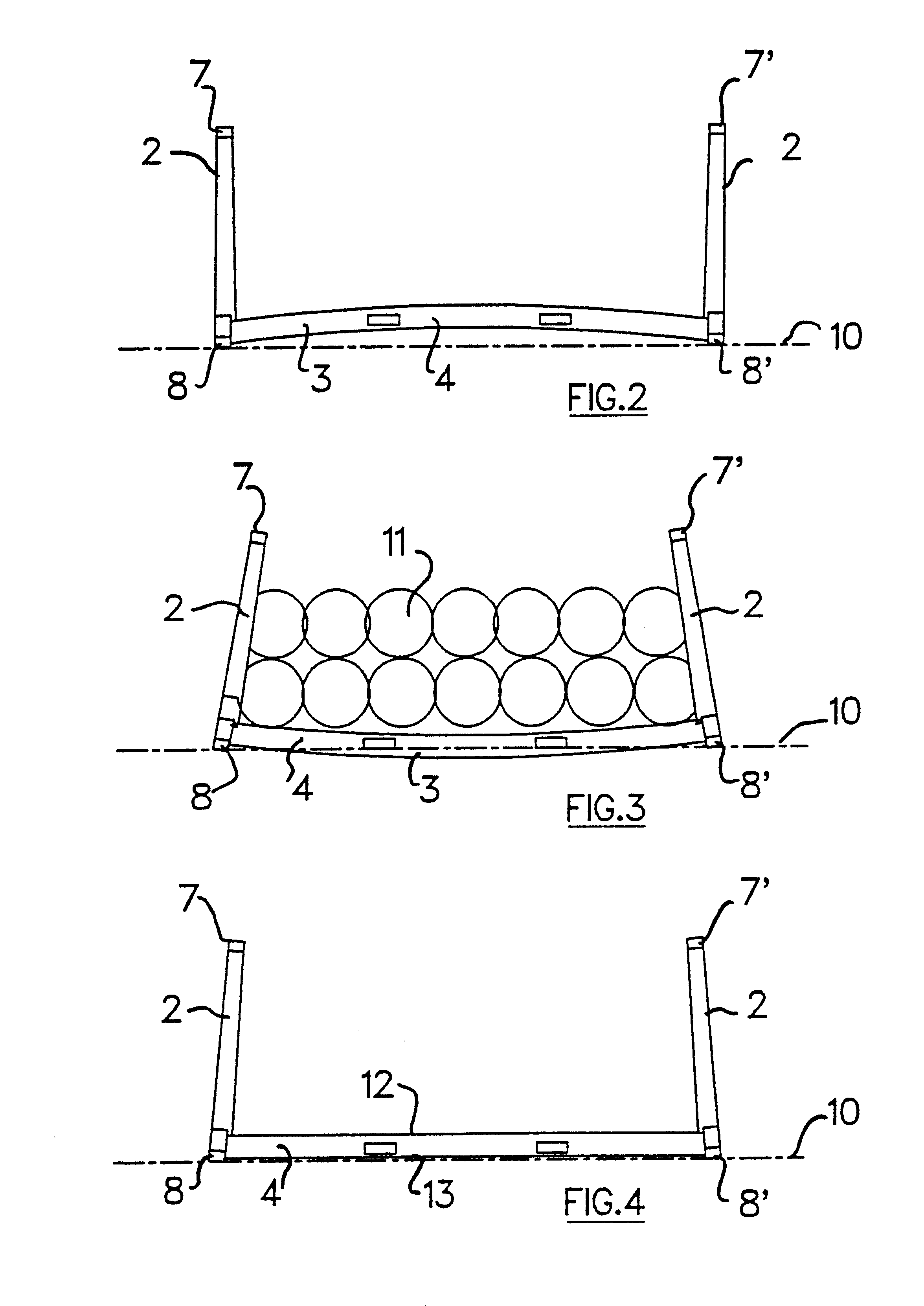

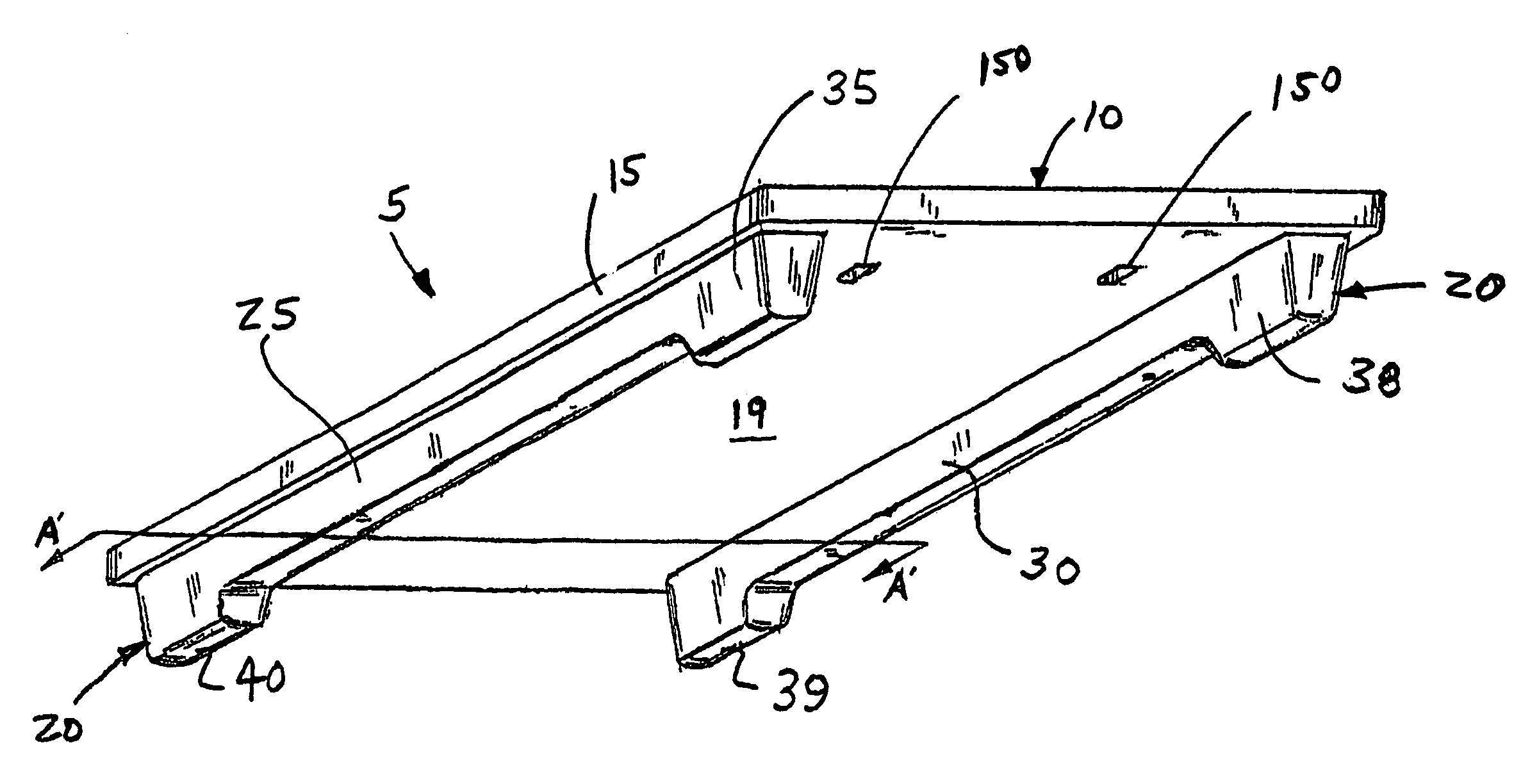

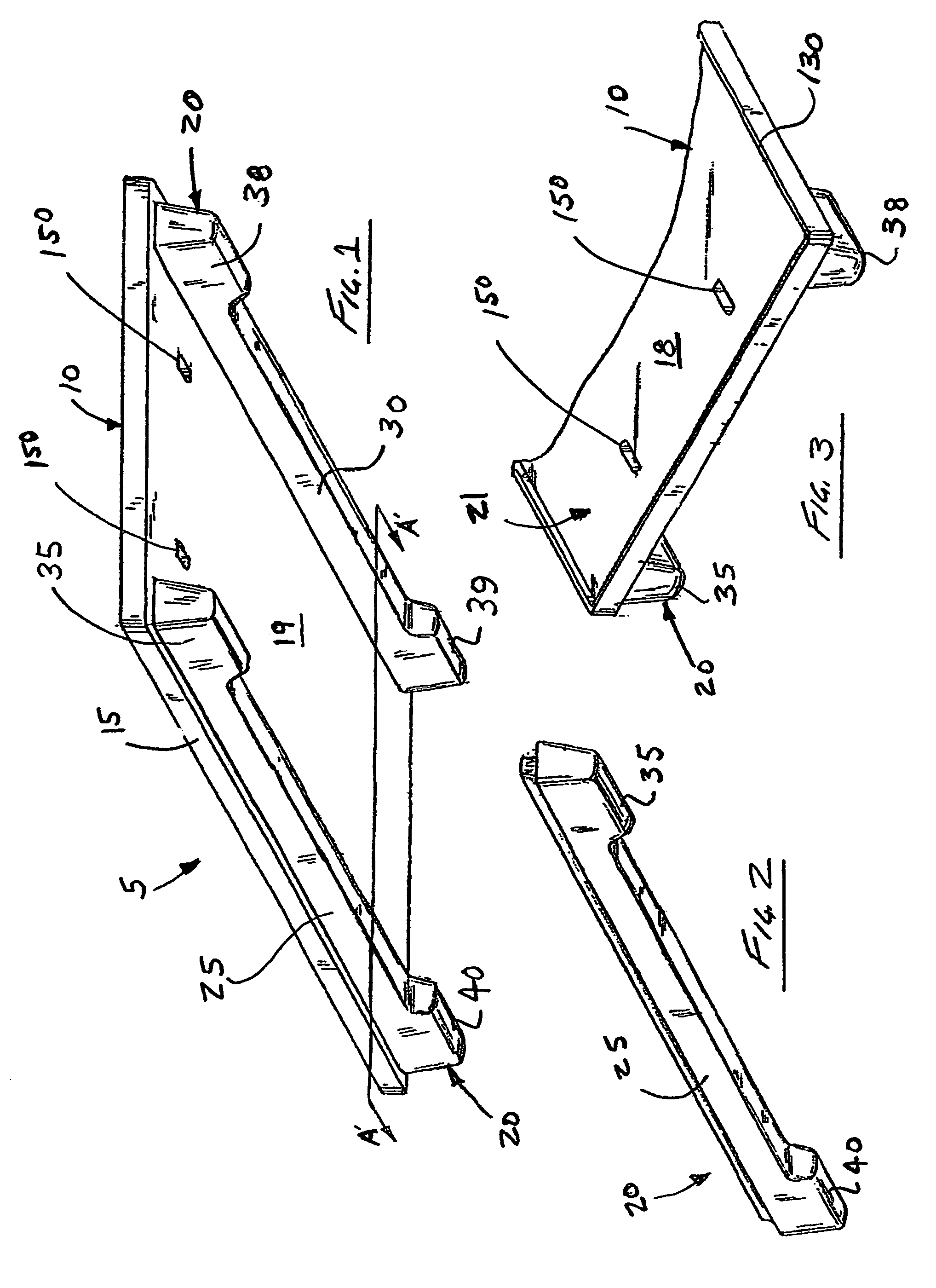

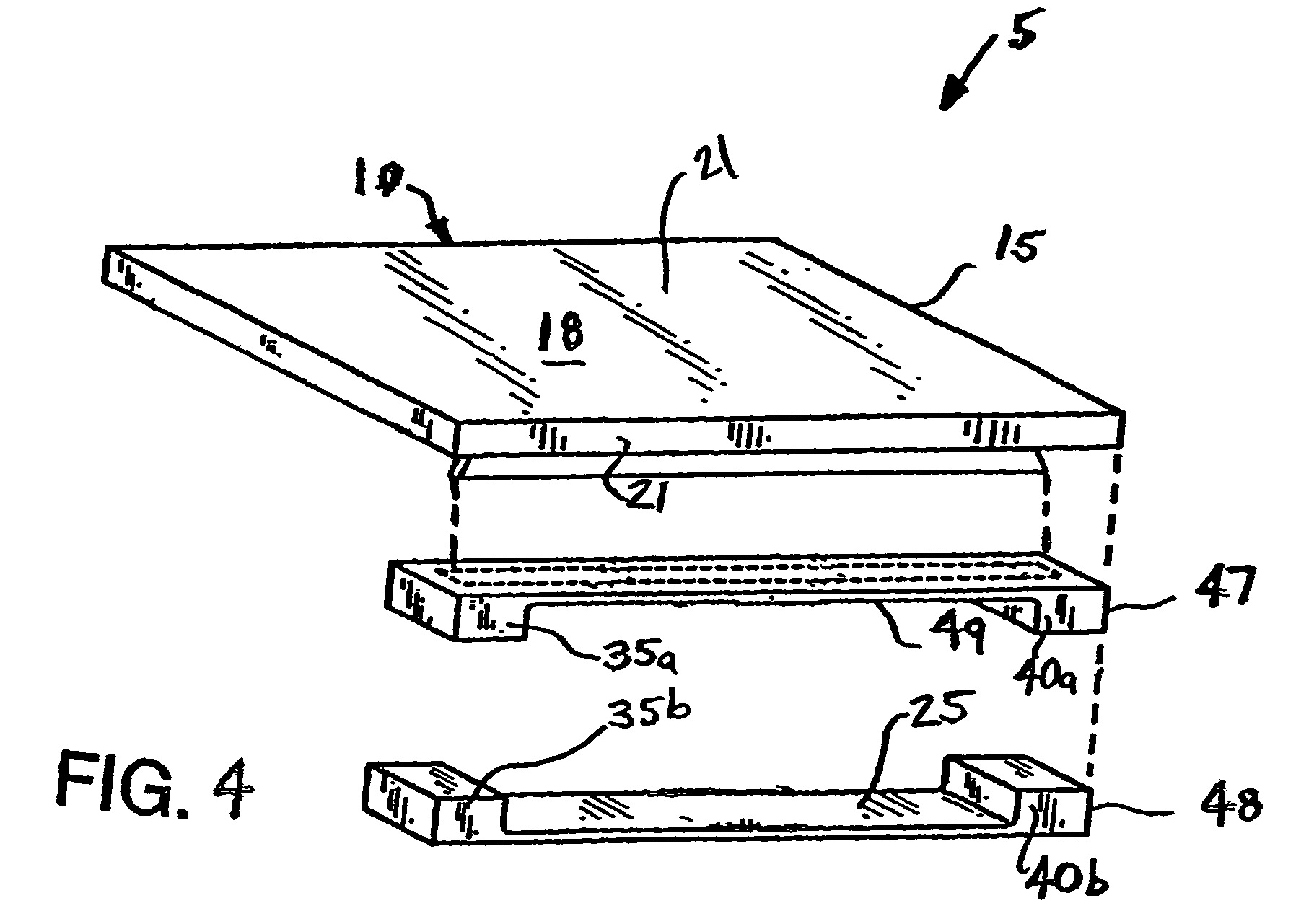

Plastic pallet

InactiveUS6216608B1Facilitate attachmentIncrease engagementRigid containersLateral positioningFastener

A plastic pallet (10) having good load bearing construction and held together without mechanical fasteners, includes deck boards (30). The deck boards include ridges (24) on an upper side (32) and a lower side (34) thereof. Deck boards are positioned transversely on stringers (12) and joined thereto by either an adhesive or thermoplastic welding processes. The stringers and deck boards may be provided with end caps (26, 42) which seal interior areas of the stringers and deck boards and prevent tearing thereof. The stringers and deck boards have interior reinforcement ribs (22,40). The cross sectional profiles of the stringers, deck boards, and end caps provide a cost effective and light weight pallet. Openings which extend between the stringers allow for either two way fork entry and / or four way fork entry. The stringers and deck boards provide flexibility in constructing pallets of various designs. The plastic pallet preferably is highly durable and fully recyclable.

Owner:POWELL JOE A

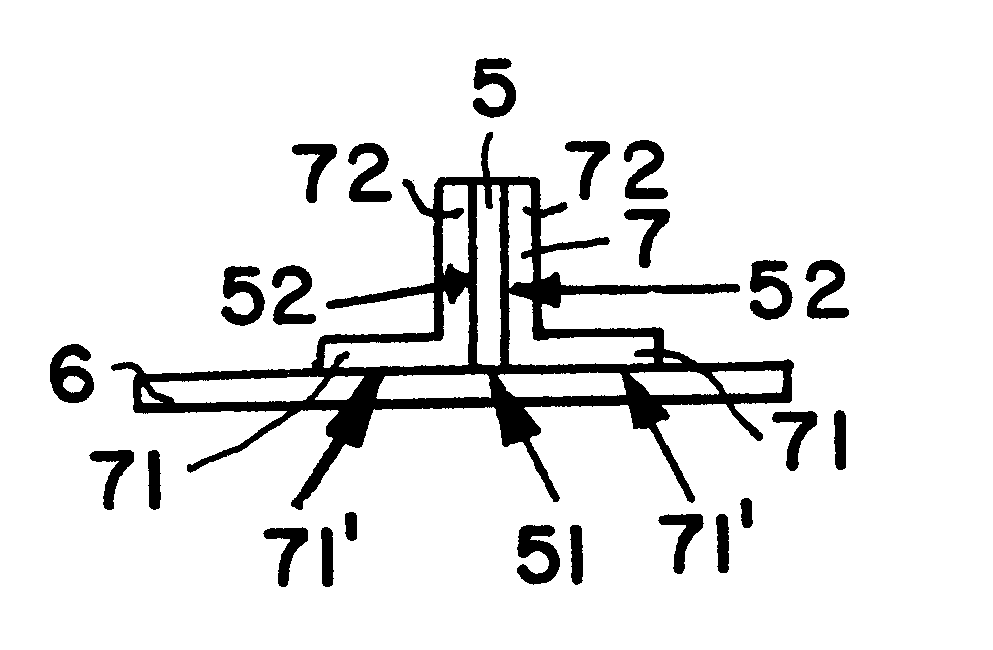

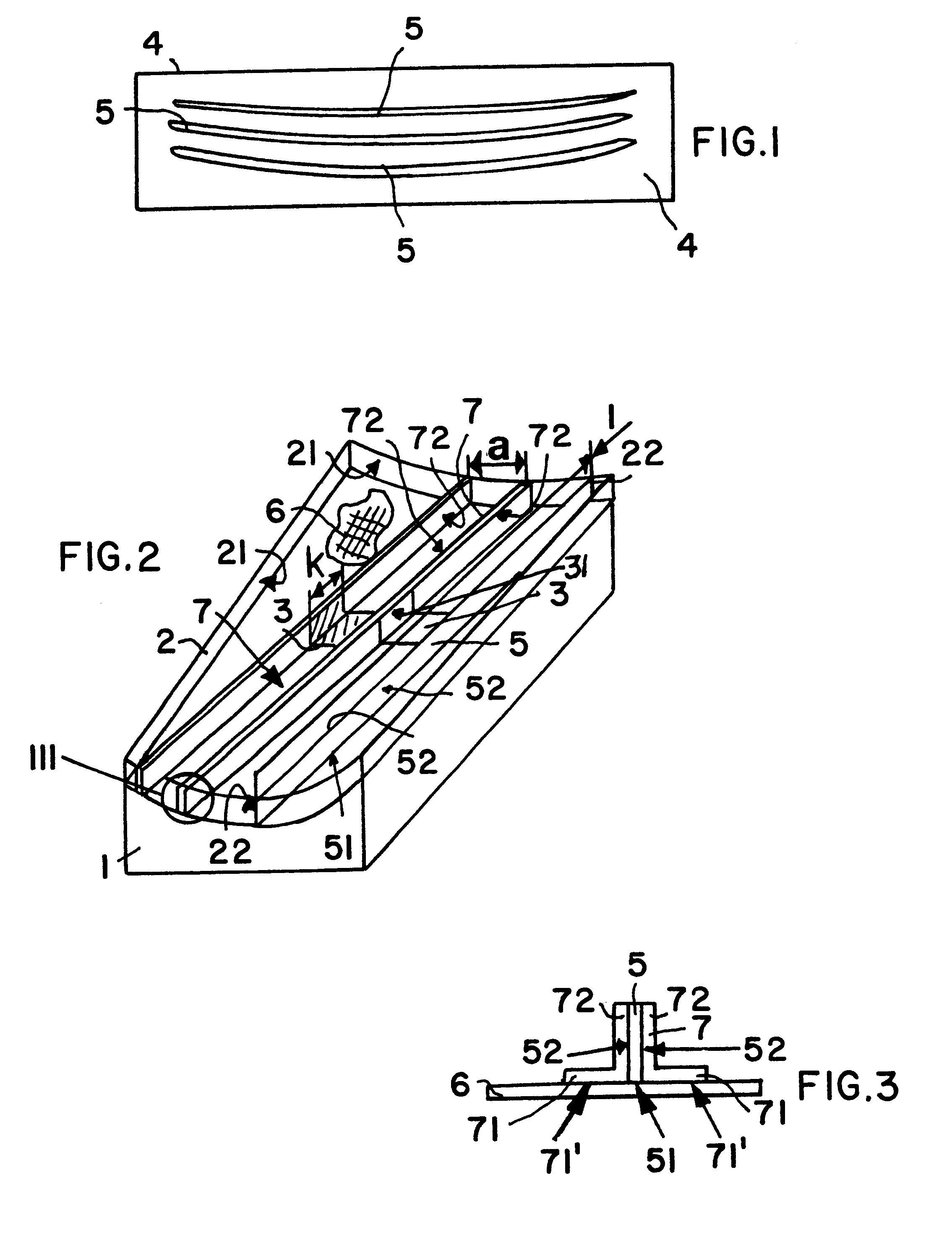

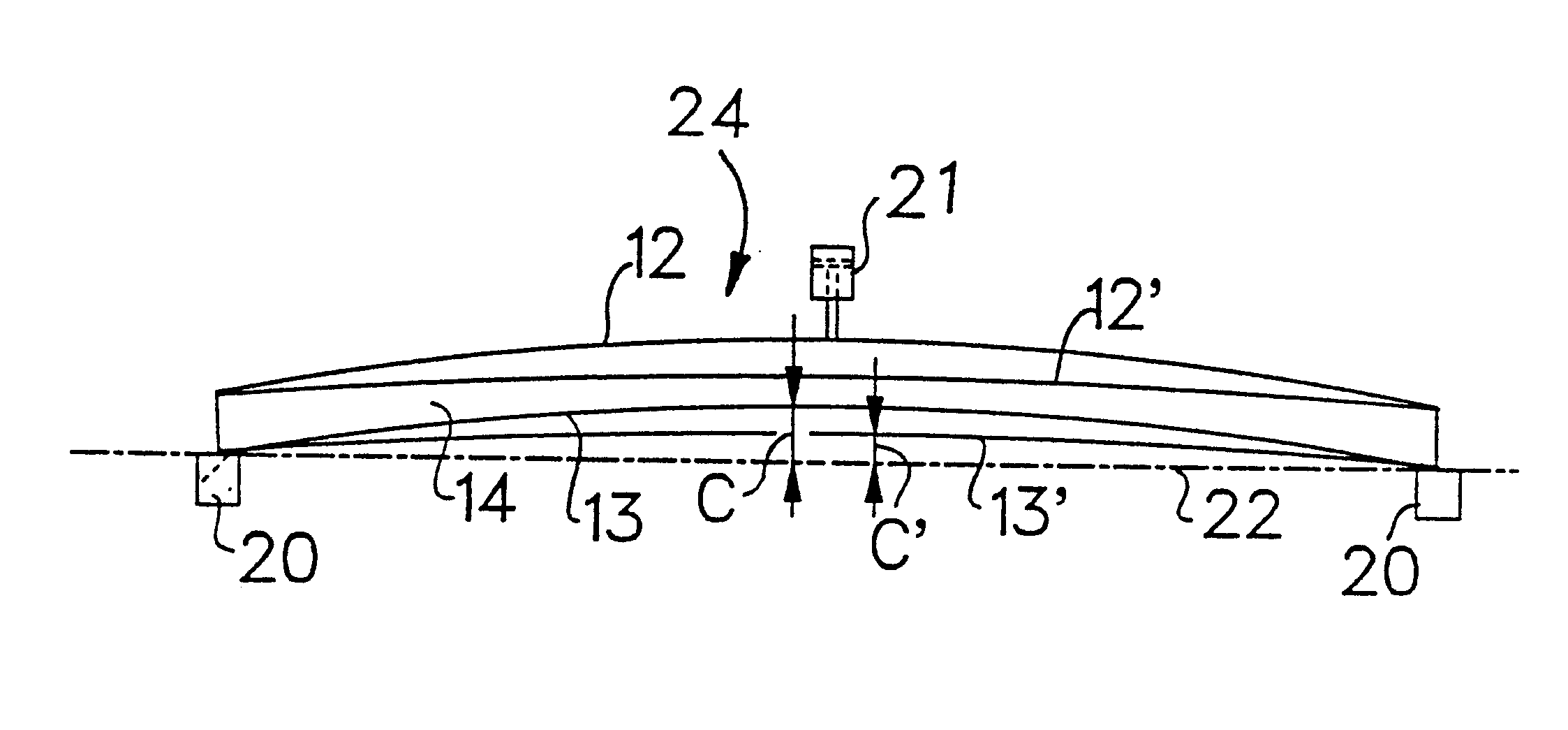

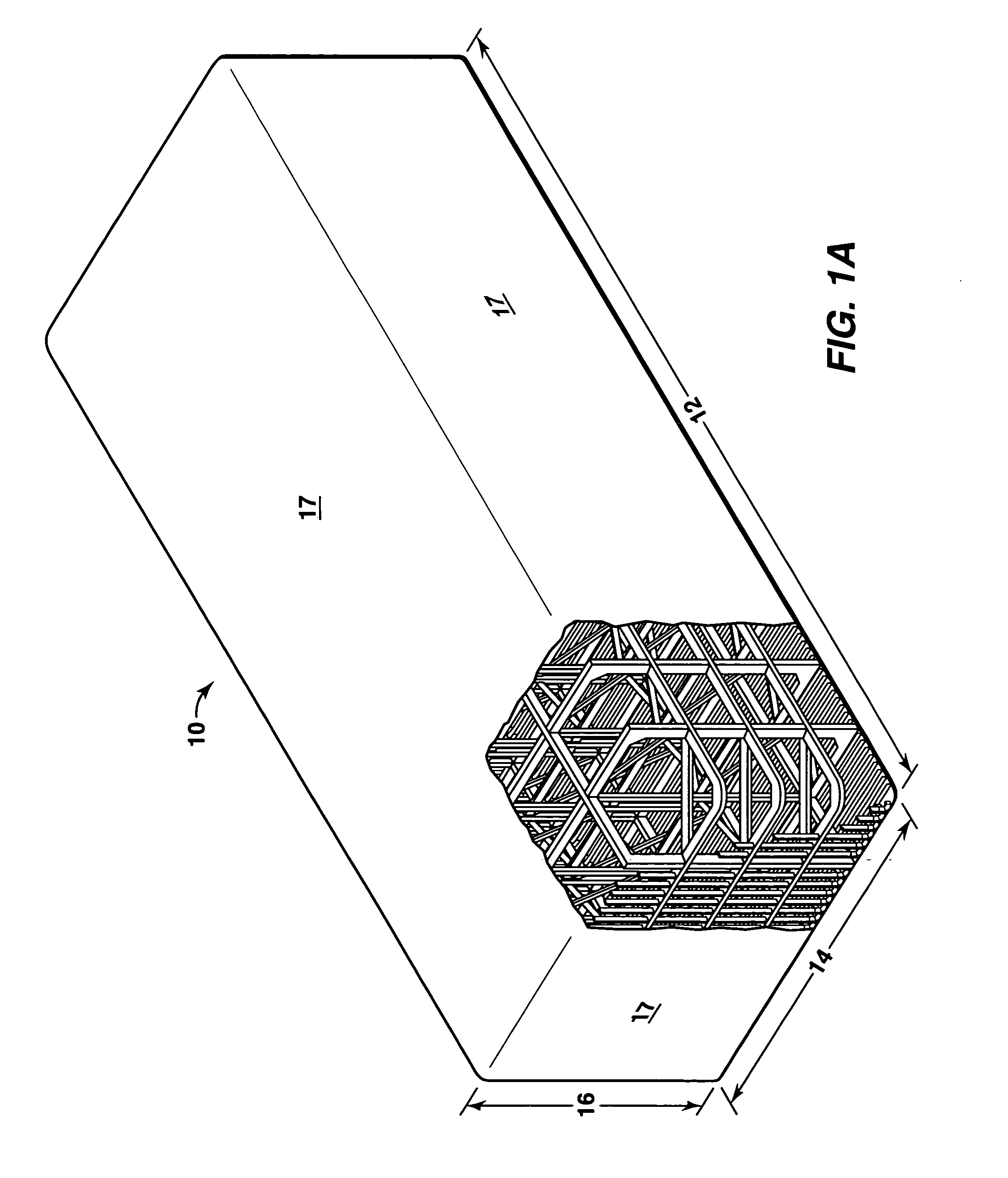

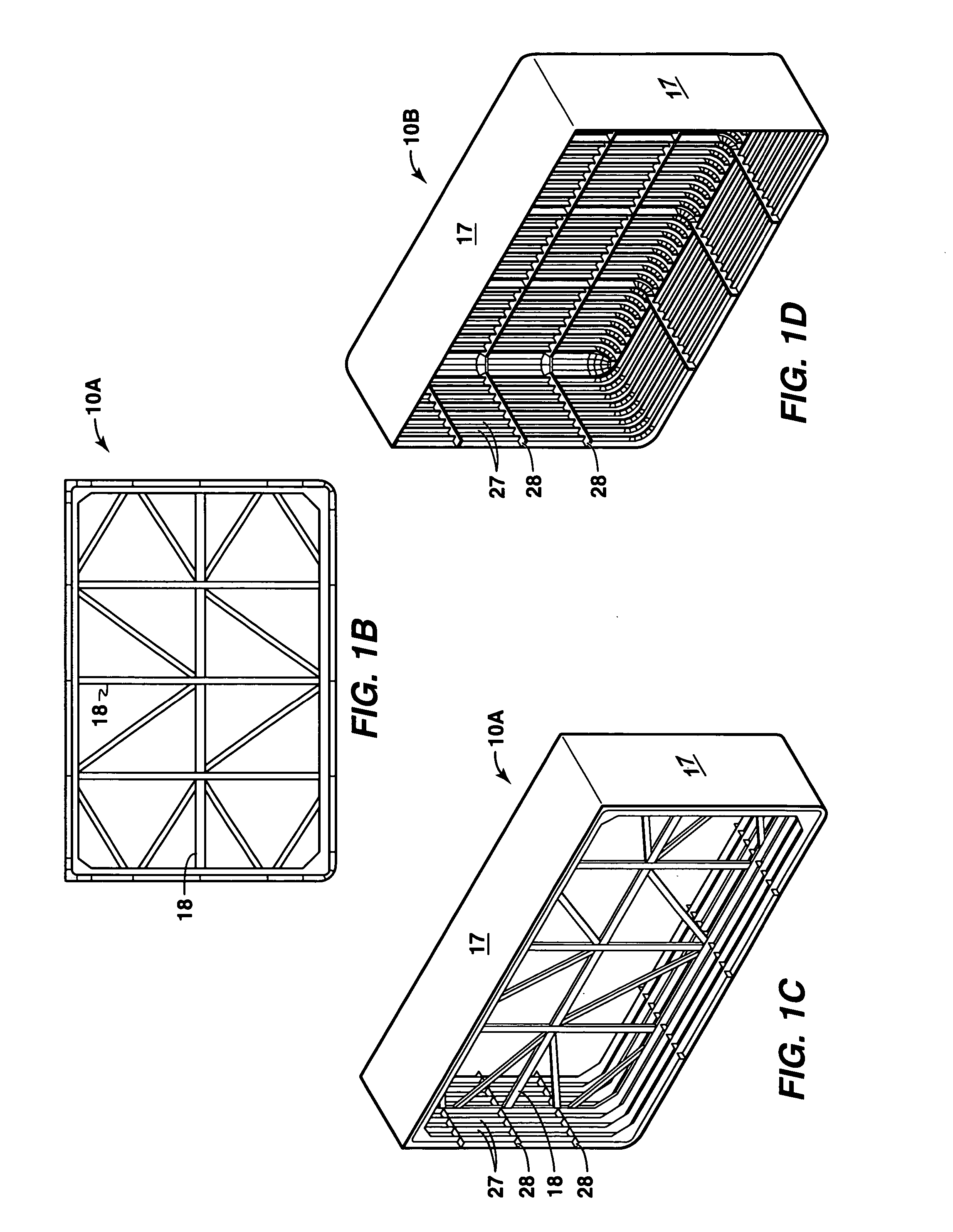

Method of fabricating a stringer-stiffened shell structure using fiber reinforced composites

A method for fabricating a stringer-stiffened shell structure using fiber composite materials involves the following steps. A fiber reinforced skin member having a specified surface curvature is laid onto a correspondingly curved mold surface of a shell mold. Stringer core blanks are cut from a cured plate of fiber composite material, whereby each blank has a narrow edge with a curvature matching the curvature of the skin member. These stiff pre-cut blanks are arranged extending along and vertically protruding from the skin member, with the narrow edges of the blanks lying in contact along the skin surface. An auxiliary frame is placed around the perimeter of the shell mold, and the ends of the stringer core blanks are received in slots in the frame to hold the blanks in proper positions. Then, stiffening profile members are laid lengthwise along and against the stringer core blanks and the adjoining areas of the skin member, whereby these profile members are made of uncured fiber composite material so that they are easily deformable along the skin member and the stringer core blanks. The assembled structure is pressurized and cured so as to integrally bond the components to each other and fully cure and harden all of the components. A stiffening stringer of the finished structure is formed by a respective stringer core blank sandwiched between two adjoining stiffening profile members.

