610MPa automobile girder steel and production method thereof

A manufacturing method, 610mpa technology, applied in the direction of temperature control, etc., can solve problems such as difficult to meet the requirements of forming process, plasticity reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

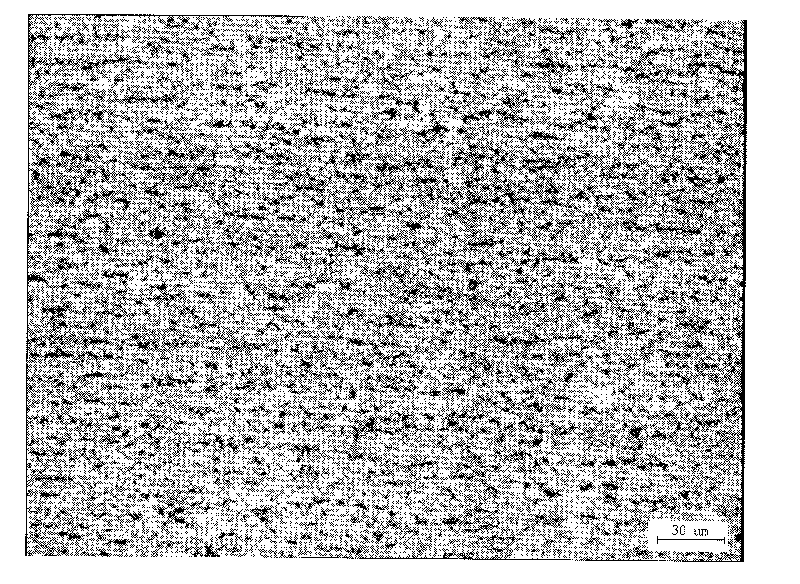

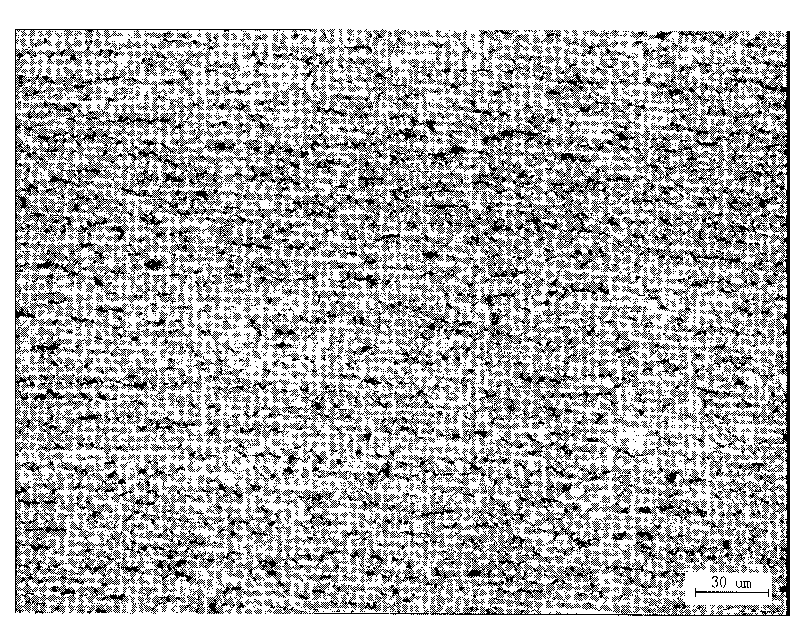

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings.

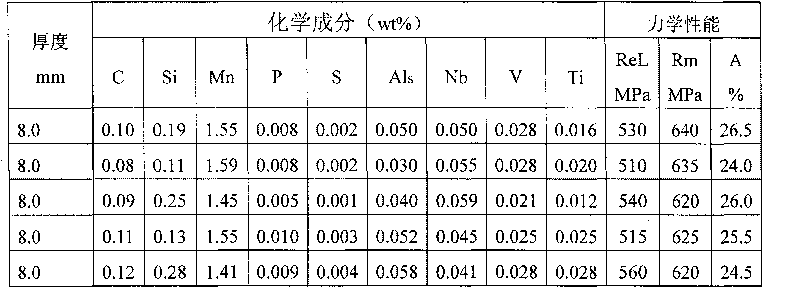

[0011] A kind of 610MPa automobile girder steel of the present invention, the mass percent (wt%) of its chemical composition is: C: 0.08~0.12; Si: 0.10~0.30; Mn: 1.40~1.60; P≤0.010; S≤0.005; Nb : 0.040~0.060; V: 0.020~0.030; Ti: 0.010~0.030; Al: 0.030~0.060, a trace amount of Ca, the rest is iron and residual trace impurities.

[0012] The preferred mass percent (wt%) of the chemical composition of a kind of 610MPa automobile girder plate steel of the present invention is: C: 0.09~0.11; Si: 0.12~0.27; Mn: 1.45~1.59; P≤0.008; S≤0.003; Nb : 0.050~0.060; V: 0.020~0.030; Ti: 0.010~0.020; Al: 0.032~0.055, trace Ca, the rest is iron and residual trace impurities.

[0013] The role of the above chemical composition and its influence on the properties of the material are as follows:

[0014] C is a very important solid solution strengthening element. Increasing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com