Owner:DAIMLER CHRYSLER AEROSPACE AIRBUS

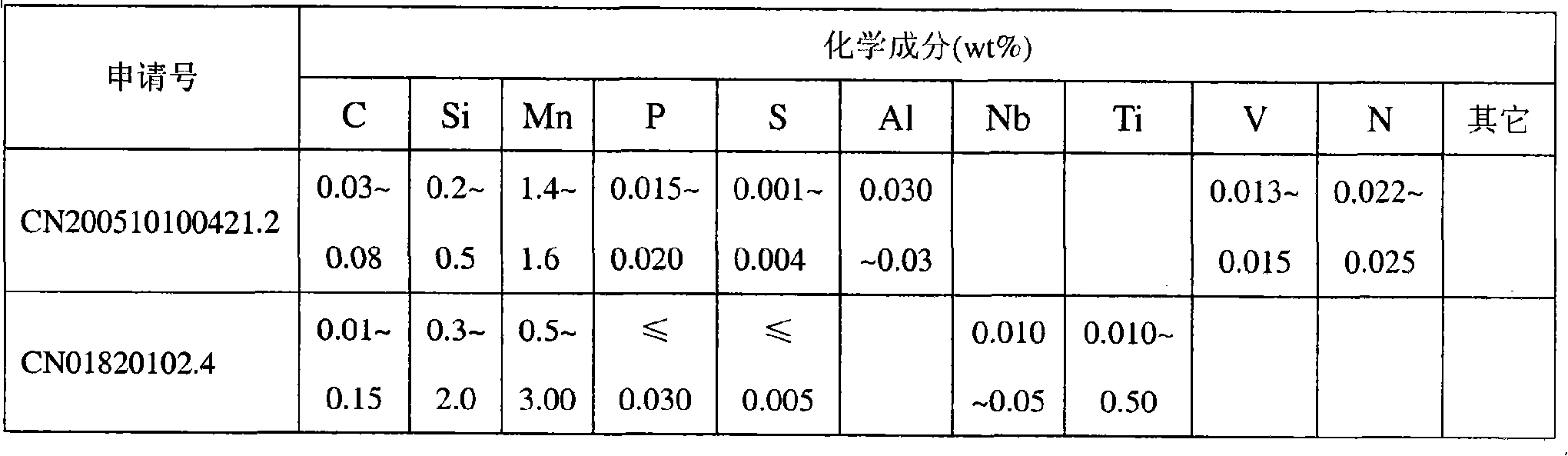

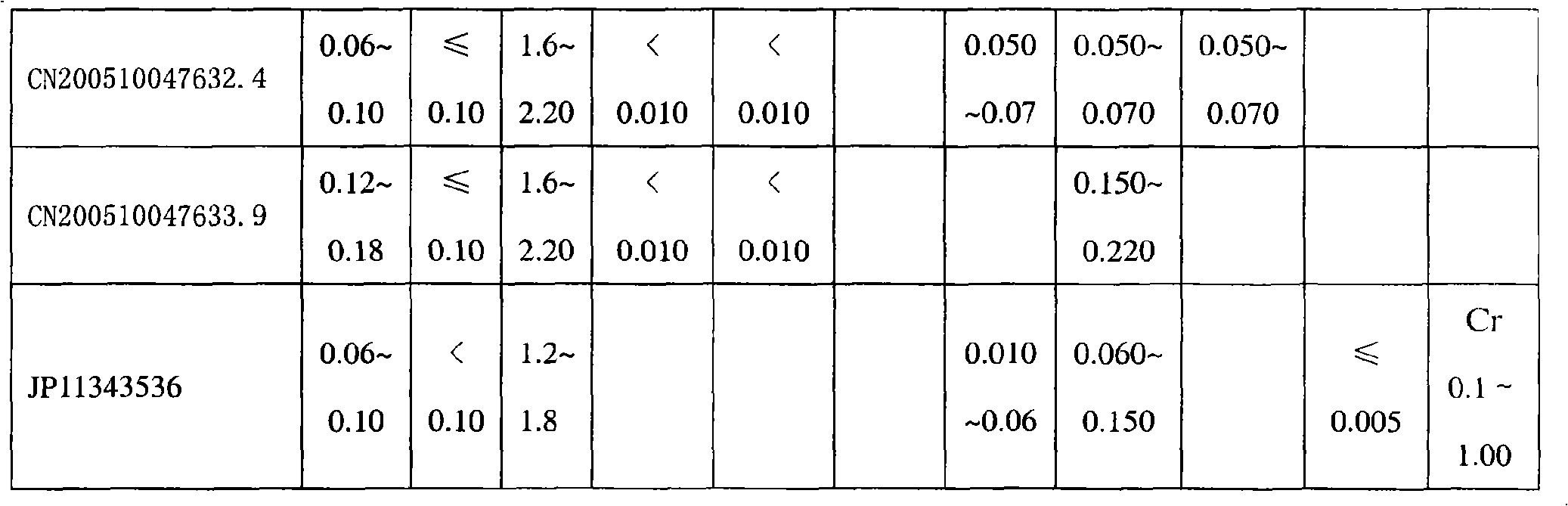

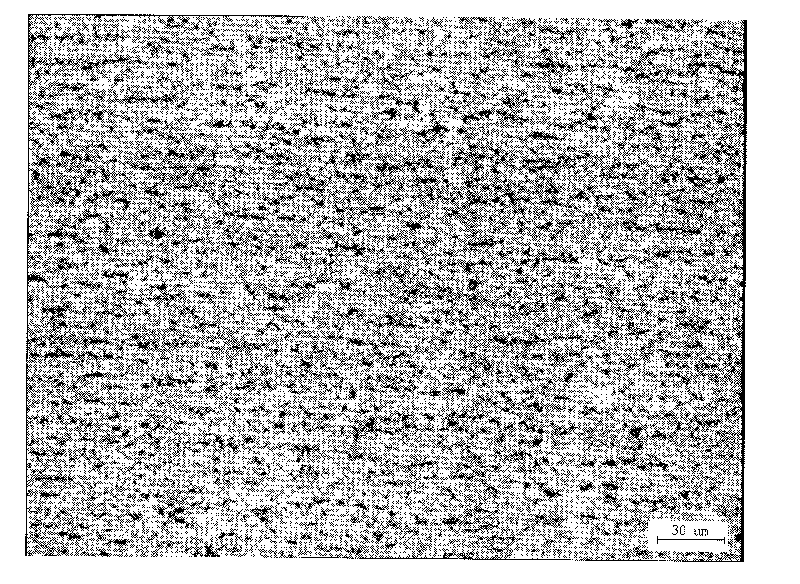

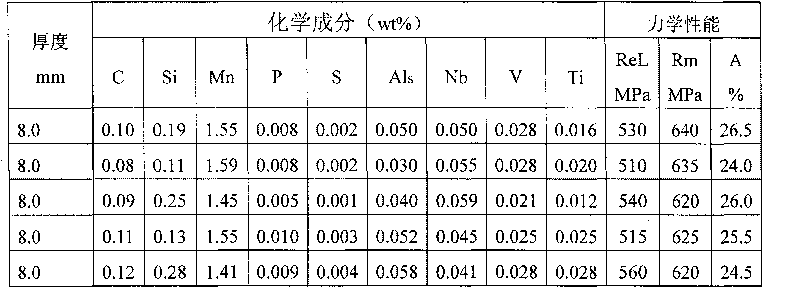

High-strength hot rolling automotive frame steel plate and manufacturing method thereof

InactiveCN101565794AEasy to produceLose weightTemperature control deviceMetal rolling arrangementsChemical compositionSheet steel

The invention provides a high-strength hot rolling automotive frame steel plate which comprises the following chemical components according to the weight percent: 0.05 to 0.10 of C, less than or equal to 0.10 of Si, 1.1 to 1.85 of Mn, less than or equal to 0.025 of P, less than or equal to 0.0030 of S, 0.015 to 0.060 of Al, less than or equal to 0.0060 of N, 0.015 to 0.050 of Nb, 0.015 to 0.150 of Ti, less than or equal to 0.0050 of Ca and the balance of Fe and inevitable impurities. The invention also provides a manufacturing method of a steel plate, comprising rolling control and cold control processes. By adopting the chemical components and reasonable production process, the yield strength of the hot rolling automotive frame steel plate can reach the grade of 550-700Mpa; and the hot rolling automotive frame steel plate has excellent cold forming performance and higher fatigue strength and is suitable for manufacturing longitudinal beams and cross beams of an automotive frame and other members.

Owner:BAOSHAN IRON & STEEL CO LTD

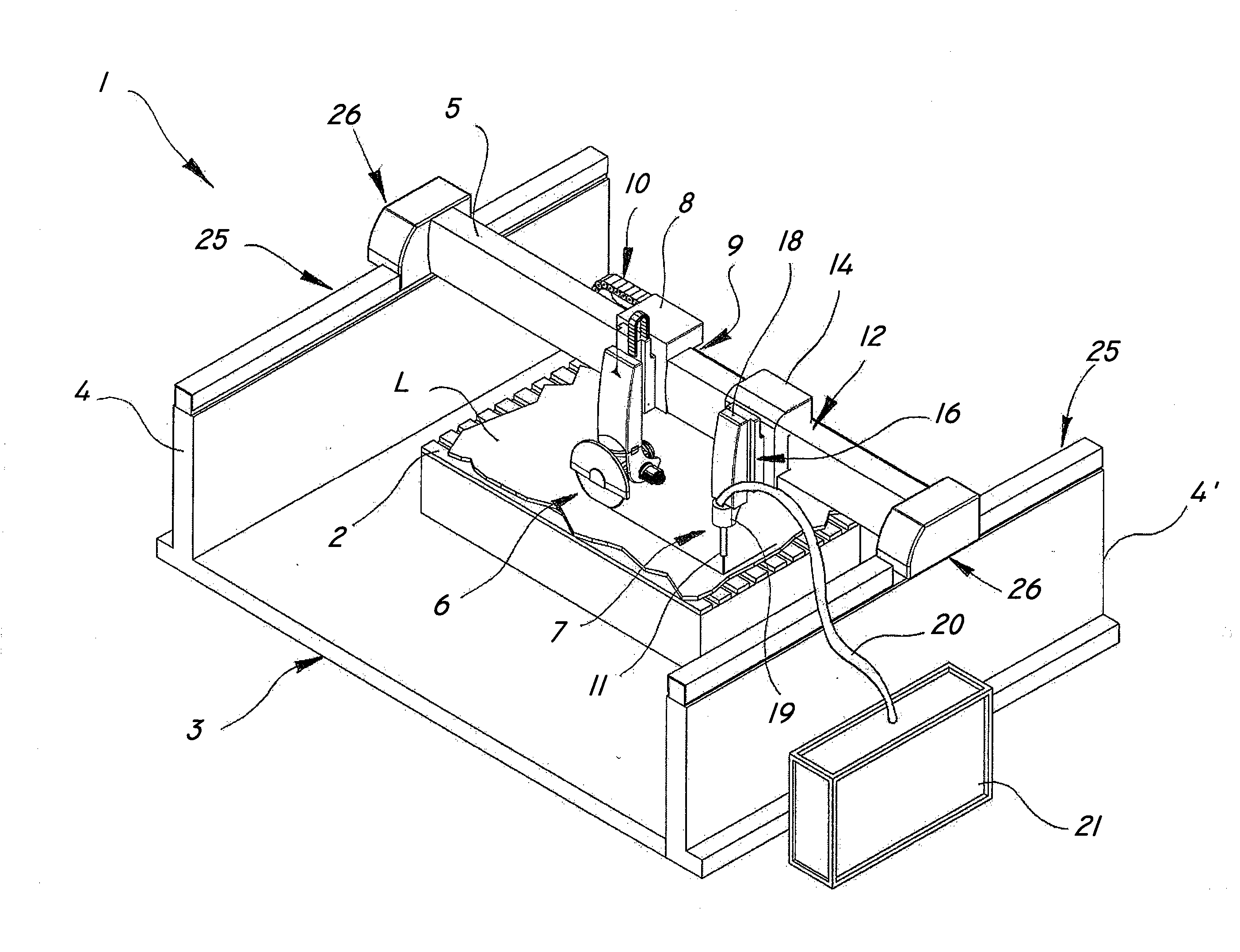

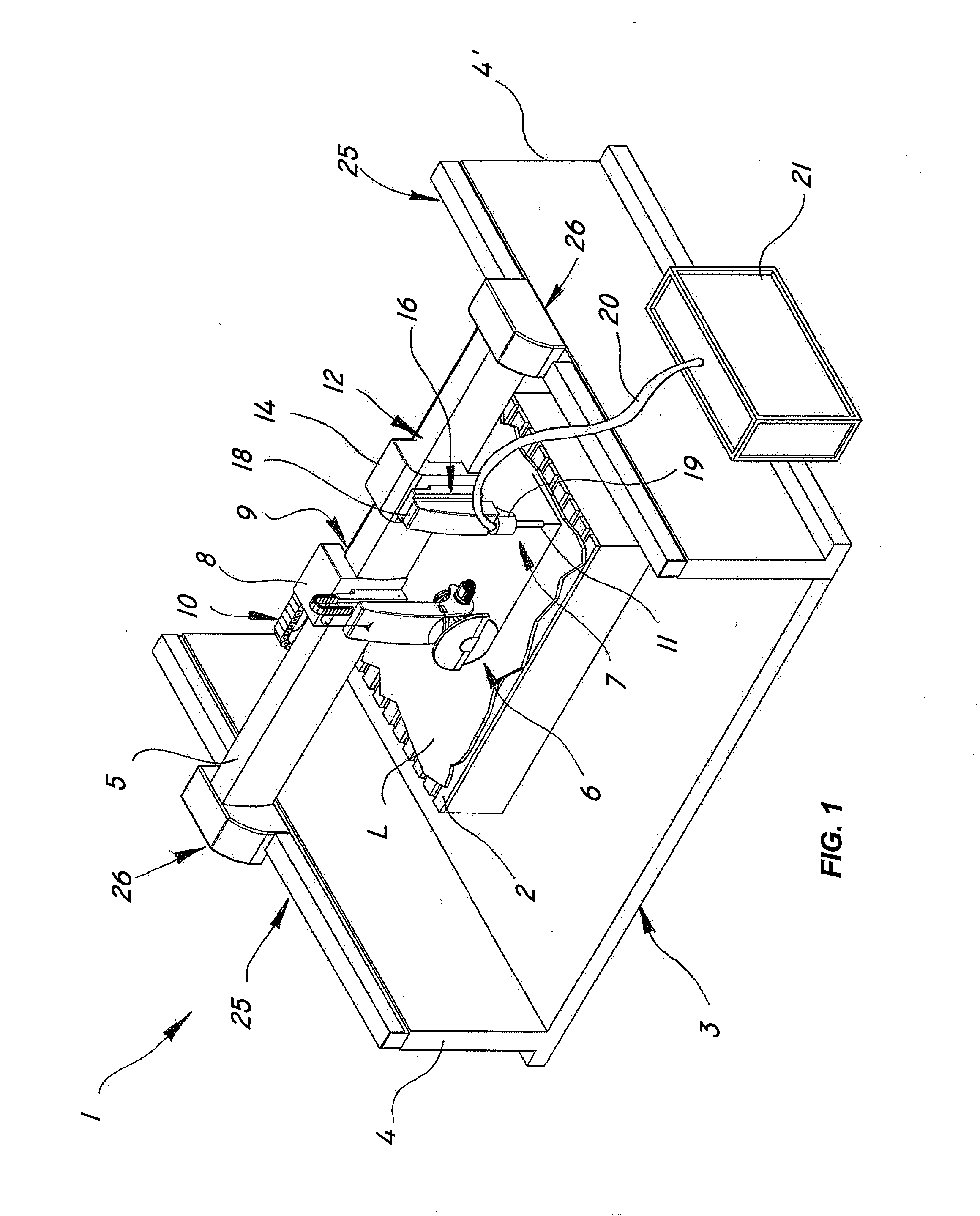

Multiple-tool machine for combined cutting of slabs of hard material

InactiveUS20080110311A1Improve efficiencyCost effectiveMetal sawing devicesGuide fencesClassical mechanicsStringer

The present invention relates to processing of hard materials, and more particularly relates to a multiple-tool machine for the combined cutting of slabs of hard materials such as stone, marble, granite, concrete, wood, metal, glass and the like. One embodiment of the present invention includes a support surface for receiving a slab; a load-bearing frame with a longitudinal beam extending over the support surface; a first disk blade cutting tool mounted on a first slide and movable along a first guide connected to the beam; a first motion imparting device for moving the first slide; a second cutting tool with a nozzle for high-pressure waterjet cutting, which is mounted in sliding relationship to a second guide coupled to the beam; and a second motion imparting device, other than the first motion imparting device, for translating the second cutting tool independently of the first cutting tool.

Owner:SIMEC SPA

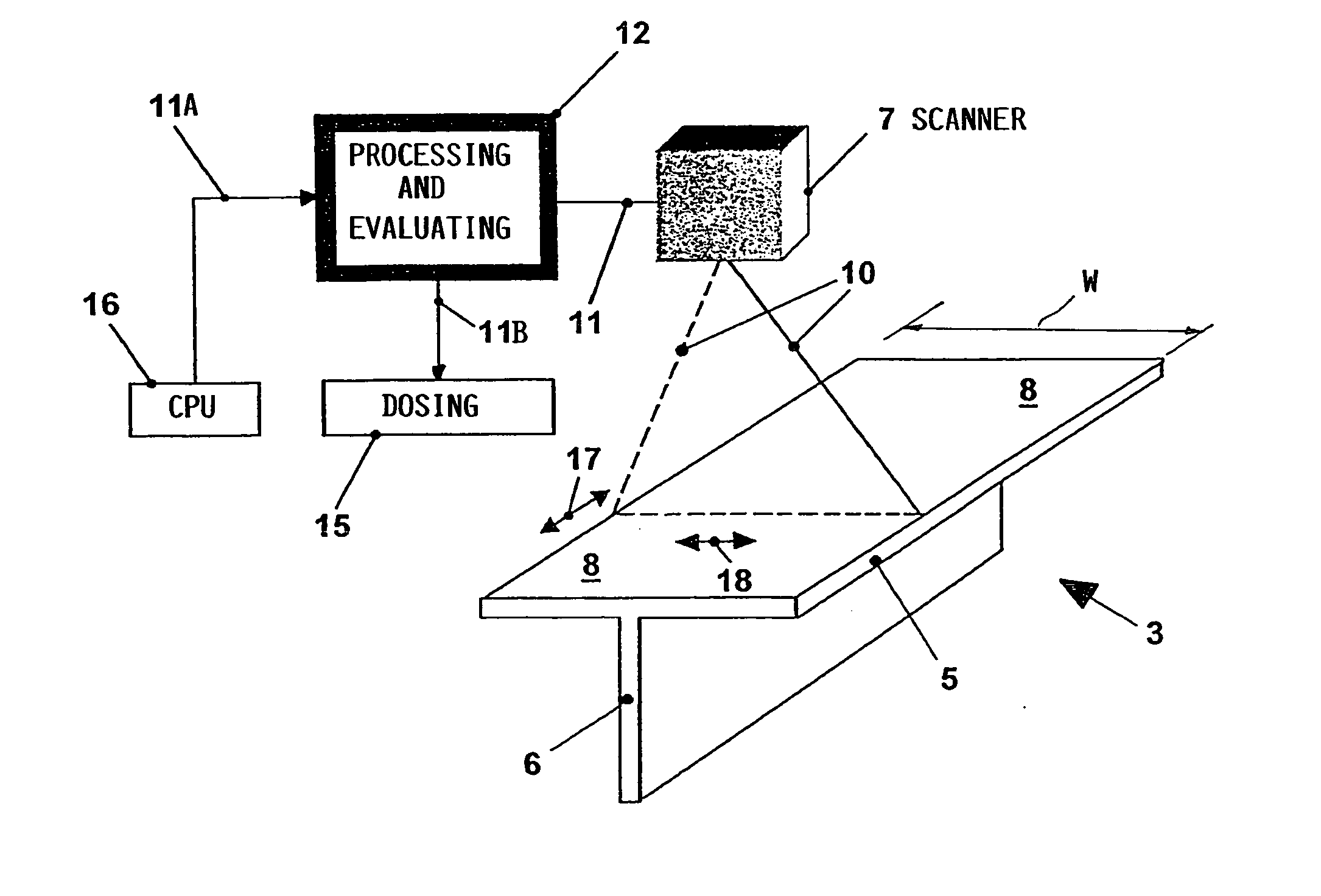

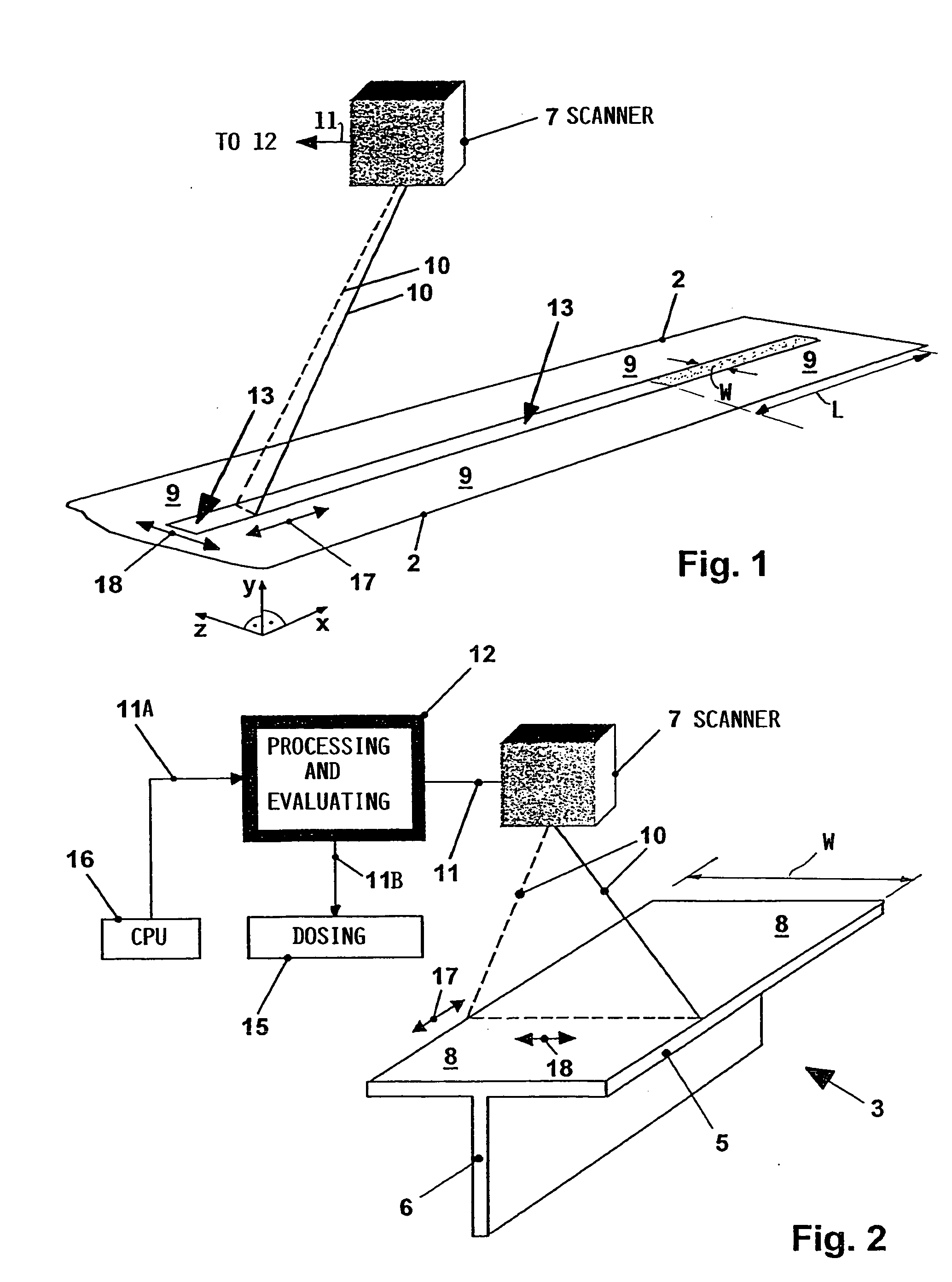

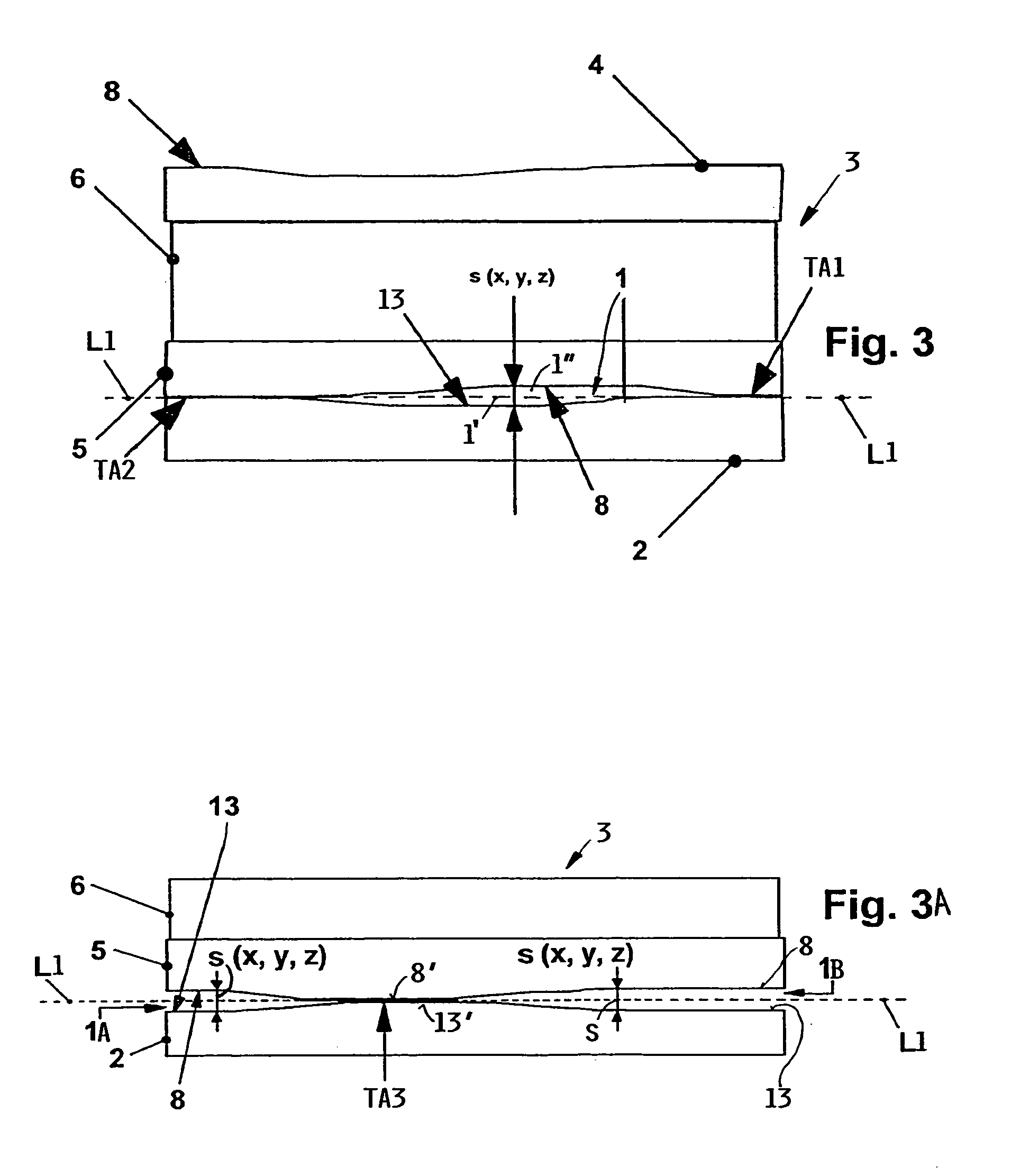

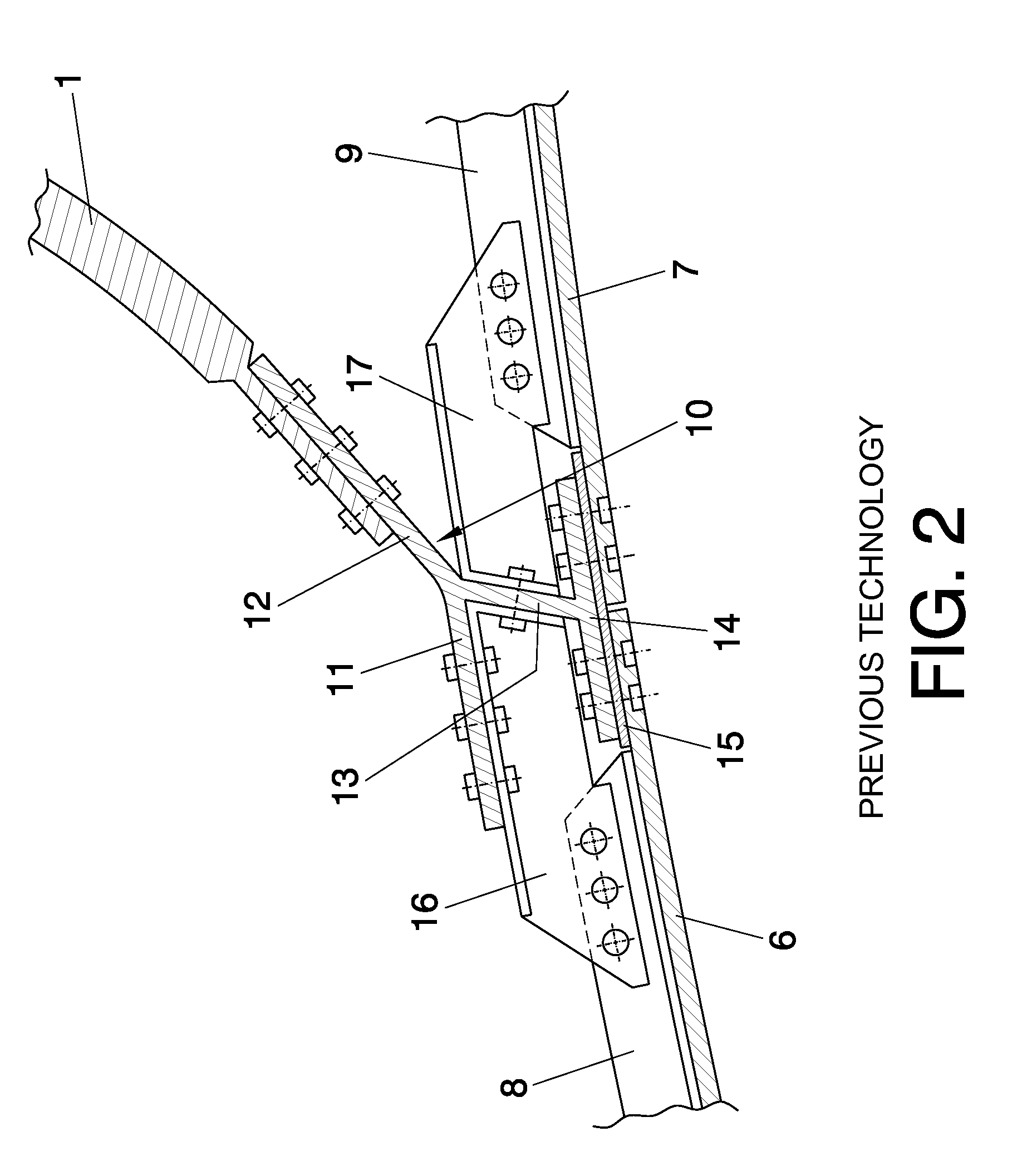

Method for avoiding air pockets in a joint between two structural components

InactiveUS20040236454A1Inhibition formationReduced dimensionLamination ancillary operationsLaminationFilling materialsControl signal

When two structural components are to be joined, for example, when an aircraft skin section is to be secured to a stringer by an adhesive bonding, it is important that the joining surface areas are plane to avoid the formation of air inclusions in the joint because air inclusions weaken the mechanical strength of the joint. Thus, a surface topography that is not plane must be smoothed out prior to the joining. For this purpose the surface areas to be joined are optically scanned to provide topographical information for each surface area that needs to be smoothed out for providing a plane joining surface. The topographical information is processed to ascertain the configuration and volume of the surface topography that needs to be filled with a filler material to produce a plane surface or at least a smooth surface without hills and dales. A respective control signal is produced and fed to a dosing equipment which supplies the exact volume of filler material required for planing or smoothing the surface topography. When smoothing is completed the two components are ready for joining for example by the application of pressure and heat to the filler material.

Owner:AIRBUS OPERATIONS GMBH

Containers

A method of assembling a platform-based container comprising a base having at least one longitudinal beam, wherein the method comprises pre-loading the longitudinal beam, prior to the completion of the assembly of the container. The beam is then used in the assembly of the container, resulting in a container which no longer takes a permanent deformation under maximum load.

Owner:CLIVE SMITH COWLEY

Aircraft pressure bulkhead assembly structure

InactiveUS20100243806A1Eliminate needAvoid the needEfficient propulsion technologiesFuselage bulkheadsAirplaneFuselage

The structure comprises: a rim angle (22) with a front portion and a rear portion, the latter being slanted upward and backward and connected to the bulkhead (1); a simple frame (18), being connected to the front portion of the bulkhead (22); a buttstrap (23), being connected between the front portion of the rim angle (22) and the skin (6, 7) of the fuselage of the aircraft; and tension fittings (24, 25), being fitted between the buttstrap (23) and the longitudinal stringers (8, 9) of the fuselage.

Owner:AIRBUS OPERATIONS SL

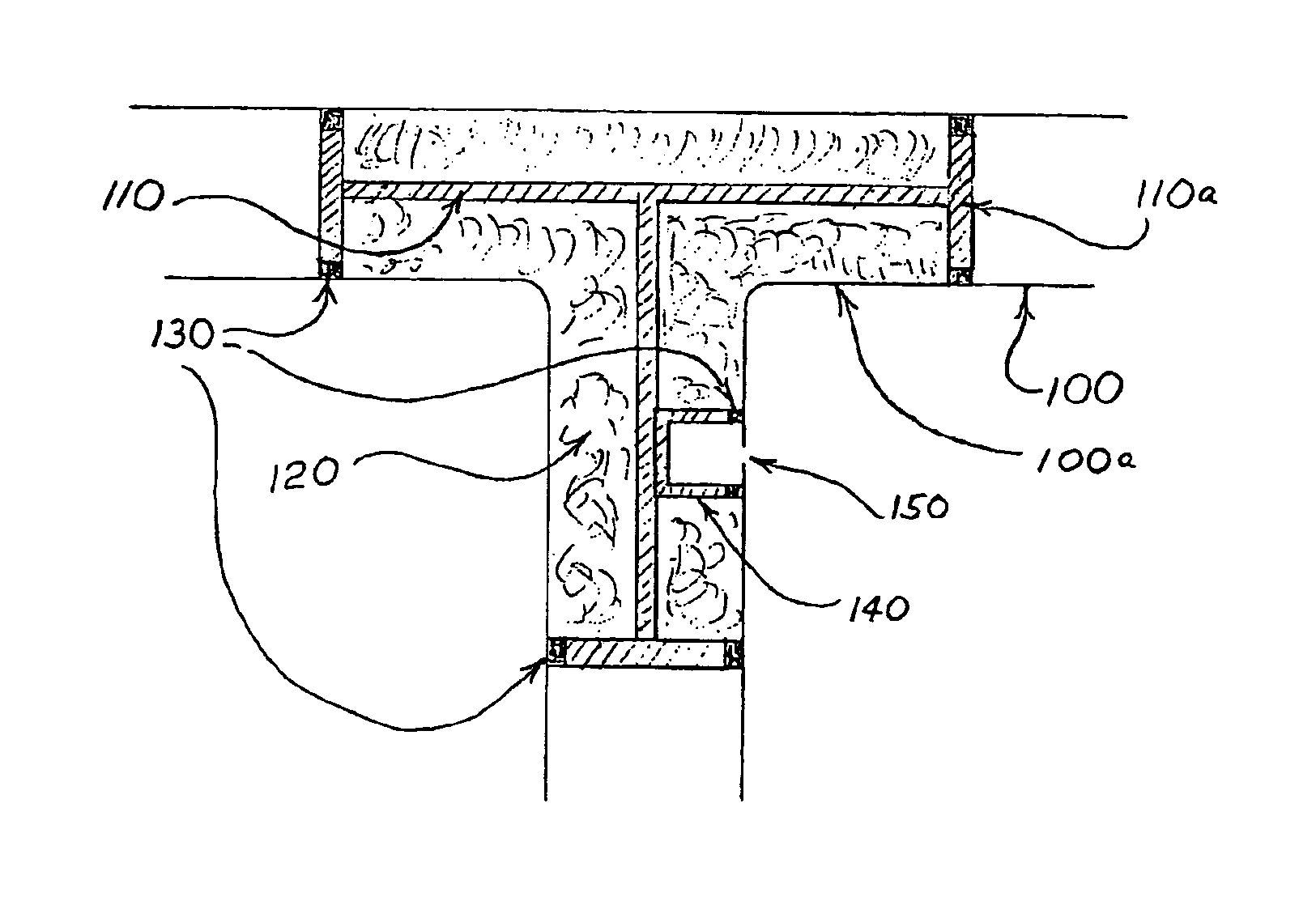

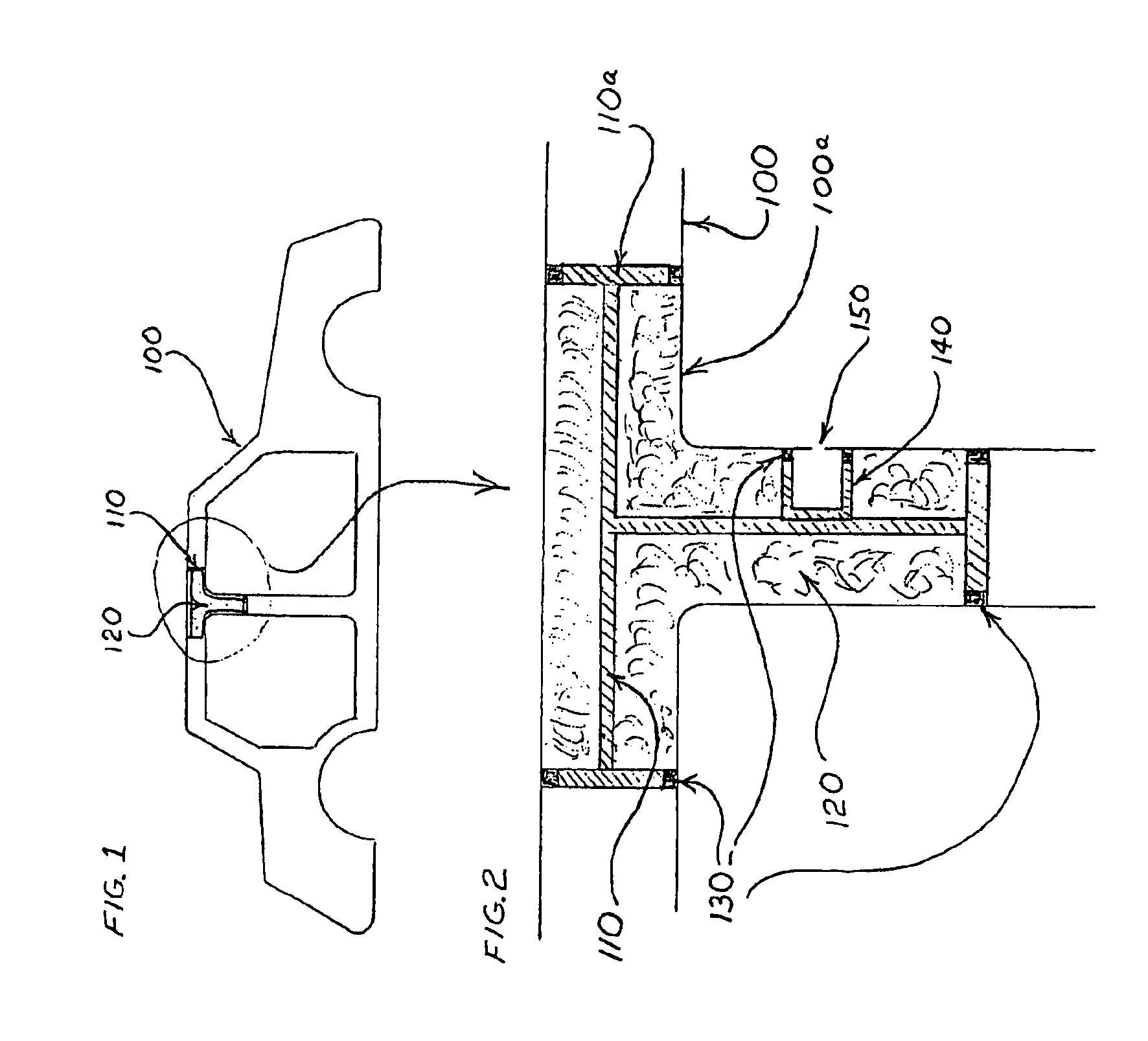

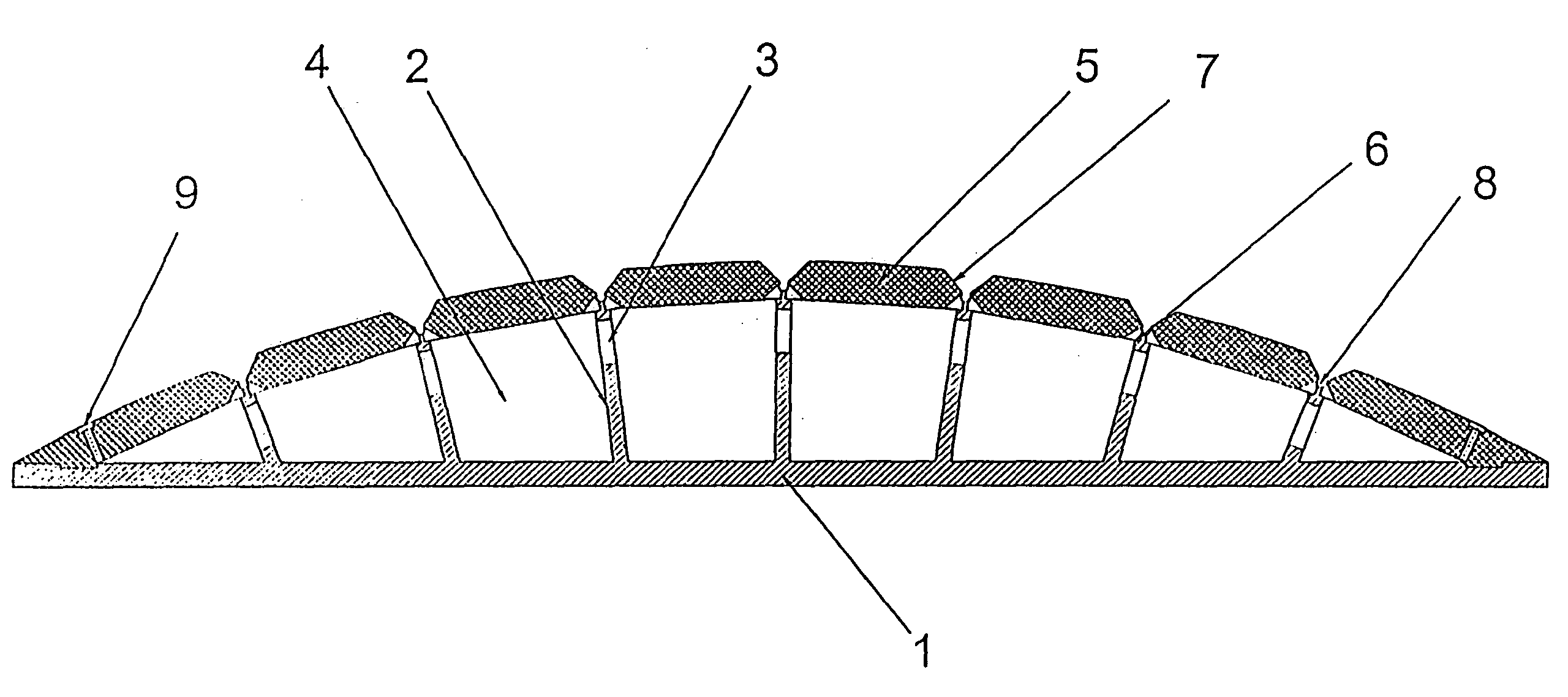

Reinforced structural body

InactiveUS6866331B2Consume energySimple structureVehicle seatsSuperstructure subunitsVehicle frameEngineering

The present invention describes a hollow structural body such as an automotive unibody or frame rail that is reinforced with a reinforcing material such as a polyurethane foam by inserting into a portion of the structural body a bulkhead-containing insert, which, in combination with the structural body at the place of insertion, creates a containment region for the reinforcing material. Uncured reinforcing material can then be added to the containment region and cured.The present invention solves a problem in the art by providing structural reinforcement to be easily and precisely placed within the structural body to provide, for example, enhanced crash resistance or improvements in acoustical properties.

Owner:DOW GLOBAL TECH LLC

Steel for extended automobile crossbeam and mfg, method thereof

This invention relates to a king-sized automobile crossbeam using steal and its manufacturing method, tiny alloy elements of Nb, Ti, V are added in the steal. Their weight percentage is that C 0.07-0.12, ,Si 0.15-0.40, Mn 1.00-1.50,P less than 0.025,S less than 0.015,Nb 0.020-0.050,V 0.025-0.050, Ti 0.010-0.030,and tiny Ca, the rest are iron and other tiny impurities. Board butt is continuous cast, rolling and cooling control technique are used in hot rolling, the butt is heated to 1180-1250 degree centigrade, the temperature is 1020 to 1060 degree centigrade after rough rolling. Then it is finish rolled through blimp, the rolling temperature is maintained at 840 to 880 degree centigrade, the coiled sheet is cooled to 560 to 620 degree centigrade through laminar flow cooling. Because of the multiple unit tiny alloy elements design of the material chemical element, strong strength is got after above process and with good plastic laminar flow, cool formability, so it is specially propitious to king-sized automobile crossbeam making of cladding forming technique.

Owner:宝钢集团上海梅山有限公司

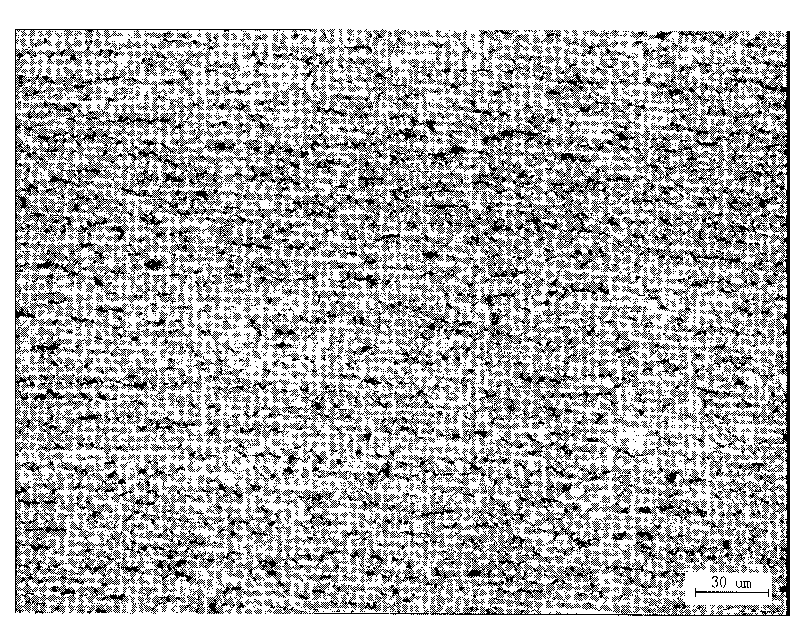

610MPa automobile girder steel and production method thereof

ActiveCN101748329AGood low temperature impact propertiesTemperature control deviceChemical compositionRoll forming

The invention discloses a 610MPa automobile girder steel, and the weight percentage (wt%) of the chemical composition of the steel is as follows: C: 0.08 to 0.12; Si: 0.10 to 0.30; Mn: 1.40 to 1.60; P: less than or equal to 0.010; S: less than or equal to 0.005; Nb: 0.040 to 0.060; V: 0.020 to 0.030; Ti: 0.010 to 0.030; Al: 0.030 to 0.060; Ca: tiny amount; and the rest is iron and residual trace impurities. The invention also discloses a production method for the 610MPa automobile girder steel, which adopts a 2250mm hot rolling line, and a continuously cast slab is heated to 1200 DEG C to 1250 DEG C; after rough rolling, the temperature is 1000 DEG C to 1050 DEG C, the continuously cast slab enters a finishing mill via a heat cover and is rolled, the finish rolling temperature is 820 DEG C to 880 DEG C, and the rolled steel coil is rapidly cooled to 530 DEG C to 580 DEG C by way of laminar cooling, and is then coiled. Since the chemical composition and the production technique are adopted, the tensile strength of an automobile girder is larger than 610MPa, the yield strength is larger than 500MPa, the specific elongation is larger than 20 percent, minus 60 DEG C longitudinal impact energy AKV is larger than 70J, and the automobile girder has excellent cold formability and high fatigue strength. The product is applicable to heavy-duty automobile members such as side members and cross members, which are produced by cold-roll forming and stamping forming techniques.

Owner:MAANSHAN IRON & STEEL CO LTD

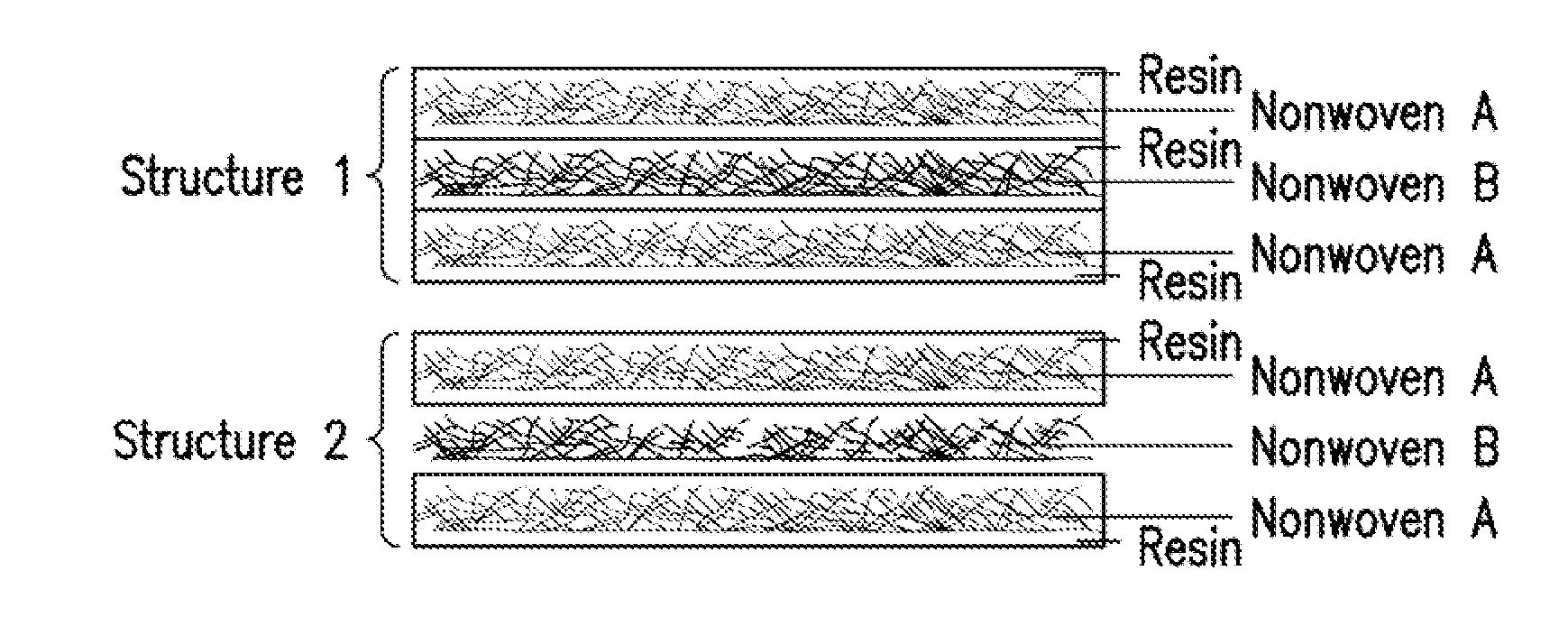

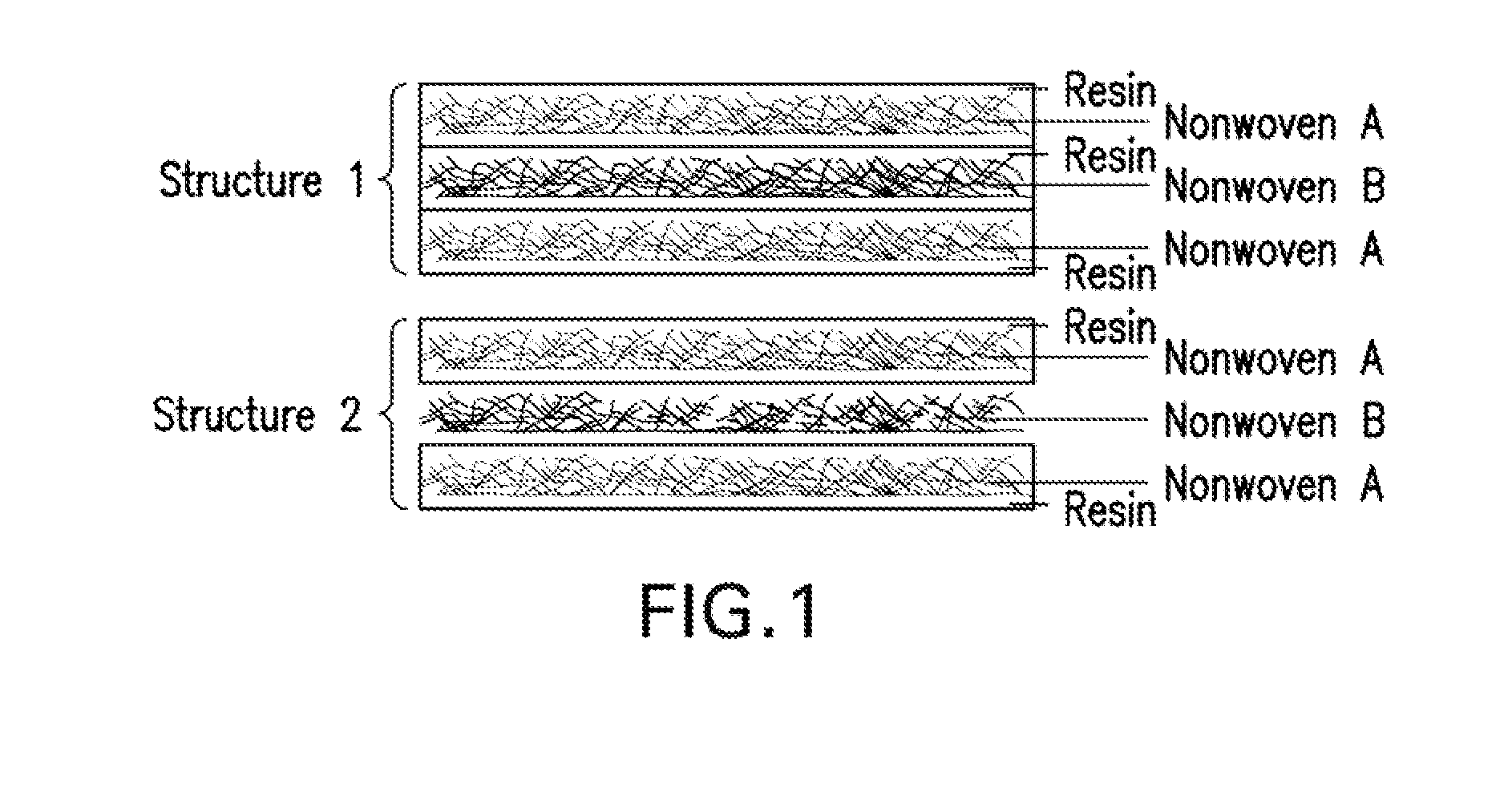

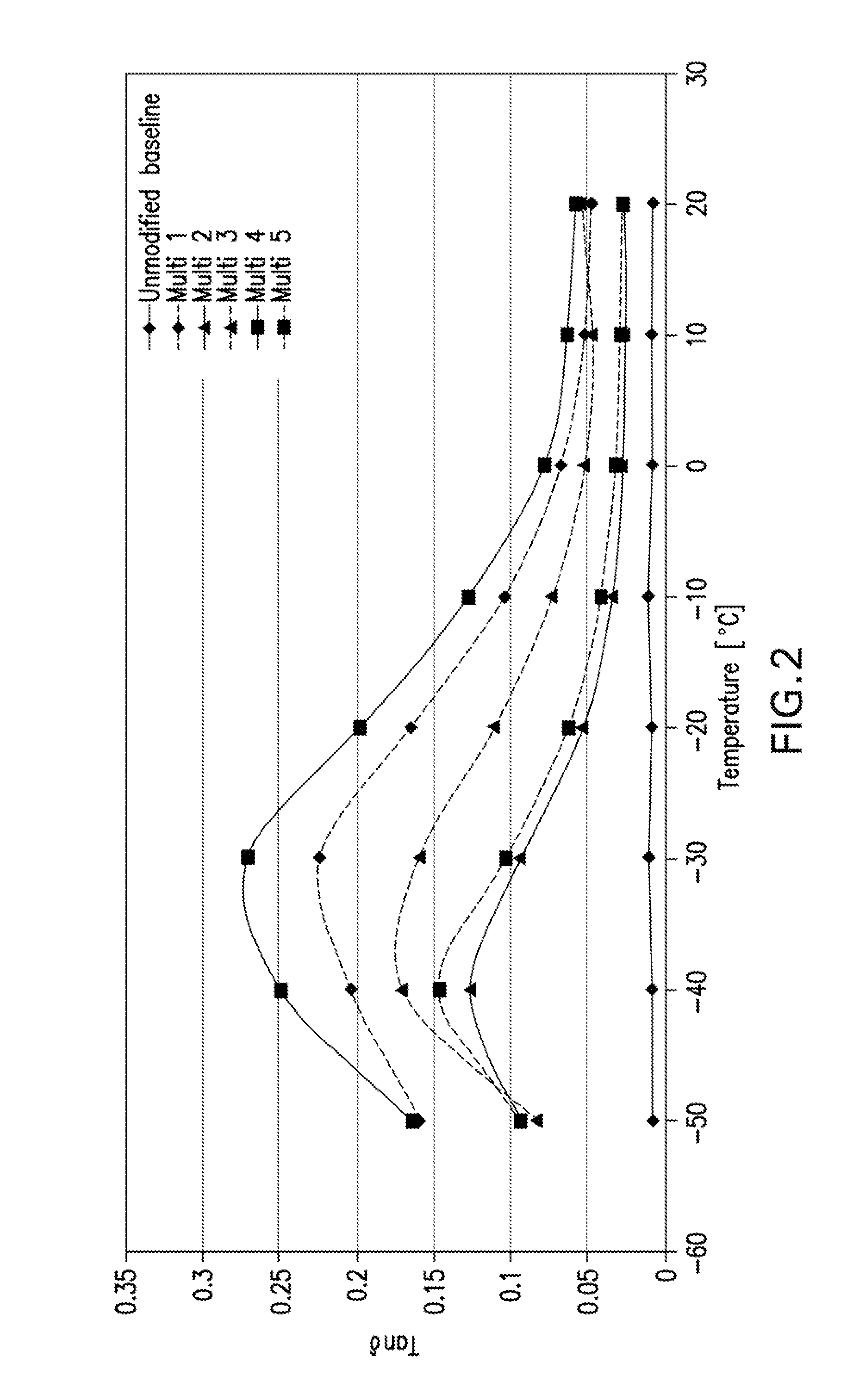

Multilayer and composition gradient structures with improved damping properties

Composite materials having favorable acoustic and vibration damping properties, while maintaining or improving other composite mechanical properties, include an interleaf layer comprising at least two different nonwoven materials in a specific sequence such that a gradient is formed in the z direction upon curing or an interleaf with a compositional gradient within its structure such that a resin interpenetration gradient is achieved upon curing. Composite materials that contain multilayered nonwoven interleaves are useful, for example, in structures found in aircrafts, such as fuselage skins, stringers and frames. Also contemplated are methods of making the composite material and the structures and aircrafts that contain the composite material.

Owner:CYTEC TECH CORP

Corrugated pallet

InactiveUS20050247240A1Improve carrying capacityHigh stackingsContainer decorationsLevel indicationsAdhesiveEngineering

A shipping pallet compatible with fork-lifts and pallet-trucks is made from stamped or die cut flat corrugated board. Stringer and cross-braces form an interlocking grid work to which a top and bottom flat sheet are attached by an adhesive. The pallet may be recycled as paper and not returned to the sender. Additional reinforcement structures may be added for heavier loads.

Owner:NELSON DUANE

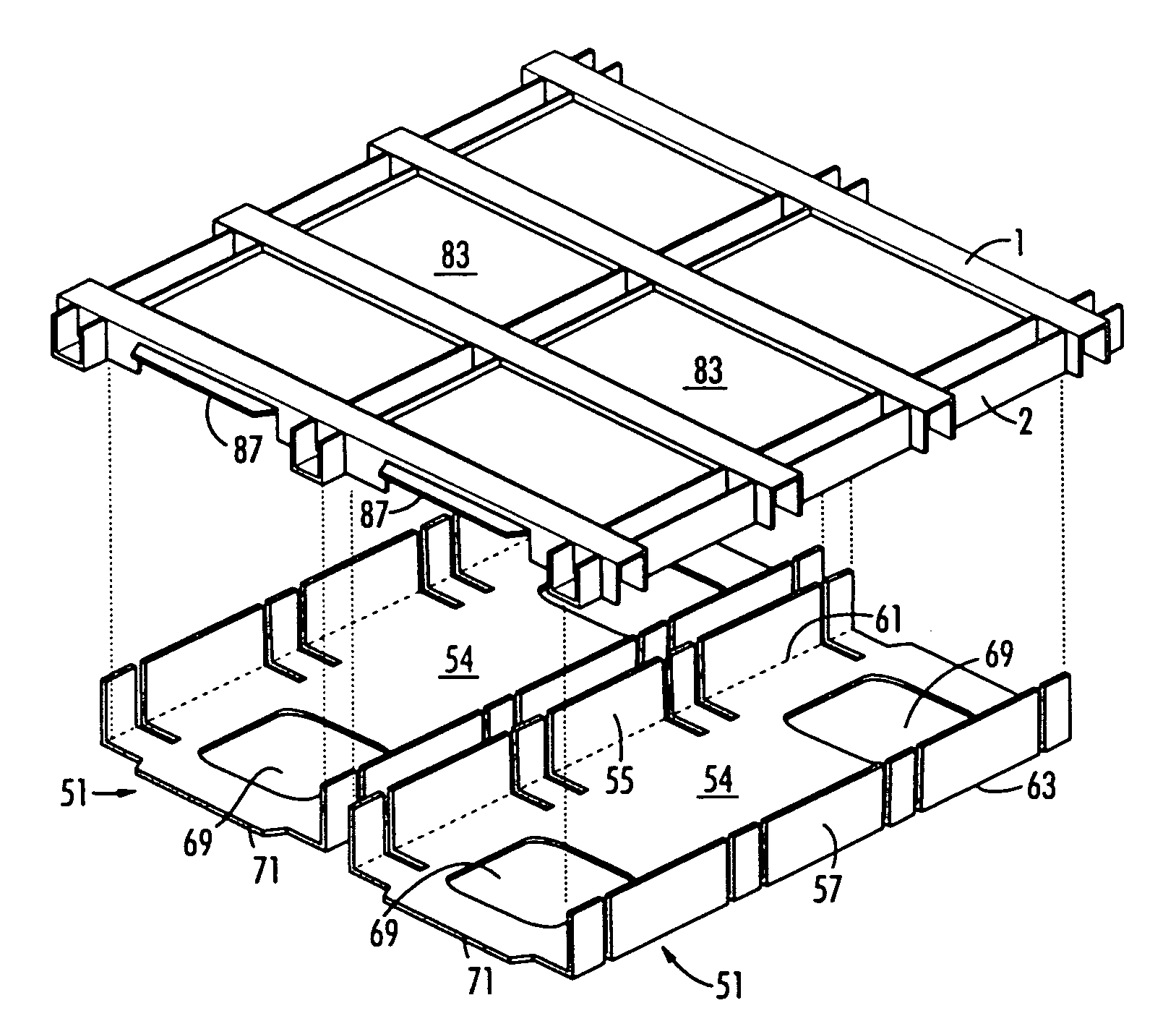

Blow molded pallet with pre-formed inserts

InactiveUS6962115B2Weight increaseLow production costDomestic articlesRigid containersEngineeringPallet

A pallet system includes a pallet body. The pallet body is formed from a first, independently formed first portion and a second blow molded second upper portion insert molded to the first portion. The pallet body may have two to eight recesses for forklift truck fork access. The second upper portion has a generally rectangular surface for carrying loads. The portions may have anti-skid properties, for example, a knurled topside surface or rubber coated bottom. At least one foot is attached to the second upper portion by insert molding. At least one runner may be attached to each foot to form part of the first portion. At least one stringer is attached to each runner to add further stability to the pallet. The runners and feet have channels or protruding members to effectively mate with the second upper portion. The system may also have top cap and tie members to affix the cap to one or more pallet bodies as well as high-friction inserts to permit the pallet from sliding on a surface or objects from sliding on the pallet.

Owner:POLY FLEX INC

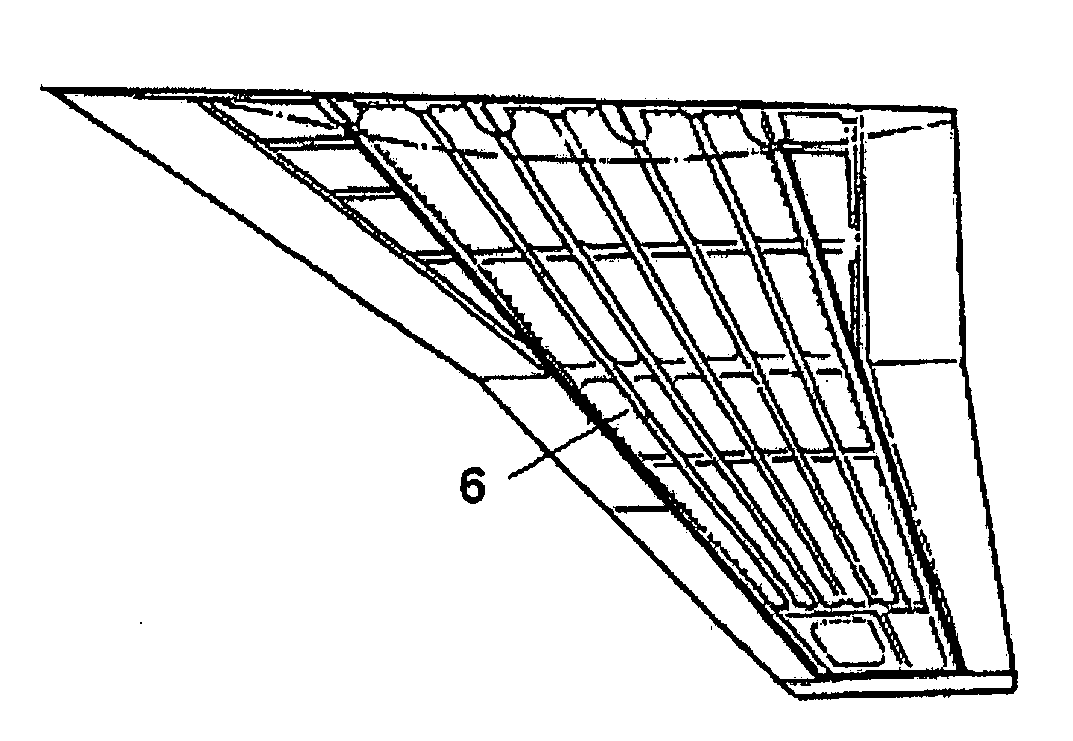

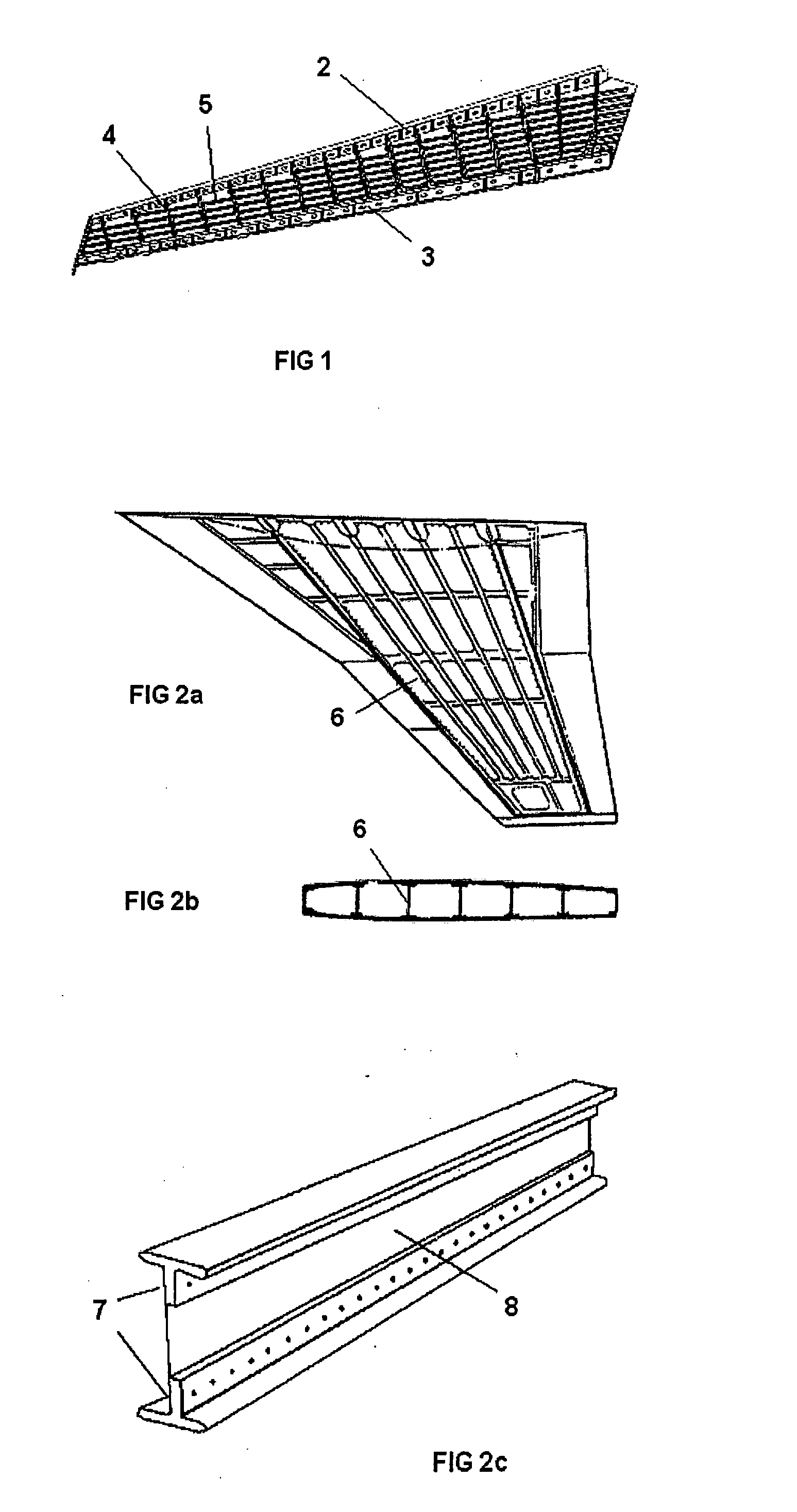

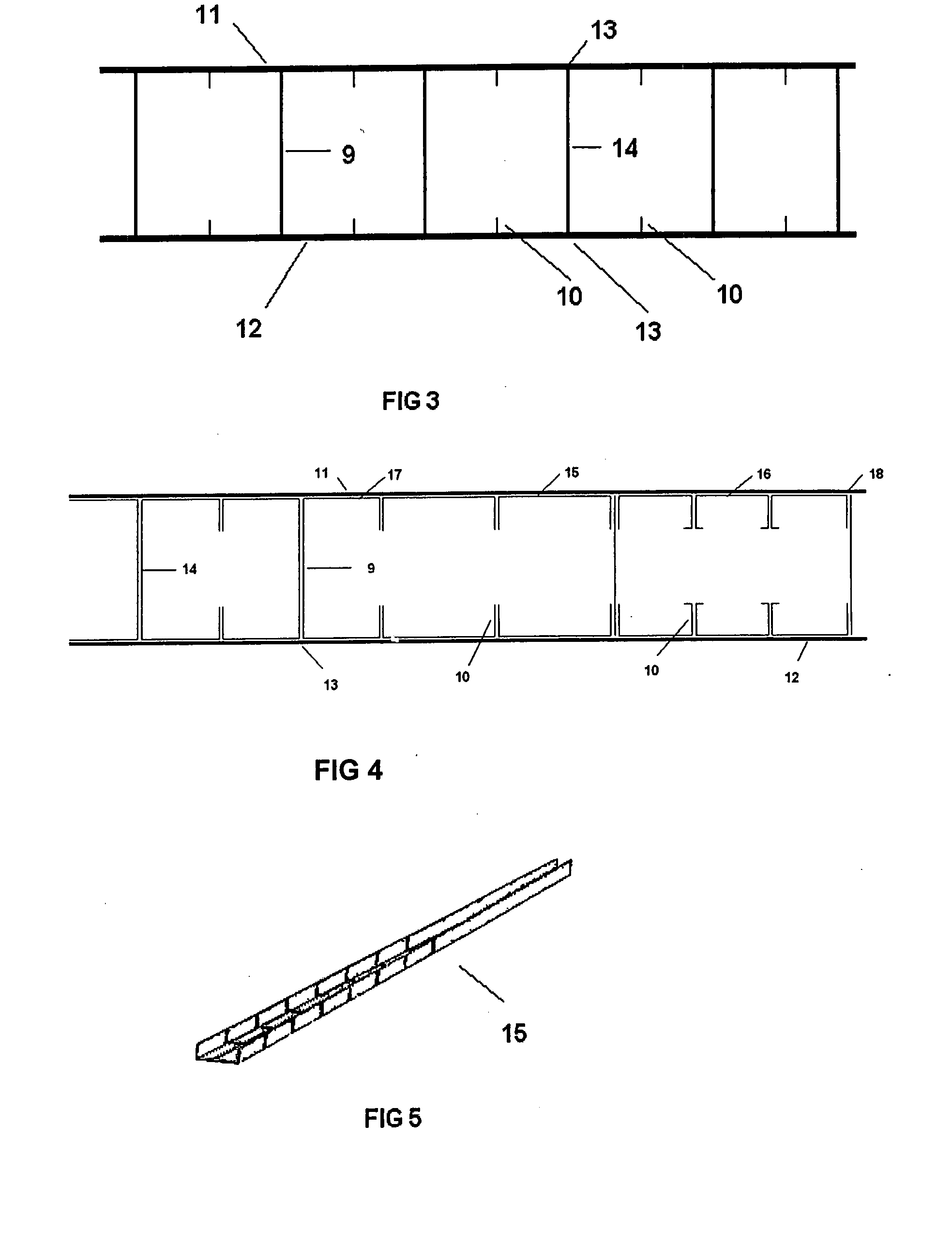

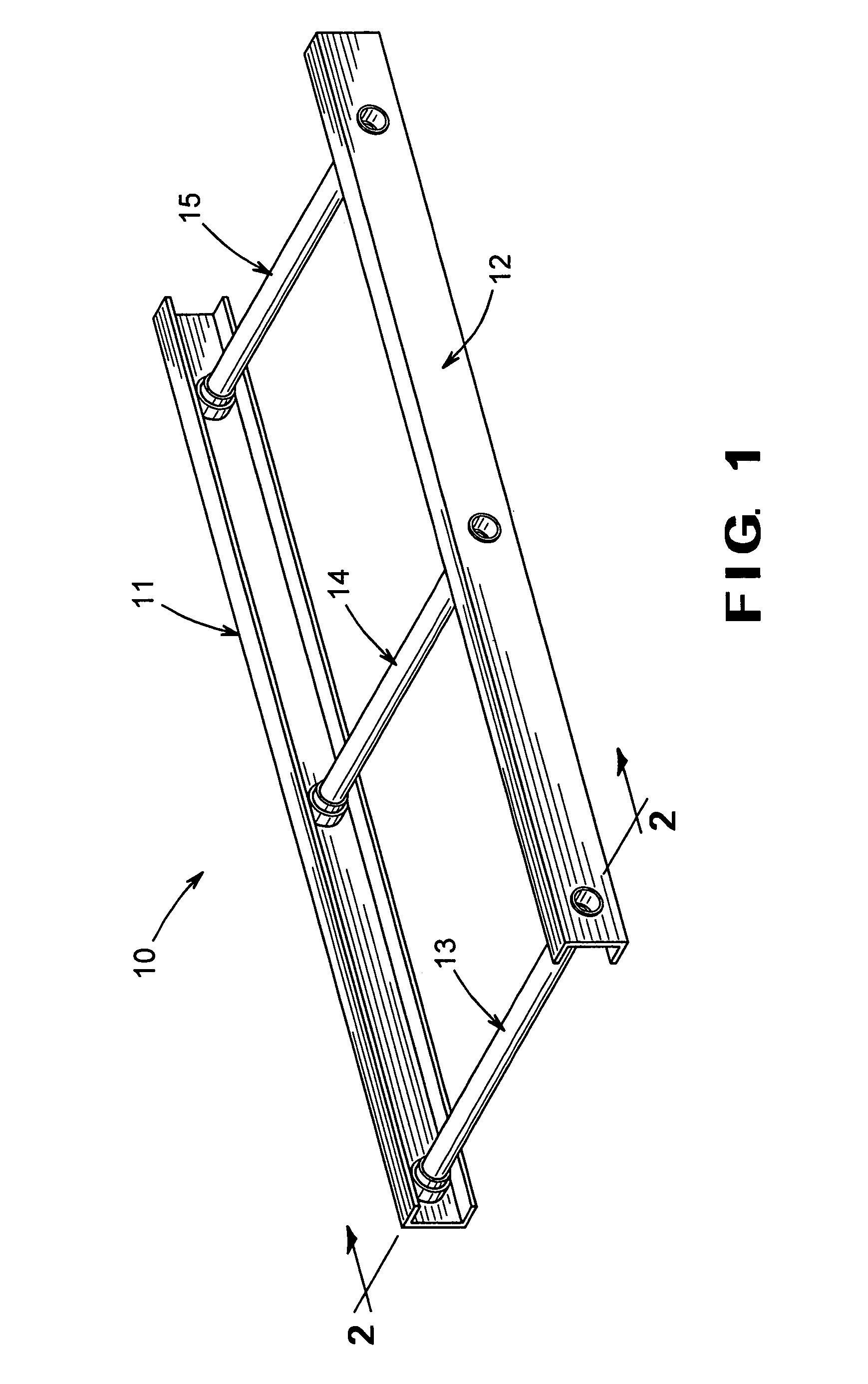

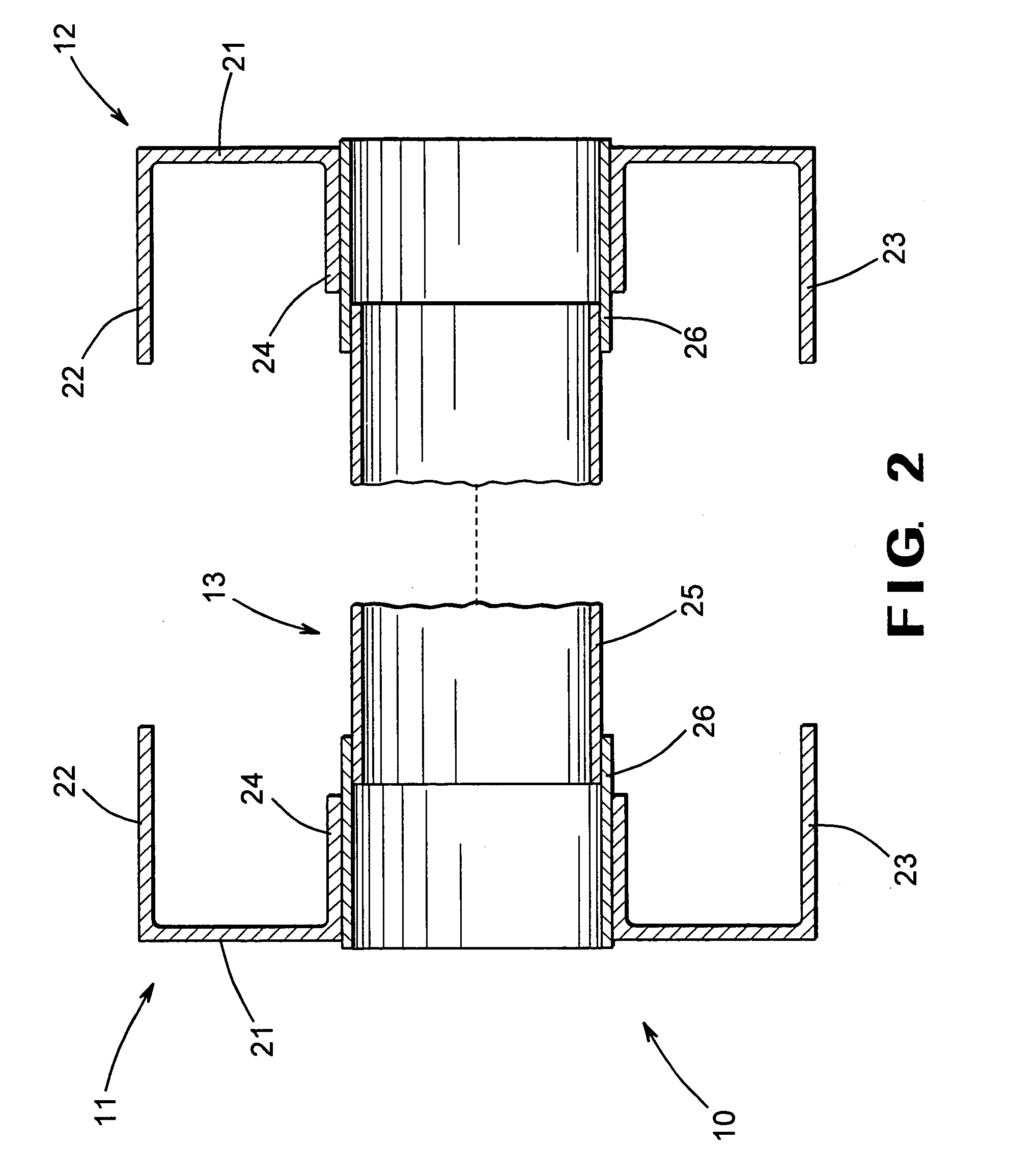

Integrated multispar torsion box of composite material

ActiveUS20080265093A1Great manufacturing cost savingLess stackedFuselage framesEfficient propulsion technologiesStringerMechanical engineering

The invention relates to an integrated multispar torsion box structure of composite material for aircraft, comprising a lower skin (12), an upper skin (11), several spars (9), each of which comprises in turn a chord (13) and a web (14), several stringers (10) in the lower skin (12) and several stringers (10) in the upper skin (11), characterized in that the mentioned integrated torsion box structure is achieved by means of joining unitary U-shaped structural elements (15), unitary U-shaped structural elements (16) with a flap and unitary C-shaped structural elements (17) with a flap. The invention also relates to a method for manufacturing an integrated multispar torsion box structure of composite material for aircraft.

Owner:AIRBUS OPERATIONS SL

Bi-metallic structural component for vehicle frame assembly

ActiveUS7144040B2Simple structureVehicle seatsVehicle body-frame connectionsVehicle frameClassical mechanics

A vehicle body and frame assembly includes a pair of longitudinally extending side rails having a plurality of transverse cross members extending therebetween. The cross member is a multiple piece structure, including a central portion having a pair of end portions secured thereto. The central portion of the cross member is preferably formed from a first metallic material, while the end portions are preferably both formed from a second metallic material. The end portions of the cross member are preferably formed from the same metallic material as the respective side rails to which they are secured. The end portions of the cross member can be secured to the ends of the central portion by any desired process, such as by magnetic pulse welding. Similarly, the cross member can be secured to the side rails by any desired process, such as by magnetic pulse welding or by conventional welding. The end portions of the cross member can extend either partially or completely through the respective side rails. If desired, a reinforcing and positioning collar can be secured to the end portions of the cross member adjacent to each of the side rails.

Owner:METALSA SA DE CV

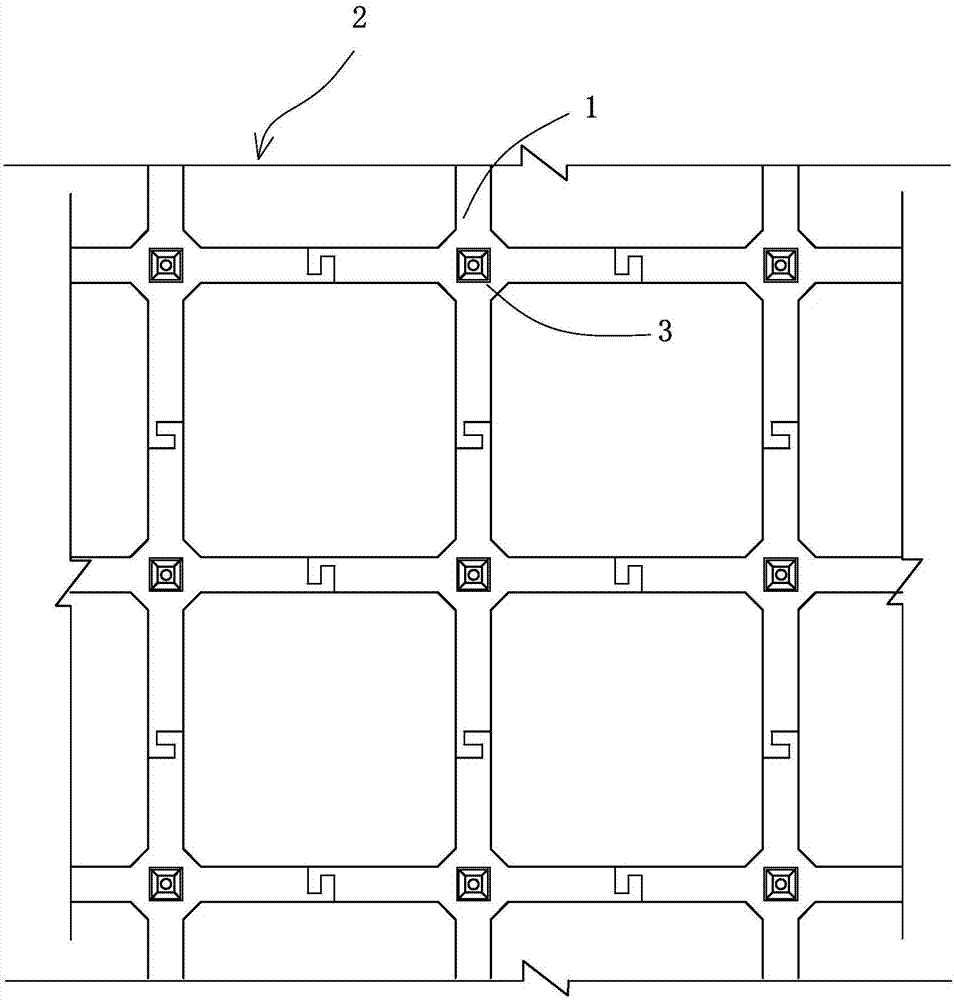

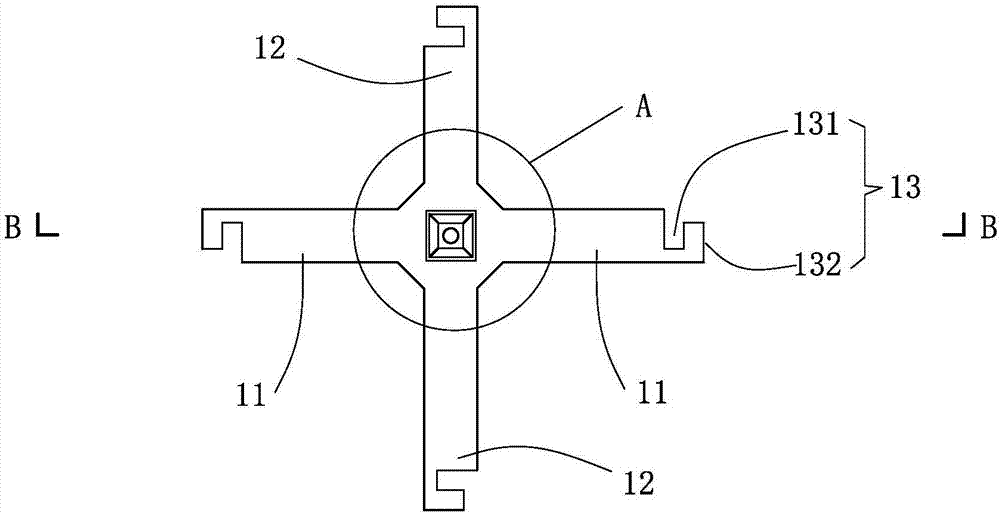

Precast lattice beam used for slope reinforcement, manufacturing method thereof and construction method for slope reinforcement adopting precast lattice beam

PendingCN107030874AEasy to manufactureEasy to installCeramic shaping apparatusExcavationsShaped beamChinese characters

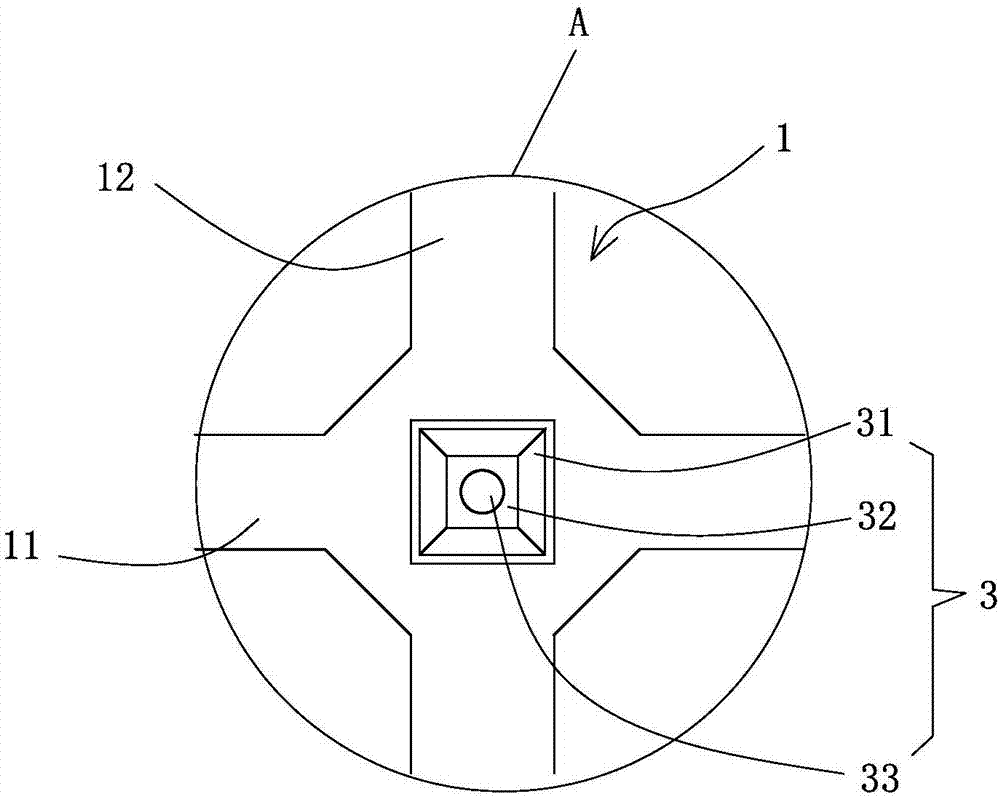

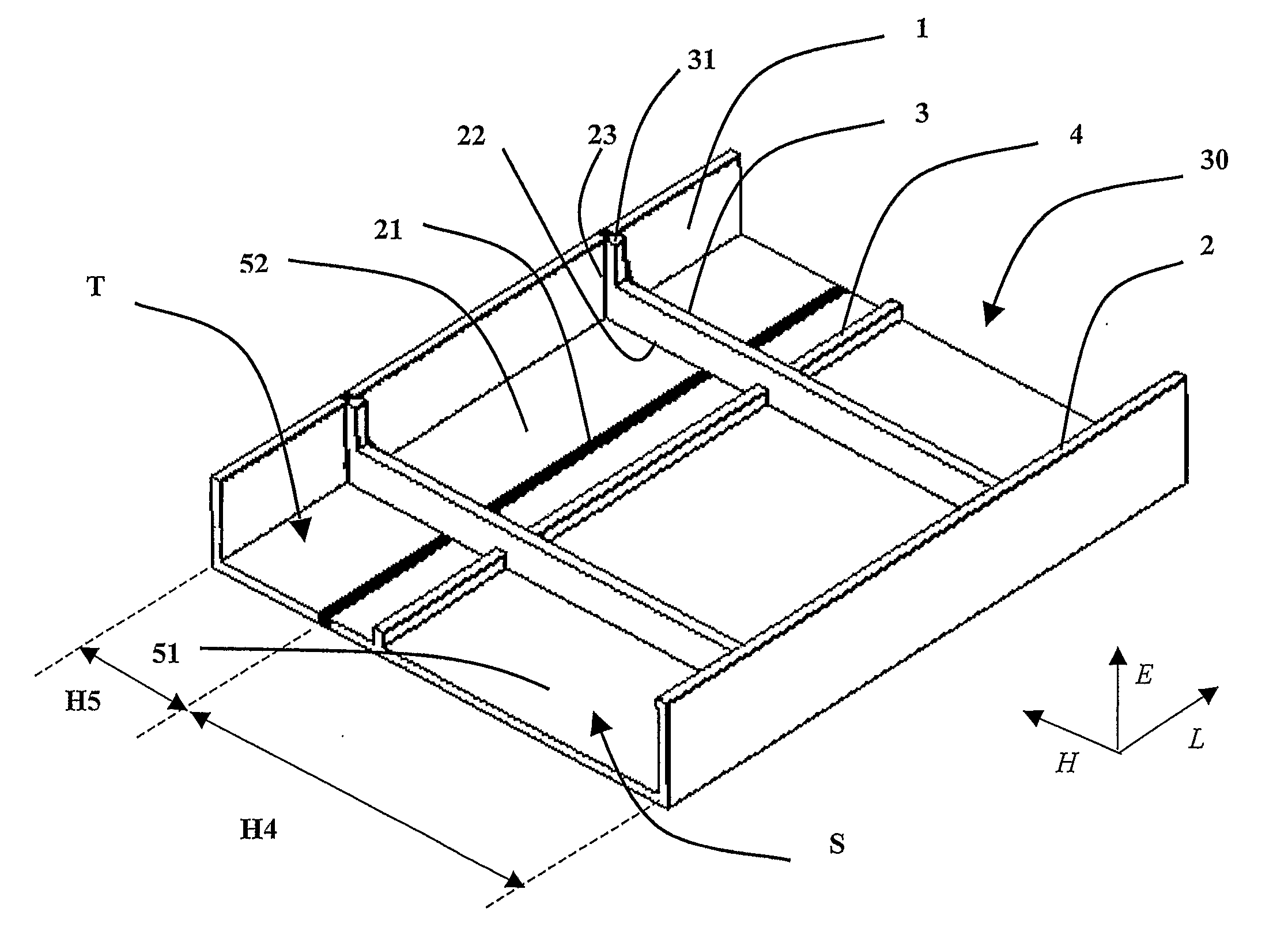

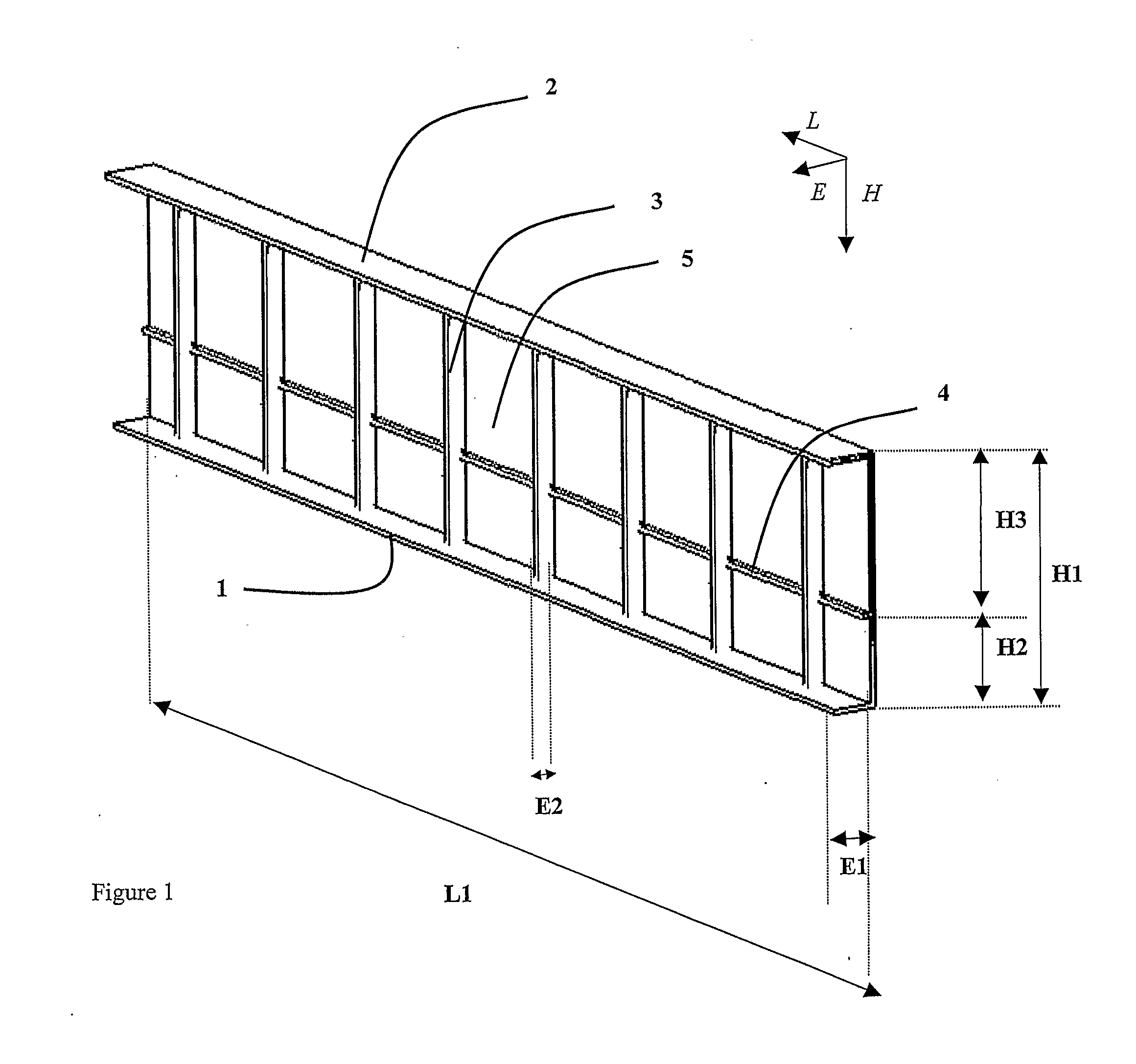

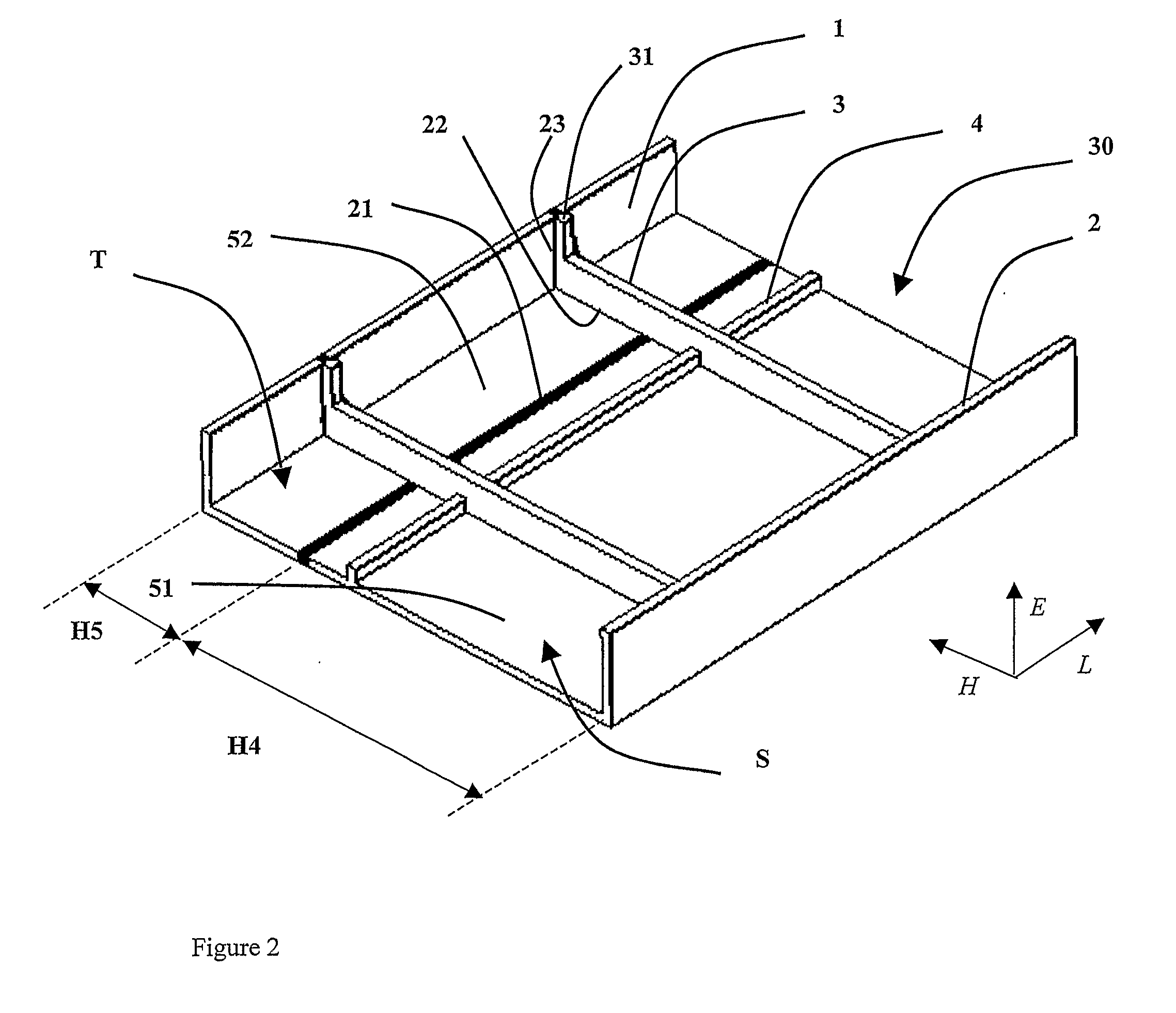

The invention provides a precast lattice beam used for slope reinforcement and a construction method for slope reinforcement adopting the precast lattice beam, as well as a slope structure reinforced by the precast lattice beam and a construction method thereof. The precast lattice beam comprises a plurality of precast cross-shaped beam units which are arranged and connected in a matrix manner; each of the cross-shaped beam units comprises a transverse beam and a longitudinal beam in intersection; an anchor head part is formed in the central interacting part of each of the cross-shaped beam units; each of the anchor head parts comprises a concrete groove and a backing plate placed on the concrete groove; an anchor hole is formed in each of the concrete grooves and the backing plates; the two end parts of the transverse beam and the two end parts of the longitudinal beam of each of the cross-shaped beam units extend respectively to form L-shaped hook parts reversed in directions; the transverse beam of each of the cross-shaped beam units is connected with that of the adjacent cross-shaped beam unit in a hooking manner through the corresponding L-shaped hook parts; the longitudinal beam of each of the cross-shaped beam units is connected with that of the adjacent cross-shaped beam unit in a hooking manner through the corresponding L-shaped hook parts; therefore the precast lattice beam is formed by splicing a plurality of structures taking the shapes of the Chinese character jing. According to the precast lattice beam used for slope reinforcement, the manufacturing method thereof and the construction method for slope reinforcement adopting the precast lattice beam, the following characteristics are achieved: on-the-spot construction steps are reduced, the construction period is shortened, the standardized management production is realized, the quality is ensured, and high efficiency and environment protection are realized.

Owner:SHENZHEN ROAD & BRIDGE CONSTR GRP

Structural Element and Method of Manufacture

In a method for manufacturing a structural element intended for aeronautical construction, at least a first and second metal block are made available, the limit of elasticity under compression of the first metal block being greater than that of the second metal block. The first metal block is machined in such a manner as to obtain a first machined monolithic part which has a first web portion and at least one stringer element whose height is such that a stringer portion extends beyond the first web portion. There is prepared, by shaping the second metal block, at least one second part having at least a second web portion capable of co-operating with the first web portion to form the web. The first monolithic part and the second part are assembled by placing the first and second web portions end-to-end over their entire common length.

Owner:AIRBUS OPERATIONS LTD

Liquefied natural gas storage tank

InactiveUS7111750B2Improve structural performanceMinimize dynamic loadContainer filling methodsGas handling applicationsEngineeringAtmospheric pressure

Substantially rectangular-shaped tanks are provided for storing liquefied gas, which tanks are especially adapted for use on land or in combination with bottom-supported offshore structure such as gravity-based structures (GBS). A tank according to this invention is capable of storing fluids at substantially atmospheric pressure and has a plate cover adapted to contain fluids and to transfer local loads caused by contact of said plate cover with said contained fluids to an internal frame structure comprised of a plate girder ring frame structure and / or an internal truss frame structure. Optionally, a grillage of stiffeners and stringers may be disposed on the plate cover and additional sifters disposed on the plate girder ring frame structure and / or an internal truss frame structure. Methods of constructing these tanks are also provided.

Owner:EXXONMOBIL UPSTREAM RES CO

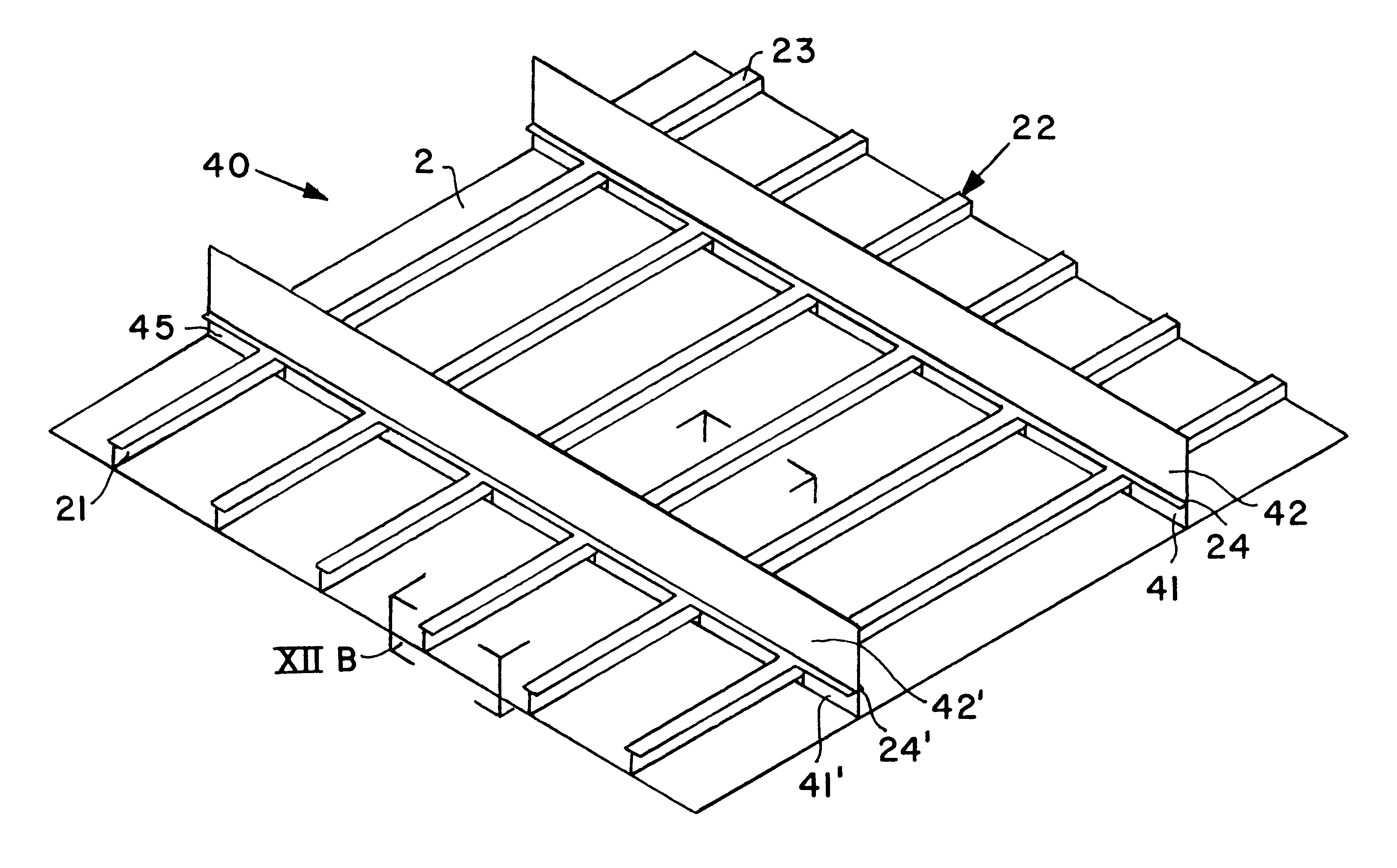

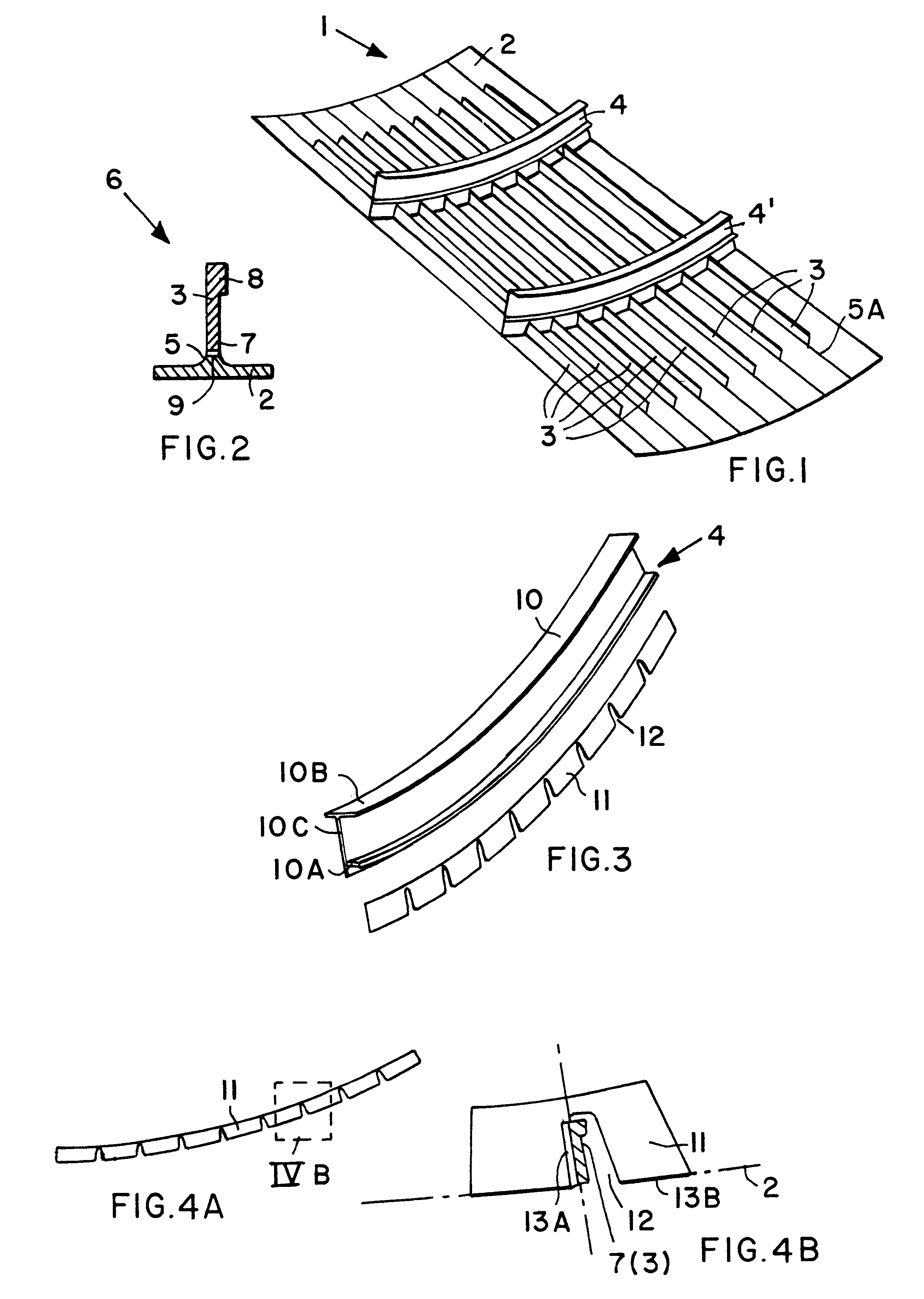

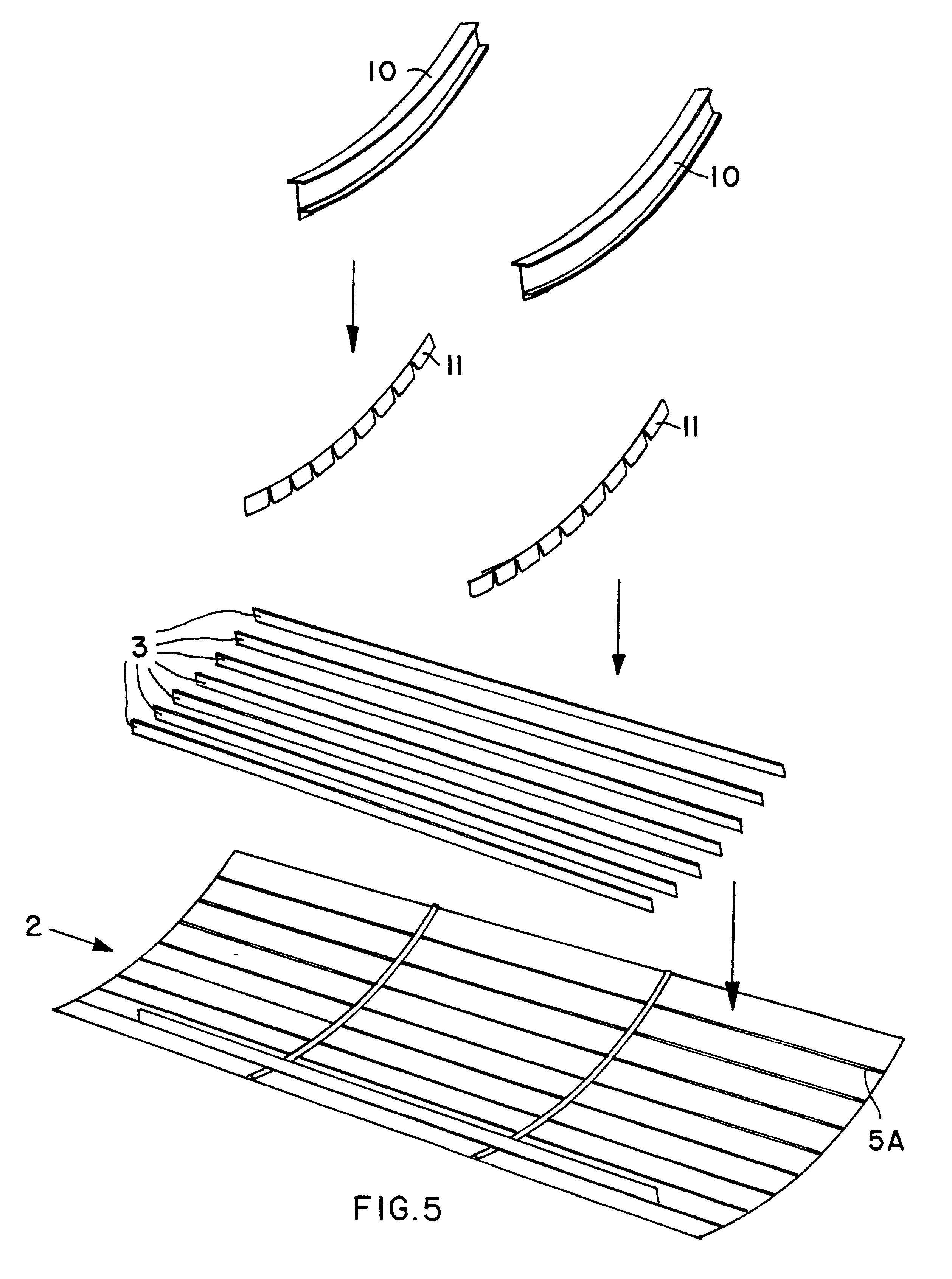

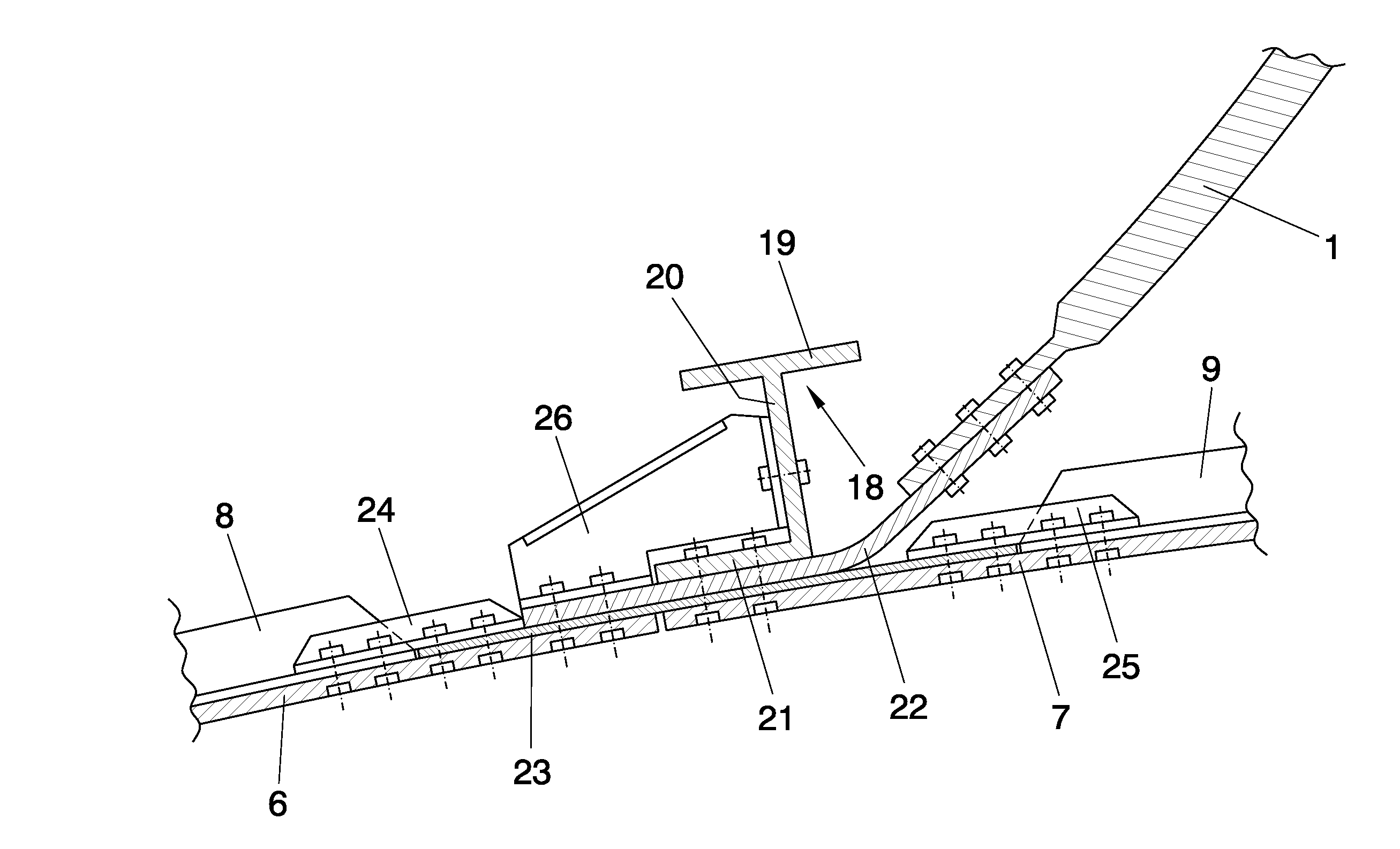

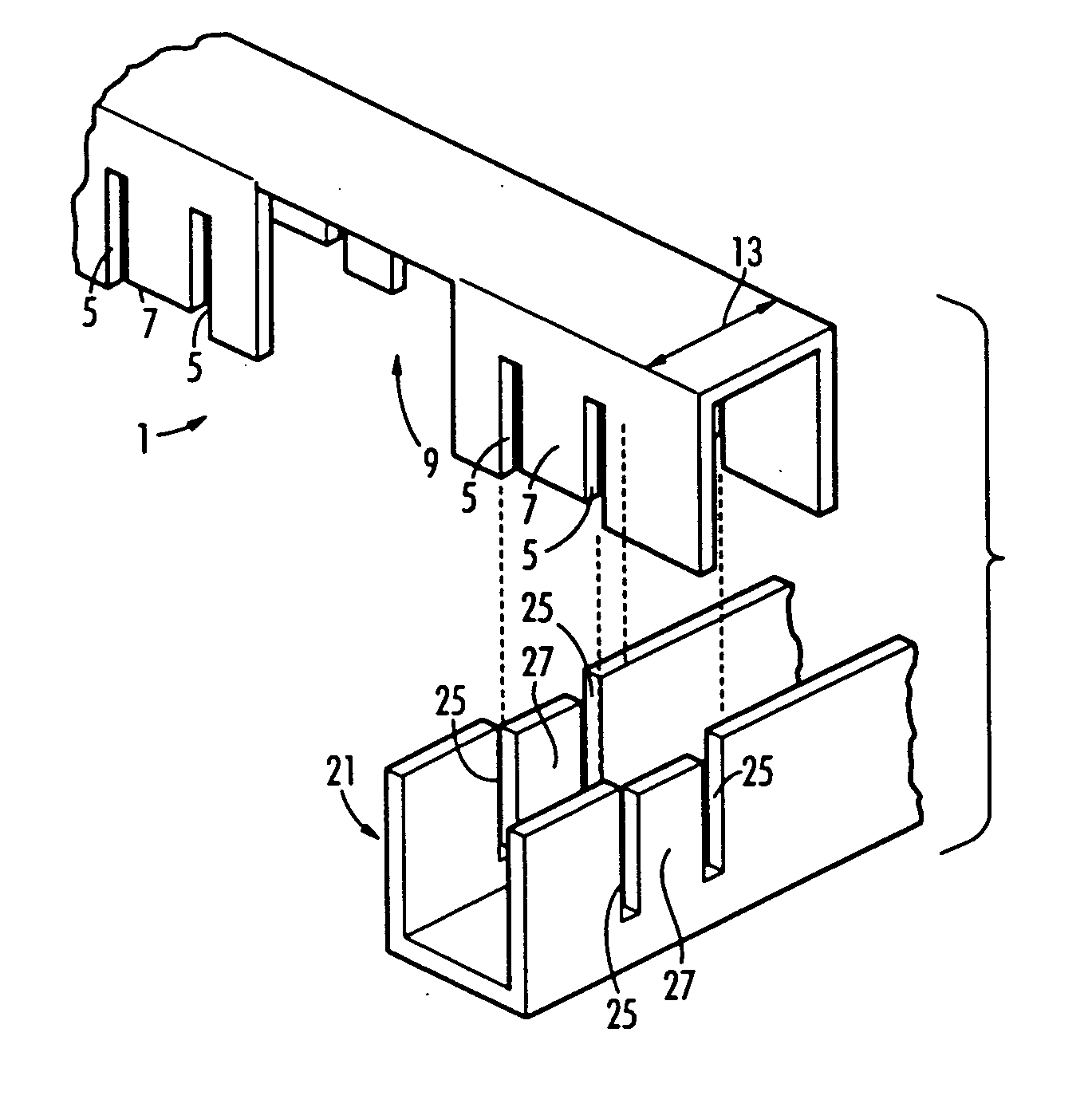

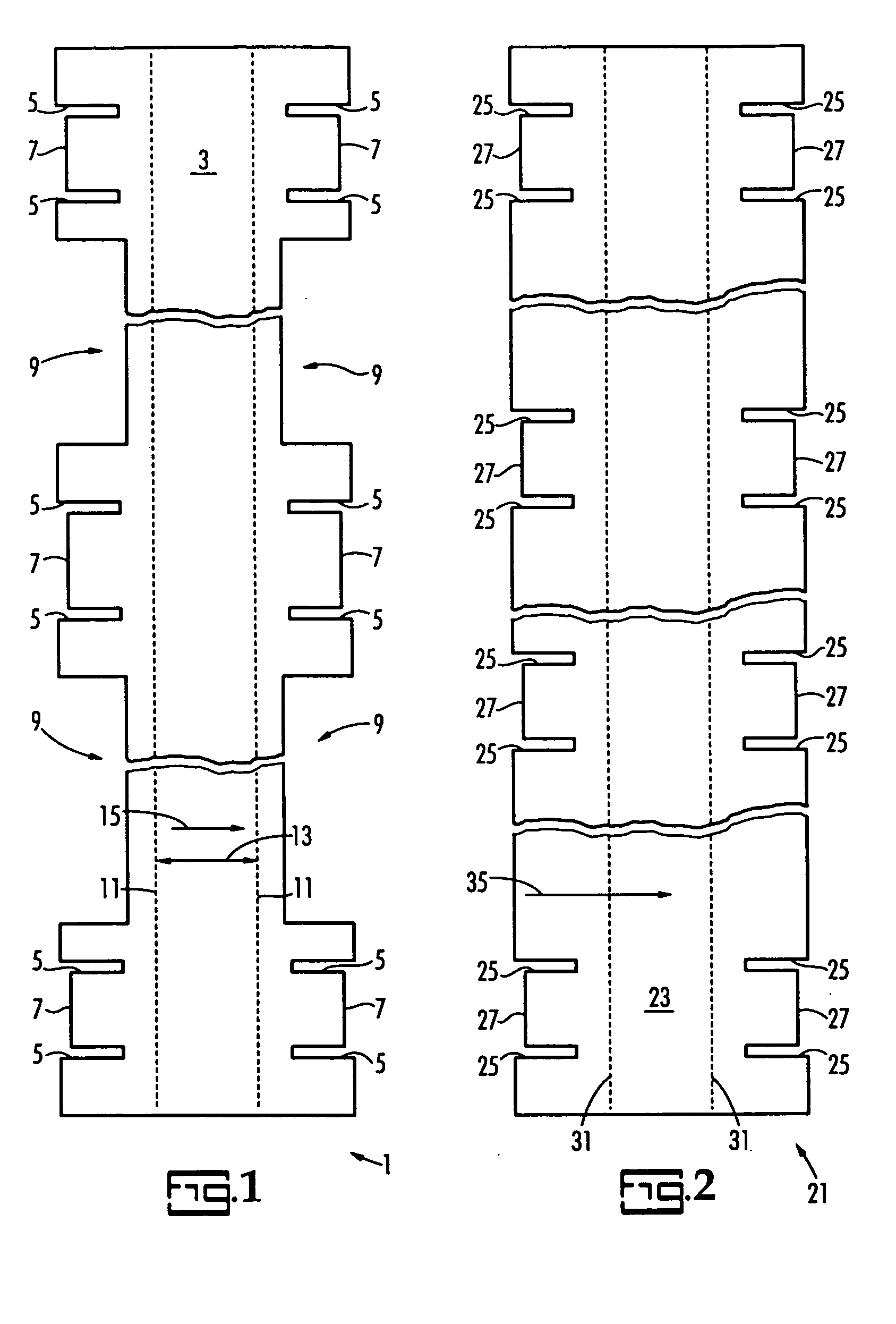

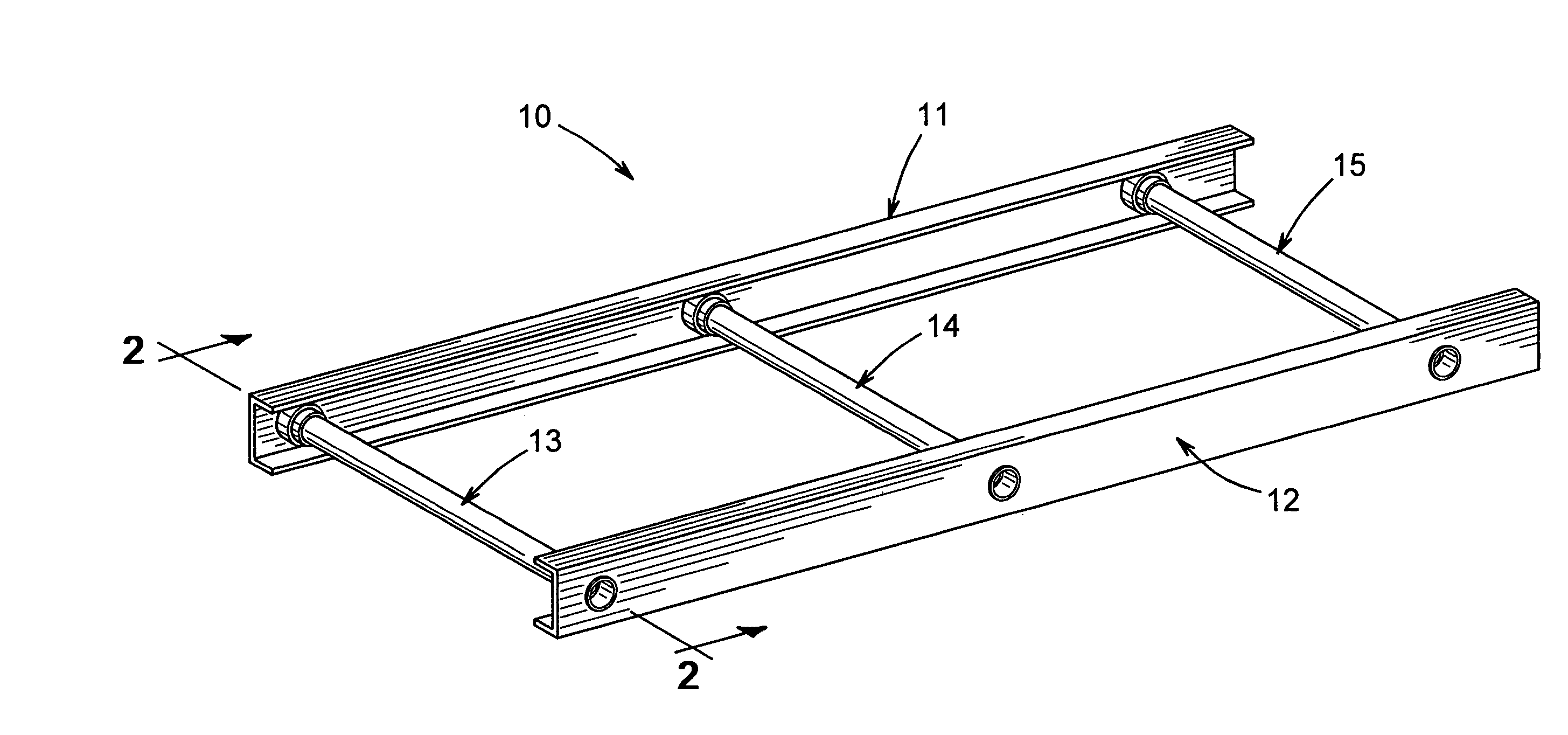

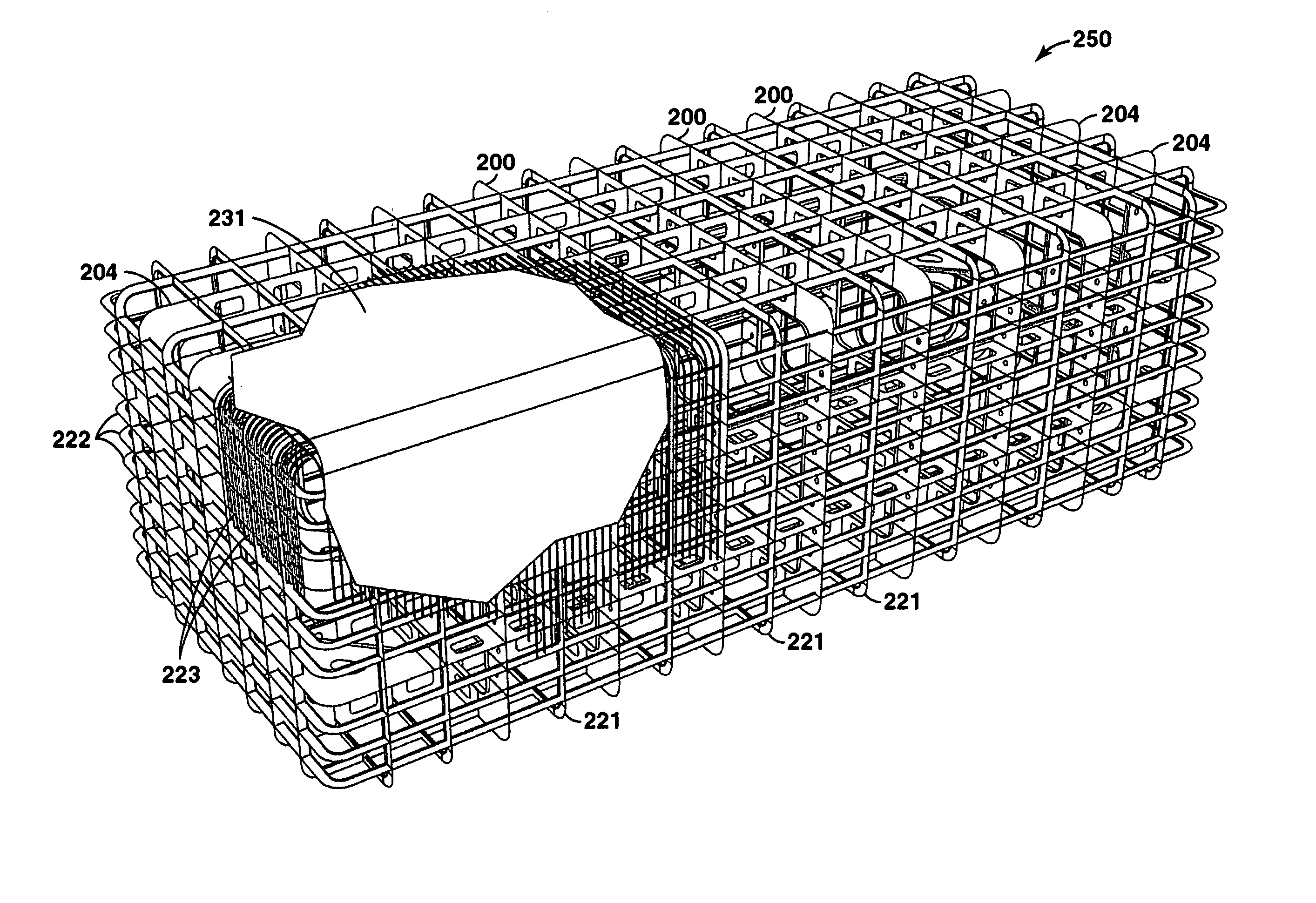

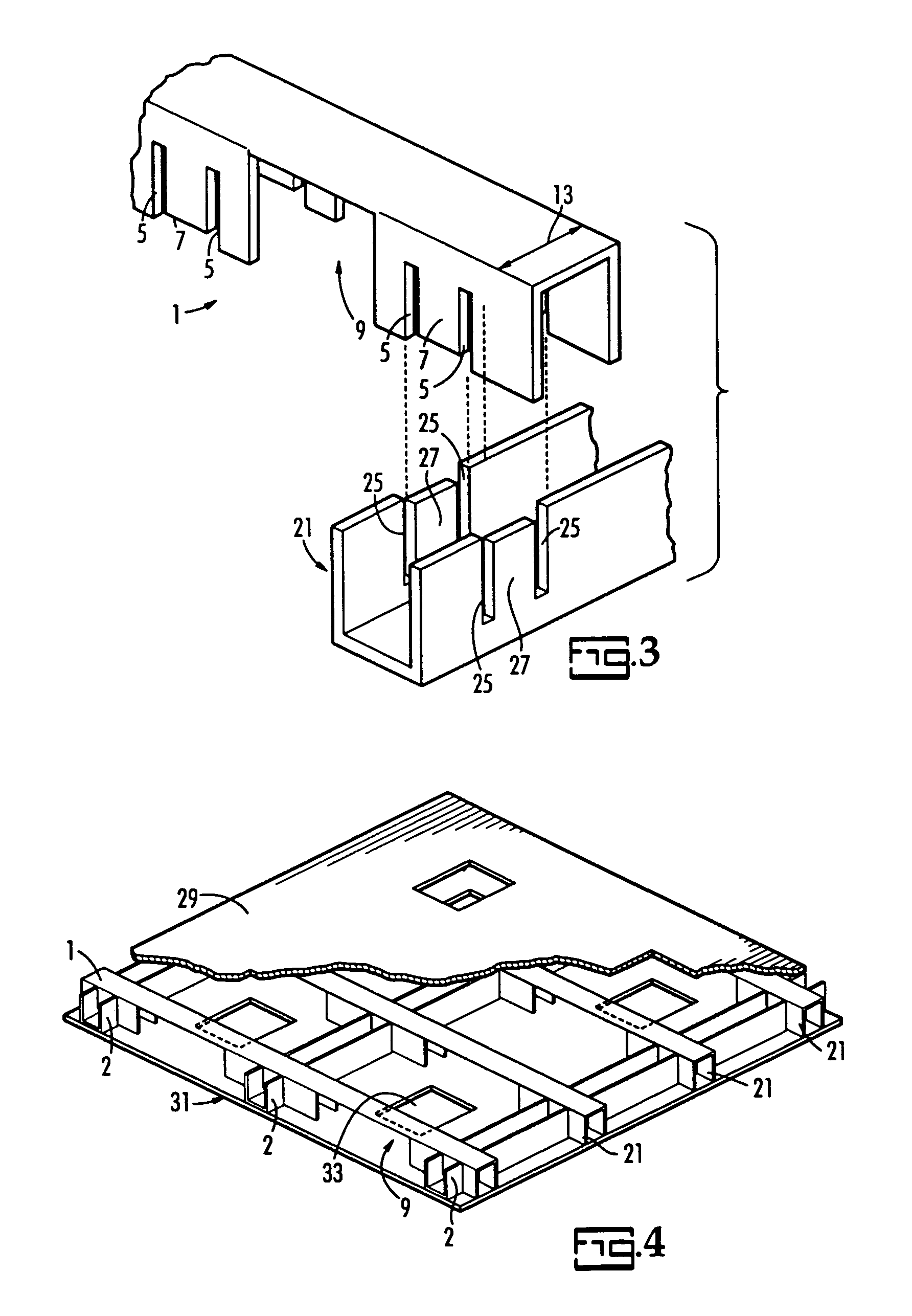

Automated fabrication of an integral fiber reinforced composite structural component using a positioning and assembly support

ActiveUS20040050498A1Precise positioningForming accuratelyLaminationEfficient propulsion technologiesGrid patternModularity

A forming jig includes a grid pattern of support walls arranged on a support base and having upper free ends located along an imaginary curved surface, and modular sectional profile members arranged on the walls to enclose a vacuum chamber within the jig. Grooves, channels and air passages between neighboring profile members communicate into the vacuum chamber. The outer surface of the profile members matches the intended inner surface of a structural component to be fabricated using the jig. In the fabrication process, a film is applied to the outer surface to pre-establish a vacuum, the film is removed while simultaneously a vacuum skin is applied, stringer members are set into the grooves, fiber skin layers are laid up, a sealant is applied around the perimeter, a structural shell is vacuumed onto the skin layers, and then this preformed component is removed from the jig, injected with resin unless the skin layers were pre-impregnated with resin, and cured.

Owner:AIRBUS OPERATIONS GMBH

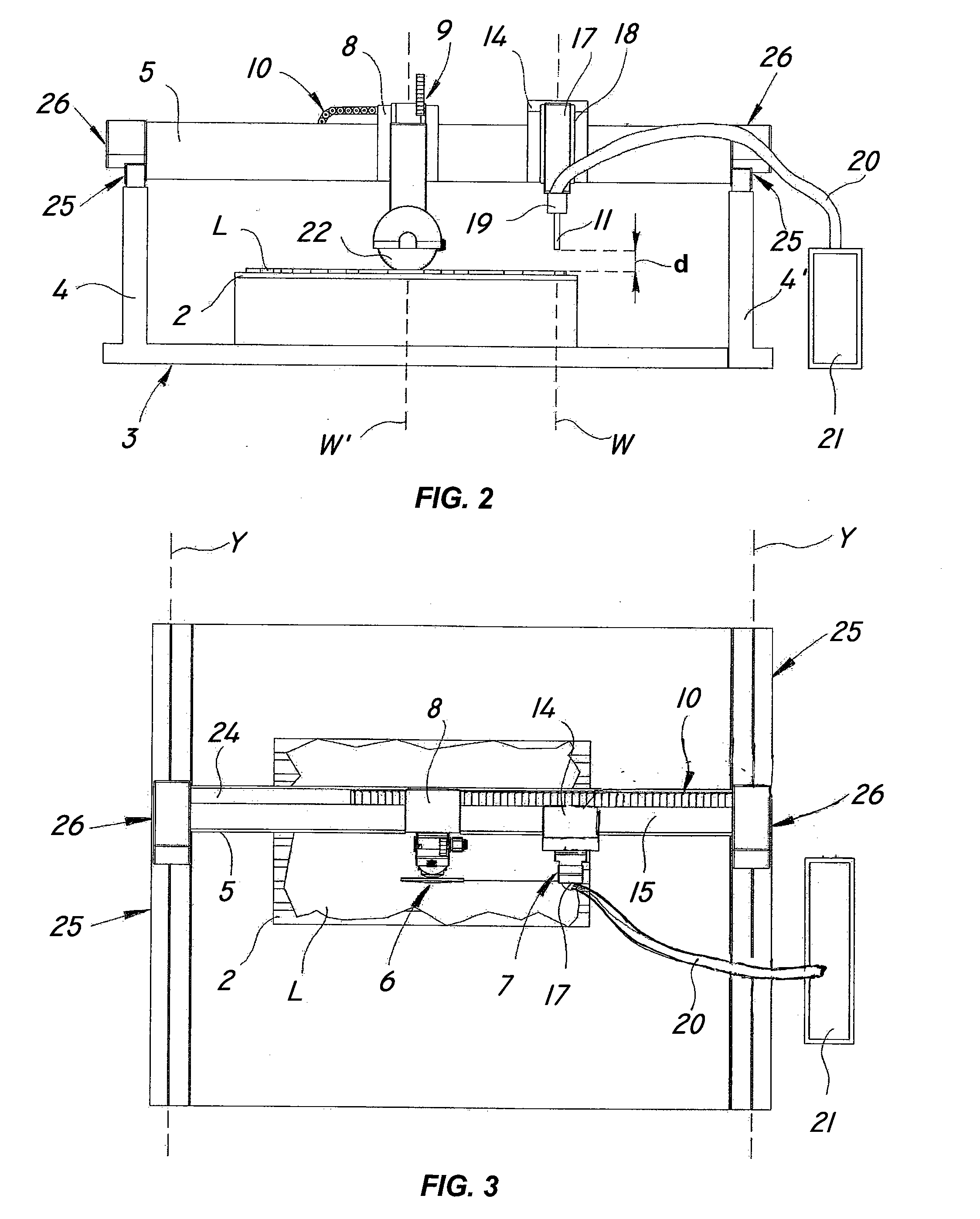

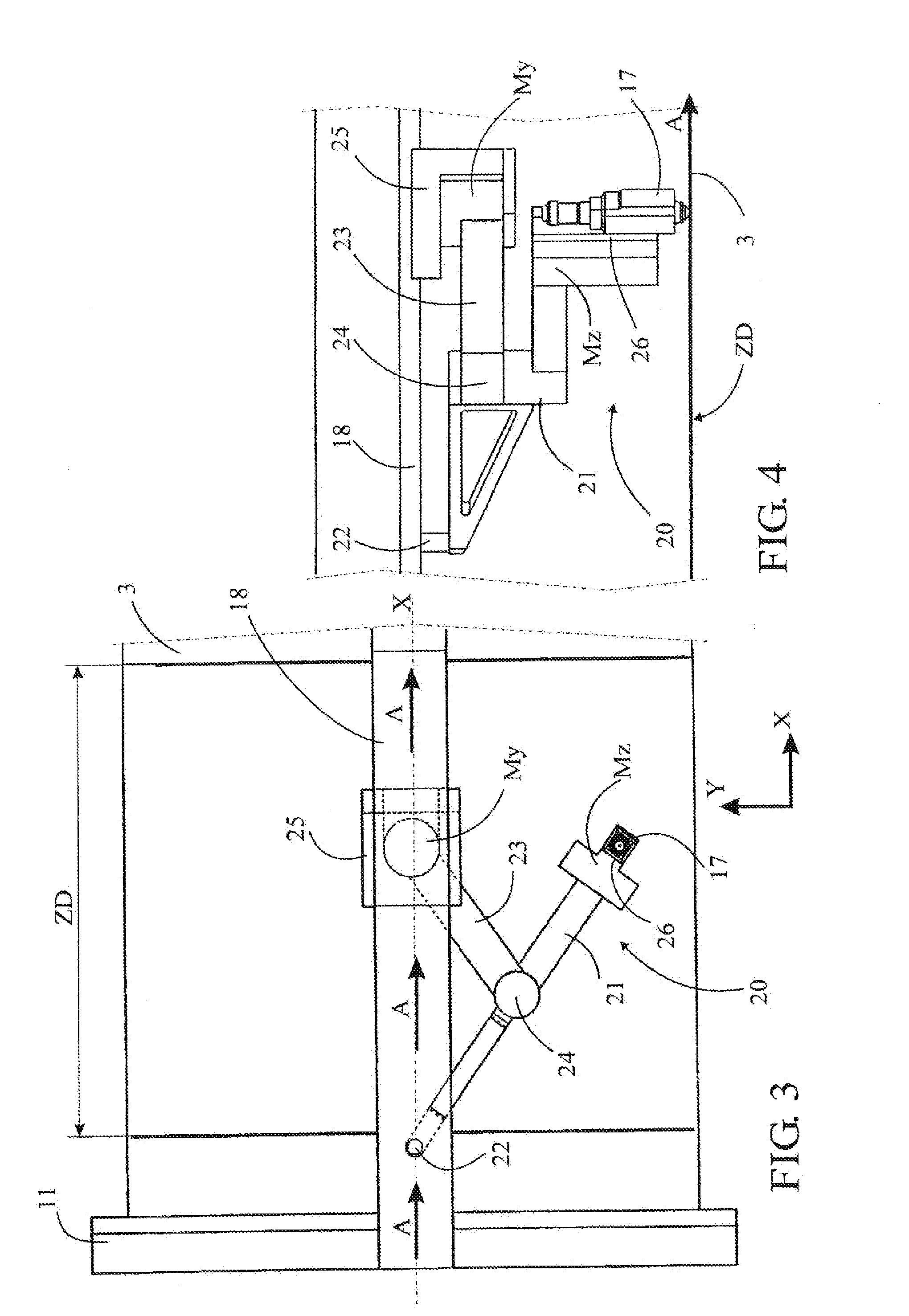

Method for cutting pieces from a strip of material and cutting machine for carrying out said method

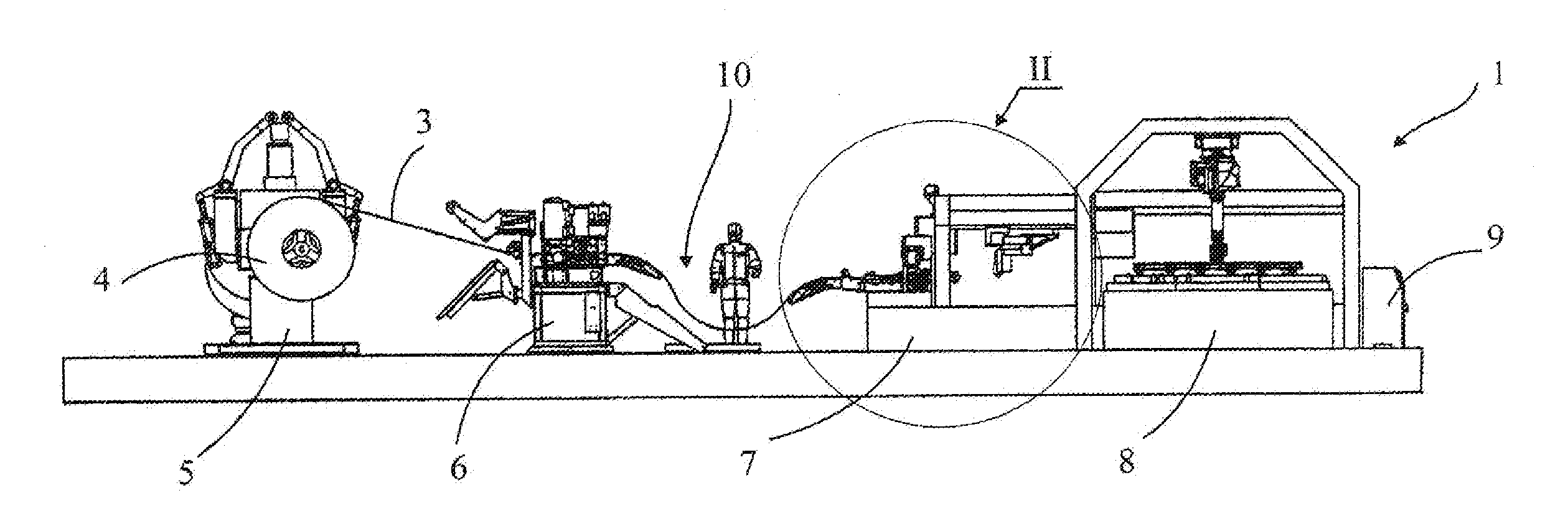

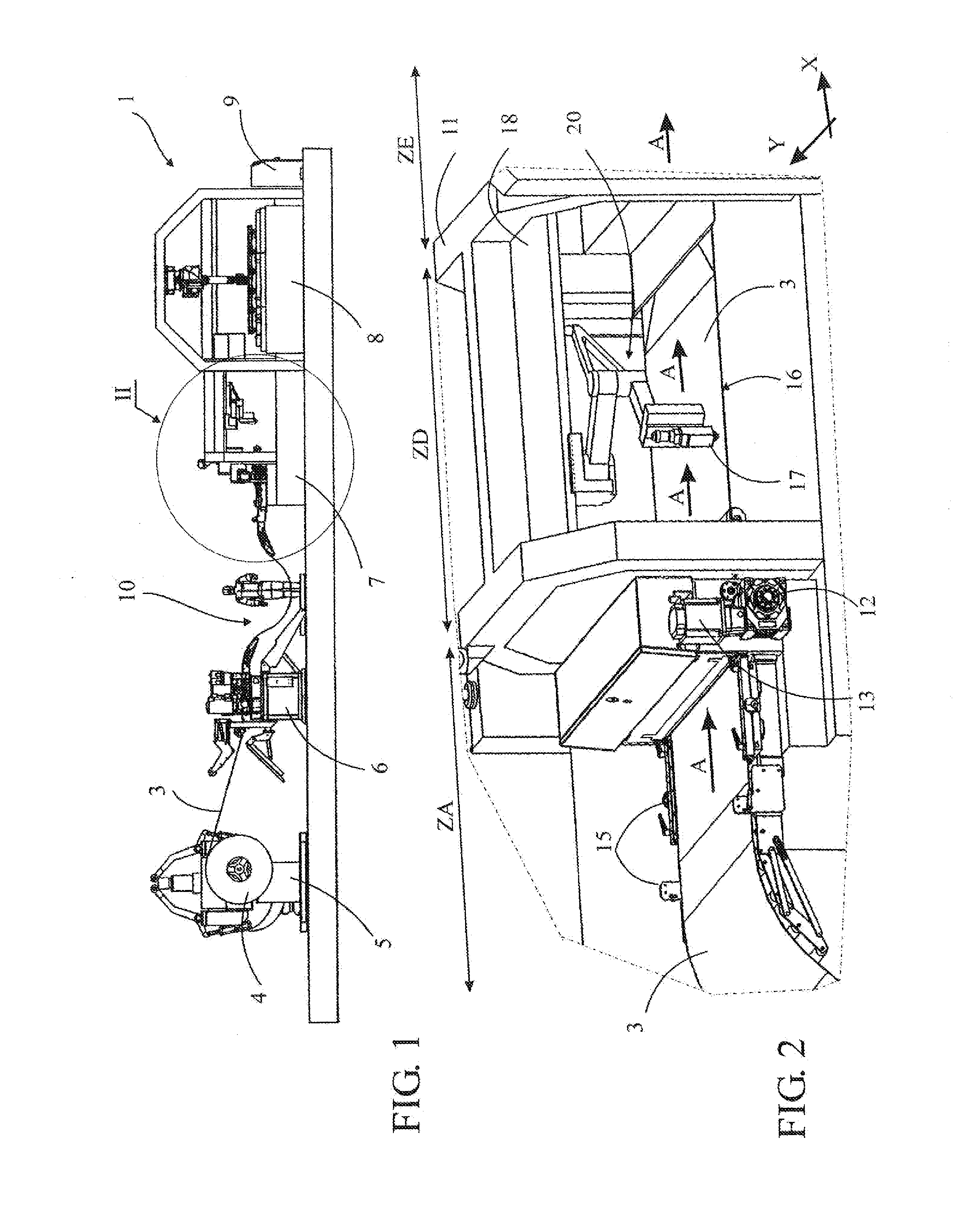

ActiveUS20150360318A1Reduce material wasteFast and efficientLaser beam welding apparatusTransverse axisActuator

A machine for flatbed cutting of pieces from a strip of material (3) wound in a coil and moving continuously. The cutting zone (ZD) comprises a cutting head (17) supported by a mobile support (20) translatably mounted on a stationary longitudinal beam (18) disposed parallel to the direction of movement (A) of the strip of material. It is coupled to a first actuator (Mx) for moving the cutting head (17) linearly along a longitudinal axis (X) parallel to the beam and comprises a variable-geometry mechanism (21-24) coupled to a second actuator (My) for moving the cutting head (17) linearly along a transverse axis (Y), perpendicular to the longitudinal axis (X). A central control unit (9) controls the actuators to move the cutting head (17) in the cutting zone (ZD) along a path determined by the contour of the pieces (2) to be cut and the speed of the material (3).

Owner:DIMECO S AS

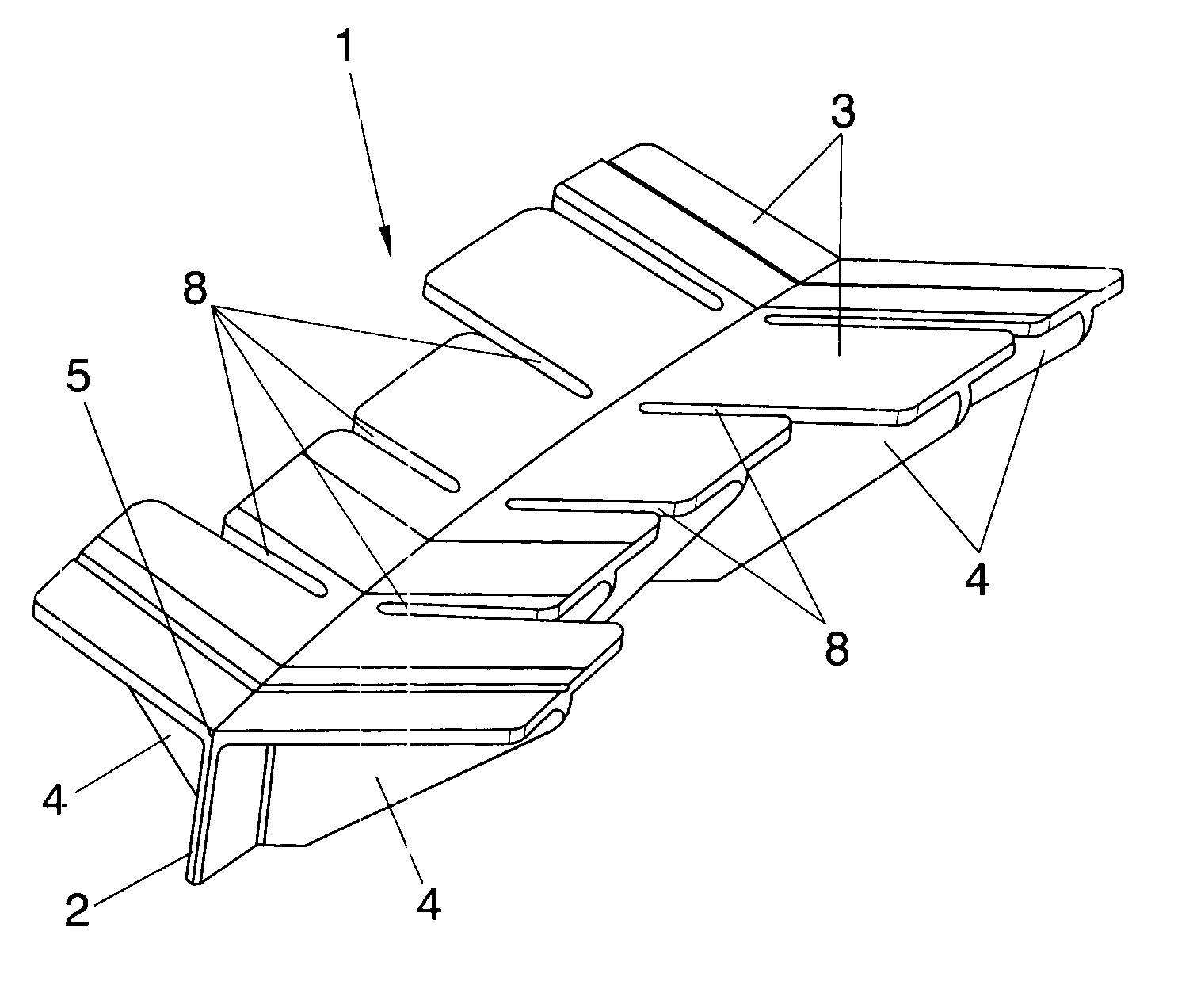

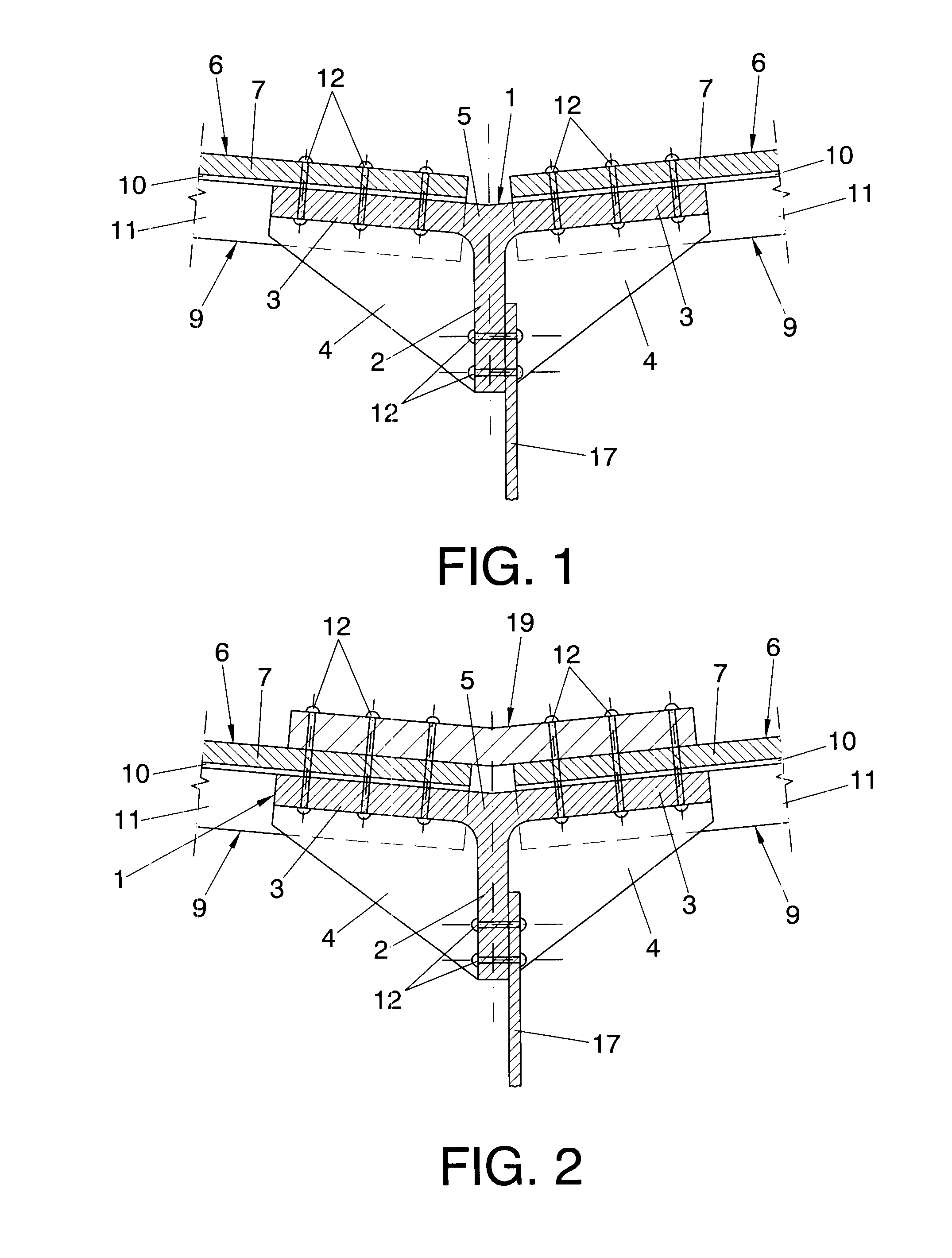

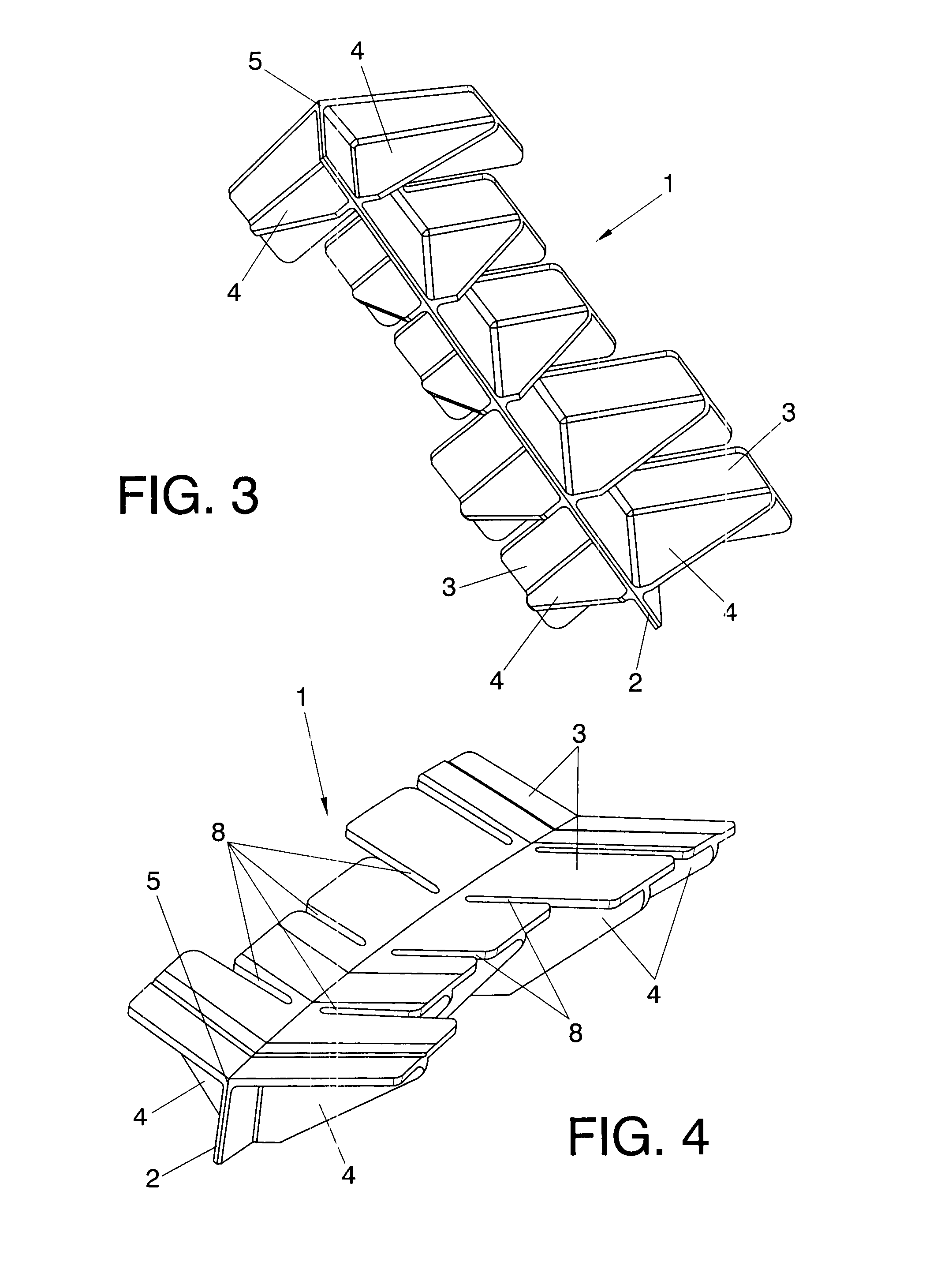

Structure for joining torsion boxes in an aircraft using a triform fitting made from non-metallic composite materials

The invention comprises a triform fitting 1, essentially made from non-metallic composite materials including several strengthening cross ribs 4 for joining symmetrical flanges 3 and a longitudinal flange 2. The symmetrical flanges3 include cross slots 8 for receiving the run-out 16 of the webs 11 of several T-shaped internal stringers 9 that form part of the torsion boxes 6. The feet 10 of the stringers 9 are joined along one of their faces to the skins 7 of the torsion boxes 6, while the end zones of the free faces of said feet 10 are placed against the outer face of the symmetrical flanges 3 of the triform fitting 1. This ensures that the symmetrical flanges 3 of the triform fitting 1 remain inside the torsion boxes 6. Alternatively, the fitting 1 may not include the cross slots 8.

Owner:AIRBUS OPERATIONS SL

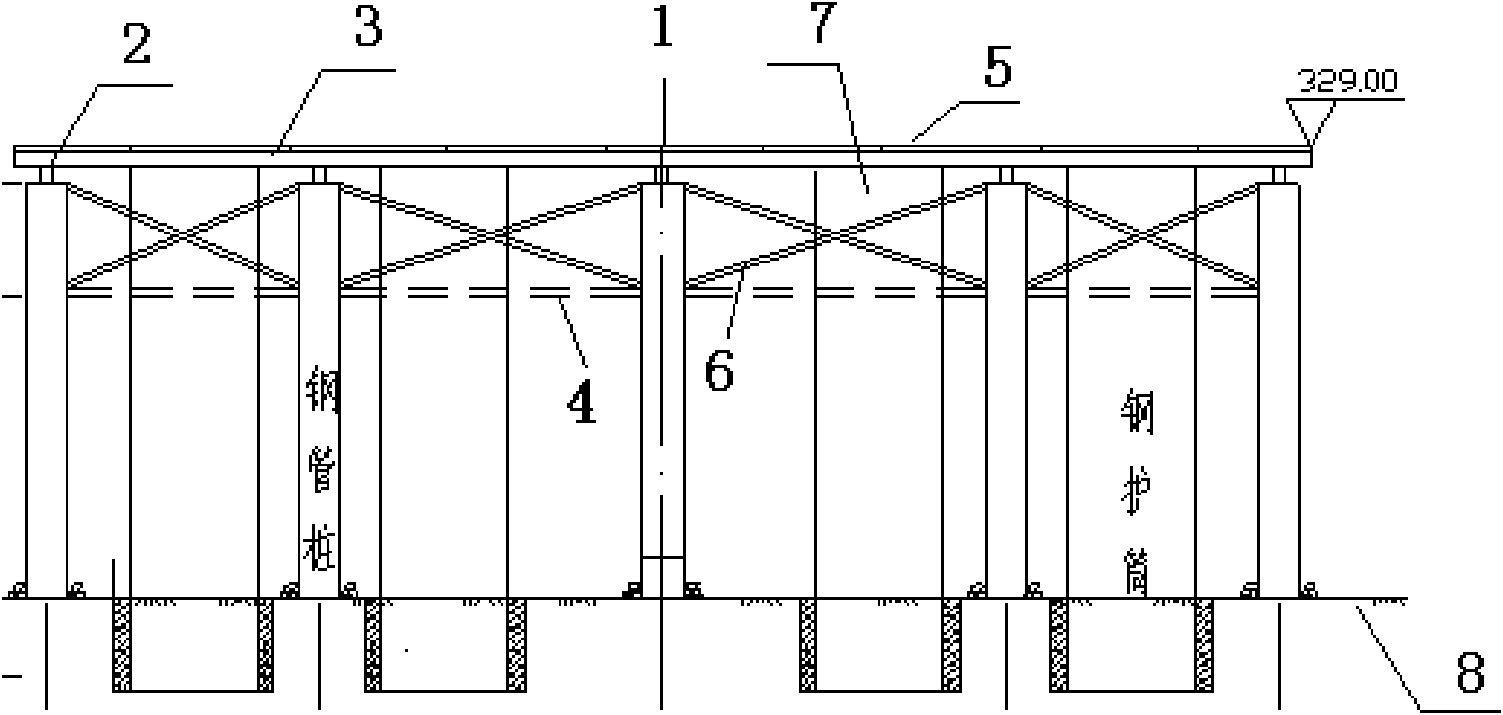

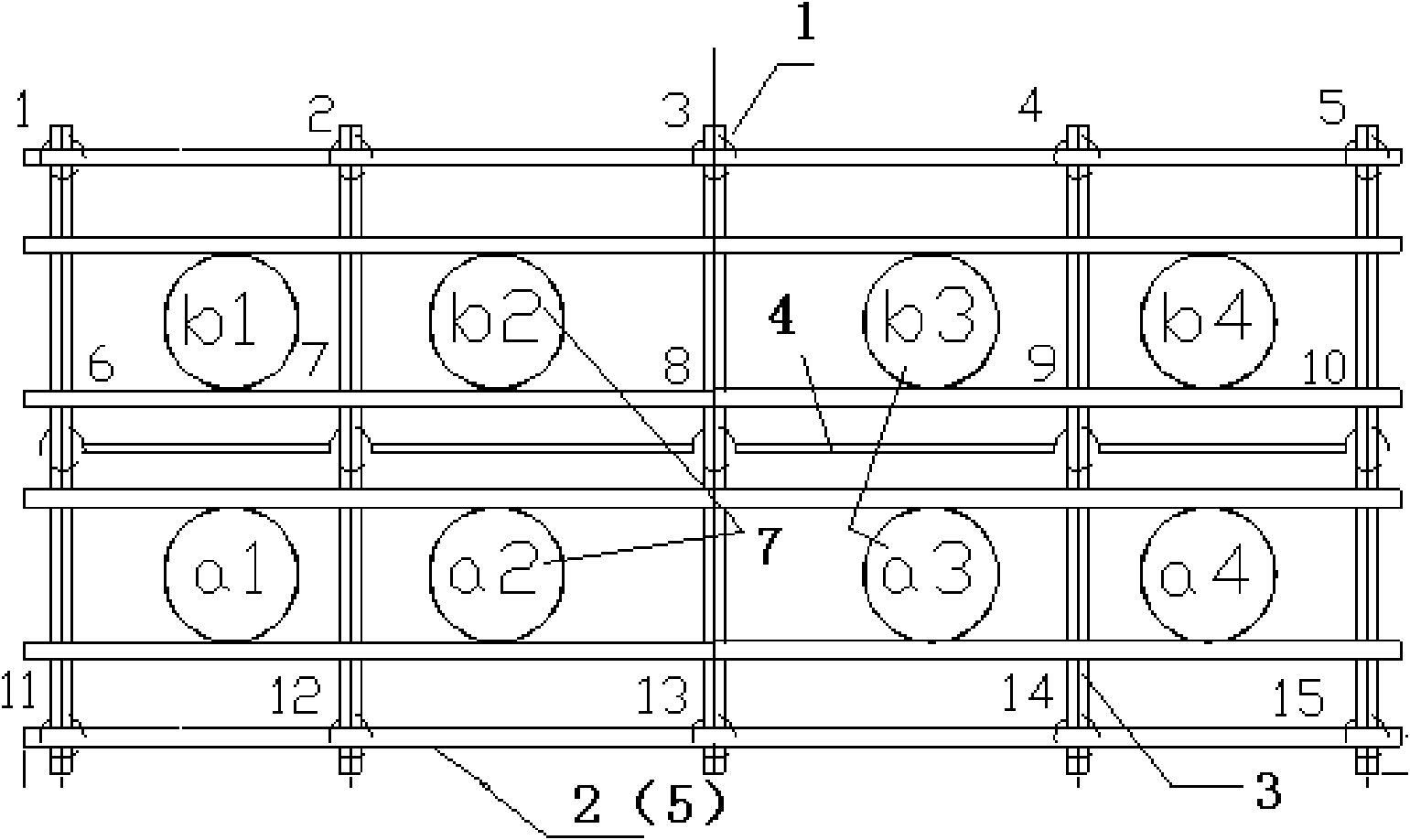

Abrupt slope bare rock drilling platform and technology in huge reservoir

ActiveCN101666081AGuaranteed stabilityFix stability issuesArtificial islandsUnderwater structuresBridge engineeringSteep slope

The invention relates to bridge engineering, in particular to an abrupt slope bare rock drilling platform and a technology in a huge reservoir and used for bridge construction. The invention is characterized in that an abrupt slope bare rock drilling device in a huge reservoir comprises steel pipe piles, a cross beam, a longitudinal beam, cross struts and a steel casing, wherein the steel pipe piles are arranged on the riverbed in a longitudinal and transverse spacing manner; the longitudinal and transverse spaces of the steel pipe piles are connected through a braced plane frame, the longitudinal cross strut and the transverse cross strut; the space surrounded by the four steel pipe piles is internally provided with the steel casing the height direction of which is parallel to the steel pipe piles; and the diameter of the pile foundation steel casing is 280cm, and the steel casing is made by rolling an A3 steel plate with the thickness of 14mm. The construction technology of the platform has 14 steps, and the invention provides the abrupt slope bare rock drilling platform and the technology in the huge reservoir, which can ensure the platform safety, easily heighten or lower the steel pipe piles, ensure the accurate in-position of a drilling machine and the pile foundation verticality, and is convenient to controlling the axial plane position of the pile foundation.

Owner:中交二公局第六工程有限公司

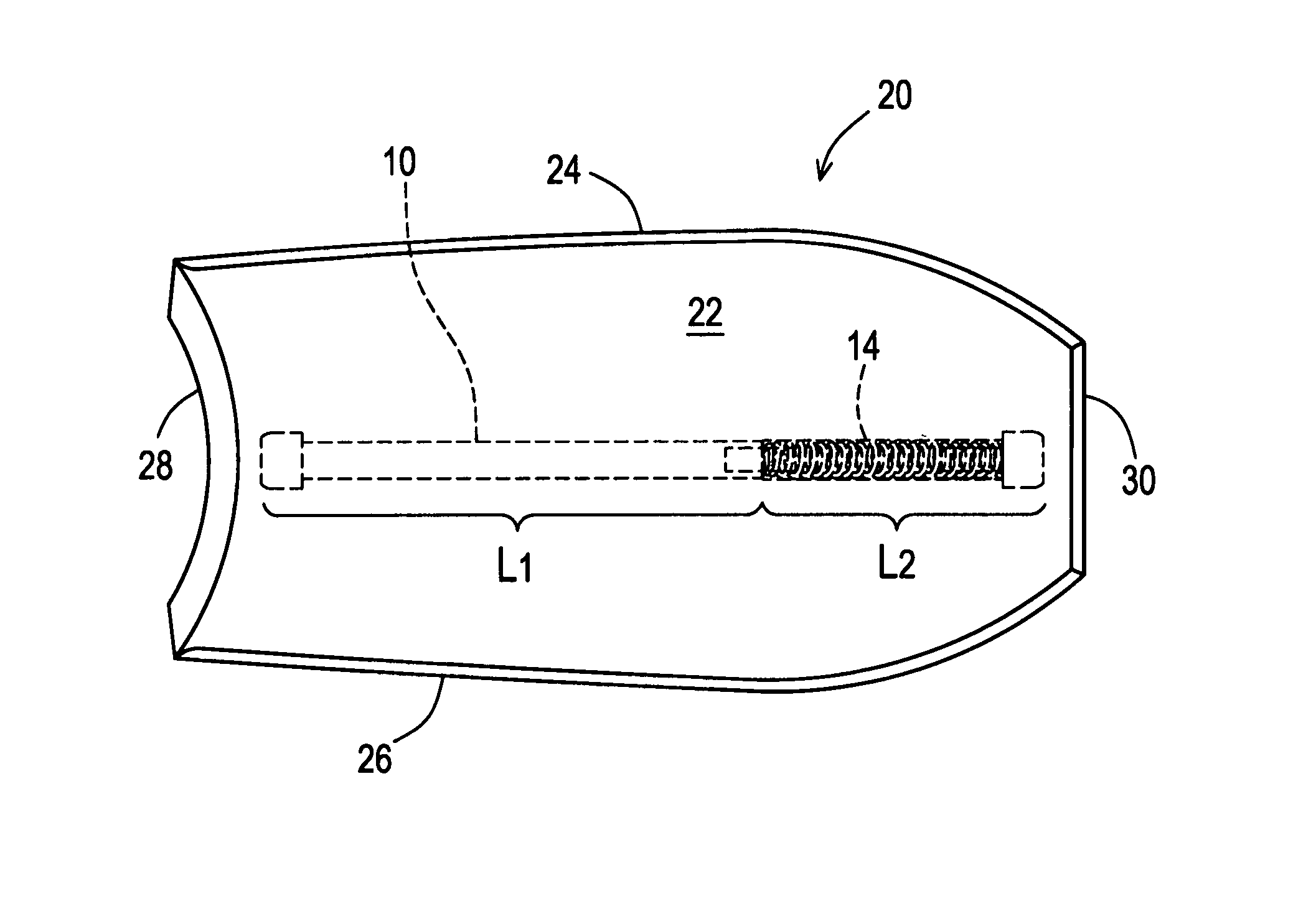

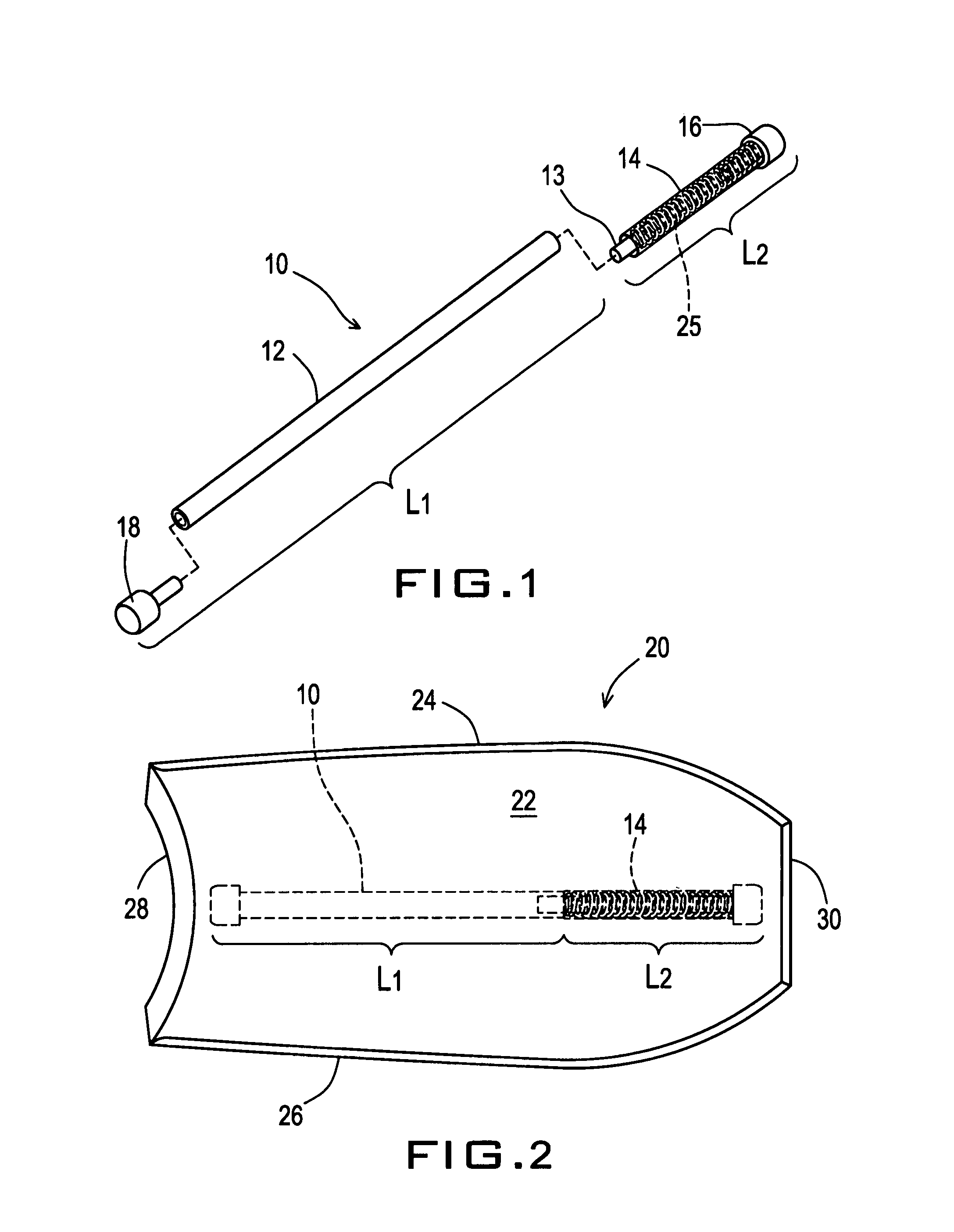

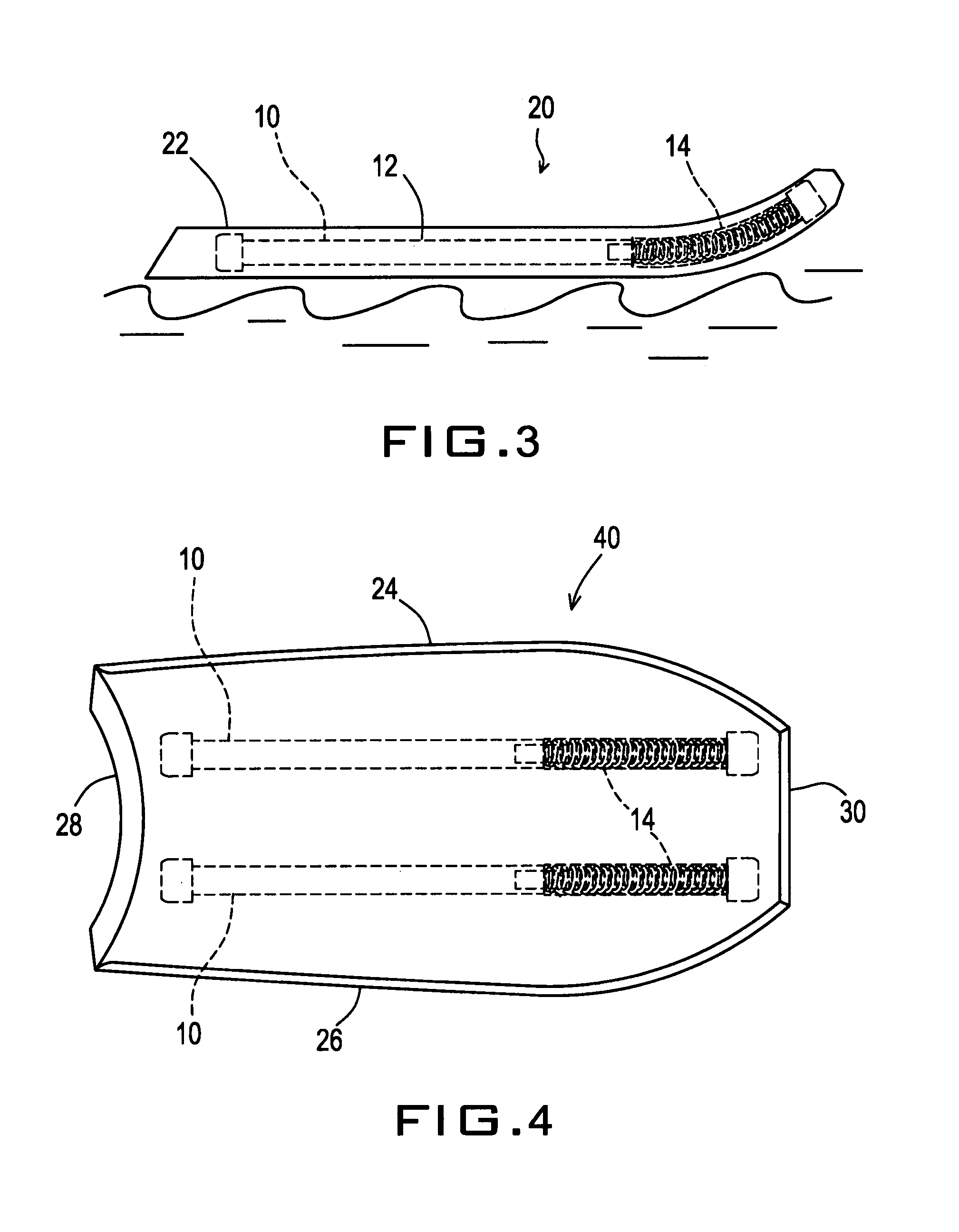

Flexible encapsulated spring stringer for bodyboard

InactiveUS7347754B1Elasticity of flexibleFlexible shapeWater sport boardsSnowboardsCoil springEngineering

A variable flexible bodyboard comprises a lightweight, generally elongated, foam core material having a top skin layer and a bottom skin layer with a front nose end and a rear tail end. The bodyboard has also an elongated stringer element having a one end and an other end, and composed of at least one stiffener material, of a defined length, to impart stiffness to the bodyboard, and at least one flexible material, of a defined length, to impart flexibility to the bodyboard. The stringer element is positioned and secured within the foam core material of the bodyboard; and a helical spring is disposed within the stringer element imparting additional resiliency to the stringer element.

Owner:CHEUNG WAH KAN

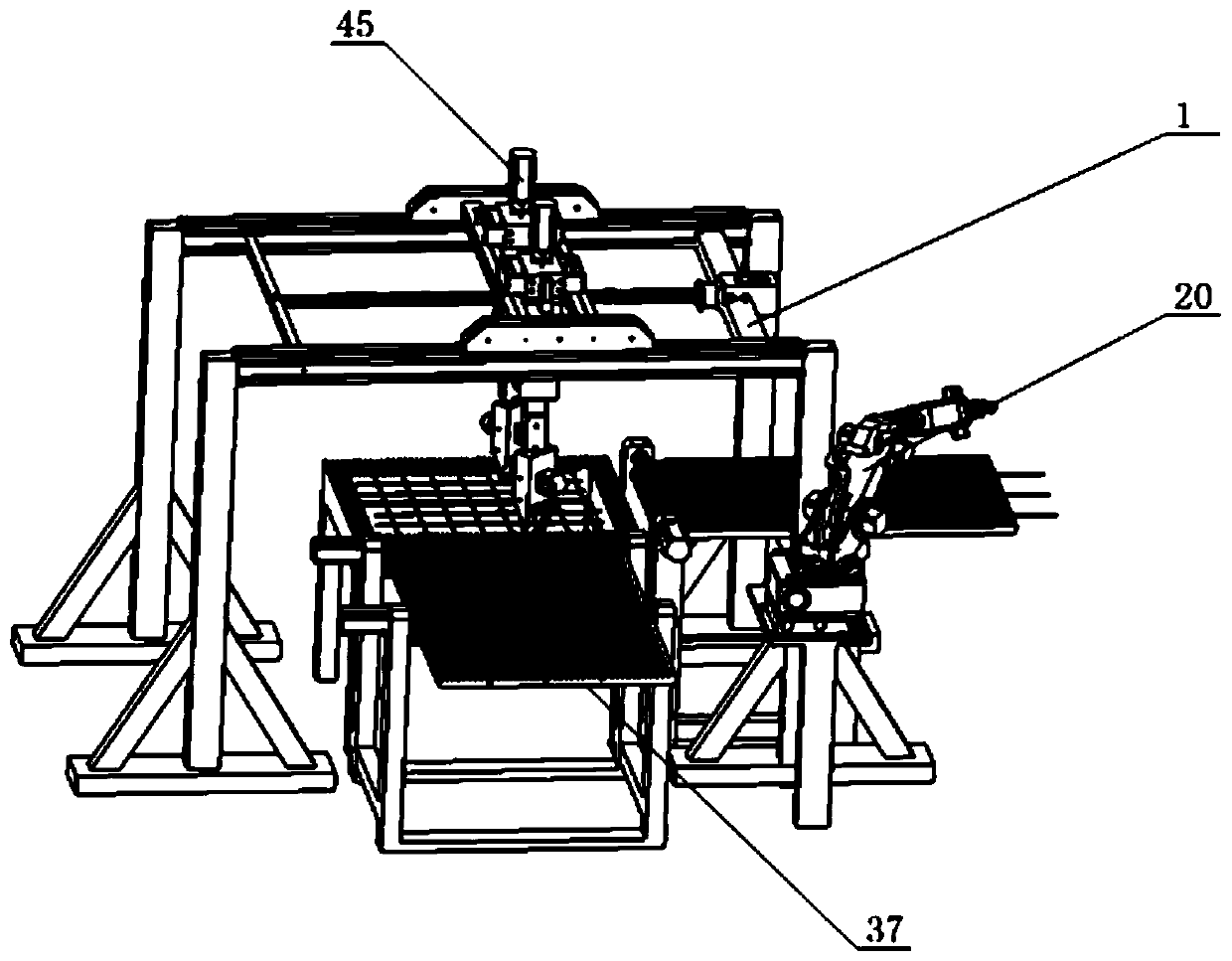

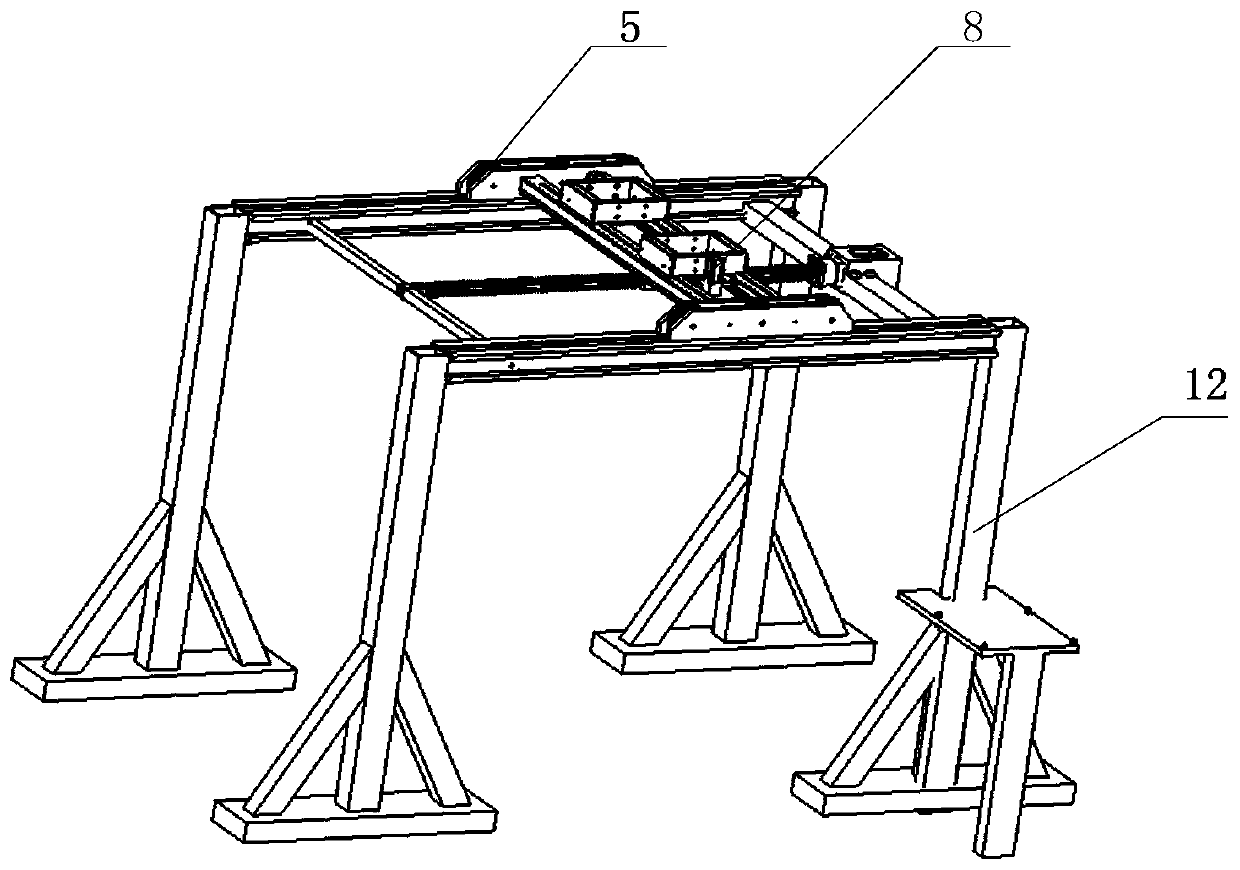

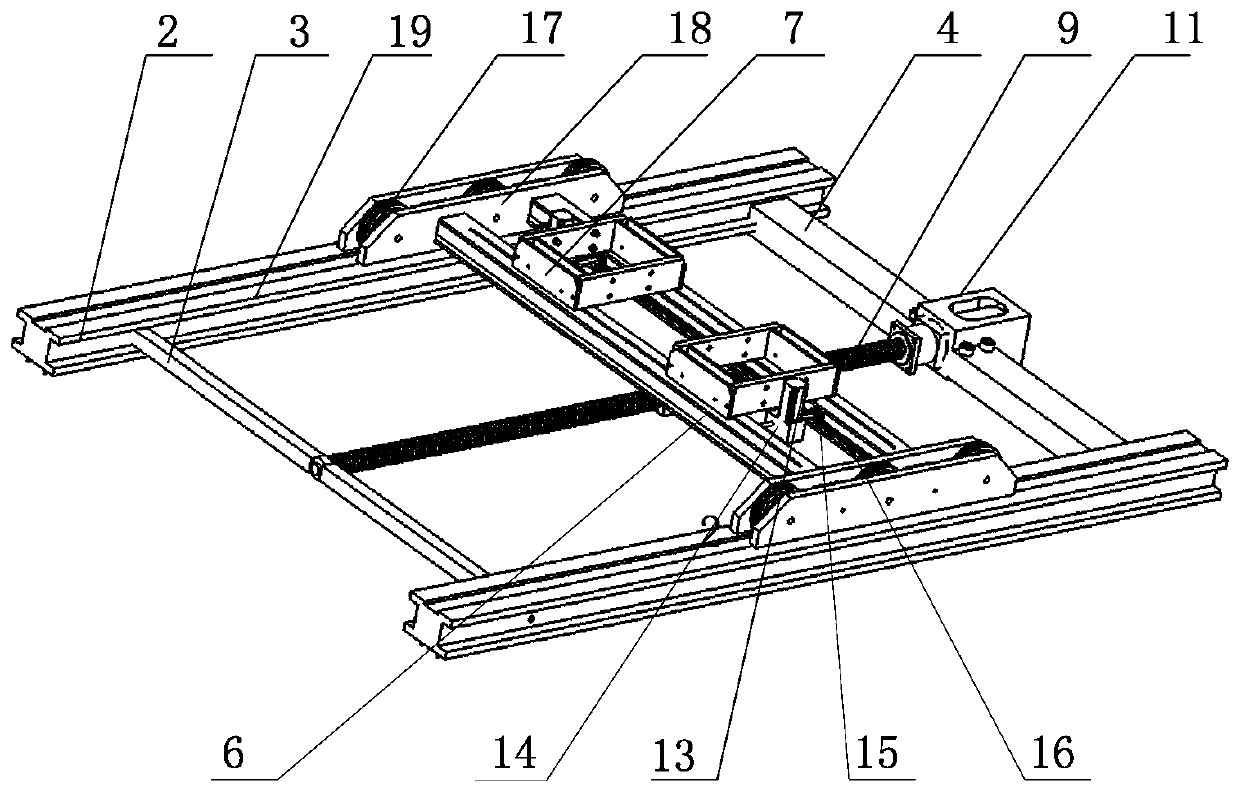

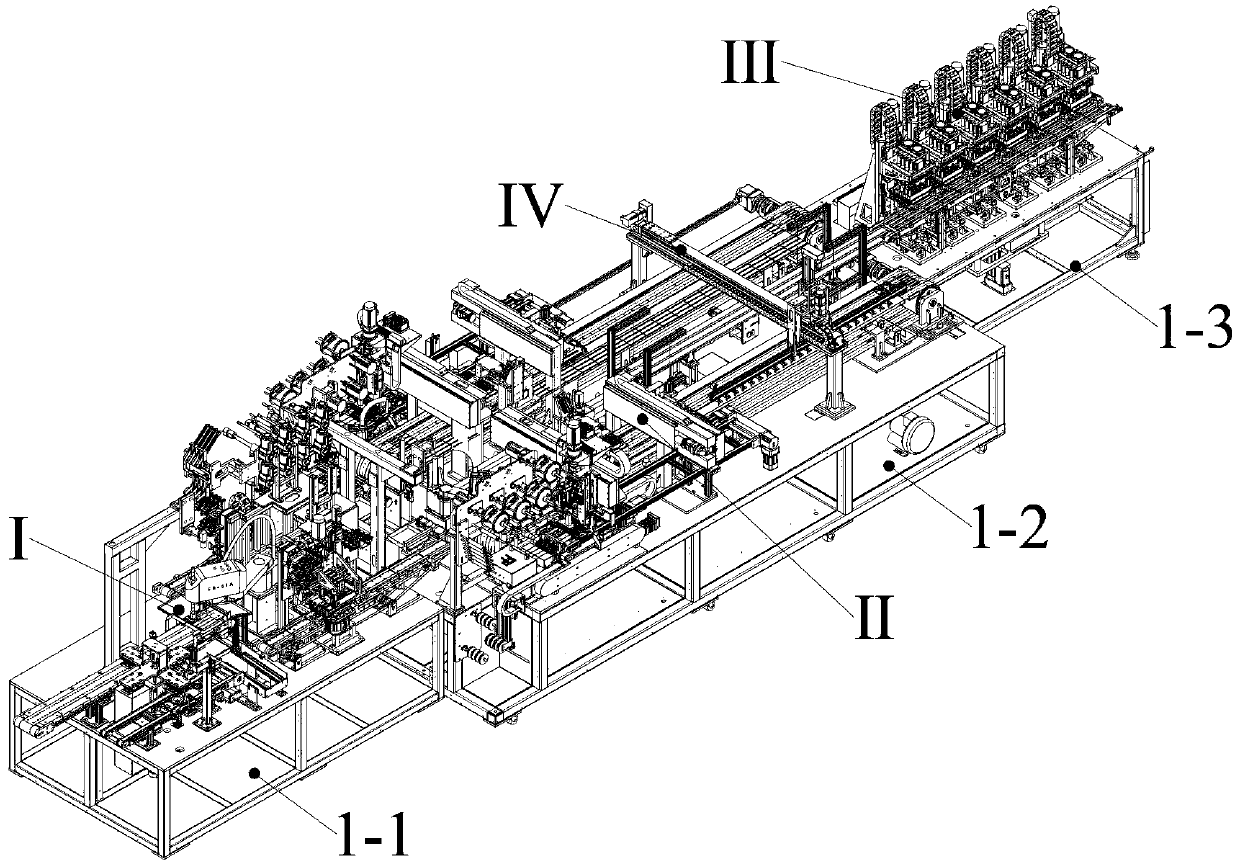

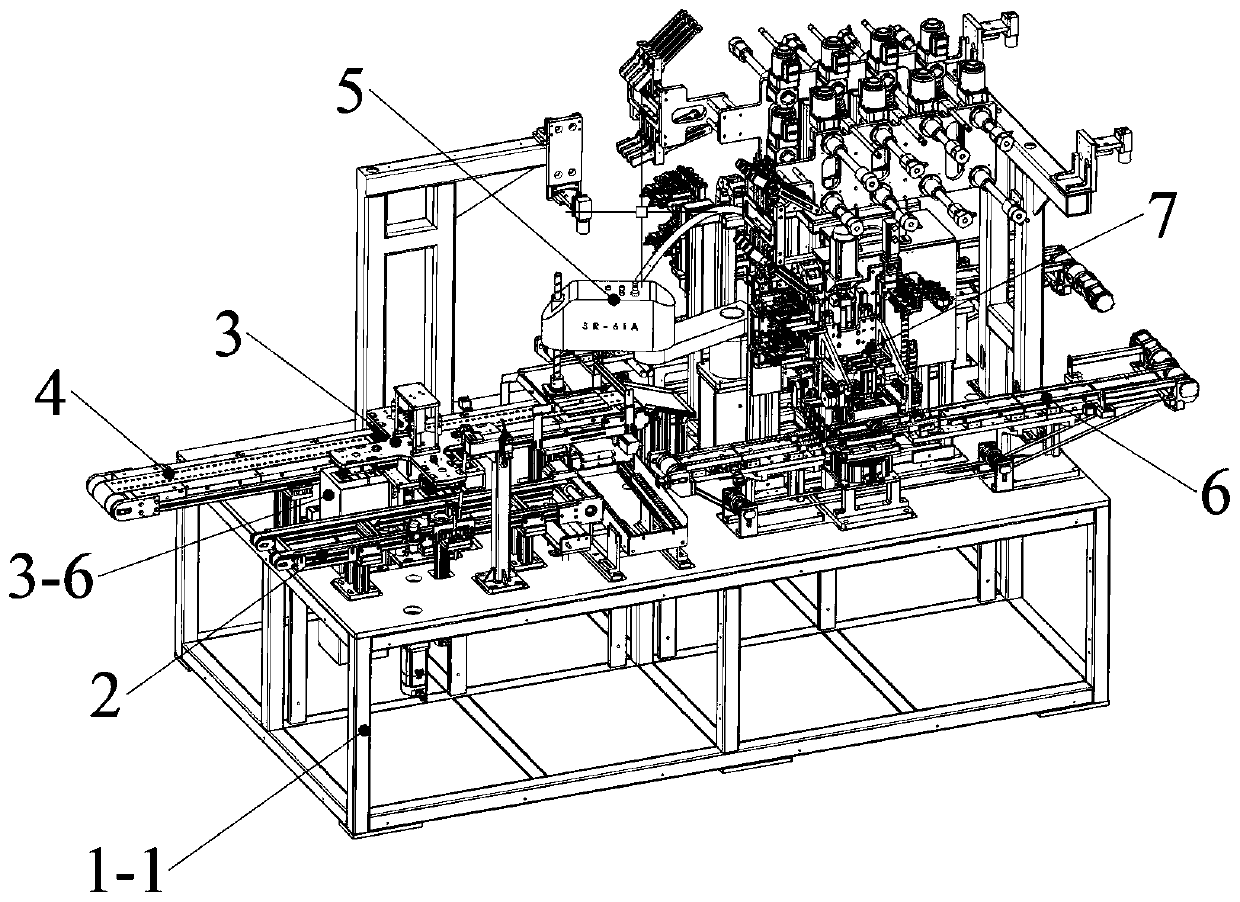

Precast concrete unit reinforcing steel bar binding machine

PendingCN110815544AHigh degree of automationReduce labor intensityCeramic shaping apparatusMesh reinforcementArchitectural engineering

The invention belongs to the technical field of construction machinery equipment, and particularly relates to a precast concrete unit reinforcing steel bar binding machine which comprises a body framemechanism, a reinforcing steel bar grabbing mechanism, a reinforcing steel bar conveying mechanism and a full-automatic binding mechanism. The body frame mechanism comprises transverse beams, a thinrod, a thick rod, transverse beam auxiliary wheel parts, longitudinal beams, longitudinal beam connecting plates, longitudinal beam driving parts, a transverse beam lead screw, a screw nut, a transverse beam lead screw motor and supporting rods. The reinforcing steel bar grabbing mechanism comprises a mechanical arm base, a worm gear case, a worm motor, a mechanical arm, a driving cylinder and a mechanical claw. The reinforcing steel bar conveying mechanism comprises a reinforcing mesh binding platform, conveying supporting frames, long reinforcing steel bar conveying rails, short reinforcingsteel bar conveying rails, long wheel motors and long wheels. The precast concrete unit reinforcing steel bar binding machine is high in automation degree and binding quality.

Owner:TIANJIN CHENGJIAN UNIV

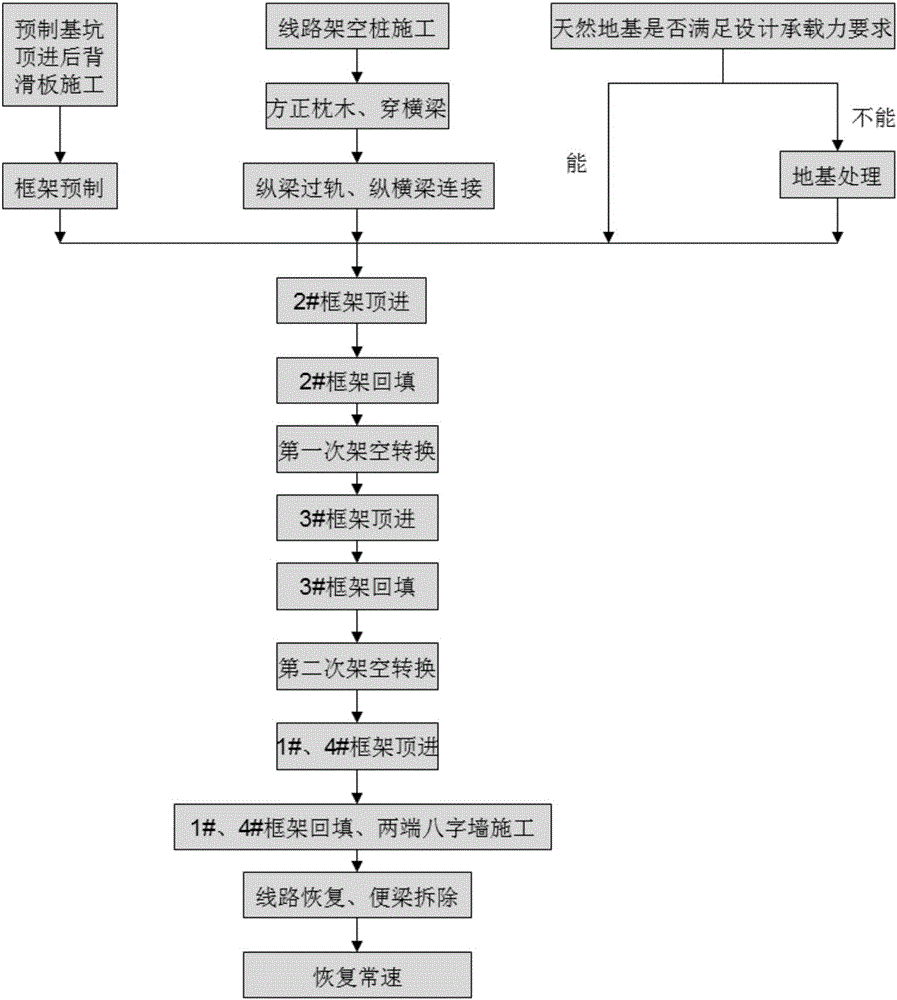

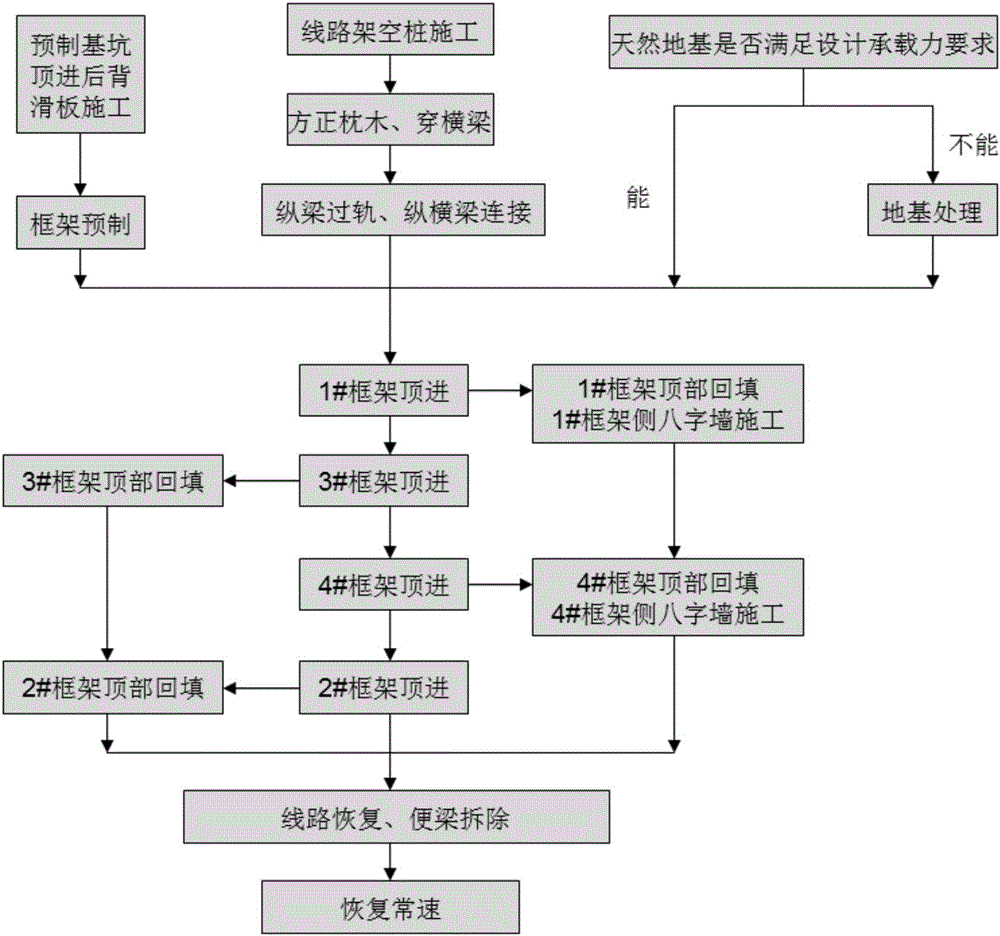

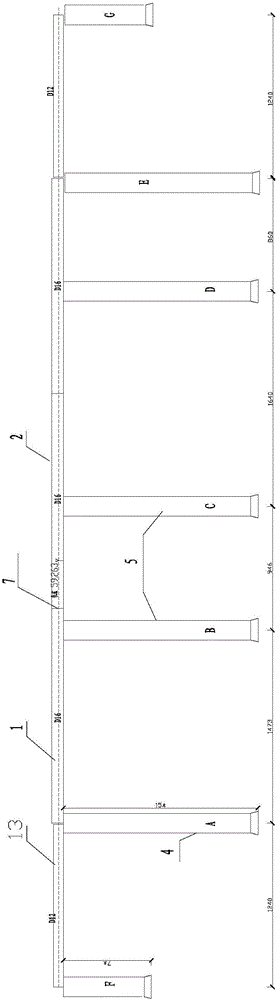

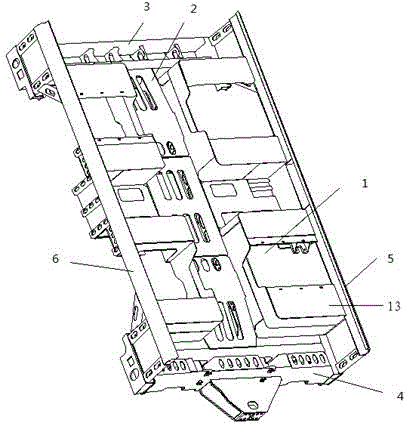

Construction method for continuous type construction auxiliary girder in jacking of railway box culvert and device for implementing construction method

The invention discloses a construction method and device for jacking continuous construction beams for railway box culverts. Excavating and pouring continuous construction beams excavate hole pile foundations, excavating prefabricated pits; prefabricating box culverts; elevating existing railways and Reinforcement, that is, to erect crossbeams first, and then erect multi-section longitudinal beams connected together on both sides of the railway to form a longitudinal beam system. The longitudinal beam system is supported on On the ground, the longitudinal beam lifts and fixes the beam and the railway rail, and the longitudinal beam is bolted with high-strength bolt groups; the prefabricated box culvert is jacked, and the box culvert section is placed on the top of the box culvert section every time it is jacked. Set up temporary piers on the side with temporary excavated pile piers, and remove the temporary excavated pile piers on the side of the box culvert section, and carry out the jacking of the next box culvert section until all box culvert sections Jacking up to the designed position; backfill the top of the separated box culvert and goafs at both ends, remove the convenience beams and temporary buttresses, and restore the line.

Owner:长沙楚泰建筑劳务有限公司

Chassis of body of hundred-percent modern city tramcar

The invention discloses a chassis of a body of a hundred-percent modern city tramcar. The chassis comprises a sleeper beam, a longitudinal beam, a first end beam, a second end beam, a first side edge beam and a second side edge beam, wherein the sleeper beam is welded to form a closed box type shaped like a Chinese character 'gong'; the longitudinal beam is welded to form a closed box type structure which penetrates through the whole body; the sleeper beam, the longitudinal beam, the end beams and the side edge beams are welded together to form a #-shaped frame structure. The chassis is formed by welding high-strength carbon steel materials, all parts are independently welded to be spliced into the chassis, and the chassis is riveted with other parts of the body. Requirements for small space of a low-floor vehicle chassis are met, and the sleeper beam and the longitudinal beam respectively form the closed box-type structure, so that the stress is uniform and is not prone to concentration, the structure is stable, the local fatigue failure is not prone to occurrence, requirements for weight control over the chassis of the whole vehicle are met, and damaged parts of the body can be independently replaced.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

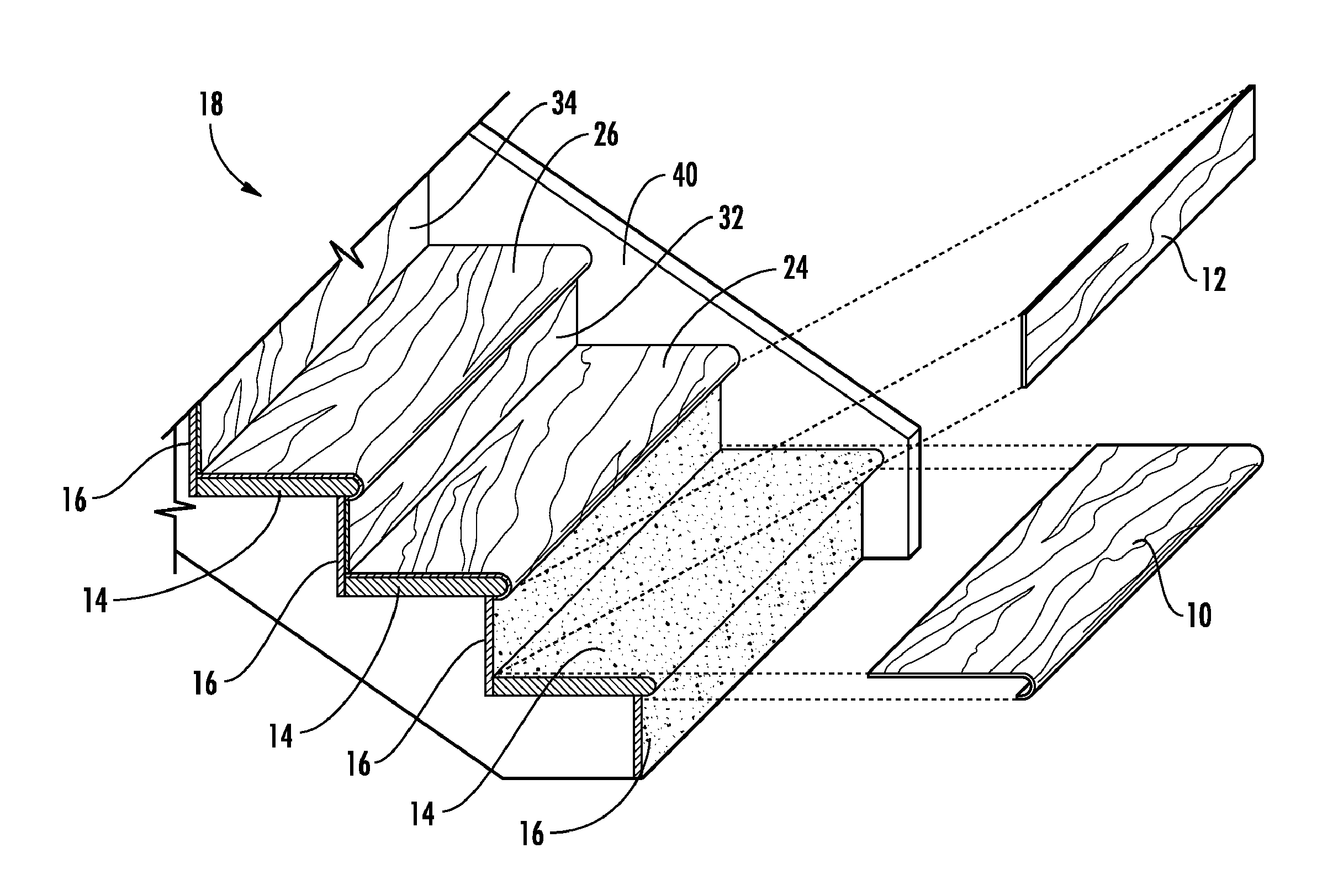

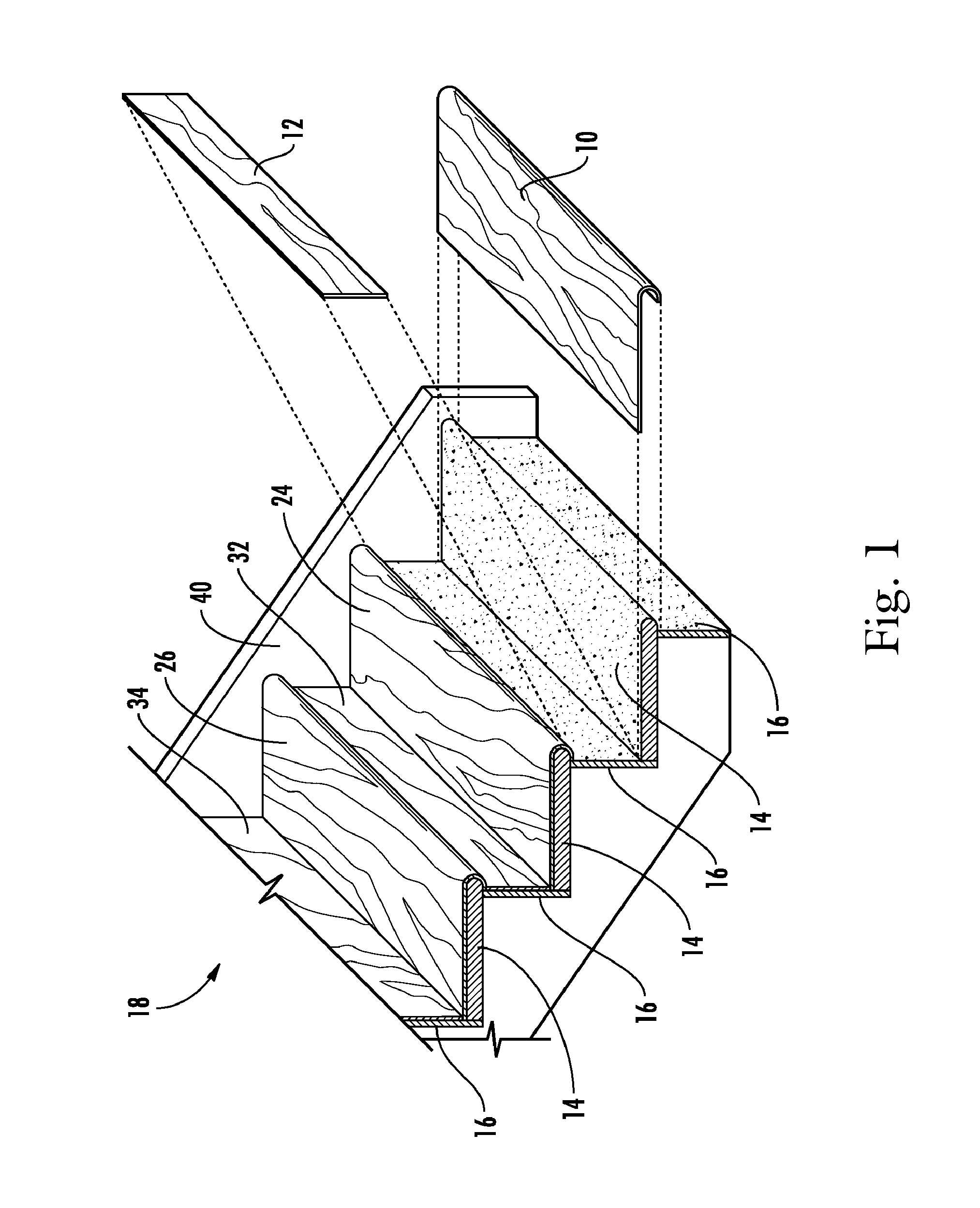

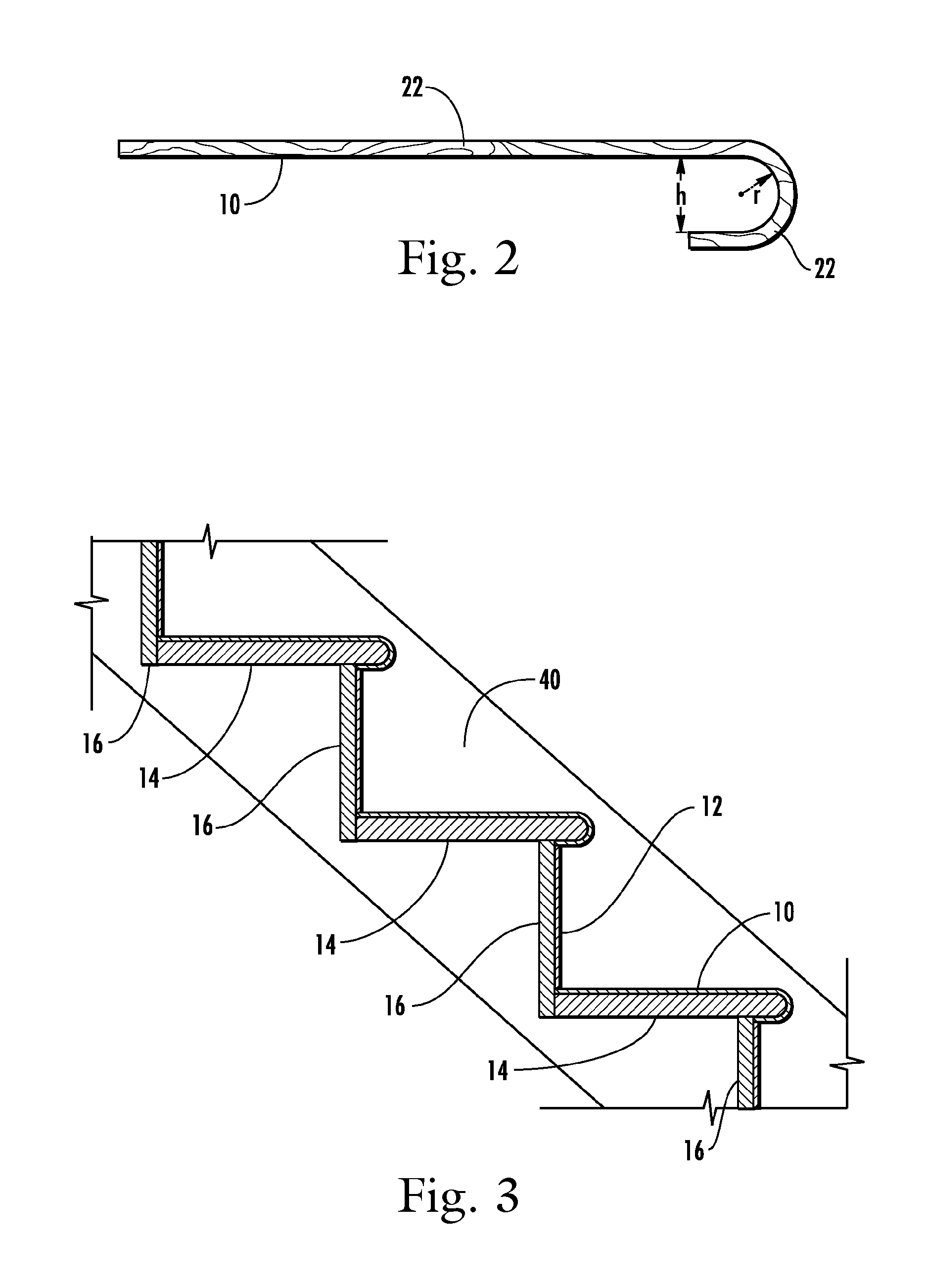

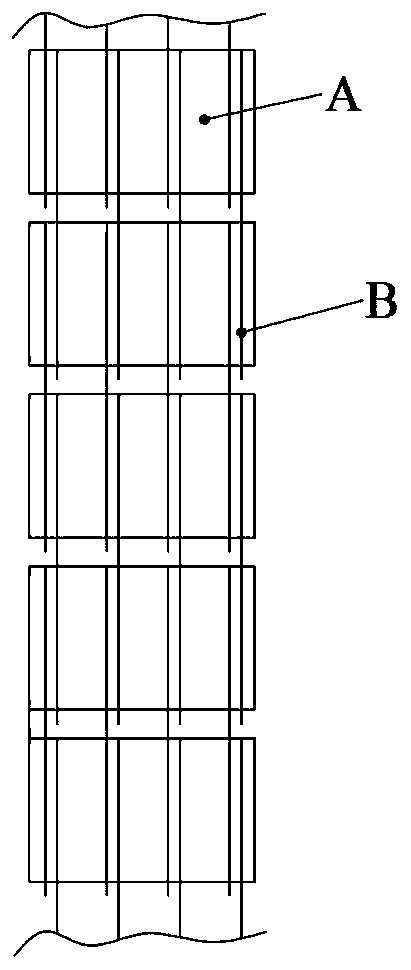

Stair tread overlay and manufacturing process

A stair tread overlay and a riser overlay made from solid wood for fitting over a conventional, exposed wooden stair having a generally rounded nose like those found in most residential general construction staircases and prefabricated staircases. The tread overlay and riser overlay cover the exterior surface of a conventional wooden stair from stringer to stringer to hide a construction grade stair tread and riser below that are made from a composite material or unsalvageable hardwood to present an attractive, solid wood surface that is finishable. One or more manufacturing processes for manufacturing a stair tread overlay and a riser overlay. The manufacturing process comprises the forming or milling of wood blanks, to fit over a conventional, exposed wooden stair having a generally rounded nose like those found in most residential and prefabricated staircases.

Owner:MCCOOL JAMES +1

IBC solar cell string welding strip welding production line and production method thereof

ActiveCN111185687AFully automatedArrangement fully automaticWelding/cutting auxillary devicesAuxillary welding devicesProduction lineStringer

The invention discloses an IBC solar cell string welding strip welding production line and a production method thereof. Compared with a conventional tabber and stringer in which the position of a metal wire is fixed by using a latter cell piece, an IBC cell cannot achieve the effect, and a net pressing clamp is needed for covering and fixing. The IBC solar cell string welding strip welding production line comprises a cell arrangement module, welding strip adding modules, a final welding module and a cell string transferring module, wherein the cell arrangement module, the welding strip addingmodules and the final welding module are sequentially arranged; and the cell string cell module is arranged at the output ends of the welding strip adding modules and transfers cell strings output bythe welding strip adding modules to the final welding module, and the welding strip adding modules comprises middle racks, welding strip feeding devices, welding strip transferring devices, light welding devices, clamp backflow devices, third cell conveyors, clamp conveyors and pressing positioning clamps. The IBC solar cell string welding strip welding production line and the production method thereof can realize full-automatic arrangement, preliminary welding and final welding of cell pieces.

Owner:HANGZHOU COMFIRMWARE TECH CO LTD

Corrugated pallet

InactiveUS7000549B2Improve carrying capacityHigh stackingsContainer decorationsLevel indicationsAdhesiveEngineering

A shipping pallet compatible with fork-lifts and pallet-trucks is made from stamped or die cut flat corrugated board. Stringer and cross-braces from an interlocking grid work to which a top and bottom flat sheet are attached by an adhesive. The pallet may be recycled as paper and not returned to the sender. Additional reinforcement structures may be added for heavier loads.

Owner:NELSON DUANE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com